Page 1

Rockwell Automation Commercial Programs

Legacy Toolkit & Support User Guide

This guide is for active participants of the Commercial Toolkit

Programs and may not be distributed to non-authorized users.

Global Commercial Programs

Welcome

Overview

Legacy Toolkit Contents

Commercial Programs FAQ

Activation FAQ

Telephone Support

Online Support

Software, Firmware and Other Updates

Support Options

International Numbers

Page 2

Welcome

To the Rockwell Automation Global Commercial Programs

Dear Partner,

Rockwell Automation is pleased to have you participate in the Program. We recognize

the value your company provides in applying our technologies to implement

customer solutions, and thank you for your support and continued participation in

this Program.

For more detailed information on the Program, please visit the Commercial Toolkit

Programs section of our Partner Relationship Management (PRM) Portal located at

https://partners.rockwellautomation.com/. This site requires a login and password.

If you have not already done so, please register for a PRM Portal account to enable

access. We recommend that you regularly visit this site to learn the latest Program

and product details. In many cases we will only be distributing information via e-mail

or posting it on the PRM Portal.

Your Toolkit contains:

• Activation Certicate containing the serial number and product key to activate the

Toolkit. Detailed information is provided in the Welcome Email you receive when your

order has been processed. Welcome kits are sent via email 5-7 days after the order is

processed.

• Media can be purchased at time of toolkit order. Please note, the most recent updates

may need to be downloaded from the support website at

http://www.rockwellautomation.com/en-us/support/product/product-downloads.html

or with Compatibility and Download webpage

https://compatibility.rockwellautomation.com/Pages/home.aspx

• Legacy Toolkit & Support User Guide including Contact information, Toolkit Contents,

FAQ, Instructions for using the Rockwell Automation Support Center, Knowledgebase,

contacting Technical Support, and other important information designed to help you

make the moast of your program benets and toolkit license.

The registered participant site will be able to use the Toolkit serial number to obtain

support in the interim. You may reach the Channel Development Team via e-mail at

rschannel@ra.rockwell.com or by phone at (0) 01.414.382.8360.

Sincerely,

Rockwell Automation

2

Page 3

Overview

• Use the instructions provided in this User Guide to obtain ecient service and

maximize the benets of your Toolkit license. Providing your authorization number for

support and serial number(s) for product updates will expedite service delivery.

• Support information specic to the Program and license purchased (support level,

serial number(s), authorization number(s), etc.) can be veried online on the Partner

Network Portal (PRM Portal) at

https://partners.rockwellautomation.com/

• Make sure you sign up on our Knowledgebase at

https://rockwellautomation.custhelp.com/ to receive proactive notication of

product updates and tech notes.

Contents

1 Rockwell Automation Legacy Toolkit Contents

2 Commercial Programs FAQ

3 Activation FAQ

4 Telephone Support

5 Online Support

6 Software, Firmware and Other Updates

7 Support Options

8 International Numbers

3

Page 4

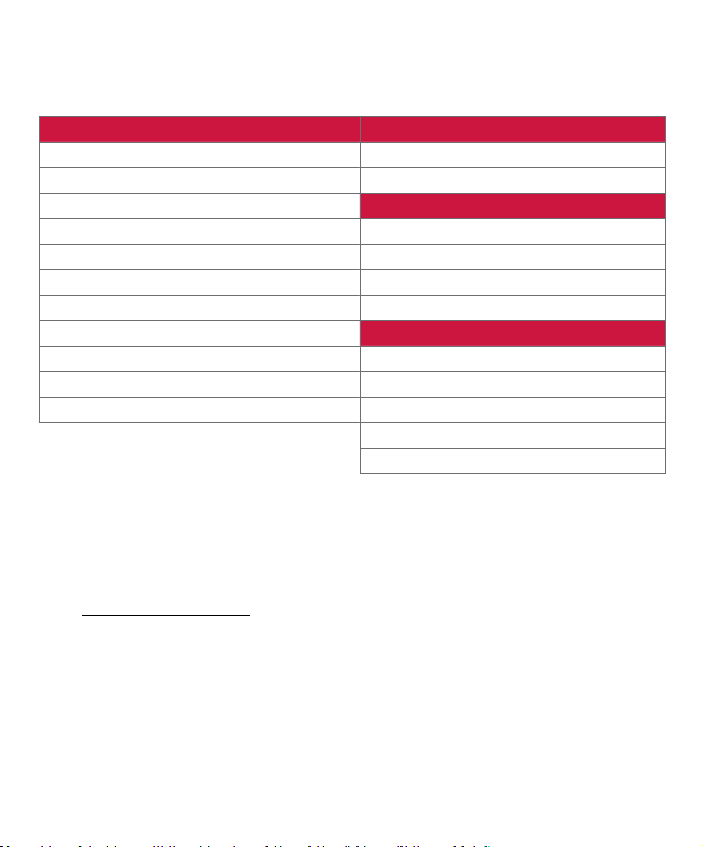

1 Legacy Toolkit Contents

*Denotes product serial number indicated on toolkit activation certicate is the parent serial number to download all activations

FactoryTalk® Historian Classic Authoring Client

FactoryTalk® Historian Classic Server 70K Tag

RSV 32 ADS Floa ting View Cli ent

RSView® 32 Active Displa y System

RSView® 32 Active Displa y Client

RSView® 32 ADS Dedic ated Clien t

RSView®32 Messenger Pro

RSView®32 WebServer

RSView® 32 Works 100 K

RSLinx® Classic Gateway

FactoryTalk® Transaction Manager Pro 70K Tags

The Legacy Toolkit is intended to provide commercial program participants access to Legacy Software. It does not include

access to Legacy Hardware Support. Legacy Hardware Support requires the purchase of a Legacy Support contract. Please

contact your Rockwell Automation sales person or authorized distributor for details.

Legacy Toolkit: For customers who require access to RSVeiw32, Historian Classic, SoftLogix, Studio 5000 Legacy for v20.04 and below select the Legacy Toolkit

“buy with” option when you shop for the Toolkit Subscription. The Legacy Toolkit provides you with the appropriate activation certicate required to use the

software highlighted above.

Note: All Toolkit software is subject to limitations as described in the license agreement. For product release notes and system requirements, please see our

web site at https://partners.rockwellautomation.com/

Legacy Software Toolkit Bundle Contents – Named & Concurrent

Data Management

Singl e Runtime Cli ent FTM/F THC

SoftLogix™ 5800

PanelBuilder® 32

RSLogix 500® PR O 1ySub ES D S/W

RSLogix™ 5 P rofessional 1 ySub ESD So ftware

Stud io 5000® Le gacy for v2 0.04 and below

FactoryTalk® Metrics Server 200 workcell

FactoryTalk® Metrics Authoring Client

FactoryTalk® View Studio

FactoryTalk® View SE Unlimi ted Serve r

FactoryTalk® View SE Client

Production Management

Desig n & Congurat ion

Peformance & Visibility

4

Page 5

2 Commercial Programs FAQ

What is the objective of the Commercial

Toolkit Programs?

The purpose of the Programs is to help

Rockwell Automation systems integrator and

machine builder customers to increase their

protability, effectiveness, and competitive edge

by providing economical access to the tools they

need to integrate Rockwell Automation products

and technology and develop integration solutions

for their customers.

Where do I nd Program details?

For Program information, please go to the

Partner Relationship Management (PRM) Portal

(https://partners.rockwellautomation.com/).

In the PRM Portal, you will nd information on the

Programs, tools to help you with our products,

your Partner Summary Report, and other details

on our products and services that are only

available to Program Participants. If you haven’t

had a chance to browse the PRM Portal, please

take a moment to do so, as PRM portal access is

one of the benets provided to you with Program

participation.

What about software that a Program

participant already owns?

Program Participants that have existing

software purchased outside the Toolkit offering

can obtain a TechConnect contract. Furthermore,

existing software can be brought into support

and resold to their customers.

For more information go to

https://rockwellautomation.custhelp.com/

Do I need additional TechConnect contracts

for GML, PLC2 or PLC3 software if the Toolkit

license my company purchased includes

support?

Yes. Toolkit Support does not include

Legacy Support. Participants may purchase

a Legacy Support contract through your

local Rockwell Automation sales oce or

Authorized Distributor.

Can a company buy one Toolkit with 8-5

Phone Support and another Toolkit with 24x7

Phone Support?

No, all participants will need to purchase all

Toolkits/installs with matching support levels.

Will a participant be able to upgrade their 8-5

Support option to 24x7 at a later time?

No. Support contracts can only be

modied at time of renewal.

5

Page 6

3 Activation FAQ

What is Media?

Media is an electronic image of all software

that is available for additional purchase at time

of Toolkit purchase. Media is provided for your

internal development use only, and external

customer distribution is prohibited. Distribution

to customers may result in program termination.

• You will have activations to the products that are

included in the license type purchased by your

company (see your Contents document).

Please Note: The media provided is property

of Rockwell Automation and may not be

resold, transferred, or used in a production or

manufacturing capacity.

Who can use media?

Media is restricted to use by active

participants of the Rockwell Automation

commercial toolkit programs and authorized

channel partners only. External customer

distribution is prohibited. Distribution to

customers may result in program termination.

Is media included in the Toolkit?

No. Media is optional and can be purchased

when the Toolkit subscription is renewed at the

end of each contract period.

Can I use media to update my customers?

Media is for internal development use only and

is not intended for end customer use. Distribution

to customers may result in program termination.

Where can I nd product release notes and

system requirements?

In the Help File of each product, or please see

our website at:

https://rockwellautomation.custhelp.com/

What if a product revises between media

releases?

If you require software updates between

media releases, you can download the latest

release of the software online. Go to

https://compatibility.rockwellautomation.com/

Pages/home.asp

Will I be able to activate all products included

in the media?

No. Which products you can activate depends

on the contents of your license. Some products

have third-party licensing restrictions prohibiting

inclusion in internal development licenses.

However, these products may be included on

media for update and demo purposes.

What do I need to activate my software

electronically?

To activate your software electronically you

will need:

• A computer with an Internet connection and web

browser (or email, telephone, or fax capability).

• FactoryTalk Activation Manager software

(the FactoryTalk Activation Manager software

application is included on your media if you

purchase).

• The software serial number and product key

(printed on the Activation Certicate document,

enclosed in a red envelope included with the

software media).

Who do I call if I need activation support?

Please access Technical Support at

https://rockwellautomation.custhelp.com/

or by phone using the numbers provided on

pages 10-11.

6

Page 7

3 Activation FAQ continued…

Where can I nd tutorials on FT Activation?

You can access FAQs, tutorials, and view

archived Q&As online at our Activations Support

site https://rockwellautomation.custhelp.com/

What if I need help installing a product?

Start with the Rockwell Automation

Knowledgebase for 24/7 technical information

and assistance:

• View technical/application notes

• Obtain software patches

• Ask questions, and much more!

• Subscribe for product/service emails

What is the difference between the “named”

and “concurrent” toolkit?

Named toolkits require the user to activate

to an internet computer or a computer with a

network network connection. Dongle activations

are not supported for named toolkits. Both

named and concurrent toolkit activations may

be borrowed.The owner or administrator of a

named toolkit assigns users and the number

of activations they will receive. The user will

receive an email to activate. The user selects

the “Activate Software” button to activate to

a selected computer. Concurrent toolkits are

also encouraged to use the “Activate Software”

workow so that

Manage License will

be populated with

the user email.

Will my Toolkit have one serial number with

FactoryTalk Activation?

Yes. You will have one serial number per

Toolkit catalog number ordered. A Toolkit license

serial number includes individual activation

keys for the software products contained in the

bundle. Your Toolkit license may include multiple

installs under the same serial number depending

on the number of installs purchased.

Where can I nd product manuals and

release notes?

The Rockwell Automation Technical

Reference Library is included on media, and

contains product manuals, technical notes, and

Knowledgebase les for on-demand installation

assistance.

What is the minimum version of the

FactoryTalk Activation Tool I need to use with

my Toolkit?

We encourage participants to use the latest

version of FactoryTalk Activation Manager. The

latest version of FactoryTalk Activation Manager

can be downloaded from our website at

https://activate.rockwellautomation.com

How is the Toolkit license activated?

The Toolkit license uses FactoryTalk

Activation. FactoryTalk Activation is part of

the Rockwell Automation FactoryTalk Services

Platform. It allows FactoryTalk enabled

products to be activated via les generated

by Rockwell Automation over the Internet. It

eliminates the dependency on physical media

to initiate activation. As a result, software

activations can be delivered, distributed, stored,

backed-up and moved electronically. Activation

les can be created with the FactoryTalk

Activation Manager software or retrieved online

from the Rockwell Automation licensing site at

https://activate.rockwellautomation.com/ and

hosted to your local server, machine, or a USB

dongle. For help with activation, click Help in the

upper right corner of the FactoryTalk Activation

Manager, or visit our Activations Support site at

at https://activate.rockwellautomation.com

7

Page 8

4 Telephone Support

How to Contact

Immediately address issues with phone support.

These specialists are ready when you need them.

Please access Technical Support at

https://rockwellautomation.custhelp.com/

or by phone using the numbers provided on

pages 10-11.

Once your contract is active, you will receive a

designated authorization number that can be

found within their Welcome Kit (wallet cards) and/

or within their account prole on Knowledgebase.

You may also verify your Support Authorization

Number, Toolkit serial number, and registered

participating site information online by accessing

your Partner Summary Report on our extranet

site at https://partners.rockwellautomation.com/

Please use your designated Authorization

Number (and phone number if you purchased

System Support) when calling for support.

These numbers can only be used for support

issues regarding products included in the

ToolkitProgram support offering.

Standard phone support hours are 8 am to 5 pm

Monday through Friday in the time zone of the

primary participant location unless a 24x7x365

support level was purchased.

You will receive an e-mail containing your toolkit

support entitlement information and credentials

via PDF attachment following the toolkit order

shipment. The PDF is formatted to print directly

onto Avery Stock Number 5371, so you can

print cards to carry with you and/or distribute

electronically to your engineers who use the

Toolkit software.

Please allow 5-7 days for receipt. The registered

participant site will be able to use the Toolkit

serial number to obtain telephone support in the

interim.

• If you want to ask questions and/or need support

regarding issues that have a direct impact

on your operation or business, you should

categorize the urgency as HIGH. In high urgency

situations, your system or process should remain

operational but at less than full capability. In

these situations, you require immediate or same

day resolution if possible.

• If your system or process is down and you

require an immediate response, you should

communicate this status to the telephone

support specialist directly and classify it as VERY

HIGH. In these situations, we leverage additional

technical support and engineering resources

to resolve your issue quickly. We expect you to

implement technical support recommendations

and to be available for immediate follow-up.

If this does not occur, we may downgrade the

urgency of your situation.

*Phone Support is not available on

Rockwell Automation observed holidays unless

you have elected for 24x7x365 support. A list of

these holidays for all regions can be found via the

Knowledgebase in article #819086.

8

Page 9

4 Telephone Support continued…

Maximize the Value of Your Call

When you call for support, we will ask you for

the following information which you will want

to have available:

• TechConnect Support agreement authorization

number.

• You can nd this on your eWallet Cards, or

access on your Partner Summary Report on the

Partner Relationship Management (PRM) Portal

at https://partners.rockwellautomation.com/

• If you cannot locate this number, we will ask you

for your name and company site location.

• Product name(s), description and series/

revision/version number

• System conguration and components, e.g.,

operating system, etc.

• Sequence of events prompting your call

• Complete error message if applicable

In addition, you should communicate to the

telephone support specialist who answers your

call the urgency of your situation so that we can

respond appropriately. Use the following as a

guide:

• If you want to ask questions and/or need support

regarding issues that have minimal or no

immediate impact on your operation or business,

you should categorize the urgency as MEDIUM. In

normal situations, you agree that it is acceptable

if your issue is not resolved on an initial call.

Make Calls

Use the designated telephone support number

listed on your support entitlement e-mail and

wallet cards, or refer to this guide for a list of

International Numbers. You can use this number

only to request support on product included in

the Toolkit TechConnect support offering. In

general, standard telephone support hours are

from 8:00 am to 5:00 pm Monday through Friday

in the time zone of the participating location

listed on your support entitlement e-mail, unless

you purchased a 24x7x365 support option.

Standard telephone support hours may vary

according to your region. Refer to your support

entitlement email for specic in ormation.

Note: 24x7 Support is not currently available

on certain products, such as FactoryTalk

ProductionCentre, certain Safety products and

KEPServer Enterprise. Toolkit Support does

not include Legacy Support. Participants may

purchase a Legacy Support contract through

your local Rockwell Automation sales or

Authorized Distributor.

9

Page 10

4 Telephone Support continued…

SM

For Customers with Active TechConnect

Direct Dial Menu – To reduce call tree navigation, enter the three-digit direct dial code from the

tables below when you call for support. Your call will be routed directly to the appropriate product

support specialist.

Rockwell Automation customers can reach technical support engineers at the Rockwell Automation

U.S. Customer Support Center by dialing (TOLL FREE) 1-888-382-1583 or 1-440-646-3434*

Select Option 3 (Technical Support), and when prompted, enter the appropriate three digit code

from the tables below.

For online technical support: https://rockwellautomation.custhelp.com/

*Available Monday through Friday from 8:00am to 6:00pm ET.

DIAL ME NU DIRECT

PACKAGED SOLUTIONS

RAPID Line Integration® 007

PLANTPAX

PlantPAx® 008

ACTIVATION

Software Activations, Copy Protection, Software

Download Issues

CONTROLLERS

ControlLogix®, FlexLogix™, Safety Processor,

Communications, Associated I/O and Instruction Set

CompactLogix™, Communications, Associated I/O

and Ins truction Set

PLC-2 ®, PLC-3® and P LC-5®, and P LC-5/250

Processor, Communications, I/O and Instruction Set

SLC™ 5 00, MicroL ogix™ Proc essor, Communications ,

Ass ociated I/O a nd Instruction S et

Pico™ Controller, Associated Software and

Instruction Set

SoftLogix™ 5 and 5 000, Ass ociated Pr ogramming

Softwar e, I/O and Instruc tion Set

Auto Max®, AutoMate (f or drives see Reli ance Electric) 106

PowerMoni tor™, RSPo wer™ (1414 S ensors, 1 402 and

140 7 Modules, 1 411 Current Transformers)

10

Support Contracts

RS Test Sta nd™ 108

ProcessLogix™ 109

Micro800™ Hardware 110

RSLogix 5000®, 500 & 5 ins tallation and fa tal error s 111

Connected Components Workbench™ 112

VISUALIZATION

FactoryTalk® View SE, RSV iew® SE, R SView® 32 200

010

ThinManager ® 201

FactoryTalk® View ME , RSView ® ME, PanelV iew™ Plus

Graph ic Terminals, S tudio 5000 V iew Design er® and

Panel View™ 550 0

100

PanelView™ Classic, Standard, Enhanced Terminals

and PanelBuilder™ Software

101

Panel View™ Comp onent and Pan elView™ 80 0 204

102

Message Displays 205

Industrial Computers and Monitors 206

103

NETLINX

104

Devic eNet, Cont rolNet, Et herNet/ IP and Associate d

RSNetWorx™ Software

105

RSLinx® Clas sic, RSLin x® Enterpris e and Factor yTalk®

Gateway

178 4 Communica tions Cards, Remote Ac cess Dial in

107

Modems, 9300-USBS

Stratix® Network Switches, 9300-ENA 303

173 2 ArmorBl ock® I/O, 1734 P OINT I/O

(not inc luding safety mo dules)

202

203

300

301

302

304

Page 11

4 Telephone Support continued…

MOTION

ControlLogix® Motion, Interface Cards and Associated Software

Kine tix® Ser vo Drive s and Motors a nd Assoc iated Sof tware

(includes Ultra 3000)

139 4, S-Clas s, GML™ Command er

CNC™ Mo tion 8500 , 8520, 923 0, 9240, 92 60, 9290, 9 440,

9 Seri es

IMC Mot ion (121, 1 23, 110, OD S Softw are), HSRV, HS TP

Alle n-Bradl ey® Leg acy Serv o Drives (1 326, 138 7, 1388 , 1391,

1392, 1398), 8720

Anor ad® Linea r Motors an d iTrak® Supp ort

DRIVES AND MEDIUM VOLTAGE PRODUCTS

Curr ent Archi tecture -Class D rive Pro ducts - Pow erFlex ® 70,

700, 7 00S, 700 L, 753, 7 55, 755T L/TR/ TM and 755 O n-Machin e

drives, power conditioning products, drive communications,

DriveExecutive™, DriveExplorer™, Connected Components

Work bench™ Sof tware, Me gaDySC ® 1608M, Mi niDySC ® 1608N,

SCR Bu s Supply and P roDySC ® 1608P

Comp act AC Driv e Product s PowerF lex® 4M/4, 4 0/40P,

400 dr ives Pow erFlex ® 523/525 /527 dri ves, Arm orStar t®

Cont rollers (2 90, 291, 2 94, 280, 2 81, 284) , ArmorC onnect®

Media (280-PWRM), Power Conditioning Products and

Connected Components Workbench™ Software

AC Le gacy driv es - PowerF lex® 700 H, 700AF E, 160, 13 05, 1336

(Clas sic), 133 6E (IM/PACT ®), 1336F (P lus II), 13 36R (Regen) ,

1336 S (Plus), 1 336T (FORC E™ Technolo gy), 133 6Z

DC Leg acy drive s - 1395, 13 97

PowerFlex® DC drives

Reliance Electric™ - LiquiFlo and Standard Drives

Medium Voltage - PowerFlex® 7000, PowerFlex® 6000 and

155 7™ Drive s, 1500 Con tactors a nd Soft St arters , 857 and 86 5

Feeder/Motor Protection Relay, OneGear™ Controllers, 1591

Load Break Switches, PowerBrick™ Technology

DATA MANAGEMENT SOFTWARE

FactoryTalk® AssetCentre, RSMACC™

RSBizWare™ (Historian™ Classic, PlantMetrics™, Scheduler™)

FactoryTalk® Historian SE

FactoryTalk® Transaction Manager, RSS ql™

FactoryTalk® Batch, RSBatch™, eProcedure®, MaterialTrack™

Manufacturing Execution Systems (MES)

PMX - ME S, CTM

FactoryTalk® VantagePoint®

INTEGRATED CONDITION MONITORING (ENTEK®)

XM®, Enpac®, Datapac®, Enwatch®, Emonitor®, Enshare®,

400

RSMACC En terprise O nline, Vibr ation Sens ors, Dynamix™

401

Data Collectors, Accelerometers, Eddy Current Probes

404

PROCESS SAFETY

AADvance® Contro l System, Tru sted® Control S ystem,

405

OptiSIS® Solution

407

LOW VOLTAGE INDUSTRIAL CONTROL COMPONENTS

408

Contactors and S tarter s, Pushbut tons, Termin al Blocks,

700 Re lays and Tim ers, Circuit Bre akers, Dis connect

410

Switches, 1497 Transformers, 4983 Surge Protection

Condition Sensing Switches (Bul. 836-840 Mechanical

Pres sure, Temper ature and Float , 808 Speed,

803 Rotating Cam Switches)

Signa ling Alarm s, Beacon s, Horns and L ights

500

(Bul. 8 54, 855)

150-154 SM C™ Smart Mo tor Contro llers and

156 Solid-State Contactors

Elec tronic Moto r Protect ion (E1 and E3 P lus, E300, 8 25

Over load Relays, 19 3-DNENCAT, 21 00-ENET EtherNet

501

Comm Mo dules, 160 8 Voltage Sag Monitors)

1606 a nd 1607 Pow er Supplies , 1609 Uninterruptible

Power Suppl y, 1492 Printer/P lotter and IFM Mod ules

900TC Temperature Controllers, 931 Conditioners,

504

937 In trinsic Sa fety Modul es

510

Motor P rotection Rela ys (Bul. 809-819, 14 09) and Motor

Windi ng Heaters (B ul. 1410)

511

Limit, Photoelectric and Proximity Switches, Connection

512

Sys tems and Medi a

Safe ty Mats (Bul . 440, 44 2), Relays and Sw itches, L aser

513

Scanners, Encoders ( Bul. 842-847)

Advanced Sensing

(54R F, 5 5RF, 56RF R FID Tags, MultiSigh t™ Sensors)

Hazardous Location Applications 812

600

CENTERLINE MOTOR CONTROL CENTERS

601

CENTE RLINE® Mot or Control C enters Sales Sup port 900

602

CENTE RLINE® Mot or Control C enters Har dware Pos t-Sales

603

Technical Support

604

CENTE RLINE® Mot or Control C enters Con guration

605

Software (CIRCE™, CenterONE® or PowerControl Builder™)

606

CENTE RLINE® Mot or Control C enters Dev iceNet, EtherNe t

607

or IntelliCENTER® Software Support

700

750

800

801

802

804

805

806

807

808

809

810

811

901

902

903

11

Page 12

5 Online Support

The Knowledgebase

The Rockwell Automation Support Center

https://rockwellautomation.custhelp.com is

your online resource for technical information,

support and assistance. Increase your

productivity by nding solutions to technical

questions more quickly – saving both time and

money.

Maintained by the same engineers who provide

your TechConnect Support, the Support Center

houses the Knowledgebase

https://rockwellautomation.custhelp.com,

an online database that we update with the

hardware and software solutions from actual

support service tickets.

The Knowledgebase, included with all

TechConnect support agreements, provides

you with access to over 70,000 technical notes,

documents and solutions. In addition, you can

submit questions and chat live with our Technical

Support engineers in your local language.

Create an Account

To begin using your TechConnect Support

contract, you need to create an account. For

information about how to create an account

watch the video tutorial posted to the Support

Center under the Support Center Training menu

or use the job aid posted in Knowledgebase

Answer 452148.

IMPORTANT NOTE: Use your email address as your

user name and anything you want as a password.

Enter your support authorization number into

your account profile to gain full access to all

Knowledgebase documents and features.

You can locate your support authorization number

on your e-Wallet Cards, or by accessing your

Partner Summary Report located on Partner

Relationship Management (PRM) Portal

https://partners.rockwellautomation.com/

Search Knowledgebase

For information about how to search the

Knowledgebase, watch the video tutorial posted

to the Support Center under the Support Center

Training menu or use the job aid posted in

Knowledgebase Answer 452148.

Explore Forums

Our forum community offers peer to peer support

on a wide range of topics. You can search for

an answer, offer a solution or start your own

forum discussion. For information on how to use

the forums, watch the video tutorial posted to

the support center under the Support Center

Training menu or use the job aid posted in the

Knowledgebase Answer 452161.

Submit Questions

The Submit Questions feature lets you email you

email a question on a specic product to a tech

support engineer. For information about how

to search the Knowledgebase, watch the video

tutorital posted to the Support Center under the

Support Center Training menu or use the job aid

posted in Knowledgebase Answer 44451.

Your question is assigned a service ticket

number. Our targeted email response time for

TechConnect customers is 24 business hours.

IMPORTANT NOTE: The ‘Submit a Question’ feature

is only available when you have entered your

TechConnect Support authorization number into

your account profile as described in the ‘Create an

Account’ section.

If you need immediate assistance, do not submit

an online support request. Instead, call the

telephone number listed on your e-Wallet Cards

(you must have purchased a toolkit with one of

our available phone support options to qualify for

phone support).

12

Page 13

5 Online Support continued…

Chat Live

Mobile friendly and available 8am-5pm local time,

chat live with our engineers for expedited issue

resolution. Visit the Knowledgebase to chat live

with Tech Support engineers at

https://rockwellautomation.custhelp.com/app/

chat/chat_launch

For information about how to chat, watch the

video tutorial posted to the Support Center under

the Support Center Training Menu or use the job

aid posted in Knowledgebase Answer 452163.

Organize Your Information

Find My TechConnect acts as your personal

information library. For information about how

to use this feature, watch the video tutorial

available at https://rockwellautomation.custhelp.

com/app/answers/answer_view/a_id/35770/loc/

en_US#__highlight

6 Software, Firmware, and Other Updates

Obtaining Updates

The Toolkit Support contract enables you to

download software updates via the Web for the

products included in your Toolkit license. Please

go to https://rockwellautomation.custhelp.com/

Your Toolkit serial number and Company Name

are required to download update les. You can

verify your registered serial number and Company

name online by accessing your Partner Summary

Report on the Partner Relationship

Management (PRM) Portal at

https://partners.rockwellautomation.com/

To download software or rmware updates, hot

xes or patches, navigate to

https://rockwellautomation.custhelp.com/

and select “Compatability and Downloads” section

from the left hand navigation.

For More Information

Visit https://www.rockwellautomation.com/

en-us/support.html or refer to the following

websites for additional information about

Rockwell Automation products and programs:

Software Registration Transfer:

https://activate.rockwellautomation.com/

Remote Support Programs:

www.rockwellautomation.com/services/

onlinephone

Partner Relationship Management (PRM) Portal:

https://partners.rockwellautomation.com/

FactoryTalk® Activation Support

If you experience a hard disk failure or an

activation related problem, you should contact

Rockwell Automation Technical Support at

https://www.rockwellautomation.com/en-us/

support.html or by phone using the call in

numbers listed on page 20. See this Guide for

a list of international numbers by country and

region, or use our Worldwide Locator online at

https://rockwellautomation.custhelp.com

Get Activation Support without picking up the

phone! Online activation support, including

Live Chat, Reference and FAQ documents,

and Activation Forum is available on the

Rockwell Automation Knowledgebase. Go to

https://rockwellautomation.custhelp.com

13

Page 14

7 Support Options

Receive unlimited access to Rockwell Automation

technical support engineers for real-time phone

and electronic support. With deep knowledge of

our hardware and software products, and remote

desktop technology, our engineers can help you

install, congure and maintain equipment and

software, obtain software updates, diagnose

and x operating problems and perform basic

programming tasks.

Toolkit Support

The toolkit license support agreement

entitles the registered participant site to

receive technical support that covers the

product families dened within the Toolkit,

and associated hardware. In order to receive

phone support, when calling in you will need to

provide your toolkit authorization number. The

authorization number can be found in your toolkit

activation welcome email.

Partner Support (System Support)

M-F, 8-5

With Partner Support (System Support), your calls

are routed to a specialized group of technical

support engineers who are trained to support

your overall Rockwell Automation control system.

You receive a dedicated, single point of contact

who will own the ticket from start to nish and

follow up to ensure your issue has been resolved.

In addition, you gain access to a monthly series of

Webinars to stay up-to-date on new products and

offerings. Partner Support (System Support) is

available for both 8-5 and 24x7 support levels.

Standard phone support hours are 8:00 am to

5:00 pm Monday-Friday (in time zone of the

primary participating location) for TechConnect

Support.

Partner Support (System Support)

365x24x7

For companies needing support after 5pm or over

the weekend for special projects or start-ups

across the region, this option extends your hours

of coverage to include weekends and holidays.

Note: 24x7x365 support is not currently available

on certain products, such as FactoryTalk

ProductionCentre and KEPServer Enterprise.

Toolkit Support does not include Legacy

Support or Process Safety Support coverage.

Participants may purchase a Legacy Support or

Process Safety Support contract at a suggested

discount through your local Rockwell Automation

Distributor or Rockwell Automation sales oce.

For additional information on the specic

features of your Toolkit support option, see

the applicable program guide on the Partner

Relationship Management (PRM) Portal at

https://partners.rockwellautomation.com/

*Phone Support is not available on

Rockwell Automation observed holidays unless

you have elected for 24x7x365 support. A list of

these holidays for all regions can be found via the

Knowledgebase in article #819086.

14

Page 15

8 International Numbers

This User Guide is designed for global use. For local language information or support you may call the

Customer Support number for your country. If your country is not included in the following list, please

call the number listed for your region.

EMEA +32.2.663.0600

Austria +43.732.38.909.99

Bahrain +971.4.321.1814

Belgium +32.2.716.84.11

Czech Republic +420.221.084.002

Denmark +4 5.70.110 .109

Finland +46(0) 771 219219

Franc e +33.825.30.31 32

Germany +49.2104.960.630

Greece +39 02 30 249 577 +39 02 30 249 578

Iceland +4 5 43 46 6006

Ireland +4 4.870.241.1802

Israel +39 0 230 249 57 7 +39 0230 24 9 578

199.119.900 (B rescia, Mi lano, Padova)

Italy

Luxembourg +32 (0) 2 716 84 1 1

Magyarorszag + 43 (0) 732 38909 99

Netherlands +31.297.543.543

South Africa +27.11.654.9700

Switzerland +41.62.889.7777

United Arab Emirates +97 1.4.321.1814

United Kingdom +44.870.241.1802

199.119.922 (Bolognia, Napoli, Roma, Torino)

Mauritius +27 (0) 860104 373

Nigeria +27 (0) 86010 4373

Norway + 45 43 46 600 6

Poland +48 (22) 459 66 0 7

Portugal +3 4 (0)93 295 90 00

Romania +420 (0)284 0 15 911

Russia +7 495 956 04 65

Slovakia +421.2.4058.1700

Spain +34.0902.309330

Sweden +46.0771.219.219

Tanzania +27 (0)86 01043 73

Asia Pa cic +613.9896.0575

Australia 1.800.809.929

China 1.080.0610.0327

India +91.11.2 16.9085

Japan 00.44.2261.2142

Korea 0030.833.0004

Malaysia 1800.80.4851

New Zealand 0800.27.27.25

Singapore 800.186.1028

Taiwan 0080.133.3332

Thailand 001.800.33 14.0008

Viet Nam +66.2.936.1500

Latin America +440.646.3434

Argentina 800.666.0320

Brazil +55.11.3618.8800

Bolivia +54.11.5554.4000

Caribbean +1.787.706.394 0

Chile 800.53.0012

Colombia 01.800.700.2107

Costa Rica,

Nicaragua, +506.262.5495

USA & Canada +440.646.3434

0800.013.1215

Honduras

Mexico 001.888.365.8677

Panama 001.800.203.3475

Paraguay +54.11.555 4.4000

Peru 0800.535.36

Uruguay +54.11.5554.4000

Venezuela 800.1.00.3062

15

Page 16

Conn ect with u s.

AAD vance, A llen-B radley, A norad, Ar morBlo ck, Arm orConne ct, Arm orStar t, Auto Max, CEN TERLINE , Center ONE, CIRCE , CNC, Comp actLog ix,

Connected Components Workbench software, ControlLogix, Datapac, DriveExecutive, DriveExplorer, Dynamix, Emonitor, Enpac, Enshare,

Enwatch, expanding human possibility, FactoryTalk, FactoryTalk Activation, FactoryTalk AssetCentre, FactoryTalk Batch View, FactoryTalk Batch,

FactoryTalk eProcedure, FactoryTalk Gateway, FactoryTalk Historian Site Edition, FactoryTalk Historian, FactoryTalk Linx, FactoryTalk Network Manager,

FactoryTalk Transaction Manager, FactoryTalk VantagePoint EMI, FactoryTalk View ME, FactoryTalk View SE, FlexLogix, GML, GuardLogix, IntelliCENTER,

iTrak , Kinetix , MegaDy SC, Micr o800, Micr oLogix , MiniDy SC, Multi Sight, On eGear, Opti SIS, Pane lBuilde r, PanelVi ew, PanelV iew 5500 , PanelV iew 800,

PanelView Classic, PanelView Component, PanelView Plus, PhaseManager, Pico, PlantPAx, PLC-2, PLC-3, PLC-5, PowerBrick, PowerControl Builder,

PowerFlex 1557, PowerFlex, PowerMonitor, ProcessLogix, ProDySC, RAPID Line Integration, RSBatch, RSBizWare, RSBizWare Historian,

RSBi zWare Pla ntMetr ics, RSB izWare Sc heduler, R SFieldb us, RSLi nx Class ic, RSLin x Enterp rise, RS Logix 50 0, RSLog ix 5000, R SLogix E mulate 50 00,

RSL ogix, RS MACC, RS NetWor x, RSPow er, RSSql , RSTestS tand, RS View, RSV iew ME, RS View SE, R SView3 2 Active Di splay Sy stem, RS View32 We bServe r,

RSV iew32, Se quenceM anager, SL C, SLC 500, S MC, Soft Logix, S tratix , Studio 5 000 Arc hitect, S tudio 50 00 Logix De signer, St udio 500 0, TechConne ct,

ThinManager, Trus ted and XM are trademarks of Rockwell Automation, Inc.

Cont rolNet, D eviceNe t and Ether Net/IP ar e tradem arks of ODVA , Inc.

Tradem arks not be longing t o Rockwel l Automa tion are pr opert y of their re spectiv e compani es.

Publication SYSINT-SP005B -EN-P – April 2021 | Supersedes Publication SYSINT-SP005A-EN-P – February 2021

Copy right © 20 21 Rockw ell Auto mation, In c. All Rig hts Rese rved. Pr inted in US A.

Loading...

Loading...