Page 1

User Manual

CHPS-Series Linear Stage

Catalog Numbers CHPS-150, CHPS-200, CHPS-250

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Kinetix, Rockwell Software, Rockwell Automation, Ultra are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

This table contains the changes made to this revision.

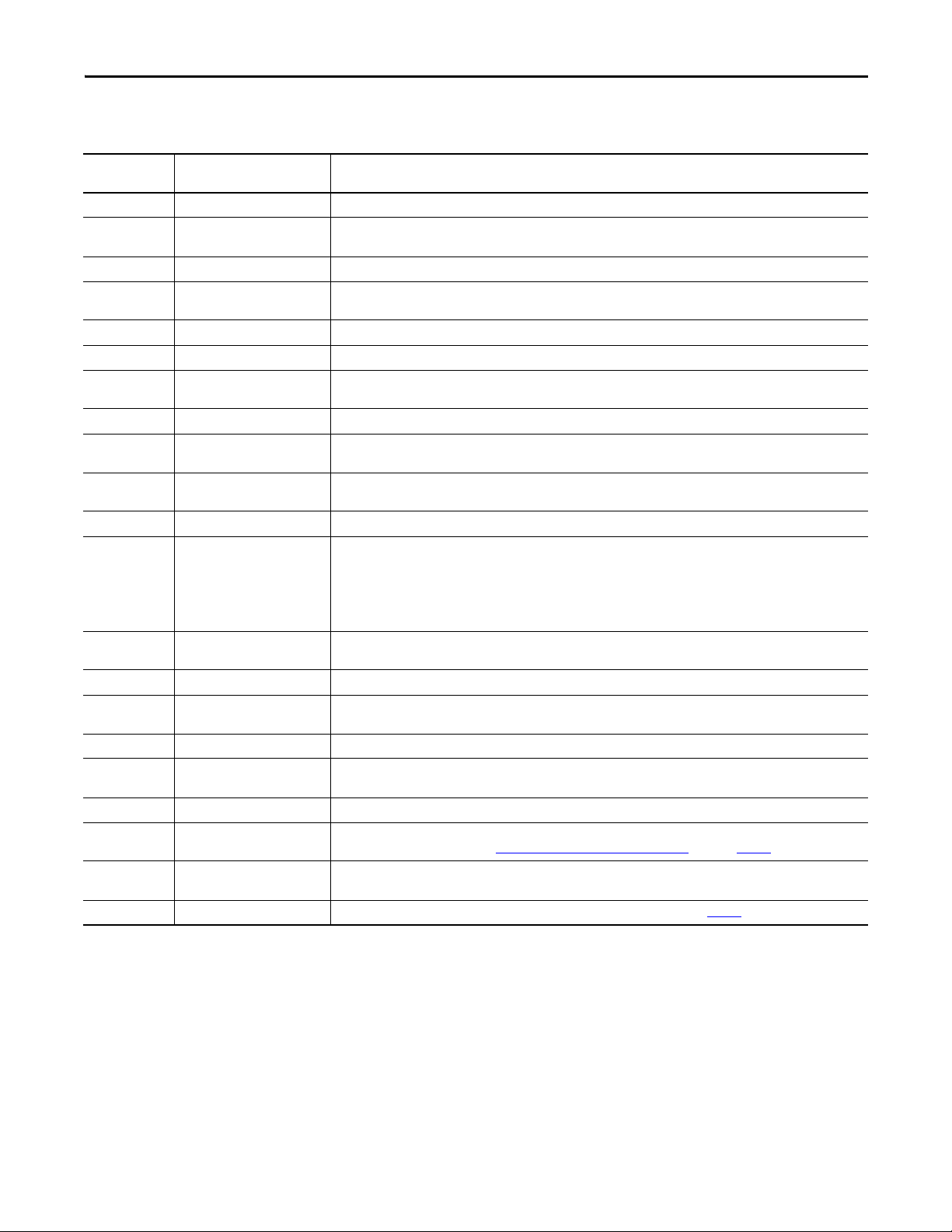

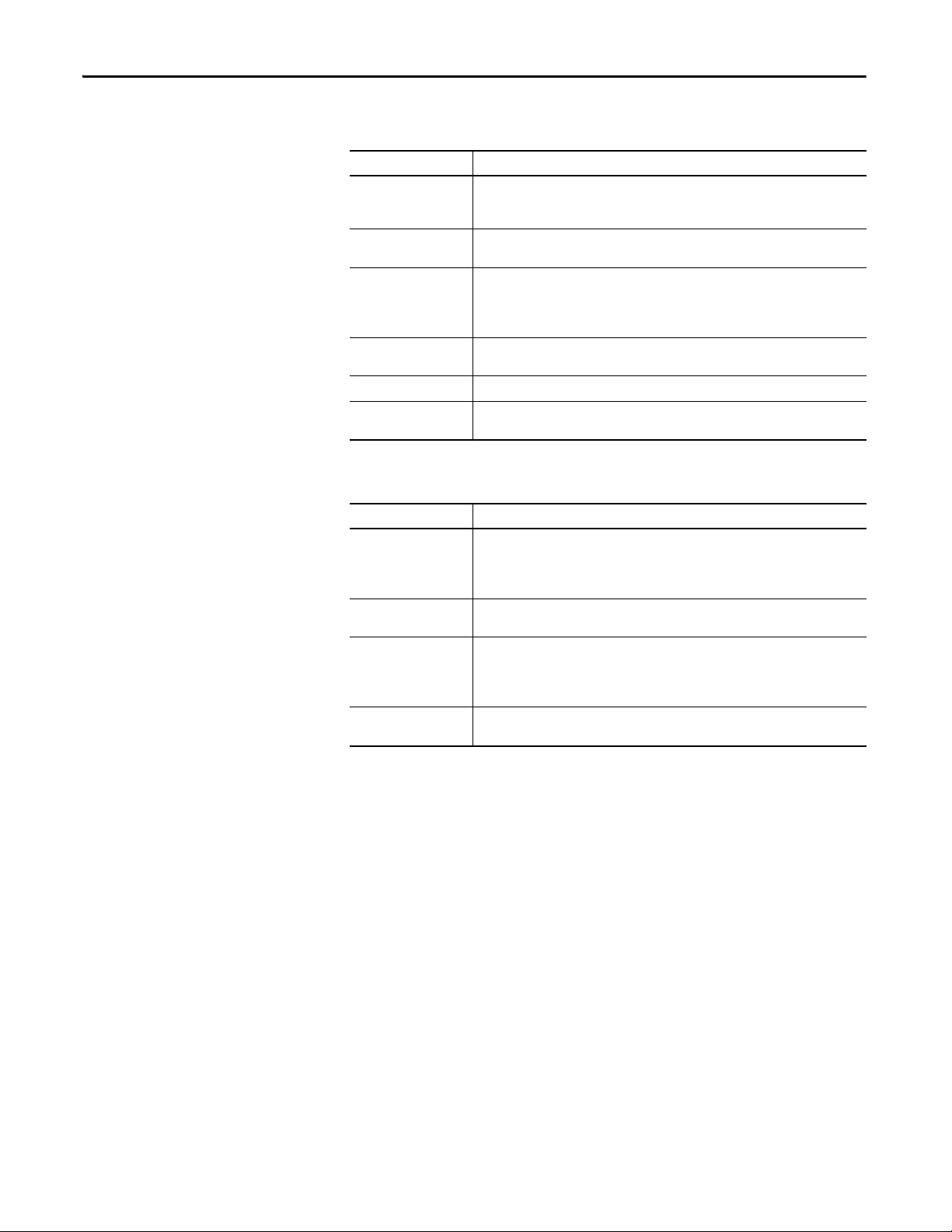

Top ic Pag e

Corrected catalog numbers 18, 29, 59, 60, 87

Added maximum velocity for Kinetix 6500 and Kinetix 300 Drives 74

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 5

Stage Safety

Understanding Your Stage

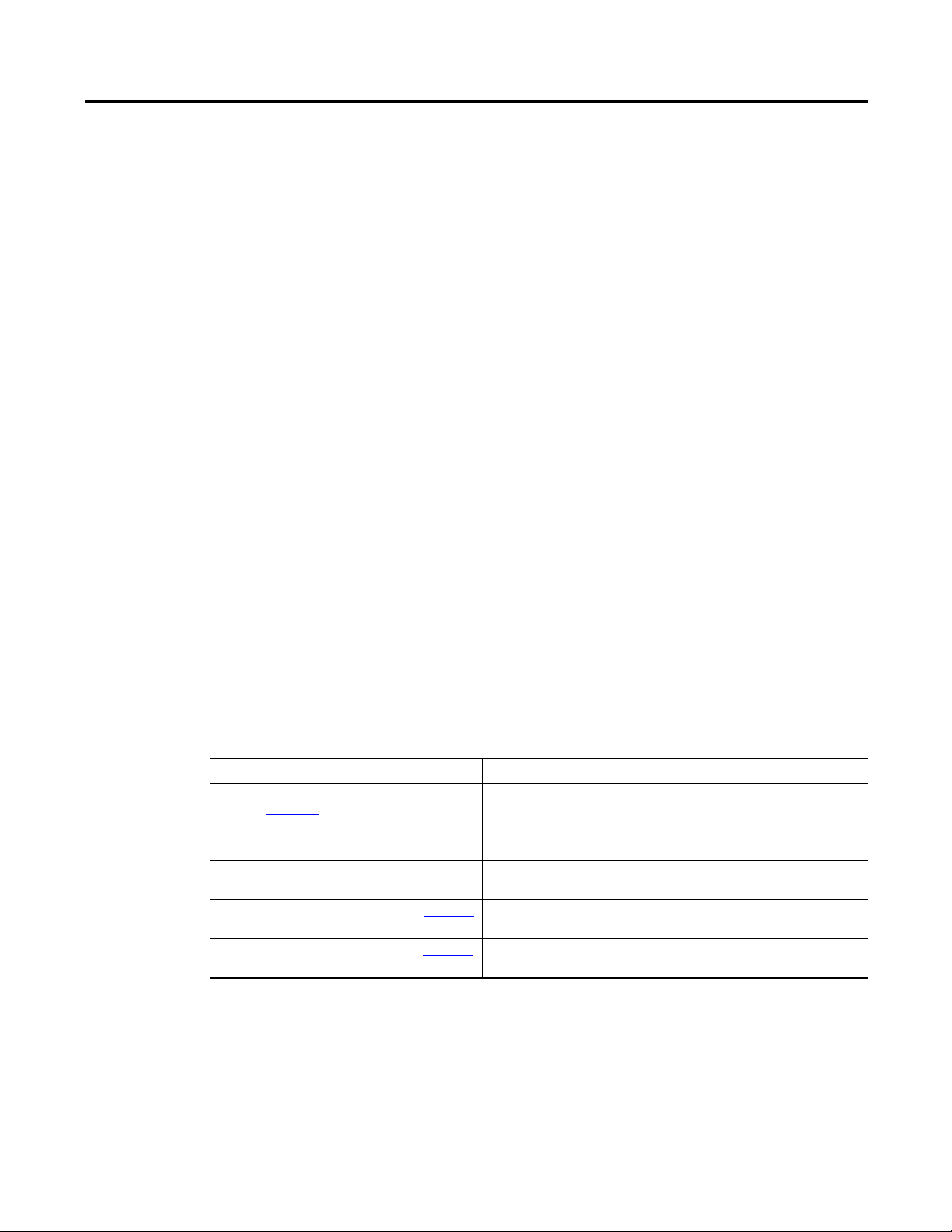

Table of Contents

Preface

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Safety Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Vertical or Incline Payload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

End Cap Impacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Air Freight Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Motor Model Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2

Identifying the Components of Your Stage . . . . . . . . . . . . . . . . . . . . . . . . . 16

Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Recommended Maintenance Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Identifying Your Stage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Planning the Stage Installation

Mounting the Stage

Connector Data

Chapter 3

Stage Mounting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

General Safety Standards for Stage Installations . . . . . . . . . . . . . . . . . 21

Mounting Restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 4

Unpacking, Handling, and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Unpacking Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Store Packaging Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Stage Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mounting the Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Before You Begin the Mechanical Installation. . . . . . . . . . . . . . . . . . . 28

Mounting the Stage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mount Your Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 5

Kinetix Servo Drive Compatible Connectors . . . . . . . . . . . . . . . . . . . . . . . 34

D-Type Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Flying Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Junction Box Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 5

Page 6

Table of Contents

Connecting the Stage

Operation Guidelines and Limit

Configuration

Limit Sensor Flying Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 6

Connecting the Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Attaching the Ground Strap and Interface Cables . . . . . . . . . . . . . . . 40

Thermal Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Optional Limit Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

TTL Differential Encoder Output Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Sine/Cos Encoder Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Hall Effect Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Motor and Hall Phasing and Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Stage Positive Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Operational Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Travel Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Calculating the Stopping Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Overtravel Limit Sensor Position Adjustment. . . . . . . . . . . . . . . . . . . 51

Bumper Stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Troubleshooting

Maintenance

Removing and Replacing Stage

Components

Chapter 8

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

PTC Thermal Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Hall Effect Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Hall to Back EMF Phasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Motor Coil Resistance Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 9

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Lubricate the Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Optical Encoder Scale Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Strip Seal Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Cover Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Chapter 10

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Cable Carrier Module Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Cable Carrier Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Strip Seal Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Stage Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Stage Side Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Strip Seal Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Stage Cover Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Side Cover Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 7

Appendix A

Table of Contents

Specifications and Dimensions

Accessories

Static and Static Moment Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Performance Specifications for 325V CHPS-Series Stage . . . . . . . . 70

Performance Specifications for 325V or

650V CHPS-Series Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

General Stage Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Accuracy Specification for the CHPS-Series Stage. . . . . . . . . . . . . . . 73

Commutation Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Limit Sensor Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

PTC Thermistor Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Encoder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Maximum Velocity for Allen-Bradley Drives. . . . . . . . . . . . . . . . . . . . 74

Environmental Specifications for CHPS-Series Stages . . . . . . . . . . . 75

CHPS-Series Stage Travel versus Weight Specifications . . . . . . . . . 75

CHPS-Series Stage Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

CHPS-Series Stage Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . 83

Appendix B

Interconnect Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Power Cable Dimensions

(catalog number 2090-XXNPMF-16Sxx) . . . . . . . . . . . . . . . 85

Feedback Cable Dimensions

(catalog number 2090-XXNFMF-Sxx). . . . . . . . . . . . . . . . . . 86

Installation, Maintenance, and Replacement Kits . . . . . . . . . . . . . . . . . . . 87

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Stacking Stages

Start-up Guide for CHPS-Series Stage

with Ultra3000 Drive and Ultraware

Software

Appendix C

Stage Stacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Specifications for Stacked Stages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Appendix D

Using This Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Wiring the CHPS-Series Stage to the Ultra3000 Drive . . . . . . . . . . . . . . 91

Linear Motor File Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Creating a CHPS-Series Stage Motor File . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Recommended Start-up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

CHPS-Series Stage and Ultra3000 Drive Troubleshooting Reference. 96

Positive Phasing Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Encoder Counting Polarity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Oscilloscope Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Oscilloscope Diagram for Ultra3000 Drive . . . . . . . . . . . . . . . . . . . . . 98

Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Commutation Diagnostics Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Self-sensing Commutation and Startup. . . . . . . . . . . . . . . . . . . . . . . . 100

Main Screen Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 7

Page 8

Table of Contents

Motor Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Faults Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix E

Mounting Bolts and Torque Values

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 9

Read this preface to familiarize yourself with the manual.

Preface

About This Publication

Who Should Use This Manual

This manual provides detailed installation instructions for mounting, wiring,

maintaining, and troubleshooting your CHPS-Series Linear Motor Driven

Stage.

This manual is intended for engineers or technicians directly involved in the

installation, wiring, and maintenance of stages. Any person that teaches, operates,

maintains, or repairs these stages must be trained and demonstrate the

competence to safely perform the assigned task.

If you do not understand the linear motor stages, contact your local Rockwell

Automation sales representative for information on training courses before using

this product.

Read this entire manual before you attempt to install your stage into your motion

system. This familiarizes you with the stage components, their relationship to

each other and the system.

After installation, check the configuration of the system parameters to be sure

they are properly set for the stage in your motion system.

Follow all instructions carefully and pay special attention to safety concerns.

Additional Resources

Resource Description

High Precision Linear Motor Driven Stages Selection Guide,

publication CHPS-SG001

Kinetix® 2000 Multi-axis Servo Drive User Manual,

publication 2093-UM001

Kinetix 6000 Multi-axis Servo Drive User Manual, publication

2094-UM001

LZ Family of Linear Motors Brochure, publication PMC-BR001 Provides product specifications, outline drawing, ratings, and wiring information to aid

LC Family of Linear Motors Brochure, publication PMC-BR002

These documents contain additional information concerning related products

from Rockwell Automation.

Provides product specifications, ratings, certifications, system interface, and wiring

diagrams to aid in product selection.

Describes how to configure and use Kinetix 2000 multi-axis servo drives.

Describes how to configure and use Kinetix 6000 multi-axis servo drives.

in product selection.

Provides product specifications, outline drawing, ratings, and wiring information to aid

in product selection.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 9

Page 10

Preface

Notes:

10 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 11

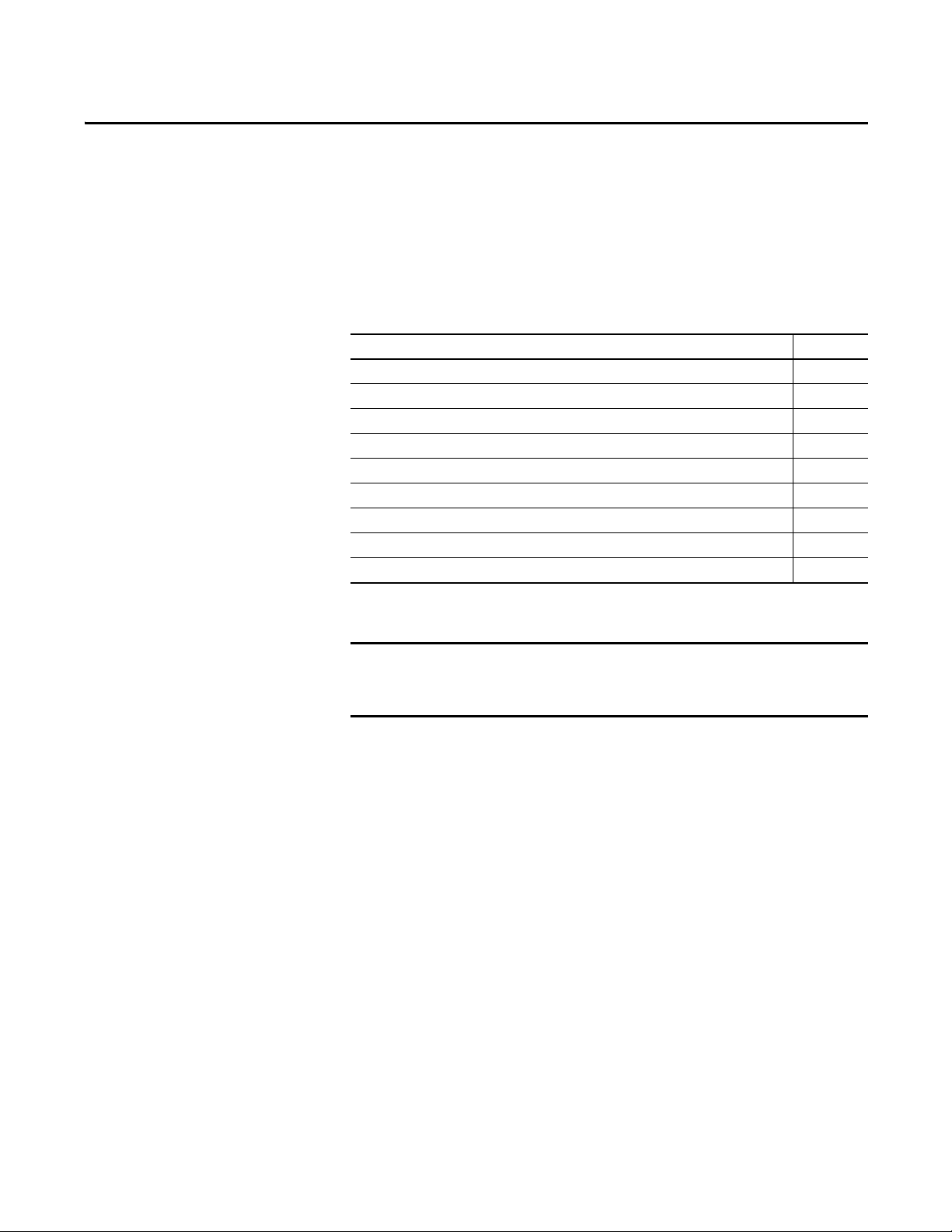

Chapter 1

IMPORTANT

Stage Safety

Top ic Pag e

Safety Labels 12

Clearances 13

General Safety 13

Heat 13

Vertical or Incline Payload 13

End Cap Impacts 13

Air Freight Transportation 14

Standards 14

Motor Model Identification 14

Any person that teaches, operates, maintains, or repairs these linear stages

must be trained and demonstrate the competence to safely perform the

assigned task.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 11

Page 12

Chapter 1 Stage Safety

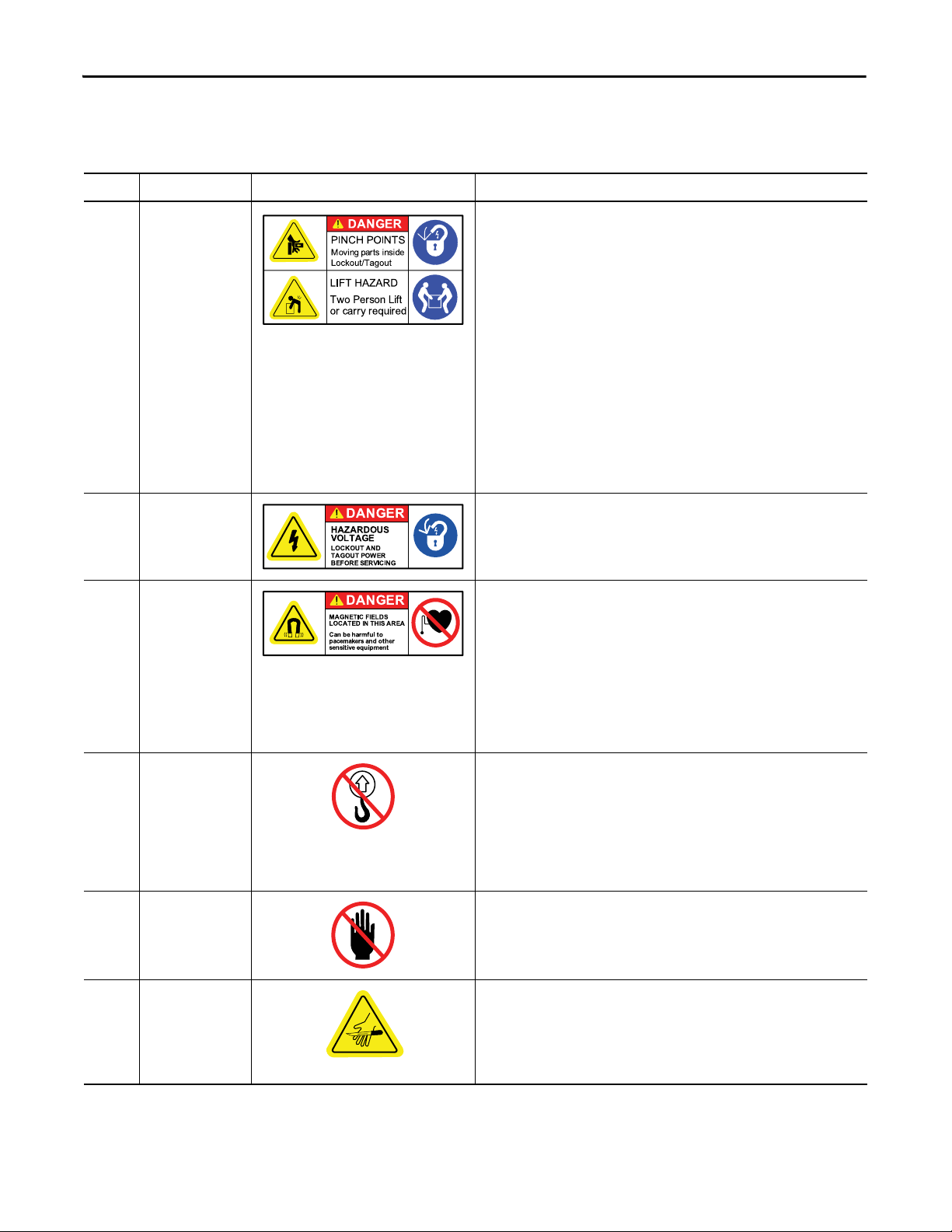

Location Title Label Details

A Danger-Pinch Points

and Heavy Objects

The linear stage presents a muscle strain hazard if one person attempts to

lift it. When attempting to move the linear stage use a two-person-lift to

prevent personal injury or damage to the linear stage.

To Installer - There exists a Crush and Cut hazard while installing the linear

stage. The linear stage weighs from 13…63 kg (28…140 lb).

To User - The Pinch Point label identifies a moving object hazard, caused by

the movement of the carriage on the linear stage. Never put fingers, hands,

or limbs near the linear stage while running motion commands. Before

executing any motion command, check that all maintenance tools have

been removed from linear stage.

All types of linear stages, especially uncovered, present a pinch point

hazard. This hazard may occur if fingers or hands come between the end

cap and a moving carriage. Always lift the linear stage by the base and

keep fingers and hands away from the opening and edges parallel to the

carriage.

B Danger-Hazardous

Voltage

The Hazardous Voltage label identifies the junction box as a hazardous

voltage area of the linear stage. To avoid injury be sure to follow LockoutTagout procedures before attempting maintenance on these linear stages.

C Danger-Strong

Magnets

The Strong Magnets label identifies non-ionizing radiation found in the

linear stage. Magnet channels inside the linear stage are constructed with

strong magnets. Strong magnets can disrupt the functionality of automatic

implantable cardioverter defibrillators (AICD); people with a pacemaker

should not work near the linear stage. Maintenance personnel working on

the linear stage should avoid the use of metallic tools and secure items

such as badge clip and other personal effects that could be attracted by the

strong magnets. Strong magnets can erase magnetic media. Never allow

credit cards or floppy disks to contact or come near the linear stage.

D Do Not Lift by

Junction Box

Do not attempt to move the linear stage by grasping the cable junction box.

Moving the linear stage in this manner will damage the linear stage and

create a pinch or crush hazard. The junction box is attached to the carriage,

which is free to move. Lifting the linear stage in this manner will allow

uncontrolled movement of the heavy base. Always use a two-person lift

and grasp the linear stage by the base at the end caps. Always keep

fingers clear of the carriage’s path of travel.

E Stay Clear

Do not put hands or objects on the linear stage cover. Doing so could

deform the cover and damage the linear stage, causing excessive wear on

the cover supports or scraping noises when the linear stage is in motion.

F Sharp Edges

Always remove strip seals before removing the top or side covers. If it

becomes necessary to remove the top or side covers or change the strip

seal, exercise care when working near or on the strip seal. The edges of

the strip seal are sharp and can cut if accidentally hit or if handled

inappropriately.

Safety Labels

To prevent injury and damage to the stage, review the safety labels and their

warning details and location before using the stage.

12 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 13

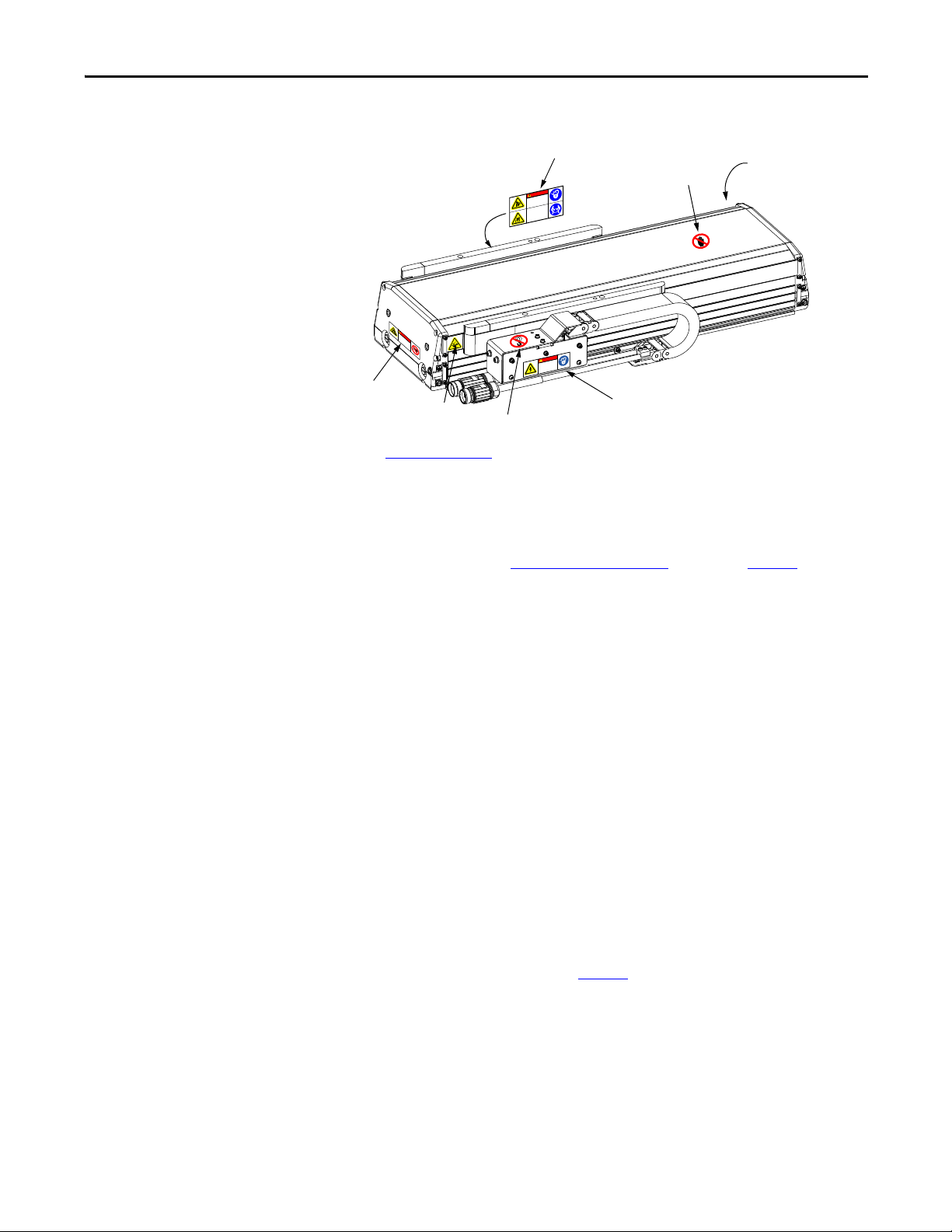

Figure 1 - Warning Label Locations

H

A

Z

A

RDOUS

VOLTAGE

LOCK

O

U

T AND

TA

GO

U

T PO

WER

BEFO

R

E

SERVICING

DANGER

DANGER

M

A

G

NE

T

IC

F

I

E

LD

S

LOC

ATE

D

IN

T

HIS

A

R

E

A

Can

be

h

ar

m

ful

t

o

pac

em

ak

ers a

nd

ot

her

sen

si

t

i

ve

equ

i

pment

LIFT HAZARD

Two Person Lift

or carry required

DANGER

PINCH POINTS

Moving parts inside

Lockout /Tagout

A

E

F

B

D

F

C

See Safety Labels on page 12 to identify call out letters.

Stage Safety Chapter 1

Clearances

General Safety

Heat

Vertical or Incline Payload

End Cap Impacts

Install the stage to avoid interference with the building, structures, utilities, other

machines and equipment that can create a trapping hazard of pinch points.

Dress cables by using the Clearance Requirements

diagram on page 23 as a guide.

Do not cross the path of motion or interfere with the cable carrier motion.

Stages are capable of sudden and fast motion. Always Lockout-Tagout stage

systems before doing maintenance. Systems integrated with stages must contain

interlock mechanisms that prevent motion while users are accessing the stage.

Rockwell Automation is not responsible for misuse, or improper implementation

of their equipment.

When running the stage at its maximum rating, the temperature of the slide can

reach 75

ºC (167 ºF).

A vertically or inclined mounted stage does not maintain position with the power

removed. Under the influence of gravity, the slide and its payload falls to the low

end of travel. Design engineers must design in controlled power down circuits or

mechanical controls to prevent the stage and its payload from being damaged

when the power fails.

The internal bumpers of the stage are designed to absorb a large impact from

uncontrolled motion. The table on page 53

lists the energy that the bumpers can

absorb before risking damage to the stage. The payload must be secured to the

slide such that it does not sheer off in the event of an impact in excess of the

bumper ratings.

The bolts securing the end caps are not be able to sustain multiple impacts and

can eventually sheer. Correct the cause of the uncontrolled motion that caused

the impact before continuing the use of the stage.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 13

Page 14

Chapter 1 Stage Safety

Air Freight Transportation

When air freighting stages special preparations and precautions must be taken.

The following information outlines the basic requirements at the publication

date of this document. However, regulations are subject to change and additional

area or carrier restrictions can be imposed. Check with your carrier or logistics

specialist regarding current local, regional, and national transportation

requirements when shipping this product.

The 200 mm or a 250 mm stages contain magnetized material, as classified by

International Air Transport Association (IATA) Dangerous Goods Regulations.

An IATA trained individual must be involved when shipping this product via

domestic or international air freight. Packing Instruction 902 provides

information regarding the preparation of this product for air transportation.

Follow these regulations for general marking and labeling requirements, the

application of Magnetized Material Handling Labels, and instructions for

preparing the Shipper's Declaration for Dangerous Goods.

As a minimum, refer to the following IATA Dangerous Goods Regulations:

• Subsection 1.5: Training

• Subsection 3.9.2.2: Classification as Magnetized Material

• Subsection 4.2: Identification as UN 2807, Magnetized Material, Class 9,

Packing Instruction 902

• Subsection 7.1.5: Marking

• Subsection 7.2: Labeling

• Subsection 7.4.1: Magnetized Material Label

• Section 8: Shipper’s Declaration for Dangerous Goods

Standards

Motor Model Identification

When shipped via ground in the United States, these products are not considered

a U.S. D.O.T. Hazardous Material and standard shipping procedures apply.

Standards and requirements applicable to this product include, but are not

limited to, the following:

• ANSI/RIA R15.06, Industrial Robots and Robot Systems Safety

Requirements - Teaching Multiple Robots

• ANSI/NFPA 79, Electrical Standard for Industrial Machinery

• CSA/CAN Z434, Industrial Robots and Robot Systems- General Safety

Requirements

• EN60204-1, Safety of Machinery. Electrical Equipment of Machines

The nameplate lists the motor model for the stage.

14 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 15

Understanding Your Stage

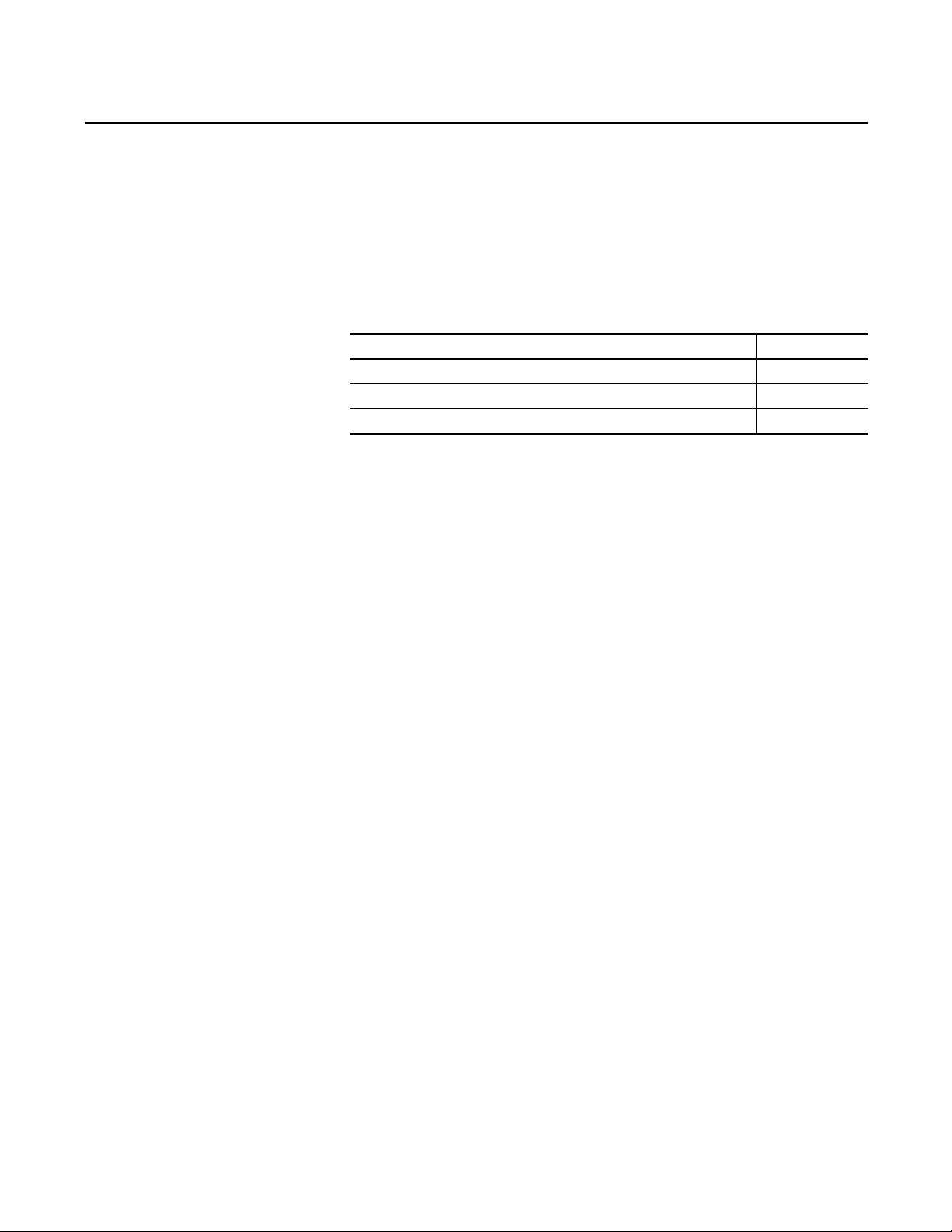

Top ic Pa ge

Identifying the Components of Your Stage 16

Recommended Maintenance Interval 18

Identifying Your Stage 18

Chapter 2

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 15

Page 16

Chapter 2 Understanding Your Stage

4

1

5 (4x)

6

7 (2x)

8

9 (2x)

10

(4x)

2

(4x)

3

15

21

6

14

(4x)

13

12

11

17

16 (2x)

18

19

20

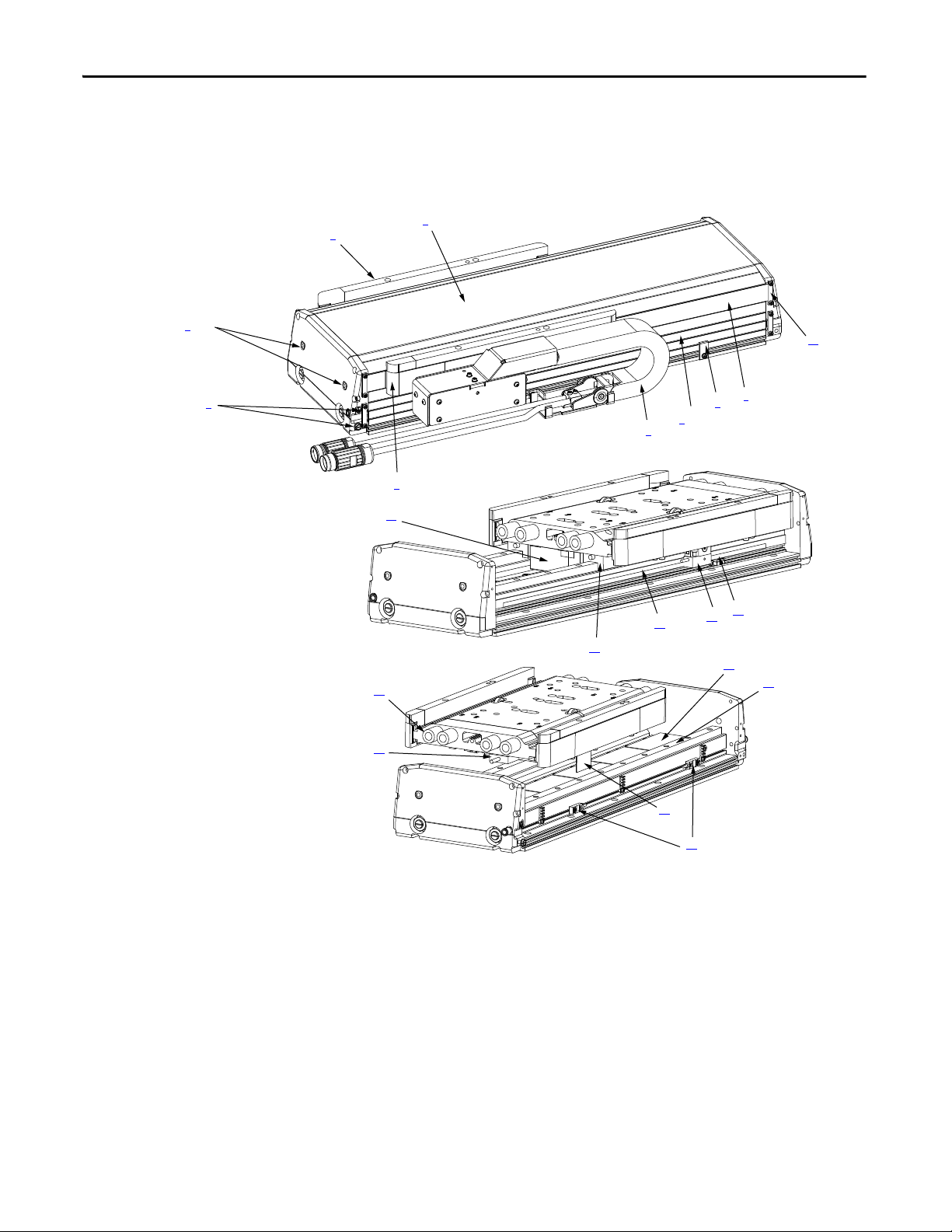

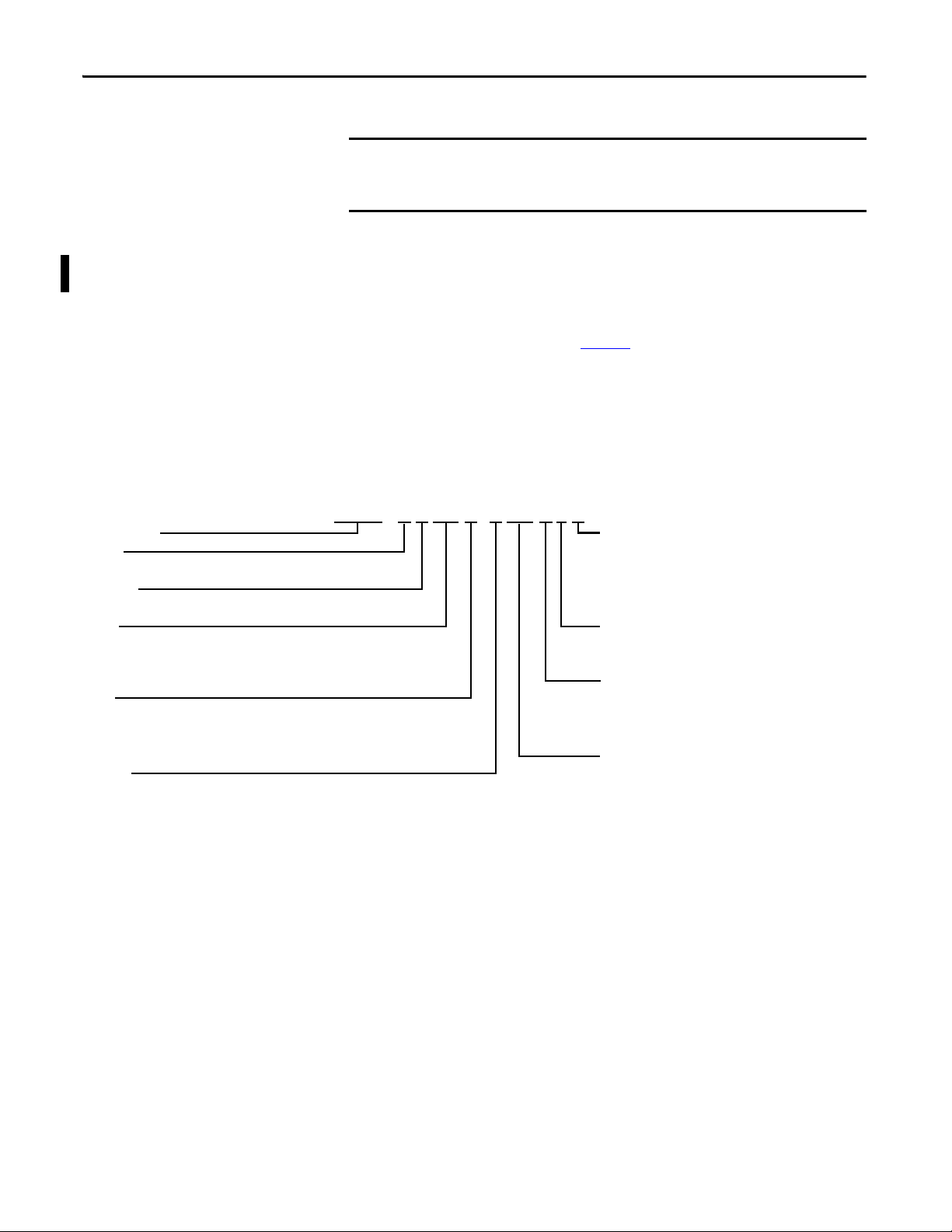

Identifying the Components of Your Stage

Use the diagrams and descriptions to identify individual stage components.

Figure 2 - Components of Your Linear Stage

16 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 17

Component Description

Understanding Your Stage Chapter 2

Component

Number

1 Ground Screw and Ground Label Use the labeled M5 x 0.8 - 6H ground screw to connect to the linear stage to a facility safety ground.

2 Bearing Lubrication Ports These capped ports provide access to the linear bearings without dismantling the stage. In addition these tapped holes

3 Stage Slide Your application hardware mounts to this slide by using provide mounting holes.

4 Stage Cover If the strip seals are used this protective cover the stage has magnetic edges to keep the upper edge of the strip seals in

5 Seal Guide These guides lets the strip seal to move smoothly around the stage slide.

6 Cable Carrier Module Facilitates quick and easy replacement. Replace the cable carrier module every 10 million cycles.

7 Stage Side Cover If the strip seals are used this protective cover the stage has magnetic edges to keep the lower edge of the strip seals in

8 Side Cover Support These supports are used on long stages to stabilize the side cover.

9 Stainless Steel Strip Seal These replaceable, flexible stainless steel strips permit the stage to move while isolating the internal mechanism of the

10 Strip Seal Clamps These clamps hold the strip seal in place. When replacing the strip seals, they are used to position it so it lays smooth against

11 Index Mark Part of the encoder system that provides a home location for the encoder.

12 Optical Encoder Readhead This encoder readhead comes in various resolutions and requires little maintenance.

13 Encoder Scale Part of the encoder system that provides an optical pattern to be read by the encoder readhead. It must be kept free of

14 Bearing These support bearings guide the slide on the bearing rail, they require periodic lubrication.

15 Motor Coil This coil is part of the two piece linear motor. When excited by a linear drive, it generates magnetic forces that interact with

16 Bearing Rail These rails provide the linear track that the slide assembly rides on, they must be kept free of debris.

17 Magnet Track This track of powerful static magnets is the other half of a li near motor. LC line ar motor option shown. LZ linear motor option

18 Limit Blade Provides a mechanical trigger to the limit sensor.

19 Limit Sensor These optional sensors output a signal when the limit blade passes in front of them. The position of these sensors can be

20 Hall Sensor Module Three Hall sensors in this module are provide for commutation startup and phase alignment. They can also be use for

21 Bumper Stop These springs absorb slide and payload energy in the event the stage loses control. See page 53 for absorption limits.

Component Description

(M10 x 15. -6H) can be used to secure lifting hooks (not provided)

place.

place.

stage from environmental contaminants.

the top and side stage covers.

The TTL encoder option provides quadrature incremental position feedback with a differential signal on a RS-422.

The Sine/Cosine encoder option provides a 1 volt peak-to-peak sine and cosine output at a period of 20 μm. The Sine/Cosine

encoder is also known as an analog encoder.

contamination for proper operation.

the magnet track creating motion. LC linear motor option shown. LZ linear motors have a different configuration.

has a magnet channel.

adjusted to suit your application, see Operation Guidelines and Limit Configuration

trapezoidal commutation of the motor.

section on page 49.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 17

Page 18

Chapter 2 Understanding Your Stage

IMPORTANT

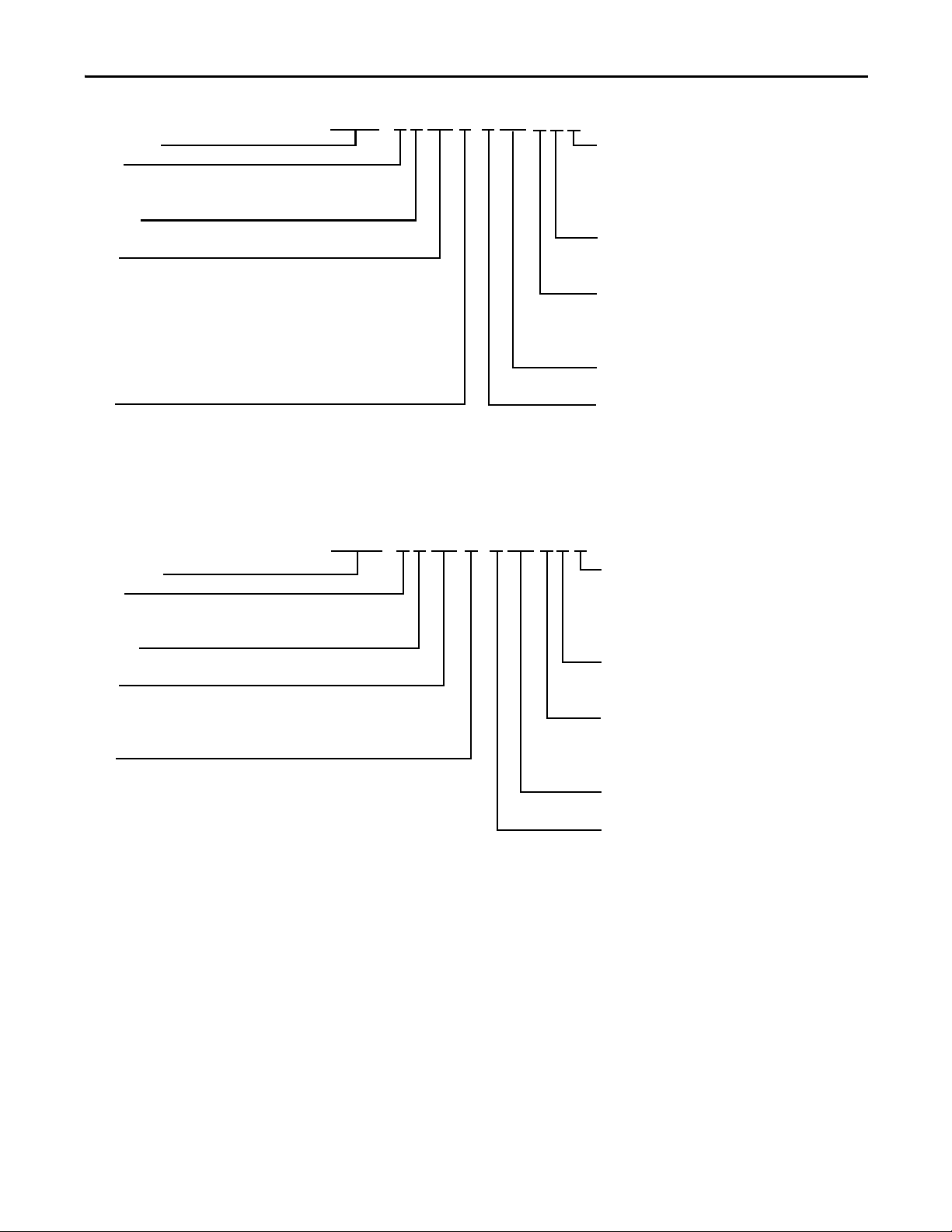

Bulletin Number

Volt age

A= 230V AC

Frame Size

6= 150 mm base

Stroke

Travel lengths sta rt at 6 cm and are avai lable in 6 cm increme nts.

For example: 006 for 6 cm travel or 054 for 54 cm travel.

Maximum travel = 120 cm.

Motor

A= LZ-030-T-120-D

B= LZ-030-T-240-D

C= LZ-030-T-240-E

Feedback

F= 1.0 micron incremental optical encoder, with integral index mark

G= 0.5 micron incremental optical encoder, with integral index mark

H= 0.1 micron incremental optical encoder, with integral index mark

I= 1V p-p sine/cosine encoder, 20 μm signal period, with integral index mark

CHPS - A 6 054 A - F LM C 2 C

Cable Management and Termination

A = No Cabl es or Cable Carrie r (Slide Junc tion Box only)

B = Cables with Flying Leads and Cable Carrier

(1)

C = Cables with Kinetix MPF Connectors and Cable Carrier

(1)

D = Cables with D-Connec tors and Cable Car rier

(1)

Limits

2 = No limits

5 = Two end of travel limits

Protection

S = Covered with strip seals (IP 30)

(2)(3)

C = Covered without strip seals

(2)

O = Open without any cover, without strip seals

LM Specifier

LM = Linear Motor

Recommended Maintenance Interval

Identifying Your Stage

Under normal stage use, follow these lubrication guidelines.

You determine the frequency of re-lubrication that is best suited to your

application as an application's environment, motion profile, and duty cycle

can effect the re-lubrication time period required.

Lubricate the stage every 6 months or 2500 km (1550 mi) of travel, which ever

comes first. Use the MPAS grease gun kit and grease cartridge (catalog numbers

MPAS-GPUMP and MPAS-CART respectively). See maintenance section for

lubrication procedures.

Refer to Maintenance beginning on page 59

for lubrication procedures.

Use the following key to identify the options that your stage is equipped with. Be

sure the information listed on the purchase order correlates to the information on

the packing slip that accompanied your stage components. Inspect the assemblies

and confirm, if applicable, the presence of specified options.

18 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 19

Bulletin Number

Volt age

A= 230V AC

B= 460V AC (LC motors only)

Frame Size

8= 200 mm base

Stroke

For -100 and -120 motor coil lengths

Travel lengths start at 6 cm and are available in 6 cm increments.

For example: 006 for 6 cm travel or 054 for 54 cm travel.

Maximum travel = 126 cm.

Travel lengths start at 8 cm and are available in 6 cm increments.

For -200 or -240 motor coil lengths.

For example: 008 for 8 cm travel or 020 for 20 cm travel.

Maximum travel = 122 cm.

Motor

A= LZ-030-T-120-D E= LC-050-200-D

B= LZ-030-T-240-D F= LC-050-200-E

C = LZ-030-T-240-E

D= LC-050-100-D

Cable Management and Termination

A = No Cables or Cable Carrier (Slide Junction Box only)

B = Cables with Flying Leads and Cable Carrier

(1)

C = Cables with Kinetix MPF Connectors and Cable Carrier

(1)

D = Cables with D-Connectors and Cable Carrier

(1)

Limits

2 = No limits

5 = Two end of travel limits

Protection

S = Covered, with strip seals (IP 30)

(2)(3)

C = Covered, without strip seals

(2)

O = Open, without cover, without strip seals

LM Specifier

LM = Linear Motor

Feedback

F = 1.0 micron incremental optical encoder, with integral index mark

G = 0.5 micron incremental optical encoder, with integral index mark

H = 0.1 micron incremental optical encoder, with integral index mark

I = 1V p-p sine/cosine encoder, 20 μm signal period, with integral

index mark

Bulletin Number

Volt age

A= 230V AC

B= 460V AC (LC motors only)

Frame Size

9= 250 mm base

Stroke

Travel lengths start at 8 cm and are available in 6 cm increments.

For example: 008 for 8 cm travel or 020 for 20 cm travel.

Maximum travel = 122 cm.

Motor

G = LZ-050-T-120-D

H = LZ-050-T-240-D

I = LZ-050-T-240-E

J = LC-075-100-D

K = LC-075-200-D

L = LC-075-200-E

Cable Management and Termination

A = No Cabl es or Cable Carrie r (Slide Junc tion Box only)

B = Cables with Flying Leads and Cable Carrier

(1)

C = Cables with Kinetix MPF Connectors and Cable Carrier

(1)

D = Cables with D-Connectors and Cable Carrier

(1)

Limits

2 = No limits

5 = Two end of travel limits

Protection

S = Covered, with strip seals (IP 30)

(2)(3)

C = Covered, without strip seals

(2)

O = Open, without cover, without strip seals

LM Specifier

LM = Linear Motor

Feedback

F = 1.0 micron incremental optical encoder, with integral index mark

G = 0.5 micron incremental optical encoder, with integral index mark

H = 0.1 micron incremental optical encoder, with integral index mark

I = 1V p-p sine/cosine encoder, 20 μm signal period, with integral

index mark

CHPS - A 8 054 F - F LM C 2 C

CHPS - A 9 054 G - F LM C 2 C

(1) Not for upside down mounting.

(2) Contact Applications Engineering for upside down mounting.

(3) Strip seal and covers required for wall mount applications.

Understanding Your Stage Chapter 2

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 19

Page 20

Chapter 2 Understanding Your Stage

Notes:

20 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 21

Chapter 3

Planning the Stage Installation

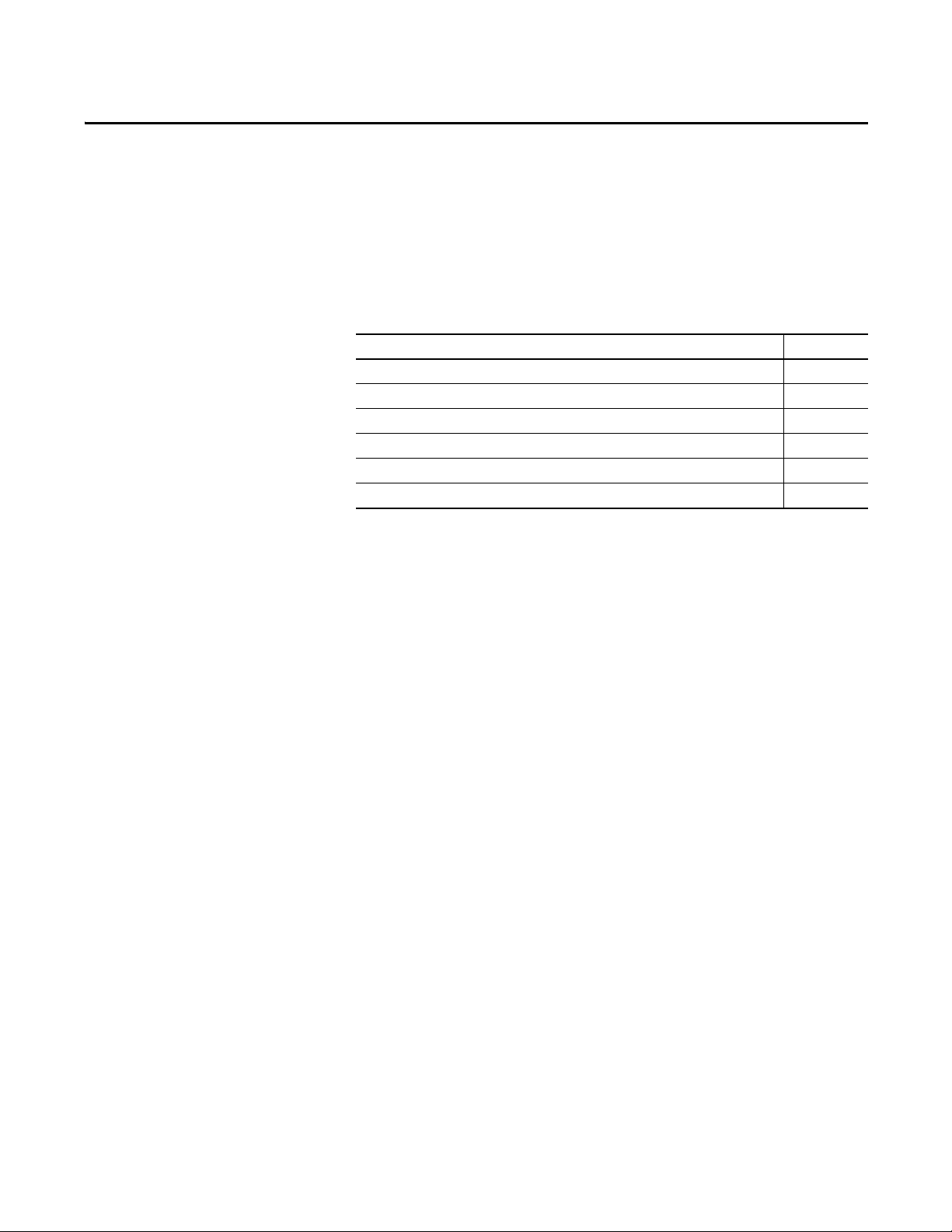

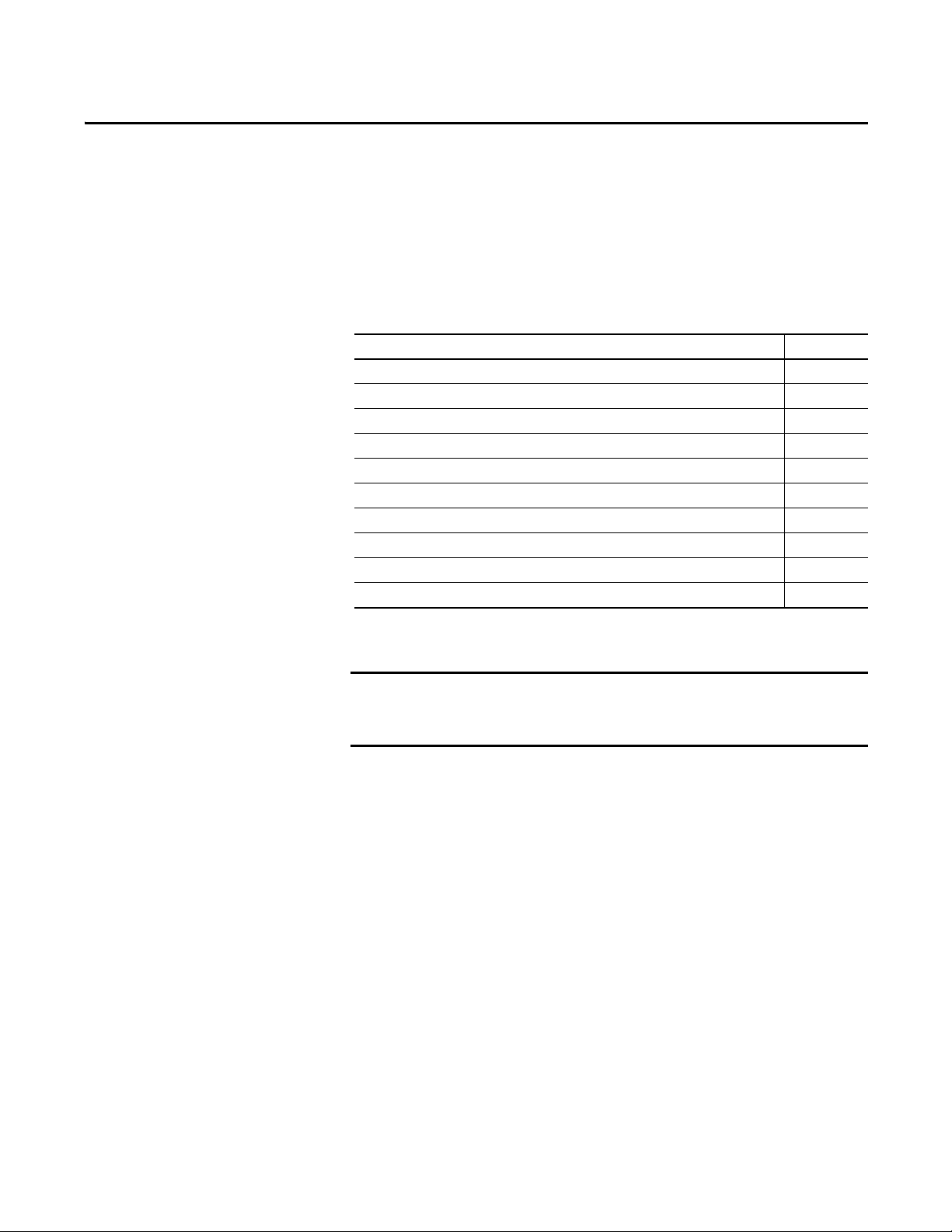

Top ic Pa ge

Stage Mounting Requirements 21

General Safety Standards for Stage Installations 21

Mounting Restrictions 21

Environmental Factors 22

Mounting Surface Restrictions 22

Clearance Requirements 23

Stage Mounting Requirements

Requirements to be met when mounting your CHPS-Series stage include the

following.

General Safety Standards for Stage Installations

General safety standards and requirements include, but are not limited to, the

following:

• ANSI/RIA R15.06, Industrial Robots and Robot Systems Safety

Requirements - Teaching Multiple Robots

• ANSI/NFPA 79, Electrical Standard for Industrial Machinery

• CSA/CAN Z434, Industrial Robots and Robot Systems- General Safety

Requirements

• EN60204-1, Safety of Machinery. Electrical Equipment of Machines

Mounting Restrictions

When locating your CHPS-Series stage include the following.

• Environmental Factors

• Mounting Surface Restrictions

• Mounting Orientation

• Clearance Requirements

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 21

Page 22

Chapter 3 Planning the Stage Installation

Environmental Factors

Factor Applicability

Temperature The stage does not require any special cooling considerations. Avoid mounting it near any

Humidity Avoid excessive humidity. Condensation on metal surfaces can cause stage corrosion. The

Access and Interference When possible, locate the system where sufficient working space is available to per form

Dust and airborne

contaminants

Vibration Install the stage in a location free of excessive vibration.

Ambient Light Have sufficient light readily available to enable inspection, testing and other functions to

heat generating objects, such as a heat register. Sustained average temperature must not

be greater than 40 °C (104 °F), nor less than 0 °C (32 °F).

maximum permissible humidity is 80% relative.

periodic maintenance.

Avoid installing where a trapping hazard or pinch point occurs as a result of interference

with the building, structures, utilities, and other machines and equipment.

Avoid placing the stage in areas where excessive dust or other airborne contaminants are

present. Chemical fumes or vapors can cause damage to internal components.

be performed on the stage.

Mounting Surface Restrictions

Mounting Orientation Restriction

Surface Stages are to be bolted or clamped to a flat, stable, and rigid surface along its entire

Ceiling - inverted surface A ceiling mount (inverted on a horizontal sur face) is not recommended. Stages mounted

Wall - horizontal Horizontal wall mount stages must be installed with the cable carrier below the stage.

Wall - vertical or incline Stages mounted vertically on a wall must have a tr avel of 1 m ( 3.28 ft) o r less. Sta ges with

length. Flatness deviation in the mounting surface must be less than or equal to

0.025 mm over a 300 x 300 mm (0.001 in. over a 12 x 12 in.) area.

Flatness must be maintained during operation of the stage.

in this orientation are subject to premature cable carrier failure.

Stages mounted horizontally on a wall must have a travel of 1m (3.28 ft) or less. Stages

with a travel length greater than 1 m (3.28 ft) are subject to premature cable carrier

failure.

a travel length greater than 1 m (3.28 ft) are subject to premature cable carrier failure.

22 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 23

Planning the Stage Installation Chapter 3

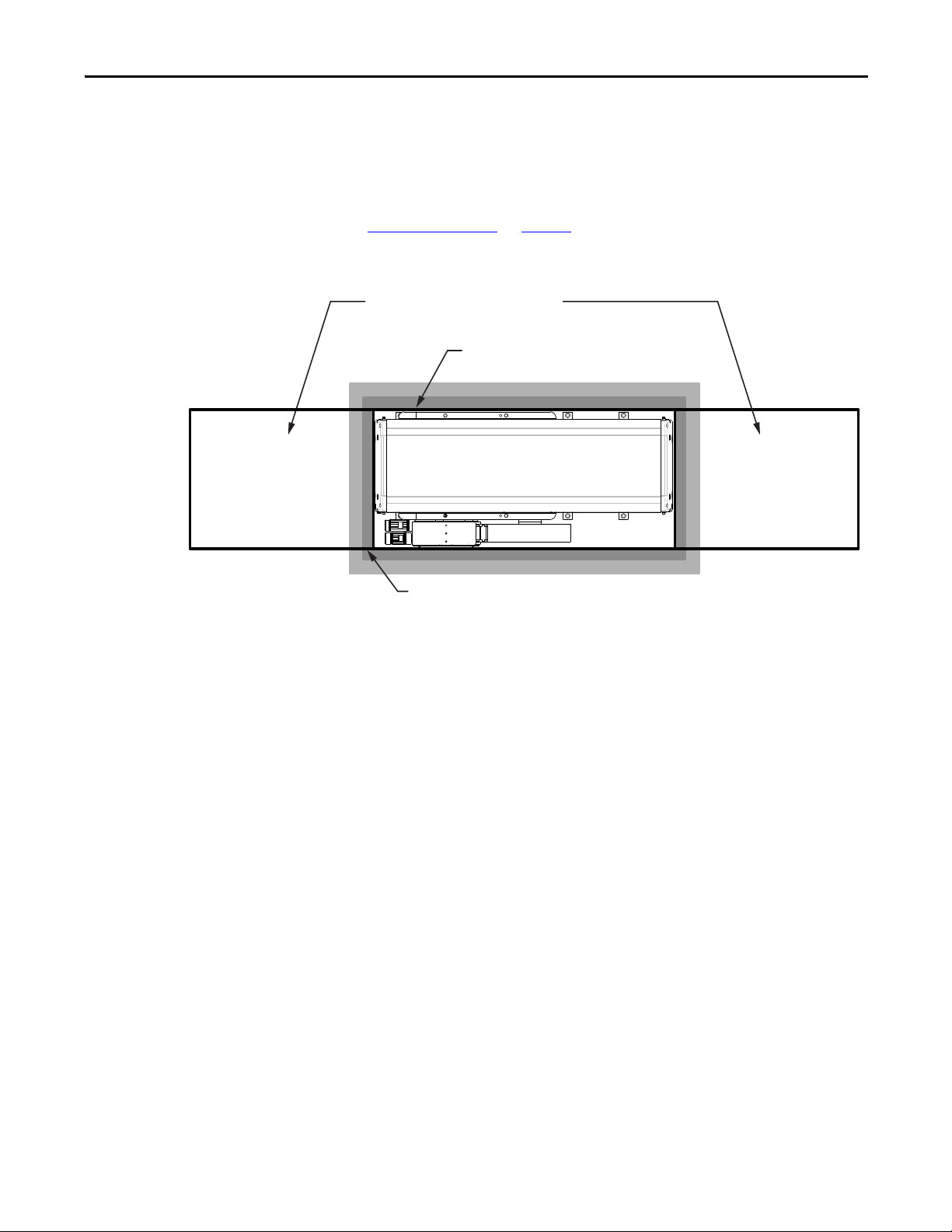

Covered Stage: 419 mm (16.5 in.)

Clearance on Both Ends for Lubrication Access

Uncovered Stage: 3.2 mm (0.125 in.)

Clearance All Around

Cabling: 19 mm (0.75 in.) Clearance for Cable Routing

Clearance Requirements

The figures depict the minimum clearances for each stage type.

Power and feedback cables can impose additional clearance requirements. Refer

to Interconnect Cables

Figure 3 - Minimum Clearance Requirements

on page 85 for connector and bend radius requirements.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 23

Page 24

Chapter 3 Planning the Stage Installation

Notes:

24 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 25

Chapter 4

IMPORTANT

Mounting the Stage

Top ic Pag e

Unpacking, Handling, and Inspection 25

Unpacking Procedure 26

Store Packaging Material 28

Stage Storage 28

Mounting the Stage 28

Before You Begin the Mechanical Installation 28

Determine the Number of Fasteners Required 28

Determine the Type of Fastener to Use 29

Mounting the Stage 31

Mount Your Application 32

Unpacking, Handling, and Inspection

Any person that teaches, operates, maintains, or repairs these stages must

be trained and demonstrate the competence to safely perform the assigned

task.

Inspect packaging to make certain no damage occurred in shipment. Document

any damage or suspected damage. Claims for damage due to shipment are usually

made against the transportation company. If you suspect damage, contact

Rockwell Automation immediately for further advice.

Be sure the information listed on the purchase order correlates to the information

on the packing slip for your stage and its accessories.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 25

Page 26

Chapter 4 Mounting the Stage

Users Manual

Packing End Caps

Desiccant

Inspect the assemblies and confirm, if applicable, the presence of specified

options.

ATT EN TI ON : Linear motor driven stages contain powerful permanent magnets

that require extreme caution during handling. Do not disassemble the stage.

The forces generated by permanent magnets are very powerful and can cause

bodily injury.

Persons with pacemakers or automatic implantable cardiac defibrillators (AICD)

must maintain a minimum distance of 0.3 m (12 in.) from magnet assemblies.

Additionally, unless absolutely unavoidable, a minimum distance of 1.5 m (5 ft)

must be maintained between magnet assemblies and other magnetic or ferrous

composite materials. Calipers, micrometers, laser equipment, and other types of

instrumentation must be nonmetallic.

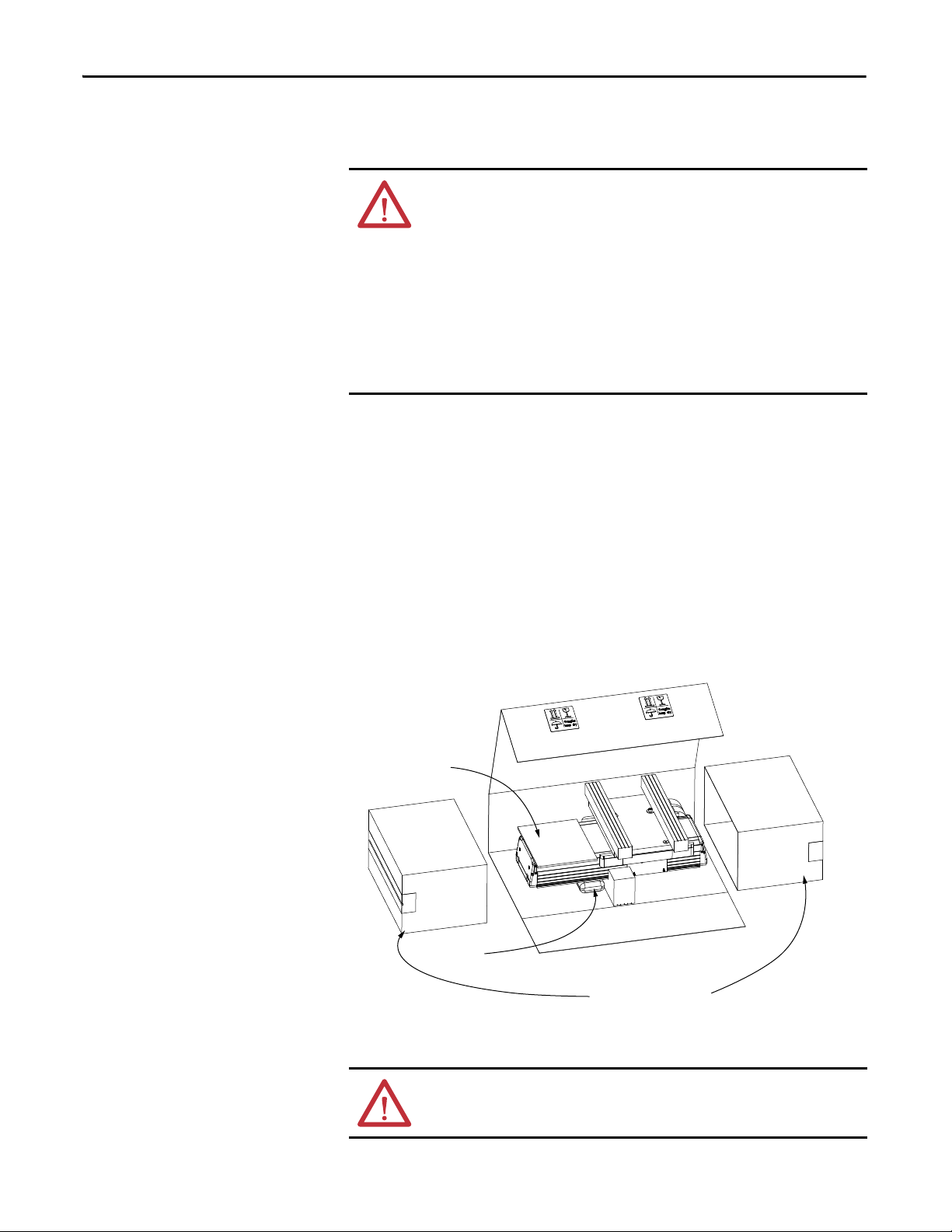

Unpacking Procedure

The following tools are recommended for unpacking the stage:

• Utility knife

• 2.5mm, 5mm, and 6mm hex keys

• Packing tape

1. Place carton on flat stable surface with the tape seam side facing you.

2. Use a utility knife to score the packing tape on the edges of the carton.

3. Lift center cover to reveal the stage.

4. Remove the packing end caps.

ATT EN TI ON : Never attempt a single-person lift. Personal injury and equipment

damage can occur if the linear stage is handled improperly.

26 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 27

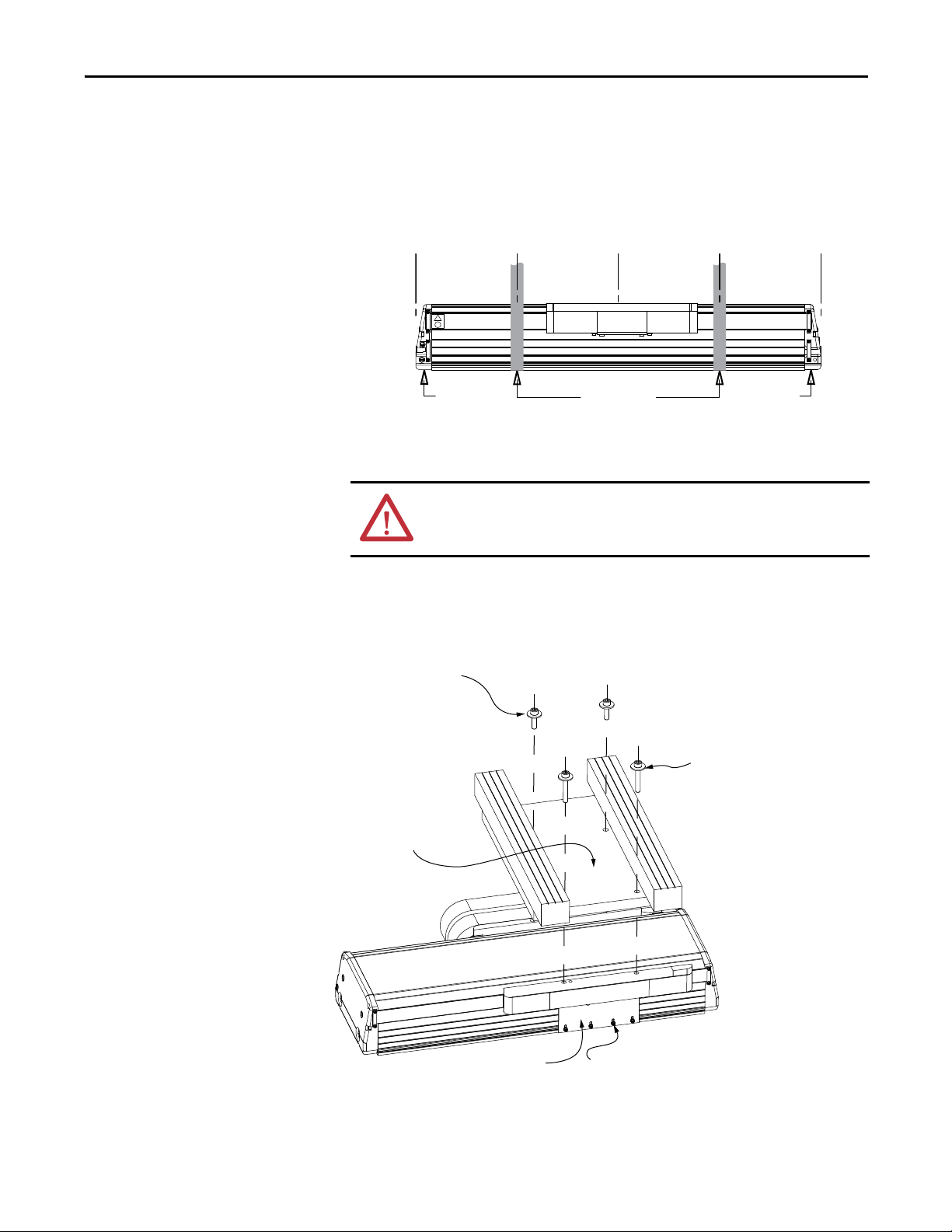

Mounting the Stage Chapter 4

Support Straps

1/4 1/4 1/4 1/4

End Cap End Cap

Shipping Brace

M6 x 30 SHCS (2x) for

CHPS-x6xxxx-xLxxx (150 mm)

M8 x 30 SHCS (2x) for

CHPS-x8xxxx-xLxxx (200 mm) and

CHPS-x9xxxx-xLxxx (250 mm)

Shipping Clamp

M3 SHCS, washer, and nut (4x)

M6 x 75 SHCS (2x) for

CHPS-x6xxxx-xLxxx (150 mm)

M6 x 75 SHCS (2x) for

CHPS-x8xxxx-xLxxx (200 mm) or

CHPS-x9xxxx-xLxxx (250 mm)

5. Remove the linear stage from the packaging supports.

• For stages shorter than 1 meter (39.3 in.), use two people and lift the

linear stage by grasping the base near the end caps only.

• For stages 1 meter (39.3 in.) or longer, use support straps at the 1/4

and 3/4 length points to avoid distorting the base. Use this support

system whenever the linear stage must be lifted.

6. Move the linear stage to a solid support surface before removing the

shipping brace.

ATT EN TI ON : The carriage is free to move once the shipping brace is removed.

Use additional care when handling the linear stage after the brace is removed.

Unexpected carriage movement can cause personal injury.

7. Remove the four socket head cap screws (SHCS) from the shipping brace.

8. Lift the shipping brace off the stage and set it aside.

10. Remove the four SHCS that secure the shipping clamp.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 27

9. Remove the plastic wrap enclosing the stage and set it aside.

Page 28

Chapter 4 Mounting the Stage

fasteners

stroke (cm) 26 (cm)+

12

----------------------------------------------------------

round down + 1

2×=

fasteners

stroke (cm) 30 (cm)+

12

-----------------------------------------------------------

round down +1

2×=

11. Remove the four square nuts loosened in the previous step, by sliding each

nut to the end of channel.

Store Packaging Material

Keep the carton in case the unit needs to be returned for warranty service or

stored for an extended period of time.

1. Tape screws and clamp hardware to the shipping brace.

2. Put end caps in their original positions on the center cover and place all

packing material inside the carton.

3. Lightly tape carton closed and store in dry place.

Stage Storage

Mounting the Stage

Store the stage in area that is clean, dry, vibration free, and at a relatively constant

temperature. Refer to Environmental Specifications for CHPS-Series Stage on

page 75

for more detailed information.

This section discusses mounting methods for your stage.

Before You Begin the Mechanical Installation

The machine designer is most qualified to determine the number and type of

fasteners to use for mounting the stage. The following information is a guide for

the decision-making process.

Determine the Number of Fasteners Required

The length of the stage determines the number of mounting fasteners that are

required.

Use one of the following equations to calculate the required mounting hardware.

Figure 4 - Fasteners Required for Stages with 150 mm and 200 mm frame size (CHPS-x6xxxxxLMxxx and CHPS-x8xxx-xLMxxx)

Figure 5 - Fasteners Required for Stages 250 mm frame size (CHPS-x9xxx-xLMxxx)

or example, if you are mounting an CHPS-B8194F-ALM02C stage.

28 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 29

Mounting the Stage Chapter 4

fasteners 19 1+202× 40 fasteners===

fasteners

194 cm + 36

12

----------------------------------

230

12

--------- 1 9 . 1 6 7===

round down 19=

1940 mm stroke length = 194.0 cm

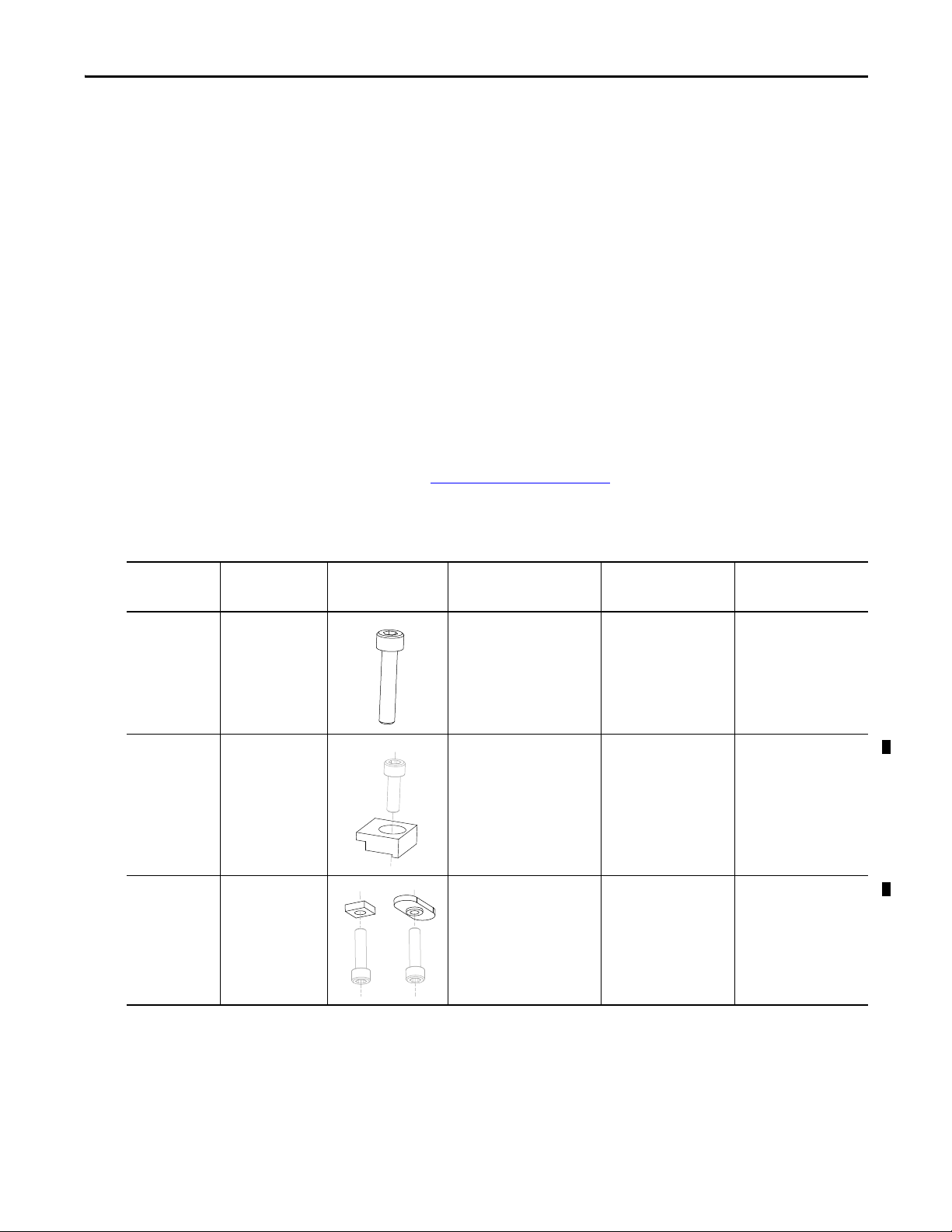

Determine the Type of Fastener to Use

Three types of fasteners that can be used to mount the stage.

• Through bolts

• Toe clamps

• Tee nut or square nut

Toe clamps are supplied with the catalog number CHPS-x6xxx stages, and

covered types of the catalog number CHPS-x8xxx and CHPS-x9xxx stages.

Refer to the Mounting Fastener Options

type.

table for an illustration of each fastener

Table 1 - Mounting Fastener Options

Tor que

Fastener Order Illustration User Supplies

(1)

Through B olt

Toe clamps MPAS-TOE M6 x 1.0 x 16 mm min Covered stages 5.5 (48)

(2)

MPAS-x-TNUT

Tee nuts

– M5 x 1.0 x 16 mm min Uncovered stages 2.3 (30)

(3)

M6 x1.0 Securing a stage from

(4)

Recommended For

beneath the mounting

surface.

N•m (lbf•in)

Tee Nut 6.7 (60)

Square Nut 2.3 (30)

(1) Through bolt mounting is not an option for catalog number CHPS-x6xxxx-xLMxxx (150 mm) stages.

(2) The tee nut mount for a catalog number CHPS-x8xxxx-xxxxx (200 mm) stage is a square nut in a tee slot.

(3) Where x is the frame size of a stage, 6 = CHPS-x6xxxx-xxxxx (150 mm), 8 = CHPS-x8xxxx-xxxxx (200 mm), 9 = CHPS-x9xxxx-xxxxx (250 mm).

(4) You supply the bolts.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 29

Page 30

Chapter 4 Mounting the Stage

IMPORTANT

120 mm

(4.72 in.)

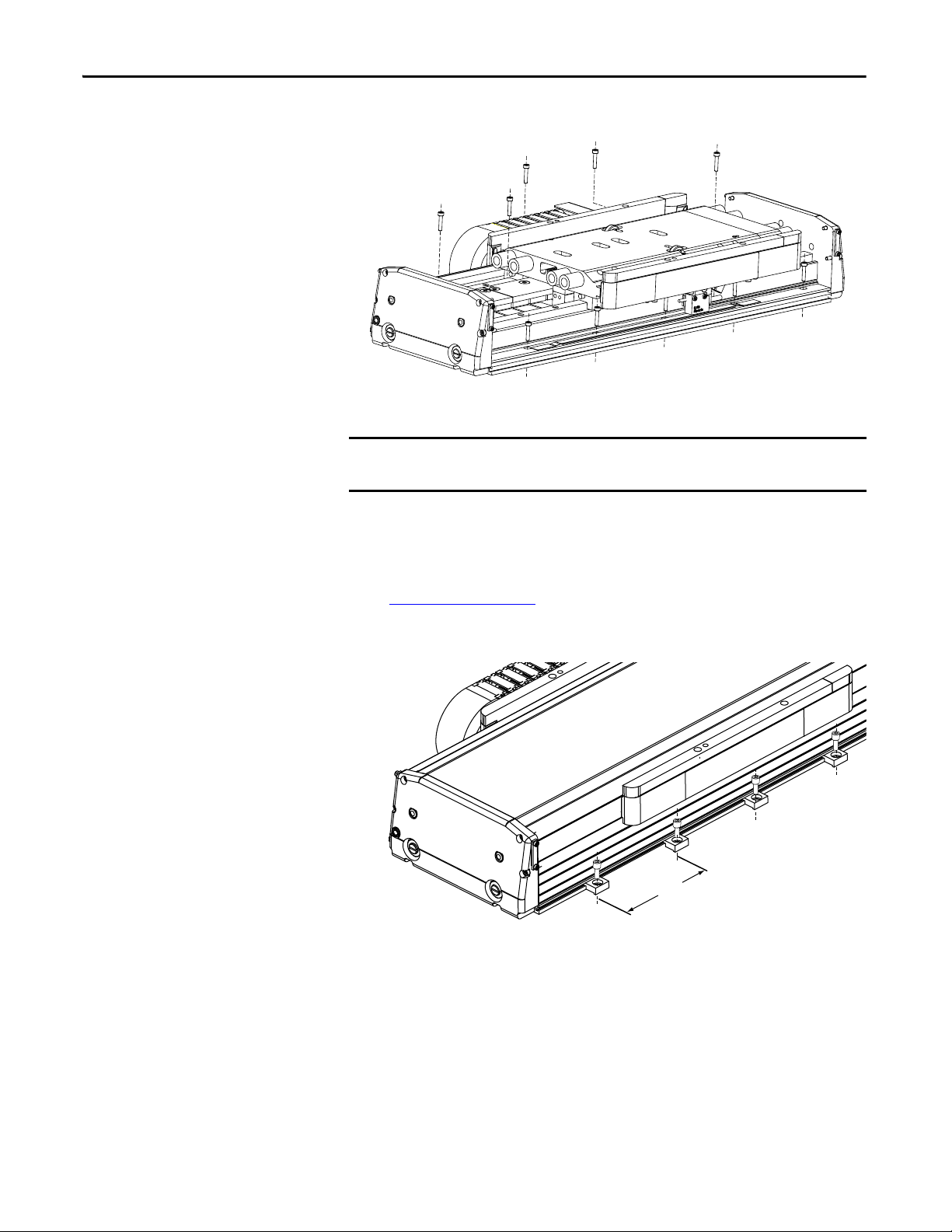

Figure 6 - Through Bolt Mounting

Through bolt mounting is not available for the catalog number

CHPS-x6xxxx-xxxxx (150 mm) stages.

An uncovered stage is a good candidate for through bolt mounting.

For covered stages, toe clamps are the easiest method for mounting. On sides of

the base secure a toe clamps every 120 mm (4.72 in) by using M6 SHCS as shown

in the Toe Clamps Mounting

diagram. Use slots formed into outside edge of the

stage base.

Figure 7 - Toe Clamps Mounting

30 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 31

Mounting the Stage Chapter 4

IMPORTANT

T-Slots

Tee nuts are used to mount the stage from underneath. Insert the tee nuts every

120 mm (4.72 in.) in tee slots on the bottom of the unit. Secure the tee nuts by

using M6 SHCS as shown in Te e Nu t M ou nt in g

Figure 8 - Tee Nut Mounting

diagram.

Mounting the Stage

Follow these steps to install a stage on its mounting surface.

1. Be sure the mounting surface is clear of any and all foreign material.

Do not use abrasives to clean the surface.

If necessary, stone the mounting surface (acetone or methanol can be

applied as cleaning agent).

2. Verify that the flatness of the surface that the stage is to be mounted.

The total indicator reading (TIR) is 0.0254 mm (0.001 in.) per 300 mm

(120 in.). TIR or runout, correlates to an overall flatness of a surface.

3. Lift the stage onto the prepared mounting surface

ATT EN TI ON : Do not attempt to move the stage by grasping the cable junction

box. Moving the stage in this manner can damage the stage and create a pinch

or crush hazard. The junction box is attached to the carrier that is free to move.

Lifting the stage in this manner causes uncontrolled movement of the heavy

base. Always use a two person lift and grasp the stage by the base at the end

caps keeping fingers clear of the carrier’s path of travel.

The two lubrication ports on each end cap (four total) are M10 x1.5 tapped through

holes and can be used to install lifting hooks supplied by the customer.

Personal injury and equipment damage can occur if stage is handled improperly.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 31

Page 32

Chapter 4 Mounting the Stage

4. Align the stage on the mounting surface, and insert the correct number of

mounting bolts. Refer to CHPS-Series Stage Dimensions beginning on

page 77

for detailed mounting dimensions.

5. Secure the stage by using all mounting holes. Torque bolts to the values

shown in the Mounting Fastener Options

table on page 29.

Mount Your Application

Mount your application to the slide by using the following bolts and torque

values:

Cat. No. Bolt Torque

N•m (lb•in)

CHPS-x6xxxx-xLMxxx M6 3.2 (48)

CHPS-x8xxxx-xLMxxx M8 10.1 (90)

CHPS-x9xxxx-xLMxxx M8 10.1 (90)

32 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 33

Connector Data

Top ic Pag e

Kinetix Servo Drive Compatible Connectors 34

D-Type Connectors 35

Flying Leads 36

Junction Box Connectors 37

Limit Sensor Flying Leads 38

Chapter 5

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 33

Page 34

Chapter 5 Connector Data

A

CB

D

E

H

L

F

G

Mating Cable: Allen-Bradley 2090-XXNPMF-16Sxx

Intercontec P/N BKUA090NN000550003500

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Intercontec P/N AKUA034NN00100035000

Mating Cable: Allen-Bradley 2090-XXNFMF-Sxx

Kinetix Servo Drive Compatible Connectors

Pin Color Wire

1 Yellow A+ TTL - Differential Sin+ Analog Differential 1V p-p

2 White/yellow A- TTL - Differential Sin- Analog Differential 1V p-p

3 Brown B+ TTL - Differential Cos+ Analog Differential 1V p-p

4 White/Brown B- TTL - Differential Cos- Analog Differential 1V p-p

5 Violet Index Mark+ TTL - Differential Index+ Differential Pulse 1V p-p

6 White/Violet Index Mark- TTL - Differential Index- Differential Pulse 1V p-p

7 Reserved — — Reserved —

8 Reserved — — Reserved —

9 White/Red +5V DC Encoder and Hall Sensor Power +5V DC Encoder and Hall Sensor Power

10 Black Common — Common —

11 Reserved — — Reserved —

12

13 Green PTC Temp+

14 White/Black Common — Common —

15 White/Green S1 TTL - Trapezoidal Hall S1 TTL - Trapezoidal Hall

16 Blue S2 TTL - Trapezoidal Hall S2 TTL - Trapezoidal Hall

17 White/Blue S3 TTL - Trapezoidal Hall S3 TTL - Trapezoidal Hall

Case Shield Shield — Shield —

The following tables identify the power and feedback pinouts for the Intercontec

circular connectors for use with standard Allen Bradley connectors.

Pin Color Signal

ARed U (A) Phase

B White V (B) Phase

CBlack W (C) Phase

D Green/Yellow Ground

Case Shield Cable Shield

With Incremental Encoder With Analog Encoder

Signal

Designations

(1)

Signal Description

PTC Thermistor PTC Temp+

Signal

Designations

(1)

Signal Description

PTC Thermistor

(1) PTC Temp- is connected to Common.

34 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 35

Connector Data Chapter 5

M

A1

A2 A3

A4

Positronic P/N CBD9W4M20000-1702.0

Mating Connector:

Positronic P/N CBD9W4F20000-1701.0

M

1

1

14

25

13

Connector Part Number AMP P/N 207464-2

Mating Connector Part Number AMP P/N 5205207-1

D-Type Connectors

Pin Color Wire

1 Yellow A+ TTL - Differential Sin+ Analog Differential 1V p-p

2 Brown B+ TTL - Differential Cos+ Analog Differential 1V p-p

3 Violet Index Mark + TTL - Differential Index+ Differential Pulse 1V p-p

4 White/Red +5V DC Encoder and Hall Sensor Power +5V DC Encoder and Hall Sensor Power

5Reserved — — — —

6

7

8

9 White/Green S1 TTL - Trapezoidal Hall S1 TTL - Trapezoidal Hall

10 Green PTC Temp+

11 Reserved — — — —

12 White Blue S3 TTL - Trapezoidal Hall S3 TTL - Trapezoidal Hall

13 Green/Yellow Shield — Shield

14 White/Yellow A- TTL - Differential Sin- Analog Differential 1V p-p

15 White/Brown B- TTL - Differential Cos- Analog Differential 1V p-p

16 White/Violet Index Mark- T TL - Differential Index- Differential Pulse 1V p-p

17 Black,

White/Black

18 Reserved — — — —

19

20

21

22 Blue S2 TTL - Trapezoidal Hall S2 TTL - Trapezoidal Hall

23 Reserved — — — —

24

25

(1) PTC Temp- is connected to Common.

The following tables identify the power and feedback pinouts for D-shell

connectors that enable custom cables to be used.

Pin Color Signal

A1 Red U (A) phase

A2 White V (B) phase

A3 Black W (C) phase

A4 Green/Yellow Ground

Case Shield Cable Shield

With Incremental Encoder With Analog Encoder

Signal

Designations

(1)

Common — Common —

Signal Description Signal Designations Signal Description

PTC Thermistor PTC Temp+* PTC Thermistor

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 35

Page 36

Chapter 5 Connector Data

Flying Leads

The following tables identify the power and feedback pinouts for flying lead this

option lest you to use your own connectors.

ATT EN TI ON : Disconnect input power supply before installing or servicing stage

Stage lead connections can short and cause damage or injury if not well secured

and insulated.

Insulate the connections, equal to or better than the insulation on the supply

conductors.

Properly ground the stage as described in the drive manual.

Color Signal

Red U (A) phase

White V (B) phase

Black W (C) phase

Green/Yellow Ground

Shield Cable Shield

With Incremental Encoder With Analog Encoder

Color Wire

Yellow A+ TTL - Differential Sin+ Analog - Differential 1V p-p

White/Yellow A- TTL - Differential Sin- Analog - Differential 1V p-p

Brown B+ TTL - Differential Cos+ Analog - Differential 1V p-p

White/Brown B- TTL - Differential Cos- Analog - Differential 1V p-p

Violet Index Mark+ TTL - Differential Index+ Differential Pulse 1V p-p

White/Violet Index Mark- TTL - Differential Index- Differential Pulse 1V p-p

Red +5V Encoder and Hall Sensor Power +5V Encoder and Hall Sensor Power

White/Red +5V Encoder and Hall Sensor Power +5V Encoder and Hall Sensor Power

Black Common — Common —

White/Black Common — Common —

Green PTC Temp+

White/Green S1 TTL - Trapezoidal Hall S1 TTL - Trapezoidal Hall

Blue S2 TTL - Trapezoidal Hall S2 TTL - Trapezoidal Hall

White/Blue S3 TTL - Trapezoidal Hall S3 TTL - Trapezoidal Hall

Green/Yellow Shield — Shield —

(1) PTC Temp- is connected to Common.

Signal

Designations

(1)

Signal Description

PTC Thermistor PTC Temp+

Signal

Designations

Signal Description

(1)

PTC Thermistor

36 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 37

Connector Data Chapter 5

Pin 1

9

16

8

Pin 1

7

6

12

Pin 1

4

D

A

B

C

E

Signals from slide

To exible feedback cable

ENCA+

ENCB+

INDEX+

POSLIM

5V

HALLS3

GND

SHIELD

GND

HALLS2

SHIELD

5V

ENCB-

ENCA-

INDEX-

HALLS1

SHIELD

HALLS3

ENCA+

ENCB+

INDEX+

POSLIM

GND

HALLS1

HALLS2

ENCAENCBINDEXNEGLIM

5V

TEMP+

NEGLIM

GND

TEMP+

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

11

12

1

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

TP1

Shield terminates to mounting hole

J3

Header 2X3, Right Angle

J4

Header 2X6 Right Angle

J2

Header 2, Right Angle

J1

Header 2x8, Vertical

Junction Box Connectors

The following diagram and tables identify the power and feedback pinouts of the

junction box connector, use this information to make custom cables

Item Description

A J1 Feedback connector, output to flex cable, Mating connector is a Molex P/N 43025-1600

B J2 Thermistor signal connector, the input from side

C J3 Hall signal connector, input from side

D J4 Encoder signal connector, input from side

E Mating power connector AMP 359780-1

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 37

Page 38

Chapter 5 Connector Data

Pin With Incremental Encoder With Analog Encoder

1Shield— Shield —

2 S3 TTL - Trapezoidal Hall S3 - TTL - Trapezoidal Hall

3 A+ TTL - Differential Sin+ Analog - Differential 1V p-p

4 B+ TTL - Differential Cos+ Analog - Differential 1V p-p

5 Index Mark+ TTL - Differential Index+ Differential Pulse 1V p-p

8 Common — Common —

9 S1 TTL - Trapezoidal Hall S1 TTL - Trapezoidal Hall

10 S2 TTL - Trapezoidal Hall S2 TTL - Trapezoidal Hall

11 A- TTL - Differential Sin- Analog - Differential 1V p-p

12 B- TTL - Differential Cos- Analog - Differential 1V p-p

13 Index Mark- TTL - Differential Index- Differential Pulse 1V p-p

15 +5V Encoder and Hall Sensor Power +5V Encoder and Hall Sensor Power

16 PTC Temp+

Table 2 - Junction Box Power Connector

Pin Color Signal

1Red U (A) phase

2 White V (B) phase

3 Black W (C) phase

4 Green/Yellow Ground

Table 3 - Junction Box J1 Connector

Signal Designation Signal Description Signal

(1)

PTC Thermistor PTC Temp+

Designation

Signal Description

(1)

PTC Thermistor

(1) PTC Temp- is connected to Common.

Limit Sensor Flying Leads

The limit sensor option comes with flying leads, regardless of the power and

feedback termination option ordered.

Color Signal Description

Brown +V

Black Load+

Blue 0V

(1) Load- is connected to 0V.

(1)

38 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 39

Chapter 6

Connecting the Stage

Top ic Page

Connecting the Stage 39

Attaching the Ground Strap and Interface Cables 40

Thermal Protection 42

Optional Limit Sensors 43

TTL Differential Encoder Output Signal 44

Sine/Cos Encoder Output Signals 45

Hall Effect Circuit 46

Motor and Hall Phasing and Sequence 46

Stage Positive Direction 48

Connecting the Stage

The installation procedure assumes you prepared your system for correct

electrical bonding and understand the importance of electrical bonding for

correct operation of the system. If you are unfamiliar with electrical bonding, the

section Attaching the Ground Strap and Interface Cables

briefly describes and

illustrates correct system grounding techniques.

ATT EN TI ON : Plan the installation of your stage so that you can perform all

cutting, drilling, tapping, and welding with it removed. Be careful to keep any

metal debris from falling into it. Metal debris or other foreign matter can

become lodged in the stage, that can result in damage to components.

SHOCK HAZARD: To avoid hazard of electrical shock, perform all mounting and

wiring of the stage prior to applying power. Once power is applied, connector

terminals can have voltage present even when not in use.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 39

Page 40

Chapter 6 Connecting the Stage

M5 x 0.8 -6H

Ground Screw

Braided Ground Wire 12 mm (0.5 in) min.

Lug

Attaching the Ground Strap and Interface Cables

The only electrical connections necessary between the stage and the drive system

are the ground strap and the two cables.

1. For electrical safety, connect the ground screw on the chassis of the stage to

the ground bus for your system.

To reduce the effects of electromagnetic interference (EMI), bond the

stage with a braided ground strap, 12 mm (0.5 in.) wide minimum, to a

grounded metal surface. This creates a low-impedance return path for

high-frequency energy.

2. Torque the ground screw at the stage to 2 N•m (18 lb•in)

3. Form a drip loop in each cable at a point directly before it attaches to the

stage. Refer to the Connecting Kinetix Type Motor and Feedback Cables

diagram for a visual example.

ATTENTION: Be sure that cables are installed and restrained to

prevent uneven tension or flexing at the cable connectors.

Excessive and uneven lateral force at the cable connectors can result in

the connector’s environmental seal opening and closing as the cable

flexes.

Failure to observe these safety procedures could result in damage to

the motor and its components.

40 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 41

Connecting the Stage Chapter 6

Align flat surfaces.

Align flat surfaces.

Power Connector

Feedback

Connector

Cable

Drip Loop

4. Attach the feedback cable, and the power cable to the stage.

ATTENTION:

Do not connect or disconnect the stage feedback cable, or

the power cable while power is applied to them.

Inadvertent pin connections can result in unexpected motion or result in

irreversible damage to the components.

For Kinetix type connectors.

a. Carefully align each cable connector with the respective motor

connector as shown in Figure 1.

b. Do not apply excessive force when mating the cable and stage

connectors. If the connectors do not go together with light hand force,

realign and try again.

ATTENTION: Be sure that cables are installed and restrained to prevent

uneven tension or flexing at the cable connectors. Excessive and uneven

lateral force at the cable connectors can result in the connector’s

environmental seal opening and closing as the cable flexes. Failure to

observe these safety procedures could result in damage to the motor

and its components.

c. Hand tighten the knurled collar five to six turns to fully seat each

connector.

Figure 9 - Connecting Kinetix Type Motor and Feedback Cables

ATTENTION: Keyed connectors must be properly aligned and hand-

tightened the recommended number of turns.

Improper alignment is indicated by the nee d for excessive force, such a s the

use of tools, to fully seat connectors.

Connectors must be fully tightened for connector seals to be effective.

Failure to observe these safety procedures could result in damage to the

motor, cables, and connector components.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 41

Page 42

Chapter 6 Connecting the Stage

Thermal Protection

Connect the stage PTC thermistor signal to the drive or control system to create

a thermal protection system.

PTC Thermistor Signal Characteristics

Temperature °C (°F) Resistance in Ohms

Up to 100 (212) ≤ 750

Up to 105 (221) ≤ 7500

Up to 110 (221) ≥ 10,000

ATT EN TI ON : PTC thermistor supplies a signal that indicates the stage

temperature limit condition. Connect this signal to control system or drive

system so it shuts down the stage power upon reaching a limit condition.

Multiple levels of stage thermal protection are strongly recommend.

The following thermal protection methods are also recommended.

• Typically digital drives use RMS current protection and or estimated

2

temperature vs. time (I

T) software protection schemes. Activated and set

these available features according to the stage model ratings for your

application.

• Set the maximum value of ± peak-current-magnitude limits of your drive

to the stage’s peak-current rating.

• For drives without stage protection features, install stage fuses (current

rating not to exceed stage continuous RMS) according to local and

National Electrical Code. Uses time-delay type fuses that are rated for the

drive PWM output voltage.

42 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 43

Connecting the Stage Chapter 6

Main

Circuit

Brown

Black

Blue

+V com

+ V

Limit

Adjustable

Positive OT Limit

on this side

Limit Sensor

cables exit here

Adjustable

Negative OT Limit

on this side

Optional Limit Sensors

Two limit sensors, positive overtravel (OT) and negative OT, provide electrical

protection for stage overtravel. Their physical location is shown in Component

Description diagram on page 16 they and can be adjusted up to 30 mm (1.2 in.)

toward the center of travel. The electric characteristics are shown here.

• Input Power: 12

…28V DC, 15 mA circuit draw + 50 mA maximum

sourcing = 65 mA total.

• Output: PNP, Open collector Normally Closed, 50 mA maximum

sourcing.

Figure 10 - Limit Sensor Orientation

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 43

Page 44

Chapter 6 Connecting the Stage

Counter clock frequency (MHz)

encoder velocity m s⁄()

resolution μm()

------------------------------------ -----------------------

4× (safety factor)=

Incremental 2 channels A and B in quadrature (90° phase shifted)

Quadrature edge separation

Reference

Index Mark pulse in synchronised to one

position count. Repeatability of position

(uni-directional) is maintained if temperature

is 15…35 °C (59…95 °F) and

speed is <250 mm/s (9.8 in./s).

ENC A+

ENC B+

Index

Mark +

Drive or

Controller

Standard RS422A

line receive circuit

Square wave dierential

line driver to EIA RS422A

120 Ω

(1)

Readhead

ENC A +,

ENC B +,

& Index Mark +

ENC A -,

ENC B -,

& Index Mark -

TTL Differential Encoder Output Signal

Use the following information to connect a stage with a TTL Differential Encoder.

The incremental encoder typically have the following quadrature edge

separation.

Encoder Typical Edge Separation @ Maximum Velocity

μm ns m/s

1 100 5

0.5 90 3

0.1 90 0.7

(1) Speeds based on 3 m maximum cable length and a minimum readhead input of 5V.

To calculate the minimum recommended counter frequency for 1

0.5

μm encoders, use the following formula.

The minimum recommend counter frequency for the 0.1

Figure 11 - TTL Differential Encoder Timing Diagram

μm encoder is 12 MHz.

(1)

μm and

44 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Figure 12 - TTL Differential Encoder Termination

(1) Total termination resistance in ohms.

Page 45

Connecting the Stage Chapter 6

Incremental 2 channels V1 and V2 dierential sinusoids in quadrature (90° phase shifted)

Dierential pulse V0 - 18°…108°

Duration 126° (electrical) Repeatability of

position (uni-directional) is maintained if

temperature is 15…35 °C and

speed is <250 mm/s

Reference

20 μm

90°

0.6 …1.2V p-p with green

LED indication and

120 Ω termination

108º

-18º

0º

Sine = (V1+)-(V1-)

Cosine = (V2+)-(V2-)

0.8…1.2V p-p

(V0+) -(V0-)

Readhead

Drive or

Controller

120 Ω

(1)

ENC A +,

ENC B +,

& Index Mark +

ENC A -,

ENC B -,

& Index Mark -

Sine/Cos Encoder Output Signals

Use the following information to connect a stage with a Sine/Cosine Encoder

option to a drive or controller that processes sine/cosine position feedback.

The sine/cos encoder amplitude is 0.90V p-p minimum up to 2 meters per

second. 0.60V p-p up to 4 meters per second.

Figure 13 - Sine/Cos Encoder Timing

Recommended termination = 120 Ω resistors, V0, V1, V2.

Figure 14 - Sine/Cos Encoder Termination

(1) Total termination resistance in ohms.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 45

Page 46

Chapter 6 Connecting the Stage

Hall S1

Hall S2

Hall S3

Hall Signal

V

+

Drive

Rp

Isink

Isink = 10 mA Maximum

Rp = External pull-up resistor

Hall Effect Circuit

Motor and Hall Phasing and Sequence

Use the following information to connect the Hall Effect circuit to your servo

drive.

• Input power: 5

• Output: NPN, Open Collector, 10 mA maximum

Consult drive manual or supplier for wiring instructions for your drive. Motor

wiring is phase and commutation sensitive. Motor Phasing Diagram

standard phase and sequence relationship of the motor when phased in the

positive direction. The Hall signals are used by a compatible three-phasebrushless servo drive to perform electronic commutation. Two types of servo

drive Hall-based commutation techniques are possible, Trapezoidal Hall Mode

and Encoder Software Mode with Hall startup. For optimal commutation and

force generation, the selected servo drive must be compatible with the motor

phasing and be wired correctly.

• Observe maximum applied voltage specification.

• Consult drive manual or supplier for drive wiring instructions. Wiring is

phase and commutation sensitive.

• Terminate per drive manual instructions.

• Hall Signals, 120

• Refer to CHPS-Series Stage Connector Data starting on page 33

termination options, pin, and wire designations.

…24 V DC, 10 mA maximum

shows the

o

Spacing, Open Collector Transistor 24V maximum.

for

ATT EN TI ON : Incorrect motor, Hall, or encoder wiring can cause runaway

conditions.

46 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 47

As shown in the Motor Phasing Diagram:

IMPORTANT

0° 60° 120° 180°

240°

300°

360°

S1

S2

S3

Back

EMF

Voltage

Digital

Hall

Signals

Linear Travel mm (in.)

LC

Motor Type

LZ

U-V

W-U

V-W

50 (1.97)

60 (2.36)

S1 in phase with W-U Back EMF

S2 in phase with U-V Back EMF

S3 in phase with V-W Back EMF

Phase sequence = S1 leads S2 leads S3. Spacing is 120°.

Figure 15 - Motor Phasing Diagram

Back EMF Voltage vs. Hall Signals

Connecting the Stage Chapter 6

Phasing direction = Slide toward positive end block,

Phasing direction = Positive stage direction.

Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014 47

Page 48

Chapter 6 Connecting the Stage

(+)

(-)

Slide End Cap + Slide = Slide Assembly

Positive Direction

Stage Positive Direction

Stage positive direction is defined by a location of a Slide End Cap.

48 Rockwell Automation Publication CHPS-UM001D-EN-P - July 2014

Page 49

Chapter 7

IMPORTANT

Operation Guidelines and Limit Configuration

Introduction

Operational Guidelines

This chapter gives you operational guidelines and limit sensor position

adjustment procedures.

Top ic Pag e

Operational Guidelines 49

Travel Limits 50

Calculating the Stopping Distance 50

Overtravel Limit Sensor Position Adjustment 51

Bumper Stops 53