Page 1

842D DeviceNet

Encoder

Catalog Numbers:

842D-60131331BDA and

842D-60131331BXA Revision 4.001

User Manual

Page 2

Important User Information Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Rockwell Automation does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Rockwell Automation office), describes

some important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Rockwell

Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

• Identify a hazard.

• Avoid the hazard.

• Recognize the consequences.

Important: Identifies information that is critical for successful

application and understanding of the product.

death, property damage or economic loss.

Page 3

Preface Using this Manual

Objectives .............................................................................P-1

Who Should Use this Manual?..............................................P-1

Purpose of this Manual .........................................................P-1

Contents of this Manual ........................................................P-2

Related Publications .............................................................P-2

Safety Precautions ............................................................... P-3

Terms and Abbreviations ......................................................P-3

Conventions Used in this Manual..........................................P-5

Rockwell Automation Support ...............................................P-5

Local Product Support ..........................................................P-5

Technical Product Support....................................................P-5

Table of Contents

Chapter 1 Overview

Chapter Objectives ...............................................................1-1

Overview of the Encoder....................................................... 1-1

Features of the Encoder........................................................ 1-1

Overview of Setting Up the Encoder..................................... 1-2

Chapter 2 Installation

Chapter Objectives ...............................................................2-1

Installing a Bulletin 842D DeviceNet Encoder....................... 2-1

Selecting Cables ................................................................... 2-1

Installing the DeviceNet Encoder..........................................2-2

Chapter 3 Configuring the DeviceNet Encoder DIP Switches

Chapter Objectives ...............................................................3-1

Setting up the 842D DeviceNet Encoder ..............................3-1

Setting the Node Address..................................................... 3-2

Setting the baud rate.............................................................3-2

Diagnostic LED ..................................................................... 3-2

Bus termination ..................................................................... 3-3

Preset function ...................................................................... 3-3

Page 4

ii

Chapter 4 Configuring the Encoder Using RSNetworx for DeviceNet

Chapter Objectives ...........................................................................4-1

What is RSNetWorx for DeviceNet? .................................................4-1

Required Equipment and Software...................................................4-1

Going Online ..................................................................................... 4-2

Installation of the EDS File ............................................................... 4-4

Offline Integration into the Network .................................................. 4-4

Accessing and Editing Parameters...................................................4-5

Enhanced Device Configuration in Offline Mode ..............................4-6

Enhanced Device Configuration in Online Mode ..............................4-7

Saving Parameter Values to EEPROM ............................................. 4-7

Restoring Parameters to EEPROM Values.......................................4-7

Setting Parameters to Default Values ............................................... 4-7

Chapter 5 Configuring a Scanner to Communicate with the Encoder

Chapter Objectives ...........................................................................5-1

Required Equipment and Software...................................................5-1

Operating Modes of the Encoder......................................................5-1

Example DeviceNet Network ............................................................ 5-4

Setting Up the Scan List ................................................................... 5-4

Mapping the Product’s Data in the Scanner .....................................5-7

Saving the Configuration .................................................................. 5-8

Chapter 6 Using DeviceNet Explicit Messaging

Chapter Objectives ..........................................................................6-1

Required Equipment ........................................................................ 6-1

Explicit Messaging Preset Example for the 1747-SDN Scanner ...... 6-1

Explicit Messaging Prest Example for the 1756-DNB....................... 6-6

Appendix A 842D Specifications and Dimensions................................. A-1

Appendix B DeviceNet Objects

Appendix Objectives.........................................................................B-1

Object Classes..................................................................................B-1

Class Code 01hex — Identity Object................................................B-1

Class Code 02hex — Message Router.............................................B-2

Class Code 03hex — DeviceNet ......................................................B-2

Class Code 04hex — Assembly .......................................................B-3

Class Code 05hex — Connection.....................................................B-4

Class Code 2Fhex — Encoder .........................................................B-7

Designation of Alarm Bits ...............................................................B-10

Designation of Warning Bits ...........................................................B-10

Designation of Cam Bits .................................................................B-10

Page 5

Preface

Using this Manual

Objectives Read this preface to become familiar with the organization of the

manual. In this preface, you will read about the following:

• Who should use this manual.

TM

absolute rotary shaft

Who Should Use this

Manual?

• An overview of the 842D DeviceNet

encoder.

• The purpose of this manual.

• Terms and abbreviations.

• Conventions used in this manual.

• Rockwell Automation support.

Use this manual if you are responsible for installing, wiring,

programming, or troubleshooting control systems that use the 842D

encoder.

This manual is intended for qualified service personnel responsible

for setting up and servicing the 842D encoder. You must have

previous experience with and a basic understanding of electrical

terminology, programming procedures, networking, required

equipment and software, and safety precautions.

Purpose of this Manual This manual is a learning and reference guide for the 842D encoder. It

describes the procedures needed to install, configure, and

troubleshoot the encoder.

Page 6

P-2 Using this Manual

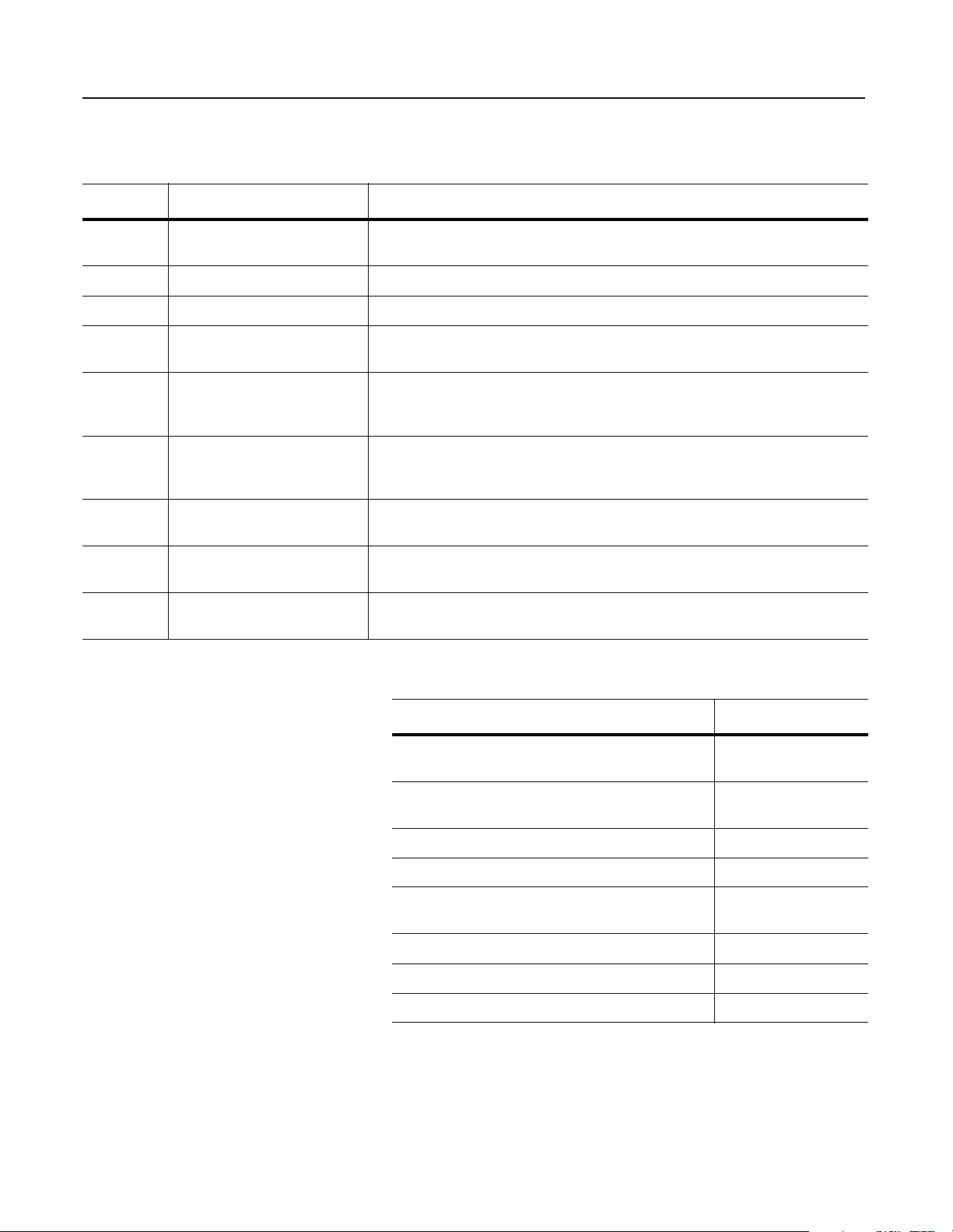

Contents of this Manual

This manual contains the following information:

Chapter Title Contents

Preface Using this Manual Describes the purpose, background and scope of this manual. Also provides

information on safety precautions and technical support.

1 Overview Provides an overview of the 842D Encoder.

2 Installation Provides a procedure for installing the 842D encoder.

3 Configuring the DeviceNet

Encoder DIP Switches

4 Configuring the Encoder

Using RSNetWorx for

DeviceNet

5 Configuring a Scanner to

Communicate with the

Encoder

6 Using DeviceNet Explicit

Messaging

A Specifications and

Dimensions

B DeviceNet Objects Defines the DeviceNet object classes, class services, and attributes that are

Describes the setting of node address, bus termination, baud rate and

PRESET function.

Provides information that you need to configure the encoder (online and

offline) over the DeviceNet networ

Provides instructions for configuring a PLC or SLC scanner to communicate

with the encoder.

Includes information you need to monitor and configure the encoder using

explicit messaging on DeviceNet. Features an example of explicit messaging.

Provides the specifications and physical dimensions of the 842D encoder.

supported by the DeviceNet encoder.

k.

Related Publications

Title Publication Number

RSNetWorx for DeviceNet Getting Results

Manual

9398-DNETGR

1747-SDN DeviceNet Scanner Configuration

Manual

1747-SDN DeviceNet Scanner Module Manual 1747-5.8

DeviceNet Media, Sensors and Distributed I/O 1485-CG001A-EN-P

DeviceNet Cable System Planning and

Installation Manual

RSLogix 5 Getting Results Guide 9399-RL53GR

RSLogix 500 Getting Results Guide 9399-RL50GR

RSLogix 5000 Getting Results Guide 9399-RLD300GR

1747-6.5.2

DN-6.7.2

Page 7

Using this Manual P-3

Safety Precautions Please read the following safety precautions carefully.

ATTENTION: Only personnel familiar with

DeviceNet products and associated machinery should

!

!

!

plan or implement the installation, start-up,

configuration, and subsequent maintenance of the

DeviceNet absolute encoder. Failure to comply may

result in personal injury and/or equipment damage.

ATTENTION: Remove all power before installing the

DeviceNet absolute encoder. Failure to disconnect

power may result in death or serious injury. Verify all

power is removed before installing the DeviceNet

absolute encoder.

ATTENTION: Hazard of equipment damage exists. If

explicit messages are programmed to frequently write

parameter data to the 842D EEPROM, the EEPROM can

exceed its life cycle and cause the product to

malfunction. Do not create a program that frequently

uses explicit messages to write parameter data to a

product. (See EEPROM Life specification on page A-1.)

Terms and Abbreviations For a complete listing of Allen-Bradley terminology, refer to the

Allen-Bradley Industrial Automation Glossary, Publication AG-7.1.

Terms Definition

DeviceNet An open network that provides probabilistic I/O control

through a managed bit-wise non-destructive multiplexing

scheme.

842D

DeviceNet

Encoder

RSNetWorx

for

DeviceNet

An Allen-Bradley encoder that communicates directly with the

DeviceNet network without requiring additional adapters. In

this manual, the terms “encoder” and “842D” are also used

when referring to the 842D DeviceNet Encoder.

A Rockwell Software application that can be used to set up

DeviceNet networks and configure connected devices.

RSNetWorx for DeviceNet (version 3.00.00) and RSLinx

(version 2.20.02) were used for examples in the manual.

Different versions may differ in appearance and procedures.

Page 8

P-4 Using this Manual

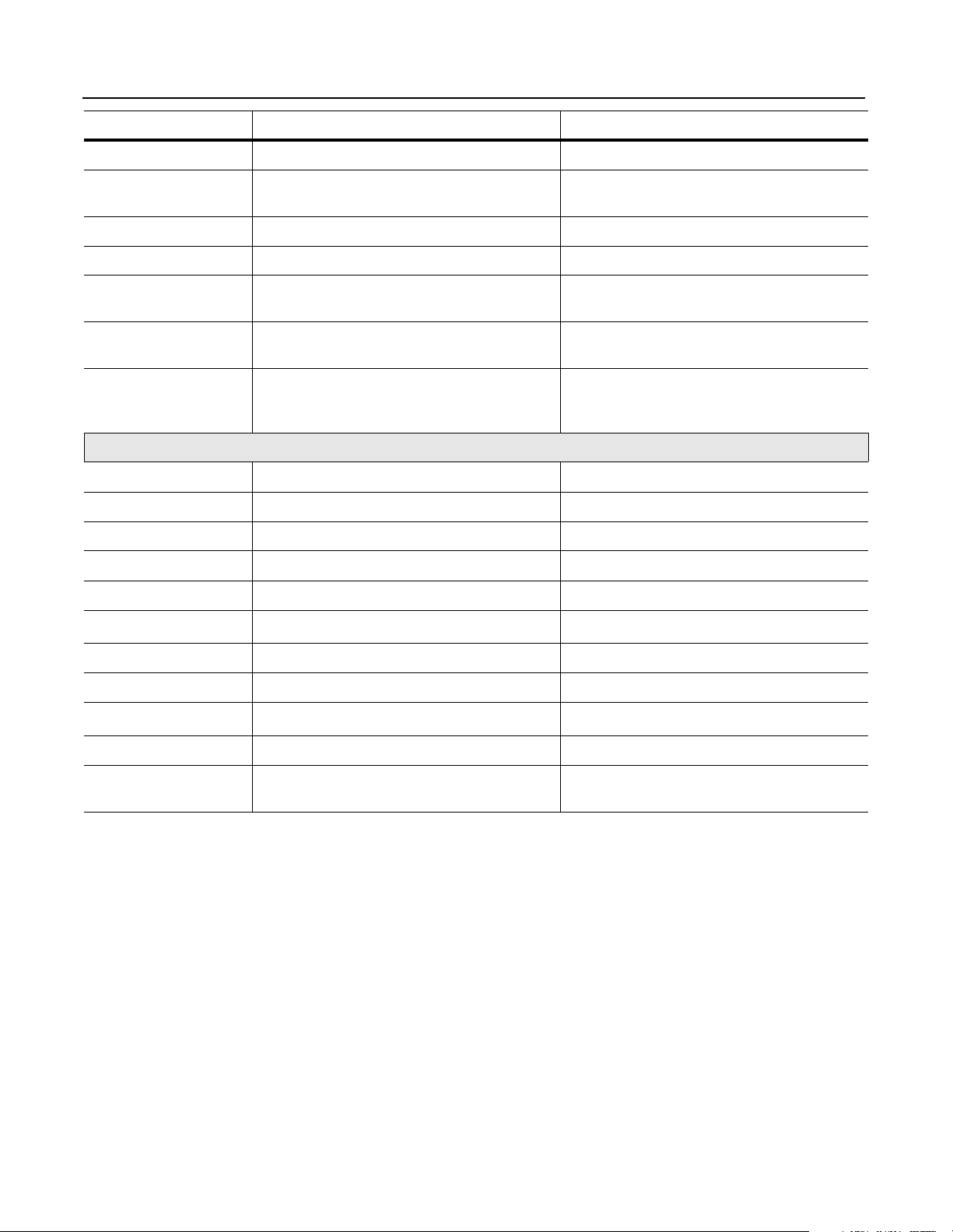

Abbreviation Full Name Definition

CAN Controller Area Network Physical layer definition

ODVA Open DeviceNet Vendor Association User organization for DeviceNet.

ID Identifier

EDS Electronic Data Sheet

ScF Scaling factor Measuring units per revolution / Single turn

resolution

Pos_calc calculated position value calculated current position value, after clearing

with Offset, ScF, Preset

Pos_num numerical position value numerical (physical) position value before

clearing with Offset, ScF, Preset

Data Types

BOOL Boolean Bit

BYTE Bit String 1 Byte (8 Bit)

WORD Bit String 2 Byte (16 Bit)

USINT Unsigned Short Integer Int (1 Byte) - (0...255)

UINT Unsigned Integer Int (2 Byte) - (0...65,535)

UDINT Unsigned Double Integer

Int (4 Byte) - (0...+2

32

-1)

SINT Signed Short Integer Int (1 Byte) - (-128...+127)

INT Signed Integer Int (2 Byte) - (-32,768...+32,767)

DINT Signed Double Integer

Int (4 Byte) - (-2

31

...+231 - 1)

LSB Least Significant Bit / Byte

MSB Most Significant Bit / Byte

Page 9

Using this Manual P-5

Conventions Used in this

Manual

Rockwell Automation

Support

The following conventions are used throughout this manual:

• Bulleted lists provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Italic type is used for chapter names and for parameter names.

• Bold type is used for names of menus, menu options, screens, and

dialog boxes.

Important: This type of paragraph contains tips or notes that have

been added to call attention to useful information.

Rockwell Automation offers support services worldwide, with more

than 75 sales/support offices, more than 500 authorized distributors,

and more than 250 authorized systems integrators located throughout

the United States alone. In addition, Rockwell Automation

representatives are in every major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for:

• Sales and order support.

• Product technical training.

• Warranty support.

• Support service agreements.

Technical Product Support

If you need to contact Rockwell Automation for technical assistance,

please call your local Rockwell Automation representative.

Refer to http://www.ab.com for updates and supporting

documentation.

Page 10

P-6 Using this Manual

Notes:

Page 11

Chapter 1

Overview

Chapter Objectives Chapter 1 provides an overview of your 842D DeviceNet absolute

encoder. In this chapter, you will read about the following:

• Function of the 842D encoder.

• Features of the 842D encoder.

• Steps for setting up the encoder.

• Required tools and equipment.

Overview of the Encoder The 842D absolute multi-turn encoder provides a total resolution of

26 bits. The single-turn position value is transmitted with 13 bits. The

number of multi-turn revolutions is 13 bits. Revolutions are counted

by the use of a gear mechanism. The bus interface is located in the

encoder and is configured as a DeviceNet slave according to

DeviceNet specification, release 2.0.

Features of the Encoder The DeviceNet network is an open, global industry-standard

communication network designed to provide an interface through a

single cable from a programmable controller directly to “smart”

devices such as sensors, push buttons, motor starters, operator

interfaces and drives.

The 842D DeviceNet encoder connects directly to the a DeviceNet

network without the need for additional adapters. Features of the

842D include:

• 26-bit absolute multi-turn operation (8192 steps per revolution x

8192 revolutions) without batteries

• Supports Polling, Cyclic, Change of State (COS) and Bit Strobed

I/O messaging

• Transmission rate up to 500 kBaud.

• Programmable functions

– Electronic alignment (PRESET or Number-SET). Electronic

alignment may be carried out via DeviceNet or via a pushbutton in the bus connector of the 842D.

– Clockwise or Counterclockwise (CW/CCW) counting

direction

Page 12

1-2 Overview

– Scaling function - Setting the single-turn resolution as well as

the number of turns. The single-turn resolution is any whole

number from 1 to 8192. The number of turns must be 1, 2, 4,

8, 16, 32, 64... up to 8192.

– Up to eight programmable cams

– Velocity Warning Flags

• Status information is available via the Network Status LED on

the back of the encoder.

• Velocity Feedback (Steps per second, RPM, or RPS)

• Diagnostic and Position Error Alarms

• Node address, Baud rate, and bus termination resistance are

selected via DIP switches under the removable cover on the back

of the encoder.

Overview of Setting Up the

Encoder

To set up the 842D DeviceNet encoder, you must perform the

following tasks:

1. Install the encoder. Refer to Chapter 2, Installation.

2. Set the encoder’s node address, transmission rate and bus

termination. Refer to Chapter 3, Configuring the DeviceNet

Encoder DIP Switches.

3. Configure the encoder’s parameters. Refer to Chapter 4,

Configuring the Encoder Using RSNetWorx for DeviceNet.

4. Configure a scanner (either PLC or SLC) to communicate with

the encoder. Refer to Chapter 5, Configuring a Scanner to

Communicate with the Encoder.

Page 13

Chapter 2

Installation

Chapter Objectives Chapter 2 provides the information that you need to install the 842D

DeviceNet encoder. In this chapter, you will read about the following:

• Cable connections.

• Installing the encoder.

Installing a Bulletin 842D

DeviceNet Encoder

Selecting Cables

To connect the encoder to the DeviceNet network, you must select an

appropriate DeviceNet drop cable. A drop line connects a node, such

as an encoder, to the DeviceNet trunk cable. Use the following

information to select appropriate cables for each connection.

Bulletin 842D DeviceNet encoders are available with a single 5-pin

micro quick disconnect or two 5-pin quick disconnects (one male and

one female) for ‘daisy chain’ connections.

Catalog Number Electrical Connection

842D-60131331BDA One 5-pin male micro QD

842D-60131331BXA Two 5-pin micro QDs (one male & one female)

Pin configurations are per the DeviceNet specification as follows:

Figure 2.1 DeviceNet Micro Connections

Female Micro

Male Micro

3

5

2 1

4

1

4

3

5

2

1Drain Bare

2V+ Red

3V- Black

4 CAN_H White

5 CAN_L Blue

Refer to the table below for recommended drop cables. .

Length Right Angle Micro Male to Straight Micro Female

1m 1485R-P1R5-F5

2m 1485R-P2R5-F5

3m 1485R-P3R5-F5

4m 1485R-P4R5-F5

5m 1485R-P5R5-F5

6m 1485R-P6R5-F5

Page 14

2-2 Installation

It is also important to determine the limitations of the trunk and drop

cables. Refer to the following table.

Data Rates 125 Kbps 250 Kbps 500 Kbps

Thick Trunk Line 500 m (1,640 ft) 250 m (820 ft) 100 m (328 ft)

Thin Trunk Line 100 m (328 ft) 100 m (328 ft) 100 m (328 ft)

Maximum Drop Length 6 m (20 ft) 6 m (20 ft) 6 m (20 ft)

Cumulative Drop Budget 156 m (512 ft) 78 m (256 ft) 39 m (128 ft)

For more information on DeviceNet cables and cable systems, refer to

the DeviceNet Cable System Planning and Installation Manual,

Publication DN-6.7.2.

Installing the DeviceNet Encoder

The following instructions explain how to physically install your

DeviceNet encoder.

1. Be sure to select the proper size flexible coupling clamp to mate

to the encoder shaft, e.g., 845-FC-*-*. See the Encoder

Accessories section in the Allen-Bradley Sensors catalog.

ATTENTION: Only personnel familiar with

DeviceNet products and associated machinery should

!

plan or implement the installation, start-up,

configuration, and subsequent maintenance of the

DeviceNet absolute encoder. Failure to comply may

result in personal injury and/or equipment damage.

2. Use the dimension drawings to determine the encoder mounting

hole locations. See Appendix A.

3. Slide the flexible coupling onto the shaft, but do not

tighten the

set screws.

4. Mount the encoder and tighten with three size M4 mounting

screws (not supplied).

5. Center the flexible coupling and tighten the set screws.

6. Rotate the machine slowly and verify that the flexible coupling is

not deforming beyond specifications.

Page 15

Chapter 3

Configuring the DeviceNet Encoder

DIP Switches

Chapter Objectives Chapter 3 provides information that you need to configure the

encoder. In this chapter, you will read about the following:

• Setting the node address.

• Setting the transmission baud rate

• Activating bus termination.

• Diagnostic LED

• The Preset function.

Setting up the 842D

DeviceNet Encoder

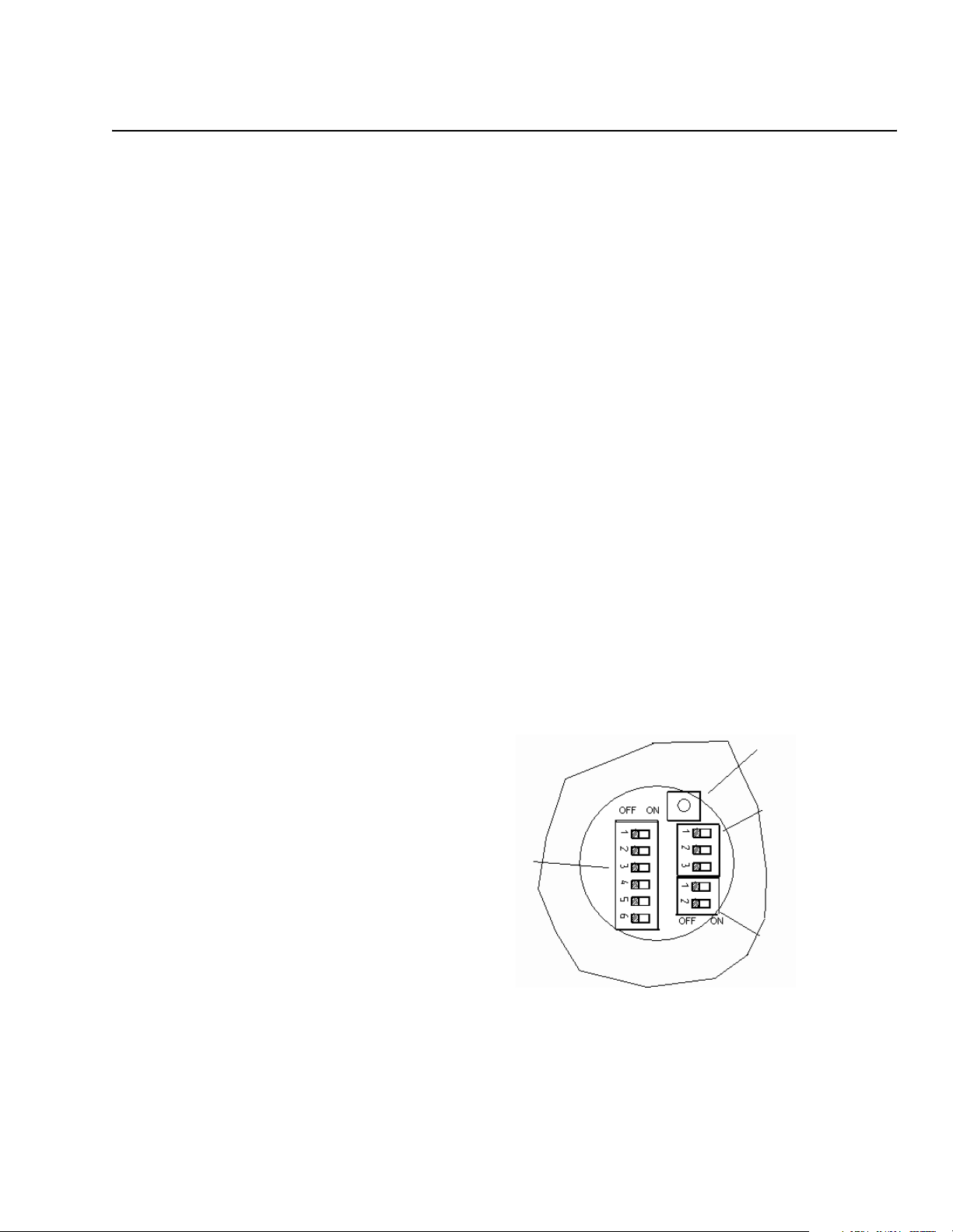

Specific features of the 842D must be configured by means of

hardware settings. (Remote setting of the DIP switches via a Node

Commissioning Tool is not supported at this time.) These features are

Node Address, Baud Rate and the DeviceNet bus termination. In

addition, the encoder can be set to a fixed position value (PRESET

function) by actuating a push-button. In order to execute this

function, the large PG plug on the rear of the encoder has to be

removed. Inside, three DIP switches and a micro push-button become

visible.

Figure 3.1 Encoder DIP Switches

Preset Position

Button

Baud Rate

Node Address

(MAC-ID)

Bus Termination

Page 16

3-2 Configuring the DeviceNet Encoder DIP Switches

Setting the Node Address

The Node Address is set via the 6-pole DIP switch. The DIP switch

settings are binary starting with switch number 1 = (2

with switch number 6 (= 2

DIP-1 DIP-2 DIP-3 DIP-4 DIP-5 DIP-6

0

2

0000000

1000001

... ... ... ... ... ... ...

11111163

0 = DIP switch is OFF

1 = DIP switch is ON

Setting the baud rate

The 3-pole DIP switch allows for setting the transmission baud rate.

DIP-1 DIP-2 DIP-3 Baud rate

0

) and ending

5

).

1

2

2

2

3

2

4

2

2

Address

5

0 0 X 125 kBaud

1 0 X 250 kBaud

0 1 X 500 kBaud

1 1 X 125 kBaud

X = don't care

0 = DIP switch is OFF

1 = DIP switch is ON

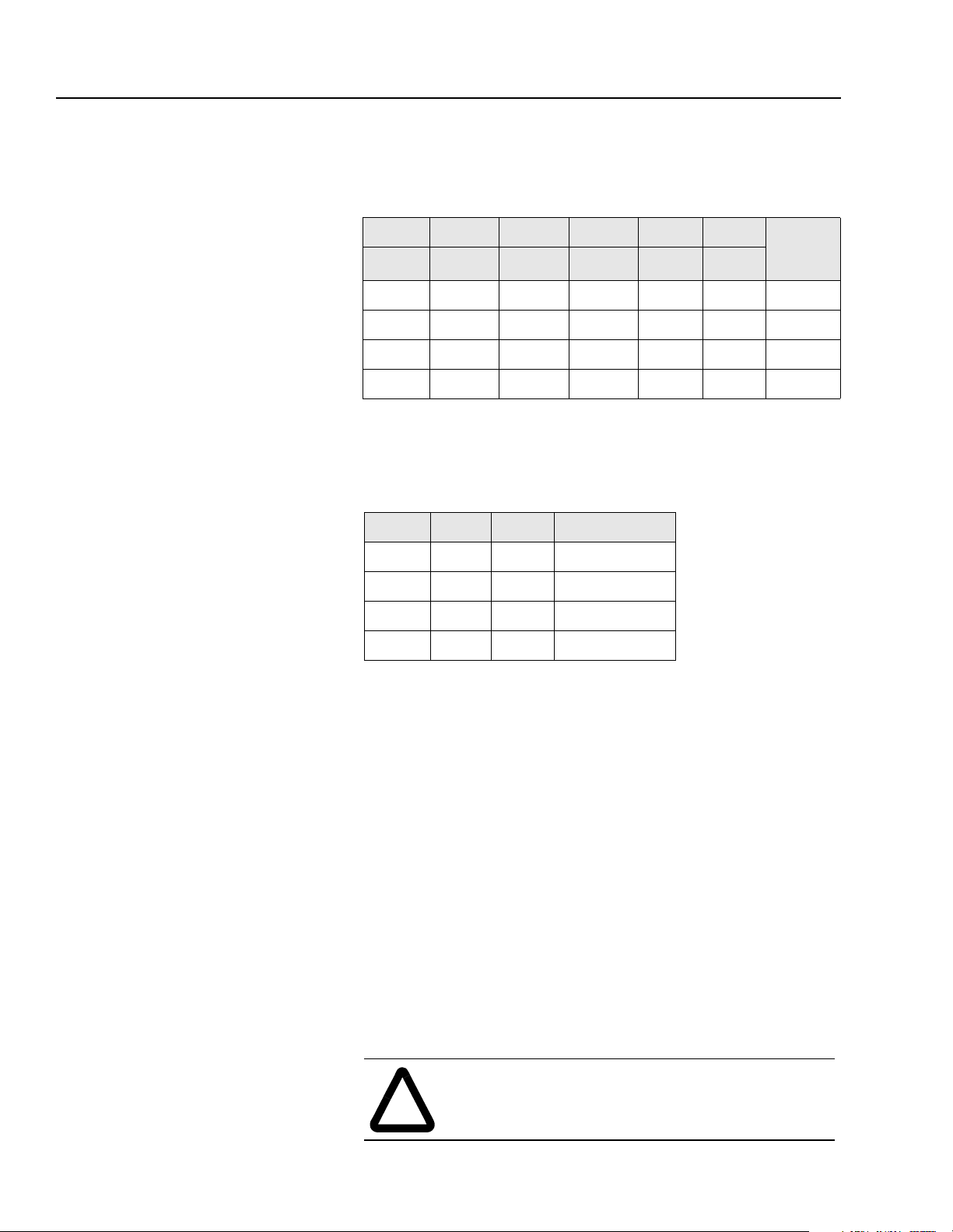

Bus termination

The recommended method for connecting DeviceNet products is to

run a “trunk line” with 120-ohm resistors connected at each end.

DeviceNet products are then connected as “drops” along the length of

the trunk line. In this configuration, the internal termination resistor

of the 842D should not be used and the bus termination DIP switches

should be in the OFF position.

When 842D encoders are connected in a “daisy chain” configuration,

the internal termination resistor may be used on the end positions

only. In this configuration, only 842D(s) at either end of the network

should have their bus termination 2-pole DIP switches placed in the

ON position. Further details on termination resistors can be found in

publication DN-6.7.2 DeviceNet Cable System Planning and

Installation Manual.

ATTENTION: If you do not use terminating resistors

as described here and in publication DN-6.7.2, the

!

DeviceNet system will not operate properly.

Page 17

Configuring the DeviceNet Encoder DIP Switches 3-3

Figure 3.2 Bus Termination Switches

ON

2

1

Bus Termination

1 and 2 OFF: not active

1 and 2 ON: active

Note: Remote setting of the DIP switches via a Node Commissioning

Tool is not supported at this time.

Diagnostic LED

Once the DIP switches have been properly set, the 842D may be

connected to a DeviceNet network. LED functions are as follows:

LED Status

Off Not connected, not on line

Green Blinking Active but not allocated by master

Green Steady Active and allocated by master

Red Blinking Minor fault and/or connection interrupt

Red Steady Critical communication fault

Preset function

The 842D ‘POSITION VALUE’ is set to zero when the PRESET

function is executed (by Reset Position Button or DeviceNet). This

predefined value is stored in the EEPROM. The factory default

PRESET value is zero.

ATTENTION: The PRESET function results in a

change of position reading. This can cause unexpected

!

The PRESET function is not intended for use in dynamic parameter

setting operations but as an electronic adjustment function during

commissioning, in order to allocate a specific value to the mechanical

rotary position of the 842D.

motion which could result in personal injury and damage

to the product or equipment. During PRESET, steps

should be taken to ensure the shaft is stationary and will

remain so.

If the PRESET value is set by DeviceNet, the value must be within

the total working range currently configured (steps per revolution and

number of revolutions).

The Reset Position Button should only be operated when the encoder

is powered and the green LED is blinking or steady.

Page 18

3-4 Configuring the DeviceNet Encoder DIP Switches

Notes:

Page 19

Chapter 4

Configuring the Encoder Using

RSNetWorx for DeviceNet

Chapter Objectives Chapter 4 provides information that you need to configure the

encoder over the DeviceNet network. In this chapter, you will read

about the following:

• RSNetWorx for DeviceNet software and the equipment required

to use it.

• Going online.

• Installing the Electronic Data Sheet (EDS) file.

• Online and offline configuration of the 842D encoder.

• Accessing, editing and saving encoder parameters.

What is RSNetWorx for

DeviceNet?

Required Equipment and

Software

RSNetWorx for DeviceNet is a Rockwell Software application that

can be used to set up DeviceNet networks and configure connected

devices. RSNetWorx for DeviceNet (version 3.00.00) and RSLinx

(version 2.20.02) were used for examples in the manual. Different

versions may differ in appearance and procedures.

RSNetWorx supports online and offline commissioning of a

DeviceNet system.

During offline commissioning, the bus network is configured and

parameters for the bus participants are set without an established

connection to the bus network. Thereafter the bus connection is made

and the user data are transferred to the master as well as to the bus

participants.

In the online commissioning the bus structure and the parameters of

the participants are configured using an established bus connection.

After installing or mounting the encoder, you can use RSNetWorx for

DeviceNet to configure or edit the encoder’s parameters.

Before configuring the encoder and editing its parameters, your PC

must be:

• Running RSNetWorx for DeviceNet. Refer to

http://www.software.rockwell.com for more information on this

product.

• Connected to and communicating with the DeviceNet network

using a DeviceNet interface such as a 1784-PCD card or a

1770-KFD adapter.

Page 20

4-2 Configuring the Encoder Using RSNetWorx for DeviceNet

Going Online To use RSNetWorx for DeviceNet, you must first set up a driver in

RSLinx. The driver provides a communications link between the

computer and DeviceNet network. Then, you can view the devices on

a DeviceNet network by going online. A device may appear as an

unrecognized device if RSNetWorx for DeviceNet does not have an

EDS file for it.

1. Start RSLinx, and select Communications > Configure Drivers

to display the Configure Drivers dialog box.

Figure 4.1 Configure Drivers Dialog Box

2. In the Available Driver Types box, select DeviceNet Drivers,

and then click Add New. The DeviceNet Driver Selection dialog

box appears.

Figure 4.2 DeviceNet Driver Selection Dialog Box

3. In the Available DeviceNet Drivers list, select the adapter

connected to your computer, and then click Select. A Driver

Configuration dialog box appears.

4. Configure the driver for your computer and network settings, and

then click OK. The Configure Drivers dialog box reports the

progress of the configuration. The Add New RSLinx Driver

dialog box appears.

Figure 4.3 Add New RSLinx Driver Dialog Box

Page 21

Configuring the Encoder Using RSNetWorx for DeviceNet 4-3

5. Type a name (if desired), and then click OK. The Configure

Drivers dialog box reappears, and the new driver is in the

Configured Drivers List

Figure 4.4 Configure Drivers Dialog Box with a DeviceNet

Driver

6. Click Close to close the dialog box. Leave RSLinx running.

7. Start RSNetWorx for DeviceNet, and then select Network >

Online. If the Browse for Network dialog box appears, RSLinx

has drivers for multiple networks. Select your DeviceNet

network, and click OK. A message appears.

Figure 4.5 DeviceNet Configuration Services Message

8. Click OK to go online. The devices in the network appear in the

Configuration view.

Figure 4.6 Online in RSNetWorx for DeviceNet

Page 22

4-4 Configuring the Encoder Using RSNetWorx for DeviceNet

Installation of the EDS File The Electronic Data Sheet, or EDS file, must be installed with

RSNetWorx. The EDS file may be downloaded from our website at

http//www.ab.com/networks/eds/

by RA Miscellaneous and then press the Search button. By selecting

the 842D encoder, you can begin downloading the 842D EDS file.

1. Go to Tools - EDS Wizard and click Next to start the process.

Figure 4.7 EDS Wizard

. Simply select DeviceNet followed

Offline Integration into the

Network

2. Follow the prompts to install the 842D EDS file.

3. Click Finish to complete the process.

After a new project is started select the 842D encoder under the

Rockwell Automation Miscellaneous category in the hardware

window. Double-click or drag and drop the 842D Multiturn Encoder

into the network view.

Figure 4.8 RSNetworx Graph View

Page 23

Configuring the Encoder Using RSNetWorx for DeviceNet 4-5

To assign a name, description and node address, double-click on the

encoder in the Graph view window. In the General tab of the Edit

dialog box, enter the node address that has been set via the six pole

DIP switch.

Figure 4.9 General Tab in the Edit Dialog Box

Accessing and Editing

Parameters

In order to modify the parameter values of the encoder on DeviceNet,

RSNetWorx offers two configuration modes:

• Class Instance Editor

• Enhanced Device Configuration

The Enhanced Device Configuration is a more comfortable way to

read and modify encoder parameters. This mode can be used online

and offline (file access only). In the Enhanced Device Configuration

mode the parameters can be stored to a file (*.dnt) for later transfer to

the device.

In order to protect parameter values against loss due to a power

failure they can be stored in the encoder EEPROM with the

"Save" service. The "Reset" service sets all parameters to default

values. The "Restore" service sets all parameters to the values

stored in the EEPROM--see page 4-7.

The Save, Reset, and Restore services can only be executed in the

Class Instance Editor.

Page 24

4-6 Configuring the Encoder Using RSNetWorx for DeviceNet

Enhanced Device Configuration in Offline Mode

The Enhanced Device Configuration is started by double-clicking on

the encoder symbol and clicking on the Parameter tab. In offline

mode the parameters are preset to the default values in the EDS file.

Figure 4.10 Device Parameters Page in the Edit Dialog Box

Parameters are displayed in numerical order in the Parameter column.

You can either scroll through the list or select a specific group of

parameters in the Groups box (for example, DeviceNet Module).

Figure 4.11 Device Parameters Arranged by Groups

Parameters labeled with a padlock represent encoder status

information and are ‘read-only’. All other data can be modified; in the

Current Value column, double-click a value to edit it.

After all parameters are set they can be stored using the File - Save

command.

Page 25

Configuring the Encoder Using RSNetWorx for DeviceNet 4-7

Enhanced Device Configuration in Online Mode

The Enhanced Device Configuration is selected by double-clicking

on the encoder symbol. In on-line mode the parameter values

currently stored in the encoder are accessed.

By clicking on the Apply or Download to Device buttons, the

parameters can be saved to the encoder. The updated encoder values

are stored in the encoder RAM and are valid immediately. Saving the

new values to the EEPROM is done with a separate command.

Saving Parameter Values to

EEPROM

Restoring Parameters to

EEPROM Values

Saving the parameter values to the EEPROM is performed in the

Class Instance Editor.

To access the Class Instance Editor, select the device in the graph

window and click on Class Instance Editor in the Device menu. Select

the service Save (16

with the ‘Send the attribute ID’ box unchecked.

Finish by clicking on the Execute button.

Figure 4.12 Class Instance Editor

In order to set the parameters to the EEPROM values, the service

Restore (15

) of the encoder object is used.

hex

) of Class 2F

hex

(encoder object), Instance 1,

hex

This is done in the Class Instance Editor . Select the service Restore

) of the object 2F

(15

hex

‘Send the attribute ID’ box unchecked. Finish by clicking on the

Execute button..

ATTENTION: The Restore function results in a

change of position reading. This can cause unexpected

!

motion which could result in personal injury and damage

to the product or equipment. During Resore, steps should

be taken to ensure the shaft is stationary and will remain

so.

(encoder object), Instance 1, with the

hex

Page 26

4-8 Configuring the Encoder Using RSNetWorx for DeviceNet

Setting Parameters to

Default Values

In order to reset the parameters to the factory default values, the

service Reset (05

Class Instance Editor. Select the service Reset (05

2F

(encoder object), Instance 1, with the ‘Send the attribute ID’

hex

) of the encoder object is used. This is done in the

hex

) of the object

hex

box unchecked. Finish by clicking on the Execute button.

Page 27

Chapter 5

Configuring a Scanner to

Communicate with the Encoder

Chapter Objectives Chapter 5 provides instructions for configuring a PLC or SLC scanner

to communicate with the encoder.

Required Equipment and

Software

Operating Modes of the

Encoder

Before configuring the scanner, your PC must be:

• Running RSNetWorx for DeviceNet. Refer to

http://www.software.rockwell.com for more information.

• Connected to and communicating with the DeviceNet network

using a DeviceNet interface such as a 1784-PCD card or a

1770-KFD adapter.

There are two fundamentally different DeviceNet protocols:

• Explicit messaging

• I/O messaging

Explicit messaging

Explicit messaging is used for modifying the device configurations,

reading diagnostic values, program upload / download, etc.

Characteristics of explicit messaging:

• Very flexible

• Less efficient because each device must interpret and generate a

response

• "Unbound" connections ("Hit and Run")

• Contents of the data field:

– Protocol information

– Instructions for service to be performed

– Internal address to which the service is to be applied

I/O messaging

I/O messaging is used for fast or time-critical data transfer. All of the

8 data bytes of the CAN telegram can be used for data transmission.

Characteristics of I/O messaging:

• Less flexible

Page 28

5-2 Configuring a Scanner to Communicate with the Encoder

• Highly efficient for both bandwidth and node processing

• "Bound" connections

• Data field contains data only

• Meaning of data is predefined

Input data specification of the 842D

The 842D encoder is an Input Device. This means the encoder only

produces (sends) data and does not consume any data from the

master.

The 842D supports the following I/O operating modes (message

connections):

• Polling

• Change of State (COS) / Cyclic

• Bit Strobed mode

All these modes can be adjusted simultaneously with different

assembly instances. To use a particular Assembly, there are installed 3

special attributes "assembly number" (Input Ass_xx) in the

manufacturer section of the encoder object. These attributes have to

be configured with the number (1...n) of the corresponding assembly

instance, containing the different data components. By default this

number is set to 1 ("Position Value").

Each of the 3 different I/O message connections is assigned its own

attribute.

The table below shows how the different data components are used:

Data Component Assembly

Position Value 1, 2, 3, 4

Velocity Value 3 Strobe, Poll 50 ms

Flag (Alarm,

Warning)

Cam State 4

2

Supported

modes

COS, Strobe,

Poll

COS, Strobe,

Poll

COS, Strobe,

Poll

Update cycle

time

0.3 ms

0.3 ms

0.3 ms

Update cycle time is the time required for the encoder to calculate a

new value for one of the listed data components. For example, the

encoder is able to send new position values in intervals of approx.

0.3ms.

Note: For all the different I/O messages applied, the number of the

configured assembly instance determines the data components to be

sent as an input data.

Page 29

Configuring a Scanner to Communicate with the Encoder 5-3

For more detail see the Assembly object manufacturer specific

functions in Appendix B.

Polling mode

The standard mode in the master-slave communication is the polling

mode. In this mode the master contacts all bus participants cyclically.

The output data are transmitted to the slaves and the input data are

read from the slaves over the course of one scan.

Because the 842D is an Input Device, output data from the master is

ignored. The Poll Command is used to trigger the transmission of

return input data in the response message.

COS mode / Cyclic mode

In Change of State (COS) mode, the encoder sends input data if the

value of one of the data components changes or at the Heartbeat Rate

(See Figure 5.4, Edit I/O Parameters Dialog Box - COS).

In addition, a Cycle Time is used to trigger the transmission of the

input data. This is done after the internal Cycle Time period has

elapsed, no matter if the value of one of the data components has

changed.

Additionally, a time delay (inhibit time) in the range of 1 msec. to

65,535 msec. can be configured to reduce the bus load.

When getting a trigger only from the "cam state" or "Flag" data

components by using Instance 2 or 4 in a COS connection, you should

set the value of "COS / Hyst." (attr. 11) to "0" (zero) to avoid a trigger

from the data component "position value" (see Appendix B).

In Cyclic mode the encoder only sends input data after the internal

Cycle Time period has elapsed.

Bit Strobed mode

The Bit_Strobe Command sends one bit of output data

to each Slave

whose node address appears in the Master's scan list.

Because the 842D encoder is an Input Device, the output data bit is

ignored. The Bit Strobe Command is only used to trigger a

transmission of return input data in the response message.

Page 30

5-4 Configuring a Scanner to Communicate with the Encoder

Example DeviceNet Network This section provides the steps that are needed to configure a simple

network that includes 1756-DNB/A scanner (Node 10) and an 842D

DeviceNet encoder (Node 03).

Setting Up the Scan List For the scanner to communicate with a product, the scanner must be

configured and the product’s node number must be added to its scan

list.

1. Go online with RSNetWorx for DeviceNet. Refer to the “Going

Online” section in Chapter 4.

2. Select Network > Single Browse Path. The devices on the

network are displayed in the configuration view.

Figure 5.1 Configuration View (Graph)

3. Right-click the DeviceNet scanner (node 10 in Figure 5.1) and

select Properties. The Scanner Module dialog box appears.

Important: If your scanner is an unrecognized device, you must

create an EDS file for it and then configure it. Click Help or refer to

your scanner documentation if you need more information. Configure

the scanner using the General and Module tabs.

4. Click the Scanlist tab. A message box prompts you to upload.

5. Click Upload. Data is uploaded from the scanner, and then the

Scanlist page appears.

Page 31

Configuring a Scanner to Communicate with the Encoder 5-5

Figure 5.2 Scanlist Page in the Device Edit Dialog Box

6. Select the Automap on Add box (a check mark will appear).

7. Under Available Devices, select the encoder, and then click >

(Right Arrow) to add it to the scanlist.

Figure 5.3 Scanlist Page in the Scanner Module Dialog Box

8. Under Scanlist, select the encoder, and then click Edit I/O

Parameters. The Edit I/O Parameters dialog box appears.

Page 32

5-6 Configuring a Scanner to Communicate with the Encoder

Figure 5.4 Edit I/O Parameters Dialog Box - COS

9. Select the type(s) of data exchange (Polled, Change of State,

and/or Cyclic). In our example, we selected Change of State.

10. Type the number of bytes that will be required for your I/O in the

Rx Size and Tx Size. See Assembly Data Format, page B-4, for

data sizes.

11. Set the scan rate:

Data

Exchange

Polled Polled Rate

Change of

State

Cyclic Send Rate

Rate to set

Heartbeat

Rate

Click Help for more information.

12. When using COS in high speed and/or high resolution

applications, it may be necessary to limit how often the device

will report to the master in order to lessen network traffic. To do

so requires either setting the hysteresis to over 10% of the

‘RESOLUTION PER REVOLUTION’ value or increasing the

‘Inhibit Time’. To increase the inhibit time to 10ms, click on the

Advanced... button under ‘Change of State/Cyclic.’ Adjust the

Inhibit Time and click OK.

Page 33

Configuring a Scanner to Communicate with the Encoder 5-7

Figure 5.5 Inhibit time

13. In the Edit I/O Parameters box, click OK. If you changed any

settings, a Scanner Applet appears and asks if it is OK to unmap

the I/O. Click Ye s to continue. The Edit I/O Parameters dialog

box closes and then the Scanner Module dialog box (Figure 5.3)

reappears. You will map the I/O in the next section in this chapter.

Mapping the Product’s Data in

the Scanner

Data from I/O messages must be mapped in the scanner. This

mapping determines where a ladder logic program can find data

transmitted on the network.

Mapping the Input I/O

In the Scanner Module dialog box, click the Input tab. (If you need to

display this dialog box, right-click the scanner in the configuration

view. See Figure 5.1.). Below, the input pages for Change of State,

Polled and Strobed are shown.

Figure 5.6 Scanner Module Dialog Box, Input Page - COS

Page 34

5-8 Configuring a Scanner to Communicate with the Encoder

Figure 5.7 Scanner Module Dialog Box, Input Page - Polled

Figure 5.8 Scanner Module Dialog Box, Input Page - Strobed

If you selected the Automap on Add box (Figure 5.2) in the

Scanlist page (Figure 5.3) and did not change any settings,

RSNetWorx has already mapped the I/O. If I/O is not mapped,

click AutoMap to map it. If you need to change the mapping,

click Advanced and change the settings. Click Help for

assistance.

Saving the Configuration After configuring a scanner, you must download it to the scanner. You

should also save it to a file on your computer.

1. In the Scanner Module dialog box, click Apply to save the

configuration to the scanner. A Scanner Configuration Applet

appears and asks if it is OK to download the changes.

2. Click Ye s to download the changes. The changes are downloaded

and then the Scanner Module dialog box reappears.

3. Click OK to close the Scanner Module dialog box.

4. Select File > Save. If this is the first time that you saved the

project, the Save As dialog box appears. Navigate to a folder, type

a file name, and click Save to save the configuration to a file.

Page 35

Chapter 6

Using DeviceNet Explicit

Messaging

Chapter Objectives Chapter 6 provides information you need to monitor and configure

the encoder using explicit messaging on DeviceNet. In this chapter,

you will read about the following:

• Required equipment.

• Messaging guidelines for the 1747-SDN scanner.

• An Explicit Messaging example.

Refer to Appendix B, DeviceNet Objects, for information on object

data support.

Required Equipment Before using messaging, your PC must be:

• Running RSLogix500 and RSLinx if you are using an SLC. Refer

to http://www.software.rockwell.com for more information on

these products.

Explicit Messaging

Examples

• Running RSLogix5000 and RSLinx for Logix platforms. Refer to

http://www.software.rockwell.com for more information on these

products.

• Connected to and communicating with the controller.

ATTENTION: The PRESET function results in a

change of position reading. This can cause unexpected

!

Explicit Messaging Preset Example for the 1747-SDN

Scanner

The SLC copies an Explicit Message into the scanner’s M0-file.

When the copy is completed the scanner moves the message into a

queue for processing. Up to 10 Explicit Messages can be in this

queue.

When the scanner receives a response message it is placed into a

queue. The first response in the queue is available from the M1-file.

When the message delete command is copied into the scanner the

message is complete and the next available response will appear in

the M1-file.

motion which could result in personal injury and damage

to the product or equipment. During PRESET, steps

should be taken to ensure the shaft is stationary and will

remain so.

Page 36

6-2 Using DeviceNet Explicit Messaging

In this example a value is sent to the preset attribute in the encoder.

The encoder stores the preset value sent in non-volatile memory.

Storing the preset value applies the preset value to the encoder

position value.

The following program fragment sends an explicit message and

confirms the message reception. The N20 user defined integer file is

used to hold message data:

Figure 6.1 1747SDN Explicit Messaging Example

Page 37

Using DeviceNet Explicit Messaging 6-3

Example Values

One of the following tables of data is sent to and received from the

1747-SDN. Values shown are in hexadecimal (even the MAC ID).

Table 1: Preset (set service) Example to position 00 00 00 00h (0 decimal)

Offset01234567

N20:000 04-------

N20:10 02 01 00 0A 10 MacID 002F 0001 000A 00 00 00 00

...--------

N20:50 02 01 00 00 90 MacID - -

---------

Table 2: Preset (set service) Example to position 01 35 D0 B2h (20304050 decimal)

Offset01234567

N20:000 04-------

N20:10 02 01 00 0A 10 MacID 002F 0001 000A D0 B2 01 35

...--------

N20:50 02 01 00 00 90 MacID - -

---------

Data Description

The table below defines the data types and is followed by their

definitions.

Table 3: Data Type (see definitions on next page)

Offset01234567

N20:0 Delete

Block Cmd

N20:10 TX ID,

Command

...--------

N20:50 RX ID,

Status

-------

Port, Size Service

Req,

MacID

Port, Size Service

Rsp,

MacID

Class Instance Attribute Preset

ValueLS W

--

Preset

ValueMSW

---------

Page 38

6-4 Using DeviceNet Explicit Messaging

TXID:

This is a one-byte integer the range of 1 to 255. The scanner

uses this value to track the transaction to completion, and

returns the value with the response that matches the

request.

STATUS:

For each upload, the status code provides the processor

with status on the device and its response:

0 = Ignore transaction block (block empty)

1 = Transaction completed successfully

2 = Transaction in progress (not ready)

3 = Error — Slave not in scan list

4 = Error — Slave off-line

5 = Error — DeviceNet port disabled or off-line

6 = Error — Transaction TXID unknown

8 = Error — Invalid command code

9 = Error — Scanner out of buffers

10 = Error — Other client/server transaction in progress

11 = Error — Could not connect to slave device

12 = Error — Response data too large for block

13 = Error — Invalid port

14 = Error — Invalid size specified

15 = Error — Connection busy

COMMAND:

A code that instructs the scanner how to administer the

request:

1 = Execute this transaction block

4 = Delete this transaction block

PORT:

The port must be zero (Channel A) on a 1747-SDN scanner.

SERVICE REQ/RSP:

The DeviceNet service request and response:

10 = Set Service Request

0 = Set Service Response

MAC ID:

The DeviceNet network address of device where the

transaction is sent. This value can range from 0 to 63. The

slave device must be listed in the scanner module's scan list

and be on-line for the Explicit Message transaction to be

completed.

See appendix B of the encoder manual for class/attribute

values, access rules, and data types.

CLASS:

002Fh is the encoder class

INSTANCE:

There is only one instance of the encoder - 0001h

ATTRIBUTE:

The value 000Ah is the Preset Value attribute.

PRESET VALUEMSW / VALUELSW:

This quadword value (limited to 03 FF FF FF) is stored in

non-volatile memory when the set service is used. Storing

the preset value applies the preset value to the encoder

position value.

SIZE:

The size of the transaction body in bytes. The transaction

body can be up to 29 words (58 bytes) in length. If the size

exceeds 29 words, an error code will be returned.

Page 39

Using DeviceNet Explicit Messaging 6-5

Explicit Messaging Preset Example for the 1756-DNB

The following is a code segment that will preset the value of the 842D

encoder’s ‘Position Value’. This can be useful for automatic homing

or automated error recovery. The following tags are used for the

explicit messaging:

• MSGY is a Message type tag

• Lsource is a UDINT type tag the value is preset to

• Ldest is a UDINT type tag that should always return with 0.

Figure 6.2 Position Value Preset

MSGY needs the service code (set) 10, the class code (encoder) 2F,

and the instance 01 (only instance) for the attribute 0A (Preset). The

preset data will be sent from the tag ‘Lsource.’ Since the ‘Preset’

attribute is a long integer (UDINT), the ‘Num. Of Elements’ is 4

bytes.

Other attributes maybe read (service code 0E) or set ( service code

10) in a similar way. Any response data would return in Ldest.

Page 40

6-6 Using DeviceNet Explicit Messaging

Figure 6.3 Message Configuration

The details where communication is addressed are also required.

'DNB' is the name of the DeviceNet module (1756-DNB) at a port

from the (1756-L1) controller, '2', to communicate with encoder at

'MACID' where MACID is a variable SINT with the destination slave

DeviceNet node address. The decimal value of the node address may

be used if a variable is not desired.

Figure 6.4 Message Configuration - Communication Tab:

Page 41

Specifications and Dimensions

842D Specifications Electrical

Code Format Natural Binary

Code Direction CW or CCW (programmable)

Electrical Interface DeviceNet Specification release 2.0

Operating Voltage 11-25V DC

Power Consumption 1.8W (75mA @ 24V DC)

Max # of Steps/Revolution 8192

Max # of Revolutions 8192

Position Forming Time 0.3msec

Delay on Power Up 1050msec

Reset Via covered rear button

Appendix A

EEPROM Write Life Greater than 100,000 cycles

Mechanical

Angular Acceleration

Moment of Inertia

Operating Speed 6000 RPM at max shaft loading

Maximum Working Speed 12,000 RPM

Starting Torque 2.5Ncm (3.5oz-in)

Shaft Loading Axial 11lb (50N), Radial 67lb (300N)

Environmenta

Housing Aluminum

Operating Temperature

Max Working Temperature

Storage Temperature

Humidity 98% Noncondensing

Protection NEMA Type 4, 13, IP66 (IEC 529)

l

5

radians/sec

5 x 10

2

35gcm

-20

-40

-40

(5.0 x 10-4oz-in-sec2)

°

C to 85°C (-4°F to +185°F)

°

C to 100°C (-40°F to +212°F)

°

C to 125°C (-40°F to +257°F)

2

Shock 100g/6msec

Vibration 20g (58 to 2000Hz),

1.5mm displacement (10 to 58Hz)

Approximate Weight 0.91kg (2lbs)

Page 42

A-2 Specifications and Dimensions

842D Dimensions

ATTENTION: Rigidly

coupling the encoder shaft

to the machine shaft will

!

cause a failure in either the

bearings of the encoder or

the bear ings of the machine

shaft.

Flexible Shaft Couplings

Angle

Diagnostic

LEDs

Parallel

Off-Set

∅59.5

(2.34)

∅53.8

(2.12)

9.98/9.99

(0.392/0.393)

8.8/9.2

(0.34/0.37)

35.94/35.98

(1.415/1.416)

7 (0.28) deep)

M4 3 Plcs

18/20

(0.71/0.79)

18

(0.71)

10

(0.39)

6

(0.24)

27.8

(1.09)

120˚

3

(0.12)

105.8

(4.16)

35˚

X

15.5

(0.61)

76

(2.99)

13

(0.51)

Screw Cover for

DIP Switches and

Reset Button

Single QD

Double QD

65

(2.56)

65

(2.56)

Diagnostic

LEDs

Single QD

M4 3 Plcs

7 (0.28) deep)

Double QD

120˚

35˚

∅48 ±0.1

(1.89)

∅48 ±0.1

(1.89)

Page 43

Appendix B

DeviceNet Objects

Appendix Objectives Appendix B defines the DeviceNet object classes, class services, and

attributes that are supported by the DeviceNet encoder. This appendix

assumes that you have experience in object programming.

Object Classes The 842D DeviceNet encoder supports the following object classes:

Class Object Page

Class Code 01

Object

— Identity

hex

01

02

03

04

05

2F

hex

hex

hex

hex

hex

hex

Identity

Message Router

DeviceNet

Assembly

Connection

Encoder

B-1

B-2

B-2

B-3

B-5

B-7

The identity object provides identification and general information

about the device.

Class Attributes

Not supported.

Instance Attributes

Attr.

ID

1 Vendor ID Get UINT Allen Bradley = 1

2 Device Type Get UINT Rockwell Misc., 115

Attribute Access Data type Description

3 Product Code Get UINT 10626

4 Revision Get UINT 4.001

5 Status Get WORD

6 Serial Number Get UDINT

7 Product Name Get Short String

842D MULTITURN

ENCODER

Services

Service Code Service Name Description

0E

05

hex

hex

Get_Attribute_Single Returns the attribute value

Reset Value = 0

Page 44

B-2 DeviceNet Objects

Class Code 02

hex

Message Router

Class Code 03

hex

DeviceNet

—

—

The Message Router Object provides a messaging connection point

through which a client may address to any object class or instance

residing in the physical devices.

Class and Instance Attributes

Not supported.

Services

Not supported.

The DeviceNet Object is used to provide the configuration and status

of a physical attachment to DeviceNet. A product must suppot one

(and only one) DeviceNet Object per physical network attachment.

Class Attributes

Attr.

ID

1 Revision Get UINT Revision = 002

Attribute Access Data Type Description

Instance Attributes

Attr.

ID

1 Node address Get USINT Range 0-63

2 Baud Rate Get USINT Range 0-2

3 BOI Get BOOL Value=1

4 Bus-OFF-Ctr. Get/Set USINT

5

Attribute Access Data Type Description

Allocation

Information

Get

Struct. of:

BYTE

USINT

Allocation choice byte

master’s Node Address

Services

Service

Code

0E

hex

10

hex

4B

hex

Service Name Description

Get_Attribute_Single Returns the attribute value

Set_Attribute_Single Changes the attribute value

Allocte_Master/

Slave_Connection_Set

Predefined master/slave

connection set is requested

Page 45

DeviceNet Objects B-3

Class Code 04

Assembly

hex

—

The Assembly Object combines attributes from different objects into

a single object. For a detailed view of the assembly data format, see

page B-4.

Class Attributes

Attr.

ID

1 Revision Get UINT Revision = 002

Attribute Access Data Type Description

Instance Attributes

Instance IDAttr

ID

1 3 Data Get ARRAY Position value

2 3 Data Get ARRAY

3 3 Data Get ARRAY Position + Velocity

4 3 Data Get ARRAY Position + CAM

Attribute Access

Data

Ty pe

Description

Position+Warning

Flag+Alarm Flag

Services

Service code Service name Description

0E

hex

Get_Attribute_Single Returns the value of an attribute

Page 46

B-4 DeviceNet Objects

Assembly Data Format

Instance Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 LSB

1

2

3

1

2

3000000MSB

0 LSB

1

2

3000000MSB

4 reserved

0 LSB

1

2

3000000MSB

4 LSB

5 Velocity value

6

Position value (Att. 12)

Position value (Att. 12)

Position value (Att. 12)

(Not available in COS)

Warning

flag (Att. 88)

Alarm flag

(Att. 85)

7MSB

0 LSB

1

2

4

3000000MSB

4

Cam 8Cam 7Cam 6Cam 5Cam 4Cam 3 Cam 2 Cam 1

Position + Velocity 8 Bytes

Position + Cams 5 Bytes

Position value (Att. 12)

Cam state

Position only 4 Bytes

Position + Flags 5 Bytes

Page 47

DeviceNet Objects B-5

Class Code 05

Connection

hex

—

The Connection Class allocates and manages the internal resources

associated with both I/O and Explicit Messaging Connections. The

specific instance generated by the Connection Class is referred to as a

Connection Instance or a Connection Object.

Important: An externally visible interface to the Connection Class

across Explicit Messaging Connections exists. Unless otherwise

noted, all services/attributes noted in the following sections are

accessible using Explicit Messaging.

A Connection Object within a particular module actually represents

one of the end-points of a Connection. It is possible for one of the

Connection end-points to be configured and “active” (e.g.,

transmitting) without the other end-point(s) being present.

Connection Objects are used to model the communication specific

characteristics of a particular Application-to-Application(s)

relationship. A specific Connection Object Instance manages the

communication-specific aspects related to an end-point.

A Connection Object on DeviceNet uses the services provided by a

Link Producer and/or Link Consumer to perform low-level data

transmission and reception functions.

Class Attributes

Not supported

Instance Attributes

Attr.

ID

1

2 Instance_Type Get USINT Indicates I/O or Messaging connection

3 transpor tclass_tri

4 Produced Cnxn

5 Consumed Cnxn

6

7 Produced Cnxn

Attribute Access Data type Description

State

gger

ID

ID

Initial Comm Char

Size

Get USINT State of the connection as defined in the

DeviceNet specification

Get BYTE

Get UINT

Get UINT

Get BYTE Defines the DeviceNet message groups that the tx/

Get UINT

The Transport Class Trigger for this instance

CAN Identifier to transmit on

CAN Identifier to receive on

rx Cnxn’s apply

Max bytes to transmit across this connection

8 Consumed Cnxn

Size

9 EPR Get/Set UINT Expected Packet Rate

12 Watchdog Action Get USINT How to handle inactivity/watchdog timeouts

Get UINT

Max bytes to receive across this connection

Page 48

B-6 DeviceNet Objects

Attr.

ID

Attribute Access Data type Description

13 Produced Cnxn

Path Length

14 Produced Cnxn

Path

15 Consumed Cnxn

Path Length

16 Consumed Cnxn

Path

Production inhibit

17

time

Get UINT Number of bytes in the produced connection path

attribute

Get ARRAY of

UINT

Path information of the desired assembly instance

(Def. 1)

Get UINT Number of bytes in the consumed connection path

attribute

Get ARRAY of

UINT

Get/Set

UINT

Specifies the application object to receive the data

consumed by this application

Defines minimum time between new data

production for COS connections

Services

Service Code Service Name Description

0E

10

05

hex

hex

hex

Get_Attribute_Single Returns the value of an attribute

Set_Attribute_Single Changes the value of an attribute

Reset Reset

16

hex

Save Save

Page 49

DeviceNet Objects B-7

Class Code 2F

— Encoder The Encoder Object contains all encoder data. All input data,

hex

parameter data and status data are included here.

Class Attributes

Attr.

ID

1 Revision Get USINT Revision = 01

2 Max. Instance Get USINT 1

Attribute Access Data Type Description

Instance Attributes

Attr. ID Attribute Access Data type Description

1

2 Attributes Get

3

5

Number of

attributes

Code

Sequence

Scaling

function control

Get USINT Number of supported attributes

ARRAY

of USINT

Get/Set BOOL

Get/Set BOOL

List of supported attributes

Direction control for counting. Defines the increasing 'POSITION

VALUE' as clockwise shaft rotation or counter clockwise as seen

facing the shaft (CW, CCW).

Scaling Enable --Enabling scaling changes the 'POSITION

VALUE' I/O data resolution to 'MEASURING UNITS PER

REVOLUTION' and 'TOTAL MEASURING RANGE'

measuring

7

8

10 Preset value Get/Set UDINT This value will be applied to the 'POSITION VALUE'.

11 COS/delta Get/Set UDINT

12 Position value Get UDINT

20 Velocity format Get/Set BYTE

units per

revolution

To t a l

measuring

range in

measuring

units

Get/Set UDINT

Get/Set UDINT

Number of distinguishable steps per revolution. Less than

physical resolution.

The steps over total measuring range. The number is

automatically adjusted to a 2^0 - 2^13 multiple of 'RESOLUTION

PER REVOLUTION'.Example: if 'RESOLUTION PER

REVOLUTION' is set to 3600 then the possible 'TOTAL

MEASURING RANGE' values will be 3600, 7200, 14400, 28800,

... 29491200.

A COS I/O message will be generated when the 'POSITION

VALUE' changes by this value. This value will be set to 5 if set to a

value larger than the 'TOTAL MEASURING RANGE'. Setting this

value to 0 disables COS messaging for 'POSITION VALUE'

changes. To lessen network traffic for high speed (4000 RPM+)

and/or high resolution (1024+ ppr) applications either: increase

the hysteresis to over 10% of the 'RESOLUTION PER

REVOLUTION' value, increase the 'Inhibit Time' ('Scanlist', 'Edit I/

O Parameters...', 'Advanced...') to 10 msec.

The current position value. This value is affected by 'PRESET

VALUE', 'RESOLUTION PER REVOLUTION', and 'SCALING

CONTROL'.

This sets the format for velocity and acceleration values. The max

and min limits for velocity and acceleration are affected as well.

– 0 = Steps per second

–1 = RPM

–2 = RPS

Page 50

B-8 DeviceNet Objects

Attr. ID Attribute Access Data type Description

22 Velocity value Get DINT

23

24

31

32

33

40

Minimum

velocity

Maximum

velocity

Acceleration

value

Minimum

acceleration

Maximum

acceleration

CAM state

register

Get/Set DINT

Get/Set DINT

Get DINT

Get/Set DINT

Get/Set DINT

Get BYTE

This is the value of the current velocity according to unit type in

'VELOCITY FORMAT'

Value of minimum velocity limit according to unit type of

'VELOCITY FORMAT'. A 'VELOCITY VALUE' under this limit will

cause a 'Min. Velocity Underrun' warning and set the warning flag.

Value of maximum velocity limit according to unit type of

'VELOCITY FORMAT'. A 'VELOCITY VALUE' over this limit will

cause a 'Max. Velocity Exceeded' warning and set the warning

flag.

Value of the current acceleration according to unit type of

'VELOCITY FORMAT'.

Value of minimum acceleration limit according to unit type of

'VELOCITY FORMAT'. An 'ACCELERATION VALUE' under this

limit will cause a 'Min. Accel. Underrun' warning and set the

warning flag.

Value of maximum acceleration limit according to unit type of

'VELOCITY FORMAT'. An 'ACCELERATION VALUE' over this

limit will cause a 'Max. Accel. Exceeded' warning and set the

warning flag.

State of all 8 cams. See “Designation of Cam Bits‘, page B-10:

– Bit 0=Cam_NO_1 State...

– Bit 7=Cam_NO_8 State

41

42

43, 46, 49,

52, 55, 58,

61, 64

44,47,50,

53, 56, 59,

62, 65

45,48,51,

54, 57, 60,

63, 66

80

81

CAM polarity

register

CAM enable

register

CAM X low limit

(0 ≤ X < 8)

CAM X high

limit (0 ≤ X < 8)

CAM X

hysteresis

(0 ≤ X < 8)

Operating

status

Single-turn

resolution

Get/Set BYTE

Get/Set BYTE

Get/Set UDINT

Get/Set UDINT

Get/Set UINT

Get USINT

Get UDINT

Polarity for the state of 8 independent CAMs (1-8), See

“Designation of Cam Bits‘, page B-10:

– 1 cam state will be active outside of the cam limits

– 0 cam state will be active inside of the cam limits

Enable / Disable 8 independent CAMs (1-8). See “Designation of

Cam Bits‘, page B-10:

– 1 cam state will be affected by position

– 0 cam state will always be 0

This is the Switch point for this cam's lower limit. The value must

be less than the 'CAM HYSTERESIS' for this cam and less than

the 'TOTAL MEASURING RANGE'

This is the Switch point for this cam's upper limit. The value must

be less than the 'TOTAL MEASURING RANGE'.

This value will be added to the 'CAM (1) HIGH LIMIT' and

subtracted from the 'CAM (1) LOW LIMIT' when calculating the

cam state. This value must be less than 'CAM (1) LOW LIMIT'.

The 'Direction: CCW' and 'Scaling: On' indicators show enabled

modes for 'CODE SEQUENCE' and 'SCALING CONTROL'.

This is the physical number of steps per revolution. This is the

maximum number for 'RESOLUTION PER REVOLUTION'.

82

Number of

distinguishable

revolutions

Get UINT

This is the number of revolutions the encoder will rotate before the

'POSITION VALUE' rolls over to 0. Must be a multiple of 2

0

between 2

and 213.

Page 51

DeviceNet Objects B-9

Attr. ID Attribute Access Data type Description

Malfunction could lead to incorrect position value. See

83 Alarms Get WORD

85 Alarm flag Get BOOL

86 Warnings Get WORD

88 Warning flag Get BOOL

“Designation of Alarm Bits‘, page B-10.

Any alarm will set the 'ALARM FLAG'.

This flag indicates a device failure that requires user intervention.

The 'ALARMS' indicate the specific failure. This value will be

reported if 'INPUT ASSY.' is set to 'Position + Flags' as bit 0 of the

5th byte.

Internal parameters exceeded. See “Designation of Warning Bits‘,

page B-10.

Any warning will set the 'WARNING FLAG'. The 'Frequency

Exceeded' warning is caused by rotating faster then 6000 RPM.

The Velocity min/max flag is caused by a 'VELOCITY VALUE'

under or over the velocity limits. The Acceleration min/max flag is

a 'ACCELERATION VALUE' under or over the acceleration limits.

The 'Cam Limits Out of Order' flag is caused by a set of cam limits

where the hysteresis value is larger then the cam lower limit, or

the higher or lower limit that is greater than the 'TOTAL

MEASURING RANGE'.

Indicates if any of the 'WARNINGS' are active. This value will be

reported if the 'INPUT ASSY’ is set to 'Position + Flags' as bit 1 of

the 5th byte."

90 Operating time Get UDINT Stores operating time for the encoder in operating hours.

91 Offset value Get DINT

Assembly

111

112

113

Number -

Polling Mode

Assembly

Number - COS/

Cyclic Mode

Assembly

Number - Bit

Strobed Mode

Get USINT

Get USINT

Get USINT

The offset value is calculated by the preset function. Shift position

value by the calculated value.

The type of input data that is sent for the Polling I/O connections.

– Position = 4 bytes

– Position + Cam State = 5 bytes

– Position + Flags = 5 bytes

– Position + Velocity = 8 bytes

– Update time: Velocity 50 mS, other modes 0.3 mS

The type of input data that is sent for the Change of State I/O

connections.

– Position = 4 bytes

– Position + Cam State = 5 bytes

– Position + Flags = 5 bytes

– Update time: 0.3 mS

– Velocity not supported.

The type of input data that is sent for the Strobed I/O connections.

– Position = 4 bytes

– Position + Cam State = 5 bytes

– Position + Flags = 5 bytes

– Position + Velocity = 8 bytes

– Update time: Velocity 50 mS, other modes 0.3 mS.

Page 52

B-10 DeviceNet Objects

Designation of Alarm Bits

(see Attribute 83)

Bit Description

0 Position error: 0=NO, 1=YES

1 Diagnostic: 0=Diagnostic OK, 1=Diagnostic error

2...11 Reserved

12...15 Manufacturer specific (not used)

Designation of Warning Bits

(see Attribute 86)

Bit Description

0 Frequency exceeded: 0=NO, 1=YES

1 Light control reserve: 0=Not reached, 1=Error

2 CPU watchdog: 0=OK, 1=Reset

3 Operating time limit warning: 0=NO, 1=YES

4 Reserved

5 Reference point: 0=Reached, 1=Not reached

6 Minimum Velocity Flag: 0=OK, 1=Under

7 Maximum Velocity Flag: 0=OK, 1=Over

Designation of Cam Bits

(See Attributes 40, 41, 42)

Bit Description

0 Cam 1 state

1 Cam 2 state

2 Cam 3 state

3 Cam 4 state

4 Cam 5 state

5 Cam 6 state

6 Cam 7 state

7 Cam 8 state

Page 53

Index

Numerics

842D

configuring to communicate with a

scanner 5-1

default settings 3-1

function 1-1

installation 2-1

setting up 1-2

specifications A-1

1747-SDN Scanner 6-1

1756-DNB/A 5-4

A

Accessing and Editing Parameters 4-5

Alarm Bits B-10

Assembly B-3

Audience for this manual P-1

Automap on Add 5-5

B

Baud rate 3-2

Bit Strobe 5-3

Bus termination 3-2

Bus Termination Switches 3-3

Connection B-5

Conventions Used in this Manual P-5

COS 5-2

Cyclic 5-2

D

Daisy chain connections 2-1

Data exchange 5-6

Default Values 4-7

Designation of Alarm Bits B-10

Designation of Cam Bits B-10

DeviceNet B-2

definition P-3

overview 1-1

DeviceNet Drivers 4-2

DeviceNet objects B-1

connection B-5

DeviceNet B-5

identify B-1

message router B-3

register B-7

Diagnostic LED 3-3

DIP Switches 3-1

Driver 4-2

Drop cable 2-1

C

Cables

selecting 2-1

Cam Bits B-10

Change of State 5-2

Characteristics 5-1

Class Instance Editor 4-5, 4-7

Communicate with the Encoder 5-1

Configuration 5-8

Configuration modes 4-5

Configure Drivers 4-2

Configuring a Scanner 5-1

Configuring the DIP Switches 3-1

E

Edit I/O Parameters 5-5

EDS file 4-4

EDS Wizard 4-4

EEPROM 3-3

EEPROM Values 4-7

Electronic Data Sheet 4-4

Encoder B-7

Encoder object 4-7

Enhanced Device Configuration 4-5, 4-6, 4-7

Examples 6-1

Explicit Messaging 6-1

Page 54

I–2 Index

F

Features 1-1

G

Going Online 4-2

Graph View 4-4

Groups 4-6

H