Rockwell Automation CENTERLINE Motor Control Center Servicing Flooded Equipment User Manual

Page 1

Instructions

CENTERLINE® Motor Control Centers

Servicing Water Damaged Equipment

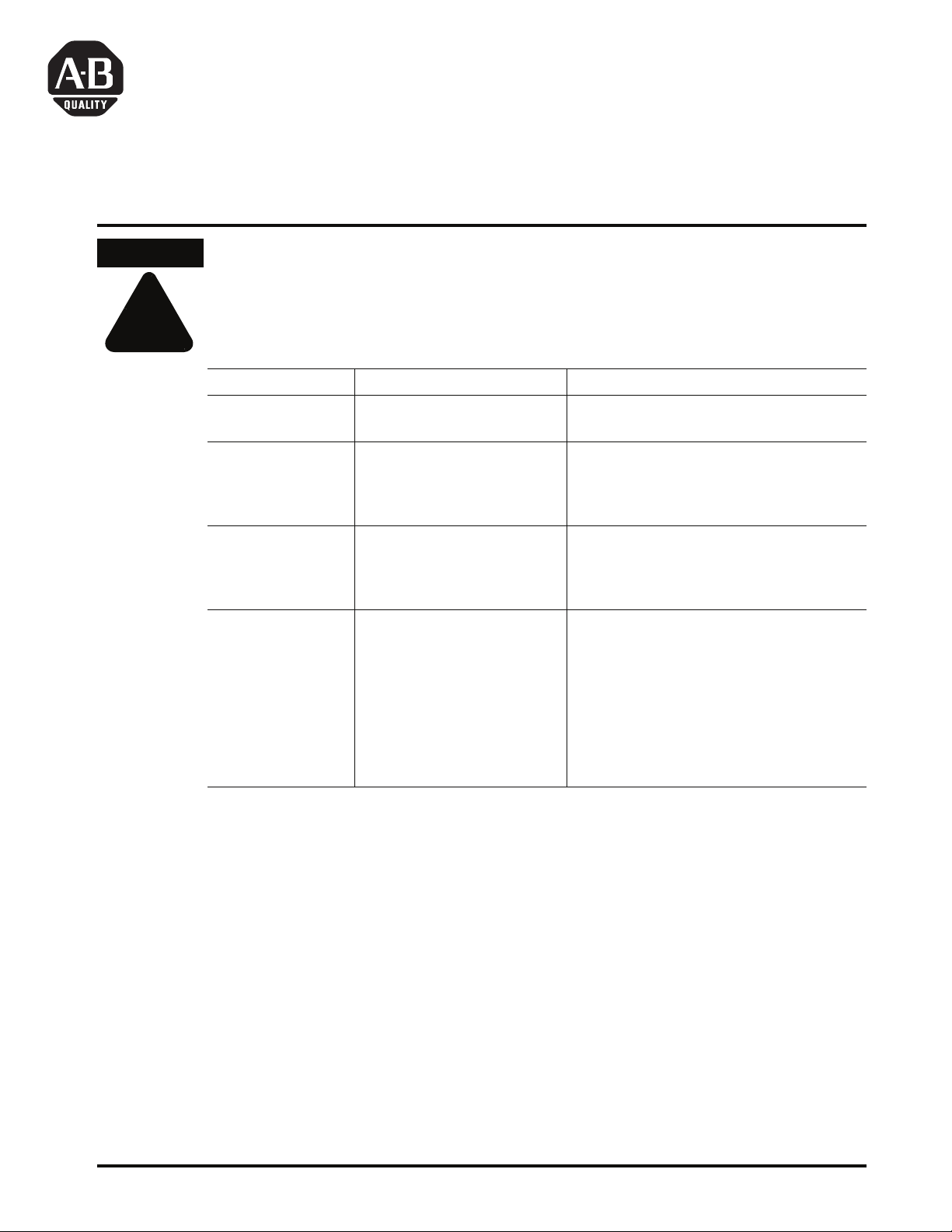

ATTENTION

!

Water-damaged Rockwell Automation electronic and electro-mechanical products normally are

presumed to be beyond repair. Damage can result from immersion, submersion or exposure to

excessive moisture brought about through flooding, fire fighting activities, hurricanes, sewage

overflows, and the like. Due to potential problems with water-borne sediments and contaminants,

damage to insulating materials, and rust and corrosion to metal parts, users should replace the

affected products in total or take other action as described in the following table:

Type Examples Required Action

Electronic products Programmable controllers, I/O

cards, drives, video displays

Normally

non-repairable

electro-mechanical

products

Normally repairable

electro-mechanical

products

Mechanical products Metal cabinets and enclosures,

Push buttons, relays, small

contactors, limit switches

Motors, large contactors,

starters

sheaves, couplings, bushings,

belts, gear reducers and

mounted bearings

Remove product from service and scrap or

discard.

Remove product from service and scrap or

discard.

Product may be repairable in some instances,

as determined by Rockwell Automation on a

case-by-case basis. Otherwise, remove

product from service and scrap or discard.

Return the product to service only following

proper cleaning, re-lubrication, repair or

replacement of any damaged components,

and inspection. Where applicable, qualified

personnel should conduct appropriate

electrical insulation resistance testing to

ensure that products and associated field

wiring are free from short circuits and

grounds.

On a normal for-fee basis, users should forward affected repairable products to an appropriate

Rockwell Automation service and repair facility for evaluation, assessment of repair costs, and

possible reconditioning following the Company's regular factory repair or remanufacturing

procedures. Users should call their local Rockwell Automation office or applicable authorized

product distributor for assistance in locating an appropriate service and repair facility and to receive

an estimate of applicable inspection and repair charges.

Users should scrap or discard all affected non-repairable products and components in a way that

eliminates the possibility of their reuse by anyone, as well as in compliance with applicable

hazardous waste and environmental laws and regulations.

Users should assume that water-immersed Rockwell Automation equipment has been damaged, and

Rockwell Automation cannot warrant or take responsibility for any damaged equipment, regardless

of its original manufacturer's warranty. Products subsequently repaired or reconditioned by

Rockwell Automation will be warranted in accordance with the Company's then current published

repair warranty.

For further important safety information refer to the NEMA publication entitled “Guidelines of

Handling Water-Damaged Electrical Equipment.”

www.nema.org/stds/water-damaged.cfm#download

1 Publication 2100-IN063A-EN-E—October 2005

Page 2

2 CENTERLINE® Motor Control Centers Servicing Water Damaged Equipment

Introduction

Instructions

The intent of this publication is to provide guidance for servicing Bulletin

2100 CENTERLINE Motor Control Centers that have been water damaged.

It is the general recommendation of Rockwell Automation that water damaged

equipment be replaced. However, in the event the user chooses to put the

water damaged equipment back into service, this publication provides

guidance restoring the motor control center.

Water damaged equipment is assumed to have been damaged.

Therefore, Rockwell Automation cannot warrant the product or take

responsibility for repaired damaged equipment.

Motor Control Center Units

Motor control devices and components are assumed to have been water

logged and damaged.

Due to potential problems because of sediments left in the components,

contaminated insulating materials and rust or corrosion to metal parts, it is

necessary to replace the items in total. Thus, plug-in unit inserts must be

replaced with new units. Water logged frame mounted controller sections must

be replaced with a new frame mounted controller sections.

Motor Control Center Sections

It is recommended that water damaged motor control center sections be

replaced. However, should the decision be made to restore the motor control

center sections, follow the steps outlined below.

For assistance ordering replacement MCC units and section, contact Rockwell

Automation or your local Allen-Bradley distributor.

ATTENTION

To prevent injury or death to personnel servicing equipment,

make sure that the motor control center remote power

source(s) is disconnected and the respective disconnect(s) is

locked in the OFF/O position.

!

1. Remove all water damaged plug-in units and properly discard. (For

removal of units, refer to the Installing and Removing Plug-in Units section

of CENTERLINE Motor Control Center Instruction Manual,

publication number 2100-IN012x-EN-P.)

Publication 2100-IN063A-EN-E—October 2005

2. Open doors, remove covers and disassemble motor control center to

permit access to the horizontal and vertical bus.

Page 3

CENTERLINE® Motor Control Centers Servicing Water Damaged Equipment 3

3. Wash down (hose down under moderate pressure) the motor control

center and the various parts with clean water. Do not use any cleaning

solvents.

4. Dry out the motor control center. It is recommended that heated dry air

be used. The temperature of the air should not exceed 85

o

(approximately 190

F).

o

C

Additional assistance is available from service companies that specialize

in airing and drying out water damaged equipment.

5. Reassemble the motor control center after it has been thoroughly dried

out. For additional assistance in reassembling the motor control center,

contact Rockwell Automation Global Manufacturing Solutions to

arrange for field service or others who specialize in water damaged

equipment restoration or replacement. Contact the Low Voltage Motor

Control Center Post Shipment Support for replacement parts.

6. Conduct an electrical bus insulation resistance test to make sure the

motor control center and field wiring are free from short circuits and

grounds. Conduct this test using an insulation resistance tester (megger)

with a potential of 500-1000 volts.

This test should be conducted phase-to-phase, phase-to-ground and

when applicable, phase-to-neutral. Typical insulation resistance values

are 50 megohms or greater. Next, check the field wiring; for example,

motor cables and/or incoming line cables.

NOTE: The insulation resistance values are affected by dampness

which may cause a considerably lower insulation resistance reading. If

this is the case and insulation resistance values are below one megohm,

it is recommended that the equipment be dried out a second time. Dry

out the motor cables by injecting a low voltage current. When the

equipment is dry, repeat the insulation resistance test. The minimum

accepted value for insulation resistance is one megohm.

7. Install the replacement plug-in units. (For installation of units, refer to

the Installing and Removing Plug-in Units section of CENTERLINE Motor

Control Center Instruction Manual, publication number

2100-IN012x-EN-P.)

Publication 2100-IN063A-EN-E—October 2005

Page 4

w

ww.ab.com/mcc

Publication 2100-IN063A-EN-E—October 20054 Copyright © 2005 Rockwell Automation, Inc. Printed in the U.S.A.

Loading...

Loading...