Page 1

AutoMax

Processor Module

M/N 57C430A

M/N 57C431

M/N 57C435

Instruction Manual JĆ3650Ć6

Page 2

E Copyright Reliance Electric Industrial Company 1996.

Motorolat 68010 and 68020 are trademarks of Motorola, Inc.

AĆBt is a trademark of AllenĆBradley Corporation.

IBMt is a trademark of International Business Machines, Inc.

Modbust is a trademark of Gould, Inc.

Multibust is a trademark of Intel Corporation.

Reliancer and AutoMaxr are registered trademarks of Reliance Electric Company

ąor its subsidiaries.

The information in this user's manual is subject to change without notice.

WARNING

ONLY QUALIFIED PERSONNEL FAMILIAR WITH THE CONSTRUCTION AND

OPERATION OF THE CONTROLLED EQUIPMENT SHOULD INSTALL, ADJUST,

OPERATE, OR SERVICE THIS EQUIPMENT. READ AND UNDERSTAND THIS

MANUAL AND OTHER MANUALS APPLICABLE TO YOUR INSTALLATION.

FAILURE TO OBSERVE THIS PRECAUTION COULD RESULT IN BODILY INJURY.

WARNING

INSERTING OR REMOVING THIS MODULE OR ITS CONNECTING CABLES MAY

RESULT IN UNEXPECTED MACHINE MOTION. POWER TO THE MACHINE

SHOULD BE TURNED OFF BEFORE INSERTING OR REMOVING THE MODULE

OR ITS CONNECTING CABLES. FAILURE TO OBSERVE THESE PRECAUTIONS

COULD RESULT IN BODILY INJURY.

CAUTION: This module contains staticĆsensitive components. Careless handling can

cause severe damage. Do not touch the connectors on the back of the module. When

not in use, the module should be stored in an antiĆstatic bag. The plastic cover should

not be removed. Failure to observe this precaution could result in damage to or

destruction of equipment.

Page 3

Table of Contents

1.0 Introduction 1Ć1...............................................

1.1 Additional Information 1Ć2....................................

1.2 Related Hardware and Software 1Ć2...........................

1.3 Compatibility with Earlier Versions 1Ć3.........................

2.0 Mechanical/Electrical Description 2Ć1...........................

2.1 Mechanical Description 2Ć1...................................

2.2 Electrical Description 2Ć3.....................................

3.0 Installation 3Ć1................................................

3.1 Wiring 3Ć1..................................................

3.2 Initial Installation 3Ć1.........................................

3.3 Module Replacement 3Ć3.....................................

3.4 OnĆBoard Battery Replacement 3Ć4............................

3.5 Processor Module Diagnostics 3Ć5............................

3.5.1 PowerĆUp Diagnostics 3Ć5..............................

3.5.2 RunĆTime Diagnostics 3Ć5..............................

4.0 Programming 4Ć1..............................................

4.1 Loading the Operating System 4Ć1............................

4.2 Accessing Processor Ports 4Ć3................................

4.3 Programmable Tick Rate 4Ć4.................................

4.4 Restrictions 4Ć5.............................................

4.4.1 Number of Processors in a Rack 4Ć5.....................

4.4.2 Rack Slot Restrictions 4Ć5..............................

4.4.3 Use with the DCS5000 M/N 57C407 Processor Module

or the 57C430 Processor Module 4Ć5....................

4.4.4 Ethernet Commands 4Ć5...............................

5.0 Diagnostics and Troubleshooting 5Ć1............................

5.1 The OK" LED Is Off 5Ć1......................................

5.2 The BAT. OK" LED Is Off 5Ć2.................................

5.3 BUS ERROR 5Ć3............................................

5.4 Common Memory Module Diagnostic Failure 5Ć6................

5.5 Incorrect Data 5Ć7...........................................

I

Page 4

Appendices

Appendix A

Technical Specifications AĆ1......................................

Appendix B

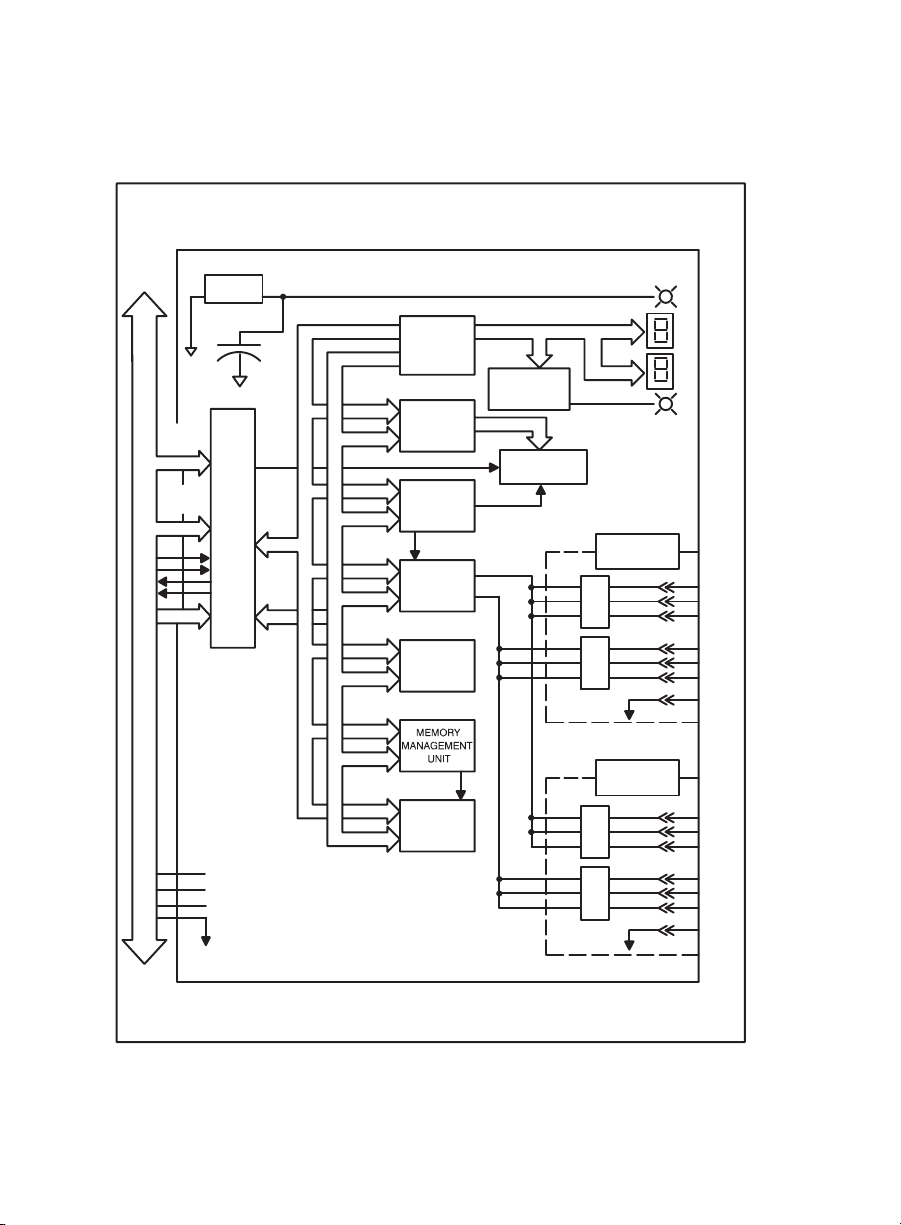

Module Block Diagram BĆ1......................................

Appendix C

Connecting the AutoMax Processor to the Personal Computer CĆ1....

Appendix D

Diagnostic LED Error Codes DĆ1..................................

Appendix E

Run Time LED Error Codes EĆ1...................................

Appendix F

Using Modems with AutoMax Systems FĆ1.........................

II

Page 5

List of Figures

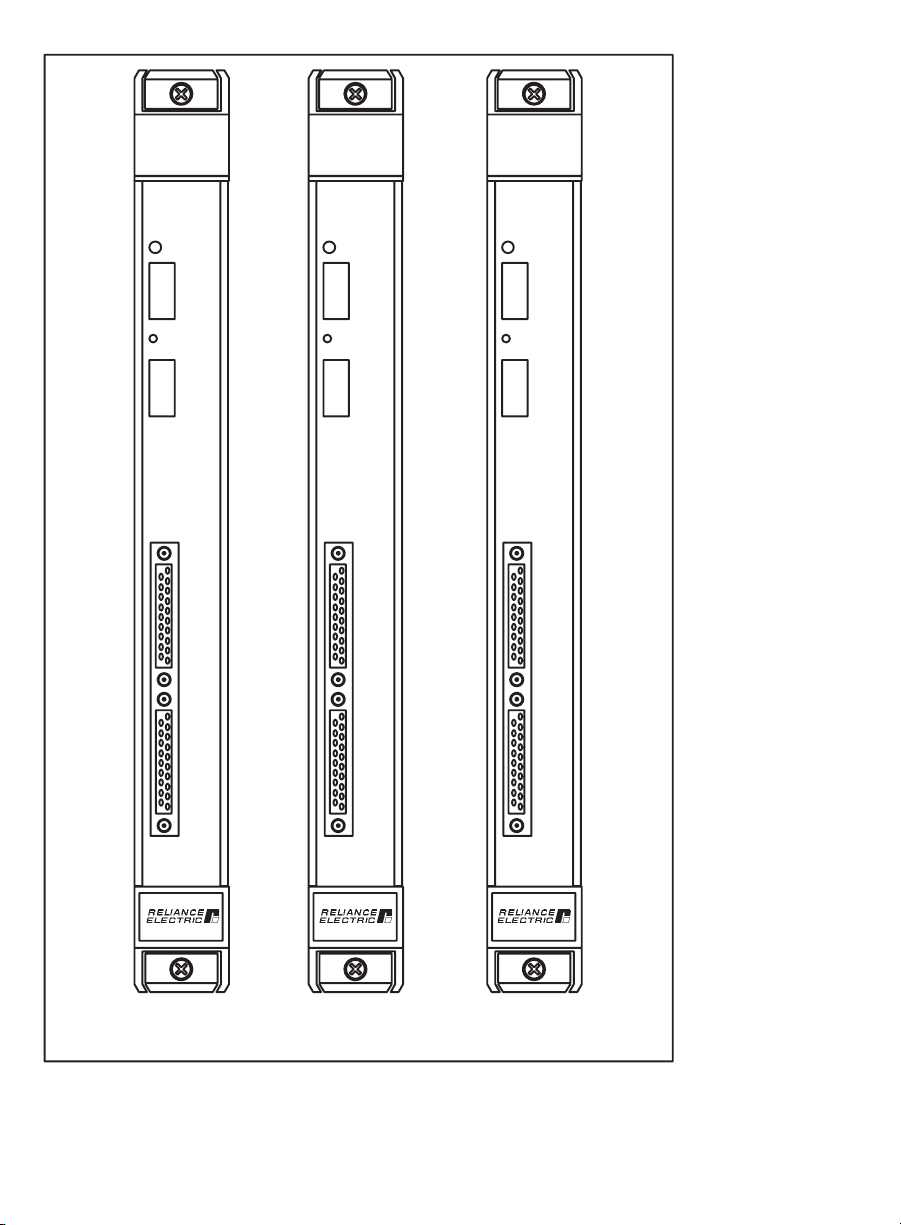

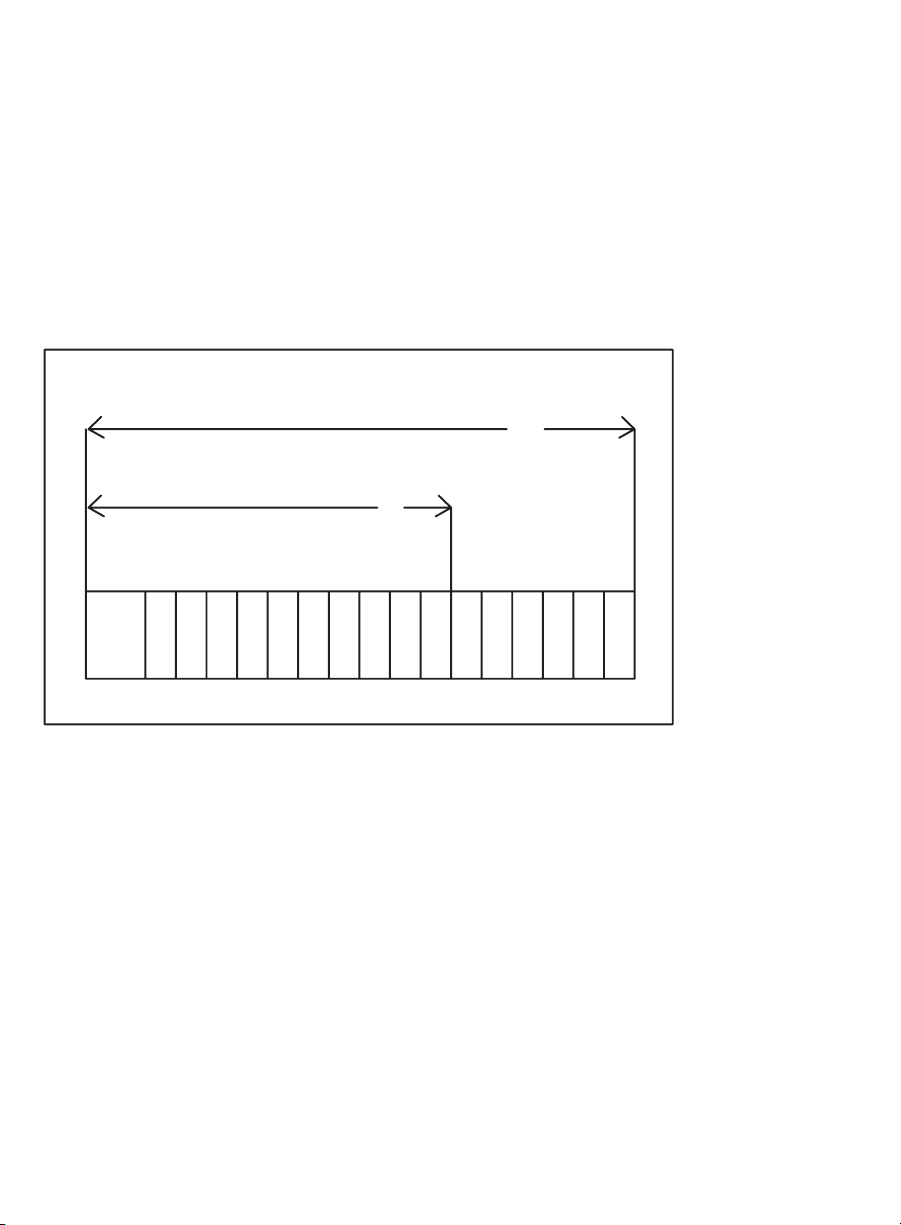

Figure 2.1 Ć Processor Module Faceplate 2Ć2...........................

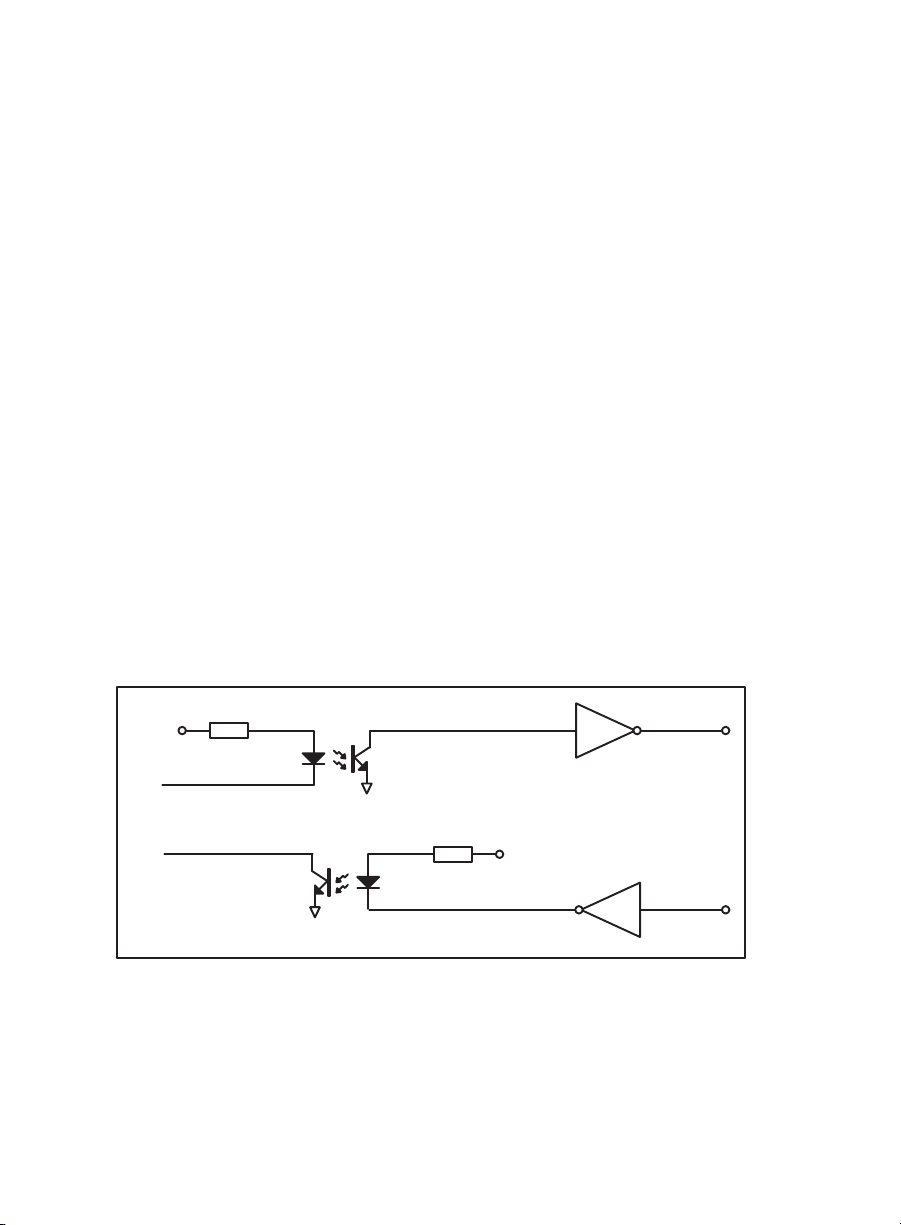

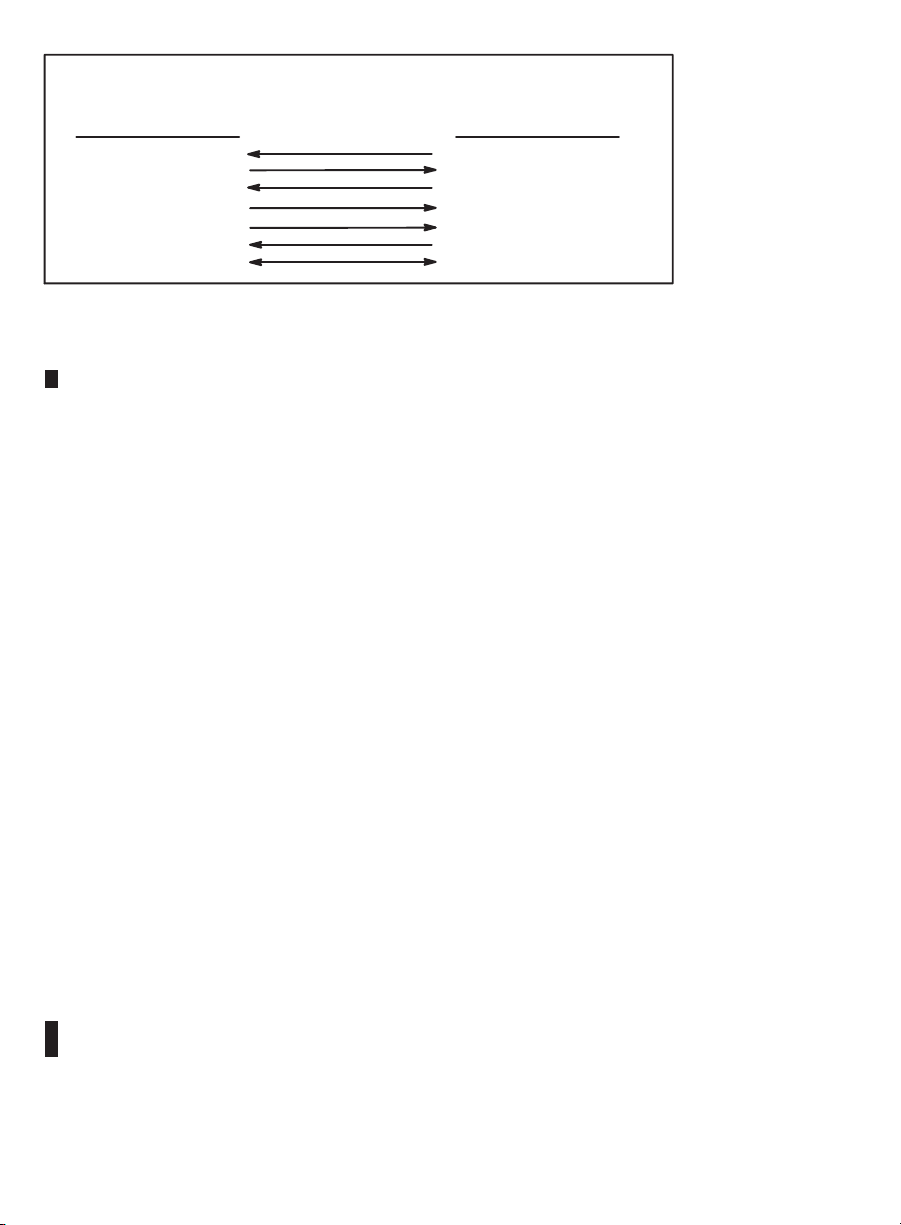

Figure 2.2 Ć Typical RSĆ232C Circuit 2Ć3................................

Figure 3.1 Ć Rack Slot Numbers 3Ć2...................................

Figure 4.1 Ć Specifying the SETUP Parameter in an OPEN Statement 4Ć4...

III

Page 6

fadfdfdasfdsfdsdsdfdsfdsfdsfsdfdsa

dfdsfdsfdfdsfdsfsadfda

fdfaddfdd

Page 7

1.0 INTRODUCTION

The products described in this instruction manual are manufactured

by Reliance Electric Industrial Company. The Automax Processor

module plugs into the backplane of an AutoMax rack and executes

application programs which in turn control other AutoMax modules in

the system. The M/N 57C430A and 57C431 Processor modules are

based on the Motorola 68010 16Ćbit microprocessor. The M/N

57C435 Processor module is based on the Motorola 68020 32Ćbit

microprocessor. All three Processors are programmed using three

highĆlevel application languages: BASIC, Control Block and Ladder

Logic.

The Processor modules have the following memory/speed

configurations:

Model CPU Speed Memory

M/N 57C430A AutoMax

6010 Processor module

M/N 57C431 AutoMax

6011 Processor module

M/N 57C435 AutoMax

7010 Processor module

Up to four AutoMax Processor modules can be used in a rack

(M/N 57C331, M/N 57C332 or M/N 57C334) to increase the

processing capability and the total memory available for application

tasks. M/N 57C430A, 57C431, and 57C435 Processors can be used

in the same rack. M/N 57C430A Processors make 135KĆ150K

available for application programs depending on which operating

system is loaded onto the Processor. M/N 57C431 and 57C435

Processors make 300K available for application programs, regardless

of which operating system is loaded onto the Processor. Multiple

Processors in a rack require the use of the Common Memory module

(M/N 57C413 or M/N 57C423) for bus arbitration and sharing of

systemĆwide information. The Common Memory module can also be

used with a single Processor module to make available an additional

128K bytes of memory for common, i.e., systemĆwide, variables.

An onĆboard lithium battery and a superĆcapacitor protect the

Processor module from power failures. Should the system lose

power, the onĆboard battery of the M/N 57C430A or 57C431

Processor can maintain the contents of RAM for a minimum of 42

days. The onboard battery of the M/N 57C435 Processor can

maintain the contents of RAM for a minimum of 186 days.

The remainder of this manual describes the functions and

specifications of the module. It also includes a detailed overview of

installation and servicing procedures.

The thick black bar shown at the rightĆhand margin of this page

will be used throughout this instruction manual to signify new or

revised text or figures.

8 mHz 256K Parity RAM

8 mHz 512K Parity RAM

25 mHz 512K Parity RAM

1Ć1

Page 8

1.1 Additional Information

You should be familiar with the following related publications to use

the AutoMax Processor correctly:

D JĆ3616Ć1 Kermit Communications Software Instruction Manual

D JĆ3618 Norton Editor Instruction Manual

D JĆ3636 Common Memory Module Instruction Manual

D JĆ3649 AutoMax Configuration Task Manual

D JĆ3675 AutoMax Enhanced Basic Language Instruction Manual

D JĆ3676 AutoMax Control Block Language Instruction Manual

D JĆ3677 AutoMax Ladder Logic Language Instruction Manual

D J2Ć3093 AutoMax Enhanced Ladder Editor

D J2Ć3094 AutoMax Enhanced Ladder Language Reference

D Your ReSource AutoMax Executive Software Loading Instructions

D Your ReSource AutoMax Programming Executive Instruction

Manual

D IEEE 518 Guide for The Installation of Electrical Equipment to

Minimize Electrical Noise Inputs to Controllers

D Your personal computer and DOS operating system manual(s).

D Other instruction manuals applicable to your hardware

configuration

1.2 Related Hardware and Software

1Ć2

M/N 57C430A contains one 256K AutoMax Processor module.

M/N 57C431 contains one 512K AutoMax Processor module.

M/N 57C435 contains one 512K AutoMax Processor module. The

Processor module is used with the following hardware and software,

which can be purchased separately:

1. IBMĆcompatible personal computer running DOS V3.1 or later.

2. ReSource AutoMax Programming Executive software (various

model numbers).

3. M/N 61C127 RSĆ232C ReSource Interface Cable. This cable is

used to connect the personal computer to the Processor module.

If you wish, you may also build your own cable using the pin

description found in Appendix C.

4. M/N 57C413B, 57C423 Common Memory module. This module

is used when there is more than one Processor in the rack.

5. RSĆ232C cable used for communicating with other devices

through the Processor ports in the rack not reserved for

connection to the personal computer. If you intend to use these

ports, you will need to build your own cable using the pin

description found in Appendix C.

6. M/N 57C331, 57C332 or 57C334 AutoMax PanelĆMount Rack.

7. M/N 57C491, M/N 57C493, or M/N 57C494 AutoMax Power

Supply Module.

Page 9

8. M/N 57C385 AutoMax Replacement Battery. Note that the

Processor module comes equipped with one (1) battery.

9. M/N 57C404A Network Communications module. This module is

used to connect racks together as a network and supports

communication with all racks on the network that contain

57C404A modules through a single Processor module. M/N

57C404 can be used to connect racks on a network; however,

you cannot communicate over the network to the racks that

contain M/N 57C404 Network modules. You must instead

connect directly to the Processors in these racks.

1.3 Compatibility with Earlier Versions

AutoMax Processor module M/N 57C430A, M/N 57C431, and

M/N 57C435 are not compatible with Version 1.0 of the AutoMax

Programming Executive software (M/N 57C304Ć57C307).

Processor module M/N 57C430A and M/N 57C431 require Version

2.0 or later of the AutoMax Programming Executive software.

M/N 57C435 requires Version 3.1 or later of the AutoMax

Programming Executive software. M/N 57C430 cannot coĆexist in the

same rack with M/N 57C430A, 57C431, or 57C435.

AutoMax Programming

Executive Software

Version 1.0

M/N 57C304, 57C305

M/N 57C306, 57C307 (updates)

Version 2.0

M/N 57C390, 57C391

M/N 57C392, 57C393 (updates)

Version 2.1D

M/N 57C391

M/N 57C393 (update)

Version 3.0

M/N 57C395

M/N 57C397 (update)

Version 3.1

M/N 57C395

M/N 57C397 (update)

Version 3.3 and later*

M/N 57C395

M/N 57C397 (update)

*Note that if you are using the AutoMax Programming Executive for

drive control applications, the Universal Drive Controller module

(B/M 57552) is supported only in Version 3.3 and later of the

Programming Executive software.

Compatible

Processor Module

M/N 57C430

M/N 57C430

M/N 57C430A

M/N 57C430A

M/N 57C430A

M/N 57C431

M/N 57C435

M/N 57C430A

M/N 57C431

M/N 57C435

M/N 57C430A

M/N 57C430A

M/N 57C430A

M/N 57C431

M/N 57C435

M/N 57C430A

M/N 57C431

M/N 57C435

M/N 57C430A

M/N 57C431

M/N 57C435

M/N 57C430A

M/N 57C431

1Ć3

Page 10

fadfdfdasfdsfdsdsdfdsfdsfdsfsdfdsa

dfdsfdsfdfdsfdsfsadfda

fdfaddfdd

Page 11

2.0 MECHANICAL/ELECTRICAL

DESCRIPTION

The following is a description of the faceplate LEDs, field termination

connectors, and electrical characteristics of the field connections.

2.1 Mechanical Description

The Processor module is a printed circuit board assembly that plugs

into the backplane of the DCS 5000/AutoMax rack. It consists of the

printed circuit board, a faceplate, and a protective enclosure. The

faceplate contains tabs at the top and bottom to simplify removing

the module from the rack. On the back of the module are two edge

connectors that connect to the system backplane. Module

dimensions are listed in Appendix A.

The faceplate of the Processor module contains two

independentlyĆisolated 25Ćpin D" shell connectors for RSĆ232C serial

I/O links. The upper port (labeled PROGRAMMER/PORT B") of the

leftmost Processor in the rack is reserved for connection to the

personal computer only. The personal computer can communicate

with all Processors in the rack through this connection.

All remaining Processor module ports (both those labeled

PROGRAMMER/PORT B" and PORT A") are available for use by

application tasks running on the respective Processors. Refer to

figure 2.1 for the Processor module faceplate and Appendix C for a

pin description.

2Ć1

Page 12

AutoMax

6010 Processor

57C430A

AutoMax

6011 Processor

57C431

AutoMax

7010 Processor

57C435

BAT.OK

1ST

OK

2ND

PROGRAMMER / PORT B

PORT A

BAT.OK

1ST

OK

2ND

PROGRAMMER / PORT B

PORT A

BAT.OK

1ST

OK

2ND

PROGRAMMER / PORT B

PORT A

2Ć2

M/N 57C430A

6010 Processor

256K

Figure 2.1 Ć Processor Module Faceplate

M/N 57C431

6011 Processor

512K

M/N 57C435

7010 Processor

512K

Page 13

The faceplate contains two green status lights and two

sevenĆsegment LEDs used for diagnostic purposes. The upper status

light, labeled BAT. OK", indicates whether the onĆboard battery is

providing sufficient voltage to retain the contents of RAM (ON) or

should be replaced (OFF). See 3.4 for directions on replacing the

battery and Appendix A for battery specifications. The lower status

light, labeled OK", indicates whether the board is operational (ON)

or should be replaced (OFF).

Five preĆassigned variables are available for use in all application

tasks to test the status of the onĆboard battery. These common

boolean variables will have the value 1 if the battery is functional and

0 if the battery is not functional. The variables are named according

to the Processor whose battery is being tested. BATTERYSTATUS0@

is used for the Processor in slot 0. BATTERYSTATUS1@ is used for

the Processor in slot 1, etc. up to slot 4.

See 3.5.1 and 3.5.2 for more information about the two

sevenĆsegment LEDs on the Processor.

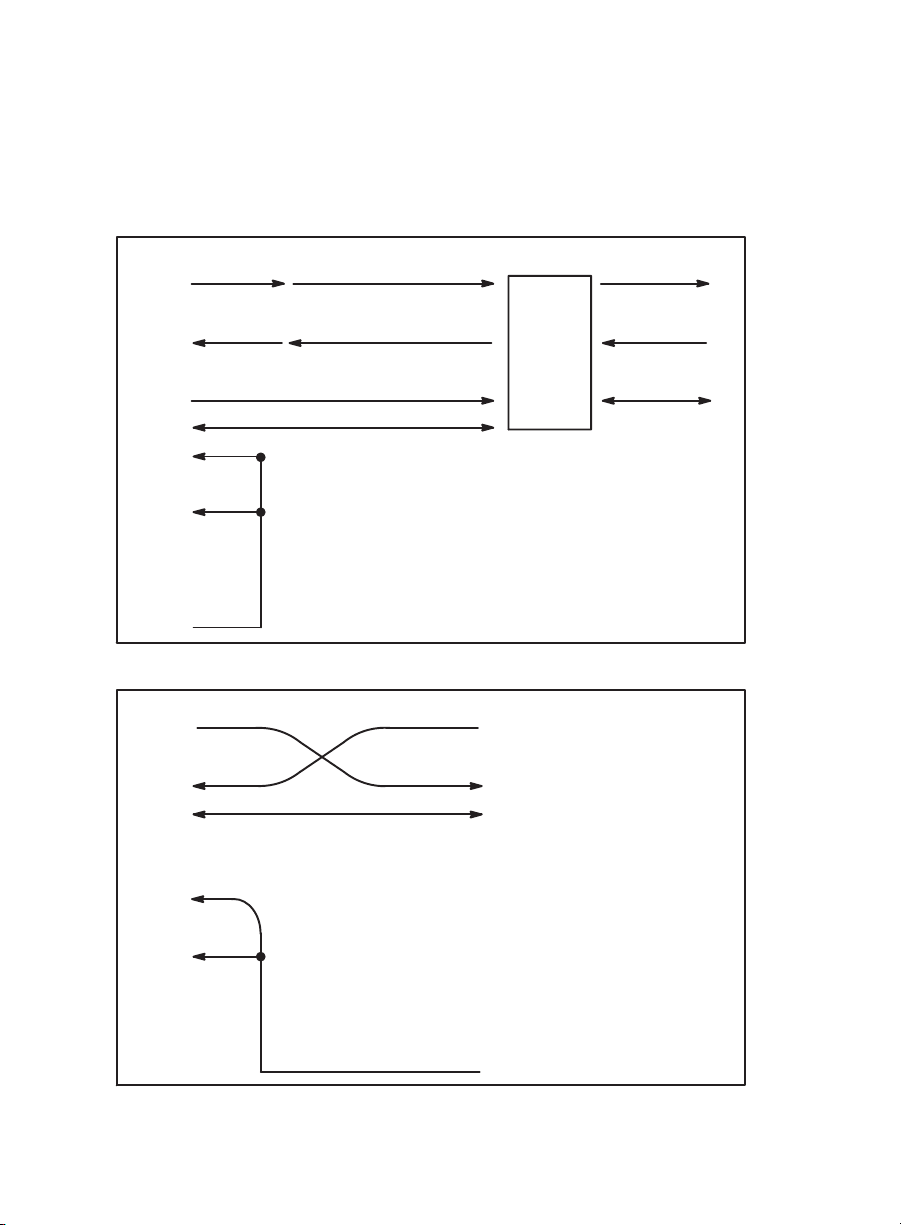

2.2 Electrical Description

The Processor module contains a local watchdog timer which must

be reset within a specified interval or the Processor will shut down

and all I/O modules will be reset (initialized to 0, FALSE, or OFF).

Byte parity is supported for all backplane address and data lines.

The superĆcapacitor on the Processor module can be charged to

more than 90% of its rated capacity in approximately 15 minutes and

is typically capable of retaining the contents of RAM memory for

approximately 10 hours should the BAT. OK" light go out and power

is removed from the Processor.

The Processor serial ports support full modem control. RSĆ232C

signals have 450V isolation to logic common. Refer to figure 2.1 for a

typical circuit diagram.

+5V

12

OPTO ISOLATOR

GND

12

OPTO ISOLATOR

GND

+5V

Figure 2.2 Ć Typical RSĆ232C Circuit

Refer to 4.2 for more information on the characteristics of the

Processor ports available to the user through application tasks.

XMIT

RECV

2Ć3

Page 14

fadfdfdasfdsfdsdsdfdsfdsfdsfsdfdsa

dfdsfdsfdfdsfdsfsadfda

fdfaddfdd

Page 15

3.0 INSTALLATION

This section describes how to install and replace the Processor

module and the onĆboard battery. M/N 57C430A and M/N 57C431

can be installed in the same rack.

DANGER

THE USER IS RESPONSIBLE FOR CONFORMING WITH THE NATIONAL

ELECTRICAL CODE AND ALL OTHER APPLICABLE LOCAL CODES. WIRING

PRACTICES, GROUNDING, DISCONNECTS, AND OVERĆCURRENT

PROTECTION ARE OF PARTICULAR IMPORTANCE. FAILURE TO OBSERVE

THIS PRECAUTION CAN RESULT IN SERIOUS BODILY INJURY OR LOSS OF

LIFE.

3.1 Wiring

To reduce the possibility of electrical noise interfering with the proper

operation of the control system, exercise care when installing the

wiring from the system to the external devices. For detailed

recommendations refer to IEEE 518.

3.2 Initial Installation

Use the following procedure to install the module:

Step 1. Turn off power to the system.

Step 2. If one or both of the RSĆ232C ports on the Processor are

Step 3. Take the module out of its shipping container. Take it out of

Step 4. Activate the onĆboard battery. When viewing the Processor

to be used by application tasks for serial communication

with devices other than the personal computer, use

shielded RSĆ232 cables. Cable connectors must be

equipped with EMI/RFIĆshielded cable clamps attached to

the cable shield. The cable shield must be grounded at

one end. The cable length must be in accordance with the

RSĆ232 specification. Be sure to label the connector so

that it can be easily reconnected later should it ever need

to be removed. A pin description can be found in

Appendix C.

the antiĆstatic bag, being careful not to touch the

connectors on the back of the module.

module from the front, you can access the battery through

the opening in the right wall portion of the Processor's

protective enclosure. Activate the battery by taking it out of

its holder and removing the tape that covers it. Replace

the battery in its holder. Make certain that the battery is

facing in the proper direction, i.e., the end marked +" on

the battery is facing the end marked +" on the battery

holder.

Note that the battery will begin to charge the

superĆcapacitor as soon as the battery is replaced in its

holder. For maximum battery life, you should not remove

3Ć1

Page 16

the tape from the battery unless you intend to turn power

on to the module immediately.

If you are in a programming checkĆout" mode during

which power may be left off for extended periods of time,

you may wish to leave the tape on the battery and use the

superĆcapacitor for backup instead. The superĆcapacitor

will typically provide 10 hours of backup. Using the

superĆcapacitor for this purpose will extend the life of the

battery.

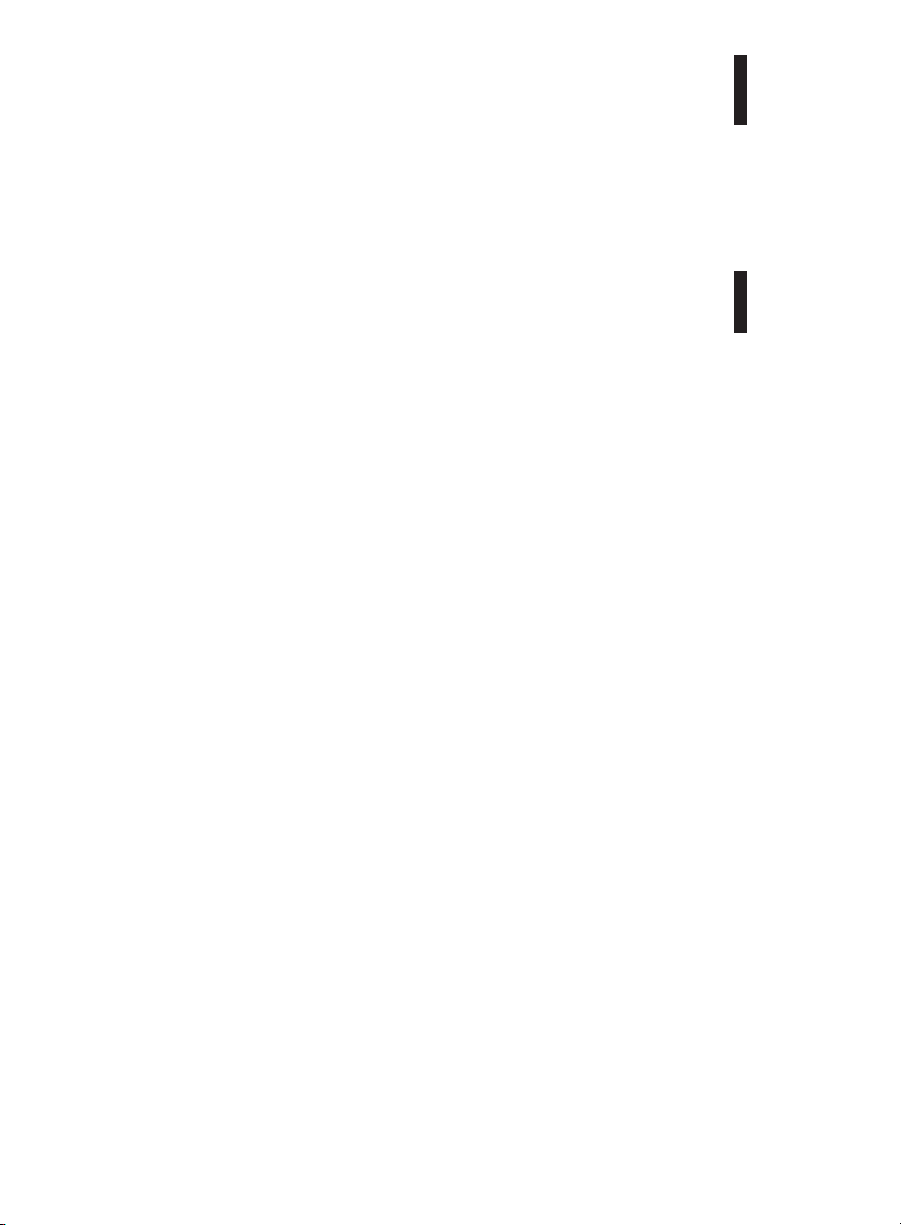

Step 5. Insert the module into the desired slot in the rack. In a

single Processor configuration, you can insert the

Processor in any slot 0-4. If the rack will contain multiple

Processors, they can only be placed in slots 1-4. In this

configuration, slot 0 is reserved for the Common Memory

module. Refer to figure 3.1.

Typical 16 Slot Rack

Typical 10 Slot Rack

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

P/S

Figure 3.1 Ć Rack Slot Numbers

Step 6. Using a screwdriver, attach cable M/N 61C127 (or your

Step 7. Turn on power to the system. The module will

Step 8. Load the operating system using the directions in 4.1.

own cable, built according to directions in Appendix C), to

the port labeled PROGRAMMER/PORT B" on the leftmost

Processor. Attach the cable from step #2 above to ports

being used to communicate with other devices.

automatically execute its powerĆup diagnostics. See 3.5.1

for more information. When diagnostics are complete, the

sevenĆsegment LEDs on the faceplate of the leftmost

Processor module will display LO", reading top to

bottom. Code LO" means that the operating system

needs to be loaded onto the Processors in the rack. See

4.1 for instructions on loading the operating system. The

LEDs on all other Processor modules in the rack should

be blank. The green OK" light on all Processors should

be lit. The BAT. OK" light on all Processors should also be

lit if the tape was removed from the batteries.

10

16

3Ć2

Page 17

3.3 Module Replacement

When you replace the Processor module in a singleĆProcessor rack,

you will need to reĆload the operating system and all application

tasks unless the new Processor already has the operating system

loaded on it and the contents of RAM are valid. In this case, you will

need to load the application tasks only.

In a multipleĆProcessor rack, if your replacement Processor does not

already have an operating system and valid RAM, you will have to

reĆload the operating system and all application tasks to all

Processors in the rack. If the new Processor has an operating

system, you need only load the application tasks that you want to run

on that particular Processor.

Use the following procedure to replace a Processor module:

Step 1. Turn off power to the system. All power to the rack, as well

Step 2. Use a screwdriver to loosen the screws holding the

Step 3. Loosen the screws that hold the module in the rack.

Step 4. Place the module in the antiĆstatic bag it came in, being

Step 5. Take the new module out of the antiĆstatic bag, being

Step 6. Activate the battery by taking it out of its holder and

Step 7. Insert the module into the correct slot in the rack. Use a

Step 8. Attach the RSĆ232C cable connector(s) to the mating half

Step 9. Turn on power to the system. The module will

Step 10. Load the operating system using the directions in 4.1.

as all power to the wiring leading to the module, should be

off.

RSĆ232C connectors to the Processor. Detach the

connectors from the module.

Remove the module from the slot in the rack.

careful not to touch the connectors on the back of the

module. Place the module and the antiĆstatic bag in the

cardboard shipping container.

careful not to touch the connectors on the back of the

module.

removing the tape that covers it. Replace the battery in its

holder. Make certain that the battery is facing in the proper

direction, i.e., the end marked +" on the battery is facing

the end marked +" on the battery holder.

screwdriver to secure the module into the slot.

on the module. Make certain that the connector is the

proper one for this module. Use a screwdriver to secure

the connector to the module.

automatically execute its powerĆup diagnostics. At the

completion of its diagnostics, the seven segment LEDs on

the faceplate should display LO" if this is the only

Processor module in the rack or the leftmost Processor in

a multiĆProcessor configuration and there is no operating

system on the Processor. The LEDs on all other Processor

modules should be blank. The green OK" light should be

lit, and the BAT. OK" should be lit if the tape was removed

from the battery.

3Ć3

Page 18

3.4 OnĆBoard Battery Replacement

WARNING

THE BATTERY USED WITH THIS DEVICE MAY PRESENT A HAZARD IF

MISTREATED. DO NOT RECHARGE, DISASSEMBLE, HEAT ABOVE 100_C

(212_F), INCINERATE, OR SWALLOW. REPLACE BATTERY WITH RELIANCE

ELECTRIC M/N 57C385 ONLY. DISPOSE OF USED BATTERY PROMPTLY. FAILURE

TO OBSERVE THIS PRECAUTION COULD RESULT IN BODILY

INJURY.

See section 5.2 for a list of the possible reasons that the BAT. OK"

light on the Processor faceplate can shut off. If you need to replace

the battery, the superĆcapacitor will provide a typical 10 hours of

backĆup power between the time the BAT. OK" light goes off and

power is removed from the rack, and the time you insert and activate

the new battery. If you replace the battery within this time limit, you

will not need to reĆload the operating system and application tasks.

Complete battery specifications can be found in Appendix A.

Use the following procedure to replace the battery on the Processor

module.

Step 1. Turn off power to the system. All power to the rack, as well

Step 2. Use a screwdriver to loosen the screws holding the

Step 3. Loosen the screws that hold the module in the rack.

Step 4. Take the old battery out of the holder. Remove the tape

Step 5. ReĆinsert the module into the correct slot in the rack. Use a

Step 6. ReĆattach the connector(s) to the mating half on the

Step 7. Turn on power to the rack. The module will automatically

as all power to the wiring leading to the module, should be

off.

connectors to the module. Remove the connectors from

the module.

Remove the module from the slot in the rack, being careful

not to touch the connectors on the back of the module.

from the new battery and insert it in the holder. Make

certain that the battery is facing the proper direction.

screwdriver to secure the module into the slot.

module. Make certain that the connector is the proper one

for this module. Use a screwdriver to secure the connector

to the module.

execute its powerĆup diagnostics. The green OK" light

should be lit, and the BAT. OK" should be lit. If this

Processor or any Processor in the rack displays code

LO", you will need to reĆload the operating system. See

4.1 for more information.

3Ć4

Page 19

3.5 Processor Module Diagnostics

This section describes the Processor module powerĆup and runĆtime

diagnostics.

3.5.1 PowerĆUp Diagnostics

When you first turn on power to the Processor module or cycle

power, it will run diagnostics on the Eprom and RAM memory,

memory management unit, watchdog timer, parity, interrupts, and

SIO.

If more than one Processor is located in the rack, the leftmost

Processor will also run diagnostics on the Common Memory module.

While running diagnostics, which take approximately 5-15 seconds,

the Processor modules in the rack will display the code dd". When a

module has completed its diagnostics, the LED on the faceplate

labeled OK" will be turned on.

Should a malfunction be detected, all Processors in the rack will be

shut down and the status code indicating which diagnostic failed will

remain on the LED display of the Processor at fault. See Appendix D

for a list of powerĆup diagnostic error codes.

After diagnostics are complete, the Processor begins periodically

resetting its watchdog to indicate that it is functioning correctly. In a

multiple Processor configuration, all of the Processors in the rack will

begin resetting the system watchdog located on the Common

Memory module in addition to resetting their own watchdogs. The

Processor module will reset its own watchdog regardless of whether

the operating system is loaded or not.

Should any watchdog be allowed to expire at any time after

powerĆup diagnostics are complete, all Processors in the rack will be

shut down. If application tasks are currently running in the rack, they

will be stopped. The green LED labeled OK" on the faceplate of the

module at fault will be turned off. This Processor will assert a signal

on the backplane to reset (set 0, FALSE, or OFF) all local and remote

I/O modules.

3.5.2 RunĆTime Diagnostics

During runĆtime, i.e., while executing application tasks, the Processor

continuously performs realĆtime checking of byte parity on the RAM.

The memory management unit (MMU) checks for errors such as

writing to locations that are readĆonly. Should any malfunction be

detected, an error code will be displayed on the LEDs and the

Processors in the rack will be either stopped or completely shut

down, depending upon the severity of the error. See Appendix E for

a list of runĆtime error codes.

Serious hardware malfunctions, however, can result in application

tasks that are currently running being stopped, the OK" indicator

being turned off, and the Processor being shut down. Once a

Processor module has shut down, it will not execute any instructions

or respond to commands from the personal computer until it is reset

by cycling power.

3Ć5

Page 20

fadfdfdasfdsfdsdsdfdsfdsfdsfsdfdsa

dfdsfdsfdfdsfdsfsadfda

fdfaddfdd

Page 21

4.0 PROGRAMMING

For information about programming, see the AutoMax language

instruction manuals and the AutoMax Executive instruction manual

referenced in 1.1.

The remainder of this section describes how to load the operating

system, or runbase, onto the Processor(s) in the rack and how to

access the available Processor ports through application tasks. Note

that you cannot load a Version 1.0 runbase on a 57C430A or M/N

57C431 Processor module. You must load the runbase from the

Version 2.0 or Version 3.0 Programming Executive software. The M/N

57C435 Processor requires the runbase from the Version 3.1 or later

Programming Executive software. You will not be able to load the

operating system using an earlier version of the Programming

Executive software.

4.1 Loading the Operating System

Before you can go onĆline to any rack in the system, the operating

system, or runbase, for the AutoMax Processor module(s) must be

loaded to the local rack from the personal computer on which you

have installed the AutoMax Executive software. The operating

system, which oversees the operation of the CPU and the execution

of application tasks, is provided in three versions: 6010/6011 Ć

Standard, 6010/6011 Ć Ethernet, and 7010 Ć Standard. The 6010/6011

Ć Standard or 6010/6011 Ć Ethernet operating system can be used

with M/N 57C430A or M/N 57C431 Processors. In order to use the

Ethernet functions that allow communication over Ethernet using the

TCP/IP protocol, an Ethernet Network Interface module (M/N

47C440) must be installed in the rack and the Ethernet operating

system must be used. The Ethernet operating system is also required

if any of the following functions are used in BASIC tasks:

READVAR%, WRITEVAR%, FINDVAR!, and CONVERT%. The 7010 Ć

Standard operating system, which supports all of the Ethernet

functions, must be used with the M/N 57C435 Processor.

When you load the operating system to the Processor modules in the

rack, you will be prompted for which operating system you want to

load for the M/N 57C430A and M/N 57C431 Processors. The 7010 Ć

Standard operating system will be loaded onto all M/N 57C435

Processors. Note that if you have loaded the 6010/6011 Ć Standard

operating system and then you use the Ethernet functions in an

application task, the Processor will display error code 4A on its LEDs

when you try to put the task into run.

The 6010/6011 Ć Ethernet operating system will occupy

approximately 121K or RAM, leaving 135K available for application

tasks on the M/N 57C430A Processor. The 6010/6011 Ć Standard

operating system will occupy approximately 106K or RAM, leaving

150K available for application tasks on the M/N 57C430A Processor.

The M/N 57C431 Processor makes 300K available for application

tasks, regardless of which operating system is used. The M/N

57C435 Processor also makes 300K available for application tasks.

The operating system(s) will be loaded at the maximum baud rate

available for the Processors being used. If you are using 6010/6011

and 7010 Processors in the same rack, make sure the leftĆmost

Processor is a 7010 (M/N 57C435) Processor. This will allow the

operating systems to be loaded at 19200 baud. If the leftmost

4Ć1

Page 22

Processor in the rack is a M/N 57C430A or M/N 57C431, the

operating system(s) will be loaded at 9600 baud. At 9600 baud, it will

require approximately two minutes to load each operating system to

Processors in the rack. Although they are similar, the operating

systems for the 6010/6011 and 7010 Processor are different. If there

are 6010/6011 and 7010 Processors mixed in the same rack, loading

the operating systems will take approximately twice as long as it

would if there were only one type of Processor in the rack.

Follow the directions below to load the operating system(s) for all

Processor modules in the local rack at one time. You can then load

the operating system(s) to all racks on all networks in the system.

Note: If you load an operating system into a Processor(s) that

already contains one, the new operating system will write over

the existing operating system, and any tasks in the Processor(s)

will be deleted.

1. If you have not already done so, turn on the personal computer

and run the AutoMax Executive by typing

AUTOMAX2

or

AUTOMAX3

2. Turn on power to the rack. You will note that the leftmost

Processor module in the rack displays the letters L" and O"

(reading top to bottom). This code prompts you to Load the

Operating system. Because Processor modules have onĆboard

battery backup, you will need to reĆload the operating system

only when enhancements become available, when you change

the password for the rack using the PWOS.EXE utility or when a

Processor module in the rack is replaced.

3. If you have not already done so, connect the personal computer

to the leftmost processor in the rack, following the directions

in 4.4.

4. Enter a <CR> at the initial screen. If you are using AutoMax

Version 2, select F10 for Load Operating System". If you are

using AutoMax Version 3, select Load Operating System" from

the Commands menu. Note that you will see the message Local

OS invalid Ć Direct connection only" before you load the

operating system for the first time. The AutoMax Executive

software will load the operating system onto all Processor

modules in the local rack at the normal baud rate. The AutoMax

Executive will display on the screen the portion (%) of the

operating system that has been loaded.

5. When installation begins, the code L" O" will disappear from the

two sevenĆsegment LEDs on the leftmost Processor module. The

LEDs should be blank. If any error codes appear on the LEDs of

the leftmost Processor, the loading was not successful. Repeat

step 4 above.

6. You can now load the operating system to other racks in the

system connected to the local rack (the rack to which your

personal computer is connected) through 57C404A Network

Communication modules. For any network containing 57C404

Network Communication modules, you must connect directly to

each rack on the network to load the operating system (see steps

1Ć5 above).

4Ć2

Page 23

All Processors in all racks on a network containing only 57C404A

modules can be accessed and loaded through the single

connection at the local rack. Note that you do not need to

establish a network connection through the ONĆLINE menu to

load an operating system over a network. The loading procedure

is always performed through Load Operating System on the

Commands menu.

To load the operating system over a network(s) connected to the

local rack through 57C404A Network Communication modules,

select Load Operating System" from the Commands menu

again. Select N" to load the operating system over the

network(s). Then select A" to load the standard operating system

or E" to load the Ethernet operating system. At this point, you

have three choices:

Ć enter A" to load the operating system to all drops on all

networks that do not already have an operating system.

When the procedure is complete, the system will print the

drop numbers that have not been loaded to the screen.

Ć enter O" to load the operating system to all drops on all

networks, regardless of whether the Processors in those

drops already have an operating system. This option will

write over all operating systems that exist in all Processors on

all networks. It will also require that you reĆload any tasks that

exist on those Processors. Note that this option requires the

password to be entered.

Ć enter the slot number of the Network module representing

the network you want to load over. If you select this option,

you will also be able to choose to load the operating system

to one drop, all drops on this network where there is no

operating system, or to load the operating system to all

drops on this network regardless of whether there is an

existing operating system. This third option will require that

you reĆload any tasks that exist on the Processors whose

operating systems were overĆwritten. If you choose the third

option, the system will print the drop numbers that have not

been loaded to the screen. The password is required to

overĆwrite any existing operating system.

Enter your choice and <CR>.

4.2 Accessing Processor Ports

All Processor ports in the rack except the port

PROGRAMMER/PORT B" in the leftmost Processor are available to

the user. A port can be accessed using the OPEN statement (OPEN

PORTA or OPEN PORTB) in BASIC tasks running on the specific

Processor on which the port is located. Refer to JĆ3675 for more

information on the OPEN statement.

Refer to figure 4.1 for information about the OPEN statement SETUP

parameter for the AutoMax Processor. Defaults are indicated by (D).

4Ć3

Page 24

hex number

0D00

1514131211109876543210

OPTIONAL TERMINATION

CHARACTERS FOR INPUT

STATEMENTS

1: XĆON, XĆOFF HANDSHAKE

ENABLED (D)

1: HARD COPY DEVICE

0: NON HARD COPY DEVICE (D)

1: ECHO ON (D)

0: ECHO OFF

0: 7ĆBIT CHARACTERS

1: 8ĆBIT CHARACTERS (D)

0: ODD PARITY (D)

1: EVEN PARITY

0: PARITY DISABLED (D)

1: PARITY ENABLED

0: 1 STOP BIT (D)

1: 2 STOP BITS

0: HARDWARE HANDSHAKING

DISABLED (D)

0D00 = Default Setting

Figure 4.1 Ć Specifying the SETUP Parameter in an OPEN Statement

1: HARDWARE HANDSHAKING

ENABLED

4.3 Programmable Tick Rate

Control Block, BASIC, and PC tasks can be executed at a fixed scan

rate. The scan rate for a Control Block task is set using the

SCAN_LOOP function; the scan rate for a BASIC task is set using the

START EVERY statement; the scan rate for a PC task is set in the

editor. (In addition, a BASIC task can be delayed by using the DELAY

statement.) All of these scan rates can be specified in terms of ticks.

The programmable tick rate" allows you to change the definition of

the tick. By changing the tick, the time base for tasks is changed.

This change allows you to run a task at a scan rate other than the

default of 5.5 msec. It also allows you to execute application tasks at

more easily understood scan times (5.0 msec or 10.0 msec.).

The tick rate is set using the Rack Configurator in the AutoMax

Programming Executive Version 3.1 or later. It is not available when

using previous versions of the Programming Executive. The tick rate

can be set when a Processor module is added or modified. The

programmable tick rate can be set in increments of 0.5 msec.

between 0.5 msec and 10.0 msec. For compatibility, the default tick

rate is 5.5 msec. The tick rate is defined separately for each

Processor in a rack.

The tick rate is transferred when the configuration object code is

transferred to the Processor. The tick rate is set on the Processor

immediately when the configuration is loaded.

4Ć4

Page 25

A Control Block task containing the CML block must not be present

when a tick rate of other than 5.5 msec. is used. If a Control Block

task with the CML block is installed and the tick rate is not 5.5 msec.,

the task installation will fail.

A tick rate below 2.0 msec is not recommended for 6010/6011

Processors due to system overhead. A Control Block task containing

with at most 15 average blocks (an average block has a 70

execution time) can run with a 2.0 msec. tick rate; a task with 30

blocks can run at 3.0 msec.

4.4 Restrictions

This section describes limitations and restrictions on the use of this

module.

4.4.1 Number of Processors in a Rack

A maximum of four Processor modules may be plugged into the

rack. M/N 57C430A, M/N 57C431, and M/N 57C435 can be used in

the same rack.

4.4.2 Rack Slot Restrictions

A Processor module can occupy any slot from 0Ć4 in the 6, 10 or

16Ćslot AutoMax rack. If the rack will contain multiple Processors, slot

0 must contain a Common Memory module and slots 1Ć4 can contain

Processors.

4.4.3 Use with the DCS5000 M/N 57C407 Processor

Module or the 57C430 Processor Module

A M/N 57C430A, M/N 57C431, or M/N 57C435 Processor module

cannot be used in a rack that also contains a M/N 57C407 Processor

module or a 57C430 Processor module.

A rack can contain either 1) DCS5000 Processors only, or 2)

M/N 57C430A, 57C431, and 57C435 Processors only. You can,

however, connect the racks together over a network.

msec

4.4.4 Ethernet Commands

All tasks using Ethernet commands must be run on the leftĆmost

Processor in the rack.

4Ć5

Page 26

fadfdfdasfdsfdsdsdfdsfdsfdsfsdfdsa

dfdsfdsfdfdsfdsfsadfda

fdfaddfdd

Page 27

5.0 DIAGNOSTICS AND

TROUBLESHOOTING

This section explains how to troubleshoot the Processor module and

field connections. If the problem cannot be corrected by following the

instructions below, the module is not userĆserviceable.

WARNING

WHEN WRITING TO OUTPUTS, BE CAREFUL TO INSURE THAT NO UNEXPECTED

MACHINE MOTION WILL RESULT. FAILURE TO OBSERVE THIS PRECAUTION

COULD RESULT IN BODILY INJURY OR DAMAGE TO EQUIPMENT.

5.1 The OK" LED Is Off

Problem: The OK" LED on the Processor module faceplate is off.

The possible causes of this problem are the following: the Processor

has failed its powerup diagnostics, the watchdog timer has been

allowed to expire, or the power supply is malfunctioning. If the power

supply is functioning correctly, i.e., providing sufficient power to the

rack, the Processor module must be replaced. Use the following

procedure to isolate a problem with the power supply:

DANGER

THE CONNECTOR ON THE FACEPLATE OF THE POWER SUPPLY IS AT LINE

VOLTAGE WHEN AC POWER IS APPLIED. DISCONNECT ALL POWER FROM

THE POWER SUPPLY BEFORE HANDLING THE WIRING. FAILURE TO OBSERVE

THIS PRECAUTION COULD RESULT IN SEVERE BODILY INJURY OR LOSS OF

LIFE.

Step 1. Verify that the power supply is receiving 115V AC power.

If the power is on, the POWER ON" LED on the power

supply faceplate should be lit, indicating the presence of

115V AC power. If the LED is not lit, check the wiring to the

faceplate terminals marked 120VAC L1" and L2".

Step 2. Verify that there has been no short circuit.

A. If you are using Power Supply M/N 57C491:

If the power is on, the P/S READY" LED on the power

supply faceplate should be on. If the LED is off, use the

following procedure to isolate the problem.

a) Turn off power to the Rack and all connections.

Wait until the LEDs on the faceplate of the Power

Supply have gone out. Use a screwdriver to loosen

the screws holding the Power Supply module in the

Rack. Slide the module out about one inch to

ensure that the backplane connections have been

broken. Do not take the module out of the Rack.

5Ć1

Page 28

b) Turn on power to the Rack. If the P/S FAULT LED

turns on, the problem lies in the Rack backplane.

Go on to step 2c.

If the P/S READY LED does not light, the Power

Supply module is malfunctioning and needs to be

replaced.

c) Turn off power again. Wait until all LEDs on the

faceplate of the Power Supply module have gone

out. Use a screwdriver to disconnect the terminal

strip from the Power Supply module. Do not

remove the wires from the terminal strip.

d) Remove the module from the Rack and verify that

card edge connectors are clean and that the

connectors on the backplane are in good

condition.

e) ReĆinsert the Power Supply module. Use a

screwdriver to reĆconnect the terminal strip to the

Power Supply module. Turn on power to the Rack.

If the problem is not corrected, replace the Rack.

B. If you are using Power Supply M/N 57C493:

The FAULT LED on the Power Supply module should

always be off when input power is on, the Power

Supply output voltage is within proper limits, and the

watchdog alarm coming from the backplane is not

active. If the Power Supply FAULT LED is on, use the

following procedure to isolate the problem.

a) Turn off power to the rack and all connections.

b) Replace the Processor module whose OK LED was

off.

c) Turn on power to the rack. If the Power Supply

FAULT LED turns on, the problem is with the Power

Supply.

Step 3. Verify that the power supply output is sufficient to power

all of the modules in the rack.

Check the total power requirements for the modules in the

rack against the power supply output.

5.2 The BAT. OK" LED Is Off

Problem: The BAT. OK" LED on the Processor module faceplate is

off. The possible causes of this problem are the following:

D the tape covering the battery has not been removed

D the battery is not facing in the proper direction

D the battery is missing

D the battery is malfunctioning

D the power supply is malfunctioning

To correct the problem, first turn off power to the rack. Refer to steps

1Ć3 in section 3.4 for instructions on taking the Processor module out

of the rack to inspect the battery. If the tape is still covering the

battery, remove it. If the battery is missing or not facing in the proper

direction, insert the battery with the +" end facing the +" marking

5Ć2

Page 29

on the battery holder. If none of the above actions correct the

problem, replace the battery.

5.3 BUS ERROR

Problem: Codes 31" or 50" through 58" appear on the Processor

module's LEDs. These codes signify that a bus error occurred when

the system attempted to access an I/O module. The possible causes

of this error are the following: a missing module, a module in the

wrong slot, or a malfunctioning module. It is also possible that the

user has attempted to write to the wrong registers on a module

through an application task. Use the following procedure to isolate a

bus error:

Step 1. Determine where the bus error occurred.

Connect the personal computer to the rack and run the

ReSource AutoMax Programming Executive. Display the

error log for the Processor that indicates the error. The

error log should indicate the address that caused the bus

error or a line number in a BASIC or Control Block

application task. The address will be displayed in

hexadecimal notation. To decode the address, follow the

directions below.

a. To determine the slot number where the bus error

occurred, convert the hex address into a bit pattern

and decode in decimal notation as follows:

Most Significant 16 Bits

BIT

31 30 29 28 27 26 25 24 22 21 20 19 18 17 1623

00 0010

0 = Forced

1 = Unforced

BYTE

BIT #

THIS RACK

SLOT #

5Ć3

Page 30

b. To determine the register in the slot where the bus

error occurred, take the slot number you decode in

THIS RACK SLOT #" and decode the least significant

16 bits according to the type of module found in the

slot:

Any Local I/O Module*

Least Significant 16 Bits

BIT

1514131211109876543210

REGISTER

A Remote I/O Module (M/N 57C416)

Least Significant 16 Bits

BIT

1514131211109876543210

000

BIT

1514131211109876543210

000

The bit number being accessed may be determined from word

bit#=BYTEBIT#+(8*b)

If BYTE BIT # and 8*b = 0, address may have been accessed

as a word (integer) or bit 0 of byte 0.

DROP

A Network Communications Module (M/N 57C404)

REMOTE

RACK SLOT

Least Significant 16 Bits

DROP

REGISTER

REGISTER

b

b

b

5Ć4

* The hexadecimal number represents the Multibus

address of the error. Therefore, the standard Reliance

register number for any type of module can be decoded

from this figure and the figure in part a. For more specific

information, e.g., drop number, use the applicable figures

that follow.

Page 31

A Modbus Interface Module (M/N 57C414)

Least Significant 16 Bits

BIT

1514131211109876543210

R

where R is a local register address, which may be used with the I/O monitor.

Determine the Modbus register number from the following table:

R (Decimal) Modbus Register (Decimal)

ăă64ă-ă319

ă320ă-ă575

ă576ă-ă1599

1600ă-ă2623

BIT

1514131211109876543210

where R is a local register address, which may be used with the I/O monitor.

Determine the AĆB register number from the following table:

R (Decimal)

ăă64ă-ă319

ă320ă-ă575

ă576ă-ă1599

1600ă-ă2623

[(R - 64)*16] + BYTE BIT#+8*b+1

[(R - 320)*16] + BYTE BIT # + 8*b + 10001

(R - 576) + 30001

(R - 1600) + 40001

An AllenĆBradley Interface Module (M/N 57C418)

Least Significant 16 Bits

R

AĆB

File

B0

B1

N0

N1

AĆB Register

(Decimal)

R-64

R - 320

R - 576

R - 1600

b

b

An AutoMate Interface Module (M/N 57C417)

Least Significant 16 Bits

BIT

1514131211109876543210

R

where R is a local register address, which may be used with the I/O monitor.

Determine the AutoMate register number from the following table:

R (Decimal)

ăă64ă-ă319

ă320ă-ă575

ă576ă-ă1599

1600ă-ă2623

AutoMate Register (Octal)

0000.00 - 0377.17

0400.00 - 0777.17

ăăĂ2000 - 3777

ăăĂ4000 - 5777

b

5Ć5

Page 32

c. When you have determined the slot and register

address at which the bus error occurred, go on to the

steps below. If THIS RACK SLOT #" referred to a

Remote I/O or Network module, make certain you are

working with the card in the remote or network drop

when you go on to the remaining steps in this section.

Step 2. Verify that there is a module in the slot and that the I/O

Step 3. Verify that the module can be accessed.

Step 4. Verify that the user application software is correct.

Step 5. Verify that the hardware is working correctly.

definitions in the configuration are correct for the module.

Refer to figure 3.2. Verify that the register numbers defined

in the configuration are valid for the module.

For remote I/O installations, also verify that the master slot

and remote drop number are defined correctly.

Use the I/O Monitor function in the ReSource AutoMax

Programming Executive to display the registers on the

module. If the personal computer is able to monitor the

registers, the problem lies in the application software (refer

to step 4). If you cannot monitor the registers, the problem

is in the hardware (refer to step 5).

If a BASIC task caused the bus error, the error log will

contain the statement number in the task where the error

occurred. If a Control Block or Ladder Logic task caused

the error, you will need to search the task for any instances

where you wrote to an input.

Verify the hardware functionality by systematically

swapping out the module in question, the Processor

module(s) or slave Remote I/O module, and the

backplane. After each swap, if the problem is not

corrected, replace the original item before swapping out

the next item.

5.4 Common Memory Module Diagnostic

Failure

Problem: The green LED on a Common Memory module located in

slot 0 is off, and a Processor module in the rack displays codes 4.0.

through 4.6. These error codes mean that the Common Memory

module has failed one of its powerĆup diagnostics.

Systematically swap out the Common Memory module and the

Processor module(s). After each swap, if the problem is not

corrected, replace the original item before going on to the next item.

If the problem persists, take all of the modules except the Common

Memory module and one Processor module out of the rack. If the

problem is now corrected, another module in the rack is causing the

problem. Replace the remaining modules one at a time until the

problem reappears. If none of these tests reveals the problem, try

replacing the backplane.

5Ć6

Page 33

5.5 Incorrect Data

Problem: The data used by application tasks is either always off,

always on, or different than expected. The possible causes of this are

the following: a module in the wrong slot, a programming error, or a

malfunctioning module.

Step 1. Verify that all inputs to the rack are wired to the correct

Step 2. Verify that the input circuit on each input module is

Step 3. Verify that each module can be accessed.

Step 4. For all modules in the rack, verify that the configuration

Step 5. Verify that the application programs running in the rack

Step 6. Verify that the hardware is working correctly.

devices.

Confirm that all connections at the terminal strip are tight.

Connect a voltmeter to the proper points on the terminal

strip and toggle each device. Verify that the device is

generating the correct voltage or current, depending upon

the module you are testing. If the voltage or current is

incorrect, there is a problem with the external device, its

power supply, or the wiring to the terminal strip.

Check the cable for continuity between the faceplate

connector and the terminal strip.

working correctly.

Toggle the input devices to verify that the LED associated

with each is also toggling. If it is not toggling, either the

LED or the input module itself is malfunctioning.

Connect the personal computer to the rack and run the

ReSource AutoMax Programming Executive.

Stop all programs that may be running.

Use the I/O Monitor function to display the individual I/O

points or registers on the module, whichever is

appropriate. If the points can be monitored, the problem

lies in the application software (refer to steps 4 and 5). If

the points cannot be monitored, the problem lies in the

software (go on to step 6).

references the correct slot and register locations. For

remote I/O installations, also verify that the master slot and

drop number are referenced correctly.

are correct.

Check to see that the application programs that reference

the symbolic names associated with the hardware in the

rack have declared those names COMMON.

To test local I/O, systematically swap out the module in

question and the Processor module(s). If the problem

persists, take all of the modules except the module in

question and one Processor out of the rack. If the problem

is now corrected, one of the other modules in the rack is

causing the problem. Reconnect the other modules one at

a time until the problem reappears. If none of these tests

reveals the problem, replace the backplane.

To test the remote I/O system, first verify that the remote

I/O system is communicating with the drop that contains

the module being tested. Next, by systematically

5Ć7

Page 34

swapping out modules, determine whether the module

being tested is the only module that is not working

correctly. If more than one module is not working correctly,

the problem most likely lies in the remote I/O system.

Refer to the instruction manual for the M/N 57C416

Remote I/O Communications module for more information.

If the problem does not lie in the remote I/O system, it

probably involves the remote rack.

To test the remote rack, systematically swap out the

module being tested and the slave Remote I/O module. If

the problem persists, take all of the modules except the

slave Remote I/O module and the module being tested out

of the rack. If the problem is now corrected, one of the

other modules in the rack is malfunctioning. ReĆconnect

the other modules one at a time until the problem

reappears. If the problem appears to be neither in the

remote I/O system nor in the remote rack replace the

backplane.

5Ć8

Page 35

Appendix A

Technical Specifications

M/N 57C430A

Ambient Conditions

D Storage temperature: -40_CĆ85_C

D Operating temperature: 0_CĆ60_C

D Humidity: 5Ć90% nonĆcondensing

Maximum Module Power Dissipation

D 15 Watts average

Dimensions

D Height: 11.75 inches

D Width: 1.25 inches

D Depth: 7.37 inches

System Power Requirements

D 5 Volts: 3000 mA average

D +12 Volts: 100 mA average

D -12 Volts: 100 mA average

Battery Specifications

D Type: Lithium

D Size: AA

D Voltage: 3.6 Volts

D Amp. Hrs.: 2.0

Memory Retention

D Minimum holdĆup with battery: 42 days

D Typical holdĆup with battery: 333 days

D Minimum holdĆup without battery: 10 minutes

D Typical holdĆup without battery: 10 hours

D Maximum chargeĆup time: 15 minutes

Serial Port Specifications

D Type: RSĆ232C

D Electrical Isolation: 450 Volts

D Voltage: +/-12 Volts

D Maximum current per channel: +/-30 mA

AĆ1

Page 36

Appendix A (Continued)

Technical Specifications

M/N 57C431

Ambient Conditions

D Storage temperature: -40_CĆ85_C

D Operating temperature: 0_CĆ60_C

D Humidity: 5Ć90% nonĆcondensing

Maximum Module Power Dissipation

D 15 Watts average

Dimensions

D Height: 11.75 inches

D Width: 1.25 inches

D Depth: 7.37 inches

System Power Requirements

D 5 Volts: 3000 mA average

D +12 Volts: 100 mA average

D -12 Volts: 100 mA average

Battery Specifications

D Type: Lithium

D Size: AA

D Voltage: 3.6 Volts

D Amp. Hrs.: 2.0

Memory Retention

D Minimum holdĆup with battery: 42 days

D Typical holdĆup with battery: 333 days

D Minimum holdĆup without battery: 10 minutes

D Typical holdĆup without battery: 10 hours

D Maximum chargeĆup time: 15 minutes

Serial Port Specifications

D Type: RSĆ232C

D Electrical Isolation: 450 Volts

D Voltage: +/-12 Volts

D Maximum current per channel: +/-30 mA

AĆ2

Page 37

Appendix A (Continued)

Technical Specifications

M/N 57C435

Ambient Conditions

D Storage temperature: -40_CĆ85_C

D Operating temperature: 0_CĆ60_C

D Humidity: 5Ć90% nonĆcondensing

Maximum Module Power Dissipation

D 15 Watts average

Dimensions

D Height: 11.75 inches

D Width: 1.25 inches

D Depth: 7.37 inches

System Power Requirements

D 5 Volts: 3000 mA average

D +12 Volts: 100 mA average

D -12 Volts: 100 mA average

Battery Specifications

D Type: Lithium

D Size: AA

D Voltage: 3.6 Volts

D Amp. Hrs.: 2.0

Memory Retention

D Minimum holdĆup with battery: 186 days

D Typical holdĆup with battery: 8.2 years

D Minimum holdĆup without battery: 10 minutes

D Typical holdĆup without battery: 10 hours

D Maximum chargeĆup time: 15 minutes

Serial Port Specifications

D Type: RSĆ232C

D Electrical Isolation: 450 Volts

D Voltage: +/-12 Volts

D Maximum current per channel: +/-30 mA

AĆ3

Page 38

fadfdfdasfdsfdsdsdfdsfdsfdsfsdfdsa

dfdsfdsfdfdsfdsfsadfda

fdfaddfdd

Page 39

ADDRESS

I/O BUS

ADDRESS

BUS

DATA

MULTIBUS

Appendix B

Module Block Diagram

Processor Module (57C430A)

LITHIUM

BATTERY

SUPER

CAPACITOR

B

U

S

I

N

T

E

R

F

A

C

E

DATA

ADDRESS

68010

MPU

PIO

TIMER

BAUD RATES

2

CHANNEL

UART

16K X 16

EPROM

WATCHDOG

TIMER

INTERRUPT

CONTROLLER

REAL TIME CLOCK

DC/DC

CONVERTER

X

M

I

T

R

C

V

BATTERY

OK

OK

2

XMIT

4

RTS

20

DTR

3

RECV

5

CTS

6

DSR

COM

+5V

+12V

-12V

128K X 16

PARITY

RAM

DC/DC

CONVERTER

X

M

I

T

R

C

V

2

XMIT

4

RTS

20

DTR

3

RECV

5

CTS

6

DSR

COM

BĆ1

Page 40

ADDRESS

I/O BUS

ADDRESS

BUS

DATA

MULTIBUS

Appendix B (Continued)

Module Block Diagram

Processor Module (57C431)

LITHIUM

BATTERY

SUPER

CAPACITOR

B

U

S

I

N

T

E

R

F

A

C

E

DATA

ADDRESS

68010

MPU

PIO

TIMER

BAUD RATES

2

CHANNEL

UART

16K X 16

EPROM

WATCHDOG

TIMER

INTERRUPT

CONTROLLER

REAL TIME CLOCK

DC/DC

CONVERTER

X

M

I

T

R

C

V

BATTERY

OK

OK

2

XMIT

4

RTS

20

DTR

3

RECV

5

CTS

6

DSR

COM

BĆ2

+5V

+12V

-12V

256K X 16

PARITY

RAM

DC/DC

CONVERTER

X

M

I

T

R

C

V

2

XMIT

4

RTS

20

DTR

3

RECV

5

CTS

6

DSR

COM

Page 41

ADDRESS

I/O BUS

ADDRESS

BUS

DATA

MULTIBUS

Appendix B (Continued)

Module Block Diagram

Processor Module (57C435)

LITHIUM

BATTERY

SUPER

CAPACITOR

B

U

S

I

N

T

E

R

F

A

C

E

DATA

ADDRESS

68020

MPU

PIO

TIMER

2

CHANNEL

UART

32K X 8

EPROM

WATCHDOG

TIMER

INTERRUPT

CONTROLLER

REAL TIME CLOCK

X

M

T

R

C

V

BATTERY

DC/DC

CONVERTER

I

OK

OK

2

XMIT

4

RTS

20

DTR

3

RECV

5

CTS

6

DSR

COM

+5V

+12V

-12V

128K X 32

PARITY

RAM

DC/DC

CONVERTER

X

M

I

T

R

C

V

2

XMIT

4

RTS

20

DTR

3

RECV

5

CTS

6

DSR

COM

BĆ3

Page 42

fadfdfdasfdsfdsdsdfdsfdsfdsfsdfdsa

dfdsfdsfdfdsfdsfsadfda

fdfaddfdd

Page 43

Appendix C

Connecting the AutoMax Processor

to the Personal Computer

If it is necessary to prepare a cable to connect a personal computer to the

AutoMax Processor, follow the steps below. See the PC3000 User Manual

(J2Ć3096) for more information about connecting the PC3000 processor to the

personal computer.

WARNING

THE FOLLOWING INSTRUCTIONS ARE INTENDED ONLY TO ALLOW

FABRICATION OF PROPER CONNECTIONS BETWEEN RELIANCE EQUIPMENT

AND USERĆPROVIDED PROGRAMMING DEVICES. THE USER MUST READ AND

UNDERSTAND ALL APPLICABLE INSTRUCTION MANUALS PRIOR TO

OPERATING THE EQUIPMENT. FAILURE TO OBSERVE THIS PRECAUTION

COULD RESULT IN BODILY INJURY.

1. Determine whether your programming terminal contains a 9Ć or 25Ćpin male

connector.

2. Cut a suitable length (not to exceed 10 feet) of 22Ćgauge, multiĆconductor

cable.

3. Follow the connector manufacturer's instructions and make cable

connections using figure 1 or 2, whichever is applicable.

4. Check for grounds, shorts, and continuity using an Ohm meter.

Programming Terminal End of Cable

25ĆPin Female Connector

SIGNAL PIN#

RECV ă3

XMIT ă2

CTS ă5

RTS ă4

DTR 20

DSR ă6

COM ă7

Reliance End of Cable

25ĆPin Male Connector

PIN# SIGNAL

ă2 XMIT

ă3 RECV

ă4 RTS

ă5 CTS

ă6 DSR

20 DTR

ă7 COM

Figure 1

CĆ1

Page 44

Programming Terminal End of Cable

9ĆPin Female Connector

SIGNAL PIN#

Reliance End of Cable

25ĆPin Male Connector

PIN# SIGNAL

RECV ă2

XMIT ă3

CTS ă8

RTS ă7

DTR ă4

DSR ă6

COM ă5

Figure 2

ă2 XMIT

ă3 RECV

ă4 RTS

ă5 CTS

ă6 DSR

20 DTR

ă7 COM

User Serial Ports

All AutoMax Processor module ports except for the port labeled

PROGRAMMER/PORT B" on the leftmost Processor in the rack are available to

the user to connect to an external device which will be controlled by application

tasks running on the Processor. Refer to the Enhanced BASIC Language

Instruction Manual (JĆ3675) for more information. Note that with AutoMax

Processor modules, you can use the statements OPEN PORTA or OPEN PORTB.

Note: if you do not enable bit 15 (hardware handshaking) in the SETUP parameter of

the OPEN statement, only pins 2, 3, and 7 of the port you OPEN will be meaningful.

Pin# I/O Function

2 O This signal contains transmitted data.

3 I This signal contains received data

4 O Transmit status. This signal is true whenever the transmitter is sending

5 I This signal enables the transmitter. It must be true for the transmitter to

6 I This signal enables the receiver. It must be true in order for the receiver

7 Signal ground.

10 O This signal is an isolated +12 Volt which can be used as an enable

20 O This signal indicates receiver status. The signal is true whenever the

See the following page for examples.

characters. It is used to bracket" a character transmission. It can be

used to enable/disable any type of external equipment, such as a

triĆstate transmit modem, which requires an enable signal to output

characters. Refer to the OPEN statement in the Enhanced BASIC

Language manual (JĆ3675) for details concerning the operation of the

modem enable signal (RTS pin on connector).

send a character. This signal is typically used for hardware flow control.

It is meaningful only if hardware handshaking has been enabled.

to accept characters. If the signal becomes false while a message is

being received, any characters being received will be deleted and an

error will be reported to the application software. This signal is

meaningful only if hardware handshaking has been enabled.

or equipment ready indicator. The signal is always on whenever

power is applied to the Processor.

receiver can accept characters, i.e., when the receive buffer is not

full. When the receive buffer fills to within a specified limit (53

characters), the signal is turned off. The signal can be used to

disable another transmitter. It is meaningful only when hardware

handshaking has been enabled.

CĆ2

Page 45

Appendix C

(Continued)

The following figures describe typical user port pin configurations.

Modem Transmit Enable

with No Flow Control

AutoMax Processor

TXD

2

RXD

3

RTS

4

7

CTS

5

TRANSMIT

RECV

MODEM ENABLE

SIGNAL COM

User Equipment

M

O

D

E

M

TRANS

RECV

SIG COM

DSR

6

20

NC

+12V

10

AutoMax Processor

2

TXD

RXD

3

7

4

CTS

5

DSR

6

20

10

XMIT is always enabled

RCV is always enabled

NOTE: CTS and DSR must be asserted when hardware

handshaking has been enabled (bit 15 in setup parameter

of OPEN statement).

Cable Break Detect

User Equipment

(2) (to user Trans pin)

(3) (to user Recv pin)

(7) (to user Sig Com)

(must be asserted, +5 to +12 volt

level, wire to pin 10 on AutoMax

RSĆ232 connector or to user Equip

Ready pin on RSĆ232 connector)

CĆ3

Page 46

OneĆDirectional Flow Control

(Hardware Handshaking)

AutoMax Processor

2

TXD

RXD

3

7

4

Appendix C

(Continued)

(2)

(3)

(7)

User Equipment

The user transmitter is

disabled or shut off when

the AutoMax receiver is full.

In this configuration no

characters are lost by the

AutoMax task receiving

characters.

5

DSR

6

20

10

DTR

+12V

BiĆDirectional Flow Control

AutoMax Processor

2

TXD

RXD

3

7

4

CTS

5

DSR

6

(5) (Transmit Enable)

(Hardware Handshaking)

User Equipment

2

(to user Trans pin)

3

(to user Recv pin)

7

(to user Sig Com)

4

5

(Trans Enable)

6

CĆ4

20

10

DTR

+12V

20

10

(Recv Buffer Status)

In this configure bin, no

characters are lost by the

AutoMax task or user equipment

receiving characters.

Page 47

Appendix D

Diagnostic LED Error Codes

Processor Overload

00 CPU overload

Corrective action: move one or more application tasks to other Processor

modules in the racks, or make scan times longer.

PowerĆUp Diagnostics

The following error codes are displayed while the Processor module performs

powerĆup diagnostics.

0.0. EPROM failed

0.1.Ć 0.3. Bad CPU

0.4. Internal bus error test failure

0.5. Parity test failure

0.6. External bus error test failure

0.7. Processor in the wrong slot

1.0. Ć 1.6. RAM failure

2.0. I/O protection failure

2.1. PIO failed

2.2. PC accelerator failed

2.3. 8253 timer/counter failed

2.4. SIO failure

2.5. Communications interrupt failed

2.6. SIO interrupt failed

2.7. 8253 counter timer interrupt failed

2.8. Local watchdog failed

3.0. Bad backplane

3.1. Multibus parity test failure

4.0. Ć 4.5. Common memory RAM failure

4.6. Common memory system watchdog failure

5.0 Processors with incompatible EPROMs in the rack

Corrective action: replace the Processor (M/N 57C430A, 57C431, or 57C435), or

replace the Common Memory module (M/N 57C413) if error codes 4.0.Ć 4.6.

remain on.

Run Time Errors

02 Task or configuration checksum failure

Corrective action: clear the error.

Runbase Booting

The following status/error codes are displayed while you load the runbase, or

operating system, onto the Processor module(s) using the AutoMax

programming software. All of the following codes except 6.5. apply to the top port

of the Processor module, labeled Programmer/Port B".

5.1 Incompatbile runbase downloaded

6.0. Unexpected interrupt on upper port of processor

6.1. Parity error

6.2. Receiver overrun

6.3. Framing error

DĆ1

Page 48

6.4. Serial port fatal error

6.5. Illegal interrupt on lower port of processor

6.6. Transmit interrupt error

6.7. Runbase integrity lost

6.8. Bad runbase checksum

6.9. Transmit buffer error

7.0. MultiĆprocessor runbase download in progress

7.1. Disconnect timeĆout during download

7.2. Spurious interrupt received

Corrective action: 6.3. may be caused by attempting AutoMax ONĆLINE

PROGRAMMING functions before the runbase is loaded onto the Processor

module(s) in the rack. In this case, exit the ONĆLINE PROGRAMMING menu and

download the runbase. 7.0 is a status message only. For all other error codes,

cycle power and try to load the runbase again.

Loading the Runbase over the Network

8.0. Bad message length specified for network message

8.1. Bad destination drop

8.2. Transmitting drop inactive

8.3. Destination port unallocated

8.4. Destination port busy

8.5. Did not receive expected response

8.6. Spurious network interrupt received

8.7. Network message is being transmitted

Corrective action: 8.0. and 8.1. are caused by a failed Processor in the leftmost

slot. For 8.2., check the coax cable; then try replacing the network module. For

8.3. Ć 8.5., check the destination Network module, then the leftmost Processor in

the destination rack. For 8.6. and 8.7., cycle power and try to load the runbase

again.

Miscellaneous Process Errors

8.8. Processor failure

Corrective action: replace Processor module.

DĆ2

Page 49

Appendix E

Run Time LED Error Codes

WARNING

ONLY QUALIFIED PERSONNEL FAMILIAR WITH THE CONSTRUCTION AND

OPERATION OF THE CONTROLLED EQUIPMENT SHOULD INSTALL, ADJUST,

OPERATE, OR SERVICE THIS EQUIPMENT. READ AND UNDERSTAND THIS

MANUAL AND OTHER MANUALS APPLICABLE TO YOUR INSTALLATION.

FAILURE TO OBSERVE THIS PRECAUTION COULD RESULT IN BODILY INJURY.

WARNING

INSERTING OR REMOVING THIS MODULE OR ITS CONNECTING CABLES MAY

RESULT IN UNEXPECTED MACHINE MOTION. POWER TO THE MACHINE

SHOULD BE TURNED OFF BEFORE INSERTING OR REMOVING THE MODULE

OR ITS CONNECTING CABLES. FAILURE TO OBSERVE THESE PRECAUTIONS

COULD RESULT IN BODILY INJURY.

STOP ALL Error Codes

The following hardware and software error codes cause all tasks running in the

rack to stop.

10 Event count underflow

11 Event count overflow

12 Hardware event timeĆout

13 Runbase boot error

14 Processor overlap limit exceeded

15 External watchdog timeĆout detected

17 Address error detected

18 Spurious interrupt or hardware failure

19 Power failure detected

1A Watchdog on this Processor failed

1b Hardware event count limit exceeded

1C Illegal instruction detected

Ć too many WAITs (max. 32768)

Ć not enough SETs (BASIC tasks)

Ć too many SETs (max. 32767)

Ć not enough WAITs (BASIC tasks)

Ć interrupt time exceeded programmed timeĆout

limit in a Control Block task

Ć a check on the runbase failed

Ć ran out of processing capacity (time)

Ć another processor in the same rack stopped

Ć caused by a read/write to an invalid address

Ć too many interrupts set without being

acknowledged

Ć program too long

Ć collective scans too fast

Ć runbase software fault

Ć bad Processor module

Ć bad EPROMs

EĆ1

Page 50

1d Privilege violation detected

1E UnĆimplemented instruction detected