Page 1

Bulletin 825-P Modular Protection System

Quick Start Guide

Page 2

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Important User

Information

IMPORTANT

Because of the variety of uses for the products described in this publication, those

responsible for the application and use of this control equipment must satisfy

themselves that all necessary steps have been taken to assure that each application

and use meets all performance and safety requirements, including any applicable laws,

regulations, codes, and standards.

The illustrations, charts, sample programs and layout examples shown in this guide

are intended solely for purposes of example. Since there are many variables and

requirements associated with any particular installation, Rockwell Automation does

not assume responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the Application,

Installation and Maintenance of Solid-State Control (available from your local AllenBradley distributor), describes some important differences between solid-state

equipment and electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

This guide Does Not replace the User Manual, publication

825-UM004_-EN-P, and is intended for qualified service

personnel responsible for setting up and servicing these

devices. You must have previous experience with and a

basic understanding of electrical terminology, configuration

procedures, required equipment, and safety precautions.

Reproduction of the contents of this copyrighted publication, in whole or part,

without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

:

ATTENTION

Identifies information about practices or circumstances

that can lead to personal injury or death, property damage

or economic loss.

!

2

Page 3

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Attention statements help you to:

• Identify a hazard

•Avoid a hazard

• Recognize the consequences

European

Communities (EC)

IMPORTANT

Tra demark List

DeviceNet and the DeviceNet logo are trademarks of the Open Device Vendors

Association (ODVA).

Microsoft Windows is a registered trademark of the Microsoft Corporation.

Identifies information that is critical for successful

application and understanding of the product.

Directive Compliance

The 825-P Modular Protection System is CE marked for installation within the

European Union and EEA regions. It has been designed and tested to meet the

following directives.

EMC Directive

TIP

This product has been designed for environment A (heavy

industrial). Use of this product in environment B (light

industrial or domestic) can cause unwanted electromagnetic

disturbances in which case the user could be required to

take adequate mitigation measures.

This product is tested to meet the Council Directive 89/336/EEC Electromagnetic

Compatibility (EMC) by applying the following standards, in whole:

• EN 60947-4-1 — Low-Voltage Switchgear and Controlgear: Part 4: Contactors

and Motor Starters - Section 1: Electromechanical Contactors and Motor

Starters

• EN 60947-5-1 — Low-Voltage Switchgear and Controlgear: Part 5: Control

Circuit Devices and Switching Elements - Section 1: Electromechanical

Control Circuit Devices

This product is intended for use in an industrial environment.

33

Page 4

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage as

amended by 93/68/EEC by applying the safety requirements of EN 60947-4-1 and

EN 60947-5-1. For specific information required by EN 60947-4-1 and EN 60947-51, see the appropriate sections in this publication.

To obtain a copy of the 825-P’s Declaration of Conformity (DoC), contact your local

Allen-Bradley distributor or go to http://www.ab.com.certification/#CEmark.

Introduction

Follow these steps to successfully commission the 825-P Modular Protection System.

Table A: Commissioning Procedure

Step Description

1 General Precautions

2 Hardware Installation

3 Wiring Installation

4 Front Panel Operation

5 System Configuration

6 Port 4 Settings

7 Programming General Parameters

8 Programming Operational Parameters

9 Programming Protection Functions

10 Output Relay and Input Assignments

4

Page 5

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

General

Precautions

ATTENTION

!

ATTENTION

!

ATTENTION

!

ATTENTION

Have only qualified personnel service this equipment. If

you are not qualified to service this equipment, you can

injure yourself or others, or cause equipment damage.

Equipment components are sensitive to electrostatic

discharge (ESD). Undetectable permanent damage can

result if you do not use proper ESD procedures. Ground

yourself, your work surface, and this equipment before

removing any cover from this equipment.

Disconnect or de-energize all external connections before

opening this device. Contact with hazardous voltages and

currents inside this device can cause electrical shock

resulting in injury or death.

To install an option card the relay must be de-energized and

then reenergized. When reenergized, the relay will reboot.

Therefore, de-energize the protected motor before

installing the option card to prevent damage to the motor.

Hardware

Installation

!

IMPORTANT

IMPORTANT

Relay Mounting

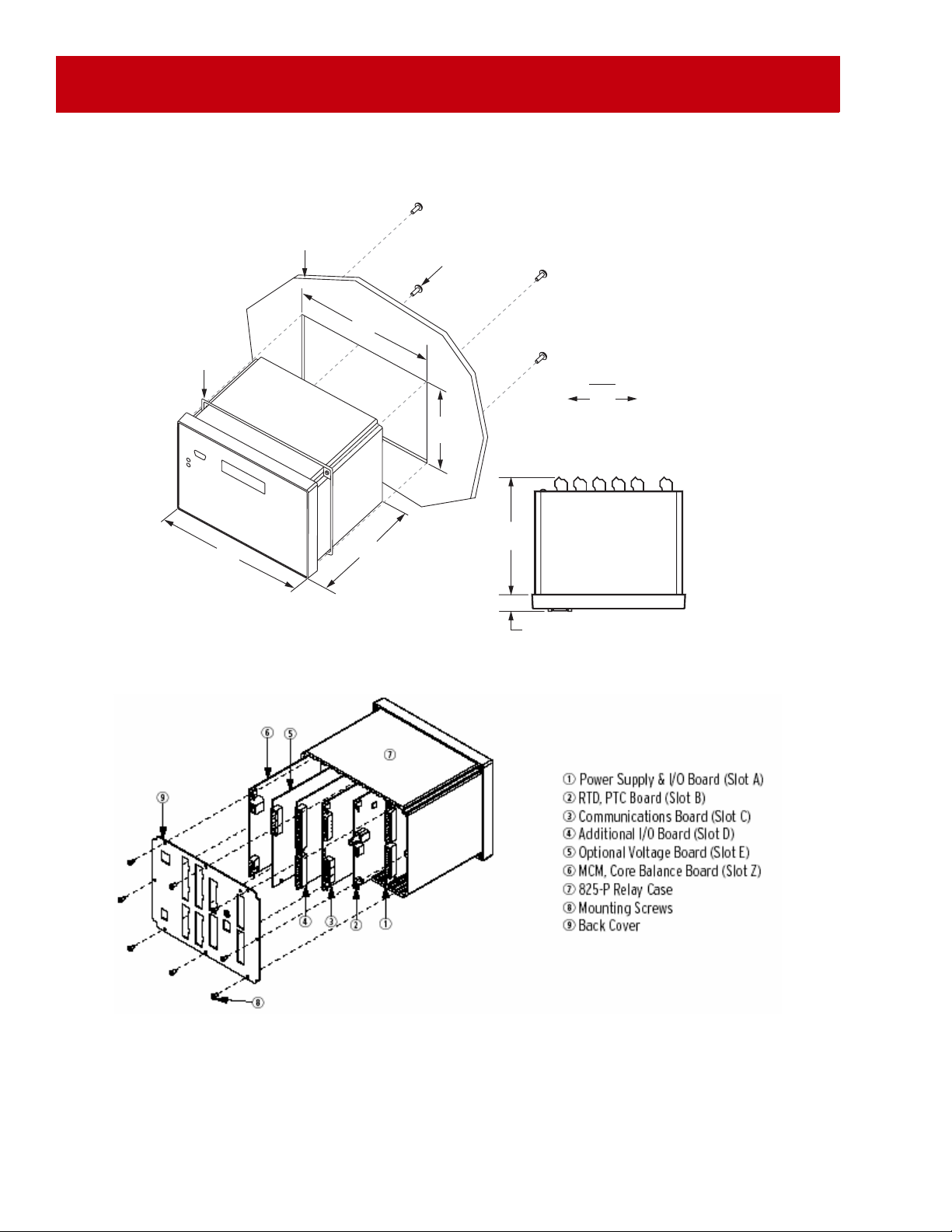

Figure 1 Mounting and Dimensions

For complaince to IEC standards regarding thermal

overload protection, set the SERVICE FACTOR to a

value: 1.05…1.20.

For a properly configured device, the settings in the Main

Settings and Overload Settings groups should be adjusted

according to the motor and system requirements. Settings

in other groups can be programmed as desired.

55

Page 6

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

➀

➁

186.0

(7.32)

➂

Legend

mm

(in)

➀ Mounting Panel–maximum thickness 6.5 mm

➁ #8 x 1/2 inch mounting screw;

Torque specification = 0.9...1.3 N.m (8...12 Lb-in)

➂ Gasket

147.4

(5.80)

20.8

(0.82)

192.0

(7.56)

144.0

(5.67)

138.0

(5.43)

Option Cards

Figure 2 Inserting Option Cards

6

Page 7

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

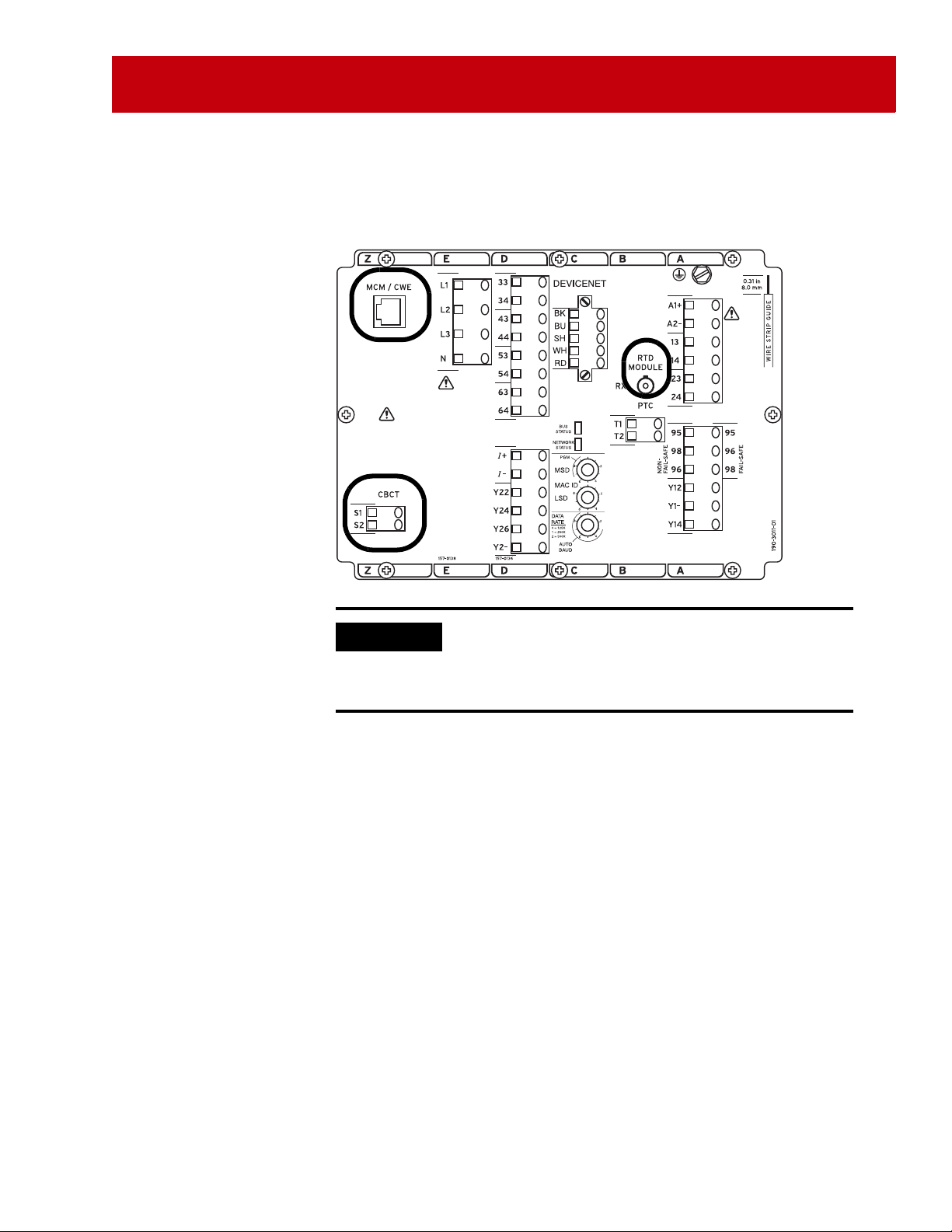

Converter Modules and Optional Core Balance CT, RTD Scanner

Figure 3 Converter Module, CBCT, and RTD Scanner Connections

IMPORTANT

1. The 825-P relay is not EMC-Tested for converter module connecting cable

lengths greater than the 4-meter cable that is supplied.

2. Up to 12 RTDs can be monitored when an external 825-PR12D RTD Scanner

is used. There are separate trip and warning settings for each RTD.

3. A simplex 62.5/125 um fiber-optic cable with ST connector is needed for

connecting the external RTD module to the 825-P. (Fiber optic cable is not

supplied. Contact your local Allen-Bradley distributor.)

Settings associated with options or accessories (converter

module, voltage input card, expansion I/O card, RTD

scanner) require their installation or connection prior to

being made available for configuration.

77

Page 8

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

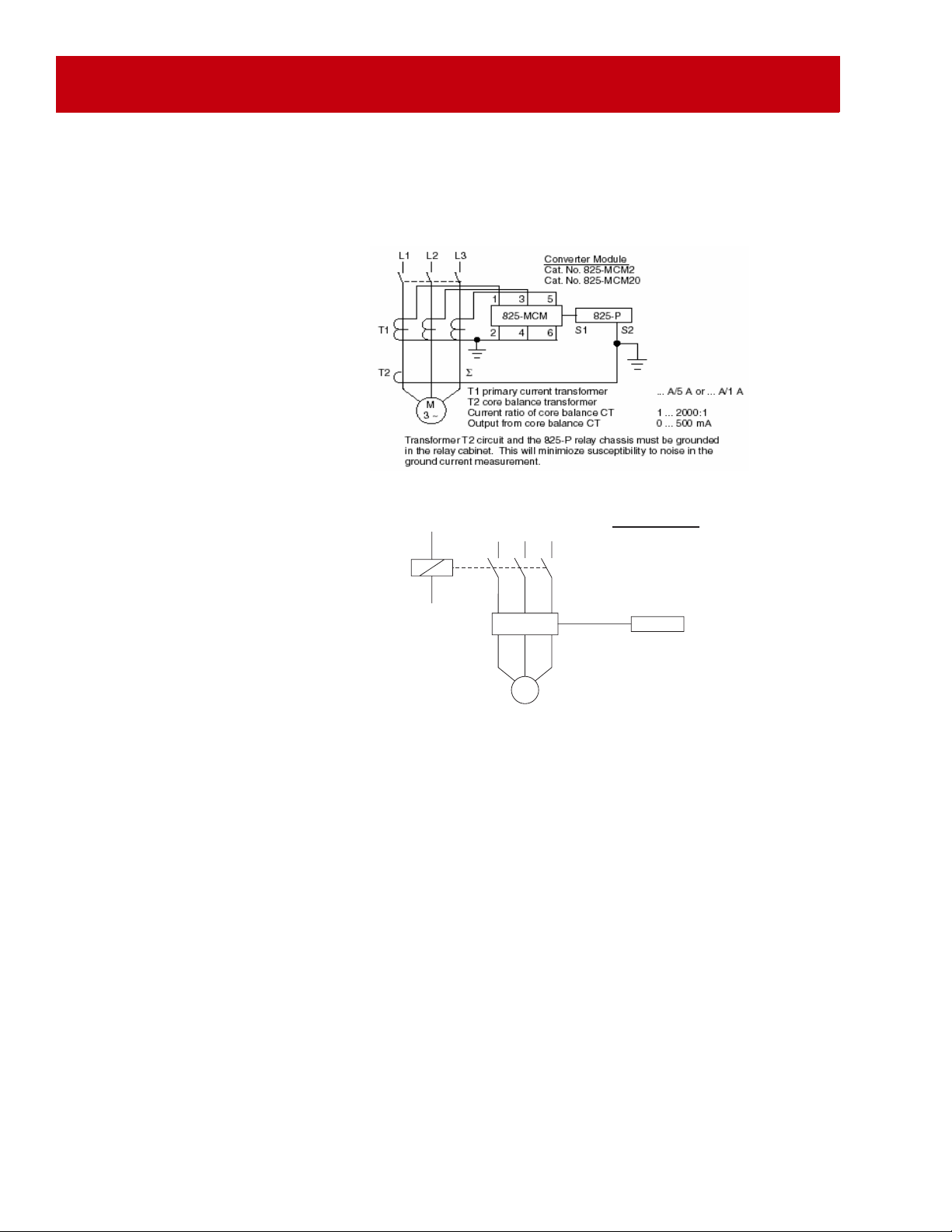

Wiring

Installation

Main Circuit

Figure 4 Relay with Phase CTs and CoreBalance CT

Figure 5 Relay without Phase CTs

L3L2L1

A1

K1

A2

13 5

642

Converter Module

Cat. No. 825-MCM2

Cat. No. 825-MCM20

Cat. No. 825-MCM180

Cat. No. 825-MCM630

Cat. No. 825-MCM630N

825-P825-MCM

3 ~

M

8

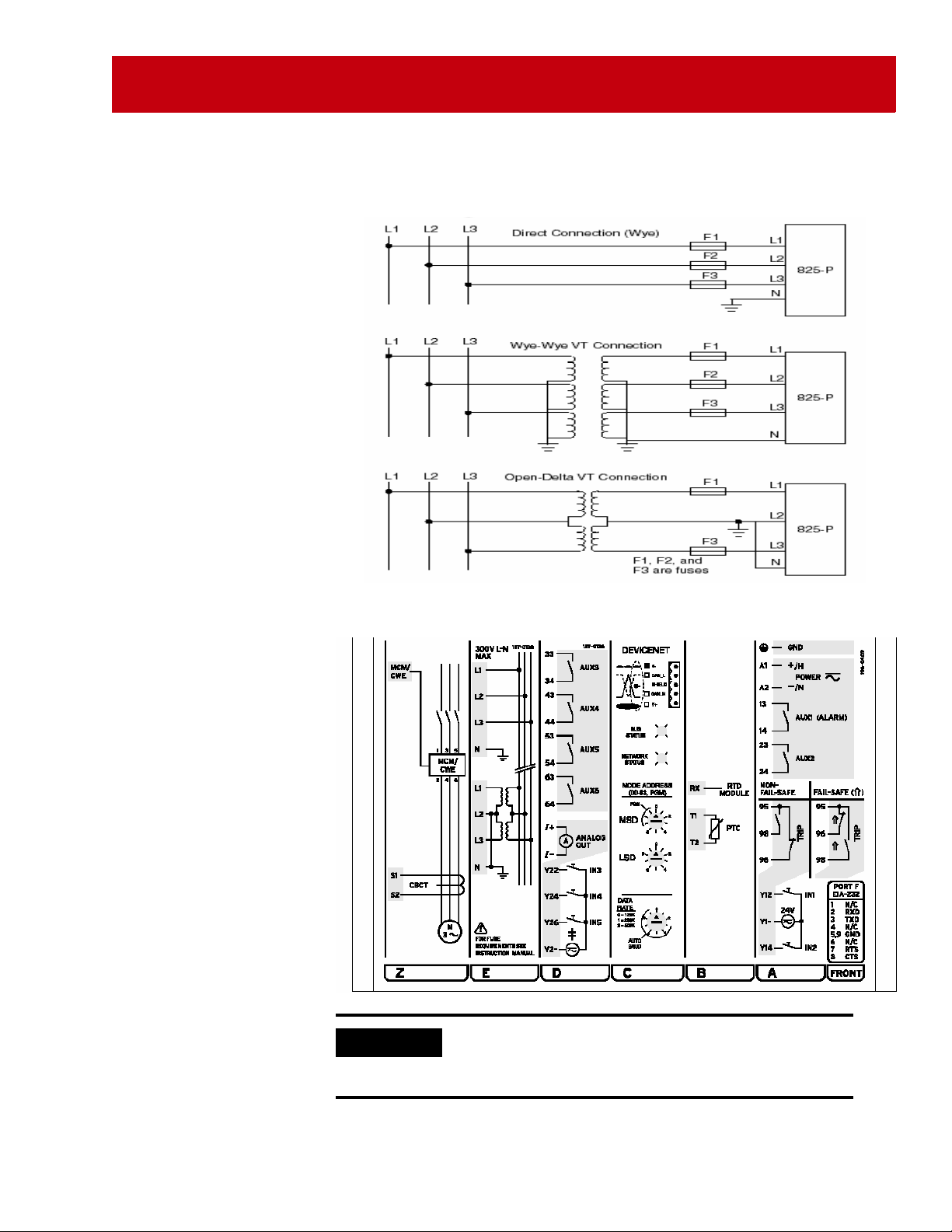

Page 9

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 6 Voltage Connections (Optional Card Cat. No. 825-PVS required)

Figure 7 Input/Output

Slots C, D and E are for option cards. Rated supply voltage is 110...240V AC or 110...250V DC

IMPORTANT

Be sure to properly label and connect the Trip relay

terminals according to the programmed behavior; factory

default setting is “Fail-Safe”.

99

Page 10

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

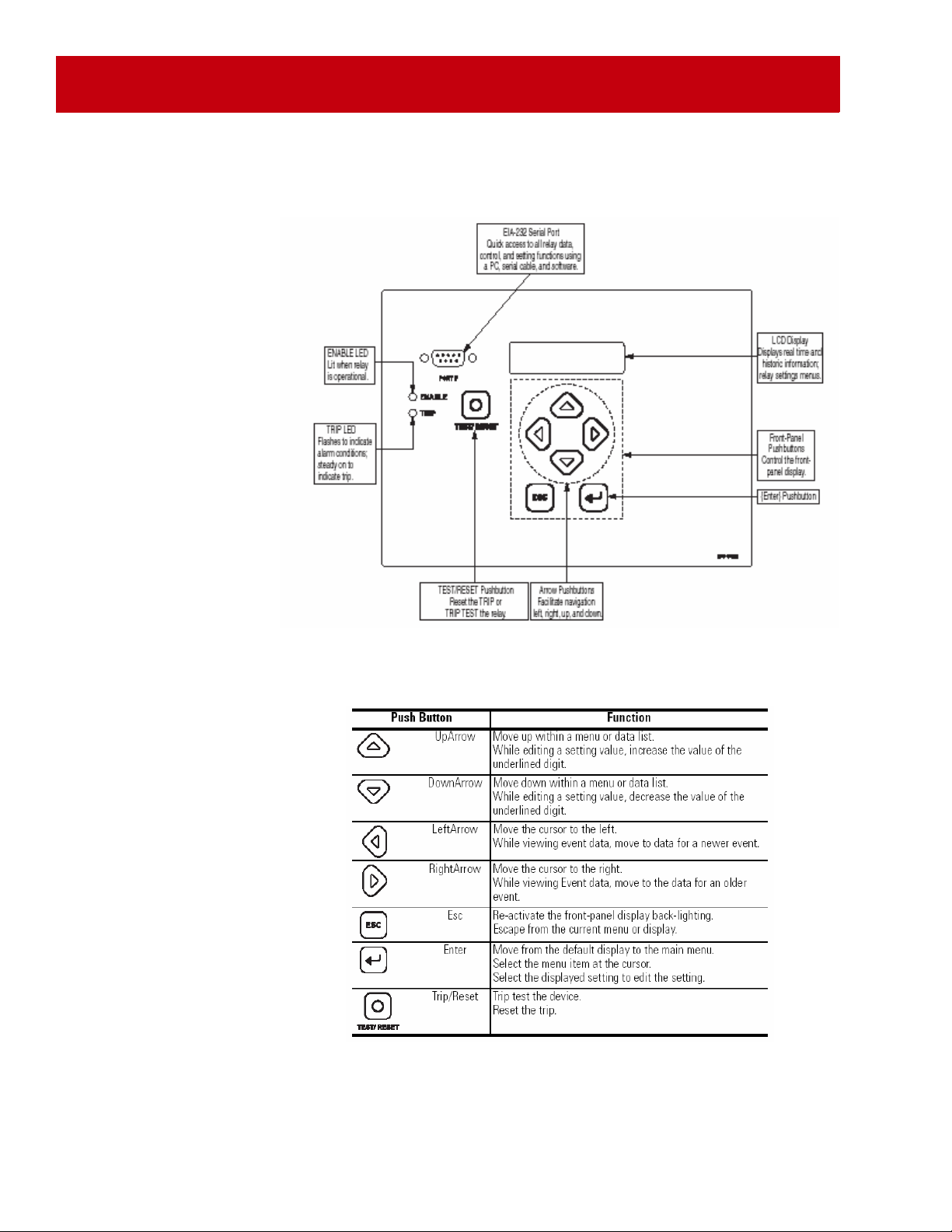

Front Panel

Operation

Figure 8 Relay Front Panel

The following table provides a description for each programming key’s function.

Table B: Front Panel Programming Key Description

10

Page 11

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Saving Settings

System

Configuration

It is important to note that programmed values become operational only after they

have been saved to memory. The programming system will prompt to save settings

when the user navigates higher up in the programming menu by pressing the ESCape

key. The front panel display is as follows:

Save Changes?

Y

es No

To save changes, place the cursor at “Yes” and press the Enter key.

The 825-P displays “STATUS FAILURE” on initial start-up and after a hardware

configuration change. The second line of the display identifies the cause of failure; if

more than one configuration change is found, the highest priority error is identified.

To remove the failure, the new system hardware configuration must be manually

accepted. Use the following procedure with the front panel programming keys:

1. Select “Status” from the MAIN menu and press the Enter key. The front

panel displays the following:

Confirm Hardware

Config (Enter)

2. Press the Enter key. The front panel displays the following:

Accept Config?

Yes No

3. Position the cursor at “Yes” and press the Enter key. The 825-P

programming system checks parameter settings to ensure that no

interdependency setting errors exist. If none exist, the front panel displays the

following:

Config Accepted

Enter to Restart

1111

Page 12

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

IMPORTANT

4. Press the Enter key. The 825-P reboots and the “Enable” LED

illuminates with the following displayed on the front panel.

If the system check finds interdependency setting errors,

the front panel display:

Settings Mismatch

An example of mismatched settings is the correlation

between the Motor FLA and Phase CT Ratio settings.

Review setting values to determine where the mismatch

exists or, if little or no programming has been performed

yet, reset the 825-P relay to factory default values using the

following path:

MAIN > Reboot/Restore > Restore Defaults

The front panel then displays:

Restore Default?

o Yes

N

Position the cursor at “Yes” and press the Enter key.

The 825-P relay will reboot at this point.

Return to the first step of the System Configuration

process.

825-P MODULAR

PROT SYSTEM

If the LCD display COMMFLT WARNING, configuration of the Port 4 is

required. See next section.

12

Page 13

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Port 4 Settings

The Port 4 settings configure slot C for communications. Factory default settings are

for DeviceNet communications. Use the following path with the front panel

programming keys to access the Port 4 settings:

MAIN > Set/Show > Port > Port 4

The following table provides direction for the proper settings associated with each

communication option.

Table C: Communication Settings

Setting Prompt Setting Range DeviceNet Modbus Empty

COMM INTERFACE

PROTOCOL ASC, MOD MOD MOD MOD

SPEED 300 … 38,400 bps 19,200 19,200 19,200

PARITY O, E, N N N N

MODBUS SLAVE ID 1 … 248 248 1 to 247 1

❶ A 232 setting is possible, although not typical.

IMPORTANT

❶ 232, 485 232 485 232

The 825-P displays “COMMFLT Warning” on initial

power-up with factory default settings when the hardware

installed in Slot C is as follows:

- Empty

- Modbus

- DeviceNet, but not powered

1313

Page 14

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Programming

General

Parameters

Use the following path with the front panel programming keys to access the general

parameter settings:

MAIN > Set/Show > Port

MAIN > Set/Show > Date/Time

MAIN > Set/Show > Password

Port: In addition to configuring Slot C (Port 4) for communications as described in

Step 4, settings are available for configuring the Port F (front panel) RS 232

communications. Port F is available for computer connection.

Date/Time: Program the date (day, month, year) and time (hour, minutes, seconds)

with the settings available here.

Password: The 825-P provides the ability to set password protection to limit access

to the programmable settings from the front panel. Password protection is disabled

from the factory.

See Appendix A for more details.

14

Page 15

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Programming

Operational

Parameters

Use the following path with the front panel programming keys to access the

operational parameter settings:

MAIN > Set/Show > Relay > [Group]

Table D: Operational Parameters

Group Description

Main Settings Basic system settings related to three-phase power source (e.g. line voltage

rating and frequency), motor rated current, and transformer (current and

voltage) data.

I/O Settings Settings related to configuration of the optional analog output.

Trip Inhibit Settings to configure the blocking of tripping functions. These settings

coordinate with assignment of a discrete input for “Block Protection”.

Relay Behavior Settings for configuring the output relays.

Timer Settings On-delay and off-delay timer settings for enhanced control capability of the

auxiliary output relays.

Front Panel Settings Settings for controlling the front panel LCD operation.

Display Settings Settings to select data that is displayed in the rotating status

See Appendix A for more details

1515

Page 16

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Programming

Protection

Parameters

Use the following path with the front panel programming keys to access the

protection parameter settings:

MAIN > Set/Show > Relay > [Group]

Table E: Protection Parameters

Group Description

Overload Settings Thermal overload

Short Ckt Settings Short circuit

GF-CB Settings Ground/earth fault (core balance method)

GF-Res Settings Ground/earth fault (residual method)

Jam Settings Mechanical jam (overcurrent)

Undercurrent Settings Current-based underload detection

Current Imb Settings Current imbalance (asymmetry)

Prot. Disable Settings to disable protection elements during motor starting for a

user-specified time period

Start Monitoring Stall protection on motor start (current-time based)

Star-Delta Settings Settings for star-delta control

Start Inhibt Set Settings for starts/hour and antibackspin

Phase Rev Settings Phase reversal (sequence)

Speed Sw Set Stall protection on motor start (speed switch input monitoring)

PTC Settings Thermistor monitoring

RTD Settings RTD settings for use with optional RTD Scanner

Undervoltage Settings Voltage monitoring with optional voltage input card

Overvoltage Settings Voltage monitoring with optional voltage input card

VAR Settings Reactive power

Underpower Settings Power-based underload detection

Power Factor Settings Displacement power factor monitoring

Freq Settings Line frequency monitoring

Load Control Settings Settings for relay control based on motor loading

Output Relay and

Input Assignments

16

See Appendix A for more details.

After the operational and protection parameter values are set, the next step is to

assign these functions to the relays.

Page 17

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

ATTENTION

Protection elements have no effect until they are assigned

to the Trip relay or an auxiliary relay.

!

To assign functions to the output relays and inputs, use the following path:

MAIN > Set/Show > IO Assign

TIP

The relay outputs will function as a N.C. contacts when the

relay behavior setting is Fail-Safe (Y), and will function as a

N.O. contacts when the relay behavior setting is Non-FailSafe (N).

1717

Page 18

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Trip Relay Assign

The 825-P allows mapping of only protection trip elements to the Trip output relay.

Settings are presented as bit-enumerated strings. The second line of the display

identifies a given bit’s associated function. To assign a function to the Trip relay,

simply program a value “1” in the bit location for each element you desire to assign

using the TRIP A through TRIP D settings. The front panel display appears as

follows:

TRIPA=1

0110000

OVERLOAD

Table F: Trip Relay Settings

Bit

01234567

TRIP A Overload Undercurrent Jam Current

Imbalance

TRIP B VAR Underpower Under-

voltage

TRIP C Start Time Freq 1 Freq 2 RTD (Other) RTD

TRIP D Comm Idle Comm Loss Remote Trip Comm Fault Reserved Reserved Reserved Reserved

TIP

Over-voltage Phase

Make sure the Trip relay terminals (95, 96 and 98) are

labeled to correspond with the relay behavior setting

Short Circuit RTD - W/B PTC Ground Fault

(Res)

Reversal

(Ambient)

Power Factor Speed

Switch

PTC Error RTD Error MCM Error

Ground Fault

(CB)

(Fail-Safe or Non-Fail-Safe).

18

Page 19

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

AUX# Assign

The 825-P allows mapping of protection (trip and warning) and general-purpose

control elements to the auxiliary outputs. Assign functions to the auxiliary relays in

the same manner as performed with the Trip relay settings.

Table G: Auxiliary Relay Functions

Bit

01 234567

AUX# A Overload Undercurrent Jam Current

Imbalance

AUX# B VAR Underpower Under-voltage Over-voltage Phase

AUX# C Start Time Freq 1 Freq 2 RTD (Other) RTD

AUX# D Comm Idle Comm Loss Remote Trip Comm Fault Reserved Reserved Reserved Reserved

AUX# E Overload

Warn

AUX# F VAR Warn Underpwr Warn Undervolt Warn Overvolt Warn Speed Sw

AUX# G RTD-Amb

Warn

AUX# H Stopped State Running State Starting State Star Starting

Undercurrent

Warn

Setting Warn General Warn Load Ctl Upper Load Ctl

Jam Warn Curr Imbal

Warn

State

Short Circuit RTD - W/B PTC Ground Fault

(Res)

Reversal

(Ambient)

RTD-W/B

Warn

Warn

Lower

Delta

Starting

State

Power Factor Speed

Switch

PTC Error RTD Error MCM Error

Pwr Factr Warn Gnd Flt-CB

Warn

Freq 1 Warn Freq 2 Warn RTD-Othr

Timer 1 Timer 2 Short Ckt

Start Command Network

Control

Ground Fault

(CB)

Gnd Flt-Res

Warn

Warn

Warn

Reserved

TIP

The AUX# A through AUX# D bytes are used to map trip

functions to the output. The AUX# E through AUX# H

bytes are used to map warning and status functions to the

output.

1919

Page 20

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

IN# Assign

The 825-P provides the ability to assign a control function to each discreet input.

Table H shows the available control functions and the method of assigning them.

Table H: Input Function Assignment

IN#

0 Emergency Start

1 Disable Settings

2 Trip Reset

3 Timer 1

4 Timer 2

5 Speed Switch

6 Block Protection

7 Speed 2

0 Breaker/Contactor Auxiliary

1 Remote Trip

TIP

The 825-P allows only one selection per input assignment.

Once a selection is assigned, it is not available to other

inputs.

Analog Output

The expansion I/O option provides an isolated 4…20mA DC analog current output

with a variety of output parameters. Use the Analog Output Select setting to select a

parameter from the list of available options. Table I shows description and scaling of

the output for different parameters selections.

Table I:

20

Page 21

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Appendix A:

Menu Structure

Figure 12 Menu Structure

Instantaneous

Thermal

See Fig. 13 for more details.

Motor Use Data

IMPORTANT

Visibility of some settings depends upon the system

hardware configuration. For example, RTD settings are

viewable only when the optional RTD Scanner is

connected and communicating with the 825-P relay.

Power Up

or

Steps back one level

Main Menu

or

Meter

Display Events

Events

See Fig. 14 for more details

Reset Events

Reset Statistics

See Fig. 15 for more details

Motor Monitor

Targets

Relay

Port Row 6

IO Assign Row 7

Date/Time Row 8

Password Row 9

See Fig. 17, 18 & 19 for more details Row 10

Show/Set

See Fig. 16 for more details.

Status

Row 1

Row 2

Row 3

Row 4

Row 5

See Fig. 20

Reset TCU

Reboot Relay

Restore Default

Reboot/Restore

Reset Access Lvl

Front-Panel Access Lvl

Reset

2121

Page 22

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 13 Main Menu > Meter

Meter Steps back one level

Instantaneous

L1 Curent

L1 Angle

L2 Current

L2 Angle

L3 Current

L3 Angle

GF Curr (Core B)

GF-CB Angle

GF Curr (Resid.)

GF-RES Angle

Average Current

Motor Load

Current Imbalance

VAB

VAB Angle

VBC

VBC Angle

VCA

VCA Angle

Average Line

Voltage Imbal.

Real Power

Reactive Power

Apparent Power

Power Factor

Frequency

22

Page 23

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 13 Main Menu > Meter

Meter Steps back one level

Thermal

Max Winding RTD

Max Bearing RTD

Ambient RTD

Max Other RTD

RTD1

RTD2

RTD3

RTD4

RTD5

RTD6

RTD7

RTD8

RTD9

RTD10

RTD11

RTD12

Motor Load

Therm Cap Used

RTD %TCU Used

Thermal Trip In

Time to Reset

2323

Page 24

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 14 Main Menu > Events

Events Steps back one level

Display Events

Date

Time

Type

Locked Rotor Torque

L1 Current

L2 Current

L3 Current

RES

CB

VAB

VBC

VCA

VG

Reset Events

24

Page 25

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 15 Main Menu > Motor Monitor

Motor

Monitor

Last Reset Date

Last Reset Time

Running Time

Stopped Time

Time Running

Number of Starts

Emergency Starts

Steps back one level

Motor Use Data

Reset Statistics

2525

Page 26

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 16 Main Menu > Targets Targets

Row 1 Row 6

49T (Overload Trip) VARA (VAR Warning)

LOSSTRIP (Undercurrent Trip)

JAMTRIP (Jam Trip)

49UBT (Current Imbalance Trip)

50P1T (Short Circuit Trip)

RTDT (RTD (Widing/Bearing) Trip)

PTCTRIP (PTC Trip)

50G1T (Ground Fault (Residual) Trip)

37PA (Underpower Warning)

27P2T (Undervoltage Warning)

59P2T (Overvoltage Warning)

SPDSAL (Speed Switch Warning)

81D1A (Frequency 1 Warning)

81D2A (Frequency 2 Warning)

OTHALRM (RTD (Other) Warning)

Row 2 Row 7

VART (VAR Trip) AMBALRM (RTD (Ambient) Warning)

37PT (Underpower Trip)

27P1T (Undervoltage Trip)

59P1T (Overvoltage Trip)

47T (Phase Reversal Trip)

55T (Power Factor Trip)

SPDSTR (Speed Switch Trip)

50N1T (Ground Fault (Core Balance) Trip)

SALARM (Setting Warning)

WARNING (General Warning)

LOADUP (Load Control (Upper))

LOADLOW (Load Control (Lower))

TIMER1T (Timer 1)

TIMER2T (Timer 2)

50P2T (Short Circuit Warning)

Row 31 Row 8

SMTRIP (Start Time Trip) STOPPED (Stopped State)

81D1T (Frequency 1 Trip)

81D2T (Frequency 2 Trip)

OTHTRIP (RTD (Other) Trip)

AMBTRIP (RTD (Ambient) Trip)

PTCFLT (PTC Error Trip)

RTDFLT (RTD Error Trip)

MCMFLT (MCM Error Trip)

RUNNING (Running State)

STARTING (Starting State)

STAR (Star (Wye) Starting State)

DELTA (Delta Starting State)

START (Start Command)

Reserved

Reserved

Row 4 Row 9

COMMIDLE (Comm Idle Trip) IN1 (Input 1 State)

COMMLOSS (Comm Loss Trip)

REMTRIP (Remote Trip)

COMMFLT (Comm Fault Trip)

Reserved

Reserved

Reserved

Reserved

IN2 (Input 2 State)

IN3 (Input 3 State)

IN4 (Input 4 State)

IN5 (Input 5 State)

Reserved

Reserved

Reserved

Row 5 Row 10

49A (Overload Warning) TRIP (Trip Relay State)

LOSSALRM (Undercurrent Warning)

JAMALRM (Jam Warning)

46UBA (Current Imbalance Warning)

RTDA (RTD (Winding/Bearing) Warning)

55A (Power Factor Warning)

50N2T (Ground Fault (Core Balance) Warning)

50G2T (Ground Fault (Core Balance) Warning)

AUX1 (Auxiliary Relay 1 State)

AUX2 (Auxiliary Relay 2 State)

AUX3 (Auxiliary Relay 3 State)

AUX4 (Auxiliary Relay 4 State)

AUX5 (Auxiliary Relay 5 State)

AUX6 (Auxiliary Relay 6 State)

Reserved

Steps back one level

26

Page 27

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 17 Main Menu > Show/Set

Show/Set Steps back one level

RELAY

PORT Main Settings

Overload Set

IO ASSIGN Short Ckt Set

TRIP RELAY ASSIGN GF-CB Settings

AUX1 ASSIGN GF-Res Settings

AUX2 ASSIGN Jam Settings

AUX3 ASSIGN Undercurrent Set

AUX4 ASSIGN Current Imb Set

IN1 ASSIGN Prot. Disable

IN2 ASSIGN Start Monitoring

Star-Delta Set

DATE/TIME Start Inhibt Set

DATE Speed Sw Set

TIME PTC Setting

RTD Setting

PASSWORD Undervoltage Set

New PW Overvoltage Set

VAR Settings

Underpower Set

Power Factor Set

Freq Settings

Phase Rev Set

Load Control Set

I/O Settings

Trip Inhibit

Relay Behavior

Timer Settings

Front Panel Set

Display Set

2727

Page 28

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 17 Main Menu > Show/Set

Port Steps back one level

PORT F

SPEED

DATA BITS

PARITY

STOP BITS

PORT TIMEOUT

HDWR HAND SHAKING

PORT 4

COMM INTERFACE

PROTOCOL

SPEED

PARITY

MODBUS SLAVE ID

28

Page 29

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 18 Main Menu > Show/Set > Relay Relay Steps back one level

Main Settings GF-Res Settings RTD Settings

UNIT ID LINE 1 GF-RES TRIP LEVL RTD ENABLE

UNIT ID LINE 2 GF-RES TRIP DLAY RTD RESET MODE

PHASE ROTATION GF-RES WARN LEVL RTD1 LOCATION

RATED FREQ. GF-RES WARN DLAY RTD1 TYPE

DATE FORMAT

PHASE CT RATIO JAM TRIP LEVEL RTD1 WARN LEVEL

MOTOR FLA JAM TRIP DELAY RTD2 LOCATION

TWO SPEED ENABLE JAM WARN LEVEL RTD2 TYPE

nd

CT RATIO-2

MOTOR FLA-2

CORE B. CT RATIO UC TRIP LEVEL RTD3 LOCATION

PHASE VT RATIO UC TRIP DELAY RTD3 TYPE

LINE VOLTAGE UC WARN LEVEL RT D3 TRIP LEVEL

XFMER CONNECTION UC WARN DELAY RTD3 WARN LEVEL

nd

Overload Set

OVERLOAD ENABLE

OL RESET MODE CI TRIL LEVEL RTD4 TRIP LEVEL

OL RESET LEVEL CI TRIL DELAY RT D4 WARN LEVE L

SERVICE FACTOR CI WARN DELAY RTD5 LOCATI ON

MOTOR LRC CI WARN DELAY RTD5 TYPE

LOCKD ROTOR TIME

ACCEL RACTOR PROT INHIBT TIME RTD5 WARN LEVEL

RUN STATE TIME K OL INHIBT TIME RTD6 LOCATION

MOTOR LRC-2

MOTOR LRT-2

ACCEL FACT-2

RUN ST TC-2

OL WARN LEVEL MAX STAR TIME RTD7 TYPE

START INH. LEVEL

STOP COOL TIME STARTS/HR. RTD7 WARN LEVEL

OL RTD BIASING? MIN. OFF TIME RTD8 LOCATION

nd

nd

nd

nd

Short Ckt Set

SC TRIP LEVEL

SC TRIP DELAY SS TRIP DELAY RTD8 WARN LEVEL

SC WARN LEVEL

SC WARN LEVEL

GF-CB Setting

GF-CB TRIP LEVEL PTC RESET MODE RTD9 WARN LEVEL

GF-CB TRIP DELAY RTD10 LOCATION

GF-CB WARN LEVEL

GF-CB WARN DELAY

Jam Settings

JAM WARN DELAY RTD2 TRIP LEVEL

Undercurrent Set

UC START INHIBIT RTD4 LOCATION

Current Imb Set

Prot. Disable

Start Monitoring

START MOTOR TIME RTD6 TRIP LEVEL

Start-Delta Set

STAR-DELTA ENABL RTD7 LOCATION

Start Inhibt

RESTART BLK TIME RTD8 TYPE

Speed Sw Set

SS WARN DELAY RTD9 LOCATION

PTC Setting

PTC ENABLE RTD9 TRI P LEVEL

RTD1 TRIP LEVEL

RTD2 WARN LEVEL

RTD4 TYPE

RTD5 TRIP LEVEL

RTD6 TYPE

RTD6 WARN LEVEL

RTD7 TRIP LEVEL

RTD8 TRIP LEVEL

RTD9 TYPE

RTD10 TYPE

RTD10 TRIP LEVEL

RTD10 WARN LEVEL

RTD11 LOCATION

RTD11 TYPE

RTD11 TRIP LEVEL

RTD11 WARN LEVEL

RTD12 LOCATION

RTD12 TYPE

RTD12 TRIP LEVEL

RTD12 WARN LEVEL

WIND TRIL VOTING

BEAR TRIP VOTING

TMP RTD BIASING?

2929

Page 30

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 19 Main Menu > Show/Set >

Relay Cont’d

Relay Cont’d

Undervoltage Set Load Control Set

UV TRIP LEVEL LOAD CONTROL SEL

UV TRIP DELAY

UV WARN LEVEL

UV WARN DELAY

Overvoltage Set

OV TRIP LEVEL

OV TRIP DELAY

OV WARN LEVEL

OV WARN DELAY ANALOG OG OUT SEL

LD CTL CUR UPPER

LD CTL CUR LOWER

LD CTL PWR UPPER

LD CTL PWR LOWER

LD CTL TCU UPPER

LC CTL TCU LOWER

I/O Settings

VAR Setting Trip Inhibit

NEG VAR TRIP CURRENT INBALANC

POS BAR TRIP

VAR TRIP DELAY

NEG VAR WARN LEV

PAS VAR WARN LEV

VAR WARN DELAY

Underpower Set

UP TRIP LEVEL

UP TRIP DELAY

UP WARN LEVEL TRIP FAIL-SAFE

UP WARN DELAY

Power Factor Set

PF LAG TRIP LEVEL

PF LD TRIP LEVEL

PF TRIP DELAY

PF LAG WARN LEVEL

PF LD WARN LEVEL

PF WARN DELAY ON DELAY T1

Freq Settings

FREQ1 TRIP LEVEL

FREQ1 TRIP DELAY

FREQ1 WARN LEVEL

FREQ1 WARN DELAY LCD TIMEOUT

FREQ2 TRIP LEVEL

FREQ2 TRIP DELAY

FREQ2 WARN LEVEL TIME & DATE

FREQ2 WARN DELAY

Phase Rev Set

PH REV. ENABLE

JAM

GROUND FAULT

SHORT CIRCUIT

UNDERCURRENT

START INHIBIT

PTC

RTD

Relay Behavior

AUX1 FAIL-SAFE

AUX2 FAIL-SAFE

AUX3 FAIL-SAFE

AUX4 FAIL-SAFE

AUX5 FAIL-SAFE

AUX6 FAIL-SAFE

Timer Settings

OFF DELAY T1

ON DELAY T2

OFF DELAY T2

Front Panel Set

LCD CONTRAST

Display Set

GROUND CURRENT

CURRENT IMBALANC

FREQUENCY

THERM CAP USED

VOLTAGE IMBALANC

POWER

RTD TEMPERATURE

Steps back one

level

30

Page 31

Quick Start Guide — Allen-Bradley Bulletin 825-P Modular Protection System

Figure 20 Main Menu > Status

Status Steps back one level

Definition

FID Firmware identifier string

CID Firmware checksum identifier

Identity Code Relay configuration identification

L1

L2

L3

RES

CB

VA

VB

VC

PS_Vdc Power supply status

FPGA FPGA programming unsuccessful, or FPGA failed

GPSB General Purpose Serial Bus

HMI Front-Panel FGPA programming unsuccessful, or Front-Panel FPGA failed

RAM Volatile memory integrity

ROM Firmware integrity

CR_RAM Integrity of settings in RAM and code that runs in RAM

Non_Vol Integrity of data stored in nonvolatile memory

Clk_Bat Clock battery integrity

Clock Clock functionality

PTC Integrity of PTC

RTD Integrity of RTD module/communications

MCM/CWE Integrity of current board and MCM/CWE

Voltage Integrity of voltage board

I/O_Crd Integrity of I/O card

Com_Crd Integrity of DeviceNet card and network

MAC_ID DevineNet card specific card identification

ASA Manufacturer identifier for DevieNet

DN_Rate DeviceNet card network communications data speed

DN_Status DeviceNet connection and fault status

Relay Enabled

DC offset in hardware circuits of current channels

DC offset in hardware circuits of voltage channels

3131

Page 32

Publication 825-QS001A-EN-P - August 2004

© 2004 Rockwell International. All Rights Reserved. Printed in USA

Loading...

Loading...