Page 1

Page 2

Reliance is a registered trademark of Reliance Electric and its subsidiaries..

The information in this user's manual is subject to change without notice. ReliĆ

ance Electric Industrial Company assumes no responsibility for errors that may

appear in this user's manual.

WARNING

THIS UNIT AND ITS ASSOCIATED EQUIPMENT MUST BE INSTALLED,

ADJUSTED, AND MAINTAINED BY QUALIFIED PERSONNEL WHO ARE

FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF ALL EQUIPMENT

IN THE SYSTEM AND THE POTENTIAL HAZARDS INVOLVED. FAILURE TO

OBSERVE THESE PRECAUTIONS COULD RESULT IN BODILY INJURY

WARNING

INSERTING OR REMOVING THIS MODULE OR ITS CONNECTING CABLES MAY

RESULT IN UNEXPECTED MACHINE MOVEMENT. TURN OFF POWER TO THE

MACHINE BEFORE INSERTING OR REMOVING THE MODULE OR ITS

CONNECTING CABLES. FAILURE TO OBSERVE THESE PRECAUTIONS COULD

RESULT IN BODILY INJURY.

CAUTION

THIS MODULE CONTAINS STATICĆSENSITIVE COMPONENTS. CARELESS

HANDLING CAN CAUSE SEVERE DAMAGE.

DO NOT TOUCH THE CONNECTORS ON THE BACK OF THE MODULE. WHEN

NOT IN USE, THE MODULE SHOULD BE STORED IN AN ANTIĆSTATIC BAG. THE

PLASTIC COVER SHOULD NOT BE REMOVED. FAILURE TO OBSERVE THIS

PRECAUTION COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE

EQUIPMENT.

Page 3

Table of Contents

1.0 Introduction 1Ć1...............................................

2.0 Mechanical/Electrical Description 2Ć1...........................

2.1 Mechanical Description 2Ć1...................................

2.2 Electrical Description 2Ć1.....................................

3.0 Installation 3Ć1................................................

3.1 Wiring 3Ć1..................................................

3.2 Initial Installation 3Ć1.........................................

3.3 Module Replacement 3Ć5.....................................

4.0 Programming 4Ć1..............................................

4.1 Register Organization 4Ć1....................................

4.2 Local I/O Definition 4Ć2.......................................

4.2.1 Single Register Reference 4Ć3...........................

4.2.2 Bit Reference 4Ć3......................................

4.2.3 Examples of Local I/O Definitions 4Ć4....................

4.3 Remote I/O Definition 4Ć4.....................................

4.3.1 Single Register Reference 4Ć5...........................

4.3.2 Bit Reference 4Ć6......................................

4.3.3 Examples of Remote I/O Definitions 4Ć6..................

4.4 Reading and Writing Data in Application Tasks 4Ć6...............

4.4.1 BASIC Task Example 4Ć7...............................

4.4.2 Control Block Task Example 4Ć7.........................

4.5 Using Interrupts in Application Tasks 4Ć8.......................

4.5.1 BASIC Task Example 4Ć9...............................

4.5.2 Control Block Task Example 4Ć9.........................

4.6 Using the External Strobe Input 4Ć10............................

4.7 Restrictions 4Ć11.............................................

4.7.1 Writing Data to Registers 4Ć11............................

4.7.2 Interrupts in Remote I/O Racks 4Ć11......................

4.7.3 Feedback Element in a Drive System 4Ć11.................

5.0 Diagnostics and Troubleshooting 5Ć1............................

5.1 Incorrect Data 5Ć1...........................................

5.2 Bus Error 5Ć3...............................................

5.3 Interrupt Problems 5Ć4.......................................

5.3.1 No Interrupts 5Ć5......................................

5.3.2 Hardware Event TimeĆOut 5Ć5...........................

5.3.3 Hardware Event Count Limit Exceeded 5Ć5...............

5.3.4 Illegal Interrupt Detected 5Ć6............................

I

Page 4

Technical Specifications AĆ1......................................

Module Block Diagram BĆ1......................................

Field Connections CĆ1...........................................

Related Components DĆ1........................................

II

Page 5

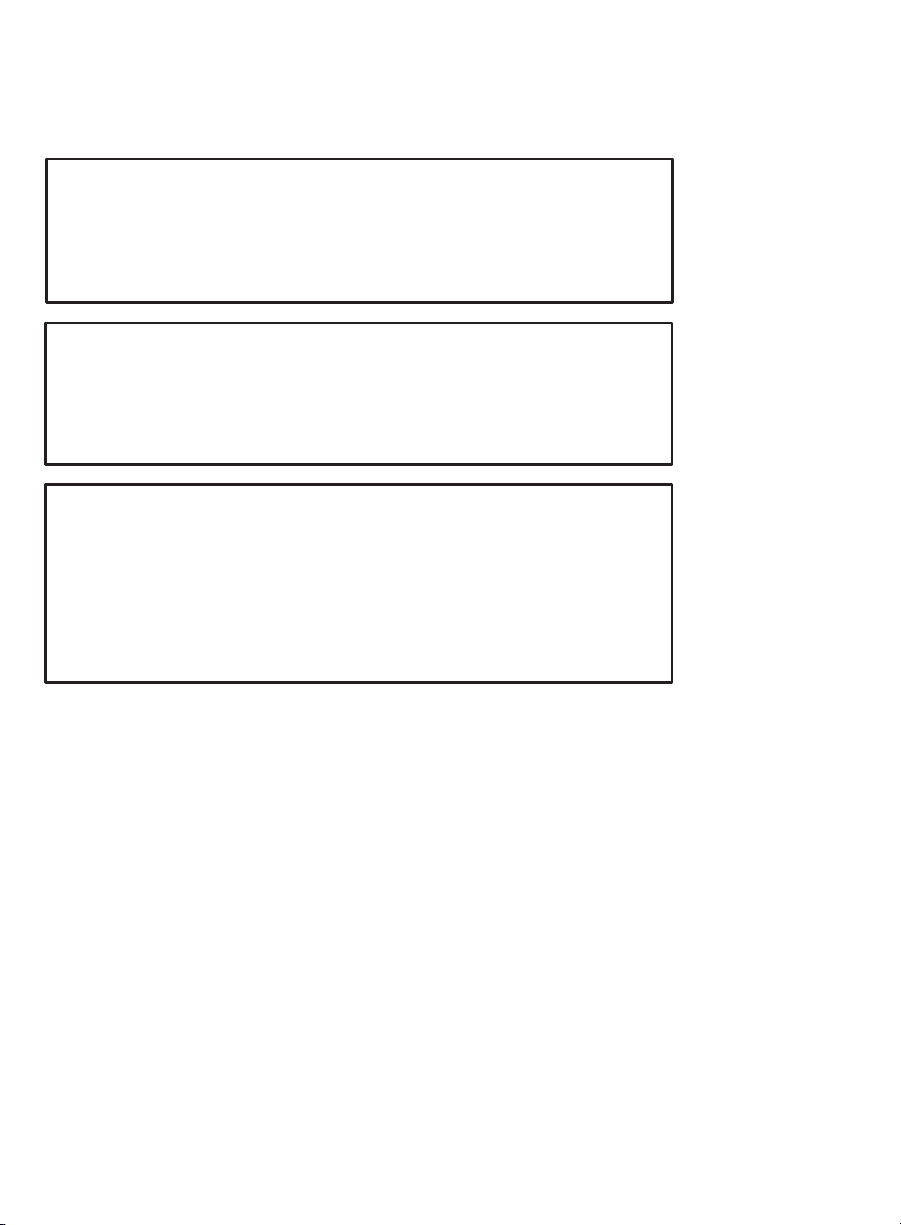

Figure 2.1 Ć External Strobe Input Circuit 2Ć2............................

Figure 2.2 Ć Low Leakage Requirement for Devices Driving Strobe Input 2Ć2

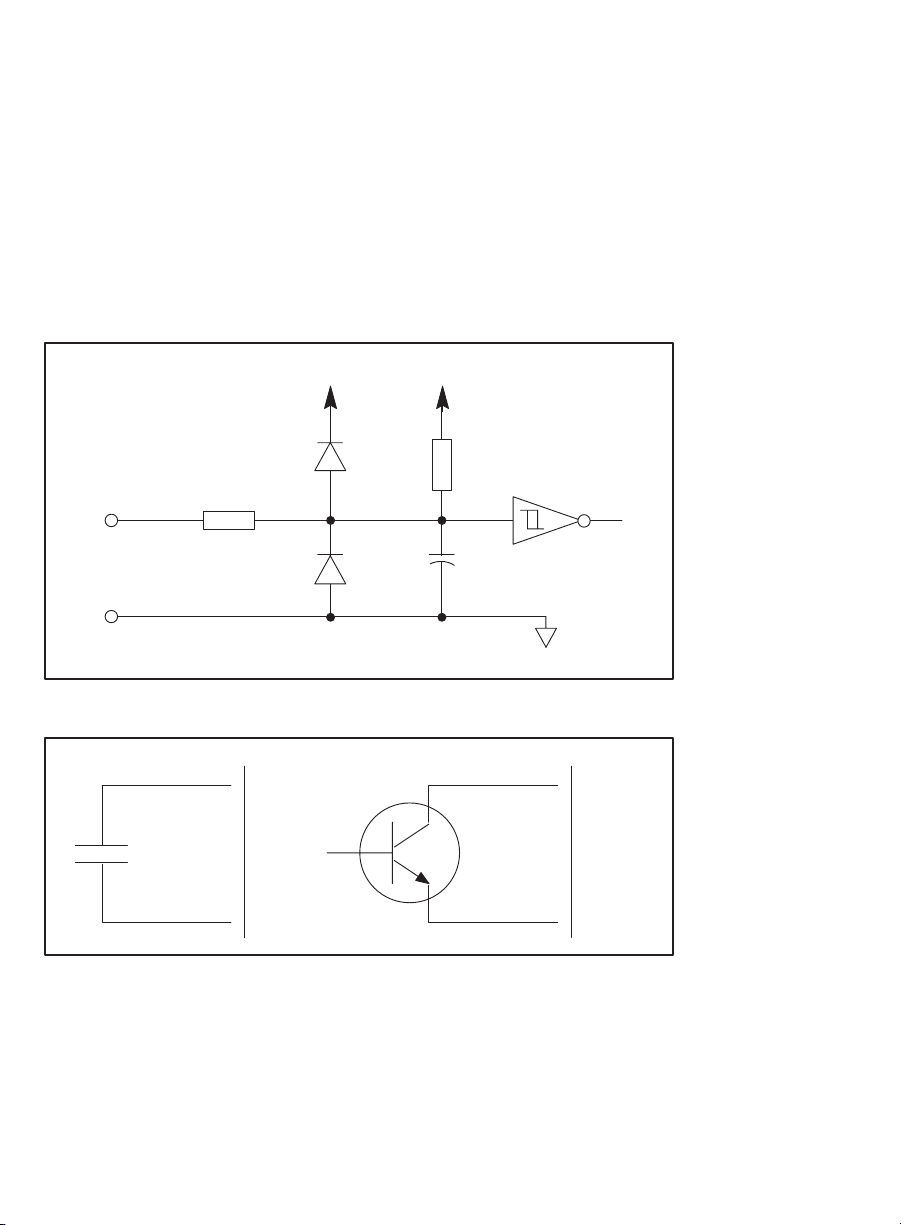

Figure 2.3 Ć Module Faceplate 2Ć3.....................................

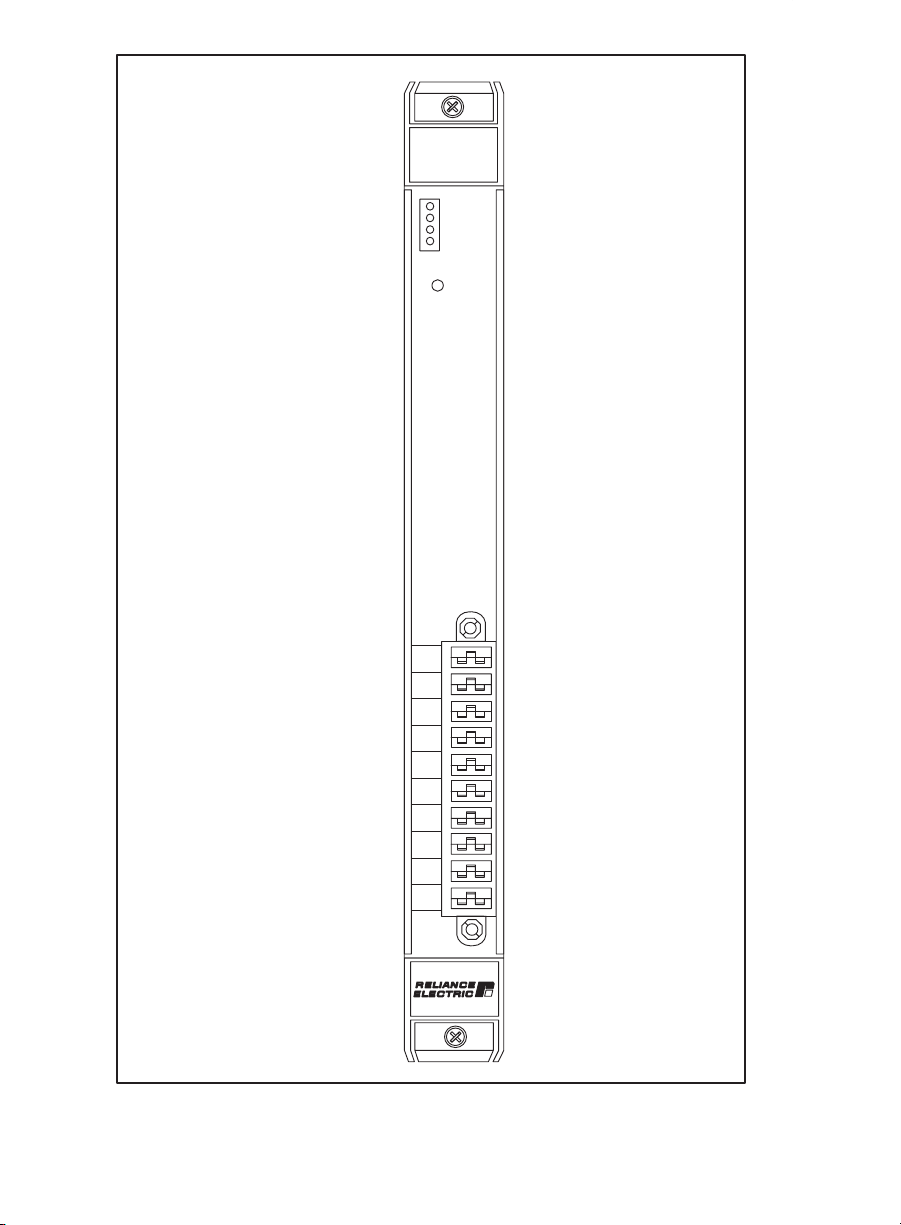

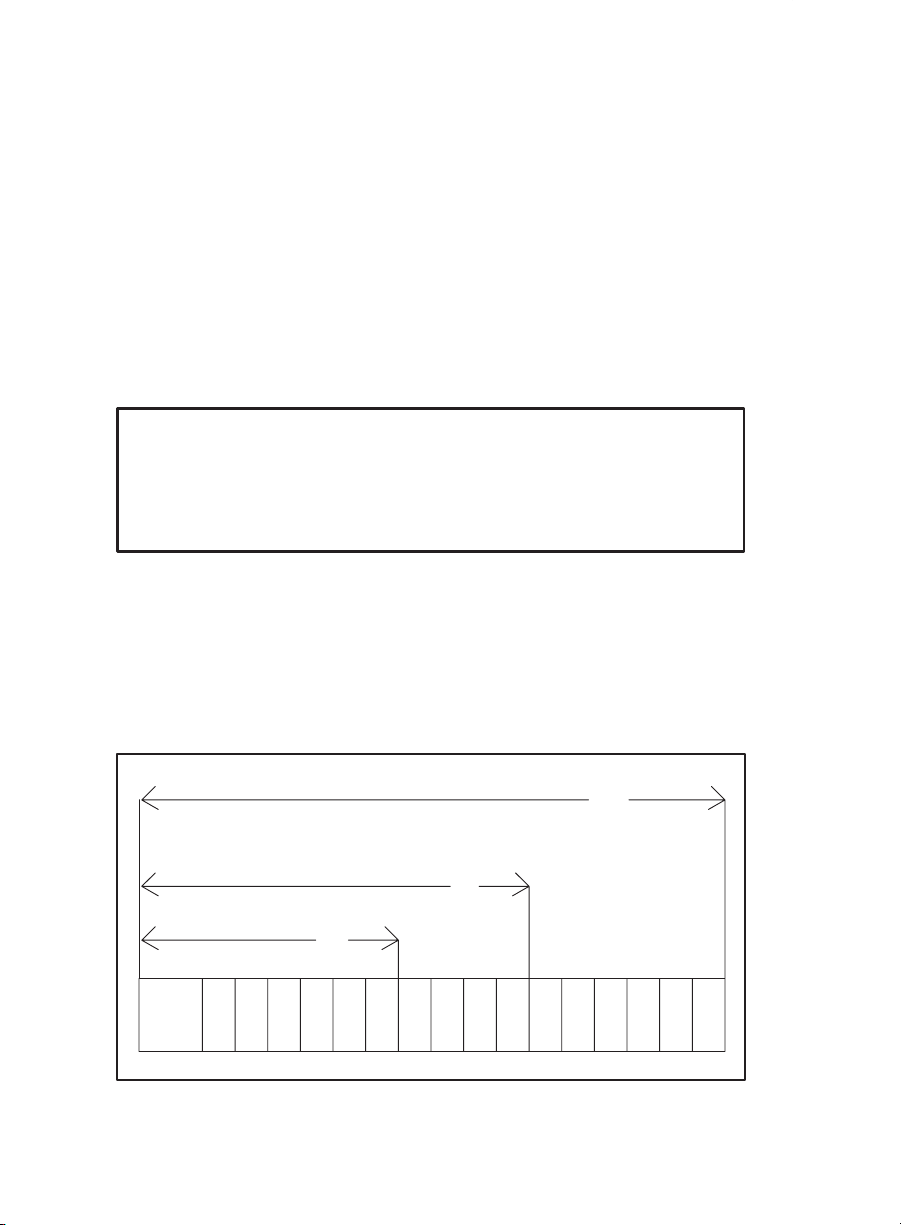

Figure 3.1 Ć Rack Slot Numbers 3Ć1...................................

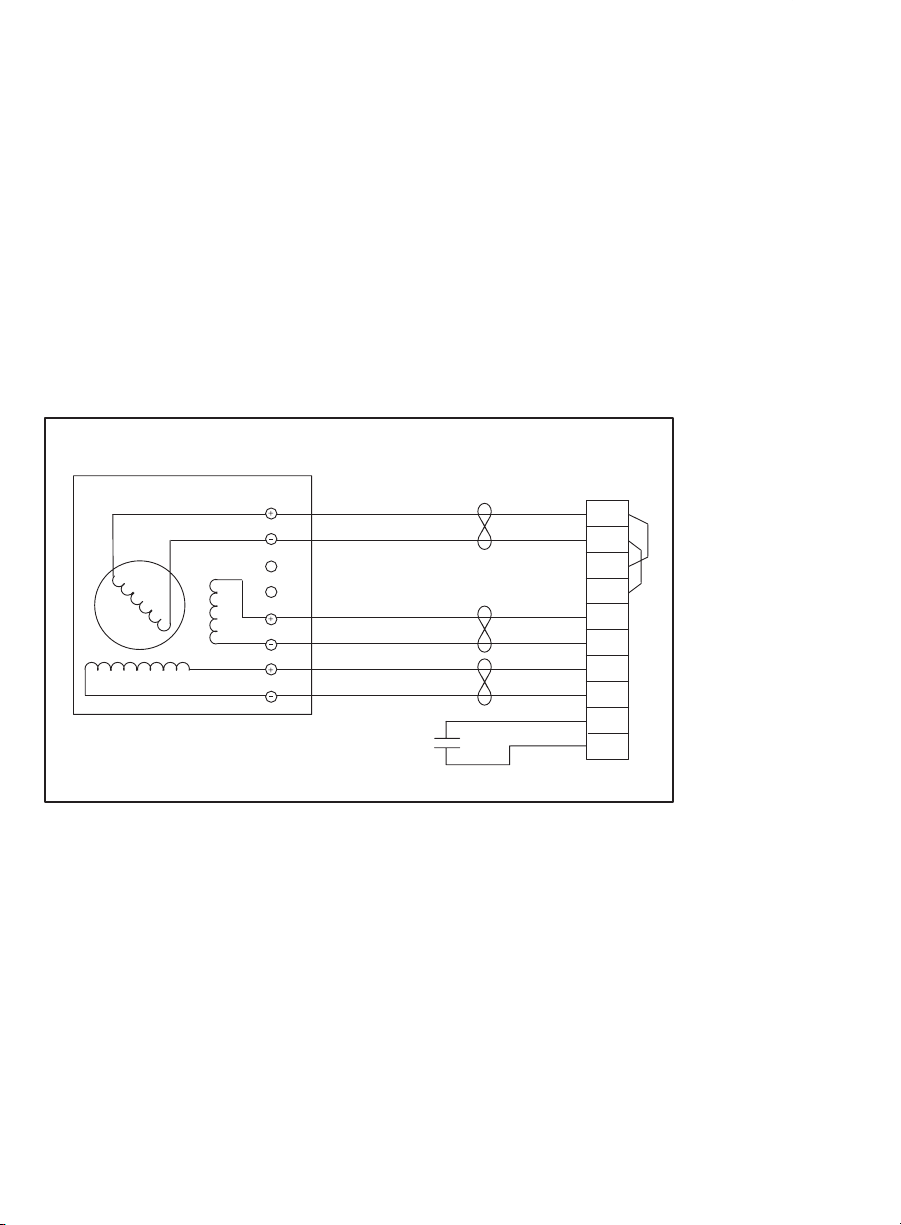

Figure 3.2 Ć Typical M/N 57C360 Resolver Field Connections 3Ć2..........

Figure 3.3 Ć Typical M/N 57C361 Resolver Field Connections 3Ć3..........

Figure 3.4 Ć Changing the Direction of Rotation 3Ć4......................

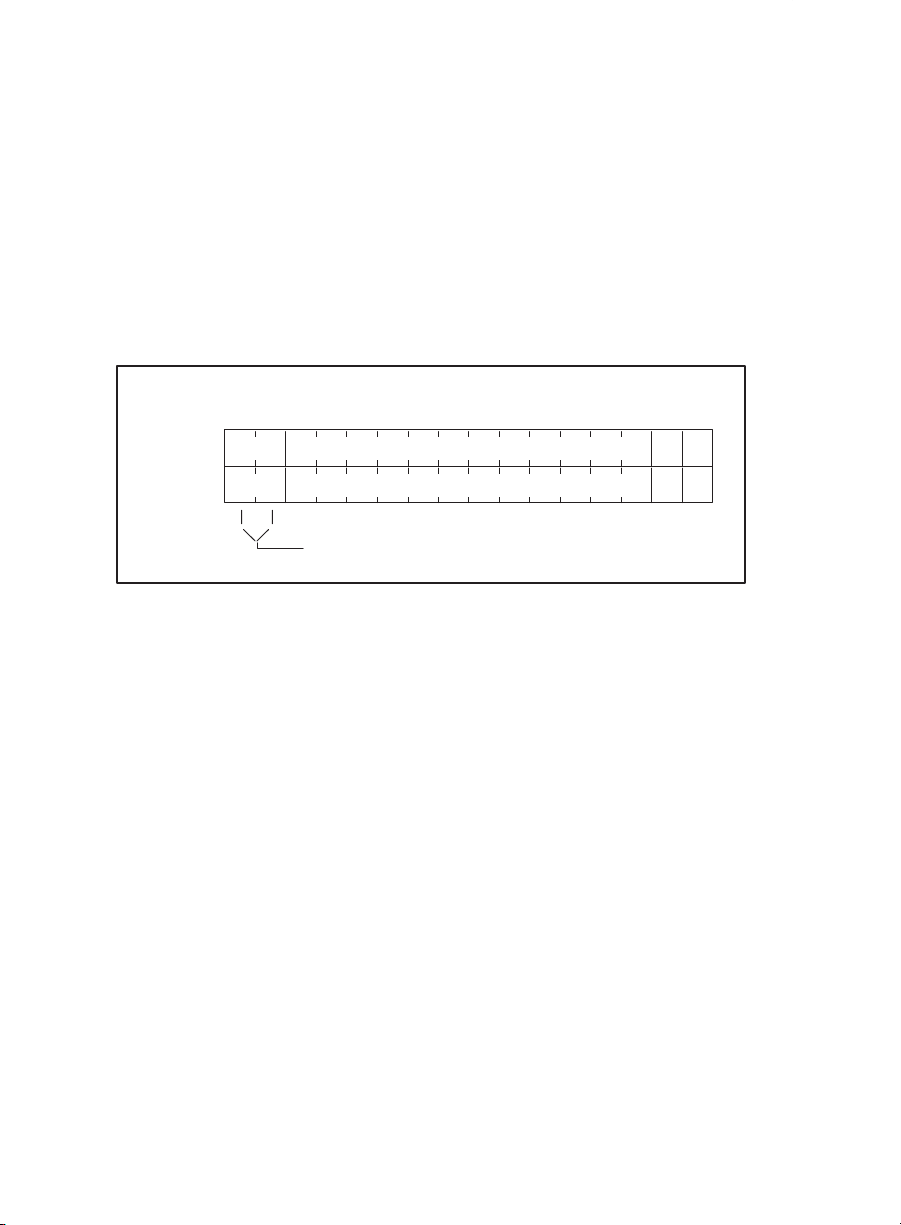

Figure 4.1 Ć Resolver Data Registers 4Ć1...............................

Figure 4.2 Ć Interrupt Control Registers 4Ć2.............................

Figure 4.3 Ć Resolver Update Register 4Ć2..............................

Figure 4.4 Ć Module in a Local Rack 4Ć3................................

Figure 4.5 Ć Module in a Remote Rack 4Ć5..............................

III

Page 6

Page 7

The Resolver Input Module is used to input the angular position of a

resolver rotor to the DCS 5000 system. The module provides 12Ćbit

resolution of one revolution and a 2Ćbit revolution counter. The

resolver position may be sampled from 500 microseconds to 32.767

seconds. An external strobe input is provided to permit

synchronization of the DCS 5000 system to an external event. The

module can be programmed to interrupt on every sample.

Typically, this module is used to input rotary shaft position for the

purpose of determining shaft position or velocity.

This manual describes the functions and specifications of the

module. It also includes a detailed overview of installation and

servicing procedures, as well as examples of programming methods.

Related publications that may be of interest:

JĆ2611 DCS 5000 PRODUCT SUMMARY

JĆ3600 DCS 5000 ENHANCED BASIC LANGUAGE

JĆ3601 DCS 5000 CONTROL BLOCK LANGUAGE

JĆ3602 DCS 5000 LADDER LOGIC LANGUAGE

JĆ3629 DCS 5000 REMOTE I/O INSTRUCTION MANUAL

JĆ3630 DCS 5000 PROGRAMMING TERMINAL

JĆ3635 DCS 5000 PROCESSOR MODULE INSTRUCTION

IEEE 518 GUIDE FOR THE INSTALLATION OF ELECTRICAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

MANUAL

EQUIPMENT TO MINIMIZE ELECTRICAL NOISE

INPUTS TO CONTROLLERS FROM EXTERNAL

SOURCES

1Ć1

Page 8

Page 9

2.0 Mechanical/Electrical Description

The following is a description of the faceplate LEDs, field termination

connectors, and electrical characteristics of the field connections.

2.1 Mechanical Description

The input module is a printed circuit board assembly that plugs into

the backplane of the DCS 5000 rack. It consists of the printed circuit

board, a faceplate, and a protective enclosure. The faceplate

contains tabs at the top and bottom to simplify removing the module

from the rack. Module dimensions are listed in Appendix A.

The faceplate of the module contains a female connector socket and

5 LED indicators for module status, including one light that indicates

when the board is operational (on) or malfunctioning (off).

Input signals are brought into the module via a multiconductor cable

(M/N 57C373; see Appendix D). One end of this cable attaches to the

faceplate connector, while the other end of the cable has stakeĆon

connectors that attach to a terminal board for easy field wiring. The

faceplate connector socket and cable plug are keyed to prevent the

cable from being plugged into the wrong module.

On the back of the module are two edge connectors that attach to

the system backplane.

2.2 Electrical Description

The input module contains a tracking resolverĆtoĆdigital converter that

produces a 12Ćbit digital number proportional to one electrical

revolution of a resolver. The digital position may be sampled in one of

two ways. The most common method is to specify the sampling

period. The period may range from a low of 500 microseconds to a

high of 32.7675 seconds, in increments of 500 microseconds.

The second method is to sample the position when an external event

occurs. This method is useful when it is necessary to synchronize the

DCS 5000 with the occurrence of a particular event. Using an

external strobe input is a simple method of synchronizing your

application software to the exact position of an object when an

external event occurs. See figure 2.1 for details about the electrical

characteristics of the external strobe input circuit. Because of the high

input impedance of the strobe input, the device driving the input

must have low leakage. See figure 2.2.

The module can be programmed to generate an interrupt whenever it

does a periodic sample. This mode allows you to synchronize task

execution with the conversion of new data. The converted data will

be latched when the interrupt is generated.

The module contains a 2Ćbit electronic counter that can count a total

of 4 electrical resolver revolutions. This 2Ćbit counter is contained in

the most significant two bits of resolver position, registers 0 and 1.

This counter is reset whenever power is turned on to the system or a

board reset command occurs.

2Ć1

Page 10

The module produces a 26 volt rms 2381 Hertz sine wave reference

output signal which is capable of driving a 400 ohm load. This

reference signal is transformerĆisolated and shortĆcircuit protected

through a current limiter. The module also receives 11.8 volt rms sine

and cosine signals from the resolver, as well as the 26 volt rms

reference.

There are 5 LEDs on the faceplate of the module. The top LED,

labeled DIRECTION, indicates the direction of rotation of the resolver.

When it is on, the resolver is rotating clockwise. The next LED,

labeled FDBK OK, indicates that the resolver is connected to the

module. The next LED, labeled CCLK OK, indicates that the common

clock is on. The fourth LED, labeled IPS OK, indicates that the

isolated power supply is working. Finally, the bottom LED, labeled

OK, indicates whether the common clock is on and the isolated

power supply is functional. See figure 2.3.

+12V +12V

1

M

9

10

100k

2200 pf

40106

Figure 2.1 Ć External Strobe Input Circuit

9

10

Figure 2.2 Ć Low Leakage Requirement for Devices Driving Strobe Input

2Ć2

0V

9

10

Page 11

RESOLVER

INPUT

OK

DE

P3

C

B

1

2

3

4

5

6

7

8

9

1

0

3

2

1

F

G

6

7

8

Figure 2.3 Ć Module Faceplate

2Ć3

Page 12

Page 13

3.0 INSTALLATION

3.1 Wiring

The installation of wiring should conform to all applicable codes.

To reduce the possibility of electrical noise interfering with the proper

operation of the control system, exercise care when installing the

wiring from the system to the external devices. For detailed

recommendations, refer to IEEE 518.

You should use twisted pair (2 twists per inch) wiring to/from the

resolver.

3.2 Initial Installation

Use the following procedure to install the module:

WARNING

INSERTING OR REMOVING THIS MODULE OR ITS CONNECTING CABLES MAY

RESULT IN UNEXPECTED MACHINE MOTION. POWER TO THE MACHINE

SHOULD BE TURNED OFF BEFORE INSERTING OR REMOVING THE MODULE

OR ITS CONNECTING CABLES. FAILURE TO OBSERVE THESE PRECAUTIONS

COULD RESULT IN BODILY INJURY.

Step 1. Remove power from the system. Power to the rack as well

Step 2. Take the module out of its shipping container. Take the

Step 3. Insert the module into the desired slot in the rack. Refer to

Typical 16 Slot Rack

Typical 10 Slot Rack

Typical 6 Slot Rack

P/S

0123456789101112131415

as all power to the wiring leading to the module should be

off.

module out of the antiĆstatic bag. Be careful not to touch

the connectors on the back of the module.

figure 3.1. Use a screwdriver to secure the module into the

slot.

16

10

6

Figure 3.1 Ć Rack Slot Numbers

3Ć1

Page 14

Step 4. Mount the terminal strip (from cable assembly M/N

57C373) on a panel. The terminal strip should be mounted

to allow easy access to the screw terminals. Be sure that

the terminal strip is close enough to the rack so that the

cable will reach between the terminal strip and the

module. The cable assembly is approximately 60 inches

long.

Step 5. Attach the resolver but leave the mechanical coupling

between the resolver and the motor unconnected.

Fasten the field wires from the resolver to the terminal

strip. Typical field connections are shown in figures 3.2

and 3.3.

Use twistedĆpair wire, connected as shown, for the cabling

between the resolver and the terminal strip in the control

enclosure. Recommended twistedĆpair wire is Belden

9497 cable or equivalent. Maximum operating cable length

is dependent upon the type of cable you use.

Make certain that all field wires are securely fastened.

M/N 57C360 RESOLVER

REFERENCE

SINE

COSINE

REFERENCE VOLTAGE: 26 Vrms

SINE VOLTAGE: 11.8 Vrms

COSINE VOLTAGE: 11.8 Vrms

Figure 3.2 Ć Typical M/N 57C360 Resolver Field Connections

Terminal Strip

in Control

R1

FROM MODULE

R2

Enclosure

ă1

ă2

ă3

ă4

S1

TO MODULE

S3

S2

S4

ă5

ă6

ă7

ă8

ă9

10

3Ć2

Page 15

M/N 57C361 RESOLVER

REFERENCE

SINE

COSINE

REFERENCE VOLTAGE: 26 Vrms

SINE VOLTAGE: 11.8 Vrms

COSINE VOLTAGE: 11.8 Vrms

Figure 3.3 Ć Typical M/N 57C361 Resolver Field Connections

Terminal Strip

in Control

A

FROM MODULE

B

Enclosure

ă1

ă2

ă3

ă4

D

TO MODULE

F

G

E

ă5

ă6

ă7

ă8

ă9

10

Step 6. Insert the cable assembly's (M/N 57C373) field terminal

connector into the mating half on the module. Use a

screwdriver to secure the connector to the module.

Note that both the module and the terminal strip connector

are equipped with keys". These keys should be used to

prevent the wrong cable from being connected to the

module in the event that the connector needs to be

removed for any reason and then reattached later.

At the time of installation, rotate the keys on the module

and the connector so that they can be connected together

securely. It is recommended that, for modules so

equipped, the keys on each succeeding module in the

rack be rotated one posistion to the right of the keys on

the preceeding module.

If you use this method, the keys on a particular connector

will be positioned in such a way as to fit together only with

a specific module, and there will be little chance of the

wrong connector being attached to a module.

Step 7. Check the wiring and be sure all connections are tight.

Step 8. With the resolver mechanically disconnected from the

motor, turn on power to the rack. Use an oscilloscope to

test the sine and the cosine signals from the resolver.

These signals, measured at the terminal strip, should be a

sine wave of approximately 33.4 VpĆp (11.8 Vrms +/10%).

Step 9. Verify the installation by using the Programming Executive

Software. Refer to the AutoMax Programming Executive

Manual (JĆ3630 or JĆ3684) for more information.

Use the I/O MONITOR function for local I/O or remote I/O,

depending upon where the module is located. Set register

4 to a value of 1. Read register 2 and verify that bit 10 is

set. If it is not, set register 3 to a value of 64.

3Ć3

Page 16

Monitor register 0. Verify that it contains numbers

proportional to the shaft position of the resolver and that

the numbers increase as the resolver is rotated clockwise.

The direction of rotation can be reversed by switching the

polarity of either the sine or the cosine wires. See figure 3.4.

CLOCKWISE ROTATION = COUNT UP

SIN +

SINE

SIN -

COSINE

COS +

COS -

RESOLVER

57C411

CLOCKWISE ROTATION = COUNT DOWN

SIN +

SINE

COSINE

SIN -

COS +

COS -

RESOLVER

57C411

CLOCKWISE ROTATION = COUNT DOWN

SIN +

SINE

COSINE

SIN -

COS +

COS -

RESOLVER

57C411

NOTE 1: All wires should be twisted pairs.

NOTE 2: Reversing the polarity of the wires as shown will

also change the perceived shift angle by 180 elecĆ

trical degrees.

3Ć4

Figure 3.4 Ć Changing the Direction of Rotation

Step 10. If the external strobe input is being used, the shaft should

be rotated to a fixed position and stopped. The external

strobe input should now be closed. Verify that register 1

contains the same data as register 0.

Step 11. Turn off power to the rack. Connect the mechanical

coupling between the resolver and the motor. Turn on

power to the system.

Page 17

3.3 Module Replacement

WARNING

INSERTING OR REMOVING THIS MODULE OR ITS CONNECTING CABLES MAY

RESULT IN UNEXPECTED MACHINE MOTION. POWER TO THE MACHINE

SHOULD BE TURNED OFF BEFORE INSERTING OR REMOVING THE MODULE

OR ITS CONNECTING CABLES. FAILURE TO OBSERVE THESE PRECAUTIONS

COULD RESULT IN BODILY INJURY.

Use the following procedure to replace a module:

Step 1. Turn off power to the rack and all connections.

Step 2. Use a screwdriver to loosen the screws holding the

Step 3. Loosen the screws that hold the module in the rack.

Step 4. Place the module in the antiĆstatic bag, being careful not

Step 5. Take the new module out of the antiĆstatic bag it came in,

Step 6. Insert the module into the desired slot in the rack. Use a

Step 7. Attach the field terminal connector (M/N 57C373) to the

Step 8. Turn on power to the rack.

connector to the module. Remove the connector from the

module.

Remove the module from the slot in the rack.

to touch the connectors on the back of the module. Place

the module in the cardboard shipping container.

being careful not to touch the connectors on the back of

the module.

screwdriver to secure the module into the slot.

mating half on the module. Make certain that the

connector is the proper one for this module (see step 6 in

3.2 Initial Installation). Use a screwdriver to secure the

connector to the module.

3Ć5

Page 18

Page 19

4.0 PROGRAMMING

This section describes how the data is organized in the module and

provides examples of how the module is accessed by the application

software. For more detailed information refer to the DCS 5000

Enhanced BASIC Language Instruction Manual (JĆ3600).

4.1 Register Organization

The input module contains a total of five 16Ćbit registers. Registers 0

and 1 contain resolver position data. The resolverĆtoĆdigital converter

provides 12 bits of resolution. Register 0 is updated with new position

information at the rate specified in register 4. Register 1 is updated

whenever the EXTERNAL STROBE goes from false to true. These

registers are read only. Refer to figure 4.1.

register 0

register 1

bits

resolver data

resolver external latch data

electronic revolution counter

Figure 4.1 Ć Resolver Data Registers

Registers 2 and 3 are the interrupt status and control registers. Both

registers contain the same information. Register 2 is read only.

Register 3 is read/write. If the module is located in a remote rack, you

must read the status from register 2. With the exception of bit 6 and

bit 12, this register is controlled by the operating system and must

not be manipulated by the user. Refer to figure 4.2.

For this module to operate properly, the common clock signal must

be present on the backplane. The common clock signal isa4mhz

clock that can be connected to all the I/O modules in the rack. It can

be generated from a number of DCS 5000 I/O modules. If this

module is to drive the common clock, bit 6 must be set.

0123456789101112131415

00

00

4Ć1

Page 20

bits

register 2

register 3

0123456789101112131415

R RRRRRRR RR Ć Ć ĆRRR

RW R R RW R R R R RW RW Ć Ć Ć RW RW RW

bits

register 4

ăăă Interrupt allocated

Interrupt line ID

ăăăăInterrupt clock enable

ăăăăInterrupt enabled

Module fault

ăResolver not connectedă

ăăăăăCommon clock off

Isolated power fault

External strobe reset

Position angle increasing

External strobe status

Interrupt flag status

Figure 4.2 Ć Interrupt Control Registers

Register 4 contains the update period for reading the resolver

position. Each count in this register is equivalent to 500

microseconds. The update period may range from 500 microseconds

to 32.7675 seconds. Refer to figure 4.3.

0123456789101112131415

update period

Figure 4.3 Ć Resolver Update Register

4.2 Local I/O Definition

Before any application program can be written, it is necessary to

configure, or set, the definitions of systemĆwide variables, i.e. those

that must be globally accessible to all tasks. This section describes

how to configure the input module when it is located in the same rack

as the processor module that is referencing it. Refer to figure 4.4.

4Ć2

Page 21

Processor Module

POWER

SUPPLY

120V

LINK

GND

275 W

RESOLVER

INPUT

57C411

0

0

POWER ON

P S READY

SYSTEM READY

BLOWN FUSE

NORMAL

DE

F

C

B

G

L2

L1

3

6

2

7

1

8

FUSE

BATTERY

BACKĆUP

57491

OK

REMOTEPROGRAM

1

2

3

4

5

6

7

OK

8

9

10

11

12

13

14

DE

15

F

C

B

G

0

1

2

3

C1

4

5

P3

DE

6

F

C

B

G

7

C2

8

9

10

11

C3

12

13

14

15

C4

6

6

3

3

7

7

2

2

1

8

1

8

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

DE

15

C1

C2

10

11

C3

12

13

14

15

C4

DE

15

F

F

C

C

B

G

B

0

1

2

3

4

5

6

7

8

9

G

0

1

2

3

C1

4

5

6

7

C2

8

9

10

11

C3

12

13

14

15

C4

6

6

3

3

7

7

2

2

1

8

1

8

0

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DE

15

F

C

B

G

0

1

2

3

C1

4

5

6

7

C2

8

9

10

11

C3

12

13

14

15

C4

6

3

7

2

1

8

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

DE

15

C1

C2

10

11

C3

12

13

14

15

C4

DE

15

F

C

B

0

1

2

3

4

5

6

7

8

9

3

2

F

C

G

B

G

0

1

2

3

C1

4

5

6

7

C2

8

9

10

11

C3

12

13

14

15

C4

6

6

3

7

7

2

1

8

1

8

Module

Figure 4.4 Ć Module in a Local Rack

4.2.1 Single Register Reference

Use this method to reference a 16Ćbit register as a single input.

Resolver input data, update period, and interrupt control registers are

typically referenced using this method. The symbolic name of each

register should be as meaningful as possible:

nnnnn IODEF SYMBOLIC_NAME%[ SLOT=s, REGISTER=r]

4.2.2 Bit Reference

Use this method to reference individual inputs on the module.

Common clock status and control bits are typically referenced using

this method. The symbolic name of each bit should be as meaningful

as possible:

nnnnn IODEF SYMBOLIC_NAME@[ SLOT=s, REGISTER=r, BIT=b]

where:

nnnnn Ć BASIC statement number. This number may range from

1Ć32767.

4Ć3

Page 22

SYMBOLIC_NAME% Ć A symbolic name chosen by the user and

ending with (%). This indicates an integer data type and all

references will access register r".

SYMBOLIC_NAME@ Ć A symbolic name chosen by the user and

ending with (@). This indicates a boolean data type and all

references will access bit number b" in register r".

SLOT Ć Slot number that the module is plugged into. This number

may range from 0Ć15.

REGISTER Ć Specifies the register that is being referenced. This

number may range from 0Ć4.

BIT Ć Used with Boolean data types only. Specifies the bit in the

register that is being referenced. This number may range from 0Ć 15.

4.2.3 Examples of Local I/O Definitions

The following statement assigns the symbolic name POSITION% to

register 0 of the input module located in slot 4:

1020ăăIODEF POSITION%[ SLOT=4, REGISTER=0]

The following statement assigns the symbolic name CCLK_ON@ to

bit 6 of register 3 on the input module located in slot 7:

2050ăăIODEF CCLK_ON@[ SLOT=7, REGISTER=3, BIT=6]

4.3 Remote I/O Definition

This section describes how to configure the module when it is

located in a rack that is remote from the processor module

referencing it. Refer to figure 4.5.

4Ć4

Page 23

Drop 0

Remote I/O Master

Processor Module

I/O Module

Master Rack

Remote I/O Slave

Drop 7

Remote I/O Slave

Drop 2

Figure 4.5 Ć Module in a Remote Rack

4.3.1 Single Register Reference

Use this method to reference a 16Ćbit register as a single input.

Resolver input data and update period registers are typically

referenced using this method. The symbolic name of each register

should be as meaningful as possible:

nnnnnăăRIODEF SYMBOLIC_NAME%[ MASTER_SLOT=m,

ăăăăDROP=d, SLOT=s, REGISTER=r]

Remote I/O Slave

Drop 1

4Ć5

Page 24

4.3.2 Bit Reference

Use this method to reference individual inputs on the module.

Common clock status and control bits are typically referenced using

this method. The symbolic name of each bit should be as meaningful

as possible:

nnnnnăăRIODEF SYMBOLIC_NAME@[ MASTER_SLOT=m,

ăăăăDROP=d, SLOT=s, REGISTER=r, BIT=b]

where:

nnnnn Ć BASIC statement number. This number may range from

1Ć32767.

SYMBOLIC_NAME% Ć A symbolic name chosen by the user and

ending with (%). This indicates an integer data type and all

references will access register r".

SYMBOLIC_NAME@ Ć A symbolic name chosen by the user and

ending with (@). This indicates a boolean data type and all

references will access bit number b" in register r".

MASTER_SLOT Ć Slot number that the master remote I/O module is

plugged into. This number may range from 0Ć15.

DROP Ć Drop number of the slave remote I/O module that is in the

same rack as the input module. This number may range from 1Ć7.

SLOT Ć Slot number that the module is plugged into. This number

may range from 0Ć15.

REGISTER Ć Specifies the register that is being referenced. This

number may range from 0Ć4.

BIT Ć Used with boolean data types only. Specifies the bit in the

register that is being referenced. This number may range from 0Ć15.

4.3.3 Examples of Remote I/O Definitions

The following statement assigns the symbolic name SHAFT% to

register 0 on the input module located in slot 4 of remote I/O drop 3.

This remote drop is connected to the remote I/O system whose

master is located in slot 15 in the master rack:

1020ăăRIODEF SHAFT%[ MASTER_SLOT=15, DROP=3,

ăăăSLOT=4, REGISTER=0]

The following statement assigns the symbolic name CLCK_EN@ to

bit 6 of register 3 on the input module located in slot 7 of remote I/O

drop 2. This remote drop is connected to the remote I/O system

whose master is located in slot 6 in the master rack:

2050ăăRIODEF CLCK_EN@[ MASTER_SLOT=6,

ăăăDROP=2, SLOT=7, REGISTER=3, BIT=6]

4.4 Reading and Writing Data in Application Tasks

In order for an input module to be referenced by application

software, it is first necessary to assign symbolic names to the

physical hardware. This is accomplished with either IODEF or

RIODEF statements in the configuration task.

4Ć6

Page 25

Each application program, or task, that wishes to reference the

symbolic names assigned to the input module may do so by

declaring those names COMMON.

The frequency with which tasks read their inputs and write their

outputs depends on the language being used. Control block tasks

read inputs once at the beginning of each scan and write outputs

once at the end of scan. BASIC tasks read an input and write an

output for each reference throughout the scan.

The following is an example of a configuration task for the input

module:

1000 !

1001 ! resolver input

1002 !

1005 IODEF RESOLVER_IN%[SLOT=4, REGISTER=0]

1006 IODEF RESOLVER_IN_EXT%[SLOT=4, REGISTER=1]

1010 !

1011 ! common clock enable

1012 !

1015 IODEF CCLK_EN@[SLOT=4, REGISTER=3, BIT=6]

1020 !

1021 ! A/D update period

1022 !

1025 IODEF UPDATE_TIME%[SLOT=4, REGISTER=4]

1050 !

1051 ! Place any additional configurationăstatements here

1052 !

2000 END

4.4.1 BASIC Task Example

This example will read the resolver input once every second and

store the value in the symbol CURRENT_VALUE". The resolver

position will be sampled every 100 milliseconds.

1000 COMMON RESOLVER_IN% \!Resolver data(periodic)

1010 COMMON CCLK_EN@ \!common clock enable

1020 COMMON UPDATE_TIME% \!Update period for resolver conversion

1400 !

1500 LOCAL CURRENT_VALUE% \!Current value of analog input

1900 !

2000 UPDATE_TIME% = 200 \!0.1 second conversion

2010 CCLK_EN@ = TRUE \!turn on the clock

4000 !

4001 ! Place any additional initialization software here

4002 !

5000 START EVERY 1 SECONDS

5010 CURRENT_VALUE% = RESOLVER_IN%

10000 END

The symbolic names defined as COMMON" reference the inputs

defined in the sample configuration task above. The symbolic name

CURRENT_VALUE% is local to the BASIC task and does not have I/O

associated with it. Refer to the DCS 5000 Enhanced BASIC

Language Instruction Manual (JĆ3600) for more information.

4.4.2 Control Block Task Example

The following example will read the resolver data every 55

milliseconds and store the inverted value in the symbol READING".

The resolver's shaft position will be sampled every 500

microseconds.

1000 COMMON RESOLVER_IN% \!Resolver data (periodic)

1010 COMMON CCLK_EN@ \!Common clock enable

1020 COMMON UPDATE_TIME% \!Update period forĂresolver conv.

1400 !

1500 LOCAL READING% \!Current negative value of input

1600 !

4Ć7

Page 26

2000 UPDATE_TIME% = 1 \!500 microsecond conversion

2010 CCLK_EN@ = TRUE \!Turn on the clock

4000 !

4001 ! Place any additional initialization software here

4002 !

4998 ! Scan every 55 msec.

4999 !

5000 CALL SCAN_LOOP( TICKS=10)

5010 CALL INVERTER( INPUT= RESOLVER_IN%,OUTPUT=READING%)

10000 END

The symbolic names defined as COMMON" reference the inputs

defined in the sample configuration task above. The symbolic name

READING%" is local to the BASIC task and does not have I/O

associated with it. Refer to the DCS 5000 Control Block Language

Instruction Manual (JĆ3601) for more information.

4.5 Using Interrupts in Application Tasks

The input module supports an interrupt on the periodic

resolverĆtoĆdigital conversion. Interrupts are used to synchronize

software tasks with the resolverĆtoĆdigital conversion. Conversion

rates may be specified from 500 microseconds up to a maximum of

32.7675 seconds in increments of 500 microseconds.

In order to use interrupts on the input module, it is necessary to

assign symbolic names to the interrupt control register. This is

accomplished with IODEF statements in the configuration task. Note

that interrupts cannot be used with modules located in remote racks.

Only one task may act as a receiver for a particular hardware

interrupt. That task should declare the symbolic names assigned to

the interrupt control register on the input module as COMMON. Once

this has been done, any reference to those symbolic names within

the task will reference the bits or register defined in the configuration

task.

The following is an example of a configuration task for an input

module using interrupts:

1000 !

1001 ! resolver data

1002 !

1005 IODEF RESOLVER_IN%[SLOT=4, REGISTER=0]

1006 IODEF RESOLVER_IN_EXT%[SLOT=4, REGISTER=1]

1010 !

1011 ! interrupt status and control register (used by the operating system)

1012 !

1014 IODEF STROBE_STATUS@( SLOT=4, REGISTER=2,BIT=14)

1015 IODEF ISCR%[SLOT=4, REGISTER=3]

1016 IODEF STROBE_ACK@( SLOT=4, REGISTER=3,BIT=12)

1020 !

1021 ! common clock enable

1022 !

1025 IODEF CCLK_EN@[SLOT=4, REGISTER=3, BIT=6]

1030 !

1031 ! resolver conversion period

1032 !

1035 IODEF UPDATE_TIME%[SLOT=4, REGISTER=4]

1050 !

1051 ! Place additional configuration statements here

1052 !

2000 END

This configuration defines all of the information most commonly used

on the module. Unused definitions should be deleted by the user.

4Ć8

Page 27

4.5.1 BASIC Task Example

The following is an example of a BASIC task that handles interrupts

from the input module defined in section 4.4.

1000 COMMON RESOLVER_IN% \!Resolver data

1005 COMMON ISCR% \!Interrupt status & control

1010 COMMON CCLK_EN@ \!Common clock enable

1020 COMMON UPDATE_TIME% \!Resolver conversion time

1200 LOCAL RESOLVER_VALUE% \!Resolver value

2000 !

2001 ! Define the conversion parameters

2002 !

2010 UPDATE_TIME% = 1000 \!Convert every .5 seconds

3000 !

3001 ! The following statement connects the name RESOLVER_EVENT to the

3002 ! interrupt defined in ISCR%. The event name chosen should

3003 ! be as meaningful as possible. The watchdog timeout has

3004 ! been set to 120 clock ticks (660 msec). If the time between

3005 ! interrupts exceeds this value, a severe error will be declared

3006 ! and the system will be stopped. For more information refer to the

3007 ! DCS 5000 Enhanced BASIC Language Instruction Manual (JĆ3600).

3008 !

3010 EVENT NAME=RESOLVER_EVENT,

3011 ăăINTERRUPT_STATUS=ISCR%,TIMEOUT=120

4000 !

4001 ! The following statement enables common clock from this module

4002 ! If there is more than one interrupt task in a chassis, the task

4003 ! that enables common clock should always be the lowest priority

4004 ! task.

4005 !

4010 CCLK_EN@ = TRUE \!Common clock enable

5000 !

5001 ! Place additional initialization software here

5002 !

6000 !

6001 ! The next statement synchronizes the task with the external

6002 ! event via the interrupt. Task execution will be suspended

6003 ! until the interrupt occurs. If this task is the highest

6004 ! priority task waiting to execute at the time of the

6005 ! interrupt, it will become active. If it is not the

6006 ! highest priority task, it will remain suspended until

6007 ! all higher priority tasks have executed, at which point

6008 ! it will become active.

6009 !

6010 WAIT ON RESOLVER_EVENT

7000 !

7001 ! The next statements perform the interrupt service routine

7002 !

7010 RESOLVER_VALUE% = RESOLVER_IN%

10000 END

4.5.2 Control Block Task Example

The following is an example of a control block task that handles

interrupts from the input module defined in section 4.4.

1000 COMMON RESOLVER_IN% \!Resolver data

1005 COMMON ISCR% \!Interrupt status & control

1010 COMMON CCLK_EN@ \!Common clock enable

1020 COMMON UPDATE_TIME% \!Resolver conversion time

1200 LOCAL RESOLVER_VALUE% \!Resolver value

2000 !

2001 ! Define the conversion parameters

2002 !

2010 UPDATE_TIME% = 100 \!Convert every 50 milliĆseconds

3000 !

3001 ! The following statement connects the name RESOLVER_EVENT to

3002 ! the interrupt defined in ISCR%. The event name chosen should

3003 ! be as meaningful as possible. The watchdog timeout has

3004 ! been set to 12 clock ticks (66 msec). If the time between

3005 ! interrupts exceeds this value, a severe error will be declared

3006 ! and the system will be stopped. For more information refer to the

3007 ! DCS 5000 Enhanced BASIC Language Instruction Manual (JĆ3600).

3008 !

3010 EVENT NAME=RESOLVER_EVENT, &

3011 ăăINTERRUPT_STATUS=ISCR%, TIMEOUT=12

4Ć9

Page 28

4000 !

4001 ! The following statement enables common clock from this module.

4002 ! If there is more than one interrupt task in a chassis, the task

4003 ! that enables common clock should always be the lowest priority

4004 ! task.

4005 !

4010 CCLK_EN@ = TRUE \!Common clock enable

5000 !

5001 ! Place additional initialization software here

5002 !

6000 !

6001 ! The next statement synchronizes the task with the external

6002 ! event via the interrupt. Task execution will be suspended

6003 ! until the interrupt occurs. If this task is the highest

6004 ! priority task waiting to execute at the time of the

6005 ! interrupt, it will become active. If it is not the

6006 ! highest priority task, it will remain suspended until

6007 ! all higher priority tasks have executed, at which point

6008 ! it will become active.

6009 !

6010 CALL SCAN_LOOP(TICKS=9, EVENT=RESOLVER_EVENT)

7000 !

7001 ! The next statements perform the interrupt service routine

7002 !

7010 CALL PULSE_MULT(INPUT= RESOLVER_IN%, MULTIPLIER=16385, &

10000 END

OUTPUT= RESOLVER_VALUE%)

4.6 Using the External Strobe Input

At the time of the external event, the resolver position is transferred to

register 1, where it will remain until the next event occurs. If your

application software is reading the resolver position at a periodic rate

(register 0), the difference between register 0 and register 1

represents the amount of travel from the time that the event occurred

until the current scan of the application software. A typical application

would be detecting the leading edge of an object moving on a

conveyor.

The data captured by the strobe input will be as accurate as the

external device driving the input. Note that when a strobe input has

occurred, you must reset the input so that another one can occur.

This is accomplished by writing a 1" to bit 12 of register 3.

The following is an example of a control block task that handles the

strobe input from the input module defined in section 4.4.

1000 COMMON RESOLVER_IN% \!Resolver data

1001 COMMON RESOLVER_IN_EXT% \!Strobe resolver data

1005 COMMON ISCR% \!Interrupt statusă& control

1010 COMMON CCLK_EN@ \!Common clock enable

1020 COMMON UPDATE_TIME% \!Resolver conversion time

1030 COMMON STROBE_STATUS@ \!Strobe status

1040 COMMON STROBE_ACK@ \!Strobe acknowledge

1200 LOCAL RESOLVER_VALUE% \!Resolver value

1210 LOCAL STROBE_RESET@ \!Strobe state

1220 LOCAL PERIOD_DISTANCE% \!Resolver travel scan/scan

1230 LOCAL EVENT_DISTANCE% \!Resolver travel from event to scan

2000 !

2001 ! Define the conversion parameters

2002 !

2010 UPDATE_TIME% = 100 \!Convert every 50 milliseconds

3010 EVENT NAME=RESOLVER_EVENT,INTERRUPT_STATUS=ISCR%, &

ąąTIMEOUT=12

4010 CCLK_EN@ = TRUE \!Common clock enable

6008 !

6010 CALL SCAN_LOOP( TICKS=9, EVENT=RESOLVER_EVENT)

7000 !

7001 ! The next statements catch the occurence

7002 ! of the strobe and reset it.

7003 !

7010 CALL TRANSITION ( INPUT= STROBE_STATUS @, &

7020 STROBE_ACK@= NOT STROBE_RESET@

OUTPUT=STROBE_RESET@)

4Ć10

Page 29

7025 !

7026 ! The next statement calculates the distance

7027 ! traveled from the occurrence of the external

7028 ! event until this scan.

7029 !

7030 CALL PULSE_MULT( INPUT=RESOLVER_IN%,ăăăă&

7036 ! The next statement calculates the distance traveled

7037 ! from the last scan until this scan.

7039 !

7040 CALL PULSE_MULT( INPUT=RESOLVER_IN%, &

7046 !

7047 ! The next statement calculates the correction

7048 ! required to synchronize the external event to

7049 ! the program.

7050 !

7060 CALL DIFFERENCE( INPUT1=PERIOD_ DISTANCE%, &

10000 END

RESET=-STROBE_RESET@,ăă&

INITIAL_VALUE =RESOLVER_IN_EXT%, &

MULTIPLIER=16385,ăăăăăăăăă&

OUTPUT=EVENT_DISTANCE%)

MULTIPLIER=16385, &

OUTPUT=PERIOD_DISTANCE%)

INPUT2=EVENT_DISTANCE%, &

OUTPUT=RESOLVER_VALUE%)

4.7 Restrictions

This section describes limitations and restrictions on the use of this

module.

4.7.1 Writing Data to Registers

Registers 0Ć2 are read only and may not be written to by the

application software. Attempts to write to them will cause a bus error

(severe system error). The following are examples from programs

that write to the module and should therefore be avoided:

a. Referencing the module on the left side of an equal sign in a LET

statement in a control block or BASIC task.

b. Referencing a resolver input as an output in a control block

function.

4.7.2 Interrupts in Remote I/O Racks

This module cannot be used in the interrupt mode in a remote rack.

4.7.3 Feedback Element in a Drive System

When this module is used with a resolver in a drive control system,

you must incorporate an independent method of determining that

this module is actually reading proper motor RPM. It is necessary to

determine this because this module is not capable of detecting a loss

of feedback in all situations, such as, for example, a broken coupling

between the motor and resolver.

4Ć11

Page 30

WARNING

LOSS OF, OR OTHERWISE IMPROPER, RESOLVER SIGNAL CAN RESULT IN

UNCONTROLLED MOTOR SPEED. PROVIDE AN INDEPENDENT METHOD OF

SHUTTING DOWNEQUIPMENT IFTHIS SHOULDOCCUR. FAILURE TO OBSERVE

THIS PRECAUTION COULD RESULT IN BODILY INJURY AND IN DAMAGE TO,OR

DESTRUCTION OF, THE EQUIPMENT.

You must also determine the maximum safe operating speed for the

motor, connected machinery, and material being processed. Then,

either verify that the system is incapable of reaching that speed, or

else incorporate the necessary hardware/software to ensure that this

limit will never be exceeded.

WARNING

THE PURCHASER IS RESPONSIBLE FOR ENSURING THAT DRIVEN

MACHINERY, ALL DRIVE TRAIN MECHANISMS, AND THE WORKPIECE IN THE

MACHINE ARE CAPABLE OF SAFE OPERATION ATMAXIMUM SPEEDS. FAILURE

TO OBSERVE THESE PRECAUTIONS COULD RESULT IN BODILY INJURY AND IN

DAMAGE TO, OR DESTRUCTION OF, THE EQUIPMENT.

4Ć12

Page 31

5.0 DIAGNOSTICS AND TROUBLESHOOTING

This section explains how to troubleshoot the module and field

connections.

5.1 Incorrect Data

Problem: The data is either always off, always on, or different than

expected. The possible causes of this error are a module in the

wrong slot, a programming error, or a malfunctioning module. It is

also possible that the input is either not wired or wired to the wrong

device. Use the following procedure to isolate the problem:

Step 1. Verify that the input module is in the correct slot and that

Step 2. Verify that the module can be accessed.

Step 3. Verify that the user application program is correct.

Step 4. Verify that the resolver is wired correctly.

the I/O definitions are correct.

Refer to figure 3.1. Verify that the slot number being

referenced agrees with the slot number defined in the

configuration task. Verify that the register number and the

bit number are correct.

For remote I/O installations, also verify that the master slot

and drop numbers are defined correctly. Refer to the DCS

5000 Remote I/O Instruction Manual (JĆ3629) for more

detailed information on configuring your remote I/O

system.

Connect the programming terminal to the system and run

the ReSource Software. Use the I/O MONITOR function to

display the four registers on the input module. Repeat

steps 7 and 8 in section 3.2.

Review the programming examples in sections 4.4, 4.5,

and 4.6. Make certain that the I/O definitions in your

configuration task are correct and that the task(s) using

this module have declared these variables COMMON.

Verify that an update period has been written to register 4.

Recall that each count is 500 microseconds (.0005

seconds). This value specifies the frequency with which

the resolver position will be converted to digital numbers.

Verify that the common clock has been turned on. The

CCLK OK" LED on the faceplate of the module should be

lit. If the common clock is not present on the backplane,

the module will not convert the resolver position to digital

values. If the common clock is being generated from this

module, remember that bit 6 in register 3 must be set.

Remove power from the system. Disconnect the

mechanical coupling between the resolver and the motor.

Confirm that all the terminal strip connections are tight.

Refer to figures 3.2 and 3.3. Appendix C also lists the

terminal strip connections.

Apply power to the rack only.

5Ć1

Page 32

If everything is working properly but the direction of

rotation is backwards, it may be reversed by switching the

polarity of either the sine or the cosine wires as shown in

figure 3.4.

Step 5. Verify that the input circuit is working properly.

Connect an oscilloscope to the proper points on the

terminal strip and confirm that the voltages are correct.

The resolver reference voltage across TB 1 and 2 should

be a nominal 26 Vrms.

If it is 26 Vrms, check the jumpers on the terminal strip.

One jumper should connect TB 1 and 3. Another jumper

should connect TB 2 and 4. Rotate the resolver's shaft and

measure the sine voltage (TB 5 and 6) and cosine voltage

(TB 7 and 8). Both voltages should range from 0 volts to

approximately 11.8 Vrms.

If the resolver reference (TB 1 and 2) is not a nominal 26

Vrms, measure the DĆC resistance of the resolver.

Disconnect the resolver cable from the terminal strip (TB 1

and 2) and measure the resistance across the

disconnected wires.

The resistance should be in the range of 35 to 125 ohms.

If the resistance is within this range, the input module is

malfunctioning and should be replaced. If the resistance is

not within this range, disconnect the cabling from the

resolver and measure the resistance directly on the

resolver.

If this resistance is reading within the 35 to 100 ohm

range, the resolver is operating properly. Check the

cabling for a possible short. If the resistance is not within

the 35 to 100 ohm range, the resolver is malfunctioning

and should be replaced. If the problem is still present,

check the cable for a possible short.

Reconnect the resolver cable at TB 1 and 2.

Remove power from the rack. Reconnect the mechanical

coupling between the resolver and the motor. Reapply

power to the system.

Step 6. Verify that the hardware is working properly.

WARNING

INSERTING OR REMOVING THIS MODULE OR ITS CONNECTING CABLES

MAY RESULT IN UNEXPECTED MACHINE MOTION. POWER TO THE

MACHINE SHOULD BE TURNED OFF BEFORE INSERTING OR REMOVING

THE MODULE OR ITS CONNECTINGCABLES. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN BODILY INJURY.

If all of the proper signals are present and the values are

still not correct, the problem lies in the hardware. Verify the

hardware functionality by systematically swapping out

modules. After each swap, if the problem is not corrected,

replace the original item before swapping out the next

item.

5Ć2

Page 33

To test local I/O, first replace the input module. Next,

replace the processor module (s). If the problem persists,

take all of the modules except one processor module and

the input module out of the backplane. If the problem is

now corrected, one of the other modules in the rack is

malfunctioning. Reconnect the other modules one at a

time until the problem reappears. If none of these tests

reveals the problem, replace the backplane.

To test remote I/O, first verify that the remote I/O system is

communicating with the drop that contains the input

module being tested. Next, by systematically swapping

out modules, determine whether the input module is the

only module that is not working.

If more than one module is not working correctly, the

problem most likely lies in the remote I/O system. Refer to

the the DCS 5000 Remote I/O Instruction Manual (JĆ3629)

for additional information. If the problem does not lie in the

system, it probably involves the remote rack.

To test the remote rack, first replace the input module. If

the problem persists, take all of the modules out of the

remote backplane except the slave remote I/O module

and the input module. If the problem is now corrected,

one of the other modules in the rack is malfunctioning.

Reconnect the other modules one at a time until the

problem reappears. If the problem proves to be neither in

the remote I/O system nor in the remote rack, try replacing

the backplane.

Problem: A 31" or 16" appears on the processor module's LED.

This error message indicates that there was a bus error when the

system attempted to access the module. The possible causes of this

error are a missing module, a module in the wrong slot, or a

malfunctioning module. It is also possible that the user has attempted

to write to the wrong registers on the module. Use the following

procedure to isolate a bus error:

Step 1. Verify that the input module is in the correct slot and that

Step 2. Verify that the module can be accessed.

the I/O definitions are correct.

Refer to figure 3.2. Verify that the slot number being

referenced agrees with the slot number defined in the

configuration task. Verify that the register number is in the

range of 0Ć4.

For remote I/O installations, also verify that the master slot

and remote drop number are defined correctly.

Refer to the DCS 5000 Remote I/O Instruction Manual

(JĆ3629) for more information on configuring your remote

I/O system.

Connect the programming terminal to the system and run

the ReSource Software. Use the I/O MONITOR function to

display the four registers on the input module. If the

programmer is able to monitor the inputs, the problem lies

in the application software (refer to step 3). If the

5Ć3

Page 34

programmer cannot monitor the inputs, the problem lies in

the hardware (refer to step 4).

Step 3. Verify that the user application program is correct.

Registers 0 through 2 of the input module cannot be

written to. If a BASIC task caused the bus error, the error

log will contain the statement number in the task where

the error occurred. If a control block task caused the error,

you will need to search the task for any instances where

you wrote to an input.

Step 4. Verify that the hardware is working correctly.

Verify the hardware functionality by systematically

swapping out modules. After each swap, if the problem is

not corrected, replace the original item before swapping

out the next item.

To test local I/O, replace the input module, the processor

modules (s), and finally the backplane.

For remote I/O, determine whether the input module is the

only module that is not working. If it is not, the problem

most likely lies in the remote I/O system. Refer to the DCS

5000 Remote I/O Instruction Manual (JĆ3629) for additional

information. If the problem does not lie in the remote I/O

system, it probably involves the remote rack.

To test the remote rack, systematically swap out the input

module, the slave remote I/O module, and finally the

backplane. After each swap, if the problem is not

corrected, replace the original item before going on to the

next swap. If none of these actions correct the problem,

troubleshoot the remote I/O system.

5.3 Interrupt Problems

Problem: No interrupts at all or too many (unexpected) interrupts,

signified by error codes on the screen. Note that this module must be

in the same rack as the processor module that is to receive the

interrupts. Go through the following steps first before going on to the

more specific troubleshooting steps.

Step 1. Verify that the input module is in the correct slot and that

Step 2. Verify that the user application program is correct.

5Ć4

the I/O definitions are correct.

Refer to figure 3.2. Verify that the slot number being

referenced agrees with the slot number defined in the

configuration task.

Verify that the configuration task contains the proper

interrupt control definitions. Refer to the example in

section 4.6.

Verify that the application program that uses the symbolic

names defined in the configuration task has defined those

names as COMMON.

Compare your interrupt task with the examples given in

sections 4.5.1 and 4.5.2. Make certain that the actions

shown in the examples are performed in the same order in

your task.

Page 35

5.3.1 No Interrupts

Problem: The program does not execute, but no error codes are

displayed on the processor module faceplate. If interrupts are never

received by the application program and the timeout parameter in

the event definition was disabled, the task will never execute.

The watchdog timer for this module should never be disabled. Before

you can determine why the program did not execute, you must first

set the timeout parameter in the event definition. Run the program

again and proceed to section 5.3.2.

5.3.2 Hardware Event TimeĆOut

Problem: All tasks in the chassis are stopped and error code 12"

appears on the faceplate of the processor module. The interrupt has

either never occurred or is occurring at a slower frequency than the

value specified in the timeout parameter in the event definition. Use

the following procedure to isolate the problem.

Step 1. Verify that the timeout value is set correctly.

Check the value specified in the timeout parameter in the

event definition. The unit is in ticks. Each tick is equal to

5.5 msec. The timeout value should be at least 2 ticks

greater than the interrupt frequency. It can reasonably

range up to 1.5 times the interrupt frequency.

Step 2. Verify that the user application program is correct.

Review the examples in section 4.5. Make certain that

common clock has been enabled.

Step 3. Verify that the hardware is working correctly.

Systematically swap out the input module, the processor

module (s), and the backplane. After each swap, if the

problem is not corrected, replace the original item before

swapping out the next item.

5.3.3 Hardware Event Count Limit Exceeded

Problem: All tasks in the chassis are stopped and error code 1b"

appears on the faceplate of the processor module. A hardware

interrupt has occurred but no task is waiting. Use the following

procedure to isolate the problem:

Step 1. Verify that the user application program is correct.

Verify that your interrupt response task contains either a

WAIT ON event" or CALL SCAN_LOOP" statement that

will be executed. Check carefully to determine whether a

higher priority task is preventing the interrupt response

task from running. Make certain that the ordering of your

statements agrees with the examples in section 4.5.

Step 2. Verify that the hardware is working correctly.

Verify the hardware functionality by systematically

swapping out the input module, the processor module (s),

and the backplane. After each swap, if the problem is not

corrected, replace the original item before swapping out

the next item.

5Ć5

Page 36

5.3.4 Illegal Interrupt Detected

Problem: All tasks in the chassis are stopped and error code 1F"

appears on the faceplate of the processor module. A hardware

interrupt has occurred but no event has been defined.

Step 1. Verify that the user application program is correct.

Verify that your interrupt response task contains an

EVENT" statement that will be executed. Check carefully

to determine whether a higher priority task is preventing

the interrupt response task from running. Make certain

that the ordering of your statements agrees with the

examples in section 4.5.

Step 2. Verify that the hardware is working correctly.

Verify the hardware functionality by systematically

swapping out the input module, the processor module (s),

and the backplane. After each swap, if the problem is not

corrected, replace the original item before swapping out

the next item.

5Ć6

Page 37

Appendix A

Technical Specifications

Ambient Conditions

D Storage temperature: -40_ CĆ85_ C

D Operating temperature: 0_ CĆ60_ C

D Humidity: 5Ć90% nonĆcondensing

Maximum Module Power Dissipation

D 10 Watts

Dimensions

D Height: 11.75 inches

D Width: 1.25 inches

D Depth: 7.375 inches

System Power Requirements

D 5 Volts: 1700 ma

D +12 Volts: 95 ma

D -12 Volts: 95 ma

Resolver Specifications

D Frequency of operation: 2381 Hz

D Minimum rotor impedance: 400 Ohms

D Transformer ratio: 26/11.8

External Strobe Minimum Trigger Time

D 1 millisecond

AĆ1

Page 38

Page 39

Appendix B

Module Block Diagram

BUS

ADDRESS

ID BUS

ADDRESS

BUS

CONTROL

LINES

CCLK

ADDRESS

DECODER

CONTROL

GATE

DATA BUS

CCLK

TIMER

COUNTER

INTERRUPT

LOGIC

4mHz

OSC

CCLK

TIMER

PRESET

CCLK

INTERRUPT

MULTIBUS

CONTROL

LOGIC

RESOLVER INPUT MODULE (57C411)

I

S

O

REFERENCE

L

A

SINEWAVE

T

GENERATOR

I

2381 Hz

O

N

GATE

STROBE

TIMER

INTERĆ

RUPT

LATCH

EXTERĆ

NAL

TRIGĆ

GER

LATCH

STROBE

ĂI

S

O

RESOLVER

ANALOG

L

A

CONVERTER

T

ĂI

O

N

ISOLATED

+/- 15 VDC

POWER SUPPLY

ISOLATION

AND

DIGITAL

TO

(+)

REF OUT

(-)

(+)

REF IN

(-)

(+)

SINE

(-)

(+)

COSINE

(-)

DIRECTION

IPS OK

1 MEG OHM

(+)

EXT. TRIGGER

(-)

BOARD OK

TB

1

2

3

4

5

6

7

8

BIAS

9

10

Multibus is a Trademark of Intel Corporation.

CCLK ON

BĆ1

Page 40

Page 41

Appendix C

Field Connections

Pin

No.

10

Function

1

2

3

4

5

6

7

8

9

Reference Output (+) Brown

Reference Output (-) White/Brown Stripe

Reference Input (+) Red

Reference Input (-) White/Red Stripe

Sine Input (+) Orange

Sine Input (-) White/Orange Stripe

Cosine Input (+) Yellow

Cosine Input (-) White/Yellow Stripe

External Trigger (+) Green

External Trigger (-) White/Green Stripe

Wire Color

Code

CĆ1

Page 42

Page 43

Appendix D

Related Components

800123ĆR Ć Resolver (X1) (57C360)

800123ĆS Ć Resolver (X2)

800123ĆT Ć Resolver (X5)

800123Ć2R Ć Resolver (X1) (57C361)

800123Ć2S Ć Resolver (X2)

800123Ć2T Ć Resolver (X5)

57C373 Ć Terminal Strip/Cable Assembly

This assembly consists of a terminal strip, cable, and mating connector. It is used

to connect field signals to the faceplate of the input module.

Designed for both footĆmounting and CĆface mounting.

Designed for directĆcoupling.

DĆ1

Page 44

Page 45

Page 46

Publication J-3640-1 - June 1990

Copyright © 2002 Rockwell Automation, Inc.. All rights reser ved. Printed in U.S.A.

Loading...

Loading...