PAD-T-M: 3574.3259.02

/01.00

/CI/1/EN

R&S®UPV-K9/-K91

LTE/UMTS/GSM Mobile Phone Tests

Operating Manual

Version 3.3.1.84

Operating Manual

1402.0043.12 – 10

© 2020 Rohde & Schwarz GmbH & Co. KG

Muehldorfstr. 15, 81671 Munich, Germany

Phone: +49 89 41 29 - 0

Fax: +49 89 41 29 12 164

E-mail: info@rohde-schwarz.com

Internet: http://www.rohde-schwarz.com

Subject to change – Data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

The following abbreviations are used throughout this manual:

R&S®UPV-K9/-K91 is abbreviated as R&S UPV-K9/-K91

R&S UPV-K9/-K91 Contents

Operating Manual 1402.0043.12 - 10 3

Contents

1 Overview ................................................................ .............................. 9

2 Preparation and Start of the Application Software ........................ 10

2.1 Required Measuring Instruments and Accessories ...............................................10

2.2 Installing the Software ..............................................................................................15

2.3 Verification of the Installation ..................................................................................17

2.4 Test Setup ...................................................................................................................18

2.5 Starting the Application Software ............................................................................22

2.6 Options (General settings) ........................................................................................27

2.6.1 Mouth Calibration Frequency Range ...........................................................................27

2.6.2 Standard ......................................................................................................................28

2.6.3 Select Standard at Startup ...........................................................................................28

2.6.4 Release ........................................................................................................................28

2.6.5 Select Release at Startup ............................................................................................28

2.6.6 Ear Simulator ...............................................................................................................29

2.6.7 Select Ear Simulator at Startup ...................................................................................29

2.6.8 Artificial Mouth .............................................................................................................29

2.6.9 Select Artificial Mouth at Startup ..................................................................................29

2.6.10 System Simulator .........................................................................................................29

2.6.11 Hands-free Settings .....................................................................................................29

2.6.12 Activation Signal for Distortion Tests ...........................................................................29

2.6.13 Show Operator Instructions .........................................................................................30

2.6.14 R&S CMU Remote Control ..........................................................................................32

2.6.15 R&S CMU Subsystem .................................................................................................32

2.6.16 R&S CMW Remote Control .........................................................................................32

2.6.17 Noise Calibration Configuration ...................................................................................33

2.6.18 R&S UPP Remote Control ...........................................................................................40

2.6.19 Input Switcher ..............................................................................................................41

2.6.20 Report settings .............................................................................................................41

2.6.21 Generate Temporary Export Files ...............................................................................41

2.6.22 Generate Temporary Image Files ................................................................................42

2.6.23 Store Results of Further Measurements ......................................................................42

2.6.24 Do not Change Scale for Further Meas. ......................................................................42

R&S UPV-K9/-K91 Contents

Operating Manual 1402.0043.12 - 10 4

2.6.25 Store Loaded Curve Data to Results ...........................................................................42

2.6.26 Enable Remote Control ...............................................................................................42

3 Calibration ......................................................................................... 43

3.1 Calibration Devices....................................................................................................43

3.2 Microphone Calibration .............................................................................................45

3.3 Calibration of Artificial Ear .......................................................................................47

3.3.1 Calibration of Ear Type 1 .............................................................................................47

3.3.2 Calibration of Ear Type 3.2 Low Leakage ...................................................................48

3.3.3 Calibration of Ear Type 3.2 High Leakage ...................................................................48

3.3.4 Calibration of Ear Type 3.3 ..........................................................................................49

3.3.5 Calibration of Ear Type 3.4 ..........................................................................................51

3.4 Calibration of Artificial Mouth for Handset Tests ...................................................51

3.5 P.50 Speech Spectrum Calibration ..........................................................................53

3.6 P.501 Speech Spectrum Calibration ........................................................................54

3.7 Calibration of CMU Speech Codec...........................................................................55

3.8 Calibration of CMW Speech Codec ..........................................................................56

3.9 Calibration of Ambient Noise Field ..........................................................................57

3.10 Calibration of Noise Field for “Speech Quality in Presence of Background Noise”

Test ..............................................................................................................................60

3.10.1 Connections .................................................................................................................60

3.10.2 Establishing the Remote Control Connection between R&S UPV and R&S UPP ......61

3.10.3 Prerequisites ................................................................................................................61

3.10.4 Configuration ................................................................................................................61

3.10.5 Switcher Support..........................................................................................................67

3.10.6 Selection of Background Noise Signals .......................................................................70

3.10.7 Starting the Calibration Process ..................................................................................70

3.10.8 Stopping and Resuming the Calibration Process ........................................................71

3.10.9 Preparatory Measurements for Delay Measurement ...................................................73

3.10.10 Delay Measurement .....................................................................................................74

3.10.11 Preparatory Measurements for Equalization ...............................................................77

3.10.12 Shared Equalization Method ........................................................................................80

3.10.13 Individual Equalization Method ....................................................................................80

3.10.14 Level Adjustment .........................................................................................................81

3.10.15 Equalization .................................................................................................................81

3.10.16 Final Test of All Ambiances .........................................................................................84

3.10.17 Calibration Sections and Resuming Points .................................................................84

3.10.18 Calibration Report ........................................................................................................86

R&S UPV-K9/-K91 Contents

Operating Manual 1402.0043.12 - 10 5

3.11 Synchronization of CMW clock ................................................................................89

3.11.1 Preparations .................................................................................................................89

3.11.2 Starting the Synchronization Process ..........................................................................90

3.11.3 Stopping the Synchronization Process ........................................................................91

3.11.4 Steps of Synchronization Process ...............................................................................91

3.11.5 Options after Termination of Synchronization .............................................................95

3.11.6 Synchronization Report ...............................................................................................96

4 Data Entry for Reporting .................................................................. 98

4.1 Operator ......................................................................................................................98

4.2 Test object ..................................................................................................................98

5 Measurements ................................................................................... 99

5.1 General ........................................................................................................................99

5.2 Starting Measurements .............................................................................................99

5.3 Functionality and Control of the Measurement Macros ......................................101

5.3.1 Zooming .....................................................................................................................101

5.3.2 Changing the Scale of the Graph ..............................................................................102

5.3.3 Cursor ........................................................................................................................102

5.3.4 Data Point Size ..........................................................................................................102

5.3.5 Entering a Comment ..................................................................................................102

5.3.6 Storing a Hardcopy of the Graph ...............................................................................102

5.3.7 Making Additional Measurements ..............................................................................103

5.3.8 Storing and Loading Curves ......................................................................................103

5.3.9 Storing Curves as Limit Curves .................................................................................104

5.3.10 Deleting Additional Curves in the Measurement Graph ............................................104

5.3.11 Creating a Report.......................................................................................................104

5.3.12 Closing the Measurement Window ............................................................................104

5.4 Applicability of Measurements and Equipment Depending on the Release .....104

5.5 Sending Frequency Response and Loudness Rating .........................................105

5.5.1 Sending Frequency Response ..................................................................................105

5.5.2 Sending Loudness Rating ..........................................................................................105

5.5.3 Sending Tests Using Artificial Voice According to ITU-T P.50 or Single-Talk Speech

according to ITU-T P.501 as Test Signal ...................................................................107

5.6 Receiving Frequency Response and Loudness Rating.......................................107

5.6.1 Receiving Frequency Response ................................................................................108

5.6.2 Receiving Loudness Rating .......................................................................................109

5.6.3 Receiving Tests Using Artificial Voice according to ITU-T P.50 or Single-Talk Speech

according to ITU-T P.501 as Test Signal ...................................................................110

R&S UPV-K9/-K91 Contents

Operating Manual 1402.0043.12 - 10 6

5.7 Sidetone Masking Rating (STMR) ..........................................................................111

5.7.1 STMR Tests Using Artificial Voice according to ITU-T P.50 or Single-Talk Speech

according to ITU-T P.501 as Test Signal ...................................................................112

5.8 Sidetone Delay .........................................................................................................113

5.9 Roundtrip Delay .......................................................................................................114

5.10 Receiving Impairments ...........................................................................................116

5.11 Jitter Buffer Management Behaviour .....................................................................118

5.12 Echo Loss (TCLw)....................................................................................................119

5.13 Stability Margin ........................................................................................................120

5.14 Stability Loss ............................................................................................................121

5.15 Echo Control Characteristics .................................................................................122

5.16 Sending Distortion ...................................................................................................125

5.17 Receiving Distortion ................................................................................................129

5.18 Idle Channel Noise Sending ...................................................................................132

5.19 Idle Channel Noise Receiving .................................................................................134

5.20 Ambient Noise Rejection ........................................................................................136

5.21 Speech Quality in Presence of Ambient Noise .....................................................138

5.21.1 Setup ..........................................................................................................................138

5.21.2 Connections ...............................................................................................................139

5.21.3 Switcher Support........................................................................................................139

5.21.4 Prerequisites ..............................................................................................................141

5.21.5 Measurement .............................................................................................................141

5.21.6 Continuing Aborted Measurements ...........................................................................143

5.21.7 Typical Problems during measurement .....................................................................143

5.21.8 Additional operations when finished ..........................................................................145

5.21.9 Extended Speech Quality Measurements .................................................................145

5.21.10 Continuing Aborted Extended Measurements ...........................................................146

5.22 UE Send Clock Accuracy ........................................................................................147

5.23 Notes on Hands-Free Measurements ....................................................................148

5.23.1 General Remarks .......................................................................................................148

5.23.2 Test Setup ..................................................................................................................148

5.23.3 Acoustic Calibration for Hands Free Tests ................................................................150

5.24 “Utilites” Measurements .........................................................................................151

5.24.1 Sidetone Distortion.....................................................................................................151

5.24.2 Gain Variation Tests ..................................................................................................152

5.24.3 Delay Measurements .................................................................................................153

5.24.4 Background Noise Measurements .............................................................................154

R&S UPV-K9/-K91 Contents

Operating Manual 1402.0043.12 - 10 7

6 Customizing Measurements .......................................................... 156

6.1 Editing Parameters ..................................................................................................157

6.2 Editing Limit Curves ................................................................................................158

7 Measurements with Electric Connections .................................... 159

7.1 Introduction ..............................................................................................................159

7.2 Calibration Values for Electric Connections .........................................................159

7.2.1 Electric Connection Replacing Artificial Ear ..............................................................159

7.2.2 Electric Connection Replacing Artificial Mouth ..........................................................160

7.2.3 Electric Connection Replacing Encoder ....................................................................160

7.2.4 Electric Connection Replacing Decoder ....................................................................160

7.3 Performing the Measurements ...............................................................................160

8 Automatic Test Sequences ............................................................ 161

8.1 Creating and Editing a Sequence ...........................................................................161

8.2 Remote Control of R&S CMU200 within a Sequence ...........................................162

8.3 Remote Control of R&S CMW500 within a Sequence ..........................................163

8.4 Starting an External Executable within a Sequence ............................................164

8.5 Opening an Existing Sequence ..............................................................................164

8.6 Running a Sequence ...............................................................................................165

8.7 Running a Single Measurement out of a Sequence .............................................165

8.8 Reporting on Sequence Results ............................................................................165

9 Reporting, Storing, Loading and Deleting Results ...................... 166

9.1 Result Files ...............................................................................................................166

9.2 Report Settings ........................................................................................................166

9.3 Generating a Single Report ....................................................................................167

9.4 Generating a Sequence Report ..............................................................................167

9.5 Selection Report ......................................................................................................167

9.6 Preview Window.......................................................................................................168

9.7 Storing and Loading Curves ...................................................................................169

9.8 ASCII Result Files ....................................................................................................169

9.9 Deleting Results .......................................................................................................169

10 Remote Controlled Start of Testcases via GPIB .......................... 170

10.1 Preparations .............................................................................................................170

10.2 Starting a Measurement ..........................................................................................170

10.3 Reading the Results ................................................................................................170

R&S UPV-K9/-K91 Contents

Operating Manual 1402.0043.12 - 10 8

10.4 Determining the Termination of a Measurement ..................................................173

11 Terminating the Application .......................................................... 174

12 Appendix A Settings on the Radio Communication Tester

R&S CMU200 ................................................................................... 175

12.1 Settings for GSM:.....................................................................................................175

12.2 Settings for UMTS WCDMA FDD: ...........................................................................178

13 Appendix B Settings on the Radio Communication Tester

R&S CMW500 .................................................................................. 182

13.1 Settings for LTE: ......................................................................................................182

13.2 Settings for UMTS WCDMA FDD: ...........................................................................185

13.3 Settings for GSM:.....................................................................................................187

14 Appendix C Troubleshooting ................................ ......................... 189

14.1 Error Message 2908 During Installation ................................................................189

14.2 Damaged Setup File is Reported ............................................................................189

14.3 Damaged Results File is Reported.........................................................................189

14.4 A Test is Not Starting Properly ...............................................................................189

14.5 A Calibration Value is Missing or No Device is Selected for a Required

Calibration Type .......................................................................................................189

14.6 The Receiving Noise Test Produces an Overrange Error ...................................190

14.7 ARL for the Sending Distortion Test Cannot be Adjusted ..................................190

14.8 A Measurement Using a Custom Limit Curve Produces an Error ......................190

14.9 Other Problems of Unknown Reason ....................................................................190

R&S UPV-K9/-K91 Overview

Operating Manual 1402.0043.12 -10 9

1 Overview

The acoustic transmission and reproduction quality of a mobile phone is its most

important characteristic in everyday use. Even the most visually appealing design and

wonderfully sophisticated operating concept are not much use, when you cannot or

can hardly understand what is being said at the other end. Improvements in voice

quality achieved with wideband and super-wideband codecs as well as with modern

noise suppression and echo cancelling techniques have to be verified. In voice calls

over IP-based IMS connections like Voice over LTE, the processing delay in the mobile

phone as well as its ability to cope with packet delay jitter and packet loss is important

and has to be tested.

Instruments and methods for measuring acoustic characteristics are therefore essential

tools for assessing the quality and suitability of a mobile phone.

These tests are based on standards for 3GPP mobile phones. The test methods are

stipulated in 3GPP TS 26.132 and the values to be attained in 3GPP TS 26.131.

As of release 4 of the GSM 51.010 standard (successor to GSM 11.10), even GSM

mobile phones may be tested to 3GPP TS 26.132.

The R&S® UPV-K9 and R&S® UPV-K91 options (LTE/UMTS/GSM Mobile Phone

Tests) of the Audio Analyzer R&S® UPV, called herein below “UPV”, are now available

for measuring the acoustic characteristics of LTE, UMTS and GSM mobile phones.

The measurements are in line with 3GPP TS 26.131, TS 26.132 and TS 51.010 and

have been validated in conjunction with Wideband Radiocommunication tester

R&S® CMW500 by an independent test house for conformance testing on LTE, UMTS

and GSM mobile phones.

The current version of the software supports 3GPP TS 26.131 and TS 26.132 up to

Release 15.

From version 2.3.1.47 of the software, a new “Release” menu is available which allows

you to determine and start the test cases applicable to a given combination of speech

codec bandwidth, type of tested device (handset, headset or handheld, desktop or

vehicle-mounted hands-free) and release number of the test specifications.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 10

2 Preparation and Start of the Application

Software

2.1 Required Measuring Instruments and Accessories

The R&S® UPV audio analyzer with the options as described below is required for the

measurements.

The mobile phone under test is connected via the RF interface using Wideband Radio

Communication Tester R&S® CMW500, called herein below R&S® CMW500. Legacy

support for the Universal Digital Radio Communication Tester R&S® CMU200, called

herein below CMU200,is also provided. These testers simulate a base station for the

mobile phone so that a speech call can be set up.

The R&S® CMW500 must be equipped with the options R&S® CMW-B400B (Audio

Board) and R&S® CMU-B405A (Speech Board) in addition to the options required for

the signaling of the respective radio access technology. For detailed information on the

configuration of the R&S® CMW500 please contact your R&S sales office.

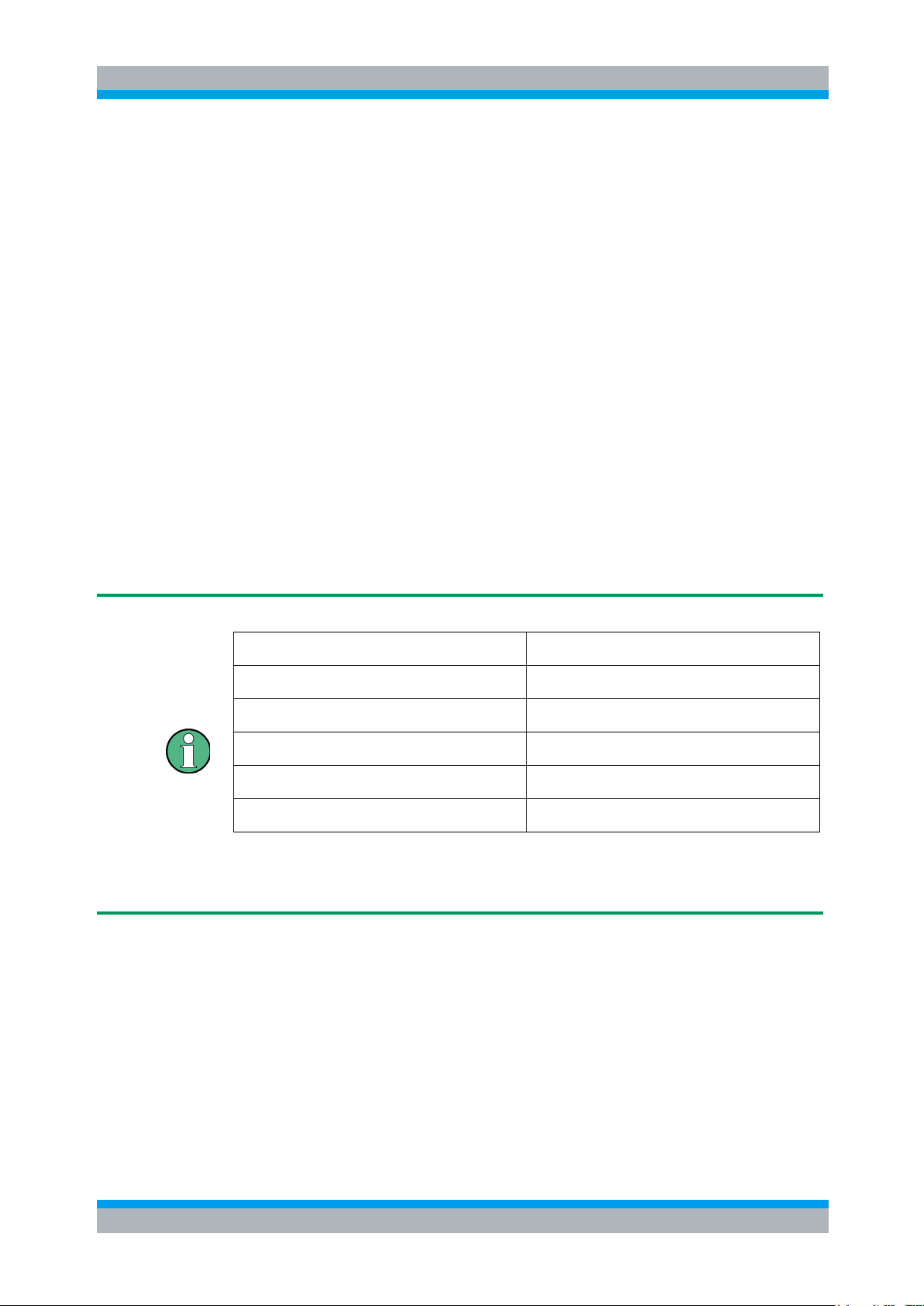

The firmware version in the R&S CMW500 must be the following or later:

Base

3.7.170

Audio

3.7.21

LTE Signaling

3.7.70 (SUA only), 3.7.10

Data Application

3.7.50

WCDMA Signaling

3.7.22

GSM Signaling

3.7.30

If using newer versions, make sure that the installed versions are compatible with each

other.

For GSM, the R&S® CMU200 must be equipped with the options R&S® CMU-B21

(signaling unit), R&S® CMU-B52 (speech coder/decoder) and the appropriate software

options for the GSM band used.

For WCDMA (UMTS), the option R&S® CMU-B69 is required. Wideband-AMR tests

require option R&S® CMU-K46 for both GSM and/or WCDMA (UMTS).

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 11

The firmware version in the R&S® CMU200 must be 5.04 or higher.

Acoustic devices such as an artificial mouth, artificial ear and other accessories are

required for the measurements. The following equipment from Brüel & Kjær or

G.R.A.S. is normally used:

Table 1: Equipment for mobile phone tests

Device

Description

Type (examples)

Telephone test head

(up to Release 8)

Device for fixing the DUT in the

prescribed position

B&K 4602B

Wideband ear simulator

(up to Release 8)

IEC 711 type occluded ear

simulator with adapters for

connection to the ear piece of the

DUT

B&K 4195 (type 3.2)

Artificial mouth

(up to Release 8)

Special loudspeaker for

simulation of the mouth

B&K 4227 or G.R.A.S. 44AB or

44AA (with power amplifier)

Head and torso simulator

Head and torso simulator with

artificial ear (type 3.3) and

artificial mouth, alternative to the

abovementioned devices,

mandatory since Release 9

B&K 4128D

(NB and WB only)

B&K 5128-D-111

(SWB, but not according to ITU-T

P.58, two artificial ears)

Head Acoustics HMS II.3

(SWB)

Driver amplifier for artificial mouth

(required for B&K 4227 and

B&K 4128)

Buffer amplifier to deliver the

required current into the 5 Ω load

impedance of the loudspeaker

B&K 2735

Second (left) artificial ear for head

and torso simulator B&K 4128

Required for hands-free tests and

adjustment of the background

noise field for “speech quality in

presence of ambient noise”

B&K 4159C

Handset fixture for Head and

Torso simulator

Required to position the handset

on the artificial head, and to apply

a defined force with the earpiece

against the pinna

B&K 4606 for B&K 4128 and B&K

5128 (included with B&K 4128D

and B&K 5128D)

Head Acoustics HHP II.1 or

HHP IV for HMS II.3

Measurement microphone

½” or ¼” measurement

microphone for measurement of

artificial mouth output during

calibration. This microphone can

use the preamplifier of the

artificial ear type 3.2 if existing.

Use a ¼” measurement

microphone for calibration of the

HATS mouth.

B&K 4938 with preamplifier B&K

2670 for calibration of the HATS

mouth and as reference

microphone for background noise

tests

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 12

Device

Description

Type (examples)

Acoustic calibrator

Sound level calibrator for

calibrating the measuring

microphone

B&K 4231 with ¼” adapter

DP0775

Microphone power supply

Power supply and preamplifier for

the measuring microphone

B&K 2829, 5935L or 2690A0S2

or G.R.A.S. 12AD or 12AA

With the amplifier set to 0 dB, the microphone power supply B&K 2690A0S2 produces

too much noise for measuring idle noise and distortion. It is therefore advisable to set

a gain of 20 dB.

From Release 9 of TS 26.132, the use of the HATS is mandatory for handset and

headset measurements. From Release 10, only artificial ear type 3.3 (anatomically

shaped soft pinna) may be used. For Super-Wideband testcases the artificial ears and

artificial mouth of the HATS must support the SWB frequency range of approximately

100 Hz to 14 kHz.

A cable with a BNC connector and special small or angled banana plugs is required for

connecting the P.51 artificial mouth, as the space between the mouth connectors and

the LRGP test head (B&K 4602B) is too small for common banana plugs.

The transformer supplied with option R&S UPV-K9 can only be used with the MMS test

signal. It must be connected between generator output 1 of Audio Analyzer R&S UPV

and the connector of the artificial mouth. The transformer matches the impedance of

the loudspeaker in the artificial mouth to that of the generator output of the R&S UPV.

Without this transformer, the available power is too low for driving the artificial mouth.

Alternatively, a power amplifier, preferably with a voltage gain of approx. 0 dB, can be

connected between generator output and mouth instead of the transformer. In this

case, the gain set must be kept absolutely stable after calibration.

For tests using artificial voice according to ITU-T P.50 or real speech according to

ITU-T P.501, a power amplifier is required. It may also be required for high-level

activation signals with high crest factor.

For connection to the audio input and output of the radio communication tester

R&S® CMW500, use BNC cables and the UP-Z1 adapters (XLR to BNC) supplied with

R&S® UPV-K9. Connect R&S UPV generator output 2 to CMW AF1 IN and CMW AF1

OUT to R&S UPV analyzer input 2.

For connection to the "Speech" connector of the Digital Radio Communication Tester

R&S® CMU200 a cable with male (analyzer) and female (generator) XLR connector is

supplied.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 13

UPV Analyzer

Generator

5

1

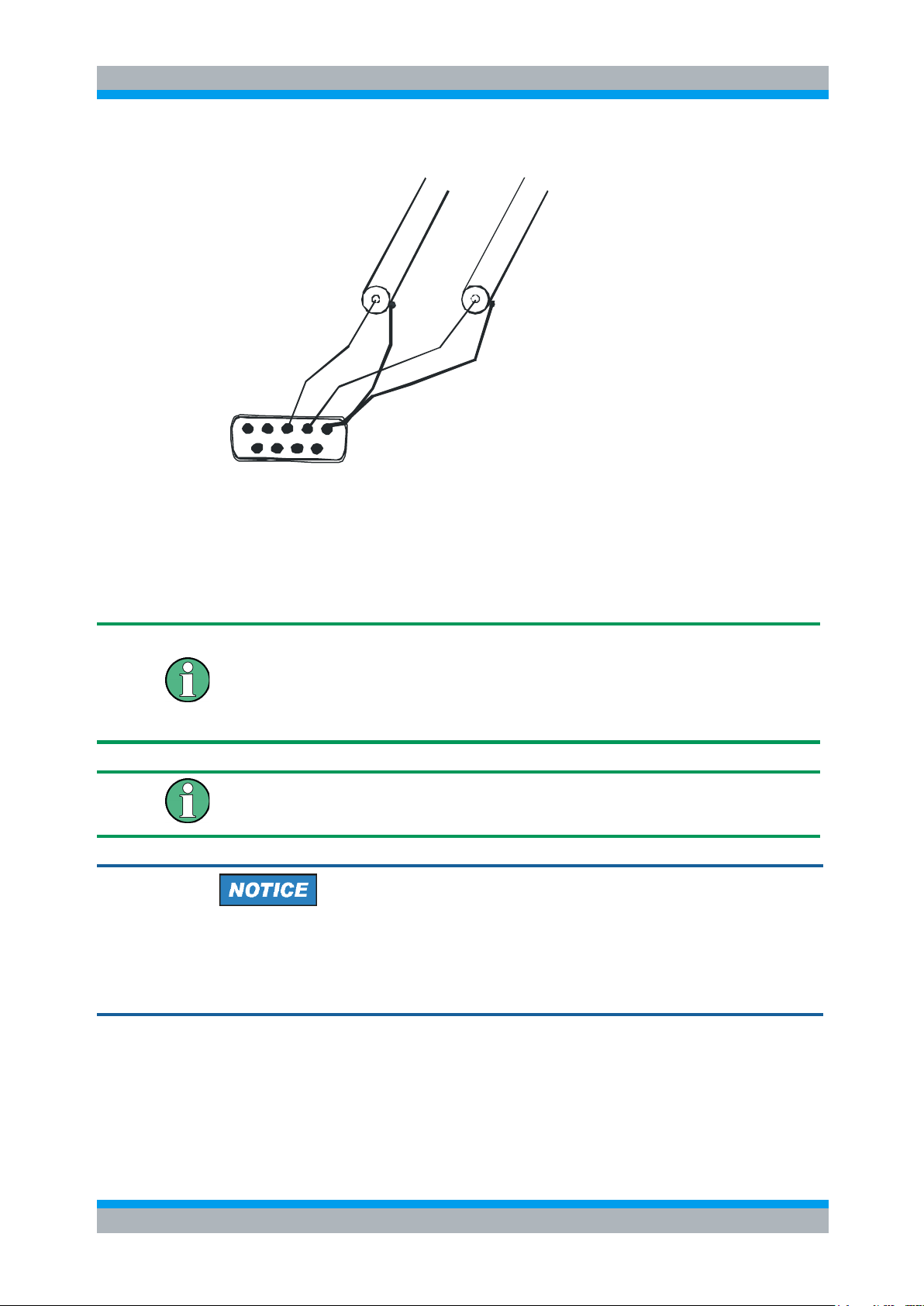

Figure 2-1: Assignment of 9-contact speech connector on R&S CMU front panel

This cable is configured for connection to link handler #1 in the R&S CMU200.

Depending on the R&S CMU hardware, link handler #2 in the R&S CMU200 can also

be used for GSM; in this case, the supplied adapter must be inserted between the

cable and the speech connector on the R&S® CMU200.

The R&S® CMU200 connects pin 1 and 3 of the R&S® UPV generator output to the

equipment grounding conductor of the mains. If an external power amplifier is used,

care must be taken that the external power amplifier does not connect R&S® UPV

generator output pin 2 to the equipment grounding conductor of the mains. If

available, a balanced connection to the power amplifier should be preferred.

If the CODEC calibration fails, the adapter has most likely to be inserted.

An external power amplifier should be switched on after the UPV-K9x program has

been started, and switched off before the program is ended. This prevents the artificial

mouth from undue power loading by setups, which are loaded external to the

application.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 14

An external USB keyboard and a mouse must be connected to the R&S UPV.

R&S UPV-K9x does not support the use of headphones. Do not connect headphones

to the R&S UPV during mobile phone tests. High-level signals may be present at the

headphone connector.

The R&S UPV audio analyzer must be equipped as follows:

● R&S UPV firmware version 4.0.4.159 or higher.

● License Key R&S UPV-K9 installed.

● License Key R&S UPV-K91 installed.

● For use of test signal according to ITU-T P.50 and distortion, tests with CSS or

customer specific activation signal License Key UPV-K9101 or higher must be

installed.

● For the use of requirements and test, methods according to Release 10 of TS

26.131 and TS 26.132, License Key UPV-K9102 or higher must be installed.

● For the use of requirements and test, methods according to Release 11 of TS

26.131 and TS 26.132, License Key UPV-K9103 or higher must be installed.

● For the use of requirements and test, methods according to Release 12 of TS

26.131 and TS 26.132, License Key UPV-K9104 or higher must be installed.

● For the use of requirements and test, methods according to Release 13, 14 or 15

of TS 26.131 and TS 26.132, License Key UPV-K9105 or higher must be installed.

● License Key UPV-K9105 includes UPV-K9104, UPV-K9103, UPV-K9102 and

UPV-K9101.

● For testcases 7.11, 8.11, 9.11 and 10.11 (“echo control characteristics”), option

R&S UPV-B3 (second analog generator) is required.

● For testcases 7.10.4, 8.10.4, 9.10.4 and 10.10.4 (“delay and speech quality in

conditions with packet arrival time variations and packet loss”) and for testcases

7.13, 8.13, 9.13 and 10.13 (“Jitter buffer management behavior”), option R&S®

UPV-K63 (listening quality analysis POLQA) is required in addition.

For testcases 7.12 and 8.12 (“speech quality in the presence of ambient noise”), the

following additional equipment and options are required:

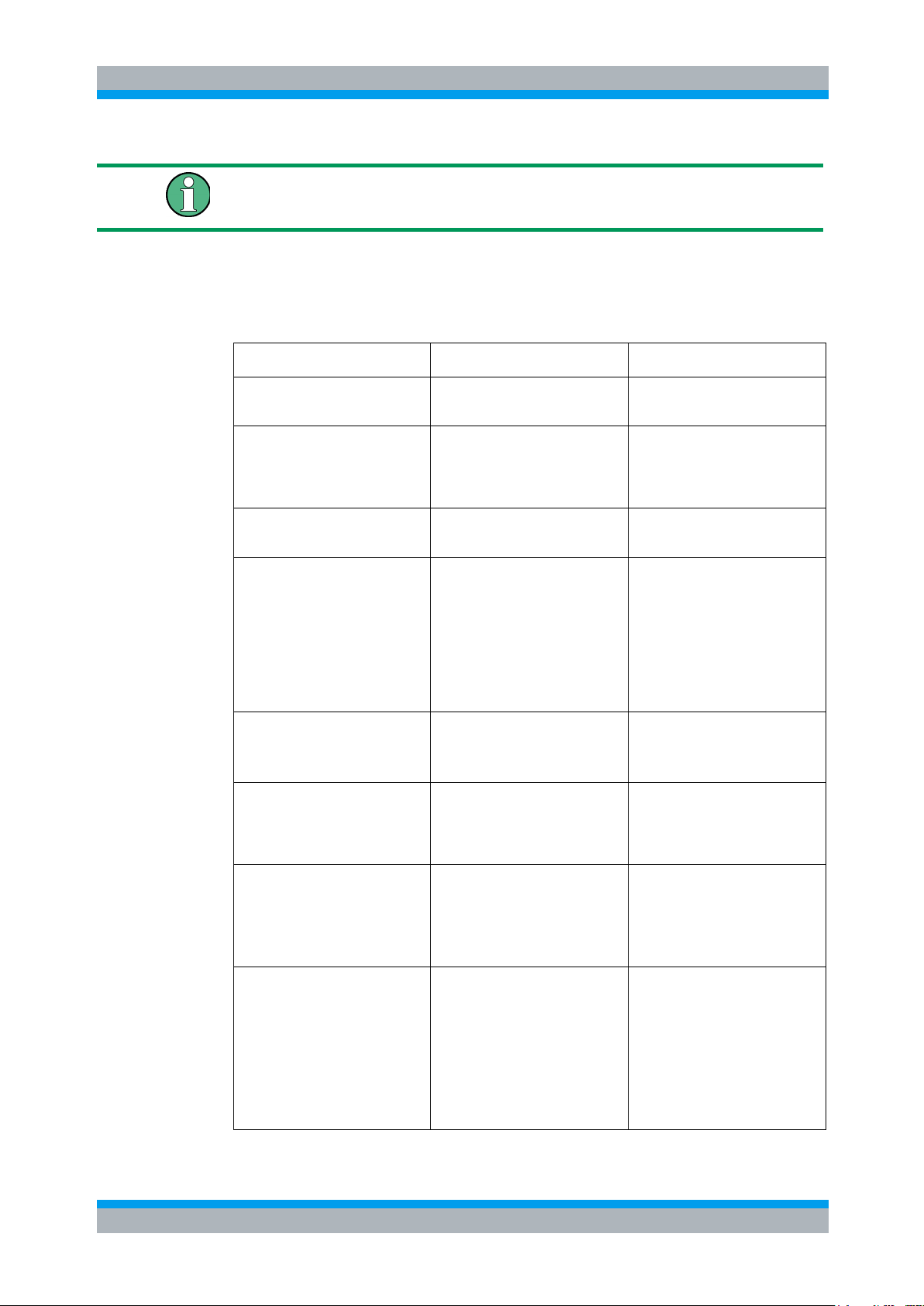

Description

Instrument Type

Ordering Number

R&S UPV-K98

Background noise control

software acc. ETSI ES 202 396-1

1424.2003.02

R&S UPV-K101

Measurements using background

noise acc. ETSI TS 103 106 and

EG 202 396-3

1424.2203.02

R&S UPP200

Audio Analyzer two channels

1411.1003.02

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 15

R&S UPP-B8

Eight-channel generator

1411.2700.02

R&S UP-Z8A

8-channel analog cable for

R&S UPP-B8

1411.3206.02

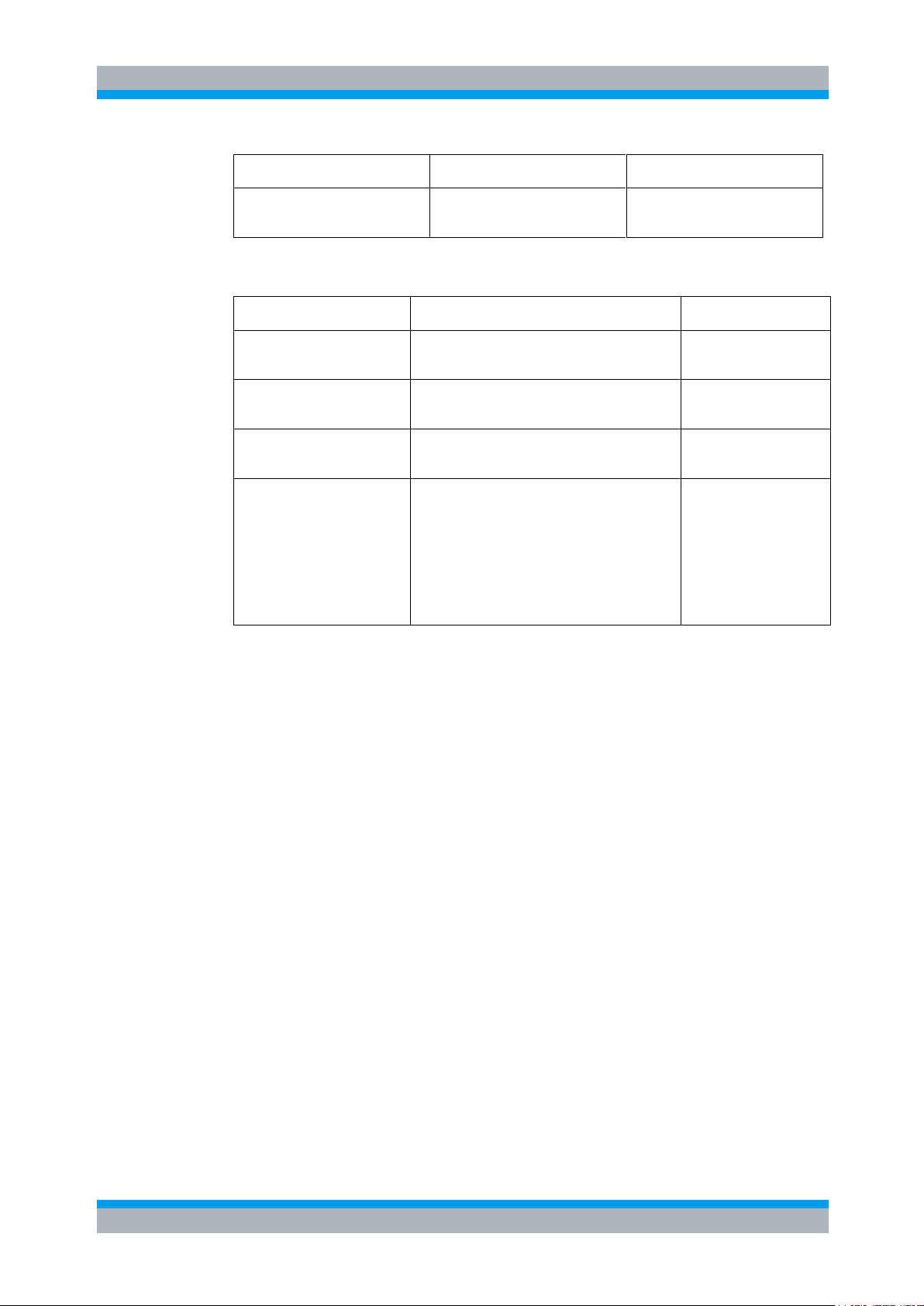

The following equipment not supplied by Rohde & Schwarz is also required:

Device

Description

Type (examples)

2 Pairs of full-range speakers

Frequency response at least

100 Hz to 10 kHz

Behringer Truth B2031A

Subwoofer

Frequency response at least

40 Hz to 120 Hz

M-Audio SBX-10

5 Speaker cables

XLR male – XLR female

length approx. 10m

4 Speaker stands

The base plane of the speaker should be

adjusTable such that the tweeter of the speaker

is at the same height as the artificial ears of the

head-and-torso simulator. With the B2031A

speakers, the tweeter is about 31 cm above the

base. With the Bruel & Kjaer HATS, the

entrance of the artificial ear is about 60 cm

above the base.

2.2 Installing the Software

The application program requires license keys R&S UPV-K9 and R&S UPV-K91 to be

installed. The application program and the license keys are installed together with

license key UPV-K9105 in the factory in case a new R&S UPV is ordered together with

these options. If the options are ordered separately, the license keys as well as the

installation instructions are part of the delivery.

The program required and the associated files are in the folder “UPV-K9x Software” on

the installation CD supplied with the R&S UPV-K91 option. It is recommended to copy

the files MCRInstaller.exe, CRRuntime_32bit_13_0_12.msi, UPV-

K9x_33184.msi, and dotNetFx40_Full_x86_x64.exe from the folder “UPV-

K9x Software” on the installation CD to drive D: on the R&S UPV hard disk drive, e.g.

to a folder named “D:\R&S Software\UPV-K9x\Version 3.3.0”. Run the file UPV-

K9x_33184.msi to start the installation. Follow the instructions of the installer on the

screen. If prompted to do so, also run dotNetFx40_Full_x86_x64.exe. If this

runtime library has to be installed on a UPV with Windows XP, copy installer

“wic_x86_enu.exe” to the UPV hard disk and run it before installing the .Net 4.0

runtime library.

Subsequently, run also MCRInstaller.exe and

CRRuntime_32bit_13_0_12.msi.exe.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 16

Note (1)

MCRInstaller.exe must be run, unless UPV-K9x software version 3.0.3.56 or

higher or UPV-K9y software version 3.0.0.65 (or higher) is already installed on the

R&S UPV.

Note (2)

If a UPV-K9y software version below 3.0.0.65 is installed it is recommended to update

to the latest version (currently 3.1.0.69).

Note (3)

Prior to an upgrade of UPV-K9x software from version 2.3.1 or below the program

“MATLAB

®

Component Runtime” must be de-installed using the windows tool “Add or

Remove programs” (XP) or “Programs and Features” (Win7) respectively.

Note (4)

In case it is desired to run an older version of the UPV-K9y software, the old version of

MCRInstaller.exe (from the older version UPV-K9y installation CD) must be reinstalled after installation of the new version.

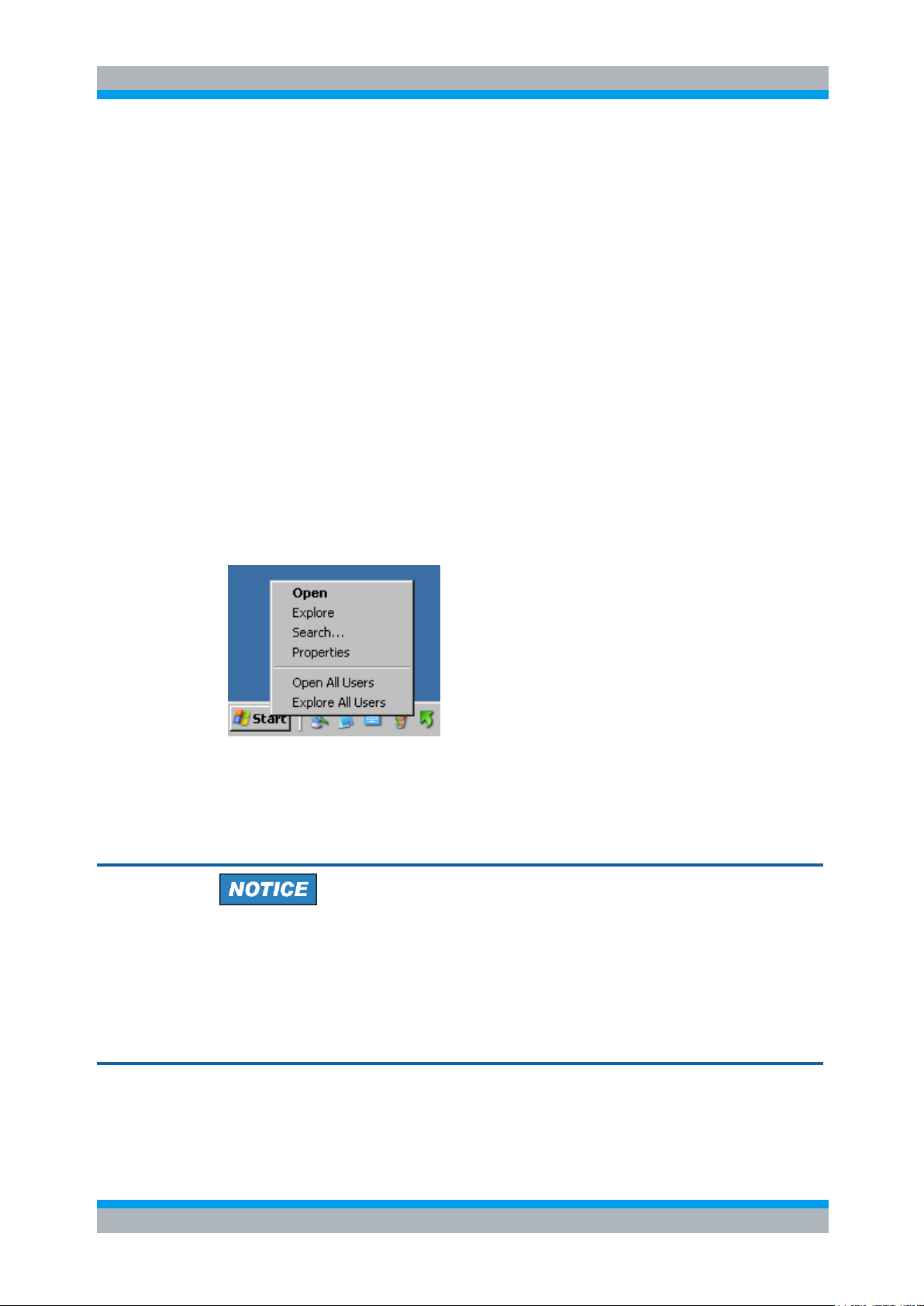

To have full control over minimized windows, it is recommended to set the windows

taskbar to “Auto-hide”, on top of other windows. Right-click on the Windows Start

button and click “properties”.

Figure 2-2: Context menu for taskbar

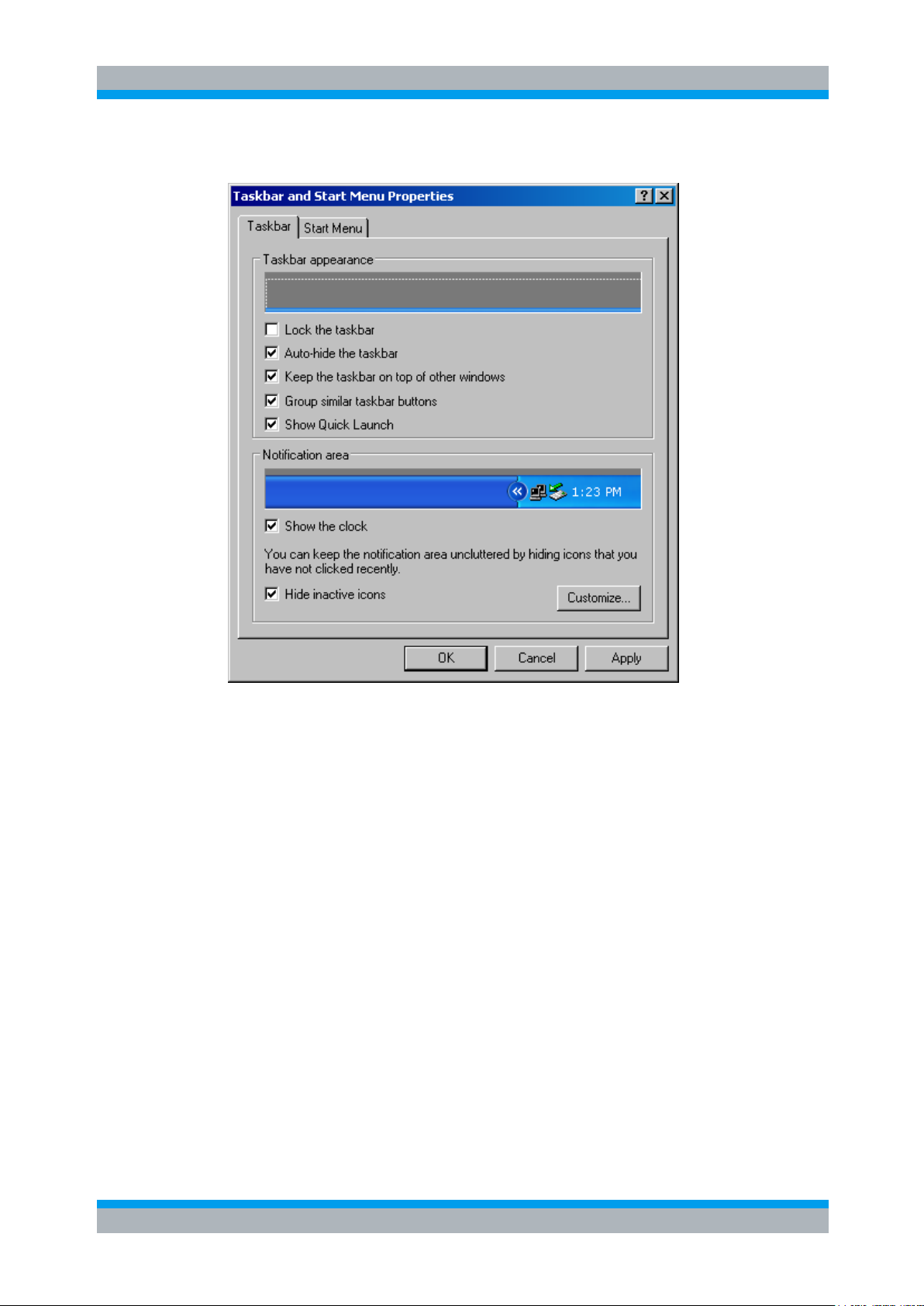

In the properties window, click tab “Taskbar” and activate “Auto-hide the taskbar” and

“Keep the taskbar on top of other windows”. Click “Apply” and close the window.

UPV-K101 does not support super-wideband and fullband evaluation of speech quality

in background noise according to ETSI TS 103 281. For this measurement an upgrade

license (ACOPT 35) to the batch calculator has to be obtained directly from Head

Acoustics GmbH in Herzogenrath, Germany (www.head-acoustics.com).

For an update of UPV-K101 to SWB / FB evaluation, use version 2.1.200 of the Head

Batch Processor. Newer versions are not tested with this version of UPV-K91.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 17

Figure 2-3: Properties window for taskbar

2.3 Verification of the Installation

After the installation, check the existence of the subfolder “UPV-K9x Mobile Phone

Tests” in “C:\Program Files\Rohde&Schwarz”. This subfolder must contain 90

files plus 2 more subfolders: “General_Data” containing 33 files and “3GPP_Data”

with subfolder ”No_Overwrite” containing 124 files and subfolder “Overwrite”

containing 990 files.

If the software reports a missing key code at the first start, delete folder “D:\3GPP” (if

existing) and install the missing key code before starting the software again.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 18

2.4 Test Setup

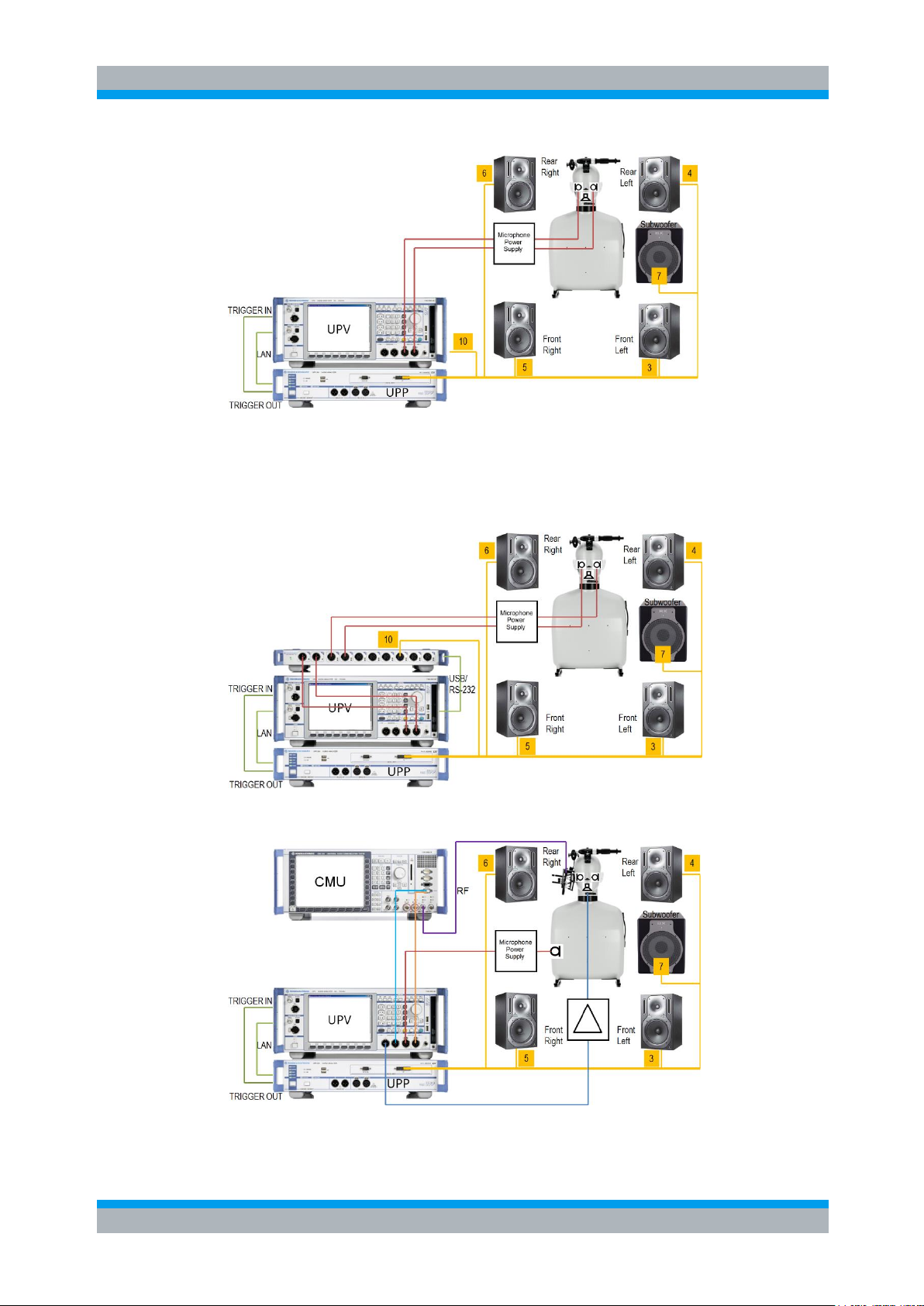

Figure 2-4: Test setup and connection of external components with R&S CMU200

Figure 2-5: Test setup and connection of external components with R&S CMW500

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 19

Figure 2-6: Test setup and connection of external components with input switcher R&S UPZ and

R&S CMU200

Figure 2-7: Test setup and connection of external components with input switcher R&S UPZ and

R&S CMW500

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 20

Figure 2-8: Test setup and connection of external components for the adjustment of the background

noise field

Generator channel 10 is the reference channel for the delay measurement. If no

switcher is used, it has to be connected according to the instructions from the K9x

software.

Figure 2-9: Test setup and connection of external components with input switcher UPZ for the

adjustment of the background noise field

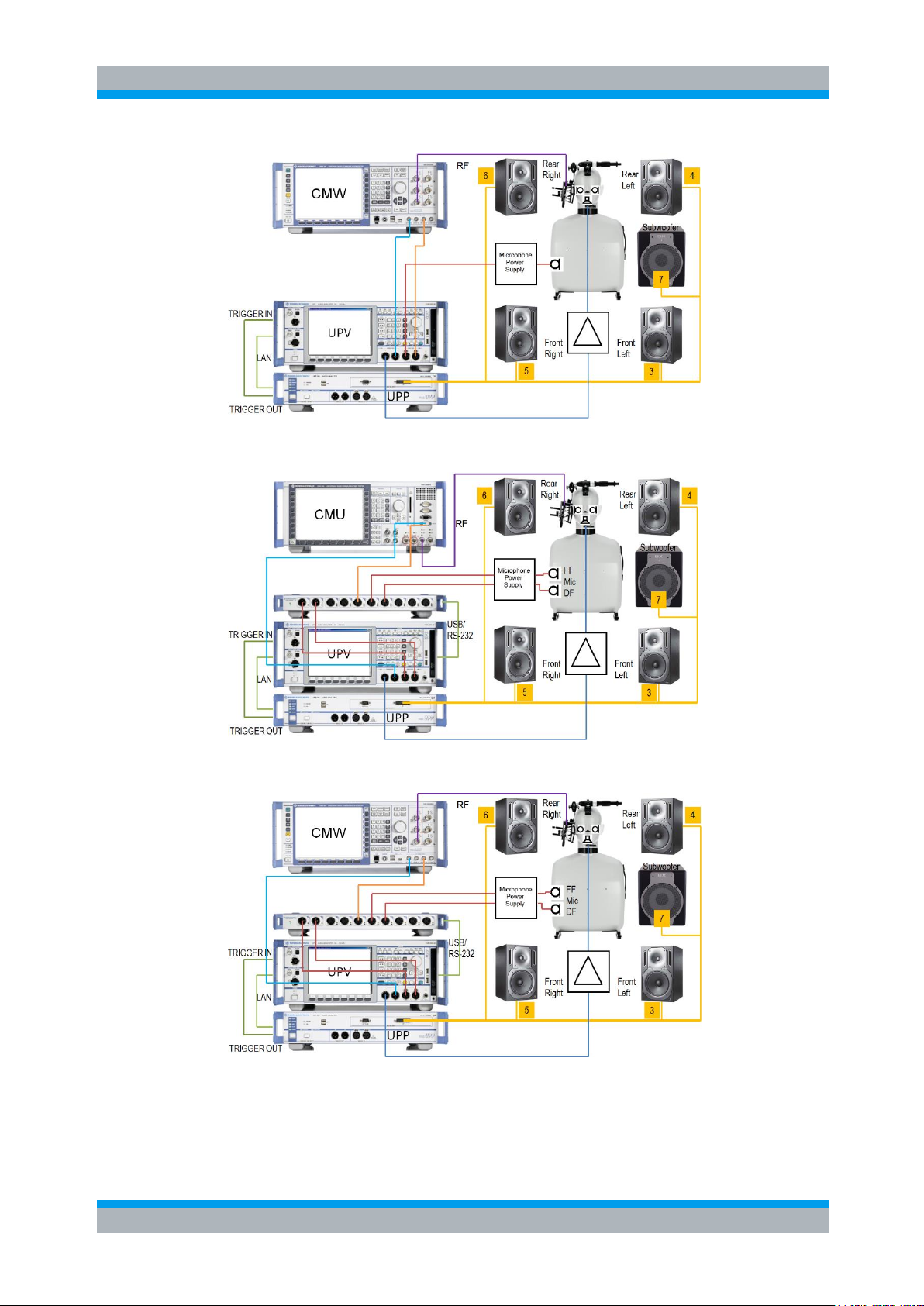

Figure 2-10: Test setup and connection of external components with CMU200 for measurements with

background noise field

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 21

Figure 2-11: Test setup and connection of external components with R&S CMW500 for

measurements with background noise field

Figure 2-12: Test setup and connection of external components with R&S CMU200 and input switcher

R&S UPZ for measurements with background noise field

Figure 2-13: Test setup and connection of external components with R&S CMW500 and input

switcher R&S UPZ for measurements with background noise field

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 22

In case of hum noise in one or more of the speakers, it may be necessary to insert an

isolating audio transformer between the output of UPP-B8 and the input of the speaker.

It may also help to connect the speaker to the same power outlet as the UPP.

Switching of connections between tests is required for binaural measurements

(handsfree tests and tests of binaural headsets) and for calibration, in particular for the

adjustment of the background noise reproduction. In the setups in Figure 2-4,

Figure 2-5, Figure 2-8, Figure 2-10 and Figure 2-11, connections have to be changed

manually between tests and even during the background noise adjustment. This can

be avoided by using an R&S UPZ12 input switcher as shown in Figure 2-6, Figure 2-7,

Figure 2-9, Figure 2-12 and Figure 2-13.

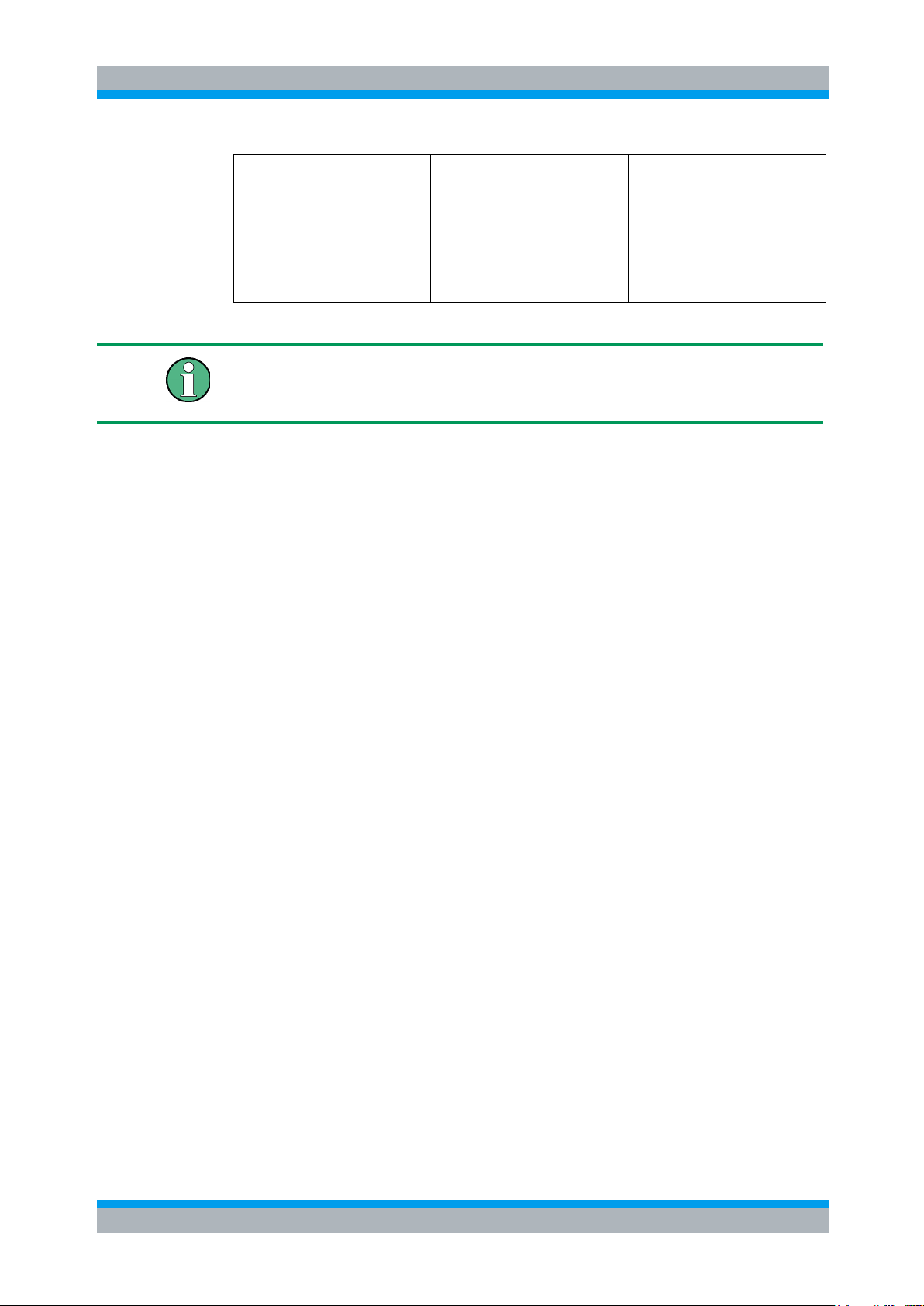

Table 2: Assignment of R&S UPZ switcher connectors

UPZ Input

Connected Device

1

Second (left) artificial ear

2

First (right) artificial ear

3

Decoder output

4

Free field microphone

5

Diffuse field microphone

6

R&S UPP-B8 output 10

A

R&S UPV analyzer input 1

B

R&S UPV analyzer input 2

2.5 Starting the Application Software

After installation, the program can be started by double-clicking the Icon “UPV-K9x

Mobile Phone Tests” or by clicking “R&S UPV Applications UPV-K9x Mobile Phone

Tests” in the “Programs” menu.

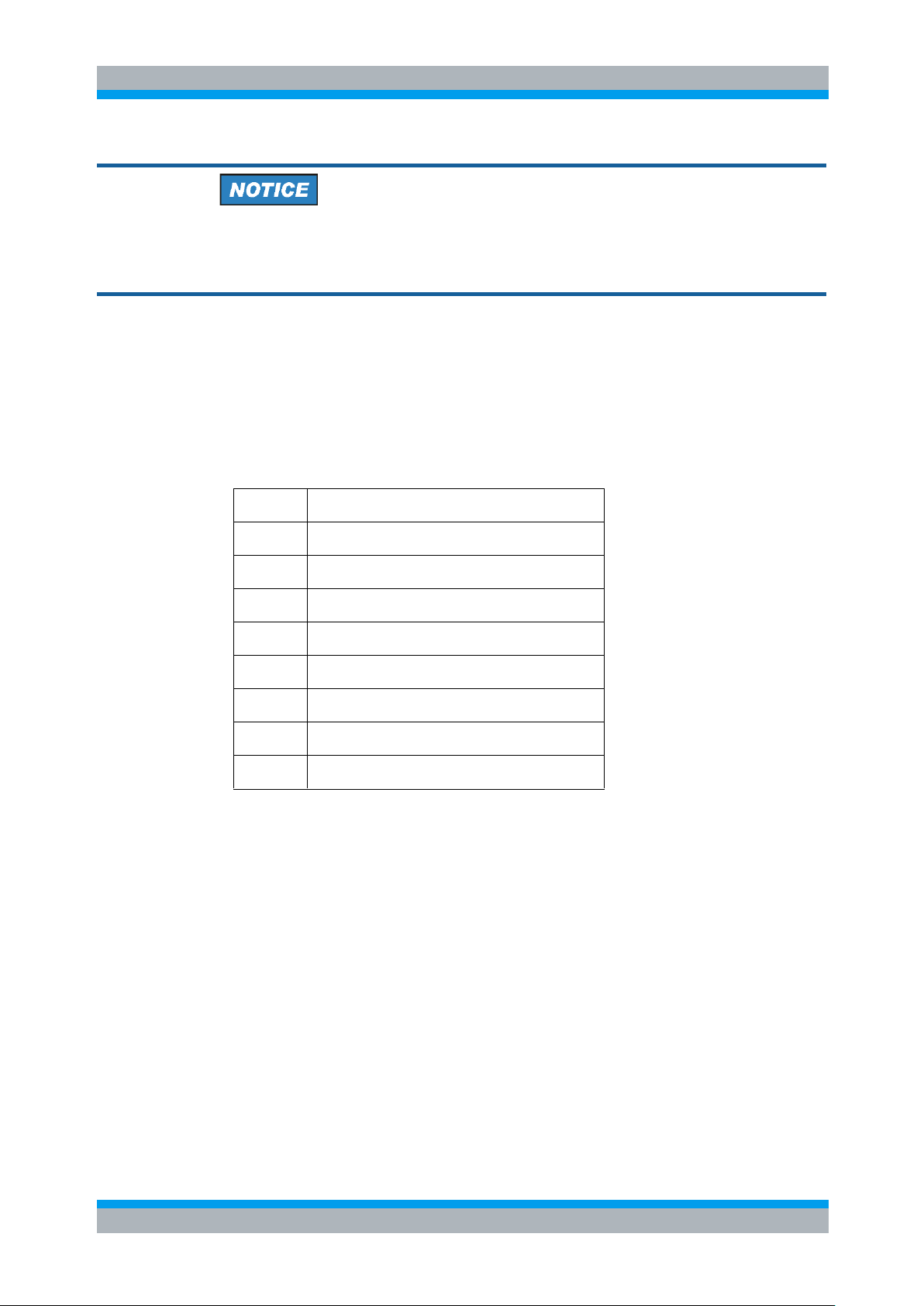

At the first start of the program, selection windows appear for the standard according to

which the measurements should be made, and for the artificial ear and artificial mouth

used.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 23

Figure 2-14: Query window for selection of applied standard

If “none” is selected in the standard selection window, all measurements appear in the

“Measurement” menu. If a standard is selected, all measurements appear in the

“Measurement” menu, but compliant measurements are checked in the menu. If “Allow

only selected measurements” is checked, non-compliant measurements are

suppressed in the Measurement menu. “Non-standard handset” and “non-standard

hands free” select handset or hands-free tests, respectively, which can be customized.

The next window is for selection of relevant measurements according to tested device

type, codec bandwidth, test signal and Release of the 3GPP standards TS 26.131 and

TS 26.132. All test cases relevant for the selected combination will be offered in the

“Release” menu.

Figure 2-15: Query window for the Release menu

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 24

Figure 2-16: Query window for selection of artificial ear

Figure 2-17: Query window for selection of artifical mouth

When the checkbox “Do not show this dialog again” is checked, the corresponding

selection window will not appear at the program start in future. However, the selection

is still available in the “Options” menu (see below). After the last of the four selection

windows has been closed, the main window of the R&S UPV-K9 opens.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 25

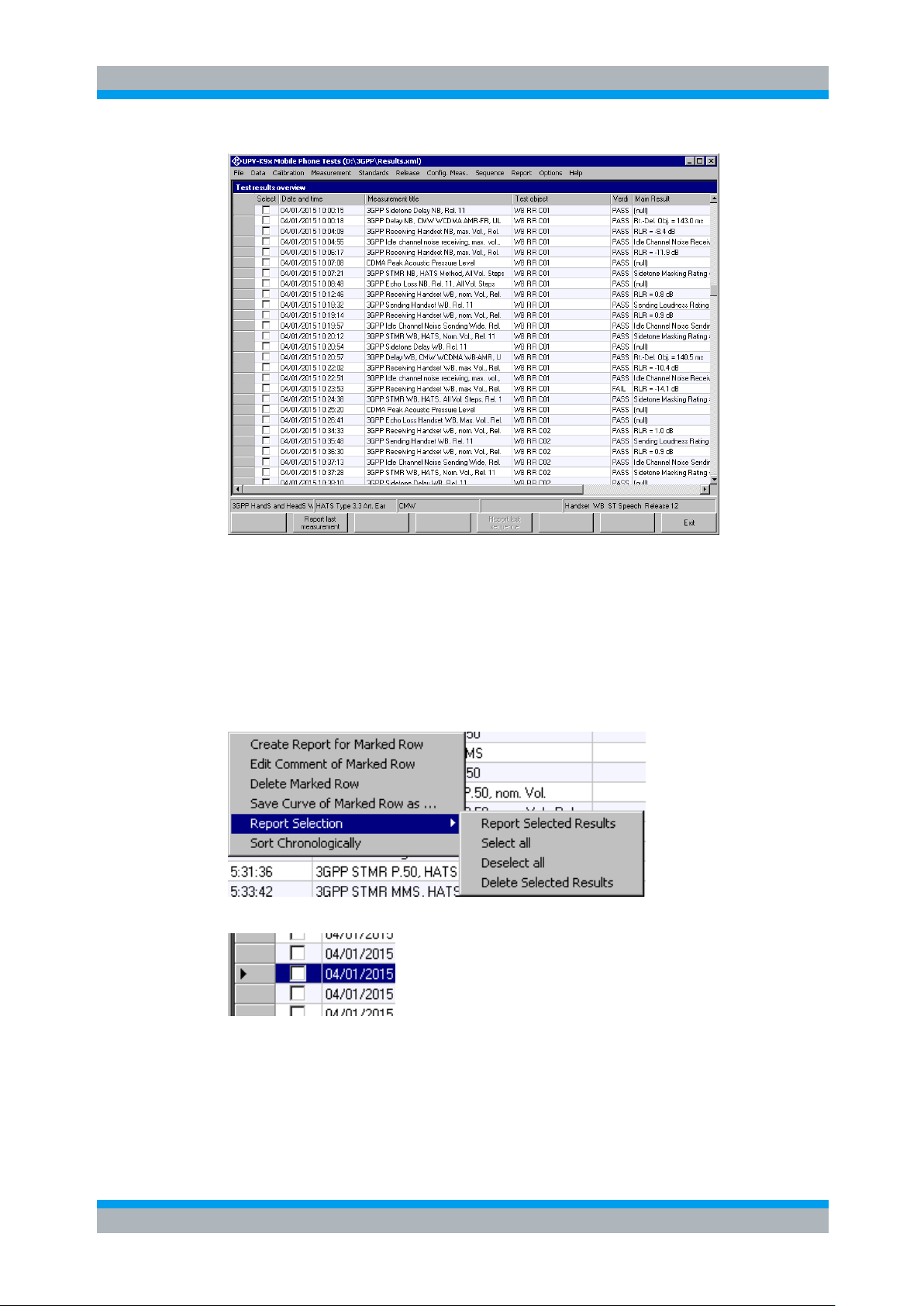

Figure 2-18: Main window

Initially the data grid in the center of the screen, which shows that the result overview is

empty. The screenshot in Figure 2-18 shows an example after a number of

measurements have been made.

By clicking with the right mouse button on the data grid, a context menu opens which

allows you to create a report of a result marked by a solid triangle in the respective row

header, to edit the comment for a marked result, to delete the marked result or to

export one of the curves in the marked result graph to an ASCII format.

Figure 2-19: Context menu of the result data grid

Figure 2-20: A triangle in the row header indicates a marked row

The “Report Selection” submenu allows you to report on or delete a selection of

results, which have been marked in the “Select” column of the data grid. To select or

unselect a result, click the checkbox in the “Select” column of the respective row.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 26

If the results have been sorted alphabetically according to one of the columns by

clicking on the respective column header, the chronological order can be restored

using the context menu item “Sort Chronologically”.

Operating Concept

R&S 3GPP mobile phone tests consist of the main user interface window, which allows

general settings, calibration routines, data handling, automatic sequencing and

reporting tools, and of test macros for basic measurement types defined in the

standards. Each measurement type provides a set of parameters (R&S UPV setup

files, limits etc.) which are defined in separated measurement definition files, one for

each test case.

Do not attempt to modify files with extensions “set”, “sup”, “xml”, “cal” “seq” or “mdf”,

using a text editor. Any change with a text editor may make the files unusable and

cause malfunction of the software.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 27

2.6 Options (General settings)

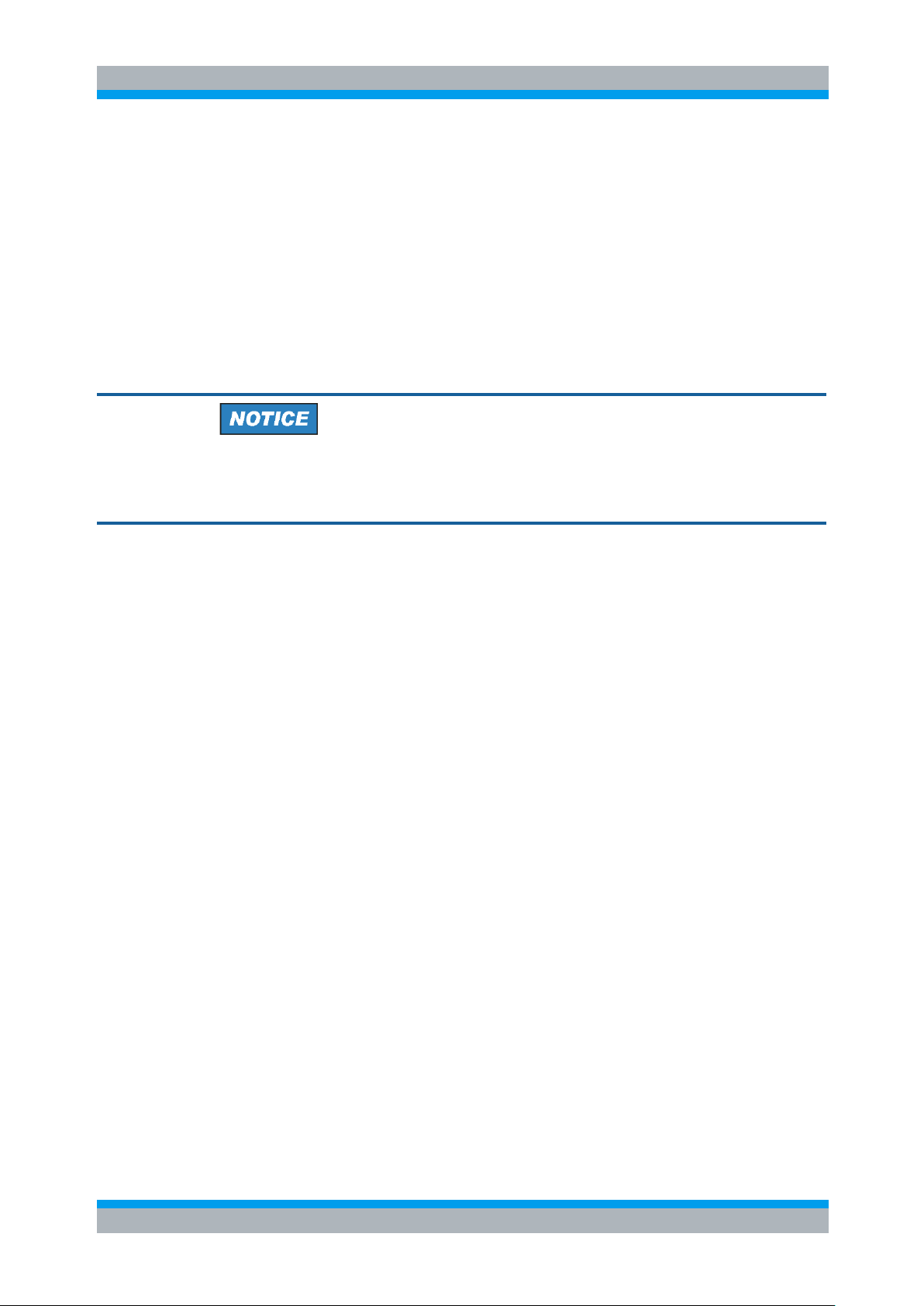

Figure 2-21: Options menu

The “Options” menu in the main window allows changing a set of general settings like

ear type and mouth type used, which are valid for all or at least a plurality of the tests.

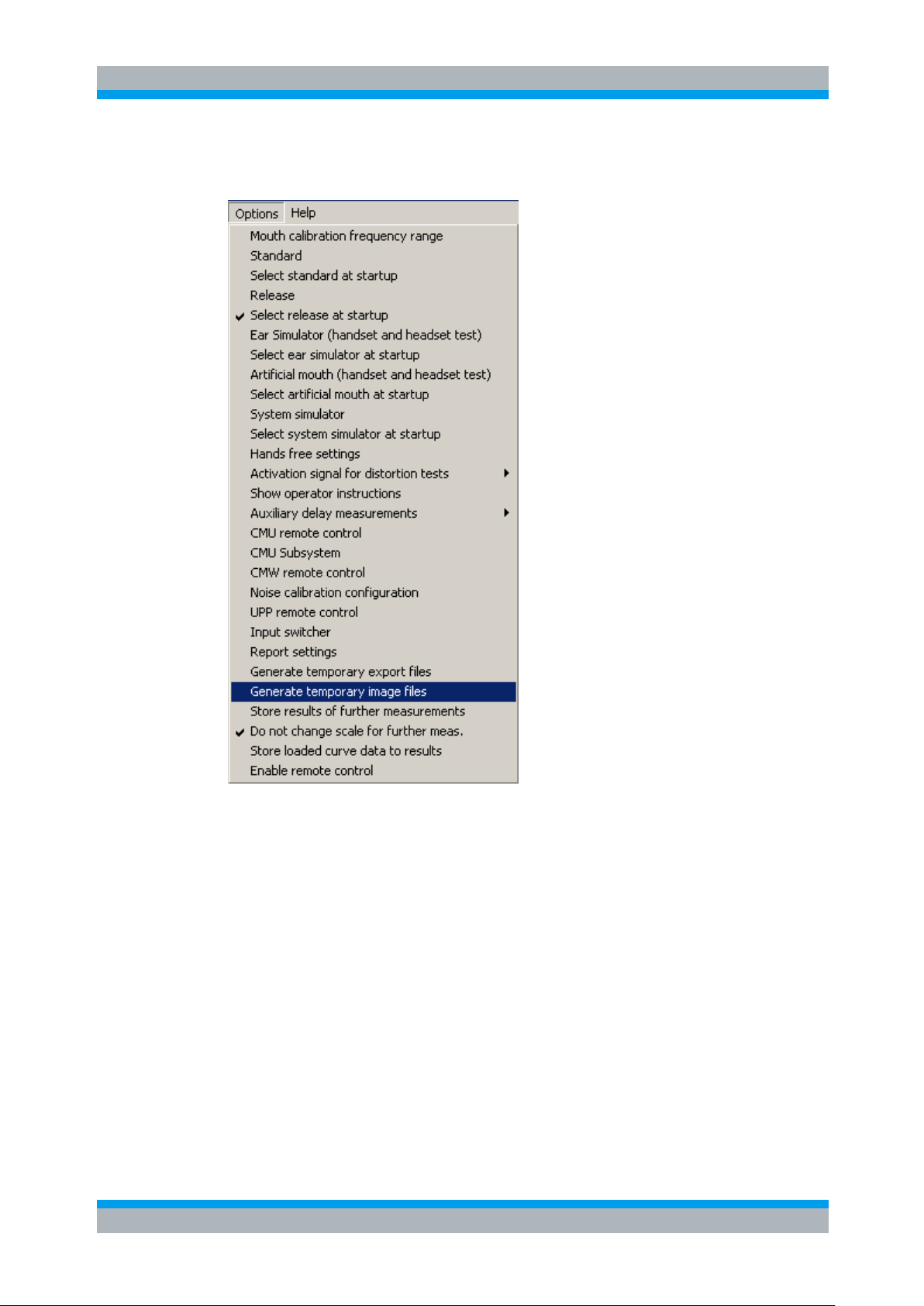

2.6.1 Mouth Calibration Frequency Range

For narrowband and wideband tests, the mouth frequency response is equalized

between 90 Hz and 9000 Hz. For super-wideband and full band tests, a wider

frequency range from 90 Hz to 17800 Hz is required. As not all types of artificial

mouths support this wider frequency range, “Mouth calibration frequency range" allows

you to select the desired frequency range before the start of the calibration of the

artificial mouth.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 28

Figure 2-22: Mouth calibration frequency range

The frequency range for super-wideband and fullband tests is identical, as in 3GPP TS

26.132 the test definitions for fullband refer to those for super-wideband.

As the wideband and narrowband frequency ranges are included with the superwideband frequency range, there is only one mouth calibration required for each

artificial mouth in use.

2.6.2 Standard

“Standard” allows selecting one of the available standards. Measurements belonging to

this standard will be checked in the measurement menu. If “Allow only standard

measurements” is checked, it is not possible to start single measurements, which do

not belong to the standard.

2.6.3 Select Standard at Startup

If “Select standard at startup” is checked, the selection window for the standard is

opened at each start of the program.

2.6.4 Release

“Release” opens the window to select type of tested device, codec bandwidth, test

signal and Release of 3GPP standards TS 26.131 and 26.132 to be applied. Any

change in these settings will re-build the “Release” menu with the applicable test

cases.

2.6.5 Select Release at Startup

If “Select release at startup” is checked, the selection window for the “Release” menu

is opened at each start of the program.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 29

2.6.6 Ear Simulator

“Ear simulator” allows selecting the type of ear simulator used. For details on the

handling of calibration data, see section 3 Calibration below.

2.6.7 Select Ear Simulator at Startup

If “Select ear simulator at startup” is checked, the selection window for the ear

simulator is opened at each start of the program.

2.6.8 Artificial Mouth

“Artificial mouth” allows selecting the type of artificial mouth used. For details on the

handling of calibration data, see section 3 Calibration below.

2.6.9 Select Artificial Mouth at Startup

If “Select artificial mouth at startup” is checked, the selection window for the artificial

mouth is opened at each start of the program.

2.6.10 System Simulator

“System simulator” allows selecting the type of system simulator used. For details on

the handling of calibration data, see section 3 Calibration below.

2.6.11 Hands-free Settings

“Hands-free settings” allows selecting the acoustic instruments used for hands free

testing. It is possible to use an ITU-T P.51 artificial mouth together with a free field

microphone, a HATS with one artificial ear or a HATS with two artificial ears. If two

artificial ears are used, the decoder has to be disconnected from analyzer input 2 and

the second artificial ear has to be connected to it for receiving measurements. Do not

forget to re-connect the decoder for any measurement in sending direction.

2.6.12 Activation Signal for Distortion Tests

In the sub-menu to “Activation signal for distortion tests”, signals can be imported to

the test system. If more than one imported signal is available, it is possible to choose

one of them for actual use.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 30

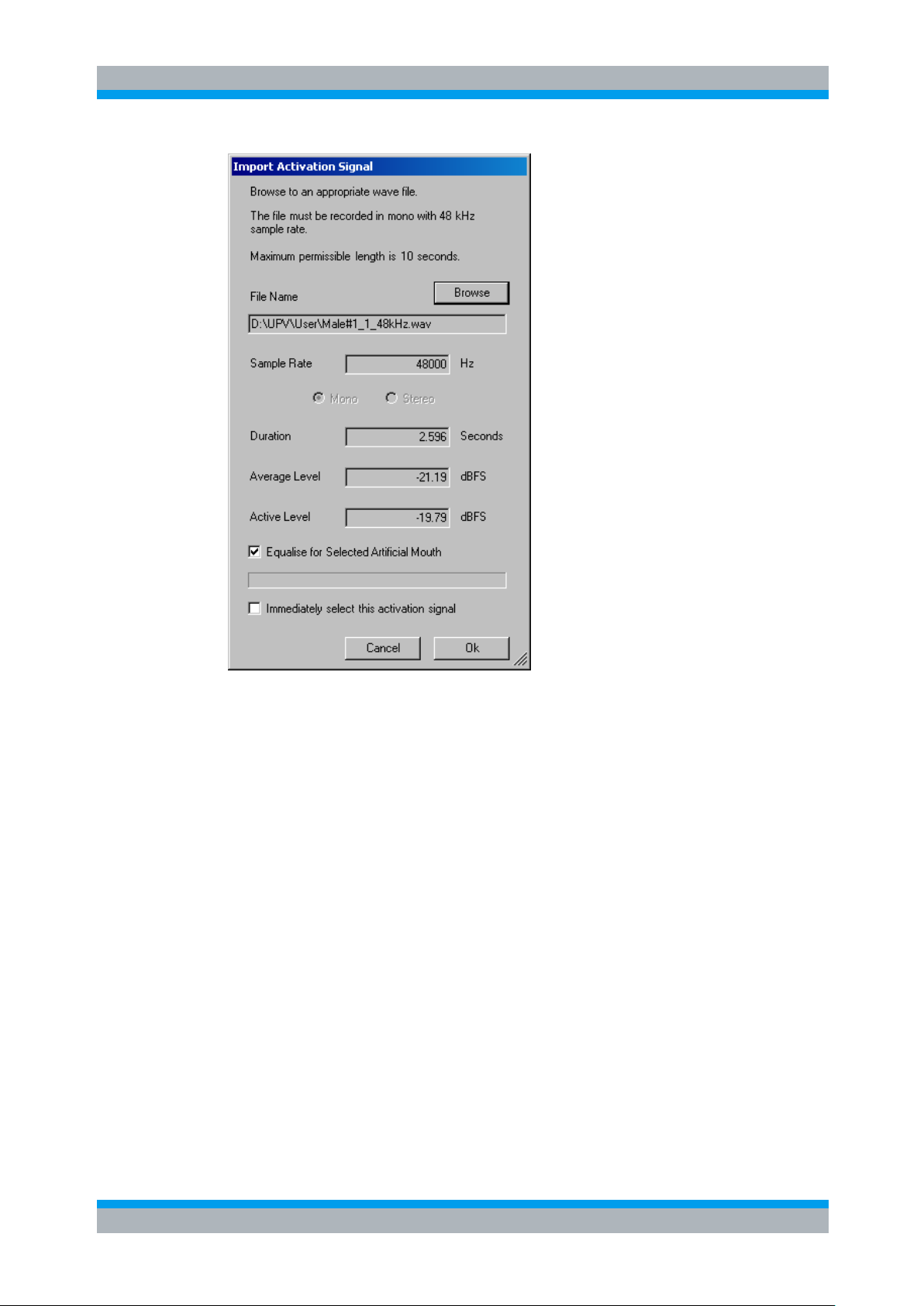

Figure 2-23: Window for import of activation signals

Use the “Browse” button to select a wave file, which fulfills the conditions shown on top

of the window. The selected signal is analyzed and checked for appropriateness. Note

that a high crest factor of the signal may overdrive the codec or artificial mouth. If

“Equalize for Selected Artificial Mouth” is activated, the file is immediately equalized for

the selected artificial mouth when the “Ok” button is clicked. Otherwise or when the

mouth calibration has been re-done or a different artificial mouth has been selected in

the meantime, the signal is equalized automatically immediately before the sending

distortion test starts.

If “Immediately select this activation signal” is checked, the signal is selected for use

when the “Ok” button is clicked.

2.6.13 Show Operator Instructions

If “Show operator instructions” is checked, instructions to the operator are displayed in

a window before the measurement starts. The operator may be prompted to position

the mobile in a defined way or to set the volume to a certain setting.

Auxiliary delay measurements

For the alignment of the acquisition with the arrival of the test signal at the analyzer

input, an auxiliary end-to-end delay measurement is performed before the main

measurement.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 31

The item “Auxiliary delay measurements → Configure” allows you to select the

measurement method (sine burst or cross correlation), the test signal for the cross

correlation method (composite source signal or real speech word “five”) and the re-use

of a delay value which has been measured for the same device under test on the same

path for a previous test. A maximum age has to be specified for the use of existing

delay values to avoid the use of outdated values.

Figure 2-24: Window for configuration of auxiliary delay measurements

The recommended method for auxiliary delay measurement is cross-correlation using

the real speech word “five” as test signal. Re-use of existing delay results speeds up

the tests, which is particularly helpful in automatic test sequences. It avoids changing

of the test setup when uplink and downlink delay values are required for echo loss and

stability loss tests.

However, if changes are done in the setup, which could have an influence on the endto-end delay, like changing the device under test, the codec or codec rate etc., the

auxiliary delay measurement has to be re-run. If a different device under test is

selected in menu item “Data → Test object → Select …” the memorized auxiliary delay

values are automatically invalidated. In all other cases, the operator has to invalidate

them using menu item “Auxiliary delay measurements → Invalidate all existing values”.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 32

2.6.14 R&S CMU Remote Control

If it is intended to remote control a R&S CMU200 from a sequence of this program,

menu item “CMU remote control” can be used to select the communication interface

(GPIB or RS-232) and, if multiple devices are found, to select one of them.

Figure 2-25: Window for configuration of the R&S CMU remote control

For remote control via RS-232, an external USB-to-serial converter has to be

connected and installed. For remote control via GPIB, the R&S VISA has to be

installed. The installer for the R&S VISA is distributed with the Option R&S UPV-K91.

For details of the remote control, see 8 Automatic Test Sequences and the operation

manuals of the R&S CMU200.

2.6.15 R&S CMU Subsystem

In “CMU subsystem”, one of the communication standards / GSM frequency bands can

be selected. This allows sequences to be run in different GSM bands without changing

the subsystem in every single CMU control instance in the sequence.

2.6.16 R&S CMW Remote Control

For clock adjustment in Voice over LTE (VoLTE), and for roundtrip delay

measurements using the wideband radiocommunication tester R&S CMW500 as

system simulator, the R&S CMW500 has to be remote controlled from the R&S UPVK9 program. Available remote control interfaces are TCP/IP (LAN), GPIB and USB.

The item “CMW Remote Control” in the options menu allows selecting the device and

the interface to be used. For TCP/IP connections, enter the device name

("CMW50050-", followed by the serial number) or the current IP address of the

R&S CMW500. For GPIB connection, use the connector labelled “IEEE 488 CH1” on

the backplane of the R&S CMW500.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 33

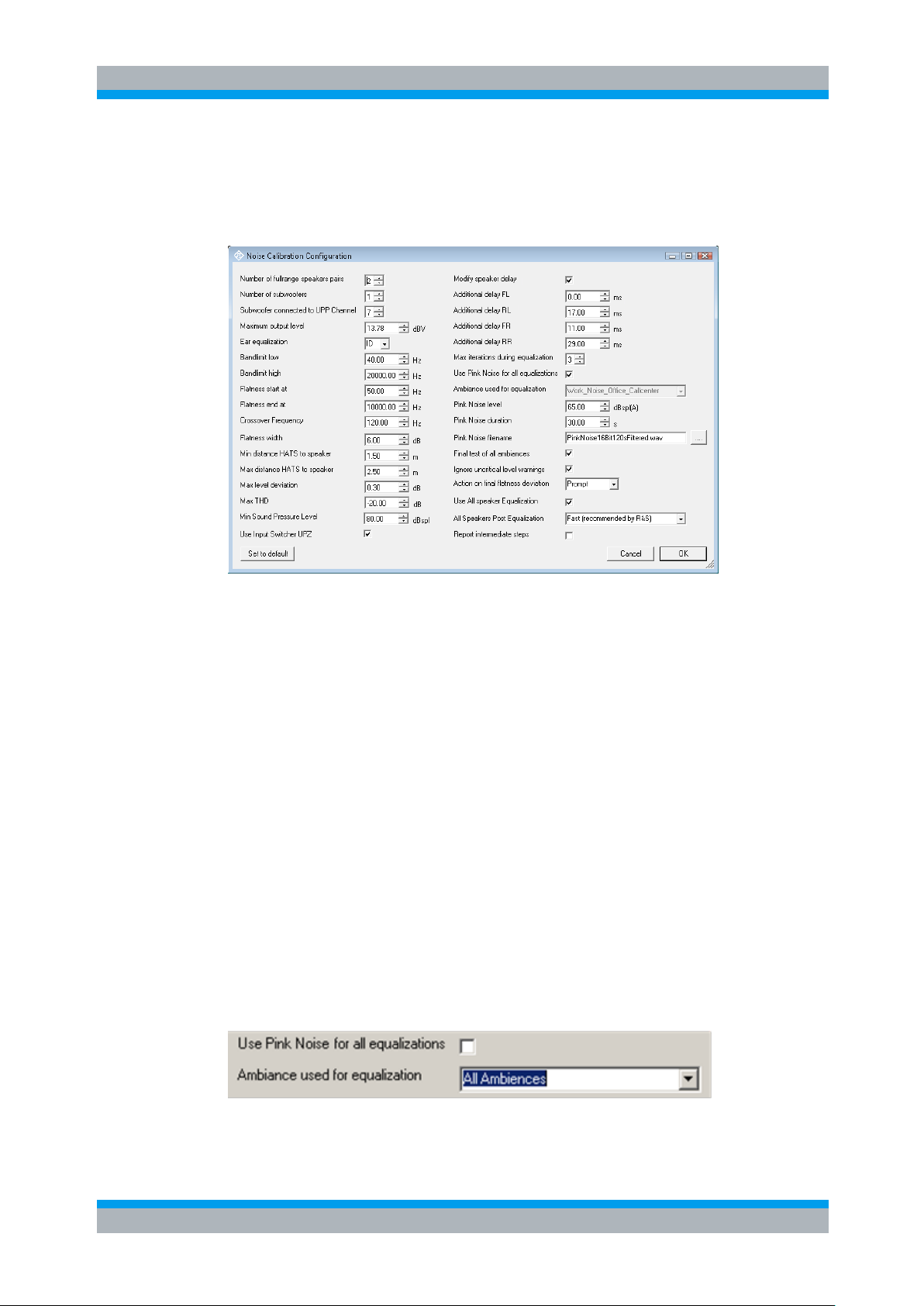

2.6.17 Noise Calibration Configuration

In “Noise Calibration Configuration”, parameters for the background noise field used for

the “Speech Quality in Presence of Ambient Noise” test can be set.

Figure 2-26: Window for configuring the background noise calibration

The configuration of the noise field calibration comprises

● Choice of the calibration method

● Speaker configuration

● Bandwidth and tolerance settings

● Other settings

The configuration is saved in the settings of the R&S UPV-K9x program, so that it has

to be done at least once and can then be re-used as long as the speaker configuration

and calibration methods do not need to be changed.

Equalization Method

Three different equalization methods are available with different trade-off between

required measurement time and achieved accuracy:

1. Individual equalization and level alignment for each ambient noise condition

The complete equalization procedure is repeated for each ambient noise condition.

This allows equalizing individual responses of each noise condition and obtains best

matching equalization results. The required measurement time is the highest of all

three alternatives and requires at least eight hours.

Figure 2-27: Setting for the individual speaker equalization of each ambient noise condition

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 34

2. Equalization using pink noise and individual level alignment for each ambient noise

condition

The room response is measured using stochastic pink noise. The obtained

equalization is used for all ambient noise conditions. The stochastic nature of the pink

noise ensures that the energy is distributed evenly of the complete bandwidth.

Required calibration time is about three hours.

Figure 2-28: Configuration of pink noise for speaker equalizations

The level of the pink noise can be chosen between 40 and 70 dBspl(A). For obtaining a

similar level as with the noise fields, it should be chosen as 60 dBspl(A) or higher.

The pink noise duration (and averaging time for the measurement) can be chosen

between 10 s and 120 s. Recommended duration is 30 s, which equals the averaging

time for equalization with real ambient noise condition. An increased averaging time

increases the accuracy in particular at the low frequency end.

Alternative to the default pink noise file, a user-defined pink noise file can be loaded. It

must be located in the working directory (i.e. “D:\3GPP”) and be at least 120 seconds

long.

3. Equalization using a selected one of the ambient noise conditions and individual

level alignment for each ambient noise condition.

This method determines the equalization using one of the available ambient noise

conditions as test signal. This equalization is then used for all ambient noise

conditions. Only the level is aligned individually for each ambient noise condition. The

measurement time is about 3 hours.

Figure 2-29: Selection of ambient noise for the speaker equalization

As the result of this method depends on the spectral distribution of the energy in the

chosen noise condition, this method cannot be generally recommended.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 35

Speaker Configuration

Currently only the following two configurations are supported:

1. Four full-range speakers without subwoofer

Figure 2-30: Settings for using four speakers without subwoofer

2. Four full-range speakers with one subwoofer

Figure 2-31: Settings for using four speakers with one subwoofer

The speakers have to be connected as follows:

● Full-range speaker front left: R&S UPP generator channel 3

● Full-range speaker rear left: R&S UPP generator channel 4

● Full-range speaker front right: R&S UPP generator channel 5

● Full-range speaker rear right: R&S UPP generator channel 6

● The subwoofer (if existing) can be connected to one of the channels 7 … 9

according to the configuration setting.

Bandwidth and Tolerance

The permissible tolerance of the equalized spectrum is stipulated by the standards to

be ±3 dB and cannot be changed. For special cases it is, however, possible to raise

the lower end of the tolerance template if the room has acoustic drawbacks (standing

waves, structure-borne noise) which cannot be improved with acoustic means.

Figure 2-32: Bandwidth and tolerance settings

“Bandlimit low” limits the transmission frequency range of the speaker setup by

applying a highpass filter. This sets the lower end of the equalized frequency range.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 36

It is recommended to suppress frequencies below the 50 Hz third octave, which means

to set the bandlimit low to about 44.5 Hz. For other third octaves, the recommended

lower band limit is fc / 1.122 with fc being the center frequency of the third octave. The

value of “Flatness start at” is automatically adapted to an increased lower band limit if

required.

“Bandlimit high” sets the upper frequency limit for the equalization. The default value of

20,000 Hz should not be altered.

“Flatness starts at” sets the lower frequency limit for the tolerance check. The standard

ETSI EG 202 396-1 stipulates a value of 50 Hz.

“Flatness ends at” sets the upper frequency limit for the tolerance check. The standard

ETSI EG 202 396-1 stipulates a value of 10,000 Hz.

Ear Equalization

Combobox “Ear Equalization” allows setting the equalization for both artificial ears to

the equalization applied with the recording of the ambient noise condition.

Figure 2-33: Selection of ear equalization

Besides diffuse field equalisation (“DF”) and free field equalization (“FF”), a so-called

“independent of direction” (“ID”), equalization can be applied. This equalization curve

must be imported for each artificial ear in use with menu item “Calibration → ID

(Independent of Direction) Equalization → ... ”.

Figure 2-34: Import of ID equalization data

An average ID equalization curve is provided with file ID_equalization.veq.

Alternatively, an individually determined curve can be loaded.

If an equalization curve of the chosen type is missing for one of the artificial ears in

use, the calibration procedure is aborted with an appropriate error message.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 37

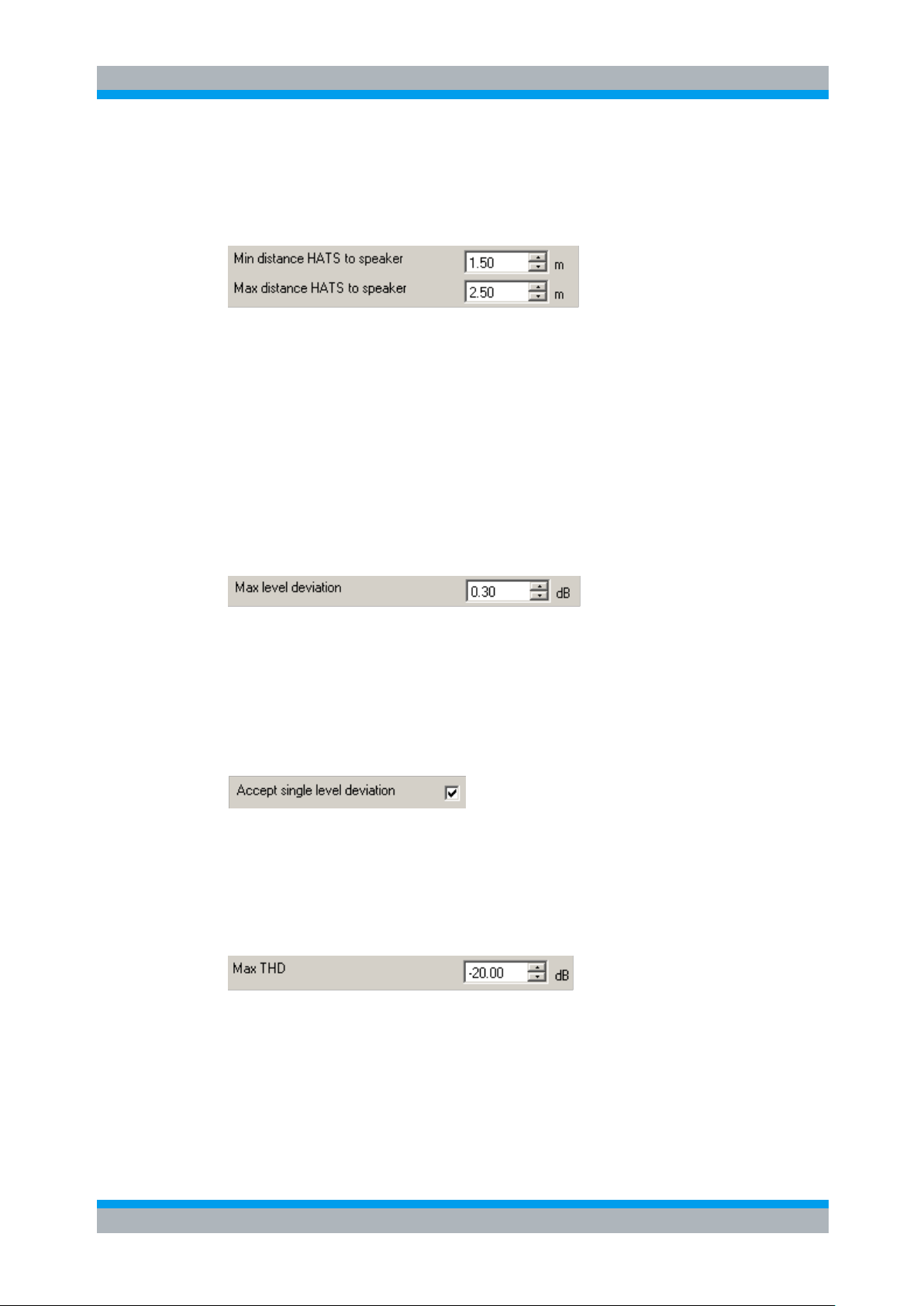

Speaker Distance Range

The following controls allow specifying a restricted range for the distance between

each speaker and the artificial ears of the HATS:

Figure 2-35: Setting the range for the speaker distance

This allows detecting for example swapped ear connections, because the delay from

the speaker to the contra-lateral ear takes a detour over wall reflections. The default

values are appropriate for the room size specified in standard ETSI EG 202 396-1.

The distance between full-range speakers and artificial ears is determined by delay

measurements. The distance between the subwoofer and the HATS must be

measured by the operator and entered in the configuration window.

Level Tolerance

The control

Figure 2-36: Control for maximum allowable level deviation

Defines the maximum allowable tolerance for the level adjustment. Higher accuracy

usually requires more iteration steps (up to 5), and is possibly not even adjusTable with

this maximum number of iterations. Is the required tolerance not reached, the operator

is prompted in a message box whether to start more iterations or accept the tolerance.

If the adjustment process is to run automatically without operator interaction, this

message can be deactivated with checking tick box “Accept single level deviation”.

Figure 2-37: Deactivation of window prompting to accept a level of tolerance

Harmonic Distortion Limit

A violation of the harmonic distortion specified in “Max THD” can be a sign for clipping

in a speaker due to overrange.

Figure 2-38: Entry of THD limit

If a speaker generally has higher distortion, this value can be increased. If a THD value

above the specified limit is detected, the operator has the following options:

● Reduce the gain settings in the speaker and repeat the measurement.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 38

● Cancel the calibration process, reduce the setting in “Maximum output level” and

restart the calibration process.

Figure 2-39: Entry of THD limit

● Accept the observed THD value and continue without modification of parameters.

Additional Delay Modification for Each Speaker

According to ETSI ES 202 396-1, in all test rooms each loudspeaker signal should be

delayed additionally with an individual value in order to increase the diffusity of the

noise field and avoid comb filter effects. The operator can modify the individual delays,

which are added to the delays determined in the delay measurement step. Maximum

allowed value is 50 ms.

Figure 2-40: Entry of additional speaker delay

It is also possible to disable the additional delay. Then only the delays determined in

the delay measurement step are applied.

Maximum Iteration Count for Equalization Steps

The following control can be used to set the number of iteration steps for the

equalization of individual speakers and of speaker pairs.

Figure 2-41: Entry of maximum iteration count

Additional iteration steps improve the equalization accuracy on the cost of increased

measurement time. The iteration process continues until either a flatness better than 1

dB is achieved or the maximum number of iteration steps id reached.

More than three iteration steps cannot be expected to improve the equalization

significantly. Maximum input number is 5 iterations. A value of 1 disables iteration

altogether. In this case, the equalization function is calculated from the first measured

frequency response.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 39

Final Spectrum Check

If the following tick box is activated, the equalization of all ambiences is finally checked,

and the flatness and absolute level difference is determined.

Figure 2-42: Checkbox for final equalization test of all ambient noise files

This measurement takes approximately 20 minutes and can also be started after the

calibration has been finalized.

The result of this check is stored in the database and appears in the report of the

calibration process. A “Fail” in a single ambience only has influence on the total verdict

if the ambiences had been chosen to be equalized individually (see above).

Refinement of Total Spectrum Equalization

Activating the following tick box enables an algorithm, which tries to improve the result

of the total equalization into a tolerance scheme of ±3 dB.

Figure 2-43: Activating refinement of the total spectrum equalization

Figure 2-44: Selection of the total spectrum equalization method

This is attempted by a re-equalization of single speakers. It is possible to choose

between the algorithm recommended in ES 202 396-1 and a proprietary algorithm

developed by R&S. The standard algorithm requires at least 1 hour in addition to the

preceding adjustment process and is not in all cases successful. The R&S algorithm is

faster and has so far been successful in more cases. Alternatively, it is recommended

to optimize the speaker positioning in the room and re-run the adjustment process.

Minimizing Operator Interaction

After the initial plausibility check and delay measurements it is desirable to run the

calibration process without operator supervision. The settings required for this must be

made before starting the calibration process.

A “Fail” of the final check of the total equalization may be caused by an unexpected

background noise in the test room. In this case, it is possible to repeat the check to

avoid an immediate fail.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 40

The combo box “Action on final flatness deviation” allows you to select the action to be

taken in case of a failing final check of the total equalization.

Figure 2-45: Selection of the action performed if the final equalization check fails

“Prompt” leads in case of a fail to a message box where the operator can choose

● to repeat the final check

● to cancel the calibration process in order to improve the acoustic properties of the

speaker setup in the room, or

● continue the measurement with this check being finally failed.

Choose “Retry once” or “Retry twice” for unattended operation.

Report of Intermediate Results

For thorough investigation of a failed adjustment, it may be helpful to get reports of the

results of individual and pair-wise equalization of the loudspeakers. This can be

activated with the checkbox “Report intermediate steps”.

Figure 2-46: Selection of the addition of intermediate adjustment results to the report

2.6.18 R&S UPP Remote Control

This dialog allows you to detect and connect an R&S UPP with option R&S UPP-B8 on

the LAN, to be used as playback system for the background noise generation.

Figure 2-47: Window for connecting to an R&S UPP on the LAN

A click on the “find devices...” button searches the local area network for audio

analyzers and fills the combobox next to the button with the computer names and IP

addresses of the found devices. Select the appropriate instrument in the combobox

and click “Ok”.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 41

2.6.19 Input Switcher

“Input Switcher” allows configuring the use of an R&S UPZ input switcher connected to

the R&S UPV RS-232 port, to switch analyzer input 2 between sending tests and

binaural receiving tests.

If “Use UPZ input switcher for all connections” is activated, all audio signal sources

including reference microphones and reference channel 10 of UPP-B8 are connected

via the switcher.

Figure 2-48: Switcher window

2.6.20 Report settings

“Report settings” allows defining the type of information, which should appear in the

reports. For details on reporting, see section 8 Automatic Test Sequences below.

2.6.21 Generate Temporary Export Files

If “Generate temporary export files” is checked, some of the measurement macros

create result.exp with result value and verdict, and, if applicable, curve.exp or

abscurve.exp and relcurve.exp files with curve data in ASCII format. This

function is provided for compatibility with R&S UPL-B9.

R&S UPV-K9/-K91 Preparation and Start of the Application Software

Operating Manual 1402.0043.12 -10 42

2.6.22 Generate Temporary Image Files

Item “Generate temporary image files” causes the measurement macros to store a

screenshot of the measurement window after completion of the test to a file

Image.TIF for use by a remote controlling host.

2.6.23 Store Results of Further Measurements

If “Store results of further measurements” is checked, curves and calculated values like

loudness ratings are also stored for additional measurements started with the “Add

Measurement” key. They will appear in reports of the respective measurements.

2.6.24 Do not Change Scale for Further Meas.

Menu item “Do not change scale for further meas.” deactivates the automatic Y-axis

scaling if the curve of an additional measurement leaves the plot area partially or

totally.

2.6.25 Store Loaded Curve Data to Results

If “Store loaded curve data to results” is checked, curves loaded from file with the

“Load Curve” softkey are stored to the results database and will appear in reports of

the respective measurements.

2.6.26 Enable Remote Control

Menu item “Enable remote control” activates the interface of the program for remote

control using the client ControlK9.exe.

R&S UPV-K9/-K91 Calibration

Operating Manual 1402.0043.12 -10 43

3 Calibration

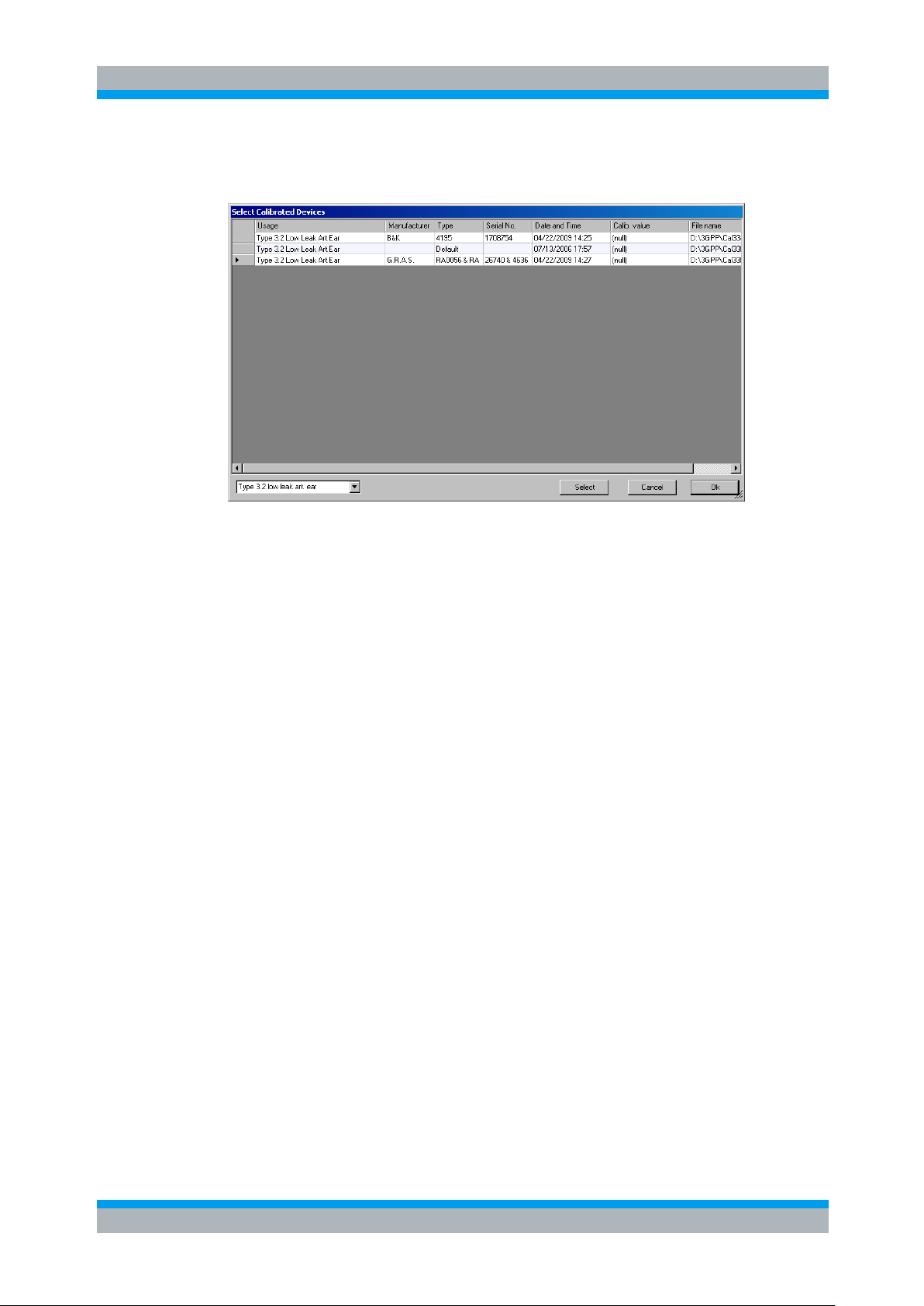

3.1 Calibration Devices

R&S UPV-K9 allows you to simultaneously storing calibration values for multiple

individuals of the same type. This allows switching devices without the requirement for

re-calibration. However, regular re-calibration is recommended in order to assure the

correct function of the used devices.

Figure 3-1: Calibration menu

For every device to be calibrated, an entry must be created using “Calibration New

device” in the main menu. This menu item opens an entry window to specify the

calibrated device. A category of device must be chosen from the combo box on top.

Type, manufacturer and serial number are entered into the text boxes below. The

entries are confirmed by clicking on the “Save and close” button. If the box

“Immediately select this device” is checked, the device is selected for immediate use

with the “Save, select and close” button.

R&S UPV-K9/-K91 Calibration

Operating Manual 1402.0043.12 -10 44

For ease of use, a “default” device is present and selected for each device type

(category) upon first start of the program.

Figure 3-2: Input window for information about calibrated device

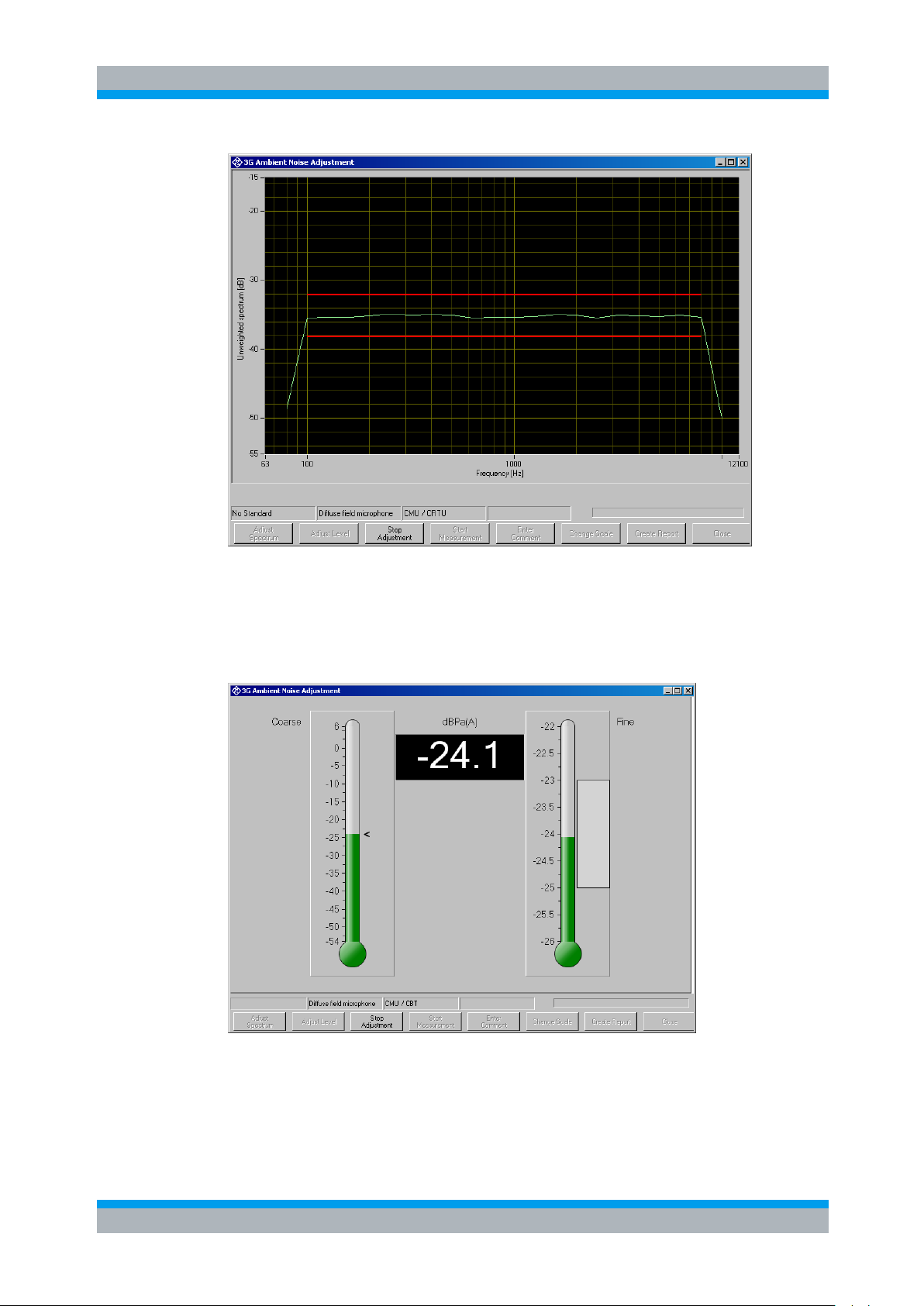

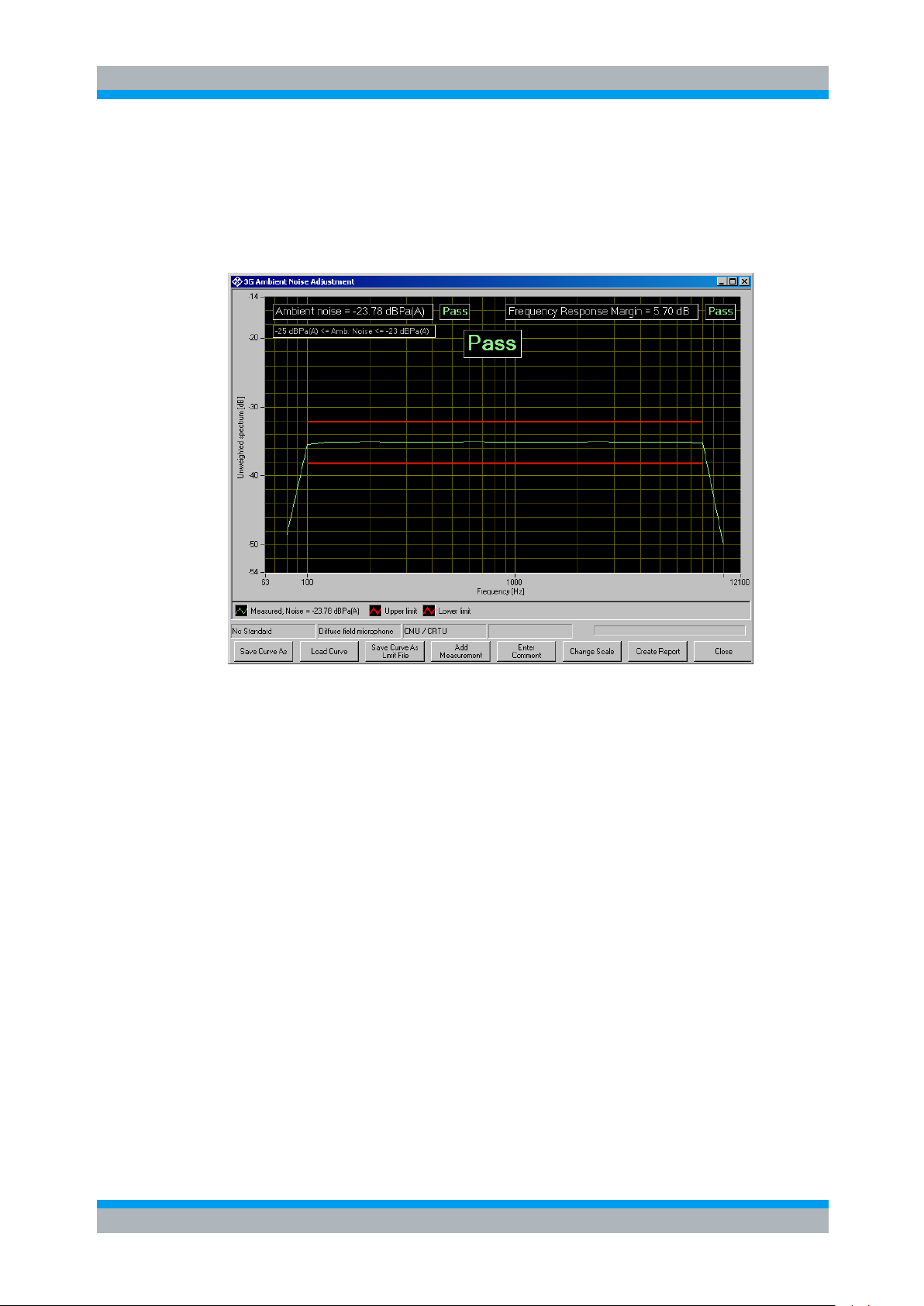

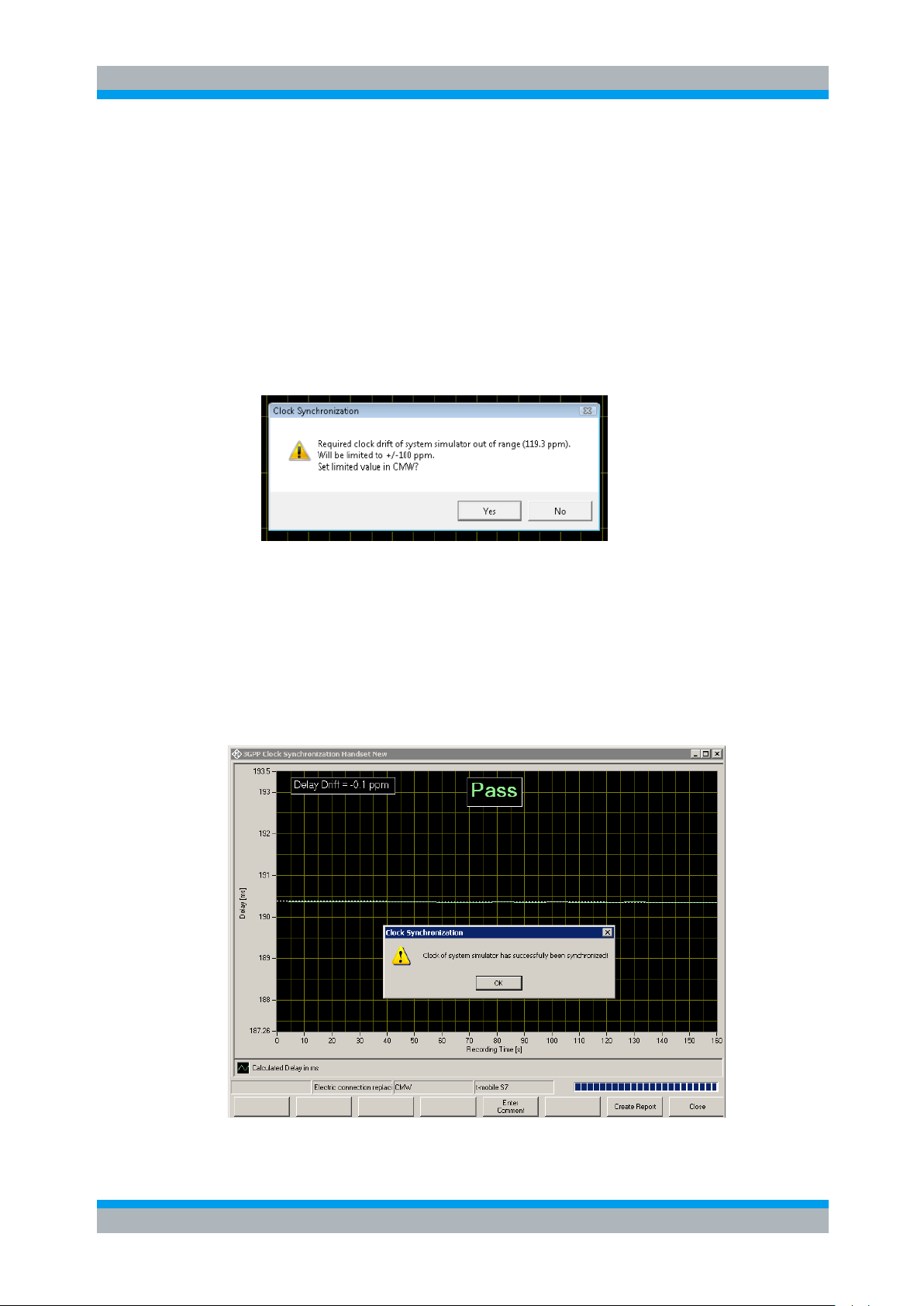

Before a device can be calibrated or used, it must be selected. This can be done from