Page 1

User Manual

E300 Electronic Overload Relay

Bul. 193/592

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Product Overview

Table of Contents

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Modular Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Simplified Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sensing Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Communication Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Digital Expansion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Analog Expansion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operator Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Module Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sensing Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Control Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Communication Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Optional Add-On Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Optional Expansion I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Optional Operator Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Optional Expansion Bus Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . 18

Protection Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Standard Current-Based Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ground Fault Current Based Protection. . . . . . . . . . . . . . . . . . . . . . . . 19

Voltage and Power Based Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Applications: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation and Wiring

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Receiving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Unpacking/Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Base Relay Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Control Module to Sensing Module Assembly. . . . . . . . . . . . . . . . . . . . . . 23

Communication Module to Control Module Assembly . . . . . . . . . . . . . 24

Expansion Bus Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Expansion Bus Digital & Analog I/O Modules and Power Supply

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Expansion Bus Operator Station Installation . . . . . . . . . . . . . . . . . . . . . . . 26

Expansion Bus Network Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Starter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

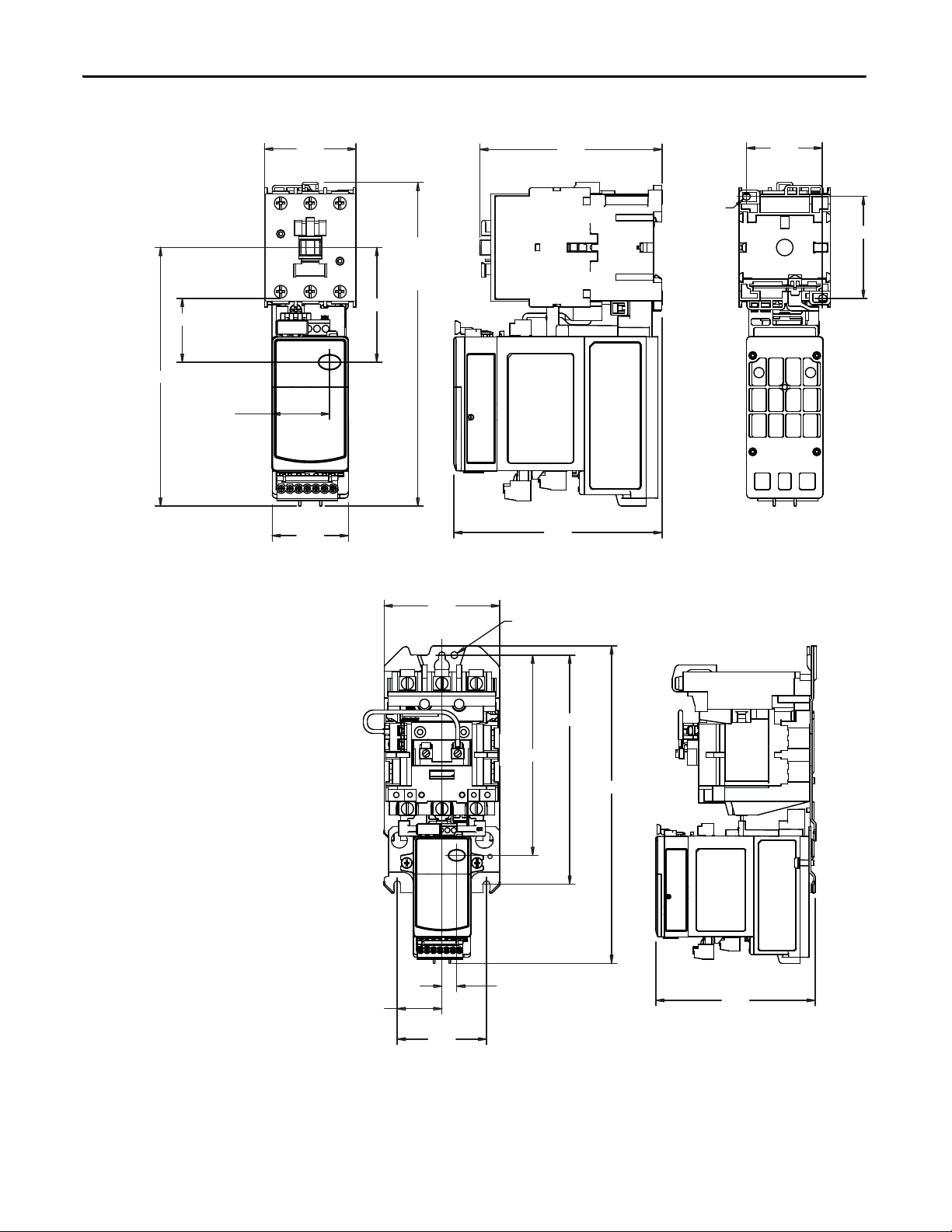

Starter Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DIN Rail / Panel Mount Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 3

Page 4

Table of Contents

System Operation and Configuration

Expansion Bus Peripherals Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Sensing Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Expansion Digital Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Expansion Analog Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Expansion Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Short-Circuit Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Fuse Coordination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Typical Motor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

External Line Current Transformer Application . . . . . . . . . . . . . . . . . . . . 44

Control Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Device Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Administration Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Operation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Invalid Configuration Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Option Match . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Enable Option Match Protection Trip (Parameter 186). . . . . . . . . . 55

Enable Option Match Protection Warning (Parameter 192) . . . . . 56

Control Module Type (Parameter 221). . . . . . . . . . . . . . . . . . . . . . . . . 56

Sensing Module Type (Parameter 222) . . . . . . . . . . . . . . . . . . . . . . . . . 57

Communication Module Type (Parameter 223). . . . . . . . . . . . . . . . . 57

Operator Station Type (Parameter 224) . . . . . . . . . . . . . . . . . . . . . . . . 58

Digital I/O Expansion Module 1 Type (Parameter 225) . . . . . . . . . 58

Digital I/O Expansion Module 2 Type (Parameter 226) . . . . . . . . . 59

Digital I/O Expansion Module 3 Type (Parameter 227) . . . . . . . . . 59

Digital I/O Expansion Module 4 Type (Parameter 228) . . . . . . . . . 60

Analog I/O Expansion Module 1 Type (Parameter 229) . . . . . . . . . 60

Analog I/O Expansion Module 2 Type (Parameter 230) . . . . . . . . . 61

Analog I/O Expansion Module 3 Type (Parameter 231) . . . . . . . . . 61

Analog I/O Expansion Module 4 Type (Parameter 232) . . . . . . . . . 62

Option Match Action (Parameter 233). . . . . . . . . . . . . . . . . . . . . . . . . 62

Security Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Device Configuration Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Device Reset Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Firmware Update Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Security Configuration Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

I/O Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Input Pt00 Assignment (Parameter 196). . . . . . . . . . . . . . . . . . . . . . . . 64

Input Pt01 Assignment (Parameter 197). . . . . . . . . . . . . . . . . . . . . . . . 65

Input Pt02 Assignment (Parameter 198). . . . . . . . . . . . . . . . . . . . . . . . 65

4 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 5

Operating Modes

Table of Contents

Input Pt03 Assignment (Parameter 199) . . . . . . . . . . . . . . . . . . . . . . . 66

Input Pt04 Assignment (Parameter 200) . . . . . . . . . . . . . . . . . . . . . . . 66

Input Pt05 Assignment (Parameter 201) . . . . . . . . . . . . . . . . . . . . . . . 67

Output Pt00 Assignment (Parameter 202) . . . . . . . . . . . . . . . . . . . . . 68

Output Pt01 Assignment (Parameter 203) . . . . . . . . . . . . . . . . . . . . . 68

Output Pt02 Assignment (Parameter 204) . . . . . . . . . . . . . . . . . . . . . 69

Activate FLA2 with Output Relay (Parameter 209) . . . . . . . . . . . . . 69

Expansion Bus Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Expansion Bus Trip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Expansion Bus Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Emergency Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Introduction to Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Overload (Network) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Monitor (Custom) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Protective Trip and Warning

Functions

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Current Based Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Overload Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Phase Loss Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Ground Fault Current Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Stall Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Jam Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Underload Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Current Imbalance Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Line Under Current Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Line Over Current Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Line Loss Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Voltage Based Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Under Voltage Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Over Voltage Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Voltage Imbalance Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Phase Rotation Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Frequency Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Power Based Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Real Power (kW) Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Reactive Power (kVAR) Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Apparent Power (kVA) Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Power Factor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Control-Based Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Test Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Operator Station Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Remote Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 5

Page 6

Table of Contents

Start Inhibit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Hardware Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Configuration Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Option Match. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Expansion Bus Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Non-Volatile Storage Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Test Mode Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Chapter 6

Commands

Metering and Diagnostics

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Trip Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Configuration Preset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Clear Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Clear Operating Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Clear History Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Clear %TCU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Clear kWh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Clear kVARh. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Clear kVAh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Clear Max kW Demand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Clear Max kVAR Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Clear Max kVA Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Clear All . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Chapter 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Device Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Percent Thermal Capacity Utilized. . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Time to Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Time To Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Current Trip Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Voltage Trip Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Power Trip Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Control Trip Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Current Warning Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Voltage Warning Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Power Warning Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Control Warning Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Input Status 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Input Status 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Output Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Operator Station Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Device Status 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Device Status 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

6 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 7

Table of Contents

Firmware Revision Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Control Module ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Sensing Module ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Operator Station ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Expansion Digital Module ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Operating Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Starts Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Starts Available. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Time to Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Month . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Day . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Minute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Second . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Invalid Configuration Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Invalid Configuration Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Mismatch Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Current Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

L1 Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

L2 Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

L3 Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Average Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

L1 Percent FLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

L2 Percent FLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

L3 Percent FLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Average Percent FLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Ground Fault Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Current Imbalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Voltage Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

L1-L2 Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

L2-L3 Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Average L-L Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

L1-N Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

L2-N Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

L3-N Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

244

Average L-N Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Voltage Imbalance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Phase Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Power Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Power Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

L1 Real Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

L2 Real Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

L3 Real Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Total Real Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

L1 Reactive Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 7

Page 8

Table of Contents

L2 Reactive Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

L3 Reactive Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Total Reactive Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

L1 Apparent Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

L2 Apparent Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

L3 Apparent Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Total Apparent Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

L1 Power Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

L2 Power Factor Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

L3 Power Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Total Power Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Energy Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

kWh 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

kWh 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

kWh 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

kWh 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

kWh 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

kVARh Consumed 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

kVARh Consumed 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

kVARh Consumed 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

kVARh Consumed 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

kVARh Consumed 10-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

kVARh Generated 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

kVARh Generated 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

kVARh Generated 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

kVARh Generated 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

kVARh Generated 10-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

kVARh Net 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

kVARh Net 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

kVARh Net 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

kVARh Net 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

kVARh Net 10-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

kVAh 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

kVAh 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

kVAh 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

kVAh 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

263

kVAh 10-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

kW Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Max kW Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

kVAR Demand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Max kVAR Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

kVA Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Max kVA Demand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Trip / Warning History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Trip History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Warning History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Trip Snapshot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

8 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 9

EtherNet/IP Communications

Table of Contents

Trip Snapshot L1-L2 Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Trip Snapshot L2-L3 Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Trip Snapshot L3-L1 Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Trip Snapshot Total Real Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Trip Snapshot Total Reactive Power . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Trip Snapshot Total Apparent Power . . . . . . . . . . . . . . . . . . . . . . . . . 277

Trip Snapshot Total Power Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Chapter 8

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Network Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Determining Network Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Setting the IP Network Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

EtherNet/IP Node Address Selection Switches . . . . . . . . . . . . . . . . 282

Assign Network Parameters via the BOOTP/ DHCP Utility . . . 283

Assign Network Parameters Via a Web Browser & MAC Scanner

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Other Factors to Consider When Assigning Network Parameters 285

Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Duplicate IP Address Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

DNS Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Electronic Data Sheet (EDS) File Installation. . . . . . . . . . . . . . . . . . . . . . 288

Download the EDS File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

View & Configure Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Viewing Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Automation Controller Communications. . . . . . . . . . . . . . . . . . . . . . . . . 295

I/O Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Logix Configuration with Add-On Profile. . . . . . . . . . . . . . . . . . . . . 296

Logix Configuration with a Generic Profile. . . . . . . . . . . . . . . . . . . . 301

E-mail/Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

E-mail Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Text Notifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Firmware Updates

Troubleshooting

Chapter 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Firmware Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Upgrading Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Chapter 10

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Advisory LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Power LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Trip/Warn LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 9

Page 10

Table of Contents

Resetting a Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Trip/Warn LED Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . 320

Appendix A

Specifications

Parameter List

EtherNet/IP Information

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Electromagnetic Compatibility Specifications. . . . . . . . . . . . . . . . . . . . . . 326

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Metering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Protection Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Appendix B

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Appendix C

Common Industrial Protocol (CIP) Objects. . . . . . . . . . . . . . . . . . . . . . . 371

Identity Object — CLASS CODE 0x0001 . . . . . . . . . . . . . . . . . . . . 372

Message Router — CLASS CODE 0x0002 . . . . . . . . . . . . . . . . . . . . 374

Assembly Object — CLASS CODE 0x0004 . . . . . . . . . . . . . . . . . . . 374

Instance 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Instance 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

Instance 120 - Configuration Assembly Revision 2 . . . . . . . . . . . . . 376

Instance 120 - Configuration Assembly Revision 1 . . . . . . . . . . . . . 386

Instance 144 – Default Consumed Assembly. . . . . . . . . . . . . . . . . . . 386

Instance 198 - Current Diagnostics Produced Assembly. . . . . . . . . 386

Instance 199 - All Diagnostics Produced Assembly . . . . . . . . . . . . . 388

Connection Object — CLASS CODE 0x0005. . . . . . . . . . . . . . . . . 390

Discrete Input Point Object — CLASS CODE 0x0008. . . . . . . . . 393

Discrete Output Point Object — CLASS CODE 0x0009. . . . . . . 394

Analog Input Point Object — CLASS CODE 0x000A . . . . . . . . . 396

Analog Output Point Object — CLASS CODE 0x000B. . . . . . . . 397

Parameter Object — CLASS CODE 0x000F . . . . . . . . . . . . . . . . . . 398

Parameter Group Object — CLASS CODE 0x0010. . . . . . . . . . . . 399

Discrete Output Group Object — CLASS CODE 0x001E . . . . . 399

Control Supervisor Object — CLASS CODE 0x0029 . . . . . . . . . . 400

Overload Object — CLASS CODE 0x002c . . . . . . . . . . . . . . . . . . . 401

Base Energy Object — CLASS CODE 0x004E. . . . . . . . . . . . . . . . . 401

Electrical Energy Object — CLASS CODE 0x004F . . . . . . . . . . . . 403

Wall Clock Time Object — CLASS CODE 0x008B . . . . . . . . . . . 405

DPI Fault Object — CLASS CODE 0x0097. . . . . . . . . . . . . . . . . . . 406

DPI Warning Object — CLASS CODE 0x0098 . . . . . . . . . . . . . . . 410

MCC Object — CLASS CODE 0x00C2. . . . . . . . . . . . . . . . . . . . . . 413

Comm Adapter Info Object — CLASS CODE 0x0C8 . . . . . . . . . 414

E300 Status Object — CLASS CODE 0x0375. . . . . . . . . . . . . . . . . 414

10 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 11

Product Overview

Chapter 1

Overview

The E300™ Electronic Overload Relay is a microprocessor-based electronic

overload relay designed to protect three-phase or single-phase AC electric

induction motors rated from 0.5…65,000 A. Its modular design, communication

options, diagnostic information, simplified wiring, and integration into Logix

makes this the ideal overload for motor control applications in an automation

system. The E300 Electronic Overload Relay provides flexibility, reduces

engineering time, and maximizes uptime for important motor starter

applications.

Modular Design

Users can select the specific options needed for their motor starter application.

The E300 Electronic Overload Relay consists of three modules: sensing, control

and communications. Users have choices in each of the three with additional

accessories to tailor the electronic motor overload for their application’s exact

needs.

• Wide current range

• Sensing capabilities (Current, Ground Fault Current, and/or Voltage)

• Expansion I/O

• Operator interfaces

Communication Options

Users can select from multiple communication options which integrate with

Logix based control systems. Developers can easily add the E300 Electronic

Overload Relay to Logix based control systems using Integrated Architecture

tools such as Add-on Profiles, Add-on Instructions, and Faceplates.

• EtherNet/IP (DLR)

• DeviceNet

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 11

Page 12

Chapter 1 Product Overview

Diagnostic Information

The E300 Electronic Overload Relay provides a wide variety of diagnostic

information to monitor motor performance, proactively alert users to possible

motor issues, or identify the reason for an unplanned shut down. Information

includes:

• Voltage, Current, & Energy

• Tri p / Warni ng His to ri es

• % Thermal Capacity Utilization

• Time to Trip

• Time to Reset

• Operational Hours

• Number of Starts

• Tri p S nap sh ot

Simplified Wiring

The E300 Electronic Overload Relay provides an easy means to mount to both

IEC and NEMA Allen-Bradley contactors. A contactor coil adapter is available

for the 100-C contactor, which allows the user to create a functional motor

starter with only two control wires.

12 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 13

Product Overview Chapter 1

193 - ESM - VIG - 30A - C23

592

Module Type

ESM Sensing Module

Sensing Module Type

VIG Current, Ground Fault Current,

Voltage, & Power

IG Current & Ground Fault Current

ICurrent

Sensing Module Mounting Style

C23 Mounts to 100-C09…-C23 Contactor

C55 Mounts to 100-C30…-C55 Contactor

C97 Mounts to 100-C60…-C97 Contactor

D180 Mounts to 100-D115…-D180 Contactor

S2 Mounts to Bulletin 500 NEMA Size 0-2 Contactor

S3 Mounts to Bulletin 500 NEMA Size 3 Contactor

S4 Mounts to Bulletin 500 NEMA Size 4 Contactor

T DIN Rail / Panel Mount with Power Terminals

E3T Replacement DIN Rail / Panel Mount with Power Terminals for an E3 Plus Panel Mount Adapter

P DIN Rail / Panel Mount with Pass-thru Power Conductors

CT DIN Rail / Panel Mount with Pass-thru Power Conductors (used with External CTs)

Bulletin Number

193 IEC Overload Relay

592 NEMA Overload Relay

Sensing Current Range

30A 0.5…30 A

60A 6…60 A

100A 10…100 A

200A 20…200 A

193 - EIO - 43 - 120

Module Type

EIO I/O Only Control Module

EIOGP I/O and Protection Control Module

(External Ground Fault Sensing

and PTC)

I/O Count

63 6 Inputs / 3 Relay Outputs

43 4 Inputs / 3 Relay Outputs

42 4 Inputs / 2 Relay Outputs

22 2 Inputs / 2 Relay Outputs

Bulletin Number

193 IEC Overload Relay

Control Voltage

24D 24V DC

120 110…120V AC, 50/60 Hz

240 220…240V AC, 50/60 H

193 - ECM - ETR

Module Type

ECM Communication Module

Communication Type

ETR EtherNet/IP with Dual Ethernet Ports

DNT DeviceNet

Bulletin Number

193 IEC Overload Relay

Catalog Number Explanation

E300 Electronic Overload Relay modules have their own catalog number. The

catalog numbers are explained below.

Sensing Module

Control Module

Communication Module

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 13

Page 14

Chapter 1 Product Overview

193 - EXP - DIO - 42 - 120

Module Type

EXP Expansion Module

I/O Type

DIO Digital I/O

Bulletin Number

193 IEC Overload Relay

Communication Type

120 110…120V AC, 50/60 Hz Inputs

240 220…240V AC, 50/60 Hz Inputs

24D 24V DC Inputs

I/O Count

42 4 Inputs / 2 Relay Outputs

193 - EXP - AIO - 31

Module Type

EXP Expansion Module

I/O Type

AIO Analog I/O

Bulletin Number

193 IEC Overload Relay

I/O Count

31 3 Universal Analog Inputs / 1 Analog Output

193 - EOS - SCS

Module Type

EOS Operator Station

I/O Type

SCS Starter Control Station

SDS Starter Diagnostic Station

Bulletin Number

193 IEC Overload Relay

193 - EXP - PS - AC

Module Type

EXP Expansion Module

Func tion Type

PS Expansion Bus Power Supply

Bulletin Number

193 IEC Overload Relay

Supply Voltage

AC 110-240V AC, 50/60Hz control voltage

DC 24V DC control voltage

Digital Expansion Module

Analog Expansion Module

Operator Station

Power Supply

14 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 15

Product Overview Chapter 1

Module Description

The E300 Electronic Overload Relay is comprised of three modules. All three

modules are required to make a functional overload relay.

• Sensing Module

• Control Module

• Communication Module

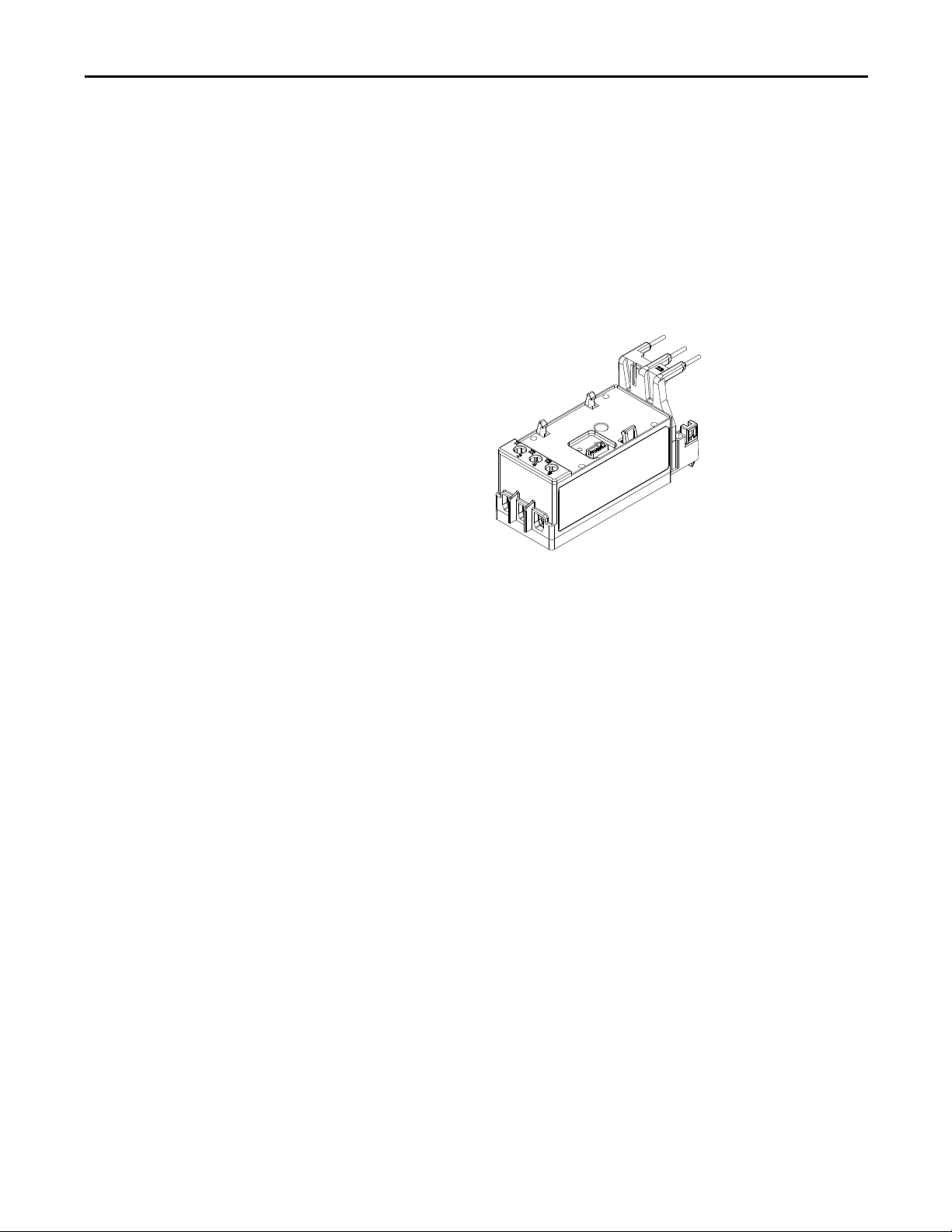

Sensing Module

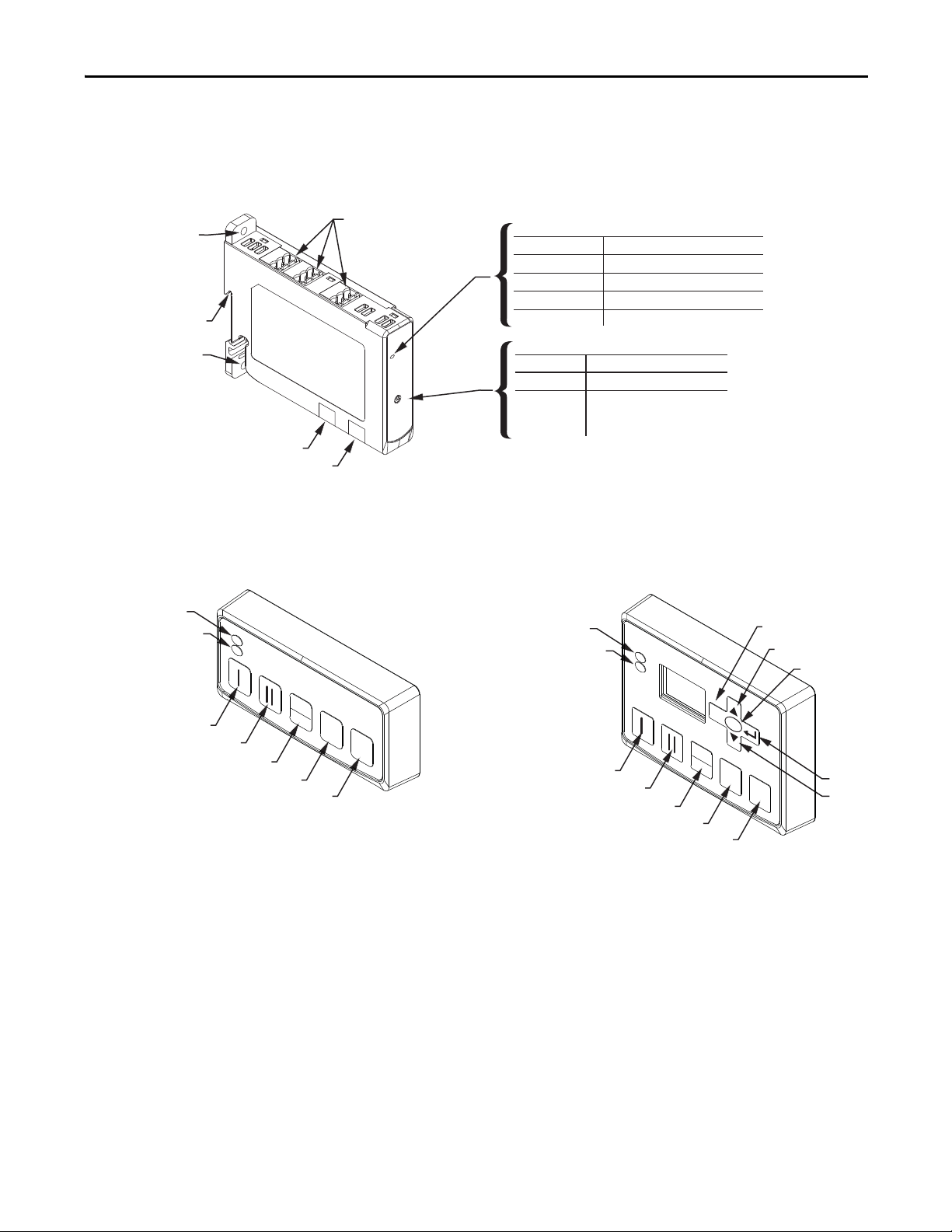

Figure 1 - Sensing Module

The sensing module electronically samples the current, voltage, power, and

energy data consumed by the electric motor internal to the module. Users can

pick from one of three varieties of the sensing modules depending on the motor

diagnostic information that is needed for the motor protection application:

rrent Sensing

• Cu

• Current and Ground Fault Current Sensing

• Current, Ground Fault Current, Voltage, and Power Sensing

T

current ranges for each of three varieties of sensing module are shown below:

he

• 0.5…30 A

• 6…60 A

• 10…100 A

• 20…200 A

Users can choose how the sensing module mechanically mounts inside the

rical enclosure. The following mounting mechanisms are available for the

elect

sensing module.

• Mount to the load side of an Allen-Bradley Bulletin 100 IEC Contactor

• Mount to the load side of an Allen-Bradley Bulletin 500 NEMA

Cont

actor

• DIN Rail / Panel Mount with power terminals

• Replacement DIN Rail / Panel Mount with power terminals for an

Al

len-Bradley E3 Plus panel mount adapter

• DIN Rail / Panel Mount with pass-thru power conductors

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 15

Page 16

Chapter 1 Product Overview

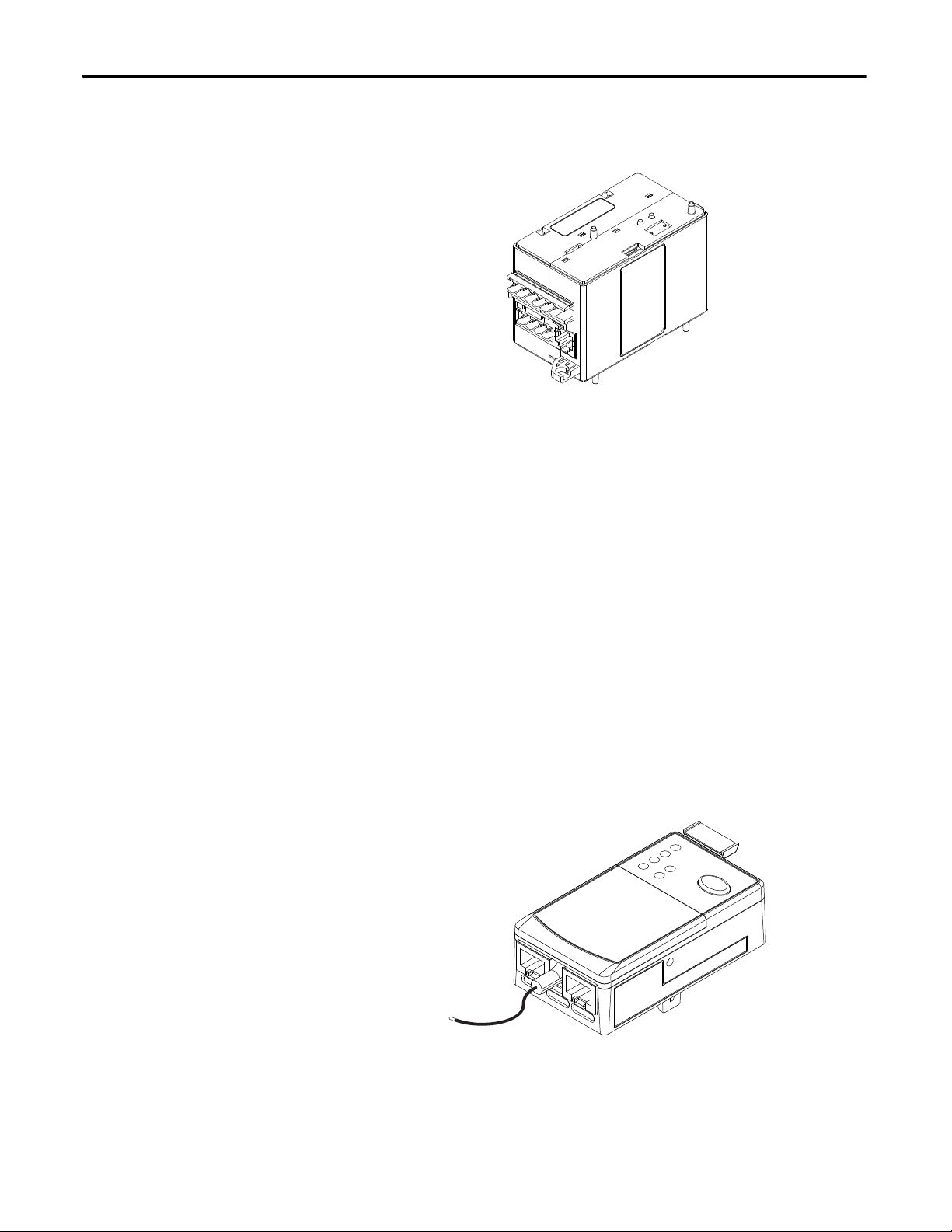

Control Module

Figure 2 - Control Module

The control module is the heart of the E300 Electronic Overload Relay and can

attach to any sensing module. The control module performs all of the protection

and motor control algorithms and contains the native I/O for the system. The

control module has two varieties:

• I/O only

• I/O and prote

ction (PTC & External Ground Fault Current Sensing)

The control module is offered in three control voltages:

• 110…120V AC, 50/60Hz

• 220…240V AC, 50/60Hz

• 24V D

Ext

ernal control voltage is required to power the E300 Electronic Overload Relay

and

activate the digital inputs.

C

Communication Module

Figure 3 - Communication Module

The communication module allows the E300 Electronic Overload Relay to be

integrated into an automation system, and it can attach to any control module.

All communication modules allow the user to set the node address with rotary

16 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 17

Product Overview Chapter 1

turn dials, and it provides diagnostic LEDs to provide system status at the panel.

The E300 Electronic Overload Relay supports two network protocols:

• EtherNet/IP

• DeviceNet

The

E300 EtherNet/IP Communication Module has two RJ-45 connectors that

funct

ion as a switch. Users can daisy chain multiple E300 Electronic Overload

Relays with Ethernet cable, and the module supports a Device Level Ring (DLR).

Optional Add-On Modules

Optional Expansion I/O

The E300 Electronic Overload Relay allows the user to add additional digital and

analog I/O to the system via the E300 Electronic Overload Relay Expansion Bus

if the native I/O count is not sufficient for the application on the base relay. Users

can add up to four additional Digital I/O Expansion Modules that have 4 inputs

(120V AC, 240V AC, or 24V DC) and 2 relay outputs.

Users can also add up to four additional Analog I/O Expansion Modules, which

have three independent universal analog inputs and one isolated analog output.

The independent universal analog inputs can accept the following signals:

• 4…20 m

• 0…20 mA

• 0…10V DC

• 1…5V DC

• 0…5V DC

• RTD Sensors (Pt, Cu, Ni, & NiFe)

• NTC Sensors

o

The is

signa

diagnostic values:

lated analog output can be programmed to reference a traditional analog

l (4…20 mA, 0…20 mA, or 0…10V DC) to represent the following

• Average %FLA

• %TCU

• Ground Fault Current

• Current Imbalance

• Average L-L Voltage

• Voltage Imbalance

• To ta l kW

• To ta l kVA R

• To ta l kVA

• To ta l P ow er Fa cto r

• User Defined Value

A

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 17

Page 18

Chapter 1 Product Overview

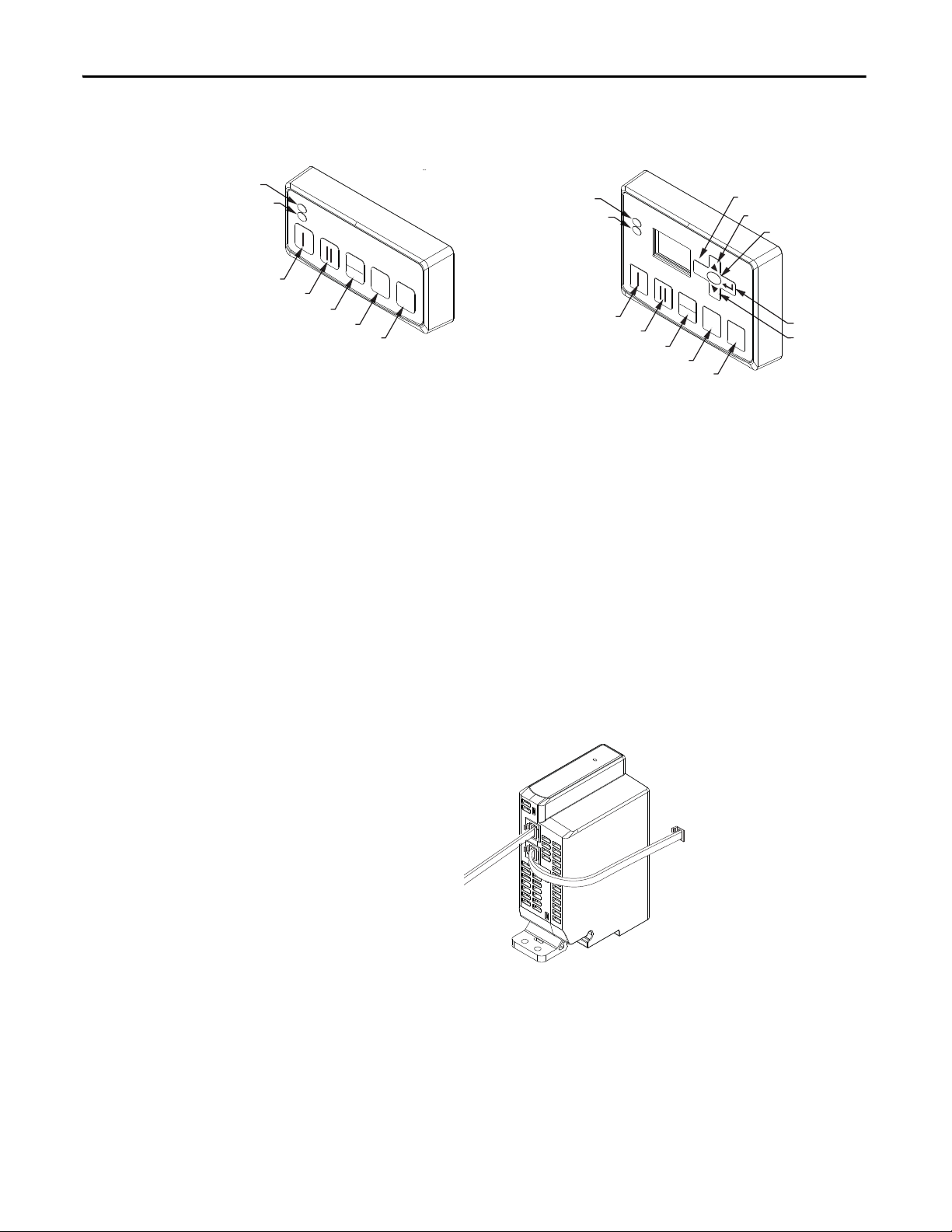

Control Station Diagnostic Station

Optional Operator Station

Figure 4 - Operator Stations

Power LED

Trip / Warn LED

Start Forward / Speed 1

Start Reverse / Speed 2

Local / Remote

Escape

Up

Select

ESC

SELECT

0

RESET

Enter

Down

Stop

LOCAL

REMOTE

Reset

Power LED

Trip / Warn LED

0

RESET

Start Forward / Speed 1

Start Reverse / Speed 2

Local / Remote

Stop

LOCAL

REMOTE

Reset

The E300 Electronic Overload Relay offers the user the capability to add one

operator interface to the Expansion Bus. There are two types of operator stations

that the user can chose from: control station or a diagnostic station. Both types of

operator stations mount into a standard 22 mm push button knockout, and they

provides diagnostic LEDs which allow the user to view the status of the E300

Electronic Overload Relay from the outside of an electrical enclosure. Both

operator stations provide push buttons which can be used for motor control

logic, and they both can be used to upload and download parameter

configuration data from the base relay. The diagnostic station contains a display

and navigation buttons that allows the user to view and edit parameters in the

base relay.

Optional Expansion Bus Power Supply

Figure 5 - Expansion Bus Power Supply

The E300 Electronic Overload Relay expansion bus provides enough current to

operate a system that has (1) Digital Expansion Module and (1) Operator

Station. An E300 Electronic Overload Relay system that contains more

expansion modules will need supplemental current for the Expansion Bus. The

E300 Electronic Overload Relay offers users two types of Expansion Bus Power

Supplies: AC (110…240V AC, 50/60 Hz) and DC (24V DC). One Expansion

Bus Power Supply supplies enough current for a fully loaded E300 Electronic

18 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 19

Product Overview Chapter 1

Overload Relay Expansion Bus (four Digital Expansion Modules, four Analog

Expansion Modules, and one Operator Station).

Protection Features

Standard Current-Based Protection

All versions of the E300 Electronic Overload Relay provide the following motor

protection functions:

• Thermal Overload (51)

• Phase Loss

• Current Imbalance (46)

• Undercurrent – load loss (37)

• Overcurrent – load jam (48)

• Overcurrent – load stall

• Start Inhibit (66)

Ground Fault Current Based Protection

The E300 Electronic Overload Relay sensing modules and control modules with

a ground fault current option provides the following motor protection function:

• Ground Fault – zero sequence method (50N)

Voltage and Power Based Protection

The E300 Electronic Overload Relay sensing modules with voltage sensing

provides the following motor protection functions:

• Undervoltage (27)

• Overvoltage (59)

• Phase Reversal (47) – voltage based

• Over and Under Frequency (81) – voltage based

• Voltage Imbalance (46)

• Over and Under Power (37)

• Over and Under Leading/Lagging Power Factor (55)

• Over and Under Reactive Power Generated

• Over and Under Reactive Power Consumed

• Over and Under Apparent Power

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 19

Page 20

Chapter 1 Product Overview

Applications:

The E300 Electronic Overload Relay can be used with the following across the

line starter applications:

• Non-Reversing Starter

• Reversing Starter

• Wye (Star) / Delta Starter

• Two -s pe ed Motors

• Low and Medium Voltage with 2 or 3 Potential Transformers

• With or Without Phase Current Transformers

• With or Without Zero-sequence Core Balanced Current Transformer

20 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 21

Installation and Wiring

Chapter 2

Introduction

Receiving

Unpacking/Inspecting

Storing

This chapter provides instructions for receiving, unpacking, inspecting, and

storing the E300™ Electronic Overload Relay. Assembly, installation, and wiring

instructions for common applications are also included in this chapter.

It is the responsibility of the user to thoroughly inspect the equipment before

accepting the shipment from the freight company. Check the item(s) received

against the purchase order. If any items are damaged, it is the responsibility of the

user not to accept delivery until the freight agent has noted the damage on the

freight bill. Should any concealed damage be found during unpacking, it is again

the responsibility of the user to notify the freight agent. The shipping container

must be left intact and the freight agent should be requested to make a visual

inspection of the equipment.

Remove all packing material from around the E300 Electronic Overload Relay.

After unpacking, check the item’s nameplate catalog number against the purchase

order.

The E300 Electronic Overload Relay should remain in its shipping container

prior to installation. If the equipment is not to be used for a period of time, it

must be stored according to the following instructions in order to maintain

warranty coverage:

• Store in a clean, dry location.

• Store within an ambient temperature range

-40…+85 °C (-40…+185

of

• Store within a relative humidity range of 0…95%, non-condensing.

• Do not store where the device could be exposed to a corrosive atmosphere.

• Do not store in a construction area.

°F).

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 21

Page 22

Chapter 2 Installation and Wiring

General Precautions

If the E300 Electronic Overload Relay is being deployed in an environment with

an ambient temperature greater than 30 °C (86 °F), please refer to the

Environmental Specifications on page 325

derating. In addition to the specific precautions listed throughout this manual,

the following general statements must be observed.

ATT EN TI ON : The E300 Electronic Overload Relay contains electrostatic

discharge (ESD) sensitive parts and assemblies. Status control precautions are

required when installing, testing, servicing, or repairing this assembly.

Component damage may result if ESD control procedures are not followed. If

you are not familiar with static control procedures, refer to Allen-Bradley

publication 8000-SB001_-en-p, “Guarding Against Electrostatic Damage”, or

any other applicable ESD protection handbook.

ATT EN TI ON : An incorrectly applied or installed E300 Electronic Overload Relay

can result in damage to the components or reduction in product life. Wiring or

application errors (e.g., incorrectly figuring the FLA setting, supplying incorrect

or inadequate supply voltage, connecting an external supply voltage to the

thermistor terminals, or operating or storing in excessive ambient

temperatures) may result in malfunction of the E300 Electronic Overload Relay.

for the appropriate temperature

Base Relay Assembly

ATT EN TI ON : Only personnel familiar with the E300 Electronic Overload Relay

and associated machinery should plan to install, start up, and maintain the

system. Failure to comply may result in personal injury or equipment damage.

ATT EN TI ON : The purpose of this user manual is to serve as a guide for proper

installation. The National Electrical Code (NEC) and any other governing

regional or local code will overrule this information. Rockwell Automation

cannot assume responsibility for the compliance or proper installation of the

Electronic Overload Relay or associated equipment. A hazard of personal

E300

injury and/or equipment damage exists if codes are ignored during installation.

ATT EN TI ON : The earth ground terminal of the E300 Electronic Overload Relay

shall be connected to a solid earth ground via a low-impedance connection.

The following section illustrates the E300 Electronic Overload Relay base relay

assembly instructions.

22 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 23

Installation and Wiring Chapter 2

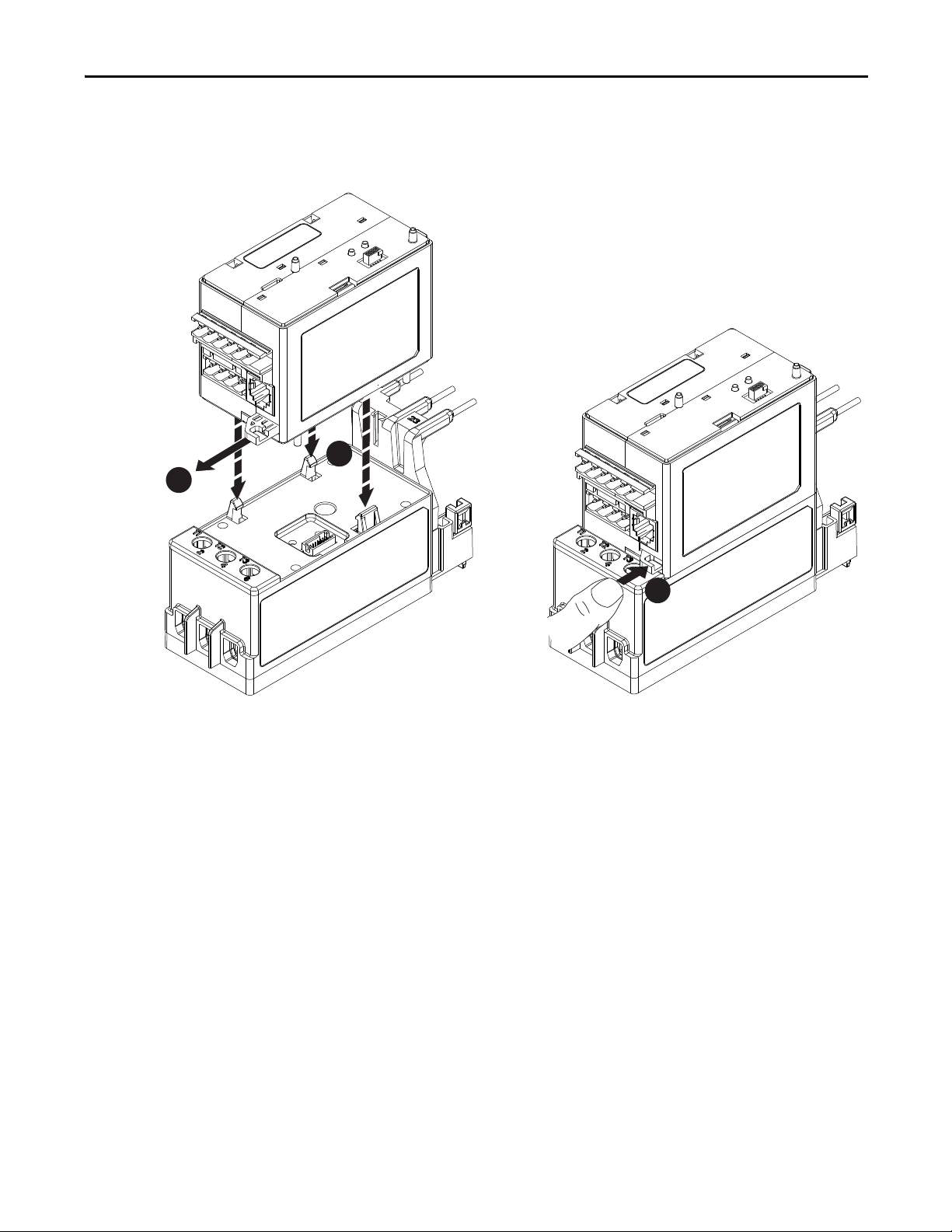

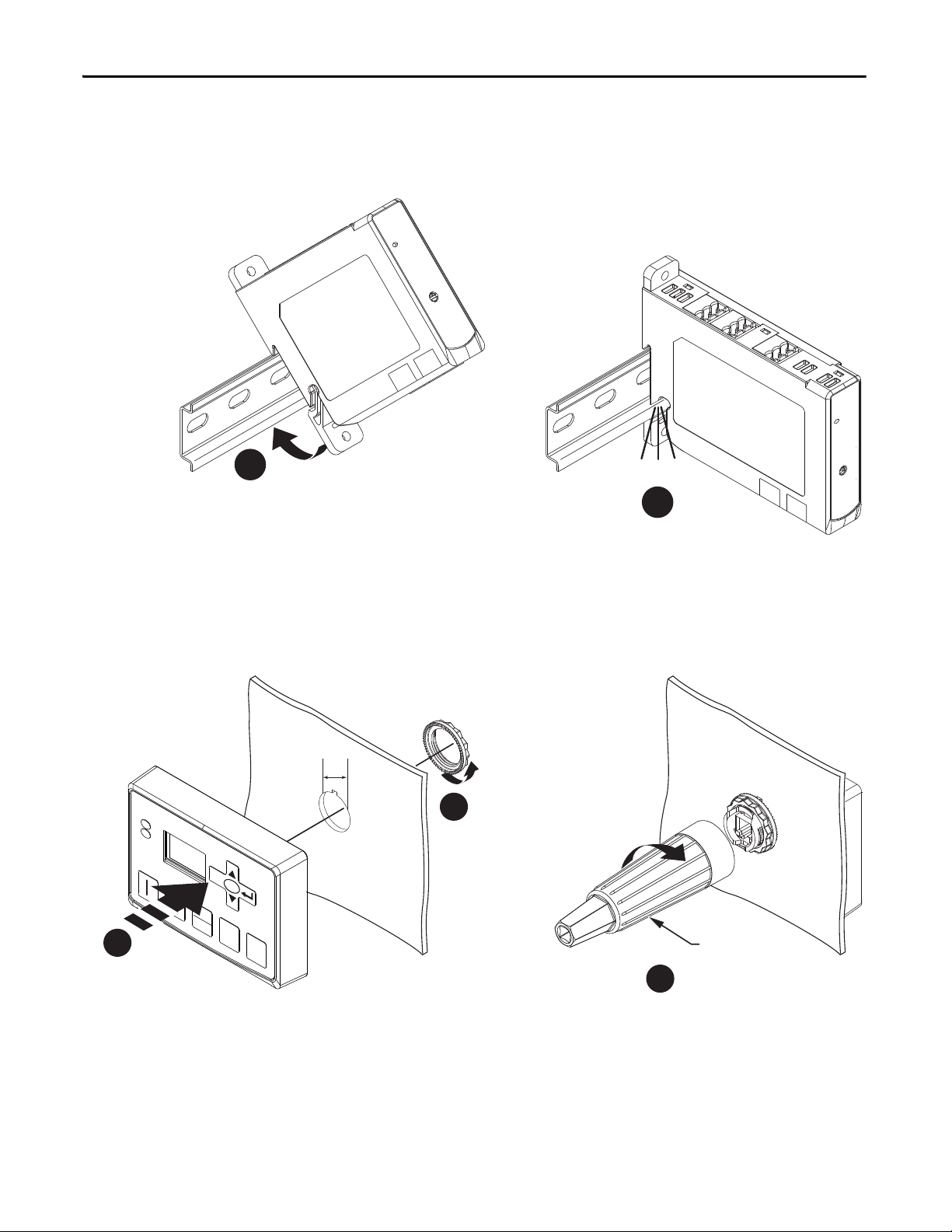

Control Module to Sensing Module Assembly

1

Any E300 Control Module can connect to any E300 Sensing Module. The

illustrations below show the steps required to make this connection.

Figure 6 - Control Module to Sensing Module Assembly\

2

3

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 23

Page 24

Chapter 2 Installation and Wiring

1

3

2

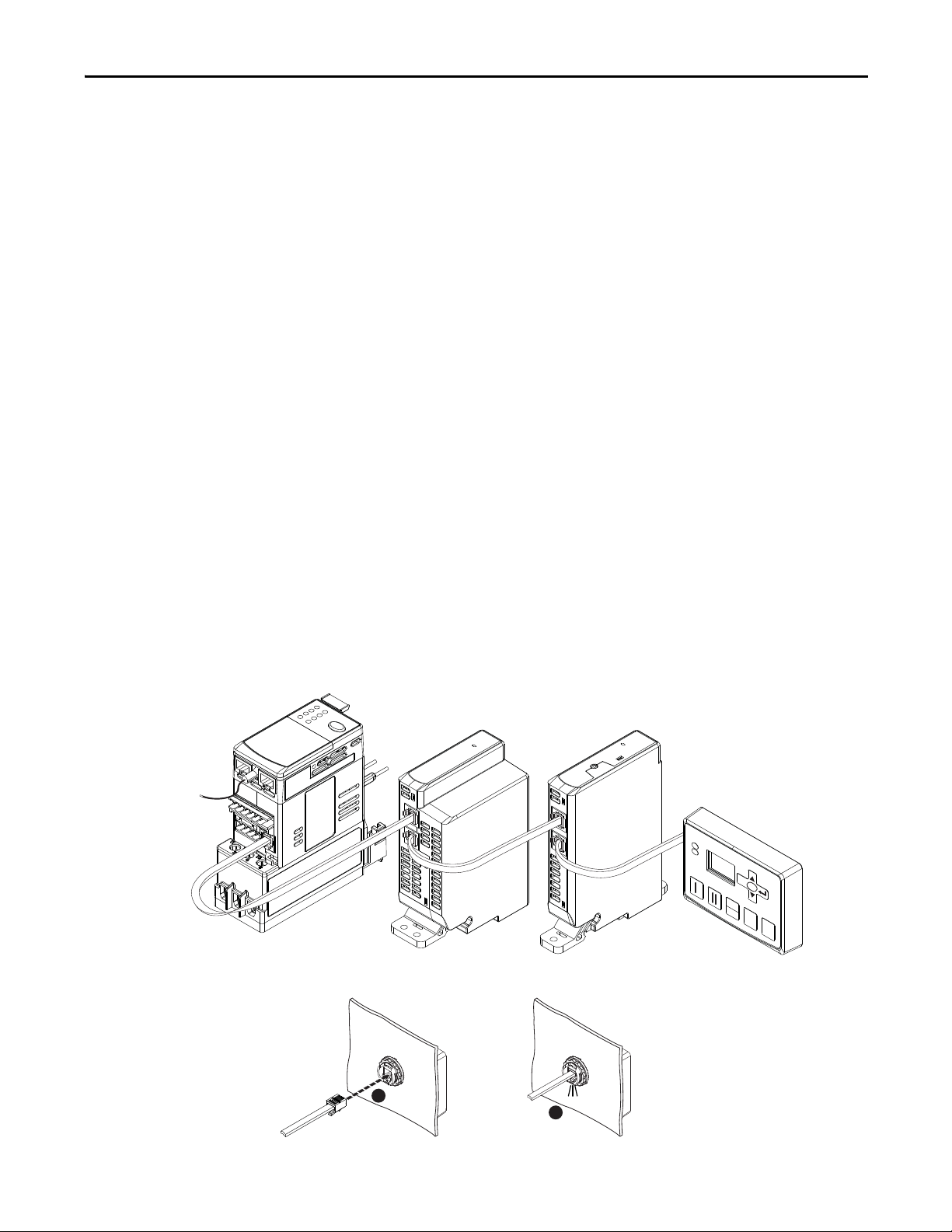

Communication Module to Control Module Assembly

Any E300 Communication Module can connect to any E300 Control Module.

The illustrations below show the steps required to make this connection.

Figure 7 - Communication Module to Control Module Assembly

24 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 25

Installation and Wiring Chapter 2

Start Forward / Speed 1

Start Reverse / Speed 2

Local / Remote

Stop

Reset

Start Forward / Speed 1

Start Reverse / Speed 2

Local / Remote

Stop

Up

Down

Reset

Escape

Power LED

Trip / Warn LED

Power LED

Trip / Warn LED

Enter

Select

0

RESET

LOCAL

REMOTE

0

RESET

SELECT

ESC

REMOTE

LOCAL

Control Station Diagnostic Station

Expansion Bus Peripherals

Panel Mount

Hole

DIN Rail Mount

Panel Mount Hole

Expansion Bus Out

Expansion Bus In

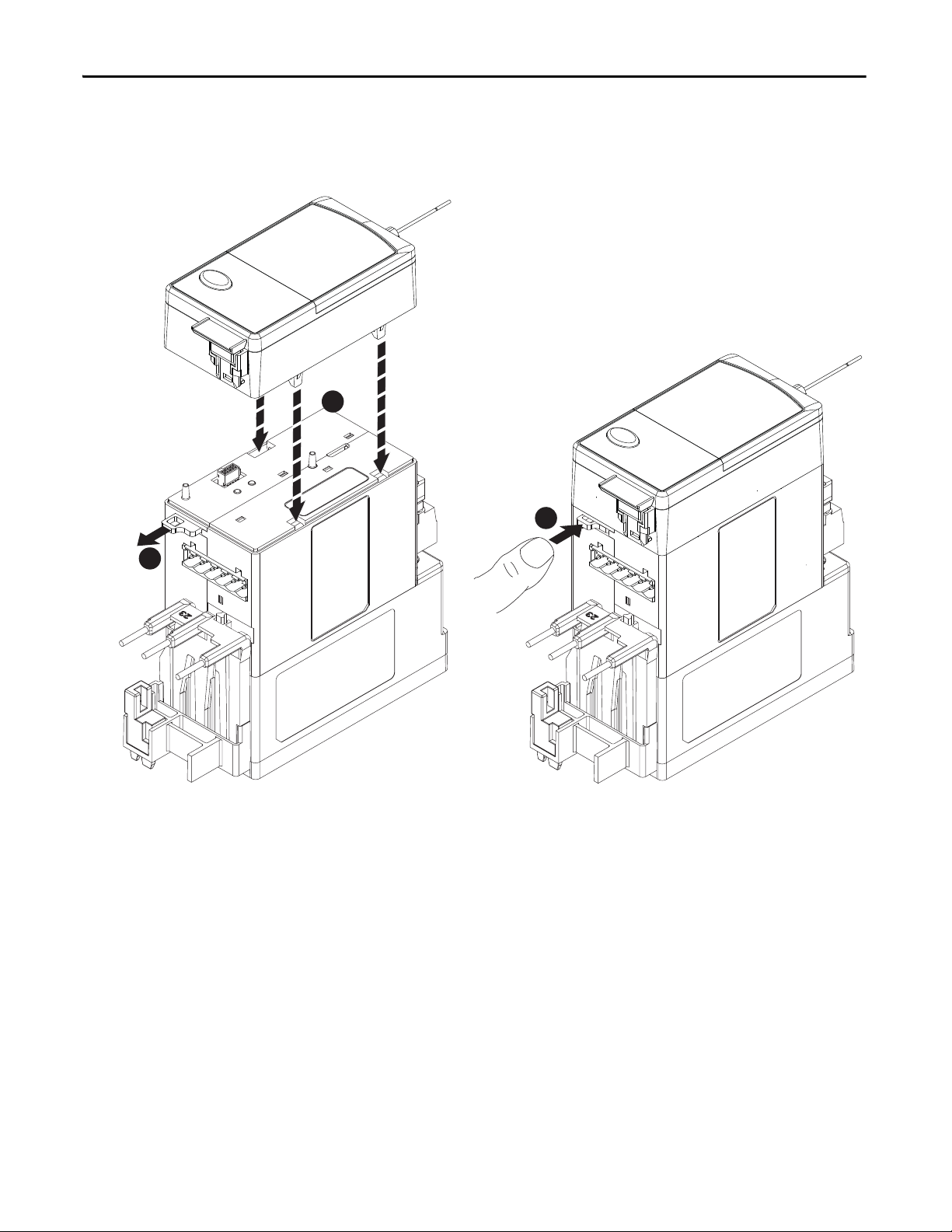

The E300 Electronic Overload Relay offers a range of Expansion Digital and

Analog I/O modules that simply connect to the E300 Electronic Overload

Relay’s Expansion Bus.

Figure 8 - Expansion Bus Peripherals

Removable I/O Terminals

3

2

4

4T

1

3T

1T

2T

Color

Blinking Green

Green Module OK and active

Module Number Selector

Number

1 - 4

1T - 4T

Note: If the expansion bus does not have an operator station, then the

last expansion module number must be set to terminated.

Status LED

Description

O

No power applied

Module OK with no connection

Red Error Detected

Description

Module number

Module number with

expansion bus terminating

resistor applied

Users can also add one of the two available operator stations to the end of the

Expansion Bus.

Figure 9 - Expansion Operator Stations

The following illustrations show how to mount and connect the E300 Electronic

Overload Relay expansion bus I/O modules, expansion power supplies, and

operator stations.

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 25

Page 26

Chapter 2 Installation and Wiring

1

2

Click

2

1

1.7 N.m

(15 lb-in)

0

RESET

SELECT

ESC

REMOTE

LOCAL

800F-AW2

3

22 mm

Expansion Bus Digital & Analog I/O Modules and Power Supply Installation

Figure 10 - Expansion Bus Digital& Analog I/O Modules and Power Supply

Expansion Bus Operator

Figure 11 - Expansion Bus Operator Station

Station Installation

Expansion Bus Network Installation

26 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

The E300 Electronic Overload Relay will support up (4) Expansion Digital I/O

modules, (4) Expansion Analog I/O modules, and (1) Operation Station. The

E300 Base Relay can supply enough power for (1) Expansion Digital I/O module

and (1) Operator Station. Any other combination of E300

Expansion Bus

Page 27

Installation and Wiring Chapter 2

0

RESET

SELECT

ESC

REMOTE

LOCAL

Click

1

2

peripherals will require an Expansion Bus Power Supply which connects as the

first module on the Expansion Bus.

Users will set the address dial of the Expansion Digital Module to a unique digital

module address number (1-4). If the Expansion Digital Module is the last device

on the Expansion Bus, set the address to the address value that enables in the

internal terminating resistor (1T-4T). A power cycle is required when changes

are made to the address dial.

Users will set the address dial of the Expansion Analog Module to a unique

analog module address number (1-4). If the Expansion Analog Module is the last

device on the Expansion Bus, set the address to the address value that enables in

the internal terminating resistor (1T-4T). A power cycle is required when

changes are made to the address dial.

Users will connect the E300 Base Relay to the Expansion Module’s Input Port

using the supplied Expansion Bus cable. Users will add the next Expansion

Module by connecting the supplied Expansion Bus cable to the Output Port of

the previous Expansion Module and into the Input Port of the additional

Expansion Module. The Operator Stations is the last device on the E300

Expansion Bus; it only has an Input Port with an internal Expansion Bus

terminating resistor.

If the user supplied Expansion Bus cable is not long enough for the installation,

1-meter (Cat. No. 193-EXP-CBL-1M) and 3-meter (Cat. No.

193-EXP-CBL-3M) Expansion Bus cables are available as accessories. The E300

expansion bus can support a maximum distance of 5 meters (16 ft.).

Figure 12 - Expansion Bus Network Installation

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 27

Page 28

Chapter 2 Installation and Wiring

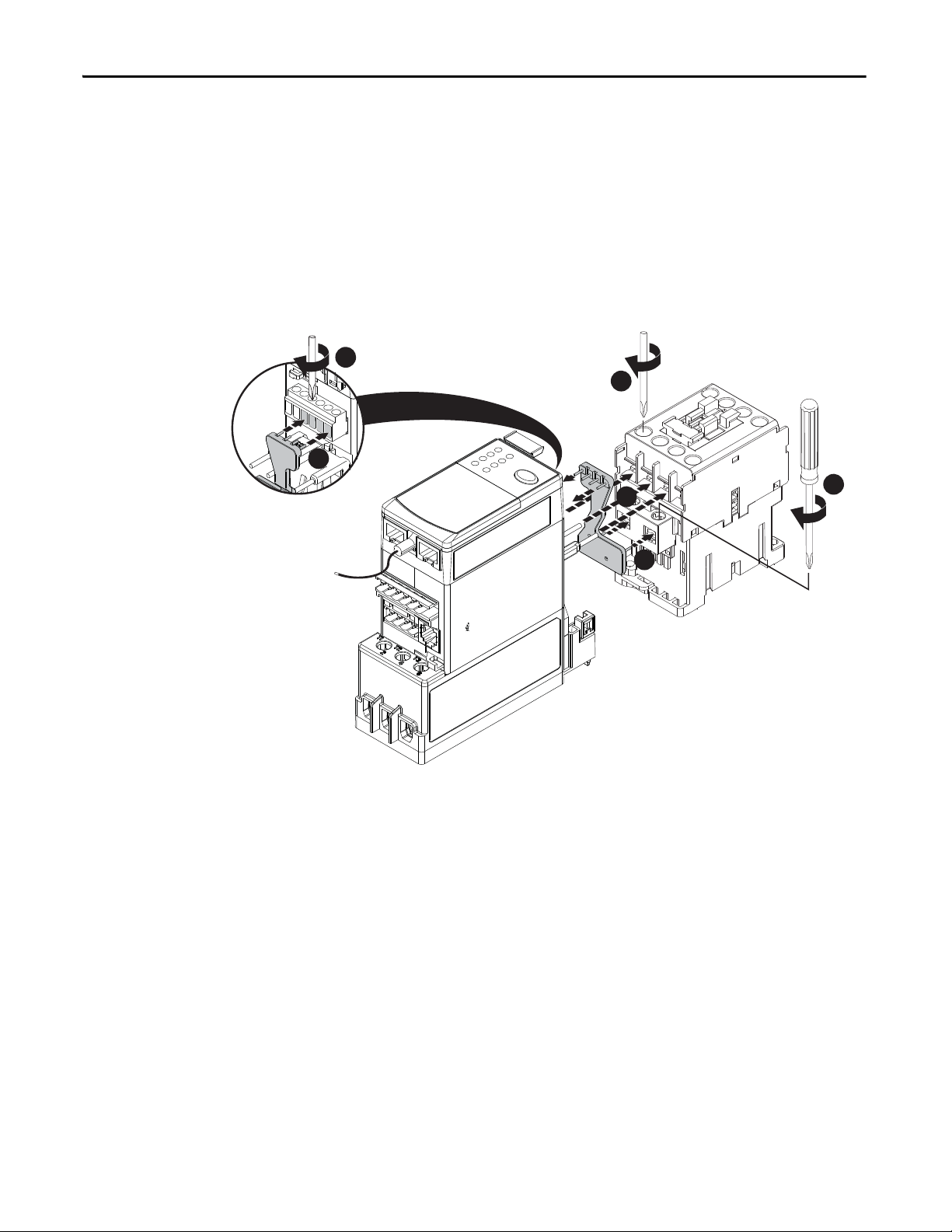

Starter Assembly

5 - 7 lb-in

IN1

The following illustrations show how to assemble an E300 Electronic Overload

Relay as a motor starter with an Allen-Bradley Bulletin 100-C contactor.

100-C09…-C55 Starter Assembly Installation

The starter assembly installation instructions are for use with E300 Sensing

Module catalog numbers 193-ESM-___-___-C23 and 193-ESM-___-___-C55

Figure 13 - 100-C09…-C55 Starter Assembly Installation

6

9 - 22 lb-in

IN0

A2

R04

R03

A1

4

5

3

2

7 -11 lb-in

1

28 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 29

Installation and Wiring Chapter 2

45

(1.76)

87

(3.40)

60 (2.3

35

(1.37)

n 5 (0.18)

190 (7.49)

37 (1.47)

122 (4.81)

29 (1.14)

122

(4.78)

152 (5.98)

67 (2.65)

FROM

CONTACTOR

MTG. HOLE

FROM

CONTACTOR

MTG. HOLE

(ADD 5 mm (0.19 in.)

FOR CONTACTOR COIL

ON LINE SIDE)

37 (1.48)

122 (4.81)

29 (1.13)

190 (7.49)

67 (2.65)

152 (5.98)

45

(1.76)

122

(4.78)

104

(4.10)

35

(1.374)

60 (2.36)

n 5 (0.18)

(ADD 5 mm (0.19 in.)

FOR CONTACTOR COIL

ON LINE SIDE)

FROM

CONTACTOR

MTG. HOLE

FROM

CONTACTOR

MTG. HOLE

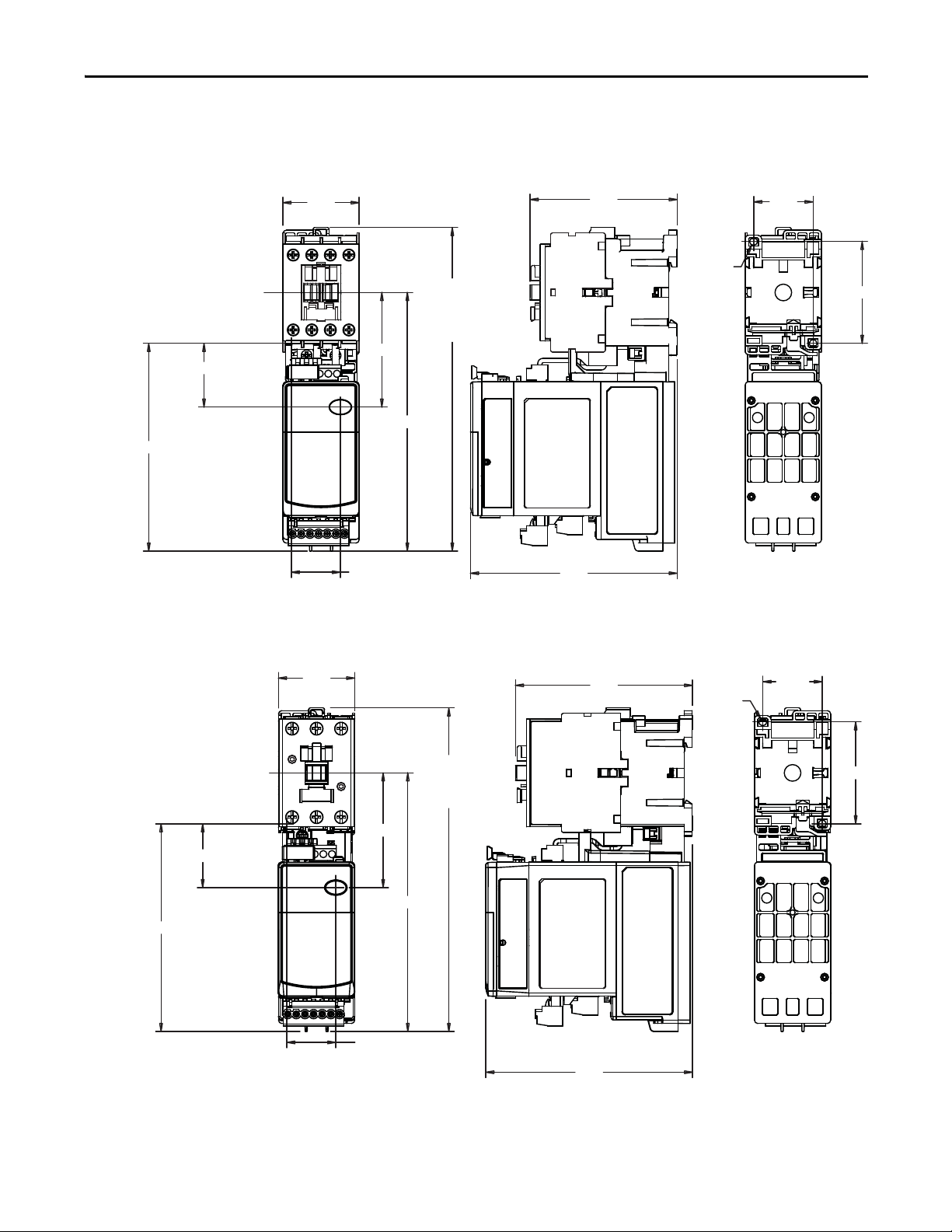

Starter Dimensions

Approximate dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes.

Figure 14 - E300 Sensing Module 193-ESM-___-__-C23 with 100-C09…-C23 Contactor

Figure 15 - E300 Sensing Module 193-ESM-___-__-C55 with 100-C30…-C37 Contactor

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 29

Page 30

Chapter 2 Installation and Wiring

54

(2.12)

45 (1.76)

190 (7.49)

107

(4.21)

60 (2.

45 (1.75)

n 5 (0.18)

37 (1.48)

34 (1.34)

122

(4.82)

152 (5.98)

67 (2.65)

FROM

CONTACTOR

MTG. HOLE

FROM

CONTACTOR

MTG. HOLE

(ADD 5 mm (0.19 in.)

FOR CONTACTOR COIL

ON LINE SIDE)

180 (7.06)

157 (6.17)

249 (9.78)

35 (1.38)

70

(2.75)

12 (0.46)

n 6 (0.22)

90

(3.56)

125

(4.91)

Figure 16 - E300 Sensing Module 193-ESM-___-__-C55 with 100-C43…-C55 Contactor

Figure 17 - E300 Sensing Module 592-ESM-___-__-S2 with NEMA Contactor Size 0 and Size 1

30 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 31

Installation and Wiring Chapter 2

219 (8.63)

184 (7.24)

276 (10.85)

n 6 (0.22)

100

(3.94)

40 (1.58)

80

(3.15)

125

(4.91)

12 (0.46)

45

(1.764)

135 (5.32)

30

(1.18)

n 5 (0.17)

6 (0.24)

6 (0.217)

9 (0.33)

148 (5.83)

4 (0.154)

46 (1.81)

4 (0.14)

126

(4.94)

101 (3.96)

4 (0.16)

8 (0.30)

q

Figure 18 - E300 Sensing Module 592-ESM-___-__-S2 with NEMA Contactor Size 2

DIN Rail / Panel Mount Dimensions

Approximate dimensions are shown in millimeters (inches). Dimensions are not

intended to be used for manufacturing purposes.

Figure 19 - E300 Sensing Module 193-ESM-___-30A-E3T and 193-ESM-___-60A-E3T

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 31

Page 32

Chapter 2 Installation and Wiring

2 x 4.5 (0.18) dia.

22.5

(0.89)

80.75 (3.18)

120

(4.73)

98 (3.86)

87 (3.43)

2 x 4.5 (0.18) dia.

22.5

(0.89)

80.75 (3.18)

120

(4.73)

98 (3.86)

87 (3.43)

Expansion Bus Peripherals Dimensions

Approximate dimensions are shown in millimeters. Dimensions are not intended

to be used for manufacturing purposes.

Figure 20 - E300 Digital Expansion Module 193-EXP-DIO-___

Figure 21 - E300 Expansion Analog Module 193-EXP-AIO

32 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 33

Figure 22 - E300 Expansion Power Supply 193-EXP-PS-___

120

(4.73)

80.75 (3.18)

45

(1.77)

4x 4.5 (0.18) dia

98

(3.86)87(3.43)

12

(0.47)

22.5 (0.89) dia.

18.5

(0.73)

13.5 (0.53)

100

(3.94)

70

(2.76)

Installation and Wiring Chapter 2

100

(3.94)

45 (1.77)

Figure 23 - E300 Starter Control Station 193-EOS-SCS

18.5

(0.73)

13.5

(0.53)

Figure 24 - E300 Starter Diagnostic Station 193-EOS-SDS

22.5 (0.89) dia.

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 33

Page 34

Chapter 2 Installation and Wiring

Terminals

Sensing Module

Table 1 - E300 Sensing Module Wire Size and Torque Specifications

Wire Type Conductor Torque

Single

Stranded/Solid [AWG]

Multiple

Single

Flexible-Stranded with Ferrule Metric

Multiple

Single

Coarse-Stranded/Solid Metric

Multiple

Cat. No.

193-ESM-_ _ _-30A-_ _ _

193-ESM-_ _ _-60A-_ _ _

592-ESM-_ _ _-30A-_ _ _

592-ESM-_ _ _-60A-_ _ _

#14…6 AWG

22 lb-in.

#10…6 AWG

30 lb-in.

2.5…16 mm2

2.5 N•m

6…10 mm2

3.4 N•m

2.5…25 mm2

2.5 N•m

6…16 mm2

3.4 N•m

193-ESM-_ _ _-100A-_ _ _

592-ESM-_ _ _-100A-_ _ _

#12…1 AWG

35 lb-in.

#6…2 AWG

35 lb-in.

4…35 mm2

4 N•m

4…25 mm2

4 N•m

4…50 mm2

4 N•m

4…35 mm2

4 N•m

34 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 35

Control Module

193-EIOGP-42- _ _ _

193-EIOGP-22- _ _ _

Sensing Module Latch

Power / PTC

Terminals

Expansion Bus Connector

Relay / Ground Fault

Terminals

R13

R14

S1

S2

A1

A1

A2

IN2

IN3

IT1

IT2

R13

R14

S1

S2

193-EIO-63- _ _ _

193-EIO-43- _ _ _

R13

R14

R23

R24

A1

A1

A2

IN2

IN3

IN4

IN5

R13

R14

R23

R24

A1

A1

A2

IN2

IN3

A1

A1

A2

IT1

IT2

Input / Output

Terminals

Communication

Module Latch

IN1

IN0

A2

A1

R04

R03

Figure 25 - E300 Control Module Terminal Designations

Installation and Wiring Chapter 2

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 35

Page 36

Chapter 2 Installation and Wiring

R24R23

RELAY 2RELAY 1

R14R13

IN3

IN2

Additional Inputs for 193-EIO-63-_ _ _

IN0

IN1

A2

PE

A1A1

A1

R03

R04

A2

IN5

IN4

(+)

(-)

RELAY 0

S2S1

RELAY 1

R14R13

IN3

IN2

IN0

IN1

A2

A1A1

A1

R03

R04

A2

IT2

IT1

(+)

(-)

RELAY 0

193-EIOGP-_ _-_ _ _193-EIO-_ _-_ _ _

PE

Ground

Fault

PTC

Additional Inputs for 193-EIOGP-42-_ _ _

+

t

Table 2 - E300 Control Module Wire Size and Torque Specifications

Cat. No.

Wire Type Conductor Torque

193-EIO-_ _-_ _ _

193-EIOGP-_ _-_ _ _

Single 24...12 AWG

Stranded/Solid [AWG]

Flexible-Stranded with Ferrule

Metric

Coarse-Stranded/Solid Metric

Multiple

(stranded only)

24...16 AWG

5 lb-in

Single 0.25…2.5 mm

Multiple

0.5...0.75 mm

0.55 N•m

Single 0.2...2.5 mm

Multiple

0.2...1.5 mm

0.55 N•m

2

2

2

2

Figure 26 - Control Module Wiring

36 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 37

Expansion Digital Module

IN0 IN1 INC

IN2 IN3

RS2

R04 R14 RC3

Figure 27 - E300 Expansion Digital Module Terminal Designations

Installation and Wiring Chapter 2

Table 3 - E300 Expansion Digital Module Wire Size and Torque Specifications

Wire Type Conductor Torque

Single 24...12 AWG

Stranded/Solid [AWG]

Multiple

(stranded only)

Single 0.25…2.5 mm

Flexible-Stranded with Ferrule Metric

Multiple

Single 0.2...2.5 mm

Coarse-Stranded/Solid Metric

Multiple

Cat. No.

193-EXP-DIO-42-_ _ _

24...16 AWG

5 lb-in

0.5...0.75 mm

0.55 N•m

0.2...1.5 mm

0.55 N•m

2

2

2

2

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 37

Page 38

Chapter 2 Installation and Wiring

R04 R14 RC3

IN0 INCIN1 IN2 IN3

Source

+

-

IN1+ IN1- RS1

IN2+ IN2- RS2

OUT+OUT-

IN0+ IN0- RS0

Figure 28 - E300 Expansion Digital Module Wiring Diagram

Expansion Analog Module

Figure 29 - E300 Expansion Analog Module Terminal Designations

38 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 39

Installation and Wiring Chapter 2

Analog Current Input Analog Voltage Input

24V DC

Power

Supply

INx+

IN

x

-

+

-

Current

Input

Device

INx+

-

V

+V

INx-

Analog Voltage or Current Output

+

Out

-

Out+

Device

-

2 Wire RTD

INx+

INx-

INx-

3 Wire RTD

INx+

RS

x

Table 4 - E300 Expansion Analog Module Wire Size and Torque Specifications

Wire Type Conductor Torque

Single 24...12 AWG

Stranded/Solid [AWG]

Flexible-Stranded with Ferrule Metric

Coarse-Stranded/Solid Metric

Multiple

(stranded only)

Single 0.25…2.5 mm

Multiple

Single 0.2...2.5 mm

Multiple

Figure 30 - E300 Expansion Analog I/O Modules 193-EXP-AIO-__

Cat. No.

193-EXP-AIO-31

24...16 AWG

5 lb-in

0.5...0.75 mm

0.55 N•m

0.2...1.5 mm

0.55 N•m

2

2

2

2

Rockwell Automation Publication 193-UM015B-EN-P - June 2014 39

Page 40

Chapter 2 Installation and Wiring

A1 A2

A1 A2

Source

+

-

Expansion Power Supply

Figure 31 - E300 Expansion Power Supply Terminal Designations

Table 5 - E300 Expansion Power Supply Wire

Wire Type Conductor Torque

Stranded/Solid [AWG]

Flexible-Stranded with Ferrule Metric

Coarse-Stranded/Solid Metric

Size and Torque Specifications

Single 24...12 AWG

Multiple

(stranded only)

Single 0.25…2.5 mm

Multiple

(stranded only)

Single 0.2...2.5 mm

Multiple

(stranded only)

Figure 32 - E300 Expansion Power Supply Wiring Diagram

Cat. No.

193-EXP-PS-_ _

24...16 AWG

5 lb-in

0.5...0.75 mm

0.55 N•m

0.2...1.5 mm

0.55 N•m

2

2

2

2

40 Rockwell Automation Publication 193-UM015B-EN-P - June 2014

Page 41

Installation and Wiring Chapter 2

Grounding

Short-Circuit Ratings

The following grounding recommendations are provided to ensure EMC

requirements during installation

.

• The earth ground terminal of the E300 Electronic Overload Relay shall be

connected to a solid earth ground via a low-impedance connection.

• Wire the green shield wire of the Cat. No. 193-ECM-ETR into the earth

ound terminal of the E300 control module.

gr