Page 1

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Document title

Instruction Manual

HG2-S and HG2-XL

© 2009-2018; Rotronic AG E-M-HG2-S-XL-V3.0

Page 2

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Standard Supply Package

Advisory Notice

Document Type

Document title

1

2

Contents of the Standard Supply Package HG2-S:

• HG2-S HygroGen2 generator

• HG2-DES Desiccant cell filled with molecular sieve (pre-installed)

• IEC mains cable

• HG2-FILL Water fill syringe (with tube)

• HC2-S-S HC2-S control probe (pre-installed) with calibration certificate1

• Sample Loop connector cover plugs

• This Manual

• Chamber door (according to customer's order)2

• HW4 software ID number

• USB memory stick including saved test data and user manual

Contents of the Standard Supply Package HG2-XL:

• HG2-XL HygroGen2 generator with integrated door

• 2 x HG2-DES Desiccant cells filled with molecular sieve (pre-installed)

• IEC mains cable

• HG2-FILL Water fill syringe (with tube)

• HC2-S-S HC2-S control probe (pre-installed) with calibration certificate1

• Sample Loop connector cover plugs

• This Manual

• HW4 software ID number

• USB memory stick including saved test data and user manual

The calibration certificate included will vary according to the country of supply.

In some countries, the chamber door is delivered with the HygroGen2. Due to the diversity of chamber doors

and bungs, these are normally ordered separately and may be delivered in separate packaging.

© 2009-2018; Rotronic AG E-M-HG2-S-XL-V3.0

Page 3

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Table of Contents

Table of Contents

Document Type

Document title

1 Scope of Document 6

1.1 Introducing the HygroGen2 6

1.2 Temperature and Humidity References 6

1.3 Optional Enhanced Features: AutoCal, External Reference,

Range Extensions and Remote Control 7

2 Setting up the HygroGen2 9

2.1 Physical Location 9

2.2 Electrical Supply 9

i. Power Isolation 9

ii. Earthing 9

iii. Earth Leakage Current 9

iv. Overcurrent Protection 9

v. Voltage Rating 9

vi. Mains Filtration 10

vii. Conductive Pollution 10

2.3 HygroGen2 Assembly 11

HG2-S 11

i. HygroGen2-S Doors 12

ii. Desiccant Cell 12

iii. External Sample Loop 12

iv. HC2-S Control Probe 12

HygroGen2-XL 13

i. HygroGen2-XL Door 14

ii. HygroGen2-XL Shelves 14

iii. HygroGen2-XL Cable Management 15

iv. Desiccant Cells 15

v. External Sample Loop 16

vi. HC2-S Control Probe 16

2.4 Water Reservoir 17

i. To fill the HygroGen2: 17

ii. To empty the HygroGen2: 18

iii. Ultra-violet sterilisation lamp 18

3 HygroGen2 - Basic Operation 19

3.1 Switching On 19

3.2 Upgrading HygroGen2 Firmware 20

Updating HygroGen2 firmware from earlier version 1.x or 2.x 20

Updating HygroGen2 firmware from earlier version 3.x 20

Updating HW4 version 24

3.3 Configuration Mode Settings 27

Network Settings 27

Date and Time Settings 29

International Keyboard 29

External Monitor 29

Touch Screen Calibration 30

3.4 HygroGen2 Touchscreen Interface 31

Controller Home Screen 31

i. Navigation (items 1, 10 & 14) 31

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 4

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Table of Contents

Table of Contents

Document Type

Document title

ii. Temperature and Humidity Set-Points (items 3 & 7) 32

iii. Temperature and Humidity Control (items 5 & 9) 32

Trend Screen 33

i. Trace selection (item 4) 33

ii. Trend Axes (items 2 & 3) 33

Programmer Screen 34

i. Program Selection (items 1 & 2) 34

ii. Step Selection (item 3) 34

iii. Run/Stop (item 4) 34

iv. Edit Program (item 5) 35

Edit Program Screen 35

i. Select a Program to Edit 35

ii. Edit a Program Name 35

iii. Edit a Step 35

iv. Insert or Delete a Step (items 6 & 7) 36

v. Ramp or Soak (item 2) 36

vi. Timing Tolerances (items 10 & 11) 36

vii. Temperature only Program (item 12) 36

viii. Programmer Screen 36

Settings Screen 37

i. Activation of Enhanced Features 37

ii. HygroGen Information 38

iii. Remote Support 38

iv. Connections to Network File Servers 40

4 HygroGen2 Enhanced Features 41

4.1 AutoCal 43

Top Level Menu and Programmer Function 43

AutoCal Reference 43

AutoCal Screen 43

AutoCal Program Edit 44

Tolerance and Sample Size 45

AutoCal Operation and Best Practices 45

Customising the PDF Calibration Certificate 47

Reference Information 48

4.2 External MBW/RH Systems Calibration Reference (AutoCal+) 49

Connecting and Configuring MBW/RHS External Reference 50

Measurement Type and Corrections 53

Corrections 54

Calibration Info 55

Advanced (Command Line interface) 55

Best Practices and Precautions 55

i. Dew/Frost control 56

ii. Mirror Cleaning 56

iii. Decontamination of HygroGen2 chamber 56

iv. Super Cooled Water: Dew or Frost Films. Force Frost Threshold 56

v. Extremes of Temperature and Humidity 57

4.3 Remote Control 57

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 5

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Table of Contents

Table of Contents

Document Type

Document title

Remote Screen Share 57

RemoteAPI 60

4.4 Range Extensions 64

5 General Operational Considerations 65

Water in the Chamber 65

Below Ambient Temperature Operation 65

Above Ambient Temperature Operation 66

Probe Insertion Depth 66

Protective Filters 67

Low Water Level Alarm 67

Water Level Indicator Calibration 67

5.2 Switching off the HygroGen2 68

Shut Down 69

Transit 69

5.3 Preparing the Unit for Transit or Storage 70

6 HW4 Embedded 71

6.1 HW4 Set Up and Getting Started 71

6.2 HW4 Installation and Registration 72

6.3 HW4 Support 72

6.4 Data Logging in HW4 73

Test Instrument Data 73

Control HC2-S 74

7 External PC Peripherals 75

7.1 USB Keyboard and Mouse 75

International Keyboard Layouts 75

7.2 External Monitor 76

8 Servicing and Maintenance 77

8.1 Control HC2-S Calibration 77

Removing Control HC2-S HG2-S 77

Removing Control HC2-S HG2-XL 77

8.2 Desiccant 78

Changing Desiccant 79

Choice of Desiccant 80

8.3 HygroGen2 Cleaning 81

External surfaces 81

Air Inlet Filters – HG2-S 81

Air Inlet Filters – HG2-XL 81

Chamber 82

Purging internal pipes 82

8.4 Annual Servicing of HygroGen2 82

A1: Calibration Reference Options 83

A1.1 Internal RH Probe Reference 83

A1.2 External RH Probe Reference 84

A1.3 Chilled Mirror Reference 84

A2: Temperature Control 87

A3: Validation – Requirements and Accessories 88

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 6

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Table of Contents

Table of Contents

Document Type

Document title

B2: HygroGen2 / Screen Messages 90

B3: HygroGen2-S Specification 91

B4: HygroGen2-XL Specification 92

B5: HygroGen2 Order Codes: 93

C1: HygroGen2 Warranty Statement 96

C2: Manufacturer & Service Centre Contact Information 97

D1: HygroGen2 Uncertainty Framework - Internal RH Probe 98

D2: HygroGen2 Uncertainty Framework - External RH Probe 99

D3: HygroGen2 Uncertainty Framework - Chilled Mirror Reference 100

D4: Dew Point Uncertainty Analysis 101

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 7

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

6 of 102

Document title

1 Scope of Document

This instruction manual refers to both HygroGen2 models: HG2-S and HG2-XL, running

software version 3.0. To determine the software version that your instrument is running, please

refer to the Settings Screen as shown in section 3.4.5. For version 1.x.x, the software revision

number is displayed by pressing the “HG Info” button; for version 2.0, select “Info” from the

“Service” drop-down menu; for version 2.1 and later, select “HygroGen2 Info” from the

“Support” drop-down menu. Equivalent manuals are available on www.rotronic.com for

HygroGen2 instruments running software versions 1.x. and 2.x.

For instructions on how to upgrade to version 3.0 please see Section 3.2.

1.1 Introducing the HygroGen2

The HygroGen2 is a generator of controlled relative humidity and temperature environments,

primarily for use in calibrating humidity instrumentation, but is also well suited to the

calibration of temperature instrumentation, particularly those used for the measurement of

temperature in air.

It is a completely self-contained, portable unit requiring no external resources except mains

power. This allows technicians to perform calibrations in the laboratory, workshop or on-site.

The HygroGen2 is available in the standard HG2-S version - with 2 litre chamber – and, as of

2016, a larger HG2-XL - with 20 litre chamber.

The HygroGen2 uses a mixed flow method for generating the %rh required by the user. A

desiccant cell provides a source of low humidity and a piezoelectric humidifier generates high

humidity. A Peltier element is used for heating and cooling the chamber. Measurement and

control is provided by a combination of a ROTRONIC HC2-S probe, an embedded Platinum

Resistance Thermometer (PRT) and a multi-loop controller. Set-points are entered using the

touchscreen front panel display.

1.2 Temperature and Humidity References

The HygroGen2 creates stable temperature and humidity conditions uniformly within its test

chamber. Instruments under test (IUTs) are inserted through the chamber door, or placed

directly inside, and compared to a reference to calibrate and monitor their performance so that

any appropriate adjustments can be made.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 8

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

7 of 102

Document title

There are three main relative humidity (RH) calibration reference types that can be used with

the HygroGen2. Each has its own advantages and disadvantages, so the reference chosen

should be determined by the uncertainty of measurement required.

• Internal control RH probe reference

• External RH probe reference

• Chilled Mirror Hygrometer reference

Corresponding temperature references integrated in the above may be used or additional

external temperature references employed (for example, platinum resistance thermometers

(PRTs)).

It is vital to consider the comparison of temperatures measured by the reference, the

HygroGen2 and IUTs. Because RH is significantly dependent on temperature, temperature

measurement should be optimised to get meaningful RH results.

For more details, please see A1: Calibration Reference Options and Appendices D1 to D4 on

Uncertainty.

1.3 Optional Enhanced Features: AutoCal, External Reference, Range

Extensions and Remote Control

With the introduction of software version 2.0, the HygroGen2 comes with optional Enhanced

Feature upgrades: AutoCal and RH/Temperature Range Extensions. Version 2.1 has more

additions to the Enhanced Features range: AutoCal+ and Remote Control. Further

enhancements are in development and will be released in subsequent versions.

All Enhanced Features are activated by the application of a licence key, available via your

ROTRONIC dealer, and can be added to any HygroGen2. Older units with serial numbers prior

to HG2-VCT-1280 may require a service in order to enable network features required for

Remote Control.

Low Temperature and Humidity Range Extensions extend the limits of points that can be

set on the instrument, creating chamber conditions down to -5 °C and from 2 %rh up to

99 %rh.

AutoCal allows you to pre-program a series of set-points and times, and record the

instrument‘s progression through them in a PDF Calibration Certificate which is written to an

external USB disk drive. Any values recorded on ROTRONIC HC2-S probes attached to the

HygroGen2 via USB adaptors are recorded in the certificate. Probes can be set to automatically

adjust to match the HygroGen2 reference probe at predetermined values.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 9

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

8 of 102

Document title

Remote Screen Share (Formerly Remote Control) gives the ability to remotely control the

HygroGen2 over a network using the open source VNC protocol.

RemoteAPI gives the ability to remotely control and interrogate the HygroGen2 using a series

of text based commands over a network; users can write their own software to log and control

the HygroGen2.

MBW External Reference (formerly AutoCal+) extends the functionality of AutoCal and

RemoteAPI, by integrating MBW/RHS chilled mirror hygrometers (supplied separately) as the

external reference.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 10

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

9 of 102

Document title

2 Setting up the HygroGen2

2.1 Physical Location

To ensure correct operation please ensure that:

1. The unit is level and stable;

2. There is at least 15 mm clearance underneath and at least 100 mm at the back of the unit to enable

adequate air flow;

3. There is adequate access to the electrical mains connection at the rear of the unit.

Note: The feet on the rear panel are for standing the unit for service purposes and to ensure a

sufficient air gap behind the unit. The unit will not operate in the vertical position.

2.2 Electrical Supply

i. Power Isolation

The unit is supplied with a mains cord set. The unit should be disconnected from the electrical

supply before the unit is moved, cleaned or has water added or removed.

ii. Earthing

This unit must be earthed. Provision for the safety earth is made through the electrical mains

connection (see Figure 2(8) below) to which all parts of the unit requiring earthing are

internally connected. An earthed electrical supply is required.

iii. Earth Leakage Current

Due to RF filtering, there is an earth leakage current, within the limits specified in EN 610101:2001. This may affect mains power circuits protected by Residual Current Device (RCD) or

Ground Fault Detector (GFD) type circuit breakers (particularly if used in multiples or with

other equipment with an earth leakage current on the same supply circuit).

iv. Overcurrent Protection

To protect the internal circuitry against excess currents, the mains supply to the unit must be

connected with the mains cord set provided with the unit and to an appropriate mains supply.

v. Voltage Rating

The unit is designed to work within the limits of a 110-230 VAC 50-60 Hz mains supply with

voltage fluctuations up to ± 10% of the nominal voltage. The unit is rated impulse-withstand

(overvoltage) category II of IEC 60364-4-443. Where occasional voltage transients over 2.5 kV

are expected or measured, it may be necessary that the power installation to the unit includes a

transient limiting device.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 11

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

10 of 102

Document title

vi. Mains Filtration

If there is risk of power spikes or breaks, it is recommended that an Uninterruptable Power

Supply (UPS) is used to provide continued power and mains filtration. This should be rated

according to the HygroGen2 power specifications (see Appendix B3) and the time required to

run/shut down during power outage.

vii. Conductive Pollution

The unit is rated Pollution Degree 2 and must not be operated in environments where

conductive pollutants (for example, carbon) may enter the unit. This includes excessive

moisture ingress.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 12

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

11 of 102

Document title

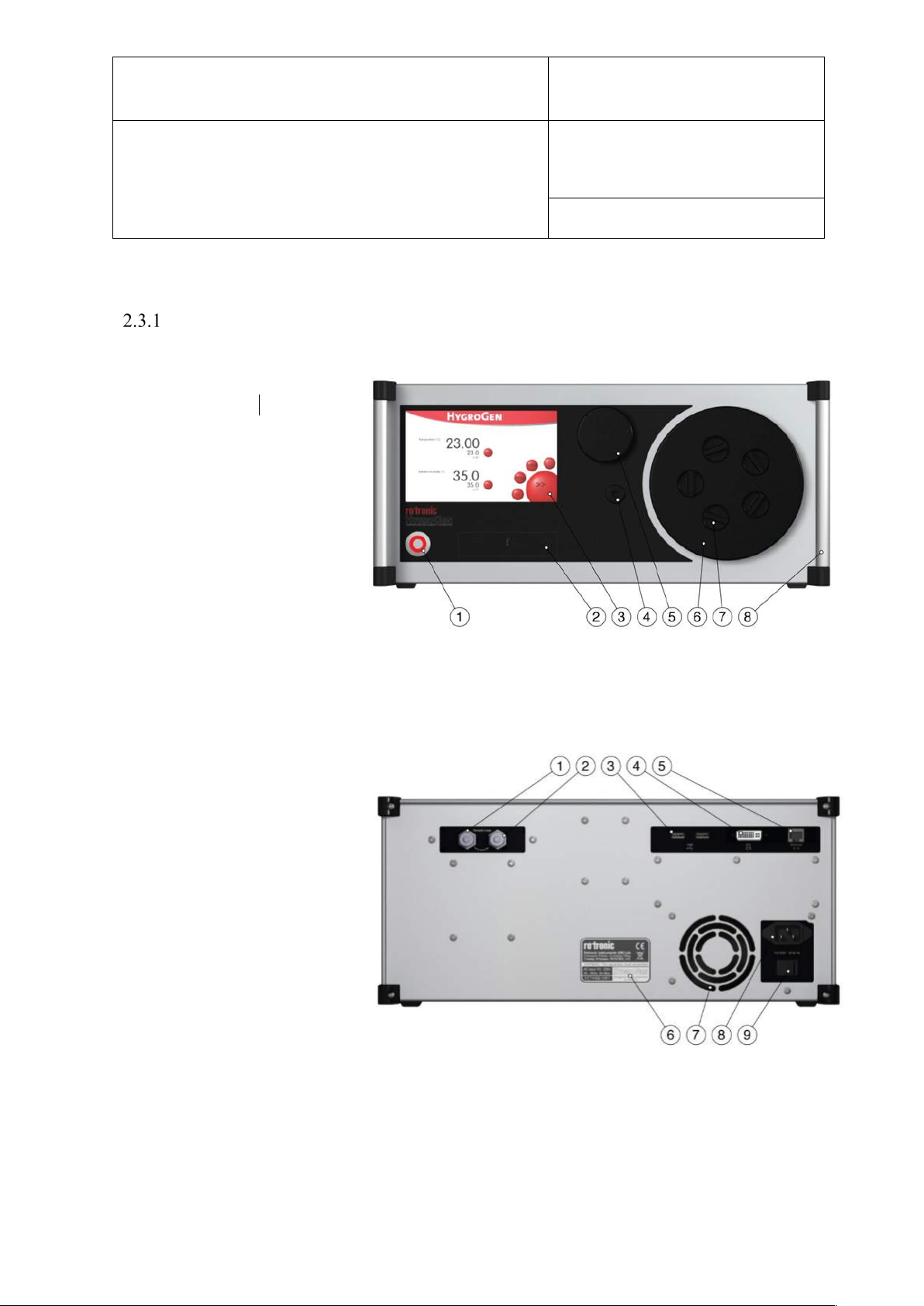

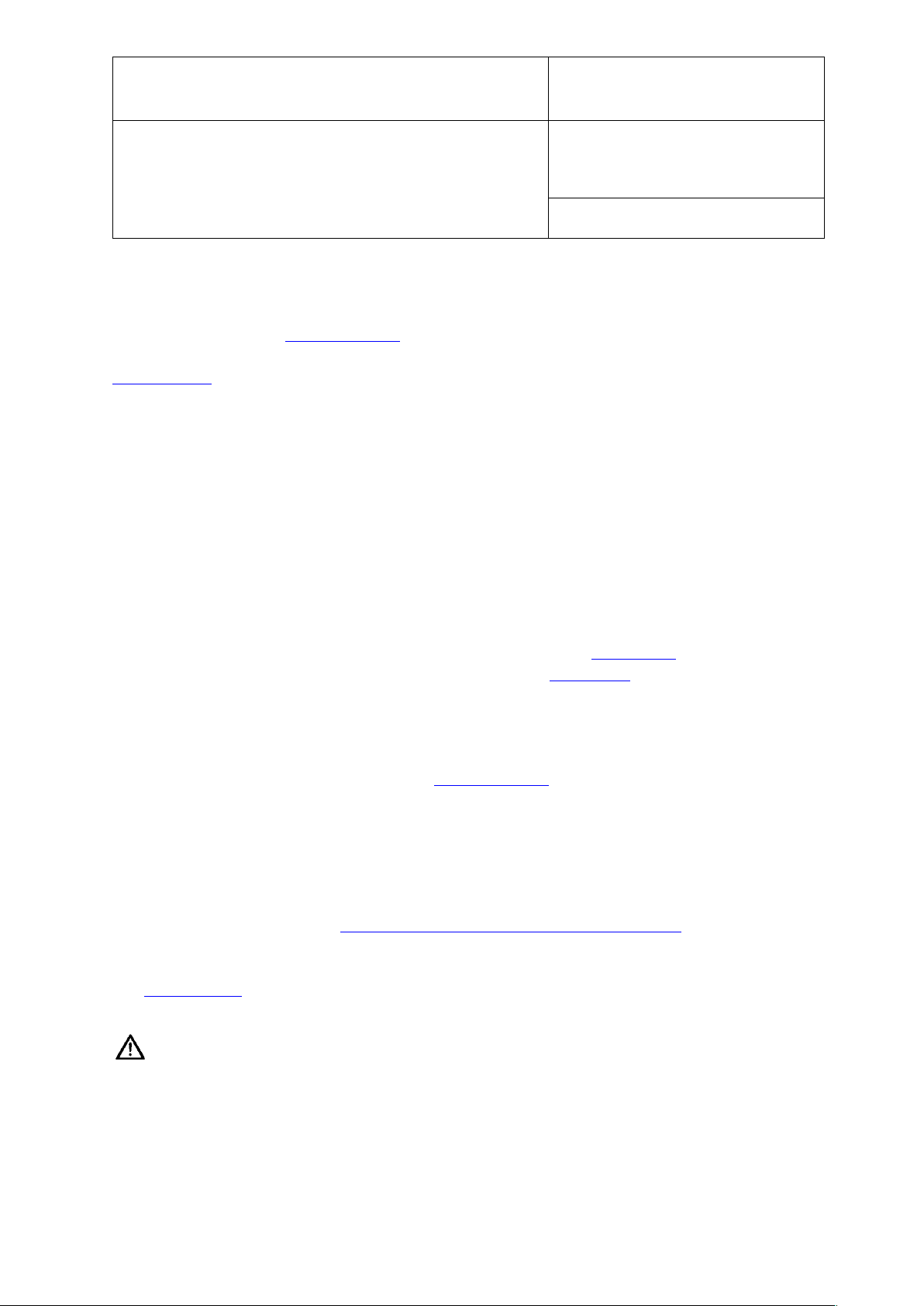

Figure 1: Front of HygroGen2-S

Figure 2: Rear of HygroGen2-S

2.3 HygroGen2 Assembly

HG2-S

1) Power switch

2) USB ports (7) (8

3) Touch screen controller

4) Water port

5) Desiccant cell

6) Chamber door

7) Probe aperture bung

8) Handle

1) Sample loop return

2) Sample loop outlet

3) USB ports (2)

4) DVI monitor interface

5) Ethernet socket

6) Type label

7) Fan outlet

8) Electrical mains connection

9) Power switch

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 13

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

12 of 102

Document title

i. HygroGen2-S Doors

The HygroGen2-S does not come supplied with a door. There are various standard and

customized versions available, depending on the intended use for the instrument, the use of an

external reference (see Appendix A1.2) and the instruments under test. Figure 1(6) above

shows the 15 mm 5-port version (part code: HG2-D-11111). Other options are listed in

Appendix B4.

To access the HygroGen2 chamber, remove the door. Grip firmly and twist the door anticlockwise. In the event that this proves difficult, cool the chamber first. Occasional instrument

application of silicone grease around the door “O” ring seal will ease movement.

Replacement can be in any position and requires only a gentle clockwise twist.

Before using your HygroGen2, make sure that the door is secured and that all probe apertures

not in use are sealed with a bung (see Figure 2(7) above) or an appropriate alternative seal.

ii. Desiccant Cell

The unit should be supplied with the desiccant cell in place (see Figure 1(5) above). For further

details and best practice for desiccant handling, please see section 8.2.

iii. External Sample Loop

Unless an external sampling system is to be used

(see “External Sample Loop Operation” in Appendix A1.3),

ensure the sample loop caps (Figure 2(1) and (2) above) are firmly secured.

iv. HC2-S Control Probe

The HygroGen2 chamber conditions are monitored and controlled by a ROTRONIC HC2-S

HC2-S-S RH and temperature probe. Depending on the circumstances and whether external

references are being used (see Appendix A1.2 External RH Probe Reference), this probe may

need to be removed for regular calibration.

See Section 8.1.1 for details on removing the control HC2-S probe.

Note: For speed of response, this probe must be employed without a protective filter.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 14

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

13 of 102

Document title

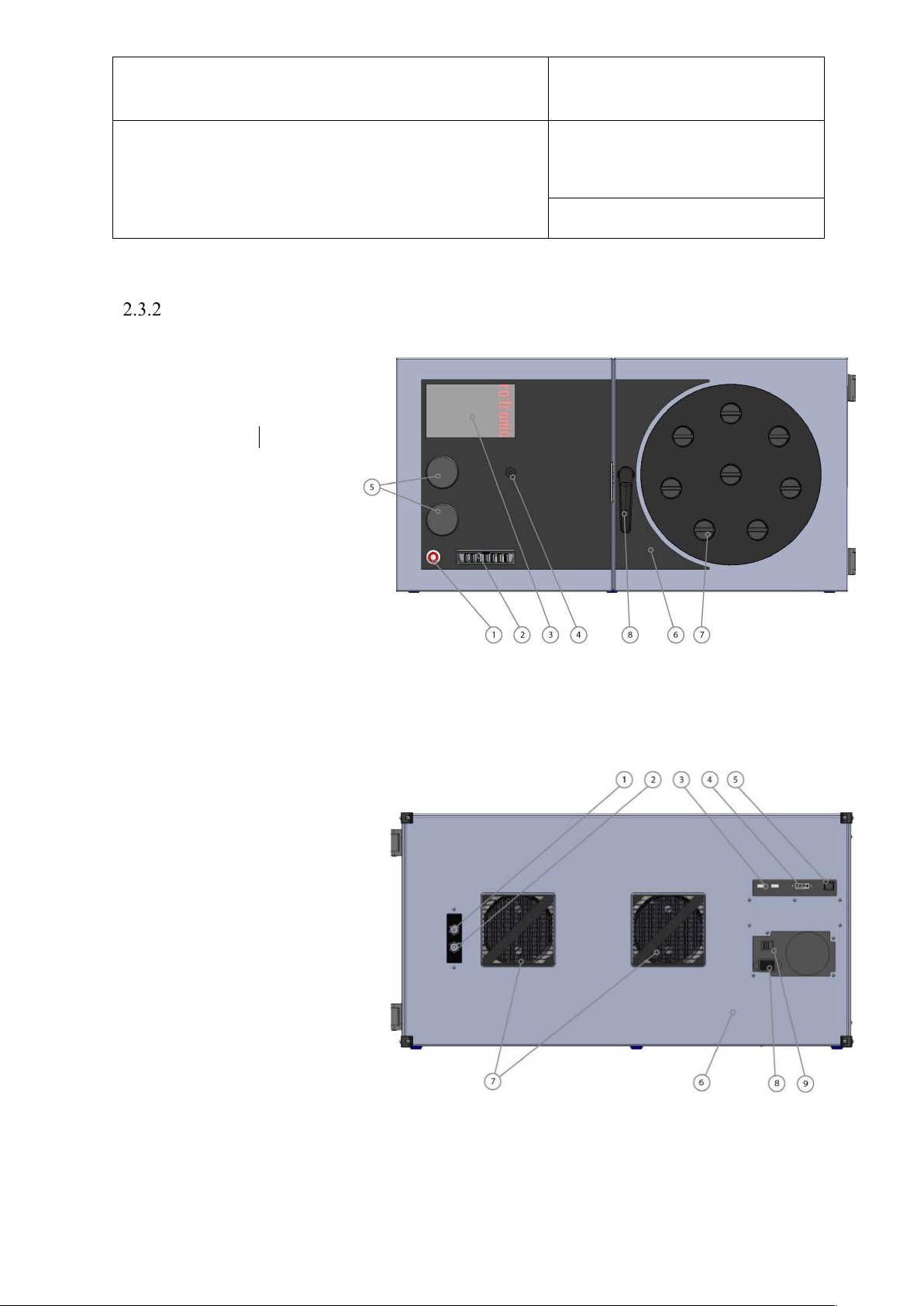

Figure 3: Front of HygroGen2-XL

Figure 4: Rear of HygroGen2-XL

HygroGen2-XL

1) Power switch

2) USB ports (7) (7)

3) Touch screen controller

4) Water port

5) Desiccant cell

6) Chamber door

7) Probe aperture bung

8) Chamber door handle

1) Sample loop return

2) Sample loop outlet

3) USB ports (2)

4) DVI monitor interface

5) Ethernet socket

6) Type label

7) Fan inlets and filter covers

8) Electrical mains connection

9) Power switch

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 15

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

14 of 102

Document title

Figure 5: HygroGen2-XL with 19 x 30mm ports

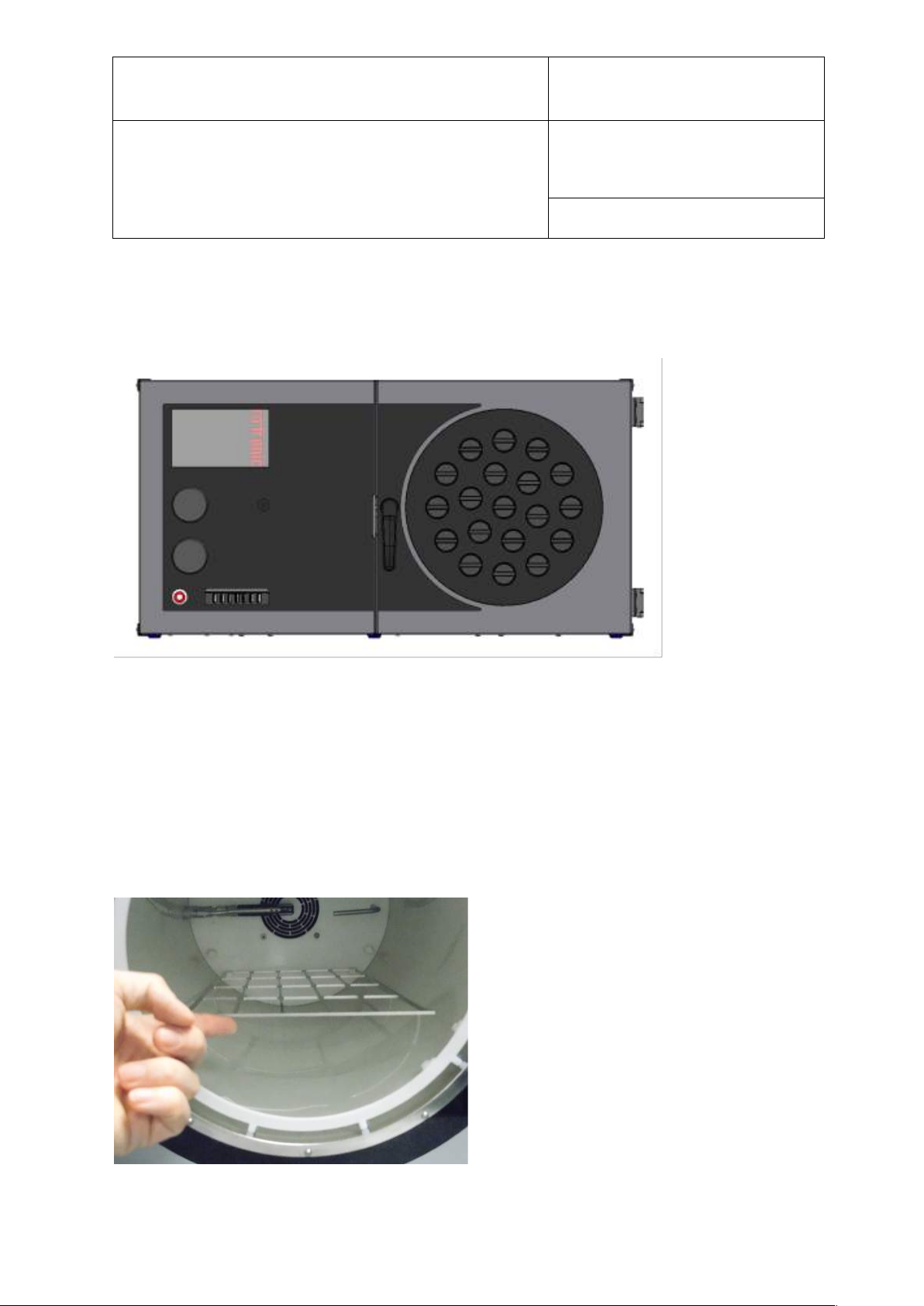

Figure 6: HygroGen2-XL shelving system

i. HygroGen2-XL Door

The HygroGen2-XL is supplied with a door, though customised versions are available. At the

time of preparing this manual, the standard configuration has 8 x 30 mm ports; there is also a

19 x 30 mm port version available.

Before using your HygroGen2, make sure that the door is secured and that all probe apertures

not in use are sealed with a bung or an appropriate alternative seal.

ii. HygroGen2-XL Shelves

The HygroGen2-XL has three removable shelves, which secure into clips at the back of the

chamber and rest on lugs at the front. Secure each shelf into the clips at the back and lower the

front of the shelf into place.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 16

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

15 of 102

Document title

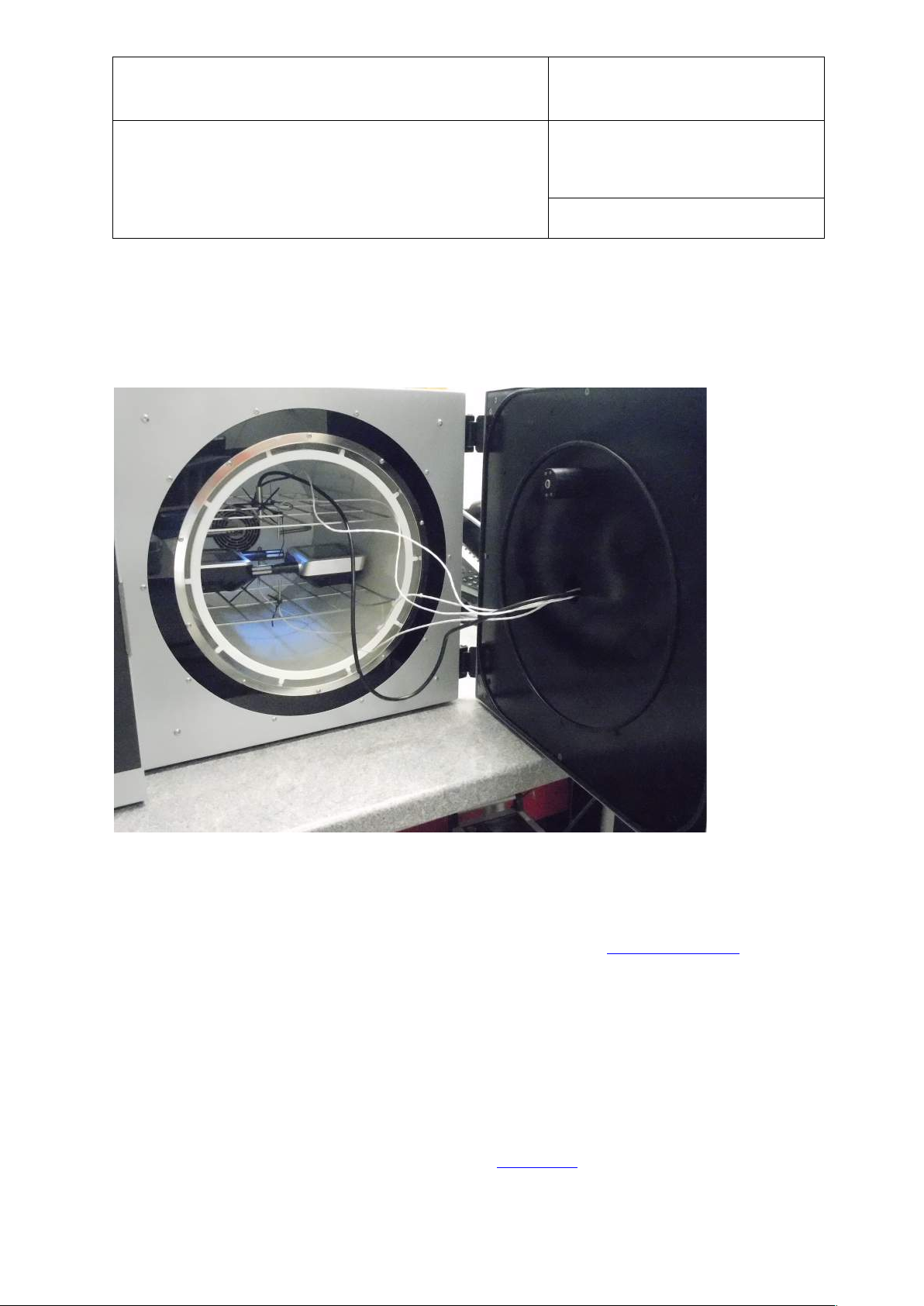

Figure 7: HygroGen2-XL cable management through chamber door

iii. HygroGen2-XL Cable Management

For devices placed wholly inside the chamber, it is recommended to secure cables to the

shelves using cable-ties and run the cables through a spare port in the door. The port can be

sealed using either a cable-gland bung, e.g. HG2-B8-L or some other appropriate

sealing/insulation.

iv. Desiccant Cells

The HygroGen2-XL is supplied with two desiccant cells in place (Figure 3(5) above). The

instrument will use the top desiccant cell by default and automatically switch over to using the

bottom one, should the top one need recharging. The instrument will display “Desiccant Low”

and the desiccant cell can removed and recharged. Should it be left, and the bottom one

become equally run down, the instrument will continuously switch between the two cells; the

drying function will be impaired until at least one is recharged. The desiccant cell currently in

use is displayed on the Settings screen on the desiccant level indicator.

Please note the desiccant indicator will only give a meaningful reading after it has been running

for more than -15% power for more than a minute through a particular cell. For further details

and best practice for desiccant handling, please see section 8.2.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 17

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

16 of 102

Document title

v. External Sample Loop

Unless an external sampling system is to be used (see “External Sample Loop Operation” in

Appendix A1.3), ensure the sample loop caps (Figure 2(1) and (2) above) are firmly secured.

vi. HC2-S Control Probe

The HygroGen2 chamber conditions are monitored and controlled by a ROTRONIC HC2-S

HC2-S-S RH and temperature probe. Depending on the circumstances and whether external

references are being used (see Appendix A1.2 External RH Probe Reference), this probe may

need to be removed for regular calibration.

See Section 8.1.2 for details on removing the control HC2-S.

Note: For speed of response, this probe must be employed without protective filters.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 18

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

17 of 102

Document title

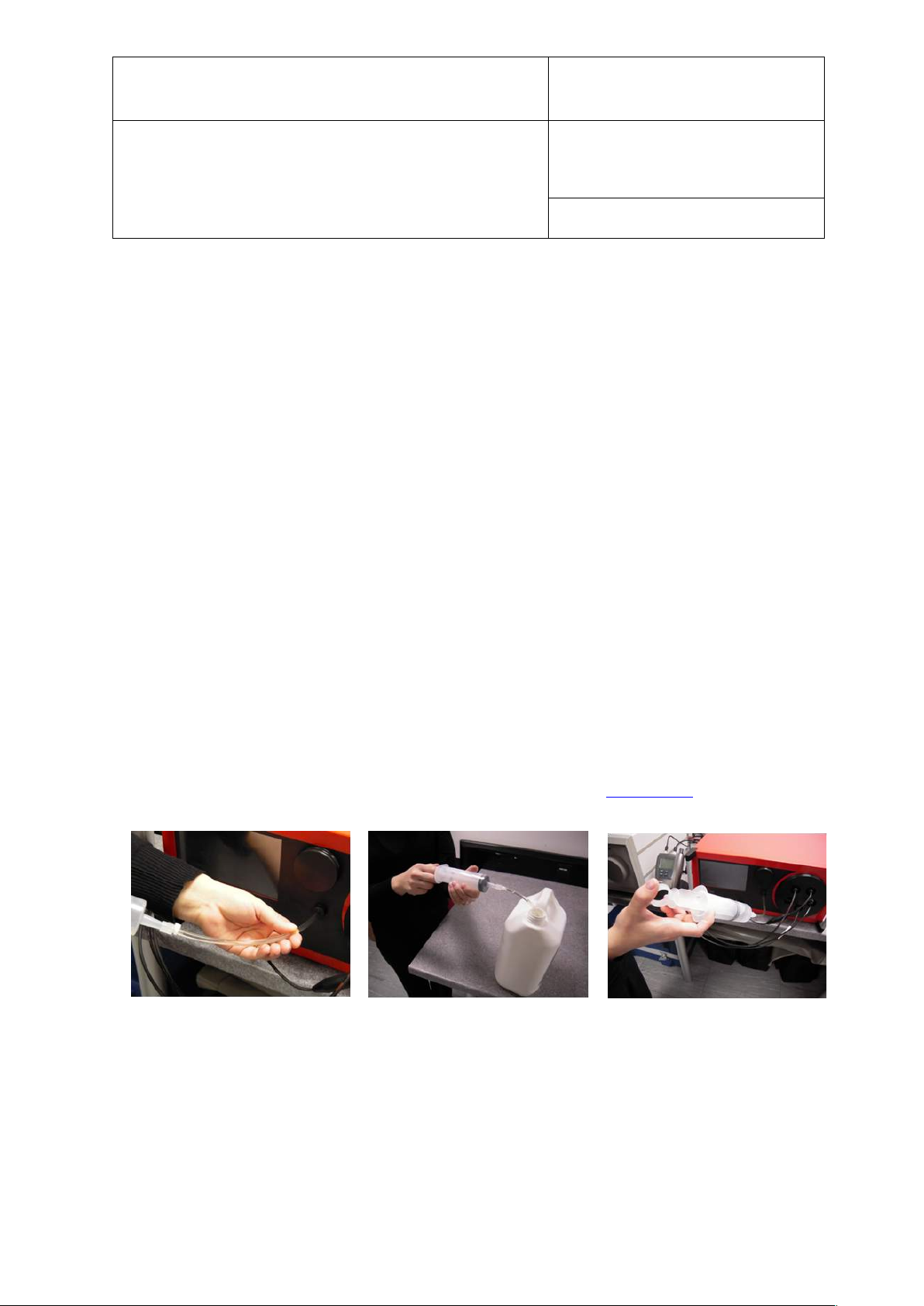

Figure 8: How to fill and empty the Water Reservoir

2.4 Water Reservoir

The HygroGen2 requires 50-80 ml of demineralised water in the internal reservoir.

Either reverse osmosis (RO) or de-ionised water is recommended. It is NOT recommended to

use distilled water as this readily absorbs atmospheric CO2 to form carbonic acid which can

corrode components within the humidifier.

Insufficient water will deactivate the humidification system. As long as extreme care is taken

not to overfill the water reservoir, the HygroGen2 may be filled and emptied either with the

unit powered up or shut down.

i. To fill the HygroGen2:

a. Insert the tube of the dosing syringe, with the plunger fully depressed, 10 mm into the water

port and extract any residual water by drawing out the plunger.

b. Depress the collar on the water port (Figure 1(4) above) and remove the dosing syringe tube.

Wipe up any spilt water with an absorbent cloth immediately.

c. Fill the dosing syringe with 80 ml of demineralised water. Insert the end of the dosing syringe

tube firmly back into the water port and discharge the syringe steadily. (If water leaks during

this operation the filler tube is not correctly inserted in the water port.)

d. Depress the collar on the water port to remove the dosing syringe tube. Wipe up any spilt

water with an absorbent cloth immediately.

e. A water level indicator is shown in the Settings Screen (see section 3.4.5).

Caution: Do not overfill the HygroGen2

Overfilling of the unit will result in poor humidification and, in extreme cases, water may be

pumped into the chamber. If the HygroGen2 is overfilled, the humidifier should be fully

emptied and then refilled with 50-80 ml of water (as described above). If there is water present

in the chamber of the HygroGen2, this should be removed using an absorbent cloth. Ensure the

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 19

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

18 of 102

Document title

HygroGen2 is switched off and the mains power unplugged before manually drying the

chamber.

ii. To empty the HygroGen2:

a. Insert the tube of the dosing syringe, with the plunger fully depressed, 10 mm into the water

port and extract any water by drawing out the plunger.

b. Depress the collar on the water port to remove the dosing syringe tube. Wipe up any spilt

water with an absorbent cloth immediately.

c. Water discharged from the HygroGen2 may be stored safely and reused at a later date.

Note: The HygroGen2 should always be emptied if it is being shipped or stored (see

section 5.3 Preparing the Unit for Transit or Storage). This will prevent ingress of water

into the chamber should the unit be inverted and prevent possible frost damage.

iii. Ultra-violet sterilisation lamp

As a precaution against any microbial and algae water contamination, HygroGen2 incorporates

an Ultra Violet (UV) sterilisation lamp within the water reservoir. No user intervention is

required - HygroGen2 auto-cycles the process.

Under no circumstance should the water reservoir be opened by non-qualified personnel.

Direct exposure to UV lamps can cause burns or blindness.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 20

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

19 of 102

Document title

3 HygroGen2 - Basic Operation

This applies to all HygroGen2 models. For details on the operation of optional Enhanced

Features, see section 4.

3.1 Switching On

a. Ensure the electrical mains supply is correctly plugged in and switched on.

b. Switch the unit on by pressing the Power Switch (see Figure 1(1) above) once.

c. The fans within the unit will switch on giving an immediate audible indication the unit is

powered.

d. The controller will power up and display the controller home screen (as shown in Figure 12).

On power up:

• The temperature and humidity set-points default to the last set values.

• The temperature and humidity control defaults to the last set condition.

If the “Low Water Level” alarm is displayed, then the unit should be filled as described in

section 2.4. Humidification is disabled until water is filled.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 21

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

20 of 102

Document title

3.2 Upgrading HygroGen2 Firmware

To determine the latest version of the HygroGen2 firmware, please consult the ROTRONIC

website:

https://www.rotronic.com/en-gb/humidity-measurement-feuchtemessungtemperaturmessung/humidity-measurement-feuchte-messung/humidity-calibrationkalibrierung/hygrogen2/hygrogen2-s.html

The firmware version your HygroGen2 is running can be determined via the Settings screen,

selecting the “Support” drop-down menu and choosing “HygoGen2 Information”. For further

details see Section 3.4.7.

Updating HygroGen2 firmware from earlier version 1.x or 2.x

If upgrading from version 1.x or 2.x a FULL CLEAN INSTALL is required. Please see

separate documentation:

https://www.dropbox.com/s/73u16w6sd5l67fp/E-M-HG2-S-V3.0Installation%20instruction.pdf?dl=0

Updating HygroGen2 firmware from earlier version 3.x

a. On a PC, download the latest version 3.x.x.x of the HygroGen2 Controller Software via

https://www.rotronic.com/en-gb/humidity-measurement-feuchtemessungtemperaturmessung/humidity-measurement-feuchte-messung/humidity-calibrationkalibrierung/hygrogen2/hygrogen2-s.html

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 22

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

21 of 102

Document title

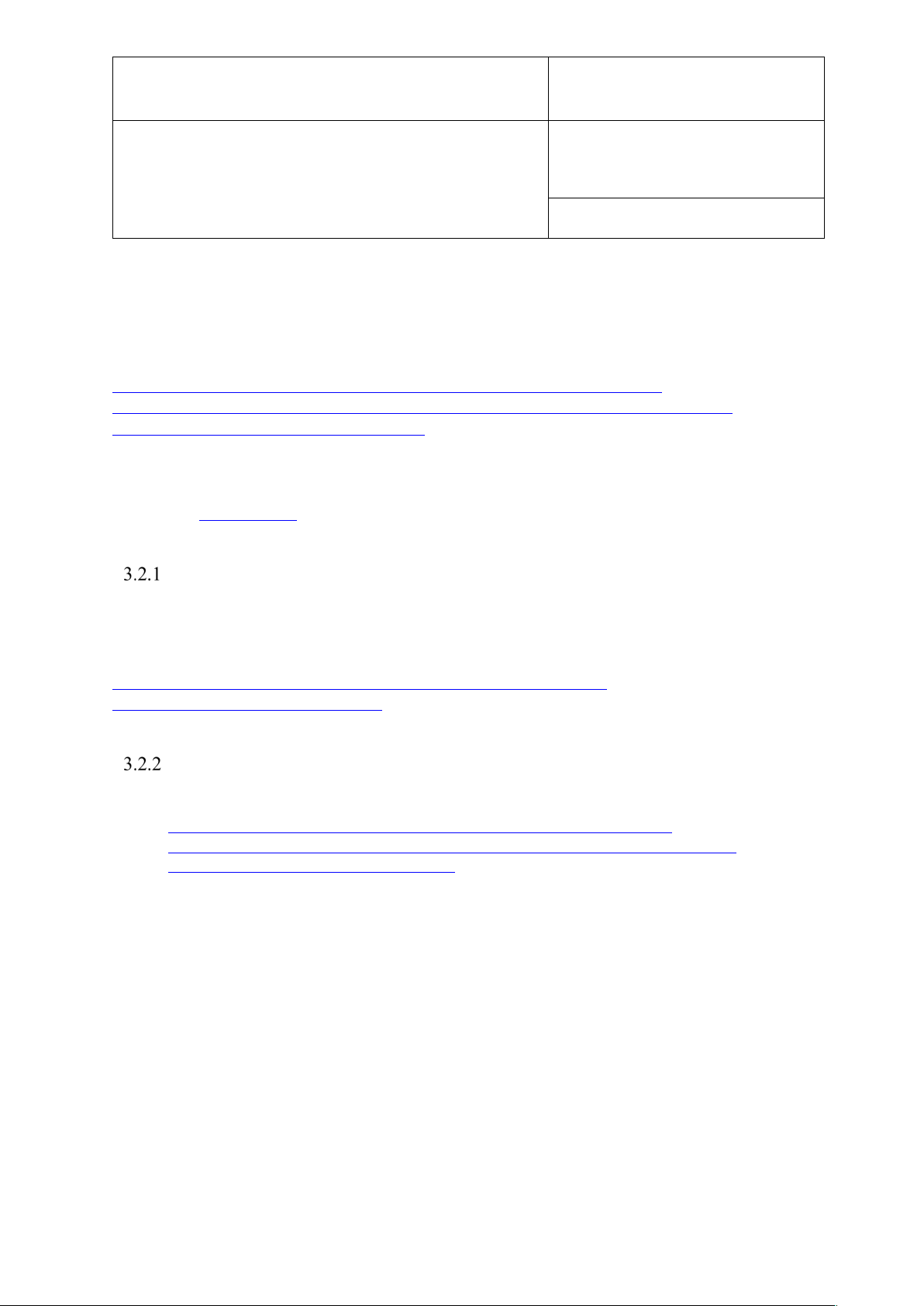

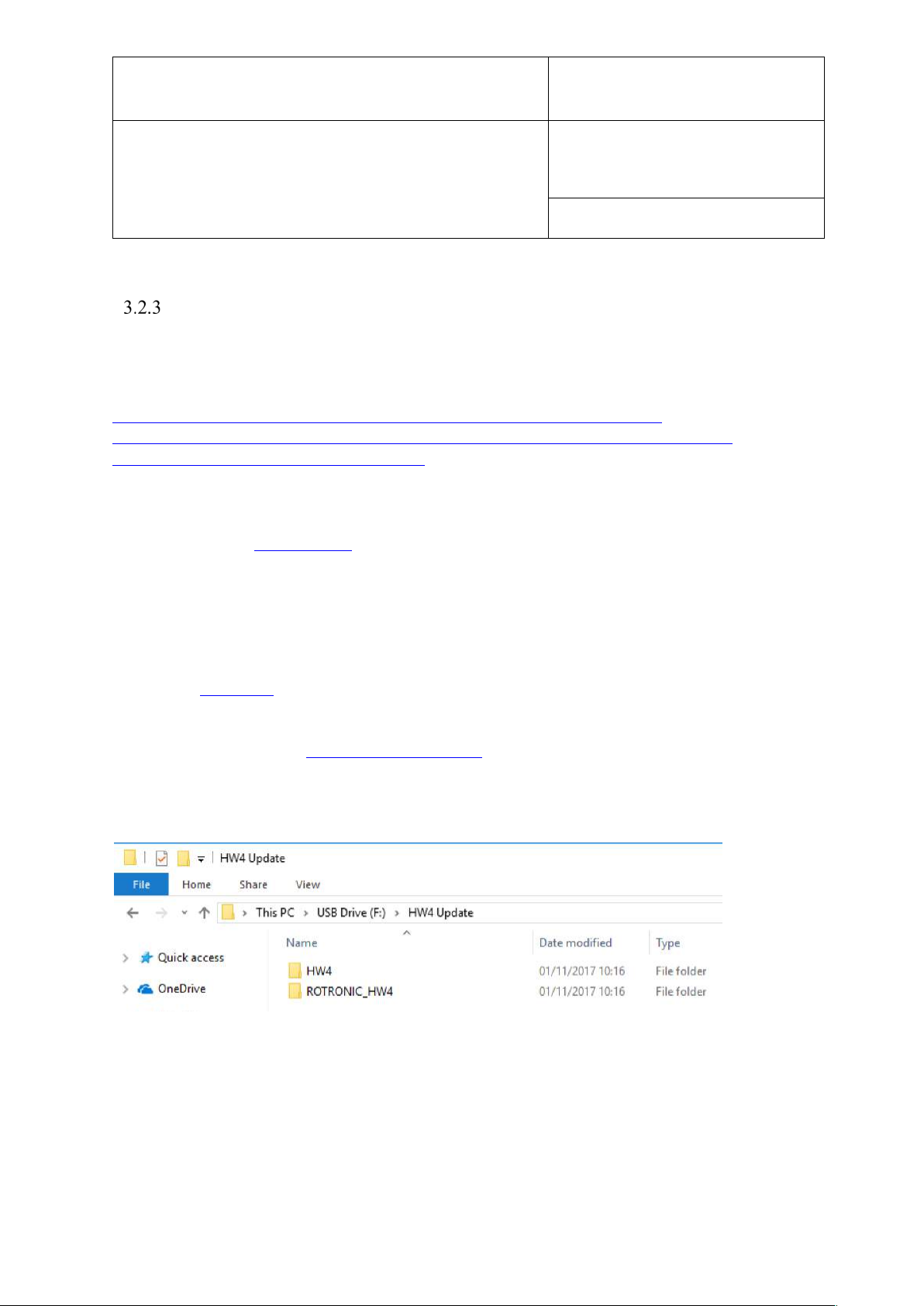

b. Unzip this file to the root of a USB stick.

The file structure should look like this when completed successfully:

Any other file structure, or root director folder name will result in the HygroGen2 not finding

the updater.

c. If going on to update HW4, make a note of your HW4 serial number, by launching HW4 and

clicking Registration on the startup screen (see section 6.2 for further details).

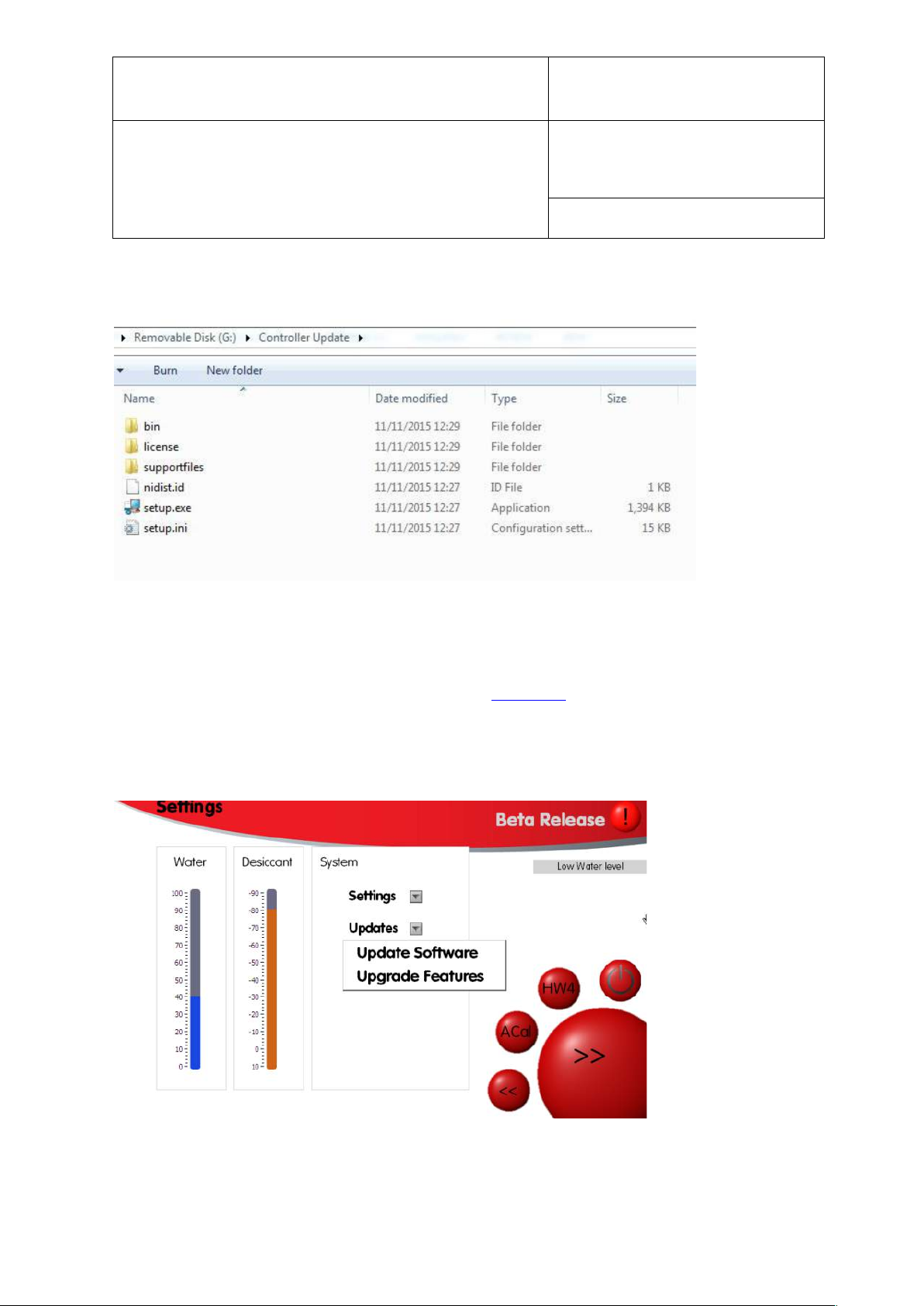

d. Reboot the HygroGen2 into Configuration Mode, by going into the Settings, then select “Update

Software” from the “Updates” drop-down menu.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 23

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

22 of 102

Document title

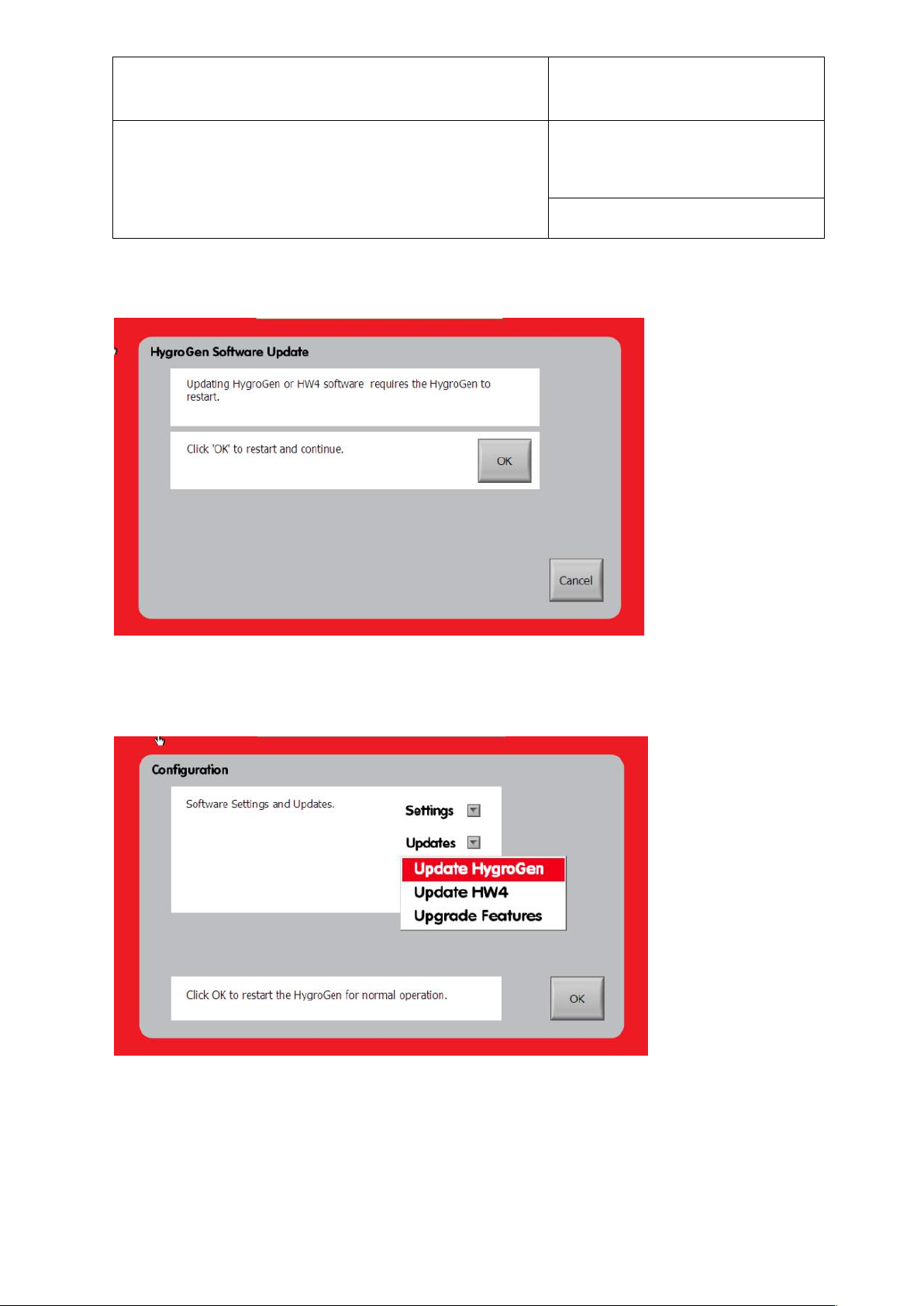

e. Click OK to reboot the HG2 into configuration mode.

f. Insert the USB stick into any port in the HygroGen2.

g. Select “Update HygroGen“ from the “Updates“ drop-down menu.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 24

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

23 of 102

Document title

h. The sceen will go black and an installation interface appear. Follow the on screen instructions,

and agree to the terms and conditions.

i. At the end of the process, click Next and the HygroGen2 Configuration Mode page will

reappear.

j. Click OK to reboot into Operational Mode or continue below to update the built-in HW4

software.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 25

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

24 of 102

Document title

Updating HW4 version

To determine the latest version available of the HygroGen2 built-in HW4 software, please

consult the ROTRONIC website:

https://www.rotronic.com/en-gb/humidity-measurement-feuchtemessungtemperaturmessung/humidity-measurement-feuchte-messung/humidity-calibrationkalibrierung/hygrogen2/hygrogen2-s.html

The HW4 software version your HygroGen2 is running can be determined via the Settings

screen, selecting the “Support” drop-down menu and choosing “HygoGen2 Information”. For

further details see Section 3.4.7.

Please ensure the HygroGen2 is running the latest version of the firmware before updating

HW4 (see section above).

a. If you have not already made a note of your HW4 serial key, please ensure you are in Operational

Mode and launch HW4, and then identify the key selecting ‘Registration’ from the startup screen

(see section 6.2 for further details).

b. On a PC, download HW4 v3.8 for Hygrogen2.

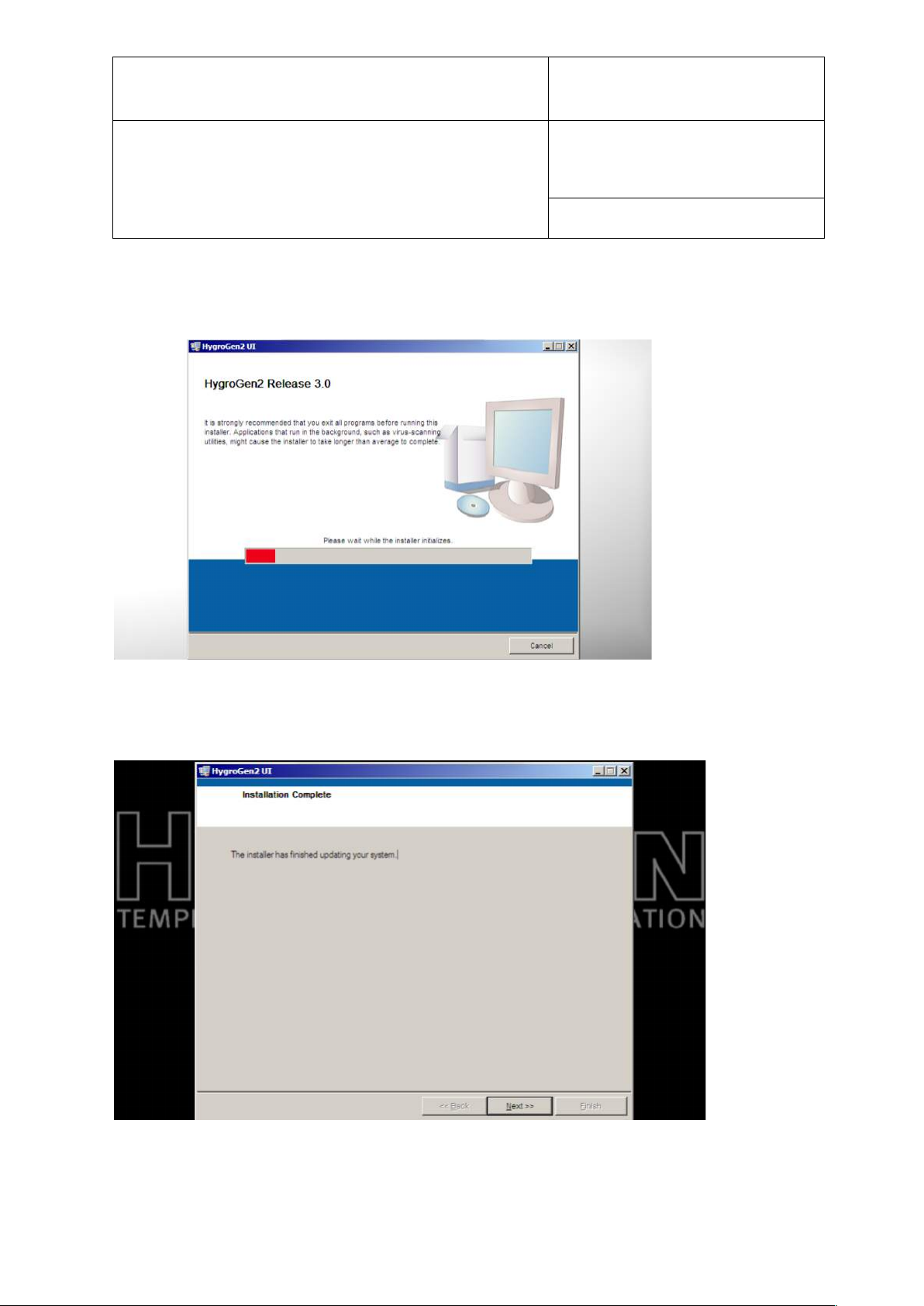

c. Unzip this file to the root of the same USB stick. The file structure should look like this when

completed successfully:

It is essential the folder in the root director is called “HW4 Update”.

d. Safely eject the USB stick from the PC.

e. On the HygroGen2, if not already in Configuration Mode, go to the Settings Page and select

“Update Software” from the “Updates” drop-down menu. Press OK and the HygroGen2 will

reboot into Configuration Mode.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 26

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

25 of 102

Document title

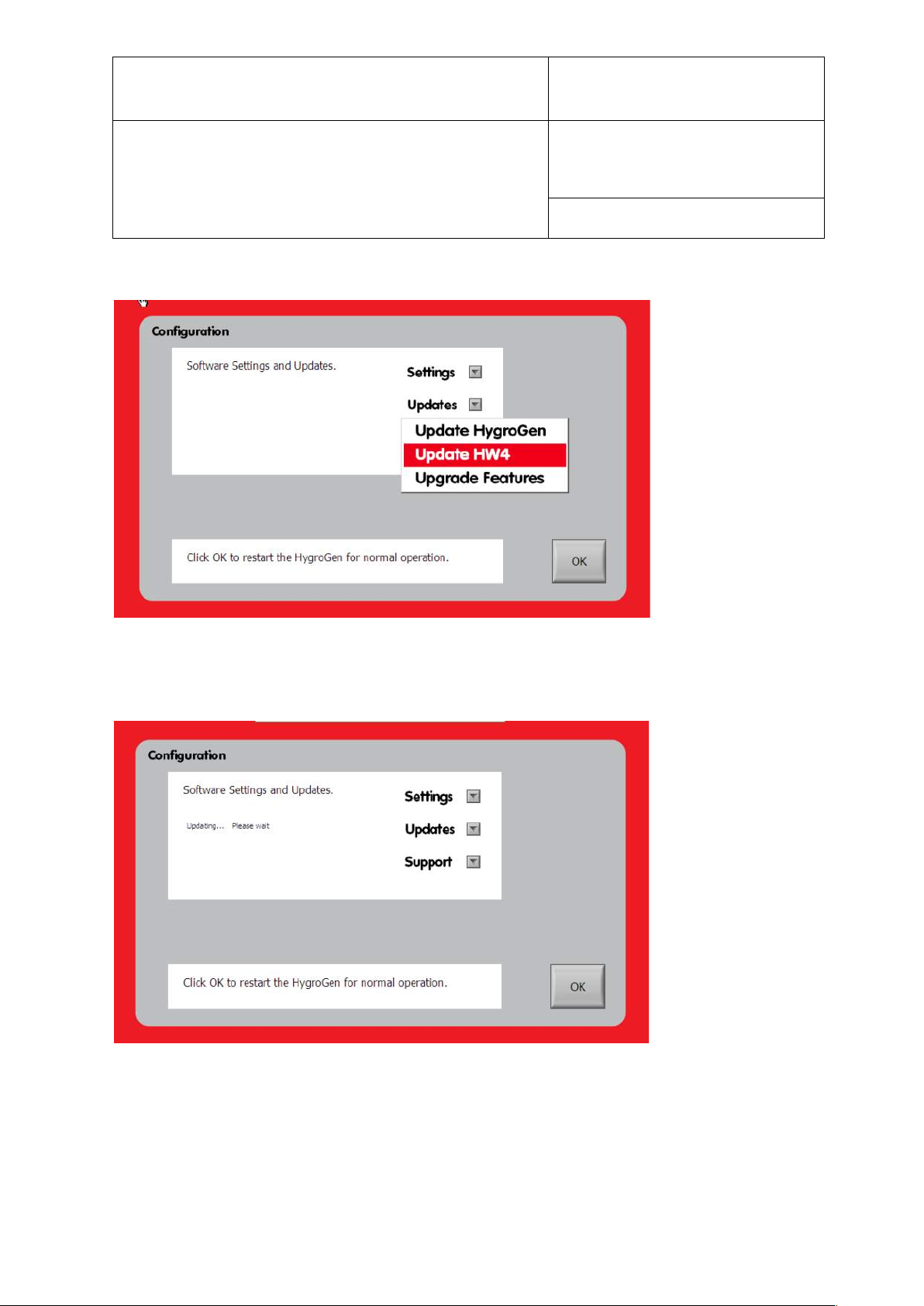

f. Select Updates and then Update HW4.

g. Observe the on-screen progress

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 27

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

26 of 102

Document title

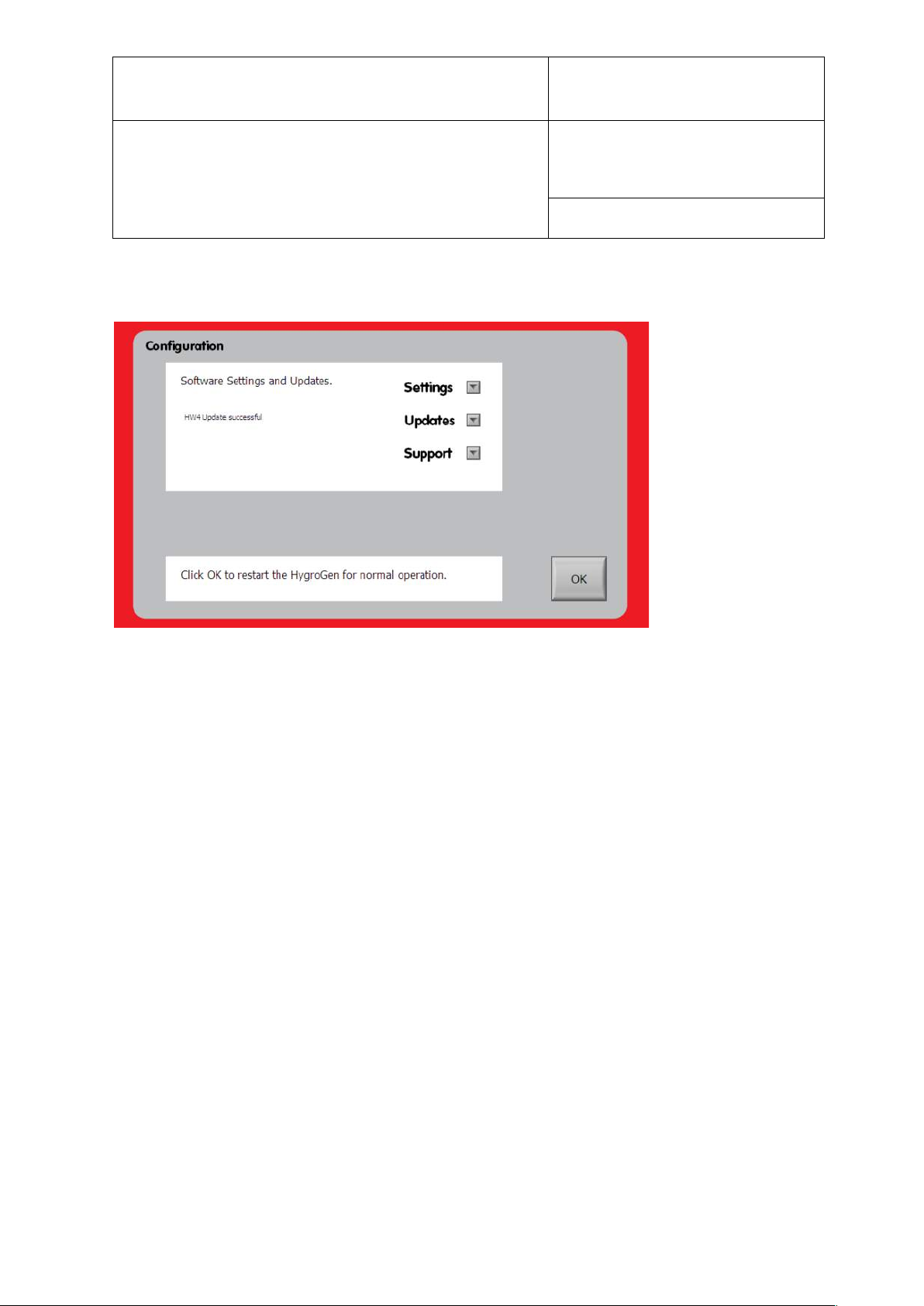

h. When complete, the HG2 will report HW4 Update Succesful.

i. Click OK to reboot.

j. The HygroGen2 will return to standard mode. Start HW4 and re-enter the registration code

recorded previously to enable full operation.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 28

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

27 of 102

Document title

Figure 9: Configuration Mode

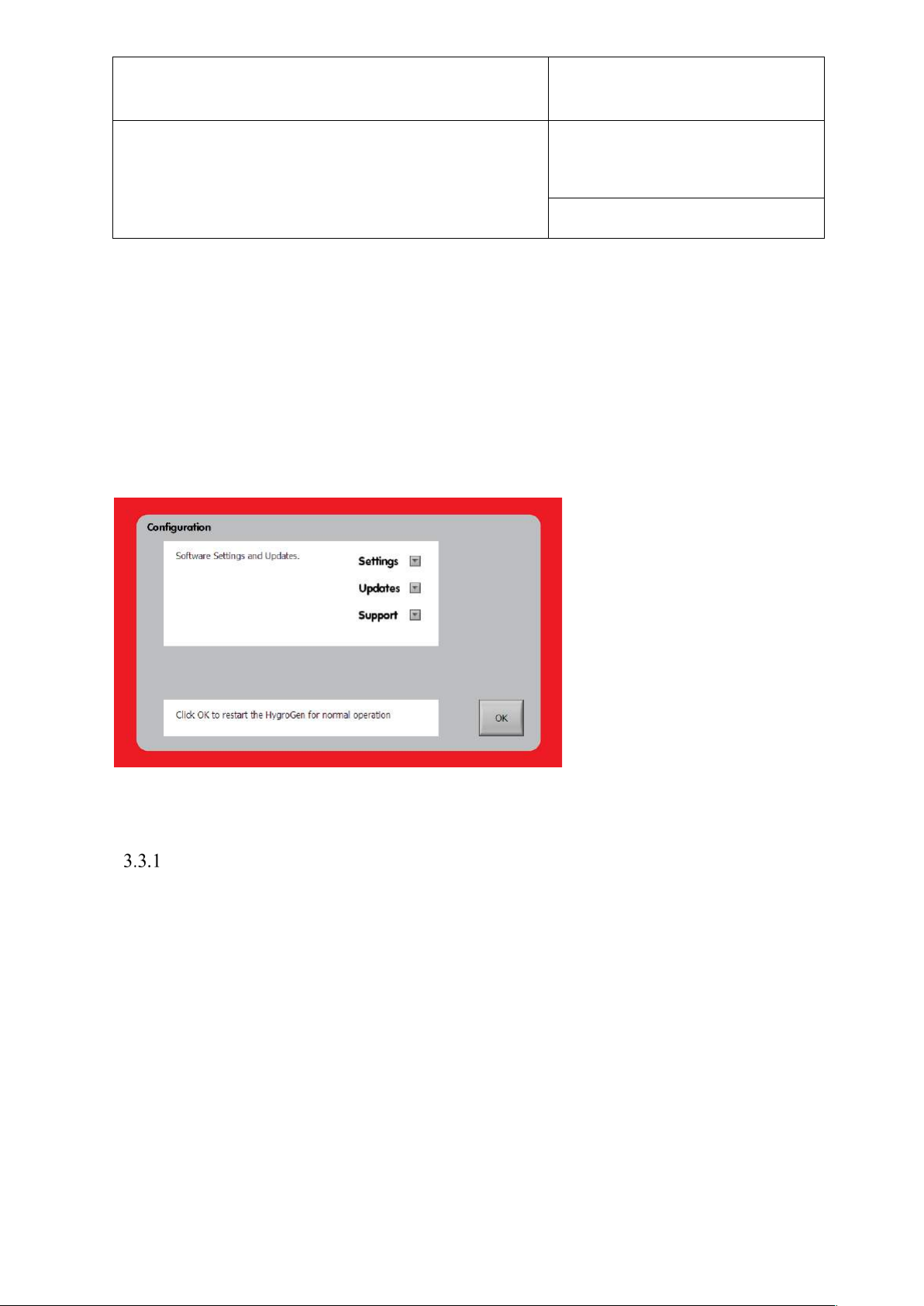

3.3 Configuration Mode Settings

Certain settings on the HygroGen2 must be made in Configuration Mode. From Standard

Operation Mode, go to the Settings screen, then the “Settings” drop-down menu and select

either “Network”, “Date and Time”, “Touchscreen”, or “Update Software”. All four options

effectively do the same thing (i.e. reboot the HygroGen2 into Configuration Mode); press

“OK” to restart the HygroGen2.

Network Settings

Prior to machine serial number VCT-HG2-1281, the network port on the back of the

HygroGen2 was physically disabled. Since this unit, and for every unit that has received a

service since January 2013, the network port has been physically enabled, but its functionality

has been disabled in software.

As of v2.1, there is an option to enable the functionality, which is required for the Remote

Control/Support Enhanced Feature. If you do not intend to use the Remote features, the

Network functionality can still be enabled, to no disadvantage, but some organisations may

stipulate it is turned off before the instrument can be used.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 29

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

28 of 102

Document title

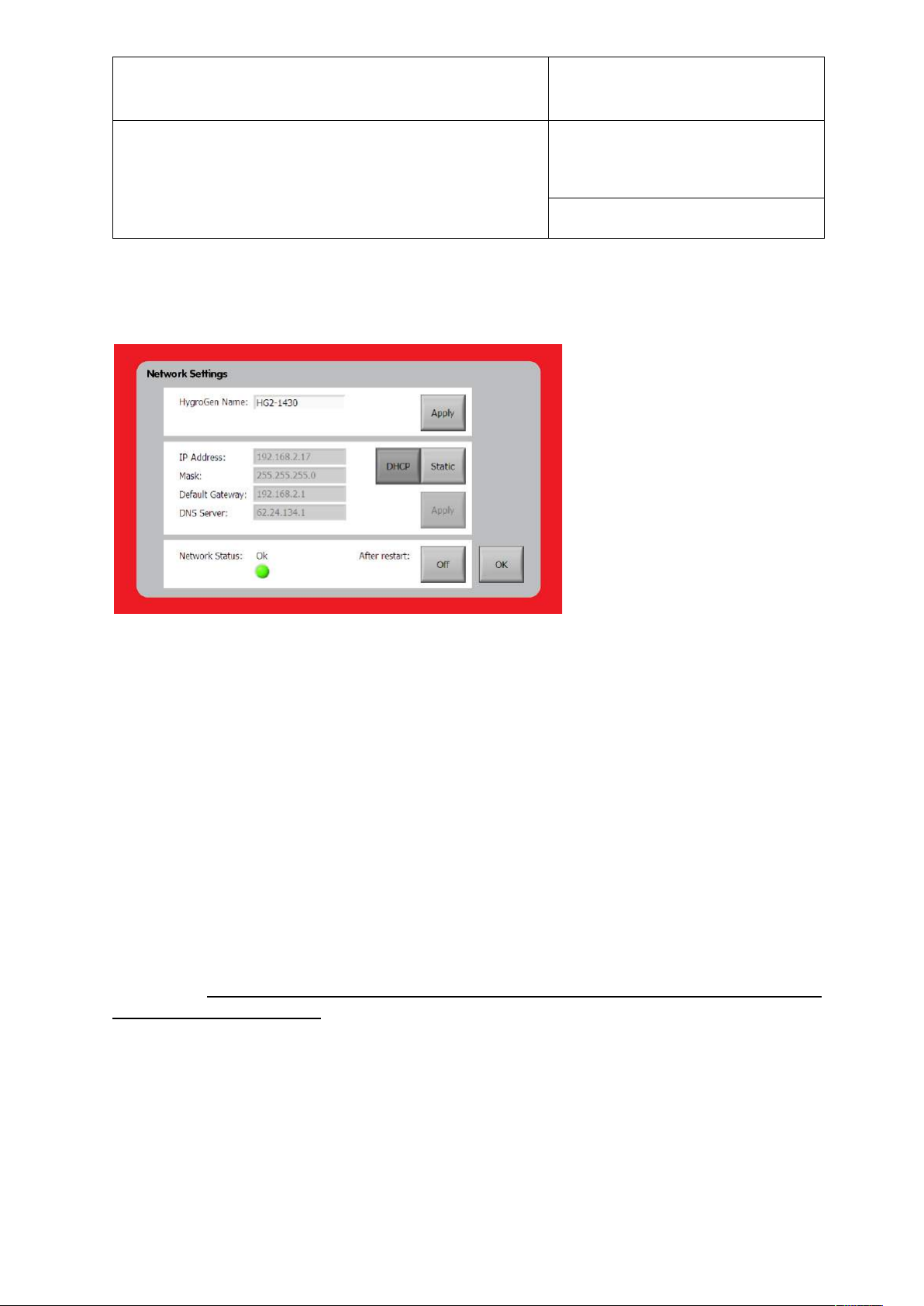

Figure 10: Network Settings

By default, when v2.1 is installed, the network port functionality is disabled. To enable it,

select “Network” from the “Settings” drop-down menu from within the Configuration Mode

“Settings and Updates” screen.

To turn on the functionality, press the “After restart” button so that it shows “On”. Review and

accept the legal disclaimer that pops up in order to continue. Press OK to go back to the

“Settings and Updates” screen and then press OK to restart. The instrument will restart back

into Configuration Mode to complete the next step. When rebooted, please reselect “Network”

via the “Settings” drop-down menu.

Plug the HygroGen2 into your network using a standard RJ-45 Ethernet cable. If network

functionality is not configured, “Network Status” will show as “down”. If it is configured, and

assuming the network cable is attached to other networking hardware, it will show as “OK”,

otherwise it will show as “unplugged”.

PLEASE note: if your instrument has serial number VCT-HG2-1280 or earlier and has

NOT been serviced since January 2013, your instrument requires a physical modification.

Please contact your ROTRONIC distributor who will arrange for this operation to be

performed. Without this modification, the Network Status will show as “unplugged” even

if it is plugged in correctly. Please also note, physical modifications made by anyone other

than Authorised Service Centres will void the HygroGen2 warranty.

With the HygroGen2 plugged into a network, IP settings need to be configured. Networking

addressing can be set to obtain an address automatically via DHCP, if your network supports it,

or manually via “Static”. Please contact your local IT administrator for advice, if unsure. You

may be required to advise the network hardware (MAC) address of the instrument. This can be

found in the “HygroGen2 Info” via the “Support” drop-down menu.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 30

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

29 of 102

Document title

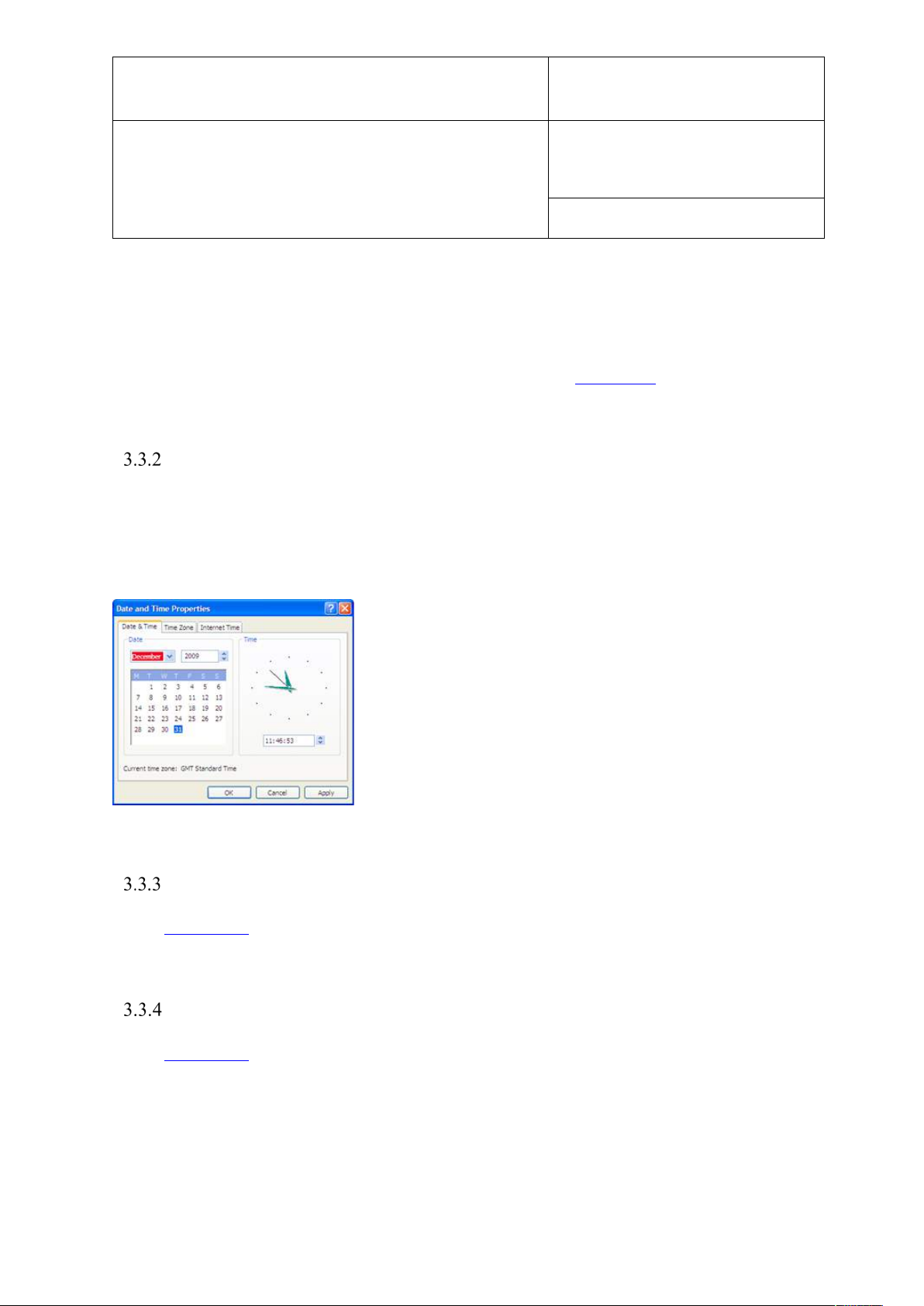

Figure 11: Date and Time Properties

The IP address assigned to your instrument will be reported in the Network Settings interface

and via the “HygroGen2 Info” screen. The HygroGen2 will assign itself a network

name/identity. This can be changed within the interface. It is recommended to change it to the

instrument’s serial number, though local network policies may require something else.

Operation of the Remote Control functionality is described in section 4.3.

Date and Time Settings

Date and time stamps are included in AutoCal and HW4 logged data.

To adjust these settings, select the “Date and Time” option from the “Settings” drop-down

menu on the “Settings and Updates” screen.

International Keyboard

Please Section 7.1 for details about configuring external input peripherals. NB Configuration

mode is not required to alter this setting.

External Monitor

Please Section 7.2 for details about configuring external output peripherals. NB Configuration

mode is not required to alter this setting.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 31

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

30 of 102

Document title

Touch Screen Calibration

Should the touch screen calibration be significantly awry – which can happen when upgrading

from version 1.x to version 2.0 – you can realign the touch screen calibration. You may wish to

plug in a USB mouse to perform this step.

Select the “Touch Screen” option from the “Settings” drop-down menu on the “Settings and

Updates” screen. Pressing the touch screen button will begin a four-point calibration. Press the

cross in each corner of the screen as directed.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 32

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

31 of 102

Document title

Figure 12: HygroGen2 Home Screen

3.4 HygroGen2 Touchscreen Interface

The HygroGen2 controller consists of four top level screens that are accessed using the forward

or back buttons in a loop:

Please note: the Programmer Screen is replaced by the AutoCal Screen when AutoCal is

activated. The standard Programmer functionality is still available, however. Please see section

4.1 for more details.

Controller Home Screen

1) Menu (drop down)

2) Chamber temperature

3) Temperature set-point

4) Heating power

5) Temperature control

6) Chamber humidity

7) Humidity set-point

8) Humidification power

9) Humidity control

10) Previous screen

11) Prog/ACal function

12) HW4 software

13) Power off

14) Next screen

i. Navigation (items 1, 10 & 14)

The user can navigate to different screens using the drop-down menu (item 1) or can scroll

through the four main screens using items 10 & 11.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 33

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

32 of 102

Document title

ii. Temperature and Humidity Set-Points (items 3 & 7)

At any time, the user can change humidity or temperature set-points by simply touching the

set-point on the screen. A pop-up will appear and either the touch screen or, when connected,

the keyboard/mouse may be used to input desired values.

Note: To aid a smooth and efficient transition between temperature set-points, the controller is

programmed to suspend humidification during changes in temperature. Once the chamber

temperature is within 0.7 °C of the temperature set-point, the humidity control is activated.

When set-point combinations are programmed that resolve a low dew point condition (i.e.

0 °C, 5 %rh = -36 °C dew point), make sure that the desiccant is dry enough to achieve the

desired value. Check the desiccant condition on the Settings screen (Figure 16) and consult

maintenance records to establish when the desiccant was last changed. Stabilisation time to low

RH conditions will be longer than normal as the chamber and internal surfaces need to be very

dry.

iii. Temperature and Humidity Control (items 5 & 9)

The temperature and humidity control can be set to automatic or off. Automatic mode results in

the unit attempting to adjust to the temperature (or humidity) in the chamber to match the setpoint value. When switched off the HygroGen2 does not control the parameter.

When off, the control buttons are grey.

When on, but not stable, the control buttons are red.

When on and stable, the control buttons are green.

Temperature indicator is green when the control PT100 temperature sensor (see Appendix A2)

is within 0.01 °C of the set-point and the control temp is within 0.01 °C of the internal (HC2-S)

reference temperature sensor.

RH indicator is green when the RH reference is within 0.1%rh of the set point and the control

RH is within 0.05 %rh of the internal (HC2-S) reference humidity sensor.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 34

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

33 of 102

Document title

Figure 13: Trend Screen

Trend Screen

The Trend Screen shows the instrument’s chamber conditions and the set-points the instrument

is programmed to reach.

1) Trend

2) y-axis

3) Time axis

4) Trace selection

i. Trace selection (item 4)

The traces displayed can be selected using the buttons (item 4)

ii. Trend Axes (items 2 & 3)

The y-axis (item 2) is self-scaling; the x-axis (time) (item 3) can be adjusted by clicking

anywhere along it and typing in the desired timescale.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 35

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

34 of 102

Document title

Figure 14: Programmer

Programmer Screen

The HygroGen2 programmer function enables the user to automate a sequence of RH and/or

temperature set-points. If the AutoCal function is enabled the Programmer function is only

available via the Home menu (Figure 12: item 1).

The HygroGen Programmer function can accommodate 20 programs with up to 200 steps each.

Programs are edited via the Edit Program (Figure 15).

1) Program name & number

2) Program selection

3) Step selection

4) Run/stop program

5) Edit program

i. Program Selection (items 1 & 2)

Item 1 identifies the program number and title. You can use the “<<” and “>>” buttons to

scroll through the saved programs.

ii. Step Selection (item 3)

Use the Step Selection buttons (item 3) to select the program step at which the program will

start. The temperature and humidity set-points (SP) for the selected step are displayed.

iii. Run/Stop (item 4)

Start the selected program running at the selected step using the “>” button. The total time the

program has been running, and the time left on the current step are displayed. Use the Stop

button to halt the program before it has completed.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 36

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

35 of 102

Document title

Figure 15: Edit Program

iv. Edit Program (item 5)

Use this button to go to the Edit Program screen (see Figure 15).

Edit Program Screen

1) Graphic indicator

2) Ramp/Soak control

3) Temperature set-point

4) Humidity set-point

5) Step duration

6) Insert step

7) Delete step

8) Scroll to view steps

9) Program title

10) Temperature tolerance

11) Humidity tolerance

12) Temperature only

13) Programmer

i. Select a Program to Edit

Select the desired program by clicking on the program button and entering the desired program

number.

ii. Edit a Program Name

To edit the program name click on it (USB keyboard required) (item 9).

iii. Edit a Step

Each program comprises at least one step. Each step can be edited. Enter the desired step setpoints and duration (items 3, 4 & 5). A graphical representation of the step is shown to help

visualise the sequence.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 37

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

36 of 102

Document title

iv. Insert or Delete a Step (items 6 & 7)

Use the insert and delete buttons to add and remove steps. If there are more than 7 steps in the

program use the scroll bar (item 8) to view.

v. Ramp or Soak (item 2)

Set temperature and humidity to either ramp or soak using item 2. A soak is where the

HygroGen maintains the temperature and humidity in the chamber constant for the duration of

the step, within the tolerances set (items 10 & 11). A ramp is where the HygroGen changes the

selected set-point at a rate determined by the subsequent set-point value and the current step

duration.

vi. Timing Tolerances (items 10 & 11)

For each program, temperature and humidity stabilisation values can be defined (items 10 &

11). Once the chamber conditions are within this tolerance, the step duration timing begins. If

set to zero, no stabilisation criteria are applied and the timing of the step duration begins

immediately.

vii. Temperature only Program (item 12)

Humidity timing and control can be removed from a program using the ‘Temperature Only’

button.

viii. Programmer Screen

Click the ‘Prog’ button (item 13) to return to the Programmer screen.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 38

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

37 of 102

Document title

Figure 16: Settings Screen

Settings Screen

1) Water level display

2) Desiccant condition display

3) Settings menu

4) Updates menu

5) Support menu

The water level and desiccant level indicators show approximate levels only. The desiccant

level indicator is updated only when the HygroGen2 is drying at more than 15% power and

will take a few minutes to update. This is to ensure the desiccant sensor is reading the correct

value. See section 8.2 for more details.

The drop-down menus (items 3, 4 & 5) allow navigation to screens that are detailed later in this

document.

i. Activation of Enhanced Features

Enhanced Features can be activated via the “Upgrade Features” option on the “Updates” dropdown menu in Configuration Mode, or via the Settings screen in Standard Operation Mode.

See section 4 for more details about Enhanced Features.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 39

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

38 of 102

Document title

Figure 17: HygroGen Information

ii. HygroGen Information

General instrument information including serial numbers, software versions, network

parameters and enabled features can be found on the HygroGen Information screen. This can

be found on the “Support” dropdown menu On the Configuration screen and the Settings

screen (when in normal use).

iii. Remote Support

Figure 18: Remote Support

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 40

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

39 of 102

Document title

Your HygroGen2 can be configured so that ROTRONIC support engineers can connect to your

HygroGen2 and to its support network so that they can remotely control your HygroGen2.

The feature requires the HygroGen2 to be connected to a network, and the instrument to be

appropriately configured for network access. See section Section 3.3.1 Network Settings.

To enable the Remote Support functionality, select the “Remote Support” option from the

“Support” drop-down menu on the Settings screen. The “On”/”Off” button enables/disables the

functionality.

Please note, the Remote Support functionality establishes a Virtual Private Network (VPN)

tunnel back to the Rotronic support network. Outgoing VPN connections must be permitted on

your local network for it to work. Some IT administrators may block this functionality.

If the HygroGen2 can establish a connection back to the support network, it will show

“Connected” in green. Please advise your Rotronic support representative of the Remote

Support IP address so that they can connect to your instrument.

Please note: the Remote Support connectivity will remain active until it is disabled, even if

the HygroGen2 is rebooted.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 41

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

40 of 102

Document title

iv. Connections to Network File Servers

With the HygroGen2 connected to a LAN, the instrument has the ability to connect to a

network file server for the storage of HW4 log files (see Section 6.4) and [Enhanced Feature]

AutoCal calibration data (see Section 4.1).

Figure 19: Connection to Remote File Server

To connect to a network file server, select the “File Save Location” option from the “Settings”

drop-down menu on the Settings screen. Enter the network file server path in the format

“\\<server ip or network address>\folder” and enter the username and password for the file

share.

If a successful connection is made, a green ‘Connected’ indicator appears. To establish a

conection with a different file server, press the green ‘Disconnect’ button and put in the new

server details.

Please note, for security reasons the network file server path and user credentials have to be reentered every time the HygroGen2 is restarted.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 42

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

41 of 102

Document title

4 HygroGen2 Enhanced Features

There are up to six Enhanced Features currently available for the HygroGen2. There are

various combination bundle packs available at discount rates; please see HygroGen2 datasheet

for details or contact your ROTRONIC dealer.

Low Temperature and Humidity Range Extensions extend the limits of points that can be

set on the instrument, creating chamber conditions down to -5 °C and from 2 %rh up to

99 %rh.

AutoCal allows you to pre-program a series of set-points and times, and record the

instrument’s progression through them in a PDF Calibration Certificate which is written to an

external USB disk drive. Any values recorded on ROTRONIC HC2-S probes attached to the

HygroGen2 via USB adaptors are recorded in the certificate. Probes can be set to automatically

adjust to match the HygroGen2 reference probe at predetermined values.

Remote Screen Share (Formerly Remote Control) gives the ability to remotely control the

HygroGen2 over a network using the open source VNC protocol.

RemoteAPI gives the ability to remotely control and interrogate the HygroGen2 using a series

of text based commands over a network; users can write their own software to log and control

the HygroGen2.

MBW External Reference extends the functionality of AutoCal and/or RemoteAPI, by

integrating MBW/RHS chilled mirror hygrometers (supplied separately) as the external

reference.

Please see the following sections for detailed descriptions of the operation of each of the

Enhanced Features.

Feature Activation

HygroGen2 features are enabled by the application of an activation code. Please purchase an

activation code for the desired features from your ROTRONIC dealer. You will need to

supply your HygroGen2 serial number (see rear of instrument) when ordering the code.

Alternatively, go to the Settings screen and select the appropriate feature from the Settings

drop-down menu and supply the code as given in the format “XXXXXX.YY-Z-ABC”.

To activate Enhanced Features on your HygroGen2, you will need a USB keyboard plugged

into the HygroGen2 to type in the supplied code, which will be a 16-digit string of numbers

and letters in CAPITALS. The code will activate all the features you have purchased. If you

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 43

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

42 of 102

Document title

have previously purchased one or more features and you want to add another, a new code will

be supplied enabling both/all features.

To activate the upgrade features, go to the Settings screen, select the “Updates” drop-down

menu and choose “Upgrade Features”. Type in the supplied code, ensuring there are no extra

characters or spaces at the end of the string. The green lights will light up displaying the

purchased Enhanced Features, which will be available immediately.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 44

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

43 of 102

Document title

4.1 AutoCal

Top Level Menu and Programmer Function

With AutoCal activated, the AutoCal screen (see Figure 13) is displayed instead of the

Programmer Function Screen. The standard Programmer functionality, as described in section

3.4.3 is still available but is accessed via the drop-down menu in the top left hand corner of the

screen.

AutoCal Reference

The standard version of AutoCal uses the internal control HC2-S as its reference. AutoCal+ is

an extension to AutoCal which enables the selection of an external MBW/RHS dew point

hygrometer as an external reference. For more details on using AutoCal+, see section 4.2. For a

more in-depth discussion of references and calibration traceability, please see Appendices A1:

Calibration Reference Options and A2: Temperature Control.

AutoCal Screen

As ROTRONIC probes are added via the USB ports, the individual probe slots are populated

within the AutoCal Screen. During an AutoCal calibration run, probes can be adjusted, or not,

as desired, for each probe. Select individual probes by selecting the “Adjust” button.

Figure 20: Adding HC2-S probes and selecting to adjust

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 45

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

44 of 102

Document title

AutoCal Program Edit

Pressing the Edit button calls up the AutoCal Program Edit screen.

Figure 21: AutoCal Program Edit Screen

Set-points are programmed in an identical way to the standard Programmer. However, the

green buttons take on a different function; they are now used to determine the adjustment

points. Probes that are selected for adjustment within the AutoCal Screen will be adjusted at

points that are selected here. Only one temperature point can be selected and must be selected

as the first adjustment point. This is because of the way the HC2-S probes work: if temperature

is adjusted, corresponding adjustments for RH are made at the same time. This policy is

enforced by the software: greyed out buttons refer to options that are not possible, a dark green

button is a point not selected for adjustment and bright green is a point selected for adjustment.

Points can be set for a minimum duration of 15 minutes; please ensure sufficient time is

allowed for the probe to stabilise. A duration of at least an hour is strongly recommended,

longer for extremes of temperature or RH. The timing of a set-point will begin when the

chamber is within the set tolerance. Take particular care to allow sufficient time to allow for

stabilisation of probes with particular protection filters applied.

It is not possible to select different adjustment points for different probes. If this is desired,

please run a new program at a later time.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 46

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

45 of 102

Document title

Tolerance and Sample Size

As with the Standard Programmer, for each program, temperature and humidity stabilisation

values can be defined. Once the chamber conditions are within this tolerance, the step duration

timing begins. If set to zero, no stabilisation criteria are applied and the timing of the step

duration begins immediately. The number of samples recorded in the AutoCal certificate can

also be defined from 5 to 50; working backwards from the end of each set-point duration,

values for temperature and humidity are recorded on the calibration certificate every 2 minutes

for the number of samples selected. This determines the minimum set-point duration above an

absolute minimum of 15 minutes.

To change these parameters, click the number next to each one. For example, for Sample Size: (as an

example, in figure 15, the number ‘20’). This will show the number entry window:

Figure 22: Number Entry Window

AutoCal Operation and Best Practices

Once the program and adjustment points are determined, programs are started by pressing the

“Play” (>) button. After a successful run, provided AutoCal has successfully communicated

with the probe under test for every selected sample point at every set-point, AutoCal saves a

time-stamped PDF calibration certificate to a USB drive plugged into the HygroGen2, or an

external network drive (see Section 3.4.5.iv). The same information is stored in a

corresponding .csv file. If, for any reason, communication with the probe under test is

interrupted (by unplugging the probe, for example), only the .csv file will be saved, with the

associated data actually recorded. Included in each file is the program name, set- and

adjustment-points, probe serial numbers and relevant calibration reference information. It is,

further, possible to upload a custom logo and other user and reference information (see section

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 47

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

46 of 102

Document title

4.1.7). A separate PDF is generated for each probe. NB: AutoCal will not run unless a USB

drive is detected by the HygroGen2 or a network file share has been configured.

Before selecting a probe for adjustment, it is recommended to perform an initial assessment

calibration run without adjustment selected. At the end of the run, examine the saved PDF

calibration certificate and determine whether you want to re-run the program with adjustment

selected.

At the first adjustment-point to be applied, AutoCal will initially delete any previously saved

calibration points stored on the probe. This is recorded on the certificate. It will then apply the

values of the reference probe as a corrected value. This value is determined at the instant the

correction is saved and is not an average of the previously recorded points as shown in the

calibration certificate; these are shown in the certificate to give the user an estimate of stability.

Please note, for probes with adjustment selected, AutoCal will always attempt to make an

adjustment. If the correction is smaller than the resolution of the probe itself, the adjustment

may not be applied.

If, at the end of the run, the probe has acknowledged all instructions it has been sent, the

“Completed“ button will turn green on the AutoCal screen and the PDF is saved to the USB

drive. Details of the probe’s progress throughout the run can be viewed via the “Details”

button.

Please note, the performance of a HC2-S within its stated specification is based on temperature

adjustment being made at 23 °C. AutoCal does permit the adjustment to be made at other

temperatures. However, this is only recommended when the operational environment of the

probe being adjusted is only ever at another specific temperature, e.g. a stability cabinet at

40 °C. Adjustments made at temperatures other than 23 °C risk comprising the probe’s ability

to meet its specification within the range of optimal performance: 18 to 28 °C.

Please note that HW4 cannot be used at the same time as AutoCal.

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 48

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

47 of 102

Document title

Customising the PDF Calibration Certificate

Figure 23: Edit AutoCal Certificate

The PDF certificate can be customised by selecting “Edit Certificate” from the AutoCal Screen

(Figure 13) or selecting “AutoCal” from the Settings menu on the Settings screen. It is possible

to enter user and company information and to upload a custom logo.

To upload a logo, save it as a file “logo.jpg” to the root directory of a USB stick. Insert the

USB into the HygroGen2. The HygroGen2 will detect the file and display your image. Select

“Upload Logo”. The logo will be uploaded to the unit and will appear automatically sized and

positioned on the PDF certificate below the “Rotronic HygroGen” logo.

Figure 24: Upload Logo

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 49

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

48 of 102

Document title

Enter company information in the Edit AutoCal Certificate Contact Information screen.

Figure 25: Edit AutoCal Certificate Contact Information

Reference Information

Information about the calibration of the reference probe itself can be entered by pressing

“Configure Reference” in the AutoCal Screen (Figure 13) or selecting “Reference” from the

“Settings” drop-down menu on the Settings screen,

Figure 26: Edit AutoCal Reference

© 2017; Rotronic AG E-M-HG2-S-XL-V3.0

Page 50

E-M-HG2-S-XL-V3.0

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroGen2: Humidity and Temperature Generator

with AutoCal, MBW External Reference, Remote Screen

Share, RemoteAPI and Range Extension options.

Instruction Manual

Instruction Manual for Software

Version 3.0

Document Type

Page

49 of 102

Document title

and selecting the “Reference Info” from the “Control HC2-S” drop-down menu.

Figure 27: Edit AutoCal Reference Information

Reference calibration information can be entered here, including the last and next-due

calibration dates and any comments.

When an AutoCal run is started, the user is warned should the reference calibration be out of

date and prompted to update the reference information should the reference probe have been

swapped out. The user is further asked to confirm that the operator name to be printed on the

certificate does not require changing. If a probe that has previously been used and has reference