Page 1

IBM PC I/O Scanner

(Cat. No. 6008-SI)

User Manual

Page 2

Important User InformationImportant User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes and

standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for example. Since there are many variables

and requirements associated with any particular installation, Allen-Bradley

does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, “Safety Guidelines For The

Application, Installation and Maintenance of Solid State Control”

(available from your local Allen-Bradley office) describes some important

differences between solid-state equipment and electromechanical devices

that should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen-Bradley Company, Inc. is

prohibited.

Throughout this manual we make notes to alert you to possible injury to

people or damage to equipment under specific circumstances.

WARNING: Tells readers where people may be hurt if

procedures are not followed properly.

CAUTION: Tells readers where machinery may be damaged

or economic loss can occur if procedures are not followed

properly.

Warnings and Cautions:

identify a possible trouble spot

tell what causes the trouble

give the result of improper action

tell the reader how to avoid trouble

Important: We recommend that you frequently back up your application

programs on an appropriate storage medium to avoid possible data loss.

Page 3

Summary of Changes

Preface

Changes to Software

Use this document with revision 1.2 of the host software package for the

IBM PC I/O Scanner. The host software has been updated to use Microsoft

and Borland compilers.

The new information is marked with a vertical black bar in the margin.

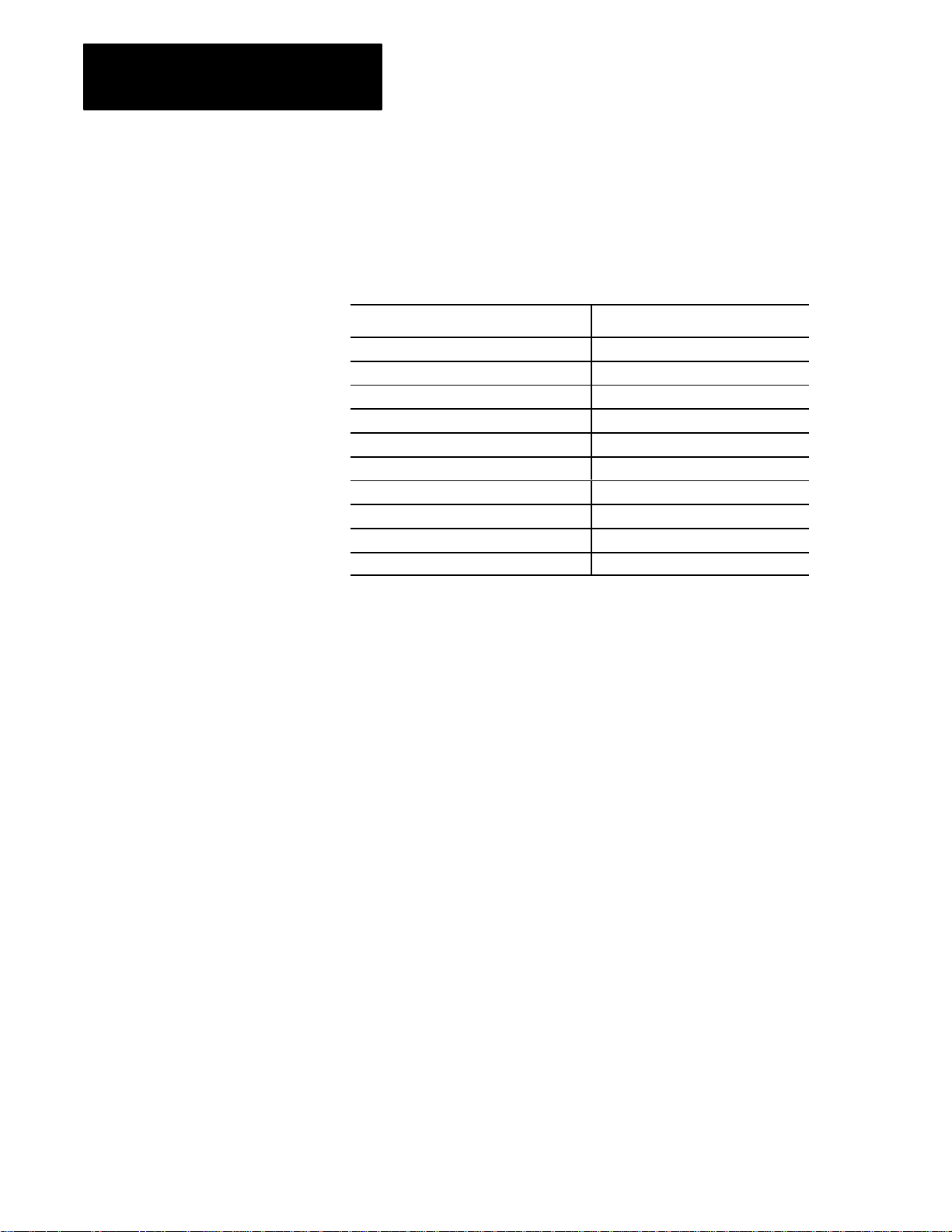

You'll find this new information: On page:

Contents of host software package 41

Borland compiler

installing

compiling and linking

using the /d option

Microsoft compiler

installing

compiling and linking

43

412

411

45

414

i

Page 4

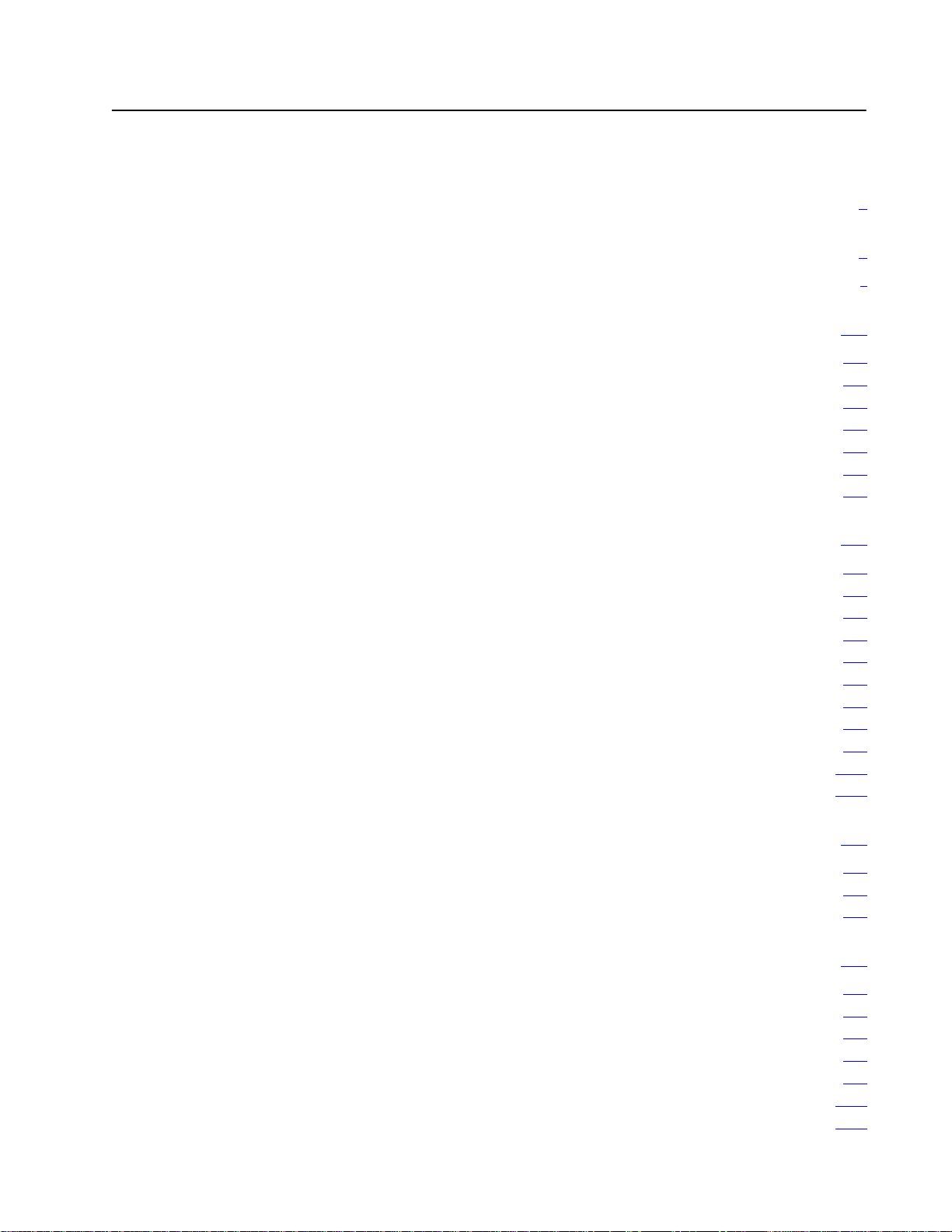

Table of Contents

Important User Information

Summary of Changes

Changes

to Software

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using This Manual 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual's

Audience 11

Related

Required Hardware 11

Required Software 12

Source Code 12

Conventions 12

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Scanner Concepts 21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

How Does the Scanner Relate to 1771-I/O 21

Terms 23

I/O Addressing 25

What the Scanner Does 26

Operating Modes 27

Global

Data Paths 28

Scanner Commands 29

Host Watchdog 210

Scanner Watchdog 210

Objectives

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RAM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

i

i

Installation 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Using the Scanner with Other Products 31

Installation Procedure 35

Objectives

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Overview 41. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Disk Inventory 41

Installing the Borland Version 43

Installing

Writing Your Program 47

Compiling and Linking the Borland C++ 2.0 Version 412

Compiling and Linking the Borland Turbo C++ 1.0 Version 413

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Microsoft V

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

ersion 45. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . .

Page 5

Table of Contentsii

Compiling and Linking the Microsoft C 5.1 or 6.0 Version 414. . . . . . . .

Further

Information

415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup, Status, and Shutdown 51. . . . . . . . . . . . . . . . . . . . .

Chapter

Overview 51

Startup 52

Host Watchdog 56

Scanner

Shutdown 512

Discrete

Chapter

Direct Image Table Access 61

Library Routines 64

Print or Display Image Table 69

Timing

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

of Discrete I/O

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

610. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scanner Management 71. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Overview 71

Data Structure (Packet) 72

Executing a Management Request 73

Autoconfigure and Link Status Information 715

Configuration

Fault and Fault Dependent Group Information Byte 717

Confirmation Status Codes 719

Print or Display Results 720

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

Information Byte

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

716. . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfer 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Overview 81

QBT Data Structure (Packet) 82

Queueing a Block Transfer 84

Time

Polling

Confirmation Status Codes 811

Print or Display Results 812

Unsolicited Block Transfer 813

Block Transfer to PLC5's in Adapter Mode 813

Block Transfer to a 1771-DCM 817

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

to Completion

for Completion

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contents iii

General Support Features 91. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Timing Loops 91

Date and T

Command Translation 95

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ime Stamp

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Diagnostic Program 101. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Starting the Program 102

Program Operation 103

Objectives

101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Troubleshooting the I/O Scanner 111

Objectives

111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

Header Definitions A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Using This Manual

Chapter

1

Manual's

Audience

Objectives

This manual describes the operation and use of the IBM PC I/O Scanner

(cat. no. 6008-SI) with the supplied host software driver. After reading this

manual, you should be able to:

install the scanner board in your computer

write a program that runs on your computer to control the scanner for

your application

diagnose and correct most of the problems that might occur.

This manual begins with an introduction to I/O scanner concepts and

proceeds to detailed instructions on how to install and program your

scanner.

We assume that you have experience in system development and

integration and in writing software for the IBM Personal Computer family

or compatibles. We also assume that you have a working knowledge of the

C programming language, including the concepts of structures and

pointers. Prior knowledge of Allen- Bradley 1771 Series I/O products is

helpful but not essential.

Related Publications

Required Hardware

Use this manual with its companion manual, the I/O Concepts Manual.

Refer to the manuals that accompany the 1771 Series I/O modules and

hardware you intend to use with your system.

You need a computer from the IBM Personal Computer series, such as the

PC/AT or PC/XT, or a compatible such as the Allen-Bradley Industrial

Terminal T50, T60, and T35. The scanner board is installed inside the

computer.

The choice of 1771 Series I/O modules depends on your application.

A printer attached to your computer may be helpful but is not required.

1-1

Page 8

Chapter 1

Using This Manual

Required

Software

Source Code

Conventions

You need the MS–DOS operating system, version 3.0 or higher. If you’re

using the Microsoft C version of the scanner driver software, you’ll need a

Microsoft C compiler, version 5.1 or higher (version 6.0 recommended). If

you’re using the Borland C version of our software, you’ll need a Borland

C compiler, Turbo C++ 1.0 or higher (Borland C++ 2.0 recommended).

Source code for library routines and the interrupt handler is available for a

nominal charge. To obtain source code, you must contact Order Services

and request 6008-SIDC software. They will ship you a license agreement.

Return the signed agreement. A-B source code will be supplied on

3.5-inch and 5.25-inch diskettes.

In this manual, this type is used for special names, such as names of files

and C language identifiers.

The hexidecimal equivalent of selected error codes and commands are

given in the header definition files found in appendix A at the back of this

manual.

Numbers in this document are in decimal unless otherwise noted. Binary

numbers are marked with a trailing (binary), and hexadecimal numbers

with a trailing (hex); for example, 11010(binary) = 26 = 1A(hex).

Bits are numbered so that bit 0 is the low-order bit. For example, bit 4 is

four bits left of bit 0 and has a value of 2

4

=16. Following C conventions,

array subscripts start at 0.

1-2

Page 9

I/O Scanner Concepts

Chapter

2

Chapter

Objectives

How Does the Scanner Relate to 1771-I/O

This chapter explains basic concepts and provides an overview of the

operation of the IBM PC I/O Scanner. After reading this chapter you

should understand:

how we use certain words with special meanings in this manual

how information moves between your program and the outside world

how your program can issue commands to affect operation of the

scanner

how the safety features, called watchdogs, work

The scanner uses the 1771 Remote I/O protocol to communicate with

Allen–Bradley I/O modules. You don’t have to know the specifics of the

protocol to use the scanner with the I/O modules, but you do need to know

a few terms.

The scanner is an Allen–Bradley card that you install in the host computer

(or host). Typical hosts are the IBM PC/AT class (including the

Allen–Bradley T50, T60, and T35 Industrial Terminals and 6121 Industrial

Computer) and the IBM PC/XT class of machines (including the

Allen–Bradley 6120 Industrial Computer).

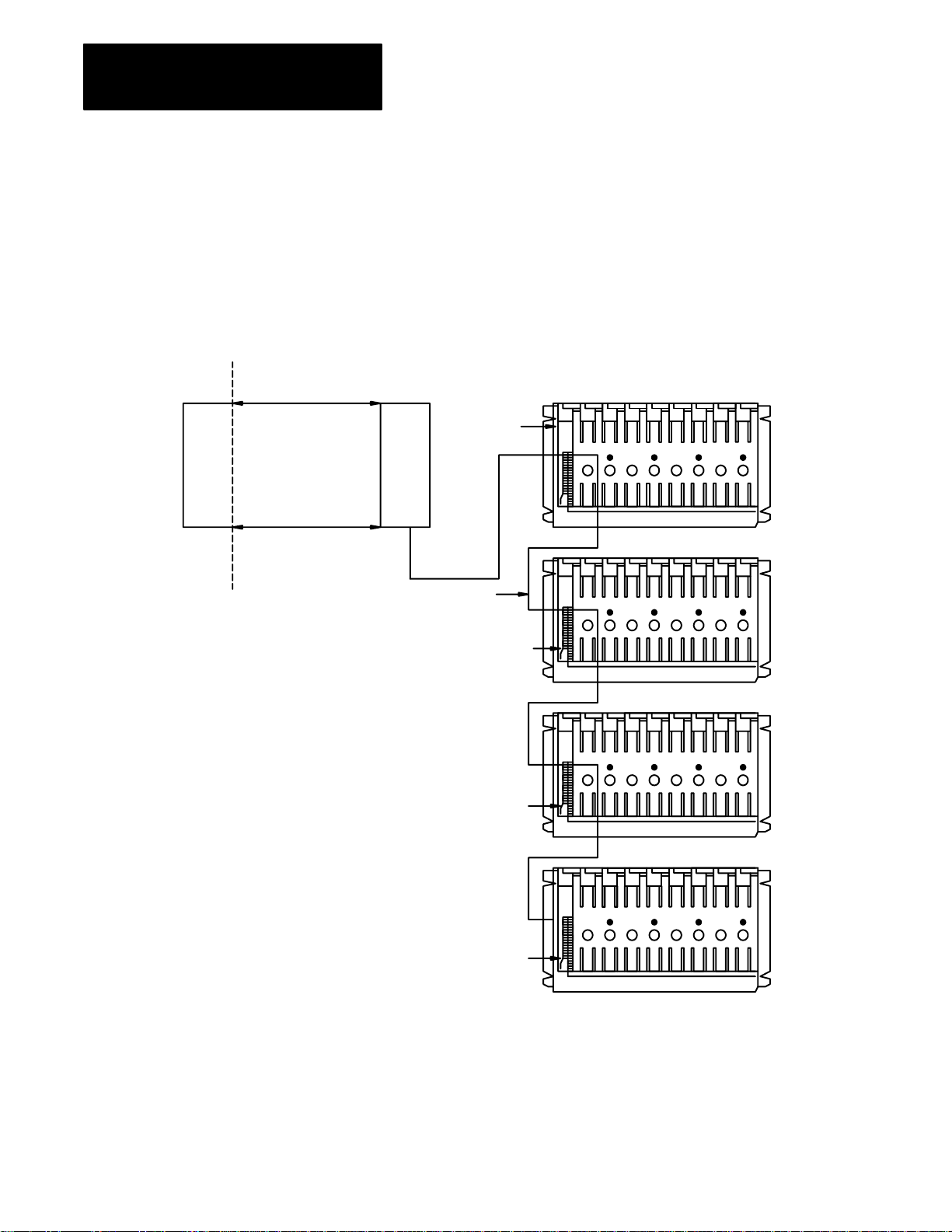

IBM PC Hardware

Host

Processor

(i.e. 80286)

IBM PC

1771-I/O Protocol

6008-SI

1771-I/O Hardware

1771-AS

or

1771-ASB

or

1771-DCM

1771-I/O Bus

1771-JAB

Universal I/O

Single

Point

I/O

2-1

Page 10

Chapter 2

I/O Scanner Concepts

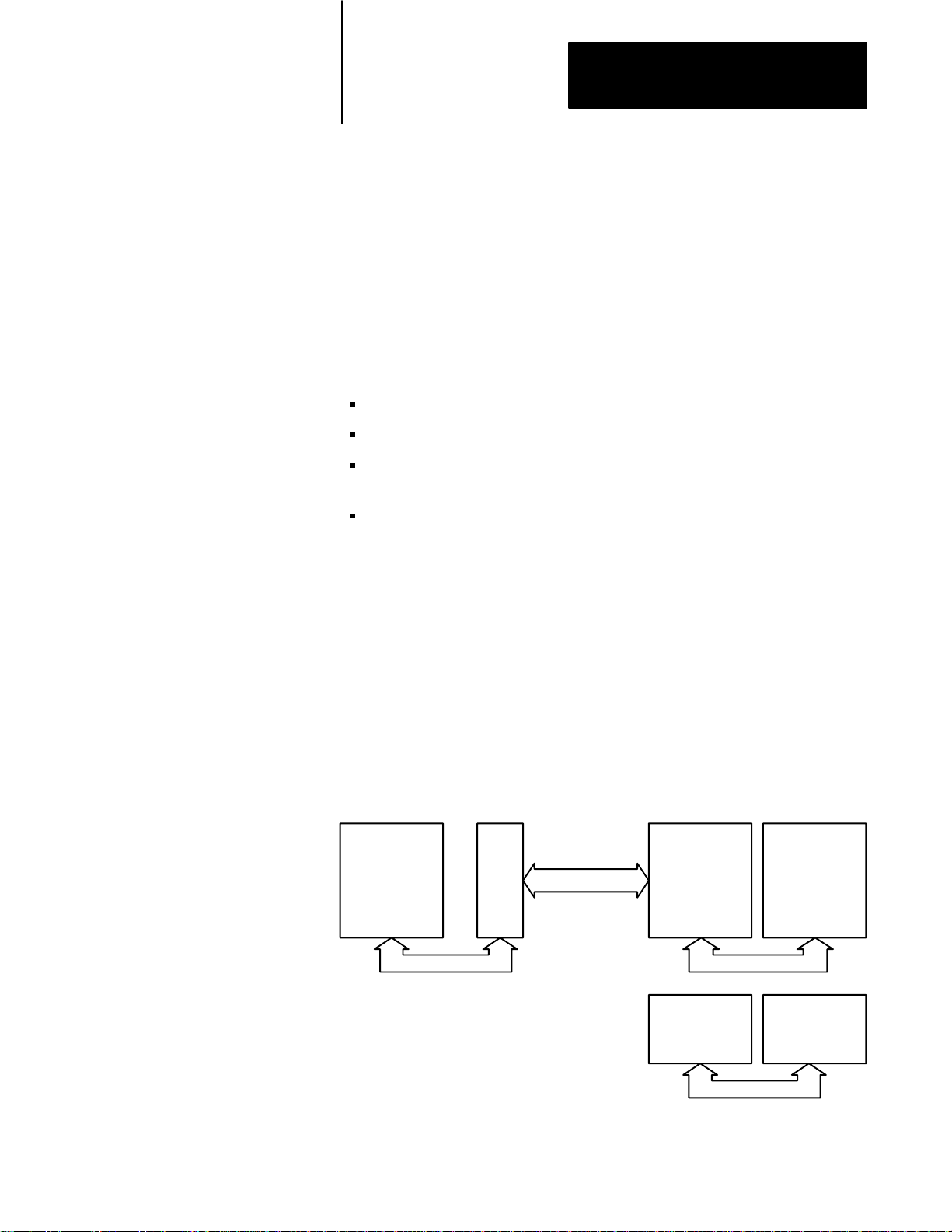

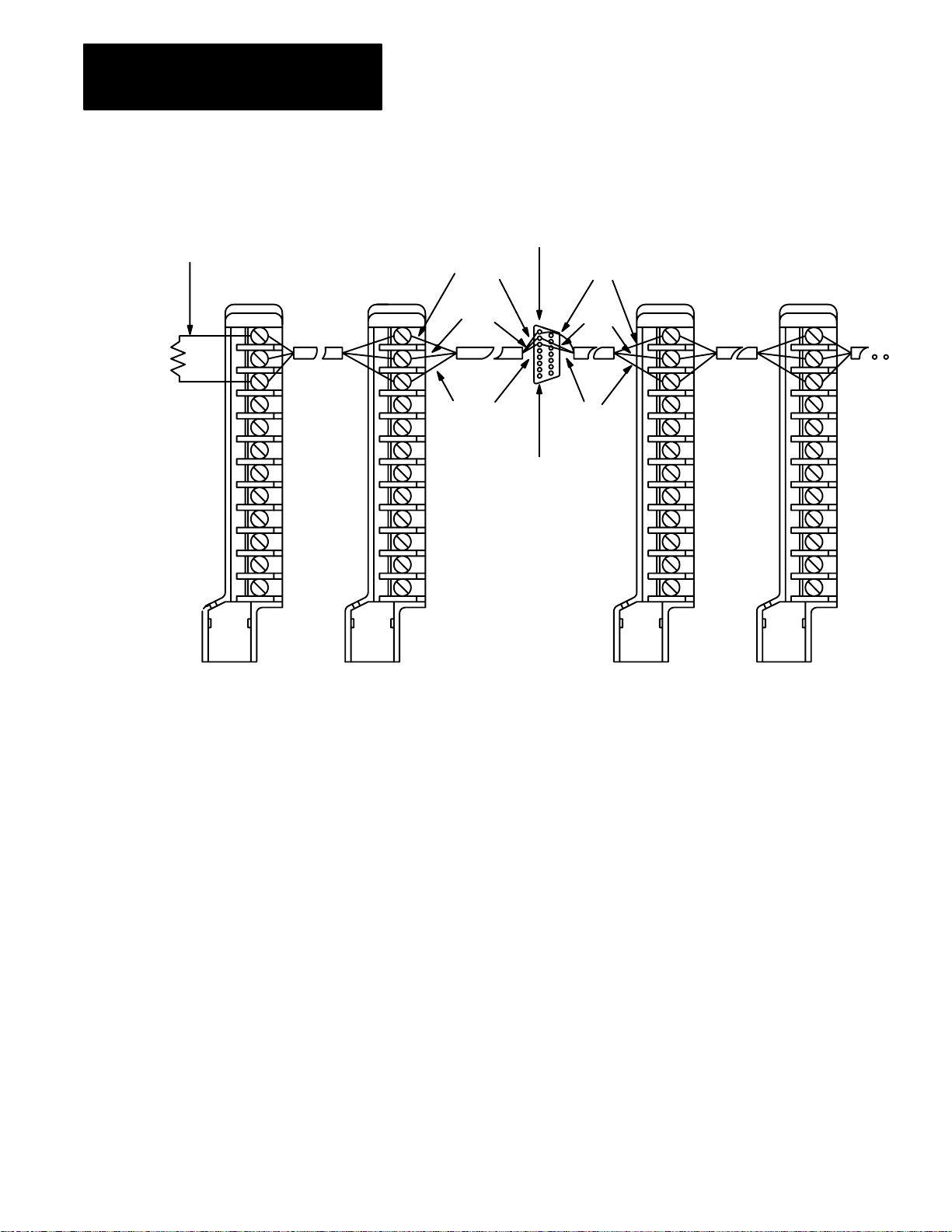

I/O modules sit in one or more chassis. An I/O chassis is a housing that

holds one adapter and 1, 2, 4, 8, 12, or 16 I/O modules. The adapter is the

communication interface between the scanner and the chassis. The scanner

communicates with the adapter through shielded two–conductor

twisted–pair cable (the “blue hose”). In turn, the adapter monitors and

controls the I/O modules through the backplane of the chassis. You can

connect up to 16 chassis to the scanner on the blue hose. You can combine

chassis in any way that results in 8 or less rack addresses.

Adapter

Industry

Host

Processor

I/O Chassies can contain 8 bit,

16-bit, or 32-bit discrete I/O

modules. Analog, and/or

intelligent I/O modules.

You address them using 1/2 slot,

1-slot or 2-slot addressing

Bus

I/O Chassis

SI Scanner

Remote I/O Cable

I/O Chassis

Adapter

I/O Chassis

Adapter

2-2

I/O Chassis

Adapter

14652

Page 11

Chapter 2

I/O Scanner Concepts

We can divide I/O, and therefore I/O modules, into discrete and intelligent

modules.

Discrete I/O is characterized by one terminal (or point) per I/O image table

bit. Your program handles discrete I/O through I/O image tables, where

each input or output terminal corresponds to one of the 1024 input and

1024 output image table bits (64 x 16 bits = 1024 bits.)

The input image table is an area of memory that monitors the terminals of

discrete input modules. When an input switch is closed, the corresponding

bit is set (1). The output image table is an area of memory that controls

output terminals of output modules. After a bit is set to 1, the

corresponding switch is closed or the terminal is energized.

A standard–density module is a discrete input or output module that has 4,

6, or typically 8 input or output terminals. A high–density module is a

discrete input or output module that has 16 input or output terminals. A

quad–density module is a discrete input or output module that has 32 input

or output terminals.

Terms

Intelligent I/O is characterized by the transmission of one or more 16–bit

words in a particular format to or from an I/O module. A block transfer

(BT) is the transmission of data to or from an intelligent I/O module. A

BT read or read BT transfers information (typically analog input and status

data) from the module to the host; a BT write or write BT transfers data

(typically analog output and configuration data) from the host to the

module.

You should become familiar with these terms used to describe the I/O

subsystem.

Input image table: An area of memory that monitors input terminals of

input modules. When an input switch is closed, its corresponding input bit

is set. 64 16–bit words (1024 points) are available.

Output image table: An area of memory that controls output switches of

output modules. When a bit is set, its corresponding output is energized.

64 16–bit words (1024 points) are available.

Discrete I/O: I/O characterized by one terminal per image table bit

(terminal and point are the same).

Standard density module: Discrete I/O module having four, six, or

typically eight input or output points.

High density module: Discrete I/O module having 16 input or output

points.

2-3

Page 12

Chapter 2

I/O Scanner Concepts

Quad density module: Discrete I/O module having 32 input or output

points.

I/O chassis: One of four different housings sized to hold either four, eight,

twelve, or sixteen discrete I/O modules.

Slot: Position in an I/O chassis the width of one discrete I/O module.

I/O group: An addressing concept representing 16 input bits (one input

image table word) and

16 output bits (one output image table word).

In hardware, an I/O group can represent one or two slots in an I/O chassis.

It has an address number.

Half–slot addressing: Addressing where an I/O group represents a half of

a slot.

One–slot addressing: Addressing where an I/O group represents one slot.

Two–slot addressing: Addressing where an I/O group represents two

slots.

I/O rack number: An addressing concept representing 8 I/O groups. An

I/O rack number can be distributed over one, two, three, or four I/O

chassis; or two rack numbers can be assigned to one I/O chassis, depending

on chassis size and your application requirements.

Module address: An address that defines the physical location of the

module in the I/O chassis by its I/O rack number and starting slot number.

I/O update: The scanner’s serial scan of all I/O chassis in the I/O

subsystem. This scan is asynchronous to scans between the scanner and

host processor.

Scan list: A list specifying the order in which I/O adapters are to be

scanned. It is specified by the host and sent to the scanner module as a

scanner management command. Although a maximum of 16 I/O adapters

is allowed, the scan list can specify a maximum of 64 I/O adapters. This is

done to allow the scanner to scan adapters more than once during its scan

cycle if more frequent updates are desired.

2-4

Block transfer: The transfer of data to or from an intelligent I/O module

up to 64 words at a time.

Scanner management request: A command from the host to the scanner

used to control and configure the scanner board.

Page 13

Chapter 2

I/O Scanner Concepts

Fault dependent group: A group of I/O adapters treated as a single entity

for the purposes of fault detection. If one of the defined group faults all in

the group are in fault.

I/O Addressing

You assign each adapter an I/O rack number (0 to 7) by setting switches on

the adapter. A rack may be single chassis; or two to four chassis may be

comprised in one rack number; or a single chassis can be addressed as two

racks. It is not necessary to assign rack numbers sequentially: for instance,

you could have a full rack 0, half a rack in rack 3, and a quarter rack in

groups 6–7 of rack 7.

For addressing purposes, each rack is equivalent to a block of 8 I/O groups

in the I/O image table. Groups within a rack are numbered from 0 to 7.

An I/O group is two 16–bit words, one from the output image table and

one from the input image table, with the same address. (Please refer to the

I/O Concepts Manual for more information.) In most applications, only

the input word or only the output word is used in any given I/O group.

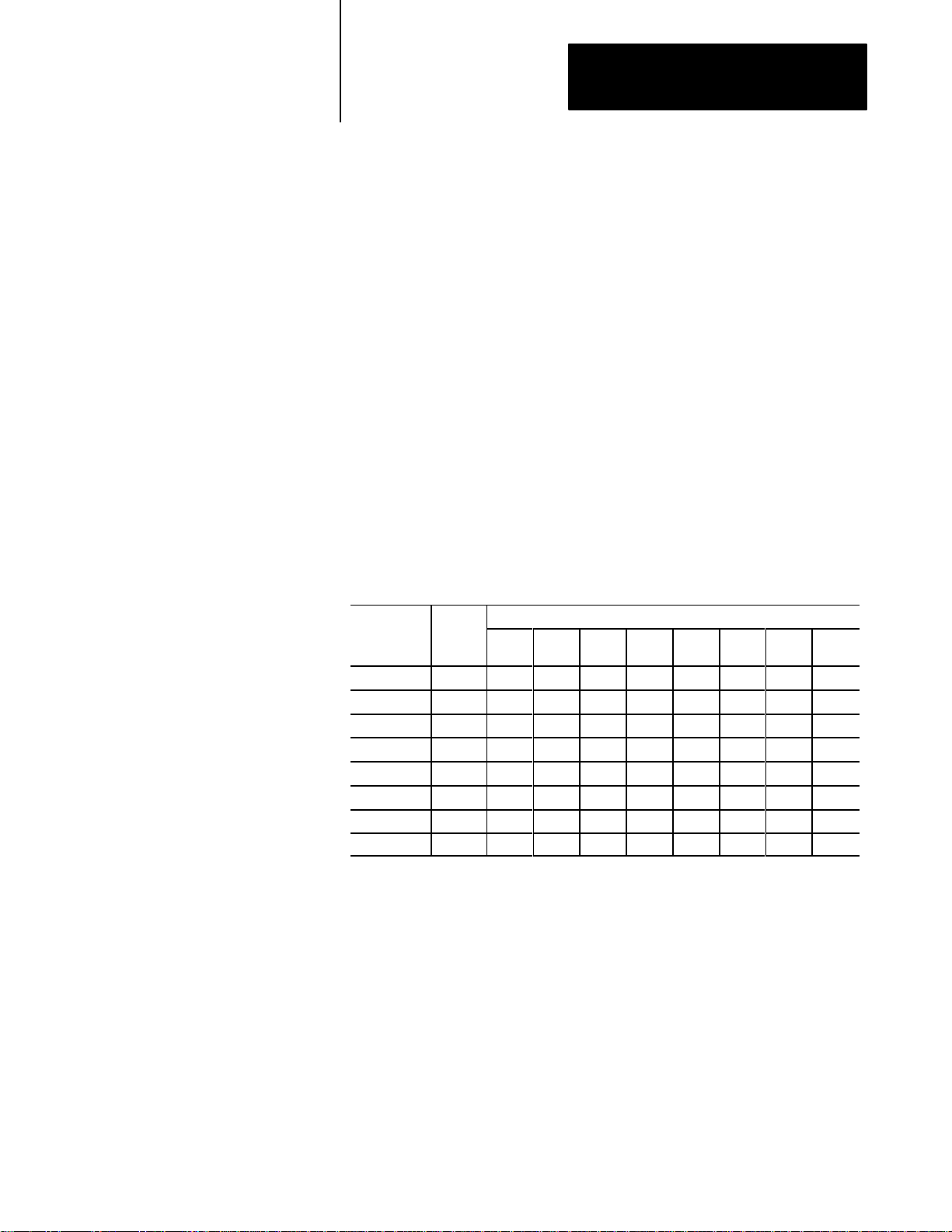

Here is an example layout of the output image table:

Group

word #

(hex) rack

00-07 0 xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

08-0F 1 xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

10-17 2 xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

18-1F 3 xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

20-27 4 xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

28-2F 5 xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

30-37 6 xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

38-3F 7 xxxx xxxx xxxx xxxx xxxx xxxx xxxx xxxx

0 1 2 3 4 5 6 7

The word numbers above can be used as subscripts. (We’ll look closely at

that in chapter 6, Discrete I/O.) Each 16–bit word corresponds to 16

discrete I/O terminal positions, terminal 17 octal (15 decimal) to the

high–order bit and terminal 00 to the low–order bit.

Just as each I/O group has an address, so does each adapter. Adapter

addresses are used in the scan list (see, What the Scanner Does, below).

The adapter address is the address of the first I/O group covered by the

adapter, divided by 2. This is numerically the same as (rack x 4) +

(starting group / 2), where the rack and group are both numbered from 0 to

7 as shown above. If you prefer, you can think of 1/4 racks being

numbered from 0 to 3, and then the adapter address is (rack x 4) +

(quarter).

2-5

Page 14

Chapter 2

I/O Scanner Concepts

A slot is a position in an I/O chassis for one I/O module. In one–slot or

single–slot addressing, an I/O group represents a single slot. In two–slot or

double–slot addressing, an I/O group represents two slots.

What

the Scanner Does

The scanner runs asynchronously in relation to the host. When either one

wants to get the other’s attention, it must issue a hardware interrupt.

Information is passed through a global RAM. Both the host and the

scanner have the ability to postpone servicing an interrupt if in the middle

of another interrupt–driven task.

The scanner maintains a scan list, which is a list of adapters to be serviced

by the scanner. A given adapter may appear once, several times, or not at

all in the scan list. (The scan list is empty until you perform

AUTOCONFIGURE at which point AUTOCONFIGURE puts every

adapter in the list once.) The scan list starts as simply the list of adapters,

each occurring once, but your program can issue a scanner command to

alter the scan list.)

An exchange (or an adapter scan) is the scanner’s interchange of

information with one adapter. During an exchange, the scanner may

receive data or status information from the adapter or send data or

commands to the adapter, or both. Both block transfers and discrete I/O

transfers can be done during the same exchange if the adapter’s chassis

contains both kinds of I/O modules.

After servicing each adapter, the scanner looks at its command queue to

see if any commands are waiting. If so, and if the current operating mode

allows, the scanner executes one command. If the scanner has a

confirmation of this command or of a previously executed command, it

puts the confirmation in the global RAM and interrupts the host.

2-6

The scan list is circular: each time the scanner reaches the end of the scan

list it starts again at the beginning. An I/O scan (sometimes called just a

scan) is one complete cycle by the scanner through the scan list, from any

point to the same point.

Every time the host interrupts the scanner, the scanner puts a marker in the

scan list at the point of the adapter most recently scanned. If the scanner

works its way through the scan list to the same point without receiving an

interrupt from the host, the scanner interrupts the host. (If the scan list

contains no adapters, the scanner waits for 5 ms before interrupting the

host.)

Page 15

Chapter 2

I/O Scanner Concepts

Thus you can be certain that the I/O image tables are refreshed once per

scan list. Partial refreshes take place more frequently if your program

executes a lot of block transfers or management requests: whenever the

global ram is transferred the I/O image tables are refreshed as far as the

scanner has got in the scan list since the last interrupt. Your program can

also force a partial refresh: see the update function in chapter 6, Discrete

I/O.

Operating

Modes

Global RAM

The scanner has three modes of operation: program, test, and run modes.

Discrete inputs are read in all three modes.

In program mode no discrete outputs are sent to the adapters, and the

adapters are instructed to hold all discrete outputs reset (zero). The

scanner holds any block transfer requests in its queue without servicing

them.

In test mode the adapters are still instructed to hold discrete outputs

reset, but the scanner sends discrete information to them. Block

transfers can proceed in test mode, but their outputs will be held reset.

In run mode discrete output information is sent to the adapters, and the

adapters are permitted to update the output modules. Block transfers

may be performed.

When your program first starts up scanner operation, the scanner is in

program mode. Your program must issue a command to change to run

mode.

The scanner has a 2048–byte area of RAM that we call a global RAM,

shared by both the IBM PC and the scanner. This is not a true global

RAM, because the host and the scanner can’t access it at the same time.

Instead, the host and the scanner exchange control of the global RAM by

means of interrupts. When the scanner interrupts the host, the scanner is

turning over control of the global RAM to the host. When the host

interrupts the scanner, either the host has the global RAM and wants to

return it or the host doesn’t have the global RAM but wants access to it.

Access to the global RAM is ultimately controlled by hardware and by

scanner firmware. For the host side, we supply an interrupt handler or

interrupt service routine that is automatically invoked whenever the

scanner interrupts the host. Our interrupt service routine copies

information as needed between your program’s data area and the global

RAM.

2-7

Page 16

Chapter 2

I/O Scanner Concepts

Because our interrupt handler takes care of all details of the global RAM,

you don’t have to be concerned with the bits and bytes. You should know

that the global RAM contains two kinds of information:

the I/O image tables are comprised of an output image image table and

an input image table. Every time control of the global RAM is

transferred, the interrupt routine copies new inputs to your program’s

data area from the global RAM and new outputs from your program’s

data area to the global RAM.

a mailbox area is where the host can send commands to the scanner and

the scanner sends back confirmations and data. A list of commands is

given later in this chapter.

Data

Paths

Here is the path followed by a discrete input bit:

An external device causes an input of a discrete input module to turn

“on.”

When next asked by the adapter, the input module reports the new input

information. The adapter updates its internal input image table by

setting the bit corresponding to the particular input point.

When next scanned by the scanner, the adapter reports the new input

information. The scanner updates the input image table in the global

RAM by setting the bit corresponding to the particular input point.

The host interrupt handler reads the input image information in the

global RAM and copies it to a duplicate input image table available to

your program. Your program now knows that an input on a particular

input module is “on.”

The path of an output bit is essentially the reverse of the input path:

Your program sets a bit in its output image table. Your program knows

that this bit maps to an output on a particular output module.

2-8

The scanner interrupts the host, the interrupt handler copies your

program’s output image for that rack to the global RAM.

When the scanner next scans the adapter controlling the particular

output module, it tells the adapter to update its output image table with

the new information.

The adapter tells the discrete output module to update its outputs with

the new information.

Page 17

Chapter 2

I/O Scanner Concepts

The discrete output module turns on the output. Any external device

attached to the output module then activates.

For timing information, please see Timing of Discrete I/O in chapter 6,

Discrete I/O.

Scanner Commands

There are two types of scanner commands, block transfers and

management requests. There are two block transfer commands (BT

commands):

block transfer read

block transfer write

A management request affects the operation of the scanner itself. There

are six management requests:

set mode changes the scanner’s operating mode to program, test, or run

mode

autoconfigure goes on the link to see what devices are attached

scan list changes the order in which adapters are scanned, and their

relative frequency

link status asks the scanner to report all information it has about the

adapters that are connected

setup changes the baud rate and connects or disconnects the line

termination resistor

fault dependent group designates one or more groups of adapters such

that, if one adapter in a group is faulted, the scanner instructs the others

to be faulted also

The control/status and general data areas are used to transfer scanner

management commands to the scanner and provide status information to

the host. In addition, this area of the global RAM is used for block

transfers between the host and intelligent I/O devices in the I/O system.

2-9

Page 18

Chapter 2

I/O Scanner Concepts

Host Watchdog

Scanner W

atchdog

Suppose that your program crashes, either because of logic errors or

because of operator intervention. Or suppose that through logic errors

your program gets into an infinite loop. In these cases the program is no

longer sending meaningful information to the scanner through the interrupt

handler. There is no way for the interrupt service routine (ISR) to

recognize all possible host program failures reliably, so instead a “host

watchdog’’ scheme has been implemented.

In essence, your program must take a particular action every so often (by

default, every second). If the ISR recognizes that the required action has

not been taken recently enough, the ISR infers that your program has failed

and simply stops talking to the scanner. The scanner in turn recognizes this

as a host failure and goes off the link within 50 ms; all the adapters go

inactive and output terminals go to last state or reset as determined by

switches you set on the chassis.

We’ll tell you about the necessary programming steps in chapter 5, Startup,

Status, and Shutdown.

If the host computer doesn’t respond to an interrupt from the scanner

within 100 ms or less, the scanner assumes that the host hardware and

BIOS is no longer active. In this case the scanner goes off the link, and 50

ms later the adapters set the output modules in last state or reset according

to your switch settings. The scanner then goes into its power–up sequence,

waiting for new startup commands from the host.

This scanner watchdog feature lets you end one program run and start

another without cycling host power. Even if your program locks up the

host computer, if you are able to do a soft reset (

Ctrl–Alt–Del) the scanner

is ready and waiting for your program. More importantly, if your program

fails or is interrupted, even by a reboot of the computer, all discrete outputs

are in last state or reset, according to the switches you set on the adapters.

2-10

Page 19

Installation

Chapter

3

Chapter

Objectives

Using the Scanner with Other Products

This chapter explains how to install the IBM PC I/O Scanner. After

reading this chapter you should be able to:

determine whether you already have hardware or software products

installed that would conflict with the scanner

configure the scanner board for a suitable address in your host’s RAM

install the scanner board in the host

connect the 1771 Series I/O cable to the scanner.

In this manual, we do not explain how to cable and configure 1771 Series

I/O products. For that information, please refer to the manuals that came

with those products.

You need to be aware of possible hardware or software conflicts between

other products and the scanner. In this section we point out the hardware

and software features in the scanner that might lead to conflict with other

products, and where possible we tell you how to avoid those conflicts.

However, there are so many add-ons available that we cannot guarantee

that the scanner works with any particular one.

Hardware Interrupt

On the system board, the scanner can use interrupt request lines IRQ3,

IRQ5, IRQ10, and IRQ12. These interrupt request lines are selected by

positioning the jumper located on the scanner board. Results are

unpredictable if any other devices use these lines. In particular, you can’t

have two IBM I/O scanners operating in the same host, since the host

software cannot direct Allen-Bradley I/O calls to a particular scanner

board.

Allen-Bradley products that use the IRQ3 include the 1784-KTP and the

6121-CBB ‘combo’ card (used with the 6120 and 6121 Industrial

Computers).

3-1

Page 20

Chapter 3

Installation

IBM’s Technical Reference Manuals show line IRQ3 used by the

secondary serial port (COM2 device). If you have 2 serial ports active on

your host computer and you have selected IRQ3, you must disable COM2

before installing the scanner board. (Many multi-junction cards have

jumpers to disable this port; see your manufacturer’s documentation for

details.)

CAUTION: If you have other cards that use the interrupt line

you have selected, (IRQ3, IRQ5, IRQ10, or IRQ12), physically

disconnect them to avoid damaging the 6008-SI or other cards.

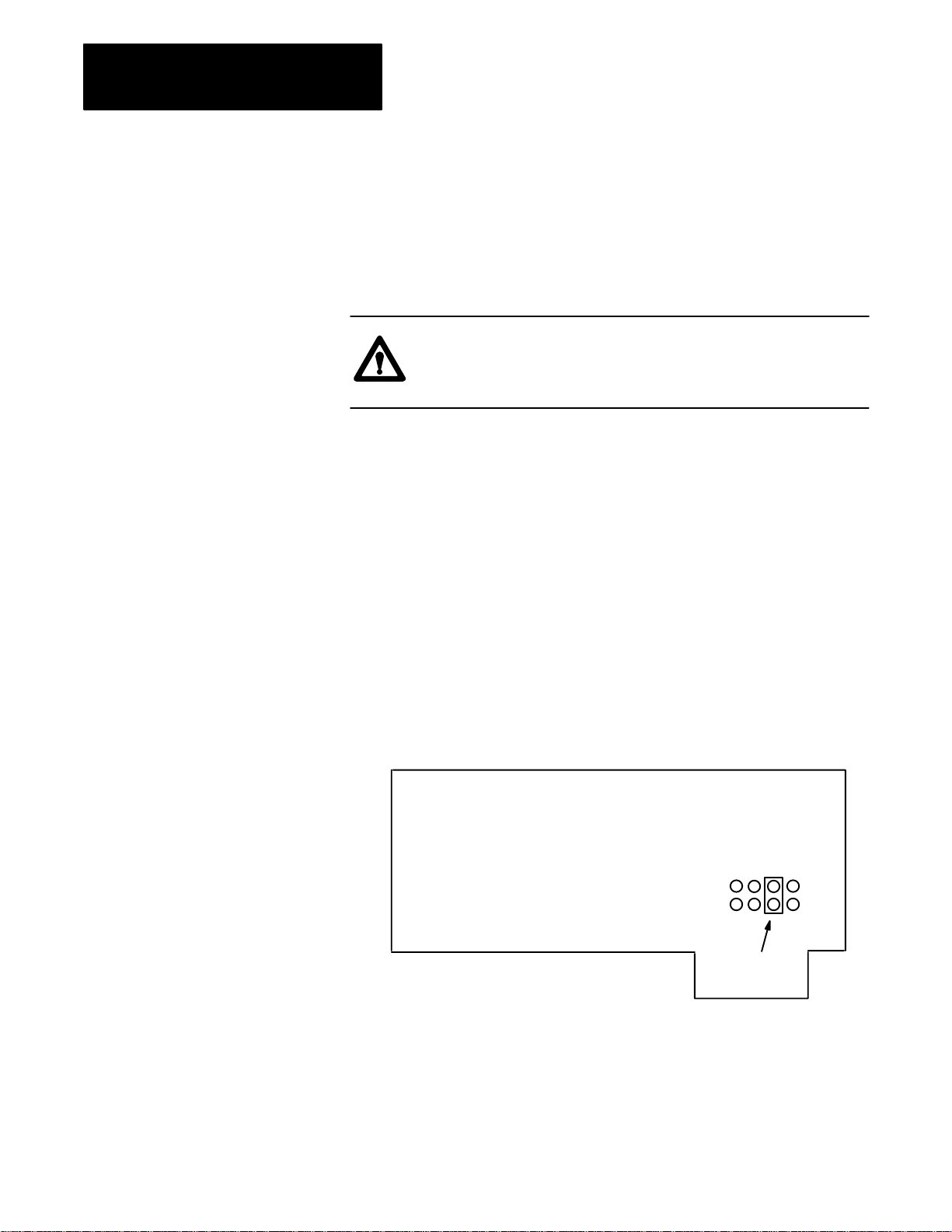

To change the interrupt request line setting, complete these steps:

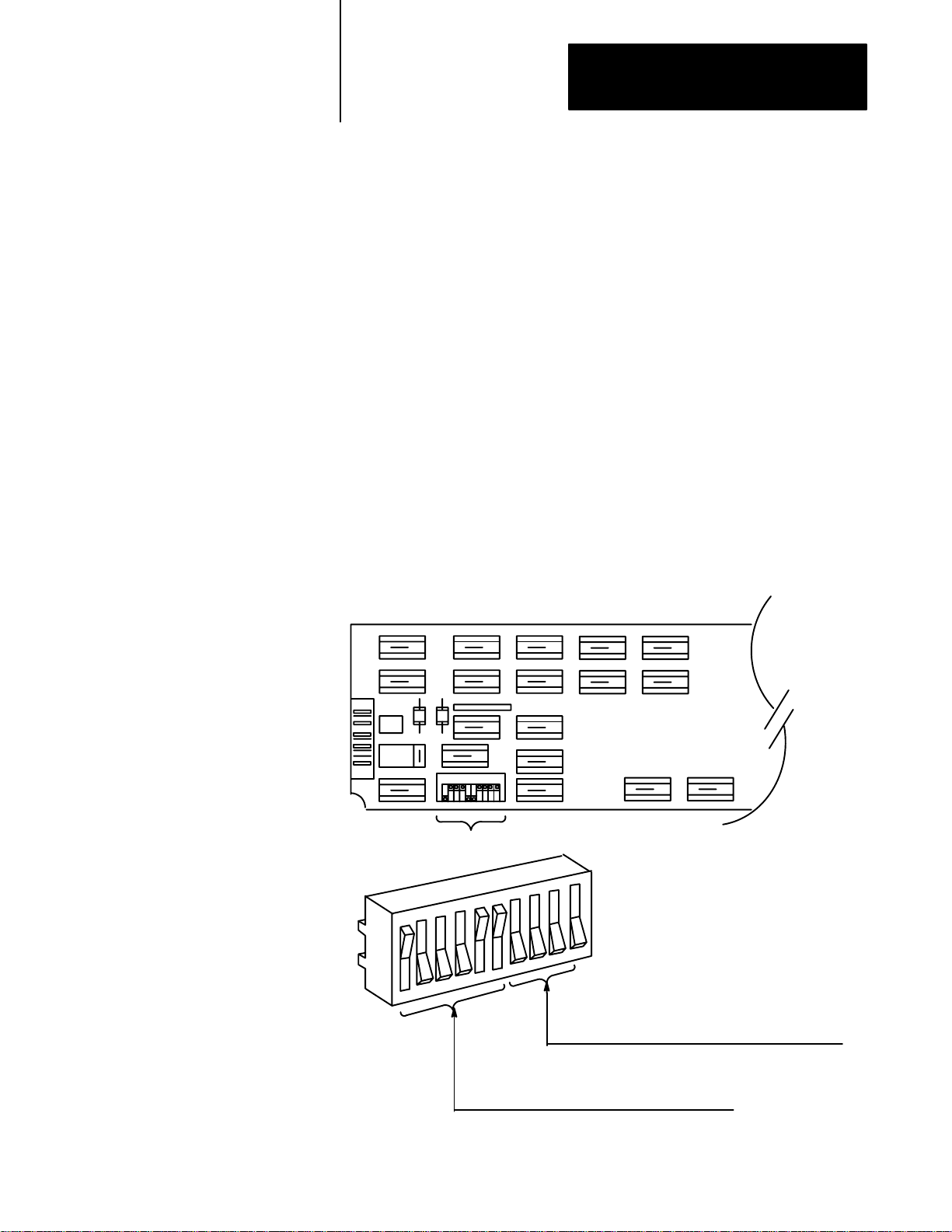

1. Remove the cover from the computer that contains the I/O scanner.

2. Remove the I/O scanner from the computer.

3. Remove the four screws securing the daughterboard to the main

board. Unplug and remove the daughterboard.

4. Locate the double row of stake pins on the main board (see

Figure 3.1). A jumper plug connects 2 pins to select the interrupt

request line.

Figure 3.1

Location

of Interrupt Request Line Jumper Plug

Note: Interrupt line designations are

not actually shown on the board.

11

20

Default setting

IRQ3

35

3-2

Page 21

Chapter 3

Installation

5. To change the setting, pull the jumper off the pins and reposition it on

the pins for the interrupt line you desire. See Table 3.A for interrupt

request line definitions.

Table 3.A

Interrupt

Request Line Definitions

Interrupt Line: Explanation:

IRQ3 Default setting. Conflicts with COM2 port on machines so equipped.

Conflicts with the KTP card.

IRQ5 This setting conflicts with the hard disk controller when the card is

used in an IBMXT or AT clone. This setting would also conflict with

the LPT2 port on machine so equipped.

IRQ10 Not available on IBMXT. Not assigned on 1784T50 or IBMAT, but

may conflict with 3rd party boards.

IRQ12 Not available on IBMXT. Not assigned on 1784T50 or IBMAT, but

may conflict with 3rd party boards.

6. Write your application software to use the newly selected interrupt

request line setting.

Software Interrupt

The host receives interrupts from the scanner through the selected line

(IRQ3, IRQ5, IRQ10, or IRQ12). Table 3.B lists the software interrupt

vectors.

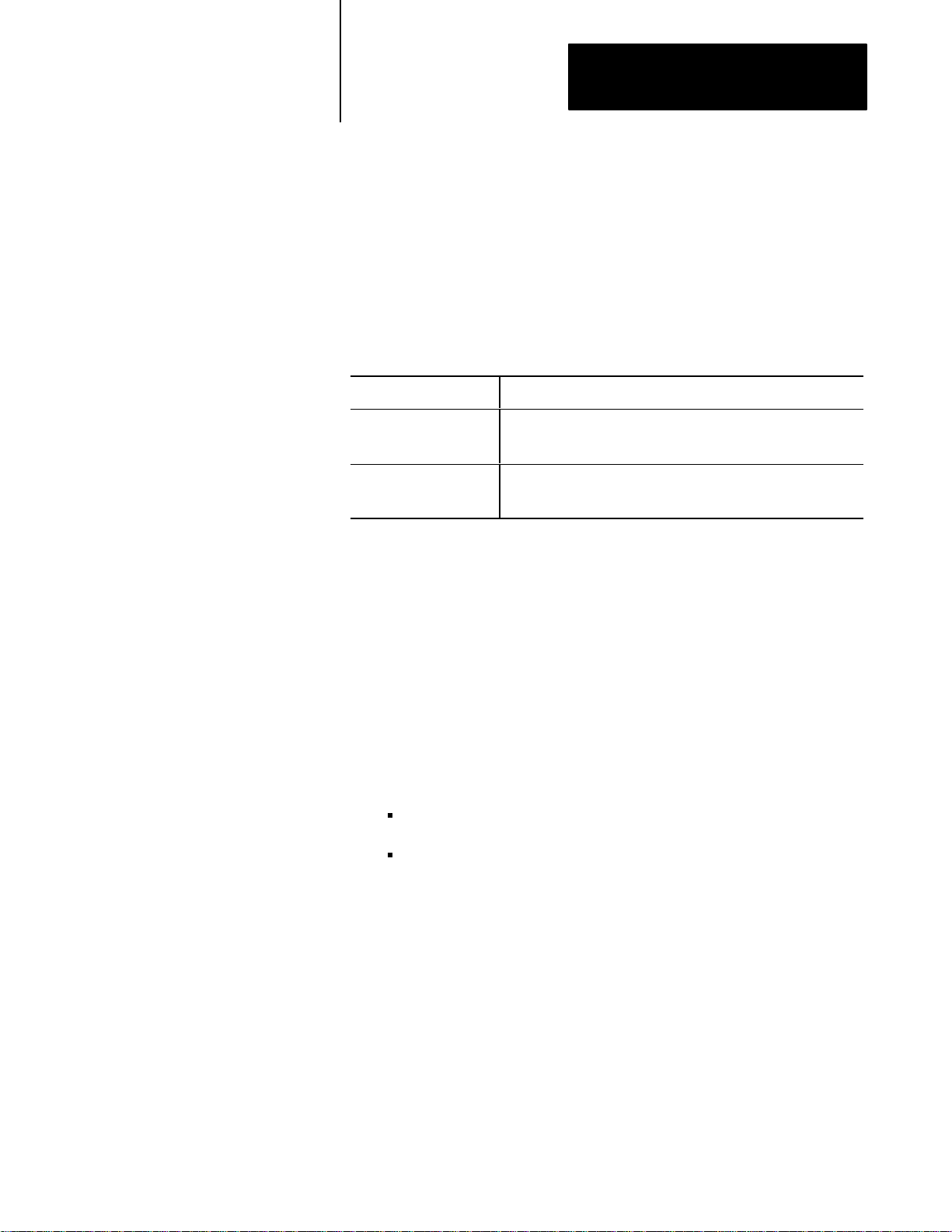

Table 3.B

Software

Interrupt Line: Software Interrupt Vector:

IRQ3 0Bh

IRQ5 0Dh

IRQ10 072h

IRQ12 074h

Interrupt V

ectors

Results are unpredictable if you have any other hardware that uses

interrupt IRQ3, IRQ5, IRQ10, or IRQ12 (It is likely that the other software

simply ceases functioning while your scanner 0 interface program is

running, but we cannot guarantee that this is the only result).

The scanner driver routines also use the timer follow–on interrupt, number

1Ch. After its own processing, the scanner code will call any previously

set follow–ons to interrupt 1Ch. If the other software is taking too great a

portion of system resources, your scanner application program may not

operate correctly.

3-3

Page 22

Chapter 3

Installation

Despite IBM recommendations to the contrary, some resident software

uses the system timer hardware interrupt, number 8, rather than the

follow-on described in the preceding paragraph. The scanner may work

erratically or may fail to work at all if such programs are active when a

scanner program is started.

I/O Ports

The scanner does not use any I/O ports.

RAM Address

DIP switches on the scanner board let you configure it to any starting

address in RAM, from 0400(hex) to FC00(hex), in increments of

4000(hex) = 16 K bytes. (The scanner cannot be configured to operate in

extended or expanded memory.) The scanner board occupies 1801(hex)

(6K+1) bytes beginning at the address you select. You are responsible for

selecting an address that starts at a free 6K+1 byte range.

The documentation for each of your add-on boards should tell you which

addresses (if any) it uses in system RAM. In addition, we can tell you

about the following common memory uses:

monochrome display memory: B000(hex)-B7FF(hex)

color/graphics display memory: B800(hex)-BFFF(hex)

Enhanced Graphics Adapter memory: C000(hex)-C3FF(hex) for the

BIOS, plus an area that could be as large as A000(hex)-BFFF(hex),

depending on the display mode

hard disk BIOS (on the PC XT, not the PC AT):

C800(hex)-CBFF(hex) for the first controller, CC00(hex)-CFFF(hex)

for the second controller if a second one is installed

cartridge ROM reserved area: E000(hex)-EFFF(hex) on some systems

ROM BIOS: F000(hex)-FFFF(hex)

Use the above information, and documentation from the manufacturers of

your add-on boards, to select an area of memory that is available for the

scanner. During the installation process you’ll set switches according to

the memory area you select.

3-4

Page 23

Chapter 3

Installation

Installation

Procedure

The procedure of installing the scanner board in the host has three main

steps:

1. Set the scanner board switch block for the memory address you

selected earlier.

2. Plug the scanner into a slot in the host computer.

3. Connect the I/O cable to the scanner.

In this section we’ll look at those steps in detail.

Switch Settings

The scanner board has one block of ten DIP switches to be set at

installation time.

Figure 3.2

Switch Location on Scanner Board

Dip

Switches

(Close)

on

(Open)

off

Set switches 710 open for PC/XT (6120)

Set switches 710 closed for PC/AT (T50, 6121, 6122)

(photo shows switches set for PC/AT)

Set switches 1-6 set for RAM address.

(photo shows switches set for RAM address C4000)

3-5

Page 24

Chapter 3

Installation

The factory sets the switches for memory address C000(hex) for an IBM

PC AT or other machine with a 16-bit bus. If you’re running on a PC XT

or another 8-bit bus machine, or if you want to configure the scanner at an

address other than C000(hex), you’ll have to change the switches.

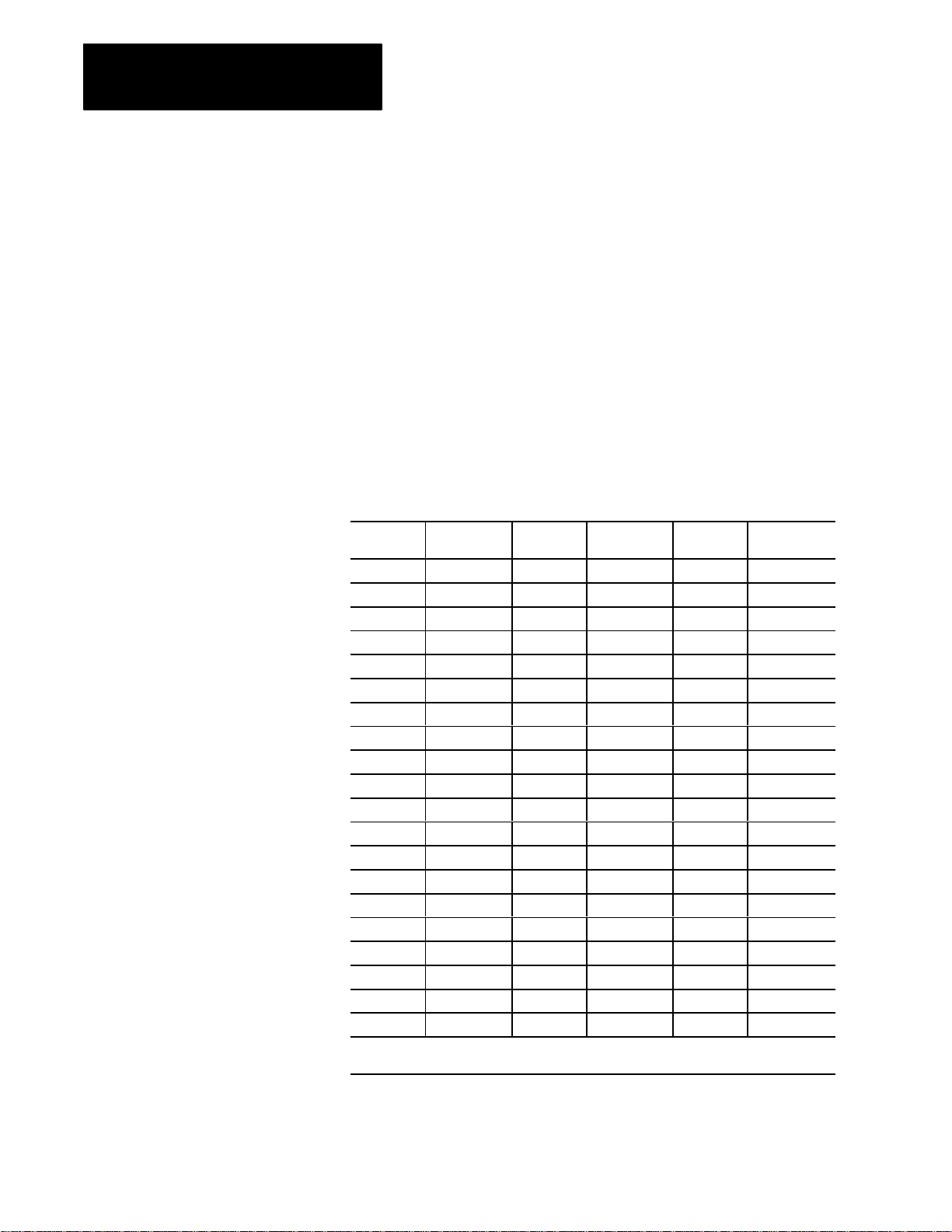

First set switches 7 through 10 to all closed for a PC AT or similar, all open

for a PC XT or similar. The factory setting is all closed, for a PC AT or

other machine with a 16-bit bus.

Next set switches 1 through 6 for the memory address you selected.

Table 3.C shows the correct setting of switches 1 through 6, in that order,

for every hex address below F000, where

O is an open switch and c is a

closed switch:

Table 3.C

Dip

Switch Settings for Memory Address (Switches 1 through 6)

Hex

Address

0400 Occ ccc 5000 ccO cOc A000 ccc OcO

0800 cOc ccc 5400 OcO cOc A400 Occ OcO

0C00 OOc ccc 5800 cOO cOc A800 cOc OcO

1000 ccO ccc 5C00 OOO cOc AC00 OOc OcO

1400 OcO ccc 6000 ccc OOc B000 ccO OcO

1800 cOO ccc 6400 Occ OOc B400 OcO OcO

1C00 OOO ccc 6800 cOc OOc B800 cOO OcO

2000 ccc Occ 6C00 OOc OOc BC00 OOO OcO

2400 Occ Occ 7000 ccO OOc C000 ccc cOO

2800 cOc Occ 7400 OcO OOc C400 Occ cOO

2C00 OOc Occ 7800 cOO OOc C800

3000 ccO Occ 7C00 OOO OOc CC00 OOc cOO

3400 OcO Occ 8000 ccc ccO D000 ccO cOO

3800 cOO Occ 8400 Occ ccO D400 OcO cOO

3C00 OOO Occ 8800 cOc ccO D800

4000 ccc cOc 8C00 OOc ccO DC00 OOO cOO

4400 Occ cOc 9000 ccO ccO E000 ccc OOO

4800 cOc cOc 9400 OcO ccO E400 Occ OOO

4C00 OOc cOc 9800 cOO ccO E800 cOc OOO

1

Not available for the IBM PC XT

2

Recommended for IBM PC AT computers with EGA and VGA graphics

Switch

Setting

Hex

Address

9C00 OOO ccO EC00 OOc OOO

Switch

Setting

Hex

Address

1

cOc cOO

2

cOO cOO

Switch

Setting

3-6

Page 25

Chapter 3

Installation

Plugging in the Board

The scanner board requires two slots. (Any two adjacent slots will do: the

board doesn’t have to be plugged into any particular slot.) The Installation

and Setup manual from IBM, or the corresponding manual from the maker

of your host computer, explains in detail how to install any add-on board.

(See the Internal Option Installation Instructions section in the IBM

manual.)

Host Bus Speed

The scanner is designed to operate on a standard 6 to 8 Mhz IBM AT bus.

Newer 386 PC compatibles operate their busses at faster rates (11 or 12

Mhz) with no wait states. The scanner will not synchronize properly at

these higher rates and will return a 102 error code at the completion of the

setup command. Most of the faster 386 PC compatibles have a setup

screen that allows you to choose the standard IBM AT bus speed. The

standard bus speed must be chosen in order for the scanner to operate

properly.

Attaching the I/O Cable

The 1771 Series I/O cable (the “blue hose”) terminates in a 15-pin female

D-shell connector, and the scanner has a 15-pin male connector accessible

through the rear cover of the host computer. Connect the cable to the

scanner and your installation is complete.

Table 3.D

I/O Cable Connections

1771

Scanner: Cable: Adapter:

pin 8 blue terminal 1

pin 7 shield terminal 2

pin 6 clear terminal 3

3-7

Page 26

Chapter 3

Installation

Line Termination

Resistor

1

2

3

4

5

6

7

8

9

10

11

12

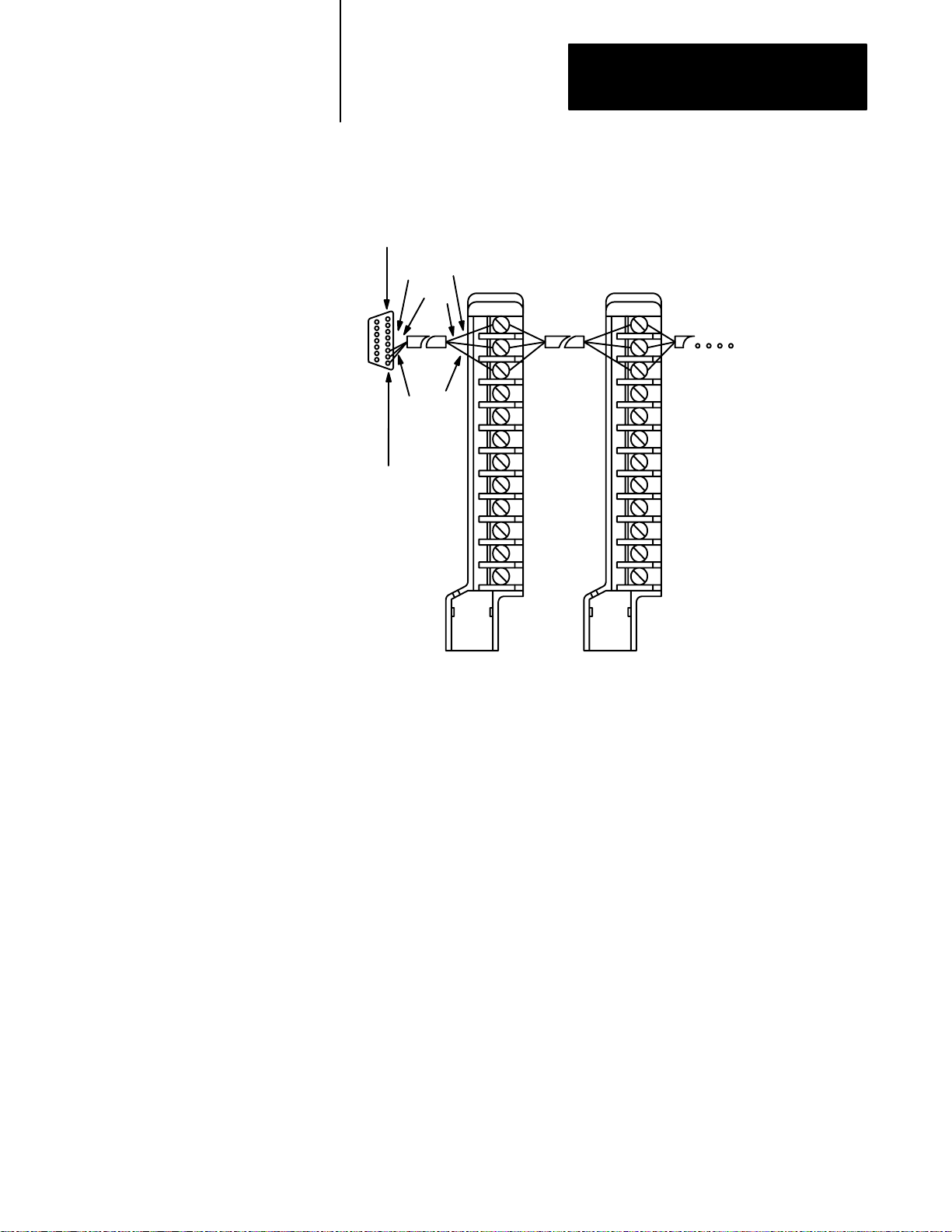

Figure 3.3

Connecting

1

2

3

4

5

6

7

8

9

10

11

12

1771 I/O Cable in Parallel

Pin 8

Blue

Shield

White

Pin 1

D-shell

Connector

(back view)

Twinaxial Cable

Blue

Shield

White

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

Swingarm

1771WB

Swingarm

1771WB

Swingarm

1771WB

Note:

• Use the setup command to disconnect the shunt

line termination resistor in the scanner.

• You can connect a maximum of 16 swingarms.

• Use termination resistor on the last swingarm.

Swingarm

1771WB

14864

3-8

Page 27

Chapter 3

Installation

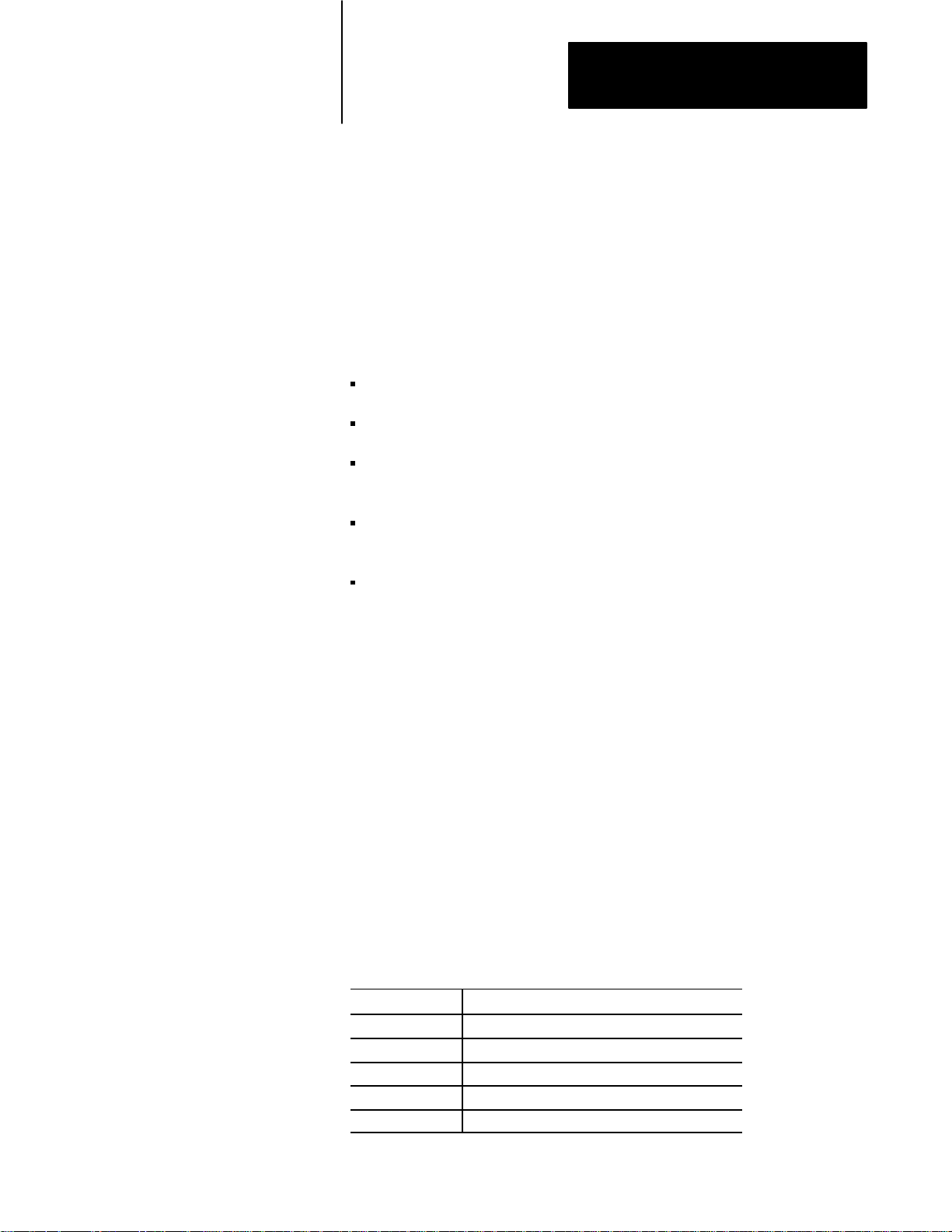

D-shell

Connector

(back view)

Figure 3.4

Connecting

Pin 1

White

Blue

Twinaxial

Cable

Pin 8

1771 I/O Cable in Series

Blue

Shield

Twinaxial

Cable

White

Swing-Arm Swing-Arm

1771-WB 1771-WB

Note:

• Use the setup command to disconnect the shunt

line termination resistor in the scanner.

• You can connect a maximum of 16 swingarms.

• Use termination resistor on the last swingarm.

14865

3-9

Page 28

Chapter

Programming Overview

4

Chapter

Objectives

Disk Inventory

This chapter gives you a general overview of the programming process.

After reading this chapter you should be able to:

identify the purpose of every file on your distribution disk

install the software on your hard disk (if you have one)

recognize the special features of source code for a program that

interfaces with the scanner

select names for your variables that won’t conflict with the names in the

programs we supply

select the necessary options to compile and link a scanner interface

program.

The host software is shipped on a single 720K (3.5”) diskette, for use with

Borland and Microsoft compilers. The disk contains an include file

required with all your programs; run–time libraries in the small, compact,

medium, large, and huge memory models; and source and executable code

for the diagnostic program described in chapter 10, User Diagnostic

Program.

The host software package also includes two 360K 5.25-inch diskettes, one

for use with Borland compilers and the other for use with Microsoft

compilers. The combined contents of these two diskettes is identical to the

contents of the 720K diskette.

Table 4.A lists the contents of the host software package.

Table 4.A

Contents

File: Contents:

H_6008SI.H include file

6008SI?M.LIB run-time libraries compiled with Microsoft C 6.0A

6008SI?B.LIB run-time libraries compiled with Borland C++ 2.0

U_D1M.EXE user diagnostic program (Microsoft C version)

U_D1B.EXE user diagnostic program (Borland C version)

of Host Software Package

4-1

Page 29

Chapter 4

Programming Overview

Table 4.B lists the rest of the files that make up the source code for the user

diagnostic program:

Table 4.B

Code for the User Diagnostic Program

Source

File: Contents:

U_D1.C main program

U_D1.H include file for the U_*.C files

U_BT.C single block transfers

U_BTC.C continuous block transfers

U_BTM.C multiple block transfers

U_DISC.C fullscreen discrete I/O

U_GET.C keyboard handler

U_GROUP.C singlegroup discrete I/O

U_MR.C management requests

U_PICK.C main menu

We provide the diagnostic program source files so that you have extended

examples of successful programming for the scanner. You should feel free

to experiment by modifying them, though we cannot support any modified

program versions.

Important: All of the files on the diskettes are Copyright

(C)Allen-Bradley Company and may not be distributed or copied (other

than from the distribution disk to your hard-disk or working diskette)

without our permission.

All of the source files are identical between the two diskettes. The

run-time libraries are different and have different names, as explained

below. The executable programs work the same, but contain different code

because they were compiled with different compilers.

If your system is equipped with a hard disk, please read the installation

hints for the Borland or Microsoft version, below. (We provide hints rather

than firm instructions because your hard disk could be organized in many

ways for system development.)

If your system doesn’t have a hard disk, you can write and run scanner

programs using just floppy drives. Please consult your compiler and linker

manuals for instructions on organizing your floppy disks.

4-2

Page 30

Chapter 4

Programming Overview

Installing the Borland Version

This section provides installation suggestions. Feel free to modify this

procedure according to your own configuration.

Important: We recommend that you make backup copies of the

distribution disks and keep the originals in a safe place, away from your

computer and away from stray magnetic fields.

Please make sure that your compiler is installed according to Borland’s

instructions before you follow the procedure below.

If you have a: Then:

3.5inch floppydisk drive Write protect the supplied 720K diskette (or your backup copy) by

sliding the write-protect tab so that a hole shows through the

diskette casing. Insert the diskette in the floppydisk drive.

5.25inch floppydisk drive Write protect the supplied 360K diskette labeled `Borland C version'

(or your backup copy) by applying a standard adhesive foil

write-protect tab. Insert the diskette in the floppydisk drive.

In the command examples below, we assume you’re using the a: drive, so

please substitute b: if appropriate. We also assume that your hard disk is

drive c: –– again, please substitute another drive letter if appropriate.

There are two main approaches: either copy the scanner’s include file and

libraries into the directories with the compiler–supplied files, or copy the

scanner files into the work directory where you’ll be developing software.

Method 1: Scanner files in same directories as compiler files

1. Change to the root directory for the compiler. If you used Borland’s

default installation, the command will be one of the following:

for Borland C++ 2.0: cd \borlandc

for Turbo C++ 1.0: cd \tc

The command will be different if you performed an installation to a

directory other than Borland’s default.

2. Copy the header file and libraries, like this:

copy a:h_6008si.h c:include

copy a:6008si?b.lib c:lib

You’ll see five libraries copied, for the small, compact, medium,

large, and huge memory models.

3. Create your development directory using the md command, and

change to that directory by using the cd command.

4-3

Page 31

Chapter 4

Programming Overview

4. Create an EXAMPLES directory under your development directory,

using this command:

md examples

5. Copy the user diagnostic program (source code and executable) to

this directory by typing the commands

copy a:u*.? c:examples

copy a:u_d1b.exe c:examples\u_d1.exe

If you wish, you can print the source files (approximately 35 pages)

by using this command:

print examples\u_*.?

Method 2: Scanner files in development directory

1. Create your development directory using the md command, and

change to that directory by using the cd command.

2. Copy the header file and libraries, like this:

copy a:h_6008si.h c:

copy a:6008si?b.lib c:

You’ll see five libraries copied, for the small, compact, medium,

large, and huge memory models.

3. Create an EXAMPLES directory under your development directory,

using this command:

md examples

4. Copy the user diagnostic program, source code and executable, to this

directory by typing these commands:

copy a:u*.? c:examples

copy a:u_d1b.exe c:examples\u_d1.exe

If you wish, you can print the source files (approximately 35 pages)

by using this command:

4-4

print examples\u_*.?

Page 32

Chapter 4

Programming Overview

Installing the Microsoft Version

This section provides installation suggestions. Feel free to modify this

procedure according to your own configuration.

We recommend that you make backup copies of the distribution disks and

keep the originals in a safe place, away from your computer and away

from stray magnetic fields.

Please make sure that your compiler is installed according to Microsoft’s

instructions before you follow the procedure below.

If you have a: Then:

3.5inch floppydisk drive Write protect the supplied 720K diskette (or your backup copy) by

sliding the write-protect tab so that a hole shows through the

diskette casing. Insert the diskette in your diskette drive.

5.25inch floppydisk drive Write protect the supplied 360K diskette labeled `Microsoft C

version' (or your backup copy) by applying a standard adhesive foil

write-protect tab. Insert the diskette in your diskette drive.

In the command examples below, we assume you’re using the a: drive, so

please substitute b: if appropriate. We also assume that your hard disk is

drive c: –– again, please substitute another drive letter if appropriate.

There are two main approaches: either copy the scanner’s include file and

libraries into the directories with the compiler–supplied files, or copy the

scanner files into the work directory where you’ll be developing software.

Method 1: Scanner files in same directories as compiler files

1. Change to the root directory for the compiler. If you used Microsoft’s

default installation of C 6.00, the command is:

for Microsoft C 6.0: cd \c600

If you have an earlier version of Microsoft C, or installed Microsoft

C 6.0 to a non–default directory, the proper cd command depends on

the directory you chose when you installed the compiler.

2. Copy the header file and libraries, like this:

copy a:h_6008si.h c:include

copy a:6008si?m.lib c:lib

You’ll see five libraries copied, for the small, compact, medium,

large, and huge memory models.

3. Create your development directory using the md command, and

change to that directory by using the cd command.

4-5

Page 33

Chapter 4

Programming Overview

4. Create an EXAMPLES directory under your development directory,

using this command:

md examples

5. Copy the user diagnostic program (source code and executable) to

this directory by typing these commands:

copy a:u*.? c:examples

copy a:u_d1m.exe c:examples\u_d1.exe

If you wish, you can print the source files (approximately 35 pages)

by using this command:

print examples\u_*.?

Method 2: Scanner files in development directory

1. Create your development directory using the md command, and

change to that directory by using the cd command.

2. Copy the header file and libraries, like this:

copy a:h_6008si.h c:

copy a:6008si?b.lib c:

You’ll see five libraries copied, for the small, compact, medium,

large, and huge memory models.

3. Create an EXAMPLES directory under your development directory,

using this command:

md examples

4. Copy the user diagnostic program, source code and executable, to this

directory by typing these commands:

copy a:u*.? c:examples

copy a:u_d1m.exe c:examples\u_d1.exe

If you wish, you can print the source files (approximately 35 pages)

by using this command:

4-6

print examples\u_*.?

Page 34

Chapter 4

Programming Overview

Writing Your Program

In chapters 5 through 9, we’ll explain the details of writing application

programs to communicate with the scanner. But first we’ll give you a

bird’s-eye view.

Header Files

Every source program must contain these two lines:

#include <stdio.h>

#include <H_6008SI.H>

STDIO.H is the standard header file supplied with your compiler.

H_6008SI.H is supplied on your scanner driver disk and defines constants,

variables, and functions that your program needs.

Your program may need other header files in addition to these two. If so,

you can add #include lines before or after the reference to H_6008SI.H.

However, H_6008SI.H must come later in your source file than STDIO.H.

Program Skeleton

Before making reference to any other routines in the scanner driver library,

your program must call either setup_6008 or start_6008 as described in

chapter 5, Startup.

After the last reference to other library routines, but before exiting, you

must call the stop_6008 function; please see the “Shutdown” section of

chapter 5. If your program crashes or exits normally without calling

stop_6008, you may have to reset the host computer (

Ctrl-Alt-Del or

cycle power) to continue operating.

Between the startup and shutdown calls, your program must use the

host_active macro to tell the scanner that your program is still active.

By default, your program must do this at least once a second, but you can

change the interval through programming. For full discussion of safety

issues and programming, please see chapter 5, Host Watchdog.

4-7

Page 35

Chapter 4

Programming Overview

Here’s a sample program skeleton:

#include <stdio.h>

#include <h_6008si.h>

void main(argc, argv)

int argc; char *argv[ ];

{

QMR pkt;

. . .

status = setup_6008(1, 1, 3, 0, &pkt);

if ( status != OK ) {

));

}

. . .

/* application logic here, including calls to host_active( )

*/

. . .

stop_6008( );

}

printf(“setup failed: command=%s status=%s\n”,

xlat_cmd(status), xlat_conf(pkt.qmr_stat));

if ( status != C_AUTOCONF && status != C_SETUP )

printf(“scanner fatal error %d\n”, fatal_6008(

abort( );

As explained in chapter 5, if setup fails the setup_6008 function returns

the number of the failed command and leaves the specific error status in

the packet. The sample above above uses xlat routines, described in

chapters 7 and 9, to display the meanings of the codes in plain English.

Once the setup procedure has succeeded, the scanner and host are talking

and your program can proceed. Your program must call host_active as

explained above.

4-8

Also, your program should periodically monitor global variable

g_act_scnr to make sure that communications are still active. (Refer to

chapter 5, Scanner Status, for complete information on g_act_scnr and

other scanner monitoring features.)

Page 36

Chapter 4

Programming Overview

Defined Constants

In their appropriate places in this manual we’ll tell you about various

constants defined in the header file H_6008SI.H. There are three

constants that are not used by our routines but are defined for your

convenience, and we’ll list them now:

MAXGROUP is the maximum number of module groups, 64. Groups

in the I/O image tables are therefore numbered from 0 to

MAXGROUP-1.

MAXMOD is the maximum number of modules or slots, 132.

MAXADAPT is not the maximum number of adapters (which is 16) but

the number of possible adapter addresses, 32. (An adapter address is the

same as a quarter-rack address, 8 x rack +group / 2.) For instance, when

specifying fault dependent groups (chapter 7, “Scanner Management”)

you’ll give MAXADAPT group numbers to account for everywhere an

adapter might be addressed.

Defined Type Bool

It’s convenient to think of several variables and function values as

Boolean: that is, their value can be only true or false. We define the type

Bool for such values. Bool is equivalent to int, but use of a specially

defined type provides better program documentation.

We also define the two Bool constants OK and NOT_OK, equivalent to 0

and 1 respectively. This definition reflects the C language convention that

0 indicates no error and a nonzero value indicates an error.

Several library routines return status of OK or NOT_OK, and you can also

use those constants in your program. An example is presented in the user

diagnostic program source code, which we explain next.

Extended Example

Your distribution disk contains a complete sample program that exercises

all aspects of the scanner operation through commands you enter from the

keyboard. (Chapter 10, “User Diagnostic Program,” is a user’s guide for

the U_D1 program.)

Please take a minute to look at the source code for the main module,

U_D1.C. The program includes header files STDIO.H and H_6008SI.H

indirectly, through header file U_D1.H.

4-9

Page 37

Chapter 4

Programming Overview

The main program displays identification on the screen and then calls

options (in the same source file) to read and interpret command line

options.

Next the main program calls init (also in the U_D1.C source file). In turn,

init calls setup_6008 and checks for status. If the setup was unsuccessful,

init displays a message and abort execution rather than returning to main.

If setup succeeded, init returns control to main. The main program then

goes into a loop that monitors the scanner activity code g_act_scnr and

calls pick (in source file U_PICK.C) to get a command from the

keyboard.When you enter a command to quit the program, pick returns a

status of NOT_OK to the main program, which terminates the main

program loop. The main program then calls stop_6008 and exits.

You’ll notice that we declare init and options as Bool type functions:

they’ll be returning a value of OK or NOT_OK. pick is declared Bool (in

the header file U_D1.H.) We also have a Bool variable called status that

we use as an “OK to proceed” sentinel. As soon as status takes on a value

of NOT_OK the remaining code is bypassed until the stop_6008

shutdown call.

You may also notice what looks like a violation of the rule we stated

earlier, that setup_6008 or start_6008 must precede calls to any other

routines in our library, and that no calls can follow stop_6008. Actually,

we oversimplified that rule when we stated it. The true rule is that

setup_6008 or start_6008 must be the first call that interacts with the

scanner and stop_6008 must be the last. But it’s OK to call any of the

following routines before startup or after shutdown: sysdate, systime,

sysstamp, pr_array, pr_globl (though some values displayed may not be

meaningful), xlat_cfg, xlat_cmd, xlat_conf, xlat_flt, xlat_opst.

Avoiding Compile Time Name Conflicts

When you write your program, you need to make sure that the variable

names you pick don’t conflict with the variable names in our library or

your compiler’s library. This section and the next tell you how to avoid

conflicts with our names; please consult your compiler manual for hints on

avoiding conflict with its names.

4-10

Page 38

Chapter 4

Programming Overview

File H_6008SI.H defines constants according to a logical pattern. The

first few letters of each constant’s name tells you how it’s used, as follows:

Constant: Definition:

C_ scanner commands (listed in chapter 7, Executing a Management Request, and

chapter 8, Queueing a Block Transfer)

CM_

SC_ confirmation status values (listed in chapters 7 and 8, Confirmation Status Codes)

SF_ fault status bits and values (listed in chapter 7, Autoconfigure and Link Status

SL_ link (adapter) configuration status bits and values (listed in chapter 7, Autoconfigure

SO_ operating status bits (listed in chapter 5, Scanner Status)

MAX

scanner operating modes (program, test, and run; listed in chapter 7)

Information)

and Link Status Information)

user program limits (listed above, in Defined Constants)

C compilers treat capitals and lower case differently, so it’s OK to select

names that begin with c_, cm_, and so on. But stay away from local or

global variable names beginning with any of the above character sequences

in capitals.

Avoiding Link Time Errors

You eventually link one of our supplied libraries with your program.

Please plan now to avoid naming conflicts. (You need to be concerned

only with the names of your functions and extern variables. Your static,

auto, and register variable names can’t conflict with ours.)

Link time name conflicts could show up in two ways. The linker could

refuse to create an executable program. But most likely the link would

proceed with no indication of anything wrong, and your routine would be

linked in and exclude our routine (or the compiler’s library routine) of the

same name. Then your program would crash (or give wrong results) when

one of our routines called your routine instead of the “standard” routine.

Bugs like these can be hard to uncover, so it’s best to avoid them in the

first place. Borland’s TLINK linker offers the /d option to diagnose this

sort of problem. We recommend you use the /d option if you’re using

Borland’s Turbo C++ or Borland C++ to develop your application.

In this manual you’ll see the names of almost all the functions in the

libraries we supply, and naturally you should not use any of those names

for your own code. In addition, the libraries have a few internal support

routines whose names begin with io_ or IO_, and you should avoid those

names also.

4-11

Page 39

Chapter 4

Programming Overview

Names of global variables in our libraries begin with g_. In addition, the

libraries contain a number of undocumented internal global variables

whose names begin with _q.

In summary, you can create conflicts with names in our libraries by naming

functions and extern variables beginning with g_, _q, io_, or IO_. To be

safe, stay away from those names and from the names of functions

documented in this manual.

Compiling and Linking the

Borland C++ 2.0 Version

These notes present a simple way of compiling and linking your

application program with the scanner code. This way may or may not be

the best way for your development. There are many alternatives –

Borland’s Integrated Development Environment, make files and project

files, and so on. You should evaluate the alternatives and decide which

way is most productive for you.

Decide which memory model you will use (small, compact, medium, large,

or huge). Please see the discussion of memory models in your compiler

manual. In the command below, replace %%%% with the first letter of the

memory model, in lower case.

Use this command to compile and link your program in one step:

BCC –N –K –w –m%%%% –lcd yourprogname.c 6008si%%%%b.lib

Important: –lcd upper/lower case is significant in public names; diagnose

duplicate names in libraries.

The options we recommend are listed in Table 4.C.

Table 4.C

Options

for Compile and Link

4-12

Options: Description:

-N stack checking turned on

-K default 'char' is 'unsigned char'

-w show warnings at compile time

-m select memory model

-O turn off optimization

-d set up for debugging

-v link with debugging information

We recommend against the –a option (align structure members by word).

Our library routines were compiled without it, and may not be compatible

with code you compile with that option.

Page 40

Chapter 4

Programming Overview

For information on selecting or excluding the 8087 or 80287 math

coprocessor, please see the Borland manual sections on the –f options.

Our libraries are compatible with any –f option because they contain no

floating-point operations.

Example 1: Your program is called APPLIC.C. You have selected the

small (s) memory model. The combined command to compile and link

would be

BCC

–N –K –w –ms –lcd applic.c 6008sisb.lib

Borland C++ will compile applic.c as applic.obj and link it as applic.exe.

Example 2: If your program is in several source modules, you can list

them on the command line. If you have chosen medium model, the

command is

BCC

–N –K –w –mm –lcd control.c contr1.c contr2.c 6008simb.lib

The three source files will be compiled and linked as CONTROL.EXE.

Example 3: You have many source files –– U_D1.C, U_BT.C, and so on

–– to be compiled and linked in a program called U_D1B.EXE. Header

files are not in the same directory as source code, but are in directory

c:\dev\hdr. The following command will compile and link in small model.

BCC

–N –K –w –ms –lcd –Ic:\dev\hdr –eU_D1B U_*.C 6008sisb.lib

This is quite similar to the command we used to create the U_D1B

program on your distribution disk.

Compiling and Linking the Borland Turbo C++ 1.0 Version

The procedure is exactly the same as for Borland C++ 2.0, except that you

begin the command with TCC rather than BCC.

TCC –N –K –w –m%%%% –lcd yourprogname.c 6008si%%%%b.lib

4-13

Page 41

Chapter 4

Programming Overview

Compiling and Linking the Microsoft C 5.1 or 6.0 Version

These notes present a simple way of compiling and linking your

application program with the scanner code. This way may or may not be

the best way for your development. There are many alternatives –

Microsoft’s Programmer’s Workbench, make files, and so on. You should

evaluate the alternatives and decide which way is most productive for you.

Decide which memory model you will use (small, compact, medium, large,

or huge). Please see the discussion of memory models in your compiler

manual. In the command below, replace %%%% with the first letter of the

memory model, in upper case.

Use this command to compile and link your program in one step:

CL /J /A%%%% /W3 yourprogname.c /link 6008si%%%%m

The options we recommend are listed in Table 4.D.

Table 4.D

Options

for Compile and Link

Options: Description:

/J default 'char' is 'unsigned char'

/A select memory model

/W3 show warnings at compile time

/link select scanner library

/Od turn off optimization

/Zi set up for CodeView debugging

4-14

We recommend against the /Zp option (pack structure members). Our

library routines were compiled without it, and may not be compatible with

code you compile with that option.

For information on selecting or excluding the 8087 or 80287 math

coprocessor, please see the Microsoft manual sections on the /FP options.

Our libraries are compatible with any /FP option because they contain no

floating–point operations.

Example 1: Your program is called APPLIC.C. You have selected the

small (S) memory model. The combined command to compile and link

would be

CL /J /AS /W3 applic.c /link 6008sism

Microsoft C will compile applic.c as applic.obj and link it as applic.exe.

Page 42

Chapter 4

Programming Overview

Example 2: If your program is in several source modules, you can list

them on the command line. If you have chosen medium model, the

command is

CL /J /AM /W3 applic.c /link 6008simm

The three source files will be compiled and linked as CONTROL.EXE.

Example 3: You have many source files –– U_D1.C, U_BT.C, and so on

–– to be compiled and linked in a program called U_D1M.EXE. Header

files are not in the same directory as source code, but are in directory

c:\dev\hdr. The following command will compile and link in small model.

Further Information

CL /J /AS /W3 /FeU_D1M /Ic:\dev\hdr U_*.C /link

6008sism

This is quite similar to the command we used to create the U_D1M

program on your distribution disk.

The next few chapters of this manual explain programming features:

Chapter 5, Startup, Status, and Shutdown, explains features that must be

in every scanner interface program, including how to start and stop

scanner operation, status monitoring, and the host watchdog.

Chapter 6, Discrete I/O, explains how to read single-point inputs and

write outputs.

Chapter 7, Scanner Management, explains how to issue management

requests that modify the operation of the scanner.

Chapter 8, Block Transfer, explains how to read data from, and write

data to, intelligent I/O modules.

Chapter 9, General Support Features, explains how to write timing

loops, time-stamp a file or printout, and translate a numeric scanner

command to English.

4-15

Page 43

Chapter 4

Programming Overview

The last two chapters are concerned with diagnostics:

Chapter 10, User Diagnostic Program, tells you how to use the

diagnostic program that we included on your distribution disks.

Chapter 11, Troubleshooting, has some questions and answers to help

you in diagnosing problems.

4-16

Page 44

Chapter

5

Startup, Status, and Shutdown

Chapter

Overview

Objectives

This chapter explains features that must be in every scanner program.

After reading this chapter, you should be able to write code that:

tells the scanner to start operation

lets the scanner know that your program is still active (the host

watchdog)

makes sure that the scanner is still active