Page 1

PowerFlex 755/755T

Integrated Safety Functions

Option Module

Catalog Number 20-750-S4

User Manual

Original Instructions

Page 2

PowerFlex 755/755T Integrated Safety Functions Option Module User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WA RN I NG : Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential

Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory

requirements for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 3

About Safe Stop and Safe

Monitor Functions

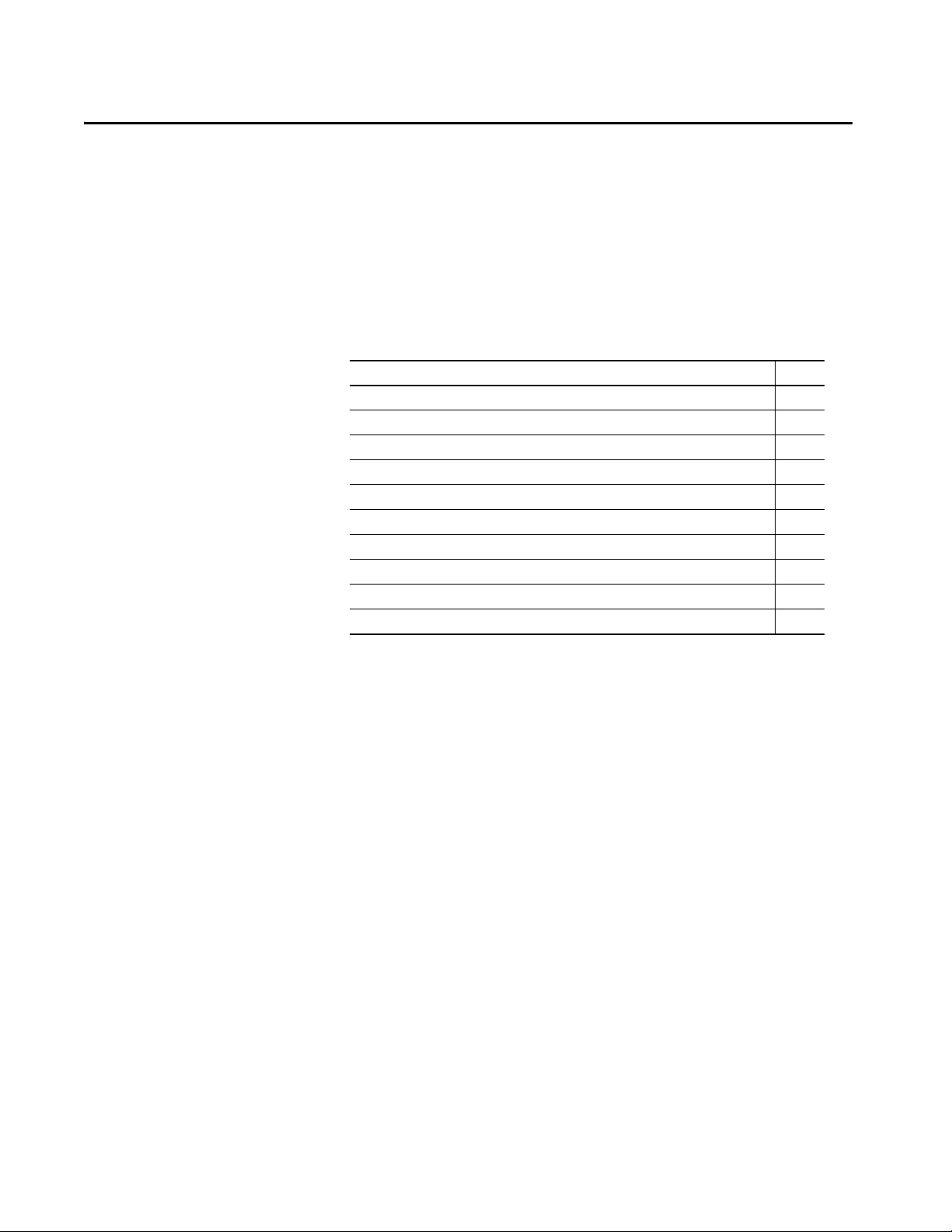

Table of Contents

Preface

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Product Firmware and Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 1

What Is the Integrated Safety Functions Option Module? . . . . . . . . 15

Compatible Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Compatible Safety Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Safety Application Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Safety Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Important Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Stop Category Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Performance Level and Safety Integrity Level (SIL) CL3 . . . . . . 19

Proof Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PFD and PFH Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PFD and PFH Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Safety Data for Safe Torque Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Safety Data for Safe Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Safety Data for Safety I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Spurious Trip Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Safety Reaction Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Considerations for Safety Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Encoder Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Supported Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Encoder Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

General Encoder Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Digital AqB Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sine/Cosine and Hiperface Diagnostics . . . . . . . . . . . . . . . . . . . . . 27

Contact Information If Safety Option Failure Occurs . . . . . . . . . . . . 28

Chapter 2

Installation Remove Power to the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Access the Control Pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Set the SAFETY and Hardware ENABLE Jumpers . . . . . . . . . . . . . . 31

Install the Safety Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Feedback Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Power Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 3

Page 4

Table of Contents

Chapter 3

Safety I/O Safety Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Safety Input Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Latch Input Error Operation in Single Channel Mode. . . . . . . . 39

Single Channel Safety Input Status Data . . . . . . . . . . . . . . . . . . . . 40

Dual-channel Safety Input Operation . . . . . . . . . . . . . . . . . . . . . . . 41

Equivalent Dual-channel Input Operation. . . . . . . . . . . . . . . . . . . 42

Complementary Dual-channel Input Operation . . . . . . . . . . . . . 43

Standard Input Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Safety Input Safety Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Safety Input Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Determining Safety Input Alarm Type . . . . . . . . . . . . . . . . . . . . . . 48

Safety Input Alarm Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Input Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Use With PowerFlex 750-Series ATEX Option Module . . . . . . 50

Safety Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Safety Output with Test Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Single-channel Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Latch Output Error Operation in Single Channel Mode . . . . . . 52

Dual-channel Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Latch Output Error Operation in Dual Channel Mode . . . . . . . 53

Safety Output Safety Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Commanding Safety and Test Outputs. . . . . . . . . . . . . . . . . . . . . . 57

Safety Output Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Determining Safety Output Alarm Type . . . . . . . . . . . . . . . . . . . . 59

Safety Output Alarm Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Test Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Standard Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Test Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Power Supply Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Test Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Test Output Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Test Output Ready . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Chapter 4

Drive-based Safe Stop

Functions

4 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Safety Output Assembly Safe Stop Function Tags. . . . . . . . . . . . . . . . 65

Safety Input Assembly Safe Stop Function Tags. . . . . . . . . . . . . . . . . . 66

Safety Function in Response to Connection Event . . . . . . . . . . . . . . . 68

Connection Loss Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Connection Idle Action. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Safe Torque Off Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Safe Torque Off Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Safe Torque Off Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Safe Torque Off Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Safe Torque Off Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Safe Torque Off Stopping Action and Source . . . . . . . . . . . . . . . . 74

Page 5

Controller-based Safety

Functions

Table of Contents

STO Safety Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Safe Stop 1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Safe Stop 1 Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Safe Stop 1 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Safe Stop 1 Stopping Action and Source . . . . . . . . . . . . . . . . . . . . . 78

Timed Safe Stop 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Monitored Safe Stop 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

SS1 Safety Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Safe Brake Control Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Safe Brake Control Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Safe Brake Control Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Safe Brake Control Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Safe Brake Control Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

SBC Safety Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Connecting a Safety Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Chapter 5

Drive Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Before Adding the Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . 95

Drive Safety Instruction Example . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Pass-through Data Using Standard I/O Mode . . . . . . . . . . . . . . . . . . . 96

Pass-through Data Using Integrated Motion . . . . . . . . . . . . . . . . . . . . 98

SFX Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

SFX Instruction Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Standard I/O Mode –

Configuration, Programming,

and Operation

Chapter 6

Safety Assembly Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Configure Safety in the Logix Designer Application. . . . . . . . . . . . . 104

Add a PowerFlex 755 Drive/755T Drive Product to the

Safety Controller Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Add an Option Module to a PowerFlex 755 Drive. . . . . . . . . . . 106

Using a 20-750-ENETR Dual-port EtherNet/IP Option

Module with a 20-750-S4 Option Module. . . . . . . . . . . . . . . . . . 124

Safety Configuration Signature and Ownership . . . . . . . . . . . . . 126

Reset Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Safety Tags in Standard Routines . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Standard Tags in Safety Routines (tag mapping). . . . . . . . . . . . . 126

Standard and Safety Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Safety Function Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Pass-through Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Falling Edge Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Understand Integrated Safety Drive Replacement. . . . . . . . . . . . . . . 130

Replace an Integrated Safety Drive in a GuardLogix System . . 130

PowerFlex 755 IO Mode Using SFX, SS1, and SLS Instructions. . 133

Studio 5000 Logix Designer Application Configuration . . . . . 133

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 5

Page 6

Table of Contents

Integrated Motion –

Configuration, Programming,

and Operation

Programming Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Chapter 7

Safety Assembly Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Configure the Integrated Safety Function Option Module in

the Logix Designer Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Add a PowerFlex 755 Drive to the Controller Project. . . . . . . . 144

Understand Module Properties Categories . . . . . . . . . . . . . . . . . . . . . 145

Module Properties>General Category. . . . . . . . . . . . . . . . . . . . . . 146

Module Properties>Connection and Safety Categories . . . . . . 149

Motion Safety>Actions Category . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Motion Safety>Primary Feedback Category . . . . . . . . . . . . . . . . 153

Motion Safety>Secondary Feedback Category . . . . . . . . . . . . . . 155

Motion Safety>Scaling Category. . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Motion Safety>Discrepancy Checking Category . . . . . . . . . . . . 157

Motion Safety>STO Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Motion Safety>SS1 Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Motion Safety>SBC Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Motion Safety>Input Configuration Category. . . . . . . . . . . . . . 161

Motion Safety>Test Output Category . . . . . . . . . . . . . . . . . . . . . 162

Motion Safety>Output Configuration Category . . . . . . . . . . . . 163

Axis Properties > Actions > Safety Actions . . . . . . . . . . . . . . . . . 164

Module Properties > Associated Axes Motor and Load

Feedback Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Generate the Safety Network Number (SNN) . . . . . . . . . . . . . . 166

Safety Configuration Signature and Ownership . . . . . . . . . . . . . 167

Reset Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Replace an Integrated Safety Drive in a GuardLogix System . . 168

Motion Direct Commands in Motion Control Systems. . . . . . 169

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Motion and Safety Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Motion Safety Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Safety Function Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Safe Monitor Network Communication. . . . . . . . . . . . . . . . . . . . 179

Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Application Example - Using SFX, SS1, and SLS Instructions

with Integrated Motion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Studio 5000 Logix Designer Application Configuration . . . . . 185

Programming Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Chapter 8

Monitoring and

Troubleshooting

6 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Monitor Status Using Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 195

Module Status Indicator (DS1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Network Status Indicator (DS2). . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Motion Output Status Indicator (DS3) . . . . . . . . . . . . . . . . . . . . 197

Safety Fault Indicator (DS4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Page 7

Table of Contents

Safety Fault Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Understand Safety Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Safety Supervisor State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Safety Core Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Safe Torque Off Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Safe Stop 1 Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Safe Brake Control Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

SS2, SOS, SLS, SLP, and SDI Faults. . . . . . . . . . . . . . . . . . . . . . . . 202

Safety Feedback Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Safety Fault Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Monitor Status with a HIM or Software . . . . . . . . . . . . . . . . . . . . . . . 205

Fault Messages on HIM, Drive Module, and Connected

Components Workbench Software . . . . . . . . . . . . . . . . . . . . . . . . 205

Monitor Status Using Integrated Motion . . . . . . . . . . . . . . . . . . . . . . 210

Out-of-Box State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Recognize Out-of-Box State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Restore the Drive to Out-of-Box State. . . . . . . . . . . . . . . . . . . . . . 214

Safety Function Validation

Checklist

Specifications, Certifications,

and CE Conformity

Appendix A

Safe Stop 1 (SS1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Safe Stop 2 (SS2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Safe Operating Speed (SOS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Safely-limited Speed (SLS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Safely-limited Position (SLP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Safe Direction (SDI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Safe Feedback Interface (SFX). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Safe Brake Control (SBC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Appendix B

Integrated Safety Functions Option Module Specifications . . . . . . 233

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Machinery Directive (2006/42/EC) . . . . . . . . . . . . . . . . . . . . . . . 236

EMC Directive (2014/30/EU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Waste Electrical and Electronic Equipment (WEEE) . . . . . . . . 237

Safety I/O Assemblies and

Safety Attributes

Appendix C

Safety Assembly Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Safety Feedback Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Safe Stop Function Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Explicit Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Example: Read SS1 Fault Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 7

Page 8

Table of Contents

Appendix D

Parameter Data Parameters and Settings in a Linear List . . . . . . . . . . . . . . . . . . . . . . . . 253

Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Host Config Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

8 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 9

Preface

This user manual explains how to use PowerFlex® 755 drives and PowerFlex

755T drive products in safety applications up to safety integrity level 3 (SIL 3),

performance level e (PLe), category 4.

This user manual is intended for people that design, install, configure, or

troubleshoot safety applications that use the Integrated Safety Functions

option module (catalog number 20-750-S4).

This user manual covers using network safety with drives in Standard I/O

mode and Integrated Motion mode. All chapters apply to both modes with the

following exceptions:

• Chapter 6

using Integrated Motion mode.

• Chapter 7

you are using Standard I/O mode.

IMPORTANT You must have a basic understanding of electrical circuitry and familiarity

is specific to Standard I/O mode and can be skipped if you are

is specific to Integrated Motion mode and can be skipped if

with PowerFlex 755 drives and PowerFlex 755T drive products. You must also

be trained and experienced in the creation, operation, and maintenance of

safety systems.

Summary of Changes

Conventions

This user manual describes the safety requirements, including probability of

dangerous failure on demand (PFD) and average frequency of a dangerous

failure (PFH) per hour values and application verification information (see

PFD and PFH Data on page 21

This publication contains new and updated information as indicated in the

following table.

Top ic Pa ge

Added attention statement regarding ambient temperature to Environmental Specifications in

Appendix B.

This manual identifies parameter names by listing the parameter number first,

followed by the name in brackets. For example, P7 [STO Fault Type].

Both the Host Config and Device Config parameters exist for this option

module and the parameter numbers overlap. For example, there is a P3 [Device

Config Identity State] and a P3 [Host Config Safety State]. Host Config

parameters reside on the Host (that is, the drive) side of the option module and

are specific to supporting the option module. Device Config parameters reside

on the option module itself.

).

235

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 9

Page 10

Preface

Throughout this manual, the PowerFlex 755/755T Integrated Safety

Functions option module is also referred to as the Integrated Safety Functions

option module.

Throughout this manual, the PowerFlex 755TL low harmonic drives,

PowerFlex 755TR regenerative drives, PowerFlex 755TM drive systems are

also referred to as PowerFlex 755T drive products.

The PowerFlex 755 drive is used for the examples in this manual.

Terminology

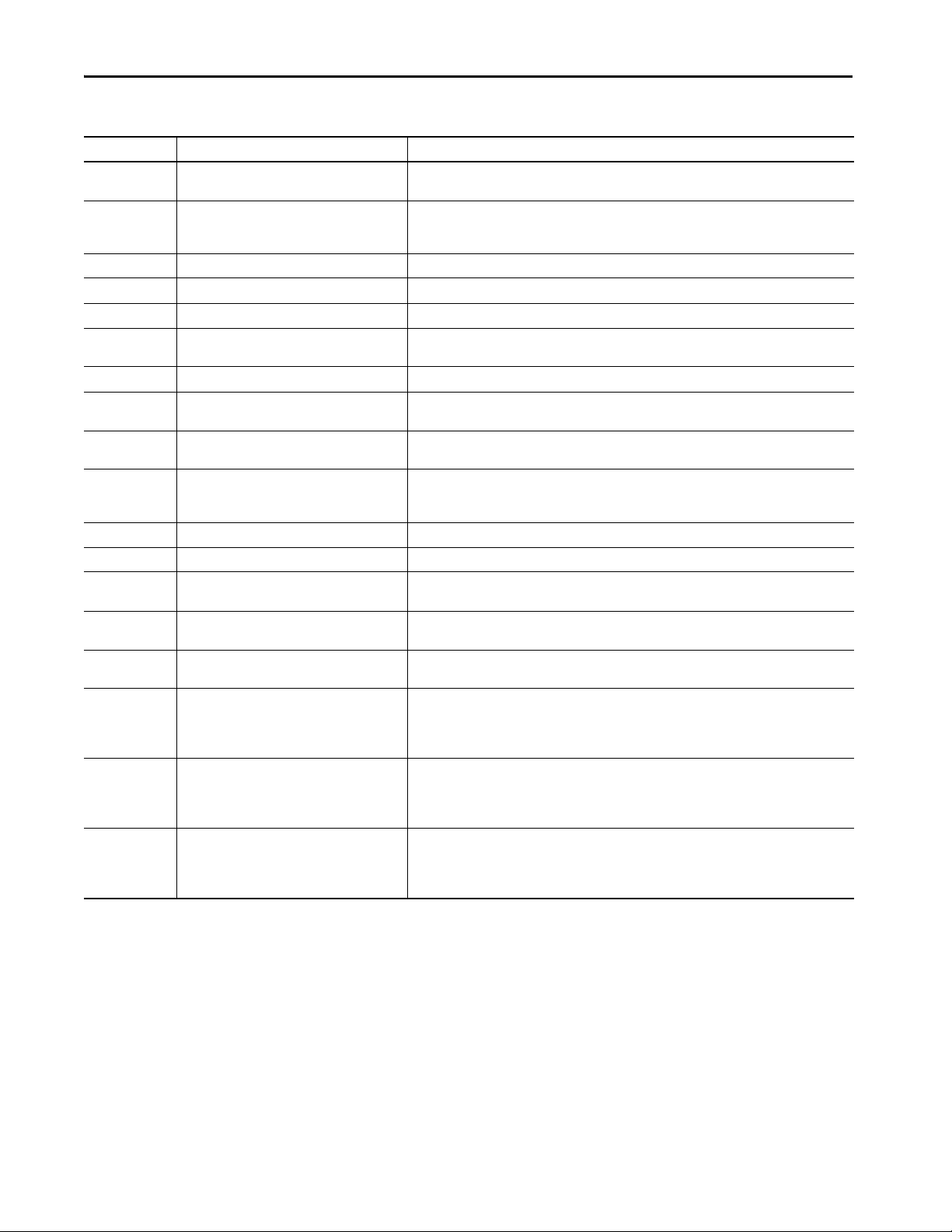

Ta b l e 1 defines the abbreviations that are used in this manual.

Table 1 - Abbreviations and Definitions

Abbreviation Full Term Definition

Timed SS1 Timed Safe Stop 1 Timed SS1 and Safe Stop 1 time-controlled (SS1-t) are synonymous. Both mean a safe stop where the

SS1-t Safe Stop 1 time-controlled

Monitored SS1 Monitored Safe Stop 1 Monitored SS1 and Safe Stop 1 ramp-monitored (SS1-r) are synonymous. Both mean a safe stop where

SS1-r Safe Stop 1 ramp-monitored

1oo2 One out of Two Refers to the behavioral design of a dual-channel safety system.

CAT Category

CL Claim Limit

CIP™ Common Industrial Protocol Protocol for industrial automation applications and trademarked by ODVA, Inc.

EN European Norm The offi cial European Standard.

ESD Emergency Shutdown Systems

ESPE Electro-sensitive Protective Equipment

HFT Hardware Fault Tolerance

HIM Human Interface Module A module that is used to configure a device.

IEC International Electrotechnical Commission

IGBT Insulated Gate Bi-polar Transistors Typical power switch that is used to control main c urrent.

ISO International Organization for Standardization

NC Normally Closed

NO Normally Open

OSSD Output Signal Switching Device

motor speed is decelerated to zero and o nce the maximum stop-time elapses, torque is removed from

the motor.

• Safe Stop 1 time-controlled (SS1-t) is according to EN/IEC 61800-5-2.

the motor speed is reduced to standstill within deceleration limits and once standstill speed is reached

or the maximum stop-time elapses, torque is removed from the motor.

• Safe Stop 1 ramp-monitored (SS1-r) is according to EN/IEC 61800-5-2.

Classification of the safety-related parts of a control system in respect of their resistance to faults and

their subsequent behavior in the fault condition, and which is achieved by the structural arrangement

of the parts, fault detection, and/or by their reliability (source ISO 13849-1).

The maximum SIL rating that can be claimed for a safety-related electrical control system subsystem in

relation to architectural constraints and systematic safety integrity (source IEC 62061).

A system, usually independent of the main control system, which is designed to shut down an

operating system safely.

An assembly of devices and/or components working together for protective tripping or presencesensing purposes and includes as a minimum:

•A sensing device.

• Controlling/monitoring devices.

• Output signal-switching devices (OSSD).

The HFT equals n, where n+1 faults could cause the loss of the safet y function. An HFT of one means

that two faults are required before safety is lost.

The International Electrotechnical Commission (IEC) is the organization that prepares and publishes

international standards for all electrical, electronic, and related technologies.

The International Organization for Standardization is an international standard-setting body that is

composed of representatives from various national standards organizations.

A set of contacts on a relay or switch that are closed when the relay is de-energized or the switch is deactivated.

A set of contacts on a relay or switch that are open when the relay is de-energized or the switch is deactivated.

The component of the electro-sensitive protective equipment (ESPE) connected to the control system

of a machine. When the sensing device is actuated during normal operation, the device responds by

going to the OFF-state.

10 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 11

Preface

Table 1 - Abbreviations and Definitions (Continued)

Abbreviation Full Term Definition

PELV Protective Extra Low Voltage

PES Programmable Electronic Systems

PFD Probability of Dangerous Failure on Demand The average probability of a system to fail to perform its design function on demand.

PFH Average Frequency of a Dangerous Failure per hour The average frequency of a system to have a dangerous failure occur per hour.

PL Performance Level EN ISO 13849-1 safety rating

PM Permanent Magnet

SBC Safe Brake Control Controls safety discrete outputs that actuate a brake. Sets timing between brake and Safe Torque Off.

SDI Safe Direction

SELV Safety Ex tra Low Voltage Circuit

SFX Safety Feedback Interface

SIL Safety Integrity Level A measure of a products ability to lower the risk that a dangerous failure could occur.

SLP Safely-Limited Position Prevents the motor shaft from exceeding one or more specified position limits.

SLS Safely-Limited Speed

SNN Safety Network Number

SOS Safe Operating Stop

SS1-r Safe Stop 1 Ramp Monitored

SS1-t Safe Stop 1 Time Controlled

STO Safe Torque Off

An electrical system where the voltage cannot exceed ELV under normal conditions, and under singlefault conditions, except earth faults in other circuits.

System for control, protection, or monitoring based on one or more programmable electronic devices,

including all elements of the system such as power supplies, sensors and other input devices, data

highways and other communication paths, and actuators and other output devices.

In permanent magnet (PM) motors, magnets mounted on or embedded in the rotor, couple with the

current-induced internal magnetic fields of the motor generated by electrical input to the stator.

Monitors position of a motor to detec t movement of more than a defined amount in the unintended

direction.

A secondary circuit that is designed and protected so that, under normal and single fault conditions, its

voltages do not exceed a safe value.

A GuardLogix® Drive Safety interface that scales feedback position into position units and feedback

velocity into position units per time unit. Feedback Position and Velocity are read from a Safety Input

assembly to an integrated Safe Speed drive.

Monitors the speed of a motor and sets the SLS Limit output if the speed exceeds the Active Limit input

value.

Uniquely identifies a network across all networks in the safety system. You are responsible for

assigning a unique number for each safety network or safety subnet within a system.

Prevents the motor from deviating more than a defined amount from the stopped position. The drive

provides energy to the motor to enable it to resist ex ternal forces.

Safe stop where the motor speed is decelerated to zero and once the maximum stop-time elapses,

torque is removed from the motor.

Safe Stop 1 ramp-monitored (SS1-r) is according to EN/IEC 61800-5-2 and is Stop Category 1, as

defined in IEC 60204

Safe stop where the motor speed is reduced to standstill within deceleration limits and once standstill

speed is reached or the maximum stop-time elapses, torque is removed from the motor.

Safe Stop 1 time-controlled (SS1-t) is according to EN/IEC 61800-5-2 and is Stop Category 1, as defined

in IEC 60204

The Safe Torque Off (STO) function is used to help prevent unexpected motor rotation during an

emergency while the drive remains connected to the power supply. When STO is activated, the torque

power cannot reach the drive, which stops and prevents any motor shaft rotation.

Safe Torque Off (STO) is according to EN/IEC 61800-5-2 and is Stop Category 0 as defined in IEC 60204.

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 11

Page 12

Preface

Product Firmware and Release Notes

Product firmware and release notes are available online within the Product

Compatibility and Download Center.

1. From the Search bar on http://www.ab.com

Downloads.

2. Search for your product.

, choose Compatibility and

3. On the search results page, find the firmware and release notes for your

product. If no firmware/release notes are available, the module is still

shipping with its original firmware release.

IMPORTANT Both standard connections to the drive and safety connections to the card

must be closed to update the Integrated Safety Functions Module.

See the Product Compatibility and Download Center Quick Start Guide,

publication PCDC-QS001

firmware and release notes.

, for instructions on how to find and download

12 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 13

Preface

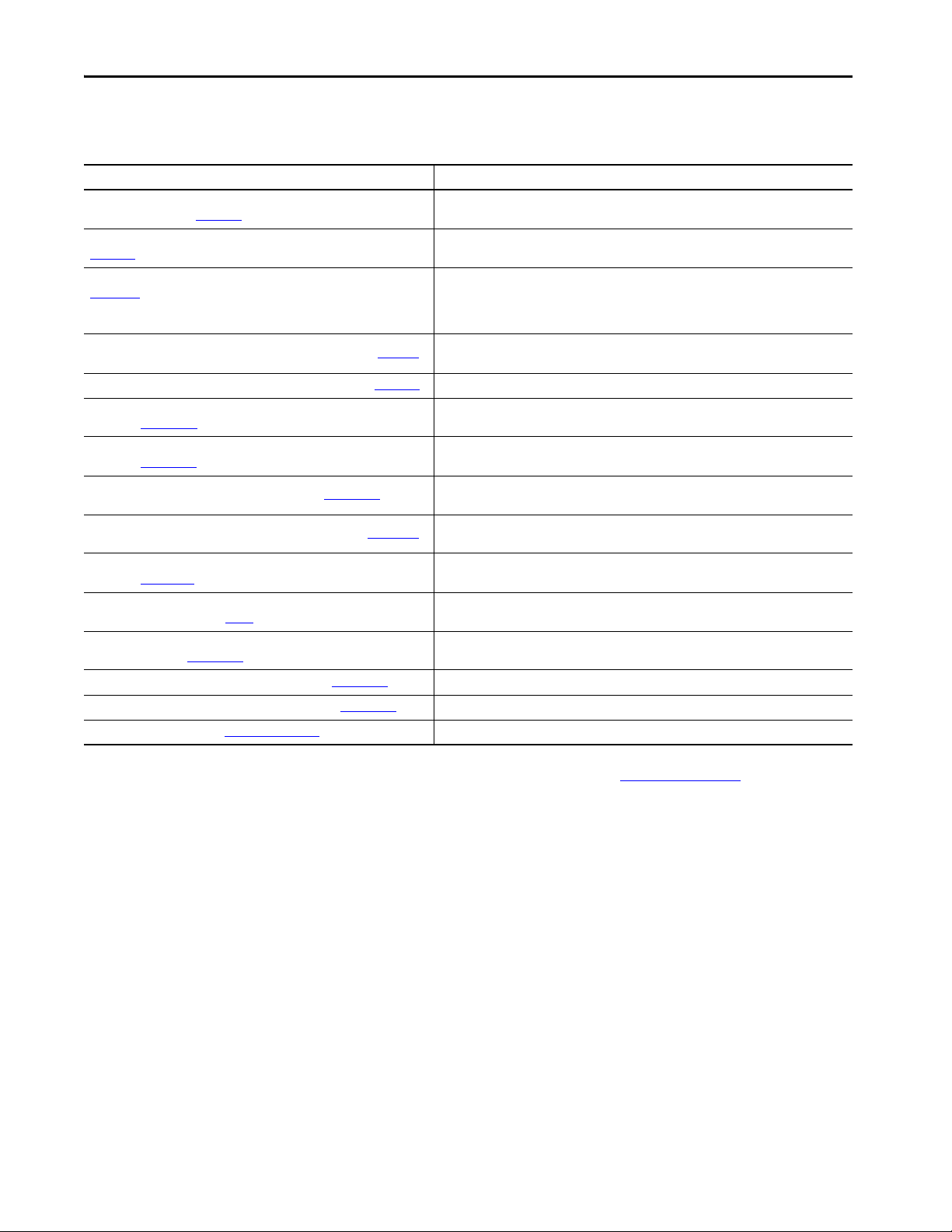

Additional Resources

These documents contain additional information concerning related Rockwell

Automation products.

Resource Description

PowerFlex 750-Series Products with TotalFORCE® Control Installation

Instructions, publication 750-IN100

PowerFlex 755TM IP00 Open Type Kits Installation Instructions, publication

750-IN101

PowerFlex Drives with TotalFORCE Control Programming Manual, publication

750-PM100

PowerFlex 750-Series AC Drive Installation Instructions, publication

PowerFlex 750-Series AC Drives Programming Manual, publication

Enhanced PowerFlex 7-Class Human Interface Module (HIM) User Manual,

publication

GuardLogix Safety Application Instruction Set Reference Manual,

publication 1756-RM095

EtherNet/IP Network Devices User Manual, publication ENET-UM006

EtherNet/IP Device Level Ring Application Technique, publication ENET-AT007

System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

Safety Guidelines for the Application, Installation, and Maintenance of

Solid-State Control, publication

GuardLogix 5580 and Compact GuardLogix 5380 Controller Systems Safety

Reference, publication 1756-RM012

ControlLogix® 5580 Controllers User Manual, publication 1756-UM543 Provides information on how to use standard ControlLogix 5580 controllers.

CompactLogix™ 5380 Controllers User Manual, publication 5069-UM001 Provides information on how to use standard CompactLogix 5380 controllers.

Product Certification s website, ro k.auto/cer tificatio ns

20HIM-UM001

750-IN001

750-PM001

SGI-1.1

Provides the basic steps to install PowerFlex 755TL low harmonic drives, PowerFlex 755TR

regenerative drives, and PowerFlex 755TM drive systems.

Provides instructions to install IP00 Open Type kits in user-supplied enclosures.

Provides detailed information on:

• I/O, control, and feedback options

• Parameters and programming

• Faults, alarms, and troubleshooting

Provides information on how to install the Safe Torque Off option module in PowerFlex 750Series drive.

Provides information on how to mount, install, and configure PowerFlex 750-Series drives.

Provides information for using the 20-HIM-A6 HIM module to configure PowerFlex 750-Series

drives and the Safe Torque Off option module.

Provides information that describes the GuardLogix Safety Application Instruction set.

Describes how to configure and use EtherNet/IP devices to communicate on the EtherNet/IP

network.

Describes Device Level Ring (DLR) topologies, configuration considerations, and diagnostic

methods.

Information, examples, and techniques that are designed to minimize system failures caused by

electrical noise.

Describes important differences between solid-state control and hard wired electro mechanical

devices.

Provides information on safety application requirements for GuardLogix 5580 and Compact

GuardLogix 5380 controllers in Studio 5000 Logix Designer® applications.

Provides declarations of conformity, certificates, and other certification details.

You can view or download publications at rok.auto/literature

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 13

.

Page 14

Preface

Notes:

14 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 15

Chapter 1

About Safe Stop and Safe Monitor Functions

This chapter provides information on safety considerations for the Integrated

Safety Functions option module.

Top ic Pa ge

What Is the Integrated Safety Functions Option Module? 15

Compatible D rives 17

Compatible Safety Controllers 17

Safety Application Requirements 18

Safety Certification 18

Proof Tests 20

PFD and PFH Definitions 20

PFD and PFH Data 21

Safety Reaction Time 23

Contact Information If Safety Option Failure Occurs 28

What Is the Integrated Safety Functions Option Module?

The Integrated Safety Functions option module provides a networked STO

(Safe Torque Off) function via an EtherNet/IP® network. It is also equipped

for Integrated (drive-based) Timed SS1, Monitored SS1, and Safe Brake

Control, which operate in the drive and are activated through the network

safety connection.

The Integrated Safety Functions option module also supports select controllerbased EN/IEC 61800-5-2 safety functions operating in GuardLogix® 5580 or

Compact GuardLogix 5380 controllers that use the EtherNet/IP network to

communicate with the safety I/O. This support includes the new safety

function instructions that are provided on the Drive Safety tab in the Logix

Designer application.

The Integrated Safety Functions option module includes these features:

• Is designed to remove power from the gate firing circuits of the drive

output power devices (IGBTs). With the power removed, the drive

output power devices cannot turn on to generate AC power to the

motor.

• Can be used in combination with other safety devices to satisfy the

requirements of IEC 61508, EN/IEC 61800-5-2 SIL 3, ISO 13849-1

PLe, and Category 4 for Safe Torque Off (STO).

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 15

Page 16

Chapter 1

When used for safe speed monitoring, the drive can be configured for single- or

dual-feedback to achieve the following safety ratings:

• Single-feedback configurations using safety encoders provide up to SIL

2 PLd capability.

• Dual-feedback configurations provide up to SIL 3 PLe capability when

discrepancy testing (either velocity, position, or both) is enabled. Safety

functions that use position check have up to SIL 2 PLd capability. In this

configuration, at least one encoder (the primary encoder) has to comply

with SIL 2, PL d. The second encoder can be a standard encoder.

IMPORTANT The Integrated Safety Functions option module is suitable for performing

mechanical work on the drive train or affected area of a machine only. It

does not provide electrical safety.

ATT EN TI ON : The Integrated Safety Functions option module does not

remove dangerous voltages at the drive output. Before performing any

electrical work on the drive or motor, turn off the input power to the drive,

and follow all safety procedures. See Remove Power to the System

on

page 30 for more information.

IMPORTANT Multiple safety option modules in a single drive are not allowed. Only one of

these safety option modules can be installed in the drive:

• PowerFlex® 750-Series Safe Torque Off option module

(catalog number 20-750-S)

• PowerFlex 750-Series Safe Speed Monitor option module

(catalog number 20-750-S1)

• PowerFlex 755/755T Integrated Safety - Safe Torque Off option module

(catalog number 20-750-S3)

• PowerFlex 755/755T Integrated Safety Functions option module (catalog

number 20-750-S4)

ATTENTION: If two output IGBTs fail in the drive, when the Integrated Safety

Functions option module has controlled the drive outputs to the Off state, the

drive can provide stored energy for up to 180° of rotation in a 2-pole motor

before torque production in the motor stops.

ATT EN TI ON : The STO function only disables motor torque. A mechanical

force on the motor shaft such as suspended loads, back pressure in a pump or

fan, can cause motor rotation.

IMPORTANT Do not use this option module as a control for starting or stopping the drive.

16 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 17

Chapter 1

Compatible Drives

The Integrated Safety Functions option module is compatible with these

PowerFlex 755 drives and PowerFlex 755T drive products:

• PowerFlex 755 drives (v14.xxx or later)

• PowerFlex 755TL low harmonic drives (v4.xxx or later)

• PowerFlex 755TR regenerative drives (v4.xxx or later)

• PowerFlex 755TM common bus inverters (v4.xxx or later)

IMPORTANT The Integrated Safety Functions option module is not compatible with

PowerFlex 753 drives.

Integrated safety functions are controlled via the embedded Ethernet port on

the drive only. The 20-750-ENETR can still be used, but only in conjunction

with the embedded Ethernet port by being in Tap mode (safety messages must

go through the embedded Ethernet port on drive).

The following Add-on Profiles (AOPs) are needed depending on the drive and

type of control used:

Product Standard Control Integrated Motion

755 v5.03 (or later) v19.00.00 (or later)

755T v5.04 (or later) Future

Compatible Safety Controllers

A GuardLogix safety controller is required for use of the Integrated Safety

Functions option module that is used in Network mode control (‘Safety’,

‘Standard and Safety’, or ‘Motion and Safety’ used for Connection type). The

following GuardLogix controllers can be used:

Controller

GuardLogix 5580 safety controller v31 (or later)

Compact GuardLogix 5380 safety controller v31 (or later)

Studio 5000 Logix Designer® Application Version /

Controller Firmware

IMPORTANT The Integrated Safety Functions option module is not supported by

GuardLogix 5570 and GuardLogix 5370 (or earlier) safety controllers.

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 17

Page 18

Chapter 1

Safety Application Requirements

Safety Certification

Create, record, and verify the safety signature as part of the required safety

application development process. The safety controller creates the safety

signature, which consists of an identification number, date, and time that

uniquely identifies the safety portion of a project. This signature covers all

safety logic, data, and safety I/O configuration.

If the Drive Safety Function Instructions are used in the safety application,

special consideration must be taken to verify the application. See Appendix A

for guidance on verifying the drive safety function instructions.

For safety system requirements, including information on the safety network

number (SNN), verifying the safety signature, and functional verification tests,

see the GuardLogix Controller Systems Safety Reference Manuals that are

listed in the Additional Resources

The TÜV Rheinland group has approved the PowerFlex 755 Integrated Safety

Functions option module (catalog number 20-750-S4) as suitable for use in

integrated safety applications:

• Up to and including SIL 3 according to IEC 61508

• Up to and including SIL CL3 according to IEC 62061

• Up to and including PLe (Category 4) according to ISO 13849-1.

on page 13.

In these applications, the removal of motion-producing power is considered to

be the safe state. All components in the system must be chosen and applied

correctly to achieve the desired level of operator safeguarding.

Important Safety Considerations

You are responsible for these system safety considerations:

• Set-up, safety rating, and validation of any sensors or actuators

connected to the system.

• Complete a system-level risk assessment, and reassess the system anytime

a change is made.

• Certification of the system to the desired safety Performance Level/

Safety Integrity Level.

• Project management and proof testing.

• Programming the application software and the safety option module

configurations in accordance with the information in this manual.

• Access control to the system.

• Analyze all configuration settings and choose the proper setting to

achieve the required safety rating.

• Validation and documentation of all safety functions used.

IMPORTANT Only qualified, authorized personnel that are trained and experienced in

functional safety can plan, implement, and apply functional safety systems.

18 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 19

Chapter 1

ATT EN TI ON : When designing your system, consider how various personnel

can interact with the machine. Additional safeguard devices can be required

for your specific application.

ATT EN TI ON : In circumstances where external influences (for example,

suspended loads that can fall) are present, additional measures (for

example, mechanical brakes) can be necessary to help prevent any hazard.

Stop Category Definitions

There are three stop categories:

• Stop Category 0 is achieved with immediate removal of power to the

machine actuators, which results in an uncontrolled coast-to-stop. An

STO accomplishes a Stop Category 0 stop.

• Stop Category 1 is achieved with a Ramp to Stop followed with

immediate removal of power to the machine actuators. This can be

achieved using SS1 with STO.

• Stop Category 2 is a controlled stop with power left available to the

machine actuators. This can be achieved using controller-based SS2 /

SOS with the PowerFlex 755T drive products.

IMPORTANT When designing the machine application, consider timing and distance for a

coast-to-stop (Stop Category 0 or Safe Torque Off). For more information on

stop categories and Safe Torque Off, see EN 60204-1 and EN/IEC 61800-5-2.

Performance Level and Safety Integrity Level (SIL) CL3

For safety-related control systems, Performance Level (PL), according to

ISO 13849-1, and SIL levels, according to IEC 61508 and EN 62061, include

a rating of the ability of the system to perform its safety functions. All safetyrelated components of the control system must be included in both a risk

assessment and the determination of the achieved levels.

See the ISO 13849-1, IEC 61508, and EN 62061 standards for complete

information on requirements for PL and SIL determination.

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 19

Page 20

Chapter 1

Proof Tests

PFD and PFH Definitions

IEC 61508 requires you to perform various proof tests of the equipment that is

used in the system. Proof tests are performed at user-defined times. For

example, proof tests can be once a year, once every 15 years, or whatever time

frame is appropriate.

The Integrated Safety Functions option module has a useful life of 20 years, no

proof test required. Other components of the system, such as safety I/O

devices, sensors, and actuators can have different useful life times.

IMPORTANT The time frame for the proof test interval depends on the specific

application.

Safety-related systems can be classified as operating in either a Low Demand

mode, or in a High Demand/Continuous mode.

• Low Demand mode: where the frequency of demands for operation,

made on a safety-related system, is no greater than one per year, or no

greater than twice the proof-test frequency.

• High Demand/Continuous mode: where the frequency of demands for

operation, made on a safety-related system, is greater than once per year,

or greater than twice the proof test interval.

The SIL value for a low-demand safety-related system is directly related to

order-of-magnitude ranges of its average probability of failure to perform its

safety function on demand or, simply, average probability of dangerous failure

on demand (PFD

The SIL value for a High Demand/Continuous mode safety-related system is

directly related to the average frequency of a dangerous failure (PFH) per hour.

avg

).

20 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 21

Chapter 1

PFD and PFH Data

These PFD

and PFH calculations are based on the equations from Part 6 of

avg

EN 61508 and show worst-case values.

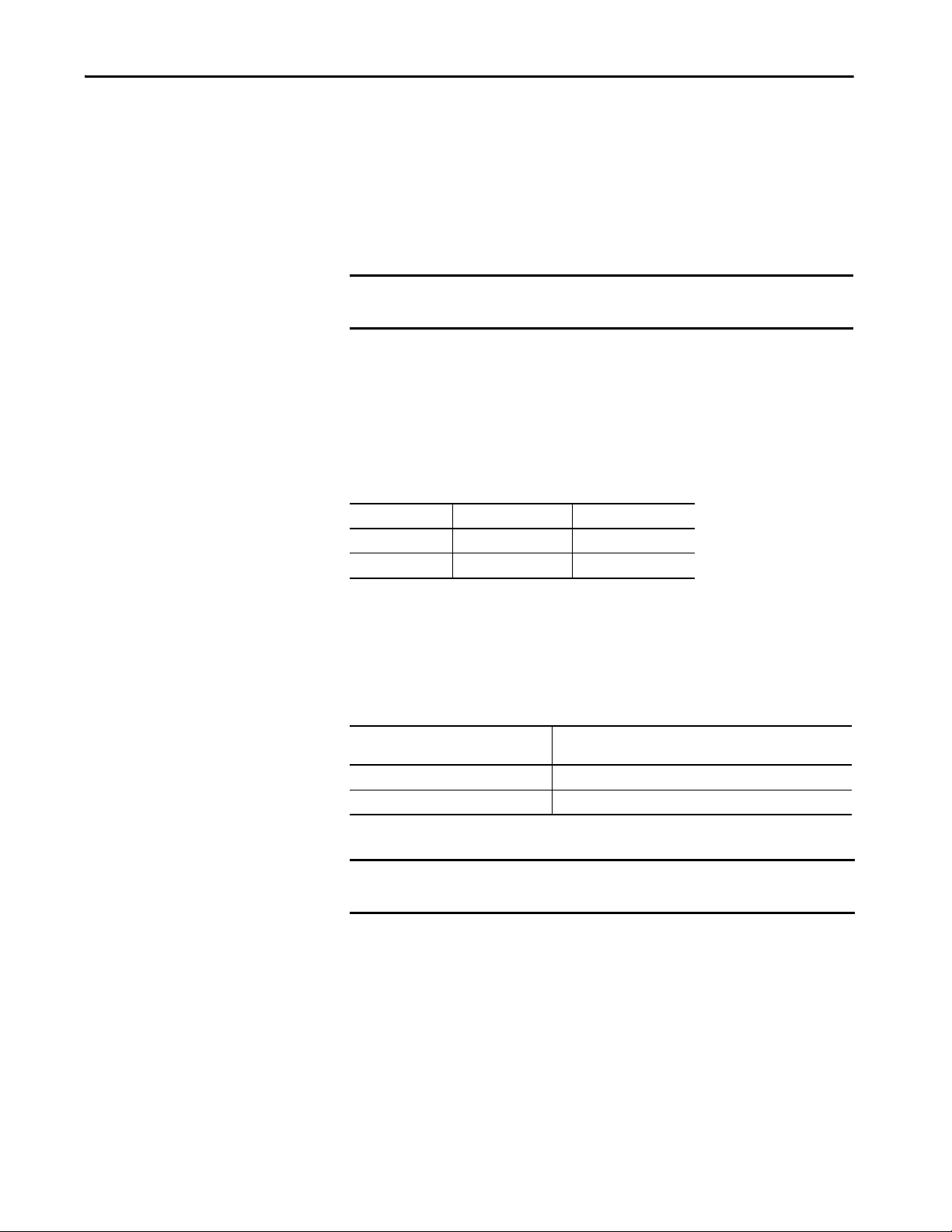

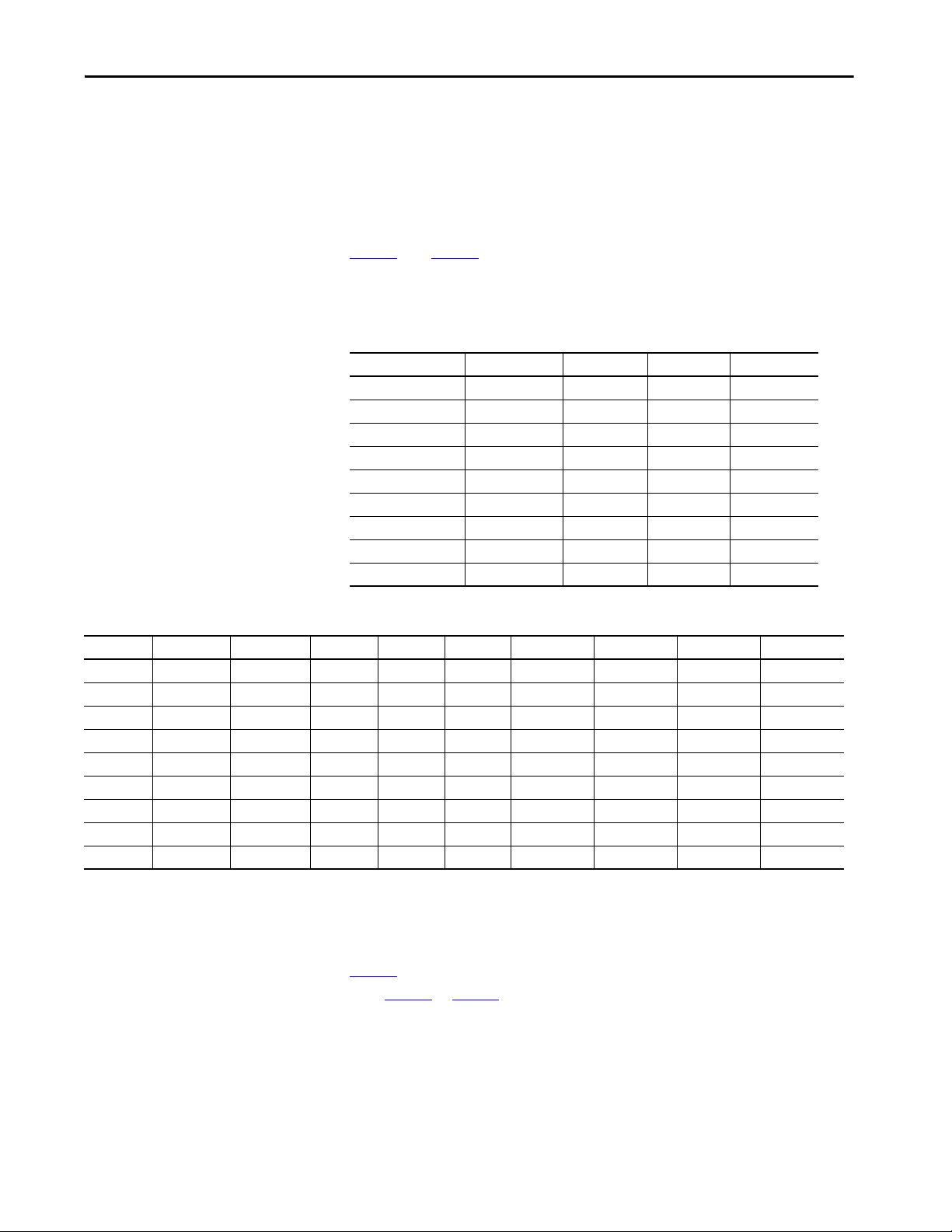

Safety Data for Safe Torque Off

Ta b l e 2 , and Ta b l e 3 provide PFD

(STO) or Timed Safe Stop 1 functions. These values apply when Safety

Instance is set to ‘Safe Stop Only – No Feedback’.

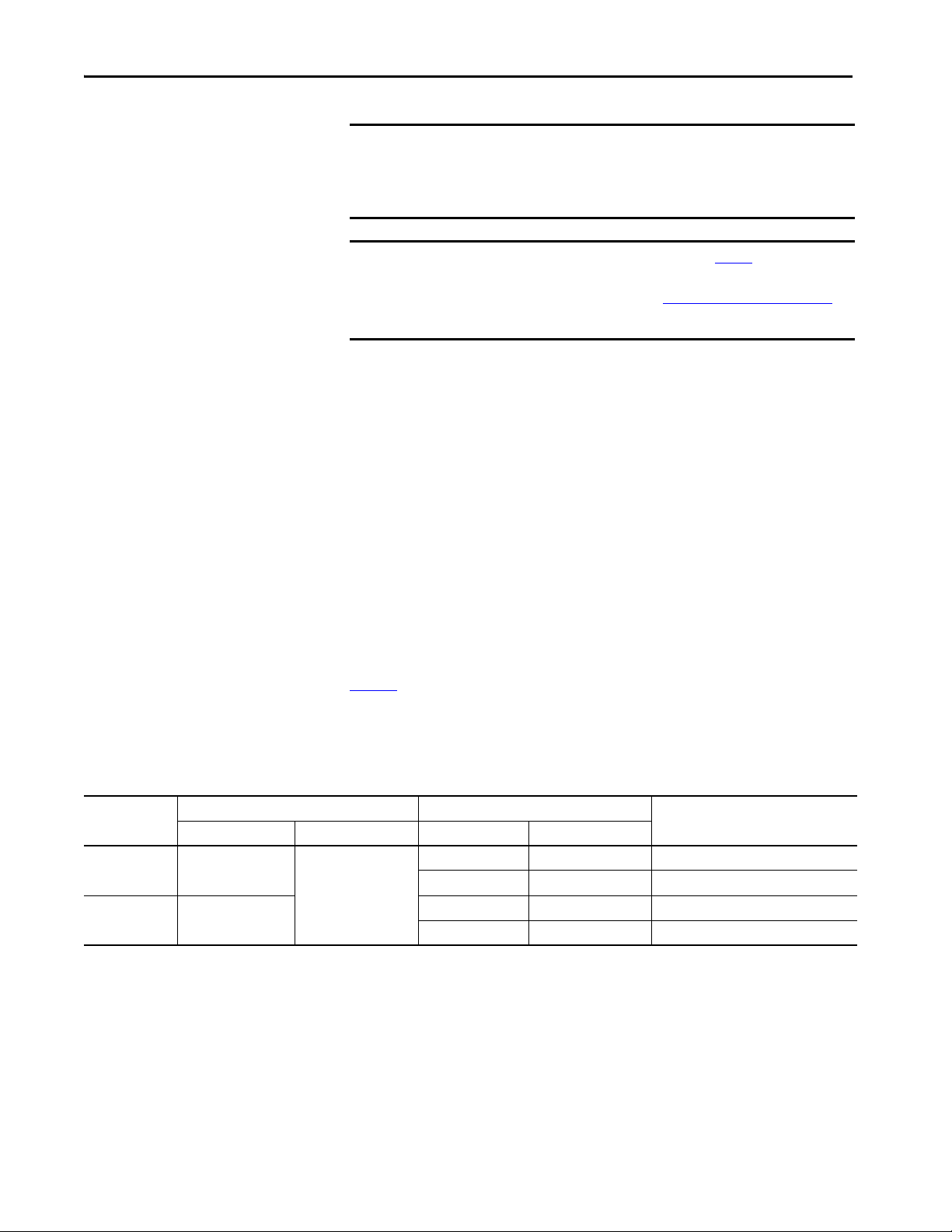

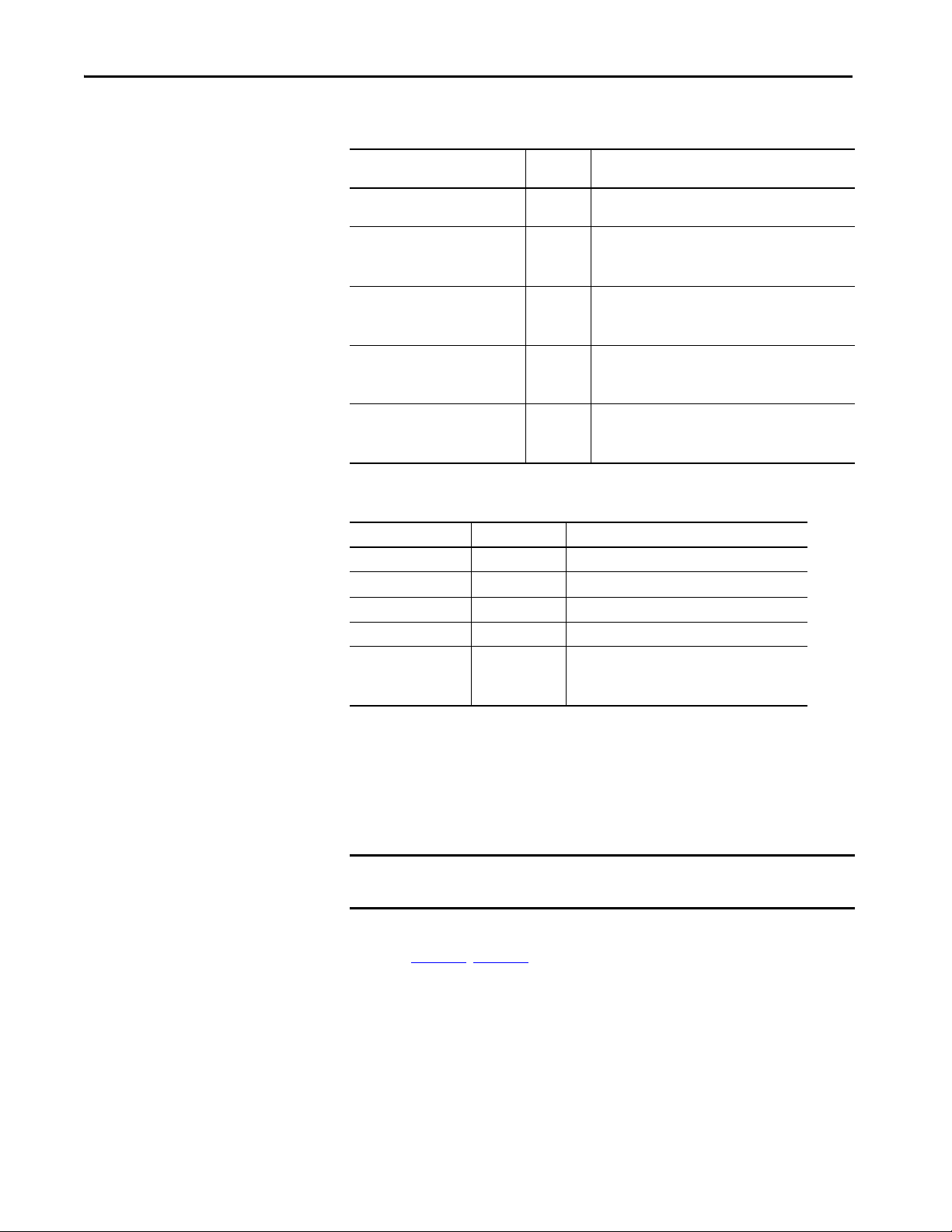

Table 2 - PFD and PFH for PowerFlex 755 Drives STO and Timed SS1

Attribute Frames 1…7 Frame 8 Frame 9 Frame 10

PFD

(average)

PFH (1/hour) 4.77E-10 2.09E-9 3.14E-9 4.19E-9

SIL 3 3 3 3

PL e e e e

Category 4 4 4 4

years 204.1 (high) 93.3 (high) 69.1 (high) 55.1 (high)

MTTF

D

% 97.5% (medium) 97.4% (high) 97.5% (high) 97.5% (high)

DC

avg

HFT 1 (1oo2) 1 (1oo2) 1 (1oo2) 1 (1oo2)

Mission time 20 years 20 years 20 years 20 years

4.08E-5 1.81E-4 2.73E-4 3.64E-4

and PFH values for the Safe Torque Off

avg

Table 3 - PFD and PFH for PowerFlex 755T Drive Products STO and Timed SS1

Attribute Frames 5 and 6 Frames 7 and 8 Frame 9 Frame 10 Frame 11 Frame 12 Frame 13 Frame 14 Frame 15

PFD

(average)

PFH (1/hour) 5.24E-10 2.96E-9 3.25E-9 3.55E-9 3.85E-9 4.15E-9 4.45E-9 5.05E-9 5.65E-9

SIL 333333333

PLeeeeeeeee

Category444444444

MTTF

D

% 97.4% (high) 97.0% (high) 97.0% (high) 97.0% (high) 97.0% (high) 96.9% (high) 96.9% (high) 96.9% (high) 96.9% (high)

DC

avg

HFT 1 (1oo2) 1 (1oo2) 1 (1oo2) 1 (1oo2) 1 (1oo2) 1 (1oo2) 1 (1oo2) 1 (1oo2) 1 (1oo2)

Mission time 20 years 20 years 20 years 20 years 20 years 20 years 20 years 20 years 20 years

4.49E-5 2.56E-4 2.82E-4 3.08E-4 3.34E-4 3.60E-4 3.86E-4 4.38E-4 4.9 0E-4

years 187.5 (high) 102.6 (high) 87.8 (high) 76.7 (high) 68.1 (high) 61.2 (high) 55.6 (high) 47 (high) 40.7 (high)

Safety Data for Safe Feedback

Ta b l e 4 provides PFD

from Ta b l e 2

or Ta b l e 3 for safety functions that require safe encoder feedback.

Safety functions using safe encoder feedback include drive based Monitored

Safe Stop 1 and controller-based safety functions SS1, SS2, SOS, SLS, SLP, and

SDI.

and PFH values to add to the PFD

avg

and PFH values

avg

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 21

Page 22

Chapter 1

In general, the PFD

Ta b l e 2

and Ta b l e 3 when Safety Instance is set to ‘Single Feedback

and PFH values from Ta b l e 4 should be added to

avg

Monitoring’ or ‘Dual Feedback Monitoring’.

When using Dual Feedback Monitoring, enable Discrepancy Testing.

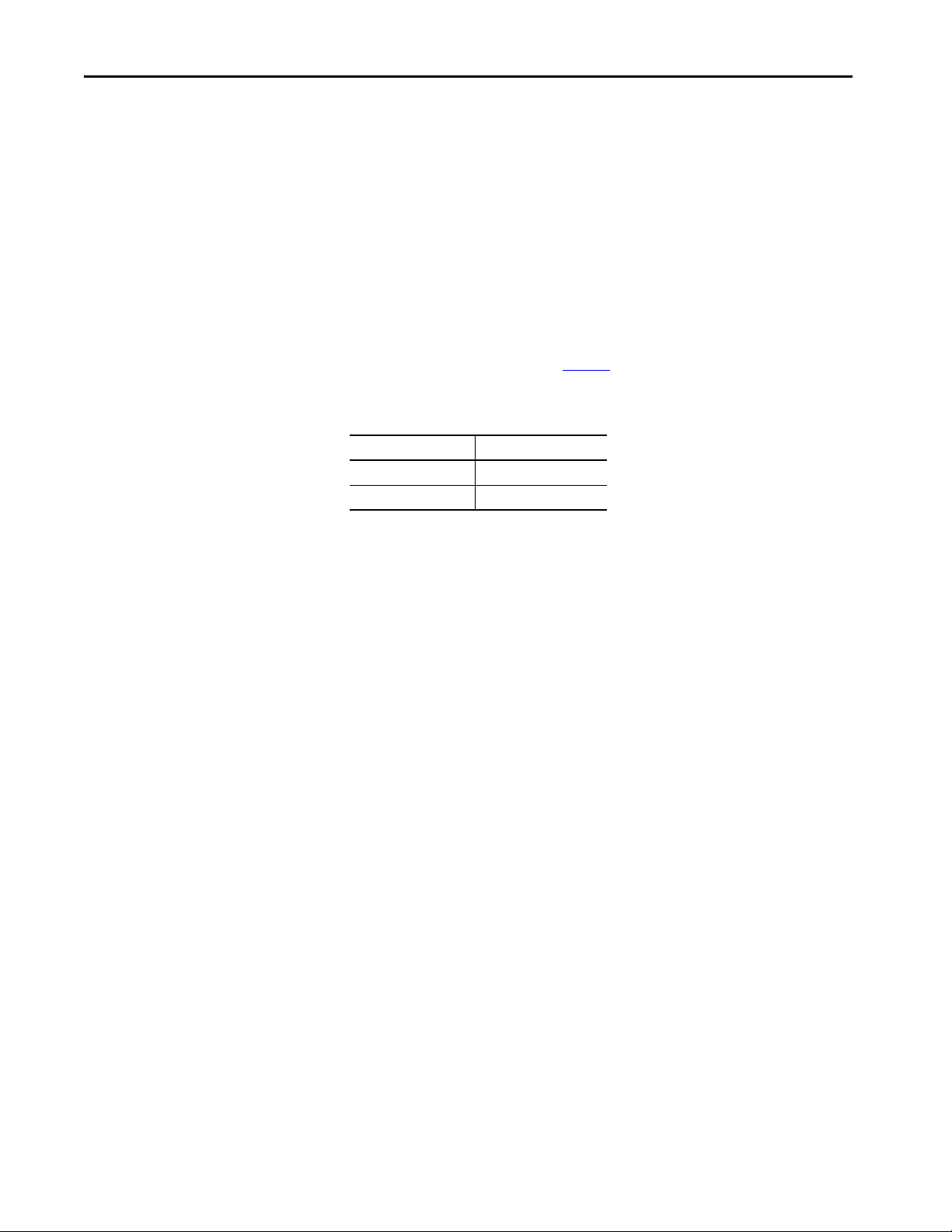

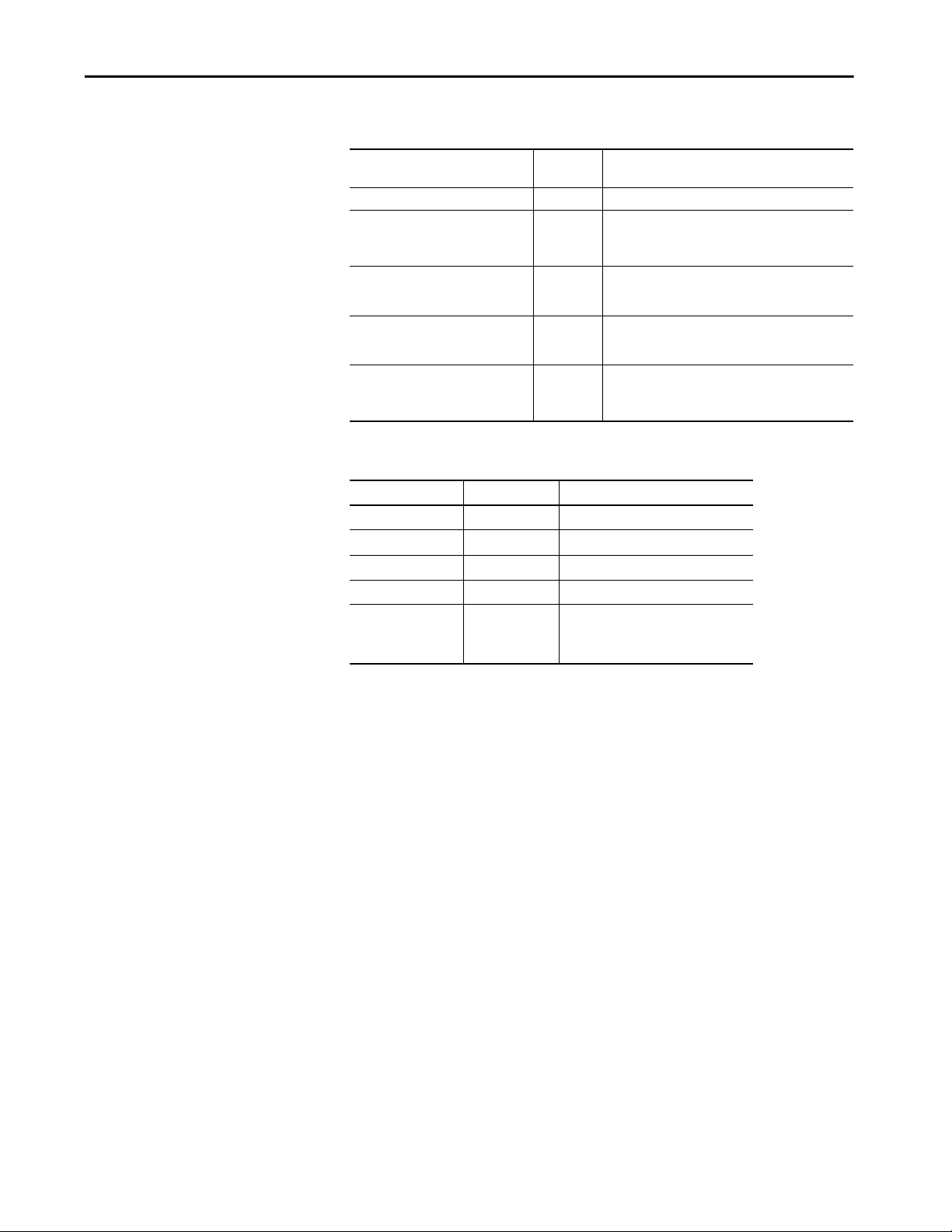

Table 4 - PFD or PFH to Add When Safety Functions Use Safety Feedback

Attribute Single Encoder Feedback

PFD (average) 6.75E-4 4.32E-5

PFH (1/hour) 7.70E-9 4.93E-10

SIL 2 3

PL d e

Category 3 4

MTTFD years 1446.7 (high) 1427.7 (high)

DCavg% 90.0% (medium) 99.0% (high)

HFT 1 (1oo2) 1 (1oo2)

Mission time 20 years 20 years

(1) Dual channel values apply with discre pancy checking configured.

Dual Encoder

(1)

Feedback

The safe motion-monitoring option can be configured for single feedback or

dual feedback to achieve the following safety rating:

• Single feedback configurations provide up to SIL 2 PLd capability.

• Dual-feedback configurations provide up to SIL 3 PLe capability when

discrepancy testing (either velocity, position, or both) is enabled.

IMPORTANT Achievable safety rating depends on each system component. For Safe

Feedback, the safety rating of the selected encoders may limit the safety

rating of the system.

Safety Data for Safety I/O

The Integrated Safety Functions option module provides four safety inputs

and two safety outputs. Ta b l e 5

provides PFD

safety functions that use this Safety I/O.

Table 5 - PFD or PFH to Add When Safety Functions Use Safety I/O

Attribute Single Channel Safety I/O Dual Channel Safety I/O

PFD (average) 3.35E-4 2.49E-4

PFH (1/hour) 3.83E-9 2.84E-9

SIL 2 3

PL d e

Category 2 4

MTTFD years 1064.9 (high) 1998.0 (high)

and PFH values to add for

avg

22 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 23

Chapter 1

Table 5 - PFD or PFH to Add When Safety Functions Use Safety I/O

Attribute Single Channel Safety I/O Dual Channel Safety I/O

DCavg% 96.4% (high) 94.2% (high)

HFT 0 (1oo1) 1 (1oo2)

Mission time 20 years 20 years

IMPORTANT Single channel safety I/O is only certified for use in functional safety

applications with process safety times greater than or equal to 300 ms; or

applications with demand rates less than or equal to 1 demand per 30

seconds.

IMPORTANT If single channel safety I/O is used, pulse testing (external pulse testing for

safety inputs, pulse testing for safety outputs) MUST be enabled on the

single channel I/O points.

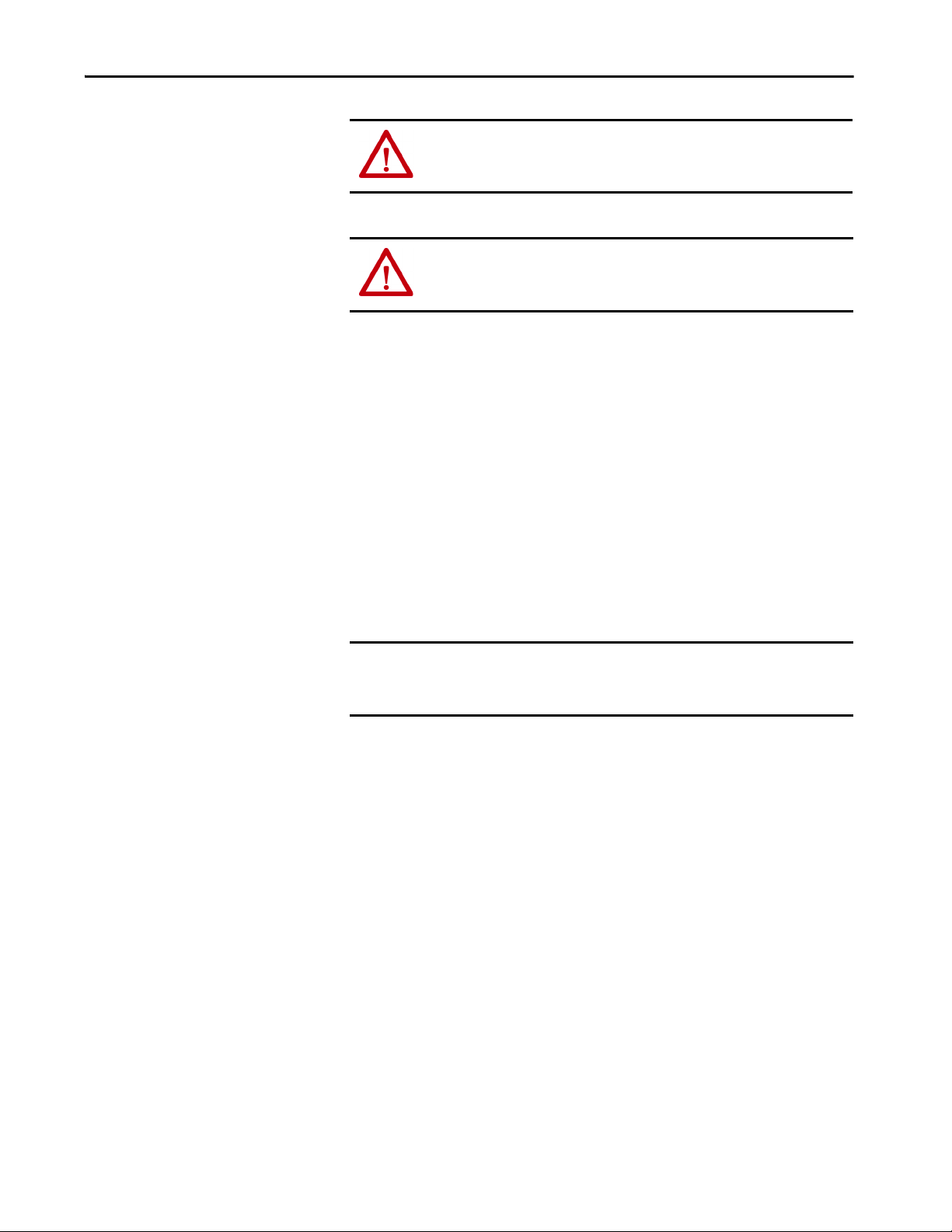

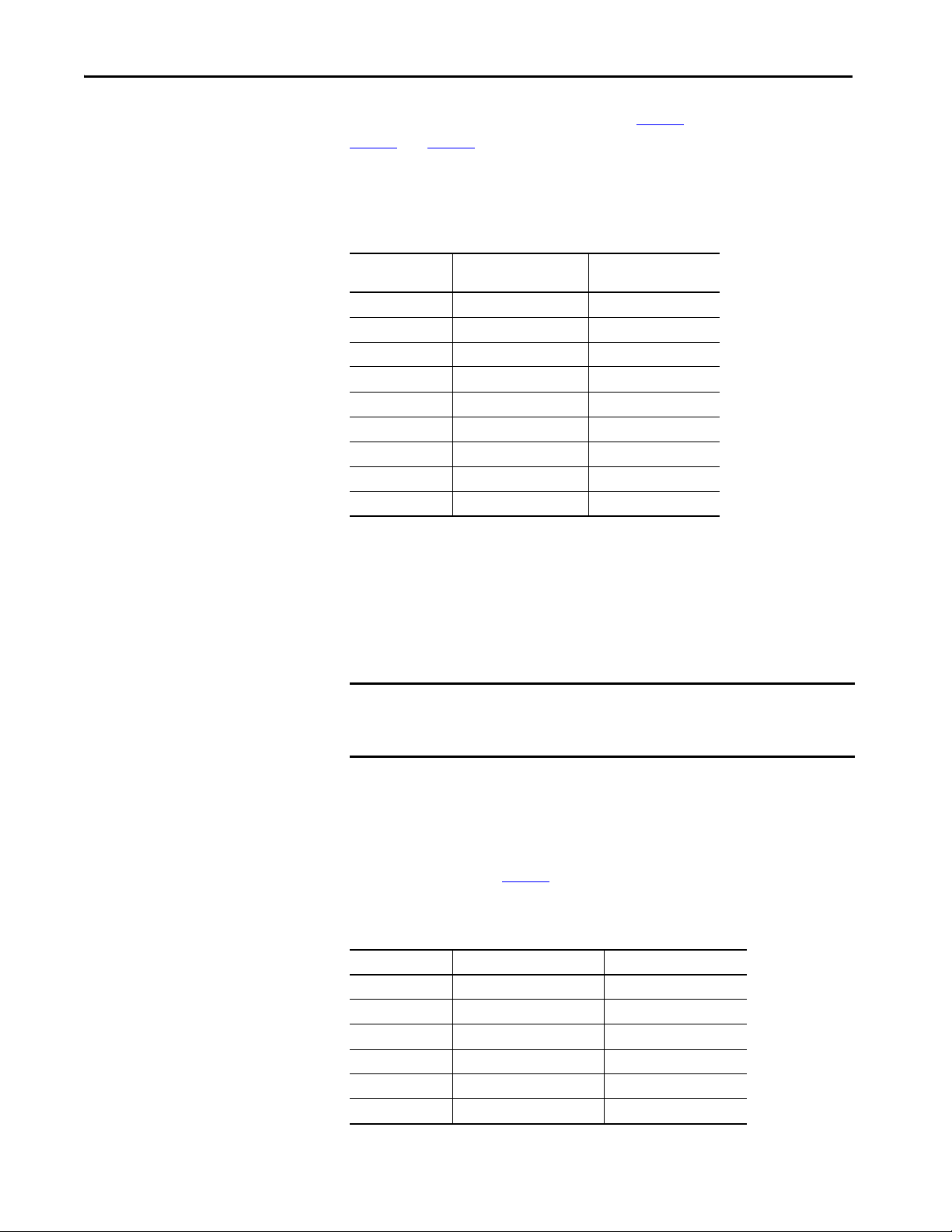

Spurious Trip Rate

Safety Reaction Time

Ta b l e 6 shows the Spurious Trip Rate (STR) and Mean Time to Failure

Spurious (MTTF

) values for the Integrated Safety Functions option

Spurious

module, calculated according to the ISA TR-84 method.

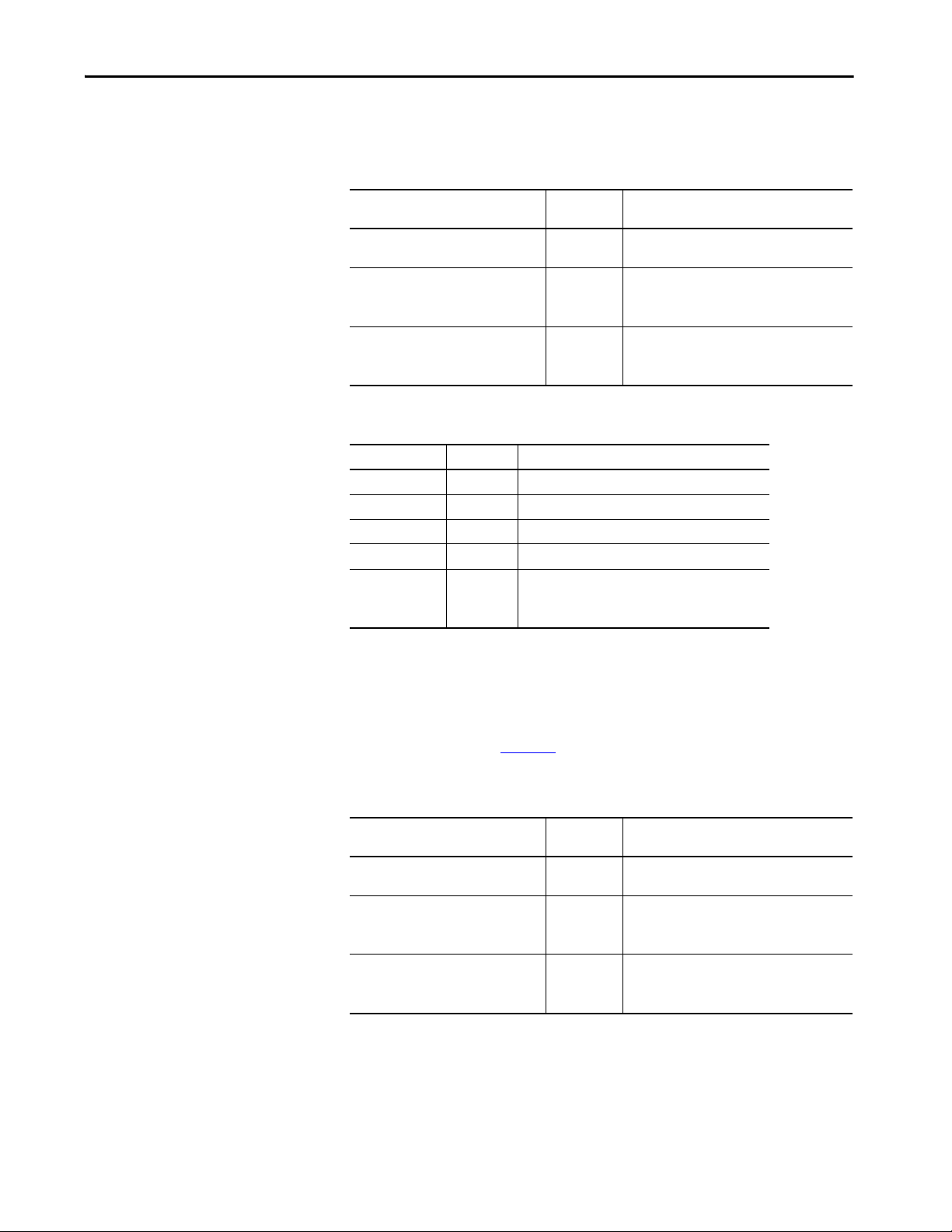

Table 6 - STR and MTTF Spurious Values

Attribute Value

Spurious Trip Rate 3.00E-6

MTTFSpurious (years) 37.0

The safety reaction time is the length of time from a safety-related event as

input to the system until the system is in the safe state. Ta b l e 7

shows the safety

reaction time from an input signal condition that triggers a safe stop, to the

initiation of the configured Stop Type. For details on how to calculate system

reaction times with GuardLogix controllers, see the GuardLogix Controller

Systems Safety Reference Manuals listed in the Additional Resources

on

page 13.

Table 7 - Safety Reaction Time

Drive Family Network STO Reaction Time, Max

PowerFlex 755 drives (firmware revision 13 or later), Frames 1…10

PowerFlex 755TL low harmonic drives, Frames 7…15

PowerFlex 755TR regenerative drives, Frames 7…15

PowerFlex 755TM, Frames 8…15

PowerFlex 755TL low harmonic drives, Frames 5 and 6 26 ms

15 ms

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 23

Page 24

Chapter 1

IMPORTANT An input signal condition that is present for less than the reaction time may

not result in the safety function being performed. Repeated requests of the

safety function for less than the reaction time can result in a spurious

detection of a fault.

Considerations for Safety Ratings

Encoder Considerations

IMPORTANT In network STO Mode, the safety reaction time in Ta bl e 7

does not include

the connection reaction time limit. See the GuardLogix Controller Systems

Safety Reference Manuals, listed in the Additional Resources

on page 13, for

details.

The achievable safety rating of an application that uses the Integrated Safety

Functions option module that is installed in PowerFlex 755/755T drive

products is dependent upon many factors, drive options, and the type of motor.

A safety rating up to and including SIL 3, PLe, and Category 4 can be achieved.

This section describes factors to consider when using an encoder with the

Integrated Safety Functions option module.

Supported Encoders

Ta b l e 8 describes the supported encoder types based on the feedback card that

is used and the physical terminal it is connected to. You must determine the

safety capability of a system based on the supported encoder types and the

encoder diagnostics that are described in this chapter.

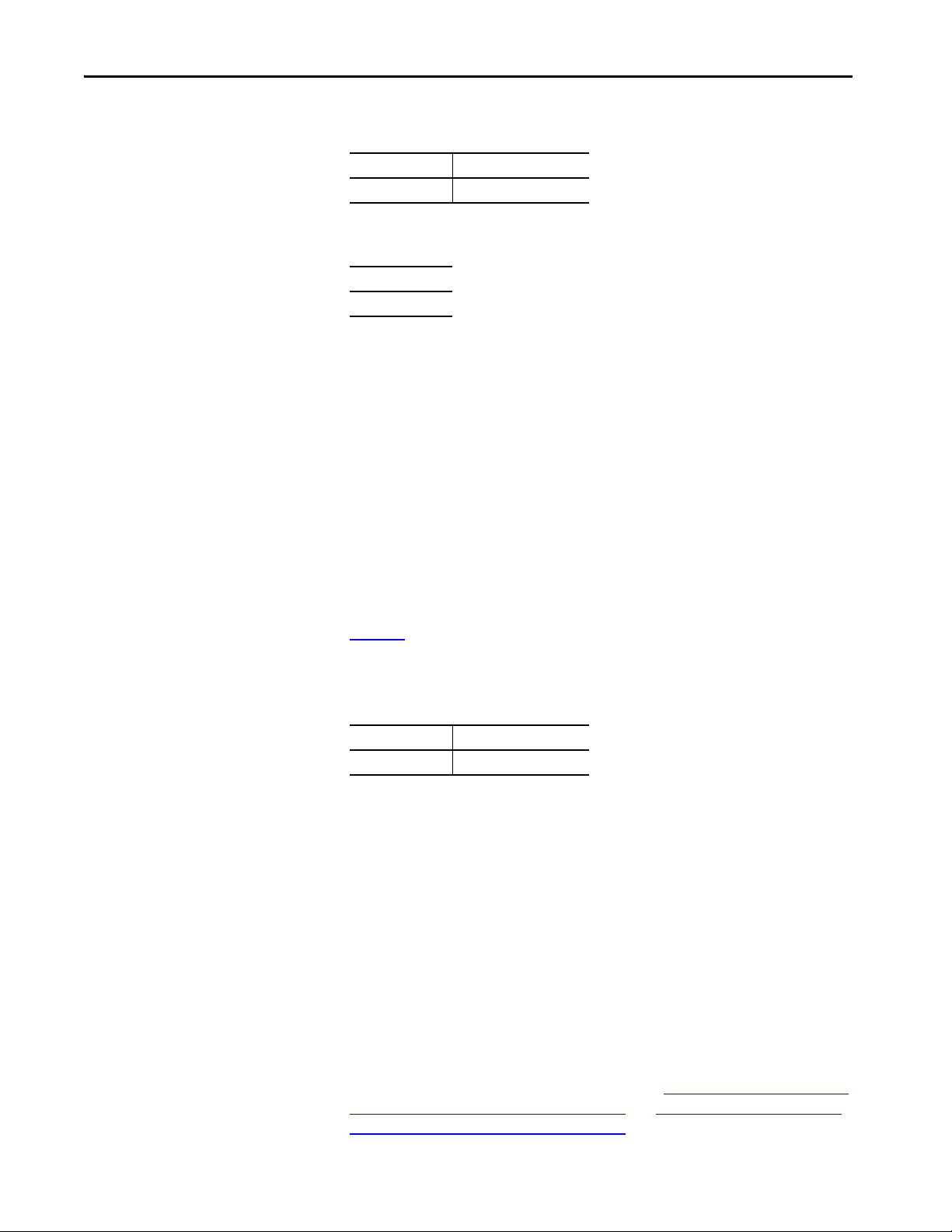

Table 8 - Supported Feedback Cards and Encoder Types

Feedback Option

20-750-UFB-1 Sine/Cosine

20-750-DENC-1 Digital AqB

Primary Channel Secondary Channel

Encoder Type Encoder Motion Axis Encoder Type Encoder Motion Axis

Not Used Not Used SIL 2/PL d with safety rated encoder

Motor Feedback

Digital AqB Load Feedback SIL 3/PL e

Not Used Not Used SIL 2/PL d with safety rated encoder

Digital AqB Load Feedback SIL 3/PL e

Encoder Diagnostics

Depending on the encoder type, the module performs several diagnostic tests

on encoder signals to detect faults in the encoder. You must determine if the

combination of the selected encoder device type and the diagnostics that are

described in this chapter will satisfy the required safety function rating. The

use of non-safety, standard encoders my require further analysis and assessment

activties.

24 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Achievable System Safety Rating

Page 25

Chapter 1

General Encoder Diagnostics

The following encoder diagnostics are available for all supported encoder

types:

•Encoder Voltage Monitoring (Configurable)

• Maximum Speed Limit (Configurable)

• Maximum Acceleration (Configurable)

•Maximum Encoder Input Frequency

• Dual Encoder Velocity and/or Position Discrepancy (Configurable)

IMPORTANT These diagnostics are based on the capability of the chosen encoder and its

rated limits. They do not provide a safety-rated safety function.

Encoder Voltage Monitoring

The voltage monitoring diagnostic samples the voltage being supplied to the

encoder to confirm that its level is within its configured range. If the voltage

monitoring diagnostic detects a voltage that is out of the configured range, the

safety feedback instance reports a voltage monitoring fault and causes the

module to enter the safe state.

The following voltage monitoring ranges are supported:

• 4.75…5.25V (Recommended setting when using 20-750-DENC-1 card

with the 12V Jumper in the ‘Storage’ position)

• 11.4…12.6V (Recommended setting when using 20-750-DENC-1 card

with the 12V Jumper in the ‘Enabled’ position)

• 7…12V (Recommended setting when using 20-750-UFB-1)

If a voltage range is not specified, then the voltage monitoring diagnostic is not

performed.

Maximum Speed Limit

The maximum speed limit diagnostic detects when encoder speed is above a

configured limit. If the speed of the encoder is greater than the configured max

speed limit, an exceeded max speed fault is reported by the safety feedback

instance. This causes the module to enter the safe state.

If the encoder being used specifies a maximum speed, set the maximum speed

limit configuration value to this value or lower. If the limit is configured as 0,

this diagnostic is not be performed.

Maximum Acceleration

The maximum acceleration diagnostic detects when encoder acceleration is

above a configured limit. If the module detects that the acceleration of the

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 25

Page 26

Chapter 1

encoder has exceeded the configured limit, a max acceleration fault is reported

by the safety feedback instance. This causes the module to enter the safe state.

If the encoder being used specifies a maximum acceleration, set the maximum

acceleration configuration value to this value or lower. If the maximum

acceleration is configured as 0, this diagnostic is not performed.

Maximum Encoder Input Frequency

The maximum encoder input frequency diagnostic confirms that the safety

feedback signals do not exceed the maximum frequency (encoder counts per

second) supported by the module. This value is not configurable and has fixed

values based on the encoder type. Ta b l e 9

on encoder type.

Table 9 - Maximum Frequency of Encoder Types

Encoder Type Max Frequency

Digital AqB 250 kHz

Sine/Cosine and Hiperface 163.8 kHz

shows the maximum frequency based

If the module detects an encoder input frequency above the limit, a max

frequency fault is reported in the safety feedback instance and the module

enters the safe state.

Dual Encoder Velocity and/or Position Discrepancy

The dual encoder velocity and position discrepancy diagnostic confirms that

the position and/or velocity of the two encoders match within a configurable

tolerance. The position and velocity discrepancy limits are individually

configurable; setting the limit to a value of 0 disables the diagnostic check. If

the module detects that the difference between the position and/or velocity of

both encoders is outside the configured limit, a discrepancy error is reported in

both safety feedback instances and the module enters the safe state. This

diagnostic is only available when the module is configured in a dual feedback

configuration.

26 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 27

Chapter 1

Digital AqB Diagnostics

The following diagnostic functions are implemented in the module to perform

diagnostics for digital AqB encoders:

• Inverse Signal Monitoring

• Quadrature Error Detection

Inverse Signal Monitoring

The inverse signal monitoring diagnostic confirms that the inverted and noninverted signals are always at opposite signal levels. If the module detects a noninverted signal, a feedback signal lost fault is reported in the safety feedback

instance and the module enters the safe state. This diagnostic is meant to detect

encoder wiring errors, such as open, short, or short to power.

Quadrature Error Detection

The quadrature error detection confirms that the A and B signals from the

digital AqB encoder do not change simultaneously. This diagnostic is also

referred to as an exclusive bit check. If the module detects a quadrature error,

the safety feedback instance reports a quadrature error fault and enters the safe

state. A simultaneous change indicates an error with the encoder wiring or an

issue with the encoder itself.

Sine/Cosine and Hiperface Diagnostics

The following diagnostic functions are implemented in the module to perform

diagnostics on Hiperface and or Sine/Cosine type encoders:

2

•Sin

+ Cos2 Vector Length Monitoring

• Zero-crossing Detection

• Signal Offset (Sine/Cosine Encoder Type Only)

Sin 2+ Cos2 Vector Length Monitoring

The Sin2 + Cos2 vector length monitoring diagnostic confirms that the sine

and cosine signals are sinusoidal and 90° apart. This diagnostic is meant to

detect errors in the wiring of the encoder and problems within the encoder

itself. Ta b l e 1 0

this diagnostic. Ta b l e 1 1

module detects that the amplitude and or phase of the signals is out of range,

the safety feedback instance reports a Sin

placed in the safe state.

describes the tolerance of encoder output signal amplitudes for

describes the phase tolerance of the diagnostic. If the

2

+ Cos2 fault and the module is

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 27

Page 28

Chapter 1

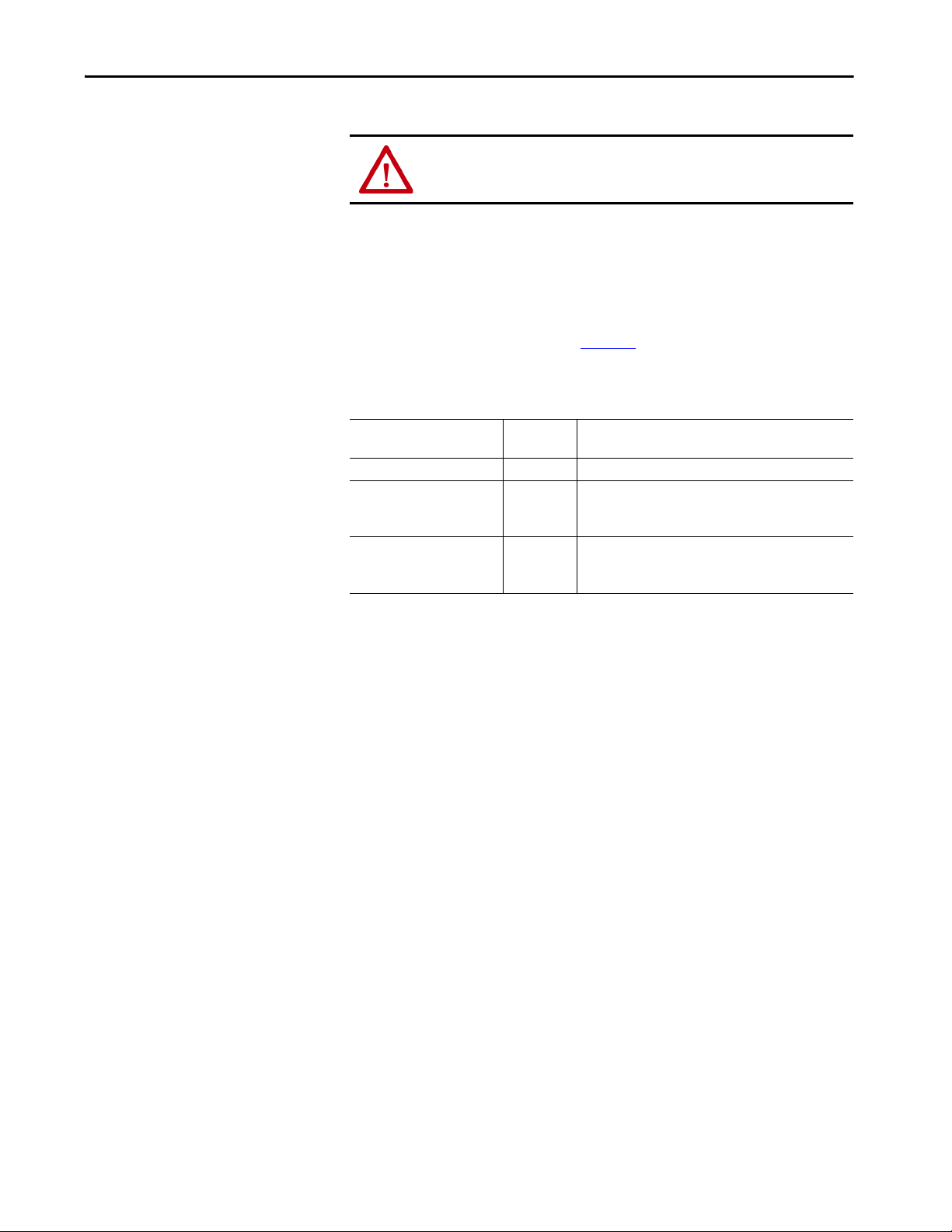

Table 10 - Sin2 + Cos2 Vector Length Monitoring Amplitude Range

Max Min

1.3 Vpp 0.7 Vpp

Table 11 - Sin2 + Cos2 Vector Length Monitoring Phase Tolerance

Tol era nc e

90º ± 20º

Zero-crossing Detection

The zero-crossing detection diagnostic confirms that the sine and cosine

signals have a similar offset to ground. The offset tripping point is ± 50 mV. If

the offset of the sine and cosine signals is greater than the tripping point, the

zero-crossing detection diagnostic will fail, a signal lost fault is reported in the

safety feedback instance, and the module is placed in the safe state.

Contact Information If Safety Option Failure Occurs

Signal Offset

The signal offset diagnostic confirms that a Sine/Cosine type encoder is

producing the proper offset on the Sine and Cosine signals. This diagnostic is

not performed when the feedback device type is configured as Hiperface.

Ta b l e 1 2

and or Cosine signals are outside the tolerance range, the safety feedback

instance reports a signal offset fault and the module is placed in the safe state.

Table 12 - Signal Offset Tolerance

Max Min

3.0V 2.0V

If you experience a failure with any safety-certified device, contact your local

Allen-Bradley distributor to request any of these actions:

describes the offset tolerance of the diagnostic. If the offset of the Sine

• Return the device to Rockwell Automation so the failure is

appropriately logged for the catalog number that is affected and a record

is made of the failure.

• Request a failure analysis (if necessary) to determine the probable cause

of the failure.

In case of malfunction or damage, no attempts at repair should be made. The

option module should be returned to the manufacturer for repair. Do not

dismantle the option module.

For more information about replacing drives, see Replace an Integrated Safety

Drive in a GuardLogix System on page 130 and Replace an Integrated Safety

Drive in a GuardLogix System on page 168.

28 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 29

Chapter 2

Installation

This chapter provides installation, jumper settings, and wiring for the

Integrated Safety Functions option module.

Top ic Pa ge

Remove Power to the System 30

Access t he Control Pod 30

Set the SAFETY and Hardware ENABLE Jumpers 31

Install the Safety Option Module 32

I/O Wiring 34

Cabling 34

ATT EN TI ON : The following information is a guide for proper installation.

Rockwell Automation does not assume responsibility for the compliance or

the noncompliance to any code, national, local, or otherwise for the proper

installation of this equipment. A hazard of personal injury and/or equipment

damage exists if codes are ignored during installation.

IMPORTANT Installation must be in accordance with the instructions in this user manual

and the installation instructions for your drive.

Only qualified, authorized personnel that are trained and experienced in

functional safety can plan, implement, and apply functional safety systems.

IMPORTANT During installation and maintenance, check your drive firmware release

notes for known anomalies and verify that there are not safety-related

anomalies.

The Integrated Safety Functions option module is intended to be part of the

safety-related control system. Before installation, perform a risk assessment that

compares the Integrated Safety Functions option module specifications and all

foreseeable operational and environmental characteristics of the control

system.

A safety analysis is required to determine how often to test the safety function

for proper operation during the life of the machine.

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 29

Page 30

Chapter 2

Panel-mo unted D rives

Drives in Cabinet Enclosures

Remove Power to the System

Before performing any work on the drive, remove all power to the system.

ATT EN TI ON :

• Electrical Shock Hazard. Verify that all sources of AC and DC power are deenergized and locked out or tagged out in accordance with the requirements

of ANSI/NFPA 70E, Part II.

• To avoid an electric shock hazard, verify that the voltage on the bus

capacitors has discharged before performing any work on the drive. Measure

the DC bus voltage at the +DC and -DC terminals or test points. The voltage

must be zero. For the location of the terminal block and test point sockets,

see the manual for your drive:

• PowerFlex® 750-Series AC Drive Installation Instructions,

publication

• PowerFlex 750-Series Products with TotalFORCE® Control Installation

Instructions, publication 750-IN100

• PowerFlex 755TM IP00 Open Type Kits Installation Instructions,

publication 750-IN101

• In Safe Torque Off mode, hazardous voltages may still be present at the

motor. To avoid an electric shock hazard, disconnect power to the motor and

verify that the voltage is zero before performing any work on the motor.

750-IN001

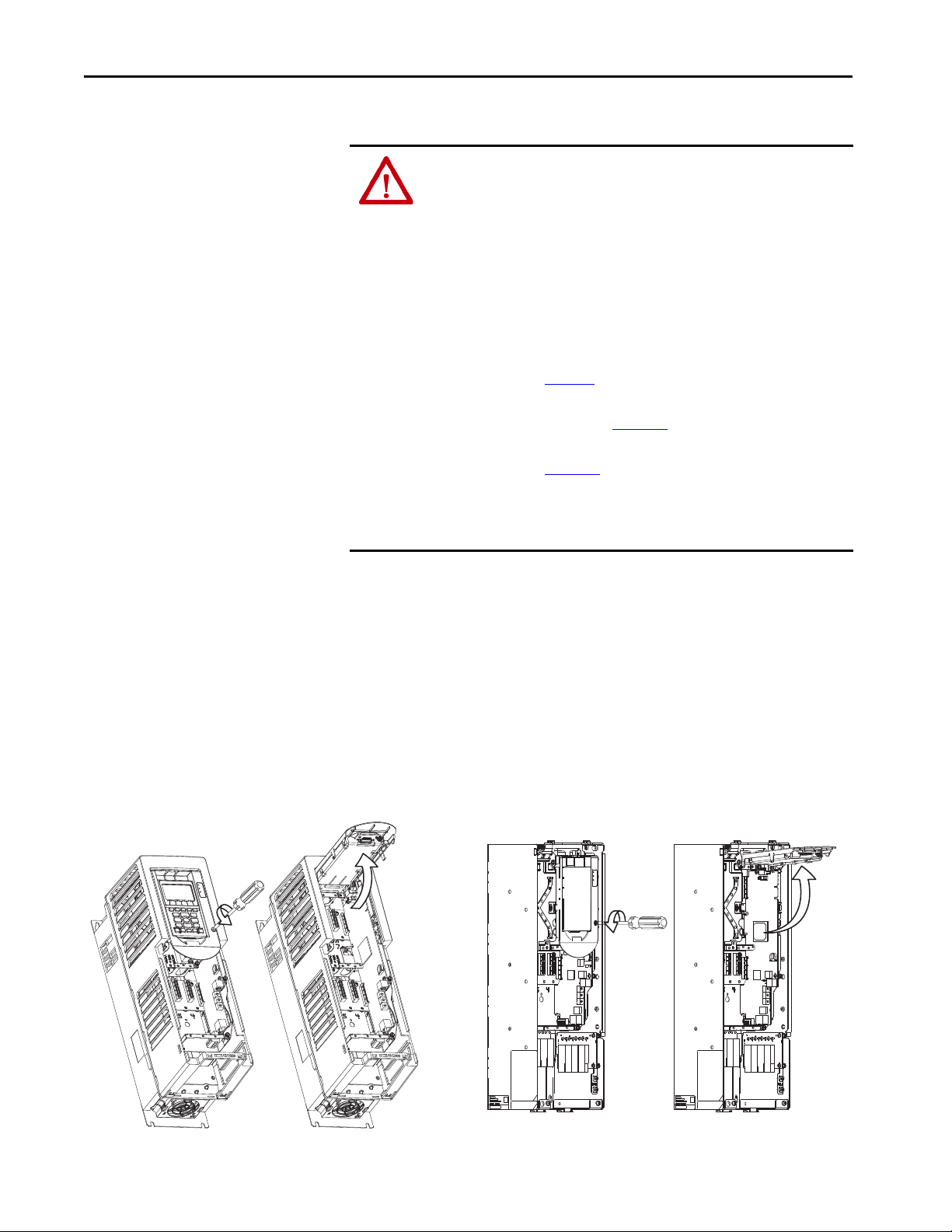

Access the Control Pod

The option module is installed in the drive control pod. Different drives have

different ways to access the control pod. To access the control pod, follow these

steps.

1. Remove the door or cover.

2. Loosen the retention screw on the HIM cradle.

3. Lift the cradle until the latch engages.

See the installation instructions for your drive for more information.

Figure 1 - Access the Control Pod.

30 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 31

Chapter 2

PowerFlex 755 AC Drive

SAFETY Jumper

(jumper is removed)

Hardware ENABLE Jump er

(jumper in place)

PowerFlex 755T Drive Products

SAFETY Jumper

(jumper is removed)

Hardware ENABLE Jumper

(jumper in place)

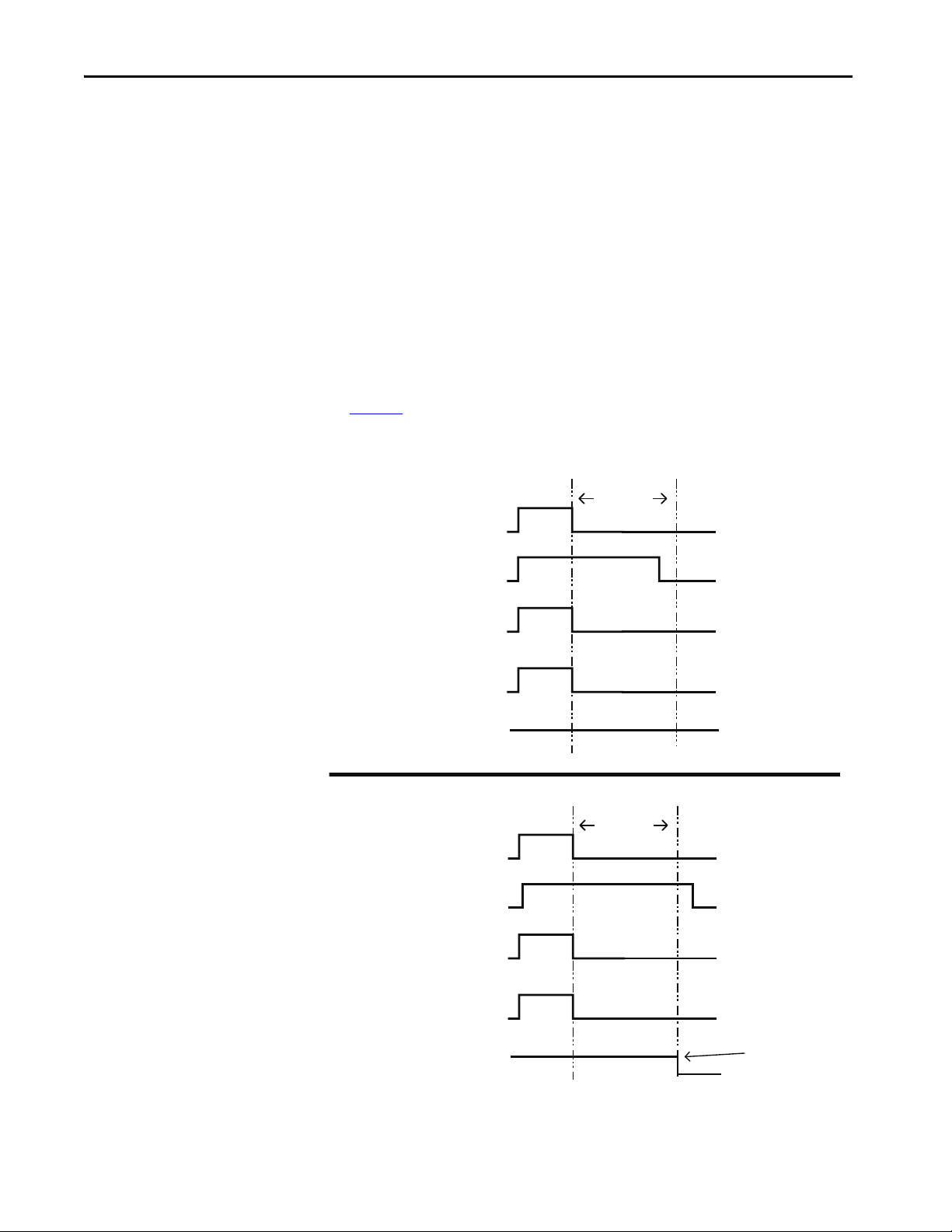

Set the SAFETY and Hardware ENABLE Jumpers

The PowerFlex 755/755T drive products ship with the safety jumper

(SAFETY) installed.

If the Integrated Safety Functions option module is installed, the control board

SAFETY jumper must be removed. If the SAFETY jumper is not removed, a

‘Safety Jumper In’ fault occurs.

IMPORTANT PowerFlex 755 drives (frames 8…10) control boards do not have a SAFETY

jumper.

If the Integrated Safety Functions option module is installed, the control board

hardware ENABLE jumper must be installed. If the hardware ENABLE

jumper is not installed, a ‘HW Enbl Jmpr Out’ fault occurs (only frames 1…7

of PowerFlex 755 drives and all frame sizes of PowerFlex 755T drive products).

Figure 2 - PowerFlex 755 Drives Jumper Locations, Frames 1…7

Figure 3 - PowerFlex 755T Drive Products Jumper Locations (all frame sizes)

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 31

Page 32

Chapter 2

Install the Safety Option Module

To install the Integrated Safety Functions option module in a drive port, follow

these steps:

1. Firmly press the module edge connector into the desired port.

IMPORTANT The Integrated Safety Functions option module can be installed in

ports 4, 5, or 6 when used in Standard I/O mode. When used in an

Integrated Motion application, the Integrated Safety Functions

option module must be installed in Port 6.

2. Tighten the top and bottom retaining screws.

– Recommended torque = 0.45 N•m (4.0 lb•in)

– Recommended screwdriver = T15 Hexalobular

IMPORTANT Do not overtighten the retaining screws.

IMPORTANT Only one safety option module can be installed in a drive. Multiple

safety option modules or duplicate safety option module

installations are not supported.

Figure 4 - PowerFlex 755 Drives, Frames 1…7

32 Rockwell Automation Publication 750-UM005C-EN-P - February 2021

Page 33

Chapter 2

Feedback Installation Guidelines

Follow these guidelines for the Integrated Safety Functions option module.

Feedback Devices

The Integrated Safety Functions option module can be used with one of the

following feedback devices when safe feedback monitoring is used:

• Dual-incremental Encoder module, catalog number 20-750-DENC-1

• Universal Feedback module catalog number 20-750-UFB-1

Only one feedback card can be used in conjunction with the Integrated Safety

Functions module. For information on the supported encoder types for a given

feedback device, see Encoder Considerations

Port Assignment

Follow these guidelines for port assignment:

• The Integrated Safety Functions option module and the feedback device

must be installed on the same backplane using ports 4, 5, or 6.

• When used in an Integrated Motion application, the Integrated Safety

Functions option module must be installed in port 6.

• Only one safety option module can be installed in a drive. Multiple

safety options or duplicate safety option installations are not supported.

in Chapter 1.

Jumper Settings

Follow these guidelines for jumper settings:

• Verify the hardware enable jumper (ENABLE) on the main control

board is installed. See Figure 2

the drive will fault when powered up.

• Verify the safety enable jumper (SAFETY) on the main control board is

removed (Frames 1…7 only). See Figure 2

or Figure 3 for location. If not installed,

or Figure 3 for location.

Rockwell Automation Publication 750-UM005C-EN-P - February 2021 33

Page 34

Chapter 2

Si0

SC

Si1

SC

SP

To1

Si2

SC

Si3

To0

So0

SC

So1

NC

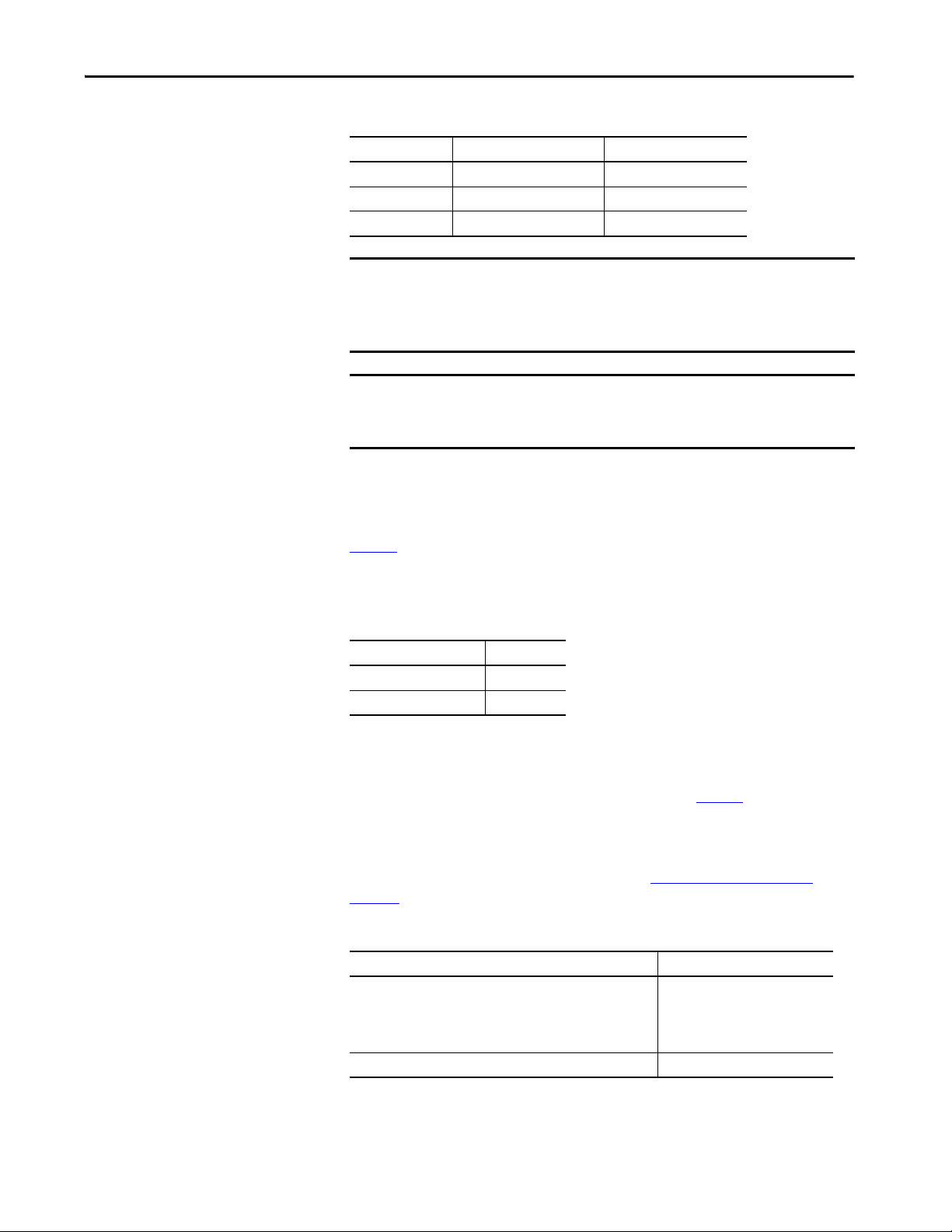

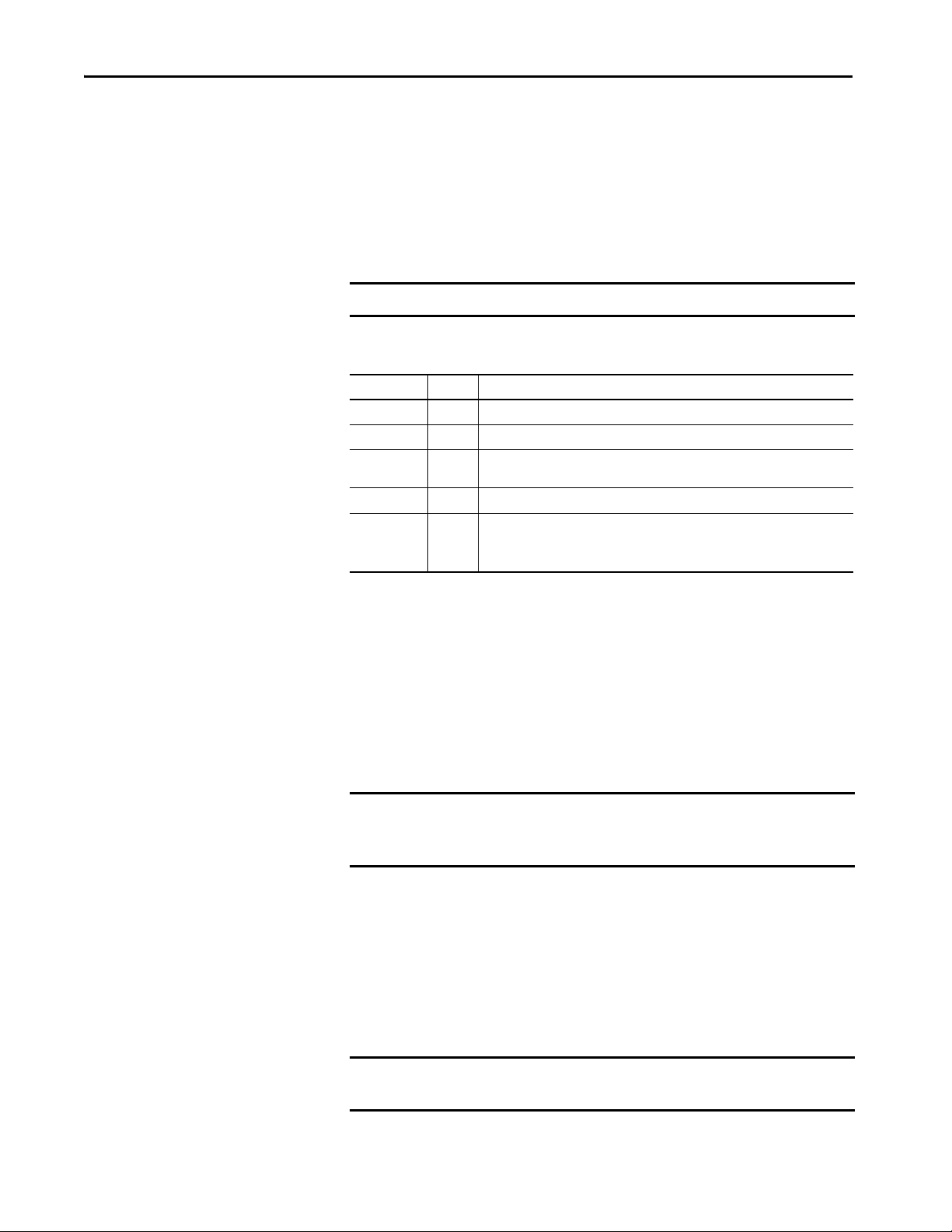

I/O Wiring

This section describes the onboard safety I/O and wiring considerations. A

power supply must be connected between the SP and SC terminals in order for

the safety I/O to be used. See Power Supply Requirements

on page 35 for

information on selecting a power supply.

IMPORTANT External 24V power is only required to the module when hardwired safety is

used. It is NOT required when the module is used for networked safety

operation.

Table 13 - Terminal Designation

Terminal Name Description

To1 Test Output 1 Test 24V DC output 1

Si2 Safety Input 2 Safety 24V DC input 2

SC Safety Common Safety power common

Si3 Safety Input 3 Safety 24V DC input 3

To0 Test Output 0 Test 24V DC output 0

NC No Connection