Page 1

This manual links to Knowledgebase Article Logix 5000 Controller Fault

Codes for fault codes; download the spreadsheets now to ensure offline

access.

CompactLogix 5380 and

Compact GuardLogix 5380

Controllers

Bulletin 5069

User Manual

Original Instructions

Page 2

CompactLogix 5380 and Compact GuardLogix 5380 Controllers User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc

Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements

for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 3

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1

CompactLogix 5380 and Compact

GuardLogix 5380 Systems and

Controllers

How to Power CompactLogix

5380 Controllers

Minimum Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CompactLogix 5380 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5069-L310ER-NSE No Stored Energy (NSE) Controller . . . . . 16

CompactLogix 5380 Process controllers . . . . . . . . . . . . . . . . . . . . . 16

Compact GuardLogix 5380 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Design the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Controller Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Features Supported by Compact GuardLogix 5380 Controllers

Via the Safety Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Power the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 2

Two Types of Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

MOD Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

MOD Power Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SA Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Track SA Power Bus Current Draw . . . . . . . . . . . . . . . . . . . . . . . . . 32

Use a 5069-FPD Field Potential Distributor to Create a

New SA Power Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SA Power - Additional Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

How to Power Compact

GuardLogix 5380 Controllers

Chapter 3

Two Types of Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

MOD Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MOD Power Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SA Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Track SA Power Bus Current Draw . . . . . . . . . . . . . . . . . . . . . . . . . 44

Use a 5069-FPD Field Potential Distributor to Create a

New SA Power Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Restrictions When You Connect SA Power to a Compact

GuardLogix 5380 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

SA Power - Additional Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 3

Page 4

Table of Contents

Chapter 4

Safety Concept of Compact

GuardLogix 5380 Controllers

Functional Safety Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

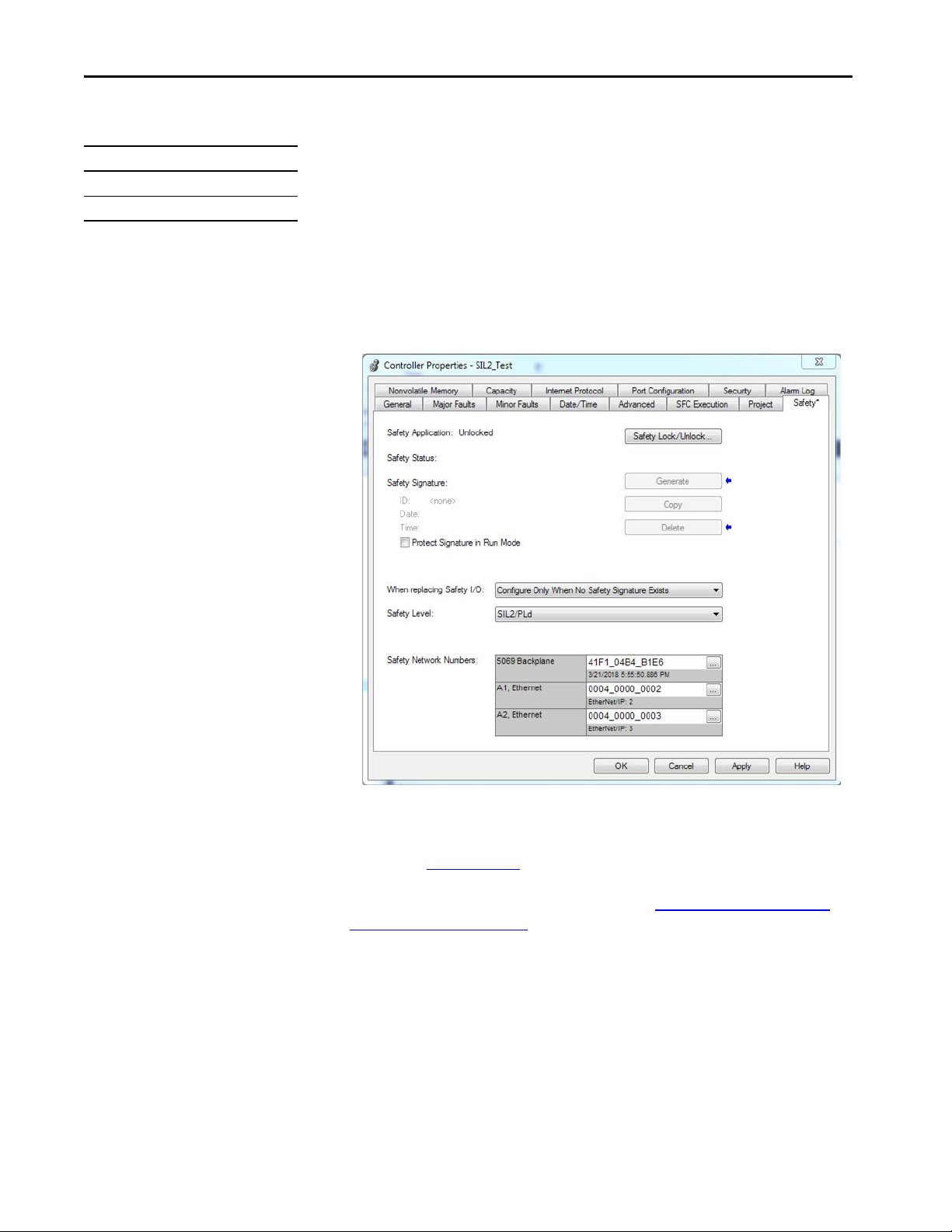

Safety Network Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Safety Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Distinguish Between Standard and Safety Components . . . . . . . . . . 53

Controller Data-flow Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Safety Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 5

Connect to the Controller Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Connection Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Connect an Ethernet Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Connect a USB Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Set the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Other Methods to Set the IP Address . . . . . . . . . . . . . . . . . . . . . . . 60

Use a Secure Digital Card to Set the Controller IP Address . . . 60

Duplicate IP Address Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Duplicate IP Address Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

DNS Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Update Controller Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Firmware Upgrade Guidelines for Safety Controllers . . . . . . . . . 63

Controller Firmware and Logix Designer Application

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Determine Required Controller Firmware. . . . . . . . . . . . . . . . . . . 65

Obtain Controller Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

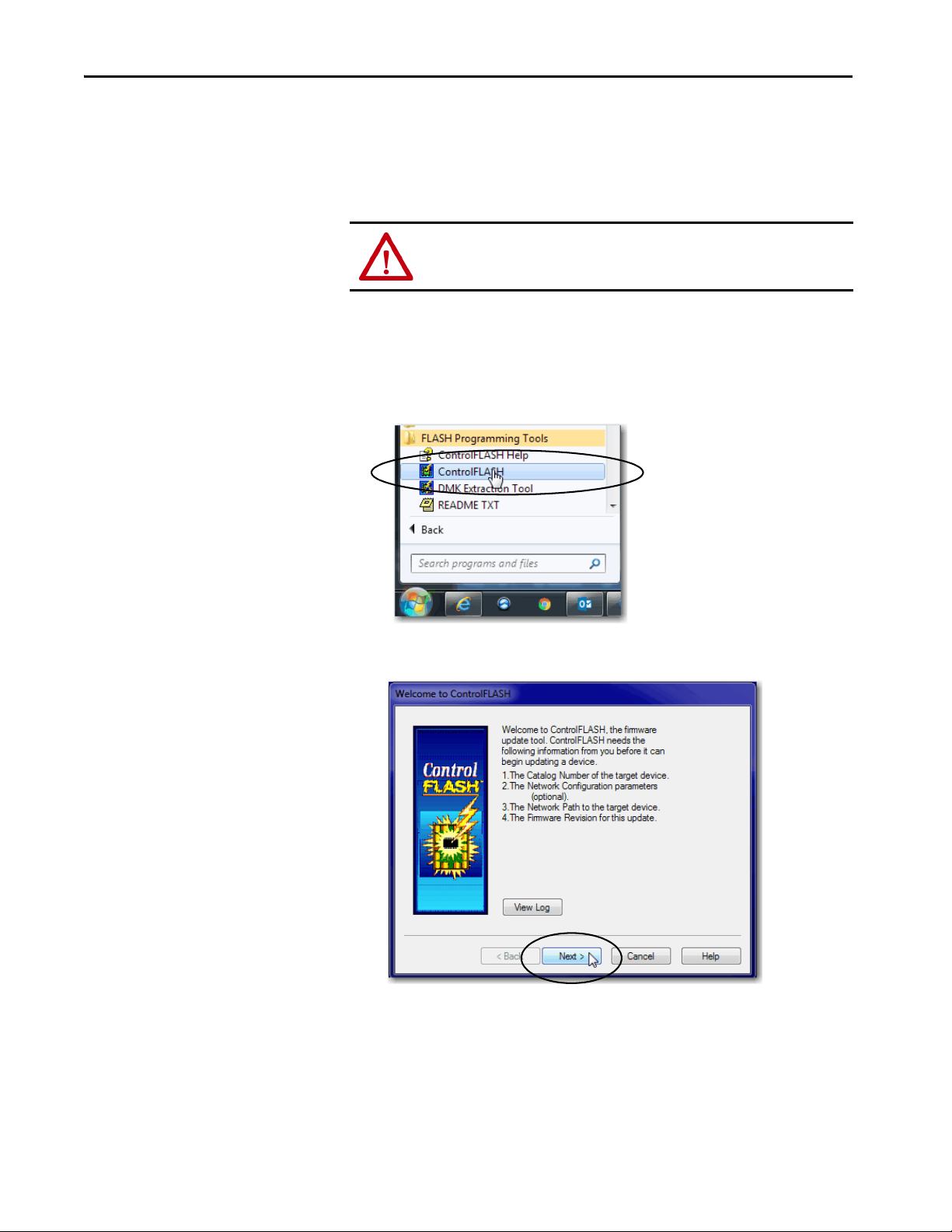

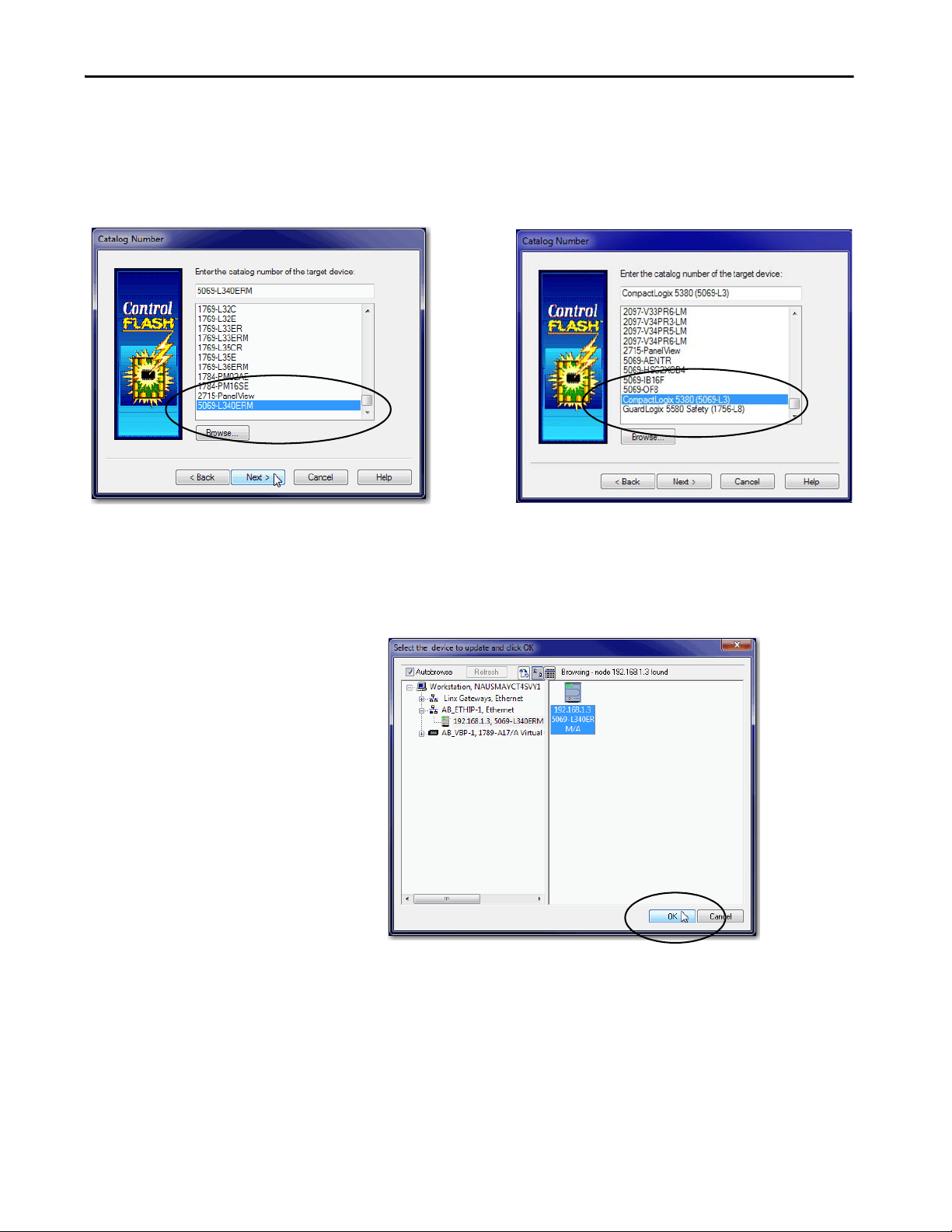

Use ControlFLASH Software to Update Firmware. . . . . . . . . . . 66

Use AutoFlash to Update Firmware. . . . . . . . . . . . . . . . . . . . . . . . . 70

Controllers with Firmware Earlier than Revision 31. . . . . . . . . . . . . . 73

Chapter 6

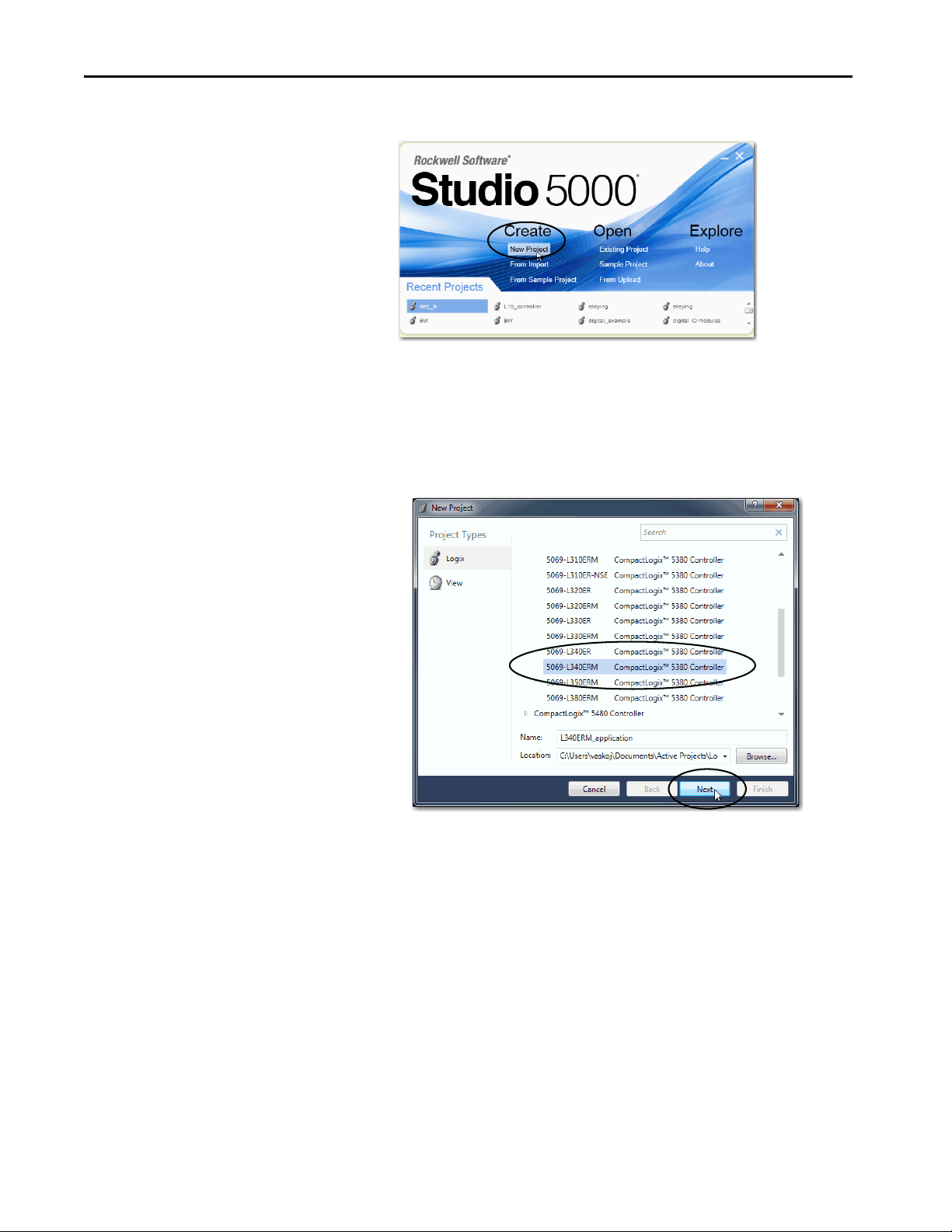

Start to Use the Controller Create a Logix Designer Application Project. . . . . . . . . . . . . . . . . . . . . 75

Additional Configuration for a Compact GuardLogix Controller . 78

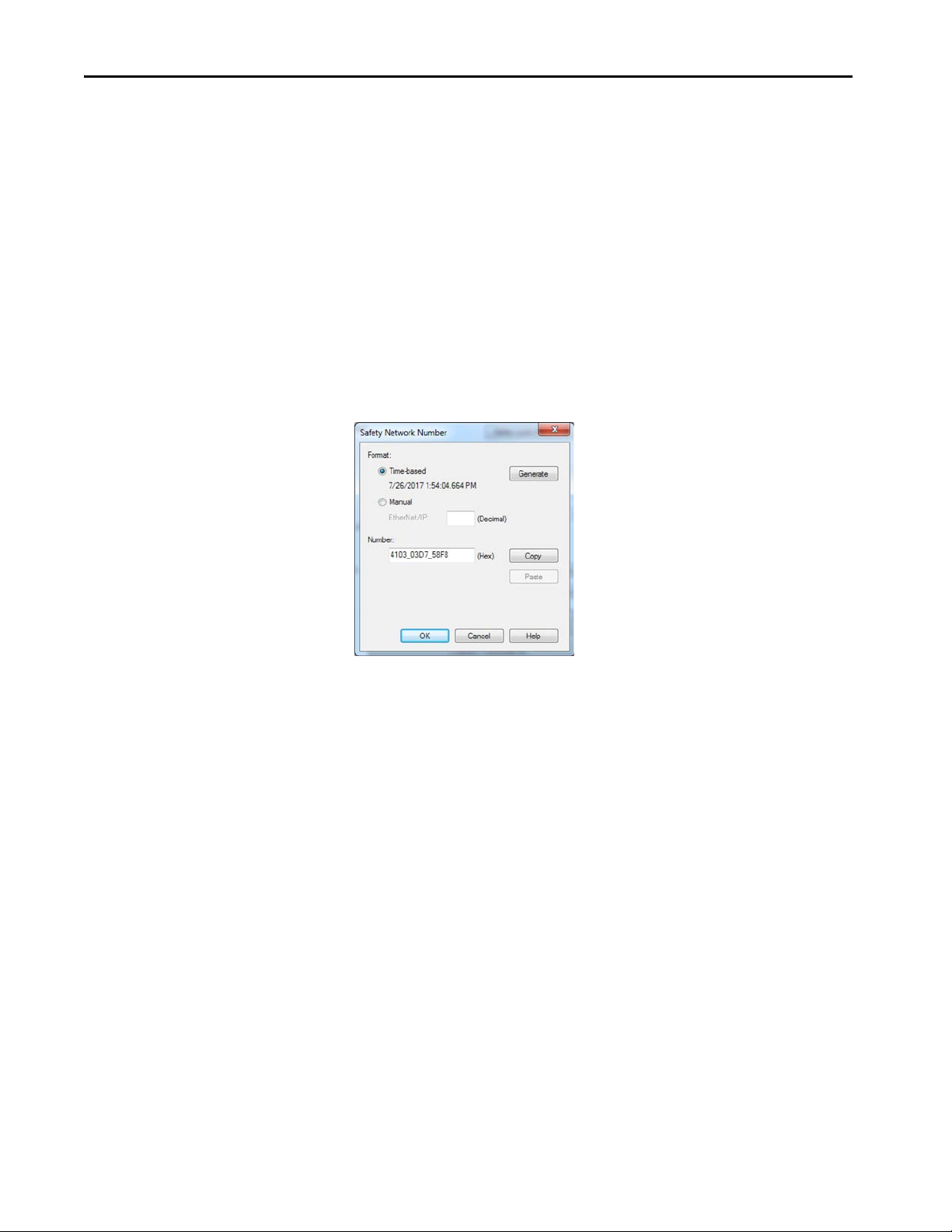

Assign the Safety Network Number (SNN). . . . . . . . . . . . . . . . . . 78

Copy and Paste a Safety Controller Safety Network Number

(SNN). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

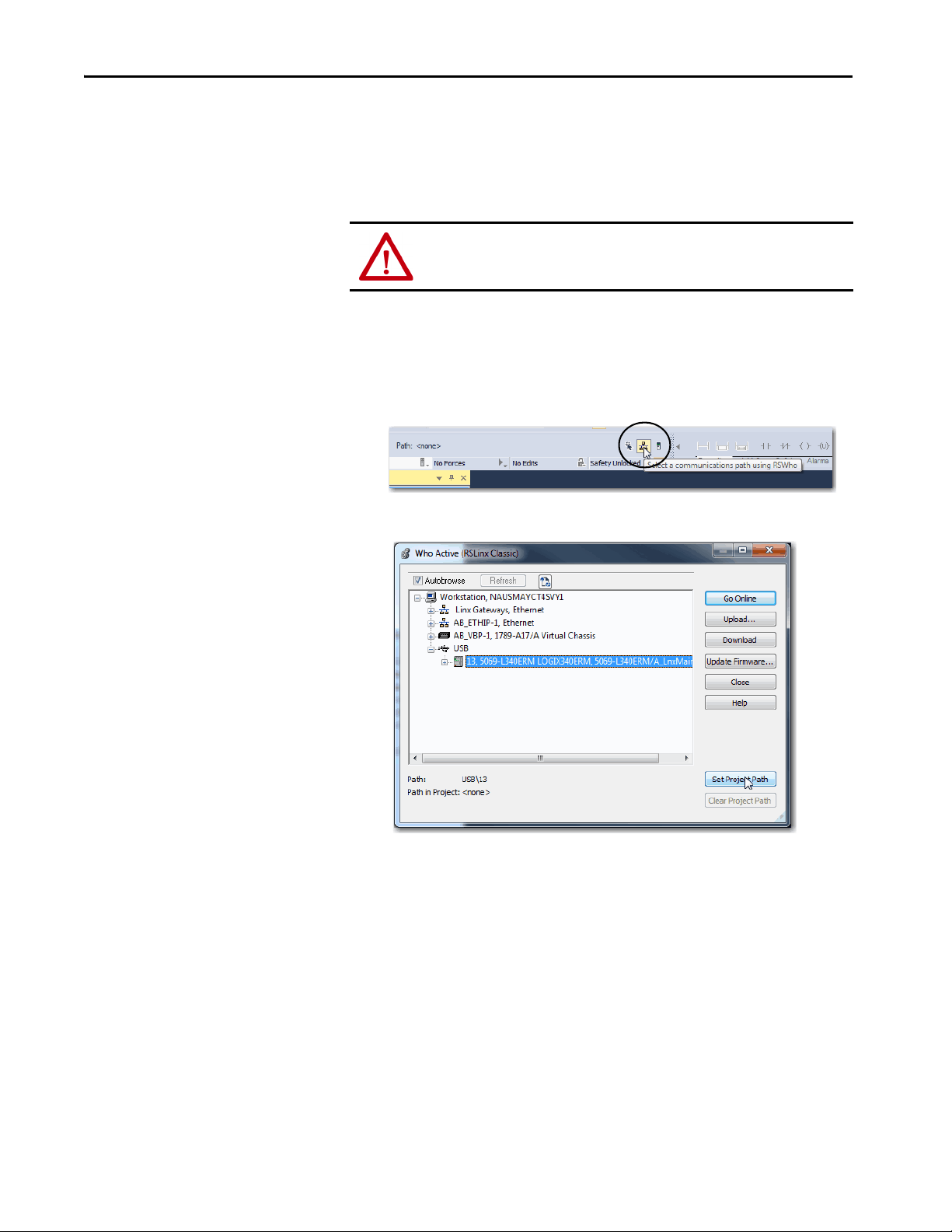

Go Online with the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Use RSWho. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Use a Recent Communications Path . . . . . . . . . . . . . . . . . . . . . . . . 87

Additional Considerations for Going Online with a Controller . . . 88

Match Project to Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Firmware Revision Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Additional Considerations for Going Online with a Compact

GuardLogix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Safety Signature and Safety-locked and -unlocked Status . . . . . . 90

Checks for Going Online with a GuardLogix Controller. . . . . . 91

4 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 5

Table of Contents

Download to the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Use Who Active. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Use the Controller Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Additional Considerations for Download to a

Compact GuardLogix Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Upload from the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Use Who Active. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Use the Controller Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Additional Considerations for Upload to a

Compact GuardLogix Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Choose the Controller Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . 99

Use the Mode Switch to Change the Operation Mode . . . . . . . 100

Use the Logix Designer Application to Change the

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Change Controller Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Reset Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Stage 1 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Stage 2 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Chapter 7

Use the Secure Digital Card Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Considerations for Storing and Loading a Safety Project . . . . . . . . . 110

Store to the SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Load from the SD Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Controller Power-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

User-initiated Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Other Secure Digital Card Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Chapter 8

EtherNet/IP Network Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

EtherNet/IP Network Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Nodes on an EtherNet/IP Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Devices Included in the Node Count. . . . . . . . . . . . . . . . . . . . . . . 121

Devices Excluded from the Node Count. . . . . . . . . . . . . . . . . . . . 122

EtherNet/IP Network Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Device Level Ring Network Topology. . . . . . . . . . . . . . . . . . . . . . 124

Linear Network Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Star Network Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Integrated Architecture Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

EtherNet/IP Network Communication Rates . . . . . . . . . . . . . . . . . . 127

Simple Network Management Protocol (SNMP) . . . . . . . . . . . . . . . 129

Use a CIP Generic MSG to Enable SNMP on the Controller. 129

Use a CIP Generic MSG to Disable SNMP on the Controller 131

Socket Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 5

Page 6

Table of Contents

Chapter 9

Use EtherNet/IP Modes Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Available Network Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Enterprise-level Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Device-level Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

EtherNet/IP Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Dual-IP Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Linear/DLR Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Overlapping IP Address Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Configure the EtherNet/IP Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Configure Dual-IP Mode in the Logix Designer Application . 144

Configure Dual-IP Mode in RSLinx Classic Software. . . . . . . . 146

Configure Linear/DLR Mode in the

Logix Designer Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Configure Linear/DLR Mode in RSLinx Classic Software . . . 150

Change the EtherNet/IP Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Change the EtherNet/IP Mode in the

Logix Designer Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Change the EtherNet/IP Mode in RSLinx Classic Software . . 155

DNS Requests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

DNS Request Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

SMTP Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Use Socket Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Send Message Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Software Display Differences for EtherNet/IP Modes . . . . . . . 160

Chapter 10

Manage Controller

Communication

Connection Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

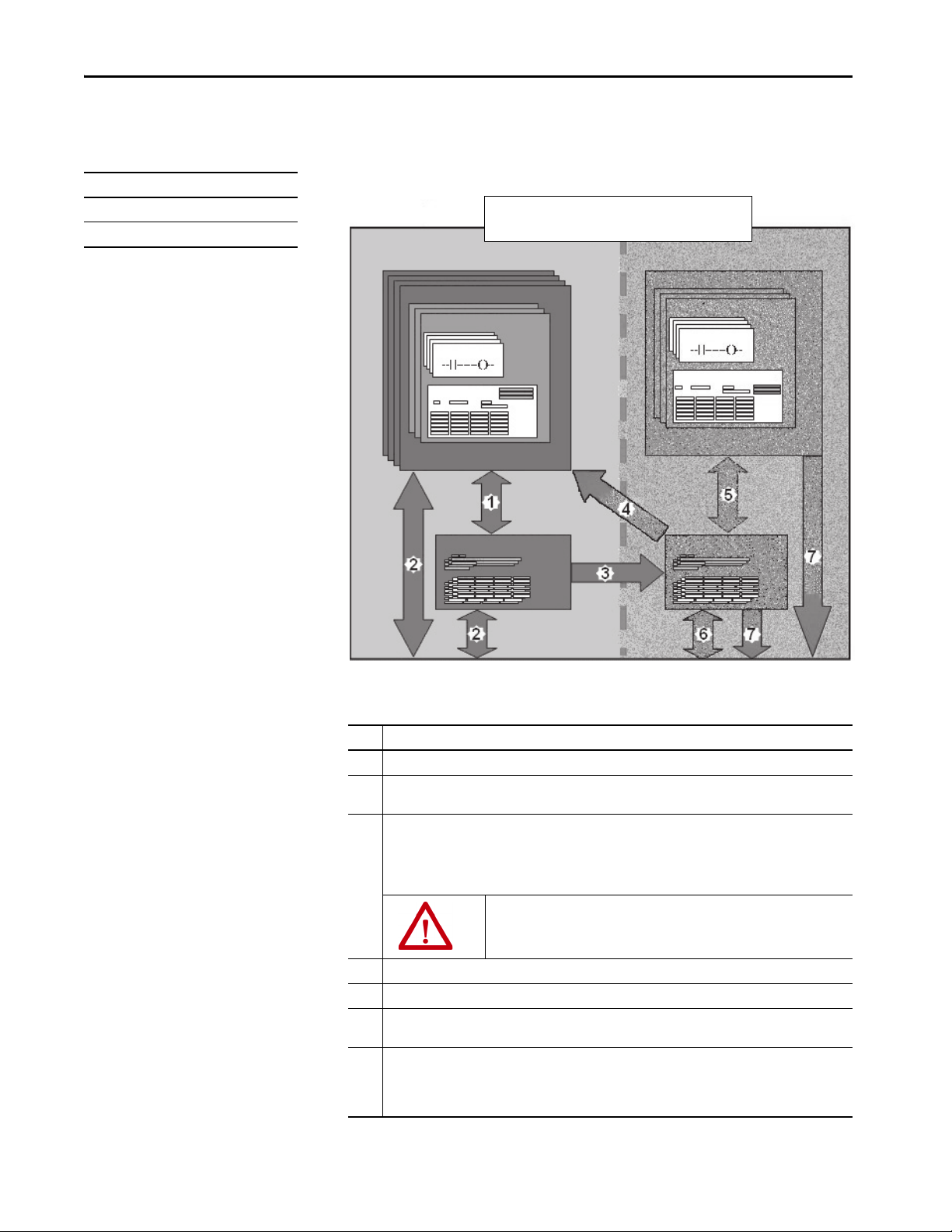

Controller Communication Interaction with Control Data. . . . . . 164

Produce and Consume (Interlock) Data. . . . . . . . . . . . . . . . . . . . . . . . 165

Requested Packet Interval (RPI) of Multicast Tags . . . . . . . . . . 166

Send and Receive Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Determine Whether to Cache Message Connections . . . . . . . . 168

Chapter 11

Standard I/O Modules Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Add Local I/O Modules to a Project . . . . . . . . . . . . . . . . . . . . . . . 171

Electronic Keying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Remote I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Add Remote I/O Modules to a Project . . . . . . . . . . . . . . . . . . . . . 179

Add to the I/O Configuration While Online . . . . . . . . . . . . . . . . . . . 187

Modules and Devices That Can Be Added While Online . . . . 187

Determine When Data Is Updated . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Input Data Update Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Output Data Update Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

6 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 7

Table of Contents

Chapter 12

Safety I/O Devices Add Safety I/O Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Configure Safety I/O Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Using Network Address Translation (NAT) with

CIP Safety Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Set the SNN of a Safety I/O Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Change a Safety I/O Device SNN. . . . . . . . . . . . . . . . . . . . . . . . . . 196

Copy and Paste a Safety I/O Device Safety Network Number

(SNN). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Connection Reaction Time Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Safety I/O Device Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Configuration Via the Logix Designer Application . . . . . . . . . . 201

Reset Safety I/O Device to Out-of-box Condition. . . . . . . . . . . 202

I/O Device Address Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Replace a Safety I/O Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Configuration Ownership. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Replacement with ‘Configure Only When No Safety

Signature Exists’ Enabled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Replacement with ‘Configure Always’ Enabled. . . . . . . . . . . . . . 211

Chapter 13

Develop Standard Applications Elements of a Control Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Event Task with Compact 5000 I/O Modules . . . . . . . . . . . . . . 217

Task Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Scheduled and Unscheduled Programs . . . . . . . . . . . . . . . . . . . . . 221

Routines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Parameters and Local Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Program Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Programming Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Extended Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Access the Module Object from an Add-On Instruction . . . . . . . . . 227

Monitor Controller Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Monitor I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Determine If I/O Communication Has Timed Out . . . . . . . . . 229

Determine If I/O Communication to a Specific I/O Module

Has Timed Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Automatic Handling of I/O Module Connection Faults . . . . . 230

Sample Controller Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 7

Page 8

Table of Contents

Chapter 14

Develop Safety Applications Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Safety Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Safety Task Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Safety Task Execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Safety Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Safety Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Safety Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Safety Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Valid Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Program Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Produced/Consumed Safety Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Configure the SNN for a Peer Safety Controller Connection. 240

Produce a Safety Tag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Consume Safety Tag Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Safety Tag Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Create Tag Mapping Pairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Monitor Tag Mapping Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Safety Application Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Safety-lock the Compact GuardLogix 5380 Controller . . . . . . 251

Set Passwords for Safety-locking and Unlocking. . . . . . . . . . . . . 253

Generate the Safety Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Programming Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Monitor Safety Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

View Status Via the Online Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

View Status Via the Safety Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Monitor Safety Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Utilize Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Safety Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Nonrecoverable Controller Faults. . . . . . . . . . . . . . . . . . . . . . . . . . 264

Nonrecoverable Safety Faults in the Safety Application . . . . . . 264

Recoverable Faults in the Safety Application . . . . . . . . . . . . . . . . 265

View Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Develop a Fault Routine for Safety Applications . . . . . . . . . . . . . . . . 267

Use GSV/SSV Instructions in a Safety Application. . . . . . . . . . . . . . 268

Chapter 15

Develop Motion Applications Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Motion Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Program Motion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Obtain Axis Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

8 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 9

Table of Contents

Chapter 16

Troubleshoot the Controller Automatic Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Considerations for Communication Loss Diagnostics . . . . . . . . . . . 276

Controller Diagnostics with Logix Designer . . . . . . . . . . . . . . . . . . . . 276

Warning Symbol in the I/O Configuration Tree . . . . . . . . . . . . 277

Categories on I/O Module Properties Dialog . . . . . . . . . . . . . . . 278

Notification in the Tag Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Fault Information in the Controller Properties Dialog Box. . . 282

Port Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Advanced Time Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Controller Diagnostics with Linx-based Software . . . . . . . . . . . . . . . 289

Controller Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Home Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Tasks Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Diagnostics Web Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Ethernet Port Web Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Advanced Diagnostics Web Pages. . . . . . . . . . . . . . . . . . . . . . . . . . 295

Browse Chassis Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Other Potential Issues to Troubleshoot . . . . . . . . . . . . . . . . . . . . . . . . 298

Continuous Task Sends Output Data at High Rate. . . . . . . . . . 298

Immediate Output Instructions Issued at High Rate. . . . . . . . . 298

Integrated Motion On an EtherNet/IP Network Traffic

Priority Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Appendix A

Status Indicators Status Display and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

General Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Compact GuardLogix Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . 303

Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Major Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

I/O Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Controller Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

RUN Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

FORCE Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

SD Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

OK Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

EtherNet/IP Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

NET A1 and NET A2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 308

LINK A1 and LINK A2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . 308

Power Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

MOD Power Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

SA Power Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Thermal Monitoring and Thermal Fault Behavior . . . . . . . . . . . . . . 310

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 9

Page 10

Table of Contents

Appendix B

Security Options Disable an Ethernet Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Disable the Ethernet Port on the Port Configuration Tab. . . . 312

Disable the Ethernet Port with a MSG Instruction . . . . . . . . . . 313

Disable the 4-character Status Display. . . . . . . . . . . . . . . . . . . . . . . . . . 315

Disable All Categories of Messages . . . . . . . . . . . . . . . . . . . . . . . . . 316

Disable Individual Categories of Messages . . . . . . . . . . . . . . . . . . 318

Disable the Controller Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Studio 5000 Logix Designer Application Version 33.00.00

and Later . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Studio 5000 Logix Designer Application Version 32.00.00

or Earlier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Controller Web Page Default Settings. . . . . . . . . . . . . . . . . . . . . . 321

Use a CIP Generic MSG to Disable the Controller Web Pages 322

Use a CIP Generic MSG to Enable the Controller Web Pages 324

Appendix C

Change Controller Type Change from a Standard to a Safety Controller . . . . . . . . . . . . . . . . . 327

Change from a Safety to a Standard Controller . . . . . . . . . . . . . . . . . 328

Change Safety Controller Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

10 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 11

Preface

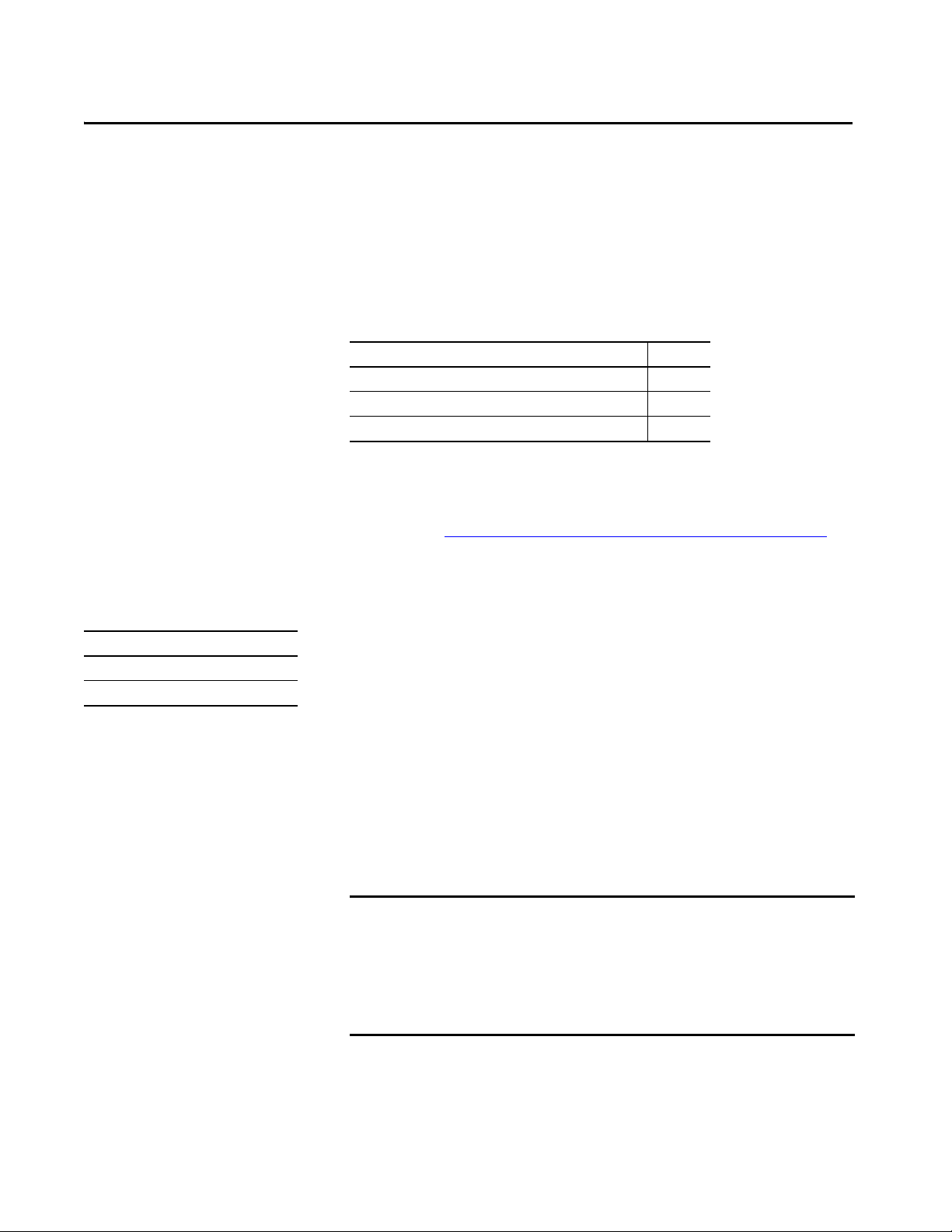

Summary of Changes

Catalog Numbers

This manual contains new and updated information as indicated in the

following table.

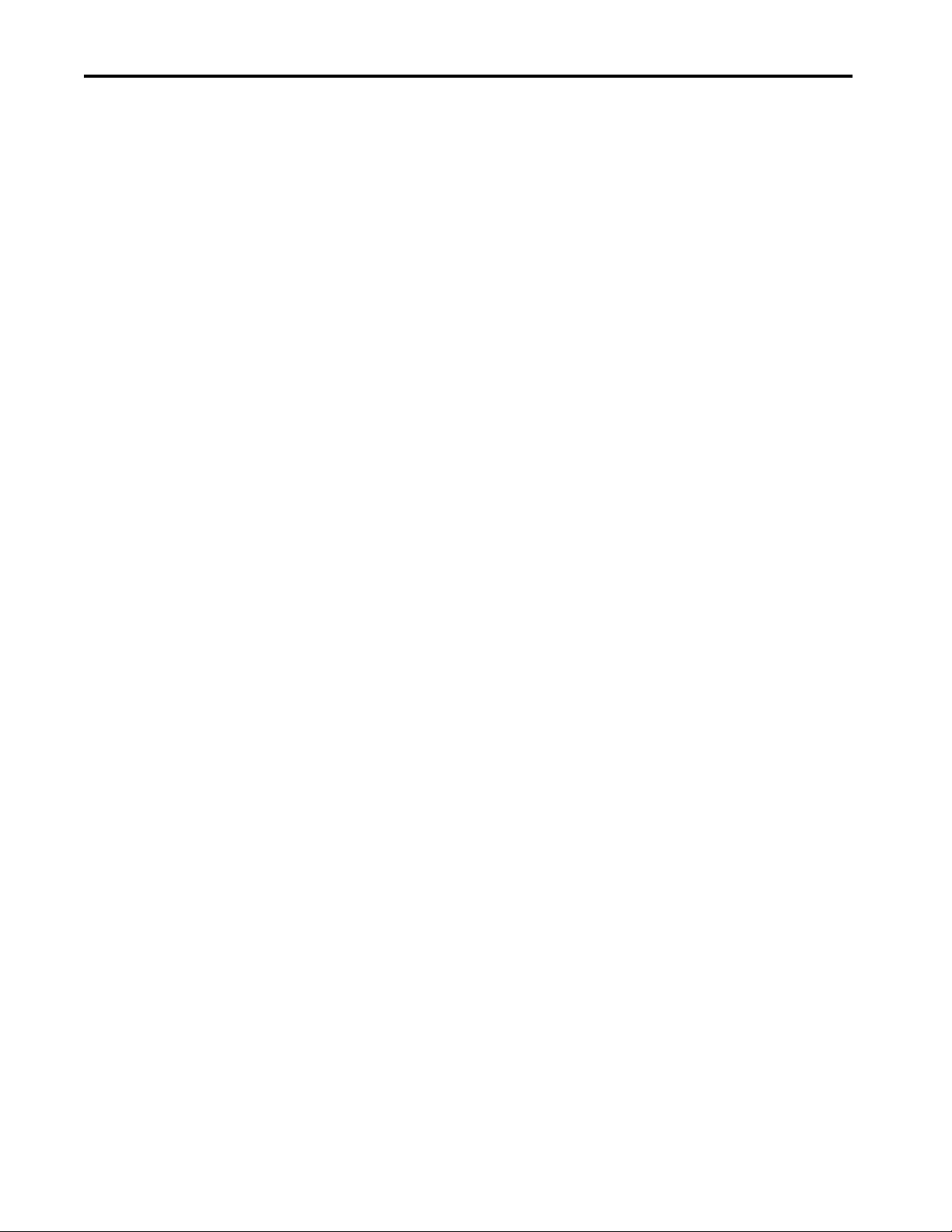

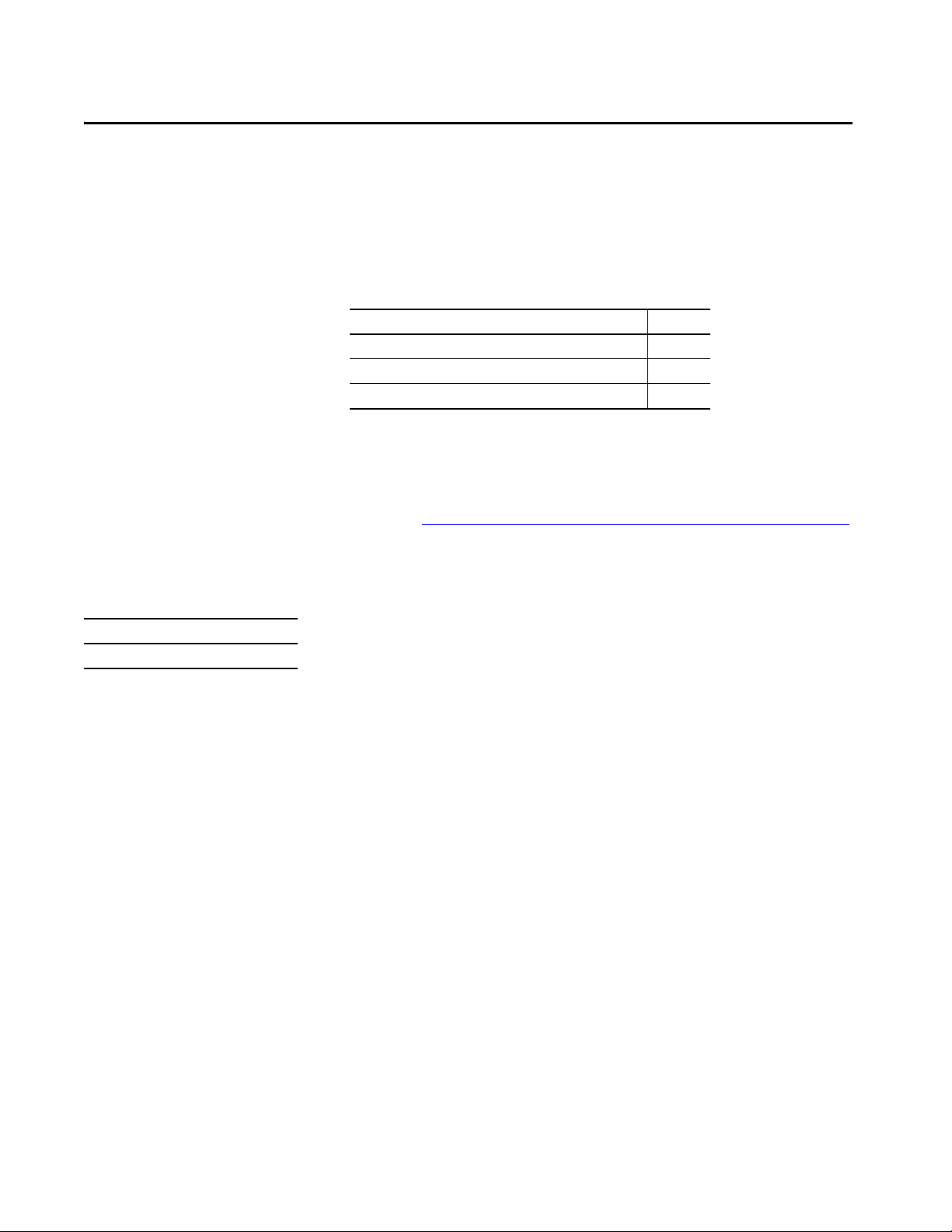

Top ic Pag e

Added CompactLogix™ 5380 Process controllers. Throughout

Updated safety signature definition. 53

Added Simple Network Management Protocol (SNMP). 129

Added Automatic Diagnostics. 275

Added Considerations for Communication Loss Diagnostics. 276

Updated the Disable Controller Web Pages procedure. 320

This publication is applicable to these controllers:

CompactLogix 5380 Standard Catalog Numbers: 5069-L306ER, 5069-L306ERM, 5069-L310ER, 5069-L310ERM,

5069-L310ER-NSE, 5069-L320ER, 5069-L320ERM, 5069-L320ERMK,

5069-L330ER, 5069-L330ERM, 5069-L330ERMK, 5069-L340ER, 5069-L340ERM,

5069-L350ERM, 5069-L350ERMK, 5069-L380ERM, 5069-L3100ERM

CompactLogix 5380 Process Catalog Numbers: 5069-L320ERP, 5069-L340ERP

Compact GuardLogix® 5380 SIL 2 Catalog Numbers: 5069-L306ERS2, 5069-L306ERMS2, 5069-L310ERS2, 5069-L310ERMS2,

5069-L320ERS2, 5069-L320ERS2K, 5069-L320ERMS2, 5069-L320ERMS2K,

5069-L330ERS2, 5069-L330ERS2K, 5069-L330ERMS2, 5069-L330ERMS2K,

5069-L340ERS2, 5069-L340ERMS2, 5069-L350ERS2, 5069-L350ERS2K,

5069-L350ERMS2, 5069-L350ERMS2K, 5069-L380ERS2, 5069-L380ERMS2,

5069-L3100ERS2, 5069-L3100ERMS2

Compact GuardLogix 5380 SIL 3 Catalog Numbers: 5069-L306ERMS3, 5069-L310ERMS3, 5069-L320ERMS3, 5069-L320ERMS3K,

5069-L330ERMS3, 5069-L330ERMS3K, 5069-L340ERMS3, 5069-L350ERMS3,

5069-L350ERMS3K, 5069-L380ERMS3, 5069-L3100ERMS3

Overview

This manual provides information on how to design a system, operate a

CompactLogix or Compact GuardLogix-based controllers system, and develop

applications.

You must be trained and experienced in the creation, operation, and

maintenance of safety systems.

For information on Safety Integrity Level (SIL) and Performance Level (PL)

requirements and safety application requirements, see the GuardLogix 5580

and Compact GuardLogix 5380 Controller Systems Safety Reference Manual,

publication 1756-RM012.

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 11

Page 12

Preface

Notes:

12 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 13

Chapter 1

CompactLogix 5380 and Compact

GuardLogix 5380 Systems and Controllers

This chapter describes features and functions that are associated with the

CompactLogix™ 5380 and Compact GuardLogix® 5380 controllers.

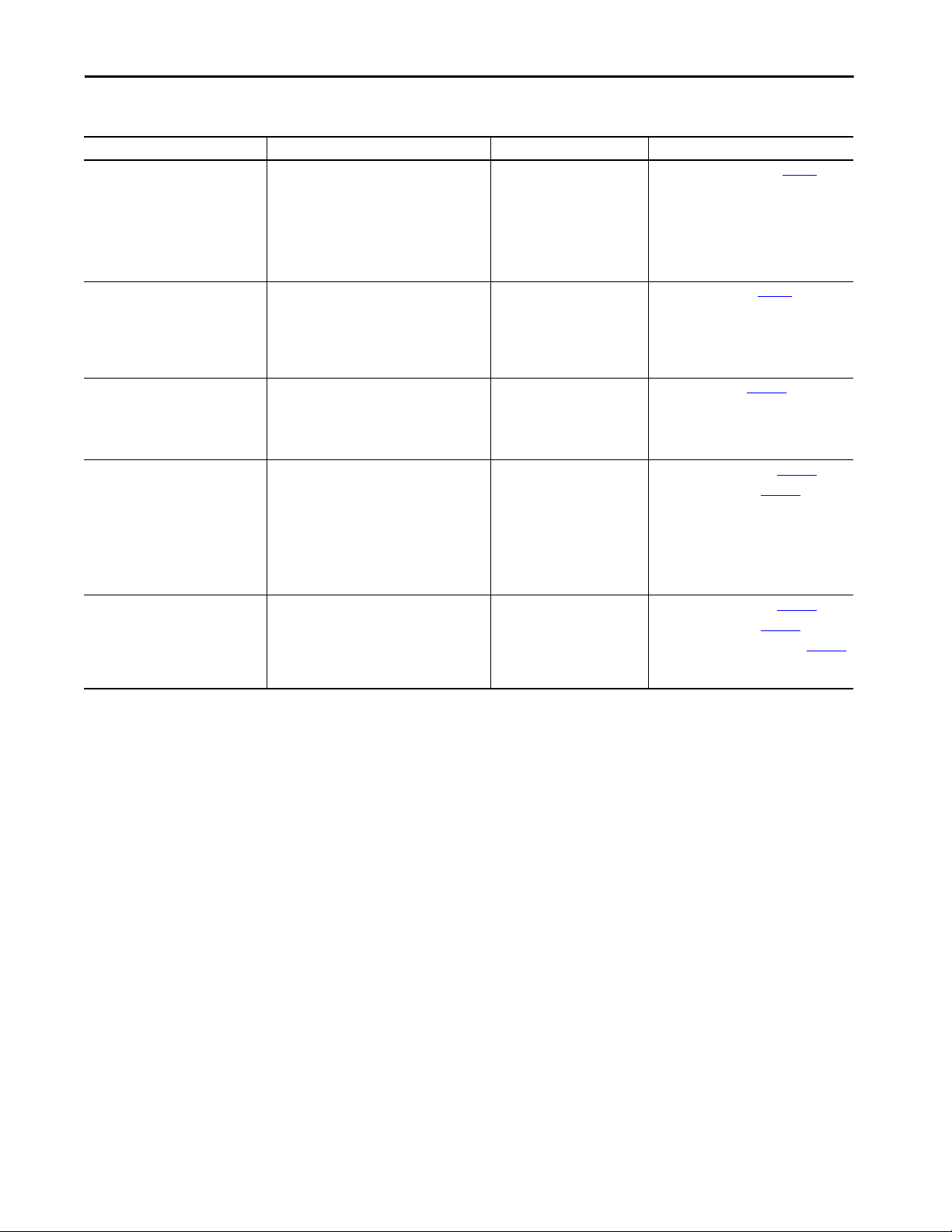

Top ic Pa ge

Minimum Requirements 13

CompactLogix 5380 System 15

Compact GuardLogix 5380 System 17

Design the System 20

Controller Features 22

Power the Sy stem 26

Minimum Requirements

Applies to these controllers:

CompactLogix 5380

Compact GuardLogix 5380 SIL 2

Compact GuardLogix 5380 SIL 3

The controllers have minimum requirements.

• CompactLogix 5380 and Compact GuardLogix 5380 controllers have

minimum hardware requirements. For more information on the

hardware requirements, see Tab le 1 on pag e 20

.

• The controller firmware revision must be compatible with the software

version that you use. For more information, see Controller Firmware

and Logix Designer Application Compatibility on page 64.

• Programming software

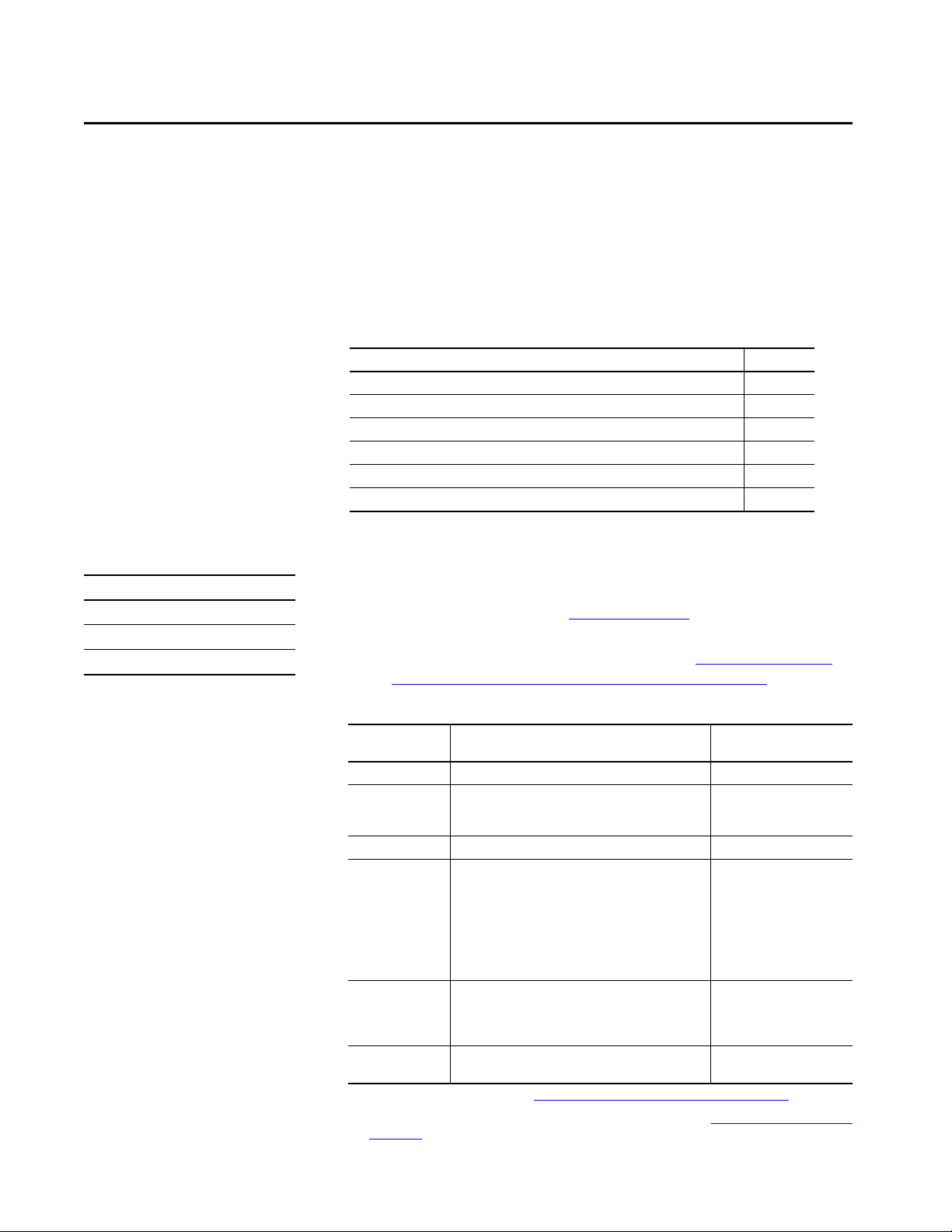

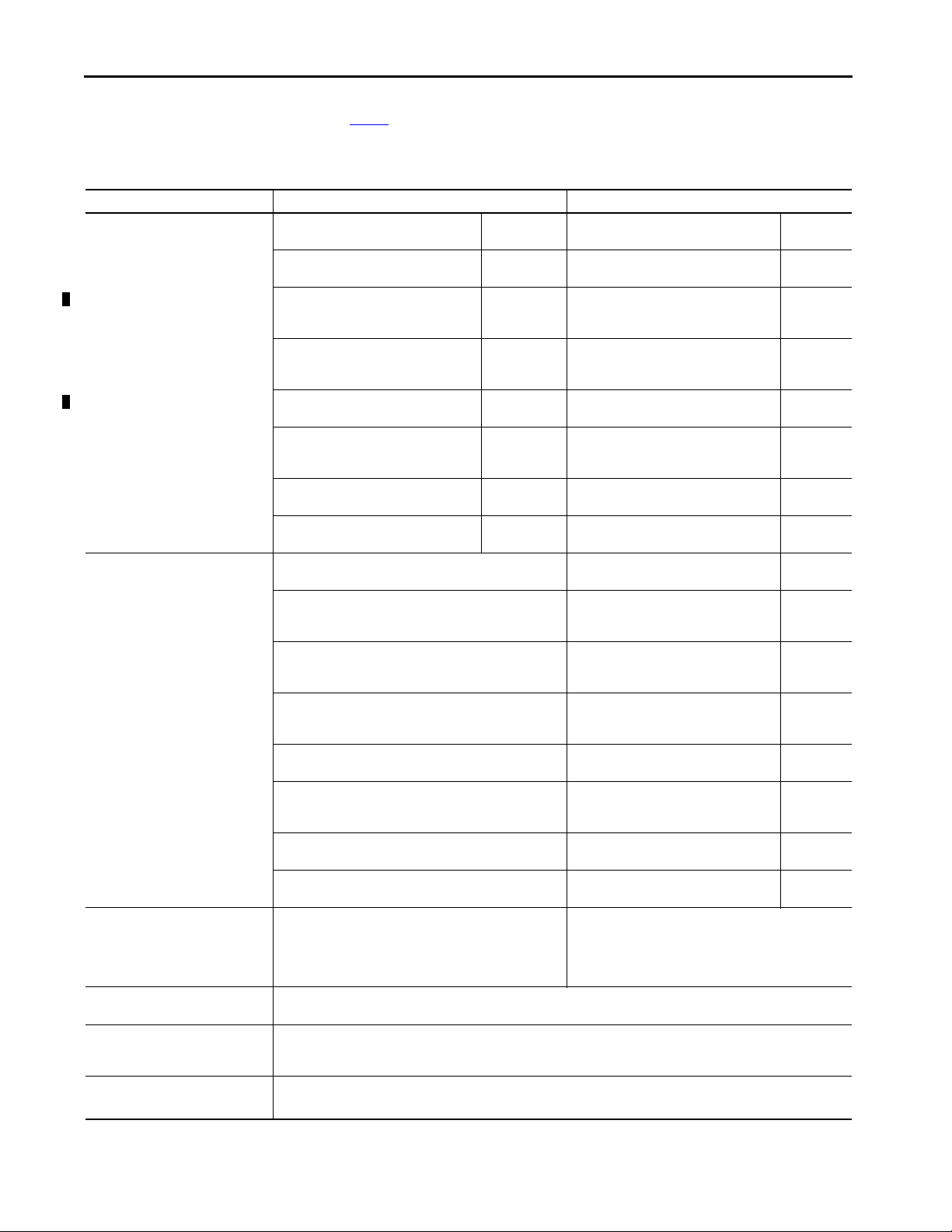

System Cat. No. Studio 5000 Logix

CompactLogix 5069-L320ER, 5069-L340ERM Version 28.00.00 or later

CompactLogix 5069-L306ER, 5069-L306ERM, 5069-L310ER,

CompactLogix 5069-L350ERM, 5069-L380ERM, 5069-L3100ERM Version 30.00.00 or later

Compact GuardLogix

SIL 2 Controllers

Compact GuardLogix

SIL 3 Controllers

Compa ctLogix

Process Controllers

(1) For more information on safety ratings, see Safety Concept of Compact GuardLogix 5380 Controllers on page 51.

(2) For compatible Linx-based communication software and ControlFLASH™ software, see the Product Compatibility and Download

Center (PCDC).

5069-L310ER-NSE, 5069-L310ERM, 5069-L320ERM,

5069-L330ER, 5069-L330ERM, 5069-L340ER

5069-L306ERS2, 5069-L306ERMS2, 5069-L310ERS2,

(1)

5069-L310ERMS2, 5069-L320ERS2, 5069-L320ERS2K,

5069-L320ERMS2, 5069-L320ERMS2K, 5069-L330ERS2,

5069-L330ERS2K, 5069-L330ERMS2, 5069-L330ERMS2K,

5069-L340ERS2, 5069-L340ERMS2, 5069-L350ERS2,

5069-L350ERS2K, 5069-L350ERMS2, 5069-L350ERMS2K,

5069-L380ERS2, 5069-L380ERMS2, 5069-L3100ERS2,

5069-L3100ERMS2

5069-L306ERMS3, 5069-L310ERMS3, 5069-L320ERMS3,

(1)

5069-L320ERMS3K, 5069-L330ERMS3,

5069-L330ERMS3K, 5069-L340ERMS3, 5069-L350ERMS3,

5069-L350ERMS3K, 5069-L380ERMS3, 5069-L3100ERMS3

5069-L320ERP, 5069-L340ERP Version 33.00.00 or later

Designer® Application

Version 29.00.00 or later

Version 31.00.00 or later

Version 32.00.00 or later

(2)

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 13

Page 14

Chapter 1 CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers

IMPORTANT If safety connections or safety logic are required for your application, then

you must use a Compact GuardLogix controller.

IMPORTANT This equipment is supplied as open-type equipment for indoor use. It must

be mounted within an enclosure that is suitably designed for those specific

environmental conditions that are present and appropriately designed to

prevent personal injury resulting from accessibility to live parts.

The enclosure must have suitable flame-retardant properties to prevent or

minimize the spread of flame, complying with a flame spread rating of 5VA

or be approved for the application if nonmetallic. The interior of the

enclosure must be accessible only by the use of a tool.

For more information regarding specific enclosure type ratings that are

required to comply with certain product safety certifications, see the

• Compact GuardLogix 5380 SIL 2 Controllers Installation Instructions,

• Compact GuardLogix 5380 SIL 3 Controllers Installation Instructions,

publication 5069-IN014.

publication 5069-IN023.

Waste Electrical and Electronic Equipment (WEEE)

At the end of its life, this equipment should be collected separately from any

unsorted municipal waste.

14 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 15

CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers Chapter 1

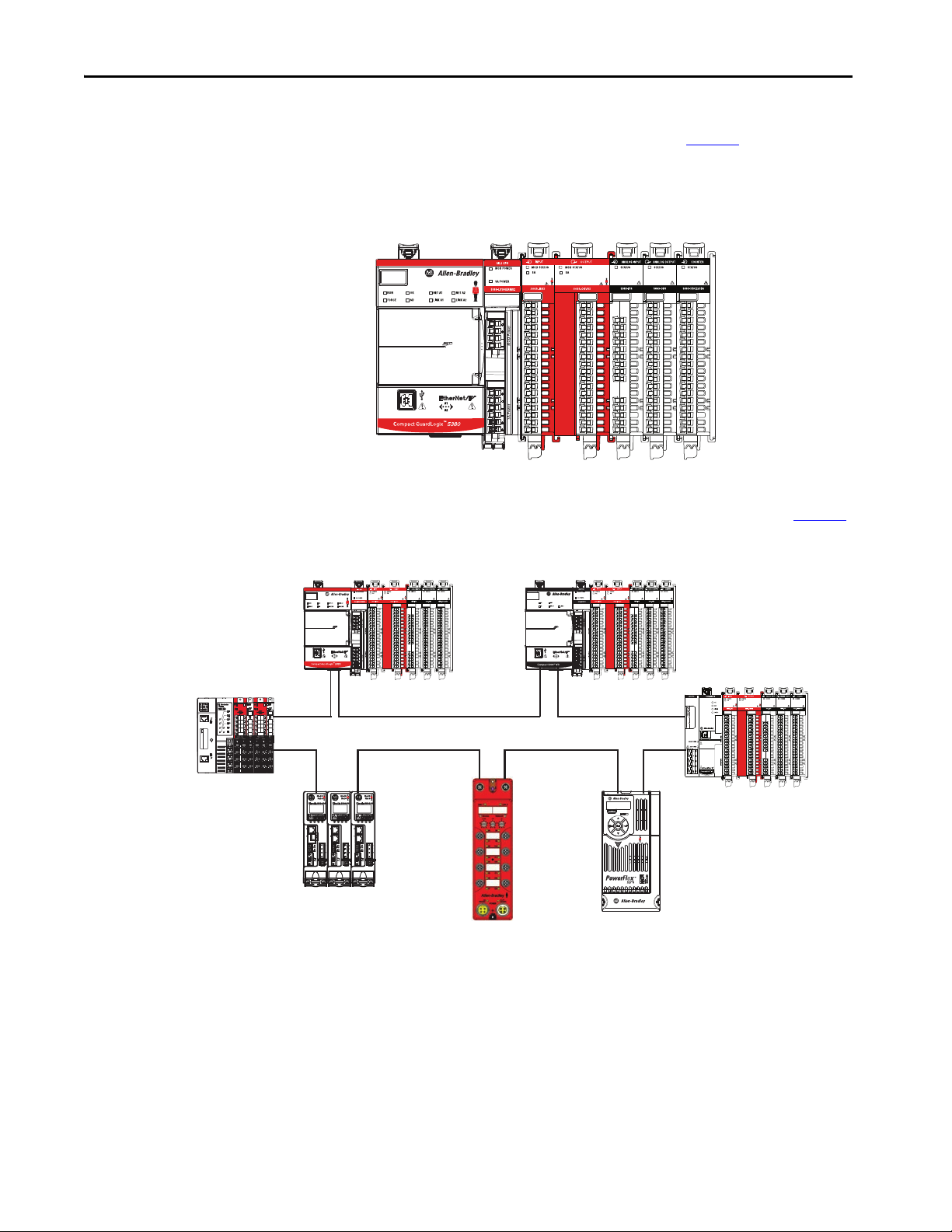

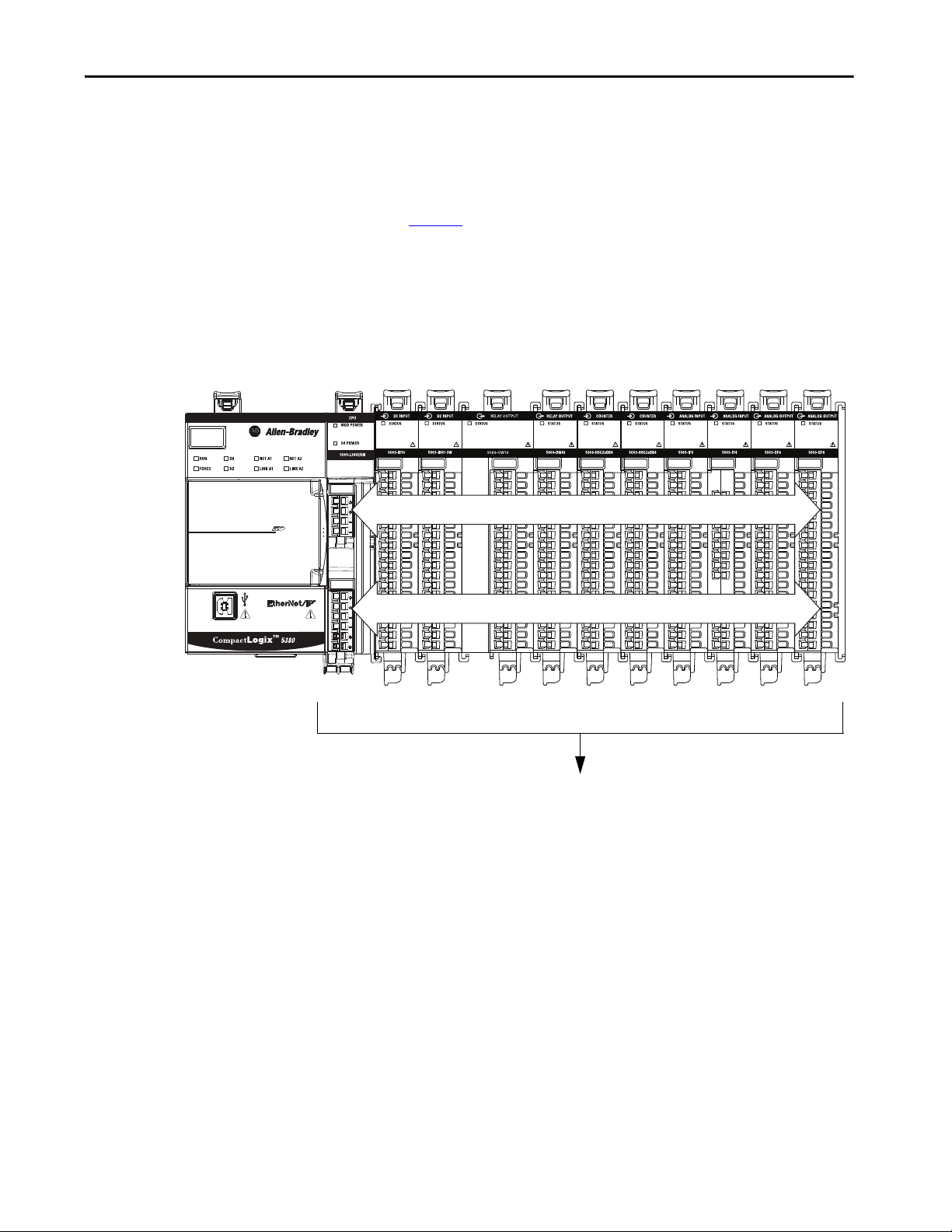

CompactLogix 5380 Controller

Compact 5000™ I/O Analog and Digital Modules

CompactLogix 5380 Controller

Compact 5000 I/O Modules

Compact 5000 I/O EtherNet/IP Adapter

Compact 5000 I/O Modules

1734-AENTR Adapter

1734 POINT I/O™ Modules

PanelView ™ Plus 7

Ter m in al

Stratix® 5400 Switch

PowerFlex® 527 Drive

Kinetix® 5500 Drive

CompactLogix 5380 System

CompactLogix 5380 control systems are DIN rail-mounted systems that can

operate in various applications.

One of the simplest controller configurations is a standalone controller with

I/O assembled in one chassis, as shown in Figure 1

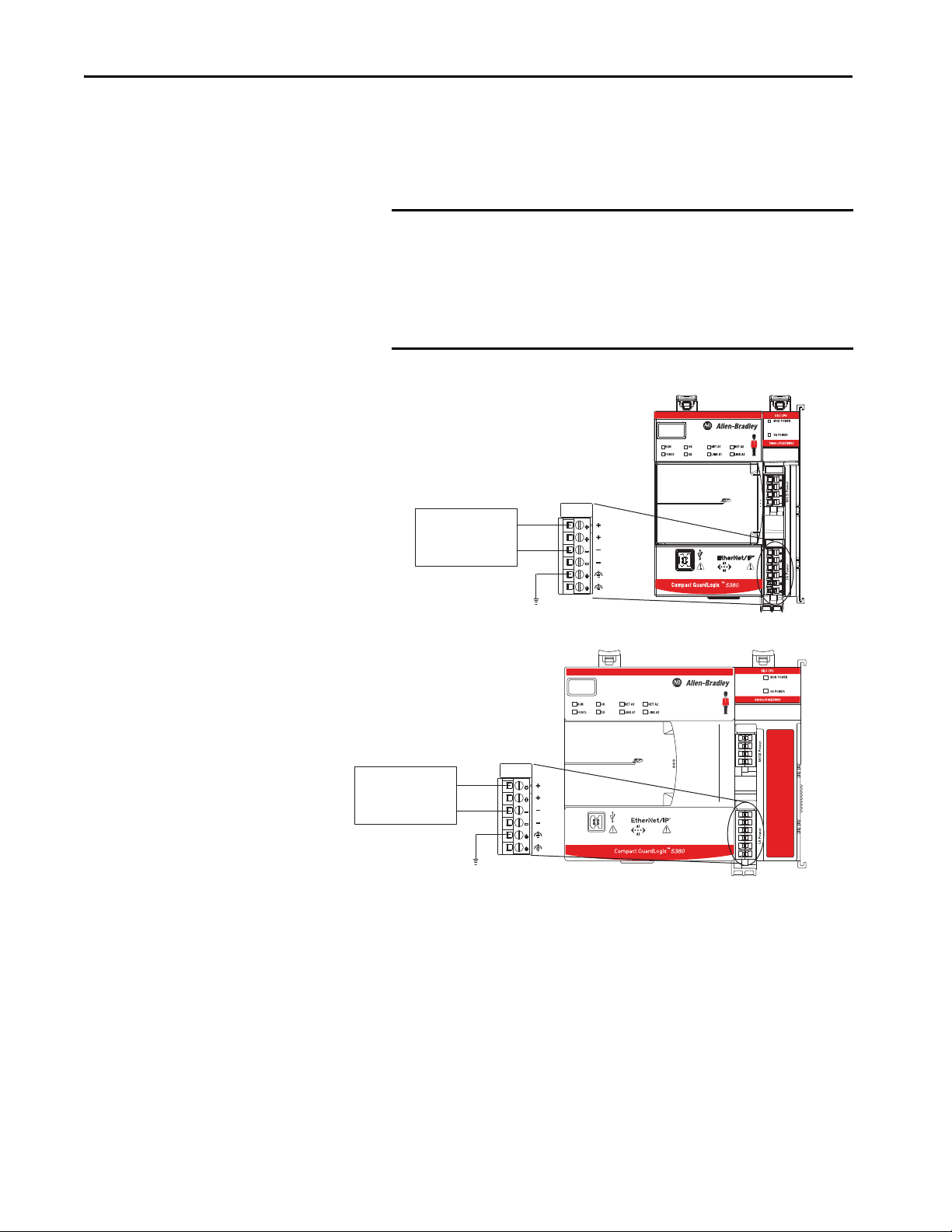

Figure 1 - CompactLogix 5380 Controller in a Standalone System

.

The controllers can also operate in more complex systems with devices that are

connected to the controller via an EtherNet/IP™ network, as shown in

Figure 2

.

Figure 2 - CompactLogix 5380 Controller in a More Complex System

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 15

Page 16

Chapter 1 CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers

5069-L310ER-NSE No Stored Energy (NSE) Controller

The NSE controller is intended for use in applications that require the installed

controller to deplete its residual stored energy to specific levels before

transporting it into or out of your application.

The residual stored energy of the NSE controller depletes to 400μJ or less in 40

seconds.

WARNING: If your application requires the NSE controller to deplete its

residual stored energy to 400 μJ or less before you transport it into or out of

the application, complete these steps before you remove the controller.

1. Turn off power to the chassis.

2. Wait at least 40 seconds for the residual stored energy to decrease to

After you turn off power, the controller’s OK status indicator transitions

from Green to Solid Red to OFF.

400 μJ or less before you remove the controller.

There is no visual indication of when the 40 seconds has expired. You m ust

track that time period.

IMPORTANT The Real Time Clock (RTC) does not retain its time and date when the power

is off.

Some applications require that the installed controller to deplete its residual

stored energy to specific levels before transporting it into or out of your

application. This requirement can include other devices that also require a wait

time before removing them. See the documentation of those products for more

information.

CompactLogix 5380 Process controllers

CompactLogix 5380 Process controllers (5069-L320ERP, 5069-L340ERP) are

extensions of the Logix 5000 controller family that focus on plantwide process

control, and support motion.

The process controllers come configured with a default process tasking model

and dedicated PlantPAx® process instructions that are optimized for process

applications, and that improve design and deployment efforts.

The process controllers are conformal coated to add a layer of protection when

exposed to harsh, corrosive environments.

16 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 17

CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers Chapter 1

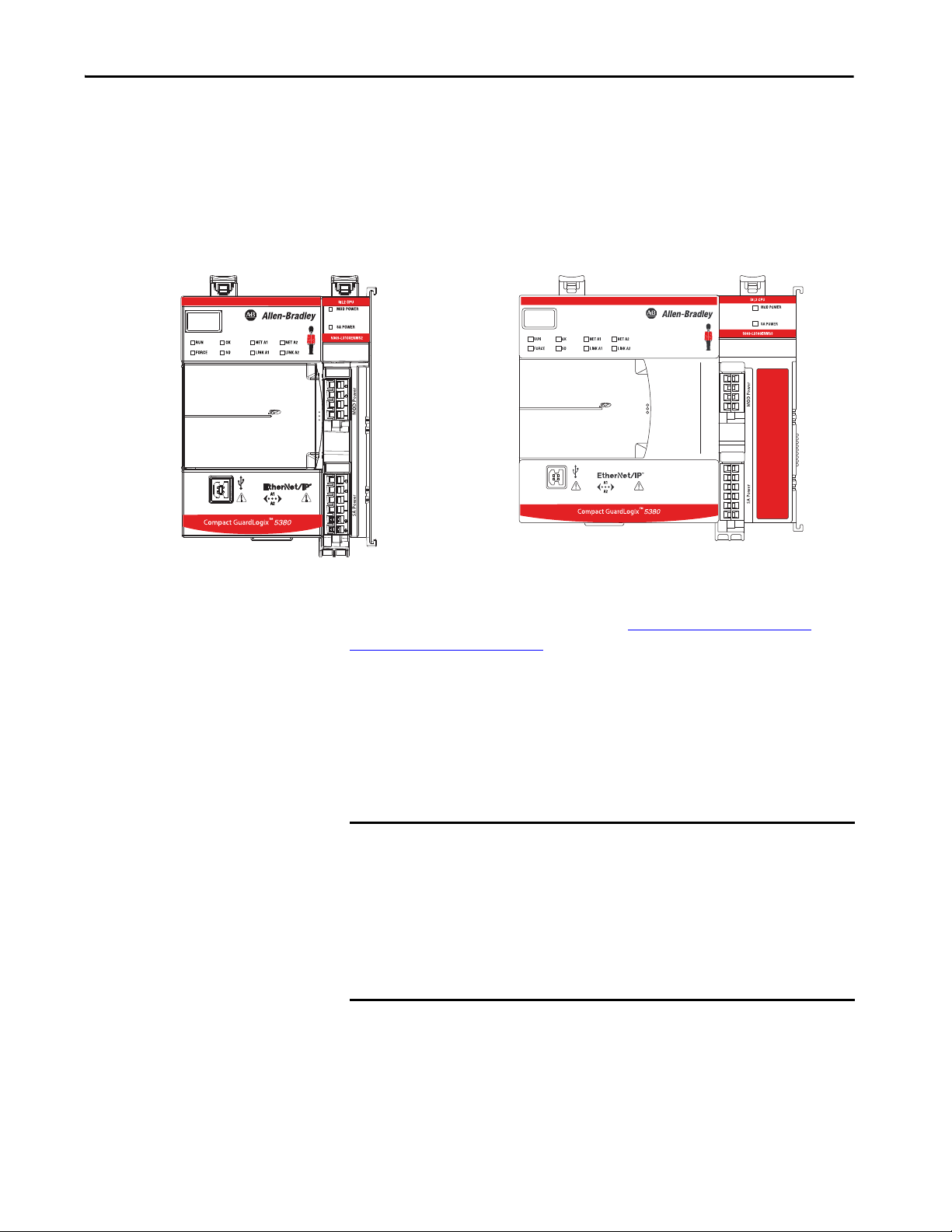

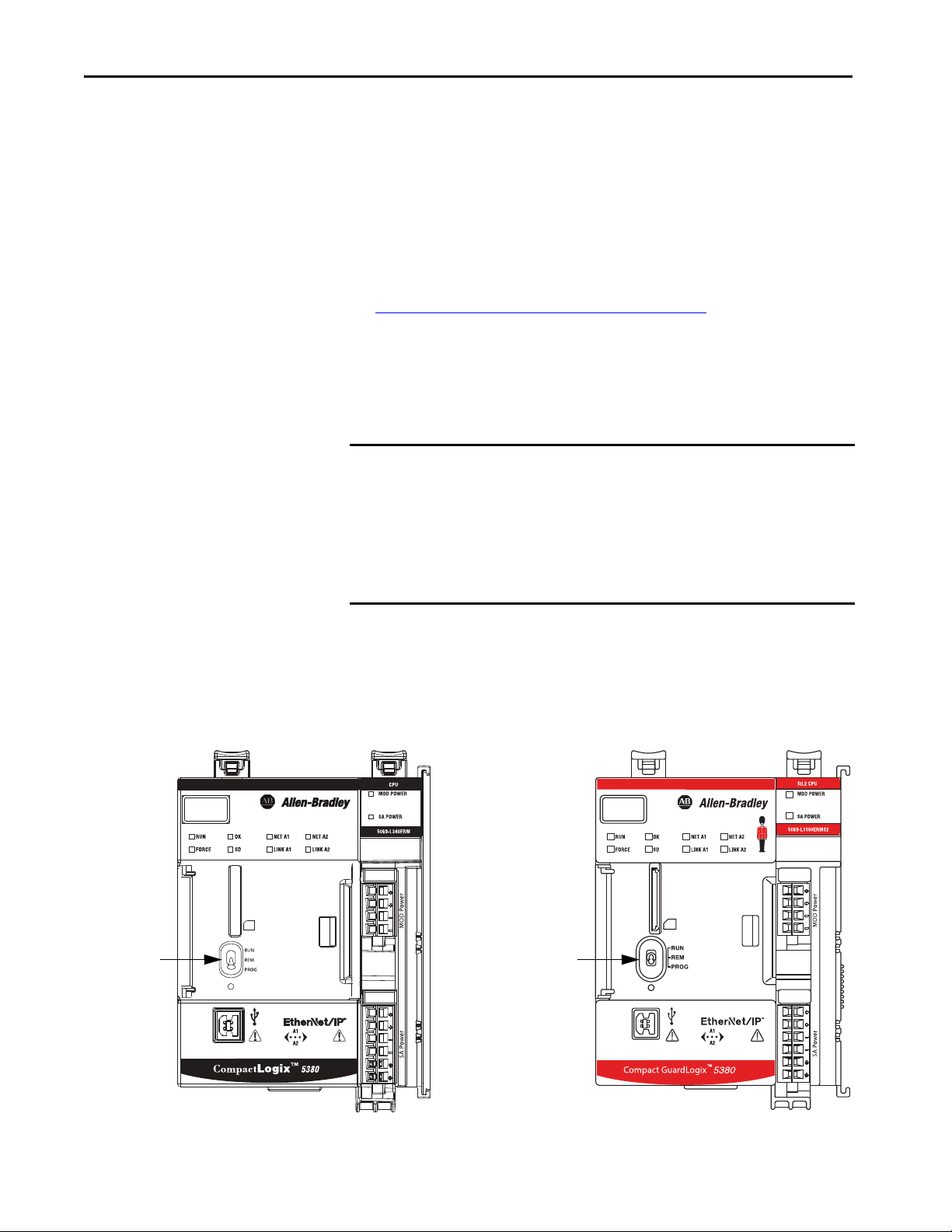

Compact GuardLogix 5380 System

Compact GuardLogix 5380 SIL 2 and SIL 3 controllers are programmable

automation controllers with integrated safety.

For SIL 3/PLe safety applications, the Compact GuardLogix 5380 SIL 3

controller system consists of a primary controller with an internal safety

partner, that function together in a 1oo2 architecture.

Compact GuardLogix 5380 SIL 2 Controller Compact GuardLogix 5380 SIL 3 Controller

For more information on safety ratings, see Safety Concept of Compact

GuardLogix 5380 Controllers on page 51.

The Compact GuardLogix system can communicate with safety I/O devices

via CIP Safety™ over an EtherNet/IP™ network (Guard I/O™ modules,

integrated safety drives, integrated safety components).

With a Compact GuardLogix controller, you can interface to standard I/O via

standard tasks while you interface with safety I/O via the safety task.

IMPORTANT For the safety task, Compact GuardLogix 5380 controllers support Ladder

Diagram only.

For standard tasks, Compact GuardLogix 5380 controllers support:

• Ladder Diagram (LD)

• Structured Text (ST)

• Function Block Diagram (FBD)

• Sequential Function Chart (SFC)

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 17

Page 18

Chapter 1 CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers

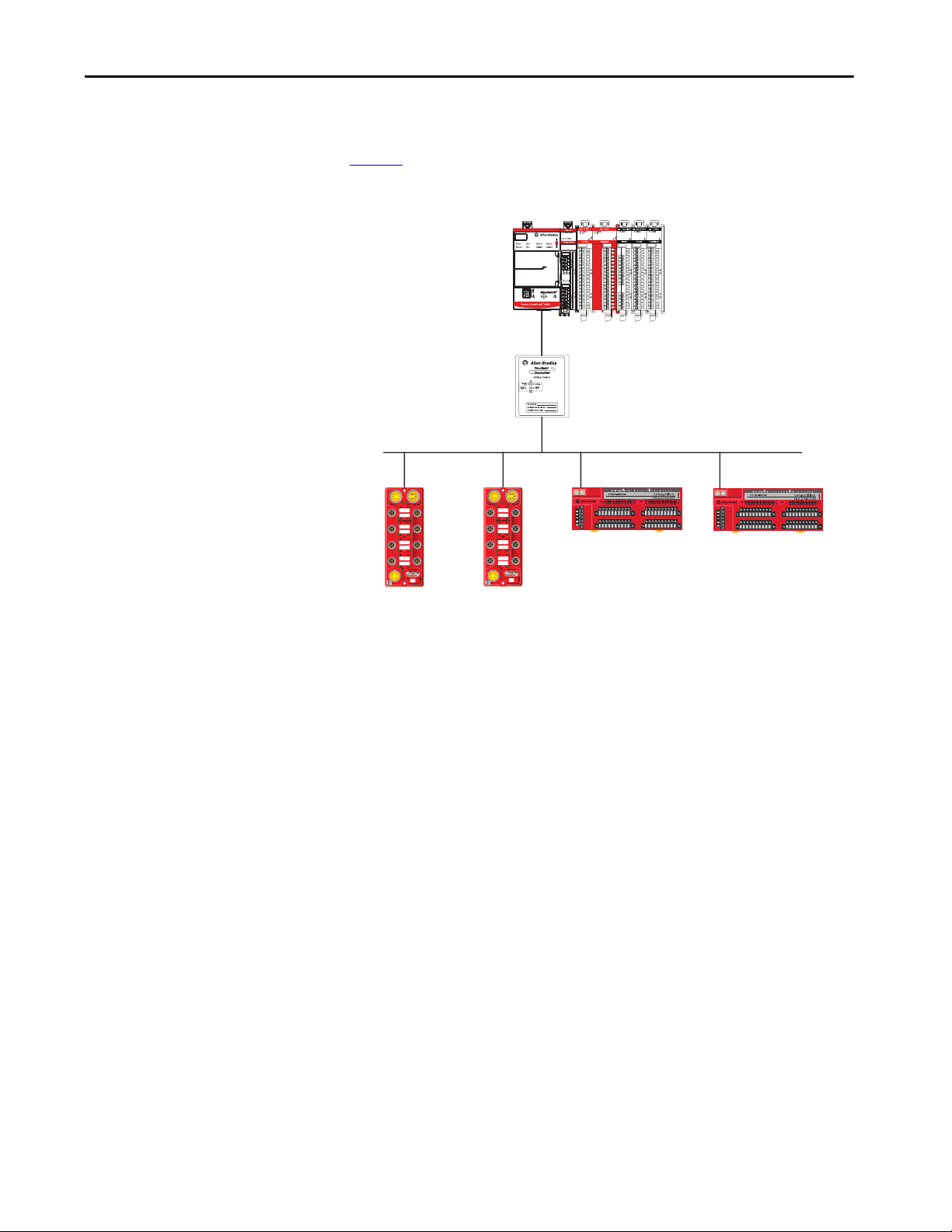

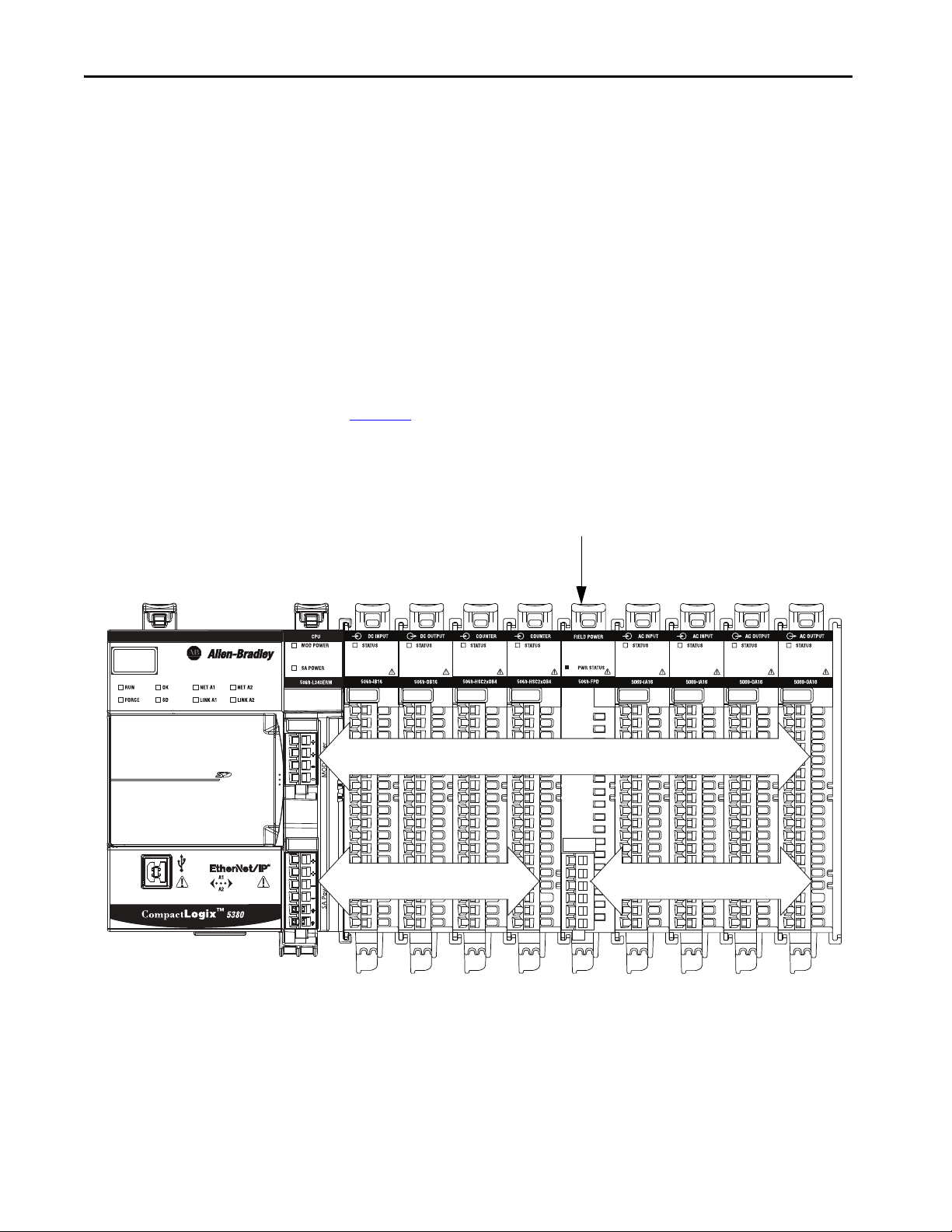

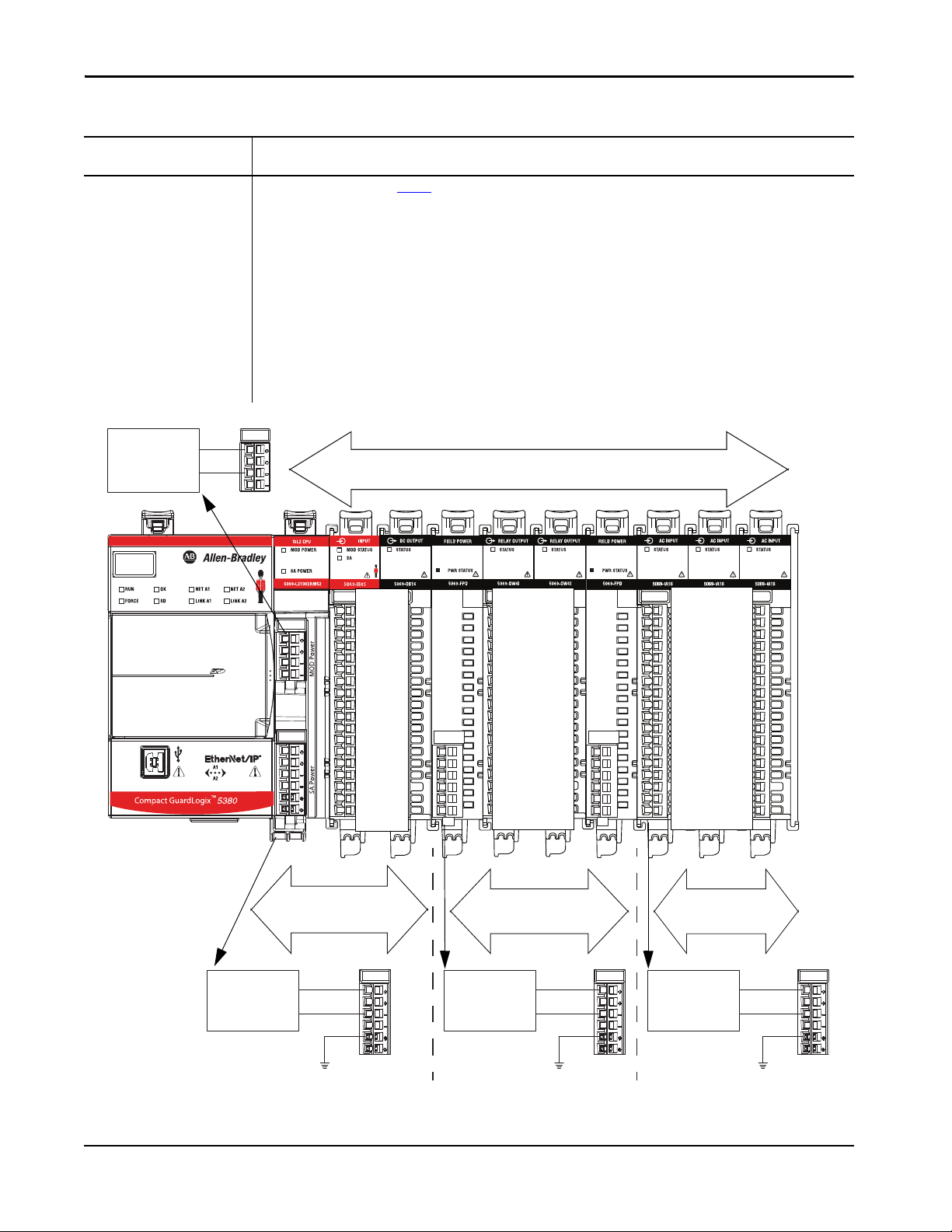

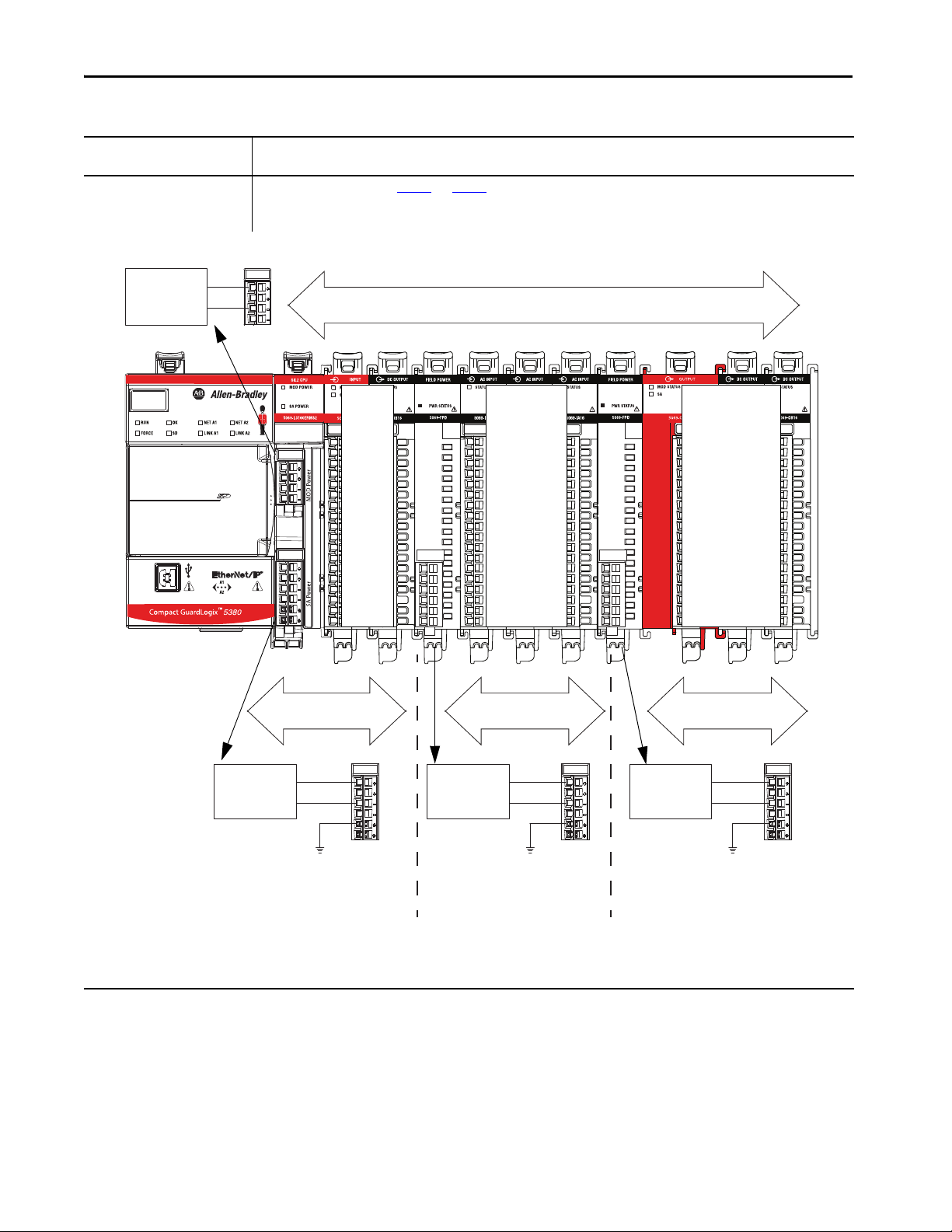

Compact GuardLogix 5380 Controller Compact 5000 I/O Safety Digital, Standard Analog, and

Standard Digital Modules

Compact 5000 I/O EtherNet/IP Adapter

Compact 5000 I/O Analog, Digital, and

Safety Modules

PowerFlex® 527 Drive

(CIP Safety enabled)

Kinetix® 5500 Drives

(with Safe Torque

Off functionality)

1732ES ArmorBlock® Guard I/O™

Module

1734 POINT I/O Adapter

1734 POINT I/O Modules

1734 POINT Guard I/O™ Modules

Compact GuardLogix 5380 SIL 2 or SIL 3 Controller

Compact 5000 I/O Safety, Analog, and Digital

Modules

Compact 5000 I/O EtherNet/IP Adapter

Compact 5000 I/O Analog, Digital, and

Safety Modules

The controllers can operate in various applications that range from standalone

systems that contain local I/O modules, as shown in Figure 3

Figure 3 - Compact GuardLogix 5380 Controller in a Standalone System

The controllers can also operate in more complex systems with devices that are

connected to the controller via an EtherNet/IP network, as shown in Figure 4

.

.

Figure 4 - Compact GuardLogix 5380 Controller on an EtherNet/IP DLR Network

18 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 19

CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers Chapter 1

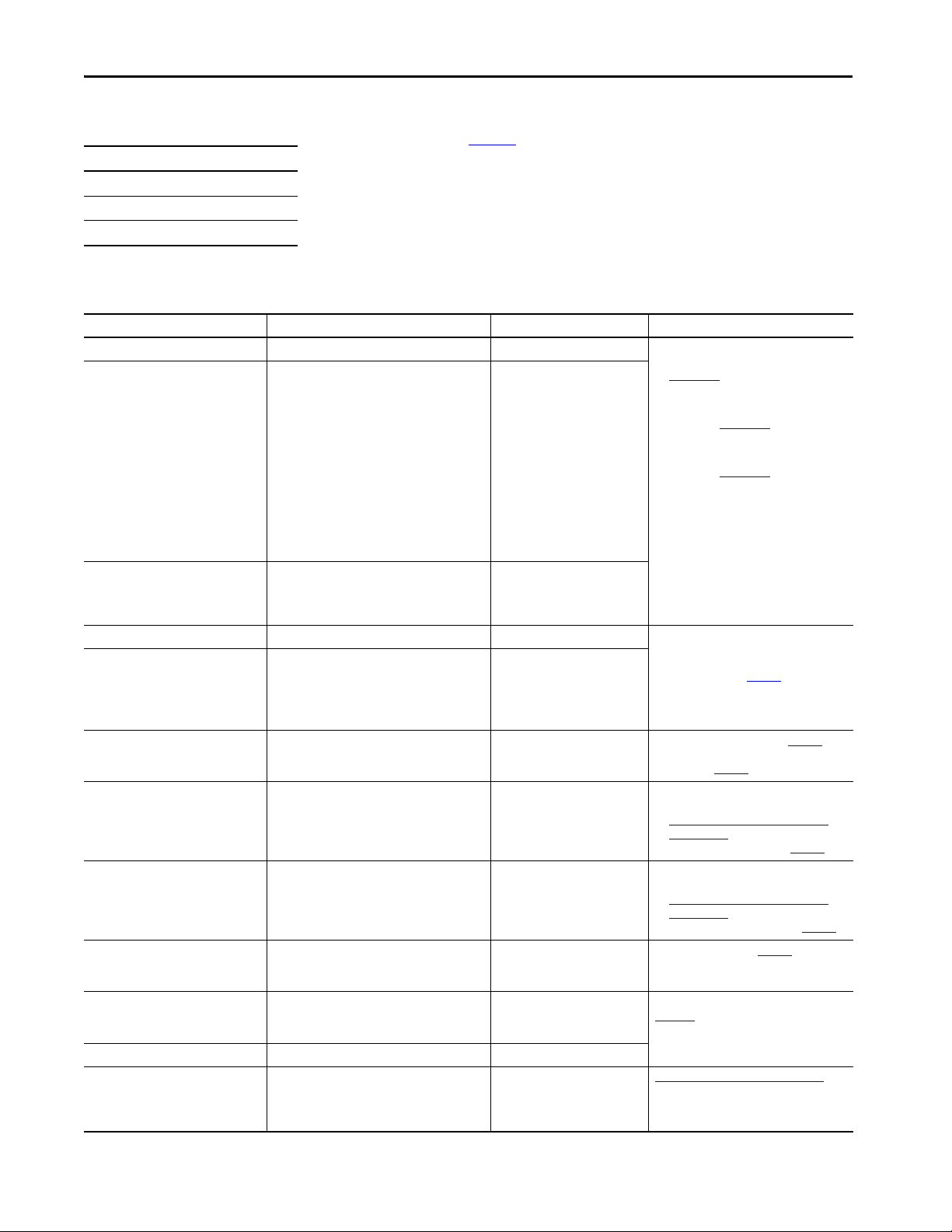

1791DS CompactBlock™

Guard I/O™ Module

DeviceNet Network

1788 EtherNet-to-DeviceNet

Linking Device

1732DS ArmorBlock

Guard I/O Module

1732DS ArmorBlock

Guard I/O Module

1791DS CompactBlock

Guard I/O Module

Compact GuardLogix 5380 SIL 2 or SIL 3 Controller

Compact 5000 I/O Safety, Analog, and Digital Modules

Compact GuardLogix 5380 controllers can communicate with safety devices

on a DeviceNet® network via a 1788-EN2DN linking device, as shown in

Figure 5

Figure 5 - Compact GuardLogix 5380 Controller Connected to Devices on a DeviceNet Network

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 19

Page 20

Chapter 1 CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers

Design the System

Applies to these controllers:

CompactLogix 5380

Compact GuardLogix 5380 SIL 2

Compact GuardLogix 5380 SIL 3

When you design a system, you must decide what system components your

application needs. Ta b l e 1

describes components that are commonly used in

CompactLogix 5380 and Compact GuardLogix 5380 control systems.

Table 1 - System Components

Component Purpose Required For More Information

DIN rail Mounting system Yes • CompactLogix 5380 Controllers

End cap (5069-ECR)

IMPORTANT: The end cap ships with

the controller.

Removable terminal blocks (RTBs) Connect these power types to the controller:

External power supply

External power supply

Studio 5000 Logix Designer application Configure the project that is used to define

Linx-based communication software Used as follows:

ControlFLASH software Update controller firmware Yes • For compatible ControlFLASH software,

USB programming port Complete tasks that only require a temporary

Ethernet port A1 Connects to these network types:

Ethernet port A2 Connect to device-level networks —

Secure Digital (SD) card

IMPORTANT: The 1784-SD2 card ships

with the controller.

(1)

(1)

The end cap covers the exposed interconnections

on the last module in the system.

If you do not install the end cap before powering

the system, equipment damage or injury from

electric shock can result.

IMPORTANT: You install the end cap after the

last module is installed on the DIN rail. This

design helps to prevent the end cap from going

beyond the locked position.

If you push the end cap beyond the locked

position or insert it from the backwards direction,

you can damage the MOD power bus and SA

power bus connector.

•MOD power

•SA power

Provides Module (MOD) Power to the system Yes

Provides Senso r/Actuator (SA) Power to the

system

controller activity during system operation

• Assign the controller an IP address

• Maintain communication over the EtherNet/IP

network

connection to the controller, for example, when

you download a project or update firmware

•Enterprise-level network

•Device-level network

Store data, such as the controller project and

diagnostics that are required by technical support

to obtain information if non-recoverable

controller faults occur.

Yes

Yes

Yes - Only if the system requires

SA power.

If the system does not require SA

power, the external power supply

is not needed.

Yes • Minimum Requirements on page 13

Yes • For compatible Linx-based

— Connect a USB Cable on page 59

— Chapter 9, Use EtherNet/IP Modes on

We recommend that you leave the

SD card installed, so if a fault

occurs, diagnostic data is

automatically w ritten to the card.

Installation Instructions, publication

5069-IN013

• Compact GuardLogix 5380 SIL 2

Controllers Installation Instructions,

publication 5069-IN014

• Compact GuardLogix 5380 SIL 3

Controllers Installation Instructions,

publication 5069-IN023

Power the System on page 26

• Create a Logix Designer Application

Project on page 75

communication software and, see the

Product Compatibility and Download

Center (PCDC).

• Connect to the Controller on page 57

see the

Product Compatibility and Download

Center (PCDC).

• Update Controller Firmware on page 63

page 135

Use the Secure Digital Card on page 107

20 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 21

CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers Chapter 1

Table 1 - System Components (Continued)

Component Purpose Required For More Information

Ethernet cables Used as follows:

• Access the controller from the workstation

over an EtherNet/IP network to set IP address,

update firmware, download, and upload

projects

• Connect controller to an EtherNet/IP network

and perform tasks that are required for normal

operations

USB cable Access the controller directly from the

workstation to set IP address, update firmware,

download, and upload projects.

The USB port is intended for temporary local

programming purposes only and not intended for

permanent connection.

Integrated Safety I/O devices on an

EtherNet/IP network

Connected to safety input and output devices, for

example, Compact 5000 I/O safety modules or

Guardmaster® Multifunctional Access B ox.

IMPORTANT: CompactLogix 5380 controllers

cannot use safety devices.

Compact 5000 I/O modules Used as follows:

• Local standard I/O modules that are installed

in the CompactLogix 5380 system

• Remote standard I/O modules that are

accessible via the EtherNet/IP network

• Local safety I/O modules that are installed in

the CompactLogix 5380 system

• Remote safety I/O modules that are accessible

via the EtherNet/IP network

Devices that are installed on an

EtherNet/IP network

Dependent upon device type. Examples include:

• Remote standard I/O modules

• Remote safety I/O modules

• Ethernet switches

• Motion control devices, such as drives

• HMI devices

(1) We strongly recommend that you use separate external power supplies for MOD power and SA power, respectively.

Yes. Connect an Ethernet Cable on page 58

Yes - Only if you perform tasks

Connect a USB Cable on page 59

that are listed in the previous

column via the USB port.

You can also perform the tasks via

the controller Ethernet ports.

Yes for Compact GuardLogix 5380

Safety I/O Devices on page 191

controllers.

Yes • Standard I/O Modules on page 169

• Safety I/O Devices on page 191

Yes. • Standard I/O Modules on page 169

• Safety I/O Devices on page 191

• Develop Motion Applications on page 269

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 21

Page 22

Chapter 1 CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers

Controller Features

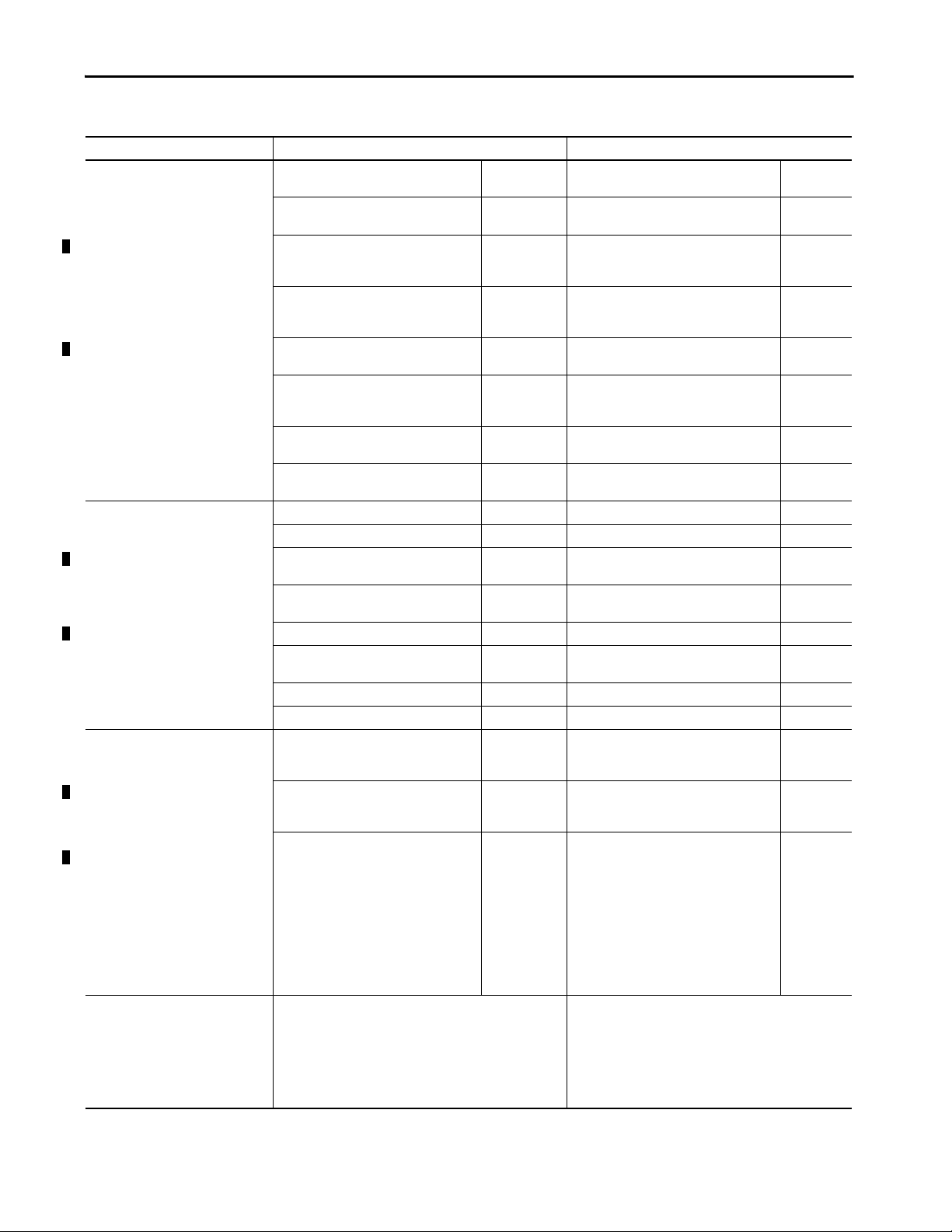

Ta b l e lists features available on the controllers. The features are described in

detail in the rest of this manual.

CompactLogix 5380 and Compact GuardLogix 5380 Controller Features

Feature CompactLogix 5380 Controllers Compact GuardLogix 5380 Controllers

User memory 5069-L306ER, 5069-L306ERM 0.6 MB 5069-L306ERS2, 5069-L306ERMS2,

5069-L310ER, 5069-L310ER-NSE, 5069L310ERM

5069-L320ER, 5069-L320ERM, 5069-L320ERP 2 MB 5069-L320ERS2, 5069-L320ERS2K,

5069-L330ER, 5069-L330ERM 3 MB 5069-L330ERS2, 5069-L330ERS2K,

5069-L340ER, 5069-L340ERM, 5069-L340ERP 4 MB 5069-L340ERS2, 5069-L340ERMS2,

5069-L350ERM 5 MB 5069-L350ERS2, 5069-L350ERS2K,

5069-L380ERM 8 MB 5069-L380ERS2, 5069-L380ERMS2,

5069-L3100ERM 10 MB 5069-L3100ERS2, 5069-L3100ERMS2,

Safety memory — 5069-L306ERS2, 5069-L306ERMS2,

Controller tasks • 32 tasks

Communication ports • 1 - USB port, 2.0 full-speed, Type B

EtherNet/IP network topologies

supported

EtherNet/IP modes • Linear/DLR mode

• 1000 programs/task

• Event tasks; all event triggers

• 2 - Embedded Ethernet ports, 10 Mbps, 100 Mbps, 1 Gbps

•Device Level Ring (DLR)

•Star

•Linear

• Dual-IP mode - Available with the Logix Designer application, version 29.00.00 or later.

1 MB 5069-L310ERS2, 5069-L310ERMS2,

5069-L306ERMS3

5069-L310ERMS3

5069-L320ERMS2, 5069-L320ERMS2K,

5069-L320ERMS3, 5069-L320ERMS3K

5069-L330ERMS2, 5069-L330ERMS2K,

5069-L330ERMS3, 5069-L330ERMS3K

5069-L340ERMS3

5069-L350ERMS2, 5069-L350ERMS2K,

5069-L350ERMS3, 5069-L350ERMS3K

5069-L380ERMS3

5069-L3100ERMS3

5069-L306ERMS3

— 5069-L310ERS2,

5069-L310ERMS2,

5069-L310ERMS3

— 5069-L320ERS2, 5069-L320ERS2K,

5069-L320ERMS2, 5069-L320ERMS2K,

5069-L320ERMS3, 5069-L320ERMS3K

— 5069-L330ERS2, 5069-L330ERS2K,

5069-L330ERMS2, 5069-L330ERMS2K,

5069-L330ERMS3, 5069-L330ERMS3K

— 5069-L340ERS2, 5069-L340ERMS2,

5069-L340ERMS3

— 5069-L350ERS2, 5069-L350ERS2K,

5069-L350ERMS2, 5069-L350ERMS2K,

5069-L350ERMS3, 5069-L350ERMS3K

— 5069-L380ERS2, 5069-L380ERMS2,

5069-L380ERMS3

— 5069-L3100ERS2, 5069-L3100ERMS2,

5069-L3100ERMS3

•32 tasks

31 standard tasks

1 safety task

• 1000 programs/task

• Event tasks; all event triggers

0.6 MB

1 MB

2 MB

3 MB

4 MB

5 MB

8 MB

10 MB

0.3 MB

0.5 MB

1 MB

1.5 MB

2 MB

2.5 MB

4 MB

5 MB

22 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 23

CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers Chapter 1

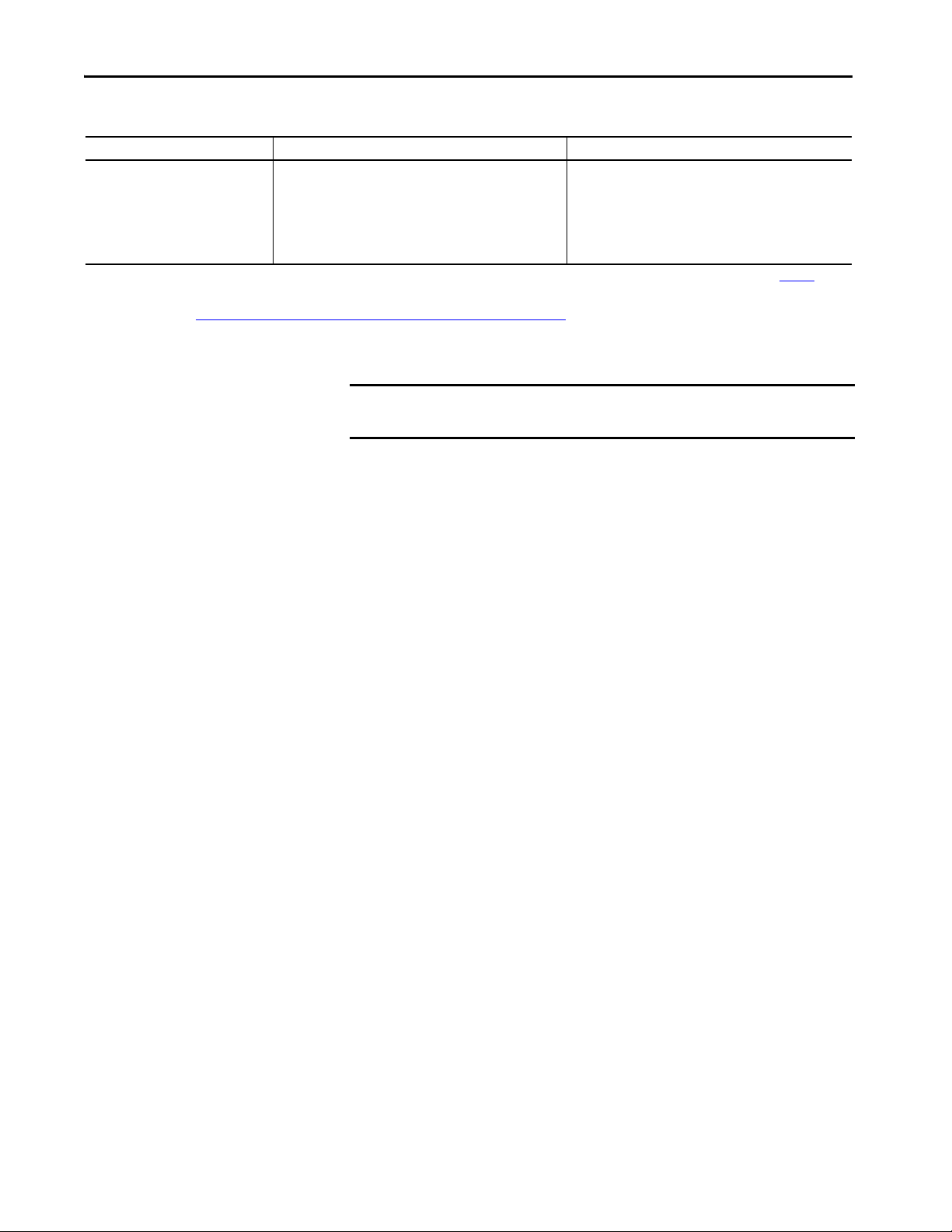

CompactLogix 5380 and Compact GuardLogix 5380 Controller Features (Continued)

Feature CompactLogix 5380 Controllers Compact GuardLogix 5380 Controllers

EtherNet/IP nodes supported, max

Integrated motion axes supported

Only controllers with an ‘M’ or ‘P’ in the

catalog number support motion.

Local I/O modules, max 5069-L306ER, 5069-L306ERM, 5069-L310ER,

Programming languages • Ladder Diagram (LD)

(1)

5069-L306ER, 5069-L306ERM 16 nodes 5069-L306ERS2, 5069-L306ERMS2,

5069-L306ERMS3

5069-L310ER, 5069-L310ER-NSE,

5069-L310ERM

24 nodes 5069-L310ERS2, 5069-L310ERMS2,

5069-L310ERMS3

5069-L320ER, 5069-L320ERM, 5069-L320ERP 40 nodes 5069-L320ERS2, 5069-L320ERS2K,

5069-L320ERMS2, 5069-L320ERMS2K

5069-L320ERMS3, 5069-L320ERMS3K

5069-L330ER, 5069-L330ERM 60 nodes 5069-L330ERS2, 5069-L330ERS2K,

5069-L330ERMS2, 5069-L330ERMS2K,

5069-L330ERMS3, 5069-L330ERMS3K

5069-L340ER, 5069-L340ERM, 5069-L340ERP 90 nodes 5069-L340ERS2, 5069-L340ERMS2,

5069-L340ERMS3

5069-L350ERM 120 nodes 5069-L350ERS2, 5069-L350ERS2K,

5069-L350ERMS2, 5069-L350ERMS2K,

5069-L350ERMS3, 5069-L350ERMS3K

5069-L380ERM 150 nodes 5069-L380ERS2, 5069-L380ERMS2,

5069-L380ERMS3

5069-L3100ERM 180 nodes 5069-L3100ERS2, 5069-L3100ERMS2,

5069-L3100ERMS3

5069-L306ERM 2 axes 5069-L306ERMS2, 5069-L306ERMS3 2 axes

5069-L310ERM 4 axes 5069-L310ERMS2, 5069-L310ERMS3 4 axes

5069-L320ERM, 5069-L320ERP 8 axes 5069-L320ERMS2, 5069-L320ERMS2K,

5069-L320ERMS3, 5069-L320ERMS3K,

5069-L330ERM 16 axes 5069-L330ERMS2, 5069-L330ERMS2K,

5069-L330ERMS3, 5069-L330ERMS3K

5069-L340ERM, 5069-L340ERP 20 axes 5069-L340ERMS2, 5069-L340ERMS3 20 axes

5069-L350ERM 24 axes 5069-L350ERMS2, 5069-L350ERMS2K,

5069-L350ERMS3, 5069-L350ERMS3K

5069-L380ERM 28 axes 5069-L380ERMS2, 5069-L380ERMS3 28 axes

5069-L3100ERM 32 axes 5069-L3100ERMS2, 5069-L3100ERMS3 32 axes

8 modules 5069-L306ERS2, 5069-L306ERMS2,

5069-L310ER-NSE, 5069-L310ERM

5069-L306ERMS3, 5069-L310ERS2,

5069-L310ERMS2, 5069-L310ERMS3

5069-L320ER, 5069-L320ERM, 5069-L320ERP 16 modules 5069-L320ERS2, 5069-L320ERS2K,

5069-L320ERMS2, 5069-L320ERMS2K,

5069-L320ERMS3, 5069-L320ERMS3K

(2)

5069-L330ER

, 5069-L330ERM

5069-L340ER, 5069-L340ERM, 5069-L340ERP,

5069-L350ERM, 5069-L380ERM,

5069-L3100ERM

(2)

,

31 modules 5069-L330ERS2, 5069-L330ERS2K,

5069-L330ERMS2, 5069-L330ERMS2K,

5069-L330ERMS3, 5069-L330ERMS3K,

5069-L340ERS2, 5069-L340ERMS2,

5069-L340ERMS3, 5069-L350ERS2,

5069-L350ERS2K,5069-L350ERMS2,

5069-L350ERMS2K, 5069-L350ERMS3,

5069-L350ERMS3K, 5069-L380ERS2,

5069-L380ERMS2, 5069-L380ERMS3,

5069-L3100ERS2, 5069-L3100ERMS2,

5069-L3100ERMS3

• For the safety task, Compact GuardLogix controllers support

• Structured Text (ST)

• Function Block Diagram (FBD)

• Sequential Function Char t (SFC)

Ladder Diagram only.

• For standard tasks, Compact GuardLogix controllers support:

– Ladder Diagram (LD)

– Structured Text (ST)

– Function Block Diagram (FBD)

– Sequential Function Chart (SFC)

16 nodes

24 nodes

40 nodes

60 nodes

90 nodes

120 nodes

150 nodes

180 nodes

8 axes

16 axes

24 axes

8 modules

16 modules

31 modules

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 23

Page 24

Chapter 1 CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers

CompactLogix 5380 and Compact GuardLogix 5380 Controller Features (Continued)

Feature CompactLogix 5380 Controllers Compact GuardLogix 5380 Controllers

Supported Controller Features • Data access control

• Firmware Supervisor

• Secure Digital (SD) card

• Standard Connections

(1) A node is an EtherNet/IP device that you add directly to the I/O configuration, and counts toward the node limits of the controller. For more information on EtherNet/IP nodes, see page 121.

(2) When you use this controller with the Logix Designer application, version 29.00.00, the application limits the number of local I/O modules in the project to 16. For more information, see

Knowledgebase Article 5380 CompactLogix controllers limited to 16 local Compact 5000 I/O modules in V29 of Studio 5000.®

With the Logix Designer application, version 30.00.00 or later, the controller supports as many as 31 local I/O modules.

• Data access control

• Firmware Supervisor

• Secure Digital (SD) card

• Standard Connections

• Safety Connections

IMPORTANT When you use a CompactLogix 5380 or Compact GuardLogix 5380 controller,

you do not need to configure a System Overhead Time Slice value.

24 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 25

CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers Chapter 1

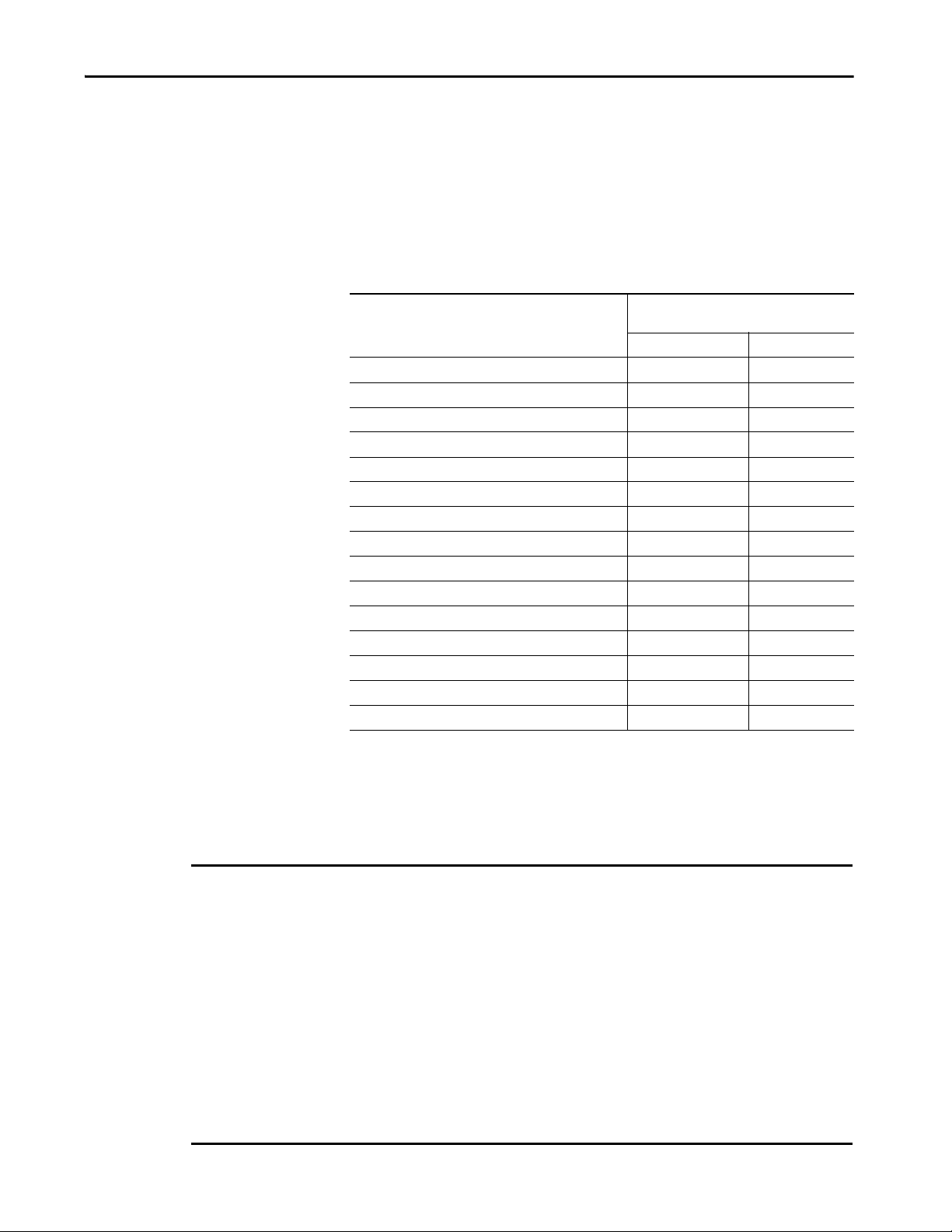

Features Supported by Compact GuardLogix 5380 Controllers Via the Safety Task

You can use the Compact GuardLogix 5380 controllers in safety applications

via the Safety task in the Logix Designer application.

In the Logix Designer application, the Safety task supports a subset of features

that are supported in the standard task as listed in this table.

Feature Studio 5000 Logix Designer Application,

Add-On Instructions X X

Instruction-based alarms and events — X

Tag-based alarms — X

Contro ller lo gging X X

(1)

Event ta sks

Function Block Diagrams (FBD) — X

Integrated motion X

Drive Safety Instructions X —

Ladder Diagram (LD) X X

Language switching X X

License-based source protection — X

Import program components — X

Export program components X X

Sequential Function Chart (SFC) routines — X

Structured Text (ST ) — X

(1) While the safety task cannot be an Event task, standard Event tasks can be triggered with the use of the Event instruction in the

safety task.

(2) Compact GuardLogix 5380 SIL 2 controllers are compatible with Studio 5000 Logix Designer Application, version 31 or later.

Compact GuardLogix 5380 SIL 3 controllers are compatible with Studio 5000 Logix Designer Application, Version 32 or later

(3) Limited to the use of Drive Safety Instructions wi th Kinetix 5700 ERS4 drives.

Version 31 or Later

Sa fety Task St anda rd Tas k

—X

(3)

(2)

X

IM PORTANT Safety Consideration

Compact GuardLogix 5380 controllers can produce standard tags as unicast or multicast, but they can only

produce safety tags as unicast. The controllers can consume safety tags as either unicast or multicast.

When you configure a produced safety tag, you are only allowed to configure unicast connection options.

Logix Designer does not allow you to configure multicast connection options.

When you configure a consumed tag, you must consider the capabilities of the producer:

• If the producer in the I/O tree of this controller is a GuardLogix 5580 or Compact GuardLogix 5380

controller, and you are consuming a safety tag, you must configure the consumed tag to use unicast.

• If the producer in the I/O tree of this controller is a GuardLogix 5570 or GuardLogix 5560 controller, or a

Compact GuardLogix 5370 controller, the safety consumed tag can be configured as either unicast or

multicast. A GuardLogix 5560 controller requires Studio 5000 Logix Designer application version

19.00.00 or later for unicast produce/consume safety tags.

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 25

Page 26

Chapter 1 CompactLogix 5380 and Compact GuardLogix 5380 Systems and Controllers

Power the System

Applies to these controllers:

CompactLogix 5380

Compact GuardLogix 5380 SIL 2

Compact GuardLogix 5380 SIL 3

The controller provides power to the system as follows:

• MOD Power - System-side power that powers the system and lets

modules transfer data and execute logic.

System-side power is provided through the MOD Power RTB.

• SA Power - Field-side power that powers some Compact 5000 I/O

modules and field-side devices that are connected to them.

Field-side power is provided through the SA Power RTB.

There are specific considerations and restrictions that you must be aware of

before you connect MOD power and SA power to a CompactLogix 5380

system or to a Compact GuardLogix 5380 system.

For more information on how to connect MOD power and SA power to the

different systems, see the following:

• How to Power CompactLogix 5380 Controllers - Chapter 2 on page 27

• How to Power Compact GuardLogix 5380 Controllers - Chapter 3 on

page 37

26 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 27

Chapter 2

How to Power CompactLogix 5380 Controllers

Top ic Pag e

Two Type s of Powe r 27

MOD Power 29

SA Power 30

This chapter explains how to power standard CompactLogix™ 5380

controllers.

For information on how to power Compact GuardLogix® 5380 controllers, see

Chapter 3, How to Power Compact GuardLogix 5380 Controllers on page 37

.

Two Types of Power

Applies to these controllers:

CompactLogix 5380

The CompactLogix 5380 controllers provide power to the system as follows:

• MOD Power - System-side power that powers the system and lets

modules transfer data and execute logic.

System-side power is provided through the MOD Power RTB.

• SA Power - Field-side power that powers some Compact 5000™ I/O

modules and field-side devices that are connected to them.

Field-side power is provided through the SA Power RTB.

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 27

Page 28

Chapter 2 How to Power CompactLogix 5380 Controllers

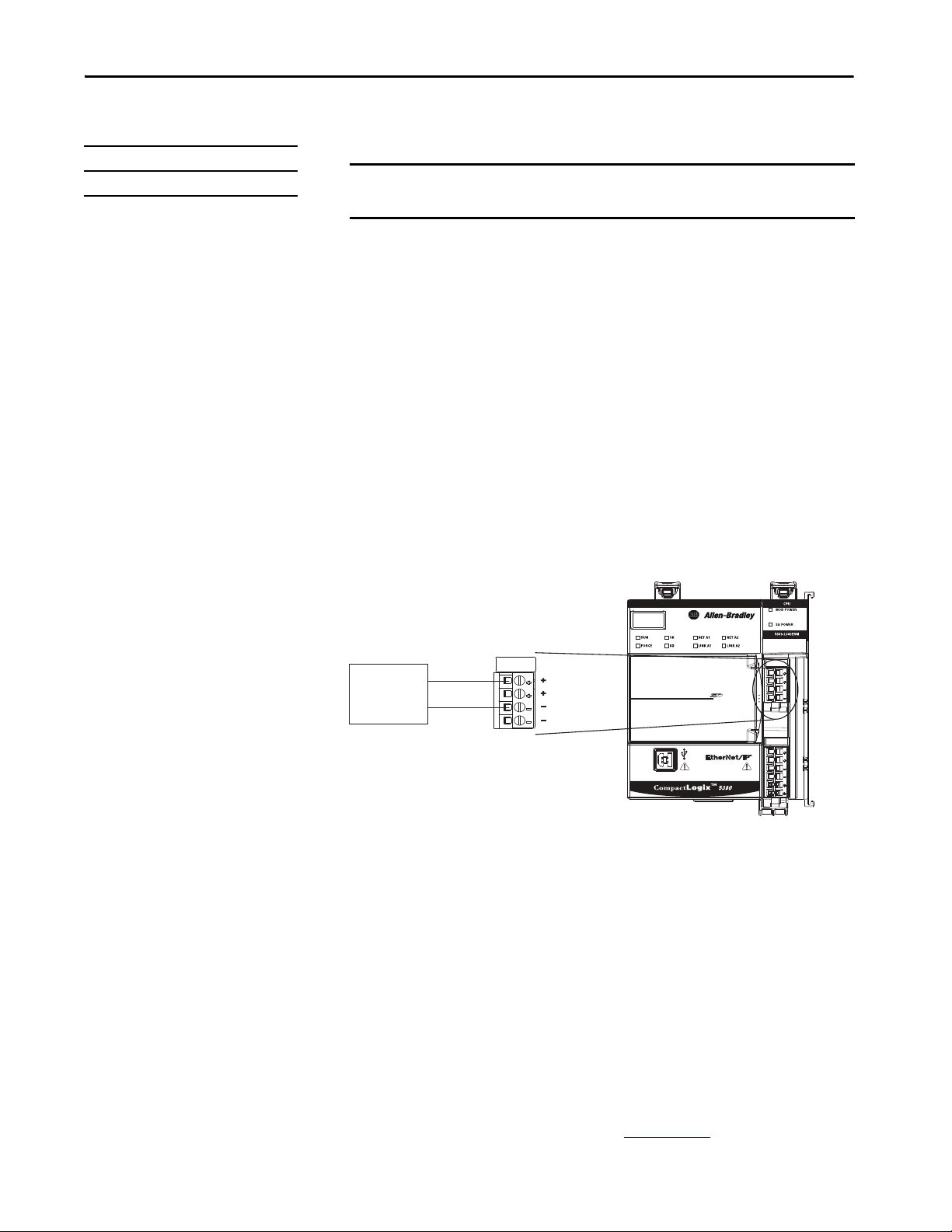

MOD Power

Connection

SA Power

Connection

Connect external power supplies to the RTBs to provide MOD power and

SA power. Figure 6

Figure 6 - MOD Power and SA Power RTBs on a CompactLogix 5380 Controller

shows the RTBs on a CompactLogix 5380 controller.

Power begins at the controller and passes across the Compact 5000 I/O

module internal circuitry via power buses.

MOD power passes across a MOD power bus, and SA power passes across a SA

power bus. The MOD power bus and SA power bus are isolated from each

other.

IMPORTANT We recommend that you use separate external power supplies for MOD

power and SA power, respectively. This practice can help prevent unintended

consequences that can result if you use one supply.

If you use separate external power supplies, the loss of power from one

external power supply does not affect the availability of power from the

other supply. For example, if separate MOD and SA external power supplies

are used and SA power is lost, MOD power remains available for the

CompactLogix 5380 controller and Compact 5000 I/O modules. As such, data

transfer continues in the system.

For more information on how to connect MOD power and SA power, see the

CompactLogix 5380 Controllers Installation Instructions, publication

5069-IN013

28 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 29

How to Power CompactLogix 5380 Controllers Chapter 2

24V DC

Power

Supply

+

–

MOD Power

Applies to these controllers:

CompactLogix 5380

MOD power is a DC power source that is required to operate a

CompactLogix 5380 system.

IMPORTANT You can only use DC power on the MOD power bus. Do not connect AC power

to the MOD power bus.

Remember the following:

• Every module in the CompactLogix 5380 system draws current from the

MOD power bus and passes the remaining current to the next module.

• MOD power lets Compact 5000 I/O modules transfer data and the

controller execute logic.

• A CompactLogix 5380 system uses only one MOD power bus.

• The total continuous current draw across the MOD power bus must not

be more than 10 A, max, at 18...32V DC.

• We recommend that you use an external power supply that is adequately

sized for the total MOD power bus current draw in the system.

Yo u m us t co ns id er inrush current requirements when you calculate the

total MOD power bus current draw in the system.

Figure 7 - External Power Supply Provides MOD Power

MOD Power Bus

When the MOD power source is turned on, the following occurs.

1. The CompactLogix 5380 controller draws current from the MOD

power bus and passes the remaining current through to the next module.

2. The next module draws MOD power bus current and passes the

remaining current through to the next module.

3. The process continues until MOD power bus current needs are met for

all modules in the system.

For more information on the current that the Compact 5000 I/O modules

draw from the MOD power bus, see the Compact 5000 I/O Modules

Specifications Technical Data, publication 5069-TD001

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 29

.

Page 30

Chapter 2 How to Power CompactLogix 5380 Controllers

SA Power

Applies to these controllers:

CompactLogix 5380

SA power provides power to devices that are connected to some of the

Compact 5000 I/O modules in the CompactLogix 5380 system. SA power is

connected to the controller via an SA power RTB.

Remember the following:

• Some Compact 5000 I/O modules draw current from the SA power bus

and pass the remaining current to the next module.

• Some Compact 5000 I/O modules only pass current along the SA

power bus to the next module.

• A CompactLogix 5380 system can have multiple SA power buses. The

first SA power bus starts at the controller and passes across the I/O

modules that are installed to the right of the controller.

You use a 5069-FPD field potential distributor to establish a new SA

power bus. The new SA power bus is isolated from the SA power bus to

its left in the system.

For more information on how to use a 5069-FPD field potential

distributor in a CompactLogix 5380 system, see page 34

.

• If the SA power source uses DC voltage, the total continuous current

draw across the SA power bus must not be more than to 10 A, max at

18…32V DC.

• We recommend that you use an external power supply that is adequately

sized for the total SA power bus current draw on an individual bus.

Yo u m us t co ns id er inrush current requirements when you calculate the

total SA power bus current draw in the system.

30 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 31

How to Power CompactLogix 5380 Controllers Chapter 2

AC or DC

Power

Supply

+

–

• Connections to an SA power bus use a shared common. All inputs that

draw current from an SA power bus to power field-side devices have a

return through circuitry to the SA - terminal on the SA power

connector.

IMPORTANT Each SA power bus has a shared common unique to that bus

because SA power buses are completely isolated from each other.

That is, the SA power bus that the CompactLogix 5380 controller

establishes has a shared common. If you use a 5069-FPD field

potential distributor to establish a new SA power bus in the system,

that second bus has its own shared common for modules that draw

current from it.

Figure 8 - External Power Supply Provides SA Power

When the SA power source is turned on, the following occurs.

1. The CompactLogix 5380 controller draws current from the SA power

bus and passes the remaining current through to the next module.

IMPORTANT The level of current that the CompactLogix 5380 controller draws

from the SA power bus is negligible.

It draws 10 mA (DC Power), 25 mA (AC power).

2. The next module completes one of these tasks.

– If the module uses SA power, the module draws current from the SA

power bus and passes the remaining current through to the next

module.

– If the module does not use SA power bus current, the module passes

the remaining current through to the next module.

3. The process continues until all SA power bus current needs are met for

the modules on the SA power bus.

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 31

Page 32

Chapter 2 How to Power CompactLogix 5380 Controllers

If your system includes AC and DC modules that require SA power, you must

use a 5069-FPD field potential distributor to establish a separate SA power bus

and separate the module types on the isolated SA power buses.

For more information on the current that the Compact 5000 I/O modules

draw from the SA power bus, see the Compact 5000 I/O Modules

Specifications Technical Data, publication 5069-TD001

.

Track SA Power Bus Current Draw

We recommend that you track the SA power bus current draw, max, per

module, and collectively for the CompactLogix 5380 system.

You must make sure that the Compact 5000 I/O modules that are installed on

an SA power bus do not consume more than 10 A. If so, you must establish

another SA power bus.

Consider the following with this example:

• The values in this example represent a worst-case calculation. That is, all

modules that draw SA power bus current, draw the maximum available

on the module.

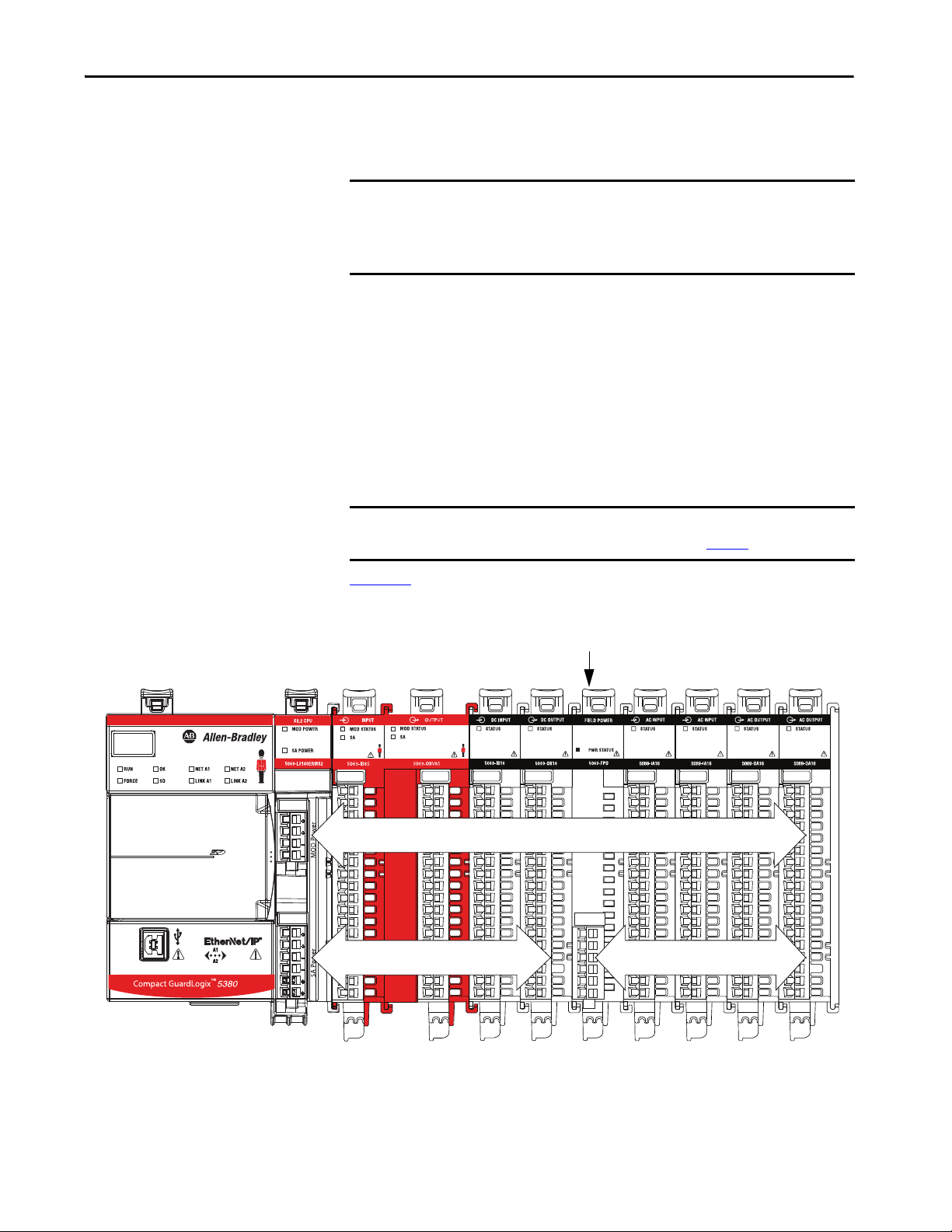

• Not all modules that are shown in Figure 9

use SA power bus current.

For example, the 5069-ARM and 5069-OW4I modules only pass SA

power bus current to the next module.

Other modules that do not use SA power bus current, but are not shown

in the graphic, include the 5069-OB16, 5069-OB16F, 5069-OX4I, and

5069-SERIAL modules.

32 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 33

How to Power CompactLogix 5380 Controllers Chapter 2

Continuous MOD Power Bus Limited to 10 A, Max

Continuous SA Power Bus Limited to 10 A, Max

SA Power Bus Current, Max,

Per Mo dule

10 mA

System SA Power Bus Current, Max = 7.160 A

200 mA 200 mA 150 mA 0 mA 3 A 3 A 100 mA 100 mA 150 mA 250 mA

• System SA power bus current, max, is calculated as each module draws

SA power bus current. The calculation begins with the controller. The

controller SA power bus current draw used for the calculation is 10 mA

for DC power

In Figure 9

, after the 5069-IB16 module in slot 1 draws SA power bus

current, the system SA power bus current, max, is 210 mA.

After the 5069-IB16 module in slot 2 draws SA power bus current, the

system SA power bus current draw is 410 mA. This process continues

until the system SA power bus current, max, is 7.160 A.

Figure 9 - CompactLogix 5380 System - Calculate SA Power Bus Current Draw

Rockwell Automation Publication 5069-UM001G-EN-P - August 2020 33

Page 34

Chapter 2 How to Power CompactLogix 5380 Controllers

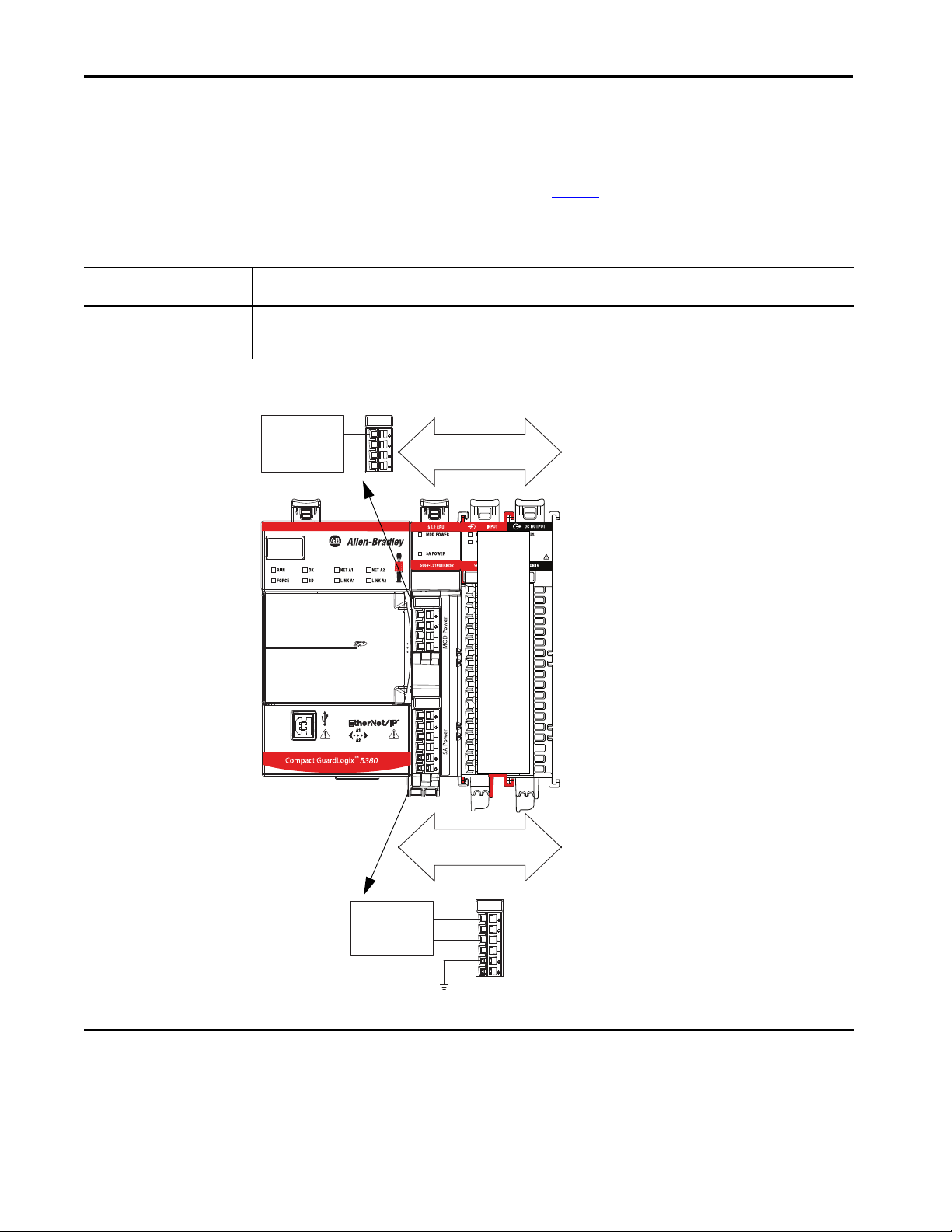

MOD Power Bus

First SA Power Bus Second SA Power Bus

5069-FPD Field Potential Distributor

Use a 5069-FPD Field Potential Distributor to Create a New SA Power Bus

You can use a 5069-FPD field potential distributor to establish a new SA power

bus in a CompactLogix 5380 system.

The field potential distributor blocks the current that passes across the SA

power bus to its left. At that point, the field potential distributor establishes a

new SA power bus for modules to the right. The new SA power bus is isolated

from the SA power bus to its left in the system.

You can connect either a 24V DC or 120/240V AC external power supply to a

5069-FPD field potential distributor in a CompactLogix 5380 system.

Figure 10

shows a CompactLogix 5380 system that uses a 5069-FPD field

potential distributor to create a second SA power bus.

Figure 10 - CompactLogix 5380 System - Create a New SA Power Bus

You can install multiple 5069-FPD field potential distributors in the same

system, if necessary.

34 Rockwell Automation Publication 5069-UM001G-EN-P - August 2020

Page 35

How to Power CompactLogix 5380 Controllers Chapter 2

SA Power - Additional Notes

• Other examples of system configurations that use multiple SA power

buses include:

– The modules in the system collectively draw more than 10 A of SA

power. That is, the maximum current that one SA power bus

can provide.

– The modules in the system must be isolated according to module

types, such as digital I/O and analog I/O modules.

– The modules in the system are isolated according to the type of

field-side device to which they are connected.

For example, you can separate modules that are connected to fieldside devices that use DC voltage from modules that are connected to

field-side devices that require AC voltage.

• The actual current in CompactLogix 5380 system changes based on the

operating conditions at a given time.

For example, the SA power bus current draw on some modules is

different if all channels power field devices or half of the channels power

field devices.

• Some Compact 5000 I/O modules use field-side power but do not draw

it from a SA power bus. The modules receive field-side power from an

external power supply that is connected directly to the I/O module.

For example, the 5069-OB16 and 5069-OB16F modules use Local

Actuator (LA) terminals on the module RTB, that is, LA+ and LA–

terminals for all module channels.

In this case, you can use the same external power supply that is

connected to the SA power RTB on the controller to the LA+ and LA–

terminals.