Page 1

Type SUP040R

02

ENGLISH

EN

02

OPERATING INSTRUCTIONS

Read these instructions carefully before using the machine.

Page 2

1

1

2

3

4

5

6

26

7

8

9

10

• 2 •

17

22

18

23

11

12

13

14

19

20

24

21

25

15

16

Page 3

2

3

4

5

8

11

6

9

12

7

10

13

• 3 •

Page 4

SAFETY REGULATIONS

Never allow water to come into contact

with any of the electrical parts of the machine: Danger of short circuit! Hot water

and steam may cause burning!

Intended Use

The machine is intended to be used in small of ces/organisations only.

The appliance is not to be used by persons

(including children) with reduced physical,

mental or sensory abilities or with scarce experience and/or expertise, unless they are supervised by a person responsible for their safety,

or they are instructed by this person on how to

properly use the machine.

or feet. Do not let the power cord hang freely

from tables or shelves.

For the Safety of Others

Ensure that children cannot play with the machine and/or the packaging materials. Never

direct the jet of hot water and/or steam towards yourself or others. Do not touch the hot

water wand with bare hands. Always use the

handles or knobs provided.

Danger of Burns

Do not touch the hot water wand and/or the

co ee/product dispensing spout.

Fire Safety Precautions

In case of re, use carbon dioxide (CO2) extinguishers. Do not use water or dry powder extinguishers.

Power Supply

The machine must be connected to the power

supply by the service provider, in accordance

with its speci cations.

Power Cord

Never use the machine if the power cord is defective.

Report any defects in the cord and/or plug to

the service provider immediately. Do not pass

the power cord around corners, over sharp

edges or over hot objects and keep it away

from oil. Do not use the power cord to carry

or pull the machine. Do not pull out the plug

by the power cord nor touch it with wet hands

• 4 •

Suitable Location for Operation

and Maintenance

The machine should be installed by the service

provider in accordance with the safety regulations in force at the time of installation.

The machine may only be moved by the service

provider.

Do not use the machine outdoors.

Avoid placing open ames and/or incandescent objects near the machine in order to avoid

melting or other damage to the machine housing. Do not use in places where the temperature may drop to a level equal to and/or lower

than 0°C. If the machine has been exposed to

Page 5

such conditions alert the service provider, who

will carry out a safety check.

Cleaning

Before cleaning the machine, the power button

must be switched to OFF (0) and the plug must

be removed from the power socket. Wait also

for the machine to cool down. Never immerse

the machine in water! It is strictly forbidden to

tamper with the internal parts of the machine.

Do not clean the machine using a jet of water.

The appliance and its components must be

cleaned and washed following a period of inactivity.

Using Milk

Milk must be used and stored in accordance

with the instructions given on the manufacturer's original packaging.

We accept no liability for use of milk unsuitable

for human consumption.

Milk must be kept cold, as high temperatures

make it become acid - this is a natural characteristic of milk. For this reason, the Cappuccinatore must be cleaned after each use, as described in the manual.

For thorough cleaning, the Cappuccinatore can

be detached and disassembled, and its parts

can be put in a dishwasher (not professional

type).

The washing process in the dishwasher may

cause the surface of the Cappuccinatore parts

to tarnish or the graphics to fade, especially if

aggressive detergents are used.

This is a normal phenomenon and does not

a ect in any way the correct operation of the

milk system.

Storing the Machine

If the machine is to remain inactive for a long

time, turn it o and unplug it. Store the machine in a dry place, out of the reach of children. Keep it protected from dust and dirt.

Repairs / Maintenance

In case of failure, problems or a suspected fault

resulting from a fall, immediately remove the

plug from the power socket and alert the service provider or specialised technician.

Never attempt to operate the machine if it is

faulty. Only the service provider and/or technician may carry out servicing operations and

repairs on the machine.

• 5 •

Page 6

CONTENTS

Machine Use - User Manual

1 GENERAL INFORMATION ...................................... 7

1.1 Intended Use of the Machine .......................................7

1.2 To Simplify Manual Reading.........................................7

1.3 How to Use these Operating Instructions .....................7

1.4 Machine Identi cation .................................................7

1.5 Technical Speci cations ...............................................8

1.6 Residual Risks ..............................................................8

2 MACHINE COMPONENTS ...................................... 8

2.1 Control Panel Description ............................................9

3 USING THE MACHINE .......................................... 9

3.1 Switching on the Machine ...........................................9

3.2 Warm-up and Rinsing ................................................10

3.3 Rinse/Self-Cleaning Cycle...........................................10

3.4 Eco-friendly: Stand-by ...............................................10

3.5 Adjusting the Dispensing Spout ................................. 10

3.6 Co ee Brewing ..........................................................11

3.7 Emptying the Co ee Grounds Drawer .......................11

3.8 Brewing a Cappuccino ...............................................12

3.9 Latte Macchiato .........................................................12

3.10 Dispensing Hot Water.................................................13

3.11 "SPECIAL" Products ....................................................13

4 USING THE MACHINE WITH CREDITS .................. 15

5 CLEANING AND MAINTENANCE ........................... 15

5.1 Cleaning the Hot Water / Steam Wand .......................15

5.2 Cleaning the Co ee Grounds Drawer ..........................16

5.3 Cleaning the Drip Tray ................................................16

5.4 Cleaning the Cappuccinatore (After Each Use) ............16

6 MACHINE WARNINGS ........................................ 18

8.7 Opening the Upper Lid ............................................... 23

8.8 Filling the Water Tank.................................................24

8.9 Filling the Co ee Bean Hopper ...................................24

8.10 Closing the Upper Lid ................................................. 25

8.11 Electrical Connection..................................................25

8.12 Setting the Language (Upon First Use) ......................25

8.13 First Use - Use After a Long Period of Inactivity ..........26

8.14 Measuring and Adjusting Water Hardness .................26

8.15 "INTENZA+" Water Filter ...........................................27

8.16 Adjusting the Co ee Grinder ......................................29

8.17 Adjusting the "Aroma" - Amount of Ground Co ee ....30

8.18 Adjusting Brewed Products ........................................30

9 MACHINE PROGRAMMING ................................. 33

9.1 Accessing the Programming Mode .............................33

9.2 Programming Controls ...............................................34

9.3 Credits Menu ..............................................................35

9.4 Beverage Menu ..........................................................36

9.5 Machine Menu ...........................................................38

9.6 Setting the PASSWORD ..............................................42

10 CLEANING AND MAINTENANCE ........................... 43

10.1 Cleaning Intervals ......................................................43

10.2 Cleaning the Water Tank ............................................ 43

10.3 Thorough Cleaning of the Cappuccinatore .................43

10.4 Brew Group - Weekly Cleaning ...................................45

10.5 Cleaning the Brew Group with “Co ee Clean Tablets” .46

10.6 Brew Group Lubrication .............................................48

10.7 Descaling ...................................................................49

11 MACHINE DISPOSAL .......................................... 52

12 TROUBLESHOOTING .......................................... 53

7 HANDLING AND STORAGE .................................. 20

7.1 Handling ....................................................................20

7.2 Storage ......................................................................20

8 INSTALLATION .................................................. 20

8.1 Safety Regulations ....................................................20

8.2 Stop Functions ...........................................................21

8.3 List of Accessories Supplied ........................................21

8.4 Assembly-Siting .........................................................22

8.5 Disposal of Packaging ................................................22

8.6 Installing the Container Base .....................................22

• 6 •

Page 7

1 GENERAL INFORMATION

1.1 Intended Use of the Machine

This machine automatically brews:

- Co ee and espresso co ee using co ee beans;

- Hot beverages using hot water dispensed via the steam

wand;

- Milk-based beverages using the supplied Cappuccinatore.

The structure of the machine and its elegant housing have been

designed for use in small o ces, businesses and institutions.

Important.

Misuse voids all forms of warranty, releasing the

Manufacturer from any responsibility for damage to persons and/or property.

The following are considered misuse:

- Any use other than the intended use and/or employ-

ing methods other than those described in this manual;

- Any operation on the machine in breach of the instruc-

tions provided in this manual;

- Any use following tampering with machine compo-

nents and/or alteration of its safety mechanisms;

- Use of the machine outdoors.

In such cases the user shall bear the costs of repair.

1.2 To Simplify Manual Reading

Various kinds of symbols are used in this manual to highlight the

di erent hazard or competence levels.

The warning triangle indicates

important instructions for the

safety of the machine's users.

Carefully follow these instructions to avoid serious injury!

Various symbols are used in this manual to indicate the competences of each user.

User: A person who uses the machine to brew beverages

and who can clean the machine, where instructed

to do so in the manual. Users are NOT allowed to

perform operations which are the competence of

the Service Provider/Supply Operator or Technician. On detecting machine malfunctions and/or

faults, users should contact the Service Provider

only.

Machine Use - User Manual

Service Provider/Supply Operator:

Company or person responsible for normal ma-

chine installation, start-up and suspension of

service. On detecting machine malfunctions, the

service provider should request the assistance of

the maintenance technician.

Technician: Personnel quali ed to perform unscheduled

maintenance operations and provide assistance

with the machine.

Technicians may carry out all operations described

in this manual without requiring explicit authorisation.

This symbol is used to highlight information that

is particularly important to ensure optimal use of

the machine.

1.3 How to Use these Operating Instructions

This manual constitutes an integral part of the

machine, and should be read carefully. It contains

information regarding installation, maintenance and

proper use of the machine.

Always refer to this manual before carrying out any operation.

Keep these operating instructions in a safe place and make them

available to anyone who may use the co ee machine. If this

manual is lost or damaged, a copy should be requested from the

service provider immediately. For further information or if you

experience problems not completely or su ciently covered in

these instructions, please contact the service provider.

1.4 Machine Identi cation

The machine is identi ed by the model name and serial number

shown on the special plate.

The plate contains the following information:

• Name of the Manufacturer

• CE marking

• Machine model

• Serial number

• Manufacturing year

• Some technical speci cations:

- Power supply voltage (V);

- Power supply frequency (Hz);

- Electrical power consumption (W).

• 7 •

Page 8

Machine Use - User Manual

Note: When contacting the Service Provider, always refer to this plate, and to the machine's spe-

ci c data shown on it.

1.5 Technical Speci cations

Technical Speci cations

Power Supply and Nominal Voltage-Power Rating

See plate attached to the back of the appliance

Machine Housing Material

metal - thermoplastic material

Size (w x h x d)

334 x 574 x 452 (mm)

Weight

approx. 22 kg

Power Cord Length

1.2 m

Water Tank Capacity

4.0 litres

Co ee Grounds Drawer Capacity

40 grounds

Control Panel

On the front

A-weighted Sound Pressure Level:

Less than 70 dB

Pump Pressure

Max. 1.5 MPa (15.0 bar)

Water Connections (for water network version only)

maximum pressure 0.8 MPa (8 bar)

minimum pressure 0.15 MPa (1.5 bar)

Operating Conditions

Minimum temperature: above 10°C

Maximum temperature: below 40°C

Maximum humidity: below 95%

Safety Devices

Boiler pressure safety valve

Safety thermostat

Subject to engineering and manufacturing changes due

to technological improvements.

1.6 Residual Risks

The dispensing outlet has no guards to prevent accidental hand

contact with co ee, hot beverages and/or steam.

2 MACHINE COMPONENTS

Note: The “key to components” includes all machine models; check which one matches your ma-

chine. Certain functions may not be available.

1 Tank lid with lock

2 Water tank

3 Control panel

4 Cappuccinatore

5 Hot water / steam wand

6 Service compartment access door (to be used by the Ser-

vice provider only)

7 Co ee bean hopper

8 Accessory drawer

9 Cappuccinatore compartment cover

10 Dispensing spout

11 Cup holder grill

12 Full drip tray oat

13 Drip tray

14 Co ee grounds drawer

15 ON/OFF button

16 Chassis plug

17 "Espresso" button

18 "Co ee" button

19 Display

20 "Cappuccino" button

21 "Latte Macchiato" button

22 "Hot Water" button

23 "Special Beverages" button

24 "Cappuccinatore Cleaning Cycle" button

25 "Stand-by" button

26 Group compartment drawer

• 8 •

Page 9

2.1 Control Panel Description

Note: All possible controls are described here.

Refer to the following sections for the operating

modes.

Some buttons in the control panel have a double

function. The double function is only activated in

certain moments during the machine operation or when

accessing the programming mode. The additional function is indicated by the icon under the machine button.

Machine Use - User Manual

3 USING THE MACHINE

Before start using the machine check that the water tank and the

co ee bean hopper are lled and that the machine is properly

clean.

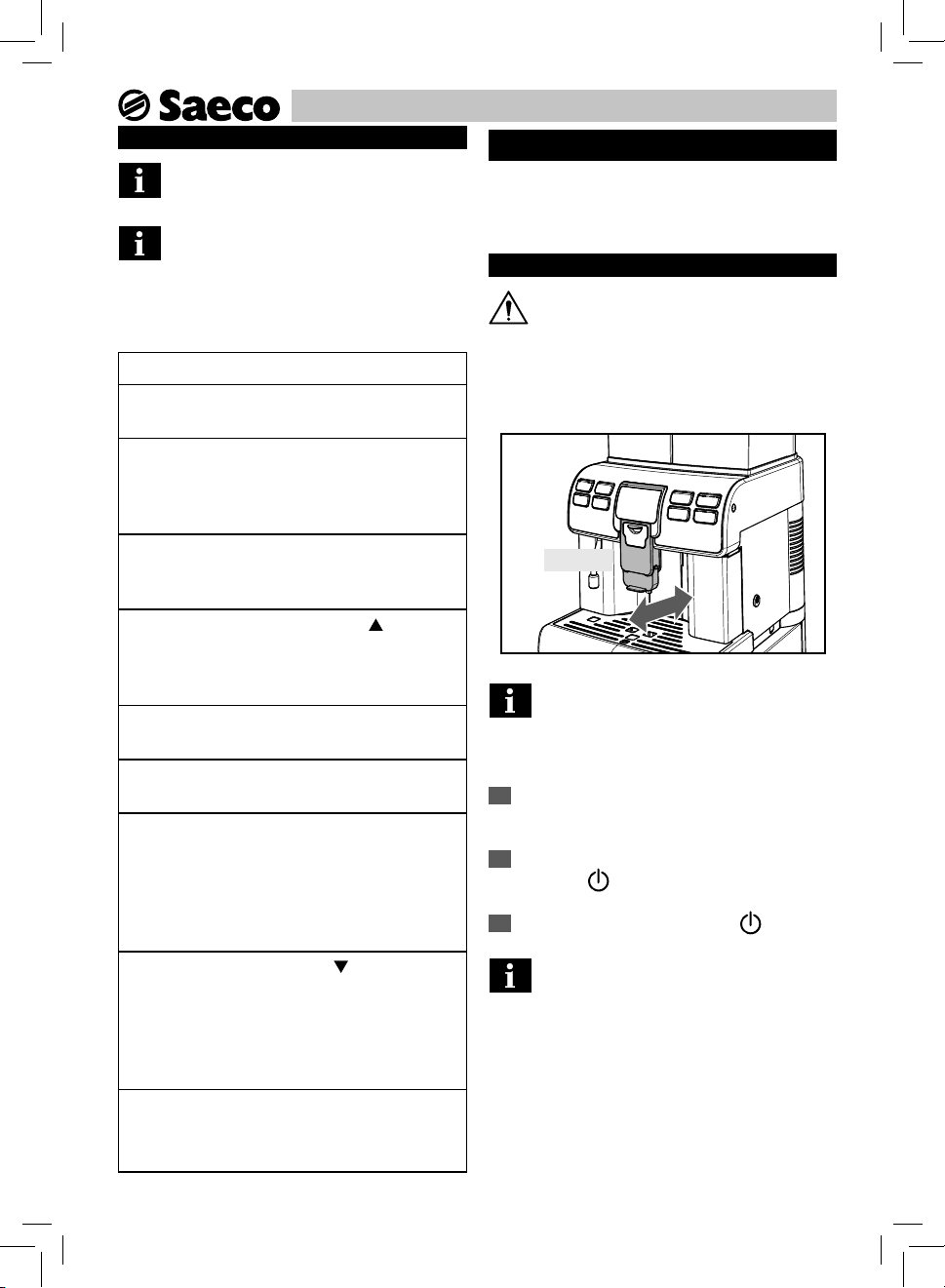

3.1 Switching on the Machine

Warning! Connection to the power supply should

be carried out exclusively by the service provider!

Ensure that the upper lid (1) is always locked.

Button - Description

17 "Espresso" button

When this button is pressed an espresso cup is brewed.

18 "Co ee" button - 2nd Function (OK)

When this button is pressed a co ee cup is brewed.

nd

2

Function - Press it to select the displayed option.

19 LCD Display

Displays the machine status and alarm signals, and guides the

user through the steps required to operate the machine.

20 "Cappuccino" button - 2nd Function (

When this button is pressed a cappuccino cup is brewed.

nd

2

Function - Press it to scroll the current page selection up.

21 "Latte Macchiato" button

When this button is pressed a latte macchiato cup is dispensed.

22 "Hot Water" button

When this button is pressed hot water is dispensed.

23 "Special Beverages" button - 2nd Function (ESC)

When this button is pressed, the menu for preparing other

types of beverages is accessed.

nd

2

Function - Press it to exit the selected page and/or to stop

the beverage brewing procedure.

24 "Clean" button - 2nd Function (

When this button is pressed, the machine starts an automatic

quick cleaning cycle of the Cappuccinatore.

nd

2

Function - Press it to scroll the current page selection

down.

25 "Stand-by" button

When this button is pressed, the machine Stand-by mode is

activated.

)

)

Before switching on the machine, ensure that the plug is correctly

inserted in the power socket.

CLICK!

Ensure that the dispensing spout is in correct posi-

tion. Move it horizontally until you hear the CLICK

indicating correct positioning. If this is not done, some

product might leak out of the dispensing spout.

To switch on the machine, move the power button on the

1

back of the machine to "I" (Fig.02, page 3).

After carrying out a check cycle, the machine goes into stand-

2

by mode and the "

To turn on the machine simply press the " " button (25).

3

Note: Once the warm-up is complete, the machine

primes the circuit and performs a rinse cycle of

the internal circuits. A small amount of water is dispensed

during this process. Wait for this cycle to be completed.

" button (25) blinks.

• 9 •

Page 10

Machine Use - User Manual

3.2 Warm-up and Rinsing

Upon start-up, the machine activates the warm-up phase.

1

Wait until it is completed.

HEATING UP…

Note: The bar is in progress to show that the machine is heating up the system.

Once the warm-up is complete, the machine performs a rinse

2

cycle of the internal circuits.

button (25) (if at least one co ee-based product has been

brewed).

A small amount of water will be dispensed to rinse and heat all

the machine parts; in this phase this icon is displayed.

RINSING

STOP RINSING

ESC

Wait for the cycle to nish automatically. The dispensing process

can be stopped by pressing the " " button (23).

RINSING

STOP RINSING

ESC

Note: The bar is in progress to show that the machine is performing the rinse cycle of the system.

A small amount of water is dispensed. Wait for the cycle to

3

end.

Note: The cycle can be stopped by pressing the

" " button (23).

Then, the machine is ready for use.

4

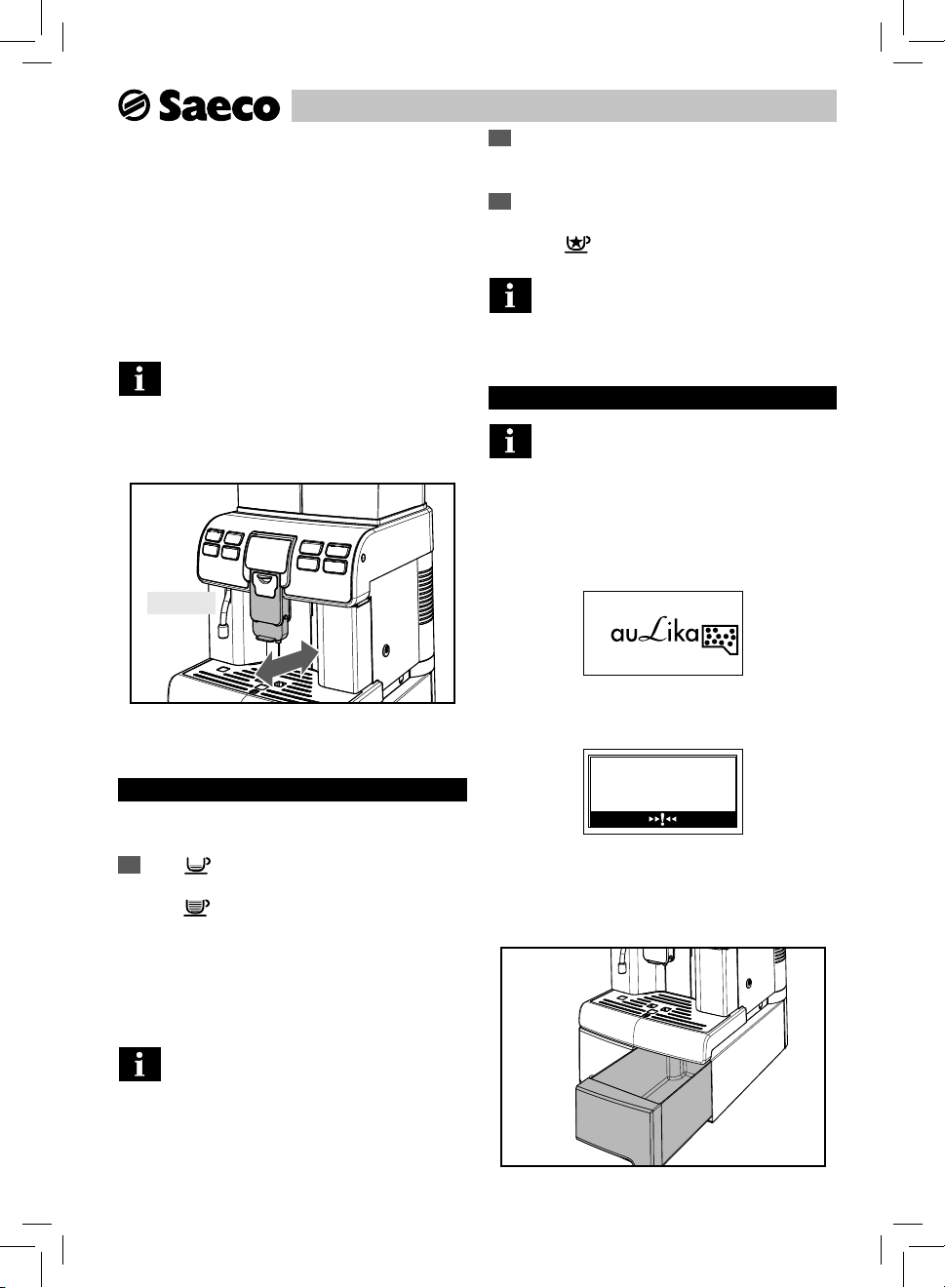

The logo is displayed indicating that the machine is ready for use.

Note: If the machine is being used for the rst

time or after a long period of inactivity, contact

the Service Provider to start it up.

3.3 Rinse/Self-Cleaning Cycle

This cycle enables rinsing the internal co ee circuits with fresh

water. The cycle is carried out:

• At machine start-up (with cold boiler);

• After priming the circuit (with cold boiler);

• During the stand-by preparation phase (if at least one co eebased product has been brewed);

• When turning o the machine, after pressing the "

• 10 •

3.4 Eco-friendly: Stand-by

The machine is designed for energy saving. The machine automatically turns o after 30 minutes of inactivity.

Note:

- During the turning o phase, the machine performs a

rinse cycle, if a co ee product has been brewed.

- Time can be programmed according to your needs

(contact the Service Provider).

To turn the machine on again, simply press either button on the

control panel (if the power button is set to "I"). In this case the

machine will go through the rinse cycle only if the boiler is cold.

3.5 Adjusting the Dispensing Spout

Most of the cups on the market can be used with this co ee machine.

The height of the dispensing spout may be adjusted to better t the

dimensions of the cups that you wish to use.

"

Manually move the dispensing spout up or down to adjust its

height.

Page 11

The recommended positions are:

- When using small cups

- When using large cups

Two cups can be placed under the dispensing spout to brew two

cups of co ee at the same time

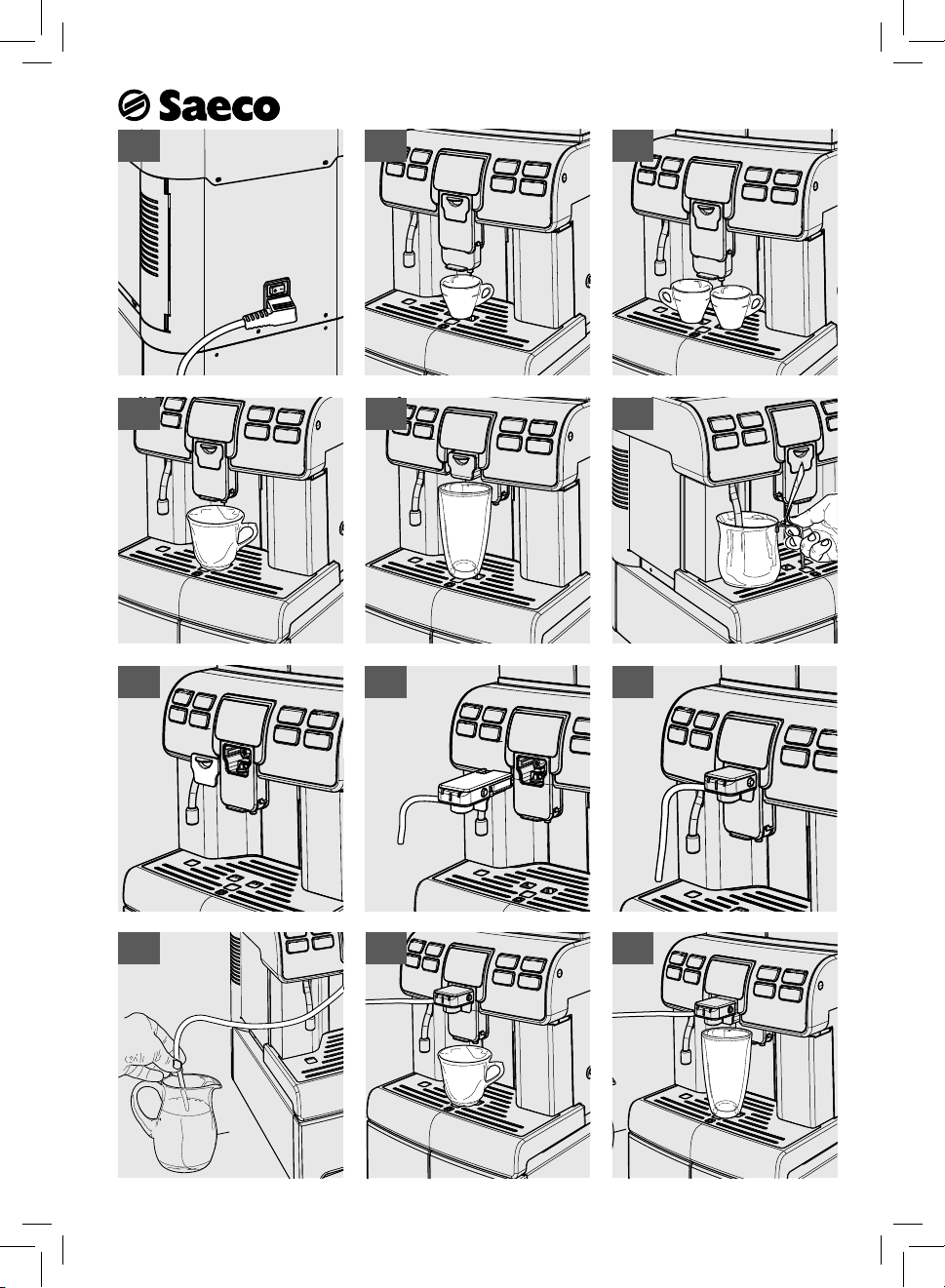

(Fig.03, page 3)

(Fig.05, page 3)

(Fig.04, page 3)

;

.

.

Machine Use - User Manual

Once the prebrewing cycle is complete, co ee begins to come

2

out of the dispensing spout.

Co ee brewing stops automatically when the set level is

3

reached. However, the co ee brewing process can be stopped by

pressing the " " button (23).

If you want to use tall glasses or mugs, push the dispensing spout to

its limit stop. In this case, you can brew only one product at a time.

(Fig.06, page 3)

brewing position, ensure that it is correctly positioned.

This can be noted through the CLICK indicating correct

positioning.

.

Note: Before brewing any product and/or when

bringing the dispensing spout back to its normal

CLICK!

If this is not done, some product might leak out of the dispensing

spout.

3.6 Co ee Brewing

To brew co ee, press and release:

The " " button (17) for a cup of espresso co ee,

1

or

the " " button (18) for a cup of co ee.

The brewing cycle then starts:

Press the desired button once to brew 1 cup of co ee.

Press the desired button twice consecutively to brew 2 cups of

co ee.

Note: The machine is set to brew a true Italian es-

presso co ee. This feature may slightly lengthen

the brewing time, allowing the intense co ee avour to

develop fully.

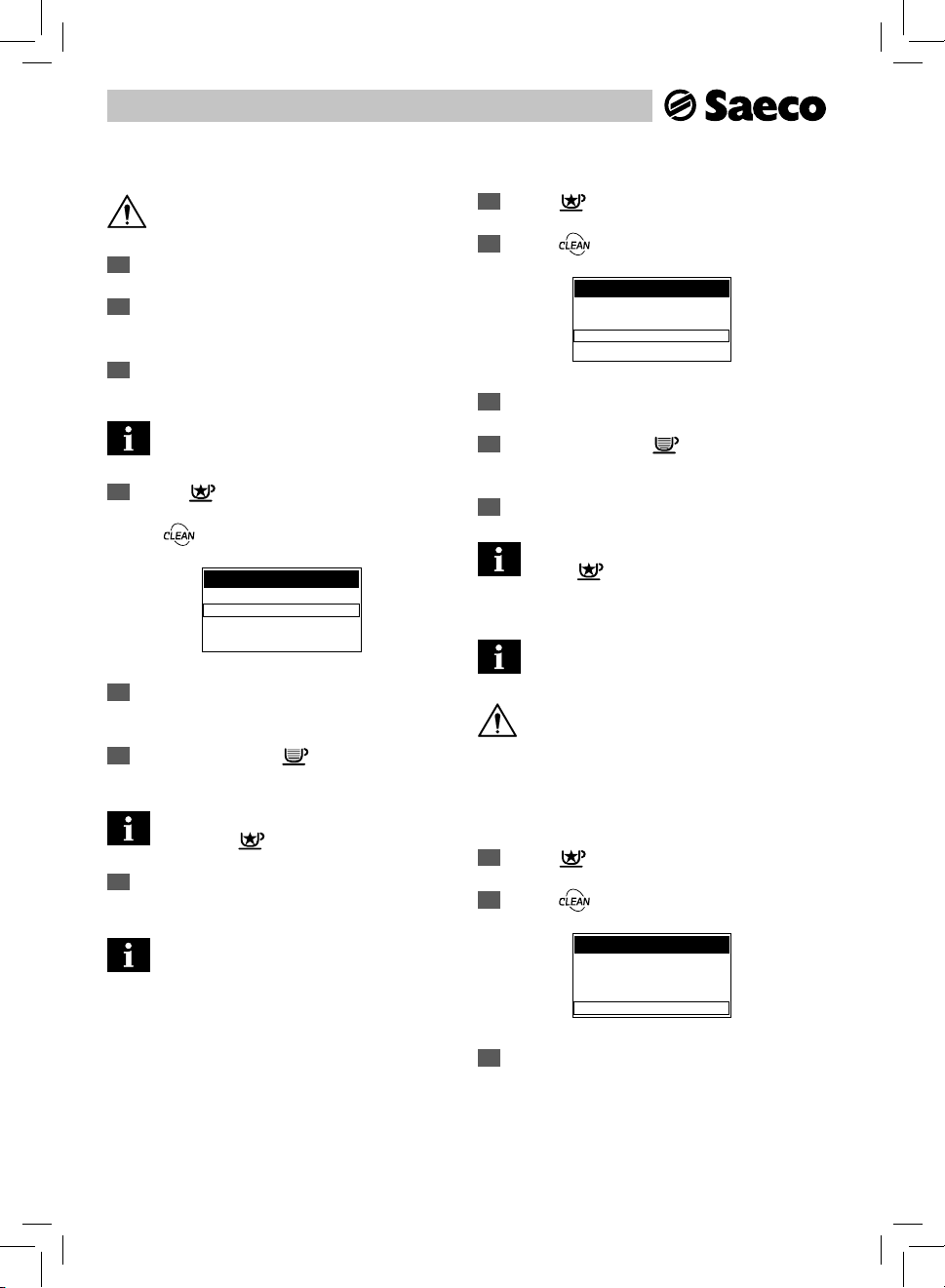

3.7 Emptying the Co ee Grounds Drawer

Note: This operation must be performed with the

machine switched on and/or in stand-by mode.

The machine will indicate when the co ee grounds drawer has

reached its maximum capacity.

The rst warning alerts the user that the co ee grounds drawer

must be emptied, but the machine can still be used to brew coffee; the display shows:

If the drawer is not emptied after several brewing cycles the machine will stop; the display shows:

EMPTY COFFEE

GROUNDS DRAWER

In this case the machine does not allow co ee to be brewed.

In order to continue to brew co ee, the co ee grounds drawer

must be emptied of used co ee.

Note: To brew 2 cups of co ee, the machine auto-

matically grinds and doses the correct amount of

co ee. Brewing two co ees requires two grinding cycles

and two brewing cycles, which the machine carries out

automatically.

• 11 •

Page 12

Machine Use - User Manual

Remove the drawer and empty out the co ee grounds in a suitable container. Only when the display shows:

Place the cup under the dispensing spout (Fig.12, page 3).

4

Press the " " button (20).

INSERT COFFEE

GROUNDS DRAWER

may the co ee grounds drawer be inserted into the machine.

When inserting the drawer, the display shows:

The machine is now ready to brew co ee.

3.8 Brewing a Cappuccino

The machine allows a cappuccino to be brewed quickly and easily

with the touch of a button.

Danger of burns! Brewing may be preceded by

small jets of hot water.

Important Note: Clean the Cappuccinatore immediately after using it to froth milk (see section

5.4). Clean the suction hose externally with a damp cloth.

This way, all parts will be perfectly clean and free of any

milk residue. If this cycle is not carried out, 10 minutes after completion of the last brewing operation the machine

suggests performing a cleaning cycle.

Remove the cover from the front side (Fig.08, page 3).

1

Note: The cover can be placed on the machine side

using the integrated magnet.

Insert the Cappuccinatore into its seat until it locks into place

2

(Fig.09-10, page 3). Check that it cannot slide away.

The machine needs a preheating time.

5

After preheating, the machine starts brewing the cappuc-

6

cino.

CAPPUCCINO

STOP MILK

ESC

At this stage, the machine dispenses frothed milk. You can stop

7

the dispensing process by pressing the " " button (23).

After dispensing milk, the machine brews co ee. You can stop

8

the brewing process by pressing the " " button (23).

CAPPUCCINO

STOP COFFEE

ESC

Enjoy your cappuccino like at the co ee bar.

After using the Cappuccinatore, clean it as described in sec-

9

tion 5.4.

Remove the container and clean it if necessary.

10

3.9 Latte Macchiato

Important Note: Clean the Cappuccinatore immediately after using it to froth milk (see section

5.4). Clean the suction hose externally with a damp cloth.

This way, all parts will be perfectly clean and free of any

milk residue. If this cycle is not carried out, 10 minutes after completion of the last brewing operation the machine

suggests performing a cleaning cycle.

Warning: Before using the Cappuccinatore, clean

it as described in section 5.4.

Insert the clean pipe directly into the milk container (Fig.11,

3

page 3).

Note: To ensure better results when preparing a

cappuccino, use cold milk.

• 12 •

The machine allows a cup of latte macchiato to be dispensed

quickly and easily with the touch of a button.

To dispense a cup of latte macchiato perform all the steps described in section 3.8 up to step 4.

We recommend using tall glasses for this type of preparation,

1

thus moving the dispensing spout accordingly (Fig.13, page 3).

Page 13

When the machine is ready, press the " " button (21) to

2

start dispensing the latte macchiato.

The machine prepares the latte macchiato automatically.

3

After using the Cappuccinatore, clean it as described in sec-

4

tion 5.4.

Remove the container and clean it if necessary.

3.10 Dispensing Hot Water

Dispensing may be preceded by short spurts of hot

water. Risk of burning. The hot water wand may

reach high temperatures.

Place a container under the hot water wand (Fig.07,

1

page 3).

Press the " " button (22) to start dispensing hot water

2

through the wand.

Machine Use - User Manual

Note: The "STEAM" function is displayed and can be

selected only if it has been previously activated by

the service provider; otherwise, it is not available.

The display shows the page for "special" beverages.

2

Note: This menu enables only a single brewing

process at a time. To brew more products repeat

the described procedures.

Select the desired beverage by pressing the " " (20) or

3

" " (24) button.

When the desired beverage has been selected, press the

4

" " button (18) to start the preparation.

Refer to the section relevant to the brewing of the

desired beverage.

For the preparation of milk-based beverages,

install the Cappuccinatore after washing it as de-

scribed in section 5.4.

HOT WATER

STOP HOT WATER

ESC

After dispensing, remove the container with hot water.

3

Note: You can stop the brewing process by press-

ing the " " button (23).

3.11 "SPECIAL" Products

The machine is designed to also brew products other than those

displayed on the control panel.

Note: After pressing the " " button (23), if no

product is selected, the machine goes back to the

main menu after 10 seconds.

Press the

" "

1

button (23) to access the menu.

SPECIAL BEVERAGES

LONG COFFEE

HOT MILK

AMERICAN COFFEE

STEAM

Long Co ee

This programme allows you to prepare a long co ee.

Press the

" "

1

Place a suitable cup under the dispensing spout (Fig.05,

2

page 3).

Press the " " button (18) to start the preparation.

3

After brewing, remove the co ee cup.

4

Note: You can stop the brewing process by pressing the " " button (23).

button (23) to enter the menu.

SPECIAL BEVERAGES

LONG COFFEE

HOT MILK

AMERICAN COFFEE

STEAM

• 13 •

Page 14

Machine Use - User Manual

Hot Milk

This programme allows you to prepare a hot milk.

American Co ee

This programme allows you to prepare an American co ee.

Danger of burns! Dispensing may be preceded by

small jets of hot water.

Remove the cover from the front side (Fig.08, page 3).

1

Insert the complete Cappuccinatore into its seat until it locks

2

into place (Fig.09-10, page 3). Check that it cannot slide away.

Insert the clean pipe directly into the milk container (Fig.11,

3

page 3).

Note: To ensure better results, use cold milk.

Press the

" "

4

button (23) to access the menu.

Press the " " button (24) to select "HOT MILK".

SPECIAL BEVERAGES

LONG COFFEE

HOT MILK

AMERICAN COFFEE

STEAM

Place a suitable cup under the dispensing spout (Fig.13,

5

page 3).

Con rm by pressing the " " button (18) to start the

6

preparation.

Note: You can stop the dispensing process by

pressing the

When the dispensing procedure is complete, remove the cup

7

" " button (23)

.

with milk.

Press the

" "

1

Press the " " button (24) to select "AMERICAN COFFEE".

2

Place a suitable cup under the dispensing spout (Fig.5, page 3).

3

Con rm by pressing the " " button (18) to start the

4

button (23) to access the menu.

SPECIAL BEVERAGES

LONG COFFEE

HOT MILK

AMERICAN COFFEE

STEAM

preparation.

After brewing, remove the co ee cup.

5

Note: You can stop the brewing process by pressing the " " button (23).

Steam

Note: This function is only available if previously

activated by the service provider.

Dispensing may be preceded by short spurts of hot

water. Risk of burning. The steam wand may reach

high temperatures.

This program allows steam to be dispensed in order to heat up the

beverages directly in the container.

Press the

" "

1

Press the " " button (24) to select "STEAM".

2

button (23) to access the menu.

After using the Cappuccinatore, clean it as de-

scribed in section 5.4. If this cycle is not carried

out, 10 minutes after completion of the last brewing

operation the machine suggests performing a cleaning

cycle.

Remove the container and clean it if necessary.

• 14 •

SPECIAL BEVERAGES

LONG COFFEE

HOT MILK

AMERICAN COFFEE

STEAM

Place a suitable container under the dispensing spout

3

(Fig. 7, page 3).

Page 15

Press the " " button (18) to con rm.

4

The machine heats up the system. Once the required tem-

5

perature is reached, the steam dispensing procedure is started.

To conclude the steam dispensing process, press the " "

6

button (23).

Clean the steam wand with a wet cloth after use, if necessary.

4 USING THE MACHINE WITH CREDITS

Note:This option can be enabled or disabled by

the service provider.

The machine is designed to manage beverage brewing by means

of a credit system. The number of co ee-based products brewed

is limited to the number of credits granted by the service provider.

When no credits remain, no more co ee-based products can be

brewed.

Available credits are displayed at each product brewing start.

Note: The dispensing of hot water, hot milk and

steam is not subject to credit management; it can

always be performed, provided that there is water in the

tank.

Each service provider decides independently how to manage the

granting and recharging of credits to allow the machine to be

used.

Machine Use - User Manual

• Cleaning can only be carried out when the machine is cold

and disconnected from the electric network.

• Use a soft, dampened cloth to clean the machine.

• Do not use direct jets of water.

• Do not immerse the machine in water or place any of its parts

in a dishwasher.

• Do not use sharp objects or harsh chemical products (solvents) for cleaning.

• Do not dry the machine and/or its parts using a microwave

and/or standard oven.

• All parts requiring cleaning are easily accessible, so no tools

are needed.

• Periodic maintenance and cleaning will keep the machine in

good working order for a longer time and ensure compliance

with basic hygienic standards.

Warning! The machine and its parts must in any

case be cleaned every week.

The appliance and its parts must be cleaned and

washed following a period of inactivity

5.1 Cleaning the Hot Water / Steam Wand

The hot water/steam wand must be cleaned externally with a

damp cloth after each use and, in any case, once a week.

Warning! Before performing this operation, make

sure that the wand is cold: Danger of burns!

5 CLEANING AND MAINTENANCE

As some of the parts of the appliance come in contact with water

and co ee during normal use, it is important to clean the appliance regularly.

Not doing this will ultimately make the appliance stop working

properly, and in this case repair is not covered under the warranty.

Warning! Before undertaking any maintenance

and/or cleaning operation, turn o the machine,

unplug it and wait for it to cool down.

Non-removable parts and the machine itself must be cleaned,

when not otherwise speci ed, using only cold or lukewarm water,

with a non-abrasive sponge and a damp cloth.

• 15 •

Page 16

Machine Use - User Manual

5.2 Cleaning the Co ee Grounds Drawer

The co ee grounds drawer must be emptied and cleaned whenever indicated by the machine. To carry out this operation, refer

to section 3.7.

5.3 Cleaning the Drip Tray

Empty and clean the drip tray every day. Perform this operation

also when the oat is raised.

Ensure that the Cappuccinatore, complete with all its parts, is

1

correctly inserted (Fig.10, page 3).

Insert the suction hose in a carafe containing clean water

2

(Fig.11, page 3).

Place a container under the dispensing spout (Fig.12,

3

page 3).

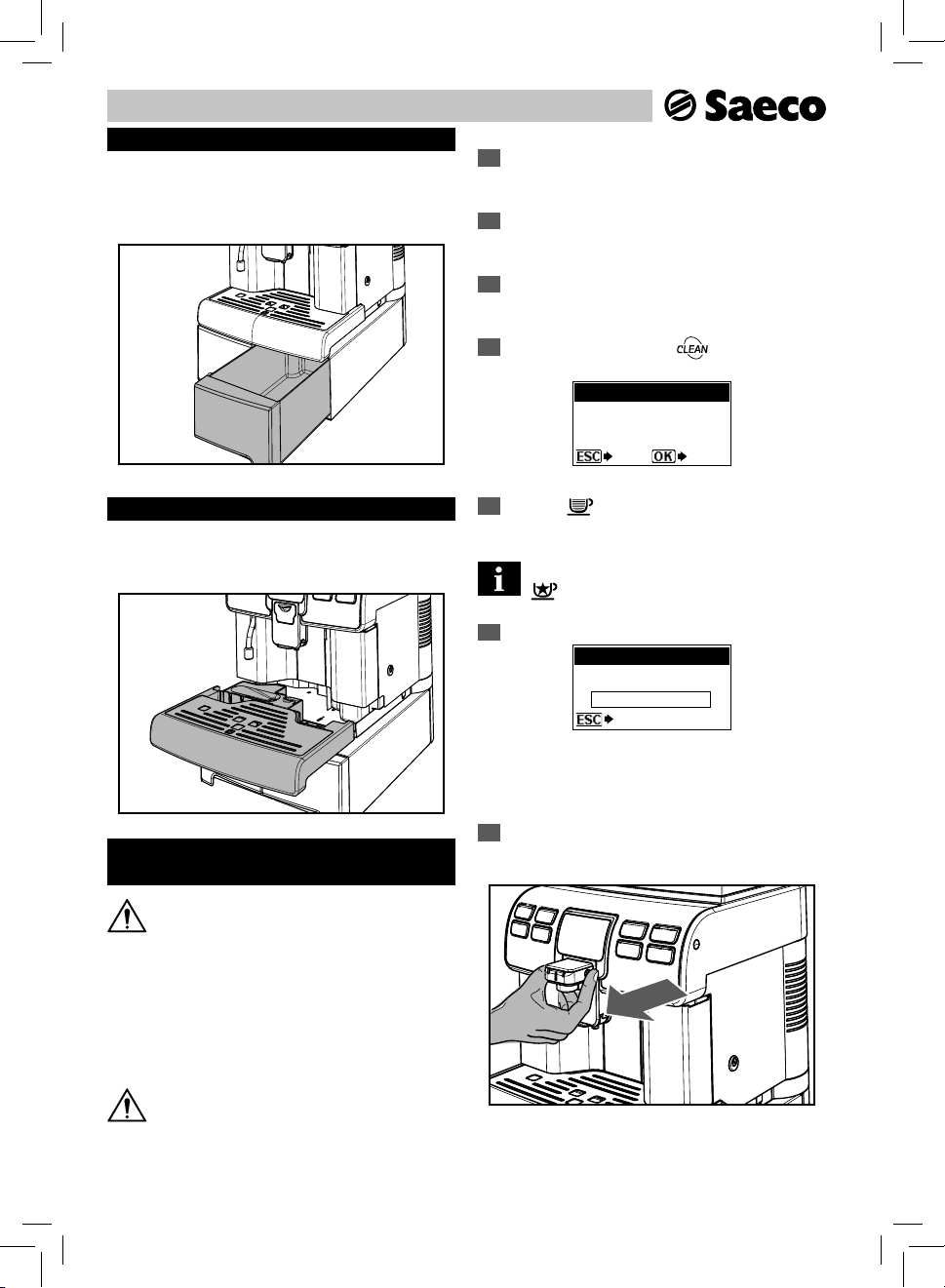

With the machine on, press the " " button (24).

4

CAPPUCCINATORE CLEANING

REPLACE MILK CONTAINER

WITH ANOTHER ONE WITH

FRESH WATER

Press the " " button (18) to start the Cappuccinatore

5

YESNO

cleaning cycle.

Note: To exit the cycle at any moment, press the

" " button (23).

The machine heats up the system.

6

CAPPUCCINATORE CLEANING

PLEASE WAIT …

5.4 Cleaning the Cappuccinatore

(After Each Use)

Warning! Failure to clean the Cappuccinatore after

use with milk may cause proliferation of bacteria

which may be harmful for the user.

The Cappuccinatore must be washed and cleaned every time it

is used.

The lack of cleaning before and after each use can a ect the correct operation of the machine.

Danger of burns! Dispensing may be preceded by

small jets of hot water.

Perform a quick cleaning procedure as follows:

• 16 •

STOP CLEANING

Once the warm-up is complete, the machine performs an assisted

wash cycle of the Cappuccinatore. Wait until the cycle is complete.

Only once the cycle is complete press the side buttons and

7

remove the Cappuccinatore.

Page 17

Place the cover back on the machine (Fig.08, page 3).

8

Important Note: It is advisable to remove the Cappuccinatore from the machine when not being

used, in order to keep it clean.

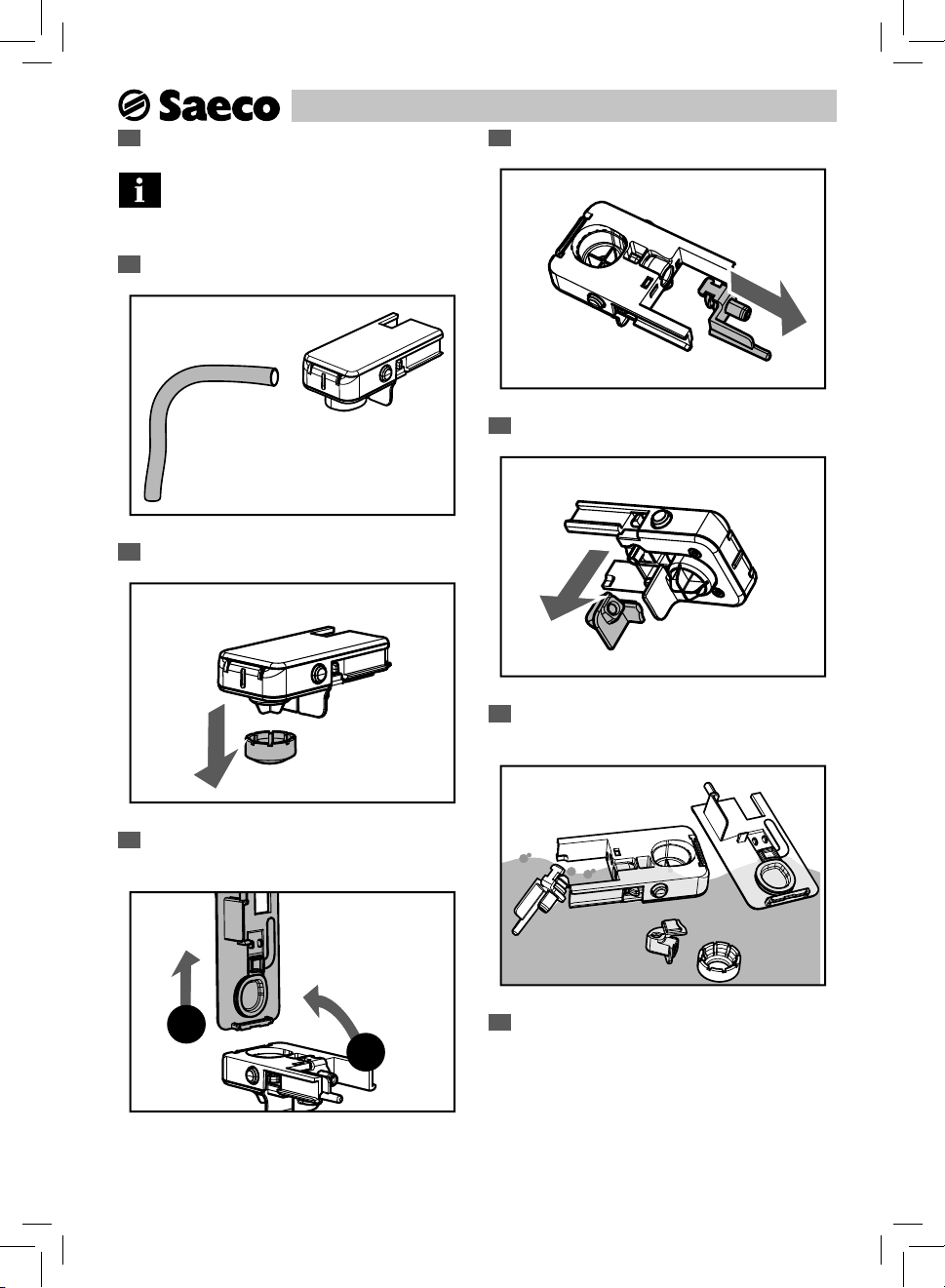

Remove the suction tube from the Cappuccinatore.

9

Remove the ring from the Cappuccinatore.

10

Machine Use - User Manual

Remove the valve from the Cappuccinatore.

12

Remove the suction tube joint from the Cappuccinatore.

13

Turn and lift the Cappuccinatore cover and remove it from the

11

Cappuccinatore body.

2

1

Wash the parts under running water.

14

Make sure any possible milk deposits/residues are removed.

After washing, reassemble the parts following the same pro-

15

cedure used for disassembly, but in reverse order.

• 17 •

Page 18

Machine Use - User Manual

6 MACHINE WARNINGS

This chapter describes all the warning messages that the machine provides to the user, and the actions that can and/or

must be performed by the user.

Help Message Displayed How to Reset the Message

CLOSE

SIDE DOOR

INSERT DRIP TRAY

INSERT COFFEE

GROUNDS DRAWER

INSERT GROUP

COMPARTMENT DRAWER

CLOSE

HOPPER DOOR

REFILL

WATER TANK

To restore the machine operation, close the service door.

Place the drip tray in its seat (Ref.13 - Page 2).

Place the co ee grounds drawer in its seat (Ref.14 - Page 2).

Place the group housing drawer in its seat (Ref.26 - Page 2).

Close or correctly place the co ee bean hopper inner lid to be able to prepare any

product.

Remove the tank and ll it with fresh drinking water.

• 18 •

INSERT BREW GROUP

INSERT

CAPPUCCINATORE

INSERT VALVE INTO

CAPPUCCINATORE

Insert the Brew Group into its seat.

The selected operation requires milk dispensing. Insert the Cappuccinatore in the

machine as speci ed in the manual.

The selected operation requires milk dispensing. Insert the previously removed

valve in the Cappuccinatore as described in the manual (see step 12 - section 5.4).

Page 19

Machine Use - User Manual

Help Message Displayed How to Reset the Message

Fill the co ee bean hopper with co ee beans.

ADD COFFEE

The machine requests a descaling cycle.

When this message is displayed, it is still possible to use the machine, but its correct

operation might be a ected.

Damages caused by failure to descale the machine are not covered by warranty.

The machine requests the "Intenza" water lter to be replaced with a new one.

Contact the Service Provider.

The machine reminds that after a few cycles it will be necessary to empty the co ee

grounds drawer (see section 3.7).

This message does not prevent the machine from brewing some more products.

EMPTY COFFEE

GROUNDS DRAWER

RESTART TO SOLVE

DESCALING

DESCALING

NEEDED.

DESCALE?

YESNO

Remove the co ee grounds drawer and empty the co ee grounds into a suitable

container.

Note: The co ee grounds drawer must be emptied only when required by

the machine and with the machine turned on and/or in stand-by mode. If

the drawer is emptied with the machine turned o , the machine will not

record the emptying operation.

Blinking red light. Machine in Stand-by.

The Stand-by settings can be changed (contact the Service Provider).

"

Press the "

button (25).

An event has occurred which needs the machine to be restarted. Take note of the

code (E xx) shown at the bottom.

Turn o the machine, wait for 30 seconds and then turn it on again. If the problem

persists, contact the service centre.

If this page is displayed after starting the machine, this means that the descaling

cycle is needed.

Contact the Service Provider.

We remind you that damages caused by failure to descale the machine

are not covered by warranty.

• 19 •

Page 20

Machine Installation - Service Provider Manual

7 HANDLING AND

STORAGE

All the operations described in chapter 7 must

be performed exclusively by the service provid-

er or a specialised technician, who shall organise all operating sequences and employ suitable means

to ensure strict compliance with the safety regulations

in force.

7.1 Handling

During handling and transportation, the machine must be kept

in vertical position, according to the instructions printed on the

packaging. Care should be taken during lifting and positioning.

Do not shake the machine.

Make sure that no one is standing in the area dur-

ing lifting and handling of the load. In di cult

conditions assign suitable personnel to monitor all movements.

7.2 Storage

The machine should be stored in accordance with the following

conditions:

- Minimum temperature: above 4°C;

- Maximum temperature: below 40°C;

- Maximum humidity: below 95%.

The machine is packed in cardboard and expanded polystyrene

packaging.

Warning! Due to the total weight of the packaged

product, machines may not be stacked higher than

three units. The machine should be stored in its original

packaging, in a place FREE from humidity and/or dust.

8 INSTALLATION

All the operations described in chapter 8 must

be performed exclusively by the service provid-

er or a specialised technician, who shall organise all operating sequences and employ suitable means

to ensure strict compliance with the safety regulations

in force.

8.1 Safety Regulations

• Read the entire instruction manual carefully.

• The machine must be connected to the mains according to

the safety regulations in force in the country where the machine is used.

• Connection to the drinking water network (for water network

machines) should be made in compliance with the safety

regulations in force in the country where the machine is to be

used.

• The socket to which the machine is connected must be:

- Compatible with the type of plug installed on the ma-

chine;

- Suitably sized to comply with the data on the plate at-

tached to the bottom of the appliance;

- Connected to an e cient earthing system.

• The power cord must not:

- Come into contact with any type of liquid: danger of elec-

tric shocks and/or re;

- Be crushed and/or come into contact with sharp surfaces;

- Be used to move the machine;

- Be used if damaged;

- Be handled with damp or wet hands;

- Be wound in a coil when the machine is in use;

- Be tampered with.

• If the power cord is damaged, it must be replaced by the

manufacturer or his service centre, or in any case by a person

with a similar quali cation.

• It is forbidden to:

- Install the machine other than as described in Chap. 8 or

outdoors.

- Install the machine in a location where water jets may be

used.

- Disable the safety measures installed by the manufacturer.

- Use the machine outdoors, next to ammable and/or ex-

plosive materials.

- Leave plastic bags, polystyrene, nails, etc, within the reach

of children, as they are potential hazards.

- Allow children to play near the machine.

- Use spare parts other than those recommended by the

manufacturer.

- Make any technical modi cations to the machine.

- Immerse the machine in any kind of liquid.

- Wash the machine using a jet of water.

- Use the machine in any manner other than as described in

this manual.

- Install the machine on top of other appliances.

- Use the machine in explosive or harsh environments, or

with high concentrations of dust or oily substances suspended in the air.

• 20 •

Page 21

Machine Installation - Service Provider Manual

- Use the machine in an environment in which a risk of re

exists.

- Use the machine to dispense products other than those it

is designed for.

• Before cleaning the machine, ensure the plug is disconnected

from the power socket; do not wash it with fuel and/or solvents of any kind.

• Do not place the machine near heating equipment (such as

stoves or radiators).

• In case of re, use carbon dioxide (CO

use water or dry powder extinguishers.

8.2 Stop Functions

The machine can be stopped by means of the power button.

8.3 List of Accessories Supplied

Manual: Instructions on how to use the machine.

Water hardness test: Quick test to determine the actual hard-

ness of the water used to prepare beverages; this test is of fundamental importance to set the water hardness in the machine.

) extinguishers. Do not

2

Power cord to connect the machine to the mains.

Lubricating oil to lubricate the Brew Group at periodic intervals

(see section 10.6).

Door safety cut-out key: it allows

the door safety (6-Page 2) to be cut out

in order to perform the co ee grinder

adjustment. (see section 8.16).

With this key the machine can be used also with

the door open, so your hands may come into

contact with the brew group while in motion: Danger of

crushing. This key must be used only by specialist technical personnel or by the service provider. Using it for any

other purpose is forbidden.

Access key to the water tank and service compartment

door: This prevents access to the water tank and brew group by

unauthorised personnel.

Cleaning brush to remove the co ee grounds from the service

compartment.

Descaling solution to remove limescale building up in the water circuit due to normal use.

"Intenza+" water lter to remove any unpleasant avours in

water and reduce water hardness. This will improve machine use.

• 21 •

Page 22

Machine Installation - Service Provider Manual

8.4 Assembly-Siting

The machine must not be installed outdoors or in

environments in which jets of water or steam are

used.

The presence of magnetic elds or proximity to

electrical machines which generate disturbances

could cause the electronic controls of the machine to

malfunction. At temperatures close to 0°C, internal parts

containing water are at risk of freezing. Do not use the

machine under these conditions.

After placing the packing container near the installation site, proceed as follows:

• Ensure that the container has not been tampered with during

transport and that the original packaging is intact and closed;

• Open the container;

• Check the condition and model of the machine;

• Check the contents of the accessories bag enclosed with the

machine (see "8.3 List of Accessories Supplied");

• Remove the machine from its original packaging;

• Remove any remaining packaging from the machine;

• Lift the machine and place it in the designated area.

To ensure correct and e cient performance of the appliance,

comply with the following recommendations:

• Room temperature: 10°C ÷ 40°C;

• Maximum humidity: 90%;

• The site should be suitably prepared for the installation of the

machine;

• The surface on which the machine is installed should be level,

solid and stable, with a gradient of max 2°;

• The location should be adequately lit, ventilated and clean,

and the power socket should be easily accessible.

Access to the machine and the plug should be kept

clear at all times, in order to allow users to easily

reach them and to leave the area immediately if required.

The following illustration shows the required access distances:

• To the keypad on the front of the appliance

• To the service units in the event of malfunction.

8.5 Disposal of Packaging

After opening the package, it is recommended that the packaging

materials are separated according to type and disposed of in accordance with the regulations in force in the country of use.

We recommend keeping the container for future

transfers or transportation.

8.6 Installing the Container Base

The containers have to be installed at the base of the machine

before starting to use the appliance.

Remove the drip tray and the group compartment drawer to

1

be able to install the containers.

The machine consists of 2 parts packed in 2 di erent packages and which should be assembled as

described in section 8.6.

• 22 •

Page 23

Machine Installation - Service Provider Manual

Open the service door with the supplied key.

2

Remove the Brew Group: Pull it by the handle and press the

3

«PRESS» button.

Lift the rear side of the inner drawer and unlock the drawer.

4

Remember that the components must be correctly aligned: Check them.

After installing the containers, re t the components and close the

door. Install the group compartment drawer and the drip tray.

8.7 Opening the Upper Lid

The upper lid should be removed in order to ll the containers.

The lid is a safety device which allows access only to authorised

personnel.

Unlock the lid with the special key supplied and remove it.

1

After unlocking the lid, lift and remove it.

2

Fix the base with the drawers by using the supplied screws.

5

Now the water tank and the co ee bean hopper can be lled.

• 23 •

Page 24

Machine Installation - Service Provider Manual

8.8 Filling the Water Tank

Before switching on the machine, the water tank should be lled

with fresh drinking water.

Warning! Before using the machine for the rst

time, wash the water tank carefully.

The tank should be lled only with fresh drinking water,

as hot water, carbonated water or other liquids will damage the machine.

Remove the safety lid as described in section 8.7.

1

Remove the lid.

2

Insert the water tank back into its seat and re t the lid.

5

8.9 Filling the Co ee Bean Hopper

Before switching on the machine, check that the hopper contains

a su cient quantity of co ee beans.

Warning! Only co ee beans must be put into the

co ee bean hopper. Ground co ee, instant co ee

or any other object may damage the machine.

Remove the co ee bean hopper lid.

1

Remove the tank - lift it using the inside handles.

3

Rinse and ll it with fresh water, making sure that the (MAX)

4

level indicated in the tank is not exceeded.

• 24 •

Note: The hopper may feature a di erent safety

system according to the regulations applicable in

the country of use of the machine.

Page 25

Machine Installation - Service Provider Manual

Slowly pour the co ee beans into the hopper.

2

If the water tank is not inserted, check that no coffee beans fall into the tank compartment. If this

happens, remove them to avoid any malfunctions.

Re t the co ee bean hopper lid.

3

8.10 Closing the Upper Lid

After re lling and during normal operation the upper safety lid

must always be tted and locked using the special key, in order to

prevent access to unauthorised people.

In order to lock the upper lid (1), place and close it using the

1

special supplied key.

8.11 Electrical Connection

This operation must only be performed by specialist technical personnel or by the service provider.

The machine is designed to work with single-phase voltage

matching the rating indicated on the identi cation plate (section

1.4 "Machine Identi cation").

Before plugging in the machine, make sure that the power button

is switched to "0".

The Service Provider makes and is responsible for the electrical

connection of the machine.

The machine should be connected to the mains using the plug

installed on the power cord, in accordance with:

• The Laws and Regulations in force at the place and time of

installation;

• The information shown on the technical speci cations plate

on the side of the machine.

Warning: The electric socket which the appliance

is connected to must be easily accessible by the

user, in order to allow it to be easily disconnected from

the mains when necessary.

It is forbidden to:

• Use extensions of any kind.

• Replace the original plug.

• Use adapters.

8.12 Setting the Language (Upon First Use)

At rst start up, the machine requires you to select and store the

desired language for the display of messages. This allows you to

adjust the parameters of the beverages to the typical parameters

of the country where the machine is used.

LANGUAGE

ITALIANO

ENGLISH

DEUTSCH

FRANÇAIS

Select the language by pressing the " " (24) or " "

1

(20) button.

Press the

2

3

" " button (18)

The machine starts the system warm-up.

to store the language.

• 25 •

Page 26

Machine Installation - Service Provider Manual

Note: Upon rst use, once the warm-up is com-

plete the machine primes the circuit and performs

a rinse cycle of the internal circuits. During this process, a

small amount of water is dispensed. Wait for this cycle to

be completed.

8.13 First Use - Use After a Long Period

of Inactivity

For a perfect Espresso: Rinse the co ee circuit if using the

machine for the rst time or after a long period of inactivity.

These simple operations allow you to always brew excellent coffee. They have to be performed:

A) At rst start-up;

B) When the machine remains inactive for a long time (more

than 2 weeks).

Empty the water tank, wash and rinse it and ll it with fresh

1

water (see section 8.8).

Place a large container under the dispensing spout (Fig.05,

2

page 3).

Press the " "button to start the brewing procedure.

3

The machine will brew co ee through the dispensing spout

4

(10, page 2). Wait until the procedure is complete and empty the

container.

Repeat the operations from step 2 to step 4 for 3 times, then

5

continue with step 6.

Place a container under the hot water wand (Fig.07,

6

page 3).

8.14 Measuring and Adjusting Water Hardness

Measuring water hardness is very important in order to correctly

manage the "INTENZA+" lter and the frequency with which the

machine must be descaled.

Immerse the water hardness test strip - provided with the

1

machine - in water for 1 second.

Note: The test strip is only valid for one measure-

ment.

Check how many squares change colour and refer to the ta-

2

ble.

Hardness 4

Hardness 3

Hardness 2

Hardness 1

The numbers correspond to the settings indicated in the fol-

3

lowing machine adjustments.

HARDNESS 4 (hard)

HARDNESS 3 (medium)

HARDNESS 2 (soft)

HARDNESS 1 (very soft)

Press the " " button (22) to start dispensing HOT WATER.

7

When the hot water dispensing procedure is complete,

8

empty the container.

The machine is now ready for use.

• 26 •

Enter the programming mode as described in section 9.1.

4

MENU

CREDITS MENU

BEVERAGE MENU

MACHINE MENU

To select the "MACHINE MENU" option, press the " "

5

button (24).

Page 27

Machine Installation - Service Provider Manual

MENU

CREDITS MENU

BEVERAGE MENU

MACHINE MENU

Press the " " button (18) for access.

6

MACHINE MENU

GENERAL MENU

DISPLAY MENU

WATER MENU

MAINTENANCE

Press the " " button (24) until the "WATER MENU" op-

7

tion can be selected.

MACHINE MENU

GENERAL MENU

DISPLAY MENU

WATER MENU

MAINTENANCE

Press the " " button (18) for access.

8

WATER MENU

HARDNESS

WATER NET

ENABLE FILTER

ACTIVATE FILTER

Press the " " button (18) to enter the "HARDNESS" menu.

9

Note: The machine is supplied with standard adjustments, suitable for most of the uses.

8.15 "INTENZA+" Water Filter

Water is a key element for a good espresso co ee, and should therefore always be ltered in a professional manner. That is why all

Saeco machines are equipped with the INTENZA+ lter. This lter

is easy to use and its sophisticated technology is e ective in preventing limescale build-up. This way, water will always be perfect

and will give a much more intense aroma to your espresso co ee.

The “INTENZA+” water lter can be installed only

if the machine is NOT connected to the water net-

work.

The descaling lter should be replaced whenever

indicated by the machine.

move the anti-scale lter from the water tank.

Measuring water hardness is very important in

order to correctly manage the "INTENZA+" water

lter and the frequency with which the machine must be

descaled.

Remove the "INTENZA+" water lter from its package. The

1

lter should be set according to the measurements performed to

set water hardness.

Use the water hardness test strip provided with the machine. Set

the "Intenza Aroma System" as speci ed on the lter package

(see section 8.14).

Before descaling, re-

HARDNESS

1

2

3

4

Press:

10

The " " button (24) to increase the value

or

the " " button (20) to decrease the value.

Press the " " button (18) to con rm the selected change.

11

After adjusting water hardness install the lter (Intenza+), as

described in the following section. Then, exit the programming

page as described in section 9.2.

A = Soft water

B = Hard water (standard)

C = Very hard water

• 27 •

Page 28

Machine Installation - Service Provider Manual

Immerse the "INTENZA+" water lter vertically in cold water

2

(with its opening positioned upwards) and delicately press its

sides so as to let the air bubbles out.

Enter the programming mode as described in section 9.1.

3

MENU

CREDITS MENU

BEVERAGE MENU

MACHINE MENU

To select the "MACHINE MENU" option, press the " "

4

button (24).

MENU

CREDITS MENU

BEVERAGE MENU

MACHINE MENU

Press the " " button (18) for access.

9

ACTIVATE FILTER

ACTIVATE FILTER?

YESNO

Note: To exit the procedure, press the " " button (23).

Press the " " button (18) to continue.

10

ACTIVATE FILTER

INSERT FILTER.

FILL THE TANK

Remove the tank from the machine and empty it. Remove

11

the small white lter from the tank and store it in a dry place

sheltered from dust.

Press the " " button (18) for access.

5

MACHINE MENU

GENERAL MENU

DISPLAY MENU

WATER MENU

MAINTENANCE

Press the " " button (24) until the "WATER MENU" op-

6

tion can be selected.

MACHINE MENU

GENERAL MENU

DISPLAY MENU

WATER MENU

MAINTENANCE

Press the " " button (18) for access.

7

Press the " " button (24) until the "ACTIVATE FILTER" op-

8

tion can be selected.

WATER MENU

HARDNESS

WATER NET

ENABLE FILTER

ACTIVATE FILTER

• 28 •

Put the lter into the empty tank. Press it until its limit stop.

12

Fill the tank with fresh drinking water and reinsert it into the

13

machine.

Page 29

Machine Installation - Service Provider Manual

Press the " " button (18) to con rm the introduction of

14

the new lter.

ACTIVATE FILTER

EMPTY DRIP TRAY

Remove and empty the drip tray (13-page 2). When the drip

15

tray is empty, re t it in the machine and press the " " button

(18) to con rm that the procedure is completed.

ACTIVATE FILTER

PLACE A CONTAINER

UNDER THE

WATER SPOUT

Place a large container under the hot water wand (Fig.07,

16

page 3).

Press the " " button (18) to con rm.

17

The machine allows the co ee grinder to be slightly adjusted in

order to adapt it to the kind of co ee used. For any adjustments,

use the lever placed on the inner side of the machine service compartment.

With the machine turned on, open the service compartment

1

door by using the appropriate key.

Disable the safety microswitch by inserting the key as shown

2

in the gure.

Wait until the machine stops dispensing the necessary water to

activate the lter.

ACTIVATE FILTER

At the end of the cycle, remove the container that you had previously placed under the hot water wand.

Note: At the end of the procedure, the display au-

tomatically returns to the product brewing page.

If the water lter is not available, insert the small white

lter previously removed (see step 11) into the tank.

8.16 Adjusting the Co ee Grinder

Warning! Do not pour ground and/or instant cof-

fee into the co ee bean hopper. Do not put any

material other than co ee beans into the hopper. The

co ee grinder contains moving parts that may be dangerous. Therefore, do not insert ngers and/or other objects.

Turn o the machine by pressing the ON/OFF button and

remove the plug from the socket before carrying out any

type of operation inside the co ee bean hopper.

Warning! Disabling the safety microswitch entails

a danger for the operator to come into contact

with the moving parts of the appliance. Enable the safety

device again right after completing the adjustment.

Turn the lever by only one notch at a time during the grinding

3

phase. Brew 2-3 cups of co ee to verify changes in grind.

1

2

The reference marks indicate the grind setting. You can set di erent degrees of grind with the following references:

1 - Fine Grind

2 - Coarse Grind

• 29 •

Page 30

Machine Installation - Service Provider Manual

8.17 Adjusting the "Aroma" Amount of Ground Co ee

The machine allows you to program the amount of co ee to be

ground for preparing each cup of co ee.

Warning! The Aroma adjustment lever must only

be turned when the co ee grinder is stopped. Ad-

justment must be performed before brewing co ee.

For any adjustments, use the lever placed on the inner side of the

machine service compartment.

Open the service compartment door with the appropriate

1

key.

8.18 Adjusting Brewed Products

The machine allows you to adjust the product length according to

your needs and to the cup features.

The product length in the cup can be set with two methods:

1 Numeric method

2 Visual method

Numeric Method

To set the length with this method, enter the "BEVERAGE

MENU" and program each available beverage from the keypad.

This system requires the user to carry out a subsequent check of

the actual quantity of product brewed in the cup.

The procedure for programming a cappuccino, with detailed operational sequences, is explained as an example.

Enter the programming mode as described in section 9.1.

1

MENU

CREDITS MENU

BEVERAGE MENU

MACHINE MENU

The reference marks indicate the amount of ground co ee which

has been set. You can set di erent amounts with the following

references:

3

4

3 - Minimum co ee amount (about 7 grams)

4 - Maximum co ee amount (about 11 grams)

• 30 •

To select the "BEVERAGE MENU" option, press the " "

2

button (24).

MENU

CREDITS MENU

BEVERAGE MENU

MACHINE MENU

Press the " " button (18) for access.

3

BEVERAGE MENU

ESPRESSO

COFFEE

CAPPUCCINO

LATTE MACCHIATO

Page 31

Machine Installation - Service Provider Manual

To select the "CAPPUCCINO" option, press the " " but-

4

ton (24).

Press the " " button (24) to select the "COFFEE LENGTH"

11

menu.

BEVERAGE MENU

ESPRESSO

COFFEE

CAPPUCCINO

LATTE MACCHIATO

Press the " " button (18) for access.

5

CAPPUCCINO

PREBREWING

COFFEE TEMPERATURE

COFFEE LENGTH

MILK QUANTITY

Press the " " button (18) to access the "PREBREWING"

6

menu.

PREBREWING

OFF

LOW

HIGH

Press the " " (24) or " " (20) button to select the de-

7

sired value. Then press the " " button (18) to con rm and exit.

Press the " " button (24) to select the "COFFEE TEM-

8

PERATURE" menu.

CAPPUCCINO

PREBREWING

COFFEE TEMPERATURE

COFFEE LENGTH

MILK QUANTITY

CAPPUCCINO

PREBREWING

COFFEE TEMPERATURE

COFFEE LENGTH

MILK QUANTITY

Press the " " button (18) for access.

12

COFFEE LENGTH

185

Press the (24) " " or (20) " " button to select the de-

13

sired value and then let the bar advance; the number on the side

identi es the bar value (in pulses).

Then press the " " button (18) to con rm and exit.

Press the " " button (24) to select the "MILK QUANTITY"

14

menu.

CAPPUCCINO

COFFEE TEMPERATURE

COFFEE LENGTH

MILK QUANTITY

DEFAULT

Press the " " button (18) for access.

15

MILK QUANTITY

Press the " " button (18) for access.

9

COFFEE TEMPERATURE

LOW

NORMAL

HIGH

Press the " " (24) or " " (20) button to select the de-

10

sired value. Then press the " " button (18) to con rm and exit.

18

Press the (24) " " or (20) " " button to select the de-

16

sired value and then let the bar advance; the number on the side

identi es the bar value (in seconds).

Then press the " " button (18) to con rm and exit.

When this phase is completed, the beverage is programmed. We

recommend performing a visual check of the result. To restore the

factory settings of a single beverage, proceed as follows.

• 31 •

Page 32

Machine Installation - Service Provider Manual

Note: The factory settings can be restored for

each single beverage and the restored settings

will be applied only to that speci c beverage. To restore

the other beverages' settings, enter the menu and restore

the settings.

Press the " " button (24) to select the "DEFAULT" menu.

17

CAPPUCCINO

COFFEE LENGTH

MILK QUANTITY

DEFAULT

MENU

CREDITS MENU

BEVERAGE MENU

MACHINE MENU

Press the " " button (18) for access.

3

MACHINE MENU

GENERAL MENU

DISPLAY MENU

WATER MENU

MAINTENANCE

Press the " " button (18) to enter the "GENERAL MENU".

4

Press the " " button (18) for access.

18

DEFAULT

RESTORE

FACTORY DATA?

YESNO

Note: The restoring operation deletes the stored

data de nitely. To quit the procedure press the

" " (23) button.

Press the " " button (18) to con rm.

19

The beverage factory settings have been restored. Press the " "

button (23) once or more times to exit.

Visual Method

This method allows the product length to be set by the service

provider via keypad in visual mode, i.e. the product quantity is

adjusted while being brewed. This function is disabled by default,

but it can be activated in order top perform a quicker setting procedure.

Enter the programming mode as described in section 9.1.

1

MENU

CREDITS MENU

BEVERAGE MENU

MACHINE MENU

GENERAL MENU

ECOMODE

STAND-BY SETTINGS

SELF LEARNING

SET PASSWORD

To selec t the "SELF LEARNING" option, press the " " but-

5

ton (24). Press the " " button (18) for access.

SELF LEARNING

OFF

ON

To select the "ON" option, press the " " button (24).

6

Press the " " button (18) to con rm.

Press the " " button (23) to exit the programming mode.

When the function is active, press the button of the beverage that

you wish to set and stop the brewing process when desired, as

shown on the display. The procedure for programming a cappuccino is explained as an example. Before carrying out the programming procedure, prepare the machine as described in section 3.8.

Place a cup under the dispensing spout (Fig.12, page 3).

7

Press and hold the " " button (20) until the "MEMO"

8

message is displayed, then remove your nger. The machine is

now programming.

MEMO

To select the "MACHINE MENU" option, press the " "

2

button (24).

• 32 •

Page 33

Machine Installation - Service Provider Manual

The machine starts the milk dispensing phase. The "STOP

9

MILK" message is displayed.

MEMO

STOP MILK

ESC

At this stage, press the " " button (23) when the desired

amount of milk in the cup is reached.

Immediately after that, the machine starts the co ee brew-

10

ing phase. The "STOP COFFEE" message is displayed.

MEMO

STOP COFFEE

ESC

At this stage, press the " " button (23) when the desired

amount of co ee in the cup is reached.

Now the " " button (20) has been programmed. Whenever

the button is pressed and released, the machine will brew the

same amount that has just been set.

Note: The length of all the products, except

“AMERICAN COFFEE” and “STEAM”, can be pro-

grammed with this procedure.

9 MACHINE PROGRAMMING

All the operations described in chapter 9 must

be performed exclusively by the service provid-

er or a specialised technician, who shall organise all operating sequences and employ suitable means

to ensure strict compliance with the safety regulations

in force.

The specialist technician or the service provider can change some

of the machine operating parameters to suit the needs of the users.

9.1 Accessing the Programming Mode

Proceed as follows to access the programming page.

Turn o the machine using the power button.

1

When the programming procedure is completed, enter the programming mode and reset the "SELF LEARNING" parameter to

"OFF", in order to prevent other users from accidentally changing

the quantities.

Turn on the machine using the power button and...

2

while the machine checks the functions, press the buttons in the

following sequence.

• 33 •

Page 34

Machine Installation - Service Provider Manual

1

4

If the sequence was correct, the programming menu opens.

MENU

CREDITS MENU

BEVERAGE MENU

MACHINE MENU

Sections 9.3, 9.4 and 9.5 list all the functions available in these

menus.

Note: The above mentioned procedure can be used

to access the programming menu also when the

machine is cold and has not reached the operating temperature. To execute certain programs (e.g. DESCALING)

the machine will manage the procedure automatically

and heat up according to the manufacturer's settings.

3

2

9.2 Programming Controls

When the machine menus are accessed, the buttons on the keypad take on new functions.

" " "page up/change" button (20)

This button allows you to:

1 Browse the pages within a menu;

2 Change the parameters when they are made editable using

the "OK" button.

" " "page down/change" button (24)

This button allows you to:

1 Browse the pages within a menu;

2 Change the parameters when they are made editable using

the "OK" button.

" " (OK) button (18)

This button allows you to:

1 Select the function displayed;

2 Con rm the parameter/value when it is made editable.

" " "ESC" button (23)

This button allows you to exit without changing the parameter

edited or selected.

Note: Press it repeatedly to exit the programming page.

Note: After 3 minutes of inactivity the machine

exits the programming mode and returns to the

standard operating mode.

The menus should be PASSWORD-protected.

If the PASSWORD is set on the default value (0000),

it will not be requested. It should be changed upon

1st use to prevent unauthorised access. After this change,

it should be entered again at each access, every time the

display shows:

INSERT PASSWORD

0 0 0 0

Refer to section 9.6 on how to set the PASSWORD.

• 34 •

Page 35

Machine Installation - Service Provider Manual

9.3 Credits Menu

This menu allows you to manage the machine credits to avoid undesired product brewing. Credit management is not active for hot

water, hot milk and steam dispensing.

CREDITS MENU

To manage machine operation with credits.

ADD CREDITS

RESET CREDITS This function allows you to reset all the credits in the machine.

SHOW CREDITS

OFF

This function allows you to add credits to the machine.

This function allows the credits to be displayed in the main page.

Note: Regardless of the parameter chosen, the “CREDIT CONTROL”

function must be enabled, otherwise the credits are not displayed

by the machine.

To deactivate credits display.

Note: The credit number is always displayed when the

minimum level of 30 credits is reached, in order for the

user to contact the service provider.

CREDIT CONTROL

ON

OFF

ON

To activate credits display.

This function activates the credit control.

This function deactivates the credit control operation.

This function activates the operation mode with credit control.

• 35 •

Page 36

Machine Installation - Service Provider Manual

9.4 Beverage Menu

BEVERAGE MENU

LATTE MACCHIATO

SPECIAL BEVERAGES

ESPRESSO

COFFEE

CAPPUCCINO

HOT WATER

To manage beverage dispensing.

LONG COFFEE

HOT MILK

AMERICAN COFFEE

STEAM

To manage espresso co ee brewing parameters.

To manage co ee brewing parameters.

To manage cappuccino brewing parameters.

To manage latte macchiato dispensing parameters.

To manage hot water dispensing parameters.

To access special beverages management.

To manage long co ee brewing parameters.

To manage hot milk dispensing parameters.

To manage American co ee brewing parameters.