Page 1

Solid-State

Level Sensors

USER MANUAL

840E

Page 2

Important User Information

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid-State Controls (Publication SGI-1.1 available

from your local Rockwell Automation sales office or on-line at http://www.ab.com/manuals/gi) describes some

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this

difference, and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying

this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting

from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables

and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment,

or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of safety considerations.

Identifies information about practices or circumstances that can cause an

explosion in a hazardous environment, which may lead to personal injury or

death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding

of the product.

Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you:

• identify a hazard

•avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g., drive or motor) to alert

people that dangerous voltage may be present.

Labels may be located on or inside the equipment (e.g., drive or motor) to alert

people that surfaces may be dangerous temperatures.

Page 3

Table of Contents

Table of Contents

1 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.1 Designated Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Installation, Commissioning, and Operation . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Operational Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Product Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 DC PNP Version with M12 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 AC Version with Valve Connector NPT 1/2 . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Functional Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Performance Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Operating Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1

Page 4

Safety Instructions

1 Safety Instructions

1. 1 Designated Use

The Bulletin 840E is a level switch for all kinds of fluids and is used in tanks, containers and

pipelines. The device has been safely built with state-of-the-art technology and meets the

applicable requirements and EC Directives. It can, however, be a source of danger if used

incorrectly or for anything other than the designated use.

1. 2 Installation, Commissioning, and Operation

Only personnel familiar with these types of products and associated machinery should plan or

implement the installation, start-up, configuration, and subsequent maintenance of the

Bulletin840E level switch.

ATTENTION: Installation and commissioning must be

carried out by qualified individuals. Failure to comply may

result in personal injury or equipment damage.

1. 3 Operational Safety

• Functional safety

The Bulletin 840E level switches were developed according to the standards EN60068 and

EN 61326.

• Hazardous areas

The Bulletin 840E is not approved for use in intrinsic safety (hazardous area) applications.

1. 4 Return

Before returning a device to Rockwell Automation, be sure to remove all fluid residue. This is

particularly important if the fluid is a health hazard, e.g. flammable, toxic, caustic, carcinogenic,

etc.

ATTENTION: Do not return a measuring device if you are not

absolutely certain that all traces of hazardous substances have

been removed, e.g. substances which have penetrated crevices

or diffused through plastic.

2

Page 5

Product Identification

2 Product Identification

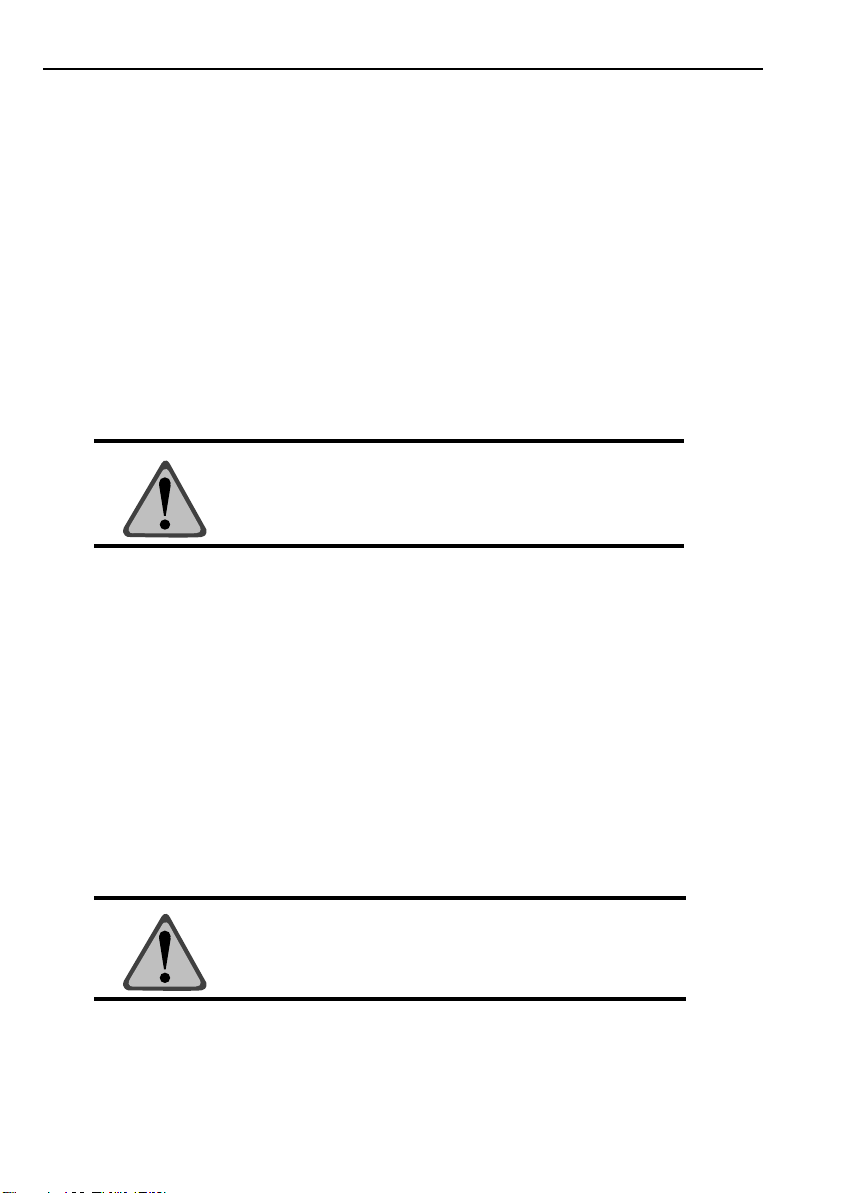

Figure 2.1: Nameplate

Notes:

• Specifications and ratings may differ from those shown in Figure 1, depending on particular

model. Refer to product nameplate or catalog for actual ratings and specifications.

• The series number indicates the version of the switch. A change in the series letter does not

have any effect on the compatibility.

3

Page 6

Installation

3 Installation

3. 1 Dimensions

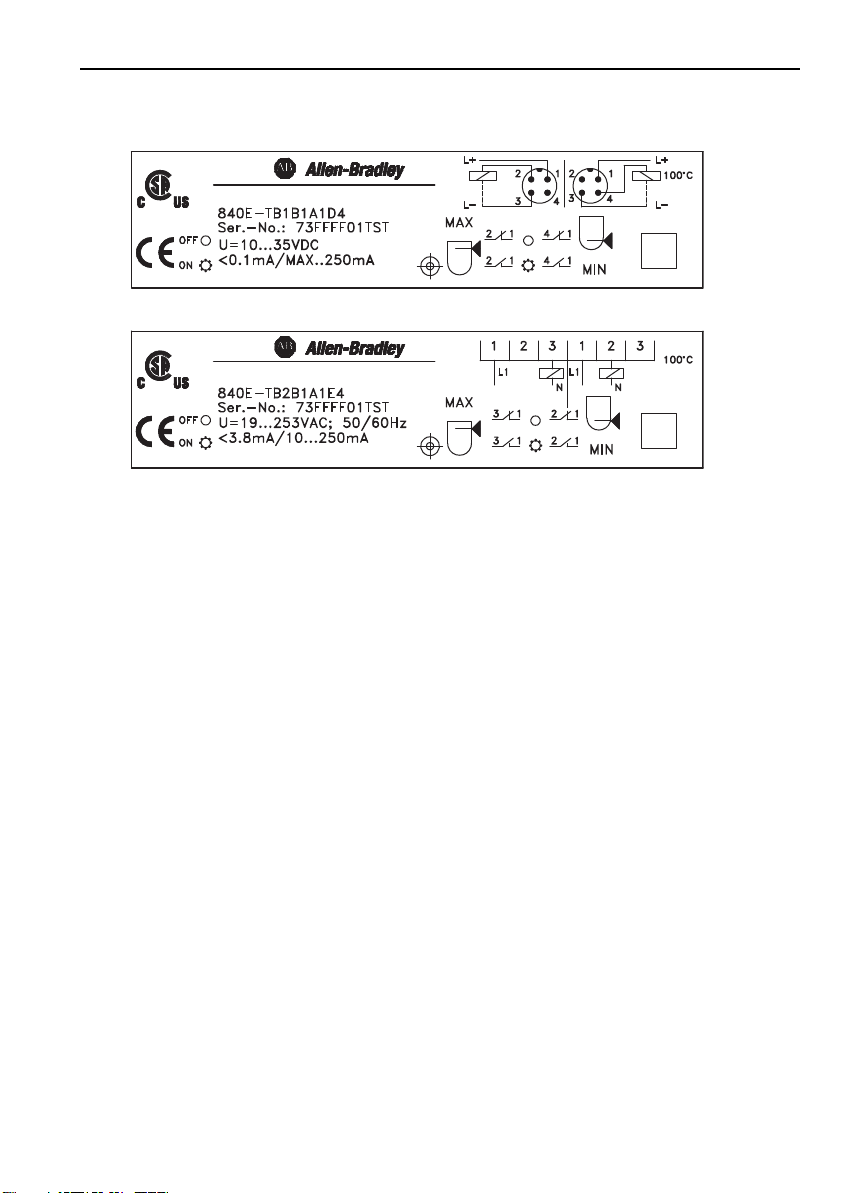

3.1.1 1/2 in. NPT and 3/4 NPT Process Connection [mm (in.)]

68.5

(2.70)

22.7

(0.89)

M12

1/2 in. NPT

VALVE

40

(1.57)

36

(1.42)

51.5

(2.03)

Figure 3.1: NPT Dimensions

Ø40

(Ø1.57)

161

(6.34)

63.9

(2.52)

47.9

(1.89)

1/2 in. NPT

OR

3/4 in. NPT

63.9

(2.52)

47.9

(1.89)

1/2 in. NPT

OR

3/4 in. NPT

4

Page 7

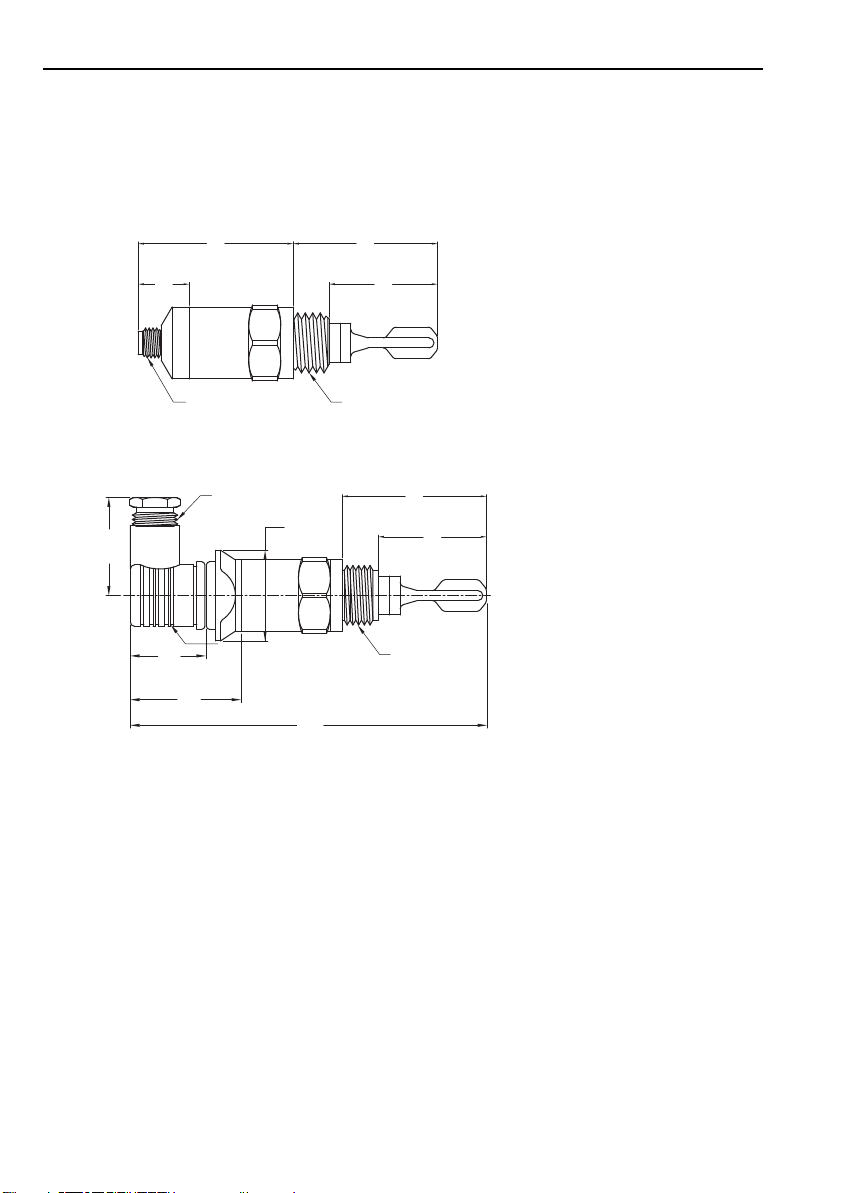

3.1.2 G 1/2 Process Connection [mm (in.)]

22.7

(0.89)

68.5

(2.70)

63.9

(2.52)

38

(1.50)

16

(0.63)

G 1/2

M12

63.9

(2.52)

38

(1.50)

16

(0.63)

161

(6.34)

G 1/2

40

(1.57)

Ø40

(Ø1.57)

51.5

(2.03)

36

(1.42)

1/2 in. NPT

VALVE

840E-TB2B3A1E4 G 1/2 2-WIRE 19…253V AC 100 °C 1/2 NPT Valve Connector

840E-TB2B2A1E4 3/4 in. NPT 2-WIRE 19…253V AC 100 °C 1/2 NPT Valve Connector

840E-TB2B1A1E4 1/2 in. NPT 2-WIRE 19…253V AC 100 °C 1/2 NPT Valve Connector

840E-TB1B3A1D4 G 1/2 3-WIRE PNP 10…35V DC 100 °C M12 Connector

840E-TB1B2A1D4 3/4 in. NPT 3-WIRE PNP 10…35V DC 100 °C M12 Connector

840E-TB1B1A1D4 1/2 in. NPT 3-WIRE PNP 10…35V DC 100 °C M12 Connector

Description

Catalog Number

Figure 3.2: G 1/2 Dimensions

Installation

3.1.3 Product Selection

5

Page 8

Installation

Ra < 3.2 µm

3. 2 Installation Instructions

3.2.1 Handling

Figure 3.3: Hold by the housing, not by the sensor fork

Figure 3.4: Do not bend, shorten or lengthen.

6

Page 9

3.2.2 Mounting Examples

A

B

B

A

A

~13 (0.5)

~10.5 (0.41)

~3 (0.12)

~2 (0.08)

~30 (1.2)

mm (in.)

Installation

Figure 3.5: A = Switchpoint, B = Switching Hysteresis

7

Page 10

Installation

BDA

C

A

B

C

D

= 0...10000 mm²/s

= 0... 2000 mm²/s

minimum

DN 50 (2.0)

[mm (in.)]

( 0...15.50 in²/s)

( 0...3.10 in²/s)

3.2.3 Viscosity and Build-up

Figure 3.6: Take into account viscosity and build-up.

8

Page 11

3.2.4 Sensor Fork Alignment

!

OFF

ON

O

F

F

O

N

= 0...10000 mm²/s

= 0... 2000 mm²/s

( 0...15.50 in²/s)

( 0...3.10 in²/s)

Figure 3.7: Align Sensor Fork (note mark)

Installation

9

Page 12

Wiring

889D-F4AC-2

14

(0.56)

31.8

(1.25)

889D-R4AC-2

4 Wiring

4. 1 DC-PNP Version with M12 Connector

Operating Mode MAX (NC Contact) Operating Mode MIN (NO Contact)

12

12

R

R = External Load

I = 250 mA Maximum

U = 10...35 V DC

2

1

3

4

L– L+

0.5 A

1 - Brown

2 - White

3 - Blue

14

14

L– L+

Figure 4.1: DC-PNP Wiring

4.1.1 Mating Cables [mm (in.)]

2 m (6.5 ft) PVC Cable

with 4-pin micro (M12x1) connector and

ratcheted epoxy-coated zinc coupling nut.

Catalog number: 889D-F4AC-2

2 m (6.5 ft) PVC Cable

with 4-pin micro (M12x1) right-angle

connector and ratcheted epoxy-coated zinc coupling nut.

Catalog number: 889D-R4AC-2

2

1

3

4

R

(0.56)

1 - Brown

3 - Blue

4 - Black

0.5 A

47

(1.85)

14

10

Note: Other cable lengths are available and shielded cables may be required for some analog

output applications – refer to the On-Machine Connectivity catalog (publication

#M115-CA001A-EN-P) for additional information.

Page 13

4.1.2 DC-PNP Operation

...

U– (DC)

1

MAX MIN

2

1

2

1

Wiring

4

4

1

U

< 3 V < 3 V

IIII

U

(PNP)

L+

–L+ –L+ – L+ –

Green

Figure 4.2: DC-PNP Operation

Green light ON:

Sensor is connected to power supply and operational

Yellow light ON:

Sensor is immersed in liquid

Red light ON:

Overload or short-circuit in load circuit

- Rectify the short circuit

- Reduce maximum load current to below 250 mA

Green light OFF:

Error: No power supply

- Check plug, cable and power supply

Red light flashing:

Internal sensor error or sensor corroded

-Replace device

Red

Yellow

Light On

Light Off

< 100 µA< 100 µA

++

11114224

11

Page 14

Wiring

1

3

0.5 A

L1

R

13

13

12

12

Operating Mode MAX Operating Mode MIN

PE

(Ground)

N

>19 V

12

3

0.5 A

L1

R

PE

(Ground)

N

>19 V

R = External Load

I = 250 mA Maximum

U = 19...253V AC

1Brown

2Blue

3 Black

GND Yellow/Green

4. 2 AC Version with Valve Connector NPT 1/2

Figure 4.3: AC Wiring.

4.2.1 Mating Cables

Optional cordset 2 m (6.5 ft) DIN valve. Catalog number: 889V-RZ3ABE-2

12

Page 15

4.2.2 AC Operation

MAX MIN

50...60 Hz

L1

V21<V21<

U

< 4 mA< 4 mA

U

N

L1

N

L1

N

L1

N

11112332

IIII

U~(AC)

1

3

1

3

1

2

1

2

Light On

Light Off

Green

Red

Wiring

Figure 4.4: AC Operation

Green light ON:

Sensor is connected to power supply and operational

Red light ON:

Mode of operation MAX (overfill protection): sensor is immersed in liquid

Mode of operation MIN (dry running protection): sensor is immersed in liquid

Green light OFF:

Error: No power supply

- Check plug, cable and power supply

Red light flashing:

Error: Overload or short-circuit in load circuit

- Rectify the short circuit

- Reduce maximum load current to below 250 mA

Error: Internal sensor error or sensor corroded

-Replace device

13

Page 16

Wiring

MAX

MIN

MAX

MAX

–>

–>

–>

.2.1

.2.1

.2.1

MIN

Green Yellow Green Yellow

Green Yellow Green Yellow

Green Red Green Red

4. 3 Functional Test

Use test magnet supplied with the sensor to test level switch functionality.

Figure 4.5: Functional Test

14

Page 17

5 Technical Data

5. 1 Power Supply

DC-PNP with M12 connector

10...35 V DC Supply voltage

< 825 mW Power consumption

< 15 mA Current consumption

AC with NPT 1/2 valve connector

19...253 V AC Supply voltage

< 810 mW Power consumption

< 3.8 mA Current consumption

5. 2 Performance characteristics

Switching delay 0.5 s when covering

1.0 s when free

Resolution < 0.5 mm (0.02 in.)

Maximum error 13.0 +/- 1 mm (0.51 in. +/- 0.04 in.)

Repeatability +/- 0.5 mm (+/- 0.02 in.)

Hysteresis 3.0 +/- 0.5 mm (0.12 in. +/- 0.02 in.)

Settling time < 2 s

Technical Data

Reference operating conditions

Ambient temperature: 23 °C (73 °F)

Process pressure: 14.5 psi

Medium: Water

Medium density: 1

Medium temperature: 23 °C (73 °F)

Installation from above

Density setting: > 0.7 SGU

15

Page 18

Technical Data

32

(0)

32

(0)

T

P

212

(100)

158

(70)

140 (60)

104 (40)

68 (20)

-40

(-40)

-40

(-40)

86

(30)

140

(60)

T

a

°F (°C)

°F (°C)

176*

(80)*

122

(50)

-13**

(-25)**

-4

(-20)

-4

(-20)

5. 3 Operating Conditions

Ambient temperature range -40...+70 °C (-40...+158 °F)

Process temperature range -40...+100 °C (-40...+212 °F)

Storage temperature range -40...+85 °C (-40...+185 °F)

Shock resistance EN 60068-2-27 (30 g)

Vibration resistance EN 60068-2-64

Process pressure -14.5...580 psi

Degree of protection NEMA 4X (IP66/67) DC - M12 connector

IP65 AC - Valve connector

Media Liquid

Density > 0.7 SGU

Viscosity 1...10 000 cSt

Gas content Stagnant mineral water

Solids content < 5 mm(0.20 in.) diameter

16

Page 19

Back Cover

Page 20

Pub. No. 10000061888 Ver 0.0

© 2009 Rockwell Automation. Printed in the U.S.A

September 16, 2009

Loading...

Loading...