Page 1

USER'S MANUAL

➢ To ensure safe usage and full performance of this product, please be sure to read through this

manual completely.

➢ To ensure immediate access whenever needed, store this manual in a safe location.

➢ Unauthorized copying, quotation, or translation of this manual, in whole or in part, without the

written approval of Roland DG Corp., is prohibited.

➢ The contents of this document and the specifications of this product are subject to c hange without

notice.

➢ Roland DG Corp. assumes no responsibility for any loss or damage relating to this product, regard-

less of any defect in this product or this manual. Such loss or damage, whether direct or indirect,

includes, but is not limited to, that arising from the specifications or performance of this product,

that due to failure of the product to perform, and that arising from any article made using this

product.

Page 2

For the USA

FEDERAL COMMUNICATIONS COMMISSION

RADIO FREQUENCY INTERFERENCE

STATEMENT

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules.

These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated

in a commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference

to radio communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Unauthorized changes or modification to this system can void

the users authority to operate this equipment.

The I/O cables between this equipment and the computing

device must be shielded.

For Canada

CLASS A NOTICE

This Class A digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

NOTICE

Grounding Instructions

Do not modify the plug provided - if it will not fit the outlet, have

the proper outlet installed by a qualified electrician.

Check with qualified electrician or service personnel if the

grounding instructions are not completely understood, or if in

doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding

plugs and 3-pole receptacles that accept the tool’s plug.

Repair or replace damaged or worn out cord immediately.

Operating Instructions

KEEP WORK AREA CLEAN. Cluttered areas and benches

invites accidents.

DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use

power tools in damp or wet locations, or expose them to rain.

Keep work area well lighted.

DISCONNECT TOOLS before servicing; when changing

accessories, such as blades, bits, cutters, and like.

REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure the switch is in off position before plugging in.

USE RECOMMENDED ACCESSORIES. Consult the owner’s

manual for recommended accessories. The use of improper

accessories may cause risk of injury to persons.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don’t leave tool until it comes to a complete

stop.

CLASSE A AVIS

Cet appareil numérique de la classe A respecte toutes les

exigences du Règlement sur le matériel brouilleur du

Canada.

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Page 3

Contents

To Ensure Safe Use .......................................................................................................................4

Pour utiliser en toute sécurité ..................................................................................................11

Important Notes on Handling and Use ...........................................................................................18

About the Documentation for This Machine...................................................................................19

Chapter 1 Getting Started ..............................................................................................................21

1-1 Machine Highlights ............................................................................................................................................. 22

Features ......................................................................................................................................... 22

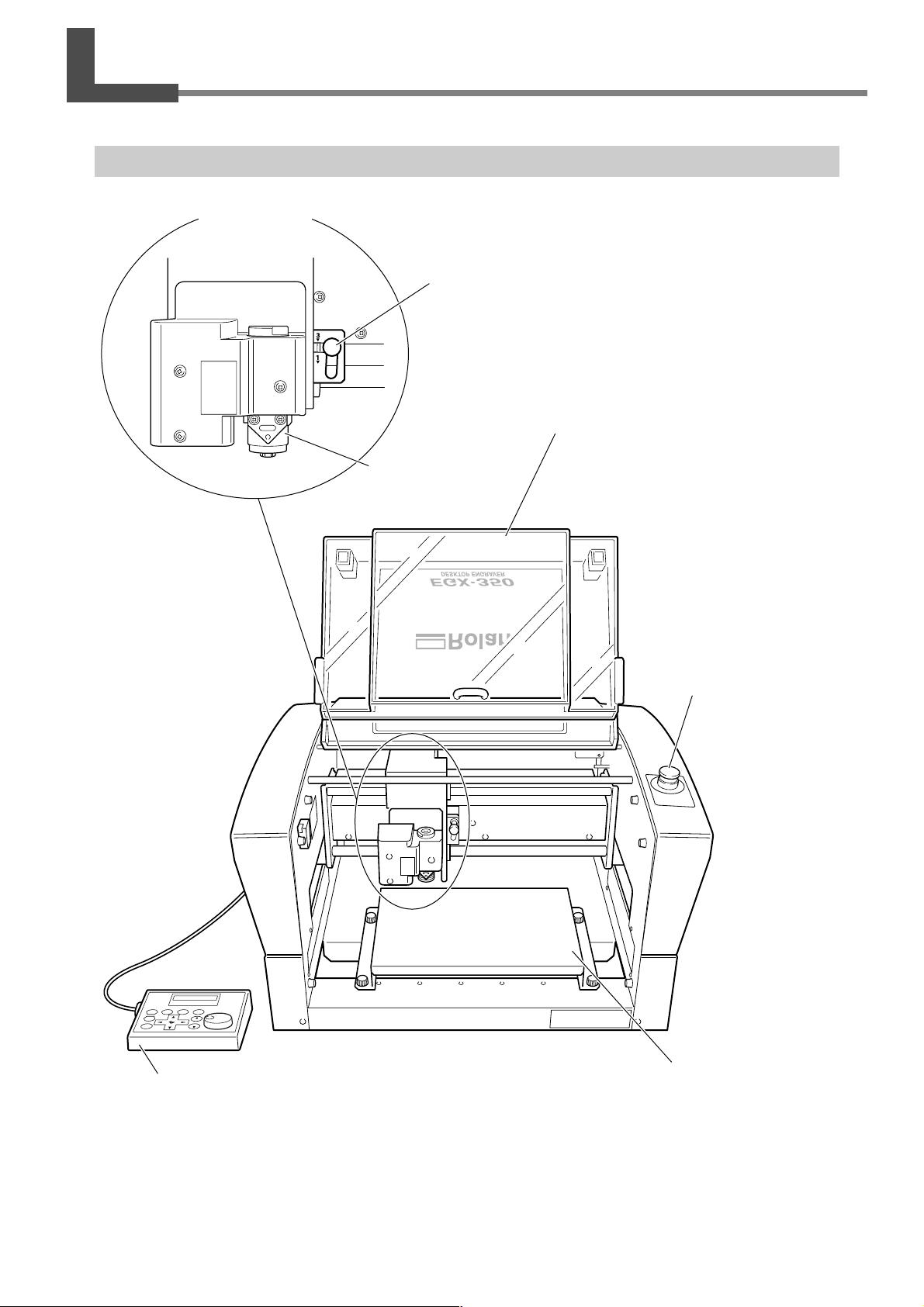

1-2 Part Names and Functions ...............................................................................................................................23

Front and Interior........................................................................................................................... 23

Side ............................................................................................................................................... 24

Chapter 2 Installation and Setup....................................................................................................25

2-1 Checking the Included Items ...........................................................................................................................26

2-2 Installation ............................................................................................................................................................27

About Emplacement and Installation............................................................................................. 27

Installation Environment................................................................................................................ 27

Unpacking..................................................................................................................................... 29

2-3 Cable Connections............................................................................................................................................. 30

Connecting the Handy Panel ......................................................................................................... 30

Connecting the Power Cord .......................................................................................................... 31

Connecting a Computer Via a Communication Cable ................................................................... 32

2-4 Selecting the Language ...................................................................................................................................... 33

Selecting the Language Used for Text on the Display Screen......................................................... 33

2-5 Before Starting Operations..............................................................................................................................35

Spindle Run-in (Warm-up)............................................................................................................. 35

Chapter 3 Basic Operation...............................................................................................................37

3-1 Types of Emergency Stops to Ensure Safety.................................................................................................38

How to Perform an Emergency Stop.............................................................................................. 38

To Cancel an Emergency Stop ....................................................................................................... 38

Emergency Stop Due to Opening or Closing the Front Cover........................................................ 39

3-2 Starting and Quitting ......................................................................................................................................... 40

How to Start the Machine.............................................................................................................. 40

Shutdown ...................................................................................................................................... 41

3-3 Using the Handy Panel ...................................................................................................................................... 42

3-4 Moving the Cutter.............................................................................................................................................. 43

Terms Indicating the Cutter Position.............................................................................................. 43

Viewing the Cutter Position........................................................................................................... 43

Manual Movement ........................................................................................................................ 44

Moving to a Specific Position Automatically ................................................................................. 45

3-5 Spindle Operation .............................................................................................................................................. 47

Starting and Stopping Spindle Rotation ......................................................................................... 47

Adjusting the Spindle Speed.......................................................................................................... 48

3-6 Pausing and Stopping Cutting ..........................................................................................................................49

Pausing and Resuming Cutting ...................................................................................................... 49

Stopping Cutting............................................................................................................................ 50

Chapter 4 Engraving..........................................................................................................................51

4-1 Flow of Engraving Operations......................................................................................................................... 52

4-2 Mounting a Workpiece...................................................................................................................................... 54

1

Page 4

Contents

4-3 Selection of the Cutter (Usage Examples)................................................................................................... 55

4-4 Cutter Installation Method 1 (With Nose Unit) ........................................................................................ 56

Installing a Character Cutter (With Nose Unit) .............................................................................. 5 6

Important Notes When Using the Nose Unit................................................................................. 61

4-5 Cutter Installation Method 2 (No Nose Unit)............................................................................................ 62

Installing a Character Cutter (With No Nose Unit) ........................................................................ 62

4-6 Cutter Installation Method 3 (Diamond Scraper)...................................................................................... 67

Installing a Diamond Scraper ........................................................................................................ 67

4-7 Cutter Installation Method 4 (End mill)........................................................................................................ 71

Installing a End Mill....................................................................................................................... 71

4-8 Setting the XY Origin Point............................................................................................................................. 75

Setting the XY Origin Point (Home Position) ................................................................................. 75

4-9 Performing Engraving......................................................................................................................................... 76

Performing Engraving .................................................................................................................... 76

Adjusting the Cutter Feed Rate During Engraving (Override)......................................................... 77

Executing Repeated Cutting........................................................................................................... 78

Chapter 5 Feature reference............................................................................................................79

5-1 Attaching the Vacuum Adapter for Chip Cleaning ...................................................................................... 80

Using the Vacuum Adapter ............................................................................................................ 80

5-2 The Position of the Lock Lever .......................................................................................................................82

5-3 Surface Leveling of the Workpiece Table ...................................................................................................... 83

5-4 Menu List ..............................................................................................................................................................84

Main Menu.................................................................................................................................... 84

Submenus...................................................................................................................................... 85

Origin-setting Menu ...................................................................................................................... 86

Pause Menu ................................................................................................................................... 86

Copy Menu.................................................................................................................................... 87

5-5 Description of Menu Items ..............................................................................................................................88

Main Menu.................................................................................................................................... 88

I/O Menu (Submenu)..................................................................................................................... 89

Others Menu (Submenu) ............................................................................................................... 90

Adjustment Menu (Submenu) ........................................................................................................ 91

Origin-setting Menu ...................................................................................................................... 92

Pause Menu ................................................................................................................................... 93

Copy Menu.................................................................................................................................... 93

Chapter 6 Maintenance ....................................................................................................................95

6-1 Daily Care............................................................................................................................................................. 96

Cleaning ........................................................................................................................................ 96

Cleaning Inside the Front Cover .................................................................................................... 96

Cleaning Around the Spindle ........................................................................................................ 97

6-2 Maintenance and Inspection............................................................................................................................. 98

Spindle Maintenance..................................................................................................................... 98

Chapter 7 Troubleshooting ..............................................................................................................99

7-1 Troubleshooting (Engraving)...........................................................................................................................100

The cutting-in depth is not uniform (when using the nose unit)................................................... 100

The cutting-in depth is not uniform (when not using the nose unit). ........................................... 100

The cutter leaves tracks at places where cutting-in starts or where lines change direction.......... 100

An engraved bottom surface is rough or burring remains............................................................ 100

Engraved lines are uneven or wavy.............................................................................................. 100

7-2 Troubleshooting (Operation) .........................................................................................................................101

The power does not come on...................................................................................................... 101

Initialization is not performed or initialization fails..................................................................... 101

2

Page 5

Contents

Operations are ignored................................................................................................................ 101

Abnormal cutting is performed.................................................................................................... 101

The spindle doesn’t rotate during engraving. ............................................................................... 101

Descent doesn’t stop (when automatic Z control is on)............................................................... 101

The USB cable came loose during engraving. ............................................................................. 102

7-3 Responding to a Message ...............................................................................................................................103

7-4 Responding to an Error Message..................................................................................................................104

Chapter 8 Appendix ........................................................................................................................107

8-1 Examples of Settings for Cutting Parameters............................................................................................108

Example Settings ......................................................................................................................... 108

Tips for Fine-tuning ..................................................................................................................... 108

8-2 Location of Power Rating and Serial Number Label................................................................................109

8-3 Interface Specifications.................................................................................................................................... 110

Serial Connector.......................................................................................................................... 110

Expansion Connector .................................................................................................................. 111

8-4 Main Unit Specification....................................................................................................................................112

Dimensions of Outline ................................................................................................................ 112

Work area.................................................................................................................................... 113

Workpiece-table Installation-area Dimensional Drawing............................................................ 114

Main Specifications ..................................................................................................................... 115

System Requirements for USB Connection.................................................................................. 115

Company names and product names are trademarks or registered trademarks of their respective holders.

http://www.rolanddg.co.jp/Copyright © 2007 Roland DG Corporation

3

Page 6

To Ensur e Safe Use

Improper handling or operation of this machine may result in injury or damage to property. Points which

must be observed to prevent such injury or damage are described as follows.

About WARNING and CAUTION Notices

WARNING

CAUTION

Used for instructions intended to alert the user to the risk of death or severe

injury should the unit be used improperly.

Used for instructions intended to alert the user to the risk of injury or material

damage should the unit be used improperly.

Note: Material damage refers to damage or other adverse eff ects caused with

About the Symbols

The symbol alerts the user to important instructions or warnings. The specific meaning of

the symbol is determined by the design contained within the triangle. The symbol at left means

"danger of electrocution."

The symbol alerts the user to items that must never be carried out (are forbidden). The

specific thing that must not be done is indicated by the design contained within the circle. The

symbol at left means the unit must never be disassembled.

The symbol alerts the user to things that must be carried out. The specific thing that must be

done is indicated by the design contained within the circle. The symbol at left means the pow er cord plug must be unplugged from the outlet.

respect to the home and all its furnishings, as well to domestic animals

or pets.

4

Page 7

To Ensure Safe Use

Incorrect operation may cause injury.

WARNING

Be sure to follow the operation procedures described in this documentation.

Never allow anyone unfamiliar with the

usage or handling of the machine to touch

it.

Incorrect usage or handling ma y lead to an accident.

Keep children awa y fr om the machine.

The machine includes areas and components

that pose a hazard to children and ma y result in

injury, blindness, choking, or other serious accident.

Never operate the machine while tir ed or

after ingesting alcohol or any medication.

Operation requires unimpaired judgment. Impaired judgment may result in an accident.

Conduct operations in a clean, brightly lit

location.

Working in a location that is dark or cluttered

may lead to an accident, such as becoming caught

in the machine as the result of an inadvertent

stumble.

WARNING

Never attempt to disassemble, repair, or

modify the machine.

Doing so may result in fire, electrical shock, or

injury. Entrust repairs to a trained service technician.

CAUTION

Never climb or lean on the machine.

The machine is not made to support a person.

Climbing or leaning on the machine may dislodge components and cause a slip or fall, resulting in injury.

Never use the machine for any purpose

for which it is not intended, or use the

machine in an undue manner that exceeds

its capacity .

Doing so may result in injury or fire.

Never use a cutting tool that has become

dull. Perform frequent maintenance to

keep and use the machine in good working order.

Unreasonable usage may r esult in fire or injury.

For accessories (optional and consumable

items, power cord, and the like), use only

genuine articles compatible with this machine.

Incompatible items may lead to an accident.

Before attempting cleaning, maintenance,

or attachment or detachment of optional

items, disconnect the power cord.

Attempting such operations while the machine

is connected to a power source may result in

injury or electrical shock.

5

Page 8

To Ensure Safe Use

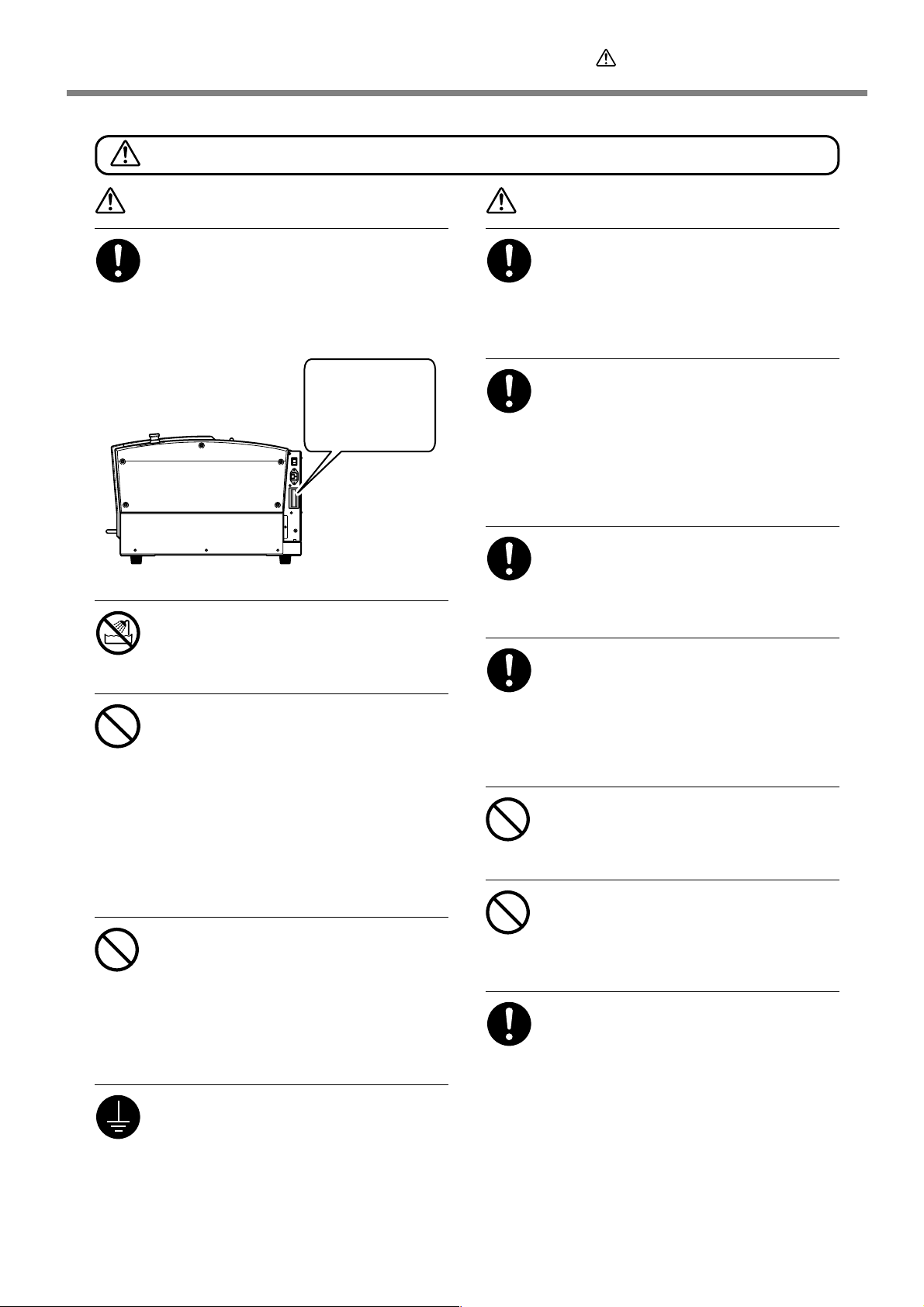

This machine weighs 34 kg (75 lb .)

The cutting waste or workpiece may catch fire or pose a health hazard.

CAUTION

Unloading and emplacement are operations that must be performed by 2 persons or more.

T asks that r equire undue effort when performed

by a small number of persons may r esult in physical injury. Also , if dropped, such items ma y cause

injury.

WARNING

Never attempt to cut magnesium or any

other such flammable material.

Fire may occur during cutting.

Keep open flame a wa y from the work area.

Cutting waste may ignite. Powdered material is

extremely flammable, and even metal material

may catch fire.

CAUTION

Install in a location that is level and stab le.

Installation in an unsuitable location may cause

an accident, including a fall or tipover.

CAUTION

W ear dust goggles and a mask. W ash a way

any cutting waste remaining on the hands.

Accidentally swallowing or inhaling cutting waste

may be hazardous to the health.

When using a vacuum cleaner to take up

cutting waste, exer cise caution to pre vent

fire or dust explosion.

T aking up fine cuttings using an or dinary vacuum

cleaner may cause danger of fire or explosion.

Check with the manufacturer of the vacuum

cleaner. When the safety of use cannot be determined, clean using a brush or the like, without using the vacuum cleaner.

6

Page 9

To Ensure Safe Use

Danger of pinching, entanglement, and burns.

WARNING

Never attempt operation while w earing a

necktie, necklace, loose clothing, or glo ves.

Bind long hair securely.

Such items may become caught in the machine,

resulting in injury .

Securely fasten the cutting tool and workpiece in place. After securing in place,

make sure no wrenches or other articles

have inadv ertently been left behind.

Otherwise such articles may be thrown from

the machine with force, posing a risk of injury.

Exercise caution to avoid being pinched

or becoming caught.

Inadvertent contact with certain areas may cause

the hand or fingers to be pinched or become

caught. Use care when performing operations.

WARNING

Caution: cutting tool.

The cutting tool is sharp. To avoid injury, exercise caution.

Caution: high temperatur es.

The cutting tool and spindle motor become hot.

Exercise caution to avoid fire or burns.

7

Page 10

To Ensure Safe Use

Danger of electrical short, shock, electrocution, or fire

WARNING

Connect to an electrical outlet that complies with this machine’ s ratings (f or voltage, frequency, and current).

Incorrect voltage or insufficient current may

cause fire or electrical shock.

Ratings

Never use out of doors or in any location

where exposure to water or high humidity may occur . Never touch with wet hands.

Doing so may result in fire or electrical shock.

Never allow any foreign object to get inside. Never expose to liquid spills.

Inserting objects such as coins or matches or

allowing beverages to be spilled into the ventilation ports may result in fire or electrical shock.

If anything gets inside, immediately disconnect

the power cord and contact your authorized

Roland DG Corp. dealer.

Never place an y flammable object nearby .

Never use a combustible aerosol spray

nearby. Never use in any location where

gases can accumulate.

Combustion or explosion may be a danger.

Handle the power cord, plug, and electrical outlet correctly and with care. Never

use any article that is damaged.

Using a damaged article may result in fire or

electrical shock.

WARNING

When using an extension cord or power

strip, use one that adequately satisfies the

machine’s ratings (for voltage, frequency,

and current).

Use of multiple electrical loads on a single electrical outlet or of a lengthy extension cord may

cause fire.

When the machine will be out of use for a

prolonged period, disconnect the power

cord.

This can prevent accidents in the event of current leakage or unintended startup.

Connect to ground.

This can prevent fir e or electrical shock due to

current leakage in the event of malfunction.

Position so that the power plug is within

immediate reach at all times.

This is to enable quick disconnection of the

power plug in the event of an emergency. Install

the machine next to an electrical outlet. Also,

provide enough empty space to allow immediate access to the electrical outlet.

Never use cutting oil.

This machine is not designed for the flow of

cutting oil. Oil may get inside the machine and

cause fire or electrical shock.

Never use a pneumatic blower.

This machine is not compatible with a pneumatic

blower. Cutting waste may get inside the machine and cause fire or electrical shock.

If sparking, smoke, burning odor, unusual

sound, or abnormal operation occurs, immediately unplug the power cord. Never

use if any component is damaged.

Continuing to use the machine may r esult in fire,

electrical shock, or injury. Contact your authorized Roland DG Corp. dealer.

8

Page 11

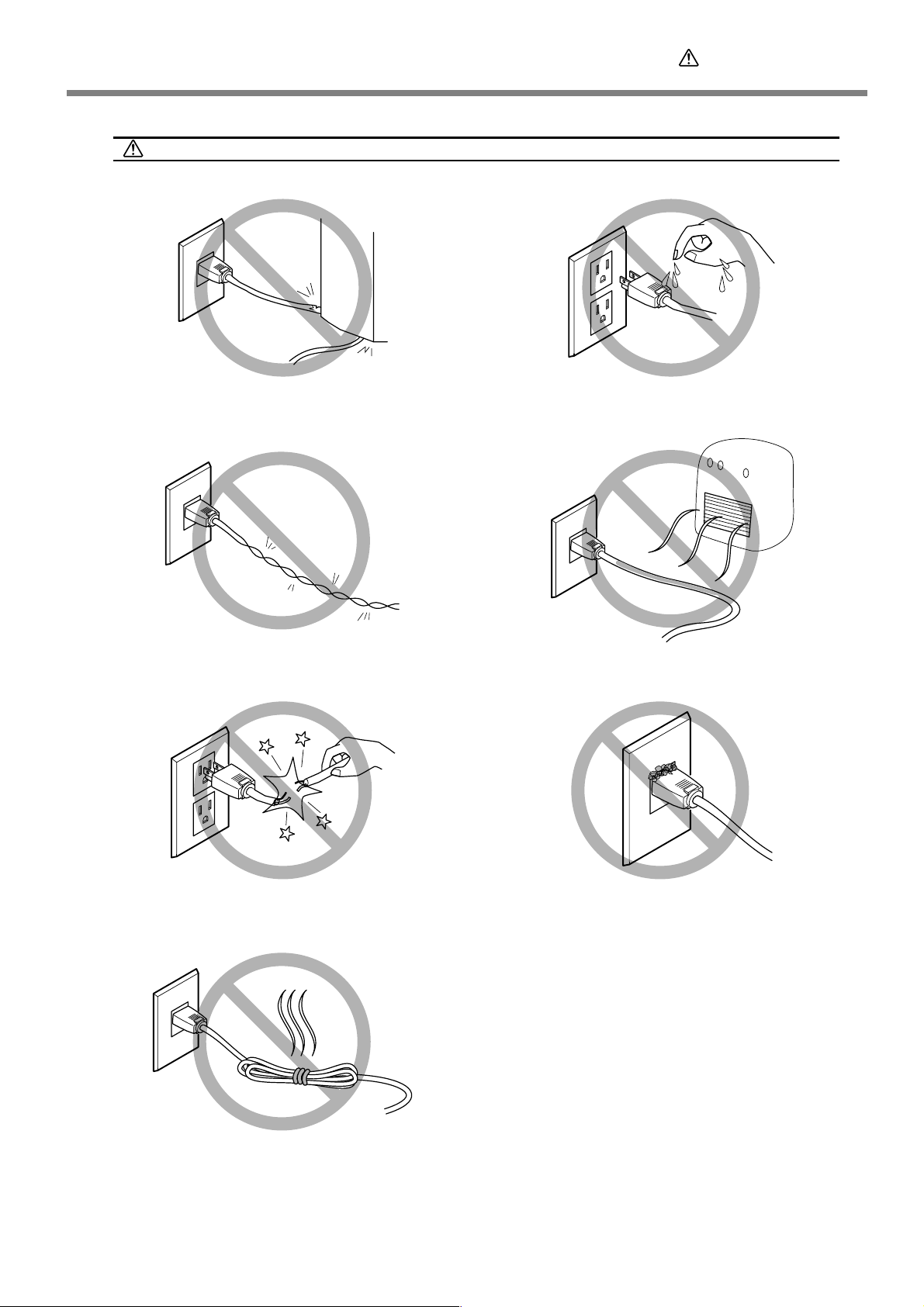

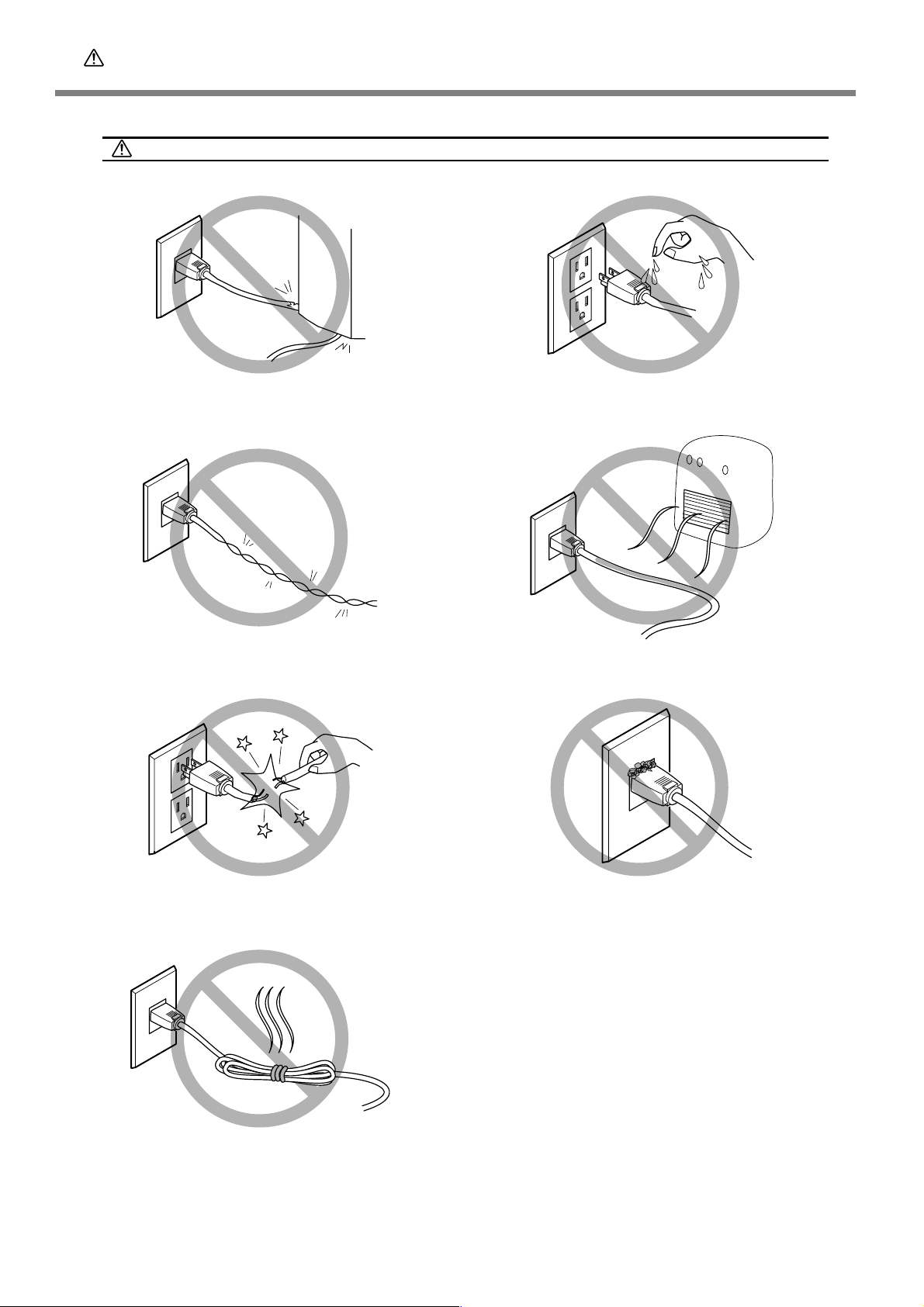

Important notes about the power cord, plug, and electrical outlet

To Ensure Safe Use

Never place any object on top or subject to

damage.

Never bend or twist with undue force.

Never allow to get wet.

Never make hot.

Never pull with undue force.

Never bundle, bind, or roll up.

Dust may cause fire.

9

Page 12

To Ensure Safe Use

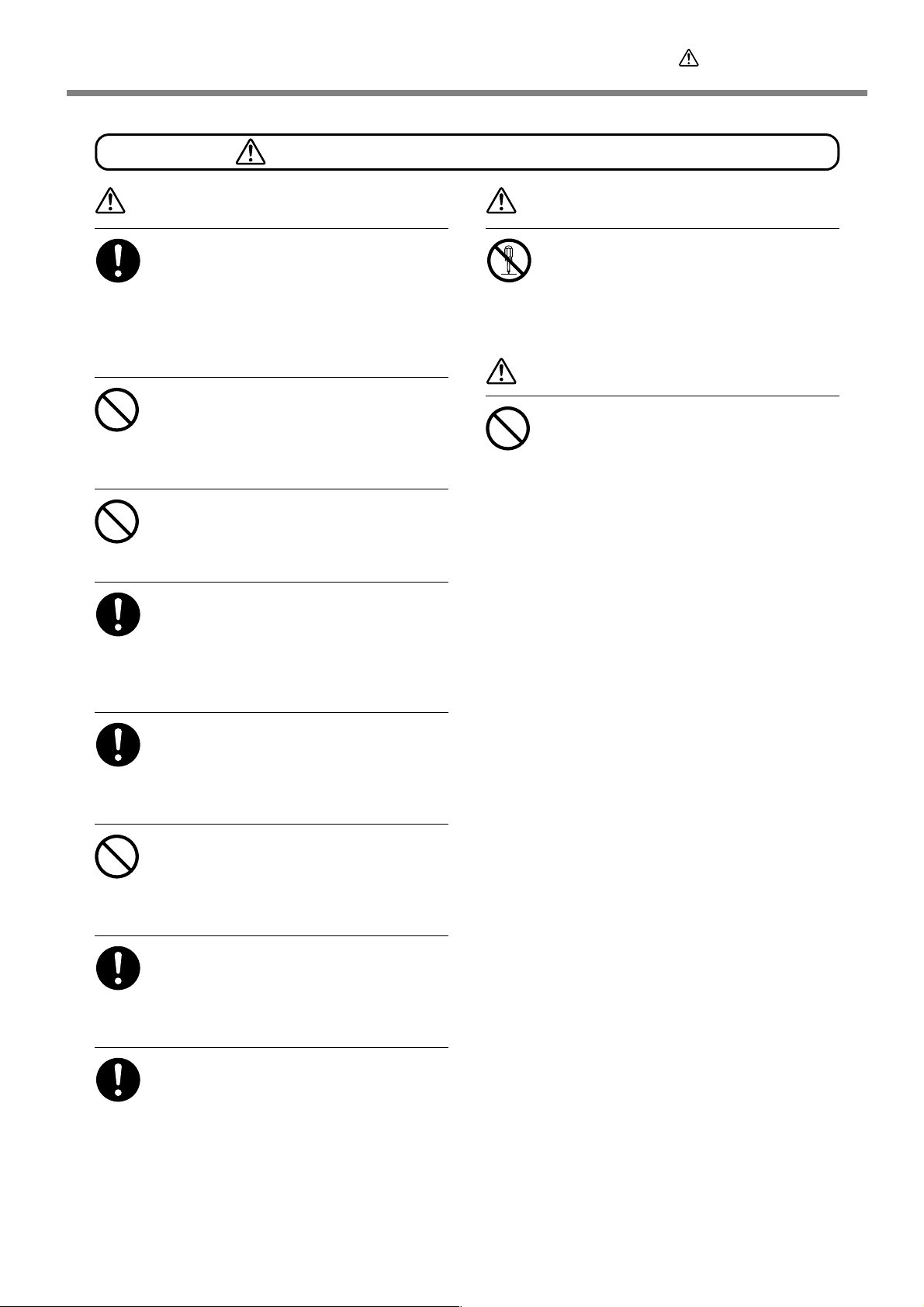

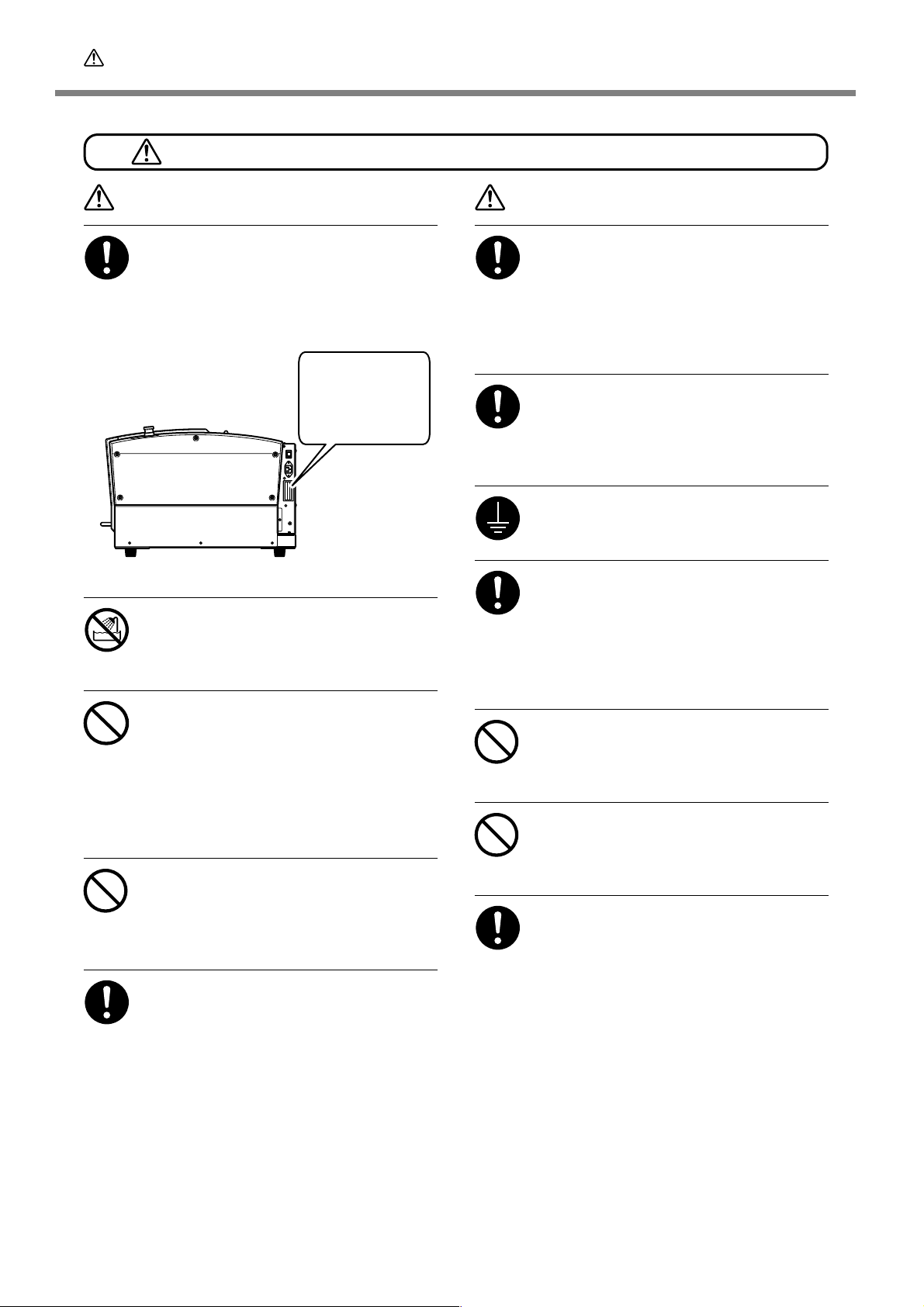

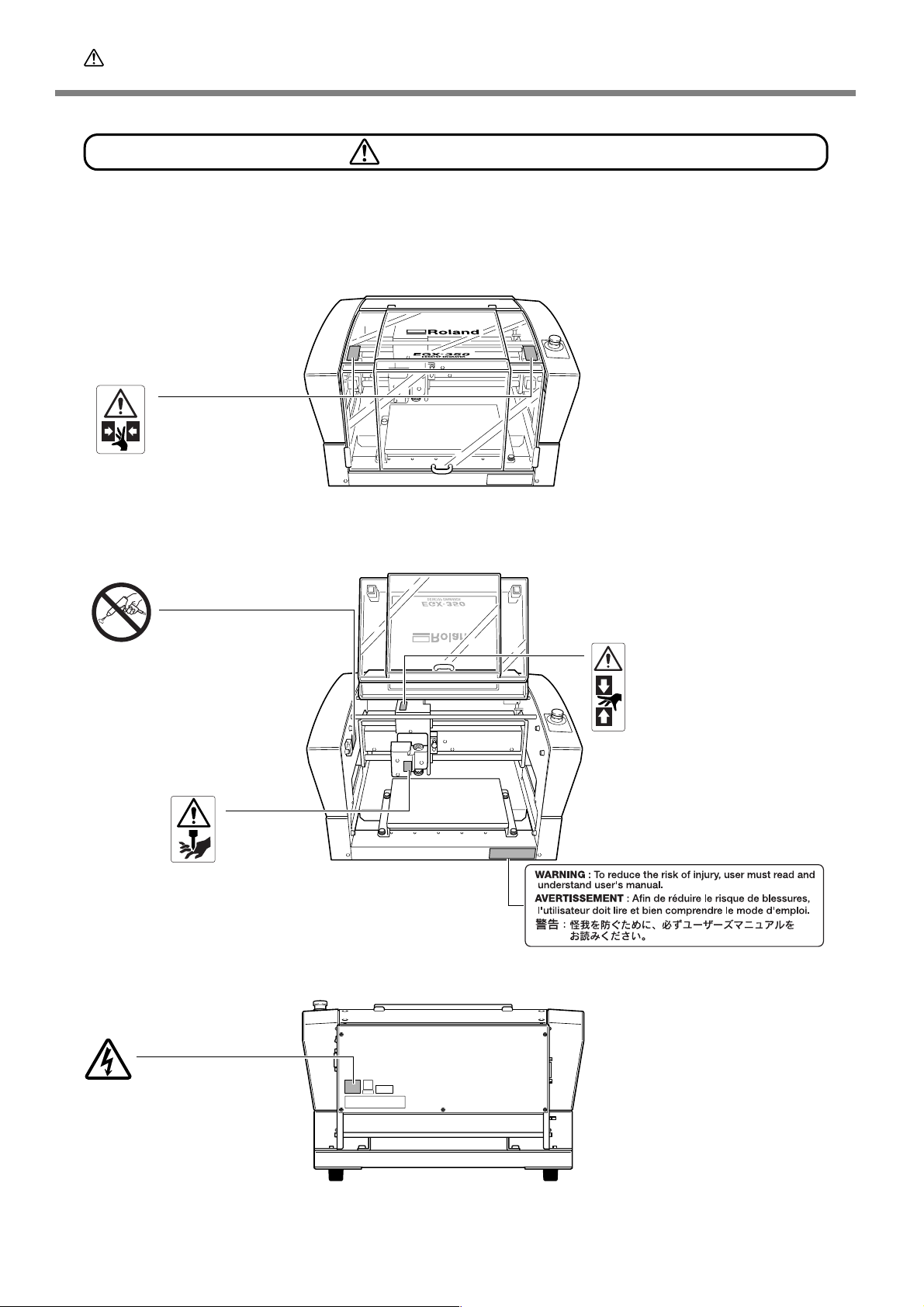

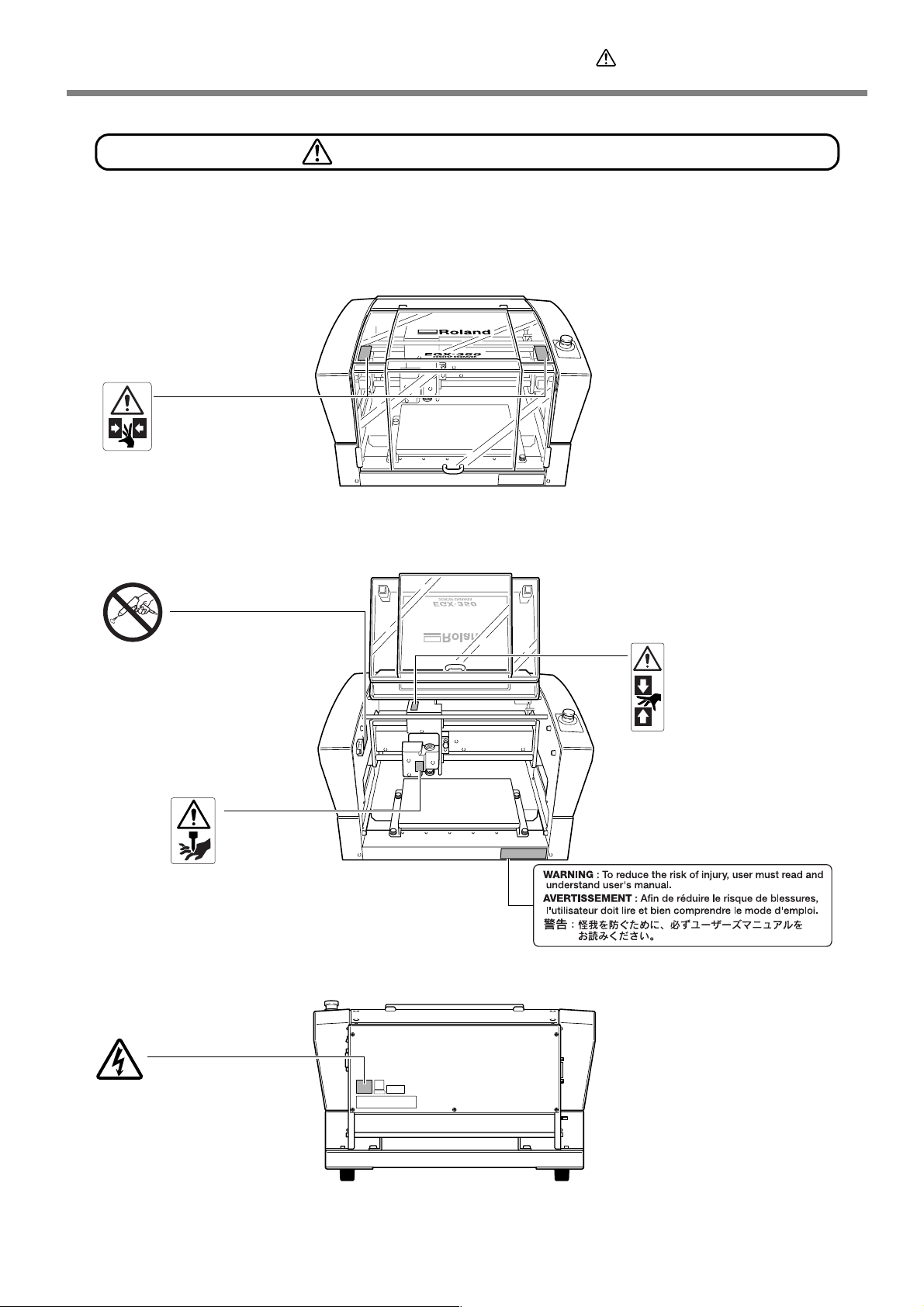

Warning Labels

Warning labels are affixed to make areas of danger immediately clear. The meanings of these

labels are as follo ws. Be sure to heed their warnings.

Also, never r emove the labels or allow them to become obscured.

Top

Caution: Pinching Hazard

Be careful not to allow the fingers to

become pinched when loading media

or closing covers.

Never use a pneumatic blower.

This machine is not compatible with

a pneumatic blower. Cutting waste

may get inside the machine and

cause fire or electrical shock.

Caution: Sharp Tool

Inadvertent contact may

cause injury.

Front/Inside

Caution: Pinching Hazard

Contact during operation may

cause the hand or fingers to

become pinched, resulting in

injury.

Rear

Caution: High Voltage

Cover removal may pose hazard of

shock or electrocution due to high

voltage.

10

Page 13

Pour utiliser en toute sécurité

La manipulation ou l'utilisation inadéquates de cet appareil peuvent causer des blessures ou

des dommages matériels. Les précautions à pr endre pour prévenir les blessur es ou les dommages

sont décrites ci-dessous.

Avis sur les avertissements

Utilisé pour avertir l'utilisateur d'un risque de décès ou de blessure grave en

ATTENTION

PRUDENCE

À propos des symboles

cas de mauvaise utilisation de l'appareil.

Utilisé pour avertir l'utilisateur d'un risque de blessure ou de dommage matériel

en cas de mauvaise utilisation de l'appareil.

* Par dommage matériel, il est entendu dommage ou tout autre effet

indésirable sur la maison, tous les meubles et même les animaux

domestiques.

Le symbole attire l'attention de l'utilisateur sur les instructions importantes ou les

avertissements. Le sens précis du symbole est déterminé par le dessin à l'intérieur du triangle.

Le symbole à gauche signifie "danger d'électrocution."

Le symbole avertit l'utilisateur de ce qu'il ne doit pas faire, ce qui est interdit. La chose

spécifique à ne pas faire est indiquée par le dessin à l'intérieur du cercle. Le symbole à gauche

signifie que l'appareil ne doit jamais être démonté.

Le symbole prévient l'utilisateur sur ce qu'il doit faire. La chose spécifique à faire est indiquée

par le dessin à l'intérieur du cercle. Le symbole à gauche signifie que le fil électrique doit être

débranché de la prise.

11

Page 14

Pour utiliser en toute sécurité

L’utilisation incorrecte peut causer des blessures

ATTENTION

S’assurer de suivre les procédures

d’utilisation décrites dans la documentation. Ne jamais permettre à quiconque ne

connaît pas le fonctionnement ou la

manutention de l’appareil de le toucher.

L’utilisation ou la manutention incorrectes

peuvent causer un accident.

Garder les enfants loin de l’appareil.

L’appareil comporte des zones et des

composants qui présentent un danger pour les

enfants et qui pourraient causer des blessures,

la cécité, la suffocation ou d’autres accidents

graves.

Ne jamais faire fonctionner l’appareil

après avoir consommé de l’alcool ou des

médicaments, ou dans un état de fatigue.

L ’utilisation de l’appareil exige un jugement sans

faille. L’utilisation avec les facultés affaiblies

pourrait entraîner un accident.

Utiliser l’appareil dans un endroit propre

et bien éclairé.

T ra vailler dans un endroit sombr e ou encombré

peut causer un accident; l’utilisateur risque, par

exemple, de trébucher malencontreusement et

d’être coincé par une partie de l’appareil.

ATTENTION

Débrancher le câble d’alimentation avant

de procéder au nettoy age ou à l’entr etien

de l’appareil, et avant d’y fixer ou d’en

retirer des accessoires en option.

Tenter ces opérations pendant que l’appareil est

branché à une source d’alimentation peut causer

des blessures ou un choc électrique.

Ne jamais tenter de démonter , de réparer

ou de modifier l’appareil.

Le non-respect de cette consigne risque de

provoquer un incendie, un choc électrique ou

des blessures. Confier les réparations à un

technicien ayant la formation requise.

PRUDENCE

Ne jamais grimper ni s’appuyer sur la

machine.

La machine n’est pas conçue pour supporter le

poids d’une personne. Grimper ou s’appuyer sur

la machine peut déplacer des éléments et causer

un faux pas ou une chute, ce qui causerait des

blessures.

Ne jamais utiliser l’appareil à des fins

autres que celles pour lesquelles il est

conçu. Ne jamais l’utiliser de manière abusive ou d’une manière qui dépasse sa

capacité.

Le non-respect de cette consigne peut causer

des blessures ou un incendie.

Ne jamais utiliser un outil de coupe

émoussé. Procéder fréquemment aux

travaux d’entretien pour gar der l’appareil

en bon état de fonctionnement.

L’usage abusif peut causer un incendie ou des

blessures.

Utiliser uniquement des accessoires

d’origine (accessoires en option, articles

consommables, câble d’alimentation et

autres articles semblables), compatibles

avec l’appar eil.

Les articles incompatibles risquent de causer des

accidents.

12

Page 15

Pour utiliser en toute sécurité

Le poids de cet appareil est de 34 kg (75 lb.)

Les débris de coupe peuvent s ’enflammer ou présenter un

risque pour la santé.

PRUDENCE

Le déchargement et la mise en place

doivent être faits par au moins ****

personnes.

Les tâches qui exigent un effort trop grand si

elles sont exécutées par un petit nombre de

personnes peuvent être cause de blessures. La

chute d’articles très lourds peut aussi causer des

blessures.

ATTENTION

Ne jamais tenter de couper du magnésium

ni aucun autre matériau inflammable.

Un incendie pourrait se produire pendant la

coupe.

Ne pas approcher une flamme nue de

l’espace de travail.

Les rognures de coupe peuv ent s’enflammer . Les

matériaux pulvérisés sont extrêmement

inflammables et même le métal peut s’enflammer .

PRUDENCE

Installer l’appareil à un endroit stable et

plat.

Installer l’appareil à un endroit ina pproprié peut

provoquer un accident grave comme le

renversement ou la chute.

PRUDENCE

Porter des lunettes de protection et un

masque. Rincer toutes les rognures de

coupe qui pourraient rester collées aux

mains.

Avaler ou respirer accidentellement des

rognures de coupe peut êtr e dangereux pour la

santé.

Si un aspirateur est utilisé pour ramasser

les rognur es de coupe, faire preuv e de prudence pour empêcher que la poussière

s’enflamme ou explose.

Ramasser des rognures fines à l’aide d’un

aspirateur ordinaire peut créer un risque

d’incendie ou d’explosion. Vérifier auprès du

fabricant de l’aspirateur. Dans les cas où il est

impossible de déterminer si un aspirateur peut

être utilisé sans danger, se servir d’une brosse

ou d’un article semblable plutôt que d’un

aspirateur.

13

Page 16

Pour utiliser en toute sécurité

Certains éléments peuvent présenter un risque de pincement,

d’emmêlement, de brûlure ou d’autres dangers.

ATTENTION

Ne jamais faire fonctionner l’appareil si on

porte une cravate, un collier ou des

vêtements amples. Bien attacher les

cheveux longs.

Ces vêtements ou ces objets peuvent être

coincés dans l’appareil, ce qui causerait des

blessures.

Fixer solidement l’outil de coupe et la

pièce à travailler. Une fois qu’ils sont fixés

solidement, s’assurer qu’aucun outil ni

aucun autre objet n’a été laissé en place.

Si tel était le cas, ces objets pourraient être

projetés avec force hors de l’appareil et causer

des blessures.

ATTENTION

Faire preuve de prudence pour éviter

l’écrasement ou le coincement.

La main ou les doigts peuvent être écrasés ou

coincés s’ils entrent en contact avec certaines

surfaces par inadvertance. Faire preuve de prudence pendant l’utilisation de l’appareil.

Attention : outil de coupe.

L ’outil de coupe est acéré. Faire preuve de prudence pour éviter les blessures.

Attention : températures élevées.

L’outil de coupe et le moteur chauffent. Faire

preuve de prudence pour éviter un incendie ou

des brûlures.

14

Page 17

Pour utiliser en toute sécurité

Risque de décharge ou de choc électrique, d’électrocution ou d’incendie

ATTENTION

Brancher à une prise électrique conforme

aux caractéristiques de cet appareil (tension, fréquence et courant).

Une tension incorrecte ou un courant insuffisant

peuvent causer un incendie ou un choc

électrique.

Caractéristiques

Never use out of doors or in any location

where exposure to water or high humidity may occur . Never touch with wet hands.

Doing so may result in fire or electrical shock.

Ne jamais insérer d’objet étranger dans

l’appareil. Ne jamais e xposer l’appareil aux

déversements de liquides.

L’insertion d’objets comme des pièces de

monnaie ou des allumettes, ou le déversement

de liquides dans les orifices de ventilation

peuvent causer un incendie ou un choc

électrique. Si un objet ou du liquide s’infiltre dans

l’appareil, débrancher immédiatement le câble

d’alimentation et communiquer avec le

représentant Roland DG autorisé.

Ne jamais placer d’objet inflammable à

proximité de l’a ppareil. Ne jamais utiliser

de produit inflammable en aérosol à

proximité de l’a ppareil. Ne jamais utiliser

l’appareil dans un endroit où des gaz

peuvent s’accumuler.

Une combustion ou une explosion pourraient

se produire.

Mise à la terre.

La mise à la terre peut prévenir un incendie ou

un choc électrique dus à une fuite de courant

en cas de défaillance.

ATTENTION

Manipuler le câble d’alimentation, la fiche

et la prise électrique correctement et a vec

soin.

Ne jamais utiliser un article endommagé, car cela

pourrait causer un incendie ou un choc

électrique.

Si une rallonge ou une bande

d’alimentation électrique sont utilisées,

s’assurer qu’elles correspondent aux

caractéristiques de l’appareil (tension,

fréquence et courant).

L ’utilisation de plusieurs charges électriques sur

une prise unique ou une longue rallonge peut

causer un incendie.

Si l’appareil doit rester inutilisé pendant

une longue période, débrancher le câble

d’alimentation.

Cela peut prévenir les accidents en cas de fuite

de courant ou de démarrage accidentel.

Placer l’appareil de façon à ce que la fiche

soit facile d’accès en tout temps.

Ainsi, l’appareil pourra être débranché

rapidement en cas d’urgence. Installer l’a ppareil

près d’une prise électrique. En outre, prévoir

suffisamment d’espace pour que la prise

électrique soit facile d’accès.

Ne jamais utiliser d’huile de coupe.

Cet appareil n’est pas conçu pour traiter l’huile

de coupe. L’huile peut s’infiltrer à l’intérieur et

causer un incendie ou un choc électrique.

Ne jamais utiliser d’air sous pression.

Cet appareil n’est pas conçu pour être nettoyé

à l’aide d’un appareil soufflant. Des rognures de

coupe peuvent s’infiltrer à l’intérieur et causer

un incendie ou un choc électrique.

S’il se produit des étincelles, de la fumée,

une odeur de brûlé, un bruit inhabituel ou

un fonctionnement anormal, débrancher

immédiatement le câble d’alimentation.

Ne jamais utiliser si un composant est

endommagé.

Continuer à utiliser l’appareil peut causer un

incendie, un choc électrique ou des blessures.

Communiquer avec le r eprésentant Roland DG

Autorisé.

15

Page 18

Pour utiliser en toute sécurité

Remarques importantes à propos du câble d'alimentation, de la fiche et de la prise électrique

Ne jamais déposer aucun objet sur le câble, sur la fiche

ou sur la prise car cela risque de les endommager.

Ne jamais plier ni tordre le câble avec une

force excessive.

Ne jamais laisser l'eau toucher le câble, la

fiche ou la prise.

Ne jamais chauffer le câble, la fiche ou la

prise.

16

Ne jamais tirer sur le câble ou la fiche avec

une force excessive.

Ne jamais plier ni enrouler le câble.

La poussière peut causer un incendie.

Page 19

Pour utiliser en toute sécurité

Vignettes d'avertissement

Des vignettes d'avertissement sont apposées pour qu'il soit facile de repérer les zones

dangereuses. La signification des vignettes est donnée ci-dessous. Respecter les a vertissements.

Ne jamais retirer les vignettes et ne pas les laisser s'encrasser.

Haut

Attention : Risque de pincement

Faire attention de ne pas coincer les

doigts pendant le chargement du

support ou lors de la fermeture du

couvercle.

Ne jamais utiliser d’air sous

pression.

Cet appareil n’est pas conçu pour

être nettoyé à l’aide d’un appareil

soufflant. Des rognures de coupe

peuvent s’infiltrer à l’intérieur et

causer un incendie ou un choc

électrique.

Attention : outil coupant

Un contact imprudent

risque d’entraîner une

blessure.

Avant/intérieur

Attention : risque de

pincement

Un contact pendant le

fonctionnement peut

coincer la main ou les

doigts ce qui risque de

causer des blessures.

Arrière

Attention : voltage élevé

Il peut être dangereux de retirer le

couvercle puisqu’il y aurait des risques

de chocs électriques ou

d’électrocution à cause du voltage

élevé.

17

Page 20

Important Notes on Handling and Use

This machine is a precision device. To ensure the full performance of this machine, be sure to observe the

following important points. Failure to observe these may not only result in loss of perf ormance, but may also

cause malfunction or breakdown.

This machine is a precision device.

➢Handle carefully, and never subject the machine to impact or excessive force.

➢Use within the range of specifications.

➢Diligently keep clean of cutting waste.

➢Never needlessly touch anywhere inside the machine except for locations specified in this manual.

Install in a suitable location.

➢Install in a location that meets the specified conditions for temperature, relative humidity, and the like.

➢Install in a quiet, stable location offering good operating conditions.

➢Never install in out of doors.

This machine becomes hot.

➢Never cover the ventilation holes with cloth, tape, or anything else.

➢Install in a well-ventilated location.

About Cutters

➢Use a cutter that is suitable for the workpiece and the cutting method.

➢The tip of the cutter is breakable. Handle with care, being careful not to drop it.

18

Page 21

About the Documentation for This Machine

Documentation Included with the Machine

The following documentation is included with the machine.

User's Manual (this manual)

This describes important notes for ensuring safe use, and explains how to install and operate the machine. Be

sure to read it first.

It does not describe how to operate your computer or how to use the programs.

Roland Software Package Software Guide

This explains how to install included program and other software and details.

Be sure to read this, when connecting the machine to a computer.

Roland EngraveStudio Software Guide

This explains how to install included program and other software and details.

Dr. Engrave User's Manual (electronic-format manual)

This manual explains how to use the included engraving program. It describes procedures ranging from how to

design a nameplate or the like to engraving operations. Read it if you're using this program.

The manual is in electronic format, and no printed document is included. Y ou can find it on the included Roland

Software Package CD-ROM.

3D Engrave User's Manual (electronic-format manual)

This manual explains how to use the included program for three-dimensional engraving and for creating reliefs.

It describes procedures ranging from how to design reliefs and the like to cutting operations. Read it if you're

using this program.

The manual is in electronic format, and no printed document is included. Y ou can find it on the included Roland

Software Package CD-ROM.

EngraveStudio User's Manual (electronic-format manual)

This is the documentation for using the included three-dimensional (relief) engraving program. It describes the

steps from designing text and shapes to engrave on wooden signs and the like through to the engraving operations. Read it if you're using this program.

The manual is in electronic format, and no printed document is included. Y ou can find it on the included Roland

EngraveStudio CD-ROM.

Virtual MODELA User's Manual (electronic-format manual)

This is the documentation for a program that creates previews by simulating cutting using 3D Engrave. It describes all the steps from receiving data created using 3D Engrave to simulation of cutting operations. Read it if

you're using this program.

The manual is in electronic format, and no printed document is included. Y ou can find it on the included Roland

Software Package CD-ROM.

19

Page 22

20

Page 23

Chapter 1

Getting Started

21

Page 24

1-1 Machine Highlights

Featur es

➢ Engraving and relief-cutting on a single machine

This machine achieves expressive, high-quality engraving of a wide range of types, from flat engraving to threedimensional reliefs.

➢ Outstanding basic performance

The spacious operating area measuring 40 millimeters high b y 305 millimeters wide b y 230 millimeters deep and the

high-speed spindle that turns at up to 20,000 rpm make for rapid engraving. W orkpieces up to 40 millimeters thick can

be accommodated.

➢ Accommodates a wide variety of engraving materials

The machine can engr ave a wide r ange of workpiece materials, from plastics, acrylics, and other resin-based materials

to light metals such as aluminum and brass.

➢ Designed for ease of use

You control machine operation using a handy panel that is separate from the machine. This lets you control the

machine from a location affording a clear view of the workpiece and tool. You can also make the settings for the

machine simply and easily while viewing the display screen on the handy panel.

➢ Automatic Z control feature

The machine offers an automatic Z control feature that makes possible engr aving at a uniform depth, even on workpieces

with wavy surfaces.

(Trackable undulation height: gentle undulations of about 1 millimeter)

➢ High levels of safety

A front cover and an emergency-stop button are standard features of the machine.

22

Chapter 1 Getting Started

Page 25

1-2 P art Names and Functions

Fr ont and Interior

Spindle head *

Lock lever

This locks or unlocks the spindle head.

☞ P. 82, "The Position of the Lock Lever"

Front cover

To ensure safety, opening this during engraving

Spindle unit

or spindle rotation causes an emergency stop to

occur.

☞ P. 39, "Emergency Stop Due to Opening or Closing the Front Cover"

Handy panel

This is used to perform cutter movement and other

machine operations, and to make various settings.

☞ P. 42, "Using the Handy Panel."

Emergency Stop button

Pressing this stops

operation of the

machine.

☞ P. 38, "Types of Emergency Stops to Ensure

Safety"

Workpiece table

The workpiece to be engraved is mounted on this.

* In this manual, the mechanisms around the spindle unit, including the spindle motor, are called the “spindle head.”

Also, the rotary-axis area inside the spindle unit is called the “spindle.”

Chapter 1 Getting Started

23

Page 26

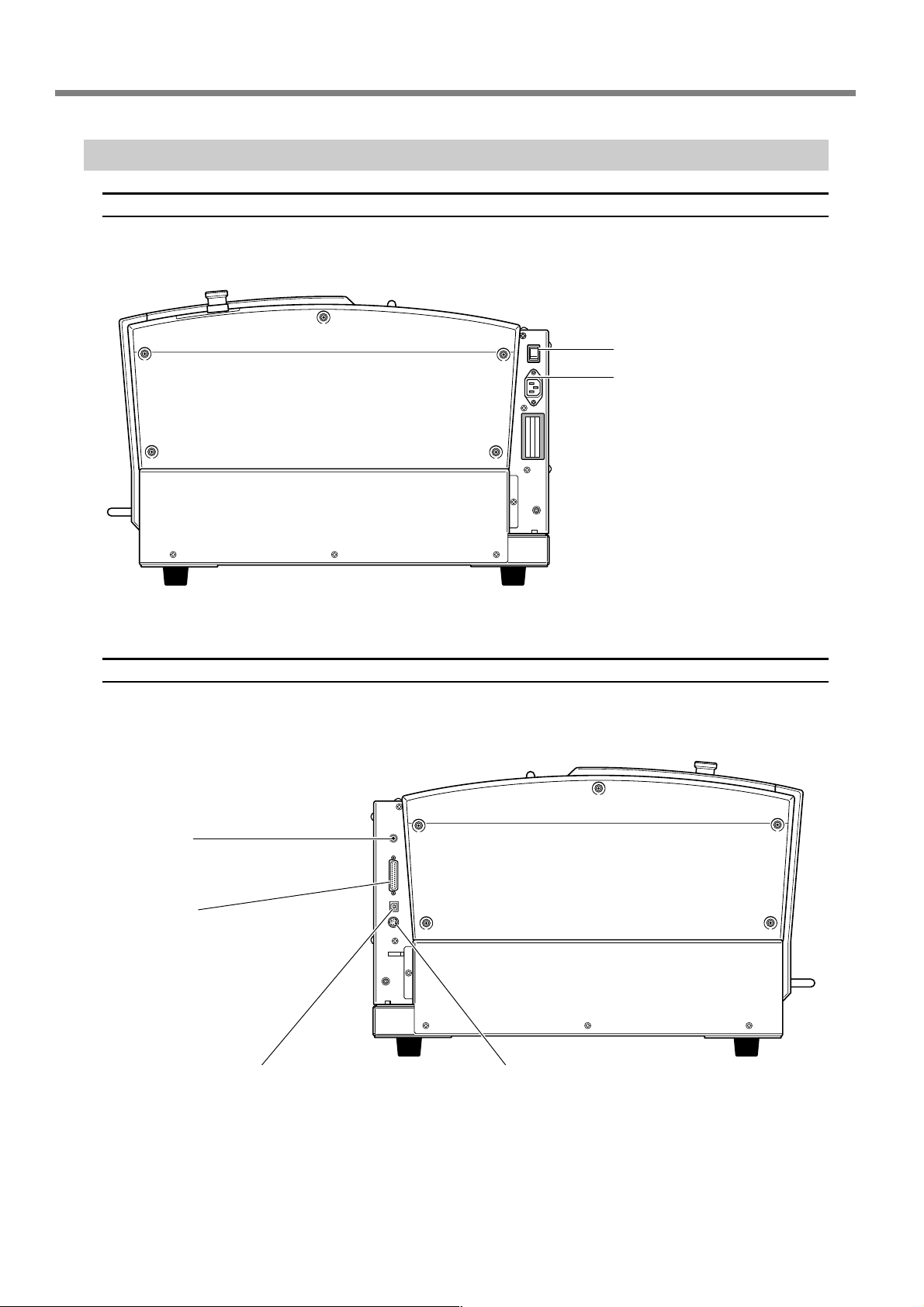

1-2 Part Names and Functions

Side

Right side

Power switch

Power-cord connector

Left side

Expansion port

This is a connector for external equipment.

☞ P. 111, “Expansion Connector”

Serial connector

This is for connecting a serial (RS-232Ccompliant) cable.

☞ P . 32, “Connecting a Computer Via a Communication Cable”

USB connector

This is for connecting a USB cable.

☞ P. 32, “Connecting a Computer Via

a Communication Cable”

Handy-panel connector

This is for connecting the handy panel.

☞ P. 30, “Connecting the Handy Panel”

24

Chapter 1 Getting Started

Page 27

Chapter 2

Installation and Setup

25

Page 28

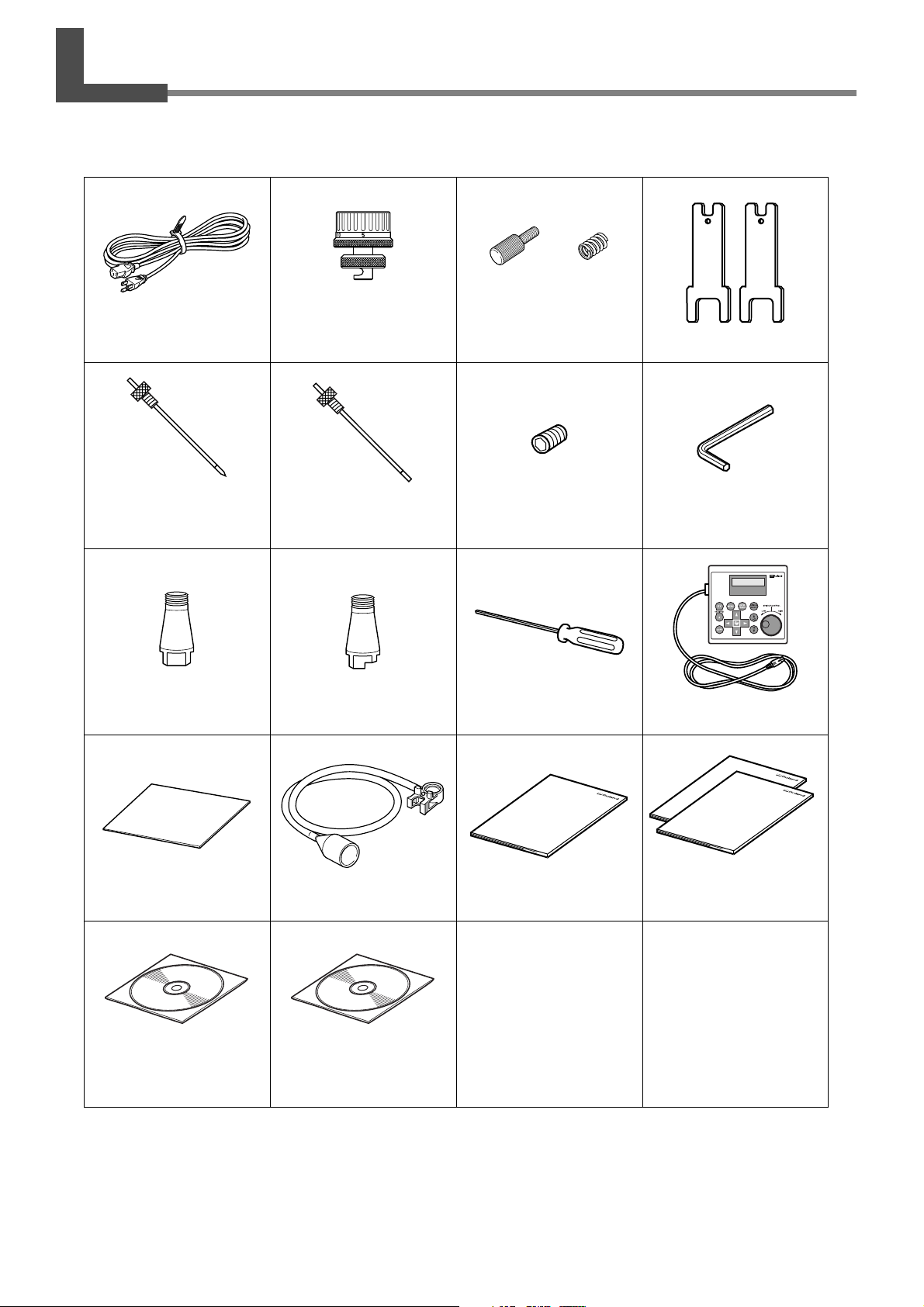

2-1 Checking the Included Items

The following items are included with the machine. Make sure they are all present and accounted for.

Power cord

Character cutter

(diameter 3.175 mm,

with cutter holder)

Collet

(diameter 3.175 mm)

Depth regulator nose

(nose unit)

Flat cutter

(diameter 3.175 mm,

with cutter holder)

Collet

(diameter 4.36 mm)*1,*2

Retaining

screw

Noes-unit retainer

Spare tool retaining screw

Hexagonal screwdriver

Spring

Wrench

Hexagonal wrench

Handy panel

26

Software guide

(Roland Software Package)

Adhesive sheet Vacuum-adapter set User’s Manual

Roland Software Package

CD-ROM

*1: This is for diameter-4.36 mm character or flat cutters. It cannot be used with diamond scrapers or end mills.

*2: Never use a diameter-4.36 mm cutter at a spindle speed of 15,000 rpm or higher. T here is danger of damage to the

spindle unit due to vibration.

Roland Engrave Studio

CD-ROM

(Roland Engrave Studio)

Chapter 2 Installation and Setup

Page 29

2-2 Installation

About Emplacement and Installation

WARNING

The weight of the machine alone is 34 kg (75 lb.). Perform unloading and emplacement with care.

Unloading and emplacement are operations that must be performed by 2 persons

or more.

Tasks that require undue effort when performed by a small number of persons ma y result

in physical injury. Also, if dropped, such items may cause injury.

Installation Environment

Install in a quiet, stable location offering good operating conditions. An unsuitable location can cause accident, fire,

faulty operation, or breakdown.

WARNING

WARNING

WARNING

WARNING

Install in a location that is level and stable.

Installation in an unsuitable location may cause an accident, including a fall or tipover.

Never install in a location exposed to open flame.

Cutting waste may ignite. Powdered material is extremely flammable, and even metal

material may catch fire.

Never install close to any flammable object or in a gas-filled location.

Combustion or explosion may be a danger.

Never install out of doors or in any location where exposure to water or high

humidity may occur.

Doing so may result in fire or electrical shock.

WARNING

➢ Never install in a location subject to wide fluctuations in temperature or humidity.

➢ Never install in a location subject to shaking or vibration.

➢ Never install in a locations where the floor is tilted, not level, or unstable.

➢ Never install in a dusty or dirty location, or out of doors.

➢ Never install in a location exposed to direct sunlight or near air-conditioning or heating equipment.

➢ Never install in a location exposed to considerable electrical or magnetic noise, or other forms of electromagnetic

energy.

Position so that the power plug is within immediate reach at all times.

This is to enable quick disconnection of the power plug in the event of an emergency.

Install the machine next to an electrical outlet. Also, provide enough empty space to allo w

immediate access to the electrical outlet.

Chapter 2 Installation and Setup

27

Page 30

2-2 Installation

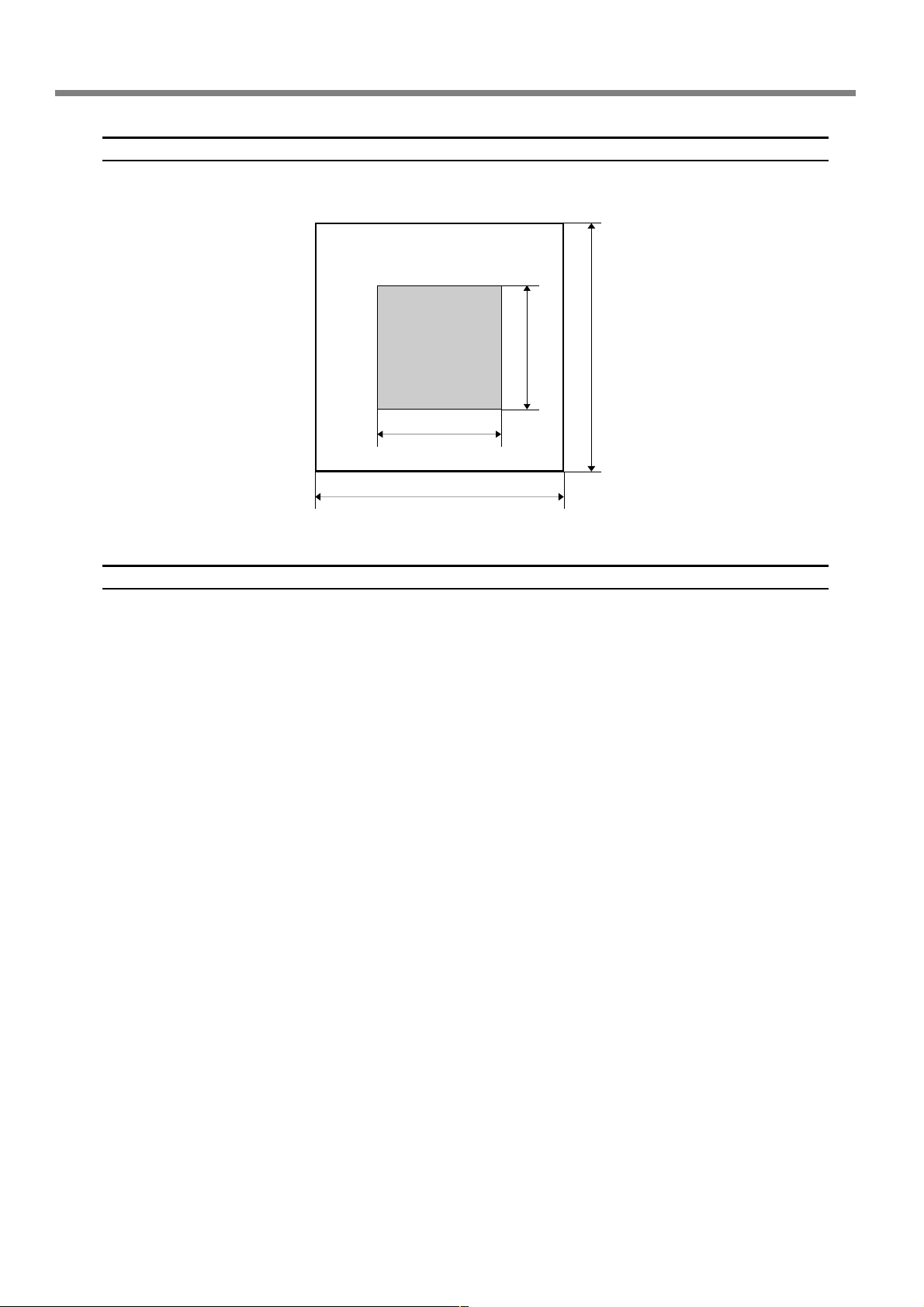

Installation Space

Ensure that at least the following amount of space is available.

Work space

Installation space

1.0 m (3.3 ft.)

1.0 m (3.3 ft.)

2.0 m (6.6 ft.)

2.0 m (6.6 ft.)

Height of Installation

The height of installation should be 0.6 m (23.7 in.) or higher above the work floor.

This machine is desktop type. Please decide the height of installation so that y ou can easily reac h the emergenc y stop

button when operating this machine.

28

Chapter 2 Installation and Setup

Page 31

2-2 Installation

Unpacking

Retaining materials are attached to protect the machine from vibration during shipment. Remov e these after emplacement.

➢ Remove all Retaining materials. Any that remain may cause faulty operation or breakdown when the power is

switched on.

➢ The Retaining materials are required when moving the mac hine to a different location. Store them carefully so that

they do not get misplaced.

WARNING

Carry out these operations before you connect the power cord.

Inadvertent powerup may result in pinched hands or other injury.

Procedure

Make sure the power cord is not connected.

➊

➋

Hexagonal wrench

➌

Remove retainer A.

Retainer A

Slowly move the spindle head in the direction of the arrow.

Take care not to subject it to strong impact.

➍

Spindle head

Retainer B Retainer C

Hexagonal wrench

Remove retainers B and C.

Chapter 2 Installation and Setup

29

Page 32

2-3 Cable Connections

Connecting the Handy Panel

Make sure the power to the machine is switched off before attempting to connect or disconnect cables.

Connecting the handy panel while the power is on makes the handy panel unusable.

Left side

Insert fully and

securely.

Handy panel

Cable clamp

30

Chapter 2 Installation and Setup

Page 33

Connecting the Power Cord

2-3 Cable Connections

WARNING

WARNING

WARNING

WARNING

WARNING

This machine requires a single-phase commercial power outlet, which rated at 1.3 A or higher ( for 100 to 120 V) or

0.6 A or higher (for 220 to 240 V).

Right side

Connect to an electrical outlet that complies with this machine's ratings (for voltage and frequency).

Incorrect voltage or insufficient current may cause fire or electrical shock.

Handle the power cord, plug, and electrical outlet correctly and with care. Never

use any article that is damaged.

Using a damaged article may result in fire or electrical shock.

When using an extension cord or power strip, use one that adequately satisfies the

machine's ratings (for voltage, frequency, and current).

Use of multiple electrical loads on a single electrical outlet or of a lengthy extension cor d

may cause fire.

Connect to ground.

This can prevent fire or electrical shock due to current leakage in the event of malfunction.

Connect to an electrical outlet. Never connect directly to a power distribution

panel or other such fixed wiring equipment.

Doing so increases the hazard of fire or electrical shock.

Electrical outlet

Power cable

Chapter 2 Installation and Setup

31

Page 34

2-3 Cable Connections

Connecting a Computer Via a Communication Cable

USB cable

At this time, keep the cable unconnected until you carry out this operation.

Follow the instructions in the separate Roland Software Package Software Guide to make the connection.

☞ P. 19, "About the Documentation for This Machine"

➢Never connect two or more machines to one computer.

➢Use a shielded USB cable having a length of 3 m (10 ft.) or less.

➢Never use a USB hub.

USB port

USB cable

Computer

At this time, keep the cable unconnected until you carry out

this operation.

Left side

Serial cable

Using a serial cable requires making the settings for the communication parameters with the computer.

For the serial cable, use a separately available XY-RS-34 from Roland DG Corp.

☞ P. 85, "Submenus," p. 110, "Serial Connector"

Secure in place with the screws.

Left side

32

RS-232C connector

Computer

Chapter 2 Installation and Setup

Serial cable

Page 35

2-4 Selecting the Language

Selecting the Language Used for Text on the Display Screen

Procedure

➊

➋

Close the front cover.

Hold down and turn on the

power switch.

ON

➌

➀➁

Use or to select the

➀

language.

Press to confirm.

➁

Chapter 2 Installation and Setup

33

Page 36

2-4 Selecting the Language

➍

Switch off the power switch.

OFF

34

Chapter 2 Installation and Setup

Page 37

2-5 Before Starting Operations

Spindle Run-in (Warm-up)

In any of the following cases, perform run-in (warm-up) operation for the spindle. Failure to do so may result in

unstable spindle rotation.

➢ When using for the first time after purchase

➢ After moving the machine and reinstalling it at a different location

➢ After replacing the spindle unit

➢ When using in a low-temperature environment

How to Perform Run-in (Warm-up) Operation

Carry out the following steps 1 through 4.

☞ P. 47, “Starting and Stopping Spindle Rotation”

Step 1

Speed : 5,000 rpm

Rotation time : 15 minutes

Step 2

Speed : 10,000 rpm

Rotation time : 10 minutes

Step 3

Speed : 15,000 rpm

Rotation time : 10 minutes

Step 4

Speed : 20,000 rpm

Rotation time : 15 minutes

Chapter 2 Installation and Setup

35

Page 38

36

Page 39

Chapter 3

Basic Oper ation

37

Page 40

3-1 Types of Emergency Stops to Ensur e Saf ety

How to Perform an Emergency Stop

Press the Emergency Stop button.

Operation stops immediately.

Emergency

Stop button

To Cancel an Emergency Stop

Procedure

➊

➋

Switch off the power switch.

OFF

Turn the button in the direction of the

arrows.

38

Emergency

Stop button

Chapter 3 Basic Operation

Page 41

3-1 Types of Emergency Stops to Ensure Safety

Emergency Stop Due to Opening or Closing the F ront Cover

T o ensure safety, opening the front cover during engraving or spindle rotation causes an emergenc y stop to occur, and

the message shown below appears on the display screen. Oper ation cannot be resumed by closing the front co v er. To

resume, switch off the power, then start up again.

☞ P. 40, “Starting and Quitting”

Front cover

Chapter 3 Basic Operation

39

Page 42

3-2 Starting and Quitting

How to Start the Machine

Follow the procedure below to start the machine. When startup is complete, the machine is ready for use.

Procedure

➊

➋

Close the front cover.

Switch on the power switch.

A message like the one shown in the figure

appears on the handy panel’s display screen.

ON

40

Note: “XXX” indicates the version number of the machine’s firmware.

Chapter 3 Basic Operation

Page 43

3-2 Starting and Quitting

➌

Main screen

When the screen shown in the figure at left appears after

approximately three seconds, press

The spindle head moves to a location on the inner-left side of the

machine. This operation is called “initialization.”

The default for the language used for on-screen display is English.

To change the display language to Japanese, refer to the page indicated below and change the language setting.

☞ P. 33, "Selecting the Language Used for Text on the Display Screen"

When initialization ends, the screen changes to a display like that

shown at left (the mainscreen). This completes initialization.

.

Shutdown

Dark

OFF

Make sure the machine is not in operation, then turn off the power switch.

The display screen on the handy panel goes

dark.

Chapter 3 Basic Operation

41

Page 44

3-3 Using the Handy P anel

Display screen

Menus, messages, and the like are displayed

here.

Dial

This adjusts the spindle’s speed of rotation.

Indication used in this manual:

☞ P. 48, "Adjusting the Spindle Speed"

MENU Button

Pressing this changes the menu screen. Also,

pressing this when at the origin-setting menu

returns the screen to the coordinate display

view (the main menu).

Indication used in this manual:

Enter/Pause button

This executes a selected on-screen item or

confirms a selected item or value.

Confirming an item or value displays the setting enclosed between angled brackets

("<>"). Pressing this during engraving pauses

operation and displays the Pause menu.

Indication used in this manual:

Spindle button

Holding this down for one second or longer

while the spindle is stopped makes spindle

rotation start. Pressing this during spindle

rotation makes the rotation stop. (When rotation is stopped, holding the button down

for one second or longer is not necessary.)

Indication used in this manual:

☞ P. 47, "Star ting and Stopping Spindle Rotation"

X/Y-axis Origin Set button

This sets the reference point for the cutting

position.

Indication used in this manual:

☞ P. 75, "Setting the XY Origin Point (Home Position)"

Z-axis Origin Set button

This sets the reference point for the cutting

position.

Indication used in this manual:

☞ P. 62, "Cutter Installation Method 2," p. 71, "Cutter Installation

Method 4"

Copy button

This calls up the menu for the copy feature.

Indication used in this manual:

☞ P. 78, "Executing Repeated Cutting"

Movement buttons

These move the cutter forw ard and backward, and

to the left and right. You also use them to select

items and change settings at menu screens.

Indication used in this manual:

☞ P. 44, "Manual Movement"

Z-axis Movement buttons

These move the cutter up and down.

Indication used in this manual:

☞ P. 44, "Manual Movement"

Feed button

Pressing a Movement or Z-axis Movement

button while holding down this button

makes the tool move rapidly.

Indication used in this manual:

☞ P. 44, "Manual Movement"

42

Chapter 3 Basic Operation

Page 45

3-4 Mo ving the Cutter

Terms Indicating the Cutter Position

This manual uses the following terms to indicate the position of the cutter.

➢ Coordinates

Numerical values indicating the location of the cutter

➢ Origin

The point of origin for the coordinates

➢ X-axis coordinate

The distance along the X axis from the origin point

➢ Y -axis coordinate

The distance along the Y axis from the origin point

➢ Z-axis coordinate

The distance along the Z axis from the origin point

Viewing the Cutter Position

The cutter position is displayed on the handy panel’s main screen.

The figure below shows the main screen w hen the cutter has mo ved from the origin point b y 50 millimeters along the

X axis, 30 millimeters along the Y axis, and 20 millimeters along the Z axis.

In the indication of coordinates used on this machine, a unit of “1” corresponds to 0.01 millimeter.

Main screen

Origin

20 mm

This position is displayed as

“X = 5000, Y = 3000, Z = 2000.”

50 mm

30 mm

Chapter 3 Basic Operation

43

Page 46

3-4 Moving the Cutter

Manual Movement

When the screen on the handy panel displays any one of the messages shown in the figure below, you can move the

cutter manually using the movement buttons.

☞ P. 84, "Menu List"

Handy panel

Movement along all axes

(X, Y, and Z)

Movement along only the X

and Y axes

+

Y

+

-

X

Movement along only the Z

axis

(“XXX” is “DOWN,” “SURFACE,” or “UP.”)

Movement buttons

➢ Each single press of , , , , or performs movement by 0.01 millimeter.

➢ Holding down , , , , or performs slow continuous movement.

➢ Holding down while pressing and holding , , , , or performs r apid

continuous movement.

+

X

-

Y

Z

-

Z

+

Z

-

Z

-

X

+

Y

+

X

-

Y

44

Important!

This operation is not possible in the following cases.

➢ When engraving is in progress

➢ When operation is paused

Chapter 3 Basic Operation

Page 47

Moving to a Specific Position Automatically

Procedure

Close the front cover.

➊

3-4 Moving the Cutter

➋

➌

At the main screen, press twice.

Press , , , or to select the movement destination.

➢ HOME

This is the location where the X- and Y-axis coordinates are both

“0” (the XY origin point). When movement b y this operation is per formed, to avoid contact with the workpiece, the mac hine first rises

to the highest point along the Z axis, and then performs movement.

☞ P. 75, “Setting the XY Origin Point (Home Position)”

➢ VIEW

This is the inner-left location on the workpiece table. You use it in

situations such as when mounting or removing a workpiece, or

when checking the state of the workpiece.

➢ Z0

This is the location where the Z-axis coordinate is “0.”

☞ P. 62, “Cutter Installation Method 2,” p. 71, “Cutter Installation Method 4,” and p.

92,“Origin-setting Menu”

➢ Z1

This is the location of the cutting-in depth when cutting the

workpiece.

☞ P. 92, “Origin-setting Menu”

➢ Z2

This is the height location along the Z axis when performing noload feed of the cutter during cutting.

☞ P. 92, “Origin-setting Menu”

Chapter 3 Basic Operation

45

Page 48

3-4 Moving the Cutter

➍

When the front cover is open, the screen shown in the figure below is displayed, and the cutter doesn’t move.

After three seconds the message disappears and the screen returns to the original menu.

Press .

The cutter moves to the selected location.

46

Chapter 3 Basic Operation

Page 49

3-5 Spindle Operation

Starting and Stopping Spindle Rotation

This manually starts and stops rotation of the spindle. You perform the operation using the handy panel.

☞ P. 35, "Spindle Run-in (Warm-up)"

Procedure

Close the front cover.

➊

➋

Spindle rotation speed

At the main screen, press and hold for one second

or longer.

A beep is heard, and the spindle starts to turn.

➌

This operation cannot be performed in the following situations.

➢ When the machine is performing some operation

➢ When the front cover is open (in which case the screen shown in the figure below is displayed)

☞ P. 103, “Responding to a Message”

Press .

The spindle stops turning, a beep is heard.

Chapter 3 Basic Operation

47

Page 50

3-5 Spindle Operation

Adjusting the Spindle Speed

Spindle speed

To adjust the speed of spindle rotation, turn

on the handy panel.

The setting for the spindle speed can be made only on

the machine. Any setting made on the computer is ignored.

FastSlow

48

Chapter 3 Basic Operation

Page 51

3-6 P ausing and Stopping Cutting

Pausing and Resuming Cutting

This pauses cutting through operation using the hand y panel. This enables you to move the cutter to the VIEW position

and check the status of the workpiece, then resume cutting at the location where you paused operation.

Procedure

➊

➋

➀➁

While cutting is in progress, press .

Movement of the cutter pauses. Rotation of the spindle does not

stop at this time.

The display screen shown at left appears.

Use to select “VIEW.”

➀

Press to confirm.

➁

Rotation of the spindle stops, and the cutter moves to the VIEW

position.

☞ P. 45, “Moving to a Specific Position Automatically”

➌

➀➁

Use or to select “CONT.”

➀

Press to confirm.

➁

The cutter returns to the location where paused, and cutting resumes.

Selecting “VIEW” or “CONT.” while the front cover is open makes

the message shown in the figure below appear . After three seconds

the message disappears and the screen returns to the original menu.

Close the front cover , then redo the selection of the operation item.

Chapter 3 Basic Operation

49

Page 52

3-6 Pausing and Stopping Cutting

Important!

Before opening the front cover while operation is paused, first make sure that rotation of the spindle is stopped. For

safety , opening the front co ver w hile the spindle is turning makes the mac hine perform an emergenc y stop. Be sure to

note that if this happens, it’s necessary to quit the operation and start over from the beginning.

☞ P. 39, “Emergency Stop Due to Opening or Closing the Front Cover”

Other operations possible while paused

➢ Starting or stopping spindle rotation

☞ P. 47, “Starting and Stopping Spindle Rotation”

➢ Changing the spindle speed

☞ P. 48, “Adjusting the Spindle Speed”

➢ Changing the feed rate of the cutter

☞ P. 77, “Adjusting the Cutter Feed Rate During Engraving (Override)”

Stopping Cutting

This stops cutting through operation using the handy panel. Unlike pausing operation, cutting cannot be resumed.

Procedure

➊

➋

➀➁

While cutting is in progress, press .

Movement of the cutter pauses. Rotation of the spindle does not

stop at this time.

The display screen shown at left appears.

Use to select “STOP.”

➀

Press to confirm.

➁

The cutter moves to the highest location on the Z axis, then stops.

If the spindle is rotating, its rotation stops here.

50

Chapter 3 Basic Operation

Page 53

Chapter 4

Engr aving

51

Page 54

4-1 Flo w of Engraving Operations

1.

Startup

Switch on the power switch to start the machine.

☞ P. 40, “How to Start the Machine”

ON

2.

Mounting the Workpiece

Mount the workpiece to engrave on the table.

☞ P. 54, “Mounting a Workpiece”

To next page

52

Chapter 4 Engraving

Page 55

4-1 Flow of Engraving Operations

Cutter Installation and Basic Engraving Settings

3.

Install the cutter to use for engraving. On this machine, you also set the Z-axis engraving origin

point at this time. The methods you use for installation and the settings differ depending on

whether you’re using the nose unit and on the cutter type. This manual describes the following

four variations. Use these as a reference to select the optimal cutter for the purpose and use the

appropriate methods for installing the cutter and making the settings.

➢ Character cutter or flat cutter (with the nose unit)

☞ P. 56, “Cutter Installation Method 1 (With Nose Unit)”

➢ Character cutter or flat cutter (no nose unit)

☞ P. 62, “Cutter Installation Method 2 (No Nose Unit)”

➢ Diamond scraper

☞ P. 67, “Cutter Installation Method 3”

➢ End mill

☞ P. 71, “Cutter Installation Method 4 (End mill)”

Setting the XY Origin Point

4.

Set the engraving origin point for the X and Y axes.

☞ P. 75, “Setting the XY Origin Point (Home Position)”

Performing Engravings

5.

When all the preparations are complete, send the engraving data from the computer and carry out

engraving.

☞ P. 76, “Performing Engraving”

Chapter 4 Engraving

53

Page 56

4-2 Mounting a Workpiece

WARNING

CAUTION

When Using an Adhesive Sheet

Never inadvertently touch the computer or handy panel while performing this

task.

Unintended operation of the machine may result in injury.

Caution: cutting tool.

The cutting tool is sharp. To avoid injury, exercise caution.

Affix the adhesive sheet to the

workpiece table, then place the

workpiece on the adhesive sheet and

press down on it from abo ve to secure

it in place.

Adhensive sheet

On this machine, you can also use optionally av ailable items to secure the workpiece in place: a center vise (ZV-23C)

or a vacuum table (ZV -23A). For detailed information about these optional items, contact your authorized Roland DG

Corp. dealer.

Workpiece

Workpiece table

54

Chapter 4 Engraving

Page 57

4-3 Selection of the Cutter (Usag e Examples)

This machine can use cutters of a wide variety of types that have a diameter of 3.175 millimeters or 4.36 millimeters.

Use an appropriate collet for the cutter’s diameter and type. For other cutters that can be used with the machine,

contact your authorized Roland DG Corp. dealer.

The table below shows samples of cutter usage, including use with or without a nose unit.

Important!

Use diameter-4.36 mm cutters at speeds of 15,000 rpm or lo wer. Use at higher speeds poses danger of damage to the