Page 1

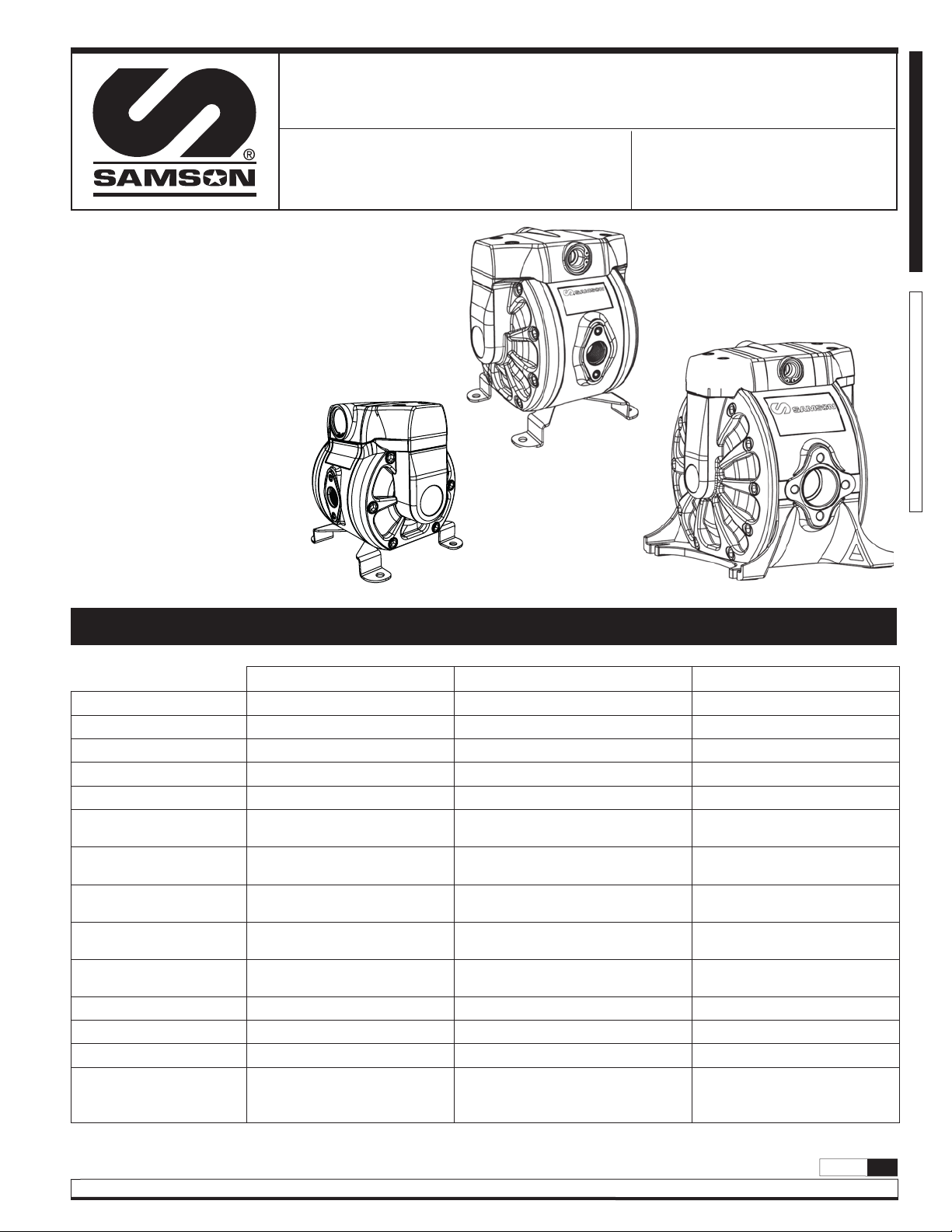

1/2" DOUBLE DIAPHRAGM PUMP DF30 (38 l/min)

1/2" DOUBLE DIAPHRAGM PUMP DF50 (50 l/min)

1" DOUBLE DIAPHRAGM PUMP DF100 (100 l/min)

Technical data 1

Warnings and cautions 2

Description 2

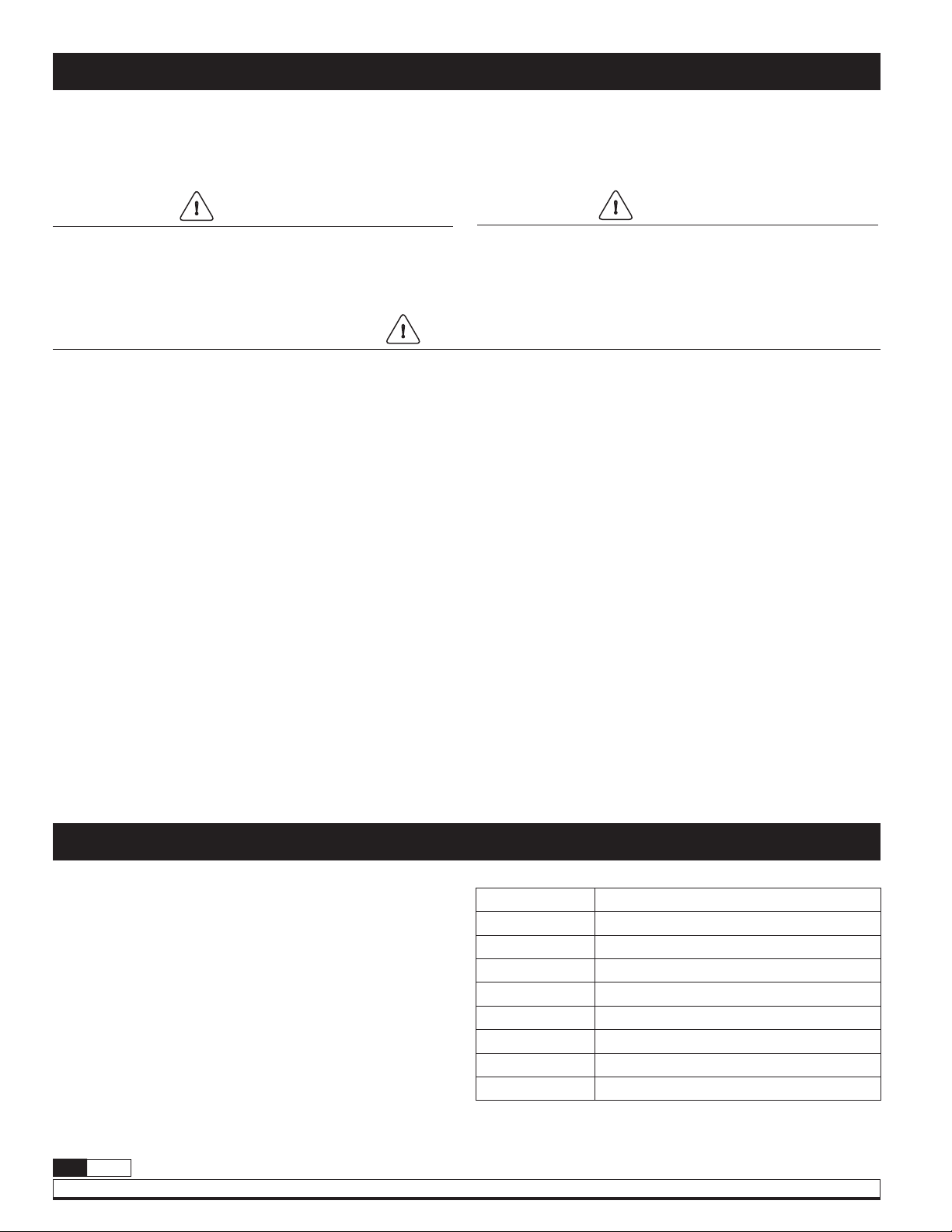

Capacity curves 3

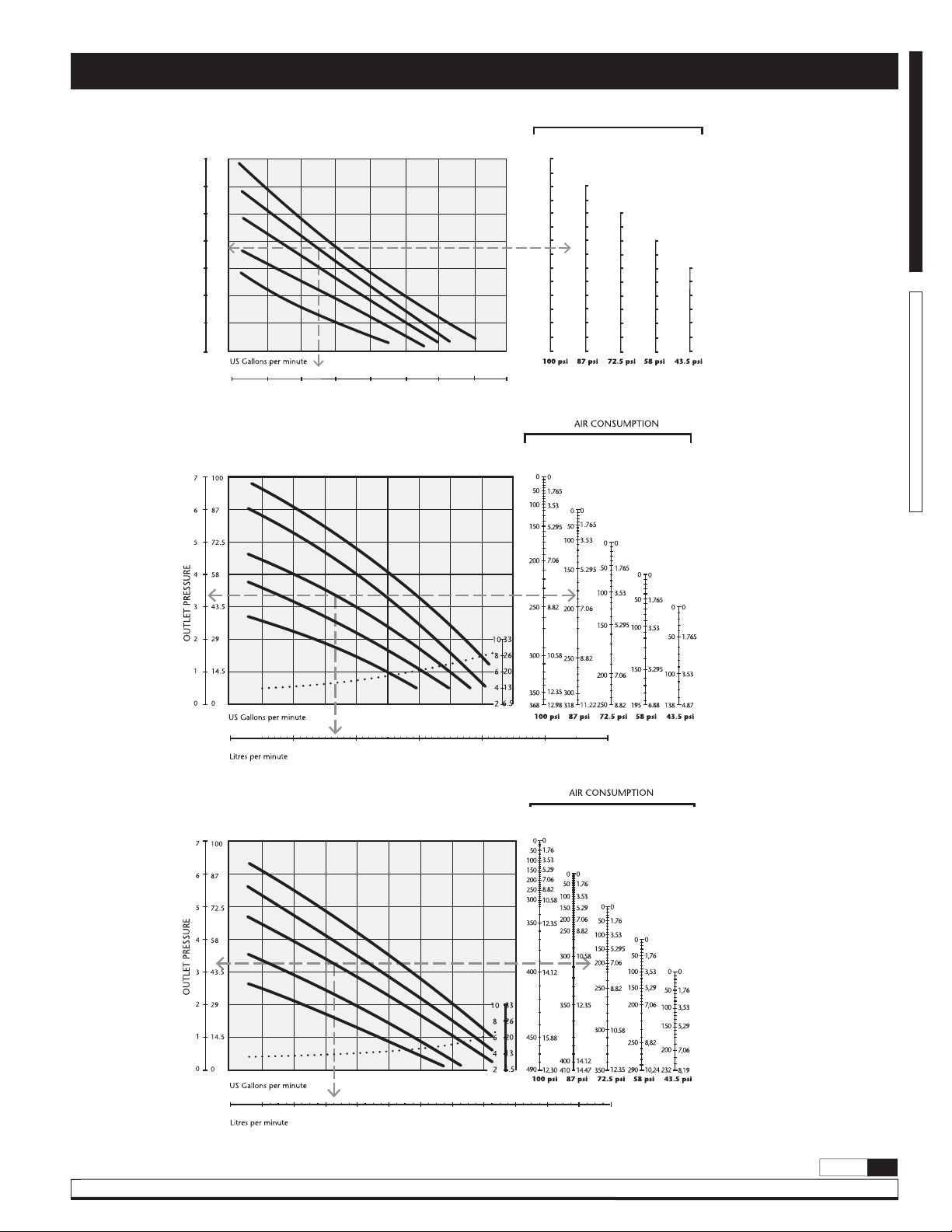

Dimensions 4

Installation 5

Operating instructions 6

Composite body parts:

DF30 / DF30T 7

DF50 / DF50T composite 8

DF50 / DF50T metallic 9

DF100 10

Troubleshooting 12

Maintenance guide 13

Operation and maintenance manual

DF50

DF30

Codes:

5530XX/ 5520XX

5510XX

ENGLISHESPAÑOL

DF100

Ratio

Maximum free flow

Delivery per stroke

Air pressure operating range

Solid in suspension max size

Maximum suction head

Weight

Fluid inlet (single inlet)

Fluid inlet (double inlet)

Fluid outlet

Air inlet

Wetted part materials

Noise level

Temperature range (see

material temperature range

on page 2)

Product customization

Technical data

DF30 DF50 DF100

1:1 1:1 1:1

10 gal/min (38 l/min) 13.21 gal/min (50 l/min)

2.37 oz (0,07 l) 3.38 oz (0,1 l)

43.51 to 100 psi (3 a 7 bar) 43.5 psi - 100 psi (3 a 7 bar) 43.5 psi - 100 psi (3 a 7 bar)

0.12 in (3 mm) 0.12 in (3 mm) 0.16 in (4 mm)

13.2 ft (4 m) dry

26.25 ft (8 m) wet

4.85 lb (2, 2 kg) 7.72 lb (3,5 kg) metallic

1/2" (BSP - NPT (F) 1/2" NPSM (F) and flange with metallic body

2 x 3/8" BSP - NPT (F) 2 x 3/8" NPSM (F) with metallic body

1/2" BSP - NPT (F) 1/2" NPSM (F) and flange with metallic body

3/8" NPSM (F) 3/8" NPSM (F) 3/8" NPSM (F)

See model specifications See model specifications See model specifications

80 db 80 dB 80 dB

19.69 ft (6 m) dry

26.25 ft (8 m) wet

6.17 lb (2,8 kg) plastic

(BSP- NPT (F) and flange with plastic body)

(BSP - NPT (F) with plastic body)

(BSP - NPT (F) plastic body)

0 - 158 ºF (0 - 70 ºC) 0 - 158 ºF (0 - 70 ºC) 0 - 158 ºF (0 - 70º C)

26.42 gal/min (100 l/min)

8.45 oz (0,25 l)

14.76 ft (4,5 m) dry

22.97 ft (7 m) wet

15.87 lb (7,2 kg) metallic

14.33 lb (6,5 kg) Plastic

1" BSP/NPT (F) and flange

_

1" BSP/NPT (F) and flange

* (oz,ft,gal/min) all in EEUU units

2013_12_17-16:30

R. 12/13 855 822

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

1

Page 2

Warnings and cautions

In this document you will find warnings and cautions for installation, use

and maintenance of the Direcflo pumps.

Warning

This symbol aware that there is a danger of serious bodily injury or death

if you ignore the warning described.

Warning

Carefully read the instructions and warnings before operating the equipment!

• This equipment is for professional use only

• Do not degrade the integrity of the equipment. Use only original

replacement components from Samson Corporation.

• Fluids not suitable for the pump can cause damage to the pump unit

and involve risk of serious personal injury.

• Always consult Samson Corporation if you have any questions about

the compatibility within the fluids and the pump materials, including

elastomers.

• Install and use the pump according to all local and national regulations

and abide all health and safety laws or legislation.

• The pump can produce fluid pressures equal to the air supply pressure.

Do not exceed the maximum allowable pressure of 100 psi (7 bar) air

supply. The total hydraulic pressure (differential pressure + system)

should never exceed 100 psi (7 bar).

• Never use a pump that leaks, that is damaged, that is corroded or

otherwise it may lack the capacity to contain the fluid.

• Frequently check that the bolts on the diaphragm cover of the pump are

torqued correctly.

Here’s the meaning of symbols you may find in this document and general

warnings that you should keep in mind.

Caution

This symbol aware that there is a danger of personal injury or property

damage if you ignore the caution described.

• Do not use a model with aluminium wetted surfaces to pump fluids for

human consumption, there is a possibility of trace contamination of lead.

• Danger of explosion if used 1,1,1-trichloroethane, methylene chloride

or other halogenated hydrocarbon solvents with aluminium wetted

materials. It could cause serious injury and property damage.

• Inside the pump, diaphragms separate the fluid that is being pumped

from the air supply. If a diaphragm breaks, the fluid can leak out of the

air exhaust and contaminate the environment.

• When handling hazardous fluids, always route the air exhaust into a

suitable container and locate it in a safe place.

• When the fluid source level is situated higher than the pump, (flooded

suction), the outlet tank must be at a higher level than the product to

prevent spills.

• For pumps handling hazardous fluids that are a danger to humans or to

the environment, install a suitable container surrounding the pump to

prevent any leaks or spills.

• Ensure that the operators of this equipment are trained on the operation

and limitations. Use safety equipment as safety goggles or other

equipment required.

Description

Air operated double diaphragm pumps are air-powered, reciprocating

positive displacement pumps with two pumping chambers. Two

diaphragms, centrally located in the chambers, separate the compressed

air (dry side) from the fluid being pumped (wet side). A shaft transmits

2013_12_17-16:30

the reciprocating motion of one diaphragm to the other. A directional valve

alternatively distributes the air from one chamber to the other; thus a

reciprocating movement of the diaphragms is created. With each stroke,

fluid is discharged by one of the diaphragms whilst the opposite

diaphragm sucks new fluid into the expanding chamber. Check valves, two

on the discharge side and two on the suction side, control and direct the

fluid flow.

2

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Material Temperature range

PTFE 5 ºC - 105 ºC / 41 ºF - 221 ºF

NBR 10 ºC - 80 ºC / 50 ºF - 176 ºF

Acetal 10 ºC - 90 ºC / 50 ºF - 194 ºF

®

Hytrel

10 ºC - 90 ºC / 50 ºF - 194 ºF

Neopreno -18 ºC - 93 ºC / 0 ºF - 200 ºF

Santoprene

Viton

Polypropylene

®

®

®

-29 ºC - 135 ºC / -20 ºF - 275 ºF

-10 ºC - 120 ºC / -4 ºF - 248 ºF

10 ºC - 80 ºC / 50 ºF - 176 ºF

Page 3

Capacity curves

DF30

DF50

HEAD

100

7

6

5

4

3

2

OUTLET PRESSURE

1

0

BAR

100 psi / 7 bar

87

87 psi / 6 bar

72.5

58

43.5

72.5 psi / 5 bar

58 psi / 4 bar

43.5 psi / 3 bar

29

14

0

PSI

0 2.6 5.8 7.4 10.5

0 5 10 15 20 25 30 35 40

Litres per minute

HEAD

100 psi / 7 bar

87 psi / 6 bar

72.5 psi / 5 bar

58 psi / 4 bar

43.5 psi / 3 bar

AIR CONSUMPTION

SCFM

Nl/min

00.0

0.00

59.3

2.01

Nl/min

2.21

2.51

2.89

3.37

3.94

4.61

5.36

6,21

7.16

8.19

9.32

10.54

11.85

SCFM

SCFM

0.00

0.00

19.8

0.67

Nl/min

50.8

78.9

104.1

126.3

145.6

162

175.5

186.1

193.7

198.4

200.3

Nl/min

SCFM

1.72

0.00

0.00

2.67

25.6

0.87

Nl/min

3.53

57.1

4.28

85.4

4.94

110.5

5.49

132.4

5.95

151.1

6.31

166.7

6.57

179.1

6.73

188.3

6.79

194.3

SCFM

1.94

0,00

0.00

2.89

20.3

0.69

Nl/min

3.74

50.8

4.49

77.6

5.12

100.8

5.65

120.3

6.07

136.3

6.38

148.6

6.59

157.3

SCFM

1.72

0,00

0.00

2.63

12.5

0.42

3.42

39

1.32

4.08

62.5

2.12

4.62

83

2.81

5.04

100.5

3.41

5.33

115

3.90

SCFM

Nl/min

SCFM

Nl/min

SCFM

Nl/min

SCFM

ENGLISHESPAÑOL

65.3

73.9

85.3

99.4

116.2

135.8

158.2

183.2

211.1

241.6

274.9

310.9

349.7

Nl/min

Feet

Meter

PSI

BAR

0 2.6 5.28 7.4 10.5 13.2 16

NPSH

0 10 20 30 40 50 60

DF100

HEAD

100 psi / 7 bar

87 psi / 6 bar

72.5 psi / 5 bar

58 psi / 4 bar

43.5 psi / 3 bar

PSI

BAR

0 2.6 5.28 7.4 10.5 13.2 16 18.5 21 23.7 26 29 31.7

0 10 20 30 40 50 60 70 80 90 100 110 120

*Tested at room temperature, using water. Flooded pump with 3.5 inches, (80 mm), positive suction head.

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Meter

NPSH

Feet

Nl/min

SCFM

Nl/min

SCFM

Nl/min

SCFM

Nl/min

SCFM

Nl/min

SCFM

R. 12/13 855 822

2013_12_17-16:30

3

Page 4

Dimensions

DF30 / DF30T

A B C D E F G H I J K L M N P

5.12" 6.3" 6.38" 4.13" 4.8" 0.31" 5.51" 5.31" 2.76"

130 mm 160 mm 162 mm 105 mm 122 mm 8 mm 140 mm 135 mm 70 mm 145 mm 24 mm 41 mm

1/2" BSP

NPT

5.71"

3/8" BSP

NPT

0.94"

M6

1,61"

Only DF30T

DF50 / DF50T

A B C D E F G H

6.14" 6.3" 6.57" 4.13" 4.8" 0.31" 5.75" 5.51"

156 mm 160 mm 167 mm 105 mm 122 mm 8 mm 146 mm 140 mm

H I J K L M N P

5.51" 2.76"

140 mm 70 mm 150 mm 24 mm 41 mm

1/2" BPS NPT

NPSM

5.91"

3/8" NPSM

0.94"

M6

1.61"

Only DF50T

DF100

A B C D E F G H I J K L

8.5" 7.44" 8.94" 6.89" 6.06" 0.35" 7.24" 8.27" 3.72"

216 mm 189 mm 227 mm 175 mm 154 mm 9 mm 184 mm 210 mm 94,51 mm 210 mm

2013_12_17-16:30

4

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

1"BSP

NPT

8.27"

3/8" NPSM

Page 5

Installation

Installation recommendations

• Remove the pump from its package and install it on the chosen location.

• Try to minimize the suction head. Install the pump as close as possible

to the fluid being pumped.

• Remember to have enough space around the pump to perform

maintenance tasks.

• Keep in mind to connect the inlet and outlet of the pump correctly.

• In case of diaphragm pump failure, the air exhaust will expell the

product being pumped.

• When the pump is installed in a place where a spill of fluid can cause

an environmental impact, the exhaust should be directed to a place.

where this spill could be contained.

• When installing the pump in its place, use brackets to secure its base.

• Fasten all bolts with the torques contained in this manual.

DF pumps are very easily configured and easy to install.

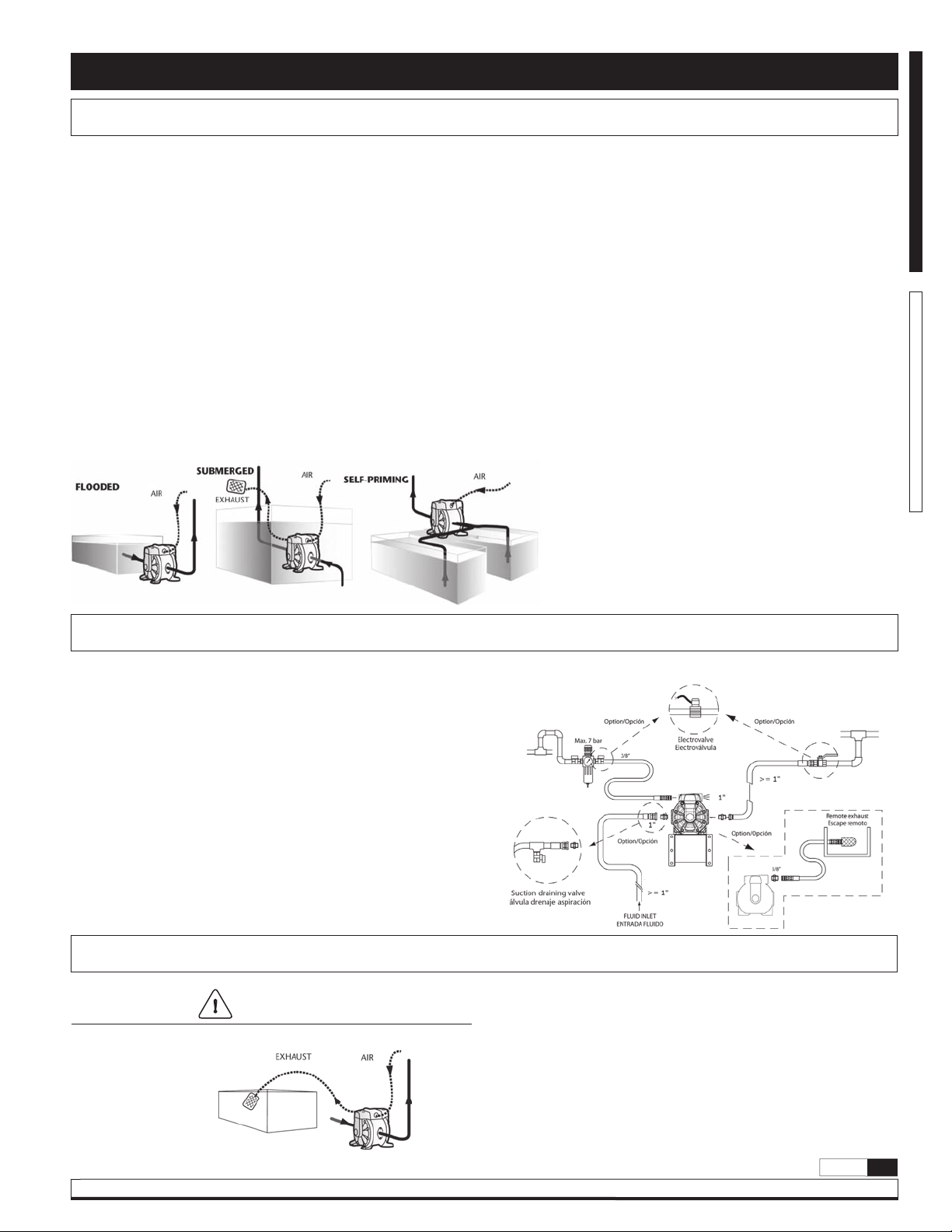

Flooded:

The pumping system was designed with positive pressure at the inlet. This

is the best possible installation when you need to evacuate the liquid from

the drum or tank, or when working with viscous fluids.

Not recommended for hazardous fluids.

Self-priming:

Pump is designed to generate vacuum. It is possible to evacuate all the air

from a hose or pipe without damaging the pump. Maximum suction height

is 19.69 ft (6 m), with the suction hose empty and up to 26.25 ft (8 m)

with the hose primed. (See page 1 for corresponds suction lift).

Submerged:

All pumps can be immersed in fluids. It is important to verify that all

components that are in contact with the fluid are chemically compatible.

In this case, air exhaust and fluid must be carried by hoses (optional air

connection).

NOTE: Use a pressure regulator with built-in filter inlet.

NOTE: The compressed air supply must be between 43.5 psi

(3 bar) and 100 psi (7 bar).

ENGLISHESPAÑOL

Recommended installation

The figure below shows the recommended configuration for the installation of a diaphragm pump.

Read the warnings and recommendations of the previous page before starting.

Air exhaust disposal

Warning

• Optional kit is required for remote exhaust.

The pump exhaust should be directed to a safe place, away from people,

animals and food.

• Remove the muffler.

• Connect a hose to the exhaust port of the pump and install the muffler

at the end of the hose. Use a hose with the same diameter as the

exhaust port. (If the hose is more than 5 feet (1.5 m), consult your

dealer or Samson Corporation).

• Have a moat, a protective housing, etc. at the end of the hose.

2013_12_17-16:30

R. 12/13 855 822

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

5

Page 6

Installation

Warning

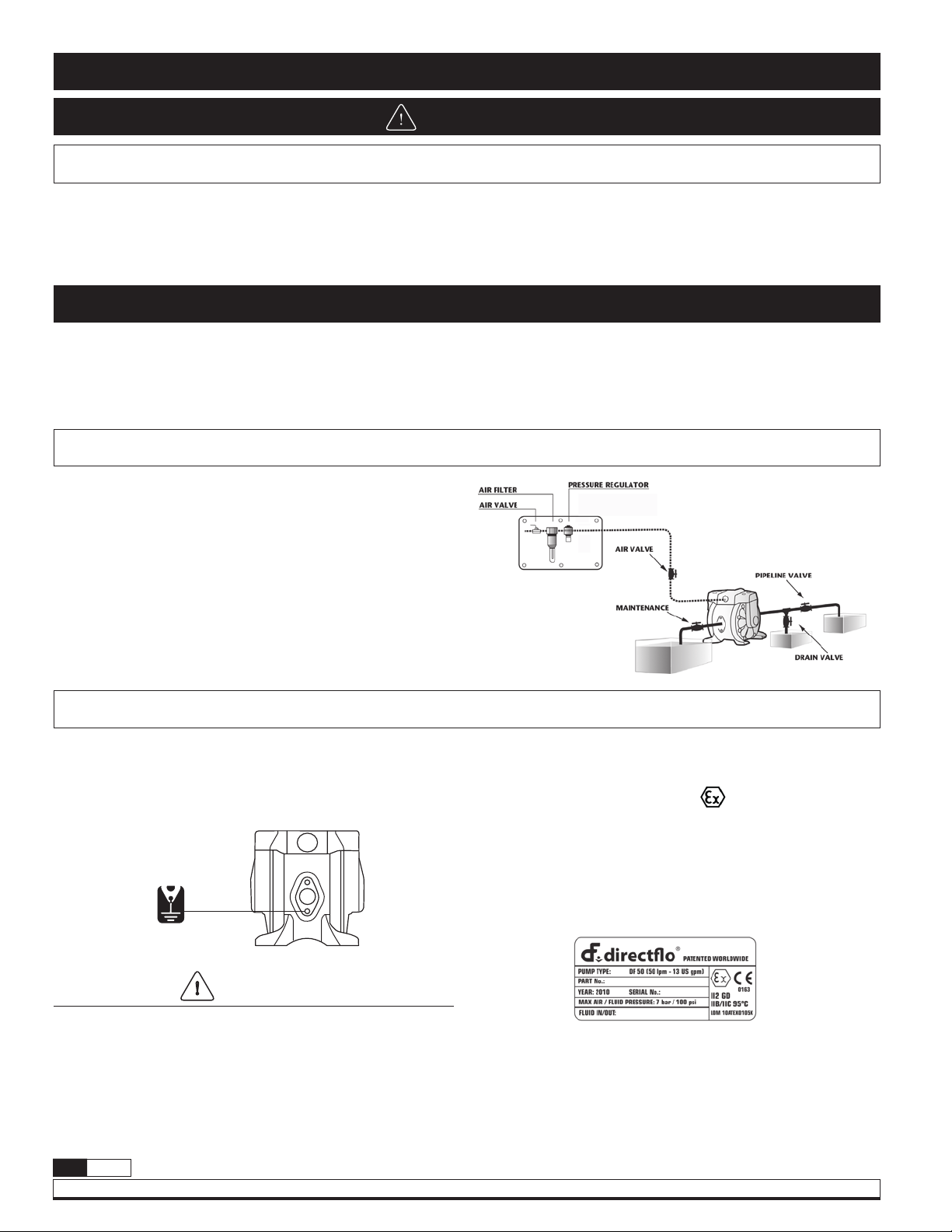

Air connection

To ensure that the air supply is sufficient to meet the demand of the pump,

the diameter of the pipe must be equal to the diameter of the supply port

of the pump. Choose auxiliary air treatment equipment and fittings with

sufficient airflow to exceed the air consumption of the pump. In addition,

Operating instructions

This pump is self-priming.

To prime it the first time, you must connect the air pump supply to a low

pressure using the pressure regulators while keeping the outlet valve open.

When fluid begins to flow from the pump outlet, the pump is primed. For

Stopping the pump

• Close the inlet valve of the pump and stop the air supply.

• Make sure for your safety that the air valve is closed.

• Turn off the air compressor, or close the valve on the air supply side of

the auxiliary equipment.

• Close the discharge valve on the discharge side, then begin to slowly

open the drain valve and discharge pressure fluid.

• Open the air valve of the pump, turn on the pump and flush the

remaining fluid.

• After ensuring that the pump was turned off and the pressure was released,

fully open and close the regulator valve and drain valve of the pump.

peripheral air treatment equipment must be installed as close as possible

to the pump unit.

The use of a coupler to connect the hoses aids future operation and

maintenance tasks.

regulation of fluid pressure, the unit must be supplied with an air pressure

between 43.5 and 100 psi (3 and 7 bar). Adjust the discharge valve on the

discharge side to control flow. For the performance characteristics of the

pump see the capacity curve shown on page 3.

Grounding the pump

• When installing the pump, be sure to perform grounding in the

specified location.

• Also connect ground wires for the auxiliary equipment and piping.

• Use a grounding cable of at least 12 gauge (2.0 mm

STICKER THAT SHOWS

THE POSITION OF THE

GROUND WIRE

2013_12_17-16:30

2

).

Warning

• Connect grounding wires to the pump, piping and all other equipment too.

• When the pump operates ungrounded or with an incorrect connection,

friction between parts and abrasion caused by some fluids that flow

inside the pump, can generate static electricity. Moreover, according to

the type of fluid pump and the installation environment (such as gases

in the air or the type of the surrounding facilities) static electricity can

cause fire or electric shock.

• If the pump you have purchased is valid for Atex, a specific Atex manual

will accompany this one. Read this manual before operating the pump.

• If the unit is marked with the symbol,

it can be used in potentially

explosive atmospheres. Below this symbol, in the nameplate of the

pump, are indicated the areas for which the equipment is approved. You

will also find the maximum allowable surface temperature in the same

plate.

6

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Page 7

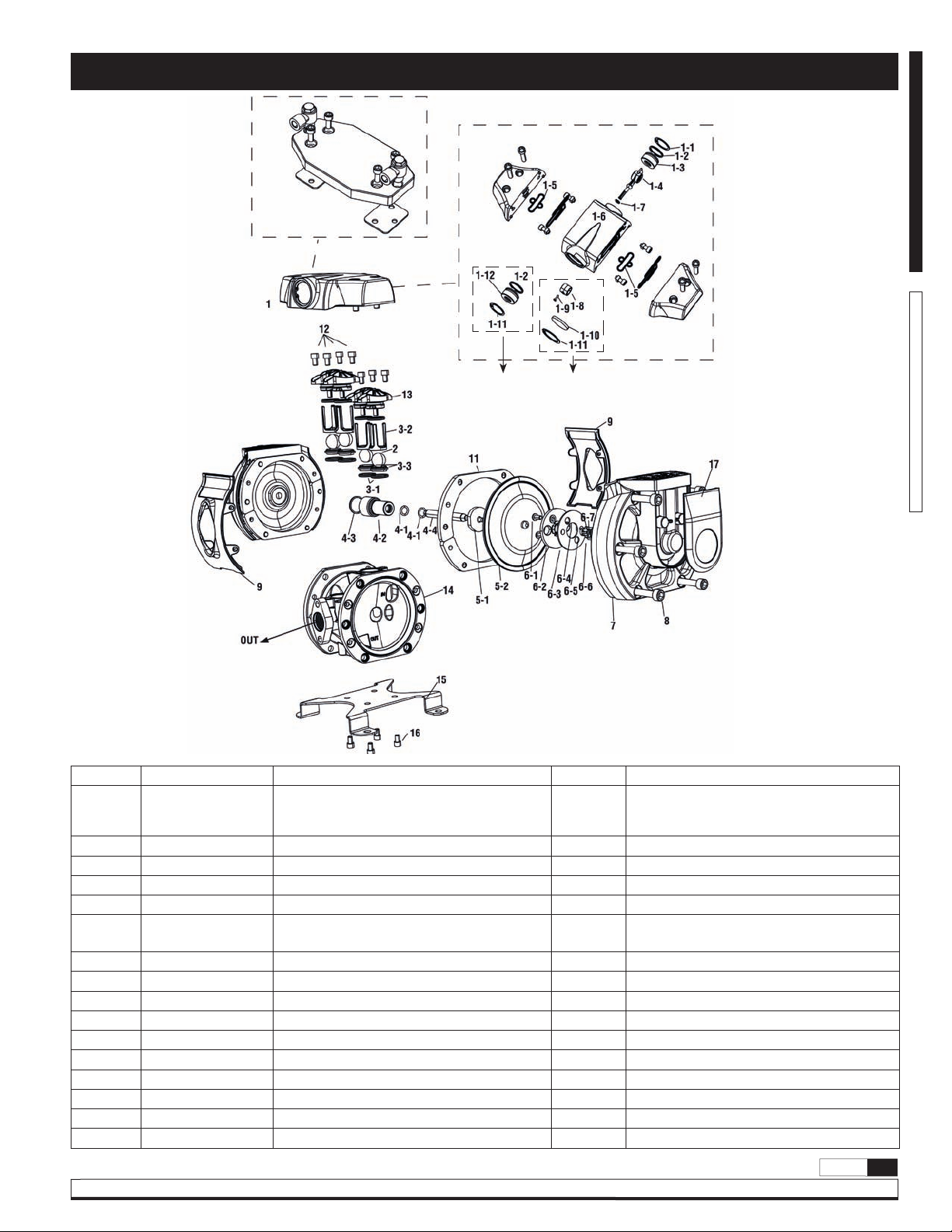

DF30 and DF30T

Composite body pump parts

ENGLISHESPAÑOL

Externally controlled

Directional valve is sold do a

kit. Assembled and verified in

Samson.

Driven

exhaust

Normal

exhaust

No. Code Description Qty. Notes

Normal exhaust

1 Table 1 Directional Valve 1 Options:

Driven exhaust

Externally controlled

2 Table 2 Balls -

3 Table3 Ball check seats / O-rings / Ball guides -

4 Table 4 Bushing / Seal / Push rod -

5 Table 5 Diaphragms -

6 Kit (558301) Air sensors - Not available in externally controlled models

7 755117 Diaphragm cover 2 (Not sold as a kit)

8 940380 Diaphragm cover bolts 12 (Not sold as a kit)

9 Table 9 Pump shields 2 (Not sold as a kit)

11 855420 Diaphragm cover washers 4 (Not sold as a kit)

12 940319 Valves cap bolts 8 (Not sold as a kit)

13 Table 13 Valves caps 2 (Not sold as a kit)

14 Table 14 Body 1 (Not sold as a kit)

15 855414 Pump support 1 (Not sold as a kit)

16 940319 Support bolts 4 (Not sold as a kit)

17 855646 Cover 2 (Not sold as a kit)

R. 12/13 855 822

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

2013_12_17-16:30

7

Page 8

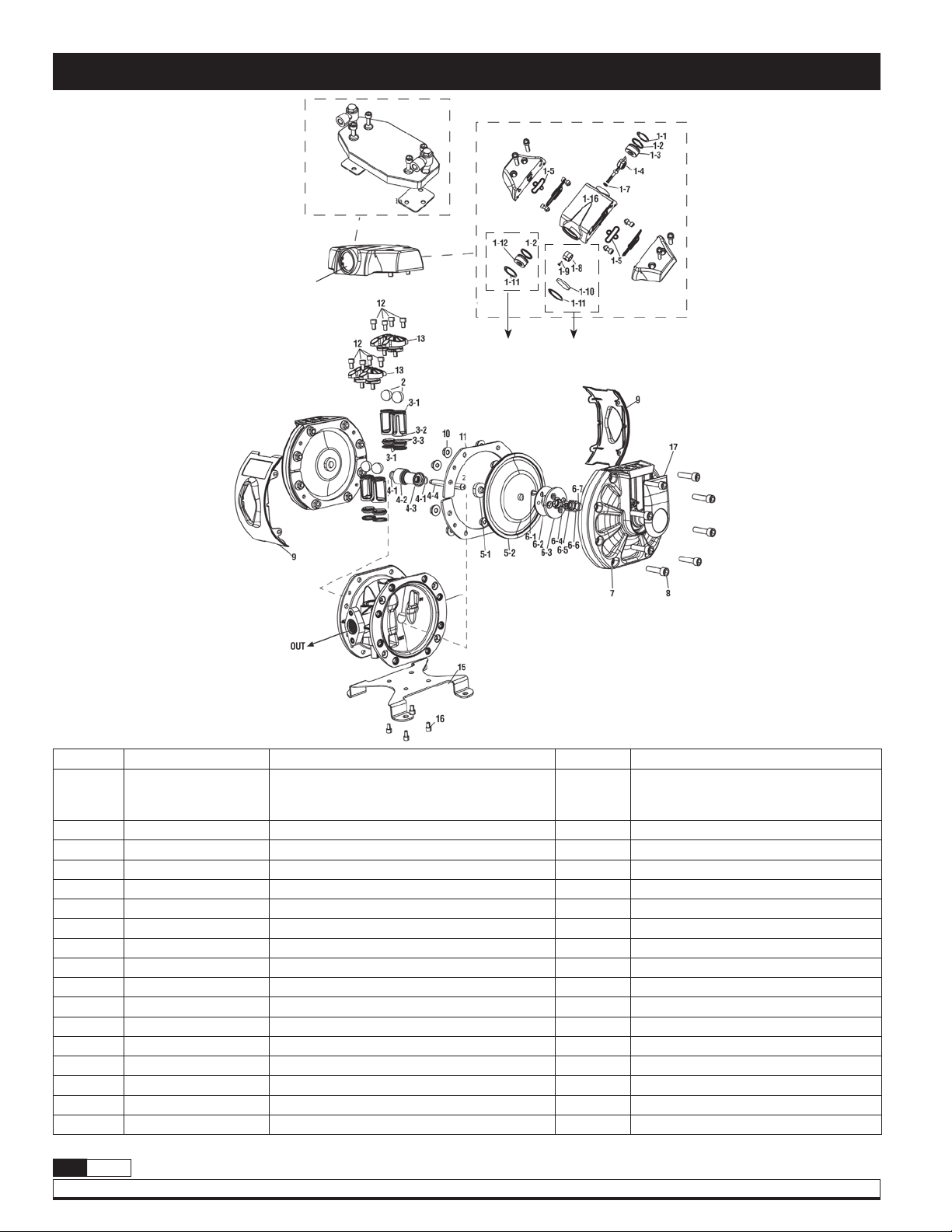

DF50 and DF50T Composite pumps

All instances

Externally

controlled

1

Composite body pump parts

Directional valve is sold do a

kit. Assembled and verified in

Samson.

Driven

exhaust

Normal

exhaust

No. Code Description Qty. Notes

Normal exhaust

1 Table 1 Directional valve 1 Options:

Driven exhaust

Externally controlled

2 Table 2 Balls -

3 Table 3 Ball check seats / O-rings / Ball guides -

4 Table 4 Bushing / Seal / Push rod -

5 Table 5 Diaphragms -

6 Kit (558301) Air sensor - Not available with externally controlled models

7 755106 Diaphragm cover 2 (Not sold as a kit)

2013_12_17-16:30

8 940380 Diaphragm cover bolts 16 (Not sold as a kit)

9 Table 9 Pump shields 2 (Not sold as a kit)

10 941126 Diaphragm cover nuts 16 (Not sold as a kit)

11 855413 Diaphragm cover washers 4 (Not sold as a kit)

12 940319 Valves cap bolts 8 (Not sold as a kit)

13 Table 13 Valves caps 2 (Not sold as a kit)

14 Table 14 Body 1 (Not sold as a kit)

15 855414 Pump support 1 (Not sold as a kit)

16 940319 Support bolts 4 (Not sold as a kit)

17 855601 Cover 2 (Not sold as a kit)

8

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Page 9

DF50 y DF50T Metallic

Externally

controlled

Composite body pump parts

ENGLISHESPAÑOL

Directional valve is sold do a

kit. Assembled and verified in

Samson.

1

Driven

exhaust

Normal

exhaust

No. Code Description Qty. Notes

Normal exhaust

1 Table 1 Directional valve 1 Options:

Driven exhaust

Externally controlled

2 Table 2 Balls -

3 Table 3 Ball check seats / O-rings / Ball guides -

4 Table 4 Bushing / Seal / Push rod -

5 Table 5 Diaphragms -

6 Kit (558301) Air sensor - Not available with externally controlled models

7 755106 Diaphragm cover 2 (Not sold as a kit)

8 940380 Diaphragm cover bolts 16 (Not sold as a kit)

9 Table 9 Pump shields 2 (Not sold as a kit)

10 940506 Pump shield bolts 8 (Not sold as a kit)

12 940319 Valves cap bolts 8 (Not sold as a kit)

13 Table 13 Balls caps 2 (Not sold as a kit)

14 Table 14 Body 1 (Not sold as a kit)

17 855601 Side cover 2 (Not sold as a kit)

R. 12/13 855 822

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

2013_12_17-16:30

9

Page 10

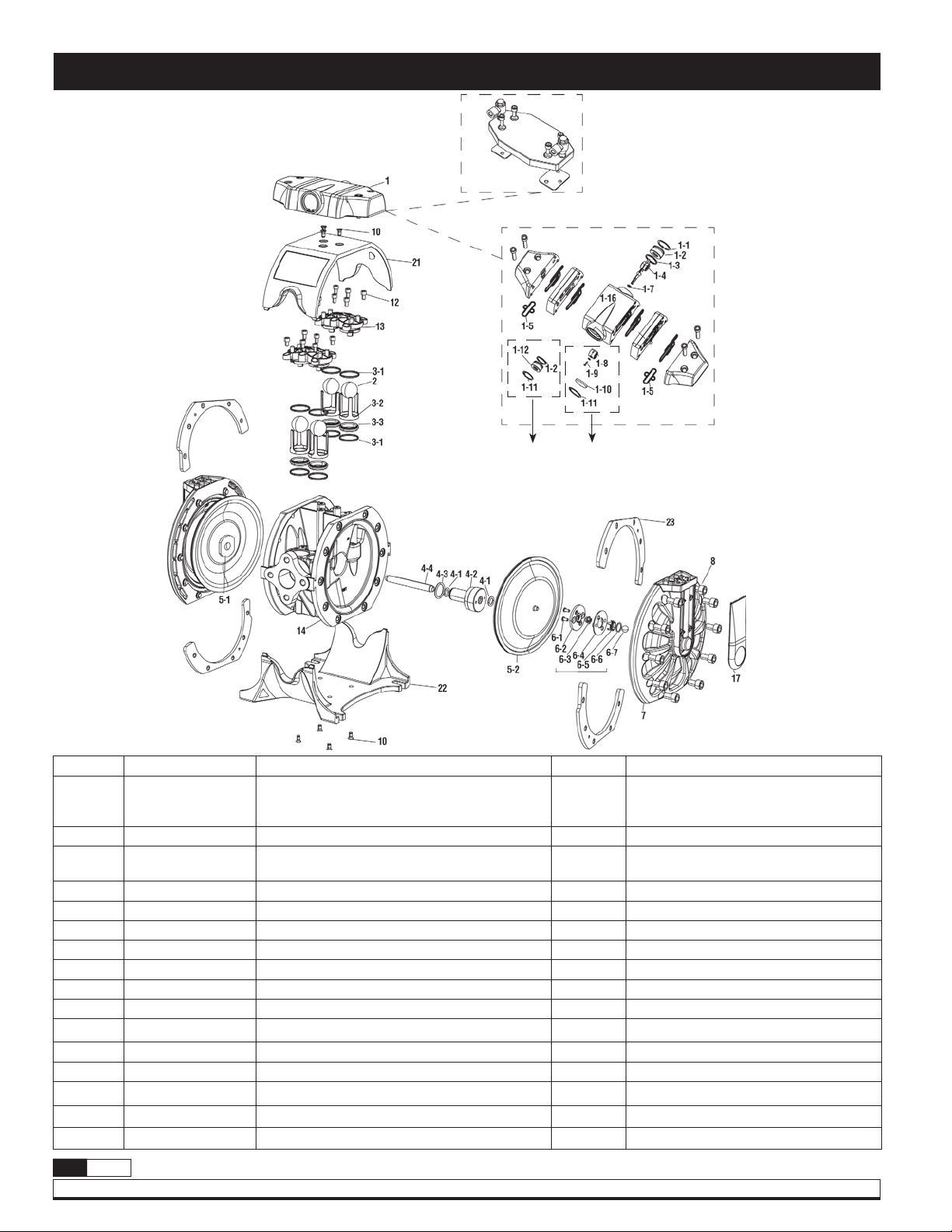

DF100

Composite body pump parts

Externally

controlled

Directional valve is sold do a

kit. Assembled and verified in

Samson.

Driven

exhaust

Normal

exhaust

No. Code Description Qty. Notes

Normal exhaust

1 Table 1 Directional valve 1 Options:

Driven exhaust

Externally controlled

2 Table 2 Balls -

3 Table 3

Ball check seats / O-rings /

Ball guides

-

4 Table 4 Bushing / Seal / Push rod -

5 Table 5 Diaphragms -

6 Kit (558301) Air sensor - Not available with externally controlled models

2013_12_17-16:30

7 755111 Diaphragm cover 2 (Not sold as a kit)

8 940334 Diaphragm cover bolts 20 (Not sold as a kit)

10 940914 Diaphragm cover nuts 7 (Not sold as a kit)

12 940319 Diaphragm cover washers 12 (Not sold as a kit)

13 Table 13 Valves caps 2 (Not sold as a kit)

14 Table 14 Body 1 (Not sold as a kit)

17 855604 Cover 2 (Not sold as a kit)

21 Table 9 Upper shield 1 (Not sold as a kit)

22 Table 9 Lower shield 1 (Not sold as a kit)

23 855416 Shield attachment 4 *Only for composite

10

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Page 11

Pumps repair kit codes

Table 1 Table 2 Table 3

Pump size Samson code Directional valve Kit code Balls Kit code Ball valves seats / Seals / Cages Kit code

DF30 553010X Standard 558300.300 PTFE 558319 Stainless steel / Viton / Polypropylene 558316

552010X Standard 558300.300 ACETAL 558321 Stainless steel / Viton / Acetal 558315

552011X Standard 558300.300 ACETAL 558321 Stainless steel / Viton / Acetal 558315

DF50

DF100

Pump size Samson code Bushing / Seals / Shaft Kit code Diaphragms Kit code Air sensor Kit code

DF30 553010X PTFE / Viton / Stainless steel 558326.001 HYTREL 558337.001 Standard 558301

DF50

DF100

552015X Standard 558300.300 PTFE 558319 Stainless steel / Viton / Polypropylene 558316

552016X Standard 558300.300 ACETAL 558321 Stainless steel / Viton / Acetal 558315

552021X Standard 558300.300 ACETAL 558321 Stainless steel / Viton / Acetal 558315

552026X Standard 558300 .300 ACETAL 558321 Stainless steel / Viton / Acetal 558315

551010X Standard 558350 .300 ACETAL 558365 Stainless steel / NBR / Acetal 558357

551015X Standard 558350 .300 PTFE 558363 Stainless steel / Viton / Polypropylene 558360

DF 55x xxx

Table 4 (See note at the bottom of the page) Table 5 (See note at the bottom of the page) Table 9

552010X PTFE / NBR / Stainless steel 558304.001 HYTREL 558303.001 Standard 558301

552015X PTFE / Viton / Stainless steel 558307.001 HYTREL 558303.001 Standard 558301

552016X PTFE / Viton / Stainless steel 558307.001 HYTREL 558303.001 Standard 558301

552021X PTFE / Viton / Stainless steel 558307.001 HYTREL 558303.001 Standard 558301

552026X PTFE / Viton / Stainless steel 558307.001 HYTREL 558303.001 Standard 558301

551010X PTFE / NBR / Stainless steel 558352.001 HYTREL 558368.001 Standard 558301

551015X PTFE / Viton / Stainless steel 558353.001 HYTREL 558368.001 Standard 558301

ENGLISHESPAÑOL

DF 55x xxx

*For pumps prior to February 2013 (serial nº prior to 329041/250) the replacement kit has to be ordered without the .001 suffix

Table 9 PUMP SHIELD - (Not sold a kit one piece per code)

DF30 DF30T DF50 DF50T DF100

A = Aluminum - 755108.370

P = PP 855645

IN: ASK SAMSON

OUT: 855625 OUT: 855625 LOWER: 855636

855625.370

IN: 755109 UPPER: 755113

OUT: 755108 LOWER: 755114

IN: 855626 UPPER: 855637

Table 13 VALVE CAPS (Not sold a kit one piece per code)

DF30 DF50 DF100

A = Aluminum - 855107 855112

B = Conductive PP 855654 855654 855653

C = Acetal 855620 855620 D = Conductive Acetal 855629 855629 855635

N = Electroless Nickel Plated Aluminum - 755107.001 755112.001

P = PP 855609 855609 855633

S = SS - ASK SAMSON ASK SAMSON

Table 14 WETTED PUMP BODY (Not sold a kit one piece per code)

DF30 DF30T DF50 DF50T DF100

A = Aluminum - - 755104 755105 755110.300

B = Conductive PP 755402.300 - 755215.300 - 755315.300

C = Acetal

- -

755213.300 855619.300 -

D = Conductive Acetal 755401.300 - 755214.300 - 755314.300

N = Electroless Nickel Plated Aluminum - - ASK SAMSON - ASK SAMSON

P = PP 755400.300 - 755212.300 855608.300 755312.300

S = SS - - 755050 - 755051.300

R. 12/13 855 822

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

2013_12_17-16:30

11

Page 12

Troubleshooting

The pump does not work.

Cause Recommended measure

The discharge valve on the discharge side is not open. Open the discharge valve on the discharge side.

No air supply. Turn on the compressor and open the air valve and air regulator.

The air supply pressure is low. Check the compressor and the configuration of the air line.

Air leaks in connecting elements. Check the connection elements and the tightening of the screws.

The air pipes or ancillary equipment is clogged with mud. Check and clean the air line.

The exhaust port (muffler) of the pump is clogged with mud. Check and clean the exhaust port and muffler.

The fluid pipe is clogged with mud. Check and clean the fluid line.

Pump is clogged with mud. Remove, inspect and clean the pump body.

The pump runs but no fluid comes out.

Cause Recommended measure

The valve on the suction side is not open. Open the valve on the suction side.

Too much suction or discharge height. Confirm the configuration of the pipe and reduce the height of the same.

Fluid pipe discharge side (including the filter) is clogged with mud. Check and clean the fluid line.

Pump is clogged with mud. Dismantle the pump, check and clean.

The ball and ball seat is worn or damaged. Inspect and replace parts.

The flow is decreasing.

Cause Recommended measure

The air supply pressure is low. Check the compressor and the configuration of the air line.

The air line or peripheral equipment clogged with mud. Check and clean the air line.

Valve discharge side drive will not open normally. Adjust the discharge valve discharge side.

The air mixes with the fluid. Replenish fluid and check the configuration of the pipe on the suction side.

Cavitation occurs. Adjust air supply pressure and discharge pressure and reduce the suction.

Vibrations. Adjust air supply pressure and discharge pressure. Reduce the flow of

Ice formation in the air exhaust. Remove ice from the air bypass valve and check and clean the air filter.

The fluid line (including the filter) plugged with mud. Check and clean the fluid pipe and strainer.

The exhaust port (muffler) of the pump is clogged with mud. Check and clean the exhaust port and muffler.

Pump is clogged with mud. Remove, inspect and clean the pump body.

the inlet valve to adjust pressure and volume of fluid.

Use a pipe in the exhaust air that the ice does not form in the muffler.

Leakage of fluid through the hollow exhaust (silencer).

Cause Recommended measure

The diaphragm is damaged. Remove and inspect the pump and replace the diaphragm.

Irregular noise.

Cause Recommended measure

The air supply pressure is too high. Adjust air supply pressure.

2013_12_17-16:30

The pump is clogged with sludge particles larger than the diameter allowed. Remove, check and clean the pump body.

Irregular vibration.

Cause Recommended measure

The elements of connection and the support of the pump are loose. Review each element of connection and tighten the screws.

The air supply pressure is too high. Adjust air supply pressure.

The range and ball valve vibrates. Adjust air supply pressure and exhaust pressure.

12

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Page 13

In fluid with air bubbles.

Cause Recommended measure

Diaphragm damaged. Replace diaphragm.

Suction hose loose or broken. Tighten or replace.

Powered air leak pressure of 3 to 7 bar.

Cause Recommended measure

Wear directional valve. Replace directional valve components.

No start-up and is leaking air without cycles.

Cause Recommended measure

Stiff air sensors. Change air sensor.

Wear directional valve. Replace.

Troubleshooting

ENGLISHESPAÑOL

Repair and maintenance procedures

Directional valve

There are several models of directional valves mounted on diaphragm

pumps DF. Externally controlled directional valve, directional valve with

remote exhaust and normal exhaust. To identify the one you have

DF_ _ _

Kit DIRECTIONAL VALVE normal exhaust

Pos. Description Qty. Material

1 Air inlet circlip 1 Steel

2 O-ring 1 NBR

3 Inlet adaptor 1 Steel

4 Pivoting arm 1 Elastollan Delrin

5 Distributor lower seal 2 NBR

A

6 Directional valve body 1 Aluminium

7 O-ring 1 NBR - PTFE

8 Sealing drum 1 Elastollan Delrin

9 Bolt 1 Stainless steel

10 Muffler 1 Brass

11 Air outlet circlip 1 Steel

X

X

X

purchased, go to the following chart with your product code, which can

be found on the nameplate of the pump, in the case externally controlled

see the parts drawing for your pump on pages 7-10.

X

X

B

X

X

Kit DIRECTIONAL VALVE normal exhaust

Pos. Description Qty. Material

1 Air inlet circlip 1 Steel

2 O-ring 2 NBR

3 Inlet adaptor 1 Steel

4 Pivoting arm 1 Elastollan Delrin

5 Distributor lower seal 2 NBR

6 Directional valve body 1 Aluminium

7 O-ring 1 NBR - PTFE

8 Sealing drum 1 Elastollan Delrin

9 Bolt 1 Stainless steel

11 Air outlet circlip 2 Steel

12 Outlet adaptor 1 Steel

X

X

X

Maintenance (to remove the pivoting arm):

1. Remove 1, 2 ,3 , 10, 11, 12

2. Remove 9

3. Remove 4, 7, 8

R. 12/13 855 822

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

2013_12_17-16:30

13

Page 14

Repair and maintenance procedures

Torques necessary for the proper functioning of the pump

For proper operation of the pump and to prevent accidents which may damage equipment and in the worst case, people, you must periodically review

the torques of the diaphragms covers and the DIRECTIONAL VALVE. In the next table are shown the appropriate torques for this purpose:

Diaphragm cover 70.81 lbf·in (8 N·m)

Torques DF30

Directional valve 44.25 lbf·in (5 N·m)

Valve cap 30.9 lbf·in (2 N·m) composite

Diaphragm cover 48.67 - 53.1 lbf·in (5,5 - 6 N·m)

Torques DF50

Directional valve 44.25 lbf·in (5N·m)

Valve cap 35.4 lbf·in (4 N·m) Aluminium - 30.9 lbf·in (2 N·m) composite

Diaphragm cover 137.7 lbf·in (15 N·m)

Torques DF100

Directional valve 44.25 lbf·in (5 N·m)

Valve cap 35.4 lbf·in (4 N·m) Aluminium - 30.9 lbf·in (2 N·m) composite

Diaphragm replacement

Before any intervention: DISCONNECT AIR SUPPLY OF THE PUMP.

IT IS NOT NECESSARY TO REMOVE THE PUMP FROM THE FLUID LINE.

1. Close fluid valves.

2. Drain the fluid inside the pump. Anticipate a drainage of fluid from inside

the pump.

3. Remove the directional valve while being careful not to damage the

seals shown in the first figure.

4. Remove the diaphragm cap.

NOTE: To tighten these screws you must use a torque wrench

calibrated to (see torque table in this page).

5. Remove the cover by gently pulling back.

6. Remove the used diaphragm and place the new one in the proper

position.

Assemble components.

Remove the side cover on the right of the fluid inlet as shown in the figure,

following the procedure to “Replace diaphragms".

Once the shaft is visible, use the following procedures:

1. Remove the shaft from its housing by pulling it from one end.

2013_12_17-16:30

The Teflon® sleeve is threaded into the body. To remove use snap ring

pliers in the two holes indicated in the figure.

3

A

4

6

5

Pushing rod

2. Once the cap has been removed, remove the quad ring inside the

pump body.

3. Replace the kit following the correct order shown in the assembly

drawing.

Reassemble the pump in reverse order.

14

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Page 15

Repair and maintenance procedures

Ball valves replacement

1. Close fluid valves.

2. Drain the fluid from inside the pump. Anticipate a drainage of fluid

from inside the pump.

3. Loosen the screws to remove the directional valve. Take special care with

the seals.

4. Remove the valve cover by loosening the screws with an Allen

wrench. Take note of the orientation of the cap, as it is critical to

replace it correctly during reassembly.

Attention

To avoid fluid restriction and leakages, follow the position of the vall

checks guides in teh figure above. the valves cups must be placed with the

area indicated in the figure below facing the body.

5. Install a new set of valves according to these assembly drawings.

Ensure that the ball guides are assembled as shown in the figure on

the left, and tighten the screws with a maximum torque (see torque

table page 14).

6. Assemble the directional valve with being careful not to damage

the O-rings and tighten the screws with a maximum torque of

44.25 lbf·in (5 N·m).

ENGLISHESPAÑOL

Air sensor (only for models with )

The air sensors are on the inside part of the diaphragm covers. To access

them, follow the procedure for “Replacing diaphragms".

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Once removed the covers following procedure:

1. Remove the two screws that secure the air sensor to the top.

2. Remove all components of the sensor. Clean the area.

3. Introduce new components in the order shown.

4. Fit the cover on the pump and tighten the screws to the body of the

pump. Maximum tightening torque (see torque table page 14).

Fit the remaining components in reverse order.

R. 12/13 855 822

2013_12_17-16:30

15

Page 16

www.samsoncorporation.com

2013_12_17-16:30

Distributed by

16

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Page 17

1/2" BOMBA DE MEMBRANA SERIES DF30 (38 l/min)

1/2" BOMBA DE MEMBRANA SERIES DF50 (50 l/min)

1" BOMBA DE MEMBRANA SERIES DF100 (100 l/min)

Datos técnicos 17

Advertencias y preacuciones 18

Descripción 18

Curvas de capacidad 19

Dimensiones 20

Instalación 21

Modos de operación 22

Despices y repuestos de la bomba:

DF30 / DF30T 23

DF50 / DF50T composite 24

DF50 / DF50T metálica 25

DF100 26

Anomalías y soluciones 28

Reparación y mantenimiento 29

Guía de servicio técnico y mantenimiento

DF50

DF30

Código:

5530XX

5520XX

5510XX

DF100

ENGLISHESPAÑOL

Datos técnicos

DF30 DF50 DF100

Ratio

Máximo caudal salida libre

Desplazamiento por

embolada

Rango de presión

Max. tamaño de partículas en

suspensión

Altura máxima de succión

Peso

Entrada de fluido (cuerpo

con entrada simple)

Entrada de fluido (cuerpo

con entrada doble)

Salida de fluido

Entrada de aire

Partes húmedas

Nivel de fluido

Rango de temperaturas de

trabajo (consultar

característica de los

materiales en página 18).

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

1:1 1:1 1:1

38 l/min (10 gal/min) 50 l/min (13.21 gal/min) 100 l/min (26.42 gal/min)

0,07 l (2.37 oz) 0,1 l (3.38 oz) 0,25 l (8.45 oz)

3 a 7 bar (43.51 to 100 psi) 3 a 7 bar (43.5 psi - 100 psi) 3 a 7 bar (43.5 psi - 100 psi)

3 mm (0.12 in) 3 mm (0.12 in) 4 mm (0.16 in)

4 m (13.2 ft) seco

8 m (26.25 ft) húmedo

2, 2 kg (4,85 lb)

1/2" BSP - NPT (H)

2 x 3/8" BSP - NPT (H)

1/2" BSP - NPT (H)

3/8" NPSM (H) 3/8" NPSM (H) 3/8" NPSM (H)

Ver especificaciones de los modelos Ver especificaciones de los modelos Ver especificaciones de los modelos

80 db 80 dB 80 dB

6 m (19.69 ft) seco

8 m (26.25 ft) húmedo

3,5 kg (7.72 lb) metálica

2,8 kg (6.17 lb) plástica

1/2" NPSM (H) y bridas cuerpo metálico

(BSP- NPT (H) para cuerpo plástico)

2 x 3/8" NPSM (H) y bridas cuerpo metálico

(BSP - NPT (H) para cuerpo plástico)

1/2" NPSM (H) (BSP - NPT (H) para cuerpo

plástico)

4,5 m (14.76 ft) seco

7 m (22.97 ft) húmedo

7,2 kg (15.87 lb) metálica

6,5 kg (14.33 lb) plástica

1" BSP - NPT (H) y brida

_

1" BSP/NPT (H) y brida

0 - 70 ºC (0 - 158 ºF) 0 - 70 ºC (0 - 158 ºF) 0 - 70 ºC (0 - 158 ºF)

R. 12/13 855 822

2013_12_17-16:30

17

Page 18

Advertencias y preacuciones

En este documento usted encontrará advertencias y precauciones

para la instalación, uso y mantenimiento de las bombas Direcflo.

Advertencia

Este símbolo alerta de que si no se siguen las instrucciones indicadas se

puede producir una situación de lesión grave o muerte.

Advertencia

¡Lea atentamente el manual de instrucciones y sus advertencias antes de empezar a operar con el equipo!

• Este equipo es únicamente para uso profesional.

• No altere la integridad del equipo. Use solamente componentes

originales de Samson Corporation.

• Los fluidos no adecuados para la bomba pueden causar daños a la

unidad de la bomba e implicar riesgo de graves daños personales.

Consulte siempre al distribuidor de Samson Corporation si se tiene

alguna duda sobre la compatibilidad de los fluidos con los materiales

de la bomba, incluyendo los elastómeros.

• Instale y use siempre la bomba según la normativa y la legislación

sanitaria y de seguridad, tanto local como nacional.

• La bomba puede producir presiones de fluido iguales a la presión de

alimentación del aire. No exceder la presión máxima permitida de

alimentación de aire de 7 bar (100 psi). La presión hidráulica total

(presión del sistema + presión diferencial) no deberá exceder nunca

7 bar (100 psi).

• No utilice nunca una bomba que tenga fugas o daños, esté corroída o

de otra forma carezca de la capacidad para contener el fluido

interno o la presión del aire.

• Comprobar con frecuencia que los tornillos de las tapas de la bomba

están correctamente ajustados.

• No use modelos cuya parte húmeda esté basada en aluminio para

A continuación le indicamos el significado de los símbolos y mencionamos

unas advertencias generales que usted debe tener en cuenta.

Atención

Este símbolo alerta de daños o destrucción del equipamiento si no se

siguen las instrucciones.

productos de consumo humano, es posible que existan trazas de plomo.

• Peligro de explosión si se usa 1,1,1-tricloroetano, cloruro de metileno

u otros disolventes de hidrocarburos halogenados en sistemas de

fluido a presión que tengan componentes de aluminio humedecido.

Podría causar graves daños materiales y personales incluso mortales.

• En el interior de la bomba, dos membranas separan el fluido bombeado

de la alimentación de aire. Si se rompe una membrana, el fluido puede

salir proyectado por el orificio de evacuación de aire.

• Cuando se manejen fluidos peligrosos, conecte siempre el orificio de

evacuación de aire a un recipiente adecuado y situado en un lugar

seguro. (Sistema de conexión opcional a petición del cliente. No se

suministra con el equipo).

• Cuando la fuente de producto se encuentre a un nivel más elevado que

la bomba (aspiración inundada), la impulsión deberá ser dirigida por un

tubo a un nivel más alto que el producto para impedir los derrames

causados por derivación sifónica.

• En las bombas que manejen fluidos peligrosos para las personas o el

medio ambiente, se debe instalar algún tipo de recipiente o contenedor

para recoger posibles fugas y evitar su derrame.

• Asegúrese de que el operario de este equipo esté formado en cuanto a

la operación, limitaciones y uso de equipamiento de seguridad como

gafas de seguridad u otro equipamiento requerido.

Descripción

La bomba de membrana neumática es una bomba aspirante e impelente

de desplazamiento positivo, accionada por aire y con dos cámaras de

bombeo. Dos membranas ubicadas centralmente en las cámaras, separan

el aire comprimido (lado seco) del fluido bombeado (lado húmedo). Las

2013_12_17-16:30

membranas están conectadas entre sí mediante un eje flotante cuyo

funcionamiento permite la minimización del flujo pulsante. Una válvula

(motor neumático) distribuye el aire de una cámara a la otra

alternativamente, produciendo así un movimiento recíproco de las

membranas.

En cada embolada, una de las membranas desplaza el fluido, mientras que

la membrana opuesta aspira nuevo fluido al interior de la cámara de

expansión. Cuatro válvulas de bola, dos en el lado de aspiración y dos en

el lado de impulsión, controlan y dirigen el flujo del fluido.

18

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Materiales Temperatura de trabajo

PTFE 5 ºC - 105 ºC / 41 ºF - 221 ºF

NBR 10 ºC - 80 ºC / 50 ºF - 176 ºF

Acetal 10 ºC - 90 ºC / 50 ºF - 194 ºF

®

Hytrel

10 ºC - 90 ºC / 50 ºF - 194 ºF

Neopreno -18 ºC - 93 ºC / 0 ºF - 200 ºF

Santoprene

Viton

TM

®

-29 ºC - 135 ºC / -20 ºF - 275 ºF

-10 ºC - 120 ºC / -4 ºF - 248 ºF

Polipropileno 10 ºC - 80 ºC / 50 ºF - 176 ºF

Page 19

Curvas de capaciad

DF30

DF50

HEAD

100

7

6

5

4

3

2

OUTLET PRESSURE

1

0

BAR

100 psi / 7 bar

87

87 psi / 6 bar

72.5

58

43.5

72.5 psi / 5 bar

58 psi / 4 bar

43.5 psi / 3 bar

29

14

0

PSI

0 2.6 5.8 7.4 10.5

0 5 10 15 20 25 30 35 40

Litres per minute

HEAD

100 psi / 7 bar

87 psi / 6 bar

72.5 psi / 5 bar

58 psi / 4 bar

43.5 psi / 3 bar

AIR CONSUMPTION

SCFM

Nl/min

00.0

0.00

59.3

2.01

Nl/min

2.21

2.51

2.89

3.37

3.94

4.61

5.36

6,21

7.16

8.19

9.32

10.54

11.85

SCFM

SCFM

0.00

0.00

19.8

0.67

Nl/min

50.8

78.9

104.1

126.3

145.6

162

175.5

186.1

193.7

198.4

200.3

Nl/min

SCFM

1.72

0.00

0.00

2.67

25.6

0.87

Nl/min

3.53

57.1

4.28

85.4

4.94

110.5

5.49

132.4

5.95

151.1

6.31

166.7

6.57

179.1

6.73

188.3

6.79

194.3

SCFM

1.94

0,00

0.00

2.89

20.3

0.69

Nl/min

3.74

50.8

4.49

77.6

5.12

100.8

5.65

120.3

6.07

136.3

6.38

148.6

6.59

157.3

SCFM

1.72

0,00

0.00

2.63

12.5

0.42

3.42

39

1.32

4.08

62.5

2.12

4.62

83

2.81

5.04

100.5

3.41

5.33

115

3.90

SCFM

Nl/min

SCFM

Nl/min

SCFM

Nl/min

SCFM

ENGLISHESPAÑOL

65.3

73.9

85.3

99.4

116.2

135.8

158.2

183.2

211.1

241.6

274.9

310.9

349.7

Nl/min

Feet

Meter

PSI

BAR

0 2.6 5.28 7.4 10.5 13.2 16

NPSH

0 10 20 30 40 50 60

DF100

HEAD

100 psi / 7 bar

87 psi / 6 bar

72.5 psi / 5 bar

58 psi / 4 bar

43.5 psi / 3 bar

PSI

BAR

0 2.6 5.28 7.4 10.5 13.2 16 18.5 21 23.7 26 29 31.7

0 10 20 30 40 50 60 70 80 90 100 110 120

*Ensayo realizado con agua a temperatura ambiente y bomba inundada en 80 mm de succión positiva.

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Meter

NPSH

Feet

Nl/min

SCFM

Nl/min

SCFM

Nl/min

SCFM

Nl/min

SCFM

Nl/min

SCFM

R. 12/13 855 822

2013_12_17-16:30

19

Page 20

Dimensiones

DF30 / DF30T

A B C D E F G H I J K L M N P

130 mm 160 mm 162 mm 105 mm 122 mm 8 mm 140 mm 135 mm 70 mm

5.12" 6.3" 6.38" 4.13" 4.8" 0.31" 5.51" 5.31" 2.76" 5.71" 0.94" 1.61"

1/2" BSP

NPT

145 mm

3/8" BSP

NPT

24 mm

M6

41 mm

Solo DF30T

DF50 / DF50T

A B C D E F G H

156 mm 160 mm 167 mm 105 mm 122 mm 8 mm 146 mm 140 mm

6.14" 6.3" 6.57" 4.13" 4.8" 0.31" 5.75" 5.51"

H I J K L M N P

140 mm 70 mm

5.51" 2.76" 5.91" 0.94" 1.61"

1/2" BPS NPT

NPSM

150 mm

3/8" NPSM

24 mm

M6

41 mm

Solo DF50T

DF100

A B C D E F G H I J K L

216 mm 189 mm 227 mm 175 mm 154 mm 9 mm 184 mm 210 mm 94,51 mm

8.5" 7.44" 8.94" 6.89" 6.06" 0.35" 7.24" 8.27" 3.72" 8.27"

2013_12_17-16:30

20

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

1"BSP

NPT

210 mm

3/8" NPSM

Page 21

Instalación

Recomendaciones para la instalación

• Retire la bomba de la caja e instálela en el lugar elegido.

• Trate de reducir al mínimo la altura de aspiración.

• Recuerde disponer de espacio suficiente alrededor de la bomba para

realizar las tareas de mantenimiento.

• Tenga siempre en cuenta usar correctamente la entrada y la salida de la

bomba.

• En caso de fallo del diafragma el escape de aire de la bomba puede

contener lodo.

• Cuando la bomba se instala en un lugar en el que pueda tener lugar un

impacto en el medio ambiente, el escape debe orientarse hacia un lugar

donde no haya impacto ambiental.

• Cuando instale la bomba en su lugar, utilice los soportes en la base y

asegure la bomba fijándola con los tornillos de amarre.

• Apriete todos los tornillos de las tapas de la bomba.

IN UNDAD A SUMERGI DA ASPIRA CIÓN

Las bombas DF son muy flexibles y fáciles de instalar.

Inundada:

El sistema de bombeo se diseñó para presión positiva en la aspiración.

Esta es la mejor forma de instalación cuando se necesite evacuar todo el

líquido del bidón o depósito, o cuando se trabaje con fluidos viscosos. No

recomendada para fluidos peligrosos.

Aspiración:

La bomba DF está diseñada para generar vacío en la aspiración. Es posible

evacuar todo el aire de una manguera o tubería sin dañar la bomba. La

altura máxima de succión es de 6 m con la manguera de succión vacía y

hasta 8 m con la manguera cebada (ver página 17).

Sumergido:

Todas las bombas DF se pueden sumergir en los fluidos. Es importante

que verifique que todos los componentes que están en contacto con el

fluido son químicamente compatibles. En este caso, las salidas de aire y

fluido deben ser conducidas al exterior mediante mangueras. (Sistema de

conexión de aire opcional).

NOTA: Utilice un regulador de presión con filtro

incorporado en la entrada de aire.

NOTA: La presión de alimentación de aire debe estar

comprendida entre 3 bar (43,5 psi) y 7 bar (100 psi).

ENGLISHESPAÑOL

Instalación recomendada

La siguiente figura muestra la configuración recomendada para

la instalación de una bomba de diafragma.

Lea atentamente las advertencias y recomendaciones de la

página anterior para realizar dicha instalación.

Disposición del escape exterior

Advertencia

El escape de la bomba debe estar orientado hacia un lugar seguro,

alejado de la circulación humana, de animales y de alimentos.

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

• Es necesario el kit opcional de salida conductiva.

• Retire el silenciador.

• Conecte una manguera con conexión a tierra al orificio de escape de la

bomba e instale el silenciador en la punta de la manguera. Utilice una

manguera del mismo diámetro que el orificio de escape. (Si la

manguera mide más de 5 metros consulte al distribuidor o nuestra

oficina regional).

• Disponga un foso, una caja de protección, etc. en el extremo de la

manguera.

R. 12/13 855 822

2013_12_17-16:30

21

Page 22

Instalación

Advertencia

Conexión toma de aire

Para que el suministro de aire sea suficiente para satisfacer la demanda de

la bomba, el diámetro de la tubería debe ser igual al diámetro del orificio de

suministro de la bomba. También elija equipos auxiliares y materiales con

suficiente flujo de aire para el consumo de aire de la bomba.

Modo de operación

Esta bomba es auto-cebante. Para cebarla la primera vez, es conveniente

conectar el aire a la bomba a la presión deseada con el regulador de presión,

manteniendo la válvula de salida abierta.

Cuando el fluido empieza a salir, la bomba está cebada. Para su regulación

Parada de la bomba

• Cierre la válvula de entrada de fluido de la bomba y corte el suministro de aire.

• Compruebe por su seguridad que la válvula de aire de la bomba esté cerrada.

• Apague el compresor de aire o cierre la válvula en el lado de suministro

de aire de los equipos auxiliares.

• Cierre la válvula de impulsión en el lado de descarga, comience a abrir

lentamente la válvula de drenaje y descargue el fluido bajo presión.

• Abra la válvula de aire de la bomba, ponga en funcionamiento la bomba

y descargue el fluido remanente.

• Después de asegurarse de que la bomba se apagó y la presión se liberó,

abra completamente el regulador y cierre la válvula de aire y la válvula

de drenaje de la bomba.

También considere el uso y la estabilidad de la presión de aire. Además,

el equipo periférico debe estar instalado lo más cerca posible de la unidad

de la bomba.

El uso de un acoplador para conectar cada manguera facilita la operación

y las tareas de mantenimiento.

mediante presión de fluido se debe alimentar con presión de aire comprendida

entre 3 y 7 bar (43.5 - 100 psi). Ajuste la válvula de impulsión en el lado de

descarga. Para la relación entre el flujo, la presión de suministro de aire y la

presión de descarga, vea la curva de capacidad en la página 19.

Opción Conexión a tierra

• Cuando instale la bomba, asegúrese de realizar la conexión a tierra en

el lugar especificado.

• Conecte también conductores a tierra para los equipos auxiliares y las tuberías.

• Utilice un cable con conexión a tierra de por lo menos 2,0 mm

ESTA ETIQUETA

MUESTRA LA POSICIÓN

DEL CABLE A TIERRA

2013_12_17-16:30

2

(12 gauge).

• Si la bomba que ha adquirido es válida para Atex, a este manual lo

acompañará uno específico para Atex. Lea este manual antes de operar

con la bomba.

• Si la bomba viene marcada con el símbolo

en atmósferas potencialmente explosivas. Debajo de este símbolo, en

las placa de identificación de la bomba, vienen indicadas las zonas para

las que el equipo está aprobado. Encontrará también la temperatura de

superficie máxima permitida en la placa de su bomba.

Advertencia

• Asegúrese de conectar conductores a tierra para la bomba, tuberías y otros

equipos conectados.

• Cuando la bomba opera sin conexión a tierra o con una conexión incorrecta,

la fricción entre las piezas y la abrasión causada por algunos fluidos que

fluyen dentro de la bomba pueden generar electricidad estática. Además,

según el tipo de fluido a bombear y el ambiente de la instalación (como

gases en el aire o el tipo de las instalaciones circundantes) la electricidad

estática puede ser causa de incendio o choque eléctrico.

22

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

, esta puede ser usada

Page 23

DF30 and DF30T

Pilotaje externo

Despiece y repuestos de la bomba

Escape

conducido

Escape

normal

ENGLISHESPAÑOL

El distribuidor de aire se vende

como kit.

Ensamblado y verificado en

Samson.

SALIDA

Nº Referencia Descripción Cant. Nota

Escape normal

1 Tabla 1 Motor de aire 1 Opciones:

Escape conducido

Pilotaje externo

2 Tabla 2 Bolas -

3 Tabla 3 Asiento / Junta / Jaula -

4 Tabla 4 Casquillo / Junta / Eje -

5 Tabla 5 Diafragmas -

6 Kit (558301) Sensor de aire - No disponible con pilotaje externo

7 755117 Tapas de diafragma 2 (No se vende como kit)

8 940380 Tornillo tapas diafragma 12 (No se vende como kit)

9 Tabla 9 Carenas 2 (No se vende como kit)

11 855420 Tornillos 4 (No se vende como kit)

12 940319 Tornillos tapas válvula 8 (No se vende como kit)

13 Tabla 13 Tapas válvula 2 (No se vende como kit)

14 Tabla 14 Cuerpo 1 (No se vende como kit)

15 855414 Embellecedor 1 (No se vende como kit)

16 940319 Tornillos de soporte 4 (No se vende como kit)

17 855646 Cover 2 (No se vende como kit)

R. 12/13 855 822

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

2013_12_17-16:30

23

Page 24

DF50 and DF50T Composite

Despiece y repuestos de la bomba

Pilotaje externo

El distribuidor de aire se vende

como kit.

Ensamblado y verificado en

Samson.

Escape

conducido

Escape

normal

SALIDA

Nº Referencia Descripción Cant. Nota

Escape normal

1 Tabla 1 Motor de aire 1 Opciones:

Escape conducido

Pilotaje externo

2 Tabla 2 Bolas -

3 Tabla 3 Asiento / Junta / Jaula -

4 Tabla 4 Casquillo / Junta / Eje -

5 Tabla 5 Diafragmas -

6 558301 Sensor de aire - No disponible con pilotaje externo

7 755106 Tapas de diafragma 2 (No se vende como kit)

2013_12_17-16:30

8 940380 Tornillo tapas de diafragma 16 (No se vende como kit)

9 Tabla 9 Carenas 2 (No se vende como kit)

10 941126 Tuercas cámaras 16 (No se vende como kit)

11 855413 Arandela cámaras 4 (No se vende como kit)

12 940319 Tornillos tapas válvula 8 (No se vende como kit)

13 Tabla 13 Tapas válvula 2 (No se vende como kit)

14 Tabla 14 Cuerpo 1 (No se vende como kit)

15 855414 Soporte de la bomba 1 (No se vende como kit)

16 940319 Tornillos de soporte 4 (No se vende como kit)

17 855601 Embellecedor 2 (No se vende como kit)

24

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Page 25

DF50 y DF50T Metálica

Despiece y repuestos de la bomba

ENGLISHESPAÑOL

Pilotaje externo

El distribuidor de aire se vende

como kit.

Ensamblado y verificado en

Samson.

SALIDA

Escape

conducido

Escape

normal

Nº Referencia Descripción Cant. Nota

Escape normal

1 Tabla 1 Motor de aire 1 Opciones:

Escape conducido

Pilotaje externo

2 Tabla 2 Bolas -

3 Tabla 3 Asiento / Junta / Jaula -

4 Tabla 4 Casquillo / Junta / Eje -

5 Tabla 5 Diafragmas -

6 558301 Sensor de aire - No disponible con pilotaje externo

7 755106 Tapas de diafragma 2 (No se vende como kit)

8 940380 Tornillo tapas diafragma 16 (No se vende como kit)

9 Tabla 9 Carenas 2 (No se vende como kit)

10 940506 Tornillos 8 (No se vende como kit)

12 940319 Tornillos tapas válvula 8 (No se vende como kit)

13 Tabla 13 Tapas válvula 2 (No se vende como kit)

14 Tabla 14 Cuerpo 1 (No se vende como kit)

17 855601 Embellecedor 2 (No se vende como kit)

R. 12/13 855 822

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

2013_12_17-16:30

25

Page 26

DF100

Despiece y repuestos de la bomba

Pilotaje externo

El distribuidor de aire se vende

como kit.

Ensamblado y verificado en

Samson.

Escape

conducido

Escape

normal

Nº Referencia Descripción Cant. Nota

Escape normal

1 Tabla 1 Motor de aire 1 Opciones:

Escape conducido

Pilotaje externo

2 Tabla 2 Bolas -

3 Tabla 3 Asiento / Junta / Jaula -

4 Tabla 4 Casquillo / Junta / Eje -

5 Tabla 5 Diafragmas -

6 558301 Sensor de aire - No disponible con pilotaje externo

2013_12_17-16:30

7 755111 Tapas de diafragma 2 (No se vende como kit)

8 940334 Tornillo tapas diafragma 20 (No se vende como kit)

10 940914 Tornillos carenas 7 (No se vende como kit)

12 940319 Tornillos tapas válvula 12 (No se vende como kit)

13 Tabla 13 Tapas válvula 2 (No se vende como kit)

14 Tabla 14 Cuerpo 1 (No se vende como kit)

17 855604 Embellecedor 2 (No se vende como kit)

21 Tabla 9 Carena superior 1 (No se vende como kit)

22 Tabla 9 Carena inferior 1 (No se vende como kit)

23 855416 Arandela de apriete 4 *Solo disponible para bombas plásticas

26

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Page 27

Despiece y repuestos de la bomba

Tabla 1 Tabla 2 Tabla 3

Tamaño Código Samson Motor de aire Código kit Bolas Código kit Asiento de bola / Junta / Jaula Código kit

DF30 553010X Estándar 558300.300 PTFE 558319 Acero inoxidable / Viton / Polipropileno 558316

552010X Estándar 558300.300 ACETAL 558321 Acero inoxidable / Viton / Acetal 558315

552011X Estándar 558300.300 ACETAL 558321 Acero inoxidable / Viton / Acetal 558315

DF50

DF100

Tamaño Código Samson Casquillo / Junta / Eje Código kit Diafragmas Código kit Carenas Código kit

DF30 553010X PTFE / Viton / Acero inoxidable 558326.001 HYTREL 558337.001 Estándar 558301

DF50

DF100

552015X Estándar 558300.300 PTFE 558319 Stainless steel / Viton / Polypropylene 558316

552016X Estándar 558300.300 ACETAL 558321 Acero inoxidable / Viton / Acetal 558315

552021X Estándar 558300.300 ACETAL 558321 Acero inoxidable / Viton / Acetal 558315

552026X Estándar 558300 .300 ACETAL 558321 Acero inoxidable / Viton / Acetal 558315

551010X Estándar 558350 .300 ACETAL 558365 Acero inoxidable / NBR / Acetal 558357

551015X Estándar 558350 .300 PTFE 558363 Acero inoxidable / Viton / Polipropileno 558360

DF 55x xxx

Tabla 4 (Ver nota en pie de página) Tabla 5 (Ver nota en pie de página) Tabla 9

552010X PTFE / NBR / Acero inoxidable 558304.001 HYTREL 558303.001 Estándar 558301

552015X PTFE / Viton / Acero inoxidable 558307.001 HYTREL 558303.001 Estándar 558301

552016X PTFE / Viton / Acero inoxidable 558307.001 HYTREL 558303.001 Estándar 558301

552021X PTFE / Viton / Acero inoxidable 558307.001 HYTREL 558303.001 Estándar 558301

552026X PTFE / Viton / Acero inoxidable 558307.001 HYTREL 558303.001 Estándar 558301

551010X PTFE / NBR / Acero inoxidable 558352.001 HYTREL 558368.001 Estándar 558301

551015X PTFE / Viton / Acero inoxidable 558353.001 HYTREL 558368.001 Estándar 558301

ENGLISHESPAÑOL

DF 55x xxx

* Nota1 Para modelos con número de serie anterior a febrero 2013, (nº de serie desde 328099 /001) los kits han de solicitarse sin el sufijo .001.

Table 9 Carenas - (No se venden como Kit una unidad por código)

DF30 DF30T DF50 DF50T DF100

A = Aluminio - 755108

P = PP 855645

IN: PREGUNTE A SAMSON

OUT: 855625 OUT: 855625 LOWER: 855636

855625

IN: 755109 UPPER: 755113

OUT: 755108 LOWER: 755114

IN: 855626 UPPER: 855637

Table 13 Tapa de válvulas (No se venden como Kit una unidad por código)

DF30 DF50 DF100

A = Aluminio - 855107 855112

B = PP Conductivo

855654

855654 855653

C = Acetal 855620 855620 -

D = Acetal Conductivo 855629 855629 855635

N = Aluminio con Niquel químico - 755107.001 755112.001

P = PP 855609 855609 855633

S = SS - PREGUNTE A SAMSON PREGUNTE A SAMSON

Table 14 Cuerpo de bomba (No se venden como Kit una unidad por código)

DF30 DF30T DF50 DF50T DF100

A = Aluminio - - 755104 755105 755110.300

B = PP conductivo 755402.300 - 755215.300 - 755315.300

C = Acetal - - 755213.300 855619.300 D = Acetal conductivo 755401.300 - 755214.300 - 755314.300

N = Aluminio con Niquel químico - - PREGUNTE A SAMSON - PREGUNTE A SAMSON

P = PP 755400.300 - 755212.300 855608.300 755312.300

S = SS - - 755050 - 755051.300

R. 12/13 855 822

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

2013_12_17-16:30

27

Page 28

Posibles averías y soluciones

La bomba no funciona.

Causa Medida a tomar

La válvula de impulsión en el lado de descarga no está abierta. Abra la válvula de impulsión en el lado de descarga.

No llega aire. Encienda el compresor y abra la válvula de aire y el regulador de aire.

La presión de suministro de aire es baja. Revise el compresor y la configuración de la tubería de aire.

Fugas de aire en elementos de conexión. Revise los elementos de conexión y el apriete de los tornillos.

La tubería de aire o el equipo auxiliar está obstruido con lodo. Revise y limpie la tubería de aire.

El orificio de escape (silenciador) de la bomba está obstruido con lodo. Revise y limpie el orificio de escape y el silenciador.

La tubería de fluido está obstruida con lodo. Revise y limpie la tubería de fluido.

La bomba está obstruida con lodo. Desmonte, revise y limpie cuerpo de la bomba.

La bomba funciona pero el fluido no sale.

Causa Medida a tomar

La válvula en el lado de succión no está abierta. Abra la válvula en el lado de succión.

Demasiada altura de aspiración o altura de descarga. Confirme la configuración de la tubería y reduzca la altura de la misma.

La tubería de fluido del lado de descarga (incluido el filtro) está obstruida con lodo. Revise y limpie la tubería de fluido.

La bomba está obstruida con lodo. Desmonte la bomba, revísela y límpiela.

Las bolas y el asiento de la bola están desgastados o dañados. Revise y reemplace piezas defectuosas.

El flujo está disminuyendo.

Causa Medida a tomar

La presión de suministro de aire es baja. Revise el compresor y la configuración de la tubería de aire.

La tubería de aire o el equipo periférico está obstruido con lodo. Revise y limpie la tubería de aire.

La válvula de impulsión del lado de descarga no se abre normalmente. Ajuste la válvula de impulsión del lado de descarga.

El aire se mezcla con el fluido. Vuelva a llenar de fluido y revise la configuración de la tubería del lado de succión.

Se produce cavitación. Ajuste la presión de suministro de aire y la presión de descarga y reduzca la

Se producen vibraciones. Ajuste la presión de suministro de aire y la presión de descarga. Disminuya el

Formación de hielo en el escape de aire. Elimine el hielo de la válvula de desvío de aire y revise y limpie el filtro de aire.

La tubería de fluido (incluido el filtro) está obstruida con lodo. Revise y limpie la tubería de fluido y el colador.

El orificio de escape (silenciador) de la bomba está obstruido con lodo. Revise y limpie el orificio de escape y el silenciador.

La bomba está obstruida con lodo. Desmonte, revise y limpie el cuerpo de la bomba.

Fugas de fluido por el orifico de escape (silenciador).

Causa Medida a tomar

El diafragma está dañado. Desmonte y revise la bomba y reemplace el diafragma.

2013_12_17-16:30

Ruido irregular.

Causa Medida a tomar

La presión de suministro de aire es demasiado alta. Ajuste la presión de suministro de aire.

La bomba está obstruida con lodo de partículas más grandes que el diámetro

permitido.

altura de aspiración.

flujo de la válvula de entrada para ajustar la presión y el volumen de fluido.

Utilice una tubería en el escape de aire para que el hielo no se forme en el

silenciador.

Desmonte, revise y limpie el cuerpo de la bomba.

28

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Page 29

Posibles averías y soluciones

El fluido sale con burbujas de aire.

Causa Medida a tomar

Membrana dañada. Sustituya la membrana.

Manguera de succión suelta o rota. Apriete o sustituya.

Fuga aire alimentado a presión entre 3 y 7 bar.

Causa Medida a tomar

Desgaste del pivote del motor de aire. Cambie el motor de aire.

No arranca y queda fugando aire sin hacer ciclos.

Causa Medida a tomar

Sensores de aire agarrotados. Cambie sensor de aire.

Tambor de salida del pivote desgastado. Cambie.

Reparación y mantenimiento

Motor de aire

ENGLISHESPAÑOL

Existen varios modelos de motor de aire para todas las bombas de

diafragma DF. Motor para pilotaje mediante PLC, motor de aire con salida

conducida y con salida no conducida. Para diferenciar la que usted ha

adquirido acuda al siguiente diagrama con el código de su producto, el

DF_ _ _

Kit motor de aire salida no conducida

Pos. Descripción Cant. Material

Anillo seguridad entrada de

1

2 Junta tórica 1 NBR

3 Casquillo de entrada 1 Acero

4 Pivote 1 Elastollan Delrin

A

5 Junta inferior distribuidor 2 NBR

6 Cuerpo motor de aire 1 Aluminio

7 Junta tórica 1 NBR-PTFE

8 Tambor pivotante 1 Elastollan Delrin

9 Tornillo + arandela 1 Acero inox.

10 Silencioso 1 Bronce

11 Anillo seguridad salida de aire 1 Acero

aire

X

X

1 Acero

X

cual podrá encontrar en la placa identificativa de la bomba, en el caso de

motor pilotado consulte el despiece correspondiente a su bomba. Para la

reposición o mantenimiento consulte los despieces de las páginas 23 a

la 26.

X

X

B

X

X

Kit: motor de aire salida conducida

Pos. Description Qty. Material

Anillo seguridad entrada

1

2 Junta tórica 2 NBR

3 Casquillo de entrada 1 Acero

4 Pivote 1 Elastollan Delrin

5 Junta inferior distribuidor 2 NBR

6 Cuerpo motor de aire 1 Aluminio

7 Junta tórica 1 NBR-PTFE

8 Tambor pivotante 1 Elastollan Delrin

9 Tornillo + arandela 1 Acero inox.

11 Anillo seguridad salida de aire 2 Acero

12 Casquillo de salida 1 Acero

de aire

X

X

X

1 Acero

Mantenimiento (para cambiar pivote):

1. Retire 1, 2 ,3 , 10, 11, 12

2. Retire 9

3. Extraiga 4, 7, 8

R. 12/13 855 822

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

2013_12_17-16:30

29

Page 30

Reparación y mantenimiento

Pares de apriete necesarios para el correcto funcionamiento de la bomba

Para un correcto funcionamiento de la bomba y para evitar accidentes donde se puedan dañar equipos y en el peor de los casos personas, es

conveniente la revisión periódica de los pares de apriete de las tapas y el motor neumático de la bomba solidarios al cuerpo mediante sus

correspondientes tornillos. A continuación se especifican los pares de apriete adecuados para este fin:

Tapas laterales 8 N·m (70,81 lbf·in)

Par de apriete DF30

Motor de aire 5 N·m (44.25 lbf·in)

Tapa válvula 2 N·m (30.9 lbf·in) bombas plásticas

Tapas laterales 5,5 - 6 N·m (48.67 - 53.1 lbf·in)

Par de apriete DF50

Motor de aire 5 N·m (44.25 lbf·in)

Tapa válvula 4 N·m (35.4 lbf·in) Aluminio - 2 N·m (30.9 lbf·in) Plástico

Tapas laterales 15 N·m (137.7 lbf·in)

Par de apriete DF100

Motor de aire 5 N·m (44.25 lbf·in)

Tapa válvula 4 N·m (35.4 lbf·in) Aluminio - 2 N·m (30.9 lbf·in) Plástico

Cambio de membranas

ANTES DE CADA INTERVENCIÓN: DESCONECTAR LA ALIMENTACIÓN

DE AIRE DE LA BOMBA NO ES NECESARIO DESMONTAR LA BOMBA DE

LA LÍNEA DE IMPULSIÓN DE FLUIDO.

1. Cerre las válvulas de fluido.

2. Drene el fluido del interior de la bomba. Prever un posible

derramamiento de fluido del interior de la bomba.

3. Retire el distribuidor de aire con mucho cuidado de no dañar las

juntas existentes entre el distribuidor y el cuerpo.

4. Desmonte la tapa de membrana.

5. Extraiga la tapa tirando suavemente hacia atrás.

6. Extraiga la membrana usada. Fíjese en la posición de la misma al extraerla.

Coloque la nueva en la posición adecuada. Y monte la tapa de nuevo.

Desmonte la tapa lateral derecha según la entrada de fluido tal como se indica

en la figura, siguiendo el procedimiento para “Cambio de membranas".

Una vez que se visualiza el eje, seguir los siguientes procedimientos:

1. Extraiga el eje de su alojamiento tirando de él por uno de sus extremos.

2013_12_17-16:30

El casquillo de Teflon

®

se encuentra roscado en el cuerpo. Para desmontar

use un útil que se aloja en los dos taladros que se indican en la figura.

3

A

4

6

5

Eje central

2. Una vez extraido el casquillo desmonte la tórica del interior del cuerpo

de la bomba.

3. Monte el nuevo kit de eje central comprobando el correcto orden en

el montaje de los componentes.

Proceda al montaje de la bomba en orden inverso.

30

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Page 31

Procedimientos de reparación y mantenimiento

Cambio de las válvulas de bola

1. Cierre las válvulas de fluido.

2. Drene el fluido del interior de la bomba. Prever un posible

derramamiento de fluido del interior de la bomba.

3. Afloje los tornillos para desmontar el motor de aire. Preste especial

cuidado a las juntas.

4. Desmonte la tapa de las válvulas aflojando los tornillos con una llave

Allen. Recuerde la posición de estas tapas al retirarlas. Es

imprescindible colocarlas en la misma posición.

5. Monte un nuevo conjunto de las bolas con las jaulas siguiendo el

esquema de posicionamiento de las jaulas. Una colocación incorrecta

producirá el funcionamiento incorrecto de la bomba.

Atención

Para evitar restricción de fluido y fugas, respete la posición de las guías

de las bolas que se muestra en la imagen.

Las tapas de válvula deben ser colocadas con la zona indicada en la

imagen inferior mirando hacia el cuerpo.

6. Monte la tapa de válvulas comprobando el correcto montaje de las

tóricas y en la misma posición que se retiraron. Vea en la página 33

el par de apriete necesario y apriete los tornillos siguiendo una

secuencia en cruz.

Monte el motor de aire prestando atención de no dañar las juntas

existentenes entre distribuidor y cuerpo. Apriete los tornillos con un par

de apriete máximo de 5 N·m.

ENGLISHESPAÑOL

Sensor de aire (solo para bombas con motor de aire)

Los sensores de aire están alojados en las tapas. Para acceder a ellos

seguir el procedimiento para “Cambio de membranas".

Una vez desmontadas las tapas seguir el procedimiento siguiente:

1. Desmonte los 2 tornillos que fijan el sensor de aire a la tapa.

2. Extraiga todos los componentes del sensor. Limpie el alojamiento de

posibles suciedades.

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

3. Introduzca los nuevos componentes en el orden indicado.

4. Monte la tapa en la bomba y apriete los tornillos de fijación al cuerpo

de la bomba. Vea par de apriete en la página 30.

Monte el resto de componentes siguiendo el orden inverso.

R. 12/13 855 822

2013_12_17-16:30

31

Page 32

www.samsoncorporation.com

2013_12_17-16:30

Distributed by

32

855 822 R. 12/13

Samson Corporation • One Samson Way • N.C. 28778 Swannanoa USA • Phone (828) 686-8511 • Fax (828) 686-8533

Loading...

Loading...