Page 1

Installation Instructions

Bulletin 842D DeviceNet MultiĆTurn Absolute Encoders

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Specifications

Electrical

Code Format Natural Binary

Code Direction CW or CCW (programmable)

Electrical Interface DeviceNet specification release 2.0

Operating Voltage 11ć25V DC (24V DC recommended)

Power Consumption 1.8W (75mA @ 24V DC)

Max # of Steps/Revolution 8192

Max # of Revolutions 8192

Position Forming Time 0.3msec

Delay on Power Up 1050msec

Preset Position Via covered rear button or DeviceNet

Mechanical

Angular Acceleration 5 x 105 radians/sec

Moment of Inertia 35gcm

Operating Speed 6000 RPM at max shaft loading

Starting Torque 2.5Ncm (3.5oz-in)

Shaft Loading Axial 11lb (50N)

2

(5.0 x 10-4oz-in-sec2)

Radial 67lb (300N)

Electrical Connections

As shown in the selection guide, 842D DeviceNet encoders

are available with one 5-pin male micro quick-disconnect or

two 5-pin micro quick-disconnects (one male and one female).

Pin configurations are per the DeviceNet specifications as

follows.

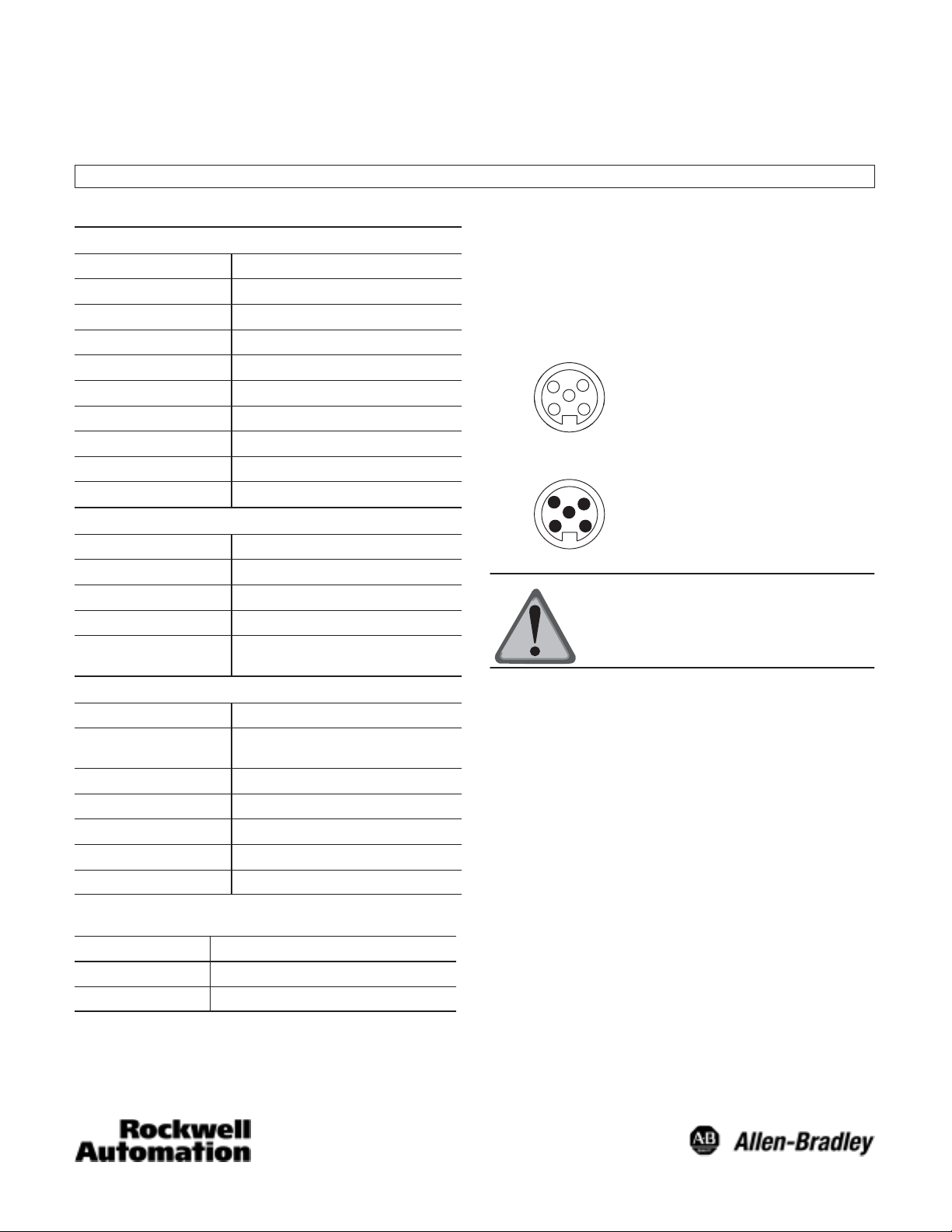

Female Micro

4

3

5

2 1

Male Micro

4

3

5

21

2

1 Drain Bare

2 V+ Red

3 V- Black

4 CAN_H White

5 CAN_L Blue

ATTENTION: Wiring must be in

accordance with the National Electric

Code and applicable local codes and

ordinances.

Environmental

Housing Aluminum

Temperature

Humidity 98% noncondensing

Protection NEMA Type 4, 13, IP66 (IEC 529)

Vibration 20g/10-2000Hz

Approximate Weight 0.91kg (2lbs)

-20_C to 85_C (-4_F to +185_F)ĊOperating

-40_C to 125_C (-40_F to +257_F)ĊStorage

Shock 100g/6msec

Selection Guide

Catalog Number Electrical Connection

842D-60131331BDA One 5 pin male micro QD

842D-60131331BXA Two 5 pin micro QDs (one male & one female)

Manuals and Software

Commissioning the 842D DeviceNet encoder requires an

Electronic Data Sheet (EDS) file be loaded on the system

running the bus management software. Typically, the EDS file

is loaded on a computer running RSNetWorx for DeviceNet.

The EDS file may be downloaded from our website at:

www.ab.com/networks/eds/. Simply select “DeviceNet,”

“RA-Miscellaneous” and press the “Search” button. Select the

842D encoder. This will allow you to download file

00010073002E0400.eds. The User’s Manual may also be

downloaded from our website at:

www.ab.com/manuals/sn/ER.htm.

Saving Parameter Values to EEPROM

Unless parameter values are saved to EEPROM, changes

made to parameter values will not be restored when power is

cycled. In RSNetWorx parameter values are saved to

EEPROM via the Class Instance Editor. Please see the User’s

Manual for further details.

1

Page 2

Mounting Instructions

1. Be sure to select the proper size flexible coupling clamp to

mate to the encoder shaft, e.g., 845–FC–*–*. See

Encoder Accessories in Sensors catalog.

ATTENTION: Do not rigidly connect

the encoder shaft to the machine; this

will cause premature failure of the

encoder or machine bearings. Always

use a flexible coupling.

Flexible Shaft Couplings

Angle

Setting the MAC–ID (node address),

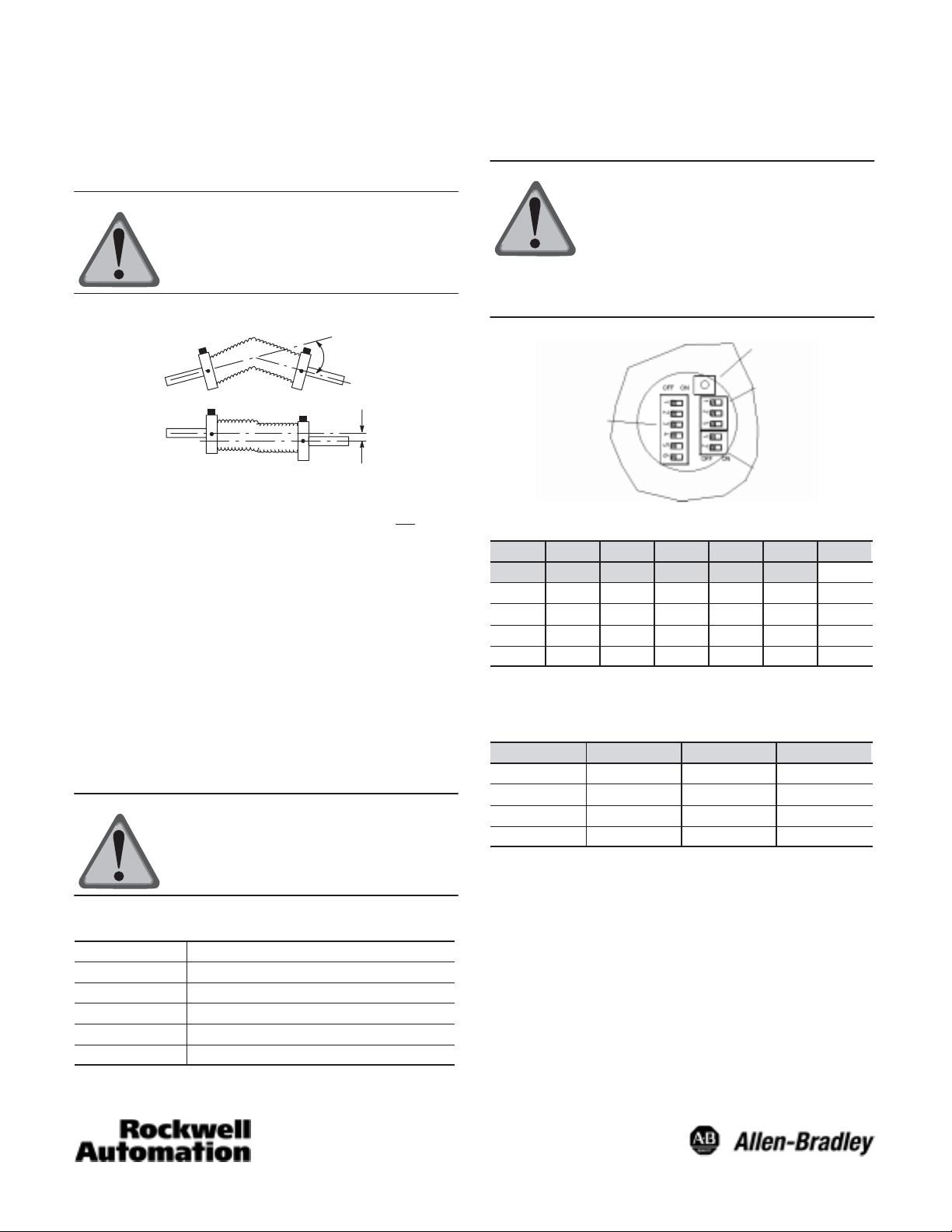

Baud Rate and Bus Termination Dip Switches

ATTENTION: Connecting this product

to an operational DeviceNet network

with improperly set DIP switches

usually will cause the entire network to

stop communicating. Baud rate setting

must be the same as the rest of the

network and the MAC–ID must be

different than the rest of the network.

Preset Position

Button

Baud Rate

Parallel

OffĆSet

2. Use the dimension drawings to determine the encoder

mounting hole locations.

3. Slide the flexible coupling onto the shaft, but do not

tighten

the set screws.

4. Mount the encoder and tighten with three size M4

mounting screws (not supplied).

5. Center the flexible coupling and tighten the set screws.

6. Rotate the machine slowly and verify that the flexible

coupling is not deforming beyond specifications.

7. Align machine to its mechanical zero or home position.

Remove slotted cover located on the back of the encoder

and press the preset position button to change the position

value to the preset value (the factory preset value is zero).

Replace cover.

Preset

To preset the position of the encoder, remove the slotted cover

from the back of the encoder and press the button inside.

ATTENTION: Pressing the preset position

button results in a change of position

reading. This can cause unexpected

motion which could result in damage to

the product, equipment, or personal injury.

Mac-ID

Bus

Termination

MAC-ID

DIP-6 DIP-5 DIP-4 DIP-3 DIP-2 DIP-1 Address

5

2

0 0 0 0 0 0 0

0 0 0 0 0 1 1

... ... ... ... ... ... ...

1 1 1 1 1 1 63

4

2

3

2

2

2

1

2

0

2

0 = DIP switch is OFF

1 = DIP switch is ON

Baud Rate

DIP-3 DIP-2 DIP-1 Baud rate

X 0 0 125 kBaud

X 0 1 250 kBaud

X 1 0 500 kBaud

X 1 1 125 kBaud

X = don’t care

0 = DIP switch is OFF

1 = DIP switch is ON

Indicator

LED Status

Off Not connected not onĆline

Green Blinking Active but not allocated by master

Green Steady Active and allocated by master

Red Blinking Minor fault and/or connection interrupt

Red Steady Critical communication fault

2

Page 3

Bus Termination

The recommended method for connecting DeviceNet products

is to run a “trunk line” with 120 ohm resistors connected at

each end. DeviceNet products are then connected as “drops”

along the length of the trunk line. In this configuration, the

internal termination resistor of the 842D should not be used

and the bus termination DIP switches should be off.

When 842D encoders are connected in a “daisy chain”

configuration, the internal termination resistor may be used on

the end positions only. In this configuration, the end 842D(s)

should have their bus termination DIP switches turned on.

Further details on termination resistors can be found in

publication DN–6.7.2 DeviceNet Cable System Planning and

Installation Manual.

ATTENTION: If you do not use

terminating resistors as described here

and in publication DN–6.7.2, the

DeviceNet cable system will not

operate properly.

ON

12

Bus termination

1 and 2 OFF: not active

1 and 2 ON: active

Note: Remote setting of the DIP switches via a Node

Commissioning Tool is not supported at this time.

3

Page 4

Dimensions—mm (in)

35.94/35.98

(1.415/1.416)

∅53.8

(2.12)

8.8/9.2

(0.34/0.37)

9.98/9.99

(0.392/0.393)

18

(0.71)

18/20

(0.71/0.79)

∅59.5

(2.34)

3 (0.12)

10 (0.39)

6 (0.24)

27.8

(1.09)

105.8 (4.16)

Diagnostic

LEDs

Screw Cover for

DIP Switches and

Reset Button

Single QD Single QD

65 (2.56)

M4 x 7 (0.28) deep on

a 48.0 (1.89) diameter

bolt circle 3 places

120_ apart

120_

18.8

(0.74)

70

(2.756)

13

(0.51)

35_

∅

"

48 0.1

(1.89)

Diagnostic

LEDs

Screw Cover for

DIP Switches and

Reset Button

Double QD Double QD

65 (2.56)

M4 x 7 (0.28) deep on

a 48.0 (1.89) diameter

bolt circle 3 places

120_ apart

Visit our web site at:

4

http://www.ab.com/sensors

35_120_

∅

"

48 0.1

(1.89)

Publication 75008–146–01(C)

Document 910 000 103 871

July 2002

Printed in USA

Loading...

Loading...