Saeco Atlante 500, Atlante 700 Use And Maintenance Manual

Vending Machine

UK

WARNING: This instruction manual is intended exclusively for specialized personnel.

USE AND MAINTENANCE

English

2

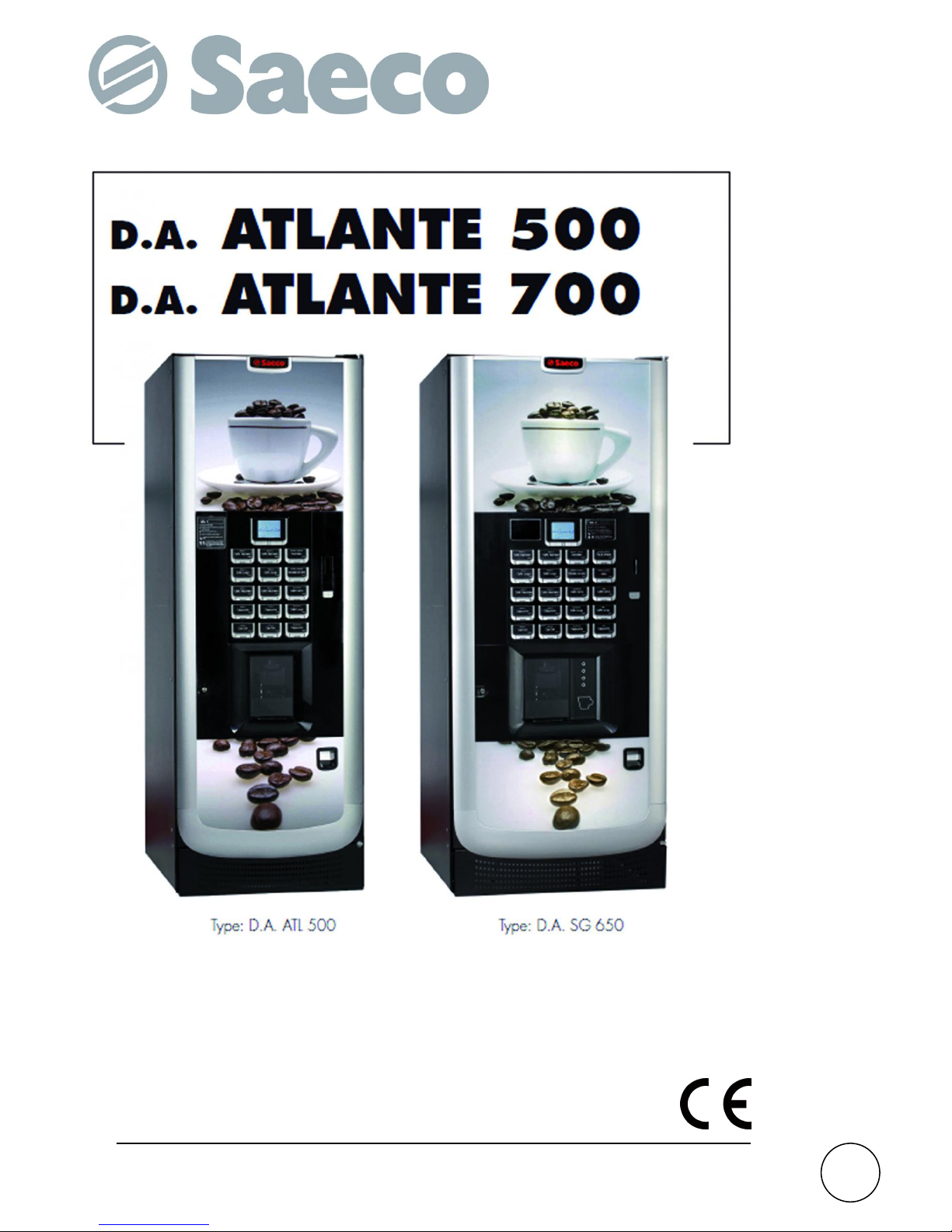

MAIN PARTS

ATLANTE 500 MAIN PARTS

1 Door lock

2 Display

3 Product keypad

4 Coin slot

5 Coin return button

6 Instruction plate

7 Dispensing outlet door

8 Coin return slot

English

3

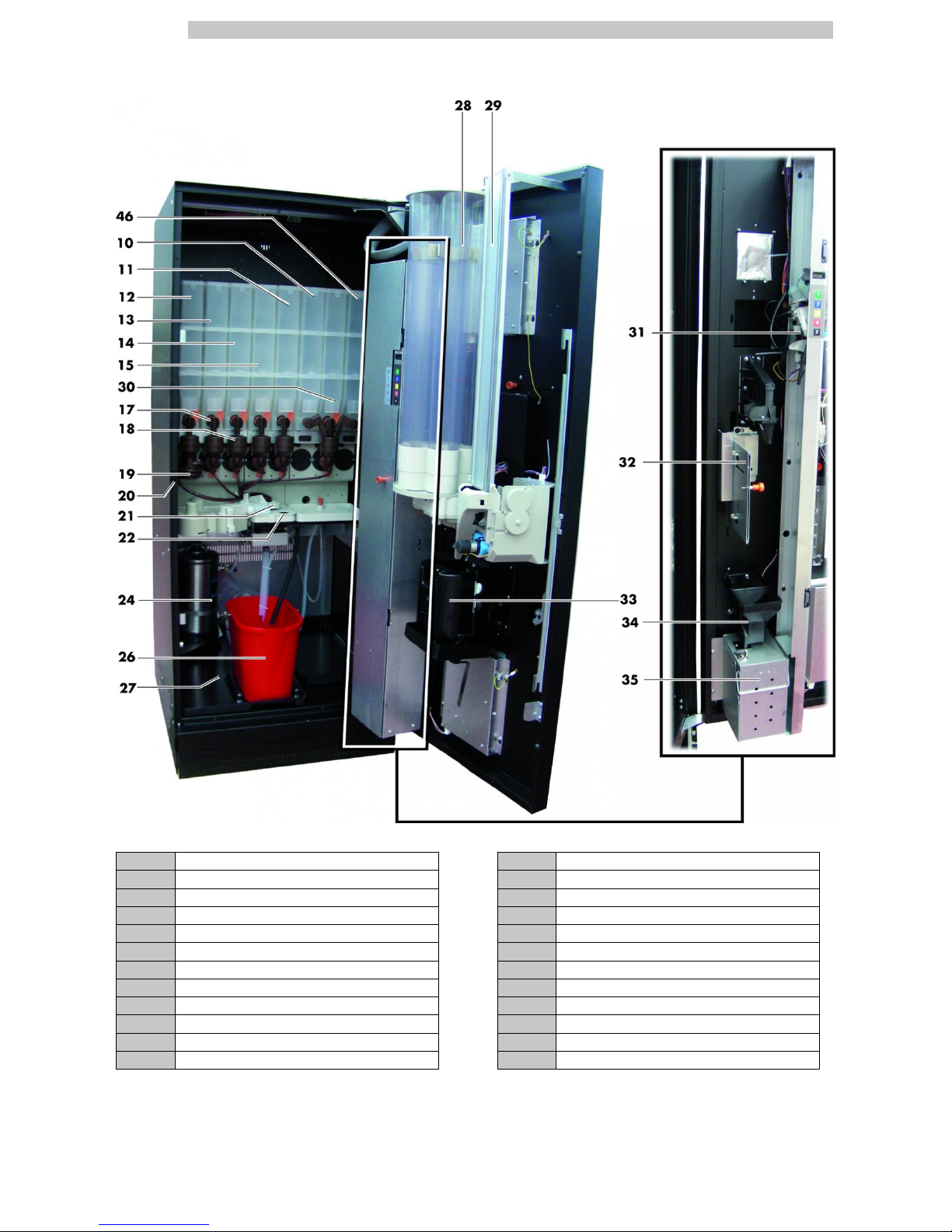

ATLANTE 500 1 GRINDER VERSION MAIN PARTS

9 Coffee bean hopper C 23 Coffee Group

12 Container 1 (instant products) 25 Coffee ground channel

13 Container 2 (instant products) 26 Fluid discharge tank

14 Container 3 (instant products) 27 Collecting tray

15 Container 4 (instant products) 28 Cup dispenser

16 Coffee grinder 29 Stirrer dispenser

17 Instants opening 30 Sugar container

18 Mixer 31 CPU card

19 Spiral mixer 32 Change-giving coiner support

20 Safety switch 33 Dispensing outlet

21 Dispensing arm 34 Coin return duct

22 Drip Tray 35 Coin box set

English

4

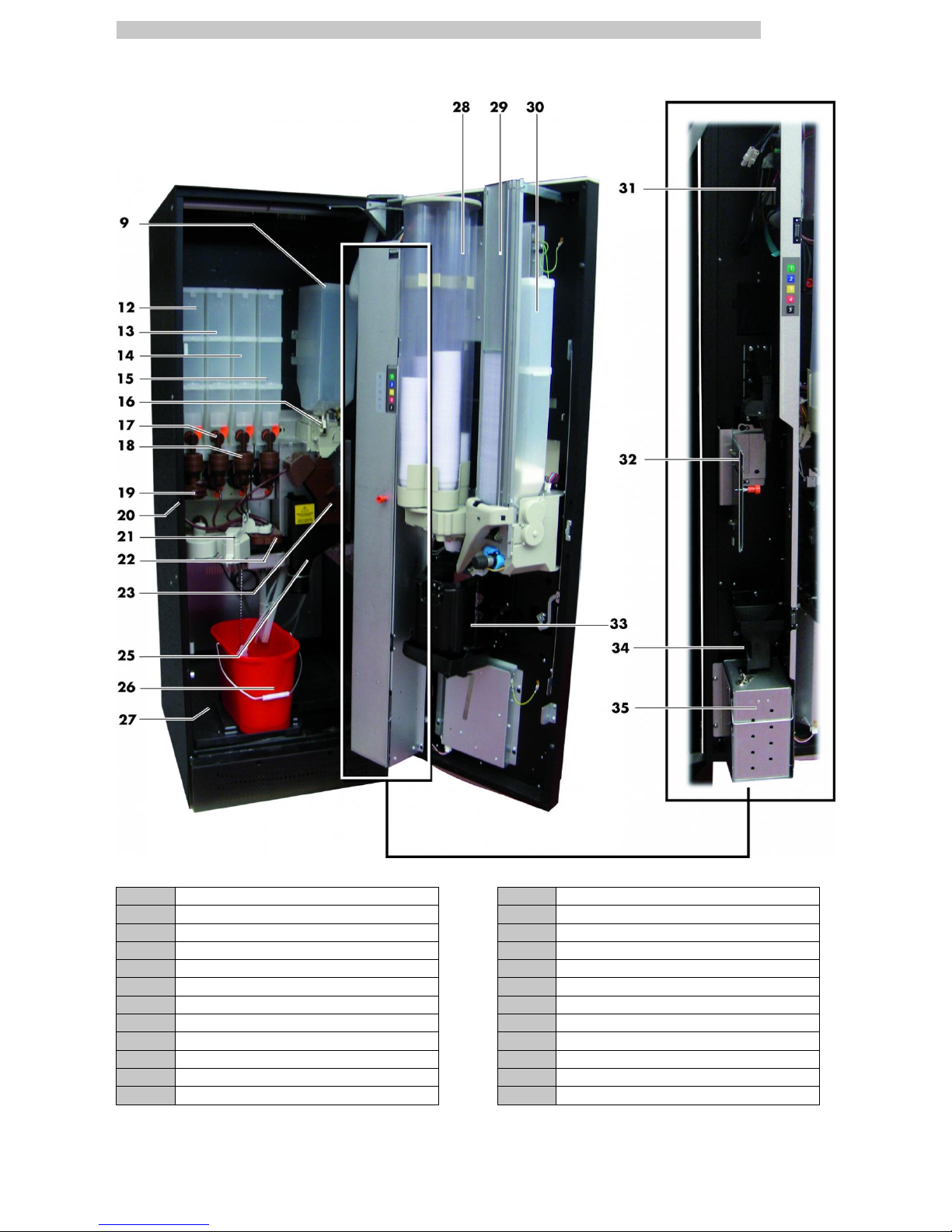

ATLANTE 500 2 GRINDER VERSION MAIN PARTS

9 Coffee bean hopper C 25 Coffee ground channel

12 Container 1 (instant products) 26 Fluid discharge tank

13 Container 2 (instant products) 27 Collecting tray

14 Container 3 (instant products) 28 Cup dispenser

15 Container 4 (instant products) 29 Stirrer dispenser

16 Coffee grinder 30 Sugar container

17 Instants opening 31 CPU card

18 Mixer 32 Change-giving coiner support

19 Spiral mixer 33 Dispensing outlet

20 Safety switch 34 Coin return duct

21 Dispensing arm 35 Coin box set

22 Drip Tray 48 Coffee bean hopper K

23 Coffee Group

English

5

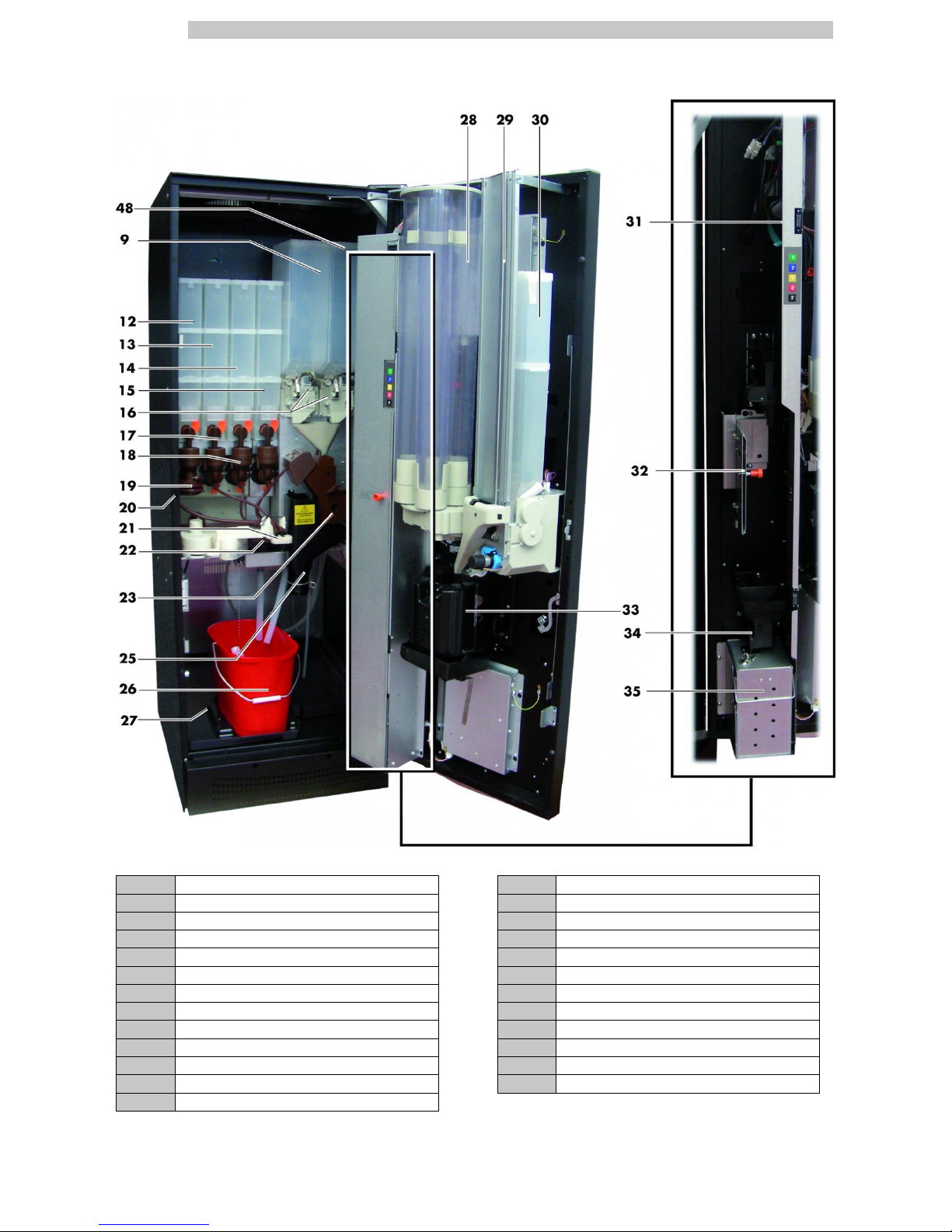

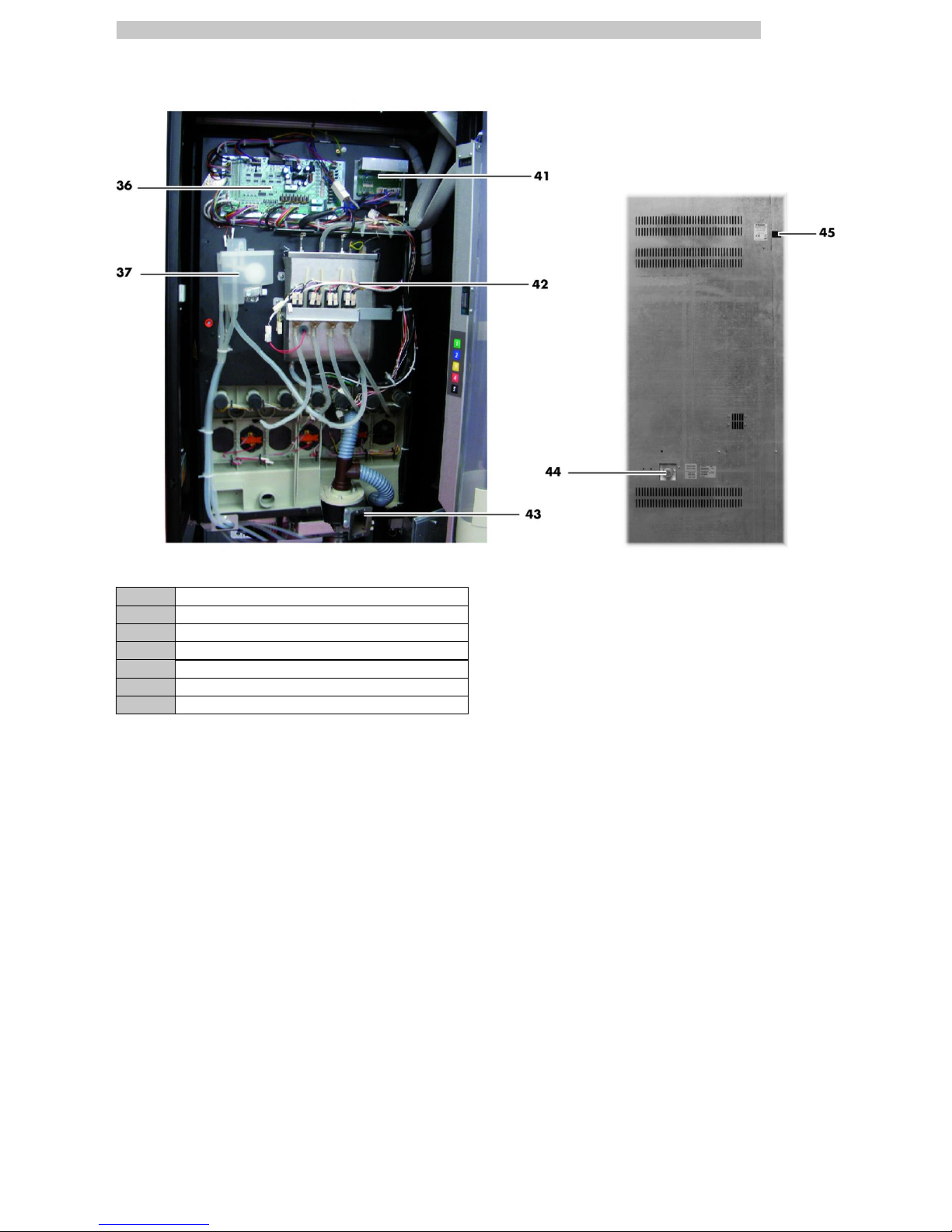

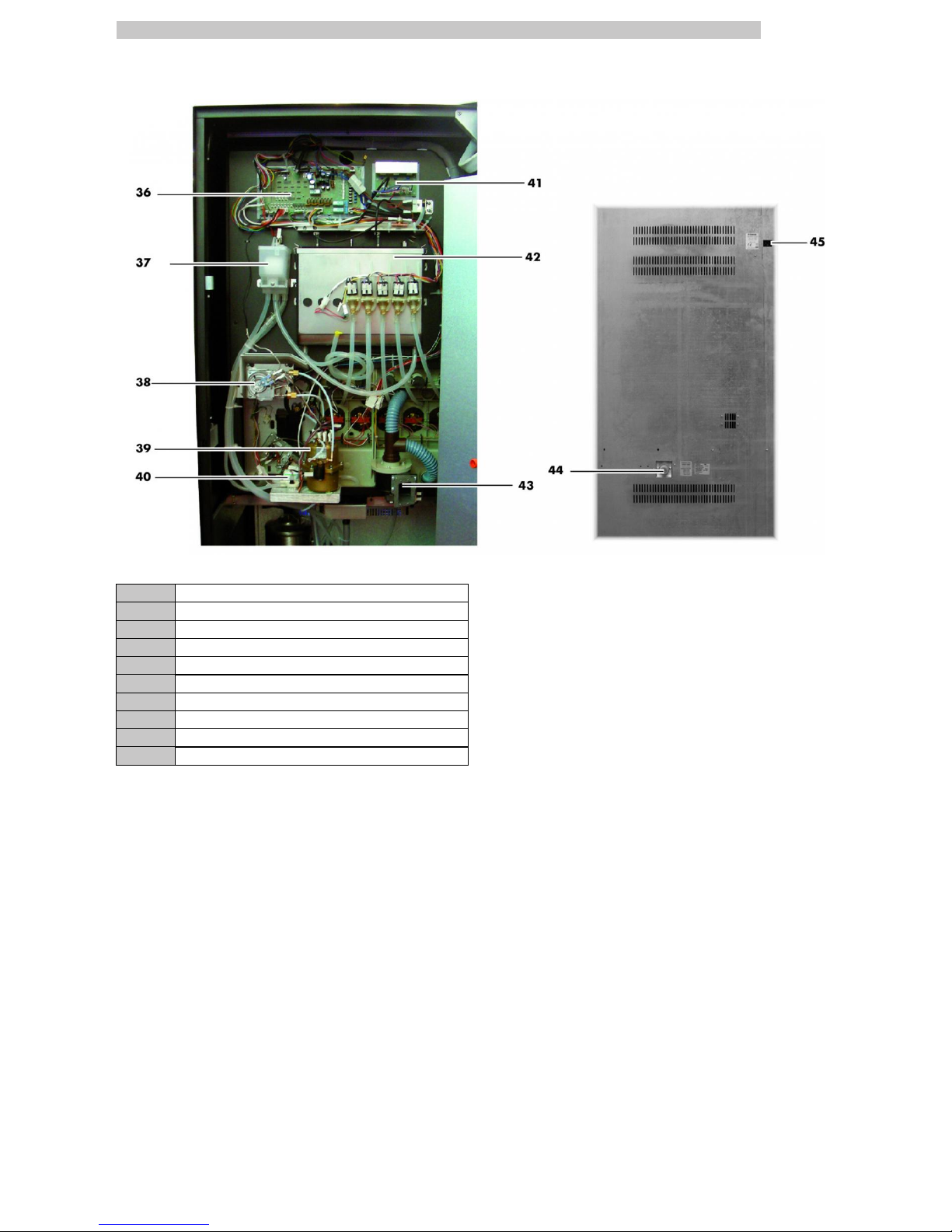

ATLANTE 500 1 & 2 GRINDER VERSION MAIN PARTS

36 Power Board

37 Air break device

39 Coffee boiler

40 Pump

41 Triac board

43 Suction unit

44 Water connection coupling

45 Power cord socket

English

6

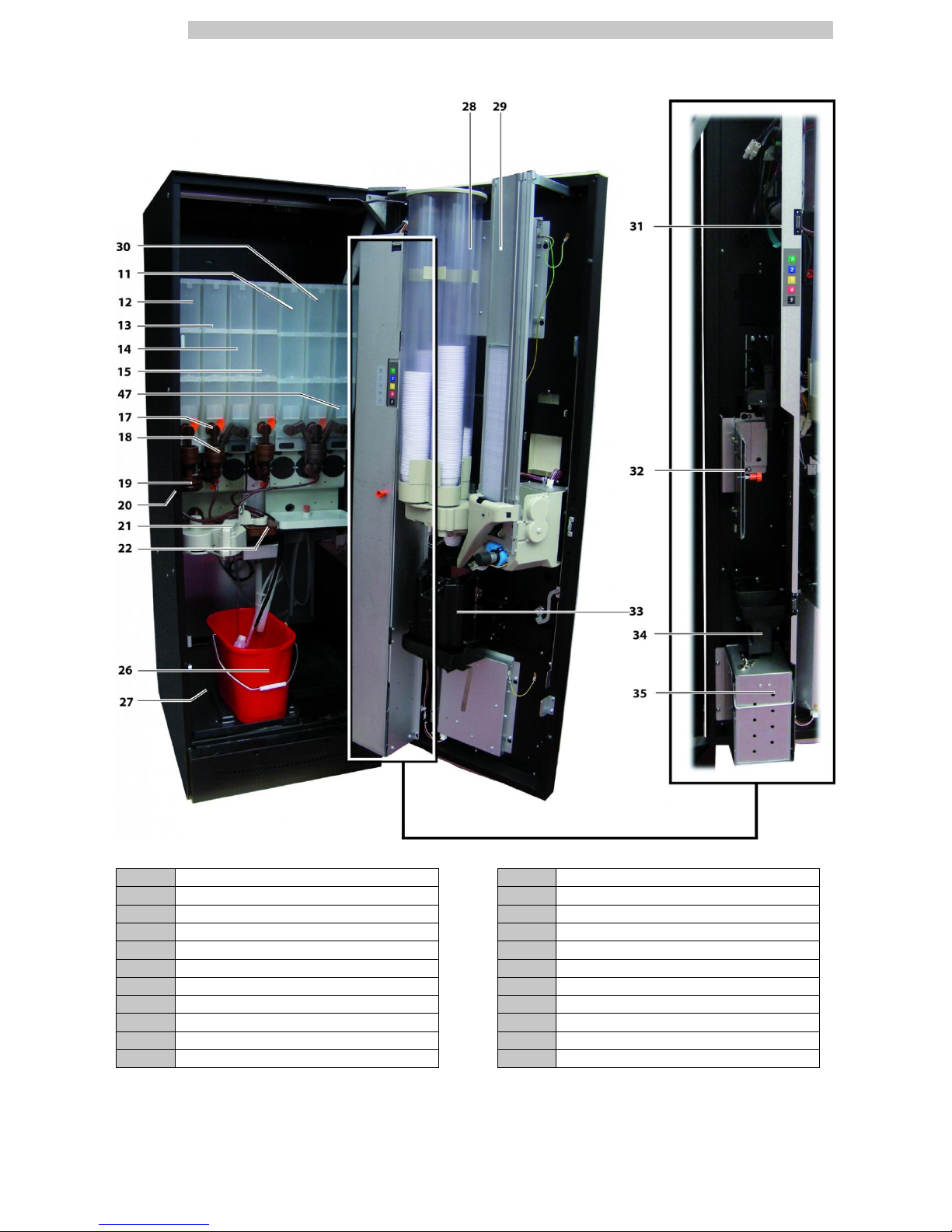

ATLANTE 500 INSTANT VERSION MAIN PARTS

11 Container 5 (instant products) 26 Fluid discharge tank

12 Container 1 (instant products) 27 Collecting tray

13 Container 2 (instant products) 28 Cup dispenser

14 Container 3 (instant products) 29 Stirrer dispenser

15 Container 4 (instant products) 30 Sugar container

17 Instants opening 31 CPU card

18 Mixer 32 Change-giving coiner support

19 Spiral mixer 33 Dispensing outlet

20 Safety switch 34 Coin return duct

21 Dispensing arm 35 Coin box set

22 Drip Tray 47 Container 7 (instant products)

English

7

ATLANTE 500 INSTANT VERSION MAIN PARTS

36 Power Board

37 Air break device

41 Triac board

42 Instant product boiler

43 Suction unit

44 Water connection coupling

45 Power cord socket

English

8

ATLANTE 700 MAIN PARTS

1 Door lock

2 Display

3 Product keypad

4 Coin slot

5 Coin return button

6 Instruction plate

7 Dispensing outlet door

8 Coin return slot

English

9

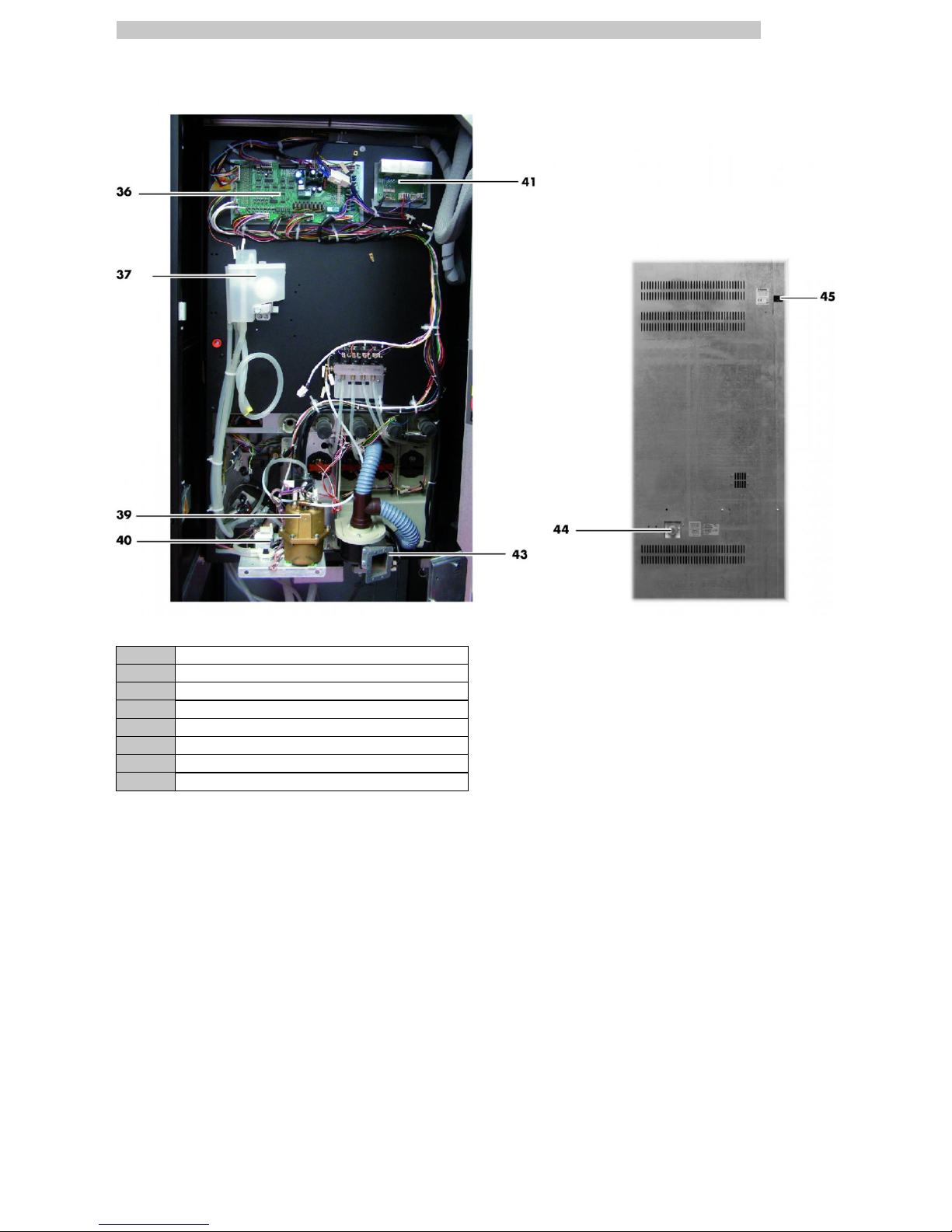

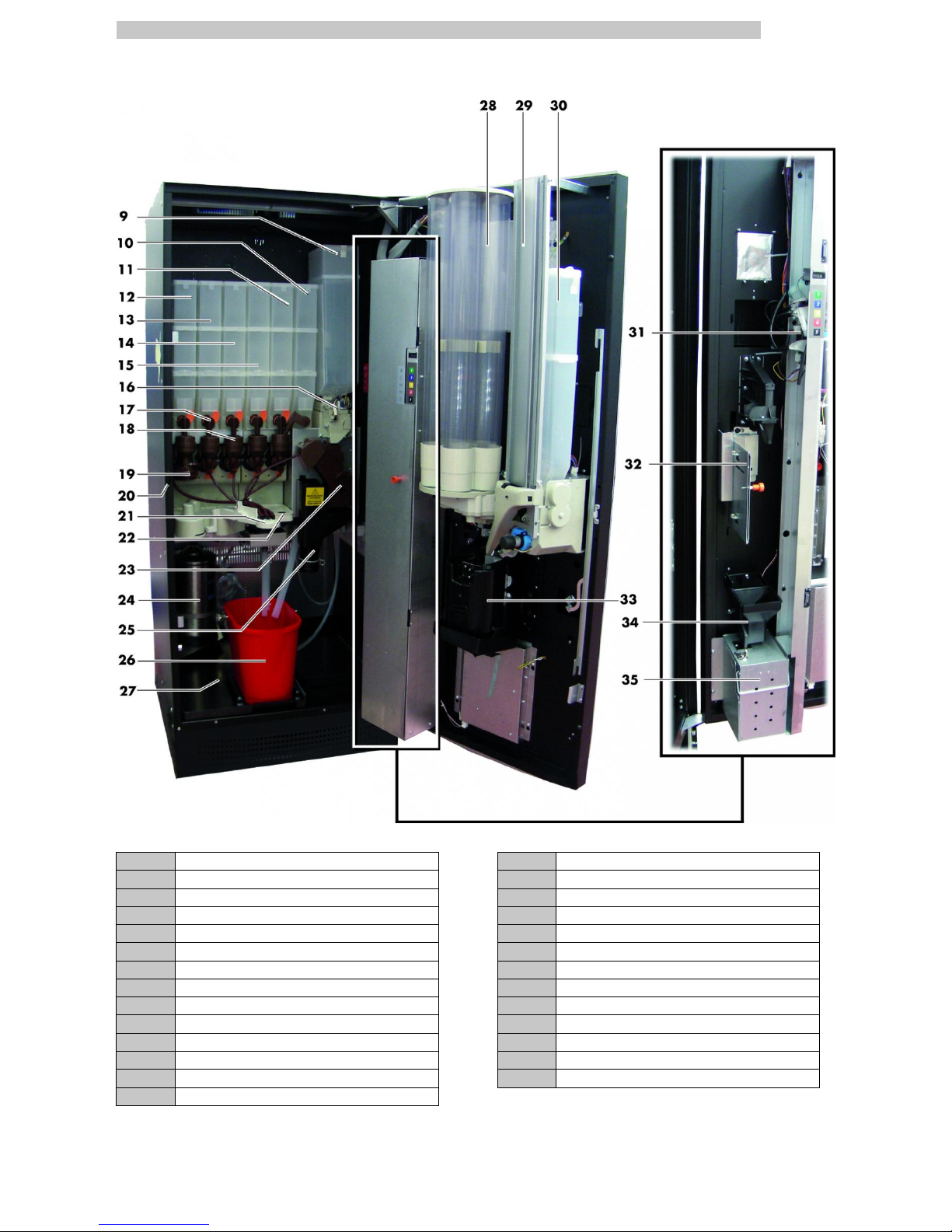

ATLANTE 700 1 GRINDER VERSION MAIN PARTS

9 Coffee bean hopper C 23 Coffee Group

10 Container 6 (instant products) 24 Descaler device

11 Container 5 (instant products) 25 Coffee ground channel

12 Container 1 (instant products) 26 Fluid discharge tank

13 Container 2 (instant products) 27 Collecting tray

14 Container 3 (instant products) 28 Cup dispenser

15 Container 4 (instant products) 29 Stirrer dispenser

16 Coffee grinder 30 Sugar container

17 Instants opening 31 CPU card

18 Mixer 32 Change-giving coiner support

19 Spiral mixer 33 Dispensing outlet

20 Safety switch 34 Coin return duct

21 Dispensing arm 35 Coin box set

22 Drip Tray

English

10

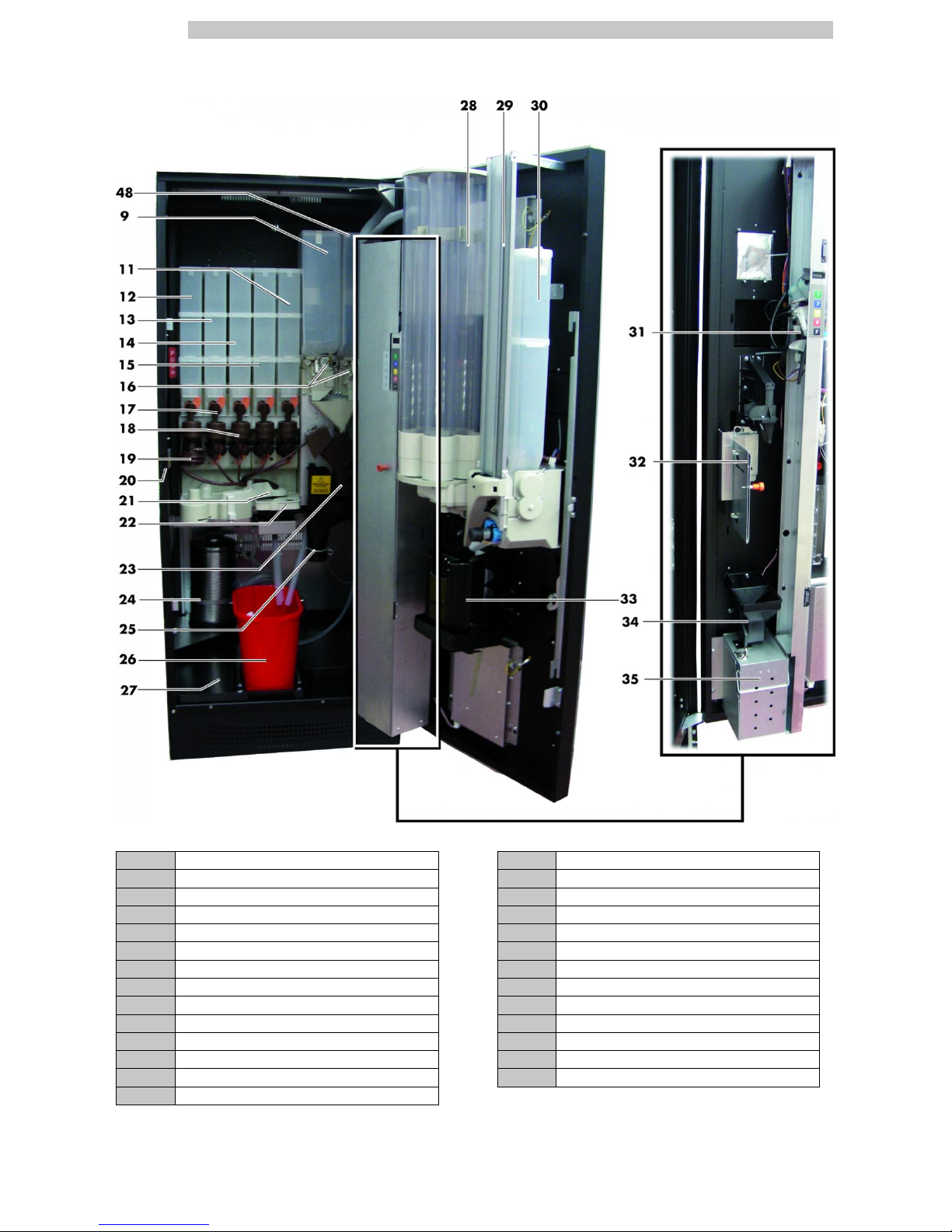

ATLANTE 700 2 GRINDER VERSION MAIN PARTS

9 Coffee bean hopper C 24 Descaler device

11 Container 5 (instant products) 25 Coffee ground channel

12 Container 1 (instant products) 26 Fluid discharge tank

13 Container 2 (instant products) 27 Collecting tray

14 Container 3 (instant products) 28 Cup dispenser

15 Container 4 (instant products) 29 Stirrer dispenser

16 Coffee grinder 30 Sugar container

17 Instants opening 31 CPU card

18 Mixer 32 Change-giving coiner support

19 Spiral mixer 33 Dispensing outlet

20 Safety switch 34 Coin return duct

21 Dispensing arm 35 Coin box set

22 Drip Tray 48 Coffee bean hopper K

23 Coffee Group

English

11

ATLANTE 700 1 & 2 GRINDER VERSION MAIN PARTS

36 Power Board

37 Air break device

38 Steam boiler

39 Coffee boiler

40 Pump

41 Triac board

42 Instant product boiler

43 Suction unit

44 Water connection coupling

45 Power cord socket

English

12

ATLANTE 700 INSTANT VERSION MAIN PARTS

10 Container 6 (instant products) 24 Descaler device

11 Container 5 (instant products) 26 Fluid discharge tank

12 Container 1 (instant products) 27 Collecting tray

13 Container 2 (instant products) 28 Cup dispenser

14 Container 3 (instant products) 29 Stirrer dispenser

15 Container 4 (instant products) 30 Sugar container

17 Instants opening 31 CPU card

18 Mixer 32 Change-giving coiner support

19 Spiral mixer 33 Dispensing outlet

20 Safety switch 34 Coin return duct

21 Dispensing arm 35 Coin box set

22 Drip Tray 46 Container 8 (instant products)

English

13

ATLANTE 700 INSTANT VERSION MAIN PARTS

36 Power Board

37 Air break device

41 Triac board

42 Instant product boiler

43 Suction unit

44 Water connection coupling

45 Power cord socket

English

14

CONTENTS

MAIN PARTS

2

1 INTRODUCTION TO THE MANUAL

15

1.1 INTRODUCTION

15

1.2 SYMBOLS USED

15

2 INFORMATION ON THE VENDING

MACHINE

16

2.1 INFORMATION FOR THE MAINTENANCE

TECHNICIAN

16

2.2 DESCRIPTION AND INTENDED USE

16

2.3 VENDING MACHINE IDENTIFICATION

17

2.4 ATLANTE 500 TECHNICAL SPECIFICATIONS

18

2.5 ATLANTE 700 TECHNICAL SPECIFICATIONS

19

3 SAFETY

20

3.1 INTRODUCTION

20

3.2 GENERAL SAFETY REGULATIONS

20

3.3 OPERATORS' REQUIREMENTS

20

3.4 SAFETY DEVICES

21

3.5 RESIDUAL RISKS

21

4 HANDLING AND STORAGE

22

4.1 UNLOADING AND HANDLING

22

4.2 STORAGE

22

5 INSTALLATION

23

5.1 WARNING

23

5.2 UNPACKING AND POSITIONING

23

5.3 USE OF DIFFERENT-SIZED STIRRERS

24

5.4 LABEL APPLICATION

25

5.5 FITTING THE COFFEE GROUNDS BAG

32

5.6 FITTING THE PAYMENT SYSTEMS

33

5.7 CONNECTION TO WATER MAINS

33

5.8 CONNECTION TO THE ELECTRIC NETWORK

34

6 DESCRIPTION OF CONTROLS FOR ATLANTE

500

35

6.1 DISPLAY

35

6.2 KEYPAD

35

6.3 KEY DESCRIPTION IN STANDARD OPERATION

MODE

35

6.4 CPU CARD KEYS

35

6.5 5-BUTTON KEYPAD

36

7 DESCRIPTION OF CONTROLS FOR ATLANTE

700

37

7.1 DISPLAY

37

7.2 KEYPAD

37

7.3 KEY DESCRIPTION IN STANDARD OPERATION

MODE

37

7.4 CPU CARD KEYS

37

7.5 5-BUTTON KEYPAD

37

8 SUPPLY AND STARTING UP

38

8.1 CONTAINER CONFIGURATION

38

8.2 INSTANT PRODUCT SUPPLY

39

8.3 SUGAR SUPPLY

39

8.4 COFFEE BEAN SUPPLY

39

8.5 DOSE CALIBRATION

39

8.6 COFFEE GRINDING CALIBRATION

40

8.7 SETTING THE WATER CAPACITY FOR INSTANT

PRODUCT SOLENOID VALVES

40

8.8 STIRRER SUPPLY

40

8.9 CUP SUPPLY

41

8.10 FIRST START-UP OF THE VENDING MACHINE

41

8.11 WATER CIRCUIT FILLING

41

8.12 CLEANING THE PARTS IN CONTACT WITH

FOODSTUFFS

42

8.13 USE OF THE VENDING MACHINE

42

9 PROGRAMMING AND MAINTENANCE

MENU

43

9.1 KEY DESCRIPTION OF PROGRAMMING AND

MAINTENANCE PHASES

43

9.2 PROGRAMMING MENU

43

9.3 MAINTENANCE MENU

67

9.4 MACHINE READY / FREE BUTTON

71

9.5 RESET

71

10 OPERATION AND USE

72

10.1 BEVERAGE SELECTION

72

10.2 SNACK PRODUCTS

72

11 CLEANING AND MAINTENANCE

73

11.1 GENERAL NOTES FOR CORRECT OPERATION

73

11.2 CLEANING AND SCHEDULED MAINTENANCE

73

11.3 NON-SCHEDULED MAINTENANCE

80

11.4 PROGRAMMING KEY

81

11.5 SOFTWARE UPDATE

82

12 TROUBLESHOOTING

84

13 STORAGE DISPOSAL

88

13.1 CHANGE OF LOCATION

88

13.2 INACTIVITY AND STORAGE PERIODS

88

14 INSTRUCTIONS FOR END-OF-LIFE

DISPOSAL TREATMENT

89

14.1 INFORMATION FOR THE USER

89

English

1

15

1 INTRODUCTION TO THE MANUAL

1.1 Introduction

This publication is an integral part of the vending

machine and must be read carefully to ensure the

machine is used correctly and in compliance with

essential safety requirements.

This manual contains the technical information

required for the correct use, installation, cleaning, and

maintenance of the vending machine.

Always refer to this publication before carrying out any

operation.

Manufacturer: SAECO Vending S.p.A.

Località Casona, 1066 40041 Gaggio Montano

Bologna, Italy

This publication should be kept carefully, together with

the vending machine throughout its operational life,

even in case of changes of ownership.

If this manual is damaged or lost, a copy may be

requested from the manufacturer or the technical

service by indicating the data contained on the data

plate on the rear side of the vending machine.

All the images in this manual refer to the ATLANTE 700

model.

1.2 Symbols used

This publication contains various warnings which indicate

different degrees of danger or skills required.

The symbol is integrated with a message suggesting use

procedures or actions and providing useful information for

the correct operation of the machine.

Warning

Indicates dangerous situations for the users, supply

operators and maintenance technicians dealing either with

the vending machine or the product to be dispensed.

Prohibition notice

It is used to highlight actions/operations not to be

performed.

Important

Indicates the operations for keeping the vending machine

in good working order.

Recommended solutions

Indicates alternative procedures that make the

programming and/or maintenance operations quicker.

User

Indicates the user of the vending machine. This person is

not authorized to carry out any cleaning or maintenance

operation.

Supply operator

Indicates operations to be carried out only by personnel in

charge of supplying and cleaning the vending machine.

Maintenance operations requiring a Maintenance Technician are

not to be performed by the supply operator.

Maintenance Technician

Indicates operations to be carried out by qualified personnel in

charge of maintenance.

The Maintenance Technician is the only person authorized to

keep the MICROSWITCH ENABLING KEY, by which the

security systems can be disabled.

English

2

16

2 INFORMATION ON THE VENDING MACHINE

2.1 Information for the

Maintenance Technician

The vending machine must be installed in a well-lit, dry

area, away from bad weather and dust, on a floor

suitable to support its weight.

To guarantee the correct operation and reliability over

time, the following is recommended:

• ambient temperature: from +1°C to +25°C;

• maximum humidity: 90% (not condensed).

For special installations not covered in this publication,

please contact the dealer or the local importer. If this is

not possible, please contact the Manufacturer directly.

The technical service is available for any explanation or

information regarding the correct operation of the vending

machine and to satisfy any request for spare parts supply

or technical assistance.

The Maintenance Technician must carefully read and

respect the safety warnings contained in this manual so

that every intervention concerning installation, starting up,

use and maintenance will be safely carried out.

It is the Maintenance Technician’s absolute responsibility

to give the keys to access the inside of the vending

machine to another operator (Supply Operator), provided

that the Maintenance Technician bears full responsibility

for all work carried out.

This manual is an integral part of the machine and must be

always read carefully before performing any operation.

2.2 Description and intended use

The vending machine is intended for automatic distribution of

coffee and hot beverages (decaffeinated coffee, cappuccino,

chocolate, etc.) and is programmable for every single type of

dispensing dosage. The instant products must be consumed

immediately, and cannot be preserved for a long time.

Any other use is to be considered improper and therefore

dangerous.

Do not place any product inside the vending machine which

may be dangerous as a result of unsuitable temperatures.

Improper use of the vending machine invalidates all

warranties. The Manufacturer declines any liability for

damage to property or injury to persons.

Improper use also includes:

• any use of the vending machine other than the intended use

and/or according to procedures which are not described in this

publication;

• any intervention on the vending machine which differs from the

instructions given in this publication;

• any alteration of components and/or safety devices without prior

consent of the Manufacturer or carried out by personnel not

authorized for such operations;

• any location of the vending machine not provided in this manual.

English

2

17

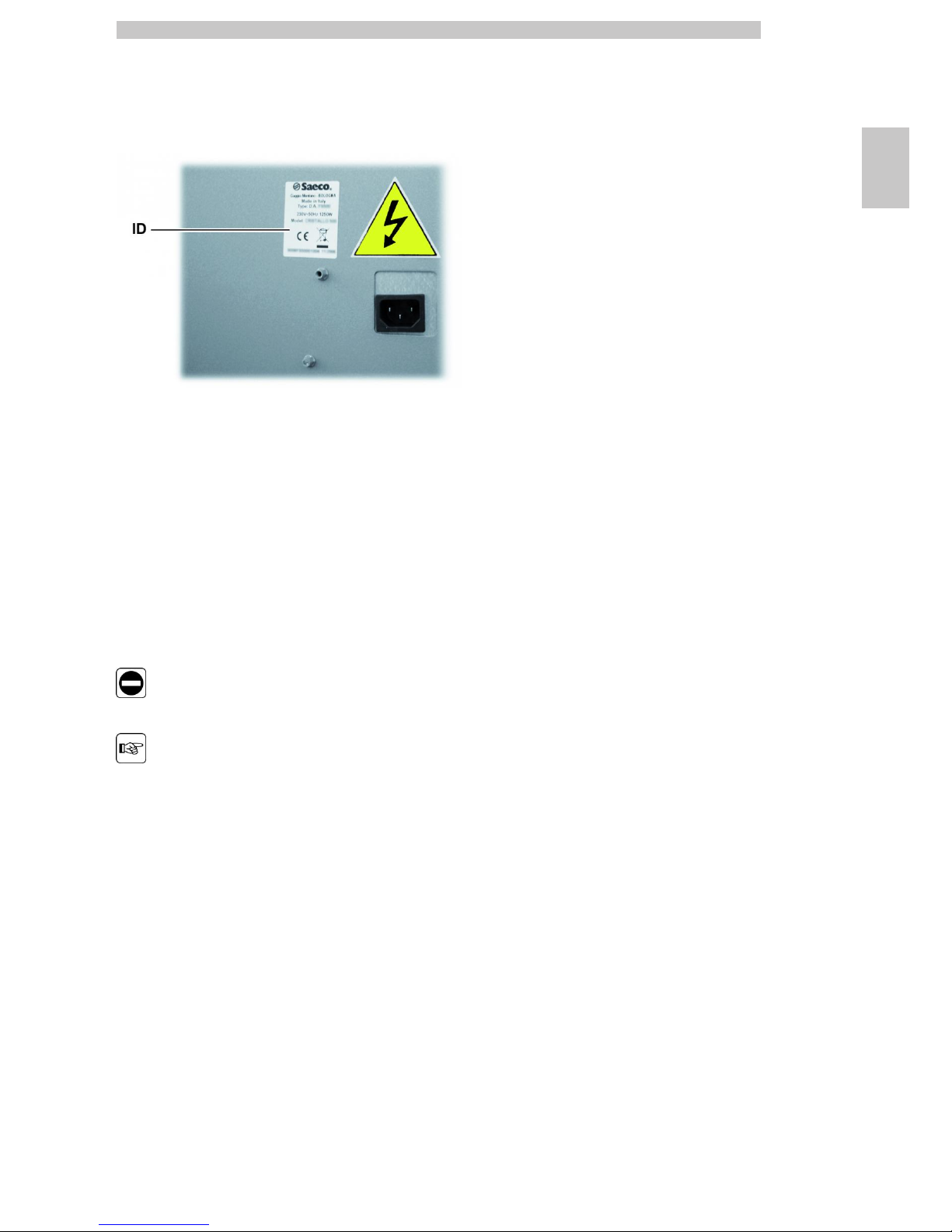

2.3 Vending Machine Identification

The vending machine is identified by the name, model and serial

number which can be found on the relevant data plate.

ID Data plate

The following data can be found on the plate:

• name of Manufacturer;

• marks of compliance;

• model;

• serial number;

• year and month of manufacture;

• supply voltage (V);

• supply frequency (Hz);

• electrical power consumption (W).

It is strictly forbidden to tamper with or modify the

data plate.

When contacting the technical service, always refer to

this plate by indicating the technical data shown on it.

English

2

18

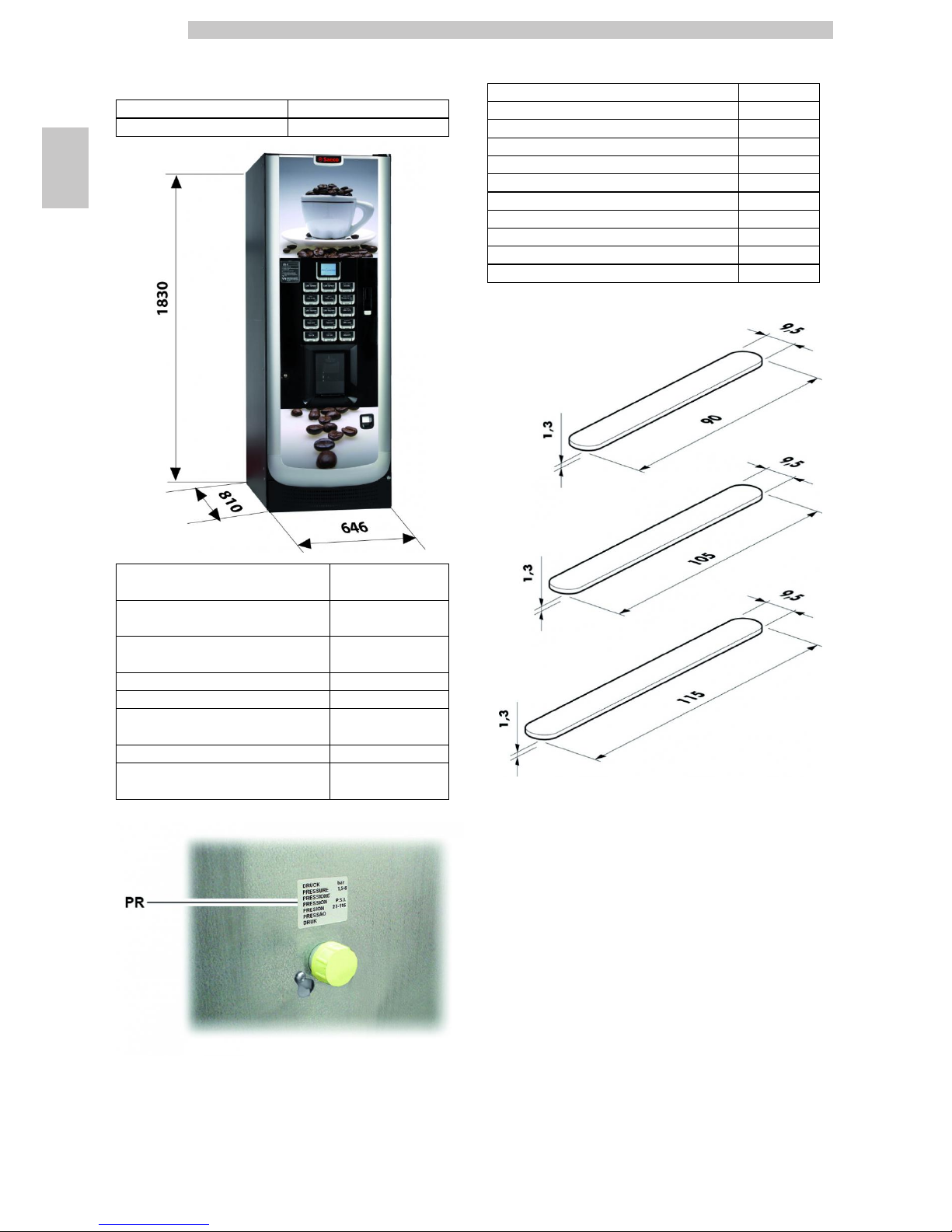

2.4 ATLANTE 500 Technical

Specifications

Dimensions (w x h x d) 646 x 1830 x 810 mm

Weight 162 kg

Power consumption see data plate

Supply voltage see data plate

Electric voltage frequency see data plate

Power cord length 2500 mm

Water mains connection 3/4"

Min. water inlet pressure

0,15 MPA (1,5

bar)

Max. water inlet pressure 0,8 MPA (8 bar)

A-Weighted sound pressure level less than 70 dB

PR

Data plate showing minimum and maximum

water supply pressure

Container capacity

Coffee beans (1 Grinder model) 3,5 kg

Coffee beans (2 Grinders model) 2,6 + 2,6 kg

Freeze-dried coffee (Instant Model) 1,2 kg

Decaffeinated coffee 1 kg

Hot Chocolate 3 kg

Milk 2,5 kg

Lemon tea 3 kg

Barley 1 kg

Sugar 3 kg

Cups N° 550

Stirrers N° 550

Stirrer size

English

2

19

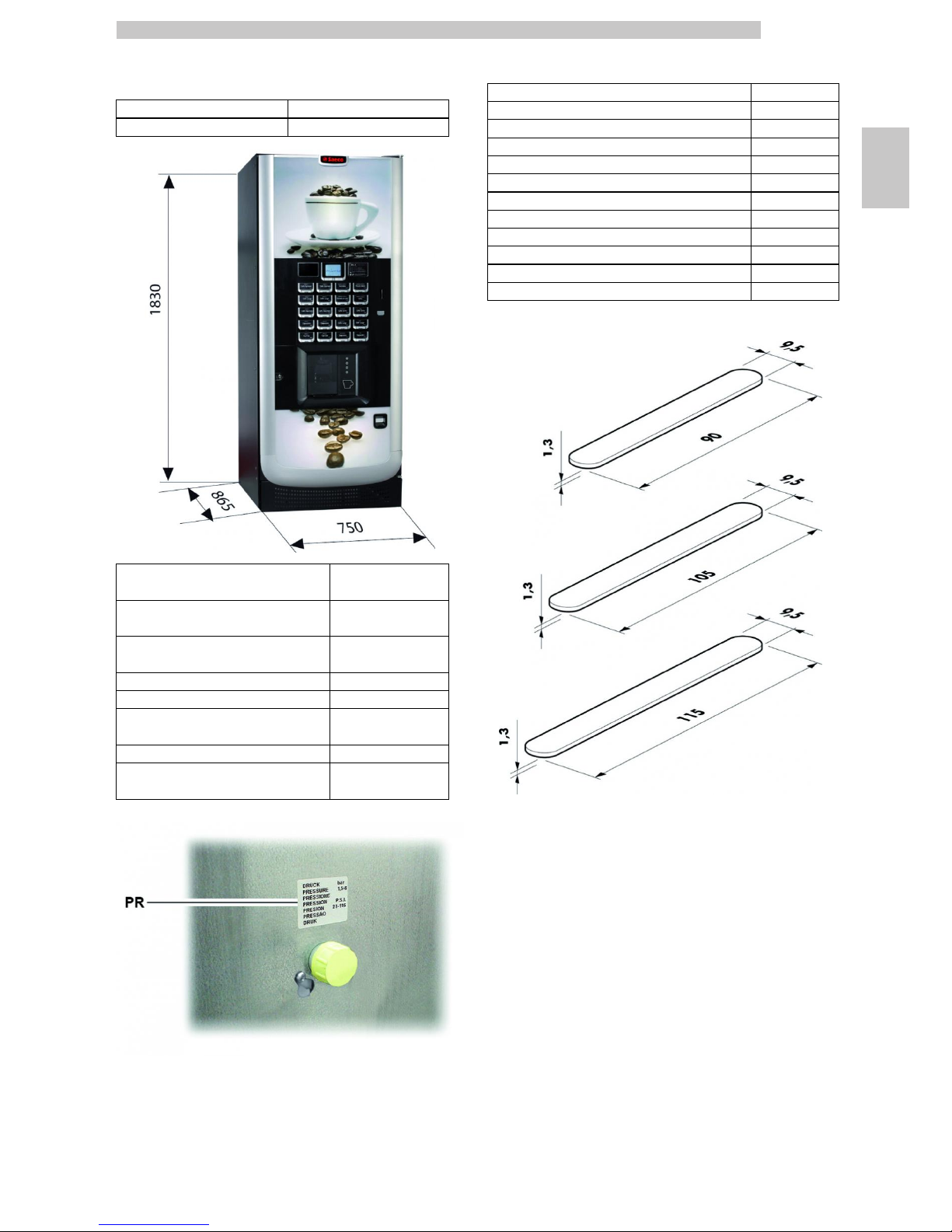

2.5 ATLANTE 700 Technical

Specifications

Dimensions (w x h x d) 750 x 1830 x 865 mm

Weight 184 kg

Power consumption see data plate

Supply voltage see data plate

Electric voltage frequency see data plate

Power cord length 2500 mm

Water mains connection 3/4"

Min. water inlet pressure

0,15 MPA (1,5

bar)

Max. water inlet pressure 0,8 MPA (8 bar)

A-Weighted sound pressure level less than 70 dB

PR

Data plate showing minimum and maximum

water supply pressure

Container capacity

Coffee beans (1 Grinder model) 4,2 kg

Coffee beans (2 Grinders model) 3,5+ 3,5 Kg

Freeze-dried coffee (Instant Model) 1,2 kg

Decaffeinated coffee 1 kg

Hot Chocolate 3 kg

Milk 2,5 kg

Lemon tea 3 kg

Barley 1 kg

Sugar (Espresso version, 1 and 2 grinders) 4,5 kg

Sugar (Instant version) 4 Kg

Cups N° 700

Stirrers N° 550

Stirrer size

English

3

20

3 SAFETY

3.1 Introduction

In compliance with the Low Tension Directive 2006/95/EC

(which replaces the directive 73/23/EEC and following

amendments) and CE Marking Directive 93/68/EEC,

SAECO Vending has drawn up a technical file of the

ATLANTE 500 and ATLANTE 700 vending machine held

at its plants. The following regulations were taken into

account during the design phase:

- EN 55014 - EN 61000-4-4

- EN 6100-3-2 - EN 61000-4-5

- EN 61000-3-3 - EN 61000-4-11

- EN 61000-4-2 - EN 60335-2-75

- EN 61000-4-3 - EN 60335-1

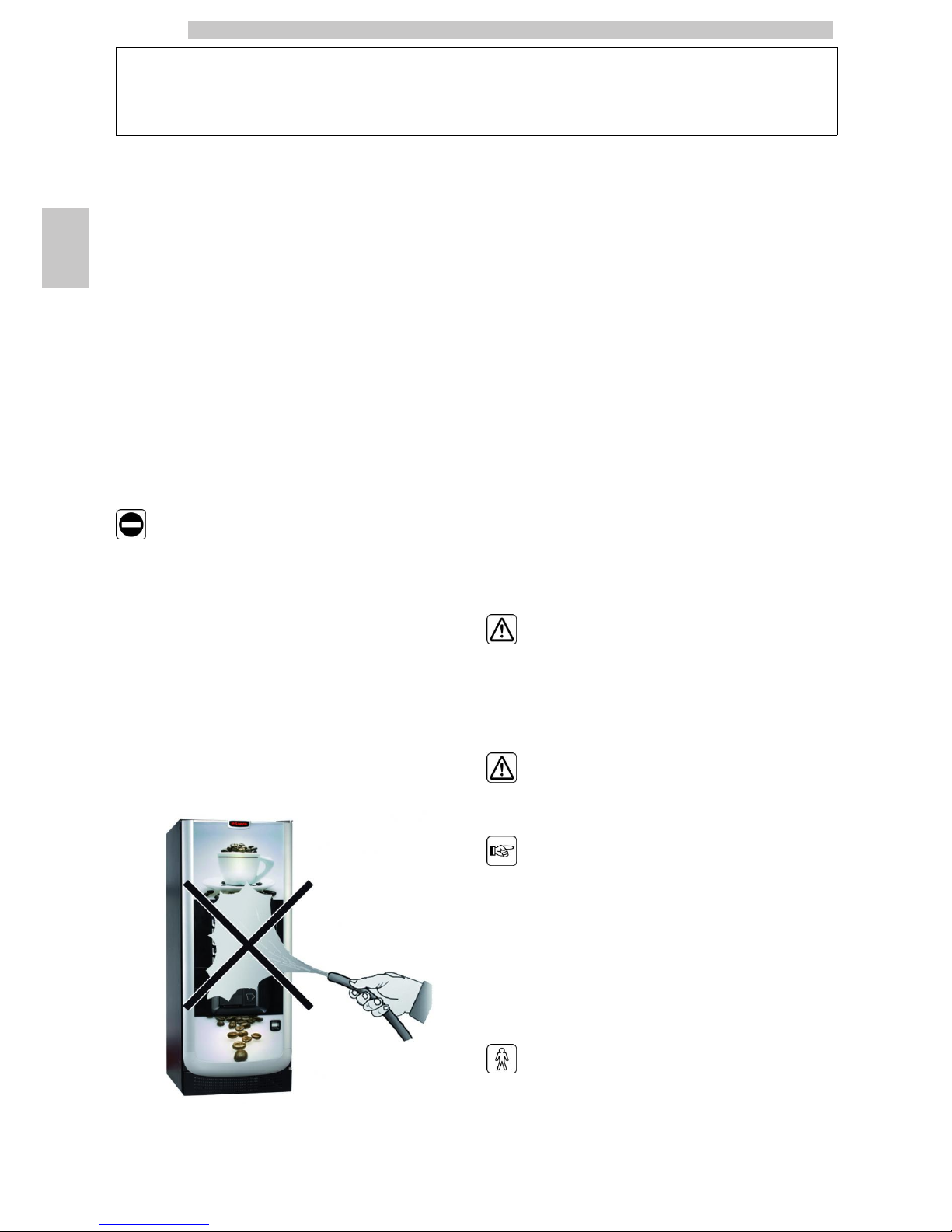

3.2 General safety regulations

It is forbidden to:

• tamper with or disable the safety systems installed on the

vending machine;

• carry out maintenance on the vending machine without

unplugging it first;

• install the vending machine on the outside. It is advisable to place

it in a dry place where the temperature does not drop below

1°C, in order to prevent any possible freezing.

• use the vending machine for purposes other than those indicated

in the sale contract and in this publication;

• connect the appliance to the mains using multi-sockets or

adapters;

• use water jets to clean the vending machine.

It is compulsory to:

• check the electrical power line for conformity;

• use original spare parts;

• read the instructions contained in this publication and in the

enclosed documents carefully;

• use personal protection devices during installation, testing and

maintenance operations;

• Use a new gasket kit every time you disconnect and then

connect again the machine to the water supply.

Precautions for preventing human errors:

• make the operators aware of safety issues;

• handle the vending machine, either packaged or unpackaged, in

safe conditions;

• have a thorough knowledge of the installation procedures, its

operation and limits;

• dismantle the vending machine in safe conditions, in accordance

with the environmental protection and health and safety laws in

force.

To prevent machining residues from coming into

contact with the beverages, dispense about 0.5 l water

for each dispensing path before definitely starting the

vending machine. The dispensed beverages can be

consumed only after performing this operation.

In case of failure or malfunctioning, please refer only to

the qualified personnel of the technical service.

The Manufacturer declines any liability for any damage

caused to property or injury caused to persons as a

result of failure to observe the safety regulations

described here.

3.3 Operators' requirements

Three operators with different skills are required in order

to guarantee the safety of the vending machine:

User

Access to the internal part of the vending machine is

forbidden to the user.

English

3

21

Supply operator

The Maintenance Technician assigns the safekeeping of the

access key to the Supply operator who is in charge of

product supply, external cleaning, and starting up /

stopping of the vending machine.

The Supply Operator is not authorized to carry out

operations which are indicated as being the duties of

the Maintenance Technician in this publication.

Maintenance Technician

The Maintenance Technician is the only person authorized to intervene

and start programming procedures, and perform adjusting, setting up and

maintenance operations on the vending machine.

Access to the service area is restricted to persons having knowledge

and pratical experience of the appliance, in particular as far as safety

and hygiene are concerned.

3.4 Safety devices

The vending machine is equipped with:

• a safety switch which cuts out the voltage to all the inside

components any time the front door is opened.

• a safety switch located on the dispensing outlet door,

which blocks the nozzle arm cycle whenever the door is

opened.

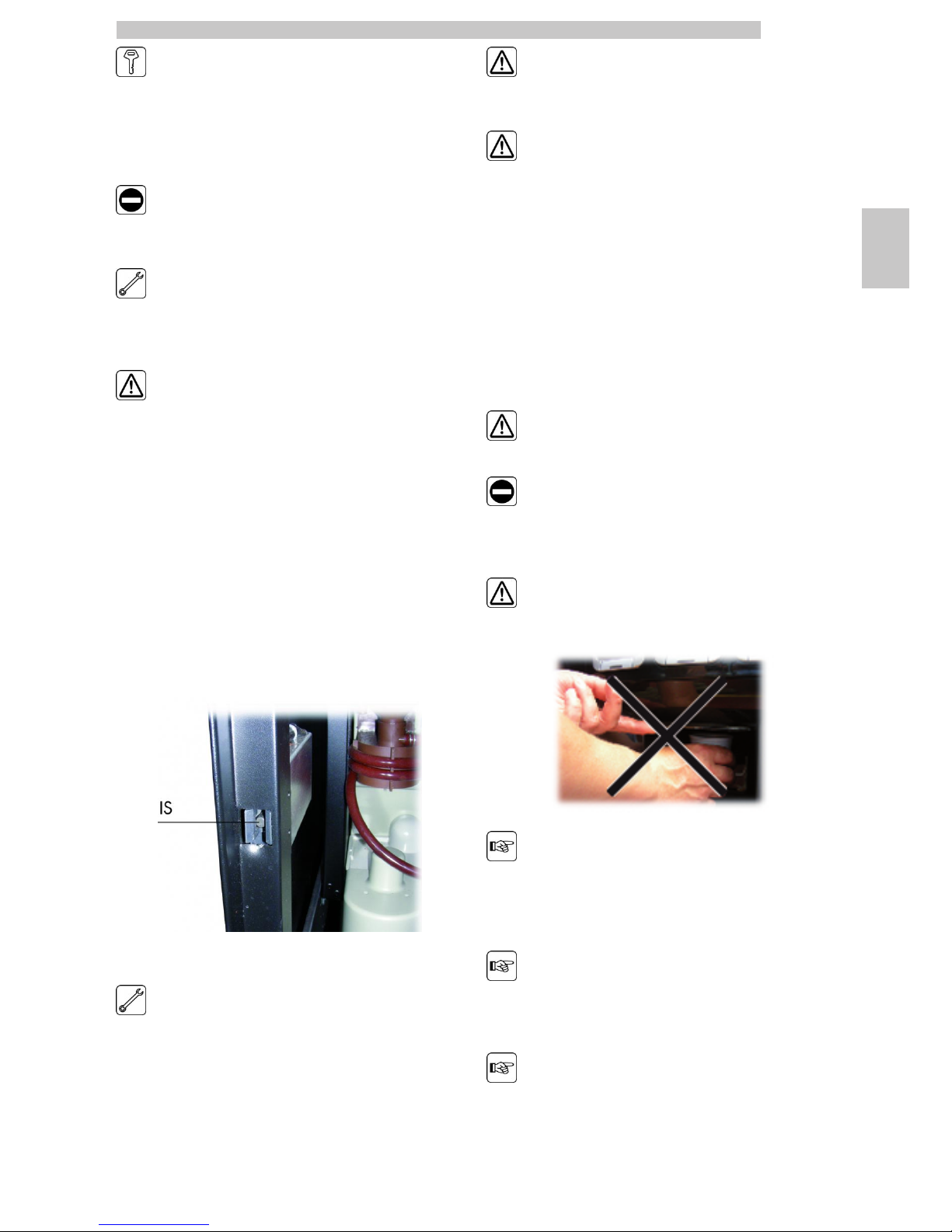

IS Safety switch

Maintenance Technician

In case of programming or setting up operations only the

Maintenance Technician can intervene by inserting the

relevant key into the safety switch and resetting the

voltage even if the door is open.

This operation, necessary for starting up the vending

machine, disables the safety system.

It must therefore be carried out by qualified personnel

(Maintenance Technician) aware of the risks resulting

from the presence of live or moving components.

3.5 Residual risks

The dispensing outlet is protected by the door interlocked

by the safety switch.

If it is opened during the brewing cycle, mechanical

movement is blocked, but if brewing has already started, it

continues up to the end of the cycle.

Risk of scalding if hands are placed inside the outlet

during brewing.

It is forbidden to open the door and take out the cup

or put hands inside the outlet during dispensing,

before the brewing cycle is complete.

Before removing the cup from the outlet, please wait

for the message “REMOVE CUP” on display.

If the outlet door is opened during the brewing cycle,

the message “CLOSE SERVICE DOOR” will be

displayed; the nozzle arm stops and will not restart

until the door is closed.

It is not possible to brew further beverages if the

previous cup is not taken out (see the “Dispensing

outlet microswitch” menu item).

Before brewing another beverage, check that the

previous one has been taken out and that the cup

support is empty.

English

4

22

4 HANDLING AND STORAGE

4.1 Unloading and handling

Unloading and handling operations after transportation

must be carried out only by qualified personnel and using

suitable equipment.

The vending machine is placed on a pallet, protected by a

sack, by a shrink film and four angle bars.

Use a fork-lift to unload the vending machine from the

transport vehicle.

The vending machine must always be kept in the

upright position.

Avoid:

• dragging the vending machine;

• overturning or laying the vending machine flat during

transport and handling;

• shaking the vending machine;

• lifting the vending machine with ropes or cranes;

• leaving the vending machine exposed to the elements, in

humid areas or close to heat sources.

4.2 Storage

If the vending machine is not installed immediately, it

should be stored in a sheltered area, conforming to the

following instructions:

• the packaged vending machine must be stored in a closed,

dry area at a temperature between 1°C and 40°C;

• do not put other appliances or boxes on the vending

machine;

• it is always good practice to protect the vending machine

from any deposits of dust or other material.

English

5

23

5 INSTALLATION

5.1 Warning

The vending machine cannot be installed outdoors;

avoid placing it in areas where the temperature is less

than 1°C or more than 25°C and in particularly dump

or dusty areas.

Before unpacking, check that the installation area complies

with the following specifications:

• the power socket must be located in an easily accessible

area, not more than 1.5 meters away;

• the socket voltage must comply with that on the

identification plate;

• the surface or floor must NOT have a gradient of more

than 2°.

The vending machine must be installed on a flat

surface.

If the vending machine needs to be positioned close to a

wall, it is necessary to leave a space of at least 15 cm

between the back and the wall in order to keep the air

outlet grille free.

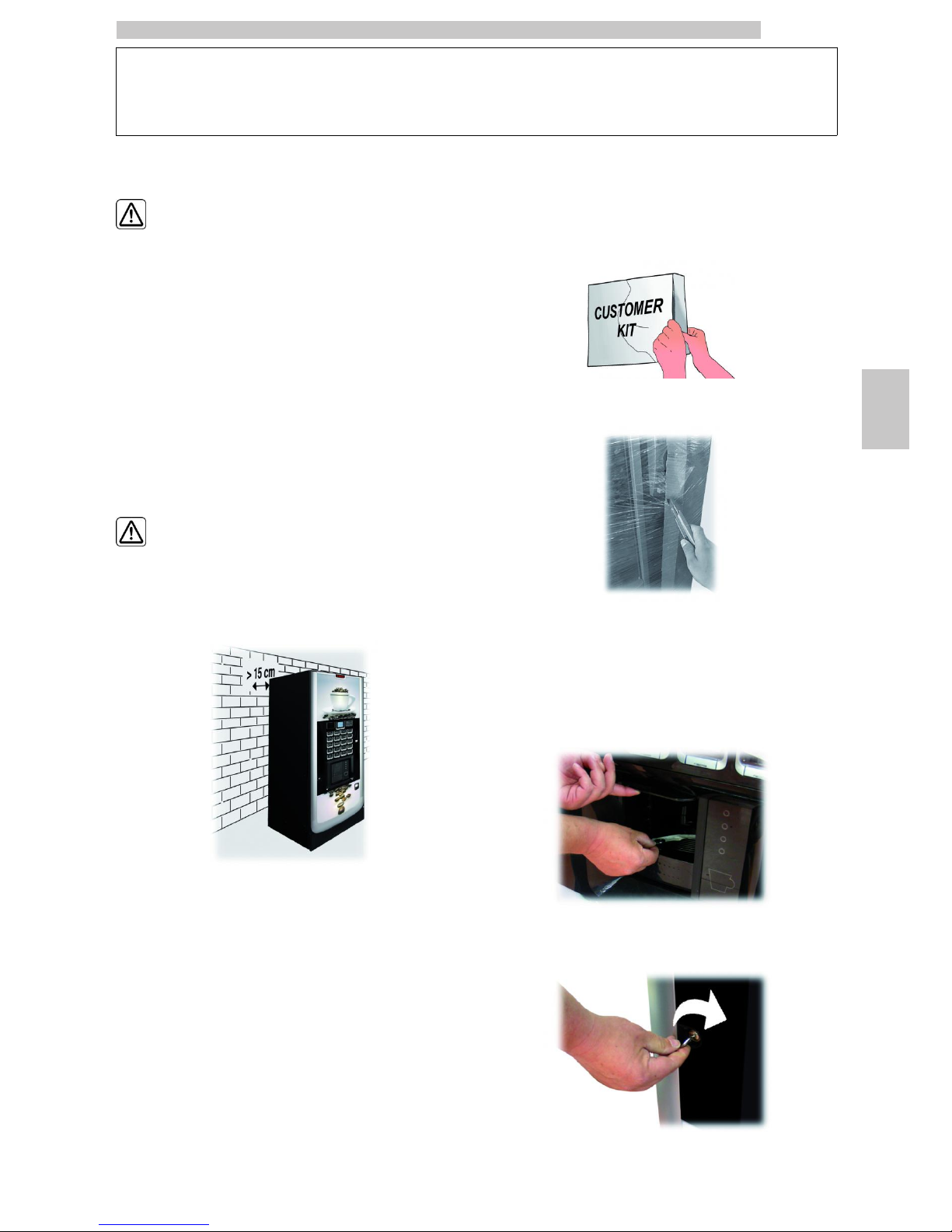

5.2 Unpacking and positioning

On receipt of the vending machine make sure that it has

not been damaged during transportation and that package

has not been tampered with or that internal parts have not

been removed.

A bag, called “CUSTOMER KIT”, is supplied with the

vending machine. It contains the following items:

• Instruction booklet

• Power cord

• Door safety microswitch disabling keys (Maintenance

Technician)

• Product labels and prices

• Instruction plate

• Coin box labels.

Remove the transparent protective film and the four angle

bars.

If damage of any kind is found, the courier must be

informed and notice must be given to the importer or the

seller immediately.

If these are not in the purchaser’s country, please contact

the manufacturing company directly.

Take the key from the dispensing outlet.

Insert the key into the lock, turn clockwise and open the

door.

English

5

24

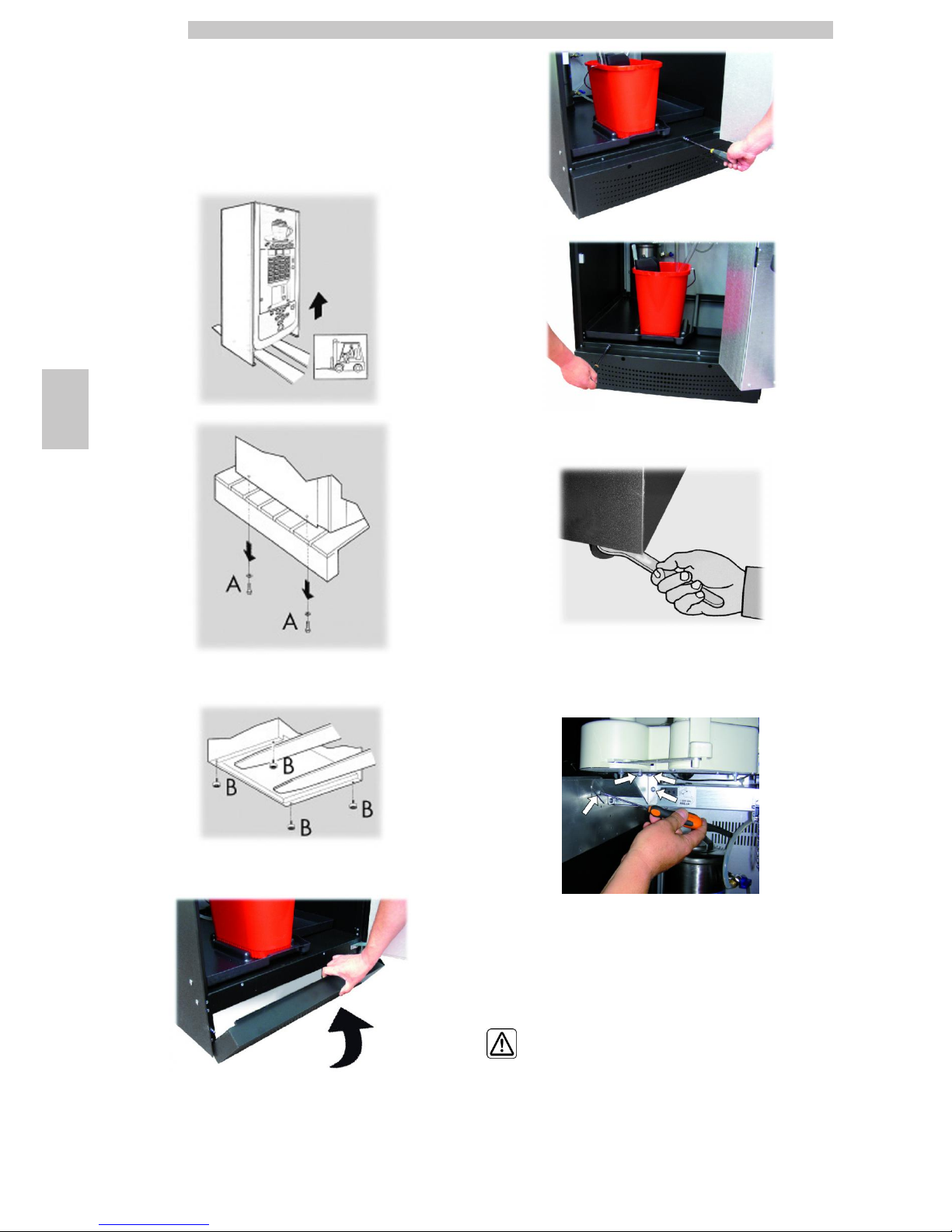

From the discharge tank, take out the accessory packet

containing the following items:

- 4 feet;

- 1 key for the brew group.

Lift the pallet in a way that the four fixing A screws can be

removed.

Screw the four supporting feet B.

Assemble the base by tightening the two screws as shown in the figure.

Adjust the levelling using the relevant feet.

Before operating the machine, unscrew the 4 screws to remove the

central plate support bracket.

5.3 Use of different-sized stirrers

The vending machine is delivered with the stirrer set

designed for use of 90 mm stirrers.

If 90 mm stirrers are used, make sure that the rubber

pin is inserted in the hole.

English

5

25

To substitute the 90 mm stirrers with those of 105 mm or

115 mm proceed as follows:

• Unfasten the two screws fixing the stirrer guide;

• Move the stirrer guide into the hole corresponding to the

desired dimension and tighten the two screws.

5.4 Label application

5.4.1 Product labels

Remove the cup dispenser and unscrew the 4 knobs

holding the keypad panel in place.

Remove the protection and disconnect the connectors.

Withdraw the keypad panel.

Insert the product labels.

Check the exact position of the labels against the selection

key.

English

5

26

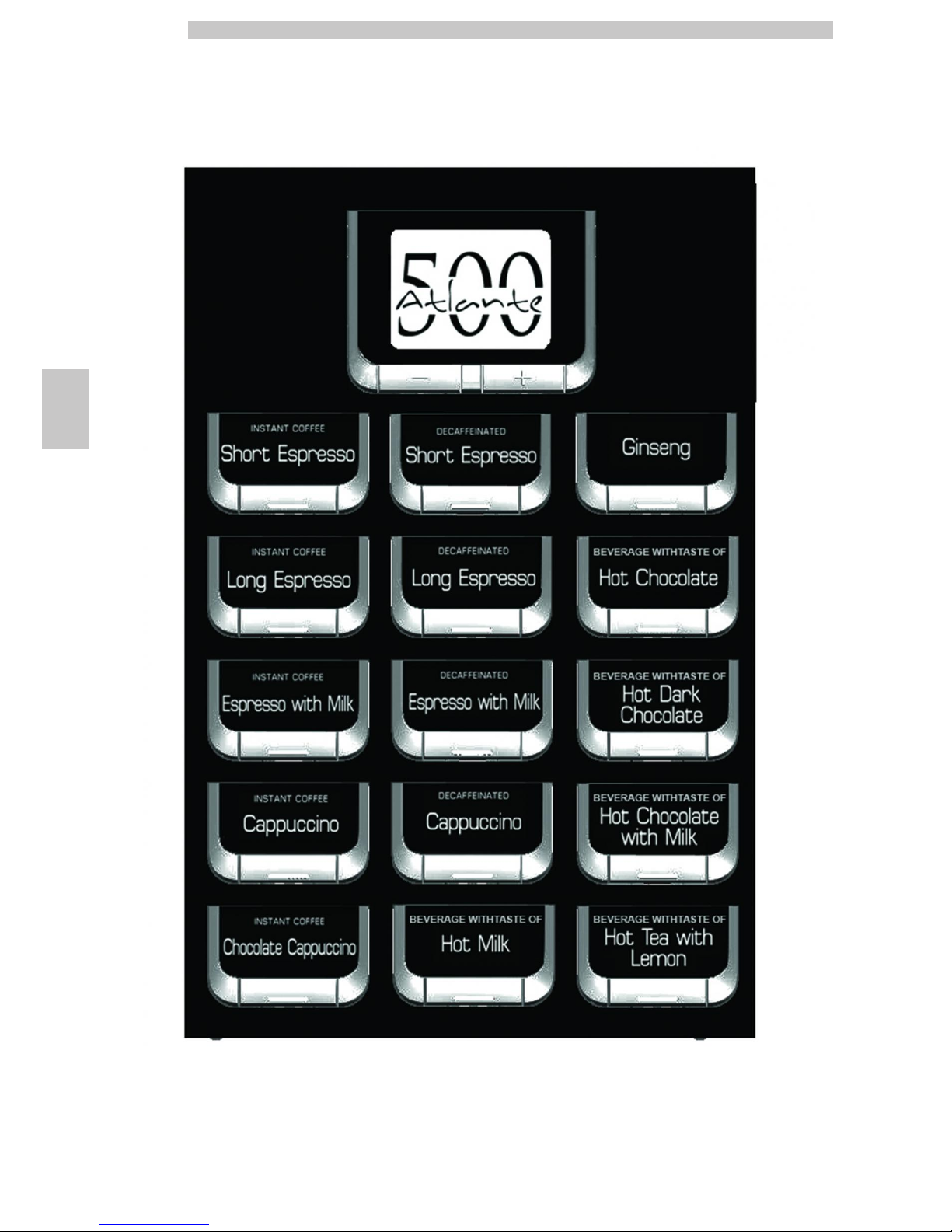

Standard product configuration

Atlante 500 Instant

English

5

27

Standard product configuration

Atlante 700 Instant

English

5

28

Standard product configuration

ATLANTE 500 1 macina

Loading...

Loading...