Sam4s NR-500R, NR-500 Service Manual

ELECTRONIC CASH REGISTER

CONTENTS

NR-500 Series

ELECTRONIC CASH REGISTER

Manual

1. Precaution Statements

2. Product Specifications

3. Installation and Operation

4. Disassembly and Assembly

5. Maintenance and Adjustment

6. Exploded Views and Parts List

7. PCB Layout and Parts List

8. Troubleshooting

9. Block diagram

10. Wiring Diagram

11. Schematic Diagrams

SERVICE

About this Manual

This service manual describes how to

perform hardware service maintenance for

the SAM4S NR-500 Series

Electronic Cash

Register.

Notes

Notes may appear anywhere in the

manual. They describe additional

information about the item.

Precaution symbols

. Indicates a Safety Precaution that

applies to this part component.

. Indicates the part or component is an

electro-statically sensitive device

. Use

caution when handling these parts.

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

ȱ

Copyright

གྷȱ2017ȱbyȱShinȱHeungȱPrecision.ȱ

ȱȱȱȱAllȱrightȱreserved.ȱ

Thisȱ manualȱ mayȱ not,ȱ inȱ wholeȱ orȱ inȱ part,ȱ

beȱ copied,ȱ photocopied,ȱ reproduced,ȱ

translatedȱorȱ convertedȱ toȱ anyȱ electronicȱ orȱ

machineȱȱreadableȱ fromȱ withoutȱ priorȱ

writtenȱ permissionȱ of

ȱ

Shinȱ Heungȱ

Precisionȱ.ȱ

ServiceȱManualȱ6thȱEdition.ȱ

Oct.ȱ2017ȱ

V1.6ȱ

ȱ

PrintedȱinȱKOREAȱ

SAM4S NR-500 SERIES

ȱ

ȱ

ȱ

ȱ

Overview of thi s E CR

This serv ice manual pr ovi des the technical information for many individual c o mponent systems, c ircuits and

giv es an anal y si s of the operations performed by the cir c uits. If you need more t ec hnical i nform ation, pl ease

contact our service branc h or R& D c enter. Schematics and specificat ions provide the needed informat ion for

the accurate t r oubleshooting.

All i nform ation in t his manual is subject to change without prior notice. Therefore, you must check the

correspondence of your manual with your machine. No par t of this manual may be copied or repr oduc ed in any

form or by any means, without t he pr ior written c onsent of Shin Heung Precision .

Note: Before using t his Electronic Cash Register (ECR) for the first t ime, leave it powered on in the REG mode

for at least twenty-f our hour s. This allows the MS Lithium battery, which mai ntains the memory of the

ECR while the power is of f, to c har ge c ompletely.

“Proper disposal of batter ies is required. Refer to your local codes f or disposal requir ements.”

Note: The socket outlet shall be installed near the equipment and shall be easily accessible.

SAM4S NR-500 SERIES 1-1

1 Precaution Statements

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1 Safety Precautions

1. Be sure that all buil t-in protective devi ces are

replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its as semblies, be

sure to r e s tor e all protect ive devices , incl uding

nonmetallic control knobs and compartment covers.

3. Make sure there are n o ca binet openings through

which people - particularly children - might insert

fingers and contact dangerous voltages.

Such open ings include excess ively wide cabinet

ventilation slots and improperly fitted covers and

drawers.

4. Design Alteration Warning:

Never al ter or add to the mechan ical or electrical

design of the ECR. Unauthorized alterations might

creat e a sa fety hazard. Also, any desi g n ch anges or

additions will void the manufacturer’s warranty.

5. Components, parts and wiring that appear to have

overheated or that are otherwise damaged should be

replaced with parts that meet the original

specifications. Always determine the cause of

damag e or over- hea ting, and correct an y potentia l

hazards.

6. Observe the original lead dress, especially near the

following areas : sharp edges, and especially the AC

and high voltage supplies.

Always inspec t for pin ched, out-of-pl ace, or frayed

wiring. Do not change the spacing between components and the prin ted circui t board. Check the A C

power cord for damage. Make sure that leads and

components do not touch thermally hot parts.

7. Product Safety Notice:

Some electrical and mechanical parts have special

safety-related c ha racteristicswhich might not be

obvious from visual inspection.

These sa fety featu res and th e protection they give

might be lost if the replacement component differs

from the origin al - even if the repla cement is rat ed

for higher voltage, wattage, etc.

Components that are critical for safety are indicated

in the circuit di agram by shading, (

) or ( ).

Use replacement components that have the same

ratings, especially for flame resistance and dielectric

strength specifications. A replacement part that

does not have the same safety characteristics as the

original might create shock, fire or other hazards.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose used batteries according to the manufacturer’s

instructions.

ATTENTION

ll y a danger d’explosion s’il y a remplacement incorrect

de la batterie.

Remplacer uniquement avec une batterie du même type

ou d’un type équivalent recommandé par le constructeur.

Mettre au rebut les batteries usagées conformément aux

inst ruc tion s du fabrica nt.

1 Precaution Statements

1-2 SAM4S NR-500 SERIES

1-2 Servicing Precautions

WA RNING: First read the-Safety Precautions-section of this manual. If some unforeseen circumstance creates a conflict

between the servicing and safety precautions, always follow the safety precautions.

WA RNING: An electrolytic capacitor installed with the wrong polarity might explode.

1. Servicing precautions are printed on the cabinet.

Follow them.

2. Always unplug the units AC power cord from the AC

power source before attempting to:

(a) Remove or reinstall any component or assembly

(b) Disconnect an electrical plug or connector

(c) Connect a test component in parallel with an

electrolytic capacitor

3. Some components are raised above the printed circuit

board for safety. An insulation tube or tape is

sometimes used. The internal wiring is sometimes

clamped to prevent contact with thermally hot

components. Reinstall all such elements to their

original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the portion around the

serviced part has not been damaged.

5. Check the insulation between the blades of the AC

plug and accessible conductive parts

(examples : metal panels and input terminals).

6. Insulation Checking Procedure:

Disconnect the p ower cord from the AC sour ce an d

turn the power s witch ON. C onnect an ins u lation

resistance meter (500V) to the blades of AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see above)

should be greater than 1 megaohm.

7. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

8. Always connect an instrument’s ground lead to the

instrument chassis ground before connecting the

positive lead ; always remove the instrument’s ground

lead last.

1-3 Precautions for Electrostatic Sensitive Devices (ESDs)

1. Some semiconductor (solid state) devices are easily

damaged by static electricity. Such components are

called Electrostatic Sensitive Devices (ESDs);

examples include integrated circuits and some fieldeffect transistors. The following techniques will reduce

the occurrence of component damage caused by static

electricity.

2. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known earth

ground. Alternatively, wear a discharging wrist-strap

device. (Be sure to remove it prior to applying power

- this is an electr ic shock precauti on.)

3. After removing an ESD-equipped assembly, place it

on a conductive surface such as aluminum foil to

prevent accumulation of electrostatic charge.

4. Do not use freon-propelled chemicals. These can

generate electrical charges that damage ESDs.

5. Use only a grounded-tip soldering iron when

soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device. Many

solder removal devices are not rated as anti-static;

these can accumulate sufficient electrical charge to

damage ESDs.

7. Do not remove a replacement ESD from its protective

package until you are ready to install it. Most

replacement ESDs are packaged with leads that are

electrically shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective material

from the leads of a replacement ESD, touch the

protective material to the chassis or circuit assembly

into which the device will be installed.

9. Minimize body motions when handling unpackaged

replacemen t ESDs. Moti ons such as brushin g cloth es

together, or lifting a foot from a carpeted floor can

generate enough static electricity to damage an ESD.

SAM4S NR-500 SERIES 2-1

2 Product Specifications

Specifications are correct at the time of printing. Product specifications are subject to change without notice.

See below for product specifications.

2-1 General Specification

Item Description Remark

Processor

x RENESAS CPU R5F5631ECDFB (RX-631 , 32-Bit)

Memory

x RAM(DATA)

SRAM (R1LV0408DSP-5SI) : 4Mbits

SRAM (R1LV0408DSP-5SI) : 4Mbits (Option)

x ROM(PGM)

CPU ON CHIP FLASH ROM : 16Mbits

x FISCAL ROM

OTP-ROM(AT27LV020A) : 2Mbits (Default)

OTP-ROM(AT27LV040A) : 4Mbits (Option)

Selectable

Selectable

Backup Battery

x Type : MS Lithium, 3.0V 11mAh

x Part Name : MS920S

x Charging Time : 24 Hours

x Life : 3 Years

Data Storage

x 180 Days

When battery is Full charged

Interface Serial

(RS-232C)

x Flow Control :

ᐭG DTR / DSR : H/W Flow Control

ᐮG XON / XOFF : S/W Flow Control

x Baud Rate : 1200 / 2400 / 4800 / 9600 / 19200 / 115200 Bps

x Connector : Serial#1 / DSUB9F (Female)

Serial#2 / RJ45

Serial#3 / RJ45

x Voltage Supply : +5V/150mA supplies at #9-Pin of DSUB9 Connector,

#1-pin RJ45 Connector.

USB

x USB A-Type (Default)

Transfer Type : BULK

Speed : 12 Mbps (USB 2.0 Full-Speed)

Power : Self-Powered

ETHERNET x 10/100 base-T (Option)

GPRS x Built-in type (Option)

SD CARD

x 1-Slot [ MICRO SD CARD (Internal) ] (Option)

x 1-Slot [ SD CARD (external) ] (Option)

Printer

x Model : LTP01-245-11

x Print Speed : 70mm/sec, 15 Lines/sec

x Type : Thermal Dot Line Printing

x Resolution : W 8 dots/mm x H 16 dots/mm

x Paper End Sensor (Reflecting Photo Sensor)

Detail Spec refer to Next

Page

Display

x Operator : 192 x 64 dot, Graphic LCD, Blue backlight(White LED)

x Customer : 16set x 2 line + Icon , Negative , Blue backlight(White LED)

Key Board

x Raised Key : 48 key (with CAP), NR-500R

x Flat Key : 90 key (with water proof), NR-500

Drawer x 24V / 15 ȍ Solenoid (Recommend)

Power Consumption x Regularity : Approx. 10W

Power Source x AC/DC Adapter : 9V / 2.5A

Environment Condition

x Temperature : 0 ~ 35

x humidity : 30% ~ 80% RH

Dimensions(mm)

x 400(W) x 450(D) x 266(H)

with Drawer

Weight x 11.5 Kg (Set Only)

Table2-1 General Specification

2 Product Specifications

2-2 SAM4S NR-500 SERIES

2-2 Appearance

2-2 A. Appearance Dimensions (mm)

Figure2-1 Dimensions

2-2 B. Location Feature

Figure2-2 Location Feature

£G Printer Cover

¤G Key Board

¥G Drawer

¦G Customer Display

§G Operator Display

¨G Mode Ke y

©G RS-232 Serial I/F Connector

NR-500R (Raised Keyboar d)

NR-500

(Flat K ey boar d)

2 Product Specifications

SAM4S NR-500 SERIES 2-3

2-3 Thermal Printer Specification

2-3 A. Printer Specification (58mm*1station or 2station)

Item Description Remark

Model

x LTP01-245-11

Print Method

x Thermal Dot Line Printing

Printing Format

T otal Dots Per Line

x 384 Dots

Dot Pitch

x Vertical : 0.125 mm

x Horizontal : 0.125 mm

Printing Speed

x 70mm/sec, 15 L ines/sec

Printing Direction

x Unidirectional Friction Feed

Paper Feeding

Feeding Method

x Friction Feed

Minimum Feed Pitch

x 0.0625 mm

Maximum Feeding Speed

x 75 mm/sec (At 8.5V of Motor Voltage )

Power Supply Volt

Power Voltage

x 4.2~9.5V (Recommend)

TPH / Motor

Circuit Input Voltage

x 3.3V

Head Control / Sensor

Printer Head

Heat Element Density

x 8 Dots/mm (0.125mm/Dot)

(1step 0.0625mm)

Total Head Elements

x 384 Dots/Dot Line

Available Printing Width

x 48 mm (384 Dots)

Line Feed Moto r

x 1-2 Phase Bi-Polar Stepping Motor

Sensor

Head Temperature

x Thermistor

Out-of-paper Detection

x Reflection type p hoto interrupter

Platen Position Detection

x Mechanical Switch

(Option)

Reliability Life

x 50km or more

Dimension (mm)

x 70.3 (W) ×32.7 (D) ×15.3 (H)

Weight

x Approx. 44 g

Table2-2 Thermal Printer Specificat ion

2 Product Specifications

2-4 SAM4S NR-500 SERIES

2-3 B. Paper Specification

Item Description Remark

Pape r T y pe

x Single-ply Thermal Paper Roll

Pape r Size

x 57.5 mm±0.5 (Width) × Ø 70 mm or less

Specified Paper

x Original Paper No : HPK-110 (Hansol paper XT)

Table2-3 Paper Specif ications

Note: The following paper can be used instead of the specified paper above.

TF50KS-E2D: Nippon paper industries Co.,Ltd.

PD 150R, PD160R-N : O ji paper Co.,Ltd.

F380 : Kansaki specialty papers, Inc. (US A )

2-3 C. Character Specification.

Item Description Remark

Chara cter Structure

x 12(W) × 24(H) Font

Character Size

x 1.25 mm(W) ×3.0 mm(H)

Column Pitch

x 1.5 mm

Line Pitch

x 4mm (Including 8-dot line spacing)

x 3.75 mm (Including 6-dot line spacing)

SPEED 40mm/s

SPEED 30mm/s

Number of Column

x 32(12×24 Dots/Character)

Table2-4 Character Specification

2-4 Power Specification

Item Description Remark

Input Volta ge

x AC 100-240V, 50-60Hz (Min : 90V, Max : 265V)

Power Consumpti on

x Regularity : Approx. 10W

Output Voltage

x DC 9V / 2.5A

Powe r Adap ter Output

Table2-5 Power Specif ication

2 Product Specifications

SAM4S NR-500 SERIES 2-5

2-5 Interface Specification

2-5 A. RS-232C Serial Interface

2-5 A-(a) Specification

Item Description Remark

Data Transmission

x Serial

Synchronization

x Asynchronous

Hand Shaking

(Flow Control)

x H/W : DTR / DSR

x S/W : XON / XOFF

XON : ASC Code 11h

XOFF : ASC Code 13h

Signal Level

x Logic”1” (MARK) : -3V ~ -15V

x Logic”0” (SPACE) : +3V ~ +15V

Baud Rate

x 1200 / 2400 / 4800 / 9600 / 115200 bps

Data Word Length

x 8 Bit

Parity

x None

Connector

x DSUB9F (Female) / RJ45

Voltage Supply

x +5V/150mA is supplied at #9-Pin of D-SUB Connector,

#1-Pin of RJ45 Connector.

For Bar Code Reader

or other devices

Table2-11 RS-232C Specification

2-5 A-(b) Cable Connection

7

8

4

5

1

2

)RSD( 6

)C.N( 7

)DXT( 3

)RTD( 4

)G.F(

)C.N( 1

ELAMEF

6

3

)DXR( 2

)G.S( 5

)C.N( 8

C P

NIP9 EDIS

trohS)niP 8,6(&

)niP 7,

4(

)RSD( 6

)C.N( 7

)DX

T( 3

)RTD( 4

ELAM

)G.F(

)C.N( 1

ELAM

D'B NO RCE

ELAMEF

ROTCENNOC

)DXR( 2

)G.S( 5

)C.N( 8

RCE

NIP9 EDIS

)C.P ot R.C.E( tuoyaL elbaC

ecafretnI laireS C232-SR

C P

ROTCENNOC

Figure2-4 RS232C Cable Connection (9Pin to 9Pin)

)RSD( 6

)STR( 7

)RSD( 6

)G.S( 7

)DXT( 3

)RTD( 4

)DXT( 3

)STC( 4

)G.F()G.F(

)C.N( 1)C.N( 1

ELAM

ELAM

ELAMEF

)DXR( 2

)G.S( 5

)STC( 8

)DXR( 2

)STR( 5

trohS)niP 8,6(&)niP 7,4(

6

7

3

4

1

D'B NO RCE

RCE

NIP9 EDIS

)RTD( 02

2

5

8

RETNIRP/TSOH

NIP52 EDIS

)P52 TSOH ot R.C.E( tuoyaL elbaC

ecafretnI laireS C232-SR

NIP52 TSOH

ROTCENNOC

ELAMEF

ROTCEN

NOC

Figure2-5 RS232C Cable Connection (9Pin to 25Pin)

2 Product Specifications

2-6 SAM4S NR-500 SERIES

2-5 A-(c) RS-232C I/F Cable (DSUB 9 PIN MALE TYPE)

Figure2-6 RS-232C Cable

2-5 A-(d) Signal Description (DSUB Connector)

Pin No. Signal Name Signal Direction Function

BODY Frame GND - Frame Ground

2 RXD Input Receive Data

3 TXD Output Transmit Data

4 DTR Output

This Signal indicates whether the ECR(NR-500) is busy. (H/W flow control)

ᐭG MARK(Logic1) : The ECR is busy

ᐮG SPACE(Logic0) : The ECR is not busy

The host transmits a data to the ECR, after confirming th i s signal.

When XON/XOFF flow control is selected, the host does not check this signal.

5 Signal GND - Signal Ground

6 DSR Input

This signal indicates whether the host computer or receipt printer can receive data. (H/W

flow control)

ᐭG MARK(Logic1) : The host can receive a data.

ᐮG SPACE(Logic0) : The host can not receive a data

The ECR transmits a data to the host or receipt printer, after confirming this signal.

When XON/XOFF flow control i s sel ected, the prin ter does not check this signal.

9 VCC Output VCC(+5V/150mA) is supplied at #9-Pin of DSUB9 Connector.*CAUTION*

Table2-12 RS-232C S ignal Description

2-5 A-(e) Signal Description (RJ-45 Connector)

Pin No. Signal Name Signal Direction Function

1 VCC Output VCC(+5V/150mA) is supplied at #1-Pin of RJ-45 Connector. *CAUTION*

2 DSR Input

This signal indicates whether the host computer or receipt printer can receive data. (H/W

flow control)

ᐭGMARK(Logic1) : The host can receive a data.

ᐮGSPACE(Logi c0) : The host can not receive a data

The ECR transmits a data to the host or receipt printer, after confirming this signal.

3 TXD Output Transmit Data

4 RXD Input Receive Data

7 Signal GND - Signal Ground

8 DTR Output

This Signal indica tes whether the ECR(NR-500) is busy. (H/W flow control)

ᐭGMARK(Logic1) : The ECR is busy

ᐮGSPACE(Log ic0) : The ECR is not bu sy

The host transmits a data to the ECR, after confirming this signal.

Table2-13 RS-232C Signal Description

2 Product Specifications

SAM4S NR-500 SERIES 2-7

2-5 A-(f) RS-232C I/F Cable (RJ-45 CONNECTOR TYPE)

5(RTS)

6(CTS)

3(TXD)

7(S.GND)

2(DSR)

7(RTS)

8(CTS)

5(S.GND)

3(TXD)

4(DTR)

8(DTR)

4(RXD)

6(DSR)

2(RXD)

Figure2-7 RS232C Cable Connection (RJ- 45 to DSUB 9Pin)

5(RTS)

7(S.GND)

8(DTR)

3(TXD)

4(RXD)

4(RTS)

7(S.GND)

6(DSR)

2(TXD)

3(RXD)

6(CTS)

2(DSR)

5(CTS)

20(DTR)

Figure2-8 RS232C Cable Connection (RJ- 45 to DSUB 25Pin)

Caution: T he V CC is supplied for the barcode or device power source. The Suppl y Cur r ent 150mA is

total value including Serial #1 and Serial #2 P ower Consumption. If the Total Power Consumption

of the attached dev ices is exceeded t he specifi c ation(150mA ) , the system stops the VCC of

D-SUB & RJ45 Connec tor

Caution: If the device with 5V/150mA is connected t o S er ial #1, t he V CC of Seri al #2 can not use.

If the devi c e with 100mA is connect ed to Serial #1, Other device with 50mA can be connected

to Serial #2 Port.

15m

15m

2 Product Specifications

2-8 SAM4S NR-500 SERIES

2-5A-(g) H/W Flow Control Timing

When DT R/DSR f low control is select , bef ore transmi tt ing a data, the E CR checks whether the host is BUSY

or not.

If the host is BUSY, ECR does not transmit a data to the host. If the host is not BUSY, ECR t r ansmits a data to

the Host. The host i s t he same. Refer to the Interface Part of Chapter 7(Special Circuit Diagram s).

2-5 A-(h) S/W Flow Control Timing

When XON/ XOFF flow control is selected, the ECR transmits XON(ASCII 11h) or XOFF(ACSII 13h) signal

through the Serial Data Line. I f the ECR i s busy, the printer transmits XOFF(ASCII 13h) to host t hrough the

Serial Data Line. Then the host recognizes that the ECR i s busy. So, the host does not transmit a data to the

ECR. If the ECR is released from busy, the ECR transmits XON(ASCII 11h) to host through the Serial Data

Line. Then the host recognizes that the ECR is not busy. And the host transmits a data to the ECR.

2 Product Specifications

SAM4S NR-500 SERIES 2-9

2-5 Interface Specification

2-5 B. USB Interface

2-5 B-(a) USB Specification

Item Description Remark

Transfer T y pe Ɣ BULK

Data Signal

Ɣ Bi-Direction, Half-Duplex

Ɣ Differential Signal Pair (D+ / D-)

Data Format

Ɣ NRZI Format

Ɣ Zero Bit Stuffing after 6 Ones

Transceiver

Ɣ Differential Common Mode Range : 0.8 ~ 2.5[V]

Ɣ Differential Receive Sensitivity : 200[mV]

Ɣ Single End Receive Threshold : 0.8 ~ 2.5[V]

Speed Ɣ 12 Mbps (USB 2.0 Full-Speed)

Power Ɣ Supply Self Power

Cable & Connector

Ɣ Cable : 5m / 2m

Ɣ Connector : A-type

Support Spec Ɣ USB 2.0 Full-Speed

2-5 B-(b) USB Signal Description

Pin No Signal Name Color Function

SHELL Shield Drain Wire Frame GND

1 VBUS Red 2 D- White Differential Data Line

3 D+ Green Differential Data Line

4 GND Black Signal GND

2-5 B-(c) USB Interface Cable

NR-500 SIDE

USB A TYPE USB A TYPE

( USB I/F CABLE )

USB B TYPE USB A TYPE

OTHER

DEVICE

SIDE

2 Product Specifications

2-10 SAM4S NR-500 SERIES

2-5 Interface Specification

2-5 C. ETHERNET Interface (Option)

2-5 C-(a) ETHERNET Signal Specification

Pin No Signal Name Signal Direction Function

1 ENET TX+ OUT Ethernet Tra nsmit Data Line (+)

2 ENET TX- OUT Ethernet Transmit Data Line(-)

3 ENET RX+ IN Ethernet Receive Data Line(+)

4N.C -5N.C -6 ENET RX- IN Ethernet Receive Data Line(-)

7N.C -8N.C --

2-5 C-(b) ETHERNET Interface Cable

NR-500 SIDE

1

8

1

8

MAX 100M

5(N.C)

7(N.C)

8(N.C)

4(N.C)

5(N.C)

6(ENET RX-)

7(N.C)

1(ENET TX+)

2(ENET TX-)

3(ENET RX+)

6(ENET RX-)

1(ENET TX+)

2(ENET TX-)

3(ENET RX+)

4(N.C)

8(N.C)

( NR-500 to HOST IRC I/F CABLE )

7(N.C)

8(N.C)

6(ENET RX-)

7(N.C)

2(ENET TX-)

3(ENET RX+)

4(N.C)

6(ENET RX-)

4(N.C)

2(ENET TX-)

3(ENET RX+)

5(N.C)

1(ENET TX+)

8(N.C)

5(N.C)

1(ENET TX+)

( NR-500 to HUB IRC I/F CABLE )

OTHER

DEVICE

SIDE

2 Product Specifications

SAM4S NR-500 SERIES 2-11

2-6 Drawer Kick-Out Specification

2-6 A. Drawer Signal Description

Pin No Signal Name Direction Function

1 S.G - Signal GND

2 DRA WER OUT Drawer Kick-Out Driver Sign al

3 DRA_COMP IN Drawer Open / Close Signal

4 +24V - Supply DC +24V

5--N.C

6 F.G - Frame GND

6

1

( DRAWER CONNECTOR )

5HFRPPHQG9ȍ6 ROHQRLG

2 Product Specifications

2-12 SAM4S NR-500 SERIES

MEMO

SAM4S NR-500 SERIES 3-1

3 Installation and Operation

3-1 System Configuration

Figure 3-1 System Configuration

3 Installation and Operation

3-2 SAM4S NR-500 SERIES

3-2 Installation

3-2 A. Paper Roll Installation

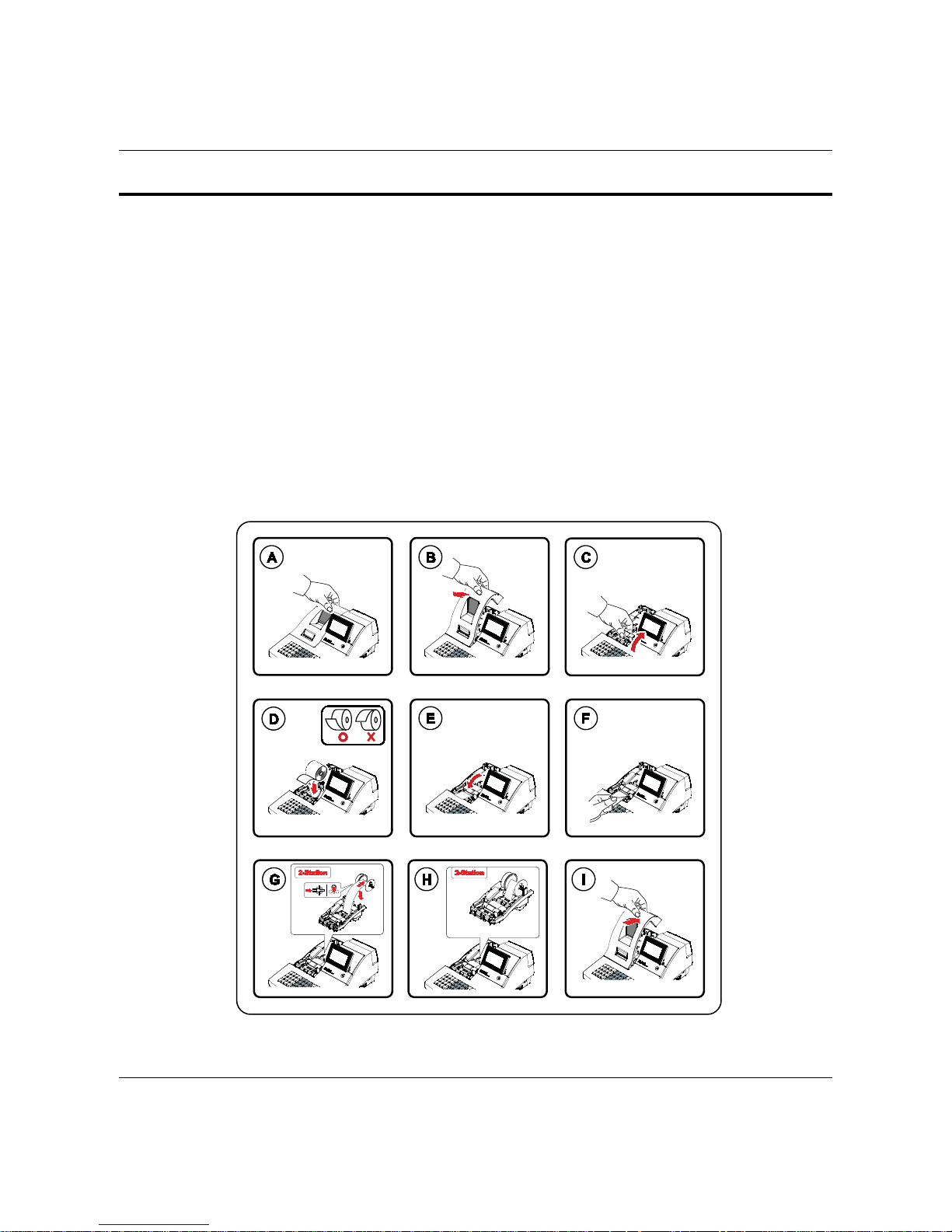

1. Remove the printer cover. (Fig 3-2 (A),(B))

2. Open the housi ng c over. (F ig 3-2 (C) )

3. Insert t he paper roll as shown. (Fig 3- 2 (D))

4. Be sure to note the correct direction that the paper comes off the rol l. (F ig 3-2 (D) )

5. Pull out a smal l amount of paper as shown. Then close the housing cov er. (Fig 3-2 (E))

6. Passing the l eading edge of t he paper thr ough the cutter slot. Tear off the ex c ess paper.(Fig 3-2(F) )

7. In case of 2station feed the leading edge of t he paper in about 150m m and f ol d the t i p i n 20m m . I nsert the

leading edge of the paper into the sl ot on the Spool W inding. (Fig 3-2(G) )

8. Insert t he Spool W inding i n 2~3 tur ns and place it on the Paper Suppl y. If it loosen, tur n to ti ghten i t. (Fi g

3-2(H))

9. Replace the printer c over. (F ig 3-2 (I))

Figure 3-2 Paper Installation

3 Installation and Operation

SAM4S NR-500 SERIES 3-3

3-2 B. RS-232C Serial Cable Installation

1.Connect the RS-232C serial cable to the RS-232C seri al port on the right side of E CR.

2.Secure the serial cable with screws.

3.Connect or the other end of the RS-232C serial Cabl e to your host computer.

Figure 3-3 Cable I nstallation

3-2 C. Options

No. Item Description Remark

1 Water Proof Raised Keyboard (Option)

2 Memory SRAM 4MBITs (4MBITs * 1) (On Main PBA) Factory option

3 Pulley Winding Spool motor & Pulley Factory option

Table 3-1 Option

3-2 D. Supplies

No. Item Description Remark

1 Paper Roll

1EA(1-station)

2 EA (2-sta ti on)

2 Mode Key VD, REG, Z, P, C

3 User Manu al 1 EA

4 Spool 1 EA (2-station only)

Table 3-2 Supplies

3 Installation and Operation

3-4 SAM4S NR-500 SERIES

3-3 Operation

Note: Before using t his Electronic Cash Register ( E CR) for the first t ime, leave it powered ON in t he REG mode

for a at l east 24 hours. Thi s allows the MS-Lithium Rechargeable battery, which maintains t he ECR’s

memor y while the power is OFF, to full y c har ge.

3-3 A. Mode Switch

The position of the Mode Key determ ines the action of t he E CR. The modes are as shown in Table 3-3.

Figure3-4 Mode Switch Table3-3 Mode Switch Function

The mode switch can be used to access the fol lowing key lock posi tions.

KEY Accessible Position Remark

VOID VOID, OFF, Register(REG), Manager(X)

REG OFF, Reg ister(REG)

Z VOID, OFF, Register(REG), Manager(X), Clear Totals(Z)

P VOID, OFF, Register(REG), Manager(X), Clear Totals(Z), Program(PGM)

C

VOID, OFF, Register(REG), Manager(X), Clear Totals(Z), Program(PGM), Service

Mode(S)

ALL POSITIONS

Table3-4 Key Function

Note : The Key can be removed from the key lock in the OFF or REG position.

Mode Function

VOID Use to void (correct) items outside of a sale.

OFF The Register is inoperable.

REG Use for norm al registrations.

X Use to read registe r reports an d perform o ther manager functions.

Z Use to read register reports and reset totals to zero.

PGM Use to program the register.

S

Use for H/W tests and special setting. The S position is hidden

position reserved for dealer access.

3 Installation and Operation

SAM4S NR-500 SERIES 3-5

3 Installation and Operation

3-6 SAM4S NR-500 SERIES

3-3 B. Key Board Matrix

1 32

4 65

7 98

DETL

FEED

ERROR

CORR

LEVEL2

PRICE

INQ

VOID

X/TIME

RETURN

NOSALE

0

.

00

CLEAR

LEVEL1

CANCEL

%1

5

8

10

11

9

6

12

7

1

4

2

3

RA

(PAGE

˨

)

CHARGE1

(˦)

CHECK

(

˨

)

PO

(PAGE

˦

)

CASH

CONV1

SUB

TOTAL

RCPT

FEED

SERVICE

RCPT

ON/OFF

CHECK#

PLU

Figure3-5 Raised Keyboard (NR- 510R / NR-520R)

27 45 39 33 3 21 15 9 51

#NOSALE

57

26 44 38 32 2 20 14 8 50

RCPT

ON/OFF

56

28 46 40 34 4 22 16 10 52

52 43 37 31 1 19 13 7 49

RCPT

FEED

55

VOID

58

29 47 41 35 5 23 17 11 53

RETURN

59

30 48 42 36 6 24 18 12 54

CANCEL

60

87

PLU

CLEAR

RA

(PAGE

˦

)

DETL

FEED

ERROR

CORR

54

21

000

CHARGE1

(˦)

9

%1X/TIME

CLERK

PO

(PAGE

˨

)

CHECK

(˨)

6

SBTL

3

CASH

.

Figure3-6 Flat Keyboard (NR-510 / NR- 520)

3 Installation and Operation

SAM4S NR-500 SERIES 3-7

3-3 C. Initial Clear

The init ial clear f unction allows you to exi t any register activ ity and retur n to a beginni ng or cleared state.

Any transaction that is in progress will be exited and totals for t hat transaction will not be updated.

1.Move to the PROGRAM MODE.

2.Turn the power switch loc ated on the right si de of the register to the OFF position.

3.Pr ess and hold t he k ey posi tion where the SUBTOTAL key is located on the default keyboard layout.

8

5

11

10

12

7

9

6

4

1

3

2

RA

CHARGE1

(˦)

CHECK

(

˨

)

PO

CASH

CONV1

SUB

TOTAL

51

VOID

57

50

#NOSALE

56

52

49

FEED

55

RETURN

58

53

ERROR

CORR

59

54

CANCEL

60

87

PLU

CLEAR

RA1

RECEIPT

ON/OFF

54

21

000

CHARGE1

(˦)

9

%1X/TIME

CLERKPO1

CHECK

(˨)

6

SBTL

3

CASH

.

Figure3-7 I nitial Clear Key for NR-510R/NR-520R F igure3-8 Ini tial Cl ear K ey for NR-510/NR- 520

4.Whi le continuing to hold the SUBTOTAL k ey, turn the power switch to the ON positi on. When the “INITIAL

CLEAR” message displays release the SUBTOTAL key.

5.Pr ess the CASH key.

6. Press the CASH key. The message "INITIAL CLEAR OK” prints when the initial clear is complete. To

resume operati ons, y ou will need to sign on a clerk.

ARE YOU SURE?

Y=CASH N=CLEAR

INITIAL CLEAR

ENTER CASH KEY

3 Installation and Operation

3-8 SAM4S NR-500 SERIES

3-3 D. All Clear

This step insures that the cash register i s clear ed of any t otals or progr am m ing. Af ter t hi s procedure, t he cash

register is ready for programming and oper ation.

WARNING: This is a one time procedu re. Do not repeat this p rocedure after the cash register is

programmed, it causes all programs an d totals to b e erased and to b e default.

Note : You need “ C Key ” to execute a SERVICE M ODE.

1.Move to the SERVICE MODE.

2.Turn the power switch loc ated on the right si de of the register to the OFF position.

3.Pr ess and hold t he key position where the A(CHECK) key i s l oc ated on the default keyboard layout.

4. Continue to hold the appropriate key while turning the power switch to the ON position. The message

“RAM ALL CLEAR" displays.

5.Pr ess the upper left k ey of t he keyboard, then the l ower left key, then the upper r ight key, and f i nally press

the lower right k ey.

3

A

4

1

2

Figure3-9 <Raised Keyboard – NR-510R / NR-520R>

1

2

3

A

4

.

Figure3-10 <Flat Keyboard – NR-510 / NR-520>

3 Installation and Operation

SAM4S NR-500 SERIES 3-9

6.T he S E RVICE M ODE m enu displays. The RAM Clear pr oc edur e is complete and the receipt prints.

Figure3-11 A ll Clear K ey S equenc e & P r int Sheet

2014/05/12 MON 09:00

* * * * * * * * * * * * * * * *

MEMORYALL C LEAR OK

* * * * * * * * * * * * * * * *

MEMORY ALLOC A TION

RAM 8Mbits OK

RAM 1 OK

RAM 2 OK

TTL AVAIL : 851968 Bytes

TTL USED : 327850 Bytes

================

VERSION INFORMAT ION

= = = = = = = = = = = = = = = =

VERSION : NR-500 : STD 00.001

CHECKSUM : 084F

BOOT/APP : BFBC/4893

PLUs USED : 60/2000

KEYBOARD : 90 KEYs

03.27 2014

CLERK 00 No.000001 00000

3 Installation and Operation

3-10 SAM4S NR-500 SERIES

3-3 E. Self Test

Before the test. You will find ‘SELF TEST’ menu.

1. Move to the SERVICE MODE.

2. Press the ‘1’ to select ‘SELF TEST’.

3-3 E-(a) Test Printer

1. From the SELF TE S T menu, Pr ess ‘2’ to select PRINTER.

2. From the PRINTER menu, Press ‘1’ to select PRINT T EST.

3. After printing, The drawer is opened. Then the printer test i s finished.

4. Press the ‘CLEAR’ key to return to S E LF TEST menu.

3-3 E-(b) Test Display

1. From the SELF TEST m enu, Press ‘3’to select DISPLAY.

2. From the DISPLAY menu, Press ‘1’ to select LCD TEST.

3. Press the ‘CASH’ key 2 times to finish LCD TEST.

4. Press the ‘CLEAR’ key to ret ur n to SELF TEST menu.

3-3 E-(c) Test Key Board

1. From the SELF TEST m enu, Press ‘4’to select KEYBOARD.

2. From the KEYBOARD menu, Press ‘1’ to select KEYBOARD TEST.

3. Press any key you want on the key board.

4. The key name of pressed key will be showed on the LCD.

5. Press the ‘CLEAR’ key to return to SE LF TEST menu.

3-3 E-(d) Test Mode Switch

1. From the SELF TEST m enu, Press ‘4’to select KEYBOARD.

2. From the KEYBOARD menu, Press ‘2’ to select MODE KEY TEST.

3. Turn the mode switch to any posit ion.

4. The corresponding Mode name will be showed on the LCD.

5. Press the ‘CLEAR’ key to return to SE LF TEST menu.

3-3 E-(e) Test SERIAL1 (COM1)

1. From the SELF TEST menu, Pr ess ‘5’ to select INTERFACE.

2. Install the serial loop back test jig. (S hor t “pin 2 , 3” , ” pin 4 , 6” ) of DSUB connector.

3. From the INTERFACE menu, Press ‘1’ to select SERIAL 1.

4. If error occ ur s, the message “ ** NG ** “ i s di spl ay ed on LCD and the Buzzer beep.

5. Press the ‘CLEAR’ key to return to SE LF TEST menu.

3-3 E-(f) Test SERIAL2 (COM2)

1. From the SELF TEST menu, Pr ess ‘5’ to select INTERFACE.

2. Install the serial loop back test j ig. (Short “ pin 3 , 4” , ” pin 2 , 8” ) of RJ-45 connector.

3. From the INTERFACE menu, Press ‘2’ to select SERIAL 2.

4. If error occ ur s, the message “ ** NG ** ” i s di spl ay ed on LCD and the Buzzer beep.

5. Press the ‘CLEAR’key to return to SELF TEST menu.

SELF TEST

1. BATCH TEST

2. PRINTER

3. DISPLAY

4.KEYBOARD

5.INTERFACE

6.RTC

Figure3-11 SELF TEST MENU

3 Installation and Operation

SAM4S NR-500 SERIES 3-11

3-3 E-(g) Test SERIAL3 (COM3)

1. From the SELF TEST menu, Pr ess ‘5’ to select INTERFACE.

2. Install the serial loop back test j ig. (Short “ pin 3 , 4” , ” pin 2 , 8” ) of RJ - 45 connector.

3. From the INTERFACE menu, Press ‘3’ to select S E RIAL 3.

4. If error occ ur s, the message “ ** NG ** ” is displayed on LCD and the Buzzer beep.

5. Press the ‘CLEAR’ key to return to SE LF TEST menu.

3-3 E-(h) USB HOST TEST

1. From the SELF TEST menu, Pr ess ‘5’ to select INTERFACE.

2. Put the USB Memory Stick to the USB Host port.

3. From the INTERFACE menu, Press ‘3’ to select USB HOST.

4. If USB i s OK , “ ** OK ** “ message will be displayed.

5. Press the ‘CLEAR’key to return to SELF TEST menu.

Note : When the ports is unconnected with the cable , the Error occur.

3-3 E-(i) EXTERNAL SD TEST

1. From the SELF TEST menu, Pr ess ‘5’ to select INTERFACE.

2. Put the External SD card.

3. From the INTERFACE menu, Press ‘4’ to select EXTERNAL SD.

4. If EXTERNAL SD card is OK, “ ** OK ** “ message will be displayed.

5. Press the ‘CLEAR’ key to retur n to SELF TEST m enu.

3-3 E-(j) MICRO SD TEST

1. From the SELF TEST menu, Pr ess the ‘5’ to select INTERFACE.

2. Put the MICRO SD card.

3. From the INTERFACE menu, Press ‘5’ to selec t MICRO SD.

4. If M ICRO SD card i s OK , “ ** OK ** “ message will be displayed.

5. Press the ‘CLEAR’ key to return to S E LF TEST menu.

3 Installation and Operation

3-12 SAM4S NR-500 SERIES

3-3 F. Flash ROM Updated by SD

The NR-500 Series Flash ROM program is contained in a binary file. This file contains both the Boot

program area and t he Appli c ation program ar ea.

1. Copy binary file to the root of the SD card. : SD:/update/

2. Insert the SD card int o the register. (The S D slot is l ocated inside the printer compartment . Remov e

the security screw and open the flap securi ng the SD slot. Insert the SD card unti l you hear a click sound

and the SD card is l oc k ed in.)

Boot Area Update

3. At the NR-500 Series, move to the SERVICE MODE.

4. Press the ȡ key and theȣ key to select menu and press the CASH key to confirm. Select the

7.PROGRAM BACKUP menu.

5. Select the 1.SD menu.

6. Select the 6.BOOT UP SD menu.

7. After a short pause, the register will display confirmation of the successful download with the message

“DOWNLOAD 100 % FINISHED! !.

8. Turn the ECR power switch OFF/O N and proceed direc tly to t he next step: Application Update.

ProgramArea Update

9. Set the SERVICE MODE.

10. Press the upper right key and the lower right key. A rapid beep-beep- beep sound will be heard. Release

the upper right k ey and the lower right k ey.

11. Press the ȡ key and theȣ key to select m enu and press the CASH key to confirm. Select the 2.SD

CARD menu.

12. The display will flash (Current program is being erased), after a few seconds, the display will continue to

flash, but at a slower rate. T his continues for about 1-m inute while the new program is being l oaded.

When the load is complete, a rapid beep-beep-beep sound will be heard again the display will stop

flashing and display a blue color to c onfirm update com pletion.

13. Power the register OFF. The FLASH RO M update is complete.

14. Remove the SD card from t he r egister.

15. Perform a memory all clear on the ECR. The ECR is now ready to program or to load a prev iously

saved end-user program.

3-3 G. Flash ROM Updated by PC

Update Files

To complet e the fir mware update, you will be supplied with the following files:

x DownLoad.exe (The update ut ility program)

x Binary file

PC Connection Cable

YOU MUST USE Port #1. Use the following cable:

x P ar t # 522120 (Register DB-9MF COM 1 to PC DB- 9F)

Boot Area Update

1. Connect the Serial Cable From ECR to PC.

2. At the register, move to t he SERVICE MODE.

Loading...

Loading...