Page 1

Installation Instructions

MP-Series Electric Cylinders

Catalog Numbers MPAR-x1xxxB, MPAR-x1xxxE, MPAR-x2xxxC,

MPAR-x2xxxF, MPAR-x3xxxE, MPAR-x3xxxH

Topic Page

Important User Information 2

Catalog Number Explanation 3

About the MP-Series Electric Cylinders 4

Before You Begin 5

Install the Electric Cylinder 8

Mount the Electric Cylinder 10

Change Connector Orientation 12

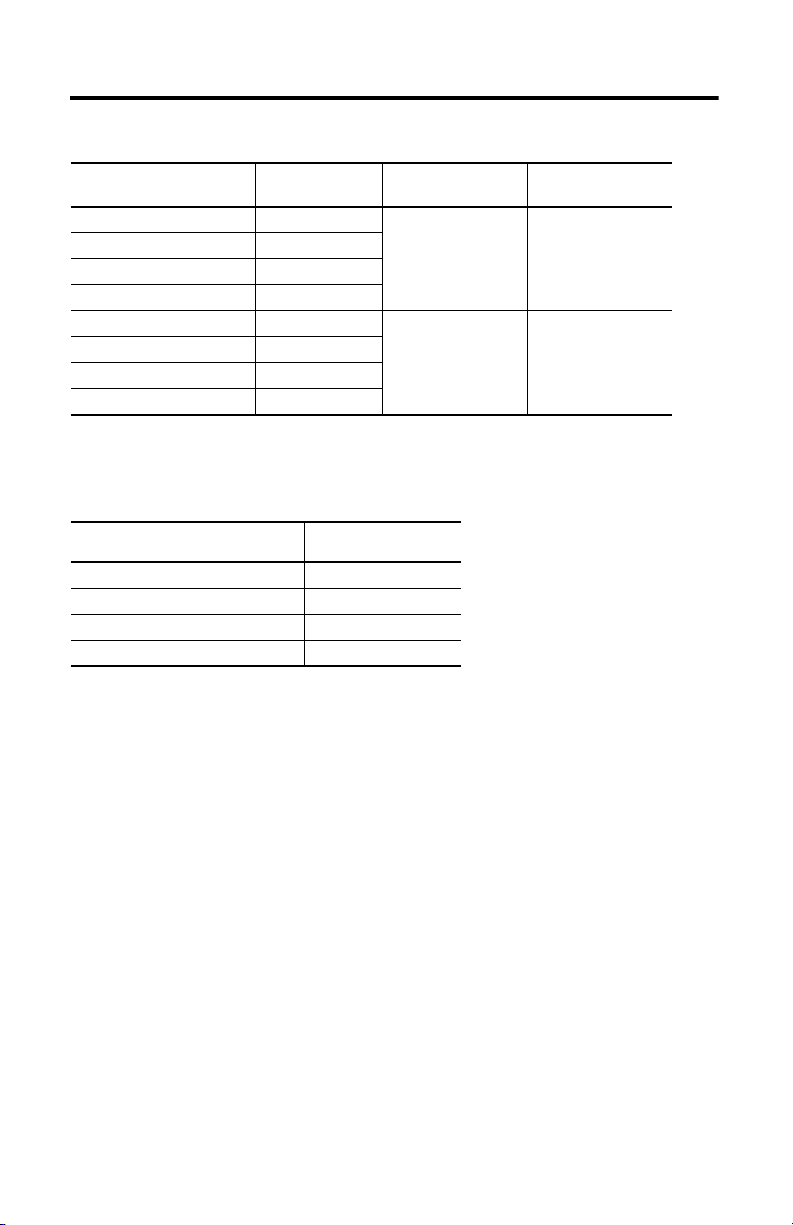

Dimensions 13

Connector Data 19

Commissioning 20

Maintenance 35

Troubleshooting 36

Accessories 38

Specifications 42

Additional Resources 47

Page 2

2 MP-Series Electric Cylinders

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for

the Application, Installation and Maintenance of Solid State Controls (Publication SGI-1.1

Automation® sales office or online at http://www.rockwellautomation.com/literature/

between solid-state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide

variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibil ity or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNIN G: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from your local Rockwell

) describes some important differences

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard and recognize the

consequences.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to alert people that

surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 3

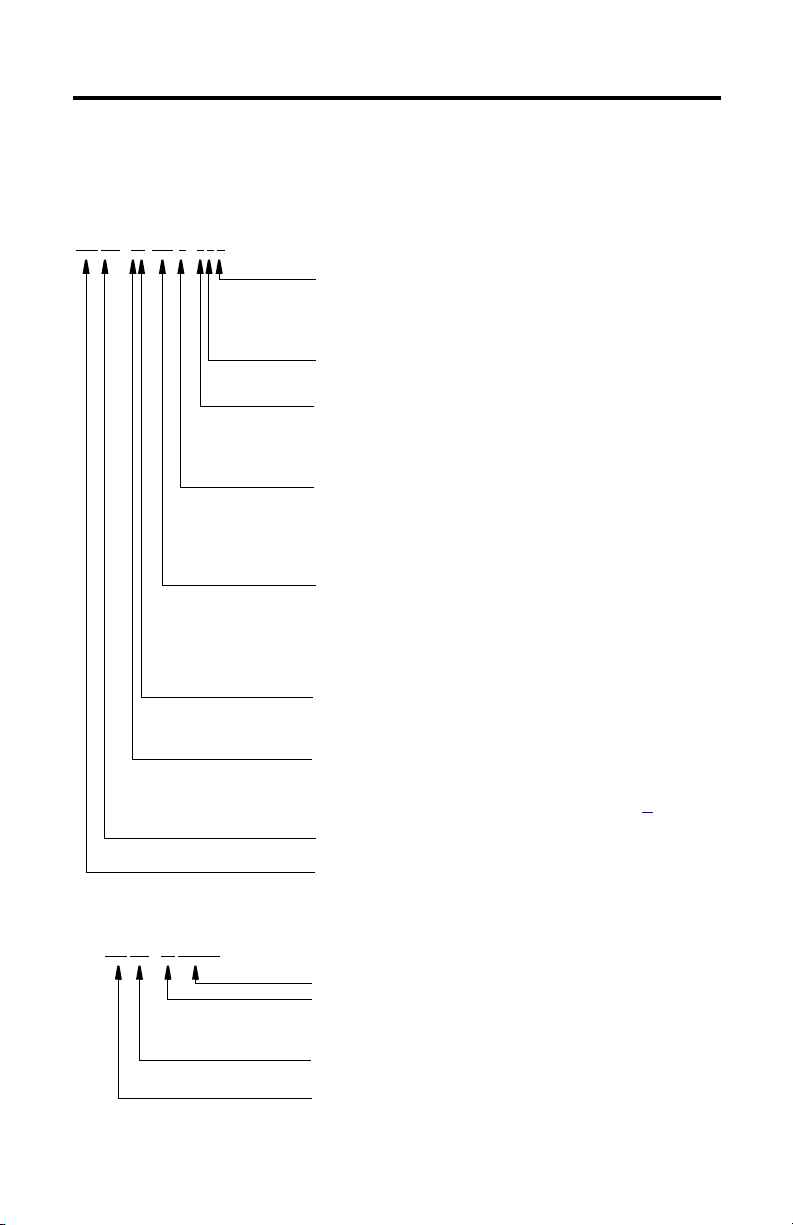

Catalog Number Explanation

Motor Mounting

(1)

A = Axial (in-line)

B = Top (parallel)

D = Left (parallel)

E = Right (parallel)

Holding Brake

(1)

2 = No Brake

4 = 24V DC Brake

Feedback

(1)

A =

B =

M = Multi-turn, absolute high-resolution encoder, frame size 63 only

V = Multi-turn, absolute high-resolution encoder, frame size 32 and 40 only

Mechanical Drive/Screw Lead, Motor Type

B = 3.0 mm/rev (0.118 in./rev)

C = 5.0 mm/rev (0.197 in./rev)

E = 10.0 mm/rev (0.394 in./rev)

F = 12.7 mm/rev (0.50 in./rev)

H = 20.0 mm/rev (0.787 in./rev)

Rod Stroke Length

100 = 100 mm (3.94 in.)

200 = 200 mm (7.87 in.)

300 = 300 mm (11.81 in.)

400 = 400 mm (15.75 in.)

600 = 600 mm (23.62 in.)

800 = 800 mm (27.56 in.)

Actuator Fram e Size

1 = 32

2 = 40

3 = 63

Voltage Class

A = 200V

B = 400V

X = Actuator cylinder replacement part ( refer to Actuator Cylinders on page 41

for ordering

examples)

Actuator Type

AR = Actuator Rod

Bulletin Number

MP = MP-Series®

(1) This field does not apply to actuator cylinder replacement parts.

MP AR - xx xxx x - x x x

MP AR - xx xxxxxx

Accessory Item Number

Accessory Type

NA = Axial (in-line) Mounting Accessor y

NP = Parallel Mounting Accessory

NE = Rod-end Accessory

Actuator Type

AR = Actuator Rod

Bulletin Number

MP = MP-Series or TL-Series ® Actuator Accessory

Catalog numbers consist of various characters, each of which identifies a specific version or

option for that component. Use the catalog numbering chart below to understand the

configuration of your actuator.

MP-Series Electric Cylinders 3

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 4

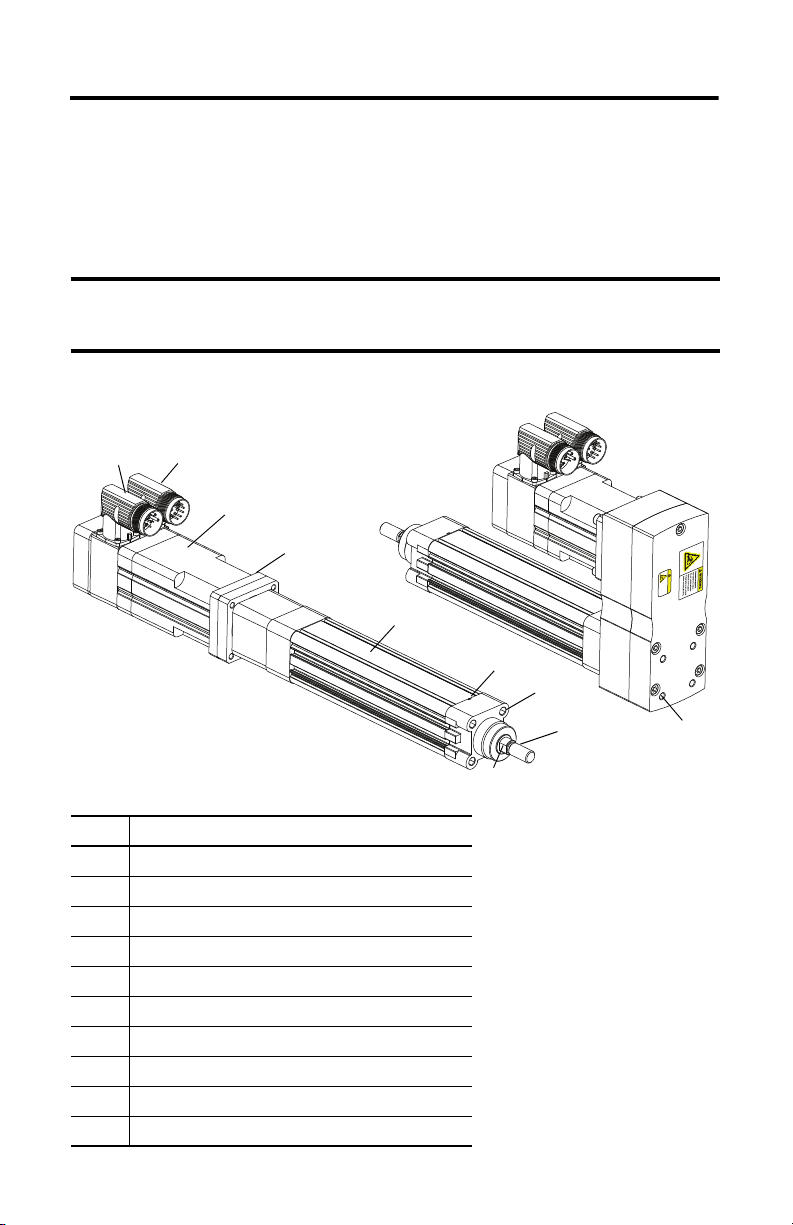

4 MP-Series Electric Cylinders

IMPORTANT

CA

U

TION

Ho

t

surfa

c

e.

Do

n

ot

to

uch

.

8

7 (x4)

5

9

6

4 (x4)

1

3

MPAR-A1100E-V2A MP-Series Electric Cylinder

2

MPAR-A1100E-V2B MP-Series Electric Cylinder

10 (x4)

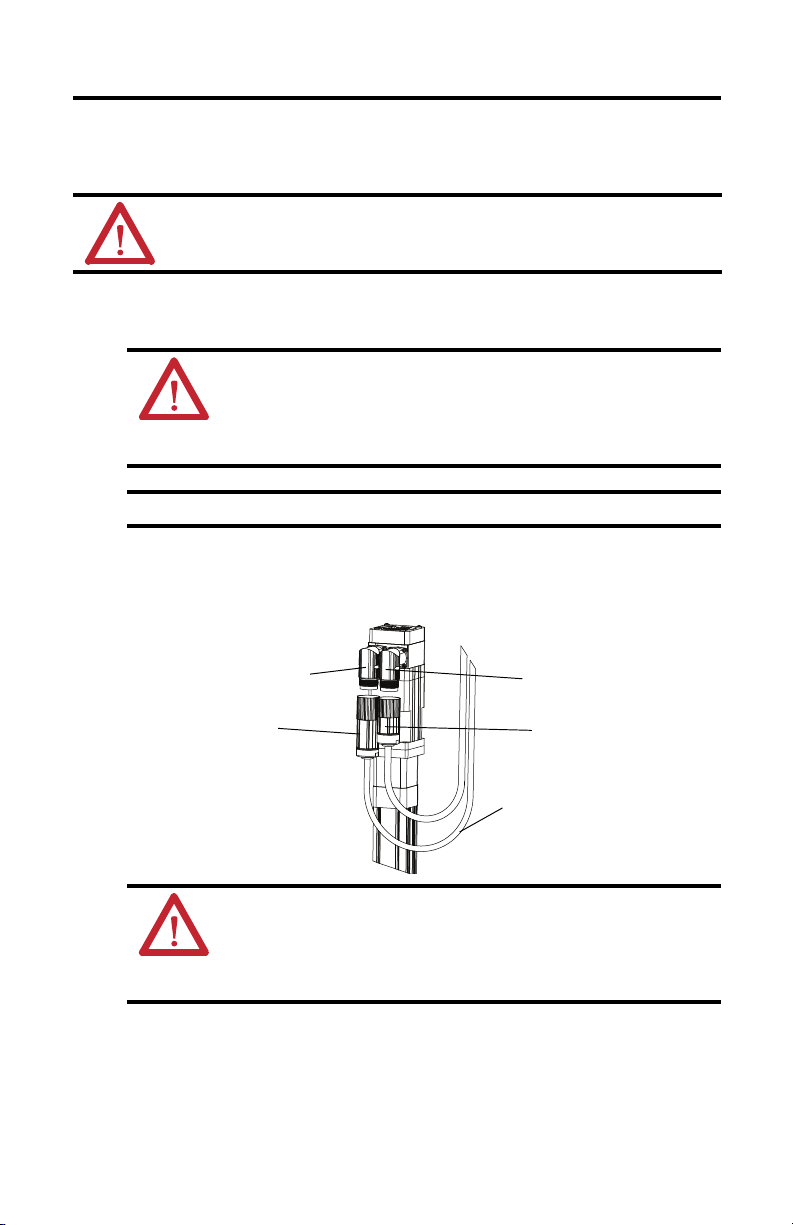

About the MP-Series Electric Cylinders

MP-Series electric cylinders feature multi-turn high resolution encoders and are available with

24V DC brakes. The MP-Series motor rotates a ballscrew drive that converts rotary motion into

linear movement. This linear movement results in the piston rod extending and retracting from

the electric cylinder housing.

The MP-A/B xxxxx-x2x electric cylinders are non-braking. When there is no input torque, the

piston rod can be moved freely. You can achieve self-locking of your motion system by using

motors with an integrated brake or with high self-braking torque.

The MP-Series electric cylinders have been designed for exact positioning at high speeds.

Item Description

1 Power connector

2 Feedback connector

3MP-Series motor

4 Motor mounting bolts

5Actuator cylinder

6Breather port

7 Hollow bolts with internal treads for fastening

8Piston rod

9 Wrench flats for counteracting torque on piston rod

10 Accessories mounting holes

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 5

MP-Series Electric Cylinders 5

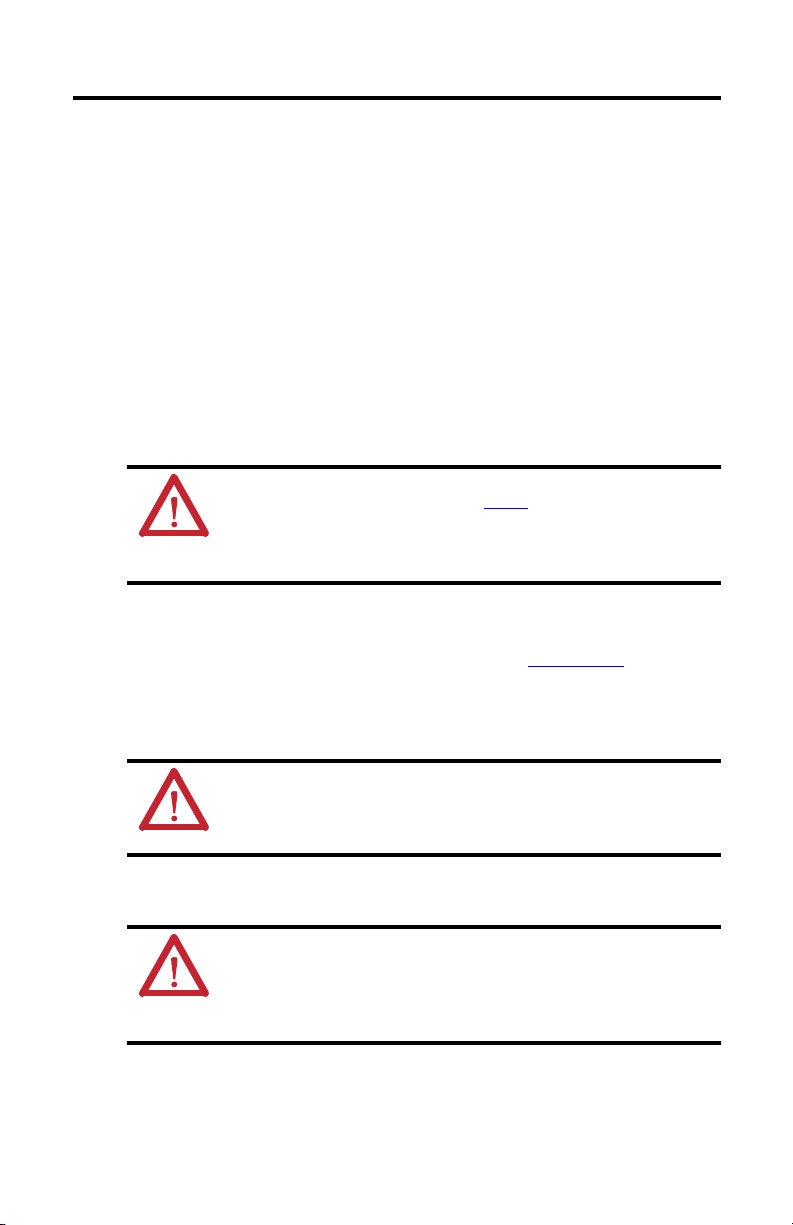

Before You Begin

Remove all packing material, wedges, and braces from within and around the item. After

unpacking, verify the nameplate catalog number against the purchase order.

1. Remove packaging polyethylene foil and cardboard.

The packing materials are recyclable, except for oiled paper, which is waste.

2. Remove the electric cylinder carefully from its shipping container.

Consider the weight of the electric cylinder. Depending on the design, the electric

cylinder can weigh up to 20.6 kg (45.4 lb).

3. Visually inspect the electric cylinder for damage.

4. Examine the electric cylinder frame, piston shaft, and hollow bolts for defects.

5. Notify the carrier of shipping damage immediately.

ATTENTION: Do not attempt to open and modify the electric cylinder beyond changing

motor connector orientation as described on page

employee can service the internal working of the electric cylinder or motor.

Failure to observe these safety precautions could result in personal injury or damage to

equipment.

Planning Your Installation

Refer to the Kinetix® Motion Control Selection Guide, publication GMC-SG001, for the

specifications and additional products referenced in this section:

• This product can be operated in compliance with the relevant safety regulations only if

the maximum loading limits are observed.

12. Only a qualified Allen-Bradley®

ATTENTION: The electric-cylinder is not intended to be used in applications where

side-loading occurs. Loads must be guided and supported. Aligned load with the

line-of-motion of the piston rod.

Side loading will reduce the lifetime of the elec tric-cylinder.

• If you are mounting your electric cylinder in a vertical or sloping position, include safety

measures that will control the workload should the spindle nut fail.

ATTENTION: Uncontrolled moving masses can cause injury or damage to proper ty.

If there is a spindle nut fracture inside the actuator cylinder due to wear, the working

mass will drop down.

Check whether additional external safety measures are required to prevent damage in

the event of a spindle nut fracture.

• Corrosive environments reduce the service life of electric cylinders.

• Depending on the workload, the piston rod will bend. Refer to the piston-rod deflection

specifications for limitations.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 6

6 MP-Series Electric Cylinders

IMPORTANT

• Motor feedback, auxiliary feedback, and I/O connector kits are not included, but can be

purchased separately.

• Factory manufactured feedback and power cables are available in standard cable lengths.

They provide environmental sealing and shield termination. Contact your Allen-Bradley

sales office or refer to the selection guide for cables.

Electric Cylinders with Brake Option

The brake option on this servo motor is a spring-set holding brake that releases when voltage is

applied to the brake coil. A separate power source is required to disengage the brake. This power

source can be applied by a servo motor controller or manual operator control.

If system main power fails, holding brakes can withstand occasional use as stopping brakes.

However, this creates rotational mechanical backlash that is potentially damaging to the system,

increases brake wear, and reduces brake life.

An unpowered electric cylinder will require a brake to maintain its position if the force on the

actuator exceeds the Back Drive Force listed in Kinetix Linear Motion Specifications Technical

Data, publication GMC-TD002.

A brake can be use with the actuator to keep it from backdriving, typically in vertical

applications. A brake may be used for safety reasons or for energy savings allowing the actuator to

hold position when unpowered.

Holding brakes are not designed to stop rotation of the motor shaft, nor are they intended to be

used as a safety device. They are designed to hold a motor shaft at 0 rpm for up to the rated

brake holding torque.

The recommended method of preventing motor shaft rotation is a four step process: first,

command the servo drive to 0 rpm; second, verify the motor is at 0 rpm; third, engage the

brake; and fourth, disable the drive.

Disabling the drive removes the potential for brake wear caused by a badly-tuned servo system

oscillating the shaft.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 7

MP-Series Electric Cylinders 7

Preventing Electrical Noise

Electromagnetic interference (EMI), commonly called electrical noise, can reduce motor

performance. Effective techniques to counter EMI include filtering the AC power, using

shielded cables, separating signal cables from power wiring, and practicing good grounding

techniques.

Follow these guidelines to avoid the effects of EMI:

• Isolate the power transformers or install line filters on all AC input power lines.

• Physically separate signal cables from motor cabling and power wiring. Do not route

signal cables with motor and power wires, or over the vent openings of servo drives.

• Ground all equipment by using a single-point parallel ground system that employs

ground bus bars or large straps. If necessary, use additional electrical-noise reduction

techniques to reduce EMI in noisy environments.

Refer to System Design for Control of Electrical Noise Reference Manual, publication

GMC-RM001

, for additional information on reducing the effects of EMI.

Build and Route Cables

Knowledgeable cable routing and careful cable construction improves system electromagnetic

compatibility (EMC).

Follow these steps to build and install cables.

1. Keep wire lengths as short as physically possible.

2. Route signal cables (encoder, serial, analog) away from motor and power wiring.

3. Separate cables by 0.3 m (1 ft) minimum for every 9 m (30 ft) of parallel run.

4. Ground both ends of the encoder cable shield and twist the signal wire pairs to prevent

electromagnetic interference (EMI) from other equipment.

ATTENTION: High voltage can be present on the shield of a power cable if the shield is not

grounded.

Make sure there is a connection to ground for any power cable shield.

Failure to observe these safety precautions could result in personal injury or damage to equipment.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 8

8 MP-Series Electric Cylinders

IMPORTANT

Install the Electric Cylinder

The installation must comply with all local regulations and use of equipment and installation

practices that promote electromagnetic compatibility and safety.

ATTENTION: Unmounted electric cylinders, disconnected mechanical couplings, and disconne cted

cables are dangerous if power is applied.

Disassembled equipment should be appropriately identified (tagged-out) and access to electrical

power restricted (locked-out).

Failure to observe these safety precautions could result in personal injury.

ATTENTION: Make sure that cables are installed and restrained to prevent uneven tension or

flexion at the cable connectors.

Excessive and uneven lateral force at the cable connectors may result in the connector’s

environmental seal opening and closing as the cable flexes.

Failure to observe these safety precautions could result in damage to the electric cylinder motor

and its components.

ATTENTION: Damage may occur to the electric cylinder bearings and the feedback device if a

sharp impact to the piston rod is applied during installation. Do not strike the piston rod with tools

during installation or removal.

Do not attempt to rotate the piston rod during installation. Rotating the piston rod will break the

mechanism that allows the electric cylinder to extend and retract.

Failure to observe these safety precautions could result in damage to the electric cylinder and its

components.

Follow these steps to install the electric cylinder.

1. Provide sufficient clearances in the area of the electric cylinder for it to stay within its

specified operating temperature range.

Refer to Specifications

the electric cylinder unless forced air is blown across the electric cylinder for cooling.

Keep other heat producing devices away from the electric cylinder.

2. Make sure the mounting surface supports the electric cylinder evenly so that it is free of

mechanical stress and distortion.

The evenness of support surface should be

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

on page 42 for the operating temperature range. Do not enclose

Position the electric cylinder so that all of the operating parts are accessible and the

breather port is not covered.

ATT EN TI ON : Do not modify the settings of the screws and the threaded pins.

The electric cylinder must not be fastened by the front cover alone when used with high

loads.

Heavy tensile strain may cause the screws in the cover to pull out.

0.2 mm (0.008 in.).

Page 9

MP-Series Electric Cylinders 9

IMPORTANT

Wrench F lat

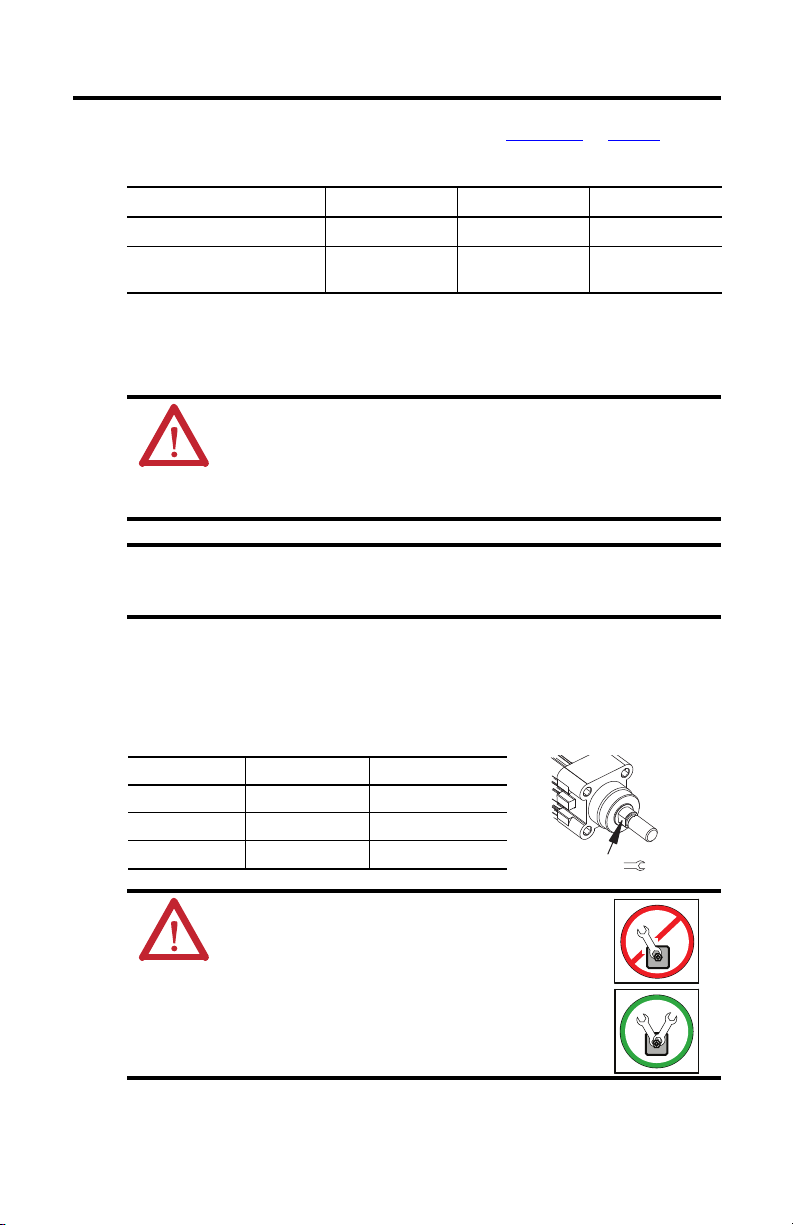

3. Attach mounting accessories to the electric cylinder; see Accessories

on page 38.

Tighten the fastening screws evenly.

Attribute Frame 32 Frame 40 Frame 63

Internal thread of cover screws M6 M6 M8

Tightening torque, max

(1) Unless otherwise noted, the torque value has a ±20% tolerance.

(1)

5 N•m

(3.69 lb•ft)

5 N•m

(3.69 lb•ft)

9 N•m

(5.90 lb•ft)

4. Attach rod-end accessories and the workload.

Be sure the workload center of gravity is centric to the piston rod.

ATTENTION: Damage may occur to the electric cylinder bearings and the feedback

device if sharp impact to the piston rod is applied during installation. Do not strike the

piston rod with tools during installation or removal.

Failure to observe these safety precautions could result in damage to the electric c ylinder

and its components.

Do not twist or rotate the piston rod. If the piston rod is rotated, the absolute position

of the electric cylinder will be lost and the absolute home position must be

re-e stablished.

When fastening a rod-end accessory or workload to the piston rod, use two wrenches.

Use one wrench to tighten the mounting nut or rod-end accessory and the other, on the

piston-rod wrench flats, to counteract the applied torque. Be sure that the torque is not

applied to the piston rod and that the piston rod does not rotate.

Frame Size Piston Rod Thread Wrench Flats Width

32 M10 x 1.25 10 mm

40 M12 x 1.25 13 mm

63 M16 x 1.5 17 mm

ATTENTION: Do not rotate the piston rod during installation.

Rotating the piston rod will break the mechanism that lets the

electric cylinder ex tend and retrac t. Use two wrenches to install

the workload.

Failure to observe these safety precautions could result in

damage to the electric cylinder and its components

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 10

10 MP-Series Electric Cylinders

If you are using a coupling piece attachment, catalog number MPAR-NE3612x, or

trunnion mounting kit, catalog number MPAR-NA1635xx, see Accessories

for torque values.

If you are using a rod guide accessory, catalog number MPAR-NE34xxx or

MPAR-NE150xxx, adjust the guides of the workload and the electric cylinder so that

they are exactly parallel. This avoids excessive wear on the guide.

on page 38

Mount the Electric Cylinder

1. Use stainless steel fasteners to mount your electric cylinder to your application.

2. Attach power and feedback cables after the electric cylinder is mounted, and use a drip

loop in the cable to keep liquids away from the connectors.

BURN HAZARD: Outer surfaces of the motor can reach high temperatures, 65 °C

(149 °F), during electric cylinder operation. Take precautions to prevent accidental

contact with hot surfaces. Failure to observe these safety precautions can result in

personal injury.

ATT EN TI ON : Consider electric-cylinder surface temperature when selecting

motor-mating connections and cables. Failure to observe these safety precautions can

result in personal injury or damage to equipment.

ATT EN TI ON : Keyed connectors must be properly aligned and hand-tightened the

recommended number of turns.

Improper connector alignment is indicated by the need for excessive force, such as the

need for the use of tools, to fully seat connectors.

Failure to observe these safety precautions could result in damage to the motor and

cable, and their components.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 11

MP-Series Electric Cylinders 11

IMPORTANT

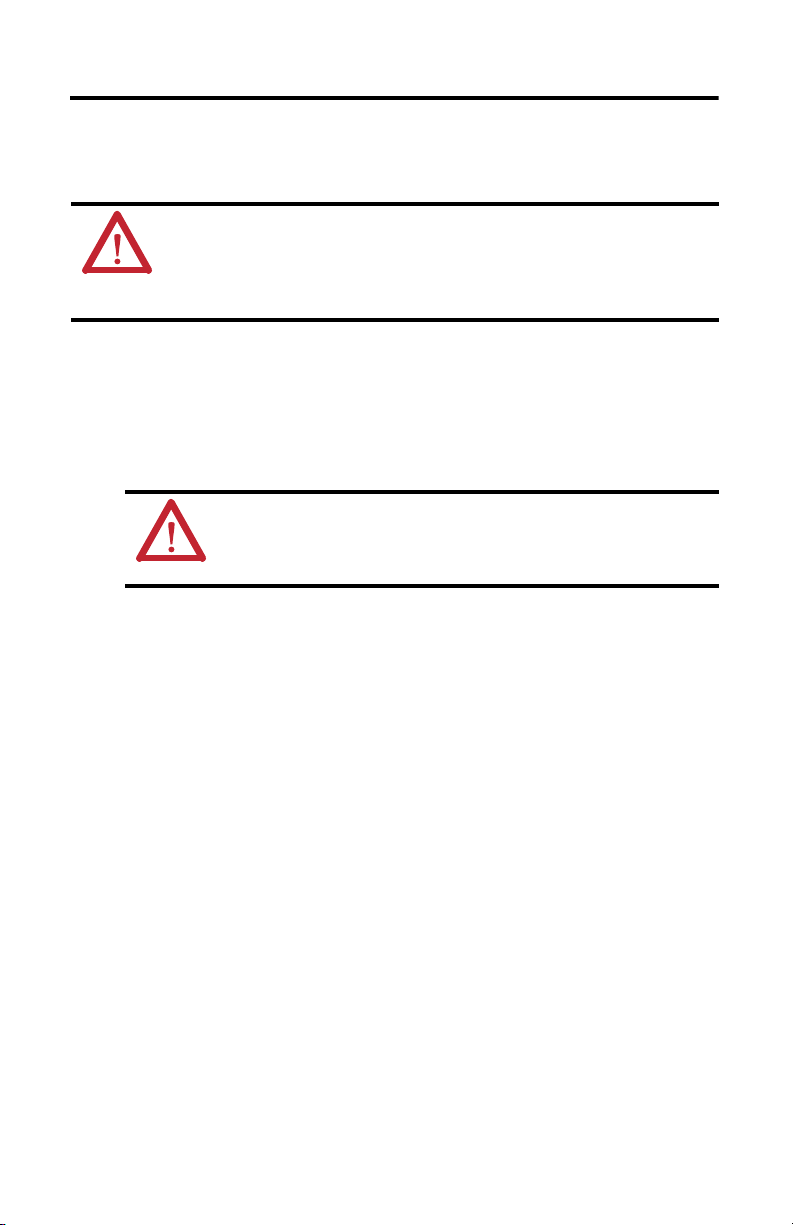

Flat Surface

with Logo on Top

Top of connector is relative to motor orientation.

Feedback Connector

Drip Loop

Power Connector

Flat Sur face

with Logo on Top

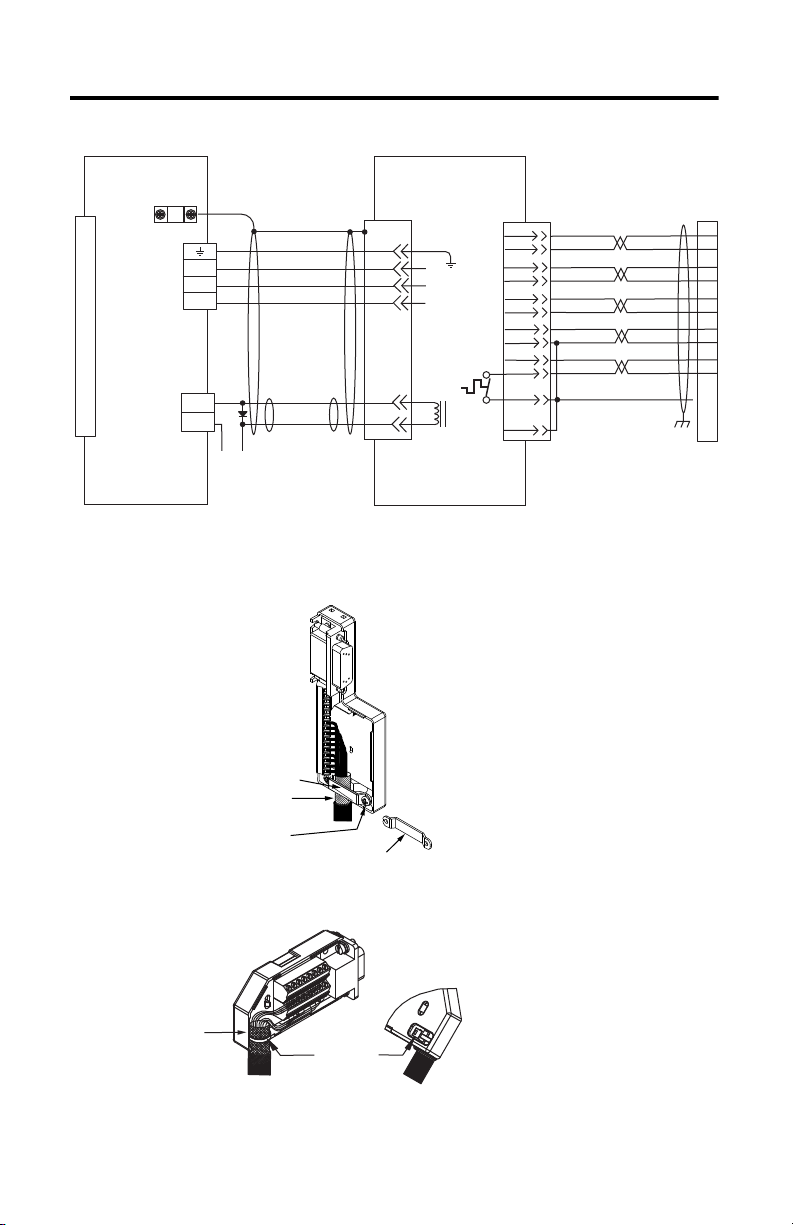

Attach Motor Cables

Follow these steps to attach the power and feedback cables after the electric-cylinder is mounted.

ATTENTION: Consider electric-cylinder surface temperature when selecting motor-mating

connections and cables.

Failure to observe these safety precautions can result in personal injury or damage to equipment.

1. Carefully align each cable connector with the respective motor connector as shown in

the following diagram.

ATTENTION: Keyed connectors must be properly aligned and hand-tightened the

recommended number of turns.

Improper connector alignment is indicated by the need for excessive force, such as the

need for the use of tools, to fully seat connectors.

Failure to observe these safety precautions can result in damage to equipment.

Remove the O-ring from the motor connector.

2. Fully seat the feedback connector and the power/brake connector and hand tighten the

collar one-quarter turn.

ATTENTION: Make sure that cables are installed and restrained to prevent uneven

tension or flexion at the cable connectors. Excessive and uneven lateral force at the cable

connectors may result in the connector’s environmental seal opening and closing as the

cable flexes. Failure to observe these safety precautions can result in damage to the

electric-cylinder motor and its components.

3. Form a drip loop in the cable to keep liquids away from the connectors.

4. Verify the continuity and functionality of the thermal switch signals, TS+ and TS-.

These signals are transmitted through the feedback cable that connects the motor to its

controlling drive.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 12

12 MP-Series Electric Cylinders

Change Connector Orientation

You can rotate the circular DIN-connector housings up to 180° in either direction.

ATTENTION: You can rotate the connectors into a fixed position during installation of the electric

cylinder and keep them in that position without further adjustment. Strictly limit the applied

forces and the number of times the connector is rotated to be sure that connectors meet the

requirements of IP66 for the motor portion of the electric cylinder.

Failure to observe these safety precautions can result in damage to the motor and its components

Follow these steps to rotate the DIN connectors.

1. Mount and fully seat a mating cable on the connector.

2. Grasp the connector and cable plug by their housings and slowly rotate them to the

outside of the motor.

If necessary, repeat this step for each connector (feedback or power/brake).

ATT EN TI ON : Apply force only to the connectors; do not apply force to the cable. Do not

use tools, for example, pliers and vise-grips, to assist with the rotation of the connector.

Failure to observe these safety precautions can result in personal injury or damage to

equipment.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 13

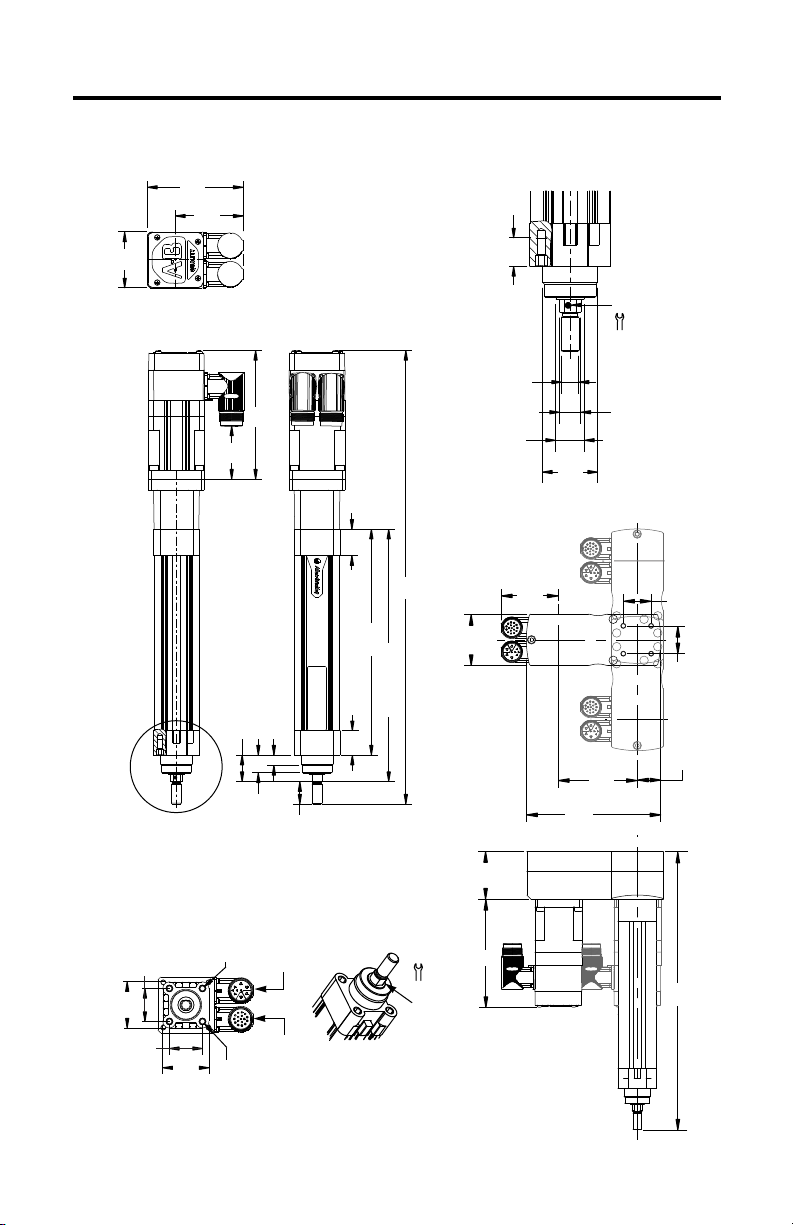

Dimensions

Detail A

+ = Plus Stroke Length

See Detail A

MP-Series Electric Cylinders (frame 32)

Dimensions ZJ, L7, and L71 are with

piston rod fully retracted.

Dimensions are in mm (in.).

Flat for wrench.

Bulletin MPAR-x1xxxx-xxA (in-line configuration)

Power/Bra ke

Connector

Feedback

Connector

MPAR-x1xxxx-xxB

MPAR-x1xxxx-xxD

MPAR-x1xxxx-xxE

Bulletin MPAR-x1xxxx-xxB/D/E

(parallel configuration)

55.0

(2.16)

MP-Series Electric Cylinders 13

94

(3.70)

66.5

(2.62)

16.0

(0.63)

10

LB

LE

26

10.0

(1.02)

(0.39)

32.5

(1.28)

45.5

(1.79)

32.5

(1.28)

45.5

(1.79)

M6 (x4)

6.0 (0.24)

18

(0.71)

22

(0.87)

(x4)

26

(1.02)

L7

122+

(4.80) +

148 ±1.0 +

(5.83 ± 0.04)+

24

(0.94)

M10x1.25

Ø16.0

(0.63) h9

66.5

(2.62)

60

(2.36)

56.0

(2.20)

LB

Ø30.0

(1.18) d11

157

92.5 ± 1

(6.18)

12.0

(0.47)

(3.64 ± 0.04)

32.5

32.5

L71

27.5

(1.28)

(1.28)

(1.08)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 14

14 MP-Series Electric Cylinders

MP-Series Electric Cylinder Dimensions (in-line configuration, frame 32)

(1)

Electric Cylind er Cat. No.

MPAR-x1100B-V2A 445.7 (17.55)

MPAR-x1200B-V2A 545.7 (21.48)

MPAR-x1300B-V2A 645.7 (25.42)

MPAR-x1400B-V2A 745.7 (29.36)

MPAR-x1100E-V2A 470.7 (18.53)

MPAR-x1200E-V2A 570.7 (22.47)

MPAR-x1300E-V2A 670.7 (26.41)

MPAR-x1400E-V2A 770.7 (30.34)

(1) If you are ordering an MPAR-x1xxxx-V4x actuator with brake, add 36.1 mm (1.42 in.) to dimensions L7 and LB.

(2) If you are ordering an MPAR-x1xxxx-V4x actuator with brake, add 33.4 mm (1.31 in.) to dimension LE.

L7

mm (in.)

(1)

LB

mm (in.)

126.5 (4.98) 52.4 (2.06)

151.5 (5.96) 77.2 (3.04)

(2)

LE

mm (in.)

MP-Series Electric Cylinder Dimensions (parallel configuration, frame 32)

Electric Cylind er Cat. No.

MPAR-x1100B-V2B/D/E 326.0 (12.8)

MPAR-x1200B-V2B/D/E 426.0 (16.8)

MPAR-x1300B-V2B/D/E 526.0 (20.7)

MPAR-x1400B-V2B/D/E 626.0 (24.6)

(1) For complete dimensions of the parallel configuration elec tric cylinders, use the

in-line dimensions for an electric cylin der with the same rod-stroke length and the

dimensions from this table.

L71

mm (in.)

(1)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 15

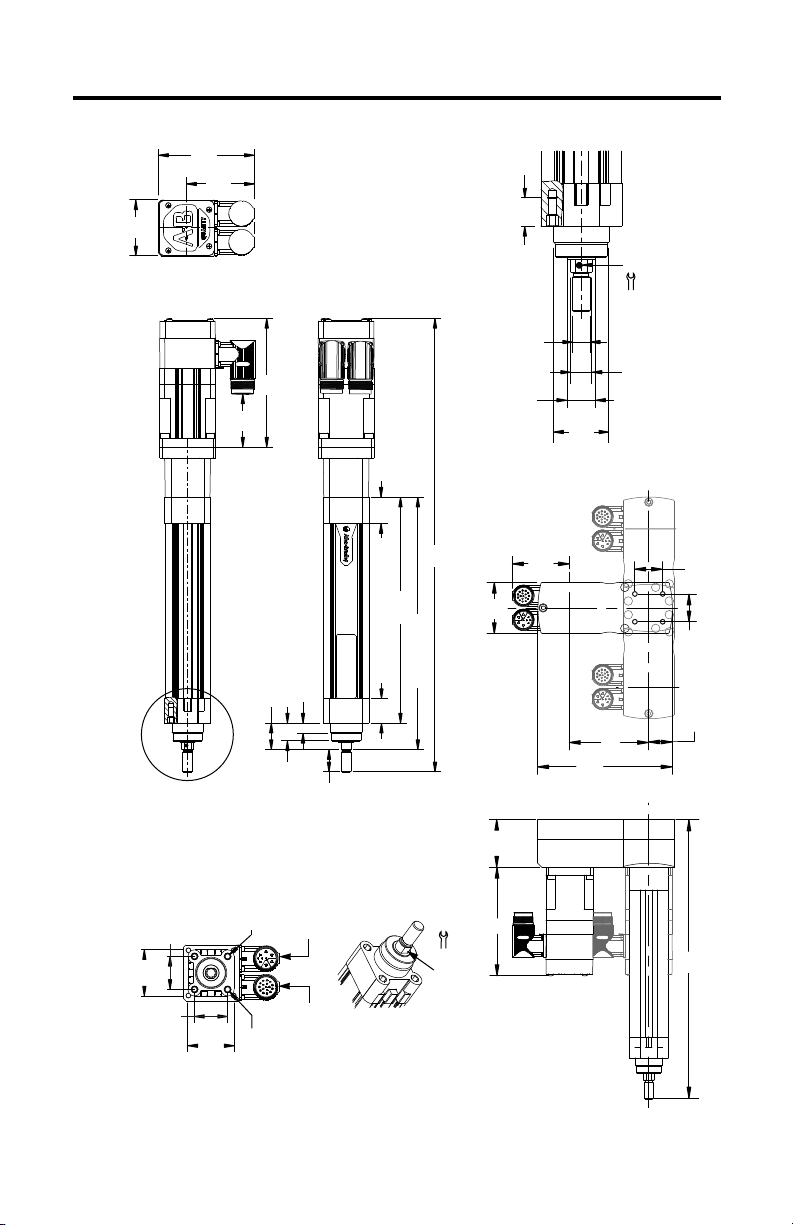

MP-Series Electric Cylinders 15

PW

LC

LB

AD

C

GC

HC

L71

54

(2.12)

54

(2.12)

38

(1.50)

38

(1.50)

6.0 (0.24)

(x4)

M6 (x4)

30

(1.18)

10.5

(0.413)

28.5

(1.12)

24

(0.94)

30

(1.18)

146.5+

(5.77) +

176.5 ± 1.0 +

(6.95 ± 0.04) +

L7

LB

LE

P

AD

HD

21.5

(0.85)

38

(1.50)

38

(1.50)

Ø35.0

(1.38) d11

Ø20.0

(0.79) h9

16.0

(0.63)

M12x1.25

16.0

(0.63)

13

+ = Plus Stroke Length

Power/Bra ke

Connector

Feedback

Connector

See Detail A

MP-Series Electric Cylinders (frame 40)

Dimensions ZJ, L7, and L71 are with

piston rod fully retracted.

Dimensions are in mm (in.).

Flat for wrench.

Bulletin MPAR-x2xxxx-xxA (in-line configuration)

MPAR-x2xxxx-xxB

Detail A

MPAR-x2xxxx-xxD

MPAR-x2xxxx-xxE

Bulletin MPAR-x2xxxx-xxB/D/E

(parallel configuration)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 16

16 MP-Series Electric Cylinders

MP-Series Electric Cylinder Dimensions (in-line, frame 40)

(1)

Electric Cylinde r

Cat. No.

MPAR-x2100C-V2A 501.2 (19.73)

MPAR-x2200C-V2A 601.2 (23.67)

MPAR-x2300C-V2A 701.2 (27.61)

MPAR-x2400C-V2A 801.2 (31.54)

MPAR-x2600C-V2A 1001.2 (39.42)

MPAR-x2100F-V2A 492.1 (19.37)

MPAR-x2200F-V2A 592.1 (23.31)

MPAR-x2300F-V2A 692.1 (27.25)

MPAR-x2400F-V2A 792.1 (31.19)

MPAR-x2600F-V2A 992.1 (39.06)

(1) If you are ordering an MPAR-x2xxxC-V4x actuator with brake, add 36.1 mm (1.42 in.) to dimensions L7 and LB.

If you are ordering an MPAR-x2xxxF-V4x actuator with brake, add 39.0 mm (1.54 in.) to dimensio ns L7 and LB.

(2) If you are ordering an MPAR-x2xxxC-V4x actuator with brake, add 33.4 mm (1.31 in.) to dimension LE.

If you are ordering an MPAR-x2xxxF-V4x actuator with brake, add 24.7 mm (0.97 in. ) to dimension LE.

L7

mm (in.)

(1)

LB

mm (in.)

151.5

(5.96)

140.1

(5.52)

(2)

LE

mm (in.)Pmm (in.)ADmm (in.)HDmm (in.)

77.2 (3.04) 55.0 (2.17) 66.5 (2.62) 94.0 (3.70)

65.1 (2.56) 70.0 (2.76) 74.0 (2.91)

109.0

(4.29)

(2)

C

mm (in.)

(1)

CG

mm (in.)PWmm (in.)

MP-Series Electric Cylinder Dimensions (parallel, frame 40)

Electric Cylinde r

Cat. No.

MPAR-x2100C-V2B/D/E 356.5 (14.03)

MPAR-x2200C-V2B/D/E 456.5 (17.97)

MPAR-x2300C-V2B/D/E 556.5 (21.91))

MPAR-x2400C-V2B/D/E 656.5 (25.84)

MPAR-x2600C-V2B/D/E 856.5 (33.72)

MPAR-x2100F-V2B/D/E 369.5 (14.55)

MPAR-x2200F-V2B/D/E 469.5 (18.48)

MPAR-x2300F-V2B/D/E 569.5 (22.42)

MPAR-x2400F-V2B/D/E 669.5 (26.36)

MPAR-x2600F-V2B/D/E 869.5 (34.23)

(1) For complete dimensions of the parallel configuration elec tric cylinders, use the in-line dimensions for an electric cylinder with the

same rod-stroke length and the dimensions from thi s table.

(2) The tolerance for this dimension is ±1.0 mm (0.04 in.).

L71

mm (in.)

LC

mm (in.)HCmm (in.)

56.0 (2.20) 157.0 (6.18) 91.5 (3.60) 27.0 (1.06) 60.0 (2.36)

69.0 (2.72) 188.5 (7.42) 102.5 (4.035) 38.0 (1.50) 86.0 (3.38)

Actuators are designed to metric dimensions. Inch dimensions are approximate conversions from

millimeters. Dimensions without tolerances are for reference.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 17

MP-Series Electric Cylinders 17

+ = Plus Stroke Length

Power/ Brake

Connector

See Detail A

MP-Series Electric Cylinders (frame 63)

Dimensions are in mm (in.).

Dimensions ZJ, L7, and L71 are

with piston rod fully retracted.

Feedback

Connector

Flat for wrench.

Detail A

Bulletin MPAR-x3xxxx-xxA (in-line configuration)

Bulletin

MPAR-x3xxxx-xxB/D/E

(parallel configuration)

MPAR-x3xxxx-xxB

MPAR-x3xxxx-xxD

MPAR-x3xxxx-xxE

HD

AD

P

LB

LE

36

34

37

15

(1.46)

(0.59)

28.5

(1.12)

32

(1.26)

(1.42)

177+

(1.34)

(6.97) +

214 ± 1.0 +

(8.42 ± 0.04) +

L7

17.0

(0.67)

17

M16x1.5

20.0

(0.79)

Ø28.0

(1.10 h9

Ø45.0

(1.77) d11

AD

110

(4.33)

120 ±1.0

(4.72 ± 0.04)

255

82

(3.23)

(10.04)

56.5

56.5

(22.2)

(22.2)

45

(1.77)

75.5

56.5

(2.97)

56.5

(2.22)

(2.22)

75.5

(2.97)

M6 (x4)

6.0 (0.24)

LB

L71

(x4)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 18

18 MP-Series Electric Cylinders

MP-Series Electric Cylinder Dimensions (in-line, frame 63)

(1)

Electric Cylinde r

Cat. No.

MPAR-x3100E-M2A 603.8 (23.77)

MPAR-x3200E-M2A 703.8 (27.71)

MPAR-x3300E-M2A 803.8 (31.65)

MPAR-x3400E-M2A 903.8 (35.58)

MPAR-x3600E-M2A 1103.8 (43.46)

MPAR-x3800E-M2A 1303.8 (51.33)

MPAR-x3100H-M2A 574.8 (22.63)

MPAR-x3200H-M2A 674.8 (26.57)

MPAR-x3300H-M2A 774.8 (30.50)

MPAR-x3400H-M2A 874.8 (34.44)

MPAR-x3600H-M2A 1074.8 (42.31)

MPAR-x3800H-M2A 1274.8 (50.19)

(1) If you are ordering an MPAR-x3xxxE-M4x actuator with brake, add 34.5 mm (1.36 in.) to dimensions L7 and LB.

If you are ordering an MPAR-x3xxxH-M4x actuator with brake, add 48.5 mm (1.91 in.) to dimensions L7 and LB.

(2) If you are ordering an MPAR-x3xxxE-M4x actuator with brake, add 34.5 mm (1.36 in.) to dimension LE.

If you are ordering an MPAR-x3xxxH-M4x actuator with brake, add 48.5 mm (1.91 in.) to dimension LE.

L7

mm (in.)

(1)

LB

mm (in.)

178.8

(7.04)

149.8

(5.90)

(2)

LE

P

mm (in.)

mm (in.)ADmm (in.)HDmm (in.)

121.5

89.4

(4.78)

(3.52)

92.5

98.3

(3.64)

(3.87)

MP-Series Electric Cylinder Dimensions (parallel, frame 63)

Electric Cylinde r

Cat. No.

MPAR-x3100x-M2B/D/E 428.0 (16.85)

MPAR-x3200x-M2B/D/E 528.0 (20.79)

MPAR-x3300x-M2B/D/E 628.0 (24.72)

MPAR-x3400x-M2B/D/E 728.0 (28.66)

MPAR-x3600x-M2B/D/E 928.0 (36.53)

MPAR-x3800x-M2B/D/E 1128.0 (44.41)

L71

mm (in.)

80.9

(3.19)

83.9

(3.30)

125.7

(4.95)

132.8

(5.23)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

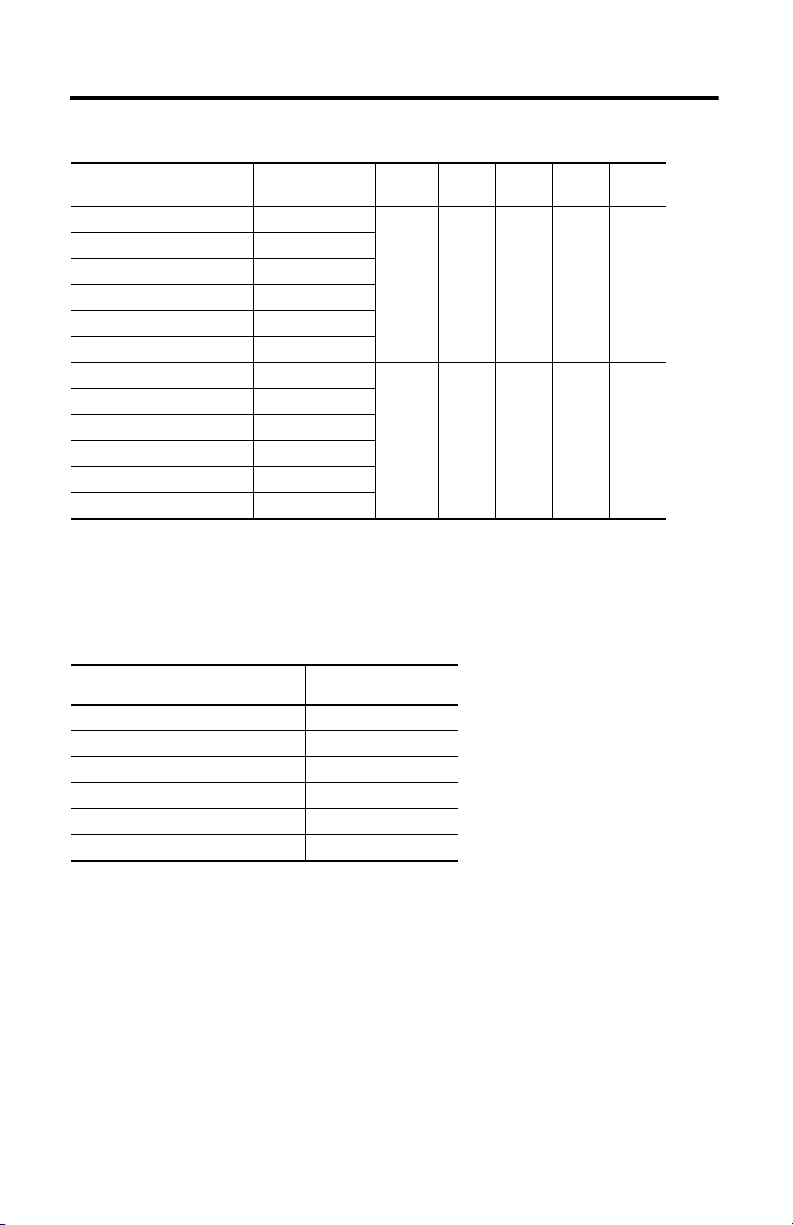

Page 19

MP-Series Electric Cylinders 19

Intercontec P/N

BEDC0091NN00000217000

Intercontec P/N

AEDC113NN00000222000

Connector Data

This table lists the signal descriptions for feedback, power, and brake connector pins on the

electric cylinder.

Feedback Power and Brake

Signal Name

Pin

MPAR-Axxxxx

(200V class)

1 Sin+ Sin+ A Phase U

2 Sin- Sin- B Phase V

3 Cos+ Cos+ C Phase W

4 Cos- Cos- D Ground

5 Data+ Data+ E Reserved

6 Data- Data- F MBRK+

7

Reserved

8H

9+5V DC L

10 Common Case Cable shield and

11 Reserved +9V DC

12 Common

13 TS+ TS+

14 TS- TS-

15

Reserved Rese rved16

17

Case Shield Shield

(1) Power pins A, B, C, and D may be labeled as U, V, W, and GND respectively. Brake pins F and G may be

labeled as + and - respectively. Reserved pins E and H may be numbe red 1 or 2.

(2) Brake+ and Brake- are available only on elec tric cylinders with a brake.

Signal Name

MPAR-Bxxxxx

(400V class)

Reserved

Pin Signal Name

(1)

(1)

(1)

(1)

(1)

(1) (2)

GMBRK-

(1) (2)

Reserved

GND

11

1

12

13

16

10

9

17

1415

4

8

6

7

5

ACBD

G

F

E

L

H

2

3

ATTENTION: Be sure that cables are installed and restrained to prevent uneven tension or

flexion at the cable connectors. Excessive and uneven force at the cable connector may result in

damage to the housing and contacts as the cable flexes. Failure to observe these safety

precautions can result in damage to the motor and its components.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 20

20 MP-Series Electric Cylinders

Mating Cables

Connector Cable Type Cable Cat. No.

Feedback Premolded 2090-CFBM7DD-CEAAxx (standard) or

Flying lead 2090-CFBM7DF-CEAAxx (standard) or

Power With brake wires 2090-CPBM7DF-xxAAxx (standard) or

Without brake wires 2090-CPWM7 DF-xxAAxx (standard) or

2090-CFBM7DD-CEAFxx (continuous-flex)

2090-CFBM7DF-CEAFxx (continuous-flex)

2090-CPBM7DF-xxAFxx (continuous-flex)

2090-CPWM7DF-xxAFxx (continuous-flex)

Commissioning

This section provides guidelines for using RSLogix™ 5000 software to configure your

electric-cylinder servo drive system.

Required Files

Firmware revisions and software versions required to support the electric cylinders include the

following:

• Kinetix 2000 or Kinetix 6000 multi-axis drives

– RSLogix 5000 software, version 16.00 or later

– Firmware revision 1.96 or later

– For RSLogix 5000 software, version 16.xx,

use Motion Database file, version 4_23_0 or later

– For RSLogix 5000 software, version 17.xx or later,

use Motion Database file, version 5_15_0 or later

• Kinetix 6200 multi-axis drives

– Firmware revision 1.30 or later

– For RSLogix 5000 software, version 17.xx,

use MPAR_5_19_11.cmf or later

• Kinetix 6500 multi-axis drives

– Firmware revision 1.11 or later

– For RSLogix 5000 software, version 18.xx,

use MPAR_5_19_11.cmf or later

• Kinetix 300 single-axis drives

– For RSLogix 5000 software, version 17.xx or later

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 21

MP-Series Electric Cylinders 21

IMPORTANT

– use Kinetix 300 drive MotionView OnBoard web interface

• Kinetix 350 single-axis Ethernet drives

– RSLogix 5000 software, version 20.xx or later

– Firmware revision 1.30 or later

• Ultra™ 3000 drives

– Firmware revision 1.52 or later

– Motion Database (.mdb) file, dated April 2010 or later

• Motion Analyzer software, version 4.7 or later

Download these files from http://www.rockwellautomation.com/support

Automation Technical Support at (440) 646-5800 for assistance.

. Contact Rockwell

Configure Your Electric Cylinder

Configure the electric-cylinder by using the basic parameter settings described in this section.

Use the procedure appropriate for your motion axis.

Drive Refer to:

Kinetix 350

Kinetix 2000

Kinetix 6000

Kinetix 6200

Kinetix 6500

Ultra3000 Configure Your Electric Cylinders with Ultraware Software

Kinetix 300 Configure the Kinetix 300 Drive for Electric Cylinders on page 32

Configure Your Elec tric Cylinder with RSLogix 5000 S oftware immediately below, and Tune Your Electric

Cyli nde r with RSLogix 5000 Software on page 27.

on page 30.

ATTENTION: Moving parts can cause injuries. Before running the electric c ylinder, make sure all

components are secure and safeguards are in place to prevent access to the path of moving

machinery.

Safeguards should prevent access to the electric cylinder until all motion has stopped.

Check that the electric cylinder is clear of foreign matter and tools. Objects hit by the moving

piston rod can become projectiles that can cause personal injury or damage to the equipment.

It is your responsibility to verify that the servo control system safely controls the electric

cylinder with regard to maximum force, acceleration, and speed.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 22

22 MP-Series Electric Cylinders

Configure Your Electric Cylinder with RSLogix 5000 Software

Use the following procedure to configure the drive for your electric-cylinder.

The procedure assumes the electric-cylinder and the Kinetix 350, Kinetix 2000, Kinetix 6000,

Kinetix 6200, or Kinetix 6500 servo drive are installed and wired as one axis of the motion

system.

ATTENTION: Incorrect parameter settings may result in uncontrolled motion with the potential for

damage to the electric cylinder.

Initiating a motion command on an electric cylinder with an incorrect Position mode setting may

result in damage to the electric cylinder and the machine in which it is installed.

1. Enter these parameters in the Axis Properties tabs of RSLogix 5000 software for the

electric cylinder.

Axis Properties

Tab

Drive/Motor Motor Catalog

Parameter Entry/Selec tion

Number

Drive Resolution 200,000

Drive Counts per Motor Rev

Select one from the list

MPAR-A1xxxB-V2x

MPAR-A1xxxB-V4x

MPAR-A1xxxE-V2x

MPAR-A1xxxE-V4x

MPAR-A2xxxC-V2x

MPAR-A2xxxC-V4x

MPAR-A2xxxF-V2x

MPAR-A2xxxF-V4x

MPAR-A3xxxE-M2x

MPAR-A3xxxE-M4x

MPAR-A3xxxH-M2x

MPAR-A3xxxH-M4x

MPAR-B1xxxB-V2x

MPAR-B1xxxB-V4x

MPAR-B1xxxE-V2x

MPAR-B1xxxE-V4x

MPAR-B2xxxC-V2x

MPAR-B2xxxC-V4x

MPAR-B2xxxF-V2x

MPAR-B2xxxF-V4x

MPAR-B3xxxE-M2x

MPAR-B3xxxE-M4x

MPAR-B3xxxH-M2x

MPAR-B3xxxH-M4

x

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 23

MP-Series Electric Cylinders 23

Axis Properties

Tab

Conversion Positioning Mode Linear

Dynamics Maximum Speed

(1) The default value is 5% more than your actu ator-rated maximum speed. Do not command maximum speed in your application in

excess of the rated speed.

(2) Accelerations in excess of these values may lead to reduction of the l ife of your actuator.

Parameter Entry/Selection (with applicable distance unit settings )

Metric English

Setting the Positioning Mode to Rotary can cause damage to the

electric cylinder or the mach ine due to incorrect positioning

Conversion Constant 66666.667 drive cnts/1.0 mm for 1693333.3 drive cnts/1.0 in. for

MPAR-x1xxxB-V2x

MPAR-xI1xxxB-V4x

Conversion Constant 20000 drive cnts/1.0 mm for 508000 drive cnts/1.0 in. for

MPAR-x1xxxE-V2x

MPAR-x1xxxE-V4x

MPAR-x3xxxE-M2x

MPAR-x3xxxE-M4x

Conversion Constant 40000 drive cnts/1.0 mm for 1016000 drive cnts/1.0 in. for

MPAR-x2xxxC-V2x

MPAR-x2xxxC-V4x

Conversion Constant 15748.0315 drive cnts/1.0 mm for 400000 drive cnts/1.0 in. for

MPAR-x2xxxF-V2x

MPAR-x2xxxF-V4x

Conversion Constant 10000 drive cnts/1.0 mm for 254000 drive cnts/1.0 in. for

MPAR-x3xxxH-M2x

MPAR-x3xxxH-M4x

(1)

150 mm/s (default 157.5 mm/s) 5.91 in/s (default 6.20 in/s)

MPAR-x1xxxB-xxx

500 mm/s (default 525 mm/s) 19.68 in/s (default 20.67 in/s)

MPAR-x1xxxE-xxx

250 mm/s (default 262.5 mm/s) 9.82 in/s (default 10.33 in/s)

MPAR-x2xxxC-xxx

640 mm/s (default 672 mm/s) 24.61 in/s (default 25.84 in/s)

MPAR-x2xxxF-xxx

500 mm/s (default 525 mm/s) 19.68 in/s (default 20.67 in/s)

MPAR-x3xxxE-xxx

1000 mm/s (default 1050 mm/s) 41.34 in/s (default 43.41 in/s)

MPARx3xxxH-xxx

(2)

Maximum Acceleration

Maximum Deceleration

6000 mm/s/s 236.22 in/s/s

(2)

6000 mm/s/s 236.22 in/s/s

Maximum Acceleration Jerk Use default values, or adjusted for your application

Maximum Deceleration Jerk Use default values, or adjusted for your application

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 24

24 MP-Series Electric Cylinders

2. Click the Homing tab.

3. Set parameters for either absolute homing or torque level-to-marker homing as shown on

this table.

Parameter Absolute Ho ming Value Torque Level-to-marker Homing Value

Mode Absolute Active

Position 0, typical 0, typical

Offset N/A 0 mm

Sequence Immediate Torque level-to-marker

Direct ion N/A R everse bidi rectional

Tor que Lev el N/A 30 %, min

Speed N/A 10 mm/s (1.97 in/s)

Return Speed N/A 10 mm/s (0.39 in/s)

Greater if the system friction, force, or weight exceeds 30% of

the Continuous Force Rating at any point in the range of

motion

ATT EN TI ON : Avoid excessive force while homing the electric cylinder. Do not exceed

10 mm/s (0.4 in/s) during a home routine.

Speeds greater than 10 mm/s (0.4 in/s) may damage the electric cylinder when the

piston rod reaches the end of travel.

4. Complete these steps for absolute homing.

a. Use motion direct commands to slowly jog your axis to your application's home

location, being sure to not exceed 10 mm/s (0.4 in/s).

b. Issue the Motion Direct Command (MAH) to set the home position on your axis.

5. Click the Limits tab.

6. Enter these parameters.

Parameter Entry/Selection (with applicable distance unit settings)

Hard Travel Limits Check if hardware limits are in use. Use the Motion Analyzer

Soft Travel Limits Check if software limits are in use. Use the Motion Analyzer

Maximum Positive Enter value that is within the piston-rod mechanical travel.

Maximum Negative Enter value that is within the piston-rod mechanical travel.

maximum stopping distance in your application to set negative and positive limits.

maximum stopping distance in your application to set negative and positive limits.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

software to determine th e

software to determine th e

Page 25

MP-Series Electric Cylinders 25

IMPORTANT

IMPORTANT

7. Set overtravel limits according to the maximum speed of the servo drive system and the

payload of the application.

Set travel limits and direction of tuning moves in reference to piston-rod star ting

position. Leave adequate travel for the piston rod to complete its moves while

tuning.

ATTENTION: Software overtravel must be set prior to initiating the tuning process.

Check the starting position of the piston rod and allow for adequate travel.

Insufficient travel while auto tuning will trigger the software overtravel or cause an

end-stop impact.

ATTENTION: Care should be taken to not exceed the physical travel limits of the electric

cylinder. Doing so will cause the electric cylinder to reach the mechanical end of stroke.

An impact at the end of stroke can physically damage the screw and internal

components of the electric cylinder.

You can determine the deceleration distance before the piston rod contacts the end of

travel based on the deceleration rate of the load, and the available peak force from the

motor/ballscrew combination. Use the Motion Analyzer

software to calculate the

minimum deceleration distance at the maximum speed of your application.

Do not exceed the maximum energy specified for end-of-travel impacts.

Cat. No. Impact Energy, max

MPAR-x1xxxx-xxx 0.0001 J

MPAR-x2xxxx-xxx 0.0002 J

MPAR-x3xxxx-xxx 0.0004 J

Maximum Velocity for End-stop Impact with No Load

Extended Mass

g (oz)

Cat. No.

MPAR-x1100B-xxx 239 (8.4) 28.9 (1.14)

MPAR-x1200B-xxx 308 (10.8) 25.5 (1.00)

MPAR-x1300B-xxx 377 (13.9) 23.0 (0.91)

MPAR-x1400B-xxx 446 (15.7) 21.2 (0.83)

MPAR-x1100E-xxx 269 (9.5) 27.3 (1.07)

MPAR-x1200E-xxx 338 (11.9) 24.3 (0.96)

MPAR-x1300E-xxx 407 (14.36) 22.2 (0.87)

Impact Velocity, max

mm/s (in/s)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 26

26 MP-Series Electric Cylinders

IMPORTANT

Maximum Velocity for End-stop Impact with No Load (continued)

Cat. No.

MPAR-x1400E-xxx 476 (16.8) 20.5 (0.81)

MPAR-x2100C-xxx 399 (14.1) 31.7 (1.25)

MPAR-x2200C-xxx 488 (17.2) 28.6 (1.12)

MPAR-x2300C-xxx 577 (20.4) 26.3 (1.03)

MPAR-x2400C-xxx 666 (23.5) 24.5 (0.96)

MPAR-x2600C-xxx 844 (29.8) 21.8 (0.86)

MPAR-x2100F-xxx 469 (16.5) 29.2 (1.15)

MPAR-x2200F-xxx 558 (19.7) 26.8 (1.05)

MPAR-x2300F-xxx 647 (22.82) 24.9 (0.98)

MPAR-x2400F-xxx 736 (26.0) 23.3 (0.92)

MPAR-x2600F-xxx 914 (32.2) 20.9 (0.82)

MPAR-x3100E-xxx 938 (33.1) 29.2 (1.15)

MPAR-x3200E-xxx 1066 (37.6) 27.4 (1.08)

MPAR-x3300E-xxx 1194 (42.1) 25.9 (1.02)

MPAR-x3400E-xxx 1322 (46.6) 24.6 (0.97)

MPAR-x3600E-xxx 1578 (55.7) 22.5 (0.86)

MPAR-x3800E-xxx 1834 (64.7) 20.9 (0.82)

MPAR-x3100H-xxx 938 (33.1) 29.2 (1.149)

MPAR-x3200H-xxx 1066 (37.6) 27.4 (1.08)

MPAR-x3300H-xxx 1194 (42.1) 25.9 (1.02)

MPAR-

x3400H-xxx 1322 (46.6) 24.6 (0.97)

MPAR-x3600H-xxx 1578 (55.7) 22.5 (0.88)

MPAR-x3800H-xxx 1834 (64.7) 20.9 (0.82)

Extended Mass

g (oz)

Impact Velocity, max

mm/s (in/s)

Absolute position is maintained while the motor feedback cable is connected to the drive. If the

cable is disconnected or if a motor fault is repor ted by the drive, the absolute home position

must be re-established.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 27

MP-Series Electric Cylinders 27

TIP

IMPORTANT

Tune Your Electric Cylinder with RSLogix 5000 Software

This section shows the steps to tune electric cylinders with RSLogix 5000 software, version 16:

• Tuning your electric cylinder requires you to calculate and configure the loop gain based

on the actual measured inertia.

• By setting travel limits, your application minimum deceleration is defined.

Follow these steps to tune your electric cylinder.

1. In the Axis Properties dialog box, click the Fault Actions tab.

2. Click Set Custom Stop Action.

These parameter settings work best if the electric cylinder is installed in a horizontal

(table top) or a wall mount (vertical) orientation.

3. In the Custom Stop Action Attributes dialog box, set the Brake Engage and the Brake

Release delay times to the values listed in Specifications

4. Reduce the default Stopping Time Limit from 10 seconds to 0.5 seconds.

on page 42.

To prevent the rod from moving or falling when installed in a vertical orientation, the

Stopping Time Limit must be set to 0.99 seconds or less.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 28

28 MP-Series Electric Cylinders

IMPORTANT

IMPORTANT

5. Click the Tune tab and enter these parameters:

• Travel Limit - Set to within software limits

• Speed (velocity)

• To r q u e / F o r c e

Set travel limits and direction of tuning moves in reference to the piston-rod starting

position. Leave adequate travel for the piston rod to complete its moves while

tuning.

ATT EN TI ON : Software overtravel must be set prior to initiating the tuning process.

Check the piston-rod starting position and allow for adequate travel.

Insufficient travel while auto tuning will trigger the software overtravel or cause an

end-stop impact.

Check Torque Offset, as shown below, only if the electric cylinder is installed in a

non-horizontal mount position.

6. Click Start Tuning to access the Motion Initiation dialog box.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 29

7. Click Yes to begin tuning the electric cylinder.

ATTENTION: Motion occurs immediately after clicking Yes.

Tuning is complete when the Tune Servo dialog box opens.

8. Click OK to exit Tuning.

The Tune Results dialog box opens.

MP-Series Electric Cylinders 29

9. If you are satisfied with the tuning results, click OK; otherwise, continue with Calculate

and Configure the Loop Gain.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 30

30 MP-Series Electric Cylinders

Calculate and Configure the Loop Gain

Calculate a position loop bandwidth based on the actual measured inertia values from the Tune

Results dialog box.

In this example, the Tune Results dialog box shows a default Position Loop Bandwidth of

45.14153 Hz and a Load Inertia Ratio of 6.8707952.

1. Calculate the Corrected Position Bandwidth.

Corrected Position Loop Bandwidth = (Initial Position Loop Bandwidth Result/(Initial

Load Inertia Ratio Result +1)

For example, 5.73532 = 45.14153/7.8707952.

2. Enter the Corrected Position Bandwidth value 5.73532 as the Position Loop

Bandwidth.

3. Click OK.

4. Answer the remaining dialog boxes to apply the values.

The proper Position Bandwidth results in a stable starting point from which you can adjust the

gains to fit your application requirements.

Configure Your Electric Cylinders with Ultraware Software

These steps assume that an electric cylinder and an Ultra3000 drive are installed and wired as one

axis of a motion system.

For help using Ultraware software as it applies to setting up your electric cylinder, refer to

Additional Resources

software.

1. Connect a serial cable, catalog number 2090-DAPC-D09xx, to the CN3 connector on

your Ultra3000 drive.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

on page 47. This procedure assumes that you are familiar with Ultraware

Page 31

MP-Series Electric Cylinders 31

2. Apply AC input power to the Ultra3000 drive.

When communication with the Ultra3000 drive is established, the Ultra3000 Motor

Database dialog box opens.

3. Click Cancel.

Ultraware software begins scanning for online drives. When a drive is found, an Online

Drive icon opens in the Workspace.

4. Double-click the Online Drive icon to view the main Drive Set-up dialog box.

5. Verify that the data in the Model Field is correct for your electric cylinder.

6. From the Displayed Units pull-down menu, choose User.

This programs Ultraware software to make distance moves in User Units (mm or in.).

7. Expand the Motor Encoder Units menu and enter the appropriate values from the table.

The drive default User Units are in motor revolutions. The table converts the displayed

User Units into units used for linear motion, either millimeters or inches.

Accelerations in excess of 6000 mm/s/s (236.2 in/s/s) may shorten the life of your

actuator. Use the values in this table to limit the acceleration and deceleration of your

actuators to 6000 mm/s/s (236.2 in/s/s).

Cat. No.

MPAR-x1xxxB

MPAR-x1xxxxE

MPAR-x2xxxC

MPAR-x2xxxF

MPAR-x3xxxE

MPAR-x3xxxH

Screw

mm/rev (in./rev)

3.0

(0.12)

10.0

(0.39)

5.0

(0.20)

12.7

(0.50)

10.0

(0.39)

20.0

(0.79)

Encoder

periods/rev

128

128

128

128

1024

1024

Veloci ty Scal e

mm/s (in/s)

43690.67

(1109742.93)

13107.20

(332922.88)

26214.40

(665845.76)

10320.63

(262144.00)

104857.60

(2663383.04)

52428.80

(1331691.52)

Posit ion Sc ale

mm (in.)

43960.67

(1116601.02)

13107.20

(332922.88)

26214.40

(665845.76)

10320.63

(262144.00)

104857.60

(2663383.04)

52428.80

(1331691.52)

Acceleration Scale

mm/s/s (in/s/s)

43960.67

(1116601.02)

13107.20

(332922.88)

26214.40

(665845.76)

10320.63

(262144.00)

104857.60

(2663383.04)

52428.80

(1331691.52)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 32

32 MP-Series Electric Cylinders

Configure the Kinetix 300 Drive for Electric Cylinders

These steps assume that an electric cylinder and the Kinetix 300 drive are installed and wired as

one axis of a motion system.

For help using the Kinetix 300 drive as it applies to setting up your electric cylinder, refer to

Additional Resources

300 drive.

1. Run MotionView Onboard software.

2. From the Drive Organizer, click Motor.

3. Verify that your electric cylinder model is displayed in the Motor Model field.

4. Click Change Motor.

The motor model will automatically update to the correct model number.

on page 47. This procedure assumes that you are familiar with the Kinetix

5. Click Yes twice.

6. Verify the motor model matches the electric cylinder model connected to the drive

7. Click OK.

8. From the Drive Organizer, click General.

9. Using values from the following table, enter Accel Limit, Decel Limit, and User Units.

User Units can be entered in rev/mm or rev/in. Your choice determines the unit of

measure for the axis.

Cat. No.

MPAR-x1xxxB-Vxx 120000 0.33333 (8.46667)

MPAR-x1xxxE-Vxx 36000 0.10000 (2.54000)

MPAR-x2xxxC-Vxx 72000 0.20000 (5.08000)

MPAR-x2xxxF-Vxx 28346 0.07874 (2.00000)

MPAR-x3xxxE-Mxx 36000 0.10000 (2.54000)

MPAR-x3xxxH-Mxx 18000 0.05000 (1.27000)

Accel/Decel Limits

rpm/s

User Units

rev/mm ( rev/in.)

10. From the Drive Organizer, click Homing.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 33

MP-Series Electric Cylinders 33

IMPORTANT

11. Enter values from the following table.

These values are recommended; your application may require different values.

Parameter Metric English

Home Accel/Decel 10.0000 mm/s

Home Offset 0.0000 mm 0.0000 in.

Home Velocity Fast 10.0000 mm/s 0.3937 in/s

Home Velocity Slow 10.0000 mm/s 0.3937 in/s

Home Switch Input B1

2

0.3937 in/s

2

12. Select recommend homing method ID = 33, Home to marker, Reverse.

13. Set overtravel limits according to the maximum speed of the servo drive system and the

payload of the application.

Set travel limits and direction of tuning moves in reference to piston rod starting

position. Leave adequate travel for the piston rod to complete its moves while

tuning.

ATTENTION: Software overtravel must be set prior to initiating the tuning process.

Check the starting position of the piston rod and allow for adequate travel.

Insufficient travel while auto tuning will cause the software overtravel to trigger an

end-stop impact.

ATTENTION: Care should be taken to not exceed the physical travel limits of the electric

cylinder. Doing so will cause the electric cylinder to reach the mechanical end-of-stroke.

Impacting the mechanical end-of-stroke can physically damage the screw and internal

components of the electric cylinder.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 34

34 MP-Series Electric Cylinders

IMPORTANT

You can determine the deceleration distance before the piston rod contacts the end of

travel based on the deceleration rate of the load, and the peak force available from the

motor/screw combination. Use Motion Analyzer

deceleration distance at the maximum speed of your application.

A positive-direction move command denotes a rod extend operation, a

negative-direction move command denotes a retract operation.

software to calculate the minimum

Tune Your Product Name/Title with MotionView OnBoard Software

1. From the Drive Organizer, select General.

2. From the Drive Mode pull-down menu, choose Autotune.

3. Enable the motor.

4. From the Drive Organizer, select Dynamics.

5. Click Autotune.

The Autotune dialog box opens with the default set to Velocity Tuning.

6. Check Velocity Tuning or Position Tuning or both.

7. Follow the instructions in the dialog box.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 35

MP-Series Electric Cylinders 35

Maintenance

Follow these steps to maintain your electric cylinder.

1. Remove power to the electric cylinder and lock-out tag-out the power source.

2. Check the axial play of the piston rod for wear of the spindle nut.

Wear on the electric cylinder leads to increased noise.

ATTENTION: If a worn spindle nut breaks on a vertically- or diagonally-mounted electric

cylinder, the workload will fall. Uncontrolled moving mass can cause personal injury or

damage to equipment.

3. Clean the electric cylinder with a soft cloth, if necessary, by using any non-abrasive

cleaning solution.

4. Lightly dampen a soft cloth with isopropyl alcohol and wipe the piston rod and seal.

5. Lubricate the piston rod with a fine layer of LUB-KC1 grease from Klueber at

http://www.klueber.com/

Storage

Store your electric cylinder for a minimal amount of time in a clean and dry location within

Specifications on page

42.

.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 36

36 MP-Series Electric Cylinders

Troubleshooting

This table describes some possible anomalies and steps you can take to correct them.

Troubleshooting

Description Possible Cause Corrective Action

Axial play too large. Wear.

Replace actuator cylinder.

Send to Rockwell Automation for repair.

Check the electric cylinder is free of stress and

evenly supported

0.2 mm (0.008 in.).

Squeaking noises or vibrations.

Piston rod does not move.

Distortions.

Needs tuning. Modify control parameters.

Running noises of the spindle

support (with strokes 300 mm

(11.81 in.) and high positioning

speeds).

Jamming in mechanical end

position, after traveling at excessive

speed or into end position.

Load is too large.

Ambient temperature too low

(increased breakaway torque in

initial run due to increasing viscosity

of the lubricants in the spindle

system).

Lubricate piston rod. See Maintenance on

page

35.

Modify positioning speed.

Normal, no impairment of function.

Loosen jamming manually.

1. Switch off power supply.

2. Remove motor and coupling housing.

3. Turn drive shaft.

Reduce speed for reference travel.

Provide software end positions, at least

0.25 mm (0.01 in.) from the mechanical end

positions (stops).

Reduce load mass.

Reduce positioning speed.

Return for repairs.

Reduce load mass.

Reduce positioning speed.

If necessary, allow higher current with servo

motors (see operating instructions for the

motor).

Controller/drive not enable. Enable controller/drive.

No response from electric cylinder.

Controller/drive faulted. Reset the controller/drive.

Improper/failed wiring. Check the wiring.

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Increase ambient temp erature.

Page 37

Troubleshooting (continued)

Description Possible Cause Corrective Action

Electric cylinder is enabled but not

operating or is operating erratically.

Electric cylinder is operating but is not

up to rated speeds/forces.

Actuator cannot move load.

Electric cylinder moves or vibrates

when piston rod is in motion.

Actuator is overheating.

Feedback cable may be damaged. Test the feedb ack cable.

Feedback wiring may be incorrect. Verify correct feedback wiring.

Motor phases are wired incorrectly

or in incorrect order.

Amplifier may be improperly tuned. Check gain settings.

Amplifier may be set up improperly

for electric cylinder used.

Force is too large for the capacity of

the electric cylinder or too much

friction is present.

Misalignment of piston rod to load. Verify load alignment.

Amplifier has too low of a current

capacity or is limited to too low of a

current capacity.

Loose mounting. Check actuator mounting.

Amplifier is improperly tunedwrong gain setting.

Duty cycle is higher than actuator

rating.

Actuator is being operated outside

of continuous rating.

Amplifier is poorly tuned, causing

excessive current to be applied to

motor.

Verify correct motor power wiring.

Check amplifier setting for number of poles,

voltage, current, resistance, inductance,

inertia, and other motor settings.

Verify fo rce requirement s.

Verify correct amplifier and settings.

Tune amplifier.

Verify load forces and electric cylinder rating.

Adjust operation to be within continuous

operation rating.

Check gain settings.

MP-Series Electric Cylinders 37

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 38

38 MP-Series Electric Cylinders

Accessories

The following diagram and tables show the available accessories and their weights. Refer to the

Kinetix Motion Control Selection Guide, publication GMC-SG001, for dimensions.

1

2

17

16

18

9

19

20

21

22

4

3

1

2

4

7

6

5

14

9

8

4

3

11

10

12

11

15

13

Accessories

Accessory Item

Cat. No.

Frame

32 MPAR-NP174369 140 (4.94)

1

Foot mo unt

attachment

40 MPAR-NP174370 280 (9.87) 40 MPAR-NP176938 280 (9.87)

63 MPAR-NP174372 550 (19.40) 63 MPAR-NP176940 550 (19.40)

32 MPAR-NA174376 240 (8.46)

Flange

2

mounting

40 MPAR-NA174377 280 (9.88) 40 MPAR-NA161847 300 (10.58)

63 MPAR-NA174379 690 (24.34) 63 MPAR-NA161849 710 (25.04)

32 MPAR-NA174411 130 (4.58)

Trunnion

3

flange

40 MPAR-NA174412 240 (8.46) 40 MPAR-NA161853 260 (9.17)

63 MPAR-NA174414 600 (21.16) 63 MPAR-NA161855 640 (22.57)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Weigh t,

approx.

g (oz)

Accessory Item

Foot mo unt

attachment

1

(corrosion

resistant)

Flange

mounting

2

(corrosion

resistant)

Trunnion

flange

3

(corrosion

resistant)

Cat. No.

Frame

Weight,

approx.

g (oz)

32 MPAR-NP176937 140 (4.94)

32 MPAR-NA161846 240 (8.46)

32 MPAR-NA161852 150 (5.29)

Page 39

Accessories (continued)

MP-Series Electric Cylinders 39

Accessory Item

Trunnion

4

support

Swivel flange

5

(pin, narrow)

Clevis foot

7

(weld-on)

Clevis foot

9

(pin)

Swivel flange

11

(pin, wide)

12 Clevis foot

Clevis foot

13

(spherical

bearing)

Foot mou nting

15

kit

Cat. No.

Frame

32 MPAR-NA32959 130 (4.58)

40 MPAR-NA32960 400 (14.11) 40 MPAR-NA161875 330 (11.64)

63 MPAR-NA32961 480 (16.93) 63 MPAR-NA161876 440 (11.64)

32 MPAR-NP174383 90 (3.17)

40 MPAR-NP174384 120 (4.23) 40 MPAR-NP31741 295 (10.40)

63 MPAR-NP174386 320 (11.29) 63 MPAR-NP31743 655 (23.10)

32 MPAR-NP31747 105 (3.70)

40 MPAR-NP31748 160 (5.64) 40 MPAR-NP174398 125 (4.41)

63 MPAR-NP31747 365 (12.87) 63 MPAR-NP174400 280 (9.88)

32 MPAR-NA31761 220 (7.76)

40 MPAR-NA31762 300 (10.58) 40 MPAR-NP174405 100 (3.53)

63 MPAR-NA31764 580 (20.46) 63 MPAR-NP174407 250 (8.82)

32 MPAR-NP174390 100 (3.53)

40 MPAR-NP174391 150 (5.29) 40 MPAR-NP176945 150 (5.29)

63 MPAR-NP174393 370 (13.05) 63 MPAR-NP176947 370 (13.05)

32 MPAR-NP33890 170 (6.00)

40 MPAR-NP33891 240 (8.46) 40 MPAR-NP161841 210 (7.41)

63 MPAR-NP33893 520 (18.34) 63 MPAR-NP161843 450 (15.87)

32 MPAR-NP5561 160 (5.64)

40 MPAR-NP5562 270 (9.52) 40 MPAR-NA163526 390 (13.76)

63 MPAR-NP5564 605 (21.34) 63 MPAR-NA163528 890 (31.39)

32 MPAR-NA174991 240 (8.46)

40 MPAR-NA174992 310 (10.93) 40 MPAR-NA31769 360 (12.70)

63 MPAR-NA174993 510 (17.99) 63 MPAR-NA31771 880 (31.0)

Weigh t,

approx.

g (oz)

Accessory Item

Trunnion

support

4

(corrosio n

resistant)

Clevis foot

6

(spherical

bearing)

Swivel flange

8

(spherical

bearing)

10 Swivel flange

Swivel flange

11

(corrosio n

resistant)

Clevis foot

12

(corrosio n

resistant)

Trunnion

14

mounting kit

Clevis foot

16

(right angle)

Cat. No.

Frame

32 MPAR-NA161874 200 (7.05)

32 MPAR-NP31740 185 (6.53)

32 MPAR-NP174397 85 (3.00)

32 MPAR-NP174404 75 (2.64)

32 MPAR-NP176944 100 (3.53)

32 MPAR-NP161840 120 (4.23)

32 MPAR-NA163525 210 (7.41)

32 MPAR-NA31768 290 (10.23)

Weight,

approx.

g (oz)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 40

40 MP-Series Electric Cylinders

MP-Series Electric Cylinders Rod-end Accessories

Accessory Item

17 Rod eye

Rod clevis

18

(threaded rod)

Rod clevis

19

(corrosio n

resista nt)

Self-aligning

21

rod coupl er

Cat. No.

Frame

32 MPAR-NE9261 70 (2.47)

40 MPAR-NE9262 110 (3.53) 40 MPAR-NE195583 110 (3.53)

63 MPAR-NE9263 210 (7.41) 63 MPAR-NE195584 210 (7.41)

32 MPAR-NE32954 140 (4.94)

40 MPAR-NE10767 210 (7.41) 40 MPAR-NE6145 170 (6.00)

63 MPAR-NE10768 500 (17.64) 63 MPAR-NE6146 390 (13.76)

32 MPAR-NE13569 110 (3.88)

40 MPAR-NE13570 180 (6.35) 40 MPAR-NE36126 180 (6.35)

63 MPAR-NE13571 400 (14.11) 63 MPAR-NE36127 250 (8.82)

32 MPAR-NE6140 210 (7.41)

40 MPAR-NE6141 220 (7.76)

63 MPAR-NE6142 650 (22.93)

Weight,

approx.

g (oz)

Accessory Item

Rod eye

17

(corrosion

resistant)

19 Rod clevis

20 Coupling piece

Cat. No.

Frame

32 MPAR-NE195582 70 (2.47)

32 MPAR-NE6144 110 (3.88)

32 MPAR-NE36125 110 (3.88)

MP-Series and TL-Series Electric Cylinders Rod Guide (item 22) Accessories

Rod Guide

Cat. No.

MPAR-NE34494 32 100 (3.9) 1.7 (3.75)

MPAR-NE34496 200 (7.9) 1.9 (4.19)

MPAR-NE34497 320 (12.6) 2.1 (4.63)

MPAR-NE150290 400 (15.7) 2.3 (5.07)

MPAR-NE34500 40 100 (3.9) 2.7 (5.95)

MPAR-NE34502 200 (7.9) 3.0 (6.61)

MPAR-NE34504 320 (12.6) 3.4 (7.50)

MPAR-NE150291 400 (15.7) 3.7 (8.16)

MPAR-NE34505 500 (19.7) 4.0 (8.82)

MPAR-NE34514 63 100 (3.9) 5.9 (13.01)

MPAR-NE34516 200 (7.9) 6.4 (14.11)

MPAR-NE34518 320 (12.6) 7.0 (15.43)

MPAR-NE34519 400 (15.7) 7.4 (16.31)

MPAR-NE34520 500 (19.7) 7.9 (17.42)

Stroke Length

mm (in.)

Frame

Weigh t, approx .

kg (lb)

Weigh t,

approx.

g (oz)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 41

Trunnion Mounting Kit

MP-Series Electric Cylinders 41

Cat. No. Frame

Size

Tor que

N•m (lb•ft)

MPAR-NA163525 32 4…5 (2.9…3.7)

MPAR-NA163526 40 8…9 (5.9…6.6)

MPAR-NA163528 63 18…20 (13.3…14.5)

Coupling Piece Attachment

Cat. No.

MPAR-NE36125 32 5.9 (4.35) 34 (25.1) 12 (8.8)

MPAR-NE36126 40 5.9 (4.35) 61 (45.0) 22 (16.2)

MPAR-NE36127 63 9.9 (7.3) 148 (109.2) 57 (42.0)

(1) Torque applies to mounting screws with standard threads and strength class 8.8. Apply torque evenly to mounting screws.

(2) Torque applies to lock nut on piston rod.

(3) Torque that the coupling can transmit with coefficient of friction μ = 0.1 and 10 x safety margin at maximum permissible tightening torque.

Frame

Size

Max Torque

N•m (lb•ft)

(1)

Max Torque

N•m (lb•ft)

(2)

Max Torque

N•m (lb•ft)

(3)

Actuator Cylinders (weight of replacement cylinder)

Actuator Cylinder

Cat. No.

(1)

Weigh t,

approx.

Actuator Cylinder

Cat. No.

kg (lb)

MPAR-X1100B 1.1 (2.43) MPAR-X2100C 1.7 (3.75) MPAR-X3100E 3.8 (8.38)

MPAR-X1200B 1.4 (3.09) MPAR-X2200C 2.2 (4.85) MPAR-X3200E 4.6 (10.14)

MPAR-X1300B 1.7 (3.75) MPAR-X2300C 2.6 (5.73) MPAR-X3300E 5.4 (11.90)

MPAR-X1400B 2.1 (4.63) MPAR-X2400C 3.1 (6.83) MPAR-X3400E 6.3 (13.89)

MPAR-X1100E 1.1 (4.63) MPAR-X2600C 4.0 (8.82) MPAR-X3600E 7.9 (17.46)

MPAR-X1200E 1.4 (3.09) MPAR-X2100F 1.8 (3.97) MPAR-X3800E 9.5 (20.94)

MPAR-X1300E 1.8 (3.97) MPAR-X2200F 2.3 (5.07) MPAR-X3100H 3.8 (8.38)

MPAR-X1400E 2.1 (4.63) MPAR-X2300F 2.8 (6.17) MPAR-X3200H 4.6 (10.14)

MPAR-X2400F 3.2 (7.05) MPAR-X3300H 5.4 (11.90)

MPAR-X2600F 4.2 (9.26) MPAR-X3400H 6.3 (13.89)

(1) Replacement actuator cylind er example, if ordering a replacement cylinder for electric cylinder cata log number MPAR-A2100C-V2A the replacement

actuator cylinder is catalog number MPAR-X2100C.

See the MP-Series and TL-Series Replacement Parts Installation Instructions, publication

MPAR-IN002

, for procedures to replace electric cylinder parts and to obtain other replacement

part catalog numbers.

(1)

Weigh t,

approx.

Actuator Cylinder

Cat. No.

kg (lb)

MPAR-X3600H 7.9 (17.42)

MPAR-X3800H 9.5 (20.94)

(1)

Weight,

approx.

kg (lb)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 42

42 MP-Series Electric Cylinders

Specifications

Brake Specifications

Electric

Cylinder

Cat. No.

MPAR-A/B1xxxB 300 (67) 0.43…0.53 23 9 18

MPAR-A/B1xxxE 350 (79)

MPAR-A/B2xxxC 525 (118)

MPAR-A/B2xxxF 800 (180) 0.46…0.56 58 20 42

MPAR-A/B3xxxE 2364 (531) 0.45…0.55 50 20 110

MPAR-A/B3xxxH 1625 (365) 0.576…0.704 110 25 160

(1) Brake release time delay with voltage applied.

(2) Brake engage time delay with voltage removed and MOV used for arc suppression.

(3) Brake engage time delay with volta ge removed and diode used for arc suppression.

Holding

Force

N (lb)

Coil Current

at 24V DC

A

Brake Response Time

(1)

Release

ms

Engage (using external

arc-suppression device)

MOV

(2)

ms

Environmental Specifications

Attribute Value

Temperature, ambient 0…40 °C (32…104 °F)

Temperature, atorage -25…60 °C (-13…140 °F)

Relative humidity (noncondensing) 5…95%

Shock 20 g peak, 6 ms duration

Vibration 2.5 g peak @ 30…2000 Hz

Diode

(3)

ms

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 43

Electric Cylinders (weight of cylinder with non-brake motor)

MP-Series Electric Cylinders 43

Electric Cylinder

Cat. No.

Weigh t,

approx.

kg (lb)

(1)

Electric Cylinder

Cat. No.

MPAR-x1100B-V2A 2.6 (5.73) MPAR-x2100C-V2A 3.7 (8.16)

MPAR-x1100B-V2B/D/E 3.5 (7.72) MPAR-x2100C-V2B/D/E 4.4 (9.70)

MPAR-x1200B-V2A 2.9 (6.39) MPAR-x2200C-V2A 4.1 (9.04)

MPAR-x1200B-V2B/D/E 3.8 (8.377) MPAR-x2200C-V2B/D/E 4.9 (10.80)

MPAR-x1300B-V2A 3.2 (7.05) MPAR-x2300C-V2A 4.6 (10.14)

MPAR-x1300B-V2B/D/E 4.1 (9.04) MPAR-x2300C-V2B/D/E 5.3 (11.68)

MPAR-x1400B-V2A 3.5 (7.72) MPAR-x2400C-V2A 5.0 (11.02)

MPAR-x1400B-V2B/D/E 4.5 (9.92) MPAR-x2400C-V2B/D/E 5.8 (12.79)

MPAR-x1100E-V2A 3.0 (6.61) MPAR-x2600C-V2A 6.0 (11.02)

MPAR-x1100E-V2B/D/E 3.8 (8.377) MPAR-x2600C-V2B/D/E 6.7 (14.77)

MPAR-x1200E-V2A 3.3 (7.27) MPAR-x2100F-V2A 4.2 (9.26)

MPAR-x1200E-V2B/D/E 4.1 (9.04) MPAR-x2100F-V2B/D/E 6.5 (14.33)

MPAR-x1300E-V2A 3.6 (7.94) MPAR-x2200F-V2A 4.7 (10.36)

MPAR-x1300E-V2B/D/E 4.5 (9.92) MPAR-x2200F-V2B/D/E 7.0 (15.43)

MPAR-x1400E-V2A 4.0 (8.82) MPAR-x2300F-V2A 5.2 (11.46)

MPAR-x1400E-V2B/D/E 4.8 (10.58) MPAR-x2300F-V2B/D/E 7.5 (16.53)

MPAR-x2400F-V2A 5.6 (12.34)

MPAR-x2400F-V2B/D/E 7.9 (17.42)

MPAR-x2600F-V2A 6.6 (14.55)

MPAR-x2600F-V2B/D/E 8.9 (19.62)

Weigh t,

approx.

kg (lb)

Electric Cylinder

Cat. No.

(1)

MPAR-x3100E-M2A 9.5 (20.94)

(1)

MPAR-x3100E-M2B/D/E 13.6 (29.98)

(1)

MPAR-x3200E-M2A 10.3 (22.71)

(1)

MPAR-x3200E-M2B/D/E 14.4 (31.75)

(1)

MPAR-x3300E-M2A 11.1 (24.47)

(1)

MPAR-x3300E-M2B/D/E 15.2 (33.51)

(1)

MPAR-x3400E-M2A 11.9 (26.23)

(1)

MPAR-x3400E-M2B/D/E 16.1 (35.49)

(1)

MPAR-x3600E-M2A 13.5 (29.76)

(1)

MPAR-x3600E-M2B/D/E 17.7 (39.02)

(2)

MPAR-x3800E-M2A 15.2 (33.51)

(2)

MPAR-x3800E-M2B/D/E 19.3 (42.55)

(2)

MPAR-x3100H-M2A 9.3 (20.50)

(2)

MPAR-x3100H-M2B/D/E 13.2 (29.10)

(2)

MPAR-x3200H-M2A 10.1 (22.27)

(2)

MPAR-x3200H-M2B/D/E 14.0 (30.86)

(2)

MPAR-x3300H-M2A 10.9 (24.03)

(2)

MPAR-x3300H-M2B/D/E 14.8 (32.63)

(2)

MPAR-x3400H-M2A 11.7 (25.79)

(2)

MPAR-x3400H-M2B/D/E 15.7 (34.61)

MPAR-x3600H-M2A 13.4 (29.54)

MPAR-x3600H-M2B/D/E 17.3 (38.14)

MPAR-x3800H-M2A 15.0 (33.07)

MPAR-x3800H-M2B/D/E 18.9 (41.67)

(1) If you are ordering an MPAR-x1xxxx-V4x or MPAR-x2xxxC-V4x electric c ylinder with brake, add 0.2 kg (0.4 lb).

(2) If you are ordering an MPAR-x2xxxF-V4x electric cylinder with brake, add 0.4 kg (0.9 lb ).

(3) If you are ordering an MPAR-x3xxxE-V4x electric cylinder with brake, add 1.0 kg (2.2 lb).

(4) If you are ordering an MPAR-x3xxxH-M4x electric cylinder with brake, add 1.7 kg (3.7 lb).

Weigh t,

approx.

kg (lb)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

Page 44

44 MP-Series Electric Cylinders

BR+

BR-

D

C

B

A

F

G

W

V

U

0

1

2

3

4

5

6

7

8

9

10