Page 1

Bulletin 5370

CVIM

USER–PAK Option

(Catalog No. 5370–UPK)

User Manual

ALLEN-BRADLEY

Page 2

ALLEN-BRADLEY

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Application Considerations for Solid State

Controls” (Publication SGI-1.1) describes some important differences

between solid state equipment and hard–wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

1992 Allen-Bradley Company, Inc.

Page 3

Table of Contents

USER–PAK Option

User Manual

A–B

Using This Manual

Introduction to the

USER–PAK Option

Installation

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Contents 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cautions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trademarks 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security Levels 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Menu Modifications 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Serial Port Messages 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Runtime Displays 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy and Paste Functions 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading CVIM / USER–PAK Configurations 2–5. . . . . . . . . . . . . . . . . . .

Connect and Use a Mouse 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Two USER–PAK Memory Cards 3–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the USER–PAK Option 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Setup Card 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Setup Mode with USER–PAK Installed 3–5. . . . . . . . . . . . . . . .

Getting Started / Using the

Security Levels

Modifying the CVIM Menus

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Some Questions and Answers about System Security 4–1. . . . . . . . . . . . .

Accessing the Setup Mode 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security Levels 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security Level Indication 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Passwords 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Security ON/OFF 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lost Passwords – Using the Installation / Key Card 4–8. . . . . . . . . . . . . . .

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deletion 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary – Effects of Deletion 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deletion Procedure 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example – Menu Item Deletion 5–4. . . . . . . . . . . . . . . . . . . . . . . .

The Cascade Effect 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Text Modification 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Table of Contents

USER–PAK Option

User Manual

Searching for Text 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Text String Search 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dictionary ID Search 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Text 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Examples of Modifying Text 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Archiving Menu Modifications 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Requirement 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Custom Serial

Port Messages

Creating Custom Runtime

Displays

ii

Chapter 6

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Some Questions and Answers about Custom Serial Port Messages 6–1. . .

Creating Custom Serial Port Messages 6–2. . . . . . . . . . . . . . . . . . . . . . . . .

Example of a Serial Port Message String 6–2. . . . . . . . . . . . . . . . . . . . .

Basic Steps for Creating Custom Serial Port Messages 6–3. . . . . . . . . .

Defining Strings 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Transmit Now 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining the Serial Port 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Erase Port Data 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Buffer: Wait / No Wait 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232 Port Connections and Configuration 6–8. . . . . . . . . . . . . . . . . . . .

Equipment Connections 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Serial Port Parameters 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7

Chapter Objectives 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Some Questions and Answers about Custom Runtime Displays 7–1. . . . .

Initial Setup: Selecting and Defining the Viewport 7–3. . . . . . . . . . . . . . .

Using the Define Viewport Menu 7–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Viewport Type 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Pick & Place 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Border and Background Colors 7–8. . . . . . . . . . . . . . . .

Selecting Display Pages and Page Numbers 7–9. . . . . . . . . . . . . .

Erase Port Data 7–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Text and Tool Viewport Contents 7–12. . . . . . . . . . . . . . . . . . . . . .

Using the Define String Menu 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting String Direction 7–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting String Width 7–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting String Color 7–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Pick & Place 7–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Copy and Paste Features 7–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Graph Viewports 7–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Variable 7–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining the Variable 7–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents

USER–PAK Option

User Manual

Setting the Style 7–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Variable Color 7–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Variable Tool 7–22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining the Graph 7–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining the Viewport Limits – Upper and Lower 7–23. . . . . . . . .

Defining the Event 7–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Strings for Serial

Ports and Viewports

Chapter 8

Chapter Objectives 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering (or Modifying) String Text 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Valid Elements of String Text 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Literal Text 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Codes 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Characters: N, /, %, # 8–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The N (newline) character 8–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

/ Character Code Indicator 8–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

% Formula Indicator 8–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

# (Index) Character 8–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Formatting Codes 8–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conditional Color–coding 8–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extended Conditional Color–coding 8–14. . . . . . . . . . . . . . . . . . . .

Draw Line Codes 8–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plot Line Codes 8–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Color Codes 8–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of Codes and Indicators 8–20. . . . . . . . . . . . . . . . . . . . . . . . . .

Defining the Event 8–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Repeat String 8–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Serial Port Message Example 8–30. . . . . . . . . . . . . . . . . . . . . . . . . .

Text and Tool Viewport Examples 8–33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 1 – Creating a Special Character 8–34. . . . . . . . . . . . . . . . . . . .

Example 2 – Using the Change Color Code 8–35. . . . . . . . . . . . . . . . . . .

Example 3 – Using the Draw Line Code 8–36. . . . . . . . . . . . . . . . . . . . .

Example 4 – Using Repeat String and # (Index) Character 8–37. . . . . . .

Example 5 – Using Data Codes and # (Index) Character 8–39. . . . . . . . .

Example 6 – Conditionally Displaying a Text String 8–41. . . . . . . . . . . .

Example 7 – Using Formulas and Plot Line Codes 8–42. . . . . . . . . . . . .

Using Copy and Paste

Chapter 9

Chapter Objectives 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Copy and Paste 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example – Tool Copy and Paste 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Example – Viewport Copy and Paste 9–3. . . . . . . . . . . . . . . . . . . . . . . .

Example – String Copy and Paste 9–4. . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 6

Table of Contents

USER–PAK Option

User Manual

Loading CVIM / USER–PAK

Configurations

Connecting and Using a

Mouse

Character Codes

ASCII Commands for the

USER–PAK Option

Chapter 10

Chapter Objectives 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading CVIM / USER–PAK Configurations 10–1. . . . . . . . . . . . . . . . . . .

Checking Available Memory 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Objective A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements and Considerations A–1. . . . . . . . . . . . . . . . . . . . .

Connections – CVIM Module Hardware Series A and B A–1. . . . . . . .

Configuring the CVIM Module A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using a Mouse A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Mouse and Trackball Supported A–3. . . . . . . . . . . . . . . . . . . .

Appendix B

Objective B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

Objective C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII Commands C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Force Print Command C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Force Print for Viewport Strings C–1. . . . . . . . . . . . . . . . . . . . . . .

Force Print for Serial Port Strings C–2. . . . . . . . . . . . . . . . . . . . . .

Write String Data Command C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read String Data Command C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Suspend / Resume Serial Port Output Command C–3. . . . . . . . . . . . . . .

Write Display Command (Enhancement) C–3. . . . . . . . . . . . . . . . . . . . .

Index

Tables

1.A

4.A

8.A

8.B

8.C

B.1

B.2

iv

Chapter Descriptions 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

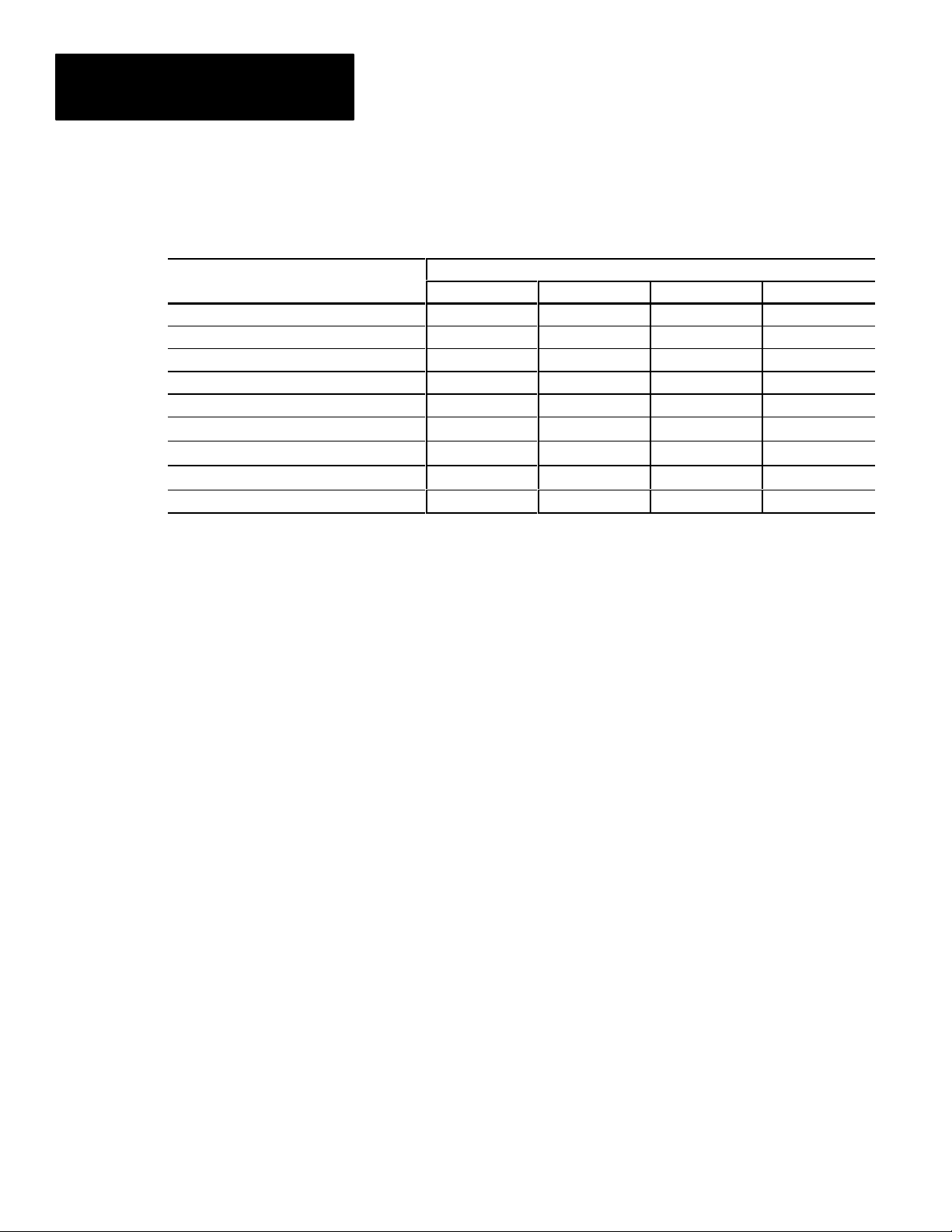

Functions/Features at each Security Level 4–4. . . . . . . . . . . . . . . . . . . .

Data Codes 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Color Codes for Strings 8–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Characters and Indicators for Defining Strings 8–20. . . . . . . . . .

ASCII Control Codes (Serial Ports Only) B–1. . . . . . . . . . . . . . . . . . . .

Character Codes (Serial Ports and Viewports) B–2. . . . . . . . . . . . . . . . .

Page 7

Chapter

Chapter Objectives

Manual Contents

A–B

1

Using This Manual

Contents

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Contents 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cautions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trademarks 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The objective of this chapter is to provide an overview of the contents and

organization of this manual, to describe the intended audience, and to list

related publications.

The contents of this manual are briefly described in

Table 1.A

Chapter Descriptions

Table 1.A below.

Ch/App Title Description

1 Using This Manual Provides an overview of the manual.

2

3 Installation

4

5 Modifying the CVIM Menus

6

7

8

9 Using Copy and Paste

10

A

B Character Codes

C

Introduction to the

USER–PAK Option

Getting Started / Using

Security Levels

Creating Custom Serial Port

Messages

Creating Custom Runtime

Displays

Defining Strings for Serial

Ports and Viewports

Loading CVIM / USER–PAK

Configurations

Connecting and Using a

Mouse

ASCII Commands for the

USER–PAK Option

Previews the main features and capabilities of

the USER–P AK option.

Describes how to install the USER–PAK

option into the CVIM module, and discusses

the use of the two memory cards.

Describes how to access the setup mode, and

how to set up the different security levels.

Describes how to delete menu items, and how

to modify the text of menu items.

Describes how to create custom messages for

transmission through a serial port.

Describes how to create custom displays

which appear during runtime.

Describes how to enter string text, use valid

string elements, and set event and repetition

parameters for strings.

Describes how to use the Copy and Paste

functions to copy the settings directly from one

tool to another of the same type, copy one

string to another, or copy one viewport or

serial port to another.

Describes how to load specific portions of

CVIM / USER–P AK configurations.

Describes how to connect and use a mouse

for interfacing with the CVIM screen menus.

Lists the ASCII characters and CVIM module

graphics characters that can be generated

within strings using the character codes.

Describes the serial port ASCII commands

which apply specifically if the USER–PAK

option is installed.

1–1

Page 8

Chapter 1

Using This Manual

Intended Audience

Cautions

Before using this manual, you should be familiar with the CVIM module

features and the procedures used in configuring the CVIM module for

operation.

• For information regarding the CVIM module, refer to the CVIM User’s

Manual, Cat. No. 5370–ND001 (Series B) and Addendum.

• If you plan to use the CVIM communications port (RS–232), refer also to

the CVIM Communications Manual, Cat. No. 5370–ND002 (Series B).

• If you plan to use other software option packages along with the

USER–PAK option, refer to the user’s manuals for the respective software

package as necessary.

Notices of caution are included when the CVIM module or peripheral

equipment could be damaged if the listed procedure is not followed. The

following format is used:

CAUTION:

This is the format used for a caution.

Related Publications

Trademarks

1–2

The following manuals are cited for reference in this manual:

• User’s Manual, Bulletin 5370–CVIM, Cat. No. 5370–ND001 (Series B)

and Addendum, also referred to as the CVIM User’s Manual in this

publication.

• Communications Manual, Bulletin 5370–CVIM, Cat. No. 5370–ND002

(Series B) also referred to as the CVIM Communications Manual in this

publication.

The following trademarks apply to products mentioned in this manual:

USER–PAK Option – Allen–Bradley Cat. No. 5370–UPK

CVIM Module – Allen–Bradley Cat. No. 5370–CVIM

MATH–PAK Option – Allen–Bradley Cat. No. 5370–MPK

OCR–PAK Option – Allen–Bradley Cat. No. 5370–OCR

Page 9

Chapter

Chapter Objectives

A–B

2

Introduction to the USER–PAK Option

Contents

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security Levels 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Menu Modifications 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Serial Port Messages 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Runtime Displays 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy and Paste Functions 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading CVIM / USER–P AK Configurations 2–5. . . . . . . . . . . . . . . . . . . . . .

Connect and Use a Mouse 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This chapter briefly describes the features and capabilities of the USER–PAK

option package.

Security Levels

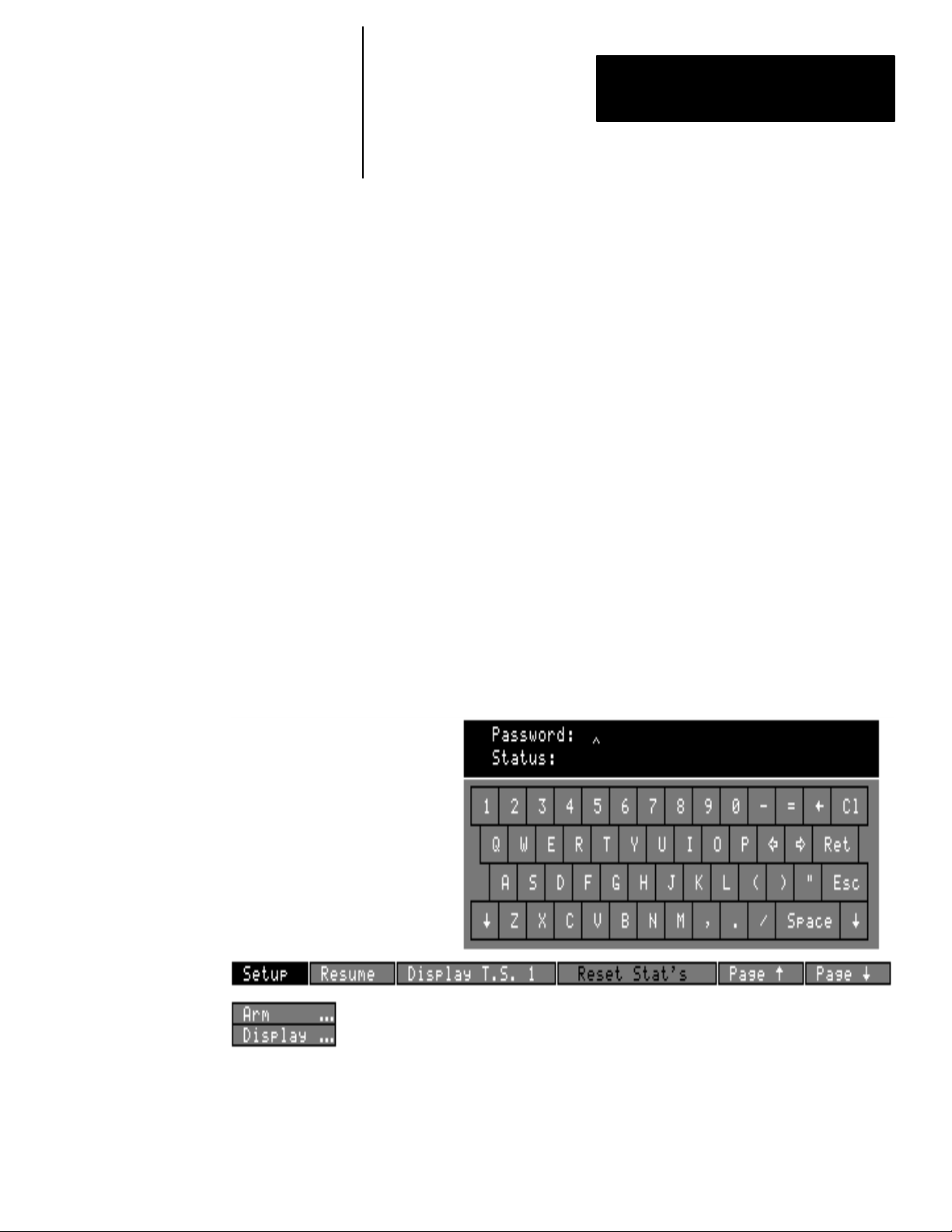

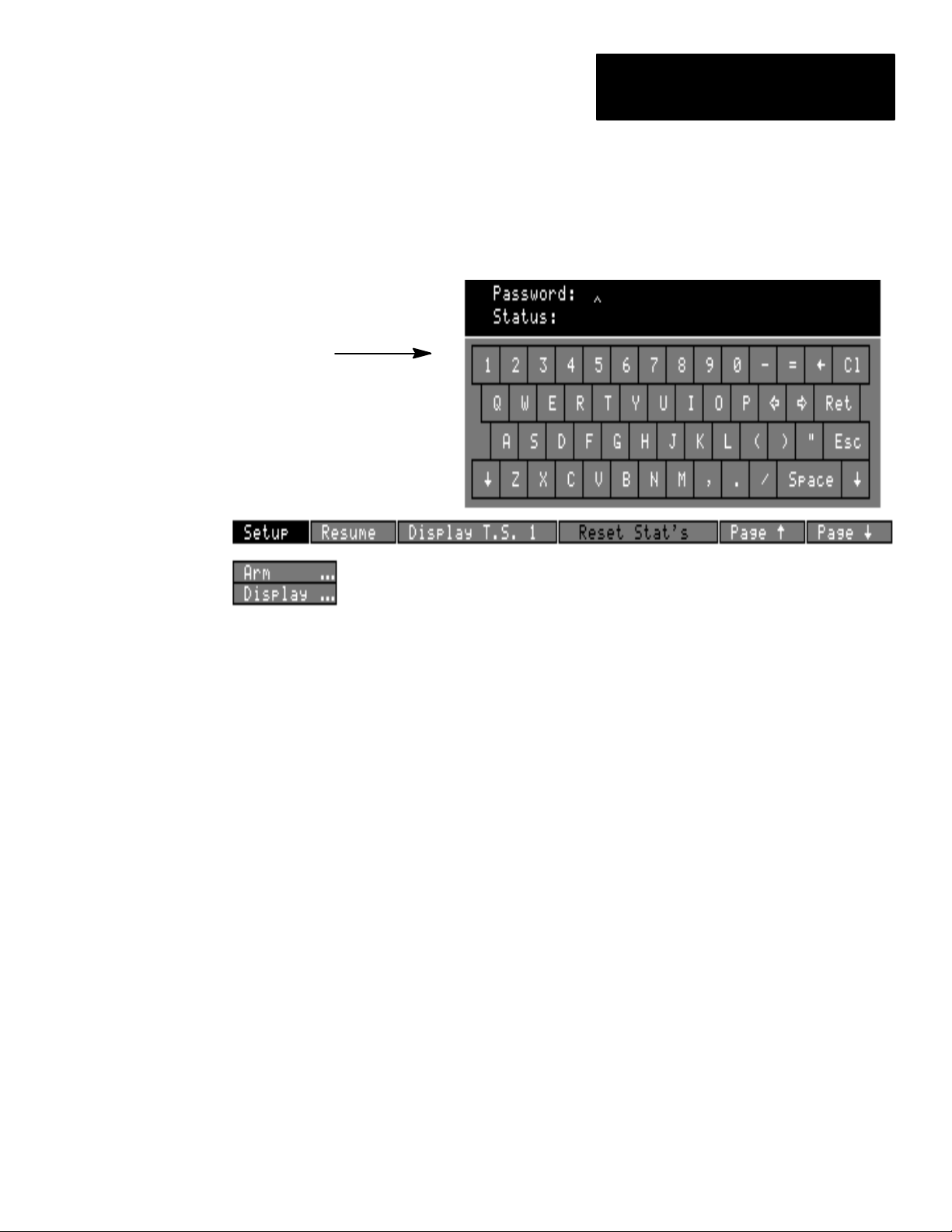

When USER–PAK is installed in your CVIM module, access to the setup

mode can require the use of a password. The password is entered through a

pop–up keyboard which appears automatically when you attempt to enter the

setup mode (as shown below).

2–1

Page 10

Chapter 2

Introduction to the USER–PAK Option

The USER–PAK option enables access to four different levels of interaction;

we refer to these different levels as “security levels.” The different security

levels allow for implementation of a hierarchical system of access to and

responsibility for the CVIM module setup.

Three security levels are defined within the setup mode, each allowing a

different level of interaction with CVIM / USER–PAK features:

• ADMINISTRATOR – Full access to CVIM / USER–PAK features.

• MANAGER – Mid–level access to CVIM / USER–PAK features.

• USER – Lower–level access to CVIM / USER–PAK features.

Access to the above security levels is controllable through the assignment of

a specific password for each level.

Access to CVIM runtime menus and displays does not require a password –

this “runtime” level of interaction can be considered as a fourth level of

security.

Custom Menu Modifications

The USER–PAK option allows the ADMINISTRATOR to modify the CVIM

module user–interface in two ways – through deletion of menu items from

the CVIM pop–up menus, and/or modification of text.

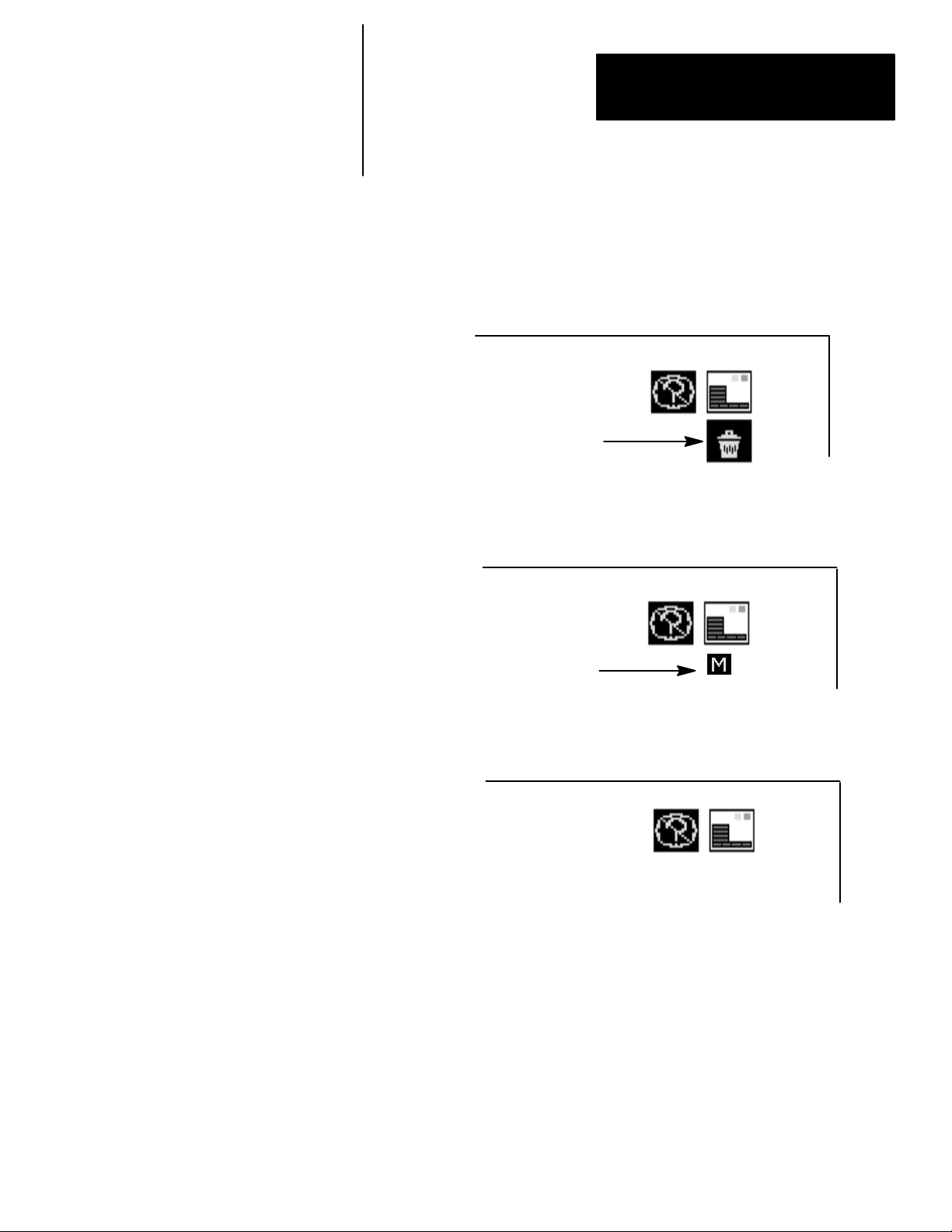

Deletion: A menu item is marked for deletion at the ADMINISTRATOR

level; menu items marked for deletion do not appear on the monitor screen at

the USER level. Any subsequent menu(s) that would have been accessible

through the use of the deleted menu item are unavailable as well.

“Trash can”

icon open

(icon is green when open)

Delete function

enabled

To enable the delete function, you pick the “trash can” icon, which appears at

the ADMINISTRATOR level; then you select or “mark” menu items for

deletion.

2–2

Page 11

Chapter 2

Introduction to the USER–PAK Option

Text Modification: The USER–PAK option enables the ADMINISTRATOR

to modify the text of menu items, and of on–screen messages such as the

help messages or the power–up title banner. To modify text, you use the

Change Text feature (accessed from the Env. menu).

Custom Serial Port Messages

For communication between the CVIM module and a remote device, the

CVIM module has a serial port (CVIM module series A has one serial port,

series B or later, two serial ports). With the USER–PAK option installed,

you can create your own custom serial port messages for transmission

through the serial port. The messages consist of ASCII characters. These

messages are transmitted automatically by the CVIM module – they need

not be “solicited” (requested by command) by the connected device.

You create serial port messages using the Config. Output feature, which

becomes available on the Env. menu with the USER–PAK option installed.

2–3

Page 12

Chapter 2

Introduction to the USER–PAK Option

Within each message you can send literal text, results and other data on

specific tools, statistical data, and other information. You also define the

conditions under which a serial message is transmitted – the message can be

sent after each inspection, or only upon certain conditions, such as the failure

of a specific tool, for instance.

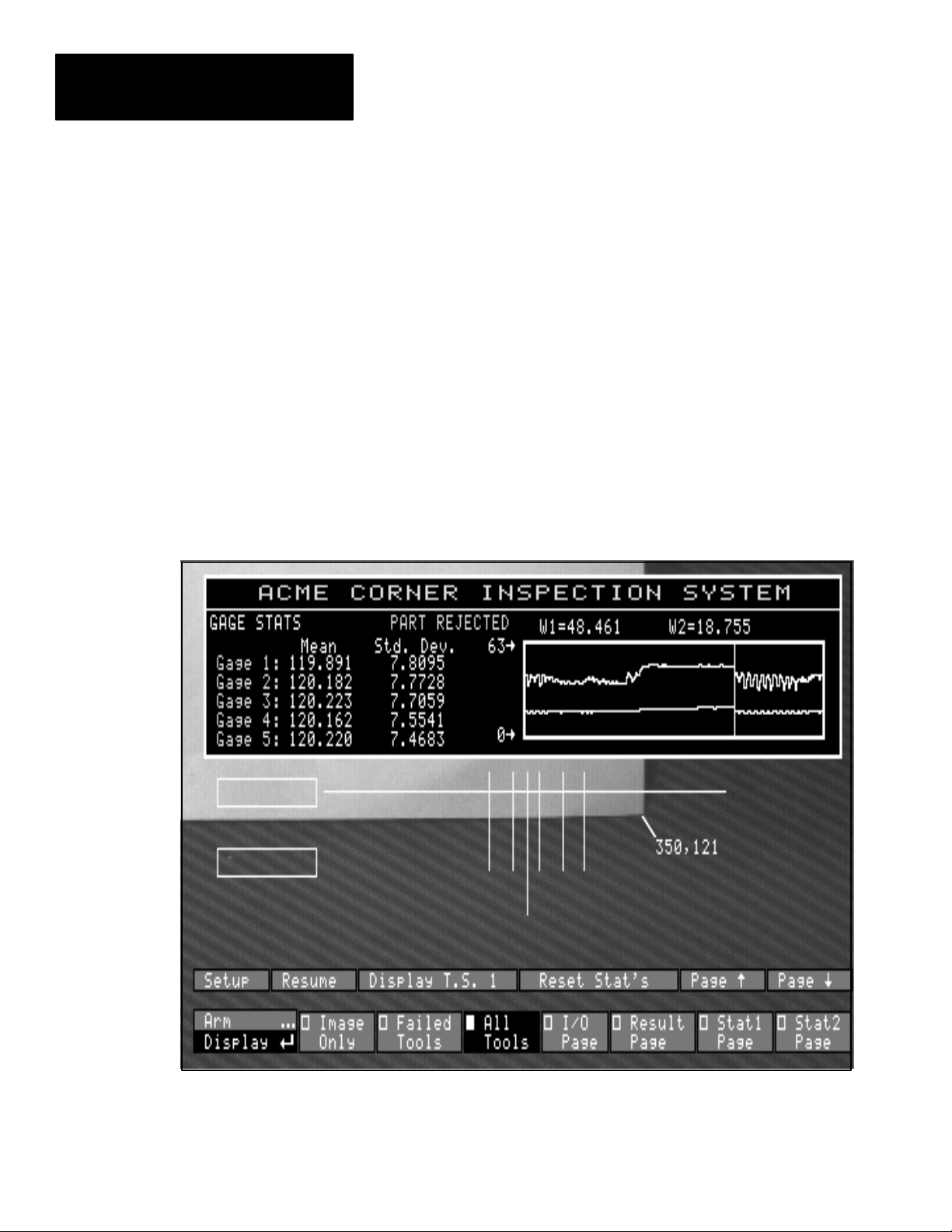

Custom Runtime Displays

Runtime displays are those displays which appear on the monitor while the

CVIM is operating in run mode. You create custom runtime displays by

configuring “viewports,” using the Config. Output feature, which becomes

available on the Env. menu with the USER–PAK option installed. You select

display borders and background color, and you define the viewport contents.

Viewports can contain text, numerical data, line graphics, and real–time

graphs. You also define the conditions under which viewport contents are

displayed – the contents can be displayed after each inspection, or only upon

certain conditions, such as the failure of a specific tool, for instance.

2–4

Page 13

Chapter 2

Introduction to the USER–PAK Option

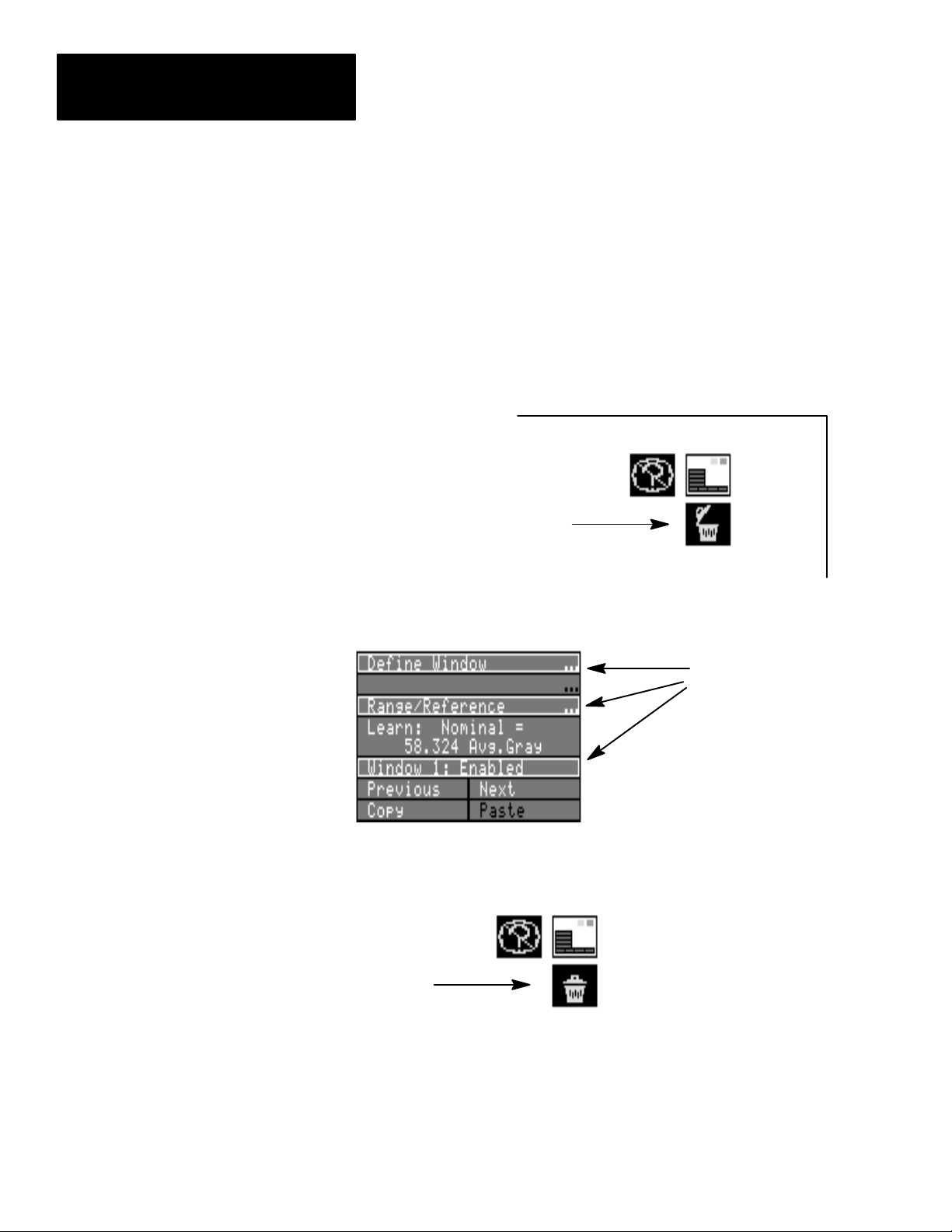

Copy and Paste Functions

Loading CVIM / USER–PAK Configurations

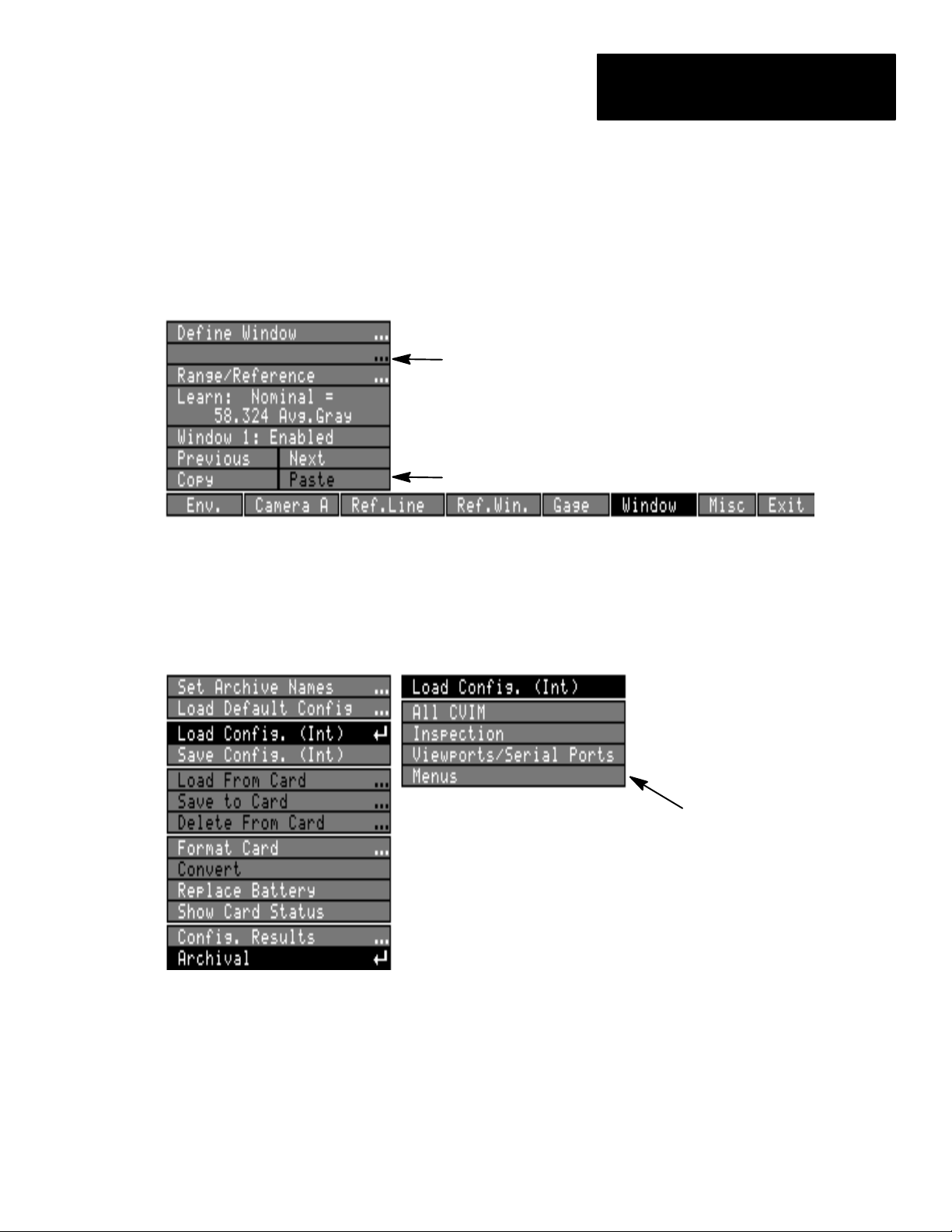

With the USER–PAK option installed, you can copy the settings from one

gage or window to another using the Copy and Paste menu items which are

part of the new USER–PAK menus, and which become part of the previous

CVIM gage and window menus. You can also copy the contents of serial

ports or viewports and their respective strings.

Window menu

Copy and Paste

With USER–PAK installed, you can selectively load portions of the default

configuration or the internally stored configuration. This allows you, for

example, to load previously–stored user interface modifications, while

retaining a new CVIM inspection configuration.

Connect and Use a Mouse

Archival menu

With the USER–PAK option installed, you can connect a mouse or trackball

to a CVIM serial port, and use the mouse to configure the CVIM, instead of

the light pen.

Load Config ( Int )

menu

2–5

Page 14

Chapter

Chapter Objectives

A–B

3

Installation

Contents

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The T wo USER–PAK Memory Cards 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the USER–PAK Option 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Setup Card 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Setup Mode with USER–PAK Installed 3–5. . . . . . . . . . . . . . . . .

This chapter describes how to install the USER–PAK option in the

Allen–Bradley 5370–CVIM machine vision system, including the use of the

two memory cards on which the USER–PAK option software resides.

The Two USER–PAK Memory Cards

Installing the USER–PAK Option

The USER–PAK option is provided on two different memory cards. These

two cards are labeled Installation / Key card and Setup card respectively.

The purpose of each card is described below:

• Installation / Key card – This card serves two purposes: Use this card to

install the USER–PAK option into the CVIM module. Use this card also

to access the setup mode in the case of lost passwords.

Important: Because this card can be used to override the CVIM system

security (see Chapter 4), it is suggested that this card be kept in a secure

place when not in use, and that access to this card be allowed only to the

appropriate authorized personnel.

• Setup card – Insert this card into the Archive Memory slot after the

USER–PAK option has been installed. This card must remain in the

Archive Memory slot during setup mode in order to access most of the

USER–PAK option capabilities.

This section describes how to install the USER–PAK option.

Installing More than One Option: The USER–PAK option is entirely

compatible with any of the other CVIM option packages. You can install

the option packages in any order, with this exception – you must install

the MATH–PAK option before installing the USER–PAK option.

Installing the MATH–PAK option after installing the USER–PAK option

nullifies the USER–PAK option; if this happens, you must reinstall the

USER–PAK option.

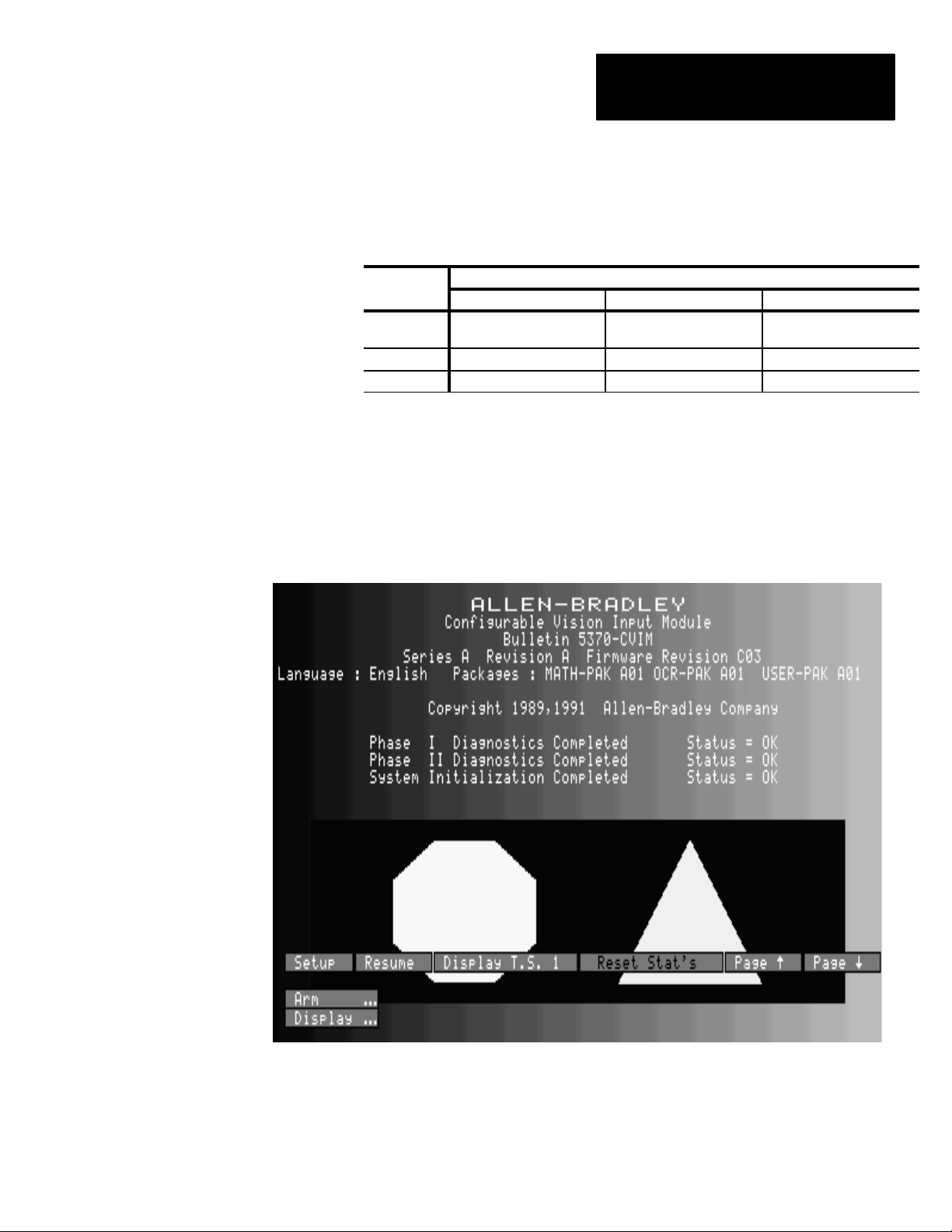

Required Firmware: The CVIM system must have the Revision C03 (or

higher) firmware before the USER–PAK option can be installed (the

3–1

Page 15

Chapter 3

Installation

firmware revision is listed on the title banner on the monitor screen

following powerup).

One–Time Installation: You need only install the USER–PAK option once;

once installed, the USER–PAK option remains installed for all subsequent

powerups.

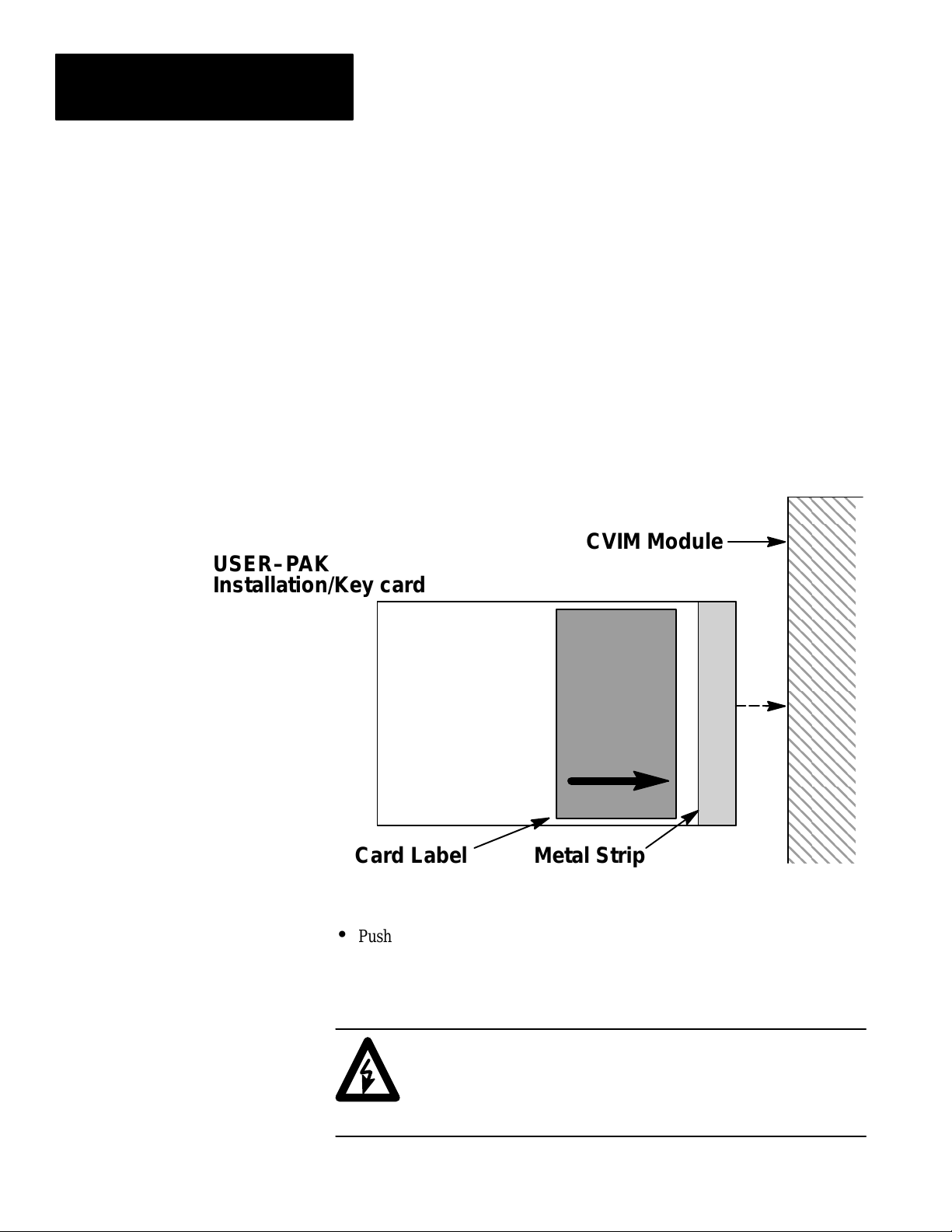

To install the USER–PAK option in your CVIM module:

• Remove DC power from the CVIM module by pulling out the DC PWR /

LOCK handle on the power supply module as far as it will go.

• Insert the Installation / Key card into the Archive Memory slot on the

CVIM module. Insert the end with the metal strip facing right:

USER–PAK

Installation/Key card

Card Label Metal Strip

•

Push in the DC PWR / LOCK handle as far as possible. This applies DC

power to the CVIM module, and starts the loading sequence.

CVIM Module

3–2

CAUTION:

Do not remove power to the CVIM module during loading

of the USER–PAK option. Doing so may damage the

CVIM module.

Page 16

Chapter 3

Installation

The top three LEDs on the CVIM module indicate the progress of the

three–phase loading process, as follows:

LEDs

Pass/Fail

Trigger 1 Green Green Off

Trigger 2 Off Green Green

1

Red–to–yellow–

to–green

USER–PAK Loading Phase

2 3

Green

Red–to–yellow–

to–green

The loading process requires about 45 seconds, with each phase taking

about 15 seconds. When the loading process is complete, the CVIM

module begins its normal powerup sequence.

• Verify that the USER–PAK option is installed by checking the title banner

on the monitor after power–up; if the USER–PAK option is installed,

there is a message on the banner indicating the presence of the

USER–PAK option.

• Remove the Installation / Key card from the Archive Memory slot.

Card Security: Because the Installation / Key card can be used to

override the CVIM system security (see Chapter 4), it is suggested that

this card be kept in a secure place when not in use, and that access to this

card be allowed only to the appropriate authorized personnel.

3–3

Page 17

Chapter 3

Installation

Using the Setup Card

To access most, but not all, of the USER–PAK features while in setup mode,

the Setup card must be inserted.

To insert the Setup card:

• Insert the Setup card into the Archive Memory slot on the CVIM module

with the card’s metal strip facing right.

• Leave the Setup card in the Archive Memory slot as required during your

configuration of the CVIM module.

Setup Card Requirement: Most USER–PAK features require the Setup

card be inserted; the only features which do not require the Setup card are

Change Password (see Chapter 4), and the Copy and Paste feature for

tools (see Chapter 9). When the Setup card must be inserted to access a

feature, this is specifically stated within the description of the feature in this

manual.

Removing the Setup Card: You may remove the Setup card from the

CVIM module at any time – except when the Memory Active LED on the

CVIM module is ON. The Memory Active LED goes ON during setup mode

when certain USER–PAK features are used.

CAUTION:

Do not remove the Setup card from the Archive Memory slot

when the Memory Active LED on the CVIM module is ON.

Doing so will cause the CVIM module to shut down, which

will result in the loss of your working configuration (the

internally–stored configuration is not effected).

Restarting the CVIM module: If the CVIM module operation has shut

down due to Setup card removal with the Memory Active LED ON, restart

the CVIM module when appropriate by cycling CVIM module power off and

on again.

3–4

Page 18

Chapter 3

Installation

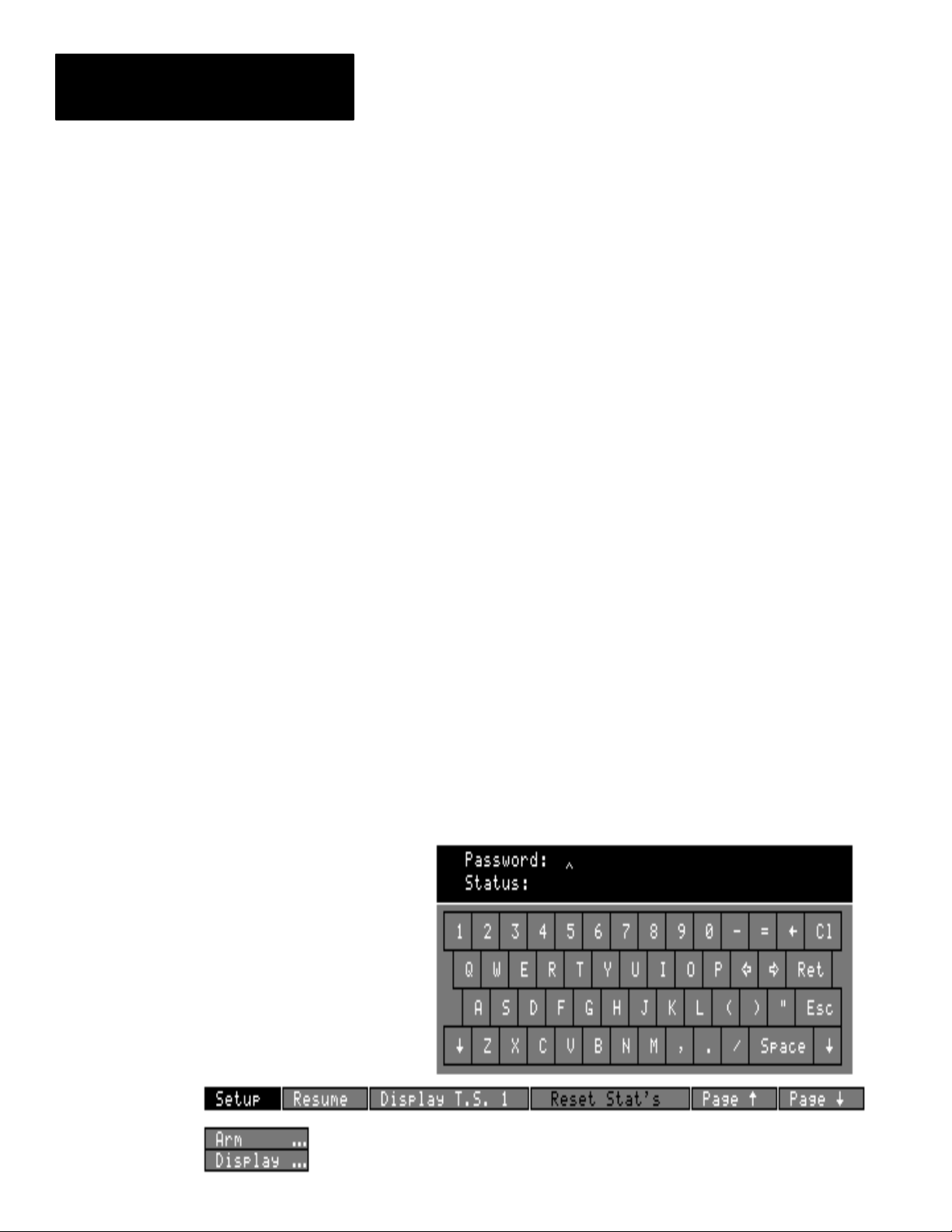

Accessing Setup Mode

with USER–PAK Installed

Password entry

keyboard

Upon installation of the USER–PAK option, access to the setup mode

requires the use of a password. The password is entered through a pop–up

keyboard which appears when you pick the Setup box:

Note: The password requirement for entry can be disabled; see Chapter 4 for

more information on entering the setup mode.

3–5

Page 19

Chapter

Chapter Objectives

A–B

4

Getting Started / Using the Security Levels

Contents

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Some Questions and Answers about System Security 4–1. . . . . . . . . . . . .

Accessing the Setup Mode 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security Levels 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Passwords 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Security ON/OFF 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lost Passwords – Using the Installation/Key Card 4–8. . . . . . . . . . . . . . . .

This chapter describes:

• How to enter the setup mode with the USER–PAK option installed.

• Each of the security levels.

• How to change passwords.

• How to enter setup mode using the Installation / Key Card.

Some Questions and Answers about System Security

This section introduces security by posing some questions and answers.

What type of system security does USER–PAK provide?

With the USER–PAK option installed, access to the setup mode requires a

password (unless security is turned OFF – see Setting Security ON/OFF in

this chapter). The password requirement can help provide assurance against

unauthorized modification of the CVIM configuration, and help prevent

unauthorized personnel from taking the CVIM module out of run mode.

What are “security levels?”

The USER–PAK system security enables access to four different levels of

interaction; we refer to these different levels as “security levels.”

Three security levels are defined within the setup mode, each allowing a

different level of interaction with CVIM / USER–PAK features:

• ADMINISTRATOR – Full access to CVIM / USER–PAK features.

• MANAGER – Mid–level access to CVIM / USER–PAK features.

• USER – Lower–level access to CVIM / USER–PAK features.

Access to CVIM runtime menus and displays does not require a password –

this “runtime” level of interaction can be considered as a fourth level of

security.

Why have different security levels available?

The different security levels allow for implementation of a hierarchical

system of access to and responsibility for the CVIM module setup. For

4–1

Page 20

Chapter 4

Getting Started / Using the Security Levels

instance, a system “administrator” can be designated; this person would have

access to the ADMINISTRATOR level. The ADMINISTRATOR could be

responsible for creating restrictions to the menu items available at the user

level (through menu item deletion), for modifying menu item text, and for

maintenance and security of the passwords which allow access to the

different levels.

A “manager” can be designated, having access to the MANAGER level (that

is, having access to any deleted menus items). Designated “users” would

have access to the USER level; a “user” cannot, for example, modify menus,

change passwords, or set security ON or OFF. The “user” is able to use the

other USER–PAK and base CVIM module capabilities, except those deleted

from the menus at the system administrator level. Finally, at the “runtime”

level, only use of runtime menus and displays is available.

How do you enter a password for access to the setup mode?

You enter the password through the password keyboard; this keyboard

appears automatically when you select Setup on the runtime screen.

Accessing the Setup Mode

What happens if a password is lost?

Entry to the setup mode can be enabled through the use of the USER–PAK

Installation/Key card, should passwords be lost. See “Lost Passwords –

Using the Installation/Key Card” later in this chapter.

After USER–PAK installation, accessing the setup mode requires entry of a

password (unless security has been turned off – see “Setting Security

ON/OFF” later in this chapter).

To enter the setup mode from run mode or standby mode:

• Pick the Setup box on the runtime display, which causes the password

keyboard to appear.

• Enter the appropriate password on the keyboard, and then pick Ret.

4–2

Page 21

Chapter 4

Getting Started / Using the Security Levels

Listed below are further considerations for accessing the setup mode:

First Time Entry – Default Password: For entering the setup mode the

first time after installing the USER–PAK option, the default 3–character

password is A–B.

The initial entry will access the ADMINISTRATOR level of the setup mode.

Non–unique passwords: If the same password is assigned for two or more

levels, the password will access the highest level for that password.

Case–sensitivity: Password entry is case–sensitive. Use the “shift” arrow

key (lower left/right corners) to access the lower–case keyboard if necessary.

Password Display: The characters you select will appear as asterisks to the

right of Password: in the keyboard display.

Security Levels

Incorrect password: If you have not entered the password correctly, the

Status: line in the keyboard will display Incorrect Password:

If this happens, simply try entering the password again. You can try as many

times as is necessary to correctly enter the password.

No Keyboard – Setup Mode entered Directly:

If, when you pick the

Setup box, the CVIM module goes directly to setup mode, this indicates

Security has been turned OFF (see “Setting Security ON/OFF” later in this

chapter to display the password entry keyboard with security OFF).

When you enter the setup mode with USER–PAK installed, you enter one of

three security levels of the setup mode – ADMINISTRATOR, MANAGER,

or USER level (see “Accessing the Setup Mode” in this chapter). A fourth

security level is the “runtime” level – access to runtime menus and displays

during run mode – which does not require a password.

You cannot change your current security level directly within setup mode.

To change security levels, you must exit to run mode, then reenter setup

mode using the appropriate password for the security level you want to enter.

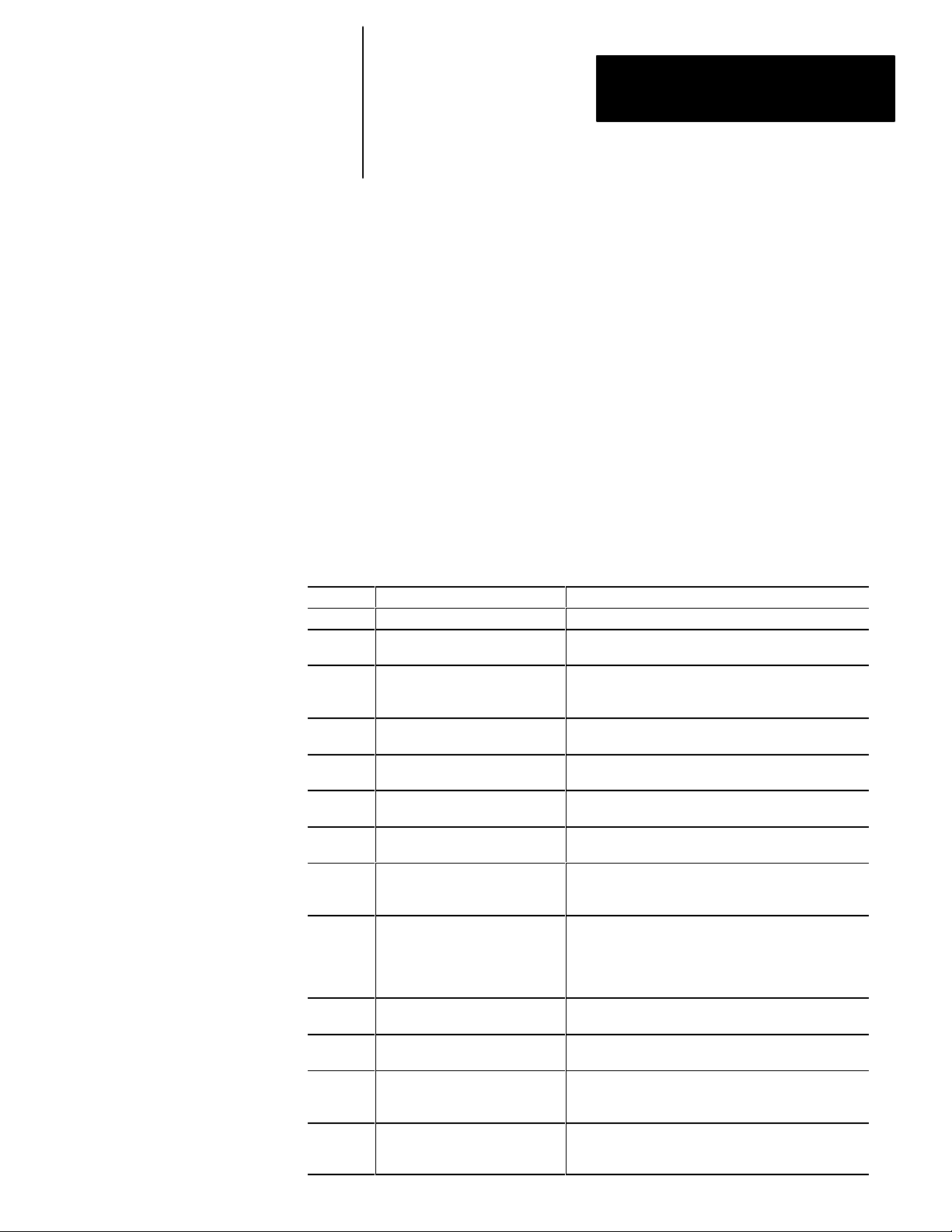

The different security levels each allow a different level of interaction with

the base CVIM module functions and USER–PAK functions. Table 4.A

summarizes the features and functions available at each security level.

4–3

Page 22

Chapter 4

s/

Functions/

Getting Started / Using the Security Levels

Table 4.A

Functions/Features at each Security Level

Function

Features

Change Password

Set Security ON/OFF

Change Text

Menu Item Deletion

Access Deleted Menu Items

Define Serial Ports

Define Viewports

(Base CVIM) Setup Mode Functions

All Runtime Menus/Displays

1

Menu item deletion can be used to selectively delete (deny access to) setup mode functions that are otherwise available at the USER level.

2

Availability of functions at USER level depends on which menu items are deleted.

1

Administrator Manager User Runtime

n

n

n

n

n n

n n

n n

n n

n n

Security Level

n

n

n

n

2

2

2

n

As shown in Table 4.A, the ADMINISTRATOR level allows access to all the

USER–PAK option and base CVIM functions, including exclusive access to

the first four functions listed.

The ADMINISTRATOR for a given system can thus be assigned sole

responsibility for: creating restrictions to the menu items available at the

user level (through menu item deletion); for modifying menu item text; for

setting Security ON/OFF; and/or for assigning the passwords which allow

access to the different levels.

4–4

Note that the subset of features available at the MANAGER and USER

levels is identical, except that the MANAGER has access to menu items

which have been deleted, while the USER does not. Thus the degree of

difference in available features at these two levels, for a given system, is

determined by the ADMINISTRATOR (through menu item deletion).

Page 23

Chapter 4

Getting Started / Using the Security Levels

Security Level Indication

While in setup mode with the USER–PAK option installed, the icons in the

upper right corner of the screen indicate the current security level:

“Trash can” icon

(Administrator Level)

At the ADMINISTRATOR level, the trash can icon appears on the screen.

Changing Passwords

“M” icon

(Manager Level)

If you have entered the MANAGER level, the letter “M” is displayed.

If you have entered the USER level, no security–level icon is displayed.

This section describes the procedure for changing passwords. Passwords can

be changed at the ADMINISTRATOR level only.

Assigning unique passwords: In order to create the availability of

access to each of the different security levels, you must assign a unique

password to each level. If the same password is assigned for two or more

levels, the password will access the highest level for that password.

4–5

Page 24

Chapter 4

Getting Started / Using the Security Levels

For example, if a particular password is used for both the

ADMINISTRATOR and MANAGER levels, using that password will access

the ADMINISTRATOR level. This means, in this case, the MANAGER

level will not be accessible.

Default Password: When first installed, the USER–PAK option assigns the

default 3–character password A–B to all three security levels. Before you

can access each different security level, you must assign a unique password

to each level.

Note: It is suggested, for greater security, that the passwords for the

respective security levels be changed as soon as possible upon installing

the USER–PAK option.

Effect of Password Change: After changing a password, the new password

is immediately stored in non–volatile memory; the next time you want to

enter the setup mode at the security level for which you have just changed

the password, you must use the new password.

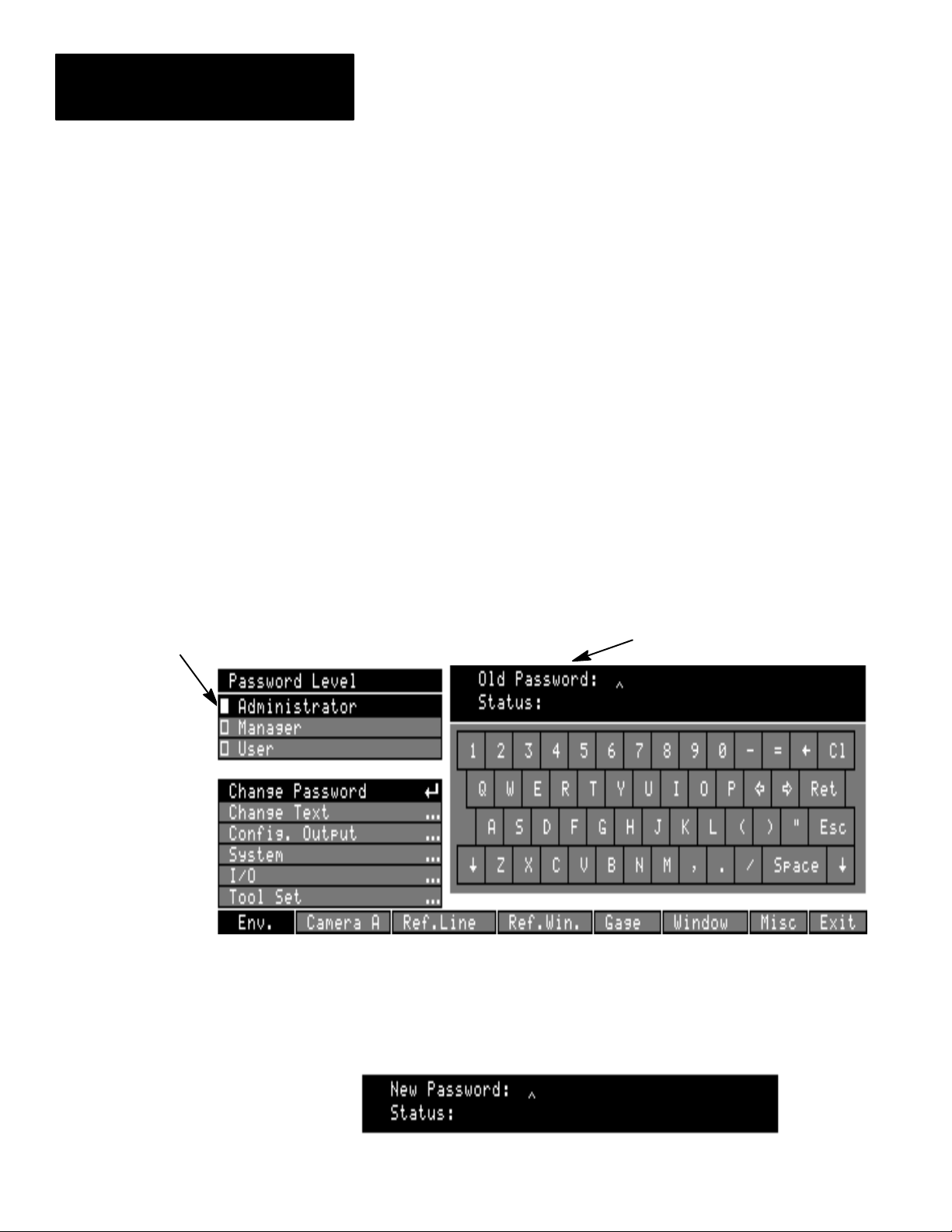

Security level selected

To change a password:

• Pick Env. → Change Password to access the Password Level menu

and display the keyboard:

Password keyboard

• Pick the security level – Administrator, Manager, or User – for which

you are changing the password, on the Password Level menu.

• Enter the old (current) password for the selected level, or the

ADMINISTRATOR level password, using the password keyboard, and

then pick Ret.

4–6

• Enter the new password, and pick the Ret key.

Page 25

Chapter 4

Getting Started / Using the Security Levels

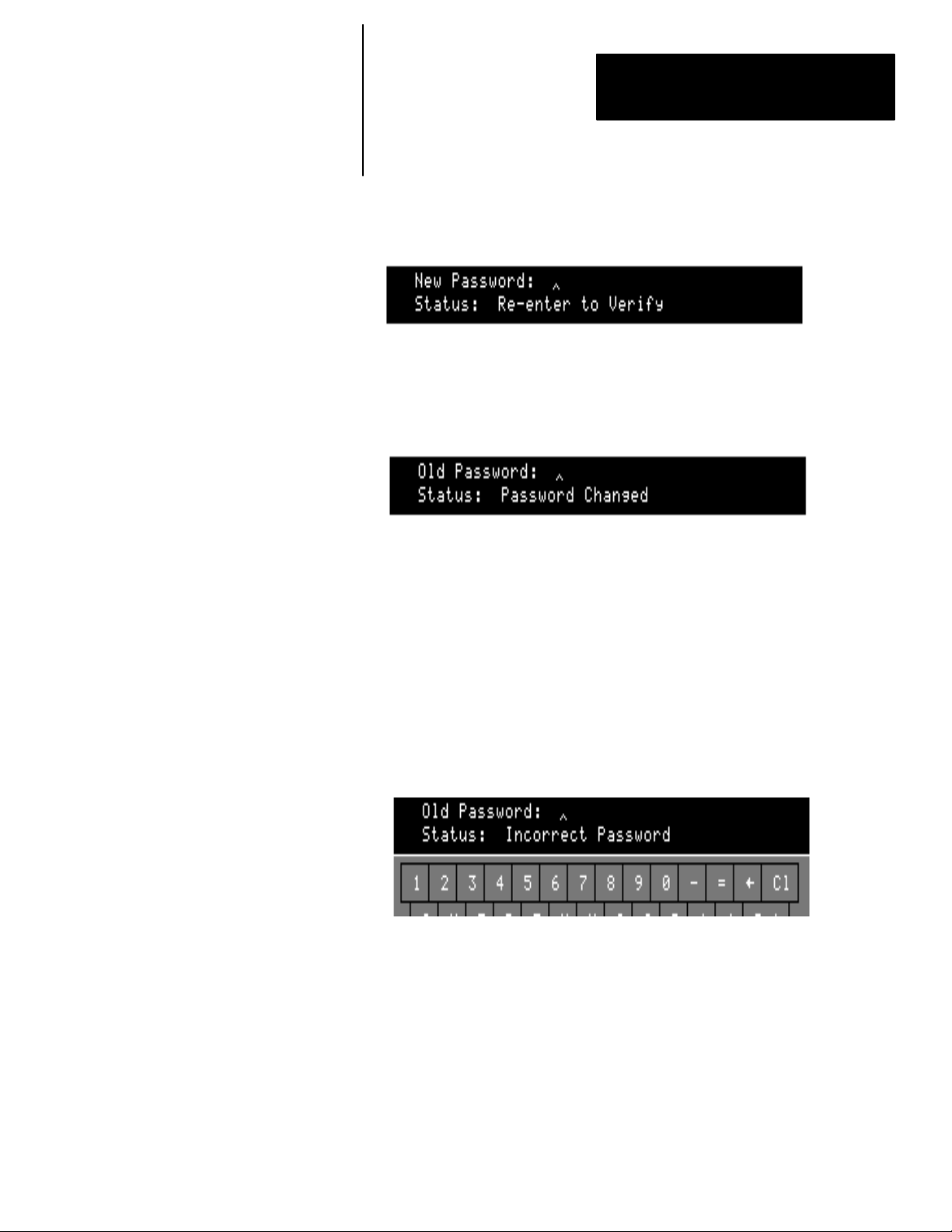

Once you enter the new password, the keyboard prompts you to reenter

the password in order to verify:

• Enter the new password again and pick the Ret key.

If the verification failed, go back to the “Enter the new password” step,

and repeat the procedure from that point. When verification is successful,

the Status: message indicates you have changed the password:

Listed below are further considerations for changing the password:

Case–sensitivity: Password entry is case–sensitive. Use the “shift” arrow

key (lower left/right corners) to access the lower–case keyboard if necessary.

Password Display: The characters you select will appear as asterisks to the

right of Password: in the keyboard display.

Password length / valid characters: You can enter from one to 16

characters (alphanumeric only) for the new password.

Incorrect password: If you have not entered the old password correctly, the

Status: line in the keyboard will display Incorrect Password:

If this happens, simply try entering the password again. You can try as many

times as is necessary to correctly enter the password.

Exit without changing: If you want to exit the procedure without changing

the password, pick the Esc key before completing the verification step.

4–7

Page 26

Chapter 4

Getting Started / Using the Security Levels

Setting Security ON / OFF

The USER–PAK option allows the ADMINISTRATOR to disable security

(that is, remove the password requirement) for entry into the setup mode.

Below are descriptions of the effects of having Security: ON (enabled) and

Security: OFF (disabled):

• Security: ON – A password is required for access to the setup mode.

Whenever you pick the Setup box, the password keyboard will appear

(see “Accessing the Setup Mode” in this chapter).

• Security: OFF – No password is required for entry to the setup mode.

When you pick the Setup box, the CVIM module goes directly to setup

mode.

Security Level accessed with Security OFF: With Security OFF,

picking the Setup box accesses the USER level of the setup mode, unless

the USER level shares a common password with one or both of the other

levels. In this case, the security level entered will be the highest level

available through the common password.

Displaying password keyboard with Security OFF: In order to display

the password entry keyboard with security OFF, hold the tip of the light

pen down upon the Setup box until the keyboard appears (about two

seconds). If you are using a mouse, place the cursor over the Setup box,

and hold the left mouse button down until the keyboard appears.

Lost Passwords – Using the Installation / Key Card

To set Security to ON or OFF (available at ADMINISTRATOR level only):

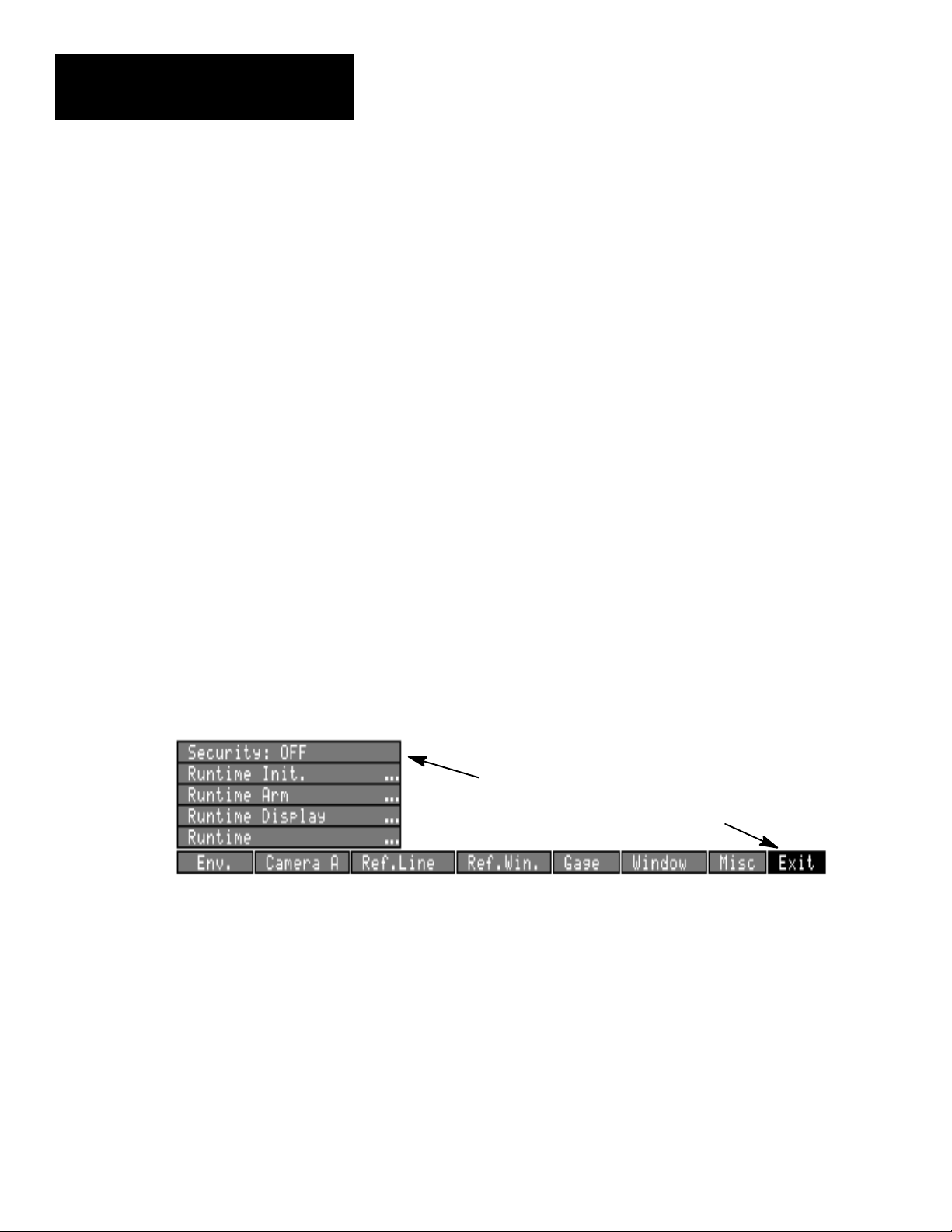

• Pick Exit box on the main menu to access the Exit menu:

Security: box

Exit: box

• Pick the Security box to toggle the setting between ON and OFF.

Default Setting: The default setting is Security: ON.

The USER–PAK option provides a method to effectively override the

password security feature, and enter the setup mode at the

ADMINISTRATOR level. This is accomplished through the use of the

Installation / Key card. This “Key” method of entry is especially important if

the password for the administrator level is lost or is otherwise unavailable.

4–8

Page 27

Chapter 4

Getting Started / Using the Security Levels

To enter the setup mode using the Installation / Key card, complete these

steps:

• If the CVIM module is in setup mode, go to run mode.

• Insert the Installation / Key card into the Archive Memory slot on the

CVIM module.

• Pick the Setup box on the runtime menu to display the password entry

keyboard (Note: If Security has been set to OFF, hold the tip of the light

pen down upon the Setup box until the keyboard appears. If you are using

a mouse, place the cursor over the Setup box, and hold the left mouse

button until the keyboard appears).

• Enter the 3–character default password A–B on the password entry

keyboard, and pick the Ret key.

After entering the setup mode at the ADMINISTRATOR level, it is possible

to change the password for the ADMINISTRATOR level – or any other

level. While the Installation / Key card is inserted, the default password

A–B can be used as the “old password” when changing passwords (see

“Changing Passwords” earlier in this chapter).

4–9

Page 28

Chapter

Chapter Objectives

A–B

5

Modifying the CVIM Menus

Contents

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deletion 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ext Modification 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Archiving Menu Modifications 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Requirement 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The USER–PAK option provides two different ways of modifying the CVIM

module menus. This chapter describes both how to:

• Delete items from CVIM module screens.

• Modify the text of the CVIM module’s menus and help messages.

Note: The above capabilities are available at the ADMINISTRATOR level

only.

Deletion

The USER–PAK option allows you to remove items from the CVIM pop–up

menus, and other on–screen features. By deleting items, the

ADMINISTRATOR can customize the USER level interface, limiting the

user’s access to a subset of CVIM module functions.

A menu item, or other interactive feature, is marked for deletion by the

ADMINISTRATOR; the marked item subsequently is not displayed on the

screen at the USER level. Any subsequent menu(s) that would have been

accessible through the use of a deleted menu item are unavailable as well.

Summary – Effects of Deletion

Deletion affects functionality and appearance of the items differently at each

of the setup mode security levels:

• Administrator Level – Items can be marked for deletion at this level

only. Although items marked for deletion are altered in appearance (an

orange border is added), they retain normal functionality.

• Manager Level – Item deletion does not effect this level; that is, all menu

items are always available, and their appearance is unaltered, regardless

of menu deletions.

• User Level – Items marked for deletion do not appear on–screen at this

level, and thus are not available to the user.

5–1

Page 29

Chapter 5

Modifying the CVIM Menus

Deletion Procedure

Marking an item for deletion involves just a few basic steps (the following

steps assume the ADMINISTRATOR level is accessed):

• Insert the Setup card into the Archive Memory slot on the CVIM module.

• Access the appropriate menu(s) so the item to be deleted is currently

displayed on the monitor screen.

• Activate the delete function – pick the “trash can” icon so the top of the

“trash can” is open. This indicates the delete function is active.

“Trash can”

icon open

(icon is green when open)

Delete function

enabled

• Pick the item(s) to mark for deletion. Marked items are highlighted with

an orange border:

Menu Items Marked

for Deletion

• To unmark a marked item, pick the item again.

• To deactivate the menu delete function when finished, pick the “trash

can” icon so that it appears that the top of the “trash can” is closed.

“Trash can”

icon closed

(icon is red when closed)

Here are some additional considerations when marking items for deletion:

Delete function

disabled

5–2

Paired Menu Items: Paired menu items occupying a single line, such as

Copy/Paste, and Previous/Next, should be deleted as a pair. Otherwise

menu items may overlap when displayed.

Range of Effect: If an item which is marked for deletion is part of a

menu which appears in more than one place, it is deleted from each menu

Page 30

Chapter 5

Modifying the CVIM Menus

where it normally appears, for both toolsets. For example, if you delete a

color selection item from the Color Selection menu for a string, the item

is deleted from any occurrence of the Color Selection menu – including

Color Selection for viewport border and background, and for Graph

variables. Other examples of menus which appear in more than one place

include the Range / Output menu, and the Threshold / Filter menu.

Menu Justification: When menu items are deleted from a menu, the

remaining items, when displayed, will be “justified,” or repositioned,

downward and to the left, as necessary, so that these remaining menu

items are contiguous.

Deletable Items: Almost any item can be deleted, including items such as

slide bar cursors (which appear when Threshold / Filter is selected, for

example), vernier arrows (used within the Pick & Place function), and

menu titles.

Non–Deletable Items: Certain menu and screen items can never be

deleted, because of the nature of their function. These items include:

– The help icon and menu–hide icon (the two icons in the upper right

corner of the monitor).

– The handles which appear on tools when Pick & Place is activated.

– The slide bar (which appears when Threshold / Filter is selected, for

example). However, the slide bar cursors can be deleted.

– The Exit box on the Main menu.

– The Runtime box on the Exit menu.

– The Goto Runmode box on the Runtime menu.

– The keyboard and calculator pad, and their keys.

Picking an item that cannot be deleted displays this message:

5–3

Page 31

Chapter 5

Modifying the CVIM Menus

Example – Menu Item Deletion

Several items on the Define Window menu are marked for deletion, as

shown below:

“Trash can”

icon open

Menu Items Marked

for Deletion

As a result of the menu deletions marked in the example above, this

shortened version of the Define Window menu appears at the USER level:

Define Window menu at the

User Level (deleted items do

not appear).

5–4

Page 32

Chapter 5

Modifying the CVIM Menus

The Cascade Effect

If all items except one have been deleted from a menu, and the one

remaining menu item has a three dot leader, the “cascade effect” occurs at

the USER level.

The cascade effect is this: At the USER level, the subsequent menu or

function appears in place of the single menu item.

For example, if you delete all items from the Define Window menu, except

P&P Process Win. box, when you pick the Define Window box at the

USER level, the screen would look like this:

(Define Window menu does

not appear at the User Level).

As you can see, the Define Window menu does not appear. In this case,

since the P&P Process Win. box is the only item available on the Define

Window menu, picking the Define Window menu would activate the P&P

Process Win. function.

The P&P Process Win.

function is activated.

5–5

Page 33

Chapter 5

Modifying the CVIM Menus

Text Modification

The USER–PAK option enables you to modify the text of menu items, and of

on–screen messages such as the help messages or the title banner.

Note: To modify text, you must be at the ADMINISTRATOR level.

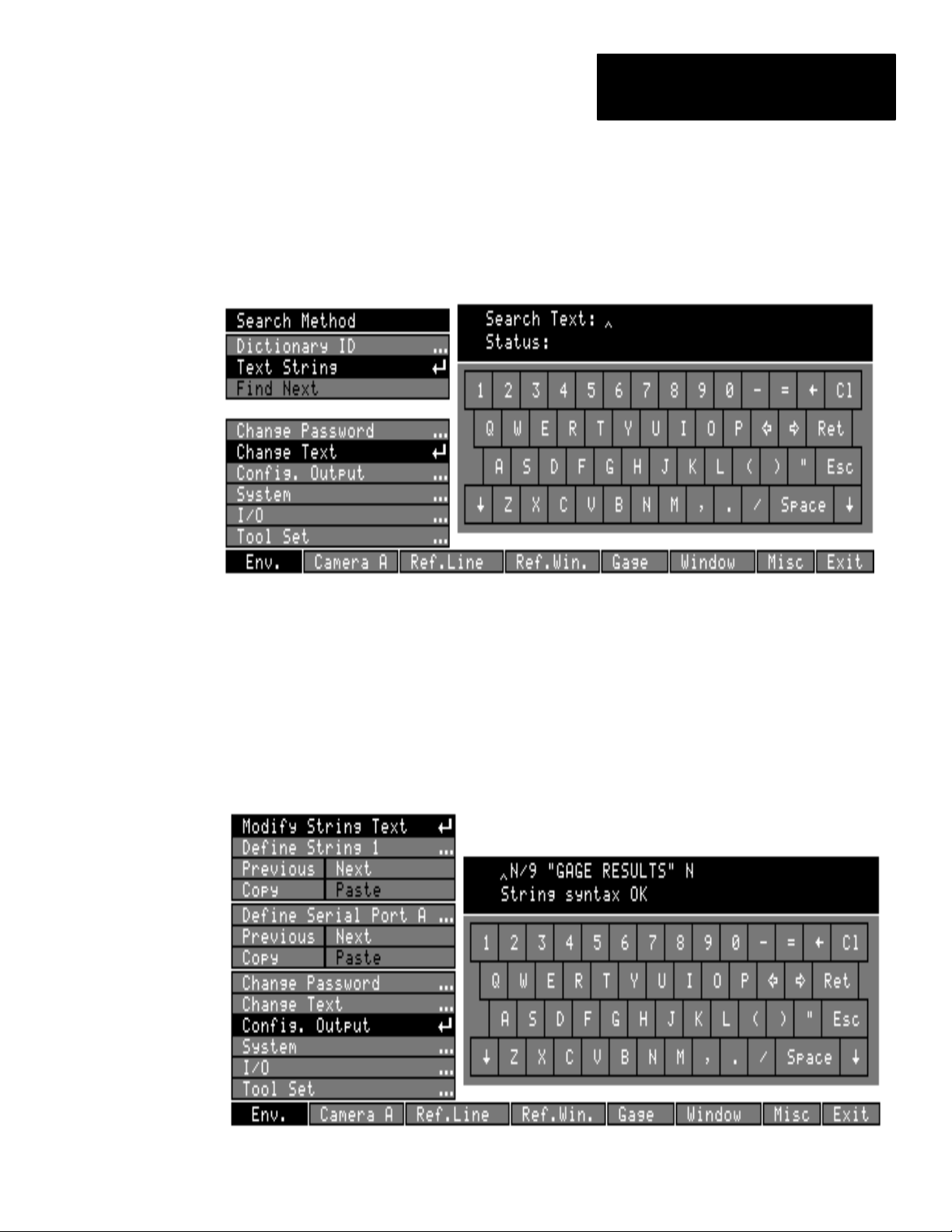

To modify text, you pick the Change Text item (on the Env. menu), and

then search for specific entries within CVIM text “dictionary.” After

locating an entry, you then edit the entry as necessary. To begin to modify

text:

• Insert the Setup card into the Archive Memory slot.

• Pick the Env. box on the main menu.

• Pick the Change Text box. This displays the Search Method menu:

Search Method menu

Change Text box

5–6

Searching for Text

All text used in the CVIM module user interface (menu items, help

messages, etc.) is contained in a “dictionary” in CVIM memory; individual

entries are referenced by a “dictionary ID” number. Dictionary entries

include single–word terms (like “gage” or “window”), multiple–word terms

(“Define Gage”), and complete sentences (such as help messages).

You can use either of two search methods for finding the entry you want to

modify:

• Dictionary ID – If you know the dictionary ID number of an entry you

want to edit, you can use the dictionary ID to find that entry.

• Text String – You use the Text String option just like the search feature

on a word processor. That is, you can enter a word, part of a word, or

multiple–word text string to search among the CVIM “dictionary” of

terms, in order to find a specific entry.

A third item on the Search Method menu, Find Next, is enabled after either

Dictionary ID or Text String is selected. The Find Next feature is discussed

where appropriate in each of the two search procedure sections.

Page 34

Chapter 5

Modifying the CVIM Menus

Text String Search

To use the Text String method for accessing a dictionary entry to modify,

follow this procedure:

• First, pick the Text String box on the Search Method menu to access

the Search Text: entry keyboard. The keyboard’s display area includes

two fields, Search Text: and Status:

• Enter the text item, or a portion of the text item, that you want to modify,

on the keyboard. Your entry appears in the Search Text: field:

• Pick the Ret key; the CVIM then searches the entries in its dictionary, in

numerical order, for the first entry containing the text string you entered.

5–7

Page 35

Chapter 5

Modifying the CVIM Menus

When you pick the Ret key, one of two results can occur:

(1) No dictionary entry is found to contain the text you entered; the

Status: box returns the message Sub–text Not Found. If this

happens, try entering a different string.

(2) A dictionary entry containing the search text is found; the text of

that dictionary entry appears in the New Text: field now located over

the keyboard. The dictionary ID number of the entry is listed in the

Status: field of the keyboard display (it is suggested that you record

this ID number; you can use it later to quickly access the specific

dictionary entry again, in case you want to edit it again).

• The dictionary entry that is found may not be the specific entry you want

to change. In this case, pick the Find Next: box to locate the next

dictionary entry containing the search text. Repeatedly pick the Find

Next: box until the desired entry is located.

• When the desired entry is listed in the New Text: field, edit the entry as

necessary (see “Editing Text” later in this chapter).

Here are some additional considerations when searching for text strings:

Case–Sensitivity: The search text is not case–sensitive.

Reenabling Find Next: The Find Next: box is disabled after a

dictionary entry is modified. To use the same search string again after

modifying an entry, you must reenter the search string, and pick Ret.

Dictionary ID Search

To use the Dictionary ID method for accessing an entry to modify, follow

this general procedure:

• First, pick the Dictionary ID box on the Search Method menu to access

the ID entry keyboard. The keyboard’s display area includes two fields,

Dictionary ID: and Status:

• Enter the dictionary ID number of the entry you want to edit. Your entry

appears in the Dictionary ID: field in the keyboard display.

5–8

Page 36

Chapter 5

Modifying the CVIM Menus

• Pick the Ret key. One of two results can occur:

(1) If the dictionary ID number you entered is not defined, the Status:

field returns the message Invalid Dictionary ID. If this happens, try

entering a different dictionary ID number.

(2) If the dictionary ID number you entered is defined, the text of that

dictionary entry appears in the New Text: field now located over the

keyboard. The dictionary ID number of the entry is listed in the

Status: field of the keyboard display:

• The New Text: entry listed may not be the specific entry you want to

change. If it is not, you can either:

(1) Enter a different dictionary ID number, or

(2) Pick the Find Next: box, which increments the dictionary ID

number, and displays the text string for that ID number. Repeat until

the specific entry you want to modify is located.

• When the New Text: entry listed is the entry you want to change, edit the

text as necessary (see “Editing Text” later in this chapter).

Reenabling Find Next: The Find Next: box is disabled after a

dictionary entry is modified. To use the Find Next box again, you must

enter a dictionary ID number again.

5–9

Page 37

Chapter 5

Modifying the CVIM Menus

Editing Text

After you find the entry you want to modify (the entry is displayed in the

New Text: field), edit the entry text using the following keys:

Left / Right

Arrows

←→ Left/right arrows: Use to move cursor on the same line. For some

dictionary entries, such as help messages, all of a line cannot be

displayed at once, so you must use the right arrow initially to display

the remainder of the line.

EOL Character (displayed)

Up / Down

Arrows

EOL

Character

(keyboard)

↑↓ Up/down arrows: Use to jump from line to line when editing

multiple–line entries. In some dictionary entries, such as those which

store help messages or multiple–line menu entries, the text is stored on

multiple lines. An EOL character (↵ ) is present at the end of a line

whenever a subsequent line of text follows.

5–10

← Backspace: Use to delete the character to the left of the cursor.

Cl Clear: Use to delete the entire entry.

EOL End of Line: Use to start a new line of text (shown as EOL on the

keyboard, and as ↵ in the keyboard display area).

Note: If you modify the text of a menu item which has multiple lines

(such as the runtime display options menu available during run mode),

Page 38

Chapter 5

Modifying the CVIM Menus

use the EOL character to create enough lines to account for all the

lines in the menu item, in order to have the background color filled in

for all lines (even if some lines have no text).

For example, the All Tools menu item on the runtime menu contains

two lines. Within the All Tools dictionary entry, there is an EOL ( ↵ )

character after the word All which creates another line within the

dictionary entry. The diagram below shows the effect that removing

the EOL character would have on the displayed menu item:

With EOL

Character

Without

EOL

Character

Esc Escape: Use to abandon any changes you make. Pick the Esc key (or

pick any other menu item) before picking the Ret key.

When you have finished editing an entry: You have these options –

(1) Pick the Ret key; the dictionary entry is changed to the text you have

entered. The Status: field displays the message Dictionary Entry

Changed.

(2) Pick the Esc key to exit from the edit without changing the text. The

search string or dictionary ID is displayed. The entry will remain as last

edited.

To restore the original text to a modified entry: Locate the dictionary

entry you want to restore (if it is not currently displayed), using either search

method. When the desired entry appears in the New Text: field:

• Pick Cl, and then pick Ret. The Status: field displays the message –

Base CVIM Text Restored (if the text has not been previously modified,

the Status: field displays the message – Invalid Replacement Text).

To restore all the original menus and text, or load previously stored

modifications, see “Archiving Menu Modifications” later in this chapter.

5–11

Page 39

Chapter 5

Modifying the CVIM Menus

Here are some additional considerations when editing text:

Multiple Menu Usage of a Dictionary Entry: In some cases, the same

dictionary entry is used in more than one menu. Modifying the entry will

affect all menus containing that entry.

For example if you modify the dictionary entry Gage to read Gauge, the

change is seen both on the main menu, and in the Gauge 1: Enabled box,

as shown in the diagram below, because both used the same dictionary entry.

Words Used in Multiple Entries: In some cases, a word may be used in

more than one dictionary entry. Thus, to modify all occurrences of that

word, you must modify each of the dictionary entries where it appears.

For example, if you modify the dictionary entry Gage to read Gauge, the

Define Gage box remains unchanged, as shown below, because it uses a

different dictionary entry:

“Define Gage” is not affected by modification of the dictionary

entry “Gage” to read “Gauge.”

“Gauge” now appears in these two menu

items, both of which use the same dictionary

entry.

Maximum Size / Truncation: A text modification is truncated upon entry if

it exceeds the maximum size (four lines, 47 characters per line). Also, upon

display, a dictionary entry which is too long to fit into its respective display

area (such as a menu box) is truncated to fit the area.

Restricted Dictionary Entries: Certain dictionary entries cannot be

modified, because doing so would affect the functionality of the respective

menu item. If you locate a restricted dictionary entry, the Status message in

the keyboard display area shows this message: ID ## cannot be changed.

An example of a restricted entry is shown below:

5–12

Other Restrictions: Menu items which are a part of installed software

options (other than the USER–PAK option) are not listed among the

dictionary entries, and will not be located when you search for text, nor will

the text in the title banner which identifies the CVIM module firmware series

and revision number, and the installed options. Thus these items cannot be

edited.

Page 40

Chapter 5

Modifying the CVIM Menus

Examples of Modifying Text

Example 1: We want to change the runtime menu item Result Page to

Gage Result, a name which identifies the custom display we have created to

replace the Result Page display.

To do this:

• Pick Env.→ Change Text box to display the Search Method menu.

• Pick the Text String box. This displays the keyboard.

• Using the keyboard, enter these characters: RESULT

and pick the Ret key. This locates the Result Page dictionary entry and

displays the first line:

• Pick Clr to clear the entry.

• Enter these characters: Gage (EOL)

(The EOL character is on the shift keyboard). The New Text area will be

empty at this point – this is because picking the EOL character creates a

blank second line, which is displayed in the New Text area.

• Enter these characters on the second line: _ Results (where _ is a

space character)

• To review the first line, use the ↑ arrow key on the shift keyboard:

• Pick the Ret key. The Status: field displays the message Dictionary

Entry Changed.

Having changed the dictionary entry, when you next display the runtime

Display menu, the Result Page box will be changed to read Gage Results.

5–13

Page 41

Chapter 5

Modifying the CVIM Menus

Example 2: We want to change the Env.→ System→ Units menu item,

CM, to MM to reflect the actual range of measurements in our inspections.

Change CM

to read MM

To do this:

• Pick Env.→ Change Text box to display the Search Method menu.

• Pick the Text String box.

• Using the keyboard, enter the string CM and pick the Ret key.

This locates and displays the CM dictionary entry.

• Edit the entry to read MM and pick the Ret key. The Status: field

displays the message Dictionary Entry Changed.

Having changed the dictionary entry, when you next display the Env.→

System→ Units menu, the CM item will be changed to read MM.

Note: The selected Units entry also appears in the Learn box on the

Gage menu, when you select Learn for a Gage set to Linear operation.

5–14

MM (or other selected

unit) appears here

Page 42

Chapter 5

Modifying the CVIM Menus

Archiving Menu Modifications

Memory Requirement

Menu modifications, if saved internally, can be accessed in a separate

configuration called the Menus configuration. This allows you to load

previously stored menu modifications specifically, while retaining other parts

of the configuration. To restore the original menus and text, you can load the

default Menus configuration from internal storage. See Chapter 10 for more

information regarding the saving and loading of configurations.

Menu item deletion and text modifications are stored in an area of CVIM

memory which has also been designated for storing window templates, and

configurable output (serial ports and viewports). If there is a shortage in

remaining allocated memory while attempting deletion and/or text editing,

the respective modification feature will not work.

To check the amount of allotted memory remaining, refer to “Checking

Available Memory” in Chapter 10.

5–15

Page 43

Chapter

Chapter Objectives

A–B

6

Creating Custom Serial Port Messages

Contents

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Some Questions and Answers about Custom Serial Port Messages 6–1. . .

Creating Custom Serial Port Messages 6–2. . . . . . . . . . . . . . . . . . . . . . . . .

Defining the Serial Port 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232 Port Connections and Configuration 6–8. . . . . . . . . . . . . . . . . . . .

This chapter describes how to use the Config. Output feature of the

USER–PAK option to create custom serial port messages, including how to:

• Select and define a serial port

• Define serial port strings

• Connect and configure the CVIM serial port for communication

Some Questions and Answers about Custom Serial Port Messages

This section introduces custom serial port messages, by posing some

questions, and answering them.

What are custom serial port messages?

For communication between the CVIM module and a remote device, the

CVIM module has a serial port (CVIM module series A has one serial port,

series B or later, two serial ports). With the USER–PAK option installed,

you can create your own custom serial port messages for transmission

through the serial port. The messages consist of ASCII characters.

What types of information can be sent?

Within each message you can send literal text, results and other data on

specific tools, statistical data, and other information.

How do you create custom serial port messages?

You create serial port messages using the Config. Output feature, which is

part of the Env. menu (when the USER–PAK option is installed).

The format of a message is defined by a “string.” The string consists of text

which specifies the format and content of the message, the condition under

which the message is transmitted, and repetition parameters, which can be

used to transmit the message multiple times for the same condition.

How do you determine when a custom serial port message is sent?

When defining a message string, you select the “event” which causes the

string to be sent. The string can be sent after each inspection, or only upon

certain conditions, such as the failure of a specific tool, for instance.

6–1

Page 44

Chapter 6

Creating Custom Serial Port Messages

How many strings can be defined?

The CVIM module can store up to 340 strings, depending on how much of

the CVIM module’s memory is used for other purposes.

Can the custom serial port messages coexist with the standard RS–232

port communications with a host device?

The custom serial port messages may interfere with the transmission of the

response to a command from an RS–232 device. For this reason, a command

is available which allows you to disable and enable the transmission of

custom serial port messages (see Appendix C).

Do you need to set up any CVIM module parameters when using custom

serial port messages?

Yes, you need to select ASCII protocol, and select the appropriate baud rate

for the RS–232 port you are using.

Creating Custom Serial

Port Messages

You create a custom serial port message by defining a “string” for a given

serial port. It is the content and definition of the string that determine what

information will be sent through the serial port, and when it will be sent.

Using the string entry keyboard, you enter specific “elements” – literal text,

and/or codes of various types – which result in the transmission of one or

more corresponding “fields” comprising the serial port message.

Also, aside from defining the string content, you must specify the “event” for

each string – that is, the circumstances under which the string is transmitted.

You can also utilize a string repetition feature to transmit a single message

multiple times for the same event.

Example of a Serial Port Message String

This section provides an example of a serial port message string, for the

purpose of demonstrating string text, and the resulting message content.

Assume the gage 1 result for an inspection is 25.3, and the string text is

“Gage 1 Result =” g1

6–2

where the g1 in the string text is a “data code” which represents the results

from gage 1. The message transmitted would be these ASCII characters –

Gage_1_Result_= _ _ _25.300 (where _ indicates a space character)

For a listing of the entire ASCII character set, refer to Appendix B.

Page 45

Viewport Border

Chapter 6

Creating Custom Serial Port Messages

Basic Steps for Creating Custom Serial Port Messages

To create a custom serial port message:

• Insert the Setup card into the Archive Memory slot on the CVIM module.

• Pick the Env. → Config. Output boxes to display the Config. Output

menu; this may display a viewport (if a viewport is currently selected):

Previous / Next boxes

Viewport 1 selected

Config. Output box selected

• Select the specific serial port (A or B) you are going to use for

communication using the corresponding Previous/Next boxes.

Picking Next box repeatedly cycles though the selection of Viewports

1–40, then Serial Port A, Serial Port B, then Viewports 1–40, etc.

Picking the Previous box when Viewport 1 is displayed would select

Serial Port B; picking Previous again would select Serial Port A.

• Define one or more “strings” for the selected serial port:

− Select the string, using the corresponding Next/Previous boxes.

String 1 selected

− Pick the Enter String Text box to display the string entry keyboard.

Using the string entry keyboard, you enter specific string “elements”

6–3

Page 46

Chapter 6

Creating Custom Serial Port Messages

– literal text, and/or codes of various types – for the string (see

Chapter 8 for more information on elements of string text).

Enter String Text box