Page 1

DriveLogix™ 5730

Controller

for PowerFlex® 700S Drives

with Phase II Control

Firmware Version

15.04

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation

and Maintenance of Solid State Controls (Publication SGI-1.1 available from your

local Rockwell Automation sales office or online at http://

www.rockwellautomation.com/literature) describes some important differences

between solid state equipment and hard-wired electromechanical devices. Because

of this difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of safety

considerations.

WARNING: Identifies information about practices or

circumstances that can cause an explosion in a hazardous

!

environment, which may lead to personal injury or death, property

damage, or economic loss.

Important: Identifies information that is critical for successful application

and understanding of the product.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Shock Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that dangerous voltage may

be present.

Burn Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that surfaces may be at

dangerous temperatures.

PowerFlex is a registered trademark of Rockwell Automation, Inc.

DriveExplorer, DriveExecutive, and SCANport are trademarks of Rockwell Automation, Inc.

PLC is a registered trademark of Rockwell Automation, Inc.

Page 3

Summary of Changes

Manual Updates

This information summarizes the changes to the DriveLogix5730 Controller

for PowerFlex 700S Drives with Phase II Control, publication 20D-UM003,

since the July 2004 release.

Change See Page...

Added information for contacting Technical Support and updated Controller Firmware

Revision information

Updated information and example for specifying task priorities 1-7

Updated information on controller fault response settings 3-2, 3-6, 3-8,

Updated the System Requirements for configuring DriveLogix Motion 4-1

Updated the Coarse Update Period setting from 4ms to 2ms 4-9

Updated the tables for parameter links and parameter settings for configuring

DriveLogix Motion

Updated the Communicating with Devices on an EtherNet/IP Link procedures to reflect

the support of duplicate IP address detection.

Added information regarding updated MSG packet size. 6-19

Added information regarding updated MSG packet size. 7-9

Added a new Appendix for application restrictions C-1

Preface-2

and 3-12

4-18 and

4-19

6-4

Page 4

soc-2

Page 5

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Summary of

Changes

Preface Overview

Chapter 1 What is DriveLogix5730?

Chapter 2 Placing and Configuring the Drive

Manual Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i-1

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Contacting Tech Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Controller Firmware Revision. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Loading Controller Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Using CompactFlash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Developing Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Selecting a System Overhead Percentage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Understanding the Virtual Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

De-energizing the Drive to Connect or Disconnect a Cable . . . . . . . . . . . . . . . . . . . . . . . 2-1

Understanding the Interface to the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Determining When the Controller Updates the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Placing and Configuring the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Inhibiting the Drive Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Using DriveExecutive Lite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Accessing Drive Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Monitoring Drive Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Configuring the Controller’s Response to a Connection Failure . . . . . . . . . . . . . . . . . . 2-22

Recommended Programming Techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Chapter 3 Placing and Configuring Local I/O

De-energizing the Drive to Connect or Disconnect a Cable . . . . . . . . . . . . . . . . . . . . . . . 3-1

Understanding How the DriveLogix5730 Supports

I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Placing Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Validating I/O Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Estimating RPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Determining When the Controller Updates I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Configuring the CompactBus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Configuring Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Accessing I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Direct Connections for I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Monitoring I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Configuring I/O Modules Using the Generic 1769-MODULE . . . . . . . . . . . . . . . . . . . 3-17

Page 6

ii

Chapter 4 Configuring DriveLogix Motion

De-energizing the Drive to Connect or Disconnect a Cable . . . . . . . . . . . . . . . . . . . . . . . 4-1

About this Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Programming the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Launching DriveExecutive from RSLogix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Configuring the Drive with DriveExecutive Software. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Downloading the Settings and Links to the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Additional Testing and Programming is Necessary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Supported Motion Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Chapter 5 Communicating with Devices on a Serial Link

De-energizing the Drive to Connect or Disconnect a Cable . . . . . . . . . . . . . . . . . . . . . . . 5-1

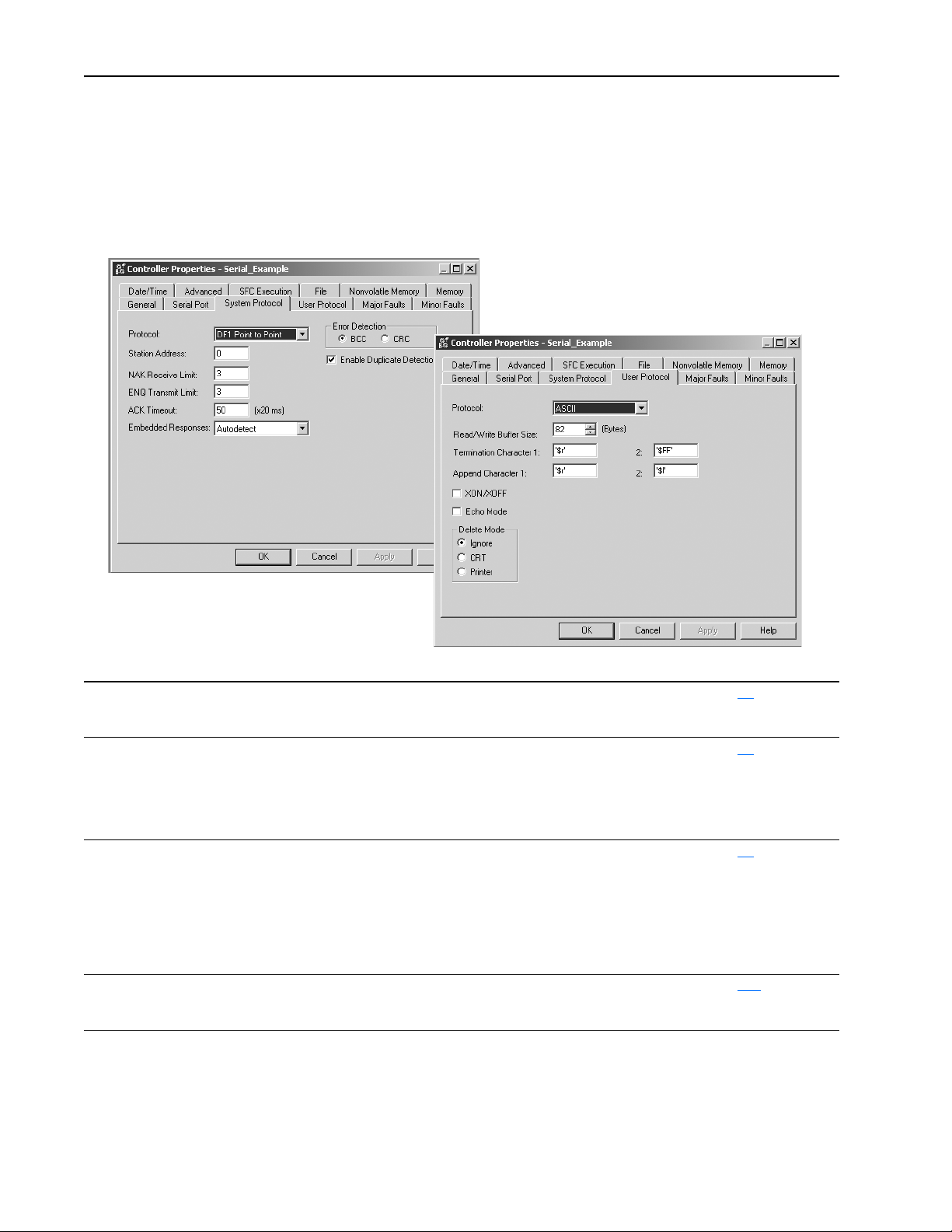

Configuring Your System for a Serial Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Example 1: Workstation Directly Connected to a DriveLogix Controller. . . . . . . . . . . . . 5-6

Example 2: Workstation Remotely Connected to a DriveLogix Controller . . . . . . . . . . . 5-7

Example 3: DriveLogix Controller to a Bar Code Reader. . . . . . . . . . . . . . . . . . . . . . . . 5-10

Chapter 6 Communicating with Devices on an EtherNet/IP Link

De-energizing the Drive to Connect or Disconnect a Cable . . . . . . . . . . . . . . . . . . . . . . . 6-1

Communicating Through the Embedded EtherNet/IP Option. . . . . . . . . . . . . . . . . . . . . . 6-2

Controller Connections Over EtherNet/IP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Configuring Distributed I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Adding a Remote Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Producing and Consuming Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Using a MSG Instruction to Send an Email. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Example 1: DriveLogix5730 Controller and

Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Example 2: Controller to Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Chapter 7 Communicating with Devices on a ControlNet Link

De-energizing the Drive to Connect or Disconnect a Cable . . . . . . . . . . . . . . . . . . . . . . . 7-1

Configuring Your System for a ControlNet Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Configuring Distributed I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Scheduling the ControlNet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Sending Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Producing and Consuming Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Chapter 8 Communicating with Devices on a DeviceNet Link

Guidelines for Configuring Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Example 1: DriveLogix Controller and Remote I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Example 2: DriveLogix5730 Controller to DriveLogix5730 Controller . . . . . . . . . . . . . 7-19

Example 3: DriveLogix Controller to Other Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

De-energizing the Drive to Connect or Disconnect a Cable . . . . . . . . . . . . . . . . . . . . . . . 8-1

Example: Controlling I/O Over DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Page 7

Chapter 9 Communicating with Devices on a DH485 Link

De-energizing the Drive to Connect or Disconnect a Cable . . . . . . . . . . . . . . . . . . . . . . . 9-1

Understanding How the DriveLogix5730 Controller Supports DH485 Communications 9-1

Configuring Your System for a DH-485 Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Planning a DH-485 Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Installing a DH-485 Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Browsing a DH-485 Network Remotely. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Appendix A DriveLogix5730 Controller Specifications

DriveLogix5730 Controller Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

DriveLogix5730 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

DriveLogix5730 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Real-Time Clock Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Controller LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Embedded EtherNet/IP Option LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Battery Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Appendix B Access Procedures

Removing Power from Drive and Compact I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Opening Door Over Power Structure and Main Control Board . . . . . . . . . . . . . . . . . . . . B-2

Removing the Control Cassette from Frame 1-6 Size Drives. . . . . . . . . . . . . . . . . . . . . . B-2

Removing the Outside Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Removing the Inside Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Connecting the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Installing the Embedded EtherNet/IP Option Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Installing the DriveLogix5730 Expansion Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Installing the Compact I/O Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Installing the Communications Daughtercard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

iii

Appendix C Application Restrictions

Additional Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Hold Last State and User-Defined Safe State Not Supported. . . . . . . . . . . . . . . . . . . . . . C-3

Index

Page 8

iv

Page 9

Overview

Preface

Who Should Use This Manual

Purpose of this Manual

This manual is intended for qualified personnel. You must be able to

program and operate Adjustable Frequency AC Drive devices and

programmable controllers.

This manual guides the development of projects for DriveLogix controllers.

It provides procedures on how to establish communications:

• with the following networks

– ControlNet

– DeviceNet

– EtherNet/IP

– serial

• with the following devices

– PowerFlex® 700S drive

– controllers

– I/O

– workstations

– PanelView terminals

Page 10

p-2 Overview

Related Documentation

If you are: Use this publication:

a new user of a Logix5000 controller

This quick start provides a visual, step-by-step overview of the basic steps

you need to complete to get your controller configured and running.

an experienced user of Logix5000 controllers

This system reference provides a high-level listing of configuration

information, controller features, and instructions (ladder relay, function

block diagram, and structured text).

any user of a Logix5000 controller

This common procedures manual explains the common features and

functions of all Logix5000 controllers.

For Read this document Document number

Information on the DriveLogix Instruction Set Logix5000 Controllers General Instruction Set Reference

Information on function block programming Logix controllers. Logix5000 Controllers Process Control/Drives Instruction

Execution times and memory use for instructions Logix5000 Controllers Execution Time and Memory Use

Information on selecting CompactLogix and Compact I/O

components and modules

Information on installing, configuring, and using Compact

Analog I/O modules

Information on installing, configuring and using PowerFlex

700S drives

Information on the DriveLogix Motion Control Instruction Set Logix Controller Motion Instruction Set 1756-RM007…

Information on installing an ControlNet communications

daughtercard (Coax)

Information on installing an ControlNet communications

daughtercard (Fiber)

Information on installing an EtherNet/IP communications

daughtercard

Information on installing an DeviceNet communications

daughtercard

Information on installing 1769-SDN DeviceNet Scanner

Module

Information on using 1769-SDN DeviceNet Scanner Module Compact I/O 1769-SDN DeviceNet Scanner Module 1769-UM009…

Information on converting from Phase I PowerFlex 700S and

DriveLogix5720 to Phase II PowerFlex 700S and

DriveLogix5730

Information on the basic installation of PowerFlex 700S drives

and DriveLogix5730 controllers

Allen-Bradley publications are available on the internet at

www.rockwellautomation.com/literature.

These core documents address the Logix5000 family of controllers:

Logix5000 Controllers Quick Start

publication 1756-QS001

Logix5000 Controllers System Reference

publication 1756-QR107

Logix5000 Controllers Common Procedures

publication 1756-PM001

DriveLogix-specific information is also available:

1756-RM003…

Manual

1756-RM006…

Set Reference Manual

Reference Manual

Compact I/O Selection Guide 1769-SG001…

Compact I/O Analog Modules User Manual 1769-UM002…

®

PowerFlex 700S Phase II User Manual 20D-UM006…

ControlNet Communications Daughtercard Installation

Instructions

ControlNet Communications Daughtercard Installation

Instructions

EtherNet/IP Communications Daughtercard Installation

Instructions

DeviceNet Communications Daughtercard Installation

Instructions

Compact I/O 1769-SDN DeviceNet Scanner Module 1769-IN060…

PowerFlex 700S Conversion Guide

Phase I to Phase II Control

Quick Start - PowerFlex 700S High Performance AC Drive 20D-QS001…

1756-RM087…

1788-IN002…

1788-IN005…

1788-IN054…

1788-IN053…

20D-AT001…

Contacting Tech Support

For Automation and Control Technical Support:

Title Online at…

Rockwell Automation Technical Support http://support.rockwellautomation.com/knowledgebase

Page 11

Overview p-3

Controller Firmware Revision

General Precautions

This revision on the DriveLogix 5730 User Manual corresponds to the

following:

• Version 15.04 and later controller firmware

• Version 15.xx and later RSLogix 5000 programming software

• Version 3.02 and later DriveExecutive programming software

Class 1 LED Product

ATTENTION: Hazard of permanent eye damage exists when

using optical transmission equipment. This product emits intense

!

light and invisible radiation. Do not look into module ports or

fiber optic cable connectors.

ATTENTION: This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

!

precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with

static control procedures, reference A-B publication 8000-4.5.2,

“Guarding Against Electrostatic Damage” or any other applicable

ESD protection handbook.

ATTENTION: Only qualified personnel familiar with the

PowerFlex 700S Drive and associated machinery should plan or

!

implement the installation, start-up and subsequent maintenance

of the system. Failure to comply may result in personal injury

and/or equipment damage.

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing

!

any work on the drive. Measure the DC bus voltage at the +DC &

–DC terminals of the Power Terminal Block. The voltage must be

zero.

Page 12

p-4 Overview

Notes:

Page 13

Chapter 1

What is DriveLogix5730?

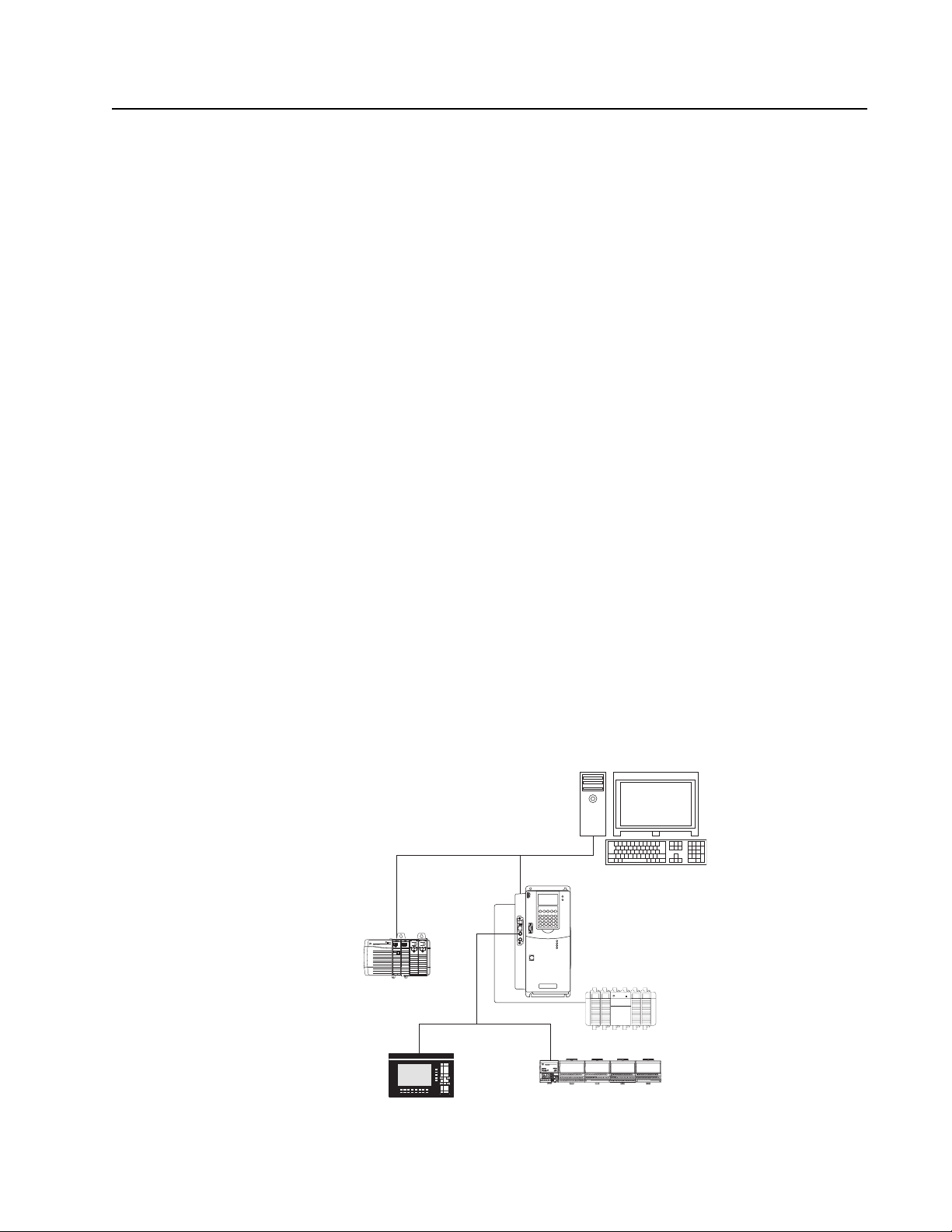

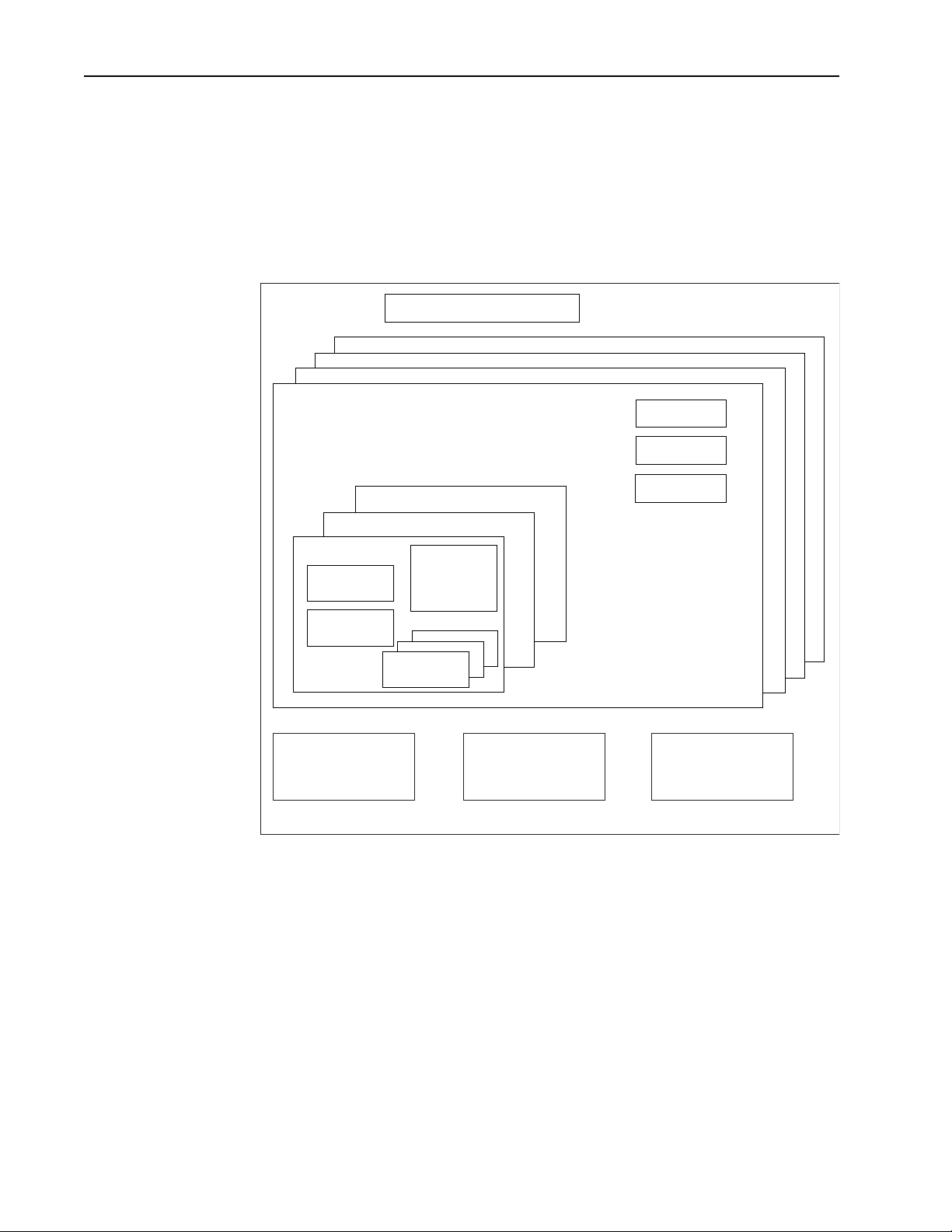

The DriveLogix controller is part of the Logix environment. The

DriveLogix controller provides a distributed control system built on these

components:

• The DriveLogix5730 controller has one RS-232 port. The controller

supports the Logix instructions.

• RSLogix 5000 programming software that supports every Logix

controller.

• Direct connection to host PowerFlex 700S drive.

• Compact I/O modules that provide a compact, DIN-rail or panel

mounted I/O system.

• Embedded EtherNet/IP option provides communication over an

EtherNet/IP network.

• 1788 communication daughtercard that provides communication over a

standards-based ControlNet, EtherNet/IP, DeviceNet or third party

network.

ControlLogix

Controller

The newer DriveLogix5730 controller offers significant performance and

capacity improvements over the DriveLogix5720 controller. It offers:

• increased user memory up to 1.5 Mbytes

• CompactFlash for non-volatile memory storage

• extended I/O capacity up to 16 I/O modules

• integrated EtherNet/IP support, including control of distributed I/O

• Run/Rem/Prog switch

ahw0783.eps

EtherNet/IP

DriveLogix

with

Local I/O

ControlNet

Remote

Work

Station

PanelView

Flex I/O

Page 14

1-2 What is DriveLogix5730?

Loading Controller Firmware

De-energizing the Drive to Connect or Disconnect a Cable

ATTENTION: Severe injury or death can result from electrical

shock or burn. Verify that the voltage on the bus capacitors has

!

discharged before connecting to the communication ports.

Measure the DC bus voltage at the +DC & -DC terminals on the

Power Terminal Block. The voltage must be zero.

During the process of loading controller firmware you will need to connect

or disconnect a programming or network cable at the controller. You should

do this only if the drive is de-energized.

1. Turn off and lock out input power. Wait five minutes.

2. Verify that there is no voltage at the drive’s input power terminals.

3. Measure the DC bus voltage at the +DC & -DC terminals on the Power

Terminal Block. The voltage must be zero.

4. Connect or disconnect the programming or network cable.

5. Turn power back on and proceed with loading firmware.

Loading Firmware

The controller ships with working firmware. You may decide to upgrade the

firmware. To load firmware, you can use:

• ControlFlash utility that ships with RSLogix 5000 programming

software.

• AutoFlash that launches through RSLogix 5000 software when you

download a project to a controller that does not have the current

firmware.

• a 1784-CF64 CompactFlash card with valid memory already loaded.

The firmware is available with RSLogix 5000 software or you can

download it from the support website:

1. Go to: http://support.rockwellautomation.com/

2. In the left column (frame), select “Firmware Updates” under “Technical

Support.”

3. Select the desired firmware revision.

The download process will require you to enter the serial number of your

RSLogix 5000 programming software.

If you load (flash) controller firmware via the ControlFlash or AutoFlash

utilities, you need a serial or EtherNet/IP connection to the controller.

Flashing via an EtherNet/IP connection is faster than the serial connection.

Page 15

What is DriveLogix5730? 1-3

The controller’s EtherNet/IP configuration settings are maintained during a

flash process.

If you load firmware via an EtherNet/IP connection, browse through the

network port, across the virtual backplane, and select the appropriate

controller.

Using ControlFlash to load firmware

You can use ControlFlash to load firmware through either an Ethernet

connection (an IP address must already be assigned to the Ethernet port) or

a serial connection.

1. Make sure the appropriate network connection is made before starting.

2. Start the ControlFlash utility. Click Next when the Welcome screen

appears.

3. Select the catalog number of the controller and click Next.

4. Expand the network until you see the controller. If the required network

is not shown, first configure a driver for the network in RSLinx software.

If you use an Ethernet connection to load the firmware (which is much

faster than the serial connection), the utility will require a valid IP

address before connecting to the controller.

5. Select the controller and click OK.

6. Select the revision level to which you want to update the controller and

click Next.

7. To start the update of the controller, click Finish and then click Yes.

8. After the controller is updated, the status box displays Update complete.

Click OK.

9. To close ControlFlash software, click Cancel and then click Yes.

Page 16

1-4 What is DriveLogix5730?

Using AutoFlash to load firmware

You can use AutoFlash to load firmware through either an Ethernet

connection (an IP address must already be assigned to the Ethernet port) or

a serial connection.

1. Make sure the appropriate network connection is made before starting.

2. Use RSLogix 5000 programming software to download a controller

project. If the processor firmware does not match that project revision,

AutoFlash automatically launches.

3. Select the catalog number of the controller and click Next.

4. Expand the network until you see the controller. If the required network

is not shown, first configure a driver for the network in RSLinx software.

If you use an Ethernet connection to load the firmware (which is much

faster than the serial connection), the utility will ask for a valid IP

address before connecting to the controller.

5. Select the controller and click OK.

6. Select the revision level to which you want to update the controller and

click Next.

7. To start the update of the controller, click Finish and then click Yes.

8. After the controller is updated, the status box displays Update complete.

Click OK.

9. To close AutoFlash software, click Cancel and then click Yes.

Using a CompactFlash card to load firmware

If you have an existing DriveLogix5730 controller that is already configured

and has firmware loaded, you can store the current controller user program

and firmware on CompactFlash and use that card to update other

controllers.

1. Store the controller user program and firmware of a currently configured

DriveLogix5730 controller to the CompactFlash card.

Make sure to select Load Image On Power-up when you save to the card.

2. Remove the card and insert it into a DriveLogix5730 controller that you

want to have the same firmware and controller user program.

3. When you power up the second DriveLogix5730 controller, the image

stored on the CompactFlash card is loaded into the controller.

Page 17

What is DriveLogix5730? 1-5

Using CompactFlash

The 1784-CF64 CompactFlash card provides nonvolatile memory storage

for the DriveLogix5730 controller. The card stores the contents of the

controller memory (program logic and tag values) and the controller

firmware at the time that you store the project. Storing information to the

CompactFlash card is like storing a snapshot of controller memory at a

given time.

ATTENTION: If you configured the CompactFlash card to

“restore on power up” and you make changes to a project, such

!

as online edits or changes to tag values, you must store the

project to the CompactFlash card again after you make changes.

Otherwise, your changes are not saved and you will lose those

changes on the next power cycle to the controller.

Tag values stored in flash are a snapshot at the time of the store. During a

program restore the processor tag values will be equal to tag data stored on

flash.

The locking tab on the front of the controller helps hold the CompactFlash

card in its socket.

ATTENTION: Do not remove the CompactFlash card while the

controller is reading from or writing to the card, as indicated by a

!

flashing green CF LED. This could corrupt the data on the card

or in the controller, as well as corrupt the latest firmware in the

controller.

The CompactFlash card supports removal and insertion under power.

ATTENTION: When you insert or remove the card while

backplane power is on, an electrical arc can occur. This could

!

cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before

proceeding. Repeated electrical arcing causes excessive wear to

contacts on both the module and its mating connector. Worn

contacts may create electrical resistance that can affect module

operation.

See the Logix5000 Controllers Common Procedures Programming Manual,

publication 1756-PM001, for steps on storing an image on the

CompactFlash card.

Page 18

1-6 What is DriveLogix5730?

Developing Programs

The controller operating system is a preemptive multitasking system that is

IEC 1131-3 compliant. This environment provides:

• tasks to configure controller execution

• programs to group data and logic

• routines to encapsulate executable code written in a single programming

control application

task 1

program 1

main routine

language

task 8

program 32

controller fault handler

configuration

status

watchdog

program (local)

tags

fault routine

other routines

controller (global) tags I/O data system-shared data

40012.eps

Defining tasks

A task provides scheduling and priority information for a set of one or more

programs. You can configure tasks as continuous, periodic, or event. Only

one task can be continuous. The DriveLogix5730 controller supports as

many as eight tasks.

A task can have as many as 32 separate programs, each with its own

executable routines and program-scoped tags. Once a task is triggered

(activated), all the programs assigned to the task execute in the order in

which they are grouped. Programs can only appear once in the Controller

Organizer and cannot be shared by multiple tasks.

Page 19

What is DriveLogix5730? 1-7

Specifying task priorities

Each task in the controller has a priority level. The operating system uses

the priority level to determine which task to execute when multiple tasks are

triggered. You can configure periodic tasks to execute from the lowest

priority of 15 up to the highest priority of 1. A higher priority task will

interrupt any lower priority task. The continuous task has the lowest priority

and is always interrupted by a periodic task.

The DriveLogix5730 controller uses a dedicated periodic task at priority 7

to process I/O data. This periodic task executes at the Requested Packet

Interval (RPI) you configure for the CompactBus, which can be as fast as

once every 1 ms. Its total execution time is as long as it takes to scan the

configured I/O modules.

How you configure your tasks affects how the controller receives I/O data.

Tasks at priorities 1 to 6 take precedence over the dedicated I/O task. Tasks

in this priority range can impact I/O processing time. If you configure the I/

O RPI at 1ms and you configure a task of priority 1 to 6 that requires 500 µs

to execute and is scheduled to run every millisecond, this leaves the

dedicated I/O task 500 µs to complete its job of scanning the configured I/

O.

However, if you schedule two high priority tasks (1 to 6) to run every

millisecond, and they both require 500 µs or more to execute, no CPU time

would be left for the dedicated I/O task. Furthermore, if you have so much

configured I/O that the execution time of the dedicated I/O task approaches

1 ms (or the combination of the high priority tasks and the dedicated I/O

task approaches 2 ms) no CPU time is left for low priority tasks (8 to 15).

TIP: For example, if your program needs to react to inputs and control

outputs at a deterministic rate, configure a periodic task with a priority

higher than 7 (i.e., 1 through 6). This keeps the dedicated I/O task from

affecting the periodic rate of your program. However, if your program

contains a large amount of math and data manipulation, place this logic in a

task with priority lower than 7 (i.e., 8 through 15), such as the continuous

task, so that the dedicated I/O task is not adversely affected by your

program.

Important: When using a DriveLogix5730 controller with Compact I/O, all

application program tasks must have an assigned priority of 8

through 15 in order that they do not interfere with the proper

operation of the Compact I/O.

Page 20

1-8 What is DriveLogix5730?

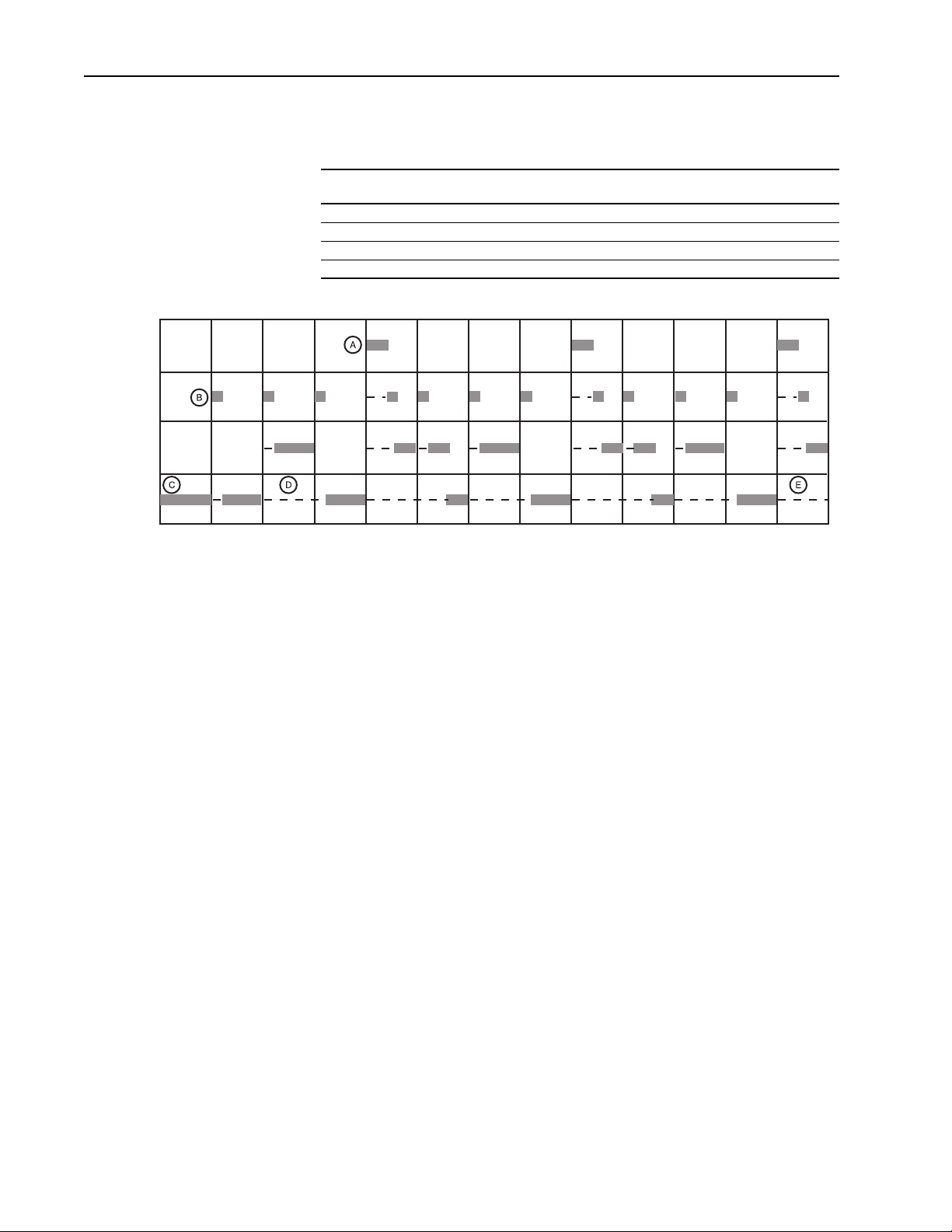

The following example shows the task execution order for an application

with two periodic tasks and one continuous task.

Example

Task: Priority Level: Task Type:

1 5 periodic task, executes every 20 ms 2 ms 2 ms

2 7 dedicated I/O task (5 ms RPI) 1 ms 3 ms

3 10 periodic task, executes every 10 ms 4 ms 8 ms

4 none (lowest) continuous task 25 ms 60 ms

Tas k 1

Tas k 2

Tas k 3

Tas k 4

030252015105 454035 50 656055

Time (ms)

Notes:

Execution Time:

A. The highest priority task interrupts all lower priority tasks.

Worst Case

Completion Time:

task_example.eps

B. The dedicated I/O task can be interrupted by tasks with priority levels 1

to 6. The dedicated I/O task interrupts tasks with priority levels 8 to 15.

This task runs at the selected RPI rate scheduled for the DriveLogix5730

system (2ms in this example).

C. The continuous task runs at the lowest priority and is interrupted by all

other tasks.

D. A lower priority task can be interrupted multiple times by a higher

priority task.

E. When the continuous task completes a full scan it restarts immediately,

unless a higher priority task is running.

Defining programs

Each program contains program tags, a main executable routine, other

routines, and an optional fault routine. Each task can schedule as many as

32 programs.

The scheduled programs within a task execute to completion from first to

last. Programs that are not attached to any task show up as unscheduled

programs. You must specify (schedule) a program within a task before the

controller can scan the program.

Page 21

What is DriveLogix5730? 1-9

Defining routines

A routine is a set of logic instructions in a single programming language,

such as ladder logic. Routines provide the executable code for the project in

a controller. A routine is similar to a program file or subroutine in a PLC or

SLC controller.

Each program has a main routine. This is the first routine to execute when

the controller triggers the associated task and calls the associated program.

Use logic, such as the Jump to Subroutine (JSR) instruction, to call other

routines.

You can also specify an optional program fault routine. The controller

executes this routine if it encounters an instruction-execution fault within

any of the routines in the associated program.

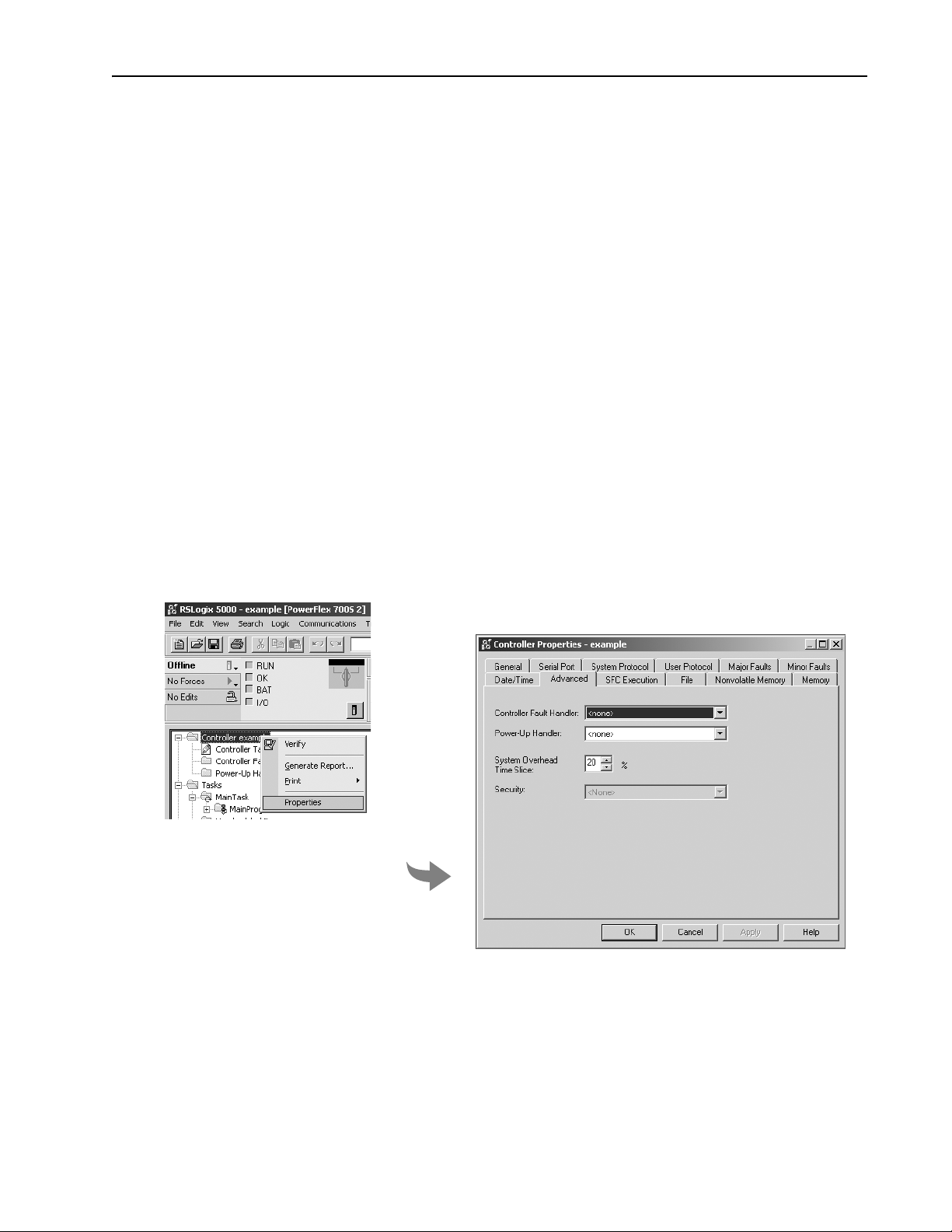

Selecting a System Overhead Percentage

1. View properties for the controller and select the Advanced

The Controller Properties dialog lets you specify a percentage for system

overhead. This percentage specifies the percentage of controller time

(excluding the time for periodic tasks) that is devoted to communication and

background functions.

ahw0757.eps

ahw0758.eps

System overhead functions include:

• communicating with programming and HMI devices (such as RSLogix

5000 software)

• responding to messages

• sending messages

Page 22

1-10 What is DriveLogix5730?

The controller performs system overhead functions for up to 1 ms at a time.

If the controller completes the overhead functions in less than 1 ms, it

resumes the continuous task.

As the system overhead percentage increases, time allocated to executing

the continuous task decreases. If there are no communications for the

controller to manage, the controller uses the communications time to

execute the continuous task. While increasing the system overhead

percentage decreases execution time for the continuous task, it does

increase communications performance. However, increasing the system

overhead percentage also increases the amount of time it takes to execute a

continuous task - increasing overall scan time.

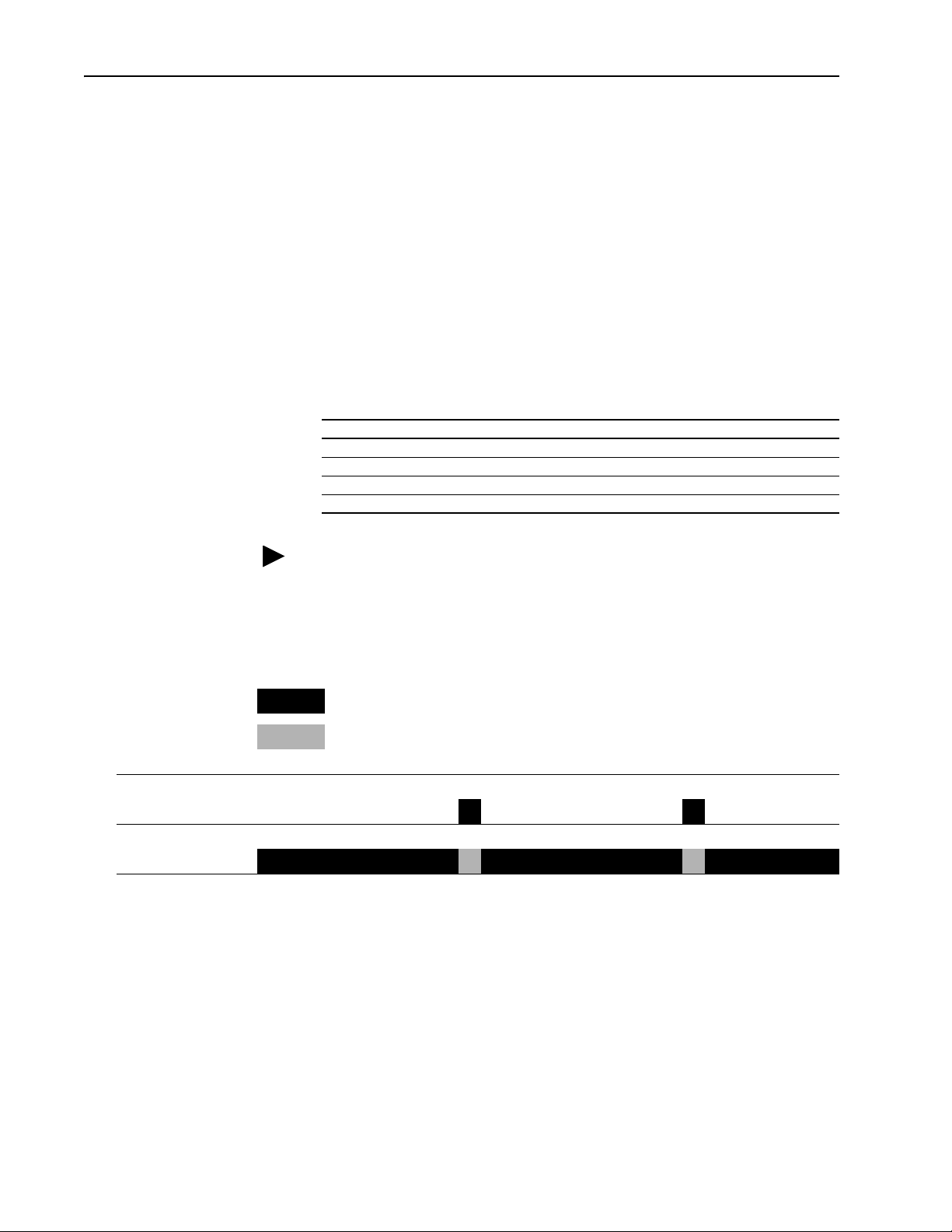

The following table shows the ratio between the continuous task and the

system overhead functions:

At this time slice: The continuous tasks runs for: And then overhead occurs for up to:

10% 9 ms 1 ms

20% 4 ms 1 ms

33% 2 ms 1 ms

50% 1 ms 1 ms

periodic

system overhead

continuous task

TIP: For typical DriveLogix applications, a setting of 20-33% is

recommended.

At the default time slice of 10%, system overhead interrupts the continuous

task every 9 ms (of continuous task time), as illustrated below.

Legend:

Task executes.

Task is interrupted (suspended).

1 ms 1 ms

9 ms 9 ms

0 5 10 15 20 25

elapsed time (ms)

Page 23

periodic task

system overhead

continuous task

system overhead

continuous task

What is DriveLogix5730? 1-11

The interruption of a periodic task increases the elapsed time (clock time)

between the execution of system overhead, as shown below.

1 ms 1 ms 1 ms 1 ms 1ms

1 ms 1 ms

9 ms of continuous task time 9 ms of continuous task time

0 5 10 15 20 25

elapsed time (ms)

If you increase the time slice to 20%, the system overhead interrupts the

continuous task every 4 ms (of continuous task time).

1 ms 1 ms 1 ms 1 ms 1 ms

4 ms 4 ms 4 ms 4 ms 4 ms

5 10152025

elapsed time (ms)

system overhead

continuous task

periodic task

system overhead

continuous task

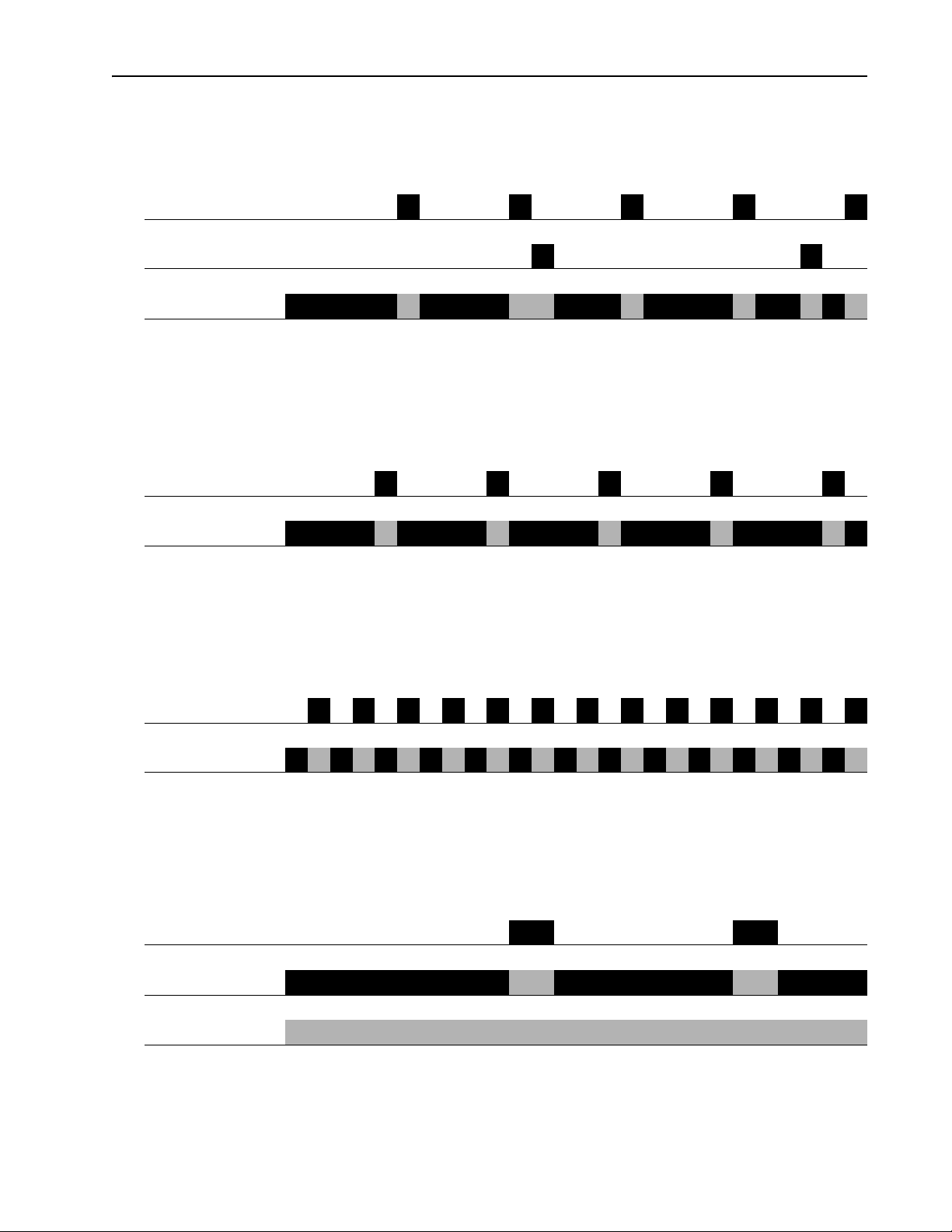

If you increase the time slice to 50%, the system overhead interrupts the

continuous task every 1 ms (of continuous task time).

1 ms

1 ms

5 10152025

elapsed time (ms)

If the controller only contains a periodic task(s), the system overhead

timeslice value has no effect. System overhead runs whenever a periodic

task is not running.

5 10152025

elapsed time (ms)

Page 24

1-12 What is DriveLogix5730?

Understanding the Virtual Backplane

The DriveLogix5730 system has a five-slot virtual backplane. The

controller, drive and other components occupy different assigned slots on

the backplane.

Virtual Backplane

Slot 0Slot 1Slot 2Slot 3Slot 4

DrvieLogix5730

Controller

Embedded

EtherNet Option

PowerFlex 700S

Drive

Compact I/O NetLinx

Daughtercard

Page 25

De-energizing the Drive to Connect or Disconnect a Cable

Chapter 2

Placing and Configuring the Drive

ATTENTION: Severe injury or death can result from electrical

shock or burn. Verify that the voltage on the bus capacitors has

!

discharged before connecting to the communication ports.

Measure the DC bus voltage at the +DC & -DC terminals on the

Power Terminal Block. The voltage must be zero.

During the process of placing and configuring the drive you will need to

connect or disconnect a programming or network cable at the controller.

You should do this only if the drive is de-energized.

1. Turn off and lock out input power. Wait five minutes.

Understanding the Interface to the Drive

2. Verify that there is no voltage at the drive’s input power terminals.

3. Measure the DC bus voltage at the +DC & -DC terminals on the Power

Terminal Block. The voltage must be zero.

4. Connect or disconnect the programming or network cable.

5. Turn power back on and proceed with placing and configuring the drive.

The DriveLogix controller supports a direct connection to the drive

consisting of 21 inputs and 21 outputs. The tag names and data types

associated with the inputs and outputs are determined by the

communication format selection. Currently, the following five

communications formats are available:

• Speed Control – for typical speed regulated applications

• Position Control – for typical positioning applications

• Motion Control - for use with Logix motion commands

• User-Defined 1 – for general use as required.

• User-Defined 2 - for general use as required.

Each communication format contains a number of pre-defined tags and

user-defined tags.

The pre-defined tag names and data types correspond with the associated

parameters, within the drive’s firmware, that are necessary to support the

selected communications format. Links must be established in the firmware,

using DriveExecutive software, to support the pre-defined tags. Linking is a

software mechanism that configures data flow within the drive’s firmware.

The links within the firmware to support the pre-defined tags are protected

Page 26

2-2 Placing and Configuring the Drive

and must be present. If the associated links are not present, or are deleted,

the communication connection between the controller and drive will be lost.

The user-defined tags are made up of a fixed number of REAL (floating

point) and DINT (double integer) data types. Links are not required within

the drive’s firmware to support these tags. Therefore, links may be created

and deleted as desired without having an affect on the communication

connection between the controller and the drive. The user-defined tags may

be used to address application specific data needs not covered by the

pre-defined tags.

Mapping for Inputs and Outputs

For each of the 21 inputs and 21 outputs, there is a dedicated parameter

within the drive, for a total of 42 parameters. Selecting a communication

format defines the data types for each input and output. It also determines

the data type for the dedicated parameter in the drive. The selection also

configures parameters 601 [From DL DataType] and 625 [To DL

DataType], which indicate the data types for each dedicated parameter

within the drive.

Determining When the Controller Updates the Drive

The DriveLogix controller follows a producer/consumer model for the drive

connection, similar to the interface to an I/O module. The drive acts as both

an input module, producing data for the controller; and an output module,

consuming data from the controller. Although the producer/consumer

model multi-casts data, all data in the drive connection is exclusive to the

DriveLogix controller.

The controller updates the input and output data in the drive connection

asynchronously to the logic scan, consistent with the way it handles other I/

O data. All input data from the drive is read in a single block and all output

data is written to the drive in a single block.

You must configure the Requested Packet Interval (RPI) rate for the drive.

This setting affects how fast the controller reads and writes the data in the

drive interface.

TIP: If you want data to remain constant throughout one scan, make a copy

of the data at the beginning of the scan and use the copy throughout the

scan.

The Drive consumes data from the DriveLogix controller every 2

milliseconds, and produces data to the controller every 2 milliseconds. The

drive updates the inputs and outputs to the controller asynchronous to both

the program scan and I/O scan of the controller.

Page 27

Placing and Configuring the Drive 2-3

Placing and Configuring the Drive

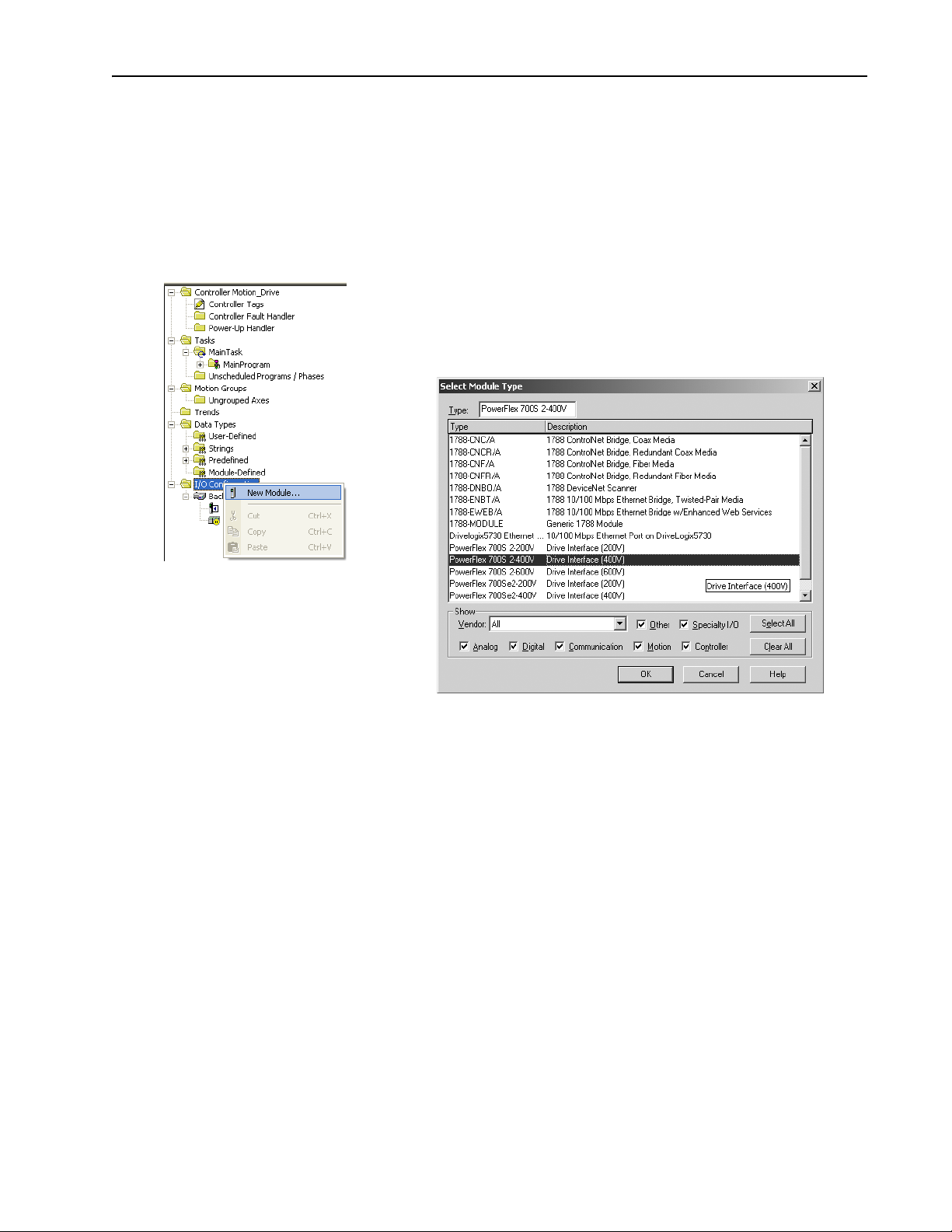

1. In the Controller Organizer, select the I/O Configuration folder. Right-click

the selected folder and select New Module.

When you create a project for the DriveLogix controller in RSLogix 5000,

the Controller Organizer automatically displays the local DIN rail for

Compact I/O. You must add the PowerFlex 700S drive to the configuration,

in a manner similar to adding an I/O module. The Controller Organizer

automatically places the drive in slot two.

2. Select the drive (PowerFlex 700S 2-400V in this example).

ahw0771.tif

ahw0772.tif

Important: You must select the correct voltage rating for the drive, when

adding the drive. You can find this on the drive data nameplate.

Page 28

2-4 Placing and Configuring the Drive

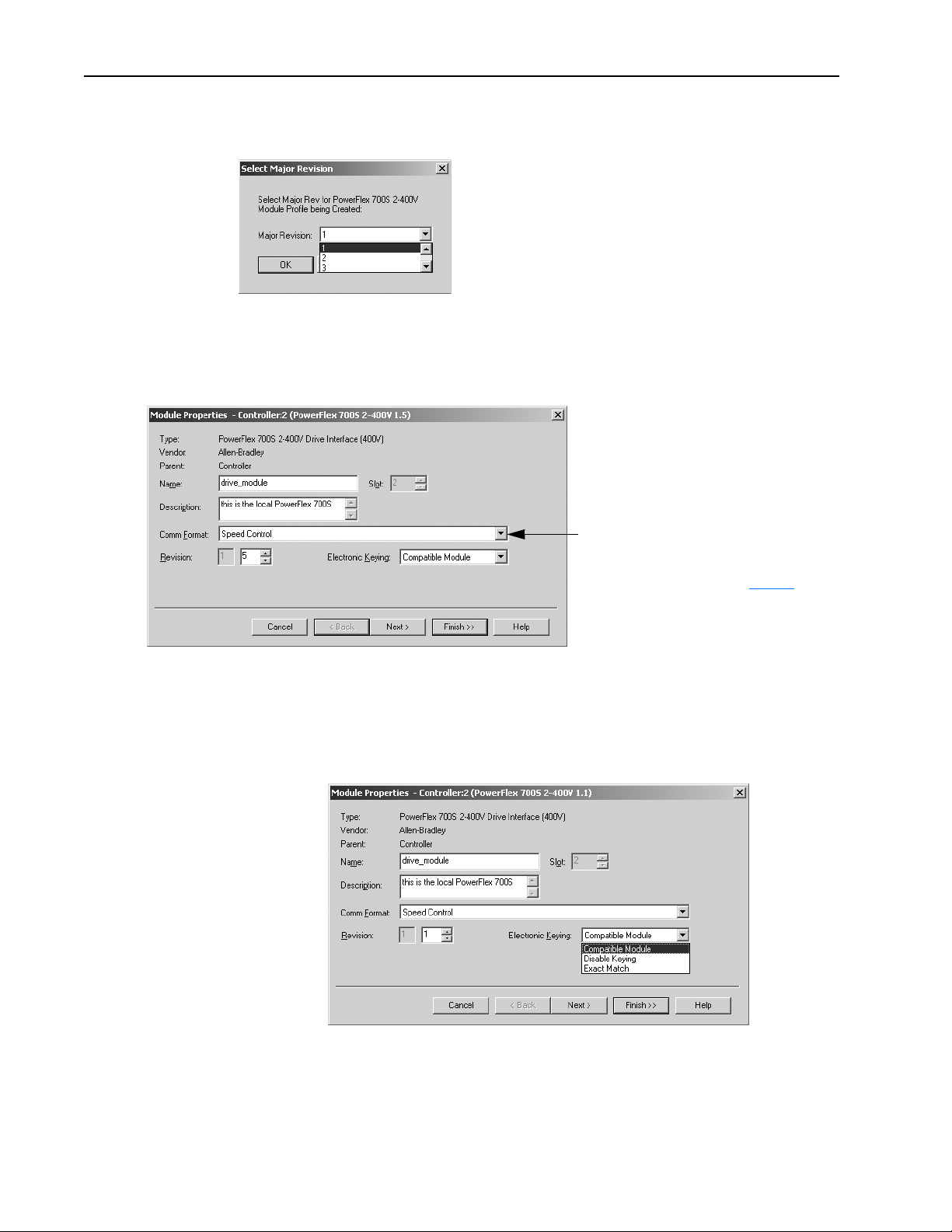

3. Select the Major Revision.

ahw0773.tif

4. Configure the drive. Use the module properties wizard to specify characteristics for the

module. Click Next to continue through the wizard.

5. Name the drive and specify the Comm Format. Click finish when you are done. The

completed module appears in the Controller Organizer.

ahw0774.tif

The selection you make for the Comm Format

determines the communication format for the

connection to the drive. This determines the

tag names and data types. See page 2-5

Once you complete adding a module, you

cannot change this selection.

Electronic Keying

Electronic keying has no effect on drive module. However, the default

setting (Compatible Module) is recommended.

ahw0775.tif

.

Selecting “Compatible Module” allows you to enter the drive firmware

minor revision.

Page 29

Placing and Configuring the Drive 2-5

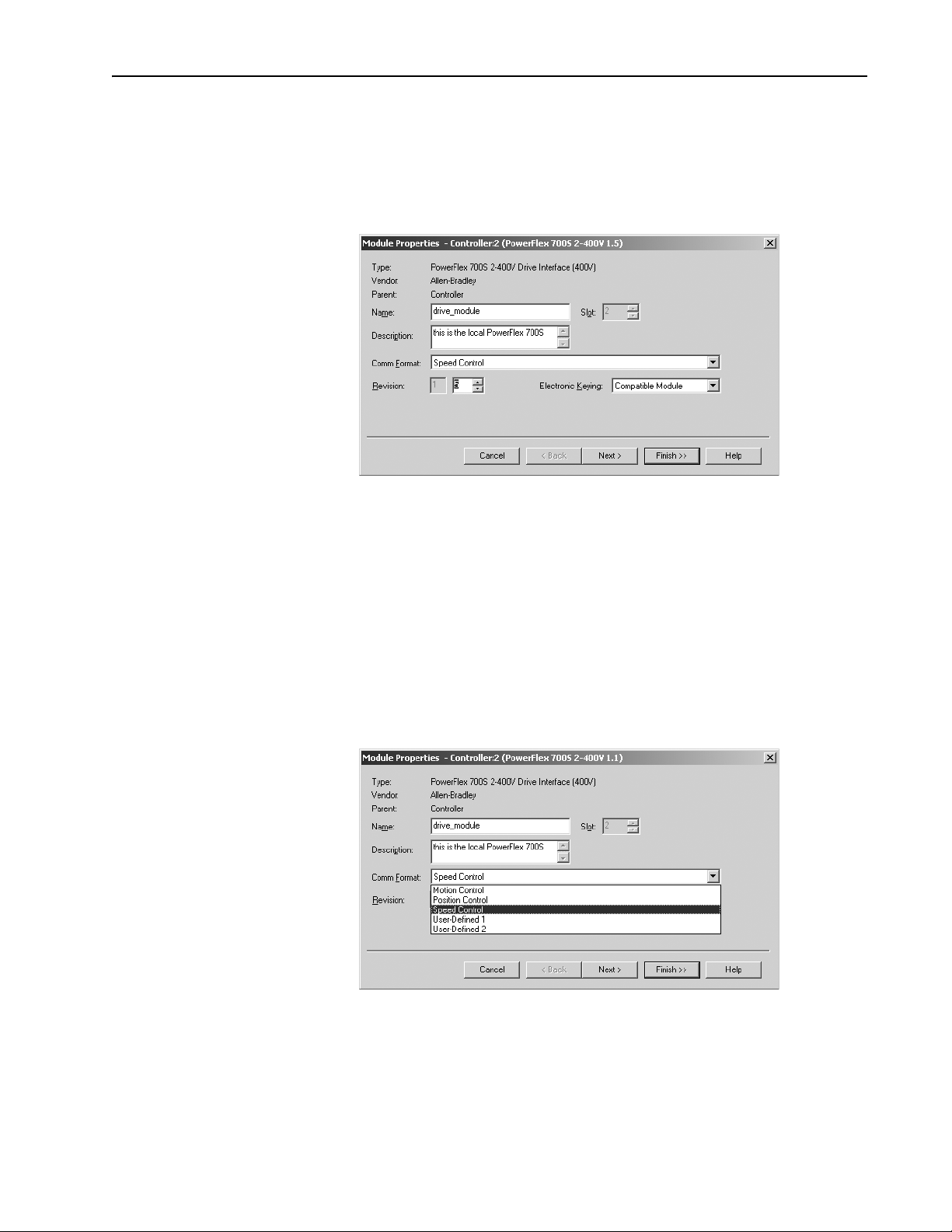

Revision

You must enter the correct drive VPL firmware revision, in order to launch

DriveExecutive and create the appropriate links for the selected

communication format. Determine the firmware revision by viewing

parameter 314 [VPL Firmware Rev] in the drive.

ahw0776.tif

Communication Formats

The communication format determines the data structure, tag names, and

required links for communication to the drive. Each communication format

has been structured to meet the requirements of a specific type of

application (Speed Control, Position Control, or general purpose), and

supports a different data structure. The links within the PowerFlex 700S

required to support the selected format are also different. Any of the

available communication formats create one direct connection to the drive.

You select the communication format when you configure the drive module.

ahw0777.tif

The default communication format for the drive is Speed Control. The tags

are created as controller-scoped tags. The following tag structure shows the

Page 30

2-6 Placing and Configuring the Drive

ahw0778.tif

Speed Control format. The tag structure for this example’s drive connection

has the tag name of “drive_module”.

The following tables show the tag names and their relationship to

parameters in the drive. These examples use a module name of

“drive_module”.

Table 2.A Mapping for Speed Control Communication Format

Controller Output Tag Element Drive Parameter Linked Parameter

LogicCommand 602 [FromDriveLogix00] 151 [Logic Command]

SpeedRef1 603 [FromDriveLogix01] 10 [Speed Ref 1]

TorqueRef1 604 [FromDriveLogix02] 111 [Torque Ref 1]

SpdTorqModeSelect 605 [FromDriveLogix03] 110 [Speed/TorqueMode]

TorqueStep 606 [FromDriveLogix04] 116 [Torque Step]

SpdRegDroop 607 [FromDriveLogix05] 86 [Spd Reg Droop]

UserDefinedRealData[0] 608 [FromDriveLogix06] User Defined

UserDefinedRealData[1] 609 [FromDriveLogix07] User Defined

UserDefinedRealData[2] 610 [FromDriveLogix08] User Defined

UserDefinedRealData[3] 611 [FromDriveLogix09] User Defined

UserDefinedRealData[4] 612 [FromDriveLogix10] User Defined

UserDefinedRealData[5] 613 [FromDriveLogix11] User Defined

UserDefinedRealData[6] 614 [FromDriveLogix12] User Defined

UserDefinedRealData[7] 615 [FromDriveLogix13] User Defined

UserDefinedRealData[8] 616 [FromDriveLogix14] User Defined

UserDefinedRealData[9] 617 [FromDriveLogix15] User Defined

UserDefinedIntegerData[0] 618 [FromDriveLogix16] User Defined

UserDefinedIntegerData[1] 619 [FromDriveLogix17] User Defined

UserDefinedIntegerData[2] 620 [FromDriveLogix18] User Defined

UserDefinedIntegerData[3] 621 [FromDriveLogix19] User Defined

UserDefinedIntegerData[4] 622 [FromDriveLogix20] User Defined

Controller Input Tag Element Drive Parameter Linked Parameter

LogicStatus 626 [To DriveLogix00] 155 [Logic Status]

FilteredSpdFdbk 627 [To DriveLogix01] 71 [Filtered SpdFdbk]

MotorTorqueRef 628 [To DriveLogix02] 303 [Motor Torque Ref]

OutputCurrent 629 [To DriveLogix03] 308 [Output Current]

MCStatus 630 [To DriveLogix04] 555 [MC Status]

LocalIOStatus 631 [To DriveLogix05] 824 [Local I/O Status]

UserDefinedRealData[0] 632 [To DriveLogix06] User Defined

UserDefinedRealData[1] 633 [To DriveLogix07] User Defined

UserDefinedRealData[2] 634 [To DriveLogix08] User Defined

UserDefinedRealData[3] 635 [To DriveLogix09] User Defined

UserDefinedRealData[4] 636 [To DriveLogix10] User Defined

UserDefinedRealData[5] 637 [To DriveLogix11] User Defined

UserDefinedRealData[6] 638 [To DriveLogix12] User Defined

UserDefinedRealData[7] 639 [To DriveLogix13] User Defined

UserDefinedRealData[8] 640 [To DriveLogix14] User Defined

UserDefinedIntegerData[0] 641 [To DriveLogix15] User Defined

UserDefinedIntegerData[1] 642 [To DriveLogix16] User Defined

UserDefinedIntegerData[2] 643 [To DriveLogix17] User Defined

UserDefinedIntegerData[3] 644 [To DriveLogix18] User Defined

UserDefinedIntegerData[4] 645 [To DriveLogix19] User Defined

UserDefinedIntegerData[5] 646 [To DriveLogix20] User Defined

Page 31

Placing and Configuring the Drive 2-7

Table 2.B Mapping for Position Control Communication Format

Controller Output Tag Element Drive Parameter Linked Parameter

LogicCommand 602 [FromDriveLogix00] 151 [Logic Command]

SpeedRef1 603 [FromDriveLogix01] 10 [Speed Ref 1]

PositionControl 604 [FromDriveLogix02] 740 [Position Control]

CoarsePositTrgt 605 [FromDriveLogix03] 748 [CoarsePosit Trgt]

PtPtPositRef 606 [FromDriveLogix04] 758 [Pt-Pt Posit Ref]

PositOffset1 607 [FromDriveLogix05] 753 [Posit Offset 1]

UserDefinedRealData[0] 608 [FromDriveLogix06] User Defined

UserDefinedRealData[1] 609 [FromDriveLogix07] User Defined

UserDefinedRealData[2] 610 [FromDriveLogix08] User Defined

UserDefinedRealData[3] 611 [FromDriveLogix09] User Defined

UserDefinedRealData[4] 612 [FromDriveLogix10] User Defined

UserDefinedRealData[5] 613 [FromDriveLogix11] User Defined

UserDefinedRealData[6] 614 [FromDriveLogix12] User Defined

UserDefinedRealData[7] 615 [FromDriveLogix13] User Defined

UserDefinedRealData[8] 616 [FromDriveLogix14] User Defined

UserDefinedIntegerData[0] 617 [FromDriveLogix15] User Defined

UserDefinedIntegerData[1] 618 [FromDriveLogix16] User Defined

UserDefinedIntegerData[2] 619 [FromDriveLogix17] User Defined

UserDefinedIntegerData[3] 620 [FromDriveLogix18] User Defined

UserDefinedIntegerData[4] 621 [FromDriveLogix19] User Defined

UserDefinedIntegerData[5] 622 [FromDriveLogix20] User Defined

Controller Input Tag Element Drive Parameter Linked Parameter

LogicStatus 626 [To DriveLogix00] 155 [Logic Status]

FilteredSpdFdbk 627 [To DriveLogix01] 71 [Filtered SpdFdbk]

OutputCurrent 628 [To DriveLogix02] 308 [Output Current]

LocalIOStatus 629 [To DriveLogix03] 824 [Local I/O Status]

PositionStatus 630 [To DriveLogix04] 741 [Position Status]

PositionFdbk 631 [To DriveLogix05] 762 [Position Fdbk]

PositionActual 632 [To DriveLogix06] 763 [Position Actual]

PositionError 633 [To DriveLogix07] 769 [Position Error]

UserDefinedRealData[0] 634 [To DriveLogix08] User Defined

UserDefinedRealData[1] 635 [To DriveLogix09] User Defined

UserDefinedRealData[2] 636 [To DriveLogix10] User Defined

UserDefinedRealData[3] 637 [To DriveLogix11] User Defined

UserDefinedRealData[4] 638 [To DriveLogix12] User Defined

UserDefinedRealData[5] 639 [To DriveLogix13] User Defined

UserDefinedIntegerData[0] 640 [To DriveLogix14] User Defined

UserDefinedIntegerData[1] 641 [To DriveLogix15] User Defined

UserDefinedIntegerData[2] 642 [To DriveLogix16] User Defined

UserDefinedIntegerData[3] 643 [To DriveLogix17] User Defined

UserDefinedIntegerData[4] 644 [To DriveLogix18] User Defined

UserDefinedIntegerData[5] 645 [To DriveLogix19] User Defined

UserDefinedIntegerData[6] 646 [To DriveLogix20] User Defined

Page 32

2-8 Placing and Configuring the Drive

Table 2.C Mapping for Motion Control Communication Format

Controller Output Tag Element Drive Parameter Linked Parameter

UserDefinedRealData[0] 602 [FromDriveLogix00] User Defined

UserDefinedRealData[1] 603 [FromDriveLogix01] User Defined

UserDefinedRealData[2] 604 [FromDriveLogix02] User Defined

UserDefinedRealData[3] 605 [FromDriveLogix03] User Defined

UserDefinedRealData[4] 606 [FromDriveLogix04] User Defined

UserDefinedRealData[5] 607 [FromDriveLogix05] User Defined

UserDefinedRealData[6] 608 [FromDriveLogix06] User Defined

UserDefinedRealData[7] 609 [FromDriveLogix07] User Defined

UserDefinedRealData[8] 610 [FromDriveLogix08] User Defined

UserDefinedRealData[9] 611 [FromDriveLogix09] User Defined

UserDefinedRealData[10] 612 [FromDriveLogix10] User Defined

UserDefinedRealData[11] 613 [FromDriveLogix11] User Defined

UserDefinedIntegerData[0] 614 [FromDriveLogix12] User Defined

UserDefinedIntegerData[1] 615 [FromDriveLogix13] User Defined

UserDefinedIntegerData[2] 616 [FromDriveLogix14] User Defined

UserDefinedIntegerData[3] 617 [FromDriveLogix15] User Defined

UserDefinedIntegerData[4] 618 [FromDriveLogix16] User Defined

UserDefinedIntegerData[5] 619 [FromDriveLogix17] User Defined

UserDefinedIntegerData[6] 620 [FromDriveLogix18] User Defined

UserDefinedIntegerData[7] 621 [FromDriveLogix19] User Defined

UserDefinedIntegerData[8] 622 [FromDriveLogix20] User Defined

Controller Input Tag Element Drive Parameter Linked Parameter

LogicStatus 626 [To DriveLogix00] 155 [Logic Status]

UserDefinedRealData[0] 627 [To DriveLogix01] User Defined

UserDefinedRealData[1] 628 [To DriveLogix02] User Defined

UserDefinedRealData[2] 629 [To DriveLogix03] User Defined

UserDefinedRealData[3] 630 [To DriveLogix04] User Defined

UserDefinedRealData[4] 631 [To DriveLogix05] User Defined

UserDefinedRealData[5] 632 [To DriveLogix06] User Defined

UserDefinedRealData[6] 633 [To DriveLogix07] User Defined

UserDefinedRealData[7] 634 [To DriveLogix08] User Defined

UserDefinedRealData[8] 635 [To DriveLogix09] User Defined

UserDefinedRealData[9] 636 [To DriveLogix10] User Defined

UserDefinedRealData[10] 637 [To DriveLogix11] User Defined

UserDefinedRealData[11] 638 [To DriveLogix12] User Defined

UserDefinedIntegerData[0] 639 [To DriveLogix13] User Defined

UserDefinedIntegerData[1] 640 [To DriveLogix14] User Defined

UserDefinedIntegerData[2] 641 [To DriveLogix15] User Defined

UserDefinedIntegerData[3] 642 [To DriveLogix16] User Defined

UserDefinedIntegerData[4] 643 [To DriveLogix17] User Defined

UserDefinedIntegerData[5] 644 [To DriveLogix18] User Defined

UserDefinedIntegerData[6] 645 [To DriveLogix19] User Defined

UserDefinedIntegerData[7] 646 [To DriveLogix20] User Defined

Page 33

Placing and Configuring the Drive 2-9

Table 2.D Mapping for User-Defined 1 Communication Format

Controller Output Tag Element Drive Parameter Linked Parameter

LogicCommand 602 [FromDriveLogix00] 151 [Logic Command]

UserDefinedRealData[0] 603 [FromDriveLogix01] User Defined

UserDefinedRealData[1] 604 [FromDriveLogix02] User Defined

UserDefinedRealData[2] 605 [FromDriveLogix03] User Defined

UserDefinedRealData[3] 606 [FromDriveLogix04] User Defined

UserDefinedRealData[4] 607 [FromDriveLogix05] User Defined

UserDefinedRealData[5] 608 [FromDriveLogix06] User Defined

UserDefinedRealData[6] 609 [FromDriveLogix07] User Defined

UserDefinedRealData[7] 610 [FromDriveLogix08] User Defined

UserDefinedRealData[8] 611 [FromDriveLogix09] User Defined

UserDefinedRealData[9] 612 [FromDriveLogix10] User Defined

UserDefinedRealData[10] 613 [FromDriveLogix11] User Defined

UserDefinedRealData[11] 614 [FromDriveLogix12] User Defined

UserDefinedRealData[12] 615 [FromDriveLogix13] User Defined

UserDefinedRealData[13] 616 [FromDriveLogix14] User Defined

UserDefinedIntegerData[0] 617 [FromDriveLogix15] User Defined

UserDefinedIntegerData[1] 618 [FromDriveLogix16] User Defined

UserDefinedIntegerData[2] 619 [FromDriveLogix17] User Defined

UserDefinedIntegerData[3] 620 [FromDriveLogix18] User Defined

UserDefinedIntegerData[4] 621 [FromDriveLogix19] User Defined

UserDefinedIntegerData[5] 622 [FromDriveLogix20] User Defined

Controller Input Tag Element Drive Parameter Linked Parameter

LogicStatus 626 [To DriveLogix00] 155 [Logic Status]

UserDefinedRealData[0] 627 [To DriveLogix01] User Defined

UserDefinedRealData[1] 628 [To DriveLogix02] User Defined

UserDefinedRealData[2] 629 [To DriveLogix03] User Defined

UserDefinedRealData[3] 630 [To DriveLogix04] User Defined

UserDefinedRealData[4] 631 [To DriveLogix05] User Defined

UserDefinedRealData[5] 632 [To DriveLogix06] User Defined

UserDefinedRealData[6] 633 [To DriveLogix07] User Defined

UserDefinedRealData[7] 634 [To DriveLogix08] User Defined

UserDefinedRealData[8] 635 [To DriveLogix09] User Defined

UserDefinedRealData[9] 636 [To DriveLogix10] User Defined

UserDefinedRealData[10] 637 [To DriveLogix11] User Defined

UserDefinedRealData[11] 638 [To DriveLogix12] User Defined

UserDefinedIntegerData[0] 639 [To DriveLogix13] User Defined

UserDefinedIntegerData[1] 640 [To DriveLogix14] User Defined

UserDefinedIntegerData[2] 641 [To DriveLogix15] User Defined

UserDefinedIntegerData[3] 642 [To DriveLogix16] User Defined

UserDefinedIntegerData[4] 643 [To DriveLogix17] User Defined

UserDefinedIntegerData[5] 644 [To DriveLogix18] User Defined

UserDefinedIntegerData[6] 645 [To DriveLogix19] User Defined

UserDefinedIntegerData[7] 646 [To DriveLogix20] User Defined

Page 34

2-10 Placing and Configuring the Drive

Table 2.E Mapping for User-Defined 2 Communication Format

Controller Output Tag Element Drive Parameter Linked Parameter

LogicCommand 602 [FromDriveLogix00] 151 [Logic Command]

UserDefinedRealData[0] 603 [FromDriveLogix01] User Defined

UserDefinedRealData[1] 604 [FromDriveLogix02] User Defined

UserDefinedRealData[2] 605 [FromDriveLogix03] User Defined

UserDefinedRealData[3] 606 [FromDriveLogix04] User Defined

UserDefinedRealData[4] 607 [FromDriveLogix05] User Defined

UserDefinedRealData[5] 608 [FromDriveLogix06] User Defined

UserDefinedRealData[6] 609 [FromDriveLogix07] User Defined

UserDefinedRealData[7] 610 [FromDriveLogix08] User Defined

UserDefinedRealData[8] 611 [FromDriveLogix09] User Defined

UserDefinedRealData[9] 612 [FromDriveLogix10] User Defined

UserDefinedRealData[10] 613 [FromDriveLogix11] User Defined

UserDefinedIntegerData[0] 614 [FromDriveLogix12] User Defined

UserDefinedIntegerData[1] 615 [FromDriveLogix13] User Defined

UserDefinedIntegerData[2] 616 [FromDriveLogix14] User Defined

UserDefinedIntegerData[3] 617 [FromDriveLogix15] User Defined

UserDefinedIntegerData[4] 618 [FromDriveLogix16] User Defined

UserDefinedIntegerData[5] 619 [FromDriveLogix17] User Defined

UserDefinedIntegerData[6] 620 [FromDriveLogix18] User Defined

UserDefinedIntegerData[7] 621 [FromDriveLogix19] User Defined

UserDefinedIntegerData[8] 622 [FromDriveLogix20] User Defined

Controller Input Tag Element Drive Parameter Linked Parameter

LogicStatus 626 [To DriveLogix00] 155 [Logic Status]

UserDefinedRealData[0] 627 [To DriveLogix01] User Defined

UserDefinedRealData[1] 628 [To DriveLogix02] User Defined

UserDefinedRealData[2] 629 [To DriveLogix03] User Defined

UserDefinedRealData[3] 630 [To DriveLogix04] User Defined

UserDefinedRealData[4] 631 [To DriveLogix05] User Defined

UserDefinedRealData[5] 632 [To DriveLogix06] User Defined

UserDefinedRealData[6] 633 [To DriveLogix07] User Defined

UserDefinedRealData[7] 634 [To DriveLogix08] User Defined

UserDefinedRealData[8] 635 [To DriveLogix09] User Defined

UserDefinedRealData[9] 636 [To DriveLogix10] User Defined

UserDefinedIntegerData[0] 637 [To DriveLogix11] User Defined

UserDefinedIntegerData[1] 638 [To DriveLogix12] User Defined

UserDefinedIntegerData[2] 639 [To DriveLogix13] User Defined

UserDefinedIntegerData[3] 640 [To DriveLogix14] User Defined

UserDefinedIntegerData[4] 641 [To DriveLogix15] User Defined

UserDefinedIntegerData[5] 642 [To DriveLogix16] User Defined

UserDefinedIntegerData[6] 643 [To DriveLogix17] User Defined

UserDefinedIntegerData[7] 644 [To DriveLogix18] User Defined

UserDefinedIntegerData[8] 645 [To DriveLogix19] User Defined

UserDefinedIntegerData[9] 646 [To DriveLogix20] User Defined

For each of the communication formats, drive_module:O.LogicCommand

and drive_module:I.LogicStatus are provided as DINT data types. In

addition to these tags, the control bits for each are also available as Boolean

values with tag names that correspond to the control bits in the drive. This

gives you the option of programming the Logic Command and Status words

at the Boolean level or as an integer value.

Not all 32-bits within parameter 151 [Logic Command], are directly visible

in the PowerFlex 700S. To view all 32-bits, refer to parameter 152 [Applied

LogicCmd].

Page 35

Placing and Configuring the Drive 2-11

Inhibiting the Drive Connection

Check the inhibit box to

inhibit the connection to

the drive

RSLogix 5000 programming software allows you to inhibit the controller’s

connection to the drive, in the same way you inhibit its connection to an I/O

module. Inhibiting the drive module shuts down the connection from the

controller to the drive. When you create the module you can choose to

inhibit it. After you have created the module you can inhibit or un-inhibit it

by manipulating its properties window.

ATTENTION: Inhibiting a drive module breaks the controller’s

connection to the drive. In this situation, the controller can

!

neither start or stop the drive, nor read the status of the drive. The

drive can continue to operate based on its parameter settings and

inputs. To avoid potential personal injury and damage to

machinery, make sure this does not create unsafe operation.

On the Connection tab during creation or in the Properties window

When you inhibit the drive module, the Controller Organizer displays a

yellow attention symbol

If you are: Inhibit the drive module to:

offline put a place holder for the drive module to indicate that configuration is not yet complete.

The inhibit status is stored in the project. When you download the project, the module is still inhibited.

online stop communication to the drive.

If you inhibit the drive while you are connected to the module, the connection to the module is closed. By default,

the PowerFlex 700S drive will fault. The data inputs to the drive will either hold last state, or reset to zero data

based on the setting of parameter 385 [Lgx CommLossData].

If you inhibit the drive but a connection to the module was not established (perhaps due to an error condition or

fault), the module is inhibited. The module status information changes to indicate that the module is inhibited and

not faulted.

over the module.

!

ahw0779.tif

If you uninhibit the drive (clear the check box), and no fault condition occurs, a connection is made to the drive.

To inhibit a module from logic, you must first read the Mode attribute for

the module using a GSV instruction. Set bit 2 to the inhibit status (1 to

Page 36

2-12 Placing and Configuring the Drive

ahw0514.tif

inhibit or 0 to uninhibit). Use a SSV instruction to write the Mode attribute

back to the module. For example:

Using DriveExecutive Lite

1. If not already done, enter the drive firmware revision. Click the Finish button to apply the

revision data.

In order to launch DriveExecutive Lite from within RSLogix 5000, the

drives power rating must be selected. The drive firmware revision must be

applied prior to selecting the power rating.

ahw0779.tif

Page 37

Placing and Configuring the Drive 2-13

2. In the Controller Organizer, select the PowerFlex 700S drive. Right-click the drive module and select Properties.

3. Select the Power tab.

4. Select the correct Drive Rating. This data can be found on the PowerFlex 700S data nameplate.

ahw0780.tif

ahw0781.tif

TIP: If your drive’s power rating does not appear as a selection, you do not

have the DriveExecutive Lite database file for your drive. To create a

database file, connect to the drive with DriveExecutive Lite. This will

automatically create the database. You can also download the database file

from http://www.ab.com/drives/data.html

Page 38

2-14 Placing and Configuring the Drive

5. Once the power rating is selected, apply your changes by selecting the Apply button.

6. Select the Setup tab.

7. Enter the file name for your DriveExecutive Lite parameter file, then click the Apply button.

ahw0784.tif

8. Click the DriveExecutive button to launch DriveExecutive Lite.

ahw0782.tif

ahw0785.tif

Page 39

9. When asked to create a new DriveExecutive Lite file, select yes.

ahw0786.tif

DriveExecutive will then launch and open the

newly created file

Placing and Configuring the Drive 2-15

ahw0787.tif

Page 40

2-16 Placing and Configuring the Drive

Viewing the Communication Interface to the Controller

DriveExecutive Lite has a setup screen that details the communication

interface between the controller and drive. From this screen, the relationship

between drive parameters and controller tags is presented for the selected

communication format. You can create additional links within the drive for

use with the user-defined tags in the controller.

1. To view the setup screen select Display DriveLogix from the Drive drop-down menu. Then select the From DriveLogix tab.

ahw0788.tif

ahw0789.tif

Page 41

2. To send additional data from the drive to the controller, go to the To DriveLogix tab.

Click the button in front of the

UserDefinedRealData[0] tag

Placing and Configuring the Drive 2-17

ahw0790.tif

ahw0791.tif

3. Select the desired source (parameter 307 [Output Voltage] in this example) in the resulting window.

Configuring the Drive’s Response to a Connection Failure or Controller

Mode Change

The drive contains several parameters that allow you to configure the drive’s

response to communication loss to the controller. From the drive’s

perspective, a communication loss can come in the following two forms.

• The controller closes the connection (for example, the connection is

inhibited).

• A general failure occurs causing the connection to time out.

Parameter 386 [Lgx OutofRunCnfg] configures the drive’s response to the

controller is removed from the Run Mode. Parameter 387 [Lgx Timeout

Page 42

2-18 Placing and Configuring the Drive

Cnfg] configures the drive’s response to a general connection failure as

detected by the drive. Parameter 388 [Lgx Closed Cnfg] configures the

drive’s response to the controller closing the connection. All of these

parameters configure the drive’s response to these exception events in the

following ways: ignore, alarm, fault and coast to stop, fault and ramp to

stop, fault and stop in current limit.

Parameter 385 [Lgx CommLossData] determines what the drive does with

data from the controller when communication is lost. It determines if the

drive resets the data to zero or holds the data in its last state.

Configure these parameters, using DriveExecutive Lite. Locate them in the

Fault/Alm Config group of the Utility file.

ahw0792.tif

Page 43

Using Existing DriveExecutive Lite Files

Before using an existing DriveExecutive Lite file, verify the firmware

revision, communication format, and power rating in the drive file match the

data entered in drive module properties in your DriveLogix application.

1. Select Properties from the Drive menu.

ahw0793.tif

Placing and Configuring the Drive 2-19

2. View the revision and ratings on the General tab of the Properties window.

3. Refer to Viewing the Communication Interface to the Controller on page 2-16, to view

the communication format.

ahw0794.tif

Page 44

2-20 Placing and Configuring the Drive

4. In RSLogix 5000, go to the Setup tab of the Proper ties window. Click the Browse button. Select the

existing DriveExecutive file (Existing Drive.dno in this example). Click the open button.

ahw0785.tif

5. Click the Apply button

and then launch DriveExecutive.

ahw0795.tif

ahw0796.tif

ahw0797.tif

Page 45

Placing and Configuring the Drive 2-21

Accessing Drive Data

Drive data is displayed as structures of multiple tags. The names and data

structures are based on the selected communication format. The

programming software automatically creates the necessary structures and

tags when you configure the drive module. Each tag name follows this

format:

ModuleName:Type.MemberName.SubMemberName.Bit

where:

This address variable: Is:

ModuleName Identifies the module name entered during the drive module

configuration

Type Type of data

I = input

O = output

MemberName Specific data from the drive; depends on the selected communication

format.

For tags associated with pre-defined data links, this name will be the

same as the corresponding parameter name in the drive.

SubMemberName Specific data related to a MemberName

Bit (optional) Specific bit of a DINT data value

Monitoring Drive Data

Refer to Communication Formats on page 2-5

The DriveLogix controller offers different levels at which you can monitor

the drive module. You can:

• configure the drive module so that the controller faults if the drive loses

its connection to the controller.

• use the programming software to display fault data

• program logic to monitor fault data so you can take appropriate action

for sample tag names.

Page 46

2-22 Placing and Configuring the Drive

Configuring the Controller’s Response to a Connection Failure

Check this box to configure the drive

module to generate a major fault if it loses

its connection to the controller

You can configure the drive module to generate a major fault in the

controller if the drive loses its connection to the controller.

ahw0798.tif

If you do not configure the major fault to occur, you should monitor the

drive module status. If the drive loses its connection to the controller:

• Outputs remain in their last

• Inputs remain in their last state

• By default the drive will fault

ATTENTION: If a drive loses its connection to the controller,

the controller and other I/O modules continue to operate based

!

on old data from the drive, and the drive can continue to operate

based on old data from the controller. To avoid potential personal

injury and damage to machinery, make sure this does not create

unsafe operation.

Configure the drive to generate a controller major fault when the drive loses

its connection to the controller. Or, monitor the status of the drive module.

Page 47

Placing and Configuring the Drive 2-23

Monitoring the drive module

Each communication format provides a drive status word that will indicate

when a drive fault or alarm occurs. To view this data through the

programming software:

1. In the Controller Organizer, select Controller Tags. Right-click on the selected icon and select Monitor Tags.

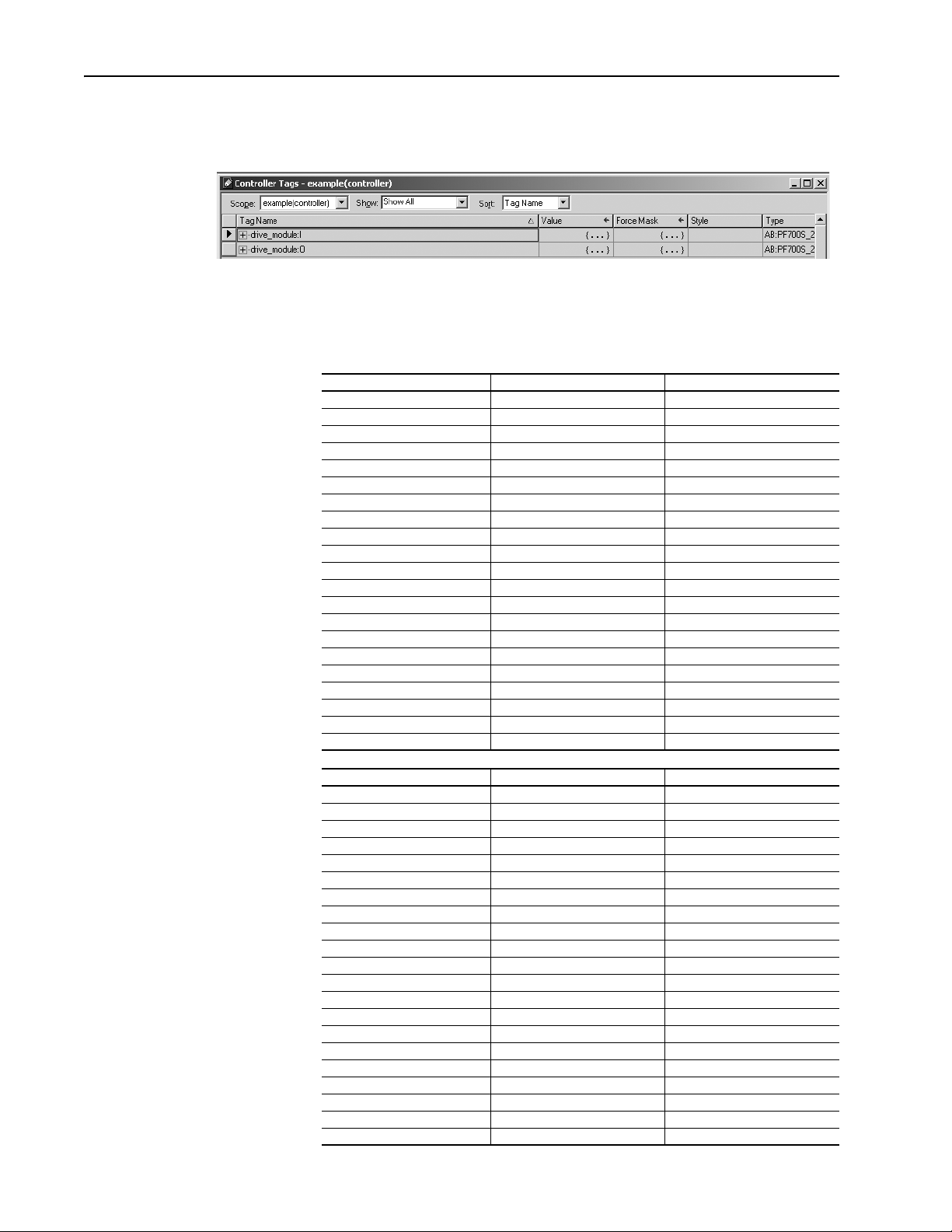

ahw0799.tif

2. Expand the data as necessary.

ahw0800.tif

Page 48

2-24 Placing and Configuring the Drive

You can write logic to monitor these bits and take appropriate action if a

fault or alarm occurs. For example, you may want a drive alarm to turn on a

warning lamp and a drive fault to sound an alarm and set the motor brake.

Example: Energizing Alarm Lamp, Siren and Brake in Response to Fault and Alarm

Status Bits

Given this configuration, the following logic checks the fault and alarm

drive status bits.

ahw0801.tif

ahw0802.tif

Page 49

Placing and Configuring the Drive 2-25

Recommended Programming Techniques

Naming Tags

Use a convention when naming tags and consistently follow it. The

following convention is used internally at Allen-Bradley:

<prefix>_<function>_<suffix>