Page 1

User Manual

PowerFlex® 6000 Medium Voltage Variable Frequency Drive

Publication 6000-UM001B-EN-P

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Introduction

Drive System Layout

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

What Is Not in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Commissioning Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cascaded “H” Bridge (CHB) Topology . . . . . . . . . . . . . . . . . . . . . . . . 10

Simplified Electrical Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Standards Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Elevation Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Isolation Transformer Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Isolation Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Isolation Transformer Temperature Monitor . . . . . . . . . . . . . . . . . . . 21

Isolation Transformer Auxiliary Cooling Fans . . . . . . . . . . . . . . . . . . 22

Top-mounted Main Cooling Fan(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Incoming Line Power Cable Connections . . . . . . . . . . . . . . . . . . . . . . 22

Outgoing Motor Cable Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Door Position Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Voltage Sensing Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power Module Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Power Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Hall Effect Current Sensors (HECs) . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Top-mounted Main Cooling Fan(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

LV Control Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Control Unit (all modules). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

PLC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

UPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setup and Operation

Chapter 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Main Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Drive Setup and Configuration Controls . . . . . . . . . . . . . . . . . . . . . . . 34

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Operation Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Setup and Monitor Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 3

Page 4

Table of Contents

Main Interface Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Set Frequency (Hz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Drive Operation Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

View Version Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Alarm History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Trends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

View Voltage, Current or Frequency Trends . . . . . . . . . . . . . . . . . . . . 42

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Confirm Bypass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Choose Local/Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Open/Close Drive Input and Output Contactors . . . . . . . . . . . . . . . 46

Open/Close Bypass Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

User Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Change User Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setup Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

View/Change P or T Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Restore “P” or “T” Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Parameters and Function Codes

Preventative Maintenance and

Component Replacement

Chapter 4

P Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

T Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Alarm List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Chapter 5

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Regular Maintenance Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Physical Checks (No Medium Voltage or Control Power) . . . . . . . . . . . 79

Power Connection Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Physical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Medium Voltage Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Maintenance after a Fault Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Final Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Isolation Transformer Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Replace/Clean Door Mounted Air Filters. . . . . . . . . . . . . . . . . . . . . . . 81

Inspect Top Mounted Main Cooling Fans . . . . . . . . . . . . . . . . . . . . . . 82

Replace Top Mounted Main Cooling Fans. . . . . . . . . . . . . . . . . . . . . . 83

Fan Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Inspect Isolation Transformer Auxiliary Cooling Fans . . . . . . . . . . . 85

Replace Isolation Transformer Auxiliary Cooling Fans. . . . . . . . . . . 86

Inspect Isolation Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Inspect Voltage Sensing Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 5

Table of Contents

Replace Voltage Sensing Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Inspect Door Position Limit Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Replace Door Position Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Power Module Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Inspect, Clean, or Replace Door Mounted Air Filters. . . . . . . . . . . . 90

Inspect or Replace Top Mounted Main Cooling Fans . . . . . . . . . . . 90

Inspect Power Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Replace Power Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Replace Power Module Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Inspect or Replace HECS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Inspect or Replace Door Position Limit Switch . . . . . . . . . . . . . . . . 100

LV Control Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Inspect AC/DC Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Replace AC/DC Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Inspect UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Replace UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Replace UPS Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Inspect PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Inspect/Replace Control Unit or Control Boards . . . . . . . . . . . . . . 108

Inspect the HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Replace the HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Replace LV Control Relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Replace LV Control Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . 114

Inspect Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Inspect Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Inspect Pilot Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Inspect Locking and Interlocking Devices . . . . . . . . . . . . . . . . . . . . . 116

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Inspect LV Component Terminal and Plug-in Connections . . . . 117

Inspect Medium Voltage Cable Connections . . . . . . . . . . . . . . . . . . 117

Inspect Power Cable and Control Wire Terminals . . . . . . . . . . . . . 117

Inspect Transformer Secondary Windings. . . . . . . . . . . . . . . . . . . . . 117

Inspect Power Module Input and Output Power Connections . . 118

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Review Firmware and Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Inspect/Review Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Technical Specifications

Catalog Number Explanation

Preventative Maintenance Schedule

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 5

Appendix A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Appendix C

PowerFlex 6000 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Page 6

Table of Contents

Appendix D

Spare Parts

Torque Requirements

Index

Spare Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Appendix E

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

6 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 7

Preface

Introduction

Who Should Use This Manual

What Is Not in This Manual

This document provides procedural information for managing daily or recurring

tasks involving PowerFlex 6000 medium voltage variable frequency drives.

This manual is intended for use by personnel familiar with operating medium

voltage and solid-state variable speed drive equipment. The manual contains

material that enables operation and regular maintenance of the drive system.

This manual provides information specific to maintaining the PowerFlex 6000

medium voltage variable frequency drive. It does not include topics such as:

• Dimensional and electrical drawings generated for each customer’s order

• Spare parts lists compiled for each customer’s order

Please refer to the following documents for additional product detail or

instruction relating to PowerFlex 6000 drives:

• PowerFlex 6000 Medium Voltage Variable Frequency Drive Shipping,

Handling, and Installation Instructions (6000-IN006_-EN-P

document provides procedural information for physically unloading,

moving, and installing PowerFlex 6000 medium voltage drives.

• PowerFlex 6000 Medium Voltage Variable Frequency Drive

Commissioning Manual (6000-IN007_-EN-P

information for commissioning PowerFlex 6000 medium voltage drives.

). This document provides

). This

Additional Resources

Rockwell Automation provides the site- and installation-specific electrical and

design information for each drive during the order process cycle. If they are not

available on site with the drive, contact Rockwell Automation.

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and

You can view or download publications at

http:/www.rockwellautomation.com/literature/

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Provides general guidelines for installing a Rockwell

Automation industrial system.

other certification details.

. To order paper copies of

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 7

Page 8

Preface

General Precautions

Service and Support

ATT EN TI ON : This drive contains ESD (Electrostatic Discharge) sensitive parts

and assemblies. Static control precautions are required when installing, testing,

servicing or repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with static control

procedures, reference Allen-Bradley publication 8000-4.5.2, “Guarding Against

Electrostatic Damage” or any other applicable ESD protection handbook.

ATT EN TI ON : An incorrectly applied or installed drive can result in component

damage or a reduction in product life. Wiring or application errors, such as,

undersizing the motor, incorrect or inadequate AC supply, or excessive ambient

temperatures may result in malfunction of the system.

ATT EN TI ON : Only personnel familiar with the PowerFlex 6000 Adjustable

Speed Drive (ASD) and associated machinery should plan or implement the

installation, start-up and subsequent maintenance of the system. Failure to

comply may result in personal injury and/or equipment damage.

Commissioning Support

After installation, Rockwell Automation is responsible for commissioning

activities for the PowerFlex 6000 product line. Contact your local Rockwell

Automation sales representative to arrange commissioning.

Rockwell Automation support includes, but is not limited to:

• quoting and managing product on-site start-ups

• quoting and managing field modification projects

• quoting and managing customer in-house and on-site product training

The user or its representatives are responsible for pre-commissioning activities to

prepare the drive for commissioning. Failure to complete these activities prior to

the commissioning process will delay the start-up of the drive. Please refer to the

Pre-commissioning Checklist in the PowerFlex 6000 Medium Voltage Variable

Frequency Drive Shipping, Handling, and Installation Instructions

(6000-IN006_-EN-P

).

8 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 9

Chapter 1

Introduction

Around the world, Allen-Bradley® PowerFlex® medium voltage drives from

Rockwell Automation have built a reputation for providing efficient and reliable

motor control for industry's most demanding applications. From the hardware

designed to help optimize production to the power of networked control

platforms, users can quickly and easily gain access to valuable information from

their systems. Better information leads to higher asset availability, reduced energ y

and maintenance costs, and asset and personnel protection - all resulting in an

increased return on your investment and real bottom-line savings. No matter

where your applications are located - and whether your requirements are simple

or complex, count on PowerFlex medium voltage drives for the optimal solution.

Safety Considerations

SHOCK HAZARD: Energized industrial control equipment can be dangerous.

Severe injury or death can result from electrical shock, burn, or unintended

actuation of control equipment. Hazardous voltages may exist in the drive

cabinet even with the input circuit breaker in the off position. If it is necessary

to work in the vicinity of energized equipment, the safety related work

practices outlined in Electrical Safety requirements for Employee Work places

must be followed. Before attempting any work, verify the system has been

locked out and tested to have no potential.

Lockout and tagout the device feeding power to the input of the drive before

performing any drive maintenance or component replacements. After the input

device cabinet doors are opened, immediately test the outgoing power cables

feeding the drive with a live-line tool (hot stick) while wearing high voltage

gloves. Repeat the live-line tool (hot stick) testing at the drive incoming line

power cable connections to verify that medium voltage is not present. Pay special

attention to any capacitors connected to medium voltage that can retain a charge

for a period of time. Only after the drive equipment has been verified as isolated

and de-energized can subsequent work be performed. Even though the input to

the drive may be open, it is still possible for hazardous voltage to be present.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 9

Page 10

Chapter 1 Introduction

Refer to national and local safety guidelines for detailed procedures on how to

safely isolate the equipment from hazards.

ATT EN TI ON : The national and local electrical codes outline provisions for safely

installing and working on electrical equipment. Installation must comply with

specifications regarding wire type, conductor sizes, branch circuit protection

and disconnect devices. Failure to do so may result in personal injury and/or

equipment damage.

Environmental Conditions

How it Works

• Elevation above sea level must be less than 1000 m (3250 ft)

• Ambient air temperature must be between 0...40°C (32...104°F)

(1)

.

(2)

.

• Relative humidity must be less than 90%, non-condensing.

• The drive must be installed indoors; there must be no dripping water or

other fluids in the room.

• Cooling air must be clean without significant concentrations of sand,

corrosive or conductive dust (defined by IEC 721-1 as being less than

0.2 mg/m

of dust), or explosive gas.

• Free from significant vibration.

• The drive must be anchored on a level floor. Please refer to the dimension

drawing for the anchor point sizes and locations.

For the equipment to operate in conditions other than those specified, consult

the local Rockwell Automation Sales Office.

Cascaded “H” Bridge (CHB) Topology

The proven CHB topology combines an integrally mounted phase shifting

isolation transformer and series-connected power modules for each phase. In

addition to stepping down the input voltage, the isolation transformer also

provides two other principal functions:

• Mitigate common mode voltage stress so motors with standard insulation

levels can be used.

• Reduce Total Harmonic Distortion (THD), due to the phase shifting of

its secondary windings, so input side harmonics don’t negatively impact

the plant or utility power grid.

(1) Options are available for operation up to 3000 m.a.s.l. However, these must be stated at the time of order and cannot be retrofitte d

in the field.

(2) Options are available for ambient temperatures up to 50 ºC. However, these must be stated at the time of order and cannot be

retrofitted in the field.

10 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 11

Introduction Chapter 1

Input Power

3 Phase AC

Power Modules

Isolation

Transformer

A number of identical low voltage power modules are series-connected

(cascaded) together to produce the medium voltage levels required to operate the

motor.

The voltage step for each module is relatively small and a Pulse Width

Modulation (PWM) switching pattern is used so output harmonics and torque

pulsations at the motor are minimal, even at lower speeds. This technology is

very motor friendly so standard motors can be used for new applications and it

also is ideal for retrofitting existing motors. This also allows for the motor cable

lengths required for most applications, without the requirement for output

filtering.

This power module concept makes maintenance quick and easy. Each module has

powerful built in diagnostics to identify and isolate a module needing

replacement, in the unlikely event of a failure. This minimizes power module

replacement time, so process uptime is maximized.

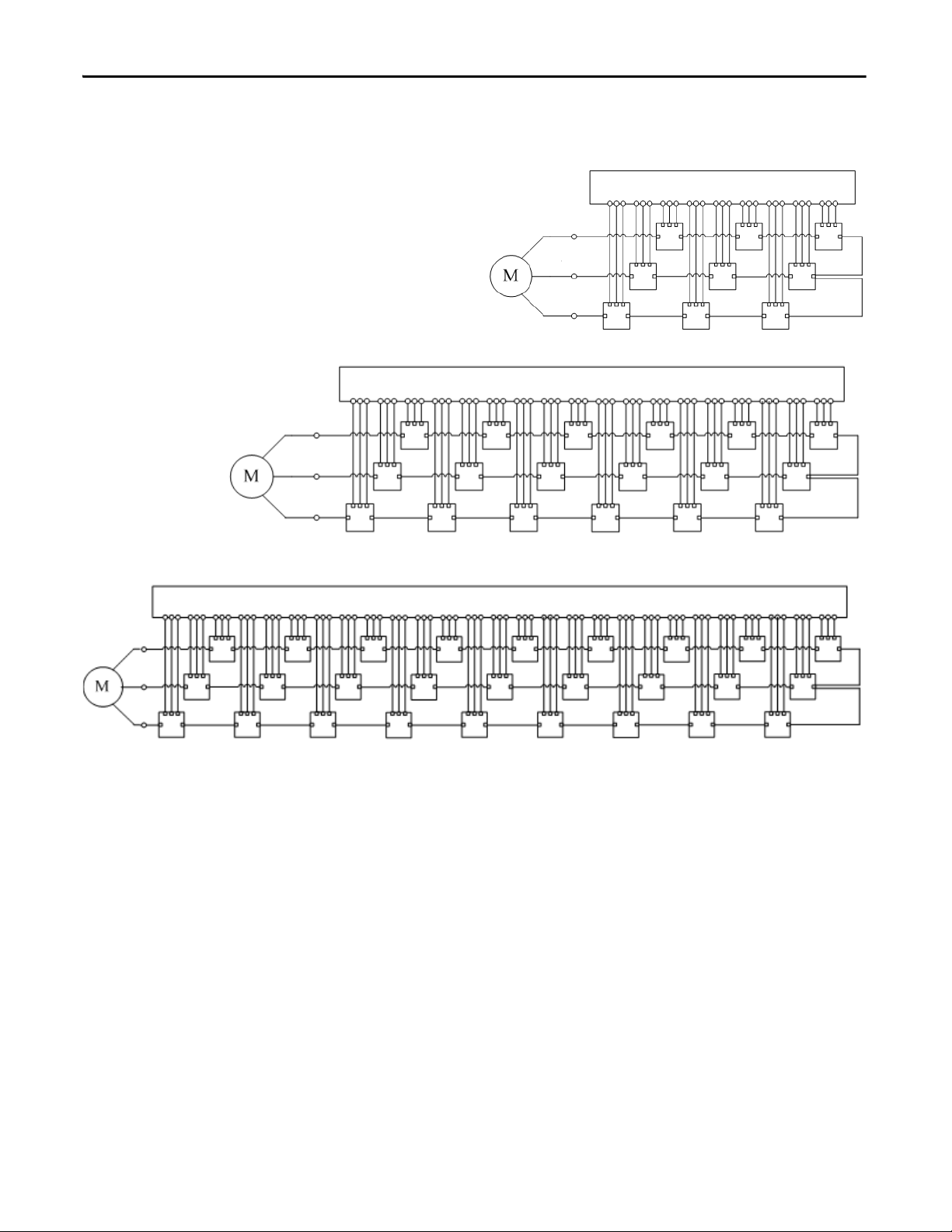

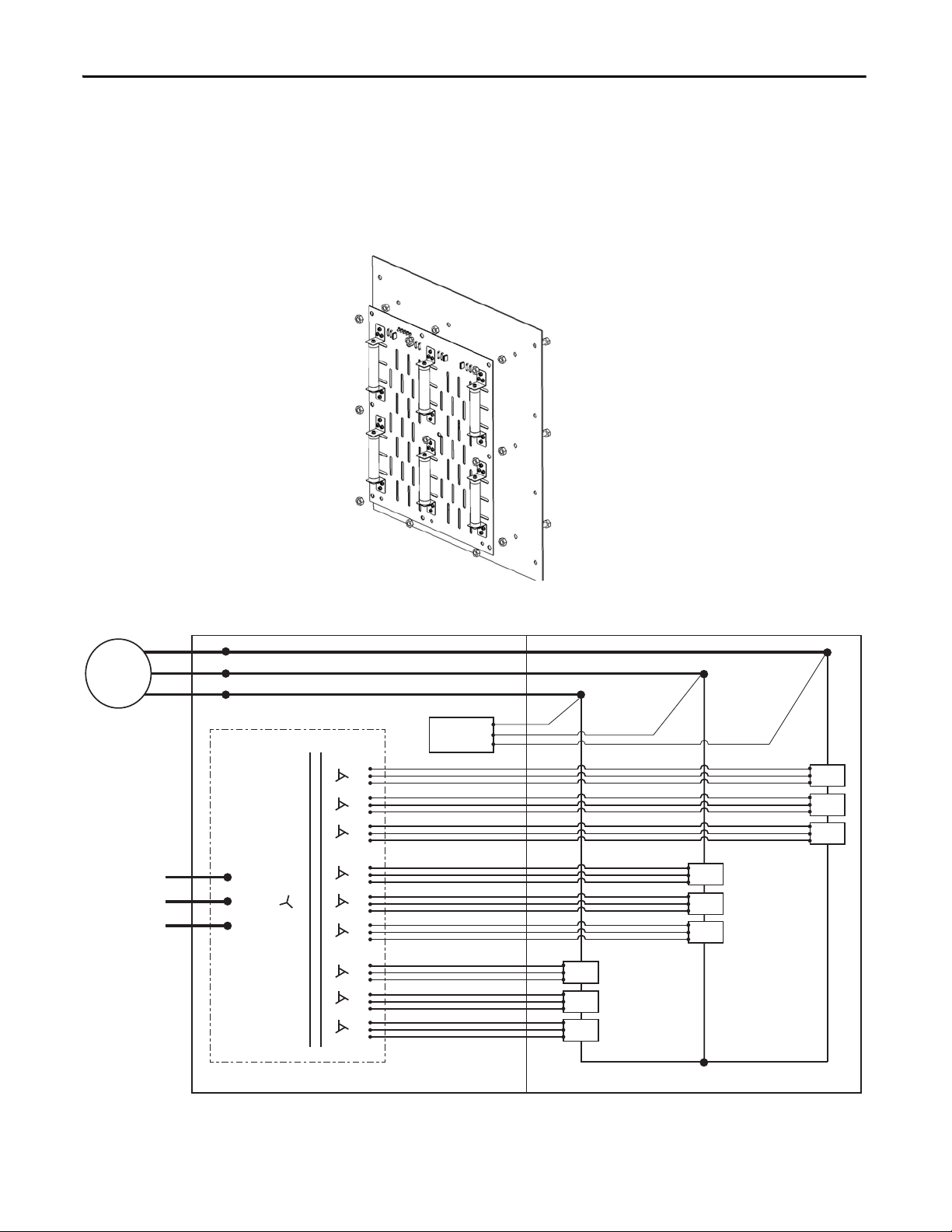

Figure 1 - 6/6.6 kV Example Power Structure

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 11

Page 12

Chapter 1 Introduction

Isolation Transformer Secondary Windings

U

V

W

Isolation Transformer Secondary Windings

U

V

W

Isolation Transformer Secondary Windings

U

V

W

Simplified Electrical Diagrams

Figure 2 - 3000V / 3300V (18 Pulse - 9 Power Modules)

Figure 3 - 6000V /6600V (36 Pulse - 18 Power Modules)

Figure 4 - 10,000V (54 Pulse - 27 Power Modules)

12 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 13

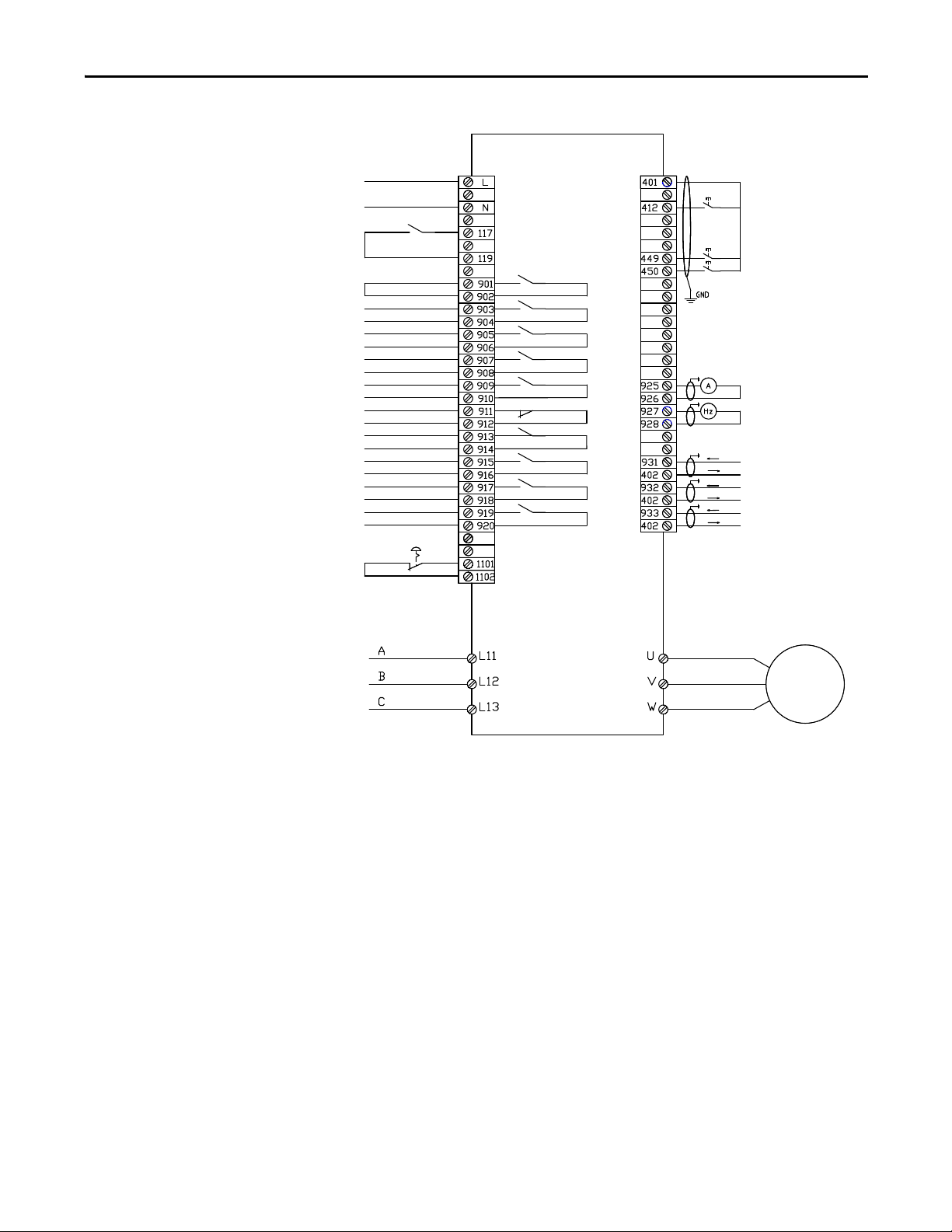

Figure 5 - Connectivity Overview

Reset

Start

Stop

Analog Output Current

4-20 mA

Analog Output Frequency

4-20 mA

Analog set 4-20 mA

Analog spare 4-20 mA

Analog spare 4-20 mA

AC220V Control Power

MV Closed

Customer Input Contact

Permit Close MV

MV Closed Indicator

Warning Indicator

Fault Indicator

Running Indicator

Stop Indicator

Ready Indicator

Remote Control Indicator

Permit to Close Customer

Emergency/Fault Trip

Emergency Stop

MV Pre-Closed

MV Closed

War nin g

Fau lt

Running

Stop

Ready

Control

Permit Close CB

Tri p

Three-p hase

Induction

Motor

Introduction Chapter 1

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 13

Page 14

Chapter 1 Introduction

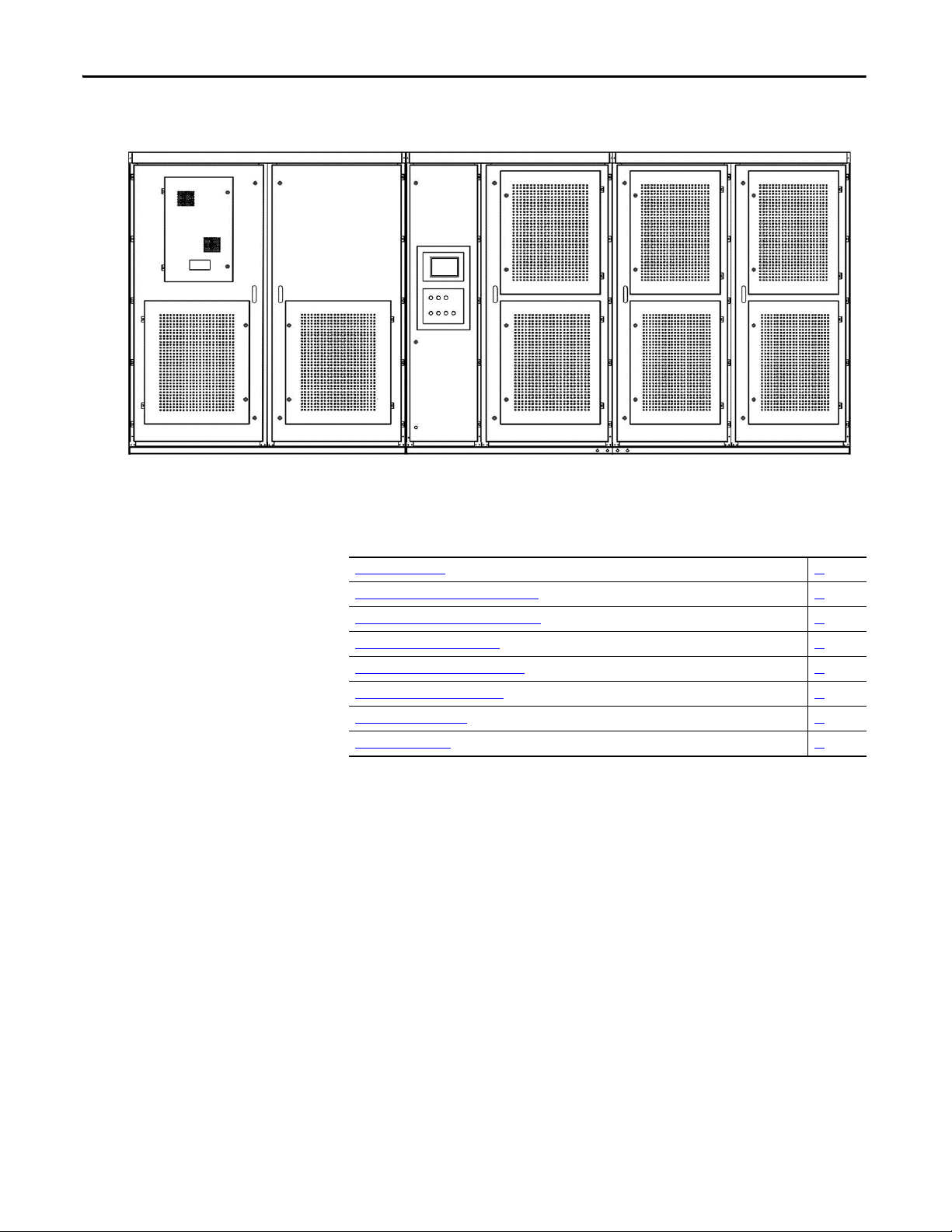

Generous space for terminating incoming line

cables.

Generous space for terminating outgoing load

cables.

Integrally mounted Multi-pulse Isolation

Transformer (3 wire s in & 3 wires out) ensures

low line side harmonics and high input power

factor

Cabinet ships in two sections to minimize

shipping and handling issues.

All Power Modules are identical to minimize

spare parts.

All Power Modules are designed for easy

removal and replacement to minimize MTTR.

Power Module has a PWM pattern to reduce

output harmonics

All MV doors are electrically interlocked with

input switching device

Isolation Transformer Temperature Monitor

All door filters can be changed while the drive

is running

All cooling fans are internally powered by a

dedicated winding in the Isol ation Transfor mer

– no separate fan power supply is needed from

customer

All MV doors are lockable

Intuitive, easy-to-use, color touchscreen HMI

Many communication modules are available,

such as EtherNet I/P and Profibus DP

Automatic switchover (no trip) to internally

supplied control power if customer-supplied

single phase control power is lost

On-line UPS supplied as standard

Incoming Line Cables

Outgoing Load Cables

Isolation Transformer

Power Module s

Door

Filters

Tra ns fo rm er

Tem p er at u re

Monitor

Cooling Fans

HMI

Figure 6 - PowerFlex 6000 Principal Components

14 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 15

Introduction Chapter 1

Standards Compliance

Technical specifications and relevant standards in the manufacture, testing, and

acceptance of equipment include:

Standard Number Standard Description

IEEE 519 Electrical and Electronics Engineers Institute Harmonics Control Requirements

IEC 60146 Semiconductor Converters–Specification of Basic Requirements

IEC 60038:1983 IEC Standard Voltages

IEC 60050-151:2001 International Electrotechnical Vocabulary, Chapter 151: Electrical and Magnetic Devices

IEC 60050-551:1999 International Electrotechnical Vocabulary, Chapter 551: Power Electronics

IEC 60076 Electric Power Transformer

IEC 60721-3-1:1997 Classification of Environmental Conditions, Part 3: Classification of Groups of Environmental

Parameters and their Severities. Section 1: Storage

IEC 60721-3-2:1997 Classification of Environmental Conditions, Part 3: Classification of Groups of Environmental

Parameters and their Severities

IEC 60721-3-3:2008 Classification of Environmental Conditions, Part 3: Classification of Groups of Environmental

Parameters and their Severities. Stationary Use at Weather-protected Locations

IEC 61000-2-4:2002 Electromagnetic Compatibility (EMC), Part 2, Environment, Chapter 4: Compatibility Levels in

Industrial Plants for Low Frequency Conducted Disturbances

IEC 61000-4-7:2002 Electromagnetic Compatibility (EMC) Part 4: Testing and Measurement Techniques, Chapter 7:

General Guide on Harmonics and Inter-harmonics Measurements and Instrumentation, for

Power Supply Systems and Equipment Connected Thereto

IEC 61800-3:2004 Adjustable Speed Electrical Power Drive Systems, Part 3: EMC Requirements and Specific Test

Methods

IEC 61800-4:2004 Adjustable Speed Electrical Power Drive Systems, Part 4: General Requirement—Rating

Specifications for AC Power Drive Systems above 1000V AC and not Exceeding 35 kV

IEC 60757-1983 Code for Designation of Colors

IEC 106:1989 Environment Condition Guides for Specifying Performance Rating of Equipment

IEC 61508.1-7 Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems

GB/T 2900.18-2008 Electrotechnical terminology—Low Voltage Apparatus (IEC60050-441:1984)

GB/T 3859.1-2013 Semiconductor Converters. Specification of Basic Requirements (IEC60146-1-1:1991)

GB/T 3859.2-2013 Semiconductor Converters. Application Guide (IEC60146-1-2:1991)

GB/T 3859.3-2013 Semiconductor Converters. Transformers and Reactors (IEC 60146-1-3,1991)

GB 7678-87 Semiconductor Self-commutated Converters

GB 3797-2005 Electric-driving Control Gear, Part 2: Electric- driving Control Gear Incorporating Electronic

Devices

GB/T 14549-93 Quality of Electric Energy Supply Harmonics in Public Supply Network

GB 4208-2008 Degrees of Protection Provided by Enclosures (IP Code) (IEC 60529:1989)

GB/T 16935.1-2008 Insulation Coordination for Equipment within Low Voltage Systems, Part 1: Principles,

Requirements, and Tests (IEC 60664-1:1992)

GB 156-2007 Standard Voltages

GB/T 1980-2005 Standard Frequencies

GB/T 2423.10 Electric and Electronic Products—Basic Environmental Test Regulations for Electricians—

Guidelines for Vibration (sine)

GB/T 2681 Colors of Insulated Conductors Used in Electrical Assembly Devices

GB 2682 Colors of Indicator Lights and Push Buttons Used in Electrical Assembly Devices

GB/T 4588.1-1996 Specification for Single and Double-sided Printed Boards with Plain Holes

GB/T 4588.2-1996 Sectional Specification: Single and Double-sided Printed Boards with Plated-through Holes

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 15

Page 16

Chapter 1 Introduction

Standard Number Standard Description

GB 10233.2005 Basic Test Method for Low Voltage Switchgear and Controlgear

GB 12668.4-2006 Adjustable Speed Drive Electrical System, Part 4: General Requirement for Voltage up to 35 kV

GB 12668.3-2006 Adjustable Speed Drive Electrical System, Part 3: EMC Requirement and Testing Method

GB 12668.701-2013 Adjustable Speed Drive Electrical System, Part 701: Communication

GB/T 15139-94 General Technical Standard for Electrical Equipment Structure

GB/ 13422-2013 Semiconductor Converters—Electrical Test Methods

IEEE 519-1992 Practices and Requirements for Harmonic Control in Electrical Power Systems

GB/T 12668.4-2006 Adjustable Speed Electrical Power Drive Systems, Part 4: General Requirements. Rating

Specifications for AC Power

GB1094.11-2007 Power Transformer, Part 11: Dry-type Transformer

16 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 17

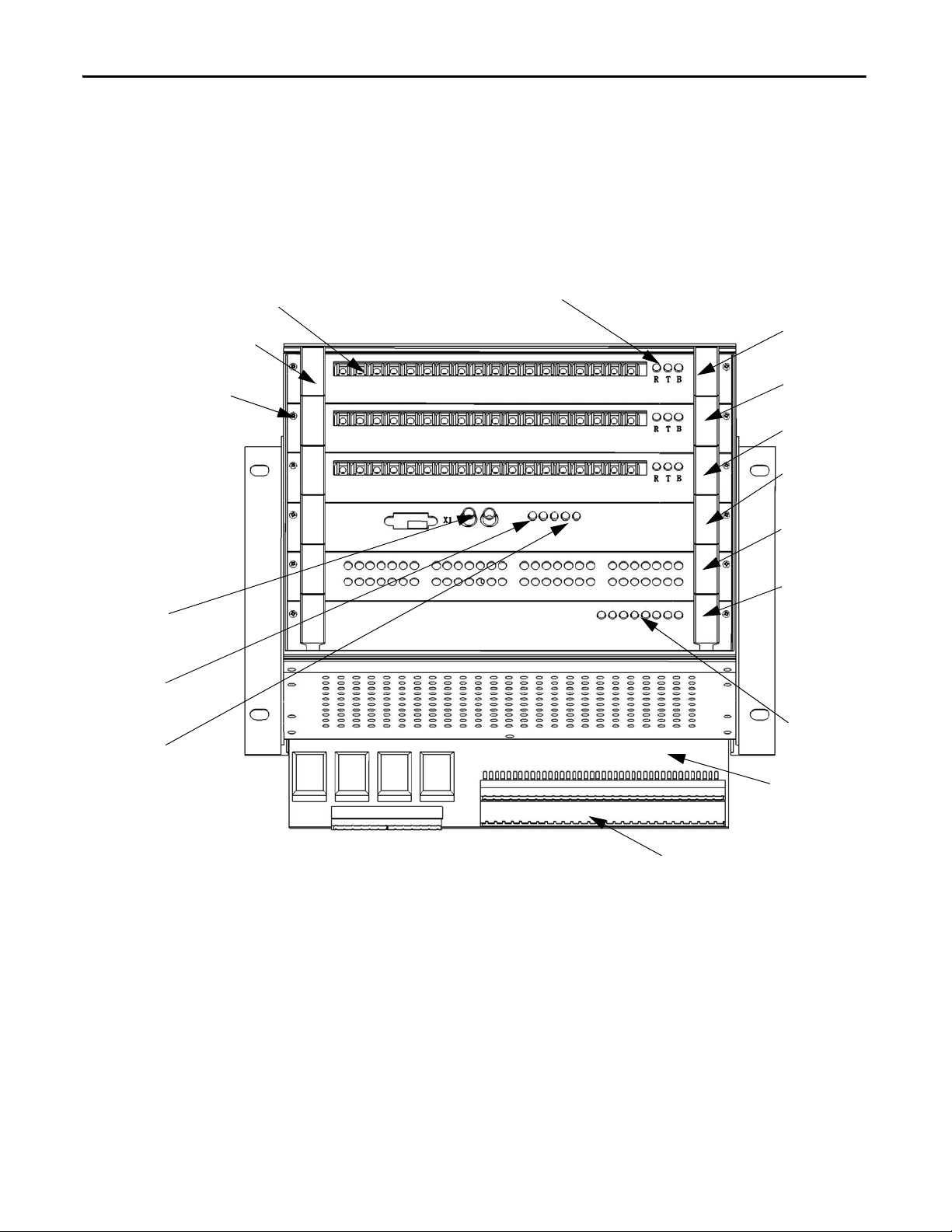

Chapter 2

Isolation Transformer Cabinet Power Module Cabinet LV Control

Cabinet

Drive System Layout

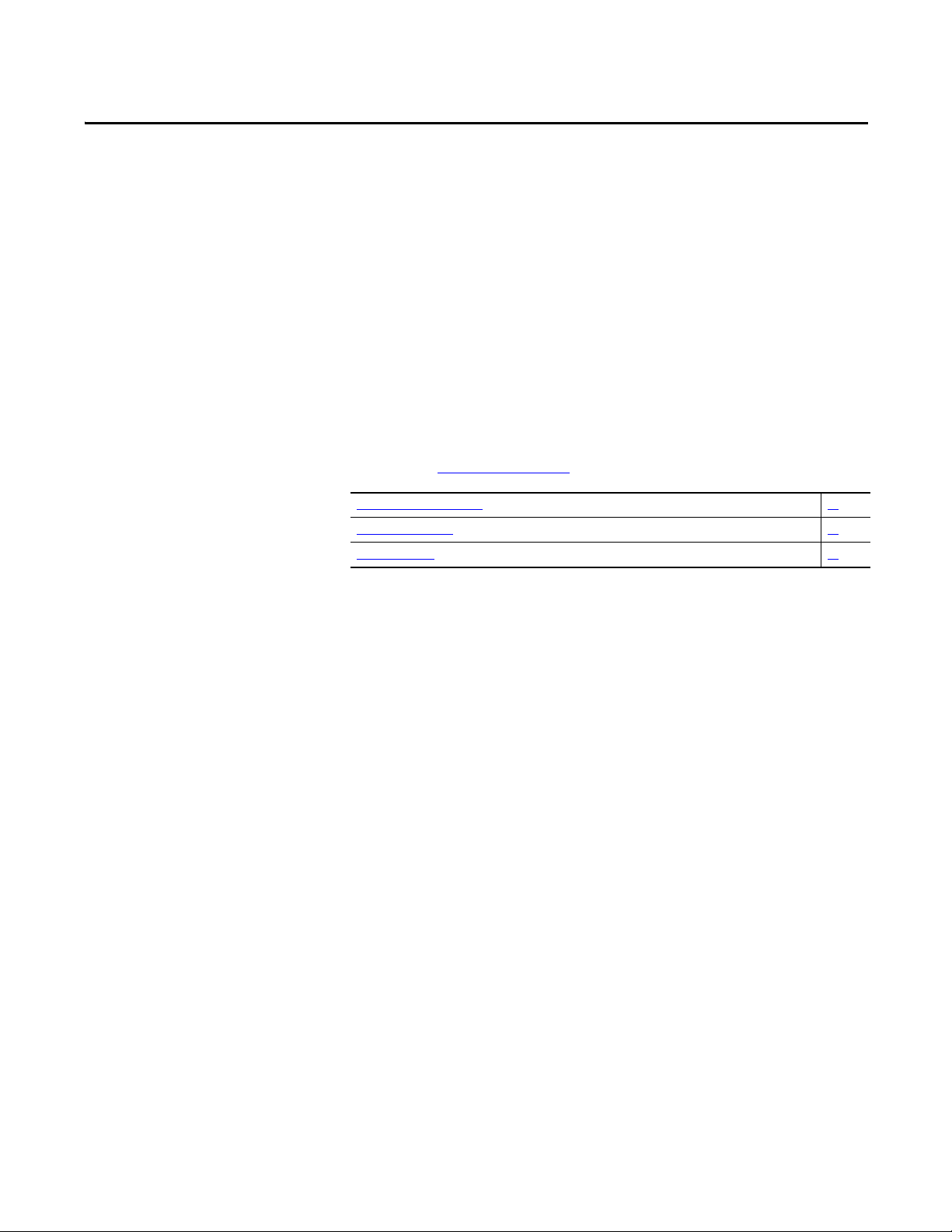

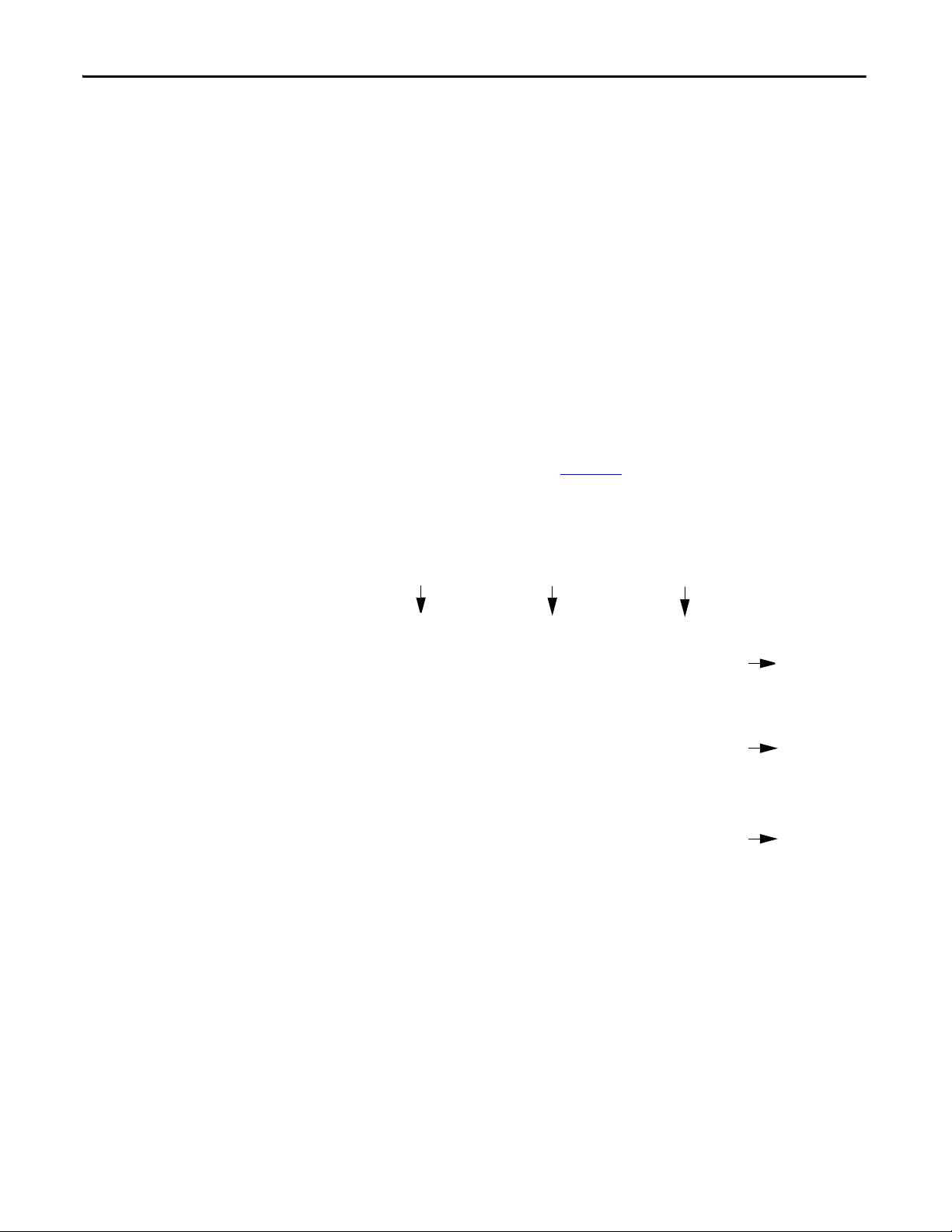

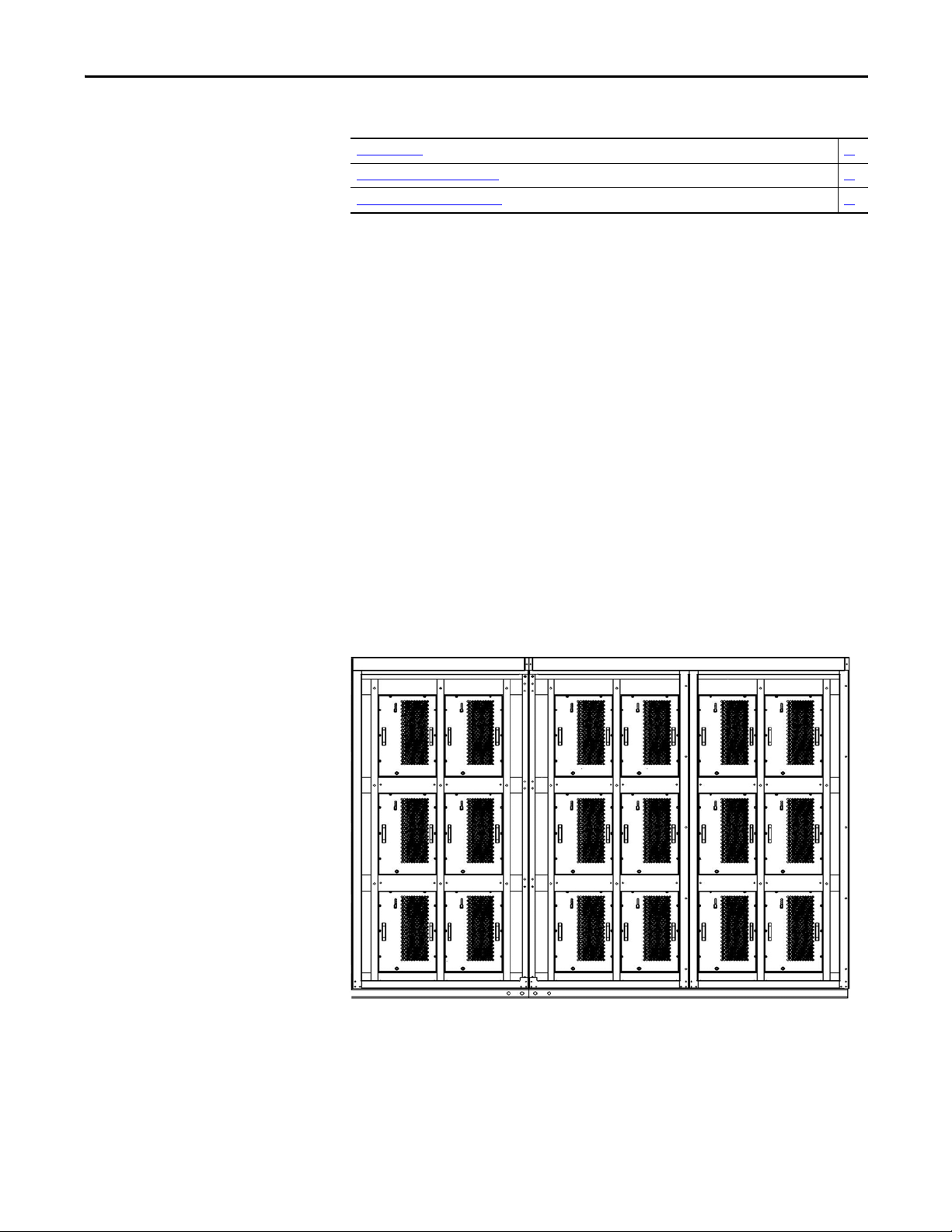

There are two basic power cell configurations offered in the PowerFlex 6000

product line. For a drive amperage rating

design is supplied. Fixed-mounted modules are shipped installed in the drive. For

a drive amperage rating of >200 A, a drawout power module design is supplied.

The PowerFlex 6000 drive is shipped in two sections, the Isolation Transformer

Cabinet and the Power Module/LV Control Cabinet. Refer to PowerFlex 6000

Medium Voltage Variable Frequency Drive Shipping, Handling, and Installation

Instructions (6000-IN006_-EN-P

Isolation Transformer Cabinet 18

Power Module Cabinet 25

LV C ont ro l Ca bin et 29

≤200 A, a fixed-mounted power module

).

Elevation Drawings

Figure 7 - Fixed-mounted Power Module Drive Configuration

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 17

Page 18

Chapter 2 Drive System Layout

Isolation Transformer Cabinet Power Module CabinetLV C ont ro l Ca bin et

Figure 8 - Drawout Power Module Drive Configuration

Isolation Transformer Cabinet

Isolation Transformer 20

Isolation Transformer Temperature Monitor 21

Isolation Transformer Auxiliary Cooling Fans 22

Top-mounted Main Cooling Fan(s) 22

Incoming Line Power Cable Connections 22

Outgoing Motor Cable Connections 22

Door Position Limit Switch 23

Voltage Sensing Board 24

18 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 19

Drive System Layout Chapter 2

Isolation Transformer

Cable Clamp

Volt age S ensing

Board

Door Position

Limit Switches

L11

L12

L13

U

V

W

Isolation Transformer

Auxiliary Cool ing Fans

Power Cable Connections

to Power Modules

Incoming Line Power

Cable Connections

Outgoing Motor Power

Cable Connections

Top-mounted Main

Cooling Fan(s)

Cable Clamp

Voltage Sensing

Board

Isolation Transformer

Door Position

Limit Switches

L13 L12

L11

WV U

Incoming Line Power

Cable Connections

Outgoing Moto r Power

Cable Connections

Isolation Transformer

Auxiliary Cool ing Fans

Top-mounted Main

Cooling Fans

Figure 9 - Isolation Transformer Cabinet (Fixed-mounted Power Module Drive Configuration)

Figure 10 - Isolation Transformer Cabinet (Drawout Power Module Drive Configuration)

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 19

Page 20

Chapter 2 Drive System Layout

PRIMARY WINDING INPUT

SECONDARY WINDING OUTPUT

C (L3) B (L2) A (L1)

U

V

W

Isolation Transformer

The primary winding of the isolation transformer is rated for the voltage of the

distribution system. It is connected to the distribution system by the incoming

line power cables. The secondary windings of the isolation transformer are

connected to the inputs of the power modules. The secondary winding voltage is

typically 690V, to feed the low voltage power modules.

There are between 9 and 27 three-phase secondary side windings, dependent on

the motor voltage requirements. The phase relationship between the secondary

windings are optimized to provide the highest reduction of line side harmonics.

The isolation transformer’s three-phase primary coils are oriented C, B, and A

from left to right, as viewed from the front. The secondary windings are also

divided into three principal sections from top to bottom. The upper third are to

feed the power modules in the U output phase. The middle third are to feed the

power modules in the V output phase. The bottom third are to feed the power

modules in the W output phase (Figure 11

Figure 11 - Isolation Transformer Primary and Secondary Winding Orientation

).

The secondary windings are brought out to corresponding vertical isolated standoffs on the body of the transformer (orientated C, B, and A from left to right as

viewed from the front).

20 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 21

Drive System Layout Chapter 2

For drives with fixed-mounted power modules, the U and W phase

interconnections to the isolation transformer secondary windings are on the

front of the isolation transformer and the connections to the V phase are on the

rear of the isolation transformer. The power cable connections to the power

modules are made at the factory. Therefore, the field power cable connections

need to be made at the isolation transformer secondary winding termination

points (see 6000-IN006_-EN-P

).

For drives with drawout power modules, all of the interconnections between the

isolation transformer secondary windings and the power modules are made in the

rear of the isolation transformer and the connection to the power modules are

also in the rear. The power cable connections to the isolation transformer

secondary winding termination point are made at the factory. Therefore, the field

power cable connections must be made at the power module input points (see

6000-IN006_-EN-P

).

Isolation Transformer Temperature Monitor

A discrete transformer temperature monitor is mounted on the LV door in the

isolation transformer cabinet. Three temperature sensors are embedded in the

isolation transformer. The monitor can be set to indicate an alarm condition or a

trip condition, dependent on the temperature detected.

Figure 12 - Isolation Transformer Temperature Monitor

A separate user manual from the manufacturer is included in the documentation

package.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 21

Page 22

Chapter 2 Drive System Layout

Isolation Transformer Auxiliary Cooling Fans

Six fans are mounted directly underneath the isolation transformer to force air

directly through the windings - to ensure reliable cooling. A baffle structure

surrounds the periphery of the transformer structure to ensure the cooling air

does not bypass the interior of the transformer windings. These fans are powered

by a tertiary winding in the isolation transformer. Separate fan control power is

not required.

Top-mounted Main Cooling Fan(s)

The top mounted cooling fan(s) work with the auxiliary cooling fans to ensure

reliable cooling of the isolation transformer. They ensure the air is exhausted

from the cabinet by creating an induced draft.

Incoming Line Power Cable Connections

The incoming line cables connect to the line side terminals on the isolation

transformer. Incoming line cables can be brought in through the top or bottom of

the isolation transformer cabinet. Generous working space is provided, if stress

cones are required. See publication 6000-IN006_-EN-P

for additional details.

Outgoing Motor Cable Connections

The outgoing motor cables connect to a cable stand-off assembly on the cabinet

side sheet (Fixed-mounted Power Module configuration) or to the cable standoffs mounted on the Isolation Transformer (Drawout Power Module

configuration).

The outgoing motor cables connect to output phase of the power module array.

Outgoing motor cables can be brought in through the top or bottom of the

isolation transformer cabinet. Generous working space is provided. See

publication 6000-IN006_-EN-P

for additional details.

22 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 23

Drive System Layout Chapter 2

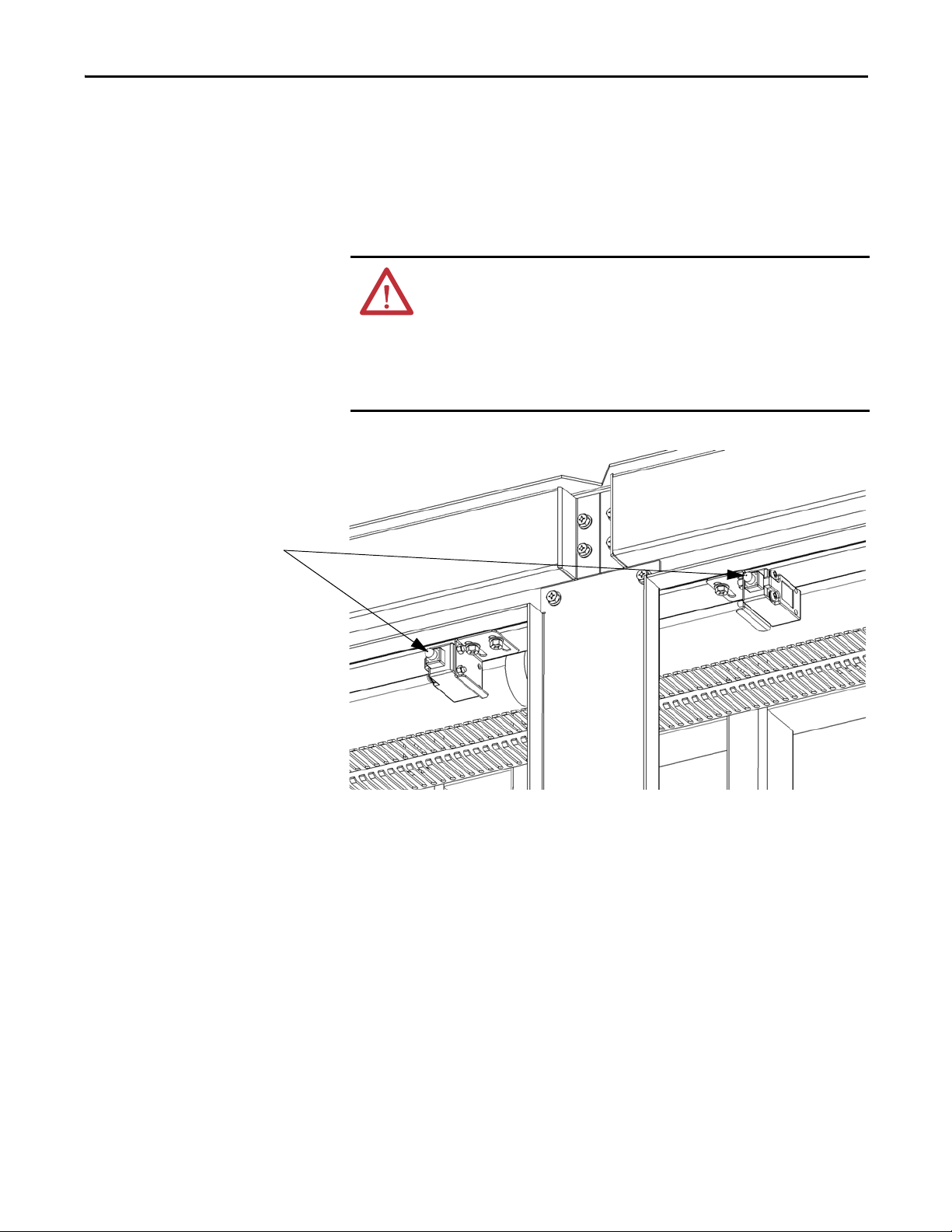

Door Position Limit Switch

Door Position Limit Switch

Each cabinet door that allows access to medium voltage components is lockable

and also has a Guardmaster® safety limit switch. If the cabinet door is opened

when the input switching device feeding power to the drive is closed, the input

device will be tripped off.

ATT EN TI ON : The door position interlock is a safety feature. It must not be used

solely as a part of the plant operation process to ensure the drive has been

disconnected from input medium voltage. Keep the medium voltage doors

locked as standard practice. If access to the medium voltage rated cabinets is

required, always go to the input device feeding the drive to verify if it is open.

Lock out and tagout the input device before performing any work on the drive

or bypass units.

Figure 13 - Door Position Limit Switch Location

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 23

Page 24

Chapter 2 Drive System Layout

L11

L12

L13

A1

B1

C1

A2

B2

C2

A3

B3

C3

A4

B4

C4

A5

B5

C5

A6

B6

C6

A7

B7

C7

A8

B8

C8

A9

B9

C9

U

V

W

PC A1

PC A2

PC A3

PC B1

PC B2

PC B3

PC C1

PC C2

PC C3

U

V

W

Input power

3-phase AC

any voltage

Isolation Transformer

Motor

Volt age Sens ing

Board

Isolation Transformer Cabinet Power Module/LV Control Cabinet

Voltage Sensing Board

The Voltage Sensing Board (VSB) is connected to the drive output terminals that

connect to the motor. The VSB converts motor voltage to low voltage levels

which allows the drive to monitor the output voltage to the motor.

Figure 14 - Voltage Sensing Board

Figure 15 - Power Cabling Overview (3.3 kV Fixed-mounted Power Module Configuration)

24 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 25

Power Module Cabinet

Drive System Layout Chapter 2

Power Modules 26

Hall Effect Current Sensors (HECs) 28

Top-mounted Main Cooling Fan(s) 28

Figure 16 - Fixed-mounted Power Module Configuration

Figure 17 - Drawout Power Module Configuration

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 25

Page 26

Chapter 2 Drive System Layout

Input U

Input V

Input W

Fuse 1

Fuse 2

Three-phase Diode

Rectifier Bridge

DC Bus

Capacitor Network

Single Phase IGBT

Inverter Network

IGBT 1 IGBT 2

Output A Output B

D1 D2 D3

D4 D5 D6

C1 R1

C2 R2

C3 R3

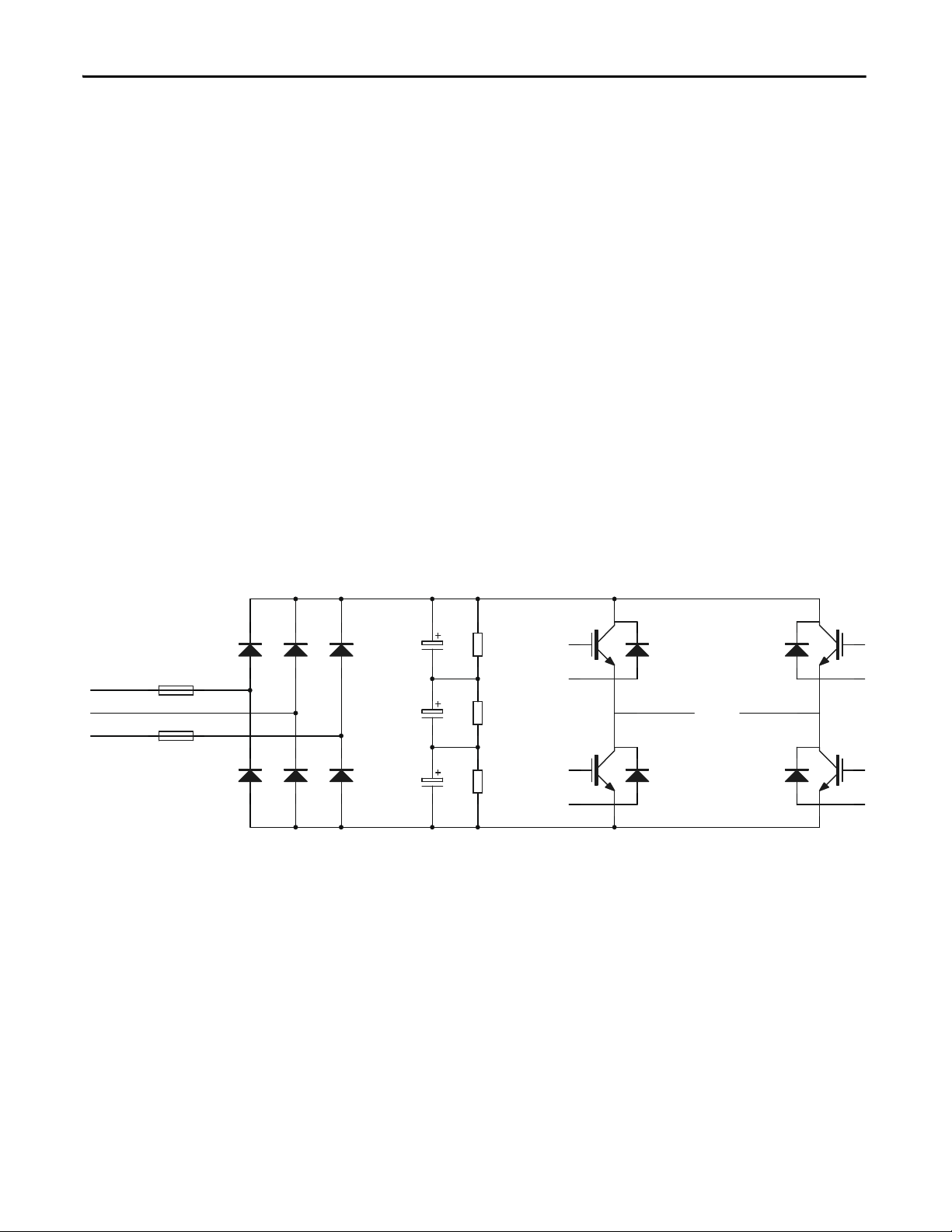

Power Modules

Power Modules are available in a wide variety of amperage ratings relating to the

required motor current. Power Modules rated up to and including 200 A are

fixed-mounted in the drive and ship already installed.

Drawout power modules are supplied for a drive current rating of >200 A. The

power modules are shipped separately and must be installed in the cabinet. A

Power Module lift cart is included and shipped together with the other

components.

Basic Principle of Power Module

The Power Module combines a three phase rectifier and an “H” bridge inverter,

powered from the secondary side windings of the Isolation Transformer. After

rectifying and filtering, it outputs AC current with variable frequency and

variable voltage under the control of four IGBTs using a PWM switching pattern.

Several Power Modules, after being connected in series and superposed, can

output three-phase AC current with adjustable frequency and voltage to control

an AC motor.

Figure 18 - Low Voltage Power Module

Control signals to the Power Module and the feedback signals from the Power

Module are transmitted by fiber optic cables which provide electrical isolation

between the medium voltage and low voltage sections of the drive, and protects

against electromagnetic interference.

Although the voltage produced by each power unit is typically less than 690V, the

voltage-to-ground can reach the VFD rated output voltage, if operating at rated

frequency.

The control signals from the main control unit, through the optical-electrical

converter, are sent to the Power Module control board for further processing and

to the corresponding gate drive circuits to turn the IGBTs on or off.

26 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 27

Drive System Layout Chapter 2

Line Terminals

Fuse

Optic Fiber Socket

and Status Indicator

Output Terminal

The status information of the Power Module is transmitted through the

electrical-optical converter and sent to the main control unit. When there is a

fault, the main control unit sends control signals to lockout or bypass the affected

Power Module.

The Power Module cabinet consists of Power Modules, current transformers and

high-voltage cable.

The Power Modules are divided evenly into three phases (U, V, and W). The

units in each phase are connected end-to-end at the output terminals. Then

individual phases are formed, using a star connection. Current transformers are

installed into the U phase and W phase.

Different models of Power Modules are used for VFDs of different power ratings

(Figure 19

Figure 19 - Typical Fixed-mounted Power Module

).

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 27

Page 28

Chapter 2 Drive System Layout

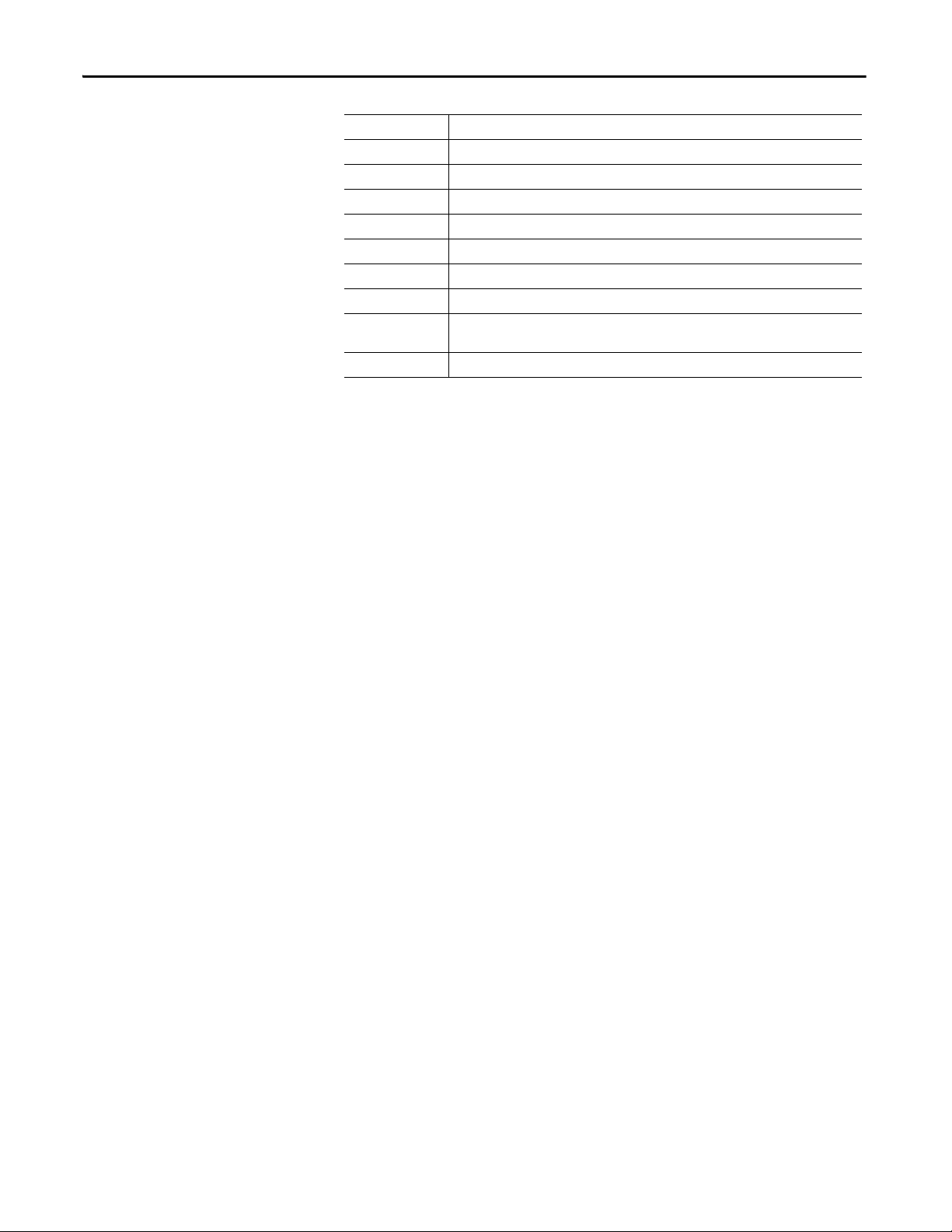

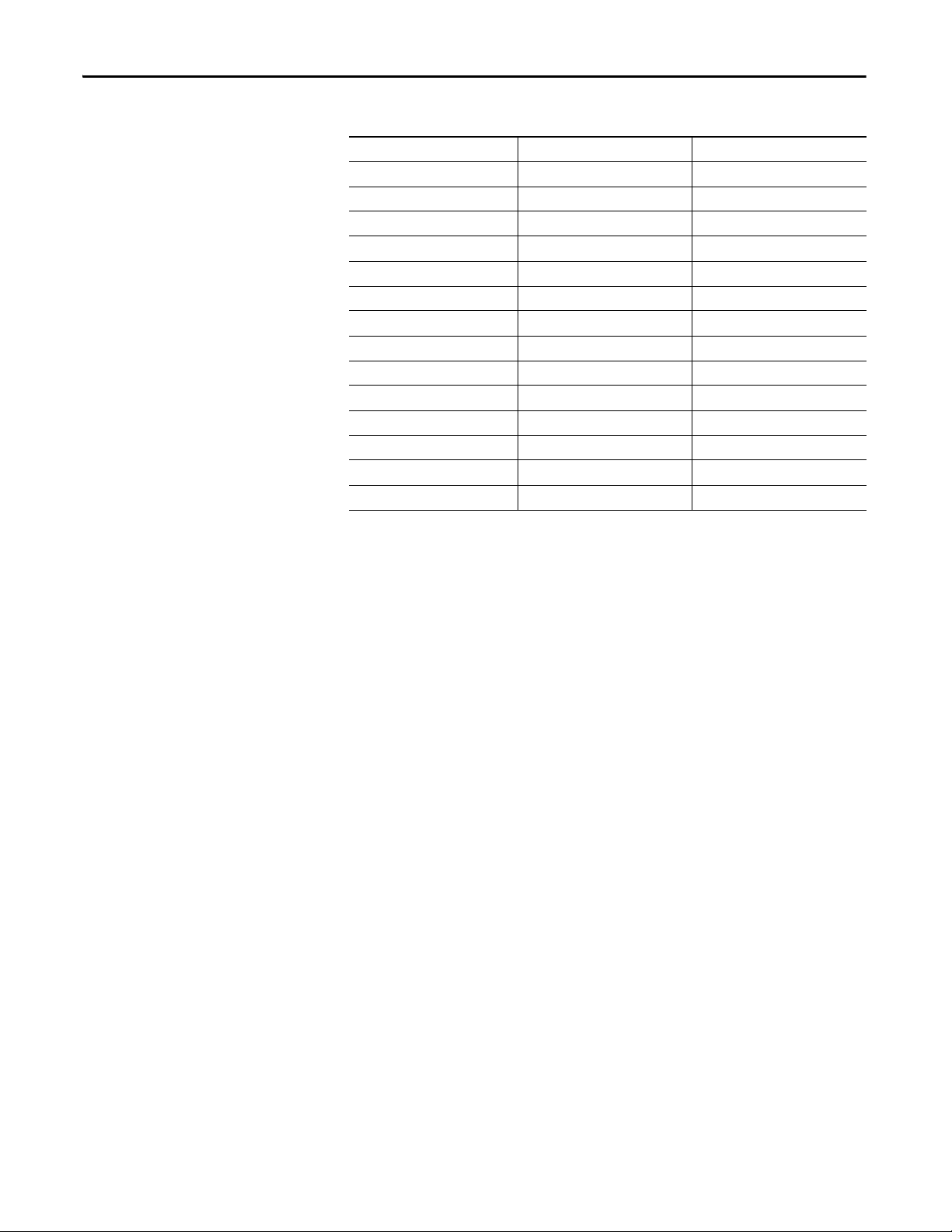

Table 1 - Power Module Ratings

Catalog Number Spare Part Number Current Rating (Amps)

TPUxx/030-AC3 HTPUXX/030-AC3-R 30

TPUxx/040-AC3

TPUxx/050-AC3 HTPUXX/050-AC3-R 50

TPUxx/060-AC3 HTPUXX/060-AC3-R 60

TPUxx/075-AC3 HTPUXX/075-AC3-R 75

TPUxx/080-AC3

TPUxx/100-AC3 HTPUXX/100-AC3-R 100

TPUxx/120-AC3 HTPUXX/120-AC3-R 120

TPUxx/150-AC3

TPUxx/180-AC3 HTPUXX/180-AC3-R 180

TPUxx/200-AC3 HTPUXX/200-AC3-R 200

TPUxx/300-AC3

TPUxx/380-AC3 HTPUXX/380-AC3-R 380

TPUxx/420-AC3 HTPUXX/420-AC3-R 420

HTPUXX/040-AC3-R 40

HTPUXX/080-AC3-R 80

HTPUXX/150-AC3-R 150

HTPUXX/300-AC3-R 300

Hall Effect Current Sensors (HECs)

The Hall Effect Current Sensors are current transformers capable of measuring

current throughout the output frequency range of the drive. They monitor the

current waveform in each of the phases going to the motor and provide feedback

to the control system.

Top-mounted Main Cooling Fan(s)

The Top-mounted Cooling Fans ensure reliable cooling of the Power Modules.

They draw cool air in through the vents in the Power Module Cabinet doors,

through the Power Modules, and exhaust the heated air out through the top of

the cabinet.

28 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 29

Drive System Layout Chapter 2

Control Unit

PLC

LV C irc uit B rea ker s

LV Control Relays

UPS

LV Control Cabinet

Control Unit (all modules) 30

PLC 32

HMI 32

UPS 32

The LV Control Cabinet consists of the Control Unit, the human-machine

Interface (HMI), PLC, AC/DC power supplies, contactors and relays.

The HMI is located on the front door of the LV Control Cabinet, where an

operator can setup, monitor, and control the drive.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 29

Page 30

Chapter 2 Drive System Layout

Tra ns ce iv er

Indicators

PWM Board A

PWM Board B

PWM Board C

CPU Board

Analog Signal

Processor Board

(AT)

Digital Signal

Processor Board

(DT)

Status Indicators

Interface Terminals

Fiber Optic Sockets

Board

Handle

Board

Mounting

Screw

HMI

Commu nication

Interface

Power Indication

Status

DB Board

Control Unit (all modules)

The control unit provides the core functionality of the variable frequency drive.

This includes controlling the power modules to produce the required output

voltage and frequency, monitoring the power modules, motor voltage, and motor

current to provide alarm and trip signals based on the information.

Figure 20 - PowerFlex 6000 Interface

The CPU Board accepts external inputs through the connected communication

network, hard-wired control devices or user interactions via the HMI to

determine the actions required of the drive. The CPU Board also monitors

motor voltage and current as well as internal inputs from the PLC, analog and

digital signal processor boards and Power Modules. It uses these inputs in its

motor control and protection algorithms to determine the necessary actions to

be taken and outputs to be set. In combination with the PWM Boards, the CPU

board sends the necessary optical PWM control signals to the Power Modules to

allow the Power Modules to output the required voltage and frequency to the

motor

30 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 31

Figure 21 - Control Unit Layout

HMI

PWM Board A

DCS

Phase A

Power Module s

Fieldbus

VSB

HECS

PLC

Communication

Board

PWM Board B PWM Board C

Phase C

Power Modules

DT

AT

DB

CPU Board

Phase B

Power Modules

RJ45 Modbus TCP/IP

RS-485

Modbus

Modbus

Drive System Layout Chapter 2

Table 2 - Control Unit description

Board Function

PWM Board A, B, C Output PWM and control signals to Power Modules

CPU Board Process analog input signals, switch and fault information, control DA and switch signal output,

Analog Signal

Processor Board (AT)

Digital Signal

Processor Board (DT)

DB Board Acts as a base board in the Control Unit and interfaces the digital and analog signal cables

Connector

HMI Communication

Interface

Fiber Optic Socket Connection between Power Modules and Control Unit (two per module)

Interface Terminals Connects external inputs, outputs and the CPU Board

Status Indicators

Phase control board

transceiver indicator

light

CPU Board Indicator Lights

5V 5V power supply indicator

3.3V 3.3V power supply indicator

FPGA FPGA healthy indicator

DSP1 DSP1 healthy indicator

DSP2 DSP2 healthy indicator

Collect and process fault and state information from Power Modules to CPU board

Each phase PWM board can control up to nine power cells

realize V/F algorithm, set and change parameters in communication with HMI

Collect and process analog input signals to CPU Board, output analog signals processed by DT

board

Collect and output digital signals, digital to analog conversion function

Connection between HMI and Control Unit. Provides inputs from the HMI and PLC to the CPU

Board

B: board healthy indicator

T: transmit data to power module indicator

R: receive data from power module indicator

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 31

Page 32

Chapter 2 Drive System Layout

Power Input

Extend I/O Extend I/OPlug inPLC Plug in Plug in

EtherNet/IP Port

Digital Signal Processor Board Indicator Lights

HVEN Allow High voltage switching on indicator

RUN Drive Running indicator

Fault Drive is in fault state

Trip Drive is in trip state; any fault can result in trip

Alarm Drive in alarm state

Reserved

PLC

The PowerFlex 6000 uses a Micro850 PLC to perform many of its internal

control functions. The PLC controls and monitors the cooling fans, input and

bypass switching devices, door switch status, etc. The PLC is also responsible for

interfacing with the user's automation control system via many optional

communication protocols. Standard communication protocols are EtherNet/IP,

Modbus/TCP Server and Modbus RTU. Optional communication modules are

available to support other communication protocols.

Figure 22 - PLC Location

HMI

The PowerFlex 6000 HMI is a PanelView Plus 700 series, catalog number 2711PT7C4D9.

The HMI is connected to the Master Control board through a communication

interface (standard RJ45 EtherNet/IP connection). The HMI configures

operating parameters and input operation commands, and displays the operation

status, operation parameters, and fault messages.

UPS

32 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

The UPS supplies power to the LV Control cabinet using internal batteries if the

customer-supplied control power and isolation transformer control power is off.

The UPS provides control power in the event of transient power loss to ensure

the drive control can operate without interruption.

Page 33

Setup and Operation

User

Setup

R&D

Set Several

P Parameters

Set Several

P Parameters

Set All

P Parameters

Set All

T Parameters

View K

Parameters

Settings

Default

Select

Language

Select

Bypass Mode

Operation

No

Bypass

Manual

Bypass

Auto

Bypass

Local/

Remote

Switch

Status

Open/Close

Switch

Local /

Remote

Local/

Remote

Switch

Status

Switch

Status

Tre nd s

V

I

Act. Freq.

Alarm

Alarm Status

Alarm History

Set Frequency

Start/Stop/Reset

Accel/Decel

Main Operation

Data Display

Set Frequency

Actual Frequenc y

Motor Voltage

Motor Current

Status Info.

Version Info.

Home

Main Interface

1

2

3

5

6

7

Screen Layout

1Top Menu Bar

2 Status Bar

3Set and Monitor Box

4 Actual Frequency Display Box

5 Version Information Box

6Actual Date and Time

7Operation Bar

4

Chapter 3

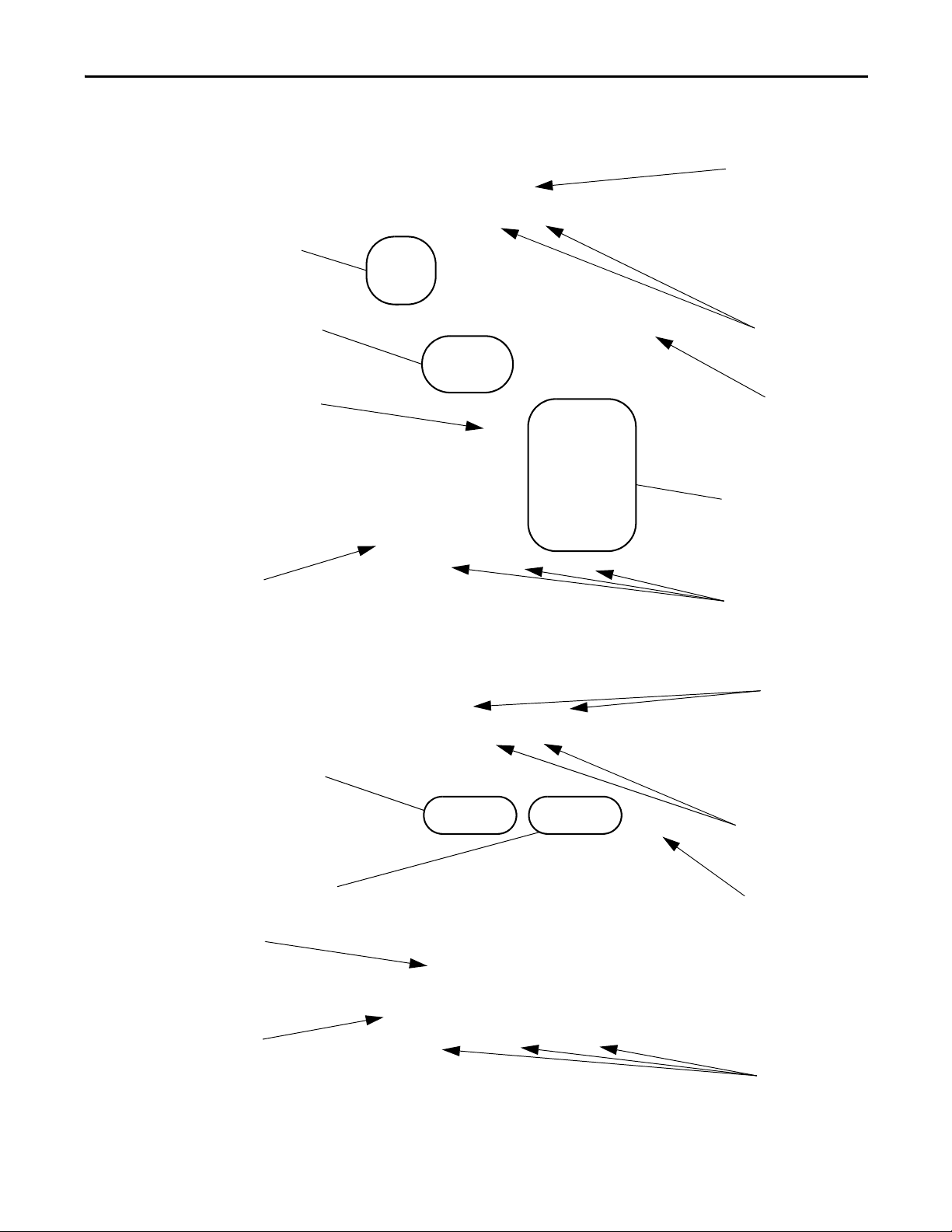

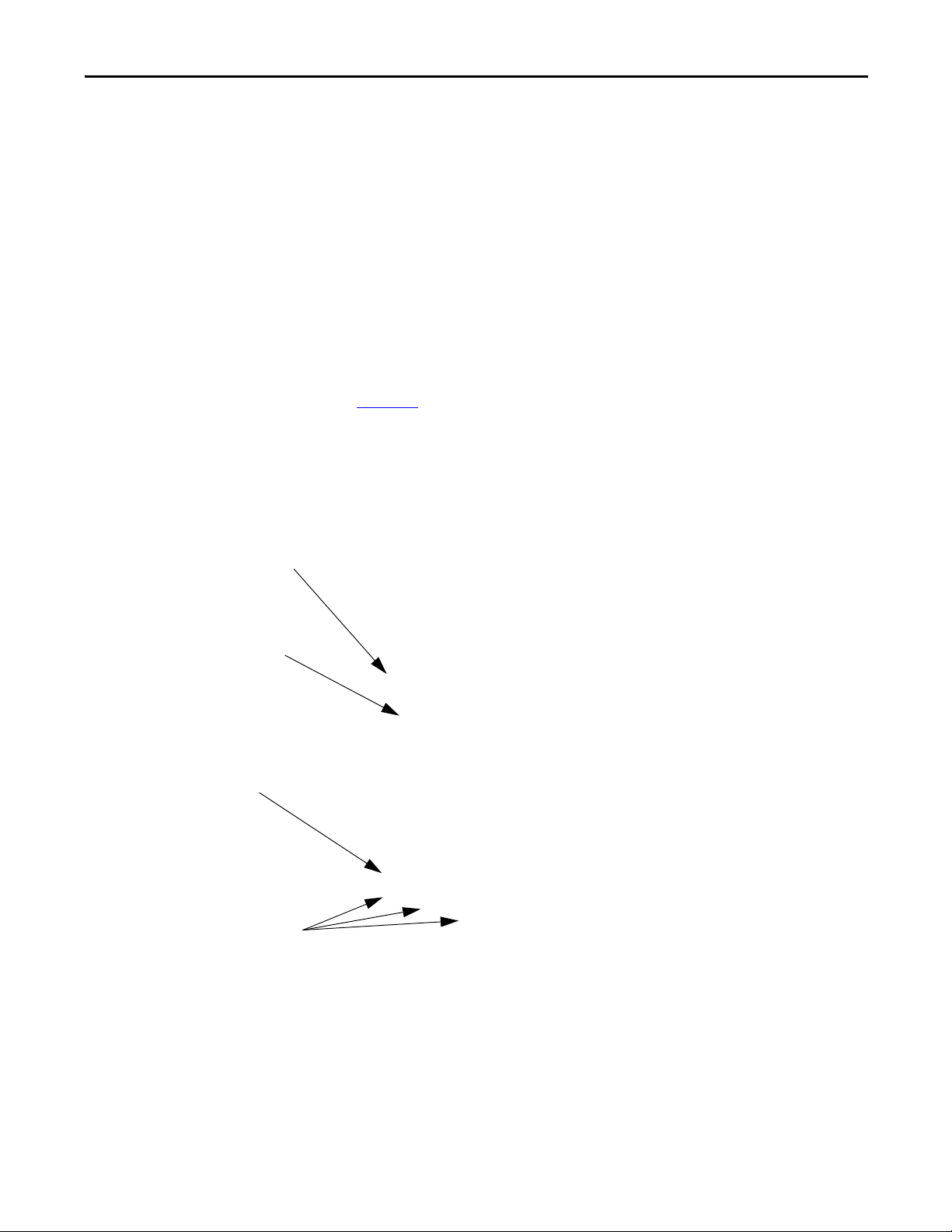

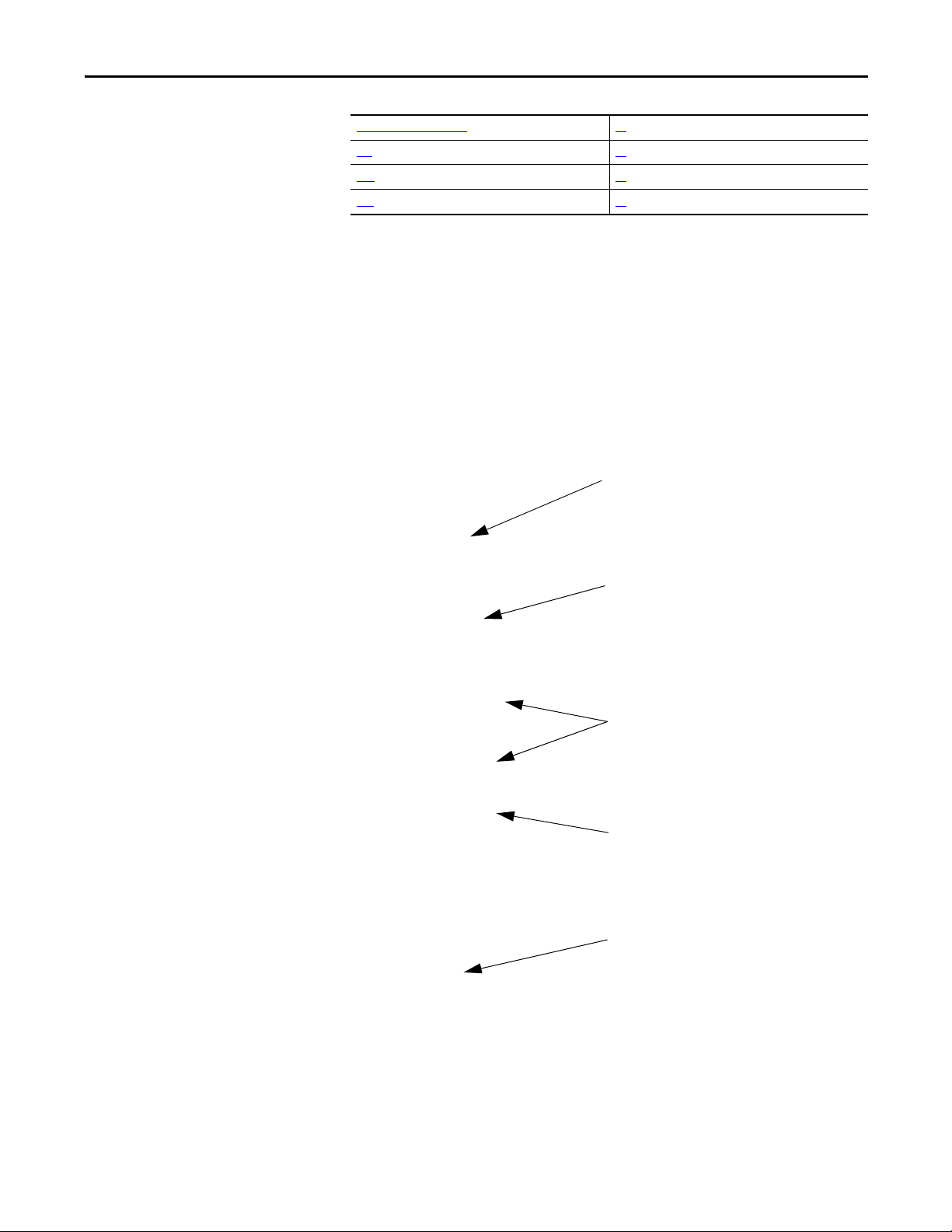

Overview

Main Interface

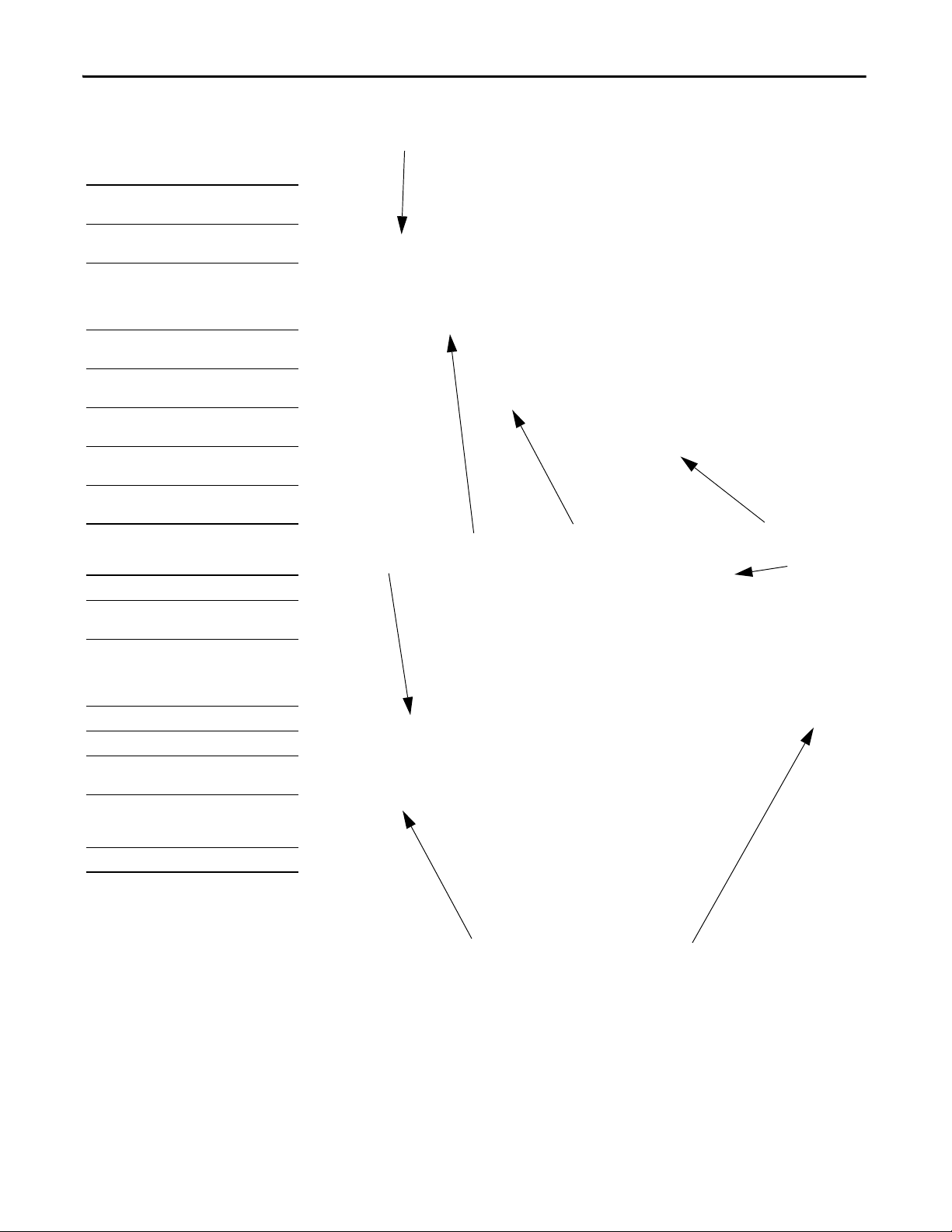

The structure of the touchscreen operation is shown in Figure 23.

Figure 23 - HMI Overview

The Main Interface Screen contains configuration and operation controls,

monitoring parameters and actual speed.

Figure 24 - Main Interface Screen

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 33

Page 34

Chapter 3 Setup and Operation

Drive Setup and Configuration Controls

There are five buttons in the Top Menu Bar. A description of the functionality is

described in Ta b l e 3

Table 3 - Setup and Configuration Controls

.

• Return to Main Interface screen

• Check warnings

• Check faults

• Reset alarm status

• Show alarm history

• Check voltage trends

• Check current trends

• Check frequency trends

• Pause tre nding

• Confirm/change bypass configuration

• Change from local to remote control

• Close/open drive contactors (auto bypass)

• Access System Settings

– Change Language

– Change Bypass Mode

• Access P and T Parameters

Status Indicators

There are eight status indicators on Status Bar.

Table 4 - St atus Indi cators

Allowed The drive is in a state that will allow MV to be applied

MVClosd Indicates that the input switching device feeding MV power to the drive is closed

Ready Drive is ready to start

Connect Being connected with medium voltage

Running The drive is running

Warn ing The system has faults or warnings

Local The system is under Local Control

Remote The system is under Remote Control

34 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 35

Setup and Operation Chapter 3

Operation Bar

Table 5 - Operation Bar Buttons

Start Starts the drive only if no fault is found during self test at startup; otherwise, this button is invalid

Accel Increases the frequency by the set step

Decel Decreases the frequency by the set step

Stop Stop output of the drive

(1)

Reset

(1) The drive must not be running to complete this operation.

Resets the drive (under fault conditions) once

Setup and Monitor Box

Main Interface Controls

The set frequency field is the only one which is user-configurable. See Set

Frequency (Hz) for instruction on how to set the frequency.

Table 6 - Monitoring Parameters

Set Frequency Frequency set for the drive (Hz)

Actual Frequenc y Actual frequency of the drive (Hz)

Motor Speed Speed of the motor (%)

Motor Voltage Voltage of the motor stator (V)

Motor Current Current of the motor stator (A)

From the Main Interface screen, you can:

Set Frequency (Hz) 36

Drive Operation Controls 37

View Version Information 38

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 35

Page 36

Chapter 3 Setup and Operation

Numpad

Cancel

Backspace

Enter

Set Frequency (Hz)

1. Press the Set Frequency: input field.

2. Press the Set Freq: input field.

3. Enter desired frequency and press .

4. Press to accept or to cancel.

36 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 37

Setup and Operation Chapter 3

Drive Operation Controls

Press the desired Drive Operation Control button, and to accept or

to cancel.

ATT EN TI ON : Drive Operation Controls will only function if using Local Control,

otherwise the following dialog appears.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 37

Page 38

Chapter 3 Setup and Operation

Will always

appear blue

The number of

Power Modu les in

the drive will

appear as blue; the

rest appear as grey

Fields show the

firmware version,

where applicable

View Version Information

Press under Ve r s i on Inf o. to view the currently installed Firmware.

The Version Information screen shows the most current firmware installed for

the applicable devices.

38 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 39

Alarm

List of Active

Alarms

Alarm Code

Quantity

Accumulated Time

Alarm

Code Alarm code. Codes beginning with W indicates a warning, codes beginning

with F indicates a fault.

QTY How many times the alarm has occurred

Acc Time Time which has elapsed since the alarm

Message Description of the warning or fault

Reset Status

Scroll to Top or

Bottom of List

Scroll Alarm

by Entry

Page Up /

Page Down

Shows Alarm History

Setup and Operation Chapter 3

If the drive encounters and alarm or warnings, will blink,

indicating an active alarm.

Press the button in the Top Menu Bar to see the active alarms.

Active Alarms Controls

Reset Status

will reset just the quantity and accumulated time of the alarms. This

function does not reset the drive.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 39

Page 40

Chapter 3 Setup and Operation

TIP

Alarm History

Press to see a detailed listed of all warnings and faults on the drive.

The controls to scroll through the alarms are the same.

Sort Alarms

Press once to sort once to sort by time. Press again to sort by message.

Current alarms appear as red; past alarms appear as gray.

40 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 41

Setup and Operation Chapter 3

Back

Y-A xis

X-axis

Tre nd C ont rol s

Zoom Y-axis in

Zoom Y-axis out

Scroll X-axis left Scroll X-axis right Pause trending

Trends

There are three different trending options, Voltage, Current, and Trends. Press

any button to view the trends.

You can view Voltage, Current, or Frequency trends. Voltage is measured in volts,

Current in amps, and Frequency in Hz.

The trend controls are the same for all three screens.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 41

Page 42

Chapter 3 Setup and Operation

TIP

View Voltage, Current or Frequency Trends

1. From the Main Interface screen, press .

2. Press , , or

in the Trends Selection

screen.

3. Use the and buttons to zoom in or out.

Press the and buttons to scroll.

The time shown in the X-axis captures 20 minutes. Scrolling left or right will

scroll in 10 minute increments.

4. Press to pause the trend capture.

5. Press to return to the Tr e nd s S el ec t io n

42 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

screen.

Page 43

Setup and Operation Chapter 3

Bypass

Configuration

Select Local/

Remote

Control

Open/Close

Drive/Bypass

Contac tors

No Bypass Cabinet

Operation

The Operation interface displays the bypass mode, control owner selection, and

contactor operation.

In this screen, you can:

Confirm Bypass Mode 43

Choose Local/Remote Operation 45

Open/Close Drive Input and Output Contactors 46

Open/Close Bypass Contactors 47

Confirm Bypass Mode

1. Press from the Main Interface screen.

2. Confirm the Bypass Configuration matches one of the three Input Sup ply

graphics.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 43

Page 44

Chapter 3 Setup and Operation

Manual Bypass Cabinet

Automatic Bypass Cabinet

Note the Contactor

Operation selection

appears when Automatic

Bypass is selected

3. To change the Bypass Mode:

a. Press .

b. Press .

c. Choose desired Bypass Mode under Select Bypass Mode

d. Press .

e. Press to confirm operation.

44 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

.

Page 45

Choose Local/Remote Operation

1. Press from the Main Interface screen.

Setup and Operation Chapter 3

2. Und er Control Owner Selection

, press either or

.

3. Select to confirm in the Select Local Control? or Select

Remote Control? dialog box.

ATT EN TI ON : This operation can only operate while drive is not running.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 45

Page 46

Chapter 3 Setup and Operation

IMPORTANT

Open/Close Drive Input and Output Contactors

Turn the 3-position on the selector switch on the front of the LV Cabinet to the

Drive position.

1. Und er Contactor Operation, press either or .

2. Select to confirm in the Close Drive Input & Output

Contactors? or Open Drive Input & Output Contactors? dialog box.

ATT EN TI ON : Operations in this graphic can only operate while on local control.

ATT EN TI ON : This operation can only operate while drive is not running.

46 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 47

Setup and Operation Chapter 3

IMPORTANT

Open/Close Bypass Contactors

Turn the 3-position on the selector switch on the front of the LV Cabinet to the

Bypass position.

1. Und er Contactor Operation, press either or .

2. Select to confirm in the Close Bypass Contactors? or Open

Bypass Contactors? dialog box.

ATT EN TI ON : Operations in this graphic can only operate while on local control.

ATT EN TI ON : This operation can only operate while drive is not running.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 47

Page 48

Chapter 3 Setup and Operation

Current Access

Level

User

Account

Settings

The Settings screen is where you can access and modify parameters, choose or

change system language, or change bypass mode.

System Settings Select Language and Bypass Mode

User Set tings View or modify User-level parameter settings

Setup Settings View or modify “P” or “T” parameters

R&D Settings For use by authorized Rockwell Automation personnel only.

System Settings

Change the HMI language or bypass mode under System Settings.

1. Press .

2. Press desired language to choose that language.

48 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 49

Setup and Operation Chapter 3

3. Select bypass mode and press to accept or to cancel.

4. Press to accept.

ATT EN TI ON : Operations in this graphic can only operate while on local control.

ATT EN TI ON : This operation can only be performed when any switch is closed.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 49

Page 50

Chapter 3 Setup and Operation

User Parameter List

User Parameter Value

Reset all Parameters

to Factory Values

Parameter Description

User Settings

You can access, view, or change the user parameters in User Settings.

Change User Parameters

1. Press .

2. The User Login dialog box appears. Press .

3. Enter the User and Password details.

Press to enter user details. Press when finished.

Press to enter password details. Press when finished.

50 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 51

Setup and Operation Chapter 3

IMPORTANT

Numpad

Cancel

Backspace

Enter

4. Press to login.

5. If the login was successful, the Current User will show as User.

6. Press .

If the login information was incorrect, you will be prompted to login again.

In the User Parameters Settings

screen, the user parameters automatically

refresh.

Press the parameter input field to change the parameter value.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 51

Page 52

Chapter 3 Setup and Operation

TIP

Press to restore all user parameters to the factory setting.

ATT EN TI ON : Operations in this graphic can only operate while on local control.

ATT EN TI ON : This operation can only operate while drive is not running.

Press to return to the Parameter Access Level

User parameter access will logout when you exit User Settings.

screen.

52 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 53

Setup and Operation Chapter 3

Page Up

Page Down

Parameter

Number

Parameter

Field

Select a Parameter

number to see the

description here

Reset Parameter

Val ues

IMPORTANT

Setup Settings

View or modify “P” or “T” Parameters in the Setup Settings interface.

View/Change P or T Parameters

You must have Setup login access to view or modify “P” or “T” parameters.

1. Press under Parameter Access Level.

The Setup Login dialog box appears. Press .

2. Enter the User and Password details.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 53

Page 54

Chapter 3 Setup and Operation

IMPORTANT

Press to enter user details. Press when finished.

Press to enter password details. Press when finished.

3. Press to login.

The Current User will now display Setup, indicating appropriate access has

been granted.

4. Once logged in, press to proceed.

If the login information was incorrect, you will be prompted to login again.

5. Press or in the Setup

Parameter Type.

6. Press the Parameter Field and enter desired value on the keypad dialog and

press .

7. Press or to Page Up or Page Down through the parameters.

54 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 55

Setup and Operation Chapter 3

Restore “P” or “T” Parameters

Press to restore the parameters to factory settings.

Press to accept or to cancel.

ATT EN TI ON : Operations in this graphic can only operate while on local control.

ATT EN TI ON : This operation can only operate while drive is not running.

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 55

Page 56

Chapter 3 Setup and Operation

Notes:

56 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 57

P Parameters

Chapter 4

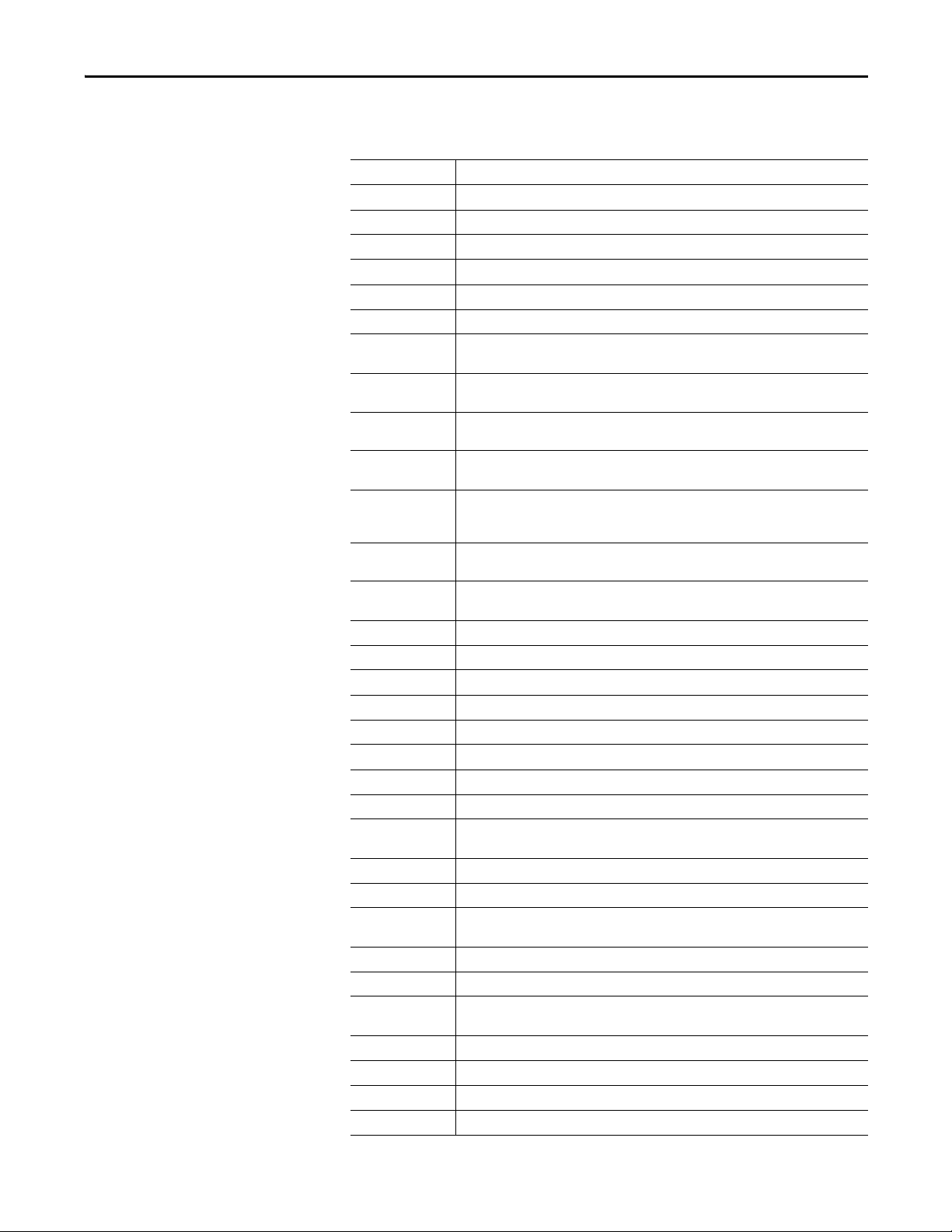

Parameters and Function Codes

Parameter

Number

P004 Command Source

P005 Restore Factory Settings

P007 Numb er Of Po wer Cells Per Phase 9 O N 0 9

P008 Motor Rotation Direction Under Local Control

P009 Motor Rotation Direction Command Selection:

P010 Power Cell Fault Mask 32767 ON 0 32767

P017 Number Of Motor Pole Pairs 2 OFF 0 100

P018 Enable Flying Start With Encoder 0 OFF 0 1

P019 Encoder Resolution 1024 OFF 0 4096

P020 Mask Bit For System Fault 32767 ON 0 32767

P021 Mask Bit For System Warning 32767 ON 0 32767

P022 Mask Bit For Logic Fault A 32767 ON 0 32767

P023 Mask Bit For Logic Fault B 32767 ON 0 32767

P024 Stop Method

P025 Flux Reduction Enable 0 ON 0 1

P026 Power Angle Threshold For Flux Reduction 0 ON 0 180

P027 Time For Flux Reducing 5000 ON 0 32767

P028 Flux Reduction Ratio 70 ON 0 100

P029 Power Angle Threshold For Flux Restore 0 ON 0 180

P040 Safe Start Condition

P089 Skip Frequency Enable

Description Default

Value

0OFF01

0: Communication Port

1: Other Sources

0OFF050

40: User Level

30: Setup Level

50: R&D Level

1OFF01

1: Forward

0: Reverse

0OFF01

0: Local

1: DCS

0ON01

0: Ramp Down

1: Coast Stop

1OFF01

0: Zero Frequency Command Required

1: Frequency Command Allowed

0ON01

0: Disable

1: Enable

Modify

Root

Lower

Limit

Upper

Limit

Rockwell Automation Publication 6000-UM001B-EN-P - October 2014 57

Page 58

Chapter 4 Parameters and Function Codes

Parameter

Number

P090 Skip Frequency 1 Lower Limit 0 ON 0 75

P091 Skip Frequency 1 Upper Limit 0 ON 0 75

P092 Skip Frequency 2 Lower Limit 0 ON 0 75

P093 Skip Frequency 2 Upper Limit 0 ON 0 75

P113 Flying Start-Initial Output Voltage Percentage (%) 5 ON 0 100

P114 Flying Start-Current Comparison Delay For Motor Speed

P115 Flying Start-Current Threshold For Successful Motor

P198 HECS Rated Current (A) 0 ON 0 5000

P199 Motor Rated Current (A) 0 ON 0 5000

P200 Ia Motor Current Memory Address 13 ON 0 500

P201 Motor Ia Scaling Correction Factor 100 ON 0 199.99

P202 Ib Motor Current Memory Address 14 ON 0 500

P203 Motor Ib Scaling Correction Factor 100 ON 0 199.99

P204 Motor Uab Voltage Address 11 ON 0 500

P205 Motor Uab Voltage Scaling Factor Correction 199.99 ON 0 199.99

P206 Motor Uac Voltage Scaling Factor Correction 199.99 ON 0 199.99

P211 Filter Time For Abnormal Output Voltage (ms) 1000 ON 0 32767

P212 Filter Time For Output Short-Circuit (ms) 10 ON 0 32767

P213 Output Short-Circuit Fault Threshold 180 ON 0 199.99

P214 Over Current Low/High Speed Region Boundary 5 ON 0 100

P215 Filter Time For Output Over Current (0.1 s) 200 ON 0 32767

P216 High-Frequency Output Over Current Threshold 120 ON 0 199.99

P217 Low-Frequency Output Over Current Threshold 70 ON 0 199.99

P218 Filter Time For Motor Over Temperature (0.1 s) 6000 ON 0 32767

P219 Motor Over Temperature Warning Threshold 110 ON 0 199.99

P220 Motor Over Temperature Fault Threshold 120 ON 0 199.99

P221 Filter Time For Output Over Voltage (ms) 100 ON 0 32767

P222 Output Over Voltage Fault Threshold 130 ON 0 199.99

P223 Output Voltage Deviation Warning Threshold 60 ON 0 199.99

P224 Output Voltage Deviation Fault Threshold 80 ON 0 199.99

P225 Motor Over Temperature Warning Cancellation

P226 Output Voltage Abnormality Warning Cancellation

P227 Ground Fault Detection Scaling Correction Factor 100 ON 0 199.99

P228 Filter Time For Ground Fault (ms) 1000 ON 0 32767

P229 Ground Fault Warning Threshold 20 ON 0 199.99

P230 Ground Fault Trip Threshold 60 ON 0 199.99

P231 Filter Time For Overspeed Fault (Upper Limit) 100 ON 0 32767

Description Default

Value

1000 ON 0 5000

Search (ms)

5ON0100

Speed Search

100 ON 0 199.99

Temperature

50 ON 0 199.99

Threshol d

Modify

Root

Lower

Limit

Upper

Limit

58 Rockwell Automation Publication 6000-UM001B-EN-P - October 2014

Page 59

Parameters and Function Codes Chapter 4

Parameter

Number

P232 Filter Time For Overspeed Fault (Lower Limit) 100 ON 0 32767

P233 Threshold Of Over-Speed Fault At Lower Frequency Limit 20 ON 0 199.99

P234 Threshold Of Over-Speed Fault At Upper Frequency Limit 20 ON 0 199.99

P235 Frequency Deviation Warning Cancellation Threshold 0.99 ON 0 199.99

P236 Frequency Deviation Warning Threshold 6 ON 0 199.99

P237 Frequency Deviation Warning Delay (ms) 8 ON 0 32767

P238 Motor Stall Fault Threshold 10 ON 0 199.99

P239 Motor Stall Fault Delay (ms) 6000 ON 0 32767

P240 Transformer Over Temperature Fault Delay (ms) 5000 ON 0 32767