Page 1

Triguard SC300E

Chassis Models

Chassis Models

Issue 4

INTRODUCTION

PURPOSE

The chassis accommodates the various system modules and their power supplies. It

comprises a 9U standard 19 inch rack mounting module cage and a printed circuit backplane.

NOTE

A ‘U’ is one unit an

equipment cabinet manufacturers as a measure of height for rack systems.

d measures 44mm (1.75 inches). The ‘U’ is an industry standard and used by

October 2005

The modules and power supplies plug into connectors on the front of the backplane. External

power and signa

Figure 2-1).

The same basic chassis is configured as a main chassis or an extension chassis by the type

of module fitted in slots A, B and C. A keying system prevents the insertion of Power Supply

Units (PSUs) of the wrong voltage type.

l connections are made via connectors on the rear of the backplane (see

SC300E SYSTEM OVERVIEW

The SC300E is a cost effective, fault tolerant control system suitable for use in industrial

situations where the control system's reliability, availability and predictable perfor

paramount importance. The SC300E is certified for use in safety applications, such as fire and

gas detection/protection and process emergency shutdown, as well as sequence and batch

process control.

mance is of

ARCHITECTURE

The two key components of the SC300E, that permit system’s availability in excess of

99.999% (about 1 hour’s downtime in 11 years) to be realised, are:

• Triple Modular Redundant architecture -

• Software Implemented Fault Tolerance -

TMR

SIFT

008-5097

Page 2

2

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

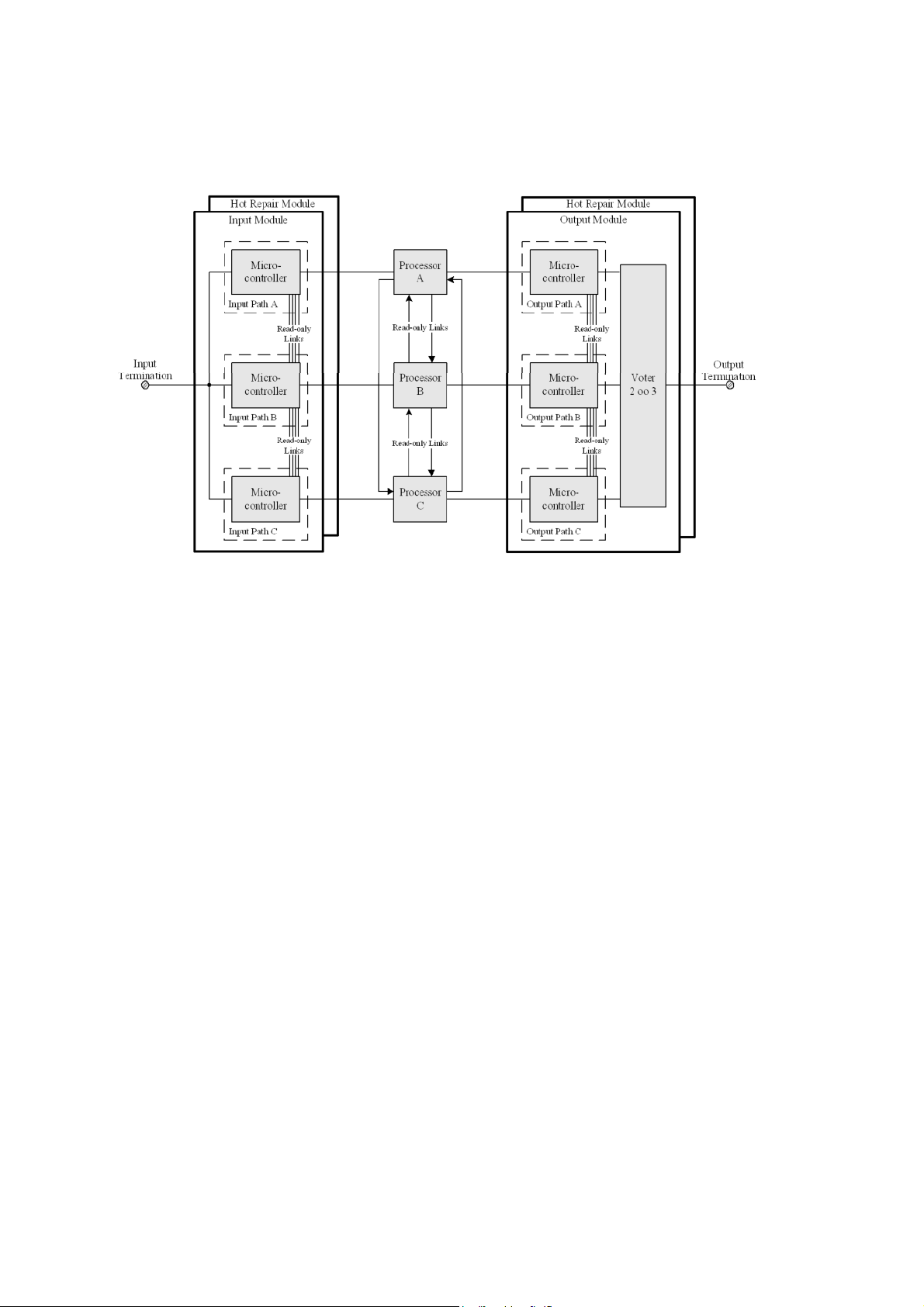

Figure 1-1. SC300E Architecture

As can be

architecture from input modules to output modules. All SC300E input and output modules

interface to three isolated I/O communications buses, each being controlled by one of the three

main

At the input modules, field signals are filtered and then split, via isolating circuitry, into three

identical, signal processing paths. Each path is controlled by a microcontroller that co

ordinates signal path proc

processor, via one of the I/O communications buses.

Each of the main processors communicates with its neighbours via read only, serial

communications links. The main processors synchronise at least once per application logic

execution cycle, and each reads the input, output and diagnostic status of its neighbours.

Each processor correlates and corrects its memory image of the current state of the system

using a 2-oo-3 software vote, logging any discrepancies found in a local diagnostic history

table.

Each processor then executes its programmed application logic and sets its respective

outputs, via the I/O communications bus, to the required state.

seen from the block diagram in Figure 1-1 a SC300E system has a fully triplicated

processor modules.

essing, testing and signal status reporting to its respective main

-

Commanded output states are received by an output module’s microcontrollers which, using 2

oo-3 hardware voters, set the outputs to the field. Any discrepancy between a commanded

output

state and the field output is detected by the microcontrollers and reported to the

appropriate main processor.

-

Page 3

Chassi

s

Model

s

October

2005–

Issue 4

3

Triguard

SC300E Chassis Models

All input and output modules can be configured to use a hot spare partner module. In the event

of failure of the main I/O module its duty is taken over (manually or automatically) by the hot

spare

partner, allowing repairs to be effected

.

HARDWARE

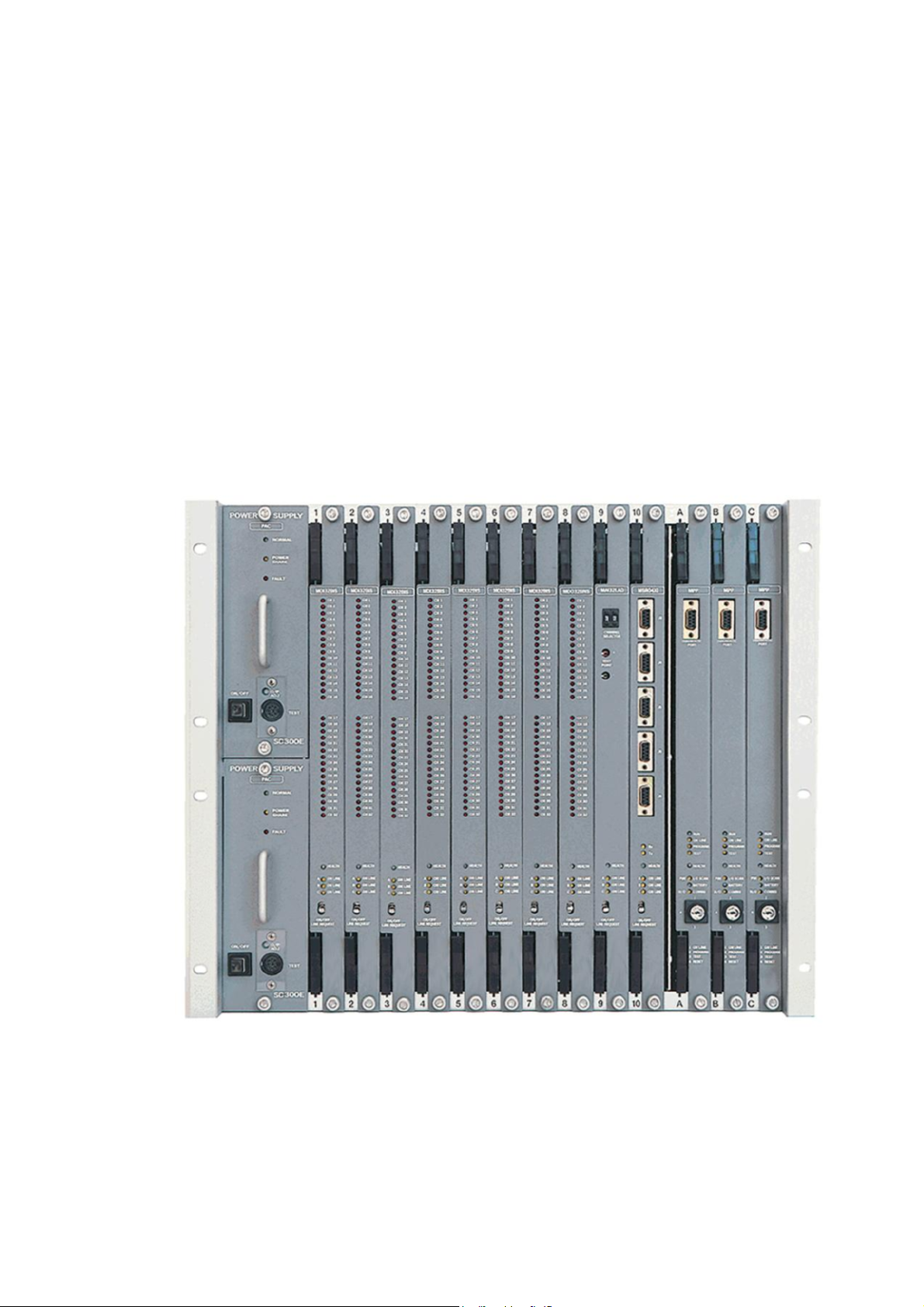

The system

can

be

comprises a main chassis and up to 14 extension chassis (of which 11 can be re

chassis,

using a multi-drop technique. Each chassis can accommodate up to 10 I/O modules so that a

fully

populated SC300E system can contain 150 I/O modules.

Blanking plates

Unpopulated slots can be covered with blanking plates if required.

circuits are accommodated mainly within a number of identical box chassis which

individually configured and interconnected to form the required system layout. A system

mote

connected via fibre optic cables) interconnected via a set of standard ribbon cables

Figure 1-2. Fully loaded chassis

Page 4

4

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

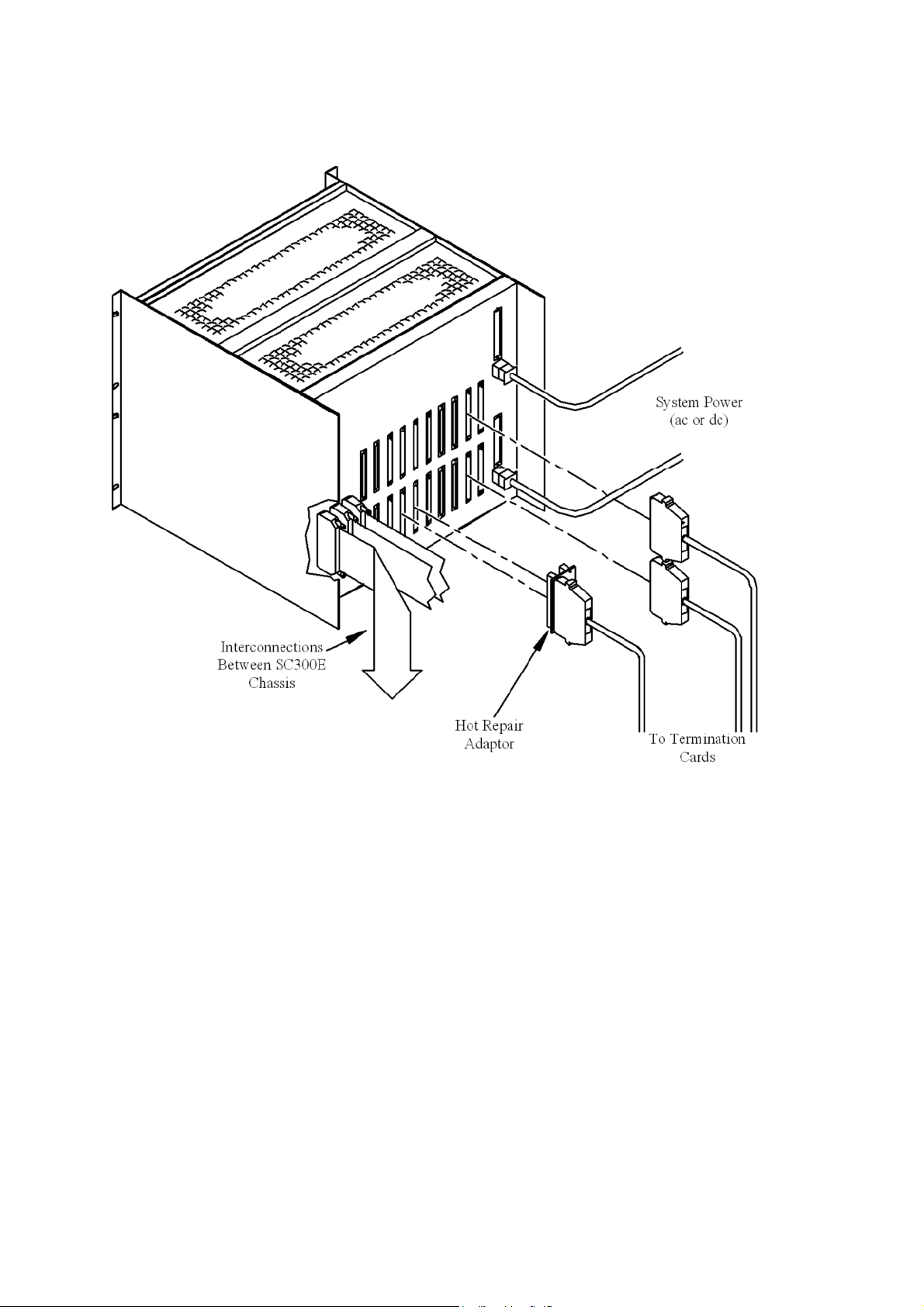

Figure 1-3. Chassis front view

Page 5

Chassi

s

Model

s

October

2005–

Issue 4

5

Triguard

SC300E Chassis Models

Figure 1-4. Chassis rear view

Page 6

6

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

Figure 1-5. Chassis rear view showing cabling arrangement

Page 7

Chassi

s

Model

s

October

2005–

Issue 4

7

Triguard

F

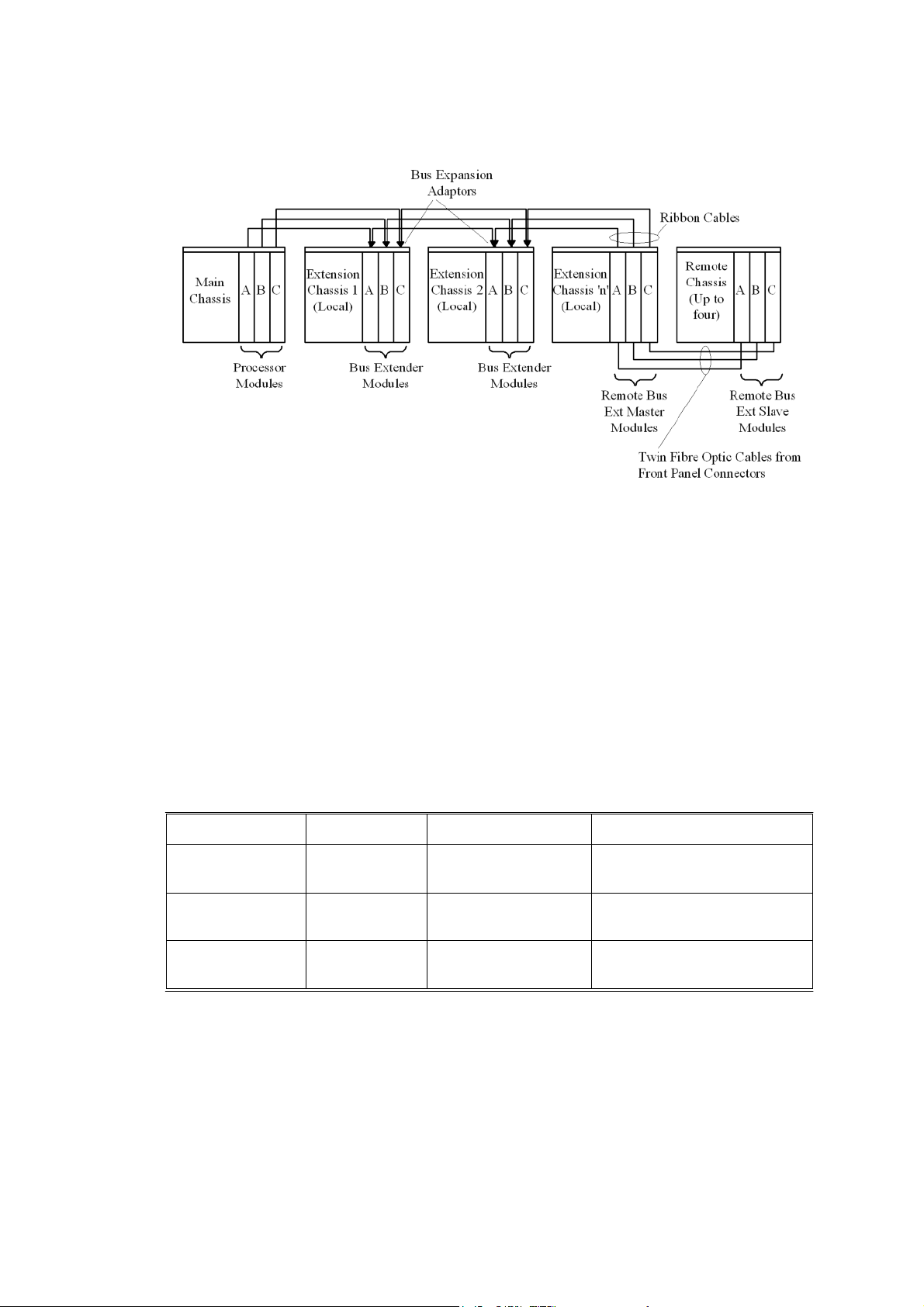

igure 1-6. Chassis interconnections for system layout with remote chassis

SC300E Chassis Models

CHASSIS TECHNICAL DATA

The chassis variants covered by this document differ only in the basic equipment (excluding I/O

modules) fitted into them and whether they can be powered from 110/230Vac or 24Vdc. Table

1-1 lists the details of each variant.

Type No

CXP10A11

CXP10D24

CXB10A11

Type

Main

Main

Extension

Table 1-1. Chassis variants

110/230Vac

24Vdc

110/230Vac

Power

Equipment fitted

3 Processors

2 Power Supplies

3 Processors

2 Power Supplies

3 Bus Extenders

2 Power Supplies

Page 8

8

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

Table 1-1. Chassis variants

Type No

CXB10D24

CXM10A11

CXM10D24

CXS10A11

CXS10D24

Type

Extension

Extension Master 110/230Vac

Extension Master 24Vdc

Extension Slave

Extension Slave

Power

24Vdc

110/230Vac

24Vdc

ASSOCIATED DOCUMENTATION

Reference

3 Bus Extenders

2 Power Supplies

3 Remote Bus Extender Masters

2 Power Supplies

3 Remote Bus Extender Masters

2 Power Supplies

3 Remote Bus Extender Slaves

2 Power Supplies

3 Remote Bus Extender Slaves

2 Power Supplies

Title

Equipment fitted

008-5100

008-5098

008-5105

008-5106

008-5115

008-5117

008-5118

008-5217

MPP Processor Module User Manual

PDC24/PAC Chassis Power Supplies User Manual

MBB Bus Extender Module User Manual

THR Hot Repair Adaptor User Manual

TBA Bus Expansion Ad

MRB04XM Remote Bus Extender Master Module User Manual

MRB01XS Remote Bus Extender Slave Module

TBT Bus Terminator User Manual

aptor User Manual

Page 9

Chassi

s

Model

s

October

2005–

Issue 4

9

SPECIFICATION

24Vdc

(

CXS10D24

):

16.2

kg

Model

Triguard

See under “Weight as supplied”

SC300E Chassis Models

Construction

Finish

Cooling

Overall size (mm)

Overall size (inches)

Weight empty

Weight as supplied (no I/O modules)

2mm aluminium alloy to BS5251(NS4)H4

Anodised

Convection cooled via ventilation holes in top and

bottom

483W x 400H x 486D

19W x 15.8H x 19.2D

8.6 kg

M

ain chassis:

110/230Vac (

24Vdc (

Extension chassis:

110/230Vac (

24Vdc (

Master remote chassis:

110/230Vac (

24Vdc (

Slave remote chassis:

110/230Vac (

surfaces

CXP10A11):

CXP10D24):

CXB10A11):

CXB10D24):

CXM10A11):

CXM10D24):

CXS10A11):

17.2 kg

15.1 kg

16.2 kg

17.2 kg

15.1 kg

16.2 kg

16.2 kg

Page 10

10

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

ENVIRONMENTAL SPECIF

The maximum ambient temperature measured at the hottest point within the Triguard system

shall

not be greater than 60 degrees centigrade.

Temperature operating:

Temperature

Humidity:

EMC/RFI

Vibration/Shock:

Certification:

General Certification:Ref. Triguard SC300E Product Guide (ref 008-5209).

storage:

Immunity:

ICATION

+5°C to +60°C

-

25°C to +70°C

5% to 95% non-condensing at ambient < 40°C

Tested and certified to IEC 1131-Part 2 1994

Tested and certified to IEC 1131-Part 2 1994

TRANSPORT AND HANDLING

The chassis must be transported and stored in its original packing material which should be

retained

for this purpose.

Page 11

Chassi

s

Model

s

October

2005–

Issue 4

11

Triguard

SC300E Chassis Models

TECHNICAL DESCRIPTIO

N

PHYSICAL

The chassis box has two s

bolted

to

top and bottom plates and to a multilayer printed board backplane that carries all

module

facilitate c

partitions

processors.

insertion/e

insertion. The PSU slots have guide pins at the lower right and, if the chassis is an ac variant,

ac power supply studs at the upper left to prevent the insertion of dc power u

connections and interconnections. The top and bottom plates are perforated to

ooling. The plates also carry guides for the I/O modules and support vertical

separating and screening the I/O modules from the power supplies and the

The front edges of the top and bottom plates are flanged to engage the

jection levers on the modules and the flanges have guide marks to assist module

ide plates with flanges to enable 19 inch rack mounting, they are

nits.

Mechanical coding blocks

All Input/Output modules carry two mechanical coding blocks equipped with pins which mate

with

holes in corresponding blocks in the chassis and prevent the module being inserted into

the wrong slot. The pins in the module coding blocks are factory installed in a pattern

determined by the module and corresponding set screws are removed from the chassis coding

blocks

to

enable fitting. Unused holes are plugged with set screws.

The chassis mechanical coding block configurations are given in Table 2-1.

Figure 2-1 shows an unpopulated chassis but the presence of ac power supply studs signifies

that

it is an ac

for other variants they would contain the modules detailed in Table 1-1.

variant. In a main chassis the three right hand slots would contain processors,

Page 12

12

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

Nomenclature

MDI32BIS (3-2-0)

MDI16BNS

MDI

32FIS

MDO32BNS

MDO16FNS

MAD32LAD/MAD

MAO04NND

MHB44IND

MSR04XI

MDI32BIS (3-2-1)

Table 2-1. Chassis/Module mechanical coding configurations

Module mechanical coding positions

Upper coding block

1 2 3 4 1 2 3 4

x x x x

x x x x

x x x x

x x x x

x x x x

x x x

x x x

x x x x

X

x x x x

x x x

Lower coding block

The coding positions shown can be used for both module and chassis settings.

For MODULE setting X = INSERT PIN

For CHASSIS setting X = REMOVE SCREW

Page 13

Chassi

s

Model

s

October

2005–

Issue 4

13

Triguard

SC300E Chassis Models

AC PSU stud

Slot for PSU 1

Slot for PSU 2

Power supply slots

1 and 2

I/O module slots

1

to

10

Upper coding

blocks

Pro ces sor slo ts

A, B,C

PSU guide pin

Module guides

Figure 2-1. Front view of unpopulated chassis

Lower coding

blocks

Page 14

14

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

BACKPLANE

Figure 2-2. Rear view of chassis showing backplane detail

The backplane is a multilayer printed circuit bo

and

carries all the interconnections and input/output connectors.

The backplane provides:

• A dual power and ground plane distribution system

• Processor to processor and processor to I/O module communicat

• ‘Rear plug up’ field I/O connectors

ard that forms the rear plate of the box chassis

ion buses

Page 15

Chassi

s

Model

s

October

2005–

Issue 4

15

Triguard

SC300E Chassis Models

• A ‘rear plug up’ expansion connector for each bus

• A rear mounted diagnostic port for each processor

• Polarised power input connectors

•

• Spade terminal earth connectors for optional chassis earthing

• Spade terminal earths for optional Field I/O cable earthing

Many of the above functions are allocated specific areas with alphabetic references on the

backplane as shown in Table 2-2.

PSU status output connectors

Table 2-2. Backplane areas and their function

Area

a

b

c I/O Field Connectors

d

Function

System bus

I/O Field Connectors

System bus

e

f

g

h

i

k Power input connectors

Expansion bus connectors

Watchdog timer connectors (not active)

Diagnostic connectors

Power supply units

PSU status connectors

Rear plug up technique

In the ‘rear plug up’ technique, connectors fitted to the front of the backplane have wire wrap

tails

protruding from the back of the board and are fitted with shrouds to form rear connectors.

The technique is used on the three expansion buses in area ‘e’ and on all the Field I/O

connectors in areas ‘b’ and ‘c’. The connectors are all DIN41612 types.

CONNECTOR DETAILS

The following pages contain details and pinouts of the backplane connectors viewed from the

rear.

Area ‘a’ -

System bus

Area ‘a’ contains the system bus connections to connector J1 on each I/O module.

Page 16

16

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

‘X’ signifies a pin fitted

Figure 2-3. Field I/O connectors ‘b’ and ‘c’ layout

Page 17

Chassi

s

Model

s

October

2005–

Issue 4

17

Triguard

SC300E Chassis Models

Areas ‘b’ and ‘c’ -

The connectors in areas ‘b’ and ‘c’ are the field connectors for the I/O modules and, apart from

pin

1c

which is always chassis earth, the pin functions depend upon the module in use in each

slot.

Refer to the User Manual for the module for details of the pin functions. Figure 2-3 shows

the

layout of the connectors; ‘x’ signifies

fitted.

None of the pins in the middle column are fitted. The ‘rear plug up’ shrouds (Figure 2-4)

fitted to all Field I/O connectors support connector retention. When I/O modules are fitted as a

Hot

Repair pair, special Hot Repair Adaptors are fitted to the appropriate Field connectors (Ref.

Section

1.6, Associated documentation).

Field I/O

a pin available for use, ‘o’ signifies that the pin is not

Figure 2-4. Field connector shroud and coders

Area ‘d’ -

The three connectors in area ‘d’ connect th

system

setting by linking them together. Figure 2-5 shows the connector layout and Figure 2-6 shows

the identification link chassis address coding for all the chassis in a system.

NOTE -

System bus

e processor modules and interface modules to the

bus. Pins 7 to 10 in columns b and c of the connectors are used for chassis address

Default setting is with no links fitted.

Page 18

18

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

UNIT

ID

‘X’ signifies a pin fitted

Figure 2-5. Connectors ‘d’ layout showing chassis address link location

Page 19

Chassi

s

Model

s

October

2005–

Issue 4

19

Triguard

SC300E Chassis Models

Figure 2-6. Chassis address link coding

Page 20

20

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

Area ‘e’ -

Connectors in area ‘e’ provide the means to extend the system bus to extension chassis. If

more than one extension chassis is to be linked in, an Expansion Bus Adaptor must be fitted

to these connectors (Ref. Section 1.6, Associated documentation).

Processor expansion bus

‘X’

signifies a pin fitted

Figure 2-7. Connector ‘e’ layout

Page 21

Chassi

s

Model

s

October

2005–

Issue 4

21

Triguard

SC300E Chassis Models

Area ‘g’ -

The connectors (26 pin IDC) in area ‘g’ are diagnostic ports, one for each processor; their

signals are the same as those available at the diagnostic ports on the processor fron

(refer to the MPP User Manual 008-5100).

Processor diagnostic ports

Areas ‘h’ -

Do not remove the clear plastic covers from the backplane areas ‘h’, the power supply

terminations

Each area ‘h’ contains the connections at the rear of the related PSU, they are not normally

available and are protected by a clear plastic cover which should not be removed.

When ac power is used an AC Stud is fitted through the backplane at the top right of each area

‘h’ (viewed from the rear) to prevent DC Power Units being fitted.

Areas ‘j’ -

Power supply unit connectors

WARNING

they are protecting may carry lethal voltages.

Power supply status

t panels

Each area ‘j’ contains the alarm connector (Figure 2-8) for the adjacent Power Supply Unit

which enables remote, volt free alarm indications. The connectors are 4 pin Phoenix Combicon.

Pins

1 and 2 are connected across a pair of relay contacts which are normally open. During

normal

operation the relay is energised and the contacts are closed but will open under fault

conditions such as:

Over tempe ratur

Over or under voltage

Relay failure

Loss of input power

Pin 3 is linked to pin 1 and pin 4 is linked to pin 2 to duplicate the output.

The PSHARE LINK above the lower alarm connector carries a signal between the two power

units

to

enable power sharing so that both units carry an equal share of the load.

e

Page 22

22

Chassi

s

Model

s

October

2005–

Issue 4

T

riguard

SC300E

Figure 2-8. PSU Alarm connectors

Areas ‘k’ -

Each Area ‘k’ contains the Power Input connector (Figure 2-9) for the related PSU, the same

input

connector, a 9-way MATE-N-LOK, can be used for either ac or dc power supplies

depending upon which type of PSU is fitted.

Power input

Figure 2-9. Power input connectors

EARTHING

The chassis metalwork is extensively and efficiently earthed to the Power Input earth via the

backplane track and the earthing

terminals

areas ‘b’ and ‘c’.

are available adjacent to the Power Input connectors and all the Field connectors in

pads on the front of the backplane. Additional earthed spade

Page 23

Chassi

s

Model

s

October

2005–

Issue 4

23

Triguard

SC300E Chassis Models

SERVICING

SCOPE

No servicing is necessary.

Do not remove the clear plastic covers from the backplane areas ‘h’, the power supply

terminations

Chassis repair is by unit replacement. A faulty chassis is not repairable in the field, it should be

replaced by a new unit and returned for repair.

SERVICE SUPPORT

WARNING

they are protecting may carry lethal voltages

SPARE PARTS

Spare parts and technical advice can be obtained from your local area office.

Loading...

Loading...