Page 1

Data Highway Plus

Interface Module

(M/N 57C442)

Instruction Manual J2-3067-5

Page 2

The information in this user’s manual is subject to change without notice.

IBM is a registered trademark of International Business Machines

Corporation. Allen-Bradley, A-B, AutoMax, Data Highway Plus, PLC, PLC-2,

PLC-5, SLC, and Reliance are registered trademarks of Rockwell

Automation.

Multibus is a trademark of Intel Corporation.

Phoenix and Combicon are registered trademarks of Phoenix Contact Ltd.

ReSource is a trademark of Reliance Electric Company or its subsidiaries.

!

ATTENTION: Only qualified electrical personnel who are familiar

with the construction and operation of this equipment and the

hazards involved should install, adjust, operate, and/or service this

equipment. Read and understand this manual and other applicable

manuals in their entirety before proceeding. Failure to observe this

precaution could result in severe bodily injury or loss of life.

!

ATTENTION: The user is responsible for conforming with all

applicable local, national, and international codes. Wiring practices,

grounding, disconnects, and over-current protection are of particular

importance. Failure to observe this precaution could result in severe

bodily injury or loss of life.

!

ATTENTION: The user must provide an external, hardwired

emergency stop circuit outside the controller circuitry. This circuit

must disable the system in case of improper operation. Uncontrolled

machine operation may result if this procedure is not followed.

Failure to observe this precaution could result in bodily injury.

!

ATTENTION: Inserting or removing a module may result in

unexpected machine motion. Power to the machine should be

turned off before inserting or removing the module. Failure to

observe these precautions could result in bodily injury.

!

ATTENTION: This module contains static-sensitive

components. Careless handling can cause severe damage. Do not

touch the connectors on the back of the module. When not in use,

the module should be stored in an anti-static bag. The plastic cover

should not be removed. Failure to observe this precaution could

result in damage to or destruction of the equipment.

Page 3

Table of Contents

1.0 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Related Hardware and Software . . . . . . . . . . . . . . . . . . . . . . 1-3

2.0 Mechanical/Electrical Description. . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Mechanical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Electrical Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3.0 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Initial Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

4.0 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Register Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Status and Control Registers . . . . . . . . . . . . . . . . . . . 4-2

4.1.2 Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.3 Global Data Registers. . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2 AutoMax Application Programming . . . . . . . . . . . . . . . . . . . 4-6

4.2.1 Variable Configuration. . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.2 Application Programming . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.3 Enabling the Data Highway Plus Interface Module. . . 4-9

4.2.4 Commands Initiated by the Data Highway Plu s

Interface Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.2.5 Commands from Remote Stations . . . . . . . . . . . . . . 4-11

4.2.6 Off-link Routing Paths. . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.2.6.1 Example of Bridging Two Data Highway Plus

Networks using 1785-- KA modules . . . . . . . . . . 4-13

4.2.6.2 Example of Bridging the DataHighway Plus

Link to a ControlNet Network. . . . . . . . . . . . . . . . 4-15

4.2.7 Programming Examples . . . . . . . . . . . . . . . . . . . . . . 4-16

5.0 Diagnostics and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 The OK LED Is OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Invalid Station Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Transmission Link Failures . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3.1 Rack Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3.2 Remote Station and Link Failure. . . . . . . . . . . . . . . . . 5-2

5.4 Bus Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

I

Page 4

Appendices

Appendix A

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B

Module Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C

Network Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . C-1

Appendix D

Data Highway Plus Interface Module

7-Segment LED Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Appendix E

GATEWAY_CMD_OK@ Status Codes . . . . . . . . . . . . . . . . . . . E-1

Appendix F

Mapping of Active Station List. . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Appendix G

Register Map for Diagnostic Counters . . . . . . . . . . . . . . . . . . . .G-1

Appendix H

Extended Status (EXT STS) Codes for Command 0F . . . . . . . . H-1

Appendix I

Converting A-B Register Numbers to AutoMax Register

and Bit Numbers for Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

Appendix J

Recommendations For Reducing Noise

On The Cable System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-1

II

Page 5

List of Figures

Figure 1.1 Connecting the AutoMax System to the

Data Highway Plus Network. . . . . . . . . . . . . . . . . . . . . 1-1

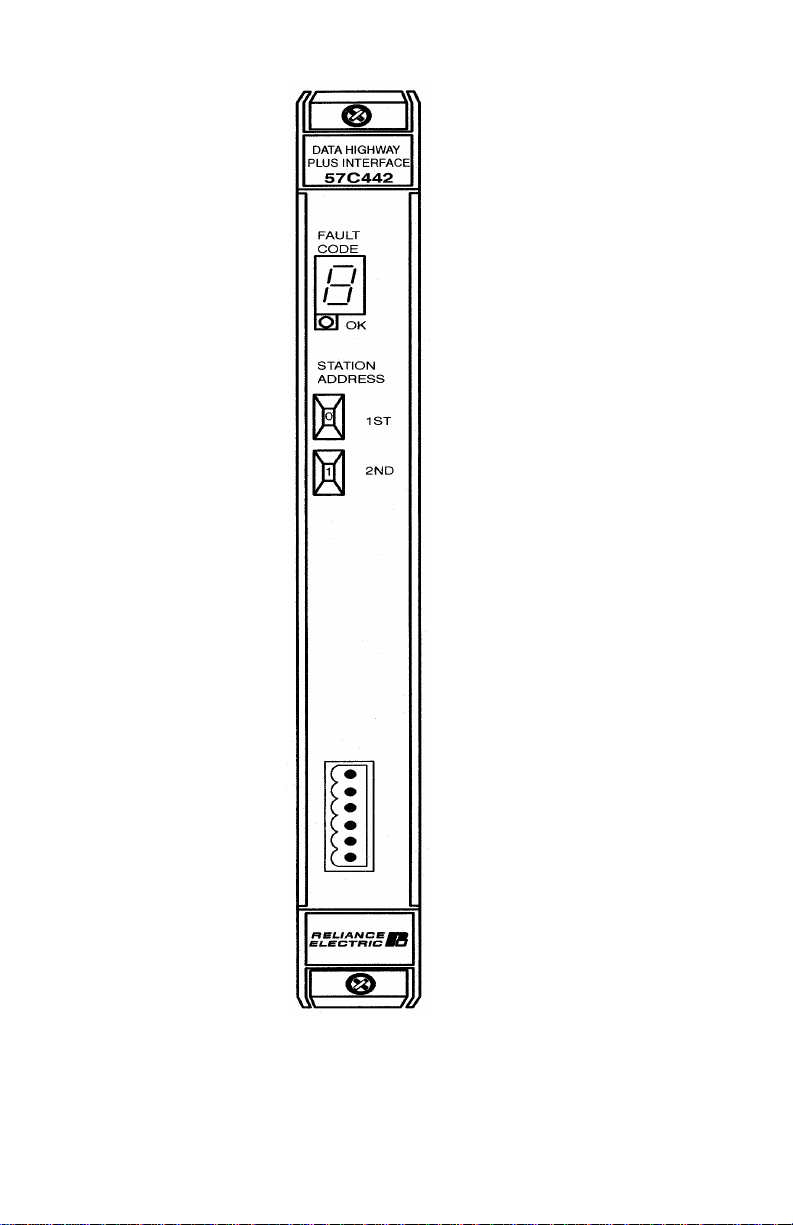

Figure 2.1 Data Highway Plus Interface Module Faceplate. . . . . . 2-2

Figure 4.1 Dual Port Memory Map. . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Figure 4.2 Status and Control Register Assignments . . . . . . . . . . 4-2

Figure 4.2 Status and Control Register Assignments

(Continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4.3 PLC-5 Data Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4.3 PLC-5 Data Image (Continued) . . . . . . . . . . . . . . . . . . 4-4

Figure 4.4 Global Data Register Assignments. . . . . . . . . . . . . . . . 4-5

Figure 4.5 Commands Used with

GATEWAY_CMD_OK@ . . . . . . . . . . . . . . . . . . . . . . 4-10

Figure 4.6 PLC-5 Command Set . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Figure 4.7 Privileged Commands in the Basic

Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Figure 4.8 Diagnostic Status Command Data . . . . . . . . . . . . . . . 4-12

Figure 4.9 Non-Privileged Commands in the Basic

Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Figure 4.10 Off-link Message Routing Bytes . . . . . . . . . . . . . . . . . 4-13

III

Page 6

IV

Page 7

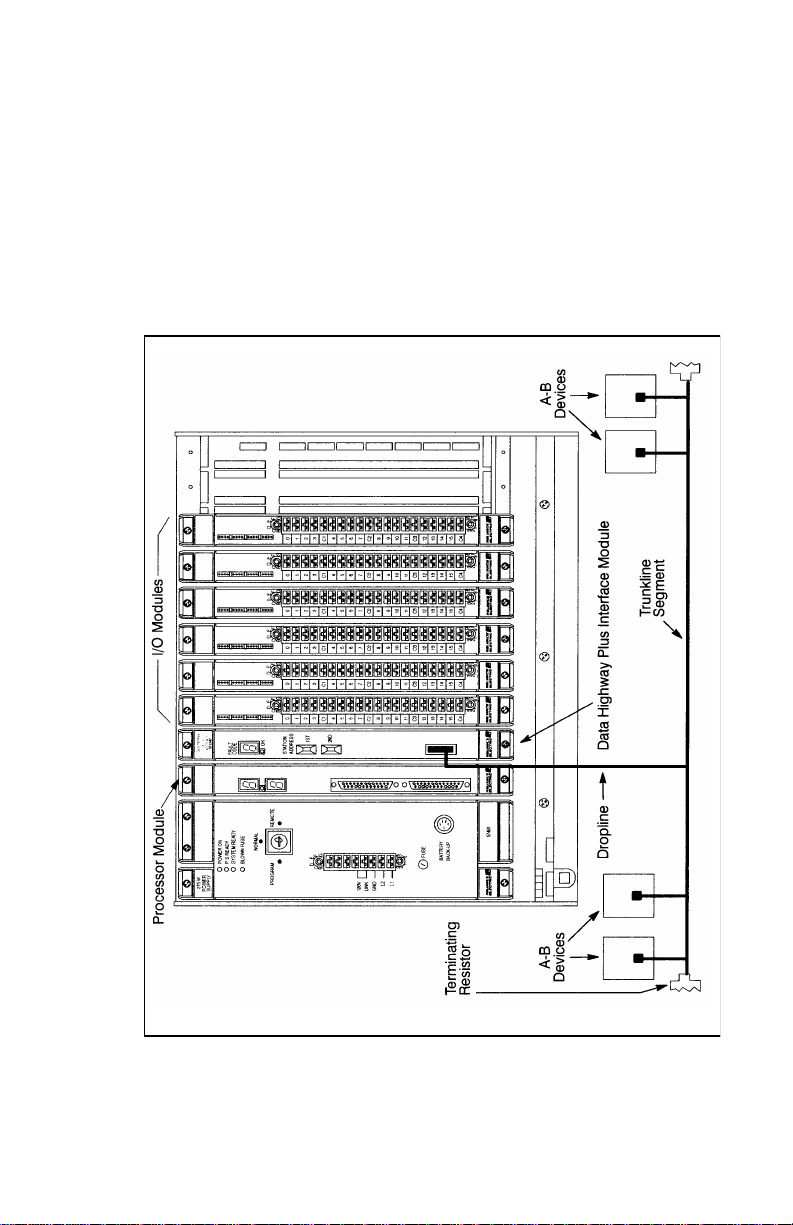

1.0 INTRODUCTION

The products described in this manual are manufactured or distributed

by RelianceElectric Industrial Company.

The Data Highway Plus Interface module (M/N 57C442) provides a

direct connection for the AutoMax system to the Allen-Bradley Data

Highway Plus network. The Data Highway Plus Interface module can be

placed in any slot in an AutoMax rack that contains at least one

AutoMax Processor, and can communicate with up to four AutoMax

Processors in that rack. The AutoMax rack containing the Data Highway

Plus Interface module appears as a single station on the Data Highway

Plus network. Figure 1.1 illustrates an AutoMax system connected to a

Data Highway Plus network.

Figure 1.1 – Connecting the AutoMax System to the Data Highway Plus Network

1-1

Page 8

Each AutoMax Processor has access to the look-alike PLC-5 or SLC

registers through the AutoMax rack backplane. The Data Highway Plus

Interface module transfers data between the PLC-5 look-alike image

and remote Allen-Bradley equipment using the Word Range Read,

Word Range Write, and Read-Modify-Write commands. The module is

capable of responding directly to these commands as well as typed

read and write commands from the PLC-5 command set and eight

other commands from the basic command set. These commands are

described in section 4.2. The individual command formats are

described in the various Allen-Bradley instruction manuals.

The remainder of this manual describes the functions and

specifications of the Data Highway Plus Interface module. It also

includes a detailed description of module installation and

troubleshooting procedures, as well as programming methods.

1.1 Additional lnformation

You must be familiar with all the instruction manuals that describe your

system configuration. This may include, but is not limited to, the

following:

• J-3636 COMMON MEMORY MODULE INSTRUCTION MANUAL

• J-3649 AutoMax CONFIGURATION TASK INSTRUCTION

• J-3650 AutoMax PROCESSOR MODULE INSTRUCTION

• J-3669 AutoMax POCKET REFERENCE

• J-3675 AutoMax ENHANCED BASIC LANGUAGE INSTRUCTION

• J-3676 AutoMax CONTROL BLOCK LANGUAGE INSTRUCTION

• J2-3093 AutoMax LADDER EDITOR INSTRUCTION MANUAL

• J2-3094 AutoMax ENHANCED LADDER LANGUAGE

• J-3677 AutoMax LADDER LOGIC LANGUAGE INSTRUCTION

• IEEE 518 GUIDE FOR THE INSTALLATION OF ELECTRICAL

• Your ReSource AutoMax PROGRAMMING EXECUTIVE

• 1770-6.5.16 Allen-Bradley Data Highway/Data Highway Plus/DH-

• Data Highway Cable Assembly and Instruction Manual

• Your personal computer and DOS operating system manuals

• Other instruction manuals applicable to your hardware

MANUAL

MANUAL

MANUAL

MANUAL

INSTRUCTION MANUAL

MANUAL

EQUIPMENT T O MINIMI ZE ELECTRI CAL NOI SE INPUTS

TO CONTROLLERS

INSTRUCTION MANUAL

485 Communication Protocol and Command Set

configuration

1-2

Page 9

1.2 Related Hardware and Software

M/N 57C442 contains one Data Highway Plus Interface module. The

module can be used with the following hardware and software:

1. M/N 57C430A, 57C431, 57C435 Automax Processor.

2. IBM -AT compatible computer running DOS version 3.1 or later.

3. M/N 61C127 RS-232C ReSource Interface cable. This cable is

used to connect the personal computer to the AutoMax Processor

module.

4. M/N 57C413 or 57C423 Common Memory module. This module is

used when there is more than one AutoMax Processor in a rack.

5. (various model numbers) ReSource AutoMax Programming

Executive software.

6. A-B Data Highway Plus cabling hardware.

The thick black bar shown on the right-hand margin of this page will be

used throughout this instruction manual to signify new or revised text or

figures.

1-3

Page 10

1-4

Page 11

2.0 MECHANICAL/ELECTRICAL DESCRIPTION

This section describes the mechanical and electrical characteristics of

the Data Highway Plus Interface module.

2.1 Mechanical Description

The Data Highway Plus Interface module is a printed circuit assembly

that plugs into the backplane of an AutoMax rack. The module consists

of a printed circuit board, faceplate, and protective enclosure. The

faceplate contains ejector tabs at the top and bottom to simplify

removing the module from the rack. See figure 2.1 for an illustration of

the module faceplate.

The 6-pin Phoenix Combicon connector on the faceplate is used to

make the connection to the Data Highway Plus network by means of a

standard twin-axial cable. Refer to Appendix C or to Data Highway Plus

documentation for the cable connections.

The two thumbwheel switches on the faceplate are used to set the

module’s stationnumber (in octal) on the Data Highway Plus network.

The upper thumbwheel switch represents the most significant digit; the

lower thumbwheel switch represents the least significant digit. If you set

the switches to invalid octal digits (8 or 9), the station number will not be

accepted and module error code ”6” will be displayed on the sevensegment LED.

For diagnostic purposes, the faceplate contains a seven-segment LED

which displays error codes. The error codes are defined in Appendix D.

A green status LED (labeled ”OK”) on the faceplate indicates when the

module is operational (ON) or when it should be replaced (OFF).

2-1

Page 12

2-2

Figure 2.2 – Data Highway Plus Interface Module Faceplate

Page 13

2.2 Electrical Description

The Data Highway Plus Interface module contains an 8 MHz

microprocessor that shares 32K of dual port memory with the AutoMax

rack backplane. This memory is accessible to both the on-board

microprocessor and AutoMax Processors in the rack. A block diagram

is shown in Appendix B. The module contains a watchdog timer which

is enabled when power is turned on to the module. The microprocessor

must reset the watchdog timer within a specified time or the

microprocessor will shut down and the status LED labeled ”OK” on the

faceplate will turn off.

At power-up, the on-board microprocessor runs diagnostics on the

microprocessor, EPROM, RAM and dual port memory, as well as

performing system-level diagnostics. As each test is run, a number is

written out to the seven-segment display. If there is a fault during these

tests, the microprocessor halts, the watchdog times out, and the sevensegment LED displays the code of the failed diagnostic. See Appendix

D for a list of error codes.

2-3

Page 14

2-4

Page 15

3.0 INSTALLATION

This section provides instructions on how to install the Data Highway

Plus Interface module.

3.1 Wiring

ATTENTION: The user is responsible for conforming with all

applicable local, national, and international codes. Wiring

practices, grounding, disconnects, and over-current protection

!

3.2 Initial Installation

!

are of particular importance. Failure to observe this precaution

could result in severe bodily injury or loss of life.

T o reduce the possibility of electri cal noise interfering with the operation

of the control system, exercise care when installing the wiring from the

control system to the external devices. For detailed recommendations

refer to IEEE 518.

Use the following procedure to install the module:

Step 1. Stop any application tasks that may be running.

ATTENTION: This equipment is at line voltage when AC

power is connected. Disconnect and lock out all ungrounded

conductors of the AC power line. Failure to observe these

precautions could result in severe bodily injury or loss of life.

ATTENTION: Inserting or removing a module may result in

unexpected machine motion. Power to the machine should be

turned off before inserting or removing the module. Failure to

!

!

observe these precautions could result in bodily injury.

Step 2. Turn off power to the rack. All power to the rack as well as all

power leading to the rack should be off.

ATTENTION: This module contains static-sensitive

components. Careless handling can cause severe damage. Do

not touch the connectors on the back of the module. When not

in use, the module should be stored in an anti-static bag. The

plastic cover should not be removed. Failure to observe this

precaution could result in damage to or destruction of the

equipment.

3-1

Page 16

Step 3. Take the module out of its shipping container. Take it out of

the anti-static bag, being careful not to touch the connectors

on the back of the module.

Step 4. Insert the module in the desired slot in the rack, making sure

it is well-seated in the rack. The module may reside in any

slot in the rack. Use a screwdriver to secure the module in the

rack.

Step 5. Set the station number of the Data Highway Plus Interface

module (in octal) using the two thumbwheel switches on the

module faceplate. The upper switch is the most significant

digit and the lower switch is the least significant digit. The

station number is read from the thumbwheel switches only at

power-up. Therefore, make sure each device on the network

has a unique station number (0--77 octal) before power is

applied. If more than one device on the network is given the

same station number, the module will not be able to

communicate and an error will be displayed.

Step 6. Connect the module to the Data Highway Plus network. Refer

to Appendix C for information on cabling and termination.

Step 7. Turn on power to the rack. An internal diagnostic routine is

automatically executed by the module. If an error is detected,

an error code is displayed on the seven-segment LED. If the

green status LED is OFF and no seven-segment error code is

displayed, a local watchdog failure has occurred. If a

diagnostic fault code other than “3”, “4”, “6”, “7”, or “C” is

displayed for more than 5 seconds, the Data Highway Plus

Interface module must be replaced.

If the thumbwheel switches are set to an invalid station

number, fault code “6” will be displayed on the sevensegment LED on the module faceplate after power-up. To

clear the invalid station number fault code, refer to section

5.2.

Step 8. After power-up diagnostics are complete, the green status

LED will go on. Verify the installation by monitoring registers

on the module. Refer to Appendix I.

3-2

Page 17

3.3 Module Replacement

Use the following procedure to replace the Data Highway Plus Interface

module:

Step 1. Stop any application tasks that may be running.

ATTENTION: his equipment is at line voltage when AC power

is connected. Disconnect and lock out all ungrounded conductors

of the AC power line. Failure to observe these precautions could

!

!

result in severe bodily injury or loss of life.

ATTENTION: Inserting or removing a module may result in

unexpected machine motion. Power to the machine should be

turned off before inserting or removing the module.Failure to

observe these precautions could result in bodily injury.

Step 2. Turn off power to the rack. All power to the rack as well as all

Step 3. Disconnect the cable from the module faceplate.

Step 4. Use a screwdriver to loosen the screws that hold the module

!

Step 5. T ake the new module out of it s shipping container. Take it out

Step 6. Insert the module in the rack, making sure that it is well-

Step 7. Set the station number of the new module to the same

Step 8. Attach the Data Highway Plus cable to the module faceplate.

Step 9. Turn on power to the rack.

Step 10. After power-up diagnostics are complete, the green status

power leading to the rack should be off.

in the rack. Take the module out of the slot in the rack.

ATTENTION: This module contains static-sensitive

components. Careless handling can cause severe damage. Do

not touch the connectors on the back of the module. When not

in use, the module should be stored in an anti-static bag. The

plastic cover should not be removed. Failure to observe this

precaution could result in damage to or destruction of the

equipment.

of the anti-static bag, being careful not to touch the

connectors on the back of the module.

seated in the rack.

number as the old module by using the two thumbwheel

switches on the module faceplate. The upper switch is the

most significant digit and the lower switch is the least

significant digit.

LED will go on. Verify the installation by monitoring registers

on the module. Refer to Appendix I.

3-3

Page 18

3-4

Page 19

4.0 PROGRAMMING

The Data Highway Plus network is a token-passing network, which

means that any device on the network can initiate communication with

any other device. Each node can also pass one word of global data with

the token. This global data is available to all other nodes on the

network.

Up to 64 devices can be connected directly to the network, with station

numbers ranging from 0 to 77 octal. Duplicate addresses are not

allowed. The network communication rate can be 57.6, 115.2, or 230.4

Kbaud, depending upon the user configuration.

This section describes how the data is organized in the module and

provides examples of how the module is accessed by the application

software. For more detailed information on programming, refer to the

AutoMax Programming Language manuals.

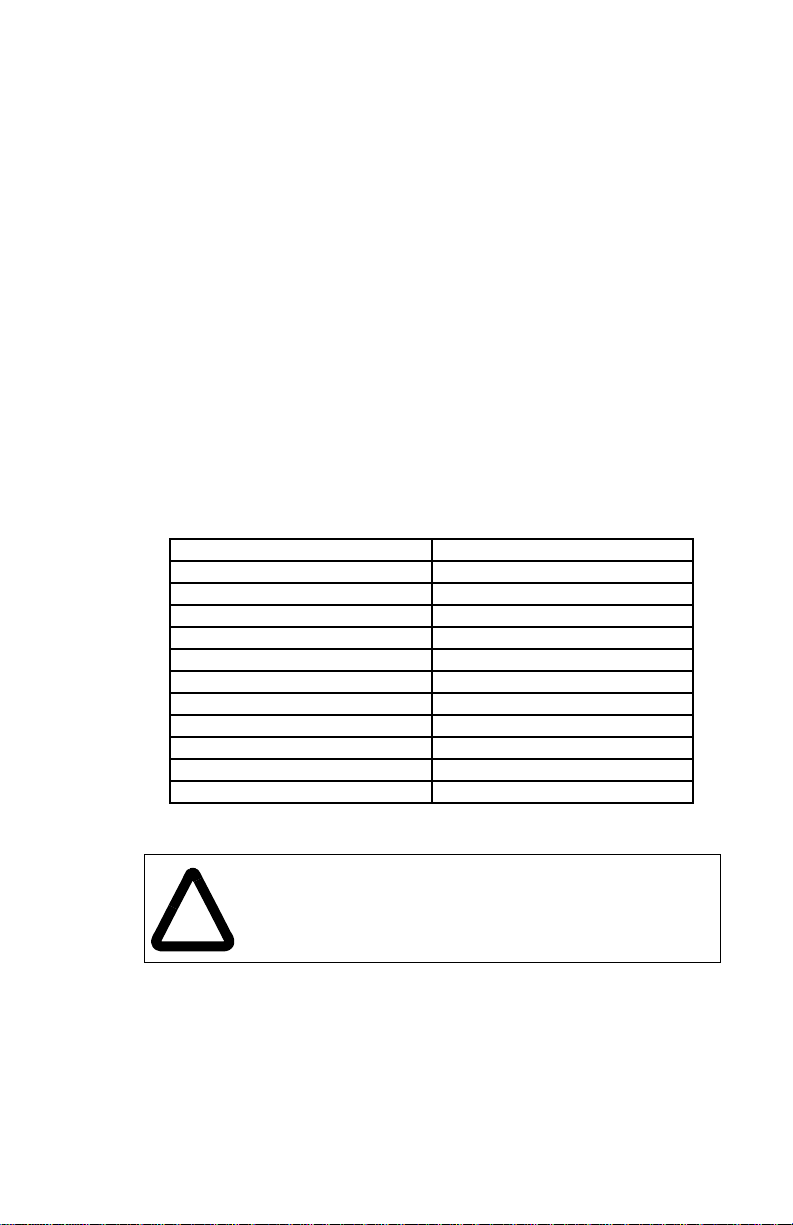

4.1 Register Organization

The Data Highway Plus Interface module contains dual-port memory

that can be accessed through the AutoMax rack backplane by

application tasks running on the AutoMax Processor as well as by the

microprocessor on the module. The memory organization is as shown

in the following diagram. The following sections describe the different

register areas in more detail.

Registers Description

0-3 Reserved

4-63 Status and control registers

64 – 1063 Binary file B3

1064 - 1087 Reserved

1088 - 2087 Binary file B4

2088 - 3087 Binary file B5

3088 - 3583 Reserved

3584 - 4095 Reserved

4096 – 4352 Global data registers

4353 - 4383 Reserved

4384 - 16383 Integer files N7 – N18

Figure 4.1 – Dual Port Memory Map

ATTENTION: Registers and bits in the data highway plus

interface module that are described as “read only” or for “system

use” only must not be written to by the user.Writing to these

!

registers and bits may result in improper system operation.

Failure to observe this precaution could result in bodily injury.

4-1

Page 20

4.1.1 Status and Control Registers

The status and control registers are described in figure 4.2. Registers

4-31 are read-write registers from the host (AutoMax Processor);

registers 32-63 are read-only.

R/W Reg# Description

R/W 4 Clear Diagnostic Counters. If this register is set to a non-zero

R/W 5 Module Control. When set to 1, bit 0 of this reg ister is used by the

R/W 6 Message Timeo ut (i n 100 ms ec. inc remen ts). The default value is

R/W 7 Data Highway Plus options. Bits in this register must be set

R/W 8-12 Station Name. The user can write a stati on name cons isting of up

R/W 22 Response Poll Period (in units of 1/8 second). This register is

value, the module software will clear the contents of the Data

Highway Plus diagnostic counters (registers 40-57). The module

software will then clear this register to indicate the counters have

been cleared. This register can be written to at any time.

user to enable the module. No communication can take place

until this bit is set. You should wait at least two seconds after

enabling the module before you send any messages on the

network. Bit 0 will be reset by the module on a hardware or

software reset. Bits 1-15 are reserved for future use.

150 (5 seconds). The value can range from 1 to 254. If a reply to

a message is not returned within this time period, the module will

return an error via the GATEWAY_ CMD_OK@ function. This

value can be changed at any time.

before you go on-line.

Use bits 0 and 1 to set the Data Highway Plus baud rate.

For this baud: Set:

57.6 Kbaud bit 0 to 0

bit 1 to 0

115.2 Kbaud bit 0 to1

bit 1 to 0

230.4 Baud bit 0 to 0

Bit 8 is used to enable transmission of this station ’ s global data. If

this bit is set to 1, the station’s global data is transmitted with the

token. The default is 0 (transmissi on of global dat a disabled). If bit

12 is set to 1, messages to stations which are off-line are not

transmitted on the network, but are returned immediately to the

module with an error code “17”. T hi s minimi z es dis r upti ons to the

network. The default for this bit is 0 (transmission to off-line

stations enabled), which is consistent with the operation of A-B

PLCs. In this case, the module will ret

urn error ”12” when a message is sent to an

off-line station.

The remaining bits are reserved for future use.

to eight ASCII characters plus a null terminator. If the name is

eight characters long, the terminator is not required. However, if

the name contains fewer than eight characters, the terminator

must be included. The default station name is “AutoMax.”

13-21 Not used.

used by the GATEWAY_CMD_OK@ function to compute the

time interval to poll for c ommand complete. The de fault value is 1,

which corresponds to a response polling period of 0.125 second.

23-31 Not used.

Figure 4.2 – Status and Control Register Assignments

4-2

Page 21

R/W Reg# Description

R/0 32 Data Highway Plus station a ddress (0-7 7 octal). The val ue comes

R/0 33 Data Highway Plus Extended Status (EXT STS) error code. Refer

R/0 34-37 Data Highway Plus active station list. This is an array of 64 bits

R/0 40-57 Data Highway Plus Diagnostics Counters. Refer to Appendix G.

R/0 61 Module Software Revision Level. A value of 100 indicates vers ion

R/0 62-63 Interface module ID (ASCII ’GTWY’)

from the thumbwheel switches on the faceplate and is updated

only on power-up. The module will not begin to communicate on

the network until the station address is properly set and bit 0 in

register 5 is set by the user. Note that the on-line Monitor function

in the AutoMax Programming Executive software will display the

station address in decimal or hexadecimal notation.

to Appendix H.

representing the status (1=active, O=inactive) of each station on

a Data Highway Plus network. Refer to Appendix F for

information on how this list is mapped to these registers. The

local station does not appear on this list.

38-39 Not used.

58-60 Not used.

1.00, and so on.

Figure 4.2 – Status and Control Register Assignments

4.1.2 Data Registers

The data image in the dual port memory appears as a subset of the

PLC-5 data table. The equivalent AutoMax and Modicon registers on

the module are shown in figure 4.3.

Multibus Access Data HighwayPlus

(AutoMax application tasks) Access

Read Only Binary file B3 Read/Write

Data Highway Plus

addresses B3:0 - B3:999

AutoMax Registers 64-1063

Read/Write Binary file B4 Read Only

Data Highway Plus

addresses B4:0 - B4:999

AutoMax Registers 1088-2087

Read/Write Binary file B5 Read/Write

Data Highway Plus

addresses B5:0- B5:999

AutoMax Registers 2088-3087

Command Buffer Area

AutoMax Registers 3584-4095

Global Registers Area

AutoMax Registers 4096-4352

Read/Write Integer file N7 Read/Write

Data Highway Plus

addresses N7;0 - N7:999

AutoMax Registers 4384-5383

Figure 4.3 – PLC-5 Data Image

4-3

Page 22

Read/Write Integer file N8 Read/Write

Data Highway Plus

addresses N8:0 - N8:999

AutoMax Registers 5384-6383

Read/Write Integer file N9 Read/Write

Data Highway Plus

addresses N9:0 - N9:999

AutoMax Registers 6384-7383

Use this file for communication

with a SLC 500 Processor

Read/Write Integer file N10 Read/Write

Data Highway Plus

addresses N10:0 - N10:999

AutoMax Registers 7384-8383

Read/Write Integer file N11 Read/Write

Data Highway Plus

addresses N11:0 - N11:999

AutoMax Registers 8384-9383

Read/Write Integer file N12 Read/Write

Data Highway Plus

addresses N12:0 - N12:999

AutoMax Registers 9384-10383

Read/Write Integer file N13 Read/Write

Data Highway Plus

addresses N13:0 - N13:999

AutoMax Registers 10384-11383

Read/Write Integer file N14 Read/Write

Data Highway Plus

addresses N14:0 - N14:999

AutoMax Registers 11384-12383

Read/Write Integer file N15 Read/Write

Data Highway Plus

addresses N15:0 - N15:999

AutoMax Registers 12384-13383

Read/Write Integer file N16 Read/Write

Data Highway Plus

addresses N16:0 - N16:999

AutoMax Registers 13384-14383

Read/Write Integer file N17 Read/Write

Data Highway Plus

addresses N17:0 - N17:999

AutoMax Registers 14384-15383

Read/Write Integer file N18 Read/Write

Data Highway Plus

addresses N18:0 – N18:999

AutoMax Registers 15384-16383

4-4

Figure 4.3 – PLC-5 Data Image

Page 23

Mapping is handled transparently by the Data Highway Plus Interface

module software. For example, if another node writes to this node at

address N7:0, the data is written starting at AutoMax register 4384, and

so on.

4.1.3 Global Data Registers

Registers 4096-4159 contain all of the global data that can exist on a

Data Highway Plus network. Each station is assigned one register.

Particular locations are meaningful only if the corresponding station is

writing global data. All registers are read only from the point of view of

the AutoMax Processor except for register 4352, which is read-write.

The global data update rate depends on the number of stations on the

network, whether the stations have global data transmission enabled,

and the communication traffic on the network.

Register Description Register Description

4096 Global data station 00 (00) 4130 Global data station 42 (34)

4097 Global data station 01 (01) 4131 Global data station 43 (35)

4098 Global data station 02 (02) 4132 Global data station 44 (36)

4099 Global data station 03 (03) 4133 Global data station 45 (37)

4100 Global data station 04 (04) 4134 Global data station 46 (38)

4101 Global data station 05 (05) 4135 Global data station 47 (39)

4102 Global data station 06 (06) 4136 Global data station 50 (40)

4103 Global data station 07 (07) 4137 Global data station 51 (41)

4104 Global data station 10 (08) 4138 Global data station 52 (42)

4105 Global data station 11 (09) 4139 Global data station 53 (43)

4106 Global data station 12 (10) 4140 Global data station 54 (44)

4107 Global data station 13 (11) 4141 Global data station 55 (45)

4108 Global data station 14 (12) 4142 Global data station 56 (46)

4109 Global data station 15 (13) 4143 Global data station 57 (47)

4110 Global data station 16 (14) 4144 Global data station 60 (48)

4111 Global data station 17 (15) 4145 Global data station 61 (49)

4112 Global data station 20 (16) 4146 Global data station 62 (50)

4113 Global data station 21 (17) 4147 Global data station 63 (51)

4114 Global data station 22 (18) 4148 Global data station 64 (52)

4115 Global data station 23 (19) 4149 Global data station 65 (53)

4116 Global data station 24 (20) 4150 Global data station 66 (54)

4117 Global data station 25 (21) 4151 Global data station 67 (55)

4118 Global data station 26 (22) 4152 Global data station 68 (56)

4119 Global data station 27 (23) 4153 Global data station 69 (57)

4120 Global data station 30 (24) 4154 Global data station 70 (58)

4121 Global data station 31 (25) 4155 Global data station 71 (59)

4122 Global data station 32 (26) 4156 Global data station 72 (60)

4123 Global data station 33 (27) 4157 Global data station 73 (61)

4124 Global data station 34 (28) 4158 Global data station 74 (62)

4125 Global data station 35 (29) 4159 Global data station 75 (63)

4126 Global data station 36 (30) 4160- Note used. Reserved for

4127 Global data station 37 (31) 4351 future use.

4128 Global data station 40 (32) 4352 This station’s global data.

4129 Global data station 41 (33)

Note that station numbers are inoctal with decimal equivalents in parentheses.

Figure 4.4 – Global Data Register Assignments

4-5

Page 24

Register 4352 is a Read/Write register from Multibus. T o transmit global

data, you must set bit 8 in the Data Highway Plus options register

(register 7) before you go on-line. The module will then pass the value

in register 4352 when it passes the token.

4.2 AutoMax Application Programming

The sections that follow describe how to configure registers in the Data

Highway Plus Interface module’s dual port memory and how to initiate

commands from the module. Link configuration and application

programming examples are provided.

4.2.1 Variable Configuration

AutoMax application tasks communicate with the Data Highway Plus

Interface module by referencing registers in the dual port memory.

These registers must first be configured using the AutoMax

Programming Executive software. In AutoMax Programming Executive

Version 3.0 and later, you define these registers using the Variable

Configurator. Specific screens are available for each module. If you are

using AutoMax Programming Executive Version 2.1 or earlier, you

define these registers using IODEF statements in the rack configuration

task. Note that ABDEF statements cannot be used with the Data

Highway Plus Interface Module.

4-6

Page 25

The format for the IODEF statement (used only in V2.1 and earlier) is

as follows:

nnnn lODEF variable name [SLOT=slot number, &

REGISTER=register number, BIT=bit number]

where:

nnnn = configuration task line number

variable_name = integer or boolean variable. Double integer

variables can beused but should be avoided because of the

possibility that all 32 bits will not transfer in one operation.

WARNING

IF YOU USE DOUBLE INTEGER VARIABLES IN THIS INSTANCE, YOU

MUST IMPLEMENT A SOFTWARE HANDSHAKE BETWEEN THE

TRANSMITTER AND RECEIVER TO ENSURE THAT BOTH THE LEAST

SIGNIFICANT AND MOST SIGNIFICANT 16 BITS HAVE BEEN

TRANSMITTED BEFORE THEY ARE READ BY THE RECEIVING

APPLICATION PROGRAM. FAILURE TO OBSERVE THIS PRECAUTION

COULD RESULT IN BODILY INJURY.

slot number = slot number of the Data Highway Plus Interface

module in the rack. This number may range from 0 to 15.

register number = Multibus register number on the Data Highway

Plus Interface module. Register numbers correspond to 16-bit

words on the module.

bit number = bit number of the I/O point in the register. Bit

numbers range from 0 to 15. Bit numbers are specified for boolean

variables only.

Any variables contained in the rack configuration are accessible by any

task on any AutoMax Processor in the rack. When AutoMax variables

are referenced in AutoMax tasks, the data is directly obtained from or

written to the register image on the module. The data storage for an

AutoMax variable mapped to an A-B

TM

register will always exist in the

Data Highway Plus module’s dual port memory.

The registers in the Data Highway Plus Interface module’s A-B register

image may be displayed using the AutoMax Programming Executive

Monitor I/O function. Refer to Appendix I for the method used to convert

A-8 register numbers so that they can be viewed using the monitor.

4-7

Page 26

4.2.2 Application Programming

Read and write commands from the Data Highway Plus Interface

module are initiated from a BASIC application task by executing the

GATEWAY_CMD_OK@ function:

GATEWAY_CMD_OK@(status%, cmd_code%, slave_drop%, &

where:

status is an integer variable representing the location where the

status resulting from the operation is stored. Refer to Appendix E for

a list of status values.

cmd_code is a variable name or expression of type integer

representing the Data Highway Plus command sent by the module.

The commands are described in section 4.2.4. Any other commands

result in a status of 1 (invalid operation) being returned.

slave_drop is variable name or expression of type integer containing

the destination station number (in decimal or hexadecimal). This is

the station number on your Data Highway Plus network. In the case

where off-link addressing is used, this is the address of the bridge

node on the local Data Highway Plus network. See section 4.2.6 for

more information.

slave_reg is a variable name or expression of type string that

specifies the starting register number on the target device. For

commands 3, 4 and 5, this is a logical address represented as an

ASCII string for PLC-3 and PLC-5 controllers. It can also be a 5-digit

octal number. For commands 1 and 2, this argument should be an

octal number. This field can also contain Data Highway Plus routing

information. Refer to section 4.2.6. For command 5 (Read-ModifyWrite), this argument can contain up to ten addresses separated by

commas. The address must exist at the target station.

master_var is a variable name or expression (usually via the BASIC

language VARPTR! function) of type double integer, representing

the physical address of the starting register on the Data Highway

Plus module to be read from/written to.

num_regs is a variable name or expression of type integer that

defines:

• for Word Range Read/Write (command 3 or 4), the number of

registers to be transferred, from 1 to 1000;

• for Read-Modify-Write (command 5), the number of addresses

to be written, in the range 1 to 10;

• for Unprotected Read/Write (command 1 or 2), the number of

registers to be transferred, from 1 to 100.

slave_reg$, master_var!, num_regs%)

4-8

The GATEWAY_CMD_OK@ function will be true if the command was

successfullycompleted. If the function is false, the returned status will

be an error code. See Appendix E for the error codes returned by the

GATEWAY_CMD_OK@ function.

Page 27

Multiple tasks can access the module. Note, however, that if more than

four tasks try to initiate messages at the same time, error code “22” will

be returned to the additional tasks attempting accesses.

4.2.3 Enabling the Data Highway Plus Interface

Module

The connection between the Data Highway Plus Interface module and

the Data Highway Plus network is configured through an AutoMax

BASIC task. The task must set the network baud rate and whether

global data for this node is enabled by setting the appropriate bits in

register 7. Values can also be set for message time-out (register 6)

response poll period (register 22), if desired. Note that values for

registers 6 and 22 can be set at any time. The final step required to put

the module on-line is to set bit 0 in register 5. Wait at least two seconds

after writing to this register before sending messages on the network.

If you are using AutoMax Programming Executive software version 2.1

or earlier, any required registers must be defined using lODEFs in the

configuration task. If you are using AutoMax Programming Executive

software version 3.0 or later, these registers are defined using the

Vari able Configurator within t he Programming Executive. The following

example illustrates one method of enabling the module.

Example 1:

In the configuration, define register 5, bit 0 as ENABLE@.

ENABLE@ [SLOT=4, REGISTER=5, BIT=O]

The application task would use the following statement to enable the

module:

10 ENABLE@=1 /! put module on-line

Example 2:

In the configuration, define the following registers:

ENABLE@ [SLOT=4, REGISTER=5, BIT=O]

TIMEOUT% [SLOT=4, REGISTER=6]

RESP_TIME% [SLOT=4, REGISTER=22J]

OPTIONS% [SLOT=4, REGISTER=7]

The application could enable the module as follows:

10 OPTIONS = 0 \! Baud rate = 57.6 kbd, no global &

data transmitted, transmit to &

vacant nodes enabled.

20 TIMEOUT% = 50 \! message timeout 5 seconds

30 RESP_TIME% = 2 \! GATEWAY CMD OK@should poll &

for response every 250 ms.

40 ENABLE@=1 \! put module on-line

50 DELAY 2 SECONDS

Example 3: Global Data

If an application is passing global data, it must enable global data and

write to the local global data register. In the configuration, define the

following registers:

ENABLE@[SLOT=4, REGISTER=5, BIT=O]

OPTIONS% [SLOT=4, REGISTER = 7]

GD%[SLOT=4, REGISTER = 4352]

and

4-9

Page 28

The application task could contain the following statements:

10 OPTIONS% = 256 \! enable global data, baud rate = &

15 GD% = 15 \! set global data

20 ENABLE% = 1 \! put module online

30 DELAY 2 SECONDS

57.6 Kbaud, transmit to vacant &

nodes enabled.

4.2.4 Commands Initiated by the Data Highway Plus

Interface Module

The commands described in figure 4.5 can be used by the AutoMax

Processor in the GATEWAY_CMD_OK@ function to initiate a

command on the Data Highway Plus Interface module. See section

4.2.2 for more information on the GATEWAY_CMD_OK@ function.

GATEWAY CMD OK@ Data Highway Plus

Command Code Desription Function

1 Unprotected Read CMD = 01, FNC = n/a

2 Unprotected Write CMD = 08, FNC = n/a

3 W ord Range Read CMD = OF, FNC = 01

4 Word Range Write CMD = OF, FNC = 00

5 Read-Modify-Write CMD = OF, FNC = 26

Figure 4.5 – Commands Used with GATEWAY_CMD_OK@

Commands 1 and 2 come from the basic command set and are

accepted by PLC-2,PLC-3, PLC-5 and SLC 500 processors. For PLC-2

controllers, addresses will be 5-digit octal numbers. For PLC-3 and

PLC-5 processors, compatibility files must exist. Refer to A-B

documentation for more information.

For communication with a SLC 500 processor, use only commands 1

and 2 and only file N9 for data transfers.

Command 1, Unprotected Read, transfers a block of data from the

target registers at the remote address to the specified AutoMax

registers on the Data Highway Plus Interface module. Data can be

transferred to any file in the PLC-5 data image area. The data is stored

in the specified registers on the Data Highway Plus Interface module. A

maximum of 100 registers can be transferred in a single request. The

transfer cannot cross file boundaries.

Command 2, Unprotected Write, transfers a block of data from the

specified AutoMax registers on the Data Highway Plus Interface

module to the target registers at the destination address. The data must

already exist in the registers on the Data Highway Plus Interface

module. Data can be transferred from any file in the PLC-5 data image

area. A maximum of 100 registers can be transferred in a single

request. The transfer cannot cross file boundaries.

Commands 3, 4 and 5 come from the PLC-5 command set. Commands

3 and 4 are accepted by PLC-3 and PLC-5 processors. Command 5 is

accepted only by PLC-5 processors. For commands

4-10

Page 29

3, 4, and 5, only logical addresses represented as ASCII strings are

supported.

Command 3, Word Range Read, transfers a block of data from the

target registers at the remote address to the specified AutoMax

registers on the Data Highway Plus Interface module. Data can be

transferred to any file in the PLC-5 data image area except the B4 file.

The data is stored in the specified registers on the Data Highway Plus

Interface module. A maximum of one file (1000 registers) can be

transferred in a single request. The transfer cannot cross file

boundaries

Command 4, Word Range Write, transfers a block of data from the

specified AutoMax registers on the Data Highway Plus Interface

module to the target registers at the destination address. The data must

already exist in the registers on the Data Highway Plus Interface

module. Data can be transferred from any file in the PLC-5 data image

area. The data is stored in the specified registers on the Data Highway

Plus Interface module. A maximum of one file (1000 registers) can be

transferred in a single request. The transfer cannot cross file

boundaries.

Command 5, Read-Modify-Write, sets or resets specified bits in

specified registers in the data table at the remote address. The data

(AND and OR masks) must already exist in the registers on the Data

Highway Plus Interface module. A maximum of ten registers can be

modified in a single request. The transfer cannot cross file boundaries.

Note: The A-B controller at the remote address may change the states

of the original bits in memory before this command (command 5) can

write the word back to memory. Therefore, some bits may

unintentionally be overwritten. To help prevent this, we suggest that

you use this command to write into the storage area of a programmable

controller’s data table, and have the controller read the word only, not

control it.

In cases where any of the commands above generates multiple

messages on the network, for example, reading or writing more

registers than can fit in one Data Highway Plus message, the module

takes care of formatting and generating the messages required. The

GATEWAY_CMD_OK@ command is complete when a reply is

received for the last message.

4.2.5 Commands from Remote Stations

The Data Highway Plus Interface module will respond to the following

incoming commands from remote stations:

Command Function Description

OF 68 Typed Read / Read Block

OF 67 Typed Write / Writ e Block

OF 01 Word Range Read / Read Block

OF 00 Word Range Write / Write Block

OF 26 Read-Modify-Write / Write Bit

OF 02 Bit Write

Figure 4.6 – PLC-5 Command Set

4-11

Page 30

For the commands shown in figure 4.6, both logical binary and logical

ASCII addresses are supported.

Command Function Description

06 07 Diagnostic Counters Reset

06 01 Diagnostic Read

06 03 Diagnostic Status

Figure 4.7 – Privileged Commands in the Basic Command Set

The Diagnostic Read command returns the values for counters as

shown in Appendix G. The Diagnostic Status command returns 17

bytes containing the following information:

Byte Value Meaning

1 FE Terminal

2 1B Terminal

3 A3 Module identifier

4 Active station list pointer low byte

5 Active station list pointer high byte

6 Diagnostic counters pointer low byte

7 Diagnostic counters pointer high byte

8 Reserved

9 Reserved

10-17 Terminal name (automatically padded with blanks)

Figure 4.8 – Diagnostic Status Command Data

Byte Value Meaning

02 n/a Protected Bit Write

00 n/a Protected Write

05 n/a Unprotected Bit Write

01 n/a Unprotected Read

08 n/a Unprotected Write

Figure 4.9 – Non-Privileged Commands in the Basic Command Set

4-12

The commands shown in figure 4.9 write directly to or read directly from

file N7 on the module. The address field is used as an offset into the

file. If the address does not exist, an error is returned.

Unprotected writes will be processed in the same manner as Protected

writes and will not be permitted to store data in the protected areas of

the PLC-5 image in the dual port memory.

Page 31

4.2.6 Off-link Routing Paths

This section describes using a Data Highway network as a bridge to link

two Data Highway Plus networks using A-B 1785-KA modules. If you

need information about other bridge networks, refer to A-8

documentation.

The routing information is added to the “slave_reg” parameter of the

GATEWAY_CMD_OK@ function. A leading exclamation mark (!) is

used to signify that routing information is included. The routing

information is added to the beginning of the string as hexadecimal

bytes separated by periods. See figure 4.10.

For a 1785-KA Data Highway bridge, the twelve routing bytes are:

Byte Value Meaning

1 LSAP 1 for a 1785-KA bridge

2 24h

3 DID_LO see below

4 DID_Hl see below

5 DNDE_LO see below

6 DNDE_Hl see below

7 LIFETIME 80h for a 1785-KA bridge

8 SID_LO see below

9 SID_Hl see below

10 SNDE_Hl see below

11 SNDE_LO see below

12 NSAP 0 for a 1785-KA bridge

Figure 4.10 – Off-link Message Routing Bytes

where:

DID is the destination node’s link ID; see A-B documentation. This is

0 for a 1785-KA bridge.

DNDE is the station address of the destination on the destination link.

For the Data Highway bridge, only the low byte is used. It consists of

the upper two bits of the Data Highway address of the remote bridge

1785-KA and the lower six bits of the Data Highway Plus address of

the final Data Highway Plus station.

SID is the link ID of the local network; see A-B documentation. T his is

0 for a 1785-KA bridge.

SNDE is the station address of this station on the local Data Highway

Plus network.

4.2.6.1 Example of Bridging Two Data Highway Plus Networks

using 1785-KA modules

In the following example, the Data Highway Plus Interface module is

station 24 octal on a Data Highway Plus network. The first 1785-KA

bridge module is at address 42 octal on the Data Highway Plus network

and 142 octal on the Data Highway network. The remote bridge module

is at station address 240 octal on the Data Highway network and 40

octal on the Data Highway Plus network. The final destination node is

at station address 4 on the remote Data Highway Plus network.

4-13

Page 32

05 REM The variables that follow define &

parameters for the &

GATEWAY CMD OK@ function

10 COMMON B3BASE%\! Represents the physical address of &

starting register on the Data Highway &

Plus module to be read from

20 LOCAL DST% \! The address of the bridge node on &

the local Data Highway Plus network

21 LOCAL STS% \! The location where the status &

resulting from the operation is stored

22 LOCAL SZE% \! The number of registers to be &

transferred

23 LOCAL CMD% \! The Data Highway Plus command &

sent by the module

30 DST% = 34

31 STS% = 0

32 SZE% = 100

33 CMD% = 3

40 IF NOT GATEWAY_CMD_ OK@( STS%, CMD%, DST%, &

“!01.24.00.00.84.00.80.00.00.14.00.00.N7:0”, &

VARPTR! (B3BASE%), SZE%) THEN 20000 \! process errors

In the example above, the routing bytes were determined as

follows.Recall that the last item in the actual ”slave_reg” parameter is

the destination file address.

Byte Value Meaning

1 LSAP 01 for a 1785-KA bridge

2 24h

3 DID_LO 00 for a 1785-KA bridge

4 DID_Hl 00 for a 1785-KA bridge

5 DNDE_LO 84h (see below)

6 DNDE_Hl 00 for a 1785-KA bridge

7 LIFETIME 80h for a1785-KA bridge

8 SID_LO 00 for a 1785-KA bridge

9 SID_HI 00 for a 1785-KA bridge

10 SNDE_HI

14h is the station number of the Data Highway

Plus module

11 SNDE_LO 00 for a 1785-KA bridge

12 NSAP 00 for a 1785-KA bridge

4-14

Page 33

Byte 5 in the routing path (DNDE_LO) is determined as follows:

The station address of the remote bridge is 240 octal (10100000).

The station address of the final Data Highway Plus station is 4

(00000100).

DNDE combines the upper two bits of the remote bridge station

address with the lower six bits of the final Data Highway Plus station

address (10000100). This is equivalent to 84h.

4.2.6.2 Example of Bridging the DH+ Link to a ControlNet Network

Using AutoMax and its 57C442 Data Highway Plus interface module to

send and receive data file values to a Control Net PLC5 through a

ControlLogix gateway. Knowledge Base Document 10628 defined the

network layout and network routing table set-ups. This document will

show the network and which parameters relate to the AutoMax.

Network Configuration

The 57C442 AutoMax Data Highway Plus module has the ability to

perform “Off-Link Routing”. This routing is used to move data from one

network to another network. This is covered as a separate subject in

the modules instruction manual. Twelve bytes of data are required in

order to program this function in the AutoMax. For the network

configuration shown above, they are:

4-15

Page 34

Byte Value Function

1 01h LS AP

2 24h Network Control Byte

3 07h Dest. Link ID - Lo

4 00h Dest. Link ID - Hi

5 01h Des t. Node Address - Lo

6 00h Des t. Node Address - Hi

7 80h Lifetime

8 05h Source Link ID – Lo

9 00h Source Link ID - Hi

10 07h Source Node Address - Lo

11 00h Source Node Address - Hi

12 00h NSAP

The Destination and Source Link ID’s and Node Addresses come from

the network configuration. The values for LSAP, Network Control Byte,

Lifetime and NSAP are constants. The twelve parameter values, in the

order shown are used with the AutoMax GATEWAY_CMD_OK@

function to program the AutoMax. They are the same for either writing

(CMD%=4) and reading (CMD%=3) data across the network.

An example of the GATEWAY _CMD_OK@ function is a basic task

which is used to either read or write to Integer file N7 in the PLCS/C

is:

NNNN IF NOT GATEWAY_CM D_OK@

(STS%, CMD%, DST%” !01,24,07,00,01,00,80,05,00,07,00.00,N7:00”,

Parameters STS%, CMD%, DST%, SZE% and N7BASE% are

discussed in the manual and are defined as LOCAL variables in the

basic task. NNNN is the line number for the function and XXXX is a line

number in the task where code to process errors is located.

VARPTR! (N7BASE%),SZE%) THEN XXXX

4-16

4.2.7 Programming Example

This section contains examples of initiating commands by using the

GATEWAY_CMD_OK@ function within an AutoMax task. In the

following examples, each register is defined in the configuration for the

rack as follows. For example,

B3BASE%[SLOT=4, REGISTER=64]

N7BASE%[SLOT=4, REGISTER=4384]

The statements above are used in the following examples. The

VARPTR! function is used to return a double integer value for the

address of the specified argument.

s

Page 35

Example 1: Command 3, Word Range Read

In the example below, the Data Highway Plus Interface module is

reading 100 words from file N7:0 in the PLC at station address 0. The

data read is stored in the local B3 file. The variable B3BASE% is

defined in the rack configuration.

10 COMMON B3BASE% \! Represents the physical address of &

the starting register on the &

Data Highway Plus module to be

read from

20 LOCAL DST% \! The address of the destination node&

on the local Data Highway Plus network

21 LOCAL STS% \! The location where the status

resulting from the operation is stored

22 LOCAL SZE% \! The number of registers to be &

transferred

23 LOCAL CMD% \! The Data Highway Plus command &

sent by the module

30 DST% = 0

31 STS% = 0

32 SZE% = 100

33 CMD% = 3

40 IF NOT GATEWAY_CMD_OK@(STS%, CMD%, DST%, “N7:0”, &

VARP TR!(B3BASE%), SZE%) THEN 20000 \! process errors &

at line 2000

Example 2: Command 4, Word Range Write

In the example below, the Data Highway Plus Interface module is

writing 100 words from the local N7 file to the file address N10:10 in the

PLC at station address 0. The variable N7BASE% is defined in the rack

configuration.

10 COMMON N7BASE%\! Represents the physical address of&

the starting register on the &

Data Highway Plus module to be &

written to

20 LOCAL DST% \! The address of the destination node

on the localData Highway Plus network

21 LOCAL STS% \! The location where the status &

resulting from the operation is stored

22 LOCAL SZE% \! The number of registers to be &

transferred

23 LOCAL CMD% \! The Data Highway Plus command sent

by The module

30 DST% = 0

31 STS% = 0

32 SZE% = 100

33 CMD% = 4

40 IF NOT GATEWAY_CMD_OK@(STS%, CMD%, DST%, “N10:10, &

VARP TR!(N7BASE%), SZE%) THEN 20000 \! process errors at&

line 20000

4-17

Page 36

Example 3: Command 5, Read-Modify-Write

In the example below, the Data Highway Plus Interface module writes

to three addresses in a PLC, N7:0, N7:2, and N7.4. The AND/OR mask

pairs are stored in three consecutive pairs of registers starting at

B3BASE%. The variable B3BASE% is defined in the rack configuration

10 COMMON B3BASE%\! Represents the physical address of &

the starting register on the &

Data Highway Plus module to be &

read from

20 LOCAL DST% \! The address of the destination node &

on the local Data Highway Plus network

21 LOCAL STS% \! The location where the status &

resulting from the operation is stored

22 LOCAL SZE% \! The number of registers to be &

transferred

23 LOCAL CMD% \! The Data Highway Plus command &

sent by the module

30 DST% = 0

31 STS% = 0

32 SZE% = 3

33 CMD% = 5

40 IF NOT GATEWAY_CMD_ OK@( STS%, CMD%, DST%, &

“N7:O,N7:2,N7:4”, VARPTR!(B3BASE%), SZE%) &

THEN 20000 \! process errors at line 20000

Example 4: Command 1, Unprotected Read

In the example below, the Data Highway Plus Interface module is

reading 100 words from address 2000 octal in the PLC at station

address 7. The data read is stored in the local 83 file; the variable

B3BASE% is defined in the rack configuration.

10 COMMON B3BASE%\! Represents the physical address of &

the starting register on the &

Data Highway Plus module to be &

read from

20 LOCAL DST% \! The address of the destination node &

on the local Data Highway Plus network

21 LOCAL STS% \! The location where the status &

resulting from the operation is stored

22 LOCAL SZE% \! The number of registers to be &

transferred

23 LOCAL CMD% \! The Data Highway Plus command &

sent by the module

30 DST% = 7

31 STS% = 0

32 SZE% = 100

33 CMD% = 1

40 IF NOT GATEWAY_CMD_ OK@( STS%, CMD%, DST%, “2000”,&

VARPTR! (B3BASE%), SZE%) THEN 20000 \! process errors &

at line 20000

4-18

Page 37

Example 5: Command 2, Unprotected Write

In the example below, the Data Highway Plus Interface module is

writing 100 words from the local N7 file to the file address 1234 octal in

the PLC at station address 7. The variable N7BASE% is defined in the

rack configuration.

10 COMMON N7BASE%\! Represents the physical address of &

the starting register on the &

Data Highway Plus module to be &

written to

20 LOCAL DST% \! The address of the destination node &

on the local Data Highway Plus network

21 LOCAL STS% \! The location where the status &

resulting from the operation is stored

22 LOCAL SZE% \! The number of registers to be &

transferred

23 LOCAL CMD% \! The Data Highway Plus command &

sent by the module

30 DST% = 7

31 STS% = 0

32 SZE% = 100

33 CMD% = 2

40 IF NOT GATEWAY_CMD_OK@(STS%, CMD%, DST%, “1234”,&

VARPTR! (N7BASE%), SZE%) THEN 20000 \! process errors&

at line 20000

4-19

Page 38

4-20

Page 39

5.0 DIAGNOSTICS AND TROUBLESHOOTING

This section describes how to troubleshoot the Data Highway Plus

Interface module. See Appendix D for a list of error codes that can be

displayed by the module. If the problem cannot be corrected using the

procedures below, the unit is not user-serviceable.

ATTENTION: Only qualified electrical personnel familiar with

the construction and operation of this equipment and the hazards

involved should install, adjust, operate or service this equipment.

!

5.1 The OK LED Is OFF

5.2 Invalid Station Address

Read and understand this manual and other applicable manuals

in their entirety before proceeding. Failure to observe this

precaution could result in severe bodily injury or loss of life.

Problem: The green status LED (labeled “OK”) on the Data Highway

Plus Interface module faceplate is off. The LED should be on when the

module has passed its internal diagnostics after power-up. If the green

OK status LED is off, and no error code is displayed, a local watchdog

failure has occurred. Try cycling power to the rack. If the OK status LED

remains off, replace the module.

Problem: Error code “3” or “6” appears on the Data Highway Plus

Interface module’s LED display at power-up. Error code “3” indicates a

duplicate station address. Error code “6” indicates an invalid station

address. To clear the error code, change the thumbwheel switch

settings and cycle power on the module.

5.3 Transmission Link Failures

Problem: Error codes “12”, “13”, “14”, “15”, or “17” are returned by the

GATEWAY_CMD_OK@ function. These error codes indicate various

network errors.

Verify that the cable connections to each device are secure. Check the

cable connection at the module faceplate and at the remote device.

Check the network cabling and

termination.

5.3.1 Rack Failure

If the AutoMax Processor in the rack that contains the Data Highway

Plus Interface module fails or issues a BOARD RESET command

(clears all outputs in the rack), the entire image in the Data Highway

Plus Interface module’s dual port memory is cleared. The module will

remain off-line for at least 1 second to allow application tasks to

recognize that the module went off-line.

5-1

Page 40

5.3.2 Remote Station and Link Failure

When the Data Highway Plus Interface module is not initiating

messages, but is simply responding to unsolicited commands from

remote stations, a failure in the remote stations cannot be detected by

the module itself except by monitoring the active station list

(registers 34-37).

When the module is initiating messages, a link failure is indicated by a

Response Timeout error.

5.4 Bus Error

Problem: Error codes “31” appears on a Processor module’s LED

display. This error indicates the system has a problem accessing a

module in the rack though the backplane bus. A bus error may be

caused by removal of a module, a module failure, or a rack backplane

failure.

Use the following procedure to isolate a bus error:

Step 1. Verify that all modules are in the correct slot.

Verify that the slot number being referenced in the application tasks

agrees with the slot number defined during configuration.

Step 2. Verify the station address is correct.

The thumbwheel switches used to set the station address can be

changed while the module is on-line without having any effect on the

system. On the next power up, if the thumbwheel switches define a

station that is valid, the Processor will accept it as a valid station.

Step 3. Verify that the application software is correct.

Verify that the application software is not attempting to write to READ

ONLY registers on the module.

Step 4. Verify that the hardware is working correctly.

5-2

ATTENTION: This equipment is at line voltage when AC

power is connected. Disconnect and lockout all ungrounded

conductors of the AC power line. Failure to observe this

!

precaution could result in severe bodily injury or loss of life.

Make certain that power is off before removing any module from the

rack. Systematically replace the Data Highway Plus Interface module,

the Processor module(s), and the rack/backplane, one at a time, with a

corresponding module or assembly known to be operating correctly.

After replacing each module or assembly, if the problem is not

corrected, replace the original item before going on to the next item.

Page 41

Appendix A

Technical Specifications

Ambient Conditions

• Storage Temperature: -40o C to 85o C

o

• Operating Temperature: 0

• Humidity: 5% to 95%, non-condensing

• Altitude: 1000 meter (3300 feet) without derating

Dimensions

• Height: 29.85 cm (11.75 inches )

• Width: 3.18 cm (1.25 inches )

• Depth: 18.73 cm (7.375 inches)

• Weight: 0.9 kg (2 pounds)

Maximum Power Dissipation

• 3.25 W

System Power Requirements:

• +5 VDC 650 mA

• +12 VDC (not used)

• -12 VDC (not used)

C to 60o C

A-1

Page 42

A-2

Page 43

Appendix B

Module Block Diagram

B-1

Page 44

B-2

Page 45

Appendix C

Network Connector Pin Assignments

This appendix assumes the network cable system has been installed using the

appropriate A-B Data Highway Plus instruction manual.

The faceplate of the Data Highway Plus Interface module contains a Phoenix

Combicon connector for connection to the Data Highway Plus network. Each

station is connected to the Data Highway Plus network trunk-line using a drop-line

constructed of Belden 9463 twin-axial cable (or equivalent).

The connector has 6 pins, which are numbered from the bottom. The bottom bin is

pin 1; the top pin is pin 6. Pin 1 is internally connected to 4, pin 2 to pin 5, and pin

3 to pin 6. Any connections to pins 1, 2 or 3 could also be made to 4, 5 or 6

respectively.

The CLEAR wire of the twin-axial cable should be connected to Pin 1 or 4 (bottom

pin or pin 4) of the Phoenix connector , the DRAIN (bare) wire to Pi n 2 or 5 and t he

BLUE wire to Pin 3 or 6. The color wire that is at the top on the three pin

connector on the A-B device is the color you connect to pin 1 on the connector on

the Data Highway Plus Interface module faceplate. See the figure below.

C-1

Page 46

C-2

Page 47

Appendix D

Data Highway Plus Interface Module

7-Segment LED Error Codes

The following error codes may be displayed on the 7-segment display.

.0 EPROM checksum failure

0 Gateway parameter error

.1 RAM checksum failure

1 Reply TNS error

.2 RAM AA failure

.3 RAM SS failure

3 Duplicate station detected

.4 RAM address line failure

4 Module not ready

.5 RAM address line clear failure

6 Invalid station address on thumbwheels

7 Module has not been enabled (register 5, bit 0)

.8 Data Highway Plus initialization failure

9 Module re-start in progress

.A Board Reset signal

.b Local watchdog failure

C Local port disconnected

.d AutoMax Processor watchdog failure

.E Power failure

.F Module failure

All errors except 3, 4, 6, 7, and C are fatal errors and indicate a malfunctioning

module.

D-1

Page 48

D-2

Page 49

Appendix E

GATEWAY _CMD_OK@ Status Codes

The following codes are written to the variable defined as the “status” parameter

in the GATEWAY _CMD_ OK@ function used to initiate Data Highway Plus

network data transfers from an AutoMax application task.

0 Operation successful

1 Invalid operation

3 Invalid length

4 Invalid offset

5 Invalid length + offset

6 Invalid destination (0-77 octal)

8 Invalid data type

9 Invalid route (equal to own address)

B Inconsistent response

C Module not enabled

20 Parameter specifying destination address is invalid

21 Data Highway Plus module not found or inaccessible

22 No available data path

Data Highway Plus Local and Remote Status (STS) error codes are written to the

upper byte. If the first digit is “1”, the STS code is local; if the first digit is “3”, the

STS code is remote.

11 Destination memory full, cannot accept command now

12 Destination did not acknowledge command

13 Network contention, possible duplicate station or bad cabling

14 Local Data Highway Plus port is disconnected, or no other station found

15 Timeout waiting for a reply message

16 Duplicate station detected

17 Station is off-line

18 Hardware fault

1D Transaction number mismatch

1E Duplicate transaction number

31 lllegal command or format

32 Host is malfunctioning and will not communicate

33 Remote station host is missing, disconnected, or shut down

34 Host could not complete function due to hardware fault

35 Addressing problem or memory protected rungs

36 Function disallowed due to command protection selection

37 A-B Processor is in program mode

38 Compatibility mode file missing or communication zone problem

39 Remote station cannot buffer command

3A (not used)

3B Remote station problem due to download

3C Cannot execute command due to active IPBs

3D not used)

3E (not used)

3F There is an error code in the Extended Status register

(register 33 on the Data Highway Plus Interface module).

See appendix H.

E-1

Page 50

E-2

Page 51

Appendix F

Mapping of Active Station List

The following table shows the mapping between active station addresses and the

status reported in registers 34-37.

Bit #

Register Byte

34

35

36

37

LO 70 60 50 40 30 20 10 00

HI 71 61 51 41 31 21 11 01

LO 72 62 52 42 32 22 12 02

HI 73 63 53 43 33 23 13 03

LO 74 64 54 44 34 24 14 04

HI 75 65 55 45 35 25 15 05

LO 76 66 56 46 36 26 16 06

HI 77 67 57 47 37 27 17 07

7654321 0

F-1

Page 52

F-2

Page 53

Appendix G

Register Map for Diagnostic Counters

This area contains statistics for the network as a whole and also for this station.

These values are returned to any remote station which requests them from this

station. This is also the format of data in counters returned from remote stations to

this station. These registers are read only.

Register Byte Meaning

40 LO Received ACK with bad CRC

41 LO Timeout expired with no ACKs received

42 LO NAK/illegal protocol operation received

43 LO NAK/no memory received

44 LO Received ACKJNAK too long

45 LO Token pass timeout

46 LO Claim token sequence entered

47 LO Bad CRC in received frame

48 LO NAK/bad LSAP sent

49 LO Received frame too small

50 LO Received a re-transmission of a frame

51 Message successfully sent

52 Message successfully received

53 Command successfully sent

54 Reply successfully received

55 Command successfully received

56 Reply successfully sent

57 LO Reply could not be sent

Hl (not used)

HI Transmit re-tries exhausted

HI NAK/bad LSA P received

Hl Received ACK/NAK too short

Hl Something other than ACK/NAK received

HI Token pass re-tries exhausted

HI Token claimed

HI NAK/illegal protocol operation sent

HI NAK/no memory sent

HI Received frame too long

HI Received frame aborted (line noise)

HI Number of active nodes

G-1

Page 54

G-2

Page 55

Appendix H

Extended Status (EXT STS) Codes for

Command 0F

If the value in the upper byte of the GATEWAY_CMD_OK@ “status” parameter

variable is 3F, then there is a value in the upper byte of the extended status

register (register 33 on the Data Highway Plus Interface module) which supplies

further information. The following table shows possible values for the extended

status error code.

0 (not used)

1 A field has an illegal value

2 Less levels specified in address than minimum for any address

3 More levels specified than system supports

4 Symbol not found

5 Symbol is of improper format

6 Address doesn’t point to something usable

7 File is wrong size

8 Cannot complete request; situation has changed since the start of

9 Data or file is too large

A Transaction size plus word address is too large

B Access denied, improper privilege

C Condition cannot be generated; resource is not available

D Condition already exists; resource is already available

E Command cannot be executed

F Histogram overflow

10 No access

11 Illegal data type

12 Invalid parameter or invalid data

13 Address reference exists to deleted area

14 Command execution failure for unknown reason; possible PLC-3

15 Data conversion error

16 Scanner not able to communicate with 1771 rack adapter

17 Adapter cannot communicate with module

18 1771 module response was not valid

19 Duplicated label

1A File is open; another node owns it

1B Another node is the program owner

1C-FF (not used)

the command

histogram overflow

H-1

Page 56

H-2

Page 57

Appendix I

Converting A-B Register Numbers

to AutoMax Register and Bit Numbers

for Monitoring

The A-B registers in the dual port memory of the Data Highway Plus Interface

module may be displayed using the Monitor I/O function in the AutoMax

Programming Executive. This appendix provides a method for converting the A-B

register number to a register number recognized by the Monitor I/O application.

The following table shows the correspondence between A-B register numbers and

AutoMax register numbers.

A-B File AutoMax

Address Register

B3:n 64 + n

B4:n 1088 + n

B5:n 2088 + n

N7:n 4384 + n

N8:n 5384 + n

N9:n 6384 + n

N10:n 7384 + n

N11:n 8384 + n

N12:n 9384 + n

N13:n 10384 + n

N14:n 11384 + n

N15:n 12384 + n

N16:n 13384 + n

N17:n 14384 + n

N18:n 15384 + n

I-1

Page 58

I-2

Page 59

Appendix J

Recommendations For Reducing Noise On

The Cable System

We recommend that all drive systems using 57C442 Data Highway Plus

Interface Modules and/or 57C443 AutoMax Allen-Bradley Remote I/O Scanner

Modules should be provided with 1770-SC station connectors installer per item 2

below. All drives which are connected using Data Highway Plus or Allen-Bradley

Remote I/O should include part number 43825-TC ferrite cores installed per item

3 below.

Installation recommendations:

1. When installing either the 57C442 or 57C443 module into the card rack,

make sure that its holddown screws are properly tightened at all times. The

basic design of the AutoMax has a floating ground on the backplane rather

than a solid DC ground like the PLC-5 does on its backplane. In AutoMax, it

has always been the case that the cards retaining screws have always had to

be tightened down tightly so that we could insure a good ground connection.

Also make sure that the AutoMax rack is properly grounded.

2. Always install an AB 1770-SC station connector box near the AutoMax rack

so that the drop cable from the AutoMax to the station connector box does

not exceed a length of 10 foot. Connect the drop cable and the trunkline

cables as specified in the installation manual for the station connector box.

This will result in the shield of the drop cable being isolated from the network

in the Station Connector box. Make sure that the station connector box is