Page 1

Allen-Bradley

Bulletin 5370

t

CVIM

Module

Reference

(Cat. No 5370–CVIM2)

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

death, property damage or economic loss.

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

ControlNet is a trademark; PLC is a registered trademark of Allen-Bradley Company, Inc.

Page 3

Table of Contents

CVIM2 Module

Reference Manual

Hardware Connection and

Power

CVIM2 System Configuration:

An Overview

Chapter 1

CVIM2 System Components 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting CVIM2 System Components 1–2. . . . . . . . . . . . . . . . . . . . . . .

Installing the CVIM2 Module 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Optional DC Power Supply Cable 1–3. . . . . . . . . . . . . . .

Connecting the I/O and Camera Cables 1–5. . . . . . . . . . . . . . . . . . . . . .

Connecting the I/O Interface Cable (2801–NC17, –NC17A) 1–5.

Connecting the User Interface Cable (2801–NC20A, B, C):

VGA Monitor 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the User Interface Cable (2801–NC19A, B, C):

N8 Monitor 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the User Interface Cable (2801–NC19A, B, C):

Other RS–170 Monitors 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Camera Cable: 2801–YC Camera 1–7. . . . . . . . .

Connecting the Camera Cable: 2801–YB, –YD,

and –YE Camera 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Mouse Cable 1–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Powering Up CVIM2 System 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring CVIM2 System For Mouse Operation 1–10. . . . . . . . . . . . . . .

Chapter 2

After System Powerup 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CVIM2 Configuration: Four Basic Phases 2–2. . . . . . . . . . . . . . . . . . . . . .

Major Configuration Functions 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Configuration File Names 2–3. . . . . . . . . . . . . . . . . . . . . . . .

Picking the Editors Menu 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Configuration Parameters 2–4. . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Image Acquisition Parameters 2–6. . . . . . . . . . . . . . . . . . . . .

Selecting Discrete I/O Parameters 2–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Online Operation 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Pointer Functions 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Light Pen and Mouse Operation 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Center Button and Right Button 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard Functions 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculator Keypad Functions 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Acquisition

Parameters

Chapter 3

Camera Setup Panel 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

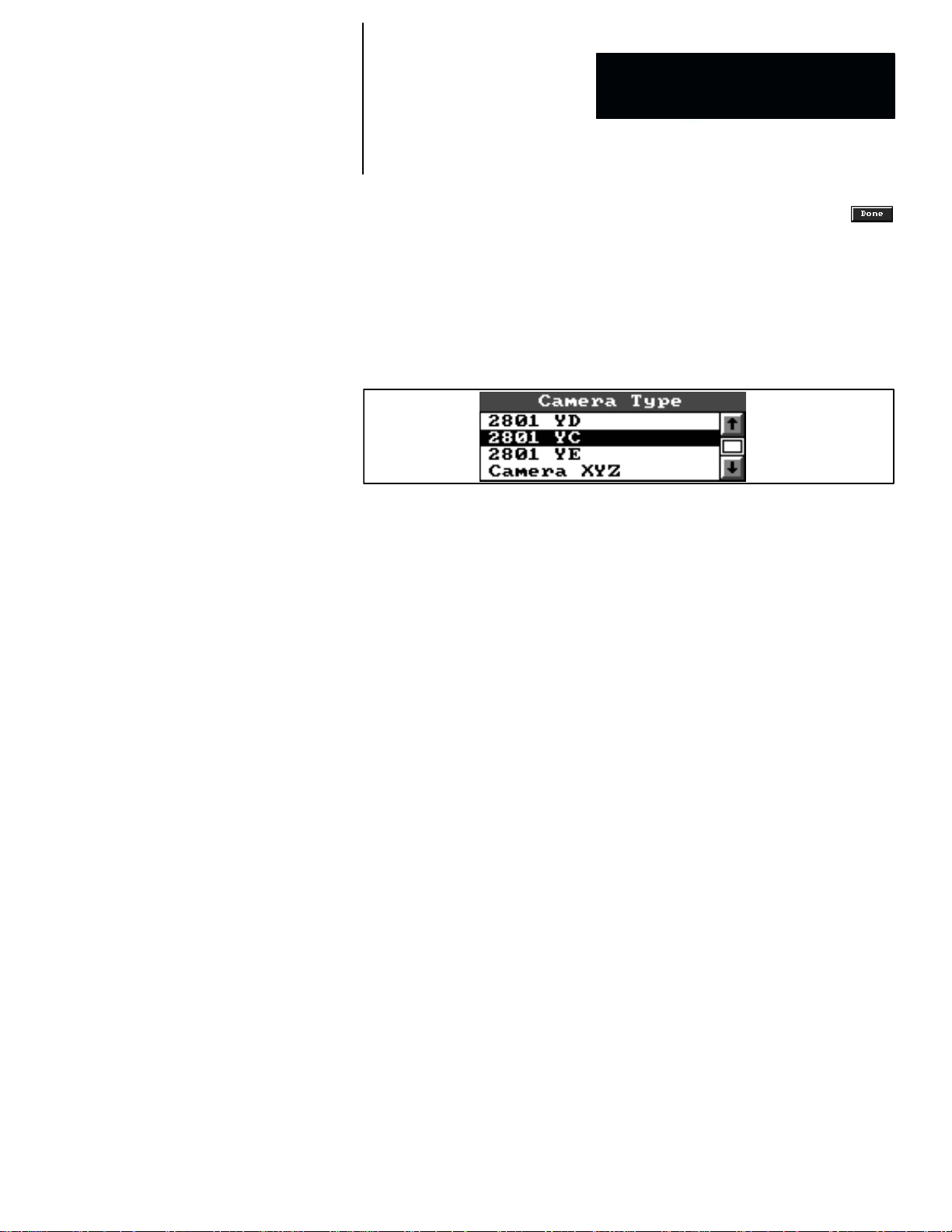

Camera Type Selection 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horizontal Resolution Selection 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Selections 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger/Rate/Source/Strobe Selections 3–5. . . . . . . . . . . . . . . . . . . . . .

Shutter Speed Selection 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Table of Contents

CVIM2 Module

Reference Manual

Image Acquisition

Parameters

Chapter 3 (continued)

Focus Function 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Light Reference Adjustment 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Light Reference Settings 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Light Probe Setup 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Light Probe Operation: General 3–12. . . . . . . . . . . . . . . . . . . . . . .

Light Probe Panel 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Light Probe “Tool Type” and Range Limits 3–13. . . . . . . . . . . . . . .

Light Probe Tool Results and Math Tool Formulas 3–14. . . . . . . . . . . . .

Calibration Setup 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Applications 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration: Basic Steps 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Setup 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Calibrate Function 3–17. . . . . . . . . . . . . . . . . . . . . . . . . .

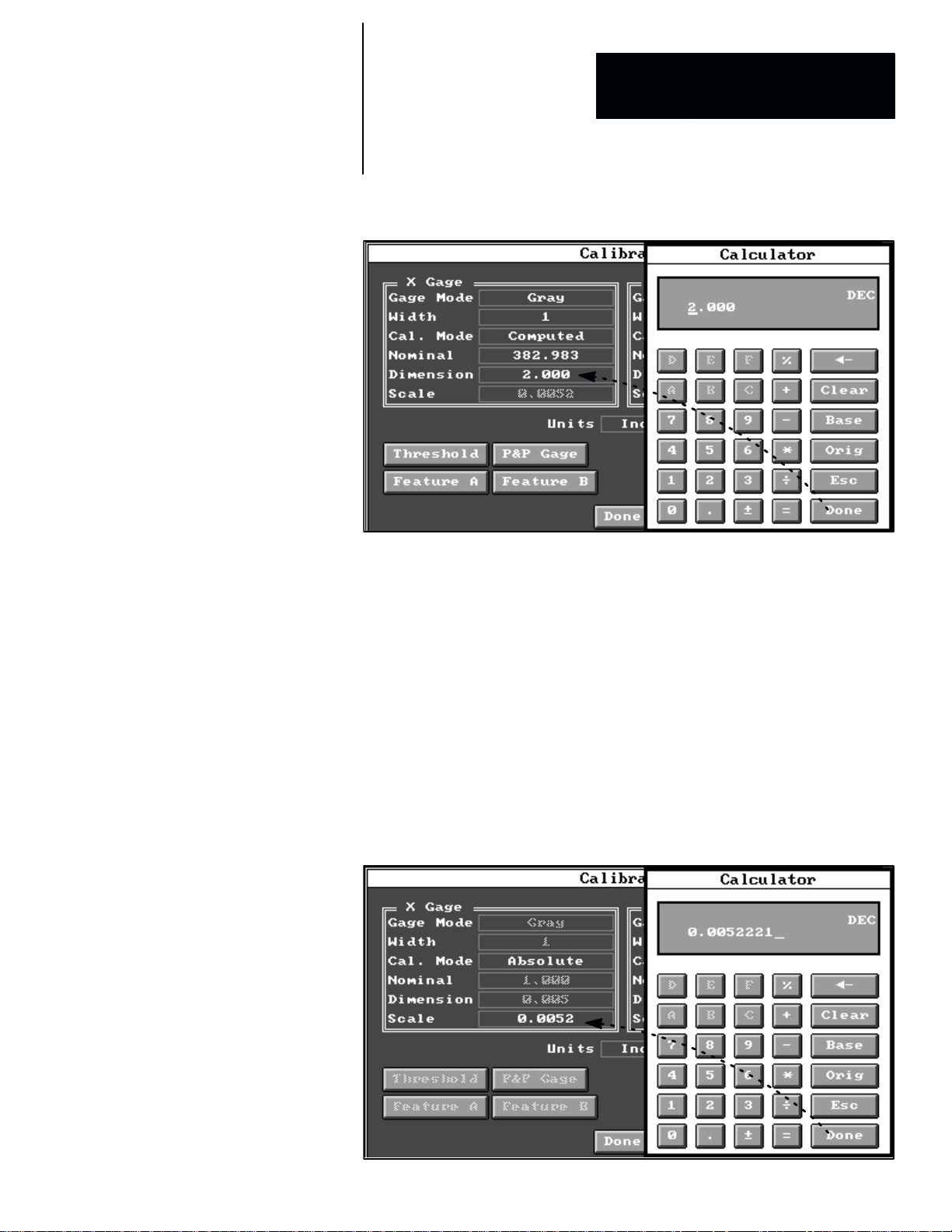

Calibrate Mode: Computed Mode vs Absolute Mode 3–19. . . . . . .

Selecting Gaging Mode (Computed Mode Only) 3–20. . . . . . . . . .

Pick and Place Functions (Computed Mode Only) 3–21. . . . . . . . .

Threshold Adjustments and Offset Selections

(Computed Mode Only) 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Units Selection 3–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing Scale Computation (Computed Mode Only) 3–23. . . . .

Entering Scale Value (Absolute Mode Only) 3–25. . . . . . . . . . . . . .

Acquisition System Settings 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Camera Type 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horizontal Reference Source 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vertical Reference Source 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camera Bank Switching 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bank Switch Mode 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bank Switch Command Input 3–31. . . . . . . . . . . . . . . . . . . . . . . . .

Bank Switch State Output 3–32. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camera Type: Selection and Editing 3–33. . . . . . . . . . . . . . . . . . . . . . . . . .

Camera Type Edit Panel 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Standard Allen–Bradley Cameras 3–34. . . . . . . . . . . . . . . .

Editing Non–Standard Cameras 3–40. . . . . . . . . . . . . . . . . . . . . . . .

Trigger Setup Panel 3–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection Configuration

ii

Chapter 4

Configuration Process 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Editor Panel 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection Names and Archive Names 4–8. . . . . . . . . . . . . . . . . . . . . .

Basic Configuration Procedure 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Inspection Name 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Acquisition Parameters 4–11. . . . . . . . . . . . . . . . . . . . . . . .

Selecting Inspection Parameters 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents

CVIM2 Module

Reference Manual

Inspection Configuration

Pick And Place Functions

Chapter 4 (continued)

Overlap Acq/Insp 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum Time 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Samples 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Range Failures 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Display Parameters 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up Image Display Panels 4–18. . . . . . . . . . . . . . . . . . . . . . .

Setting Up Results Display Panels 4–19. . . . . . . . . . . . . . . . . . . . . .

Setting Up Inspection Tools 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Toolset Edit Panel: Miscellaneous Functions 4–27. . . . . . . . . . . . . . . . . . . .

Data Fields and Buttons 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Destination Buffers 4–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options Selection Panel 4–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternate Toolset Save Option 4–34. . . . . . . . . . . . . . . . . . . . . . . . .

Toolset Register Function 4–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Manager Panel 4–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Subimage 4–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Full Image 4–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

Pick and Place Terms 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linear Gages 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Lines 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Arc Gages 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rectangular Windows 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Elliptical Windows 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circular Windows 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Arc Ring Windows 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Polygon Windows 5–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Light Probes 5–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Tools

Chapter 6

Reference Line Tool 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Reference Line Tool Configuration 6–2. . . . . . . . . . . . . . . . . .

Reference Line Tool Operations 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X only 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y only 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X then Y 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y then X 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X’, X then Y 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y’, Y then X 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Line Tool Configuration 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Selection 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 6

Table of Contents

CVIM2 Module

Reference Manual

Reference Tools

iv

Chapter 6 (continued)

Shape Selection 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filter Function 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Width Selection 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pick and Place Function 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Threshold Setting Function 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feature Selection 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Direction 6–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset 6–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nominal (“Learn”) Function 6–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Line Tool Inspection Results and Math Tool Formulas 6–25. . . .

Reference Window Tool 6–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Window Tool: Basic Elements 6–26. . . . . . . . . . . . . . . . . . . .

Reference Window Tool Edit Panel 6–27. . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Reference Window Tool Configuration 6–28. . . . . . . . . . . . . . .

Reference Window Tool Configuration 6–29. . . . . . . . . . . . . . . . . . . . . . . . .

Active Feature Selection 6–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feature Image Configuration 6–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Image Manager Panel 6–30. . . . . . . . . . . . . . . . . . . . . . . .

Saving Feature Image 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Search Window Configuration 6–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Pass vs Double Pass 6–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First Pass Configuration 6–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Masking Function 6–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stop When Selection 6–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X Scale, Y Scale Selections 6–40. . . . . . . . . . . . . . . . . . . . . . . . . . .

Scale To Selections 6–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pixel Error Parameter Selections 6–43. . . . . . . . . . . . . . . . . . . . . . .

Second Pass Configuration 6–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nominal (“Learn”) Function 6–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Window Tool Inspection Results and Math Tool Formulas 6–50.

Rotation Finder Tool 6–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Rotation Finder Tool Configuration 6–54. . . . . . . . . . . . . . . . . .

Rotation Finder Tool Configuration: Example 6–54. . . . . . . . . . . . . . . . . . .

Rotation Finder Tool Inspection Results and Math Tool Formulas 6–62. . . .

Build Reference Tool 6–64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Build Reference Tool Configuration 6–66. . . . . . . . . . . . . . . . . .

Examples: Build Reference Tool Configuration and Operation 6–67. . . . . .

Example: X Mode Operation 6–67. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Theta Operation 6–72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Build Reference Tool Inspection Results and Math Tool Formulas 6–78. . .

Tool Register Function 6–79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Table of Contents

CVIM2 Module

Reference Manual

Inspection Tools

Chapter 7

Overview: Inspection Tool Selection Process 7–1. . . . . . . . . . . . . . . . . . .

Gage Tool 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Gage Configuration 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gage Shape 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gaging Mode 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gage Operations 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

White Pixels; Black Pixels 7–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foreground Objects; Background Objects 7–8. . . . . . . . . . . . . . . . . . . .

Binary Gaging Mode: Foreground Objects 7–8. . . . . . . . . . . . . . .

Binary Gaging Mode: Background Objects 7–9. . . . . . . . . . . . . .

Gray Scale Gaging Mode: Foreground Objects 7–10. . . . . . . . . . .

Gray Scale Gaging Mode: Background Objects 7–12. . . . . . . . . . .

Edges 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linear Measure 7–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X Position 7–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y Position 7–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theta (Arc and Circle Gage Only) 7–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Wedge Angle (Arc and Circle Gage Only) 7–16. . . . . . . . . . . . . . . . . . . .

Chord Angle (Arc and Circle Gage Only) 7–17. . . . . . . . . . . . . . . . . . . .

Feature Selection Functions 7–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode 7–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All Edges 7–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Max Object 7–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Max F. Object 7–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Max B. Object 7–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Direction 7–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset 7–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gage Tool Inspection Results and Math Tool Formulas 7–24. . . . . . . . . . . .

Window Tool 7–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Window Configuration 7–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Window Shape 7–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Window Operations 7–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

White Pixels; Black Pixels 7–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

White Contours; Black Contours 7–34. . . . . . . . . . . . . . . . . . . . . . . . . . .

Target Panel 7–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contour Measurement Fields 7–36. . . . . . . . . . . . . . . . . . . . . . . . . .

Contour Options Panel 7–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pick Target Panel 7–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contour Measurement Functions 7–45. . . . . . . . . . . . . . . . . . . . . . .

Luminance 7–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Two Pass 7–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Window Tool Inspection Results and Math Tool Formulas 7–55. . . . . . . . .

Image Tool 7–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 8

Table of Contents

CVIM2 Module

Reference Manual

Inspection Tools

vi

Chapter 7 (continued)

Overview: Image Tool Operations 7–58. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Tool Edit Panel 7–59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Tool Operations: Selection 7–61. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Tool Operations: Transform 7–62. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Tool Operations: Convolve 7–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sobel X, Sobel Y Kernels 7–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Laplace Kernel 7–66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X Edge, Y Edge Kernels 7–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XY Edge Kernel 7–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Average 3x3, Average 5x5 Kernels 7–72. . . . . . . . . . . . . . . . . . . . . . . . .

User 3x3, User 5x5 Kernels 7–74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Kernel Contrast 7–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Convolution Kernels and LUT Selections 7–77. . . . . . . . . . . . . . . . . . . .

Image Tool Operations: Image Arithmetic 7–79. . . . . . . . . . . . . . . . . . . . . .

Image Subtraction: S1 – S2, S1 – S1’, S1 – T7–80. . . . . . . . . . . . . . . .

S1 – S2 7–80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S1 – S1’ 7–82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S1 – T7–83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Addition: S1 + S2, S1 + S1’, S1 + T 7–83. . . . . . . . . . . . . . . . . .

Image Tool Operations: Warning Messages 7–84. . . . . . . . . . . . . . . . . . . . .

Image Tool Shape 7–87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rectangle 7–87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Arc Ring 7–87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quad 7–89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Perspective 7–90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Tool Kernel 7–91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Tool Template 7–94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Tool

Look–Up Table (LUT) 7–95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Tool Direction 7–96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Tool Morph Passes 7–97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Tool Inspection Results and Math Tool Formulas 7–99. . . . . . . . . . .

Feature Finder Tool 7–101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feature Finder Tool: Basic Elements 7–101. . . . . . . . . . . . . . . . . . . . . . .

Feature Finder Tool Edit Panel 7–101. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Feature Finder Tool Configuration 7–103. . . . . . . . . . . . . . . . . . .

Feature Finder Tool Configuration 7–104. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Name: Feature Image Configuration 7–104. . . . . . . . . . . . . . . . . .

P&P: Search Window Configuration 7–104. . . . . . . . . . . . . . . . . . . . . . .

Passes: First and Second Pass Configuration 7–104. . . . . . . . . . . . . . . . .

First Pass Configuration 7–104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Second Pass Configuration 7–105. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Max. Number: Limiting Feature Recognition 7–105. . . . . . . . . . . . . . . . .

Page 9

Table of Contents

CVIM2 Module

Reference Manual

Inspection Tools

Chapter 7 (continued)

Nominal (“Learn”) Function 7–105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feature Finder Tool Inspection Results and Math Tool Formulas 7–107. . . .

Math Tool 7–110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Math Tool Configuration 7–112. . . . . . . . . . . . . . . . . . . . . . . . . .

Formula Components and Configuration 7–113. . . . . . . . . . . . . . . . . . . . . . .

Results 7–116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Results Sources 7–118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expanded Tool Results 7–118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Previous Results 7–119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trig Functions 7–120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Functions 7–124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Functions 7–127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Statistics Functions 7–130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous Functions 7–132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Math Tool Inspection Results and Math Tool Formulas 7–135. . . . . . . . . . . .

Math Tool Formula Examples 7–137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: ATN2 Function 7–137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: DST Function 7–138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Using Multiple Windows to Count Objects 7–139. . . . . . . . . .

Example: List Processing 7–141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Using Formulas to Perform Complex Inspections 7–142. . . . .

Example: Using a Single Math Tool to Generate Multiple Results 7–144

Profile Tool 7–147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Profile Tool: Components and Initial Setup Process 7–149. . . . . . . . . . . . . .

Profile Window 7–151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Profile Display 7–151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X Direction Profile Display 7–151. . . . . . . . . . . . . . . . . . . . . . . . . . .

Y Direction Profile Display 7–153. . . . . . . . . . . . . . . . . . . . . . . . . . .

Threshold Display 7–154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Profile Tool Configuration 7–155. . . . . . . . . . . . . . . . . . . . . . . . .

Profile Tool Operations 7–155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Position 7–156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Distance 7–157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foreground Objects; Background Objects 7–159. . . . . . . . . . . . . . . . . . . .

Edges 7–160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Direction 7–162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filter 1 and Filter 2 7–162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feature Selection Functions 7–164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode 7–165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All Edges 7–166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FG Border 7–166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BG Border 7–167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Max Object 7–167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 10

Table of Contents

CVIM2 Module

Reference Manual

Inspection Tools

Chapter 7 (continued)

Max FG Object 7–167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Max BG Object 7–167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Middle FG Object 7–167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Middle BG Object 7–168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Direction 7–168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset 7–168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Method 7–169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Threshold Adjustments and Mode Selection 7–170. . . . . . . . . . . . . . . . . . . . .

Slide Bar 7–170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Selection 7–171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixed Mode 7–171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Min+%Diff High Mode 7–172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Min+%Diff Low Mode 7–173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Min+Offset Mode 7–174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Max–Offset Mode 7–176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Morphology Filter Selection 7–177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Profile Tool Inspection Results and Math Tool Formulas 7–177. . . . . . . . . . .

Ranges 7–179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conditional Processing 7–183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Gages Tool 7–187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Multiple Gages Tool Configuration 7–189. . . . . . . . . . . . . . . . . .

Sub–Gage Operations 7–190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Width and Kernel Functions 7–190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Threshold Functions 7–191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gage Label Function 7–192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feature Selection Functions 7–193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Gages Tool Inspection Results and Math Tool Formulas 7–194. . . .

Multiple Windows Tool 7–196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview: Multiple Windows Tool Configuration 7–198. . . . . . . . . . . . . . . .

Sub–Window Operations 7–198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Threshold/Filter Functions 7–199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label Function 7–200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Windows Tool Inspection Results and Math Tool Formulas 7–200.

Thresholds, Filters, And

Morphology

viii

Chapter 8

Gaging Tools: Binary Threshold Procedures 8–2. . . . . . . . . . . . . . . . . . . .

Threshold Settings: Left and Right Cursors 8–2. . . . . . . . . . . . . . . . . .

Binary Filter 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gaging Tools: Gray Scale Edge Detection 8–5. . . . . . . . . . . . . . . . . . . . . .

Threshold and Kernel Settings 8–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Area Tools: Threshold and Morphology Functions 8–9. . . . . . . . . . . . . . .

Binary Threshold Function 8–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Binary Threshold Function (Count Black Pixels Operation Only) 8–10.

Page 11

Table of Contents

CVIM2 Module

Reference Manual

Thresholds, Filters, And

Morphology

Discrete I/O Assignments

Chapter 8 (continued)

Dynamic Threshold Function 8–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Morphology Function 8–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Morphology Selection Panels 8–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Binary Morphology 8–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gray Scale Morphology 8–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9

Discrete I/O Editor Panel:

General Information 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Panel Layout and Functions 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relation of Discrete I/O Assignments to Configuration File 9–3. . . . . .

Discrete Inputs: Interrupt Processing vs Poll Processing 9–3. . . . . . . .

Hardware Interrupt 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Polling 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module I/O Functions 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Input Selections 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bank Switch Input Selection 9–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DV Reset Input Selection 9–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In1 – In8 Input Selections 9–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Input Selection: Parts Tracking Function 9–7. . . . . . . . . . . . . . .

Output Selections 9–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Selections 9–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

+/– Selections 9–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Force Selections 9–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Status from Various +/– and Force Selections 9–15. . . . . . . . . . .

System I/O Functions 9–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Outputs 9–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote I/O Functions 9–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete I/O Signal

Timing Data 9–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environment Menu

Selections

Chapter 10

Revision Data 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration File Selection 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variables 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Variables 10–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding Variables 10–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Archiving Variables 10–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restoring Archived Variables 10–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232 Serial Port Setup 10–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote I/O Serial Port Setup 10–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable/Disable Discrete Outputs 10–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Online Operations 10–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Page 12

Table of Contents

CVIM2 Module

Reference Manual

Environment Menu

Selections

File Functions

Chapter 10 (continued)

Online Image/Tool Display Panel 10–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Tools 10–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display 10–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resume 10–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reject Queue Size 10–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rejects Held 10–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection Results Display Panel 10–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Totals Detail Panel 10–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tool Results Detail Panel 10–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 11

File Panel: Description and Use 11–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File List Column Headings 11–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Devices and Device Status 11–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File Panel Buttons 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File Types 11–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filter 11–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Devices: Definitions and Descriptions 11–6. . . . . . . . . . . . . . . . . . . . . . . . .

View 11–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy 11–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XCopy 11–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete 11–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Change 11–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Format Function 11–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recycle Function 11–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Security

Warning and Error Messages

Environment Variables

Index

x

Chapter 12

Security Levels 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Level 8 Security Setup 12–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Password Changes 12–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security Administration 12–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

View Password File 12–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Add a New User or Modify an Existing User 12–8. . . . . . . . . . . . . . . . .

Adding a New User 12–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying an Existing User 12–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete a User 12–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Administer Function 12–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Text: Menu Field 12–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Text: Button Field 12–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Access Privilege Levels 12–13. . . . . . . . . . . . . . . . . . . . . .

Security Card 12–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Appendix B

Page 13

Chapter

1

Hardware Connection and Powerup Check

This chapter shows you how to connect the CVIM2 system components and

perform a powerup check.

CVIM2 System Components

The procedures in this chapter cover only those components that are related

to the CVIM2 machine vision system, namely:

• CVIM2 module, Catalog No. 5370–CVIM2.

• Pyramid Integrator chassis:

Four–slot chassis, Catalog No. 2801–NX3.

Eight–slot chassis, Catalog No. 2801–NX4.

• Vision chassis, Catalog No. 2801–AM2

• Chassis power supply, Catalog No. 2801–NX2.

• RS–170 Video monitor: Color, 13–inch, rack–mounted, 115VAC,

Catalog No. 2801–N8.

• VGA video monitor: Catalog No. 2711–M14; 2711–MT14.

• Light pen, Catalog No. 2801–N7.

• Camera, Catalog No. 2801–YC, –YD, and –YE.

• Interface modules:

User interface box, Catalog No. 2801–N22.

User interface box, Catalog No. 2801–N26.

I/O interface box, Catalog No. 2801–N27.

Interface board, Catalog No. 2801–JMB.

• Interconnecting cables.

Additional components may be required for some CVIM2 system

configurations. These will be identified in the connection procedures.

For complete information on installing the CVIM2 system in its factory floor

location, refer to the Allen–Bradley Pyramid Integrator Installation Manual,

Publication 5000–6.2.10, which is supplied with the Pyramid Integrator

chassis.

1–1

Page 14

Chapter 1

Hardware Connection and Powerup Check

Connecting CVIM2 System Components

Before you install the CVIM2 system at its factory–floor site, you may find it

useful to connect the basic system components temporarily on a workbench

or table top.

If, however, you intend first to install the CVIM2 system at its factory–floor

site, refer to the following Allen–Bradley publications for site installation

information.

• Pyramid Integrator Installation Manual, Publication No. 5000–6.2.10.

Chapter 4, Grounding the Components, is of particular importance.

• Grounding and Wiring Guidelines, Publication No. 1777–4.1.

• Solid–state Control Safety Guidelines, Publication No. SGI–1.1.

After completing the site installation, return to this section.

Installing the CVIM2 Module

The CVIM2 module uses a DC–to–DC converter to supply power to the

cameras. The converter gets its DC voltage from either the chassis power

supply (+12VDC and –12VDC) or from an external DC power supply

(+24VDC).

When using a 2801–NX3 or –NX4 chassis, here are the situations in which

you must use an external DC power supply:

• More than three cameras are connected to a single CVIM2 module.

• Two or more CVIM2 modules are installed in a single chassis, and more

than three total cameras are connected to the modules.

• Any of cameras #4, #5, or #6 are to be used, regardless of the total

number of cameras used or the number of CVIM2 modules installed.

When using a 2801–AM2 vision chassis, an external DC power supply is not

needed; however the CVIM2 module must have the DC voltage selection

switch set to the 24V position. (The integrated power supply for the

2801–AM2 chassis provides both 12VDC and 24VDC. See Publication No.

2801–2.7, page 9, for more information about the 2801–AM2 vision chassis.)

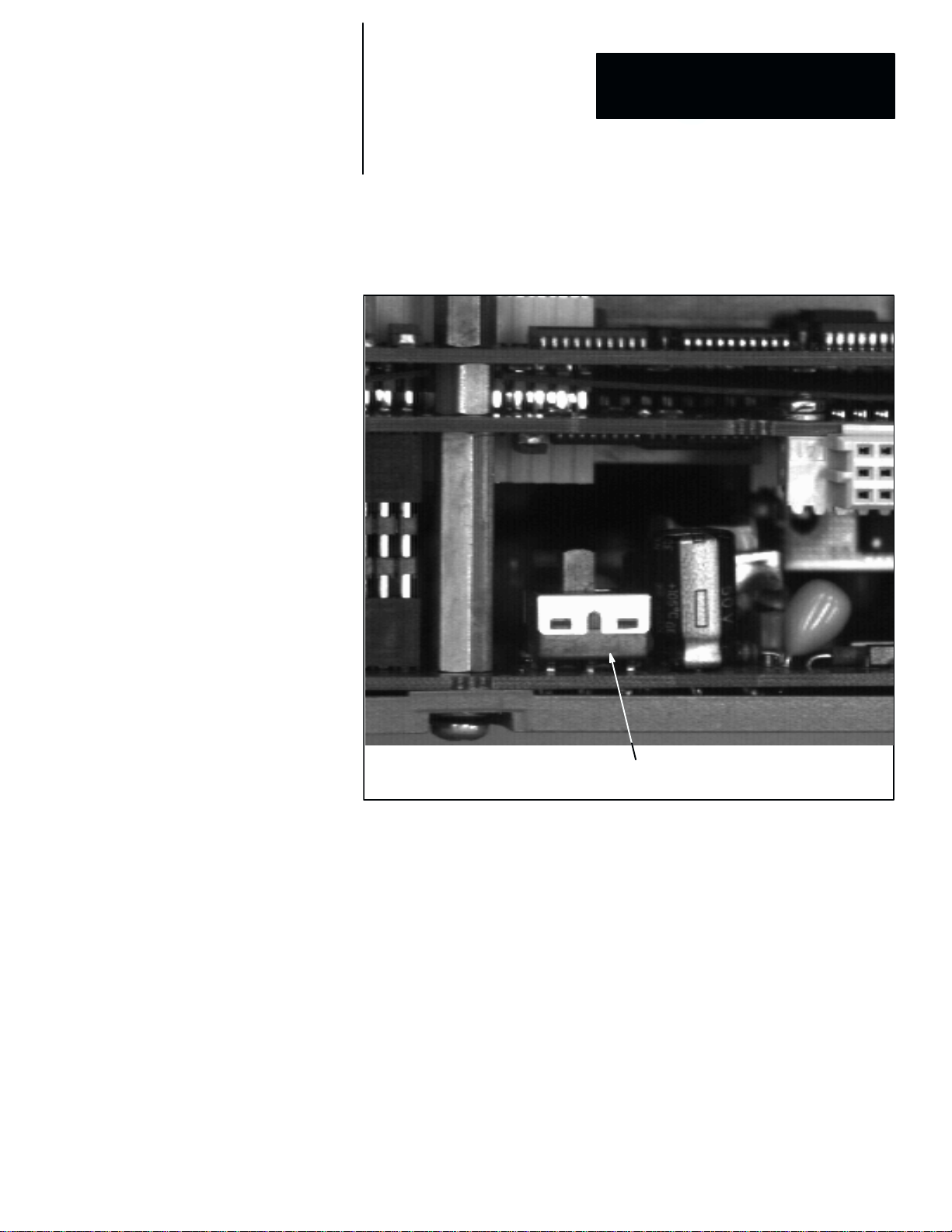

Use the following steps to set the DC voltage selection switch on the CVIM2

module:

1. Locate the DC voltage selection switch on the back of the CVIM2

module. Refer to Figure 1.1 (page 1–3).

2. Set the switch as shown in Figure 1.1 (the 12V setting) for applications

using three or fewer cameras.

3. Set the switch to the 24V position for applications using more than three

cameras, or using any of cameras #4, #5, or #6.

1–2

Page 15

Chapter 1

Chapter

Hardware Connection and Powerup Check

5

4. Install the CVIM2 module in the chassis. Tighten the thumbscrews

alternately until the module is fully seated in the chassis.

Figure 1.1 CVIM2 Module (back view): DC V oltage Selection Switch

DC Voltage selection switch

(shown in internal source position)

Installing the Optional DC Power Supply Cable

If your application requires an external +24VDC power supply, you can use

one of two Allen–Bradley DC power supply cables to connect the external

+24VDC power supply to the Pyramid Integrator chassis power supply. The

power supply must have sufficient capacity to power all of the cameras.

These are the Allen–Bradley DC power supply cables:

• Catalog No. 5120–CP3 –– for applications not requiring a fan chassis (for

cooling the Pyramid Integrator chassis power supply).

• Catalog No. 5120–CP2 –– for applications using the eight–slot chassis

and requiring a fan chassis.

Note that each cable has a set of four color–coded leads terminated with

spade lugs.

1–3

Page 16

Chapter 1

Hardware Connection and Powerup Check

Attach the color–coded leads on the DC cable to the external DC power

supply as follows:

1. Connect the triple red leads to the DC power supply’s main “+ output”

terminal.

2. If your DC power supply has a “+ sense” terminal, connect the single red

lead to that terminal. Otherwise, connect the single red lead to the “+

output” terminal, along with the triple red leads.

3. Connect the triple black leads to the DC power supply’s main “– output”

terminal.

4. If your DC power supply has a “– sense” terminal, connect the single

black lead to that terminal. Otherwise, connect the single black lead to

the “– output” terminal, along with the triple black leads.

5. Connect the molded plug on the other end of the DC power supply cable

to the Pyramid Integrator power supply front panel jack labeled “Fan

Chassis.”

6. If your application has a fan chassis and you are using the 5120–CP2

cable, connect the smaller molded plug to the jack in the fan chassis.

Finally, attach a line cord or other AC power supply cables to the DC power

supply, as appropriate for your installation.

NOTE: Do not apply AC power to the DC power supply yet.

1–4

Page 17

ММММММММ

ММММММММ

1771 CHASSIS

Ì

Ì

Ì

P

L

C

REMOTE I/O LINK

MACHINE VISION

CAMERA 6

MACHINE VISION

CAMERA 1

MACHINE VISION CAMERAS

2801–YB

2801–YD

2801–YE

CABLES CABLES

2801–NC5 (5M)

2801–NC6 (10M)

2801–NC7 (25M)

RS – 232

SERIAL COMMUNICATIONS

2801–YC

2801–NC14 (5M)

2801–NC15

(10M)

2801–NC16

(25M)

Chapter 1

Chapter

Hardware Connection and Powerup Check

5

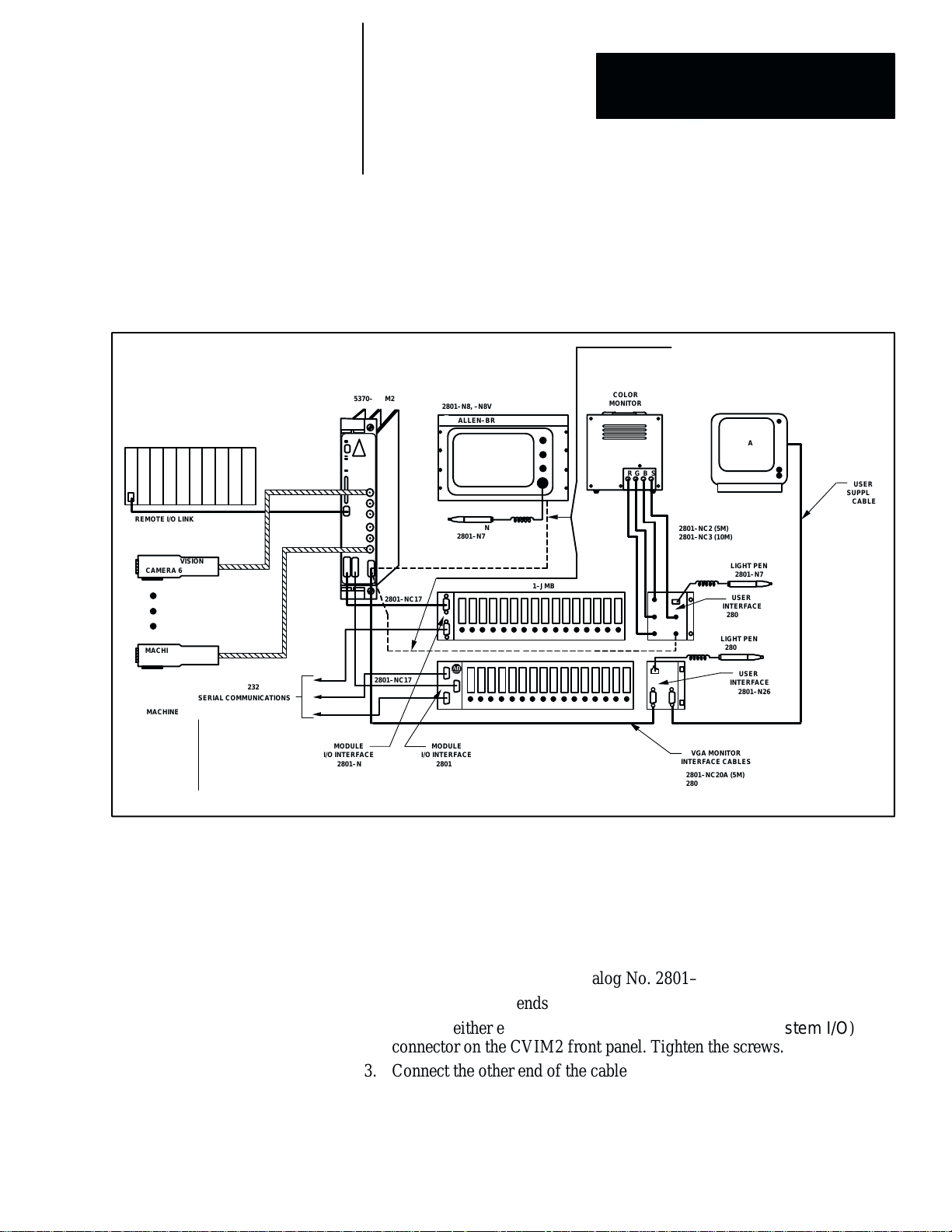

Connecting the I/O and Camera Cables

Refer to the CVIM2 interconnect diagram (Figure 1.2) for the I/O and

camera cable connections in the next steps.

Figure 1.2 CVIM2 Interconnect Diagram for I/O Cables

MONITOR INTERFACE

CABLES

2801–NC19A (5M)

2801–NC19B (10M)

5370–CVIM2

MODULE

I/O INTERFACE

2801–N21

2801–NC17

2801–NC17

2801–N8, –N8V

ALLEN–BRADLEY

LIGHT PEN

2801–N7

MODULE

I/O INTERFACE

2801–N27

2801–JMB

2801–JMB

COLOR

MONITOR

RGB S

2801–NC19C (25M)

CABLES

2801–NC2 (5M)

2801–NC3 (10M)

LP

B

G

S

R

IN

VGA MONITOR

INTERFACE CABLES

2801–NC20A (5M)

2801–NC20B (10M)

2801–NC20C (25M)

VGA

LIGHT PEN

2801–N7

USER

INTERFACE

2801–N22

LIGHT PEN

2801–N7

USER

INTERFACE

2801–N26

USER

SUPPLIED

CABLE

Connecting the I/O Interface Cable (2801–NC17, –NC17A)

Use the following steps to connect the I/O interface cable to the I/O interface

module:

1. Locate the I/O interface cable, Catalog No. 2801–NC17 or –NC17A, and

the I/O interface module, Catalog No. 2801–N21 or –N27.

NOTE: The two ends of this cable are identical.

2. Connect either end of the cable to the Module I/O (or System I/O)

connector on the CVIM2 front panel. Tighten the screws.

3. Connect the other end of the cable to the CVIM connector on the I/O

interface module. Tighten the screws.

NOTE: The I/O interface cable can be connected directly from the CVIM2

module to I/O interface module 2801–N28 on the 2801–AM2 vision chassis.

1–5

Page 18

Chapter 1

Hardware Connection and Powerup Check

Connecting the User Interface Cable (2801–NC20A, B, C): VGA

Monitor

Use the following steps to connect the user interface cable when a VGA

monitor is to be used:

1. Locate the user interface cable, Catalog No. 2801–NC20A, B, or C, and

the user interface module, Catalog No. 2801–N26.

NOTE: The two ends of this cable are identical.

2. Connect either end of the cable to the User Interface connector on the

CVIM2 front panel. Tighten the screws.

3. Connect the other end of the cable to the CVIM2 connector on the user

interface module. Tighten the screws.

4. Connect the 15–pin connector on the VGA monitor cable to the VGA

MONITOR connector on the user interface module.

5. Connect the light pen, if used, to the LIGHT PEN socket on the user

interface module.

Connecting the User Interface Cable (2801–NC19A, B, C): N8 Monitor

Use the following steps to connect the user interface cable when an

Allen–Bradley 2801–N8 color monitor is to be used:

1. Locate the user interface cable, Catalog No. 2801–NC19A, B, or C.

2. Connect the 15–pin connector on the cable to the User Interface

connector on the CVIM2 front panel. Tighten the screws.

3. Connect the other end of the cable to the VIDEO INPUT connector on

the rear panel of the N8 color monitor.

4. Connect the light pen, if used, to the LIGHT PEN socket on the N8

monitor front panel.

Connecting the User Interface Cable (2801–NC19A, B, C): Other

RS–170 Monitors

Use the following steps to connect the user interface cable when a monitor

other than the Allen–Bradley 2801–N8 is to be used:

1. Locate the user interface cable, Catalog No. 2801–NC19A, B, or C, and

the user interface box, Catalog No. 2801–N22.

2. Connect the 15–pin connector on the cable to the User Interface

connector on the CVIM2 front panel. Tighten the screws.

3. Connect the other end of the cable to the INPUT connector on the N22

box.

4. Connect the light pen, if used, to the LIGHT PEN socket on the user

interface module.

1–6

Page 19

Chapter 1

Chapter

Hardware Connection and Powerup Check

5

5. Connect the coaxial cables to the appropriate R, G, B, and SYNC

connectors on the N22 module and the monitor.

Connecting the Camera Cable: 2801–YC Camera

Use the following steps to connect the appropriate camera cable when an

Allen–Bradley 2801–YC camera is to be used:

1. Locate the appropriate camera cable, Catalog No. 2801–NC14, 15, or 16.

2. Connect one connector on the cable to the appropriate Camera

connector on the CVIM2 front panel.

3. Connect the other connector on the cable to the appropriate connector on

the camera.

Connecting the Camera Cable: 2801–YB, –YD, and –YE Camera

Use the following steps to connect the appropriate camera cable when an

Allen–Bradley 2801–YB, –YD, or –YE camera is to be used:

1. Locate the appropriate camera cable, Catalog No. 2801–NC5, 6, or 7.

2. Connect the male connector on the cable to the appropriate Camera

connector on the CVIM2 front panel.

3. Connect the female connector on the cable to the appropriate connector

on the camera.

Connecting the Mouse Cable

Assuming that the I/O interface cable is attached to the Module I/O or

System I/O connector on the CVIM2 front panel, connect the mouse cable

to the PORT B connector on I/O interface box 2801–N27.

If you intend to use the PORT A connector, you must use a gender adapter

between the mouse cable connector and the PORT A connector on the I/O

interface box.

NOTE: You may need to configure the CVIM2 system to recognize the

selected mouse port connection. The mouse configuration procedure is

detailed in the Configuring CVIM2 System for Mouse Operation section on

page 1–10.

1–7

Page 20

Chapter 1

Hardware Connection and Powerup Check

Powering Up CVIM2 System

At this point, with all basic system components connected, the CVIM2

system is ready for the powerup check.

Use the following steps to perform the powerup check:

1. Set the video monitor brightness and contrast controls to their midrange

point or other appropriate preliminary point.

CAUTION: Verify that the AC voltage source is within

limits for both the video monitor and the CVIM2 system.

2. Set the scan mode, if available on your monitor, to “under scan.”

3. Set the power switch to “off.”

4. Insert the monitor AC line cord into the AC power outlet.

5. Set the power switch to “on.”

6. Attach the CVIM2 system AC line cord or cable to the AC power outlet

or source.

7. If your system is using an external +24VDC power supply, attach the AC

line cord or cable to the AC power outlet or source.

8. Set the power switch to On. When you do, you should see the following

results:

• The DC OK light on the chassis power supply should turn on.

• All LEDs on the CVIM2 front panel should light momentarily, after

which the Pass/Fail LED should remain green.

• In about five seconds, the banner message should appear on the

monitor screen, similar to the screen shown in Figure 1.3 (page

1–9).

9. Verify that the light pen operates properly by moving it across the screen.

The cursor pointer should follow the light pen’s movement. If it does not,

verify that the DC voltage selection switch setting shown in Figure 1.1

(page 1–3) is set correctly for your application.

10. Verify that the light pen switch operates by picking one or more of the

items on the main menu. In each case, a pull–down menu should appear.

11. If a mouse is connected to PORT A or PORT B on the I/O interface

box, check the mouse for proper operation by moving it across a table

top. The mouse pointer should follow the mouse’s movement. If not,

refer to the Configuring CVIM2 System for Mouse Operation section on

page 1–10.

1–8

Page 21

Chapter 1

Chapter

Hardware Connection and Powerup Check

5

Figure 1.3 Example: Monitor Screen After Normal Powerup

Main menu

bar

If you have not yet installed the CVIM2 system at its factory–floor site, refer

to the following Allen–Bradley manuals:

• Pyramid Integrator Installation Manual, Publication 5000–6.2.10.

• Grounding and Wiring Guidelines, Publication No. 1777–4.1.

• Solid–State Control Safety Guidelines, Publication No. SGI–1.1.

These manuals contain all the information required for panel– or

rack–mounting, electrical grounding, and connecting to the I/O components.

You will have already performed in this chapter some of the steps described

in the PI installation manual. When you encounter one of those steps, verify

that you have performed it correctly, then continue.

1–9

Page 22

Chapter 1

Hardware Connection and Powerup Check

Configuring CVIM2 System For Mouse Operation

The CVIM2 system supports most serial mouse and trackball pointing

devices that are IBM PC compatible. The following devices have been

tested and have been found to work with the CVIM2 system:

• Logictech Model C7–3F–9F

• Logictech Model CC–93–9F

• Microsoft Model LR 87483

• Mouse Systems Model 900800–001/A

• Clix Model CX–30

• Interlink Electronics Durapoint (exceeds NEMA 4X, 6P, and 13)

• Mouse Systems Model TP–305 (trackball)

After you power up the CVIM2 module, if the mouse pointer will not “track”

the mouse as you move it across a table top or other flat surface, and you are

using one of the above–listed devices, use the light pen to examine the

current serial communication port configuration and reconfigure, if

necessary, the specific port that you intend to use for mouse operation.

NOTE: When a port is configured for mouse operation, it cannot be used

for other data communication purposes.

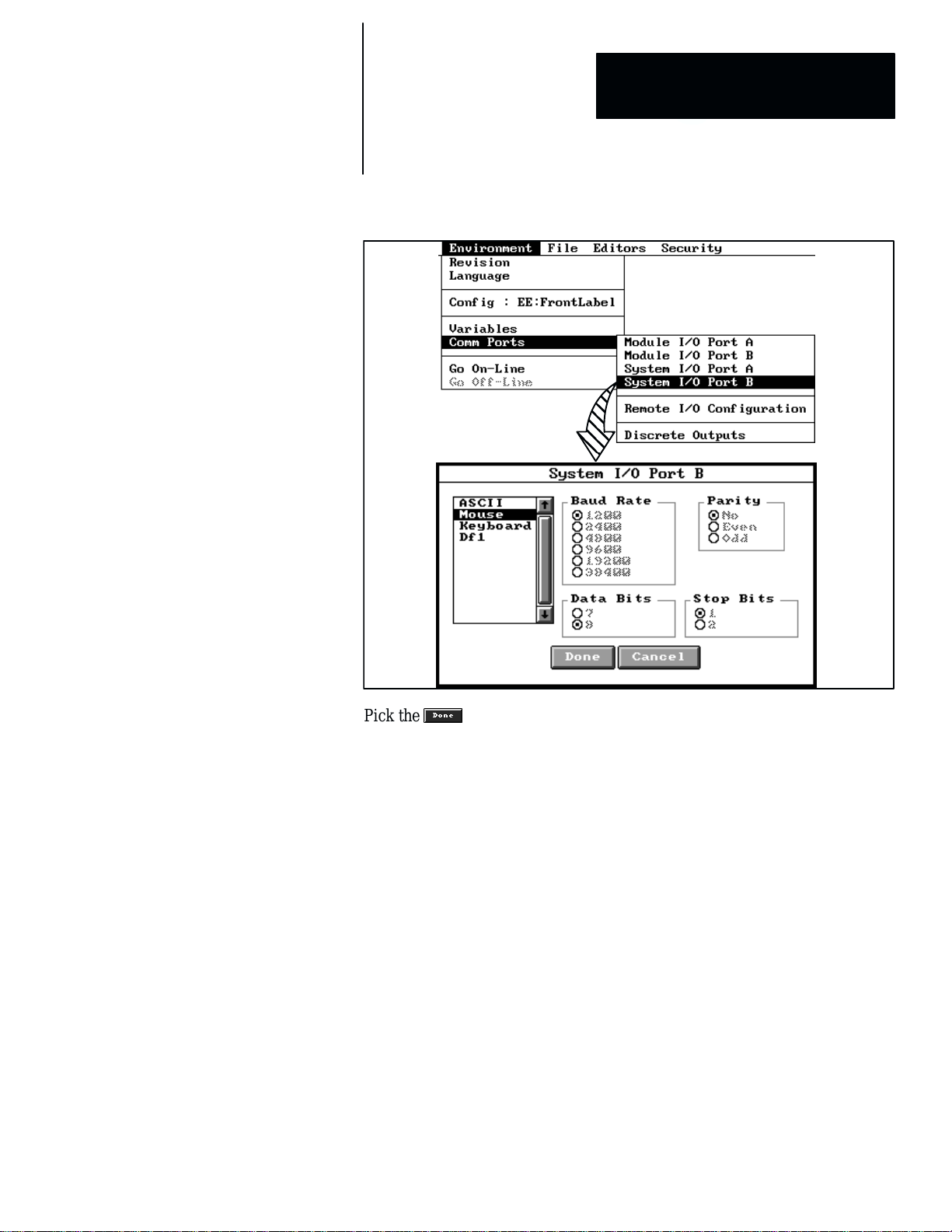

To configure a serial communication port for mouse operation, use the light

pen to pick Environment in the main menu bar. When the Environment

menu appears, pick Comm Ports. When you do, the Comm Ports menu

appears, as illustrated by the example in Figure 1.4 (page 1–11).

In the example, it is assumed that the mouse is connected to PORT B of the

I/O interface box and the I/O interface cable is connected to the System I/O

connector on the CVIM2 front panel. In this case, you would pick System

I/O Port B in the Comm Ports menu.

When you pick System I/O Port B, the System I/O Port B setup table

appears, as shown in Figure 1.4. When you then pick Mouse in the small

scrolling list, the appropriate mouse settings for baud rate, parity, data bit,

and stop bit parameters in the setup table “lock” at the values shown in the

figure.

1–10

Page 23

Chapter 1

Chapter

Hardware Connection and Powerup Check

5

Figure 1.4 Example: Setting System I/O Port B to Mouse Function

Pick the button to save the port selections and exit the port setup table,

then perform these steps to check mouse operation:

• Verify that the mouse operates properly by moving it across a table top.

The mouse pointer should follow the mouse’s movement.

If the mouse pointer does not move at this time, cycle the CVIM2 power

off (for at least five seconds), then on, to enable mouse pointer operation.

• Verify that the mouse buttons operate by picking one or more of the items

on the main menu, using the left button. In each case, a pull–down menu

should appear.

(Note that the center mouse button can perform some of the functions of

the left button, for example, picking and dragging a panel across the

screen, selecting alternate panel sizes, and operating the scrolling

functions. The right button can alternately position a panel over or under

an overlapping panel.)

For more information about mouse operations, refer to the Screen Pointer

Functions section of Chapter 2, CVIM2 System Configuration: An Overview,

starting on page 2–9.

1–11

Page 24

Chapter

2

CVIM2 System Configuration: An Overview

This chapter discusses the basic phases of system configuration and the

major configuration functions in each phase. The details of the inspection

configuration process are provided in Chapter 3, Image Acquisition

Parameters, and Chapter 4, Inspection Configuration.

The discussions that follow assume that all CVIM2 system parameters are set

to their out–of–box default state. They also assume that you are already

familiar with the CVIM2 user interface and with using the light pen and/or

mouse to “navigate” the user interface.

After System Powerup

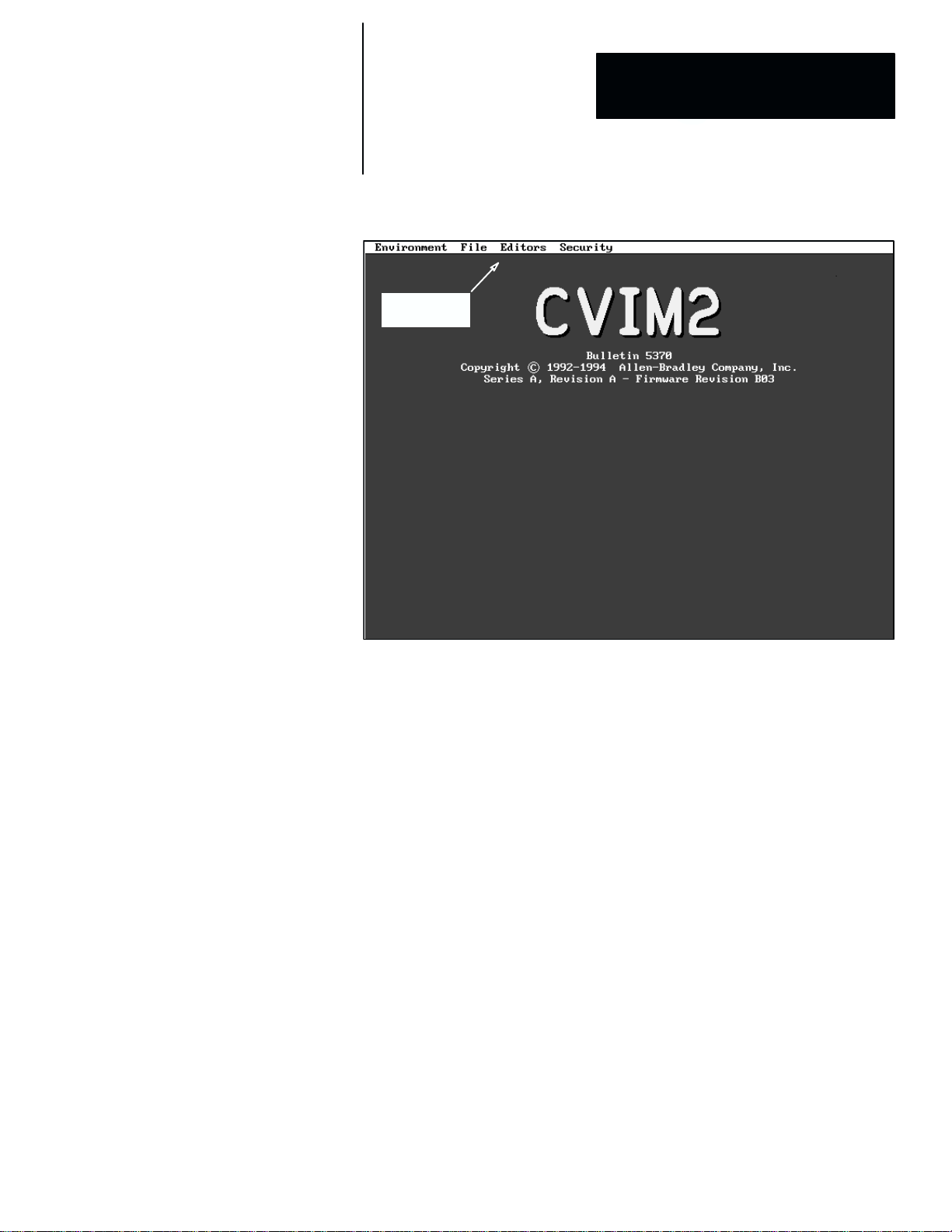

After a normal powerup, the monitor screen displays the CVIM2 “banner

message,” as shown in Figure 2.1.

Figure 2.1 Example: Monitor Screen After Normal Powerup

Main menu

bar

Note that the banner message indicates the current series and firmware

revision levels of the CVIM2 system. Along the top margin is the main menu

bar.

2–1

Page 25

Chapter 2

CVIM2 System Configuration: An Overview

CVIM2 Configuration: Four Basic Phases

Phase 1

Select

configuration

names

Configuration

File Editor:

Enter configuration

file name

Enter acquisition

configuration

file name

Enter discrete I/O

file name

*Enter message

file name

Figure 2.2 is a chart showing four basic phases that are involved in

configuring the CVIM2 system for a typical inspection application. Many

details are intentionally omitted in order to emphasize the overall picture of

the system configuration process.

Figure 2.2 Basic Phases of CVIM2 System Configuration

Phase 2 Phase 3 Phase 4

Configure

inspection

Configuration Editor:

Enter inspection

names

Acquisition Editor:

Select image

acquisition parameters

Pick Setup to enter

toolset editor

Select tool names,

and configure all

inspection tools

Select

discrete I/O

parameters

Discrete I/O Editor:

Name I/O signals, and

assign input and output

functions

Begin online

inspection

operations

Main menu bar:

Pick Environment

Environment menu:

Pick On–Line

Observe and evaluate

inspection operation

and tool results

Adjust tools if

necessary

Evaluate tool

operation offline

in setup mode

*Refer to the CVIM2 Communications Manual, Pub. No. 5370–804, for details.

2–2

Page 26

Chapter 2

Chapter

CVIM2 System Configuration: An Overview

5

Major Configuration Functions

The remainder of this chapter describes the major configuration functions

within each basic phase of the CVIM2 system configuration identified by the

chart in Figure 2.2 (page 2–2).

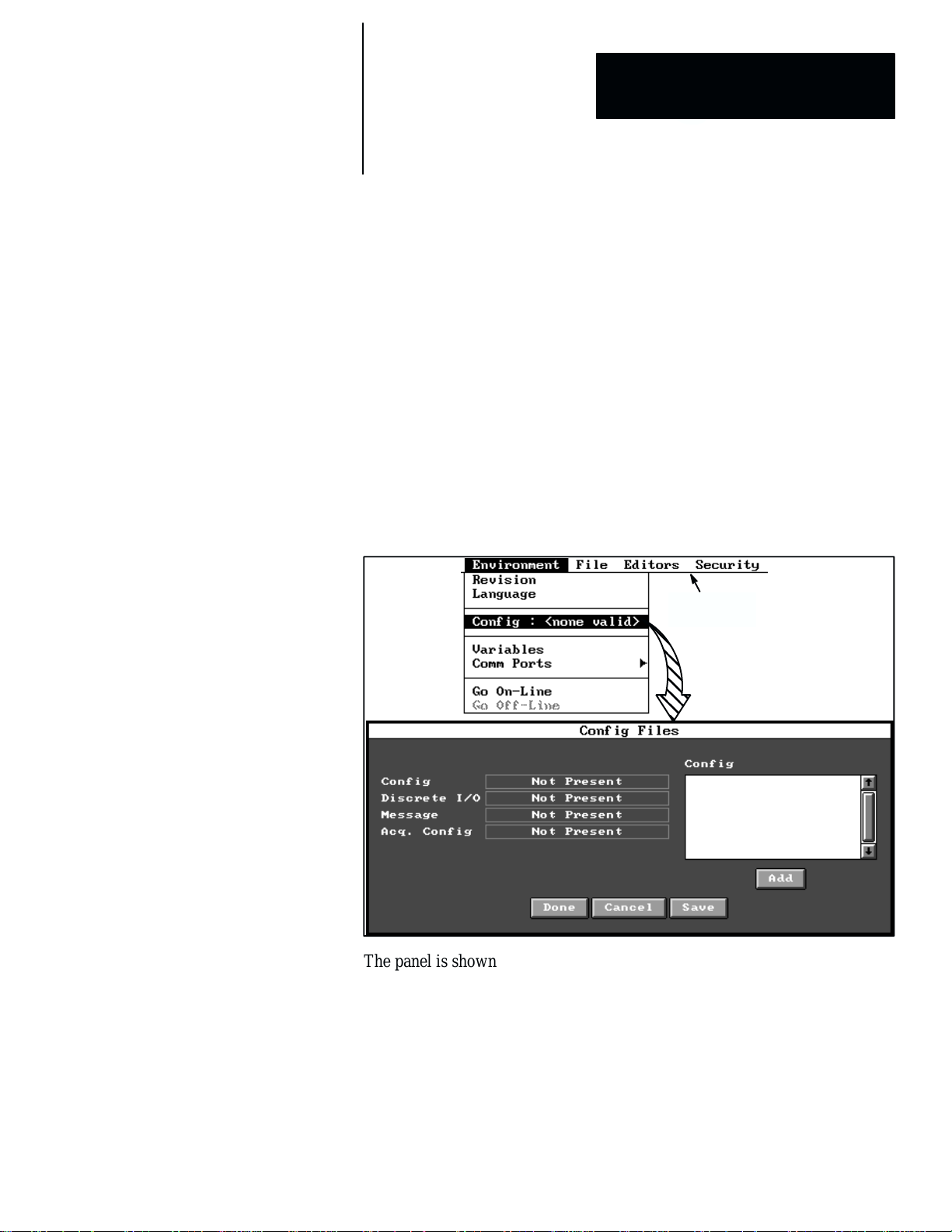

Selecting Configuration File Names

Definition: A configuration file stores information about an inspection

application, such as the names of the toolsets and the number of image

buffers used.

The first step in Figure 2.2 is taken from the Config Files panel. You can

access this panel from Environment in the main menu bar. When you pick

Config in the Environment menu, the Config Files panel appears, as shown

in Figure 2.3.

Figure 2.3 Initial Appearance of Config Files Panel

Main menu

bar

The panel is shown in its initial state, before any configuration files have

been defined. At this time, you must enter an appropriate name in the Config

and Acq. Config fields in order to continue with the configuration process.

NOTE: You can add the Discrete I/O name and/or Message name at this

time, or later. (Note that to access the Discrete I/O and Communications

Editor panels, however, you must first enter names for these panels in the

Config Files panel.)

2–3

Page 27

Chapter 2

CVIM2 System Configuration: An Overview

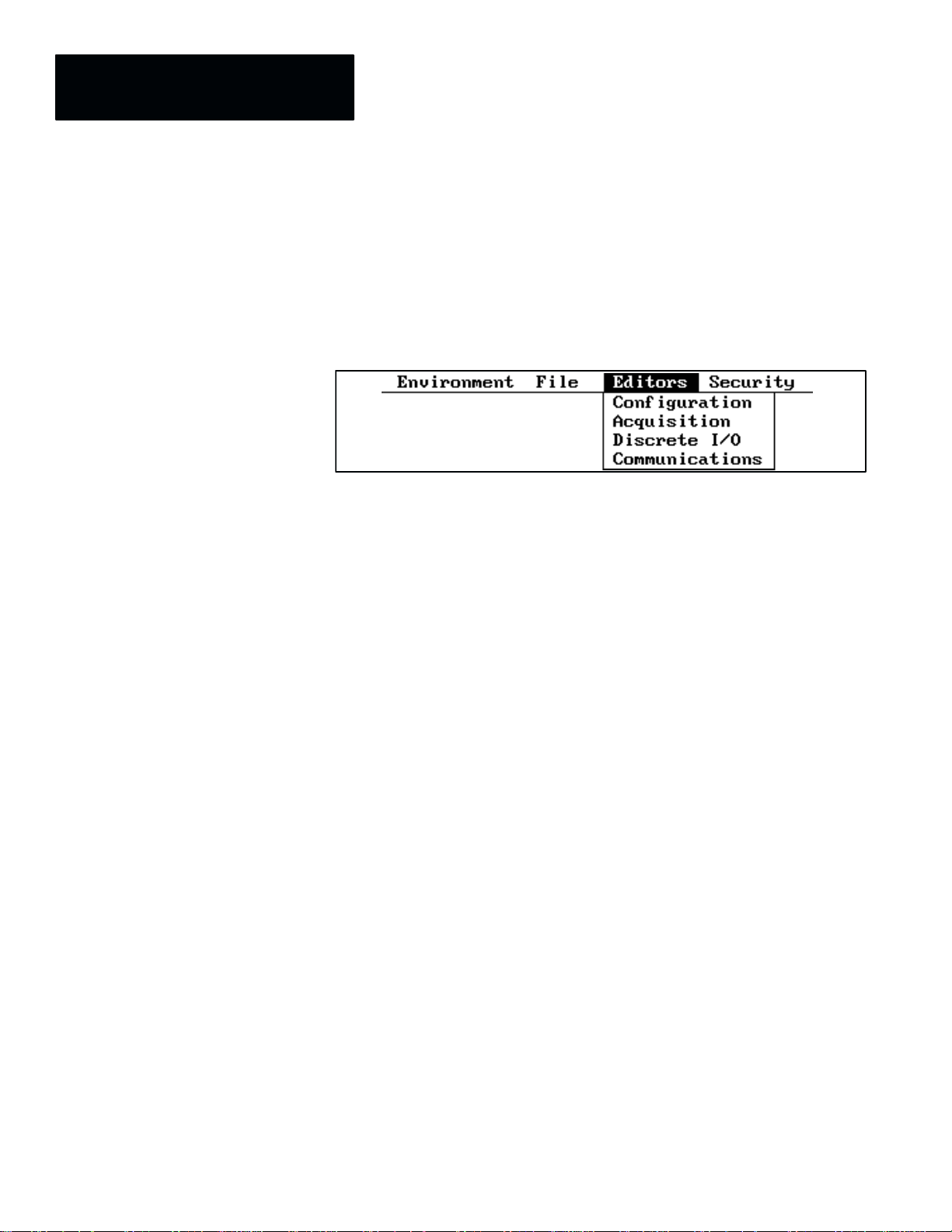

Picking the Editors Menu

The next step, after defining at least one configuration, is taken from the

Configuration Editor panel. You can access this panel from Editors in the

main menu bar. When you pick Editors, the Editors pulldown menu appears,

as shown in Figure 2.4.

Figure 2.4 The Editors Pulldown Menu

Note also that you have four choices: Configuration, Acquisition, Discrete

I/O, and Communications. Briefly, this is what they mean:

• Configuration –– Use this editor to define one or more sets of inspection

tools for your application.

• Acquisition –– Use this editor to select the camera types, numbers of

cameras, trigger sources for acquiring camera images, and other

parameters relating to the acquisition of images.

• Discrete I/O –– Use this editor to assign signals and select parameters for

discrete inputs and outputs.

• Communications –– Use this editor to create messages for data

communications using serial I/O ports or the remote I/O port.

2–4

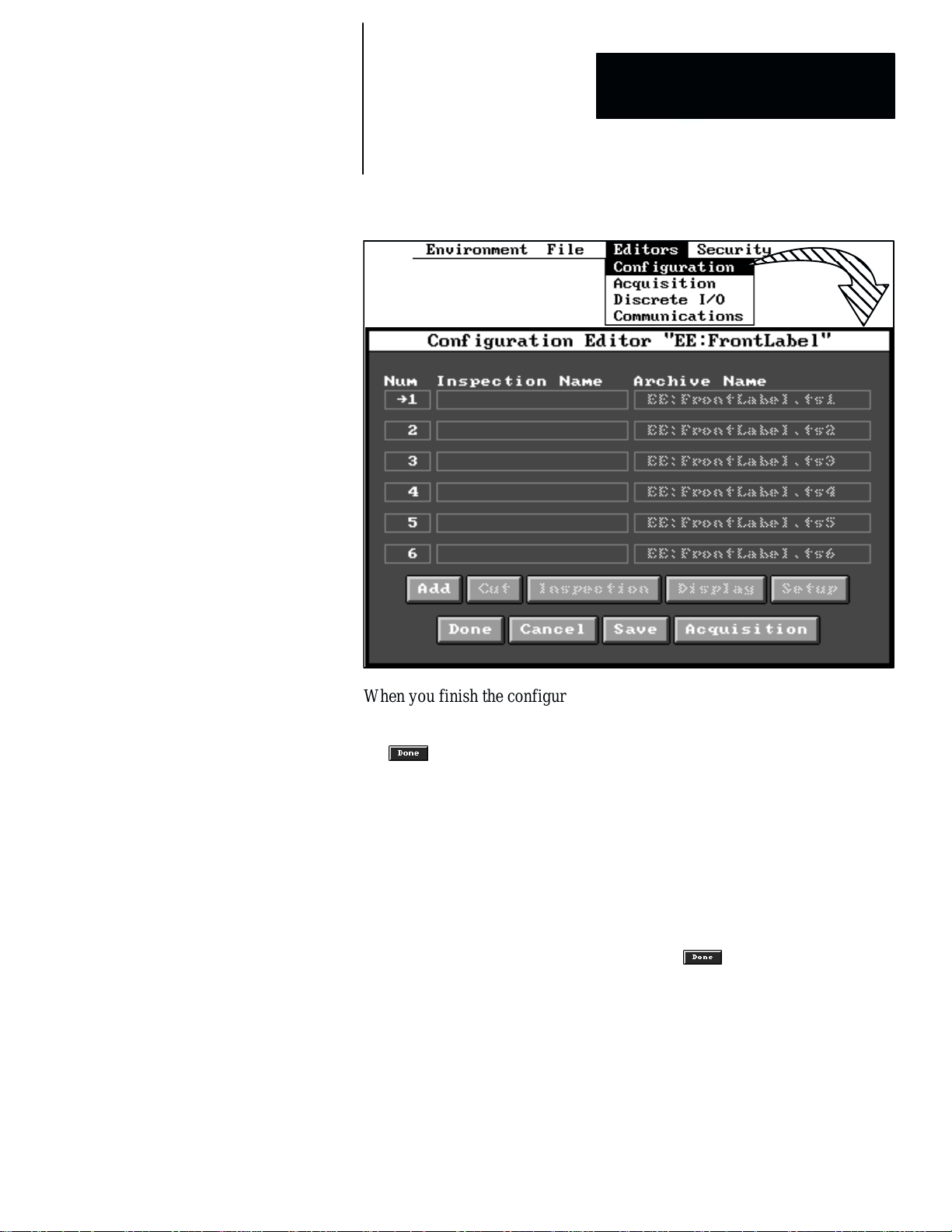

Selecting Configuration Parameters

When you pick Configuration, the Configuration Editor panel appears, as

shown in the example in Figure 2.5 (page 2–5).

The purpose of the Configuration Editor panel is to set up all of the

inspection application requirements for a single configuration file. Using this

panel, you can select the toolsets (up to six for one configuration file),

configure all of the inspection tools, set various acquisition and inspection

parameters, and perform the initial (“setup mode”) evaluations of the tools’

performance.

The CVIM2 system enters various default names for the toolsets (under the

“Inspection Name” heading and the “Archive Name” heading); however,

you can easily change any of these names to suit your inspection application.

Page 28

Chapter 2

Chapter

CVIM2 System Configuration: An Overview

5

Figure 2.5 Example: Configuration Editor Panel With Six Inspections

When you finish the configuration of at least one toolset (and also select the

image acquisition parameters, as described in the next section), you can exit

the Configuration Editor panel and return to the main menu bar by picking

the

When you place the CVIM2 system online, the system executes the currently

selected configuration file. If the system is powered down, then powered up

again, it will automatically begin online operations using the last selected

configuration file –– in this example, it would use the “FrontLabel”

configuration file.

The CVIM2 system can store multiple configuration files in the CVIM2

system’s memory; thus, you can easily change inspection applications by

accessing the Config Files panel, highlighting (picking) another Config file

name listed in that panel, and then picking the

When you return to the Configuration Editor panel, the newly selected

configuration file name will appear in the title bar of that panel.

button.

button.

2–5

Page 29

Chapter 2

CVIM2 System Configuration: An Overview

Selecting Image Acquisition Parameters

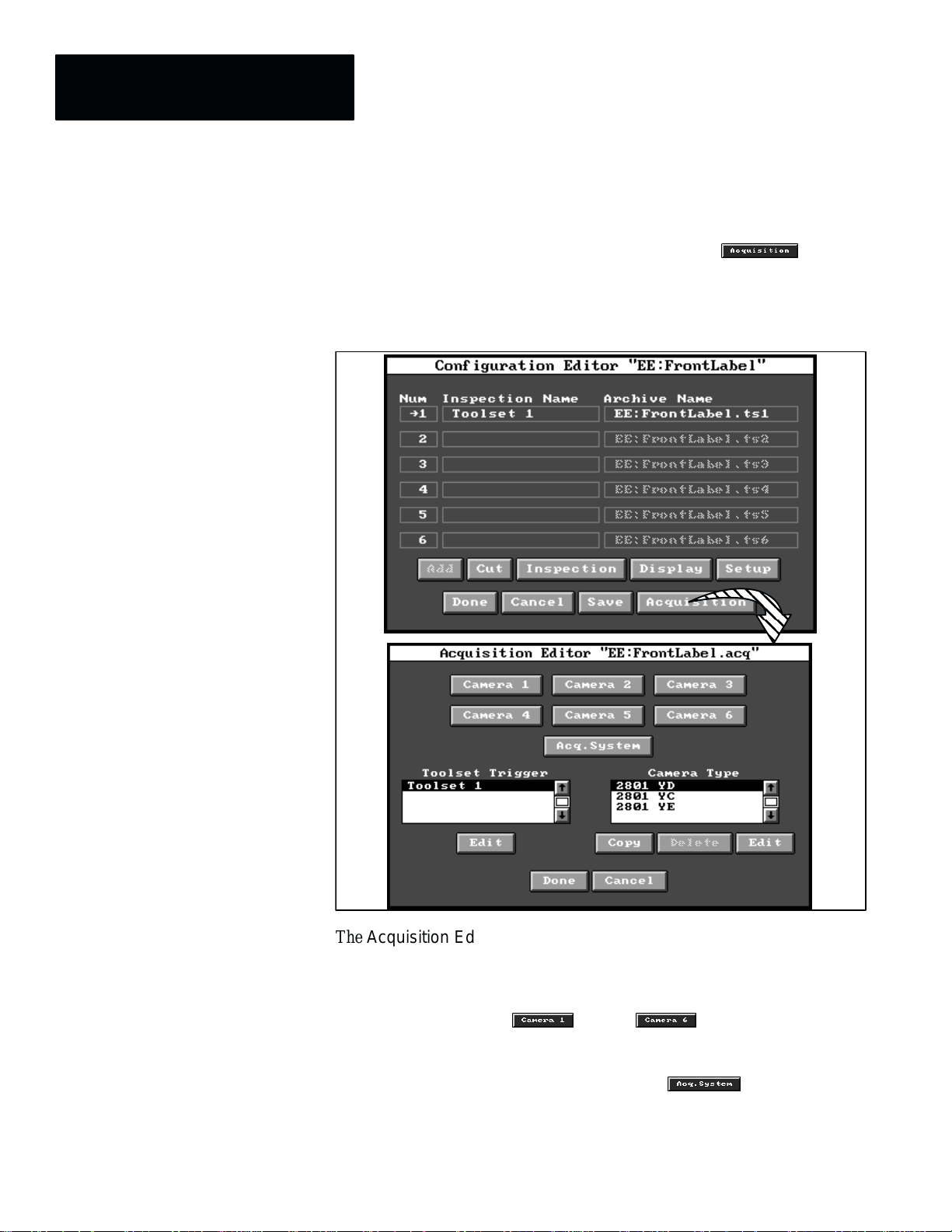

Your next step, after configuring a toolset, is to pick the button in

the Configuration Editor panel. When you pick this button, the Acquisition

Editor panel appears, as shown in the example in Figure 2.6.

Figure 2.6 Example: The Acquisition Editor Panel

2–6

The Acquisition Editor panel provides access to all of the parameters and

settings that the system uses to acquire an image for an inspection. The panel

contains two scrolling lists and several buttons, which are described briefly

as follows:

• Camera 1 – 6 –– The through buttons access the

corresponding Camera setup panels, from which you can perform focus

adjustments, light reference adjustments, and other related functions.

• Acquisition Systems Settings panel –– The button accesses

the Acquisition System Settings panel, from which you can select a

default camera enable synchronizing the CVIM2 system with external

devices or another CVIM2 system, and/or selecting parameters for

switching between camera banks 1 – 3 and 4 – 6.

Page 30

Chapter 2

Chapter

CVIM2 System Configuration: An Overview

5

• Toolset Trigger panel –– This scrolling list panel enables you to select a

Toolset Trigger edit panel, from which you can edit various trigger

parameters for a particular toolset. The adjacent button selects the

Toolset Trigger edit panel for the highlighted toolset trigger.

• Camera Type panel –– This scrolling list panel enables you to select a

Camera Type edit panel, from which you can edit various timing

parameters for a particular camera type. The adjacent

selects the Camera Type edit panel for the highlighted camera type. The

button selects the highlighted camera type for the purpose of

creating a non–standard camera type and editing its parameters. The

button deletes the highlighted camera type (non–standard only).

When you finish selecting the image acquisition parameters, you can exit the

Acquisition Editor panel and return to the Configuration Editor panel by

picking the

button.

button

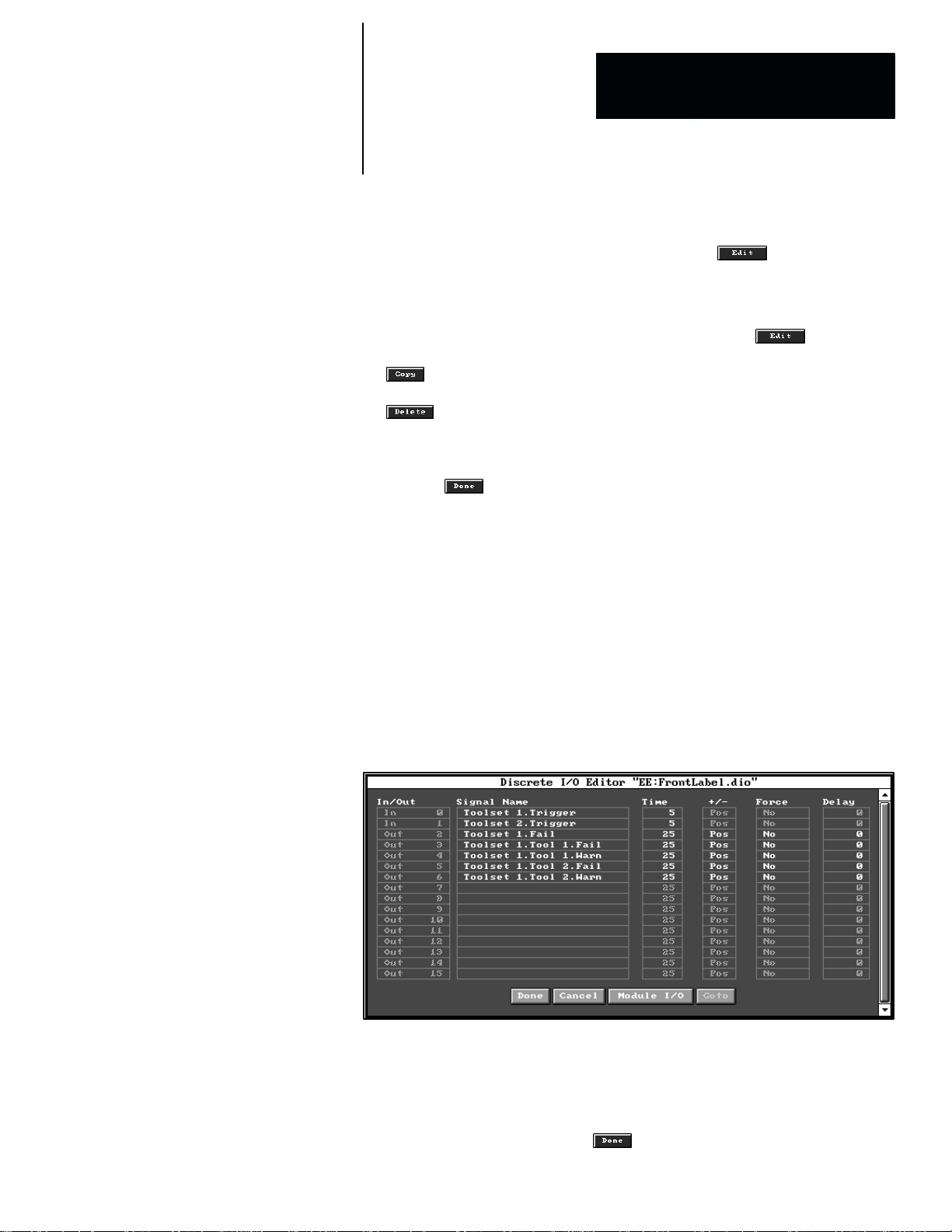

Selecting Discrete I/O Parameters

After configuring a toolset and selecting acquisition parameters, your next

step is to pick Discrete I/O in the Editors menu. You can then select and

configure the discrete inputs and outputs to be used in your application.

When you pick Discrete I/O, the Discrete I/O Editor panel appears, as

shown in the example in Figure 2.7, provided that you have added a discrete

I/O file name in the Config Files panel, as noted on page 2–3.

Figure 2.7 Example: The Discrete I/O Editor Panel

The purpose of the Discrete I/O Editor panel is to configure the trigger

inputs and assign functions to the outputs as required for a particular

application. Using this panel, you can assign signals to the trigger inputs and

specify the minimum trigger signal pulse duration, and you can assign a

specific function to each output, such as toolset failure, tool warning, and so

on. When you finish, picking the

button returns to the main menu bar.

2–7

Page 31

Chapter 2

CVIM2 System Configuration: An Overview

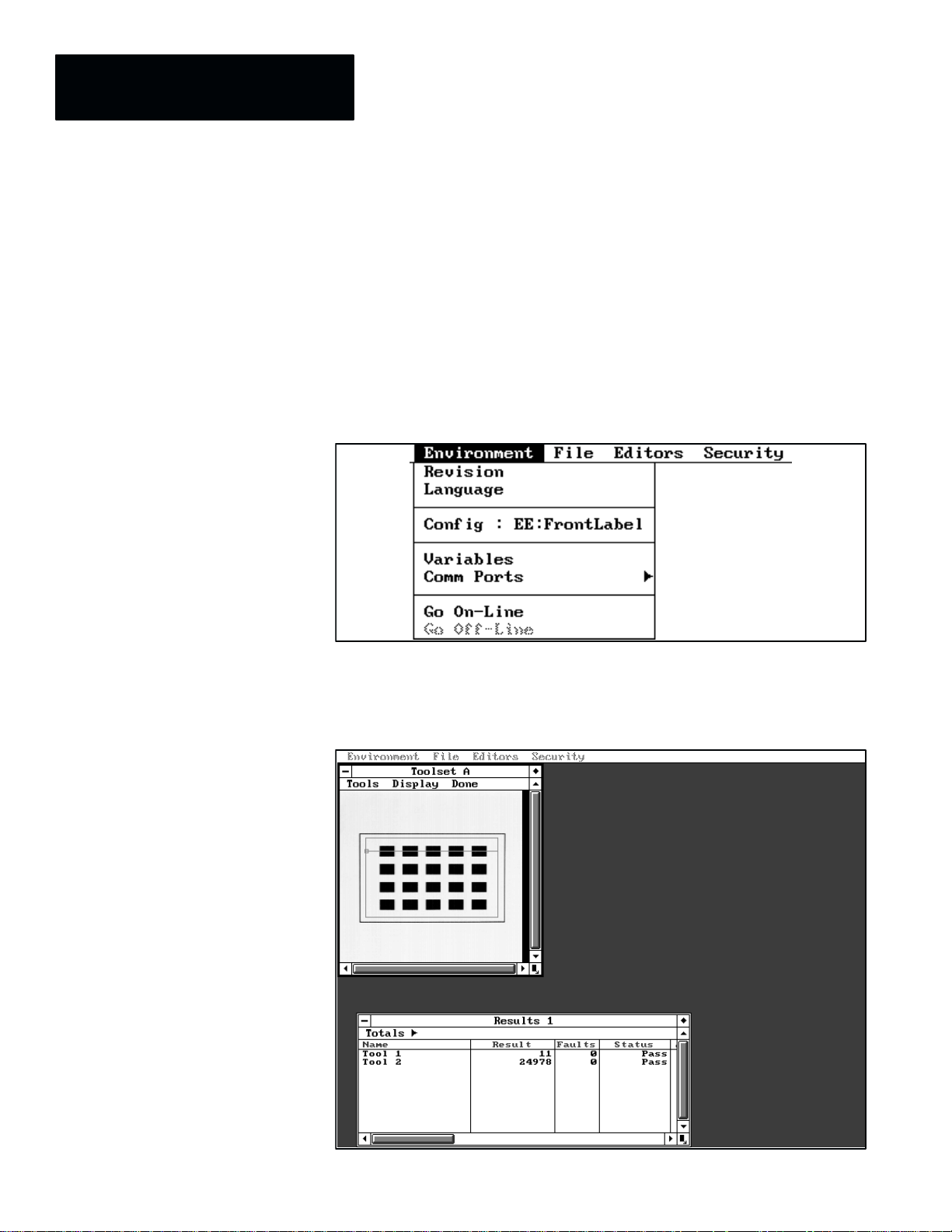

Selecting Online Operation

Normally, your last step is to pick Go On–Line in the Environment menu.

This enables the system to perform online inspection operations, which will

begin immediately if the selected trigger source is active. During online

operations, you can observe the camera image and inspection tool display

and the inspection results data display at the same time.

When you pick Environment, the Environment menu appears, as shown in

the example in Figure 2.8.

Figure 2.8 Example: The Environment Menu

When you pick Go On–Line, the system displays the camera image and

tools, and the inspection results data. Figure 2.9 shows an example of this.

Figure 2.9 Example: Online Screen Display

2–8

Page 32

Chapter 2

Chapter

CVIM2 System Configuration: An Overview

5

The display panel shows the inspection tools over the inspected image. The

menu bar in the display panel enables you to access these tools for the

purpose of making minor adjustments, and for assigning “freeze” modes,

which allow analysis of images in which one or more tools have failed their

inspection tasks.

The results panel displays the basic inspection results for each tool listed;

namely, the pass/fail status, the accumulated number of faults, and the

numerical inspection result. The “Totals” item in the menu bar accesses

additional results data, such as the number of missed triggers and various

inspection timing data.

Screen Pointer Functions

Major Pointer Function

Select or pick item

(menu item, button, selector)

Drag

(tool, tool end, panel, panel

corner)

The CVIM2 system uses a light pen and/or mouse to perform numerous

screen pointer functions such as selecting menus and menu items, picking

and placing tools, and positioning and sizing panels. Most of these functions

are performed by positioning a screen pointer over an item on the screen and

pressing the light pen tip against the screen, or “clicking” the left mouse

button (that is, pressing and releasing the button quickly), if a mouse is used.

Light Pen and Mouse Operation

The light pen and mouse can perform the same screen pointer functions, but

they differ in the method of performing those functions. Table 2.1 identifies

the major differences in the operation of these two screen pointer systems.

Table 2.1 Comparison of Light Pen and Mouse Operation

Mouse Light Pen

Position the pointer over an item on the

screen, then press and release (“click”) the

left button. The item under the pointer when

the button is released is the one selected.

Position the pointer over an item, then press

and hold the left button while dragging the

item across screen.

Release the button when the item is at its

final position.

Position light pen tip over item on screen,

then press and release light pen tip against

screen

Position the light pen tip over an item on

screen and press the tip against the screen

until a cross (+) symbol appears.

Release the light pen tip from the screen,

then drag the item across screen. Press and

release the tip against screen when the item

is at its final position.

2–9

Page 33

Chapter 2

CVIM2 System Configuration: An Overview

NOTE: In the following discussions, the use of a mouse is assumed for the

screen pointer functions. Table 2.1 compares equivalent light pen and mouse

operation.

Figure 2.10 through Figure 2.12 (page 2–13) illustrate the screen pointer

functions.

Figure 2.10 demonstrates a sequence of menu item and button picks, starting

at “Editor” in the main menu bar. In this figure, the pointer is positioned over

Editor in the main menu bar, and the left button is clicked, in order to select

the Editor menu. The pointer is then positioned over Configuration in the

Editor menu, and the left button is clicked, in order to select the

Configuration Editor panel.

Figure 2.10 Example: Sequence of Menu and Panel Selections

Pick

Pick

2–10

Pick

Page 34

Chapter 2

Chapter

CVIM2 System Configuration: An Overview

5

In the Configuration Editor panel, the pointer is positioned over the

button, and the left mouse button is clicked, to select the

Inspection panel. When the appropriate inspection parameters are entered,

the pointer is placed over the

clicked, to exit back to the Configuration Editor panel.

Figure 2.11 (page 2–12) demonstrates dragging a panel to a different position

on the screen. The pointer can be placed anywhere in the title bar and the

panel dragged to its final position.

Figure 2.12 (page 2–13) uses a “Results” panel to identify the symbols and

points that are used for manipulating a panel on the screen (some of these

points and symbols are also used on other panels). When picked, they

perform specific functions, as follows:

• Expand/contract size symbol –– If you pick this symbol (♦) in the

upper right corner, the panel will change to an alternate size (by default, it