Page 1

Quick Start

Motion Control PTO Application Building Block

Connected Components Accelerator Toolkit

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Connected Components Workbench, Micro830, Micro800, PanelView, Kinetix, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Connected Components Accelerator Toolkit Outline

Chapter 1 - Micro800 Controller PTO Axis Setup

Chapter 2 - System Validation

Getting Started CCAT with System

Design Assistant Quick Start,

publication CC-QS035

Follow this path to complete your Connected Components Accelerator Toolkit (CCAT) project.

Where to Start

RockRockwell Automation Publication CC-QS033A-EN-P - February 2014 3

Page 4

Where to Start

Notes:

4 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 5

Table of Contents

Preface

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Available Connected Components Accelerator Toolkits . . . . . . . . . . . . . . 9

Chapter 1

Micro800 Controller PTO Axis Setup

System Validation

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Configure the Kinetix 3 Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configure Your Kinetix 3 Drive and Personal Computer

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connect to Your Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configure Your Drive by Using Connected Components

Workbench Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configure the Micro800 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Change to Your Controller Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configure the PTO Channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

I/O Assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Configure Drive Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Configure Communication Attributes . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Configure Your Controller Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Configure Input Filter for High Speed Counter . . . . . . . . . . . . . . . . . . . . 36

Configure PanelView Component Terminal Communication

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connect Your Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Download Your Program to the Controller . . . . . . . . . . . . . . . . . . . . . . . . 41

Configure the IP Address for Your PanelView Component

Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Transfer Your HMI Application to the PanelView Component

Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Validate Your System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Understand the Machine Overview Screen . . . . . . . . . . . . . . . . . . . . . 46

Understand the Machine Functions Screen . . . . . . . . . . . . . . . . . . . . . 46

Explore the Command and Status Screen. . . . . . . . . . . . . . . . . . . . . . . 48

Explore the Axis Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . 50

Explore the Kinetix 3 and HSC Configuration Screen . . . . . . . . . . . 51

Explore the Advance Move Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 5

Page 6

Table of Contents

Explore the Kinetix 3 Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Explore the Fault Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Appendix A

Kinetix 3 Drive Component-class

User-defined Functional Block

Global Variables

Motion Axis Setup for PTO Building

Block

Configure a Series A Kinetix 3 Drive

PTO Application Building Block User-defined Function Block . . . . . . 59

RA_Motion_Move_Cmd User-defined Function Block . . . . . . . . 59

RA_K3_MBUS_STS User-defined Function Block . . . . . . . . . . . . . . . . . 64

RA_K3_MBUS_STS_Extended User-defined Function Block. . . . . . . 67

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Appendix C

I/O assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Motor and Load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Dynamics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Appendix D

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Configure Your Personal Computer and Kinetix 3 Drive

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Configure Your Drive with Ultraware Software. . . . . . . . . . . . . . . . . . . . . 91

Configure Your Drive for Modbus Communication Protocol . . . . . . . . 93

6 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 7

Preface

About This Publication

This quick start is designed to provide instructions for implementing a Pulse-Train Output (PTO) motion control of a

Kinetix® 3 component-class drive by using Connected Components Workbench™ software and a Micro800™ programmable

logic controller (PLC).

To assist in the design and installation of your system, application files and other information are provided by the

Connected Components Accelerator Toolkit (CCAT). The CCAT provides bills of materials (BOM), CAD drawings for

panel layout and wiring, control programs, Human-machine interface (HMI) screens, and more. With these tools and the

built-in best-practices design, the system designer is free to focus on the design of their machine control and not on design

overhead tasks.

The CCAT is available on the Connected Components Accelerator Toolkit DVD, publication CC-QR002, or through

the Rockwell Software Download and Registration System (SDRS) at

rockwellautomation/products-technologies/connected-components/tools/accelerator-toolkit.page.

The beginning of each chapter contains the following information. Read these sections carefully before beginning work in

each chapter:

• Before You Begin - This section lists the steps that must be completed and decisions that must be made before

starting that chapter. The chapters in this quick start do not have to be completed in the order in that they appear,

but this section defines the minimum amount of preparation required before completing the current chapter.

• What You Need - This section lists the tools that are required to complete the steps in the current chapter. This

includes, but is not limited to, hardware and software.

• Follow These Steps - This section illustrates the steps in the current chapter and identifies the steps that are required

to complete the examples.

http://www.rockwellautomation.com/

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 7

Page 8

Preface

Terminology

Term (abbreviation) Definition

Application Sequence Programs User-modified programs that work together with the standard state machine logic to

Auto/manual Operation When the PanelView™ Component terminal is in Auto mode, the controller logic controls

Bill of Materials (BOM) A list of components needed for your system.

Building Block (BB) Tools for accelerating and simplifying the development of a Micro800 controller-based

Computer-Aided Design (CAD) A computer-based system developed to facilitate design of mechanical parts.

Connected Comp onents Accelerator Toolkit (CCAT) Software with application files and other information to speed the design and star tup of

Connected Components Workbench Software environment for configuring or programming Micro800 controllers, PanelView

Connected Components Workbench Project A project consists of one or more of the following:

Global Variables Project variables that can be accessed by any program, including all I/O and system

State Machine Control Code Machine logic for coordinating overall machine operation based on states. The state

Tag s A PanelView Component term for variables.

User-defined Function Blocks (UDFBs) Function block instructions that can be used like standard function block instruc tions

User-defined Object (UDO) A collection of PanelView Component terminal screen objects that can be pasted into a

control what the machine does while in the abort, clear, reset, run and stop states.

the machine and monitors machine status.

When the PanelView Component terminal switches to Manual mode, the terminal takes

over control. Command buttons and numeric entry fields are available only when the

machine is in Manual mode.

application. A typical building block includes a starting Bill of Material (BOM), ComputerAided Design (CAD) drawings, Micro800 controller programs, PanelView Component

terminal applications, and a quick star t document.

component-based machines.

Component terminals, Kinetix 3 drives, and other component-level products.

• Micro800 controller configuration

• Up to 256 Micro800 controller programs, each with program local variables

• Micro800 controller global variables

• PanelView Component terminal application

• Kinetix 3 drive parameter lists

variab les.

machine broadcasts commands and receives feedback information from each of the

building blocks via user-modified application sequence programs.

within any Connected Components Workbench programming language. These can be

written by anyone using Connected Components Workbench software. Many UDFBs are

posted on the Rockwell Automation sample code website: http://

samplecode.rockwellautomation.com/idc/groups/public/documents/webassets/

sc_home_page.hcst.

new screen.

8 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 9

Additional Resources

These documents contain additional information concerning related products from Rockwell Automation.

Resource Description

Connected Components Accelerator Toolkit DVD,

publication CC-QR002

Micro800 and Connected Components Workbench Getting

Started Guide, publication 2080-QR001

Micro800 and Connected Components Workbench Application

Guide, publication 2080-QR002

Micro800 Programmable Controller External AC Power Supply

Installation Instructions, publication 2080-IN001

Micro800 Plug-in Modules User Manual,

publication 2080-UM004

Micro820 Programmable Controllers User Manual,

publication 2080-UM005

Micro830™ Programmable Controllers User Manual, publication

2080-UM002

PanelView Component Installation Instructions, publication

2711C-IN001

PanelView Component Operator Terminals User Manual,

publication 2711C-UM001

Kinetix 3 Component Servo Drives User Manual, publication 2071-

UM001

Kinetix 3 Host Commands for Serial Communication Reference

Manual, publication 2071-RM001

Kinetix 3 Component Servo Drives Installation Instruction,

publication 2071-IN001

Provides files for the Connected Component Accelerator Toolkits.

Provides information on basic Micro800 controller and Connected Components Workbench software functions.

Provides procedures for completing basic tasks in Connected Components Workbench software and for using

Connected Components Workbench software with component-class products.

Provides information on mounting and wiring the optional external power supply.

Provides information on installing Micro800 plug-in modules and accessories including wiring and

troubleshooting.

Provides information on installing Micro820 controllers including wiring and troubleshooting.

Provides information on installing the Micro830 Programmable Controller including wiring and troubleshooting.

Provides information on installing the PanelView Component HMI terminals including wiring, grounding, and

troubleshooting.

Provides information about using PanelView Component HMI terminals.

Provides a reference guide for Kinetix 3 drive systems, and accessories. It also contains procedures on how to

install, wire, and troubleshoot your drive.

Provides information on the serial communication commands, both ASCII and ModBus-RTU, for interfacing a

motion controller with the Kinetix 3 drive.

Provides information on installing your Kinetix 3 drive system.

Preface

You can view or download publications at http://www.rockwellautomation.com/literature. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation sales representative.

Available Connected Components Accelerator Toolkits

For the most up-to-date listing of available Connected Components Accelerator Toolkits and related quick starts, refer to

these resources:

• Rockwell Automation Connected Components Accelerator Toolkit website at http://

www.rockwellautomation.com/rockwellautomation/products-technologies/connected-components/tools/

accelerator-toolkit.page

• Connected Components Accelerator Toolkit Building Block Project Descriptions Quick Reference, publication

CC-QR003

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 9

Page 10

Preface

Notes:Notes:

10 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 11

Chapter 1

Micro800 Controller PTO Axis Setup

In this chapter, you configure a Pulse-Train-Output channel in a Micro800 controller to control a Kinetix 3 drive. You set

up the Modbus RTU communication for the controller to monitor drive status.

Before You Begin

Review the Getting Started CCAT with System Design Assistant Quick Start, publication CC-QS035.

What You Need

Kinetix 3 Drive Setup:

• Personal computer with an available USB port

• Connected Components Workbench software, version 6 or later

• RSLinx® Classic software

• 1203-USB converter

• 2090-CCMUSDS-48AAxx Communication cable

• Kinetix 3 drive Series B or later; firmware revision 3.005 or later

Micro800 Controller Setup:

• Personal computer with an available USB port

• Connected Components Workbench software, version 6 or later

• USB printer cable (A to B) for personal computer to Micro800 controller communication

• Micro830 or Micro850 controller with transistor output

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 11

Page 12

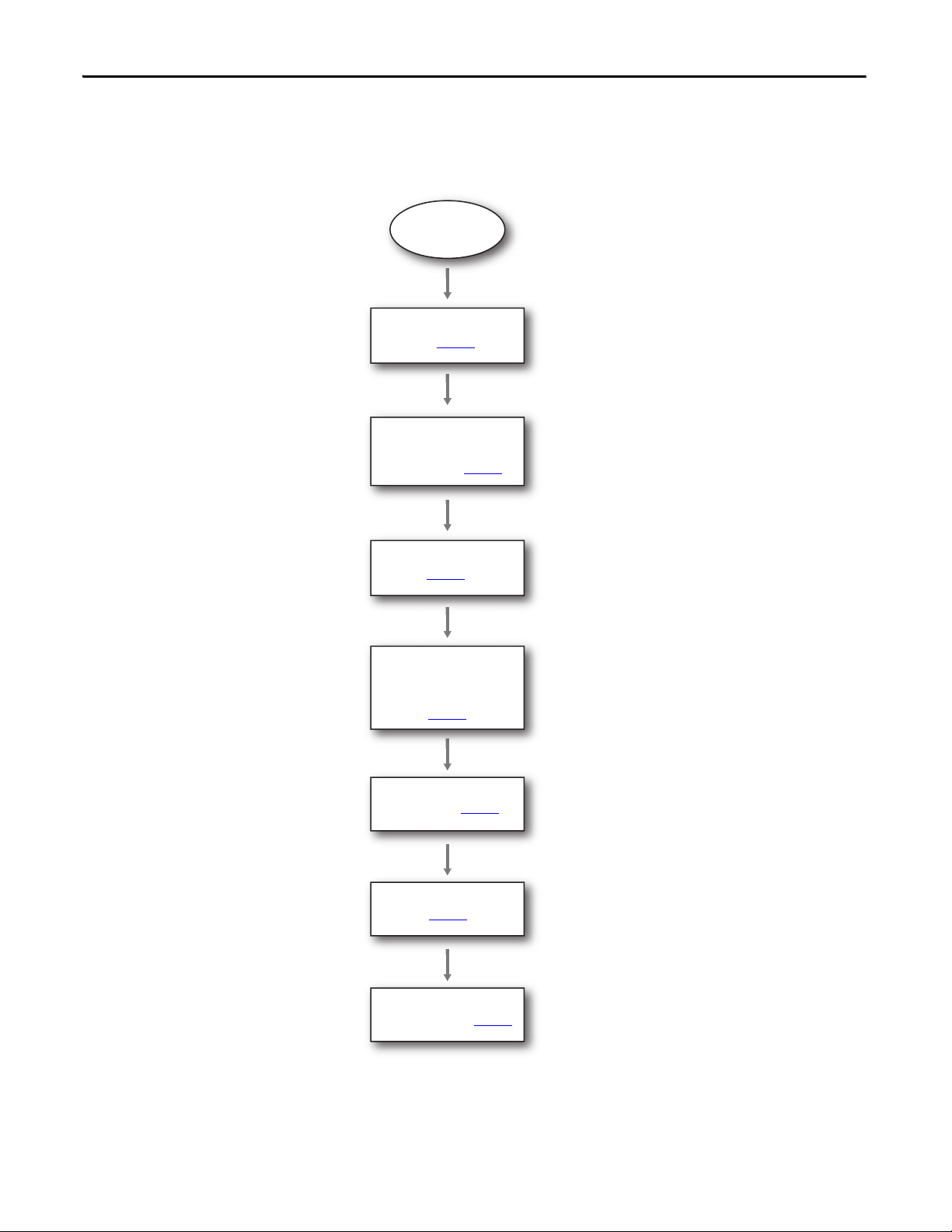

Chapter 1 Micro800 Controller PTO Axis Setup

Start

Configure the Kinetix 3 Drive

on page 13

Configure Your Kinetix 3 Drive

and Personal Computer

Connection on page 14

Connect to Your Drive on

page 18

Configure Your Drive by Using

Connected Components

Workbench Software on

page 21

Configure the Micro800

Controller on page 24

Configure the PTO Channel on

page 26

Configure Drive

Communication on page 28

Follow These Steps

Follow these steps to configure your Micro800 Controller and Kinetix 3 drive for PTO.

12 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 13

Micro800 Controller PTO Axis Setup Chapter 1

Configure the Kinetix 3 Drive

In this section, you configure your personal computer and Series B Kinetix 3 drive with firmware revision 3.005 by using

Connected Components Workbench version

attached to the side of the product.

See Figure 1 and Figure 2 to identify the Series of your Kinetix 3 drive.

Figure 1 - Label of Series B Kinetix 3 Drive - That Is Supported by Connected Components Workbench Version 6 or Later

BULLETIN 2071 Kinetix 3 Component Servo Drive, 400W

CAT. NO. 2071-AP1 SERIES B PN-185999

INSTRUCTION MANUAL 2071-IN001x-EN-P FIRMWARE VER. V03.01

Figure 2 - Label of a Series A Kinetix 3 Drive - That Is Supported by Ultraware Software Only

6 or later software. You can find the hardware series identifier on the label

MAX SHORT CIRCUIT 1000,000A

BULLETIN 2071 Kinetix 3 Component Servo Drive, 1.1A

CAT. NO. 2071-AP1 SERIES A

MAX SHORT CIRCUIT 1000,000A

INSTRUCTION MANUAL 2071-IN001x-EN-P FIRMWARE VER. V02.00

To configure a Series A Kinetix 3 drive, refer to Configure a Series A Kinetix 3 Drive in Appendix D.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 13

Page 14

Chapter 1 Micro800 Controller PTO Axis Setup

5

2

1

3

4

Configure Your Kinetix 3 Drive and Personal Computer Connection

Follow these steps to configure the connection between your personal computer and your drive.

1. Verify your Kinetix 3 drive is Series B with firmware revision 3.005 or later.

Refer to page 13 for examples.

2. Use the keypad on the front of the drive to set the following parameters.

Parameter Name Parameter Setting

Drive Address Pr0.07 248

Serial Port Configuration Pr0.09 1102

where, 2 - 19,200 Kbps Baud Rate

0 - 8 Data Bits, No Parity, 1 Stop Bit

1 - Modbus-RTU protocol

1 - RS-485

3. Connect the Kinetix 3 drive to your personal computer by using cables shown here.

Item Description

1 Kinetix 3 drive

2 1203-USB converter cable, catalog number 2090-CCMUSDS-48AAxx

3 1203-USB converter

4 USB cable

5 Personal computer with Connected Components Workbench software

If you are prompted to install drivers, use the recommended drivers.

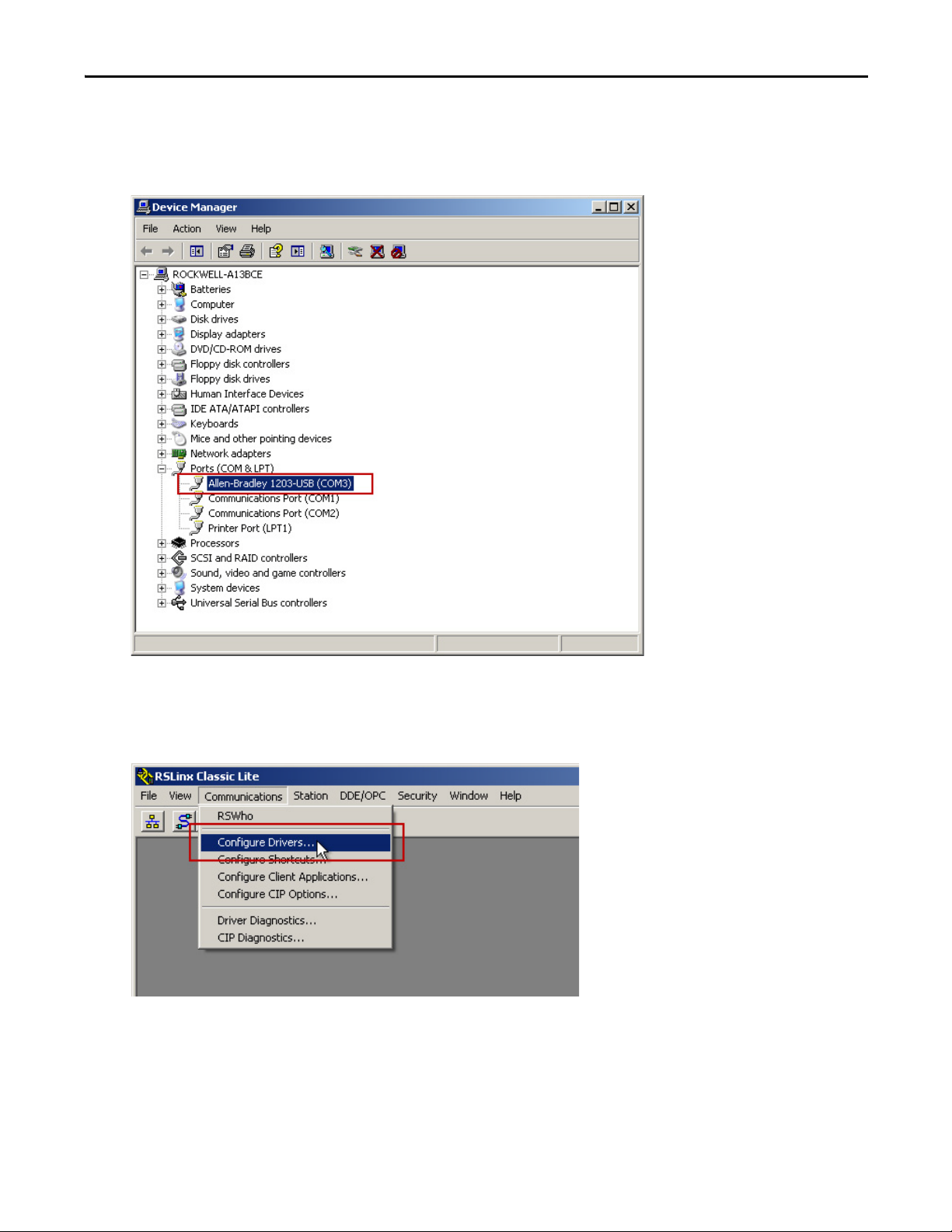

4. Verify the COM port number of the 1203-USB adapter in Device Manager on your computer, from the Start menu,

choose Run.

The Run dialog box appears.

5. Type devmgmt.msc in the Open field.

14 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 15

Micro800 Controller PTO Axis Setup Chapter 1

6. Expand the Ports (COM & LPT) group, and locate the Allen-Bradley® 1203-USB device.

The COM port is specified in parenthesis next to the device name, COM3 in this example. It can be different on

your computer.

7. Note your COM port name and close the Device Manager window.

8. To configure an RS-232 DF1 driver, start RSLinx® Classic software.

9. From the Communication menu, choose Configure Drivers.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 15

Page 16

Chapter 1 Micro800 Controller PTO Axis Setup

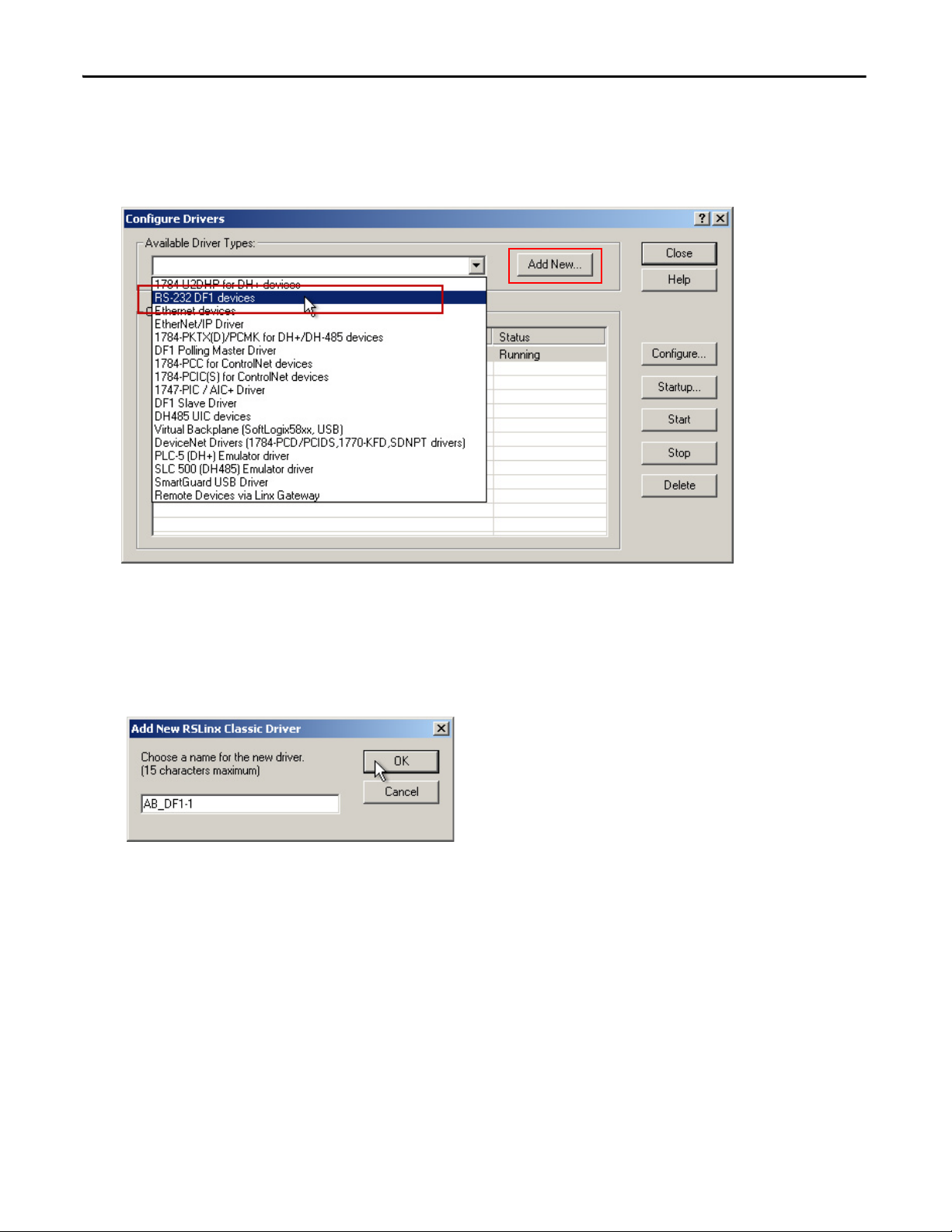

The Configure Drivers dialog box appears.

10. From the Available Driver Types pull-down menu, choose RS-232 DF1 devices.

11. Click Add New.

The Add New RSLinx Classic Driver dialog box appears.

12. Type a name for your driver,

You can use the default name, if desired.

13. Click OK.

16 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 17

Micro800 Controller PTO Axis Setup Chapter 1

IMPORTANT

a

b

c

d

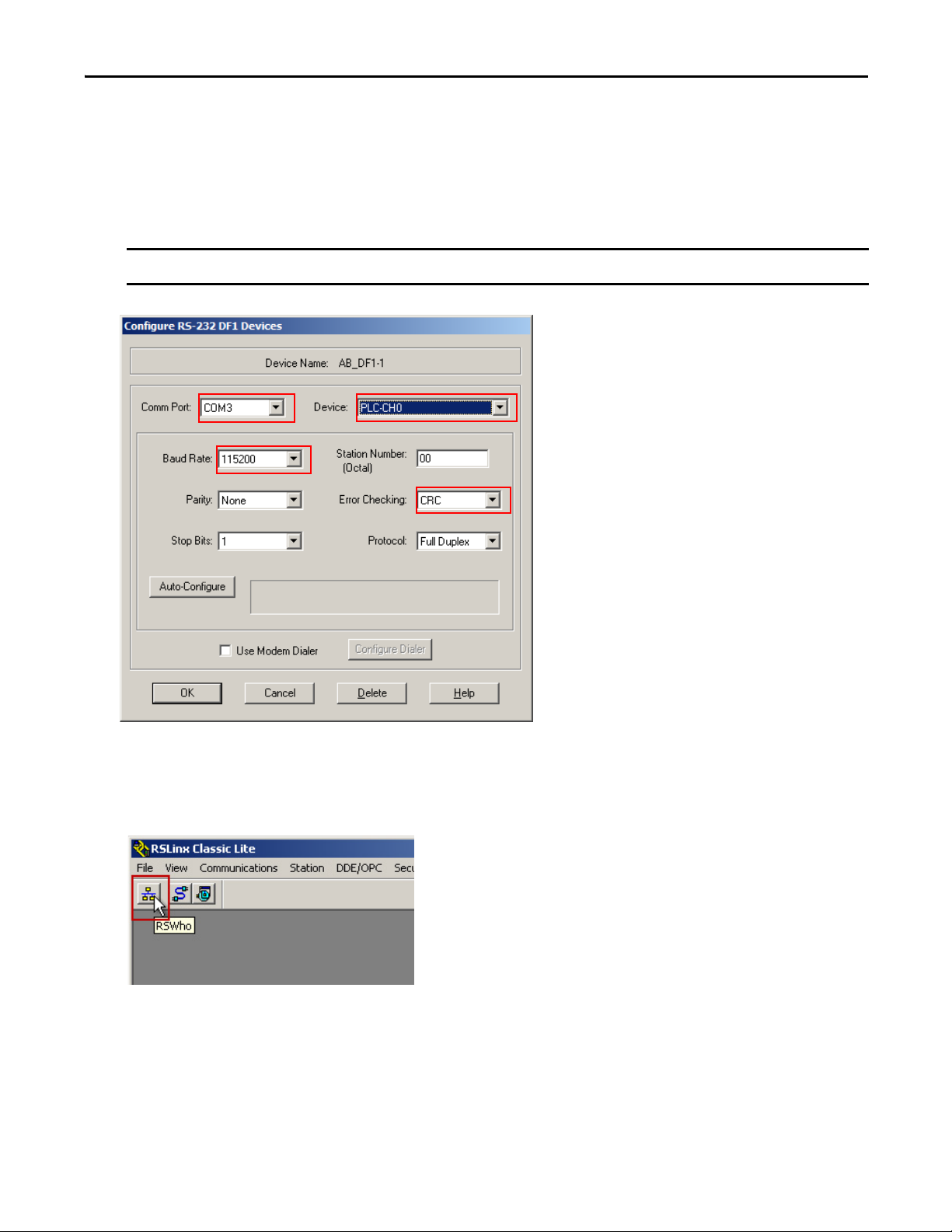

14. Configure the driver settings.

a. From the Comm Port pull-down menu, choose the port number of your 1203-USB serial adapter.

b. From the Device pull-down menu, choose PLC-CH0.

c. From the Baud Rate pull-down menu, choose 115200 baud rate.

d. From the Error Checking pull-down menu, choose CRC.

Do not click auto-configure.

15. Click OK.

16. In the RSLinx tool bar, click the RSWho icon to verify that your drive is properly communicating with RSLinx

Classic software.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 17

Page 18

Chapter 1 Micro800 Controller PTO Axis Setup

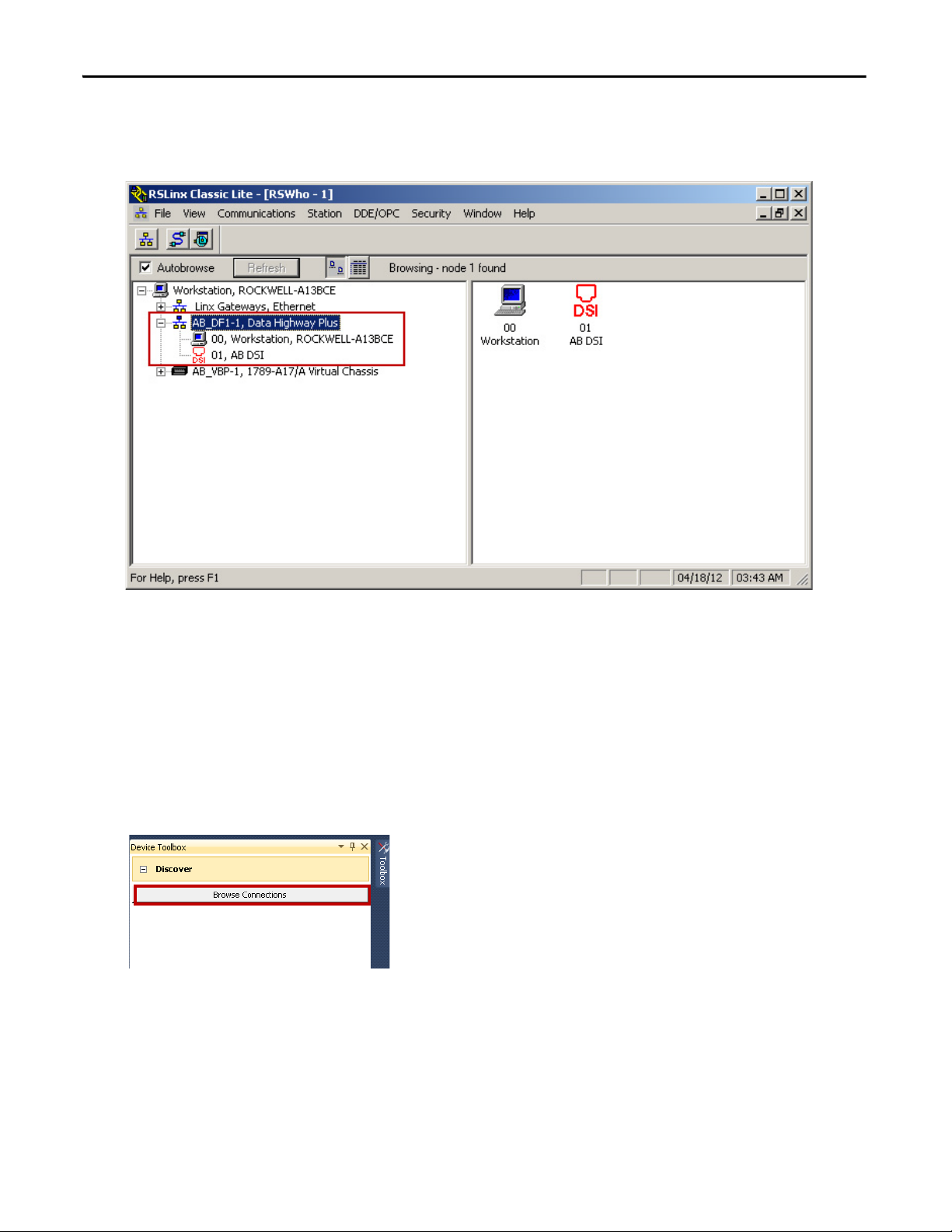

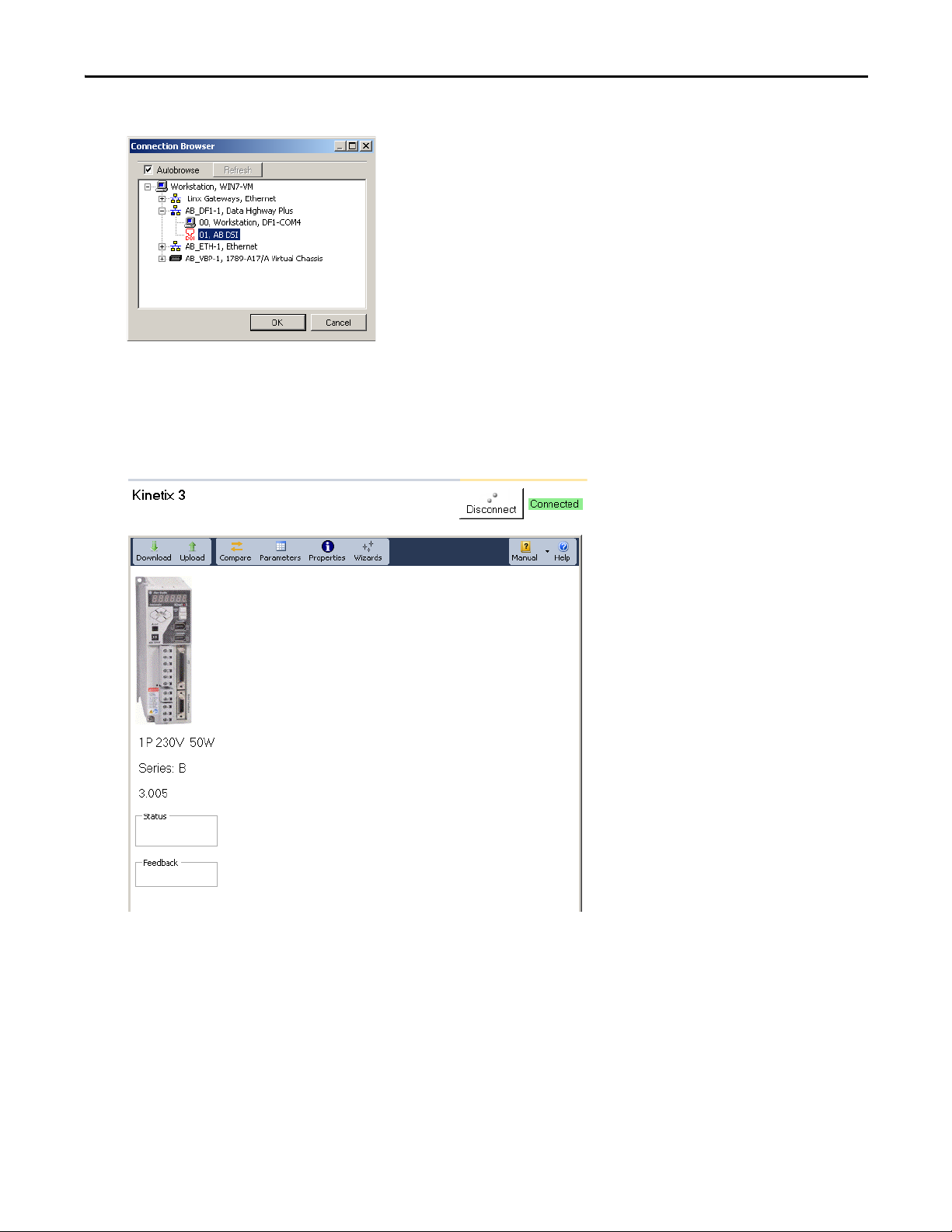

17. Expand your RS-232 DF1 driver, and verify that your drive is displayed.

It is listed as 01, AB DSI. If the drive is not displayed below the driver, check your COM port and driver settings.

18. Close RSLinx Classic software.

Connect to Your Drive

Follow these steps to connect to the Kinetix 3 drive. The Kinetix 3 drive must be Series B or later with firmware revision

3.005 or later.

1. From the Connected Components Workbench Device Toolbox, expand Discover, and click Browse Connections.

The Connection Browser dialog box appears.

18 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 19

Micro800 Controller PTO Axis Setup Chapter 1

TIP

2. From the Connection Browser, under AB_DF1-1, select your drive (01, AB DSI) and click OK.

A drive is added to the Project Organizer and the drive's Device Details window appears in the main project

workspace.

First time uploads take longer.

3. Follow these step to reset the drive to default settings.

This provides consistent drive settings.

a. From the Toolbar, click the Wizard icon.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 19

Page 20

Chapter 1 Micro800 Controller PTO Axis Setup

b. Select Kinetic 3 Startup Wizard and click Select.

c. Click Reset to Factory Settings.

The drive is resets.

d. Click Finish.

20 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 21

Micro800 Controller PTO Axis Setup Chapter 1

b

c

d

e

Configure Your Drive by Using Connected Components Workbench Software

Follow these steps to configure your drive parameters for the PTO building block.

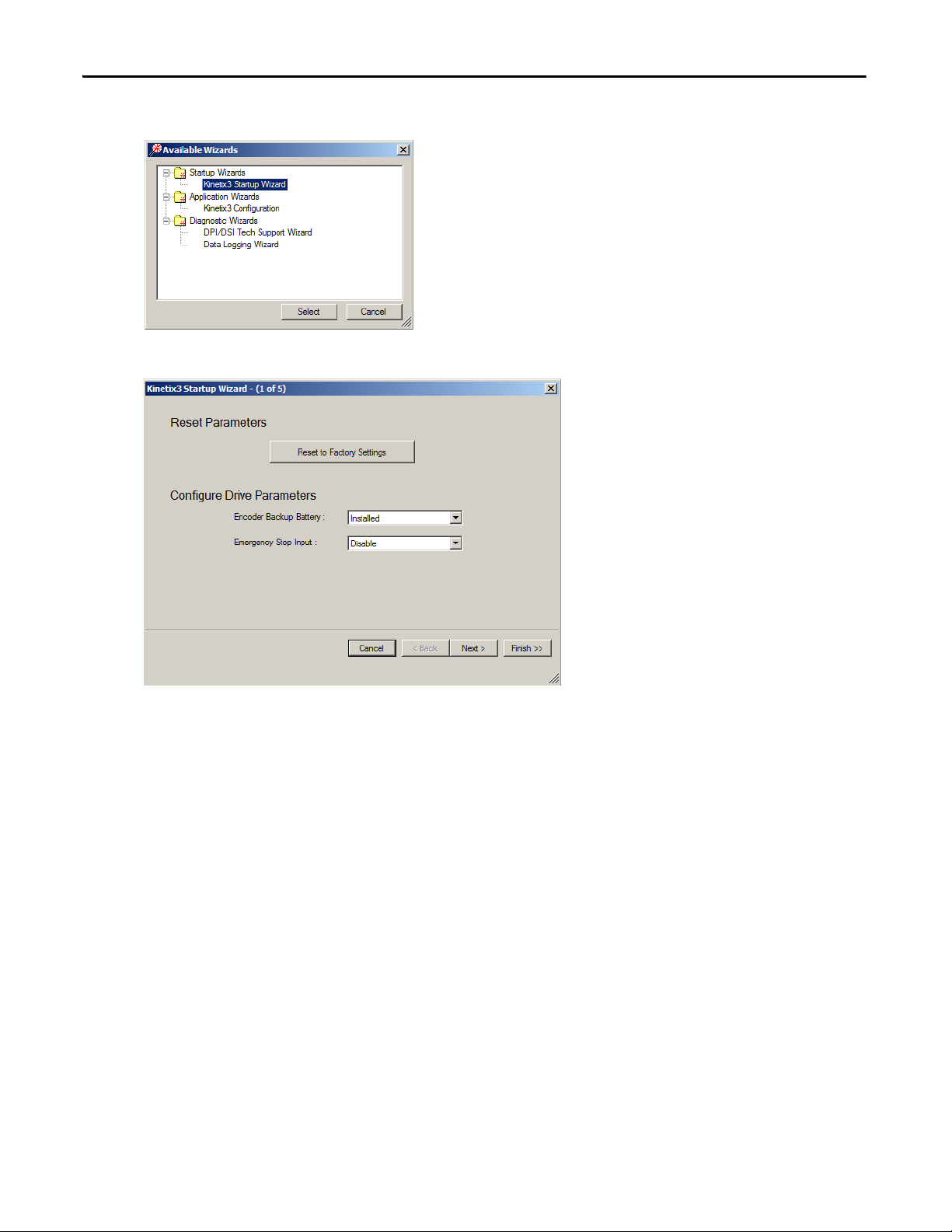

1. From the Tool bar, click the Wizard icon.

The Available Wizards dialog box appears.

2. From the list, select the Kinetix 3 Configuration wizard and click Select.

The application window appears.

3. Follow these steps to configure the Follower mode.

a. Click Next until Follower is highlighted.

b. From the Set Command Type pull-down menu, choose Step/Direction, Positive Logic.

c. From the Controller Output Type pull-down menu, choose Open Collector Input.

d. From the 1st Gear Ratio Change pull-down menu, choose Always Enable.

e. Type 1:128 for 1st Gear Ratio.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 21

Page 22

Chapter 1 Micro800 Controller PTO Axis Setup

b

c

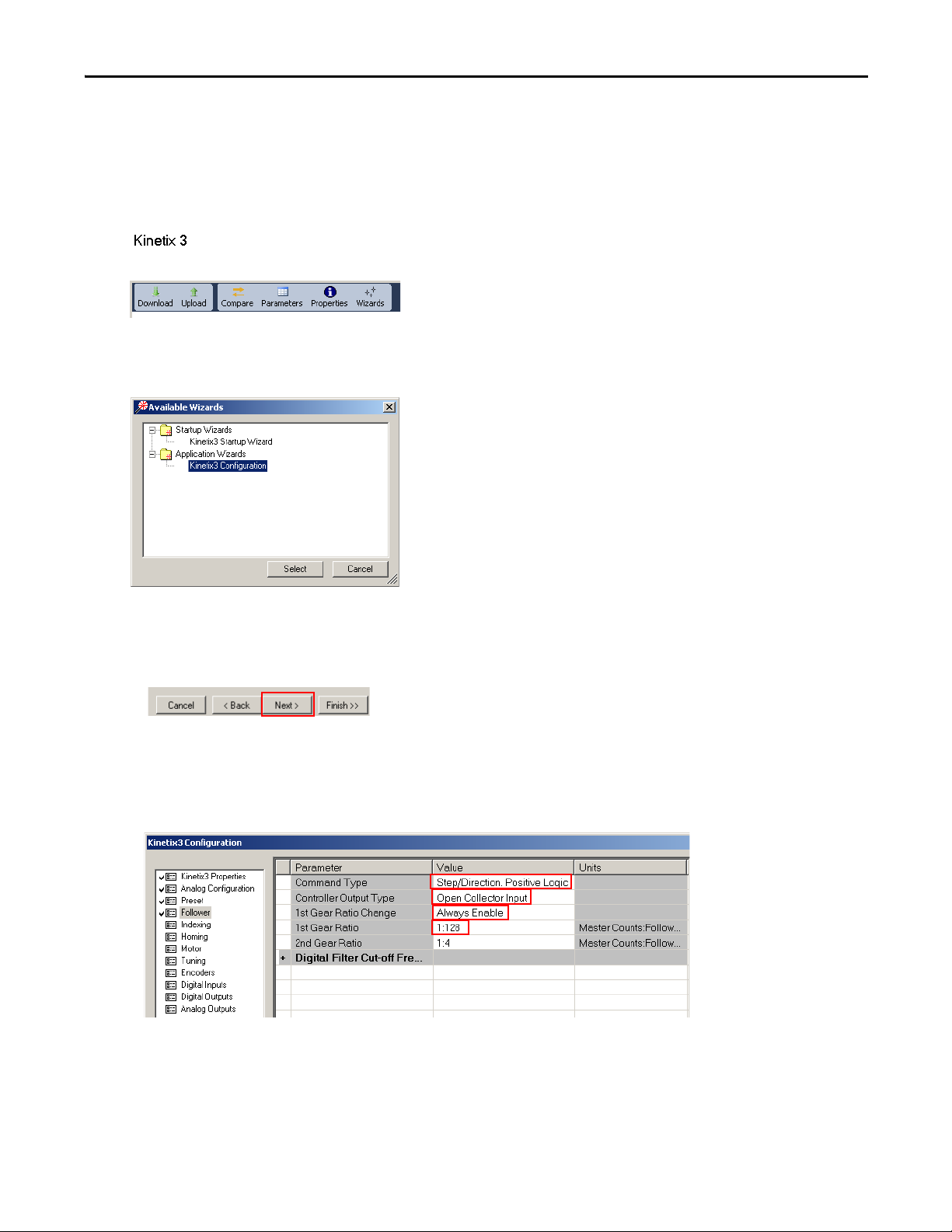

4. Follow these steps to configure the encoder.

a. Click Next to highlight Encoder.

b. Type 1:128 for the Output Ratio.

c. From the Encoder Backup Battery pull-down menu, choose Not Installed.

5. Follow these steps to auto tune your motor.

a. Choose Tuning.

b. From the right pane, click Start Autotuning.

22 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 23

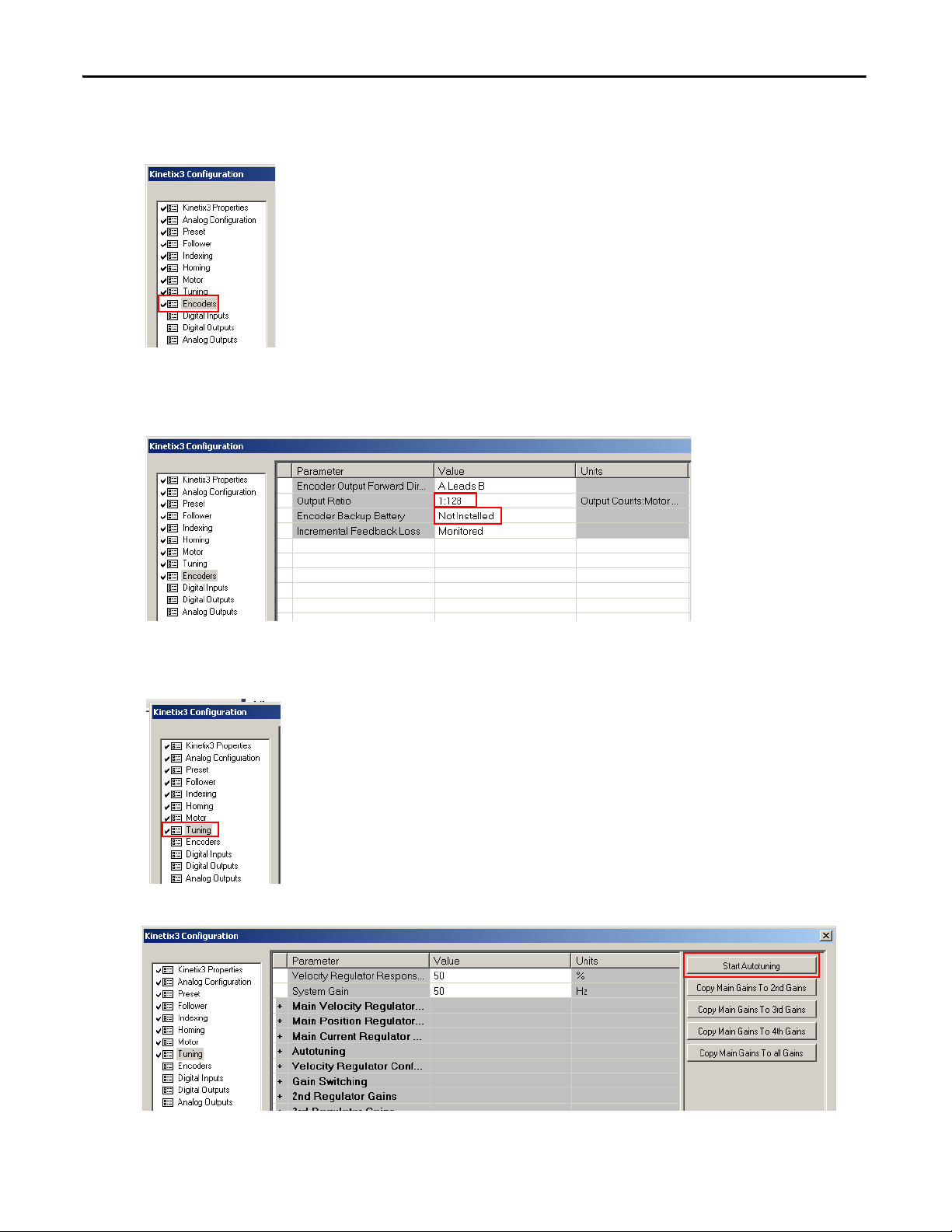

6. Follow these steps to configure the Digital Inputs.

a. Click Next to highlight Digital Inputs.

b. From Input 2 pull-down menu, choose Fault Reset.

7. Follow these steps to configure the Digital Outputs.

a. Click Next to highlight Digital Outputs.

b. From Output 1 pull-down menu, choose Ready.

Micro800 Controller PTO Axis Setup Chapter 1

8. Click Next.

9. Click Finish.

10. Save the project.

11. Click the Disconnect icon.

12. Upload the online values to project file.

13. Change the Drive Address (Pr0.07) to 1 by using the keypad interface.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 23

Page 24

Chapter 1 Micro800 Controller PTO Axis Setup

Configure the Micro800 Controller

In this section you generate or get a Connected Components Workbench project with servo drive for a PTO application.

You do this by using the CCAT generation function or download the starting project Starting_PTO_r6 from sample code.

To get a starting project go to the website:

search?site=sample_code&client=samplecode&output=xml_no_dtd&proxystylesheet=samplecode.

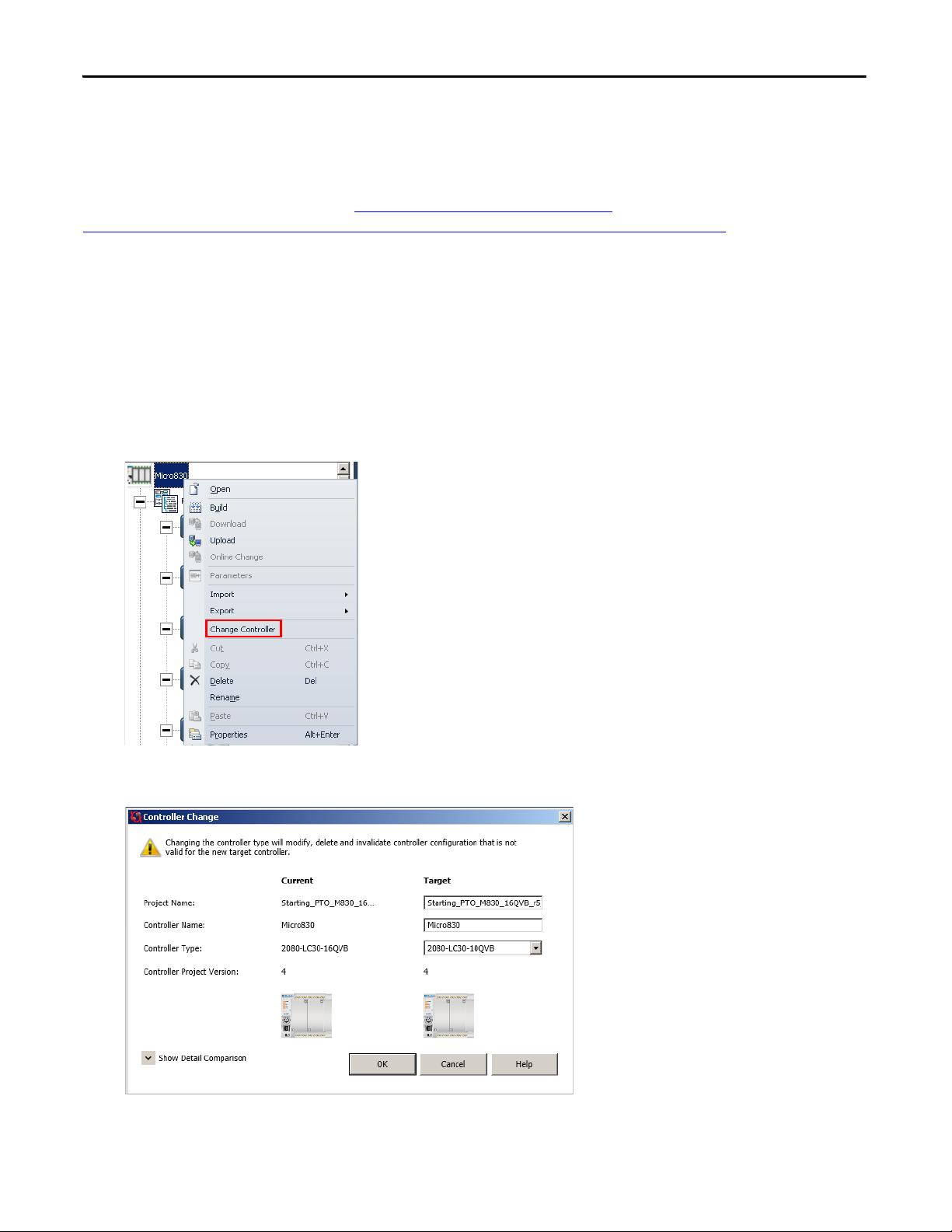

Change to Your Controller Type

If the starting project does not use your controller, this section shows you how to change it. In this Quick Start, we use

Micro800 controller catalog number 2080-LC50-24QBB.

Follow these steps to change the controller.

1. Right-click the Micro830 and choose Change Controller.

http://search.rockwellautomation.com/

The Controller Change dialog box appears.

24 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 25

Micro800 Controller PTO Axis Setup Chapter 1

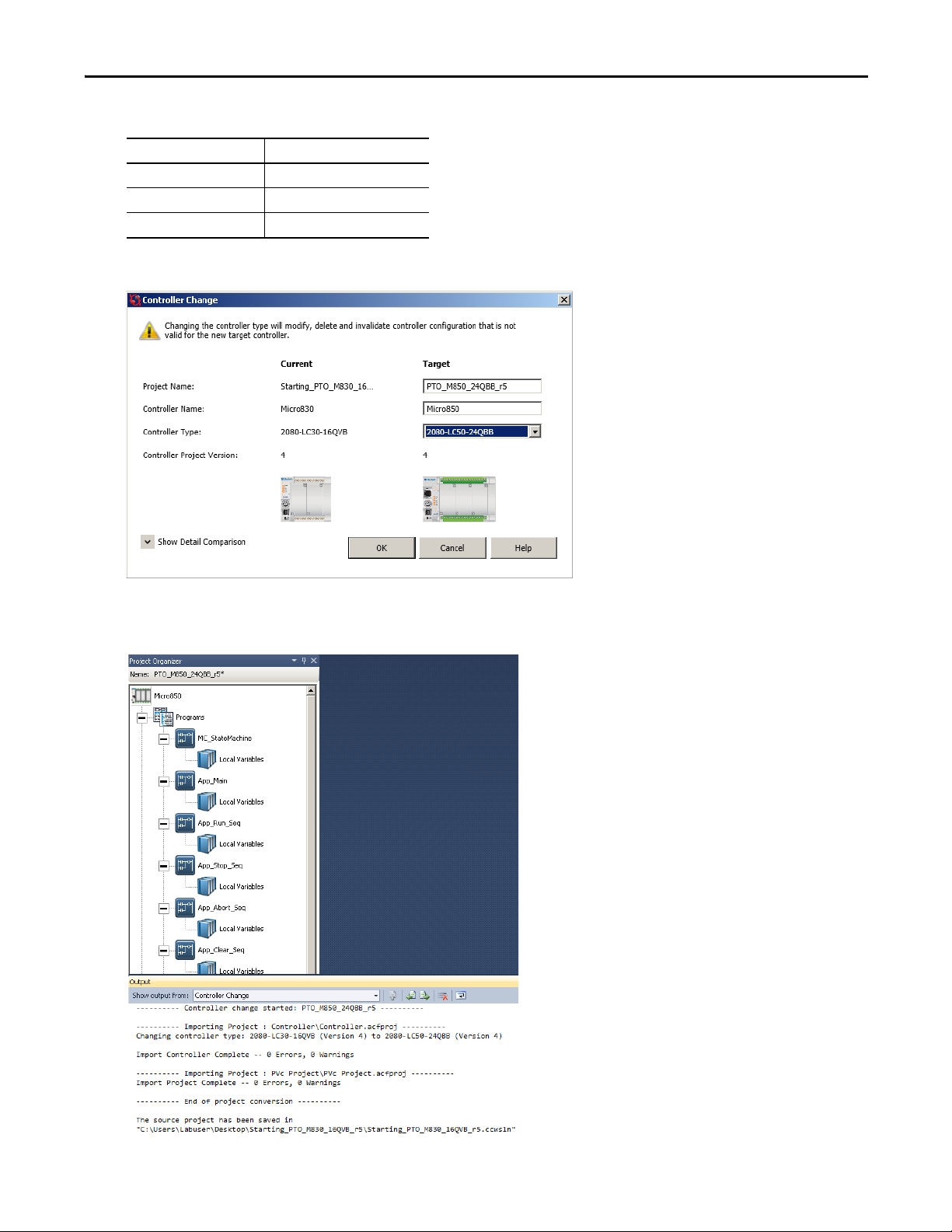

2. From the Controller Change dialog box, type and use the pull-down menu to set the following attributes.

Attribute Setting

Project Name PTO_M850_24QBB_r5

Controller Name Micro850

Controller type 2080-LC50-24QBB

3. Click OK.

A new project named, PTO_M850_24QBB_r5, is created in your My Document > CCW folder and the output

dialog box reports that the controller change is successful.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 25

Page 26

Chapter 1 Micro800 Controller PTO Axis Setup

Configure the PTO Channel

The starting project from sample code website is configured to work with the Kinetix 3 drive and wiring diagram. The

default configuration includes a PTO axis. You can find out more about the configuration in

Axis Setup in Appendix C.

For project that is generated with the CCAT generation function the PTO is not configured. You must configure it

manually by using

Appendix C as a reference.

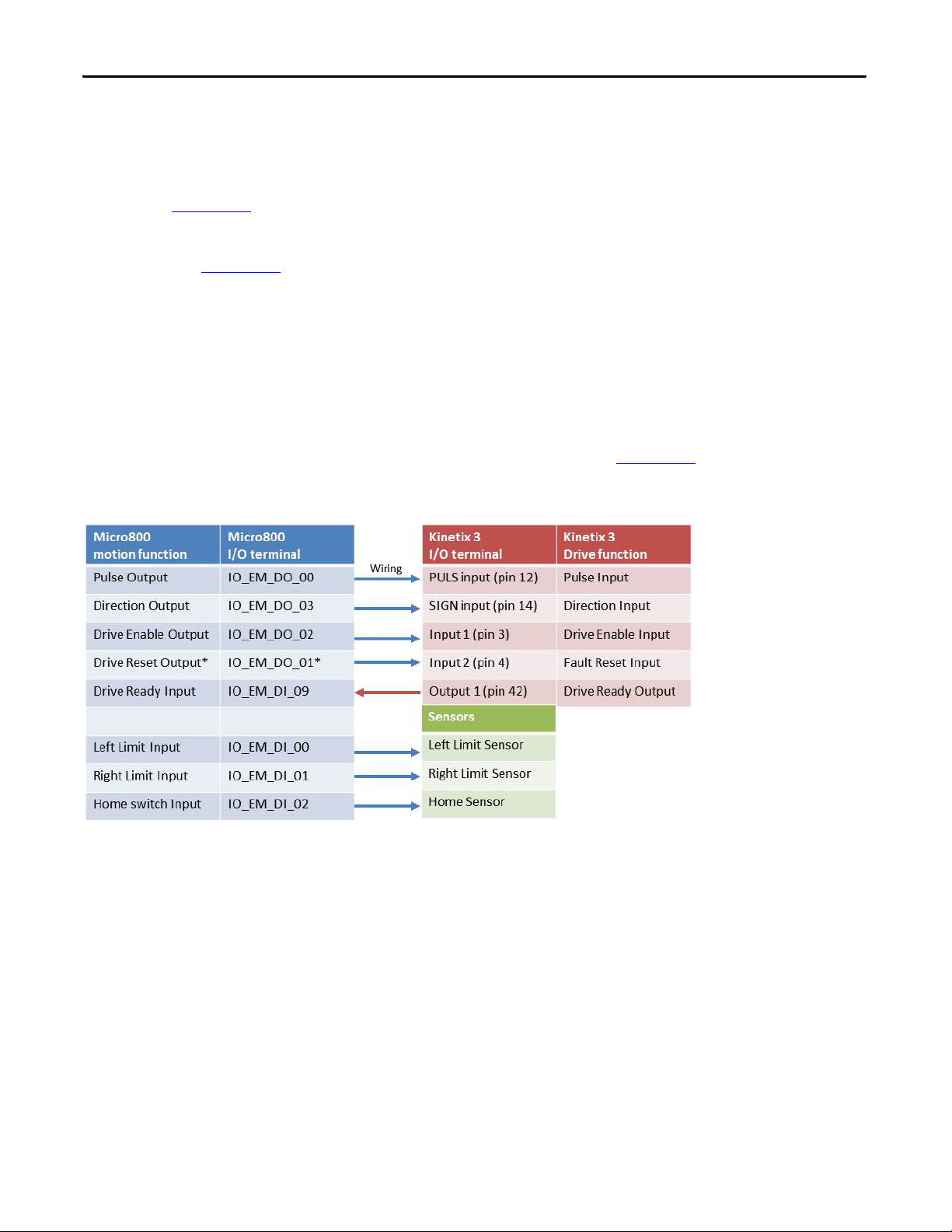

I/O Assignment

Each PTO channel has its own fixed and default I/O assignments for its motion functions. For example, PTO channel 0

uses embedded output 0 and 3 for pulse and direction signal and PTO channel 1 uses embedded output 1 and 4. If you

make any changes to the I/O assignment from the original project, also make the changes to corresponding hard-wiring.

The diagram below shows the I/O assignment for a single PTO application, downloaded from sample code website, a more

detail list of I/O assignments for double and triple PTO applications is provided in

Figure 3 - I/O Assignment for a Single PTO Application

Appendix C.

Micro800 Controller PTO

26 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 27

Micro800 Controller PTO Axis Setup Chapter 1

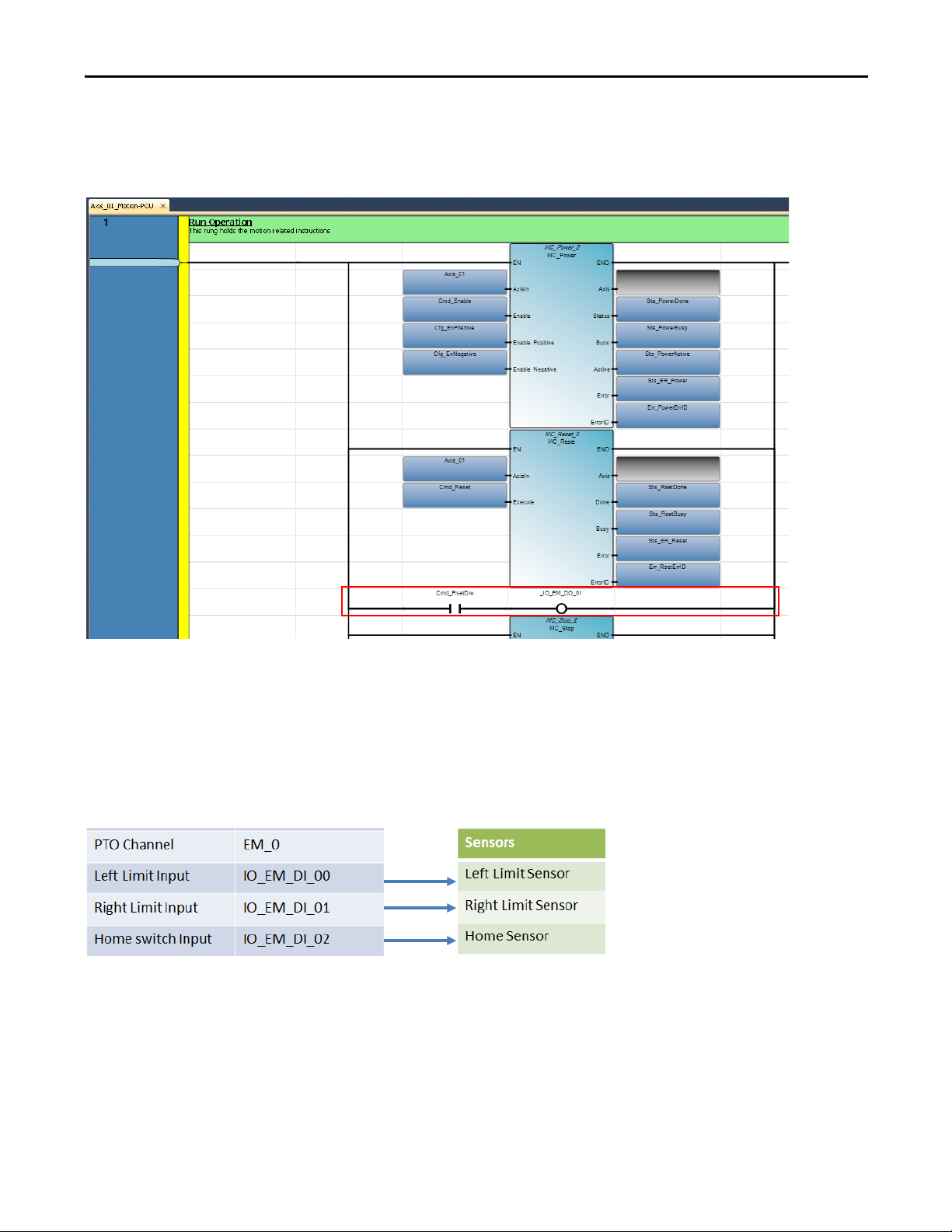

The output terminal for Drive Reset Output must be properly assigned in each ladder program. The output terminal is on

the third branch of rung

Figure 4 - Output Terminal for Drive Reset Output Assignment

one each <User-defined prefix>_Motion ladder diagram.

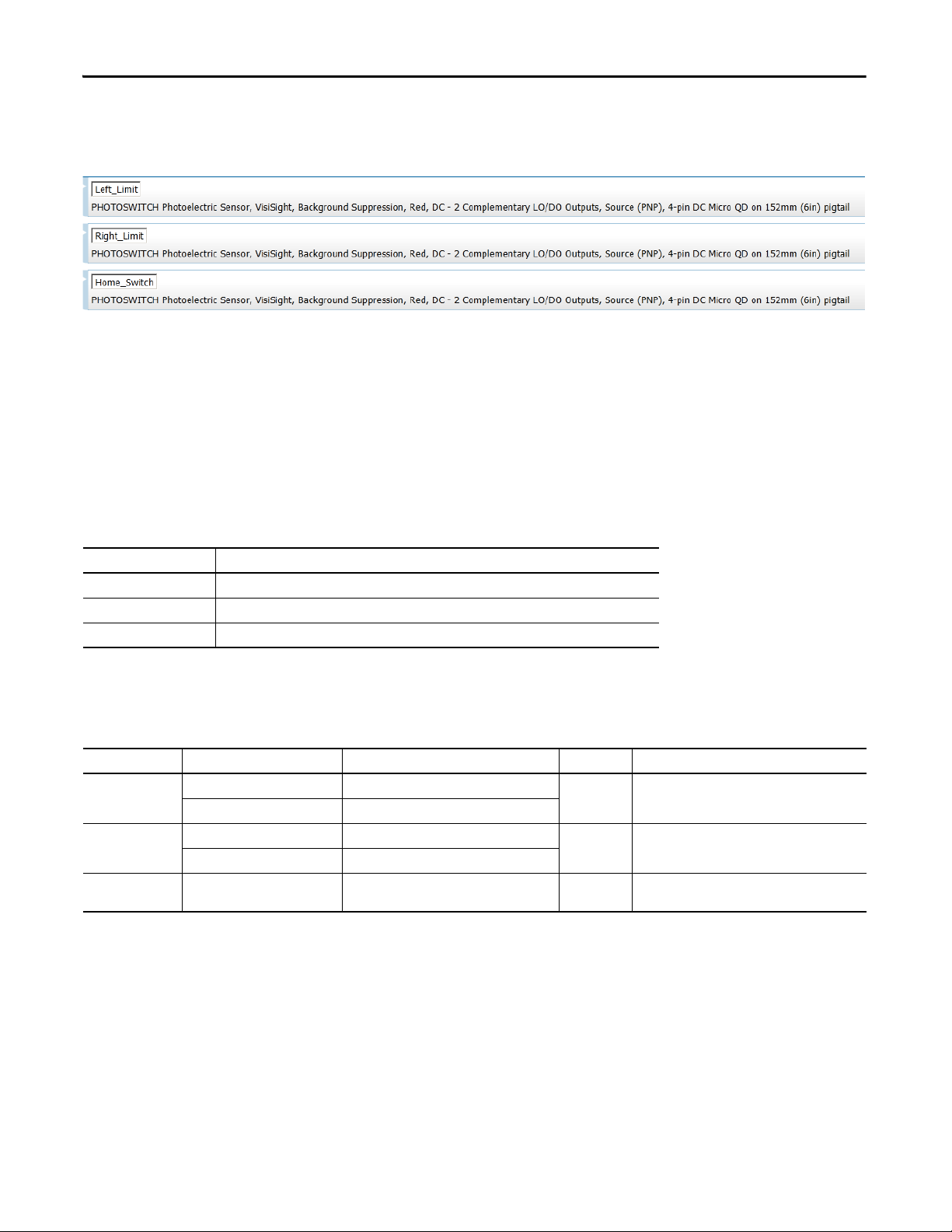

Sensors

In the I/O assignment diagram above, there is a section for sensor connections. The sensors are connected to dedicated

input terminals corresponding to the PTO channel selected.

Figure 5 - Sensor Connections

When you add a PTO application using the CCAT System Design Assistant (SDA), you must add three sensors for each

one. Identify the sensors and enter them in the Sensor section of the System Design Assistant.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 27

Page 28

Chapter 1 Micro800 Controller PTO Axis Setup

Here's an example of photoelectric type sensor selected and added in the Sensor section of SDA.

Figure 6 - Example Of Photoelectric Sensor Type

Configure Drive Communication

There is no default communication configuration in the starting project file. You must enter the attributes for the drivestatus communication you want to monitor.

Enter the attributes for the following variables.

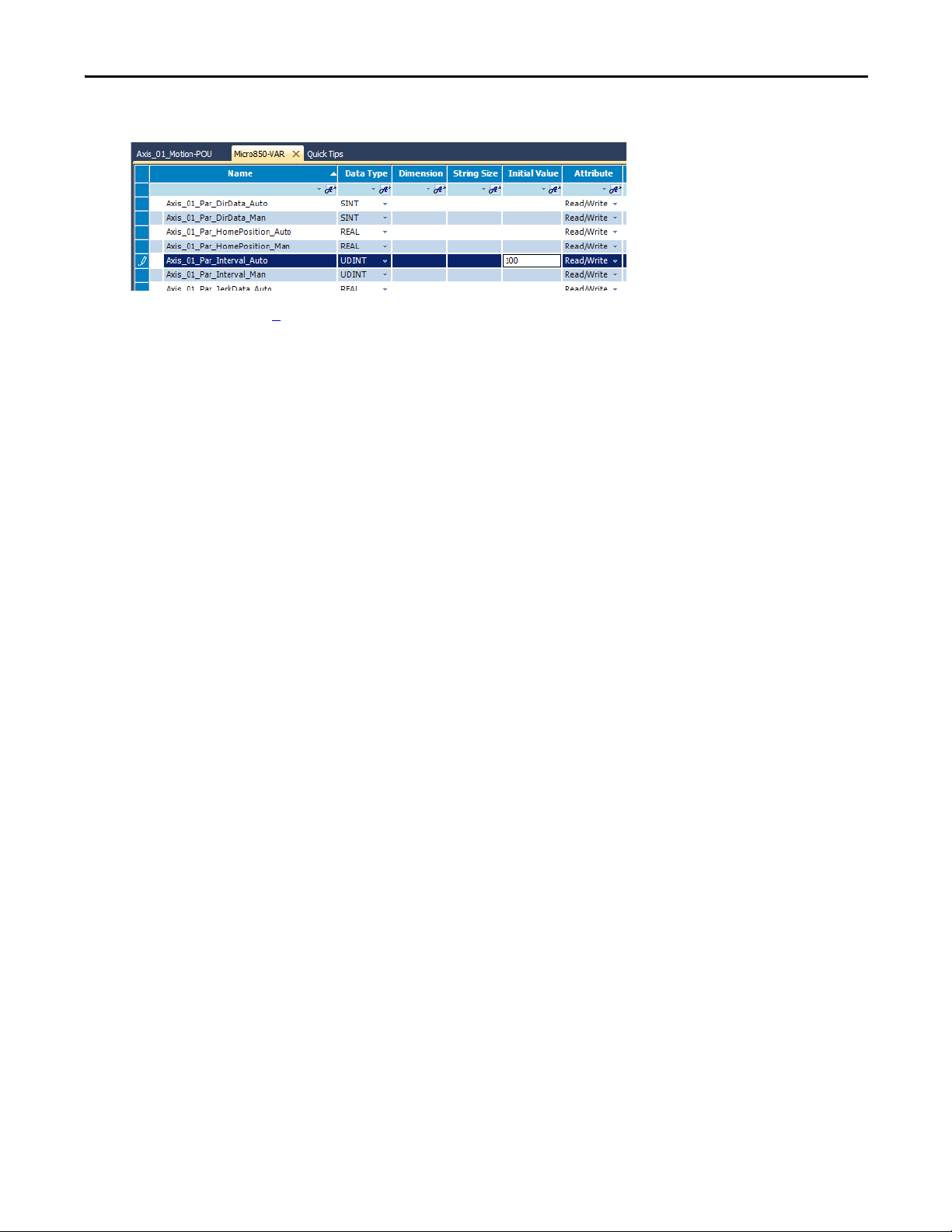

Table 1 - Communication Variables

Attribute Description

Channel Number This is the location of the SERIALISOL plug-in module on the Micro800 controller plug-in slot.

Node Address This is drive address.

Interval This is the refresh rate of the drive status in milliseconds.

The example in the table below uses the name [Axis_01] for the PTO motion building block, communicating through the

SERIALISOL plug-in module in slot 1, at a refresh rate of 100 ms interval.

Table 2 - Communication Variables Example

Attribute Global Variable Name Description Initial Value Description

Channel Number Axis_01_Cfg_Channel_Man Channel number in Manual mode control. 5 This indicates that the SERIALISOL plug-in module is

Axis_01_Cfg_Channel_Auto Channel number in Auto mode.

Node Address Axis_01_Cfg_Node Addr_Man Node address in Manual mode control. 1 This indicates that the communicating drive has an

Axis_01_Cfg_ NodeAddr _Auto Node address in Auto mode.

Interval Axis_01_Par_Interval_Man Status refresh in Manual mode control. 100 This indicates that the status refresh for the drive

in plug-in slot 1.

address of 1.

status is 100 ms.

Configure Communication Attributes

Follow these steps to configure the commutation attributes.

1. From the starting project or the project generated by the CCAT generation function, double-click Global Variables.

2. Scroll to find and select the global variable names that require updating.

28 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 29

Micro800 Controller PTO Axis Setup Chapter 1

3. Type value under the Initial Value column for each variable.

4. Repeat starting at step 1 until you have updated all six variables required for monitoring the drive status.

5. Build and download your project.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 29

Page 30

Chapter 1 Micro800 Controller PTO Axis Setup

Notes:

30 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 31

System Validation

In this chapter, you confirm the following:

• Communication between controller and PanelView Component terminal

• Controller generates the appropriate pulse output to control the motor

• Communication between controller and Kinetix 3 servo drive

The operation of the sample code and screens is also explained.

Before You Begin

• Review all steps in Chapter 1.

• Verify that all of the devices are connected as shown in the wiring diagram.

• Verify that the Micro800 controller, the Kinetix 3 drive, and the PanelView Component terminal have power

applied to them.

• Review the Getting Started CCAT with System Design Assistant Quick Start, publication CC-QS035.

Chapter 2

What You Need

• Personal computer with Connected Components Workbench software version 6 or later installed

• 6 in. (or larger) PanelView Component terminal and 1761-CBL-PM02 communication cable

• Kinetix 3 drive and 2080-CCMDSDS-48AA01 communication cable

• Micro830 or Micro850, transistor-type output controller with 2080-SERIALISOL module

• USB printer cable (A to B) for personal computer to Micro800 controller communication

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 31

Page 32

Chapter 2 System Validation

Start

Configure Your Controller

Serial Port on page 34

Configure Input Filter for High

Speed Counter on page 36

Connect Your Devices

on page 39

Download Your Program to

the Controller on page 41

Configure the IP Address for

Your PanelView Component

Ter minal on page 43

Transfer Your HMI Application

to the PanelView Component

Ter mina l on page 43

Validate Your System

on page 46

Configure PanelView

Component Terminal

Communication Settings on

Follow These Steps

Complete these steps to configure, connect your devices, down load program to the controller, transfer HMI application to

PanelView component terminal, and validate your system.

32 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 33

System Validation Chapter 2

Kinetix 3

Servo Drive

Kinetix 3

Servo Drive

Kinetix 3

Servo Drive

2080-SERIALSOL

Plug-in

2090-DAIO-D5003

Modbus

PanelView

Component

Ter min al

Micro800 48 point

Controller

1761-CBL-PM02

PTO 1 PTO 2 PTO 3

System Overview

The PTO Building Block is a device building block that consists of screen designs for PanelView Component terminal and

logic code for Micro800 controller to send pulse-train-output commands to control servo or stepper drives. Utilizing the

screen design and code, you can perform move commands, homing, and troubleshoot motion faults.

The PanelView Component terminal is connected to the embedded serial port of Micro800 controller. The two devices

communicate though CIP serial protocol over RS232C with the 1761-CBL-PM002 cable. The Kinetix 3 drive is

connected to the embedded I/O terminal of Micro800 controller for pulse-train output and other motion signals with the

2090-DAIO-D5003 cable. The Kinetix 3 drive is also connected to the 2080-SERIALISOL plug-in to monitor servo drive

status through Modbus protocol over RS485.

The figure below shows a 48 point controller supporting pulse-train output to three drives. A 24 point controller supports

pulse-train output to two drives.

Figure 7 - A 48 Point Controller Connected to Three Drives for PTO

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 33

Page 34

Chapter 2 System Validation

Configure Your Controller Serial Port

The Micro800 controller communicates with PanelView Component terminal and Kinetix 3 drive through the embedded

serial port and 2080-SERIALISOL plug-in. The embedded serial port is called channel 2 and the first plug-in slot is called

channel 5.

The following settings are used for each port.

Table 3 - Embedded Serial Port

Parameter Setting

Driver CIP Serial

Baud Rate 38400

Pari ty None

Station Address 1

Advanced Settings

Error Detection CRC

Embedded Responses After One Received

Duplicate Packet Detection TRUE

ACK Timeout (x20ms) 50

NAK Retries 3

ENQ Retries 3

Transmit Retries 3

RTS off-Delay 0

RTS Send-Delay 0

Table 4 - 2080-SERIALISOL Plug-in Module

Parameter Setting

Driver Modbus RTU

Baud Rate 19200

Pari ty None

Modbus role Modbus RTU Master

Advanced Settings

Media RS485

Data bits 8

Stop bits 1

Response Timer 200

Broadcast Pause 200

Inter-Char Timeout 0

RST Pre-Delay 0

RTS Post-Delay 0

34 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 35

Follow these steps to modify the serial port settings.

1. From the Project Organizer, double-click the Controller icon.

2. From the Controller tree select the serial port and edit the settings.

System Validation Chapter 2

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 35

Page 36

Chapter 2 System Validation

Configure Input Filter for High Speed Counter

The default input filter value can be adjusted to count the high-speed pulses from your encoder.

Follow these steps to change the input terminal filter value for your encoder input.

1. Identify the input terminal with reference to the High Speed Counter (HSC) selected for your application.

Each HSC ID corresponds to a set of input terminals.

High Speed Counter Inputs Used

HSC0 0…3

HSC1 2,3

HSC2 4…7

HSC3 6, 7

HSC4 8…11

HSC5 10, 11

2. From the Controller Organizer, select Embedded I/O.

3. Choose the input filter value for your input terminal identified in step1.

The default is 8 ms.

Set the input filter value to less than the minimum for you application. You can calculate the minimum requirement by

using this formula:

Minimum input filter (seconds) = 1/ (max revolution per second * encoder resolution per revolution)

36 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 37

System Validation Chapter 2

Configure PanelView Component Terminal Communication Settings

In the default project, the communication and controller settings have already been configured. Here are the default

settings.

Table 5 - Driver Configuration

Parameter Setting

Protocol Serial CIP

Por t RS232

Baud Rate 38400

Pari ty None

Stop Bits 1

Flow Control None

Report Errors FAS LE

Station Address 0

Protocol Full Duplex

Accept responses for station address only FAS LE

Table 6 - Controller Settings

Parameter Setting

Name PLC-1

Controller Type Micro800

Address 1

Follow these steps to modify the settings in your Connected Components Workbench project.

1. From the Project Organizer, double-click the PanelView Component terminal icon.

The Design Station is launched.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 37

Page 38

Chapter 2 System Validation

2. Click the Communication icon.

38 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 39

3. Edit the communication settings to your needs.

System Validation Chapter 2

Connect Your Devices

1. Connect the PanelView Component terminal to your controller's embedded serial port by using a 1761-CBL-PM02

cable.

1761-CBL-PM02

2. Connect your Kinetix 3 drive's IEEE1394 plug to your Micro800 controller's isolated serial port (2080SERIALISOL) by using a modified 2090-CCMDSDS-48AA01 cable.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 39

Page 40

Chapter 2 System Validation

1

B

A

234

123 4

(View in to terminal block)

Pin A1 RS485 + 485Pin B1 RS232 DCD

Pin A2 RS232/485 GNDPin B2 RS232 RXD

Pin A3 RS232 RTS Pin B3 RS232 TXD

Pin A4 RS232 CTS Pin B4 RS485 - 485

Comm0A or

Comm0B Pin

Description Signal

1 RS-232 transmit XMT

2 RS-232 receive RCV

3Reserved —

4 +5V power ground GND

5 RS-485+ DX+

6 RS-485 DX-

Pin 2

Pin 6

Pin 5

Pin 1

Back

Front

Red

Brown

Black

The modified cable can be made by removing one end to expose the conductors. See the following wiring diagram,

but note that the red wire does not need to be connected.

40 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 41

System Validation Chapter 2

Download Your Program to the Controller

Follow these steps to download your program to your controller.

1. Connect an available USB port on your personal computer to the USB programming port on your Micro800

controller by using a USB A-to-B cable.

2. Build your program.

If you are prompted to install drivers, specify to use the recommended drivers.

3. From your Connected Components Workbench project, right-click on your device icon.

4. From the Project Organizer, choose Build.

When the program is done building, the Output pane at the bottom of your project window displays a build success

message.

5. If there are errors, fix your program errors, and build the program again.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 41

Page 42

Chapter 2 System Validation

6. From the Project Organizer, right-click on your device icon and choose Download.

7. From the Connection Browser dialog box, select your controller and click OK.

8. If prompted to change the Controller mode to Remote Program, click Yes.

The program downloads and you are prompted to change the Controller mode to Remote Run.

9. Click Yes.

42 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 43

System Validation Chapter 2

Configure the IP Address for Your PanelView Component Terminal

Follow these steps to configure a static IP address on the PanelView Component terminal.

1. From the Main menu, press Communication to open the Communication screen.

2. Press Set Static IP Address.

3. Configure the IP Address and Mask values so they are in the same range as your Micro800 controller.

4. Press Main to return to the Main menu.

Transfer Your HMI Application to the PanelView Component Terminal

Follow these steps to transfer your HMI application to the PanelView Component terminal operator interface terminal.

1. Choose your HMI application.

2. From the General properties check that Validity is TRUE.

3. If Validity is FALSE, right-click PVC application and choose Validate Application.

A Validation Result dialog box shows various warning for overlap object and if the application is valid Validity

displays TRUE.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 43

Page 44

Chapter 2 System Validation

4. In the Project Organizer, right-click the PanelView Component terminal icon and choose Download.

5. In the Graphic Terminal Application Download dialog box, enter the IP address of your PanelView Component

terminal that you configured in the section above.

6. Click Download.

7. Verify that the download completed successfully.

8. From the Main menu of your PanelView Component terminal, press File Manager.

9. On the File Manager screen, select Internal as your Source.

10. Select your application.

44 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 45

11. Press Run.

System Validation Chapter 2

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 45

Page 46

Chapter 2 System Validation

a

d

c

b

a

debc

Validate Your System

In this section, you review the Machine Overview and Machine Functions screens and explore the Status and Command

screens to test the manual control of the building block.

Understand the Machine Overview Screen

The Machine Overview screen in the default project is common to all CCATs. When this screen is first loaded, you can

complete the following tasks:

a. Return to the Configuration screen and exit the program.

b. View and change current machine state.

c. Start and stop Auto mode program.

d. Go to Machine Functions screen.

Understand the Machine Functions Screen

The Machine Functions screen is also common to all CCATs. You can complete the following tasks in the Machine

Functions screen:

a. Return to Machine Overview screen.

b. Look at a particular machine function or device in detail.

c. Start and stop Auto mode program.

d. View and change current machine state.

e. Go to State Diagram for an overview of machine state.

46 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 47

System Validation Chapter 2

From Axis_01 screen in Auto mode, you can monitor the following status:

• Axis command velocity

• Axis command position

• High Speed Counter (HSC) count

•Axis status

•Servo drive status

Here you test the manual control of the Building Block. There are two manual modes for selection, Basic and Advance

modes. Press Manual and Axis_01 buttons to enter the first manual screen

.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 47

Page 48

Chapter 2 System Validation

Explore the Command and Status Screen

The left side shows the servo status indicator is describe here.

Parameter Description

Axis Enabled This status indicator displays whether the axis is ac tive and the drive is maintaining control of the motor.

Homed This status indicator displays the home status of the drive. If the status indicator is green, the drive has an absolute position refere nce. When the box is gray,

Homing This status indicator displays the homing status of the drive. When the status indicator is green, the drive has started homing and has not yet attained an

In Motion When is status indicator is green the axis is moving,

Axis Error Wh en this sta tus indica tor is gray th e motion ax is is healt hy. When the st atus indica tor is red, the re is a faul t on the mot ion axis and the error number is shown

Motion Error When this status indicator is gray the instruction has been executed properly, When the status indicator is red, there is instruction execution fault and the error

the drive is not homed.

absolute position reference, otherwise, the status indicator is gray.

in the text.

number is shown in the text.

The right side shows some numeric displays and inputs described below.

Parameter Description Range

Mode The machine is able to jog when in Maintenance mode. —

Home Mode There are five different types of homing methods. For more information, refer to the help for MC_Home instruction. 0… 4

Deceleration This is the deceleration rate that is used for jogging, in mm/s2. 0… 90,000

Acceleration This is the acceleration rate that is used for jogging, in mm/s2. 0… 90,000

Jog Speed This is the velocity for the jog axis, in mm/s. 0… 833

Posi tion This displays the axis position. Homing resets the axis position to the home value. —

HSC This displays High Speed Counter value if an encoder is properly wired and configured to the controller. —

48 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 49

System Validation Chapter 2

The bottom of the screen has control buttons that inactivate depending on the program operation mode.

Parameter Description

Servo Enable/

Disable

Start Homing This momentary-push button starts the homing process for the drive. It is available only when the drive is stopped, enabled, and while the program is in

Jog Forward This momentary-push button jogs the axis in the forward direction at the specified jog speed. This button must be held down to continue jogging. It is

Jog Reverse This momentary-push button jogs the axis in the reverse direction at the specified jog speed. This button must be held down to continue jogging. It is

Axis Config This is a Go To Button. When pressed, the Configuration page for motion axis screen appears.

Advance move This is a Go To button. When pressed the Advance Move screen appears where you can perform position and velocity control.

Drive Status This is a Go To Button. When pressed, the Drive Status screen appears.

Fault Help This is a Go To Button. When pressed an information screen appears for diagnosing motion instructions and motion axis faults.

Clear Faults When the Clear Faults button appears, you can use this momentary-push button to attempt to clear faults on the controller.

This maintain-push button enables and disables the servo drive.

Manual mode.

functional only when in Maintenance mode.

functional only when in Maintenance mode.

Follow these steps to use the Command and Status screen.

1. Press Servo Enable.

This energizes the motor, and attempts to hold it at its present position.

2. Set the deceleration, acceleration, and jog speed.

3. Press and hold Jog Forward.

The motor turns forward.

4. Release Jog Forward.

The motor stops.

5. Press and hold Jog Reverse.

The motor turns in the reverse direction.

6. Release the Jog Reverse.

The motor stops.

7. Enter your preferred homing mode (0-4).

8. Press Start Homing.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 49

Page 50

Chapter 2 System Validation

The motor begins to home according to the selected homing method shown here.

Homing Mode

Value

0x00 MC_HOME_ABS_SWITCH Homing process searches for Home Absolute switch.

0x01 MC_HOME_LIMIT_SWITCH Homing process searches for limit switch.

0x02 MC_HOME_REF_WITH_ABS Homing process searches for the Home Absolute switch and the encoder

0x03 MC_HOME_REF_PULSE Homing process searches for limit switch and the encoder reference pulse.

0x04 MC_HOME_DIRECT Static homing process with direct forcing a home position from user

Homing Mode Name Homing Mode Description

reference pulse.

reference. The function block sets current position the mechanism is in as

home position, with its position determined by the input parameter,

Posi tion.

9. Press Servo Disable.

The motor de-energizes and the Advance mode button appears.

10. Press Advance Move.

The Advance Move screen is displayed.

Explore the Axis Configuration Screen

The axis configuration screen is accessed by pressing the Axis Config button. In this screen you can configure some of the

advance settings for position and velocity control.

Parameter Description Range

Enable Positive This is a maintain-push button. Press to enable the motion to travel in the positive direction. —

Enable Negative This is a maintain-push button. Press to enable the motion to travel in the negative direction. —

Home Mode There are five different types of homing methods. For more information, refer to the help for MC_Home instruction. 0…4

Home Position Defines the initial position for when axis is homed. —

Config HSC_K3 This is a Go To Button. When pressed, the configuration screen for Kinetix 3 drive and High Speed Counter appears. —

50 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 51

Follow these steps to use the Axis Configuration screen.

1. From Command & Status Screen, press the Axis Config button.

System Validation Chapter 2

2. Press the Enable buttons for Enable Positive and Enable Negative.

Explore the Kinetix 3 and HSC Configuration Screen

The left side is where you configure communication settings and monitor the status for Kinetix 3 drive.

Parameter Description Range

Channel This is the channel on the controller that is connected to the drive. The channel number is for the left-most plug-in slot

starting with five.

Node Each drive has one node address that the building block uses to reference that drive. This address must be unique. 1…247

Interval This parameter indicates the update rate of Kinetix 3 drive parameters. 0… 65,536 ms

DrvRdy This status indicator shows if a drive is properly configured and connected. It indicates Rdy when there is a valid Kinetix 3

drive.

DrvAlarm This status indicator monitors the alarm for Kinetix 3 drive. If there is a fault, the indicator shows Drv Fault. —

AlmCode This status indicator shows the alarm code if the drive is faulted. —

5…9

—

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 51

Page 52

Chapter 2 System Validation

The right side is where you configure and monitor status of the High Speed Counter.

Parameter Description Range

HSC ID This parameter shows the ID of HSC selected. The ID selected also corresponds to the input terminals for the encoder. 0…5

HSC mode This is the HSC mode selected, refer to Micro830 and Micro850 Programmable Controllers, publication 2080-UM002 for

details.

Initial Pos This is the star ting count value during initial startup and upon reset. —

Enable Press this button to start HSC. —

Disable Press this button to stop HSC. —

Reset Press this button to reset count value to Initial Pos. —

HSC Rdy This status indicator shows if a High Speed Counter is properly configured. —

HSC Err This status indicator shows if there is a HSC fault. —

HSC Cnt This status indicator shows the count value of the HSC. —

0…9

To use the Kinetix 3 and HSC Configuration screen, do the following.

1. Press the Config HSC_K3 button.

The Kinetix 3 drive and HSC configuration screen is displayed.

2. Type the following for Kinetix 3 drive configuration.

Attribute Setting

Channel 5

Node 1

Interval 10

The Kinetix 3 drive status displays the following.

Attribute Setting

DrvRdy Rdy

DrvAlarm no fault (if there is no fault)

AlmCode 0 (if there is no fault)

52 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 53

3. Type the following for HSC configuration.

Attribute Setting

HSC ID 2

HSC mode 6

Initial Pos 0

4. Press the Enable button.

The HSC status displays the following.

Attribute Setting

HSC Rdy HSC On

HSC Err No Fault

HSC Cnt 0 (the value changes as you

rotate your encoder)

5. Press the X button.

You are returned to Axis Configuration Screen.

System Validation Chapter 2

6. Press X button again.

7. You are returned to Command & Status Screen.

Explore the Advance Move Screen

The left side shows the servo status indicators describe below.

Parameter Description Range

Move type This is a multi-selection button. Press this button to switch between Select Move, Velocity, Absolute, and Relative move types. 0… 3

Deceleration This parameter is the deceleration rate that is used for any move command initiated, in mm/s2. 0… 90,000

Acceleration This parameter is the acceleration rate that is used for any move command initiated, in mm/s2. 0… 90,000

Jerk This parameter is the rate of acceleration or deceleration used for any move command initiated. A 0 value denotes a trapezoidal

motion profile.

Direction This parameter controls the direction for velocity move. 1 = Positive direction

Velo cit y This parameter is the velocity for any move command initiated, in mm/s. 0… 833

Posi tion This parameter determines the position value and reference for relative and absolute position control respectively. —

0… 90,000

-1 = Negative direction

0 = Follow previous direction

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 53

Page 54

Chapter 2 System Validation

The right side shows some numeric displays and inputs described below.

Parameter Description

Axis Enabled The status indicator shows whether the axis is ac tive and the drive is maintaining control of the motor.

Homed This status indicator shows the home status of the drive. When the status indicator is gray, the drive is not homed. When the status indicator is green, the

Homing This status indicator displays the homing status of the drive. When this status indicator is green, the drive has started homing but has not attained an

In Motion When this status indicator is green the axis is moving.

Axis Error When this status indicator is gray, the motion axis is healthy. When it is red, there is a fault on the motion axis and the text shows the error number.

Motion Error When this status indicator is gray, the instruction executed properly. When it is red, instruction execution faulted and the text shows the error number.

HSC cnts This status indicator shows the count value of the HSC.

mm/s This display the axis velocity when the controller is controlling the axis.

mm This display the axis position. Homing resets this to the home value.

drive has an absolute position reference.

absolute position reference; other wise, it is gray.

The bottom of the screen has control buttons that are inactive depending on the program operation mode.

Parameter Description

Servo Enable/Disable This maintain push button enables and disables the servo drive.

Start Homing This momentary push button starts the homing process for the drive. It is available only when the drive is stopped and enabled while the program is in

Move This momentary push button triggers the move command according to the selection and parameters defined.

Halt This momentary push button stops the axis regardless of whether the axis has completed its previous command.

Axis Config This is a Go To Button. When pressed, the configuration page for motion axis screen is displayed.

Drive Status This is a Go To Button. When pressed, the servo drive status screen is displayed.

Fault Help This is a Go To Button. When pressed an information screen appears for diagnosing motion instructions and motion axis faults.

Clear Faults When the Clear Faults button appears, you can use this momentary push button to attempt to clear faults on the controller.

Manual mode.

To use the Advance Move screen, follow these steps.

1. Press the Select Move button once for Velocity.

54 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 55

2. Enter value for the following motion parameter for velocity control.

Parameter Val ue Description

Deceleration 100 100 mm/s

Acceleration 100 100 mm/s

Direction 1 Forwa rd

Velo cit y 100 100 mm/s

2

2

3. Press the Servo Enable button.

This energizes the motor, and it attempts to hold its present position.

4. Press the Move button.

The motor turns, accelerates, and cruises at 100 mm/s.

5. Press the Halt button.

Motor decelerates to a stop.

6. Press the Move Type button once more till Absolute is displayed.

This lets you do Absolute position control.

System Validation Chapter 2

7. Press the Start Homing button.

The motor returns to home position and resets the mm.

8. Type 500 mm for Position.

9. Press the Move button.

Motor turn to absolute position 500 and stops.

10. Press Move Type once more to Relative for Relative position control.

11. Enter 100 mm for Position.

12. Press the Move button.

Motor turns an incremental of 100 mm to position 600 mm.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 55

Page 56

Chapter 2 System Validation

Explore the Kinetix 3 Status Screen

This screen indicates the status of any configured Kinetix 3 drive. It does not work with any other servo drive.

Parameter Description

Node This parameter shows the node address of connected drive.

Comm When this status indicator is gray, communication is active. When this status indicator is red communication has breaks.

Alarm When this status indicator is grey, there are no alarms. When the status indicator is red there is an alarm.

Ready When this status indicator is green, the drive can be enabled. When the status indicator is red, the drive cannot be enabled.

Velo cit y This value is the motor feedback veloci ty in revolutions per minute.

Posi tion This value is the motor feedback position in encoder counts.

Error code This is the most recent alarm code registered by the drive.

Error text This is the alarm message associated with the most recent alarm code.

56 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 57

System Validation Chapter 2

Explore the Fault Screen

There are two separate faults in this screen. The Command Fault is fault related to the command you issued to an axis. For

example, asking the axis to move or stop with invalid parameter. The Axis Fault is fault related to the axis. For example, the

axis has detected a hard limit.

Parameter Description

Command Fault

Error code This shows the error code for motion instruction.

Error ID This shows a short name for the error.

Description This describe the error in detail.

Axis Fault

Error code This shows the error code for the motion axis.

Error ID This shows a short name for the error.

Description This describes the error in detail.

Use the Fault Screen when you encounter either Axis or Motion Error, press Fault Help for the Fault Screen to look at more

descriptive message about the error.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 57

Page 58

Chapter 2 System Validation

Notes:

58 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 59

Appendix A

Kinetix 3 Drive Component-class User-defined Functional Block

Six user-defined function blocks (UDFBs) are included with the Kinetix 3 Drive Building Block. All are used in

the device module code for returning the status of the drive, sending commands to the drive, and configuring

parameters.

PTO Application Building Block User-defined Function Block

This appendix describes the user-defined function blocks used in the PTO building block and the associated inputs and

outputs.

RA_Motion_Move_Cmd User-defined Function Block

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 59

Page 60

Appendix A Kinetix 3 Drive Component-class User-defined Functional Block

Table 7 - RA_Motion_Move_Cmd Inputs

Variab le Data type Description Range

FBEN BOOL Set this bit TRUE to enable the function block. 0, 1

AxisIn Axis_Ref Assign this to the motion axis created via the configurator. —

MoveMode INT 0: Maintenance mode, Jogging is permitted.

1: Velocity control, Motion is in Velocity Move mode.

2: Absolute control, Motion is in Absolute Position Move mode.

3: Relative control, Motion is in Relative Position Move mode.

Posi tionDa ta Real Valid only in Mode 2 and 3.

2: Absolute position.

3: Relative position.

Velo cit yDat a Real This value sets the speed of the motor. -3.40282347E+38…3.40282347E+38

AccData Real This value sets the acceleration of the motor. -3.40282347E+38…3.40282347E+38

DecData Real This value sets the deceleration of the motor. -3.40282347E+38…3.40282347E+38

JerkData Real This value sets the jerk of the motor. -3.40282347E+38…3.40282347E+38

DirData SINT Valid only in Velocity control mode. This value sets the rotating direction of the motor. -128…127

Execute BOOL Set this bit TRUE to execute motion. 0, 1

Halt BOOL Set this bit TRUE to stop motion. 0, 1

Jog_Positive BOOL Set this bit TRUE to execute jog in the positive direction.

Set this bit FALSE stops jog.

Jog_Negative BOOL Set this bit TRUE to execute jog in the negative direction.

Set this bit FALSE stops jog.

0…3

-3.40282347E+38…3.40282347E+38

0, 1

0, 1

Table 8 - RA_Motion_Move_Cmd Outputs

Variab le Data type Description Range

FBENO BOOL This variable reflects the state of FBEN. 0, 1

AxisState USINT This value returns the status of the axis with respect to the motion currently in progress. 0…7

CurrentMoveMode INT This value returns the Current Move mode. 0…3

MoveDone BOOL When Move mode is:

0 or 1: This bit is TRUE when the motor has reached the set velocity.

2 or 3: This bit is TRUE when the motion is complete.

MoveBusy BOOL This bit is TRUE when the motion axis is busy. 0, 1

MoveAct ive BOOL This bit is TRUE when the function block is in control of the axis. 0, 1

MoveAborted BOOL This bit is TRUE when the command was aborted by another command. 0, 1

Error BOOL This bit is TRUE when an error was detected. 0, 1

ErrorID UINT This value returns the motion error code. —

ErrorMsg String This value returns the command that caused the error. —

0, 1

60 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 61

Figure 8 - RA_Motion_Move_Cmd Function Block Flowchart

Start

Select Move

Mode

Error?

Correct

Para meter

Read

Motion

Para meter s

Execute

Halt?

Execute

Move?

Stop PTO

Motion

Error?

Awai t

Action

Compl eted

End

Start PTO

Yes

No

Ye s

No

Yes

No

Yes

No

Yes

Axis

Error?

No

Motion

Error?

Correc t

Para meter

Servo Off

Servo On

Clear Fault

Ye s

Kinetix 3 Drive Component-class User-defined Functional Block Appendix A

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 61

Page 62

Appendix A Kinetix 3 Drive Component-class User-defined Functional Block

Table 9 - RA_HSC_CfgAndSts Inputs

Variab le Data type Description Range

FBEN BOOL Set this bit TRUE to enable the function block. 0, 1

HscID UINT This value sets the ID in use. 0…5

HscMode USINT This value sets the HSC mode. 0…9

Enable BOOL Set this bit TRUE to enable the HSC. 0, 1

Disable BOOL Set this bit TRUE to disable the HSC. 0, 1

InitialPosition REAL This value sets the initial position after reset. -3.40282347E+38…3.40282347E+38

Reset BOOL Set this bit TRUE to reset HSC count value and HSC error. 0, 1

HPSetting DINT This value sets the High preset setting. -2147483648…2147483647

LPSetting DINT This value sets the Low preset setting. -2147483648…2147483647

Table 10 - RA_HSC_CfgAndSts Outputs

Variab le Data type Description Range

FBENO BOOL This variable reflects the state of FBEN. 0, 1

HscOK BOOL This bit is TRUE when HSC is counting. 0, 1

HscCount DINT This value return the count value. -2147483648… 2147483647

LP_Reached BOOL Low pre set reached. 0, 1

HP_Reached BOOL High preset reached. 0, 1

Underflow BOOL Underflow detected. 0, 1

Overflow BOOL Overflow detected. 0, 1

Error BOOL This bit is TRUE when an error was detected. 0, 1

ErrorCode UINT This value returns the HSC error code:

00: No error.

01: Invalid HSC Counting mode. (Can require a re-download of program to

correct).

02: Invalid high preset. (Can require a re-download of the program to correct).

03: Invalid overflow. (Can require a re-download of the program to correct).

04: Invalid underflow. (Can require a re-download of the program to correct).

05: No PLS data. (Can require a re-download of the program to correct).

06: Invalid HscID.

07: Invalid HscMode.

0…255

62 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 63

Figure 9 - RA_HSC_CFGandSTS Function Block Flowchart

Start

Initialize

HSC

Read HSC

Param eter

Rest

HSC?

Rest Initial

Count Value

Enable

HSC ?

Invalid

Parameter?

Reset HSC

HSC Counting

Disable

HSC

End

No

No

No

Yes

Yes

Yes

Yes

No

Kinetix 3 Drive Component-class User-defined Functional Block Appendix A

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 63

Page 64

Appendix A Kinetix 3 Drive Component-class User-defined Functional Block

RA_K3_MBUS_STS User-defined Function Block

This UDFB provides the basic status word for the Kinetix 3 drive. The outputs are updated at the interval

specified on the input side of the function block.

64 Rockwell Automation Publication CC-QS033A-EN-P - February 2014

Page 65

Kinetix 3 Drive Component-class User-defined Functional Block Appendix A

Table 11 - RA_K3_MBUS_STS Inputs

Variable Type Description Range

FBEN BOOL The Function Block Enable bit (FBEN) controls the operation of the function. On the rising edge of

1, 0

this bit, the function block initialization takes place. While this bit is held high, the function block

continues to execute.

Channel UINT This is the port or channel on the controller that is connected to the drive. For this UDFB, it is

2, 5, 6, 7, 8, and 9

recommended to use a 2080-SERIALISOL module instead of the embedded serial port.

NodeAddr USINT Each drive has a node address that the Modbus Master uses to reference that drive. For each

1…247

Modbus network, those addresses must be unique.

Interval UDINT This parameter controls how often the UDFB sends Modbus messages to the device, with zero

0…65,536 ms

representing the Continuous Operation mode. In Continuous mode, the drive status updates as

often as possible given the network traffic and buffer.

Table 12 - RA_K3_MBUS_STS Outputs

Variable Type Description Range

FBENO BOOL This variable reflects the state of the Function Block Enable bit (FBEN). 1, 0

FB_Q BOOL This variable shows whether the status message has completed. After the response from the

1, 0

drive has been received, this bit becomes true. It stays true until another message is sent or until

the UDFB sees a rising edge of the enable input.

CommLoss BOOL This bit signifies a communication timeout between the controller and the drive. This also

1, 0

triggers FB_Error to be true. This is cleared after a successful completion of a message to the

drive, or the UDFB sees a rising edge of the enable input.

FB_Error BOOL This bit shows that an error occurred within the UDFB. For a more detailed description of the

1, 0

error code, see FB_ErrCode.

FB_ErrCode UDINT This variable enumerates the errors that have occurred within the UDFB.

—

Bit 0 - Modbus Message Communication Error.

Bit 1 - Invalid Channel.

Bit 2 - Invalid Node Address.

ServoAlarm BOOL This bit is normally true for a ‘healthy’ drive. If the bit changes to false, there is a servo alarm

1, 0

within the drive.

With inPosn BOOL This bit is true when the motor feedback position is within the position tolerance specified by

1, 0

parameter Pr5.00 - In Position Size.

UpToSpeed BOOL) This bit is true when the motor feedback velocity is greater than the value in Pr5.04 - Up To

1, 0

Speed.

Active BOOL This bit is true when the drive is disabled and goes false when the drive is enabled. This operates

1, 0

opposite of the digital output associated with the Brake.

With inSpee d BOOL This bit is true when the motor feedback velocity is within the speed tolerance specified by

1, 0

parameter Pr5.03 - Speed Window.

PosnVal id BOOL This bit is true when the drive is connected to an absolute encoder configured with battery

1, 0

backup and it can read a valid position from the encoder.

Ready BOOL This bit is true when the drive is not faulted and can be enabled. 1, 0

CurrentLmt BOOL This bit is true when the current is being limited by the drive. The current limits are entered in

1, 0

parameters Pr4.01 - Positive Internal Current Limit, Pr4.02 - Negative Internal Current Limit,

Pr4.03 - Positive External Current Limit, and Pr4.04 - Negative External Current Limit.

Vel ocit yLm t BOOL This bit is true when the velocity is being limited by the drive. The velocity limit can be derived

1, 0

from the analog velocity input or the manual limit entered in parameter Pr2.12 - Manual

Velocity Lim it.

Rockwell Automation Publication CC-QS033A-EN-P - February 2014 65

Page 66

Appendix A Kinetix 3 Drive Component-class User-defined Functional Block

First Scan?

Initialize Variables

Run Diagnostics

Yes

No

Are Channel

and Node Address Within

Range;

Read Drive Status

End

Diagnostics?

No

Yes

Start

End

Set Error Bits

Yes

Table 12 - RA_K3_MBUS_STS Outputs (continued)

Variable Type Description Range

NearPosn BOOL This bit is true when the motor feedback position is within the position tolerance specified by

parameter Pr5.02 - Near Position Size.

War ning BOOL This bit is true when there is a warning on the drive. Warning descriptions can be seen in the

Kinetix 3 drive’s user manual. See the

Additional Resources on page 9.

InMotion BOOL This bit is true when the drive is moving as part of an index. 1, 0

InDwell BOOL This bit is true when the drive is holding position for a specified time as part of an index. 1, 0

Homed BOOL This bit is true when the drive has completed the homing sequence and has a valid home

position. This bit does not clear if the encoder exceeds its range; however, it does not have a valid

absolute position reference.

IndexSelect UINT This is binary combination representing the current index that is being acted on. If no index is in

process, it represents the value of the last index that was acted on.