Page 1

User Manual

Using the Mining, Mineral, and Cement Library

(MMCL) in RSLogix 5000 Applications

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

MMCL Deliverables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

Developing an RSLogix 5000

Application

Rules and Recommendations

Creating a New Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Configure Hardware I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Import Tags with the Data Retrieval Tool CSV Files . . . . . . . . . . . . . 10

Alias I/O Descriptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Creating User Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Program Design and Application Tips . . . . . . . . . . . . . . . . . . . . . . 14

Example Application Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Grouping of Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2

Add-On Instruction Interface Definition . . . . . . . . . . . . . . . . . . . . . . . 19

Typical Add-On Instruction Function Call . . . . . . . . . . . . . . . . . . 20

Using Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Add-On Instruction Module Parameter . . . . . . . . . . . . . . . . . . . . . 21

Global Apply Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Enable Alarming in Analog Modules . . . . . . . . . . . . . . . . . . . . . . . 22

Control Group

Using the E3 Module

Chapter 3

Group Sequence Step Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Step “Ready” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Local Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Interlock Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Power-Dip Suppression. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Enabling Automatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

E3 Installation and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Recommended Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

RSNetworx for DeviceNet Software . . . . . . . . . . . . . . . . . . . . . . . 34

E3 Operational Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DeviceNet Tag Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Exchange Data Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

RSLogix 5000 Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Publication RA-UM002B-EN-P - November 2010

Page 4

4

Inter Process Communication

Application Examples

Chapter 5

Establish produced/consumed Controller Tags . . . . . . . . . . . . . . . . . 41

Step1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Step2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Step3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Interlock Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Communication Error Interlock. . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 6

Example 1 –

One Group with Two Selectable Feeders. . . . . . . . . . . . . . . . . . . . . . . 47

Example 2 –

Two Groups with One Common Conveyor . . . . . . . . . . . . . . . . . . . . 51

Example 3 –

One Group with Two Starts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Example 4 -

Process Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Example 5 -

Inter Process Communication IPCom . . . . . . . . . . . . . . . . . . . . . . . . . 56

Additional Information

Appendix A

RSLogix 5000 Workstation Options. . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Workflow Data Retrieval Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Installation Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

New Product Satisfaction Return . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Publication RA-UM002B-EN-P - November 2010

Page 5

Preface

Introduction

Requirements

Before You Begin

This document describes how to create an application with RSLogix 5000

using the Mining, Mineral, and Cement Library (MMCL). It does not show

product installation or setup of the IT infrastructure.

Item Requirements

Software • RSLogix 5000 version 17 or later

• Data Retrieval Tool Tag Import Files

CLX_TAGS_OUT.csv

CLX_STRUCTURES_OUT.csv

Library MMCL_V200_AOI_20100501.ACD or later

Hardware ControlLogix controller, 1756-L6x, firmware revision 17.xx

Skills Knowledge of communication networks and I/O modules

(a)

These files may be generated by the Data Retrieval Tool and created automatically by the MMCL

(MMCL_HDRS_DataTool_V132.mdb).

(a)

:

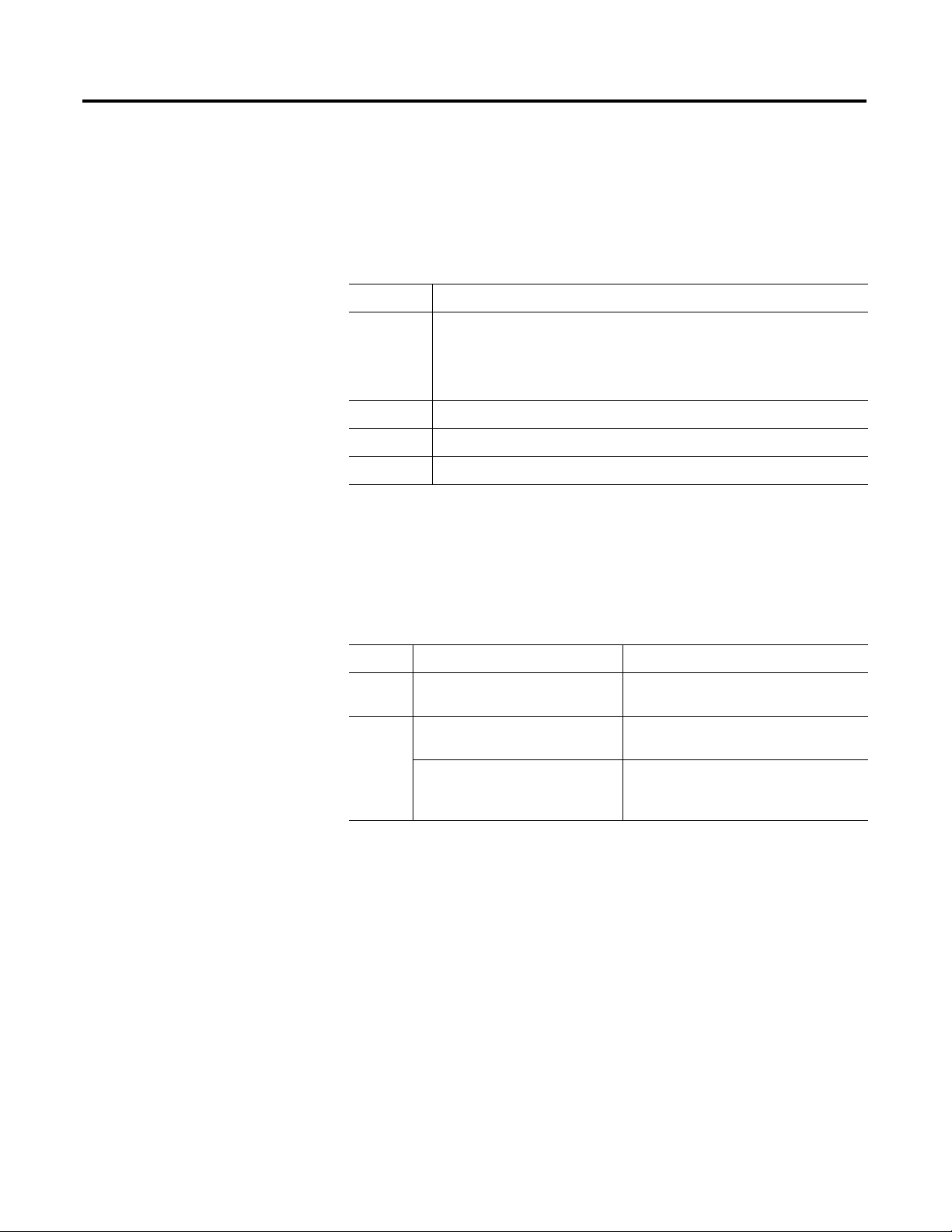

The creation of an RSLogix application is based on the MMCL and the

following data files.

Item Requirements Description

Library MMCL_V200_AOI_20100501.ACD Basic application with Add-On

Instructions, provided in the MMCL

Data

Retrieval

Tool

CLX_TAGS_OUT.csv Option to automatically create module

tags, created in the Data Retrieval Tool

CLX_STRUCTURES_OUT.csv Option to automatically create Add-On

Instruction structures, created in the Data

Retrieval Tool

5 Publication RA-UM002B-EN-P - November 2010

Page 6

6 Preface

MMCL Deliverables

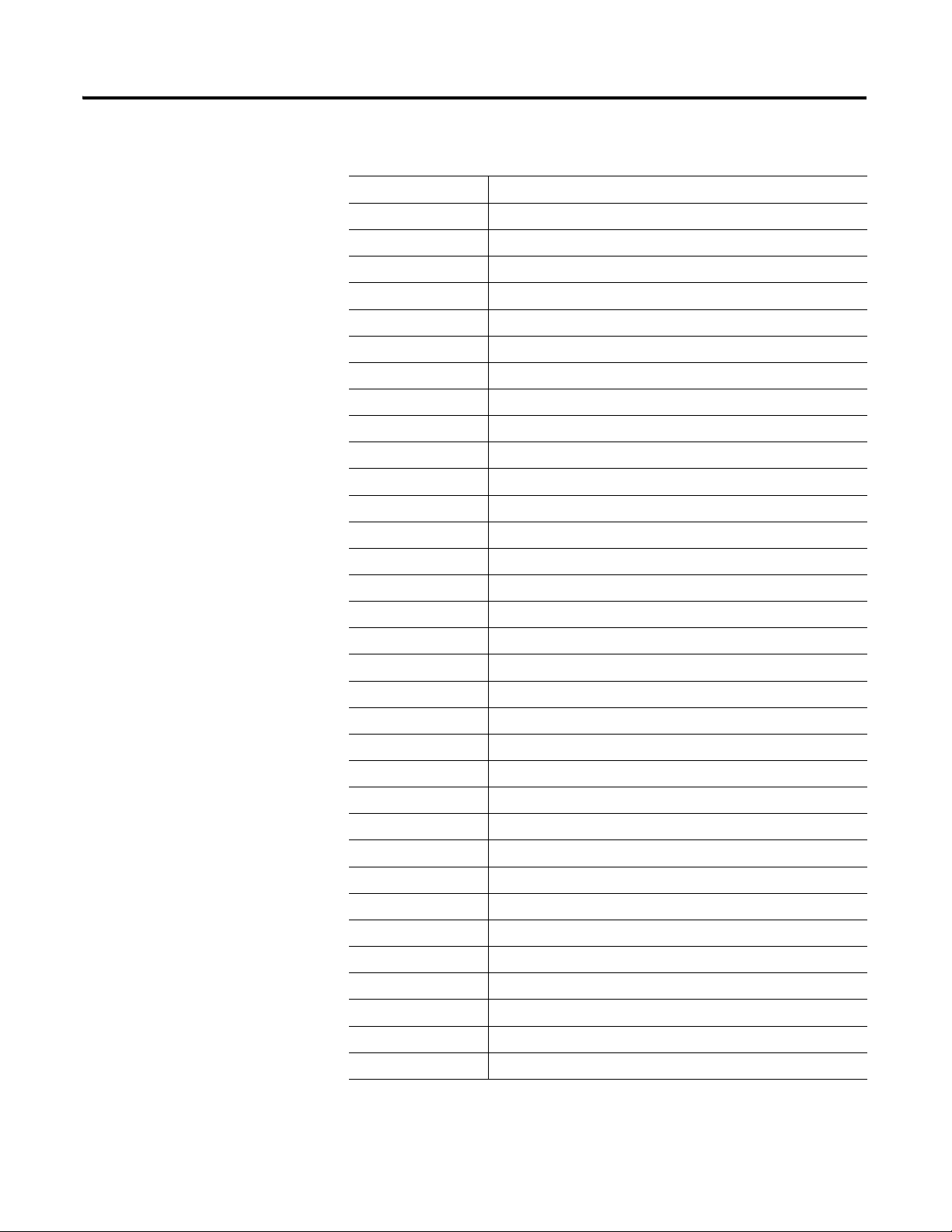

The base library project contains the following Add-On Instructions.

Name of Element Description

SysGrp_AOI System Group (one only per CLX)

CtrlGrp_AOI Control Group

MaGrp_AOI Machine Group

IPCom_AOI Inter-process Communication

MotorN_AOI Motor Normal Drive (one direction)

MotorR_AOI Motor Forward/Reverse Drive (two directions)

MotorD_AOI Motor Damper/Flap Drive

E3p_AOI RA E3 Plus Motor Starter

SubSys_AOI Sub-System

Valve1_AOI Valve with 1 Coil

Valve2_AOI Valve with 2 Coils

DigInp_AOI Digital Input

DigInp2_AOI Digital Input for two input (drift switch)

Digpulse_AOI Digital Pulse Input

AnInp_AOI Analog Input

AninpC_AOI Analog Input and Control Outputs

ActMod_AOI Actuator Module

ActPos_AOI Actuator Positioning

PidMod_AOI PID Module

MotorN_Sim_AOI Motor Normal Drive Simulator

MotorR_Sim_AOI Motor Forward/Reverse Drive Simulator

MotorD_Sim_AOI Motor Damper/Flap Drive Simulator

MotorNE3p_Sim_AOI Motor Normal Drive with E3P Simulator

MotorRE3p_Sim_AOI Motor Forward/Reverse Drive with E3P Simulator

MotorDE3p_Sim_AOI Motor Damper/Flap Drive with E3P Simulator

Valve1_Sim_AOI Valve with 1 Coil Simulator

Valve2_Sim_AOI Valve with 2 Coils Simulator

DigInp_Sim_AOI Digital Input Simulator

DigInp2_Sim_AOI Digital Input for 2 Inputs Simulator

DigPulse_Sim_AOI Digital Pulse Input Simulator

AnaInp_Sim_AOI Analog Input Simulator

ActMod_Sim_AOI Actuator Module Simulator

Publication RA-UM002B-EN-P - November 2010

PID_SIM_AOI PID Module Simulator

Page 7

Name of Element Description

L_CPU_17_AOI Processor Utilization

P_Intlk_AOI Interlocks

P_Perm_AOI Permissives

Preface 7

Reference Documents

These documents contain additional information concerning related

Rockwell Automation products.

• Integrating Mining, Mineral, and Cement Library (MMCL) into

RSLogix 5000 Software Reference Manual, publication RA-RM002

• Platform Architecture Guide rev2.0.pdf or later

Publication RA-UM002B-EN-P - November 2010

Page 8

8 Preface

Notes:

Publication RA-UM002B-EN-P - November 2010

Page 9

Chapter

IMPORTANT

1

Developing an RSLogix 5000 Application

Creating a New Project

Configure Hardware I/O Modules

1. In RSLogix, open the MMCL_V200_AOI_YYYYMMDD.acd file

provided in the MMCL.

This application contains all Add-On Instructions.

2. Under File, select Save As.

3. Type your desired project name (for example,

UserProject_yyyy_mm_dd.acd) and click Save.

All I/O modules used by the application are inserted and configured with the

I/O configuration tool.

1. Configure all hardware I/O modules located in the chassis.

For remote I/O modules (Networks), the adapters and required I/O

modules must be configured.

The I/O module Name must correspond to the Data Retrieval Tool tag designation (import file).

This is necessary for later export of I/O Module data and backup import to the Data Retrieval Tool

data base.

The backup import is used to store the proper hardware addresses, in the Data Retrieval Tool data

base.

For Tag names and Alias designations using Asset Code (AC), refer to

N_050817_HDRS_RSLogix_Concept.pdf.

9 Publication RA-UM002B-EN-P - November 2010

Page 10

10 Developing an RSLogix 5000 Application

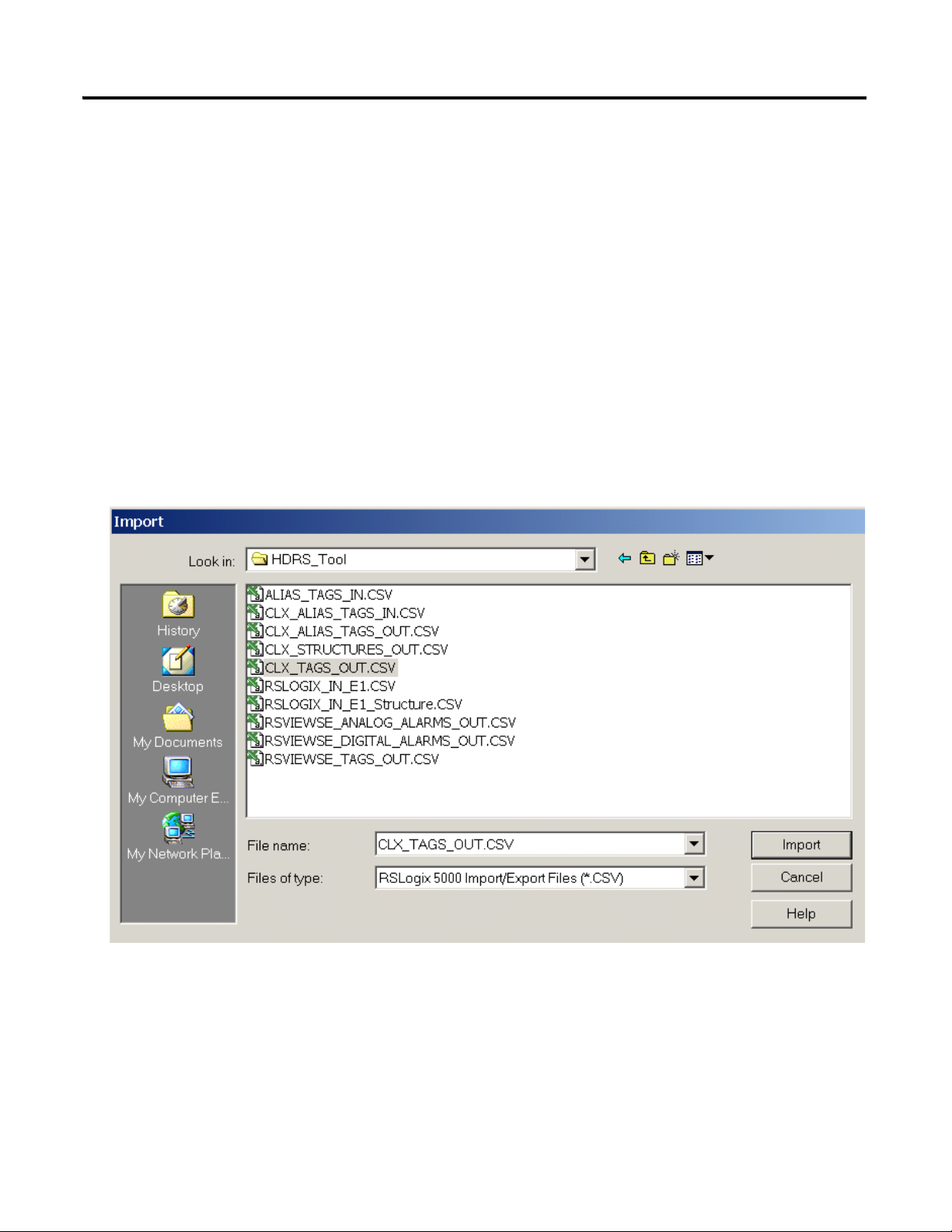

Import Tags with the Data Retrieval Tool CSV Files

When using the AC for tag designations, you can export a.csv file, from the

Data Retrieval Tool and import the data to RSLogix 5000. This import

automatically creates the tags and its members, for all devices specified in Data

Retrieval Tool. The .csv files are created by the Data Retrieval Tool export

function and imported into RSLogix 5000.

The Data Retrieval Tool export procedure is described in document:

HDRS-DataRetrievalTool_100.pdf

The RSLogix 5000 import procedure requires Microsoft ACCESS program:

MMCL_HDRS_DataTool_V132.mdb

The import procedure is described in document:

MMCL_HDRS-DataRetrievalTool_V130.pdf

1. Under Tools, select Import.

2. Browse to the CLX_TAGS_OUT.CSV file and click Import.

Publication RA-UM002B-EN-P - November 2010

3. Complete this process for the CLX_STRUCTURES_OUT.CSV file.

Refer to the Workflow Data Retrieval Tool on page 60 for more information.

Page 11

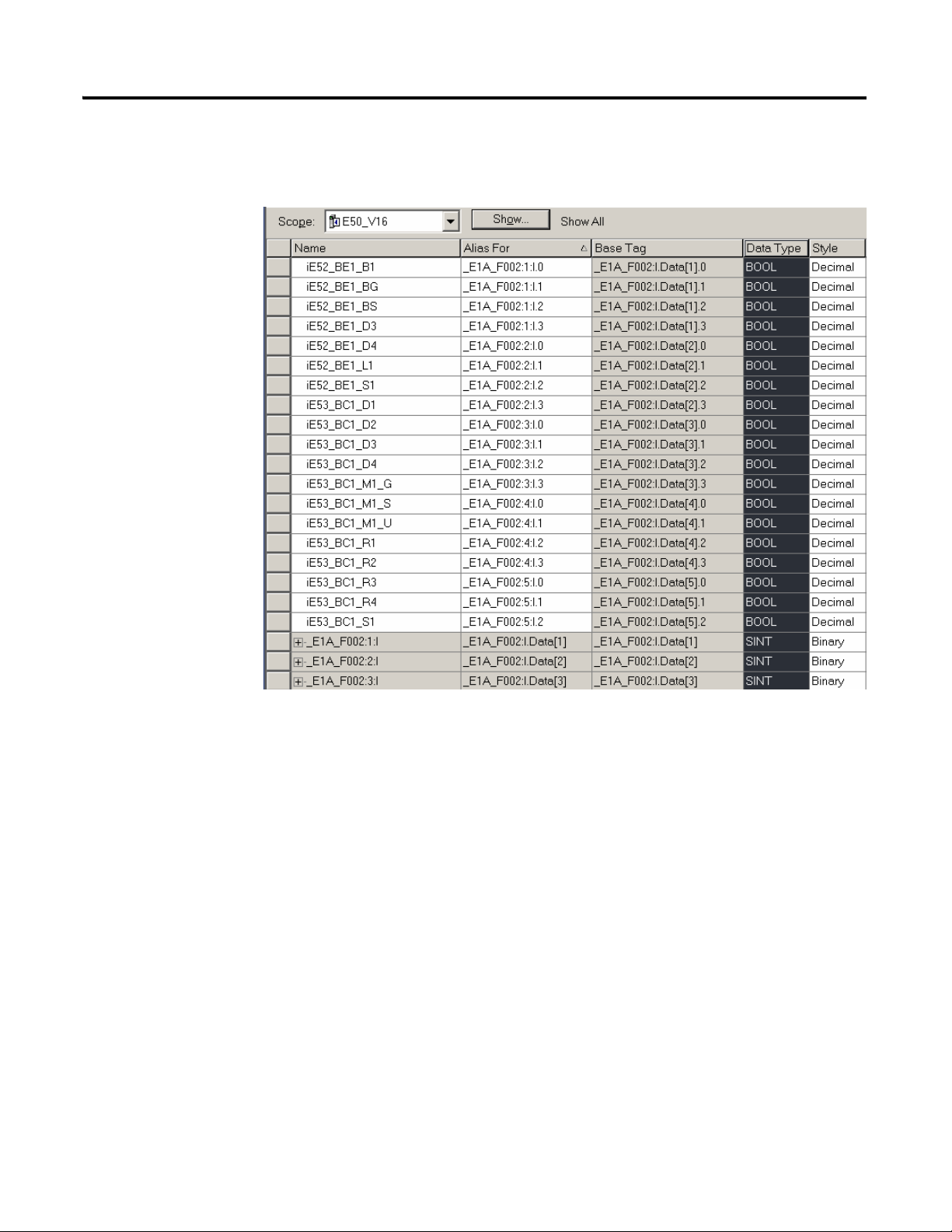

Developing an RSLogix 5000 Application 11

Tag Name imported from the Data

Retrieval Tool CSV file

I/O Address, where:

_E1A_F002 = Adapter Name

1:I.0 = Slot 1:Input Module.Bit 0

IMPORTANT

Alias I/O Descriptor

The Alias I/O descriptor specifies the exact hardware terminals and the

particular I/O module. It is therefore, necessary to know how the I/O

modules are installed and wired.

Example of Tag Properties

Do not assign the same Alias twice. We recommended that

you check for duplicate addresses prior to using the

application. Select Controller Tags and sort Alias by

ascending order, then check the list for possible

duplications.

Publication RA-UM002B-EN-P - November 2010

Page 12

12 Developing an RSLogix 5000 Application

The following is an example I/O Configuration with Controller Tags and Alias

I/O addresses:

Publication RA-UM002B-EN-P - November 2010

Page 13

Developing an RSLogix 5000 Application 13

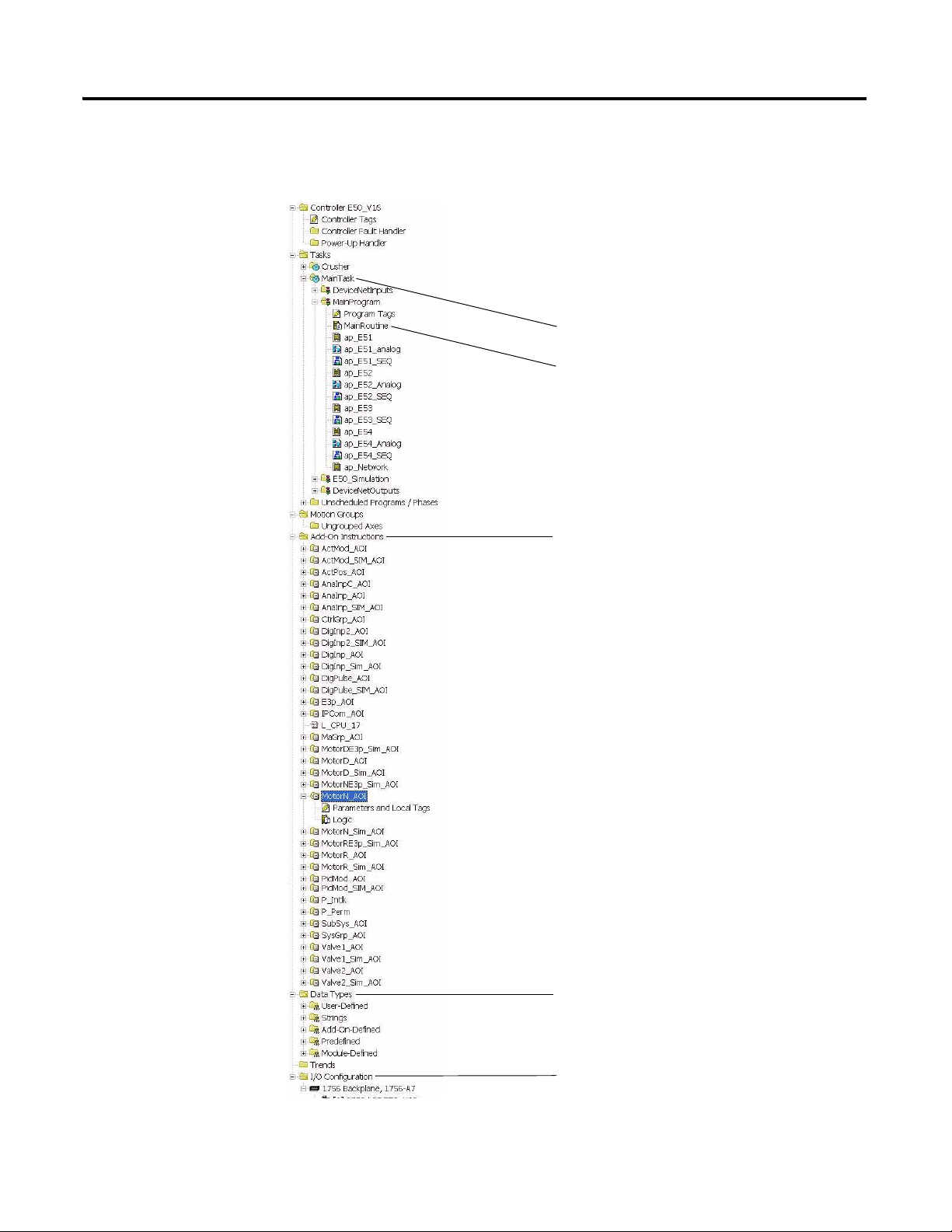

User Programs are called in the Periodic Task. This is to improve overall

system performance. To allow proper interaction between MMCL Add-On

instruction standard functions, when multiple period tasks are used, the

Period and Priority configuration for all tasks should be the same. If different

Period and Priority is configured, then customized code has to be added to

synchronize module scan in different tasks.

Periodic Task with all User Programs

Call all User Programs including. System Rungs

For example, User Program for Network Status

MMCL AOI Standard Functions called by User

All MMCL User Data Types (UDT)

All I/O modules listed here

Creating User Programs

The RSLogix 5000 project originates from the MMCL_V200_20100501.acd

file. The following program and data folders are included in the project.

Publication RA-UM002B-EN-P - November 2010

Page 14

14 Developing an RSLogix 5000 Application

Program Design and Application Tips

• User Programs can be called by the Continuous or Period Tasks. When

Periodic Tasks are used, certain rules have to be followed because the

MMCL Add-On Instruction Standard Functions are originally designed

for Continuous Tasks.

• Setup the I/O module, or device parameters, immediately after a new

module is installed.

• The System Group Module, SysGrp_AOI, must be called only once in

the application. Its input, ApplyPar, signals all analog modules to read

changed parameters on-line.

• The User Program, ap_Network, is an example that shows how to get

the Network Status from an I/O Module and make it visible to the

HMI.

• The main program, MainRoutine, contains some System Rungs. These

rungs may be extended and/or adapted as required.

• Analyze the desired functions before programming. Outline the Control

and Machine Groups. Specify the calling order and start and stop

sequences of Modules within a Group.

Publication RA-UM002B-EN-P - November 2010

Page 15

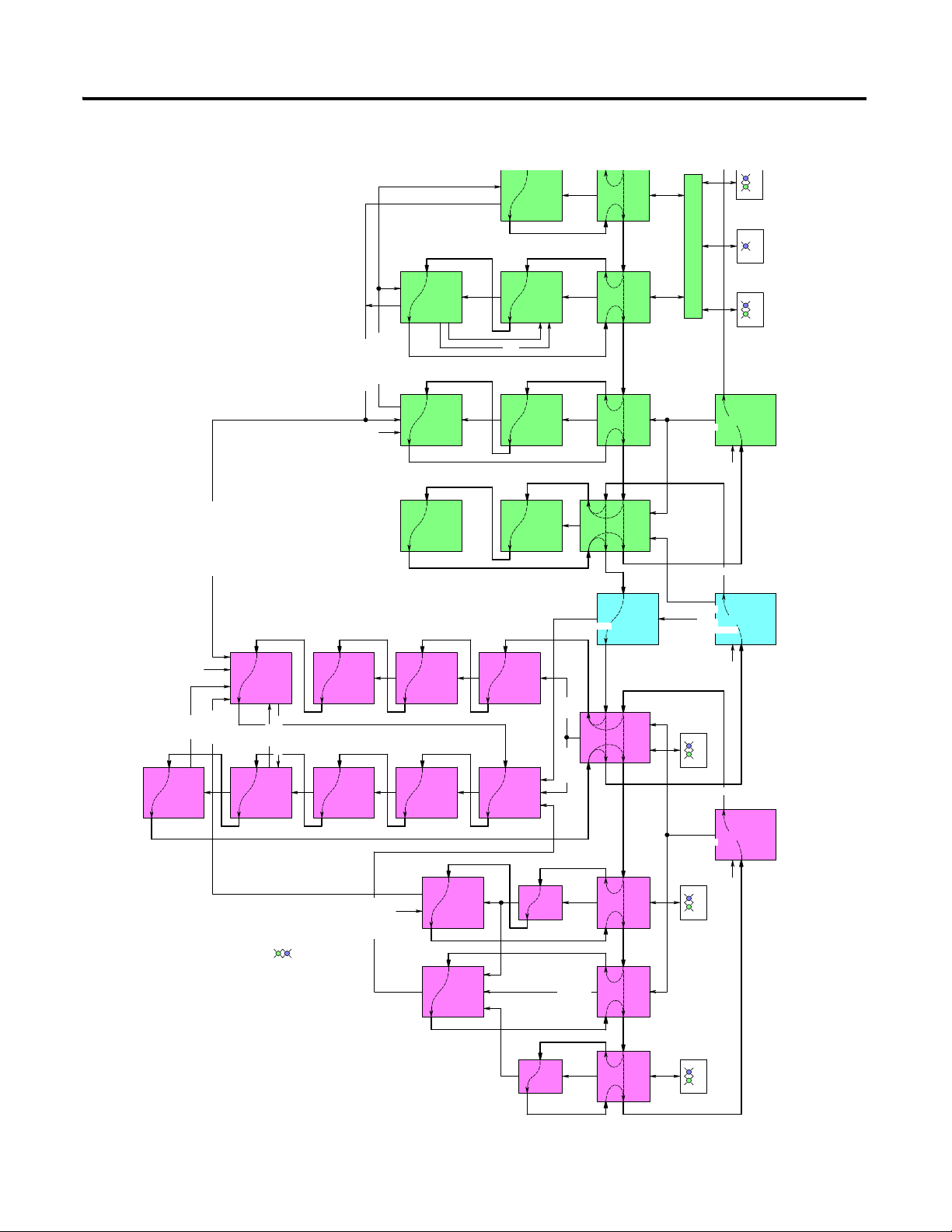

Developing an RSLogix 5000 Application 15

Bus

E51_BF1_C1

SubSys/W

E51_RF2_M1

MotorN/W

E51_FN1_M1

MotorN/W

Bus

E51_000_02

MaGrp

Bus Bus

E51_MW1_V1

Valve1/F

Level

Max

Level

Max

E51_000_00

CtrlGrp

Bus

Rotary

Feeder

Filter

Fan

Bag

Filter

Last Drive

Position

Actuator

Bus

E52_000_03

MaGrp

.0

Gate PG1

E52_PG1_Z1

ActMod/F

E52_000_03.Bus

Gate 2StandbyGate 1

Select Logic

Bus

E52_000_04

MaGrp

.0

Gate PG2

E52_PG2_M1

MotorD/W

Open

Close

E52_000_04.Bus

E52_000_01

MaGrp

Bus

E52_BE1_M1

MotorN/F

E52_BE1_M2

MotorN/W

E52_000_01.Bus

Bus

E52_000_02

MaGrp

.0

E52_FA1_M1

MotorN/F

E52_3B1_WC

PidMod/W

E52_000_02.Bus

Position Feedback

Fan

Aeration

Bucket

Elevator

E52_000_00

CtrlGrp

Bus

Throttle

Gate

E52_PG0_C1_SBY

E53_BC1_M1

MotorN/F

E53_000_00

CtrlGrp

Bus

.1

.0

.1

.0 .1

E51_BC1_FC

PidMod/W

Flow

Controller

AllRun/AllStopAllRun/AllStopAllRun/AllStop

EnAutoStart

EnAuto

E51_000_03.Bus

Legend

= HMI PreSelect (Toggle)

= HMI Sel ected Indication

/W = Warning Device

/F = Failure Device

E51 Bin Extraction / Silo Feed

Group

Master

Group

Master

Group

Master

Belt

Conveyor

E52 Bin Feed E53 Recirculation

E52_PG2_C1_SEL

.0

E51_000_04

MaGrp

E51_000_01

MaGrp

E51_000_03

MaGrp

Silo 3S1Recirc Silo 3S2

E53_BC1_C1_SEL E51_3S1_C1_SEL E51_3S2_C1_SEL

.0 .1 .0 .0 .0

Silo 3S2Silo 3S1

Recircu-

lation

Local only

operation

3S1_LM

DigInp/F

3S2_LM

DigInp/F

EnAutoStart

EnAuto

EnAuto

EnAutoStart

E51_BC2_M1

MotorR/F

E51_BC1_M1

MotorN/F

E51_RF1_M1

MotorN/F

E51_RF1_S1

ActMod/F

Speed

Actuator

Rotary

Feeder

Belt

Conveyor

RdyAuto

EnAutoStart

Distribution

Gate

E51_000_01.Bus

Belt

Conveyor

Last Drive

E51_SG1_M1

MotorD/F

Slide

Gate

E51_000_04.Bus

Level

Controller

Auxiliary

Drive

Weight

Controller

RdyAutoX/Y

E52_PG2_Z1

ActMod/F

Ctrl'd Variable=SP

Position=Feed Forward FF Setpoint SP

Ctrl'd Variable=SP

E52_3B1_W1=PV

E51_BC1_F1=PV

RdyAuto

E53_000_00.Bus

P

o

s

i

t

i

o

n

C

t

r

l

'

d

V

a

r

i

a

b

l

e

E52_000_00.Bus

Y=Recirc X=Silo

Y=3S1 X=3S2

Check

Check

Check

E51_3S1_L1=PV

E51_3S1_LC

PidMod/W

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/OI/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/OI/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Example Application Overview

PG1_C1_SEL

Publication RA-UM002B-EN-P - November 2010

Page 16

16 Developing an RSLogix 5000 Application

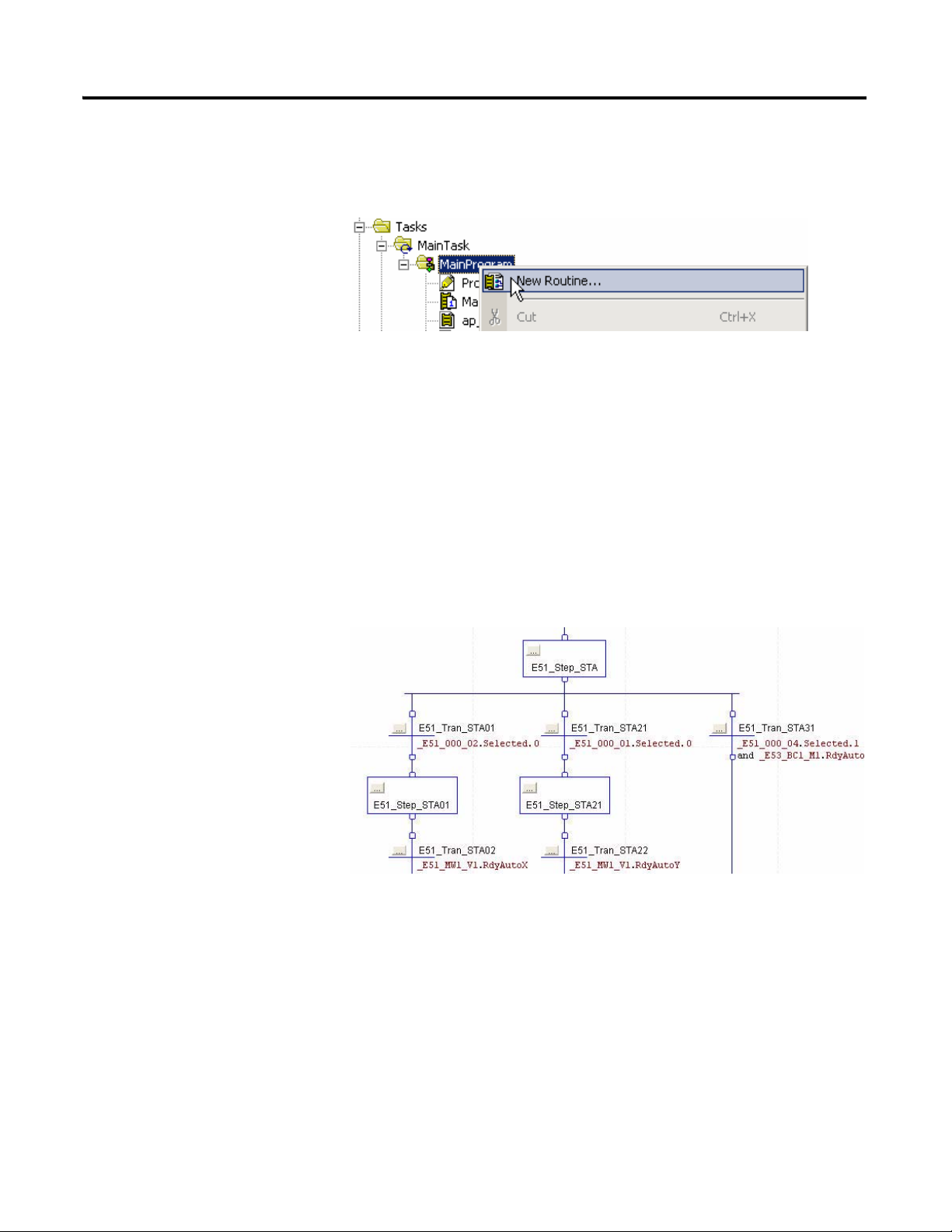

Grouping of Programs

For a clear program structure, it is recommended, to specify separate programs

for each Control Group. To start a new program, right-click the MainProgram

and select New Routine.

A Control Group may also be split functionally, using a ladder program, for

motor control I/O status and interlocking, a Sequential Function Chart

(SFC), for module start and stop sequences (including structured text) and a

Function Block Diagram (FBD), for analog process controls. The different

methods are supported by the corresponding RSLogix 5000 Editors. The

MMCL Add-On Instructions are available for Ladder, Function Block and

Structured Text.

For automatic start and stop sequences, use an SFC, especially if devices

must be stopped individually, rather than by a common shutdown command.

If, however, a common shutdown or delay time is suitable, then an SFC is not

required and a group can be stopped by the Control Group's built-in

stop-delay timer, using standard ladder interlocking only.

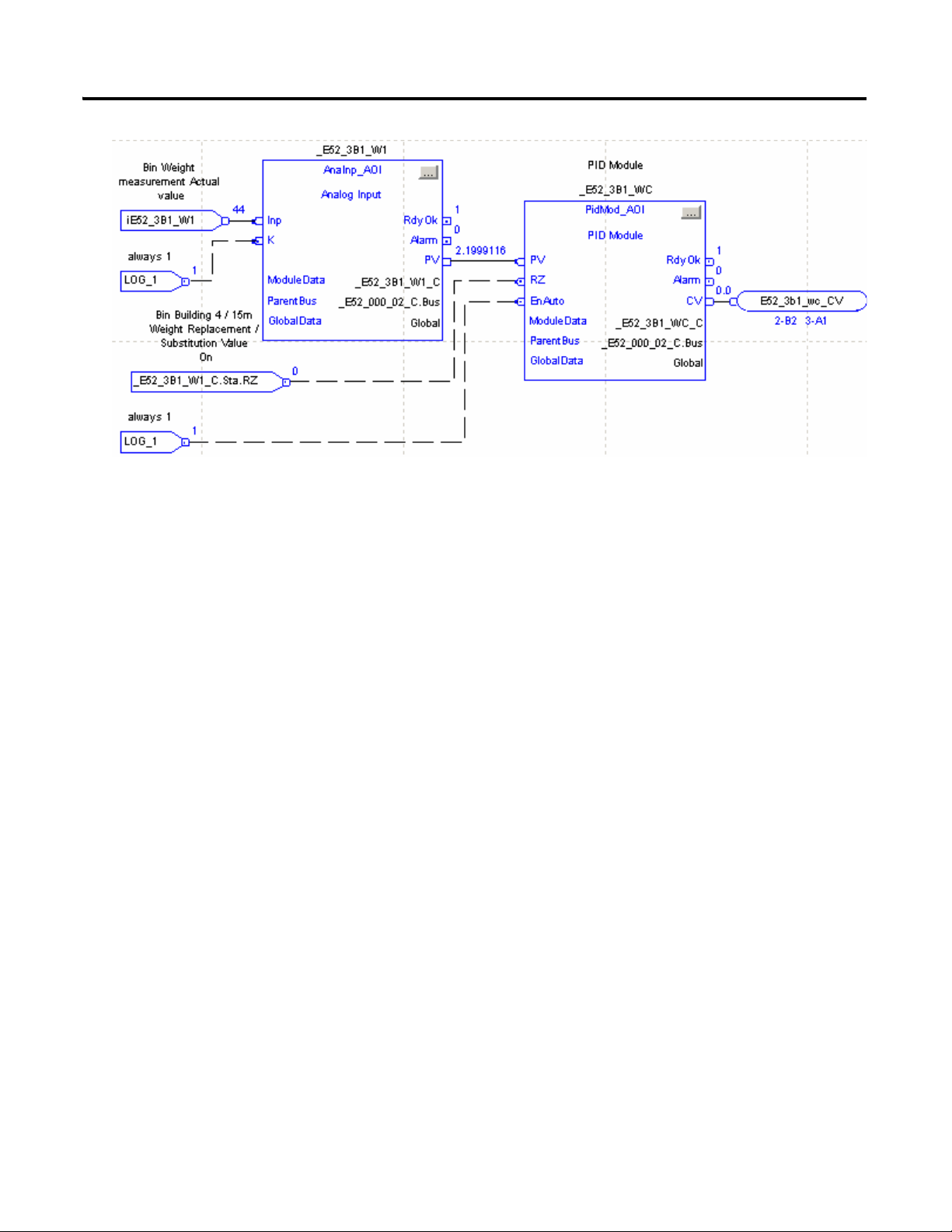

Publication RA-UM002B-EN-P - November 2010

For analog signal processing, use a FBD, which is more comprehensive,

showing the signal flow better than a Ladder diagram.

Page 17

Developing an RSLogix 5000 Application 17

Publication RA-UM002B-EN-P - November 2010

Page 18

18 Developing an RSLogix 5000 Application

Notes:

Publication RA-UM002B-EN-P - November 2010

Page 19

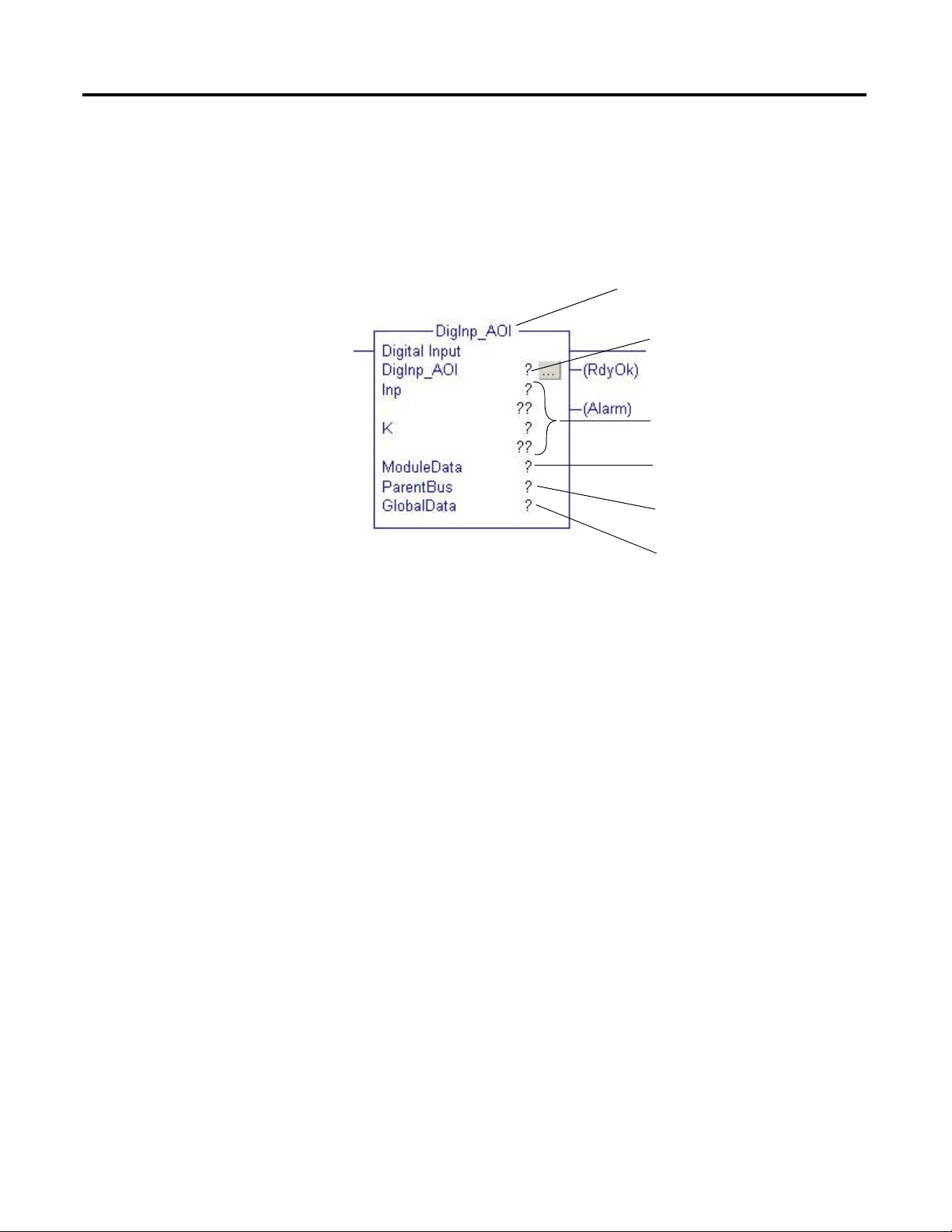

Add-On Instruction

Function Name and Description

Backing Tag, for example _512_BC3_D1

Module Data Structure, for example

_512_BC3_D1_C

I/O connection from/to application

Bus connection to Parent Module

All Modules access the same

Global Data

Interface Definition

Rules and Recommendations

Chapter

2

The Backing Tag (instance name of the Add-On Instruction) must be unique.

The name of the ModuleData Tag is the same as the Backing Tag extended by

"_C " (for control). For example, if the Backing Tag is _512_BC3_D1, then

the ModuleData Tag is _512_BC3_D1_C.

19 Publication RA-UM002B-EN-P - November 2010

Page 20

20 Rules and Recommendations

Add-On Instruction Module Data Structure

Add-On Instruction

Backing Tag

Typical Add-On Instruction Function Call

Each MMCL Add-On Instruction function has three data structures:

• All direct Inputs/Outputs are specified by the Backing Tag (instance

name of Add-On Instruction).

• The ModuleData Tag is referenced by the Add-On Instruction, this data

may be read and written by other modules/devices. It contains HMI

data (Sta, Cmd, and Val) or Parameters (Par).

• The Global Tag is used by all modules and contains common

Parameters or, for example, the interface for the Startup Warnings

(Horn/Flash) and Alarm Gong.

Publication RA-UM002B-EN-P - November 2010

Page 21

Rules and Recommendations 21

IMPORTANT

Using Parameters

It is important to set device parameters correctly in order to avoid

malfunctioning devices. After creating the tags, when importing the .csv file

from the Data Retrieval Tool, you should download the default parameter

values created by the Data Retrieval Tool, using the built in Tag

Up-/Download tool.

When you program a device, we recommend that you immediately verify the

parameter settings, according to your application.

For detailed information about parameters, see the Integrating the Mining,

Mineral, and Cement Library (MMCL) into RSLogix 5000 Reference Manual,

publication RA-RM002.

Add-On Instruction Module Parameter

The user can determine certain functions and/or the behavior of an Add-On

Instruction module by setting the parameter. The parameters are part of the

ModuleData Tag and defined as Tag members Par.xxx. Global Parameters,

that are valid for multiple Add-On Instructions, are specified by Tag members

Global.Par.xxx.

Carefully adjust and check adjust all Parameter settings

before testing your software. We recommended that you

set the parameters immediately after a new Add-On

Instruction function is applied. Make sure Module Type,

Timers [in ms], PID Gains, Filters, Alarm, Control

Thresholds, etc. are set correctly. Trouble shooting, may be

made difficult, if parameters are wrong, or not set.

Global Apply Parameter

This parameter is a special function within the System Group. If you set the

Global.ApplyPar parameter to 1, it will apply all the changes made to

parameters in the AnaInp_AOI, AnaInpC_AOI, ActMod_AOI, and

PidMod_AOI used for scaling and sample rate. If this parameter is changed,

the change does not take effect until the ApplyPar is toggled.

Publication RA-UM002B-EN-P - November 2010

Page 22

22 Rules and Recommendations

Enable Alarming in Analog Modules

To use the alarming capabilities of the AnaInp, AnaInpC and ActMod

modules, you must enable each alarm individually. This can be done by either

setting the tags <DEVICE>.EMA/.EHA/.ELA/.ENA to 1 while you are

programming the device, or by switching the tags dynamically from On to Off

through the logic program according to the application requirements.

Publication RA-UM002B-EN-P - November 2010

Page 23

Chapter

3

Control Group

The Control Group Module (CtrlGrp) provides the Human Machine Interface

(HMI) and the main control circuit, for a group of machines, or devices that

are started and stopped as an entire group. The term Group, refers to the

Asset Code (AC) definition, with the assumption that one AC Group can be

controlled by one CtrlGrp, but also may be controlled by several CtrlGrps.

The CtrlGrp accepts commands from FactoryTalk View SE. Local operator

stations, with separate start/stop pushbuttons, can also be connected. It

further accepts (for example, power failure input) or stop interlocks and it

provides outputs for the operator station, or the control room indication (for

example, mimic, alarm indication), as well as for start warning and motor

sequence control.

The CtrlGrp automatically receives/sends data from/to other modules (for

example, local enable or alarm feedback of motor modules), through its Bus

interface, in order to reduce programming workload, as well as programming

errors. The release of alarms within a group, depends on the status of the

group. If the group is active, then messages from the related modules are sent

to FactoryTalk View SE.

23 Publication RA-UM002B-EN-P - November 2010

Page 24

24 Control Group

Group Sequence Step Controller

The central part of the CtrlGrp is a seven-step controller, of which status is

available to the user. The steps 0..6 shown below, represent the actual group

status, in automatic mode. Status 0 is stopped, a normal start/stop sequence

runs the steps from 1 through 6, one after the other, and terminates at status 0,

if the group is stopped again.

Publication RA-UM002B-EN-P - November 2010

Note: An additional status "Standby" is shown for information only and has

no influence on the sequence described. The state -bit, can be used in the

application as a memory flag, to trigger an automatic start of the sequence.

Page 25

Control Group 25

Step “Ready”

Group has the ability to re-start, if step 4 “Ready” is active. Step Ready, is

active, until Group (restart) is started again. When step Ready is active, there is

a blue indication on the HMI Control- Group Popup. If the Group is restarted

with the Start button, it jumps directly to step 1 “Startup”. During this

re-starting situation, the Automatic Signal “EnAuto(X/Y)” is always true.

Only the Signal “EnAutoStart”, stays false during step 1+2 (Startup+Waiting)

and will pass over to true, if you remain at step 3 “Starting”.

The step controller not only increments steps consecutively, but may switch

(jump) to any step, in order to set a status, that complies with the new

situation. As an example, an operator Immediate Stop will, regardless of the

current status, immediately select status 0 and shutdown any control within the

group. The table below shows the additional jumps.

Start Ready Failure Normal Stop Fast Stop

Start Button

OR

Restart

Loss of last drive

AllRun=0

OR

PartRun=1

OR

Starting Pause

OR

Starting Times Out

If Parameter

FailureStopDisable=1

AND

Failure=1

Stop Button=1

OR

IntlStop.0.. 7=1

OR

FailureStopDisable=0

AND

Failure=1

ImmStop=1

IntlImmStop.0..7=1;

PowerDip

OR

OR

Publication RA-UM002B-EN-P - November 2010

Page 26

26 Control Group

* If the group has not already started a motor, status 1 and 2, will directly

pass over to status 0.

Each status change, further causes an output ResetSFC, that can be used to

initialize (reset) the Sequential Function Chart (SFC). The SFC then selects the

actual sequence (e.g. stop sequence).

Publication RA-UM002B-EN-P - November 2010

Page 27

Control Group 27

Local Operation

Interlock Release

Local operation can at any time be selected, i.e. a group may be running, while

certain machines within the same group, can be started and stopped locally.

Automatic operation uses the control sequence described above and is

transferred from the operator panel (template), by means of the group

start/stop pushbuttons and monitors for mimic displays and alarming.

Regardless of local operation, a group sequence can, at any time, be started,

when all start interlocks are satisfied.

Local operation is required for maintenance and test purposes. It is only

possible, with operator permission, to allow, or deny, local operation, for an

entire group, by means of the local button. Local operation, is always cancelled

by the CtrlGrp, if the sequence is interrupted by a Immediate Stop.

Each group can be operated with released interlocks, for commissioning, or

other special purposes. In the interlocked released mode, the inputs

IntlStart/IntlStop/IntlImmStop 0..n are inactive, however the messages are

still displayed (see CtrlGrp ModuleData Tag .Var.INR).

Power-Dip Suppression

Power-dip refers to short (less than 300 ms) main power interruptions, caused

by lighting, high voltage switching etc.

Because the main control equipment (field devices, interposing relays,

I/O-racks and PLCs as well as HMI PC's) are fed by uninterrupted power

supplies (UPS), it is possible to monitor power interruptions continuously and

prevent unnecessary shutdowns, as well as alarm messages, i.e. ignore short

power interruptions and suppress incorrect alarms caused by power outages.

Publication RA-UM002B-EN-P - November 2010

Page 28

28 Control Group

Enabling Automatic Operation

Each Control Group CtrlGrp provides two outputs, an EnAutoStart (enable

automatic start) and an EnAuto (enable automatic operation) signal, that are

used for motor control and that may be switched by Machine Group Modules

MaGrp. The bits are used in the application, to interlock the automatic

operation of modules, such as Motors/Valves etc., that use the signals as

inputs. A module will start only if both EnAutoStart AND EnAuto are ON

and it will stop if the EnAuto is OFF. A restart is only possible if the

EnAutoStart (OR the EnAuto) was set OFF for a cycle.

Note: In a chain of Devices the EnAuto Input is normally used as a process

Interlock.A following Device, has controlled his EnAuto from the previous

Module, connected to their RdyAuto.Control Group Module automatic start

/-stop timing

Publication RA-UM002B-EN-P - November 2010

Page 29

Control Group 29

EnAutoStart changes, in case of Restart conditions, to OFF, until CtrlGrp

Sequence “Starting”, then its turn ON again.

Note: Bi-directional modules as MotorR, MotorD, Valve1/2 have an

EnAutoX and an EnAutoY input, for either direction.

Signal timing EnAuto / EnAutoStart

Normal Group -start and -stop situation

Publication RA-UM002B-EN-P - November 2010

Page 30

30 Control Group

Timing situation with Restart condition (Restart Request)

Publication RA-UM002B-EN-P - November 2010

The following conditions changes the Group to “Restart Request”:

1. If any of the Alarms are on “move” - Devices such as MotorN/R/D or

Valve1,2. These Modules bring the alarm condition over the linked Bus

-chain up to the Group.

2. If the Group is in “Starting” -state and the CtrlGrp Input .PartRun is

true.

3. Or the Group is in “Running” -state and the CtrlGrp Input .AllRun

changes to false.

4. If the group is in "Starting" -state and the operator presses "Pause"

button on CtrlGrp HMI faceplate.

5. If the Group is in "Starting" -state and Starting Time Out timer times

out.

Page 31

Using the E3 Module

Chapter

4

Introduction

The E3p_AOI module is an interface block between Network (scanner) and

Motor block. Templates using the E3 module operate the same as regular

X module but with the add-on information from the E3 module:

Motor

warning status, trip status, therm., utilized and average current. The E3p_AOI

does not have a specific HMI Template. Each Motor Device with E3plus

Overload Relay will call a specific HMI Template such as

03_MotorN_E3_small or 03_MotorN_E3_largel.

There are no parameters to configure inside the E3 module structure.

31 Publication RA-UM002B-EN-P - November 2010

Page 32

32 Using the E3 Module

Principal Diagram

Publication RA-UM002B-EN-P - November 2010

Page 33

Using the E3 Module 33

IMPORTANT

E3 Installation and Wiring

Recommended Workflow

Refer to the E3 and E3 Plus Solid-State Overload Relay User Manual,

publication 193-UM002, for installation and wiring details.

System

The E3 Overload Relays provide for data exchange over the Network of

configurable Input and Output Assemblies. Inputs (Data from E3) are 8 Bytes

(4Words) and Outputs (Data to E3) are 1Byte.

Note: You can read more data out of the E3 then we have the possibility to

reach with explicit messaging. However this asynchronous messaging will

generate a high communication load at the processor.

Do not use a MSG (explicit message) operation to get data

from the E3 Device.

1. Configuration of the whole DeviceNet network related to a

DNB-Scanner Module. This is possible in Online or Offline Mode.

Remember to set the E3plus Parameter.

2. Use the DeviceNet Tag Generator to generate all Tags and Structures of

the DeviceNet Network.

3. Exchange all Data Types of E3 Data Tags which are created in the

previous step by the DeviceNet Tag Generator with common UDT,

E3_Inp and E3_Out, respectively.

4. Code programming in your application routine.

Publication RA-UM002B-EN-P - November 2010

Page 34

34 Using the E3 Module

RSNetworx for DeviceNet Software

Use the RSNetworx software to configure all E3 Overload Relays that are

connected to your network. Refer to the E3 and E3 Plus Solid-State Overload

Relay User Manual, publication 193-UM002, for more information

This document provides additional configuration information.

Publication RA-UM002B-EN-P - November 2010

Page 35

Using the E3 Module 35

E3 Operational Parameters

The following is a list of all parameters that must be set correctly in the E3. All

others that are not in this list should be left at their default value or do not take

effect with the E3p_AOI.

General Parameters

Parameter Description Required Setting

24 Trip enable See graphic on page 36

25 Warning enable See graphic on page 36

27 Single/three phase Three phases

28 FLA setting Full load amps from the motor nameplate

30 OL/PTC reset mode Manual

E3 will not reset automatically

31 OL reset level 75% (default)

User will not be able to reset E3 until therm util. is

below this value.

32 OL warning level 85% (default)

E3 will show an overload warning when therm util.

is equal or above this value.

59 Output assembly 105

60 Input assembly 100

61 Assy word 0 21 (device status)

62 Assy word 1 14 (trip status)

63 Assy word 2 4 (Therm. Util.)

64 Assy word 3 9 (Average current)

Publication RA-UM002B-EN-P - November 2010

Page 36

36 Using the E3 Module

Parameter 24 Trip enable (default)

Parameter 25 Warning enable

Publication RA-UM002B-EN-P - November 2010

Page 37

Using the E3 Module 37

DeviceNet Tag Generator

We recommend using the RSLogix 5000 tool, DeviceNet Tag Generator, to

automatically create all tags and structures in to your RSLogix 5000 project.

This tool is available on the RSLogix 5000 Optional Software CD or on the

DeviceNet Optional Tools CD.

This tool also creates additional Routines and code in your .acd project file.

The created code handles all Data exchange between the DeviceNet Scanner

Data list and your Application. This tool also creates structures and all Tags

related to each E3 with unique tag names.

The tag names take the following structure:

ScannerName_Note#_Polled_Input/Output

For example, DNB_N03_POL_I = DeviceNet Input Data from Note 3, and

DNB_N03_POL_O = DeviceNet Output Data to Note 3

The Data Type that the DeviceNet Tag Generator automatically creates is

named by the Catalog Number explanation and parameter configuration.

For example, AB_193592_EC2P_I_70847BCC

where 70847BCC is a unique code# which depends on the parameter

configuration.

Catalog Number Explanation

Publication RA-UM002B-EN-P - November 2010

Page 38

38 Using the E3 Module

Exchange Data Type

To match the tags to the E3p_AOI DataInp and DataOut, you must change

the Data Type of each E3 related Tag.

Change the tags one by one in the Controller Tag Database or use the Tag

export/import function and change the Data Type in an Excel csv file.

Note: You must know which Note Number corresponds to an E3.

Publication RA-UM002B-EN-P - November 2010

Page 39

Using the E3 Module 39

IMPORTANT

RSLogix 5000 Application

The DeviceNet Tag Generator also creates new program routines for all

DeviceNet scanner data read/write commands.

Application code example:

Always program the E3p_AOI after a Motor block. The

ParentBus is always linked to the Motor local Bus, for

example MotorName_C.Bus.

Publication RA-UM002B-EN-P - November 2010

Page 40

40 Using the E3 Module

Notes:

Publication RA-UM002B-EN-P - November 2010

Page 41

Chapter

Remote CPU

5

Inter-process Communication

The IPCom module is used for inter-process communication between two

programmable automation controllers.

With this module, the communication to a remote controller is set up and

supervising.

The main function of IPCom is to distribute the bus-data. At the same time, it

also transfers various numbers of user data, which can be allocated optionally

and, for example, used for interlocks and user data transfer to other

controllers.

The communication basis of the IPCom module uses the ControlLogix

system’s produced/consumed tags. After the programmer has created and

configured a produced/consumed tag structure, the IPCom modules plug on

to this tag, as a communication channel.

Establish Produced/Consumed Controller Tags

To establish produced/consumed controller tags, complete the following

steps.

Step1

To use the IPCom modules, you must first create and configure the link to the

remote controller.

Also, you must add the complete network, with all involved controllers, to the

I/O Configuration tree, in the RSLogix 5000 project.

Example:

41 Publication RA-UM002B-EN-P - November 2010

Page 42

42 Inter-process Communication

Step2

Create new Controller Tags. For each remote connection we have to create a

separate Tag pair. One as produced and the other as consumed type.

Example: Consumed_E2 which is linked to remote controller,

ConsumedCPU2

Produced_E2, which will produce and distribute this data.

Produced Tags have a limit of Max Consumers. It is important to specify only

the maximum number of Consumers, consuming this tag.

Publication RA-UM002B-EN-P - November 2010

Page 43

Inter-process Communication 43

Step3

Link the communication channel (produced/consumed) to IPCom module.

If more than one remote connection to the same Controller is used, an array of

IPC_Data is created and the array is extended on the required channels.

In this example, we prepared a Tag with three independent channels (to the

same Controller).

Publication RA-UM002B-EN-P - November 2010

Page 44

44 Inter-process Communication

IPCom Bus Signal Marshaling Functions Diagram

The graph below shows how the Bus is transferred through the IPCom

module and the data transmitted with Produced/Consumed function.

Publication RA-UM002B-EN-P - November 2010

Page 45

Inter-process Communication 45

Controller T ag

Master.AllRunning

Master.AllStopped

Master.Select

Slave.AllRun

Slave.AllStop

IPCom (Slave)IPCom (Ma ster)

Interlocks exchan ge

Produced

->>

Consumed

Consumed

<<-

Produced

Interlock Exchange

This graph shows how the predefined Interlock signals are linked. This

bidirectional signal exchange is used to control (select or deselect) one MaGrp

and also to bring a Group, or Device Feedback, back to the Control Group.

Publication RA-UM002B-EN-P - November 2010

Page 46

46 Inter-process Communication

IPCom.ComError CtrlGrp.MsgDisp.0

CtrlGrp

HMI-Template: Message Display

CtrlGrp.AllRun

Any .

RdyAuto

or .

Run

CtrlGrp.PartRun

Communication Error Interlock

In case of a Communication Error, all Devices on Slave IPCom will stop

immediately. The IPCom module does not have an HMI Template (popup), to

indicate this Alarm to the Operator.

To bring this information to the Operator Screen, we can use a special input at

CtrlGrp module, to show this information on the HMI CtrlGrp Popup.

Connect CtrlGrp input .MsgDisp.n to indicate our Communication Error

situation.

Furthermore, in case of failure, the CtrlGrp Input AllRun is switched off, in

order to have the possibility to restart a CtrlGrp. In this case, the CtrlGrp

changes into Ready-status.

FactoryTalk View SE Alarm List

The IPCom.Sta.CTA Tag must be added in the HMI Tag Database. This HMI

Tag is to configure as an Alarm Tag. (Sta.CTA is equal to module Output

ComError)

Publication RA-UM002B-EN-P - November 2010

Page 47

Application Examples

3

2

1

5

7

SEL

4

6

1..3 Belt conveyors mainstream

4 Silo mainstream

5..7 Belt conveyors selectable

Material Flowsheet

Chapter

6

Example 1 – One Group with Two Selectable Feeders

One Control Group with common mainstream conveyors and selectable

additional feed conveyors.

47 Publication RA-UM002B-EN-P - November 2010

Page 48

48 Application Examples

2

MotorN

5

MotorN

6

MotorN

7

MotorN

1

MotorN

AllRun

&

OR

&

&

otuAnE

otuAnE

3

MotorN

Module Outp ut: RdyAuto

Modu l e Input: EnAuto

Out: RdyA ut o Inp: EnAuto

M1.RdyAuto

CtrlGrp

MaGrp 1 MaGrp 2

0.tceleSerP

0.tceleSerP

SEL

otuAnE

tratSotuAnE

tratSotuAnE

tratSotuAnE

Legend:

Module Interlocking Diagram

Publication RA-UM002B-EN-P - November 2010

Page 49

Ctrlgrp.EnAutoStart M1.EnAutoStart

Ctrlgrp.EnAuto M1.EnAuto

Ctrlgrp.EnAutoStart

M1.RdyAuto M2.EnAuto

CtrlGrp_AOI

M1_AOI

ParentBus

CtrlGrp.Bus

M2_AOI

ParentBus

CtrlGrp.Bus

Ctrlgrp.EnAutoStart

M3_AOI

ParentBus

CtrlGrp.Bus

M3.EnAutoStart

M3.EnAuto

M2.EnAutoStart

M2.RdyAuto

SEL

MaGrp1.EnAutoStart

MaGrp1_AOI

MasterBus

CtrlGrp.Bus

SlaveBus

Dummy.Bus

M1.RdyAuto

MaGrp1.EnAuto

MaGrp1.PreSelect.0

M5.EnAutoStart

M5.EnAuto

M5_AOI

ParentBus

MaGrp1.Bus

*Machine Group 1*

*Belt conve yor 1*

*Belt conve yor 2*

*Belt conve yor 3*

*Belt conve yor 5*

M5.RdyAuto

M7.RdyAuto

*Control Group*

All devices are running in this Group

Ladder Program for Automatic Operation

CtrlGrp.AllRun

CtrlGrp.AllStop

M3.RdyAuto

M5.RdyAuto

M7.RdyAuto

SEL

SEL

M3.RdyAuto

Application Examples 49

Publication RA-UM002B-EN-P - November 2010

Page 50

50 Application Examples

SEL

M1.RdyAuto

MaGrp2.PreSelect.0

MaGrp2_AOI

MasterBus

CtrlGrp.Bus

SlaveBus

Dummy.Bus

M6.EnAutoStart

M6.EnAuto

M6_AOI

ParentBus

MaGrp2.Bus

MaGrp2.EnAuto

MaGrp2.EnAutoStart

MaGrp2.EnAutoStart

M6.RdyAuto

M7_AOI

ParentBus

MaGrp2.Bus

M7.EnAutoStart

M7.EnAuto

*Machine Group 2*

*Belt Conveyors 6*

*Belt Conveyors 7*

Publication RA-UM002B-EN-P - November 2010

Page 51

Application Examples 51

X

X

G1

G2

RF1

RF2

BC2

BC1

Material Flowsheet

Example 2 – Two Groups with One Common Conveyor

Two Control Groups using a common conveyor.

Publication RA-UM002B-EN-P - November 2010

Page 52

52 Application Examples

RF1.RdyAuto MaGrp1.Selected.0

CtrlGrp1.AllRun

CtrlGrp1

AOI

RF2.RdyAuto MaGrp1.Selected.1

CtrlGrp2.AllRun

CtrlGrp2

MaGrp1.PreSelect.0

*Machine Gr oup 1*

CtrlGrp1.Check

MaGrp1.PreSelect.1CtrlGrp2.Check

AOI

Ladder Program for Automatic Operation

AOI

*Belt conveyors 1*

MaGrp1.EnAuto

BC1.EnAutoStart

BC1.EnAuto

BC1

ParentBus

MaGrp1.Bus

AOI

*Rota ry Feeder 1*

RF1

ParentBus

MaGrp1.Bus

RF1.EnAutoStart

RF1.EnAutoBC1.RdyAuto CtrlGrp1.EnAuto

CtrlGrp1.EnAutoStart

*Belt conveyors 2*

BC2.EnAutoStart

BC2.EnAuto

BC2

ParentBus

MaGrp1.Bus

BC1.RdyAuto CtrlGrp2.RdyAuto

CtrlGrp2.EnAutoStart

AOI

AOI

MaGrp1

MasterBus

CtrlGrp1.Bus

SlaveBus

CtrlGrp2.Bus

MaGrp1.EnAutoStart

*Control Group1*

If Group selected then all Device are controlled in this Group

*Control Group2*

If Group selected then all Device are controlled in this Group

MaGrp 1

PreSelect.0 PreSelect.1

CtrlGrp1 CtrlGrp2

Module Interloc king Diagram

& &

RF1

MotorN

BC1

MotorN

.RdyAuto

.Check

AllRun AllRun

.Check

otuAnE

tratSotuAnE

tratSotuAnE

BC2

MotorN

RF2

MotorN

Module Output: RdyAuto

Modu le In put:

EnAuto

Out: RdyAuto Inp: EnAuto

Legend:

tratSotuAnE

Publication RA-UM002B-EN-P - November 2010

Page 53

Application Examples 53

Publication RA-UM002B-EN-P - November 2010

Page 54

54 Application Examples

Example 3 – One Group with Two Starts

A Control Group may be started in multiple steps, if the start-up sequence is

interrupted by switching the Group's PartRun input ON. In this case, the

CtrlGrp selects the Ready state and waits for a restart command from the

operator.

The diagram below shows how the output RdyAuto from Machine M2, can be

used to interrupt the EnAutoStart command, by control bit B=0 and

Group.PartRun=1. After restarting by the operator, the CtrlGrp starts again

with normal startup warnings. During the startup phase, the EnAutoStart is

cleared by the CtrlGrp and control bit B=1. Now Machine M3 and the

following devices will start in programmed order.

Publication RA-UM002B-EN-P - November 2010

Page 55

Application Examples 55

L

U

ONS

M2.EnAutoStart

Aux.EnStart

Aux.EnStart

LS.RdyOk

M1.RdyAuto M2.EnAuto

M2_AOI

ParentBus

CtrlGrp.Bus

*For Restart CtrlGrp Status have to change in Ready step*

LS.RdyOk

*Process Interlock*

CtrlGrp.PartRun

CtrlGrp.EnAutoStart

Example 4 Process Interlock

In this example, a Level switch (LS) will detect an Overfill situation, the

Conveyer (M2) will have to stop, until the Operator starts this group again

(Restart).

Publication RA-UM002B-EN-P - November 2010

Page 56

56 Application Examples

CtrlGrp

MaGrp1

MaGrp2

CtrlGrp

IPC1

Master

IPC2

Slave

.0

.0 .1

Remote CPU

Device_n

Device_n1

Device_y

Device_x

Program from CPU1

MOV

IPC1.Master.AllStop

*Transmit user data *

*Call IPCom module as master *

CtrlGrp.AllStop

IPC1

IPCom_AOI

(Par.MasterModule=1)

ParentBus

CtrlGrp.Bus

Source

Input_xy

Dest

IPC1.UserSend.Data[0

]

any.RdyAuto

IPC1.Master.Select

Ctrlgrp.Check

IPC1.Master.AllRun

any.RdyAuto

*PLC 1 master site *

CtrlGrp.AllRun

IPC1.Master.Select

IPC1.Master.Select

Example 5 Inter Process

Communication IPCom

Module Diagram:

Program Code:

Publication RA-UM002B-EN-P - November 2010

Page 57

Application Examples 57

Program from CPU2

MOV

MaGrp2

any.RdyAuto

IPC2.Slave.SelectMaGrp

IPC2

IPCom_AOI

(Par.MasterModule=0)

ParentBus

Dummy

IPC2.Slave.AllRunning

IPC2.Slave.AllStopped

ParentBus

IPC2.Bus

Source

IPC2.UserRec.Data[ 0]

Dest

Output_xy

*Transmit user data *

*Call IPCom module as slave *

Note: ParentBus is not connected

*PLC 2 server site*

*Control remote MaGrp *

MaGrp.PreSelect.1

any.RdyAuto

any.RdyAutoany.RdyAuto

Publication RA-UM002B-EN-P - November 2010

Page 58

58 Application Examples

Notes:

Publication RA-UM002B-EN-P - November 2010

Page 59

Additional Information

Appendix

A

RSLogix 5000 Workstation Options

Disable Duplicate Destructive Bit Detection checkbox.

59 Publication RA-UM002B-EN-P - November 2010

Page 60

60 Additional Information

Workflow Data Retrieval Tool

Publication RA-UM002B-EN-P - November 2010

Page 61

Page 62

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support/

application notes, sample code and links to software service packs, and a MySupport feature that you can customize to make the

best use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative,

or visit http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual.

You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Worldwide Locator

your local Rockwell Automation representative.

, you can find technical manuals, a knowledge base of FAQs, technical and

.

at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

, available at http://www.rockwellautomation.com/literature/.

Publication RA-UM002B-EN-P - November 2010 16

Supersedes Publication RA-UM002A- EN-P - August 2007 Copyright © 2010 Rockwell Automa tion, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...