Page 1

User Manual

RFID ICODE Handheld Interface

Bulletin Number 57RF

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Bluetooth is a trademark of Bluetooth SIG

Xenoy is trademark of General Electric Company

Intel and XScale are trademarks of Intel Corporation

Microsoft, Windows, and ActiveSync are trademarks of Microsoft Corportation

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Preface

Environment and Enclosure

Follow these guidelines for environment and enclosure information for this

equipment.

ATTENTION: This equipment is intended for use in overvoltage

Category II applications (as defined in IEC 60664-1), at altitudes up to

2000 m (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment

according to IEC/CISPR 11. Without appropriate precautions, there

may be difficulties with electromagnetic compatibility in residential

and other environments due to conducted and radiated disturbances.

This equipment is supplied as enclosed equipment. It should not

require additional system enclosure when used in locations

consistent with the enclosure type ratings stated in the Specifications

section of this publication. Subsequent sections of this publication

may contain additional information regarding specific enclosure type

ratings, beyond what this product provides, that are required to

comply with certain product safety certifications.

In addition to this publication, see:

• Industrial Automation Wiring and Grounding Guidelines, Rockwell

Automation publication 1770-4.1

requirements.

• NEMA Standards 250 and IEC 60529, as applicable, for

explanations of the degrees of protection provided by different

types of enclosure.

, for additional installation

About this Manual

Prevent Electrostatic Discharge

Follow these guidelines when you handle this equipment.

This equipment is sensitive to electrostatic discharge that can cause

internal damage and affect normal operation. Follow these

guidelines when you handle this equipment.

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wrist strap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation if available.

• Store the equipment in appropriate static-safe packaging when not

in use.

This manual describes the standard features and operation of the RFID ICODE

handheld interface. Unless otherwise stated, the operational characteristics

described herein correspond to factory default configurations and settings as

shipped from Allen-Bradley. Wherever used herein, the terms “RFID ICODE

handheld interface” or “handheld” applies to all models (except as noted).

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 3

Page 4

Preface

About RFID

About the RFID ICODE Handheld Interface

RFID (Radio Frequency IDentification) is a wireless communication technology

that uses the RF portion of the electromagnetic spectrum to transmit and receive

information from EPC (Electronic Product Code) tags. The tags can come in

many shapes and sizes -such as disks, cards, or paper labels (smart labels) - and can

store a simple identification number or a sophisticated database.

RFID technology is based on the simple idea that a reader can activate an

electronic circuit inside a tag from a distance and exchange information. An

integrated circuit inside the reader creates an alternating current. This current

generates an alternating magnetic field through the reader’s antenna that serves as

a power source for a RFID tag. This magnetic field interacts with the antenna in

the tag which, in turn, activates the tag’s integrated circuit causing the tag to

create a digital signal, which contains an encoded identifier number.

The tag then generates its own alternating magnetic field, which interacts with

the reader’s alternating magnetic field. A device inside the RFID reader senses the

variations and converts this pattern to the digital signal, which interprets the tag's

identifier code.

Designed for one-handed operation, the RFID ICODE handheld interface

features a powerful Windows® CE 5.0 operating system and an Intel® PXA270

XScale™ processor that operates up to 624 MHz. It comes standard with

Bluetooth, Wi-Fi, and serial communication ports (USB and RS-232).

Additional Resources

With its 13.56 MHz RFID integrated reader and flip-out antenna, the RFID

ICODE handheld interface can read and write ICODE ISO 15693 industry

standard RFID tags within a 3.5 in. (90 mm) range making it ideal for item

tracking, data collection, and setup/maintenance of RFID systems.

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website, http://www.ab.com

You can view or download publications at

http://www.rockwellautomation.com/literature/

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales office.

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity,

certificates, and other certification details.

. To order paper copies of

4 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 5

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Preface

Environment and Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Prevent Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About RFID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

About the RFID ICODE Handheld Interface . . . . . . . . . . . . . . . . . . . . . . . . 4

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table of Contents Chapter 1

Table of Contents

RFID ICODE Handheld Interface

Features

Quick Start Guide

Getting Started

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rechargeable Battery Pack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Memory and Mass Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Keypads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Interface Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ingress Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2

Powering up the RFID ICODE Handheld Interface . . . . . . . . . . . . . . . . 11

Reading an RFID Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Writing to an RFID Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 3

Front Components and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Rear Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Compact Flash Slot Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power Supplies, Cables, and Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operation

Chapter 4

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Charging the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Charge/Low Battery Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power/Suspend Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replacing Batteries/Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Using the RFID Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Using the Compact Flash Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Data Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Keypads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Key Repeat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 5

Page 6

Table of Contents

CE Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Transcriber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Windows CE 5.0 Desktop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Windows CE 5.0 Desktop Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Taskbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Start Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Miscellaneous Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 5

Configuration

Connections

Software

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Changing System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Taskbar and Start Menu Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chapter 6

ActiveSync® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Initial Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Subsequent Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Wireless Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Wi-Fi Companion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Wireless Zero Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting Up Identification for Remote Networks . . . . . . . . . . . . . . . . . 53

Connecting to a Mail Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Bluetooth Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Setup and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Making an ActiveSync Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Chapter 7

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Screen Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Working with Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Read/Write Times. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Reading Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Writing Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Device Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Minimize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Exit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Data Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Erase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Clear Tag History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

ASCII Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Tag Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 7

Table of Contents

Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Microsoft® Excel: Importing/Exporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Chapter 8

Troubleshooting

Specifications

Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Appendix A

Handheld Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Memory and Mass Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

User Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Socket Go Wi-Fi! P500 Wireless Card Specifications. . . . . . . . . . . . . . . 103

Physical Characteristics:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Power Consumption (3.3 V Supply):. . . . . . . . . . . . . . . . . . . . . . . . . . 103

Transmit Power: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Standards Conformance:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

802.11g: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

802.11b: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Frequency Range:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Indoor Range:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Access Protocol: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Certification/Compliance: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Signal and Pin Assignments

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 7

Appendix B

Serial Interface Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Page 8

Table of Contents

8 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 9

Chapter

1

RFID ICODE Handheld Interface Features

Features

Operating System

The RFID ICODE handheld interface uses Windows® CE 5.0 as its operating

system.

Rechargeable Battery Pack

The RFID ICODE handheld interface comes with a rechargeable Nickel Metal

Hydride (NiMH) battery pack that can provide up to six hours of operating time

on a full charge (depending on power management and use). The NiMH

technology used in the RFID ICODE handheld interface has exceptional charge

life without the “charge memory” characteristic of conventional nickel cadmium

batteries. Partially discharged batteries or extended periods with the charger left

connected will not adversely affect battery life or performance. The RFID

ICODE handheld interface can also run on six AA alkaline batteries.

Processor

The RFID ICODE handheld interface utilizes an Intel® PXA270 processor

designed specifically for high-performance, low power, portable, handheld

devices. It incorporates Intel XScale technology with on-the-fly voltage,

frequency scaling and sophisticated power management. It also complies with the

ARM Architecture V5TE instruction set.

Memory and Mass Storage

The RFID ICODE handheld interface comes standard with 128MB of

SDRAM (approximately 30MB used for the operating system) and 512MB of

internal compact flash memory. An additional 256MB of SDRAM is optionally

available. Internal compact flash memory is optionally expandable to 8+ GB. For

removable data storage or I/O cards, the RFID ICODE handheld interface is

equipped with a Compact Flash (CF) slot.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 9

Page 10

Chapter 1

Displays

The RFID ICODE handheld interface features a supertwist nematic liquid

crystal 320 x 240 QVGA-TFT color sunlight readable display with touch screen

and LED backlight.

Keypads

Keypad configurations for the RFID ICODE handheld interface include the

45-key pad and 52-key with directional pad.

Indicators

The RFID ICODE handheld interface has five programmable LED indicators

that can provide a number of useful functions including the state of keypad

modifier keys. An additional LED indicates the current charge or low battery

status.

Interface Capabilities

The RFID ICODE handheld interface comes standard with one USB port and

one RS-232 serial port. The RFID ICODE handheld interface also includes WiFi and Bluetooth®.

Durability

The case is made of General Electric Xenoy®, one of the most durable chemical

resistant materials available today.

Ingress Protection

The RFID ICODE handheld interface is completely dust-tight and can

withstand exposure to jets of water and has an IP (Ingress Protection) rating of 65

as defined by IEC standard 529.

10 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 11

Chapter

Power Supply/Battery Charger

To Unit

2

Quick Start Guide

The Quick Start Guide will give basic instructions on how to use your new RFID

ICODE handheld interface.

Powering up the RFID ICODE Handheld Interface

1. Charge the unit for a minimum of three hours prior to first use.

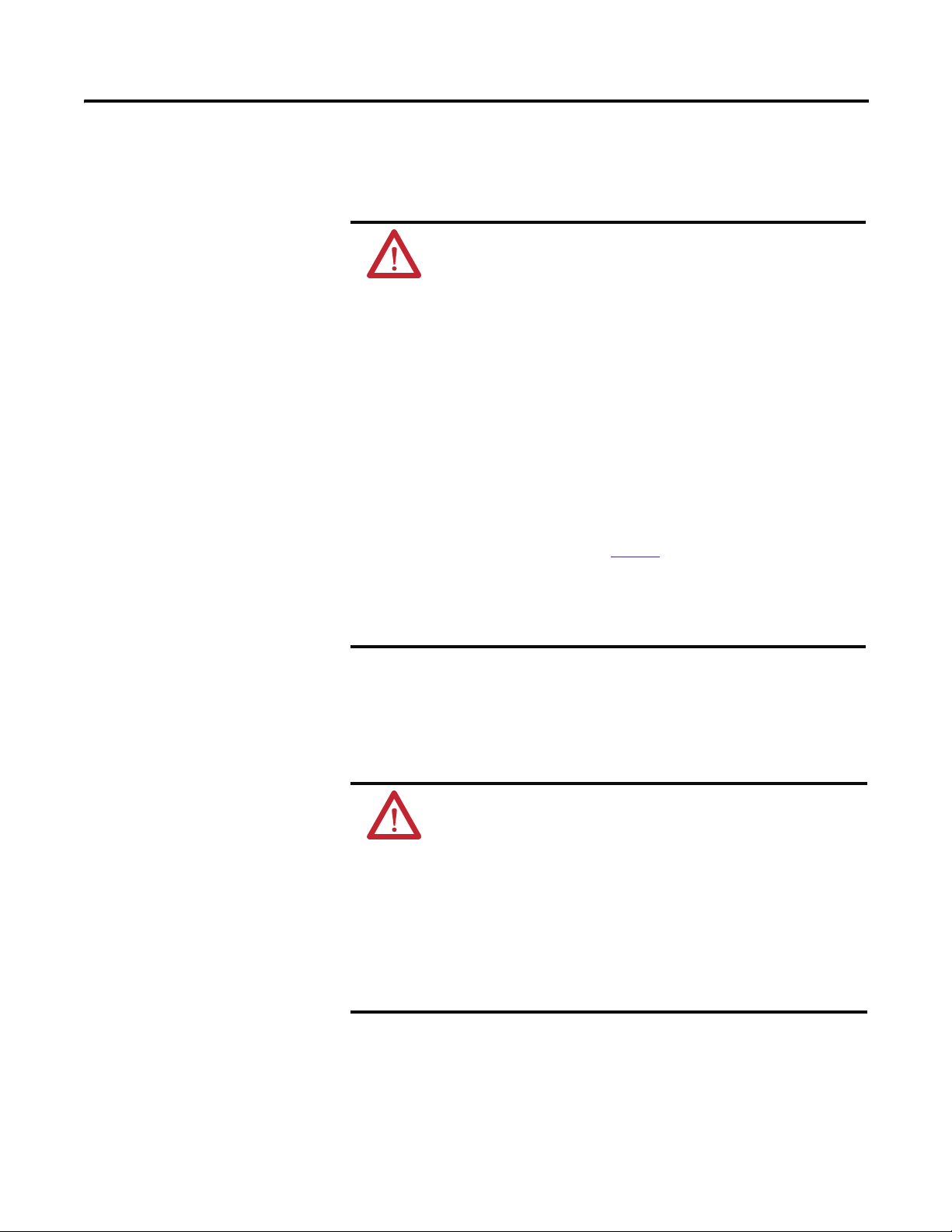

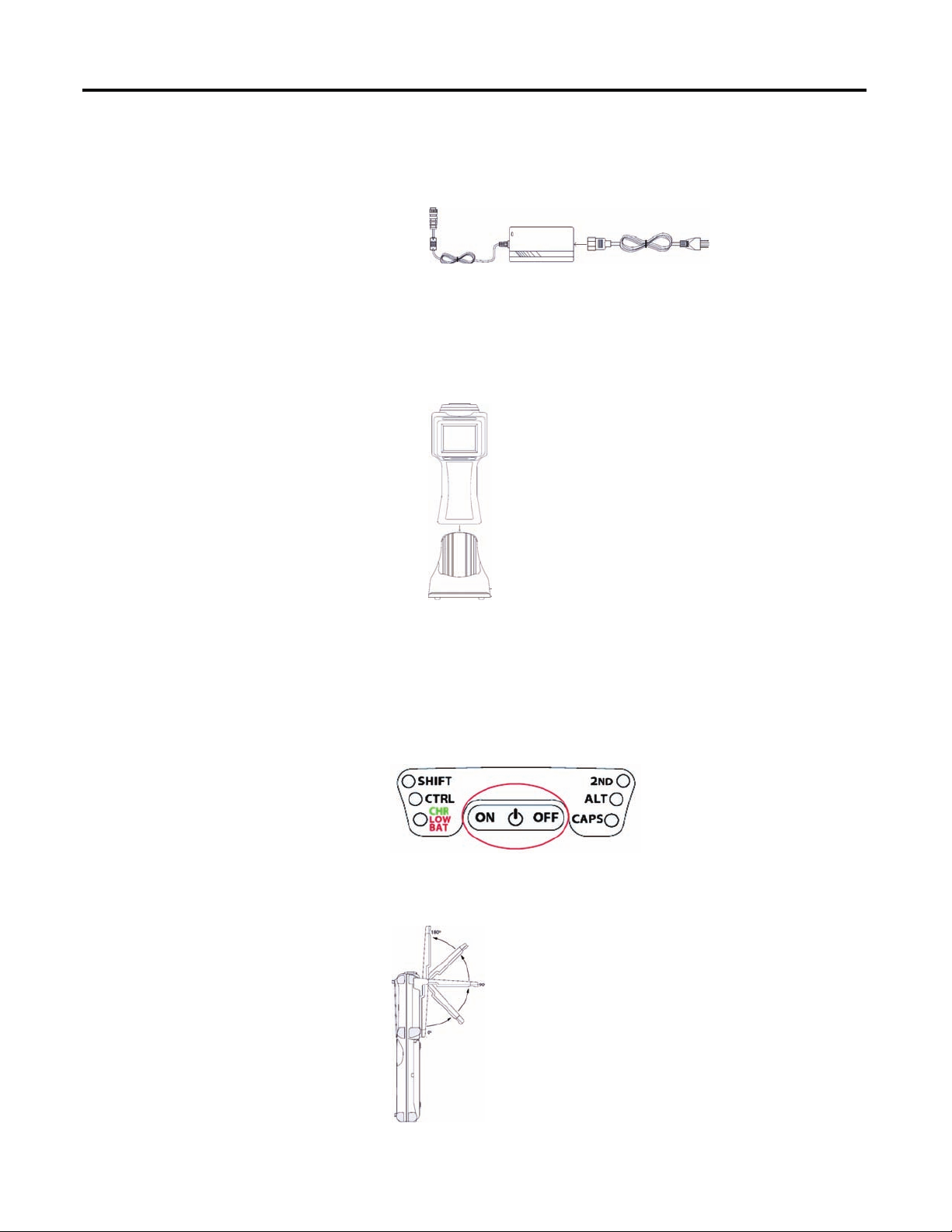

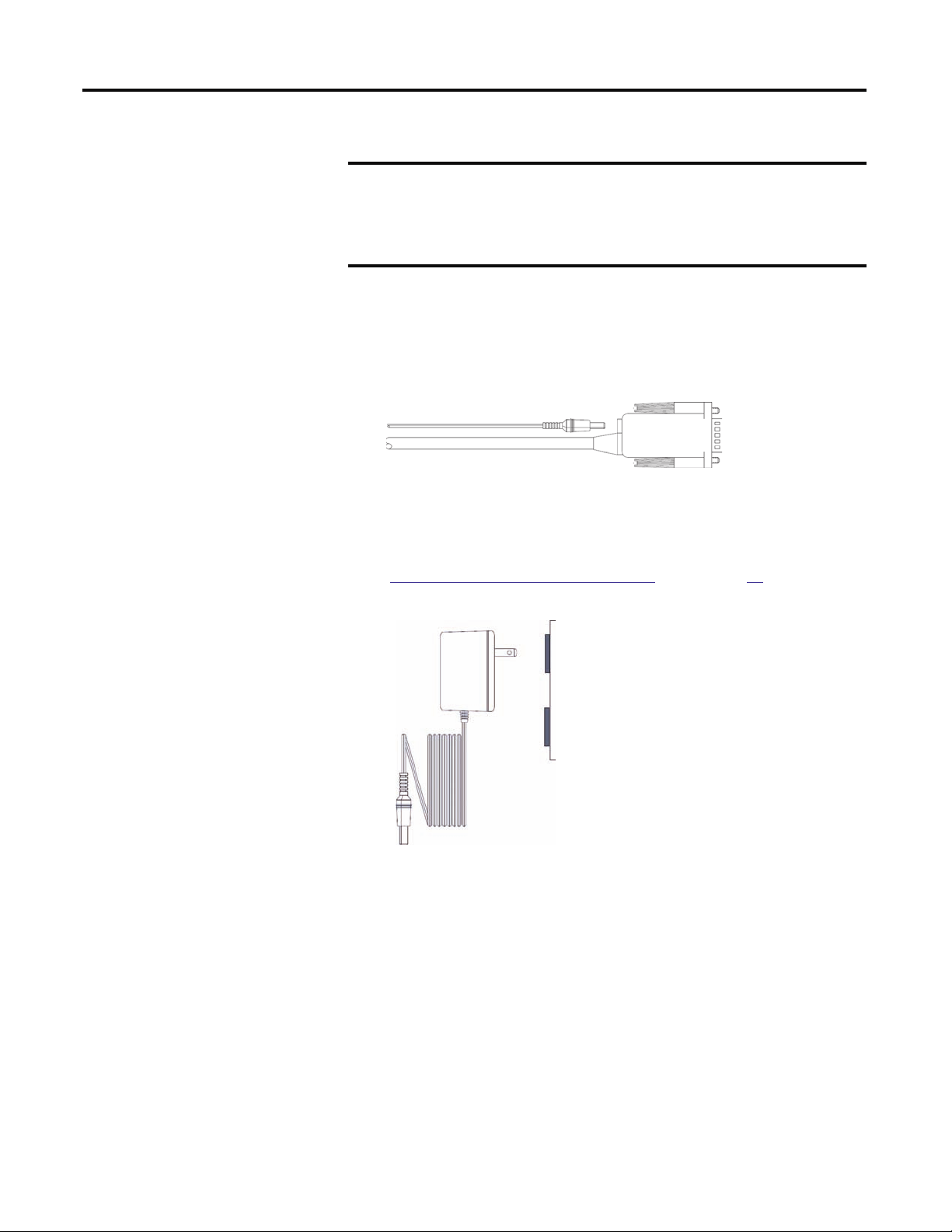

a. If you are using the wall charger and serial cable (57RF-HH-56IN,

57RF-HH-56US2):

i. Plug the power jack of the battery charger/power supply into the

corresponding cable connector as shown below.

Figure 1 - Power Jack

ii. Remove the rubber cover from the RS-232 connector on the bottom

of the RFID ICODE handheld interface. Plug the interface cable

into the connector.

iii. Plug the battery charger/power supply into a power outlet. The

Charge LED should turn on, indicating that the batteries are

charging.

Figure 2 - Power Outlet

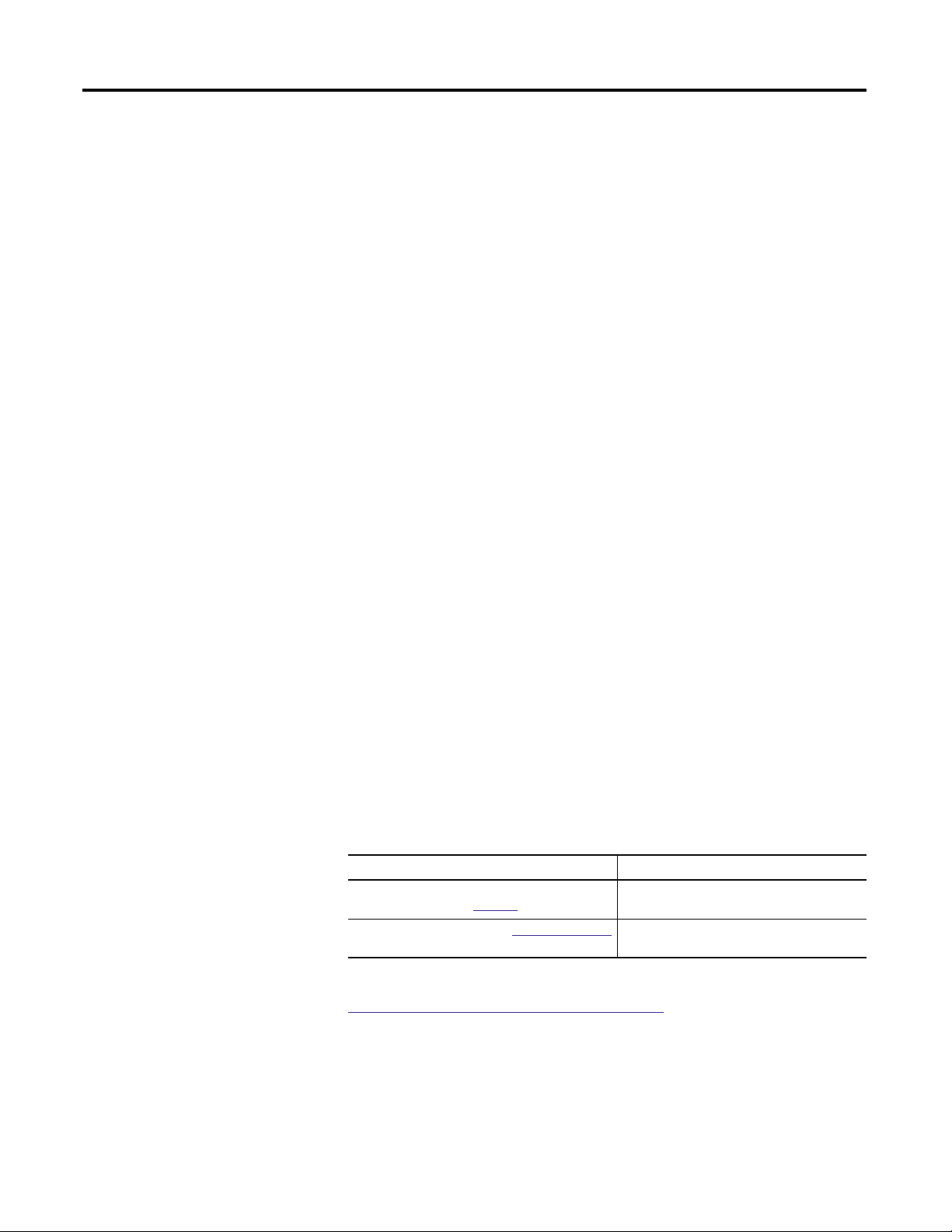

b. If you are using the charging cradle (57RF-HH-56US1):

i. Plug the two-pin connector of the power supply into the back of the

charging cradle as shown below.

Figure 3 - Charging Cradle/Power Supply

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 11

Page 12

Chapter 2

ii. Plug one end of the detachable AC cord into the power supply and

the other end into a power outlet as shown below.

Figure 4 - Power Supply Cord

iii. Remove the rubber cover from the RS-232 connector on the bottom

of the RFID ICODE handheld interface.

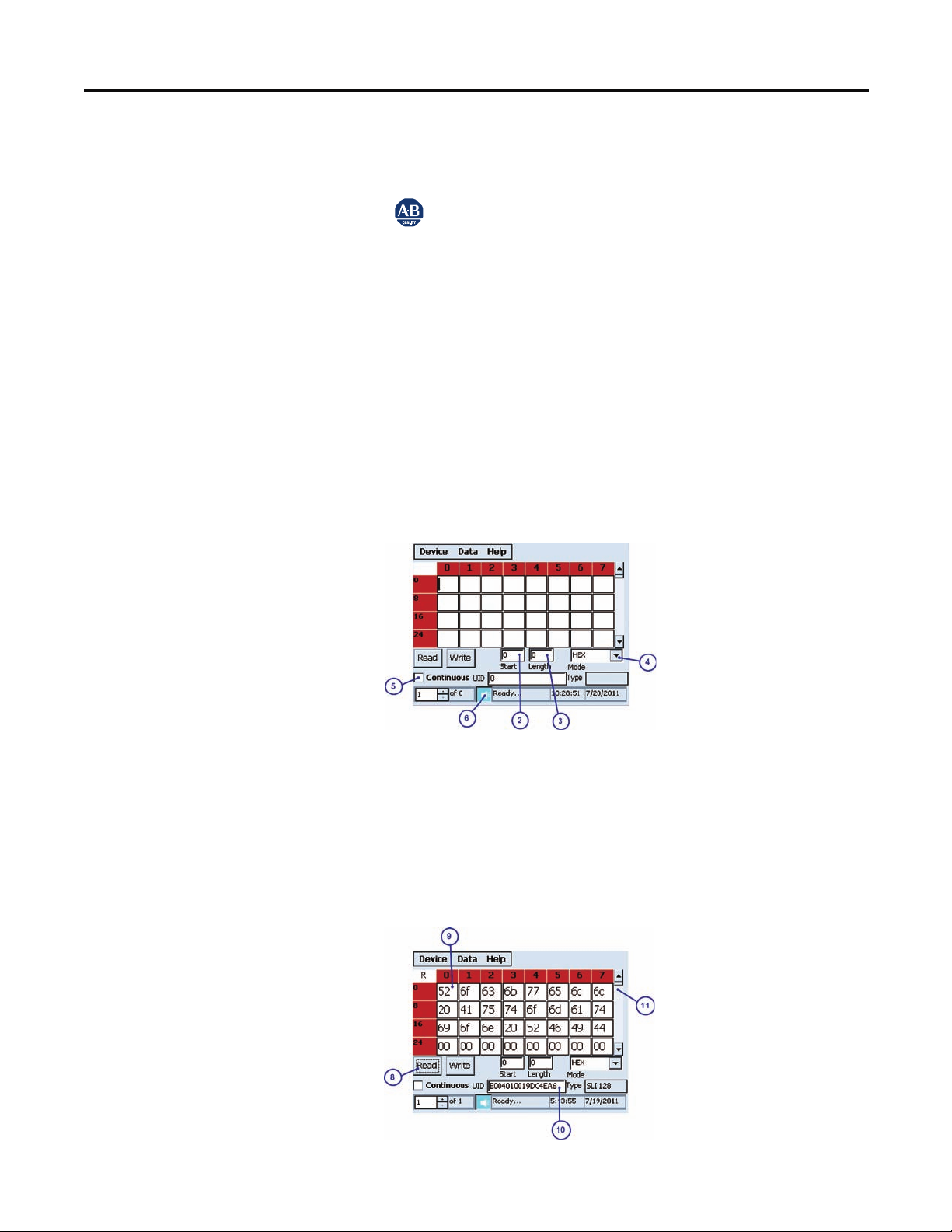

iv. Place the RFID ICODE handheld interface in the charging cradle as

shown below. The Charge LED should turn on, indicating that the

batteries are charging.

Figure 5 - Interface into Charging Cradle

2. The Charge LED will blink green when the RFID ICODE handheld

interface is fully charged. Unplug the unit or remove it from the charging

cradle.

3. Press and hold the On/Off switch for one second.

The unit should turn on and begin displaying the boot-up process. After

approximately 15 seconds, the Windows CE 5.0 desktop should appear.

Figure 6 - On/Off Switch

4. Flip the RFID module 180° as shown below. This will provide optimal tag

reading performance.

Figure 7 - RFID Module

12 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 13

Chapter 2

Reading an RFID Tag

1. Using the stylus, double-tap the RFID ICODE icon on the desktop.

The RFID application will open.

Figure 8 - RFID ICODE Application Icon

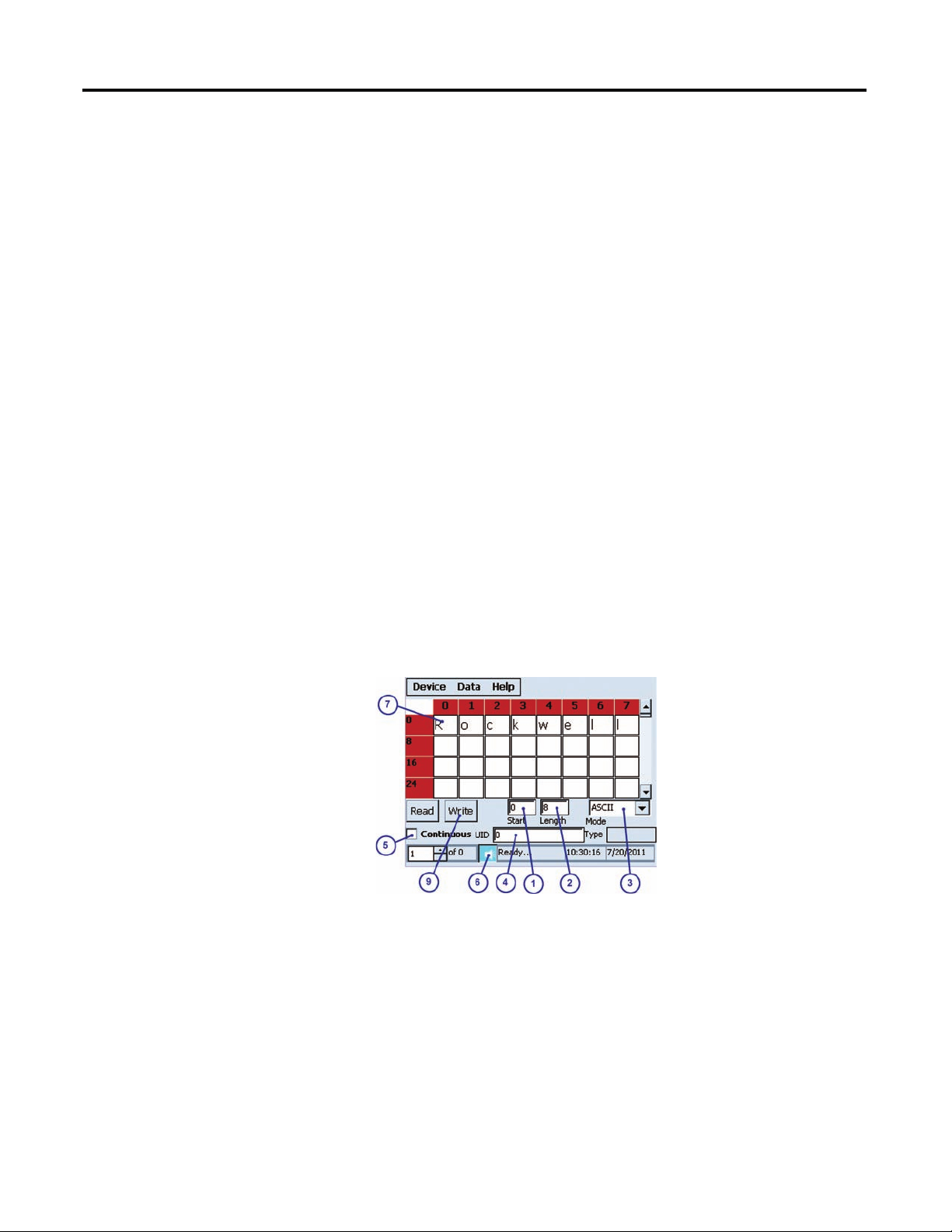

2. Double-tap in the Start field and type in 0 using the keypad. This sets the

RFID application to start reading/writing tags at the first byte available for

user data.

3. Double-tap in the Length field and type in 0 using the keypad. This sets

the RFID application to read/write the entire tag.

4. Tap the arrow next to the drop-down menu labeled “Mode”. A list should

open with these options: BIN, DEC, HEX, ASCII.

Ta p HEX to set the RFID application to read in hexadecimal mode.

5. If the checkbox labeled “Continuous” is unchecked, the RFID application

is in Single Read/Write mode and will only read/write the first tag. If the

checkbox is checked, tap the box with the stylus to clear it.

6. If the speaker symbol in the center of the bottom bar is blue, the sound is

on. If it is grey, tap it with the stylus to turn the sound on.

Figure 9 - Application Screen Shot 1

7. Place an ICODE compatible tag in range of the RFID module (typically

0.25…3 in. (6.35…76.2 mm) away, depending on tag size).

8. Tap the Read button with the stylus.

9. The handheld will beep and the data grid will display the tag data.

10. The UID field will display the tag UID (Unique Identifier).

11. Use the scroll bar on the right side of the screen to scroll through and view

the tag data.

Figure 10 - Application Screen Shot 2

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 13

Page 14

Chapter 2

Writing to an RFID Tag

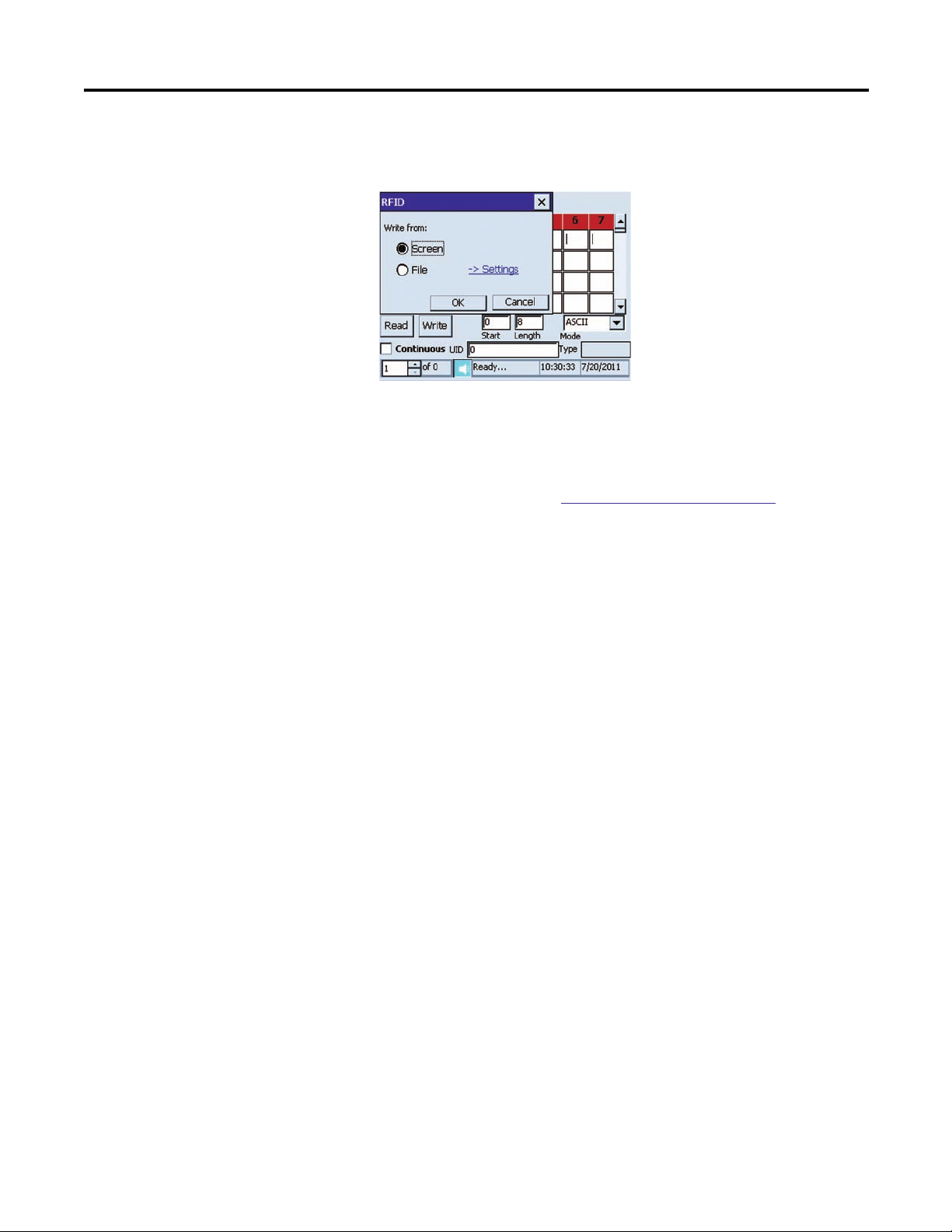

1. If the Start field is not already 0, double-tap in the field and type in 0 using

the keypad. This sets the RFID application to start reading/writing tags at

the first byte available for user data.

2. Double-tap in the Length field and type in 8 using the keypad. This sets

the RFID application to write a total of 8 bytes of data to the tag.

3. Tap the arrow next to the drop-down menu labeled “Mode” and select

ASCII from the list.

4. Double-tap the UID field and type in 0 using the keypad. This allows the

RFID application to write to any ICODE compatible tag. If there is a nonzero UID in the field, the application will only write to that specific tag.

5. If the checkbox labeled “Continuous” is unchecked, the RFID application

is in Single Read/Write mode and will only read/write the first tag. If the

checkbox is checked, tap the box with the stylus to clear it.

6. If the speaker symbol in the center of the bottom bar is blue, the sound is

on. If it is grey, tap it with the stylus to turn the sound on.

7. Tap on cell 0 using the stylus. Use the keypad to enter Rockwell in cells

0…7.

8. Place an ICODE compatible tag in range of the RFID module (typically

0.25…3 in. (6.35…76.2 mm) away, depending on tag size).

9. Tap th e Wr i t e button with the stylus. A pop-up window will appear, asking

you to choose between Wri te fr om S cr ee n and Wr ite fr om Fi le .

Figure 11 - Application Screen Shot 3

14 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 15

Chapter 2

10. Tap the radio button next to Screen.

Figure 12 - Application Screen Shot 4

11. Ta p OK. The handheld will beep, and Rockwell will be written to the tag

in cells 0…7.

12. To check that the write was successful, manually clear the screen by tapping

in cells 0…7 and pressing Backspace on the keypad.

13. Perform a single read (See Reading an RFID Tag

grid will display Rockwell in cells 0…7.

on page 13). The data

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 15

Page 16

Chapter 2

Notes:

16 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 17

Getting Started

Chapter

3

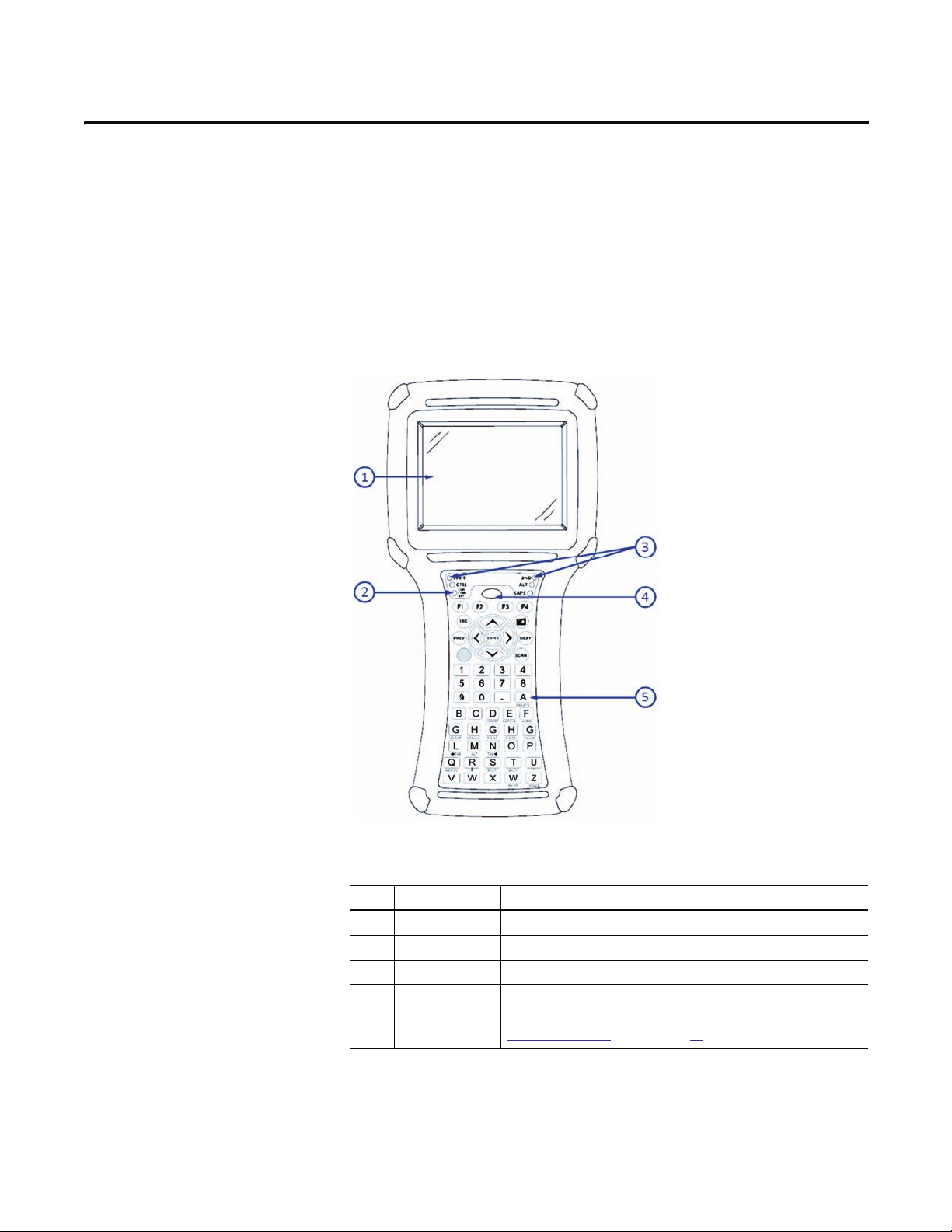

Front Components and Indicators

This section describes the components and indicators found on the front of the

RFID ICODE handheld interface.

Figure 13 - Front Components and Indicators

Table 5 - Front Components and Indicators

Item Function Description

1 Display Supertwist nematic liquid crystal display with touch screen

2 Battery Indicator Indicates low battery (red) status and charging (green) status

3 LEDs Indicates use of the SHIFT, CTRL, 2ND ALT, and CAPS modifier keys

4 On/Off Switch Controls the Power, Suspend, and Resume operations

5 Keypad 52-key directional pad shown (45-key pad also available, see the

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 17

Standard 45-key Pad

figure on page 29.

Page 18

Chapter 3

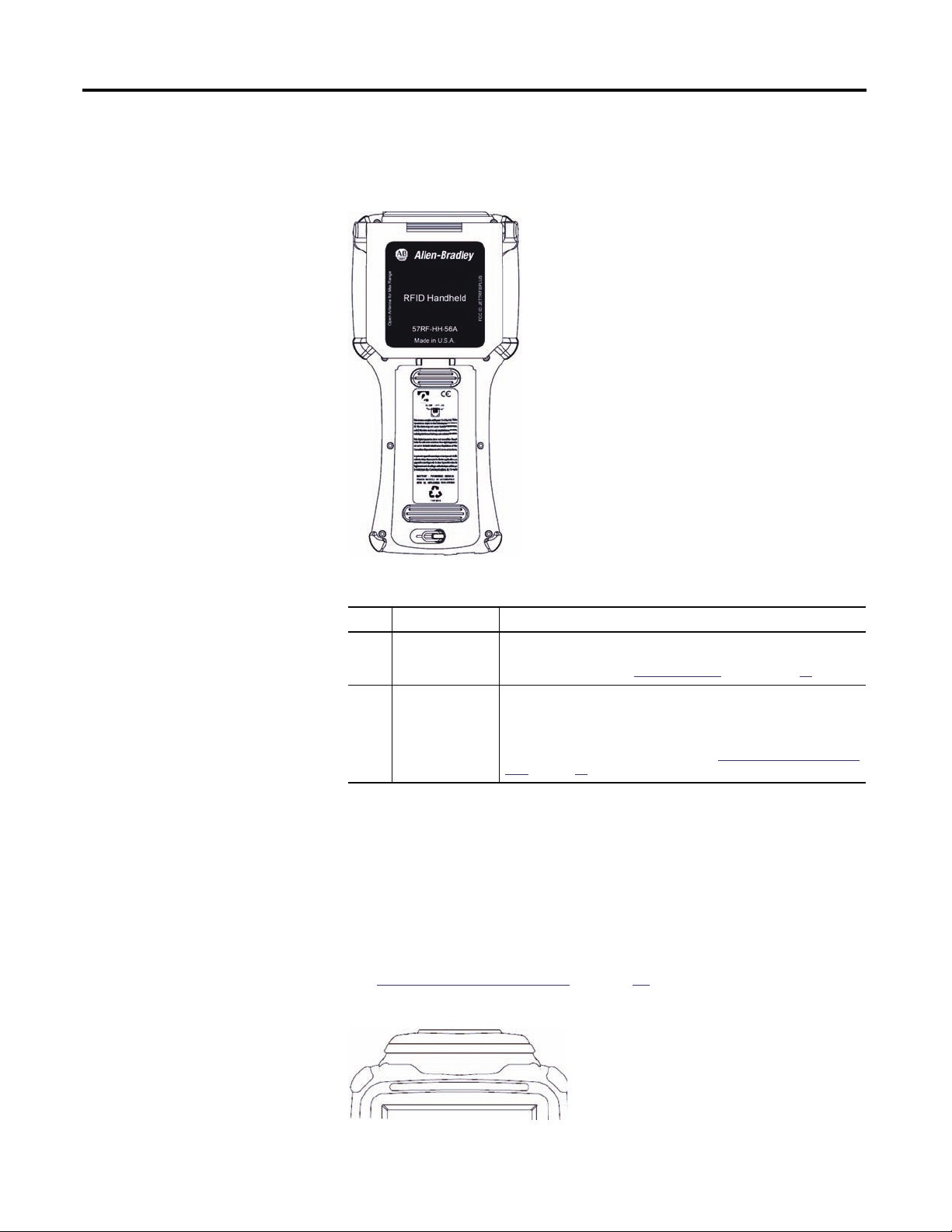

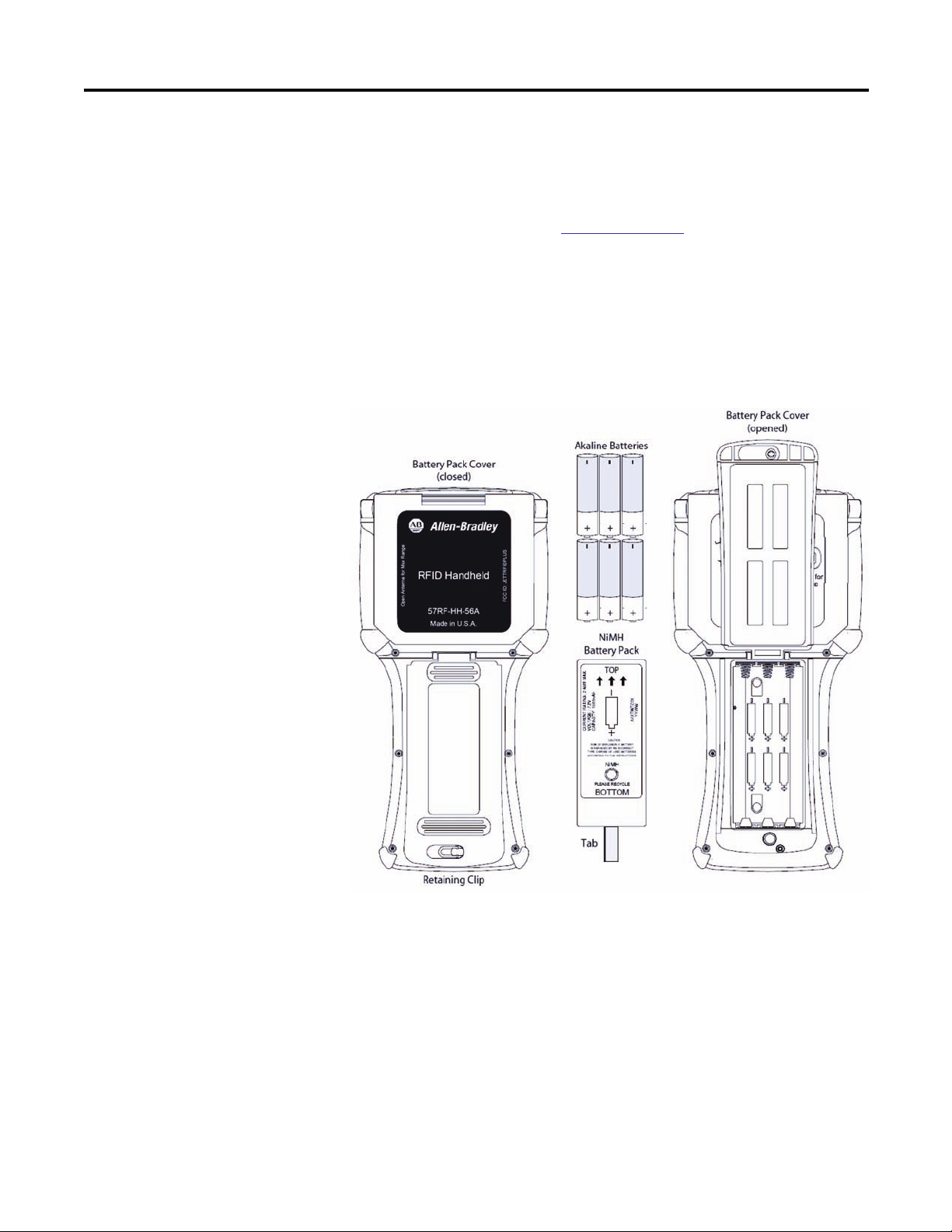

Rear Components

This section describes the components found on the rear of the RFID ICODE

handheld interface.

Figure 14 - Rear Components

Table 6 - Rear Components

Compact Flash Slot Cover

Item Function Description

1 RFID Module The RFID Module attached to the rear of the unit can read RFID tags in

2 Battery

Compartment

its storage position (shown above) or swing out up to 180° for

maximum range. See the RFID Read Range figure on page 27.

The battery compartment can store either the Nickel Metal Hydride

(NiMH) rechargeable battery pack or six AA alkaline batteries. You can

access the battery compartment by lifting up and turning the retaining

clip.

For more information using batteries, see “Replacing Batteries/Battery

Pack on page 24.”

The compact flash slot cover located on the top of the unit provides access to the

compact flash slot that stores memory and device cards. The hatch cover

thoroughly seals the RFID ICODE handheld interface to maintain a total IP65

solution. Four screws secure the cover to the top of the RFID ICODE handheld

interface. To insert device or memory cards into the compact flash slot, you must

first remove these screws using a flat head screwdriver.

For more information about inserting and removing memory and device cards,

see “Using the Compact Flash Slot

Figure 15 - Compact Flash Slot Hatch

” on page 27.

18 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 19

Chapter 3

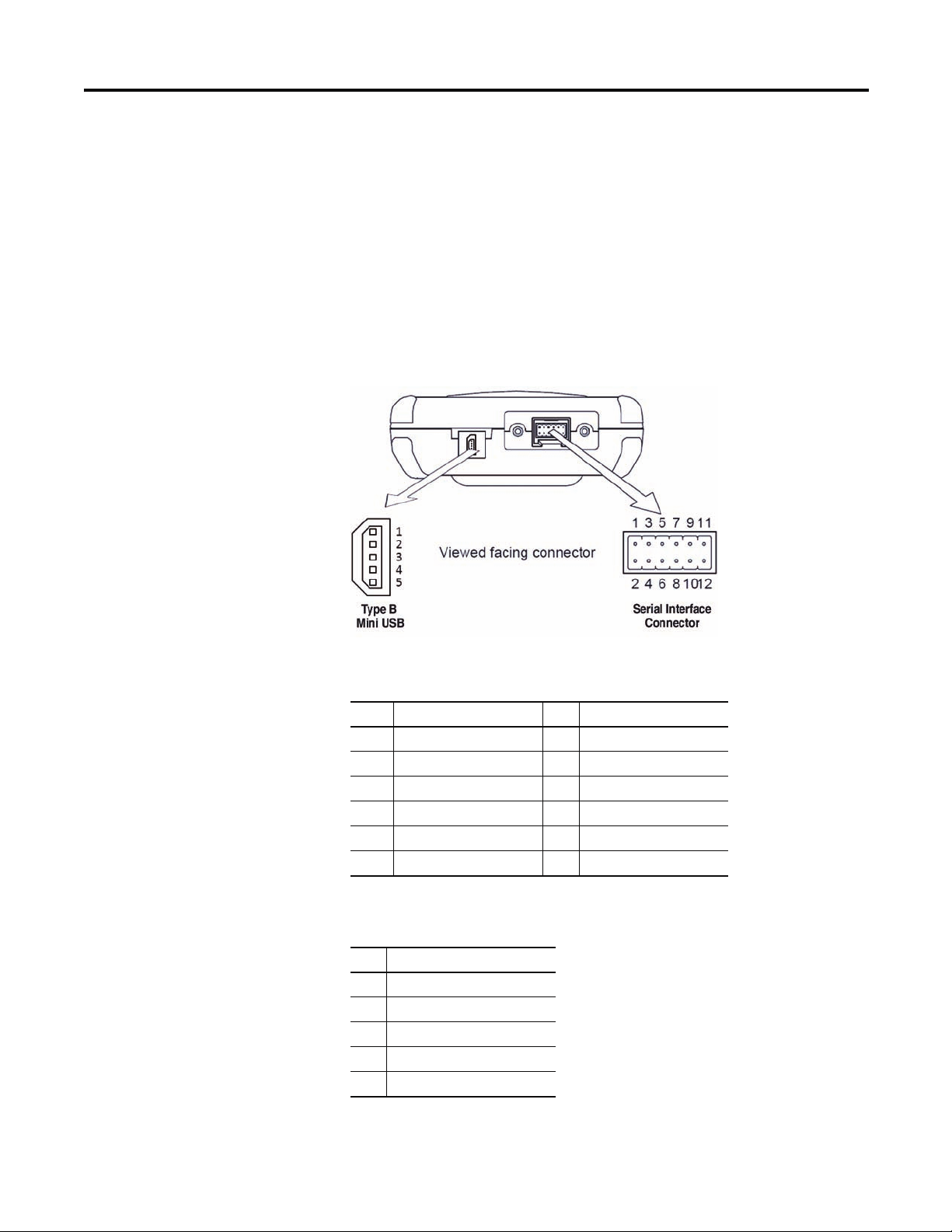

Interface Connections

This section describes the interface connectors found on the bottom of the RFID

ICODE handheld interface.

The serial interface connection system is a set of rugged interface and cable

connectors especially designed for industrial environments. It features positive

connector retention without any hardware restraints for quick connect/

disconnect operations and a contact design that prevents failure due to pin

fatigue and cable stress after repeated use. A standard Type B Mini USB

connector allows the RFID ICODE handheld interface to easily connect with

PCs and laptops.

Figure 16 - USB and Serial Interface Connectors

Table 7 - Serial Interface Pin-Outs

Pin Description Pin Description

1X1 7DSR

2 Ground 8 RTS

3RI 9DCD

4 CTS 10 11…18V DC input

5DTR 11Shield

6 TXD 12 RXD

Table 8 - USB Pin-Outs

Pin Description

1+5V DC

2Data –

3Data +

4 Device presence indicator

5Ground

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 19

Page 20

Chapter 3

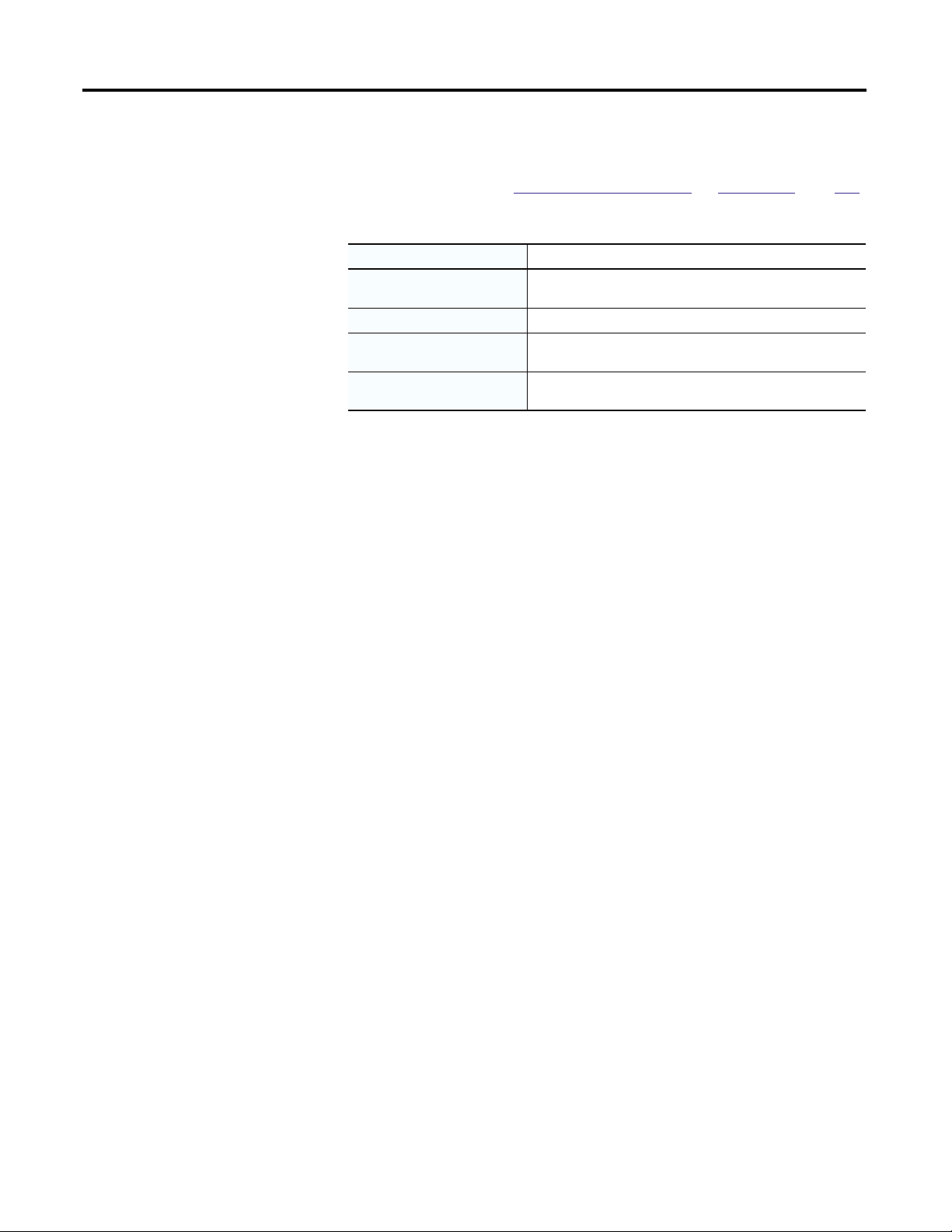

Power Supplies, Cables, and Adapters

Rockwell Automation can provide the following optional power supplies, cables,

and adapters based on communication and power requirements. For cable signal

and pin assignments, see “Signal and Pin Assignments

Table 9 - Available Power Supplies, Cables, and Adapters

Catalog Number Part Description

57RF-HH-56US1 Single position charging cradle with domestic power supply cable,

USB cable

57RF-HH-56US2 Domestic wall mount power supply, serial cable, USB cable

57RF-HH-56IN Power supply kit (includes power supply, adapters for USA,

Europe, Australia, UK, and rest of world), serial cable, USB cable

57RF-HH-56CA Serial cable, 15 ft, straight, 9-pin female connector, RS-232,

molded

” in Appendix B, page 107.

20 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 21

Operation

Chapter

4

Power

The RFID ICODE handheld interface comes with a rechargeable Nickel Metal

Hydride (NiMH) battery pack that can provide up to six hours of operating time

on a full charge (depending on power management and use).

You will need to charge the Nickel Metal Hydride (NiMH) rechargeable battery

pack a minimum of three hours prior to first use. Please note that the battery pack

will not attain maximum capacity until it has been charged and discharged

approximately four times. As a result, you may experience shorter than expected

operating time on the first few uses of the product.

NiMH batteries are an extremely stable and dependable source of electrical

energy, but can be sensitive to extreme temperature. If you charge the battery pack

in extreme hot or cold, it will not attain a full charge, and as a result will exhibit

decreased useable time until it recharges again. As a precaution against

overheating, the RFID ICODE handheld interface has built-in temperature

sensors that will suspend the charging process if the battery becomes too warm.

Because the battery pack is an electrical device, you should not expose it to

moisture or wet environments. If the battery becomes wet, wipe it dry and then

allow it to dry thoroughly for several hours before attempting to use or charge it.

Do not leave the battery pack in a fully discharged state for extended periods.

This condition may cause one or more of the cells within the battery pack to fail.

When this occurs and the battery pack is subsequently re-charged, the failed cell

will reduce the total voltage capacity of the battery pack, thus making the battery

appear to discharge faster.

Charging the Unit

The nickel metal hydride battery technology used in the RFID ICODE

handheld interface has exceptional charge life without the “charge memory”

characteristic of conventional nickel cadmium batteries. Partially discharged

batteries or extended periods with the charger left connected will not adversely

affect battery life or performance.

WARNING: Do not enable or utilize the RFID module while charging

the unit. Operation of this nature is likely to cause harmful

interference.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 21

Page 22

Chapter 4

IMPORTANT

Because the internal battery charger senses several conditions,

including temperature, you should charge the unit away from any

known, or potential, heat sources. Units exposed to temperatures in

excess of 110 °F (43.3 °C) during the charge cycle may experience

incomplete charging and reduced operating time per charge.

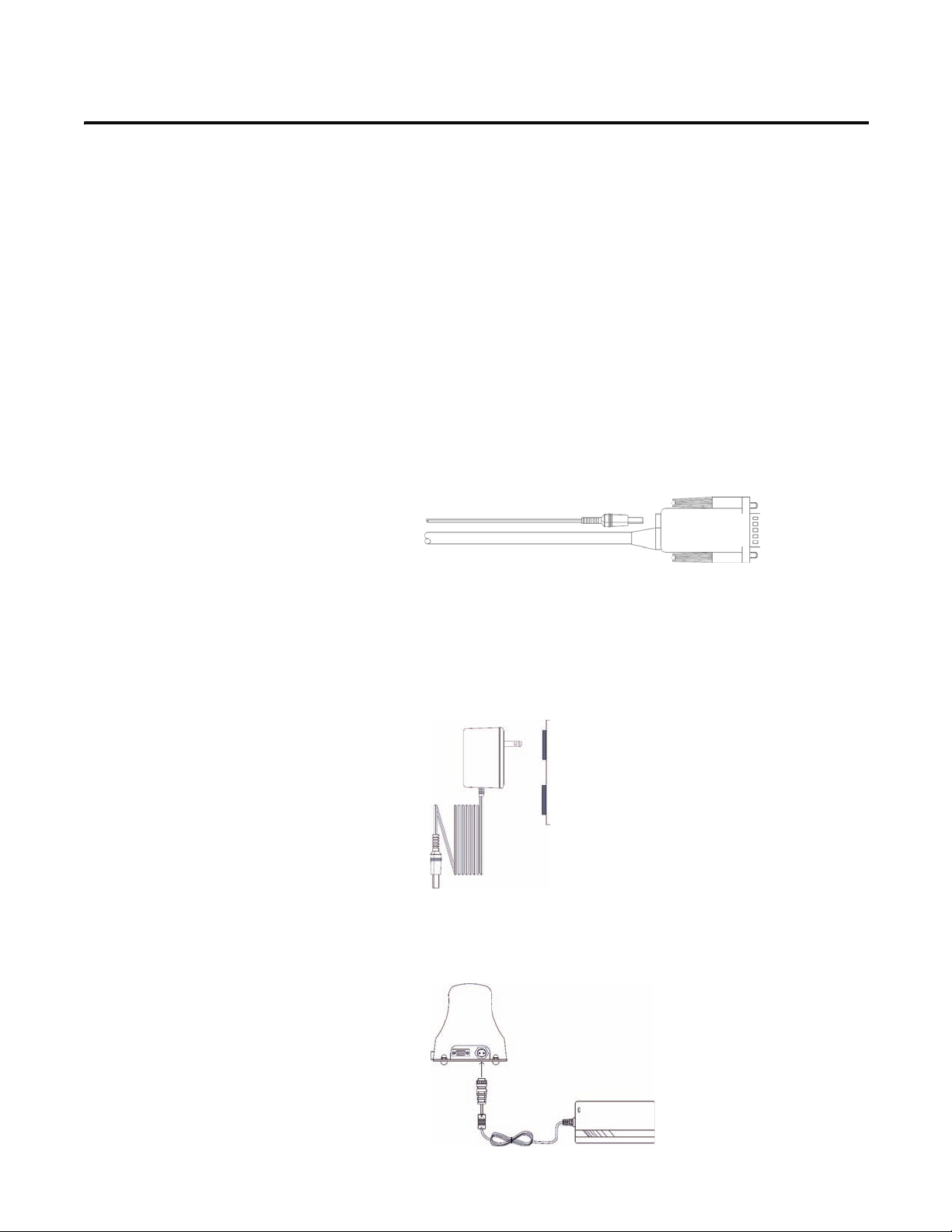

To charge the Nickel Metal Hydride (NiMH) battery pack:

1. Plug the power jack of the battery charger/power supply into the

corresponding cables connector as shown below.

Figure 17 - Power Jack

Power Supply/Battery Charger

To Unit

2. Plug the interface cable into the connector on the bottom of the RFID

ICODE handheld interface.

3. Plug the battery charger/power supply into a power outlet. The Charge

LED should turn on, indicating that the batteries are charging (see

Charge/Low Battery Indicator Functions

Figure 18 - Power Supply and Outlet

table on page 23).

4. Once the battery is fully charged (approximately four hours), you can

disconnect the power supply and run the RFID ICODE handheld

interface exclusively on battery power.

22 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 23

Chapter 4

Charge/Low Battery Indicator

When using the Nickel Metal Hydride (NiMH) battery pack, the Charge/Low

Battery LED will indicate the current battery status as shown in the table below.

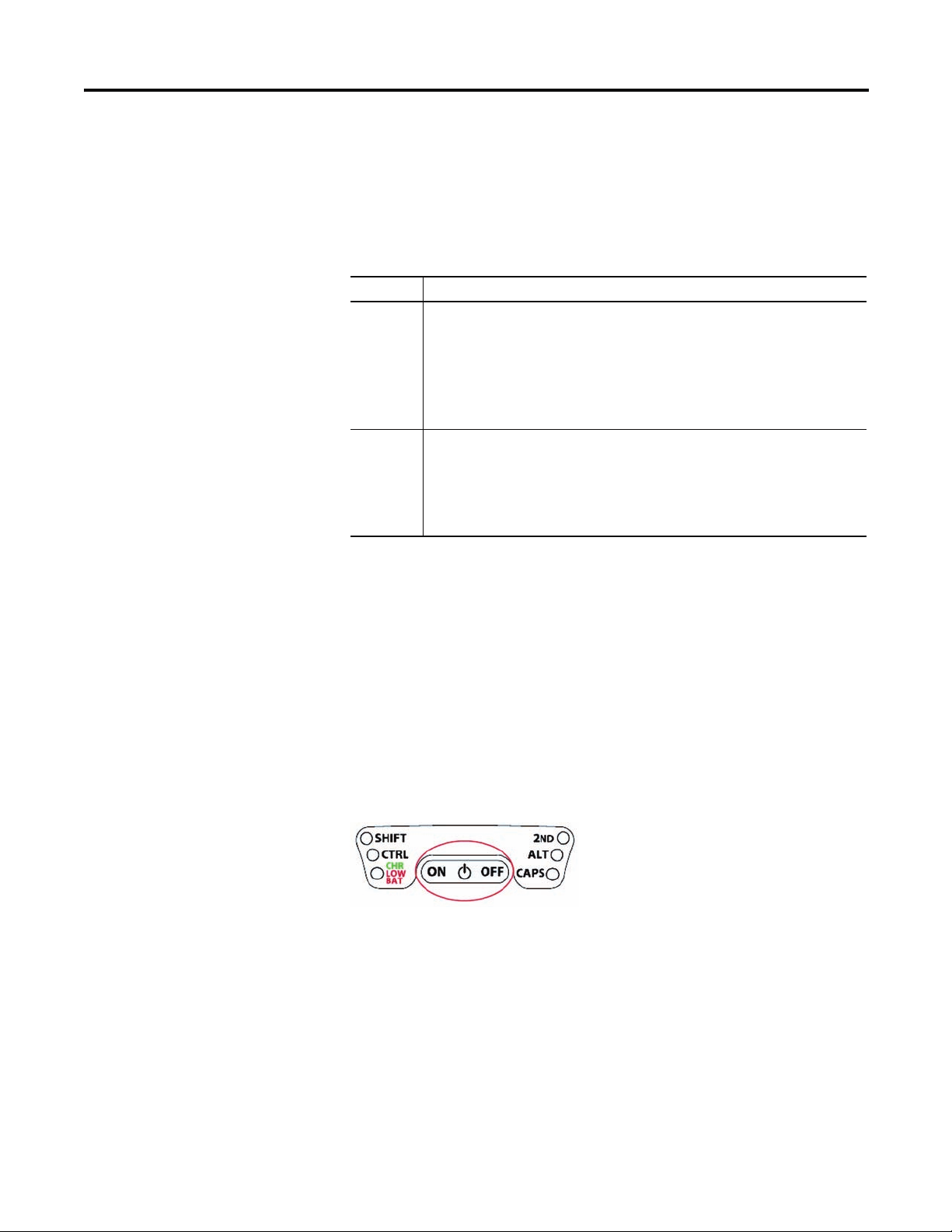

Table 10 - Charge/Low Battery Indicator Functions

Function Description

CHARGE With the power supply connected, the CHARGE/LOW BAT LED will indicate one of

LOW BAT With the power supply disconnected, the CHARGE/LOW BAT LED will indicate one

the following conditions:

• High power charge – the LED will turn solid green

• Fully/near full charge – the LED will blink green about four times a second

• Trickle charge – the LED will blink green approximately once per second when

either the battery voltage and/or temperature of the battery assembly are not

within acceptable limits

of the following conditions:

• Batteries are low – the LED will blink red once per second when there is

approximately 30 minutes of power remaining

• Batteries are very low – the LED will turn solid red when there is approximately

10 minutes of power remaining

Power/Suspend Switch

The On/Off switch is located above the keypad. Its function depends on the state

of the RFID ICODE handheld interface at the time the switch is pressed and on

the length of time that the switch is depressed. Operations that the power switch

can initiate are:

• Power on

• Power off

• Suspend

Figure 19 - Power/Suspend Switch

Power On

To power on the RFID ICODE handheld interface:

1. Press and hold the ON/OFF switch for one second.

2. The unit should turn on and begin displaying the boot-up process.

3. After approximately 15 seconds, the Windows CE 5.0 desktop should

appear.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 23

Page 24

Chapter 4

However, because there is no outward indication (such as a flashing LED) that

the RFID ICODE handheld interface is powered off or in Suspend mode, the

handheld may resume an active application it if is indeed in a suspended state.

If the unit does not power up or you cannot select any items from the desktop,

refer to “Troubleshooting

” in Chapter 8 (page 95) for more information.

Power Off

To turn off the RFID ICODE handheld interface, press and hold the On/Off

switch for approximately eight seconds. This action will also terminate running

applications and cease serial port operations.

Suspend Mode

Suspend mode allows you to suspend, but not terminate active applications. In

this mode, the display will turn off and the RFID ICODE handheld interface will

cease serial port operations. For battery-powered units, Suspend mode also

conserves battery power.

To place the unit in Suspend mode, press and release the On/Off switch.

To take the RFID ICODE handheld interface out of Suspend mode, press and

release the On/Off switch again. The display will turn on and the RFID ICODE

handheld interface will resume running any suspended application, but you must

restart any serial port operations.

If you attempt to resume immediately after suspending the RFID ICODE

handheld interface or vice versa, the unit will delay three seconds before resuming

or suspending.

Replacing Batteries/Battery Pack

WARNING: There is a risk of explosion if you replace the NiMH battery

with an incorrect type. Only use a NiMH battery supplied with your unit or

a replacement NiMH battery supplied, recommended, or approved by

Rockwell Automation.

When using alkaline batteries, replace all alkaline batteries in the RFID ICODE

handheld interface at the same time. Do not mix old and new batteries, mix

different types or brands of batteries, or dispose of the batteries in a fire. These

actions can cause battery rupture or leakage that result in personal injury or

property damage.

Remove the batteries from the RFID ICODE handheld interface when not using

the handheld for extended periods. Store the batteries in a cool, dry location at

normal room temperature.

24 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 25

Chapter 4

To replace the rechargeable battery pack or change AA batteries:

1. Turn the power off. With the unit face down, pull the battery cover

retaining clip up from its recessed slot and turn the clip in a counter

clockwise motion (see the Changing Batteries

figure below).

2. Lift the cover up and remove the batteries/battery pack.

3. If the unit contains a Nickel Metal Hydride (NiMH) battery pack, use the

tab to lift up on the battery pack and then out.

4. Close the battery cover and turn the battery cover retaining clip clockwise

to lock the cover.

Figure 20 - Changing Batteries

Power Management

Battery-powered units can utilize a rechargeable Nickel Metal Hydride (NiMH)

battery pack that has an average operating time of six hours on a full charge with

power management.

As with all battery-powered devices, the operating time is completely dependent

on the environment, device usage, and the number and type of power-drawing

peripherals attached. The battery discharge rate in a full “Power Off ” state is only

slightly higher to the self-discharge rate of the battery itself.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 25

Page 26

Chapter 4

IMPORTANT

IMPORTANT

Allowing the batteries to remain in a low or very low condition will cause

the unit to enter Suspend mode. In either case, you should save your

work and recharge the unit as soon as possible.

To lengthen the time between charges, you can perform the following actions:

• Use external power for PC Card operations whenever possible—some

PC Cards as well as extended communication via the serial port, may

require large amounts of power to operate, and can quickly drain the

batteries.

• Limit the use of backlight—minimize backlight use when you are

operating on battery power.

You can adjust the backlight timeout level through the Display settings in

the Control Panel or on some units by using the keypad.

• Shorten auto-suspend time—the RFID ICODE handheld interface is

automatically set to suspend operation to conserve battery power when

you have not used the keyboard or the stylus after three minutes. You can

increase the auto-suspend time by changing the Power settings in the

Control Panel.

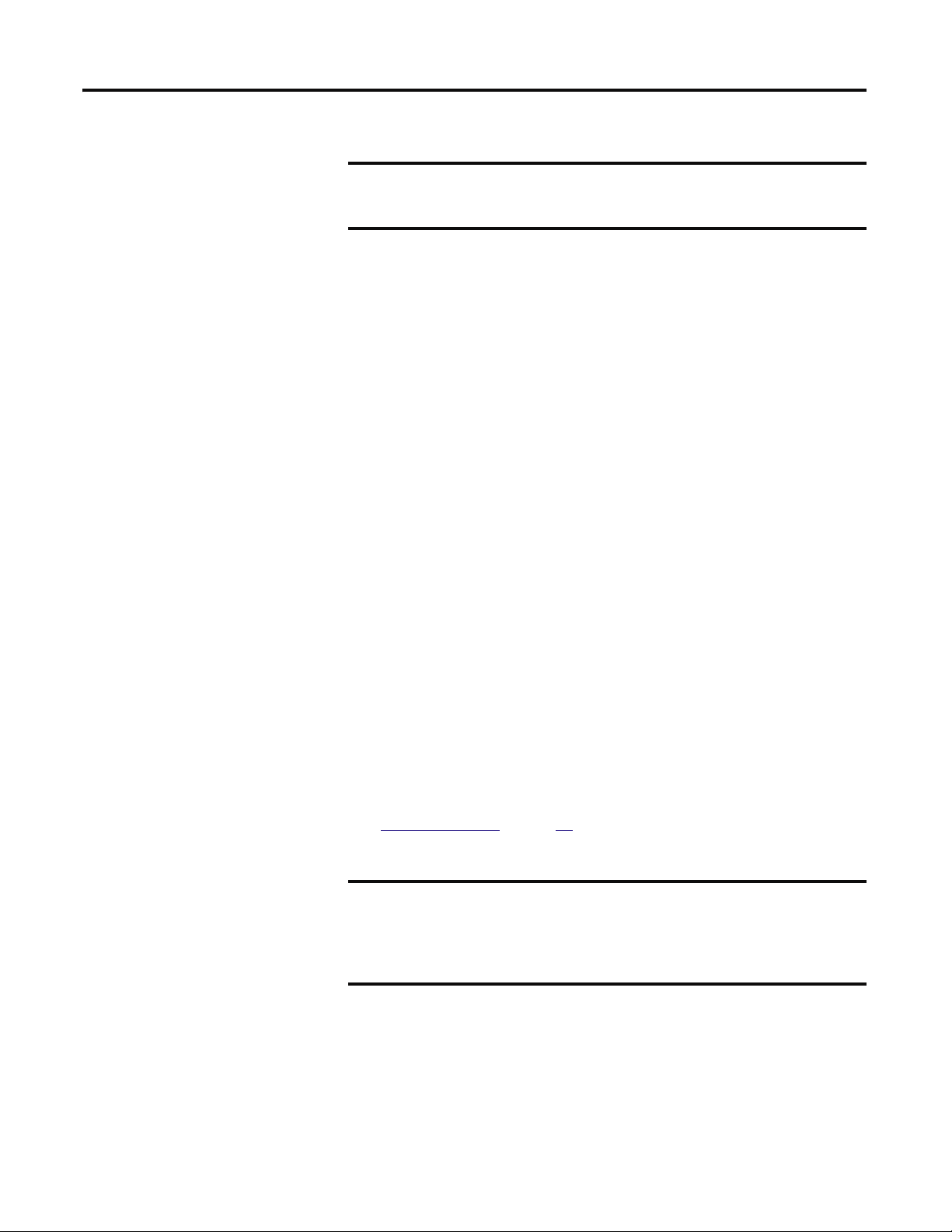

Using the RFID Module

The RFID module can read ISO-14443 and ISO-15693 RFID high frequency

(13.56 MHz) tags and smart labels. It is compatible with all

RockwellAutomation RFID ICODE tags, as well as ICODE tags from other

manufacturers.

The RFID module is totally application dependent and derives power from the

COM2 port. The RFID module has a flip-out antenna that provides a read range

of approximately 3.5 in. (90 mm) with a credit card size tag at 90° (see Figure

21—RFID Read Range

on page 27). For optimal tag reading performance, adjust

the module to either 90°or 180°.

Electronic items such as microwave ovens and cordless telephones can

affect RFID performance. The presence of metal and/or water can also

affect read range. Do not enable or utilize the RFID module with a cable

connected. Operation of this nature is likely to cause harmful

interference.

26 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 27

Figure 21 - RFID Read Range

Chapter 4

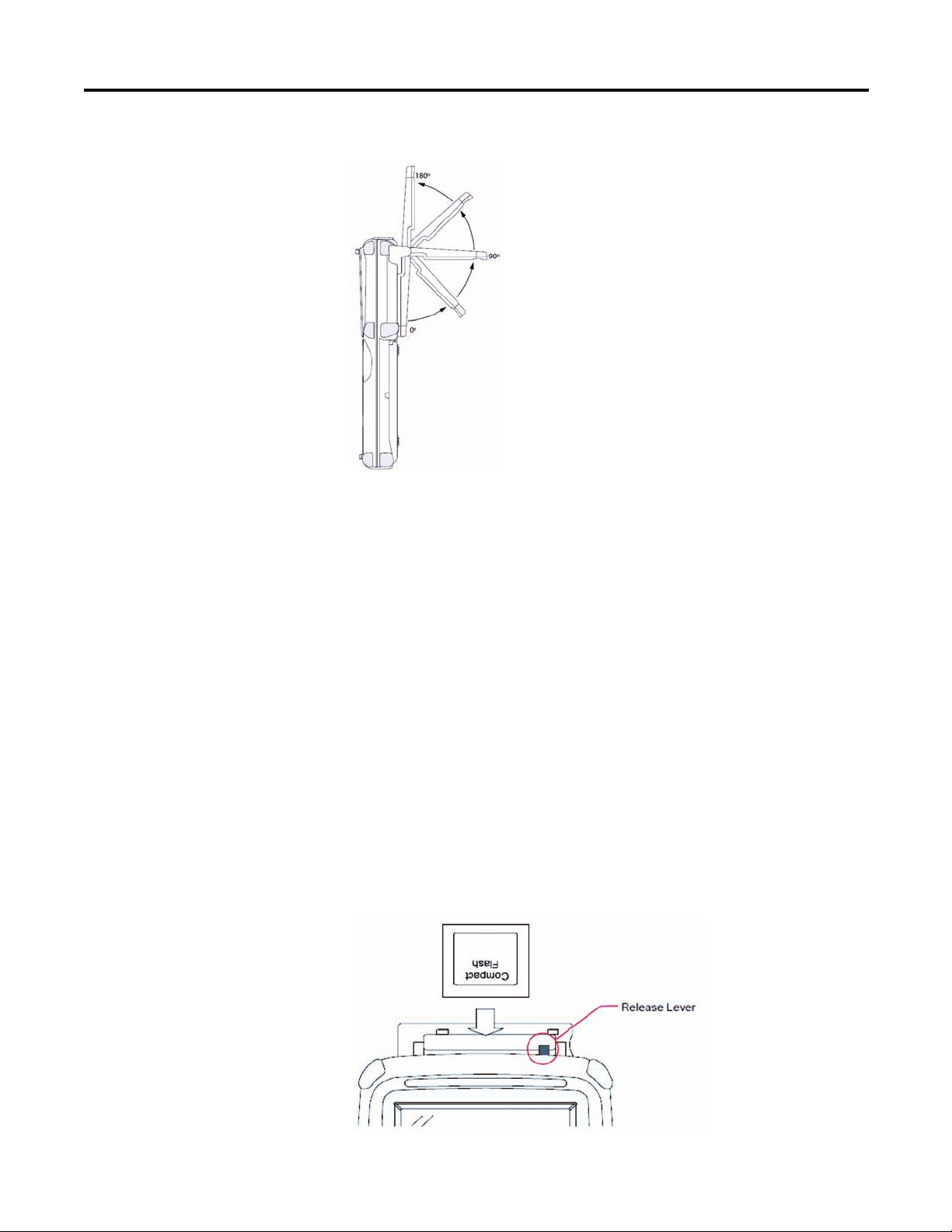

Using the Compact Flash Slot

The Compact Flash slot located on top of the RFID ICODE handheld interface

enables you to utilize Compact Flash and device cards.

If you intend to use a device card, it may also be necessary to install a driver. If so,

make sure the card is Windows CE 5.0 compatible and you have the necessary

drivers. If you are not sure, check with the card manufacturer before attempting

to install the card.

To use the compact flash slot:

1. If needed, remove any screws from the cover to access the Compact Flash

slot.

2. Insert the compact flash card into the slot with the front of the display

facing you and the top of the card pointed to the slot until it clicks and the

release lever moves upward.

Figure 22 - Using the Compact Flash Slot

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 27

Page 28

Chapter 4

3. Close the cover.

4. When inserting memory cards, a “UserCF” folder will appear when you

open My Computer. You can then copy and paste the contents of UserCF

to the other folders on the RFID ICODE handheld interface.

When inserting device cards, the RFID ICODE handheld interface will

attempt to recognize the device. If it finds a driver for the device, the RFID

ICODE handheld interface will display a dialog box for that device.

If the RFID ICODE handheld interface cannot find a driver for the

device, it will display the following dialog box:

5. If the correct card type appears, you can enter the appropriate information

in the dialog box required and then click OK to complete the installation.

Data Entry

6. To remove a card from the slot, simply push the card release lever down and

remove the card.

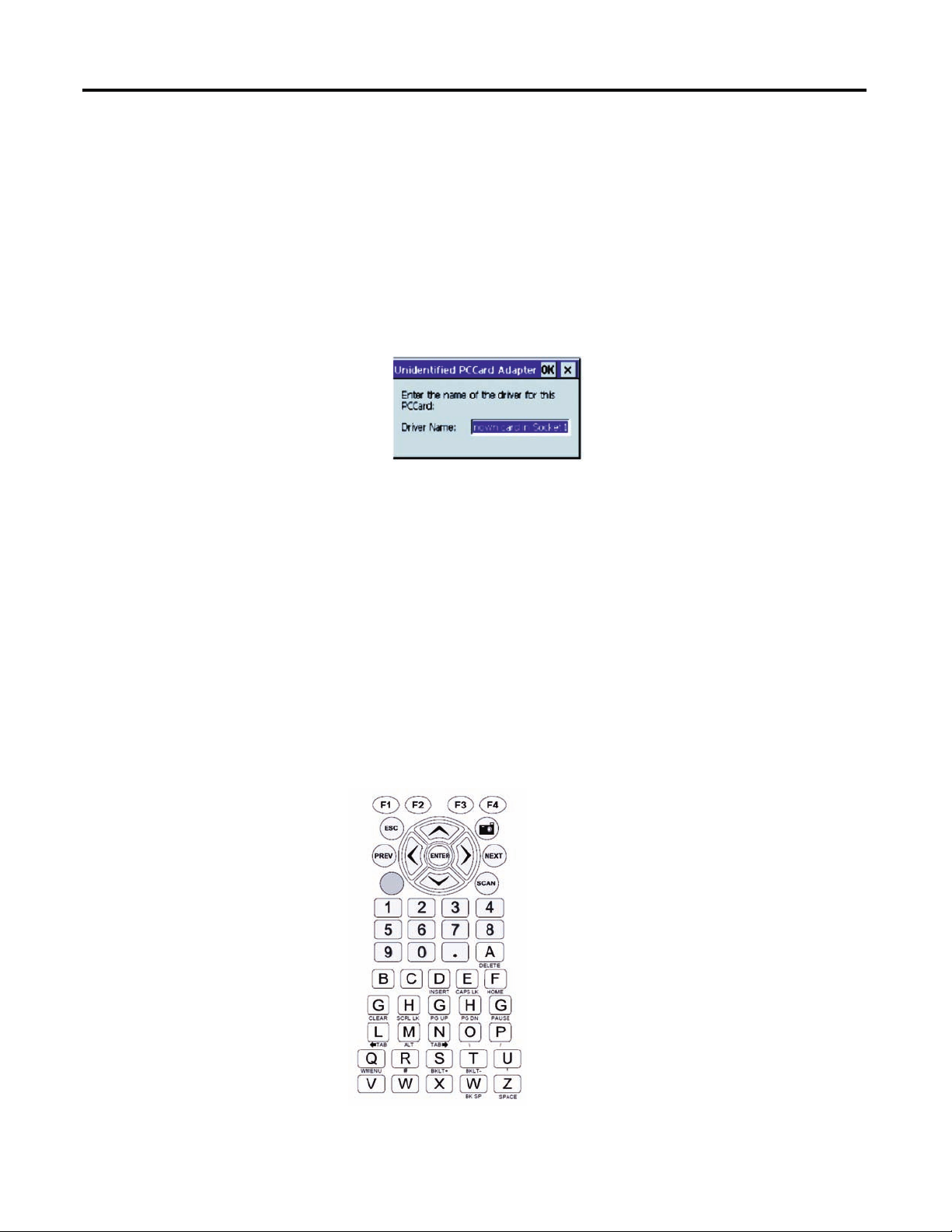

Keypads

52-Key Pads

This joystick style keypad with bezel nomenclature features easy screen

navigation and alphanumeric keypad entry and four programmable function keys.

Users can also access navigation keys and backlight control via the SHIFT key.

Figure 23 - Standard 52-key Pad

28 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 29

Chapter 4

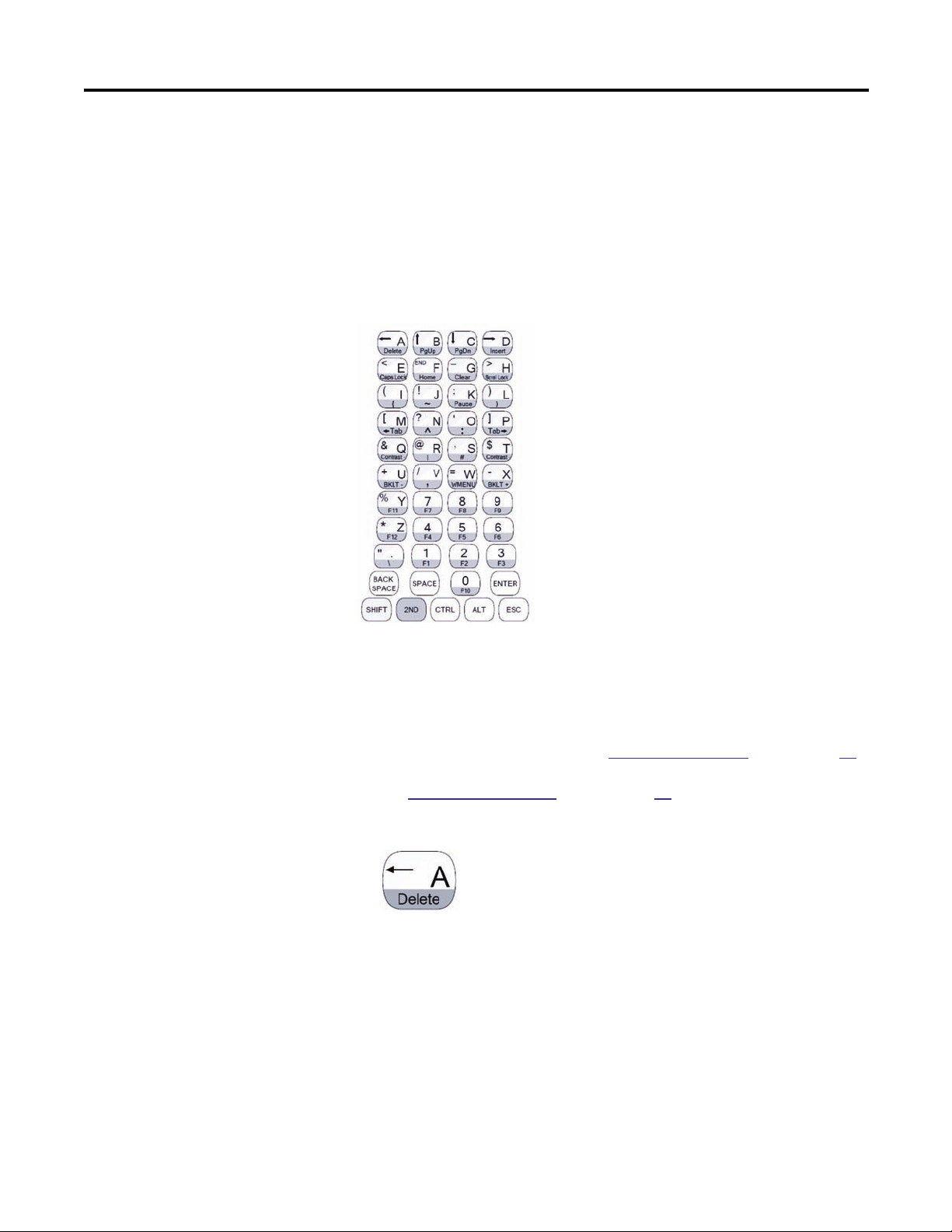

45-Key Pads

In order to provide the functionality of a full-size keyboard with only 45 keys, the

RFID ICODE handheld interface keypad makes use of modifier keys. Units

configured with the 45-key pad utilize five LED indicators (located above the

On/Off switch) to indicate the active state of the keypad modifier keys. Units

with the 45-key pad also have keypad functions to adjust contrast and backlight.

Figure 24 - Standard 45-key Pad

Modifier Keys

The following modifier keys (located on the bottom of a standard keypad) enable

you to access the various functions that can appear on a key. Modifier keys take

effect when first pressed and typically remain in effect until you press another key,

unless it is another modifier key (see the Modifier Key Actions

table on page 30).

Optionally equipped units can use LEDs to indicate the selection of a modifier

key. The Power/Suspend Switch

Figure 25 - 45-Key Pad Modifier Key

figure on page 23 provides examples of LEDs.

• CTRL and ALT Keys—operate in the same manner as on conventional

PCs, except that by default they have a one-time locking action to facilitate

one-handed operation.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 29

Page 30

Chapter 4

• SHIFT Key—unlike conventional PC keyboards, the SHIFT key enables

you to access symbols, punctuation marks and navigation arrows rather

than shift alphabetic keys to uppercase. By default, the SHIFT key has a

one-time action. However, you can press the SHIFT key twice and lock

the keypad into Shift mode, where each subsequent key press will only

access characters that appear in the upper left of a key. Pressing the SHIFT

key a third time will release Shift mode.

On standard RFID ICODE handheld interface 45-key pads, the functions

and characters accessed via the SHIFT key appear in the upper left of a key

(shaded in light grey in the Standard 45-key Pad

figure on page 29).

• 2ND Key—shifts the numeric keys to corresponding function keys

(1=F1, 2 =F2, etc.) that are found on conventional PC keyboards. It also

shifts other keys for punctuation, non-printing characters (such as Delete

and TAB), and PC key definitions (such as Page Up, Page Down, Home,

Insert and Caps Lock).

On standard RFID ICODE handheld interface 45-key pads, the functions

and characters accessed via the 2ND key appear at the bottom of a key,

(shaded in dark grey in the Standard 45-key Pad

figure on page 29).

Like the SHIFT key, the 2ND key has a default one-time action and a

locking mode (for example, pressing the 2ND key twice will lock the

keypad into 2ND mode).

Table 11 - Modifier Key Actions

Key Presses Result

A Lowercase “a”

Shift & A Move cursor left one position

2ND & A Delete character

2ND & Caps Lock & A Uppercase “A”

Key Repeat

By default, the RFID ICODE handheld interface does not automatically repeat a

key stroke when you hold down a key. However, you can enable the key repeat

function by configuring the Keyboard setting in the Control Panel.

CE Keyboard

In addition to entering data through the keypad, you can also enter data by using

the CE Keyboard. This utility displays a keyboard on the screen to allow data

entry via the Command Line or into applications where “text accessibility”

control has focus (for example, text or combo box).

30 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 31

Chapter 4

To use the CE Keyboard, select Programs>Tools>CeKeys from the Start menu.

To minimize the keyboard, click the keyboard icon that appears in the system

tray.

Figure 26 - CE Keyboard

Transcriber

Microsoft® Transcriber is a natural handwriting recognition software program

that interprets pen movement across the screen as handwriting (cursive, print, or

mixed) input. For more information, please refer to Microsoft Transcriber Help

on the RFID ICODE handheld interface.

To run Microsoft Transcriber, select Programs>Tools>Transcriber from the

Start menu.

Figure 27 - Transcriber

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 31

Page 32

Chapter 4

Windows CE 5.0 Desktop

This section provides a brief overview of the functions that appear on the

Windows CE 5.0 desktop. For information on how to change desktop settings,

refer to Windows CE help (Start>Help).

Figure 28 - Windows CE 5.0 Desktop

Windows CE 5.0 Desktop Functions

You can access the following applications, functions, and utilities from the

Windows CE 5.0 desktop:

Icon Function Description

Recycle Bin Used to restore deleted files or empty the bin to

My Device Used to navigate and view the folders and files stored

Inbox Used to send and receive e-mail by connecting to a

My Documents Used as the default storage location for documents,

Microsoft WordPad Used to create or edit text files that contain

Internet Explorer Used to view web pages.

PC Link Used to make an ActiveSync, Bluetooth, or other type

create more disk space.

on the RFID ICODE handheld interface.

POP3 or IMAP4 server.

graphics, and other files.

formatting or graphics.

of connection to another device.

32 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 33

Chapter 4

Task ba r

The taskbar at the bottom of the RFID ICODE handheld interface desktop

displays the Start button, buttons of currently running applications, the Status

Area and the Show Desktop icon.

Select the Start button to display the Start menu (see below for details). For each

open application, a button appears on the taskbar. Simply click the button to

activate the application.

The status area appears on the right and by default displays small icons for the

input panel, current time, power status, and network connections. Double-click

an icon to activate the related program.

Choosing the Show Desktop icon minimizes active applications and redisplays

the desktop. Clicking the Keyboard icon displays the Input Panel menu for data

entry.

Figure 29 - Windows CE 5.0 Desktop Taskbar

Power Status Icons

The RFID ICODE handheld interface will display power status icons (shown in

the Power Status Icons

Desktop Taskbar figure above) to indicate power use, charging status, and low

battery conditions.

Table 12 - Power Status Icons

Icon Description

Batteries are charging

Batteries are low – approximately 30 minutes or less of use remaining (the CHARGE/

LOW BAT LED will blink once per second)

Batteries are very low – approximately 10 minutes or less of use remaining (the

CHARGE/LOW BAT LED will turn solid red)

table below) in the taskbar status area (Windows CE 5.0

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 33

Page 34

Chapter 4

Start Menu

When you click Start, the Start menu appears.

Figure 30 - Start Menu

By selecting one of the icons in the Start menu (and not the name), you can:

• Program – open programs that do not appear on the desktop

• Favor ites – view a list of web sites added to your Favorites list

• Documents – view recently accessed documents and images

• Settings – access the Control Panel, establish connections, or configure

the Taskbar and Start Menu

• Help – view Help

• Start an application using the Run command

• Place the unit in Suspend mode

Miscellaneous Tools

You can access the following utility programs from the Tools menu.

Screen Capture

The Screen Capture program takes a picture of the screen and saves it as a bitmap

file (.BMP) to a designated location. You can set up the program to run from the

system tray, or by pressing a hot key.

To setup the Screen Capture program:

1. From the Start menu, select Programs>Tools>Screen Capture. The

ScreenCapture.exe dialog box appears:

By default, the Screen Capture program is set to take a picture by pressing

HotK ey1 after a five-second delay.

34 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 35

Chapter 4

IMPORTANT

2. To change the wait time before the Screen Capture program takes a

picture, press the up or down scroll bars under Capture Delay (sec). The

default value is five seconds.

3. To change the Keyboard Hot Key assignment, you must access the Hot

Key applet in the Control Panel. The default value is HotKey1.

4. To have the Screen Capture program take a picture when you click its icon

in the System Tray, check Auto run in the task bar.

Note: To deselect this option after making it active, press and hold the

icon until the Screen Capture program appears.

5. To view the picture immediately following the screen capture, check Vie w

following capture.

6. To change the default folder (My Documents) where the pictures are

stored, select the button under Store screen capture in folder.

7. Select a new location and click OK.

8. By default the Screen Capture program automatically assigns a number to

each screen capture.

The numbering scheme starts at JET00000 and increments by one after

each capture. To set this number back to JET00000, check Reset Counter.

Screen captures stored in folders other than the SystemCF folder will be

lost if you remove power from the unit.

Warm Boot

Occasionally, a program may encounter an error from which it cannot recover. In

these cases, you can perform a warm boot, which will reinitialize the unit without

affecting the contents store in virtual memory.

To perform a warm boot:

1. Select Programs>Tools>Warm Boot, the “Are you sure?” prompt appears.

2. Click Ye s to warm boot the unit.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 35

Page 36

Chapter 4

IMPORTANT

Manually Saving the Persistent Registry

The RFID ICODE handheld interface internal memory consists of SDRAM and

Flash. Typically, any changes made to the RFID ICODE handheld interface

including file creation are temporarily stored in the unit’s SDRAM. You must

then copy the files from SDRAM to internal flash memory or a removable

compact flash card to store the information permanently.

Consequently, if you do not store the information to flash memory and the unit

loses power, all information stored in SDRAM will be lost. However, whenever

you make changes that affect the registry, such and changing settings in the

Control Panel or installing software, you can permanently store registry changes

without writing to flash memory by using the Persistent Registry.

The RFID ICODE handheld interface will also store registry information

every time you perform a suspend/resume operation.

To store registry information on the RFID ICODE handheld interface

permanently:

1. From the Start menu, select Programs>Tools>SaveReg.

2. The RFID ICODE handheld interface will begin saving the registry.

3. After you successfully save the registry, a message box will appear:

4. Click OK to close the message box.

Command Prompt Windows

The command prompt window allows you to execute limited MS-DOS

command line arguments (for example, CD SystemCF, Run TEST.BAT, etc.).

To open the Command Prompt window:

1. From the Start menu, select Programs>Tools>Command Prompt. The

Command Prompt window opens:

36 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 37

Chapter 4

2. You can then type in your commands, for a list of supported commands,

type Help and press Enter.

3. To end the session, type Exit and press Enter.

SystemCF Folder

The only folder that provides non-volatile (permanent) storage is the SystemCF

folder. Information stored in other folders will be lost when you remove power

from the RFID ICODE handheld interface. You can however, have the RFID

ICODE handheld interface automatically copy files from the SystemCF to other

folders when booting up.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 37

Page 38

Chapter 4

Notes:

38 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 39

Configuration

Chapter

5

Control Panel

The table below lists the available control panel functions on the RFID ICODE

handheld interface.

Icon Function Description

Aux CF Card This function enables you to enable/disable power to CF cards

installed in the internal CF Card slot, which is not user

accessible.

Aux Switch For units with a second COM that supplies 5V DC output, use

this function to set the default power state (on or off), and test

the connected devices.

Backlight Use this function to adjust the backlight setting for the

following conditions: Line Active, Line Active Inactive, Battery

Active, and Battery Inactive.

Battery Select Select one of the following options to calibrate the power

status icons for proper use: NIMH, AC Line, or Alkaline.

Beep Select Use this function to change the frequency, volume, and duration

properties of the beep.

Certificates Use this function to import, view, or remove certificates, which

protect your personal information on the Internet, and protect

your computer from unsafe software.

CPU Speed Use this function to determine the current CPU and cold boot-up

speed. Allowable selections are 312 MHz and 624 MHz.

Date/Time Use this function to adjust the date, time, and time zone.

Dialing Use this function to adjust the dialing location settings and

Display Use this function to adjust the backlight timeout, change the

Display Rotation Use this function to rotate the screen 180° (upside down).

Hot Keys Use this function to assign functionality to the unit’s eight

Internet Options Use this function to set up connections, security settings, and

Keyboard Use this function to change the repeat delay and repeat rate.

Network and

Dial-up Connections

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 39

dialing patterns when using a modem.

background image, or change the desktop color scheme.

programmable keys.

internet related functions.

Use this function to change network adapter settings and/or set

up identification for remote networks.

Page 40

Chapter 5

IMPORTANT

Icon Function Description

Owner Use this function to enter the owner name, address, phone

numbers, notes, and network ID.

Changing System Settings

Password Use this function to enable password protection and set a

password.

PC Connection Use this function to enable direct connection to a desktop

computer.

Power Use this function to:

• Check battery power

• Set device to turn off when idle

• Set up power schemes

• Check the power levels of your system devices

Regional Settings Use this function to change the appearance of region specific

information, such as date, time, and currency.

Remove Programs This function enables you to remove programs installed in RAM.

Stylus Use this function to recalibrate the touch screen and adjust the

stylus double-click rate.

System Use this function to view system information, change the RAM

(Program/Storage memory) division, change the device name,

and change the device description.

Any time you make changes through the Control Panel (such changing the time

zone), you must also update the persistent registry to store the changes in internal

compact flash memory to make the changes permanent.

For example, to change the time zone and save the changes to the registry:

1. Select Start>Settings>Control Panel.

Click the icon, not the name.

40 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 41

Chapter 5

2. On the Control Panel, double-click Date/Time. The Date/Time

Properties dialog box appears. You can now set the date, time and time

zone.

3. To adjust the Current Time, use the scroll bars to increase or decrease the

value, or select hours, minutes, seconds or AM/PM indicator to set the

values individually.

4. To select the Time Zone, use the corresponding list.

5. To adjust the Date, either:

– Click the arrows on the calendar to select the previous/next month

– Double-click the month or year to select it from a list

– Click a day to select it

Taskbar and Start Menu Settings

6. To adjust the clock automatically for daylight savings, check the

corresponding box.

7. Click Apply to have your setting take effect.

8. Click OK to close the Date/Time Properties dialog box and return to the

Control Panel.

9. Click OK to exit the Control Panel.

10. From the Start menu, select Programs>Tools>SaveReg.

To change the Taskbar and Start Menu settings:

1. Select Start>Settings> Taskbar & Start Menu. The Taskbar and Start

Menu Properties dialog box opens.

2. Select the General tab:

3. Check Always on Top to ensure that the taskbar is always visible, even

when a program appears in a full window (maximized).

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 41

Page 42

Chapter 5

4. Check Auto hide to display the taskbar just when you point to the taskbar

area.

5. Check Show Clock to display the time of day in the taskbar.

6. Select the Advanced tab:

7. Click the Clear button to remove the contents of the documents menu.

8. Check the Expand Control Panel box to display the contents of the

Control Panel as items on the Settings| Control Panel menu.

9. Click OK to save the settings and exit the menu.

42 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 43

Connections

Chapter

6

ActiveSync

®

ActiveSync is a desktop utility program (available as a free download from

®

Microsoft

PC and the RFID ICODE handheld interface. You can also use ActiveSync to

transfer files and install programs on the handheld interface.

When connecting the RFID ICODE handheld interface to the PC via

ActiveSync, you can opt to create a partnership and subsequently have the PC

automatically recognize the handheld and synchronize information. You can also

create a temporary Guest partnership to copy files and install programs. The

following procedures describe how to make an ActiveSync connection using a

USB or serial interface cable. For information on how to make an ActiveSync

connection using Bluetooth or Wi-Fi, refer to the appropriate manual.

) that allows you to synchronize certain types of information between a

Initial Communication

To setup initial communication between the PC and the RFID ICODE

handheld interface:

1. If using the serial interface cable, connect the cable to an available COM

port on the PC and the RS-232 port on the RFID ICODE handheld

interface. If using the USB cable, connect the cable to an available USB

port on the PC and the mini USB port on the RFID ICODE handheld

interface.

2. On the PC, start ActiveSync.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 43

Page 44

Chapter 6

3. On the ActiveSync menu bar, select Connection Settings from the File

menu. The Connection Settings dialog box opens.

4. If using the serial interface cable, check the Allow connections to one of

the following box, and assign the number of the available COM port

(typically COM1). If using the USB cable, check the Allow USB

connections box.

5. Click OK to exit.

6. On the ActiveSync menu bar, select Get Connected from the File menu.

ActiveSync will then start the Get Connected wizard.

44 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 45

Chapter 6

7. Click Next. ActiveSync will start attempting to establish a connection (this

process will take several seconds).

8. On the RFID ICODE handheld interface, double-click PC Link.

The following message box appears:

9. If ActiveSync successfully establishes communications, the ActiveSync

dialog will briefly reappear on the PC and start the New Partnership dialog

wizard.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 45

Page 46

Chapter 6

10. Select your Partnership option as needed and complete the wizard. The

ActiveSync dialog box will reappear and display a status of

“Synchronizing.” For example:

11. On the RFID ICODE handheld interface, an icon indicating an

ActiveSync connection will appear in the system tray.

12. To terminate the ActiveSync connection, double-click the connection

icon to display the Connect To dialog box and click Disconnect.

46 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 47

Chapter 6

Subsequent Communication

After you install ActiveSync and establish the initial communication between the

PC and the RFID ICODE handheld interface, use the following procedure to set

up subsequent sessions:

1. If not already attached, connect an interface cable to an available COM

port on the PC and the RS-232 port on the RFID ICODE handheld

interface. Alternately, connect a USB cable to an available USB port on the

PC and the mini USB port on the handheld.

2. On the RFID ICODE handheld interface desktop, double-click PC Link

to attempt to re-establish communications.

3. When communication is successfully re-established, the New Partnership

wizard appears.

4. Select No on the PC and then click Next. A status of “Connected” should

appear in the ActiveSync window.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 47

Page 48

Chapter 6

Wireless Connections

Overview

Turning the Radio On

Before you can utilize the WLAN software, you must make sure the radio is on.

Follow the steps below:

1. Select Start>Settings>Control Panel.

2. Then double-click the AuxCF Slot applet.

3. Finally, select the Enabled radio button.

4. Wa rm b oot th e un it .

Wireless Zero Configuration Interface

The Wireless Zero Configuration interface enables you to setup, configure, and

connect to a WLAN. Whenever you turn on the handheld computer, it will

automatically start searching for any wireless network advertising its SSID

(service set identifier, or network name) and will display the Wireless

Configuration dialog box.

Figure 31 - Wireless Zero Configuration Utility

While searching for wireless networks, the handheld computer will display the

following icons in the system tray to indicate the wireless network connection

status. Double-click the WLAN Status icon to access the Wireless Network

Connection interface at any time.

Table 13 - WLAN Connection Status Icons

Icon Status

Connected to WLAN

Disconnected from WLAN

48 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 49

Chapter 6

Wi-Fi Companion

If you have the Go Wi-Fi P500 CF card, then you will have the Wi-Fi

Companion software installed on your handheld computer. Double-click any

Connection Status icon (as shown in the Connection Status Icons

to open the Wi-Fi Companian dialog box. Wi-Fi Companion performs a variety

of utility functions, such as finding available networks, power management,

certificate management, and network troubleshooting.

Figure 32 - Wi-Fi Companion Screen

table above)

The following icons will appear in the system tray to indicate the connection

status. Double-click a Connection Status icon to access Wi-Fi Companion.

Table 14 - Connection Status Icons

Icon Status

Excellent connection

Good connection

Marginal connection

Poor connection

Searching for networks

Networks available

Networks out of range but configured

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 49

Page 50

Chapter 6

IMPORTANT

Wireless Zero Configuration

Wireless Zero Configuration Requirements

Before you start, find out what security settings you need to connect to your

WLAN network. If applicable, consult with the network administrator. The

necessary settings may include one or more of the following:

• Wireless network name (SSID)

• WEP network type (Open or Shared), WEP key, WEP key format (Hex or

ASCII) and Key Index number

• Use of DHCP or Static IP to assign IP addresses

Note: To assign a static IP address to the handheld computer, use the

Network and Dial-up Connections applet in the Control Panel. Simply

double-click the P5001 icon to access the IP Address screen.

Wireless Zero Configuration Setup

To configure the handheld computer to connect to an 802.11 wireless network

using the Wireless Zero Configuration utility:

1. In the Status Bar, double-click the WLAN Connection Status icon to

access the Wireless Network Connection dialog box. This icon is also

referred to as the Wireless Zero Configuration icon.

The following scenario is for demonstration purposes only. SSIDs, keys,

and pass-phrases will be different in your particular environment.

50 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 51

Chapter 6

IMPORTANT

2. Select the Wireless Information tab.

3. If the SSID of the wireless network you want to connect to is listed,

double-click it. If the name does not appear, double-click Add New. In

either case the Wireless Properties dialog box appears as shown below.

The SSID is the network name given to a wireless access point. It defines

the wireless network to which clients may connect.

4. If needed, enter the Network Name (SSID). (This entry is case sensitive).

5. Depending on your network type, select or enter the following

information:

a. For Open networks that do not use encryption, select Disabled as the

encryption type.

b. For Open or Shared networks that use WEP encryption:

i. Select WEP as the Encryption type.

ii. Select the Authentication type: Open or Shared.

• If the key is provided automatically by the wireless access point,

then make sure The key is provided automatically box is

checked and skip to Step 5c).

• If your network administrator informs you that you have to type

in a key, clear The key is provided automatically checkbox and

continue to the next step.

iii. Enter the Network Key. For 40/64-bit keys, use either 10

hexadecimal digits or 5 ASCII characters. For 128-bit keys, use

either 26 hex digits or 13 ASCII characters.

Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011 51

Page 52

Chapter 6

IMPORTANT

iv. Enter the Key index number if different than 1.

v. If you are utilizing the 802.1x authentication method in a WEP

Open network, you will have to checkmark the Enable 802.1x

authentication checkbox.

vi. Clear the Enable 802.1x authentication checkbox if you are not

utilizing the 802.1x authentication method.

In addition, if you are using WPA as your authentication method, you may

need an additional 802.1x authentication configuration.

6. Click OK to save the settings and exit. The Wireless Information dialog

window will reappear and the handheld computer will attempt to make a

connection to that network.

7. If the connection was successful, a blue halo will appear on the icon next to

the connected wireless network name, as shown below.

8. Click OK to exit the Wireless Configuration dialog box.

9. To verify that you have a successful network connection, launch Internet

Explorer and type in a known web address. That page should appear on

your display. For example:

52 Rockwell Automation Publication 57RF-UM001A-EN-P - September 2011

Page 53

Chapter 6

IMPORTANT

Setting Up Identification for Remote Networks

To set up identification for remote networks:

1. Select Start>Settings>Control Panel.

2. Double-click Owner. The Owner Properties dialog box appears.

3. In the Network ID tab, enter the user name, password, and domain name