Rockwell Automation 1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix, 1769 Compact GuardLogix, 1789 SoftLogix User Manual

...Page 1

User Manual

DeviceNet Network Configuration

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix,

1769 Compact GuardLogix, 1789 SoftLogix, Studio 5000

Logix Emulate

Publication DNET-UM004D-EN-P

Original Instructions

Page 2

DeviceNet Network Configuration

personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

temperatures.

for Personal Protective Equipment (PPE).

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and

2 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 3

Subject

Reason

Summary of Changes

This manual includes new and updated information. Use these reference

tables to locate changed information.

Grammatical and editorial style changes are not included in this summary.

Global changes

This table identifies changes that apply to all information about a subject in

the manual and the reason for the change. For example, the addition of new

supported hardware, a software design change, or additional reference

material would result in changes to all of the topics that deal with that subject.

Updated the Legal notices. Legal information changed.

New or enhanced features

None in this release.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 3

Page 4

Page 5

Summary of Changes

DeviceNet Overview

Connect a Computer to the

Connect Devices to the Network

Configure the Network Offline

Table of Contents

Preface

Network Configuration ............................................................................. 11

Studio 5000 environment ......................................................................... 12

Additional Resources ................................................................................. 12

Legal Notices ............................................................................................... 13

Chapter 1

Choose a Single Network or Subnets ....................................................... 15

Single Network ..................................................................................... 15

Advantages to Using a Single Network ........................................ 15

Disadvantages to Using a Single Network ................................... 16

Subnets ................................................................................................. 16

Advantages to Using Subnets ....................................................... 16

Disadvantages to Using Subnets .................................................. 16

Choose a Scanner ....................................................................................... 16

Bridge Across Networks ............................................................................. 17

Choose a Baud Rate for the Network ........................................................ 19

Assign an Address to Each Device ............................................................ 20

Required Software ...................................................................................... 21

DeviceNet Network

Chapter 2

Connection Options ..................................................................................23

Set Up the DeviceNet Driver .................................................................... 24

Obtain the Driver for the Interface Device ....................................... 24

Verify that the Driver Works .............................................................. 24

Chapter 3

Before You Begin....................................................................................... 27

Set the Node Address of a Device ............................................................ 27

Set Node Address via Hardware Mechanism ................................... 28

Set Node Address via Software .......................................................... 29

Set Node Address via DeviceNet Node Commissioning Tool ......... 30

Make Sure Your Devices Are on Your Network ........................................32

Chapter 4

Before You Begin........................................................................................ 33

Create a File for the Network .................................................................... 33

Create Your Network in RSNetWorx for DeviceNet Software ............... 34

Configure Each Device ............................................................................... 35

Specify a Device Node Address ........................................................... 36

Change a Device Node Address .................................................... 37

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 5

Page 6

Table of Contents

Configure the Network Online

Automatically Configure a

DeviceNet Network

Configure Device Parameters ............................................................ 38

Configure the Scanner ............................................................................... 39

Build the Scan List............................................................................... 40

Set the Alignment Option ................................................................... 42

SoftLogix 5800 Controller ............................................................. 43

Manually Assign Each Device to a Memory Location ........................ 43

Save the Configuration File ....................................................................... 45

Generate an RSNetWorx for DeviceNet Report ...................................... 45

Go Online to Your Network ....................................................................... 47

Download Configuration to Your Network ............................................. 49

Chapter 5

Before You Begin........................................................................................ 51

Verify Communication Between the Computer and Devices ............... 52

Create a New File for the Network ............................................................ 53

Go Online to Your Network ....................................................................... 54

Configure Each Device ............................................................................... 56

Upload the Configuration of a Device ................................................ 56

Change and Download Device Configuration ................................... 56

Configure the Scanner ............................................................................... 57

Upload the Current Scanner Configuration ..................................... 58

Define the Scanner Properties ............................................................ 59

Build the Scan List............................................................................... 60

Set the Alignment Option ................................................................... 62

SoftLogix 5800 Controller ............................................................. 63

Manually Assign Each Device to a Memory Location ........................ 63

Download the Configuration to the Scanner ..................................... 65

Upload and Save the Configuration File................................................... 65

Generate an RSNetWorx for DeviceNet Report ..................................... 66

6 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Chapter 6

How AutoScan Operates .......................................................................... 69

Determine If You Can Use AutoScan ....................................................... 71

How AutoScan Affects Your Network ..................................................... 72

Install the DeviceNet Node Commissioning Tool ................................... 73

Connect Devices ......................................................................................... 73

Install a Scanner or Network Interface Devices ................................ 73

Install Other DeviceNet Devices ......................................................... 74

Set the Node Address and Baud Rate with the DeviceNet Node

Commissioning Tool ............................................................................ 75

Add the Scanner to the RSLogix 5000 Project .......................................... 75

Add the Scanner to the I/O Configuration Folder ............................. 75

Page 7

Control a Device

Interlock and Share Inputs

Table of Contents

Define the Properties of the Scanner ................................................. 76

Enable AutoScan with RSLogix 5000 Software ....................................... 77

Initiate AutoScan via the User Program .................................................. 78

Implementing AutoScan .................................................................... 78

Configure I/O Allocation Size Via the User Program ................ 80

Configure I/O Allocation Via a DeviceView Configurator......... 80

Initiate AutoScan via the User Program ...................................... 81

Initiate AutoScan via the DeviceView Configurator ................... 81

Additional Considerations Regarding AutoScan ............................. 82

Access Device Data .................................................................................... 83

Put the Scanner in Run Mode .................................................................. 84

Additional Information About AutoScan ................................................ 85

Type of Connection that the Scanner Sets Up .................................. 85

Allocating More Memory for Each Device ........................................ 85

Chapter 7

Before You Begin....................................................................................... 87

RSNetWorx Report for the Network ................................................. 88

Data Map for Each of Your Devices ................................................... 89

Add the Scanner to the Controller’s I/O Configuration ......................... 89

Conserve EtherNet/IP or ControlNet Network Bandwidth ............ 89

Add the Scanner to the I/O Configuration Folder ............................ 90

Configure the Scanner ......................................................................... 91

Determine the Address of DeviceNet Data ............................................. 92

SoftLogix 5800 Controller .................................................................. 94

Determine If a Device Has Failed ............................................................. 95

Place the Scanner in Run Mode................................................................ 96

When to Use an MSG Instruction ............................................................ 96

Determine the Parameter Number to Access .......................................... 97

Determine the Configuration of the Parameter ...................................... 97

Test the Parameter .................................................................................... 98

Enter Message Logic ................................................................................. 99

Define the Source or Destination Data ............................................ 101

Enter and Configure the MSG Instruction ...................................... 102

Set the Communication Path ............................................................ 103

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 7

Chapter 8

Interlock ................................................................................................... 105

Choose a Master Controller ............................................................... 106

Determine How Much Data to Exchange ........................................ 106

Enable Slave Mode for the Slave Scanner ........................................ 106

Map the Slave Mode Data .................................................................. 107

Page 8

Table of Contents

Communicate with a PanelView

Standard Terminal

Add the Slave to the Master Scanner’s Scan List .............................108

Map the Data of the Slave .................................................................. 109

Place Both Scanners In Run Mode .................................................... 109

Share Inputs ............................................................................................. 109

Add the Input to the First Scanner ................................................... 109

Add the Input to the Second Scanner ............................................... 109

Map the Input Data in the Second Scanner ..................................... 110

Chapter 9

Choose Data Types .................................................................................... 111

Choose a Communication Method ......................................................... 112

I/O Slave Communication ................................................................. 112

Explicit Server Communication ........................................................ 113

Explicit Client Communication ......................................................... 113

Plan and Configure I/O Slave Tags .......................................................... 113

Use a Word/Bit Format for Each Tag ............................................... 114

For Integers, Skip Every Other Word ............................................... 115

Configure an I/O Slave Tag ............................................................... 115

Set Up the Terminal on Your Network ................................................... 116

Set the Protocol .................................................................................. 116

Set the Node Address and I/O Sizes ..................................................117

Configure the Scanner to Update I/O Slave Tags .................................. 118

Add the Terminal to the Scan List ..................................................... 118

Edit I/O Parameters ........................................................................... 119

Map Input and Output Data ............................................................. 120

Address I/O Slave Tags in the RSLogix 5000 Programming Software

Project ....................................................................................................... 120

SoftLogix 5800 Controller ................................................................. 122

Plan and Configure Explicit Server Tags ................................................ 122

Assign Assembly Instances ................................................................ 123

For Integers, Skip Every Other Word ............................................... 124

Configure an Explicit Server Tag ...................................................... 124

Program the Controller to Get/Set Explicit Server Tags ....................... 125

Create an Array for the Assembly Instance ...................................... 125

Enter and Configure the MSG Instruction ...................................... 126

Set the Communication Path ............................................................ 127

Configure Explicit Client Tags ................................................................ 128

Determine the Parameter Number to Access .................................. 128

Determine the Configuration of the Parameter .............................. 129

Configure an Explicit Client Tag ...................................................... 129

8 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 9

Communicate with a

FactoryTalk View Project

Tune the Performance of a

DeviceNet Network

Failed Device

Map the Memory Location with

Advanced Mapping

Table of Contents

Chapter 10

Before You Begin...................................................................................... 132

Create a Topic for the Device .................................................................. 132

Create a Node ........................................................................................... 133

Create a Tag for the Parameter ............................................................... 134

Chapter 11

Factors that Affect Performance ............................................................. 137

I/O Parameters of Each Device ......................................................... 139

Background Poll ................................................................................. 139

Interscan Delay .................................................................................. 140

Change the Configuration of Your Network .......................................... 141

Upload the Current Configuration of the Scanner ......................... 141

Set the Interscan Delay and Poll Ratio ............................................. 142

Set the I/O Parameters of a Device ................................................... 143

Change of State or Cyclic Transfer ............................................. 143

Strobed Transfer .......................................................................... 144

Polled Transfer ............................................................................. 144

Download the Configuration to the Scanner ................................... 145

Save the Configuration File ............................................................... 145

Automate the Replacement of a

Chapter 12

Automatic Device Recovery ..................................................................... 147

Set Up Automatic Device Recovery ........................................................ 148

Choose an Electronic Key Level for a Device .................................... 148

Update Your Network Configuration File ........................................ 149

Define the Electronic Key .................................................................. 149

Enable Auto-Address Recovery for the Scanner .............................. 150

Set the ADR Settings for the Device ................................................. 151

Download the Changes to the Scanner ............................................ 151

Upload and Save the Configuration File .......................................... 152

Appendix A

Give a Value Its Own Memory Location ................................................. 153

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 9

Page 10

Page 11

Task

Optional Conditions

Required Conditions

network offline

network offline

Network Configuration

Preface

This manual describes how you can use DeviceNet modules with your

Logix5000 controller and communicate with various devices on the DeviceNet

network.

You should use this manual if you program applications that use DeviceNet

with one of these Logix5000 controllers:

• 1756 ControlLogix controllers

• 1768 CompactLogix controllers

• 1769 CompactLogix controllers

• 1789 SoftLogix 5800 controllers

• PowerFlex 700S with DriveLogix controllers

You should also understand the following:

• Networking concepts

• RSNetWorx for DeviceNet software

• RSLogix 5000 programming software

• RSLinx Classic communication software

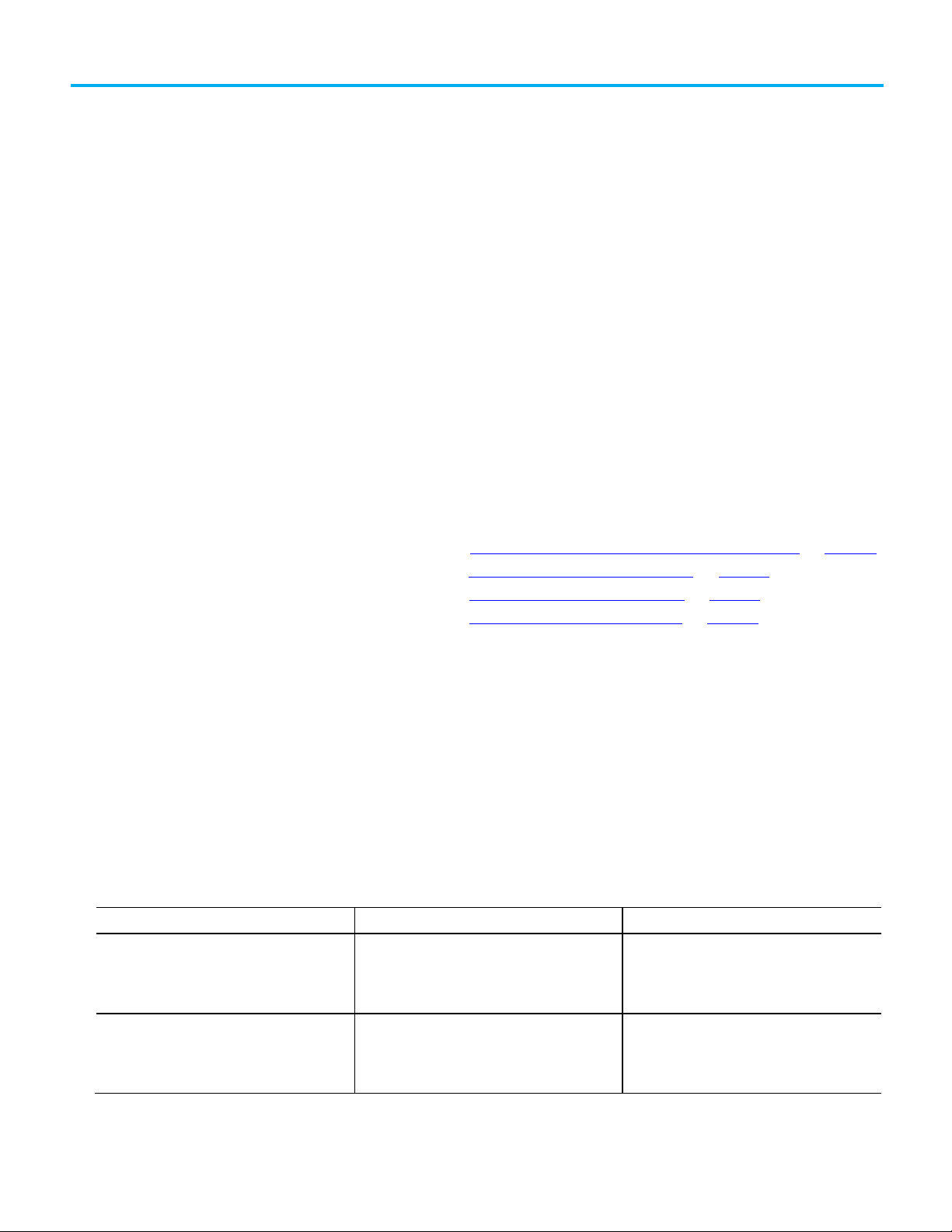

The following chapters describe how to set up a DeviceNet network:

• Chapter 2—Connect a Computer to the DeviceNet Network on page 23

• Chapter 3—Connect Devices to the Network on page 73

• Chapter 4—Configure the Network Offline on page 33

• Chapter 5—Configure the Network Online on page 33

You are not required to complete all tasks in each chapter in the exact order

presented to set up your DeviceNet application. For example, you can

configure your network offline before you connect a computer to the network.

However, there are some requirements related to the order in which you

complete tasks. For example, you must complete the tasks in chapters 2 and 3

before you can configure the network online.

The following table describes optional and required conditions to consider

when determining the order in which you plan to complete tasks in your

DeviceNet application.

Network Configuration Tasks

Connect a computer to the network • Can be completed before or after connecting

devices to the network

Can be completed before or after configuring the

•

Must be completed before configuring the network

online

Connect devices to the network • Can be completed before or after connecting a

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 11

computer to the network

Can be completed before or after configuring the

•

Must be completed before configuring the network

online

Page 12

Preface

Task

Optional Conditions

Required Conditions

online

Resource

Description

publication DNET-IN001

ADN, and 1769-SDN DeviceNet modules.

publication DNET-UM072

DeviceNet cable system.

Studio 5000 environment

Additional Resources

Configure the network offline • Can be completed before or after connecting a

computer to the network

• Can be completed before or after connecting

devices to the network

Can be completed before configuring the network

•

Configure the network online Can be completed without creating a network

configuration file offline

The Studio 5000 Automation Engineering & Design Environment® combines

engineering and design elements into a common environment. The first

element is the Studio 5000 Logix Designer® application. The Logix Designer

application is the rebranding of RSLogix 5000® software and will continue to

be the product to program Logix 5000™ controllers for discrete, process,

batch, motion, safety, and drive-based solutions.

None

• Computer must be connected to the network

before configuring the network online

• Devices must be connected to the network before

configuring the network online

12 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

The Studio 5000® environment is the foundation for the future of

Rockwell Automation® engineering design tools and capabilities. The Studio

5000 environment is the one place for design engineers to develop all

elements of their control system.

For more information on the products included in this publication, use the

publications listed in this table.

DeviceNet Modules Installation Instructions,

DeviceNet Media Design Installation Guide,

Logix5000 Controllers Common Procedures

Programming Manual, publication 1756-PM001M

Describes how to install and set up 1756-DNB, 1769-

Describes how to design, install, and troubleshoot a

Links to a collection of programming manuals that

describe how you can use procedures that are

common to all Logix5000 controller projects.

Page 13

Legal Notices

Preface

Rockwell Automation publishes legal notices, such as privacy policies, license

agreements, trademark disclosures, and other terms and conditions on the

Legal Notices

page of the Rockwell Automation website.

End User License Agreement (EULA)

You can view the Rockwell Automation End-User License Agreement ("EULA")

by opening the License.rtf file located in your product's install folder on your

hard drive.

Open Source Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses. Copies of those licenses are

included with the software. Corresponding Source code for open source

packages included in this product are located at their respective web site(s).

Alternately, obtain complete Corresponding Source code by contacting

Rockwell Automation via the Contact form on the Rockwell Automation

website:

http://www.rockwellautomation.com/global/aboutus/contact/contact.page

Please include "Open Source" as part of the request text.

A full list of all open source software used in this product and their

corresponding licenses can be found in the OPENSOURCE folder. The default

installed location of these licenses is

Files\Rockwell\Help\FactoryTalk Services Platform\Release

Notes\OPENSOURCE\index.htm

C:\Program Files (x86)\Common

.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 13

Page 14

Page 15

Topic

Page

Choose a Scanner on page 16

16 on page 16

Bridge Across Networks on page 17

16 on page 17

Choose a Baud Rate for the Network on page 19

19 on page 19

Calculate Scanner Memory Requirements

20

Assign an Address to Each Device on page 20

23 on page 20

Choose a Single Network or

Single Network

Advantages to Using a

Chapter 1

DeviceNet Overview

The Logix5000 family of controllers operates with many DeviceNet

communication modules. This chapter describes each communication module

and the preliminary tasks you must complete before your configure and

program the DeviceNet network.

Choose a Single Network or Subnets 14 on page 15

Subnets

Single Network

DeviceNet communication modules share these features:

• Interface via cabling systems using either round or flat media that

provide both power and communication

• Use network protocols

• Require no network scheduling

• Support messaging, produced/consumed data, and distributed I/O

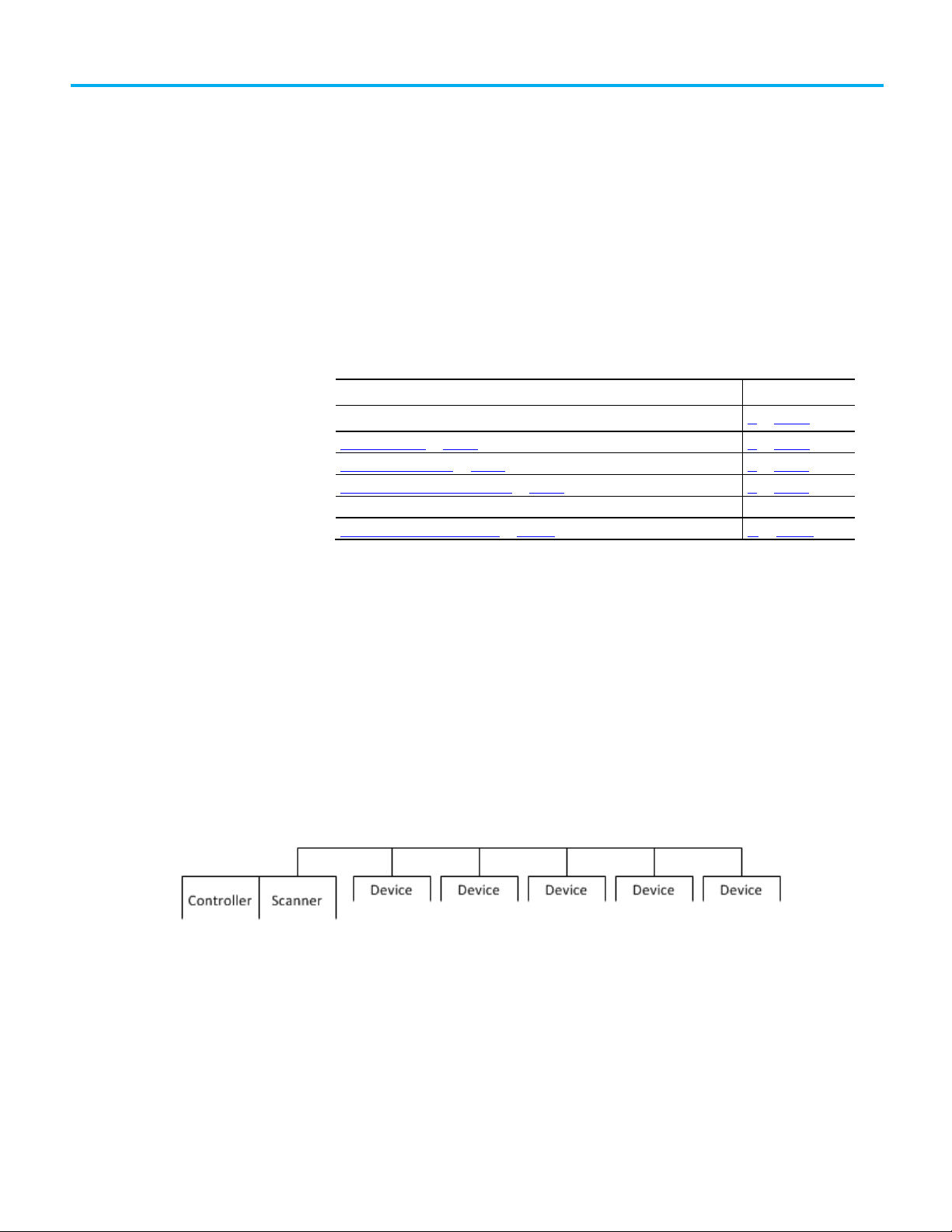

You can organize the devices on the network in a single network or several,

smaller distributed networks known as subnets.

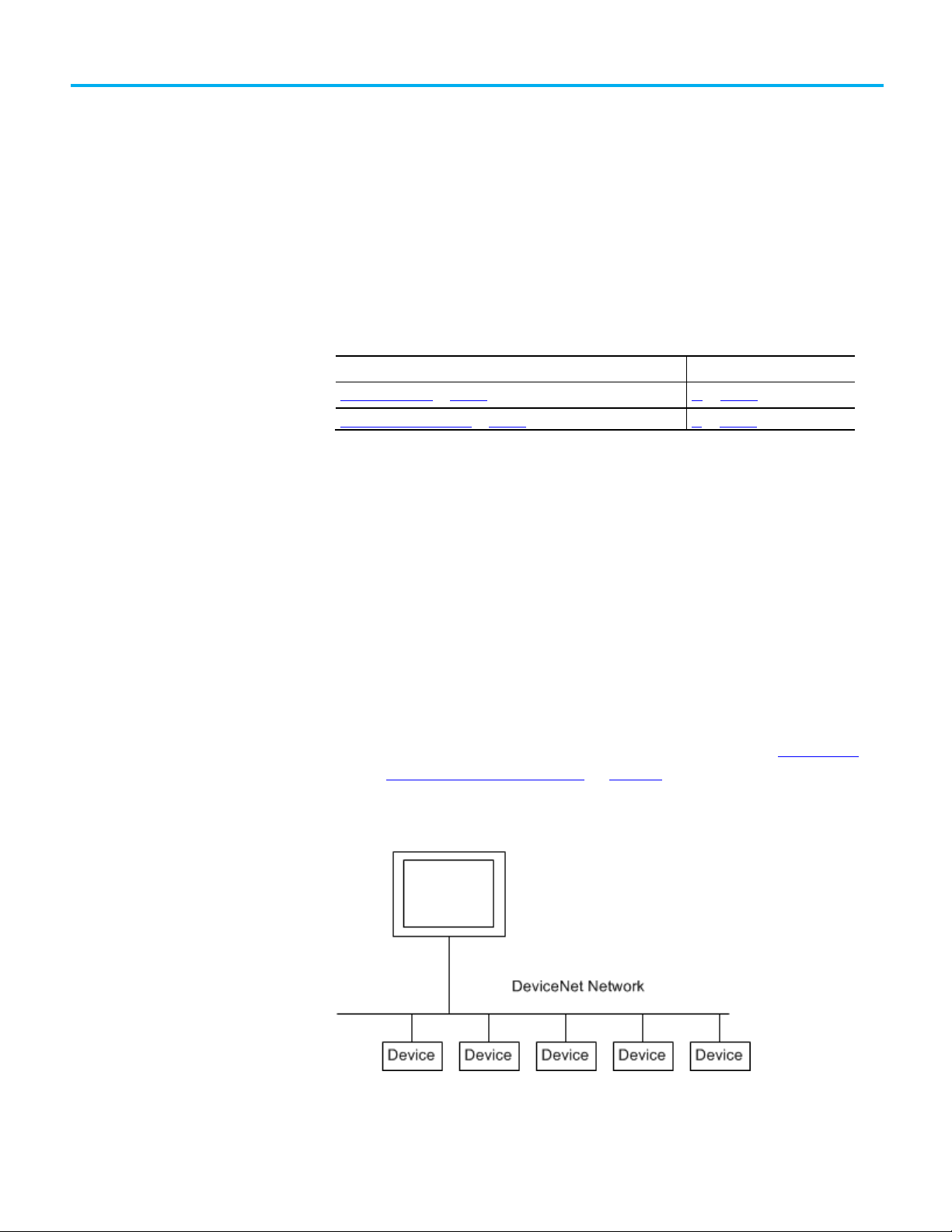

When you use a single network, you place all your devices on a single

DeviceNet network and connect the controller directly to the network via a

scanner. The following graphic shows a single network.

There are advantages to using a single network for your DeviceNet

application:

• The overall cost to install the network is lower than using subnets.

• You need to manage only a single network.

• The Logix5000 controller is local to the DeviceNet scanner. For

example, with a single network in a ControlLogix application, the 1756L64 controller is in the same ControlLogix chassis as the 1756-DNB

scanner.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 15

Page 16

Chapter 1 DeviceNet Overview

Disadvantages to Using a

Subnets

Advantages to Using

Disadvantages to Using

Choose a Scanner

Single Network

There are disadvantages to using a single network for your DeviceNet

application:

• The network must use shorter distances from one end to another.

• The more devices on the network, the slower the overall performance

of the network.

• Your network may have more power supply requirements than can be

handled by one network

• A single network can contain only up to 64 nodes

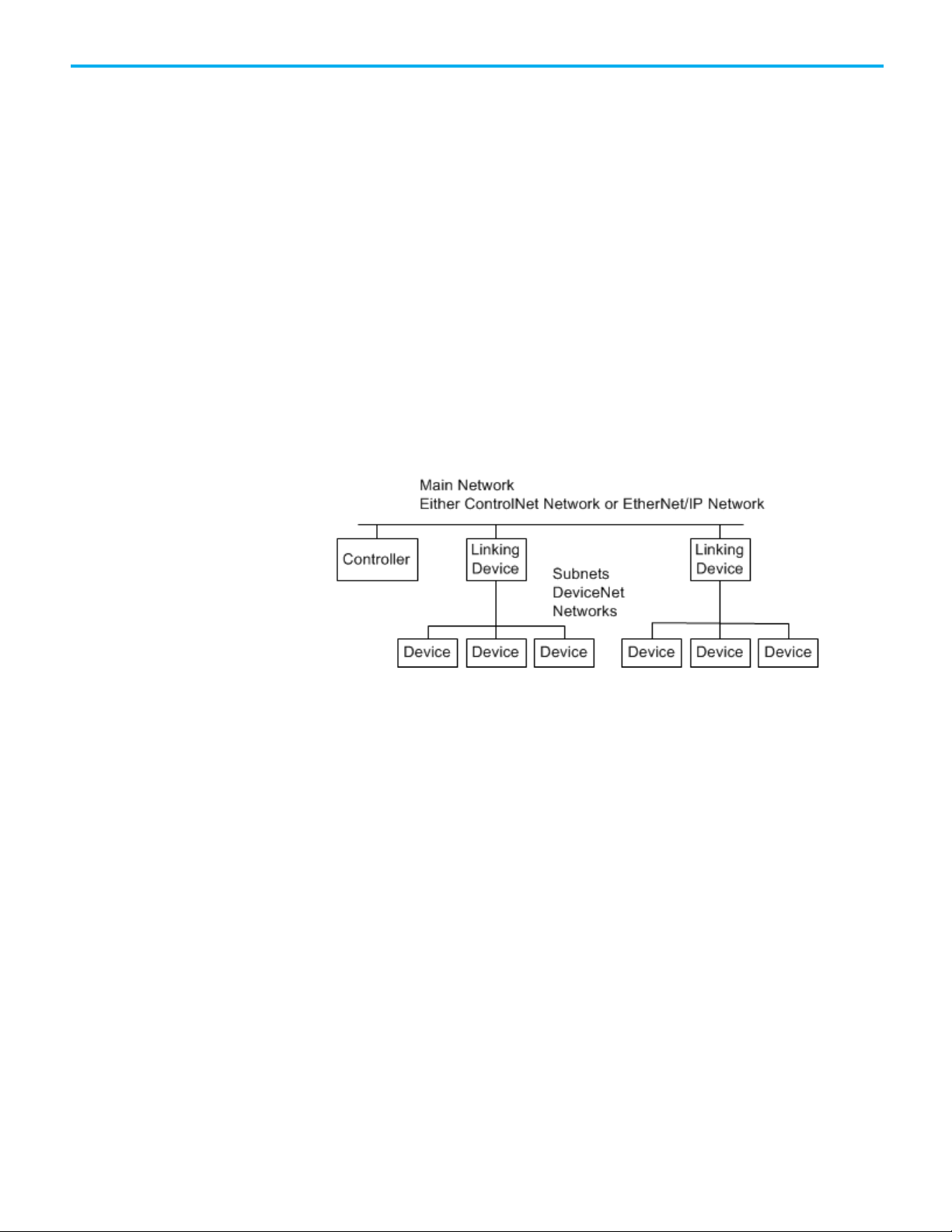

A subnet configuration is a main network that is connected to distributed

subnets using a scanner, or linking device. In this option, you must install a

ControlNet network or EtherNet/IP network, also known as a backbone, that

connects to distributed subnets using a linking device.

For example, if you choose an EtherNet/IP network backbone, you must use

1788-EN2DN linking devices to connect the subnets.

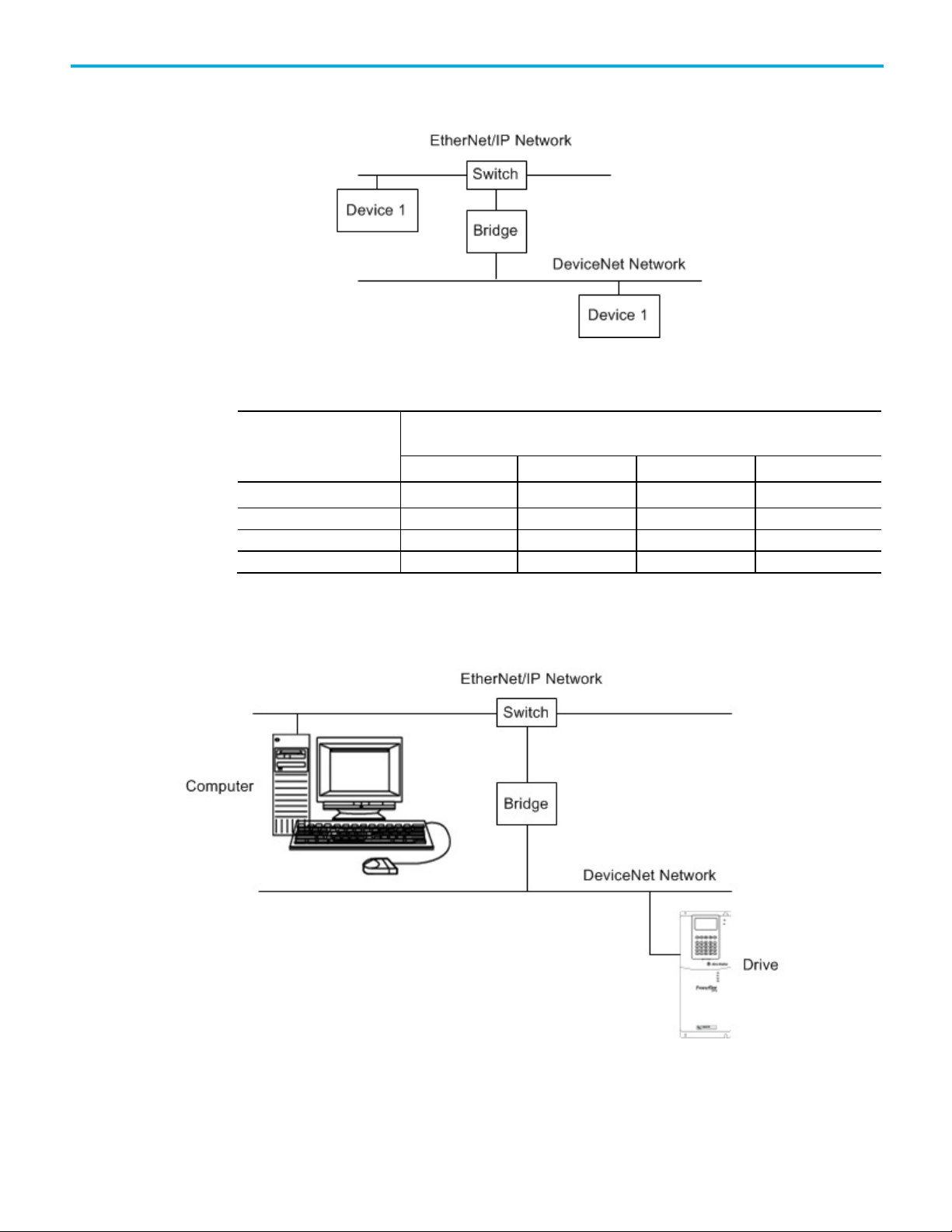

The following graphic shows a subnet network.

Subnets

Subnets

There are advantages to using subnets for your DeviceNet application:

• Typically, there are shorter runs on subnets, which allow a faster

communication rate for the DeviceNet network.

• With fewer devices on each subnet, the overall performance of the

network is faster.

• There are simpler power requirements.

There are disadvantages to using subnets for your DeviceNet application:

• The overall cost to install the network is higher than using a single

network.

• You must manage multiple networks.

• The Logix5000 controller is remote from the linking device. For

example, with subnets in a 1768 CompactLogix application, a 1768-L45

controller is remote from the 1788-CN2DN linking device.

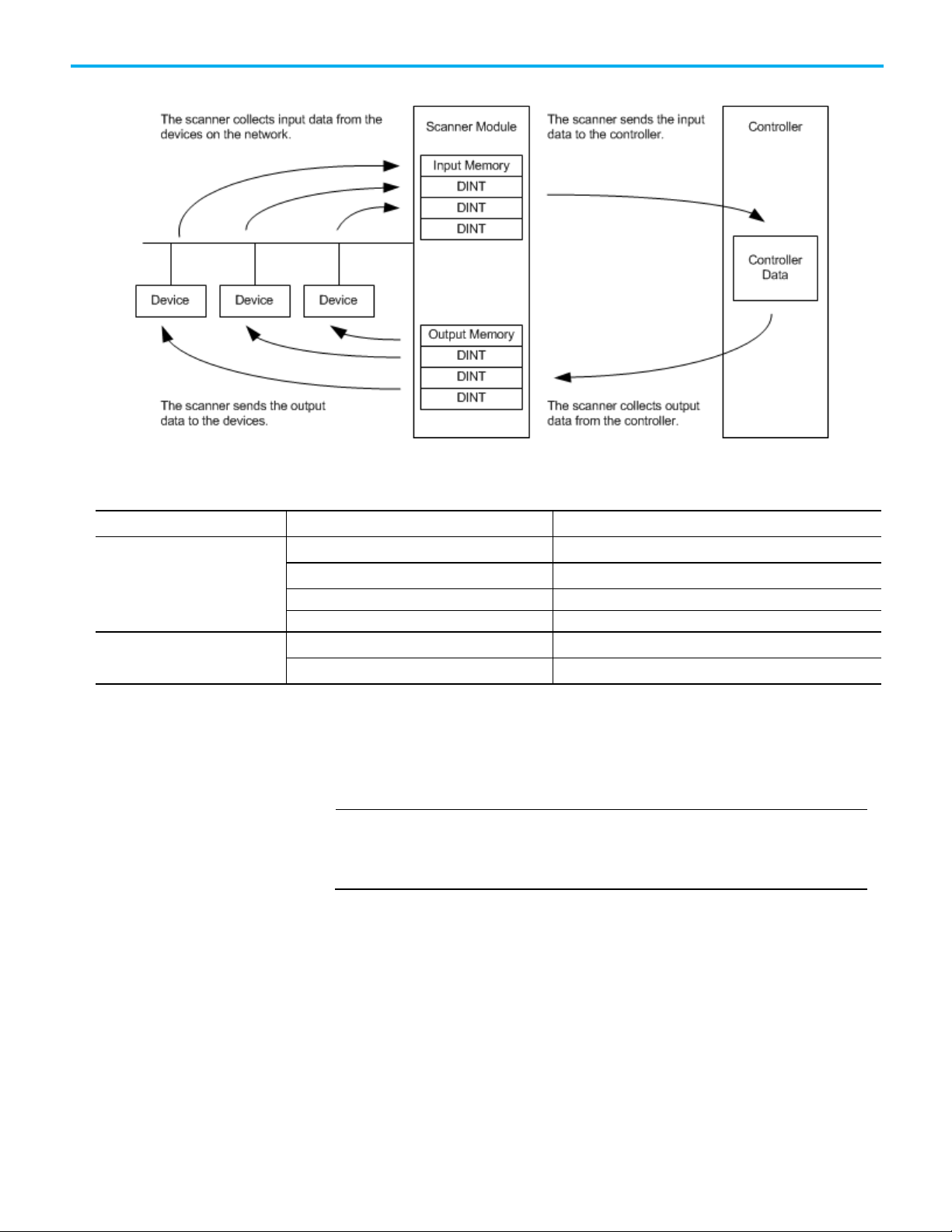

The DeviceNet scanner connects a Logix5000 controller to the devices on a

DeviceNet network. The following graphic shows how a scanner exchanges

data between a controller and devices on the DeviceNet network.

16 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 17

If you are using

And

Use this scanner

DriveLogix controller

1788-DNBO DeviceNet daughtercard

IMPORTANT

Refer to table Bridging Across Networks on page 17 for more information.

Bridge Across Networks

Chapter 1 DeviceNet Overview

The following table describes how to choose a scanner.

Single network 1768 or 1769 CompactLogix controller CompactLogix 1769-SDN modules

ControlLogix controller ControlLogix 1756-DNB modules

SoftLogix 5800 controller 1784-PCIDS card

Subnets EtherNet/IP main network EtherNet/IP to DeviceNet Linking Device 1788-EN2DN

ControlNet main network ControlNet to DeviceNet Linking Device 1788-CN2DN

Logix5000 controllers can usually communicate with devices on other

networks with no additional configuration or programming. A bridge

connects two networks.

You cannot bridge from a device on a DeviceNet network to a device on a ControlNet

nor EtherNet/IP network. You can only bridge from devices on ControlNet or

EtherNet/IP networks to devices on DeviceNet networks.

The bridge is one of the following:

• A single device with communication ports for two different networks,

such as a 1788-EN2DN linking device

• A separate communication device in the same chassis

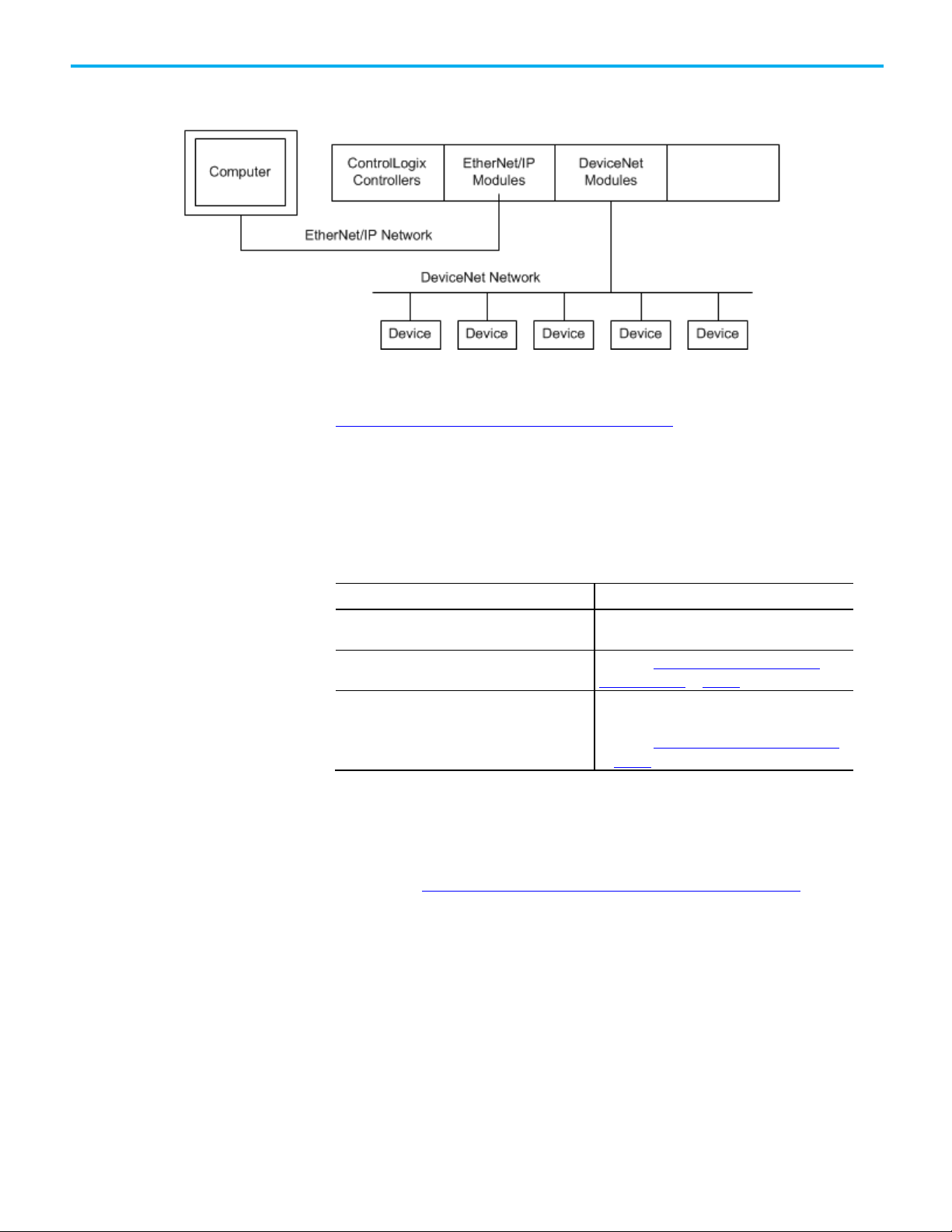

For example, the bridge device shown in the following graphic is connected to

both EtherNet/IP and DeviceNet networks. Device 1 on an EtherNet/IP

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 17

Page 18

Chapter 1 DeviceNet Overview

A device on this network

EtherNet/IP

ControlNet

DeviceNet

RS-232(1)

ControlNet

yes

yes

yes

yes

EtherNet/IP yes yes yes yes

network can communicate with Device 2 on a DeviceNet network through the

bridge.

The following table describes how communication can bridge the networks.

Bridging Across Networks

Can access a device on this network

DeviceNet no no yes no

RS-232 yes yes(2) yes yes

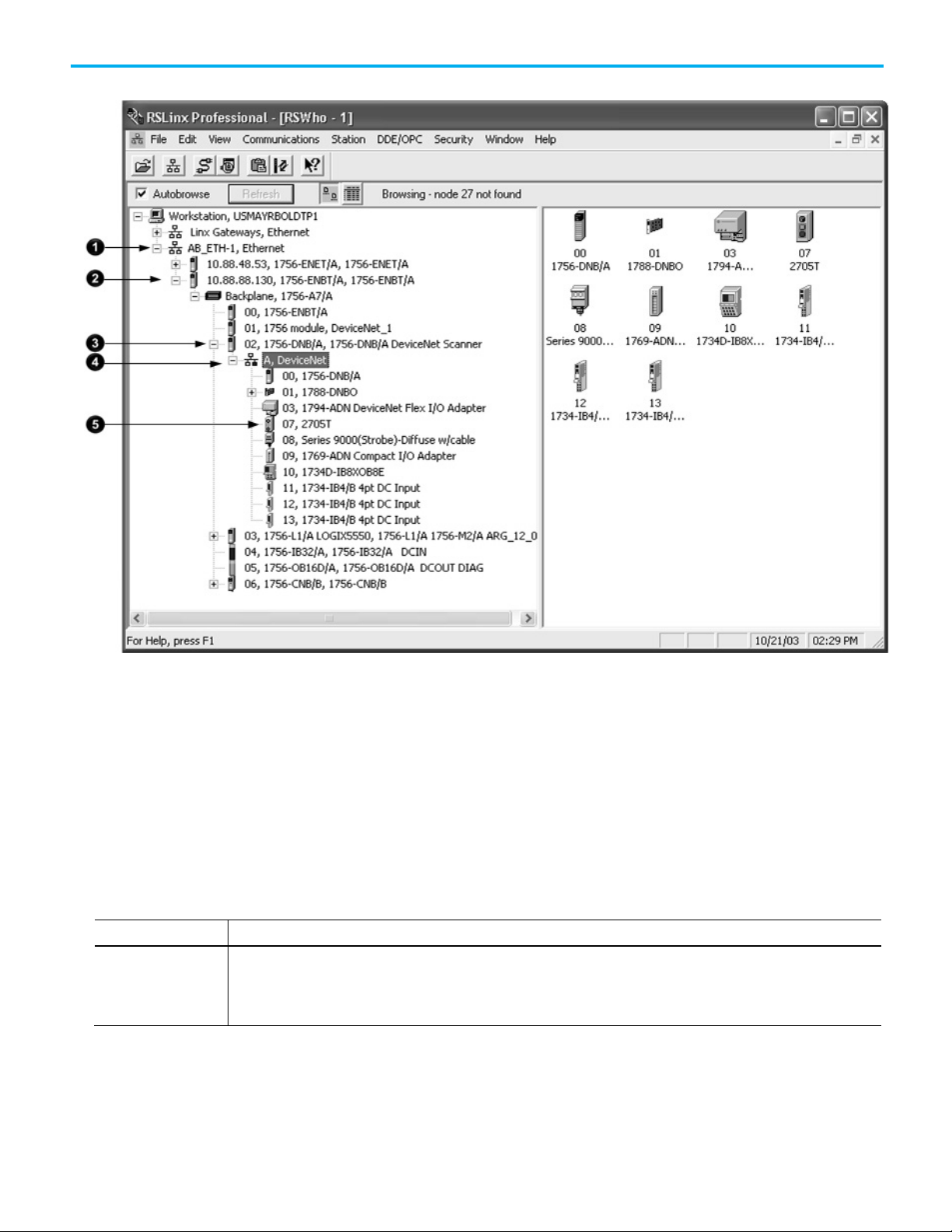

In this example, a computer configures a drive on a DeviceNet network. The

workstation bridges an EtherNet/IP network to reach the drive.

18 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

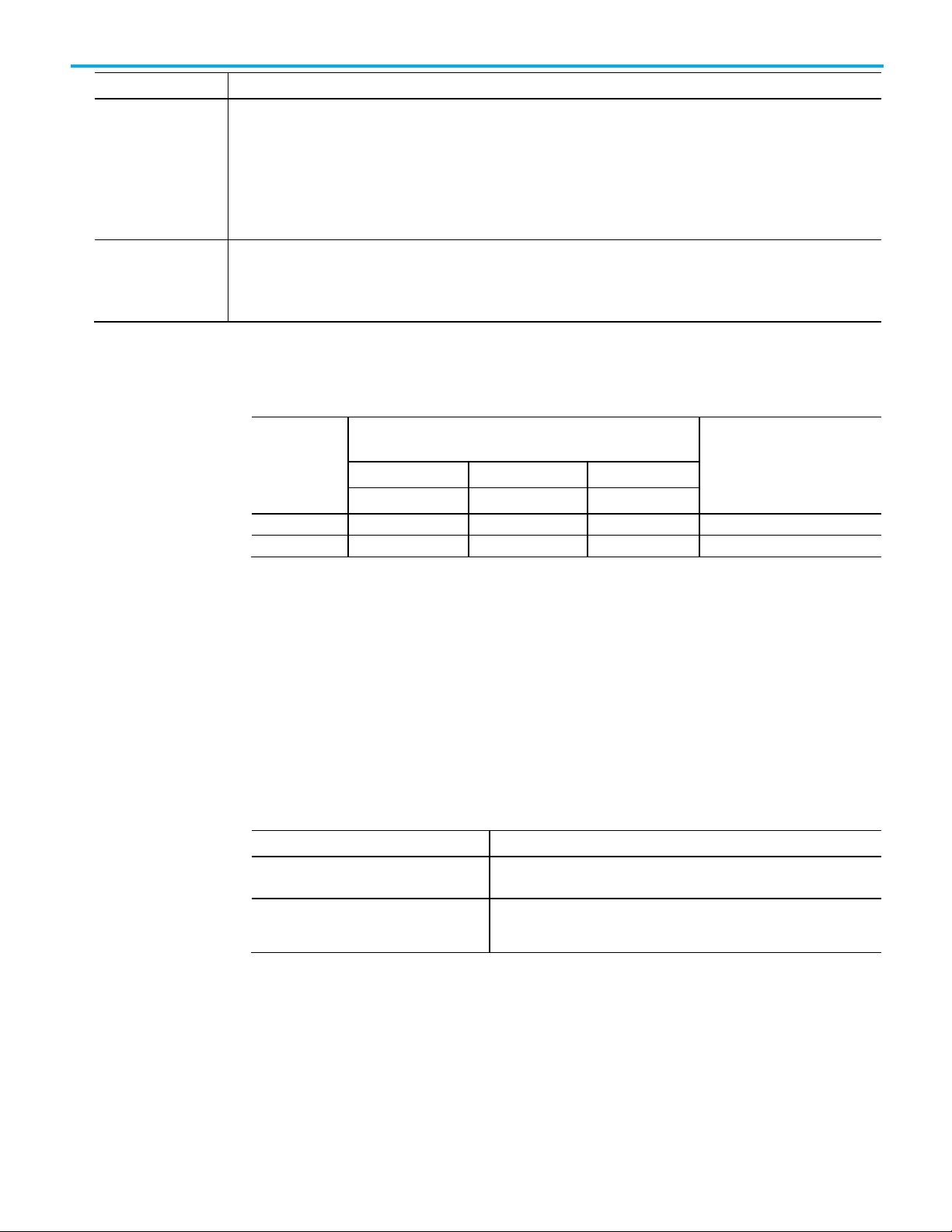

In this example, the RSLinx communication software window shows how the

DeviceNet bridge links to the EtherNet/IP network.

Page 19

Method

Description

Typically, scanners and network interfaces have a fixed baud rate.

Choose a Baud Rate for the

Chapter 1 DeviceNet Overview

You must choose a baud rate for the DeviceNet network. There are three rates

available for the network:

Network

• 125 kbps—This is the default baud rate for a DeviceNet network. It is

the easiest baud rate to use and is usually sufficient.

• 250 kbps

• 500 kbps

The following table describes the most common methods to set a baud rate.

Autobaud feature At powerup, the device automatically sets its baud rate to the baud rate of the first device it hears on the network. The baud rate

remains set until the device powers up again.

The network requires at least one device with a fixed baud rate so the autobaud devices have something against which to set.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 19

Page 20

Chapter 1 DeviceNet Overview

Method

Description

baud rate.

Baud Rate

Cumulative Drop Line Length

Flat Cable

Thick Cable

Thin Cable

250K bit/s

200m (656 ft)

250m (820 ft)

100m (328 ft)

78m (256 ft)

500K bit/s

75m (246 ft)

100m (328 ft)

100m (328 ft)

39m (128 ft)

If a device

Then

2. Connect the device to the network.

Assign an Address to Each

Switches or push button

on the device

Software Some devices require a programming device to set its address. For example, you can use the computer and the DeviceNet node

Some devices have switches or push buttons that set the baud rate as follows:

• The device reads the switch setting at powerup.

• Typically, the switch lets you select either autobaud or a fixed baud rate, that is 125 Kbps, 250 Kbps, or 500 Kbps

• If you change the switch setting, you must cycle power to the device before the change takes effect.

There are exceptions. For example, the 1756-DNB module has a push button that only lets you set the baud rate if the module is

disconnected from the network or network power is off. Once you change the baud rate, the module automatically resets to the new

commissioning tool to set the baud rate of a device. The node commissioning tool is available in either of the following methods:

• Automatically when you install RSNetWorx for DeviceNet software

• As a separate application on the RSLogix 5000 programming software CD, revision 13.0 or later

The length of the trunkline and type of cable determines which baud rates you

can use.

Maximum Distance

125K bit/s 420m (1378 ft) 500m (1640 ft) 100m (328 ft) 156 m (512 ft)

Device

If you change the baud rate of the network, make sure that all devices change

to the new baud rate. Mixed baud rates produce communication errors.

Complete the following steps to set the baud rate for the network.

1. Connect the network interface to the network and set its baud rate.

2. Connect the scanner to the network and set its baud rate.

3. For each device that has only fixed baud rates (no autobaud), set the

baud rate and connect it to the network.

4. Connect the remaining devices to the network and enable autobaud

for each of them.

has a switch to enable autobaud 1. Set the switch to autobaud.

does not have a switch to enable autobaud 1. Connect the device to the network.

2. Use RSNetWorx for DeviceNet software to enable autobaud.

To communicate on the DeviceNet network, each device requires its own

address. In general, a device can use any address in the range of 0…63.

However, we recommend that you follow the guidelines in the following table.

20 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 21

Give this device

This address

Notes

• The auto-address recovery feature also requires address 63 to be open.

Required Software

Scanner 0 If you have multiple scanners, give them the lowest addresses in sequence (0, 1…).

Any device on the network

except the scanner

Computer interface to the

network

No device 63 Always leave address 63 open. Out of the box, most DeviceNet devices are preset for address 63.

1…61 • Give the lower addresses to devices with 15 bytes or more of input or output data.

• Gaps between addresses are OK and have no effect on system performance. If you are uncertain of the

final lay-out of your system, leave gaps between addresses. This gives you some flexibility as you

develop your system.

62 If you connect a computer directly to the DeviceNet network, use address 62 for the computer.

• Many computer interface devices use this address as their default.

• The 1784-U2DN device can connect a computer directly to a DeviceNet network.

• Some devices have no switches or push button to set the address. They require software, such as

RSNetWorx for DeviceNet software to change the address. This means that you must first place it on

the network at its preset address of 63 before you can change the address.

• If another device is already using address 63, there will be an address conflict and you won’t be able to

communicate with the newly connected device.

• Leaving address 63 open makes it possible to configure a new device.

Refer to Chapter 3 on page 29 for more information on how to assign an

address to each device.

Chapter 1 DeviceNet Overview

You must use the correct software with the DeviceNet application.

• To connect your computer to the DeviceNet network, use RSLinx

communication software.

• To program the Logix5000 controller, use Logix Designer application.

• To the configure the DeviceNet network, use RSNetWorx for

DeviceNet software.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 21

Page 22

Page 23

Topic

Page

Connection Options

Chapter 2

Connect a Computer to the DeviceNet Network

This chapter shows how to connect a computer to the network. After you

physically connect a computer to the network, you must configure a driver in

RSLinx communication software to communicate over the network.

Connection Options on page 23 26 on page 23

Set Up the DeviceNet Driver on page 24 27 on page 24

After you connect a computer to the network and configure a driver in RSLinx

communication software, you can complete these tasks:

• Configure the devices on the network

• Configure network parameters

• Upload, download, monitor, and program projects for Logix5000

controllers

Some networks let you bridge to other networks in your system. This lets you

connect to one network and access devices or controllers on other networks.

To access the DeviceNet network, do one of the following:

• Connect directly to the network via the 1784-U2DN interface device. If

you connect directly to a DeviceNet network, you can access only the

devices on that network. If you use this method, refer to

Set Up the

DeviceNet Driver on page 27 on page 24.

The following graphic shows a computer connected directly to a DeviceNet

network.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 23

• Connect to a different network and bridge to the desired DeviceNet

network. This requires no additional programming.

Page 24

Chapter 2 Connect a Computer to the DeviceNet Network

RSLinx Classic Software Version

Action

U2DN interface device.

Device on page 27 on page 24.

Set Up the DeviceNet Driver

Obtain the Driver for the

Verify that the Driver Works

The following graphic shows a computer connected to a DeviceNet network

through an EtherNet/IP network used with a ControlLogix system.

For more information about installing modules on the DeviceNet network,

refer to the Rockwell Automation Literature Library at:

http://www.rockwellautomation.com/literature/

To find the installation publications specific to your module, search by the

module’s catalog number.

.

Interface Device

The requirements for setting up the DeviceNet driver depend on your version

of RSLinx Classic software.

2.50 or earlier Upgrade to version 2.51 or later to use the 1784-

2.51, 2.52, or 2.53 Proceed to Obtain the Driver for the Interface

2.54 or later The 1784-U2DN interface device driver is already

installed on the computer.

Proceed to Verify that the Driver Works on page 27

on page 24.

Follow these steps to download and install the device driver for the 1784U2DN interface device.

1. Visit http://www.rockwellautomation.com/knowledgebase/

.

2. Open tech note ID 53280 and follow the instructions to install the

driver.

24 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

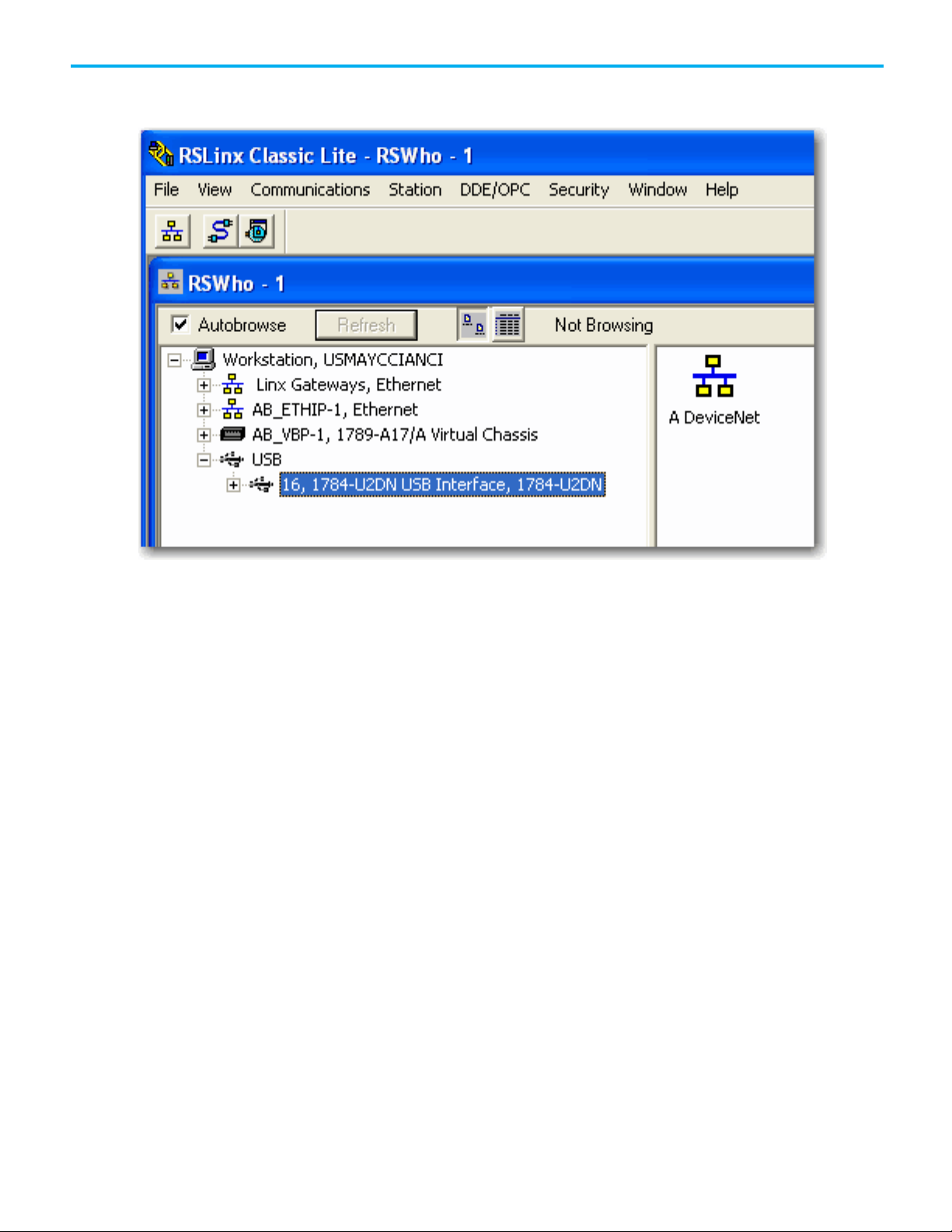

Complete the following steps to verify that the driver for the 1784-U2DN

interface device works.

1. Open RSLinx Classic software.

Page 25

2. Click the Browse button and verify that the 1784-U2DN interface

appears under USB.

Chapter 2 Connect a Computer to the DeviceNet Network

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 25

Page 26

Page 27

Before You Begin

Set the Node Address of a

Chapter 3

Connect Devices to the Network

This chapter describes how to connect a device to the network and set the

device’s address so it can communicate on the DeviceNet network.

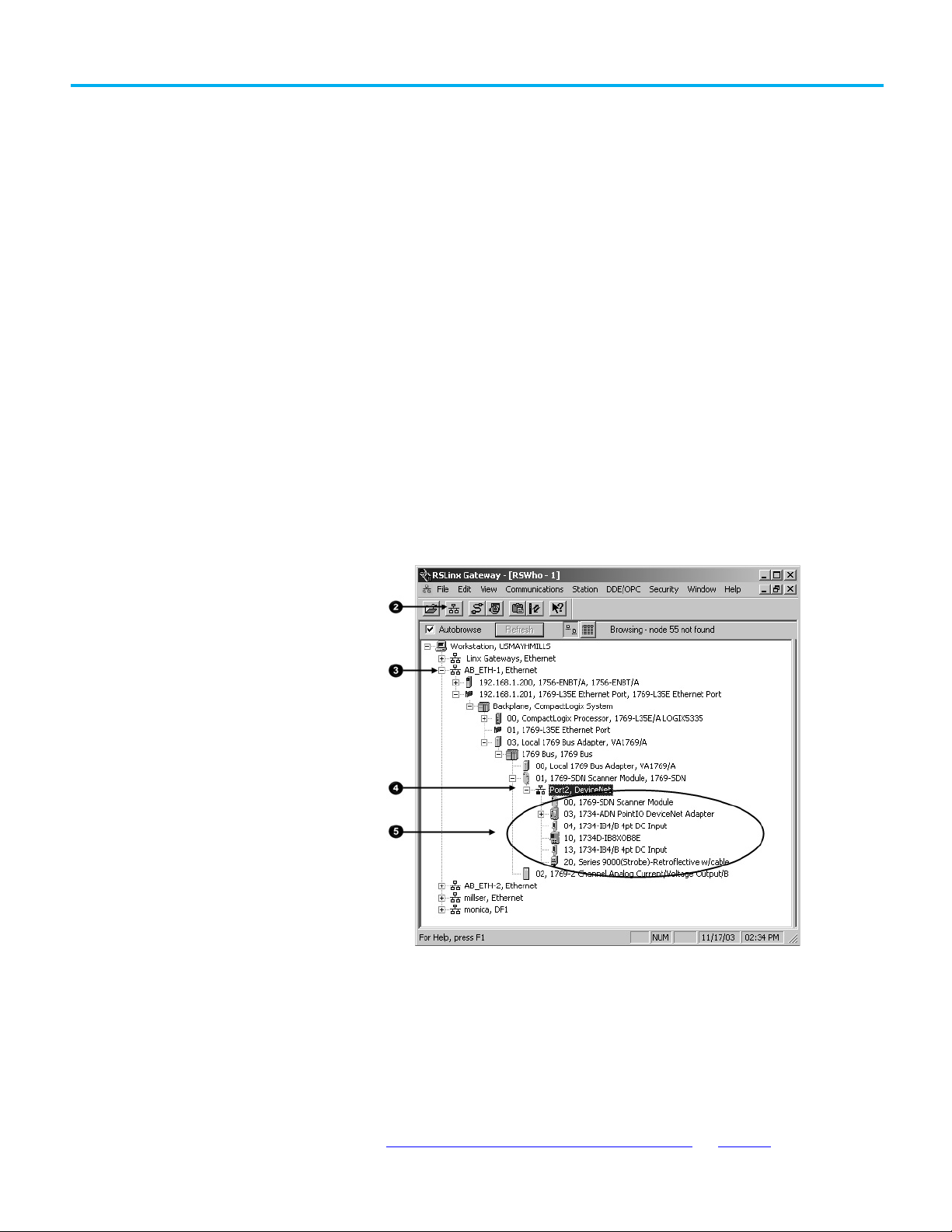

Before you use this chapter, make sure that you can see all your devices on the

DeviceNet network. Complete the following steps to see your DeviceNet

network.

1. Start RSLinx communication software.

2. Browse the network.

3. Expand a driver that lets you access the DeviceNet network.

4. Select the DeviceNet network.

5. Verify that you see all the devices that are connected to the DeviceNet

network.

Device

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 27

You can use the following options to set the node address of DeviceNet

devices. However, not all options apply to every DeviceNet device.

For example, you can use all three options with the 1756-DNB ControlLogix

DeviceNet scanner, but you can use only the second and third methods with

the 1769-SDN Compact I/O DeviceNet scanner.

• Set Node Address via Hardware Mechanism on page 28

Page 28

Chapter 3 Connect Devices to the Network

Give this address

To this device

conflicting with another device.

Mechanism

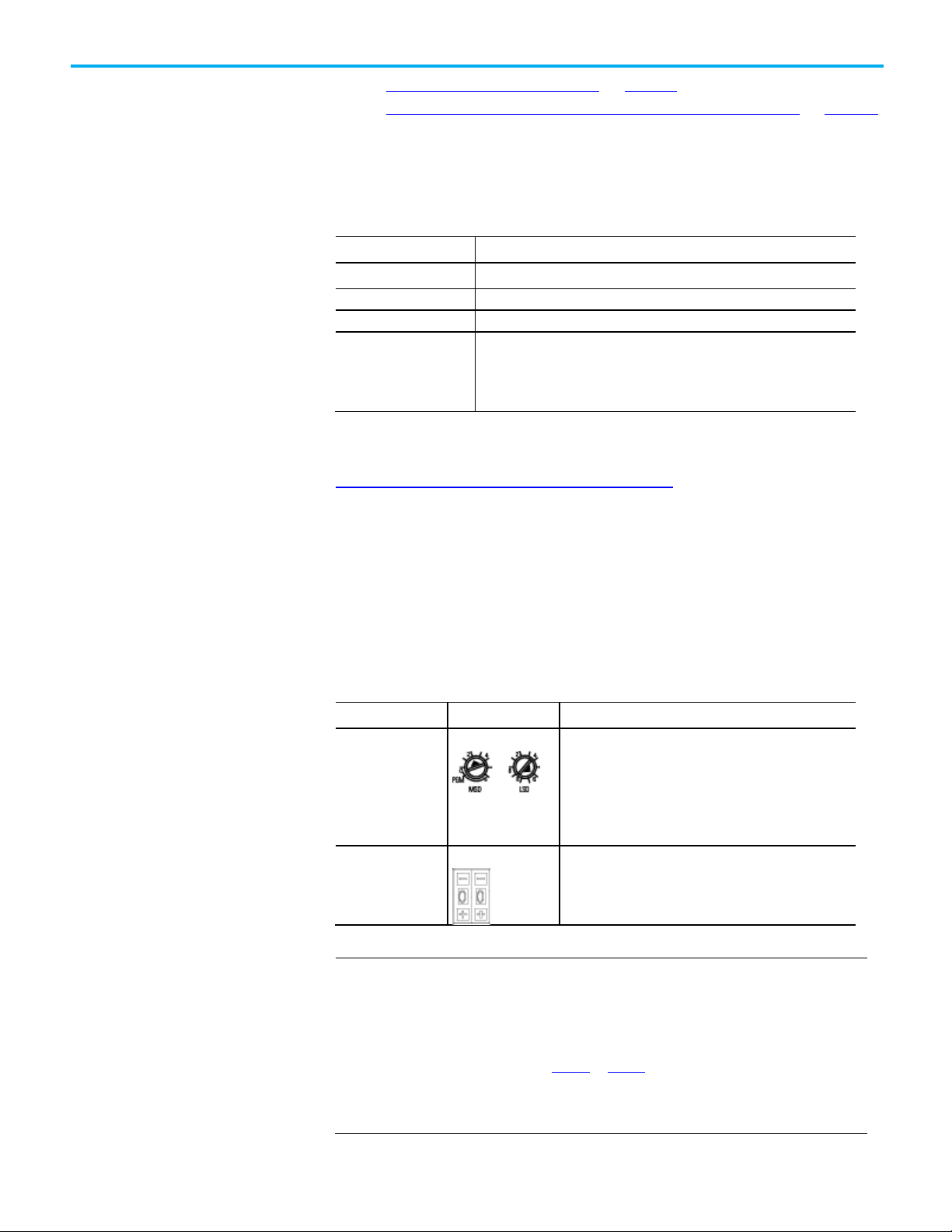

Graphic

Description

device for the change to take effect.

IMPORTANT

to set the node address.

Set Node Address via

All DeviceNet devices ship with their node addresses set to 63. To avoid

duplicate node number conditions on the network, you should change the

node address for each device to a unique number as you add it to the network.

For more information about setting the node address of DeviceNet devices,

refer to the Rockwell Automation Literature Library at:

http://www.rockwellautomation.com/literature/

• Set Node Address via Software on page 29

• Set Node Address via DeviceNet Node Commissioning Tool on page 30

0 Scanner

1…61 Devices

62 Computer interface to the network, such as a 1784-U2DN device

63 None

Out of the box, a DeviceNet communication module is preset for address 63.

Leaving address 63 open lets you get a new device on the network without

.

Hardware Mechanism

To find the publications specific to your module, search by the module’s

catalog number.

Many DeviceNet devices have a hardware mechanism that you can use to set

the node address. If a device has a hardware mechanism to set the node

address, use that mechanism.

The following table describes the two most common hardware mechanisms.

Rotary switch

Push-wheel switch

As long as a device’s hardware mechanism sets the node address to 63 or lower, you

cannot change the node address with RSNetWorx for DeviceNet software or the

DeviceNet node commissioning tool.

Make sure each device’s node address set by a hardware mechanism matches the

node address used in your RSNetWorx for DeviceNet software network configuration

file, as described on page 40 on page 36

However, if you set a device’s hardware mechanism to a number higher than 63, you

can use RSNetWorx for DeviceNet software or the DeviceNet node commissioning tool

You turn the dials of rotary switches to specific numbers

that represent the device’s node address.

You usually need a small flathead screwdriver to turn the

switches. A device reads the switches when you power it up.

If you change the address, you should cycle power to that

You set the numbers on the push-wheel switch to specific

numbers that represent the device’s node address.

.

28 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 29

IMPORTANT

IMPORTANT

page 37.

Set Node Address via

Chapter 3 Connect Devices to the Network

You must cycle power to the module for node changes set through hardware to take

effect.

You can set a device’s node address in RSNetWorx for DeviceNet software.

Software

Setting a device’s node address is only one task used when configuring a device with

RSNetWorx for DeviceNet software.

For complete information on how to configure all parameters with RSNetWorx for

DeviceNet software, including setting a device’s node address, refer to Chapter 4 on

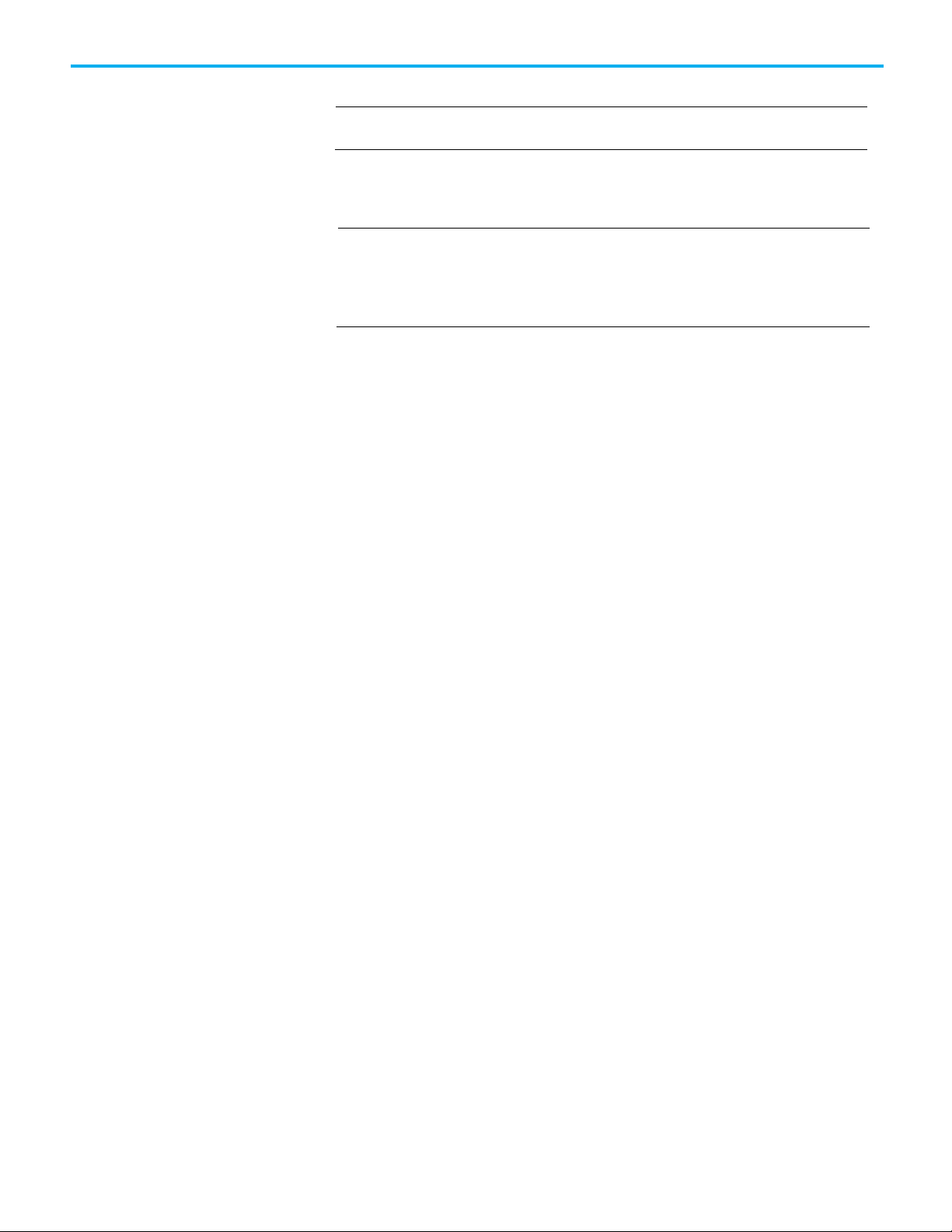

Complete the following steps to set a device’s node address in your network

configuration file. This example uses an AC drive.

1. Double-click the device.

2. Enter the DeviceNet address for the device.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 29

Page 30

Chapter 3 Connect Devices to the Network

IMPORTANT

Set Node Address via

3. Click OK to close the configuration window.

The node address assigned by RSNetWorx for DeviceNet software only takes effect if

the device does not have a hardware mechanism to set the node address or if the

device has its hardware mechanism set to a number higher than 63.

DeviceNet Node

Commissioning Tool

30 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

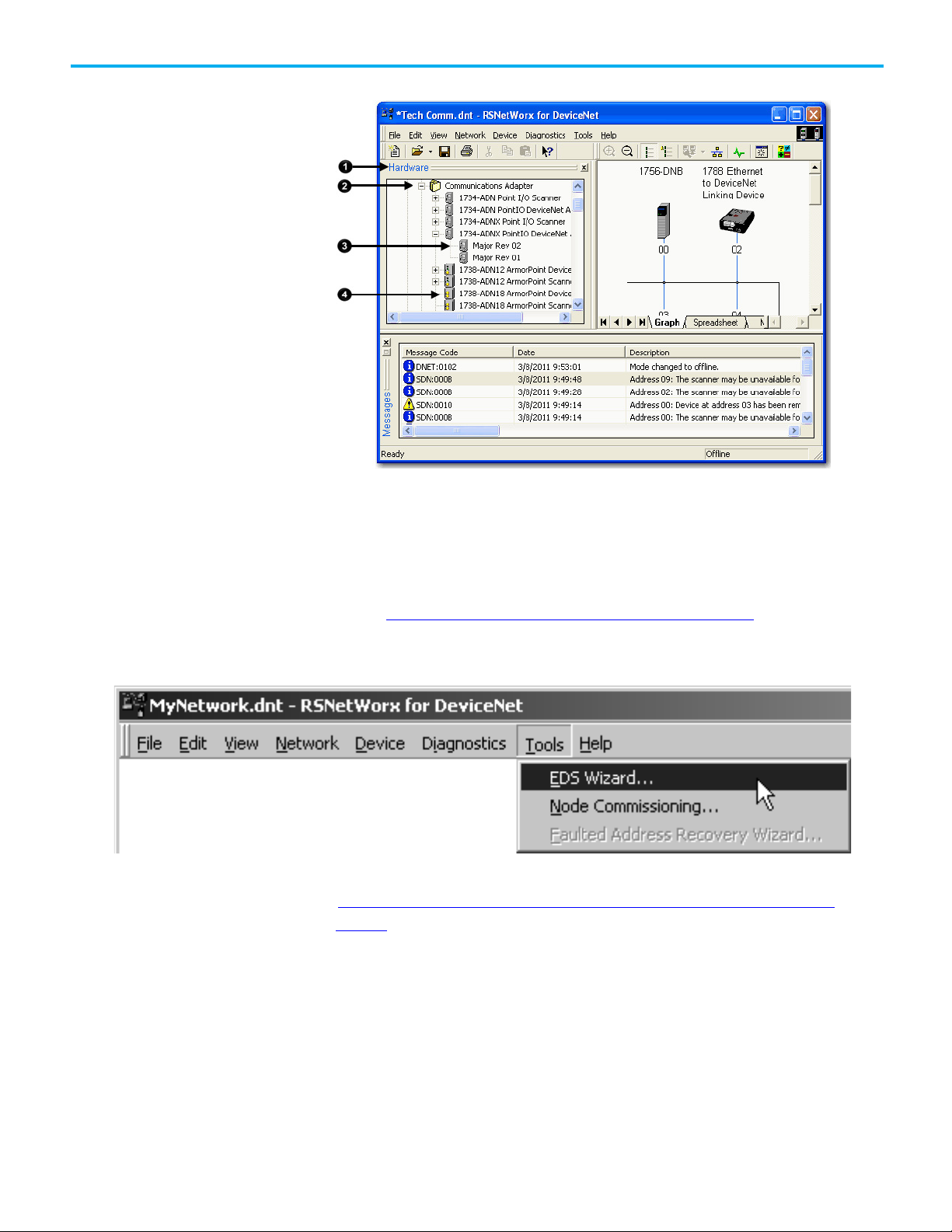

You can use the DeviceNet node commissioning tool available in RSNetWorx

for DeviceNet software to set the node addresses of devices on the DeviceNet

network. Remember the following when you decide to use the DeviceNet

node commissioning tool.

• You can only use this tool with a DeviceNet network that is online.

Page 31

Chapter 3 Connect Devices to the Network

• You can only use this tool as you add new devices to the network that

either do not have hardware mechanisms to set their node address or

have their hardware mechanism set to a number higher than 63.

If you add a device to the network with a hardware mechanism setting the

node address to 63 or lower, this tool does not change the device’s node

address.

• You should complete the tasks described in this section each time a

new device is added to the network.

• If you add more than one device to the online network before using the

DeviceNet node commissioning tool, you will experience duplicate

node address conflicts on the network because all new devices initially

use node address 63.

• Keep track of the node addresses you set with the DeviceNet node

commissioning tool and verify they match the device’s configuration

in the RSNetWorx for DeviceNet software configuration file.

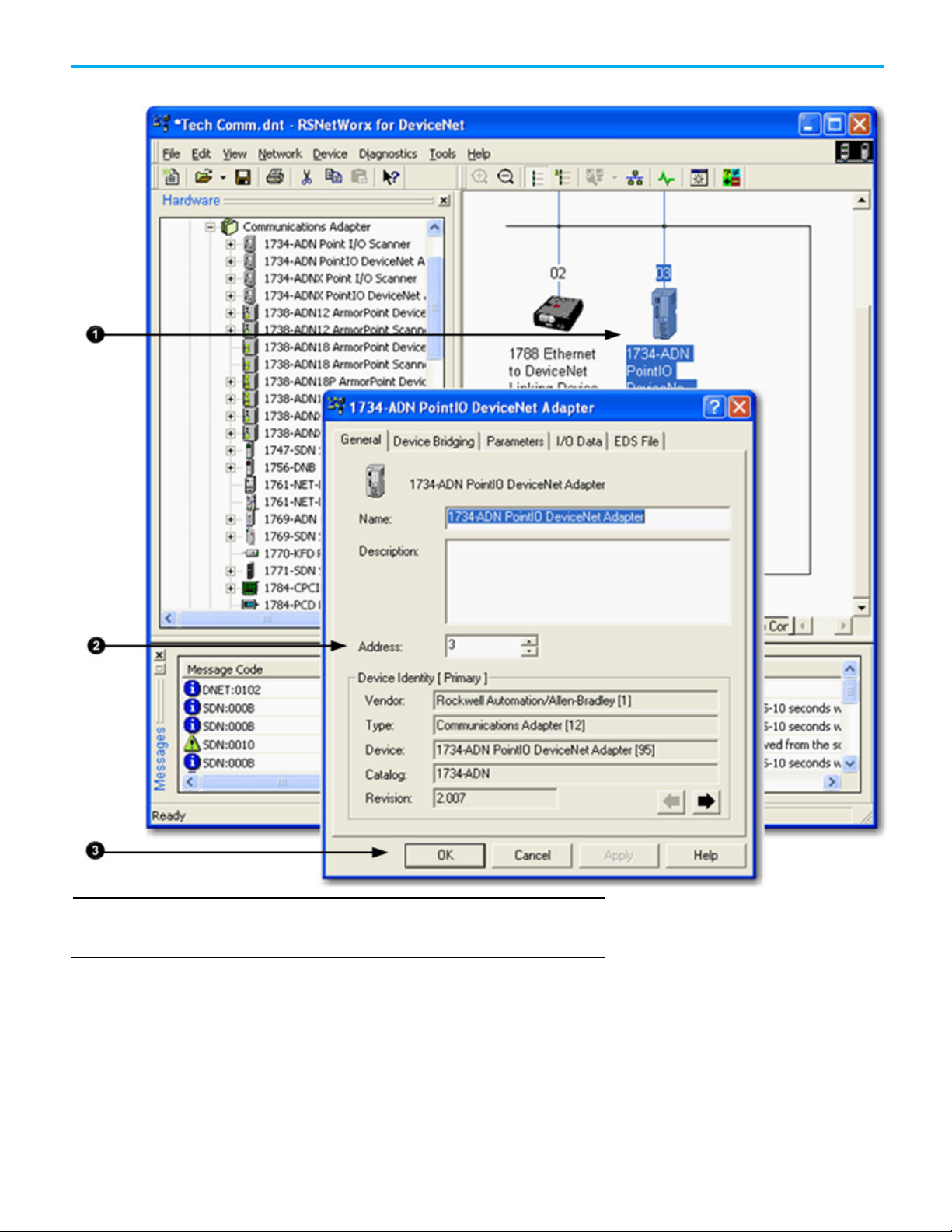

Complete the following steps to use the DeviceNet node commissioning tool

to set a device’s node address. This example uses the 1769-SDN Compact I/O

DeviceNet Scanner module.

1. Verify that the network is online.

2. Connect a device to the DeviceNet network.

3. Choose Start>Programs>Rockwell Software>RSNetWorx for

DeviceNet>DeviceNet node commissioning tool.

or

From the Tools pull-down menu in RSNetWorx for DeviceNet

software, choose Node Commissioning.

4. Click Browse.

5. On the Device Selection dialog box, check the ‘I want to input the

address for the device on the selected network’ box.

6. Browse to the DeviceNet network.

7. Type the current address for the device. Out of the box, devices use

address 63.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 31

Page 32

Chapter 3 Connect Devices to the Network

Make Sure Your Devices Are

8. Click OK.

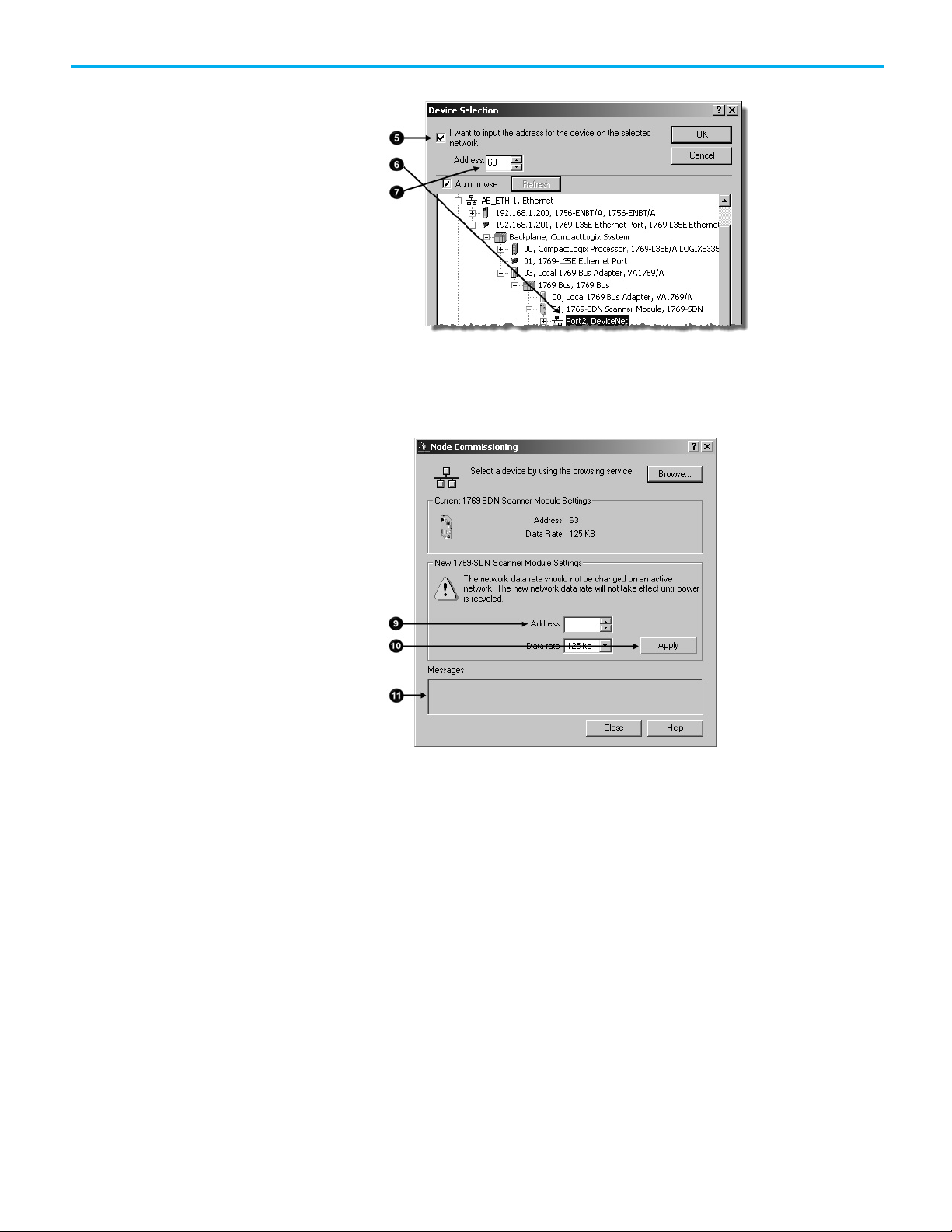

9. When you return to the Node Commissioning dialog box, enter the

new address for the device.

10. Click Apply.

11. Look for confirmation.

on Your Network

32 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

12. If you need to use the DeviceNet node commissioning tool to set

another device’s node address, return to step on page 34 and repeat

the process.

Once you have assigned a node address to each device, make sure that the

devices are communicating on the network. Complete these steps to make

sure your devices are on the network.

1. Start RSLinx communication software.

2. Go online.

3. Expand a driver that lets you access the DeviceNet network.

4. Browse to the DeviceNet network.

5. Make sure you see all the devices that are connected to the DeviceNet

network.

Page 33

Topic

Page

Create Your Network in RSNetWorx for DeviceNet Software on page 34

39 on page 34

Configure Each Device on page 35

40 on page 35

Configure the Scanner on page 39

44 on page 39

Save the Configuration File on page 45

51 on page 45

Generate an RSNetWorx for DeviceNet Report on page 45

51 on page 45

Download Configuration to Your Network on page 49

55 on page 49

Device

Address

Input Size of Device

Input Memory in

Output Size of Device

Output Memory in

PanelView terminal

3

128

32

128

32

2

I/O adapter w/ modules

5 9 3 5 2

2

drive 7 4 1 4

1

2

photoeye

9 1 1 0 0

computer interface

62

n/a

n/a

n/a

n/a

Before You Begin

Create a File for the

Chapter 4

Configure the Network Offline

This chapter describes how to configure the network offline with RSNetWorx

for DeviceNet software.

Before You Begin on page 51 38 on page 51 Create a File for the Network on page 33 38 on page 33

Before you configure the DeviceNet network, make sure you have a list of the

devices that you put on the DeviceNet network and, at minimum, the address

for each. The following table shows an example list of devices.

(Bytes)

scanner 0 n/a n/a n/a n/a

<empty>

<empty>

<empty>

63

Total

Scanner (DINTs)

43

(Bytes)

Scanner (DINTs)

2

2

2

41

Network

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 33

Complete the following steps to create a DeviceNet configuration file.

1. Start RSNetWorx for DeviceNet software.

2. Create a file.

Page 34

Chapter 4 Configure the Network Offline

Create Your Network in

3. Select DeviceNet Configuration.

4. Click OK.

5. Save the file.

Make sure you give the file a name that identifies this specific

DeviceNet network.

RSNetWorx for DeviceNet

Software

Before you configure a DeviceNet communication module in RSNetWorx for

DeviceNet software, you must add it to the network configuration file.

The finished picture should match the collection of devices that are or will be

physically connected to the DeviceNet network. If the network configuration

file you create offline does not match the physical collection of devices on the

network, you may experience issues when you go online with your project.

Complete the following steps to add each device to network configuration file.

1. Browse the hardware list for the device.

2. If there is a [+] sign next to the device, click the sign to expand the

choices in that section.

3. Double-click the major revision of the device.

We recommend that the major revision of all devices added to the

offline network match the devices that will be connected to the online

network.

4. For a device without a list of major revisions, that is, no [+] or [-] sign,

double-click the device.

34 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 35

Configure Each Device

Chapter 4 Configure the Network Offline

If the hardware list does not show a device, then RSNetWorx for DeviceNet

software requires the EDS file for the device.

To add an EDS file, follow these steps.

1. To see if an EDS file is available, go to the following site:

http://www.rockwellautomation.com/resources/eds/

2. Use the EDS wizard of RSNetWorx for DeviceNet software to register

the file and see it.

After adding devices to the network configuration file, as described in

Create Your Network in RSNetWorx for DeviceNet Software on page 39

page 34, you configure parameters for each device to define the modules’

behavior.

on

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 35

Page 36

Chapter 4 Configure the Network Offline

IMPORTANT

Refer to Configure the Scanner on page 44 on page 39 for more information.

Give this address

To this device

You can configure most devices as you add them to the network configuration file or

you can add all the devices and then configure them.

Typically, you add a network scanner to the network first. In this case, we recommend

that you add all devices to the network configuration file before configuring the

scanner. Multiple parameters that need to be configured in the scanner’s

configuration, for example, building a scan list, require you to choose from devices on

the network.

Complete these tasks when configuring DeviceNet communication modules:

Specify a Device Node Address

• Specify a Device Node Address on page 36

• Configure Device Parameters on page 38

The following options are available to set a device’s node address:

• Hardware mechanism, as described on page 30 on page 28

• RSNetWorx for DeviceNet software, as described in this chapter

• DeviceNet node commissioning tool, as described on page 33 on

page

30

All DeviceNet devices ship with their node addresses set to 63. To avoid

duplicate node number conditions on the network, you should change the

node address for each device to unique numbers.

0 Scanner

1…61 Your devices

62 Computer interface to the network, such as a 1784-U2DN device

63 None

Out of the box, a DeviceNet communication module is preset for address 63.

Leaving address 63 open lets you get a new device on the network without

conflicting with another device.

When you create your network in RSNetWorx for DeviceNet software, as

described on page 39 on page 34

addresses based on the order in which they were added to the network. The

number appears below the device’s graphic on the screen as shown below.

36 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

, devices are automatically assigned node

Page 37

Change a Device Node

Chapter 4 Configure the Network Offline

As you create the network, consider the following:

• If you used a hardware mechanism to assign a node address for a

device, that number takes precedence over any number you assign in

RSNetWorx for DeviceNet software.

Make sure the numbers assigned by the hardware mechanism and in your

configuration file are the same for each device. For example, if the node

address for a 1756-DNB ControlLogix DeviceNet Scanner is set to 2 via a

hardware mechanism, but in the RSNetWorx for DeviceNet software

configuration file, the node address is 0, you need to change the address in the

software to 2.

Address

• The node addresses that are automatically assigned as you add devices

to the configuration file do not take effect when the project is offline.

• For devices that do not have hardware mechanisms, the node number

assigned in the network configuration file takes effect when you

download the project to the DeviceNet network, as described on

page

55 on page 49.

You may need to assign a device’s node address that is different from the

number automatically assigned when the device is added to the configuration

file. Complete the following steps to assign a device a specific node address.

1. Double-click the device.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 37

Enter the node address for the device.

Page 38

Chapter 4 Configure the Network Offline

Configure Device

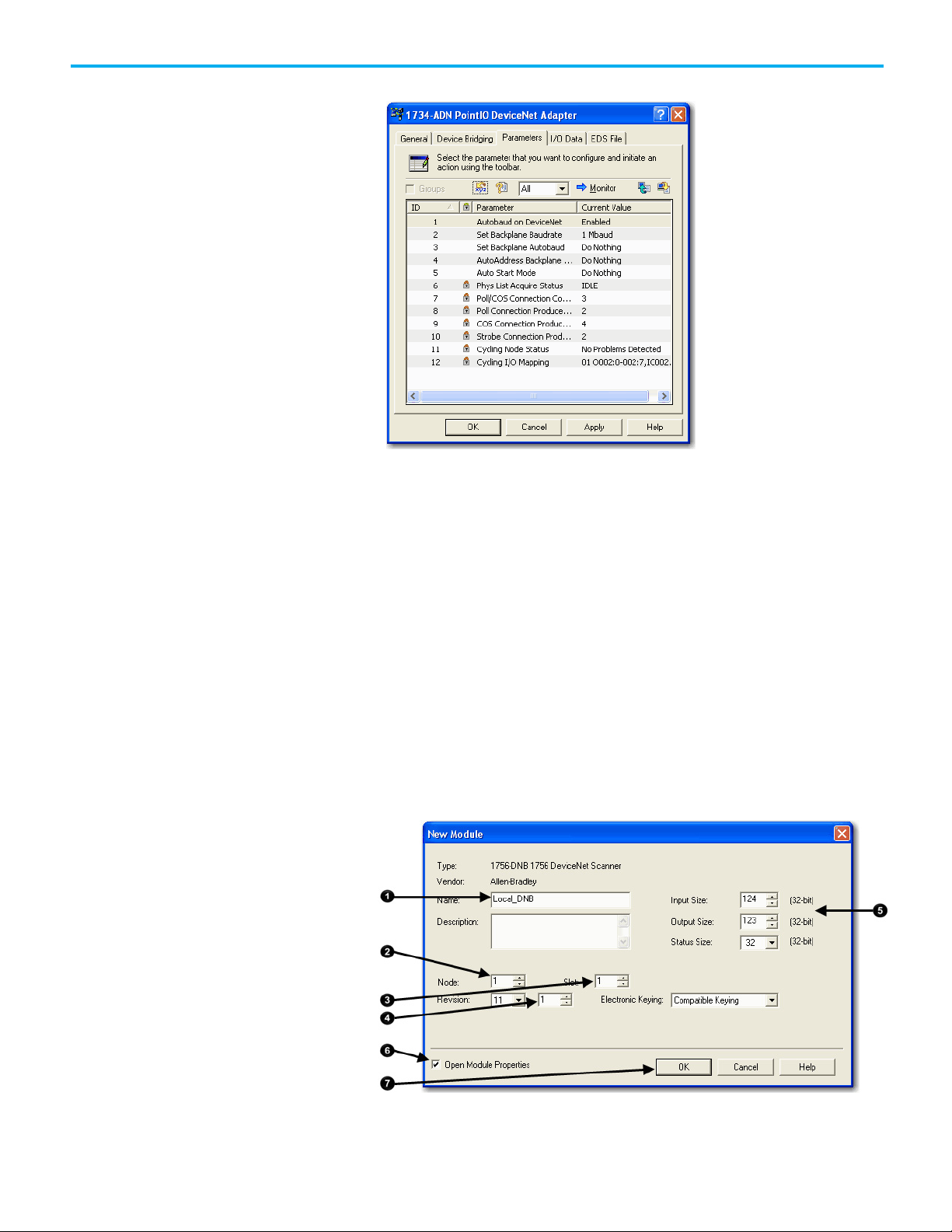

Complete the following steps to configure device parameters.

Parameters

1. Double-click the device to display the configuration dialog box.

2. Click the appropriate tab.

3. Set a parameter to the desired new value.

Typically, there are two methods to set a parameter:

• Choose a parameter from a pull-down menu

38 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 39

Configure the Scanner

Chapter 4 Configure the Network Offline

• Type a new value

4. Click Apply to apply the change and leave the configuration dialog box

open, or click OK to apply the change and close the configuration

dialog box.

Complete the following steps to configure the scanner.

1. Type a name for the scanner.

2. Enter a node number.

3. Enter the slot number.

4. Enter the minor revision.

5. Enter the size of the input and output memory maps that the scanner

will allocate for each device it detects on the network.

Valid values range from 0…32 bytes per node.

6. If you need to make additional configuration changes, such as setting

the requested packet interval (RPI), check Open Module Properties.

7. Click OK.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 39

8. If the Module Properties dialog box appears, make additional

configuration changes.

Page 40

Chapter 4 Configure the Network Offline

Build the Scan List

You can change scanner configuration on the following tabs:

• General

• Connection

• RSNetWorx

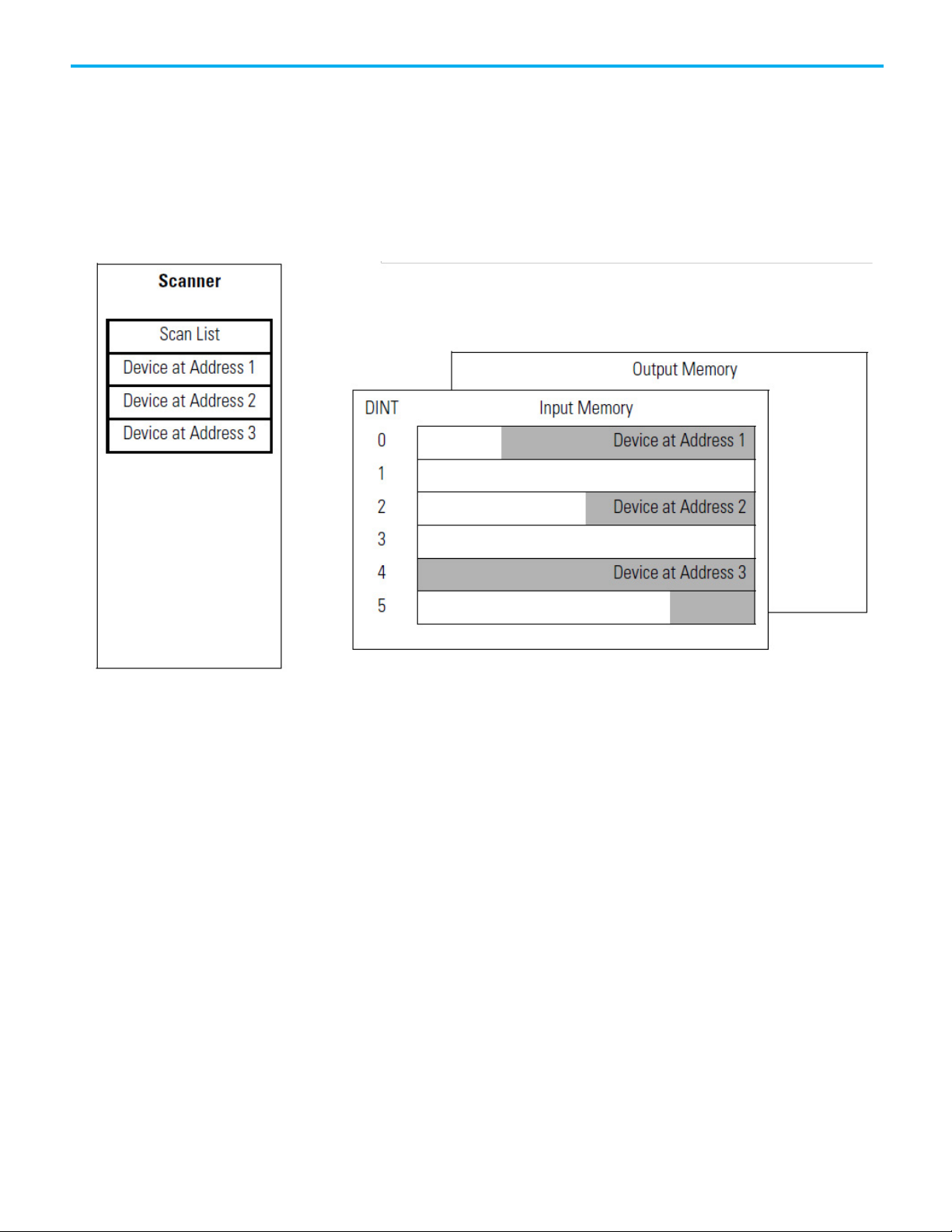

A scan list is a list of devices with which the scanner communicates. For each

device in the scanner’s scan list, the scanner sets aside input or output

memory for the data of the device.

Complete the following steps to build a scan list.

1. Double-click the scanner to open the configuration dialog box, or, if

the scanner configuration has already been uploaded and the

configuration dialog box is open, go to step 2.

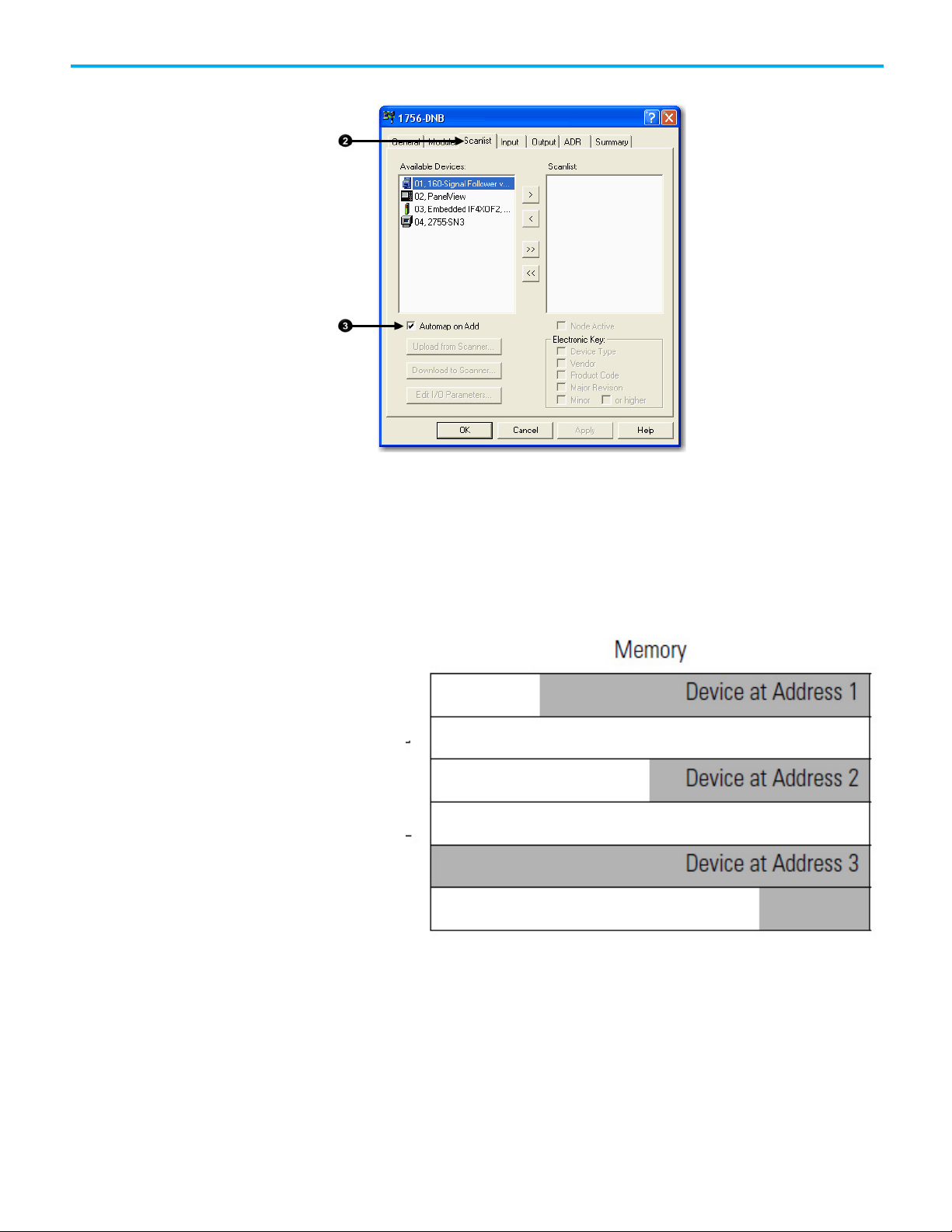

2. Click the Scanlist tab. The devices on the network appear in the

Available Devices column.

40 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 41

3. Clear or check Automap on Add.

RSNetWorx for DeviceNet software can automatically assign the

memory location for each device.

Chapter 4 Configure the Network Offline

• If you want to leave gaps between devices in the memory, as shown

below, clear the box.

Leave Gaps Between Devices

• If you want to place devices in sequential DINT’s, as shown below,

leave the box checked. When you check the box, the software

automatically assigns a memory location for each device as you add

it to the scan list.

Place Devices in Sequential DINTs

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 41

Page 42

Chapter 4 Configure the Network Offline

IMPORTANT

Set the Alignment Option

Move devices from the Available Devices column to the Scanlist

column.

If you get the following warning for a device, see

Set the I/O

Parameters of a Device on page 143 on page 167 on page 143.

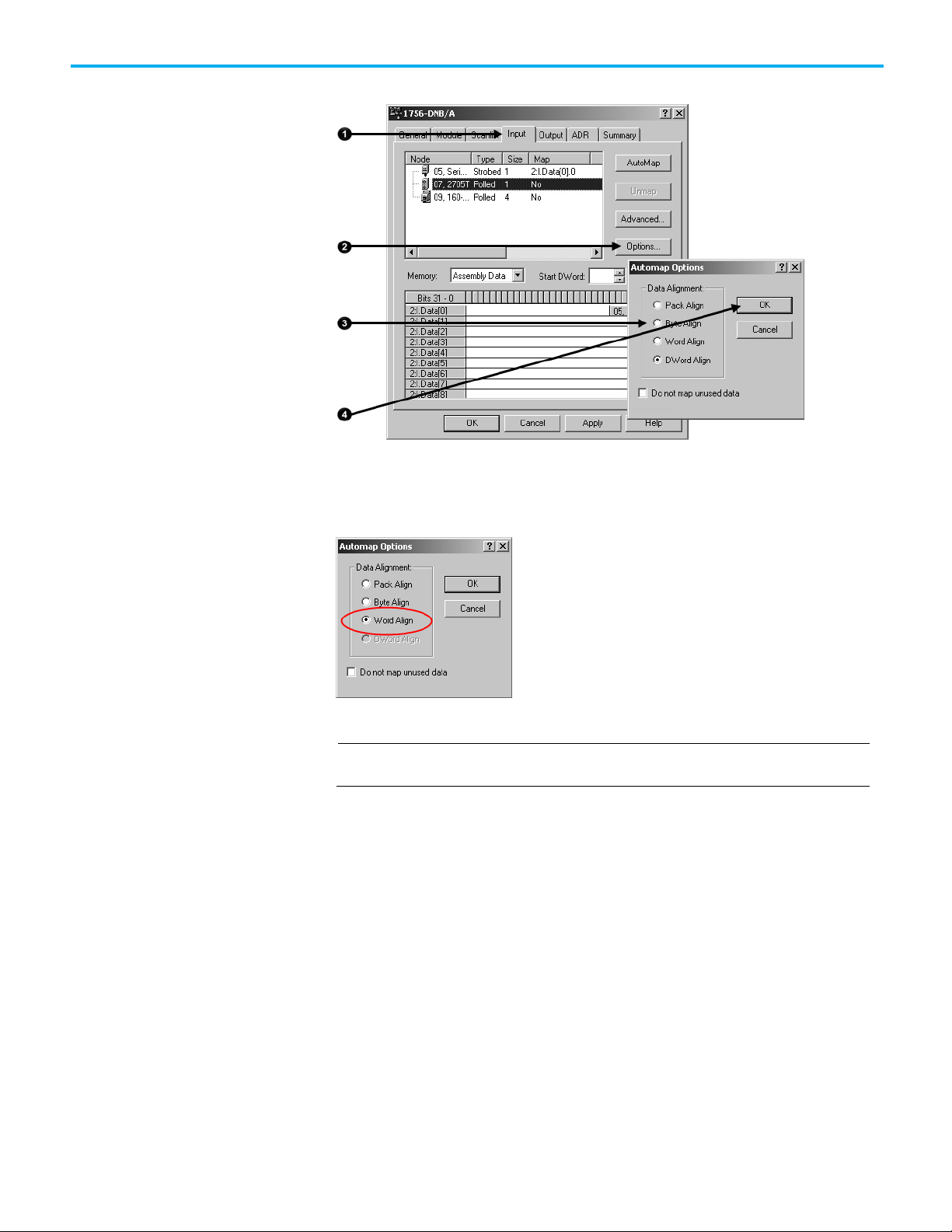

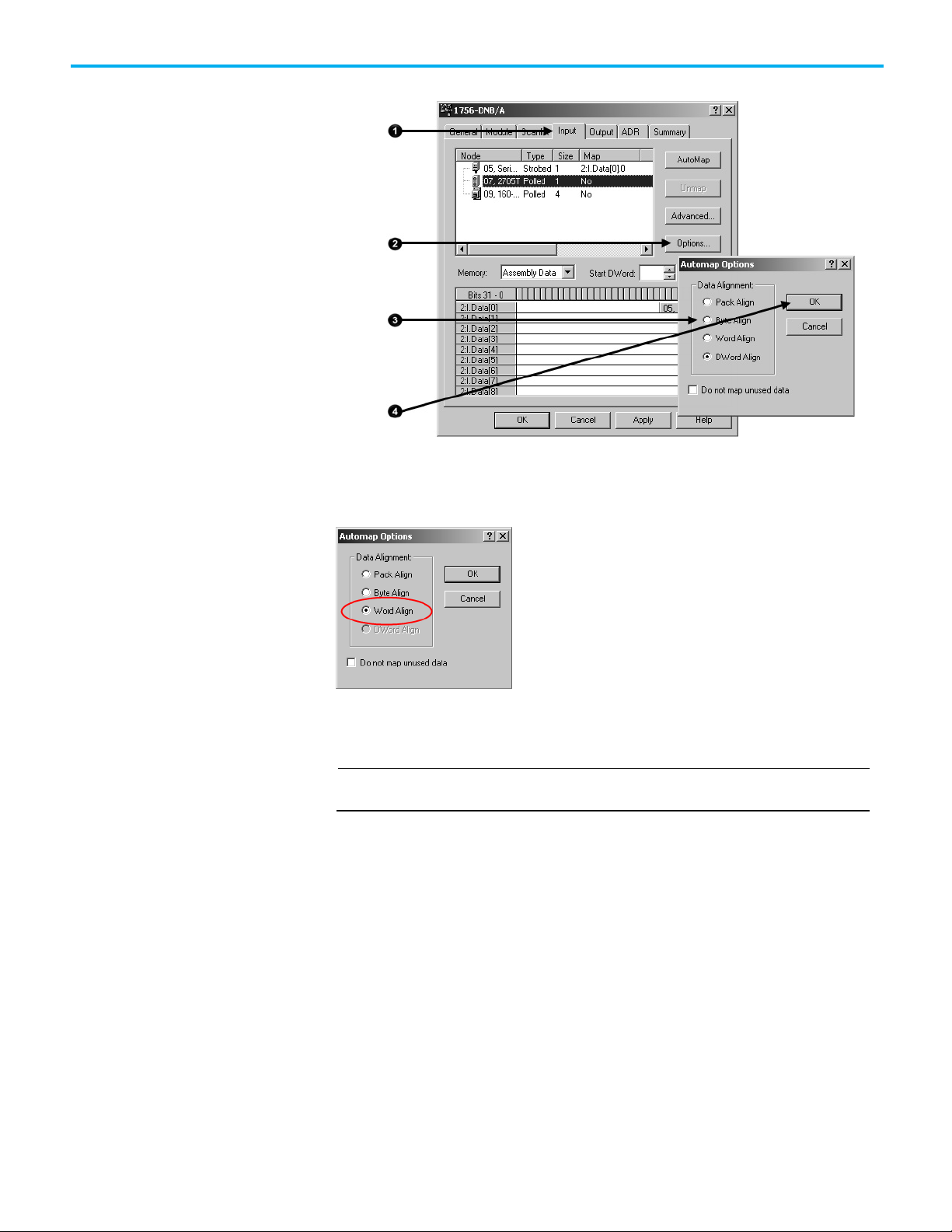

Choose a data alignment option to map the I/O data so that it is aligned on a

boundary, such as a byte, word, or double-word, or efficiently grouped

without alignment in the input or output memory map. To map I/O data so it

is grouped without alignment, click the Pack Align option.

The alignment option you choose applies to both the input and output maps.

Complete these steps to select an alignment option.

1. Click the Input tab.

2. Click Options.

3. Click the desired data alignment.

42 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 43

IMPORTANT

SoftLogix 5800 Controller

Manually Assign Each

Chapter 4 Configure the Network Offline

4. Click OK to close the Automap Options dialog box.

The SoftLogix 5800 scanner 1784-PCIDS organizes its input and output

memory in 16-bit words. For that scanner, click the Word Align option.

Device to a Memory

Location

You can manually assign locations for device data.

If you configured the software to automatically assign memory locations as devices

are added, as described on page 45, skip this section.

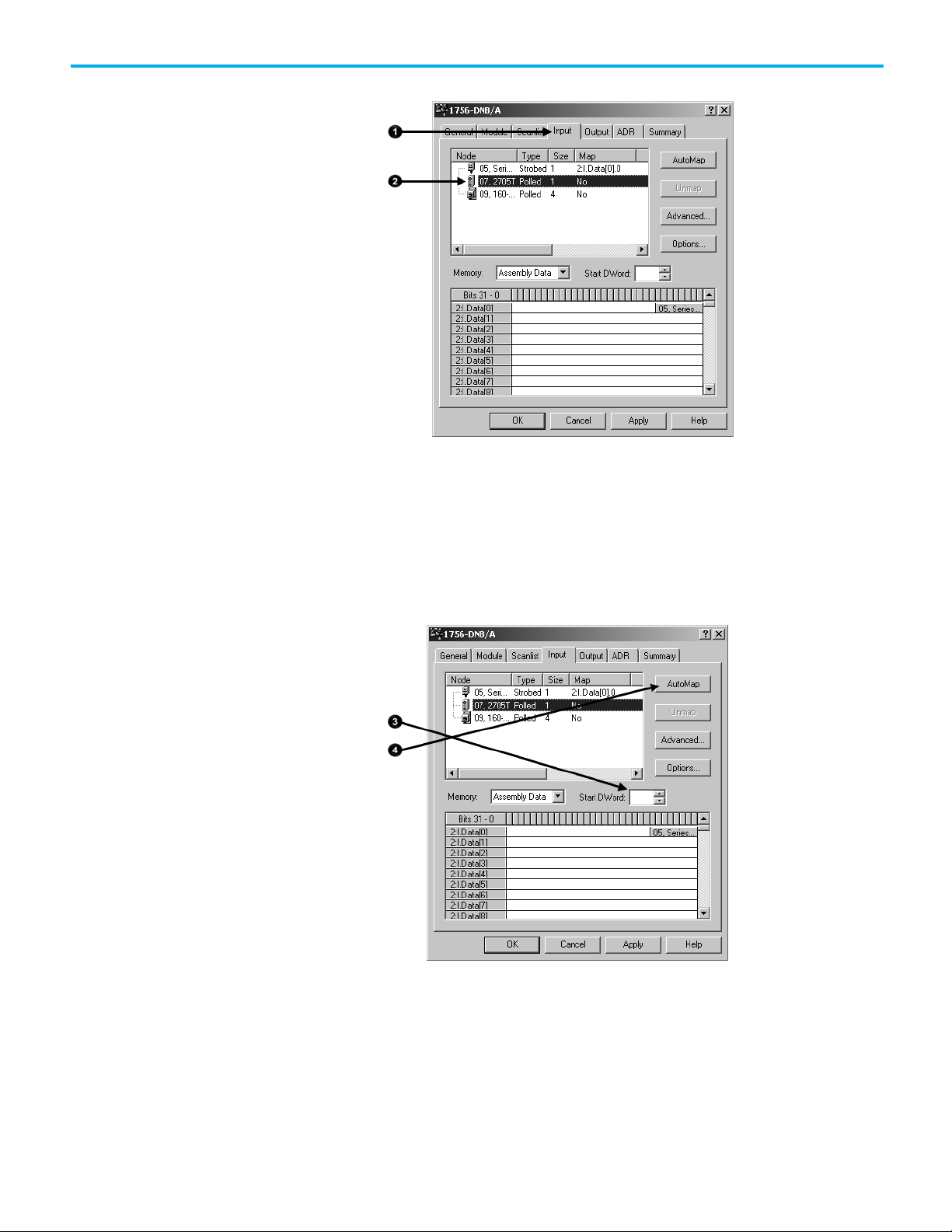

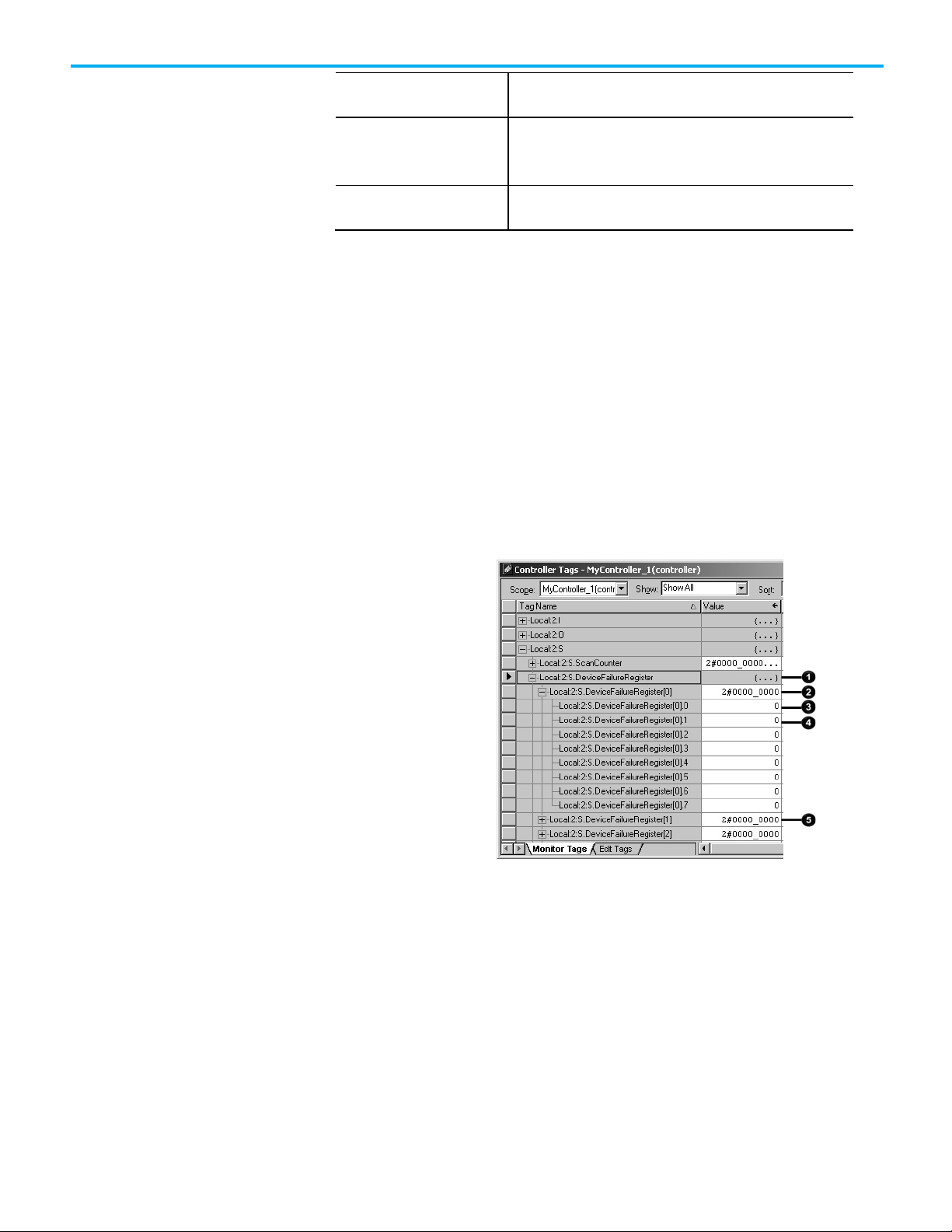

1. Click the Input tab.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 43

Page 44

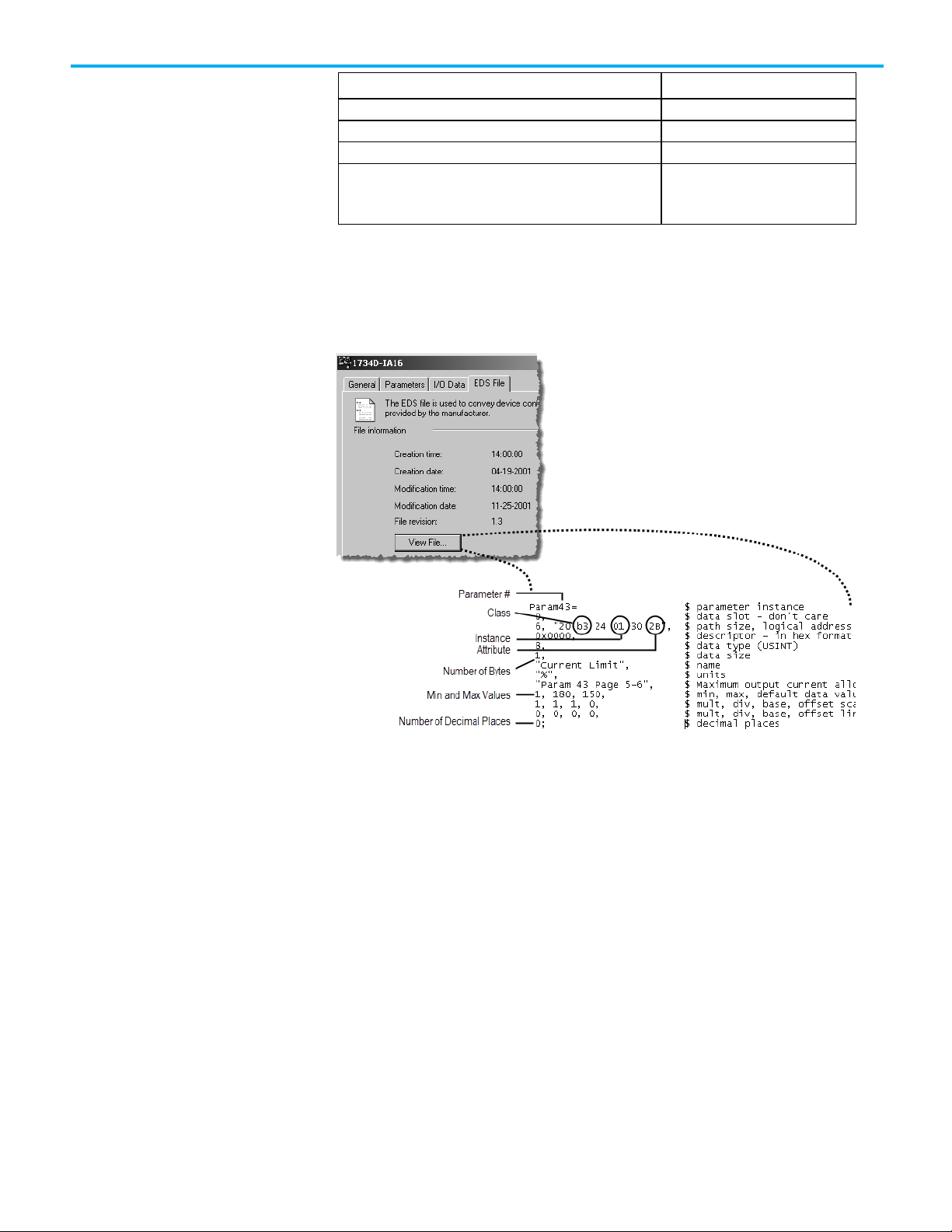

Chapter 4 Configure the Network Offline

2. Select the device.

3. In the Start DWord field, enter the element number to which you want

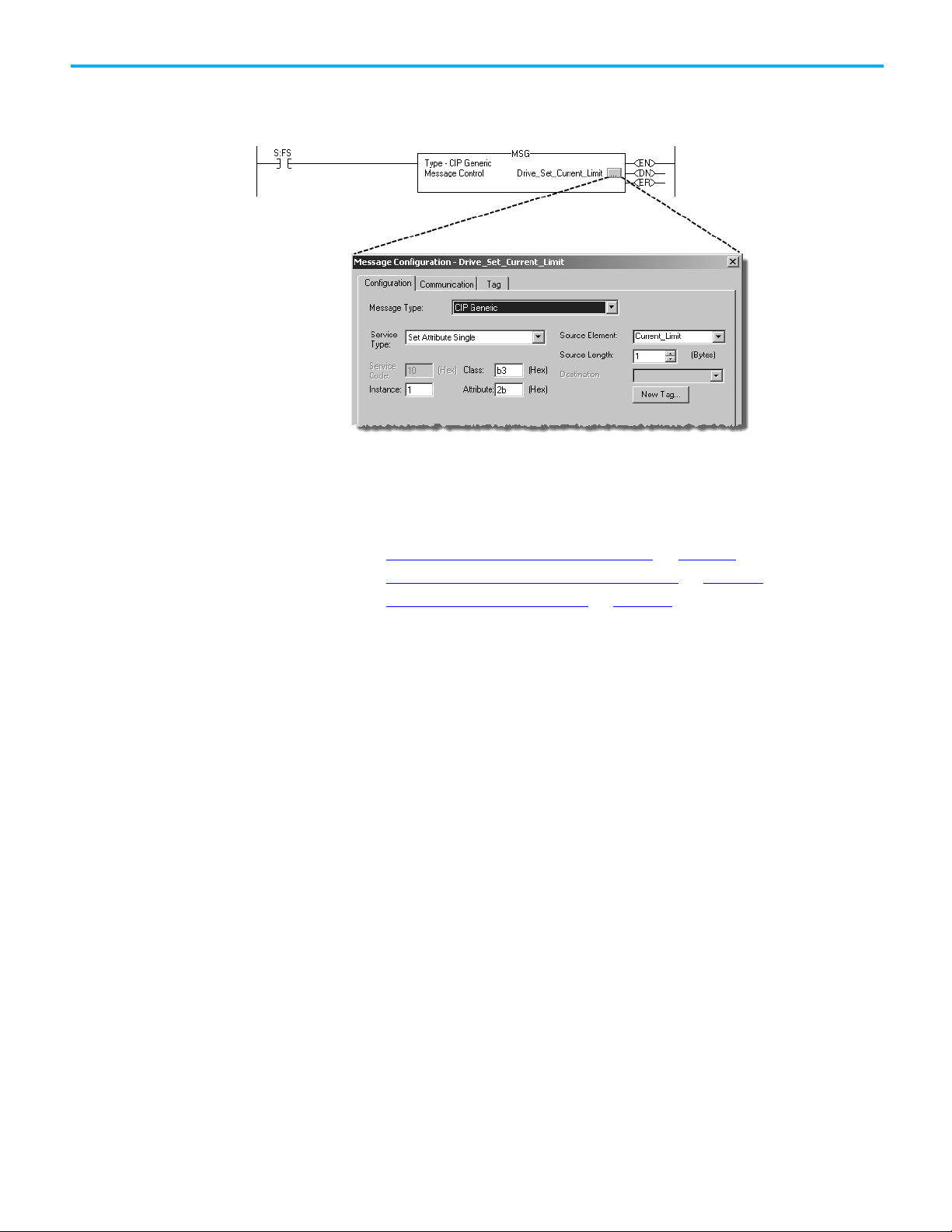

to assign the data.

This is the starting point for the data. Larger data sizes wrap to several

elements. For example, to start the data in . . . Data[3], enter 3 in the

Start DWord box.

4. Click Automap.

An entry for the device appears in the input array.

5. Click the Output tab and repeat the steps above.

6. Click OK to complete the scanner configuration.

44 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 45

Save the Configuration File

Generate an RSNetWorx for

Chapter 4 Configure the Network Offline

Sometimes, a specific input or output value may end up as the upper bytes of a

DINT in the scanner.

To make your programming easier, use advanced mapping to re-map the

value to its own memory location. For more information, see

Map the Memory

Location with Advanced Mapping on page 153 on page 184 on page 153.

After you make a change to the network, upload the entire network and save

the file. This makes sure that the offline configuration file matches the

network.

Complete these steps to save the configuration file.

DeviceNet Report

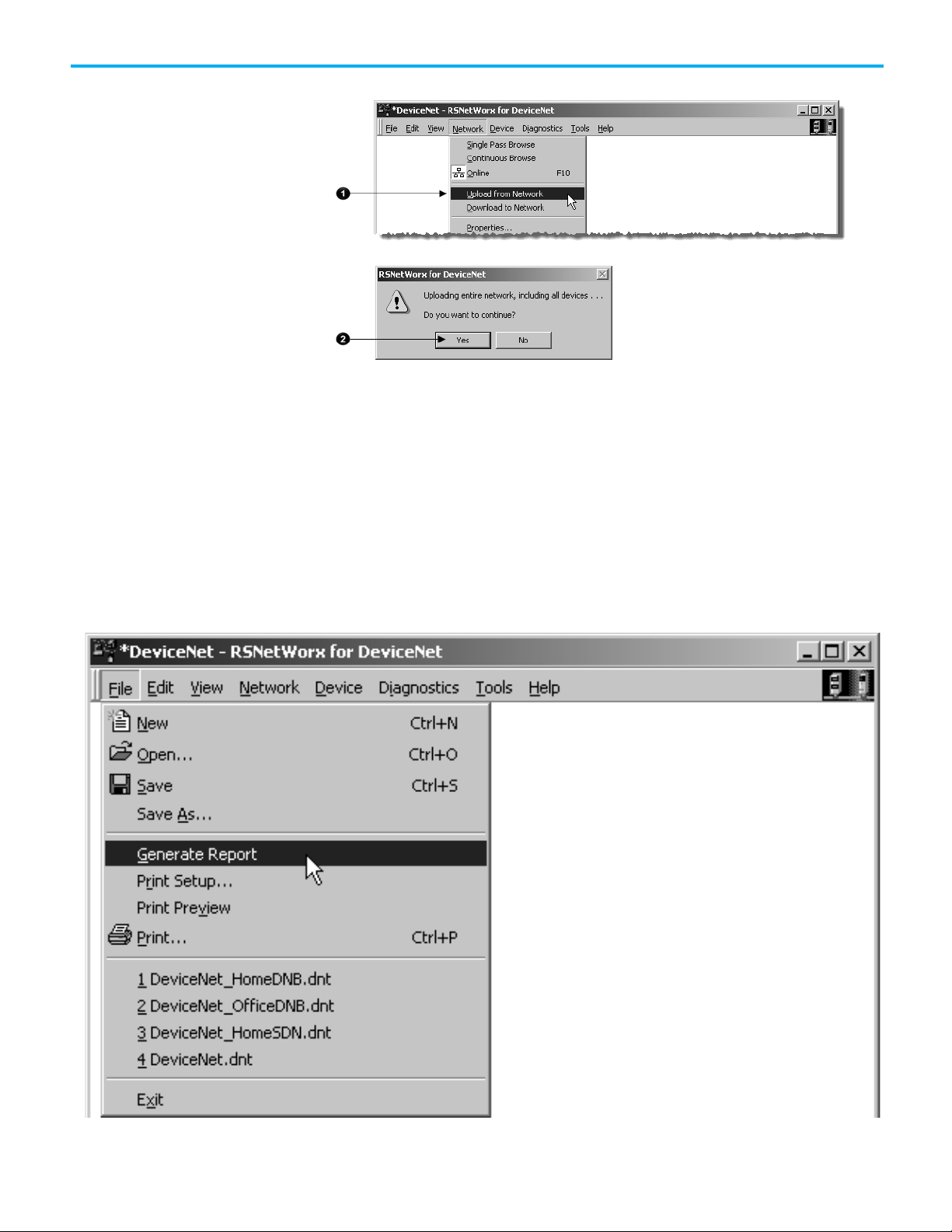

1. From the Network menu, choose Upload from Network.

2. When prompted, click Yes to upload the entire network.

3. Save the file.

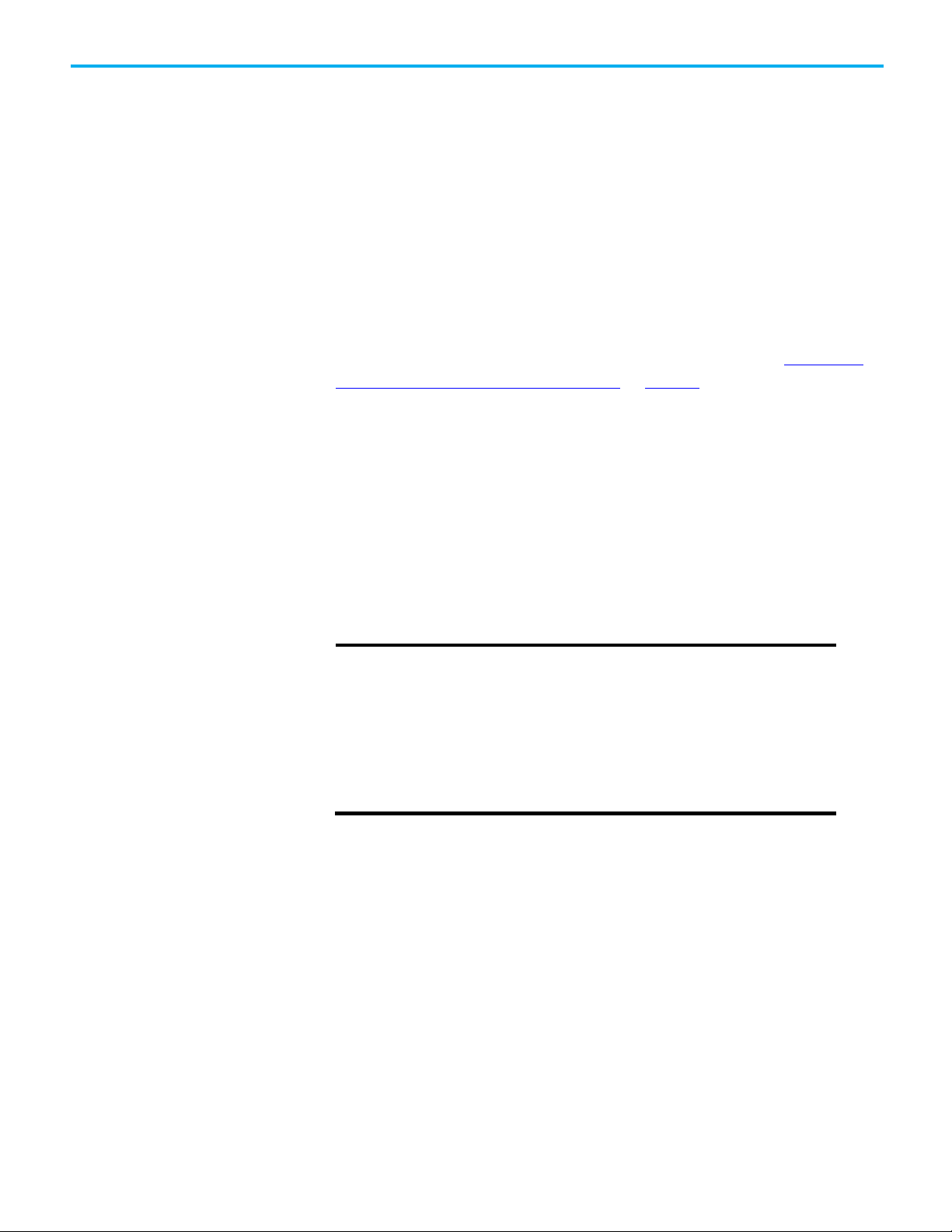

An RSNetWorx for DeviceNet report shows these items:

• Devices on the network

• Memory addresses of those devices in the scanner

• Device configurations

The report is a useful reference when you program your system. Complete the

following steps to generate a report.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 45

Page 46

Chapter 4 Configure the Network Offline

1. From the File menu in RSNetWorx for DeviceNet software, choose

Generate Report.

2. Click Generate report for entire network.

46 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 47

The report appears in your web browser.

Chapter 4 Configure the Network Offline

Go Online to Your Network

When you go online, RSNetWorx for DeviceNet software browses the

network once and shows the devices currently on the network in the new

network configuration file.

Keep in mind the following when you go online:

• RSNetWorx for DeviceNet software does not read (upload) or change

(download) the parameters of any of the devices on the network.

• The picture that results from browsing remains static. It does not show

any changes since the last browse.

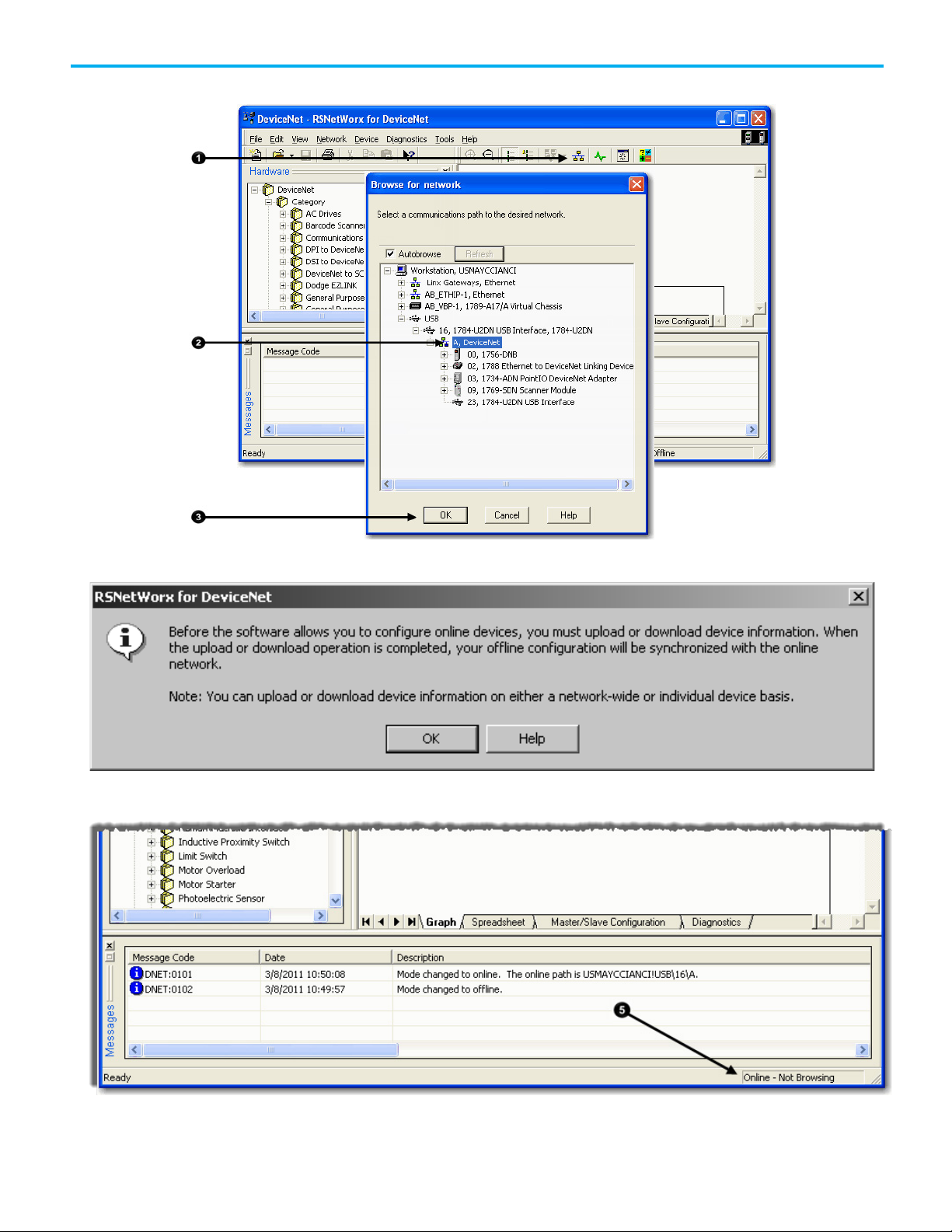

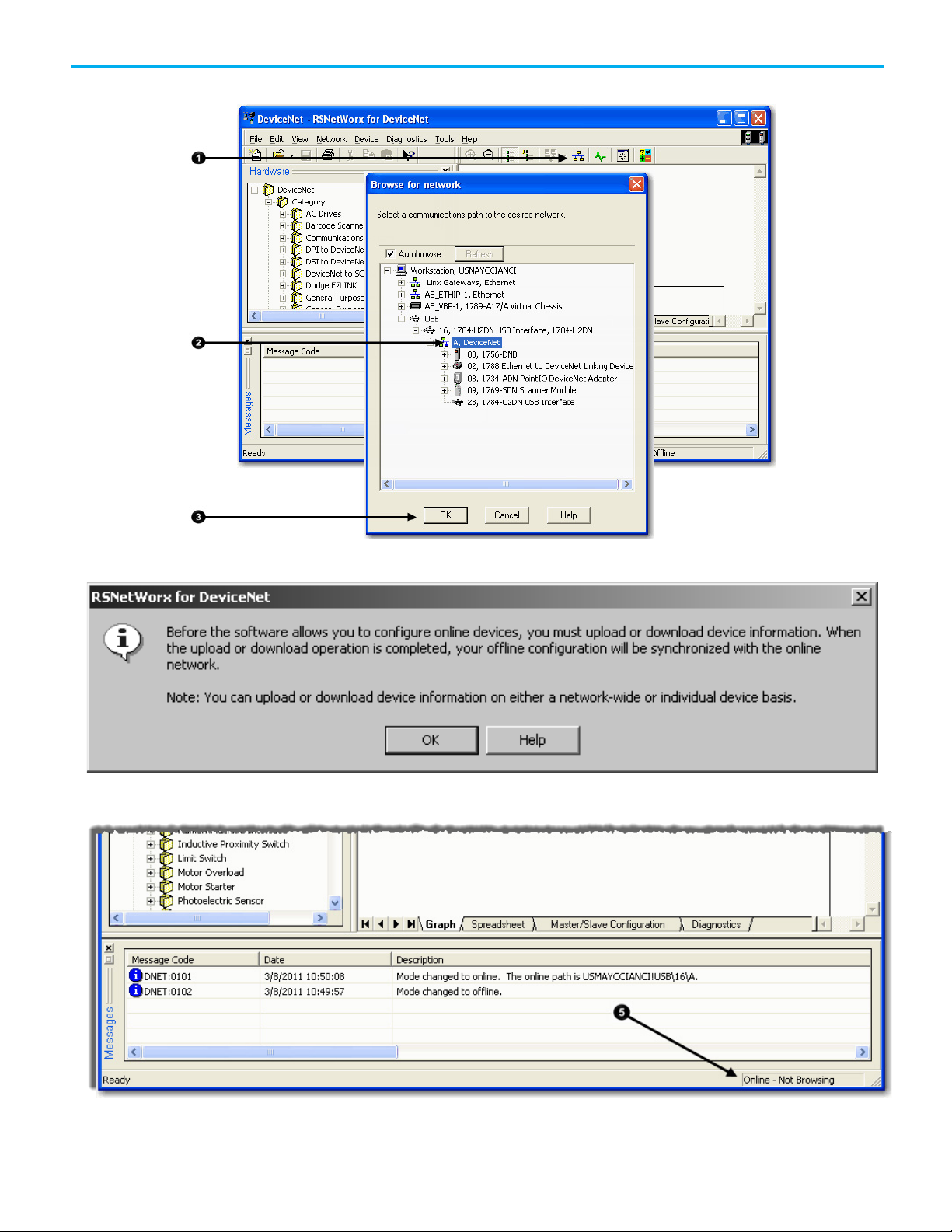

Complete the following steps to go online.

1. Click the Online button.

2. Select the DeviceNet network.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 47

Page 48

Chapter 4 Configure the Network Offline

3. Click OK.

4. When the pop-up message appears, click OK.

5. Verify that you are online.

48 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 49

IMPORTANT

• Turn off the …O.CommandRegister.Run bit of the scanner.

Download Configuration to

Your Network

Chapter 4 Configure the Network Offline

After you go online with the network configuration file you created while

offline, you can download the configuration to the network.

Before you download configuration to the network, make sure the scanner is in Idle

mode. To put the scanner in Idle mode, do one of the following:

• Place the controller in program/remote program mode.

Complete the following steps to download configuration to the DeviceNet

network.

1. From the File menu in Network>Download to Network.

2. When prompted, click Yes to download the entire network.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 49

Page 50

Page 51

Topic

Page

Verify Communication Between the Computer and Devices on page 52

58 on page 52

Create a New File for the Network on page 33

60 on page 33

Go Online to Your Network on page 47

60 on page 47

Upload and Save the Configuration File on page 65

76 on page 65

Generate an RSNetWorx for DeviceNet Report on page 45

77 on page 45

Before You Begin

Chapter 5

Configure the Network Online

This chapter explains how to configure the network online with RSNetWorx

for DeviceNet software.

Before You Begin on page 51 58 on page 51

Configure Each Device on page 35 63 on page 35

Configure the Scanner on page 39 66 on page 39

Configuring the network online reduces the number of configuration tasks

you must complete compared to configuring the network offline. Configuring

the network online has these advantages:

• Devices on the network automatically appear in your network

configuration file as soon as you go online. You do not need to add the

devices to the network configuration file.

• The network configuration file automatically matches the physical

setup of devices on the network as well as the major and minor

revisions of the online devices.

• The configuration is guaranteed to match the major and minor

revisions of the online devices.

• You can easily upload device configurations to your network

configuration file, make changes to the configuration parameters, and

download them to the device.

Before you configure the network, make sure you have a list of the devices that

are on the network and, at minimum, the node address for each of them. The

following table shows an example list of devices.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 51

Page 52

Chapter 5 Configure the Network Online

Device

Address

Input Size of Device

Input Memory in Scanner

Output Size of Device

Output Memory in

PanelView terminal

3

128

32

128

32

2

I/O adapter w/ modules

5 9 3 5 2

2

drive 7 4 1 4

1

2

photoeye

9 1 1 0 0

Verify Communication

(Bytes)

scanner 0 n/a n/a n/a n/a

<empty>

<empty>

<empty>

computer interface 62 n/a n/a n/a n/a

63

Total

(DINTs)

43

(Bytes)

Between the Computer and

To configure your network online, your computer must be able to

communicate with each device on the DeviceNet network. Use RSLinx

Devices

communication software to verify that you can communicate with all the

devices.

Scanner (DINTs)

2

2

2

41

1. Start RSLinx communication software.

2. Click the Online button.

3. Expand a driver that lets you access the DeviceNet network.

4. Select the DeviceNet network.

52 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 53

IMPORTANT

Create a New File for the

5. Make sure you see all the devices that are connected to the

DeviceNet network.

Chapter 5 Configure the Network Online

If you cannot view the network, verify that your computer is connected to the

network. Refer to Chapter 2 on page 25 for more information on how to connect the

computer to the network.

If you can view the network but cannot see all the devices that should be on the

network, verify the devices are connected to the network. Refer to Chapter 3 on page

29 for more information on how to connect the devices to the network.

Network

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 53

Before you go online, you must create a new network configuration file.

Complete the following steps to create a DeviceNet configuration file.

1. Start RSNetWorx for DeviceNet software.

2. Create a file.

Page 54

Chapter 5 Configure the Network Online

Go Online to Your Network

When you go online, RSNetWorx for DeviceNet software browses the

network once and shows the devices currently on the network in the new

network configuration file.

Keep in mind the following when you go online:

• RSNetWorx for DeviceNet software does not read (upload) or change

(download) the parameters of any of the devices on the network.

• The picture that results from browsing remains static. It does not show

any changes since the last browse.

Complete the following steps to go online.

1. Click the Online button.

2. Select the DeviceNet network.

54 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 55

3. Click OK.

Chapter 5 Configure the Network Online

4. When the pop-up message appears, click OK.

5. Verify that you are online.

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 55

Page 56

Chapter 5 Configure the Network Online

Configure Each Device

Upload the Configuration of

Change and Download

Once the devices on the DeviceNet network appear in the network

configuration file, complete these tasks to change the configuration for

a device:

a Device

• Upload the Configuration of a Device on page 56

• Change and Download Device Configuration on page 56

When you configure the network online, the devices on the network have

parameters configured. Complete the following steps to upload configuration

from a device to the network configuration file.

1. Double-click the device to open the configuration dialog box.

2. Click the Parameters tab.

Device Configuration

3. When prompted, upload the configuration from the device to the

network configuration file.

After you upload a device’s configuration to the network configuration file,

you can make changes to the configuration and download it.

Complete the following steps to change and download new configuration

parameters.

56 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

Page 57

Chapter 5 Configure the Network Online

1. Double-click the device to open the configuration dialog box, or, if the

device configuration has already been uploaded and the configuration

dialog box is open, go to step 2.

The configuration dialog box appears.

2. Click the appropriate tab.

3. Set a parameter to the desired new value.

Typically, there are two methods to change a parameter:

• Choose a parameter from a pull-down menu

• Type a new value

4. Apply the changes.

5. Click OK to close the dialog box.

6. When prompted, download the changes.

Configure the Scanner

A DeviceNet scanner manages input and output data for a controller. The

scanner receives input data from I/O devices, organizes the information into

scanner data tables, and sends the input data to the controller when the

Rockwell Automation Publication DNET-UM004D-EN-P - September 2020 57

Page 58

Chapter 5 Configure the Network Online

Upload the Current Scanner

controller requests it. In addition, when the scanner receives output data from

the controller, it sends the data to the I/O devices.

A DeviceNet scanner is the only device that can be used as a master on a

DeviceNet network. When there is only one scanner on a network, it is the

master for that network by default. When there are multiple scanners on the

same network, each device can have only one scanner designated as its

master, which is the scanner that controls its outputs.

You must configure the scanner to define how it communicates with other

devices on the DeviceNet network. When you are configuring the network

online, complete the following tasks to configure the scanner:

• Upload the Current Scanner Configuration on page 58

• Define the Scanner Properties on page 59

• Build the Scan List on page 40

• Set the Alignment Option on page 42

Configuration

58 Rockwell Automation Publication DNET-UM004D-EN-P - September 2020

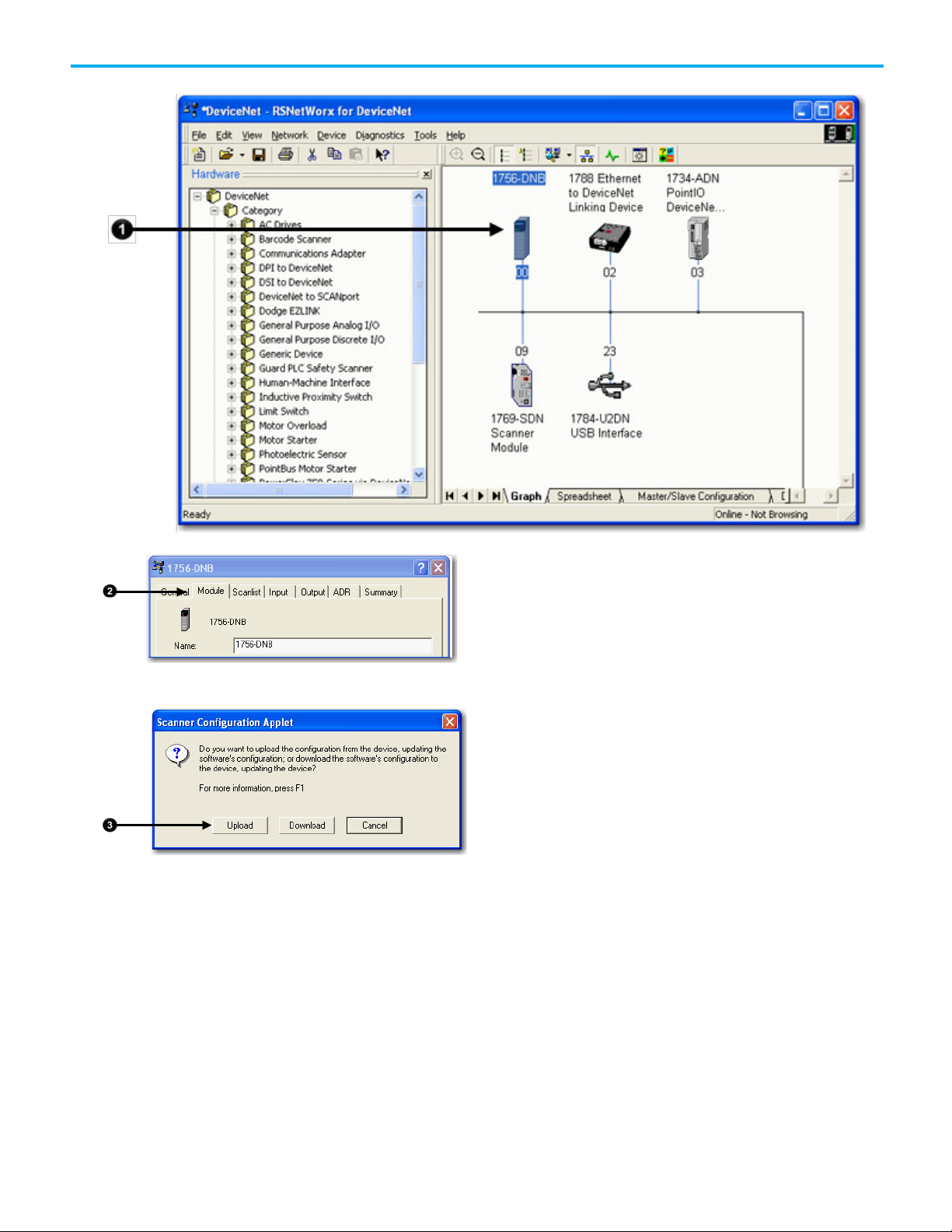

Complete the following steps to upload the current scanner configuration.

1. Double-click the scanner to open the configuration dialog box.

2. Click the Module tab.

3. When prompted, upload the configuration from the scanner.

Page 59

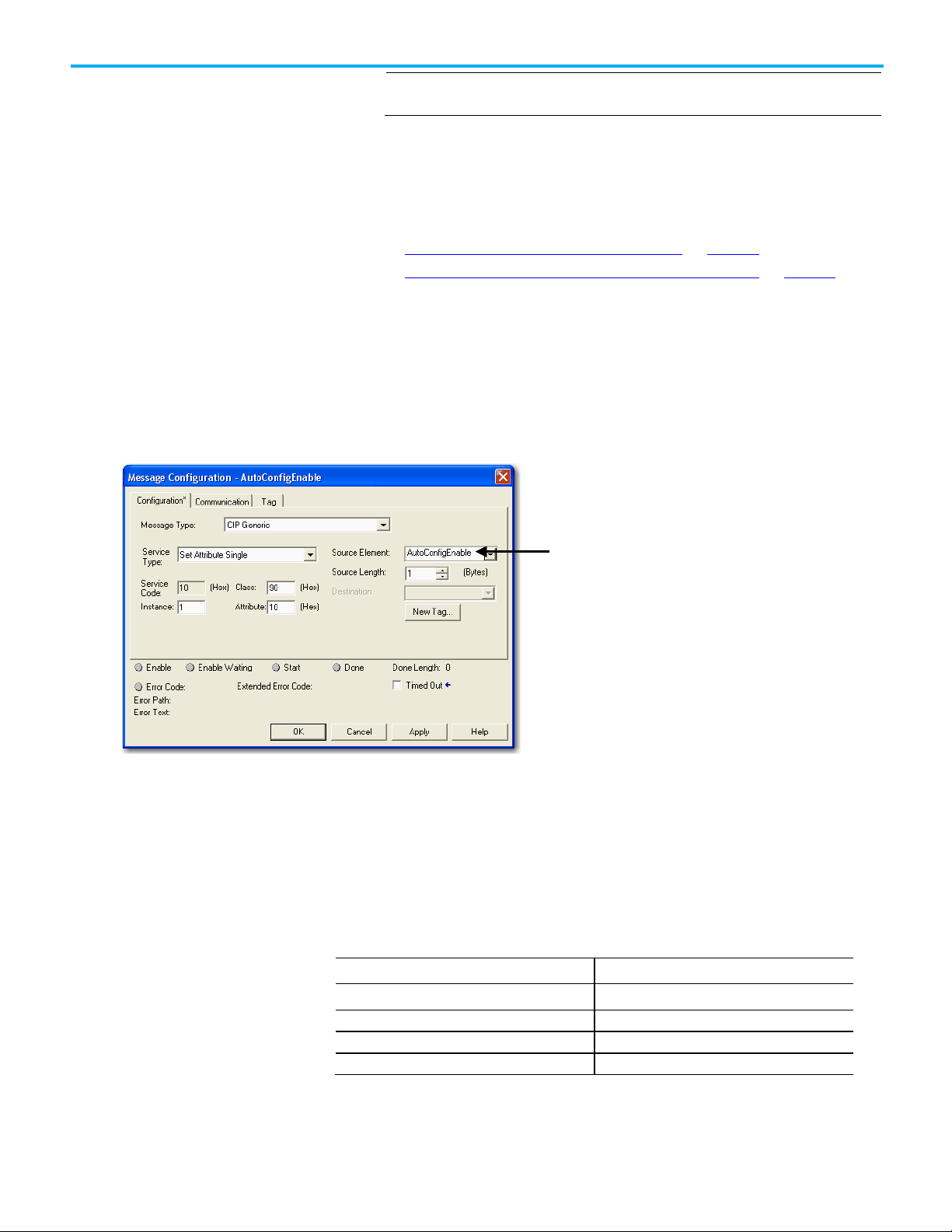

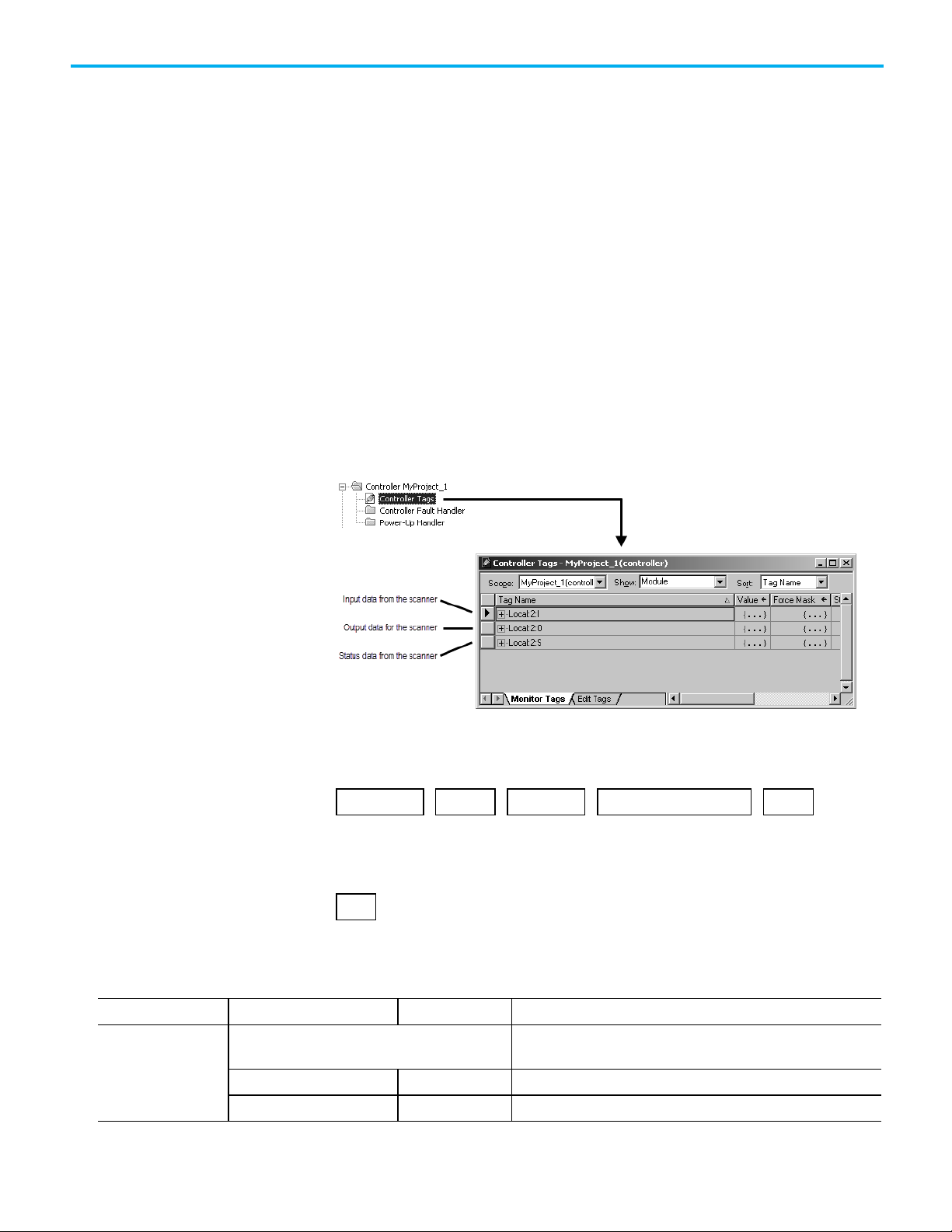

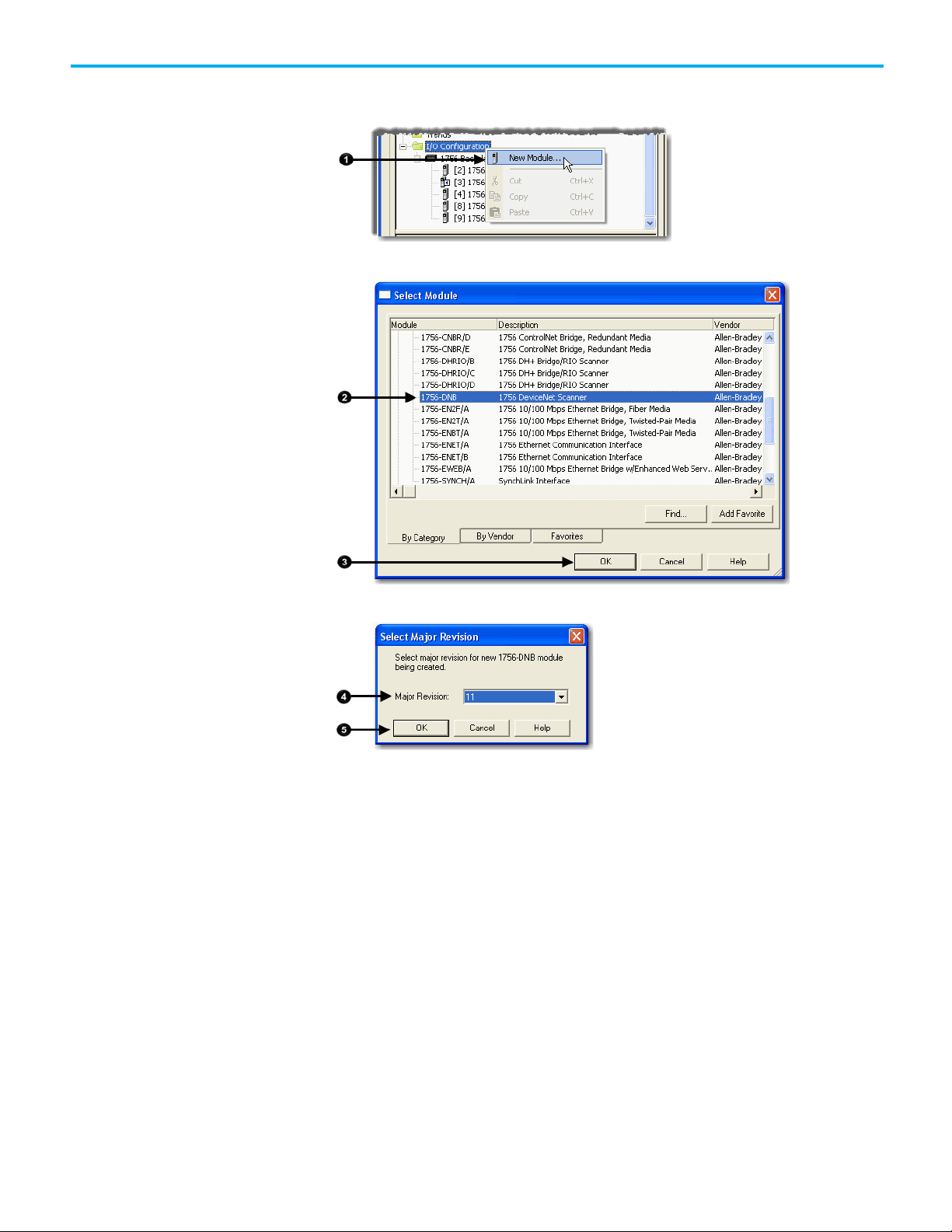

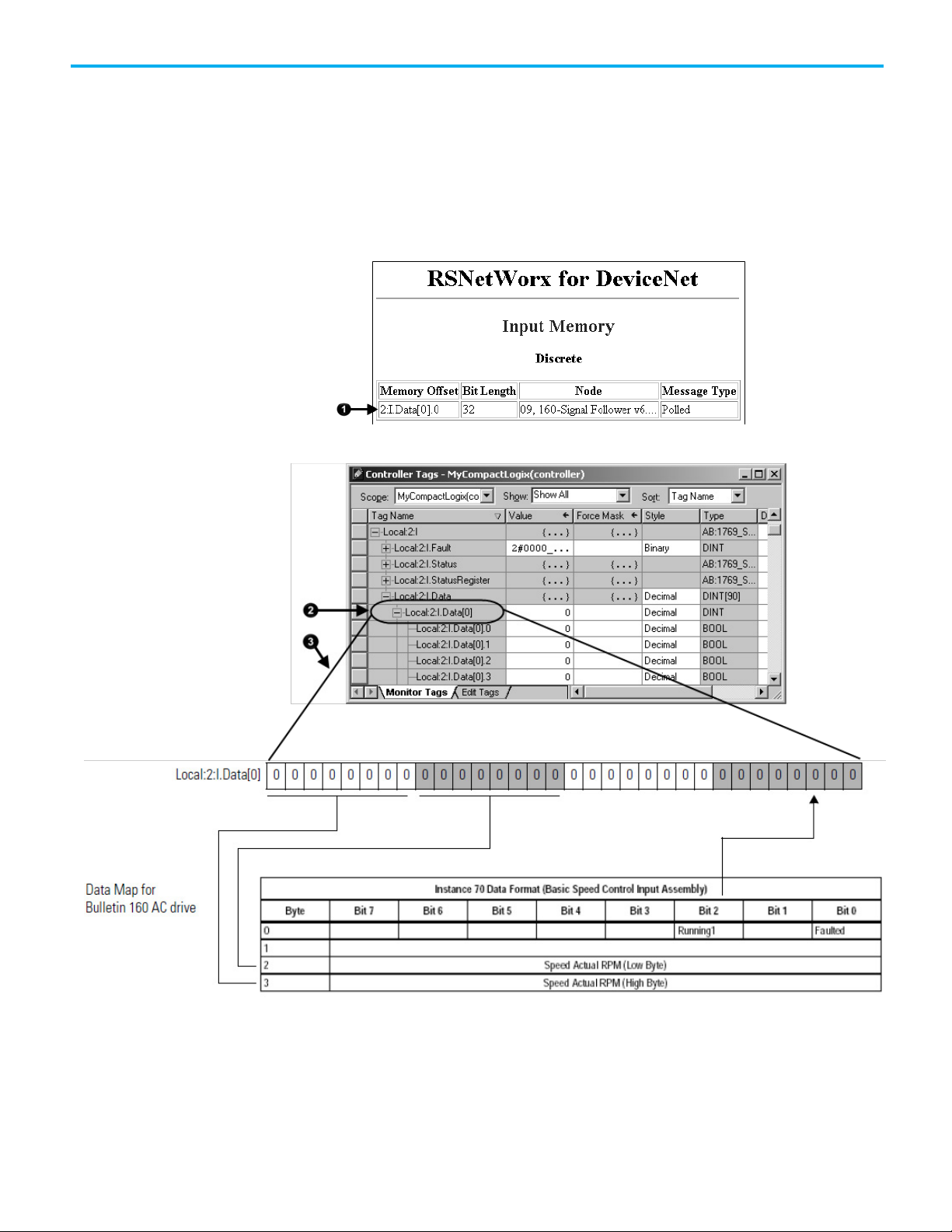

Define the Scanner