Page 1

AutoMaxrPower Supply

Modules and Racks

M/N 57C493 Power Supply Module

M/N 57C494 Power Supply Module

M/N 57C331 16ĆSlot Rack

M/N 57C332 10ĆSlot Rack

M/N 57C334 6ĆSlot Rack

Instruction Manual J2Ć3008Ć4

Page 2

DANGER

ONLY QUALIFIED ELECTRICAL PERSONNEL FAMILIAR WITH THE

CONSTRUCTION AND OPERATION OF THIS EQUIPMENT AND THE HAZARDS

INVOLVED SHOULD INSTALL, ADJUST, OPERATE, OR SERVICE THIS

EQUIPMENT. READ AND UNDERSTAND THIS MANUAL AND OTHER

APPLICABLE MANUALS IN THEIR ENTIRETY BEFORE PROCEEDING. FAILURE

TO OBSERVE THIS PRECAUTION COULD RESULT IN SEVERE BODILY INJURY

OR LOSS OF LIFE.

DANGER

THE USER IS RESPONSIBLE FOR CONFORMING WITH ALL APPLICABLE

LOCAL, NATIONAL, AND INTERNATIONAL CODES. WIRING PRACTICES,

GROUNDING, DISCONNECTS, AND OVERĆCURRENT PROTECTION ARE OF

PARTICULAR IMPORTANCE. FAILURE TO OBSERVE THIS PRECAUTION

COULD RESULT IN SEVERE BODILY INJURY OR LOSS OF LIFE.

WARNING

INSERTING OR REMOVING THE POWER SUPPLY MODULE OR ITS

CONNECTING CABLES MAY RESULT IN UNEXPECTED MACHINE MOTION.

POWER TO THE MODULE SHOULD BE TURNED OFF BEFORE INSERTING OR

REMOVING THE MODULE OR ITS CONNECTING CABLES. FAILURE TO

OBSERVE THIS PRECAUTION COULD RESULT IN BODILY INJURY.

WARNING

THE USER MUST PROVIDE AN EXTERNAL, HARDWIRED EMERGENCY STOP

CIRCUIT OUTSIDE THE PROGRAMMABLE CONTROLLER CIRCUITRY. THIS

CIRCUIT MUST DISABLE THE SYSTEM IN CASE OF IMPROPER OPERATION.

UNCONTROLLED MACHINE OPERATION MAY RESULT IF THIS PROCEDURE IS

NOT FOLLOWED. FAILURE TO OBSERVE THIS PRECAUTION COULD RESULT IN

BODILY INJURY.

CAUTION: The power supply module and racks contain staticĆsensitive components.

Careless handling cancause severe damage. Do nottouch the connectors ontheback

of the power supply module or the racks. When not in use, the power supply module

should be stored in an antiĆstaticbag. The plasticcover should not be removed. Failure

to observe this precaution could result in damage to or destruction of equipment.

Allen-Bradley and Rockwell Automation are trademarks of Rockwell Automation, Inc,.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

1.0 Introduction 1Ć1...............................................

1.1 Additional Information 1Ć1....................................

1.2 Related Hardware and Software 1Ć2...........................

2.0 Mechanical/Electrical Description 2Ć1...........................

2.1 Power Supply Module Mechanical Description 2Ć1.........

2.1.1 Power Supply Module LED Indicators 2Ć4.................

2.1.2 Power Supply Module Terminal Block 2Ć4.................

2.1.3 Power Supply Module Battery Connection

(M/N 57C493 only) 2Ć4.................................

2.1.4 Power Supply Module Keyswitch 2Ć4.....................

2.2 Power Supply Module Electrical Description 2Ć5.................

2.3 Rack Mechanical Description 2Ć5..............................

2.4 Rack Electrical Description 2Ć6................................

3.0 Installation 3Ć1................................................

3.1 Wiring 3Ć1..................................................

3.2 Initial Installation 3Ć1.........................................

3.3 Power Supply Module Replacement 3Ć5........................

3.4 Rack Replacement 3Ć6.......................................

4.0 Diagnostics and Troubleshooting 4Ć1............................

4.1 The POWER LED Is Off 4Ć1...................................

4.2 The FAULT LED is On 4Ć2....................................

I

Page 4

Appendices

Appendix A

Technical Specifications AĆ1......................................

Appendix B

External Connections BĆ1........................................

Appendix C

Rack Backplane CĆ1............................................

Appendix D

Rack Mounting Pattern DĆ1.......................................

Appendix E

Power Requirements of AutoMax Modules EĆ1.....................

II

Page 5

List of Figures

Figure 2.1 Ć 376W Power Supply Module (M/N 57C493) 2Ć2................

Figure 2.2 Ć 147W Power Supply Module (M/N 57C494) 2Ć3................

Figure 2.3 Ć 6ĆSlot Rack 2Ć6............................................

Figure 2.4 Ć 10ĆSlot Rack 2Ć6...........................................

Figure 2.5 Ć 16ĆSlot Rack 2Ć7...........................................

Figure 2.6 Ć Rack Slot Limitations 2Ć7....................................

Figure 2.7 Ć Typical Input Power Connections 2Ć8.........................

III

Page 6

Page 7

1.0 INTRODUCTION

The products described in this instruction manual are manufactured

by Reliance Electric Industrial Company.

The Power Supply module (M/N 57C493 or M/NĂ57C494) converts

115 VAC input power into the DC voltages necessary to operate the

other modules contained in the Rack. The Rack provides the

mechanical means of mounting 6 (M/N 57C334), 10 (M/NĂ57C332),

or 16 (M/NĂ57C331) DCS 5000 or AutoMax modules, as well as the

Power Supply module. The Multibust backplane in the Rack

provides two sets of bus lines for local communication among the

DCS 5000 and AutoMax modules.

The M/N 57C393 Power Supply module can provide a maximum

continuous output of 376 watts to power modules in the AutoMax

rack. The M/N 57C394 Power Supply module can provide a

maximum continuous output of 147 watts to power modules in the

AutoMax rack. When using the M/N 57C494 Power Supply module in

a 10 or 16Ćslot rack, make certain that the power requirements of the

modules in the rack do not exceed the capacity of the Power Supply

module. See Appendix E for a list of AutoMaxĆcompatible modules

and their power requirements.

This instruction manual describes the functions and specifications of

the Power Supply modules and the Rack. It also includes a detailed

overview of installation and servicing procedures.

1.1 Additional Information

You should be familiar with the instruction manuals which describe

your system configuration. This may include, but is not limited to, the

following:

D JĆ3636 COMMON MEMORY MODULE INSTRUCTION MANUAL

D JĆ3649 AutoMax CONFIGURATION TASK MANUAL

D JĆ3630 ReSource AutoMax PROGRAMMING EXECUTIVE

D JĆ3650 AutoMax PROCESSOR MODULE INSTRUCTION

D JĆ3668 DCS 5000 POCKET REFERENCE

D JĆ3669 AutoMax POCKET REFERENCE

D JĆ3675 AutoMax ENHANCED BASIC LANGUAGE

D JĆ3676 AutoMax CONTROL BLOCK LANGUAGE INSTRUCTION

D JĆ3677 AutoMax LADDER LOGIC LANGUAGE INSTRUCTION

D IEEE 518GUIDE FOR THE INSTALLATION OF ELECTRICAL

D IEEE 796STANDARD MICROCOMPUTER SYSTEM BUS

D Your ReSource AutoMax PROGRAMMING EXECUTIVE

INSTRUCTION MANUAL

INSTRUCTION MANUAL VERSION 1.0

MANUAL

INSTRUCTION MANUAL

MANUAL

MANUAL

EQUIPMENT TO MINIMIZE ELECTRICAL NOISE

INPUTS TO CONTROLLERS

1Ć1

Page 8

D Other instruction manuals applicable to your hardware

configuration

D Your personal computer and DOS operating system manual(s).

1.2 Related Hardware and Software

The Power Supply modules and Racks are sold individually.

M/NĂ57C493 contains one 376 watt Power Supply module and two

keyswitch keys. M/N 57C494 contains one 147 watt Power Supply

module and two keyswitch keys. M/N 57C331 contains one 16Ćslot

Rack. M/N 57C332 contains one 10Ćslot Rack. M/N 57C334 contains

one 6Ćslot Rack. One Power Supply module and one Rack are used

with various input, output, and special purpose modules, as well as

the following hardware and software, which can be purchased

separately:

1. AutoMax or DCS 5000 Processor modules. The following

Processor modules can be used only with the M/N 57C493

Power Supply module:M/NĂ57C430 AutoMax Processor(s) or

M/NĂ57C407 DCS 5000 Processor(s). Note that all Processors in

a single Rack must be of the same type, i.e., AutoMax and DCS

5000 Processors cannot be mixed in one Rack.

D M/N 57C430 AutoMax Processor

D M/N 57C407 DCS 5000 Processor

Note that all Processors in a single rack must be of the same

type, i.e., AutoMax and DCS 5000 Processors cannot be mixed in

the same rack.

The following AutoMax Processors can be used with the M/N

57C493 or M/N 57C494 Power Supply module. These processor

modules can be mixed in the same rack:

D M/N 57C430A

D M/N 57C431

D M/N 57C435

2. ReSource AutoMax Programming Executive software or

ReSource DCS 5000 Programming Executive software.

3. M/NĂ57C127 RSĆ232C ReSource Interface Cable. This cable is

used to connect the personal computer to the Processor module.

4. M/NĂ57C413 (or later) or M/N 57C423 (or later) Common Memory

module. This module is used when there is more than one

Processor in the Rack. Note that only M/N 57C413B (and later) or

M/N 57C423 (and later) Common Memory module can be used

with the M/N 57C494 Power Supply.

5. M/N 57C492 Battery BackĆUp. This unit is used when there is a

Common Memory module (M/N 57C413 or M/N 57C413A only),

a M/N 57C407 or M/N 57C430 Processor, or both in the Rack.

The Battery BackĆUp unit can be used only with the M/N 57C493

Power Supply.

6. M/N 57C384 Battery BackĆUp cable. This cable is used with the

Battery BackĆUp unit.

1Ć2

Page 9

2.0 MECHANICAL/ELECTRICAL

DESCRIPTION

The following is a description of the mechanical and electrical

components, as well as the characteristics of the input connections,

for the Power Supply module and Racks. Unless noted otherwise, the

descriptions that follow describe both M/N 57C493 and M/N 57C494

Power Supply modules.

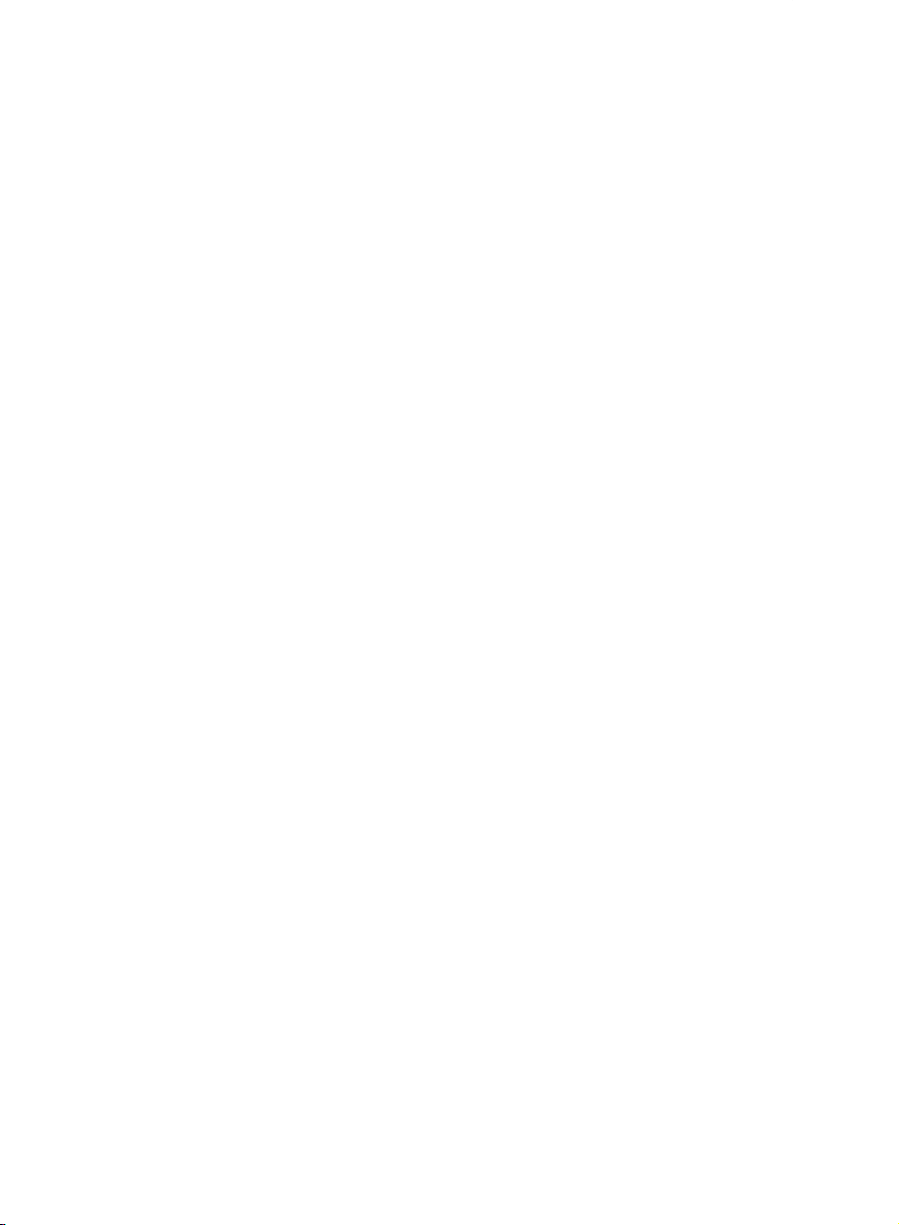

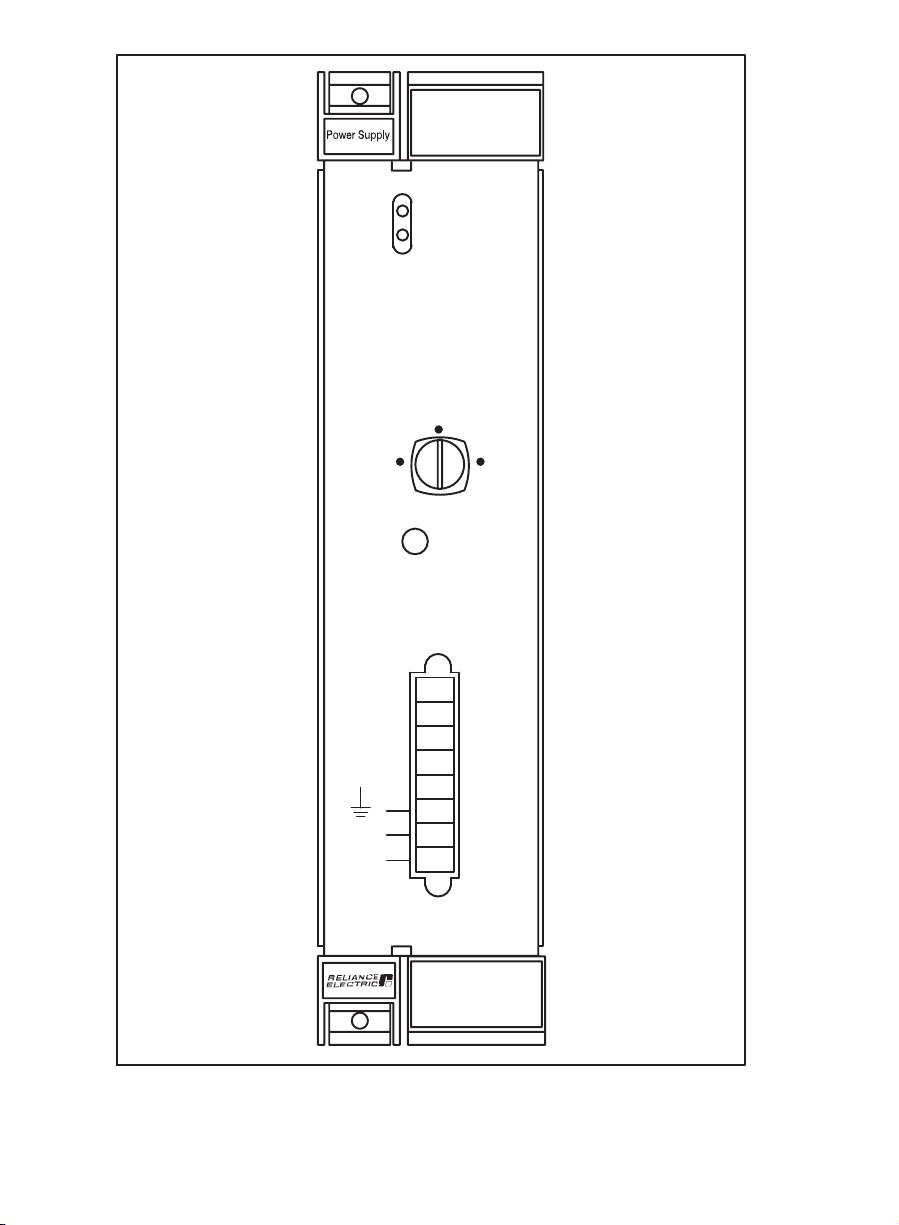

2.1 Power Supply Module Mechanical Description

The M/N 57C494 Power Supply module is a printed circuit board

assembly that plugs into the leftmost position of the 6Ć, 10Ć, or 16ĆSlot

Rack. When it is installed in a 10Ć or 16ĆSlot Rack, there will be a

oneĆslotĆwide space to the right of the Power Supply. If desired, this

space can be covered with a blank faceplate (M/N 61C599).

The M/N 57C493 Power Supply module is a printed circuit board

assembly that plugs into the leftmost position of either the 10Ć or

16ĆSlot Rack. It cannot be used with the 6ĆSlot Rack. Both modules

are enclosed in protective steel housings with integral heatsink.

Through its connection to the Multibus backplane of the Rack, the

Power Supply module provides the DC voltages necessary to power

the logic circuitry of modules in the Rack. On the faceplate of the M/N

57C493 Power Supply module are two LED indicators, a terminal

block connector, a keyswitch, a fuse, and a battery backĆup

connector. See figure 2.1.

On the faceplate of the M/N 57C494 Power Supply module are two

LED indicators, a terminal block connector, a keyswitch, and a fuse.

See figure 2.2.

2Ć1

Page 10

376W

57C493

PROGRAM

FUSE TYPE

250 V

MDA 15A

MEMORY

PROTECT

POWER

FAULT

SET

UP

BATTERY

BACK UP

2Ć2

GND

L2

120 VAC

L1

Figure 2.1Ć 376W Power Supply Module (M/N 57C493)

Page 11

147W

57C494

POWER

FAULT

PROGRAM

MEMORY

PROTECT

FUSE TYPE

250 V

MDA 5A

SET

UP

L2

120 VAC

L1

Figure 2.2Ć 147W Power Supply Module (M/N 57C494)

2Ć3

Page 12

2.1.1 Power Supply Module LED Indicators

The Power Supply module faceplate contains 2 LEDs. The green LED

labeled POWER" is lit to indicate when incoming AC power is within

the specified ranges. The red LED labeled FAULT" is normally off.

When it is on, it indicates the output voltages are not all above the

low voltage alarm thresholds or the watchdog OK signal is high.

2.1.2 Power Supply Module Terminal Block

The terminal block on the Power Supply faceplate provides the

means to connect the 115 VAC power and a ground wire from the

rack to the module. Note that terminals 1-5 (reading top to bottom)

are not functional.

The green ground wire from the Rack connects to the GND"

terminal on the faceplate of the Power Supply. Terminal L2" is the

connection for the AC neutral input line from the Rack. Terminal L1"

is the connection for the AC hot input line from the Rack. See section

3.2 for more information.

2.1.3 Power Supply Module Battery Connection

(M/N 57C493 only)

The faceplate connection labeled BATTERY BACK UP" provides the

means to connect the Battery BackĆUp (M/NĂ57C492) to the Power

Supply module. Note that the Battery BackĆUp unit is required only

when there is a DCS 5000 Processor module (M/NĂ57C407) or a

Common Memory module (M/NĂ57C413 or 57C413A only) in the

Rack. The Battery BackĆUp unit can save the contents of the

Common Memory and DCS 5000 Processor RAM in the event of a

power failure.

The keyswitch is used to reset the OK" signal on the Battery

BackĆUp. It is necessary to reset this signal if the battery fails or if the

cable is removed. See 2.1.4 and 2.2 for more information.

Note that the M/N 57C494 Power Supply module does not contain a

Battery BackĆup connection. Therefore, the above mentioned

Processor and Common Memory modules cannot be used with the

M/N 57C494 Power Supply.

2.1.4 Power Supply Module Keyswitch

The keyswitch on the faceplate routes TTL signals through the

Multibus backplane to the Processor module(s) to allow lockout of

programming functions for system security. The three positions of the

keyswitch are PROGRAM, MEMORY PROTECT, and SET UP. The

position of the keyswitch indicates the security level of the rack, i.e.,

the kind of ONĆLINE Menu operations that can be performed through

a personal computer communicating with the processors in the rack.

The MEMORY PROTECT position allows only monitoring of variables

and saving of tasks from the rack. SETUP allows the operator to

monitor all variables, modify tunable variables, and save tasks from

the rack. The PROGRAM position allows the operator to perform all

ONĆLINE Menu functions, providing the password for the rack is also

entered. See the appropriate Programming Executive instruction

manual for more information.

2Ć4

Page 13

2.2 Power Supply Module Electrical

Description

When the Power Supply module powersĆup, it executes a soft start,"

gradually increasing its output until it reaches the voltage necessary

for logic operations. At this time, the module generates an initialize

signal.

Should the AC input fall below the lower line voltage limit, the module

will generate a power fail interrupt signal at least three milliseconds

before loss of the regulated DC power to allow for orderly system

shutdown. The holdover time on loss of AC input is 20 milliseconds.

In the event of a power fail interrupt signal, 5 Volt output power is

supplied by the Battery BackĆUp (if installed, M/N 57C493 only) for

maintaining the volatile memory of DCS 5000 Processor modules

and the Common Memory module. When the regulated output power

of the Power Supply module is restored to 4.85 Volts or greater,

power will be supplied by the Power Supply module. Note that

AutoMax Processors have onĆboard battery backĆup and do not

require Battery BackĆUp unless there is a Common Memory module

(M/N 57C413 or 57C413A only) in the rack.

If Battery BackĆUp Voltage ever drops below 3.0 Volts, or the cable

between the Battery BackĆUp and M/N 57C493 Power Supply

module is disconnected with the power off, memory will be lost and

the Processor modules will not function until the Power Supply is

manually reset by turning the keyswitch on the front panel from

MEMORY PROTECT to the PROGRAM position.

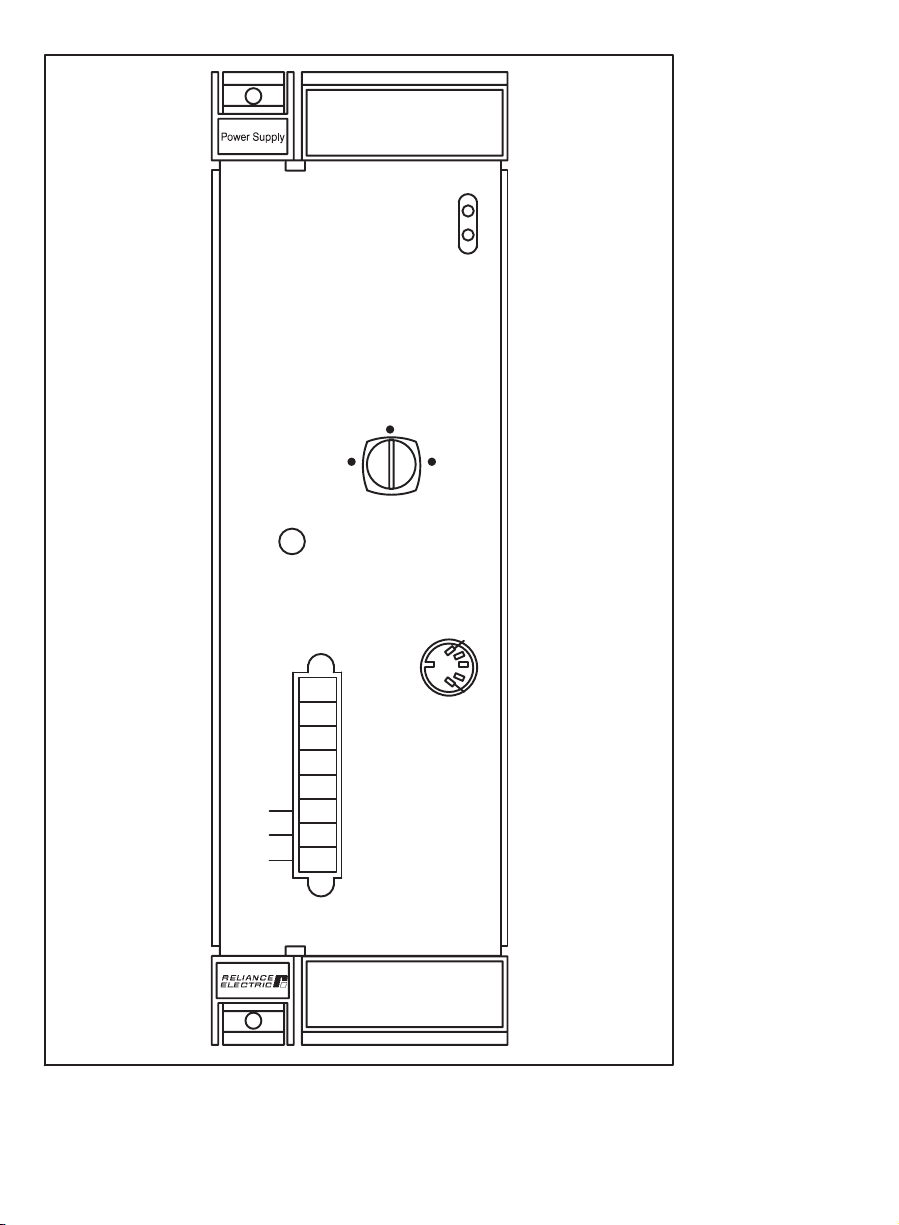

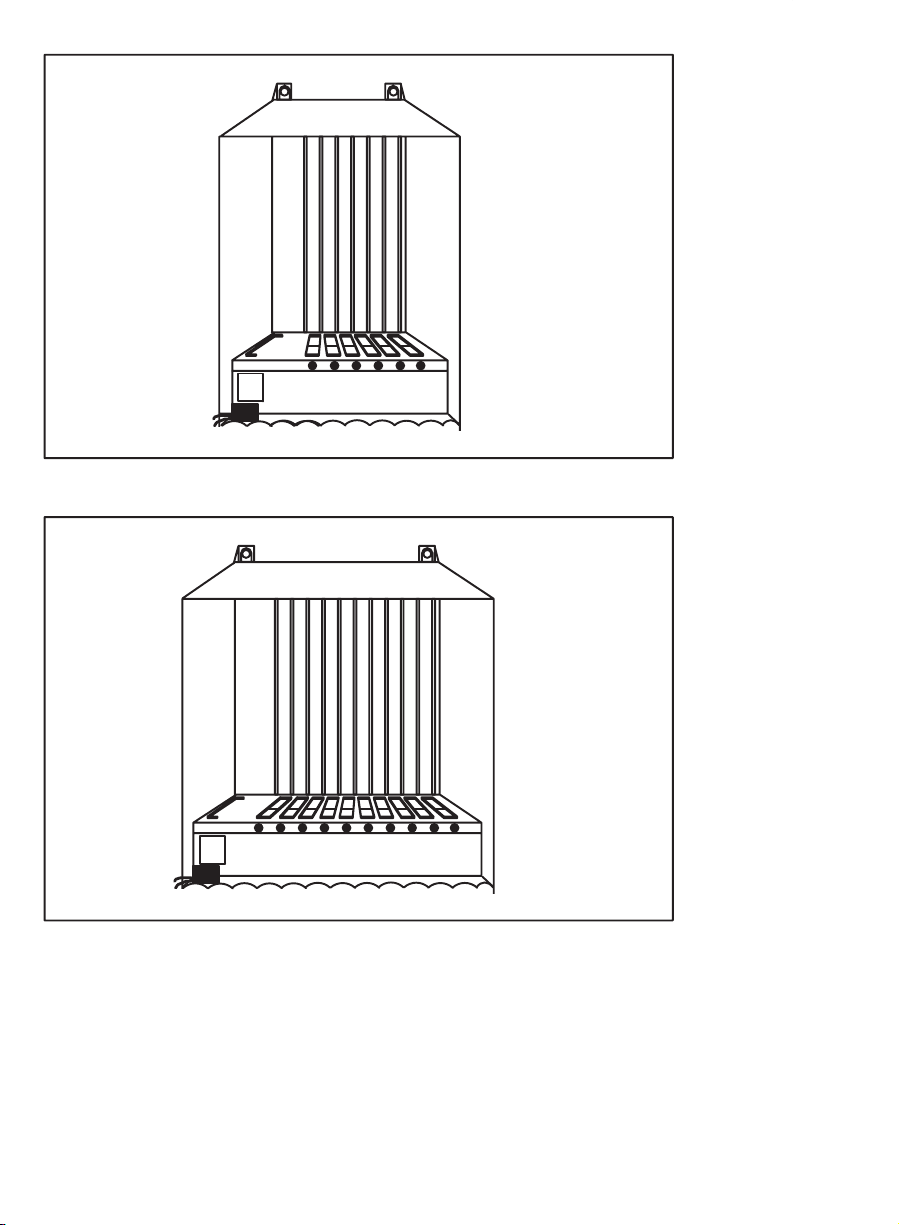

2.3 Rack Mechanical Description

The 6Ć, 10Ć, and 16ĆSlot Racks provide the mechanical means for

mounting the indicated number of DCS 5000 and AutoMax modules,

as well as the Power Supply module. All Racks are designed for

panel mounting and include builtĆin high capacity cooling fans, an

AC line filter, a surge protector, and a cable management tray. See

figures 2.3, 2.4, and 2.5.

2Ć5

Page 14

(Nameplate Bracket Removed)

Figure 2.3Ć 6ĆSlot Rack

(Nameplate Bracket Removed)

Figure 2.4Ć 10ĆSlot Rack

2Ć6

Page 15

(Nameplate Bracket Removed)

Figure 2.5 Ć 16ĆSlot Rack

Dedicated signal lines on the Multibus backplane require limitations

on slot placement for some types of DCS 5000/AutoMax modules.

See figure 2.6.

Module Slot Position

Module 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

6ĆSlot Rack:

Common

D

Memory

Processor D D D D D

DCS DC Drive

1

All Other D D D D D D

10ĆSlot Rack:

Common

D

Memory

Processor D D D D D

DCS DC Drive

2

D D D D

All Other D D D D D D D D D D

16ĆSlot Rack:

Common

D

Memory

Processor D D D D D

DCS DC Drive

2

D D D D D D D D

All Other D D D D D D D D D D D D D D D D

1

Cannot be used in a 6ĆSlot Rack.

2

Must be grouped together.

Figure 2.6Ć Rack Slot Limitations

2Ć7

Page 16

2.4 Rack Electrical Description

The Multibus backplane of the Rack supports two sets of bus lines

that serve as the electrical connection for all slots in the Rack. The P1

bus, the larger of the two electrical connectors, conforms to the IEEE

Microcomputer System Bus Standard for the P796 bus, compliance

level D16M20I16. This bus is used for communication and control

signals among the different modules in the Rack. The P2 bus, the

smaller of the two backplane electrical connectors, follows a Reliance

pin assignment as permitted by the IEEE P796 standard. The P2 bus

is used for functions such as determining the slot number of the

module. See Appendix C for a description of the pins on the Rack

backplane. See JĆ3649, JĆ3750, or J2Ć3045 for guidelines on using

nonĆReliance modules in the Rack.

The AC line filter on the Rack filters the incoming power signal before

it is transmitted to the Power Supply module. The surge protector

provides power supply protection from power surges. No other

connections to the AC line are permitted between the line filter and

the Power Supply module. See figure 2.7 for a typical input power

signal.

KVA < 50

115 VAC

HOT

115 VAC

NEUTRAL

188

189

RACK

2Ć8

Figure 2.7Ć Typical Input Power Connections

Page 17

3.0 INSTALLATION

This section describes how to install and replace the Power Supply

module and Rack.

DANGER

THE USER IS RESPONSIBLE FOR CONFORMING WITH ALL APPLICABLE

LOCAL, NATIONAL, AND INTERNATIONAL CODES. WIRING PRACTICES,

GROUNDING, DISCONNECTS, AND OVERĆCURRENT PROTECTION ARE OF

PARTICULAR IMPORTANCE. FAILURE TO OBSERVE THIS PRECAUTION

COULD RESULT IN SEVERE BODILY INJURY OR LOSS OF LIFE.

CAUTION: This equipment must be connected to a power source for which it was

designed. Verify that the available poweris 115 volts. Failure to observethis precaution

could result in damage to equipment.

3.1 Wiring

To reduce the possibility of electrical noise interfering with the proper

operation of the control system, exercise care when installing the

wiring between the system and the external devices. For detailed

recommendations refer to IEEE 518.

The external wiring to the modules in the Rack must be carefully

routed to minimize electrical noise and crosstalk between input and

output wiring. Group and bundle wire types by similar electrical

signals, being especially careful to separate lowĆ and highĆlevel

control signals and AC and DC wiring.

If the 115 VAC input signal is subject to severe harmonic distortion,

install a constant voltage transformer on the line.

3.2 Initial Installation

CAUTION:The cabinetor panelon which the rack is mounted must belocatedinanarea

away from or shielded from sources of EMI, such as radar beams and transmission

towers. Failure to observe this precaution couldresult indamage to or destruction of the

equipment.

CAUTION:Air flow around the rackmust be sufficient to dissipate the heatgeneratedby

all of the hardwarein and around the rack. Allow atleast twoinches of clearance on each

side of the rack. Avoid placing large, heatĆgenerating equipment underneath the rack

fans. Additional userĆsupplied fan cooling or air conditioning is required if the ambient

temperature exceeds 60_C. Failure to observethis precaution could result in damage to

or destruction of the equipment.

3Ć1

Page 18

CAUTION: The rack must be located in a clean environment.Do not expose the rack to

dripping water or corrosive atmospheres containing carbon dust, metal particles, or

other contaminants. Failure to observe this precaution could result in damage to or

destruction of the equipment.

Use the following procedure to install the Rack and Power Supply

module. Before you begin, make certain that you have provided

enough space for the Rack, wiring, and terminal strips or other

devices that must be mounted near the Rack. Make certain that the

panel is sturdy enough to support the Rack and all modules that it

will hold. Including connectors attached to module faceplates, a

fullyĆloaded 6ĆSlot Rack weighs approximately 40 lbs. A fullyĆloaded

10ĆSlot Rack weighs between 70 and 80 lbs. A fullyĆloaded 16ĆSlot

Rack weighs between 105Ć115 lbs.

Step 1. Mount the Rack on a panel or cabinet made of heavy

Step 2. Mount the Power Supply module in the Rack following the

gauge steel sturdy enough to hold the Rack, all of the

hardware modules that will go into the Rack, and the

terminal strip/connector assemblies for I/O modules. The

connector end of each terminal strip/connector assembly

is attached to the appropriate module faceplate. The

terminal strip end of each assembly can be mounted on

the panel itself or on lashing bars attached to the panel.

Refer to the instruction manual for each individual module

in your installation for more specific information. Follow the

procedure below to install the Rack.

a) Drill four holes in the panel using the appropriate

mounting pattern in Appendix D.

b) In each hole, screw in one 1 1/4" 20Ćthread Tap titet

bolt, leaving approximately 1/8" to 1/4" of the thread

exposed.

c) Remove the large nameplate bracket (labeled

AutoMax") from the rack by removing the three screws

near the base holding it to the cable guide area.

d) Position the Rack against the panel at a slight angle so

that the bottom is a few inches away from the panel.

Place the top of the Rack against the panel so that the

upper two bolts are visible through the larger part of

the bolt holes at the top of the Rack.

Carefully slide the Rack down so that the bolts are

wedged in the top (smaller) area of the bolt holes,

while at the same time moving the lower portion of the

Rack toward the cabinet or panel onto the lower bolts.

The lower bolts should be firmly wedged against the

upper edge of the lower bolt holes on the Rack.

Tighten all the bolts.

steps below.

a) Take the Power Supply module out of its shipping

container and antiĆstatic bag, being careful not to

touch the connectors on the back of the module.

b) Remove the two keyswitch keys which are taped to the

front of the module. Insert the module into the leftmost

and widest slot in the Rack. Use a screwdriver to attach

3Ć2

Page 19

the module to the Rack. Store the keyswitch keys in a

secure area.

c) Connect the Battery BackĆUp unit, if used. Plug one

end of the Battery BackĆUp cable into the Power

Supply module faceplate connector labeled BATTERY

BACK UP". Plug the other end of the cable into the

Battery BackĆUp unit. Rotate the keyswitch on the front

panel from Memory Protect to the Program position.

Step 3. Mount the terminal strip end of the terminal strip/connector

Step 4. Fasten wiring for the external hardware to the terminal

Step 5. Take the Processor module(s) and other modules out of

Step 6. Attach the connector ends of the terminal strip/connector

Step 7. Wire the Rack following the instructions below.

assemblies for I/O modules on the panel or on lashing

bars. The terminal strips should be mounted to permit

easy access to the screw terminals. Make certain that the

strips are close enough to the Rack so that the connecting

cables will reach between terminal strips and the modules.

Most cables are approximately 60" long.

strips. Make certain that all field wires are securely

attached. Label all terminal strips and field wires to allow

easy reconnection at a later date.

For I/O modules, note carefully that bit numbers and wire

numbers (located on wires between the faceplate

connector and terminal strip) are not the same. Refer to

the installation section of the instruction manuals

describing the I/O modules for more information.

their shipping containers and insert them into the desired

slots. See figure 2.6 for slot restrictions for certain

modules. Use a screwdriver to attach the modules to the

Rack.

assemblies to their mating halves on the appropriate

modules. Use a screwdriver to attach the connectors to

the modules. Use the cable guides at the base of the rack

to keep cables separate.

Note that in most cases both the connectors and their

mating halves are equipped with movable keys". These

keys should be used to prevent the wrong connector from

being plugged into a module in the event that the

connector needs to be removed and then reĆattached

later.

At the time of installation, rotate the keys on the connector

and the mating half on the module to mirror image

positions so that they can be connected together securely.

For all modules equipped with keys, the key on each

successive module in the Rack should be rotated one

position to the right of the key on the preceding module.

CAUTION: Do not connect incoming AC power directly to the power supply module

faceplate. Connect AC power to the correct terminals on therack only.Failuretoobserve

this precaution could result in damage to or destruction of the equipment.

3Ć3

Page 20

a) Ground the cabinet or panel on which the Rack will be

mounted. Make certain that there is an unbroken path

from the cabinet to the plant ground (earth).

b) Ground the rack with a ground wire connected to one

of the protective ground terminals provided on each

side of the rack. The ground wire color and size must

be in accordance with appropriate international and

national standards and codes.

c) Connect incoming AC power to the Rack as follows:

Rack Terminal Label

189 120 VAC

188 120 VAC + (hot)

Cover the incoming wire ends with a Fastont

connector and attach them securely to the appropriate

terminals using a screwdriver.

d) Connect the power and ground wires from the Rack to

the Power Supply module as follows:

Wire Color

black L2 L2

orange L1 L1

green - GND

The wires labeled L2 and L1 should remain twisted

together as much as possible between the Rack and

the Power Supply module.

Step 8. Using a screwdriver, reĆattach the nameplate bracket to

the base of the rack.

Step 9. Turn on power to the system.

THE POWER SUPPLY MODULE OPERATES USING AC INPUT VOLTAGE

CAPABLE OF PRODUCING SEVERE SHOCK. MAKE CERTAIN THAT THE

EXTERNAL AC SUPPLY CIRCUIT IS TURNED OFF BEFORE INSERTING OR

REMOVING THE MODULE OR ANY CONNECTING CABLES. FAILURE TO

OBSERVE THIS PRECAUTION COULD RESULT IN SEVERE BODILY INJURY OR

LOSS OF LIFE.

Wire Label

DANGER

Input

Power Supply

Faceplate Connector

3Ć4

Step 10. Verify the installation by connecting the personal computer

to the port labeled PROGRAMMER/PORT B" on the

leftmost Processor in the Rack and running the ReSource

programming software. Try to read from or write to the

registers on each of the modules in the Rack.

Page 21

WARNING

BE CAREFUL TO INSURE THAT NO UNEXPECTED MACHINE MOTION WILL

RESULT WHEN WRITING TO OUTPUTS. FAILURE TO OBSERVE THIS

PRECAUTION COULD RESULT IN BODILY INJURY.

Refer to the instruction manuals describing other

hardware in the installation for more information.

3.3 Power Supply Module Replacement

Use the following procedure to replace the Power Supply module:

Step 1. Turn off power to the Rack and all connections.

DANGER

THE POWER SUPPLY MODULE OPERATES USING AC INPUT VOLTAGE

CAPABLE OF PRODUCING SEVERE SHOCK. MAKE CERTAIN THAT THE

EXTERNAL AC SUPPLY CIRCUIT IS TURNED OFF BEFORE INSERTING OR

REMOVING THE MODULE OR ANY CONNECTING CABLES. FAILURE TO

OBSERVE THIS PRECAUTION COULD RESULT IN SEVERE BODILY INJURY OR

LOSS OF LIFE.

Step 2. Use a screwdriver to disconnect the terminal strip from the

Step 3. Use a screwdriver to loosen the screws holding the Power

Step 4. Mount the replacement Power Supply module in the Rack

Power Supply module. Do not remove the wires from the

terminal strip. Disconnect the Battery BackĆUp cable, if

used.

Remove the nameplate bracket from the rack by removing

the three screws near the base holding it to the cable

guide area.

Supply module in the Rack and remove the module, being

careful not to touch the connectors on the back. Store the

module in the antiĆstatic bag it came in.

following the steps below:

a) Take the replacement Power Supply module out of its

shipping container and antiĆstatic bag, being careful

not to touch the connectors on the back of the module.

b) Remove the two keys to the keyswitch which are taped

to the front of the module. Store the keyswitch keys in

a secure area. Use a screwdriver to disconnect the

terminal strip from the replacement Power Supply

module.

c) Insert the module into the leftmost and widest slot in

the Rack. Use a screwdriver to attach the module to

the Rack.

d) Use a screwdriver to attach the terminal strip from the

old Power Supply module to the replacement Power

Supply module. Make certain that the connector is

attached correctly by verifying that the wiring and the

terminal labels on the faceplate match as follows:

3Ć5

Page 22

Power Supply

Wire Color

black L2 L2

orange L1 L1

green - GND

e) If you are using the Battery BackĆUp unit, plug one end

of the Battery BackĆUp cable into the Power Supply

module faceplate connector labeled BATTERY BACK

UP". Plug the other end into the Battery BackĆUp unit.

Rotate the keyswitch on the front panel from Memory

Protect to the Program position.

f) Using a screwdriver, reĆattach the nameplate bracket to

the base of the rack.

Step 5. Turn on power to the system.

Step 6. Verify the installation by connecting the personal computer

to the port labeled PROGRAMMER/PORT B" on the

leftmost Processor in the Rack and running the ReSource

programming software. Try to read from or write to the

registers on each of the modules in the Rack.

WARNING

BE CAREFUL TO INSURE THAT NO UNEXPECTED MACHINE MOTION WILL

RESULT WHEN WRITING TO OUTPUTS. FAILURE TO OBSERVE THIS

PRECAUTION COULD RESULT IN BODILY INJURY OR DAMAGE TO EQUIPMENT.

Refer to the instruction manuals describing the specific

hardware in the installation for more information.

Wire Label

Faceplate Connector

3.4 Rack Replacement

Use the following procedure to replace the Rack:

Step 1. Turn off power to the Rack and all connections.

DANGER

THE POWER SUPPLY MODULE OPERATES USING AC INPUT VOLTAGE

CAPABLE OF PRODUCING SEVERE SHOCK. MAKE CERTAIN THAT THE

EXTERNAL AC SUPPLY CIRCUIT IS TURNED OFF BEFORE INSERTING OR

REMOVING THE MODULE OR ANY CONNECTING WIRES. FAILURE TO

OBSERVE THIS PRECAUTION COULD RESULT IN SEVERE BODILY INJURY OR

LOSS OF LIFE.

Step 2. Using a screwdriver, remove the nameplate bracket from

Step 3. Use a screwdriver to loosen the screws holding all

3Ć6

the rack by removing the three screws near the base

holding it to the cable guide area. Loosen all the screws

holding connectors to the modules in the Rack. Remove

the connectors. Disconnect the wires attached to the

terminal strip on the Power Supply module.

modules, including the Power Supply module, in the Rack.

Page 23

Take all of the modules out of the Rack, being careful not

to touch the connectors on the back.

Step 4. Loosen the bolts that hold the rack to panel approximately

Step 5. Position the replacement Rack against the panel at a slight

Step 6. Insert the Power Supply module into the leftmost and

Step 7. If you are using the Battery BackĆUp unit, plug one end of

Step 8. Insert the Processor module(s) and other modules. Use a

Step 9. Use a screwdriver to attach the connectors to their mating

Step 10. Connect 115 VAC power to the Rack following the

1/8"-1/4". Lift the Rack slightly while holding it against the

panel until both top bolts are positioned in the larger bolt

holes and the lower two bolts have cleared the smaller

holes. Pull the Rack away from the panel and set aside.

angle so that the bottom is a few inches away from the

panel. Place the Rack against the panel so that the upper

two bolts are visible through the larger part of the bolt

holes at the top of the Rack.

Carefully slide the Rack down so that the bolts are

wedged in the top (smaller) area of the bolt holes, while at

the same time moving the lower portion of the Rack

toward the cabinet or panel onto the lower bolts. The

lower bolts should be firmly wedged against the upper

edge of the lower bolt holes on the Rack. Tighten all the

bolts.

widest slot in the Rack. Use a screwdriver to attach the

module to the Rack.

the Battery BackĆUp cable into the Power Supply module

faceplate connector labeled BATTERY BACK UP". Plug

the other end into the Battery BackĆUp unit. Rotate the

keyswitch on the front panel from Memory Protect to the

Program postion.

screwdriver to attach the modules to the Rack.

halves on the appropriate modules.

instructions below.

CAUTION: Do not connect incoming AC power directly to the power supply module

faceplate. Connectpowerto thecorrect terminals ontherackonly.Failureto observe this

precaution could result in damage to or destruction of the equipment.

a) Make certain that there is an unbroken path from the

cabinet to the plant ground.

b) Connect incoming AC power to the Rack as follows:

Rack Terminal Label

189 120 VAC

188 120 VAC + (hot)

Cover the incoming wire ends with a Fastont

connector and attach them securely to the appropriate

terminals using a screwdriver.

c) Connect the power and ground wires from the Rack to

the Power Supply module as follows:

Input

3Ć7

Page 24

Power Supply

Wire Color

black L2 L2

orange L1 L1

green - GND

The wires labeled L2 and L1 should remain twisted

together as much as possible between the Rack and

the Power Supply module.

Step 11. Using a screwdriver, reĆattach the nameplate bracket to

the base of the rack.

Step 12. Turn on power to the system.

Step 13. Verify the installation by connecting the personal computer

to the port labeled PROGRAMMER/PORT B" on the

leftmost Processor in the Rack and running the ReSource

programming software. Try to read from or write to the

registers on each of the modules in the Rack.

WARNING

WHEN WRITING TO OUTPUTS, BE CAREFUL TO INSURE THAT NO UNEXPECTED

MACHINE MOTION WILL RESULT. FAILURE TO OBSERVE THIS PRECAUTION

COULD RESULT IN BODILY INJURY OR DAMAGE TO EQUIPMENT.

Refer to the instruction manuals describing the specific

hardware in the installation for more information.

Wire Label

Faceplate Connector

3Ć8

Page 25

4.0 DIAGNOSTICS AND

TROUBLESHOOTING

This section explains how to troubleshoot the Power Supply module

and Rack. Any problems with either the Power Supply module or the

Rack can usually be isolated by observing the condition of the LEDs

on the Power Supply module faceplate. Problems with the Rack

backplane (bus) will result in error codes on the LEDs of Processor

modules in the Rack. See JĆ3650 for more information on

troubleshooting the AutoMax Processor module.

DANGER

THE POWER SUPPLY MODULE OPERATES USING AC INPUT VOLTAGE

CAPABLE OF PRODUCING SEVERE SHOCK. MAKE CERTAIN THAT THE

EXTERNAL AC SUPPLY CIRCUIT IS TURNED OFF BEFORE INSERTING OR

REMOVING THE MODULE OR ANY CONNECTING WIRES. FAILURE TO

OBSERVE THIS PRECAUTION COULD RESULT IN SEVERE BODILY INJURY OR

LOSS OF LIFE.

If the problem cannot be determined using the troubleshooting

instructions below, the hardware is not userĆserviceable.

DANGER

SOME OF THESE STEPS ARE MADE WITH POWER ON. EXERCISE EXTREME

CARE BECAUSE HAZARDOUS VOLTAGE EXISTS. FAILURE TO OBSERVE THIS

PRECAUTION COULD RESULT IN SEVERE BODILY INJURY OR LOSS OF LIFE.

4.1 The POWER LED Is Off

Problem: the POWER LED on the Power Supply module is off. This

LED should always be on when input power is on and the input fuse

is in place and functioning correctly. If the LED is off, the module is

not receiving 120 VAC power. Use the following procedure to isolate

the problem.

Step 1. Using a voltmeter, verify that the Rack is receiving 120 VAC

power.

Step 2. Turn off power to the Rack. Wait until all of the LEDs on the

faceplate of the Power Supply module have gone out.

Verify that the connections at the Rack and the L1 and L2

connections at the Power Supply module are tight.

Step 3. Remove the fuse cap and fuse and, using an Ohm meter,

verify that the fuse is not blown. If the fuse is good,

reĆinsert it and continue with step 4.

If the fuse is blown, verify that, for M/N 57C493, it is a 15A

MDA time delay type fuse. M/N 57C494 should contain a

5A MDA time delay type fuse. A blown fuse indicates that

the Power Supply should be replaced.

Step 4. Turn on power to the Rack. If the problem is not corrected,

replace the Power Supply.

4Ć1

Page 26

4.2 The FAULT LED is On

Problem: the FAULT LED on the Power Supply module is ON. This

LED should always be off when input power is on, the Power Supply

output voltage is within proper limits, and the watchdog alarm

coming from the backplane is not active. The rack must also contain

at least one AutoMax Processor module (or, for a remote rack, a

Remote I/O module). Note that the FAULT LED will be ON if there is

no Processor (or Remote I/O module) in the rack.

Use the following procedure to determine whether the problem is

caused by a malfunctioning Power Supply or by a watchdog alarm.

Step 1. Verify that the Power Supply is securely seated in the rack.

Step 2. If you have more than one Processor in the rack, a

Step 3. Turn off power to the rack. Replace the Processor or

Step 4. If the Power Supply FAULT LED turns ON, the Power

The FAULT LED will come ON if there is not a good

connection to the rack backplane.

watchdog timeout will not be indicated by the Power

Supply FAULT LED. If the Power Supply FAULT LED is ON,

the Power Supply must be replaced.

If the rack contains a single AutoMax Processor or is a

remote rack, check the OK LED on the Processor module

or Remote I/O module. If the OK LED is OFF, it may

indicate a watchdog timeout.

Remote I/O module. Turn on power to the rack.

Supply is malfunctioning. Replace the Power Supply.

4Ć2

Page 27

Appendix A

Technical Specifications

Power Supply Module (M/N 57C493)

Ambient Conditions

D Storage temperature: -40oCĆ85oC

D Operating temperature: 0_CĆ60_C

D Humidity: 5-90% nonĆcondensing

D Altitude: operation from sea level at 60

with linear derating of 1

Dimensions

D Height: 29.8 cm 113/4inches

D Width: 10.2 cm ă4 inches

D Depth: 19.7 cm ă7

D Weight: ă3.8 kg 8

3

/4inches

1

/2lbs

System Power Requirements

D Input voltage: nominal 100/120 VAC, 85Ć132 VAC acceptable

D Current: 6 Amp at 120 VAC

D Frequency: nominal 50/60 Hz, 47Ć63 Hz acceptable range

D Protection: 15 Amp 250 VAC MDA time delay fuse

D Fault current limit: 10,000 Amps

D Maximum source rating: 50KVA

range

DC Output

D +5 VDC at 50 amps

D +/-12 VDC at 4 amps

D +/-15 VDC at 1 amp

D Maximum continuous output power: ă376 Watts

D Holdup time: 20 msec. minimum after loss of AC input

Regulation

D Nominal +5 VDC: -2.5% to +3% regulation

D Nominal +/- 12 VDC: +/-10% regulation

D Nominal +/- 15 VDC: +/- 1% regulation

Efficiency

D 75% minimum at nominal line voltage and full load

Isolation

D 1500 VDC for 1 sec input to output and input to chassis

D 700 VDC for 1 sec output to chassis

Protection

D Overvoltage: +5V 5.6V+/-0.15V

+/-12V 14.4V +/-0.6V

+/-15V 16.5V +/-0.5V

o

C to 10,000 feet (3048 meters)

o

C per 1000 feet above 5000 feet.

AĆ1

Page 28

Technical Specifications

Power Supply Module (M/N 57C494)

Ambient Conditions

D Storage temperature: -40oCĆ85oC

D Operating temperature: 0_CĆ60_C

D Humidity: 5-90% nonĆcondensing

D Altitude: operation from sea level at 60

with linear derating of 1

Dimensions

D Height: 29.8 cm 113/4inches

D Width: 7.1 cm ă2

D Depth: 19.7 cm ă7

D Weight: ă2.6 kg 5

13

/16inches

3

/4inches

3

/4lbs

System Power Requirements

D Input voltage: nominal 100/120 VAC, 85Ć132 VAC acceptable

D Current: 2.6 Amp at 120 VAC

D Frequency: nominal 50/60 Hz, 47Ć63 Hz acceptable range

D Protection: 5 Amp 250 VAC MDA time delay fuse

D Fault current limit: 10,000 Amps

D Maximum source rating: 50KVA

range

DC Output

D +5 VDC at 20 amps

D +/-12 VDC at 1 amp

D +/-15 VDC at 0.75 amp

D Maximum continuous output power: ă147 Watts

D +5 VDC output holdup time: 3 msec. minimum after loss of AC input at

D Input line loss: capable of a 1 cycle 60 Hz line loss at nominal input

line voltage

full load and minimum input line voltage

Regulation

D Nominal +5 VDC: -2.5% to +3% regulation

D Nominal +/- 12 VDC: +/-10% regulation

D Nominal +/- 15 VDC: +/- 1% regulation

Efficiency

D 65% minimum at nominal line voltage and full load

Isolation

D 1500 VDC input to output

D 700 VDC output to chassis

Protection

D Overvoltage: +5V 5.6V+/-0.15V

+/-12V 14.4V +/-0.6V

+/-15V 16.5V +/-0.5V

o

C to 10,000 feet (3048 meters)

o

C per 1000 feet above 5000 feet.

AĆ2

Page 29

Technical Specifications

16ĆSlot, 10ĆSlot and 6ĆSlot Rack

Ambient Conditions

D Storage temperature: -55oCĆ85oC

D Operating temperature: 0

D Humidity: 5Ć90% nonĆcondensing

Rack Dimensions

M/NĂ57C331 16ĆSlot Rack

D Height: 48.6 cm 191/8inches

D Width: 62.4 cm 24

D Depth: 31.1 cm 12

D Approximate Weight: 50 kg fully loaded 110 lbs

M/NĂ57C332 10ĆSlot Rack

D Height: 48.6 cm 19

D Width: 43.3 cm 171/16inches

D Depth: 31.1 cm 12

D Approximate Weight: 34ăkg fully loaded 75 lbs

M/NĂ57C334 6ĆSlot Rack

D Height: 48.6 cm 19

D Width: 27.5 cm 103/16inches

D Depth: 31.1 cm 121/4inches

D Approximate Weight: 18ăkg fully loaded 39.5 lbs

Bus Specifications

D Type: Intel Multibust

D P1 bus connector: IEEE standard P796 bus

D P2 bus connector: IEEE standard P796 modified bus

AC Line Filter:

D 10 Amp (M/N 57C331 and M/N 57C332)

D 6 Amp (M/N 57C334)

D 120/250 VAC

D 50/60 Hz

Fans

D Two (2) per Rack (M/N 57C331 and M/N 57C332)

D One (1) per Rack (M/N 57C334)

D Nominal power dissipation: 14 Watts each

o

CĆ60oC

9

/16inches

1

/4inches

1

/8inches

1

/4inches

1

/8inches

AĆ3

Page 30

Page 31

Appendix B

External Connections

Input Power to Rack

(M/N 57C331, 57C332, and 57C334)

Terminal Label Input

189 AC neutral

188 AC hot

GND Rack/earth ground

Rack (M/N 57C331 and 57C332)

to Power Supply Module (M/N 57C493)

Power Supply

Wire Color Wire Label

black L2 L2

orange L1 L1

green - GND

Rack (M/N 57C331, 57C332, and 57C334)

to Power Supply Module (M/N 57C494)

Faceplate Connector

Power Supply

Wire Color Wire Label

black L2 L2

orange L1 L1

green - GND

Faceplate Connector

BĆ1

Page 32

Page 33

Appendix C

Rack Backplane

P1 Bus

Component Side

1

Pin

Power

Supplies13

Bus

Controls1315

Bus

Controls

and

Addresses

Parallel

Interrupts

Requests

Address 43

Data 59

Power

Supplies7577 NC

NC: No connection

MOD: Modified definition of Multibus specification

NU: No usage in system; driven per Multibus specification

5

7

9NC

11

17

19

21

23

25

27

29

31

33 NC

35 MOD

37 NC

39

41

45

47

49

51

53

55

57

61

63

65

67

69

71

73

79

81

83

85

Mnemonic Description

GND

+5V

+5V

+12V

-5V

GND

BCLK

BPRN/

BUSY/

MRDC/

IORC/

XACK/

LOCK/

BHEN/

CBRQ/

CCLK/

INTA/

INT6/

INT4/

INT2/

INT0/

ADRE/

ADRC/

ADRA/

ADR8/

ADR6/

ADR4/

ADR2/

ADR0/

DATE/

DATC/

DATA/

DAT8/

DAT6/

DAT4/

DAT2/

DAT0/

GND

-12V

+5V

+5V

GND

Signal Ground

+5 VDC

+5 VDC

+12 VDC

-5 VDC

Signal Ground

Bus Clock

Bus Priority In

Bus Busy

Memory Read Command

I/O Read Command

Transfer Acknowledge

Lock

Byte Hi Enable

Common Bus Request

Common Clock

Interrupt Acknowledge

CPU Communication Interrupt

General Purpose Interrupt

General Purpose Interrupt

General Purpose Interrupt

Address Bus

Data Bus

Signal Ground

Reserved

-12V

+5 VDC

+5 VDC

Signal Ground

CĆ1

Page 34

Rack Backplane (Cont.)

P1 Bus (Cont.)

Solder Side

1

Pin

Power

Supplies24

Bus

Controls1416

Bus

Controls

and

Addresses

Parallel

Interrupts

Requests

Address 44

Data 60

Power

Supplies7678 NC

NC: No connection

MOD: Modified definition of Multibus specification

NU: No usage in system; driven per Multibus specification

6

8

10 NC

12

18

20

22

24 MOD

26 MOD

28

30

32

34

36 MOD

38 NC

40

42

46

48

50

52

54

56

58

62

64

66

68

70

72

74

80

82

84

86

Mnemonic Description

GND

+5V

+5V

+12V

-5V

GND

INIT/

BPRO/

BREQ/

MWTC/

IOWC/

PRIV/

MMUMAP

AD10/

AD11/

AD12/

AD13/

INT7/

INT5/

INT3/

INT1/

ADRF/

ADRD/

ADRB/

ADR9/

ADR7/

ADR5/

ADR3/

ADR1/

DATF/

DATD/

DATB/

DAT9/

DAT7/

DAT5/

DAT3/

DAT1/

GND

-12V

+5V

+5V

GND

Signal Ground

+5 VDC

+5 VDC

+12 VDC

-5 VDC

Signal Ground

Initialize

Bus Priority Out

Bus Request

Memory Write Commmand

I/O Write Command

Privilege

MMU Map Select

Address Bus

Address Bus

Address Bus

Address Bus

System WDOG Interrupt

General Purpose Interrupt

General Purpose Interrupt

General Purpose Interrupt

Address Bus

Data Bus

Signal Ground

Reserved

-12V

+5 VDC

+5 VDC

Signal Ground

CĆ2

Page 35

Rack Backplane (Cont.)

P2 Bus

Component Side

Pin Mnemonic Description

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

45

47

49

51

53

55

57

59

AGND

5VB

IDA0/

DB

IDA1/

DB

DB

DB

PFSN/

PFIN/

AGND

A +15V

A -15V

DB DPR0/

DB APR0/

DB APR2/

DB

KEY0/

KEY1/

WDOK/

MPOSO

MPOS2/

MPOS4/

MPOS6/

MPOS8/

MPOSA/

MPOSC/

MPOSE/

MDFLT/

MVAGND

Analog Ground

+5V Battery

Address ID #0

Dedicated High Speed Bus

Address ID #1

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Power Fail Sense

Power Fail Interrupt

Analog Ground

Analog +5 VDC

Analog +5 VDC

Data Parity 0

ADDR Parity 0

ADDR Parity 2

Dedicated High Speed Bus

Key Lock Position 0

Key Lock Position 1

Watchdog OK

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

CĆ3

Page 36

Rack Backplane (Cont.)

P2 Bus (Cont.)

Solder Side

Pin Mnemonic Description

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

AGND

5VB

DBR

DBR

IDA2/

DB

IDA3/

DBR

DBR

MPRO/

AGND

A +15V

A -15V

DPR1/

APR1/

PREN/

DIAG/

BD RST/

DB

DB

MPOS1

MPOS3/

MPOS5/

MPOS7/

MPOS9/

MPOSB/

MPOSD/

MPOSF/

MVAREF

MVAGND

Analog Ground

+5V Battery

Dedicated High Speed Bus

Dedicated High Speed Bus

Address ID #2

Dedicated High Speed Bus

Address ID #3

Dedicated High Speed Bus

Dedicated High Speed Bus

Memory Protect

Analog Ground

Analog +15 VDC

Analog -15 VDC

Data Parity 1

ADDR Parity 1

Parity Enable

Diagnostic Loop

Board Reset

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

Dedicated High Speed Bus

CĆ4

Page 37

183/8"

183/8"

Appendix D

Rack Mounting Pattern

16ĆSlot Rack

5

/16"

23

10ĆSlot Rack

13

15

/16"

6ĆSlot Rack

9

9

/16"

183/8"

Dimensions shown are between mounting hole centers.

Diameter of mounting holes: .312"

DĆ1

Page 38

Page 39

Appendix E

Power Requirements of AutoMax Modules

Note: Values are in amps.

Module

M/N 57C400 115VAC/DC Input 0.425 0 0 0 0

B/M 57401Ć1 Drive Digital I/O 0.375 0.1 0.015 0 0

M/N 57C402 24-115VAC/DC

M/N 57C403 115V High Output 1.2 0 0 0 0

M/N 57C404 Network

B/M 57405 Drive Analog I/O 1.2 0.1 0.1 0.15 0.15

M/N 57C409 Analog Input 3.05 0 0 0 0

M/N 57C410 Analog Output 2.75 0.055 0.005 0 0

M/N 57C411 Resolver Input 1.7 0.095 0.095 0 0

M/N 57C413 Common Memory 1.05 0 0 0 0

M/N 57C414 Modbus Interface 2.5 0.053 0.0075 0

M/N 57C415 24VAC/DC Input 0.625 0 0 0 0

M/N 57C416 Remote I/O

M/N 57C417 AutoMate Interface 2.5 0.053 0.0075 0

M/N 57C418 A-B Interface 2.5 0.053 0.0075 0

M/N 57C419 5-24VDC Input 0.7 0 0 0 0

M/N 57C420 5-24VDC Output 0.85 0 0 0 0

M/N 57C421 Pulsetach Input 0.9 0 0 0 0

M/N 57C422 2-Axis Servo 1.6 0 0 0 0

M/N 57C423 Common Memory 1.05 0 0 0 0

M/N 57C428 Toledo Scale

M/N 57C429 AutoMax R-Net

M/N 57C430 AutoMax Processor 3.0 0.1 0.1 0 0

M/N 57C431 AutoMax Processor 3.0 0.1 0.1 0 0

M/N 57C435 AutoMax Processor 3.0 0.1 0.1 0 0

M/N 57C440 Ethernet Interface 5.0 0.5 0.1 0 0

Description +5V +12V -12V +15V -15V

0.525 0.045 0.045 0 0

Output

2.5 0.053 0.0075 0 0

Communication

2.5 0.053 0.0075 0

Communications

2.4 0.053 0.008 0 0

Interface

2.5 0.03 0 0 0

Processor

EĆ1

Page 40

Power Requirements of AutoMax Modules

(Cont.)

Note: Values are in amps.

Module

M/N 57C441 Modbus Plus

M/N 57C442 Data Highway Plus

B/M 57552 Universal Drive

M/N 61C500 115VAC Input 1.2 0 0 0 0

M/N 61C515 24VAC/DC Input 1.2 0 0 0 0

M/N 61C540 Current Input 1.5 0.03 0 0 0

M/N 61C542 Voltage Input 1.5 0.03 0 0 0

M/N 61C544 RTD 1.5 0.03 0 0 0

M/N 61C605 8ĆCh.

M/N 61C613 16ĆChannel Analog

Description +5V +12V -12V +15V -15V

0.6 0 0 0 0

Interface

0.65 0 0 0 0

Interface

1.7 0 0 0.1 0.071

Controller

1.6 0 0 0 0

Thermocouple Input

1.25 0 0 0 0

Input

EĆ2

Page 41

Page 42

Page 43

Page 44

For additional information

1 Allen-Bradley Drive

Mayfield Heights, Ohio 44124 USA

Tel: +1 440 646-3434

http://www.rockwellautomation.com/support

Publication J2-3008-4 - September 1996

Copyright © 2011 Rockwell Automation, Inc. All rights reserved. Printed in U.S.A.

Loading...

Loading...