Page 1

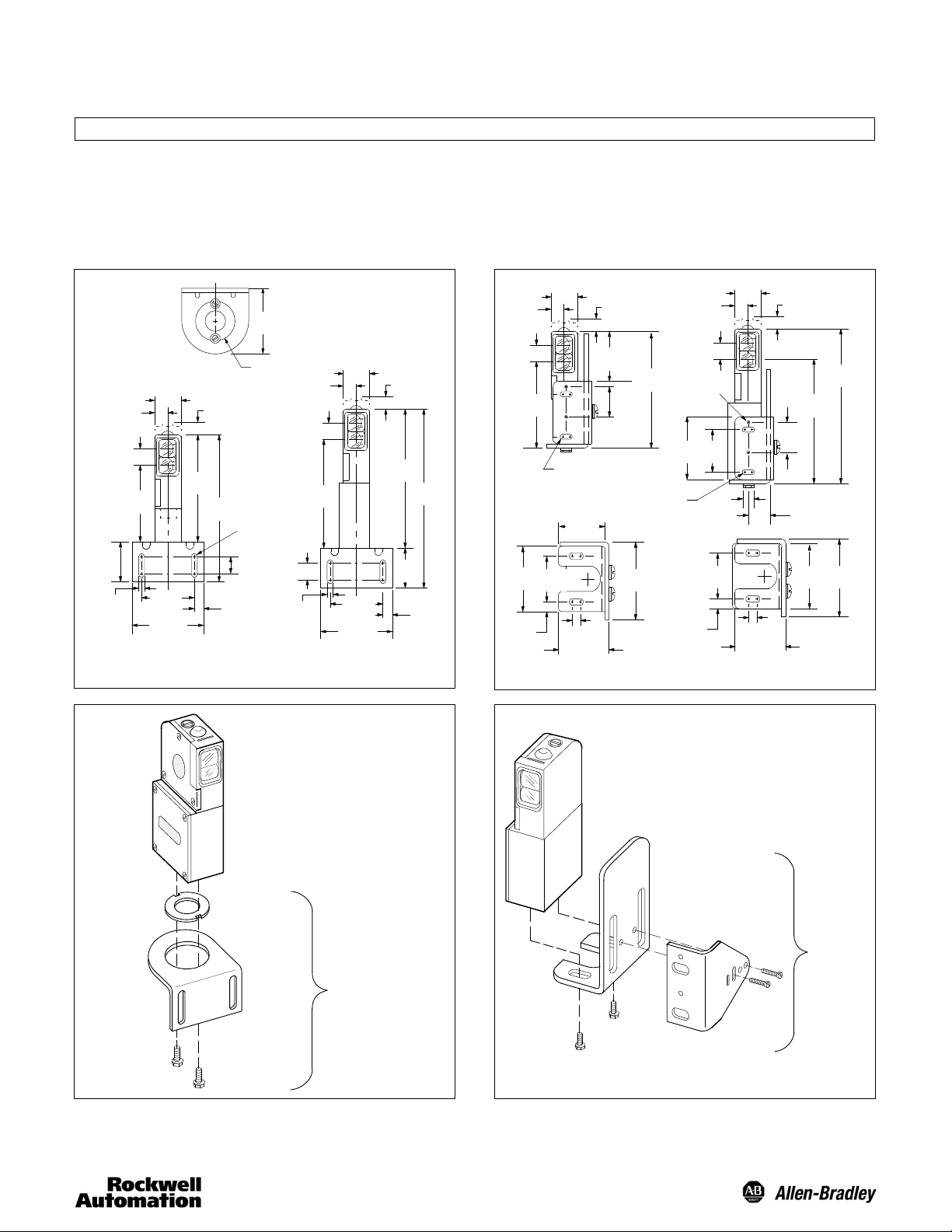

INSTALLATION INSTRUCTIONS PHOTOSWITCH

MOUNTING ASSEMBLIES FOR SERIES 5000 CONTROLS

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

GENERAL PURPOSEMOUNTINGASSEMBLY #60-1785

#60-1785 provides the most flexible means of base mounting

for the Series 5000 Control in most industrial environments. The

unique combination of mounting bracket and inner ring allows

vertical and 360

o

horizontal adjustment for mounting and align

ing the Series 5000 Control.

MATERIAL

#11 GA CRS

0.953

(24.2)

0.469

(11.9)

0.609

(15.4)

4.0

(50.8)

2656

(67.5)

(101.6)

(138.1)

2

1.703

(43.26)

0.280

(7.10)

2875

(73.0)

Control with CableBase Control with TerminalBase

0.344

(8.73)

5.438

0.325

(8.26)

2.89

(73.42)

1.75 (44.5) DIA.

CLEARANCEFOR

#1/4-20 HDW

0.75

(19.0)

0.75

(19.0)

0.609

(15.4)

0.280

(7.10)

.469

(11.9)

4.25

(106.5)

0.953

(24.2)

(50.8)

2.656

(67.5)

0.344

(8.73)

5.39

(136.9)

7.03

(178.59)

1.688

(42.9)

2

0.325

(8.26)

HEAVY DUTYMOUNTING ASSEMBLY #60-1748

#60-1748 HeavyDutyMountingAssemblyisrecommended

for installations where vibration and shock‐prone environments

require special mountings for control protection. The Heavy Duty

Mounting Assembly secures the control at two points and still pro

vides easy access for wiring, vertical adjustment, and tilt.

0.469

(11.9)

1.25

(31.7)

0.25

(6.3)

1.50

(38.1)

0.953

(24.2)

0.25 (6.3)

1.438

(61.9)

0.344

(8.73)

(25.4)

1

0.891

(23.4)

4.344

(110.3)

2.156

(54.7)

5.75

(146.4)

2.50

(63.5)

0.953

0.609

(15.4)

0.469

(11.9)

2.156

(54.7)

0.328

(8.3)

2.844

(72.3)

1.50

(38.1)

(24.2)

CLEARANCE FOR

#10‐32 HDW

1.50

(38.1)

0.25 (6.3)

1.438

(61.9)

1.828

(46.43)

0.344

(8.73)

(25.4)

1

4.109

(104.4)

CLEARANCE FOR

#10‐32HDW

2.50

(63.5)

2.156

(54.7)

0.609

(15.4)

#10‐32

THREAD

2HOLES

0.328

(8.3)

Control with CableBase Control withTerminal Base

Series 5000 Control

Washer

Bracket

Whizlock Bolts

ExplodedView

of #60-1785

Bracket

Series 5000 Control

Exploded View

of

#60-1748

Mounting

Truss

Assembly

Head

Whizlock Bolts

Screws

1

Page 2

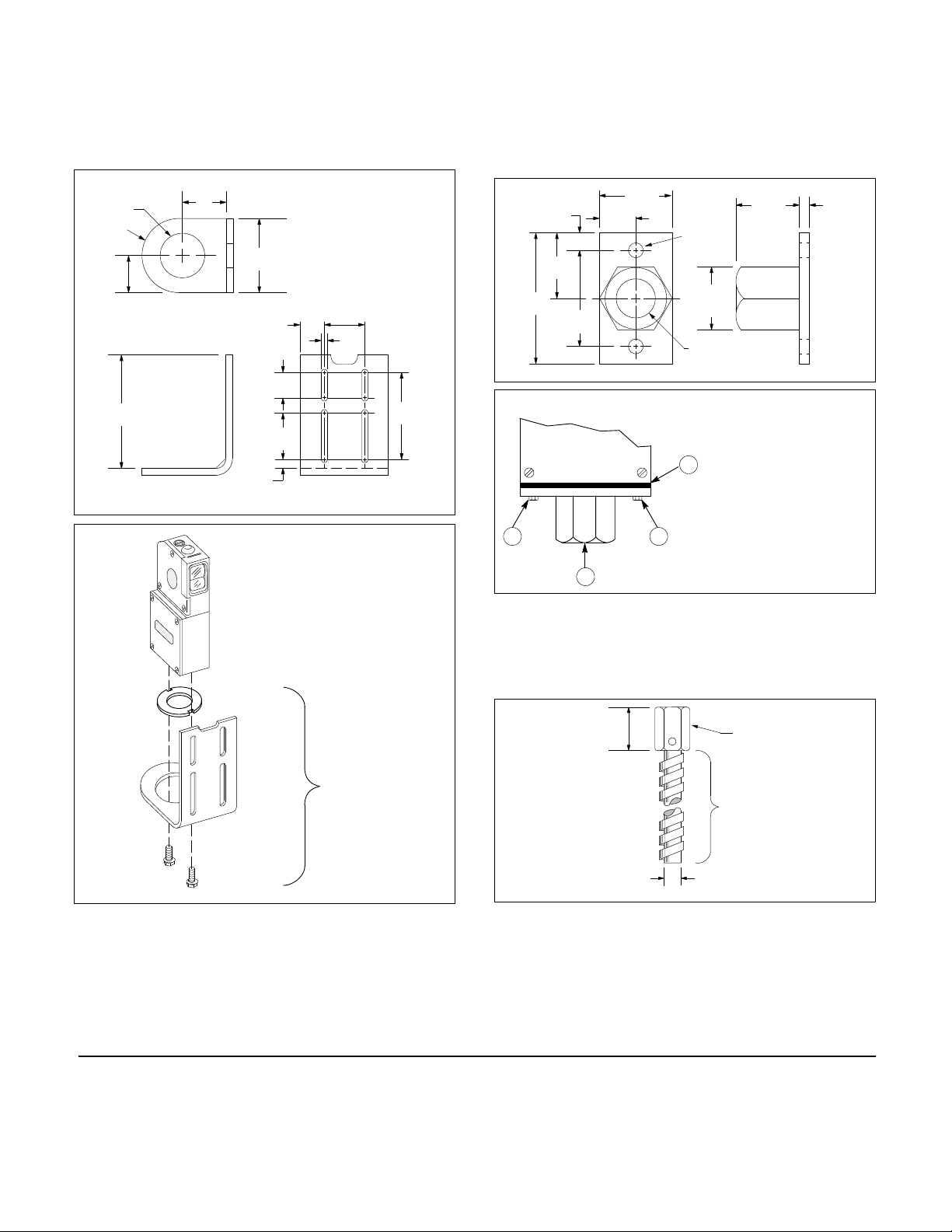

LIMITSWITCH TYPE MOUNTING ASSEMBLY #60-2230

#60-2230 Limit Switch Type Mounting Bracket combines the

possibility of mounting the bracket using standard limits with

mounting holes with a 360

o

horizontal adjustment for aligning

the Series 5000 Control.

1.450

FULLRAD.

1.720 DIA.

(44)

1.325

(34)

4.000

(102)

(37)

2.650

(67)

1.180

(30)

0.225

(6)

3.220

(82)

0.375

(4.5)

0.735

(19)

0.850

(21)

1.935

(49)

CONDUIT MOUNTING ADAPTOR #60- 2213

#60-2213 Conduit Mounting Adaptor is recommended for in

stallation where the controls will be mounted directly on 1/2

‐

inch

conduit. Two Whiz Lock type screws secure the control to the

adaptor while the gasket between the control and adaptor main

tain the NEMA 4 rating.

0.325

(8.3)

1.075

(27.3)

2.150

(54.6)

1.500

(38.1)

InstallationInstructions

3

0.560

(14.2)

1.120

(28.4)

0.220 DIA.

2PLCS.(5.6)

1.00 HEX.

REF.

(25.4)

1/2‐14 NPT

1. Mount gasket (item 2)and

2

2. Caution: Usewrench on hex flats

3

1.000

(25.4)

0.120

(3.0)

conduit adaptor (item1) to

terminal base withtwo (2)screws

(item 3) providedwith power base.

(item 1) only.When mounting to con

duit, do nottwist mounting flangeor

twist power base.

Series 5000 Control

Washer

Bracket

WhizlockBolts

Exploded View

of #60-2230

Bracket

1

ARMOURED CABLE ADAPTOR #60-1577

#60-1577 Armoured Cable Adaptor is recommended for use

with all Series 5000 CableBase where protection against mechani

cal damage to the PVC cable is required. 10 ft. (3m) of armoured

cable is supplied.

1.06

(27)

0.438

(11.1)

HEX NUT

0.687 (17.45)

ACROSS FLATS

10 FT. (3m)

FLEXIBLE

CONDUIT

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel : (1) 414.382.2000, Fax : (1) 414.382.4444

Europe/Middle East/Africa : Rockwell Automation, Vorstlaan/Boulevard du Souverain 36, 1170 Brussels, Belgium, Tel : (32) 2 663 0600, Fax (32) 2 663 0640

Paci c : Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel : (852) 2887 4788, Fax : (852) 2508 1846

Asia

2

Publication PA-8310(C)

October 1991

Loading...

Loading...