Page 1

MCR01

Resistors

Thick film rectangular

MCR01 (1005 size : 1 / 16W)

zFeatures

1) Extremely small light

Area ratio is 60% smaller than that of chip 1608, while weight ratio has been cut 75%.

2) Highly reliable chip resistor

Ruthenium oxide dielectric offers superior resistance to the elements.

3) Electrodes not corroded by soldering

Thick film makes the electrodes very strong.

4) Flat surface further facilitates mounting

Mounting can also be automated.

5) ROHM resistors have approved ISO–9001 certification.

Design and specifications are subject to change without notice. Carefully check the specification sheet supplied with the

product before using or ordering it.

zRatings

Item Conditions Specifications

Rated power

Rated voltage

Nominal resistance See Table 1.

Operating temperature

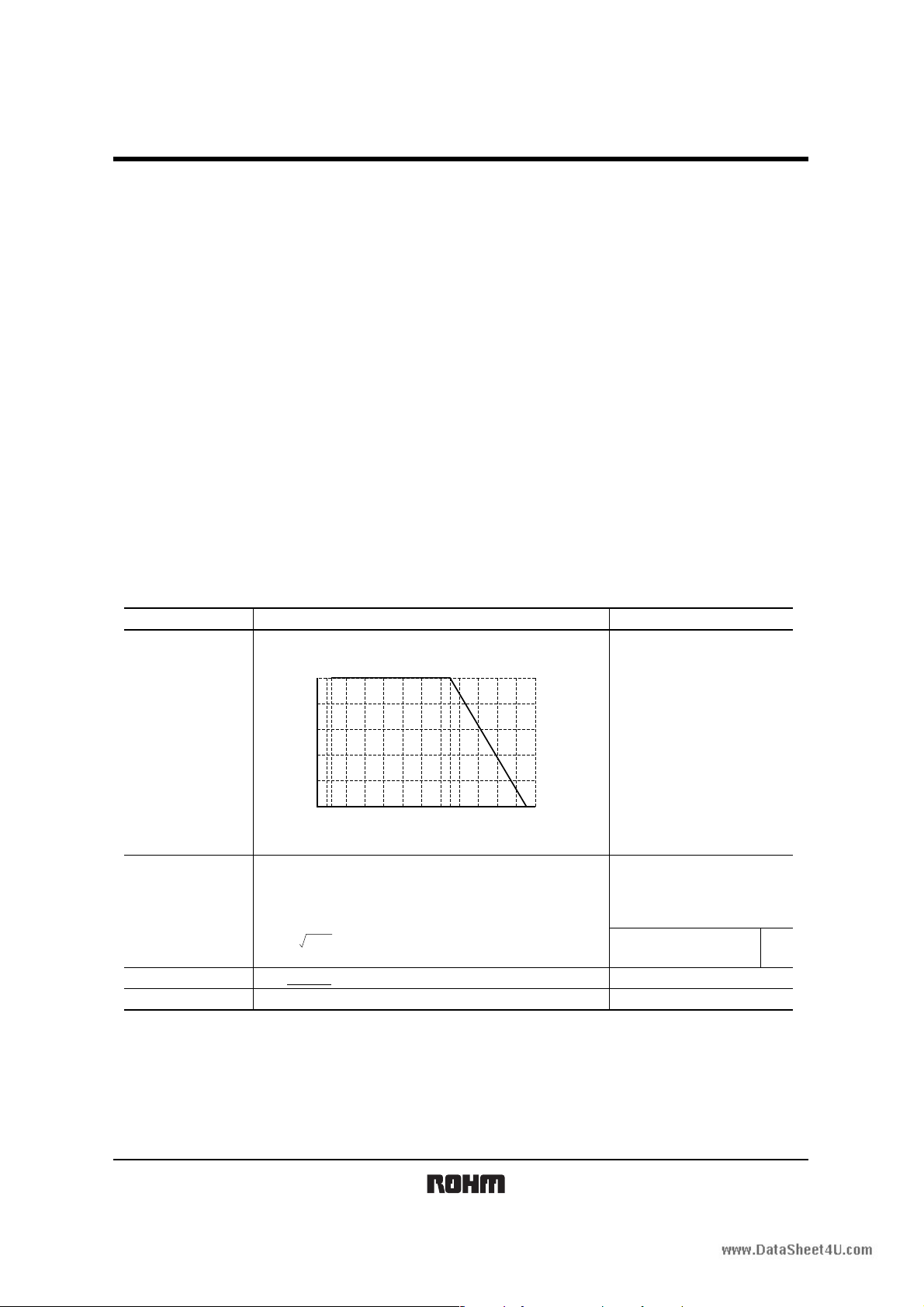

Power must be derated according to the power derating curve in

Figure 1 when ambient temperature exceeds 70°C.

100

80

60

40

POWER LOAD (%)

20

0

The voltage rating is calculated by the following equation.

If the value obtained exceeds the limiting element voltage,

the voltage rating is equal to the maximum operating voltage.

E= P×R

−55 0 70 100 125 155

AMBIENT TEMPERATURE (°C)

Fig.1

E: Rated voltage (V)

P: Rated power (W)

R: Nominal resistance (Ω)

0.063W (1 / 16W)

at 70°C

Limiting element voltage 50V

−55°C to +155°C

Rev.A 1/5

Page 2

MCR01

Resistors

Jumper type

Resistance

Rated current

Operating temperature

zBefore using components in circuits where they will be exposed to transient s such as pulse loads (short–duration, high– level loads), be cert ain to

evaluate the component in the mounted state. In addition, the reliability and performance of this component cannot be guaranteed if it is used with

a steady state voltage that is greater than its rated volt age.

z

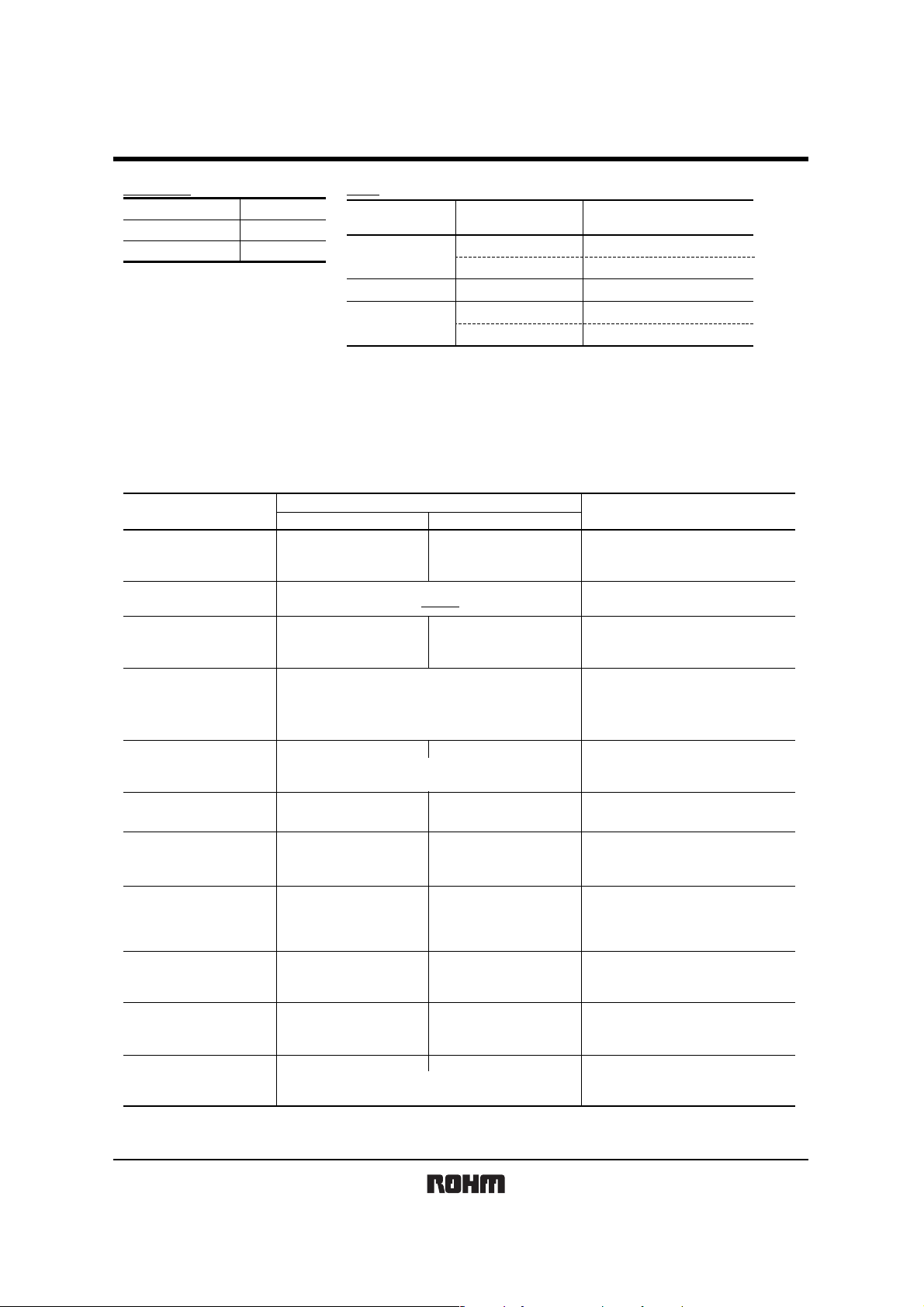

Characteristics

Table 1

Max. 50mΩ

1A

−55°C to +155°C

Resistance tolerance

J (±5%)

F (±1%)

D (±0.5%)

Resistance range

(Ω)

1.0≤R<10 +500 / −250

10≤R≤10M

10≤R≤2.2M

10≤R<100

100≤R≤1MΩ

(E24)

(E24)

(E24)

(E24)

(E24)

Resistance temperature coefficient

(ppm / °C)

±200

±100

±100

±50

Item Test conditions (JIS C 5201-1)

Resistance

Variation of resistance

with temperature

Overload

Solderability

Resistance to

soldering heat

Rapid change of

temperature

Damp heat, steady state

Endurance at 70°C

Endurance

Resistance to solvent

Bend strength of

the end face plating

Resistor type

J : ±5%

F : ±1%

D : ±0.5%

± (2.0%+0.1Ω) Max. 50mΩ

A new uniform coating of minimum of

95% of the surface being immersed

and no soldering damage.

± (1.0%+0.05Ω)

No remarkable abnormality on the appearance.

± (1.0%+0.05Ω)

± (3.0%+0.1Ω)

± (3.0%+0.1Ω)

± (3.0%+0.1Ω)

± (1.0%+0.05Ω)

± (1.0%+0.05Ω)

Without mechanical damage such as breaks.

Guaranteed value

Max. 50mΩ

See Table.1

Max. 50mΩ

Max. 50mΩ

Max. 50mΩ

Max. 50mΩ

Max. 50mΩ

Max. 50mΩ

Max. 50mΩ

Jumper type

JIS C 5201-1 4.5

JIS C 5201-1 4.8

Measurement : +25 / +125°C

JIS C 5201-1 4.13

Rated voltage (current) ×2.5, 2s.

Limiting Element Voltage×2 : 100V

JIS C 5201-1 4.17

Rosin·Ethanol (25%WT)

Soldering condition : 235±5

Duration of immersion : 2.0±0.5s.

JIS C 5201-1 4.18

Soldering condition : 260±5

Duration of immersion : 10±1s.

JIS C 5201-1 4.19

Test temp. : −55

JIS C 5201-1 4.24

°C, 93%RH

40

Test time : 1,000h to 1,048h

JIS C 5201-1 4.25.1

Rated voltage (current), 70

1.5h : ON − 0.5h : OFF

Test time : 1,000h to 1,048h

JIS C 5201-1 4.25.3

°C

125

Test time : 1,000h to 1,048h

JIS C 5201-1 4.29

23±5

°C

, Immersion cleaning, 5±0.5min.

Solvent : 2-propanol

JIS C 5201-1 4.33

°C

to +125°C 5cyc

°C

°C

°C

Rev.A 2/5

Page 3

Resistors

zExternal dimensions (Unit : mm)

1

0.2±0.1

+0.05

0.25

−0.1

1.0±0.05

6

2

3

No.

1

4

5

0.35±0.05

0.5±0.05

Thick dielectric glaze of oxide metal (only silver used for jumper)

2

Thick film of silver for electrode

3

Nickel-coated electrode

4

External electrode coated with Sn

5

Alumina substrate

6

Overcoating

z

Packaging

Reel Taping

ABD

0 2

0 4

0 6

0 8

C

ABCD

φ180

0

−1.5

φ60

+1

0

9

+1.0

0

Label

(Unit : mm)

±

0.2

φ13

0 2

0 4

0 6

0 8

EIAJ ET-7200B compliant

Material

P0

P

2

A

0

B

0

P

1

Heat crimp cover/Tape

Thick paper

(Underside paper tape) Chip resistor Square punchout hole

mount

WFEA0B

8.0±0.3 3.5±0.05 1.75±0.1 0.7±0.1 1.2±0.1

D

0

P

0

P

1

φ1.5

+0.1

4.0±0.1 2.0±0.05 2.0±0.05

0

MCR01

φD

0

P

2

F

(Unit : mm)

0

T

2

Max. 1.1

E

W

T

2

Rev.A 3/5

Page 4

Resistors

zPart designation

Part No.

MCR01

3-digit or 4-digit IEC coding system

Nominal resistance

Packaging specifications code

Part No. Code Packaging style

MZPMCR01

zDimensions

1.20

1.15

1.10

1.05

1.00

0.95

LENGTH (mm)

0.90

0.85

0.80

10 100 1k 10k 100k 1M

Fig.2 Dimensions (length)

JIS C 5201-1 4.4.2

SAMPLE SIZE : n=20pcs

MICROMETER

RESISTANCE

z

Electrical characteristics

8.0

6.0

4.0

2.0

0

– 2.0

DC RESISTANCE (%)

– 4.0

– 6.0

– 8.0

10 100 1k 10k 100k 1M

JIS C 5201-1 4.5

SAMPLE SIZE : n=20pcs

20°C 65%RH

RESISTANCE (Ω)

Fig.5 Resistance

(Ω)

Paper tape

Basisic ordering

unit (pcs)

10,000

0.70

0.65

0.60

0.55

0.50

0.45

WIDTH (mm)

0.40

0.35

0.30

10 100 1k 10k 100k 1M

(ppm/°C)

TEMPERATURE COEFFICIENT

Fig.3 Dimensions (width)

800

600

400

200

0

−200

−400

−600

−800

10 100 1k 10k 100k 1M

JIS C 5201-1 4.4.2

SAMPLE SIZE : n=20pcs

MICROMETER

RESISTANCE

JIS C 5201-1 4.8

SAMPLE SIZE : n=10pcs

25°C / 125°C

RESISTANCE

Fig.6 Variation of resistance with

temperature

Resistance tolerance

F ±1% ±5%J ±0.5%D

Specify "J" for jumper also.

THICKNESS (mm)

(Ω)

(%)

∆R/R

−1.0

−2.0

−3.0

−4.0

(Ω)

0.55

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

10 100 1k 10k 100k 1M

JIS C 5201-1 4.4.2

SAMPLE SIZE : n=20pcs

MICROMETER

RESISTANCE

Fig.4 Dimensions (thickness)

4.0

3.0

2.0

1.0

0.0

10 100 1k 10k 100k 1M

JIS C 5201-1 4.13

SAMPLE SIZE : n=10pcs

RATED VOLTAGE × 2.5TIMES : 2s

LIMITING ELEMENT VOLTAGE : 100V

RESISTANCE

(Ω)

Fig.7 Overload

(Ω)

Rev.A 4/5

Page 5

Resistors

2.0

1.5

1.0

0.5

(%)

0.0

∆R/R

−0.5

−1.0

−1.5

−2.0

JIS C 5201-1 4.18

SAMPLE SIZE : n=10pcs

SOLDERING CONDITION

: 260°C 10s

10 100 1k 10k 100k 1M

RESISTANCE

(Ω)

Fig.8 Resistance to soldering heat

4.0

3.0

2.0

1.0

(%)

0

∆R/R

−1.0

−2.0

−3.0

−4.0

10 100 1k 10k 100k 1M

JIS C 5201-1 4.25.1

SAMPLE SIZE : n=10pcs

70°C 1,000h

OVERLOAD : THE RATED VOLTAGE

RESISTANCE

(Ω)

Fig.11 Endurance at 70°C

2.0

1.5

1.0

0.5

(%)

0.0

∆R/R

−0.5

−1.0

−1.5

−2.0

10 100 1k 10k 100k 1M

Fig.14 Bend strength of

JIS C 5201-1 4.33

SAMPLE SIZE : n=10pcs

ENDURANCE WITH 90mm WIDTH

RESISTANCE

(Ω)

the end face plating

MCR01

2.0

1.5

1.0

0.5

(%)

0

∆R/R

−0.5

−1.0

−1.5

−2.0

10 100 1k 10k 100k 1M

JIS C 5201-1 4.19

SAMPLE SIZE : n=10pcs

−55°C / 125°C 5cyc

RESISTANCE

(Ω)

Fig.9 Rapid change of

temperature

4.0

3.0

2.0

1.0

(%)

0.0

∆R/R

−1.0

−2.0

−3.0

−4.0

10 100 1k 10k 100k 1M

JIS C 5201-1 4.25.3

SAMPLE SIZE : n=10pcs

125°C WITH NO LOAD 1,000h

RESISTANCE

(Ω)

Fig.12 Endurance

4.0

3.0

2.0

1.0

(%)

0

∆R/R

−1.0

−2.0

−3.0

−4.0

10 100 1k 10k 100k 1M

JIS C 5201-1 4.24

SAMPLE SIZE : n=10pcs

40°C 93%RH WITH NO LOAD

1000h

RESISTANCE

(Ω)

Fig.10 Damp heat, steady state

2.0

1.5

1.0

0.5

(%)

0

∆R/R

−0.5

−1.0

−1.5

−2.0

10 100 1k 10k 100k 1M

JIS C 5201-1 4.29

SAMPLE SIZE : n=10pcs

IPA, 5min.

RESISTANCE

(Ω)

Fig.13 Resistance to solvents

Rev.A 5/5

Page 6

Appendix

No technical content pages of this document may be reproduced in any form or transmitted by any

means without prior permission of ROHM CO.,LTD.

The contents described herein are subject to change without notice. The specifications for the

product described in this document are for reference only. Upon actual use, therefore, please request

that specifications to be separately delivered.

Application circuit diagrams and circuit constants contained herein are shown as examples of standard

use and operation. Please pay careful attention to the peripheral conditions when designing circuits

and deciding upon circuit constants in the set.

Any data, including, but not limited to application circuit diagrams information, described herein

are intended only as illustrations of such devices and not as the specifications for such devices. ROHM

CO.,LTD. disclaims any warranty that any use of such devices shall be free from infringement of any

third party's intellectual property rights or other proprietary rights, and further, assumes no liability of

whatsoever nature in the event of any such infringement, or arising from or connected with or related

to the use of such devices.

Upon the sale of any such devices, other than for buyer's right to use such devices itself, resell or

otherwise dispose of the same, no express or implied right or license to practice or commercially

exploit any intellectual property rights or other proprietary rights owned or controlled by

ROHM CO., LTD. is granted to any such buyer.

Products listed in this document are no antiradiation design.

Notes

The products listed in this document are designed to be used with ordinary electronic equipment or devices

(such as audio visual equipment, office-automation equipment, communications devices, electrical

appliances and electronic toys).

Should you intend to use these products with equipment or devices which require an extremely high level of

reliability and the malfunction of with would directly endanger human life (such as medical instruments,

transportation equipment, aerospace machinery, nuclear-reactor controllers, fuel controllers and other

safety devices), please be sure to consult with our sales representative in advance.

About Export Control Order in Japan

Products described herein are the objects of controlled goods in Annex 1 (Item 16) of Export Trade Control

Order in Japan.

In case of export from Japan, please confirm if it applies to "objective" criteria or an "informed" (by MITI clause)

on the basis of "catch all controls for Non-Proliferation of Weapons of Mass Destruction.

Appendix1-Rev1.1

Loading...

Loading...