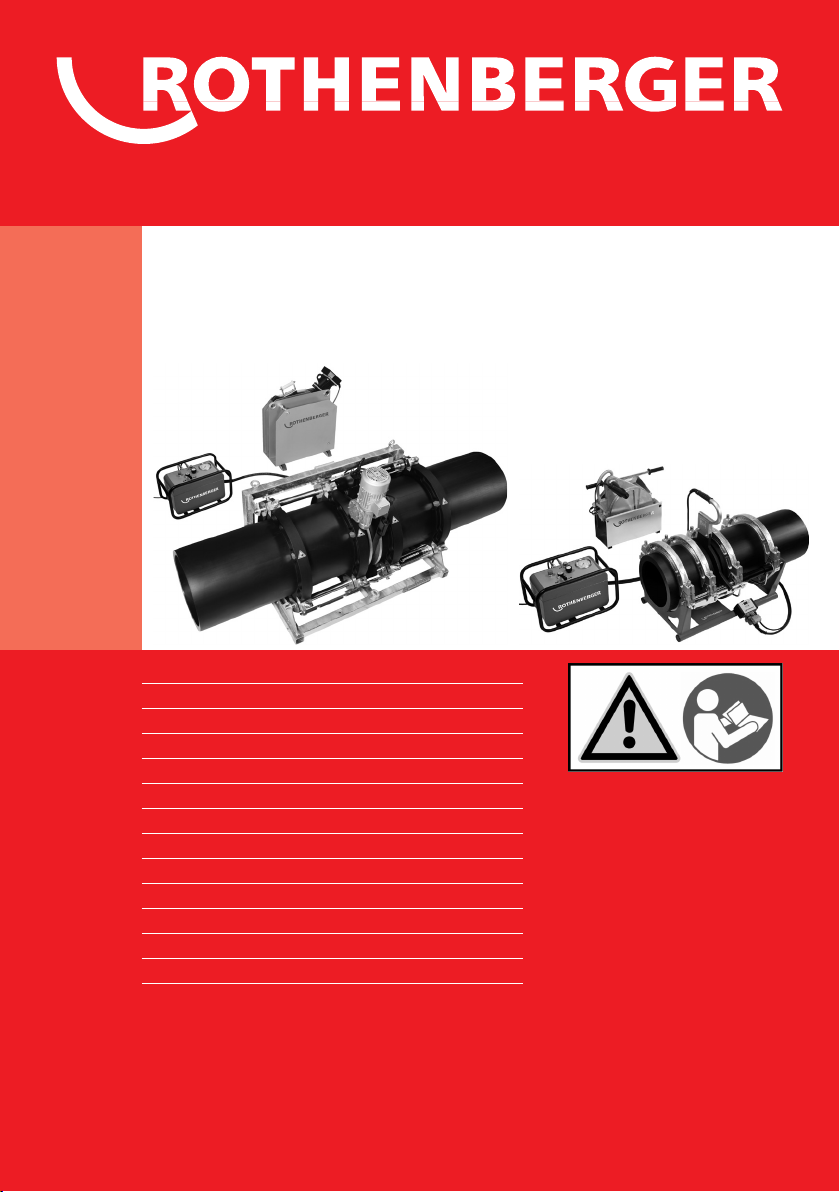

ROWELD P160-630/5-24B

Plus Professional

ROWELD P160-630/5-24B

Plus Professional

Technische Daten

Technical data

Données techniques

Datos técnicos

Dati tecnici

Technische gegevens

Dados técnicos

Tekniske data

Teknisk data

Dane techniczne

Technické údaje

Műszaki adatok

Технические характеристики

www.rothenberger.com

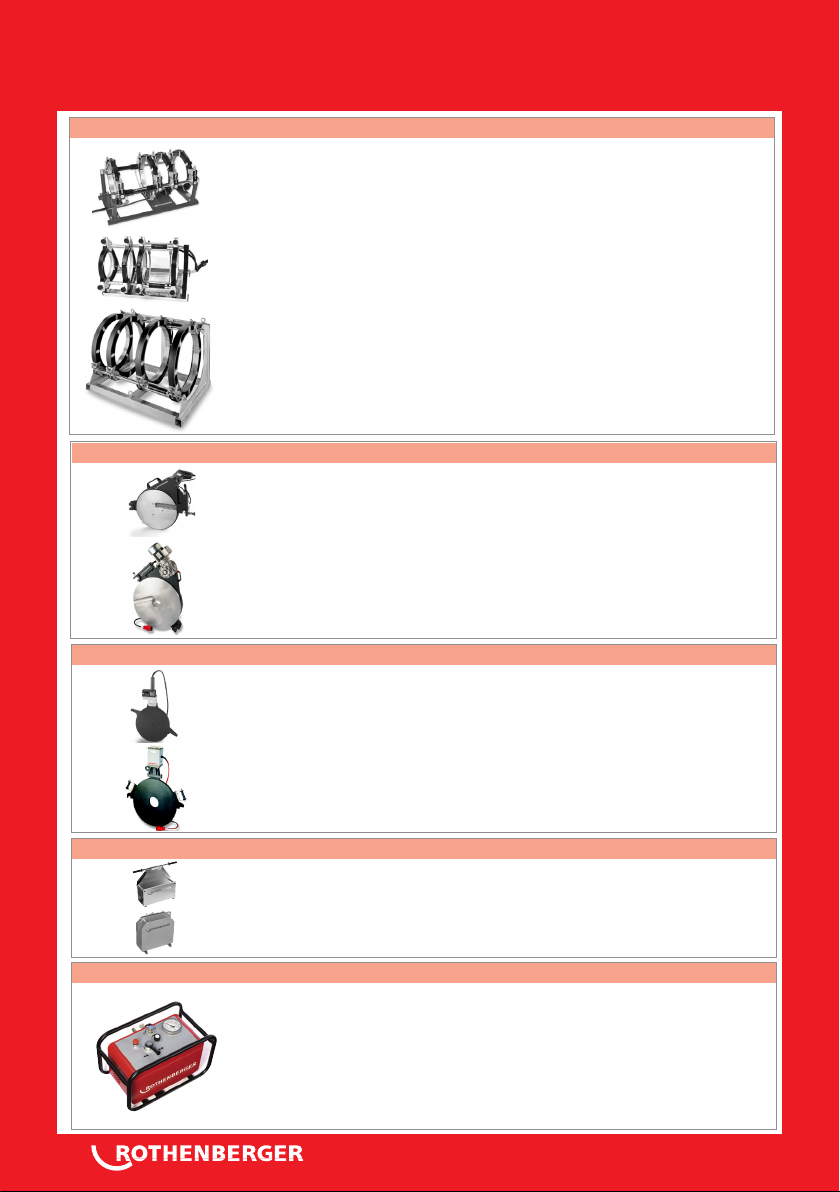

Overview

Grundmaschine / Basic machine

P160B P250B P355B

1200001027 1200001029 1200000322

P5B P8B P12B

1200000963 1200000964 1200000965

P200B

55392

P500B P630B P630B Plus

53401 53305 1200000714

P18B P24B P24B Plus

1200000966 1200000967 1200000980

Fräseinrichtung / Trimmer unit

P160/5B P200B P250/8B P355/12B

1200001043 55395 1200000802 1200001045

P500/18B P630/24B, P630/24B Plus

53405 53310

Heizelement / heating element

P160/5B P200B P250/8B P355/12B

055346H 055396H 055180H 1200000324

P500/18B P630/24B, P630/24B Plus

53406 53311

Einstellkasten / carrying frame

P160/5B P200B P250/8B P355/12B

55298 55289 55167 1200000327

P500/18B P630/24B, P630/24B Plus

53407 53312

Hydraulikaggregat Professional / hydraulic unit professional

P160/5B, P200B, P250/8B, P355/12B

55115 (230V-50Hz)

1200000905 (230V-60Hz)

P500/18B, P630/24B, P630/24B Plus

53309 (230V-50Hz)

1200000906 (230V-60Hz)

Intro

DEUTSCH - Originalbetriebsanleitung! Seite 2

Bedienungsanleitung bitte lesen und aufbewahren! Nicht wegwerfen!

Bei Schäden durch Bedienungsfehler erlischt die Garantie! Technische Änderungen vorbehalten!

ENGLISH page 4

Please read and retain these directions for use. Do not throw them away! The warranty does not cover

damage caused by incorrect use of the equipment! Subject to technical modifications!

FRANÇAIS page 6

Lire attentivement le mode d’emploi et le ranger à un endroit sûr! Ne pas le jeter ! La garantie est

annulée lors de dommages dûs à une manipulation erronée ! Sous réserve de modifications techniques!

ESPAÑOL página 8

¡Por favor, lea y conserve el manual de instrucciones! ¡No lo tire! ¡En caso de daños por errores de

manejo, la garantía queda sin validez! Modificaciones técnicas reservadas!

ITALIANO pagina 10

Per favore leggere e conservare le istruzioni per l´uso! Non gettarle via! In caso di danni dovuti ad errori

nell´uso, la garanzia si estingue! Ci si riservano modifiche tecniche!

NEDERLANDS bladzijde 12

Lees de handleiding zorgvuldig door en bewaar haar goed! Niet weggooien! Bij schade door

bedieningsfouten komt de garantieverlening te vervallen! Technische wijzigingen voorbehouden!

PORTUGUES pagina 14

Queiram ler e guardar o manual de instruções! Não deitar fora! Em caso de avarias por utilização

incorrecta, extingue-se a garantia! Reservado o direito de alterações técnicas!

DANSK side 16

Læs betjeningsvejledningen, og gem den til senere brug! Smid den ikke ud! Skader, som måtte opstå som

følge af betjeningsfejl, medfører, at garantien mister sin gyldighed! Ret til tekniske ændringer forbeholdes!

SVENSKA sida 18

Läs igenom bruksanvisningen och förvara den väl! Kasta inte bort den! Garantin upphör om apparaten

har använts eller betjänats på ett felaktigt sätt! Med reservation för tekniska ändringar!

POLSKI strony 20

Instrukcjê obslugi prosze przeczytac i przechowac! Nie wyrzucac!

Przy uszkodzeniach wynikajacych z blêdów obslugi wygasa gwarancja! Zmiany techniczne zastrzezone!

CESKY stránky 22

Návod k obsluze si prosím přečtěte a uschovejte jej! Nevyhazujte jej!

V prípade poškození zpusobeném chybnou obsluhou zaniká záruka! Technické změny jsou vyhrazeny!

MAGYAR oldaltól 24

Kérjük, olvassa el és őrizze meg a kezelési utasítást! Ne dobja el!

A helytelen kezelésből származó károsodások esetén megszûnik a jótállás! Mûszaki változtatások fenntartva!

PУCCKИЙ Страница 26

Прочтите инструкцию по эксплуатации и сохраняйте её для дальнейшего использования! B случае поломки инструмента

из-за несоблюдения инструкции клиент теряет право на обслуживание по гарантии! Bозможны технические изменения!

1

Technische Daten ROWELD Professional

P160B P200B P250B P355B P500B P630B/Plus

P5B P8B P12B P18B P24B/Plus

Grundmaschine:

Rohr – Schweißbereich Ø (mm) ......40-160 ...... 63-200 ......90-250 ........ 90-355 ......200-500 ...... 315-630

Rohr – Schweißbereich Ø (zoll) .......1 1/4 - 5“ .....................5 - 8“ .......... 5 - 12“ ...... 8 - 18“ ........ 8 - 24“

Rohr - Schweißleistung ..................SDR Reihen siehe Schweißtabellen + max. Druck Hydraulikaggregat beachten

Max. Zylinderhub (mm) ..................100 ........... 100 ............150 .............150 ........... 200 ............. 200

Gesamt – Zylinderflächen (cm²) ......3,53 .......... 3,53 ...........6,26 ............6,26 .......... 14,13 .......... 14,13/ 22,38

Hauptabmessungen:

Länge (mm) .............................705 ........... 675 ............810 .............795 ........... 1300 ........... 1300

Breite (mm) ..............................370 ........... 370 ............ 485 ............. 600 ...........900 ............. 1060

Höhe (mm) ..............................300 ........... 400 ............415 .............535 ........... 800 ............. 920

max. Gewicht * (kg) .......................30,2 ......... 27,5 ...........56,7 ............77,9 .......... 235 ............. 319,9/325,4

29,9 57,7 78,4 235,9 315,6/321,1

Fräseinrichtung:

Elektrischer Anschluss ....................230V ......... 230V .........230V ........... 230V .........400V, 3~ ..... 400V, 3~

50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

3,5A 2,9A 3,5A 3,7A 1,75A 2,55A

Aufnahme-/Abgabeleistung (W) .....750/470 .... 630/425 .....750/470 ......850/580 .... 1210/750 .... 1770/1100

Motordrehzahl (min

Leerlaufdrehzahl (min

-1

) ....................660 ........... 950 ............660 ............583 ........... 140 ............. 140

-1

) ..................126 ........... 165 ............85 ...............53 ............. 31 ............... 24

(Fräserscheibe)

Schutzklasse / Schutzart .................I / IP20 ....... I / IP20 .......I / IP20 ......... I / IP20 ....... I / IP54 ......... I / IP54

Schalldruckpegel

Schallleistungspegel

dB(A) L

dB(A) L

¦ K

..82 ¦ 3 ......... 83 ¦ 3 .........82 ¦ 3 ...........83 ¦ 3 ........ 48 ¦ 3 .......... 52 ¦ 3

pA

pA

¦ K

.93 ¦ 3 ......... 94 ¦ 3 .........93 ¦ 3 ...........94 ¦ 3 ........ 59 ¦ 3 .......... 63 ¦ 3

WA

WA

Gewicht (kg) ..................................7,6 ............ 7,0 .............15 ..............22,6 ......... 68 .............. 123

Heizelement:

Elektrischer Anschluss ....................230V ......... 230V .........230V ........... 230V .........400V ........... 400V

50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

800W 1000W 1500W 2500W 4000W 8000W

Heizelement - Durchmesser (mm) ...200 ........... 230 ............ 300 ............. 380 ........... 540 ............. 660

Schutzklasse / Schutzart .................I / IP20 ....... I / IP20 .......I / IP20 ......... I / IP20 ....... I / IP20 ......... I / IP20

Gewicht (kg) ..................................3,3 ............ 3,9 .............5,5 ..............9,1 ............ 32 ............... 49

Einstellkasten:

Gewicht (kg) ..................................4,7 ............ 4,3 .............8,2 ..............9,6 ............ 55 ............... 70

* inklusive Reduziereinsätze für den kleinsten Rohrdurchmesser

DEUTSCH2

Technische Daten ROWELD Professional

P160B, P200B, P250B, P355B P500B,P630B/Plus

P5B, P8B, P12B P18B, P24B/ Plus

Hydraulikaggregat 50Hz:

Elektrischer Anschluss ....................230V – 50 Hz - 2,5 A .......................................... 230V – 50 Hz - 5,6 A

Aufnahme-/Abgabeleistung (W) .....580 / 370 ........................................................... 1290 / 750

Pumpenfördermenge (l/min) ..........2,8 ..................................................................... 5,65

Öl – Tankinhalt (l) ...........................0,7 ..................................................................... 0,7

max. Druck (bar) ............................100 .................................................................... 100

Hydraulik - Öl .................................HLP – 46 (Art. Nr.: 53649)

Abmessungen (LxBxH, mm) ............540 x 340 x 340 ................................................. 540 x 340 x 340

Schutzklasse / Schutzart .................I / IP20 ................................................................ I / IP20

Schalldruckpegel dB(A) L

Schallleistungspegel

dB(A) L

¦ K

..74 ¦ 3 .................................................................. 77 ¦ 3

pA

pA

¦ K

.85 ¦ 3 .................................................................. 88 ¦ 3

WA

WA

Gewicht (kg) ..................................28 ...................................................................... 29

Hydraulikaggregat 60Hz:

Elektrischer Anschluss ....................230V – 60 Hz - 2,5 A .......................................... 230V – 60 Hz - 5,6 A

Aufnahme-/Abgabeleistung (W) .....670 / 370 ........................................................... 1200 / 750

Pumpenfördermenge (l/min) ..........2,45 ................................................................... 5,1

Öl – Tankinhalt (l) ...........................0,7 ..................................................................... 0,7

max. Druck (bar) ............................100 .................................................................... 100

Hydraulik - Öl .................................HLP – 46 (Art. Nr.: 53649)

Abmessungen (LxBxH, mm) ............540 x 340 x 340 ................................................. 540 x 340 x 340

Schutzklasse / Schutzart .................I / IP20 ................................................................ I / IP20

Schalldruckpegel dB(A) L

Schallleistungspegel dB(A) L

¦ K

.74 ¦ 3 .................................................................. 77 ¦ 3

pA

pA

¦ K

85 ¦ 3 .................................................................. 88 ¦ 3

WA

WA

Gewicht (kg) ..................................28 ...................................................................... 29

P160B P200B P250B P355B P500B P630B/Plus

P5B P8B P12B P18B P24B/Plus

Gesamtanlage:

Elektrische

Gesamtaufnahmeleistung (kW) ......2,1 ............ 2,0 .............2,9 ..............4,0 ............ 6,7 .............. 11,3

Abmessungen der Transportkiste:

Länge (mm) ...................................1200 ......... 1200 ..........1200 ...........1200 ......... 2240 ........... 2240

Breite (mm) ....................................800 ........... 800 ............ 800 ............. 800 ........... 1300 ........... 1300

Höhe (mm) ....................................900 ........... 900 ............900 .............900 ........... 1500 ........... 1500

Der Geräuschpegel beim Arbeiten kann 85 dB (A) überschreiten. Gehörschutz tragen! Messwerte

ermittelt entsprechend EN 61029-1:2010!

DEUTSCH 3

Technical data ROWELD Professional

P160B P200B P250B P355B P500B P630B/Plus

P5B P8B P12B P18B P24B/Plus

Basic unit:

Pipe welding range Ø (mm) ............40-160 ...... 63-200 ......90-250 ........ 90-355 ......200-500 ...... 315-630

Pipe welding range Ø (inch) ...........1 1/4 - 5“ ..................... 5 - 8“ ..........5 - 12“ ...... 8 - 18“ ........ 8 - 24“

Pipe capacity ..................................SDR series see welding tables + observe pressure max. hydraulic unit

Cylinder stroke, max (mm) .............100 ........... 100 ............ 150 ............. 150 ........... 200 ............. 200

Total cylinder surface (cm²) .............3,53 .......... 3,53 ........... 6,26 ............ 6,26 ..........14,13 .......... 14,13/ 22,38

Leading dimensions:

Length (mm) ............................705 ........... 675 ............810 .............795 ........... 1300 ........... 1300

Width (mm) .............................370 ........... 370 ............485 ............. 600 ........... 900 ............. 1060

Height (mm) ............................300 ........... 400 ............415 .............535 ........... 800 ............. 920

Weight max. * (kg) ........................30,2 ......... 27,5 ........... 56,7 ............ 77,9 .......... 235 ............. 319,9/325,4

29,9 57,7 78,4 235,9 315,6/321,1

Trimmer unit:

Power supply .................................230V ......... 230V .........230V ........... 230V .........400V, 3~ ..... 400V, 3~

50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

3,5A 2,9A 3,5A 3,7A 1,75A 2,55A

Rated power input/output (W) .......750/470 .... 630/425 .....750/470 ......850/580 .... 1210/750 .... 1770/1100

Rotary speed (min

Idle running speed (min

-1

) .......................660 ........... 950 ............660 ............583 ........... 140 ............. 140

-1

)...............126 ........... 165 ............ 85 ............... 53 ............. 31 ............... 24

(milling disc)

Protection / Protection class............I / IP20 ....... I / IP20 .......I / IP20 .........I / IP20 ....... I / IP54 ......... I / IP54

Noise pressure level

Sound power level

dB(A) L

dB(A) L

¦

K

..82 ¦ 3 ......... 83 ¦ 3 .........82 ¦ 3 ...........83 ¦ 3 ........ 48 ¦ 3 .......... 52 ¦ 3

pA

pA

¦

K

.93 ¦ 3 ......... 94 ¦ 3 .........93 ¦ 3 ...........94 ¦ 3 ........ 59 ¦ 3 .......... 63 ¦ 3

WA

WA

Weight (kg) ....................................7,6 ........... 7,0 ............. 15 .............. 22,6 ......... 68 .............. 123

Heating plate:

Power supply .................................230V ......... 230V .........230V ........... 230V .........400V ........... 400V

50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

800W 1000W 1500W 2500W 4000W 8000W

Heating plate - diameter (mm) .......200 ........... 230 ............300 .............380 ........... 540 ............. 660

Protection / Protection class............I / IP20 ....... I / IP20 .......I / IP20 .........I / IP20 ....... I / IP20 ......... I / IP20

Weight (kg) ....................................3,3 ............ 3,9 ............. 5,5 .............. 9,1 ............ 32 ............... 49

Carrying frame:

Weight (kg) ....................................4,7 ............ 4,3 ............. 8,2 .............. 9,6 ............ 55 ............... 70

* incl. reduction clamp inserts for the smallest pipe diameter

ENGLISH4

Technical data ROWELD Professional

P160B, P200B, P250B, P355B P500B,P630B/Plus

P5B, P8B, P12B P18B, P24B/ Plus

Hydraulic unit 50 Hz:

Power supply .................................230V – 50 Hz - 2,5 A .......................................... 230V – 50 Hz - 5,6 A

Rated power input/output (W) .......580 / 370 ........................................................... 1290 / 750

Pump capacity (l/min) .....................2,8 ..................................................................... 5,65

Oil tank capacity (l) ........................0,7 ..................................................................... 0,7

Pressure max. (bar) .........................100 .................................................................... 100

Hydraulic - Oil ................................HLP – 46 (no.: 53649)

Dimensions (LxWxH, mm) ..............540 x 340 x 340 ................................................. 540 x 340 x 340

Protection / Protection class............I / IP20 ................................................................ I / IP20

Noise pressure level dB(A)

Sound power level

dB(A) L

L

¦ K

..74 ¦ 3 .................................................................. 77 ¦ 3

pA

pA

¦ K

.85 ¦ 3 .................................................................. 88 ¦ 3

WA

WA

Weight (kg) ....................................28 ...................................................................... 29

Hydraulic unit 60 Hz:

Power supply .................................230V – 60 Hz - 2,5 A .......................................... 230V – 60 Hz - 5,6 A

Rated power input/output (W) .......670 / 370 ........................................................... 1200 / 750

Pump capacity (l/min) .....................2,45 ................................................................... 5,1

Oil tank capacity (l) ........................0,7 ..................................................................... 0,7

Pressure max. (bar) .........................100 .................................................................... 100

Hydraulic-oil ...................................HLP – 46 (no.: 53649)

Dimensions (LxWxH, mm) ..............540 x 340 x 340 ................................................. 540 x 340 x 340

Protection / Protection class............I / IP20 ................................................................ I / IP20

Noise pressure level dB(A)

Sound power level

dB(A) L

L

¦ K

..74 ¦ 3 .................................................................. 77 ¦ 3

pA

pA

¦ K

.85 ¦ 3 .................................................................. 88 ¦ 3

WA

WA

Weight (kg) ....................................28 ...................................................................... 29

P160B P200B P250B P355B P500B P630B/Plus

P5B P8B P12B P18B P24B/Plus

Overall length:

Total connected load (kW) ..............2,1 ............ 2,0 ............. 2,9 .............. 4,0 ............6,7 .............. 11,3

Transport case dimensions:

Length (mm) ..................................1200 ......... 1200 ..........1200 ...........1200 ......... 2240 ........... 2240

Width (mm) ...................................800 ........... 800 ............800 ............. 800 ........... 1300 ........... 1300

Height (mm) ..................................900 ........... 900 ............900 .............900 ........... 1500 ........... 1500

The noise level during operation can exceed 85 dB (A). Wear ear protection! Measurements found

in compliance with EN 61029-1:2010!

ENGLISH 5

Données techniques ROWELD Professional

P160B P200B P250B P355B P500B P630B/Plus

P5B P8B P12B P18B P24B/Plus

Machine de base:

Plage de soudage des tubes Ø (mm) ... 40-160 ...... 63-200 ......90-250 ........90-355 ...... 200-500 ...... 315-630

Plage de soudage des tubes Ø (inch) ... 1 1/4 - 5“ .....................5 - 8“ .......... 5 - 12“ ...... 8 - 18“ ........ 8 - 24“

Puissance de soudage des tubes .....les séries SDR, voir soudage livre de table + respecter max. pression unité

hydraulique

Course maxi. des vérins (mm) .........100 ........... 100 ............150 .............150 ........... 200 ............. 200

Surfaces totales des vérins (cm²) .....3,53 .......... 3,53 ...........6,26 ............6,26 .......... 14,13 .......... 14,13/ 22,38

Dimensions principales:

Longueur (mm) ........................705 ........... 675 ............810 .............795 ........... 1300 ........... 1300

Largeur (mm) ...........................370 ........... 370 ............485 .............600 ........... 900 ............. 1060

Hauteur (mm) ..........................300 ........... 400 ............415 .............535 ........... 800 ............. 920

max. Poids * (kg) ...........................30,2 ......... 27,5 ...........56,7 ............77,9 .......... 235 ............. 319,9/325,4

29,9 57,7 78,4 235,9 315,6/321,1

Equipement de fraisage:

Raccordement électrique ................230V ......... 230V .........230V ........... 230V .........400V, 3~ ..... 400V, 3~

50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

3,5A 2,9A 3,5A 3,7A 1,75A 2,55A

Puissance absorbée/-utile débitée ...750/470W . 630/425W .750/470W ... 850/580W . 1210/750W . 1770/1100W

Vitesse de rotation du moteur (min

Vitesse de rotation à vide (min

-1

) 660 ........... 950 ............660 ............583 ........... 140 ............. 140

-1

) ....126 ........... 165 ............85 ...............53 ............. 31 ............... 24

(disque de fraise)

Classe / type de protection .............I / IP20 ....... I / IP20 .......I / IP20 ......... I / IP20 ....... I / IP54 ......... I / IP54

Niveau de pression acoustique

dB(A) L

¦

K

.................................82 ¦ 3 ......... 83 ¦ 3 .........82 ¦ 3 ...........83 ¦ 3 ........ 48 ¦ 3 .......... 52 ¦ 3

pA

pA

Niveau de puissance acoustique

dB(A) L

¦

K

................................93 ¦ 3 ......... 94 ¦ 3 .........93 ¦ 3 ...........94 ¦ 3 ........ 59 ¦ 3 .......... 63 ¦ 3

WA

WA

Poids (kg) .......................................7,6 ........... 7,0 .............15 ..............22,2 ......... 68 .............. 123

Elément thermique:

Raccordement électrique ................230V ......... 230V .........230V ........... 230V .........400V ........... 400V

50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

800W 1000W 1500W 2500W 4000W 8000W

Dia. de l’élément thermique (mm) ..200 ........... 230 ............300 .............380 ........... 540 ............. 660

Classe / type de protection .............I / IP20 ....... I / IP20 .......I / IP20 ......... I / IP20 ....... I / IP20 ......... I / IP20

Poids (kg) .......................................3,3 ............ 3,9 .............5,5 ..............9,1 ............ 32 ............... 49

Caisson de rangement:

Poids (kg) .......................................4,7 ............ 4,3 .............8,2 ..............9,6 ............ 55 ............... 70

* y compris jeux d’inserts de serrage de réduction pour le plus petit diamètre du tube

FRANÇAIS6

Données techniques ROWELD Professional

P160B, P200B, P250B, P355B P500B,P630B/Plus

P5B, P8B, P12B P18B, P24B/ Plus

Unité hydraulique 50 Hz:

Raccordement électrique ................230V – 50 Hz - 2,5 A .......................................... 230V – 50 Hz - 5,6 A

Puissance absorbée/-utile débitée ...580 / 370 W ....................................................... 1290 / 750 W

Débit de la pompe (l/min) ...............2,8 ..................................................................... 5,65

Contenance du réservoir d’huile (l) .0,7 ..................................................................... 0,7

max. pression (bar) .........................100 .................................................................... 100

Huile hydraulique ...........................HLP – 46 (no.: 53649)

Dimensions (Lxlxh, mm) .................540 x 340 x 340 ................................................. 540 x 340 x 340

Classe / type de protection .............I / IP20 ................................................................ I / IP20

Niveau de pression acoustique

dB(A)

L

¦ K

.................................74 ¦ 3 .................................................................. 77 ¦ 3

pA

pA

Niveau de puissance acoustique

dB(A) L

¦ K

.................................85 ¦ 3 .................................................................. 88 ¦ 3

WA

WA

Poids (kg) .......................................28 ...................................................................... 29

Unité hydraulique 60 Hz:

Raccordement électrique ................230V – 60 Hz - 2,5 A .......................................... 230V – 60 Hz - 5,6 A

Puissance absorbée/-utile débitée ...670 / 370 W ....................................................... 1200 / 750 W

Débit de la pompe (l/min) ...............2,45 ................................................................... 5,1

Contenance du réservoir d’huile (l) .0,7 ..................................................................... 0,7

max. pression (bar) .........................100 .................................................................... 100

Huile hydraulique ...........................HLP – 46 (no.: 53649)

Dimensions (Lxlxh, mm) .................540 x 340 x 340 ................................................. 540 x 340 x 340

Classe / type de protection .............I / IP20 ................................................................ I / IP20

Niveau de pression acoustique

dB(A)

L

¦ K

.................................74 ¦ 3 .................................................................. 77 ¦ 3

pA

pA

Niveau de puissance acoustique

dB(A) L

¦ K

................................85 ¦ 3 .................................................................. 88 ¦ 3

WA

WA

Poids (kg) .......................................28 ...................................................................... 29

P160B P200B P250B P355B P500B P630B/Plus

P5B P8B P12B P18B P24B/Plus

Installation complète:

Puissance absorbée totale (kW) ......2,1 ............ 2,0 .............2,9 ..............4,0 ............ 6,7 .............. 11,3

Dimensions de la caisse de transport:

Longueur (mm) ..............................1200 ......... 1200 ..........1200 ...........1200 ......... 2240 ........... 2240

Largeur (mm) .................................800 ........... 800 ............800 .............800 ........... 1300 ........... 1300

Hauteur (mm) ................................900 ........... 900 ............900 .............900 ........... 1500 ........... 1500

Pendant le travail le niveau de bruit peut dépasser 85 dB (A). Porter une protection acoustique!

Les valeurs mesurées sont évaluées conformément à EN 61029-1:2010!

FRANÇAIS 7

Datos técnicos ROWELD Professional

P160B P200B P250B P355B P500B P630B/Plus

P5B P8B P12B P18B P24B/Plus

Máquina base:

Gama de soldadura de tubo Ø (mm) .40-160 ...... 63-200 ......90-250 ........ 90-355 ......200-500 ...... 315-630

Gama de soldadura de tubo Ø (inch) .1 1/4 - 5“ ..................... 5 - 8“ ..........5 - 12“ ...... 8 - 18“ ........ 8 - 24“

Potencia de soldadura de tubo ...... serie SDR las tablas de soldadura adjuntas + observe presión max. grupo

hidráulico

Carrera máx. cilindro (mm) .............100 ........... 100 ............150 ............. 150 ...........200 ............. 200

Superf. cilindro en total (cm²) .........3,53 .......... 3,53 ........... 6,26 ............ 6,26 .......... 14,13 .......... 14,13/ 22,38

Medidas principales:

Longitud (mm) .........................705 ........... 675 ............810 .............795 ........... 1300 ........... 1300

Anchura (mm) .........................370 ........... 370 ............485 .............600 ........... 900 ............. 1060

Altura (mm) .............................300 ........... 400 ............415 .............535 ........... 800 ............. 920

Peso max. * (kg) ............................30,2 ......... 27,5 ...........56,7 ............77,9 .......... 235 ............. 319,9/325,4

29,9 57,7 78,4 235,9 315,6/321,1

Instalación fresadora:

Conexión eléctrica .........................230V ......... 230V .........230V ........... 230V .........400V, 3~ ..... 400V, 3~

50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

3,5A 2,9A 3,5A 3,7A 1,75A 2,55A

Potencia absorbida / -útil (W) .........750/470 .... 630/425 .....750/470 ......850/580 .... 1210/750 .... 1770/1100

RPM motor (min

RPM en vacío (min

-1

)..........................660 ........... 950 ............ 660 ............ 583 ........... 140 ............. 140

-1

) ......................126 ........... 165 ............85 ...............53 ............. 31 ............... 24

(disco fresador)

Protección/Clase de protección.......I / IP20 ....... I / IP20 .......I / IP20 .........I / IP20 ....... I / IP54 ......... I / IP54

Nivel de potencia acústica

¦

dB(A) L

K

..................................82 ¦ 3 ......... 83 ¦ 3 .........82 ¦ 3 ...........83 ¦ 3 ........ 48 ¦ 3 .......... 52 ¦ 3

pA

pA

Nivel de potencia acústica

¦

dB(A) L

K

.................................93 ¦ 3 ......... 94 ¦ 3 .........93 ¦ 3 ...........94 ¦ 3 ........ 59 ¦ 3 .......... 63 ¦ 3

WA

WA

Peso (kg) ........................................7,6 ........... 7,0 .............15 ..............22,6 .......... 68 .............. 123

Elemento calefactor:

Conexión eléctrica .........................230V ......... 230V .........230V ........... 230V .........400V ........... 400V

50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

800W 1000W 1500W 2500W 4000W 8000W

Diámetro elemento calefactor (mm) ..200 ........... 230 ............ 300 ............. 380 ........... 540 ............. 660

Protección/Clase de protección.......I / IP20 ....... I / IP20 .......I / IP20 .........I / IP20 ....... I / IP20 ......... I / IP20

Peso (kg) ........................................3,3 ............ 3,9 .............5,5 ..............9,1 ............ 32 ............... 49

Caja de ajuste:

Peso (kg) ........................................4,7 ............ 4,3 .............8,2 ..............9,6 ............ 55 ............... 70

* incl. piezas tensoras reductoras para el diámetro del tubo más pequeño

ESPAÑOL8

Loading...

Loading...