Page 1

Capacitive Sensors

Bulletin Number 875F, 875L

User Manual

Original Instructions

Page 2

Capacitive Sensors User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WA RN I NG : Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 3

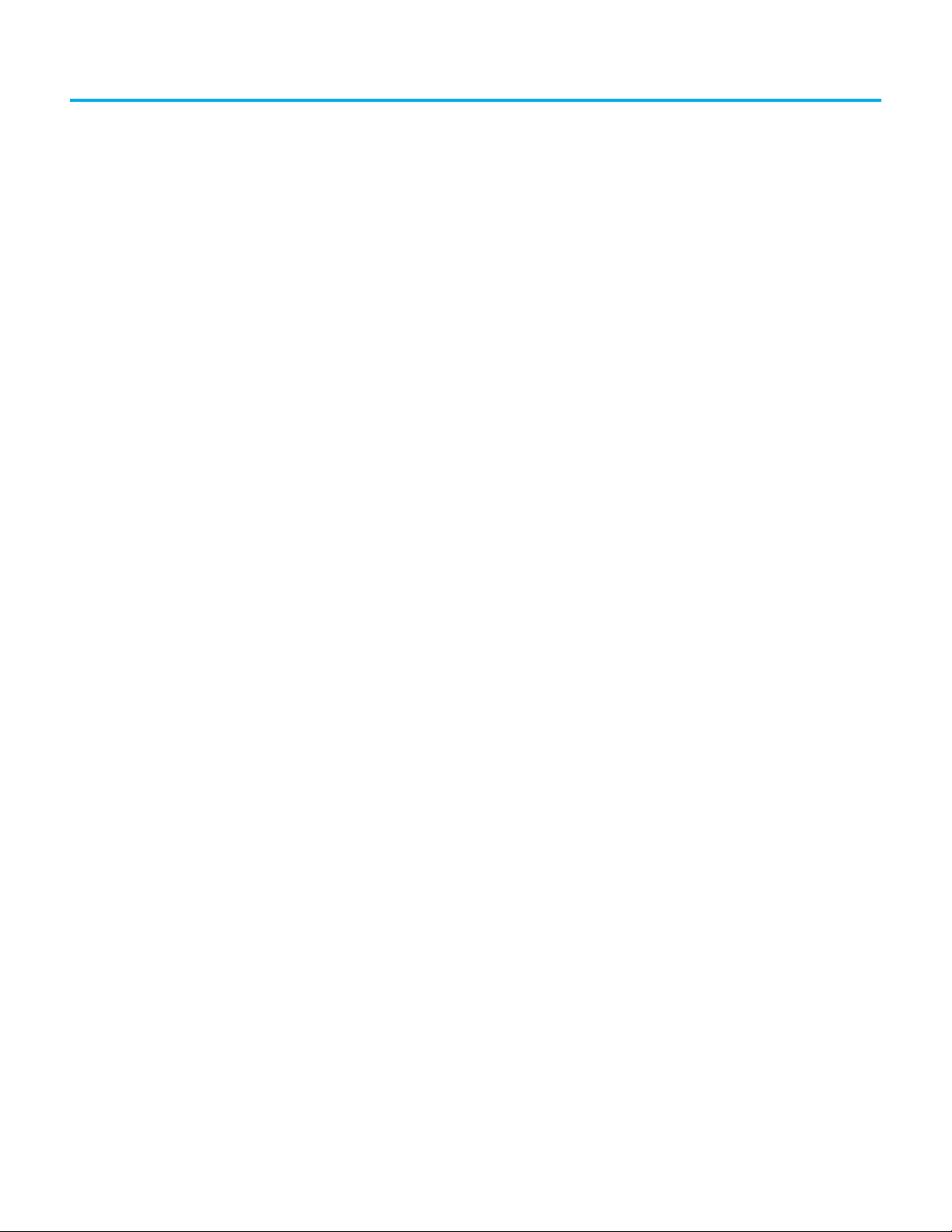

Table of Contents

Preface

Who Should Use This Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Download Firmware, AOP, EDS, and Other Files . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 1

Product Overview Non-IO-Link Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

875L AC Cylindrical Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

875F DC Flat Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IO-Link Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

875L DC Cylindrical Cap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2

Configure with IO-Link Common Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Identification Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Observation Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parameter Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Diagnosis Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3

Switch Output Configuration Sensor Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SSC (Switching Signal Channel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Switchpoint Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Hysteresis Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Margin Alarm 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Temperature Alarm (TA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

External Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Input Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Logic Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

AND Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

OR Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

XOR Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Gated SR-FF Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Timer Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Output Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Output Stage Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 3

Page 4

Chapter 4

Teach Procedure External Teach (Teach-by-wire). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Teach-by-wire Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Teach from IO-Link Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Single-point Mode Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Two-point Mode Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Windows Mode Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 5

Sensor-specific Adjustable

Parameters

Local or Remote Adjustment Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Process Data and Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Sensor Application Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Temperature Alarm Threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Safe Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Event Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Quality of Run (QoR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Quality of Teach (QoT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Filter Scaler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Status Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Appendix A

Specifications Non-IO-Link Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

875L AC Cylindrical Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

875F DC Flat Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

IO-Link Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

875L DC Cylindrical Cap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Appendix B

Parameter Values Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

SSC Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Output Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Sensor-specific Adjustable Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Diagnosis Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 5

Preface

This manual is a reference guide for Bulletin 875F and 875L capacitive

proximity sensors with IO-Link. It describes how to install, configure, and use

the device.

Who Should Use This Manual?

Ter mi nol ogy

This manual contains important information regarding installation. Qualified

personnel familiar with proximity capacitive sensors must be read and

understand this manual completely. We recommend that you read the manual

carefully before installation of the sensor. Save the manual for future use.

Te rm D ef in it i on

I/O Input/output

PD Process data

PLC Programmable logic controller

SIO Standard input/output

SP Setpoints

IODD I/O device description

IEC International Electrotechnical Commission

N.O. Normally open contact

N.C. Normally closed contact

NPN Pull load to ground

PNP Pull load to V+

Push-Pull Pull load to ground or V+

QoR Quality of run

QoT Quality of teach

UART Universal asynchronous receiver-transmitter

SO Switching output

SSC Switching signal channel

Download Firmware, AOP, EDS, and Other Files

Additional Resources

Download firmware, associated files (such as AOP, EDS, and DTM), and access

product release notes from the Product Compatibility and Download Center at

rok.auto/pcdc

.

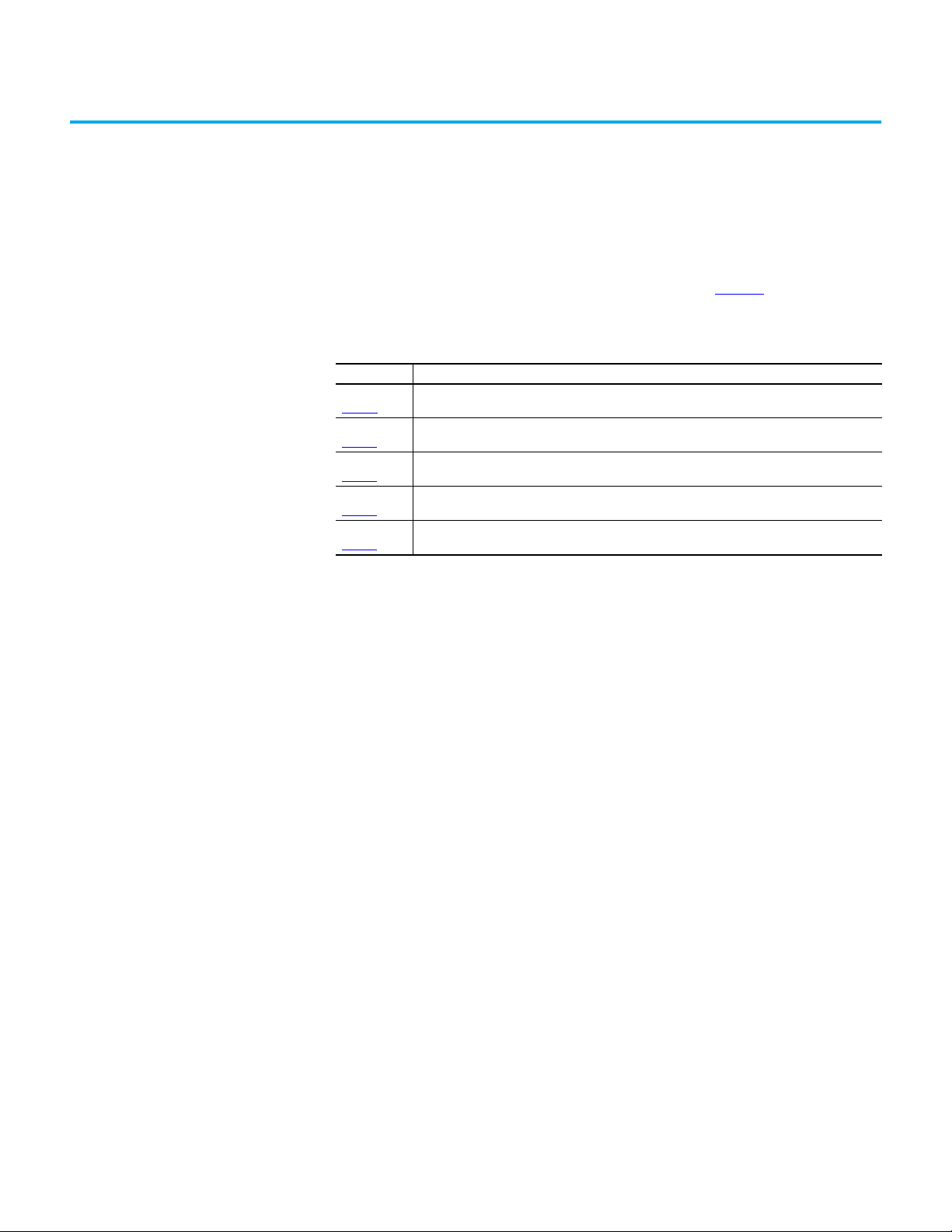

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

EtherNet/IP Network Devices User Manual, ENET-UM006

Ethernet Reference Manual, ENET-RM002

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial system.

Product Certifications website, rok.auto/certifications

. Provides declarations of conformity, certificates, and other certification details.

You can view or download publications at rok.auto/literature

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 5

Describes how to configure and use EtherNet/IP™ devices to communicate on the EtherNet/

IP network.

Describes basic Ethernet concepts, infrastructure components, and infrastructure features.

.

Page 6

Notes:

6 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 7

Product Overview

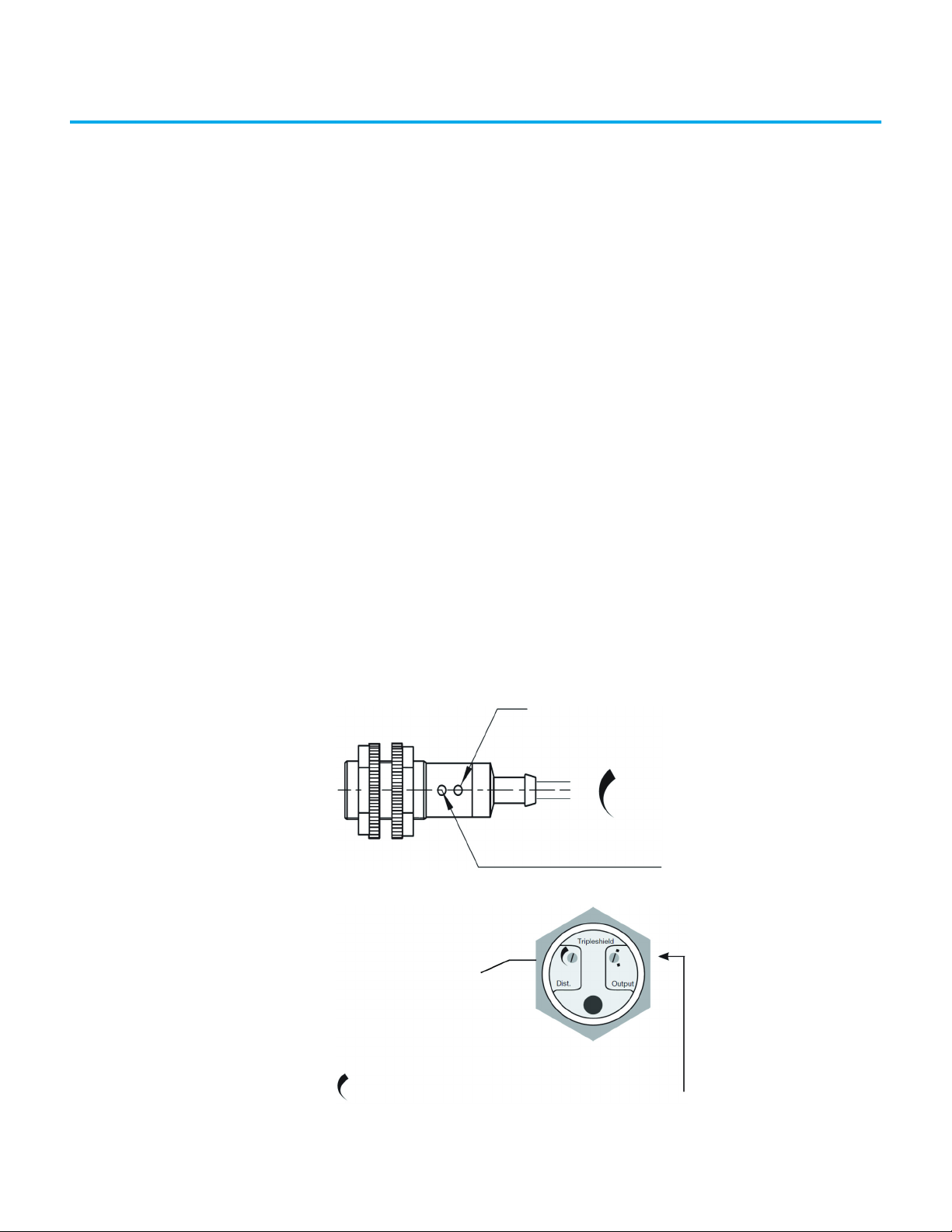

Status Indicator

Sensitivity

Max

Min

Sensitivity

Adjustment AC Models

Programmable N.O. or N.C.

)by selector switch back view)

(2-wire device back view)

Max

Min

Sensitivity

Non-IO-Link Sensors 875L AC Cylindrical Cap

• Capacitive proximity switches with either sensing distance:

- M18 housing: 8 mm (0.31 in.) flush mounted in metal or sensing

distance 12 mm (0.47 in.) non-flush mounted. Gray M18 polyester

housing with 2 m (6.6 ft) PVC cable or M12 plug.

- M30 housing: 16 mm (0.63 in.) flush mounted or 25 mm (0.98 in.)

sensing distance non-flush mounted. Gray M30 polyester housing

with 2 m (6.6 ft) PVC cable or plug.

• 2-wire AC output with make (N.O.) or break (N.C.) switching. Ideal for

use in level and plastic machinery applications.

•SCR output

• Make or break switching function

• Status indicators

• High noise immunity

• Flush and non-flush types

• Plug and cable versions

Chapter 1

Housing

Figure 1 - M18 Housing

Figure 2 - M30 Housing

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 7

Page 8

Chapter 1 Product Overview

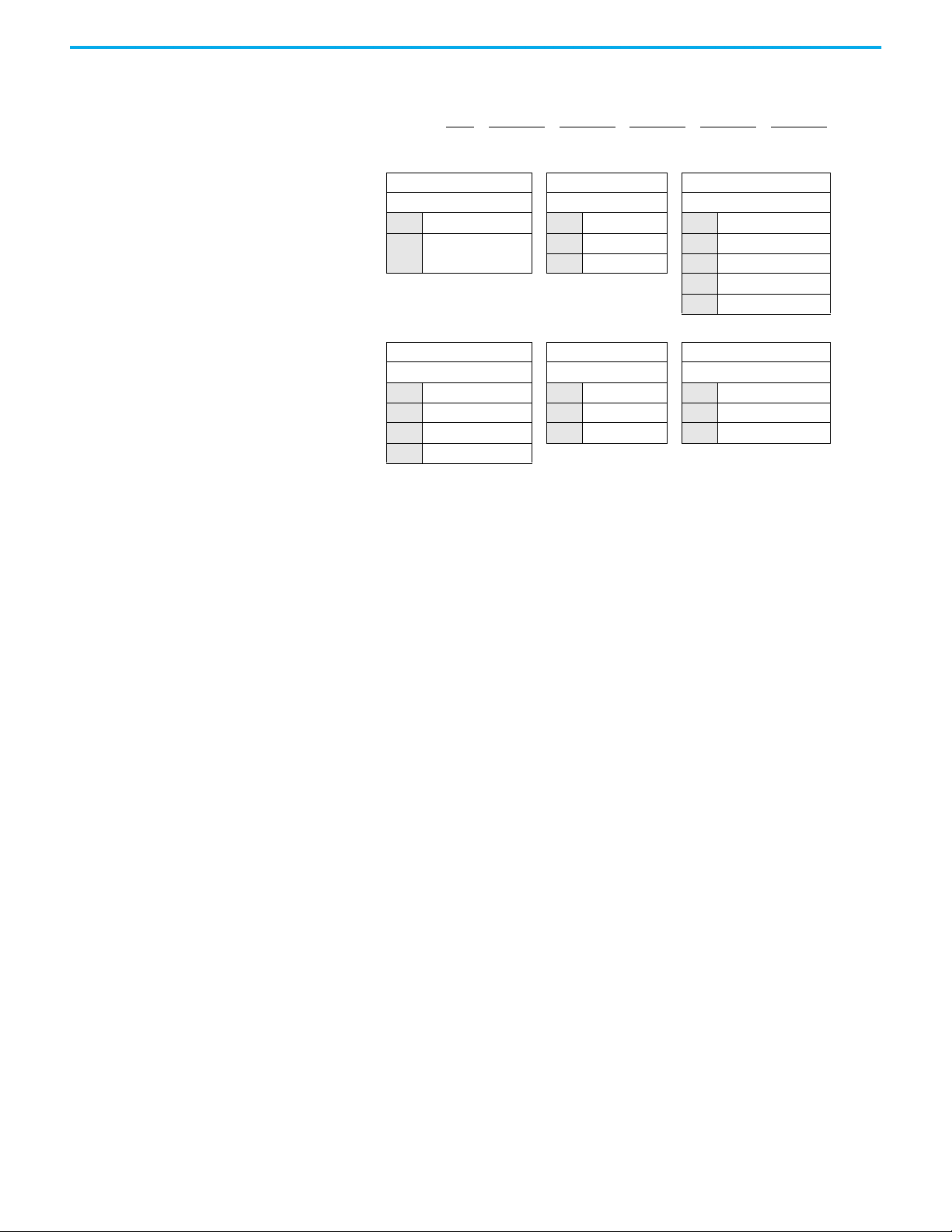

Catalog Number Explanation

875 L - F 8 N 18 A2

ab c d e f

ab c

Housing Style Shielding Sensing Distance

Code Description Code Description Code Description

Cylindrical housing

L

with threaded barrel

de f

Output Function Barrel Diameter Output Type

Code Description Code Description Code Description

N Normally open (N.O.) 18 18 mm (0.71 in.) A2 2 m (6.6 ft) PVC cable

C Normally closed (N.C.) 30 30 mm (1.18 in.) R3 AC micro connector

BN.O./N.C.

FShielded 8 8 mm (0.31 in.)

GUnshielded 12 12 mm (0.47 in.)

16 16 mm (0.63 in.)

25 25 mm (0.98 in.)

875F DC Flat Cap

• Detection of water-based fluids inside a container or tube without direct

contact with the fluids.

• The sensor detects the liquids reliably while compensating for residue

film, moisture, or foam build-up from liquids such as water, milk, bodily

fluids (blood), acid, or alkaline solutions with conductivity as high as

50 mS/cm inside or outside the container wall.

• Flexible and fast universal mounting bracket.

• The sensing principle detects only the level of the liquids while ignoring

foam, film, or build-up that would cause standard capacitive sensors to

detect faultily.

Features

• Compact housing

• Supply voltage: 10…30V DC

• Output: 100 mA, NPN or PNP preset

• Make or break switching function

• Status indication for output and power ON

• Protection: reverse polarity, short circuit, and transients

• Cable and pigtail M8 plug versions

• Excellent EMC performance

• IP65, IP66, IP67, IP68, and IP69K for hose-down applications

•c-UL-us

•Ecolab

8 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 9

Chapter 1 Product Overview

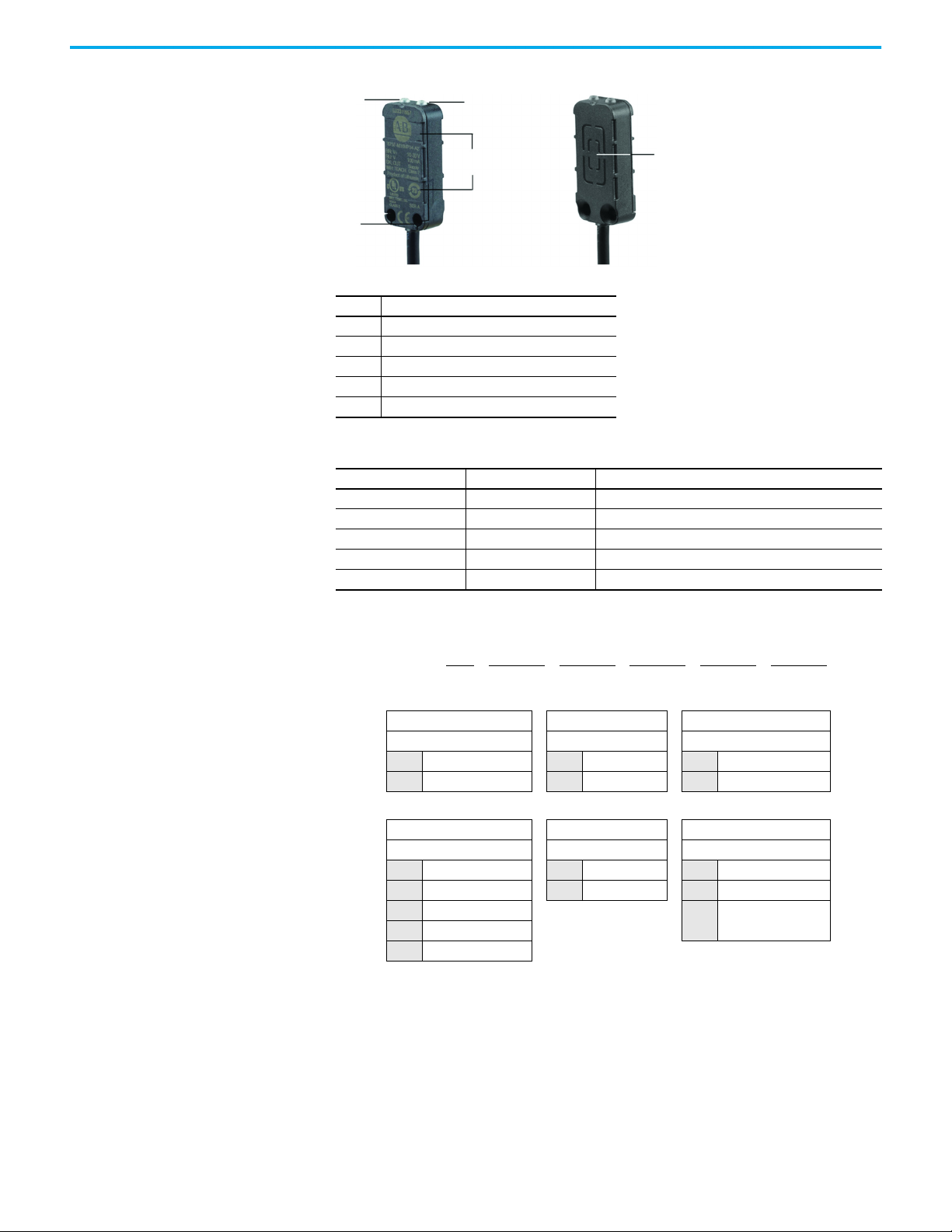

D

BA

C

E

Housing

Item Description

A Yellow status indicator (output)

B Green status indicator (power ON)

C Two M3 mounting holes

D Recessed area for cable strips, 5 mm wide (max)

E Sensing surface

Table 1 - Status Indicators

Green Status Indicator Yellow Status Indicator Output

Flashing 1 Hz OFF Full calibration (2…7 s)

Flashing 1 Hz ON Empty calibration (7…12 s)

— Flashes three times 1 Hz Successful full calibration

— Flashes three times 1 Hz Successful empty calibration

— Flashes ten times 4 Hz Unsuccessful calibration (canceled or error) (>12 s)

Catalog Number Explanation

875 F - M 10 NP 34 A2

ab c d e f

ab c

Housing Style Mounting Sensing Distance

Code Description Code Description Code Description

F Rectangular housing MFlush 10 10 mm (0.39 in.)

de f

Output Function Housing Length Output Type

Code Description Code Description Code Description

NP N.O. PNP 34 34 mm (1.34 in.) A2 2 m (6.6 ft) PVC cable

NN N.O. NPN

CP N.C. PNP

CN N.C. NPN

FP02

0.2 m (0.66 ft) PVC

cable 4-pin DC pico

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 9

Page 10

Chapter 1 Product Overview

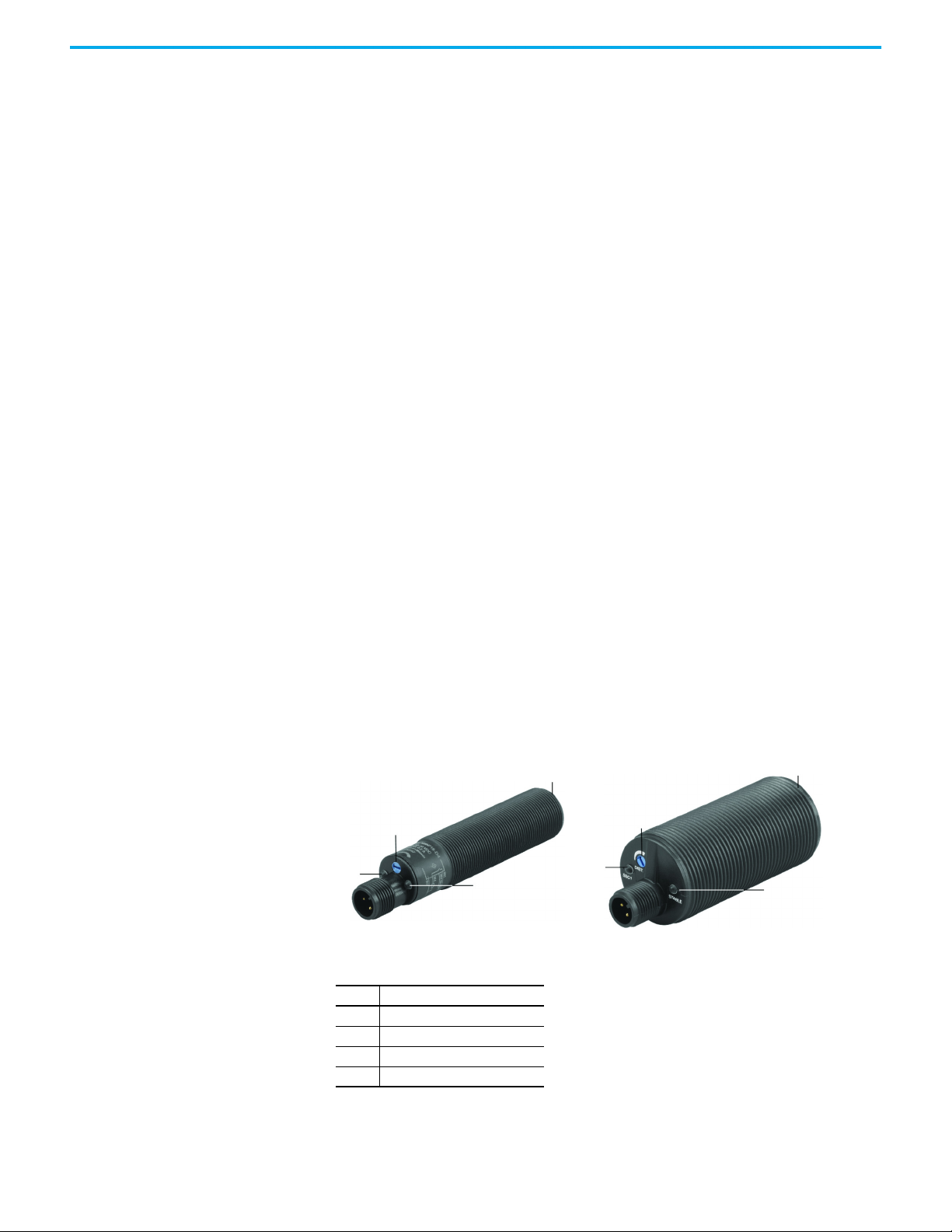

D

D

A

B

C

M18 Housing

M30 Housing

A

B

C

IO-Link Sensors 875L DC Cylindrical Cap

• The sensor can be operated in IO-Link mode once it is connected to an

IO-Link master or in standard I/O mode.

• Adjustable parameters via IO-Link interface: Sensing distance and

hysteresis.

- Sensing modes: single-point, two-point, or window mode.

- Timer functions like: on-delay, off-delay, one shot leading edge, or

trailing edge.

- Logic functions such as: AND, OR, XOR, and SR-FF.

-External input.

- Logging functions: Maximum temperatures, minimum temperatures,

operating hours, operating cycles, power cycles, minutes above

maximum temperature, minutes below minimum temperature, and

so on.

Features

• A complete family. Availability in M18 in a robust PBT housing with an

operation of 2…10 mm (0.08…0.39 in.) flush or 3…15 mm (0.12…0.59 in.)

non-flush.

• The output can be operated either as a switching output or in IO-Link

mode.

• Fully configurable via output IO-Link v 1.1. Electrical outputs can be

configured as PNP/NPN/Push-pull/External input, normally open or

normally closed.

• Timer functions can be set, such as on-delay, off-delay, and one shots.

• Logging functions: temperatures, detection counter, power cycles, and

operating hours.

• Detection modes: single-point, two-point, and window mode.

• Analog output: In IO-Link mode, the sensor generates 16-bit analog

process data output that represents the dielectric value that the sensor

measures.

Housing

Item Description

A Sensitivity adjustment

10 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

B Yellow status indicator

C Green status indicator

DSensing face

Page 11

Catalog Number Explanation

875 L - M 8 NP 18 A2

ab c d e f

ab c

Housing Style Mounting Sensing Distance

Code Description Code Description Code Description

Cylindrical housing

L

with threaded barrel

de f

Output Function Barrel Diameter Output Type

Code Description Code Description Code Description

NP N.O. PNP 18 18 mm (0.71 in.) A2 2 m (6.6 ft) PVC cable

NN N.O. NPN 30 30 mm (1.18 in.) D4 DC micro connector

CP N.C. PNP

CN N.C. NPN

Chapter 1 Product Overview

MFlush 8 8 mm (0.31 in.)

NNon-flush 12 12 mm (0.47 in.)

16 16 mm (0.63 in.)

25 25 mm (0.98 in.)

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 11

Page 12

Chapter 1 Product Overview

Notes:

12 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 13

Chapter 2

Configure with IO-Link

Bulletin 875 sensors offer five different tabs (shown in Table 2) to describe the

device functionality and operations.

Table 2 - Tab Descriptions

Tab Description

Common

(page 14

Identification

(page 15

Observation

(page 15)

Parameter

(page 16

Diagnosis

(page 17

Provides general product information about sensor specifications and IO-Link IODD information.

)

Provides sensor catalog number, series letter, product firmware, and hardware revisions.

)

Displays real-time measurement information, including distance measurement value, switching

outputs, and operation conditions.

Allows you to configure sensors by modifying parameter settings.

)

Provides information of operation status and sensor health diagnosis, and enables you to restore

)

factory default settings and physically locate the sensor for troubleshooting.

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 13

Page 14

Chapter 2 Configure with IO-Link

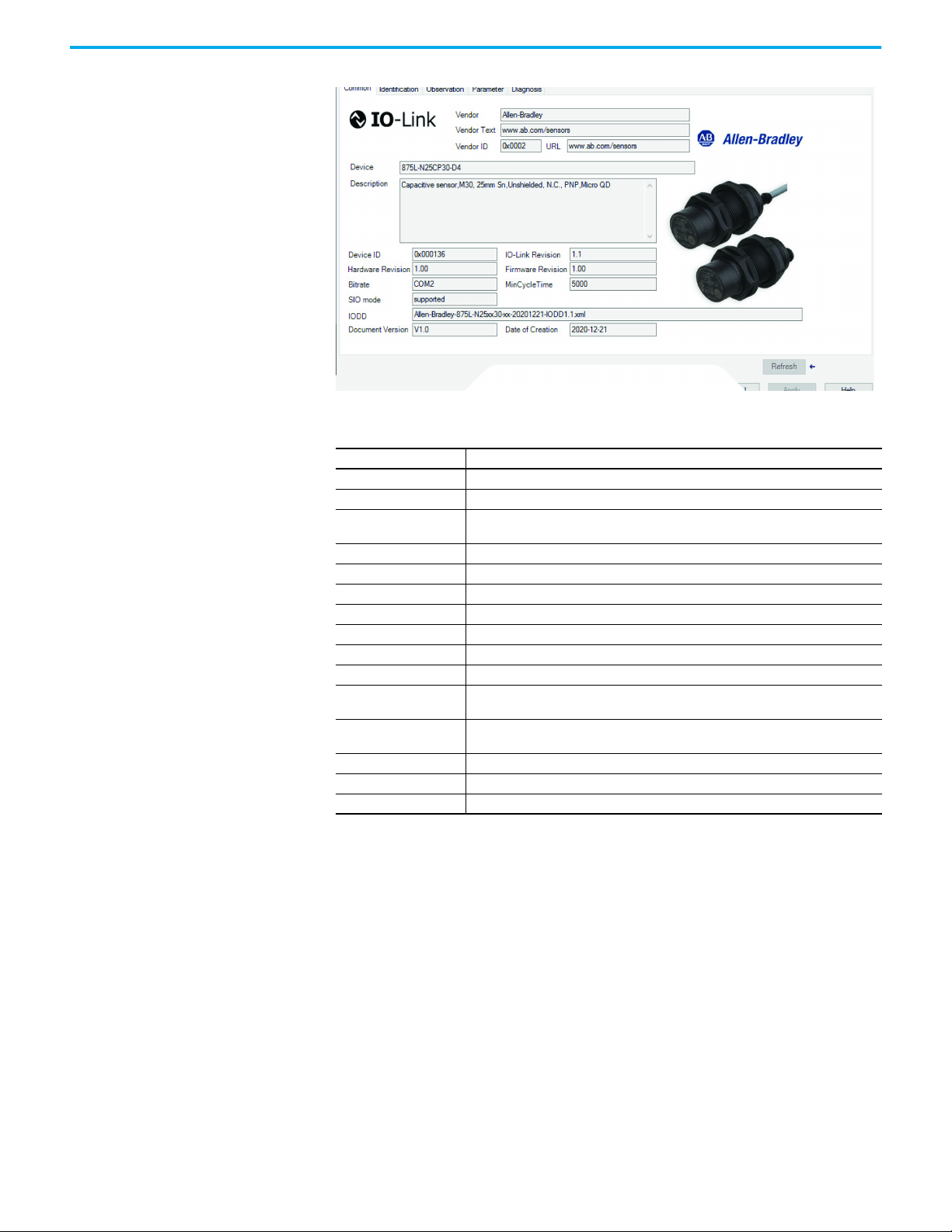

Common Tab

The Common tab contains the following device information:

Parameter Description

Vendor Provides the vendor name of the product.

Vendor Text Field that is used to describe additional product information.

Vendor ID

URL Displays the vendor URL.

Device Provides the specific catalog number of the product.

Description Describes the sensor features and range performance.

Device ID Displays the unique device ID as defined in the IO-Link specifications.

IO-Link Revision Displays the current IO-Link version that the device supports.

Hardware Revision Displays the latest sensor hardware information.

Firmware Revision Displays the latest sensor Firmware information.

Bitrate

SIO Mode

IODD Displays the complete file name of the IODD that is assigned to the product.

Document Version Displays the version control for the IODD.

Date of Creation Displays when the IODD file was creation.

Describes the vendor ID of the manufacturer of the product as designated in the

IO-Link Consortium.

Displays the supported bitrate for communications as defined in the IO-Link 1.1

standard.

Describes whether the sensor is also designed to operate without and IO-Link

connection.

14 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 15

Identification Tab

Chapter 2 Configure with IO-Link

The Identification tab contains the following device information:

Parameter Description

Device Information

Vendor Name The vendor name of the product.

Product Name The product catalog number information.

Product ID Product catalog number information with series letter.

Product Text Product description.

Serial Number Serial number of the device as unique numeric value.

User-Specific Information

Application-Specific

Tag

Revision Information

Hardware Version Hardware version of the 875 sensor that is provided as alphanumeric value

Firmware Version Firmware revision of the875 sensor that is provided as numeric value.

Device-specific name that is assigned to device for device identification. This tag is a

unique identity of each device. You can customize this read/write field.

Observation Tab The Observation tab displays real-time device status. For more information,

see Appendix B on page 37

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 15

.

Page 16

Chapter 2 Configure with IO-Link

Parameter Tab The Parameter tab allows you to configure the sensor. For more information,

see Appendix B on page 37

.

16 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 17

Chapter 2 Configure with IO-Link

Diagnosis Tab The Diagnosis tab provides information on operation status and sensor health

diagnosis. For more information, see Appendix B on page 37

.

Parameter Description

Operating hours

Number of power cycles

Event configurations See Event Configuration on page 30

Maximum temperature -

all-time high [°C]

Minimum temperature -

all-time low [°C]

Maximum temperature

since last power-up [°C]

Minimum temperature

since last power-up [°C]

Current temperature [°C] The current temperature of the sensor.

Detection counter

[cycles]

Minutes above maximum

temperature [min]

Minutes below minimum

temperature [min]

The sensor has a built-in counter that logs every full hour that the sensor has been operational, the maximum hours that can be recorded is

2,147,483,647 hours, this value can be read from an IO-Link master.

The sensor has a built-in counter that logs every time that the sensor has been powered-up, the value is saved every hour, the maximum

numbers of power cycles that can be recorded is 2,147,483,647 cycles, this value can be read from an IO-Link master.

.

The sensor has a built-in function that logs the highest temperature that the sensor has been exposed to during the full operational lifetime.

This parameter is updated once per hour and can be read from an IO-Link master.

The sensor has a built-in function that logs the lowest temperature that the sensor has been exposed to during the full operational lifetime.

This parameter is updated once per hour and can be read from an IO-Link master.

The maximum registered temperature has been since startup. This value is not saved in the sensor.

The minimum registered temperature has been since startup. This value is not saved in the sensor.

The sensor logs every time the SSC1 change state. This parameter is updated once per hour and can be read from an IO-Link master.

The sensor logs how many minutes the sensor has been operational above the maximum temperature for the sensor, the maximum number of

minutes to be recorded is 2,147,483,647. This parameter is updated once per hour and can be read from an IO-Link master.

The sensor logs how many minutes the sensor has been operational below the minimum temperature for the sensor, the maximum number of

minutes to be recorded is 2,147,483,647. This parameter is updated once per hour and can be read from an IO-Link master.

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 17

Page 18

Chapter 2 Configure with IO-Link

Notes:

18 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 19

Chapter 3

Switch Output Configuration

The sensor measures five different physical values. These values can be

independently adjusted and used as source for the Switching Output 1 or 2, in

addition to those an external input can be selected for SO2. After selecting one

of these sources, it is possible to configure the output of the sensor with an

IO-Link master following the steps that are shown in the Switching Output

configuration (Figure 3

Once the sensor has been disconnected from the master, it switches to the SIO

mode and keeps the last configuration setting.

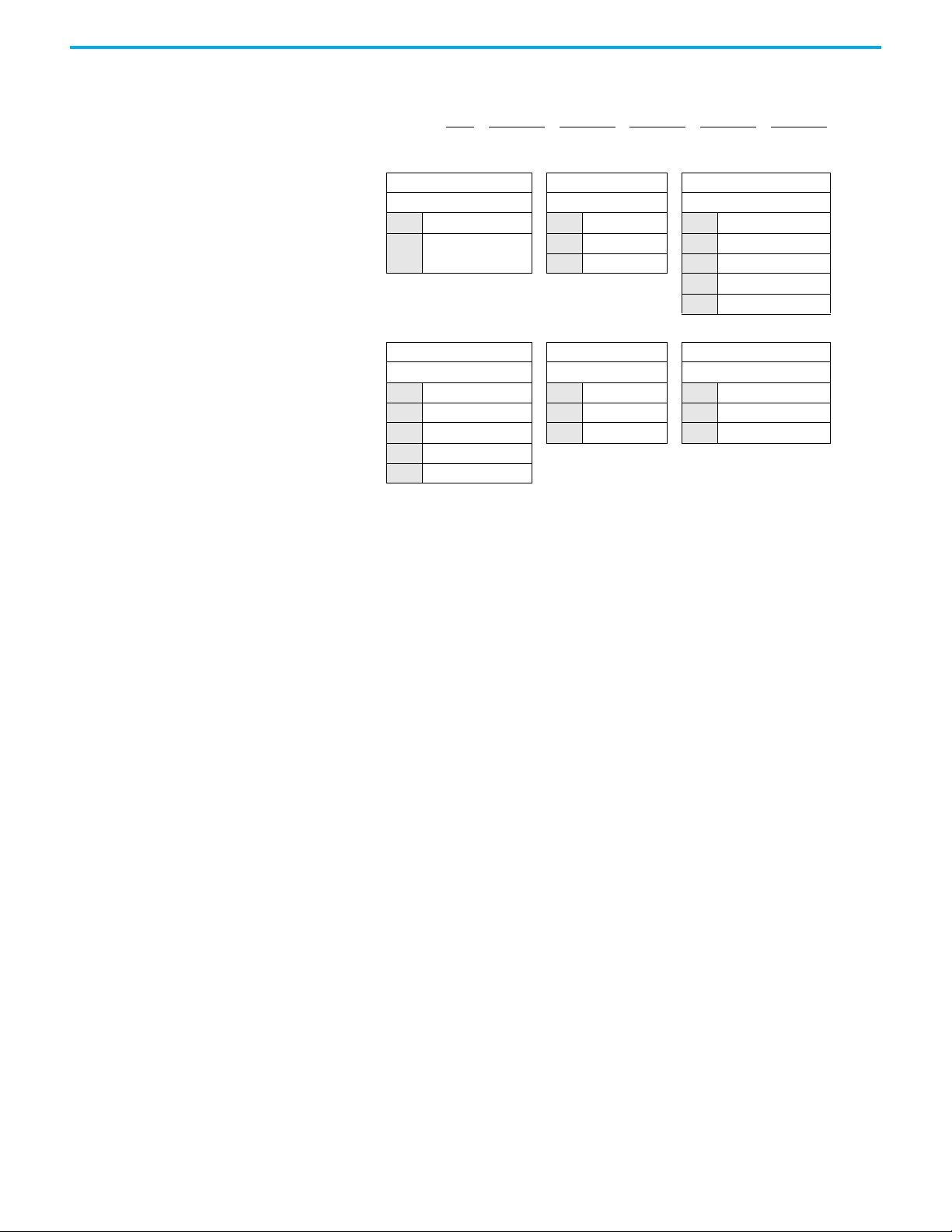

Figure 3 - Switch Output Configuration

1 2 3 4 5 6

).

Sensor front Selector

S.P., Two P.

Window,

1. SSC1

Adj. Hyst.

S.P., Two P.

Window,

2. SSC2

Adj. Hyst.

3. Dust 1

4. Dust 2

5. Temp

6. EXT-Input

A

One of

1 to 6

Selector

B

One of

1 to 6

Item Description

1 Sensor front (see page 20

2 Input selector (see page 21)

3 Logic function block (see page 21

4 Timer (see page 23

)

5 Output inverter (see page 24)

6 Output stage mode (see page 24

A

B

A

B

AND, OR,

XOR, S-R

AND, OR,

XOR, S-R

)

Logic

A - B

divider

Logic

A - B

divider

)

)

Time

delay

ON, OFF

One-shot

Time

delay

ON, OFF

One-shot

Output

inverter

N.O., N.C. NPN, PNP,

Output

inverter

N.O., N.C. NPN, PNP,

Sensor

output

Push-Pull

Sensor

output

Push-Pull

EXT-Input

Out 1

Out 2

EXTInput

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 19

Page 20

Chapter 3 Switch Output Configuration

Sensor

Sensing distance

ON OFF

SP1

Hysteresis

Sensor Front When an object (solid or liquid) approaches the face of the sensor, the

capacitance of the detecting circuit is influenced and the sensor output

changes its status.

SSC (Switching Signal Channel)

For presence (or absence of presence) detection of an object in front of the face

of the sensor, the following settings are available: SSC1 or SSC2.

The setpoints can be set from 0…10,000 units that represent the change of

capacitance of the detecting circuit. The higher value, the closer the target

appears to the sensing face of the sensor, also a higher dielectric value of the

target increases the value. For example, a metal target has a higher dielectric

value than a plastic target.

Switchpoint Mode

The switchpoint mode setting can be used to create more advanced output

behavior. The following switchpoint modes can be selected for the switching

behavior of SSC1 and SSC2.

Mode Description

Disabled

Single-point mode

Two-point mode

SSC1 or SSC2 can individually be disabled, which also disables the output if it is

selected in the input selector (the logic value is always 0).

The switching information changes, when the measurement value passes the

threshold that is defined in setpoint SP1, with rising or falling measurement values,

considering the hysteresis.

The switching information changes when the measurement value passes the threshold

that is defined in setpoint SP1. This change occurs only with rising measurement

values. The switching information also changes when the measurement value passes

the threshold that is defined in setpoint SP2. This change occurs only with falling

measurement vales. Hysteresis is not considered in this case.

Hysteresis

Sensor

ON OFF

SP2

SP1

Sensing distance

The switching information changes, when the measurement value passes the

thresholds that are defined in setpoint SP1 and setpoint SP2, with rising or falling

measurement values, considering the hysteresis.

Hyst

Hyst

Window mode

Sensor

OFF OFF

SP2

20 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

ON

window

Sensing distance

SP1

Page 21

Chapter 3 Switch Output Configuration

Hysteresis Settings

In SSC1 and SSC2 - single point mode and in windows mode the hysteresis can

be set 1…100% of the actual switching value.

(SP2 + Hysteresis < SP1) & (SP1 + hysteresis < Sensing range upper limit)

Margin Alarm 1 and 2

The safe limit between when the sensing output is switching and the value at

where the sensor can detect safely even with a slight buildup of dust can be set.

Temperature Alarm (TA)

The sensor constantly monitors the internal temperature in the front part of

the sensor. With the temperature alarm setting, it is possible to get an alarm

from the sensor if temperature thresholds are exceeded.

The temperature alarm has two separate values, one for setting the maximum

temperature and one for setting the minimum temperature.

It is possible to read the temperature of the sensor via the acyclic IO-Link

parameter data.

External Input

The output 2 (SO2) can be configured as an external input that allows external

signals to be feed into the sensor from a second sensor, a PLC, or directly from

machine output.

Input Selector This function block allows you to select any of the signals from the sensor front

to the Channel A or B.

Channel A and B: Can select between SSC1, SSC2, margin alarm 1, margin

alarm 2, temperature alarm, and external input.

Logic Function Block In the logic function block, the selected signals from the input selector can be

added a logic function directly without using a PLC - which makes decentral

decisions possible.

The logic functions available are AND, OR, XOR, and gated SR-FF.

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 21

Page 22

Chapter 3 Switch Output Configuration

A

B

Q

&

2-input AND Gate

A

B

Q

≥1

2-input OR Gate

A

B

Q

=1

2-input XOR Gate

A

B

Q

&

≥1

SR

Flip-Flop

AND Function

Boolean Expression Q = A.B Read as A AND B gives Q

OR Function

Boolean Expression Q = A + B Read as A OR B gives Q

Symbol

Symbol

Truth Table

ABQ

000

010

100

111

Truth Table

ABQ

000

011

101

111

XOR Function

Symbol

Boolean Expression Q = A + B A OR B but NOT BOTH gives Q

ABQ

000

011

101

110

Truth Table

Gated SR-FF Function

The function is designed to function as filling or emptying function with only

two interconnected sensors.

Symbol

ABQ

000

01

10

Truth Table

(1)

X

(1)

X

111

(1) X = No changes to the output.

22 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 23

Chapter 3 Switch Output Configuration

N.O.

Toff Toff Toff Toff

Presence of target

N.O.

To n To n To n

Toff

Toff

Presence of target

Presence of target

Timer This parameter can be set individually for Out1 and Out2.

The Timer allows you to introduce different timer functions by editing the

three timer parameters:

•Timer mode

•Timer scale

•Timer value

Timer Mode

Selects which type of timer function is introduced on the Switching Output.

Any one of the following is possible:

Mode Description

Disabled

This option disables the timer function no matter how timer scale and timer delay are

configured.

The activation of the switching output is generated after the actual sensor actuation.

Presence of target

Turn On delay (T-on)

Turn Off delay (T-off)

Turn ON and Turn Off

and T

delay (T

on

off

N.O.

To n To n To n

The deactivation of the switching output is delayed compared to the time of removal

of the target in the front of the sensor.

When selected both the T

and the T

on

delays are applied to the generation of the

off

switching output.

)

Each time a target is detected in front of the sensor the switching output generates a

pulse of constant length on the leading edge of the detection.

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 23

One shot leading edge

Page 24

Chapter 3 Switch Output Configuration

Presence of target

Mode Description

Similar in function to the one shot leading edge mode, but in this mode the switching

output is changed on the trailing edge of the activation.

One shot trailing edge

Timer scale

Timer value

Parameter defines if the delay specified in the Timer delay should be in milliseconds,

seconds, or minutes.

Parameter defines the actual duration of the delay. The delay can be set to any integer

value from 1… 32,767.

Output Inverter This function allows you to invert the operation of the switching output

between normally open and normally closed.

IMPORTANT

The recommended function is found in the parameters under 64 (0x40)

sub index 8 (0x08) for SO1 and 65 (0x40) sub index 8 (0x08) for SO2 does

not have any negative influence on the Logic functions or the timer

functions of the sensor as it is added after those functions.

ATTENTION: We do not recommend using the Switching logic function that is

found under 61 (0x3D) sub index 1 (0x01) for SSC1 and 63 (0x3D) sub index 1

(0x01) for SSC2 as they have a negative influence on the logic or timer

functions.

For example, this function turns an ON-delay into an OFF-delay as it is added

for the SSC1 and SSC2 and not only for the SO1 and SO2.

Output Stage Mode In this function block, you can select how the switching outputs operate:

• SO1: Disabled, NPN, PNP, or Push-Pull configuration.

• SO2: Disabled, NPN, PNP, Push-Pull, External input (Active high/Pulldown), External input (Active low/pull up), or External Teach input.

24 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 25

External Teach (Teach-by-wire)

Chapter 4

Teach Procedure

IMPORTANT

The Teach-by-wire must be first configured with an IO-Link master:

1. Select 2=Teach by wire in the Selection of local/remote adjustment

parameters 68 (0x44).

2. Select 1=Single Point Mode is already selected in SSC1 Configuration

61(0x3D), “Mode 1” 2(0x02) (this value should already be set as default).

3. Select 6=Teach-In (Active High) in Chanel 2 (SO2) 65 (0x41) sub index 1

(0x01).

Teach-by-wire Procedure

This function works in single point mode and only for SP1 in SSC1.

1. Place the target in front of the sensor and connect the teach-by-wire

input (pin 2 white wire) to V+ (pin 1 Brown wire). The yellow status

indicator flashes at a 1 Hz rate (ON 100 ms and OFF 900 ms).

2. Within 3…6 seconds the wire must be disconnected, and the yellow status

indicator flashes at a 1 Hz rate (ON 900 ms and OFF 100 ms).

3. After a successful teach, the yellow status indicator flashes at a 2 Hz rate

(ON 250 ms and OFF 250 ms).

IMPORTANT If the Teach procedure is to be canceled, do not remove the wire after

3…6 second. Keep the connection for 12 sec until the yellow status

indicator flashes at a 10 Hz rate (On 50 ms and off 50 ms).

Teach from IO-Link Master To enable teach from IO-Link master, first disable the trimmer input:

1. Select 0=Disabled in the Selection of local/remote adjustment

parameters 68 (0x44).

2. The individual team commands can be written to index 2.

Single-point Mode Procedure

Select the Switching channel to be taught:

1. Select: 1=SSC1 or 2=SSC2 in the Teach-in Select 58(0x3A) or 255 = All SSC.

2. Change the Hysteresis if requested for SSC1 or SSC2.

• SSC1 configuration 61(0x3D) Hysteresis 3(0x03).

• SSC2 configuration 62(0x3D) Hysteresis 3(0x03).

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 25

Page 26

Chapter 4 Teach Procedure

Command Sequence

1) “SP1 Single value Teach”

2) “Teach Apply”

Sensing distance

Sensor

SSC

Command Sequence

1) “SP1 Two value Teach TP1”

2) “SP1 Two value Teach TP2”

3) “Teach Apply”

Sensing distance

Sensor

SSC

Command Sequence

1) “SP1 Two value Teach TP1”

2) “SP1 Two value Teach TP2”

3) “Teach Apply”

4) “SP2 Two value Teach TP1”

5) “SP2 Two value Teach TP2”

6) “Teach Apply”

Sensing distance

Sensor

SSC

Sensing distance

SSC

Command Sequence

1) “SP1 Dynamic Teach Start”

2) “SP2 Dynamic Teach Stop”

3) “Teach Apply”

Sensor

IMPORTANT It is not recommended to change the hysteresis below the values stated

in the SSC parameter list (see page 38

).

Tea ch Command

Sequence

Single-value

Dynamic

Two-value

Description

1. #65 SP1 Single value teach

2. #64 Teach apply (optional command)

1. #71 SP1 dynamic teach start

2. #72 SP1 dynamic teach stop

3. #64 Teach apply (optional command)

1. #67 SP1 two value teach TP1

2. #68 SP1 two value teach TP2

3. #64 Teach apply (optional command)

Two-point Mode Procedure

Tea ch Command

Sequence

Two-value

Dynamic teach

Description

1. #67 SP1 two value teach TP1

2. #68 SP1 two value teach TP2

3. #64 Teach apply (optional command)

4. #69 SP2 two value teach TP1

5. #70 SP2 two value teach TP2

6. #64 Teach apply (optional command)

1. #71 SP1 dynamic teach start

2. #72 SP1 dynamic teach stop

3. #73 SP2 dynamic teach start

4. #74 SP2 dynamic teach stop

5. #64 Teach apply (optional command)

26 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 27

Windows Mode Procedure

Command Sequence

1) “SP1 Single value Teach”

3) “Teach Apply”

2) “SP2 Single value Teach”

3) “Teach Apply”

Sensing distance

Sensor

SSC

Command Sequence

1) “SP1 Dynamic Teach Start”

2) “SP2 Dynamic Teach Stop”

3) “Teach Apply”

Sensing distance

Sensor

SSC

Chapter 4 Teach Procedure

Tea ch Command

Sequence

Single-value

Dynamic

Description

1. #65 SP1 Single value teach

2. #66 SP2 Single value teach

3. #64 Teach apply (optional command)

1. #71 SP1 dynamic teach start

2. #72 SP1 dynamic teach stop

3. #73 SP2 dynamic teach start

4. #74 SP2 dynamic teach stop

5. #64 Teach apply (optional command)

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 27

Page 28

Chapter 4 Teach Procedure

Notes:

28 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 29

Chapter 5

Sensor-specific Adjustable Parameters

Besides the parameters that are directly related to output configuration, the

sensor also has various internal parameters useful for setup and diagnostics.

Local or Remote Adjustment Selection

It is possible to select how to set of the sensing distance by either select the

Trimmer, Teach-by-wire using the external input of the sensor, or to disable

the potentiometer to make the sensor tamper-proof.

Process Data and Variables When the sensor is operated in IO-Link mode, you have access to the cyclic

Process Data Variable.

By default the process data shows the following parameters as active: 16-bit

Analog value, Switching Output1 (SO1), and Switching Output 2 (SO2).

The following parameters are set as Inactive: SSC1, SSC2, DA1, DA2, TA, SC.

However, by changing the Process Data Configuration parameter, you can also

decide to enable status of the inactive parameters. This way several states can

be observed in the sensor at the same time.

Byte 0

Byte 1

Byte 2

Byte 3

31 30 29 28 27 26 25 24

MSB

23 22 21 20 19 18 17 16

LSB

15 14 13 12 11 10 9 8

SC TA DA2 DA1 SSC2 SSC1

76543210

SO2 SO1

Sensor Application Setting The sensor has three presets depending on the application:

Preset Description

Full scale range

Liquid level

Plastic pellets

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 29

The setpoints of the sensor can be adjusted at full scale and the sensing speed are set to

maximum.

This preset is used for slow-moving objects with a high dielectric value such as detection of

water-based liquids. When this function is selected, the teach and potentiometer settings are

optimized to high-range scaling. In this mode, the Filter Scaler is set to 100.

This preset is used for slow-moving objects with a low dielectric value such as detection of

plastic pellets. When this function is selected, the teach and potentiometer settings are

optimized to low-range scaling. In this mode, the Filter Scaler is set to 100.

Page 30

Chapter 5 Sensor-specific Adjustable Parameters

Temperature Alarm Threshold

The temperature where the temperature alarm activates can be changed for

the maximum and minimum temperature. This setting means that the sensor

gives an alarm in the maximum or minimum temperature is exceeded. The

temperatures can be set between -50…+150 °C (-58…+302 °F). The default

factory settings are:

• Low threshold = -30 °C (-22 °F)

• High threshold = +120 °C (+248 °F)

Safe Limits The sensor has a built-in safety margin that helps adjust the sensing up to the

setpoints with an additional safe margin. The factory settings are set to two

times the standard hysteresis of the sensor.

Event Configuration Temperature events that are transmitted over the IO-Link interface are turned

off by default in the sensor. If you want to get information about critical

temperatures detected in the sensor application, this parameter allows you to

enable or disable the following events:

Event Description

Temperature fault event The sensor detects temperature outside specified operating range.

Temperature over-run The sensor detects temperatures higher than set in Temperature Alarm threshold.

Temperature under-run The sensor detects temperatures lower than set in Temperature Alarm threshold.

Short-circuit The sensor detects if the sensor output is short-circuit.

Maintenance The sensor detects if maintenance is needed like the sensor need cleaning.

Quality of Run (QoR) The quality of run value informs about the actual sensing performance

compared to the setpoints of the sensor (the higher the value, the better quality

of detection). The value for QoR can vary to any value from 0…255%. The QoR

value is updated for every detection cycle.

Table 3 - QoR Examples

QoR Values Definitions

>150% Excellent sensing conditions, the sensor is not expected to require any maintenance issues.

Good sensing conditions, the sensor performs as well as when the setpoints were taught or setup

100%

50%

0% Poor to not reliable working sensing conditions is expected.

manually with a safety margin of two times the standard hysteresis.

• Long-term reliability is expected for all environmental conditions.

• Maintenance is not expected to be required.

Average sensing conditions.

• Short-term reliability and maintenance are expected due to environmental conditions.

• Reliable detection can be expected with restricted environmental influence.

30 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 31

Chapter 5 Sensor-specific Adjustable Parameters

Quality of Teach (QoT) The quality if teach value informs about how well the actually teach procedure

was done, meaning the margin between the actual setpoints and the

environmental influence of the sensor. The value for QoT can vary to any value

from 0…255%. The QoT value is updated after every teach procedure.

Table 4 - QoT Examples

QoT Value Definitions

> 150% Excellent teach conditions, the sensor is not expected to require any maintenance issues

Good teach conditions, the sensor has been taught with a safety mar- gin of two times the

100%

50%

0%

standard hysteresis.

• Long-term reliability is expected for all environmental conditions.

• Maintenance is not expected to be required.

Average teach conditions.

• Short-term reliability and maintenance are expected due to environmental conditions.

• Reliable detection can be expected with restricted environmental influence.

Poor teach result.

• Not reliable working sensing conditions are expected (for example, too small of a measuring

margin between the target and the surroundings).

Filter Scaler This function can increase the immunity towards unstable targets and

electromagnetic disturbances. The value can be set from 1…255, the default

factory settings is 1. A filter setting of 1 gives the maximum sensing frequency

and a setting of 255 gives the minimum sensing frequency.

Status Indication This parameter allows you to disable status indication in the sensor if you do

not want the status indicators to illuminate in your application.

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 31

Page 32

Chapter 5 Sensor-specific Adjustable Parameters

Notes:

32 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 33

Specifications

Non-IO-Link Sensors 875L AC Cylindrical Cap

Table 5 - 875L AC Cylindrical Cap Specifications

Attribute Value

Rated operating dist. (Sn)

Sensitivity 270° turn potentiometer (adjustable)

Effective operation distance (Sr) 0.9 x Sn ≤ Sr ≤ 1.1 x Sn

Usable operation distance (Su) 0.8 x Sr ≤ Su ≤ 1.2 x Sr

Repeat accuracy (R) ≤5%

Hysteresis (H) 4…20% of sensing distance

Rated operational volt (UB) 20…250V AC (ripple included)

Ripple ≤10%

Rated operating current (Ie)

Load current, min 10 mA

Voltage drop (Ud) ≤10V AC (at loads ≥20 mA)

Protection Transients

Power ON delay ≤100 ms

Frequency of operating cycles (f) 10 Hz

Indication for output ON Yellow status indicator

Degree of protection IP67 (NEMA 1, 3, 4, 6, 13)

Tem pera tur e

•875L-F8x18: 3…8 mm (factory set at 8 mm)

•875L-G12x18: 3…12 mm (factory set at 12 mm)

•875L-F16x30: 2…16 mm (factory set at 16 mm)

•875L-G25x30: 4…25 mm (factory set at 25 mm)

• Continuous: ≤500 mA

• Short-time: <2.5 A (20 ms, max)

• Operating: -25…+80 °C (-13…+176 °F)

• Storage: -40…+85 °C (-40…+185 °F)

Appendix A

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 33

Page 34

Appendix A Specifications

875F DC Flat Cap

Table 6 - 875F DC Flat Cap Specifications

Attribute Value

• Pipes diameter: Ø8 mm, min

• Wall thickness (factory settings):

Plastic 0.5…6 mm (non-conductive plastic wall)

Glass 0.5…4 mm (non-conductive glass wall)

Detection

Effective operation distance (Sr) 0.9 x Sn ≤ Sr ≤ 1.1 x Sn

Usable operation distance (Su) 0.85 x Sr ≤ Su ≤ 1.15 x Sr

Repeat accuracy (R) ≤5%

Hysteresis (H)

Rated operational volt (UB) 10…30V DC (ripple included)

Ripple ≤10%

Output functions NPN or PNP by sensor type

Output switching function N.O. and N.C by sensor type

Rated operating current (Ie) ≤100 mA

No load supply current (Io) ≤13 mA

Rated insulation voltage (UI) 75V DC

Power-ON delay (tv) ≤300 ms

Voltage drop (Ud) ≤1.5V

Protection Short circuit, reverse polarity, transients

Degree of protection IP65, IP66, IP67, IP68 @ 1.3 m and 24 h; IP69K (NEMA 1, 2, 4, 4x, 5, 12)

Tem pera tur e

Humidity range Operating and storage: 35…95%

• Wall thickness (manual setup):

≤10 mm plastic wall (best case)

≤10 mm glass wall (best case)

• Liquids: Water-based liquids such as water, milk, syrup, honey, milkshakes,

lubricates, acids, alkaline fluids, body fluids, and other high-conductive liquids

(≤50 ms)

Adjustable by IO-Link (1… 100%)

•875L-M8xx18 Factory settings: Typical 6%

•875L-N12xx18 Factory settings: Typical 15%

•875L-M16xx30 Factory settings: Typical 7%

•875L-N12xx18 Factory settings: Typical 15%

• Operating: -25…+80 °C (-13…+176 °F)

• Storage: -40…+85 °C (-40…+185 °F)

34 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 35

IO-Link Sensors 875L DC Cylindrical Cap

3 BU

2WH

4 BK

1 BN

V

V

Table 7 - 875L DC Cylindrical Cap Specifications

Attribute Value

Rated operating distance (Sn)

Sensitivity

Effective operation distance (Sr) 0.9 x Sn ≤ Sr ≤ 1.1 x Sn

Usable operation distance (Su) 0.85 x Sr ≤ Su ≤ 1.15 x Sr

Repeat accuracy (R) ≤5%

Hysteresis (H)

Rated operational volt (UB) 10…40 VDC (ripple included)

Ripple ≤10%

Rated operating current (Ie) ≤200 mA (Continuous)

No load supply current (Io) ≤20 mA

Rated insulation voltage (UI) 50V DC

Power-ON delay (tv) ≤300 ms

Operational current (Im), min >0.5 mA

Voltage drop (Ud) ≤1.0V DC @ 200 mA DC

Protection Short circuit, reverse polarity, transients

Power ON delay ≤300 ms

Degree of protection IP67, IP68/60 min, IP69K (NEMA 1, 2, 4, 4X, 5, 6, 6P, 12)

Tem pera tur e

Humidity range Operating and storage: 35…95%

Appendix A Specifications

•875L-M8xx18: 0…8 mm; adjustable distance 2…20 mm (flush type)

•875L-N12xx18: 0…12 mm; adjustable distance 3…15 mm (non- flush type)

•875L-M16xx30: 0…16 mm; adjustable distance 2…20 mm (flush type)

•875L-N25xx30: 0…25 mm; adjustable distance 4…30 mm (non-flush type)

Adjustable by potentiometer, external teach or by IO-Link settings

• Potentiometer disabled

• Potentiometer enabled

•External teach

Factory settings: Potentiometer enabled

Adjustable by IO-Link (1…100%)

•875L-M8xx18 Factory settings: Typical 6%

•875L-N12xx18 Factory settings: Typical 15%

•875L-M16xx30 Factory settings: Typical 7%

•875L-N12xx18 Factory settings: Typical 15%

• Operating: -30…+85 °C (-22…+185 °F)

• Storage: -40…+85 °C (-40…+185 °F)

Wiring Diagram

Pin Color Signal Description

1 Brown 10…40V DC Sensor supply

2 White Load Output 2/SIO mode/External input/External teach

3Blue GND Ground

4 Black Load IO-Link/Output 1/SIO mode

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 35

Page 36

Appendix A Specifications

Notes:

36 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 37

Appendix B

Parameter Values

Device Parameters

Parameter Name Index Dec (Hex) Access Default value Data range Data Type Length

Vendor Name 16 (0x10) Read-only Allen Bradley — StringT 20 bytes

Vendor Text 17 (0x11) Read-only www.ab.com — StringT 26 bytes

Product Name 18 (0x12) Read-only

Product ID 19 (0x13) Read-only

Product Text 20 (0x14) Read-only

Serial Number 21 (0x15) Read-only

Hardware Revision 22 (0x16) Read-only

Firmware Revision 23 (0x17) Read-only

Application-Specific

Tag

User Tag1 25 (0x19) Read/write *** Any string up to 32 characters StringT 32 bytes, max

User Tag2 26 (0x1A) Read/write *** Any string up to 32 characters StringT 32 bytes, max

Error Count 32 (0x20) Read-only 0 0…65,535 IntegerT 16 bit

Device Status 36 (0x24) Read-only

Maintenance Required — Read-only — — OctetStringT 3 bytes

Process-DataInput 40 (0x28) Read-only — — IntegerT 32 bit

24 (0x18) Read/write *** Any string up to 32 characters StringT 32 bytes, max

(Sensor name)

For example,

875L-N25CP30-D4

For example,

875L-N25CP30-D4

Series A

Capacitive sensor.

M30m25mm Sn

Unshielded…

(Unique serial number)

for example,

LU23123610003

(Hardware revision)

For example, v01.00

(Software version)

For example, v01.00

0 = Device is

operating properly

— StringT 20 bytes

— StringT 13 bytes

— StringT 30 bytes

— StringT 13 bytes

— StringT 6 bytes

— StringT 6 bytes

0 = Device is operating properly

1 = Maintenance required

2 = Out-of-specification

3 = Functional-Check

4 = Failure

UIntegerT 8 bit

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 37

Page 38

Appendix B Parameter Values

SSC Parameters

Parameter Name Index Dec (Hex) Access Default value Data range Data Type Length

Teach-In Select 58 (0x3A) Read/write

Teach-In Result 59 (0x3B) — — — RecordT 8 bit

Teach-in State 1 (0x01) Read-only 0 = Idle

SP1 TP1 Result 2 (0x02) Read-only 0 = Not OK

SP1 TP2 Result 3 (0x03) Read-only 0 = Not OK

SP2 TP1 Result 4 (0x04) Read-only 0 = Not OK

SP2 TP2 Result 5 (0x05) Read-only 0 = Not OK

SSC1 Parameter

(Switching Signal

Channel)

Setpoint 1 (SP1) 1 (0x01) Read/write 1000 0…10,000 IntegerT 16 bit

Setpoint 2 (SP2) 2 (0x02) Read/write 10,000 0… 10,000 IntegerT 16 bit

SSC1 Configuration

(Switching Signal

Channel)

Logic 1 1 (0x01) Read/write 0 = High active

Mode 1 2 (0x02) Read/write 1 = Single Point Mode

Hysteresis 1 3 (0x03) Read/write

SSC2 Parameter 62 (0x3E) — — — — —

Setpoint 1 (SP1) 1 (0x01) Read/write 1000 0…10,000 IntegerT 16 bit

Setpoint 2 (SP2) 2 (0x02) Read/write 10,000 0…10,000 IntegerT 16 bit

SSC2 Configuration 63 (0x3F) — — — UIntegerT 8 bit

Logic 2 1 (0x01) Read/write 0 = High active

Mode 2 2 (0x02) Read/write 1 = Single Point Mode

Hysteresis 2 3 (0x03) Read/write

60 (0x3C) — — — — —

61 (0x3D) — — — — —

1 = Switching Signal

Channel 1

875L-M8xx18: 6%

875L-N12xx18: 15%

875L-M16xx30: 7%

875L-N25xx30: 10%

875L-M8xx18: 6%

875L-N12xx18: 15%

875L-M16xx30: 7%

875L-N25xx30: 10%

0 = Default channel

1 = Switching Signal Channel 1

2 = Switching Signal Channel 2

255 = All SSC

0 = Idle

1 =Success

4 = Wait for command

5 = Busy

7 = Error

0 = Not OK

1 = OK

0 = Not OK

1 = OK

0 = Not OK

1 = OK

0 = Not OK

1 = OK

0 = High active

1 = Low active

0 = Deactivated

1 = Single Point Mode

2 = Window Mode

3 = Two Point Mode

1…100 UIntegerT 16 bit

0 = High active

1 = Low active

0 = Deactivated

1 = Single Point Mode

2 = Window Mode

3 = Two Point Mode

1…100 UIntegerT 16 bit

UIntegerT 8 bit

——

——

——

——

——

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

38 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 39

Appendix B Parameter Values

Output Parameters

Parameter Name Index Dec (Hex) Access Default value Data range Data Type Length

Channel 1 (SO1) 64 (0x40) — — — — —

0 = Disabled output

Phy Mode 1 (0x01) Read/write 1 = PNP output

Input selector 1 2 (0x02) Read/write 1 = SSC 1

Timer 1 - Mode 3 (0x03) Read/write 0 = Disabled timer

Timer 1 - Scale 4 (0x04) Read/write 0 = Milliseconds

Timer 1 - Value 5 (0x05) Read/write 0 0…32,767 IntegerT 16 bit

Logic function 1 7 (0x07) Read/write 0 = Direct

Polarity 1 8 (0x08) Read/write 0 = Not inverted (N.O.)

Channel 2 (SO2) 65 (0x41) — — — — —

Phy Mode 2 1 (0x01) Read/write 1 = PNP output

Input selector 2 2 (0x02) Read/write 1 = SSC 1

Timer 2 - Mode 3 (0x03) Read/write 0 = Disabled timer

Timer 2 - Scale 4 (0x04) Read/write 0 = Milliseconds

Timer 2 - Value 5 (0x05) Read/write 0 0…32,767 IntegerT 16 bit

Logic function 2 7 (0x07) Read/write 0 = Direct

Polarity 2 8 (0x08) Read/write

1 = Inverted (Normal

Closed)

0 = Not inverted (Normal Open)

1 = Inverted (Normal Closed)

0 = Not inverted (Normal Open)

1 = Inverted (Normal Closed)

1 = PNP

2 = NPN

3 = Push-pull

0 = Deactivated

1 = SSC 1

2 = SSC 2

3 = Margin Alarm 1 (DA1)

4 = Margin Alarm 2 (DA2)

5 = Temperature Alarm (TA)

6 = External logic input

0 = Disabled timer

1 = T-on delay

2 = T-off delay

3 = T-on/T-off delay

4 = One-shot leading edge

5 = One-shot trailing edge

0 = Milliseconds

1 = Seconds

2 = Minutes

0 = Direct

1 = AND

2 = OR

3 = XOR

4 = Gated SR-FF

0 = Disabled output

1 = PNP

2 = NPN

3 = Push-pull

4 = Digital logic input

(Active high/ Pull-down)

5 = Digital logic input

(Active low/ Pull-up)

6 = Teach-in (Active high)

0 = Deactivated

1 = SSC 1

2 = SSC 2

3 = Margin Alarm 1 (DA1)

4 = Margin Alarm 2 (DA2)

5 = Temperature Alarm (TA)

6 = External logic input

0 = Disabled timer

1 = T-on delay

2 = T-off delay

3 = T-on/T-off delay

4 = One-shot leading edge

5 = One-shot trailing edge

0 = Milliseconds

1 = Seconds

2 = Minutes

0 = Direct

1 = AND

2 = OR

3 = XOR

4 = Gated SR-FF

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

UIntegerT 8 bit

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 39

Page 40

Appendix B Parameter Values

Sensor-specific Adjustable Parameters

Parameter Name Index Dec (Hex) Access Default value Data range Data Type Length

Selection of local/remote

adjustment

(1)

68 (0x44) Read/write 1 = Trimmer input

Trimmer value 69 (0x45) Read-only — 10 … 10 000 — —

Process data configuration 70 (0x46) Read/write — — RecordT 16 bit

Analog value 1 (0x01) Read/write 1 = Enabled

Switching Output 1 2(0x02) Read/write 1 = Enabled

Switching Output 2 3 (0x03) Read/write 1 = Enabled

Switching Signal Channel 1 4 (0x04) Read/write 0 = Disabled

Switching Signal Channel 2 5 (0x05) Read/write 0 = Disabled

Margin alarm 1 6 (0x06) Read/write 0 = Disabled

Margin alarm 2 7 (0x07) Read/write 0 = Disabled

Temperature alarm 8 (0x08) Read/write 0 = Disabled

Short-circuit 9 (0x09) Read/write 0 = Disabled

Sensor Application

Temperature Alarm

Pre-set

Threshold

(2)

(3)

71 (0x47) Read/write 0 = Full scale range

72 (0x48) Read/write — — RecordT 30 bit

High Threshold 1 (0x01) Read/write 120 -50…+150 °C (-58…+302 °F) IntegerT 16 bit

Low Threshold 2 (0x02) Read/write -30 -50…+150 °C (-58…+302 °F) IntegerT 16 bit

Safe ON/OFF Limits

(4)

73 (0x49) Read/write — — RecordT 16 bit

SSC 1 - Safe limit 1 (0x01) Read/write 2 x standard hysteresis 0…100 UintegerT 8 bit

SSC 2 - Safe limit 2(0x02) Read/write 2 x standard hysteresis 0…100 UintegerT 8 bit

Event Configuration

(5)

Maintenance (0x8C30) 1 (0x01) Read/write

Temperature fault event

(0x4000)

Temperature over-run

(0x4210)

Temperature under-run

(0x4220)

Short circuit (0x7710) 5 (0x05) Read/write

Quality of Teach

Quality of Run

Filter Scaler

LED Indication

(1) See Local or Remote Adjustment Selection on page 29.

(2) See Sensor Application Setting on page 29.

(3) See Temperature Alarm Threshold on page 30.

(4) See Safe Limits on page 30.

(5) See Event Configuration on page 30.

(6) See Quality of Teach (QoT) on page 31.

(7) See Quality of Run (QoR) on page 30.

(8) See Filter Scaler on page 31.

(9) See Status Indication on page 31.

(6)

(7)

(8)

(9)

74 (0x4A) Read/write — — RecordT 16 bit

0 = Maintenance

Notification - Inactive

2 (0x02) Read/write

0 = Temperature fault

Error event - Inactive

0 = Temperature

3 (0x03) Read/write

over-run Warning

event - Inactive

0 = Temperature

4 (0x04) Read/write

under-run Warning

event - Inactive

0 = Short circuit Error

event - Inactive

75 (0x4B) Read-only — 0…255 UintegerT 8 bit

76 (0x4D) Read-only — 0…255 UintegerT 8 bit

77 (0x4D) Read/write 1 1…255 UintegerT 8 bit

78 (0x4E) Read/write 1 = Enabled

0 = Disabled

1 = Trimmer input

2 = Teach-by-wire

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

0 = SC Inactive

1 = SC Active

0 = Full scale range

1 = Liquid level

2 = Plastic pellets

0 = Notification event Inactive

1 = Notification event Active

0 = Error event Inactive

1 = Error event Active

0 = Warning event Inactive

1 = Warning event Active

0 = Warning event Inactive

1 = Warning event Active

0 = Error event Inactive

1 = Error event Active

0 = Disabled

1 = Enabled

UintegerT 8 bit

— —

— —

— —

— —

— —

— —

— —

— —

— —

UintegerT 8 bit

——

——

——

——

——

BooleanT 8 bit

40 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 41

Appendix B Parameter Values

Diagnosis Parameters

Parameter Name Index Dec (Hex) Access Default value Data range Data Type Length

Operating Hours 201 (0xC9) Read-only 0 0…2,147,483,647 [h] IntegerT 32 bit

Number of Power

Cycles

Maximum temperature

- All time high

Minimum temperature

- All time low

Maximum temperature

since power up

Minimum temperature

since power up

Current temperature 207 (0xCF) Read-only — -50…+150 °C (-58…+302 °F) IntegerT 16 bit

Detection counter SSC1 210 (0xD2) Read-only — 0…2,147,483,647 IntegerT 32 bit

Minutes above

Maximum Temperature

Minutes below

Minimum Temperature

Maintenance event

counter

Download counter 214 (0xD6) Read-only 0 0…65,536 UIntegerT 16 bit

Event Configuration 74 (0x4A) Read/write — — RecordT 16 bit

Maintenance (0x8C30) 1 (0x01) Read/write

Temperature fault

event (0x4000)

Temperature over-run

(0x4210)

Temper ature unde r-

run (0x4220)

Short circuit (0x7710) 5 (0x05) Read/write

Quality of Teach 75 (0x4B) Read-only — 0…255 UintegerT 8 bit

Quality of Run 76 (0x4D) Read-only — 0…255 UintegerT 8 bit

Filter Scaler 77 (0x4D) Read/write 1 1…255 UintegerT 8 bit

LED Indication 78 (0x4E) Read/write 1 = Enabled

Location Indicator 94 (0x5E) Read/write 1 = Enabled

202 (0xCA) Read-only 0 0…2,147,483,647 IntegerT 32 bit

203 (0xCB) Read-only 0 -50…+150 °C (-58…+302 °F) IntegerT 16 bit

204 (0xCC) Read-only 0 -50…+150 °C (-58…+302 °F) IntegerT 16 bit

205 (0xCD) Read-only — -50…+150 °C (-58…+302 °F) IntegerT 16 bit

206 (0xCE) Read-only — -50…+150 °C (-58…+302 °F) IntegerT 16 bit

211 (0xD3) Read-only — 0…2,147,483,647 [min] IntegerT 32 bit

212 (0xD4) Read-only — 0…2,147,483,647 [min] IntegerT 32 bit

213 (0xD5) Read-only 0 0…2,147,483,647 IntegerT 32 bit

2 (0x02) Read/write

3 (0x03) Read/write

4 (0x04) Read/write

0 = Maintenance

Notification - Inactive

0 = Temperature fault

Error event - Inactive

0 = Temperature

over-run Warning

event - Inactive

0 = Temperature

under-run Warning

event - Inactive

0 = Short circuit Error

event - Inactive

0 = Notification event Inactive

1 = Notification event Active

0 = Error event Inactive

1 = Error event Active

0 = Warning event Inactive

1 = Warning event Active

0 = Warning event Inactive

1 = Warning event Active

0 = Error event Inactive

1 = Error event Active

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

——

——

——

——

——

BooleanT 8 bit

BooleanT 8 bit

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 41

Page 42

Appendix B Parameter Values

Notes:

42 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

Page 43

Index

Numerics

875F

DC flat cap

875L

AC cylindrical cap

DC cylindrical cap (IO-Link)

8

specifications

7

specifications 33

specifications

A

adjustable parameter

sensor-specific

adjustment selection

local

29

remote

alarm

margin

temperature 21

alarm threshold

temperature

AND function

application

sensor setting

29

29

21

30

22

29

C

channel

switching signal

common tab

configuration

event

30

switch output 19

configure

IO-Link

13

cylindrical cap

875L AC

specifications 33

875L DC (IO-Link)

cylindrical cap (IO-Link)

875L DC

specifications

20

14

7

10

D

data

process

29

device

parameter

diagnosis

parameter

diagnosis tab 17

37

41

E

event configuration 30

external input

external teach

21

25

34

35

35

10

F

filter scaler 31

flat cap

875F DC

8

specifications

front

sensor

function

function block

20

AND

22

gated SR-FF

OR

22

XOR 22

logic

21

22

G

gated SR-FF function 22

H

hysteresis

setting

21

I

identification tab 15

indication

status

31

input

external

21

input selector

inverter

output

IO-Link

875L DC cylindrical cap

configure 13

master

sensor 10

21

24

teach

25

specifications

L

limit

safe

30

local

adjustment selection

logic

function block

21

M

margin alarm 21

mode

output stage

single-point

switchpoint

timer 23

two-point

windows

24

25

20

26

27

34

10

35

29

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 43

Page 44

N

non-IO-Link

sensor

specification

non-IO-Link sensor

O

observation tab 15

OR function

output

output stage

overview

22

inverter

24

parameter

mode

24

product

7

39

P

parameter

device

37

diagnosis

output 39

sensor-specific adjustable

SSC

value 37

parameter tab

procedure

teach

process data

product

overview

41

38

16

25

29

7

Q

QoR 30

QoT

31

quality of run

quality of teach

30

31

R

remote

adjustment selection

setting

hysteresis

single-point mode

33

7

specifications

875F DC flat cap

875L AC cylindrical cap

875L DC cylindrical cap (IO-Link)

IO-Link sensor

20

SSC

parameter

status indication

switch output

configuration

switching signal channel

switchpoint mode

21

25

33

34

33

35

35

38

31

19

20

20

T

TA 21

tab

common

14

29, 40

diagnosis

identification 15

observation

parameter

teach

external

IO-Link master

procedure

teach-by-wire 25

temperature

alarm threshold

temperature alarm

terminology

threshold

temperature alarm

timer

23

mode

two-point mode 26

17

15

16

25

25

25

30

21

5

30

23

V

value

29

parameter

variables

37

29

S

safe limit 30

scaler

filter

31

selector

input

21

sensor

application

setting

29

IO-Link

10

IO-Link specifications

non-IO-Link 7

specification

sensor front

sensor-specific

sensor-specific adjustable

44 Rockwell Automation Publication 875-UM001A-EN-P - March 2021

20

adjustable parameter

parameter

40

35

33

29

W

windows mode 27

wiring diagram

35

X

XOR function 22

Page 45

Capacitive Sensors User Manual

Rockwell Automation Publication 875-UM001A-EN-P - March 2021 45

Page 46

Rockwell Automation Support

Use these resources to access support information.

Technical Support Center Find help with how-to videos, FAQs, chat, user forums, and product notification updates. rok.auto/support

Knowledgebase Access Knowledgebase articles. rok.auto/knowledgebase

Local Technical Support Phone Numbers Locate the telephone number for your country. rok.auto/phonesupport

Literature Library Find installation instructions, manuals, brochures, and technical data publications. rok.auto/literature

Product Compatibility and Download Center

(PCDC)

Download firmware, associated files (such as AOP, EDS, and DTM), and access product

release notes.

rok.auto/pcdc

Documentation Feedback

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our

content, complete the form at rok.auto/docfeedback

.

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Automation maintains current product environmental information on its website at rok.auto/pec.

Allen-Bradley, expanding human possibility, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

EtherNet/IP is a trademark of ODVA, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752, İçerenkÖy, İstanbul, Tel: +90 (216) 5698400 EEE YÖnetmeliğine Uygundur

Publication 875-UM001A-EN-P - March 2021

Supersedes Publication XXXX-X.X .X - Month Year Copyright © 2021 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...