Saeco INCANTO rondo, INCANTO classic, INCANTO de luxe, INCANTO sirius, INCANTO easy Service Manual

...Page 1

Saeco International Group

All parts of the present service manual are the pro perty of Saeco International Group. All rights rese rved. The manufacturer

is not responsible for any errors or omissions in t he present document. Any reproduction or unauthoris ed use of this manual

without the prior written permission of the manufac turer or by contractual agreement is prohibited.

INCANTO S-CLASS

INCANTO

INCANTO rondo

INCANTO classi

c

INCANTO de luxe

INCANTO sirius

SERVICE

MANUAL

Revision: 1

from page 03 to page 110

from page 111 to page 196

INCANTO easy

INCANTO

INCANTO rapidsteam

INCANTO digital

INCANTO digital SBS

Revision: 5

Saeco

Page 2

Page 3

Saeco International Group FEB.: 2005

All parts of the present service manual are the property of Saeco International Group. All rights reserved. The manufacturer

is not responsible for any errors or omissions in the present document. Any reproduction or unauthorised use of this manual

without the prior written permission of the manufacturer or by contractual agreement is prohibited.

INCANTO S-CLASS

INCANTO rondo

INCANTO classic

INCANTO de luxe

INCANTO sirius

SERVICE

MANUAL

Revision: 1

Saeco

Page 4

Page 5

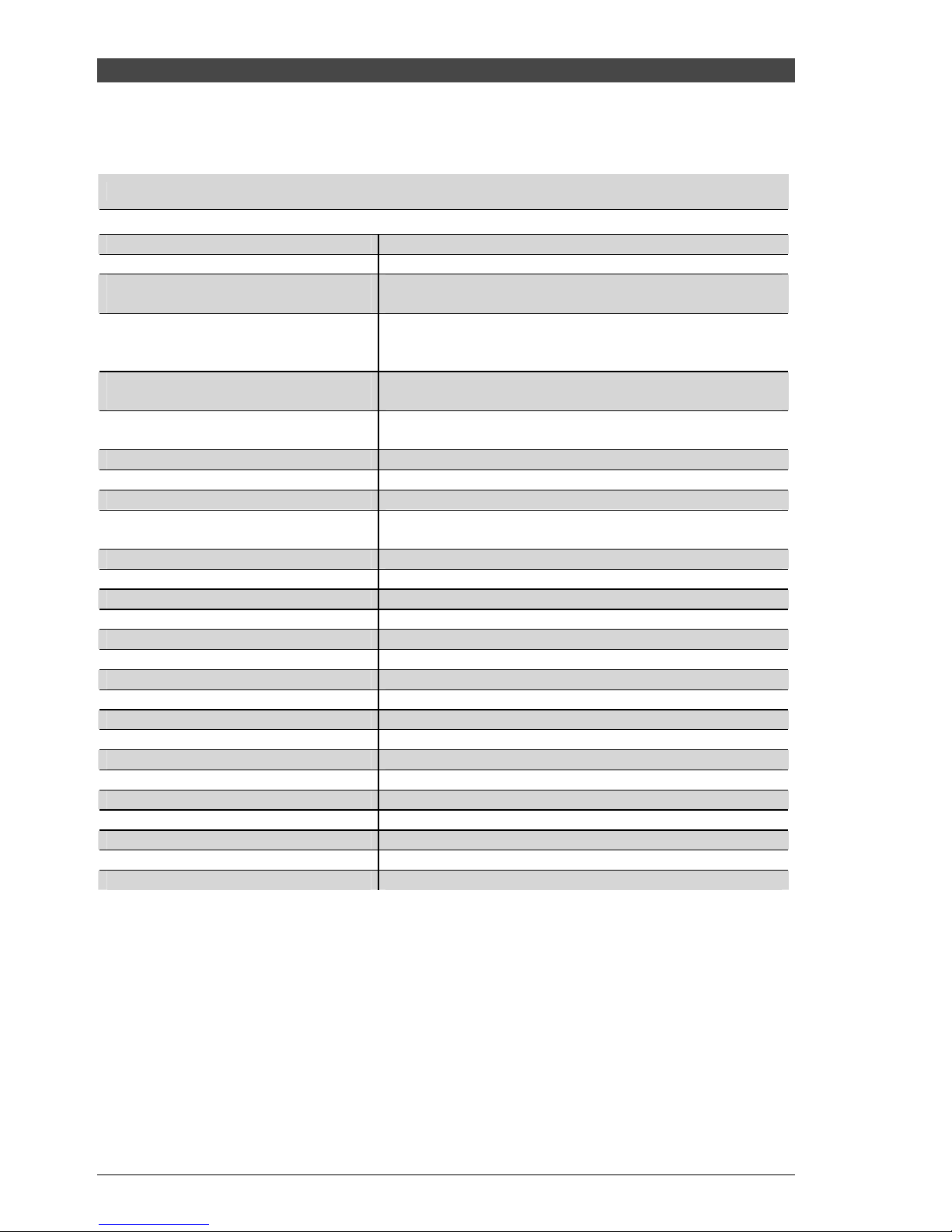

Table of contents

1. Introduction

2. Technical data

3. Operation

4. Functions and timing

5. Service programme

6. Faults

7. Repairs / Service Schedule / Final Test

8. Disassembly

9. Circuit diagrams

Saeco International Group REV.1 FEB.2005

Page 6

Page 7

CHAPTER 1

INTRODUCTION

Page

1. Documents required 1

2. Equipment 1

3. Material 1

4. Safety instructions 1

5. Overview of product range 2

Saeco International Group REV.1 FEB.2005

Page 8

Page 9

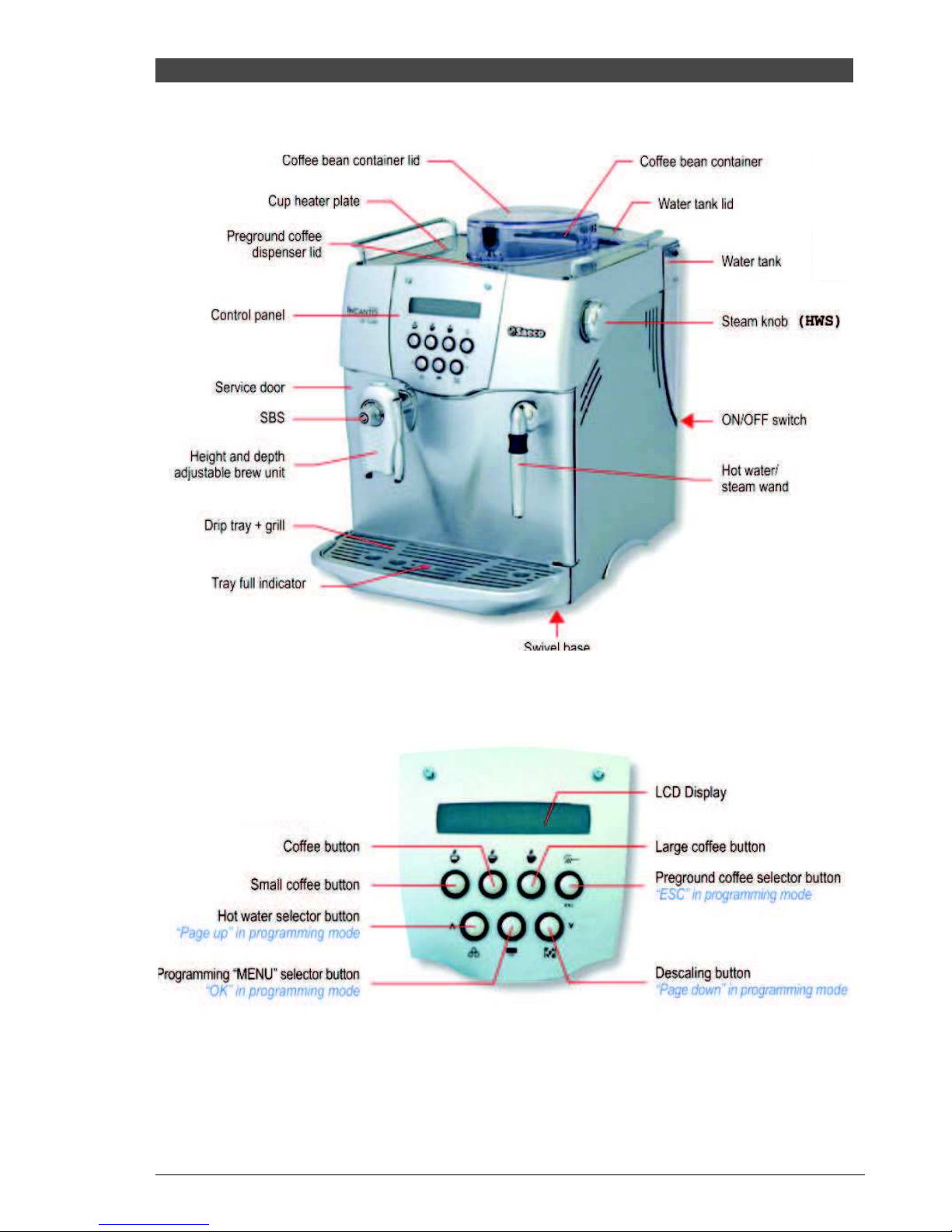

INCANTO S-CLASS 1. INTRODUCTION

Comments

Temperature measuring device Temperature range > 200ºC

Suitable for point measurements

3. Material

Bolt adhesive

Temperature resistance ≥ 2ŖŖǚȱ

ǻȱȱǼȱ

User's choice

Grease for grinder gear ! Saeco

4. Safety instructions

All prescriptions and regulations in force regarding the repair of electrical equipment must be

observed!

The machine must be disconnected from the main power supply before performing repair work.

Switching the machine off is not an adequate measure.

The Incanto coffee machine is classified under Protection Class 1. Protective devices must be

tested once the repair work has been completed (HG 701).

1. Requirements for operation

• Service manual

• Operating instructions where available

2. Equipment

In addition to an electrical workshop, the following standard tools are necessary:

Qty Description

1 Special screwdriver (Pozi) Size: PZ1

1 Special screwdriver (Pozi) Size: PZ2

1

Description Comments Brand

Heat conductive paste

Descaler Saeco

Grease solvent User's choice

Silicone grease

(food safe)

Temperature resistance ≥ 2ŖŖǚ

Saeco

User's choice

Saeco International Group REV.1 FEB.2005 Page 1/2

Page 10

1. INTRODUCTION INCANTO S-CLASS

INCANTO rondo SBS

x x

Incanto rondo

Incanto

classic

Incanto sirius

Incan

to de luxe

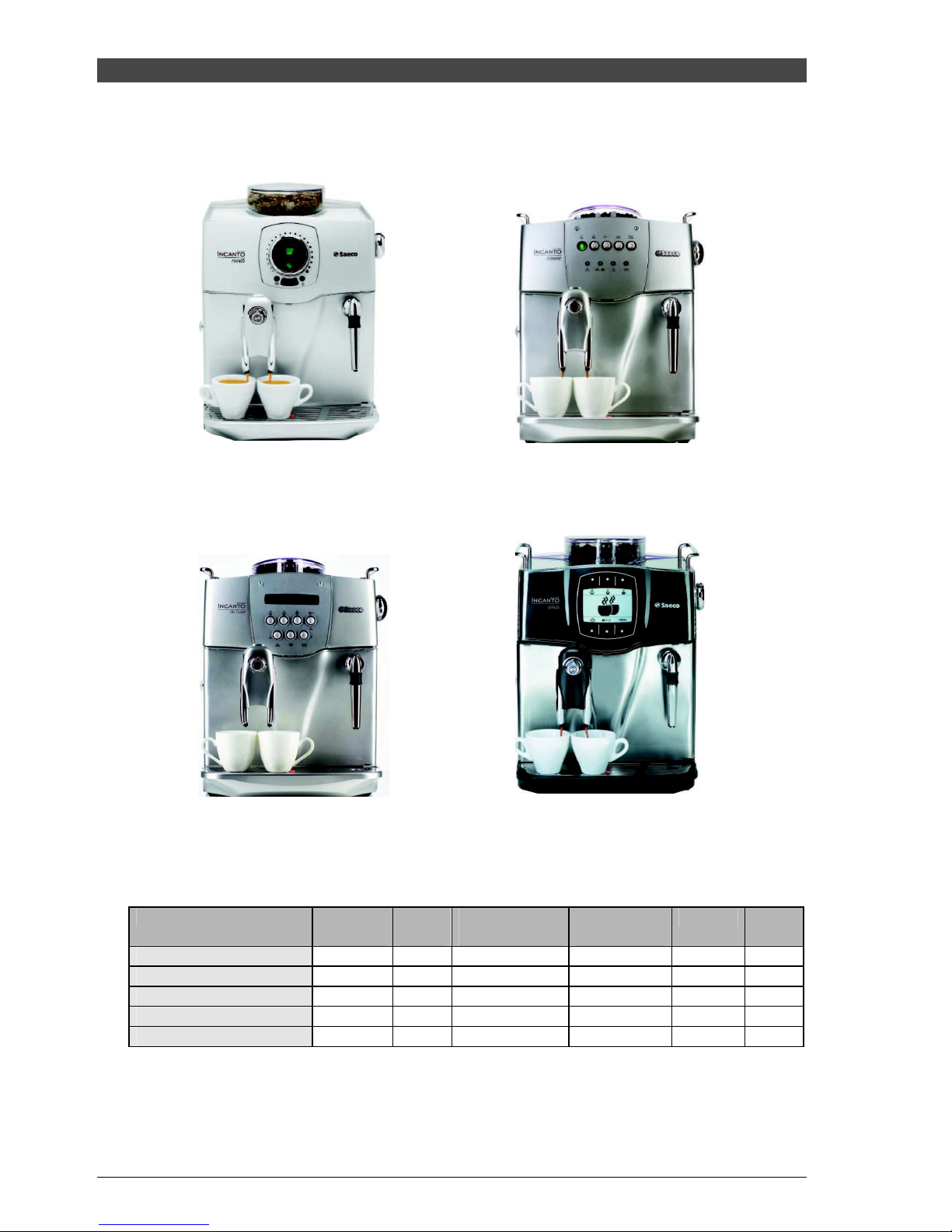

5. Overview of product range (Incanto S-CLASS)

Pre-

INCANTO rondo black

INCANTO classic

INCANTO de luxe

INCANTO sirius

brewing

x

x x x x x

x x x x x x

x x x x x x

Rapid

steam

Powder coffee

compartment

Cup

warmer

Display SBS

Page 2/2 REV.1 FEB.2005 Saeco International Group

Page 11

CHAPTER 2

TECHNICAL DATA

Page

1. Technical data (Incanto rondo) 1

2. Technical data (Incanto classic)

(Incanto de luxe)

(Incanto sirius) 2

Saeco International Group REV.1 FEB.2005

Page 12

Page 13

INCANTO S-CLASS 2. TECHNICAL DATA

Ulka reciprocating piston pump,

230V, 50 Hz, 48 W, Type EX5, 20 l/h, approx. 15 bar

Safety valve: Defibration safety valve (17 bar) connected directly to

pump.

Approx. 437W / 130ȍ on instantaneous water heater

Cup warmer: -

Approx. 1.7l max.

Boiler capacity: Approx. 1.0 ccm, 10 ml volume

1. Technical data (Incanto rondo)

INCANTO rondo

Technical data

Power supply/output: 230V 50Hz 1250W

Safety system: 170°C Safety thermostat for instantaneous water heater

Temperature monitoring:

Heating system: Instantaneous water heater (1090 W) for coffee, hot

Pump:

Water filter: In water tank, installed at outlet.

Gearmotor: Direct current, 30 - 35 V

Gear resistor:

Grinder: Flat milled grinder (ceramic discs)

Grinder motor: 230V Direct current

Second doser: Pulse control (approx. 6-12g)

Power consumption: During heating - approx. 4.5 A

Pump pressure: Max. 15 bar

Dimensions W x D x H in mm: 285/400/375

Weight: Approx. 9kg

Capacity of coffee bean container: Approx. 300g

Capacity of water tank:

De-aeration time: Approx. 10 for initial start-up

Heating time: About 45 sec.

Steam heating time: About 25 sec.

Coffee dispensing temperature: Approx. 86° C

Grinding time: 8 sec. /10g

Time to make expresso: Approx. 28 sec. for 50 ml

Time to make cup of coffee: Approx. 40 sec. for 100 ml

PTC - KTY Temperature sensors transmit respective

temperatures to electronic system

water and steam dispensing.

Saeco International Group REV.1 FEB.2005 Page 1/2

Page 14

2. TECHNICAL DATA INCANTO S-CLASS

230V 50Hz 1250W

Safety system: 170°C Safety thermostat for instantaneous water heater

Pulse control (approx. 6-12g)

Power consumption: During heating - approx. 4.5 A

About 25 sec.

Coffee dispensing temperature: Approx. 86° C

2. Technical data (Incanto classic, de luxe, sirius)

INCANTO classic, de luxe, sirius

Technical data

Power supply/output:

Temperature monitoring:

Heating system: Instantaneous water heater (1090 W) for coffee and

Pump:

Safety valve: Defibration safety valve (17 bar) connected directly to

Water filter: In water tank, installed at outlet.

Gearmotor: Direct current, 30 - 35 V

Gear resistor: Approx. 437W / 130ȍ on instantaneous water heater

Cup warmer: Foil heating (approx. 8 W / 6.3 Kȍ at room

Grinder: Flat milled grinder (ceramic discs)

Grinder motor: 230V Direct current

Second doser:

Pump pressure: Max. 15 bar

Dimensions W x D x H in mm: 285/400/375

Weight: Approx. 10kg

Capacity of coffee bean container: Approx. 300g

Capacity of water tank: Approx. 1.7l max.

Boiler capacity: Approx. 1.0 ccm, 10 ml volume

De-aeration time: Approx. 10 for initial start-up

Heating time: About 45 sec.

Steam heating time:

Grinding time: 8 sec. /10g

Time to make expresso: Approx. 28 sec. for 50 ml

Time to make cup of coffee: Approx. 40 sec. for 100 ml

PTC - KTY Temperature sensors transmit respective

temperatures to electronic system

hot water dispensing.

Pipe heating (1090 W) for steam dispensing

Ulka reciprocating piston pump,

230V, 50 Hz, 48 W, Type EX5, 20 l/h, approx. 15 bar

pump.

temperature)

Page 2/2 REV.1 FEB.2005 Saeco International Group

Page 15

Saeco International Group REV.1 FEB.2005

CHAPTER 3

OPERATION

Page

1. Operation (Incanto rondo)

1.1. Control panel 1

1.2. Operating instructions 2

2. Operation (Incanto classic)

2.1. Control panel 4

2.2. Operating instructions 5

2.3. User programme 8

3. Operation (Incanto de luxe)

3.1. Control panel 9

3.2. Operating instructions 10

3.3. User programme 14

4. Operation (Incanto sirius)

4.1. Control panel 16

4.2. Operating instructions 16

4.3. User programme 20

Page 16

Page 17

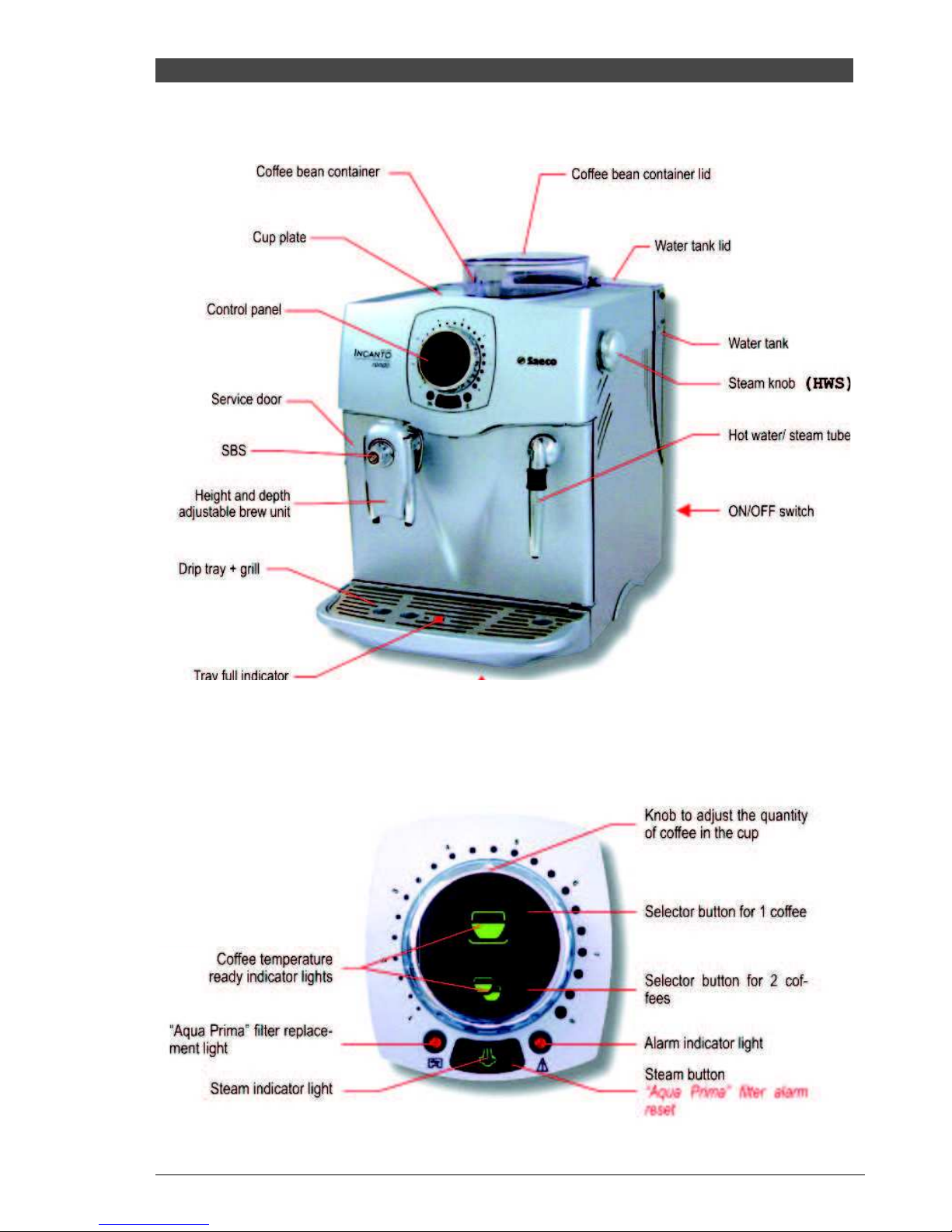

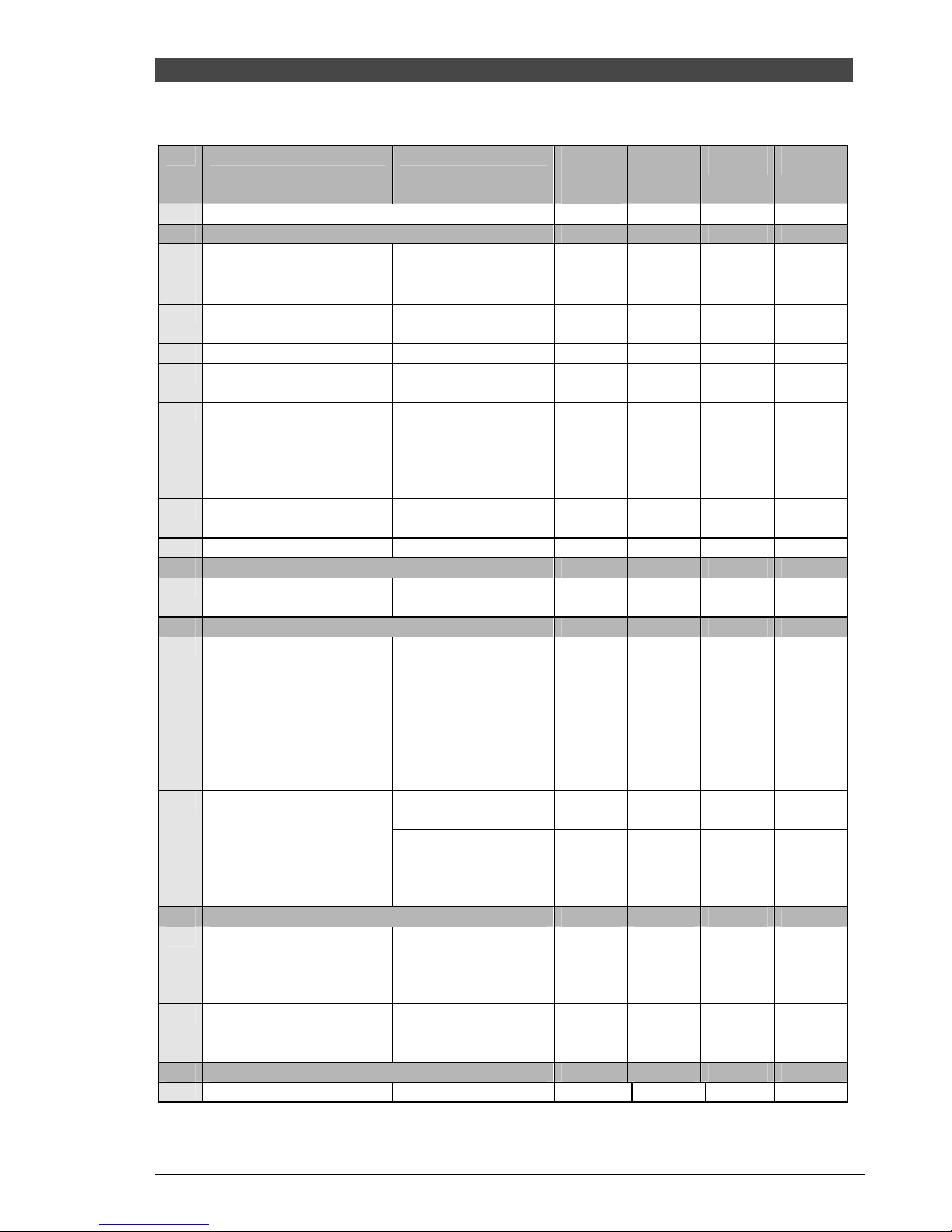

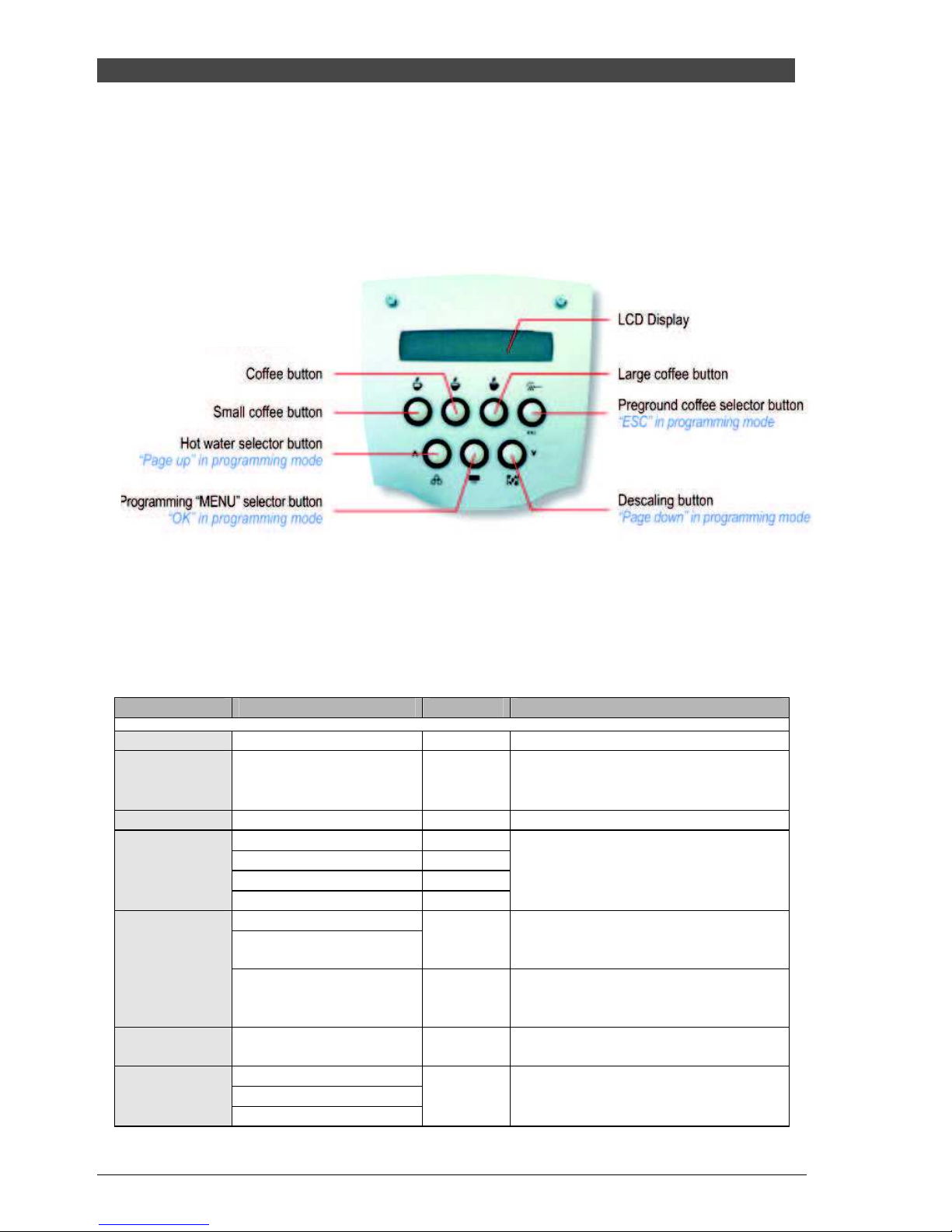

INCANTO S-CLASS 3. OPERATION

1. Operation (Incanto rondo)

1.1. Control panel

Saeco International Group REV.1 FEB.2005 Page 1/21

Page 18

3. OPERATION INCANTO S-CLASS

1

Unpack machine.

Check for damage.

Open hot water pressure

valve until water flows.

Flashes Flashes

Reset filter counter

Button 1 Coffee

Flashes

Immediate

ON

ON

Clean coffee bean container

As required.

Clean brewing unit and lubricate

Clean filter

1 x per month

1.2. Operating instructions (quick reference)

2 Install Aqua Prima filter.

3 Fill water tank

4 Fill coffee beans container.

5 Connect mains plug.

6 Turn on main switch.

7 De-aerate water circuit.

Heating stage (approx.

Ready

8 Press steam button.

9 Pre-select cup fill volume with

setting button.

10 Place cup under dispenser.

11 Press start button (coffee

button).

Action

Getting started

Comments

Wait for 30 min.

Flashes Flashes

45 sec.)

Filter LED flashes

briefly.

Making coffee

Depending on cup size. ON

Button 2 Coffee

LED 1

Coffee

Flashes Flashes

ON

Flashes

LED 2

Coffee

ON

ON

Steam

LED

Coffee dispensing / Powder coffee

12 No powder dispensed

13 Press steam button.

14 Ready

15 Steam dispensing.

Open HWS valve

16 Press steam button / deactivate

steam function.

Ready (to make coffee) ON

17 Open HWS valve

Empty dregs drawer

Empty drip tray

Clean water tank

Clean the housing

Rinse brewing unit

Descale

Dispensing steam

Hot water dispensing

Heating stage.

To warm coffee.

To froth milk.

Cool by de-aerating.

Cleaning

Storage capacity 12 tabs.

After 12 tabs.

As required.

As required.

1 x per week

Depending on water hardness.

Flashes

ON

ON

Flashes Flashes Flashes

ON

Page 2/21 REV.1 FEB.2005 Saeco International Group

Page 19

INCANTO S-CLASS 3. OPERATION

Medium water (15º-21ºdH) About every 2 months

About every 3 months

2 Fill water tank with descaler according to

the relevant instructions (Saeco descaler).

Place an appropriately sized container under the

HWS nozzle.

6 Close HWS valve

Troubleshooting

No display

No power supply to machine.

Check mains fuses / Is machine plugged in? / Is

main switch turned on?

- Pre-heat cups

- Clean brewing unit if necessary

Heating time too long, water quantity

insufficient

- Descale machine

LED 1 Coffee, LED 2 Coffee and Steam

LED flash

- Overheating: Remove hot water until only expresso

and coffee buttons are lit.

Warning LED flashes

- Dregs drawer/drip tray not installed.

- Brewing unit not installed.

- Doors not closed.

- Grinder obstructed.

- Gears obstructed

- Contact an authorised service centre.

Water hardness

Very hard water (over 21ºdH) About every 4 weeks

Hard water (15º-21ºdH) About every 6 weeks

Soft water (4-7ºdH)

Soft water (0-3ºdH)

Descaling procedure

Action

1 Remove Aqua Prima filter from water tank.

3 Open HWS valve

4 Turn machine off.

5 Turn machine on and repeat Points 3 to 5

until the descaler mixture is used up.

7 Fill tank with fresh water.

8 Rinse (until tank is empty)

9 Re-install Aqua Prima filter in water tank /

Fill tank.

Fault

Coffee is not hot enough

No hot water/steam

Hot water/steam nozzle blocked

The brewing unit cannot be removed.

Cannot dispense

Filter warning LED lights up

(MACHINE NOT LOCKED)

Warning LED lights up

Descaling frequency

Without Aqua Prima

About every 3 months

About every 6 months

Comments

Remove approx. 1/4 litre

Allow descaler to act for 10 min.

Open HWS valve

Descaling complete

- Descale if necessary

- Clean nozzle out with needle

(with machine turned off and closed rotary

valve/HWS valve).

- Close service door.

- Turn machine on (brewing unit moves to home

position)

- Install Aqua Prima filter.

Reset: Press steam button until filter warning LED

flashes

- Fill water tank.

- Fill coffee beans container.

- Empty grinds container

With Aqua Prima

About every 6 weeks

About every 2 months

About every 6 months

About every 6 months

Remedy

Saeco International Group REV.1 FEB.2005 Page 3/21

Page 20

3. OPERATION INCANTO S-CLASS

2. Operation (Incanto classic)

2.1 Control panel

Page 4/21 REV.1 FEB.2005 Saeco International Group

Page 21

INCANTO S-CLASS 3. OPERATION

Expresso

LED

Check for damage.

container.

Heating stage

(approx. 1.5 min).

Light

flashes

Light

flashes

quantity for each selection

button.

• Coffee

• Expresso

Depending on cup

size.

Programme by

keeping the coffee

selection button

pressed until the

desired quantity is

reached.

Light

flashes

For

expresso

program

ming

Light

flashes

For

coffee

program

ming

Press once = 1 cup of

coffee

Light

flashes

(flashes)

button).

Press twice = 2 cups

of coffee.

Light

flashes

2 x

interval

(flashes)

2 x

interval

dispenser.

Place powder coffee

in powder container

(1 measuring

spoonful)

Dispensing steam

2.2. Operating instructions (quick reference)

Powder

1 Unpack machine.

2 Fill water tank

3 Install Aqua Prima filter. Wait for 30 min.

4 Fill coffee beans

5 Connect mains plug.

6 Turn on main switch.

7 De-aerate water circuit.

Ready

8 Press hot water button

(about 6 sec.)

9 Programme coffee

11 Place cup under

12 Select powder button and

relevant coffee button:

Expresso / Coffee

13 Open HWS valve

Action

Getting started

Reset filter counter

Making coffee

Coffee dispensing / Powder coffee

Light

Press hot water

button

Open hot water

pressure valve until

water flows.

Filter LED flashes

briefly.

Only one coffee can

be dispensed at a

time.

Immediately ready

Comments

button

LED

Light

flashes

flashes

ON

ON

ON

ON

Light

flashes

Coffee

LED

Light

flashes

Light

flashes

ON

ON

(flashes)

ON

Hot water

LED

Light on

10 Press start button (coffee

Saeco International Group REV.1 FEB.2005 Page 5/21

Page 22

3. OPERATION INCANTO S-CLASS

14

Water removal

complete

ON

ON

ON

Empty dregs drawer

Storage capacity of 12 tablespoons (Reset - empty only when

indicated and with machine on)

Very hard water (over 21ºdH) About 2 - 4 weeks

About 4 - 6 weeks

Soft water (4-7ºdH)

About every 3 months

About every 6 months

Fill water tank with commercial

descaler according to the

relevant instructions (Saeko

descaler recommended).

Light flashes

Open HWS valve

The pipes are rinsed with

descaler at intervals. (Duration:

approx. 45 min)

ON

Hot water dispensing

Press hot water button.

15 Open HWS valve

16 Close HWS valve

17 Press hot water button.

Empty drip tray

Clean water tank.

Clean coffee bean container.

Clean the housing.

Rinse brewing unit

Clean brewing unit and lubricate

Clean filter

Descale

Water hardness

Hard water (15º-21ºdH)

Medium water (15º-21ºdH) About every 2 months

Soft water (0-3ºdH)

Or when descaling requirement indicated.

Descaling procedure

Action

Need to descale

Place an appropriately sized

Keep the descaling button

pressed for about 5 sec.

Programme end

Close HWS valve

Rinse (fill tank 2x)

Install Aqua Prima filter. Off

Immediately ready

Water removed

Steam mode

Comments

Remove the Aqua Prima filter

from the tank.

container under the HWS

nozzle.

Descaling programme is

activated.

When flow meter takes in air.

Descaling programme complete. Off

Open HWS valve

Cleaning

After 12 servings

As required.

As required.

As required.

As required.

1 x per month

According to indicator.

Descaling frequency

Without Aqua Prima

About 4 - 6 weeks

About every 6 months

ON

ON

ON

With Aqua Prima

About every 2 months

About every 3 months

About every 6 months

Descale LED indicator

Light flashes

Light flashes

ON

LED of all 5 buttons flash

Off

ON

ON

ON

ON

ON

Off

Page 6/21 REV.1 FEB.2005 Saeco International Group

Page 23

INCANTO S-CLASS 3. OPERATION

Remedy

Turn on main switch.

The machine does not switch

on.

The machine is not connected to the

mains power supply.

Check plug and connection.

The cups are cold.

Pre-heat cups.

The coffee is not hot enough.

A low temperature has been set.

Set the machine to a higher

temperature.

Only hot water is dispensed

when powder coffee is

selected.

No powder coffee has been filled.

Fill powder coffee and start

once again.

No hot water or steam.

The nozzle is obstructed.

Clean nozzle out with

needle.

Dial is closed!

The machine is switched

off!

Machine heating takes a long

time.

The machine is heavily calcified.

Descale the machine.

The brewing unit cannot be

removed.

The brewing unit has stopped in an

incorrect position.

Close doors and switch on

the machine.

The machine performs a re-

positioning.

Grind too fine.

Set grind to higher level.

Turn knob in clockwise

direction.

Coffee dispensing insufficient

or absent.

SBS is set to the right side.

Turn SBS knob to the left.

The descaling indicator flashes

(machine not locked)

- Descale

Coffee beans/grinds container LED

flashes

- Empty grinds container

(for min. 6 sec. / machine must be turned on)

Filter indicator flashes (machine not

locked)

- Replace Aqua Prima filter / turn indicator off

(press the hot water button for about 6 sec. until

filter indicator light flashes).

Fault

Troubleshooting

Cause

Cannot dispense

Water LED lights up

Water LED flashes

Coffee beans/grinds container LED

lights up

Warning LED lights up

Warning LED flashes

- Fill with fresh water

- De-aerate machine

- Fill with coffee beans

- Correctly install brewing unit, drip tray and grinds

container, and close door.

- Grinder obstructed.

- Gears obstructed

- Contact an authorised service centre.

Saeco International Group REV.1 FEB.2005 Page 7/21

Page 24

3. OPERATION INCANTO S-CLASS

LED indicator

Water

hardness

setting for

descaling

indicator

Powder

coffee

(Press to

activate an

additional

LED and then

change

descaling

interval.)

0 – very soft water (0º - 3ºdH) 800l

1 – soft water (4º - 7ºdH) 400l

2 – medium water (7º-14ºdH) 200l

3 – hard water (14º-21ºdH) 100l

4 – very hard water (over 21ºdH) 50l

1

1+2

1+2+3

1+2+3+4

1+2+3+4+5

1

1+2

1+2+3

1+2+3+4

When using

a filter, the

next interval

can be

chosen.

Pre-brewing

Coffee

ON/OFF (LED lit up means programme

activated)

Coffee Beans Low LED

2.3. User programme (Incanto classic)

The table below indicates the various settings and programmes which can be selected through the user

programme options.

Access: The machine must be turned on with the expresso and hot water buttons pressed in order to

enter the programming mode.

Function

Rinse

programme

Button

Expresso

Status

ON/OFF (LED lit up means programme

activated)

Without

filter

Water Low LED

With filter

Page 8/21 REV.1 FEB.2005 Saeco International Group

Page 25

INCANTO S-CLASS 3. OPERATION

3. Operation (Incanto de luxe)

3.1 Control panel

Saeco International Group REV.1 FEB.2005 Page 9/21

Page 26

3. OPERATION INCANTO S-CLASS

Heating stage (approx. 80 sec.) Heating

See user menu.

each selection button.

• Expresso lungo

• Coffee

• Expresso

Depending on cup size.

Programme by keeping the

coffee selection button pressed

until the desired quantity is

reached.

Quantity programme

appropriate button.

Press once = 1 cup of coffee

Press twice = 2 cups of coffee.

1 Coffee

2 Coffees

14 Press powder button and select

relevant coffee button

(expresso lungo / coffee /

expresso)

Only one coffee can be

dispensed at a time.

Select product

Powder coffee

3.2. Operating instructions (quick reference)

1 Unpack machine.

2 Install Aqua Prima filter.

3 Fill water tank

4 Fill coffee beans container.

5 Connect mains plug.

6 Turn on main switch.

7 De-aerate water circuit.

Ready

8 Activate water filter.

9 Set water hardness.

10 Programme coffee quantity for

11 Set dispensing time.

Place cup under dispenser.

12 Select programme and press

13 Place cup under dispenser.

15 Open HWS valve

16 Press hot water button.

17 Open HWS valve

18 Close HWS valve

19 Press hot water button.

Action

Getting started

Making coffee

Check for damage.

Wait for 30 min.

Self test/

Press hot water button.

Open hot water pressure valve

until water flows.

Activate counter + reset

Only machines with SBS

Coffee dispensing / Powder coffee

Dispensing steam

Hot water dispensing

Place powder coffee in powder

container (1 measuring

spoonful)

Immediately ready

Immediately ready

Water removed

Water removal complete

Steam mode

Comments

Display

Heating

Hot water

Heating

Select product

Ready for operation

Filter symbol

Select product

Ready for operation

Steam

Select hot water /

product

Ready

HOT WATER

Select hot water /

product

Ready

Select product

Ready for operation

Page 10/21 REV.1 FEB.2005 Saeco International Group

Page 27

INCANTO S-CLASS 3. OPERATION

Empty dregs drawer

Storage capacity of 12 tablespoons (Reset - empty only

when indicated and with machine on)

Descaling procedure

Remove the Aqua Prima filter. Descale

Open HWS valve

The pipes are rinsed with

descaler at intervals. (Duration:

approx. 45 min)

Machine is descaled.

Fill tank.

Rinse machine.

Press button

Close HWS valve

Rinse programme complete

Fill water tank.

Install Aqua Prima filter.

Select product

Ready for operation

The descaling indicator turns off automatically after completion of the descaling process!

Empty drip tray

Clean water tank.

Clean coffee bean container.

Clean the housing.

Rinse brewing unit

Clean brewing unit and lubricate

Clean filter

Descale

Action

Descale

Fill tank with descaler solution. Place an appropriately sized

Press descaling button

Programme end

Close HWS valve

Press descaling button

Open HWS valve

Programme end

Fill tank.

Open HWS valve

Close HWS valve

After 12 servings

As required.

As required.

As required.

1 x per week

1 x per month

According to indicator.

Cleaning

Comments

container under the HWS

nozzle.

Descale

When water tank is empty

Descaling programme complete. Rinse machine

Rinse machine.

Machine is rinsed

When water tank is empty

De-aerate

Until water is continuously

discharged.

Select product

Indication

Descale

Open dial.

Descaling complete

Close dial.

Fill water tank

Open dial.

Rinsing complete

Close dial.

Hot water

Ready for operation

Saeco International Group REV.1 FEB.2005 Page 11/21

Page 28

3. OPERATION INCANTO S-CLASS

Page 12/21 REV.1 FEB.2005 Saeco International Group

Display indicators

Press MENU/OK button.

Descale machine.

Fill water tank with fresh drinking water.

Fill coffee beans container and re-start coffee dispensing cycle.

Open the doors, remove the grinds container and empty.

Important: The grinds container must only be emptied when the machine is turned on. The

container must be removed for at least 5 sec. If the grinds container is emptied when the machine

is turned off, coffee dispensing will be locked when the machine is turned on.

Install brewing unit correctly.

Install drip tray and coffee grinds container correctly.

Close front door.

Prime the circuit (start-up).

Call authorised service centre.

Call authorised service centre.

The machine is in the heating stage; wait until this stage is

complete.

Standby

Descaling

Standby

Brewing unit locked

Ventilate

Fill water tank

Bean less

Ready

Empty the dregs

drawer

Brewing unit not

detected

Dregs drawer not

detected

Close doors

Rinse

Heat

Grinder locked

Page 29

INCANTO S-CLASS 3. OPERATION

Saeco International Group REV.1 FEB.2005 Page 13/21

Replace the Aqua Prima filter as soon as possible.

If a new filter is not available, remove the current filter and turn

off the Water Filter function (see Programming).

Important information about the Aqua Prima filter

1. Store the Aqua Prima filter in a cool place, protected from sunlight. The room temperature must

be between +5°C and +40°C.

2. Use the filter in rooms where the temperature does not exceed 60°C.

3. We recommend washing the Aqua Prima filter when the coffee machine has not been used for 3

days.

4. If the coffee machine has not been used for 20 days, we recommend replacing the filter.

5. Store unpacked filters in an airtight nylon bag and place in a refrigerator. Do not place the filter

in the freezer as this will change the filter's characteristics.

6. Immerse the filter in the water tank 30 minutes before use.

7. Once the packaging has been opened, do not store the filter without any wrapping.

8. The filter must be replaced 90 days after unwrapping or after processing 60 litres of drinking

water.

Remedy

Turn on main switch.

The machine does not switch

on.

The machine is not connected to the

mains power supply.

Check plug and connection.

The cups are cold.

Pre-heat cups.

The coffee is not hot enough.

A low temperature has been set.

Set the machine to a higher

temperature.

Only hot water is dispensed

when powder coffee is

selected.

No powder coffee has been filled.

Fill powder coffee and start

once again.

No hot water or steam.

The nozzle is obstructed.

Clean nozzle out with

needle.

Dial is closed!

The machine is switched

off!

Machine heating takes a long

time.

The machine is heavily calcified.

Descale the machine.

The brewing unit cannot be

removed.

The brewing unit has stopped in an

incorrect position.

Close doors and switch on

the machine.

The machine performs a re-

positioning.

Grind too fine.

Set grind to higher level.

Turn knob in clockwise

direction.

Coffee dispensing insufficient

or absent.

SBS is set to the right side.

Turn SBS knob to the left.

Replace water filter

Standby

Fault

Troubleshooting

Cause

Page 30

3. OPERATION INCANTO S-CLASS

Page 14/21 REV.1 FEB.2005 Saeco International Group

3.3. User programme (Incanto de luxe)

The table below indicates the various values, settings and programmes which can be read and selected

through the user programme options.

Various cleaning programmes can also be activated

Access: Access via Menu/OK button.

Menu procedure:

1. Select desired programme using the cursor buttons (arrow buttons).

2. Access appropriate item using the Menu/OK button.

3. Use the arrow buttons to handle each item.

4. Confirm with Menu/OK button.

Rinse

ON/OFF

OFF

Rinse the brewing unit with fresh water

each time the machine is turned on

(boiler temperature below 50°C).

4 – 50 l

Descaling interval depending on water

hardness.

ON

OFF

OFF

If ON, only every second flow meter

pulse is counted for water descaling

purposes (descaling interval doubled).

Heating plate ON/OFF

ON

Activate / deactivate heating plate.

Heating plate

High

Medium

Item

Standby

Language

Water hardness

Water filter

Temperature

Country

1 – 400 l

2 – 200 l

3 – 100 l

Reset

Low

Setting/Indicator

Standard

German

3

Reset filter counter (generates the

Medium

Display language

indicator to change the filter after every

60,000ml).

Adjustment of brewing temperature

(approx. +/- 2ºC)

Function

Page 31

INCANTO S-CLASS 3. OPERATION

Strong

Normal

Aroma

Coffee

Mild

Normal

Programming the dosage for the coffee

programme

(changes the grinder pulses).

Strong

Normal

Timer

00:15 – 03:00

03:00 Activates standby mode if no

dispensing takes place within a specific

time.

Time

00:00 Time setting.

00:00 Enters activation time.

Switching time

00:00 Enters activation time.

Time display

YES/NO Indicates the time on the display.

Exit: ESC button

Item

Aroma

Expresso

Aroma

Expresso lungo

Pre-brewing

Total coffee

Clock timer

Cleaning cycle Cleaning programme for brewing unit

Factory

settings

Setting/Indicator

Mild

Strong

Normal

Mild

ON

LONG

OFF

Number

Clock timer

Initialise standard data

Standard

Normal

Normal

ON

Coffee quantity indicator

ON/OFF Activates/deactivates clock timer.

Programming the dosage for the

expresso programme

(changes the grinder pulses).

Programming the dosage for the

expresso lungo programme

(changes the grinder pulses).

Coffee is moistened before actual

brewing

(better aroma)

Function

Saeco International Group REV.1 FEB.2005 Page 15/21

Page 32

3. OPERATION INCANTO S-CLASS

Display

Steam & hot

water button/Left arrow

Expresso lungo button/ ESC

Coffee button

Aroma/powder coffee selection/Right

Menu/OK button

Expresso button

ESC

< >

OK

4. Operation (Incanto sirius)

4.1 Control panel

4.2. Operating instructions (quick reference)

1 Unpack machine.

2 Install Aqua Prima filter.

2 Fill water tank

3 Fill coffee beans container.

4 Connect mains plug.

5 Turn on main switch.

6 De-aerate water circuit.

Heating stage (approx. 80 sec.) Heating

Ready

7 Set water hardness.

8 Programme coffee quantity for

each selection button.

• Expresso lungo

• Coffee

• Expresso

9 Set dispensing time.

Place cup under dispenser.

10 Elect programme and press Press once = 1 cup of coffee 1 Coffee

Action

Getting started

Check for damage.

Making coffee

Activate counter + reset

Wait for 30 min.

Self test/

Press hot water button.

Open hot water pressure valve

until water flows.

Depending on cup size.

Programme by keeping the

coffee selection button pressed

until the desired quantity is

reached.

Only machines with SBS

Comments

Heating

Hot water

Heating

Select product

Ready for

operation

Quantity

programme

Select product

Ready for

operation

Page 16/21 REV.1 FEB.2005 Saeco International Group

Page 33

INCANTO S-CLASS 3. OPERATION

Dispensing steam

Water removal complete

Select product

Ready for operation

Fill tank with descaler solution.

Press OK.

CLEANING CYCLE

appropriate button.

11 Place cup under dispenser.

12 Select aroma / Press powder

button until the powder spoon

appears and select relevant

coffee button (expresso lungo /

coffee / expresso)

13 Open HWS valve

14 Press steam/hot water button

(picture of drops appear on

display).

15 Open HWS valve

16 Close HWS valve

17 Press steam/hot water button

(picture of steam appears on

display).

Empty dregs drawer

Empty drip tray

Clean water tank.

Clean coffee bean container. As required.

Clean the housing.

Rinse brewing unit

Clean brewing unit and grease

filter.

Descale

Descaling procedure

Action

Descale

Remove the Aqua Prima filter. Descale

Press menu button.

Use arrow button to access

menu item Clean.

Go to DESCALING CYCLE

by using the arrow button.

Coffee dispensing / Powder coffee

Press twice = 2 cups of coffee

Place powder coffee in powder

container (1 measuring

spoonful)

Only one coffee can be

dispensed at a time.

Hot water dispensing

Immediately ready

Immediately ready

Water removed

Steam mode

Storage capacity of 12 tablespoons (Reset - empty only

when indicated and with machine on)

As required.

As required.

Cleaning

As required.

As required.

1 x per month

According to indicator.

Comments

Place an appropriately sized

container under the HWS

nozzle.

STANDBY

CLEANING

DESCALING CYCLE

2 Coffees

Steam

Select product

Ready for operation

HOT WATER

Select product

Ready for operation

Indication

Descale

Saeco International Group REV.1 FEB.2005 Page 17/21

Page 34

3. OPERATION INCANTO S-CLASS

Open HWS valve

The pipes are rinsed with

descaler at intervals. (Duration:

approx. 45 min)

MACHINE IS

DESCALED.

Action

Press OK.

Go to YES by using the arrow

Press OK.

Open dial.

Programme end

Close HWS valve

Fill tank.

Press button required.

Open HWS valve

Programme end

Close HWS valve

Install Aqua Prima filter.

Fill water tank.

Open HWS valve

Close HWS valve

The descaling indicator turns off automatically after completion of the descaling process!

button.

Comments

NO

YES

Indication

OPEN DESCALE

DIAL.

DESCALING

When water tank is empty

Descaling programme complete. RINSE MACHINE

RINSE MACHINE

RINSE MACHINE

MACHINE IS

When water tank is empty

FILL WATER TANK.

DE-AERATE

DE-AERATE

HOT WATER

SELECT PRODUCT.

DESCALING

COMPLETE. CLOSE

DIAL.

FILL WATER TANK

PRESS BUTTON

OPEN DIAL.

RINSED.

RINSING

COMPLETE. CLOSE

DIAL.

READY

Page 18/21 REV.1 FEB.2005 Saeco International Group

Page 35

INCANTO S-CLASS 3. OPERATION

Remedy

Does not function

No power

Check mains plug / mains

circuit breaker.

Ensure machine door is

closed.

Install brewing unit

correctly.

GRINDS CONTAINER

NOT DETECTED

Coffee grinds container not properly

installed.

Brewing unit correctly

installed.

EMPTY GRINDS

CONTAINER

Coffee grinds container full

Empty coffee grinds

container (reset only

possible if machine is turned

on)

FILL WATER TANK.

Water tank is empty.

Fill water tank

Add one level measure of

coffee powder.

No water / steam

Steam nozzle blocked.

Free opening using a thin

needle.

Increase temperature in user

programme.

Unsuitable coffee blend.

Change brand of coffee.

Coffee is no longer freshly roasted. Use fresh coffee.

Coffee has no froth.

Beans ground too coarsely or finely. Change grinding level.

Decalcify machine.

The brewing unit cannot be

removed.

The brewing unit is not in home

position.

Turn machine on, close

service door and check

dregs drawer.

(the brewing unit goes

automatically to home

position)

Fault/Indicator

BREWING UNIT NOT

DETECTED

COFFEE BEAN

CONTAINER EMPTY

Troubleshooting

Brewing unit not properly installed

or not closed.

Coffee bean container is empty. Fill coffee container.

Possible cause

GRINDER OBSTRUCTED

DE-AERATE

REPLACE WATER

FILTER

Instead of coffee, only water

is dispensed.

The coffee flows too quickly

The coffee flows too slowly

Coffee is not hot enough

Longer heating time or less

hot water.

Clean grinder.

Air in water system.

Replace water filter + reset

Coffee powder selection button is

pressed, but no coffee powder is

dispensed.

Beans ground too coarsely.

Beans ground too finely.

The cups are cold.

Boiler temperature too low.

The machine is calcified.

Open water nozzle.

user menu

Press knob and turn in the

direction of the small points.

Press knob and turn in the

direction of the large points.

Pre-heat cups.

Saeco International Group REV.1 FEB.2005 Page 19/21

Page 36

3. OPERATION INCANTO S-CLASS

Page 20/21 REV.1 FEB.2005 Saeco International Group

4.3. User programme (Incanto sirius)

The table below indicates the various values, settings and programmes which can be read and selected

through the user programme options.

Various cleaning programmes can also be activated.

Access: Selection entry via menu button.

Menu procedure:

1. Select desired programme using the cursor buttons (arrow buttons).

2. Access appropriate item using the OK button.

3. Use the arrow buttons to handle each item.

4. Confirm with Menu/OK button.

STANDBY

Display and heating OFF.

ON

RINSE

OFF

OFF

Rinses when the machine is turned on

and the temperature of the KTY is below

50°C (circuit and brewing unit).

WATER

HARDNESS

4 – 80 l

Change in water flow quantity until

descaling required (1-4).

ON

OFF

CONTRAST

-5 - +5 -3 Display contrast / Light

Steam & hot water button/Left arrow

Expresso lungo button / ESC

Coffee button

Aroma/powder coffee selection/Right arrow

Menu/OK button

Expresso button

< >

Item

HEATING PLATE

LANGUAGE

SETTINGS

WATER FILTER

ESC

OK

Setting/

Indicator

OFF

ON

Country

1 – 400 l

2 – 200 l

3 – 100 l

RESET

Standard

ON

German

3

OFF

Function

Activate / deactivate heating plate.

Heating plate

Display language

When Aqua Prima filter is used, the water

filter item must be turned ON.

When replacing the filter, the counter

must be reset.

Page 37

INCANTO S-CLASS 3. OPERATION

Function

ON

FACTORY

SETTINGS

YES

NO

Initialise standard data

ON

OFF

EXPRESSO

TEMPERATURE

Low

Medium

The user can determine the brewing

temperature (±2ºC).

TEMPERATURE

EXPRESSO

LUNGO

See expresso

Medium

The user can determine the brewing

temperature (±2ºC).

Mild

Normal

TIME

Time setting.

TIME FORMAT AM/PM

24H

12-hour or 24-hour clock

From Version 2.00.3

CLOCK TIMER ON/OFF Activates/deactivates clock timer.

00:00 Enter activation times

SWITCHING

TIME

00:00 Enter activation times

Descaling cycle YES/NO Starts automatic descaling (approx. 45

min.)

EXPRESSO

NUMBER

Counts number of times coffee is

Dispensed

(not resettable).

Item

SIGNSLTON

PRE-BREWING

COFFEE

TEMPERATURE

COFFEE SETTINGS

AROMA

SELECTION

TIME SETTING

Setting/Indicato

r

OFF

NO

LANG

High

Medium

See expresso

STRONG

TIME DISPLAY YES/NO Indicates the time on the display.

TIMER

Standard

ON

ON

Medium

Normal

03:00 Activates standby mode if no dispensing

Button tone.

The coffee comes into contact with a

small amount of water in the brewing unit

prior to the actual brewing process

(stronger aroma).

The user can determine the brewing

temperature (±2ºC).

Pre-set aroma selection (1, 2 or 3 coffee

bean setting) on display (= dosage 8g for

NORMAL ±1.5g).

takes place within a specific time (00:15

– 03:00).

Cleaning cycle

YES/NO Brewing unit cleaning programme

CLEANING

TOTAL

COFFEE

COFFEE

EXPRESSO

LUNGO

NUMBER

NUMBER

EXTRAS

Exit: ESC button

Saeco International Group REV.1 FEB.2005 Page 21/21

Page 38

Page 39

Saeco International Group REV.1 FEB.2005

CHAPTER 4

FUNCTIONS AND TIMING

Page

1. Water system 1

1.1. Water system (Incanto rondo) 1

1.2 Water system (Incanto classic)

(Incanto de luxe)

(Incanto sirius) 2

2. Electrical system -

3. Timing 3

4. Function 4

4.1. Gearmotor 4

4.2. Gear resistor 4

4.3. Water level monitoring 4

4.4. Flow meter (turbine) 5

4.5. HWD valve (steam operation) 5

4.6. Temperature sensor (KTY) 5

4.7. Grinder 6

4.8. Dosing 6

4.9. SBS Saeco Brewing System 7

4.9.1 General functions 7

4.9.2 Frothing valve function 8

4.9.3. Extraction values with SBS 9

Page 40

Page 41

INCANTO S-CLASS 4. FUNCTION/TIMING

Function

Water tank Water supply

Float Water level monitoring

Water filter Water cleaned of solid matter (one or two depending)

Flow meter (turbine) Measure flow rate

Pump Water flow/Pressure build-up

(13 to15 bar)

Safety valve Protect boiler against overpressure (opens at 17 bar)

Boiler (flow heater)

Heats water to approx. 84°C

(for brewing process)

Sensor (KTY) Transmits current temperature value to electronic

system

Thermostat Interrupts complete flow supply if overheating.

Boiler pin (Valve plug) Opens when brewing unit is aligned with water circuit

to the unit itself.

HWS valve For hot water and steam dispensing

Temp.sensor

KTY

Ventilzapfen

Brühgruppe

Schwimmer

Wasserfilter

Pumpe

Flowmeter

Heizung

1090 W

Überdruckventil

Wassertank

Durchlauferhitzer

HWD-Ventil

Heißwasser / Dampf

Wasserfilter

Getriebevor

-widerstand

2 Thermostate

Water tank

Water filter

Float

Water filter

Flow meter

Pump

Thermal sensor

KTY

Boiler

Gear resistor

Heating

1090W

Boiler pin

2x Thermostat

HWS Valve

1. Water system

1.1. Water system (Incanto rondo)

Component

Savety valve

To brew unit Hot water / steam

Saeco International Group REV.1 FEB.2005 Page 1/9

Page 42

4. FUNCTION/TIMING INCANTO S-CLASS

1 Water tank Water supply

5 Safety valve Protect boiler against overpressure (opens at 17 bar)

12 HWS valve (tea nozzle) For hot water and steam dispensing

Temp.sensor

KTY

Ventilzapfen

HWD-Ventil

Brühgruppe

Heißwasser / Dampf

Schwimmer

Wasserfilter

Pumpe

Flowmeter

Rohrheizung

Heizung

1090 W

Heizung

1090 W

Überdruckventil

Wassertank

Thermostat

170ºC

Durchlauferhitzer

Wasserfilter

Getriebevor

-widerstand

2 Thermostate

Water tank

Float

Water filter

Water filter

Flow meter

Pump

Savety valve

Thermal sensor

KTY

Boiler

Gear resistor

2x Thermostat

Heating

1090W

Boiler pin

To brew unit

Pipe heating

1090W

HWS Valve

Hot water / steam

1. 2. Water system (Incanto classic, de luxe, sirius)

Component Function

2 Water filter Water cleaned of solid matter (one or two depending)

3 Flow meter Measure flow rate

4 Pump Water flow/Pressure build-up

6 Boiler (flow heating)

7 Sensor Transmits current temperature value to electronic

8 Thermostat Turns off flow supply to entire machine if overheating.

9 Boiler pin (Valve plug) Opens when brewing unit is aligned with water circuit

10 Pipe heating Steams pre-heated boiler water for steam function.

11 Thermostat (pipe heating) Switches (pulses) pipe heating

(13 to 15 bar)

Heats water to approx. 94°C

(for brewing process)

system

to the unit itself.

Page 2/9 REV.1 FEB.2005 Saeco International Group

Page 43

INCANTO S-CLASS 4. FUNCTION/TIMING

PROG RAMMENDE

END

Timing

Gri nd er mo tor

Heatin g

Pump *

Gearmotor

auf

ab

Sta tus MS1

Sta tus MS2

Status

Heatin g stag e Coffee disp ensin g pro cessSta nd by

Pul ses

up down

app .45sec

acc. to coffe e qty

Explanation:

Two processes start when the main switch is activated:

Firstly, the gearmotor is initialised. The gears move to MS1 (lower limit switch), change rotating direction,

leave MS1 and move to the home position (about 2 mm after MS1).

The instantaneous water heater is then activated for about 1 min 30 sec., heating the water to operating

temperature, whereby heating takes place for about 60 sec. continuously and then is alternated for the rest of

the time.

After activating the start button:

1. The grinder starts operating (pulse-controlled).

2. The gears move to brewing position.

3. Pre-brewing begins (brief pump activation).

4. Main brewing process (duration of pump activation depending on selected coffee quantity).

5. The gears move to home position (dregs discarded).

3. Timing

The following time chart indicates the functions of the individual components in terms to time

H S - ON START

Saeco International Group REV.1 FEB.2005 Page 3/9

Page 44

4. FUNCTION/TIMING INCANTO S-CLASS

Page 4/9 REV.1 FEB.2005 Saeco International Group

4. Function

4.1. Gearmotor

The gearmotor is connected to the power element of the circuit board via the auxiliary heating system. In

order to perform forwards and backwards movements, the gearmotor is controlled alternately with a

positive and negative half wave. The voltage is limited by the electronic system to approx. 30 to 35 V. The

electronic system of the motor is switched off in the event of an overload. The overload is detected through

the increased power input to the gearmotor during the stoppage. The red fault LED/brewing unit lock

indicator turns on.

If the brewing unit is locked in the upward movement, the cycle is interrupted after about 8 seconds and the

control system attempts to move the brewing unit to the idle position. This occurs, for instance, when too

much powder is present in the brewing chamber. If the brewing unit is locked in the downward movement,

the motor turns off after 8 seconds and the machine is locked. This situation is indicated by the flashing

fault LED / brewing unit lock indicator. The machine must be turned off and the cause of the lock

removed.

Note: The gear wheel must always be installed so that MS1 and MS2 are positioned at the long

section of the switching cams!

4.2. Gear resistor

The heating system of the thermoblock with green marking at the connection point acts as resistor for the

gearmotor. The gearmotor cannot function in the event of a defective heating system.

The heating system (resistor) has a resistance of approx. 130 Ohm.

4.3. Water level indicator

The water level in the water tank is monitored by a float fitted with a magnet core. If the water level is too

low, the magnet is no longer within the range of the reed contact, which transmits the low water level

signal to the CPU (Water Low indicator).

MS2

Brewing position

Gear cam 2

Brewing position

MS1

Home position

Gear cam 1

Home position

Page 45

INCANTO S-CLASS 4. FUNCTION/TIMING

Saeco International Group REV.1 FEB.2005 Page 5/9

4.4. Flow meter (Turbine)

The machine is equipped with a flow rate monitoring system. The system checks whether the turbine (flow

meter) rotation speed at a particular time complies with the pre-set value. If no pulses are generated from

the turbine within 10 seconds, the current cycle is interrupted. The Fault - De-aerate signal is indicated. If

this control mechanism is activated, the machine must be de-aerated. During the Water Low signal, the

pump operates at maximum output. As soon as the pump has generated the pre-set flow, the pump output is

reduced to approx. 20 l/hr.

The water quantity is generally controlled according to the coffee quantity programmed through the flow

meter (turbine) pulses.

4.5. HWS valve (steam operation)

The HWS valve is required for water and steam dispensing, as well as during de-aeration.

If the hot water valve is opened during the brewing process, coffee flow is interrupted and the De-aerate

indicator will appear. As soon as the hot water valve is closed, the brewing process will continue.

The operating temperature during steam dispensing is approx. 125°C. The steam button is pressed to

activate steam production (without rapid steam). Steam dispensing occurs via the HWS valve.

The pump pulses the steam dispensed. This means that constant steam dispensing is ensured over a long

period of time. The flow rate of the pump is adjusted on the basis of the thermoblock temperature. If the

temperature is too low, the pump pulses are slowed down. This may occur, for instance, when the hot water

valve opens before the temperature indicator lights up (without rapid steam).

Once the steam has been dispensed, the steam valve closes and the steam button must be pressed for

normal operating mode. The overheating indicator flashes until the machine has cooled; the machine

remains locked for coffee dispensing. Cooling can be achieved by opening the HWS valve. The pump

functions at maximum output and the heating remains turned off as long as the Overheating signal remains.

These measures ensure that the cooling process is accelerated and the overheating signal will disappear

after a few seconds.

4.6. Temperature sensor (KTY 10)

The temperature sensor is a temperature-sensitive resistance mechanism, converting the boiler temperature

into an electrical signal which is measurable by the CPU.

The CPU compares this signal with the programmed reference signal and, depending on the outcome of the

comparison, controls the boiler output.

The resistance applied has a positive temperature coefficient; i.e. higher boiler temperature - higher sensor

resistance.

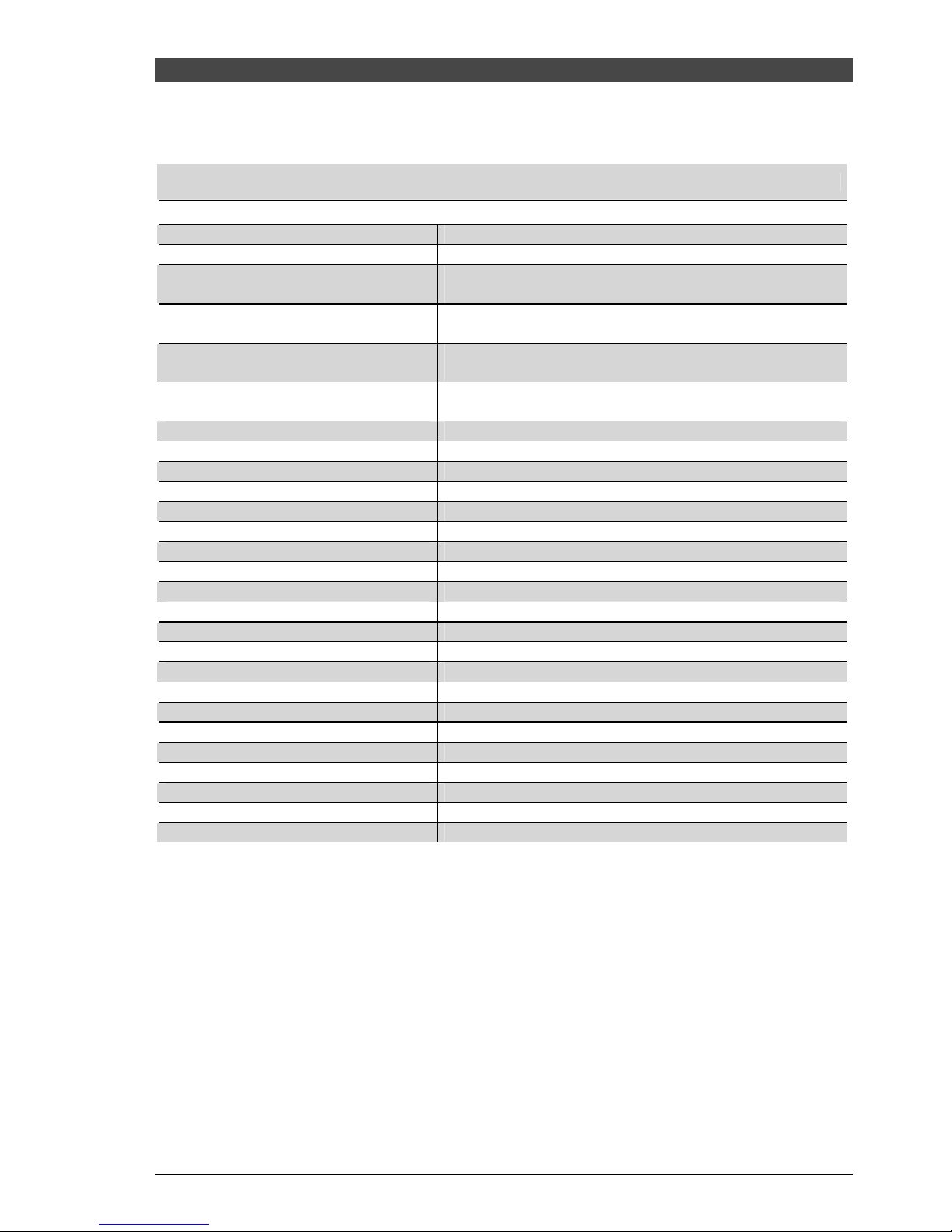

The table below indicates the trend in resistance values in relation to the temperature.

Page 46

4. FUNCTION/TIMING INCANTO S-CLASS

Page 6/9 REV.1 FEB.2005 Saeco International Group

Measured values (KTY)

Temperature Resistance (ȍ) Resistance trend (ȍ)

0 1629 0

15 1845 216

20 1922 77

40 2246 324

90 3168 922

100 3366 198

130 3979 613

140 4188 209

At room temperature the resistance is approx. 1.9Kȍ.

4.7. Grinder

The grinder is fitted with grinding discs. The grinding discs are made of ceramics.

ATTENTION: Adjust the grinding level only when the grinder is in operation!

EXCEPTION: Grinder is empty.

The grinder operates with a direct current motor and the grinding disc rotation speed is determined by a

gearmotor. The grinder motor operates with a voltage of 230V direct current.

Grinder obstructed: Gravel protection is electronically controlled. If the grinder is obstructed, the power

input to the grinder motor increases and the electronic system switches the grinder off.

If the electronic system does not receive any pulses from the grinder Hall sensor, the grinder blocked

signal will be generated.

Coffee beans low: The lack of coffee beans is detected via the power input. If there are no coffee beans in

the grinder, the motor runs without a load and, therefore, consumes less power. This is detected by the

control unit and the coffee beans low signal is generated.

4.8. Dosing

Gravel protection is electronically controlled. Two magnets positioned opposite to each other are fitted on

the grinder disc gear wheel. The Hall sensor monitors the number of rotations of the grinding discs and,

therefore, also the dose quantity.

Incanto rondo control: Via a potentiometer in the electronic system

Incanto classic control: Via service programme / test mode

Incanto de luxe control: Via aroma selection function (user menu)

Incanto sirius control: Via aroma selection function (user menu)

Page 47

INCANTO S-CLASS 4. FUNCTION/TIMING

Saeco International Group REV.1 FEB.2005 Page 7/9

4.9. SBS Saeco Brewing System

4.9.1. General functioning

The water flow speed through the brewing unit can be slowed or accelerated by means of an adjustable

flow valve (Fig. 2) which is activated by turning the knob on the front of the coffee machine.

The contact time of the water with the coffee in the brewing unit (extraction time), and consequently, the

coffee concentration, is changed accordingly, while maintaining consistent froth formation.

Fig. 1

Fig. 2

Page 48

4. FUNCTION/TIMING INCANTO S-CLASS

Page 8/9 REV.1 FEB.2005 Saeco International Group

4.9.2. Froth valve functioning

The backpressure in the froth valve and, consequently, on the membrane of the froth valve, is minimal

when the flow valve is open. Accordingly, the valve needle is kept by the spring pressure in almost home

position and the flow is at maximum (Fig. 3).

If the flow valve moves towards a minimum position, a backpressure results which creates an increased

pressure on the membrane in the valve chamber. The membrane yields to the pressure and the valve needle

further reduces the flow speed (Fig. 4).

Fig. 3 Fig. 4

Page 49

INCANTO S-CLASS 4. FUNCTION/TIMING

4.9.3. Extraction values with SBS

A comparison of the measured values (dosing quantity 9g/SBS min.; dosing quantity 9g/SBS max. and

dosing quantity 6g/SBS min.) indicates that the change from SBS min. to SBS max. corresponds with a

change in dosing quantity of 1.5g.

Note: The pre-brewing function was deactivated during measuring.

Saeco International Group REV.1 FEB.2005 Page 9/9

Page 50

Page 51

CHAPTER 5

SERVICE PROGRAMME

Page

1. Service programme (Incanto rondo) 1

1.1. Test mode 1

2. Service programme (Incanto classic) 2

2.1. Test mode 2

2.2. Diagnosis menu 4

3. Service programme (Incanto de luxe) 7

3.1. Test mode 7

3.2. Diagnosis menu 9

4. Service programme (Incanto sirius) 12

4.1. Test mode 12

4.2. Diagnosis menu 15

Saeco International Group REV.1 FEB.2005

Page 52

Page 53

INCANTO S-CLASS 5. SERVICE PROGRAMME

Pump/Flow meter

Aqua Prima LED 2 coffees Aqua Prima

Brewing unit

(Gearmotor)

Home position

Steam

1 Coffee LED

(Gear switch)

Grinder

Brewing unit switch

2 Coffees LED flashes

Door switch

Aqua Prima LED flashes

* The HWS valve must be open.

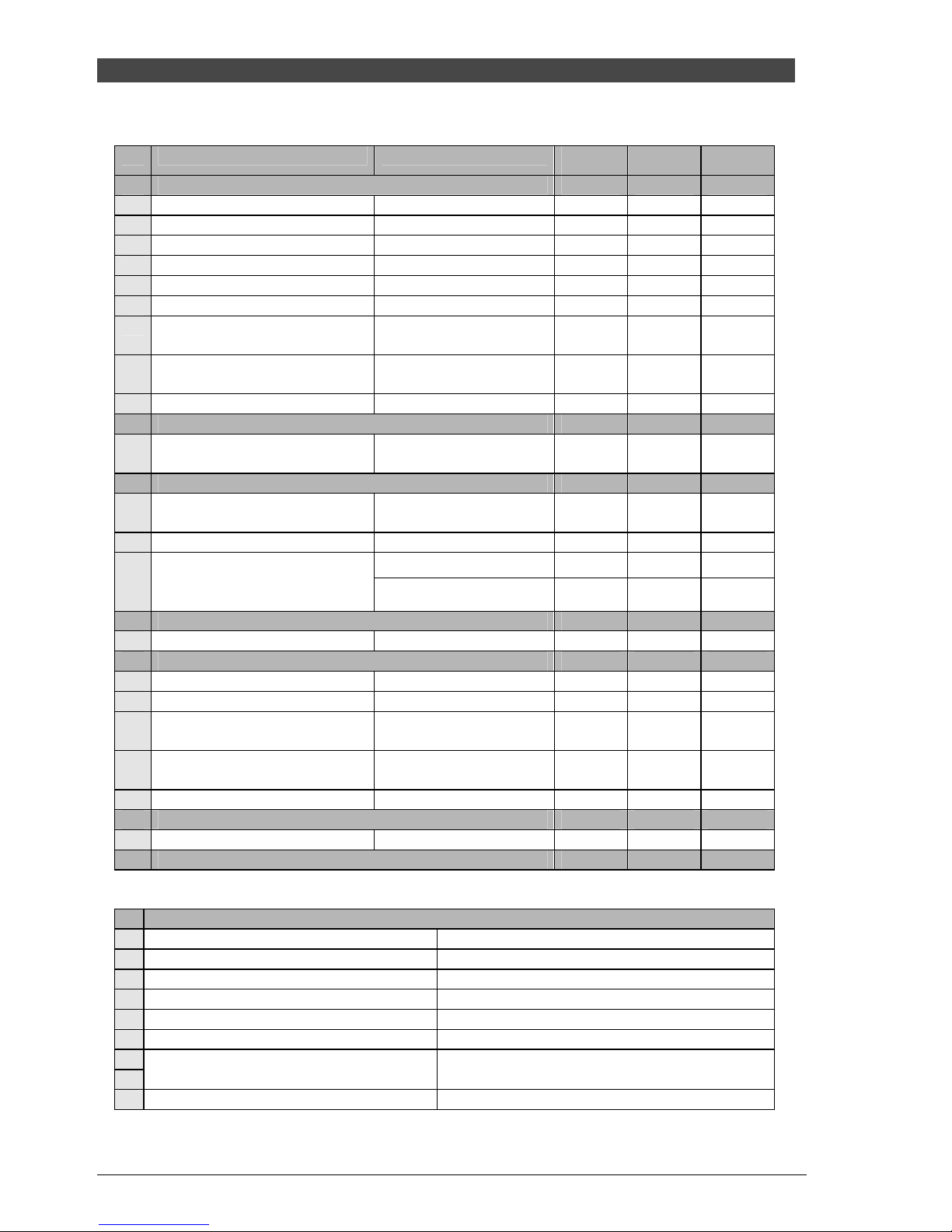

1.Service programme (rondo)

1.1.Test mode

Access: Access the service mode by turning on the machine and simultaneously pressing the 1 Coffee

and steam buttons.

Various test functions can be activated in the service mode by activating either the coffee or steam

buttons in conjunction with various coffee quantity settings.

Programme table

Function Button Control setting

LED Indicator

Cup fill volume

1 coffee

Brewing unit

(Gearmotor)

Work position

Heating 1 coffee

Steam

HWS microswitch

Reed switch

Grinds container

microswitch

Steam

Fault LED

Alarm LED

(Flow meter pulse)*

1 Coffee LED

(Gear switch)

(grinder pulses)

Steam LED lights up

1 Coffee LED lights up

Aqua Prima LED + Fault

LED flash

Saeco International Group REV.1 FEB.2005 Page 1/18

Page 54

5. SERVICE PROGRAMME INCANTO S-CLASS

Access: Access the service mode by turning on the machine and simultaneously pressing the coffee

and hot water buttons.

The various functions indicated in the table can be checked by pressing the button combinations listed

below.

Programme table (functions programme)

Microswitch status

x

Heating

x

x

+ HWS

* In order for the flow meter pulse to be indicated, the HWS valve must close once again after opening

so that the HWS microswitch re-opens.

If the HWS valve is completely open, the LED combination which lights up provides information on the

flow rate (see table below)

Ex

resso button

Coffee but

ton

Powder c

offee selector

Hot water button

Descaling button

Alarm

indicator light

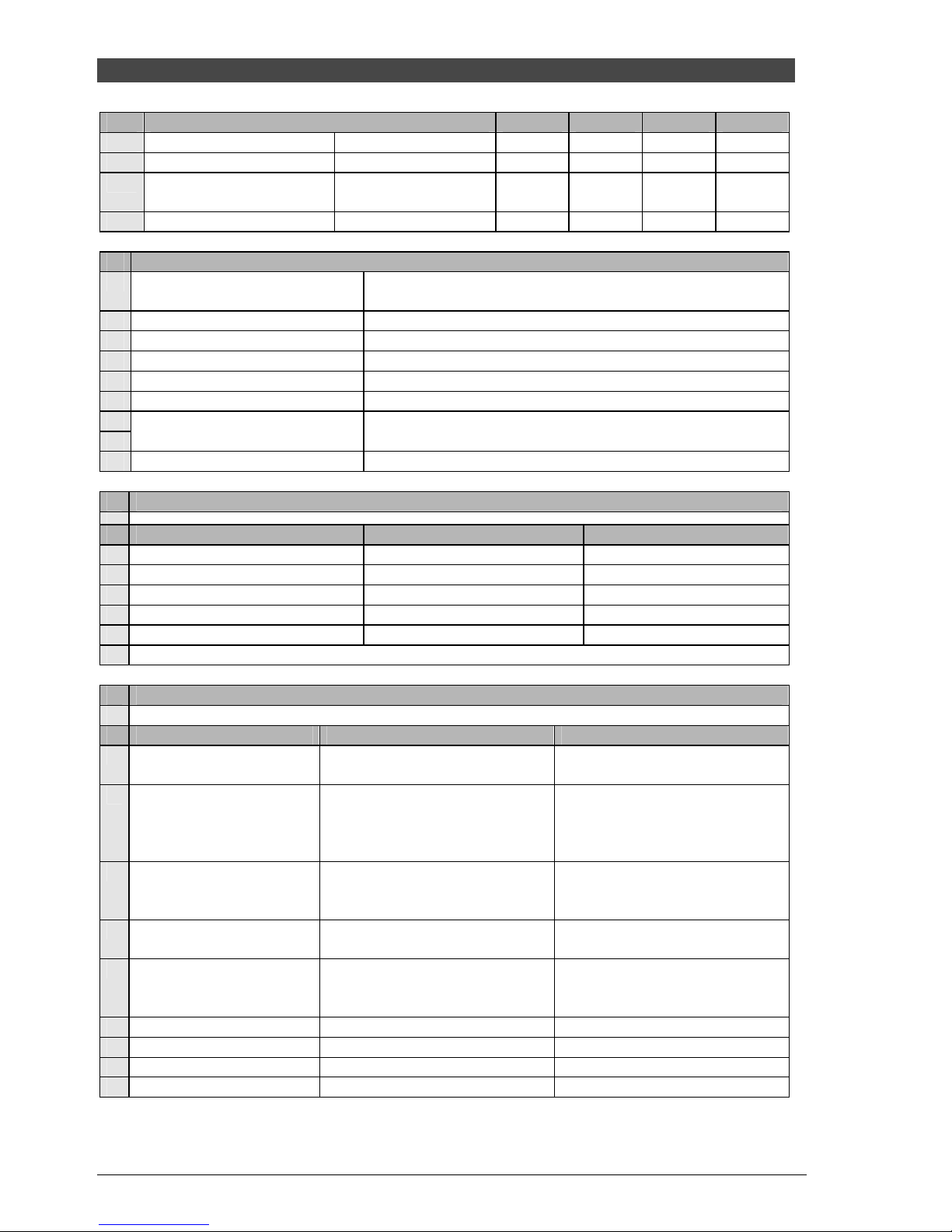

2.Service programme (Incanto classic)

2.1.Test mode

Filter warning light

Coffee bean container and

dregs drawer indicator light

Water tank and circuit

filling indicator light

Buttons Powder

Gears up

Unit down

Grinder

Coffee Expresso Hot water Descale

coffee

x

x

Powder LED

(MS2)

Expresso LED

(MS1)

Pump

Heating + LED

check

Page 2/18 REV.1 FEB.2005 Saeco International Group

x

x

+HWS

x

Fault LED

(flow meter pulses) *

Page 55

INCANTO S-CLASS 5. SERVICE PROGRAMME

Coffee button LED 64

Fault LED 1

Example: Powder button (32), Descale button (8) and Coffee Beans Low LED (2) light up = 42

Microswitch test

Reed switch

(tank removed)

Water low ON

Brewing unit

(removed)

Hot water Steam LED

Dose quantity programming

Open hot water valve and press the expresso button.

Depending on the LED combination, the dose quantity can be determined by consulting the table below

and can be changed by repeatedly pressing the coffee programme button.

Approx. dose

quantity

in grams

90 7.5 Ɓ

115 9.6 Ɓ Ɓ

Flow rate

The flow rate value must be between 40 and 60.

LED description Value

Expresso button LED 128

Powder button LED 32

Hot water button LED 16

Descale button LED 8

Water Low LED 4

Coffee Beans Low LED 2

Microswitch Control LED Status

Dregs drawer/Drip

tray

(removed)

HWS switch

(open)

Door switch

(doors open)

Grinder

pulses

95 8.0 Ɓ Ɓ

100 8.4 Ɓ

105 8.9 Ɓ Ɓ

110 9.2 Ɓ

120 10.2 Ɓ

Coffee beans low ON

Fault Off

Descale ON

Water Low

LED

Coffee Beans

Low LED

Fault

LED

Replace filter

LED

Saeco International Group REV.1 FEB.2005 Page 3/18

Page 56

5. SERVICE PROGRAMME INCANTO S-CLASS

Page 4/18 REV.1 FEB.2005 Saeco International Group

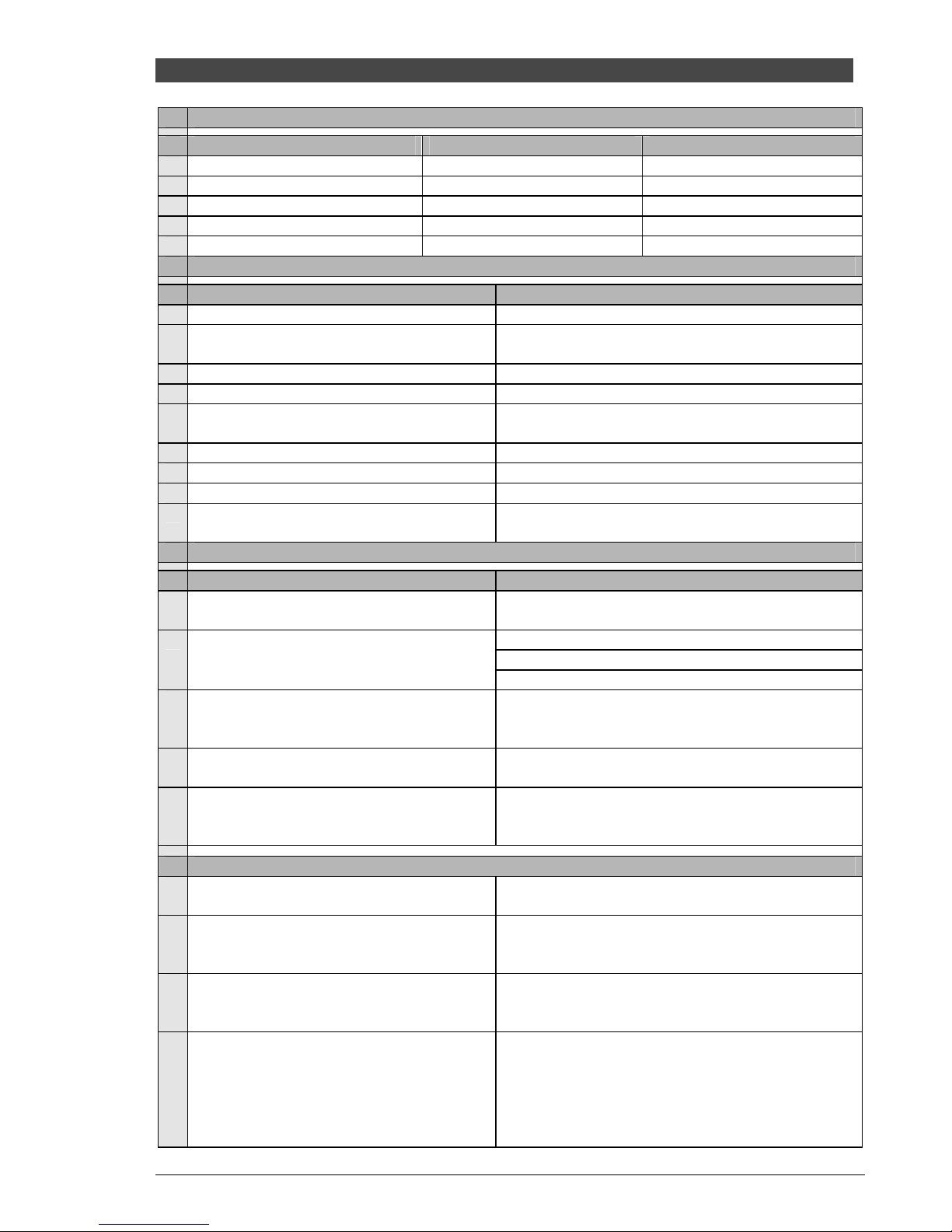

2.2. Diagnosis menu (Incanto classic)

Application of diagnosis system

The diagnosis system makes it possible to read data and enter settings into the coffee machine.

ATTENTION: Before connecting the diagnosis box, read the operating instructions (data plug

can only be connected and disconnected when both devices are unpowered).

Connection is via contact plug JP 25 of CPU.

Programme table (diagnosis menu)

COFFEE

No. of PULSES 360

50 – 1,000 Pulses +/- 1

Number of flow meter pulses for

each saved cup fill volume, where

300 pulses correspond to approx.

100 ml.

----HEATING----

PARAMETER K2 30

1 – 50 +/- 1

Do not change!

HIGH TEMP.

° C 111

70- 130°C +/- 1 If no coffee is dispensed for an

extended time (over 6 min.), the

next coffee will be heated to a

higher temperature to compensate

for cooling of the brewing unit

and the associated temperature

loss.

STEAM

25

20- 50 +/-1 Pump pulse during steam

dispensing

The higher the value, the more

pulses but more humid is the

steam.

TEMP. INCREASE

° C 10

0-50°C +/-1 The boiler temperature is

increased by a set value shortly

before brewing in order to preheat the boiler and compensate

for the temperature drop during

the first water flow.

Function/Standard Setting range Increment Comments

EXPRESSO

No. of PULSES 195

----HEATING----

PARAMETER K1 8

NORMAL TEMP.

° C 90

TEMP. OF 1st

COFFEE

° C 118

50 – 1,000 Pulses

1 – 50 +/- 1

70- 130°C +/- 1 Normal temperature is used if not

70- 130°C +/- 1 Used when dispensing the first

+/- 1

Do not change!

more than 6 min. have elapsed

since last coffee dispensed.

coffee after the machine has been

turned on, to compensate for the

high temperature loss due to the

cold brewing unit and water pipes.

Page 57

INCANTO S-CLASS 5. SERVICE PROGRAMME

PRE-BREWING

1

0 – 1

0 – Deactivate pre-brewing

1 – Activate pre-brewing

GRINDS MAXIMUM

12

5-50 +/-1 Number of cycles until "EMPTY

GRINDS CONTAINER" is

displayed.

--------------------- --------------------

---

Total water flow volume (in ml) /

not resettable

0 - 999999999 +/- 1 Total water flow (in ml) since last

filter reset (60,000 - replace filter)

58,000 - 65,500 +/- 1 The pump delivery rate is adjusted

in relation to the HOT WATER

FLOW setting by means of a

phase controlled modulator. Pump

tolerances can thus also be

adjusted. An equivalent value is

saved under HOT WATER PUMP

ADJUSTMENT.

Function Setting range Increment Comments

GRINDS COUNTER

Number

--TOTAL COFFEE-CYCLES Number

--TOTAL WATER-(ml) Number

WATER DESCALING

(ml)

WATER FILTER

(ml) Number

HOT WATER

FLOW (l/h) 20

--HOT WATER--PUMP ADJUST. 63000

WATER HARDNESS

3

MACHINE STATUS

16

--DATE OF MANUF--DAY

--DATE OF MANUF--MONTH

--DATE OF MANUF--YEAR

0-50 +/-1 Counts number of coffee cycles.

--------------------- --------------------

--------------------- --------------------

6 - 34 1/h +/- 2 1/h The pump delivery rate for hot

1 – 4

0 – 255

---------------------

---------------------

---------------------

--------------------

--------------------

--------------------

When this value reaches the

Grinds Stop value, "GRINDS

CONTAINER EMPTY" will be

displayed. (Reset by removing

dregs drawer for emptying - min.

6 sec.)

---

---

---

---

---

Coffee cycle counter /not

resettable.

Total water flow (in ml) since last

descaling / resettable

water can be expressed in litres

per hour.

Value set in user menu for

descaling interval

Programme code

This date indicates when the

machine was manufactured. This

date cannot be changed, but can

be printed.

Saeco International Group REV.1 FEB.2005 Page 5/18

Page 58

5. SERVICE PROGRAMME INCANTO S-CLASS

--SERVICE DATE-DAY

0 - 31 +/- 1

Function Setting range Increment Comments

--SERVICE DATE-MONTH

--SERVICE DATE-YEAR

0 - 12 +/- 1

1996 - 2050 +/- 1

The service date indicates the date

of the machine's last service. This

date can be changed and must be

updated at each service.

Page 6/18 REV.1 FEB.2005 Saeco International Group

Page 59

INCANTO S-CLASS 5. SERVICE PROGRAMME

Saeco International Group REV.1 FEB.2005 Page 7/18

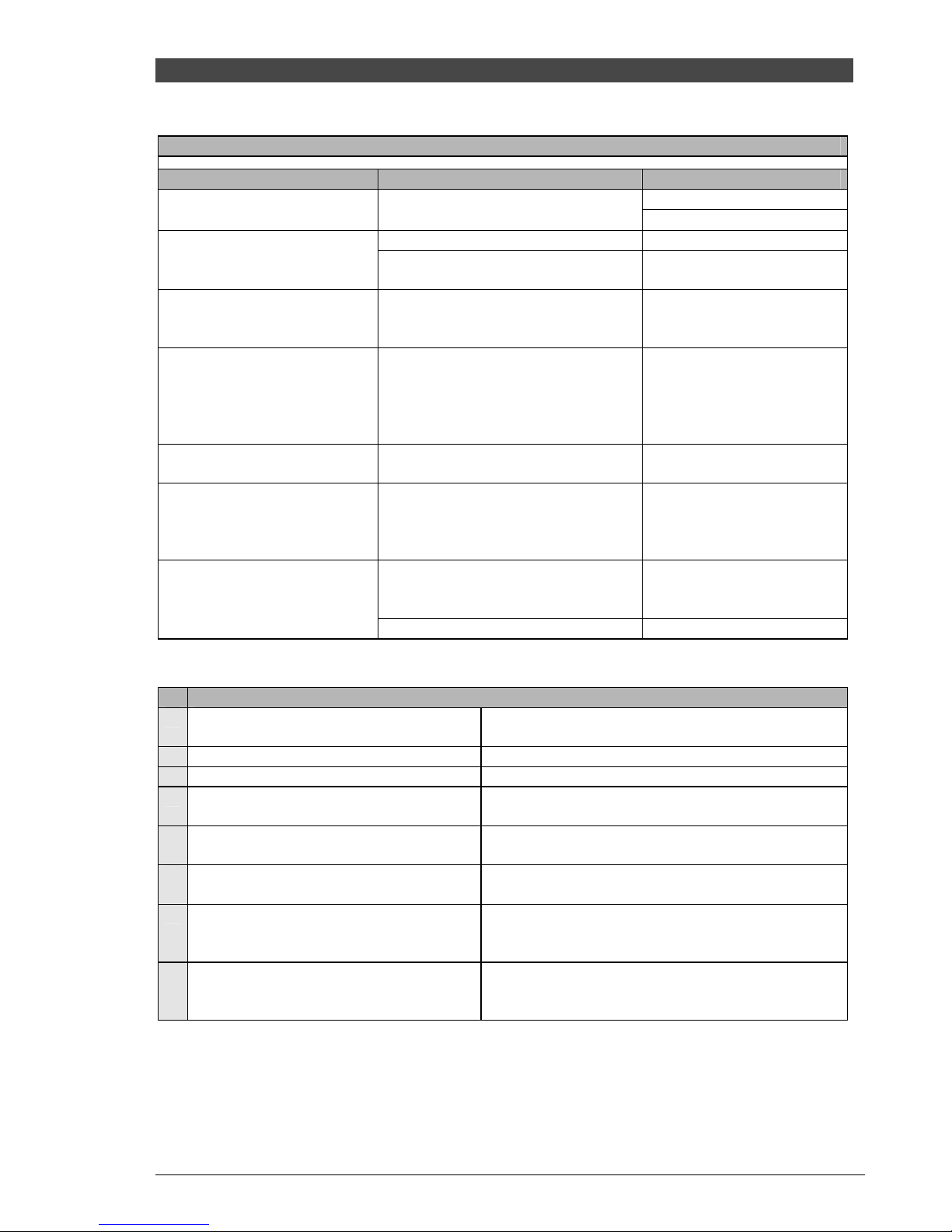

3. Service programme (Incanto de luxe)

3.1. Test mode

Access: Access the test mode from the standby mode (press 2x Menu/OK) by keeping the

EXPRESSO LUNGO and HOT WATER button pressed, whilst pressing the MENU/OK

button again.

While the buttons are kept pressed, the current software version is shown.

The various functions indicated in the table can be checked by pressing the button combinations listed

below.

Programme table (functions programme)

S5

Expresso

S3

x

x

x

S6

S5

S3

S7

D

S4

S2

S1

Buttons

Unit up

S6

Expresso

x

Coffee

S4

lungo

Powder

coffee

S2

Hot

water

S7

Menu/OK

Descale

S1

Unit down

Grinder

Pump

Heating plate

Heating system

Instantaneous water

heater

Pipe heating

Temperature

indicator

in °C

x

x

x x

x x

x x x

x

Page 60

5. SERVICE PROGRAMME INCANTO S-CLASS

Page 8/18 REV.1 FEB.2005 Saeco International Group

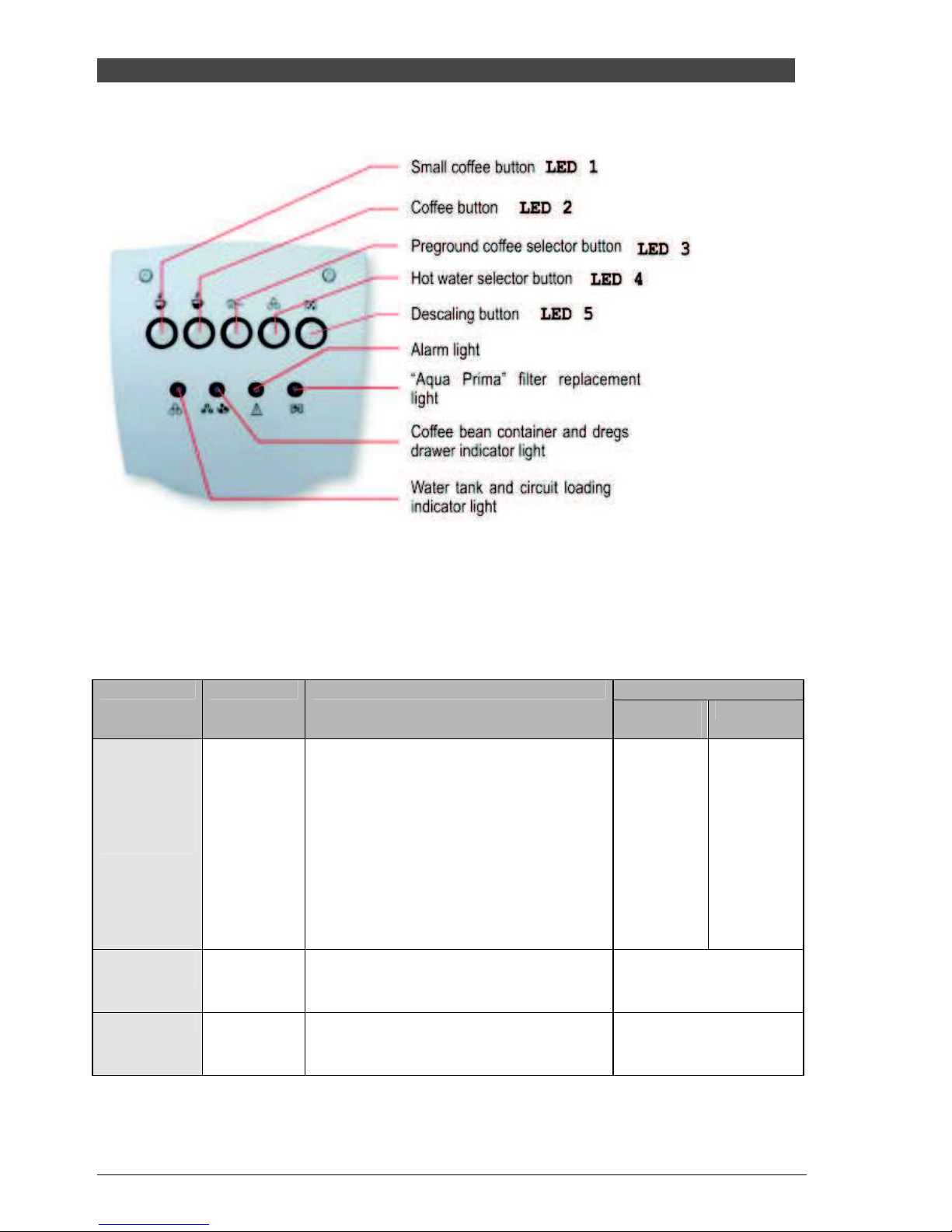

Display in test mode:

Upper display line:

Indicates the status of the microswitch (see table).

Lower display line:

Indicates the status of the operating buttons.

Flow rate

If the pump is activated during test mode and the hot water valve opened, a two-digit number

appears on the bottom right side indicating the flow rate. This value must be between 40 - 60

(should not be below 40).

Grinder power

When the grinder is activated, the grinder power is indicated instead of the flow quantity. Set

value: 6-12

The upper display line signals the activated microswitch and the Hall effect of the turbine.

The activated buttons are signalled by the lower display line (e.g. 1=S1, 2=S2, etc.).

All CPU input signals from the machine appear in the first line of the display.

1 = Brewing unit in brewing position (brewing position microswitch activated)

2 = Brewing unit in at-rest position (idle position microswitch activated)

3 = Not allocated

4 = HWS valve microswitch activated

5 = Grinds container microswitch activated

6 = Brewing unit microswitch activated

7 = Water tank full (reed contact not activated)

8 = Flow meter pulse

9 = Front door microswitch

0 = Grinder Hall sensor pulses

M = Grinder idle indicator

R = (flashing) Clock function OK

All CPU input signals from the control board appear in the second line of the display.

6 = Expresso

5 = Coffee

4 = Expresso lungo

2 = Powder coffee

3 = Hot water pre-selection

1 = Descale button

7 = Menu/OK

Exit: Switch the machine off at the main switch.

1234567890 MR (X)

123456 xx

Page 61

INCANTO S-CLASS 5. SERVICE PROGRAMME

Access: Access from the standby mode (press 2x Menu/OK) by keeping the EXPRESSO, LONG

COFFEE and HOT WATER button pressed and pressing the MENU/OK button with a slight

delay. (The user programme is also available in this mode.)

Using the button scroll to the menu item "Diagnosis" and confirm using Menu/OK.

Changing programme values: Access appropriate item using the Menu/OK button.

Change value with ARROW buttons

Save value by using Menu/OK.

Programme table (diagnosis menu):

EXPRESSO

No. of PULSES 200

50 - 1,000 Pulses

+/- 1

----HEATING----

PARAMETER K1 8

1 - 50 +/- 1

Do not change!

----HEATING----

PARAMETER K2 30

1 - 50 +/- 1

Do not change!

Coffee button

Coffee, expresso lungo button

Expresso button

LCD Display

Powder coffee button

Descaling button

Programme page back

scrolling

3.2. Diagnosis menu (Incanto de luxe)

The values below can be read and adjusted in the diagnosis menu as shown in the table.

Hot water button

Programme page scrolling

Men / OK button

Function/Standard Setting range Increment Comments

EXPRESSO LUNGO

No. of PULSES 600

COFFEE

No. of PULSES 350

50 - 1,000 Pulses

50 - 1,000 Pulses +/- 1

+/- 1

Number of flow meter pulses for

each saved cup fill volume, where

300 pulses correspond to approx.

100 ml.

Saeco International Group REV.1 FEB.2005 Page 9/18

Page 62

5. SERVICE PROGRAMME INCANTO S-CLASS

SENSOR ADJUST.

NORMAL TEMP.

° C 90

70- 130°C +/- 1 Normal temperature is used if not

more than 6 min. have elapsed since

last coffee dispensed.

TEMP. OF 1st

COFFEE

° C 118

70- 130°C +/- 1 Used when dispensing the first

coffee after the machine has been

turned on, to compensate for the high

temperature loss due to the cold

brewing unit and water pipes.

TEMP. INCREASE

° C 0

0-50°C +/-1 The boiler temperature is increased

by a set value shortly before brewing

in order to pre-heat the boiler and

compensate for the temperature drop

during the first water flow.

GRINDS STOP

12

5-50 +/-1 Number of cycles until "EMPTY

GRINDS CONTAINER" is

displayed.

WATER DESCALING

WATER FILTER

(ml) Number

Function/Standard Setting range Increment Comments

----HEATING----

HIGH TEMP.

° C 111

STEAM TEMP.

° C 125

GRINDS COUNTER

Number

TOTAL WATER

(ml) Number

(ml)

96

0 - 999999999 +/- 1

To adjust processor tolerances.

If the temperature in test mode with a

set measuring resistance of 3246Ω

exceeds or falls short of the specified

temperature value (96°C) by more

than 1°C, the value indicated in test

mode must be applied to adjust the

sensor.

No measuring resistance: Do not

change!

70- 130°C +/- 1 If no coffee is dispensed for an

extended time (over 6 min.), the next

coffee will be heated to a higher

temperature to compensate for

cooling of the brewing unit and the

associated temperature loss.

70- 135°C +/-1 No function

0-50 +/-1 Counts number of coffee cycles.

When this value reaches the Grinds

Stop value, "GRINDS CONTAINER

EMPTY" will be displayed. (Reset

by removing dregs drawer for

emptying - min. 6 sec.)

Total water flow volume (in ml) / not

resettable

Total water flow (in ml) since last

descaling / resettable

Total water flow (in ml) since last

filter reset (60,000 - replace filter)

Page 10/18 REV.1 FEB.2005 Saeco International Group

Page 63

INCANTO S-CLASS 5. SERVICE PROGRAMME

Water flow since

descaling indicator

(ml) Number

WATER RESERVE

COUNTER

NUMBER

When the water tank is full, the value

from WATER RESERVE STOP is

applied. The flow meter pulses are

counted from when the reed switch is

switched and deducted from the

value. If a beverage is chosen for

which the saved pulse number is

higher than the remaining pulses, the

message FILL WATER TANK

appears.

CLEANING CYCLE

Status NUMBER

Status of cleaning programme

0/1 (1= Programme activated)

MACHINE STATUS

36

0 - 255

Programme code

--SERVICE DATE-MONTH

0 - 12 +/- 1

Function/Standard Setting range Increment Comments

HOT WATER

FLOW (l/h) 14

HOT WATER

PUMP ADJUST. 63000

WATER RESERVE

STOP 420

CLEANING CYCLE

Counter Number

DESCALING

Counter Number

DESCALING

Status NUMBER

--DATE OF MANUF--TAG

--DATE OF MANUF--MONTH

--DATE OF MANUF--YEAR

--SERVICE DATE-DAY

--SERVICE DATE-YEAR

Exit: Switch the machine off at the main switch.

0 - 999999999 +/- 1 Water flow since the need for

descaling was signalled.

(reset via descaling procedure)

6 - 26 1/h +/- 2 1/h The pump delivery rate for hot

water can be expressed in litres per

hour.

58,000 - 65,500 +/- 1 The pump delivery rate is adjusted in

relation to the HOT WATER FLOW

setting by means of a phase

controlled modulator. Pump

tolerances can thus also be adjusted.

An equivalent value is saved under

HOT WATER PUMP

ADJUSTMENT.

---------------------

--------------------- ---------------------

--------------------- ---------------------

0 - 31 +/- 1

1996 - 2050 +/- 1

---------------------

--

--

--

Water reserve from when the read

switch is switched to pulses.

Counter the cleaning cycles

performed.

Counter the descaling cycles

performed.

Status of descaling programme

0/1 (1= Programme activated)

This date indicates when the machine

was manufactured. This date cannot

be changed.

The service date indicates the date of

the machine's last service. This date

can be changed and must be updated

at each service.

Saeco International Group REV.1 FEB.2005 Page 11/18

Page 64

5. SERVICE PROGRAMME INCANTO S-CLASS