Rosemount 2501 Operating Manual

Quick Start Guide

00825-0100-2501, Rev AA

October 2019

Rosemount™ 2501 Solids Level Switch

Rotating Paddle

Quick Start Guide October 2019

Contents

Introduction.................................................................................................................................3

Mechanical installation...............................................................................................................11

Electrical installation.................................................................................................................. 20

Configuration.............................................................................................................................25

Operation...................................................................................................................................28

Maintenance.............................................................................................................................. 31

Product certifications................................................................................................................. 33

2 Quick Start Guide

October 2019 Quick Start Guide

1 Introduction

The level switch detects the presence and absence of a process media at its

installation point, and reports it as a switched electrical output.

Note

Other language versions of this Quick Start Guide can be found at

Emerson.com/Rosemount.

1.1 Safety messages

NOTICE

Read this manual before working with the product. For personal and system

safety, and for optimum product performance, ensure you thoroughly

understand the contents before installing, using, or maintaining this

product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

• United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

• Asia Pacific- 65 777 8211

North American Response Center

Equipment service needs.

• 1-800-654-7768 (24 hours a day — includes Canada)

• Outside of these areas, contact your local Emerson representative.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

Quick Start Guide 3

Quick Start Guide October 2019

WARNING

Failure to follow safe installation and servicing guidelines could result in

death or serious injury.

• Ensure the level switch is installed by qualified personnel and in

accordance with applicable code of practice.

• Use the level switch only as specified in this manual. Failure to do so may

impair the protection provided by the level switch.

Explosions could result in death or serious injury.

• The level switch must only be installed and operated in non-hazardous

(ordinary) locations.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

• Ensure the power to the level switch is off, and the lines to any other

external power source are disconnected or not powered while wiring the

level switch.

• Ensure the wiring is suitable for the electrical current and the insulation is

suitable for the voltage, temperature, and environment.

Process leaks could result in death or serious injury.

• Ensure the level switch is handled carefully. If the process seal is

damaged, gas or dust might escape from the silo (or other vessel)

Any substitution of non-recognized parts may jeopardize safety. Repair,

e.g. substitution of components, etc. may also jeopardize safety and is

under no circumstances allowed.

• Unauthorized changes to the product are strictly prohibited as they may

unintentionally and unpredictably alter performance and jeopardize

safety. Unauthorized changes that interfere with the integrity of the

welds or flanges, such as making additional perforations, compromise

product integrity and safety. Equipment ratings and certifications are no

longer valid on any products that have been damaged or modified

without the prior written permission of Emerson. Any continued use of

product that has been damaged or modified without the written

authorization is at the customer’s sole risk and expense.

4 Quick Start Guide

October 2019 Quick Start Guide

CAUTION

The products described in this document are NOT designed for nuclearqualified applications.

• Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

• For information on Rosemount nuclear-qualified products, contact your

local Emerson Sales Representative.

Individuals who handle products exposed to a hazardous substance can

avoid injury if they are informed of and understand the hazard.

• If the product being returned was exposed to a hazardous substance as

defined by Occupational Safety and Health Administration (OSHA), a

copy of the required Safety Data Sheet (SDS) for each hazardous

substance identified must be included with the returned level switch.

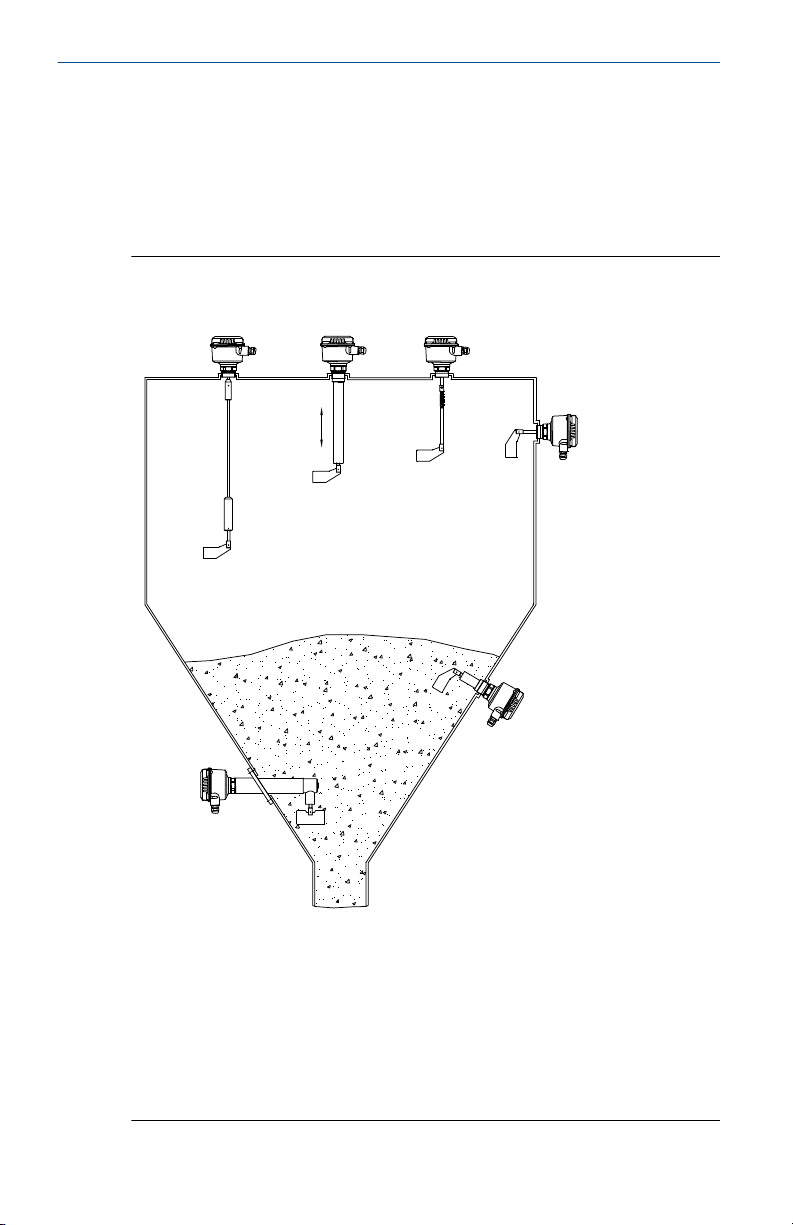

1.2 Applications

A Rosemount™ 2501 Solids Level Switch is used for monitoring the level of

bulk materials in all types of containers and silos.

The level switch can be equipped for process overpressure

pressure, and also for very high or low process temperatures.

The level switch can be used with different paddle shapes and sizes to

monitor fine and medium solids in bulk materials. See Table 4-1 for a guide

to the minimum density requirements.

Typical applications are:

• Building materials

— Lime, extruded polystyrene foam (XPS), molding sand, etc.

• Food and beverage

— Milk powder, flour, salt, etc.

• Plastics

— Plastic granulates, etc.

• Timber

• Chemicals

The level switch has a threaded, flanged, or Tri Clamp process connection for

mounting it onto a silo (or other vessel). You can mount it on a side wall of

the silo, so that it is level with the filling limit to be monitored. Alternatively,

(1)

and low

(1)

Overpressure (or blast overpressure) is the pressure caused by a shock wave over and

above normal atmospheric pressure.

Quick Start Guide 5

A B C

D

E

F

G

Quick Start Guide October 2019

if it has an extended length, mount it vertically on top of a silo to monitor the

maximum filling limit.

The length of the paddle can be up to 158 in. (4 m) with an extension tube or

up to 394 in. (10 m) with an extension rope.

The use of a sliding sleeve is recommended so that the switching point can

be changed easily during the live operation of the level switch.

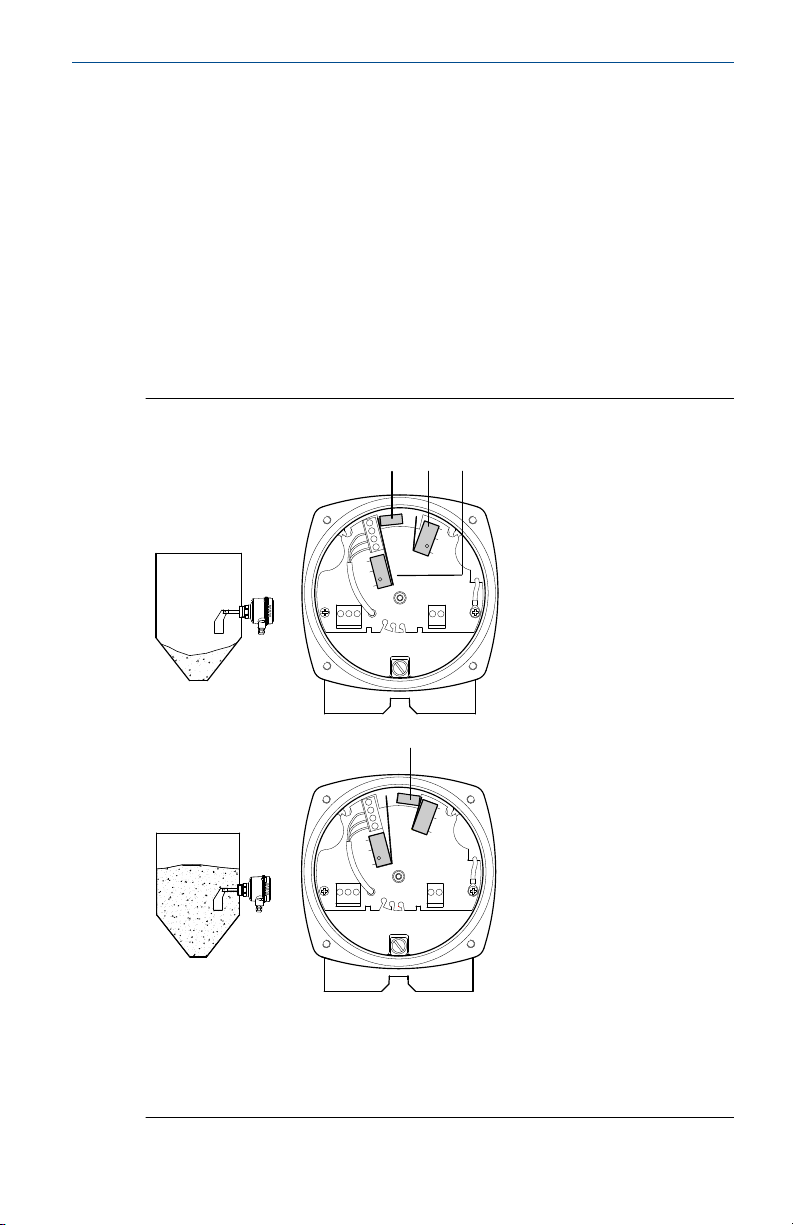

Figure 1-1: Typical Installation Examples

A. Rosemount 2501R or 2501S with the rope-extended fork length

B. Rosemount 2501M with the tube extension and optional sliding sleeve

C. Rosemount 2501L with the pendulum shaft

D. Rosemount 2501L with the boot-shaped vane paddle

E. Rosemount 2501J

F. Rosemount 2501K

G. Optional sliding sleeve

6 Quick Start Guide

B

A C D

October 2019 Quick Start Guide

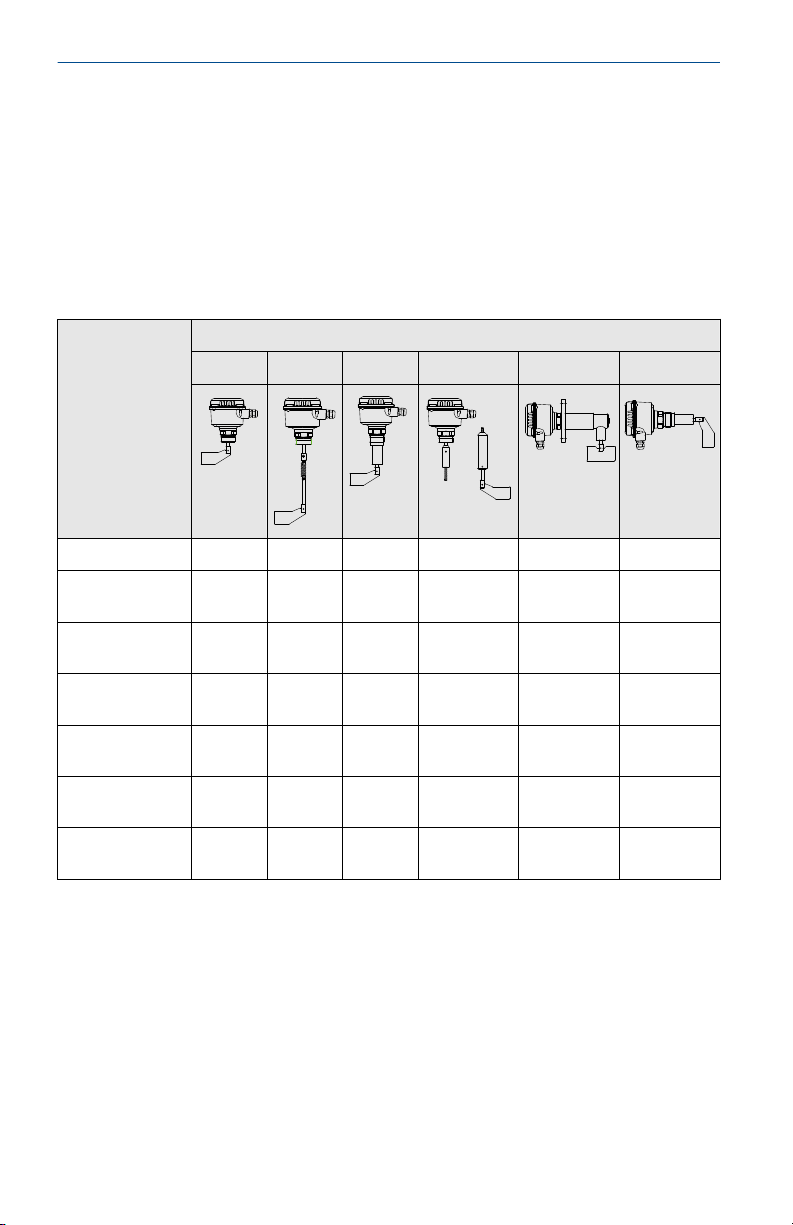

1.3 Measurement principles

Using a synchronous motor, the paddle (measuring vane) is driven to rotate

360 degrees.

When the vane of the paddle is not covered by a solids medium, a spring

pulls the motor and it switches a lug to the left position (Figure 1-2, top

illustration). The signal output indicates an 'uncovered' state and the motor

rotates the paddle.

When a solids medium covers the vane of the paddle, and causes the

rotation to stop, the lug is switched to the right position (Figure 1-2, bottom

illustration). The signal output indicates a 'covered' state due to a rising level

of material, and the motor is stopped until the vane becomes uncovered.

Figure 1-2: Switching Lug Function

A. Switching lug in left position ('uncovered' state)

B. Switching lug in right position ('covered' state)

C. Switch for stopping the motor

D. Switch for signal output

Quick Start Guide 7

Quick Start Guide October 2019

The electrical outputs vary depending on the power supply selected when

the Rosemount 2501 was ordered. See the Rosemount 2501 Product Data

Sheet for the Power Supply option codes, and Electronics for an overview of

the outputs.

1.4 Functions

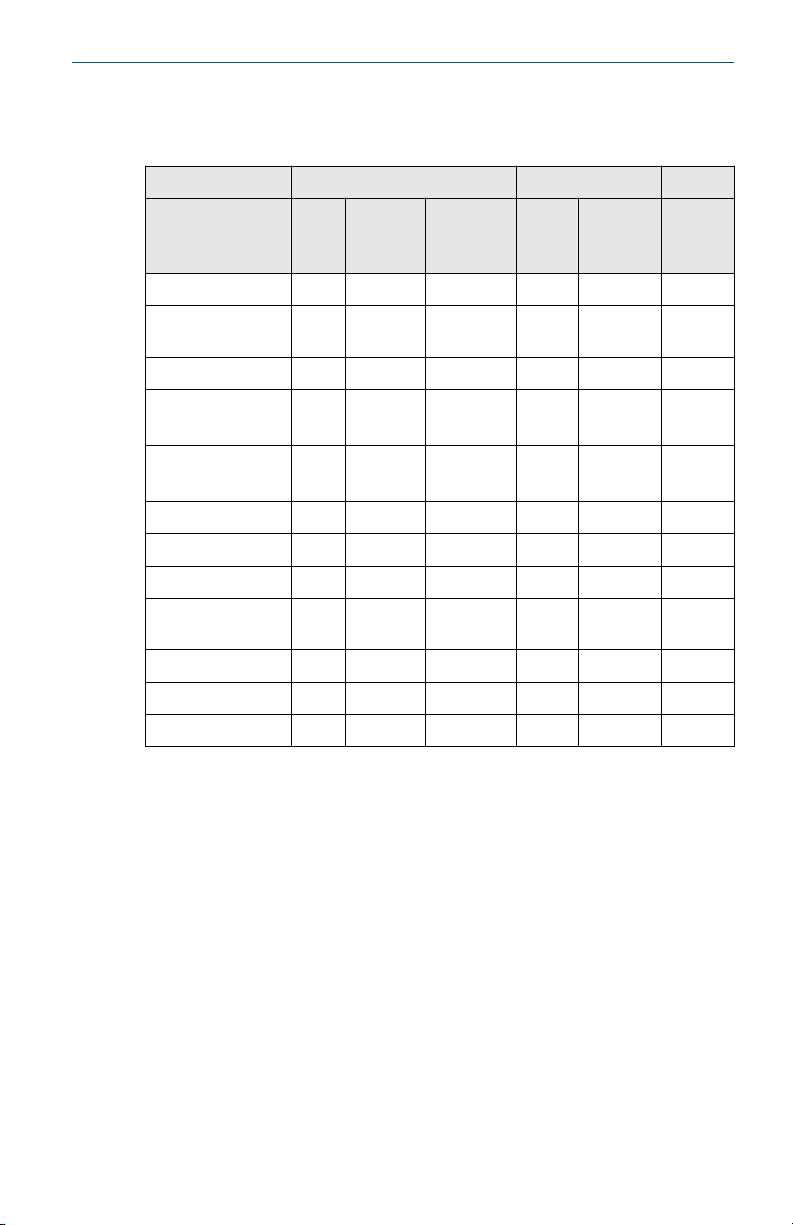

1.4.1 Selection guide

Table 1-1: Rosemount 2501 Selection Guide

Type of

installation

Full silo detection * *

On-demand

detection

Empty silo

detection

Vertical

mounting

Angled mounting

(top)

Horizontal

mounting

Angled mounting

(bottom)

(1) Consider the maximum permitted mechanical traction force.

(2) Available only with the "bearing at tube end" option.

2501L 2501M 2501R 2501S 2501K 2501J

(1)

* *

* *

* * * *

* *

* * *

* *

Model option codes

* * * *

(1)

(1)

(1)

(2)

* *

* *

*

*

8 Quick Start Guide

October 2019 Quick Start Guide

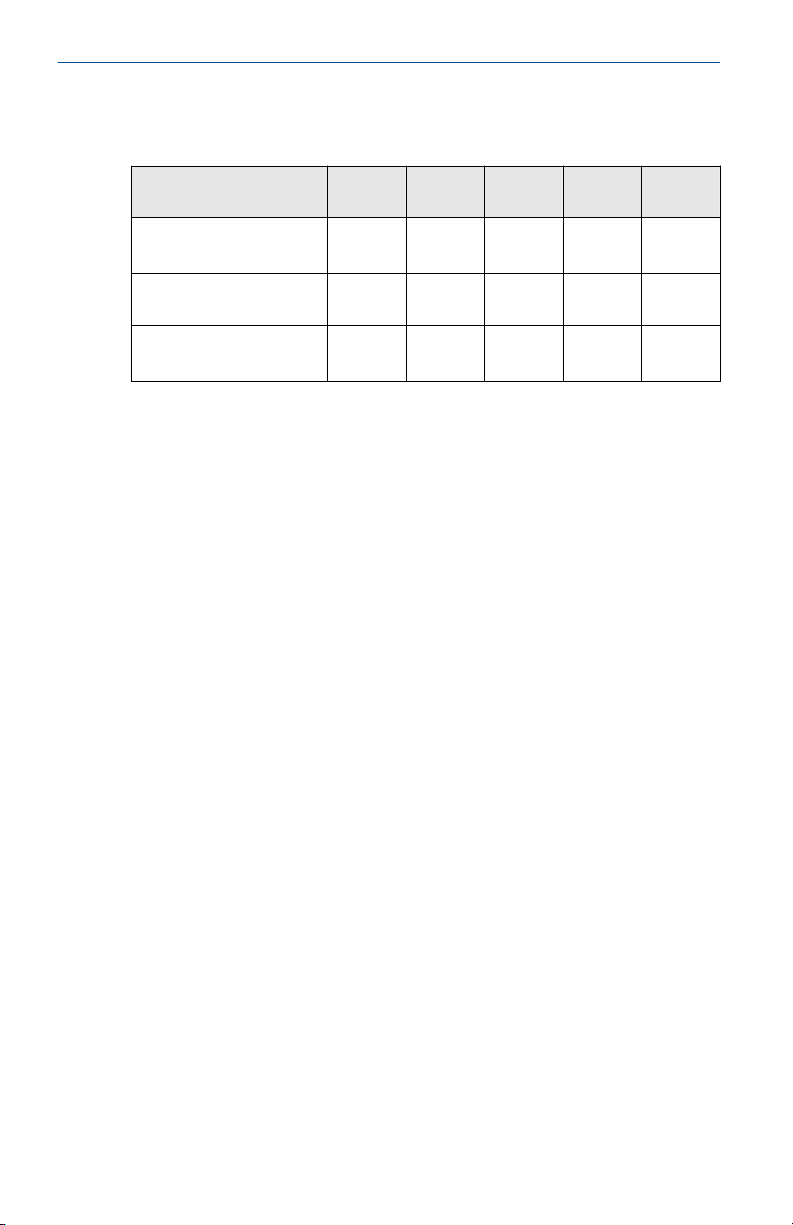

1.4.2 Shaft sealing and metal material

Table 1-2: Shaft Sealing and Metal Material

Application Sealing material

NBR FPM PTFE ALU

Animal feed press * * *

Synthetic granules,

* *

powders

Salt * * *

Dust filter

(for up to 392 °F)

Dust filter

* *

(for up to 302 °F)

Bitumen * *

Cement * *

Wood chip dryer * *

Pressure conveying

vessel, 8 bar

Sugar * *

Flour * *

Carbon black * *

(1)

Metal Bearing

* *

* *

(2)

SST 304

(1.4301)

(3)

SST

(1) Selection varies, depending on process temperature and pressure:

NBR: Maximums are 80 °C and 0.8 bar.

FPM: Maximums are 150 °C and 0.8 bar.

PTFE: Maximums are 250 °C and 0.8 bar, 80/150/250 °C and 5/10 bar.

(2) Aluminum.

(3) 316L (1.4404) stainless steel is recommended in particular cases.

Quick Start Guide 9

Quick Start Guide October 2019

1.4.3 Electronics

Table 1-3: Electronics

Power supply SPDT

Ac

version

Dc

version

Universal

voltage

(1) Single-Pole-Double-Throw contacts.

(2) Double-Pole-Double-Throw contacts.

(3) Selectable Fail Safe High or Fail Safe Low alarm output. See Wiring the universal

(4) Adjustable time delay for the switched outputs.

24 or 48 Vac or

115 or 230 Vac

24 Vdc * - - - -

24 Vdc /

22 .. 230 Vac

voltage version and Jumper Settings for Fail Safe High or Low.

(1)

* - - - -

- * * * option

DPDT

(2)

FSH/

FSL

Output

(3)

delay

(4)

Fail safe alarm

Switched signal output

The ac-voltage or dc-voltage versions of the level switch output a 'covered

paddle' or 'uncovered paddle' status signal through SPDT relay contacts.

See Wiring the ac and dc voltage versions for details.

The universal-voltage version of the level switch outputs a 'covered paddle'

or 'uncovered paddle' status signal through DPDT relay contacts.

See Wiring the universal voltage version for details.

When using the universal-voltage version of the level switch, there is an

adjustable delay for the switched signal output. Setting a delay helps to

prevent false switching of the output when there is movement of the bulk

material in a silo (or other vessel). See Figure 4-1 for details.

Fail safe alarm

The fail-safe alarm option makes it possible for the level switch to indicate a

fault using the alarm relay.

The following faults are indicated:

• Motor failure

• Gear failure

• Electronics failure (for motor power supply)

• Supply voltage failure

• Terminal wiring defect

10 Quick Start Guide

October 2019 Quick Start Guide

2 Mechanical installation

2.1 Mounting considerations

Before mounting the level switch on a silo (or other vessel), review the safety

and pre-mounting sections.

2.1.1 Safety

General safety

1. Installation of this equipment shall be carried out by suitably trained

personnel, in accordance with the applicable code of practice.

2. If equipment is likely to come into contact with aggressive

substances, it is the user’s responsibility to take suitable precautions

that prevent it from being adversely affected, thus ensuring the type

of protection is not compromised.

a. Aggressive substances: e.g. acidic liquids or gases that may

attack metals or solvents that may affect polymeric materials.

b. Suitable precautions: e.g. regular checks as part of routine

inspections or establishing from a material's data sheet that it

is resistant to specific chemicals.

3. It is the responsibility of the installer to:

a. Ensure the mechnical force exerted on the paddle by the bulk

solids does not exceed the maximum permitted for that

paddle. Refer to the technical specifications in the

Rosemount 2501 Product Data Sheet for further information.

b. Take protective measures, such as fitting an angled shield

(reverse V shape) to the silo or selecting an extension tube

option, when there are high mechanical forces.

c. Ensure that the process connection is tightened by the

correct amount of torque and sealed to prevent process

leaks.

4. Technical data

a. The Rosemount 2501 Product Data Sheet has all the technical

specifications. See Emerson.com/Rosemount for other

language versions.

Quick Start Guide 11

Loading...

Loading...