Page 1

2-Axis Servo Module

M/N 57C422B

Instruction Manual

J-3642-7

Page 2

The information in this manual is subject to change without notice.

WARNING

THIS UNIT AND ITS ASSOCIATED EQUIPMENT MUST BE INSTALLED,

ADJUSTED AND MAINTAINED BY QUALIFIED PERSONNEL WHO ARE

FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF ALL

EQUIPMENT IN THE SYSTEM AND THE POTENTIAL HAZARDS INVOLVED.

FAILURE TO OBSERVE THESE PRECAUTIONS COULD RESULT IN BODILY

INJURY

WARNING

INSERTING OR REMOVING THIS MODULE OR ITS CONNECTING CABLES

MAY RESULT IN UNEXPECTED MACHINE MOTION. POWER TO THE

MACHINE SHOULD BE TURNED OFF BEFORE INSERTING OR REMOVING

THE MODULE OR ITS CONNECTING CABLES. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN BODILY INJURY.

CAUTION

THIS MODULE CONTAINS STATIC-SENSITIVE COMPONENTS. CARELESS

HANDLING CAN CAUSE SEVERE DAMAGE.

DO NOT TOUCH THE CONNECTORS ON THE BACK OF THE MODULE. WHEN

NOT IN USE, THE MODULE SHOULD BE STORED IN AN ANTI-STATIC BAG.

THE PLASTIC COVER SHOULD NOT BE REMOVED. FAILURE TO OBSERVE

THIS PRECAUTION COULD RESULT IN DAMAGE TO OR DESTRUCTION OF

THE MATERIAL.

WARNING

RELIANCE STRONGLY RECOMMENDS THE USE OF AN EXTERNAL,

HARDWIRED EMERGENCY STOP CIRCUIT THAT WILL DISABLE THE

SYSTEM IN CASE OF IMPROPER OPERATION. UNCONTROLLED MACHINE

OPERATION MAY RESULT IF THIS PROCEDURE IS NOT FOLLOWED.

FAILURE TO OBSERVE THIS PRECAUTION COULD RESULT IN BODILY

INJURY OR DAMAGE TO EQUIPMENT

Rellance® and AutoMax@ are trademarks of Reliance Electric Company or its

subsidiaries.

Rellance™ is a registered trademark of Reliance Electric Company or its subsidiaries.

Page 3

Table Of Contents

1.0 Introduction......................................................................1-1

2.0 Mechanical/Electrical Description..................................2-1

2.1 Mechanical Description............................................2-1

2.2 Electrical Description ...............................................2-3

3.0 Installation........................................................................3-1

3.1 Wiring.......................................................................3-1

3.2 Initial Installation ......................................................3-1

3.3 Module Replacement.............................................3-11

4.0 Programming....................................................................4-1

4.1 Configuration ...........................................................4-2

4.2 Register 0: Encoder Setup.......................................4-3

4.3 Register 1: Drive Setup............................................4-4

4.4 Register 2: Switch Setup .........................................4-5

4.5 Register 3: Proportional Gain ..................................4-7

4.6 Register 4: Integral Gain..........................................4-7

4.7 Register 5: Velocity Gain.........................................4-7

4.8 Register 6: Feedforward Gain..................................4-8

4.9 Register 7: Deadband Compensation......................4-8

4.10 Register 8: Maximum Position Error........................4-9

4.11 Register 9: Maximum Velocity Error........................4-9

4.12 Register 10: In-Position Tolerance ........................4-10

4.13 Registers 11, 12: Positive Overtravel Limit............4-10

4.14 Registers 13, 14: Negative Overtravel Limit ..........4-11

4.15 Registers 15,16: Low Speed

Homing Reference.................................................4-11

4.16 Registers 17,18: Command Position .....................4-12

4.17 Registers 19, 20: Command Velocity ............. .......4-13

4.18 Registers 21, 22: Command Acceleration .............4-13

4.19 Registers 23, 24: Command Deceleration.............4-14

4.20 Registers 25, 26: Gear Ratio.......................... .......4-15

4.21 Register 27: User LEDs.........................................4-15

4.22 Register 28: Direct Drive Reference

Command..............................................................4-16

Note: Register descriptions for equivalent X and Y axis

registers are exactly the same. Although sections of

Chapter 4 are titled by X axis register number, the

equivalent Y register is given in the figure that

accompanies each register description.

I

Page 4

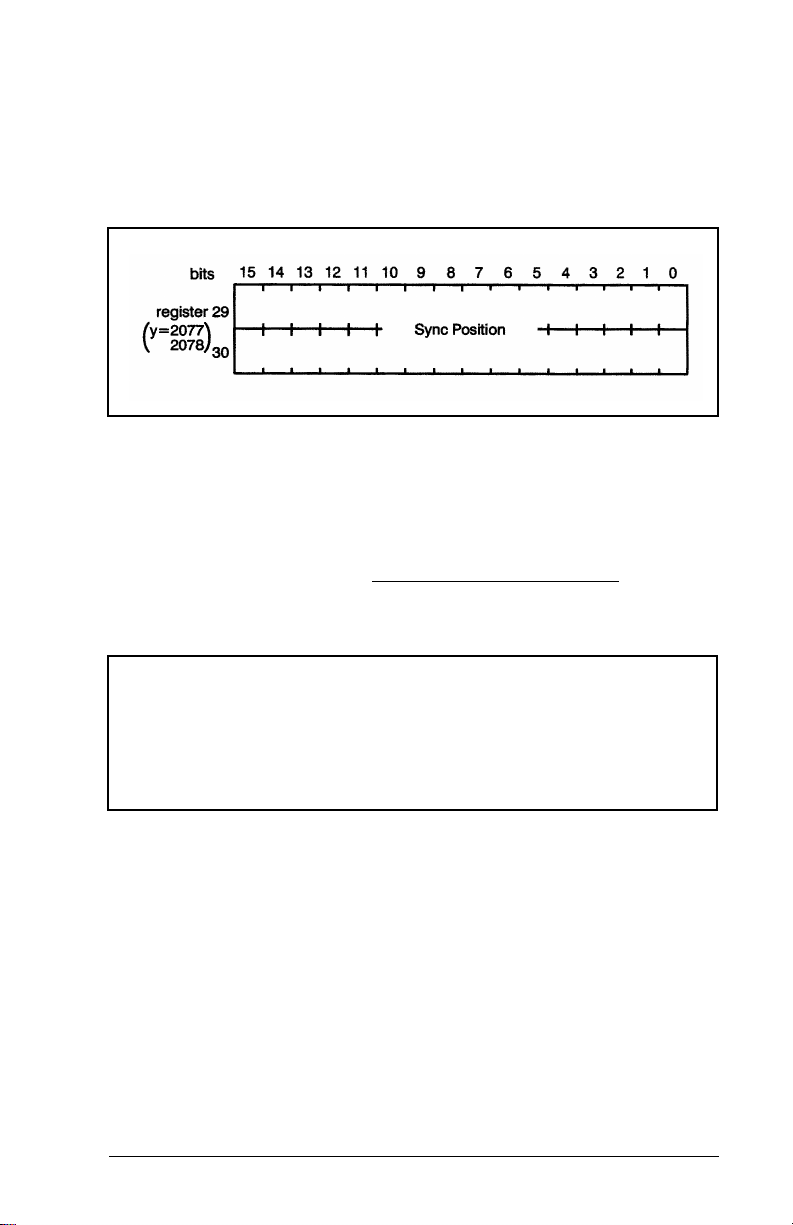

4.23 Registers 29, 30: Sync Position ............................ 4-16

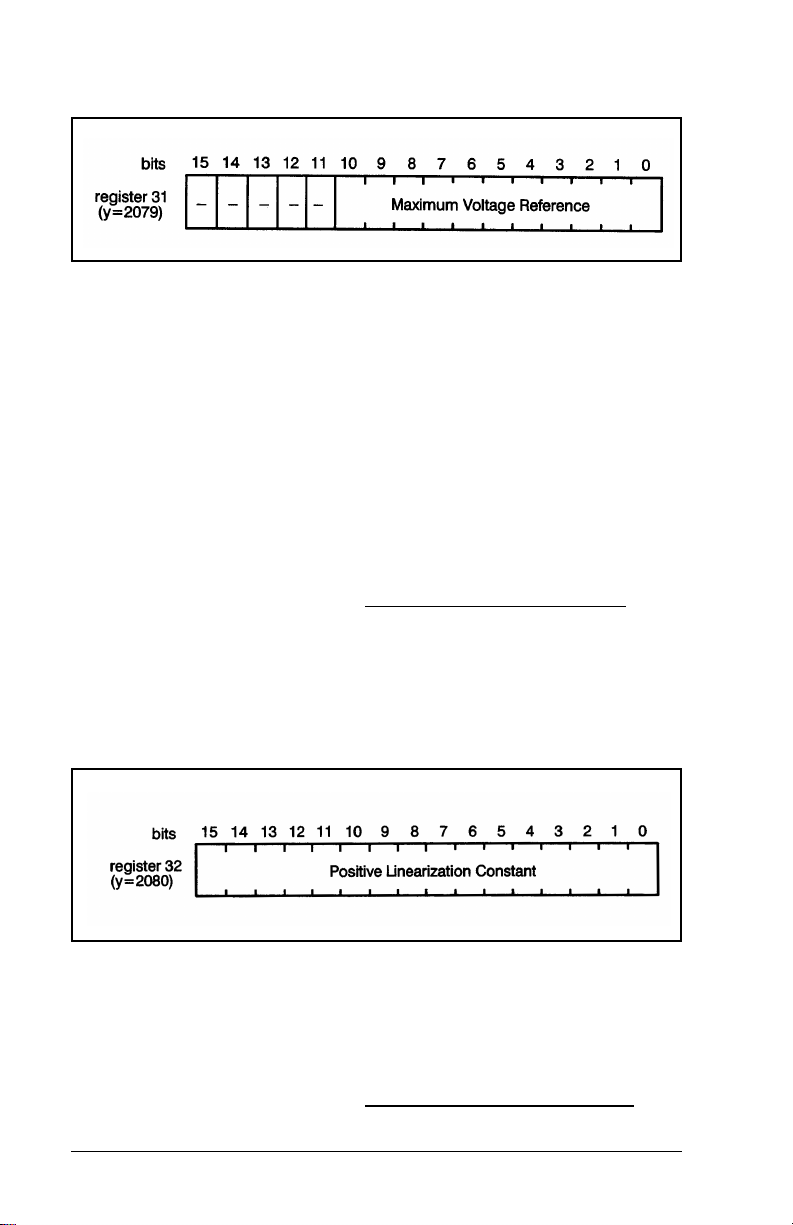

4.24 Register 31: Maximum Voltage Reference ........... 4-17

4.25 Register 32: Positive Linearization Constant ........ 4-18

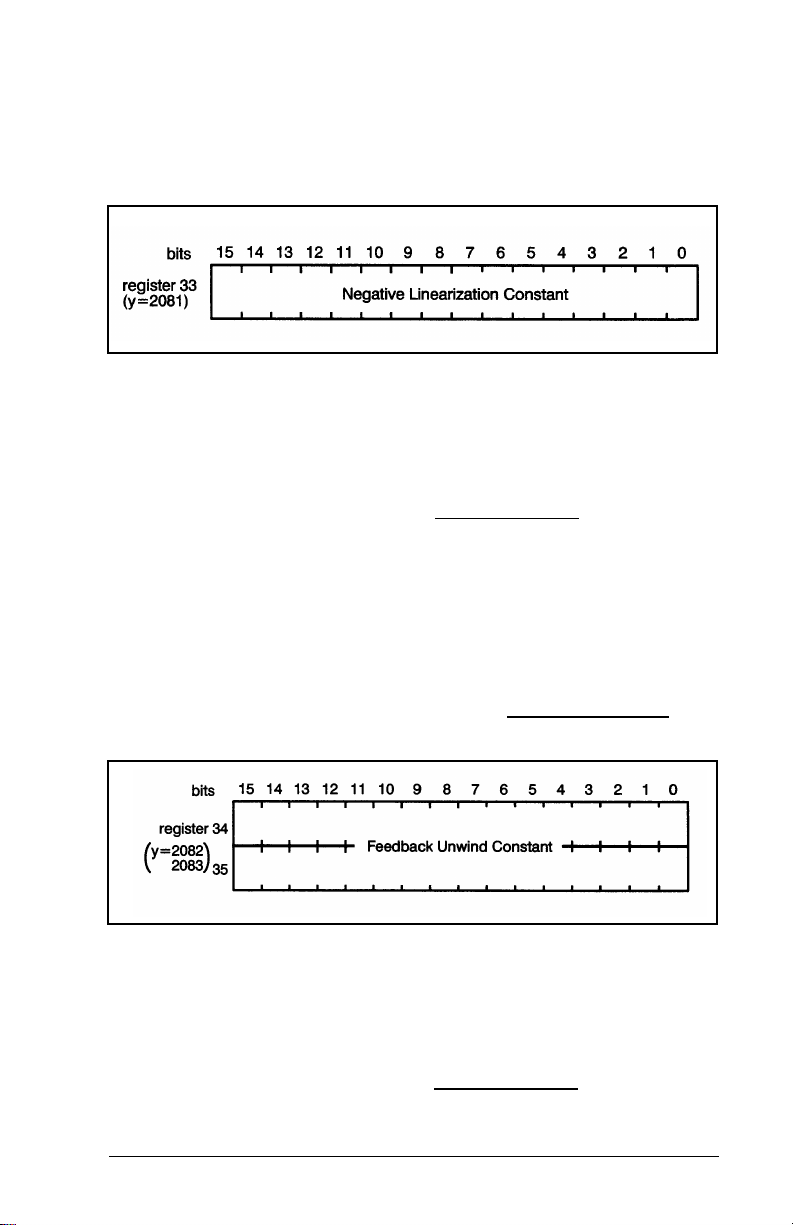

4.26 Register 33: Negative Linearization Constant....... 4-18

4.27 Registers 34,35: Feedback Unwind Constan........ 4-19

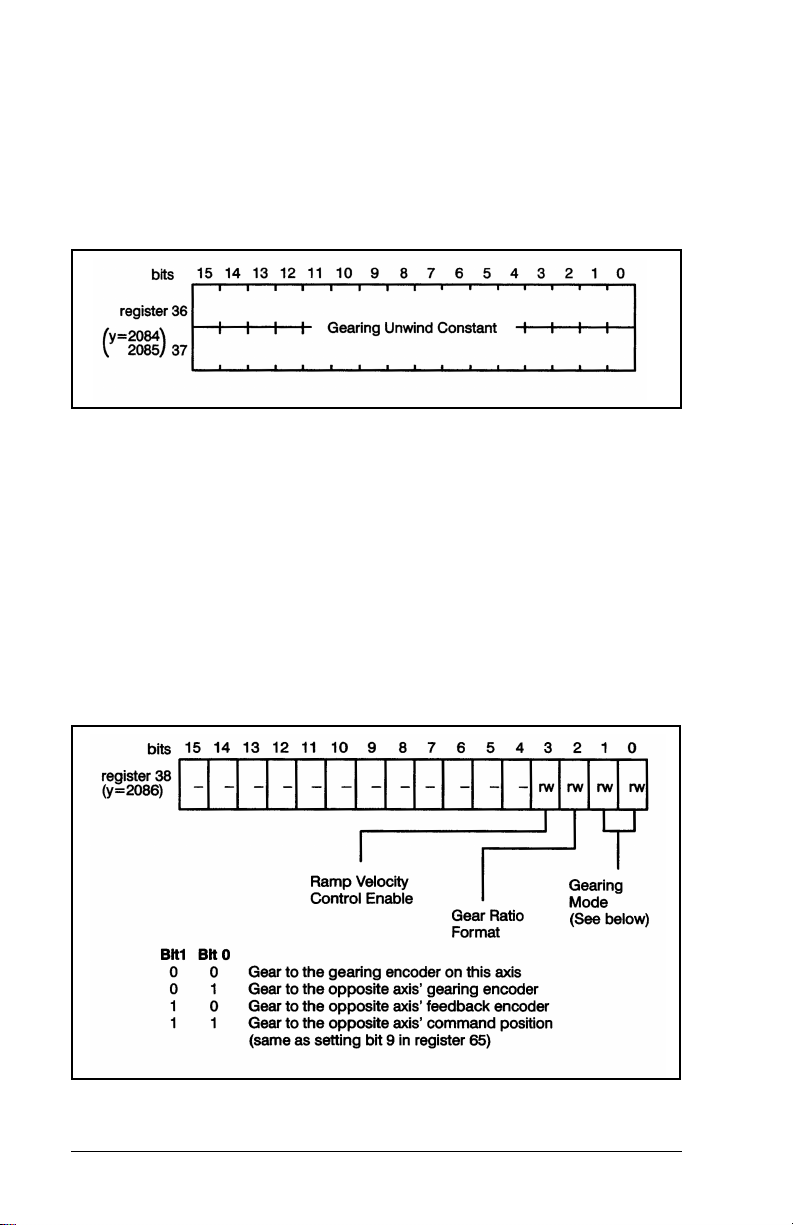

4.28 Registers 36, 37: Gearing Unwind Constant......... 4-19

4.29 Register 38: Gearing Modes, Ratio Format,

Ramp Velocity Control .......................................... 4-20

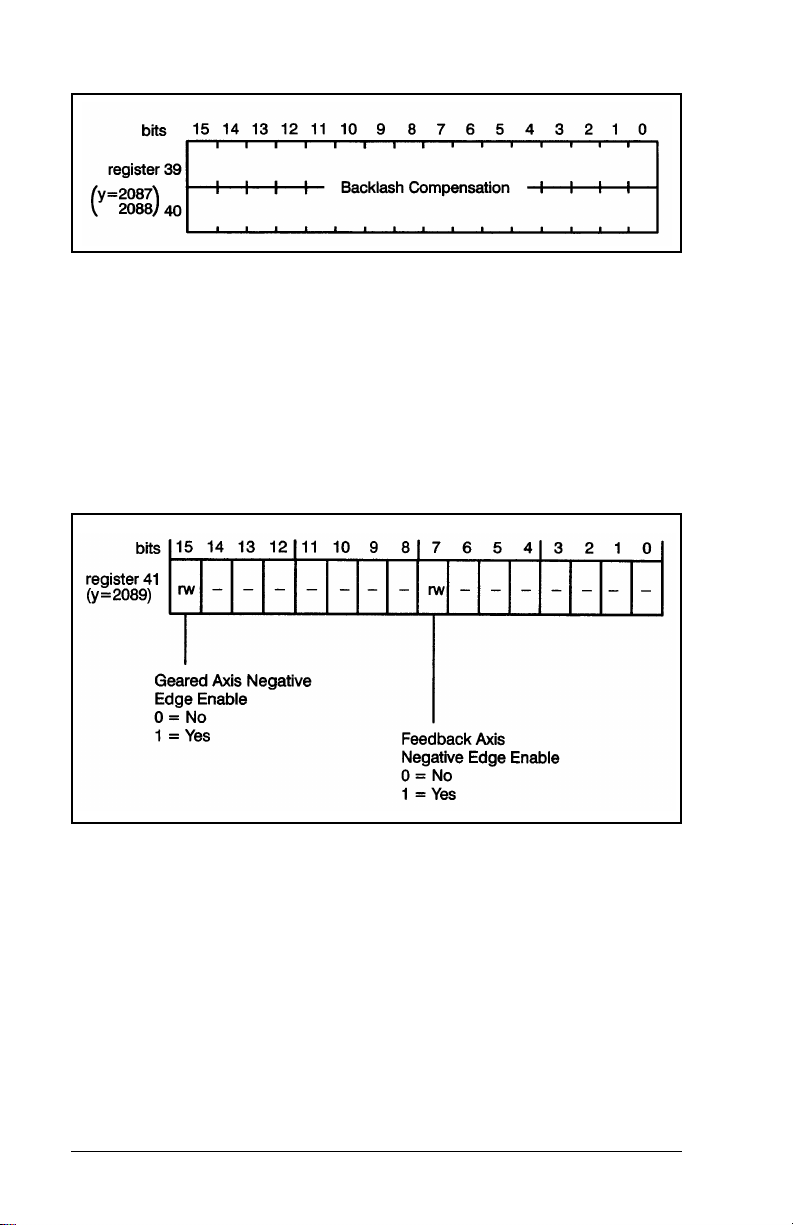

4.30 Registers 39, 40: Backlash Compensation ........... 4-21

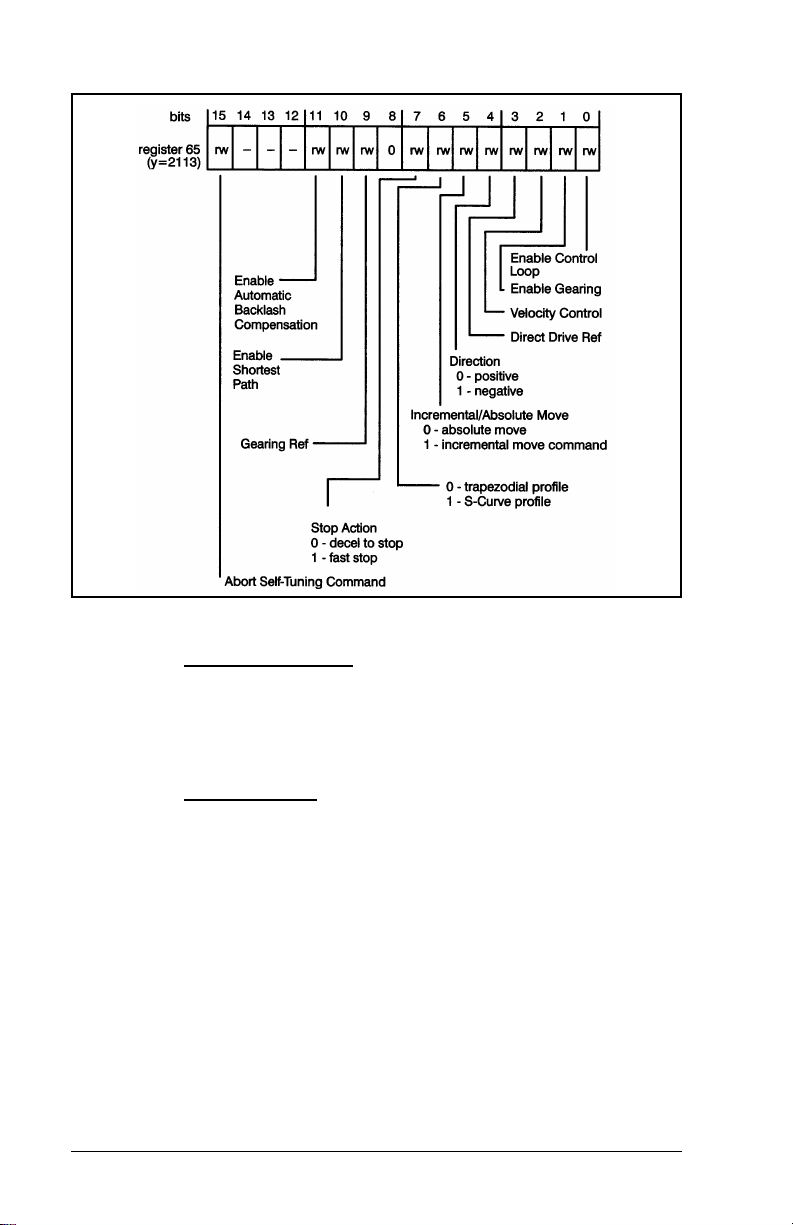

4.31 Register 41: Registration Input

Edge Detection...................................................... 4-22

4.32 Register 63: Auto-Acknowledge............................ 4-22

4.33 Register 64: Interrupt Reset.................................. 4-23

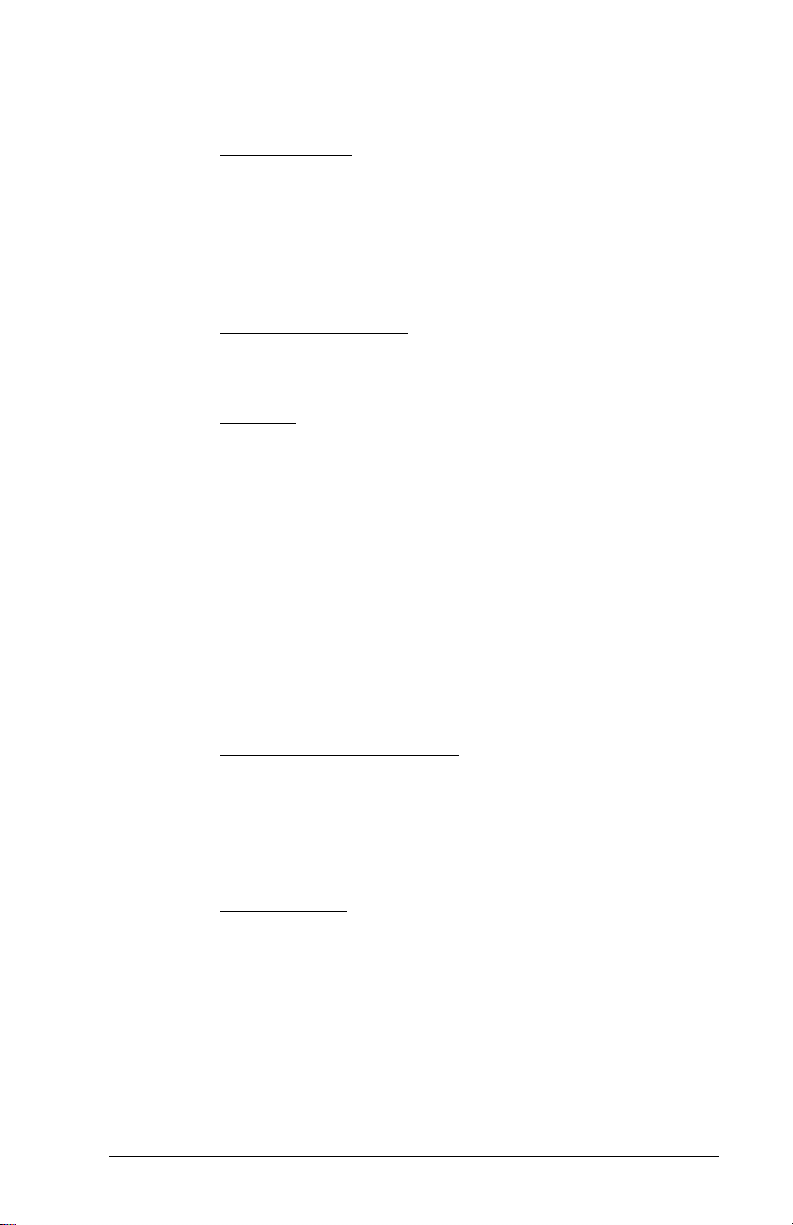

4.34 Register 65: Mode................................................. 4-23

4.35 Register 66: Command ......................................... 4-27

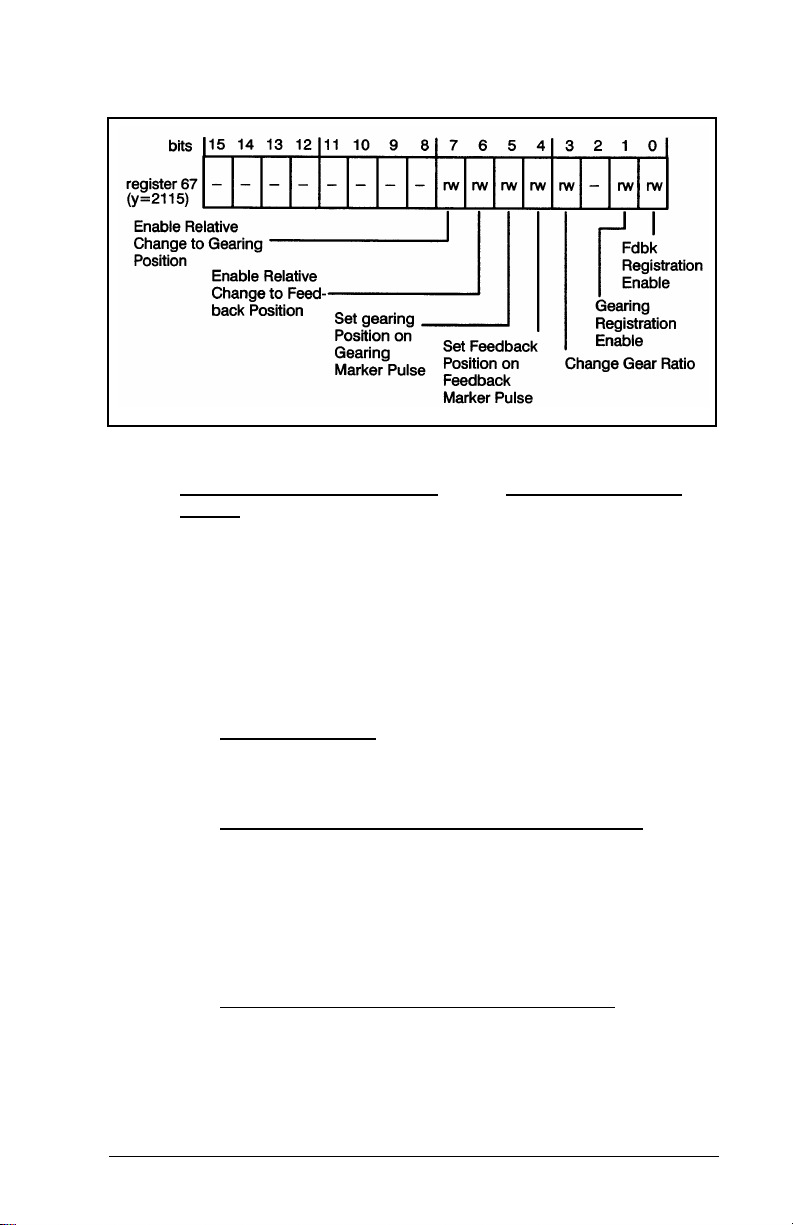

4.36 Register 67: Command ......................................... 4-32

4.37 Register 72: Status................................................ 4-34

4.38 Register 73: Fault.................................................. 4-37

4.39 Registers 74, 75: Current Feedback Position ....... 4-38

4.40 Registers 76, 77: Current Gearing Position .......... 4-39

4.41 Registers 78, 79: Current Velocity ........... ....... ...... 4-39

4.42 Register 80: Following Error.................................. 4-39

4.43 Register 81: Velocity Error .................................... 4-40

4.44 Register 82: Digital Input Status............................ 4-40

4.45 Register 83: Current Velocity Status

Update Period ....................................................... 4-41

4.46 Registers 84, 85: Feedback

Registration Position ............................................. 4-41

4.47 Registers 86, 87: Gearing

Registration Position ............................................. 4-41

4.48 Registers 99-103: Software Version Number........ 4-42

4.49 Interrupt Registers................................................. 4-42

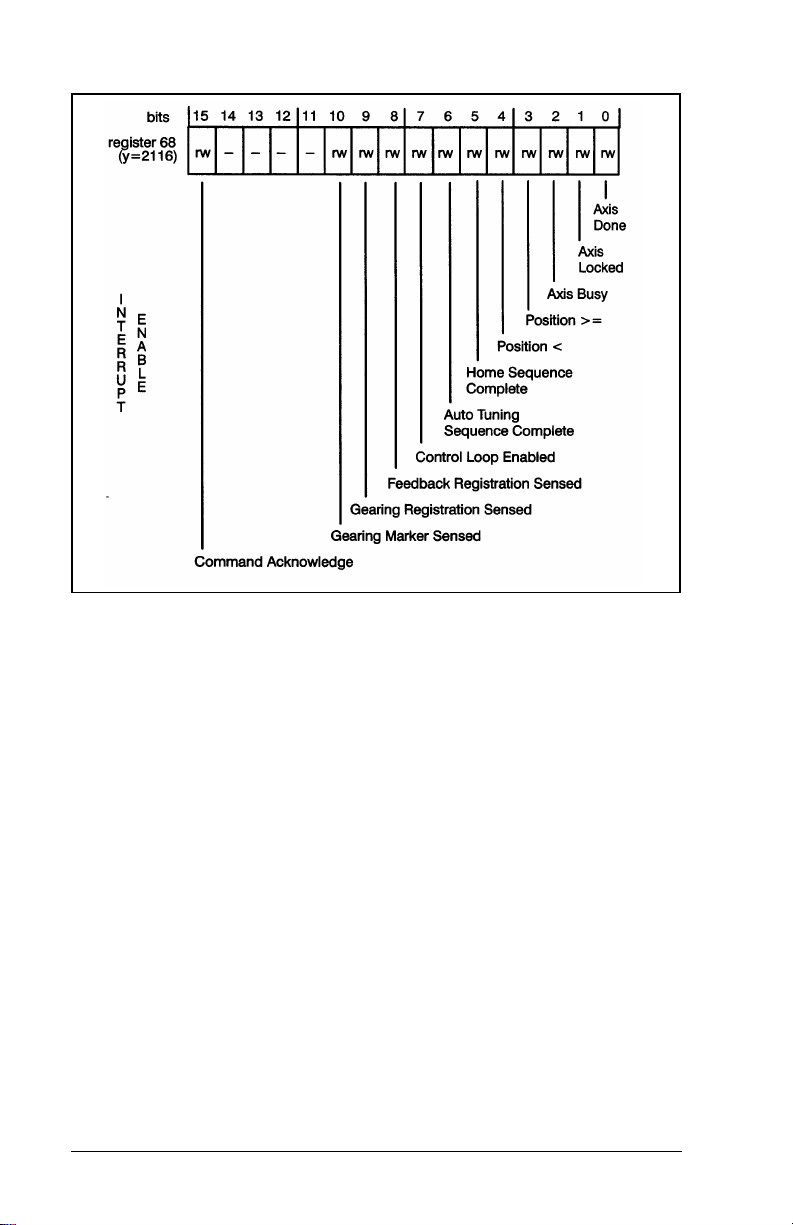

4.49.1 Registers 68/69: Interrupt Enable.............. 4-43

4.49.2 Registers 104/105: Interrupt Source.......... 4-45

4.49.3 Register 4095: Interrupt Status and Control

(ISCR) Register ......................................... 4-47

4.49.4 Sample Application Task with Interrupt ..... 4-48

Note: Register descriptions for equivalent X and Y axis

registers are exactly the same. Although sections of

Chapter 4 are titled by X axis register number, the

equivalent Y register is given in the figure that

accompanies each register description.

I

Page 5

4.50 Cam Registers.......................................................4-49

4.50.1 Register 125: Master Axis

Position Increment .....................................4-53

4.50.2 Registers 126, 127: Master Reference

Position ......................................................4-53

4.50.3 Register 128: Number of Points

in Cam Table..............................................4-54

4.50.4 Register 129:Time Between Points in

Cam Table .................................................4-54

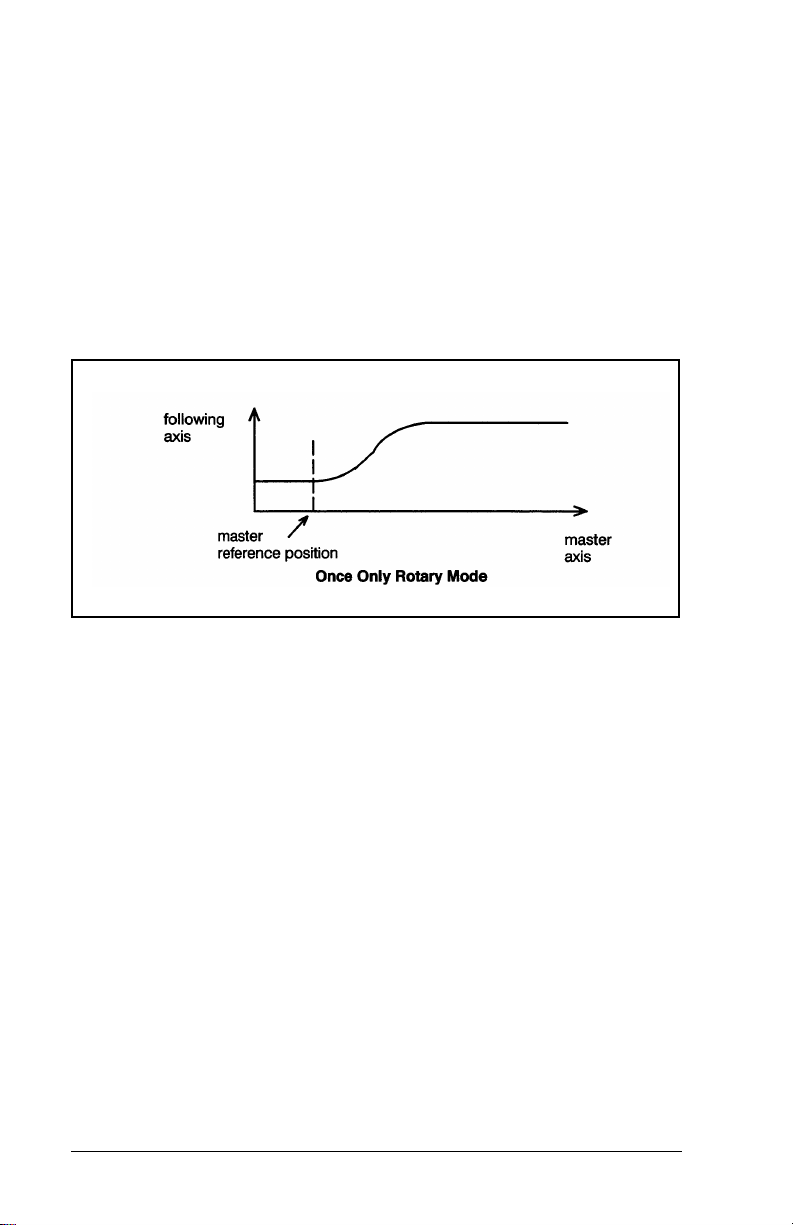

4.50.5 Register 130: Cam Mode ...........................4-54

4.50.6 Register 131: Loop Back

Point in Cam Table ....................................4-56

4.50.7 Cam Data Registers...................................4-57

5.0 Applying the Module........................................................5-1

5.1 Required System Information..................................5-1

5.2 Tuning......................................................................5-1

5.2.1 Auto-Tuning .................................................5-2

5.2.2 Manual Tuning .............................................5-2

5.3 Initialization..............................................................5-5

5.4 Homing ....................................................................5-6

5.5 Moving.....................................................................5-7

5.6 Electronic Gearing ...................................................5-8

5.7 Velocity.............. ...... ....... ...... ....... ...... ....... ...... .........5-9

5.8 Cam Mode.............................................................5-10

6.0 Restrictions ......................................................................6-1

6.1 Remote Racks.........................................................6-1

Note: Register descriptions for equivalent X and Y axis

registers are exactly the same. Although sections of

Chapter 4 are titled by X axis register number, the

equivalent Y register is given in the figure that

accompanies each register description.

III

Page 6

Appendix A

Technical Specifications ...................................................A-1

Appendix B

Module Block Diagram ......................................................B-1

Appendix C

Field Connections..............................................................C-1

Appendix D

Related Components.........................................................D-1

Appendix E

Register Summary.............................................................E-1

Appendix F

Enhancements................................................................... F-1

Appendix G

Compatibility with Earlier Versions .............. ...... ....... ...... .. G - 1

Appendix H

Configuration Task Sample...............................................H-1

Appendices

Appendix I

Digital Servo Loop Block Diagram...................................... I-1

IV

Page 7

List of Figures

Figure 2.1 - Module Faceplate......................................................2-2

Figure 2.2 - Encoder Input Circuit .................................................2-4

Figure 2.3 - Typical Registration Input Circuit...............................2-5

Figure 2.4 - Typical Digital Input Circuit ........................................2-5

Figure 3.1 - Rack Slot Numbers....................................................3-2

Figure 3.2 - Typical Encoder Connections....................................3-3

Figure 3.3 - Typical Encoder Power Supply Connections.............3-4

Figure 3.4 - Typical Limit Switch Connections ..............................3-5

Figure 3.5 - Typical Registration Input Connections .....................3-5

Figure 3.6 - Typical Drive Reference / Voltage Reference

Connections with External P/S..................................3-6

Figure 3.7 - Typical E-stop Circuit with Watchdog Output ............3-7

Figure 3.8 - Typical Drive Fault Connections................................3-8

Figure 4.1 - Encoder Configuration Register.................................4-3

Figure 4.2 - Control Loop Configuration Register .........................4-4

Figure 4.3 - Home and Overtravel Configuration Register............4-5

Figure 4.4 - Proportional Gain Register ........................................4-7

Figure 4.5 - Integral Gain Register................................................4-7

Figure 4.6 - Velocity Gain Register ...............................................4-8

Figure 4.7 - Feedforward Gain Register........................................4-8

Figure 4.8 - Deadband Compensation Register............................4-8

Figure 4.9 - Maximum Position Error ............................................4-9

Figure 4.10 - Maximum Velocity Error Register..............................4-9

Figure 4.11 - In-Position Tolerance Register ................................4-10

Figure 4.12 - Positive Overtravel Limit Registers..........................4-10

Figure 4.13 - Negative Overtravel Limit Registers........................4-11

Figure 4.14 - Low Speed Homing Reference Register .................4-11

Figure 4.15 - Command Position Registers .................................4-12

Figure 4.16 - Command Velocity Registers ..................................4-13

Figure 4.17 - Command Acceleration Registers...........................4-14

Figure 4.18 - Command Deceleration Registers...........................4-14

Figure 4.19 - Gear Ratio Registers ...............................................4-15

Figure 4.20 - User-Controlled LED Register.................................4-16

Figure 4.21 - Drive Command Reference Register.......................4-16

Figure 4.22 - Sync Position Registers...........................................4-17

Figure 4.23 - Maximum Voltage Reference Output Register........4-18

Figure 4.24 - Positive Linearization Constant Register.................4-18

Figure 4.25 - Positive Linearization Constant Register.................4-19

Figure 4.26 - Feedback Unwind Constant Registers ...................4-19

V

Page 8

Figure 4.27 - Gearing Unwind Constant Registers....................... 4-20

Figure 4.28 - Gearing Mode, Ratio Format, and Ramp

Velocity Control Register........................................ 4-20

Figure 4.29 - Backlash Compensation Registers ......................... 4-22

Figure 4.30 - Registration Edge Detection Register..................... 4-22

Figure 4.31 - Auto-Acknowledge Register.................................... 4-23

Figure 4.32 - Interrupt Reset Register.......................................... 4-23

Figure 4.33 - Mode Register......................................................... 4-24

Figure 4.34 - Command Register 66............................................ 4-28

Figure 4.35 - Command Register 67............................................ 4-33

Figure 4.36 - Status Register........................................................ 4-34

Figure 4.37 - Fault Register.......................................................... 4-37

Figure 4.38 - Current Feedback Position Registers ..................... 4-38

Figure 4.39 - Current Gearing Position Registers ........................ 4-39

Figure 4.40 - Current Velocity Registers ...................................... 4-39

Figure 4.41 - Following Error Register.......................................... 4-40

Figure 4.42 - Velocity Error Register............................................ 4-40

Figure 4.43 - Digital Input Status Register.................................... 4-40

Figure 4.44 - Current Velocity Status Update Period Register..... 4-41

Figure 4.45 - Feedback Registration Position Regiesters ............ 4-41

Figure 4.46 - Gearing Registration Position Registers................. 4-42

Figure 4.47 - Software Version Registers..................................... 4-42

Figure 4.48 - Interrupt Enable Masking Register (Status) ............ 4-44

Figure 4.49 - Interrupt Enable Masking Register (Fault) .............. 4-45

Figure 4.50 - Interrupt Source Register (Status) .......................... 4-46

Figure 4.51 - Interrupt Source Register (Fault)............................. 4-47

Figure 4.52 - Interrupt Status and Control Register...................... 4-47

Figure 4.53 - Master Axis Position Increment Register................ 4-53

Figure 4.54 - Master Regference Position.................................... 4-54

Figure 4.55 - Cam Profile Registers............................................. 4-56

Figure 4.56 - Cam Loop Back Register........................................ 4-57

Figure 4.57 - Time Cam Data Registers....................................... 4-58

Figure 4.58 - Position Cam Data Registers.................................. 4-58

VI

Page 9

CHAPTER 1

INTRODUCTION

The 2-Axis Servo Module, in conjunction with external motor

drive systems and electronic encoders, provides two axes of

closed loop point-to-point position, velocity, and acceleration

control. In addition, electronic gearing and electronic cam

allow the module to replace mechanical gear trains and

cams electronically for improved performance with no wear,

no backlash, and faster setup times. Two or more modules

can be connected together to provide synchronized control of

multiple axes.

Typically, this module is used for velocity control,

point-to-point positioning control, electronic line shaft

applications, and electronic cams requiring position

synchronization. See Appendix I for a software block

diagram of the module.

This manual describes the functions and specifications of the

module. It also includes a detailed overview of installation

and servicing procedures, as well as examples of

programming methods. See Appendix F for a list of

enhancements to the current version of the module.

Related publications that may be of interest:

• J-3675 AutoMax ENHANCED BASIC LANGUAGE

• J-3676 AutoMax CONTROL BLOCK LANGUAGE

• J-3677 AutoMax LADDER LOGIC LANGUAGE

• J-36 84 RESO URCE AutoMa x PROGRAMMIN G

• J-3675 AutoMax PROGRAMMING EXECUTIVE

INTRODUCTION

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

EXECUTIVE INSTRUCTION MANUAL VERSION 2.0

INSTRUCTION MANUAL VERSION 3.0

1-1

Page 10

• IEEE-518 GUIDE FOR THE INSTALLATION OF

ELECTRICAL EQUIPMENT TO MINIMIZE

ELECTRICAL NOISE INPUTS TO CONTROLLERS

FROM EXTERNAL SOURCES

1-2

2-Axis Servo Module M/N 57C422B

Page 11

CHAPTER 2

MECHANICAL /

ELECTRICAL

DESCRIPTION

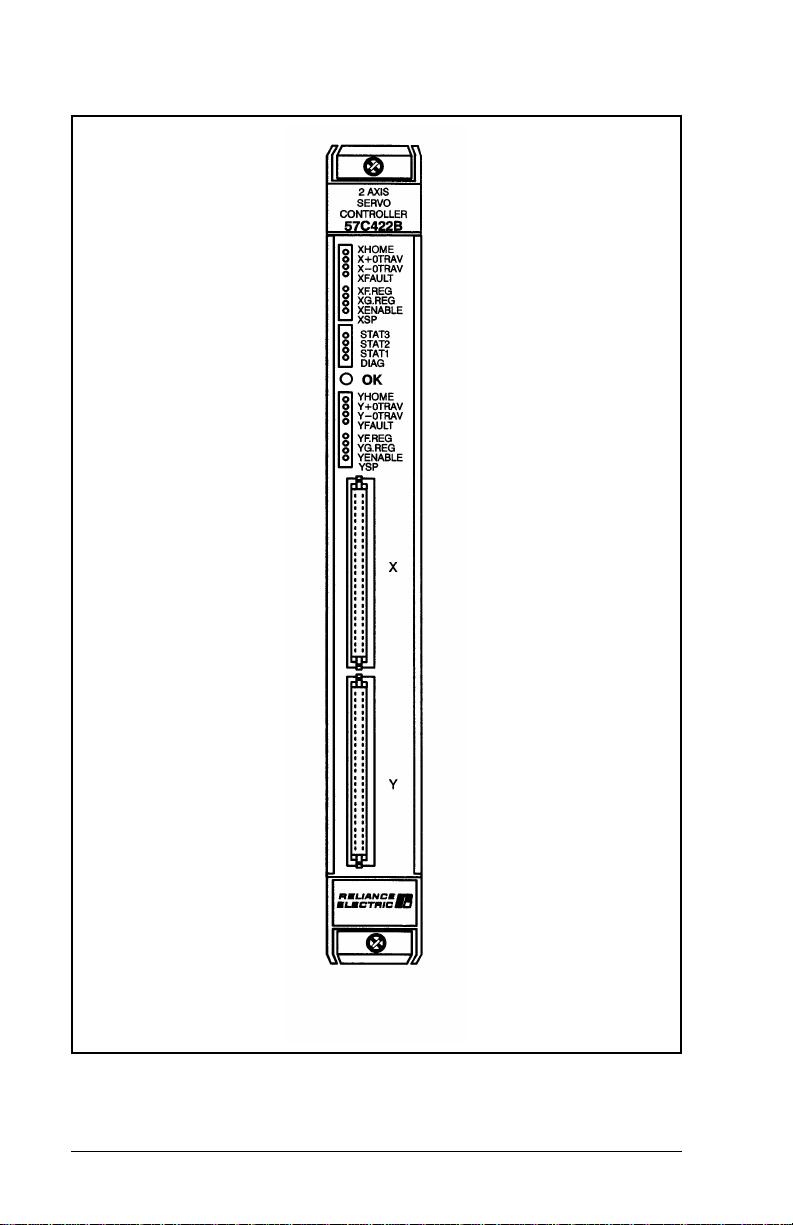

The following is a description of the faceplate LEDs, field

termination connectors and electrical characteristics of the

field connections.

2.1 Mechanical Description

The 2-Axis Servo module is a printed circuit board assembly

that plugs into the backplane of the DCS 5000/AutoMax rack.

It consists of the printed circuit board, a faceplate, and a

protective enclosure. The faceplate contains tabs at the top

and bottom to simplify removing the card from the rack.

Assembly dimensions are listed in Appendix A.

The faceplate of the module contains a 37-pin D-shell

connector socket and eight LED status indicators for each

axis. It also contains three LEDs that can be controlled from

the application software. Refer to figure 2.1.

MECHANICAL / ELECTRICA L DESCRIPTION

2-1

Page 12

Figure 2.1 – Module Faceplate

2-2

2-Axis Servo Module M/N 57C422B

Page 13

Signals are brought into the module via a multi-conductor

cable (M/N 57C377). One end of this cable attaches to the

faceplate connector, while the other end of the cable

attaches to a terminal board for easy wiring.

On the back of the module are two edge connectors that

attach to the system backplane.

2.2 Electrical Description

The module contains an 80186 microprocessor, local RAM,

and EPROM for the axis software. It also contains a dual port

memory organized as 4k x 16 for transferring data to/from

the module and the application software. Refer to the block

diagram in Appendix B.

This module also contains a watchdog timer that is used to

detect a processor failure. The processor is required to keep

resetting the watchdog before it expires. If the watchdog

expires, the processor will be halted, the green LED on the

faceplate of the module will be turned off, and dual port

memory will be locked so that the module can no longer be

accessed by application software.

M/N 57C422A and later versions of the module support

level-sensitive hardware interrupts. Interrupts are used to

trigger execution of some part of an application task and are

implemented using BASIC language hardware EVENT

statements. See Section 4.49 for more information.

Each of the two axes contain the necessary circuitry for two

encoders. One encoder is used to provide feedback to the

axis. The other encoder can be used when gearing or cam

mode is selected to provide a reference for that same axis.

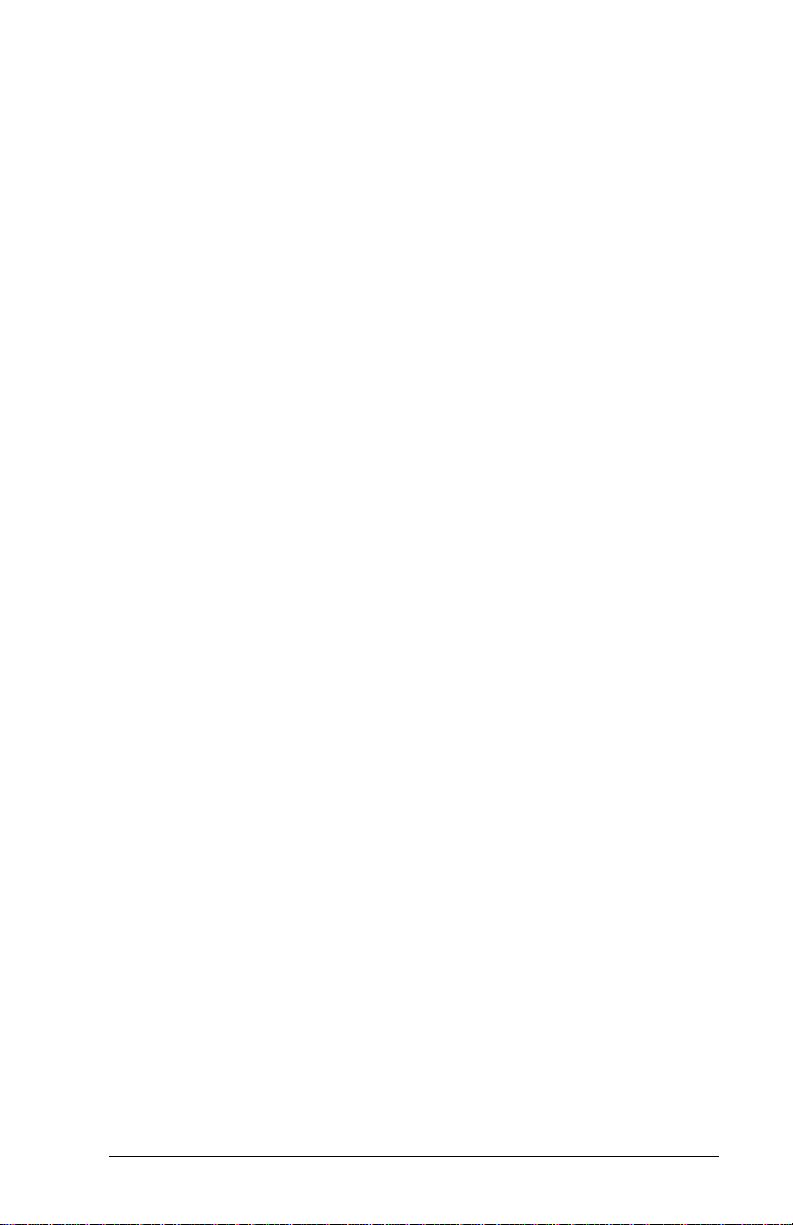

Each encoder input channel has the necessary circuitry for

an “A” channel, "B" channel, and "Z" channel. The encoder

input circuit is designed for 5 volt differential signals. A single

external power supply is required to power all of the

encoders connected to the module. Refer to figure 2.2 for a

typical encoder input circuit.

MECHANICAL / ELECTRICA L DESCRIPTION

2-3

Page 14

Figure 2.2 – Encoder Input Circuit

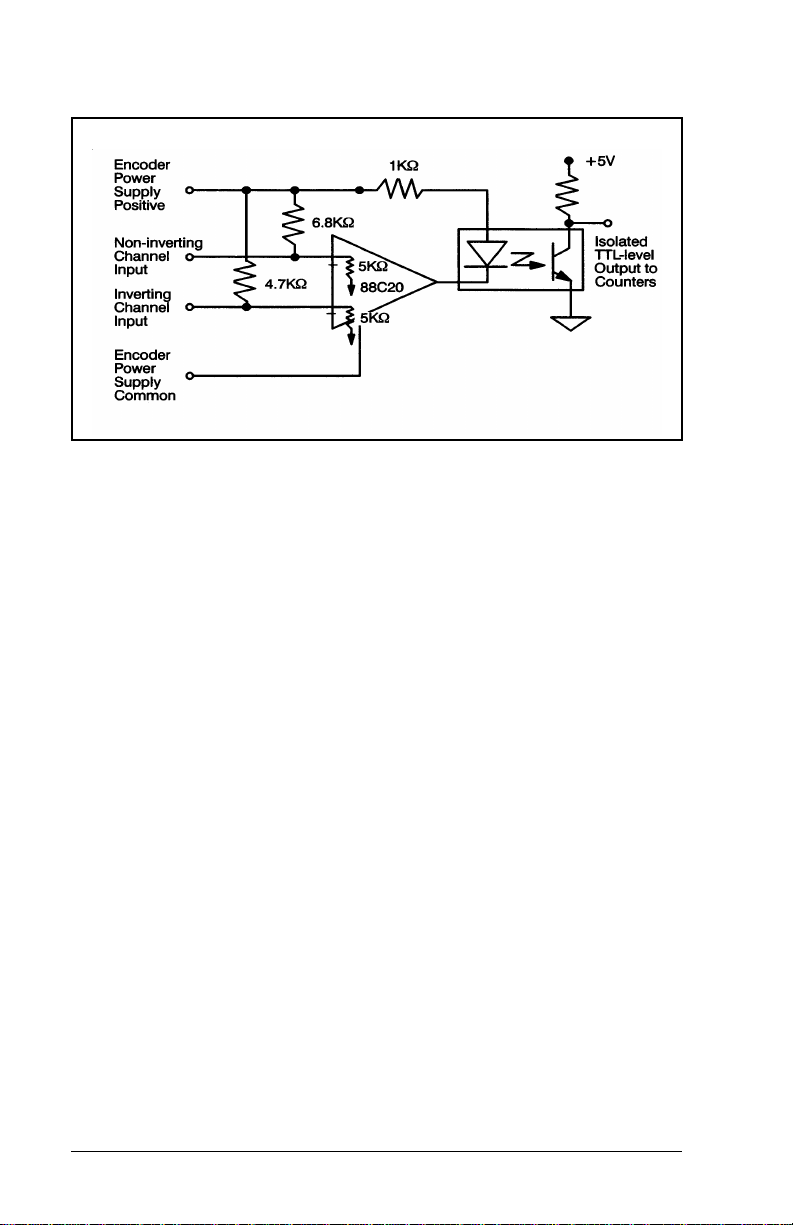

Each axis contains two registration inputs which are

connected to faceplate LEDs. One input is used with the

feedback encoder; the other is used with the gearing

reference. These registration inputs are typically used to

strobe the feedback and/or the reference position into a

group of registers for use by application software which can

synchronize the axis to an external event. The input may be

15-24 VDC only and there is a transport delay of

approximately 25 microseconds from the time that a

registration input is asserted until the isolated signal changes

state. Refer to figure 2.3 for a typical input circuit. In critical

applications, hard-wire your overtravel L/S into the

emergency stop circuit so that the drive will be disabled

regardless of the state of the control.

2-4

2-Axis Servo Module M/N 57C422B

Page 15

Figure 2.3 – Typical Registration Input Circuit

Each axis on the module contains digital inputs for the home

L/S, drive fault, positive overtravel L/S, and negative

overtravel L/S. These inputs are connected to faceplate

LEDs. Each of the inputs has a 30 Hz filter and may be 24

volts A-C or D-C. Refer to figure 2.4 for a typical input circuit.

Figure 2.4 – Typical Digital Input Circuit

Each axis contains a watchdog output which can be used by

the module to disable the drive if the module falls. The

watchdog output is a normally open relay contact. See figure

3-7.

MECHANICAL / ELECTRICA L DESCRIPTION

2-5

Page 16

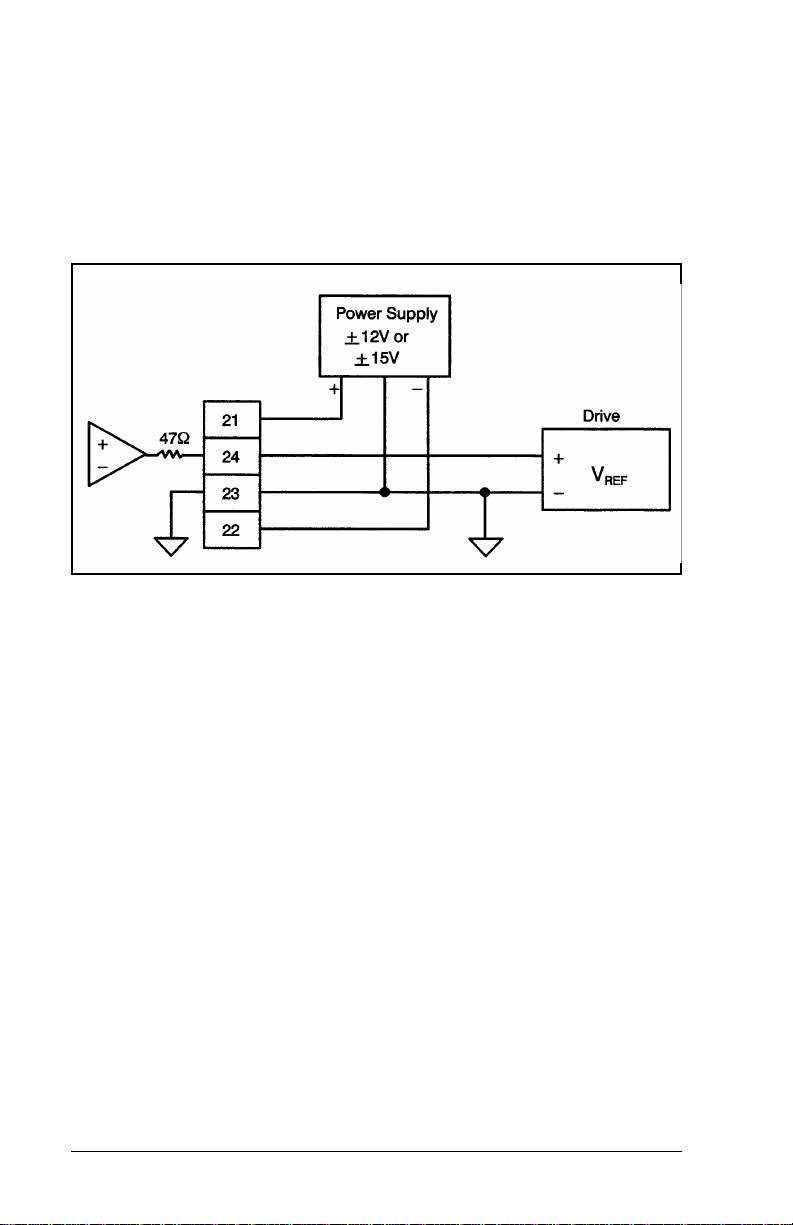

In order to provide a current or velocity reference to the servo

drive panel, each axis on the module contains a voltage

output. The voltage output has a range of +

requires an externally mounted +

12 or +15 volt power

10 Volts and

supply. The voltage output is separately isolated for each

channel. Refer to figure 3.6 for a typical output circuit and

isolated power supply connections

2-6

2-Axis Servo Module M/N 57C422B

Page 17

CHAPTER 3

INSTALLATION

This section describes how to install and remove the module

and its cable assembly.

WARNING

THE MACHINERY BUILDER AND/OR USER ARE

RESPONSIBLE FOR INSURING THAT ALL DRIVE TRAIN

MECHANISMS, THE DRIVEN MACHINE, AND PROCESS

MATERIAL ARE CAPABLE OF SAFE OPERATION AT THE

MAXIMUM SPEED AT WHICH THE MACHINE WILL OPERATE.

FAILURE TO OBSERVE THESE PRECAUTIONS COULD

RESULT IN BODILY INJURY

3.1 Wiring

DANGER

THE USER IS RESPONSIBLE FOR CONFORMING WITH THE

NATIONAL ELECTRICAL CODE AND ALL OTHER

APPLICABLE LOCAL CODES. WIRING PRACTICES,

GROUNDING, DISCONNECTS, AND OVERCURRENT

PROTECTION ARE OF PARTICULAR IMPORTANCE. FAILURE

TO OBSERVE THESE PRECAUTIONS COULD RESULT IN

SEVERE BODILY INJURY OR LOSS OF LIFE.

To reduce the possibility of electrical noise interfering with

the proper operation of the control system, exercise care

when installing the wiring from the system to the external

devices. For detailed recommendations refer to IEEE 518.

3.2 Initial Installation

Use the following procedure to install the module:

Step 1. Turn off power to the system. All power to the rack

as well as all power to the wiring leading to the

module, servo, and encoders must be off.

INSTALLATION

3-1

Page 18

DANGER

EQUIPMENT IS AT LINE VOLTAGE WHEN A-C POWER IS

CONNECTED TO THE DRIVE. ALL UNGROUNDED

CONDUCTORS OF THE A-C POWER LINE MUST BE

DISCONNECTED BEFORE IT IS SAFE TO TOUCH ANY

INTERNAL PARTS OF THIS EQUIPMENT. FAILURE TO

OBSERVE THESE PRECAUTIONS COULD RESULT IN

SEVERE BODILY INJURY OR LOSS OF LIFE.

Step 2. Take the module out of its shipping container.

Take the module out of the anti-static bag it came

in, being careful not to touch the connectors on

the back of the module.

Step 3. Insert the module into the desired slot in the rack.

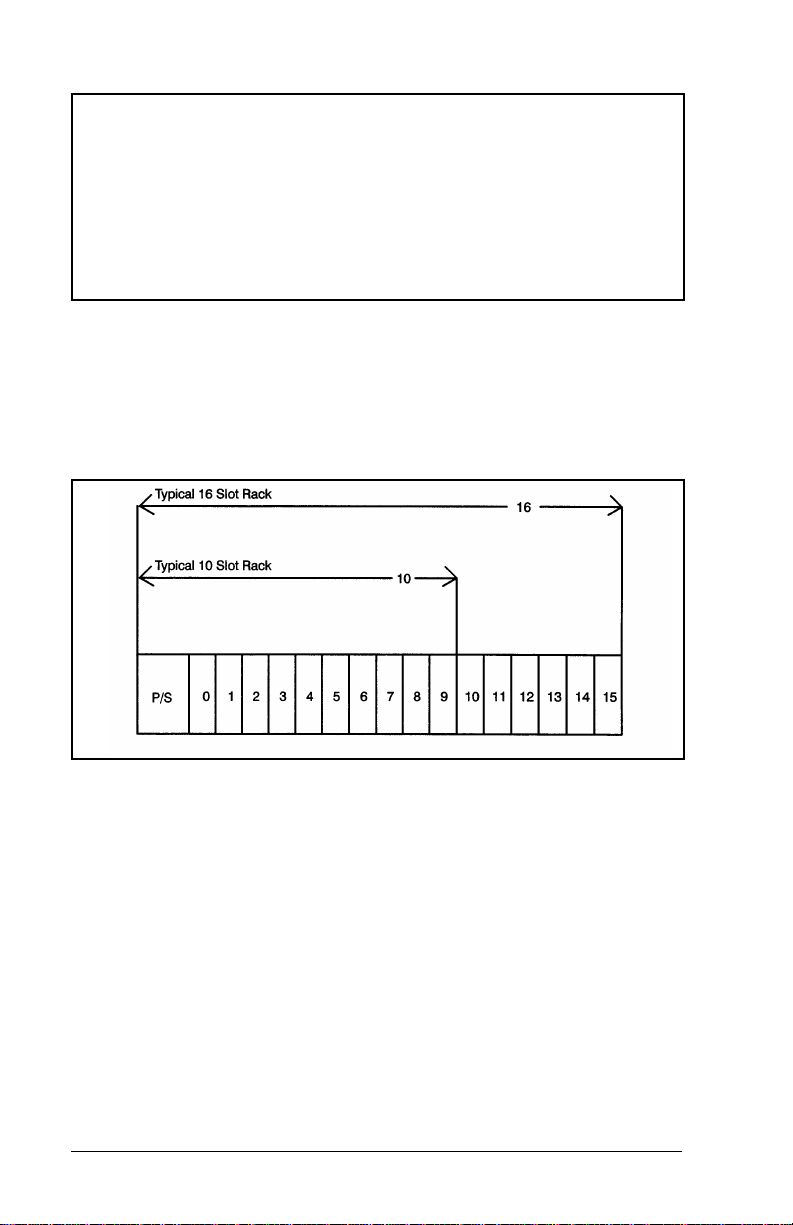

Refer to figure 3.1.

Figure 3.1 – Rack Slot Numbers

Step 4. Mount the terminal strips (M/N 57C377) on a

panel. The terminal strips should be mounted to

permit easy access to the screw terminals. Make

certain that the terminal strips are close enough to

the rack so that the cable will reach between the

terminal strips and the module.

Step 5. Verify that the feedback encoder has been

mounted on the back of the servo motor. Make

certain that the mechanical coupling between the

motor and encoder is securely fastened. If the

encoder is not mounted directly on the motor,

satisfactory performance may not be achievable.

3-2

2-Axis Servo Module M/N 57C422B

Page 19

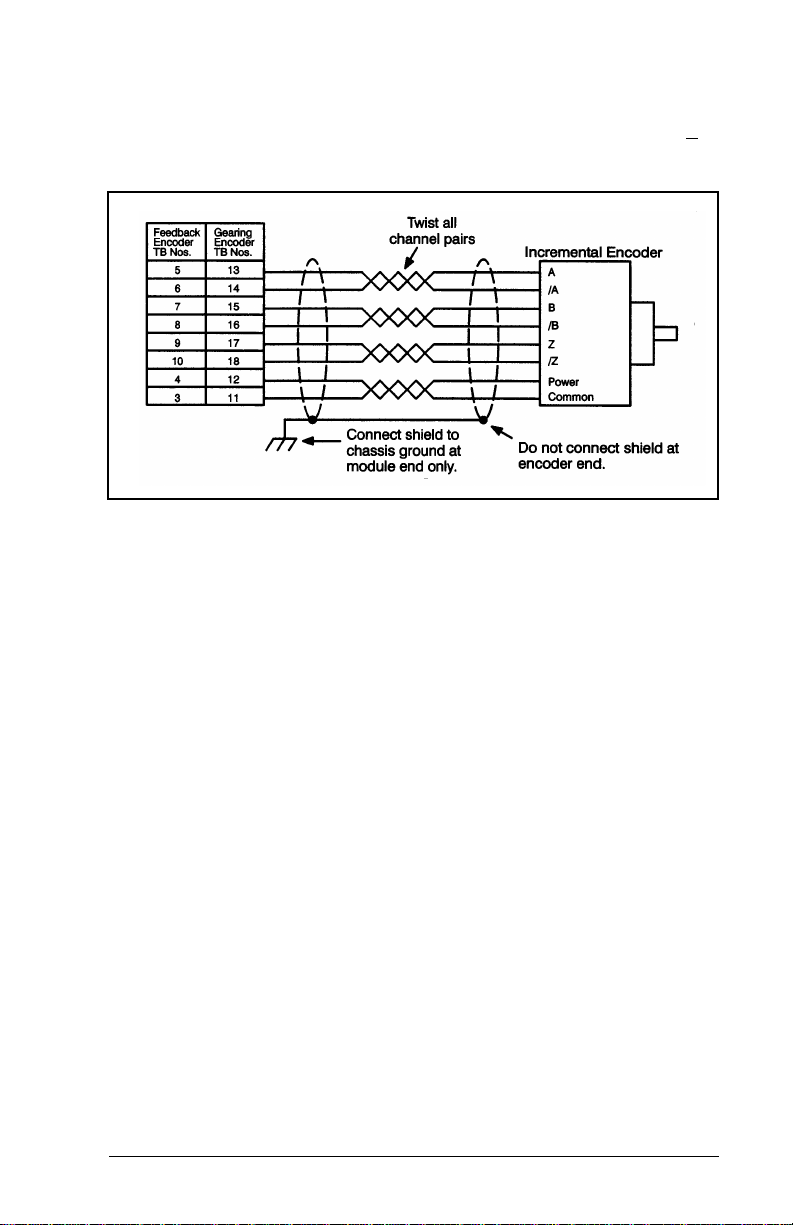

Fasten the field wires from the encoder to the

terminal strip. Typical field connections are shown

in figure 3.2. If you are not using the marker pulse

in your application, you can leave the "Z" and "Z

inputs disconnected.

Figure 3.2 – Typical Encoder Connections

Use twisted pair cabling, connected as shown in

figure 3.2, for the cabling between the encode r

and the terminal strip. If you use cabling with less

than 2 twists/inch, it should be shielded. Note that

the shield should only be connected at one end.

"

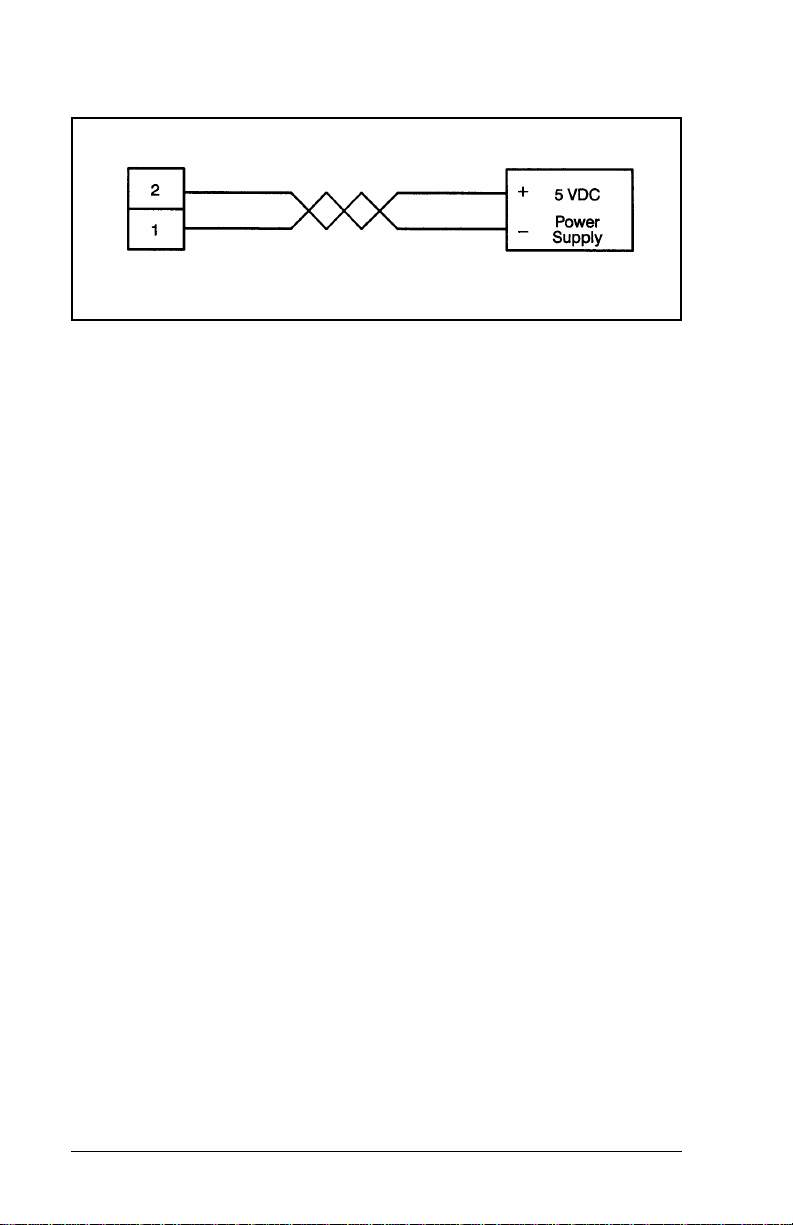

Step 6. Mount the external 5 volt power supply for the

INSTALLATION

If a feedback encoder is connected to the gearing

reference of another axis, jumper the connections

on the terminal strip.

encoders. The current rating must be sufficient for

all of the encoders that will be powered from the

supply as well, as the module. Check the

specifications of the encoder you will be using.

Fasten the field wires from the power supply to the

terminal strip. Typical field connections are shown

in figure 3.3

3-3

Page 20

.

Figure 3.3 – Typical Encoder Power Supply Connection

Use twisted pair cabling, connected as shown in

figure 3.3, for the cabling between the power

supply and the terminal strip. If you use cabling

with less than 2 twists/inch, it should be shielded.

Note that the shield should only be connected at

one end.

For best results, the power supply voltage should

be adjusted to provide 5 volts at the furthest

encoder.

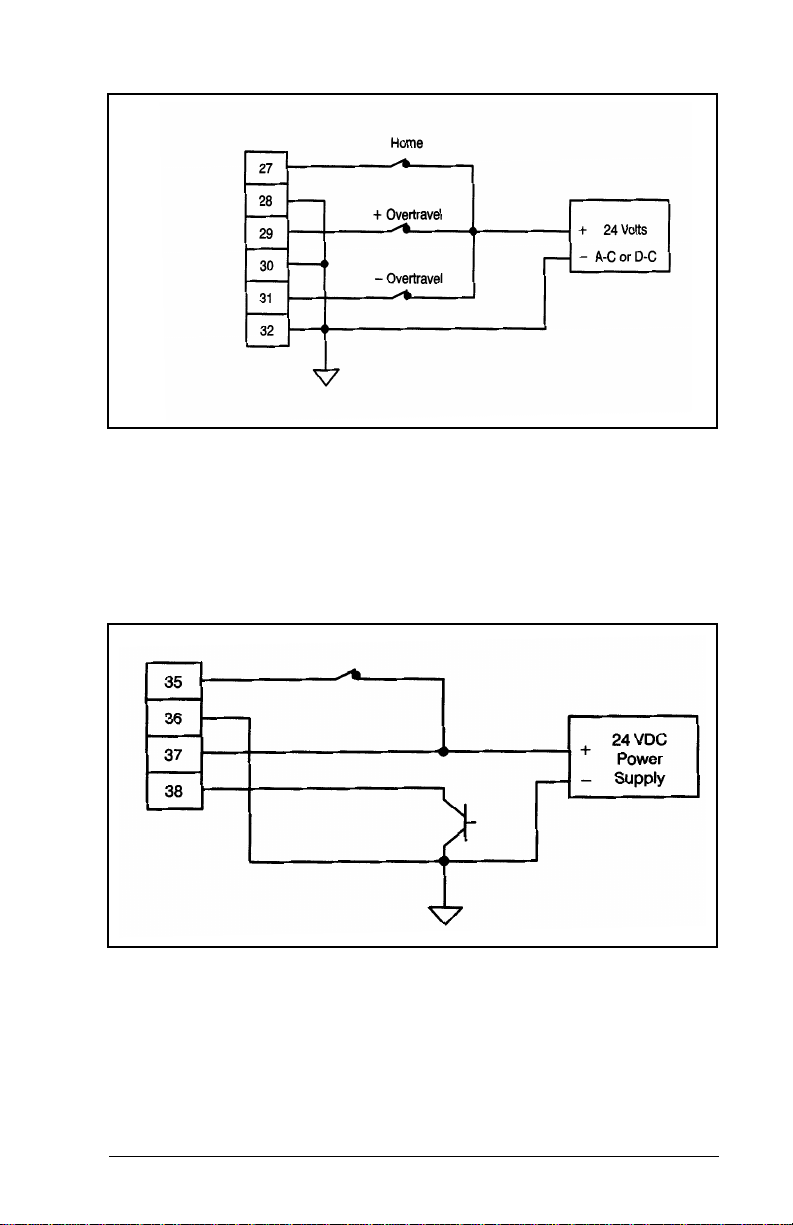

Step 7. If your application requires them, mount the home

L/S, positive overtravel L/S, and negative

overtravel L/S on your machine. Overtravel L/S

should be normally closed devices. Fasten the

field wires from the limit switches to the terminal

strip. Typical field connections are shown in figure

3.4.

3-4

2-Axis Servo Module M/N 57C422B

Page 21

Figure 3.4 – Typical Limit Switch Connections

Step 8. Mount the registration sensors on your machine if

your application requires them. Fasten the field

wires from the sensors to the terminal strip. Use

extra care in routing these wires because these

signals are not filtered on the module. Typical field

connections are shown in figure 3.5.

Figure 3.5 – Typical Registration Input Connections

Step 9. Install the servo amplifier according to the

manufacturer’s instructions. Select the proper

mode of operation for the servo amplifier (current

or velocity). Select current mode for most

applications because all tuning can then be done

INSTALLATION

3-5

Page 22

in the software. If your application has unusually

high bandwidth requirements or your servo

amplifier functions as a velocity regulator only, use

the velocity mode.

Step 10. Fasten the field wires from the drive reference and

power supply to the terminal strip. Typical field

connections are shown in figure 3.6 and 3.7.

Figure 3.6 – Typical Drive Reference/Voltage Reference

Connections with External P/S

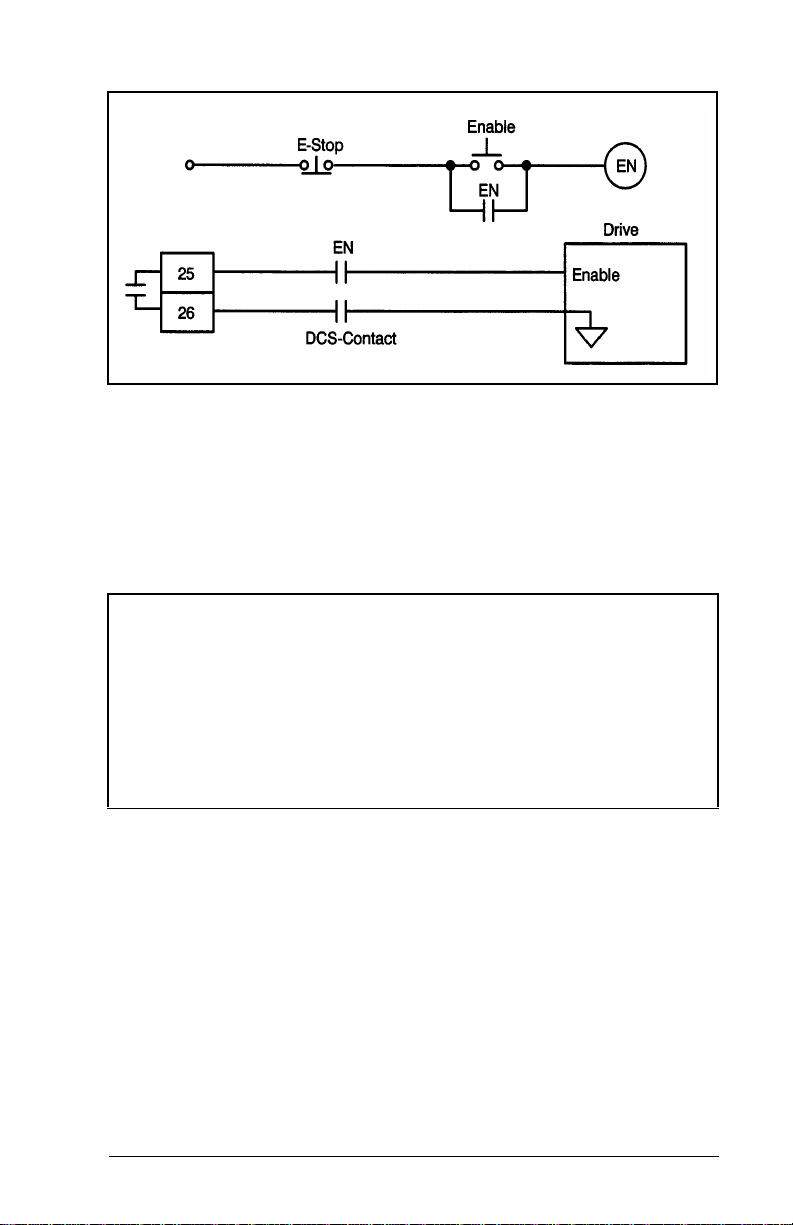

Step 11. Connect the watchdog outputs on the terminal

strip into the drive enable circuit. This signal is

used to disable the servo if a problem develops in

the module. It must be installed in combination

with a hardwired E-stop circuit as well as a pair of

contacts that are controlled from a digital output

from DCS or AutoMax software. Typical field

connections are shown in figure 3.7.

3-6

2-Axis Servo Module M/N 57C422B

Page 23

Figure 3.7 – Typical E-stop Circuit with Watchdog Output

The hardwired E-STOP ensures that you can

disconnect the drive under all conditions. The

contacts controlled by a DCS or AutoMax digital

output allow you to disable the drive in the event

of a processor failure or when faults are detected

by the application software.

WARNING

RELIANCE STRONGLY RECOMMENDS THE USE OF AN

EXTERNAL, HARDWIRED EMERGENCY STOP CIRCUIT THAT

WILL DISABLE THE SYSTEM IN CASE OF IMPROPER

OPERATION. UNCONTROLLED MACHINE OPERATION MAY

RESULT IF THIS PROCEDURE IS NOT FOLLOWED. FAILURE

TO OBSERVE THIS PRECAUTION COULD RESULT IN BODILY

INJURY OR DAMAGE TO EQUIPMENT.

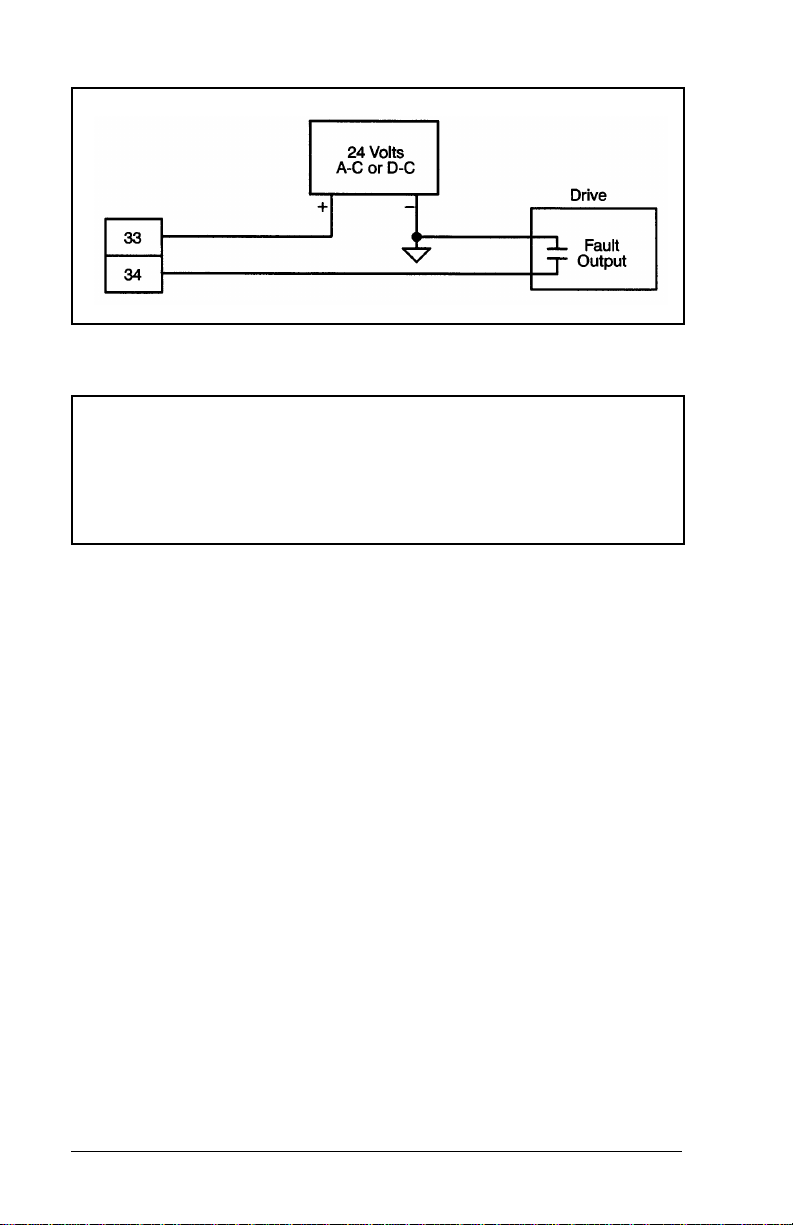

Step 12. Fasten the field wires from the drive fault inputs to

the terminal strip. This signal is used to notify the

module that a problem has developed in the

servo. It must be connected if available. Typical

field connections are shown in figure 3.8. Be sure

to use the proper connections for your servo

amplifier.

INSTALLATION

3-7

Page 24

Figure 3.8 – Typical Drive Fault Connections

DANGER

ADJUSTMENTS ARE MADE WITH THE POWER ON.

EXERCISE EXTREME CAUTION AS HAZARDOUS VOLTAGE

EXISTS. FAILURE TO OBSERVE THIS PRECAUTION COULD

RESULT IN SEVERE BODILY INJURY OR LOSS OF LIFE.

Step 13. Verify power supply connections by performing

the following operations:

a. Make certain that all connectors from the

module and the encoders are disconnected.

b. Turn on power to the system.

c. Verify that you can read 5 volts on the proper

terminal strip and encoder connectors

(terminals 1 and 2).

d. Verify that you can read ±12 volts or ±15 volts

on the proper terminal strip connectors

(terminals 21, 22, 23).

e. Turn off power and reattach the connectors to

the module.

Step 14. Verify power supply connections at the encoder by

performing the following operations:

a. Make certain that all connectors at the

encoders are disconnected.

b. Turn on power to the system.

3-8

2-Axis Servo Module M/N 57C422B

Page 25

c. Verify that you can read 5 volts on the proper

pins of the encoder connector (at the encoder).

d. Turn off power and attach the connectors to

the encoders.

Step 15. Verify wiring connections by performing the

following operations:

a. Turn on power to the system.

b. Toggle all of the following digital inputs that you

are using in your application: the home L/S,

positive overtravel L/S, negative overtravel

L/S, drive fault, feedback registration, and

gearing registration. The appropriate LED on

the faceplate of the module should change

state as the input is toggled. Because the

signal may be very brief, it may be necessary

to use an oscilloscope to verity that it is

present.

Step 16. Verify the installation by connecting the

programming terminal to the system and running

the Programming Executive Software. Note that if

you are using a version 3.0 Programming

Executive and working with the sample application

program disk shipped with the Programming

Executive software, you will need to do a rack

import operation for the files in the 57C422

subdirectory first. See J-3684 for more information

and disregard steps a and b below.

INSTALLATION

a. Load the application disk that came with your

ReSource software.

b. Compile the BASIC tasks SETUPCNF.CNF

AXISSETUP.BAS, AXISSUB.BAS, and

AXISINIT.BAS.

c. Load the configuration and BASIC tasks onto

the CPU.

d. Use the RUN ALL command to start all four

tasks.

3-9

Page 26

e. Move the cable from the programming port on

the processor to the port labeled "LOCAL

COMM".

f. Select the menu option labeled

"COMMUNICATIONS INTERFACE".

g. Type C <CR> <CR>.

h. The screen on the programming terminal

should now display the test and setup menu for

the module. You should progress sequentially

through the menu from item 1 through item 8

before attempting to use the module.

Note that when you have finished configuring and tuning

your drives, you may save all of the data to a DOS disk file.

By adding this file to AXISINIT.BAS, you can eliminate the

need to re-configure your drive each time you use the test

and setup software.

3-10

2-Axis Servo Module M/N 57C422B

Page 27

3.3 Module Replacement

WARNING

THE MACHINERY BUILDER AND/OR USER ARE

RESPONSIBLE FOR INSURING THAT ALL DRIVE TRAIN

MECHANISMS, THE DRIVEN MACHINE, AND PROCESS

MATERIAL ARE CAPABLE OF SAFE OPERATION AT THE

MAXIMUM SPEED AT WHICH THE MACHINE WILL OPERATE.

FAILURE TO OBSERVE THESE PRECAUTIONS COULD

RESULT IN BODILY INJURY.

Use the following procedure to replace a module:

Step 1. Turn off power to the rack and all connections.

Step 2. Remove the connectors from the module.

Step 3. Loosen the screws that hold the module in the

rack. Remove the module from the slot in the rack.

Step 4. Place the module in the anti-static bag IT came in,

being careful not to touch the connectors on the

back of the module. Place the module in the

cardboard shipping container.

Step 5. Take the new module out of its anti-static bag,

Step 6. Insert the module into the desired slot in the rack.

Step 7. Attach the field terminal connectors (M/N 57C377)

Step 8. Turn on power to the rack.

INSTALLATION

being careful not to touch the connectors on the

back of the module.

Use a screwdriver to secure the module into the

slot.

to the mating halves on the module. Make certain

that the connectors are the proper ones for the

module and for the specific axes.

3-11

Page 28

3-12

2-Axis Servo Module M/N 57C422B

Page 29

CHAPTER 4

PROGRAMMING

This section describes how the data is organized in the

module and provides examples of how the module is

accessed by the application software. For more detailed

information on programming, refer to J-3675, J-3676, and

J-3677.

The module contains a total of 4096 16-bit registers, one set

of 2047 registers for each servo axis. The X axis uses

registers 0-2046. The Y axis uses registers 2048-4094.

Note that there are 2 exceptions to this basic register

organization scheme: registers 64 and 4095 (interrupt

control) are used for both axes. In other words, the use

of an interrupt on either axis will require you to perform

some function In these two registers. See section 4.49

for more information on interrupts.

The following register reference conventions are used

throughout this instruction manual. All register descriptions in

the following sections are based on the X axis and are

organized in numerical order, except for interrupt and cam

registers, which are described in sections 4.49 and 4.50. The

equivalent Y axis registers are given in parentheses in the

figure that accompanies each register description. Appendix

E is a numerical register summary with page number

references.

Register numbers listed together separated by a comma

(e.g., 11, 12) signify a double precision (32-bit) value.

Register numbers listed together separated by a slash (e.g.,

104/105) indicate that both registers have a similar function

and should be considered together. This notation does not

indicate a double precision value.

For ease of locating descriptions for individual bits within

registers, bit names are underlined in the sections where the

bits are described. Bit names are placed between quotation

marks when they are only referred to. In some cases,

PROGRAMMING

4-1

Page 30

registers with individual bit descriptions are shown with the

bits broken up into groups of four for ease of interpretation in

monitoring the registers in hexadecimal format.

At times register and bit references will be in the form of

"RA,bB," where "A” is the register number and "B" is the bit

number.

4.1 Configuration

Before an application program can be written, it is necessary

to configure the definitions of variables that must be

accessible to all tasks in the rack. This section describes how

to configure the module.

If you are using V3.0 or later of the Programming Executive

software, you can configure the module using a special

software "form" that allows you to fill in the names of the

registers and bits. See the Programming Executive

instruction manual for more information on configuration

forms.

If you are using an earlier version of the programming

executive, you will need to create a configuration task to

configure the registers/bits on the module. See Appendix H,

for more information on creating a configuration task.

4-2

2-Axis Servo Module M/N 57C422B

Page 31

4.2 Register 0: Encoder Setup

Register 0 is used to configure the gearing reference and

feedback encoder inputs for the axis. Refer to figure 4.1.

Figure 4.1 – Encoder Configuration Register

The feedback encoder mode

channels from the encoder will be interpreted by the module.

If the step/direction mode is selected, a high to low transition

of Channel A causes a count. If Channel B was low, the

count is incremented. If Channel B was high, the count is

decremented.

If the step +

Channel A results in the count being incremented. A high to

low transition of Channel B results in the count being

decremented.

If the *1 quardrature is selected, only one edge of channel A

is counted. (Note that *1 quadrature is available only on B/M

57422-2C and later versions of the module.) If the *2

quadrature mode is selected, both the rising and trailing

edges of Channel A are counted. The direction is determined

from the state of Channel B.

PROGRAMMING

bits specify how the A and B

mode is selected, a high to low transition of

4-3

Page 32

If the *4 quadrature mode is selected, both edges of

Channels A and B result in counts. The direction is

determined by the channel changing state and the state of

the opposite channel. All subsequent references to counts

include the quadrature calculation.

Note: Any references to counts within this instruction

manual take into account the quadrature multiplier

selected in this register.

You can use the feedback encoder polarity

rotation of the encoder as seen by the application software.

This is analogous to swapping the encoder leads to alter the

electrical direction of rotation.

Specifying the axis as "rotary" using the feedback linear/

rotary bit causes the module to subtract or add one

revolution of counts from the command position and the

actual position whenever the encoder crosses the revolution

boundary. This allows infinite range for rotary axis. If the axis

is specified as linear, the feedback will simply increment or

decrement as the axis is moved forward or in reverse.

4.3 Register 1: Drive Setup

Register 1 is used to configure the servo drive. Refer to

figure 4. 2.

bit to change the

Figure 4.2 – Control Loop Configuration Register

The analog output

from the module should be configured to

work with the control loop on the drive (either current or

velocity).

4-4

2-Axis Servo Module M/N 57C422B

Page 33

The output polarity bit is used to alter the sign of the drive

reference for a given error. This is analogous to swapping

the wires for the drive reference.

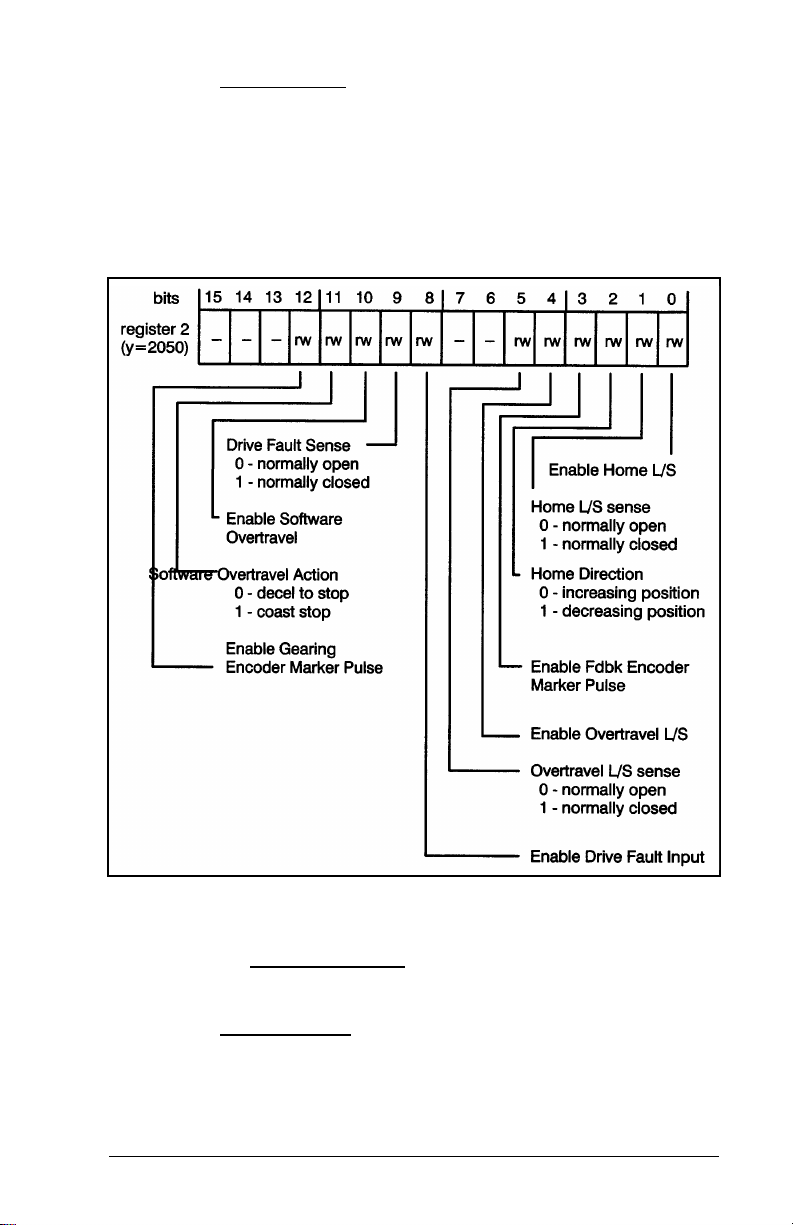

4.4 Register 2: Switch Setup

Register 2 is used to configure the home and overtravel limit

switches. Refer to figure 4.3.

Figure 4.3 – Home and Overtravel Configuration Register

If you have a home limit switch on your machine, you should

use the enable home L/S.

of the limit switch as either normally open or normally closed.

The home direction

drive will move during the initial phase of the homing

sequence.

PROGRAMMING

Y ou can define the asserted sense

bit is used to define the direction that the

4-5

Page 34

If you intend to use the feedback marker during the home

sequence, you should enable the feedback encoder marker

. Refer to section 4.35 for more information on the

pulse

“home axis” command in register 66.

To prevent your machine from moving beyond specified

physical limits, use the enable overtravel L/S

bit. You can

define the condition to be true when the limit switch is closed

(normally open) or open (normally closed). If an overtravel

limit switch is tripped during operation, the control will be

turned off and, if programmed, the drive will coast to a stop.

The machine will then have to be moved off the overtravel

limit switch before the control can be re-enabled. In critical

applications, hardwire the overtravel L/S into the emergency

stop circuit so that the drive will be disabled regardless of the

state of the control.

The drive fault input

is a simple means of shutting off the axis

control. This input can be either a fault signal from the drive

or an E-STOP push-button. You can define the asserted

sense of the input as either normally open or normally

closed. If the drive fault input is tripped, the axis control will

be disabled and, if programmed, the drive will coast to a

stop.

WARNING

RELIANCE STRONGLY RECOMMENDS THE USE OF AN

EXTERNAL, HARDWIRED EMERGENCY STOP CIRCUIT THAT

WILL DISABLE THE SYSTEM IN CASE OF IMPROPER

OPERATION. UNCONTROLLED MACHINE OPERATION MAY

RESULT IF THIS PROCEDURE IS NOT FOLLOWED. FAILURE

TO OBSERVE THIS PRECAUTION COULD RESULT IN BODILY

INJURY.

The software overtravel

bit is a programmable way of limiting

machine travel. You can define the action that occurs when

the software overtravel limit is exceeded as either a decel to

stop or a coast to stop. If you have specified a decel to stop,

the drive will decelerate at the specified rate to zero speed

and regulate about that position. If you have specified a

coast stop, the drive control will be disabled and the drive will

coast to rest. When the drive has exceeded a software

overtravel limit, and if you have specified a "decel to stop,"

the drive can be commanded to move away from the

overtravel conditio n.

4-6

2-Axis Servo Module M/N 57C422B

Page 35

You should enable the gearing marker pulse if you intend to

use it to initialize the home position of the gearing encoder.

Refer to section 4.35 for the "set gearing position" command

in register 66 for more information .

4.5 Register 3: Propo rtional Gain

Register 3 contains the proportional gain for the module. This

value is read by the module whenever the “change default

setups” command in register 66 is issued. See Section 5.2

for more information on turning.

Figure 4.4 – Proportional Gain Register

4.6 Register 4: Integral Gain

Register 4 contains the integral gain for the module. This

value is read by the module whenever the "change default

setups" command in register 66 is issued. See Section 5.2

for more information on tuning.

Figure 4.5 – Integral Gain Register

4.7 Register 5: Velocity Gain

Register 5 contains the velocity gain for the module. This

value is read by the module whenever the "change default

setups" command in register 66 is issued. See Section 5.2

for more information on tuning.

PROGRAMMING

4-7

Page 36

Figure 4.6 – Velocity Gain Register

4.8 Register 6: Feedforward Gain

Register 6 contains the feedforward gain for the module. This

value is read by the module whenever the “change default

setups” command in register 66 is issued. See section 5.2 for

more information on tuning.

Figure 4.7 – Feedforward Gain Register

4.9 Register 7: Deadband Compensation

Register 7 contains the deadband compensation for the

module. This value is read by the module whenever the

"change default setups" command in register 66 is issued.

See Section 5.2 for more information on tuning.

Figure 4.8 – Deadband Compensation Register

4-8

2-Axis Servo Module M/N 57C422B

Page 37

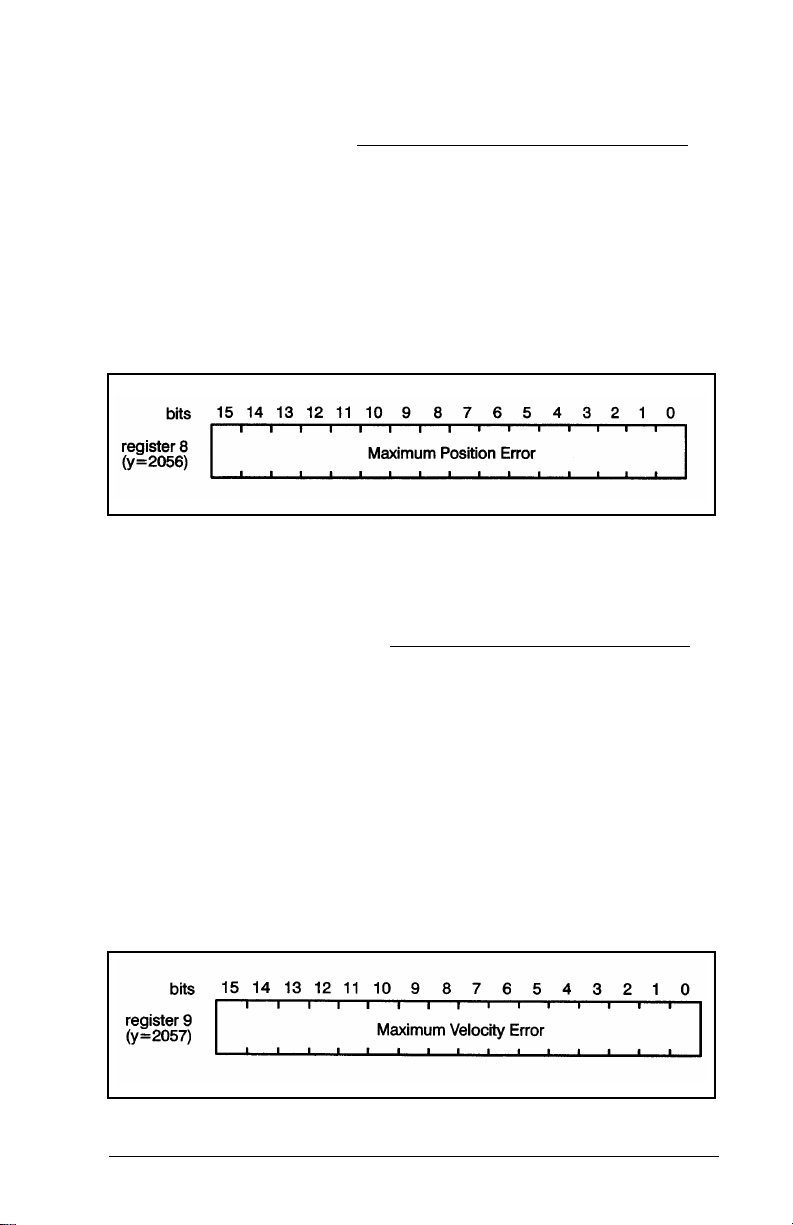

4.10 Register 8: Maximum Position Error

Register 8 contains the maximum allowable position error

that is used to determine faults. Position error is defined as

the difference between commanded and actual position. The

value depends on the system configuration and performance

required. If this limit is exceeded, the feedback will be

disabled and the appropriate fault bits will be set in the fault

register (R73). Note that register 8 will be examined by the

module even when it is in velocity mode. The module may

respond to excessive position error while running in velocity

mode.

Figure 4.9 – Maximum Position Error

4.11 Register 9: Maximum Velocity Error

Register 9 contains the maximum allowable velocity error.

Velocity error is the difference between the commanded and

the actual velocity. Excessive velocity error usually indicates

excessive acceleration, excessive deceleration, or a

disconnected encoder. The maximum velocity error is

determined using the following equation.

Maximum

Velocity Error=(max acceptable ve locity error in eng.

The result of the equation is in counts/scan. If this limit is

exceeded, the feedback will be disabled and the appropriate

fault bits will be set in the fault register (R73).

PROGRAMMING

units/sec*encoder cou nt s/ en g uni t s) (.00125)

Figure 4.10 – Maximum Velocity Error Register

4-9

Page 38

4.12 Register 10: In-Position Tolerance

Register 10 defines the tolerance within which the axis is

considered to be in-position. This value is read by the

module whenever the "enable feedback" (register 65) or

"change default setups" (register 66) command is issued.

The axis is considered to be in-position if the absolute value

of the difference between where the axis should be and

where it actually is, is less than this tolerance. This condition

is available as "axis locked" status in register 72. The

in-position tolerance is in units of encoder counts. Refer to

figure 4.11.

Figure 4.11 – In-Position Tolerance Register

4.13 Registers 11, 12: Positive Overtravel Limit

Registers 11, 12 define the positive overtravel limit. This

value is read by the module whenever the “enable feedback”

(register 65) or “change default setups” (register 66)

command is issued. This limit applies only if the axis is in the

linear mode (register 0, bit 4=0) and “software ove rtrav el ”

was enabled in register 2. The negative overtravel limit must

be algebraically less than the positive overtravel limit or a

motion fault will occur. The software overtravel limits are in

units of encoder counts.

Registers 11 -12 are also used to provide a maximum travel

for the "tune dynamics" (register 66) or "tune

limit

4-10

2-Axis Servo Module M/N 57C422B

Page 39

feedforward" (register 66) commands.

Figure 4.12 –

Positive Overtravel Limit Registers

4.14 Registers 13,14: Negative Overtravel Limit

Registers 13,14 define the negative overtravel limit. This

value is read by the module whenever the "enable feedback"

(R65) or change default setups" (R66) command is issued.

This limit applies only if the axis is in the linear mode.

(RO,b4=0) and "software overtravel" in R2 has been

enabled. The negative overtravel limit must be algebraically

less than the positive overtravel limit (R11, 12) or a motion

fault will occur. The negative overtravel limit is in units of

encoder counts.

Figure 4.13 –

Negative Overtravel Limit Registers

4.15 Registers 15,16: Low Speed Homing

Reference

Registers 15, 16 contain the low speed reference used

during the homing sequence. This value is read by the

module whenever the "home axis" (register 66) command is

issued. The low speed reference is used by the module

whenever it is attempting to locate the feedback marker

pulse. Refer to figure 4.14. The reference units are:

PROGRAMMING

4-11

Page 40

(encoder counts/sec) * 65.536

Figure 4.14 –

Low Speed Homing Reference Register

4.16 Registers 17,18: Command Position

Registers 17, 18 contain numeric parameters used in

various commands. All of the commands do not require the

use of all of the parameters in registers 17-24. Refer to figure

4.15.

Figure 4.15 – Command Position Registers

Registers 17,18 contain the command position.

read by the module whenever any of the following

commands are issued in register 66: "index/move," "define

fdbk position," "home axis," "tune gains," "define gearing

position," "set gearing position when marker occurs" and

"define sync position." The units are encoder counts.

This value is

The value is also read when any of the following commands

are issued in register 67: "enable passive homing on

feedback encoder marker pulse," "enable passive homing on

gearing encoder marker pulse,". "enable relative change in

feedback position," and "enable relative change in gearing

position."

4-12

2-Axis Servo Module M/N 57C422B

Page 41

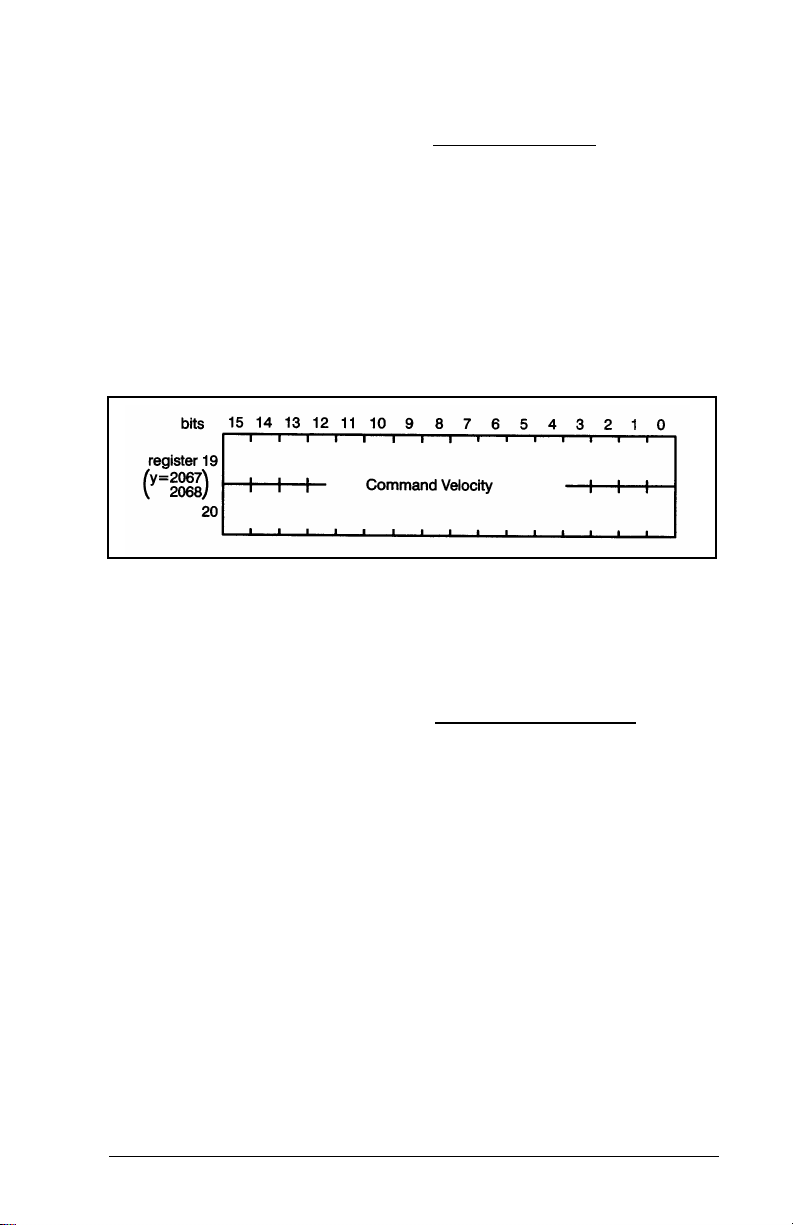

4.17 Registers 19, 20: Command Velocity

Registers 19, 20 contain the command velocity. This value is

read by the module whenever the following commands are

issued: "index/move", "home axis", "tune dynamics", "tune

feedforward", or "change velocity" in R66; or "velocity

control" in R65. The command velocity units are:

(encoder counts/sec)*65.536

The maximum speed that can be programmed is 65,536,000

counts/sec.

Figure 4.16 – Command Velocity Registers

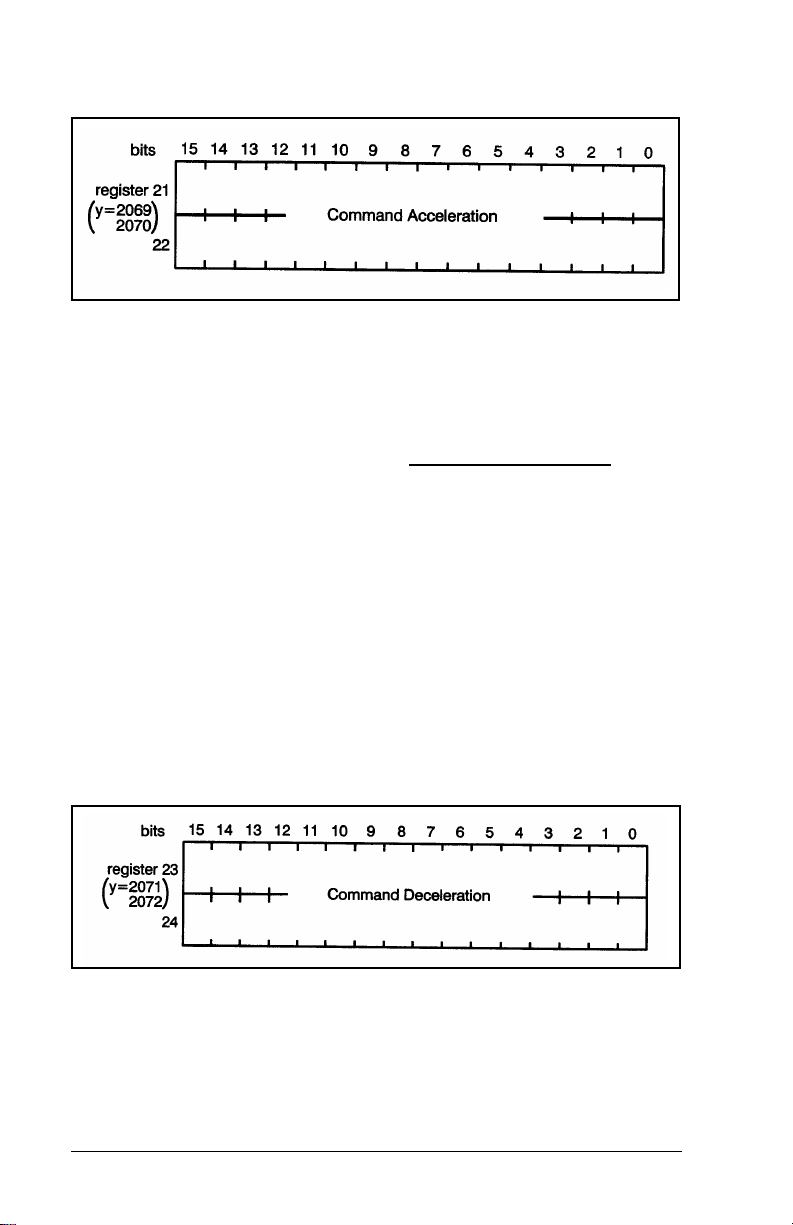

4.18 Registers 21, 22: Command Acceleration

Registers 21, 22 contain the command acceleration. This

value is read by the module whenever the following

commands are issued: “index/move", "home axis", "tune

dynamics", or "tune feedforward" in R66; or "velocity control"

in R65. The command acceleration is calculated as follows:

acceleration = (eng units/sec/sec)*(en coder counts/eng units) *.0 6 5 5 3 6

The maximum programmed value is 3.28 x 1010 encoder

counts/sec/sec. The acceleration rate and deceleration rate

(R23, 24) do not need to be equal. However, the deceleration

rate must not be less than one-fifth the acceleration rate.

PROGRAMMING

4-13

Page 42

Figure 4.17 – Command Acceleration Registers

4.19 Registers 23, 24: Command Deceleration

Registers 23, 24 contains the command deceleration. This

value is read by the module whenever the following

commands are issued: "index/move", "home axis", "tune

dynamics", or "tune feedforward" in R66; or "velocity control"

in R65. The command deceleration is calculated using the

same formula used for calculating "command acceleration"

in R21, 22. In addition, the same maximum value applies to

both command acceleration and deceleration. See section

4.18 for more information.

Note that the ratio between the deceleration rate and the

acceleration rate must be between .2 to 1 and 5 to 1. The

"stop motion" command in register 66 will use the value in

23, 24, depending on the state of the "stop action" bit in

register 65. See sections 4.34 and 4.35 for more information.

Figure 4.18 – Command Deceleration Registers

4-14

2-Axis Servo Module M/N 57C422B

Page 43

4.20 Registers 25, 26: Gear Ratio

Registers 25,26 contain the gear ratio between the feedback

and gearing reference axes. This value is read by the module

whenever the "enable gearing" (register 65) or "change gear

ratio" (register 67) command is issued. Refer to figure 4.19.

The gear ratio calculation method depends on the value of

"gear ratio format" (R38, b2). If this bit is equal to 0, the value

can be calculated with the following equation:

Gear Ratio = (feedback axis travel) * 16777216

gearing reference axis travel)

If R38, b2 is set, the gear ratio is the ratio of two 16-bit

numbers in registers 25 and 26. Register 25 is the

numerator. Register 26 is the denominator. The denominator

cannot be a negative number or 0.

If the result of the calculation is a repeating fraction, e.g., 1/3,

the module will keep track of all remainders for internal

gearing calculations. The allowable ratio range is 127:1 to

1:32767.

Note that if the gearing bit mode is set (R65, b1) and any

illegal condition is present in registers 25,26, gearing is not

enabled. If gearing is already enabled and a "change gear

ratio" command is issued (R67, b3), with illegal parameters

in registers 25,26, an illegal command fault will result.

Figure 4.19 – Gear Ratio Registers

4.21 Register 27: User LEDs

Register 27 is used to drive the three user controlled LEDs

on the faceplate of the module. These bits are read by the

module only when the "update LEDs" (register 66) command

is issued. Register 2075 (Y axis) can be used to update the

PROGRAMMING

4-15

Page 44

same user LEDs when the “update LEDs" co mma nd

(register 2114) is issued. Since this could lead to confusion,

you should only use one register (either 27 or 2075) in an

application, but not both. Refer to figure 4.20.

Figure 4.20 – User-Controlled LED Register

4.22 Register 28: Direct Drive Reference

Command

Register 28 can be used to provide a direct reference to the

drive. This value is read contin uou sl y by the mod ule

whenever the "output volts" (register 65) command is issued.

The values may range from -1984 to 1984 corresponding to

an output range of +

10 volts. Refer to figure 4.21.

Figure 4.21 – Drive Command Reference Register

4.23 Registers 29, 30: Sync Position

Registers 29, 30 contain the sync position. The sync position

register can be used to define a position where an action

needs to occur. This register is read by the module whenever

the "define sync position" (register 66) command is issued.

The sync position is used in conjunction with "position >=" or

"position <" bits in register 72. When the value in the sync

4-16

2-Axis Servo Module M/N 57C422B

Page 45

position registers is changed, the "position >=" and "position

<" bits in register 72 are undefined until another "define sync

position" command is issu ed. The sy nc position will be

compared to the actual current feedback position, an internal

value (not registers 74/75). The units are encoder counts.

Refer to figure 4.22.

Figure 4.22 – Sync Position Registers

4.24 Register 31: Maximum Voltage Reference

Register 31 limits the maximum voltage reference to the

drive. This value should be set prior to outputting any

reference to the drive.

CAUTION

ALWAYS PLACE A LIMIT ON THE MAXIMUM VOLTAGE

REFERENCE TO THE DRIVE. FAILURE TO OBSERVE THIS

PRECAUTION COULD RESULT IN DAMAGE TO OR

DESTRUCTION OF THE EOUIPMENT.

The value in register 31 is read by the module whenever the

"change default setups" command in register 66 is issued.

The value may range from 0 to 1984, corresponding to an

output range of 0 to 10 volts. Refer to figure 4.23.

PROGRAMMING

4-17

Page 46

Figure 4.23 – Maximum Voltage Reference Output Register

When the drive is configured as a velocity regulator, register

31 should be used to limit the voltage reference. This feature

is used if the drive requires less than 10 volts for full speed. If

the drive is configured as a current regulator, register 31 can

be used as a programmable current clamp. The "output

clamped" bit in register 73 will be set when the voltage

reference is limited by the value in register 31.

4.25 Register 32: Positive Lineari zation Constant

Register 32 contains the positive linearization constant for

the velocity output. This value is used by the module to

insure that the velocity output is linearly related to the

number computed by the software. Initially, this value should

be set to -1. The "tune dynamics" command in auto-tuning

will adjust this number if the drive has been configured as a

velocity regulato r.

Figure 4.24 – Positive Linearization Constant Register

4.26 Register 33: Negative Lineari zation

Constant

Register 33 contains the negative linearization constant for

the velocity output. This value is used by the module to

4-18

2-Axis Servo Module M/N 57C422B

Page 47

insure that the velocity output is linearly related to the

number computed by the software. Initially, this value should

be set to -1. The "tune dynamics" command in register 66 will

adjust this number if the drive has been configured as a

velocity regulato r.

Figure 4.25 – Positive Linearization Constant Register

4.27 Registers 34, 35: Feedback Unwind Constant

Registers 34, 35 contain the unwind constant for the

feedback encoder. Refer to figure 4.26. This parameter is

used in the rotary mode selected in register 0 (Encoder

Setup). This value is read by the module whenever the

"home axis" or "change default setup" commands (register

66) are issued. The unwind constant is equal to the number

of encoder counts per axis revolution. Use the following

equation to determine the unwind constant:

Unwind Constant = encoder counts/rev * encoder revolutions

axis revolution

Figure 4.26 – Feedback Unwind Constant Registers

4.28 Registers 36, 37: Gearing Unwind

Constant

Registers 36, 37 contain the unwind constant for the gearing

encoder. This parameter is used in the rotary mode selected

PROGRAMMING

4-19

Page 48

in register 0 (Encoder Setup). This value is read by the

module whenever the "home axis" or "change default setup"

commands in register 66 are issued. The unwind constant is

equal to the number of encoder counts per axis revolution.

Use the same formula in the gearing unwind constant and

the feedback unwind constant. See section 4.27 above for

the formula.

Figure 4.27 – Gearing Unwind Constant Registers

4.29 Register 38: Gearing Modes, Ratio Format, Ramp Velocity Control

Register 38 is used to determine gearing mode if bit 9 in

register 65 is not set (0), to select the gear ratio format, and

to enable ramp velocity control. Note that changes to

registers 38

register 65

will be ignored while gearing mode is enabled in

. See figure 4.28.

Figure 4.28 – Gearing Mode, Ratio Format, and Ramp Velocity Control Register

4-20

2-Axis Servo Module M/N 57C422B

Page 49

Note that the strobed gearing registration position (registers

86,87) and the current gearing position (registers 76, 77)

data are not affected by the selections made in register 38. X

and Y axis gearing registration and current gearing position

values will always be strobed from their respective hardware

encoder channels.

Bit 2 in register 38 selects the format of the gear ratio.

default (0) is a 32-bit number stored in registers 25,26 scaled

by 16777216. Setting bit 2 to 1 allows you to express the

gear ratio as a ratio of two 16-bit numbers in registers 25 and

26. See section 4.20 for more information.

Bit 3 in register 38 enables ramp velocity control

follower axis when the master axis is moving and gearing is

enabled, when you are changing from the non-geared to the

geared mode, or when the gear ratio is changed while

gearing is enabled. This command will limit the rate of

acceleration and deceleration until the axis is synchronized

with the master. Note that this limit applies only to trapezoidal

acceleration, not to S-curve acceleration. Once the axis is

synchronized with the master, there is no limit on

acceleration/deceleration through register 38, bit 3. When

ramped velocity control is selected, if gearing is disabled

while the follower axis is still moving, the follower axis will

continue to move at that velocity until a stop motion

command is issued in register 66, bit 6.

4.30 Registers 39, 40: Backlash Compensation

Registers 39 and 40 are used to store a signal value (in

counts) that selects the amount of backlash compensation.

The sign of the value corresponds to the approach direction.

Refer to figure 4.29.

The

on the

For example, a value of +20 entered here will mean that an

incremental move of 100 counts will result in an actual move

of 100 counts and then a stop. The same move in the

negative direction will result in the axis moving - 120 counts,

+20 counts, and then a stop.

PROGRAMMING

4-21

Page 50

Figure 4.29 – Backlash Compensation Registers

4.31 Register 41: Registration Inp ut Edge Detection

Register 41 selects which edge (rising and falling, or falling

only) of the gearing or feedback registration input will be

recognized by the module. This register is available only on

the B/M 57422-2 module.

Figure 4.30 – Registration Edge Detection Register

When bits 7 and 15 are left at the default value (0), the

module will recognize both the rising and failing edges of

registration inputs.

4.32 Register 63: Auto-Acknowledge

Register 63 is the command auto-acknowledge register.

When bit 0 is set to 1, the module will automatically clear the

command registers (66 and 67) instead of requiring an

application task to clear the command registers. The user

4-22

2-Axis Servo Module M/N 57C422B

Page 51

need only wait for the value in registers 66 and 67 to be zero

before issuing the next command.

Figure 4.31 – Auto-Acknowledge Register

4.33 Register 64: I nterrupt Reset

To reset the interrupt, the application task must write a zero

value to register 64. Note that register 64 Is used as the

Interrupt reset register for both the X-axis and the

Y-axis. See figure 4.32.

Figure 4.32 – Interrupt Reset Register

4.34 Register 65: Mode

Register 65 is a control register used to command operating

modes on the module. This register is read by the module

continuously. Refer to figure 4.33.

PROGRAMMING

4-23

Page 52

Figure 4.33 – Mode Register

The enable control loop

bit commands the module to switch

on the control loop (position/velocity) and enable the drive

reference from the module. It also causes the

microprocessor to read set-up data and reset faults when

toggled.

The enable gearing

bit commands the module to ratio the

feedback encoder to the gearing encoder. This function is

useful for electronic lineshaft applications. Note that if the

gearing function is used, register 25, 26 must contain the

gear ratio .

If gearing is enabled or disabled with ramp velocity control

disabled, the axis will accelerate or decelerate in current

limit.

If gearing is disabled with ramp velocity control enabled, it is

possible to do an absolute move while the drive is still in

motion. The new commanded position to which to move

must be either behind the current position, or farther forward

than the current position plus the distance required to

4-24

2-Axis Servo Module M/N 57C422B

Page 53

decelerate to a stop. If the position is not beyond the

distance required to decelerate, the axis will overshoot.

The velocity control

bit causes the axis to run at the velocity

defined by the command velocity input (registers 19, 20).

This mode is used to run the axis as a velocity regulator.

Velocity regulation is achieved by sending a constantly

variable position reference to the position loop. This means

the axis can still "trip" due to position error, i.e., the value in

register 80 is greater than the value in register 8.

The direct drive reference

bit commands the module to

output the value in register 28 to the drive. This command

causes the axis to function like a D/A converter.

The direction

bit specifies the relationship between the

gearing axis and feedback axis when gearing is used, or to

specify the sign of the velocity command when velocity

control is used. When gearing is active, a positive direction

indicates that the gearing and feedback axis will move in the

same direction. A negative direction indicates that they will

move in opposite directions. If you jog into the positive or

negative software travel limit, and then try to jog off the limit

by changing the state of the direction bit, the axis will remain

at the travel limit. To be able to jog off a software travel limit,

you must first turn off the velocity control bit (bit 2), and then

turn it back on with the direction bit changed. See sections

4.13 and 4.14 for more information on software overtravel

limits.

The incremental/absolute move

move to be made. If you specify an absolute move, the axis

will move to the position specified in register 17. If an

incremental move is specified, the module will add the

current value in register 17 to the position of the axis to

determine the next position.

The velocity profile

will execute when accelerating or decelerating, whether

doing an absolute move (bit 5) or velocity control (bit 2).

Using an S-Curve profile doubles the time required to

accelerate and decelerate compared with the trapezoidal

profile. Note that If you select S-Curve, you cannot change

velocity while moving (register 66 bit 8) or an illegal

command fault will be generated. See the figure below for a

sample profile comparison.

PROGRAMMING

bit specifies the type of

bit specifies the type of profile the drive

4-25

Page 54

The stop action bit defines the way that the drive will stop

when a "stop motion" command (register 66) is issued. If a

"decel to stop" is selected and the module is not in the cam

mode, the drive will ramp to a zero speed at the rate in

register 23, 24 when the motion is started. If the module was

in the time cam mode, it will complete the current cam cycle

and return to the beginning of the profile. If the module was in

position cam mode, cam execution will stop immediately. If a

"fast stop" is selected, the module will command the drive to

decelerate at the rate specified in register 23, 24 when the

"home" command is issued. If a "fast stop" is selected, a

"home", or "tune dynamics" command MUST be done to load

the "fast stop" deceleration rate. If the application does not

normally do a "home" command, you can use the mode of

homing that does not cause any motion. See section 4.35 for

more information. The feedback loop will remain enabled.

The gearing reference

bit defines the source of the gearing

reference. Bit 9 = 0 if you want the gearing reference to be

determined by register 38. If the reference is an encoder, you

4-26

2-Axis Servo Module M/N 57C422B

Page 55

must connect the encoder to the proper inputs on the

terminal strip. If you want to gear to the opposite axis

command position, set bit 9 = 1. This option does not require

you to make any external wiring connections. In this mode,

the geared axis will follow all changes to the command

position of the reference axis.

The enable shortest path

the shortest path to take when doing an absolute move in

rotary mode.

No Incremental moves can be performed if this bit is set.

If rotary mode is not selected (in register 0, bits 4 and 12),

setting the enable shortest path bit will cause an illegal

command fault.

The enable automatic backlash compensation

to enable automatic backlash compensation as specified in

registers 39 and 40.

The abort self-tuning

command. This is the only command that is accepted while

the module is doing a self-tune.

bit allows the module to determine

command is used to abort a self tuning

4.35 Register 66: Comman d

Register 66 is used to command actions from the module.

The bits in this register and in register 67 are mutually

exclusive, i.e., only one function may be selected at a time

from either register. This register is read by the module

continuously. Refer to figure 4.34.

bit allows you

PROGRAMMING

4-27

Page 56

Figure 4.34 – Command Register 66

The index/move command will cause the axis to move

according to the parameters defined in registers 17-24 and

register 65, bit 5. Once a move has been initiated, the accel

and decel rates may not be changed until the move is

complete. Velocity can be changed during a move by issuing

a "change velocity" command. Final position may be

changed during a move by issuing another index move.

The define feedback position

command will cause the

current position of the feedback to be defined by the value in

registers 17-18. The axis will not move.

The home axis

command will cause the axis to perform the

homing sequence that was defined by the bits in register 2.

Four different homing sequences for the feedback axis are

possible, depending on whether a home limit switch and

encoder marker pulse are specified in register 2. These four

sequences are described below. Note that it is also possible

to home on the feedback or gearing encoder marker pulse.

See section 4.36 for more information. When a "home"

command is issued, the deceleration rate in registers 23, 24

4-28

2-Axis Servo Module M/N 57C422B

Page 57

is saved and used for the "stop motion" command if the "stop

action" bit is set in register 65.

1. No home limit switch and no encoder marker pulse.

When the "home axis" command is issued, the value in

registers 17, 18 is assigned to the current axis position.

The axis does not move.

2. Encoder marker pulse only. When the "home axis"

command is issued, the axis moves in the specified

direction at the slow home speed (registers 15, 16) until

the marker pulse is detected. The value in registers 17,

18 is then assigned to the axis position.

3. Home limit switch only. When the "home axis" command

is issued, the axis moves in the specified direction at the

fast home speed (registers 19, 20) until the home limit

switch is detected. The axis then stops and moves in the

opposite direction at the slow home speed (registers 15,

16) until the limit switch is cleared. The value in registers

17, 18 is then assigned to the axis position.

4. Both the home limit switch and encoder marker pulse.

When the "home axis" command is issued, the axis

moves in the specified direction at the fast home speed

(registers 19, 20) until the home limit switch is detected.

The axis then stops and moves in the opposite direction

at the slow home speed (registers 15, 16) until the limit

switch is cleared. After clearing the home limit switch, the

axis continues in the same direction at slow speed until

the marker pulse occurs. The value in registers 17, 18 is

then assigned to the axis position.

Tune gains, tune dynamics

auto-tuning commands that work differently from other

commands. While the auto-tuning process is underway, the

module will not respond to any commands other than the

"abort self-tuning" command (register 65). For this reason,

you should not attempt to issue self-tuning commands for

one axis while issuing any commands to the other axis.

Normal operation of both axes should be halted while

self-tuning is being done. Only one axis at a time may be

tuned.

Note that the application software disk includes an

auto-tuning procedure. See also section 5.2 for more

information about tuning.

PROGRAMMING

, and tune feedforward gain are

4-29

Page 58

The self-tuning of an axis should always be done in the

following order:

1. Tune gains

2. Tune dynamics (if required by application)

3. Tune feedforward gain (if required by application)

The tune gains command is used to initiate self-tuning of the

control loop gains. The module will tune the gains in the

following order:

1. Deadband Compensation

2. Velocity Gain

3. Integral Gain

4. Proportional Gain

The tune gains command results in movement of the axis in

both directions. Registers 17, 18 are used to define the

tuning increment i.e., the distance that the axis will move

while attempting to auto-tune. This increment is typically

between .25 and .5 revolutions of the motor shaft.

The results obtained from the "tune gains" command are

stored in registers 3, 4, 5, and 7.

The tune dynamics

command will determine the maximum

velocity and accel and decel limits for the servo system

(motor and drive). Register 8 is used to define the maximum

allowable following error. Registers 11, 12 are used to define

the allowable travel distance, and registers 19 through 24 are

used to limit the accel, decel and velocity. The feedback

encoder should be in "linear" mode while this function is

being performed. If there are no machine limitations, these

registers may be set to any large value. In order for this

command to work properly , the motor must be able to rotate

in both directions for many revolutions. If this is not possible,

this command should not be used.

The results obtained from the tune dynamics command are

stored in registers 19 through 24. These values represent the

maximum values achievable with minimum following error.

You can exceed these values if you are not concerned with

the amount of following error or you can use a lower value if