Page 1

All parts of this document are the property of Saeco International Group.

All rights reserved. This document and all the information herein is provided without liability deriving from

any errors or omissions. Furthermore, no part may be reproduced, used or collected with the exception

of that authorised in writing or in accordance with a contractual agreement.

Service Manual

Revision 01 Jan 2013

Page 2

Page

1. Introduction

1.1 Documentation required 1

1.2 Tools and equipment required 1

1.3 Material 1

1.4 Safety warnings 1

1.5 Service Policy 2

1.6.1 External machine parts in manual machine 3

1.6.2 Internal machine parts in manual machine 4

1.7.1 External machine parts in Estrosa and Carezza 5

1.7.2 Internal machine parts in Estrosa and Carezza 6

2. Technical specifi cations

2.1 Technical specifi cations 1

2.2 Descaling frequency 1

2.3 Specifi cation for the measurement of the coffee products temperature. 2

3. User instructions

3.1 Operation, cleaning and maintenance 1

4. Operating logic

4.1.1 Water circuit 1

4.1.2 Exploded view of a water circuit in Estrosa and Carezza 2

4.1.3 Exploded view of a water circuit 3

4.1.4 Hydraulic diagram in Estrosa and Carezza 4

4.1.5 Hydraulic diagram 5

4.2.1 Wiring diagram in Estrosa and Carezza 6

4.2.2 Wiring diagram 7

4.2.3 Electrical diagram 7

4.3 Filter holder 8

4.4 Spherical cappuccino maker and nozzle 8

4.5 Flow meter 9

4.6 Anti-scale fi lter 9

5. Troubleshooting

5.1. Test Mode in Estrosa and Carezza 1

5.2. Causes and solutions 2

6. Standard inspections

6.1 Repair schedule 1

6.2 Service schedule 1

6.3 Final inspection 2

Contents

SAECO MANUAL MACHINES

Page 3

Page

7. Disassembly

7.1.1. Outer elements 1

7.1.2 Controls support 2

7.1.3 Boiler support 2

7.1.4 Pump 2

7.1.5 Boiler thermostats 3

7.1.6 Boiler 3

7.1.7 Shower and valve 3

7.1.8 Steam pipe 3

7.2.1 Outer elements Carezza/Estrosa 4

7.2.2 Pump Estrosa/Carezza 5

7.2.3 Boiler support assembly Estrosa/Carezza 5

7.2.4 Steam knob Estrosa/Carezza 5

7.2.5 Steam pipe Estrosa/Carezza 5

7.2.6 CPU/power card Estrosa/Carezza 6

7.2.7 Keyboard card Estrosa/Carezza 6

7.2.8 Filterholder locking ring Estrosa/Carezza 7

7.3 Un/installing Oetiker clamps 8

8. Notes

SAECO MANUAL MACHINES

Page 4

SAECO MANUAL MACHINES

CHAPTER 1

INTRODUCTION

Page 5

MANUAL MACHINES 01 INTRODUCTION

SAECO Page / 06

1.1 Documentation required

The following documentation is required for repairs:

• Instruction booklet of the specifi c model

• Technical documentation for specifi c model (diagrams, exploded view, sympton cure and

service manual)

1.2 Tools and equipment required

Besides standard equipment, the following tools are required:

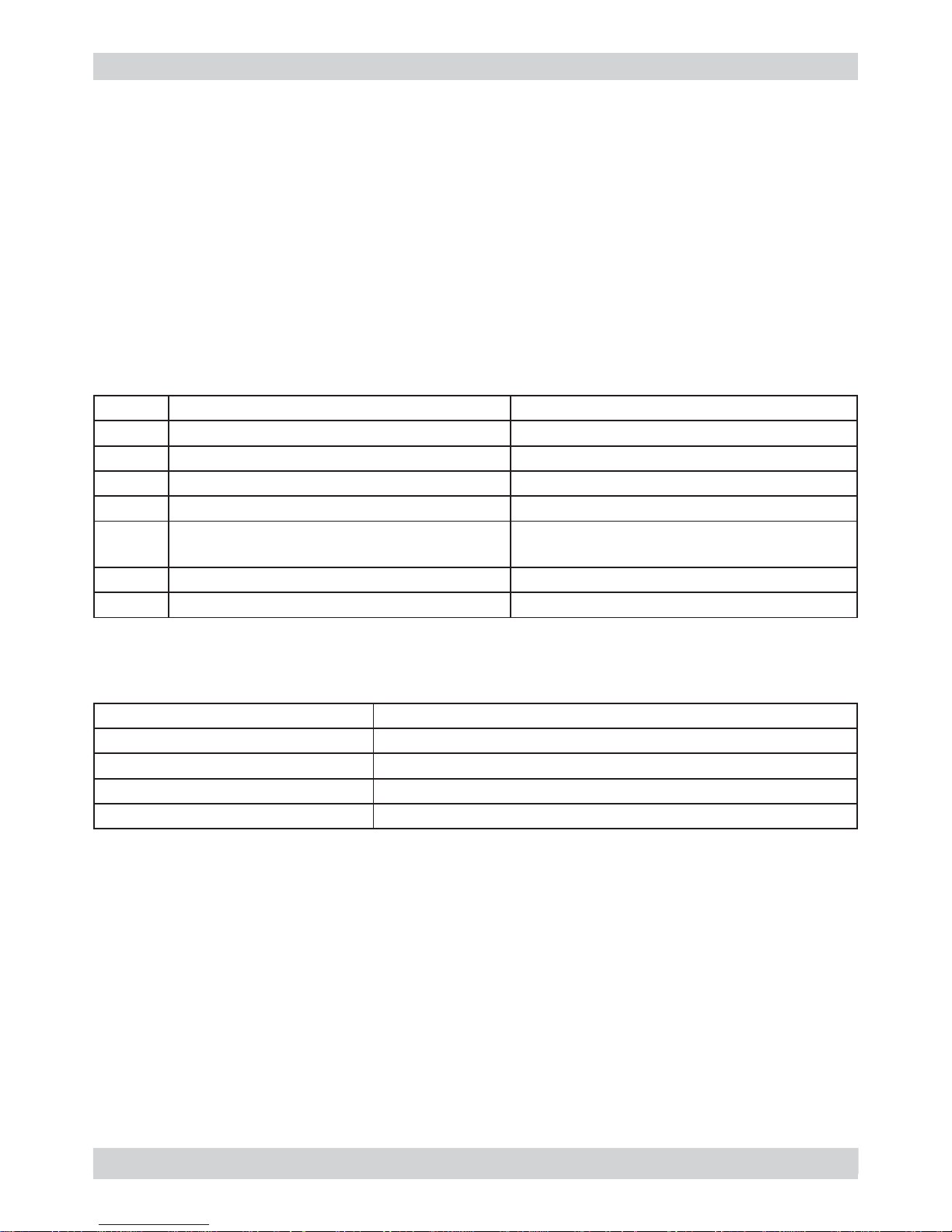

Qty. Description Notes

1 Screwdriver

1 Pliers for Oetiker clamps

1 AC - DC - Vdc tester

1 Digital thermometer Scale Limit > 150°C

1 SSC (Saeco Service Center) Programmer

(for programming and diagnosis mode)

1 Allen wrench

1 Hexagonal spanner

1.3 Material

Description Notes

Thermal grease Thermal resistance > 200°C

Descaler Saeco descaler

Degreaser Personal choice

Silicone grease Safe to use with food

1.4 Safety warnings

It is recommended to consult this Service manual of the machine before implementing any operation.

Comply with all applicable standards relating to the repair of household appliances.

Always disconnect the power plug from the mains before beginning repairs on the machine.

Simply turning off the main switch is not suffi ciently safe to prevent electrical discharges.

This household appliance is rated as insulation class I.

On completion of the repairs, insulation and dielectric rigidity tests must be performed.

01

Page 6

MANUAL MACHINES 01 INTRODUCTION

SAECO Page / 06

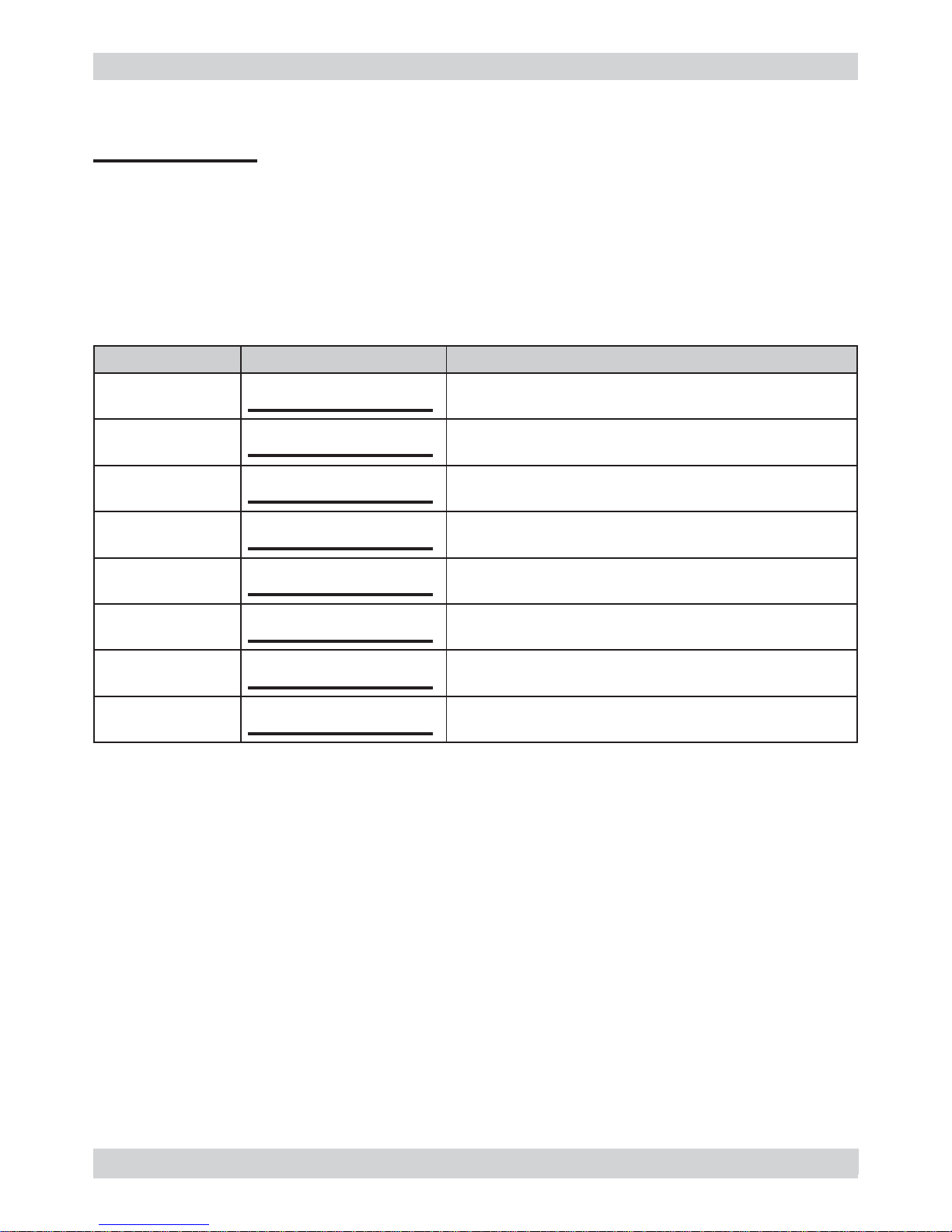

02

Components Assembly use Single components available

COFFEE

GRINDER

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine or of the Coffee Grinder on website

BREWING

UNIT

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine or of the Brewing unit on website

BOILER Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

GEAR

MOTOR

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

FILTER

HOLDER

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

MILK

CARAFE

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

THERMAL

CARAFE

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

Thermal Carafe on website

MILK ISLAND Only for OOW repairs

YES, to consult the specifi c exploded-view of the

Milk Island on website

1.5 Service POLICY grid as used for coffee machine

List of principal assembly present in all our coffee machines

For IN WARRANTY repairs is mandatory to use the single components (not the assembly) avai-

lable in the exploded views of the coffee machines or of the specifi c components. If you fi nd the

information “SEE THE EXPLODED VIEW E........” in the assembly description fi eld, it means that

the single components of the assembly are available in the other pages of the exploded view. It’s

possible to use the assembly only if there is a specifi c Symptom Cure that include this possibility

or when the single components are not available for the order.

Page 7

MANUAL MACHINES 01 INTRODUCTION

SAECO Page / 06

03

1.6.1 External machine parts in manual machine

Water tank

ON/OFF switch

Hot water/steam

dispensing pipe

Hot water/steam

dispensing knob

Nozzle

Drip tray+grille

Pressurised

fi lter holder

Selection

knob

Some machines have the spherical

cappuccino maker instead of the

nozzle

Spherical

Cappuccino maker

Page 8

MANUAL MACHINES 01 INTRODUCTION

SAECO Page / 06

1.6.2 Internal machine parts in manual machine

04

Boiler assembly

Pump assembly

Overpressure

valve

Hot water/Steam

opening - closing

knob rod

Thermal protector

Overpressure

relief valve

Thermostats

Selection knob

Filter holder ring

Page 9

MANUAL MACHINES 01 INTRODUCTION

SAECO Page / 06

05

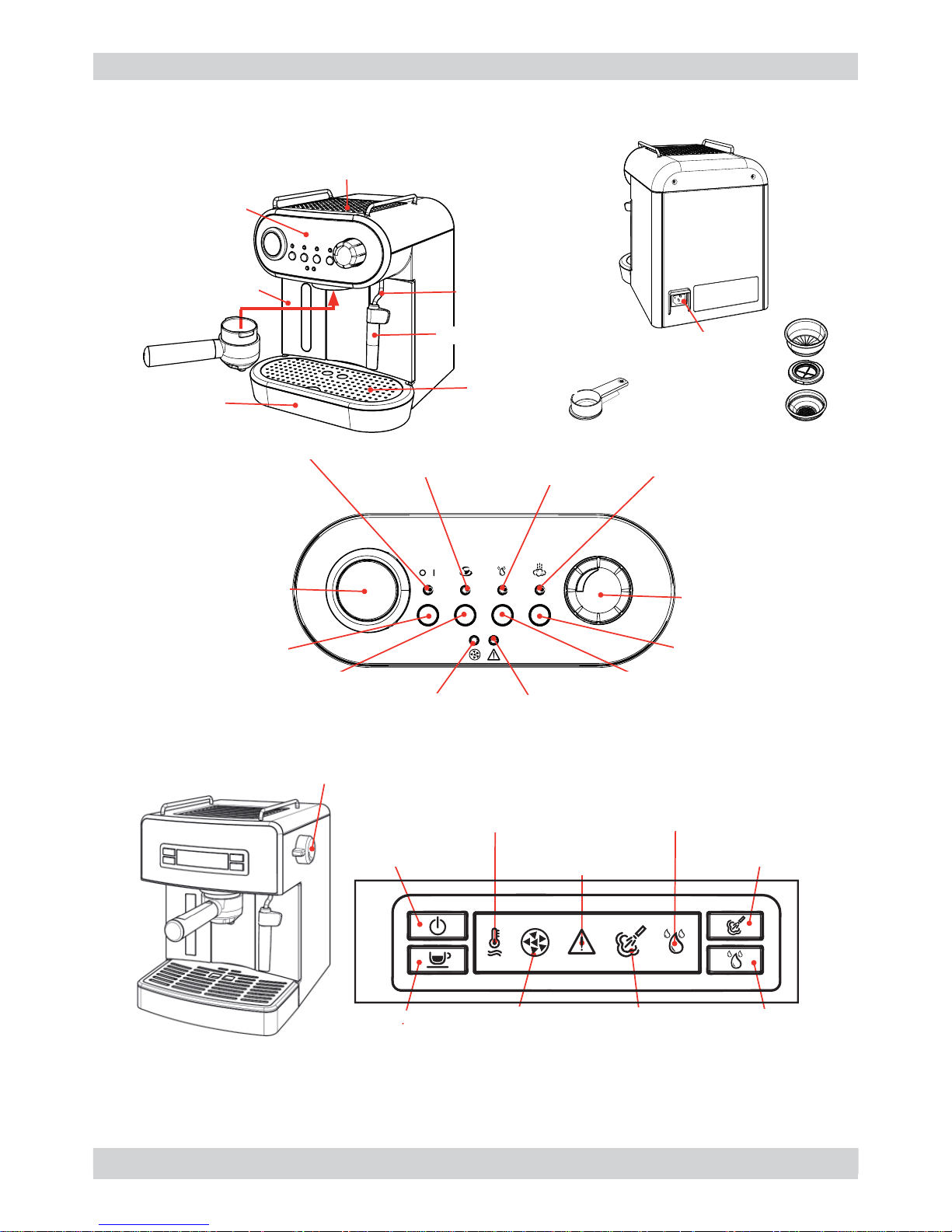

1.7.1 External machine parts in Estrosa and Carezza

Control panel

Hot water /steam

dispensing pipe

1/2 cup fi lter

Coffee measure

Power cable

connector

Water temperature

thermometer

Steam button

Rinsing button

Led “Allarm”

Led “Descaling”

On/Off button

Coffee button

Led machine “ON”

Led “Temperature”

Led “Rinsing”

Led “Steam”

Knob

Hot water /steam

Support for cups

Drip-tray

Water

tank

Cappuccinatore

Grille

Filter holder

pressurised

Led

“Descaling”

Led

“Steam”

Led

“Rinsing”

Led

““Alarm”

Led

“Temperature”

Coffee button

Rinsing button

Steam button

ON/OFF button

Knob

Hot water /steam

Page 10

MANUAL MACHINES 01 INTRODUCTION

SAECO Page / 06

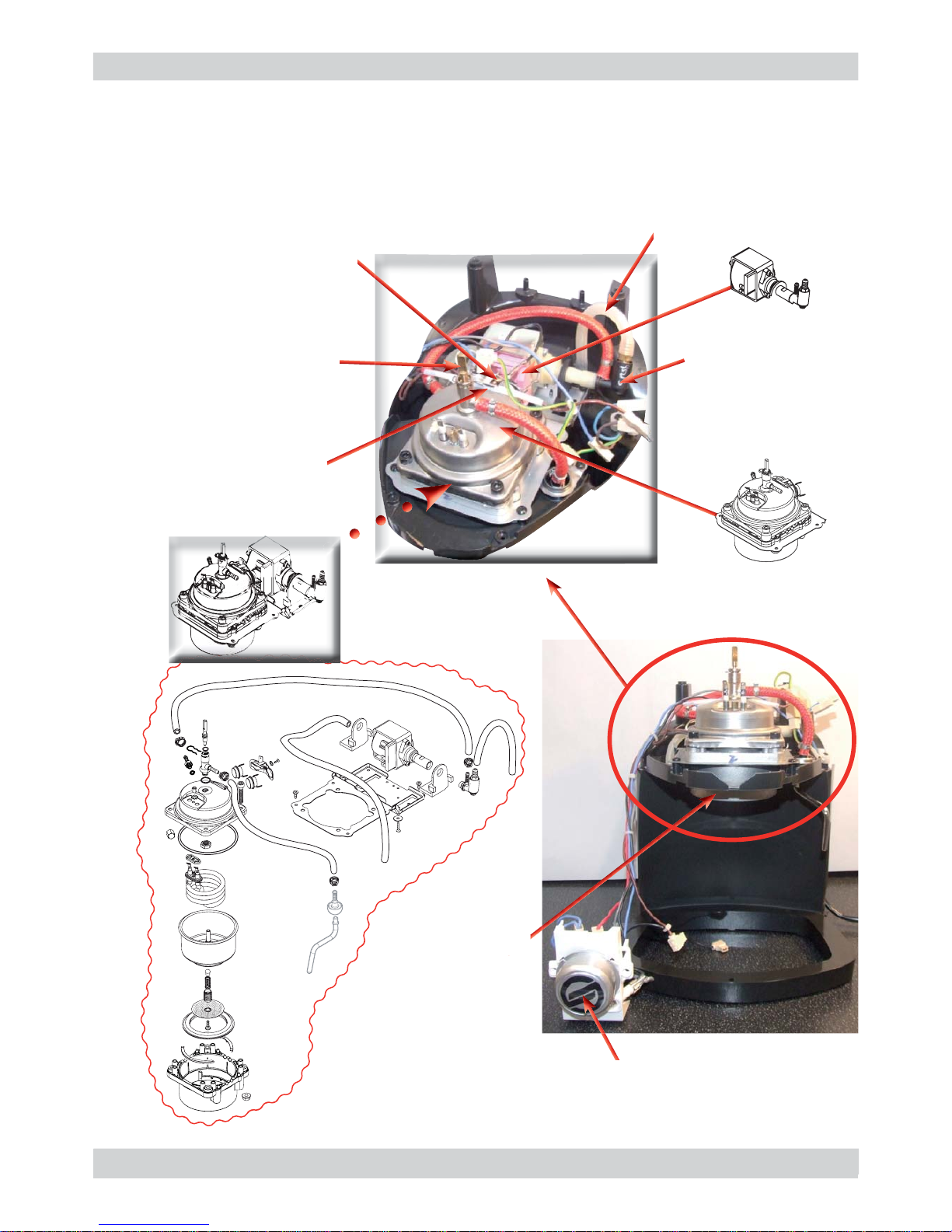

BOILER

FLOW SELECTOR

FAUCET

Filter holder

pressurised

Boiler

1.7.2 Internal machine parts in Estrosa and Carezza

Coffee

Hot water/steam

Water

tank

Pump

Boiler

Hot water/steam

Cold water

Diagram hydraulic circuit

06

Page 11

SAECO MANUAL MACHINES

CHAPTER 2

TECHNICAL SPECIFICATIONS

Page 12

MANUAL MACHINES 02 TECHNICAL SPECIFICATIONS

SAECO Page / 02

2.1. Technical specifi cations

Technical specifi cations Estrosa and Carezza

2.2. Descaling frequency

Safety system: 2 one-shot thermostats (127°C and 95°C) 1 thermal protector >

184°C

Coffee heat exchanger

output: Stainless steel

(230/120 V~) 1000 W – for coffee, hot water and steam

dispensing

Pump Ulka Type EP5/S GW approx. 13-15 bar with reciprocating piston

and 120°C cutout 48 W, 230V, 50 Hz, 120V, 60Hz 100V, 50/60 Hz

and Defond A2P03 220-240V 53W

Overpressure valve: Opening at approx. 16-18 bar

Water fi lter: In tank

Flow meter assembly Only in the single versions with the coffee amount setting

Consumption: During the heading phase of 8,2A, during the brewing phase 8,5A

Safety system: 2 one-shot thermostats 190°

Coffee heat exchanger

output: Stainless steel

1900 W 230V – for coffee, hot water and steam dispensing

Pump Ulka Type EP5/S GW approx. 13-15 bar with reciprocating piston

and 120°C cutout 48 W, 230V, 50 Hz, 120V, 60Hz 100V, 50/60 Hz

and Defond A2P03 220-240V 53W

Overpressure valve: Opening at approx. 16-18 bar

Water fi lter: In tank

Consumption: During the heading phase of 8,2A, during the brewing phase 8,5A

01

Descaling frequency

Hardness

Water hardness Without anti-scale fi lter With anti-scale fi lter

1 Soft (up to 7°dH) 240 litres (480,000 pulses) 480 litres (960,000 pulses)

2 Medium (7° - 14°dH) 120 litres (240,000 pulses) 240 litres (480,000 pulses)

3 Hard (15° - 21°dH) 60 litres (120,000 pulses) 120 litres (240,000 pulses)

4 Very hard

(over 21°dH)

30 litres (60,000 pulses) 60 litres (120,000 pulses)

Page 13

MANUAL MACHINES 02 TECHNICAL SPECIFICATIONS

SAECO Page / 02

2.3. Specifi cation for the measurement of the coffee products temperature.

The temperature is infl uenced by the fl ow from the dispenser and stratifi cation of temperatures in

the glass. In order to consider these phenomena and to introduce measures that allow comparisons in controlled conditions, below guidelines must be followed:

Conditions:

a) Water temperature in tank: 23°C (+/-2°C).

b) It must be used a plastic cup (see picture N°1).

c) It must be used a thermocouple thermometer (e.g. type K - see picture N°2).

d) The coffee machine is tested without any change of parameters or calibrations, which may

affect the temperature of products, so the measurement of temperature must be done with

machine in default factory setting.

Procedure:

1. The temperature must be measured in the cup, immediately after dispensing. Cup has to be

placed on a non-metal surface using a thermocouple thermometer.

2. The temperature in the cup is measured by immersing the probe of the thermometer up to

touch the bottom.The probe then must be moved in a circular motion for 5/6 rotations. At the

of the rotations, stop in the center of the cup.

3. The highest temperature measured during the rotations is the value we are searching for, and

that must be reported;

4. Test measurement: from end of dispensing to the end of rotations must be completed within 12

seconds.

Limits of acceptability

The acceptance limits are divided by features and products and are the following:

Espresso Coffee Italy Q.ty 25/40 gr.

Temperature of 1st product 69°C ≤ 85°C

Temperature of 2nd product 72°C ≤ 85°C

Coffee Q.ty 70/120 gr.

Temperature of 1st product 69°C ≤ 85°C

Temperature of 2nd product 72°C ≤ 85°C

Picture 1

Picture 2

02

Page 14

SAECO MANUAL MACHINES

CHAPTER 3

USER INSTRUCTIONS

Page 15

MANUAL MACHINES 03 USER INSTRUCTIONS

SAECO Page / 01

3.1 Operation, cleaning and maintenance

CLEANING AND TECHNICAL ASSISTANCE

A Empty the drip tray As necessary (fl oat)

B Clean the water tank Weekly

C Clean the fi lter holder As necessary

D Clean the casing As necessary

E Descaling cycle If signalled

01

Descaling frequency

Hardness

Water hardness Without anti-scale fi lter With anti-scale fi lter

1 Soft (up to 7°dH) 240 litres 480 litres

2 Medium (7° - 14°dH) 120 litres 240 litres

3 Hard (15° - 21°dH) 60 litres 120 litres

4 Very hard

(over 21°dH)

30 litres 60 litres

Operating the machine

1 Fill the water tank

2

Fill the coffee bean

container

3 Switch on the appliance

4

Press to switch on the

machine

/

5 Heating The heating phase begins, wait for it to fi nish

6 Machine ready The machine is ready to dispense beverages

Page 16

SAECO MANUAL MACHINES

CHAPTER 4

OPERATING LOGIC

Page 17

MANUAL MACHINES 04 OPERATING LOGIC

SAECO Page / 09

WATER TANK

FLOW METER

BOILER

STOPCOCK

THERMOSTATS

HOT WATER/STEAM

DISPENSING PIPE

DISPENSING COFFEE

FILTER HOLDER

PUMP

OVERPRESSURE VALVE

4.1.1 Water circuit

Various types for water circuit

01

- COLD WATER

- HOT WATER/STEAM

- HOT WATER

Coffee

Pump

Boiler

Hot water/steam

Water

tank

P.S.: Only the single coffee machines have a fl ow meter, which can set and save the amount

of dispensed coffee via the control board.

Page 18

MANUAL MACHINES 04 OPERATING LOGIC

SAECO Page / 09

02

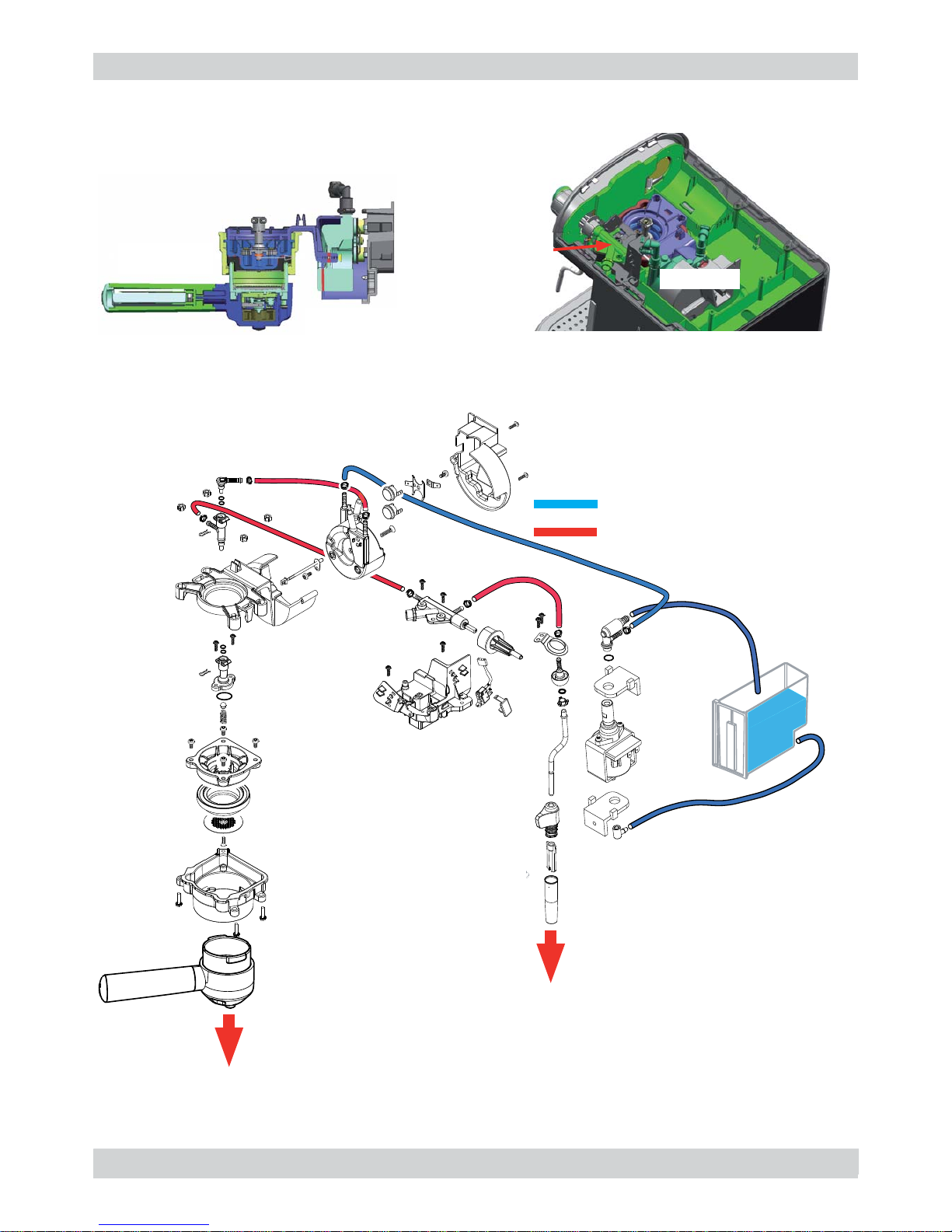

4.1.2 Exploded view of a water circuit in Estrosa and Carezza

THERMOSTATS

HOT WATER/STEAM

DISPENSING PIPE

PUMP

BOILER

OVERPRESSURE

VALVE

Page 19

MANUAL MACHINES 04 OPERATING LOGIC

SAECO Page / 09

4.1.3 Exploded view of a water circuit

03

THERMOSTATS

HOT WATER/STEAM

DISPENSING PIPE

OVERPRESSURE

VALVE

PUMP

BOILER

Page 20

MANUAL MACHINES 04 OPERATING LOGIC

SAECO Page / 09

4.1.4 Hydraulic diagram in Estrosa and Carezza

04

Page 21

MANUAL MACHINES 04 OPERATING LOGIC

SAECO Page / 09

4.1.5 Hydraulic diagram

05

Page 22

MANUAL MACHINES 04 OPERATING LOGIC

SAECO Page / 09

4.2.1 Wiring diagram in Estrosa and Carezza

06

Page 23

MANUAL MACHINES 04 OPERATING LOGIC

SAECO Page / 09

07

4.2.2 Wiring diagram

4.2.3 Electrical diagram

Page 24

MANUAL MACHINES 04 OPERATING LOGIC

SAECO Page / 09

4.4 Spherical cappuccino maker and nozzle

08

HOT WATER/STEAM

PIPE FITTING

STEAM

STEAM

HOT WATER/STEAM

PIPE FITTING

AIR FLOW

ADJUSTMENT

NEEDLE

MILK

FROTHED

MILK

STEAM

4.3 Filter holder

Pressurised and mechanical

fi lter holder

Standard

fi lter holder

Page 25

MANUAL MACHINES 04 OPERATING LOGIC

SAECO Page / 09

Anti-scale fi lter

Function:

• Reduced limescale deposits that take longer to form.

• Improved water quality.

• Better taste due to ideal water hardness

Descaling duration / effi ciency:

• - 10° dH

• 60 litres

• 2 months

To obtain a linear characteristic of its effectiveness,

throughout the duration of the descaling process, the

water is split according to the degree of hardness in a

three-phase by-pass (A, B and C).

See small picture.

Bypass

4.6 Anti-scale fi lter

09

4.5 Flow meter

1) upper body

2) fl ow meter

3) magnet

4) O-ring seal

5) lower body

A) Board

The water enters, hits against the blades of the fl ow

meter, causing it to turn.

The magnet passes beneath the board and transmits

the number of revs to it, which in turn transmits it to

the main board

Water inlet

Water outlet

1

4

5

3

A

2

Page 26

SAECO MANUAL MACHINES

CHAPTER 5

TROUBLESHOOTING

Page 27

MANUAL MACHINES 05 TROUBLESHOOTING

SAECO Page / 02

01

5.1 Test Mode in Estrosa and Carezza

ENTER IN TEST MODE:

The entering in Test mode is possible only disconnecting the machine from the main plug,

opening the steam knob and pressing the coffee button and the rinsing button at the

same time, connecting the machine to the main plug and keep pressed the buttons for 3

seconds.

After 3 seconds the Led Alarm and Led Descale turn on and the thermometer (only Gaggia

version)will move to reache the zero to confi rm the entering in TEST MODE.

TEST MODE:

At this point at every button presion will be associate the turning on of one Led and the turning

on of a load for 3 seconds. In this mode it is possible to do the machine steam out.

• ON/OFF button turn on Heater and Led ON for 3 seconds (only in Gaggia machine).

• Coffee button turn on Led coffee and move the Motor for 3 seconds.

• Rinsing button turn on Led Rinsing and Pump. Pressing again the Rinsing button the

pump will turn off.

• Steam button turn on the Led Steam.

STEAM OUT:

• Push contemporarily ON/OFF button and STEAM button will turn on Led ON and the

Led Steam.

• Keep the button pressed for 3 seconds.at the end of this time the 2 led will turn off and

Led Steam starts blinking indicating that the heater is going in steam temperature.

• During the warming up some water will fl ows out from the steam tube.

• When the heater reach the steam temperature no more power is given to the heater.

The Led Steam stop blinking and stays on for 5 seconds to guarantee that the heater is

empty of water.

• At the end of the 5 seconds the Led Steam turn off to allow the user to test the next ma

chine.

• At the end of this action the machine is empty and at the fi rst power on, the circuit rechar

ge is needed.

EXIT FROM TEST MODE:

From the test mode is possible to exit only disconnecting the machine from the main plug.

Page 28

MANUAL MACHINES 05 TROUBLESHOOTING

SAECO Page / 02

02

FAULT POSSIBLE CAUSES SOLUTION

The machine does not

switch on

No power supply Check the electrical circuit

The machine does not warm

up

The thermostats have intervened

The power supply does not reach

the boiler

Replace the thermostats (if of the

One shot type)

If they are manual, reset them

If they are automatic, they are

reset automatically

Check the electrical connections

The pump is very noisy

There is no water in the tank

The pump has disengaged from

the supports

The silicone pipe that carries the

water from the tank to the pump is

pinched or blocked

Fill the tank

Insert the pump into the supports

once again

Check the water circuit

The coffee is too cold

The fi lter holder is not inserted for

the pre-heating process

The cups are cold

Run hot water through the fi lter

holder

Pre-heat the cups with hot water

The milk does not froth

The milk is not suitable (powdered

or skimmed milk)

Dirty nozzle or Cappuccino maker

Use whole milk

Carefully clean the nozzle or the

cappuccino maker with water

The coffee flows too quickly

and does not form the cream

Little coffee in the filter holder

Grinding level too coarse

There is a missing component in

the filter holder

Increase the quantity

Use a different mixture

Verify that all the components are

in place and installed correctly

The coffee does not flow or

it flows in drops

Grinding level too fi ne

The coffee is pressed too much in

the fi lter holder

Too much coffee in the filter holder

Blocked water channels

Blocked filter in the filter holder

Use a different mixture

Agitate the coffee

Reduce the amount of coffee

Descale the machine

Carefully clean the fi lter

The coffee does not flow from

the edges

The fi lter holder has been

inserted incorrectly into the coffee

dispensing unit

The upper border of the fi lter

holder is dirty

The seal of the boiler is dirty or

worn

Too much coffee in the fi lter holder

Insert the fi lter holder correctly

Clean the edges of the fi lter holder

Clean or replace the seal

Reduce the amount of coffee

P.S.: Refi ll the water circuit when the machine is fi rst used as well as when the water in the tank

fi nishes.

5.2 Causes and solutions

Page 29

SAECO MANUAL MACHINES

CHAPTER 6

STANDARD INSPECTIONS

Page 30

MANUAL MACHINES 06 STANDARD INSPECTIONS

SAECO Page / 02

Action

1 Visual inspection (damage during transport)

2 Machine data check (plate)

3 Functional check / problem analysis

4 Opening the machine

5 Visual inspection

6 Functional tests

7 Repairing the faults encountered

8 Checking any modifi cations (view info, etc.)

9 Service activities in accordance with the operating schedule

10 Internal cleaning

11 Functional test with the machine open

12 Assembly

13 Final inspection test

14 Draining the circuit (in winter)

15 External cleaning

16 Insulation test HG 701 (dielectric)

17 Documentation

S Replacement P Cleaning

ES Visual inspection TR Noise test

D Descaling cycle R Adjustment

CF Functional check

Component Action Support/tool

Water fi lter P/S/CF

Water tank lip seal S/CF

Pipes, fi ttings and Oetiker clamps ES/CF

Hot water/steam circuit pump ES/TR/CF

Water circuit D/CF Saeco descaler

Wiring ES/CF

6.2. Service schedule

6.1. Repair schedule

01

Page 31

MANUAL MACHINES 06 STANDARD INSPECTIONS

SAECO Page / 02

Test Procedure

Support/

tool

Standard Tolerance

Coffee

2-3 Coffees for

adjustment purposes

Measuring

beaker

Noise Standard

Amount of

cream

Blow into the cup until

the cream separates

The cream should

come together

again completely

Cream colour Hazel brown

Hot water Dispense water

Steam Dispense steam

6.3. Final inspection

02

Page 32

SAECO MANUAL MACHINES

CHAPTER 7

DISASSEMBLY

Page 33

MANUAL MACHINES 07 DISASSEMBLY

SAECO Page / 08

7.1.1. Outer elements

Upper cover

RIGHT and LEFT side covers

Remove the water tank, the water drip tray, the

grille and the steam knob.

Loosen the screws as shown on the front

and rear part of the machine

Lift the cover and loosen the screws as shown

Remove the side covers

by lifting them upwards

LEFT side cover

(note the hooks

of the cover)

RIGHT side cover. Remove the connection of the

on/off switch from the cover

01

RIGHT

Page 34

MANUAL MACHINES 07 DISASSEMBLY

SAECO Page / 08

02

Remove the knob by

pulling it outwards

Remove the electrical connections

and the two bright indicators

Loosen the overpressure valve

Remove the pump from the supports

Remove the water connections and loosen the screws as shown

Loosen the screws as shown

to remove the rotating switch

7.1.2 Controls support

7.1.3 Boiler support

7.1.4 Pump

Page 35

MANUAL MACHINES 07 DISASSEMBLY

SAECO Page / 08

03

Loosen the screw as shown

Loosen the screws as shown

Loosen the screw as shown

Loosen the

screw of the

valve holder

Check the condition of the

shower, valve holder screw,

channels (holes not blocked)

and verify there is no limescale

on any of the parts

Shower

Loosen the screws as shown

Check the internal condition of the boiler

(limescale, any breakages, condition of the

O-ring seal, etc.)

When putting back the thermostats,

always apply conductive paste for the

thermostat to adhere perfectly to the

boiler

7.1.8 Steam pipe

7.1.5 Boiler thermostats

7.1.6 Boiler

7.1.7 Shower and valve

Page 36

MANUAL MACHINES 07 DISASSEMBLY

SAECO Page / 08

04

7.2.1 Outer elements Carezza / Estrosa

Remove the water tank, the water drip

tray, the grille, the steam knob and pannarello.

steam knob

pannarello

water tank

water drip tray

and grille

Upper cover

LEFT and RIGHT side covers

Loosen the screws as shown on the rear part of the

machine and lift the cover

Remove the posterior

cover lifting it upwards

Loosen the screws as shown

Remove the covers as in the pictures

Pump

Page 37

MANUAL MACHINES 07 DISASSEMBLY

SAECO Page / 08

Loosen the screws

Loosen the screws

Loosen the screws

Loosen the screws to remove the steam pipe

Remove the pump from the supports as the picture

Remove the water and electric connections

Remove the water and

electric connections

Remove the water connections

7.2.2 Pump Esrosa/Carezza

7.2.3 Boiler support assembly Esrosa/Carezza

7.2.4 Steam knob Esrosa/Carezza

7.2.5 Steam pipe Esrosa/Carezza

05

Page 38

MANUAL MACHINES 07 DISASSEMBLY

SAECO Page / 08

7.2.6 CPU/power card Estrosa/Carezza

7.2.7 Keyboard card Estrosa/Carezza

Estrosa

Carezza

Loosen the screws as shown

Loosen the screws as shown

Loosen the screws as shown

Loosen the screws, the electric connection and remove front panel as

shown

Loosen the screws, the electric

connection and remove front

panel as shown

Remove the knob

Hot

water /steam

Remove the electric connections

06

Page 39

MANUAL MACHINES 07 DISASSEMBLY

SAECO Page / 08

7.2.8 Filterholder locking ring Estrosa/Carezza

Loosen the screws

Loosen the bolt

Remove the cover pulling

it down

Remove the water

connections

07

Page 40

MANUAL MACHINES 07 DISASSEMBLY

SAECO Page / 08

1) Boiler connection

2) Other connections

Replacing the pipes

1) Use a suitable pair of pliers to

remove the clamp (as shown in the

picture)

2) Tighten the clamp as shown in the

pictures

7.3 Un/installing Oetiker clamps

1

1

2

2

08

Page 41

SAECO MANUAL MACHINES

CHAPTER 8

NOTES

Page 42

MANUAL MACHINES 08 NOTES

SAECO Page / 01

01

Loading...

Loading...