Rosemount 2501 Specifications

Product Data Sheet

00813-0100-2501, Rev AB

Rosemount™ 2501 Solids Level Switch

Rotating Paddle

January 2020

■

Universal voltage electronics

■

Rotation principle is unaffected by caking

■

Protected motor (friction clutch and double bearing)

■

Modular design

■

Temperature range from -40 to 2012 °F (-40 to 1100 °C)

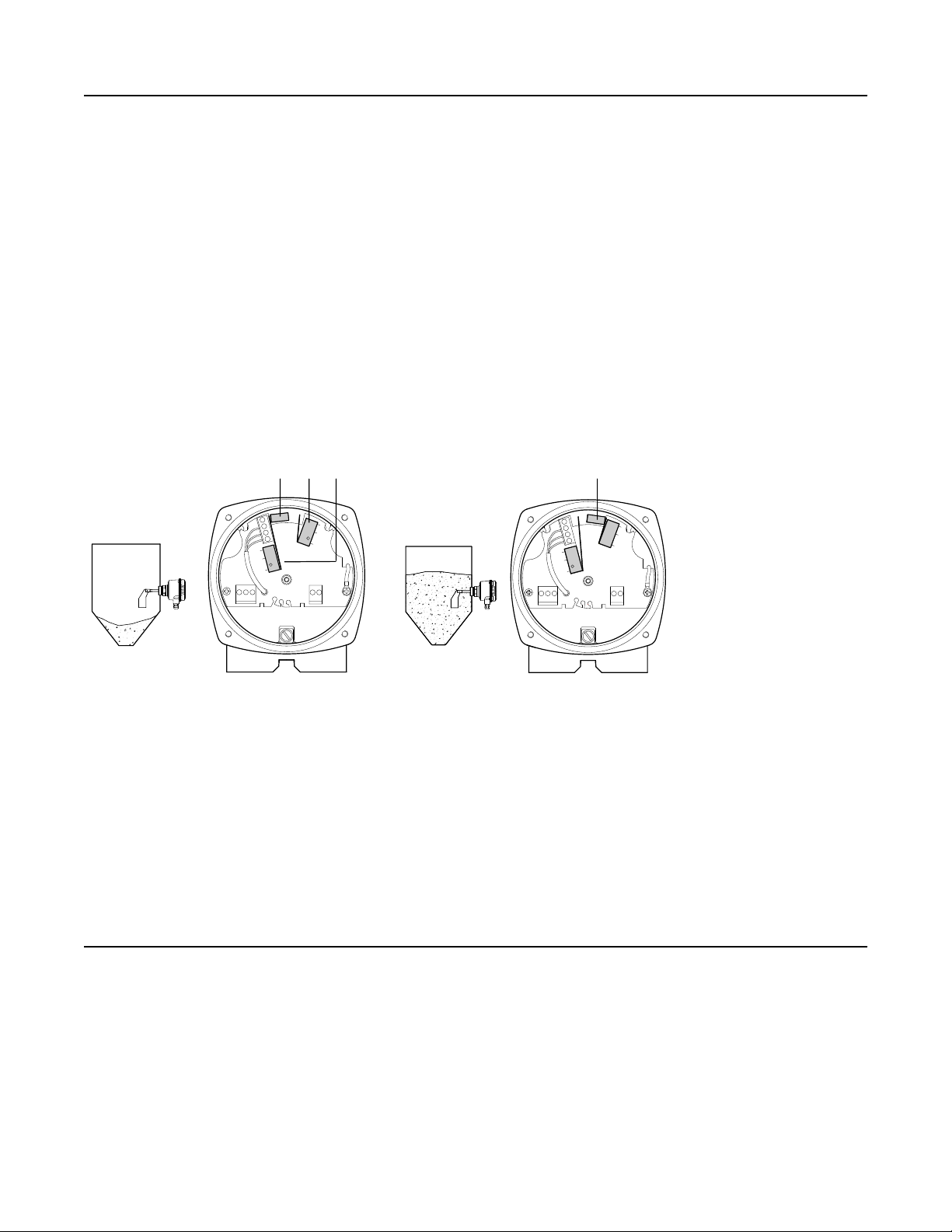

BA C D

Rosemount 2501 January 2020

Introduction

Measurement principles

The Rosemount™ 2501 Solids Level Switch uses a synchronous motor for driving a paddle (measuring vane) to rotate 360 degrees.

When the vane of the paddle is not covered by a solids medium, a spring pulls the motor and it switches a lug to the left position

(Figure 1, left illustration). The signal output indicates an 'uncovered' state and the motor rotates the paddle.

When a solids medium covers the vane of the paddle, and causes the rotation to stop, the lug is switched to the right position

(Figure 1, right illustration). The signal output indicates a 'covered' state due to a rising level of material, and the motor is stopped

until the vane becomes uncovered.

Figure 1: Switching Lug Function

A. Switching lug in left position ('uncovered' state)

B. Switching lug in right position ('covered' state)

C.

Switch for stopping the motor

D. Switch for signal output

The electrical outputs vary depending on the power supply selected when the Rosemount 2501 was ordered. See Ordering

information for the Power Supply option codes, and Electrical data for the electrical specifications.

Contents

Introduction...................................................................................................................................................................................... 2

Ordering information........................................................................................................................................................................ 5

Spares and accessories.................................................................................................................................................................... 10

Specifications.................................................................................................................................................................................. 14

Product certifications...................................................................................................................................................................... 20

Dimensional drawings..................................................................................................................................................................... 21

2 Emerson.com/Rosemount

January 2020 Rosemount 2501

Key features and benefits

■

Ideal for point level detection of most bulk solids materials

■

Simple to install, maintenance-free measurement principle

■

Reliable technology, unaffected by dust, electrostatic charge and clogging/caking

■

Robust NEMA® Type 4X housing

■

Designed for operation in temperature extremes of -40 °F to 2012 °F (-40 °C to 1100 °C)

■

Different models to suit different sizes/types of process vessels and storage silos

■

Generous space within housing with rotatable electronics, enabling easy wiring for quick installation

■

Encapsulated ball bearing with shaft sealing, ideal for dusty applications

■

Versatile installation in many types of vessel

It can be installed in vertical, horizontal, or angled positions with various extensions options available.

—

■

Compact boom length from 2¾ in. (70 mm) is particularly suited for small process vessels

(1)

, which is suitable for use in extreme process conditions

Applications

■

Materials with most density types

■

Silos/vessels with limited space or large storage silos

■

Environments with high levels of dust/ash present

■

Overfill prevention

■

High-reliability and high-safety requirements

■

High-temperature applications

(1) The NEMA Type 4X rating requires the process connection (including extension) to be stainless steel and the process temperature to not exceed 176 °F (80 °C). In

all other cases, including when a sliding sleeve is used or a Rosemount 2501 with Application Profile K, the housing is IP66/NEMA Type 4 rated.

Emerson.com/Rosemount 3

Rosemount 2501 January 2020

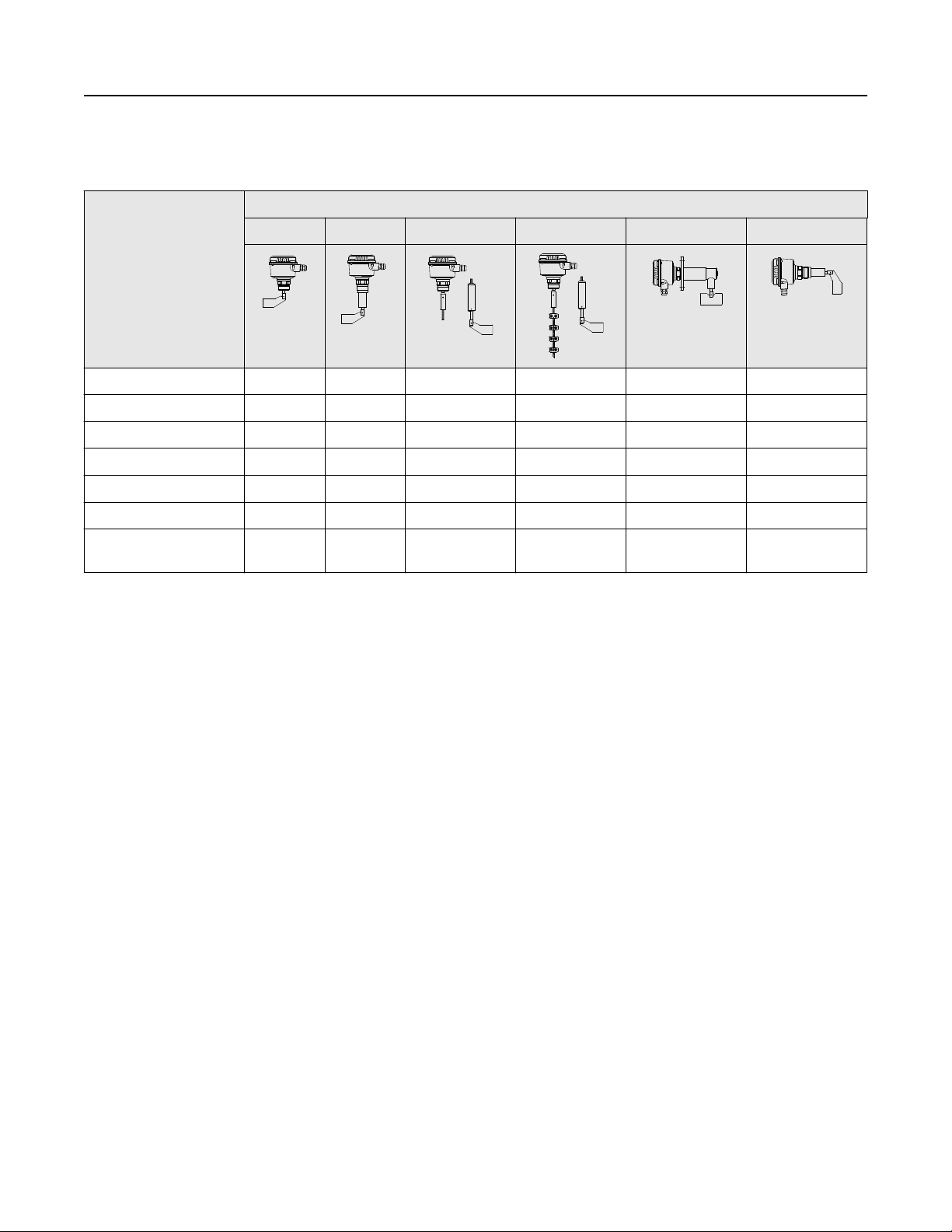

Selection guide

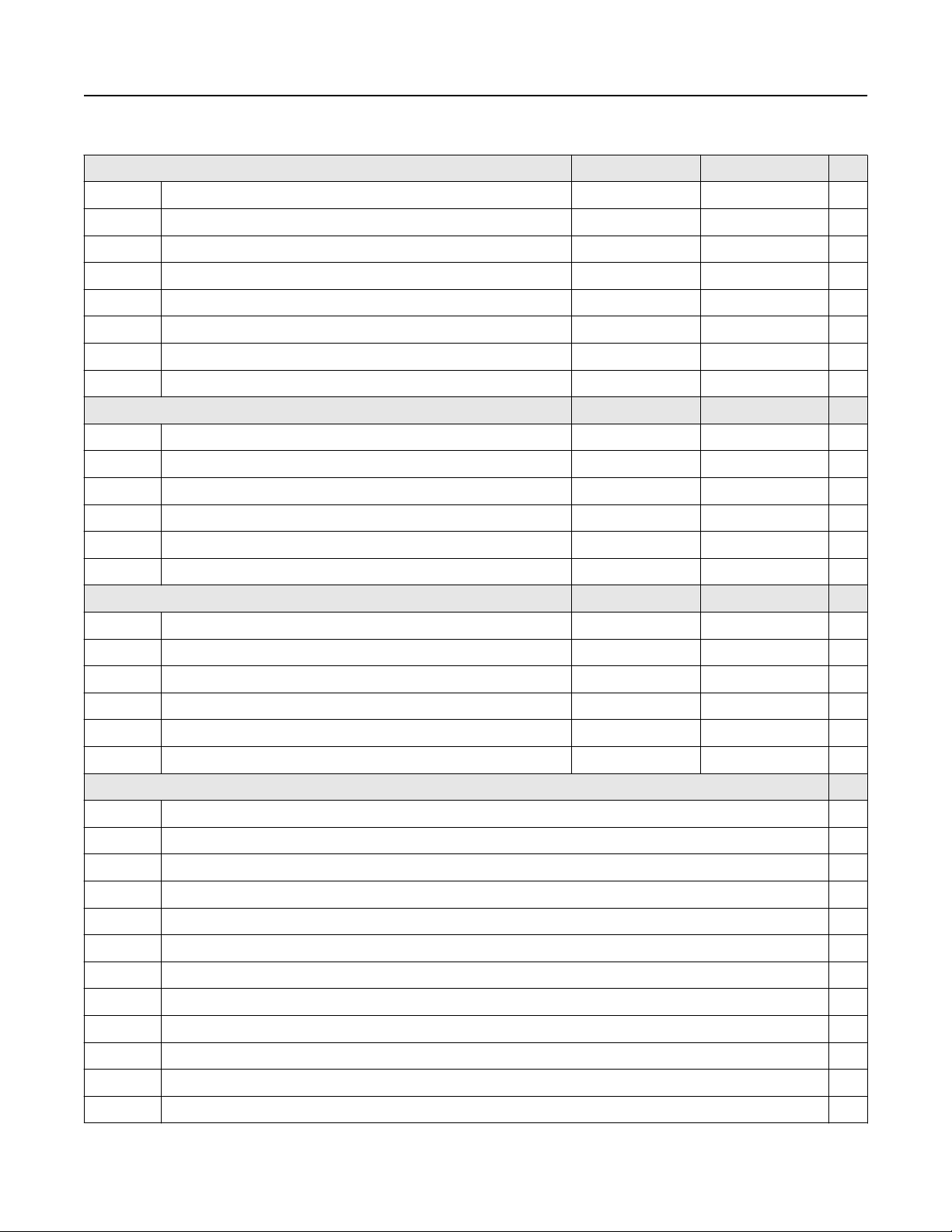

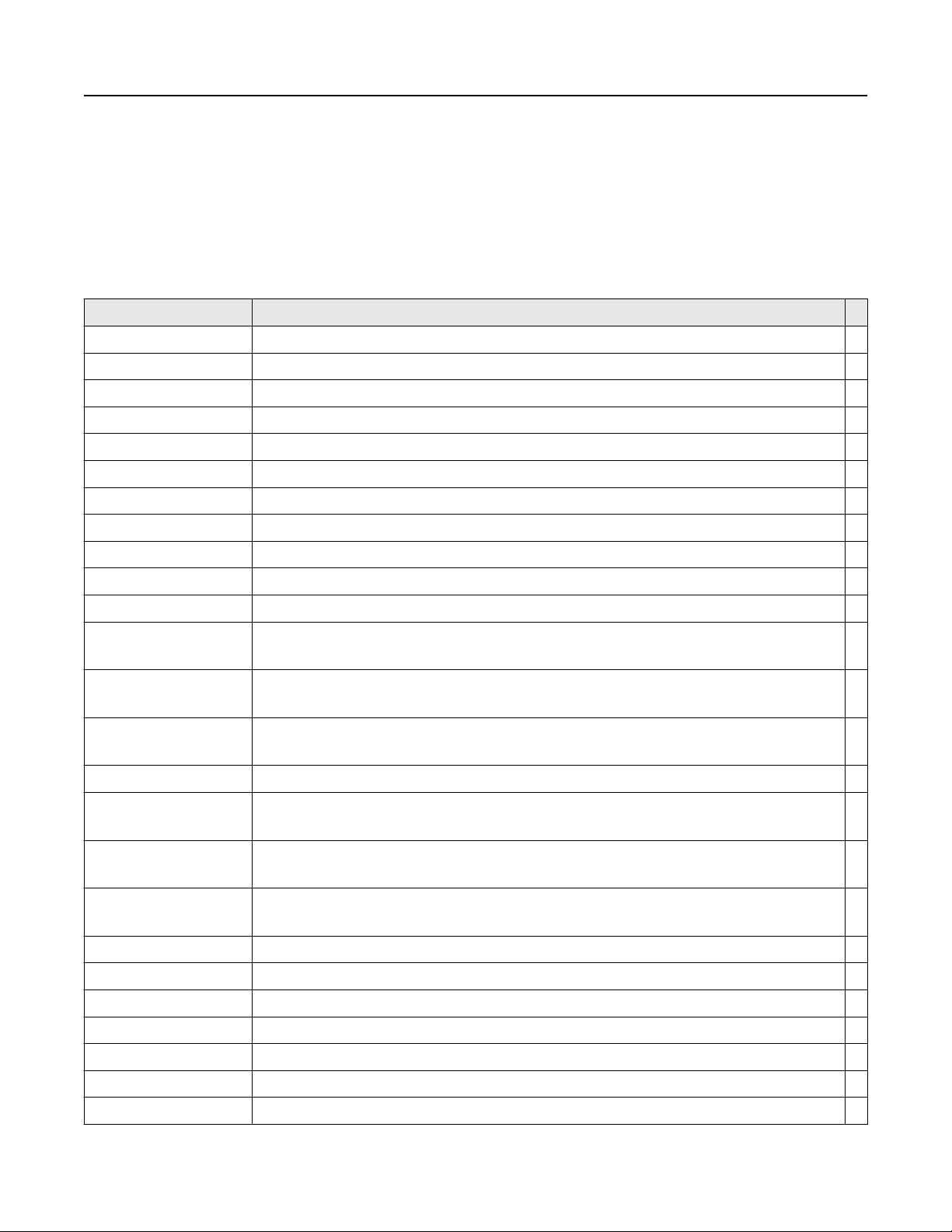

Table 1: Rosemount 2501 Selection Guide

Type of installation Model option codes

2501L 2501M 2501R 2501S 2501K 2501J

Full silo detection * *

On-demand detection * *

Empty silo detection * *

Vertical mounting * * *

Angled mounting (top) * *

(1)

(2)

* * * *

(1)

(1)

(1)

(1)

*

(1)

*

(1)

*

* *

* *

Horizontal mounting * * *

Angled mounting

* *

(bottom)

(1)

Consider the maximum permitted mechanical traction force. See Operating conditions for the maximum supported mechanical loads.

(2)

Available only with the "bearing at tube end" option (maximum of 10°).

*

*

4 Emerson.com/Rosemount

January 2020 Rosemount 2501

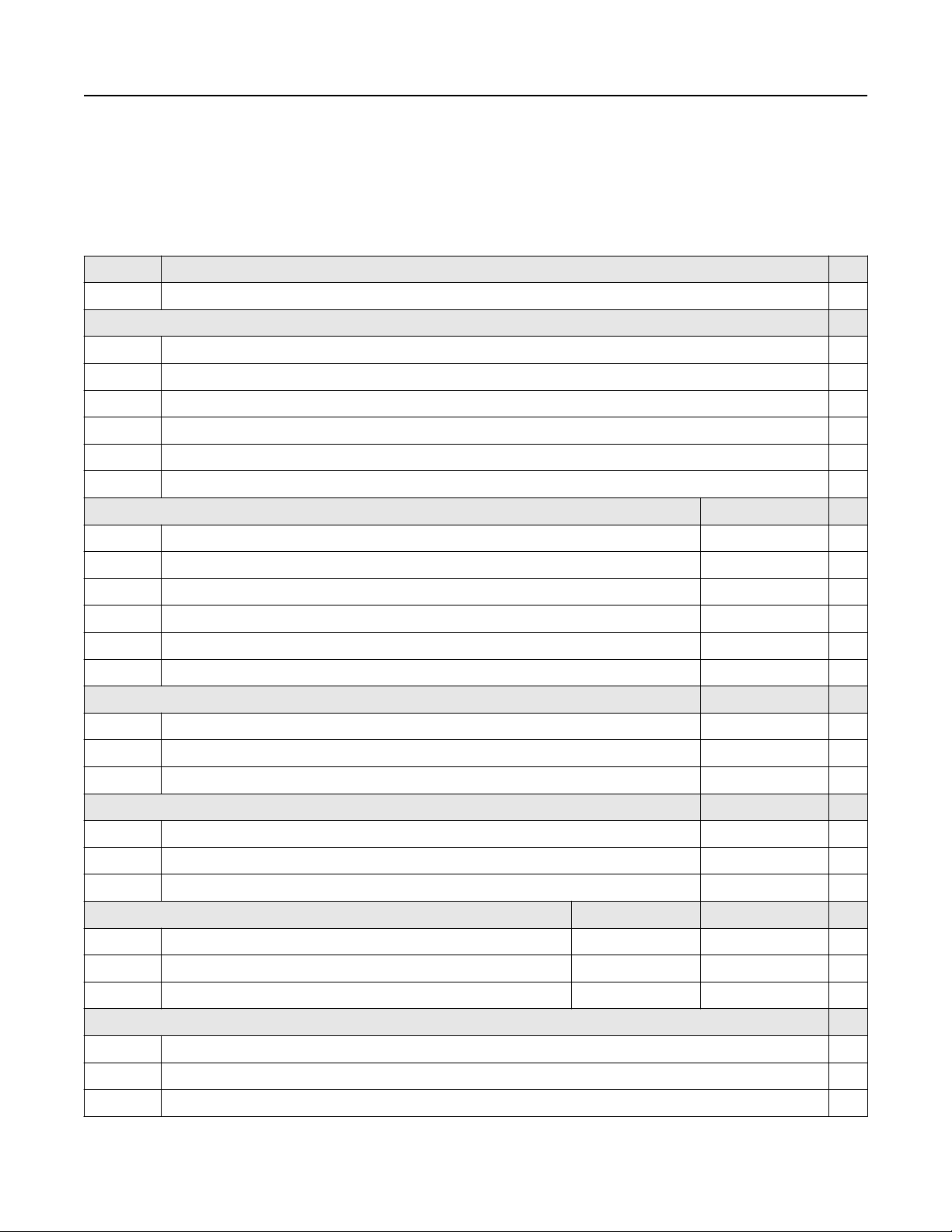

Ordering information

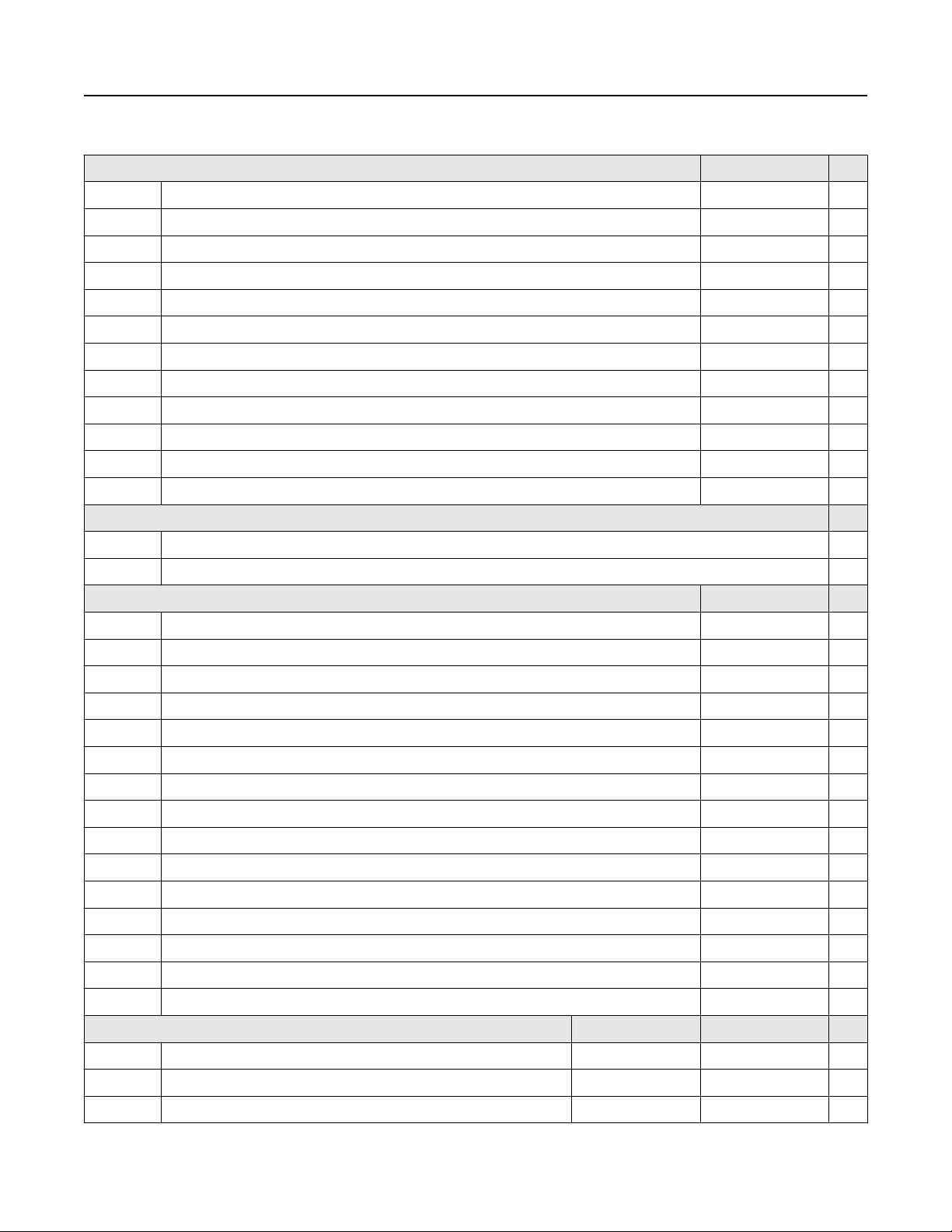

Table 2: Rosemount 2501 Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Model Product description

2501 Rosemount Solids Level Switch - Paddle ★

Application profile

L Full or empty detection in small vessel, low mechanical resistance ★

M Full detection in medium vessel, medium mechanical resistance ★

R Full detection in large vessel, medium mechanical resistance (maximum 4 kN load) ★

S Full detection in large vessel, high mechanical resistance (maximum 28 kN load) ★

J Empty detection in medium or large vessel, low or medium mechanical resistance ★

(1)

K

Operating temperature Applications

Empty detection in medium or large vessel, high mechanical resistance ★

1 Maximum 176 °F (80 °C) All ★

(2)

2

3

4

5

6

(2)

(2)

(3)(2)

(2)

Maximum 302 °F (150 °C) All except S ★

Maximum 482 °F (250 °C) All except S ★

Maximum 662 °F (350 °C) L and J only ★

Maximum 1112 °F (600 °C), All except S and K ★

Maximum 2012 °F (1100 °C) L and M only ★

Process operating pressure Temperatures

A Maximum 11.6 psi (0.8 bar) All codes ★

B Maximum 73 psi (5 bar) 1, 2, and 3 ★

C Maximum 145 psi (10 bar) 1, 2, and 3 ★

Materials of construction: process connection Applications

(4)(5)

A

(6)

D

(6)

S

Aluminum All except S ★

303/304 Stainless steel (1.4301/1.4305) All codes ★

316L Stainless steel (1.4404) L, M, and J ★

Materials of construction: extension Applications Materials (PC)

(5)(7)(8)

A

D

F

(6)(9)

(6)

Aluminum M, J, and K A and D ★

303/304 Stainless steel (1.4301/1.4305) All codes A and D ★

316L Stainless steel (1.4404) L, J and M S ★

Conduit entry/cable threads

1 M20 x 1.5, 1 off screwed cable gland for CE, ATEX, and IECEx ★

2 M20 x 1.5, 2 off screwed cable gland

4 ½-in. NPT tapered, ANSI B1.20.1 (1 off conduit + 1 off Ex-d blind plug)

Emerson.com/Rosemount 5

Rosemount 2501 January 2020

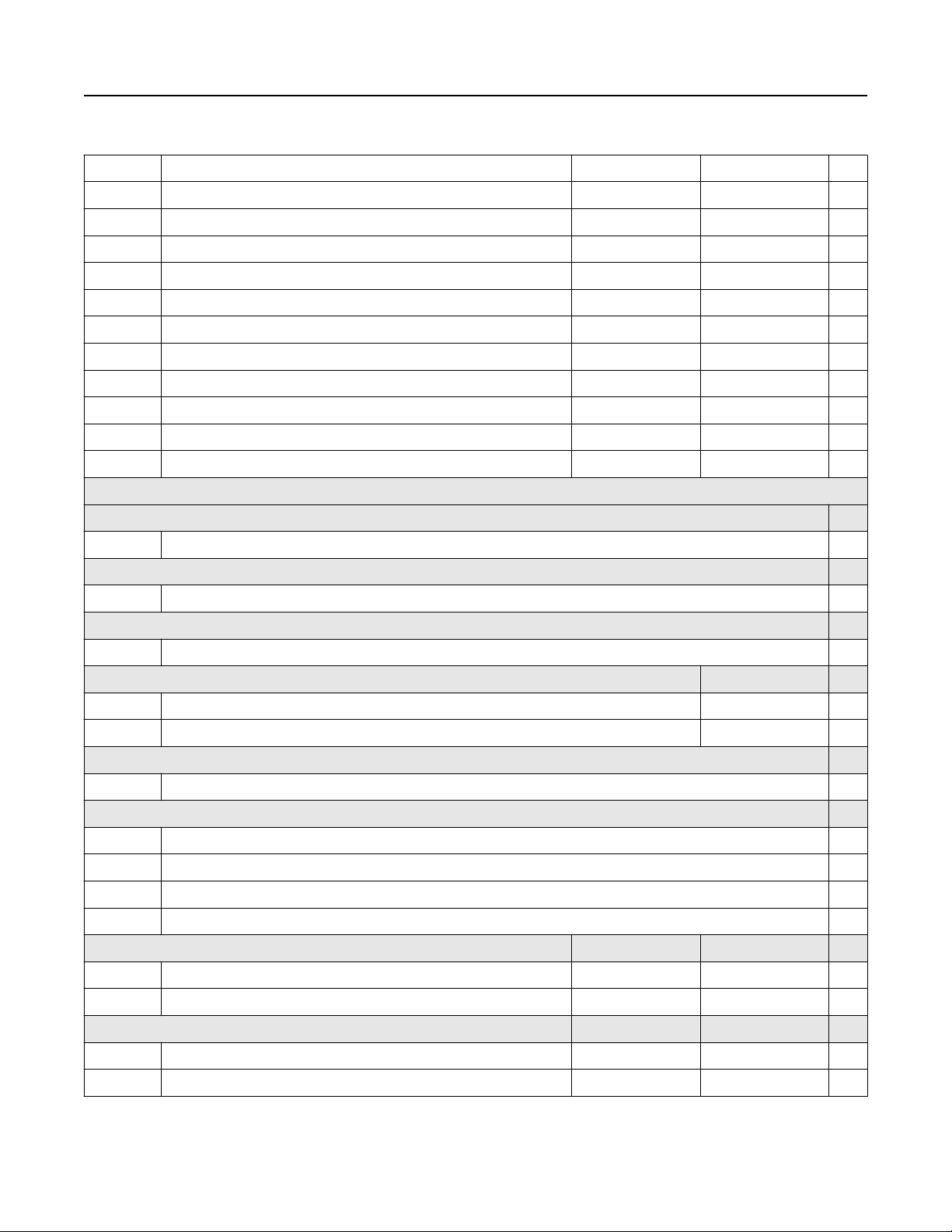

Table 2: Rosemount 2501 Ordering Information (continued)

Process connection size Applications Temperatures

(10)(11)

1

(10)

A

1-in. / 25 mm (DN25) / 25A L 1, 2, 3 ★

1¼-in. / 32 mm (DN32) / 32A All except K 1, 2, 3 ★

5 1½-in. / 40 mm (DN40) / 40A All except K All ★

(12)

2

(12)

3

2-in. / 50 mm (DN50) / 50A All except K All ★

3-in. / 80 mm (DN80) / 80A All except K All ★

4 4-in. / 100 mm (DN100) / 100A All All ★

(5)(10)(11)

B

(5)(10)(11)

C

M30 x 1.5 mm L only 1 only ★

M32 x 1.5 mm L only 1, 2, 3 ★

Process connection rating Sizes Materials (PC)

AA ASME B16.5 Class 150 flange 2, 3, and 4 All except A ★

DZ

(13)

EN1092-1 PN6 flange A and 4 All

(14)

DA EN1092-1 PN16 flange 2 and 4 All except A ★

(5)

HA

HB

(5)

150x150 flange, 4 off ø18 mm fixing holes 4 All except S ★

150x150 flange, 4 off ø14 mm fixing holes 4 All except S ★

NN For use with non-flange process connections All except 3 and 4 All ★

Process connection type Ratings Applications

★

F Flat face flange DZ, DA, HA, and HB All ★

R Raised face flange AA All ★

G BSPP (G) thread NN All except K ★

N NPT thread NN All except K ★

(5)(15)

M

(15)

C

Metric thread NN L ★

Tri Clamp NN L, M, and J ★

Power supply

A 230 Vac 50-60 Hz, motor speed: 1 revolution per minute

B 115 Vac 50-60 Hz, motor speed: 1 revolution per minute

C 48 Vac 50-60 Hz, motor speed: 1 revolution per minute

D 24 Vac 50-60 Hz, motor speed: 1 revolution per minute

E 24 Vdc, motor speed: 1 revolution per minute

F 24 Vdc / 22 to 230 Vac universal voltage, motor speed: 1 revolution per minute ★

R 230 Vac 50-60 Hz, motor speed: 5 revolutions per minute

S 115 Vac 50-60 Hz, motor speed: 5 revolutions per minute

T 48 Vac 50-60 Hz, motor speed: 5 revolutions per minute

U 24 Vac 50-60 Hz, motor speed: 5 revolutions per minute

V 24 Vdc, motor speed: 5 revolutions per minute

W 24 Vdc / 22 to 230 Vac universal voltage, motor speed: 5 revolutions per minute ★

6 Emerson.com/Rosemount

January 2020 Rosemount 2501

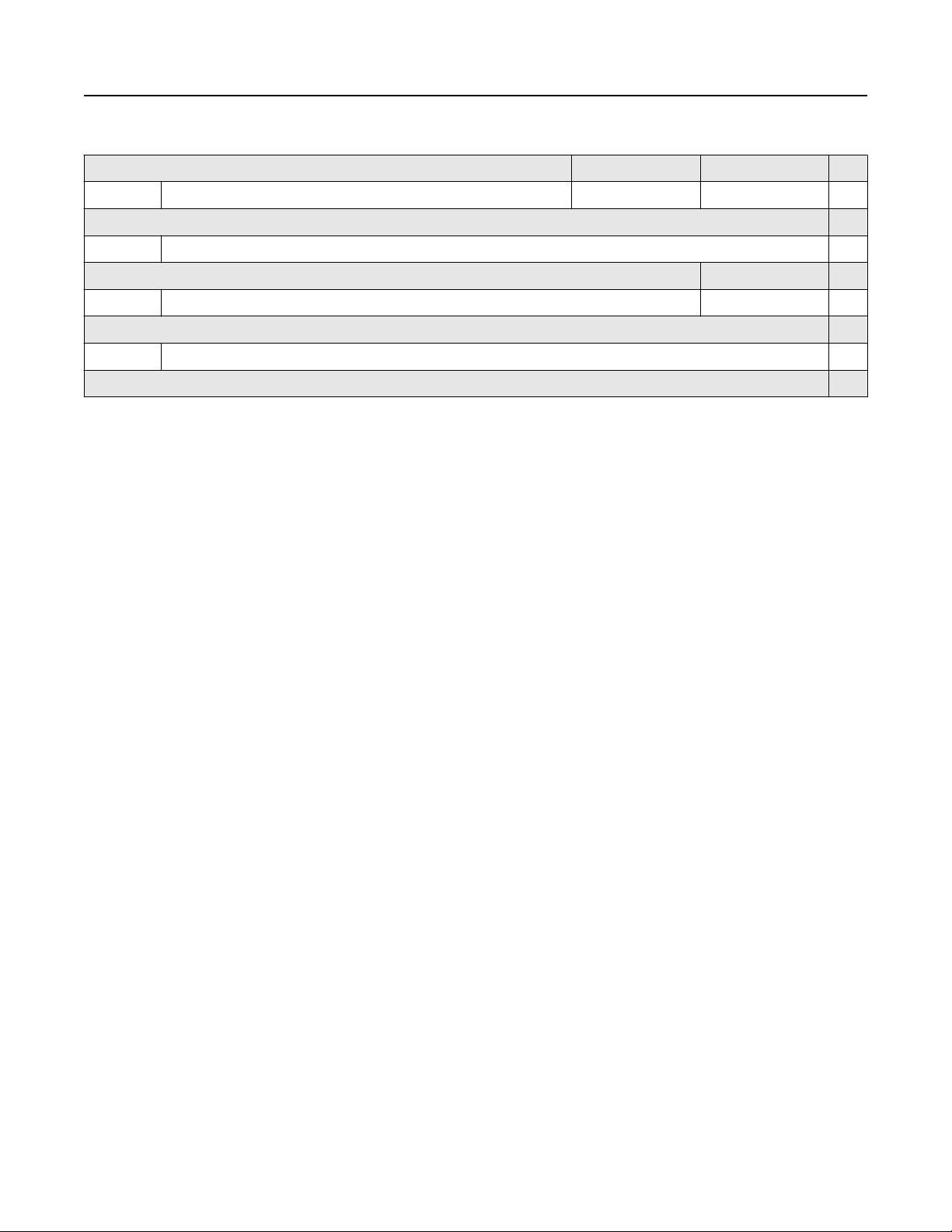

Table 2: Rosemount 2501 Ordering Information (continued)

Paddle length Applications

(16)

A

(16)

B

(16)

C

(16)

D

G Standard length 7.87-in. (200 mm) L, J, and K ★

H Standard length 9.84-in. (250 mm) L, J, and K ★

J Standard length 11.8-in. (300 mm) L, J, and K ★

R Rope fixings only (rope not included) R ★

E Extended shaft/tube, customer specified length in tenths of inches L, M, J, and K ★

M Extended shaft/tube, customer specified length in millimeters L, M, J, and K ★

F Extended rope, customer specified length in tenths of inches R and S ★

N Extended rope, customer specified length in millimeters R and S ★

Specific extended length

Standard length 2.76-in. (70 mm) L ★

Standard length 3.93-in. (100 mm) L ★

Standard length 4.92-in. (125 mm) K ★

Standard length 5.90-in. (150 mm) L, J, and K ★

00000 Factory default length (only if Paddle Length A, B, C, D, G, H, J, or R selected) ★

XXXXX Specific customer-specified length in tenths of inches or millimeters (XXXX.X inches or XXXXX mm) ★

Product certifications Conduit entries

NA No hazardous locations certifications All codes ★

(17)

ND

(17)

NK

(17)

NL

(17)

E2

(17)

E5

(17)

E7

(17)

E8

(17)

EM

(17)

K1

(17)

K7

(17)

KB

(17)

KM

(17)

KY

(17)

KZ

Measuring vane Applications Materials

ATEX Dust certification All codes

IECEx Dust certification All codes

American DIP 4

INMETRO Flameproof 4

American Flameproof/Dust certification 4

IECEx Flameproof/Dust certification 4

ATEX Flameproof/Dust certification 4

Technical Regulations Customs Union (EAC), Dust certification All codes

ATEX Flameproof/Increased Safety/Dust certification All codes

IECEx Flameproof/Increased Safety/Dust certification All codes

American and Canadian DIP 4

Safety/Dust certification All codes

American and Canadian Flameproof/Dust certification 4

American and Canadian Ordinary Location (Unclassified, safe area) certification 4

(18)

A 1.02 x 3.03 inches (26 x 77 mm), boot-shaped vane L A and D ★

B 1.10 x 3.86 inches (28 x 98 mm), boot-shaped vane L All ★

C 1.38 x 4.17 inches (35 x 106 mm), boot-shaped vane All except K All ★

Emerson.com/Rosemount 7

Rosemount 2501 January 2020

Table 2: Rosemount 2501 Ordering Information (continued)

D 1.57 x 3.86 inches (40 x 98 mm), boot-shaped vane All All ★

K 1.57 x 3.15 inches (40 x 80 mm), rectangular notched vane L D and F ★

L 1.97 x 3.86 inches (50 x 98 mm), rectangular vane All A and D ★

M 1.97 x 5.90 inches (50 x 150 mm), rectangular vane All A and D ★

N 1.97 x 9.84 inches (50 x 250 mm), rectangular vane All A and D ★

P 3.86 x 3.86 inches (98 x 98 mm), rectangular vane All All ★

Q 3.86 x 5.90 inches (98 x 150 mm), rectangular vane All A and D ★

R 3.86 x 9.84 inches (98 x 250 mm), rectangular vane All A and D ★

(6)(19)

U

(6)(19)

V

(4)

W

Y Split fin fixing for vane (vane not included) All A and D ★

Options (include with selected model number)

Calibration data certification

3.86 x 3.93 inches (98 x 100 mm), single-sided hinged vane All All ★

3.86 x 7.87 inches (98 x 200 mm), double-sided hinged vane All All ★

3.86 x 9.84 inches (98 x 250 mm), rubber vane, up to 176 °F (80 °C) All A and D ★

Q4 Certificate of functional test ★

Alarm

(20)

AF

Fail-safe alarm ★

Weather protection

P2 Weather protection cover ★

Welded flange

(21)

Paddle length

W1 Process connection flange welded to paddle tube All except A and B ★

(22)

W2

Process connection flange welded to paddle tube, including reinforcing rib All except A, B, C ★

Specific welded flange angle

XX Specific customer-specified angle of flange (0° to 45°) (maximum 30° with Welded Flange W2) ★

Paddle extension

(23)

PE1 Pendulum extension, 7.87 in. (200 mm), vertical or horizontal installation ★

PE2 Pendulum extension, 19.7 in. (500 mm), vertical installation ★

PE3 Pendulum extension, 39.4 in. (1000 mm), vertical installation ★

PE4 Rope extension, 78.7 in. (2000 mm), vertical installation ★

Sliding sleeve

(25)

S1

(24)

Temperatures Pressures

Sliding sleeve, without over-pressure All A ★

S2 Sliding sleeve, with over-pressure 1, 2, 3 All ★

Radial shaft sealing Temperatures Pressures

T1 FPM 1 A ★

T2 PTFE 1 and 2 A ★

8 Emerson.com/Rosemount

January 2020 Rosemount 2501

Table 2: Rosemount 2501 Ordering Information (continued)

Alternative component material

CM1 Ball bearings in stainless steel 1, 2, and 3 All except S ★

Housing heating

(20)

HH1 Heating of housing, for temperature range -4 to -40 °F (-20 to -40 °C) ★

Additional bearings Applications

(27)

BR1

Additional bearings for paddle extension tube M ★

Extended product warranty

WR5 5-year limited warranty ★

Typical model number: 2501 L 1 A A D 1 5 NN G A B 00000 NA D

(1)

Application code K requires a 4-in./DN100 flanged process connection.

(2)

Temperature-extended-shaft dimension is automatically added for this option, see Table 7.

(3)

Maximum overpressure is 1.45 psi (0.1 bar).

(4)

Available when Process Operating Temperature code 1 is selected.

(5)

Available when Process Operation Pressure code A is selected.

(6)

Not available when Process Operating Temperature code 6 is selected.

(7)

Not available when Application Profile J and Process Operating Temperature codes 2 or 3 are selected.

(8)

Not available when Application Profile K and Materials of Construction: Process Connection code D is selected.

(9)

Not available when Application Profile K and Materials of Construction: Process Connection code A is selected

(10)

Not available when Materials of Construction: Process Connection Material code S is selected.

(11)

Not available when Materials of Construction: Extension Material code A is selected.

(12)

Not available when Materials of Construction: Process Connection code A is selected.

(13)

Available when Operating Pressure codes A or B are selected.

(14)

Materials of Construction: Process Connection code A is not available when Process Connection Size code 4 is selected.

(15)

Not available when Process Operating Temperature codes 4, 5, or 6 is selected.

(16)

Not available when Operating Temperature code 4 is selected.

(17)

Please contact your local Emerson representative for the availability of this option.

(18)

Availability of measuring vanes depending on the selected Extension Material code.

(19)

Not available when Materials of Construction: Extension code F and Operating Temperature code 4 or 5 are selected.

(20)

Available when Power Supply code F or W is selected.

(21)

Available when Application Profile code K is selected.

(22)

Not available when customer-specified extended lengths are selected and their material is aluminum.

(23)

Available when Application Profile code L and Extension Material code D are selected.

(24)

Available when Application Profile code M is selected.

(25)

Sliding sleeve option code S1 must not be used in hazardous (classified) areas.

(26)

Not available when Process Connection Size code B is selected.

(27)

Additional bearings must be selected when Application Profile M and Materials of Construction: Extension code F are selected.

(26)

Temperatures Applications

Emerson.com/Rosemount 9

Rosemount 2501 January 2020

Spares and accessories

The specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See Materials selection for more information.

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Table 3: Spares

Part number Description

02500-1000-0001 Motor: 230 Vac (50/60 Hz), 1 revolution/minute ★

02500-1000-0002 Motor: 230 Vac (50/60 Hz), 5 revolutions/minute ★

02500-1000-0003 Motor: 115 Vac (50/60 Hz), 1 revolution/minute ★

02500-1000-0004 Motor: 115 Vac (50/60 Hz), 5 revolutions/minute ★

02500-1000-0005 Motor: 48 Vac (50/60 Hz), 1 revolution/minute ★

02500-1000-0006 Motor: 48 Vac (50/60 Hz), 5 revolutions/minute ★

02500-1000-0007 Motor: 24 Vac (50/60 Hz), 1 revolution/minute ★

02500-1000-0008 Motor: 24 Vac (50/60 Hz), 5 revolutions/minute ★

02500-1000-0009 Motor: 24 Vdc, 1 revolution/minute ★

02500-1000-0010 Motor: 24 Vdc, 5 revolutions/minute ★

02500-1000-0011 Motor: 24 Vdc and 22 to 230 Vac (50/60 Hz), universal voltage, 1 revolution/minute ★

02500-1000-0012

02500-1000-0013 Motor: 24 Vdc and 22 to 230 Vac (50/60 Hz), universal voltage, 1 revolution/minute,

02500-1000-0014

02500-1000-0015 Motor: 24 Vdc and 22 to 230 Vac (50/60 Hz), universal voltage, 5 revolutions/minute, ★

02500-1000-0016

02500-1000-0017 Motor: 24 Vdc and 22 to 230 Vac (50/60 Hz), universal voltage, 5 revolutions/minute,

02500-1000-0018

02500-1000-0021 Paddle: 1.02 x 3.03 in. (26 x 77 mm), boot-shaped vane for M30x1.5 ★

02500-1000-0022 Paddle: 1.57 x 3.86 in. (40 x 98 mm), boot-shaped vane, 304 stainless steel (1.4305) ★

02500-1000-0023 Paddle: 1.10 x 3.86 in. (28 x 98 mm), boot-shaped vane, 304 stainless steel (1.4305) ★

(1)

(1)

(1)

(1)

Motor: 24 Vdc and 22 to 230 Vac (50/60 Hz), universal voltage, 1 revolution/minute,

with fail-safe alarm

with housing heating (for temperatures of -20 to -40 °C)

Motor: 24 Vdc and 22 to 230 Vac (50/60 Hz), universal voltage, 1 revolution/minute,

with fail-safe alarm and housing heating (for temperatures of -20 to -40 °C)

Motor: 24 Vdc and 22 to 230 Vac (50/60 Hz), universal voltage, 5 revolutions/minute,

with fail-safe alarm

with housing heating (for temperatures of -20 to -40 °C)

Motor: 24 Vdc and 22 to 230 Vac (50/60 Hz), universal voltage, 5 revolutions/minute,

with fail-safe alarm and housing heating (for temperatures of -20 to -40 °C)

★

★

★

★

★

★

02500-1000-0024 Paddle: 1.38 x 4.17 in. (35 x 106 mm), boot-shaped vane, 316L stainless steel (1.4404) ★

02500-1000-0025 Paddle: 1.38 x 4.17 in. (35 x 106 mm), boot-shaped vane, 304 stainless steel (1.4305) ★

02500-1000-0026 Paddle: 1.57 x 3.86 in. (40 x 98 mm), boot-shaped vane, 316L stainless steel (1.4404) ★

02500-1000-0027 Paddle: 1.10 x 3.86 in. (28 x 98 mm), boot-shaped vane, 316L stainless steel (1.4404) ★

10 Emerson.com/Rosemount

Loading...

Loading...