Page 1

AllenBradley

VMEbus

Remote I/O

User

Scanner

(Cat.

No. 6008SV1R,

6008SV2R)

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes and

standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are

many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation, and Maintenance of Solid State Control (available from your

local Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen-Bradley Company, Inc., is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: This notation identifies information about

practices or circumstances that can lead to personal injury or

death, property damage or economic loss.

Attention statements help you to:

identify a hazard

avoid the hazard

recognize the consequences

Important: This notation identifies information that is critical for

successful application and understanding of the product.

Page 3

Table of Contents

Using This Manual pi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction pi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audience pi

Required Hardware pi

Terms

Scanner Overview 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using This Chapter 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 11

VMEbus

How the Scanner Scans 16

Comparison to 6008SV Scanner 18

Operating Modes 19

VME Master Processor Watchdog Timer 111

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relationship

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

pii

14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Scanner 21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using This Chapter 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling the Scanner 21

Setting Switches 21

Removing VME Backplane Jumpers 26

Grounding the VME Chassis 26

Inserting the Scanner 27

Determining PowerSupply Requirements 27

Connecting

Addressing

Using This Chapter 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Addressing Concept 31

Choosing an Addressing Mode 33

Addressing BlockTransfer Modules 36

Assigning Racks 37

to the Remote I/O Link

I/O

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

28. . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating with Remote I/O 41. . . . . . . . . . . . . . . . . . . .

Using This Chapter 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Devices that You Can Connect 41

Introduction

Designing

Specifying a Scan List 45

Processing

Processing Block Data 48

to Remote I/O

a Remote I/O Link

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete I/O

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contentsii

Operating

Using This Chapter 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing

Command Summary 56

SETUP command byte 13 57

description 57

parameters 58

coding sequence 58

AUTOCONFIGURE command byte 10 59

description 59

parameters 510

coding sequence 512

SCAN LIST command byte 11 513

description 513

parameters 513

coding sequence 515

FAULT DEPENDENT GROUP command byte 12 516

description 516

parameters 516

coding sequence 518

SET MODE command byte 20 519

description 519

parameters 519

coding sequence 520

LINK STATUS command byte 21 521

description 521

parameters 522

coding sequence 524

BT READ command byte 01 525

description 525

parameters 526

coding sequence 526

BT WRITE command byte 02 527

description 527

parameters 527

coding sequence 528

RESET 529

description 529

parameters 530

coding sequence 530

in SV

Compatible Mode 51. . . . . . . . . . . . . . . . . . .

Global RAM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents iii

Operating

Using This Chapter 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing

Command Summary 67

SETUP command byte 13 68

description 68

parameters 68

coding sequence 610

AUTOCONFIGURE command byte 10 611

description 611

parameters 612

coding sequence 614

SCAN LIST command byte 11 615

description 615

parameters 615

coding sequence 617

FAULT DEPENDENT GROUP command byte 12 618

description 618

parameters 618

coding sequence 620

SET MODE command byte 20 621

description 621

parameters 621

coding sequence 622

LINK STATUS command byte 21 623

description 623

parameters 624

coding sequence 627

BT READ command byte 01 628

description 628

parameters 630

coding sequence 631

BT WRITE command byte 02 632

description 632

parameters 634

coding sequence 635

CONTINUOUS BT READ command byte 06 636

description 636

parameters 638

coding sequence 639

CONTINUOUS BT WRITE command byte 07 640

description 640

parameters 642

coding sequence 643

RESET 644

in SV

Superset Mode 61. . . . . . . . . . . . . . . . . . . . .

Global RAM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contentsiv

description 644. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

parameters 645

coding sequence 645

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the Scanner 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using This Chapter 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understanding the Scanner States 71

Powering Up the Scanner 74

After Waking Up the Scanner 78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming the Scanner 81. . . . . . . . . . . . . . . . . . . . . . . . .

Using This Chapter 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Semaphore 81

Knowing When a Command Is Complete 82

Programming Examples of Each Scanner Management Command 82

Programming Block Transfers 834

Communicating with PLC5 Processor in Adapter Mode 839

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .

Troubleshooting 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using This Chapter 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indicators 91

Error Codes 92

Troubleshooting Suggestions 94

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental

Performance

VMEbus

Specifications

Specifications

Specifications

A1. . . . . . . . . . . . . . . . . . . . . . . . . . .

A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Using This Manual

Preface

Introduction

Audience

Required Hardware

This manual describes how to install and use the VMEbus remote I/O

scanners (catalog numbers 6008-SV1R and 6008-SV2R).

You should have experience in system development and integration and in

writing software for VMEbus master processors. You should also have a

working knowledge of the C programming language, including the concepts

of structures and pointers. Knowledge of Allen-Bradley 1771 I/O products

is helpful but not essential.

You need a VMEbus-compatible VME master processor to set up and

control the VMEbus remote I/O scanner. You install the scanner in a

standard 6U, full-height VME rack.

The 1771 I/O modules that the scanner monitors and controls depend on

your application. You also need an adapter in the 1771 chassis to allow

communication between the scanner and the I/O modules. You can use any

A-B adapter module or a PLC-5 processor that operates in adapter mode.

pi

Page 8

Preface

Terms

This table defines common terms:

This term: Refers to the:

scanner

VME master processor main CPU of your VME system

VME chassis frame that VME cards are mounted in

VMEbus circuit board or backplane mounted in the chassis that the scanner, the

I/O chassis AllenBradley 1771 series I/O chassis

input image table area of global memory in the scanner that contains the data from the

output image table area of global memory in the scanner that contains output data for

block transfer transfer of data between an intelligent I/O module and a scanner

general data area designated area of global VME memory, existing within the scanner,

global RAM an area of global VME memory in the scanner that can be accessed

semaphore bit bit that indicates whether part of the global RAM (the general data

scan list list that the scanner maintains internally to determine the I/O racks that

both remote scanners (catalog numbers 6008SV1R and 6008SV2R)

The VME master processor runs the application program that

accesses the scanner. A VME system can have more than one VME

master processor, each assigned different duties and both accessing

the same scanner(s).

Both the scanner and the VME master processor are mounted in the

chassis along with other VME hardware.

VME master processor, and other VME cards plug into

This is the frame that houses the I/O modules, power supply, and

adapter or PLC processor.

input terminals of input modules

When an input switch is closed its corresponding input bit in the image

table is set to 1.

terminals of output modules

When a bit is set to 1, the corresponding output turns on.

A block transfer sends as many as 64 words of data at a time.

that is used to pass information between the scanner and a VME

master processor.

Scanner commands are processed in this data area.

by both the scanner and the VME master processor(s).

This area of memory is the key means for communication between the

scanner and the VME master

area) is being used.

Typically this bit is used to prevent multiple masters or the scanner

from writing to the general data area simultaneously.

it is to scan, and the order in which it is to scan them.

You create the scan list using the AUTOCONFIGURE command or the

SCAN LIST command.

pii

Page 9

Scanner Overview

Chapter

1

Using This Chapter

Introduction

This chapter provides an overview of the scanner. This chapter describes

how the scanner relates to the VMEbus and to the remote I/O link.

If you want to read about: go to page:

introduction

VMEbus relationship 14

how the scanner scans 16

operating modes 19

VME master processor watchdog timer 111

The VMEbus scanners (catalog number 6008-SV1R and 6008-SV2R)

monitor and control remote Allen-Bradley I/O modules without using a

PLC processor. Use your VME master processor(s) to manage as many as

32 racks of remote A-B I/O (16 per scanner channel).

The scanner communicates with I/O adapters that reside in the left slot of a

remote chassis and with other products that have node adapters built into

them. The scanner transfers the information necessary to control discrete

and block-transfer data to and from the VMEbus.

The VMEbus scanner physically resides in the VME chassis. The scanner

occupies one 6U (full-height) VME slot. The scanner uses the P1

connector to interface to the VMEbus. You can use more than one scanner

in your VME system to create large and flexible I/O subsystems.

11

To the VMEbus, the scanner is a memory-mapped slave that responds to

8-bit or 16-bit accesses in either A16 or A24 address space. The scanner

can act as a VME interrupter on any of the seven VMEbus interrupt lines.

The SV1R and SV2R scanners replace the Allen-Bradley 6008-SV

scanner. The SV1R has one remote I/O channel; the SV2R has two remote

I/O channels. The SV1R and SV2R scanners have an extra embedded

communication microprocessor, which gives them more flexibility and

faster performance than the 6008-SV scanner. The new scanners are

backward-compatible with the 6008-SV scanner and offer:

continuous block-transfer operations

each remote I/O channel supports as many as 16 racks of remote I/O

configurable scan rate at 57.6, 115.2, or 230.4 kbps

VME interrupt signals change in the scanner input table

11

Page 10

Chapter

1

Scanner Overview

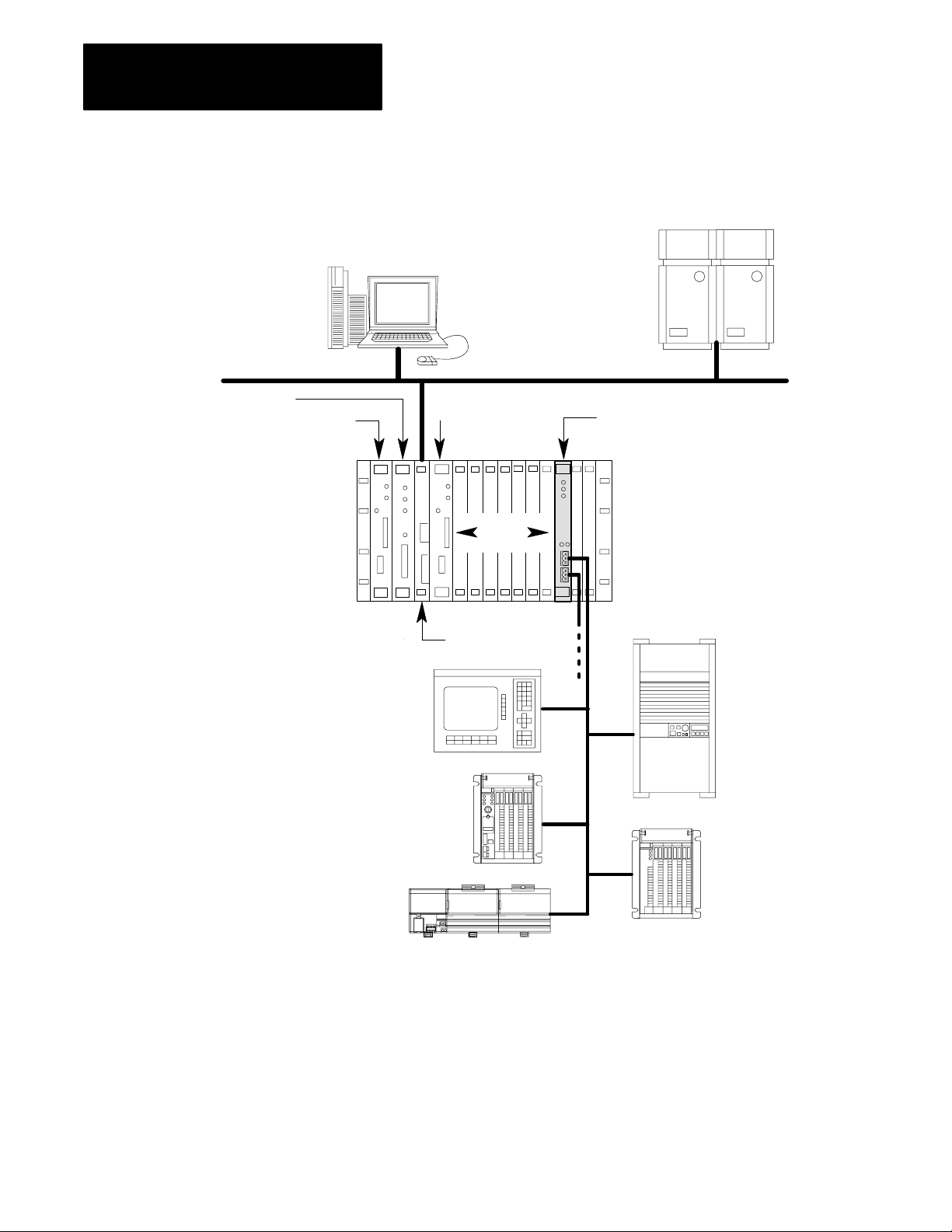

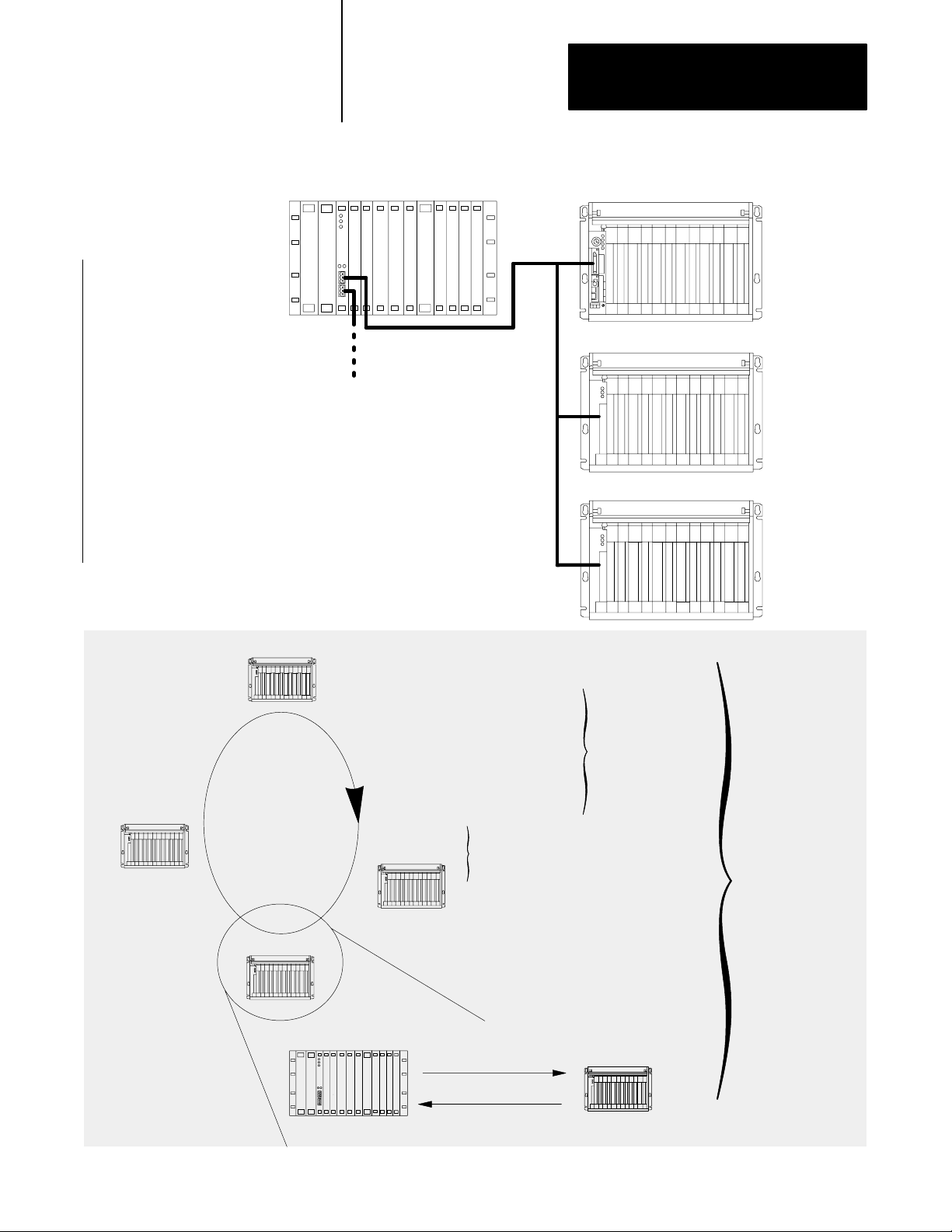

Figure 1.1

connection overview

System

HP 9000 computer

VAX computer

Ethernet network

Vision

VME CPU

VME CPU

PanelView

PLC5 processor

Ethernet

Data

remote I/O

channel B

6008SV2R

VME chassis

remote I/O

channel A

1336 drive

Flex I/O

Note: The 6008SV1R scanner is interchangeable with the 6008SV2R scanner,

except that the SV1R scanner supports only one channel of remote I/O.

12

chassis with 1771ASB

Page 11

Chapter

1

Scanner Overview

Each scanner channel supports as many as 32 physical adapters (16 logical

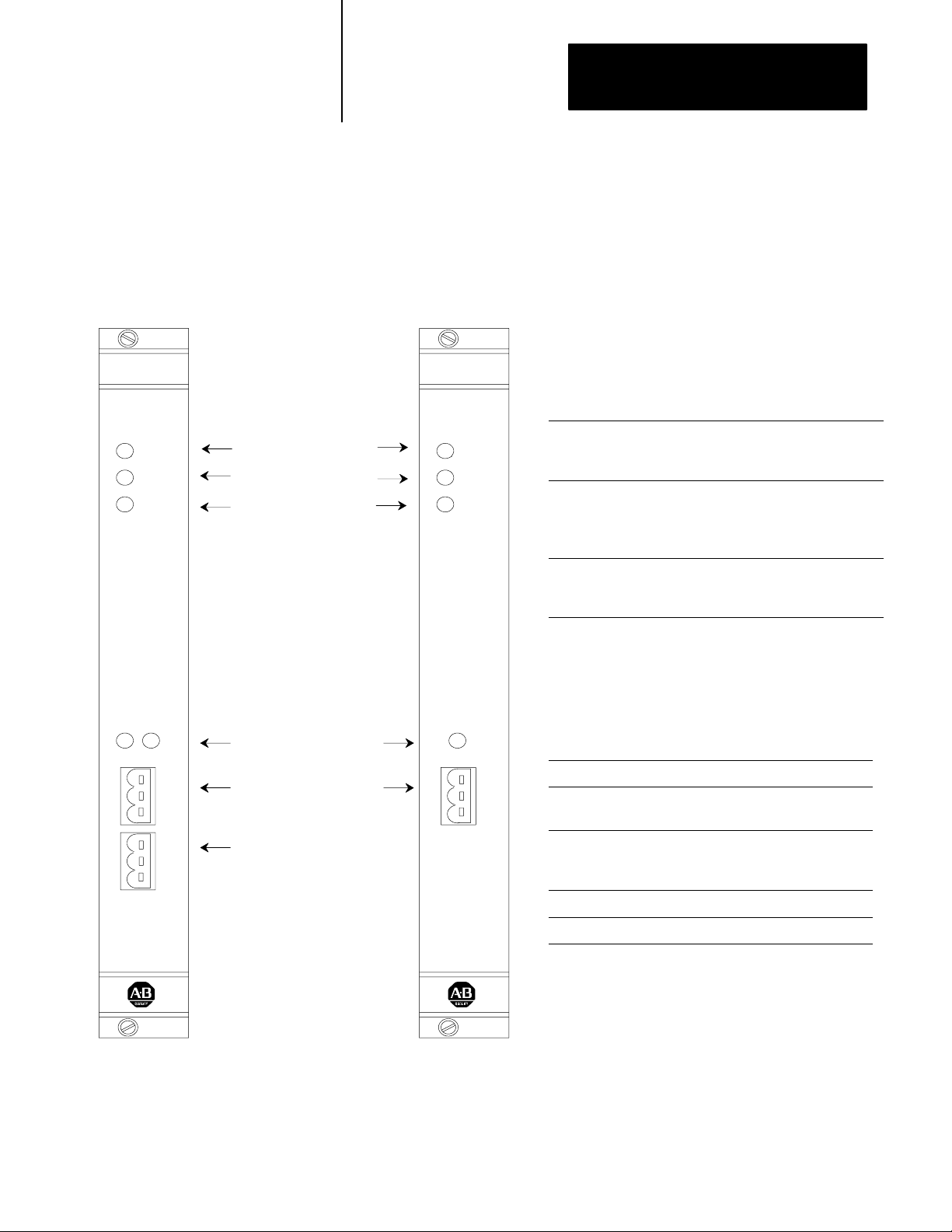

racks). Figure 1.2 shows the front panels of the scanners.

6008SV2R

6008SV2R

PWR

BPLN

COM

FLT

AB

Indicators:

power (green)

VMEbus backplane

communication (green)

fault (red)

Indicators:

channel status (green/red)

Channels:

remote I/O channel A

communication port

(factory enabled)

Figure 1.2

Scanner

front panel

6008SV1R

6008SV1R

A

PWR

BPLN

COM

FLT

Table 1.A

Significance of scanner indicators

When this

indicator:

PWR

(power)

green LED

BPLN COM

(backplane

communication)

green LED

FLT

(fault)

red LED

is: it means:

illuminated power is applied to the

module

illuminated for

approximately

a half second

illuminated the scanner board is reset,

a VMEbus access is made

to the scanner board

performing a self test, or a

fault has been detected

Table 1.B

Significance

of channel status

indicators

When the status

indicator is:

off

green is on line, in Run mode, and

the scanner:

is off line

scanning the racks in the scan list

remote I/O channel B

communication port

(factory disabled)

blinking green is on line, in Run mode, and

scanning only some of the racks in

the scan list

red has an unrecoverable fault

blinking red has a recoverable fault

13

Page 12

Chapter

1

Scanner Overview

VMEbus Relationship

The scanner complies with the VMEbus specification (revision C.1) and

responds to VME masters on the VMEbus. The scanner appears as an area

of global VME RAM to other master processors on the VMEbus. This

area contains the I/O image area, control/status area, general data area, and

interrupt ID area.

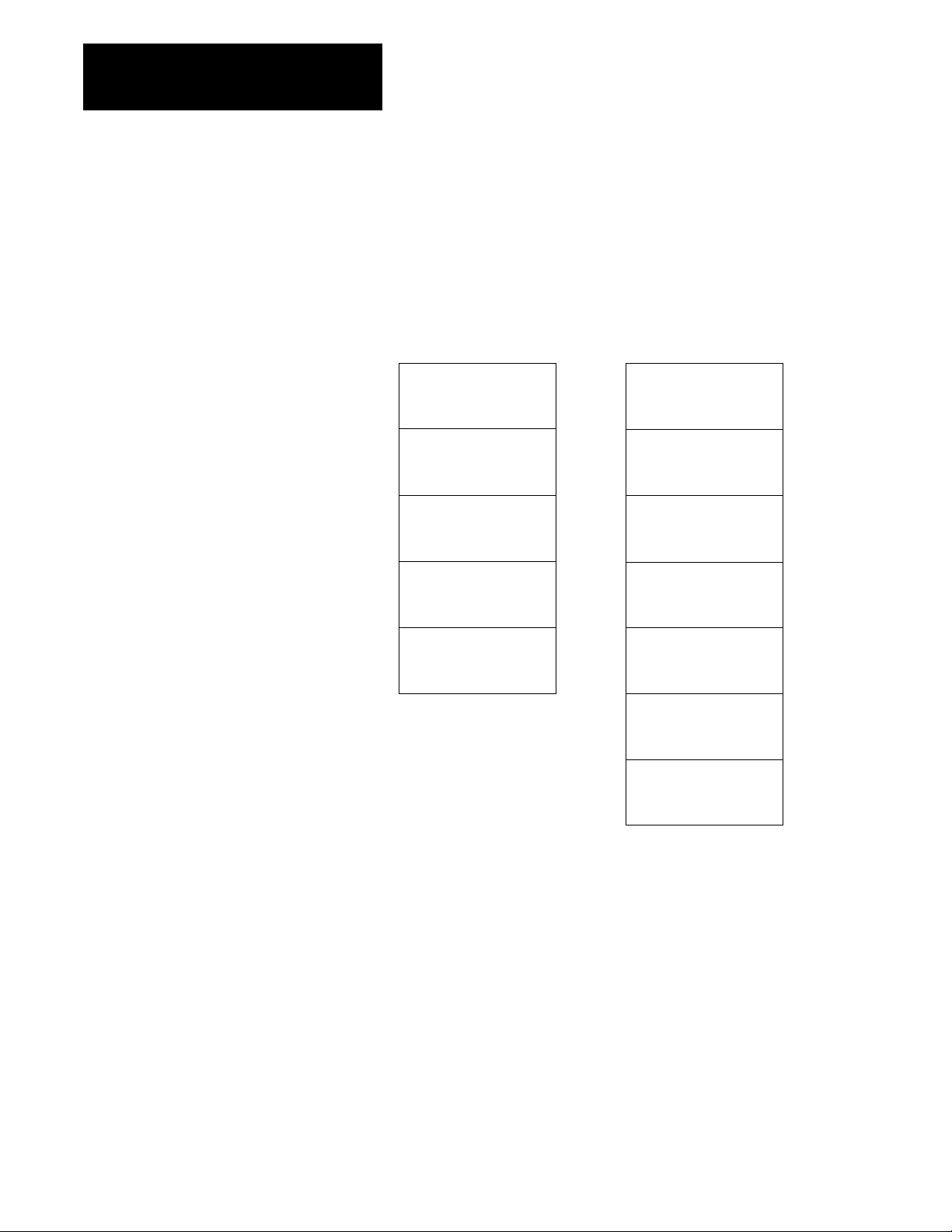

memory map for one channel

SVcompatible mode SVsuperset mode

output image table

64 words

input image table

64 words

control/status area

16 words

general data area

1872 words

output image table

128 words

input image table

128 words

control/status area

16 words

general data area

112 words

interrupt/VME ID area

32 words

continuous BT write

16 entries

(72 words each)

continuous BT read

32 entries

(72 words each)

interrupt/VME ID area

32 words

For more details on these memory areas, see chapter 5 or 6 for

SV-compatible mode or SV-superset mode, respectively.

There is no direct communication between a VME master processor and

the discrete I/O, rather the VME master processor communicates with the

I/O image table in the scanner (shown above). The VME master processor

reads the status of inputs from the input image table and controls the

outputs by writing data to the output image table.

14

Page 13

Chapter

Scanner Overview

1

These VMEbus transfers are asynchronous to the scanner’s I/O update.

This means there is no way to know exactly when the data being put in the

output image table will be sent to the appropriate I/O rack. Data is sent to

an adapter only when that adapter is being scanned. Best-case timing is if

the data is placed in the output image table just before the specified adapter

is scanned; worst-case timing is if the data is placed in the output image

table just after the specified adapter was scanned. In the worst-case

scenario, the data does not reach the specified I/O rack until the next time

that adapter is scanned.

How the Scanner Responds to VME Signals

The scanner can generate interrupts on any of seven request levels

(IRQ1-IRQ7). When a VMEbus master acknowledges the interrupt, the

scanner replies with a vector (status/id) using the odd 8 bits of the data bus.

Important: The VME master processor might “crash” if there is no

software routine written to process an interrupt from the scanner. Or, you

can use the SETUP command to configure the scanner so that it never

generates interrupts, in case no interrupt software routine has been written.

If the scanner does not generate interrupts, the application program must

“poll” the scanner to see when commands have been processed.

The scanner responds to Data Transfer Bus (DTB) cycles initiated by

masters that transfer data 16 bits at a time or 8 bits transferred in an even

and odd format (D16, D08EO). The scanner works in the 16-bit (short)

addressing mode or the 24-bit (standard) addressing mode.

The scanner responds to common VME signals as follows:

This VME

signal:

SYSFAIL

ACFAIL When the scanner recognizes an ACFAIL signal, it shuts itself down because this

SYSRESET If SYSRESET is asserted on the VMEbus, the scanner resets itself and goes

means:

When the scanner recognizes a SYSFAIL signal, it can either ignore the signal or

shut itself down, depending on how the scanner is configured. When the scanner

shuts down, the I/O serviced by the adapter either resets to a default condition or

holds all of its current values, as determined by switches on the I/O chassis

backplane. When the scanner is faulted or shut down, it asserts SYSFAIL on

the VMEbus.

means that power will soon be gone. When the scanner shuts down, the I/O

serviced by the adapter either resets to a default condition or holds all of its

current values as determined by switches on the I/O chassis backplane.

through its initialization tests. The scanner does not clear (reset to 0) the input

and output image tables. After a SYSRESET signal, you have to wake up the

scanner, the same as a powerup situation.

15

Page 14

Chapter

Scanner Overview

1

For more information, see the VMEbus specification (revision C.1)

published by VITA (VMEbus International Trade Association), 10229 N.

Scottsdale Rd., Suite B, Scottsdale, AZ, 85253, (602) 951-8866. Contact a

VITA representative for a copy.

VMEbus Address Modifier Codes

The scanner can respond to the following VMEbus address modifier codes,

depending on how you configure the scanner’s address space and response

to VME accesses.

How

the Scanner Scans

This code

(hex):

3D

39 standard (A24) nonprivileged access

2D short (A16) supervisory access

29 short (A16) nonprivileged access

means:

standard (A24) supervisory access

The scanner runs asynchronously to other VME master processors. Once

in Run mode, the scanner continuously scans all the adapters in its scan

list. The scan list identifies which adapters to scan and in what order to

scan them. An adapter can appear several times in the scan list. For more

information about using the scan list, see chapter 4.

When the scanner scans an adapter, it brings in digital input data and

places the data in the scanner’s input image table. At the same time, the

scanner sends digital output data to the adapter.

16

Page 15

VME system with scanner

(scanner using only 1 channel)

Chapter

1

Scanner Overview

remote I/O system

adapter 1

example scan list:

adapter 1

adapter 2

adapter 1

adapter 3

➂ scan adapter 1

scan

list:

adapter 1

adapter 2

adapter 1

adapter 3

➃ scan adapter 3

remote I/O channel A

remote I/O channel B

(6008SV2R only)

➄ if the VME master

processor sent a command,

execute the command and then

return to processing the scan list

if there is no command, continue

processing the scan list

adapter 2

adapter 3

command processing

➁ scan adapter 2

scanner

➀ scan adapter 1

adapter scan

output data

status and input data

scanning the

adapters in the

scan list

17

Page 16

Chapter

Scanner Overview

1

Getting the Scanner's Attention

For a VME master processor to get the scanner’s attention, it must write a

value (any value) to any byte in the scanner’s identification area. This area

is located in the last 64 bytes of the global RAM for each scanner channel.

The scanner gets the attention of a VME master processor by generating a

VMEbus interrupt to which the VME master processor must respond. This

interrupt is sent when the scanner finishes commands that a VME master

processor initiated.

Comparison to

6008SV Scanner

The 6008-SV1R and 6008-SV2R scanners replace and are backward

compatible with the Allen-Bradley 6008-SV VMEbus remote I/O scanner.

The 6008-SV1R and 6008-SV2R scanners offers these improvements:

each remote I/O channel controls as many as 32 adapters

configurable communication rate of 230.4, 115.2, or 57.6 kbps lets you

select I/O scan time

embedded communication microprocessor increases

scanner performance

VME interrupt signals change in the scanner input table

configurable VME operating mode lets you select the scanner features

you need for your application

Important: The SCAN LIST command is the only difference between the

6008-SV1R and 6008-SV2R scanners and the 6008-SV scanner. If you use

that command, you must modify the command to specify the rack size.

The 6008-SV1R and 6008-SV2R also offer improved block transfer

operations. In addition to single block transfer operations, the 6008-SV1R

and 6008-SV2R support continuous block transfer operations. A single

block transfer is a single read or write transfer to a specific intelligent I/O

module. If your application needs to continuously poll a module to receive

up-to-date data, use a continuous block transfer request. The continuous

block transfer requests uses less programming overhead than programming

a single block transfer request each time you need the data.

18

Page 17

Chapter

1

Scanner Overview

Operating

Modes

Before you begin using the scanner, you have several choices to make

concerning how the scanner operates. You need to specify how the scanner

operates in the VME system and how you want to program the scanner.

Selecting VME Operating Mode

The scanner offers two VME operating modes. The mode you select

determines the command set available to the scanner and the memory

structure the scanner uses. You set a switch on the scanner to specify the

operating mode you want.

If you want: select this VME

the scanner to operate exactly as the 6008SV scanner

This mode is compatible with the 6008SV so you can run

previouslydeveloped applications with minor modifications. Select

this mode if you are replacing a 6008SV with a 6008SV2R and do

not want to modify your application.

In any application that uses the SCAN LIST command with the

6008SV scanner, you must modify the command to specify the

rack size.

For more information see chapter 5.

the scanner to use the new commands and additional memory, as

compared to the SVcompatible mode

This mode provides additional features, as compared to the 6008SV.

For more information, see chapter 6.

operating mode:

SVcompatible

SVsuperset

Important: An application developed for one operating mode will not

work in another operating mode.

19

Page 18

Chapter

1

Scanner Overview

Selecting a Programming Mode

Select the appropriate programming mode for programming the scanner.

Table 1.C

Programming

modes

If you want these conditions: select this

• the scanner doesn't send output information to the adapters

• all module outputs are reset (off); outputs are disabled, so they

remain reset

• discrete input information is updated

• the scanner doesn't send blocktransfer requests to the adapters,

but the scanner will queue the requests from the VME

master processor

• the scanner sends output information to the adapters

• all module outputs are held reset (off) outputs are disabled, so they

remain reset

• discrete input information is updated

• the scanner sends blocktransfer requests to the adapters, but

actual outputs are disabled (reset)

• the scanner sends output information to the adapters

• input information is updated

• the scanner sends blocktransfer requests to the adapters

• all outputs are allowed to energize

programming mode:

Program

Test

Run

When your application program first starts the scanner with the SETUP

command, the scanner is in the Program mode. Your program must issue a

SET MODE command to change the scanner to Run mode.

110

Page 19

Chapter

Scanner Overview

1

VME

Master Processor

Watchdog Timer

The VME master processor must issue a valid command to the scanner at

least once in a user-specified time period (the default is 500 msec). If the

scanner fails to see a valid command from a VME master processor in this

time period (as counted by the watchdog timer), the scanner resets itself

and repeats its startup initialization sequence. This causes the I/O racks on

the link to fault within 100 msec and the I/O all turn off or remain in their

last state, depending on the switch setting on the I/O chassis.

You can disable the watchdog timer or change its timeout period with the

SETUP command.

To keep the watchdog from shutting down the scanner, periodically issue a

LINK STATUS command. This command provides the application

program with important diagnostic information about the status of the I/O

link and, at the same time, causes the least amount of overhead for the

scanner to complete the command.

To debug your application program you can select debug mode and disable

the watchdog timer using the SETUP command.

ATTENTION: Unwanted machine action can result from

disabling the VME master processor watchdog. When the VME

master processor watchdog is disabled, the scanner has no way

of knowing that communication has been lost with your VME

master processor and will continue to send data from the output

image table to the output modules.

111

Page 20

Installing the Scanner

Chapter

2

Using This Chapter

Handling the Scanner

This chapter explains how to install the scanner and connect it to a remote

I/O link. For information about programming and using the scanner, use

the flow chart preceding each chapter to determine where to find the

information you need.

If you want to read about: go to page:

handling the scanner

setting switches 21

removing VME backplane jumpers 26

grounding the VME chassis 26

inserting the scanner 27

determining power requirements 27

connecting to the remote I/O link 28

The scanner is shipped in a static-shielded bag to guard against

electrostatic damage. Electrostatic discharge can damage integrated

circuits or semiconductors in the scanner. Avoid electrostatic damage by

observing these precautions.

Remain in contact with an approved ground point while handling the

scanner (by wearing a properly grounded wrist strap).

21

Wrist strap

Setting Switches

Do not touch the backplane connector or connector pins.

When not in use, keep the scanner in its static-shielded bag.

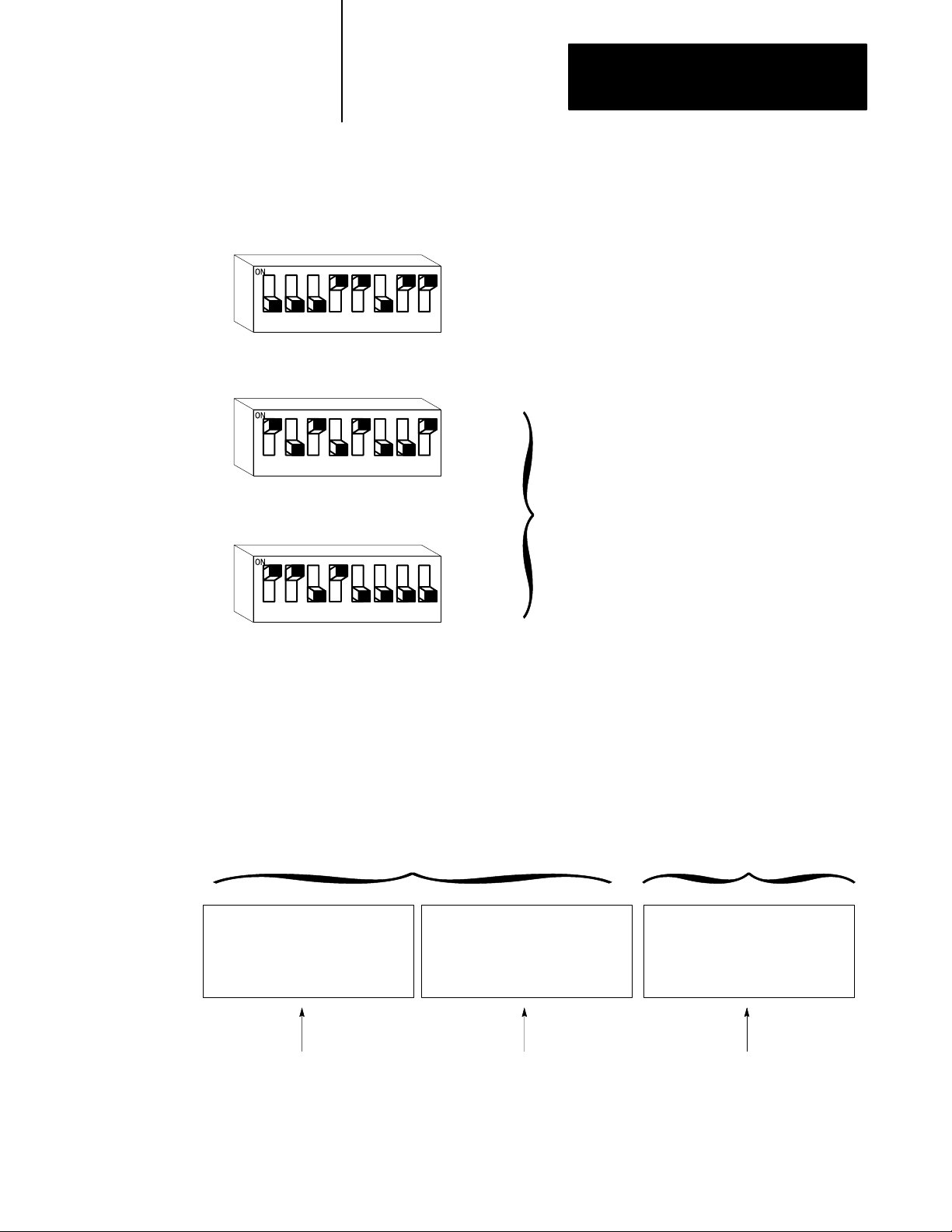

The scanner has several on-board switches you set to configure:

address space

VME operating mode

VME address space

scanner responses to VME accesses

21

Page 21

Chapter

2

Installing the Scanner

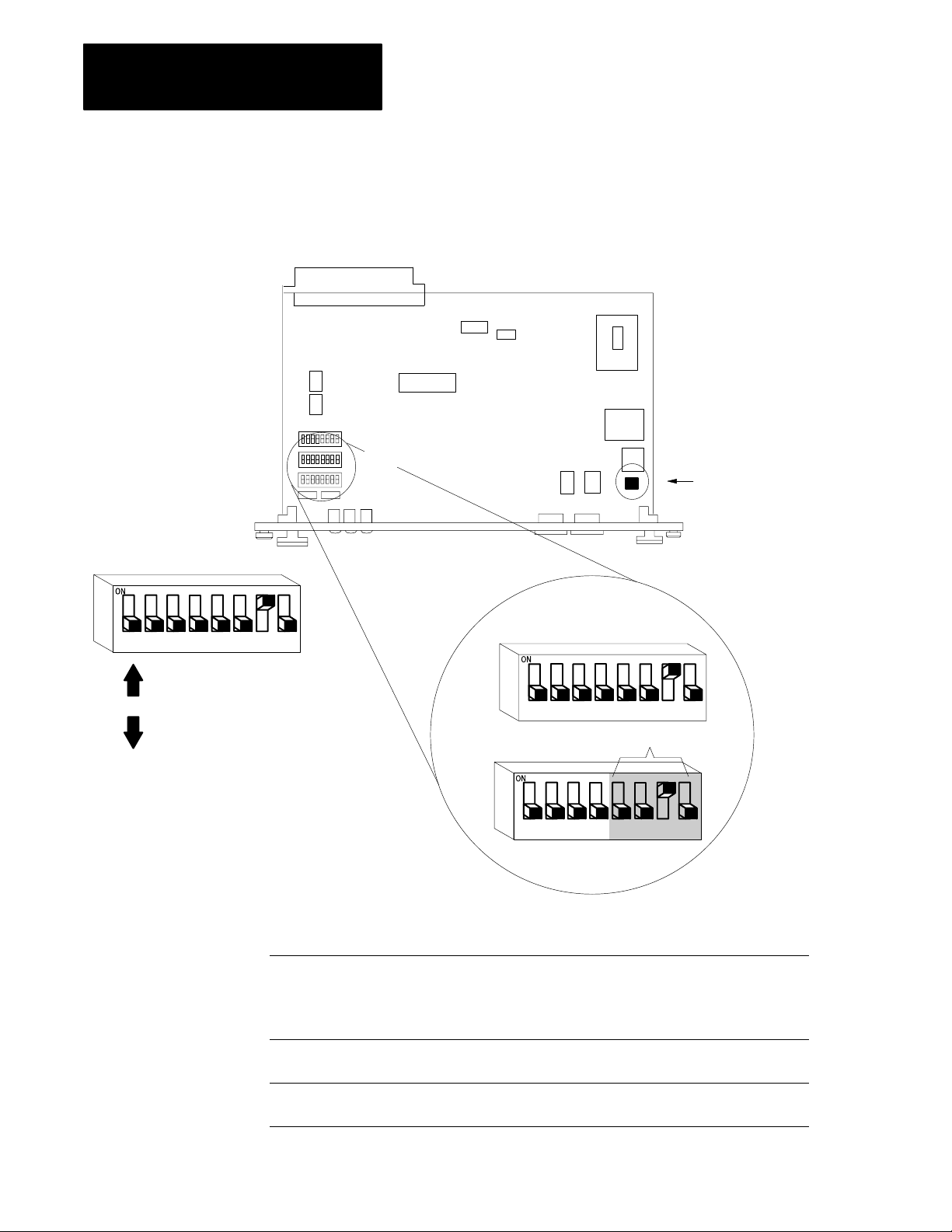

Determine the VMEbus A24/A16 Address Space

Use this diagram and the example to set SW1 and SW2 for the correct

VMEbus address space.

12345678

slide switch pushed up

on = closed = 0

slide switch pushed down

off = open = 1

SW2

SW1

Important: These pins are

for manufacturing use only

- do not jumper these pins.

A23 A22 A21 A20 A19 A18 A17 A16

SW2

12345678

reserved

A15 A14 A13 A12

SW1

12345678

22

In this VME

operating mode:

SVcompatible

SVsuperset A23 through A13 1 channel active

If there are switches not accounted for in a particular address space, such as the switches for A16A23

for SVcompatible, A16 address space, the switch position does not affect scanner operation.

these bits: are valid for this

A23 through A12 1 channel active

A23 through A13 2 channels active

A15 through A12 1 channel active

A15 through A13 2 channels active

A23 through A14 2 channels active

address space:

A24

A16

A24

Page 22

Chapter

2

Installing the Scanner

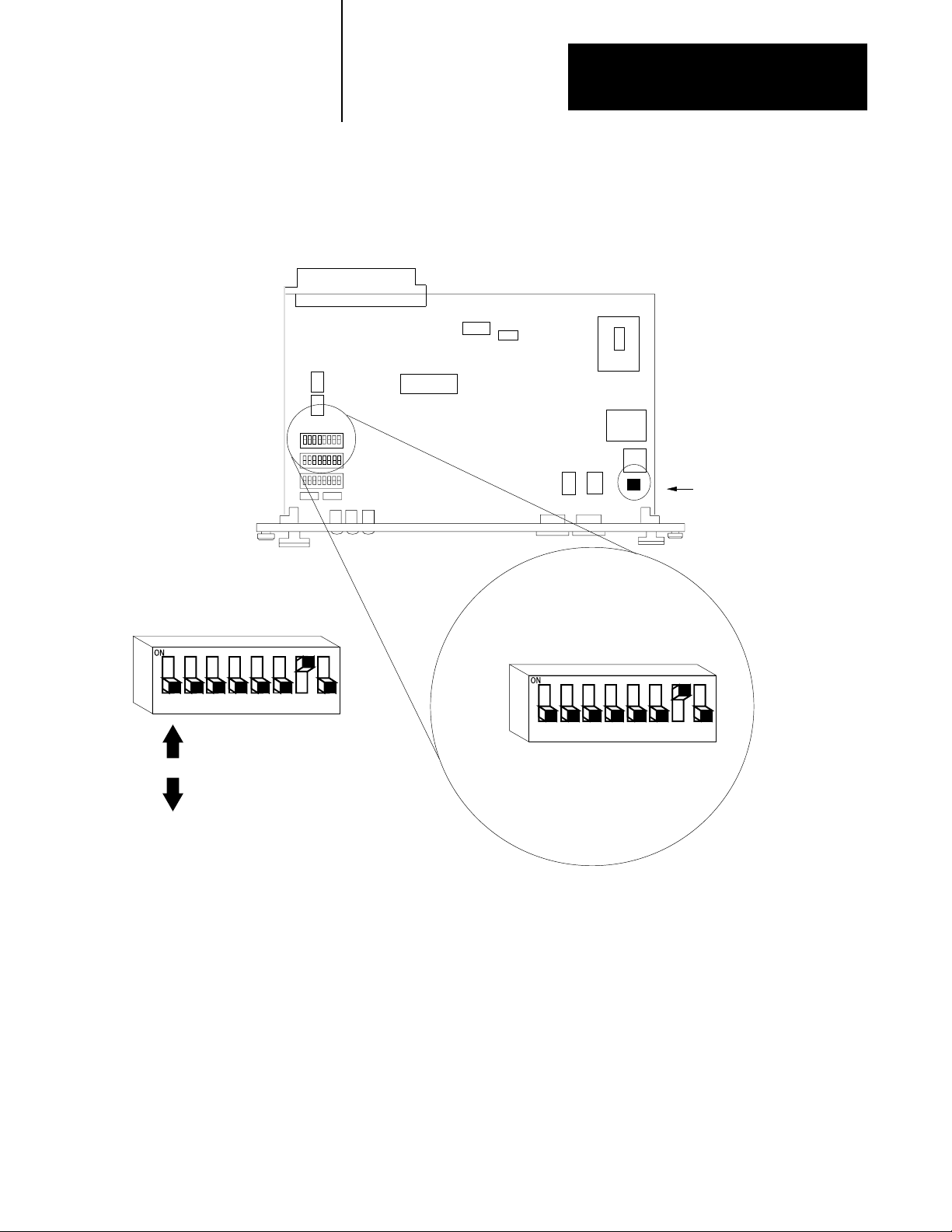

Determine the Operating Mode, Address Space, Scanner Response,

and Rack Configuration

Use this diagram and Table 2.A on page 2-4 to set SW3.

SW3

Important: These pins are

for manufacturing use only

- do not jumper these pins.

12345678

slide switch pushed up

on = closed = 0

slide switch pushed down

off = open = 1

SW3

12345678

23

Page 23

Chapter

2

Installing the Scanner

This switch: configures: with these options:

Table 2.A

settings for SW3

Switch

switch 1, 2, 3

switch 4, 5 VME operating mode switch 4 switch 5

switch 6 VME address space on A16

switch 7 how the scanner responds to

switch 8 which channels are active on only channel A is active

not used set to off

on on SV compatible

on off SV superset

off off reserved

off on reserved

off A24

Select A24 if you select SVsuperset as the VME operating mode.

on responds to nonprivileged and supervisory VME accesses

VME accesses

off responds to supervisory VME accesses

off both channel A and B are active

this switch is ignored if you are configuring the 6008SV1R

(2D, 3D, 29, and 39 address modifiers)

(29 and 39 address modifiers)

24

Page 24

For example:

12345678

12345678

SW3

SW2

Chapter

2

Installing the Scanner

These switch settings specify:

• SVcompatible mode

• A24 address space

• response to both nonprivileged and supervisory access

• only channel A is active

Switch

These switch settings specify VME address 562,000.

SW1

12345678

Specifying VME addresses

You specify the first digit (for A16) or first 3 digits (for A24) of the

address space; the remaining digits are always 0. The switches are set

from left to right. For example, to set the address space at 562,000 (hex) in

A24 with one channel active, set the bits as:

VME address space of 562,000 (hex)

A24 address mode with 1 channel active

SW1SW2

A23 A22 A21 A20 A19 A18 A17 A16 A15 A14 A13 A12

Setting

010101100010

(on) (off) (on) (off) (on) (off) (off) (on) (on) (on) (off) (on)

562

The last three digits in 562,000 (hex) address are already determined

by the scanner, so there are no switches to set.

25

Page 25

Chapter

Installing the Scanner

2

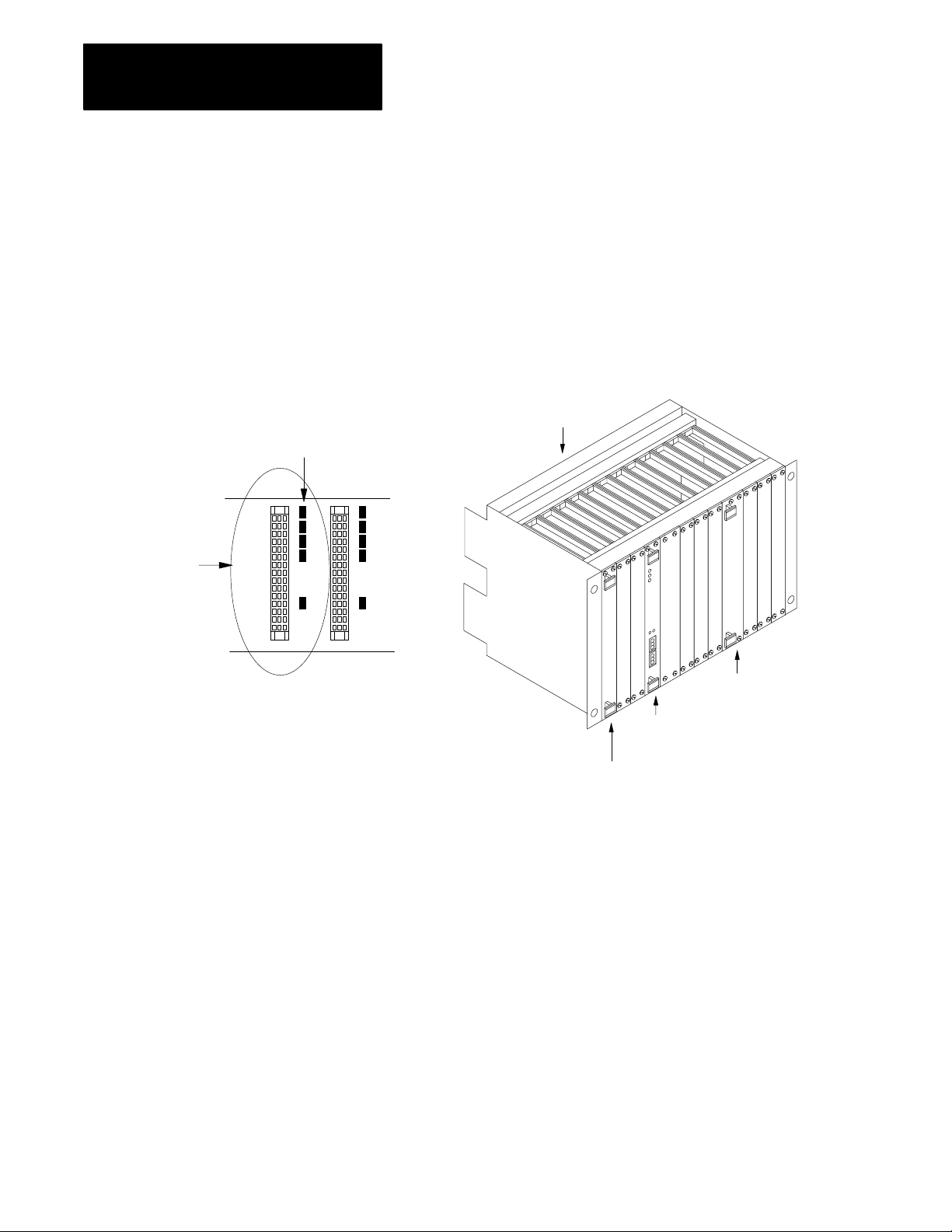

Removing

VME

Backplane Jumpers

one empty slot

(jumpers are installed)

The VMEbus has several daisy-chained control signals. Almost all

VMEbus backplanes contain jumpers for these control signals to allow

systems to operate with empty slots. There are five jumpers per VME

slot, one for each of the four bus-grant arbitration levels and one for the

interrupt-acknowledge daisy chain.

Depending on the backplane manufacturer, the jumpers can be on the

rear pins of the J1 connector or alongside it on the front of the backplane.

The scanner uses 1 slot of the VME backplane. Remove these jumpers

from the slot where you plan to insert the scanner.

remove all the backplane

jumpers in the slot where

you insert the scanner

backplane

Grounding the VME Chassis

other VME module

scanner

CPU

Allen-Bradley makes specific recommendations for properly grounding its

racks so that their operation is as safe and error-free as possible. VME

systems, on the other hand, may have no formal specifications for

grounding the VME chassis frame. Allen-Bradley recommends that you

ground the VME chassis frame and that you connect the logic ground

(common) of the VME power supply to the chassis frame’s earth ground.

The specific procedure for grounding a VME chassis varies depending on

the style of the chassis. Read the Programmable Controller Wiring and

Grounding Guidelines, publication 1770-4.1, for information on how

Allen-Bradley racks are grounded, and try to ground your VME chassis

frame in a similar way.

26

Page 26

Chapter

Installing the Scanner

2

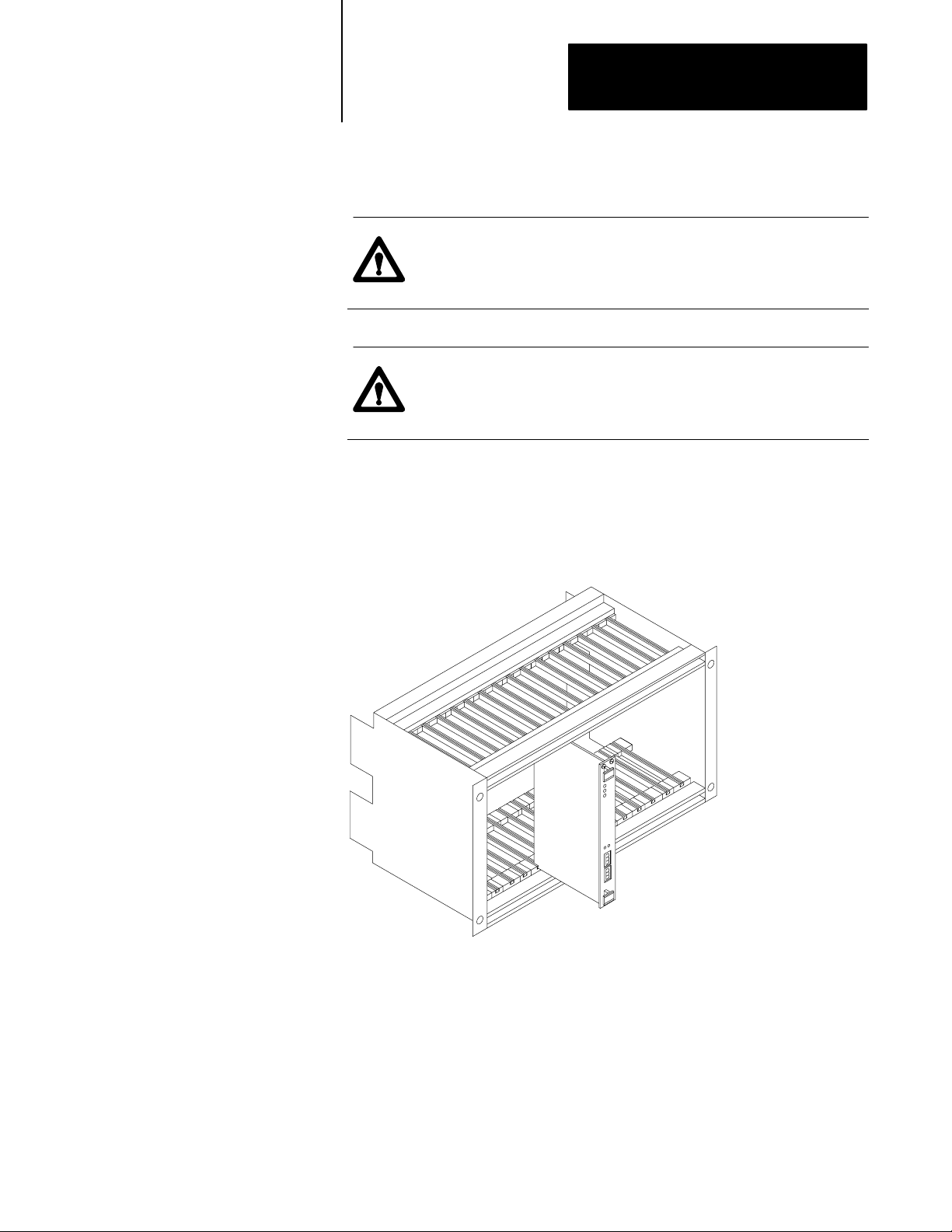

Inserting the Scanner

Insert the scanner in one slot in a 6U (full-height) VMEbus chassis.

ATTENTION: Make sure that your VME system is powered

off. The scanner is not designed to be inserted or removed from

a live system.

ATTENTION: Avoid touching the circuit board

and connectors. You might damage the board, or electrostatic

discharge might damage the board.

Use the VME chassis card guides to slide the scanner into the chassis. Use

firm pressure on the top and bottom handles of the scanner to make its

P1 connector fit firmly into the connector on the backplane. Tighten the

screws on the top and bottom of the front panel to prevent the scanner

from loosening.

Determining PowerSupply

Requirements

The scanner operates on 5V dc @ 2.3A (typical), 2.5A (maximum).

27

Page 27

Chapter

2

Installing the Scanner

Connecting to the

Remote I/O Link

Each scanner channel supports as many as 32 physical adapters. Use

1770-CD (or Belden 9463) cable. Connect a remote I/O network using a

daisy-chain or trunkline/dropline configuration.

Table 2.B

number of devices the scanner supports

Total

In this mode: the maximum number

SVcompatible

SVsuperset 16 32

of logical racks per

channel is:

8 16

and the maximum

number of physical

adapters per channel is:

Important: The maximum cable length for remote I/O depends on the

transmission rate. Configure all devices on a remote I/O link to

communicate at the same transmission rate.

Table 2.C

the correct cable length based on the link'

Choose

A remote I/O link using this

communication rate:

57.6 kbps

115.2 kbps 1,524 m (5,000 ft)

230.4 kbps 762 m (2,500 ft)

cannot exceed this

cable length:

3,048 m (10,000 ft)

s communication rate

For proper operation, terminate both ends of a remote I/O link by using

external resistors. See Table 2.D for information on whether to use a 150W

or 82W terminator.

28

Page 28

Chapter

2

Installing the Scanner

Table 2.D

Terminating

If your remote I/O link:

operates at 230.4 K bit/s

operates at 57.6 or 115.2 K bit/s, and no devices listed below are linked

Scanners 1771SN; 1772SD, SD2;

1775SR, S4A, S4B;

6008SQH1, SQH2

Adapters 1771AS; 1771ASB (series A only); 1771DCM

Miscellaneous 1771AF

connects to any device listed below:

Scanners 1771SN; 1772SD, SD2;

1775SR, S4A, S4B;

6008SQH1, SQH2

Adapters 1771AS; 1771ASB (series A only); 1771DCM

Miscellaneous 1771AF

operates at 57.6 or 115.2 K bit/s, and you do not require over 16 physical devices

the remote I/O link

You can connect a remote I/O link in one of two ways:

trunkline/dropline—from the drop line to the connector screw terminals

on the remote I/O connectors of the scanner

usethis

his

use t

resistor

rating:

82W

150W

the maximum number of

physical devices that you

can connect on the link is:

32 16

16 16

racks that you can

scan on the link is:

daisy chain—to the connector screw terminals on the remote I/O

connectors of the scanner and then to the remote I/O connector screw

terminals of the next remote I/O device

Important: The cable connections for the 6008-SV1R and 6008-SV2R

scanner are opposite from those for the earlier 6008-SV scanner. Make

sure you follow the instructions in Figure 2.1 below.

29

Page 29

Chapter

2

Installing the Scanner

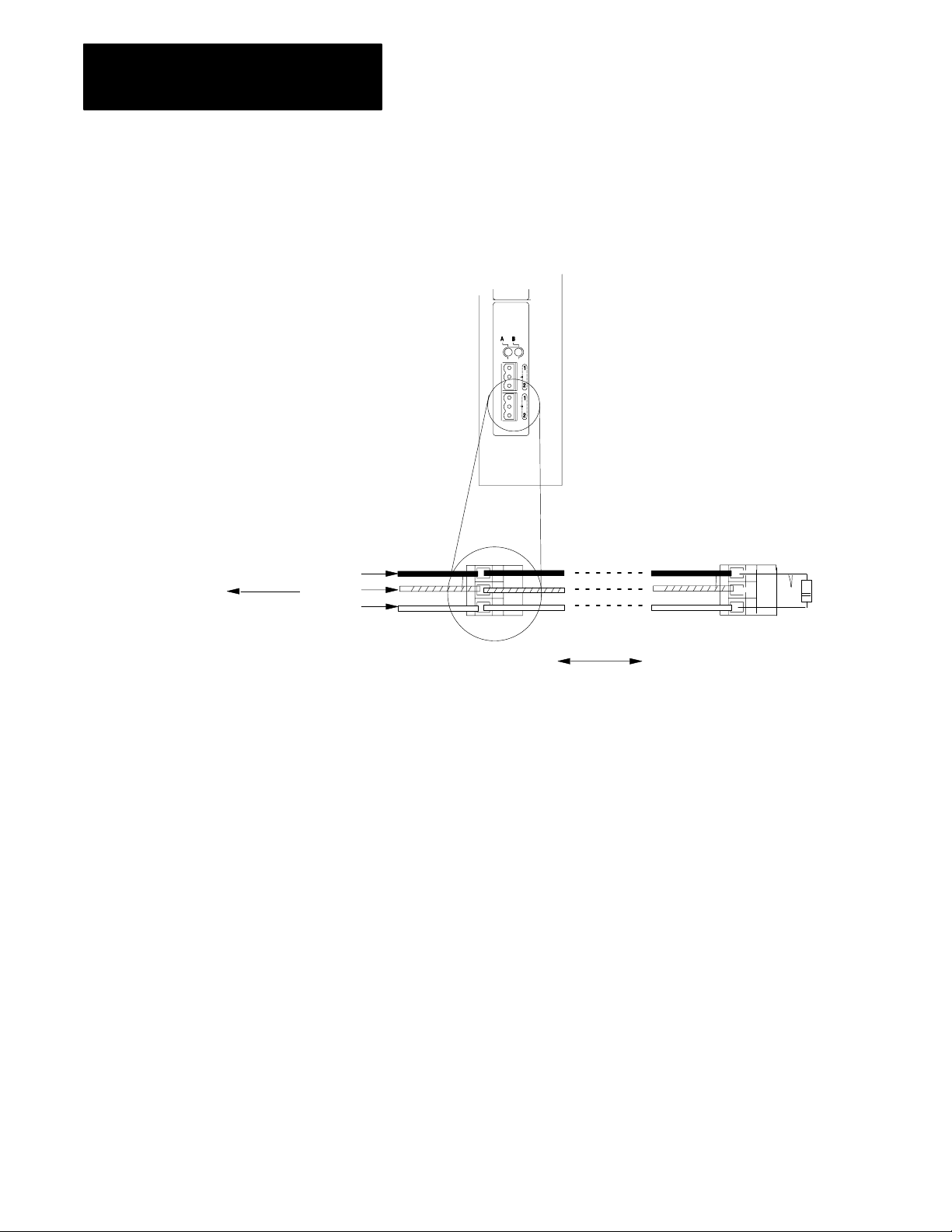

Figure 2.1

remote I/O connections

Make

To connect the remote I/O cable, do the following:

1. Run the cable (1770CD) from the processor to each

remote I/O adapter in the remote I/O system.

2. Connect the signal conductor with blue insulation to the

3pin connector terminal labeled 1 on the scanner and to

each remote I/O adapter in the remote I/O system.

3. Connect the signal conductor with clear insulation to the

3pin connector terminal labeled 2.

4. Connect the shield drain wire to the middle 3pin

terminal (it is not labeled).

5. Tie wrap the remote I/O network cable to the chassis to

relieve strain on the cable.

6. Terminate the remote I/O link by connecting an external

terminator resistor between the remote I/O terminals

labeled 1 and 2.

Important:

Last device on the remote I/O link.

Terminate both ends of a remote I/O link.

To another remote I/O device

Blue

Shield

Clear

1770CD

(Belden 9463)

82Ω or

150Ω

resistor

210

Page 30

Addressing I/O

Chapter

3

Using This Chapter

I/O Addressing Concept

Classification: Term: Relation to memory:

A specific terminal on an I/O module

I/O terminals that when combined occupy 1 word in

the input image table and 1 word in the output

image table

Combinations of bits or I/O groups I/O rack 128 input bits and 128 output bits

This chapter provides an overview of I/O addressing. This chapter also

explains the basics of how the scanner processes discrete I/O and

block-transfer data.

If you want to read about: go to page:

I/O addressing concept

choosing an addressing mode 33

addressing blocktransfer modules 36

assigning racks 37

Each terminal on an input or output module that can be wired to a field

device occupies a bit within the scanner’s input image table or output

image table.

I/O addressing maps the physical location of an I/O module terminal to a

bit location in the processor memory. I/O addressing is just a way to

segment memory:

terminal or

point

I/O group 16 input bits = 1 word in the input image table

The density of an I/O module, i.e., 8point, 16point, 32point,

directly relates to the amount of memory (bits) the module

occupies in memory. For example, a 16point input module

occupies 16 bits in the input image table.

16 output bits = 1 word in the output image table

or

8 input words and 8 output words

or

8 I/O groups

31

Figure 3.1 shows the relationship between an I/O terminal and its location

in scanner memory.

31

Page 31

Chapter

3

Addressing I/O

Figure 3.1

addressing as it relates to an I/O terminal

I/O

rack number 01

I/O group number

A

B

C

D

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

E

Input Module

(1771IAD)

0

Output Image Table

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

[

00

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Input Image Table

word

address

00

01

07

[

00

07

rack number 01

I/O group number

Output Module

(1771OAD)

1

A

B

C

D

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

E

32

Important: The scanner addresses the image table with hexadecimal

values. The addresses depend on the VME operating mode.

Page 32

Chapter

ЙЙЙЙЙЙЙЙ

3

Addressing I/O

Choosing

an

Addressing Mode

For each chassis in your I/O system, you must define how many I/O

chassis slots make up an I/O group (one word each in the input image table

and output image table); this choice is the chassis’ addressing mode.

Choose from among these available modes:

2slot

addressing

2 I/O chassis slots = 1 I/O group = 1 input image word and 1 output image word =

16 input bits and 16 output bits.

16 bits input

1slot

addressing

1 I/O chassis slot = 1 I/O group = 1 input image word and 1 output image word =

16 input bits and 16 output bits.

16 bits output

scanner memory

Rack x

Output Image Table

Word #

x

x

x

x

x

x

x

x

16 bits input and 16 bits output

1/2slot

addressing

1/2 of an I/O chassis slot = 1 I/O group = 1 input image word and 1 output image word =

16 input bits and 16 output bits.

16 bits input and 16 bits output

When you place your I/O modules in the I/O chassis slots, the module’s

density determines how quickly I/O groups form.

Word #

Input Image Table

x

x

x

x

x

x

x

x

33

Page 33

Chapter

3

Addressing I/O

0 1

Input

Terminals

00

01

02

03

04

05

06

07

Group 0

An 8point I/O module occupies

8 bits in a word. See ➀

Input

Terminals

4 5

10

11

12

13

14

15

16

17

8

and 16point examples

2 3

Input

Terminals

00

01

02

03

04

05

06

07

Group 2 Group 3

Two 8point input modules occupy 8

bits of each group. See ➁

6 7

Input

Terminals

00

01

02

03

04

05

06

07

1slot addressing

(1 I/O chassis slot = 1 I/O group = 1 input image word and 1 output

image word = 16 input bits and 16 output bits.)

scanner memory

Rack x

Word #

➂

➃

Word #

➀

➁

➂

➃

Output Image Table

0

1

2

3

4

5

6

7

0017 bits

Input Image Table

0

1

2

3

4

5

6

7

0017 bits

Input

Terminals

00

01

02

03

04

05

06

07

Group 4 Group 5

An 8point input module in group 4

occupies the first 8 bits of input word

4. The 8point output module

occupies the first 8 output bits in

output word 5. See ➂

34

Output

Terminals

00

01

02

03

04

05

06

07

Input

Terminals

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

Group 6 Group 7

16point I/O modules occupy 16 bits,

an entire word, in the image table.

See ➃

Output

Terminals

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

Page 34

Chapter

3

Addressing I/O

32point input module

32point input module

Group 0

32point

examples

0 1

32point I/O modules use the entire word

of their group and borrow the entire word

of the next group. See ➀.

Since the module is in group 0 and the

inputs for group 0 and group 1 are used,

you must:

• install an output module in group 1, or

• leave the slot empty

0 1

32point output module

1slot addressing

(1 I/O chassis slot = 1 I/O group = 1 input image word and 1 output

image word = 16 input bits and 16 output bits.)

scanner memory

Rack x

Word #

➁

Word #

➀

Output Image Table

0

1

2

3

4

5

6

7

0017 bits

Input Image Table

0

1

2

3

4

5

6

7

0017 bits

Group 0 Group 1

Since the input image table for group 1 is unavailable because it is

being used by the input module of group 0, installing a 32point output

module makes use of output image table of group 0 and 1. See ➁.

You can also install 8 or 16point output modules. But you cannot

install another input module since all the input image space for groups

0 and 1 is used by the input module of group 0.

35

Page 35

Chapter

3

Addressing I/O

When planning your system design, consider the densities of the I/O

modules you are using and choose an addressing mode that most

efficiently uses processor memory.

Choose the addressing mode for each I/O chassis by setting the chassis

backplane switch assembly.

Addressing Summary

Addressing

Mode:

2slot

1slot

1/2slot

Guidelines:

• Two I/O module slots = 1 group

• Each physical 2slot I/O group corresponds to one word (16 bits) in the input image table and one word

(16 bits) in the output image table

• When you use 16point I/O modules, you must install as a pair an input module and an output module in

an I/O group; if you use an input module in slot 0, you must use an output module in slot 1 (or it must be

empty). This configuration gives you the maximum use of I/O.

• You cannot use a blocktransfer module and a 16point module in the same I/O group because

blocktransfer modules use 8 bits in both the input and output table. Therefore, 8 bits of the 16point

module would conflict with the blocktransfer module.

• You cannot use 32point I/O modules.

• One I/O module slot = 1 group

• Each physical slot in the chassis corresponds to one word (16 bits) in the input image table and one

word (16 bits) in the output image table

• When you use 32point I/O modules, you must install as a pair an input module and an output module in

an even/odd pair of adjacent I/O group; if you use an input module in slot 0, you must use an output

module in slot 1 (or it must be empty). This configuration gives you the maximum use of I/O.

• Use any mix of 8 and 16point I/O modules, blocktransfer or intelligent modules in a single I/O chassis.

Using 8point modules results in fewer total I/O.

• One half of an I/O module slot = 1 group

• Each physical slot in the chassis corresponds to two words (32 bits) in the input image table and two

words (32 bits) in the output image table

• Use any mix of 8, 16, and 32point I/O or blocktransfer and intelligent modules. Using 8point and

16point I/O modules results in fewer total I/O.

Addressing BlockTransfer

Modules

36

Block-transfer modules occupy 8 bits in the I/O image table. Since all

block-transfer modules are bidirectional, they cannot be used to

complement either input or output modules.

To address: use the:

singleslot modules

doubleslot modules assigned rack number and the lowest group number and 0 for the

assigned I/O rack and group number of the slot in which the

module resides and 0 for the module number

When using 1/2slot addressing, use the assigned rack number

and the lowest group number and 0 for the module number.

module number

Page 36

Chapter

3

Addressing I/O

Assigning

Racks

Design Tip

The number of racks in a chassis depends on the chassis size and the

addressing mode.

If using this

chassis size:

4slot

8slot 1/2 rack 1 rack 2 racks

12slot 3/4 rack 11/2 racks 3 racks

16slot 1 rack 2 racks 4 racks

2slot

addressing,

rack type is:

1/4 rack 1/2 rack 1 rack

1slot

addressing,

rack type is:

1/2slot

addressing,

rack type is:

One I/O rack number is eight I/O groups, regardless of the addressing

mode that you select.

When assigning remote I/O rack numbers, use the following guidelines:

Each scanner channel supports as many as 16 physical I/O adapters.

The number of racks the scanner supports depends on the VME

operating mode.

This operating mode: supports as many as: with a total maximum

SVcompatible

SVsuperset 16 full racks 32

SVadapter 1 rack 0

8 full racks 16

number of adapters:

For example, you can configure 8 racks as:

8

full racks of 128 I/0 each (8 adapters)

or

16 half racks of 64 I/O each (16 adapters)

or

6 full racks of 128 I/O each and 8 quarter racks of 32 I/O each (14 adapters)

37

Page 37

Chapter

3

Addressing I/O

You can assign a remote I/O rack to a fraction of a chassis, a single I/O

chassis, or multiple I/O chassis:

I/O rack 0 I/O rack 1 I/O rack 2

01 23 45 67 01 23 45 67 01234567

16slot chassis, two racksOne

0123

4slot chassis, 1/2 rackOne 2slot chassis, 1/4 rack eachTwo

I/O rack 3

5

4

16slot chassis, one rackOne

67

16466

38

Page 38

Chapter

4

Communicating with Remote I/O

Using This Chapter

Selecting Devices that Y

Can Connect

ou

This chapter provides an overview of remote I/O communication.

If you want to read about: go to page:

selecting devices that you can connect

introduction to remote I/O 42

designing a remote I/O link 43

specifying a scan list 45

processing discrete data 46

processing block data 48

41

These are the devices you can use on a remote I/O link with the scanner.

Category: Product: Catalog

classic PLC5 processors 1785LT

enhanced PLC5 processors 1785L11B

PLC processors

(in adapter mode)

to remote I/O

to remote I/O

operator

operator

interfaces

interfaces

drives

drives

third party

devices

ethernet PLC5 processors 1785L20E

local PLC5 processors 1785L40L

VME PLC5 processors 1785V30B

Direct Communication Module for SLC Processors 1747DCM

SLC 500 Remote I/O Adapter Module 1747ASB

1791 Block I/O 1791 series

FLEX I/O 1794 series

Remote I/O Adapter Module

1slot I/O Chassis with Integral Power Supply and Adapter

2slot I/O Chassis with Integral Power Supply and Adapter 1771AM2

Direct Communication Module 1771DCM

DL40 Dataliner 2706 series

RediPANEL

PanelView Terminal

Remote I/O Adapter for 1336 AC Industrial Drives 1336RIO

Remote I/O Adapter for 1395 AC Industrial Drives

any devices incorporating AB node adapter chip sets under the

ENABLED Technology program

Number:

1785LT2

1785LT3

1785L20B

1785L30B

1785L40B

1785L60B

1785L80B

1785L40E

1785L80E

1785L60L

1785V40B

1785V40L

1771ASB

1771AM1

2705 series

2711 series

1395NA

41

Page 39

Chapter

Communicating with Remote I/O

4

Introduction

to Remote I/O

A remote I/O system lets you control Allen-Bradley I/O that is not within a

VME master processor’s chassis. The SV1R has one remote I/O channel;

the SV2R has two remote I/O channels. Each channel transfers discrete

and block-transfer data with remote I/O devices.

These components make up a remote I/O system:

Figure 4.1

Components

A VME system with an SV1R or SV2R scanner

(only one remote I/O channel is shown being used)

Each scanner channel maintains a scan list that

identifies all the racks connected to that channel.

Remote I/O link cable: Belden 9463

of a remote I/O system

Remote I/O node adapters like the 1771ASB modules

or PanelView operator interfaces addressed

as remote I/O racks.

PLC5 channel or a processor operating as

a remote I/O adapter

42

Page 40

Chapter

4

Communicating with Remote I/O

The scanner keeps a list of all of the devices connected to each channel.

Figure 4.2 shows an example scan list for one channel.

Designing

SV2R

Ch A

Ch B

a Remote I/O Link

Figure 4.2

Rack

Rack 2

Rack 3

scan list

1

Ch B Scan List

Rack

Address

1

2

3

In this example, channel B continually scans the three racks in its scan list.

Starting

Group

0

0

0

Rack

Size

Full

1/2

Full

Range

010017

020023

030037

Example

The steps for setting up a remote I/O system are:

Step: See:

1.configure the remote I/O adapter devices

2.layout and connect the remote I/O link cable

3.specify a scan list page 45

the device's user manual

•page 43 for design

•your adapter's installation information

Designing a remote I/O link requires applying:

Design Tip

remote I/O link design guidelines

cable design guidelines

Link Design Guidelines

Keep these rules in mind as you design remote I/O links:

All devices connected to a remote I/O link must communicate using the

same communication rate. The rate you choose depends on the VME

operating mode:

This VME operating mode: supports these

SV compatible

SV superset 57.6 kbps

communication rate:

57.6 kbps

115.2 kbps

115.2 kbps

230.4 kbps

43

Page 41

Chapter

Communicating with Remote I/O

4

Two channels on the same scanner cannot scan the same partial or full

rack address. Assign unique partial and full racks to each channel.

You can split rack addresses between scanner channels; however, issues

arise when performing block-data transfer. If you split remote rack

addresses between scanner channels, channel A has priority over

channel B.

A scan list can have a maximum of 16 rack numbers or a maximum of

64 physical devices connected to it using 82-Ω termination resistors.

Design Tip

Cable Design Guidelines

Specify 1770-CD (Belden 9463) cable. Connect a remote I/O network

using a daisy chain or trunk line/drop line configuration.

Important: The maximum cable length for remote I/O depends on the

transmission rate. Configure all devices on a remote I/O link to

communicate at the same transmission rate.

For trunk line/drop line configurations, use the 1770-SC station connectors

and follow these guidelines:

the length of the trunk line cable depends on the communication rate

the length of the drop cable is 30.4 m (100 cable-ft)

For more information about designing trunk line/drop line configurations,

see the Data Highway/Data Highway Plus/Data Highway II/Data

Highway-485 Cable Installation Manual, publication 1770-6.2.2.

For daisy chain configurations, determine the total cable length you need.

A remote I/O link using this

communication rate:

57.6 kbps

115.2 kbps 1,524 m (5,000 ft)

230.4 kbps 762 m (2,500 ft)

cannot exceed this

cable length:

3,048 m (10,000 ft)

44

Page 42

Chapter

4

Communicating with Remote I/O

For proper operation, terminate both ends of a remote I/O link by using

external resistors. Use either a 150W or 82W terminator.

Table 4.A

Selecting

If your remote I/O link:

operates at 230.4 K bit/s

operates at 57.6 or 115.2 K bit/s, and no devices

listed below are linked

Scanners 1771SN; 1772SD, SD2;

1775SR, S4A, S4B;

6008SQH1, SQH2

Adapters 1771AS;

1771ASB (series A only);

1771DCM

Miscellaneous 1771AF

connects to any device listed below:

Scanners 1771SN; 1772SD, SD2;

1775SR, S4A, S4B;

6008SQH1, SQH2

Adapters 1771AS;

1771ASB (series A only);

1771DCM

Miscellaneous 1771AF

operates at 57.6 or 115.2 K bit/s, and you do not

require over 16 physical devices

the external resistor

use this resistor

rating:

82W

150W

the maximum number of

physical devices that

you can connect on

the link is:

32 16

16 16

racks that you can

scan on the link is:

Specifying

a Scan List

The scan list is a map of the I/O devices the scanner channel scans. To

create the scan list, use either of these commands:

If you want: use this command:

the scanner to poll all available adapter addresses and assemble a

list with one entry for each adapter

in SVcompatible mode, there will be a maximum of 16 entries in

the scan list; in SVsuperset mode , there will be a maximum of 32

entries in the scan list

to create the scan list manually

add adapters multiple times in the scan list

there can be a maximum of 64 entries in the scan list, as long as

there are only 16 distinct physical adapters

AUTOCONFIGURE

SCAN LIST

45

Page 43

Chapter

Communicating with Remote I/O

4

Processing

Design Tip

Discrete I/O

If you need multiple updates to an I/O device during an I/O scan, enter a

logical address in the scan list more than one time. Do not assign the same

partial or full rack address to more than one channel in scanner mode.

Each channel must scan unique partial and/or full rack addresses.

The automatic configuration always displays the actual hardware

configuration, except for racks that have their global-rack inhibit bit set. In

this case, the global-rack bit overrides the automatic configuration.

Discrete I/O devices include such external devices as:

switches

relay contacts

indicator lights

control relays

motor starters

A scanner channel exchanges discrete data (digital and analog) with remote

I/O node adapters like 1771-ASB modules via the scanner I/O image table

(Figure 4.3).

Figure 4.3

I/O scan

Remote

Rack 3

Rack 2

Rack 1

adapteradapter adapter

scanner

I/O table

data exchange

VME

master

processor

46

The remote I/O scan is the time it takes for the scanner to

communicate with all of the entries in its scanlist once.

Page 44

Chapter

4

Communicating with Remote I/O

Important: The remote I/O scan for one channel is independent of and

asynchronous to the remote I/O scan for the other channel.

The status of the discrete devices is represented by a single bit in an input

or output group (word). The scanner is related to these devices as shown

in Figure 4.4.

Figure 4.4

Relationship between the scanner and I/O

The

VMEbus Subrack

VMEbus

VME

master

processor

backplane

scanner

channel

1771 I/O

chassis

1771

adapter

I/O

input

modules

output

modules

motor starter

pushbutton switch

remote

I/O link

Up to 13 more

I/O adapters

1771 I/O

chassis

PLC5

processor

in adapter

mode

operator

interface

terminal

input

modules

output

modules

15383

An external device, such as the switch shown above, causes an input of a

discrete input module to turn on. This sets a bit to a “1” condition in the

I/O module. The next time the I/O adapter scans the module, the new

information is reported to the adapter. When the scanner scans the adapter,

the corresponding bit in the I/O image table is set to a condition that

reflects the status of the external device, the switch.

47

Page 45

Chapter

Communicating with Remote I/O

4

A VME master processor then reads the input image information from the

global RAM via the VMEbus.

To generate an output, a VME master processor sets a specific bit in the

I/O image table in the scanner’s global RAM, corresponding to the desired

output device, for example a control relay.

The scanner updates the adapter during the next scan cycle. The adapter

sets the appropriate bit in the output module and the discrete output device

energizes the control relay.

Processing

Block Data

Rack 3

In addition to discrete data, the scanner can also exchange block data with

remote I/O. Block transfers are the communication of data blocks (files)

between the scanner and intelligent I/O modules. These are any I/O

modules that respond to read or write block transfers. These modules

handle data such as analog input, analog output, positioning, and

communication data.

Block-transfer instructs the scanner to transfer as many as 64 words of data

to/from a selected I/O module. The operating mode of the scanner

determines how many block-transfer requests the scanner can queue as

many as 42 requests when operating in SV-compatible mode; only 1

request when operating in SV-superset mode. Figure 4.5 shows how the

scanner handles a block-transfer.

Figure 4.5

Blocktransferring

data to remote I/O

scanner

48

Rack 2

Rack 1

adapteradapter adapter

blocktransfer

sent to adapter

scanner

block

transfer

table

Q

A

Q = queue

A = active

blocktransfer

request

VME

master

processor

Page 46

Chapter

Communicating with Remote I/O

4

The scanner processes block-transfers differently depending on the VME

operating mode. In general though, block-transfer allows the VME master

processor to read or write up to 64 16-bit words from an adapter.

In SV-compatible mode

The scanner processes single block-transfer operations. You must program

a read or write command for each data transfer in your application. The

scanner can queue as many as 42 block-transfer requests from the VME

master processor.

In SV-superset mode

The scanner processes single block-transfer operations and continuous

block-transfer operations. The single block-transfer operations work the

same as in SV-compatible mode. The only difference is that the scanner

can only queue one request from the VME master processor. Use

continuous block-transfer requests for applications that need to

continuously poll an adapter. The continuous block-transfer requests uses

less overhead than programming a single block-transfer request each time

you need the data.

For specifics on block-transfers based on VME operating mode, see

chapter 5 or 6 for SV-compatible or SV-superset mode, respectively.

Understanding the BlockTransfer Sequence

The VME master processor and scanner alternately access the scanner’s

global RAM while transferring a block transfer. See Figure 4.6 and

Figure 4.7.

49

Page 47

Chapter

4

Communicating with Remote I/O

Output Image Table

Input Image Table

Operating Status Word

Confirmation Status Word

Command Word

Address Word

BT Tag Word

Figure 4.6

Blocktransfer

❶

VME

master

processor

The scanner writes a

result code in the

confirmation status word.

See chapters 5 or 6.

sequence - sending a request

The VME master processor sends a

BT WRITE request to scanner

BT#n

The scanner copies the request parameters and data

into its internal queue. In SVcompatible mode, the

scanner can queue as many as 42 blocktransfer

requests; in SVsuperset mode, the scanner can queue

only one blocktransfer request.

❷

scanner

queue

BT#a

BT#b

BT#n

During the adapter scan, the scanner polls each adapter in the scan

list. If a blocktransfer is pending for that adapter, the scanner sends a

blocktransfer request to the adapter. The scanner doesn't receive or

send the block data until the next scan. The scanner transmits only

one blocktransfer request per adapter per scan.

❸

scan n

scanner

BT#n

1771 I/O

chassis

adapter

#n

input

modules

output

modules

410

Page 48

Chapter

4

Communicating with Remote I/O

Figure 4.7

Blocktransfer

On the previous adapter scan, the scanner sent a block

transfer request. During this scan, the adapter returns the