Page 1

Bulletin 5370

Color CVIM Module

MATH-PAK Option

(Catalog No. 5370–CMPK)

User’s Manual

ALLEN-BRADLEY

Page 2

ALLEN-BRADLEY

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Application Considerations for Solid State

Controls” (Publication SGI-1.1) describes some important differences

between solid state equipment and hard–wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

1993 Allen-Bradley Company, Inc.

Page 3

Table of Contents

Color CVIM MATH-PAK

User’s Manual

A–B

Using This Manual

Introduction to the

MATH–PAK Option

Installation

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Contents 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notice of Attention 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trademarks 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MATH-PAK Preview 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definition of a Formula 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How Formula Results Are Applied 2–2. . . . . . . . . . . . . . . . . . . . . . . . .

Accessing the MATH-PAK Features 2–4. . . . . . . . . . . . . . . . . . . . . . . .

Copy and Paste Functions 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Runtime Displays 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the MATH-PAK Option 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Formulas

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Formula Definition: Basic Steps 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting a Formula 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Formula Number(s) 4–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Defining a Formula 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing the Formula Entry Keyboard 4–5. . . . . . . . . . . . . . . . . . . . .

Using the Formula Entry Keyboard 4–7. . . . . . . . . . . . . . . . . . . . . . . . .

Example Formula Entry 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edit / Control Keys 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example of Formula Editing 4–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Operands 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Constants as Operands 4–16. . . . . . . . . . . . . . . . . . . . . . . .

Operators 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Execution Hierarchy 4–20. . . . . . . . . . . . . . . . . . . . . . . . .

Operator Usage 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mathematical Operators 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Statistical Operators 4–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Operators 4–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conditional Operators 4–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Formula Examples 4–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flagging Consecutive Rejects 4–35. . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Table of Contents

Color CVIM MATH-PAK

User’s Manual

Defining Formulas

Analysis Functions and

Runtime Displays

Chapter 4 (continued)

Creating a Shift Register 4–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Naming a Formula 4–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enabling / Disabling a Formula 4–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Copy and Paste 4–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example Copy and Paste 4–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Range Limits and Assigning Outputs 4–41. . . . . . . . . . . . . . . . . . . .

Entering Range Limits for Formulas 4–43. . . . . . . . . . . . . . . . . . . . . . . .

Inspection Statistics Table 4–44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example Range Limit Setting 4–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assigning Range Limits to Results Output Lines 4–46. . . . . . . . . . . . . .

Enabling Results and Range Limits for Corresponding Tools 4–47. . . . .

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analysis Functions 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Statistics (Learn Mode) for Failed Tools 5–2. . . . . . . . . . . . . . . . . . . . . . . .

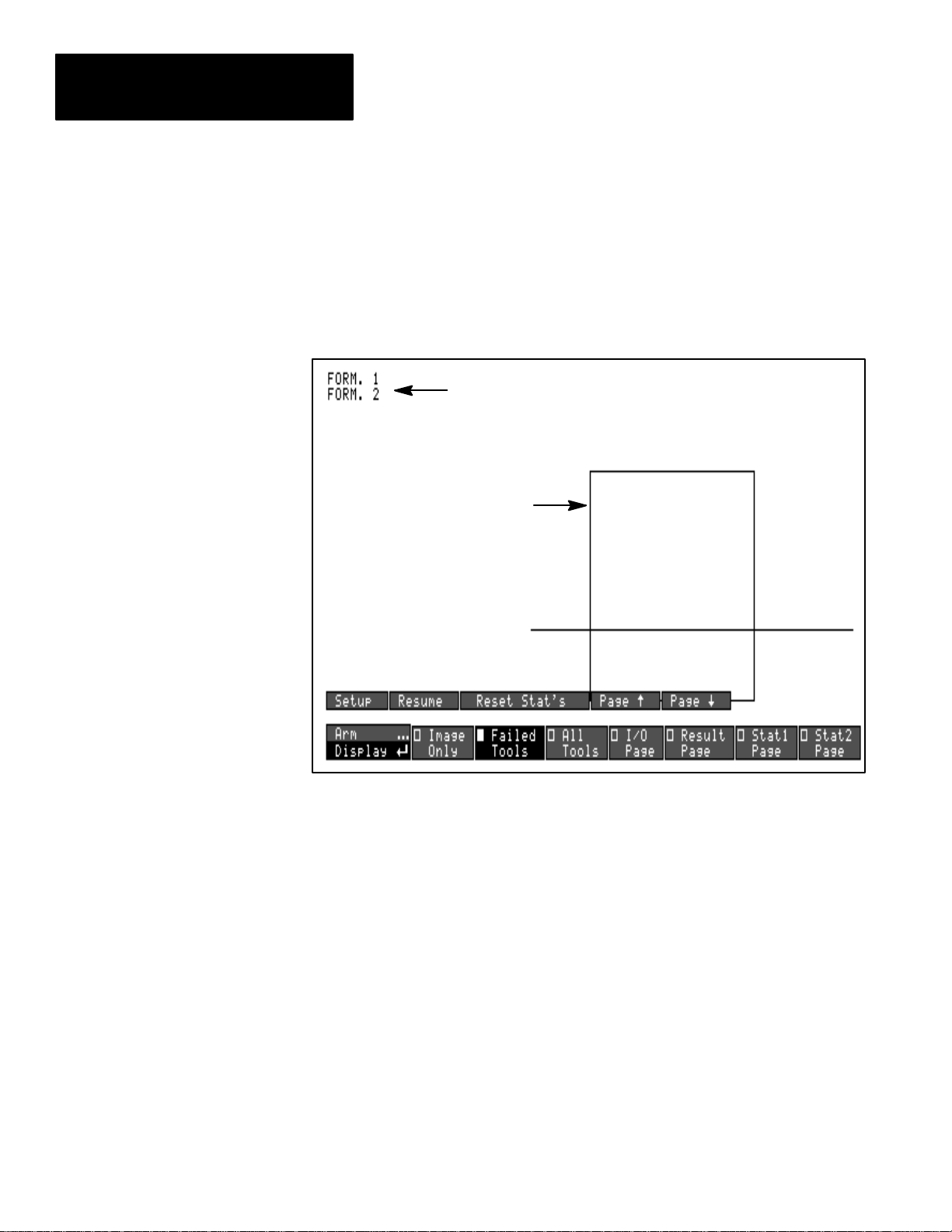

Runtime Displays 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Runtime Tools Displays 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Page 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results and Stat1 Page Displays 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Color CVIM

Communications with

MATH-PAK Installed

ii

Appendix A

Objective A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Formula Data Replaces Tool Data A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results Blocks A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Blocks A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete Bits A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

Tables

1.A Chapter Descriptions 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.A Formula numbers and corresponding gage/window numbers 4–3. .

4.B Edit / Control Keys 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.C Operand Definitions 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.D Operator Definitions 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Formula numbers and corresponding gage/window numbers A–1. .

A.2 Results Block 1 – Formula/Tool Results A–3. . . . . . . . . . . . . . . . . .

A.3 Results Block 2 – Formula/Tool Results A–4. . . . . . . . . . . . . . . . . .

A.4 Results Block 3 – Formula/Tool Results A–6. . . . . . . . . . . . . . . . . .

A.5 Configurations block numbering for formulas 1–56

(and corresponding tools) A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents

Color CVIM MATH-PAK

User’s Manual

Tables (continued)

A.6 Configuration blocks 46–77 – for formulas 9–16, 25–32, 41–56

(gages 1–32) – fault and warning ranges A–8. . . . . . . . . . . . . . . . . .

A.7 Configuration blocks (even numbered, 110–156) for formulas 1–8,

17–24, 33–40 (windows 1–24) – fault and warning ranges A–9. . . .

A.8 Discrete Input Bits for formulas and corresponding tools A–10. . . . .

Figures

2.1 Color image vs. gray-scale image 2–1. . . . . . . . . . . . . . . . . . . . . . .

2.1 Inspection results data handling without MATH–PAK formulas 2–2

2.2 Inspection results data handling when using a MATH–PAK

formula 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Accessing the MATH-PAK features 2–4. . . . . . . . . . . . . . . . . . . . .

2.4 Copy and Paste functions 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Results Page displaying formula results 2–5. . . . . . . . . . . . . . . . . .

3.1 Inserting the MATH-PAK installation card 3–2. . . . . . . . . . . . . . . .

3.2 Title banner indicating the presence of the MATH-PAK option 3–3

4.1 Selecting the formula number 4–2. . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Using the Jump box and calculator pad 4–4. . . . . . . . . . . . . . . . . . .

4.3 Accessing the formula entry keyboard pad 4–5. . . . . . . . . . . . . . . .

4.4 Switching between the two key sets of the formula entry keyboard 4–6

4.5 Edit/control keys 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Operand keys 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Operator keys (initial key set) 4–17. . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Example application, using the subtraction operator 4–22. . . . . . . . .

4.9 Example of using the DST function 4–25. . . . . . . . . . . . . . . . . . . . .

4.10 Arcsine and arctangent operation results 4–26. . . . . . . . . . . . . . . . . .

4.11 Arccosine operation results 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 Example application: Using the arctangent to calculate

an angle q 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 Example application: Using operands GAGE2 and GAGE2.3 4–28

4.14 Example application: Finding angular results greater than 90° 4–28.

4.15 Example application: Finding angular results greater than 270° 4–29

4.16 Example application, using three gages to find an

average measurement 4–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.17 Example application, using windows and the mode operator 4–32. .

4.18 Example application, using gages and the variance operator 4–33. .

4.19 Using the keyboard to set the formula name 4–37. . . . . . . . . . . . . . .

4.20 Enabling a formula 4–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.21 Copying a formula 4–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.22 Assigning range limits 4–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.23 Example: Range limits for linear gaging 4–45. . . . . . . . . . . . . . . . .

4.24 Example: Formula with conditional operation for comparing gage

results 4–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 6

Table of Contents

Color CVIM MATH-PAK

User’s Manual

Figures (continued)

4.25 Selecting output lines for range limits 4–47. . . . . . . . . . . . . . . . . . . .

4.26 Enabling the range limits and outputs for tools 4–48. . . . . . . . . . . . .

5.1 Selecting the Tool Display menu 5–1. . . . . . . . . . . . . . . . . . . . . . . .

5.2 The Range Fail box 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Runtime Display menu – setup mode 5–3. . . . . . . . . . . . . . . . . . . .

5.4 Display menu – run mode 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Formulas displayed in Failed Tools display during run mode

operation 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Formulas displayed on I/O Page display during run mode

operation 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Calculator pad for entering number of displayed

formula/tool results 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 Typical help message for the Disp. Windows option 5–7. . . . . . . . .

iv

Page 7

Chapter

Chapter Objectives

A–B

1

Using This Manual

Contents

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Contents 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cautions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trademarks 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The objective of this chapter is to provide an overview of the contents and

organization of this manual, to describe the intended audience, and to list

related publications.

Manual Contents

The contents of this manual are briefly described in

Table 1.A

Chapter Descriptions

Chapter/

Appendix

1 Using This Manual Provides an overview of the manual.

2

3 Installation

4 Defining Formulas

5

A

Analysis and Runtime

Communications with

MA TH-PAK Installed

Title Description

Introduction to the

MA TH-PAK Option

Displays

Color CVIM

Previews the main features and capabilities of

the MA TH–PAK option.

Describes how to install the MA TH-PAK option

into the Color CVIM module.

Describes how to access the MATH-PAK

formula keyboard, lists and describes the

formula operators and operands, discusses

selecting and enabling/disabling formulas,

discusses the Copy and Paste functions, and

discusses setting range limits and assigning

outputs.

Desribes the use of analysis functions and

runtime displays with MA TH-PAK installed.

Lists the effects that MATH-PAK formulas

have on the results and configuration blocks

available through the serial and parallel ports.

Table 1.A below.

Intended Audience

Before using this manual, you should be familiar with the Color CVIM

module features and the procedures used in configuring the Color CVIM

module for operation.

• For information regarding the Color CVIM module, refer to the Color

CVIM User’s Manual, Cat. No. 5370–ND009 (Series A).

1–1

Page 8

Chapter 1

Using This Manual

• If you plan to use Color CVIM communications, refer also to the Color

CVIM Communications Manual, Cat. No. 5370–ND0010 (Series A).

• If you plan to use other software option packages along with the

MATH-PAK option, refer to the user’s manuals for the respective

software package as necessary.

Notice of Attention

Related Publications

Notices of attention are included when the COLOR CVIM module or

peripheral equipment could be damaged if the listed procedure is not

followed. The following format is used:

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

The following manuals are cited for reference in this manual:

• User’s Reference Manual, Bulletin 5370–CVIMC, Cat. No. 5370–ND009

(Series A), also referred to as the Color CVIM User’s Manual in this

publication.

Trademarks

1–2

• Communications Manual, Bulletin 5370–CVIMC, Cat. No. 5370–ND010

(Series A), also referred to as the Color CVIM Communications Manual

in this publication.

The following trademarks apply to products mentioned in this manual:

Color CVIM Module – Allen–Bradley Cat. No. 5370–CVIMC

MATH–PAK Option – Allen–Bradley Cat. No. 5370–CMPK

Page 9

Chapter

Chapter Objectives

MATH-PAK Preview

A–B

2

Introduction to the MATH–PAK Option

Contents

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MATH-PAK Preview 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This chapter briefly describes the features and capabilities available with the

MATH–PAK option package installed in the Color CVIM module.

The MATH–PAK option enables your Color CVIM module to automatically

perform a variety of mathematical and/or logical operations, using formulas

that you define, on inspection data from any of the module’s analysis tools.

The MATH-PAK option is designed to give you much greater flexibility in

the use and application of the Color CVIM module’s inspection capabilities,

allowing you to quickly perform complex data manipulation on the fly. Also,

because these calculations are handled within the Color CVIM module itself,

the MATH-PAK option can help simplify the programming of, or help

eliminate the need for, an external system host computer or controller.

Definition of a Formula

A MATH-PAK formula is defined by the user. A formula consists of one or

more mathematical or logical operators, and one or more operands, which

combine to provide a mathematical or a logical (1 or 0) result.

Note: The term operator refers to the mathematical, logical, or other

operation performed, such as add, multiply, square root, cosine, AND, etc.

The term operand refers to the initial data value upon which the operations

are performed, such as a gage result, or a constant.

You can define up to 56 different formulas, each consisting of a number of

different components (operators and operands).

MATH-PAK formulas can perform a variety of operations, from simple

arithmetic to more complex trigonometric functions, square roots or statistics

values, and a number of other mathematical or logical operations. Operators

can be used alone in a formula, or in combination.

MATH-PAK formulas can perform operations on a variety of operands,

including the numerical results from a tool, tool pass/fail status, object

contour analysis results, statistics based on a tool’s results, and even the

results from other formulas.

Formula results can be logical (1 or 0), integer, or fixed point (decimal).

2–1

Page 10

Chapter 2

Introduction to the MATH-PAK Option

Example formulas: This simple formula scales a window’s results by a

constant multiplier (using the multiply operator (

*) and 2 operands –

window 4 and the constant, 0.75):

WINDOW4 * 0.75

The formula below averages the results from gages 1, 2, and 3 (using the add

operator (+) and the 3 gage operands, then using the divide operator ( / ) and

the constant, 3):

(GAGE1 + GAGE2 + GAGE3) / 3

How Formula Results Are Applied

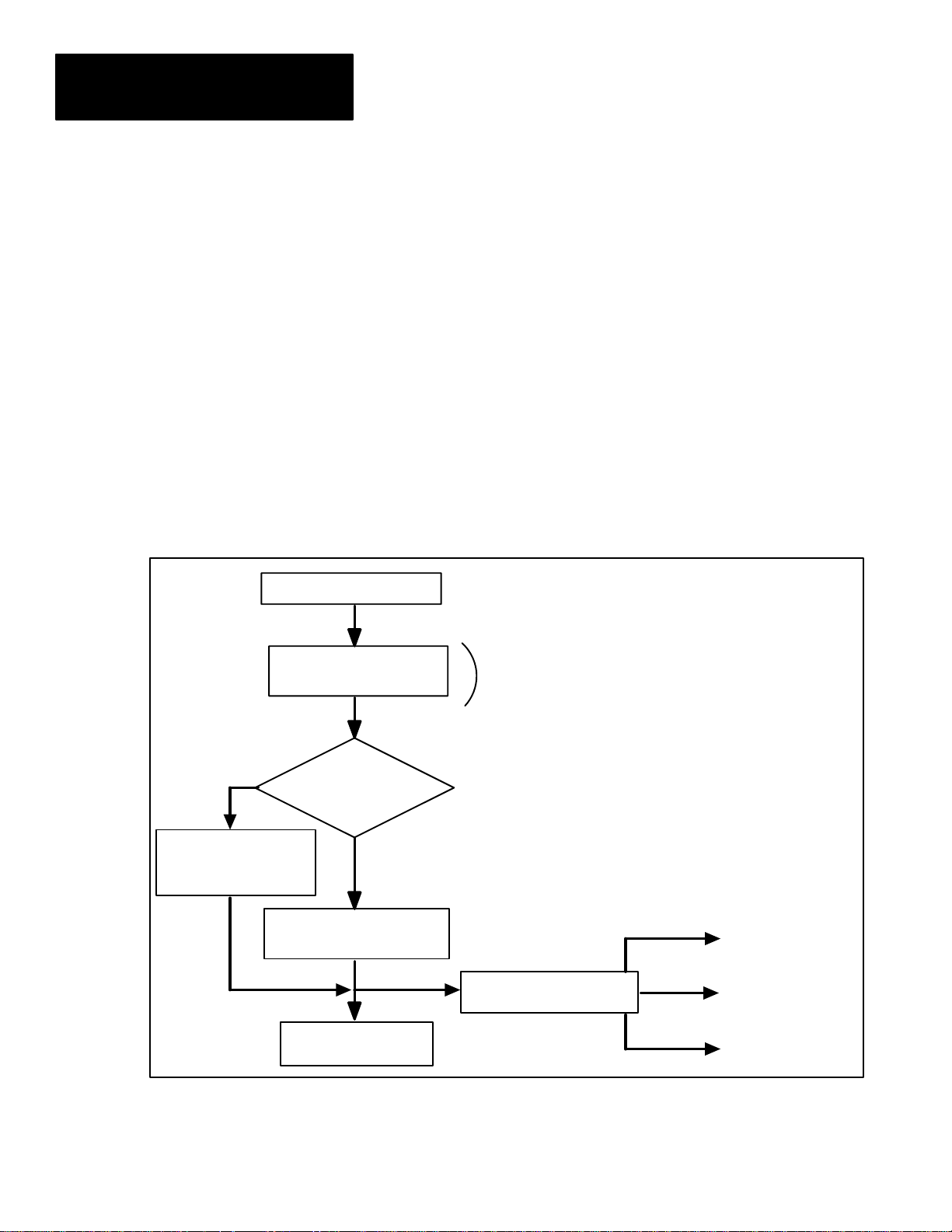

Figure 2.1 illustrates how the inspection tool results are range-checked and

applied to discrete outputs, without MATH-PAK installed.

Color CVIM Inspection

Inspection results data

from one or more tools

No

Appropriate

fault/warning bit(s)

cleared

fault/warning bit(s) set

Figure 2.1 Inspection results data handling without MATH–PAK formulas

Without

MATH-PAK

formulas, tool

results data and

pass/warn/fault

status are

available for use

Range limits

exceeded or

tool failed?

Yes

Appropriate

directly – as is.

To: Chassis

backplane

2–2

Results data stored

in Color CVIM memory

Bit(s) sent to

assigned output(s)

To: 1771 Remote

I/O port

To: RS-232 port

Upon completion of each inspection cycle, the Color CVIM module stores

the resulting inspection data from each analysis tool used in the inspection.

This information is accessible to host devices connected to the Color CVIM

through the backplane, 1771 Remote I/O port, or RS-232 port.

Page 11

Color CVIM Inspection

Inspection results

from one or more tools

Chapter 2

Introduction to the MATH-PAK Option

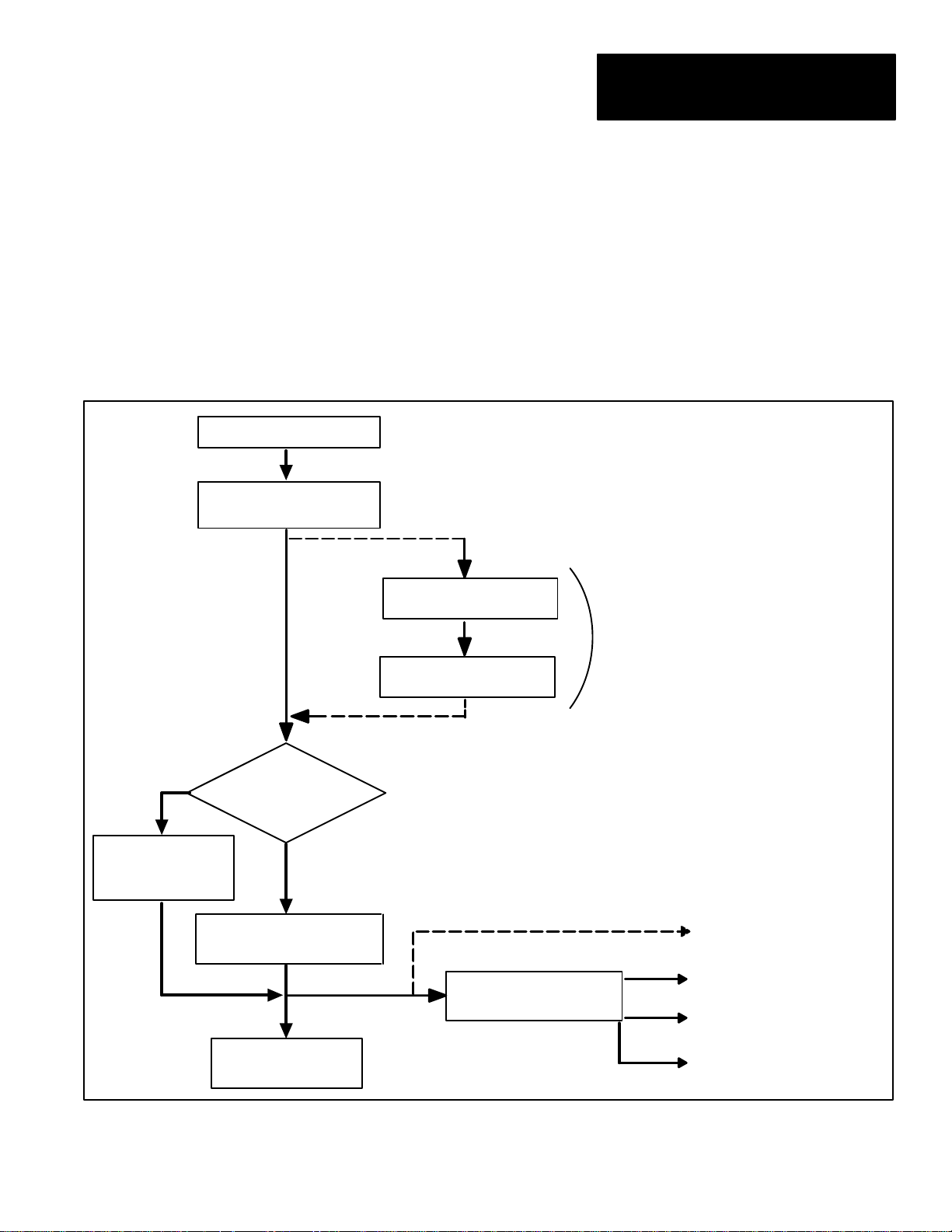

When the MATH-PAK option is installed, the results information for each

inspection is also available for use in MATH-PAK formulas. You can define

formulas to combine or manipulate, in any number of ways, the inspection

data gained from one or more tools used in the inspection.

Figure 2.2 illustrates how the inspection results can be manipulated by

formulas with MATH-PAK installed.

Figure 2.2 Inspection results data handling when using a MA TH–PAK formula

No

Appropriate

fault/warning bit(s)

cleared

fault/warning bit(s) set

Range limits

exceeded or

tool failed?

Yes

Appropriate

Bit(s) sent to

assigned output(s)

Formula manipulates

data from tool(s)

Results from formula

Results data stored in

Color CVIM memory

2: Formula results can

replace, or be provided along

with, tool results.

Using MATH-PAK

formulas, tool results

can be combined or

1

manipulated.

1: Formula results can be

range-checked instead of, or

along with, tool results.

To: MATH–PAK formula(s)

(if applicable)

To: Chassis

2

backplane

To: 1771 Remote

I/O port

To: RS-232 port

Range limits and output assignment: For each formula you define, as with

the inspection tools, you can set warning and fault range limits for the

results, and assign the range limits to discrete outputs (see Figure 2.2).

2–3

Page 12

Chapter 2

Introduction to the MATH-PAK Option

Depending on your requirements, you can configure the Color CVIM module

so that it range-checks formula results instead of, or in addition to, the initial

tool results.

Data communication: The formula results information is, as with

inspection tool results, also accessible to devices connected to the Color

CVIM module through the backplane, 1771 Remote I/O port, or RS-232 port.

Depending on your requirements, you can configure the Color CVIM module

so that formula results are accessible instead of, or in addition to, the initial

tool results.

Accessing the MATH-PAK Features

With the MATH-PAK option installed, the MATH-PAK features are accessed

through the added Config. Results box on the Archival menu. To access

the Config. Results (MATH-PAK) menu, you would:

• Pick Misc → Archival to access the Archival menu (see Figure 2.3).

• Pick Config. Results on the Archival menu.

To define a formula, you would pick Set Formula on the Archival menu.

When you do, the formula entry keyboard appears (see Figure 2.3). You then

enter a formula by picking the appropriate boxes on the formula keyboard.

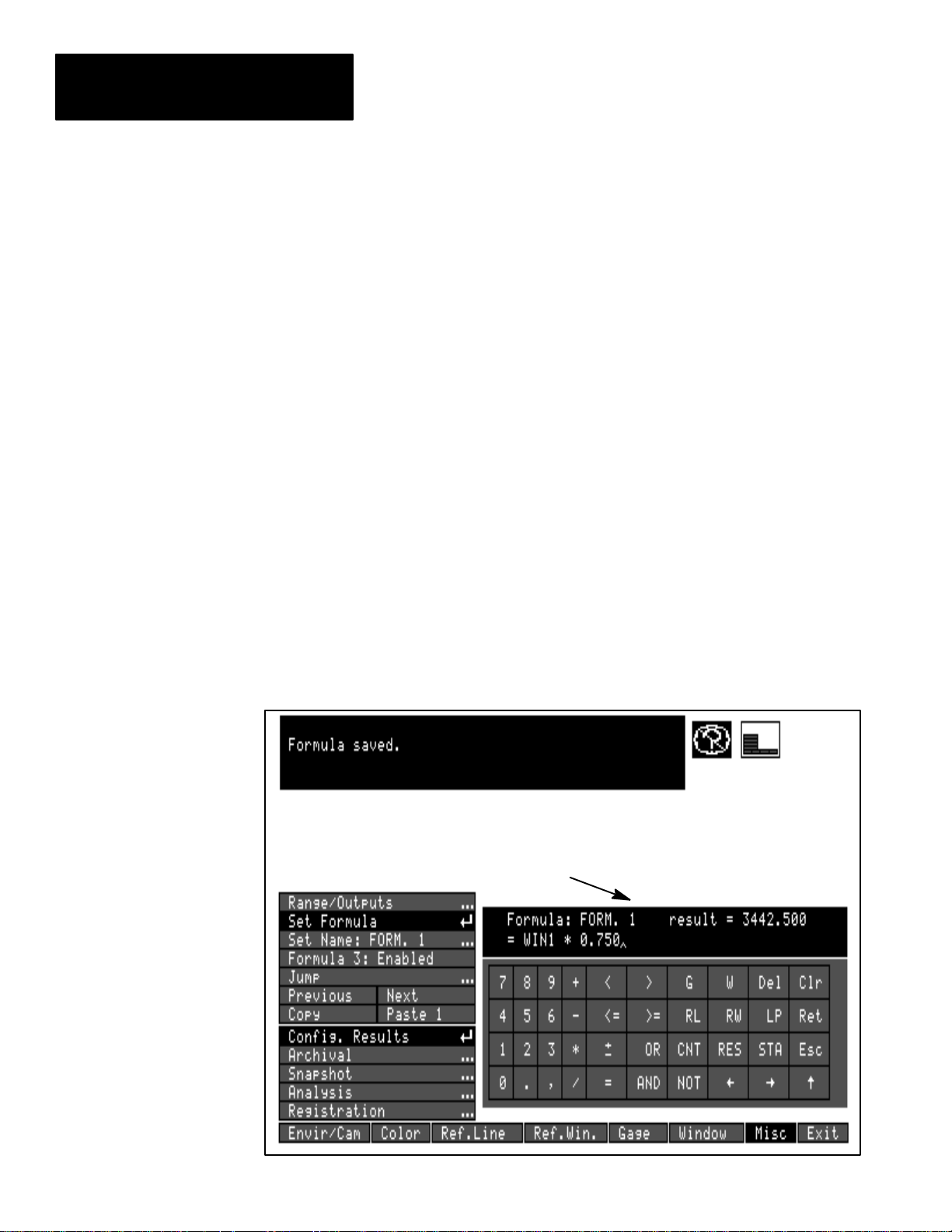

Figure 2.3 Accessing the MA TH-PAK features

Formula

entry

keyboard

2–4

Page 13

Chapter 2

Introduction to the MATH-PAK Option

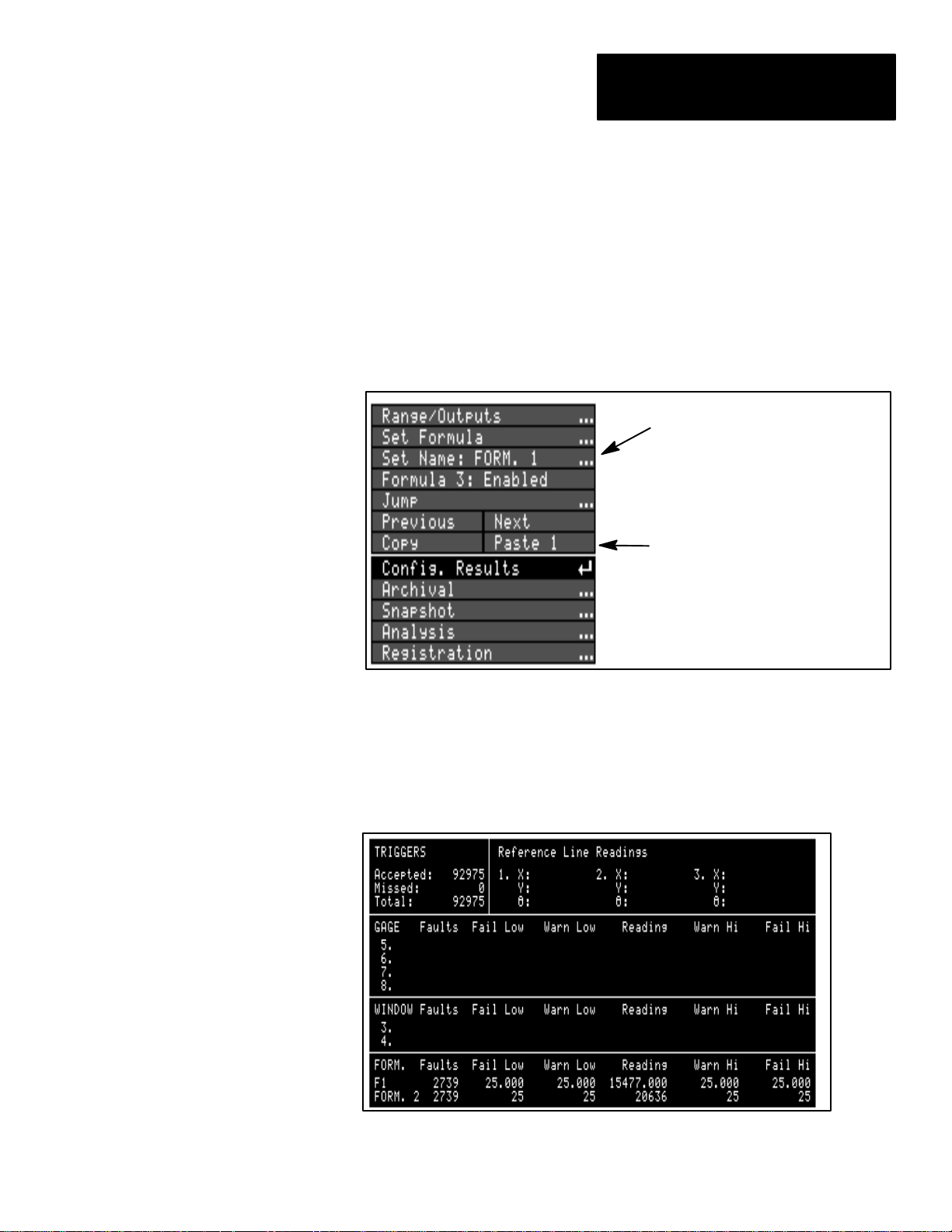

Copy and Paste Functions

You can copy the definition of one formula to another using the Copy and

Paste menu items which are part of the new MATH–PAK menus (see

Figure 2.4). After you copy one formula to another, for example, you can

make changes to the formula as necessary. This can save time and effort

during setup, especially when you want to try out different variations of a

formula you have defined, or if two or more formulas will be very similar.

Figure 2.4 Copy and Paste functions

Config. Results menu

Copy and Paste boxes

Runtime Displays

With the MATH-PAK option installed, the runtime displays can

accommodate the MATH-PAK formulas. For example, the Results page can

list the formula results along with other tool results (see Figure 2.5).

Figure 2.5 Results Page displaying formula results

2–5

Page 14

Chapter

Chapter Objectives

Installing the MATH-PAK Option

A–B

3

Installation

Contents

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the MATH-PAK Option 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This chapter describes how to install the MATH-PAK option in the

Allen–Bradley 5370–CVIMC Color CVIM module.

The MATH-PAK option is provided on the supplied memory card. This

section describes how to install the MATH-PAK option. Please note the

following considerations:

Required Firmware: The Color CVIM module must have the Revision

A02 (or higher) firmware before the MATH-PAK option can be installed

(the firmware revision is listed on the title banner on the monitor screen

following powerup).

One–Time Installation: You need only install the MATH-PAK option

once; once installed, the MATH-PAK option remains installed for all

subsequent powerups.

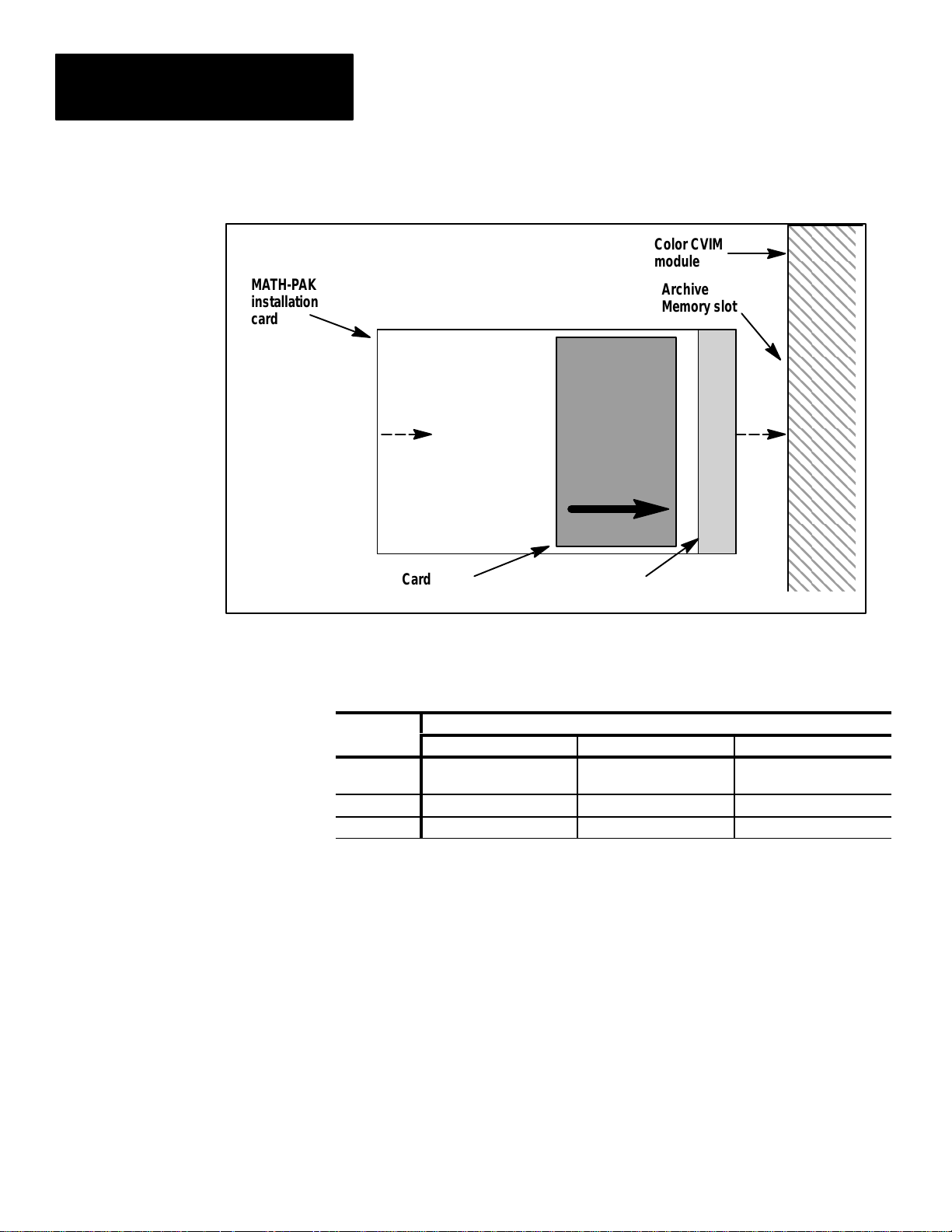

To install the MATH-PAK option in your Color CVIM module:

• Remove DC power from the Color CVIM module.

• Insert the MATH-PAK installation card into the Archive Memory slot on

the Color CVIM module. Insert the end with the metal strip facing right

(see Figure 3.1, page 3–2).

• Restore DC power to the Color CVIM module – this starts the loading

sequence.

ATTENTION: Do not remove power to the Color CVIM

module during loading of the MATH-PAK option. Doing so may

!

damage the Color CVIM module.

3–1

Page 15

Chapter 3

Installation

MATH-PAK

installation

card

Figure 3.1 Inserting the MA TH-PAK installation card

Color CVIM

module

Archive

Memory slot

Card Label

Metal Strip

The loading process requires about 45 seconds. The LEDs near the top of

the face of the Color CVIM module indicate the progress of the

three–phase loading process (with each phase taking about 15 seconds):

LEDs

Pass/Fail

Trigger 1 Green Green Off

Trigger 2 Off Green Green

1

Red–to–yellow–

to–green

MA TH-PAK Loading Phase

2 3

Green

Red–to–yellow–

to–green

When the loading process is complete, the Color CVIM module initiates

its normal powerup sequence.

• Once the powerup sequence is complete, you can verify that the

MATH-PAK option is installed by checking for the MATH-PAK

indication on the powerup title banner on the monitor; if the MATH-PAK

option is installed, it is listed as on of the “Packages” on the title banner,

along with other installed options, if any.

• Remove the MATH-PAK installation card from the Archive Memory slot.

At this point, the MATH-PAK option has been successfully installed, and can

be used as required in your Color CVIM module configurations.

3–2

Page 16

Chapter

Chapter Objectives

A–B

4

Defining Formulas

Contents

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Formula Definition: Basic Steps 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting a Formula 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining a Formula 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Naming a Formula 4–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enabling/Disabling a Formula 4–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Copy and Paste 4–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Range Limits and Assigning Outputs 4–41. . . . . . . . . . . . . . . . . . . .

This chapter describes how to configure MATH-PAK formulas, including

how to select formulas, how to access and use the formula entry keyboard to

define a formula, and how to copy formulas.

Formula Definition: Basic Steps

The MATH–PAK option enables your Color CVIM module to automatically

perform a variety of mathematical and/or logical operations, using formulas

that you define, on inspection data from any of the module’s analysis tools.

A MATH-PAK formula is defined by the user. A formula consists of one or

more mathematical or logical operators, and one or more operands, which

combine to provide a mathematical or a logical (1 or 0) result.

The result of the formula can be assigned range limits, and the range limits

can be assigned to outputs.

You can define up to 56 different MATH-PAK formulas.

Listed below are the basic steps involved in initially defining a formula:

1. Select formula – Select the number of the formula to define, taking into

consideration that results from enabled formulas can replace output from

corresponding tools.

2. Define and save formula – Define the formula by selecting and placing,

in logical sequence, the appropriate components (operands and

operators) using the formula entry keyboard, accessed through the Set

Formula box.

3. Name formula – Enter a descriptive name for the formula, if desired, by

picking the Set Name box and using the character entry keyboard.

4. Enable formula – Enable the formula, if appropriate, by picking the

Formula #: Disabled box.

5. Set range limits and assign outputs – Set range limits and assign

outputs for the formula, as required, by picking the Range/Outputs box.

4–1

Page 17

Chapter 4

Defining Formulas

Selecting a Formula

The first step in defining a formula is to select, by number (from 1–56), the

formula you want to define. The current formula number is listed in the

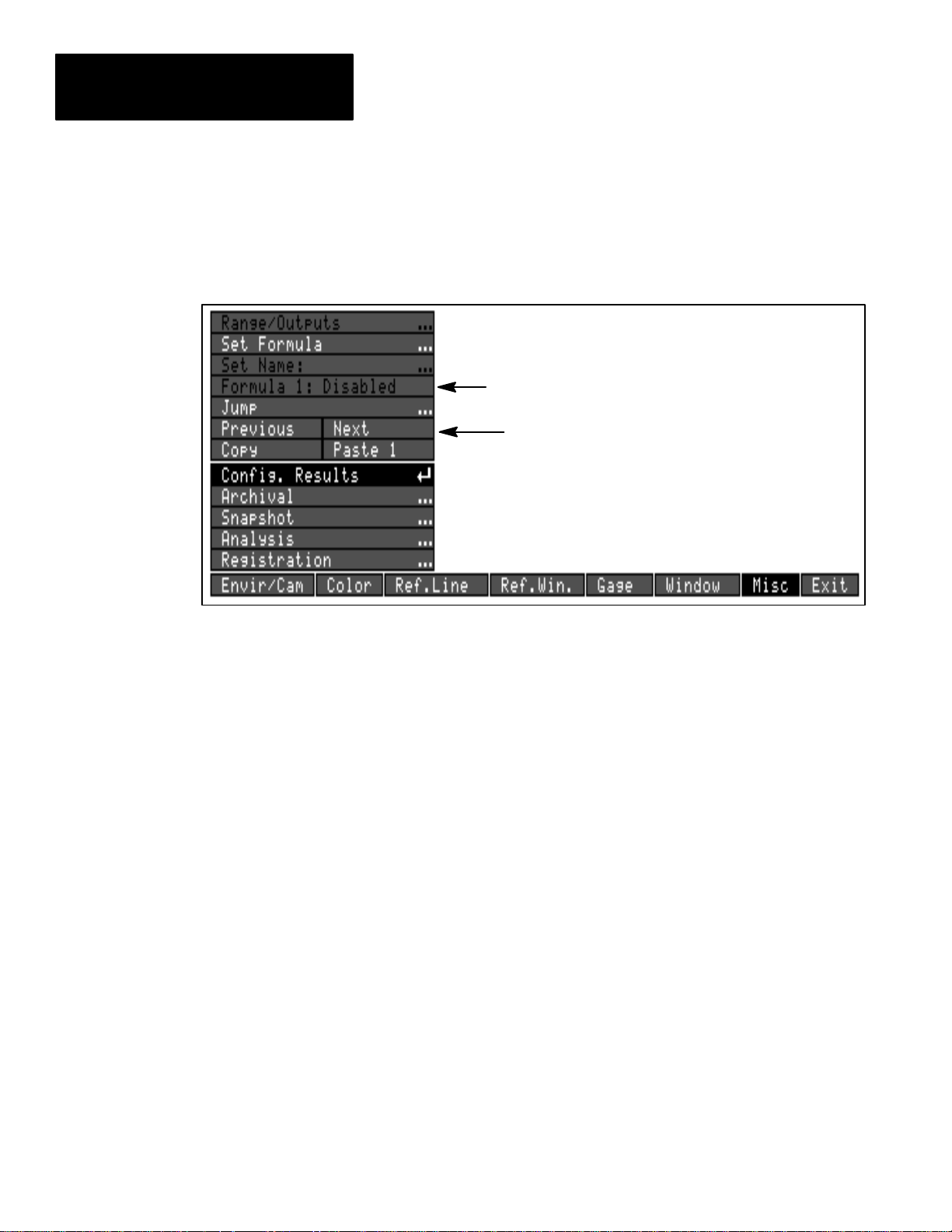

Formula #: box on the Config. Results menu (see Figure 4.1).

Figure 4.1 Selecting the formula number

Formula # box

Previous / Next boxes

In selecting the formula(s) you want to define, and also when selecting

windows and gages to define, consider the following points:

• Formulas are evaluated in numerical order: If you define formulas

which require results information from some other formula(s) from the

current inspection, make sure the formulas providing the required results

precede (in terms of numerical order) the formula requiring those results.

• Formulas prevent the use of corresponding gage and window

outputs: Any formula you select and enable will disable the use of

results outputs from a corresponding gage or window, as listed in

Table 4.A, page 4–3. Note that gages 33–64 and windows 25–48 are

not listed in Table 4.A; they are not affected by the use of formulas.

Warning message: Whenever you enable a formula, a warning message

appears, identifying the corresponding tool that is being prevented from

driving an output (see “Enabling / Disabling a Formula” on page 4–38).

• Formula results replace the results of the corresponding gage and

window in the results blocks: When you enable a formula, its

inspection results are listed in the results block, in place of the

corresponding gage or window results (as listed in Table 4.A, page 4–3).

Results blocks contain the comprehensive inspection results available by

transfer through the Color CVIM backplane, or through one of the Color

CVIM serial ports (see Appendix A for communications information).

When any formula is enabled, the Color CVIM module disables the

Range/Outputs box on the Range/Reference menu for the corresponding

tool (see “Setting Range Limits and Assigning Outputs” on page 4–41).

4–2

Page 18

Chapter 4

Defining Formulas

To avoid losing the use of particular window or gage outputs or results,

when defining formulas, select formula numbers which do not correspond to

any gages or windows you have previously defined (see Table 4.A, page

4–3), or that you intend to define. Or, define a formula to provide the result

value for a tool for which there is a conflict (see “Operands” in this chapter).

Otherwise, during setup of gages and windows, select gage and window

numbers that will not conflict with the formulas you intend use. One way to

do this is to select only gages numbered from 33–64, or windows numbered

from 25–48, which are not affected by the use of formulas.

Use Copy and Paste functions: If you define a formula that turns out to

correspond to a gage or window whose output or results block information

you wish to use, you can copy that formula to another formula number that

does not conflict (see “Using Copy and Paste” on page 4–39).

See Appendix A for communications information: Appendix A provides

more information on the specific effects that using formulas has on the

results blocks, on the configuration blocks, and on the discrete input bits.

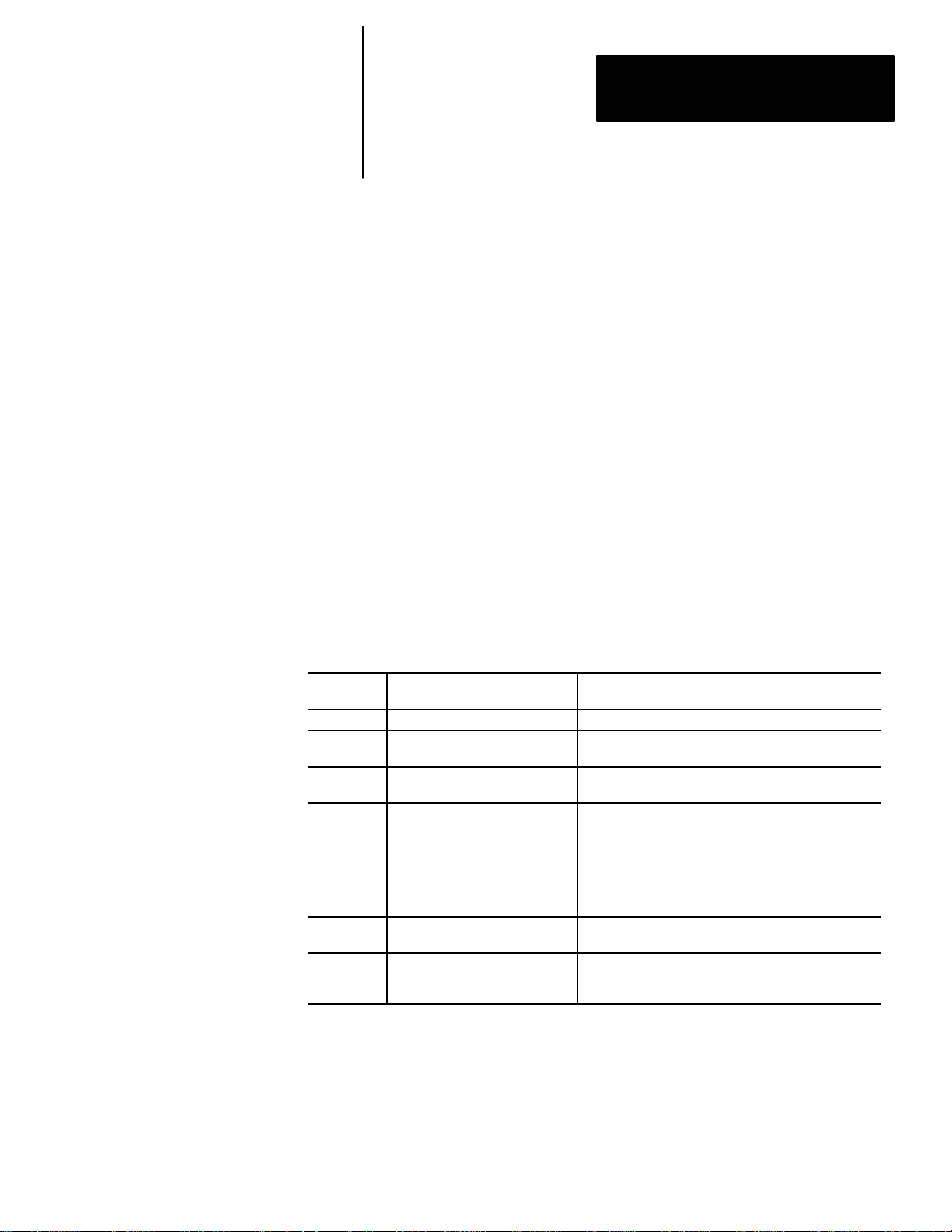

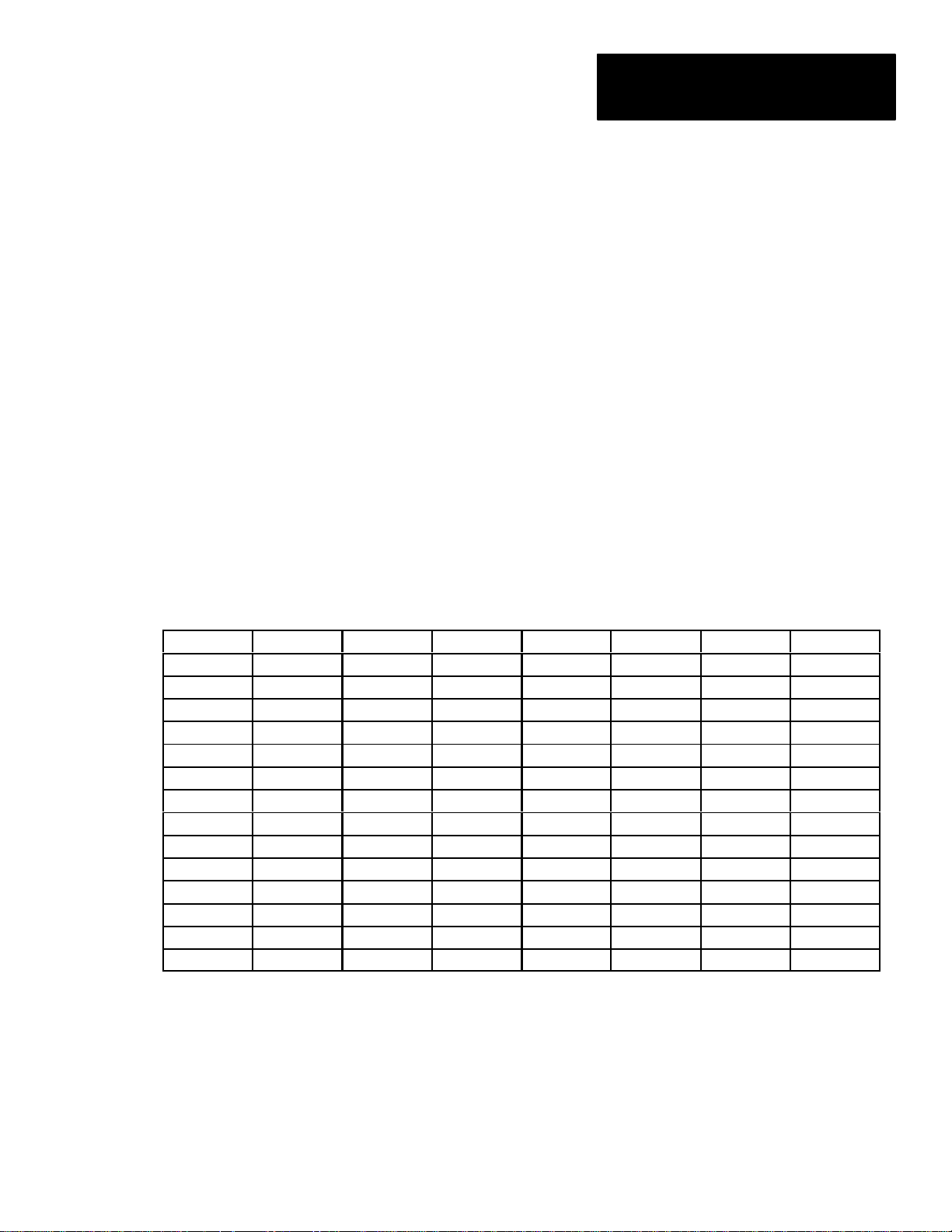

Table 4.A

Formula numbers and corresponding gage/window numbers

Formula Tool Formula Tool Formula Tool Formula Tool

1 Window 1 15 Gage 7 29 Gage 13 43 Gage 19

2 Window 2 16 Gage 8 30 Gage 14 44 Gage 20

3 Window 3 17 Window 9 31 Gage 15 45 Gage 21

4 Window 4 18 Window 10 32 Gage 16 46 Gage 22

5 Window 5 19 Window 11 33 Window 17 47 Gage 23

6 Window 6 20 Window 12 34 Window 18 48 Gage 24

7 Window 7 21 Window 13 35 Window 19 49 Gage 25

8 Window 8 22 Window 14 36 Window 20 50 Gage 26

9 Gage 1 23 Window 15 37 Window 21 51 Gage 27

10 Gage 2 24 Window 16 38 Window 22 52 Gage 28

11 Gage 3 25 Gage 9 39 Window 23 53 Gage 29

12 Gage 4 26 Gage 10 40 Window 24 54 Gage 30

13 Gage 5 27 Gage 11 41 Gage 17 55 Gage 31

14 Gage 6 28 Gage 12 42 Gage 18 56 Gage 32

Selecting the Formula Number(s)

There are two ways to select the formula number:

• Use the Previous / Next boxes to decrement / increment the formula

number, until the desired number appears (see Figure 4.1, page 4–2).

• Use the Jump box to enter the desired formula number directly (see

Figure 4.2, page 4–4).

4–3

Page 19

Chapter 4

Defining Formulas

To use the Jump box to select the formula number:

• Pick Misc → Config. Results to access the Config. Results menu.

• Pick the Jump box on the Config. Results menu. The calculator pad

appears (see Figure 4.2).

• Pick the appropriate numeric key boxes on the calculator pad to select the

desired formula number.

• When the desired formula number appears in the calculator pad display,

pick Enter on the calculator pad. This changes the selected formula to

the number on the calculator pad display.

Figure 4.2 Using the Jump box and calculator pad

Defining a Formula

Jump box

Calculator pad

Formulas can be defined in a variety of ways to perform a variety of

calculations.

Multiple operators, of different types, can be combined in different ways

within a formula. “Nesting” of operations within a formula can be employed

through the use of the parentheses. Or, a formula can consist of a single

operand, with no operators.

A first step in formula definition is to review the available operators and

operands – this information is listed in the sections “Entering Operands” and

“Entering Operators” in this chapter.

4–4

The next step in formula definition is to decide on the formula content, and

results desired from the formula – that is, determine what you want the

formula to do, based on your application requirements.

Once you have decided on the formula requirements, to define a formula, use

the formula entry keyboard, which is described in the following two sections.

Page 20

Set Formula box

Chapter 4

Defining Formulas

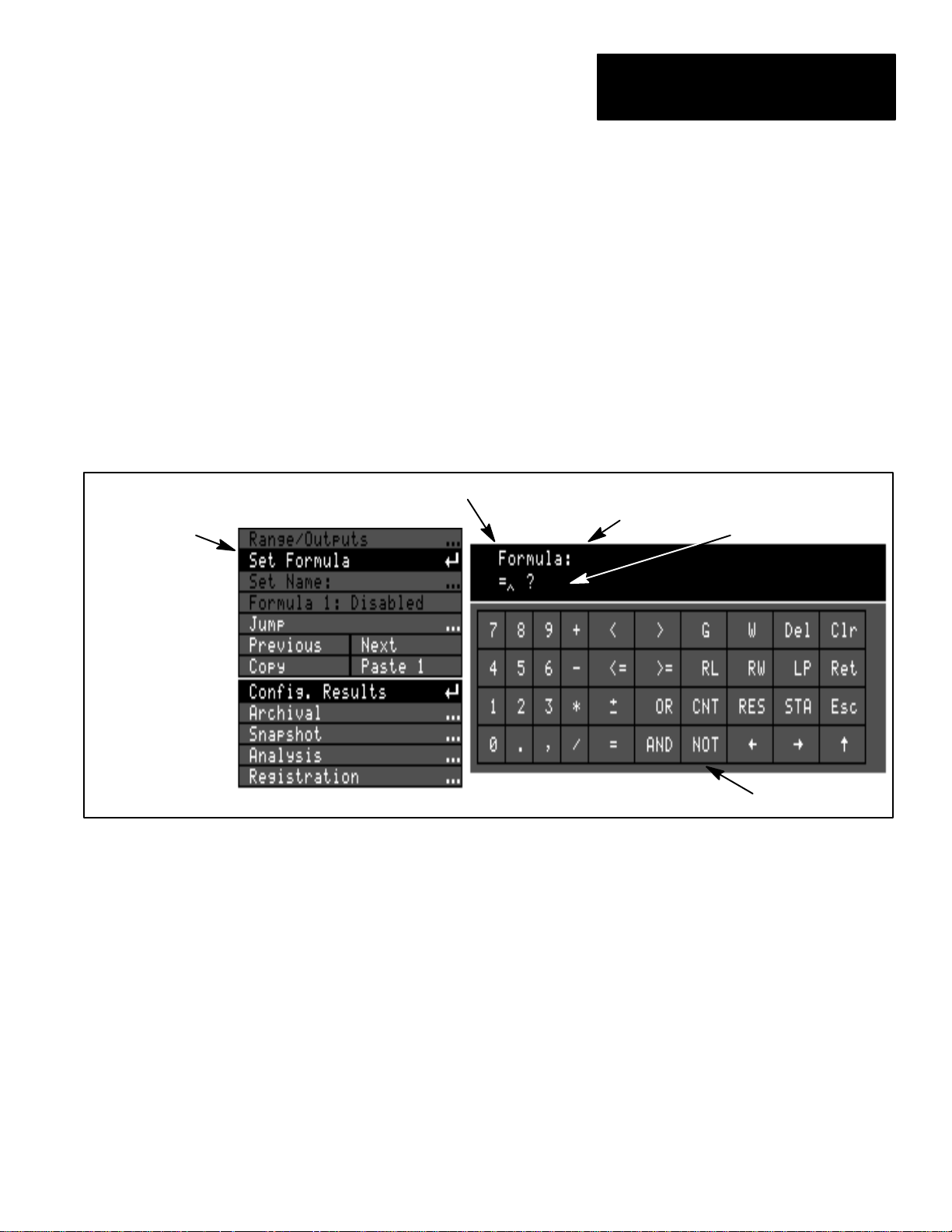

Accessing the Formula Entry Keyboard

In order to define a formula you have selected, access the formula entry

keyboard by selecting the Set Formula box. To do this:

• Pick Misc → Config. Results to access the Config. Results menu.

(see Figure 4.3).

• Pick Set Formula on the Config. Results menu. The formula entry

keyboard appears.

Figure 4.3 Accessing the formula entry keyboard

Keyboard display area

Formula name field

Formula entry field

Key Area

The formula entry keyboard enables you to select the various operands,

operators, and other elements that will make up the formula you are defining.

The keyboard has two main areas – the key area, and the display area (see

Figure 4.3).

Display area: The display area lists the formula name (which can be

user-assigned), and lists the formula components as you select them.

Key area: You pick the keys in the key area in order to select components

(operators and operands) to define the formula. The keys fall into several

general categories – operand keys, operator keys, numeric keys, edit keys,

and miscellaneous other keys.

Accessing the two key sets: The formula entry keyboard actually has two

different key sets, in order to accommodate all of the formula elements. You

can easily switch between the two key sets as necessary (see Figure 4.4).

4–5

Page 21

Chapter 4

Defining Formulas

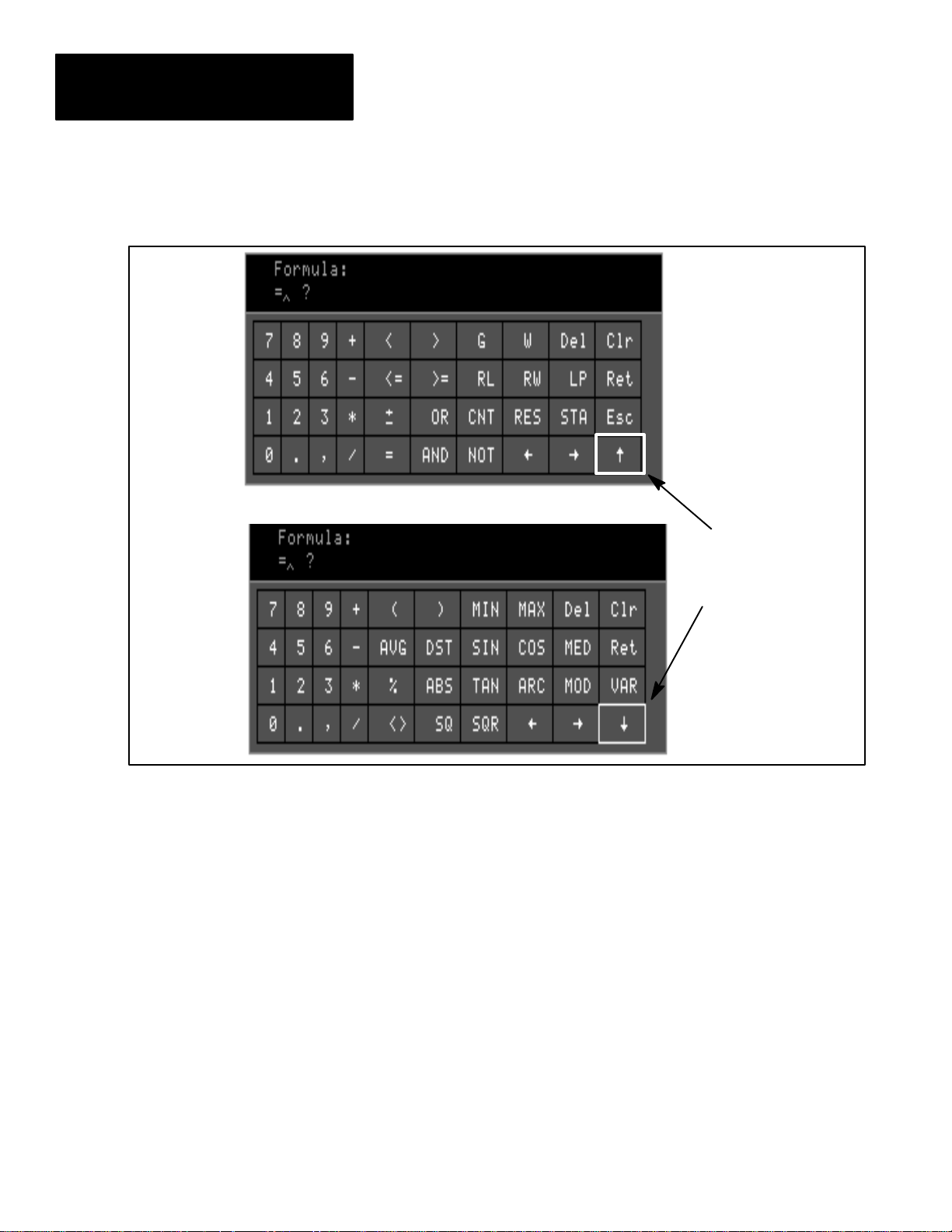

Figure 4.4 Switching between the two key sets of the formula entry keyboard

Initial

key set

Secondary

key set

Picking the up or down

arrow key switches

between the two key

sets

To switch between key sets, use the ↑ and ↓ arrow keys (see Figure 4.4):

• Pick the up (↑) arrow key to switch from the initial key set to the

secondary key set.

• Pick the down (↓) arrow key to switch back to the initial key set.

The initial key set contains all of the available operand keys, along with

various operator keys, the numeric keys, and the edit/control keys. Each of

these key types is discussed in later sections in this chapter.

4–6

The secondary key set offers additional operator types, replacing the initial

operands and some of the operators. It retains some of the initial keys,

including the numeric keys, the arithmetic keys, and the edit/control keys.

Page 22

Formula is displayed

Chapter 4

Defining Formulas

Using the Formula Entry Keyboard

To define a formula, you would generally follow the steps listed below:

• Pick Set Formula on the Config. Results menu to access the formula

entry keyboard (see Figure 4.3, page 4–5).

• Enter your formula – Pick the keys on the keyboard which correspond to

the operators, operands, and other items (decimal points, commas,

parentheses) you are using in the formula. As you pick your formula

entries, they appear in the keyboard display:

A cursor indicates the point at which the next component entered will

appear.

• You can edit the formula as you enter it, using these edit keys:

← → Pick the arrows keys (← or→) to move the cursor to the left or right

along the formula, in order to insert a component at a particular point in a

formula, or to prepare to delete a particular component.

Del Pick the Del(ete) key to erase the entry to the left of the cursor.

Clr Pick the Clr (clear) key to erase the entire formula.

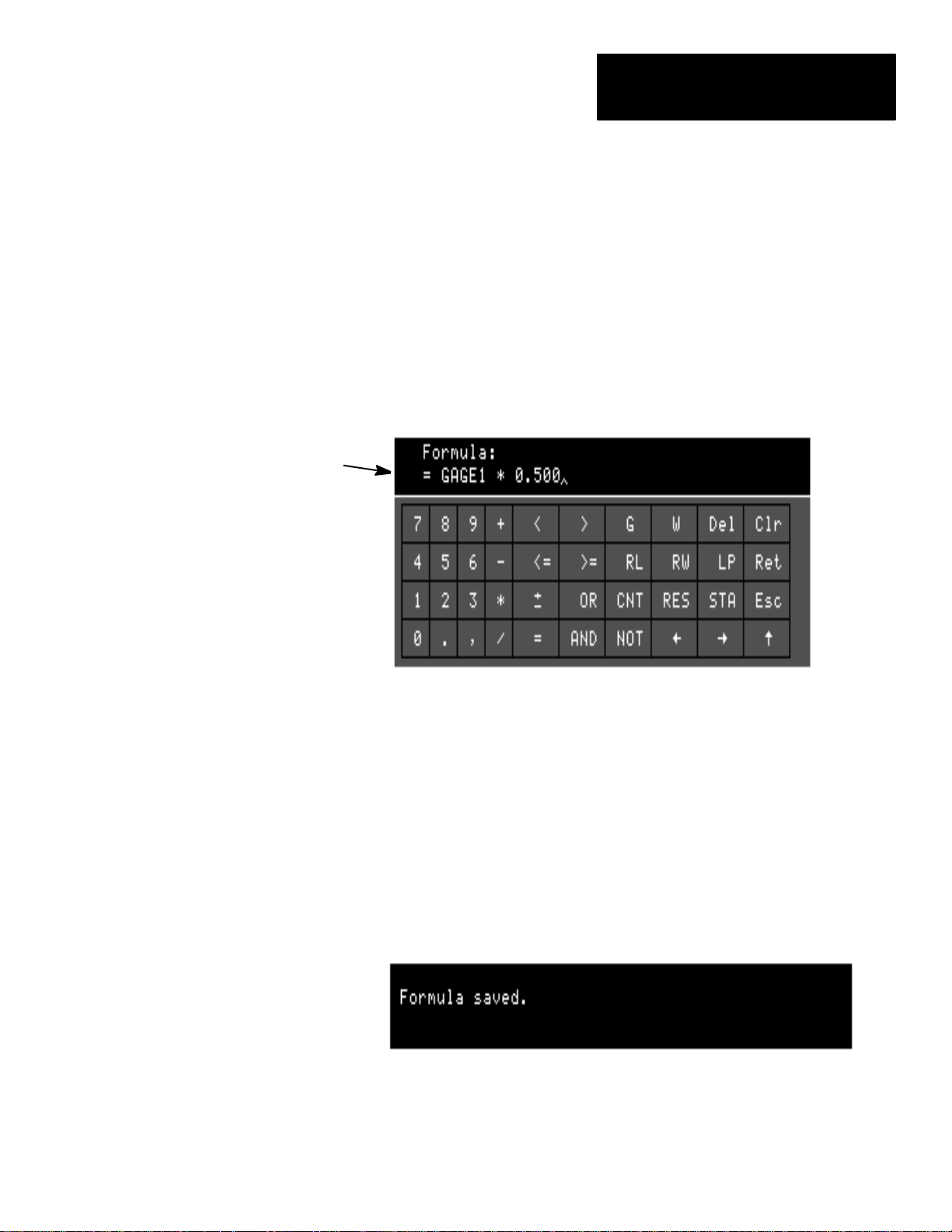

• When finished, you can pick the Ret key to save a formula, or pick the

Esc key, to restore the formula content to what it was when last saved.

When you pick the Ret key, the formula is saved, and a message appears:

You can continue to edit the formula after picking the Ret key – however,

to save the changed formula, you must pick the Ret key when finished.

Saving the formula also enables the Set Name and Formula #:

Disabled boxes on the Config. Results menu, which allow you to

enable and name the formula.

4–7

Page 23

Chapter 4

Defining Formulas

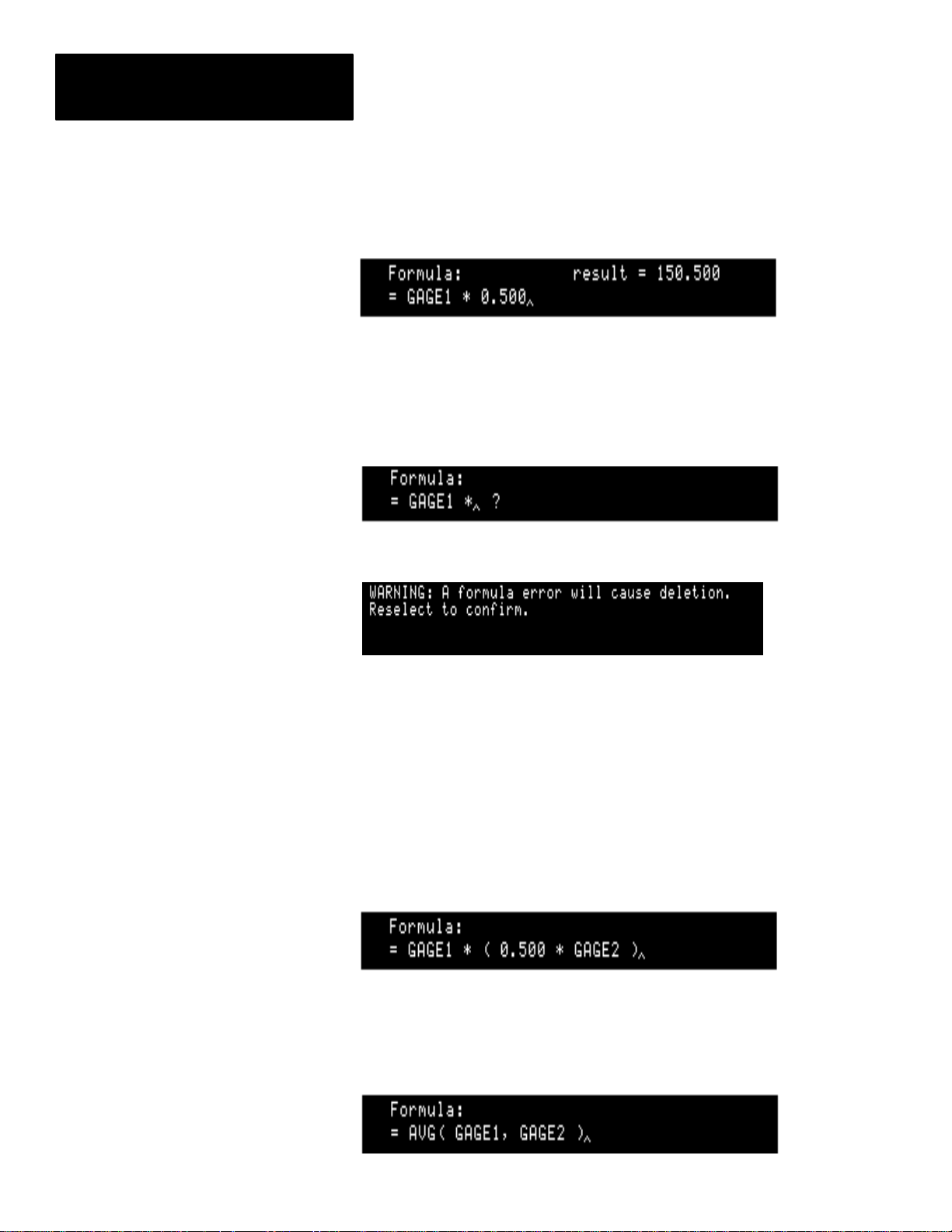

Results Display: When you pick the Ret key, and the formula is saved,

the current result of the formula is listed in the keyboard display area:

The result format is either integer, or fixed decimal point, depending on

the requirements of the operator(s) and/or operand(s) in the formula.

Question mark (?) – incorrect syntax: The question mark (?) in the

display, when present during formula entry, indicates that the formula is

incomplete as entered, and/or that the syntax for one or more of the

formula components is incorrect:

If you pick the Ret key while a (?) appears in the display, this warning

message appears at the top of the screen:

To avoid losing your current formula entry, pick any key besides the Ret

key (other than Clr or Esc). Otherwise, picking the Ret key at this point

will clear the formula entry.

• Using parentheses in formulas: Parentheses can be used when entering

formulas, in two different ways –

Prioritizing operations – You can place parentheses around an operator

and its operands in order to prioritize that operation – that is, the

operation in parentheses can be used as an operand by another operator.

“Nesting” of operations within a formula can be employed, where a

parenthetical portion is itself contained within another parenthetical

portion of the formula.

4–8

Listing operands – Some operators require that you enter one or more

operands in a parenthetical list following the operator. In these cases,

when you pick the operator, the “open” parenthesis is displayed. After

you list the operand or operands (separated by commas), you then enter

the “close” parenthesis.

Page 24

Example Formula Entry

Chapter 4

Defining Formulas

To enter this formula:

AVG (GAGE1,GAGE2) * 0.250

• Select an undefined formula (see “Selecting a Formula” in this chapter),

and pick the Set formula box to access the formula entry keyboard.

• Pick the AVG key on the formula entry keyboard (located on the

secondary key set). The formula keyboard display shows:

Formula:

Cursor

= AVG( ?

The “?” indicates the formula is incomplete to this point; the cursor

indicates the point at which the next component will be entered.

• Pick G (on the initial key set), to begin to enter the GAGE1 operand:

Formula:

= AVG( GAGE0 ?

• Pick 1, to complete the entry of the GAGE1 operand:

Formula:

= AVG( GAGE1 ?

• Pick “ , ” (comma) , then G, then 2:

Formula:

= AVG( GAGE1, GAGE2 ?

• Pick “ ) ” (close parenthesis) on the secondary key set. The formula is

now correct in syntax at this point; the “?” disappears:

Formula:

= AVG( GAGE1, GAGE2 )

• Pick “

Pick the Ret key to save the formula; a result is displayed:

” , then “.” (decimal point), then 2, then 5:

*

Formula:

= AVG( GAGE1, GAGE2 ) * 0.25

Formula: result: 602.000

= AVG( GAGE1, GAGE2 ) * 0.250

4–9

Page 25

Chapter 4

Defining Formulas

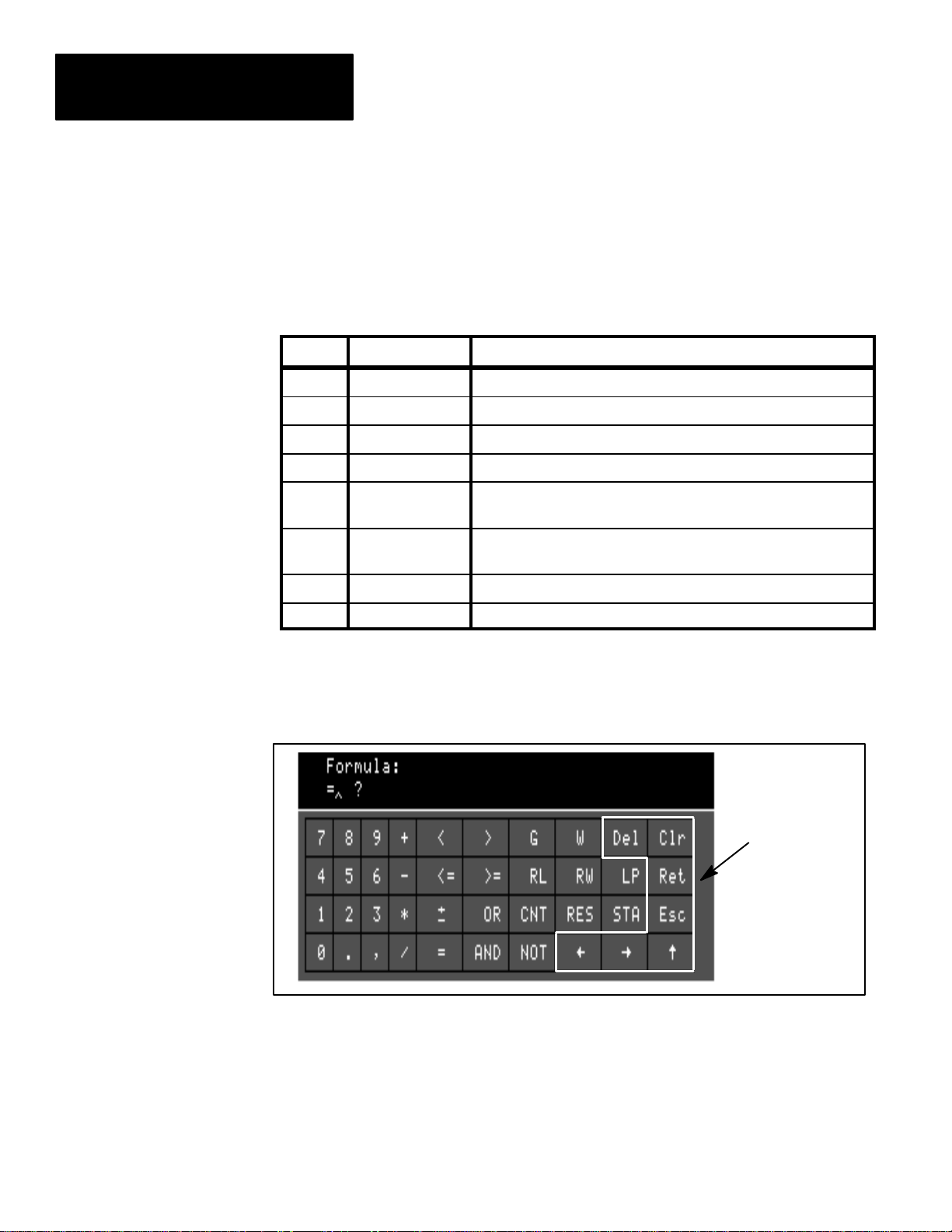

Edit / Control Keys

You can edit the contents of a formula, using the edit/control keys, which are

listed and described in Table 4.B.

Table 4.B

Edit / Control Keys

Key

Del Delete Deletes the formula item to the left of the cursor.

Clr Clear Clears the entire formula.

Ret Return Causes the formula to be saved in memory.

Esc Escape Restores the formula to its condition when last saved.

←

→

↓

↑

Name Edit / Control Function

Left arrow

Right arrow

Down arrow Selects the second keyboard from the first keyboard.

Up arrow Selects the first keyboard from the second keyboard.

Moves the cursor to the left. Picking and holding the light

pen tip down moves the cursor continuously left.

Moves the cursor to the right. Picking and holding the

light pen tip down moves the cursor continuously right.

All of the edit/control keys can be found on either of the two key sets

(Figure 4.5 shows key locations).

Figure 4.5 Edit/control keys

4–10

Edit/control

keys

To edit a formula:

← → Pick the arrows keys (← or→) to move the cursor to the left or right

along the formula, in order to insert a component at a particular point in a

formula, or to prepare to delete a particular component.

Del Pick the Del(ete) key to erase the entry to the left of the cursor.

Clr Pick the Clr (clear) key to erase the entire formula.

Page 26

Chapter 4

Defining Formulas

After editing a formula, pick either Ret or Esc:

Ret Pick the Ret key to save the formula as edited.

Esc Pick the Esc key to restore the formula to the way it was when last saved.

Example of Formula Editing

To edit this formula:

and change it to: AVG (GAGE1,GAGE3) * 1.250

AVG (GAGE1,GAGE2) * 0.250

• Pick the arrows keys (← or→) as necessary to move the cursor to the

right of the

Formula:

= AVG( GAGE1, GAGE2 ) * 0.250

GAGE2 operand:

• Pick the Del key to erase the GAGE2 operand:

Formula:

= AVG( GAGE1, ? ) * 0.250

• Pick G, then 3:

Formula:

= AVG( GAGE1, GAGE3 ) * 0.250

• Move the cursor to the right of the 0.250 operand:

Formula:

= AVG( GAGE1, GAGE3 ) * 0.250

• Pick the Del key; notice the entire 0.250 operand is erased:

Formula:

= AVG( GAGE1, GAGE3 ) * ?

• Pick 1, then “.” (decimal point), then 2, then 5:

Formula:

= AVG( GAGE1, GAGE3 ) * 1.25

After editing the formula, you can pick either Ret or Esc. Pick the Ret

key to save the formula as edited. Pick the Esc key to restore the formula

to the way it was when last saved.

4–11

Page 27

Chapter 4

Defining Formulas

Operands

With respect to MATH-PAK formulas, an operand is a symbol (such as

GAGE1 or WINDOW3.2 or 32.45) that represents a mathematical or

logical value. Operands represent such values as tool results, statistics,

constants, or formula results (see Table 4.C, starting on page 4–14, for

operand listings and descriptions).

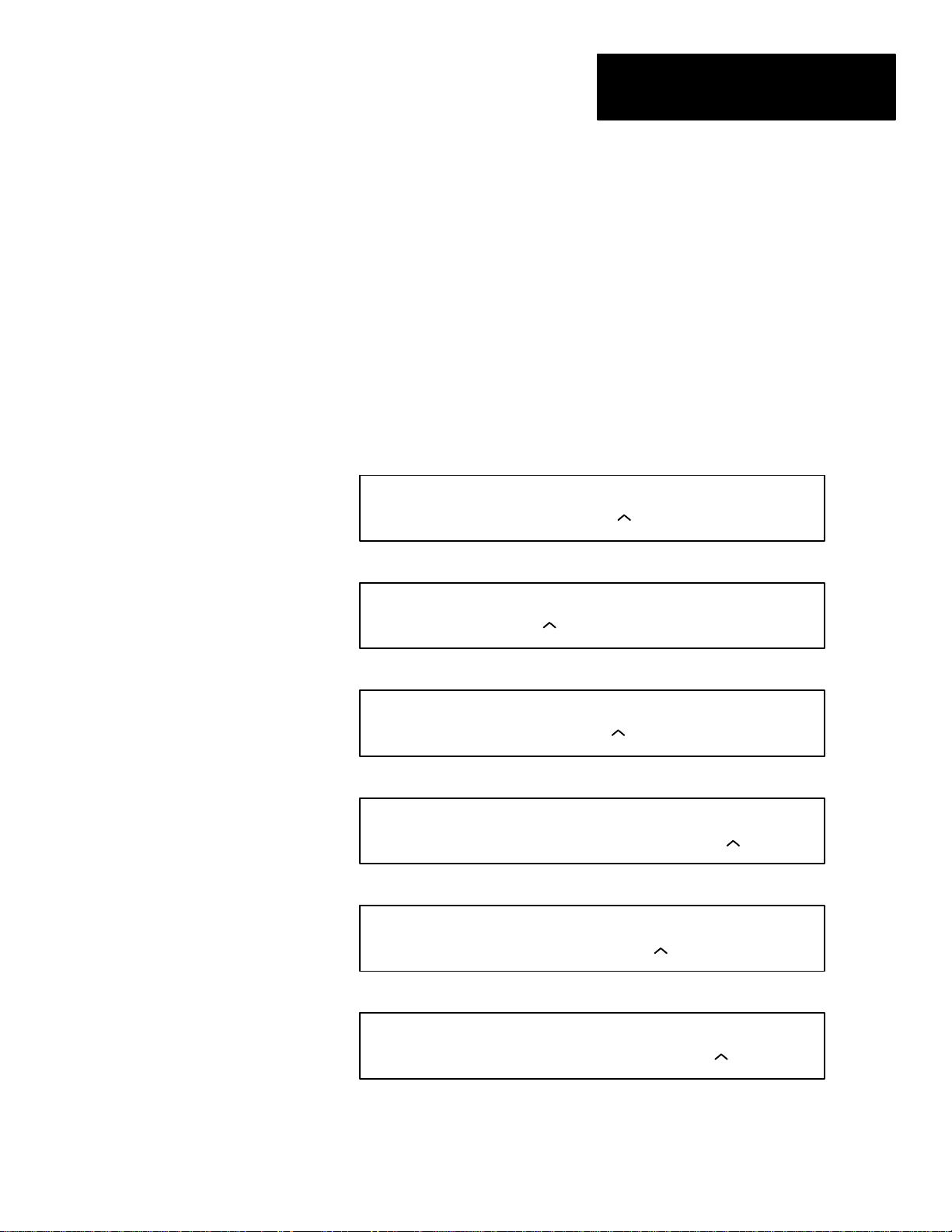

Figure 4.6 Operand keys

Initial

key set

Operand keys

To enter a particular operand in a formula:

• Pick the appropriate operand key on the formula entry keyboard – the

corresponding operand symbol appears in the display area of the

keyboard (see Figure 4.6).

• Typically you must then pick additional keys (decimal point and/or

numeric keys) to complete the operand entry.

For example, to enter the operand for gage 5 numerical results (number of

pixels, number of edges, and so on), enter the operand

GAGE5, as follows:

• Pick G on the formula entry keyboard – this will initially display the

operand

GAGE0 in the formula display area:

4–12

Formula:

= ? GAGE0

• Pick 5 – this will change the operand to GAGE5.

Formula:

= GAGE5

Page 28

Chapter 4

Defining Formulas

Using a sub-code: The operands can be defined so as to provide any of a

number of different types of results data. You do this by including a

sub-code – a decimal point and a number (refer to Table 4.C, page 4–14, for

the definitions of the valid sub-codes).

For example, to specify the pass/fail results from gage 5, in the example

above, you would enter the operand

GAGE5.2:

• Pick G on the formula entry keyboard – this will initially display the

operand

GAGE0 in the formula display area:

Formula:

= ? GAGE0

• Pick 5, then “.” (decimal point), then 2 – this will change the operand to

GAGE5.2.

Formula:

= GAGE5.2

You can see in Table 4.C, page 4–14, that the “.2” sub-code definition is

“Pass/fail condition for fault range (1 = pass, 0 = fail).” During inspections, then,

if gage 5 were to fail, the value 0 would be entered for the

operand. Conversely, if gage 5 passes, the value of 1 is entered.

Listing operands: Some operators require that you enter one or more

operands in a parenthetical list following the operator. In these cases, when

you pick the operator, the “open” parenthesis is displayed. After you list the

operands (separated by commas), you then enter the “close” parenthesis.

For example, to average the results from gages 1 and 2, enter the formula:

Gage5.2

AVG( GAGE1, GAGE2)

• Pick the AVG key on the formula entry keyboard (located on the

secondary key set). The formula keyboard display shows:

Formula:

= AVG( ?

• Pick G (on the initial key set), then 1, then “,” (comma), then G, then 2.

Formula:

= AVG( GAGE1, GAGE2 ?

• Pick “ ) ” (close parenthesis) on the secondary key set. The formula is

now correct in syntax at this point; the “?” disappears.

4–13

Page 29

Chapter 4

Defining Formulas

Table 4.C (part 1 of 3)

Operand Definitions

Key

Operand

Type

CNT Counter

G Gage

W Window

*Operand Symbol *Sub-code (s) Type of Data Returned to Formula

CNT.s

(s = 0 to 2)

GAGEn.s

(n = 1 to 64)

(s = 0 to 9)

WINn.s

(n = 1 to 48)

(s = 0 to 19)

.9

.10

.11

.12

.13

.14

.15

.16

.17

.18

.19

.0

.1

.2

.0

.1

.2

.3

.4

.5

.6

.7

.8

.9

.0

.1

.2

.3

.4

.5

.6

.7

.8

1,2

1,2

1,2

1,2

1,2

1,2

1,2

1,2

1,2

1,2

1,2

Total number of triggers.

Number of missed triggers.

Number of master range faults.

Gage measurement value (# of pixels, # of edges, etc.).

Pass/fail condition for warning range (1 = pass, 0 = fail).

Pass/fail condition for fault range (1 = pass, 0 = fail).

Second coordinate value (Y coordinate for X Position gage;

X coordinate for Y Position gage).

Number of faults detected.

Nominal value.

Fault range high.

Fault range low.

Warning range high.

Warning range low.

Window measurement value (# of pixels, # of objects, etc.).

Pass/fail condition for warning range (1 = pass, 0 = fail).

Pass/fail condition for fault range (1 = pass, 0 = fail).

Number of faults detected.

Nominal value.

Fault range high.

Fault range low.

Warning range high.

Warning range low.

Total number of objects counted before target filtering.

Perimeter value of first counted object.

Area value of first counted object.

X center value of first counted object.

Y center value of first counted object.

Inertial value of first counted object.

Theta value of first counted object.

Min radius value of first counted object.

Max radius value of first counted object.

H size value of first counted object.

L size value of first counted object.

*The letter n = tool or formula number (as appropriate). The letter s = operand subcode.

1

Window sub-codes 9-19 pertain to the object–counting operation only. The “first counted object” is the object which, among those that satisfy the filter

parameters, is closest to the upper-left corner of the window.

2

If a filter parameter is not enabled for the window, a result of –1000 is returned for that parameter.

4–14

Page 30

Table 4.C (part 2 of 3)

Operand Definitions

Chapter 4

Defining Formulas

Key

Operand

Type

RL Ref. Line

RW Ref.

Window

*Operand Symbol *Sub-code (s) Type of Data Returned to Formula

REFLn.s

(n = 1 to 3)

(s = 0 to 3)

.0

.1

.2

.3

X coordinate value of edge position on reference line.

Y coordinate value of edge position on reference line.

Pass/fail condition for reference line (1 = pass, 0 = fail).

Theta from a reference line configured for “X–X then Y” or

“Y–Y then X” rotation compensation.

REFWn.s

(n = 1 to 3)

(s = 0 to 16)

.4

.0

.1

.2

.3

.4

.5

.6

.7

.8

.9

.10

.11

.12

.13

.14

.15

.16

Number of faults detected.

Cumulative position: X coordinate value.

Cumulative position: Y coordinate value.

Cumulative angle (θ).

Cumulative pass/fail condition (1 = pass, 0 = fail).

Active feature #1 position: X coordinate value.

Active feature #1 position: Y coordinate value.

Active feature #1 score value.

Active feature #1 pass/fail condition (1 = pass, 0 = fail).

Active feature #2 position: X coordinate value.

Active feature #2 position: Y coordinate value.

Active feature #2 score value.

Active feature #2 pass/fail condition (1 = pass, 0 = fail).

Active feature #3 position: X coordinate value.

Active feature #3 position: Y coordinate value.

Active feature #3 score value.

Active feature #3 pass/fail condition (1 = pass, 0 = fail).

Number of faults detected.

.0

.1

LP Light

Probe

LPRB.s

(s = 0 to 20)

.2

.3

.4

.5

.6

.7

.8

.9

.10

.11

.12

.13

.14

.15

.16

.17

.18

.19

.20

*The letter n = tool or formula number (as appropriate). The letter s = operand sub-code.

Light probe brightness value for red channel.

Light probe brightness value for green channel.

Light probe brightness value for blue channel.

Pass/fail condition for warning range (1 = pass, 0 = fail).

Pass/fail condition for fault range (1 = pass, 0 = fail).

Number of faults detected.

Nominal value for red channel.

Fault range high for red channel.

Fault range low for red channel.

Warning range high for red channel.

Warning range low for red channel.

Nominal value for green channel.

Fault range high for green channel.

Fault range low for green channel.

Warning range high for green channel.

Warning range low for green channel.

Nominal value for blue channel.

Fault range high for blue channel.

Fault range low for blue channel.

Warning range high for blue channel.

Warning range low for blue channel.

4–15

Page 31

Chapter 4

Defining Formulas

Table 4.C (part 3 of 3)

Operand Definitions

Key

RES Formula

STA Statistics

*The letter n = tool or formula number (as appropriate). The letter s = operand sub-code.

1

The n values 1-56 can refer to either tools or formulas. If the formula corresponding to the selected n number is enabled, the formula statistics are supplied;

otherwise, the corresponding tool results are supplied. Refer to Table 4.A, page 4–3, for a listing of the formulas and corresponding tools.

2

Statistics are available only if the Color CVIM module is run in “learn” mode.

Operand

Type

Result

*Operand Symbol *Sub-code (s) Type of Data Returned to Formula

RSLTn.s

(n = 1 to 56)

(s = 0 to 2)

STATn.s

(n = 1 to 112)

(s = 0 to 4)

1,2

.0

.1

.2

.0

.1

.2

.3

.4

Formula (n) results data value.

Pass/fail condition for warning range (1 = pass, 0 = fail).

Pass/fail condition for fault range (1 = pass, 0 = fail).

Formula/tool (n) statistics: Number of samples taken.

Formula/tool (n) statistics: Minimum reading value.

Formula/tool (n) statistics: Maximum reading value.

Formula/tool (n) statistics: Mean value.

Formula/tool (n) statistics: Standard deviation value.

Entering Constants as Operands

You can, of course, enter constant values, in either integer or fixed point

(decimal) format, to act as operands in a formula, if appropriate. To do this,

use the numeric keys (0–9), and the decimal point (.) key (for fixed point

numbers) which are found on both of the two key sets (see Figure 4.4, page

4–6).

4–16

For example, to enter the constant operand 1.25:

• Pick 1, then “.” (decimal point), then 2, then 5:

Formula:

= 1.25 ?

Here are some additional considerations when entering constant values:

Integer range: Integer values entered must be within the range –32767 to

32767. Values outside this range are not accepted into the formula.

Fixed point (decimal) range: Fixed point decimal values entered must be

within the range –32767.999 to 32767.999. Values outside this range are not

accepted into the formula.

Fixed point operands are always listed with 3 decimal places – trailing 0’s

are added if necessary, or, if more than 3 decimal places are entered, the

value is truncated to three decimal places.

Negative values: Negative values are created by placing the Unary minus

(

±) operator to the immediate left of the positive constant entered.

Page 32

Chapter 4

Defining Formulas

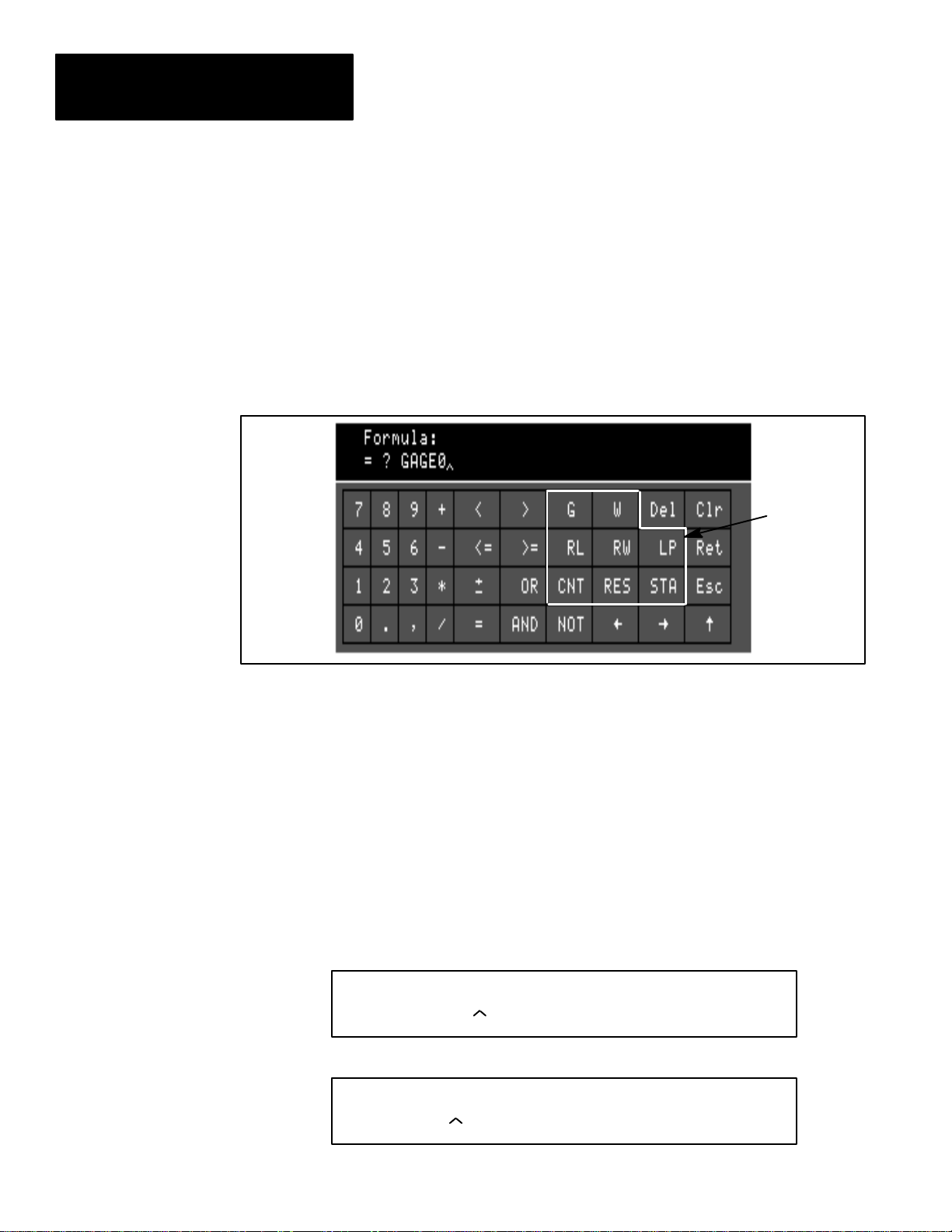

Operators

With respect to MATH-PAK formulas, an operator is a symbol (such as “+”

or “–”) or term (such as “AND” or “AVG”) that represents a mathematical or

logical operation that is to be performed. Table 4.D, starting on page 4–18,

lists the operator keys, and describes the corresponding operators.

To enter a particular operator in the formula:

• Pick the appropriate operator key on the formula entry keyboard – when

you pick an operator key, the corresponding operator symbol appears in

the display area of the keyboard (see Figure 4.7).

Note: Additional operators are located on the secondary key set, which is

accessed by picking the ↑ key on the initial key set.

Figure 4.7 Operator keys (initial key set)

Initial

key set

Operator

keys

Prioritizing operations: Place parentheses around an operator and its

operand(s) in order to prioritize that operation – that is, the result of the

operation(s) in parentheses can be used as an operand by another operator.

“Nesting” is possible, too – this allows a parenthetical portion of a

formula to be contained within another parenthetical portion.

ARC TAN ((GAGE2 – GAGE3) / (GAGE2.3 – GAGE4))

Listing operands: Some operators require that you enter one or more

operands in a parenthetical list following the operator. In these cases,

when you pick the operator, the “open” parenthesis is displayed along

with the operator. After you list the operands (separated by commas), you

then enter the “close” parenthesis.

AVG( GAGE1, GAGE2 )

4–17

Page 33

Chapter 4

Defining Formulas

Table 4.D (part 1 of 2)

Operator Definitions

Key / Symbol

Operator Type

*Result

Type

Operator Usage

Format

Operator Function

Mathematical

+ Add INT/FP X +Y Adds the right operand to the left operand.

– Subtract INT/FP X – Y Subtracts the right operand from the left operand.

*

Multiply INT/FP

X * Y

Multiplies the left operand by the right operand.

/ Divide INT/FP X / Y Divides the left operand by the right operand.

±

Unary minus INT/FP

± X

% Modulo INT/FP X % Y

ABS Absolute value INT/FP ABS(X)

When placed to the immediate left of an operand, it

negates the numeric value of the operand.

Produces the whole number remainder of the division

of the left operand by the right operand.

Produces the absolute value of the listed operand

(negates the value if it is negative).

SQ Square INT/FP SQ(X) Computes the square of the listed operand.

SQR Square root FP SQR(X) Computes the square root of the listed operand.

Computes distance from a point A to a point B – given

DST Distance FP

DST(X1,Y1,

X

2,Y2)

SIN Sine FP SIN(X)

four listed coordinate operands X

computing the square root of the sum of the squared

differences (X

and Y2–Y1).

2–X1

Computes the sine of a listed operand (angle –

assumed in degrees). Returns a fixed point number.

, Y1, X2, and Y

1

2

– by

COS Cosine FP COS(X)

TAN Tangent FP TAN(X)

Arc (prefix to

ARC

SIN, COS, or

FP

TAN)

Logical

AND Logical AND INT/FP X AND Y

OR Logical OR INT/FP X OR Y

NOT Logical NOT INT/FP NOT X

*INT=integer format. FP = fixed point (decimal) format

4–18

SIN

ARC COS (X)

TAN

Computes the cosine of a listed operand (angle –

assumed in degrees). Returns a fixed point number.

Computes the tangent of a listed operand (angle –

assumed in degrees). Returns a fixed point number.

ARC combines with SIN, COS, or TAN function, to

create the respective inverse function – arcsine,

arccosine, or arctangent. These inverse functions

produce an angular result (in degrees).

Produces a “1” result if both the left and right operands

are nonzero; otherwise, produces a “0” result.

Produces a “1” result if either the left or right operand

is nonzero; otherwise, produces a “0” result.

Used to invert a logical value – Produces a “0” result if

the operand is nonzero; produces a “1” result if

operand is 0.

Page 34

Table 4.D (part 2 of 2)

Operator Definitions

Chapter 4

Defining Formulas

Key / Symbol

Operator Type

*Result

Type

Operator Usage

Format

Operator Function

Statistical

AVG Average INT/FP AVG(X, Y, ...) Computes the average of a list of operands.

MAX Maximum INT/FP MAX(X, Y, ...) Finds the maximum numeric value among operands.

Finds the middle numeric value in a list of operands by

MED Median INT/FP MED(X, Y, ...)

sorting the list in ascending order and returning the

value located at the center position in the sorted list.

MIN Minimum INT/FP MIN(X, Y , ...) Finds the minimum numeric value in a list of operands.

MOD Mode INT/FP MOD(X, Y, ...)

Finds the listed value that appears most often. If no

value appears more than once, finds the lowest value.

Computes the variance of a list of operands. The

VAR Variance FP VAR(X, Y, ...)

variance is the sum of the square of the difference

between each operand and the average value of the

operands, divided by the number of operands.

Conditional

= Equal INT/FP X = Y

〈 〉

Not equal INT/FP

X 〈 〉 Y

Produces a “1” result if the left operand is equal to the

right operand; otherwise, produces a “0” result.

Produces a “1” result if the left operand is not equal to

the right operand; otherwise, produces a “0” result.

> Greater than INT/FP X > Y

< Less than INT/FP X < Y

>=

<=

Greater than or

equal

Less than or

equal

INT/FP X >= Y

INT/FP X <= Y

Other

. Decimal point –– ––

, Comma –– –– Used to separate the operands in a list of operands.

( Open –– –– Used with “)” to prioritize operations with a formula.

) Close –– ––

*INT=integer format. FP = fixed point (decimal) format

Produces a “1” result if the left operand is greater than

the right operand; otherwise, produces a “0” result.

Produces a “1” result if the left operand is less than the

right operand; otherwise, produces a “0” result.

Produces a “1” result if the left operand is greater than

or equal to the right operand; otherwise, produces a

“0” result.

Produces a “1” result if the left operand is less than or

equal to the right operand; otherwise, produces a “0”

result.

Used when entering a fixed point decimal value. Also

used in designating an operand sub-code.

Used with “(” to prioritize operations with a formula.

Also used to end operand listing for some operators.

4–19

Page 35

Chapter 4

Defining Formulas

Operator Execution Hierarchy

The order and priority of execution of the operations defined in a formula,

where multiple operators are used, follows that of general mathematical

rules. Operators of higher priority are executed first. In cases of equal

priority, the operators are executed from left to right.

For example, multiplication and division have higher priority than addition

or subtraction.

This formula would first divide the results of gage 2 by 3, and then add the

result to the gage 1 result:

Add operator

Divide operator

GAGE1 + GAGE2 / 3

Prioritizing operations: You can place parentheses around an operator and

its operands in order to prioritize that operation – that is, the result of the

operation in parentheses will be used as an operand by another operator.

This formula would first add the result of gage 1 and gage 2, and then divides

the result by 2:

Add operator

Divide operator

(GAGE1 + GAGE2) / 2

In defining formulas, as in general mathematical practice, it is best to use

parentheses in formulas where multiple operators are used, to ensure the

formula is executed as expected, rather than relying on priority rules.

Nesting operations within a formula: “Nesting” of operations within a

formula can be employed, where a parenthetical portion is itself contained

within another parenthetical portion of the formula.

4–20

The formula below would first add 2 to the result of gage 2, then multiply

this result by the gage 1 result, and then subtract 2 from the product:

Nested operation

(GAGE1 * (GAGE2 + 2)) – 2

Page 36

Chapter 4

Defining Formulas

Operator Usage

The MATH-PAK operators generally fall into one of four categories –

mathematical, statistical, logical, and conditional (refer to Table 4.D,

beginning on page 4–18, for a brief description of the operator types, which

are listed according to category). The operators are discussed in the

following sections, according to category.

Mathematical Operators

This section discusses the mathematical operators, which include the

arithmetic operators, trigonometric operators, inverse trigonometric

operators, and other operators.

Arithmetic operators: + – /

*

+ (addition) – Adds the two operands on either side of the “+”

– (subtraction) – Subtracts the operand on the right of the “–” from the

operand on the left.

/ (division) – Divides the operand on the left of the “/” by the

operand on the right.

* (multiplication) – Multiplies the two operands on either side of the “*”

Format / Usage: In general, enter and use the arithmetic operators in

formulas just as you would in writing an arithmetic equation – use two

operands with an operator, placing the arithmetic operator in the formula

between the two operands, as shown in the example below:

Multiply operator placed between two operands

GAGE1 * GAGE2

Arithmetic hierarchy of execution: In general, arithmetic operations are

executed from left to right, with multiplication and division operators

evaluated before either addition or subtraction, as in general practice.

Example usage: This formula averages the results from gages 1 and 2. The

formula first uses the add operator (+) to add the 2 gage operands (because

the parentheses prioritize the add operation), then uses the divide operator

( / ) to divide the result of the add operation by the constant, 2:

(GAGE1 + GAGE2) / 2

4–21

Page 37

Chapter 4

Defining Formulas

Subtraction example: The following formula uses the subtraction operator to

find the difference between two gage measurements:

GAGE2 – GAGE1

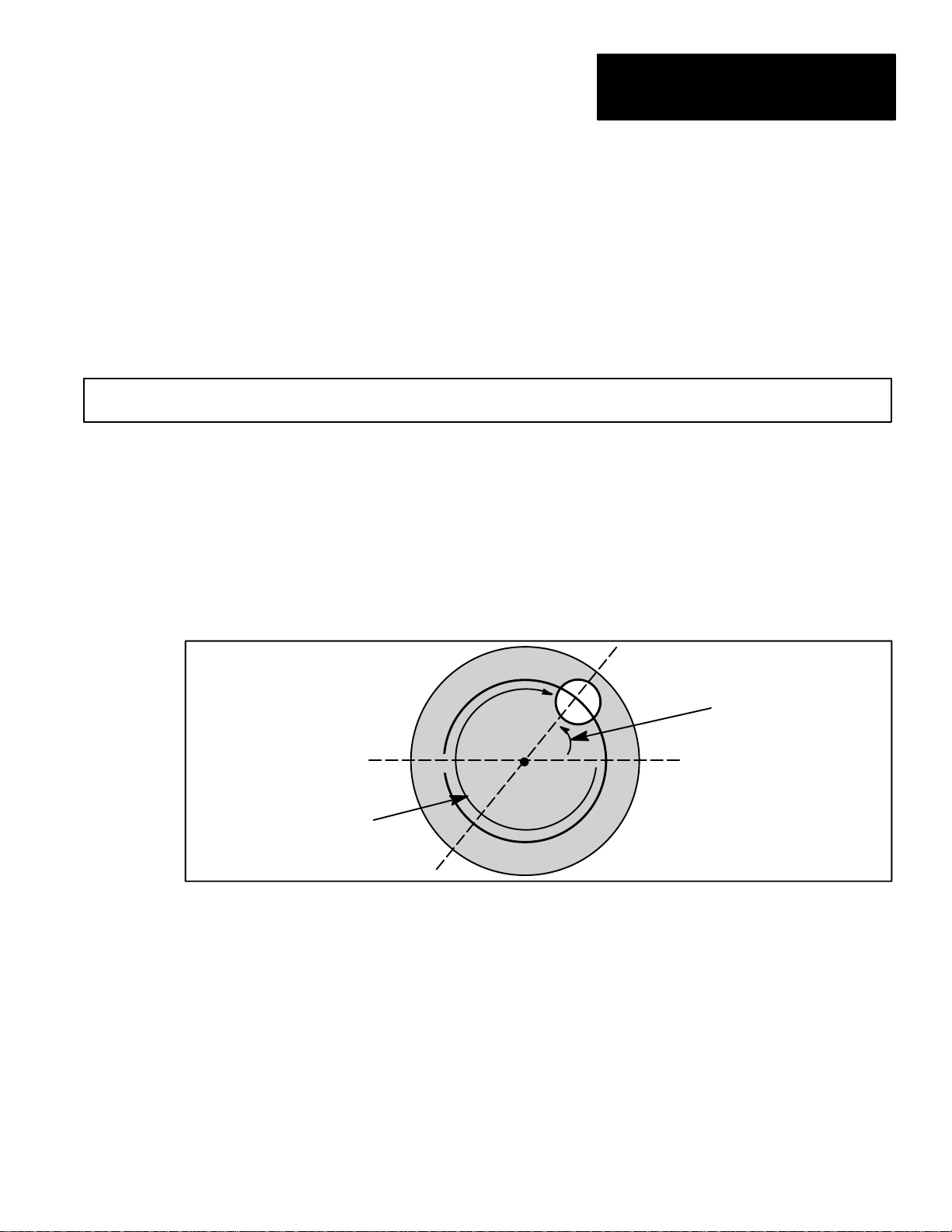

In this example, each of two gages is set to measure the X position of the

center of an object (see Figure 4.8). Two gages are used, because the objects

being measured are of different colors, so each of the two gages is assigned

the appropriate color. The above formula subtracts the gage 1 result from the

gage 2 result, yielding the horizontal distance between the two objects.

Figure 4.8 Example application, using the subtraction operator

Gage 1

X

X

Gage 2

Unary minus operator:

Format/Usage: The unary minus operator (

) negates the value to its

immediate right in the formula. The unary minus operator can be used with

1) operands, including parenthetical expressions, and 2) operator/operand

portions of the formula – that is, operators of the type that are followed by a

parenthetical listing of operands.

Formula symbol: When you pick the

key to enter the unary minus into a

formula, the “–” (minus) symbol is entered. Take care not to confuse this

with the subtraction operator, which looks the same when entered.

4–22

Example usage: Use the

operator to negate the value of an operand:

– GAGE2 * GAGE3

Use the operator to negate the value of an operator/operand:

1.250 * – AVG (GAGE2, GAGE3, GAGE4)

Page 38

Chapter 4

Defining Formulas

Modulo operator: %

Format/Usage: The modulo operator (%) performs the “long division”

operation on one operand by a second operand, and yields the whole number

remainder of that division operation. In general, use two operands, placing

the modulo operator in the formula between the two operands. The left

operand is the dividend, the right operand is the divisor.

The modulo operator can be applied in formulas, for example, to produce

binary values from decimal-based integer values.

Example usage: Use the modulo operator to calculate a 5-place “binary”

result from a gage 1 object-counting result (for values 0–31 decimal), using a

series of 10 formulas:

Formula 1:

Formula 2: GAGE1 / 2

Formula 3: RSLT2 % 2

Formula 4: RSLT2 / 2

Formula 5: RSLT4 % 2

Formula 6: RSLT4 / 2

Formula 7: RSLT6 % 2

Formula 8: RSLT6 / 2

Formula 9: RSLT8 % 2

Formula 10: RSLT9

100 + RSLT3 * 10 + RSLT1

*

For example, if the gage 1 result were 19:

Formula 1:

Formula 2: 19 / 2 (RSLT2=9)

Formula 3: 9 % 2 (RSLT3=1)

Formula 4: 9 / 2 (RSLT4=4)

Formula 5: 4 % 2 (RSLT5=0)

Formula 6: 4 / 2 (RSLT6=2)

Formula 7: 2 % 2 (RSLT7=0)

Formula 8: 2 / 2 (RSLT8=1)

Formula 9: 1 % 2 (RSLT9=1)

GAGE1 % 2

10000 + RSLT7 * 1000 + RSLT5

*

19 % 2 (RSLT1=1)

Formula 10: 1

10000 + 0 * 1000 + 0 * 100 + 1

*

*

10 + 1 (RSLT 10=10011)

In the above example, the result of formula 10 is 10011, which, if interpreted

as a binary value, would equal 19 (decimal).

4–23

Page 39

Chapter 4

Defining Formulas

Absolute value operator: ABS

Format/Usage: The absolute value operator (ABS) provides the absolute

value of the operand or expression enclosed in the following parentheses. To

use the absolute value operator, enter the ABS operator – which includes the

open parenthesis “(” – then enter the operand or expression, and then enter

the close parenthesis “).”

The absolute value operator can be used with 1) single operands, 2) operator/

operand expressions, such as arithmetic expressions, 3) operator/operand

portions of the formula – that is, operators of the type that are followed by a

parenthetical listing of operands.

Example usage: Use the absolute value operator with a parenthetical

subtraction operation, to ensure a positive result value:

ABS (GAGE2 – GAGE1)

Square operator: SQ

Format/Usage: The square operator (SQR) computes the square (an

operand multiplied by its own value) of an operand or expression enclosed in

the following parentheses. To use the square operator, enter the SQ operator

– which includes the open parenthesis “(” – then enter the operand or

expression, and then enter the close parenthesis “).”

The square operator can be used with 1) single operands, 2) operator/

operand expressions, such as arithmetic expressions, 3) parenthetical

operator/operand expressions, and 4) operator/operand portions of the

formula – that is, operators of the type that are followed by a parenthetical

listing of operands.

Example usage: Use the square operator with a linear gaging measurement to

calculate the area of a square object.

SQ (GAGE2) – WINDOW1.11

Square root operator: SQR

4–24

Format/Usage: The square root operator (SQR) computes the square root of

the operand or expression enclosed in the following parentheses. To use,

enter the SQR operator – which includes the open parenthesis “(” – then

enter the operand or expression, and then enter the close parenthesis “).”

Negative operand value: If the operand used returns a negative value, the

square root operator result is zero (0).

The square root operator can be used with 1) single operands, 2) operator/

operand expressions, such as arithmetic expressions, 3) parenthetical

Page 40

Chapter 4

Defining Formulas

operator/operand expressions, and 4) operator/operand portions of the

formula – that is, operators of the type that are followed by a parenthetical

listing of operands.

Example usage: Use the square root operator with a parenthetical expression

which adds the squares of gage 2 and gage 3, possibly to calculate a distance

(by the Pythagorean theorem):

SQR (SQ (GAGE2) + SQ (GAGE3))

Distance operator: DST

Format/Usage: The distance operator (DST) computes the distance between

two points, given the x- and y-coordinates of the two points.

Window 1

Object

identified by

color in

Window 1

The format for the DST operator: DST (X

, Y1, X2, Y2), where X1 and Y

1

1

are assumed to be the x- and y-coordinates of the first point, and X2 and Y

are assumed to be the x- and y-coordinates of the second point.

To use the distance operator, enter the DST operator – which includes the

open parenthesis “(” – then enter four operands or expressions, separated by

commas, and then enter the close parenthesis “).”

Example usage: Use the distance operator to find the distance between two

objects identified and located by two different windows:

DST (WIN1.12, WIN1.13, WIN2.12, WIN2.13)

Operands WIN1.12 and WIN1.13 indicate the x- and y-coordinates,

respectively, of the center of gravity of the object identified by color in

window 1 (see Figure 4.9). Similarly, operands WIN2.12 and

WIN2.13 indicate the x- and y-coordinates, respectively, of the center of

gravity of the object identified by color in window 2.