Page 1

Getting Results Guide

Original Instructions

FactoryTalk eProcedure Getting Results Guide

FactoryTalk Batch Components 14.00

Rockwell Automation Publication BWEPRO-GR011D-EN-P - October 2020

Supersedes Publication BWEPRO-GR011C-EN-P - February 2017

Page 2

FactoryTalk eProcedure Getting Results Guide

personal injury or death, property damage, or economic loss.

Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

for Personal Protective Equipment (PPE).

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

ATTENTION:

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD:

ARC FLASH HAZARD:

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and

2

Page 3

Preface

FactoryTalk eProcedure

The eProcedure Server

The eProcedure Client

Table of Contents

introduction

About this manual ....................................................................................... 5

Document organization ............................................................................. 5

Legal Notices ................................................................................................ 5

Additional resources ................................................................................... 6

Chapter 1

What is eProcedure? .................................................................................. 11

Benefits of eProcedure .............................................................................. 12

FactoryTalk Batch Components ............................................................... 13

FactoryTalk Batch Server ..................................................................... 13

FactoryTalk Batch View ....................................................................... 14

FactoryTalk Batch Recipe Editor ......................................................... 14

FactoryTalk Batch Equipment Editor ................................................. 15

FactoryTalk Event Archiver ................................................................. 16

FactoryTalk Batch Network Editor ..................................................... 16

FactoryTalk eProcedure Client ............................................................ 16

FactoryTalk eProcedure Server ........................................................... 16

FactoryTalk Batch Material Manager ................................................. 16

Chapter 2

Set up sample demonstrations ................................................................ 20

Add sample FactoryTalk Security users ............................................. 20

Configure sample permissions for FactoryTalk Security users....... 22

Configure the sample FactoryTalk Batch Server .............................. 24

Rebuild the recipe directory ............................................................... 26

Start the Batch and eProcedure Servers .................................................. 26

Start the sample FactoryTalk Batch Phase Simulator ............................ 28

Open the sample demonstration in the FactoryTalk Batch Phase

Simulator ............................................................................................. 29

Verify PCD communications .................................................................... 29

Effects of warm boot on control steps ..................................................... 30

Summary ..................................................................................................... 31

Chapter 3

Run a recipe using eProcedure ................................................................. 34

Check the event journal ............................................................................. 37

Summary .................................................................................................... 38

3

Page 4

Table of Contents

Introduction to instruction-

eProcedure Glossary

based phases

Index

Chapter 4

Create instruction-based phases .............................................................. 39

Create an instruction file ..................................................................... 39

Custom tags .................................................................................... 41

Assign an instruction file to a phase ........................................................ 42

Include a step verification signature template .................................. 43

Summary ..................................................................................................... 43

Appendix A

4

Page 5

About this manual

Document organization

Legal Notices

Preface

This information was developed to introduce you to the basics of FactoryTalk

eProcedure. This manual is one of a set of related manuals that describe

installing, programming, and operating the FactoryTalk® Batch system.

To review FactoryTalk Batch release notes and latest information regarding

product compatibility refer to the

Center (PCDC).

The following subjects are presented in this document:

• eProcedure documentation

• eProcedure components

• eProcedure Server

• eProcedure Client

• Introduction to instruction-based phases

• HTML-Based instruction files

• Glossary

Product Compatibility and Download

Rockwell Automation publishes legal notices, such as privacy policies, license

agreements, trademark disclosures, and other terms and conditions on the

Legal Notices

page of the Rockwell Automation website.

End User License Agreement (EULA)

You can view the Rockwell Automation End User License Agreement (EULA)

by opening the license.rtf file located in your product's install folder on your

hard drive.

The default location of this file is:

C:\Program Files (x86)\Common Files\Rockwell\license.rtf

Open Source Software Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses.

5

You can view a full list of all open source software used in this product and

their corresponding licenses by opening the oss_license.txt file located your

product's OPENSOURCE folder on your hard drive. This file is divided into

these sections:

Page 6

Preface

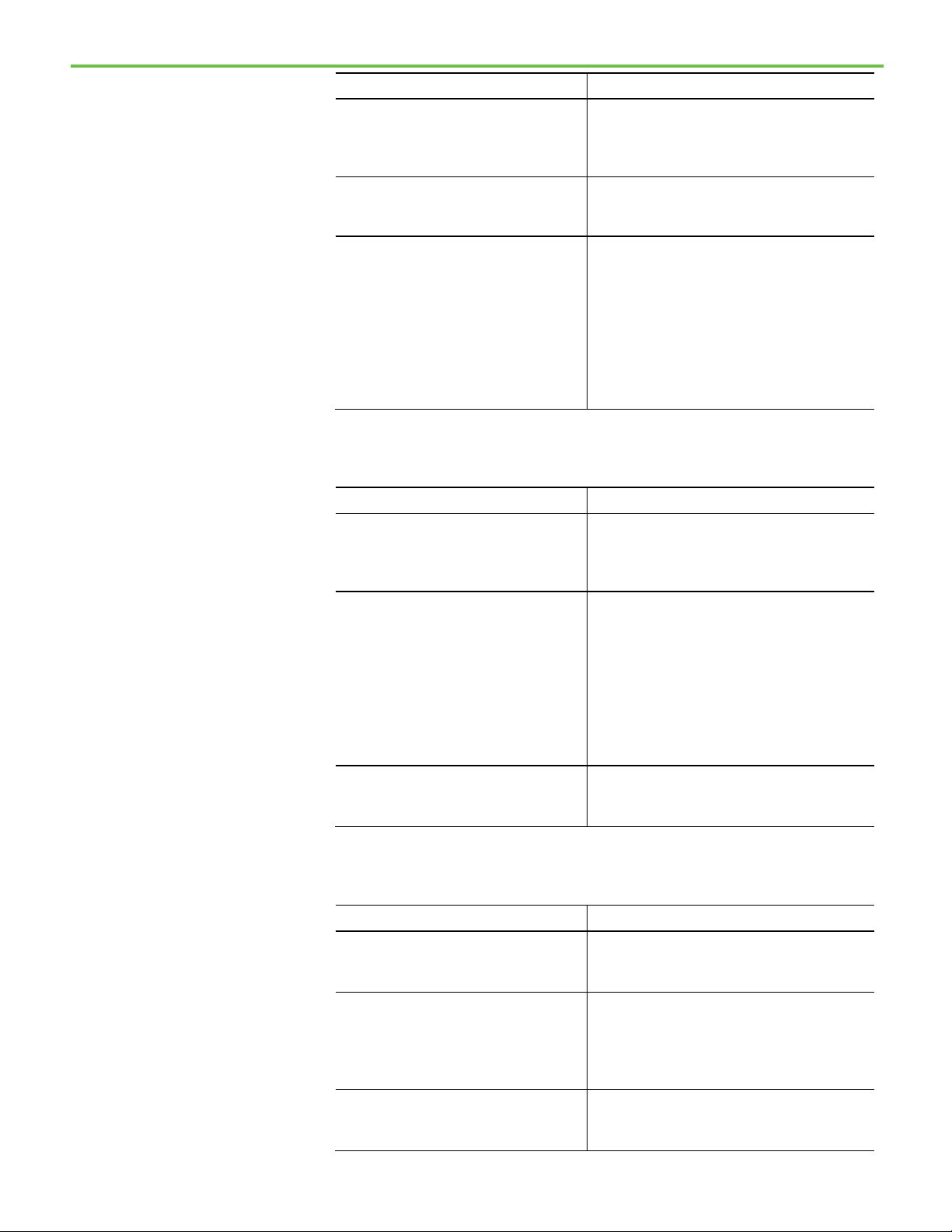

Resource

Description

Server components.

Additional resources

• Components

Includes the name of the open source component, its version number,

and the type of license.

• Copyright Text

Includes the name of the open source component, its version number,

and the copyright declaration.

• Licenses

Includes the name of the license, the list of open source components

citing the license, and the terms of the license.

The default location of this file is:

C:\Program Files (x86)\Common Files\Rockwell\Help\<product

name>\Release Notes\OPENSOURCE\oss_licenses.txt

You may obtain Corresponding Source code for open source packages

included in this product from their respective project web site(s).

Alternatively, you may obtain complete Corresponding Source code by

contacting Rockwell Automation via the Contact form on the Rockwell

Automation website:

http://www.rockwellautomation.com/global/aboutus/contact/contact.page. Please include "Open Source" as part of the request

text.

F

ollowing is a comprehensive list of documentation for the FactoryTalk®

Batch products from Rockwell Automation.

Installation, Quick Start, and Getting Results Guides

FactoryTalk Batch Components Installation and

Upgrade Guide

(BATCH-IN002)

FactoryTalk Batch View Quick Start Guide

(FTBVS-QS001)

FactoryTalk Batch View HMI Controls Quick Start

Guide

(BATCH-QS001D)

FactoryTalk Batch eProcedure® Getting Results

Guide

(BWEPRO-GR011)

Provides information and procedures for FactoryTalk

Batch system installation. Includes information for

FactoryTalk Batch Material Manager, FactoryTalk Event

Archiver, and associated FactoryTalk Batch Client and

Provides information about using FactoryTalk Batch View

to create, view, and command control recipes,

acknowledge prompts and signatures, view equipment

phases and diagnostic information, and view profile

information.

Provides a general overview of FactoryTalk Batch View

HMI Controls.

Explains the basics of FactoryTalk Batch eProcedure.

6

Page 7

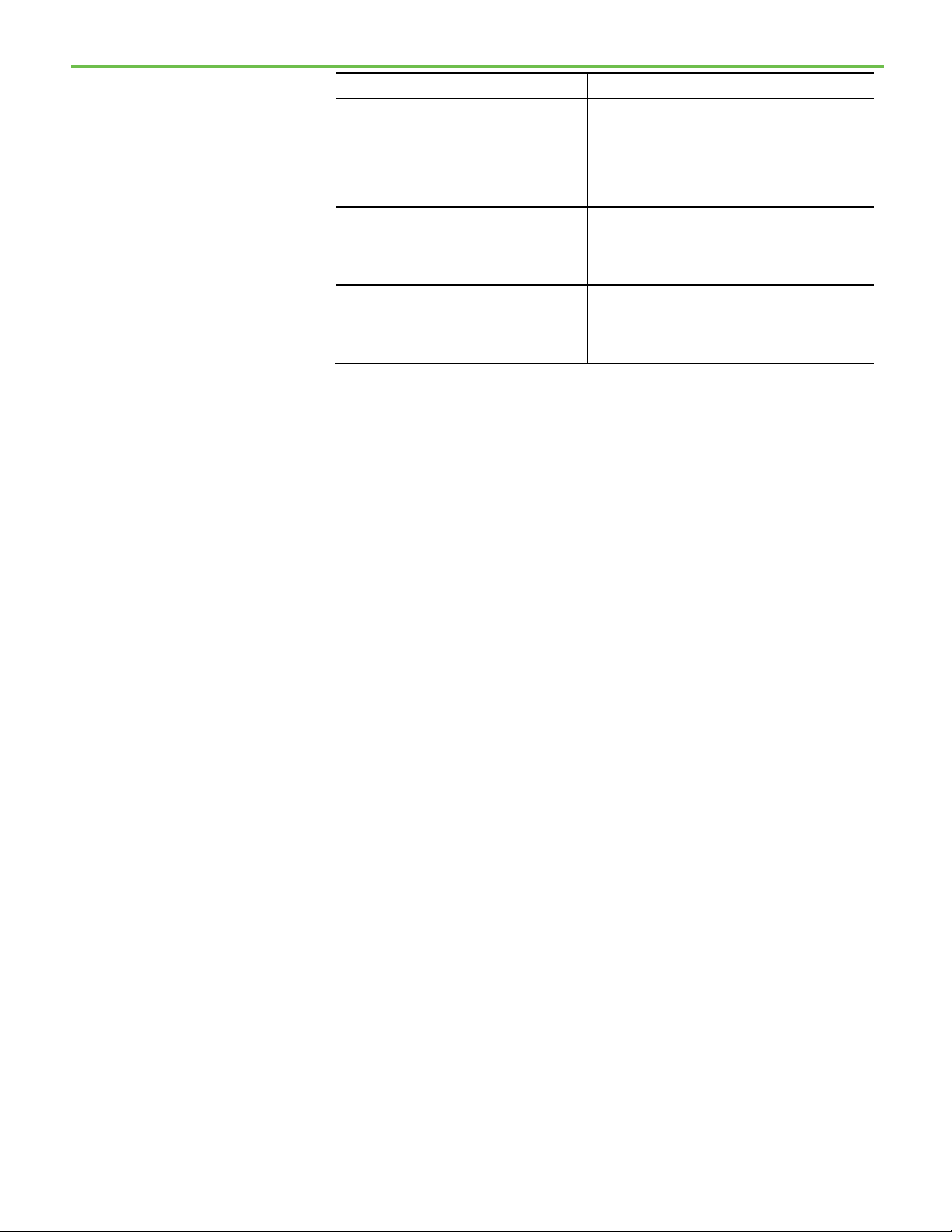

Preface

Resource

Description

FactoryTalk Batch Getting Results Guide

Introduces the basics of automated batch manufacturing

Resource

Description

FactoryTalk Batch ActiveX Controls User Guide

Provides information and instructions for using the

reference for the formulator.

FactoryTalk Batch Server.

(BATCH-GR011)

FactoryTalk Batch Material Manager Getting

Results Guide

(BWMTR-GR011)

User Guides

(BATCH-UM013)

FactoryTalk Batch Material Editor User Guide

(BWMTR-UM001)

FactoryTalk Batch Equipment Editor User Guide

(BATCH-UM004)

FactoryTalk Batch PhaseManager™ User Guide

(BATCHX-UM011)

FactoryTalk Batch Recipe Editor User Guide

(BATCH-UM006)

and the FactoryTalk Batch product components.

Introduces the basics of FactoryTalk Batch Material

Manager.

FactoryTalk Batch ActiveX Custom Controls.

Provides access to information and procedural

instructions required to configure materials and the

containers to hold them. The material data is stored in the

material database, which is used to create materialbased recipes. This information is intended as a

Provides information on creating and maintaining an

equipment database (area model). The area model is

stored in a file with a .cfg file extension and is available

to all other FactoryTalk Batch programs, including the

Recipe Editor, View, and Phase Simulator.

Describes the integration of the FactoryTalk Batch

software with the Studio 5000 Logix Designer®

application and the Logix 5000™ family of controllers.

The integration simplifies the configuration and

maintenance of the FactoryTalk Batch automation

system, provides better communication between the

FactoryTalk Batch Server and the Logix 5000 controller,

and significantly reduces the programming effort

required to develop the phase logic code that resides in

your Logix 5000 controller.

Provides instructions on using FactoryTalk Batch Recipe

Editor to create and configure master recipes for use in

batch automation. The interface is based on IEC 61131-3

sequential function charts to graphically organize recipes

into procedures, unit procedures, operations, and phases.

Build recipes using either the SFC format or a table-based

format.

FactoryTalk Batch View HMI Controls User Manual

(FTBVS-UM003)

FactoryTalk Batch View User Manual

(FTBVS-UM002)

Provides details about using FactoryTalk Batch View HMI

Controls to monitor and interact with the production

process within a FactoryTalk View SE Display Client.

Provides information and procedural instructions for

using FactoryTalk Batch View in a modern and intuitive

portal into a comprehensive batching solution for

effective operations, leveraging its own web server using

HTML5 technology to provide native connectivity into a

7

Page 8

Preface

Resource

Description

FactoryTalk eProcedure Client User Guide

Provides information and procedural instructions

reference information by the operator.

system administrator and production supervisor.

conjunction with a Human-Machine Interface (HMI).

Resource

Description

FactoryTalk Batch eProcedure Administrator Guide

Provides procedures specific to FactoryTalk Batch

operators, such as the FactoryTalk Batch Server.

(BWEPRO-UM011)

Resource

Description

(BATCH-RM001)

FactoryTalk Batch PCD Programming Reference

Provides information and instructions about the

(BWEPRO-UM001)

FactoryTalk Event Archiver User Guide (BATCHUM012)

FactoryTalk Batch View User Guide (legacy)

(FTBVS-UM001)

Administrator Guides

FactoryTalk Batch Administrator Guide

(BATCH-UM003)

required to create and command batches using the

FactoryTalk eProcedure Client, and can be used as a

Provides information and instructions specific to the

FactoryTalk Event Archiver. Intended for use by the

Provides information and instructions on how to use

FactoryTalk Batch View to initiate and execute

FactoryTalk Batch automation processing. FactoryTalk

Batch View secured objects are located in the FactoryTalk

Diagnostics and are modified using the FactoryTalk

Administration Console. A system administrator can

customize FactoryTalk Batch View security to meet the

needs of the facility. FactoryTalk Batch View is used in

Provides instructions for configuring security and

services, and implementation and use of components not

typically accessed or used by batch operators, such as

the FactoryTalk Batch Server.

(BWEPRO-UM011)

FactoryTalk Batch Material Manager Administrator

Guide

Reference Guides

FactoryTalk Batch ActiveX Controls Library

Reference Guide

FactoryTalk Batch Material Server API Technical

Reference

(BWMTR-RM001)

eProcedure, such as implementing security and

configuring the user-defined area Active Server Page.

Included are instructions for tasks specific to FactoryTalk

Batch, such as configuring security and services to

support FactoryTalk Batch eProcedure. Provides

instructions on the implementation and use of

components not typically accessed or used by batch

Provides information and instructions specific to

FactoryTalk Batch Material Manager. Intended for use by

the system administrator and database administrator.

Provides reference information and procedural

instructions for the FactoryTalk Batch ActiveX Custom

Controls.

Provides access to information regarding the interface

between the FactoryTalk Batch Material Server and the

FactoryTalk Batch Material Editor and FactoryTalk Batch.

It is intended to be used as a reference information by

those who want to develop custom interfaces.

8

Manual

(BATCH-RM004)

FactoryTalk Batch PCD interface design. It is intended to

be used as a reference guide.

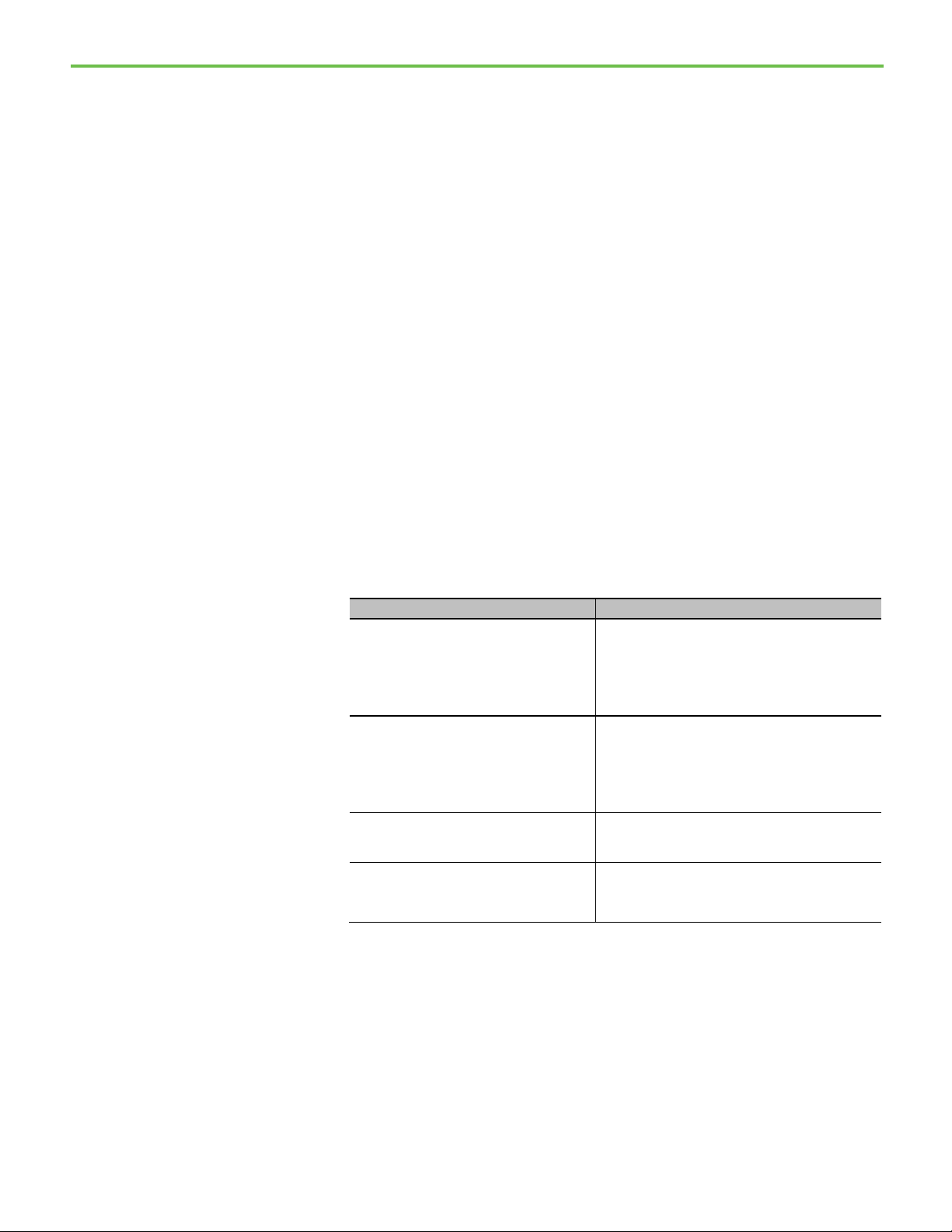

Page 9

Preface

Resource

Description

FactoryTalk Batch Server API Reference Manual

Provides information regarding the interface between the

reference by the instruction file author.

(BATCH-RM003)

FactoryTalk Batch System Files Reference Manual

(BATCH-RM005)

FactoryTalk Batch eProcedure Instruction File

Design Reference Manual

(BWEPRO-RM001)

FactoryTalk Batch Server and FactoryTalk Batch View —

the Server Application Programming Interface (API). It is

intended to be used as a reference guide by those who

want to develop custom interfaces.

Provides the technical information for configuration and

maintenance of a FactoryTalk Batch system. It can be

used as a reference information for implementation

engineers and the system administrator.

Includes information about the building of instruction

files for use in equipment database creation and recipe

development. This information is intended to be used as a

View or download publications at

http://www.rockwellautomation.com/literature. To order paper copies of

technical documentation, contact your local Allen-Bradley® distributor or

sales representative.

9

Page 10

Page 11

What is eProcedure?

Chapter 1

FactoryTalk eProcedure introduction

FactoryTalk® eProcedure® is part of the FactoryTalk Batch suite of software

components. As part of the FactoryTalk family, the FactoryTalk Batch

components increase overall plant efficiency by delivering the visibility,

control, and reporting needed to optimize manufacturing. Coordinated

execution reduces rework and improves product quality and consistency.

Real-time management of equipment utilization maximizes return on assets.

Implementing optimized recipes and procedures, increases plant capacity.

Using electronic, paperless operations improves productivity. Reduce

compliance costs by using electronic batch record implementation, paperless

manufacturing, and quality sign-offs. Lifting the compliance burden from

manufacturing reduces inventory levels and cycle times, which greatly

improves customer service.

The FactoryTalk Batch components ensure that plant floor operations are

optimized, giving quick returns on net assets. New product definitions are

deployed quickly into manufacturing. Production order information is

accurate. Business and plant-level control systems are tightly coordinated and

multiple sites operate as a team. Our completely open, configurable set of

products helps you define, manage, monitor, and control manufacturing at

local, remote, or contractor plants. Best of all, deploy the FactoryTalk Batch

components wherever needed (one at a time or all at once) to improve

productivity and plant control. The FactoryTalk Batch components include:

• FactoryTalk Batch

• FactoryTalk eProcedure

• FactoryTalk Batch Material Manager

As one of the FactoryTalk Batch components, FactoryTalk eProcedure

manages, sequences and documents the execution of manual operations.

Automating batch sheets and standard operating procedures (SOPs) through

interactive web documents, eProcedure provides the control needed to rapidly

deploy new products into manufacturing and the data collection necessary to

achieve true plant floor to enterprise-wide integration. FactoryTalk

eProcedure provides the benefits of procedure automation without the

expense of equipment automation. The FactoryTalk Batch components

incorporate the principles of batch and procedure automation, an approach

defined by ISA’s S88.01 standard.

11

Page 12

Chapter 1 FactoryTalk eProcedure introduction

Without eProcedure

With eProcedure

printout.

When the batch is complete, the completed

When the batch is complete, the electronic batch record

The data can be manually entered into a

The electronic batch record can be automatically

FactoryTalk Event Archiver.

Benefits of eProcedure

FactoryTalk eProcedure automation provides a means to automate the

execution of procedural logic associated with recipes, product grade changes,

computer setup, and computer shutdown procedures. Operators perform the

actions on the equipment, but they are prompted and guided by eProcedure.

The procedure specifies the sequence and timing of actions that can be

manually performed or performed by automation equipment.

Typical procedures that can be automated using FactoryTalk eProcedure

include:

• Batch execution

• Equipment startup and shutdown

• Product changeover

• Abnormal condition handling

FactoryTalk eProcedure reduces the amount of effort required to create and

maintain recipes, as well as minimizes the time required to collect and report

Batch data.

The following describes a typical recipe execution process, with and without

eProcedure:

A master recipe (a collection of SOPs) is

maintained in written form. The master recipe

includes instructions for the operator, places to

enter data, and places for any required

signatures.

When a batch needs to be run, the recipe is

printed and given to the operator, who reads the

instructions, manually sequences the process

and enters the required information on the

recipe document is filed.

database for recording and reporting purposes.

A master recipe is created and maintained electronically

with the FactoryTalk Batch Recipe Editor. The master

recipe includes operator instructions, report data, and

prompts for required approvals.

When a batch needs to be run, the operator adds a batch

using the eProcedure Client, steps through the

instructions, and enters the required data into the

system.

contains a complete record of the entire batch process.

transferred to any ODBC-compliant database using the

FactoryTalk eProcedure can be implemented in a completely manual

manufacturing facility or in a partially automated facility. With eProcedure,

use all manual phases or a combination of manual and automated phases

within a single recipe. Regardless of the state of automation, the

implementation process is the same.

12

The FactoryTalk Batch Equipment Editor is used to define the process

equipment, both manual and automated. The modular approach in defining

equipment is as appropriate with manual facilities as it is in automated

Page 13

FactoryTalk Batch

FactoryTalk Batch Server

facilities. As part of the configuration process, attach instruction files to each

of the manual equipment modules.

Instruction files are HTML files that include all of the required control steps

for a phase. Each control step can include textual instructions, embedded

parameter values, report fields for operator input, and submit buttons.

Control steps may also include any valid HTML component.

Once the equipment is defined, and the instruction files are created, create

recipes in the same fashion as a completely automated facility.

FactoryTalk eProcedure allows the operator to create and command batches

from remote computers using Microsoft Internet Explorer. With eProcedure,

the operator no longer needs to write processing information on a piece of

paper for submission. The operator enters the data directly into the computer

where the data is stored in an electronic batch record, which can later be

downloaded into your ODBC-compliant database.

Chapter 1 FactoryTalk eProcedure introduction

Components

FactoryTalk Batch comes with several components that interact with each

other to design, create, configure and run batch recipes.

The FactoryTalk Batch Server is the engine that runs FactoryTalk Batch. It is

the component that controls system information, phases and recipes. The

server allows integration with process-connected devices (PCDs) and thirdparty software packages. Prior to opening FactoryTalk Batch View, the

FactoryTalk Batch Server must be running and remain active during all batch

functions.

The FactoryTalk Batch Server operates as a Windows service, which means

that the FactoryTalk Batch Server can be configured to start automatically and

that control of the FactoryTalk Batch Server can be given to the Windows

Service Manager. Because the FactoryTalk Batch Server runs as a service, it

does not require an operator to log on to run. Therefore, logging on or off

Windows during operation does not disrupt the performance of the

FactoryTalk Batch Server.

13

Page 14

Chapter 1 FactoryTalk eProcedure introduction

Batch View User Manual (FTBVS-UM002).

FactoryTalk Batch View

FactoryTalk Batch Recipe

This topic describes FactoryTalk Batch View on a Windows desktop system.

FactoryTalk Batch View is the batch recipe initiation and execution program

used by the operator of the FactoryTalk Batch Automation Solution system to:

• Initiate and control the batch process

• Display a graphical representation of a running batch and its

Typically, FactoryTalk Batch View is intended to be used in conjunction with

an HMI.

Each FactoryTalk Batch View window can be customized to suit the needs of a

specific station:

Tip: The modern FactoryTalk Batch View is an innovative and intuitive user interface for your

comprehensive batch solution. It leverages state-of-the-art web technologies with scalable

graphics for consistent visualization across all devices and form factors. The zero-install browser

simplifies administration and maintenance. As the only native client application that supports the

new features in FactoryTalk Batch and eProcedure, it is the client of the future for modern batch

solutions.

For more information about the new FactoryTalk Batch View mobile solution, view the

FactoryTalk

associated data

Editor

• Specify the columns to display

• Specify the size of columns and rows

• Sort and filter on one field in certain windows

• Set the font for each FactoryTalk Batch View window

If the security is enabled for FactoryTalk Batch View, a system administrator

can use the password protection option to:

• Limit the information that is displayed

• Specify the commands that are allowed at a particular station

Using FactoryTalk Batch View, an operator can respond to electronic

signature requests that have been generated by report and recipe parameter

deviations or by a command execute request.

The FactoryTalk Batch Recipe Editor is used to graphically create and

configure recipes.

• The interface is based on IEC 61131-3 sequential function charts (SFC)

that graphically organizes recipes into procedures, unit procedures,

operations and phases along with any applicable comments.

• In addition to the SFC view, the FactoryTalk Batch Recipe Editor offers

a table view. Table-based recipes provide a mechanism for creating

simple recipes that do not require a complex recipe structure or

elaborate transition expressions. Additionally, you can view tablebased recipes and edit all recipe parameters without having to navigate

between steps.

14

Page 15

FactoryTalk Batch

Equipment Editor

Chapter 1 FactoryTalk eProcedure introduction

• The FactoryTalk Batch Recipe Editor allows you to specify sequences of

phases. The actual phase logic must be configured in the processconnected device (PCD) while the interface to the PCD must be

configured in the FactoryTalk Batch Equipment Editor.

• Recipe reports can be generated in SFC and/or descriptive format.

• If Recipe Approvals are enabled in the underlying area model, approval

signoffs are executed in the FactoryTalk Batch Recipe Editor.

• When Recipe Version Control is enabled, a version of a recipe (a read-

only, numbered snapshot of a recipe) can be saved and protected from

further editing. New work-in-progress (WIP) copies of a version allow

the recipe author to continue to make changes and updates to a recipe.

When a versioned recipe no longer matches the underlying area

model, or references a deleted or non-existent sub-recipe, it is marked

as obsolete.

The FactoryTalk Batch Equipment Editor is a graphical interface through

which a database of process equipment is defined and maintained (an area

model).

• Components defined in the FactoryTalk Batch Equipment Editor are

used to interface with process-connected devices (PCDs) in the facility.

During recipe configuration, the area model provides a list of available

units and phase classes.

• Configure phases and commands to trigger an electronic signature

request when a report or recipe parameter is out of range (parameter

deviation), or when specific commands are executed on a batch (such

as Abort Batch or Active Step Change).

• During recipe verification, the area model confirms that the

designated equipment is capable of executing the procedures.

• During recipe execution, resource arbitration functions use the area

model to allocate equipment based on recipe and operator requests.

• The area model is available to all other FactoryTalk Batch applications.

In addition to the area model, the FactoryTalk Batch Equipment Editor allows

configuration of the following:

• Communication functions

• Electronic signatures

• Enumeration sets

• Data servers

• Recipe approvals

• Recipe version control

• FactoryTalk Event Archiver functions

•

15

Page 16

Chapter 1 FactoryTalk eProcedure introduction

FactoryTalk Event Archiver

FactoryTalk Batch Network

FactoryTalk eProcedure

FactoryTalk eProcedure

FactoryTalk Batch Material

The FactoryTalk Event Archiver’s purpose is to translate the FactoryTalk Batch

tab-delimited ASCII electronic batch record files to a user-specified file type.

These electronic batch record files are maintained separately for each batch

created and viewed with a word processor or spreadsheet. Many plants have

standardized on one of the many commercially available Relational Database

Management System (RDBMS) software packages. We recommend using a

high-performance database, such as SQL Server, due to their better

robustness and performance. The Archiver collects data from each electronic

batch record file and stores it in the specified RDBMS database format.

The FactoryTalk Batch Network Editor is a utility that indicates where other

Editor

FactoryTalk Batch and FactoryTalk Batch Material servers are located on the

network. This network configuration allows for ease of integration with other

FactoryTalk Batch components and simplifies the process of reconfiguring a

multi-computer system. If FactoryTalk Batch Material Manager is also

installed the FactoryTalk Batch Network Editor is also used to indicate the

location of the material database.

Client

Server

Manager

The FactoryTalk eProcedure Client computer uses Internet Explorer to enable

operators to run batch recipes.

The FactoryTalk eProcedure Server provides the services to the FactoryTalk

Batch Server to enable the use of HTML instruction files. Prior to opening

FactoryTalk eProcedure Client, FactoryTalk eProcedure Server must be

running and remain active during all batch functions.

FactoryTalk Batch Material Manager is used to track material consumption in

batch recipes. It consists of two components: Material Server and Material

Editor.

The Material Editor provides an interface to help you create the material

database, which consists of material, lot, sublot, container, and storage

location data. The Material Server provides the communication between the

material database and the FactoryTalk Batch Server. During a batch run,

information about available containers is presented to the operator for

binding decisions. Binding is the process of mapping steps within a control

recipe to actual equipment in a plant. After a batch is run, quantities

consumed or distributed are updated in the material database for use in

inventory tracking.

16

Page 17

Chapter 1 FactoryTalk eProcedure introduction

The Material Server consists of a group of components that work together to

service various applications. The primary applications that the Material Server

services are the Material Editor, FactoryTalk Batch Server, FactoryTalk Batch

Recipe Editor, and FactoryTalk Batch Equipment Editor. Any third-party

application can also use custom solutions based on the exposed Material

Object Model (MOM).

17

Page 18

Page 19

Tip:

This guide outlines the configuration and use of the SampleDemo demonstration

step by step.

Chapter 2

The eProcedure Server

For ease of understanding, and for tutorial purposes, this guide refers to

configuring and using the sample files installed with FactoryTalk Batch. The

SampleDemo folders contain complete area models and recipes for a

simulated plant. Before running the demonstrations, you must add a

FactoryTalk Security user, configure the FactoryTalk Batch Server to

recognize the required project directories, select the initialization path and

file name, and then start the FactoryTalk Batch Server, the FactoryTalk

eProcedure Server, and the FactoryTalk Batch Phase Simulator.

files. It is recommended that you follow the directions for using this demonstration

The FactoryTalk eProcedure Server provides the services to the FactoryTalk

Batch Server to enable the use of HTML instruction files. Communication

from the eProcedure Client to the eProcedure Server is HTTP for web content.

FactoryTalk eProcedure uses OLE for Process Control (OPC) for

communications between the eProcedure Server and the FactoryTalk Batch

Server.

The eProcedure Server coordinates the following functions:

• Provides the services to the FactoryTalk Batch Server to enable the use

of HTML instruction files.

• Formats parameters and report parameters from material-based

recipes into instruction files.

This section assumes that the FactoryTalk eProcedure Client and Server have

been installed and configured. (See the FactoryTalk Batch Components Upgrade

and Installation Guide for more information.)

19

Page 20

Chapter 2 The eProcedure Server

IMPORTANT

Administrator privileges are required to perform this procedure.

Set up sample

Add sample FactoryTalk

demonstrations

Security users

The installation process placed the SampleDemo1 and SampleDemo2 folders in

the BATCHCTL share on your hard drive. Within each of these SampleDemo

folders are four subfolders that contain the files for the area model.

To set up sample demonstrations:

1. Add a FactoryTalk Security user.

2. Configure the FactoryTalk Batch Server to locate the area model.

3. Verify the recipes in the area model.

For the sample demonstrations file, create FactoryTalk user accounts for an

operator and an engineer. Create these user accounts in the FactoryTalk

Directory.

To add sample FactoryTalk Security users:

1. Select Start > Rockwell Software > FactoryTalk Administration

Console. The Select FactoryTalk Directory dialog box opens.

2. Select Network to add this user account to the FactoryTalk Network

Directory, and select OK.

3. If not already logged on to the FactoryTalk Network Directory, the Log

On to FactoryTalk dialog box opens. In User name, type the user name

for the Administrator that was configured when the FactoryTalk

Services Platform was installed.

20

Page 21

Chapter 2 The eProcedure Server

4. In Password, type the password for the Administrator.

5. Verify the Directory and select OK. The FactoryTalk Administration

Console window opens and displays the specified FactoryTalk

Directory.

6. Expand Users and Groups.

7. Right-click the Users folder, and select New > User to create a new

FactoryTalk Security user account in FactoryTalk Directory.

8. The New User dialog box opens and displays the General tab. In the

User name box, type OPER.

9. In Full name, type Operator.

10. In Password, type password, and confirm it by re-entering password

in the Confirm Password box.

11. Select Create.

12. Repeat steps 7-11, but this time in the User Name field, enter ENG and

in the Full Name field, enter Engineer.

13. Keep the FactoryTalk Administration Console open to configure

permissions for these FactoryTalk Security users in the next exercise.

21

Page 22

Chapter 2 The eProcedure Server

Configure sample

permissions for

FactoryTalk Security users

After creating the FactoryTalk security users, set up access modes for each

FactoryTalk Batch component to specify which users are permitted to view or

perform actions. Configure security settings in the FactoryTalk

Administration Console. To tighten security in the eProcedure Client, remove

the All Users group from the Full Edit policy setting.

To configure sample permissions for FactoryTalk Security users:

1. In the FactoryTalk Administration Console Explorer pane, navigate to

System > Policies > Product Policies > Batch > Equipment Editor >

Access Modes.

2. Right-click Access Modes, and then select Properties. The Access

Modes Properties dialog box opens.

22

3. In the Full Edit row, select the Configure Security browse button. The

Configure Securable Action dialog box opens.

4. Select Add. The Select User and Computer dialog box opens.

5. In the Filter Users box, select Show All.

Page 23

Chapter 2 The eProcedure Server

6. In Users, select ENG.

7. Select OK. The Configure Securable Action dialog box is updated,

showing ENG in the list of Users with the Allow checkbox selected.

8. Select OK to close the Configure Securable Action dialog box.

9. In the Access Modes Properties dialog box, select View Only.

10. In the View Only row, select the Configure Security browse button.

The Configure Securable Action dialog box opens.

11. Select Add. The Select User and Computer dialog box opens.

12. In the Filter Users box, select Show All.

13. In Users, select OPER.

14. Select OK. The Configure Securable Action dialog box is updated,

showing OPER in the list of Users with the Allow checkbox selected.

15. Select OK to close the Configure Securable Action dialog box.

16. Select OK to close the Access Modes Properties dialog box.

See the FactoryTalk Batch Administrator Guide for more information on security.

23

Page 24

Chapter 2 The eProcedure Server

IMPORTANT

IMPORTANT

Configure the sample

FactoryTalk Batch Server

To set up the sample demonstrations, configure the FactoryTalk Batch Server

to locate the folders that contain the demonstration files and to the \Restart

and bin folders where the FactoryTalk Batch Server writes data upon system

failure. Configure the FactoryTalk Batch Server in the FactoryTalk Batch

Equipment Editor.

To configure the sample FactoryTalk Batch Server:

1. Select Start > Rockwell Software > Equipment Editor. The FactoryTalk

Batch Equipment Editor opens (log on to FactoryTalk if prompted).

Administrator privileges are required to perform this procedure.

2. Select Options > Server Options. The Server Options dialog box opens

to the Project Settings tab.

24

3. In the Project Directories area, select the Primary Journal browse

button. The Select Directory dialog box opens.

4. From the Look in list, select the SampleDemo1\Journals folder, and

then select Open.

5. Select the Error Logging browse button. The Select Directory dialog

box opens.

6. From the Look in list, select the SampleDemo1\Logs folder, and then

select Open.

7. Click the Instructions browse button. The Select Directory dialog box

opens.

In order for the eProcedure Server to start, you must define the instruction

path and an instruction file for each instruction-based phase in the area

model. (See the

instructions on defining instruction-based phases.)

FactoryTalk Batch Equipment Editor User Guide

for

8. Select the Equipment Database browse button. The Select Equipment

Database dialog box opens.

9. From the Look in list, open the SampleDemo1\ Recipes folder, select

the ice_cream1.cfg file, and then select Open.

Page 25

Chapter 2 The eProcedure Server

10. In the Store Recipes Using area, select Binary Files, and then select the

Recipe Directory browse button. The Select Directory dialog box

opens.

11. From the Look in list, select the SampleDemo1\Recipes folder, and

then select Open.

12. Select the Restart Control tab.

13. Select the Primary Path browse button. The Select Directory dialog

box opens.

14. From the Look in list, select the SampleDemo1\Restart folder, and

then select Open.

15. Select the Secondary Path browse button. The Select Directory dialog

box opens.

16. From the Look in list, select the Bin folder.

17. Select the Batch Reporting tab. Leave Never (No Queue) as the default

reporting application.

18. Select OK to close the Server Options dialog box.

19. Select File >Exit to exit the FactoryTalk Batch Equipment Editor.

Tip: These steps set up the FactoryTalk Batch Server to run the tutorial steps in this

manual. There are many other settings to consider when setting up the FactoryTalk Batch

system. (See the

Options dialog box.)

FactoryTalk Batch Administrator Guide

for more information on the Server

25

Page 26

Chapter 2 The eProcedure Server

IMPORTANT

Tip:

the

Activate Rockwell Software Products

insert included with the software CD.)

IMPORTANT

Administrator privileges are required to perform this procedure.

Rebuild the recipe directory

Start the Batch and

To run the demonstration recipes, rebuild the recipe directory and verify the

recipes in the area model using the FactoryTalk Batch Recipe Editor.

To rebuild the recipe directory:

1. Select Start, point to All Programs > Rockwell Software > FactoryTalk

Batch Suite > FactoryTalk Batch, and then select Recipe Editor. The

Recipe Editor reads the area model.

2. Log on to FactoryTalk if prompted.

Administrator privileges are required to perform this procedure.

If a message to verify the recipes displays, select Cancel.

3. Select File > Rebuild Recipe Directory. When the rebuild completed,

select OK, and then select Yes to verify the recipes.

4. When the recipe verification completes, select Accept to save the

recipes, and then select Close.

5. Select File > Exit to exit the FactoryTalk Batch Recipe Editor.

eProcedure Servers

The FactoryTalk Batch and FactoryTalk eProcedure Servers may start

automatically when the computer starts. By default the FactoryTalk Batch

Server starts in production mode. If FactoryTalk Batch is not activated, run

the tutorial in demo mode. While in demo mode, the FactoryTalk Batch Server

runs for a two-hour period and then stops.

The FactoryTalk Batch Server does not start in production mode without activation. (See

To start the Batch and eProcedure Servers

1. Select Start, point to All Programs > Rockwell Software > FactoryTalk

Batch Suite > FactoryTalk Batch, and then select Batch Service

Manager. The FactoryTalk Batch Service Manager opens.

2. If the FactoryTalk Batch Server is not already listed in the Service box,

select it from the list.

26

Page 27

Tip:

The FactoryTalk Batch Service Manager must communicate with the Windows Service

displays.

Tip:

Cold Boot

Restarts the FactoryTalk Batch Server in a cold state. All journal data or recipe

Warm Boot

Restarts the FactoryTalk Batch Server, restoring the set of batches that were

batches to the batch list.

Chapter 2 The eProcedure Server

3. If the FactoryTalk Batch Server is running, select Stop.

4. If the name of the computer where the FactoryTalk Batch Server is

installed does not display in the Computer box, select the Select

Computer button. The Select Computer dialog box opens.

5. In the Enter the object name to select area, type the name of the

computer where the Batch Server is installed (or select Advanced to

search for a computer). Select OK.

Manager of the selected computer to determine what services are available. There may be

a noticeable delay as communications are established. If the Service Manager cannot

communicate with the Windows Service Manager of the selected computer, a message

6. From the Service list, select FactoryTalk Batch Server.

If No Batch Services displays in the list, the FactoryTalk Batch Server is not installed

on the selected computer. See the

Upgrade Guide

for instructions.

FactoryTalk Batch Components Installation and

7. To start the FactoryTalk Batch Server in Demo mode, select Allow

Demo Mode.

8. Select the method to use for booting the server.

content is erased upon startup.

on the batch list when the server previously terminated.

Warm All Boot

Restarts the FactoryTalk Batch Server only if it is able to restore all of the

9. Select Start/Continue. The Service State area changes from STOPPED

to START PENDING. After a few moments, RUNNING displays and

the light changes to green.

The FactoryTalk Batch Phase Simulator may start automatically and

open a window. If so, minimize the window.

27

Page 28

Chapter 2 The eProcedure Server

Tip:

Simulator for more information.

see if the Phase Simulator is started.

Start the sample

10. Select the eProcedure Server from the Service list.

11. Select the method to use for booting the server.

Cold Boot - checked Restarts the FactoryTalk eProcedure Server in a cold state. All control steps, plus all

signatures and previously-entered values associated with the control step due to

parameter deviation or cancelled step verification signatures, are removed.

FactoryTalk Batch Phase

Simulator

e

Cold Boot unchecked

(See Effects of warm boot on control steps for more information.)

Restarts the FactoryTalk

active when the server previously terminated (the control step is restarted with a

new reactivation number).

Procedure Server, restoring the control steps that were

12. Select Start/Continue. The eProcedure Server starts running.

13. Click Close to close the FactoryTalk Batch Service Manager.

If conversation becomes LOST while running in Demo mode, make sure that the Simulator is

running and try starting the server(s) again. See Start the FactoryTalk Batch Phase

FactoryTalk Batch comes with a phase logic simulation program, referred to

as the FactoryTalk Batch Phase Simulator used to simulate the batch process

without connecting to a PCD. The Phase Simulator imitates the functionality

of a data server and can communicate with the FactoryTalk Batch Server

using OPC communication protocol. The Phase Simulator is a powerful tool

for testing, experimentation and demonstration purposes. In this guide, run

the sample demonstration using the Phase Simulator.

28

Tip: If the Phase Simulator is required and OPC protocol is used for communications, the

FactoryTalk Batch Server automatically starts the Phase Simulator. Check the Windows taskbar to

To run the sample demonstration correctly, open the ice_cream1.sim file in

the Phase Simulator.

Page 29

IMPORTANT

IMPORTANT

Administrator privileges are required to perform this procedure.

Open the sample

demonstration in the

Verify PCD communications

Chapter 2 The eProcedure Server

To start the sample FactoryTalk Batch Phase Simulator

1. If the Phase Simulator is already running, maximize it from the

Windows taskbar. If the Phase Simulator is not running, select Start >

Rockwell Software > Simulator. The FactoryTalk Batch Phase

Simulator opens.

Administrator privileges are required to perform this procedure.

2. Select File > Open. The Open Simulator Configuration File dialog box

opens.

3. From the Look in list, open the Program Files > Rockwell Software >

Batch > SampleDemo1 > Recipes folder. Select the ice_cream1.sim file,

and then select Open.

4. Minimize the FactoryTalk Batch Phase Simulator window.

To open the sample demonstration, you must open the ice_cream1.sim file in

the Phase Simulator.

FactoryTalk Batch Phase

Simulator

To open the sample demonstration in the FactoryTalk Batch Phase

Simulator

1. From the File menu, select Open. The Open Simulator Configuration

File dialog box opens.

2. From the Look in list, open the Program Files (x86)\Rockwell

Software\Batch\SampleDemo1\Recipes folder. Select the

ice_cream1.sim file, and then select Open.

3. Minimize the Phase Simulator window.

Use the following instructions to verify PCD communications.

To verify PCD communications

1. Select Start, point to All Programs > Rockwell Software > FactoryTalk

Batch Suite > FactoryTalk Batch, and then select Batch Service

Manager. The FactoryTalk Batch Service Manager opens.

29

2. Make sure FactoryTalk Batch Server is selected in the Service box.

Page 30

Chapter 2 The eProcedure Server

Effects of warm boot on

3. Select Server Statistics. The FactoryTalk Batch Server Statistics dialog

box opens.

4. Select the PCD Communications tab. The Data Server Status area

displays the status of the conversation with the OPC_SIM data server

(Phase Simulator), which should be PHASES GOOD, and the

INSTRUCTIONBASEDSERVER, which should be INSTRUCTIONS

GOOD.

5. In the Tag Verify area, select Start to begin the verify process. The tag

verification process takes several minutes.

6. When the Status box shows COMPLETED, select OK to close the

FactoryTalk Batch Server Statistics dialog box.

control steps

A warm restart (boot) of the eProcedure Server has the following effects on

control steps:

• Reactivated steps are not active after a warm boot. Instead, the

previously active control step is active. The left column in Past

instructions contains the usual information (the reactivation number

is remembered). The middle column displays Reactivated Control Step

Terminated by eProcedure Server shutting down and the right

column has a check mark. An InstructionComplete event record

containing the step’s HTML is created. In addition, a ControlStepStop

event record is added. These control steps are not eligible for

reactivation.

• Control steps that were active during a warm boot of the eProcedure

Server are still active when the server starts again, but the control step

is restarted with a new reactivation number. All signatures and

previously-entered values associated with the control step due to

parameter deviation or canceled step verification signatures are

removed. A Past control step is added, which states Control Step

Terminated by eProcedure Server shutting down.

30

Page 31

Tip:

e

Procedure.

Summary

Chapter 2 The eProcedure Server

The example below shows a reactivated control step (first of the Past

instructions below) that was active when the eProcedure Client was shut

down and the eProcedure Server was then warm booted. The reactivated

control step was a reactivation of the first control step, as indicated by the

arrow.

It also shows a control step (the second of the Past instructions in the example

below) that was active when the warm boot occurred.

In this chapter, you:

• Set up the FactoryTalk Batch Server to run the sample demonstration

• Started the FactoryTalk Batch and eProcedure Servers in demo mode

• Opened the .sim file in the Phase Simulator to run the sample

demonstration

• Verified PCD communications status

This chapter provided a brief overview of the capabilities of the FactoryTalk

Batch and eProcedure Servers. (See the FactoryTalk Batch Administrator Guide

for more information about the FactoryTalk Batch Server. See the FactoryTalk

eProcedure Administrator Guide for more information about the eProcedure

Server.)

The rest of this document is designed to give you a tour through

e

Procedure using the sample demonstration. Follow the step-by-step

instructions to learn how to run instruction-based recipes using

31

Page 32

Page 33

Chapter 3

The eProcedure Client

The eProcedure Client is a web-based application used to create and

command batches. A batch is composed of a combination of processconnected phase logic and instruction files that step you, the operator,

through the manual process of producing a batch of product.

The eProcedure Client makes use of Microsoft’s Internet Explorer along with

Active Server Pages (ASPs). The eProcedure Server acts as the processconnected device and provides the information to the web pages seen in

Internet Explorer. The eProcedure Client has five views that you can access by

selecting their respective buttons.

• Equipment view

The Equipment view provides a graphical view of your facility’s

equipment, and displays run-time information that is relevant to the

type of equipment displayed. You can use the predefined hyperlinks to

access custom web pages, documents, or applications.

• Instructions vew

The Instructions view provides the ordered list of control steps for the

selected filter. You can view current, past, and/or future control steps,

as well as add a comment to a particular control step.

• Batch List vew

The Batch List view is used to create and command a batch. A batch

remains on the batch list until the operator removes it or until the

FactoryTalk Batch Server is re-started with a cold boot command.

• Procedure vew

The Procedure view provides SFC and table views of the selected batch,

unit procedure, or operation. You can command any portion of the

batch, from the procedure level down to the phase level.

• Signature List vew

The Signature List view displays a list of pending signatures and their

related commands, report parameters, etc., which are maintained on

the FactoryTalk Batch Server.

33

Page 34

Chapter 3 The eProcedure Client

Tip:

any way.

Tip:

Directory.

Run a recipe using

eProcedure

The eProcedure Client works much the same as the FactoryTalk Batch View

client except that the operator interacts with the instruction files associated

with the phases in the area model. You will create an instruction file in the

next chapter.

When you run eProcedure for the first time, the Microsoft Installer may

also start. You can either follow the prompts on the installer or press

Cancel until it closes. This does not affect

e

Procedure’s performance in

To run a recipe using eProcedure

1. Open the FactoryTalk Batch Service Manager and make sure the

FactoryTalk Batch and eProcedure Servers are running.

2. Open Internet Explorer. The eProcedure client opens to the

FactoryTalk Batch List view. (If prompted, select OK.) The

authenticated user’s name, the default user name, or <No

authenticated user> displays as the Current User.

3. Select the Log In button. The Log on to FactoryTalk dialog box opens.

When Single-SignOn is enabled and there is no Single-SignOn user

established, the

e

Procedure Client also logs the user onto the FactoryTalk

4. Type your user name in the Name box and your password in the

Password box.

5. Select OK to log on. Otherwise, select Cancel to return to the

eProcedure Client. The name of the logged on user is displayed as the

Current User. If the logon is not successful, or if you log off without

logging on a new user, the default user is logged on or <No

authenticated user> displays.

34

Page 35

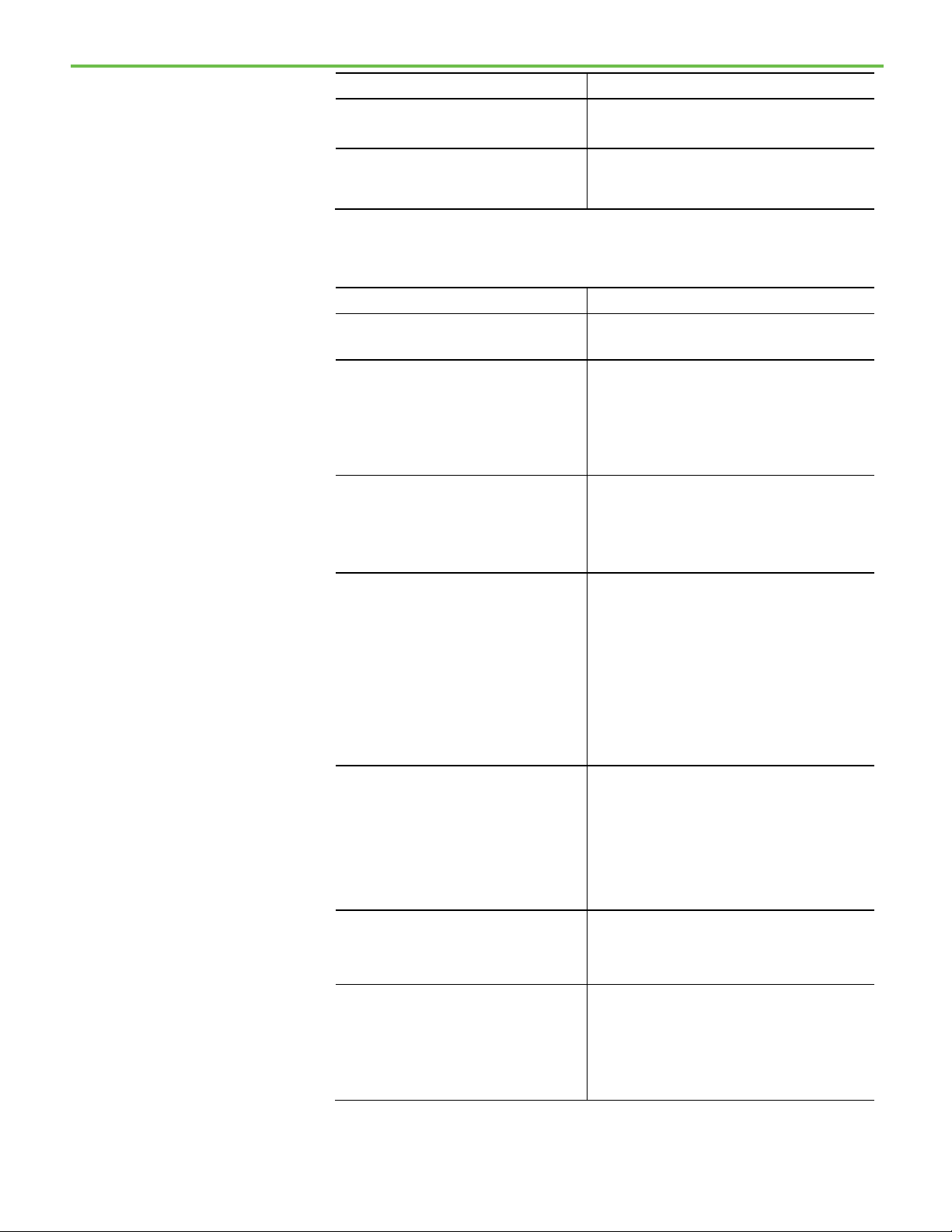

Parameter

Value

EGG_AMOUNT

180

FLAVOR_AMOUNT

48

Chapter 3 The eProcedure Client

6. Select the Add button. The Master Recipe List dialog box opens.

7. Select the CLS_FRENCHVANILLA recipe, and then select OK. The

Batch Creation dialog box opens.

8. In the Batch ID box, type BATCH_200.

9. In the Formula Values area, enter the following amounts in the Values

column:

CREAM_AMOUNT 1800

MILK_AMOUNT 1500

SUGAR_AMOUNT 700

10. In the Unit Binding area, select SP_FREEZER1 for the Freezer and

SP_MIXER1 for the Mixer, and then select Create. The batch is added

to the FactoryTalk Batch List view.

35

Page 36

Chapter 3 The eProcedure Client

11. Select the batch, and then select the Start button. The batch enters the

RUNNING state.

12. Select the Procedure button. The Procedure view displays the recipe in

an SFC. The phases change color as they activate. Use the side scroll

bar to move up and down through the SFC.

When the operator is required to interact with the instruction files, the

INSTRUCTIONS button starts flashing.

13. Select the Instructions button. The first instruction steps display.

14. Select OK to acknowledge the prompts. When asked for the amount of

each item to add, use the same amounts you entered when you created

the batch.

36

Page 37

Check the event journal

Chapter 3 The eProcedure Client

15. One of the prompts asks you to supply the agitation speed for the

mixer.

16. In the SP_MIXER1 box, type 25, and then select OK. The information

uploads to the FactoryTalk Batch Server.

17. Select the Show Future button to see all of the instructions. As a phase

activates, the instruction changes from gray to white and the OK

button activates.

37

18. Respond to the remaining prompts until the recipe completes.

19. Select the BATCHES button. Select the batch in the batch list, and then

select the Remove button. The batch is removed from the list.

The operator actions1 in eProcedure are captured in the Batch Event Journal,

which can be viewed from the FactoryTalk Batch View.

1

Action An organized activity performed on a resource in order to accomplish an

objective. Actions are grouped into categories, with some actions common to multiple

products.

Page 38

Chapter 3 The eProcedure Client

Tip:

Summary

To check the event journal

1. Open the FactoryTalk Batch View.

2. Select the Event Journal button. The Event Journal view opens.

If the Filtering area does not display, select the left split bar and drag to the right.

3. Select the Journal button. The Event Data Files dialog box opens.

4. In the Event Data Files list, select the BATCH_200 batch, and then

select OK. The event data displays on the right side of the window.

5. From the Column 1 list, select Time.

6. From the Column 2 list, select Event Type.

7. In the Filter 2 box, type Report.

8. From the Column 3 list, select (None).

9. Select the Refresh button. The data is filtered to show the entries the

operator made in the BATCH_200 batch. You may need to adjust the

column headings to view the entire message as shown in this figure.

10. Exit the FactoryTalk Batch View.

In this chapter you,

• Configured the eProcedure Client

• Ran a recipe using eProcedure

• Filtered the event journal to see the operator input

This chapter provided a brief overview of the capabilities of the eProcedure

Client. (See the FactoryTalk eProcedure Client User Guide for more information

on the eProcedure Client. See the FactoryTalk Batch View User Guide for more

information on the Event Journal.)

38

Page 39

Create instruction-based

phases

Create an instruction file

Chapter 4

Introduction to instruction-based phases

An instruction-based phase is a phase that is linked to an instruction file —

when the phase executes, the contents of the instruction file display in a

browser window.

An instruction-based phase consists of an instruction file that is assigned to

the phase.

To create instruction-based phases

1. Create the instruction file.

2. Assign the instruction file to a phase

An instruction file contains the series of steps, such as operation instructions

and operator feedback entries that present to the operator though Internet

Explorer. All the actions performed are recorded in the Event Journal for a

permanent record of the process. For example, you can add a step in the

instruction file that prompts the operator to verify a temperature; the

temperature value and the approval indication appears in the Event Journal.

For this exercise you will use Microsoft® Notepad to view an existing HTMLbased web page that uses standard HTML tags and custom HTML tags

designed for use with the eProcedure Server. To understand how the

instructions are written, see Custom tags.

39

To create an instruction file

1. Open Notepad.

2. From the File menu, select Open. Navigate to C:\Program Files\Rockwell

Software\Batch\SampleDemo1\instructions (if you did not use the default

install path, navigate to the correct location).

3. Select add_egg_1.htm and select Open.

Page 40

Chapter 4 Introduction to instruction-based phases

4. Select File > Save As, and save the htm file with the name

add_egg_demo.htm.

The file consists of several short forms, designated by the <form> and

</form> HTML tags.

5. Locate the text highlighted in the first form in the following

illustration:

6. The highlighted line tells the eProcedure client to:

Prepare <sop>UNIT</sop> for delivery of <sop>ADD_AMOUNT</sop>

KG of Egg.

This line appears as the first step in the manual phase and at run time

replaces <sop>ADD_AMOUNT</sop> with the actual amount to add to

the recipe.

7. The code and text in the second form tells the eProcedure client to:

Begin charging <sop>ADD_AMOUNT</sop> KG of Egg into

<sop>UNIT</sop>.

Press OK when complete.

8. Locate the third form in the file. Change the word Egg to Egg_Demo,

as shown here:

Note that this form also contains a text box (<INPUT TYPE="TEXT"

SIZE="20" NAME="AMOUNT_ADDED">). At run time the operator

enters the amount of Egg that was added to the recipe.

9. Select File > Save. Be sure to save the file in the

SampleDemo1/Instructions folder for the project.

40

Page 41

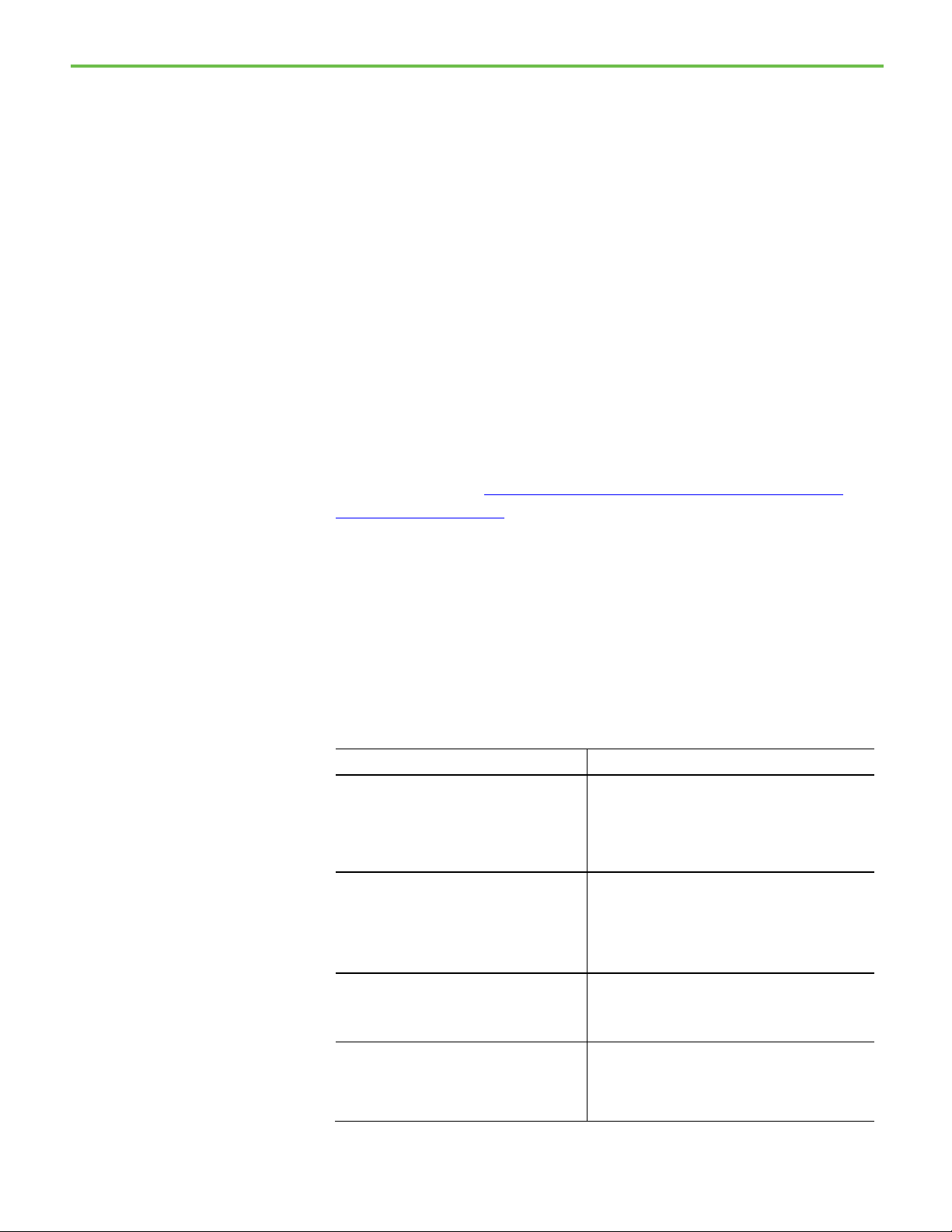

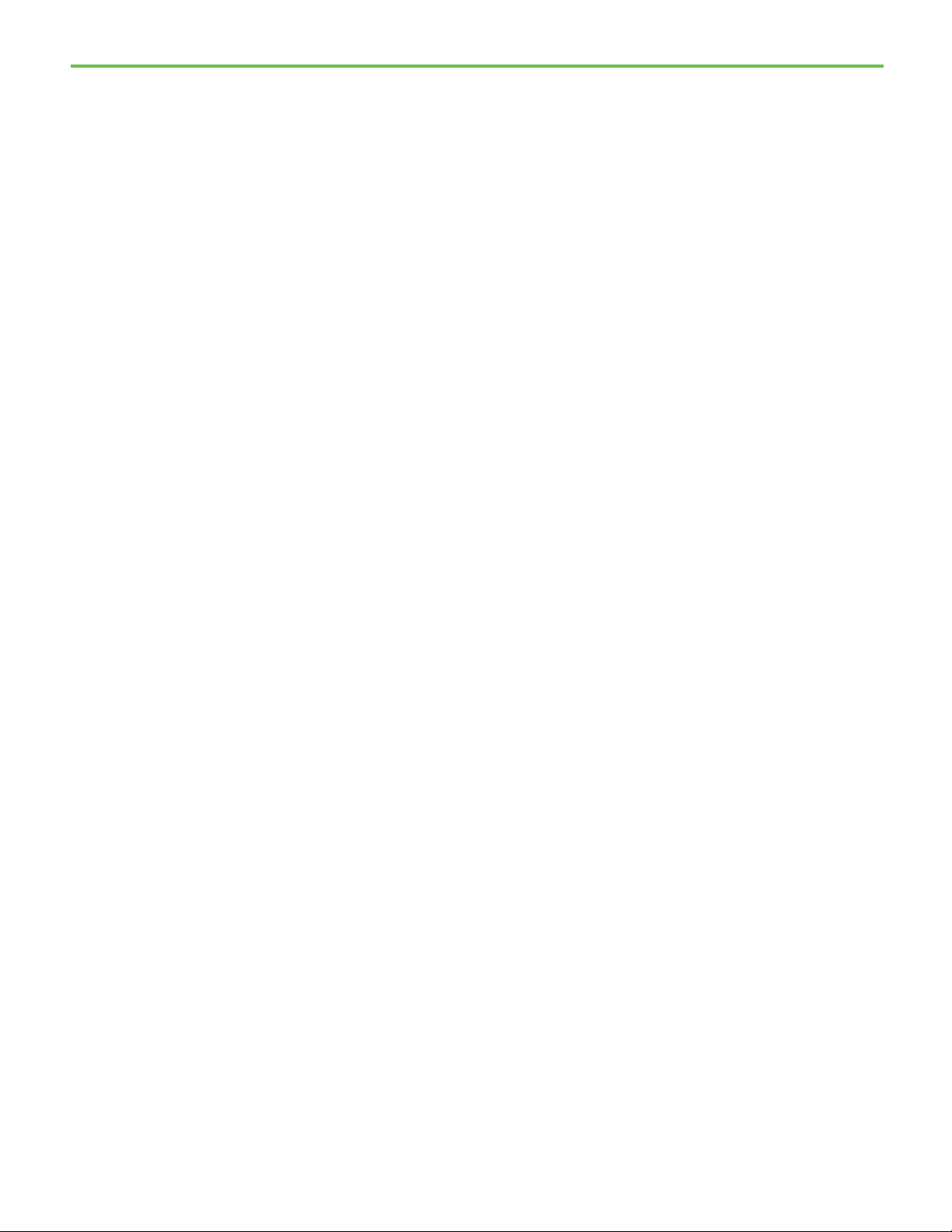

Data Type

HTML Code

Display Value

<sop>Unit</sop>

Unit name for the current phase

<sop>Phase</sop>

Current phase name

<sop>parameter.Min</sop>

Parameter minimum allowed value

<sop>parameter.LowLimit</sop>

Parameter Low limit

<sop>parameter.Default</sop>

Parameter default value

<sop>report.Value</sop>

Report value

<sop>report.LowLimit</sop>

Report low limit

<sop>report.LowLowLimit</sop>

Report low-low limit

<sop>report.HighLimit</sop>

Report high limit

sop>report.HighHighLimit</sop>

Report high-high limit

<sop>report.HighHighHighLimit</sop>

Report high-high-high limit

Custom tags

Chapter 4 Introduction to instruction-based phases

The full path is

c:\Program Files\Rockwell Software\Batch\SampleDemo1\Instructions or

\\computername\BATCHCTL\SampleDemo1\Instructions if you are

developing on a remote computer.

10. Close the file and exit Notepad.

The instructions are written using plain text. To obtain specific server-related

information, use the custom tags shown in this table.

Batch Data <sop>BatchID</sop> Batch ID of the running recipe

<sop>Cell</sop> Process cell

Parameter Data <sop>parameter.Name</sop> Parameter name

<sop>parameter.EU</sop> Parameter engineering units

<sop>parameter.Max</sop> Parameter maximum allowed value

<sop>parameter.LowLowLowLimit</sop> Parameter Low-Low-Low limit

<sop>parameter.LowLowLimit</sop> Parameter Low-Low limit

Parameter Data

(continued)

Report Data <sop>report.Name</sop> Report Name

<sop>parameter.HighLimit</sop> Parameter High limit

<sop>parameter.HighHighLimit</sop> Parameter High-High limit

<sop>parameter.HighHighHighLimit</sop> Parameter High-High-High limit

<sop>parameter.Value</sop> Parameter value

<sop>report.EU</sop> Report engineering units

<sop>report.LowLowLowLimit</sop> Report low-low-low limit

41

Electronic

Signatures

<sop>VERIFICATIONSIG=SignatureTemplate</sop> Signature template to be used for a

verification signature

Page 42

Chapter 4 Introduction to instruction-based phases

Tip:

Since you made changes to the area model, you need to stop and restart the

batches.

Assign an instruction file to

After you create the instruction file you must assign it to a phase in the

FactoryTalk Batch Equipment Editor. When the phase is activated in the

a phase

recipe, the FactoryTalk Batch Server runs the instruction file.

To assign an instruction file to a phase

1. Start the FactoryTalk Batch Equipment Editor and open the

2. Double-click the South Parlor process cell.

3. Double-click SP_MIXER1.

4. Double-click SP_ADD_EGG_M1. The Edit Equipment Module dialog

box opens to the General tab.

ice_cream1ep.cfg area model.

The Instruction File box indicates that an instruction file is already

assigned to this phase. You will replace it with the instruction file that

you just created.

5. Select the Browse button next to the Instruction File box. The

Instruction Selection box opens to display the HTML code within the

file.

6. Select add_egg_demo.htm, and then select OK twice.

7. Save the area model and exit the FactoryTalk Batch Equipment Editor.

42

FactoryTalk Batch and eProcedure Servers at this point if you want to run any

Page 43

Include a step verification

signature template

Summary

You can require a step verification signature using a specific signature

template for a control step. You can add a step verification signature to any

control step that must be signed off before recipe execution can continue. The

verification signature template is defined in the FactoryTalk Batch

Equipment Editor. The signature must be completed before recipe execution

can continue.

Chapter 4 Introduction to instruction-based phases

To include a step verification signature template

1. Open or create a blank instruction file. (See Create an instruction file

for more information.)

2. Place your cursor at the beginning of the first cell.

3. Using the correct naming conventions, enter the tagged data item.

Example:

<sop>VERIFICATIONSIG=SignatureTemplate</sop>

where SignatureTemplate is the name of the desired template.

In this chapter, you:

• Created an instruction file using Microsoft Word and FrontPage.

• Assigned the instruction file to a phase using the FactoryTalk Batch

Equipment Editor.

This chapter provided a brief overview of instruction-based phases. (See the

FactoryTalk Batch Equipment Editor User Guide for more information on

instruction-based phases.)

43

Page 44

Page 45

eProcedure Glossary

Acquiring

Acquiring is a possible state of the Firing attribute of a transition.

When the transition is in the Acquiring state, it has made non-binding

related arbitration requests for resources needed by one or more steps

following the transition.

Activation file

A text file that contains all of the activation information that is

required to license a software product and allow it to properly

function. While the file is simply plain text, the contents of the file are

protected by a signature.

Appendix A

Binding

Binding is the process of mapping steps within a control recipe to

actual equipment in a plant.

Binding (in transitions)

Binding is a possible state of the Firing attribute of a transition. When

the transition is in the Binding state, it is in the process of attempting

to bind one or more of the steps following the transition. The binding

process may involve the generation of binding prompts and/or the

generation of arbitration requests.

Comm Err

Comm Err is a possible state of the Firing attribute of a transition.

When the transition is in the Comm Err state, a communications error

with phase logic has been detected while the transition was in the

Stopping/Resetting/Pending states of the firing process. The

transition has rolled back to the beginning of the

Stopping/Resetting/Pending process and is awaiting good

45

Page 46

Appendix A eProcedure Glossary

communications and a RESTART command before re-initiating the

firing process.

Comment descriptor

In a signature dialog, the text in parentheses that indicates if the

comment field is optional, required, or not allowed.

Committed

Committed is a possible state of the Firing attribute of a transition.

When the transition is in the Committed state, it has committed to the

firing process, but is not in the process of firing because either the

transition is in the HELD state or the parent procedure is in MANUAL

mode.

Control step

One instruction in an eProcedure phase. An eProcedure phase consists

of one or more control steps. Also referred to as step, eProcedure step,

or instruction step.

Control step reactivation

Making a completed control step in an eProcedure phase active again

so that mistakenly entered values can be re-entered.

Dedicated resource

A resource used by only one step at a time inside a recipe structure.

Deviation event

A deviation event is a probable new event type for the event journals

that records the deviation information.

Diagnostics client

System components that retrieve diagnostic information from

FactoryTalk Diagnostics. Clients can be FactoryTalk system elements

or applications.

46

Page 47

Diagnostics destinations

Storage or destinations of diagnostics messages such as the

FactoryTalk Diagnostics native store, RSMACC, etc. The FactoryTalk

Diagnostics framework was designed to be extensible to allow

additional message destinations to be defined and added to the

system.

Diagnostics native store

Persistent storage of data logged by the FactoryTalk Diagnostics

subsystem. In a distributed system, these logs can reside local to the

machine. When diagnostic data is retrieved, all information from

diagnostic logs within a system can be merged. There is no implied

implementation or format of diagnostic logs in this specification.

Diagnostics message

Appendix A eProcedure Glossary

Diagnostics information furnished by a diagnostic client with selfdescribing internal structure and content.

Dynamic unit allocation

The process of binding a specific unit to a class-based unit procedure

or operation. Dynamic unit allocation can be defined only at the

procedural level.

Dynamic HTML elements

Elements, such as text areas, buttons, etc., that are used for user

interaction, or ele\-ments in which one or more event handlers are

defined. For example:

<IMG src=./images/Earl.JPG>

would not be a dynamic element, but

<IMG src=./images/Earl.JPG onclick=’msgbox "Kaboooooom!"’'>

would be a dynamic element. Clicking on it displays a message box

containing the text "Kaboooooom!".

47

Page 48

Appendix A eProcedure Glossary

Electronic signature

An electronic representation of a signature, including all associated

data. Can consist of one or two signoffs. Associated data includes

meanings for the signoffs, comments, security requirements, and

timestamps.

Equipment phase

An equipment phase is the S88 terminology for the equipment phase

and equipment phase interface. In FactoryTalk Batch, equipment

phases are configured in the FactoryTalk Batch Equipment Editor as

instances of the recipe phases. Equipment phases are bound to the

recipe at

runtime.

FactoryTalk Asset Centre

Formerly RSMACC (Rockwell Software Maintenance Automation

Control Center).

Firing attribute

The Firing Attribute (formerly the Acquiring attribute) has nine legal

states, defined as follows:

"0": Not Firing - The transition is not in the firing process.

"1": Acquiring - The transition is in the process of acquiring resources

for the following steps.

"2": Binding - The transition is in the process of binding one or more of

the following steps.

"3": Committed - The transition is committed to the firing process, but

is not proceeding due to either a HELD state, or the parent procedure

being in MANUAL mode.

"4": Stopping - The transition is waiting for one or more prior steps to

achieve a terminal state after having been issued STOP commands.

"5": Resetting - The transition is waiting for one or more prior steps to

transition to IDLE after having been issued RESET commands.

"6": Pending - The transition is waiting for one or more prior steps to

transition into a legal state for a Transfer of Control operation.

48

Page 49

"7": Paused - The transition is waiting for a RESUME command or a

return of the parent procedure to AUTO mode.

First Available binding

This is one of the ways that units are selected for binding. This is called

late unit binding or dynamic unit allocation. When automatically

selecting a unit for binding, the FactoryTalk Batch Server tries to use

the unit that the recipe can acquire first. The unit selected must meet

two criteria:

• The acquired unit must belong to the unit class of the unit