Page 1

Electric Actuator

Type 3374

Fig. 1 · Type 3374 Actuator mounted on a Type 3535 Three-way Valve

Mounting and

Operating Instructions

EB 8331-1 EN

Edition October 2007

Page 2

Contents

Contents Page

1 Design and principle of operation . . . . . . . . . . . . . . . . . . . 5

1.1 Additional equipment. . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Attachment to the valve . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Operation and setting . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Manual operation of the actuator . . . . . . . . . . . . . . . . . . . 12

4.2 Setting the additional equipment . . . . . . . . . . . . . . . . . . . . 12

4.2.1 Limit switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.2 Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Setting the digital positioner . . . . . . . . . . . . . . . . . . . . . . 14

5 Retrofitting additional electrical equipment . . . . . . . . . . . . . . 17

5.1 Limit switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Digital positioner . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.1 Calibrating the positioner . . . . . . . . . . . . . . . . . . . . . . . 22

5.3.2 Simplest method to calibrate the actuator. . . . . . . . . . . . . . . . 22

6 Dimensions in mm . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2 EB 8331-1 EN

Page 3

Safety instructions

General safety instructions

Assembly, start-up and operation of this device may only be performed by

4

trained and experienced personnel familiar with the product.

According to these mounting and operating instructions, trained personnel

refers to individuals who are able to judge the work they are assigned to

and recognize possible hazards due to their specialized training, their

knowledge and experience as well as their knowledge of the applicable

standards.

Any hazards which could be caused in the connected valve by the process

4

medium, operating pressure or moving parts are to be prevented by means

of the appropriate measures.

The actuators has been designed for use in electrical power installations.

4

For wiring and maintenance, you are required to observe the relevant safety

regulations. The actuator must be protected against unintentional

reconnection of the power supply.

Take special care when making adjustments on live parts. Do not remove

any covers!

Proper transportation and storage are assumed.

4

EB 8331-1 EN 3

Page 4

Note:

Actuators with a CE marking fulfill the requirements of the Directives 94/9/EC and

89/336/EEC.

The Declaration of Conformity is available on request.

4 EB 8331-1 EN

Page 5

Design and principle of operation

1 Design and principle of

operation

The Type 3374 Electric Actuator is used in

industrial plants as well as in heating, venti

lation and air-conditioning systems.

The linear actuator is suitable for form-fit at

tachment to various SAMSON valve series,

depending on the version with or without

fail-safe action. The actuators consist of a

reversible synchronous motor and a mainte

nance-free planetary gear with ball screw.

The synchronous motor is switched off by

torque-dependent switches when the final

positions are reached or in case of an over

load.

The motion is transmitted to the actuator

stem by the gears and ball screw.

Actuator versions with integrated yoke are

primarily used for attachment to Series

V 2001 Valves, Type 3260 (DN 65 to 150),

and Type 3214 (DN 65 to 250) Valves.

Actuator versions for central attachment using an M30 x 1.5 ring nut are preferably

combined with Series 240 Valves and

Type 3214 (DN 125 to 150) .

1.1 Additional equipment

The actuators can be equipped with addi

tional units, such as limit switches and po

tentiometers, to influence the tasks of control

equipment. In addition, the actuator can be

equipped with a digital positioner for pro

cessing standard signals in the range of

0 (2) to 10 V or 4 (0) to 20 mA.

Refer to section 5 for details on retrofitting

-

additional equipment.

-

-

-

-

EB 8331-1 EN 5

Page 6

Design and principle of operation

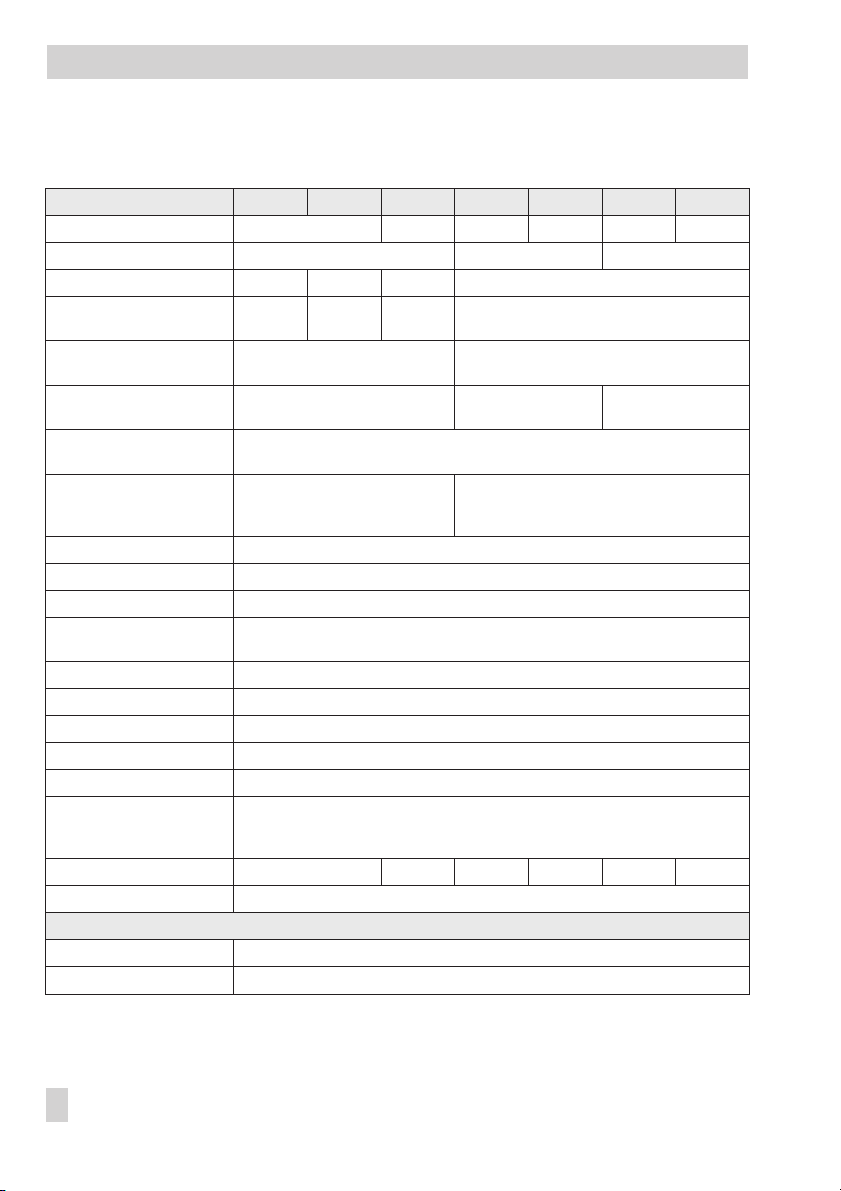

1.2 Technical data

Actuator Type 3374 -10 -11 -15 -21 -26 -31 -36

Version with Yoke Ring nut Yoke Ring nut Yoke Ring nut

Safety function Without Stem extends Stem retracts

Rated travel mm 30 15 30/15 15

Actuating time for

rated travel s

Actuating time in case of

fail-safe action s

Nominal thrust

Power supply

Power consumption VA

Without positioner

With positioner

Motor switch-off Torque-dependent

Rated temperature range 5 to 60 °C

Storage temperature range –20 to +70 °C

Degree of protection IP 54 according to IEC 529, (IP 65 with cable glands

Overvoltage category II

Design and inspection EN 61010 Edition 3.94

Class of protection II

Noise immunity EN 50082 Part 2

Noise emission EN 50082 Part 1

Manual override Using hex wrench · Adjustment impossible after fail-safe action has been triggered

Weight, approx. kg 3.2 3.3 3.9 4.0 3.5 3.6

Materials Housing and cover made of plastic (PPO glass fiber reinforced)

Additional electrical equipment

Limit switch Two travel-dependent, adjustable limit switches, perm. load 250 V AC; 3A

Potentiometer

1)

Cable glands M20 x 1.5 with metal nut, width across flats 23/24 mm

2)

Not for version with positioner

2)

240 120 240/120 120

–12

2.5 kN

Stem extends or retracts

207 V to 253 V; 50 Hz, 90 V to 127 V; 60 Hz

or 21.6 V to 27.6 V; 50 Hz (other voltages on request)

7.5/13

9.5/15

Suspended mounting position not approved

Manual adjustment of actuators with fail-safe action only possible when supply

voltage is applied (see also section 4.1)

0 to 1000Ω, (0 to 900Ωat rated travel) max. permissible current 1 mA

2kN

Stem extends

10.5/16

12.5/18

0.5 kN

Stem retracts

1)

)

6 EB 8331-1 EN

Page 7

Design and principle of operation

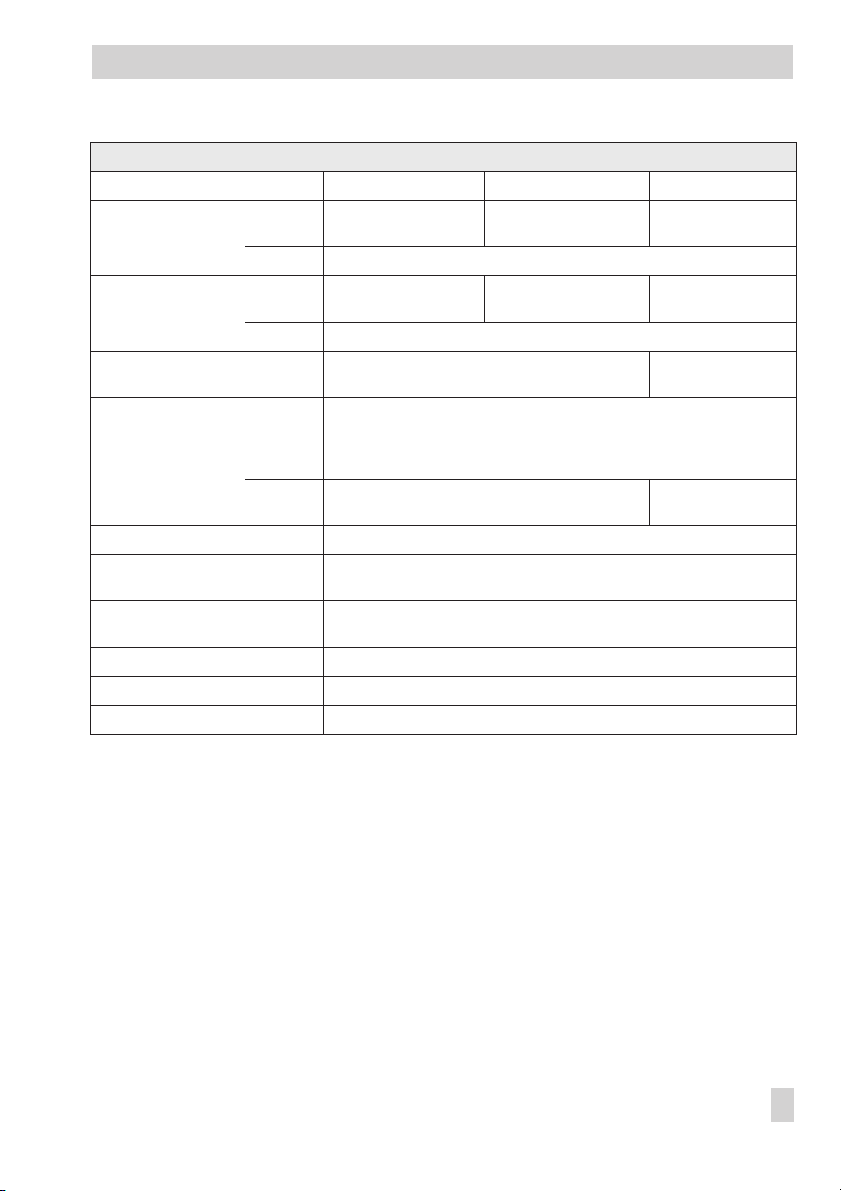

Digital positioner

1)

Operating mode 1 Operating mode 2 Operating mode 3

Input variable

2)

Range

4...20 mA, Ri = 0.05 k

2...10 V, Ri = 10 k

0...20 mA, Ri = 0.05 k

Ω

0...10 V, Ri = 10 k

Ω

Ω

Ω

As per settings

Resolution 10 Bit

Position feedback

4) 5)

signal

Characteristic

Range

4...20 mA, R

2...10 V, R

B

B

0.2≤k

5 k

≥

Ω

Ω

0...20 mA, R

0...10 V, R

Resolution 8 Bit

Increasing, actuator stem retracts or extends

as the input variable increases

0.2 k

≤

Ω

B

5 k

≥

Ω

B

As per settings

As per settings

Travel Adjustable 6 to 20 mm at 15 mm rated travel

6 to 35 mm at 30 mm rated travel

(the travel range between 12 and 35 mm has been extended to between 6

and 35 mm for 30 mm rated travel in positioner version V1.10 and higher)

Setting

Using travel calibration button

(1 mm each time the button is pressed)

As per settings

using button

1 binary input Electrically isolated, switching voltage 18 to 30 V DC, approx. 7 mA

1 binary output Electrically isolated semiconductor contact, max. 45 V DC,

min. 3 V DC, max. 25 mA

Integrated interface for SAMSON

memory pen /PC

Data transmission including settings, operating status and alarms

Transfer protocol: SAMSON SSP protocol

Retrofittable bus interface On request

Total delay time Approx. 30 ms

Accuracy

1)

Maximum two current inputs may be switched in series

2)

Maximum values ±50 mA or ±25 V

3)

SAMSON TROVIS-VIEW Operator Interface software, SAMSON memory pen

4)

Can only be taken from current or voltage signal

5)

Not when retrofittable interface is used

2.5 % without taking the dead band into account

≤

3)

3)

3)

3)

EB 8331-1 EN 7

Page 8

Installation

2 Installation

2.1 Mounting position

Installation depends on the mounting posi

tion of the valve. However, do not install the

actuator suspended downwards.

Note!

Manual override is only possible in actua

tors with fail-safe action when the power

supply is connected (see section 4.1).

-

-

2.2 Attachment to the valve

Series V 2001 (DN 15 to 80),

Type 3260 Valves (DN 65 to 150) and

Type 3214 Valves (DN 65 to 100)

1. Remove protective covers and unscrew

nut (6) from the control valve.

2. Place actuator with yoke onto the valve

and fasten with the nut (6, SW 36) using

a minimum tightening torque of

150 Nm. If necessary, retract actuator

stem slightly beforehand using the man

ual override.

3. When the plug stem (5) fits closely onto

the actuator stem (3), attach both stem

connector clamps (4) and fasten with

screws.

Series 240

the top of the coupling nut (8) is

reached. Secure position with lock nut

(9).

3. Place actuator onto valve bonnet (2.3)

and fasten with ring nut (7).

If necessary, retract actuator stem

slightly beforehand using the manual

override.

4. When the coupling nut (8) fits closely

onto the actuator stem, attach both stem

connector clamps (4) and screw tight.

5. Move actuator stem (3) to the end posi

tion (valve closed) using the manual

override or motor.

6. Align travel indicator scale (10) to the

middle of the stem connector (4) and

screw tight.

Type 3214 (DN 125 to 250)

1. Place actuator onto the valve and secure

with the ring nut (7). If necessary, retract

actuator stem slightly beforehand using

the manual override.

2. When the plug stem fits closely onto the

-

actuator stem (3), attach both stem

connector clamps (4) and screw tight.

3. Move actuator stem (3) to the end posi

tion (valve closed) using the manual

override or motor.

4. Align travel indicator scale (10) to the

middle of the stem connector (4) and

screw tight.

-

-

1. Push plug stem down to close the valve.

2. Turn coupling nut (8) until a distance of

x = 75 mm (x = 90 mm for DN 100 and

larger) between the top of the yoke and

8 EB 8331-1 EN

Page 9

Installation

Attachment to Series V 2001,

Type 3260 DN 65 to 150 and

Type 3214 DN 65 to 100

1

2.1

3

4

5

6

1

2.2

7

3

10

4

5

Attachment to Type 3214

DN 125 to 250

Attachment to Series 240

1

2.3

7

3

4

8

9

1 Actuator

2.1 Actuator yoke

2.2 Valve yoke

2.3 Bonnet

3 Actuator stem

4 Stem connector

5 Plug stem

6 Nut

7 Ring nut

8 Coupling nut

9 Lock nut

10 Travel indicator scale

x

10

5

Fig. 2 · Attachment to the valve

EB 8331-1 EN 9

Page 10

Electrical connections

3 Electrical connections

Upon installation of the electric ca

bles, you are required to observe the

regulations concerning electrical

power installations according to DIN

VDE 0100 as well as the regulations

of your local power supplier.

L

Ce

Ce

N+–LN

Establish electrical connections as indicated

on the circuit diagram on the actuator cover

-

and as illustrated in Figs. 3 and 4.

A maximum of 3 cable glands can be at

tached to the housing for cable entries.

Retracts

eL

aL

Extends

-

aL eL N

Limit switches (optional)

41 44 42 51 54 52

Fig. 3 · Terminal connections, version for three-point stepping signal

NL

Magnet in version with

fail-safe action

10 EB 8331-1 EN

Potentiometer (optional)

81 82 83 91 92 93

ea ae

Page 11

Caution!

Only connect to the main power network

4

when the power is switched off.

Only use power interruption devices

4

which ensure that the power cannot be

switched on again unintentionally.

Limit switches (optional)

41 44 42 51 54 52

Electrical connections

Particularly for 24 V, 50 Hz actuators,

4

use wires with a sufficiently large

cross-section to guarantee that the per

missible voltage tolerances are not ex

ceeded.

-

-

Load, max. 25 mA

V

mA

_

++

V

mA

_

++

13

33

32

31

Position feedback Input Binary input Binary output Power supply

Fig. 4 · Terminal connections, version with digital positioner

12

11

V

_

+

81

82

active when

voltage is

applied

83

V

_

+

84

NL

NL

Magnet in version with

fail-safe action

EB 8331-1 EN 11

Page 12

Operation and setting

4 Operation and setting

4.1 Manual operation of the

actuator

To operate the manual override, place

4 mm hex wrench on the red actuator shaft

located at the side of the housing. The hex

wrench is delivered with the actuator. It is

attached to the bottom of the housing.

Manual override is only possible in actua

tors with fail-safe action when the power

supply is connected (terminals N and L).

Set the selector switch (2, in Fig. 6) of the

actuator with positioner to the operating

mode 0 =.

-

4.2 Setting the additional

equipment

To access the additional equipment, unscrew

the four fixing screws on the cover using a

Pozidrive PZ2 screwdriver to provide

enough hold on the screw heads. Take off

the cover.

After completing the settings and establish

ing the electrical connection, refasten the

cover. To proceed, place back on the cover

and screw the cover screws in slightly to po

sition the cover before tightening them prop

erly.

Perform settings while the power is

switched on!

-

4.2.1 Limit switches

1. Use motor or manual override to move

the control valve to the position where

the switching function is to be activated.

2. Use hex wrench to turn spindle (2) for

the upper limit switch or spindle (3) for

the lower limit switch until the associated

contact cam on the cam bracket (7) trig

gers the switch contact of the upper or

lower microswitch (1).

4.2.2 Potentiometers

The gears of the potentiometers (12) and

(13) must be put onto their shafts to

correspond with the rated travel of the control valve. The rated travel inscription

“Nennhub 15” or “Nennhub 30” must be

legible. If this is not the case, pull each potentiometer gear off the shaft and put it back

on again with the reverse side of the wheel

facing upwards, ensuring it is aligned

roughly flush with the potentiometer shaft.

Zero point adjustment

1. Use motor or manual override to move

-

-

the control valve to the desired end posi

tion.

2. Place screwdriver on the slotted potenti

ometer shaft (12.1 and 13.1).

3. Calibrate potentiometer using the con

nected ohmmeter correspondingly:

Actuator stem extends:

81/82 = 0Ω; 91/93 = 0Ω;

Actuator stem retracts:

81/83 = 0Ω; 91/92 = 0Ω.

-

-

-

-

12 EB 8331-1 EN

Page 13

Limit switch

Stem retracts

Operation and setting

Metal tag

Stem extends

Rated travel inscription

12

1312.1

13.1

aae

B

15

Nennhub

12 3 75

1 Microswitch

2 Spindle upwards

3 Spindle downwards

5 Intermediate gear

7 Cam bracket

12 Gear potentiometer 1

12.1 Potentiometer shaft

13 Gear potentiometer 2

13.1 Potentiometer shaft

Fig. 5 · Performing settings

EB 8331-1 EN 13

Page 14

Operation and setting

4.3 Setting the digital positioner

In the actuator version with digital

positioner, the travel is calibrated automati

cally, allowing the travel (controlled variable

x) and the input signal (reference variable

w) of the positioner to be matched in the

best possible way. Additionally, the digital

positioner provides valve position feedback

for remote transmission.

Setting and start-up can be carried out us

ing four different operating modes. Oper

ating modes 1 and 2 work with set data

stored in the positioner's memory. The user

only needs to select the operating mode via

the selector switch (2) and press the button

(4) to start travel calibration.

Note!

Setup with operating modes 3 and 0 =

can only be performed using a SAMSON

memory pen as the storage medium, or in

connection with SAMSON's TROVIS-VIEW

Configuration and Operator Interface software and a PC or bus system. Setup with

operating modes 3 und 0 = is described

in Mounting and Operating Instructions

EB 8331-2 EN.

Settings for operating modes 1 and 2

Increasing characteristic: actuator stem re

tracts or extends as the reference variable

increases.

After the actuator has been mounted on the

valve as described in section 2.2 and the

electrical connections have been established

as described in section 3, proceed as fol

lows:

-

-

-

-

1. Set selector switch (2) with the arrow

pointing to operating mode 0 =

-

(control switched off).

2. Check mounting position of the potenti

ometer gear (12).

The gear must be put onto the potentiometer

shaft to correspond with the rated travel of

the control valve. The inscription

“Nennhub 15” (for 6 to 20 mm travel) or

“Nennhub 30” (for 6 to 35 mm travel) must

be legible from above on the associated

gear side. If this is not the case, pull the

gear off the shaft and put it back on again

with the reverse side facing upwards, allow

ing the intermediate gear to engage prop

erly.

Note!

Actuators with fail-safe action "Actuator

stem retracts" or "extends" are only designed for a rated travel of 15 mm. Do not

rearrange the gear!

Make sure that the shaft of the potentiometer

(12.1) is adjusted correctly.

3. Switch on auxiliary power and set the

reference variable to a value > 4 mA.

4. Set selector switch (2) with the arrow

pointing to operating mode 1 for 4 to

20 mA or 2 to 10 V input and alarm

signal, or set it to operating mode 2 for

0 to 20 mA or 0 to 10 V input and

alarm signal.

5. Press button (4) to start travel calibra

tion.

-

-

-

-

14 EB 8331-1 EN

Page 15

Operation and setting

Press the button briefly to obtain a travel

calibration for valve CLOSED when the actu

ator stem extends.

Direction of action: Increasing/increasing.

Hold the button pressed for longer than 3

seconds (indicated by switchover from sig

nal lamp 8 to signal lamp 9) to obtain a

travel calibration for valve CLOSED when

the actuator stem retracts.

Direction of action: Increasing/decreasing.

1 Operating mode 1

2 Selector switch

3 Operating mode2

4 Travel calibration button

5 Operating mode 0

6 Operating mode 3

7 Potentiometer counter-

clockwise or clockwise

8 Signal lamp

9 Signal lamp

10 Actuator stem extends

and retracts

11 Interface jack

12 Potentiometer gear

12.1 Potentiometer shaft

2

13

-

Caution!

The automatic travel calibration lasts

approximately twice as long as the

actuator's transit time. During this

period, the valve leaves its current

position. Calibrate the travel either

on the test bench or when the

shut-off valves in the plant are

closed.

After pressing the travel calibration but

ton (4), the actuator stem first moves as far

431 72 8

65

SAMSON

Stellungsregler

Positioner

Régulateur de position

9

-

10

11

Gear (12)

Position for rated travel 15

Gear (12)

Position for rated travel 30

Fig. 6 · Selector switch and position of potentiometer gears in version with digital positioner

Intermediate gear

Rated travel

inscription

Intermediate gear

12

B

12.1

Intermediate gear

EB 8331-1 EN 15

Page 16

Operation and setting

as it will go to the valve's CLOSED position.

Calibration is carried out when both signal

lamps (8 and 9) are lit.

Travel calibration starts after the mounting

position of the potentiometer gear (12) has

been determined automatically. This is indi

cated by signal lamp (8) for 6 to 35 mm

travel and by signal lamp (9) for 6 to

20 mm travel.

When travel calibration starts, the lower sig

nal lamp (9) blinks quickly for about 10 sec

onds. The actuator stem retracts as far as it

will go (maximum travel - valve OPEN).

Travel calibration is successfully completed

when the end position is reached. The actuator is in control operation. The actuator

stem moves to the valve position determined

by the reference variable.

-

Note!

If one of the signal lamps starts to blink

slowly after the travel calibration button has

been pressed and the actuator stem has extended to the valve's CLOSED position, the

potentiometer shaft (12.1) has been wrongly

positioned. Readjust it manually.

Do not adjust the potentiometer before the

closed position is actually reached. This is

indicated by the associated, activated limit

switch on the board (Fig. 5 on page 13).

To proceed, adjust the shaft of the potenti

ometer (12.1) by turning it gradually clock

wise or counterclockwise with a screwdriver

until the signal lamp stops blinking and is

constantly illuminated. Turn the screwdriver

counterclockwise if the upper signal lamp

-

(8) blinks, and clockwise if the lower signal

-

lamp (9) blinks, corresponding to the icons

(7). Travel calibration does not continue until

both signal lamps are illuminated at the

same time.

Note!

If both signal lamps start to blink simultaneously during travel calibration, interrupt

calibration by pressing the travel calibration

button (4) and check the mounting position

of the potentiometer gear (12) again.

If no travel motion can be determined during calibration, e.g. due to a loose or missing potentiometer gear, both signal lamps

blink alternately.

If this is the case, interrupt travel calibration

by pressing the button (4), correct the error,

and restart calibration by pressing the but

ton (4) again.

-

-

-

16 EB 8331-1 EN

Page 17

Retrofitting additional electrical equipment

Setting with limited travel range

Travel calibration is usually based on the

maximum travel of the control valve.

If, however, the maximum possible travel is

to be limited to a smaller travel end value,

press the button (4) once at the start of cali

bration while the signal lamp blinks for

10 seconds. As a result, travel calibration

via the potentiometer gear with rated travel

15 or 30 is limited to 6 mm. Each time the

button is pressed, the travel range is in

creased by 1 mm.

If, for example, a control valve designed for

15 mm is to be operated with a limited

travel range of 10 mm, press the button (4)

5 times during the 10 second time limit. The

top signal lamp (8) flashes each time the key

is pressed.

Reporting defined events

At the binary output (terminal 83 and 84),

predefined events can be indicated (see

EB 8331-2 EN) during positioner operation

and transmitted to a control room.

-

5 Retrofitting additional

electrical equipment

The actuator can be subsequently equipped

with two limit switches, two potentiometers

or a digital positioner.

Depending on the actuator version used, the

actuator board needs to be replaced as

well.

The actuator version is marked on the name

plate, e.g. model 3374-11000002000.

When ordering additional electrical equip

ment from the manufacturer, make sure to

include this model number in the order.

Caution!

When installing electrical equipment, make

sure the supply voltage and the signal input

are disconnected. Only use power interruption devices which are protected against unintentional reconnection of the power supply.

Note!

It is recommendable to slightly apply lubri

cant (e.g. Vaseline) to the spindles on the

gear faces and to the sides of the cogs.

-

-

-

EB 8331-1 EN 17

Page 18

Retrofitting additional electrical equipment

5.1 Limit switches

The retrofit kit (order no. 1400-8830) is re

quired to install limit switches. If the actuator

is not already equipped with potentiometers

or a positioner, the basic unit (order no.

1400-8829) is also required. The unit in

cludes the spindle gear (2) and the interme

diate gear (5).

Note! To mount the limit switches, the actua

tor stem must be in end position, i.e. the

stem must be either fully extended or fully

retracted. If necessary, move the stem to the

appropriate position using the manual over

ride on the side.

1. Remove the fastening screws. Push the

actuator board (1) from its guiding to

the right. Slightly lift the board and continue pushing it further towards the cable

entry.

2. Clip the spindle gear (2) onto the sleeve

(3). Make sure the lateral latch is properly engaged in the groove of the sleeve.

3. Plug intermediate gear (5) onto the spin

dle (4). Place the serrated ring (10) on

top and push it down until it will not go

any further.

4. Plug both premounted contact cams (6)

with the ring gear first onto the cam

bracket (7).

5. Push adjustment gears (8) onto their

spindles and fasten with one screw

each. Check whether the adjustment

screws can be turned easily. If not,

slightly loosen the screw again.

-

6. Turn both contact cams (6) as illustrated

-

-

-

-

-

in Fig. 7.1 corresponding with the posi

tion of the actuator stem on the cam

bracket (7).

7. Push the spacer (9) onto the spindle for

the cam bracket. Push the cam bracket

with both cams onto the spindle corre

sponding with the position of the actua

tor stem as illustrated in Fig. 7.2. Make

sure that the outermost cog of the cam

bracket (7) engages in the gearwheel of

the intermediate gear (5). In addition,

the adjustment gears (8) must engage

properly in the corresponding gears of

the contact cams (6).

8. Secure the cam bracket (7) and intermediate gear (5) with the serrated ring

(10), pushing the ring down until it will

not go any further.

9. Position the terminal board (11) at the

base of the support at a 45° angle

(approx.) with the switches facing towards the gears. Push the upper end of

the terminal board towards the gears

until the board is in a vertical position

and properly engaged in the support.

10.Push the actuator board (1) back into its

guiding. Make sure that the gears are

properly engaged. Fasten the board us

ing screws.

Adjust limit switches as described in sec

4

tion 4.2.1.

-

-

-

-

-

18 EB 8331-1 EN

Page 19

Retrofitting additional electrical equipment

8 954 32112

71110

1 Actuator board

2 Spindle gear

3 Sleeve

4 Spindle

5 Intermediate gear

6 Contact cam

7 Cam bracket

8 Adjustment gear

7.1 Position of the contact cams (6) on the cam bracket (7)

9 Spacer

10 Serrated ring

11 Terminal board with

microswitches

12 Gear in version

with potentiometer

7

6

For actuator stem

retracts extends

7.2 Position of the cam bracket (7)

5 12

B

6

8

7

For actuator stem retracts

For actuator stem extends

52

Fig. 7 · Retrofitting limit switches, in this example model 3374-11000002000, version with potentiometers

EB 8331-1 EN 19

B

Page 20

Retrofitting additional electrical equipment

5.2 Potentiometers

Actuators with a digital positioner cannot be

equipped with potentiometers.

To install the potentiometers, an actuator

board with the appropriate potentiometers

and gears (12 and 13) is required.

If the actuator is not already equipped with

limit switches, the basic unit (order no.

1400-8829) is also required. The unit in

cludes the spindle gear (2) and the interme

diate gear (5).

1. Remove the fastening screws. Push the

actuator board (1) from its guiding to

the right. Take out the board and replace it with a board with potentiometers.

2. Clip the spindle gear (2) onto the sleeve

(3) as illustrated in Fig. 7, top. Make

1 Actuator board

2 Contact cam

5 Intermediate gear

10 Serrated ring

12 Gear potentiometer 1

13 Gear potentiometer 2

-

sure the lateral latch is properly en

gaged in the groove of the sleeve.

3. Plug intermediate gear (5) onto the spin

dle (4). Place the serrated ring (10) on

top and push it down until it will not go

any further.

4. The potentiometer gears (12 and 13)

with retaining rings must be put onto

their shafts corresponding with the rated

travel of the control valve. The rated

-

travel inscription “Nennhub 15” (on the

upper side with the retaining ring) or

“Nennhub 30” (lower side) must be legi

ble from above (also see Figs. 4 and 5).

5. Push the actuator board back into its

guiding. Make sure that the gears are

properly engaged. Fasten the board using screws.

Adjust the potentiometer as described in

4

section 4.2.2.

-

-

-

10 5 2 13 12 1

Fig. 8 · Version with potentiometer

20 EB 8331-1 EN

Page 21

5.3 Digital positioner

Retrofitting additional electrical equipment

To install a positioner, a corresponding ac

tuator board and TROVIS-VIEW 3374 and

connecting cable 0450-1978 are necessary.

If the actuator is not already equipped with

limit switches, the basic unit (order no.

1400-8829) is also required. The unit in

cludes the spindle gear (2) and the interme

diate gear (5).

Note! Actuators with a digital positioner

cannot be equipped with a potentiometer.

1. Remove the fastening screws. Push the

actuator board (1) from its guiding to

the right. Take out the board and replace it with a board with positioner.

2. Clip the spindle gear (2) onto the sleeve

(3) as illustrated in Fig. 7, top. Make

sure the lateral latch is properly engaged in the groove of the sleeve.

3. Plug intermediate gear (5) onto the spin-

dle (4). Place the serrated ring (10) on

top and push it down until it will not go

any further.

4. The gear (12) on the feedback potenti

ometer, which is equipped with a retain

ing ring, must be put onto its shaft corre

sponding with the rated travel of the

control valve. The rated travel inscription

“Nennhub 15” (on the upper side with

the retaining ring) or “Nennhub 30”

(lower side) must be legible from above

(also see Figs. 4 and 5).

5. Push the actuator board (1) back into its

guiding. Make sure that the gears are

properly engaged. Fasten the board us

ing screws.

5 Intermediate gear

-

6 Contact cam

7 Cam bracket

8 Adjustment gears

10 Serrated ring

12 Gear feedback potentiometer

8751012

-

-

-

Fig. 9 · Version with positioner

without (top) and with (bottom) limit switches

EB 8331-1 EN 21

Page 22

Retrofitting additional electrical equipment

5.3.1 Calibrating the positioner

To calibrate the positioner, proceed as de

scribed in section 4 of EB 8331-2 EN.

5.3.2 Simplest method to calibrate

the actuator

If tools such as the TROVIS-VIEW software,

PC etc. are not available for calibration of

the actuator and the actuator operation with

maximum precision is not necessary, the

simplest calibration method can be per

formed as follows:

1. Position the selector switch (2) to operat-

ing mode 0 =.

2. Press down the travel calibration button

(5) for at least 15 seconds until both signal lamps light up.

3. Release the button to start calibration.

The actuator stem extends until the

torque-dependent switches switch off the

actuator.

The position of the potentiometer is

checked.

-

Mount the actuator on the valve and set

4

the positioner as described in section

-

4.3 of these instructions.

4. Re-adjust the potentiometer, if neces

sary, while observing the signal lamps.

Refer to the description given on

page 14 of EB 8331-2 EN.

After adjusting the potentiometer, the

calibration of the actuator is continued.

22 EB 8331-1 EN

-

Page 23

6 Dimensions in mm

Dimensions in mm

Version with yoke

120

294

15 (30)

50

60

193

Stem connector

Version with ring nut

204

90 (75)

30 (15)

EB 8331-1 EN 23

Page 24

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 8331-1 EN

S/Z 2007-10

Loading...

Loading...