Samlex PST-60S-12E, PST-60S-24E, PST-100S-12E, PST-100S-24E, PST-150S-12E Instructions manual

...

DC-AC Power

Inverter

Pure Sine Wave

PST-60S-12E

PST-60S-24E

PST-100S-12E

PST-100S-24E

PST-150S-12E

PST-150S-24E

PST-200S-12E

PST-200S-24E

Owner's

Manual

Please read this

manual BEFORE

installing your

inverter

OWNER'S MANUAL | Index

SECTION 1 Safety Instructions ........................................3

SECTION 2 General Information .....................................6

SECTION 3

EMC (EMI/EMS) Compliance .............................................. 13

SECTION 4

Powering Direct / Embedded Switch Mode

Power Supplies (SMPS) ....................................................... 14

SECTION 5 Principle of Operation ............................... 16

SECTION 6 Layout ........................................................ 17

SECTION 7

General Information on Lead-Acid Batteries ....................... 18

SECTION 8 Installation ................................................. 29

SECTION 9 Operation ...................................................41

SECTION 10 Protections ............................................. 43

SECTION 11 Troubleshooting Guide ........................... 46

SECTION 12 Specications ......................................... 48

SECTION 13 Warranty ..................................................52

Disclaimer of Liability

UNLESS SPECIFICALLY AGREED TO IN WRITING, SAMLEX AMERICA INC.:

1. MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER INFORMATION

PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

2. ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY

SUCH INFORMATION WILL BE ENTIRELY AT THE USERS RISK.

Samlex America reserves the right to revise this document and to periodically make changes to the content

hereof without obligation or organization of such revisions or changes.

Copyright Notice/Notice of Copyright

Copyright © 2016 by Samlex America Inc. All rights reserved. Permission to copy, distribute and /or modify this

document is prohibited without express written permission by Samlex America Inc.

2 | SAMLEX AMERICA INC.

SECTION 1 | Safety Instructions

!

i

1.1 IMPORTANT SAFETY INSTRUCTIONS AND SYMBOLS

SAVE THESE INSTRUCTIONS. This manual contains important instructions for models

PST-60S / 100S / 150S / 200S that shall be followed during installation, operation and

maintenance.

The following safety symbols will be used in this manual to highlight safety

and information:

Indicates possibility of physical harm to the user in case of non-compliance.

Indicates possibility of damage to the equipment in case of non-compliance.

Indicates useful supplemental information.

Please read these instructions before installing or operating the unit to prevent personal

injury or damage to the unit.

WARNING!

CAUTION!

INFO

1.2 SAFETY INSTRUCTIONS - GENERAL

Installation and wiring compliance

• Installation and wiring must comply with the Local and National Electrical Codes and

must be done by a certied electrician.

Preventing electrical shock

• Both the output sockets L1 and L2 of the Schuko Receptacle are LIVE/HOT and are

oating with respect to the metal chassis Ground/Earth Ground (there is NO Neutral).

Do not touch! Refer to Section 8.5.1 for details.

• Always connect the grounding connection on the unit to the appropriate grounding

system.

• Disassembly / repair should be carried out by qualied personnel only.

• Disconnect all AC and DC side connections before working on any circuits associated

with the unit. Turning the ON/OFF switch on the unit to OFF position may not entirely

remove dangerous voltages.

• Be careful when touching bare terminals of capacitors. Capacitors may retain high lethal voltages even after the power has been removed. Discharge the capacitors before

working on the circuits.

SECTION 1 | Safety Instructions

Installation environment

• The inverter should be installed indoor only in a well ventilated, cool, dry environment.

• Do not expose to moisture, rain, snow or liquids of any type.

• To reduce the risk of overheating and re, do not obstruct the suction and discharge

openings of the cooling fan.

• To ensure proper ventilation, do not install in a low clearance compartment.

Preventing re and explosion hazards

• Working with the unit may produce arcs or sparks. Thus, the unit should not be used

in areas where there are ammable materials or gases requiring ignition protected

equipment. These areas may include spaces containing gasoline-powered machinery,

fuel tanks, and battery compartments.

Precautions when working with batteries

• Batteries contain very corrosive diluted Sulphuric Acid as electrolyte. Precautions

should be taken to prevent contact with skin, eyes or clothing.

• Batteries generate Hydrogen and Oxygen during charging resulting in evolution of

explosive gas mixture. Care should be taken to ventilate the battery area and follow

the battery manufacturer’s recommendations.

• Never smoke or allow a spark or ame near the batteries.

• Use caution to reduce the risk of dropping a metal tool on the battery. It could spark

or short circuit the battery or other electrical parts and could cause an explosion.

• Remove metal items like rings, bracelets and watches when working with batteries.

The batteries can produce a short circuit current high enough to weld a ring or the

like to metal and, thus, cause a severe burn.

• If you need to remove a battery, always remove the ground terminal (Negative) from

the battery rst. Make sure that all the accessories are off so that you do not cause

a spark.

1.3 SAFETY INSTRUCTIONS - INVERTER RELATED

Preventing Paralleling of the AC Output

The AC output of the unit should never be connected directly to an Electrical Breaker

Panel / Load Centre which is also fed from the utility power / generator. Such a direct

connection may result in parallel operation of the different power sources and AC power

from the utility / generator will be fed back into the unit which will instantly damage

the output section of the unit and may also pose a re and safety hazard. If an Electrical

Breaker Panel / Load Center is fed from this unit and this panel is also required to be fed

from additional alternate AC sources, the AC power from all the AC sources (like the utility

/ generator / this inverter) should rst be fed to an Automatic / Manual Selector Switch

and the output of the Selector Switch should be connected to the Electrical Breaker Panel

/ Load Center.

4 | SAMLEX AMERICA INC.

SECTION 1 | Safety Instructions

!

!

CAUTION!

To prevent possibility of paralleling and severe damage to the unit, never

use a simple jumper cable with a male plug on both ends to connect the

AC output of the unit to a handy wall receptacle in the home / RV /

motorhome / caravan.

Preventing DC Input Over Voltage

It is to be ensured that the DC input voltage of this unit does not exceed 16.5 VDC for

the 12V versions or 33.0 VDC for the 24V versions to prevent permanent damage to the

unit. Please observe the following precautions:

• Ensure that the maximum charging voltage of the external battery charger / alternator / solar charge controller does not exceed 16.5 VDC for the 12V versions or 33.0

VDC for the 24V versions.

• Do not use unregulated solar panels to charge the battery connected to this unit.

Under cold ambient temperatures, the output of the solar panel may reach > 22 VDC

for 12V Battery System and > 44 VDC for the 24V Battery system. Always use a charge

controller between the solar panel and the battery.

• Do not connect this unit to a battery system with a voltage higher than the rated

battery input voltage of the unit [e.g. do not connect the 12V versions to 24V or 48V

battery system or the 24V versions to the 48V Battery System].

• When using Diversion Charge Control Mode in a charge controller, the solar / wind /

hydro source is directly connected to the battery bank. In this case, the controller will

divert excess current to an external load. As the battery charges, the diversion duty

cycle will increase. When the battery is fully charged, all the source energy will ow

into the diversion load if there are no other loads. The charge controller will disconnect the diversion load if the current rating of the controller is exceeded. Disconnection of the diversion load may damage the battery as well as the inverter or other DC

loads connected to the battery due to high voltages generated during conditions of

high winds (for wind generators), high water ow rates (for hydro generators). It is,

therefore, to be ensured that the diversion load is sized correctly to prevent the above

over voltage conditions.

Preventing Reverse Polarity on the Input Side

When making battery connections on the input side, make sure that the polarity of battery connections is correct (Connect the Positive of the battery to the Positive terminal

of the unit and the Negative of the battery to the Negative terminal of the unit). If the

input is connected in reverse polarity, the external DC fuse and the DC fuses inside the

inverter will blow and may also cause permanent damage to the inverter.

CAUTION!

Damage caused by reverse polarity is not covered by warranty.

SECTION 1 | Safety Instructions

Use of External Fuse in DC Input Circuit

Use UL Class T (As per UL Standard UL 248-15 / Type "HRC" as per BS88-2 or as per IEC

60269-2) or equivalent fuse of appropriate capacity within 7" of the battery Positive terminal. This fuse is required to protect DC input cable run from damage due to short circuit

along the length of the cable. Please read instructions under Section 8.4.5 - Installation.

Hard Wiring of AC Output to AC Panelboards in RVs / Motor Homes / Trailers /Campers

WARNING!

RISK OF ELECTRIC SHOCK

When this unit is installed in RV / Motor Homes / Trailers / Campers and hard-

wiring connection is used to feed the AC output of the inverter to the AC

Distribution Panelboard / Load Center in the vehicle, it is to be ensured that

the AC output is fed to the Panel Board through appropriate Residual Current

Detector (RCD) or Ground Fault Circuit Interrupter [GFCI].

SECTION 2 | General Information

2.1. DEFINITIONS

The following denitions are used in this manual for explaining various electrical

concepts, specications and operations:

Peak Value: It is the maximum value of electrical parameter like voltage / current.

RMS (Root Mean Square) Value: It is a statistical average value of a quantity that varies

in value with respect to time. For example, a pure sine wave that alternates between

peak values of Positive 329.22V and Negative 329.22V has an RMS value of 230 VAC.

Also, for a pure sine wave, the RMS value = Peak value ÷ 1.414.

Voltage (V), Volts: It is denoted by “V” and the unit is “Volts”. It is the electrical force

that drives electrical current (I) when connected to a load. It can be DC (Direct Current

– ow in one direction only) or AC (Alternating Current – direction of ow changes periodically). The AC value shown in the specications is the RMS (Root Mean Square) value.

Current (I), Amps, A: It is denoted by “I” and the unit is Amperes – shown as “A”. It is

the ow of electrons through a conductor when a voltage (V) is applied across it.

Frequency (F), Hz: It is a measure of the number of occurrences of a repeating event per

unit time. For example, cycles per second (or Hertz) in a sinusoidal voltage.

Efciency, (

in Watts.

6 | SAMLEX AMERICA INC.

η): This is the ratio of Active Power Output in Watts ÷ Active Power Input

SECTION 2 | General Information

Phase Angle, (φ): It is denoted by “φ” and species the angle in degrees by which the

current vector leads or lags the voltage vector in a sinusoidal voltage. In a purely inductive load, the current vector lags the voltage vector by Phase Angle (φ) = 90°. In a purely

capacitive load, the current vector leads the voltage vector by Phase Angle, (φ) = 90°. In

a purely resistive load, the current vector is in phase with the voltage vector and hence,

the Phase Angle, (φ) = 0°. In a load consisting of a combination of resistances, inductances and capacitances, the Phase Angle (φ) of the net current vector will be > 0° < 90°

and may lag or lead the voltage vector.

Resistance (R), Ohm, Ω: It is the property of a conductor that opposes the ow of current when a voltage is applied across it. In a resistance, the current is in phase with the

voltage. It is denoted by "R" and its unit is "Ohm" - also denoted as "Ω".

Inductive Reactance (X

opposition of a circuit element to a change of electric current or voltage due to that

element's inductance or capacitance. Inductive Reactance (X

of wire in resisting any change of electric current through the coil. It is proportional to

), Capacitive Reactance (XC) and Reactance (X): Reactance is the

L

) is the property of a coil

L

frequency and inductance and causes the current vector to lag the voltage vector by

Phase Angle (φ) = 90°. Capacitive reactance (X

oppose changes in voltage. X

and causes the current vector to lead the voltage vector by Phase Angle (φ) = 90°. The

unit of both X

tance X

tance X

effect is a tendency to cancel each other. Hence, in a circuit containing both inductances

and XC is "Ohm" - also denoted as "Ω". The effects of inductive reac-

L

to cause the current to lag the voltage by 90° and that of the capacitive reac-

L

to cause the current to lead the voltage by 90° are exactly opposite and the net

C

is inversely proportional to the frequency and capacitance

C

) is the property of capacitive elements to

C

and capacitances, the net Reactance (X) will be equal to the difference between the

values of the inductive and capacitive reactances. The net Reactance (X) will be inductive

if X

> XC and capacitive if XC > XL.

L

Impedance, Z: It is the vectorial sum of Resistance and Reactance vectors in a circuit.

Active Power (P), Watts: It is denoted as “P” and the unit is “Watt”. It is the power that

is consumed in the resistive elements of the load. A load will require additional Reactive

Power for powering the inductive and capacitive elements. The effective power required

would be the Apparent Power that is a vectorial sum of the Active and Reactive Powers.

Reactive Power (Q), VAR: Is denoted as “Q” and the unit is VAR. Over a cycle, this power

is alternatively stored and returned by the inductive and capacitive elements of the load.

It is not consumed by the inductive and capacitive elements in the load but a certain

value travels from the AC source to these elements in the (+) half cycle of the sinusoidal

voltage (Positive value) and the same value is returned back to the AC source in the (-)

half cycle of the sinusoidal voltage (Negative value). Hence, when averaged over a span

of one cycle, the net value of this power is 0. However, on an instantaneous basis, this

power has to be provided by the AC source. Hence, the inverter, AC wiring and over cur-

rent protection devices have to be sized based on the combined effect of the Active and

Reactive Powers that is called the Apparent Power.

SECTION 2 | General Information

Apparent (S) Power, VA: This power, denoted by "S", is the vectorial sum of the Active

Power in Watts and the Reactive Power in “VAR”. In magnitude, it is equal to the RMS

value of voltage “V” X the RMS value of current “A”. The Unit is VA. Please note that

Apparent Power VA is more than the Active Power in Watts. Hence, the inverter, AC wiring and over current protection devices have to be sized based on the Apparent Power.

Maximum Continuous Running AC Power Rating: This rating may be specied as “Active Power” in Watts (W) or “Apparent Power” in Volt Amps (VA). It is normally specied in “Active Power (P)” in Watts for Resistive type of loads that have Power Factor

=1. Reactive types of loads will draw higher value of “Apparent Power” that is the sum

of “Active and Reactive Powers”. Thus, AC power source should be sized based on the

higher “Apparent Power” Rating in (VA) for all Reactive Types of AC loads. If the AC

power source is sized based on the lower “Active Power” Rating in Watts (W), the AC

power source may be subjected to overload conditions when powering Reactive Type of

loads.

Surge Power Rating: During start up, certain loads require considerably higher surge of power

for short duration (lasting from tens of millisecs to few seconds) as compared to their Maximum Continuous Running Power Rating. Some examples of such loads are given below:

• Electric Motors: At the moment when an electric motor is powered ON, the rotor is

stationary (equivalent to being “Locked”), there is no “Back EMF” and the windings

draw a very heavy surge of starting current (Amperes) called “Locked Rotor Amperes” (LRA) due to low DC resistance of the windings. For example, in motor driven

loads like Air-conditioning and Refrigeration Compressors and in Well Pumps (using

Pressure Tank), the Starting Surge Current / LRA may be as high as 10 times its rated

Full Load Amps (FLA) / Maximum Continuous Running Power Rating. The value and

duration of the Starting Surge Current / LRA of the motor depends upon the winding

design of the motor and the inertia / resistance to movement of mechanical load

being driven by the motor. As the motor speed rises to its rated RPM, “Back EMF”

proportional to the RPM is generated in the windings and the current draw reduces

proportionately till it draws the running FLA / Maximum Continuous Running Power

Rating at the rated RPM.

• Transformers (e.g. Isolation Transformers, Step-up / Step-down Transformers, Power Trans-

former in Microwave Oven etc.): At the moment when AC power is supplied to a transformer,

the transformer draws very heavy surge of “Magnetization Inrush Current” for a few millisecs

that can reach up to 10 times the Maximum Continuous Rating of the Transformer.

• Devices like Infrared Quartz Halogen Heaters (also used in Laser Printers) / Quartz

Halogen Lights / Incandescent Light Bulbs using Tungsten heating elements: Tungsten

has a very high Positive Temperature Coefcient of Resistance i.e. it has lower resistance when cold and higher resistance when hot. As Tungsten heating element will be

cold at the time of powering ON, its resistance will be low and hence, the device will

draw very heavy surge of current with consequent very heavy surge of power with a

value of up to 8 times the Maximum Continuous Running AC Power.

8 | SAMLEX AMERICA INC.

SECTION 2 | General Information

• AC to DC Switched Mode Power Supplies (SMPS): This type of power supply is used as

stand-alone power supply or as front end in all electronic devices powered from Utility / Grid e.g. in audio/video/ computing devices and battery chargers (Please see Section 4 for more details on SMPS). When this power supply is switched ON, its internal

input side capacitors start charging resulting in very high surge of Inrush Current for a

few millisecs (Please see Fig 4.1). This surge of inrush current / power may reach up to

15 times the Continuous Maximum Running Power Rating. The surge of inrush current

/ power will, however, be limited by the Surge Power Rating of the AC source.

Power Factor, (PF): It is denoted by “PF” and is equal to the ratio of the Active Power

(P) in Watts to the Apparent Power (S) in VA. The maximum value is 1 for resistive types

of loads where the Active Power (P) in Watts = the Apparent Power (S) in VA. It is 0 for

purely inductive or purely capacitive loads. Practically, the loads will be a combination of

resistive, inductive and capacitive elements and hence, its value will be > 0 <1. Normally

it ranges from 0.5 to 0.8 e.g. (i) AC motors (0.4 to 0.8), (ii) Transformers (0.8) (iii) AC to

DC Switch Mode Power Supplies (0.5 to 0.6) etc.

Load: Electrical appliance or device to which an electrical voltage is fed.

Linear Load: A load that draws sinusoidal current when a sinusoidal voltage is fed to it.

Examples are, incandescent lamp, heater, electric motor, etc.

Non-Linear Load: A load that does not draw a sinusoidal current when a sinusoidal voltage is fed to it. For example, non-power factor corrected Switched Mode Power Supplies

(SMPS) used in computers, audio video equipment, battery chargers, etc.

Resistive Load: A device or appliance that consists of pure resistance (like lament

lamps, cook tops, toaster, coffee maker etc.) and draws only Active Power (Watts) from

the inverter. The inverter can be sized based on the Active Power rating (Watts) of

resistive type of loads without creating overload (except for resistive type of loads with

Tungsten based heating element like in Incandescent Light Bulbs, Quartz Halogen Lights

and Quartz Halogen Infrared Heaters. These require higher starting surge power due to

lower resistance value when the heating element is cold).

Reactive Load: A device or appliance that consists of a combination of resistive, inductive

and capacitive elements (like motor driven tools, refrigeration compressors, microwaves,

computers, audio/ video etc.). The Power Factor of this type of load is <1 e.g. AC motors

(PF=0.4 to 0.8), Transformers (PF=0.8), AC to DC Switch Mode Power Supplies (PF=0.5

to 0.6) etc. These devices require Apparent Power (VA) from the AC power source. The

Apparent Power is a vectorial sum of Active Power (Watts) and Reactive Power (VAR).

The AC power source has to be sized based on the higher Apparent Power (VA) and also

based on the Starting Surge Power.

SECTION 2 | General Information

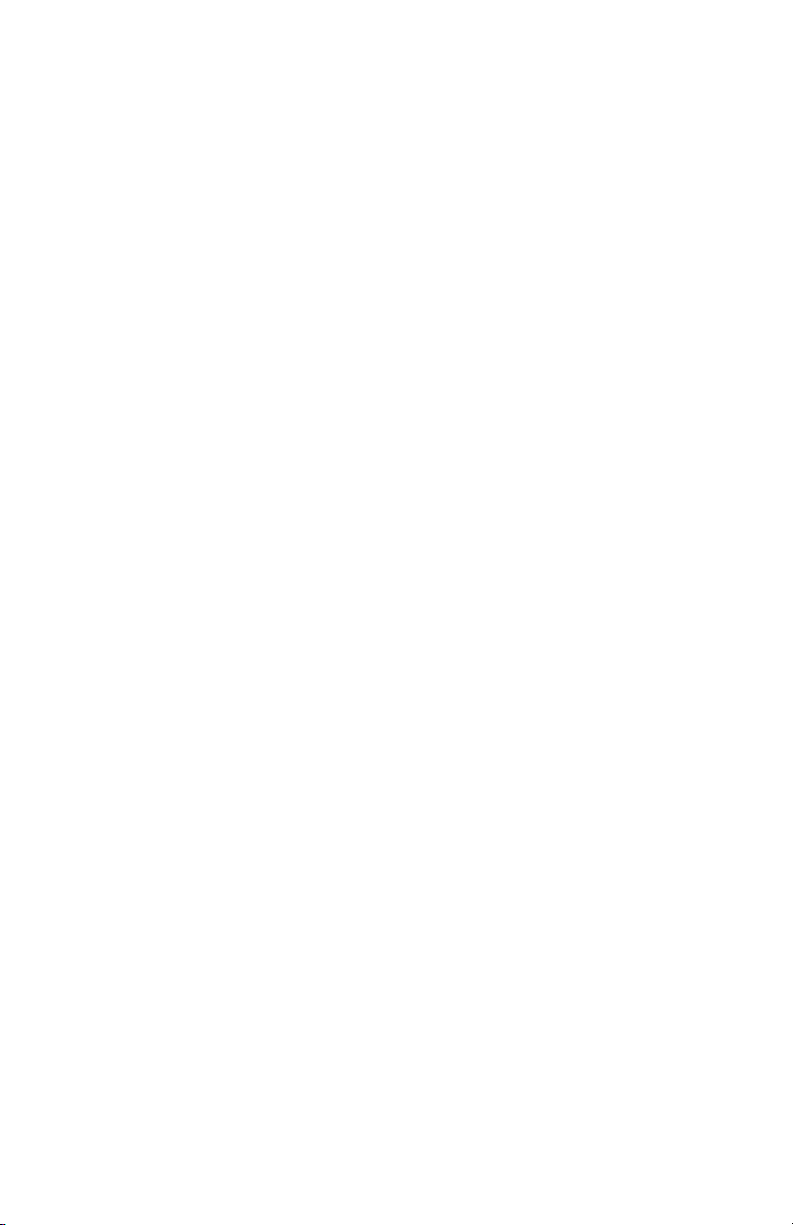

2.2 OUTPUT VOLTAGE WAVEFORMS

V

= 325.22V

PEAK

V

= 280 to 320V

360

320

280

240

VOLTS (+)VOLTS (–)

200

160

120

80

40

0

40

120

160

200

240

280

320

360

80

Pure Sine Wave

crosses Zero Volt

instantaneously

TIME

Fig. 2.1: Pure and Modied Sine Waveforms for 230 VAC, 50/60 Hz

The output waveform of the Samlex PST series inverters is a Pure Sine Wave like the

waveform of Utility / Grid Power. Please see Sine Wave represented in the Fig. 2.1 that

also shows Modied Sine Waveform for comparison.

PEAK

V

20.00 ms for 50 Hz

16.66 ms for 60 Hz

= 230 VAC

RMS

Modied Sine

Wave sits at

ZERO for some

time and then

rises or falls

Sine Wave

Modied Sine Wave

In a Sine Wave, the voltage rises and falls smoothly with a smoothly changing phase

angle and also changes its polarity instantly when it crosses 0 Volts. In a Modied Sine

Wave, the voltage rises and falls abruptly, the phase angle also changes abruptly and

it sits at zero V for some time before changing its polarity. Thus, any device that uses a

control circuitry that senses the phase (for voltage / speed control) or instantaneous zero

voltage crossing (for timing control) will not work properly from a voltage that has a

Modied Sine Waveform.

Also, as the Modied Sine Wave is a form of Square Wave, it is comprised of multiple

Sine Waves of odd harmonics (multiples) of the fundamental frequency of the Modied

Sine Wave. For example, a 50 Hz Modied Sine Wave will consist of Sine Waves with

odd harmonic frequencies of 3rd (150 Hz), 5th (250 Hz), 7th (350 Hz) and so on. The high

frequency harmonic content in a Modied Sine Wave produces enhanced radio interference, higher heating effect in inductive loads like microwaves and motor driven devices

like hand tools, refrigeration / air-conditioning compressors, pumps etc. The higher

frequency harmonics also produce overloading effect in low frequency capacitors due to

lowering of their capacitive reactance by the higher harmonic frequencies. These capacitors are used in ballasts for uorescent lighting for Power Factor improvement and in

single-phase induction motors as Start and Run Capacitors. Thus, Modied and Square

Wave inverters may shut down due to overload when powering these devices.

10 | SAMLEX AMERICA INC.

SECTION 2 | General Information

i

2.3 ADVANTAGES OF PURE SINE WAVE INVERTERS

• The output waveform is a Sine Wave with very low harmonic distortion and cleaner

power like Utility / Grid supplied electricity.

• Inductive loads like microwaves, motors, transformers etc. run faster, quieter

and cooler.

• More suitable for powering uorescent lighting xtures containing Power Factor

Improvement Capacitors and single phase motors containing Start and Run Capacitors

• Reduces audible and electrical noise in fans, uorescent lights, audio ampliers, TV,

fax and answering machines, etc.

• Does not contribute to the possibility of crashes in computers, weird print outs and

glitches in monitors.

2.4 SOME EXAMPLES OF DEVICES THAT MAY NOT WORK PROPERLY WITH

MODIFIED SINE WAVE AND MAY ALSO GET DAMAGED ARE GIVEN BELOW:

• Laser printers, photocopiers, and magneto-optical hard drives.

• Built-in clocks in devices such as clock radios, alarm clocks, coffee makers, bread-makers, VCR, microwave ovens etc. may not keep time correctly.

• Output voltage control devices like dimmers, ceiling fan / motor speed control may

not work properly (dimming / speed control may not function).

• Sewing machines with speed / microprocessor control.

• Transformer-less capacitive input powered devices like (i) Razors, ashlights, nightlights, smoke detectors etc. (ii) Some re-chargers for battery packs used in hand power

tools. These may get damaged. Please check with the manufacturer of these types of

devices for suitability.

• Devices that use radio frequency signals carried by the AC distribution wiring.

• Some new furnaces with microprocessor control / Oil burner primary controls.

• High intensity discharge (HID) lamps like Metal Halide Lamps. These may get dam-

aged. Please check with the manufacturer of these types of devices for suitability.

• Some uorescent lamps / light xtures that have Power Factor Correction Capacitors.

The inverter may shut down indicating overload.

• Induction Cooktops

2.5 POWER RATING OF INVERTERS

INFO

For proper understanding of explanations given below, please refer to deni-

tions of Active / Reactive / Apparent / Continuous / Surge Powers, Power Factor,

and Resistive / Reactive Loads at Section 2.1 under “DEFINITIONS”.

i

SECTION 2 | General Information

The power rating of inverters is specied as follows:

• Maximum Continuous Running Power Rating

• Surge Power Rating to accommodate high, short duration surge of power required

during start up of certain AC appliances and devices.

Please read details of the above two types of power ratings in Section 2.1 under

“DEFINITIONS”

INFO

The manufacturers’ specication for power rating of AC appliances and devices

indicates only the Maximum Continuous Running Power Rating. The high,

short duration surge of power required during start up of some specic types

of devices has to be determined by actual testing or by checking with the

manufacturer. This may not be possible in all cases and hence, can be guessed

at best, based on some general Rules of Thumb.

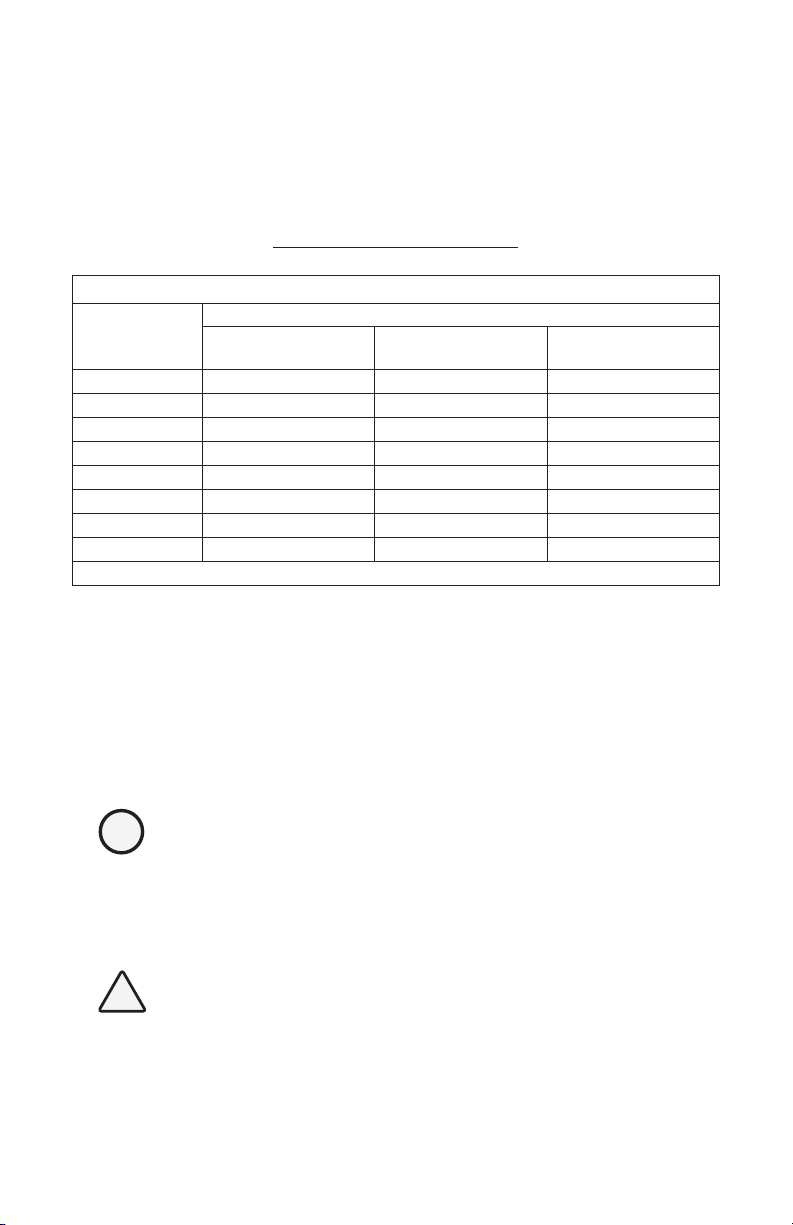

Table 2.1 provides a list of some common AC appliances / devices that require high, short

duration surge of power during start up. An “Inverter Sizing Factor” has been recommended against each which is a Multiplication Factor to be applied to the Maximum

Continuous Running Power Rating (Active Power Rating in Watts) of the AC appliance

/ device to arrive at the Maximum Continuous Running Power Rating of the inverter

(Multiply the Maximum Continuous Running Power Rating (Active Power Rating in

Watts) of the appliance / device by recommended Sizing Factor to arrive at the Maximum Continuous Running Power Rating of the inverter.

TABLE 2.1: INVERTER SIZING FACTOR

Type of Device or Appliance

Air Conditioner / Refrigerator / Freezer (Compressor based) 5

Air Compressor 4

Sump Pump / Well Pump / Submersible Pump 3

Dishwasher / Clothes Washer 3

Microwave (where rated output power is the cooking power) 2

Furnace Fan 3

Industrial Motor 3

Portable Kerosene / Diesel Fuel Heater 3

Circular Saw / Bench Grinder 3

Incandescent / Halogen / Quartz Lamps 3

Laser Printer / Other Devices using Infrared Quartz Halogen Heaters 4

Switch Mode Power Supplies (SMPS): no Power Factor correction 2

Photographic Strobe / Flash Lights 4 (See Note 2)

12 | SAMLEX AMERICA INC.

Inverter

Sizing Factor

(See note 1)

SECTION 2 | General Information

NOTES FOR TABLE 2.1

1. Multiply the Maximum Continuous Running Power Rating (Active Power Rating in

Watts) of the appliance / device by the recommended Sizing Factor to arrive at the

Maximum Continuous Running Power Rating of the inverter.

2. For photographic strobe / ash unit, the Surge Power Rating of the inverter should be

> 4 times the Watt Sec rating of photographic strobe / ash unit.

SECTION 3 | EMC (EMI / EMS) Compliance

3.1 EMC (EMI / EMS) COMPLIANCE

These inverters contain internal switching devices that generate conducted and radiated

electromagnetic interference (EMI). The EMI is unintentional and cannot be entirely

eliminated. The magnitude of EMI is, however, limited by circuit design to acceptable

levels as per limits laid down in European Standard EN 55022, Class B. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in business / commercial / industrial environments. These inverters can conduct and radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

The unit complies with European EMC Directive 2014/30/EU. Please see specications at

Section 12 for relevant European Standards.

3.2 REDUCING EMI THROUGH PROPER INSTALLATION

The effects of EMI will also depend upon a number of factors external to the inverter

like proximity of the inverter to the EMI receptors, types and quality of connecting wires

and cables etc. EMI due to factors external to the inverter may be reduced as follows:

- Ensure that the inverter is rmly grounded to the ground system of the building or

the vehicle

- Locate the inverter as far away from the EMI receptors like radio, audio and video

devices as possible

- Keep the DC side wires between the battery and the inverter as short as possible.

- Do NOT keep the battery wires far apart. Keep them taped together to reduce their

inductance and induced voltages. This reduces ripple in the battery wires and improves performance and efciency.

- Shield the DC side wires with metal sheathing / copper foil / braiding:

- Use coaxial shielded cable for all antenna inputs (instead of 300 ohm twin leads)

- Use high quality shielded cables to attach audio and video devices to one another

- Limit operation of other high power loads when operating audio / video equipment

SECTION 4 | Powering Direct / Embedded Switch

Mode Power Supplies (SMPS)

4.1 CHARACTERISTICS OF SWITCHED MODE POWER SUPPLIES (SMPS)

Switch Mode Power Supplies (SMPS) are extensively used to convert the incoming AC

power into various voltages like 3.3V, 5V, 12V, 24V etc. that are used to power various devices and circuits used in electronic equipment like battery chargers, computers,

audio and video devices, radios etc. SMPS use large capacitors in their input section for

ltration. When the power supply is rst turned on, there is a very large inrush current drawn by the power supply as the input capacitors are charged (The capacitors act

almost like a short circuit at the instant the power is turned on). The inrush current at

turn-on is several to tens of times larger than the rated RMS input current and lasts for

a few milliseconds. An example of the input voltage versus input current waveforms is

given in Fig. 4.1. It will be seen that the initial input current pulse just after turn-on is >

15 times larger than the steady state RMS current. The inrush dissipates in around 2 or 3

cycles i.e. in around 33 to 50 milliseconds for 60 Hz sine wave.

Further, due to the presence of high value of input lter capacitors, the current drawn

by an SMPS (With no Power Factor correction) is not sinusoidal but non-linear as shown

in Fig 4.2. The steady state input current of SMPS is a train of non-linear pulses instead

of a sinusoidal wave. These pulses are two to four milliseconds duration each with a very

high Crest Factor of around 3 (Crest Factor = Peak value ÷ RMS value).

Many SMPS units incorporate “Inrush Current Limiting”. The most common method is

the NTC (Negative Temperature Coefcient) resistor. The NTC resistor has a high resistance when cold and a low resistance when hot. The NTC resistor is placed in series with

the input to the power supply. The cold resistance limits the input current as the input

capacitors charge up. The input current heats up the NTC and the resistance drops

during normal operation. However, if the power supply is quickly turned off and back

on, the NTC resistor will be hot so its low resistance state will not prevent an inrush

current event.

The inverter should, therefore, be sized adequately to withstand the high inrush current

and the high Crest Factor of the current drawn by the SMPS. Normally, inverters have

short duration Surge Power Rating of 2 times their Maximum Continuous Power Rating.

Hence, it is recommended that for purposes of sizing the inverter to accommodate

Crest Factor of 3, the Maximum Continuous Power Rating of the inverter should be > 2

times the Maximum Continuous Power Rating of the SMPS. For example, an SMPS rated

at 100 Watts should be powered from an inverter that has Maximum Continuous Power

Rating of > 200 Watts.

14 | SAMLEX AMERICA INC.

NOTE: Voltage

SECTION 4 | Powering Direct / Embedded Switch

Mode Power Supplies (SMPS)

and current scales

are dierent

Input voltage

Peak inrush

current

Inrush current

Fig 4.1: Inrush current in an SMPS

Non-linear

Input Current

Voltage (+)Voltage (–)

Current (+)Current (–)

Pulse

Rated steady state

input RMS current

Peak Current

RMS Current

NOTE: Voltage

and current scales

are dierent

Input Sine

Wave Voltage

TIME

Fig. 4.2: High Crest Factor of current drawn by SMPS

Crest Factor = Peak Current = 3

RMS Current

SECTION 5 | Principle of Operation

5.1 GENERAL

These inverters convert DC battery voltage to AC voltage with an RMS (Root Mean

Square) value of 230 VAC, 50/60 Hz.

5.2 PURE SINE WAVE OUTPUT WAVEFORM

The waveform of the AC voltage is a pure Sine Waveform that is same as the waveform

of Grid / Utility power (Supplementary information on pure Sine Waveform and its

advantages are discussed in Sections 2.2 to 2.4).

Fig. 5.1 below species the characteristics of 230 VAC, 50 Hz/60 Hz pure Sine Waveform.

The instantaneous value and polarity of the voltage varies cyclically with respect to time.

For example, in one cycle in a 230 VAC, 50 Hz/60 Hz system, it slowly rises in the Positive direction from 0V to a peak Positive value “Vpeak” = + 325.22V, slowly drops to 0V, changes

the polarity to Negative direction and slowly increases in the Negative direction to a peak

Negative value “Vpeak” = - 325.22V and then slowly drops back to 0V. There are 50 such

cycles in 1 sec in 50 Hz and 60 in 60 Hz. Cycles per second is called the “Frequency” and is

also termed “Hertz (Hz)”. The Time Period of 1 Cycle is 20.00 ms for 50 Hz and 16.66 ms

for 60 Hz.

Peak Positive Voltage

PEAK = + 325.22V

+ V

V

Voltage (+)Voltage (–)

RMS = 230 VAC

0V

20.00 ms for 50 Hz

16.66 ms for 60 Hz

TIME

Peak Negative Voltage

PEAK = - 325.22V

- V

Fig. 5.1: 230 VAC, 50/60 Hz Pure Sine Waveform

5.3 PRINCIPLE OF OPERATION

The voltage conversion takes place in two stages. In the rst stage, the DC voltage of

the battery is converted to a high voltage DC using high frequency switching and Pulse

Width Modulation (PWM) technique. In the second stage, the high voltage DC is converted to 230 VAC, 50/60 Hz sine wave AC again using PWM technique. This is done by

using a special wave shaping technique where the high voltage DC is switched at a high

frequency and the pulse width of this switching is modulated with respect to a reference sine wave.

16 | SAMLEX AMERICA INC.

SECTION 6 | Layout

6

6. LAYOUT

10

PST-60S: Front

NEG – POS +

WARNING:

REVERSE POLARITY WILL DAMAGE UNIT

LEGEND

1. Power ON/OFF Switch

2. Green LED - Power Ouptut Status

3. Red LED - Overload

11

4. Red LED - Over temperature

5. “Schuko” type AC outlet

6. Cooling Fan Opening

7. Grounding Terminal - M5

8. Negative (-) DC Input Terminal

9. Positive (+) DC Input Terminal

10. Modular Jack for RC-15 Remote

Control (Bottom of Unit)

11. 50 / 60 Hz Selector Switch

Cylindrical hole

diameter 11 mm

}

with M8 Set Screw

PST-60S: Back

6

Fig. 6.1: Layout of PST-60S-12E, PST-60S-24E

10

PST-100S: Front

PST-100S: Back

NEG – POS +

WARNING:

REVERSE POLARITY WILL DAMAGE UNIT

Fig. 6.2: Layout of PST-100S-12E, PST-100S-24E

LEGEND

1. Power ON/OFF Switch

2. Green LED - Power

Output Status

3. Red LED - Over load

11

4. Red LED - Over Temperature

5. Schuko Type AC Output

Receptacle

6. Opening for Cooling Fan

7. Grounding Terminal - M5

8. DC Input “-”

9. DC Input “+”

10. Remote Control Jack

(Bottom of the unit)

11. 50 / 60 Hz Selector Switch

Cylindrical hole

diameter 11 mm

}

with M8 Set Screw

SECTION 6 | Layout

i

11 5 4 3 2 1 10

PST-200S, PST-150S: Front

9

REVERSE POLARITY WILL DAMAGE UNIT

NEG –POS +

WARNING:

8

LEGEND

1. Power ON/OFF Switch

2. Green LED - Power Output Status

3. Red LED - Over Load

4. Red LED - Over Temperature

5. “Schuko” Type AC Outlets

6. Cooling Fan Opening

7. Grounding Terminal - cylindrical

hole diameter 8 mm and M8 Set

Screw

8. DC Input “-”

9. DC Input “+”

10. Remote Control Jack

11. 50 / 60 Hz Selector Switch

Cylindrical hole

diameter 11 mm

}

with M8 Set Screw

6

PST-200S, PST-150S: Back

7

6

Fig. 6.3: Layout of PST-150S-12E, PST--150S-24E, PST-200S-12E, PST--200S-24E

SECTION 7 | General Information on Lead Acid

Batteries

7.1 GENERAL

INFO

For complete background information on Lead Acid Batteries and charging

process, please visit www.samlexamerica.com > support > white papers >

White Paper - Batteries, Chargers and Alternators.

Lead-acid batteries can be categorized by the type of application:

1. Automotive service - Starting/Lighting/Ignition (SLI, a.k.a. cranking), and

2. Deep cycle service.

Deep Cycle Lead Acid Batteries of appropriate capacity are recommended for powering

of inverters.

18 | SAMLEX AMERICA INC.

SECTION 7 | General Information on Lead Acid

Batteries

7.2 DEEP CYCLE LEAD ACID BATTERIES

Deep cycle batteries are designed with thick-plate electrodes to serve as primary power

sources, to have a constant discharge rate, to have the capability to be deeply discharged up

to 80 % capacity and to repeatedly accept recharging. They are marketed for use in recreation vehicles (RV), boats and electric golf carts – so they may be referred to as RV batteries,

marine batteries or golf cart batteries. Use Deep Cycle batteries for powering these inverters.

7.3 RATED CAPACITY SPECIFIED IN AMPERE-HOUR (Ah)

Battery capacity “C” is specied in Ampere-hours (Ah). An Ampere is the unit of measurement for electrical current and is dened as a Coulomb of charge passing through an electrical conductor in one second. The Capacity “C” in Ah relates to the ability of the battery to

provide a constant specied value of discharge current (also called “C-Rate”: See Section 7.6)

over a specied time in hours before the battery reaches a specied discharged terminal

voltage (Also called “End Point Voltage”) at a specied temperature of the electrolyte. As a

benchmark, the automotive battery industry rates batteries at a discharge current or C-Rate

of C/20 Amperes corresponding to 20 Hour discharge period. The rated capacity “C” in Ah

in this case will be the number of Amperes of current the battery can deliver for 20 Hours at

80ºF (26.7ºC) till the voltage drops to 1.75V / Cell. i.e. 10.5V for 12V battery, 21V for 24V battery and 42V for a 48V battery. For example, a 100 Ah battery will deliver 5A for 20 Hours.

7.4 RATED CAPACITY SPECIFIED IN RESERVE CAPACITY (RC)

Battery capacity may also be expressed as Reserve Capacity (RC) in minutes typically for

automotive SLI (Starting, Lighting and Ignition) batteries. It is the time in minutes a

vehicle can be driven after the charging system fails. This is roughly equivalent to the

conditions after the alternator fails while the vehicle is being driven at night with the

headlights on. The battery alone must supply current to the headlights and the computer/ignition system. The assumed battery load is a constant discharge current of 25A.

Reserve capacity is the time in minutes for which the battery can deliver 25 Amperes at

80ºF (26.7ºC) till the voltage drops to 1.75V / Cell i.e. 10.5V for 12V battery, 21V for 24V

battery and 42V for 48V battery.

Approximate relationship between the two units is:

Capacity “C” in Ah = Reserve Capacity in RC minutes x 0.6

7.5 TYPICAL BATTERY SIZES

The Table 7.1 below shows details of some popular battery sizes:

TABLE 7.1: POPULAR BATTERY SIZES

BCI* Group Battery Voltage, V Battery Capacity, Ah

27 / 31 12 105

4D 12 160

8D 12 225

* Battery Council International; ** Golf Cart

GC2** 6 220

SECTION 7 | General Information on Lead Acid

Batteries

7.6 SPECIFYING CHARGING / DISCHARGING CURRENTS: C-RATE

Electrical energy is stored in a cell / battery in the form of DC power. The value of the

stored energy is related to the amount of the active materials pasted on the battery

plates, the surface area of the plates and the amount of electrolyte covering the plates.

As explained above, the amount of stored electrical energy is also called the Capacity of

the battery and is designated by the symbol “C”.

The time in Hours over which the battery is discharged to the “End Point Voltage” for

purposes of specifying Ah capacity depends upon the type of application. Let us denote

this discharge time in hours by “T”. Let us denote the discharge current of the battery

as the “C-Rate”. If the battery delivers a very high discharge current, the battery will be

discharged to the “End Point Voltage” in a shorter period of time. On the other hand,

if the battery delivers a lower discharge current, the battery will be discharged to the

“End Point Voltage” after a longer period of time. Mathematically:

EQUATION 1: Discharge current “C-Rate” = Capacity “C” in Ah ÷ Discharge Time “T”

Table 7.2 below gives some examples of C-Rate specications and applications:

TABLE 7.2: DISCHARGE CURRENT RATES - “C-RATES”

Hours of discharge time “T” till

the “End Point Voltage”

0.5 Hrs. 2C 200A

1 Hrs. 1C 100A

5 Hrs. (Inverter application) C/5 or 0.2C 20A

8 Hrs. (UPS application) C/8 or 0.125C 12.5A

10 Hrs. (Telecom application) C/10 or 0.1C 10A

20 Hrs. (Automotive application) C/20 or 0.05C 5A

100 Hrs. C/100 or 0.01C 1A

NOTE:

When a battery is discharged over a shorter time, its specied “C-Rate” discharge current will

be higher. For example, the “C-Rate” discharge current at 5 Hour discharge period i.e. C/5 Amps will

be 4 times higher than the “C-Rate” discharge current at 20 Hour discharge period i.e. C/20 Amps.

"C-Rate" Discharge Current in Amps =

Capacity "C" in Ah ÷ Discharge Time

"T" in Hrs.

Example of C-Rate

Discharge Currents

for 100 Ah battery

7.7 CHARGING / DISCHARGING CURVES

Fig. 7.1 shows the charging and discharging characteristics of a typical 12V / 24V Lead Acid

battery at electrolyte temperature of 80°F / 26.7°C. The curves show the % State of Charge

(X-axis) versus terminal voltage (Y-axis) during charging and discharging at different C-Rates.

Please note that X-axis shows % State of Charge. State of Discharge will be = 100% - %

State of Charge. These curves will be referred to in the subsequent explanations.

20 | SAMLEX AMERICA INC.

SECTION 7 | General Information on Lead Acid

Batteries

Lead-Acid Battery Chart - 80˚F / 26.7˚C

24V 12V

16.5

33.0

16.0

32.0

15.5

31.0

15.0

30.0

14.5

29.0

14.0

28.0

13.5

27.0

13.0

26.0

12.5

25.0

Battery Voltage in VDC

12.0

24.0

11.5

23.0

11.0

22.0

10.5

21.0

10.0

20.0

9.5

19.0

9.0

18.0

0 10 20 30 40 50 60 70 80 90 100 110 120 130

CHARGE

C/100

C/20

C/10

C/5

C/3

Battery State of Charge in Percent (%)

C/5

C/10

C/20

C/40

DISCHARGE

Fig. 7.1: Charging / Discharging Curves for 12V / 24V Lead Acid Battery

7.8 REDUCTION IN USABLE CAPACITY AT HIGHER DISCHARGE RATES –

TYPICAL IN INVERTER APPLICATION

As stated above, the rated capacity of the battery in Ah is normally applicable at a discharge rate of 20 Hours. As the discharge rate is increased as in cases where the inverters

are driving higher capacity loads, the usable capacity reduces due to “Peukert Effect”.

This relationship is not linear but is more or less according to the Table 7.3.

TABLE 7.3 BATTERY CAPACITY VERSUS RATE OF DISCHARGE – C-RATE

C-Rate Discharge Current Usable Capacity (%)

C/20 100%

C/10 87%

C/8 83%

Table continues on the next page

SECTION 7 | General Information on Lead Acid

Batteries

TABLE 7.3 BATTERY CAPACITY VERSUS RATE OF DISCHARGE – C-RATE

(Continued from the previous page)

C-Rate Discharge Current Usable Capacity (%)

C/6 75%

C/5 70%

C/3 60%

C/2 50%

1C 40%

Table 7.3 shows that a 100 Ah capacity battery will deliver 100% (i.e. full 100 Ah) capacity

if it is slowly discharged over 20 Hours at the rate of 5 Amperes (50W output for a 12V

inverter and 100W output for a 24V inverter). However, if it is discharged at a rate of 50

Amperes (500W output for a 12V inverter and 1000W output for a 24V inverter) then

theoretically, it should provide 100 Ah ÷ 50 = 2 Hours. However, Table 7.3 shows that for 2

Hours discharge rate, the capacity is reduced to 50% i.e. 50 Ah. Therefore, at 50 Ampere

discharge rate (500W output for a 12V inverter and 1000W output for a 24V inverter) the

battery will actually last for 50 Ah ÷ 50 Amperes = 1 Hour.

7.9 STATE OF CHARGE (SOC) OF A BATTERY – BASED ON

“STANDING VOLTAGE”

The “Standing Voltage” of a battery under open circuit conditions (no load connected

to it) can approximately indicate the State of Charge (SOC) of the battery. The “Standing Voltage” is measured after disconnecting any charging device(s) and the battery

load(s) and letting the battery “stand” idle for 3 to 8 hours before the voltage measurement is taken. Table 7.4 shows the State of Charge versus Standing Voltage for a typical

12V/24V battery system at 80°F (26.7ºC).

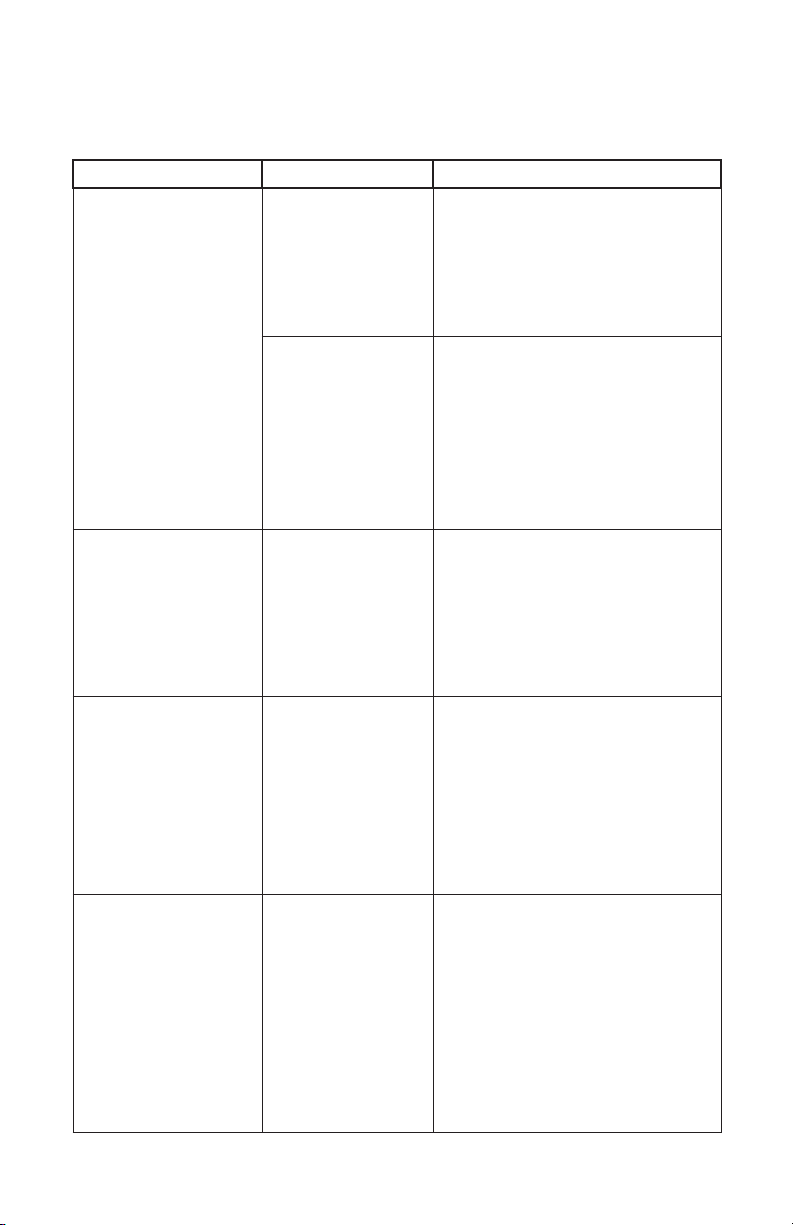

TABLE 7.4: STATE OF CHARGE VERSUS STANDING VOLTAGE

Percentage of

Full Charge

100% 2.105V 12.63V 25.26V

90% 2.10V 12.6V 25.20V

80% 2.08V 12.5V 25.00V

70% 2.05V 12.3V 24.60V

60% 2.03V 12.2V 24.40V

50% 2.02V 12.1V 24.20V

30% 1.97V 11.8V 23.60V

20% 1.95V 11.7V 23.40V

10% 1.93V 11.6V 23.20V

0% = / < 1.93V = / < 11.6V = / < 23.20V

Standing Voltage

of Individual Cells

Standing Voltage of

12V Battery

Standing Voltage

of 24V Battery

22 | SAMLEX AMERICA INC.

SECTION 7 | General Information on Lead Acid

Batteries

Check the individual cell voltages / specic gravity. If the inter cell voltage difference is

more than a 0.2V, or the specic gravity difference is 0.015 or more, the cells will require

equalization. Please note that only the non-sealed / vented / ooded / wet cell batteries

are equalized. Do not equalize sealed / VRLA type of AGM or Gel Cell Batteries.

7.10 STATE OF DISCHARGE OF A LOADED BATTERY – LOW BATTERY /

DC INPUT VOLTAGE ALARM AND SHUTDOWN IN INVERTERS

Most inverter hardware estimate the State of Discharge of the loaded battery by measuring the voltage at the inverter’s DC input terminals (considering that the DC input cables

are thick enough to allow a negligible voltage drop between the battery and the inverter).

Inverters are provided with a buzzer alarm to warn that the loaded battery has been

deeply discharged to around 80% of the rated capacity. Normally, the buzzer alarm is

triggered when the voltage at the DC input terminals of the inverter has dropped to

around 10.5V for a 12V battery or 21V for 24V battery at C-Rate discharge current of

C/5 Amps and electrolyte temp. of 80°F. The inverter is shut down if the terminal voltage

at C/5 discharge current falls further to 10V for 12V battery (20V for 24V battery).

The State of Discharge of a battery is estimated based on the measured terminal voltage

of the battery. The terminal voltage of the battery is dependent upon the following:

- Temperature of the battery electrolyte: Temperature of the electrolyte affects the

electrochemical reactions inside the battery and produces a Negative Voltage

Coefcient – during charging / discharging, the terminal voltage drops with rise in

temperature and rises with drop in temperature.

- The amount of discharging current or “C-Rate”: A battery has non linear internal

resistance and hence, as the discharge current increases, the battery terminal voltage

decreases non-linearly.

The discharge curves in Fig. 7.1 show the % State of Charge versus the terminal voltage

of typical battery under different charge /discharge currents, i.e. “C-Rates” and xed

temperature of 80°F.

NOTE: The X-Axis of the curves shown in Fig 7.1 indicates the percentage State of

Charge. % State of Discharge should be converted to % State of Charge using the

formula given below:

• % State of Charge = 100% - % State of Discharge

7.11 LOW DC INPUT VOLTAGE ALARM IN INVERTERS

As stated earlier, the buzzer alarm is triggered when the voltage at the DC input terminals of the inverter has dropped to around 10.5V for a 12V battery (21V for 24V battery)

at C-Rate discharge current of C/5 Amps. Please note that the terminal voltage relative

to a particular of State Discharge decreases with the rise in the value of the discharge

current. For example, terminal voltages for a State of Discharge of 80% (State of Charge

of 20%) for various discharge currents will be as given at Table 7.5 (Refer to Fig 7.1 for

parameters and values shown in Table 7.5):

SECTION 7 | General Information on Lead Acid

Batteries

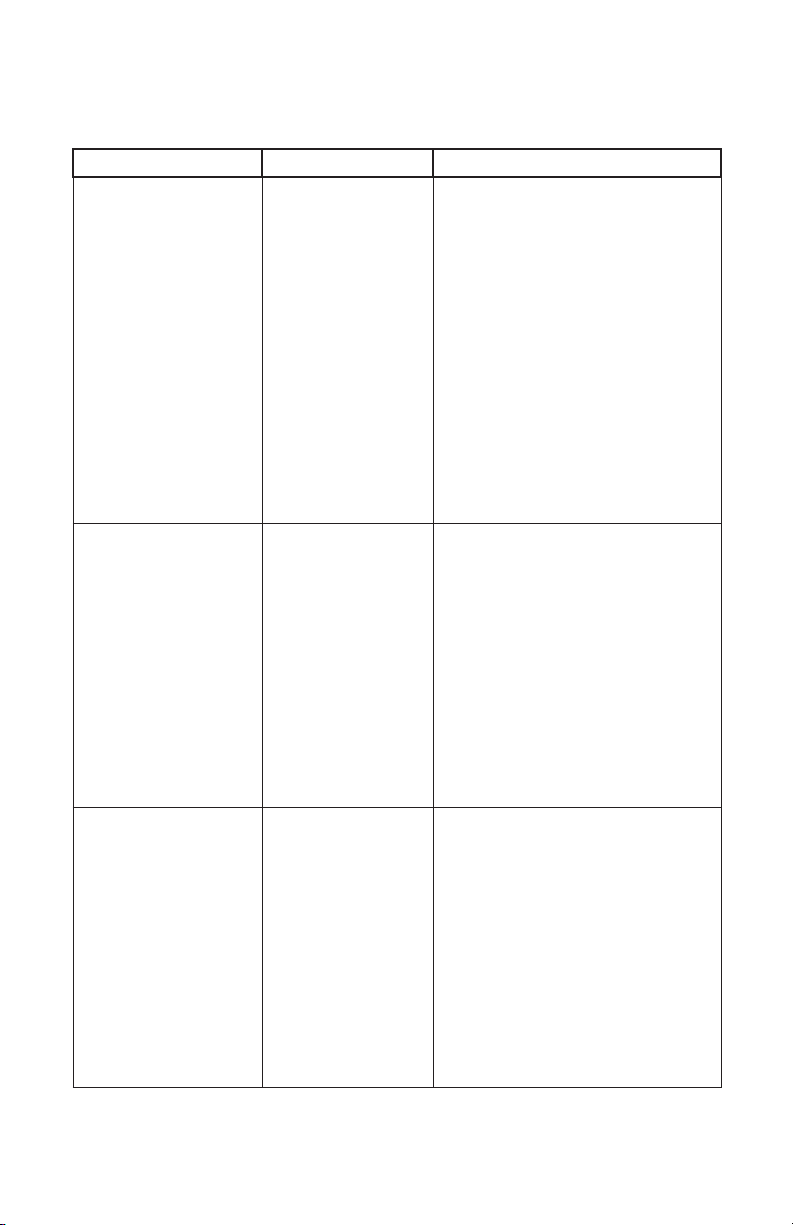

TABLE 7.5 TERMINAL VOLTAGE AND SOC OF LOADED BATTERY

Discharge Current:

C-Rate

C/3 A 10.45V 20.9V 09.50V 19.0V

C/5 A 10.90V 21.8V 10.30V 20.6V

C/10 A 11.95V 23.9V 11.00V 22.0V

C/20 A 11.85V 23.7V 11.50V 23.0V

C/100 A 12.15V 24.3V 11.75V 23.5V

In the example given above, the 10.5V / 21.0V Low Battery / DC Input Alarm would trigger at around 80% discharged state (20% SOC) when the C-Rate discharge current is C/5

Amps. However, for lower C-Rate discharge current of C/10 Amps and lower, the battery

will be almost completely discharged when the alarm is sounded. Hence, if the C-Rate

discharge current is lower than C/5 Amps, the battery may have completely discharged

by the time the Low DC Input Alarm is sounded.

7.12 LOW DC INPUT VOLTAGE SHUT-DOWN IN INVERTERS

As explained above, at around 80% State of Discharge of the battery at C-Rate discharge current of around C/5 Amps, the Low DC Input Voltage Alarm is sounded at

around 10.5V for a 12V battery (at around 21V for 24V battery) to warn the user to

disconnect the battery to prevent further draining of the battery. If the load is not disconnected at this stage, the batteries will be drained further to a lower voltage and to a

completely discharged condition that is harmful for the battery and for the inverter.

Terminal Voltage at 80% State

of Discharge (20% SOC)

12V 24V 12V 24V

Terminal Voltage When Completely

Discharged (0% SOC)

Inverters are normally provided with a protection to shut down the output of the inverter

if the DC voltage at the input terminals of the inverter drops below a threshold of around

10V for a 12V battery (20V for 24V battery). Referring to the Discharge Curves given in

Fig 7.1, the State of Discharge for various C-Rate discharge currents for battery voltage of

10V / 20V is as follows: (Please note that the X-Axis of the curves shows the % of State of

Charge. The % State od Discharge has to be converted to the % State of Charge using the

formula: % State of Charge = 100% - % State of Discharge):

- 85% State of Discharge (15% State of Charge) at very high C-rate discharge

current of C/3 Amps.

- 100% State of Discharge (0 % State of Charge) at high C-Rate discharge

current of C/5 Amps.

- 100% discharged (0% State of charge) at lower C-rate Discharge current of C/10 Amps.

It is seen that at DC input voltage of 10V / 20V, the battery is completely discharged for

C-rate discharge current of C/5 and lower.

24 | SAMLEX AMERICA INC.

SECTION 7 | General Information on Lead Acid

Batteries

In view of the above, it may be seen that a xed Low DC Input Voltage Alarm is not useful.

Temperature of the battery further complicates the situation. All the above analysis is based

on battery electrolyte temperature of 80°F. The battery capacity varies with temperature.

Battery capacity is also a function of age and charging history. Older batteries have lower

capacity because of shedding of active materials, sulfation, corrosion, increasing number of

charge / discharge cycles etc. Hence, the State of Discharge of a battery under load cannot

be estimated accurately. However, the low DC input voltage alarm and shut-down functions

are designed to protect the inverter from excessive current drawn at the lower voltage.

7.13 USE OF EXTERNAL PROGRAMMABLE LOW VOLTAGE DISCONNECTS

The above ambiguity can be removed by using an external, programmable Low Voltage

Disconnect where more exact voltage threshold can be set to disconnect the battery

based on the actual application requirements. Please consider using the following

Programmable Low Battery Cut-off / “Battery Guard” Models manufactured by Samlex

America, Inc. www.samlexamerica.com

- BG-40 (40A) – For up to 400W, 12V inverter or 800W, 24V inverter

- BG-60 (60A) - For up to 600W, 12V inverter or 1200W, 24V inverter

- BG-200 (200A) - For up to 2000W, 12V inverter or 4000W, 24V inverter

7.14 DEPTH OF DISCHARGE OF BATTERY AND BATTERY LIFE

The more deeply a battery is discharged on each cycle, the shorter the battery life. Using

more batteries than the minimum required will result in longer life for the battery bank.

A typical cycle life chart is given in the Table 7.6:

TABLE 7.6: TYPICAL CYCLE LIFE CHART

Depth of Discharge

% of Ah Capacity

10 1000 1500 3800

50 320 480 1100

80 200 300 675

100 150 225 550

NOTE: It is recommended that the depth of discharge should be limited to 50%.

Cycle Life of Group

27 /31

Cycle Life of Group 8DCycle Life of Group

GC2

SECTION 7 | General Information on Lead Acid

Batteries

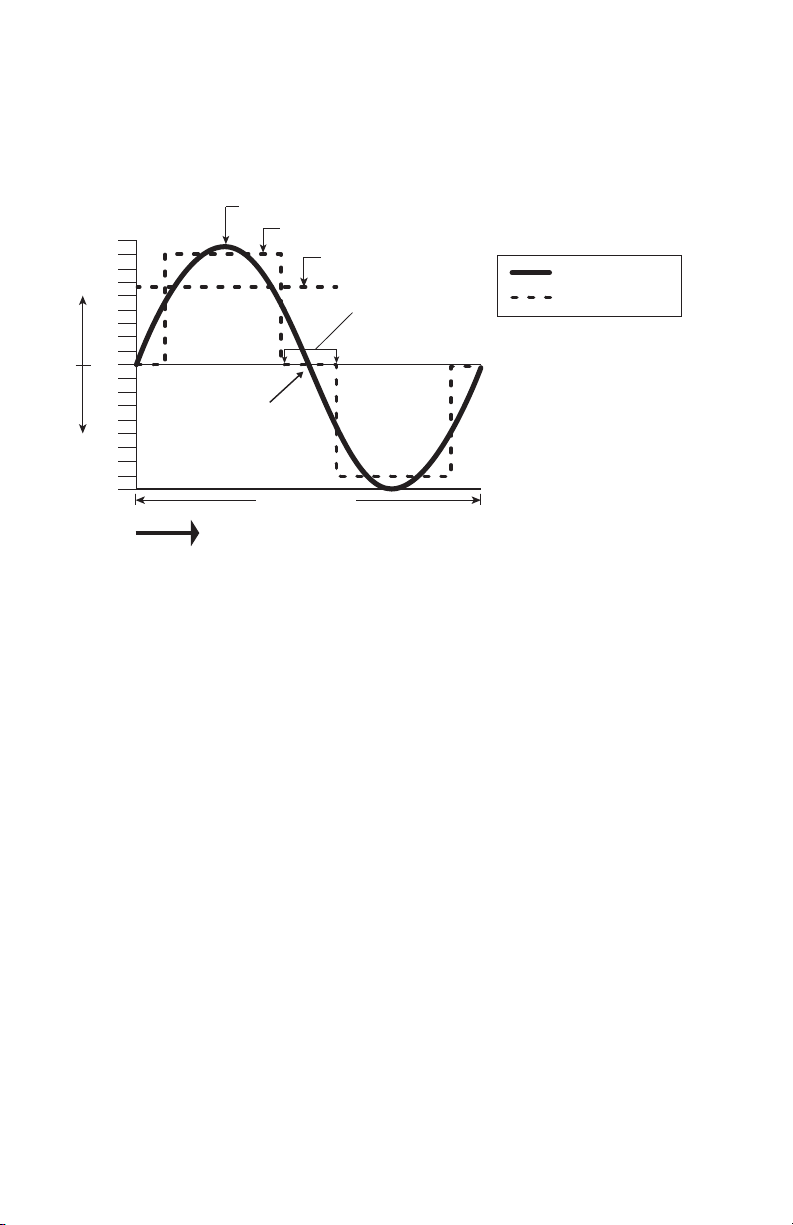

7.15 SERIES AND PARALLEL CONNECTION OF BATTERIES

7.15.1 Series Connection

Cable “A”

Battery 4 Battery 3 Battery 2 Battery 1

24V Inverter

or 24V Charger

Cable “B”

6V

6V 6V 6V

Fig 7.2: Series Connection

When two or more batteries are connected in series, their voltages add up but their Ah

capacity remains the same. Fig. 7.2 shows 4 pieces of 6V, 200 Ah batteries connected in

series to form a battery bank of 24V with a capacity of 200 Ah. The Positive terminal

of Battery 4 becomes the Positive terminal of the 24V bank. The Negative terminal of

Battery 4 is connected to the Positive terminal of Battery 3. The Negative terminal of

Battery 3 is connected to the Positive terminal of Battery 2. The Negative terminal of

Battery 2 is connected to the Positive terminal of Battery 1. The Negative terminal of

Battery 1 becomes the Negative terminal of the 24V battery bank.

7.15.2 Parallel Connection

Cable “A”

12V Inverter

or 12V Charger

Cable “B”

Battery 1 Battery 3Battery 2 Battery 4

12V

12V 12V 12V

Fig 7.3: Parallel Connection

When two or more batteries are connected in parallel, their voltage remains the same

but their Ah capacities add up. Fig. 7.3 shows 4 pieces of 12V, 100 Ah batteries connected in parallel to form a battery bank of 12V with a capacity of 400 Ah. The four Positive

terminals of Batteries 1 to 4 are paralleled (connected together) and this common Positive connection becomes the Positive terminal of the 12V bank. Similarly, the four Negative terminals of Batteries 1 to 4 are paralleled (connected together) and this common

Negative connection becomes the Negative terminal of the 12V battery bank.

26 | SAMLEX AMERICA INC.

!

SECTION 7 | General Information on Lead Acid

Batteries

7.15.3 Series – Parallel Connection

12V String 1 12V String 2

Cable “A”

12V Inverter

or 12V Charger

Cable “B”

Battery 1 Battery 3Battery 2 Battery 4

6V

6V 6V 6V

Fig. 7.4: Series-Parallel Connection

Figure 7.4 shows a series – parallel connection consisting of four 6V, 200 AH

batteries to form a 12V, 400 Ah battery bank. Two 6V, 200 Ah batteries, Batteries 1 and 2

are connected in series to form a 12V, 200 Ah battery (String 1). Similarly, two 6V, 200 Ah

batteries, Batteries 3 and 4 are connected in series to form a 12V, 200 Ah battery

(String 2). These two 12V, 200 Ah Strings 1 and 2 are connected in parallel to form a

12V, 400 Ah bank.

CAUTION!

When 2 or more batteries / battery strings are connected in parallel and are

then connected to an inverter or charger (See Figs 7.3 and 7.4), attention

should be paid to the manner in which the charger / inverter is connected

to the battery bank. Please ensure that if the Positive output cable of the

battery charger / inverter (Cable “A”) is connected to the Positive battery

post of the rst battery (Battery 1 in Fig 7.3) or to the Positive battery

post of the rst battery string (Battery 1 of String 1 in Fig. 7.4), then the

Negative output cable of the battery charger / inverter (Cable “B”) should

be connected to the Negative battery post of the last battery (Battery 4 as

in Fig. 7.3) or to the Negative Post of the last battery string (Battery 4 of

Battery String 2 as in Fig. 7.4). This connection ensures the following:

- The resistances of the interconnecting cables will be balanced.

- All the individual batteries / battery strings will see the same series resistance.

- All the individual batteries will charge / discharge at the same charging

current and thus, will be charged to the same state at the same time.

- None of the batteries will see an overcharge condition.

SECTION 7 | General Information on Lead Acid

Batteries

7.16 SIZING THE INVERTER BATTERY BANK

One of the most frequently asked questions is, "how long will the batteries last?" This

question cannot be answered without knowing the size of the battery system and the

load on the inverter. Usually this question is turned around to ask “How long do you

want your load to run?”, and then specic calculation can be done to determine the

proper battery bank size.

There are a few basic formulae and estimation rules that are used:

1. Active Power in Watts (W) = Voltage in Volts (V) x Current in Amperes (A)

x Power Factor.

2. For an inverter running from a 12V battery system, the approximate DC current required from the 12V batteries is the AC power delivered by the inverter to the load

in Watts (W) divided by 10 & for an inverter running from a 24V battery system, the

approximate DC current required from the 24V batteries is the AC power delivered

by the inverter to the load in Watts (W) divided by 20.

3. Energy required from the battery = DC current to be delivered

(A) x Time in Hours (H).

The rst step is to estimate the total AC Watts (W) of load(s) and for how long the

load(s) will operate in hours (H). The AC Watts are normally indicated in the electrical

nameplate for each appliance or equipment. In case AC Watts (W) are not indicated,

Formula 1 given above may be used to calculate the AC Watts. The next step is to

estimate the DC current in Amperes (A) from the AC Watts as per Formula 2 above. An

example of this calculation for a 12V inverter is given below:

Let us say that the total AC Watts delivered by the inverter = 1000W.

Then, using Formula 2 above, the approximate DC current to be delivered by the 12V

batteries = 1000W ÷10 = 100 Amperes, or by 24V batteries = 1000W ÷ 20 = 50A.

Next, the energy required by the load in Ampere Hours (Ah) is determined.

For example, if the load is to operate for 3 hours then as per Formula 3 above, the

energy to be delivered by the 12V batteries = 100 Amperes × 3 Hours = 300 Ampere

Hours (Ah), or by the 24V batteries = 50A x 3 Hrs = 150 Ah.

Now, the capacity of the batteries is determined based on the run time and

the usable capacity.

From Table 7.3 “Battery Capacity versus Rate of Discharge”, the usable capacity at

3 Hour discharge rate is 60%. Hence, the actual capacity of the 12V batteries to

deliver 300 Ah will be equal to: 300 Ah ÷ 0.6 = 500 Ah, and the actual capacity of the

24V battery to deliver 150 Ah will be equal to 150 Ah ÷ 0.6 = 250 Ah.

And nally, the actual desired rated capacity of the batteries is determined based on

the fact that normally only 80% of the capacity will be available with respect to the

rated capacity due to non availability of ideal and optimum operating and charging

conditions. So the nal requirements will be equal to:

28 | SAMLEX AMERICA INC.

SECTION 7 | General Information on Lead Acid

Batteries

FOR 12V BATTERY:

500 Ah ÷ 0.8 = 625 Ah (note that the actual energy required by the load was 300 Ah).

FOR 24V BATTERY:

250 Ah ÷ 0.8 = 312.5 Ah (Note that the actual energy required was 150 Ah).

It will be seen from the above that the nal rated capacity of the batteries is almost

2 times the energy required by the load in Ah. Thus, as a Rule of Thumb, the Ah

capacity of the batteries should be twice the energy required by the load in Ah.

7.17 CHARGING BATTERIES

Batteries can be charged by using good quality AC powered battery charger or from alternative energy sources like solar panels, wind or hydro systems. Make sure an appropriate

Battery Charge Controller is used. It is recommended that batteries may be charged at

10% to 13% of their Ah capacity (Ah capacity based on C-Rate of 20 Hr Discharge Time).

Also, for complete charging (return of 100% capacity) of Sealed Lead Acid Battery, it is

recommended that a 3 Stage Charger may be used (Constant Current Bulk Charging Stage

} Constant Voltage Boost / Absorption Charging } Constant Voltage Float Charging).

In case, Wet Cell / Flooded Batteries are being used, a 4-stage charger is recommended

(Constant Current Bulk Charging Stage } Constant Voltage Boost / Absorption Stage }

Constant Voltage Equalization Stage } Constant Voltage Float Stage).

SECTION 8 | Installation

WARNING!

1. Before commencing installation, please read the safety instructions

explained in Section 1 titled “Safety Instructions”.

2. It is recommended that the installation should be undertaken by a

qualied, licensed / certied electrician.

3. Various recommendations made in this manual on installation will

be superseded by the National / Local Electrical Codes related to the

location of the unit and the specic application.

8.1 LOCATION OF INSTALLATION

Please ensure that the following requirements are met:

Working Environment: Indoor use.

SECTION 8 | Installation

Cool: Heat is the worst enemy of electronic equipment. Hence, please ensure that the

unit is installed in a cool area that is also protected against heating effects of direct

exposure to the sun or to the heat generated by other adjacent heat generating devices.

Well Ventilated: The unit is cooled by convection and by forced air-cooling by temperature controlled fan. The fan draws cool air from air intake openings on the front (5, Fig

6.1a) and expels hot air through the exhaust openings next to the fan (18, Fig 6.1c). To

avoid shut down of the inverter due to over temperature, do not cover or block these

intake / exhaust openings or install the unit in an area with limited airflow. Keep a

minimum clearance of 10” around the unit to provide adequate ventilation. If installed

in an enclosure, openings must be provided in the enclosure, directly opposite to the air

intake and exhaust openings of the inverter.

Dry: There should be no risk of condensation, water or any other liquid that can enter

or fall on the unit.

Clean: The area should be free of dust and fumes. Ensure that there are no insects or

rodents. They may enter the unit and block the ventilation openings or short circuit electrical circuits inside the unit.

Protection Against Fire Hazard: The unit is not ignition protected and should not be

located under any circumstance in an area that contains highly ammable liquids like

gasoline or propane as in an engine compartment with gasoline-fueled engines. Do not

keep any flammable / combustible material (i.e., paper, cloth, plastic, etc.) near the unit

that may be ignited by heat, sparks or flames.

Closeness to the Battery Bank: Locate the unit as close to the battery bank as possible to

prevent excessive voltage drop in the battery cables and consequent power loss and reduced

efciency. However, the unit should not be installed in the same compartment as the batteries (ooded or wet cell) or mounted where it will be exposed to corrosive acid fumes and

ammable Oxygen and Hydrogen gases produced when the batteries are charged. The corrosive fumes will corrode and damage the unit and if the gases are not ventilated but

allowed to collect, they could ignite and cause an explosion.

Accessibility: Do not block access to the front panel. Also, allow enough room to access

the AC receptacles and DC wiring terminals and connections, as they will need to be

checked and tightened periodically.

Preventing Electro Magnetic Interference (EMI): The unit uses high power switching

circuits that generate RFI. This RFI is limited to the required standards. Locate any electronic equipment susceptible to radio frequency and electromagnetic interference as

far away from the inverter as possible. Read Section 3 “EMC (EMI/EMS) Compliance” for

additional information.

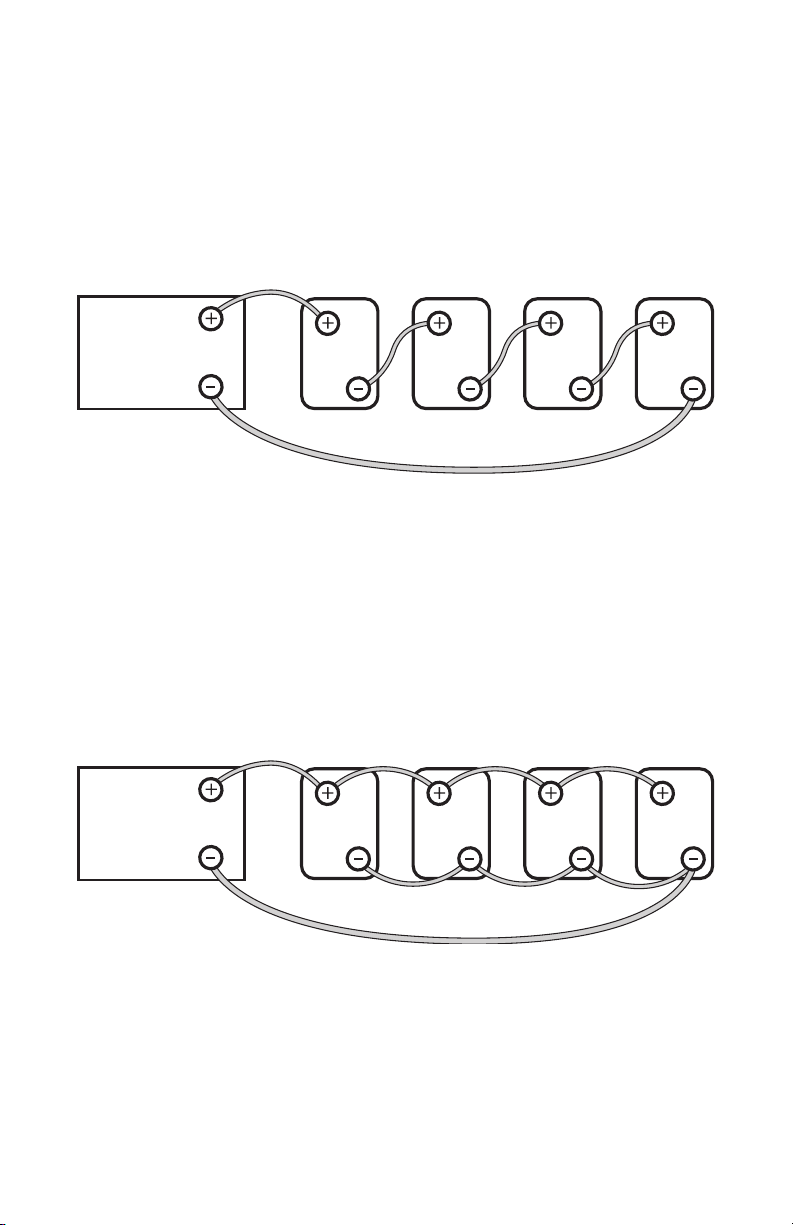

8.2 OVERALL DIMENSIONS

The overall dimensions and the location of the mounting slots are shown in Fig. 8.1 to

8.3 on next page.

30 | SAMLEX AMERICA INC.

240.6

SECTION 8 | Installation

5

5

15.3

200

230.6

240.6

15.3

5

32 12 162 12 32 1.61.6

Fig. 8.1: PST-60S-12E, PST-60S-24E Dimensions and

Mounting Slots / Dimensions (mm): 281 x 241 x 82

281

Height: 82 mm

15.3

230.6

15.3

400

5

200

5

1.6

5

Height: 82 mm

44 12 282 12 32 1.6

Fig. 8.2: PST-100S-12E, PST-100S-24E Dimensions and

Mounting Slots / Dimensions (mm): 240.6 x 400 x 82

SECTION 8 | Installation

3 80.5 225

4.5

273

282

4.5

Fig. 8.3: Dimensions and Mounting Slots for PST-150S-12E, PST-150S-24E

and PST-200S-12E, PST-200S-24E / Dimensions (mm): 282 x 415 x 101

5

Height: 101 mm

7

389

415

8.3 MOUNTING ORIENTATION

The unit has air intake and exhaust openings for the cooling fan. It has to be mounted

in such a manner so that small objects should not be able to fall easily into the unit from

these openings and cause electrical / mechanical damage. Also, the mounting orientation should be such that if the internal components overheat and melt / dislodge due to

a catastrophic failure, the melted / hot dislodged portions should not be able to fall out

of the unit on to a combustible material and cause a re hazard. The size of openings

has been limited as per the safety requirements to prevent the above possibilities when

the unit is mounted in the recommended orientations. In order to meet the regulatory

safety requirements, the mounting has to satisfy the following requirements:

- Mount on a non-combustible material.

- The mounting surface should be able to support the weight of the unit

- Mount horizontally on a horizontal surface - above a horizontal surface

(e.g. table top or a shelf).

- Mount horizontally on a vertical surface – The unit can be mounted on a vertical

surface (like a wall) with the fan axis horizontal (fan opening facing left or right).

32 | SAMLEX AMERICA INC.

!

SECTION 8 | Installation

WARNING!

Mounting the unit vertically on a vertical surface is NOT recommended (fan opening

facing up or down). As explained above, this is to prevent falling of objects into the unit

through the fan opening when the fan opening faces up. If fan opening faces down,

hot damaged component may fall out.

The surface of the unit is likely to be at an elevated temperature in conditions of higher

load and higher ambient temperature. Hence, the unit should be installed in a manner

where it is not likely to come in contact with any person.

8.4 DC SIDE CONNECTIONS

8.4.1 Preventing DC Input Over Voltage

It is to be ensured that the DC input voltage of this unit does not exceed 16.5 VDC for

the 12V versions and 33.0 VDC for the 24V versions to prevent permanent damage to

the unit. Please observe the following precautions:

- Ensure that the maximum charging voltage of the external battery charger / alternator / solar charge controller does not exceed 16.5 VDC for the 12V versions and 33.0

VDC for the 24V versions

- Do not use unregulated solar panels to charge the battery connected to this unit. Under

open circuit conditions and in cold ambient temperatures, the output of the solar panel

may be > 22 VDC for 12V nominal panel and > 44V for 24V nominal panel. Always use a

charge controller between the solar panel and the battery.

- When using Diversion Charge Control Mode in a charge controller, the solar / wind /

hydro source is directly connected to the battery bank. In this case, the controller will

divert excess current to an external load. As the battery charges, the diversion duty

cycle will increase. When the battery is fully charged, all the source energy will ow

into the diversion load if there are no other loads. The charge controller will disconnect the diversion load if the current rating of the controller is exceeded. Disconnection of the diversion load may damage the battery as well as the inverter or other DC

loads connected to the battery due to high voltages generated during conditions of

high winds (for wind generators), high water ow rates (for hydro generators). It is,

therefore, to be ensured that the diversion load is sized correctly to prevent the above

over voltage conditions.

- Do not connect this unit to a battery system with a voltage higher than the rated

battery input voltage of the unit (e.g. do not connect the 12V versions to 24V or 48V

Battery System or the 24V versions to 48V Battery System).

8.4.2 Preventing Reverse Polarity on the DC Input Side

CAUTION!

Damage caused by reverse polarity is not covered by warranty! When making

battery connections on the input side, make sure that the polarity of battery

connections is correct (Connect the Positive of the battery to the Positive termi-

SECTION 8 | Installation

!

nal of the unit and the Negative of the battery to the Negative terminal of the

unit). If the input is connected in reverse polarity, DC fuse(s) inside the inverter

will blow and may also cause permanent damage to the inverter.

8.4.3 Connection from Batteries to the DC Input Side – Sizing of Cables

and Fuses

CAUTION!

The input section of the inverter has large value capacitors connected across the

input terminals. As soon as the DC input connection loop (Battery (+) terminal

" External Fuse " Positive input terminal " Negative input terminal " Battery

(–) terminal) is completed, these capacitors will start charging and the unit will

momentarily draw very heavy current to charge these capacitors that will produce

sparking on the last contact in the input loop even when the unit is in OFF condition. Ensure that the fuse is inserted only after all the connections in the loop have

been completed so that sparking is limited to the fuse area.

Flow of electric current in a conductor is opposed by the resistance of the conductor.

The resistance of the conductor is directly proportional to the length of the conductor

and inversely proportional to its cross-section (thickness). The resistance in the conductor produces undesirable effects of voltage drop and heating. The size (thickness /

cross-section) of the conductors is specied in mm

Conductors thicker than AWG #4/0 are sized in MCM/kcmil. Table 8.1 below gives Resistance in Ohm (Ω) per Foot at 25°C / 77°F for the wire sizing recommended for use with

this inverter.

Table 8.1 Wiring Resistance per Foot

WIRE SIZE,

AWG

16 mm2 / AWG#6 0.000403 Ω / ft

2

/ AWG#4 0.000253 Ω / ft

25 mm

2

/ AWG#2 0.000159 Ω / ft

35 mm

2

/ AWG#1/0 0.000100 Ω / ft

50 mm

2

/ AWG#2/0 0.000079 Ω / ft

70 mm

2

/ AWG#3/0 0.000063 Ω / ft

95 mm

2

/ AWG#4/0 0.000049 Ω / ft

120 mm

2

or in AWG (American Wire Gauge).

RESISTANCE IN OHM (Ω)

PER FOOT AT 25°C / 77°F

Conductors are protected with insulating material rated for specic temperature e.g.