Page 1

Solid-State

Flow Sensors

USER MANUAL

839E

Page 2

Important User Information

Because of the variety of uses for the products described in this publication, those responsible for the

application and use of this control equipment must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission

of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

The illustrations, charts, sample programs and layout examples shown in the guide are intended solely for

purposes of example. Since there are many variables and requirements associated with any particular

installation, Rockwell Automation does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the Application, Installation and

Maintenance of Solid-State Control (available from your local Rockwell Automation sales office), describes

some important differences between solid-state equipment and electromechanical devices that should be

taken into consideration when applying products such as those described in this publication.

It is recommended that you save this user manual for future use.

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you identify a

hazard, avoid a hazard, and recognize the consequences.

SHO CK H AZAR D

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that dangerous voltage may be present.

BUR N HA ZARD

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that surfaces may reach dangerous temperatures.

WA RN IN G

IMP ORTA NT

AT TE NT IO N

Page 3

Table of contents

839E Solid-State Flow Sensors User Manual

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Designated use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation, commissioning and operation . . . . . . . . . . . . . . . . . 2

Operational safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

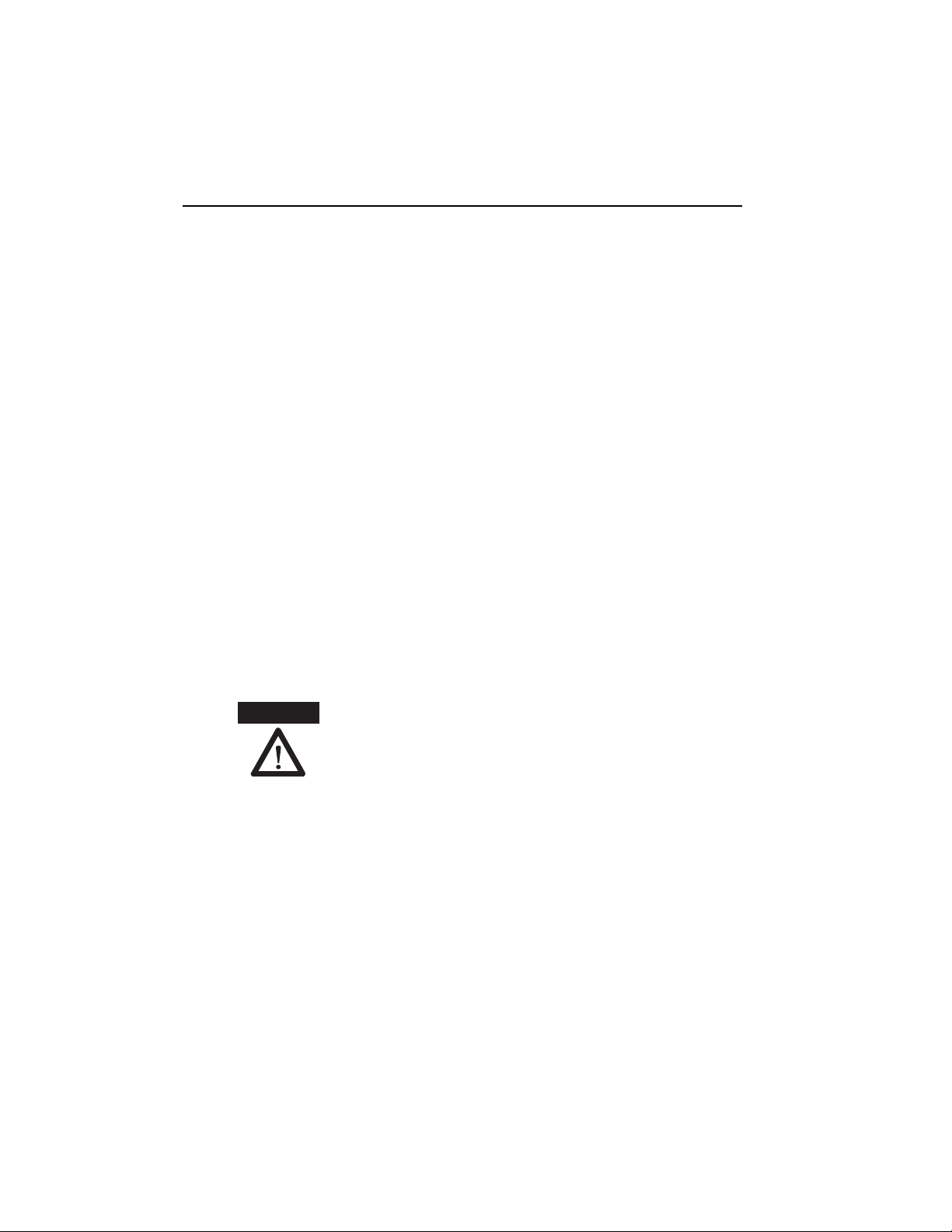

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Process connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

On-site programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Programming with personal computer and ReadWin 2000 19

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuration kit with ReadWin . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Error and warning codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Change status (release) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operating conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pub #10000004735 Ver 03, May 2012 1

Page 4

839E Solid-State Flow Sensors User Manual

AT TEN TIO N

Safety instructions

Designated use

The Bulletin 839E is a flow switch for measurement and monitoring of mass flow rates in

industrial processes. The device has been safely built with state-of-the-art technology and

meets the applicable requirements and EC Directives. It can, however, be a source of

danger if used incorrectly or for anything other than the designated use.

Installation, commissioning and operation

Only personnel familiar with these types of products and associated machinery should

plan or implement the installation, start-up, configuration, and subsequent maintenance

of the Bulletin 839E flow switch. Failure to comply may result in personal injury and/or

equipment damage.

Operational safety

• Funtional Safety

The 839E flow switch was developed according to standard IEC 61010.

• Ex-area

The 839E is not approved for use in Ex-areas.

Return

Before returning a device to Rockwell Automation, be sure to remove all fluid residue. This

is particularly important if the fluid is a health hazard, e.g. flammable, toxic, caustic,

carcinogenic, etc.

Do not return a measuring device if you are not absolutely

certain that all traces of hazardous substances have been

removed, e.g. substances which have penetrated crevices

or diffused through plastic.

2 Pub #10000004735 Ver 03, May 2012

Page 5

839E Solid-State Flow Sensors User Manual

839E-DA1BA1A3D4

53009401032

Flow (0.03…3m/s)

–40°F < T < 185°F

IP65

Product identification

Figure 1 Explanation of the nameplate — see Table below

1 Catalog number 6 Current consumption

2 Series letter 7 Wiring diagram

3 Serial number 8

Flow rate and ambient temperature

range

4 Operating voltage 9 Enclosure rating/ingress protection

5 Output 10 Approvals

Notes:

• Specifications and ratings may differ from those shown in Figure 1, depending on

particular model. Refer to product nameplate or catalog for actual ratings and

specifications.

• The series number indicates the version of the switch. A change in the series letter does

not have any effect on the compatibility—see “Change status” section.

• Approvals inlcude 3A authorized for models configured with sanitary adaptors.

Pub #10000004735 Ver 03, May 2012 3

Page 6

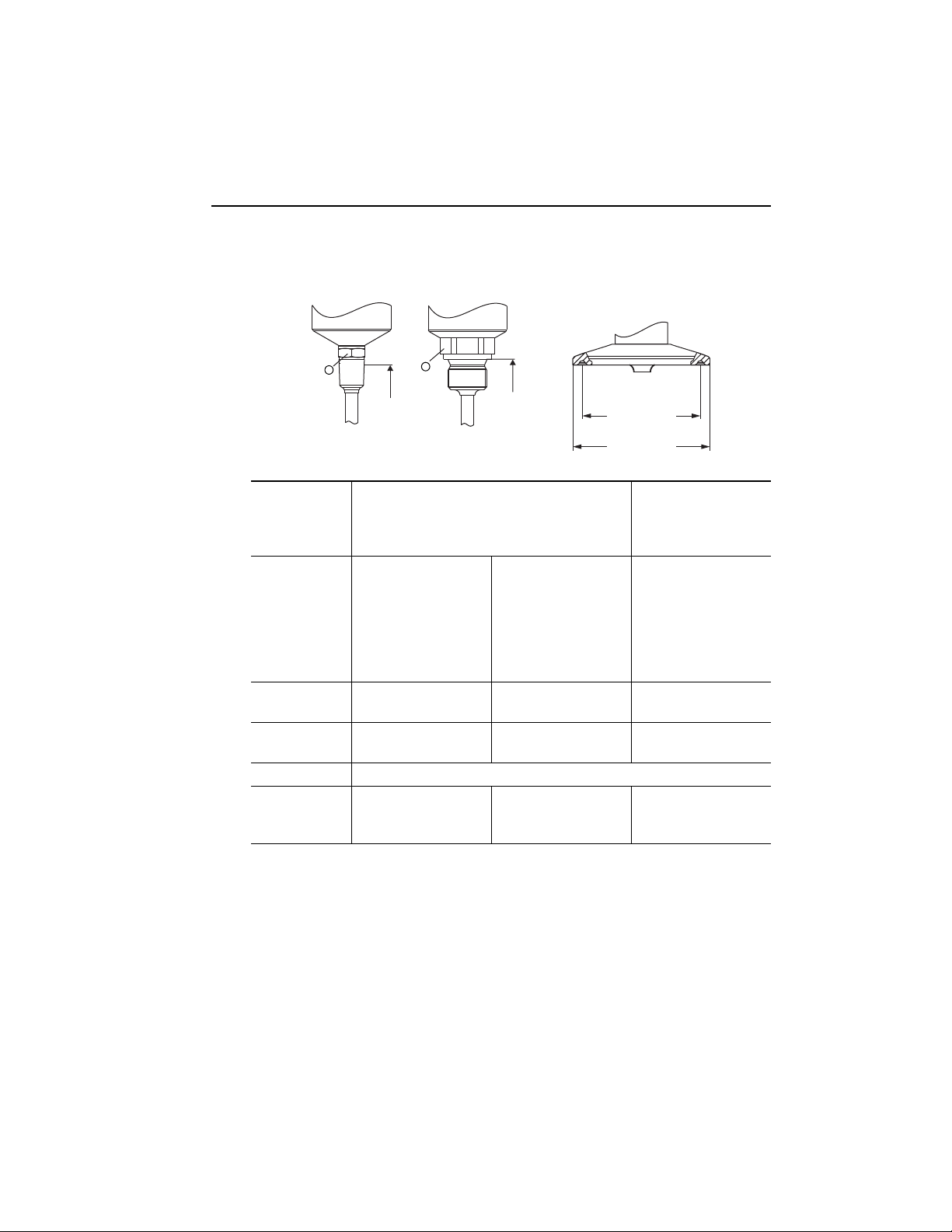

839E Solid-State Flow Sensors User Manual

M12 x 1

38.7 (1.52)

6 (0.24) Dia.

24 (0.95)

38.5 (1.515) Dia.

42.3 (1.66) Dia.

6 (0.24) Dia.

97.1

(3.82)

42.1

(1.657)

LL

Installation

Dimensions

Figure 2 Dimensions [mm (in.)]

Version L with 30 and 100 mm (1.18 and 3.94 in.)

M 12x1 connector as per IEC 60947-5-2

4 Pub #10000004735 Ver 03, May 2012

Page 7

839E Solid-State Flow Sensors User Manual

2

L

L

1

A B C

43.5 (1.71) dia.

50.5 (1.99) dia.

Process connection

The following table illustrates the versions of 839E.

Measurement and

Field of

application

Process

connection

Thread Length L114.3 mm (0.56 in.)

Thread Length L25.8 mm (0.23 in.)

Measuring and monitoring of mass flow rates

Item A

Version with thread

process connection

ANSI ¼-in. NPT

(1 = AF14) and ½-in.

NPT

(1 = AF27)

Item B

Version with thread

process connection

G ¼ (2 = AF14) and

G½

(2 = AF27) as per ISO

228

12 mm (0.47 in.)

19 mm (0.75 in.)

8.1 mm (0.32 in.)

14 mm (0.55 in.)

— —

Sensor length L Version L with 30 and 100 mm (1.18 and 3.94 in.)

Operational

range

Liquids from 0.03 to

3.0 m/s (0.1 to

9.84ft/s)

monitoring, mass flow

rates in sanitary

processes

Version with

50.8 mm (2 in.) clamp

or 25.4…38.1 mm

(1…1.5in.)

Item C

—

Pub #10000004735 Ver 03, May 2012 5

Page 8

839E Solid-State Flow Sensors User Manual

1

V

m

L

AT TEN TIO N

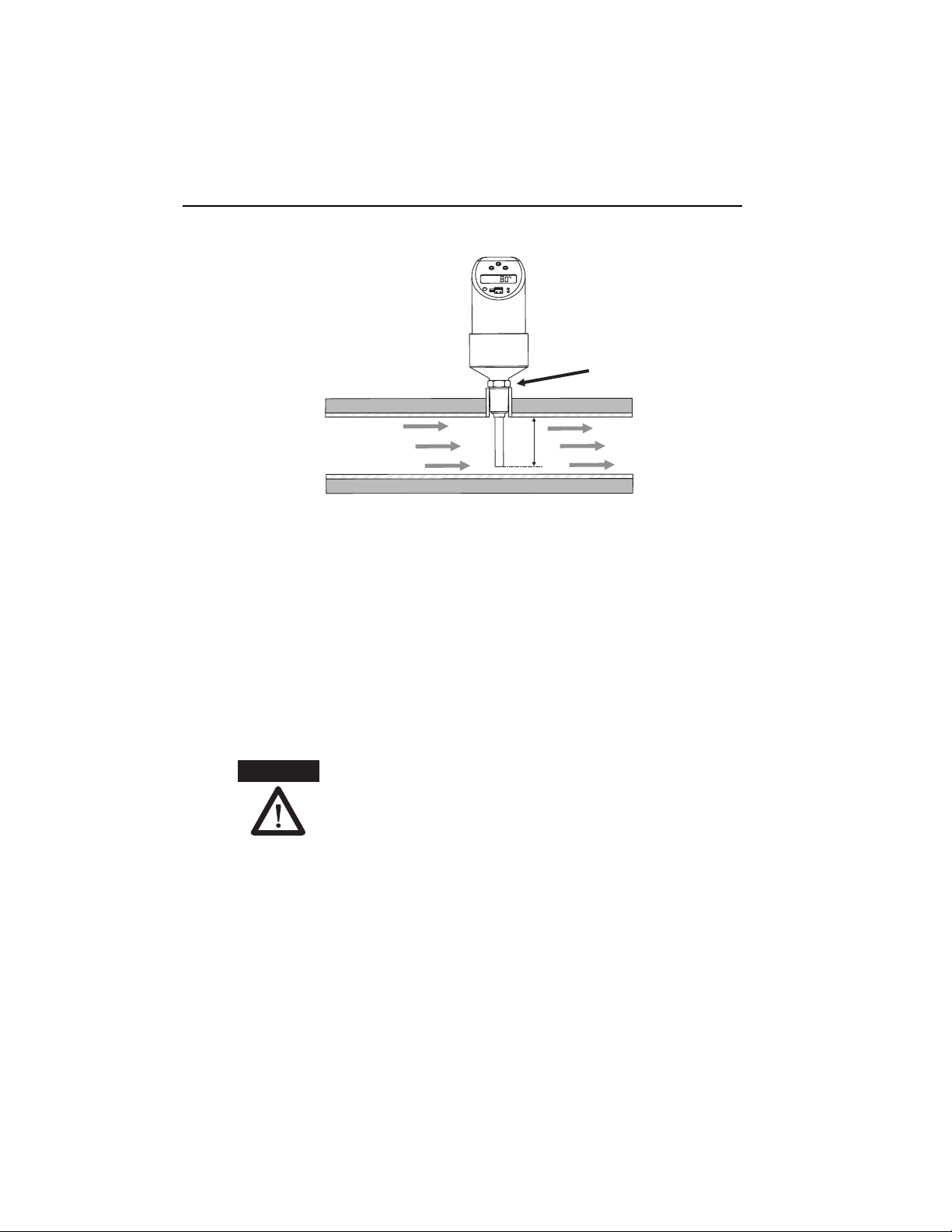

Installation instructions

Figure 3 Installing Bulletin 839E (example). Sensor length L is completely immersed in the flow

profile.

Mounting instructions:

• Any orientation

• The on-site display can be rotated electronically 180° — see “Operation” section.

• The housing can be rotated up to 310° for optimal readability and ease of wiring.

• Minimum sensor immersion length: L ≥ 10 mm (0.4 in.)

• The sensor tip should not touch the pipe wall.

• If used in a vertical pipe, the flow should be ascending.

• For a horizontal pipe, install sensor from top if pipe is completely filled with medium.

Otherwise, install sensor from side to ensure complete length of sensor is in the medium.

Do not turn the device into the process connection thread

at the housing. Always install the device at the

hexagonal-head bolt (refer to Figure 3, detail 1). Use a

suitable open-ended wrench for this task.

Note!

For correct flow measurement, the complete length of the sensor must be immersed in the

fully developed flow profile.

6 Pub #10000004735 Ver 03, May 2012

Page 9

839E Solid-State Flow Sensors User Manual

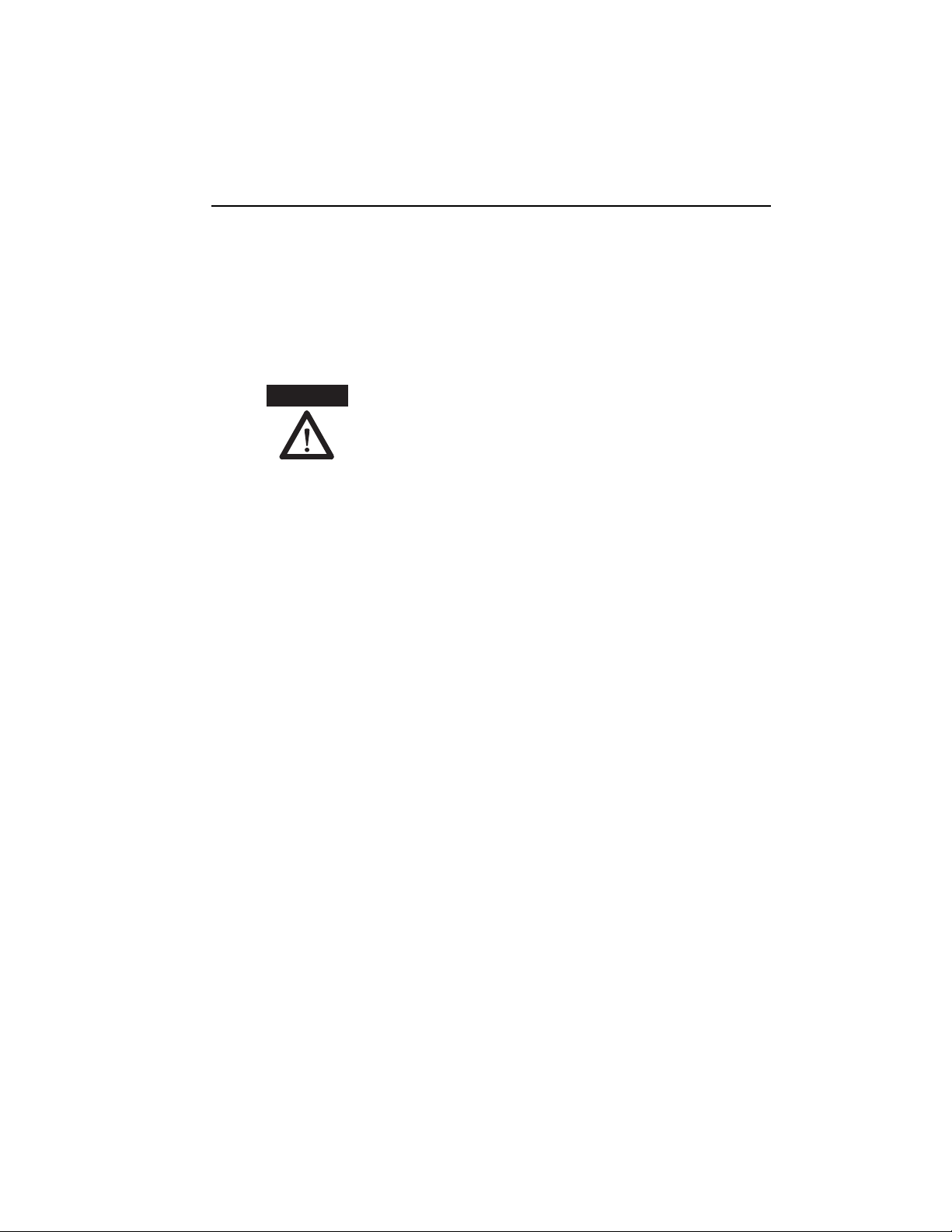

AT TEN TIO N

Installation instructions

Installation conditions

Note!

The sensor requires a fully developed flow profile for correct monitoring. For this reason,

steadying sections (5x DN) must be provided in the pipe after a pump, pipe bend, internal

fittings and cross-sectional changes.

Do not turn the device into the process connection thread

at the housing. Always install the device at the spanner flats

(Figure 4, item 1). Use a suitable open-ended wrench for

this task (see table of page 5).

• The onsite display can be rotated electronically 180°, see “Onsite operation” section.

• The upper housing section can be rotated mechanically up to 310°.

Pub #10000004735 Ver 03, May 2012 7

Page 10

839E Solid-State Flow Sensors User Manual

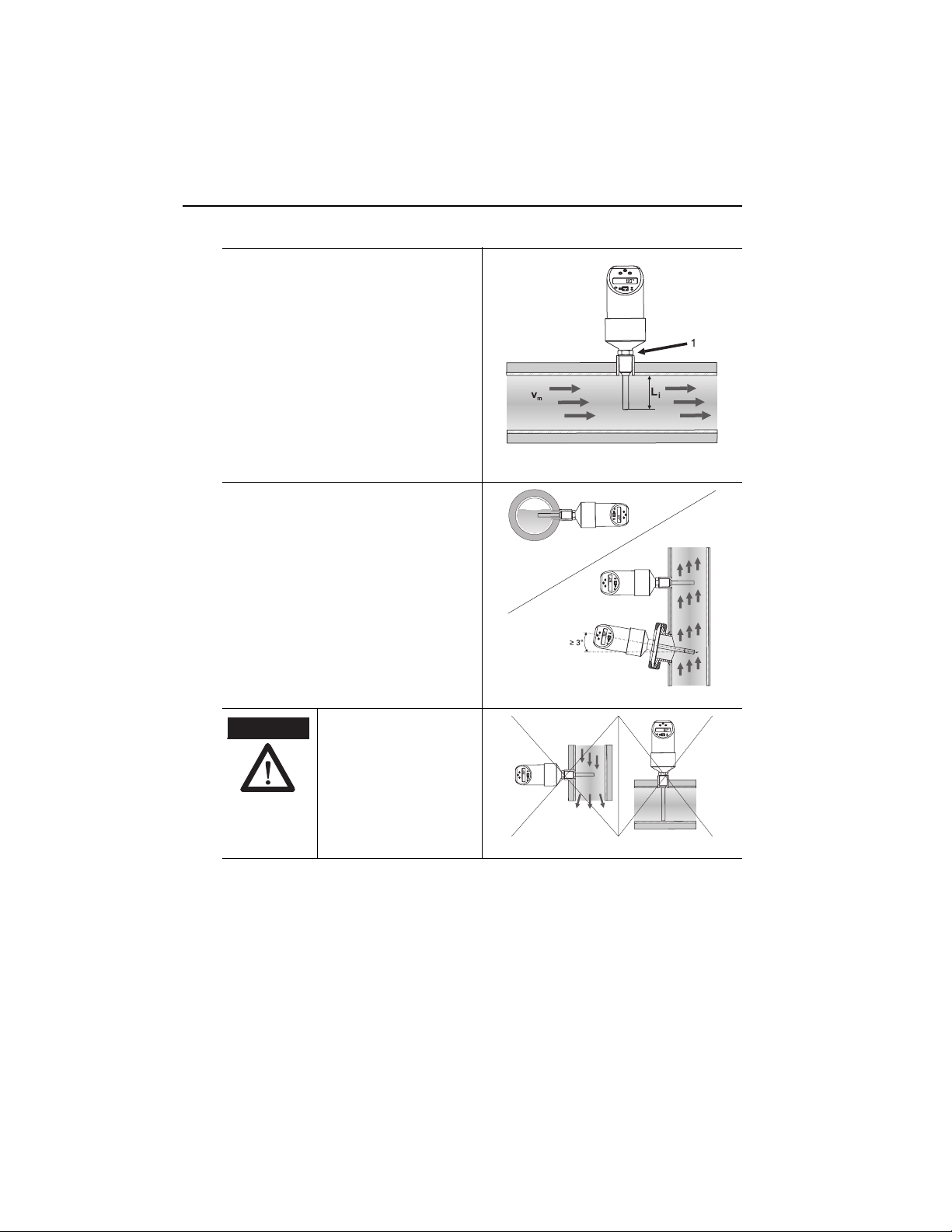

AT TEN TIO N

Wiring

• The sensor tip should be completely

surrounded by medium.

• Position the sensor tip in the area of

maximum fluid velocity (pipe center).

• Minimum sensor immersion length:

L1 ±10 mm.

Orientation:

• For horizontal pipes: lateral installation.

Note!

Installation from above (see Figure 4) only if

the pipe is completely filled with medium

during operation.

• For vertical pipes: installation in the

ascending pipeline.

• Installation of 839E by min. 3° inclination,

because of self draining.

Figure 4 Installation conditions

Figure 5 Correct orientation

• Do not install in down

pipes open towards the

end.

• The sensor tip should

never touch the pipe

wall.

Figure 6 Incorrect installation

8 Pub #10000004735 Ver 03, May 2012

Page 11

839E Solid-State Flow Sensors User Manual

4

R2

L+

L-

4…20 mA

3

12

4

R2R1

L+

L-

3

12

A1

A2

889D-R4AC-2

889D-F4AC-2

DC voltage version with M12 connector

Figure 7 DC voltage version with M12 connector

Bulletin 839E with M12x1 connector

A1: PNP switch outputs R1 and R2

A2: PNP switch output with 4…20 mA analog output

Mating cables

2 m (6.5 ft) PVC cable with 4-pin micro

(M12x1) connector and ratcheted

epoxy-coated zinc coupling nut.

Catalog number: 889D-F4AC-2

2 m (6.5 ft) PVC cable with 4-pin micro

(M12x1) right-angle connector and

ratcheted epoxy-coated zinc coupling nut.

Catalog number: 889D-R4AC-2

Note: Other cable lengths are available and

shielded cables may be required for some

analog output applications — refer to the

On-Machine Connectivity catalog for

additional information.

Pub #10000004735 Ver 03, May 2012 9

Page 12

839E Solid-State Flow Sensors User Manual

Operating ke y

Communications jac k

f or personal computer

Digital displa y

Y ello w LEDs f or s witching states

LED on = s witch closed

LED off = s witch open

LED for status

Green = ok

Red = error

Red/green blinking = warning

E

22.07

bar

Operation

On-site programming

The Bulletin 839E is programmed via three push buttons. The digital display and the light

emitting diodes (LEDs) assist in the navigation through the operating menu.

Figure 8 Location of operating keys and display elements

Background illumination of the digital display:

– White = OK status

– Red = alarm/error status

10 Pub #10000004735 Ver 03, May 2012

Page 13

839E Solid-State Flow Sensors User Manual

AT TEN TIO N

Navigating through the programming menu

Figure 9 Navigating through the programming menu

A Function group selection

B Function selection

➊ Enter the programming menu:

- Press and hold the E key for longer than 3 sec.

➋ Once in programming mode (BASE will be displayed), toggle between the Function

groups with the + and - keys

➌ To enter the Function group, press the E key

➍ Enter or change parameters with the + or - key.

- Then press the E key to return to the “Function” option

➎ Press the E key several times to return to the “Function group”

➏ Jump back to the measuring position (Home position)

- Then press the E key for longer than 3 sec.

➐ To save changes, choose YES or NO with the + or - key

- Confirm with the E key

Changes take effect only when you choose YES when asked

to save the data.

Pub #10000004735 Ver 03, May 2012 11

Page 14

839E Solid-State Flow Sensors User Manual

Navigating the “Learn” function

Figure 10 Navigating the “Learn” function using the Calibration (CAL) function group as an

example

➊ Select the HIF (Learn High Flow) or LOWF (Learn Low Flow) function with the E key

➋ Select the “RUN” function with the + key, learn function is initialized

➌ Select the “WAIT” function with the + key, press for longer than 2 sec.

➍ Accept (“learn”) the current measured value after approx. 10 sec. - “OK” appears on the

display

➎ If “NOK” (not OK) appears on the display after 60 sec., no current measured value was set

➏ Return to the CAL function group (Home position) with the E key

Notes!

1. Programming buttons [E], [-], and [+] may need to be pressed and held for several

seconds before displaying the expected response.

2. When performing a calibration the 839E may require up to 60 seconds to learn the high

or low flow rate. The display will indicate “WAIT” during the learn process.

3. After configuring the 839E to the desired settings, press and hold the [E] key until

“SAVE” appears; press the [+] or [-] key until “YES” appears. Press and hold the [E] key

until “SAVE” appears. Depending on the configuration changes the display may

indicate a number or a blinking “INIT.” Wait for the blinking “INIT” to change to another

value. This indicates the 839E is ready for operation.

12 Pub #10000004735 Ver 03, May 2012

Page 15

839E Solid-State Flow Sensors User Manual

MAX

1 2

3.5 8 …

1

2

Pressing here navigates to

Pressing here navigates to

To right display (revert to normal) navigate to and press .

80%

0%

3

3

To calibrate with setting at 100% press

100% then press .

multiple times until display shows

Structure of the operating menu

Structure of the operating menu for 1 x analog output (4…20 mA) and 1 x switch output

(839E-DCxxxxxx).

Figure 11 Operating menu: A function groups, B functions, C settings

Pub #10000004735 Ver 03, May 2012 13

Page 16

839E Solid-State Flow Sensors User Manual

1 2

1

1

2

Pressing here navigates to

Pressing here navigates to UNIT and inverts the display . To right display (revert to normal) navigate to and press .

Structure of the operating menu for two switch outputs (839E-DAxxxxxxx)

Figure 12 Operating menu: A function groups, B functions, C settings

14 Pub #10000004735 Ver 03, May 2012

Page 17

Basic settings

839E Solid-State Flow Sensors User Manual

Function

group

BASE

(basic

functions)

Function

(display) Description

Display assignment:

OFF

Display of current measured value or of configured

switch point (switch 1)

Display of current measured value or of configured

switch point (switch 1) rotated 180°

Display of current medium temperature

Display of current medium temperature rotated 180°

Factory setting: current measured valued in %

Display medium temperature unit °C or °F

Factory setting: °C

NOTE: Only visible if the current medium

temperature is selected in the DISP mode.

Measured value damping with regard to display

value and output:

0 (no damping) or 9…40 sec. (in increments of 1

second)

Factory setting: 0 sec.

Behavior as per DESINA: The PIN of the M12

connector is assigned in accordance with the

guidelines of DESINA.

(DESINA = DistributEd and Standardized INstAllation

technology for machine tools and manufacturing

systems)

CAL

(Calibration)

Pub #10000004735 Ver 03, May 2012 15

Setting for maximum flow rate occurring.

100% value

Setting for minimum flow rate occurring.

0% value

Page 18

839E Solid-State Flow Sensors User Manual

Function

Function group

OUT

(Setting for the

1st output)

OUT2 (Setting for

the 2nd output,

optional)

(display) Description

Output switching mode for channel 2: flow or

temperature

Factory setting: flow

Temperature unit selection (°C/°F)

NOTE: Function only visible if switching mode

(MODE) is set to temperature in the 2nd output.

Switch output function:

hysteresis function NC contact or NO contact (see

diagram)

4…20 mA

Enter value 5…100% in increments of 1%.

Factory setting: 50%

Or optionally for SP2:

Enter value -15…85 °C (-5…185 °F) in increments

of

1 °C (1 °F) if the switching mode (MODE) is set to

temperature.

Factory setting: 55 °C (131 °F)

Take current flow rate as SP.

Enter value 0…95% in increments of 1%.

Factory setting: 40%

Note: The value has to be at least 5% smaller than

the switch point (SP or SP2).

Or optionally for RSP2:

Enter value -20…80 °C (-4…176 °F) in increments

of

1 °C (1 °F) if the switching mode (MODE) is set to

temperature.

Factory setting: 50 °C (122 °F)

Note: The value has to be at least 5 °C (9 °F)

smaller than the switch point 2 (SP2).

16 Pub #10000004735 Ver 03, May 2012

Page 19

839E Solid-State Flow Sensors User Manual

Function

group

OUT and

OUT2

(continued)

SERV

(Service

functions)

Function

(display) Description

Can be set anywhere between 0…99 sec. in

increments of 1 second.

Factory setting: 0 sec.

Enter the device locking code.

Locking, only visible with valid operating code.

Resetting of all settings to factory settings.

Configuration counter, increments each time the

configuration is changed.

Display of last error to occur.

Simulation switch output 1: on/off with display,

optionally corresponding to switch output 2.

Pub #10000004735 Ver 03, May 2012 17

Page 20

839E Solid-State Flow Sensors User Manual

Functions of the switch point

• Hysteresis function

The hysteresis function enables two-point control via a hysteresis. Depending on the mass

flow, the hysteresis can be set via the set point SP and the reset point RSP.

• N.O. contact or N.C. contact

This switch function is freely selectable.

Figure 13 Hysteresis function, ➁ N.O. contact, ➂ N.C. contact

SP = set point; RSP = reset point

18 Pub #10000004735 Ver 03, May 2012

Page 21

839E Solid-State Flow Sensors User Manual

USB

1

2

3

Programming with personal computer and ReadWin 2000

The 839E can also be configured via personal computer and ReadWin software. An

additional configuration kit with a conversion cable (Part number 836E-NSR) is required to

interface the USB port of the PC to the programming port of the flow switch, as shown

below.

Figure 14 Programming with PC

➀ Personal computer with ReadWin configuration software

➁ Configuration kit (836E-NSR)

➂ Bulletin 839E with programming port

Figure 15 Sensor configuration with ReadWin

Pub #10000004735 Ver 03, May 2012 19

Page 22

839E Solid-State Flow Sensors User Manual

Additional operating options

In addition to the operating options listed in the “On-site programming” section, the

ReadWin configuration software provides an additional function group with further

information on the Bulletin 839E:

Function group Function (display) Description

SERV

(service

functions)

INFO (device

information)

Switching processes 1

Switching processes 2,

optional

TAG 1

TAG 2, optional

Order code Order code

Serial number Device serial number

Sensor serial number Sensor serial number

Electronics serial

number

Device revision Display of entire revision

Hardware revision Hardware version

Software revision Software version

Number of changes in switching status for

switch output 1; optionally switch output 2

Tagging, 18-digit

Electronics serial number

20 Pub #10000004735 Ver 03, May 2012

Page 23

Accessories

USB

Configuration Kit with ReadWin

The configuration kit (Catalog Number:

836E-NSR) consists of a software CD and a

conversion cable which interfaces the USB

port of the PC to the 4-pin programming

port on the sensor face.

ReadWin® 2000 software is also available free

of charge via download from

http://ab.rockwellautomation.com, select

Product Directory/Sensors & Switches/

Condition Sensors/Pressure

Sensors/Solid-State Pressure

Switches/Resources. Reference “Other

Resources” and select “ReadWin

Configurator for Windows™ 2000. zip.

839E Solid-State Flow Sensors User Manual

Pub #10000004735 Ver 03, May 2012 21

Page 24

839E Solid-State Flow Sensors User Manual

Troubleshooting

Error and warning codes

If an error occurs in the electronics, the color of the status LED changes from green to red

and the background illumination of the digital display changes from white to red. A status

LED flashing red and green displays an error or warning code, as outlined below:

• E-code for errors

In the event of an error message, the measured value is unreliable.

• W-code for warnings

In the event of a warning, the measured value is still reliable.

Error Codes

Code Explanation

E011 Device configuration faulty

E012 Error in measurement or underrange/overrange

E013 Error at heating resistor

E015 Error in EEPROM

E019 Power supply has undervoltage/overvoltage

E020 Error in Flash

E021 Internal memory error

E022 USB power supply

E027 Characteristic does not suit medium

E042

Output current can no longer be generated. Possible cause:

analog output not connected or open circuit.

22 Pub #10000004735 Ver 03, May 2012

Page 25

839E Solid-State Flow Sensors User Manual

Warning Codes

Code Explanation

W107 Simulation active

W202 Flow outside the sensor range

W209 Device start-up

W210 Configuration modified

W212 Sensor signal outside the permitted range

W250 Number of switch cycles exceeded

W260 Value for High Flow (HIF) and Low Flow (LOWF) faulty

W270 Short-circuit and overload at output 1

W280 Short-circuit and overload at output 2

Values for high flow (HIF) or low flow (LOWF) could not be

W432

determined with certainty. The device can be operated,

however.

Repair

Bulletin 839E flow switches are not repairable.

Disposal

Please pay particular attention to the local disposal regulations of your country. Ensure the

materials of the device components are separated and processed accordingly.

Change status (release)

The release number on the nameplate and in the Operating Instructions indicates the

change status of the device: XX.YY.ZZ (example 01.02.01).

XX Change in the main version.

Compatibility no longer provided. Device and Operating Instructions

change.

YY Change in functionality and operation.

Compatibility provided. Operating Instructions change.

ZZ Troubleshooting and internal modifications.

Operating Instructions do not change.

Pub #10000004735 Ver 03, May 2012 23

Page 26

839E Solid-State Flow Sensors User Manual

Technical data

Power supply

Supply voltage

• DC voltage version

18...30 V DC

Current consumption

• < 100 mA (open-circuit operation) at 24 V DC, max. 150 mA (open-circuit operation); with

reverse polarity protection

Power supply failure

• Behavior in case of overvoltage (> 30V)

The device works continuously up to 34V DC without any damage. No damage is caused to

the device in case of a short-term overvoltage up to 1 kV (as per EN 61000-4-5). If the supply

voltage is exceeded, the properties specified are no longer guaranteed.

• Behavior in case of undervoltage

If the supply voltage drops below the minimum value, the device switches off (status as if

not supplied with power = switch open).

Output

Switching capacity

• Switch status ON: Ia ≤ 250 mA

• Switch status OFF: Ia ≤ 1 mA

• Switching cycles: ≤ 10,000,000

• Voltage drop PNP: ≤ 2 V

• Overload protection

Automatic load testing of switching current; output is switched off in case of overcurrent,

the switching current is tested again every 0.5 sec.; max. capacitance load: 14 mF for max.

supply voltage (without resistive load); periodical protective disconnection in event of

overcurrent (f = 2 Hz) and ‘Warning’ display.

Signal on alarm

• Switch outputs: in safe state (switch normally open)

24 Pub #10000004735 Ver 03, May 2012

Page 27

839E Solid-State Flow Sensors User Manual

Operating conditions

• Any orientation

• Top housing section can be rotated 310°

Operating conditions: Environment

• Ambient temperature range

–40…+85 °C (–40…185 °F)

• Storage temperature

–40…+85 °C (–40…185 °F)

• Climate class

4K4H as per DIN EN 60721-3-4

• Degree of protection

IP65 complete housing

• Shock resistance

50 g as per DIN IEC 68-2-27 (11 ms)

• Vibration resistance

20 g as per DIN IEC 68-2-6 (10-2000Hz)

4 g as per guidelines of German Lloyd GL

• Electromagnetic compatibility

Interference emission as per IEC 61326, class B equipment

Interference immunity as per IEC 61326, Appendix A (industry) and

NAMUR Recommendation NE21; EMC influence: d 0.5%

Operating conditions: Process

• Process flow limits

Liquids: 0.03…3.0 m/s (0.1…9.84 ft/s)

• Process temperature limits

–20…85 °C (–4…185 °F)

Note!

The sensor can be exposed up to 130°C (266°F) without damage. Monitoring switches shut

off automatically at T ≥ 85°C (185F) and starts again at T ≤ 85°C (185°F).

• Process pressure limits

p/T load diagram as per DIN 43763 or Dittrich/Kohler (or as per ASME/ANSI PTC 19.3)

Pub #10000004735 Ver 03, May 2012 25

Page 28

839E Solid-State Flow Sensors User Manual

id " (inch) 0.37 0.62 0.87 1.37 1.87 2.37 2.87 3.87

id (mm) 9.4 15.75 22.1 34.8 47.5 60. 2 72.9 97.38

Flow ft/s

0.3 0.1 0.3 0.6 1.5 2.8 4.5 6.6 11.8

0.7 0.2 0.6 1.2 3.0 5.6 9.0 13.2 2 3.6

1.3 0.4 1.2 2.4 6.0 11.2 18.0 2 6.5 47.2

2.0 0.7 1.9 3.6 9.0 16.9 27.1 39.7 70.8

2.6 0.9 2.5 4.9 12.1 2 2.5 36.1 52.9 94.4

3.3 1.1 3.1 6.1 15.1 28.1 45.1 66.2 118.1

3.9 1.3 3.7 7.3 18.1 33.7 54.1 79.4 141.7

4.6 1.5 4.3 8.5 21.1 39.3 63.2 92.6 165.3

5.2 1.8 4.9 9.7 24.1 4 4.9 72.2 105.9 188.9

5.9 2.0 5.6 10.9 27.1 50.6 81.2 119.1 212.5

6.6 2.2 6.2 12.2 30.2 56.2 90.2 132.3 236.1

7.2 2.4 6.8 13.4 33.2 61.8 99.3 145.5 259.7

7.9

2.6 7.4 14.6 36.2 67.4 108.3 158.8 283.3

8.5

2.9 8.0 15.8 39.2 73.0 117.3 172.0 306.9

9.2

3.1 8.6 17.0 42.2 78.6 126.3 185.2 330.5

9.8

3.3 9.3 18.2 45.2 84. 3 135.3 198.5 354.2

gpm

Conversion ft/s to gpm

0.1

1.0

10.0

100.0

1000.0

0.0

10.11.0

Flow rate ft/s

Volume gpm

DN100

DN80

DN65

DN50

DN40

DN25

DN20

DN10

½" ¾"

1½" 2½"

4"

2" 3"

1"

DN

Figure 16 p/T load diagram

L = insertion length

vW = water fluid velocity = 3 m/s (9.84 ft/s)

Flow Switch Conversion

Feet per second (ft/s) to gallons per minute (gpm)

26 Pub #10000004735 Ver 03, May 2012

Page 29

839E Solid-State Flow Sensors User Manual

Pub #10000004735 Ver 03, May 2012 27

Page 30

839E Solid-State Flow Sensors User Manual

28 Pub #10000004735 Ver 03, May 2012

Page 31

839E Solid-State Flow Sensors User Manual

Pub #10000004735 Ver 03, May 2012 29

Page 32

Publication 10000004735 Ver 03 — May 2012

© 2012 Rockwell Automation. Printed in the U.S.A.

Loading...

Loading...