Saeco Aroma User Manual

All parts of this document are the property of Saeco International Group.

All rights reserved. This document and all the information herein is provided without liability deriving from

any errors or omissions. Furthermore, no part may be reproduced, used or collected with the exception

of that authorised in writing or in accordance with a contractual agreement.

Rev. 00 / May 2010

Service Manual

Revision 00 May 2010

all the information herein is provided without liability deriving from

prop

erty of Saeco International Group.

Page

1. Introduction

1.1 Documentation required 1

1.2 Tools and equipment required 1

1.3 Material 1

1.4 Safety warnings 1

1.5 Range 2

1.6.1 External machine parts 3

1.6.2 Internal machine parts 4

2. Technical specifi cations

2.1 Technical specifi cations 1

2.2 Descaling frequency 1

3. User instructions

3.1 Operation, cleaning and maintenance 1

4. Operating logic

4.1. Water circuit 1

4.2.1 Wiring diagram 3

4.2.2 Electrical diagram 3

4.3 Filter holder 4

4.4 Spherical cappuccino maker and nozzle 4

4.5 Flow meter 5

4.6 Anti-scale fi lter 5

5. Troubleshooting

5.1. Causes and solutions 1

6. Standard inspections

6.1 Repair schedule 1

6.2 Service schedule 1

6.3 Final inspection 2

7. Disassembly

7.1 Outer elements 1

7.2 Controls support 2

7.3 Boiler support assembly 2

7.4 Pump 2

7.5 Boiler thermostats 3

7.6 Boiler 3

7.7 Shower and valve 3

7.8 Steam pipe 3

7.9 Oetiker clamps 4

8. Notes

Contents

SAECO Rev. 00 / May 2010 MANUAL MACHINES

SAECO Rev. 00 / May 2010 MANUAL MACHINES

CHAPTER 1

INTRODUCTION

MANUAL MACHINES 01 INTRODUCTION

SAECO Rev. 00 /May 2010 Page / 04

1.1 Documentation required

The following documentation is required for repairs:

Instruction booklet of the specifi c model•

Technical documentation of the specifi c model (diagrams, exploded drawings)•

1.2 Tools and equipment required

Besides standard equipment, the following tools are required:

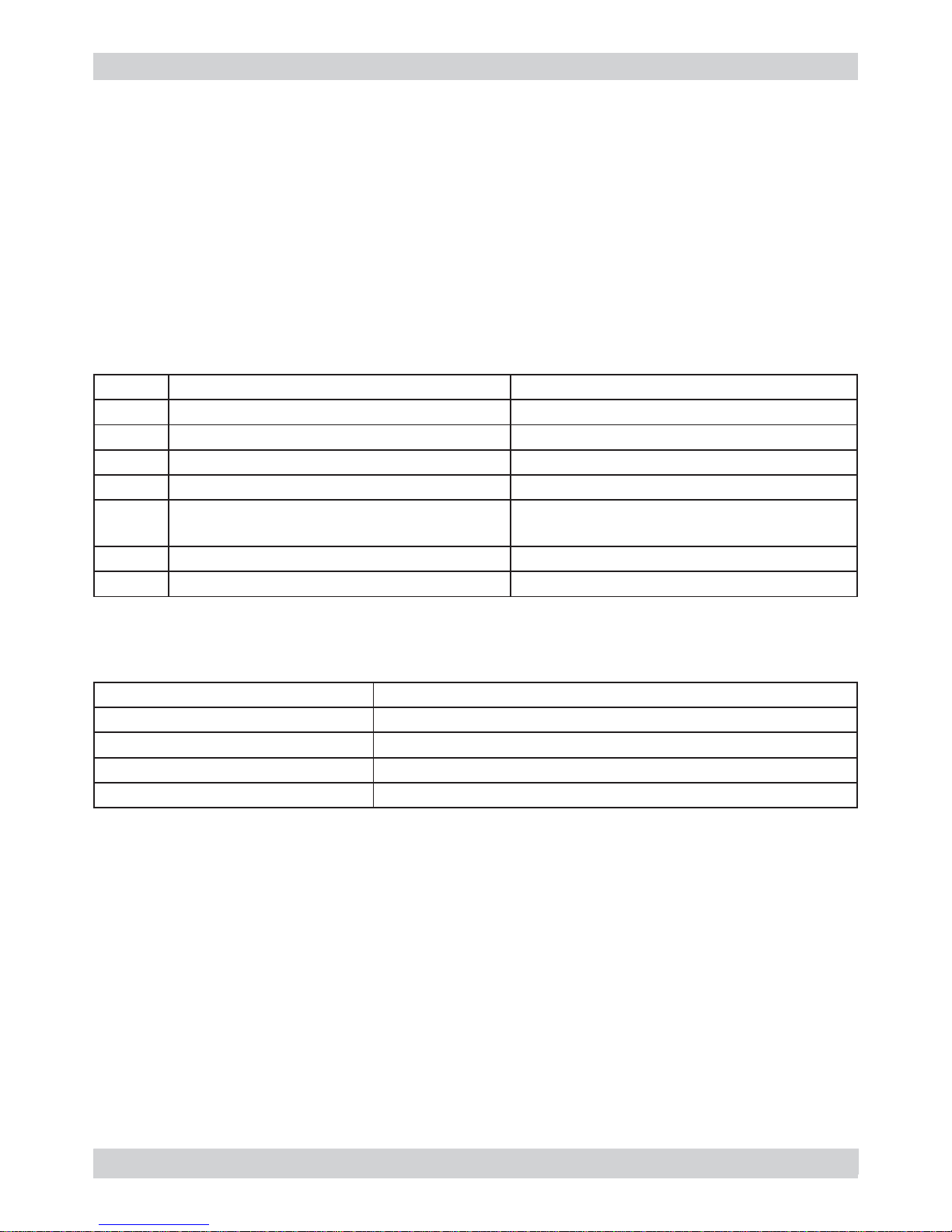

Qty. Description Notes

1 Screwdriver

1 Pliers for Oetiker clamps

1 AC - DC - Vdc tester

1 Digital thermometer Scale Limit > 150°C

1 SSC (Saeco Service Center) Programmer

(for programming and diagnosis mode)

1 Allen wrench

1 Hexagonal spanner

1.3 Material

Description Notes

Thermal grease Thermal resistance > 200°C

Descaler Saeco descaler

Degreaser Personal choice

Silicone grease Safe to use with food

1.4 Safety warnings

It is recommended to consult the technical manual of the machine before implementing any

operation.

Comply with all applicable standards relating to the repair of household appliances.

Always disconnect the power plug from the mains before beginning repairs on the machine.

Simply turning off the main switch is not suffi ciently safe to prevent electrical discharges.

This household appliance is rated as insulation class I.

On completion of the repairs, insulation and dielectric rigidity tests must be performed.

01

MANUAL MACHINES 01 INTRODUCTION

SAECO Rev. 00 / May 2010 Page / 04

1.5. Range

Pressurised fi lter holder xxxxxxxx

Filter for 1 or 2 coffees xxxxxxxx

Adaptor for E.S.E. pods xxxxx xx

Steam pipe xxxxxxxx

Steel boiler xxxxx xx

Quantity of dispensed coffee

saved in memory

x

Capacity of removable water

tank

1.5 l 1.5 l 1.5 l 2.5 l 2.5 l 1 l 1.2 l 1.5 l

Removable drip tray xxxxxxxx

02

A B

A

B

C

C

MANUAL MACHINES 01 INTRODUCTION

SAECO Rev. 00 /May 2010 Page / 04

03

1.6.1 External machine parts

Water tank

ON/OFF switch

Hot water/steam

dispensing pipe

Hot water/steam

dispensing knob

Nozzle

Drip tray+grille

Pressurised

fi lter holder

Selection

knob

Some machines have the spherical

cappuccino maker instead of the

nozzle

Spherical

Cappuccino maker

MANUAL MACHINES 01 INTRODUCTION

SAECO Rev. 00 / May 2010 Page / 04

1.6.2 Internal machine parts

04

Boiler assembly

Pump assembly

Overpressure

valve

Hot water/Steam

opening - closing

knob rod

Thermal protector

Overpressure

relief valve

Thermostats

Selection knob

Filter holder ring

SAECO Rev. 00 / May 2010 MANUAL MACHINES

CHAPTER 2

TECHNICAL SPECIFICATIONS

MANUAL MACHINES 02 TECHNICAL SPECIFICATIONS

SAECO Rev. 00 / May 2010 Page / 01

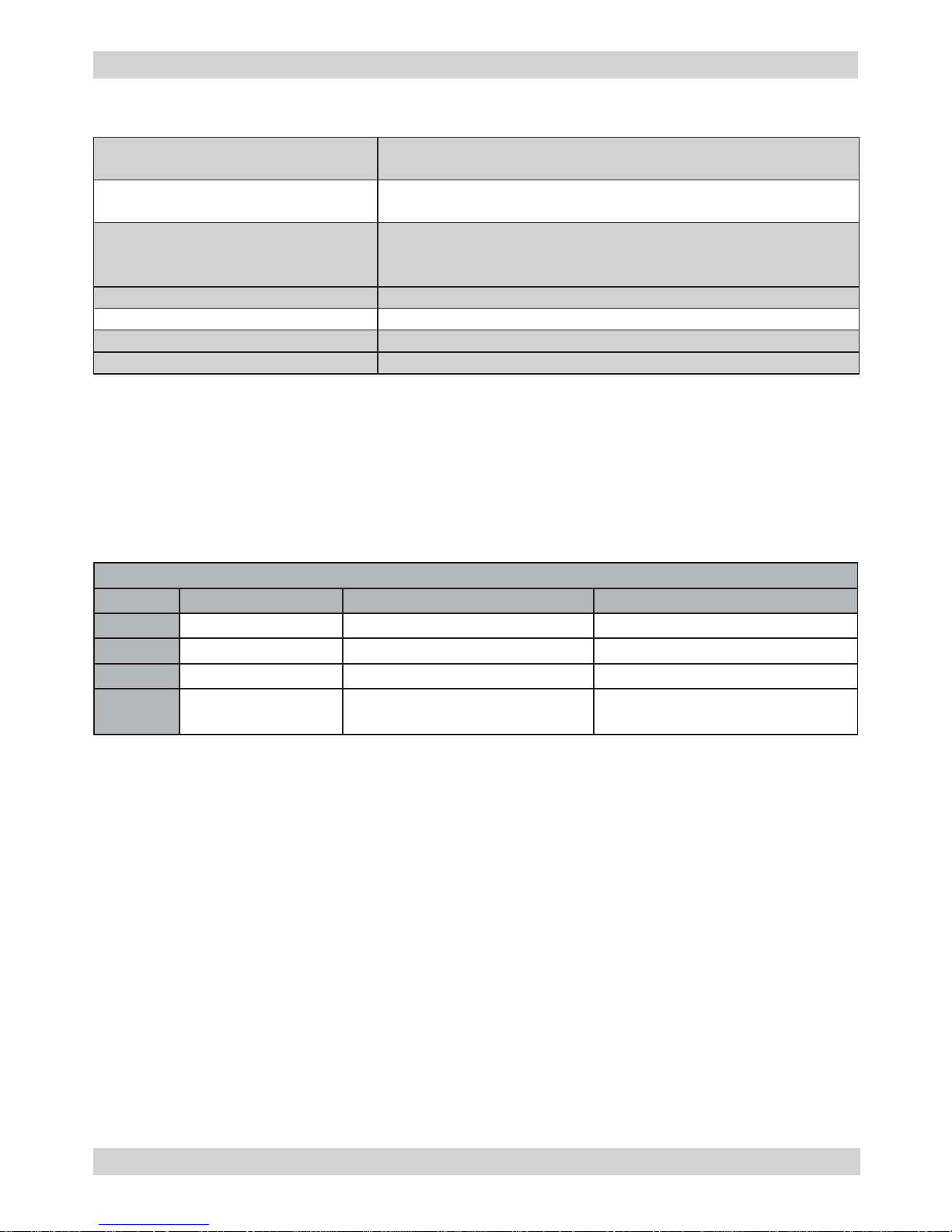

2.1. Technical specifi cations

2.2. Descaling frequency

Safety system: 2 one-shot thermostats (127°C and 95°C)

1 thermal protector > 184°C

Coffee heat exchanger output:

Stainless steel

(230/120 V~) 1000 W – for coffee, hot water and steam

dispensing

Pump Ulka Type EP5/S GW approx. 13-15 bar with reciprocating

piston and 120°C cutout 48 W, 230V, 50 Hz, 120V, 60Hz

100V, 50/60 Hz

Overpressure valve: Opening at approx. 16-18 bar

Water fi lter: In tank

Flow meter assembly Only in the single versions with the coffee amount setting

Consumption: During the heating phase - approx. 5.6 A

01

Descaling frequency

Hardness

Water hardness Without anti-scale fi lter With anti-scale fi lter

1 Soft (up to 7°dH) 240 litres (480,000 pulses) 480 litres (960,000 pulses)

2 Medium (7° - 14°dH) 120 litres (240,000 pulses) 240 litres (480,000 pulses)

3 Hard (15° - 21°dH) 60 litres (120,000 pulses) 120 litres (240,000 pulses)

4 Very hard

(over 21°dH)

30 litres (60,000 pulses) 60 litres (120,000 pulses)

Loading...

Loading...