Page 1

ALLEN-BRADLEY

Bulletin 5370 Color CVIM

Configurable Vision Input Module

Communications Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard–wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

PLC is a registered trademark of Allen-Bradley Company, Inc.

Pyramid Integrator, DTL and CVIM are trademarks of Allen-Bradley Company, Inc.

VAX is registered trademark of Digital Equipment Corporation.

Page 3

Table of Contents

Color CVIM Module

Communications Manual

A–B

Using This Manual

Introduction

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Revision 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of this Manual 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Use this Manual 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nomenclature 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trademarks 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How is Data Stored in the Color CVIM Module? 2–1. . . . . . . . . . . . . . . . .

How Does the Host DeviceRead Configuration/Results Information? 2–1.

Remote I/O (Node Adapter) 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232 Ports 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local I/O 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pyramid Integrator Backplane 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Types of Information Can Be Communicated? 2–4. . . . . . . . . . . . . .

Discrete Bit Information 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results Blocks 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Blocks 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Cables 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Addressing 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Designation 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Local I/O

Using the Remote I/O Link

Chapter 3

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Connections 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Planning OutputLine Assignments 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Output LinePlanning Sheet 3–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Using Output Signal Timing Data 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Planning Output Line Connections 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections to RS–232 Ports (2801–N27 Interface Box) 3–11. . . . . . . . . . .

Connections to RS–232 Port (2801–N21 Interface Box) 3–12. . . . . . . . . . .

Color CVIM Module I/O Interface Box Connections 3–13. . . . . . . . . . . . . .

Connections to 2801–JMB Interface 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote I/O Communications 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Functions can be Performed over the Remote I/O Network? 4–6. . .

Obtaining Inspection Result Information 4–7. . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Table of Contents

Color CVIM Module

Communications Manual

Using the Remote I/O Link

Using the RS–232 Ports

ii

Chapter 4 (continued)

Color CVIM Module Configuration Instructions 4–7. . . . . . . . . . . . . . . . .

Accessing Discrete Bit Information 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Note to PLC–2 Users: 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example Program for Accessing/Setting Discrete Bit Data 4–12. . . . . . . . .

Example Program For Accessing/Setting Discrete Bit Data (cont’d) 4–13. .

Example Program For Accessing/Setting Discrete Bit Data (Cont’d) 4–14.

Accessing Results and Configuration Information 4–15. . . . . . . . . . . . . . . .

Transferring Results Blocks 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Results Block 6 and Statistics Block Formats 4–17. . . . . . . . .

Converting Results Data 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transferring Configuration Blocks 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example Program for Accessing Results Data 4–21. . . . . . . . . . . . . . . . . . .

Example Program for Accessing Results Data, Cont’d4–22. . . . . . . . . . . . .

Example Program for Accessing Results Data, Cont’d4–23. . . . . . . . . . . . .

Example Program For Accessing Configuration Data 4–24. . . . . . . . . . . . .

Example 6008–SI Program 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 6008–SI Program (cont’d) 4–28. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232 Communications 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII and DF1 Protocols 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Connections 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Functions can be performed over the RS–232 Interfaces? 5–4. . . . .

Color CVIM Module Configuration Instructions 5–5. . . . . . . . . . . . . . . . .

ASCII Protocol 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII Character Set 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Structure 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XON/OFF Flow Control 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deactivate Forces 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Echoing Data 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable/Disable Outputs 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Forcing Local I/O 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading Configurations 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lock Command 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unlock Command 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Output Status 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Configuration Blocks 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Inspection Results 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Save Configuration 5–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select Image Displayed 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Configurable Results 5–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents

Color CVIM Module

Communications Manual

Using the RS–232 Ports

Chapter 5 (continued)

Set/Read Configurable Statistics 5–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Operation 5–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Write Configuration (W) Write Configuration (WC) 5–25. . . . . . . . . . . . . .

Command Summary 5–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Explanation of ASCII Programming Example 5–29. . . . . . . . . . . . . . . . . . .

ASCII Programming Example 5–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DF1 Protocol 5–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is DF1? 5–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DF1 Character Set 5–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Structure 5–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Structure (cont’d) 5–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACK/NAK, BCC Characters 5–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Check Character 5–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deactivate Forces 5–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Echoing Data 5–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable/Disable Outputs 5–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Forcing Local I/O 5–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading Configurations 5–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lock Command 5–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Output Status 5–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Configuration Block Command 5–43. . . . . . . . . . . . . . . . . . . . . . . . . .

Read Results Command 5–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Save Command 5–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select Image Displayed 5–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Configurable Results 5–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set/Read Configurable Statistics 5–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Operation Command 5–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unlock Command 5–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Write Configuration Blocks 5–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Summary 5–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DF1 Programming Example 5–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Pyramid

Integrator Backplane

Chapter 6

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Information can be Accessed? 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Designation 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Functions can be Performed Over the Backplane? 6–2. . . . . . . . . . .

Color CVIM Module Configuration Instructions 6–2. . . . . . . . . . . . . . . . .

Obtaining Inspection Result Information Using a PLC–5/250 6–3. . . . . . .

Manipulating Configuration Data Using a PLC–5/250 6–4. . . . . . . . . . . . .

Sample PLC–5/250 Program 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Obtaining Inspection Result Information Using a MicroVAX

Information Processor 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 6

Table of Contents

Color CVIM Module

Communications Manual

Results/Configuration Data

Overview

Discret Bit Results Bits

(Host Input and Output

Bits)

Numerical Results Data

Appendix A

Introduction A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fractional Notation A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32 Bit Integer Format A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B

Introduction B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete Bit Inputs B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete Bit Outputs B–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

Results Block Overview C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfer Signature C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results Block #1 C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results Block #2 C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results Block #3 C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results Block #4 C–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results Block #5 C–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results Block #6 C–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Statistics Block C–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Data

ASCII Conversion Table

iv

Appendix D

Configuration Block Overview D–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Block #1 D–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Blocks 2 & 3 D–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Blocks 4–35 D–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Block 36 D–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Blocks 37–39 D–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Blocks 40–45 D–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Blocks 46–109 D–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Blocks 110–205 D–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Blocks 206–213 D–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E

Page 7

Table of Contents

Color CVIM Module

Communications Manual

Tables

Table 1.A Related Publications 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2.A Example of Addressing Results Block 1 2–6. . . . . . . . . . . . .

Table 3.A Example Color CVIM Output Line Planning Sheet

Output Line Functions and Tool Assignments 3–3. . . . . . . . . . . . . . .

Table 3.B Color CVIM Module I/0 Connector 3–13. . . . . . . . . . . . . . . . .

Table 3.C I/O Interface Box (Catalog No. 2801–N21):

RS–232 Connector with Series A Color CVIM Module 3–13. . . . . . .

Table 3.D I/O Interface Box (Catalog No. 2801–N27):

RS–232 Port A Connector with Color CVIM Module 3–14. . . . . . . . .

Table 3.E I/O Interface Box (Catalog No. 2801–N27):

RS–232 Port B Connector with Color CVIM Module 3–14. . . . . . . . .

Table 3.F Color CVIM I/O Output Numbering 3–16. . . . . . . . . . . . . . . . .

Table 3.G Color CVIM Output Line Planning Sheet

Output Line Functions and Assignments 3–17. . . . . . . . . . . . . . . . . . .

Table 4.A Color CVIM Module Remote I/O Inputs

(Color CVIM Module to PLC) if Color CVIM Module

is Rack 02 (First Discrete Bits Results) 4–9. . . . . . . . . . . . . . . . . . . .

Table 4.B Color CVIM Module Remote I/O Inputs

(Color CVIM Module to PLC) if Color CVIM Module

is Rack 02 (Second Discrete Bits Results) 4–10. . . . . . . . . . . . . . . . .

Table 4.C Color CVIM Module Remote I/O Outputs (PLC to Color

CVIM Module) if Color CVIM Module is Rack 02 4–11. . . . . . . . . .

Table 5.A ASCII Command Summary 5–27. . . . . . . . . . . . . . . . . . . . . . .

Table 5.B DF1 Command Summary 5–60. . . . . . . . . . . . . . . . . . . . . . . . .

Table 6.A Shared Memory Overview 6–3. . . . . . . . . . . . . . . . . . . . . . . .

Table B.1 Discrete Bit Inputs B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B.2 Backplane Handshake Bits B–19. . . . . . . . . . . . . . . . . . . . . . . .

Table B.3 Discrete Bit Outputs B–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table C.1 Numerical Results Data–Results Block 1 C–3. . . . . . . . . . . . .

Table C.2 Numerical Results Data–Results Block 2 C–6. . . . . . . . . . . . .

Table C.3 Numerical Results Data– Results Block 3 C–8. . . . . . . . . . . .

Table C.4 Numerical Results Data–Results Block 4 C–11. . . . . . . . . . . . .

Table C.5 Numerical Results Data–Results Block 5 C–13. . . . . . . . . . . . .

Table C.6 Results Block #6 C–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table C.7 Programmable Results/Statistics Block Configuration C–16. . .

Table C.8 Statistics Block C–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table D.1 Configuration Block #1– System Environment D–2. . . . . . . .

Table D.2 Configuration Block #2 – Camera Definition D–4. . . . . . . . . .

Table D.3 Configuration Block #3 – Camera Definition D–6. . . . . . . . . .

Table D.4 Configuration Blocks #4–35 – Color Definition D–6. . . . . . .

Table D.5 Configuration Block 36 – Gray Scale Definition D–7. . . . . . .

Table D.6 Configuration Blocks #37–39 – Reference Lines 1–3D–8. . .

Table D.7 Configuration Blocks #40, 42, and 44 –

Reference Windows 1–3D–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 8

Table of Contents

Color CVIM Module

Communications Manual

vi

Tables (continued)

Table D.8 Configuration Blocks #41, 43, & 45 –

Reference Windows 1–3D–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table D.9 Configuration Blocks #46–109 – Gages 1–64 D–11. . . . . . . . .

Table D.10 Configuration Blocks #110, 112 . . . & 204 –

Windows 1–48 D–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table D.11 Configuration Blocks #110, 112 . . . & 204 –

Windows 1–48 D–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table D.12.Configuration Block #111, 113 . . . & 205 –

Windows 1–48 D–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table D.13 PoIygon Configuration Words D–15. . . . . . . . . . . . . . . . . . . .

Figures

Figure 2.1 Color CVIM Module Communications Ports 2–2. . . . . . . . .

Figure 2.2 Bit Numbering 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3.1 Local I/O Equipment Connections 3–2. . . . . . . . . . . . . . . . . .

Figure 3.2 Timing Diagram — Pulsed I/O 3–7. . . . . . . . . . . . . . . . . . . .

Figure 3.3 Timing Diagram —

Trigger #2 During Data Valid, Pulsed I/O 3–8. . . . . . . . . . . . . . . . . .

Figure 3.4 Timing Diagram — Non–Pulsed I/O 3–9. . . . . . . . . . . . . . . .

Figure 3.5 Timing Diagram– Missed Trigger 3–10. . . . . . . . . . . . . . . . . .

Figure 3.6 Pinouts– Catalog No. 2801–N27 I/O Interface Box 3–11. . . .

Figure 3.7 Pinouts– Catalog No. 2801–N21 I/O Interface Box 3–12. . . .

Figure 3.8 Local I/O Board ( Catalog No. 2801–JMB). 3–15. . . . . . . . . .

Figure 4.1 PLC–5 to Color CVIM Module– Remote I/O Link 4–2. . . . .

Figure 4.2 6008 SI IBM PC/AT Scanner to Color CVIM Module–

Remote I/O Link 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4.3 6008 SV VME Scanner to Color CVIM Module–

Remote I/O Link 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4.4 6008 SQH1/2 Q–BUS Scanner to Color CVIM Module–

Remote I/O Link 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4.5 Mini PLC–2 to Color CVIM Module– Remote I/O Link 4–3

Figure 4.6 PLC–2 to Color CVIM Module – Remote I/O Link 4–3. . . .

Figure 4.7 PLC–3 to Color CVIM Module – Remote I/O Link 4–4. . . .

Figure 4.8 PLC–5/250 to Color CVIM Module– Remote I/O Link 4–4.

Figure 4.9 Typical Hardware Layout for Remote I/O 4–5. . . . . . . . . . . .

Figure 5.1 RS–232 Equipment Connections. 5–3. . . . . . . . . . . . . . . . . .

Figure 5.2 RS–232 Cabling. 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5.3 Memory Requirements for Images and Configurations 5–12. .

Figure 5.4 Configuration Block Returned Data Format* 5–15. . . . . . . . .

Figure 5.5 Numerical Results Block Returned Data Format 5–18. . . . . . .

Figure 5.3 Discrete Bit Results Returned Data Format 5–18. . . . . . . . . . .

Figure 5.6 Memory Requirements for Images and Configurations 5–20. .

Figure 5.7 Statistics Block Returned Data Format 5–24. . . . . . . . . . . . . .

Page 9

Table of Contents

Color CVIM Module

Communications Manual

Figures (continued)

Figure 5.8 Read Configuration Block Command Bytes 3–29 5–44. . . . . .

Figure 5.9 Configuration Block Returned Data Format 5–46. . . . . . . . . .

Figure 5.10 Results Block Returned Data Format 5–49. . . . . . . . . . . . . . .

Figure 5.11 Discrete Bit Results Returned Data Format 5–49. . . . . . . . . .

Figure 5.12 Statistics Block Returned Data Format 5–55. . . . . . . . . . . . .

Figure 5.13 Write Configuration Block Command Bytes 3–29 5–58. . . .

Figure 6.1 32 Bit Long Integer Files 6–5. . . . . . . . . . . . . . . . . . . . . . . . .

Figure A.1 Fractional Notation A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 10

Using this Manual

Chapter

1

Chapter Objectives

Software Revision

Overview of this Manual

Read this chapter to familiarize yourself with the rest of the manual. You will

learn about:

• Contents of the manual.

• Intended audience.

• How to use the manual.

This manual describes how to communicate with a Color CVIM module

(Catalog No. 5370–CVIMC) with at least firmware revision A01.

This manual explains how to communicate with the Bulletin 5370 Color

Configurable Vision Input Module (Color CVIM) module using a variety of

peripheral devices.

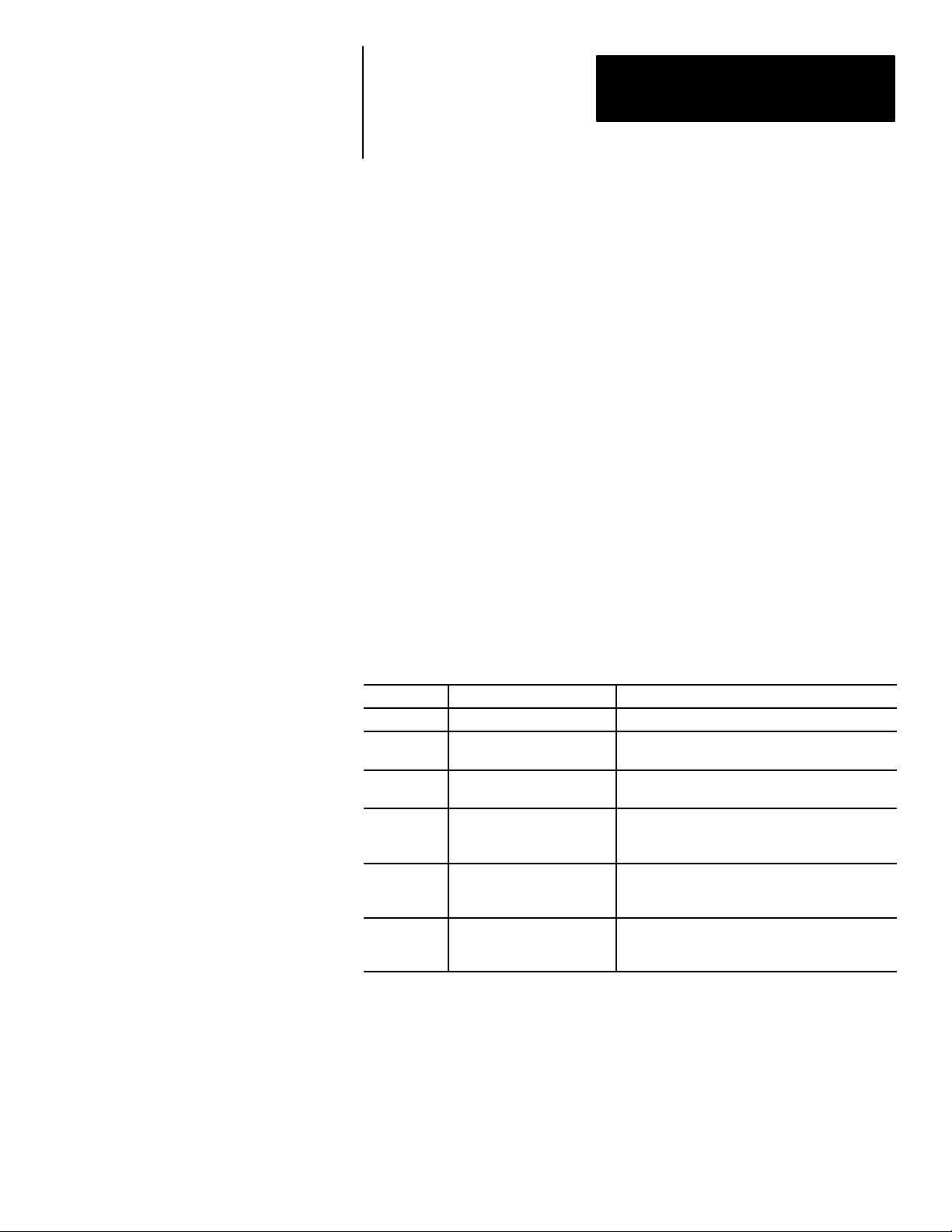

Chapter Title Purpose

1 Using This Manual Provides an overview.

2 Introduction

3 Using Local I/O

4

5 Using the RS–232 Ports

6

Using the Remote I/O Link

(Node Adapter)

Using the Pyramid

Integrator Backplane

Describes the basic options available for

communications with the Color CVIM module.

Describes how to use the discrete I/O module

(Catalog No. 2801–JMB).

Describes how to access data through the remote

I/O port with a PLC–2

Includes sample programs.

Describes how to access data through the RS–232

interfaces using ASCII and DF1 formatted

commands. Provides sample programs.

Describes how to access shared memory through

the Pyramid Integrator information processor

and/or MicroVAX

, or PLC–3, PLC–5.

. Provides sample programs.

1–1

Page 11

Chapter 1

Using this Manual

Overview of this Manual

(cont’d)

Chapter

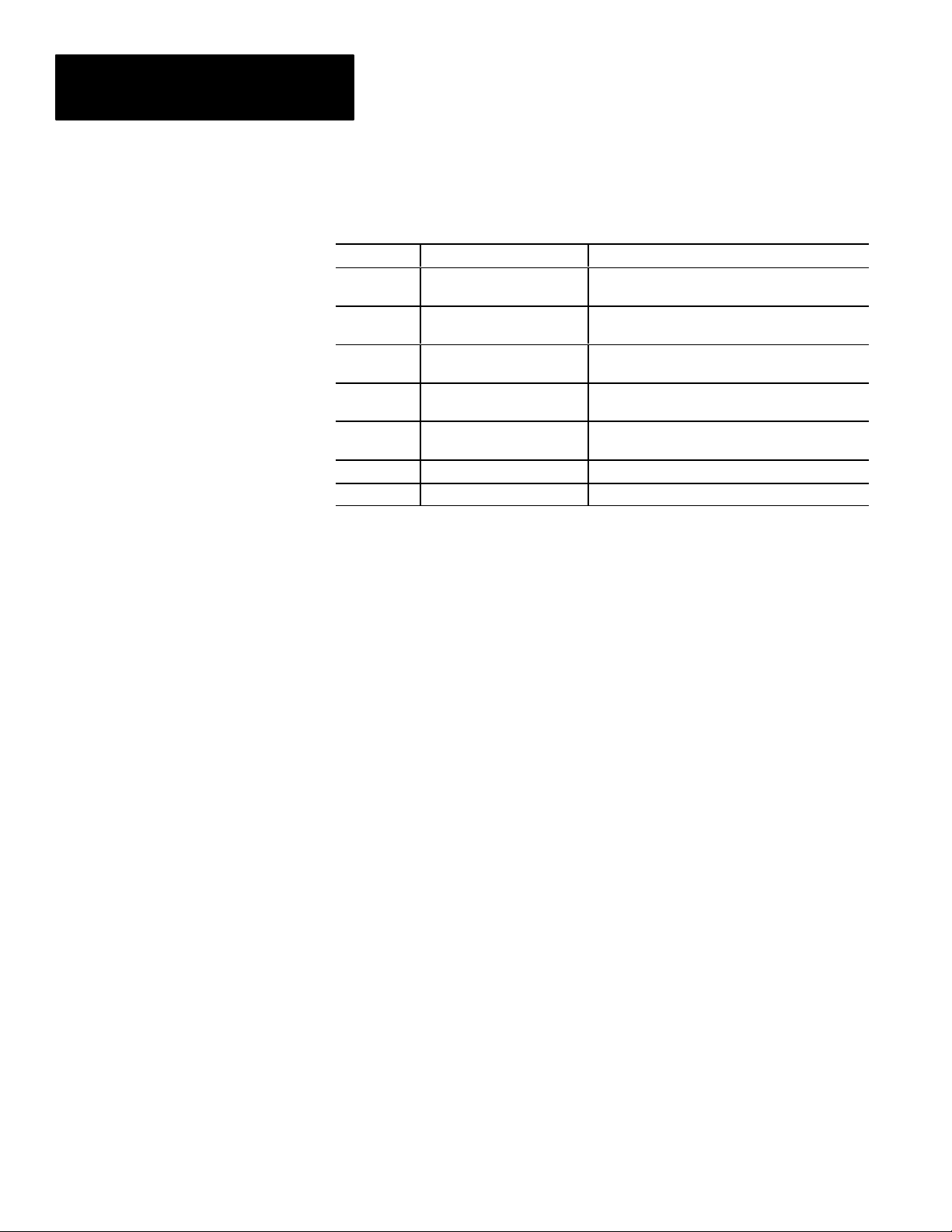

Appendix

A

Appendix

B

Appendix

C

Appendix

D

Appendix

E

Title Purpose

Results/Configuration Data

Overview

Discrete I/O Results Bits Provides a description of the 256 discrete input bits

Numerical Results Data Provides a description of inspection results data.

Configuration Data Provides information on the configuration blocks.

ASCII Conversion Chart Provides equivalent values for the ASCII character

Glossary

Index

Provides an overview of the configuration and

results data. Describes data formats.

and 256 discrete output bits.

set.

Intended Audience

This manual was written for an experienced PLCR user or computer

programmer. The user of this manual should:

• Know how to program the host device being used to communicate with

the Color CVIM module. For example, if you are using a PLC–5 to

communicate with the Color CVIM module, you must have a background

in programming a PLC–5.

• Know terms common to the computer and programmable controller

industries.

• Understand how to operate and configure the Color CVIM module before

using this manual. You may not understand many of the terms being used

unless you have read the Color CVIM User’s Reference Manual, Catalog

No. 5370–ND009.

1–2

Page 12

Chapter 1

Using this Manual

Related Publications

Publication No. Title Purpose of Publication

Catalog No.

5370–ND011

Catalog No.

5370–ND009

1772–6.8.1 PLC–2/20 Programming and Operations Manual

1772–6.8.3 PLC–2/30 Programming and Operations Manual

1772–6.8.6 Mini–PLC–2/05 Programming and Operations Manual

1772–6.8.2 Mini–PLC–2/15 Programming and Operations Manual

1775–6.7.1 PLC–3 Controller Installation and Operations Manual

1785–6.8.2 PLC–5 Family Processor Manual

5000–2.3 Allen–Bradley Pyramid Integrator Technical Overview Provides an overview of the Pyramid Integrator.

5000–2.17 Allen–Bradley Pyramid Integrator Technical Description Provides a technical description of the Pyramid Integrator.

5000–2.20 MicroVAX Information Processor Technical Description

5000–6.2.10 Allen–Bradley Pyramid Integrator Installation Manual

5000–6.2.10 Allen–Bradley Pyramid Integrator Start–up and Integration Manual

Table 1.A lists related publications that you may require:

Table 1.A

Related Publications

Color CVIM Getting Started Manual Describes the basics of the Color CVIM user interface.

Color CVIM User’s Reference Manual

Provides step–by–step procedures for the installation,

configuration and operation of the Color CVIM module.

Provides instructions on how to program a PLC–2/20

programmable controller.

Provides instructions on how to program a PLC–2/30

programmable controller.

Provides instructions on how to program a

Mini–PLC–2/05

Provides instructions on how to program a

Mini–PLC–2/15

Provides instructions on how to program a PLC–3

programmable controller.

Provides instructions on how to program a PLC–5

programmable controller.

Provides a technical description of the MicroVAX

Information Processor.

Provides instructions on installing Pyramid Integrator

devices.

Provides instructions on how to use Pyramid Integrator

devices.

programmable controller.

programmable controller.

1–3

Page 13

Chapter 1

Using this Manual

How to Use this Manual

When using this manual, we recommend that you do the following.

1. Become familiar with the Color CVIM module by reading the User’s

Reference Manual, Catalog No. 5370–ND009. If possible, use the Color

CVIM module to become familiar with its operation. Only with a

thorough understanding of the Color CVIM module will you be able to

interpret the data that is stored in its memory.

2. Read Chapters 1 and 2 of this manual. After reading these introductory

chapters, you will be able to determine which of the remaining chapters,

some or all, you will need to read. See note below.

Important Note: This manual is divided into chapters. It is not necessary

to read all of the information contained in this manual. Chapters 1 and 2

are mandatory. You can read the remaining chapters on a “need to know

basis” depending upon the information you want to read or write and the

type of host device you are using.

3. Use the programming examples provided in each section as a guide to

create your own programs. In some applications, you may be able to

simply modify the example provided.

These examples are included solely for illustrative purposes. Because the

many variables and special requirements associated with any particular

installation, Allen–Bradley Company cannot assume responsibility or

liability for their applicability to your own situation.

Nomenclature

Trademarks

1–4

In this Chapter and in subsequent chapters we refer to the Bulletin 5370

Configurable Vision Input Module as the Color CVIM module. In some

tables we use the abbreviation “PI” to indicate the PLC–5/250 Pyramid

Integrator. We have also provided a glossary in the back of this manual. Use

this glossary whenever you are unsure of the meaning of a word.

In this manual, we use the following trademarks:

CVIM is a trademark of Allen–Bradley

PLC, PLC–2, PLC–2/20, PLC–2/30, PLC–2/05,

PLC–2/15

, and PLC–3

PLC– 5, PLC–5/250

Pyramid Integrator

Dataliner

RediPANEL

DATAMYTE

is a trademark of Allen–Bradley

is a trademark of Allen–Bradley

is a registered trademark of Allen–Bradley

are registered trademarks of Allen–Bradley

are trademarks of Allen–Bradley

is a trademark of Allen–Bradley

Microsoft is a registered trademark of Microsoft Corporation

MicroVAX is a registered trademark of Digital Equipment Corporation

GW BASIC is a trademark of Microsoft Corporation

Page 14

Introduction

Chapter

2

Chapter Objectives

How is Data Stored in the Color CVIM Module?

How Does the Host Device Read Configuration/Results Information?

In this chapter we provide you with an overview of the options for

communicating with the Color CVIM module. We also describe the types of

data that can be accessed or manipulated. The descriptions in this chapter

will enable you to determine the type of communications most suitable for

your application. You then can proceed to the chapter of this manual that

describes the selected option.

The result and command data that you can access with a host device is stored

in an area of Random Access Memory (RAM) inside the Color CVIM

module. Configuration data which controls the operating instructions for the

Color CVIM module is located in a separate area of memory which can be

also be accessed through a host device. Refer to Appendix A for an overview

of configuration/results memory. Appendix B, C, and D contain tables listing

the information stored in results and configuration memory locations.

The remainder of this chapter describes the various options you have for

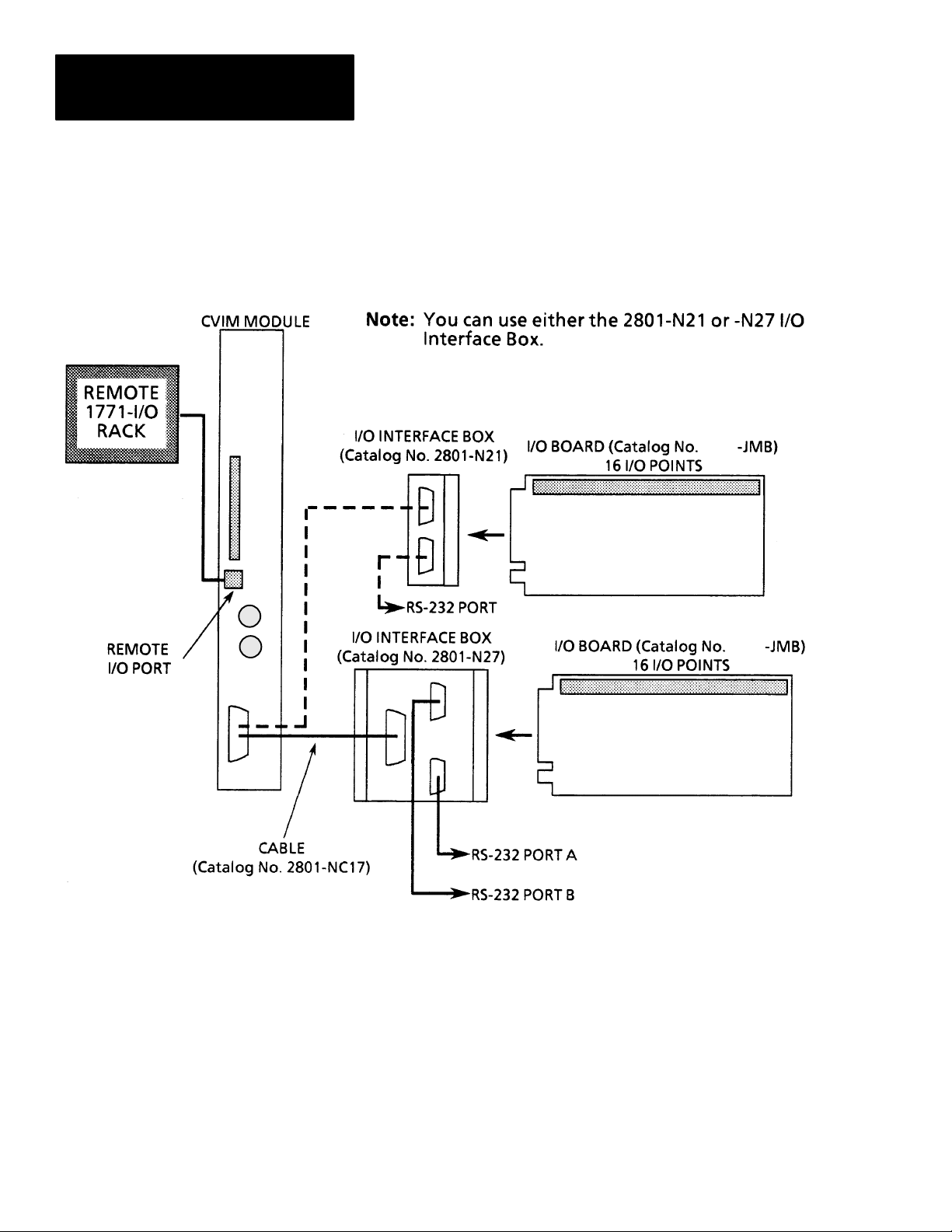

accessing this information. Refer to Figure 2.1. In summary, your host device

will be linked to the Color CVIM module through one of the following ports:

• Remote I/O (Node Adapter)

• RS–232 Interface(s)

• Pyramid Integrator Backplane

• Local I/O Board

Note: The local I/O board has sixteen discrete I/O lines. Fourteen of these lines are

outputs only . One of the remaining lines is for input, and can be connected to a

presence–sensing device to trigger an inspection process. The other line is not used.

2–1

Page 15

Chapter 2

Introduction

How Does the Host Device

Read Configuration/Results

Information? (cont’d)

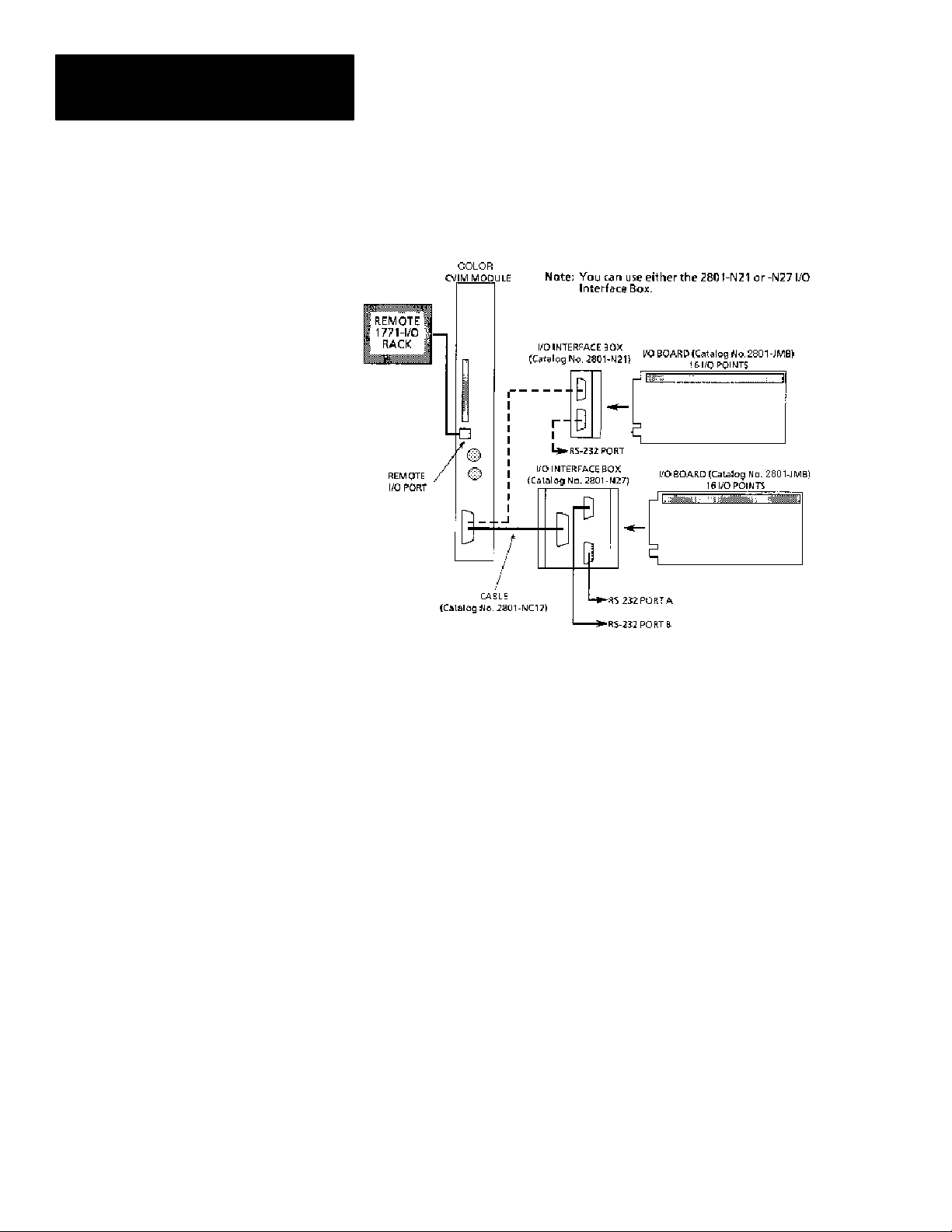

COLOR

Figure 2.1

Color CVIM Module Communications Ports

2801

A

2801

2–2

Page 16

Chapter 2

Introduction

Remote I/O (Node Adapter)

RS–232 Ports

The remote I/O port (RIO) is located on the front of the Color CVIM module

as shown in Figure 2.1. Using the remote I/O port, you can connect the

following types of devices:

• Allen–Bradley Programmable Controllers (PLC–2, –3, and –5).

• Host Computers which have the Allen–Bradley IBM Bus Scanner

(Catalog No. 6008–SI). The 6008–SI bus scanner is compatible with the

A–B 6121/22 Industrial Computer, Industrial Terminal (Catalog Nos.

1784– T50, 1784–T35), or other IBM PC/AT compatible devices.

As shown in Figure 2.1, the RS–232 ports are located on the I/O Interface

Boxes (Catalog No. 2801–N21, –N27). The I/O Interface Box is connected to

the MODULE I/O port on the front of the Color CVIM module. Using the

RS–232 interface(s) you can connect a variety of devices which use the

RS–232 standard:

• Computers

• Operator Interfaces such as Allen–Bradley Industrial Computers and

Terminals with serial ports.

Local I/O

Pyramid Integrator Backplane

• I/O modules such as the Flexible Interface Module (Catalog No.

2760–RB) or ASCII module (Catalog No. 1771–DA).

As shown in Figure 2.1, the local I/O consists of an I/O Board (Catalog No.

2801–JMB), I/O Interface Box (Catalog No. 2801–N21, –N27), an input and

up to 14 output modules as configured by the user. The Catalog No.

2801–NC17 cable connects the I/O interface box to the Color CVIM module.

Using the Pyramid Integrator backplane, you can directly communicate data

between the Color CVIM module and other devices installed in the Pyramid

Integrator chassis:

• Allen–Bradley PLC–5/250

• MicroVAX Information Processor

2–3

Page 17

Chapter 2

Introduction

What Types of Information can be Communicated?

Discrete Bit Information

Depending upon the type of interface in use, you can access some or all of

the information listed below:

• Warning and Pass/Fail data.

• Numerical inspection results.

• Configuration data.

With each inspection that the Color CVIM module performs, individual bits

are set. There are 256 bits that can be read as inputs to a host device. These

bits (part of the inspection results) indicate:

• Master fault.

• Mastership.

• Configuration fault.

• Module Busy flag.

• Missed Trigger flag.

• Results Valid flag.

• Inspection Tool Pass/Fail/Warning flags.

There are 128 bits that can be set as outputs by a host device to control the

operation of the Color CVIM module. These bits control:

• Monitor display.

• Toolset selection.

• Enable/disable and force discrete I/O.

• Selection of operation after reject.

• Memory storage location. RAM, EEPROM, RAM Card, or external host

memory.

For more information on the 256 discrete input and 128 discrete output bits

Note:

refer to Appendix B.

2–4

Page 18

Chapter 2

Introduction

Results Blocks

Configuration Blocks

Communications Cables

The results data for each inspection are stored in Random Access Memory

(RAM) and overwrite the results of the previous inspection. The data stored

in results blocks contain information regarding reference windows,

inspection gages, inspection windows, etc. For a complete description of the

results blocks, refer to Appendix C.

The user developed inspection parameters of the Color CVIM module are

stored in the Color CVIM module’s memory as configuration blocks. This

area of memory can be read or manipulated through the Remote I/O port,

RS–232 ports (A & B) or Pyramid Integrator backplane. Refer to Appendix

D for a complete description of the configuration blocks and their contents.

If you are not using the Pyramid Integrator backplane for communications,

you will have to physically link the Color CVIM module to the host device.

If you need to create a communications cable, refer to the chapter that

describes the communications port you are using.

Memory Addressing

Depending upon how you access the Color CVIM module results and

configuration memory, you will have to address the data differently. If you

refer to Appendix A, B, and C you will notice that separate columns are

provided for Backplane, RS–232, and Remote I/O communications:

Note:

The RS–232 protocols (ASCII and DF1) do not access data using word and

bit addresses. Data is read/written in blocks. We have grouped the RS–232 and

Remote I/O ports together in Appendix B, C, and D (where appropriate) for your

convenience. You can ignore word and bit addresses if you are using the RS–232

ports (A & B).

2–5

Page 19

Chapter 2

Introduction

Memory Addressing (cont’d)

When you communicate through the Pyramid Integrator backplane all of the

data words are numbered consecutively and grouped in blocks. When you

use the Remote I/O port, you select a specific block and the first word in

each block is word #0.

Table 2.A

Example of Addressing Results Block 1

Word Number

Pyramid Integrator

Backplane

32–95 0–63

RS–232 and

Remote I/O

In addition, PLC I/O bit numbers are entered in octal format when

referencing 1771 I/O, while PLC files and backplane communications

specify a decimal bit number. Figure 2.2 illustrates how bits are numbered.

Figure 2.2

Bit Numbering

Bit Number if Accessing Data Through

Remote I/O as a 1771 I/O Rack. (Octal Value)

2–6

Bit Number if Accessing Data Through the Backplane

or Remote I/O Port Using Integer Files. (Decimal V alue)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

1000100001001101

Example

Word

Page 20

Chapter 2

Introduction

Host Designation

There are four communications ports which you can use simultaneously to

access Color CVIM module data (Remote I/O, RS–232 Ports A & B, and

Backplane). Only the host can issue commands to control the operation of

the Color CVIM module. You can read discrete bits and numerical results

information through any of the four communications ports, even through

non–host devices.

The Color CVIM can operate with multiple hosts. You can select one host to

perform Color CVIM module/host configuration transfers, and another host

to perform all other Color CVIM/host operations. The first of these two hosts

is referred to as the configuration host (CFG) because it is the sole source of

configuration information. The second, referred to as the system host (SYS),

can tell the system when to trigger and control the user interface. A system

host cannot supply a new configuration.

An example of using multiple hosts is to select RS–232 A as the CFG host,

and Remote I/O as the SYS host. If you select a single device as both CFG

and SYS hosts, then that device must be labeled as such.

Note: Any Color CVIM communications port can be used for reading results

block data regardless of whether or not the device connected to the port is

selected as a host.

Note: You can select the same host (Stand Alone, Pyramid, Remote I/O,

RS–232 A or B) as both the configuration host and the system host.

2–7

Page 21

Using Local I/O

Chapter

3

Chapter Objectives

Equipment Connections

The objectives of this chapter are to help you plan:

• The number of discrete output lines (up to 14) that your application will

require.

• The function that each output line will perform in your application.

• The assignment of analysis tool “results” to output lines.

• The assignment of status signals to output lines.

• The electrical and mechanical connections of the trigger (input) and

output lines to your production equipment.

The local I/O consists of:

• I/O Interface Box (Catalog No. 2801–N21, –N27)

• I/O Board (Catalog No. 2801–JMB)

• User specified I/O modules (plug into I/O board)

• Communications Cable (2801–NC17)

As shown in Figure 3.1, the communications cable (Catalog No.

2801–NC17) is connected to the MODULE I/O port on the front of the Color

CVIM module and the connector on the I/O Interface box. The I/O board

connector slides into the connector slot on the I/O Interface Box.

3–1

Page 22

Chapter 3

Using Local I/O

Equipment Connections

(cont’d)

Figure 3.1

Local I/O Equipment Connections

A

Planning Output Line Assignments

3–2

This section provides a planning sheet that you can use to lay out the function

and tool assignments for output lines.

The term “function assignment” refers to the type of signal information that

you want an output line to carry to your production equipment.

The term “tool assignment” refers to the tool(s) that you assign to an output

line.

Note: Tools can be assigned only to output lines that you have assigned a

“results” function. These output lines will carry the “pass/fail” results signals

from the tools during each inspection.

The next section, Planning Output Line Connections, provides electrical and

timing diagrams and data. You will need to use these diagrams to correctly

identify and connect the output lines to your production equipment.

Page 23

Chapter 3

Using Local I/O

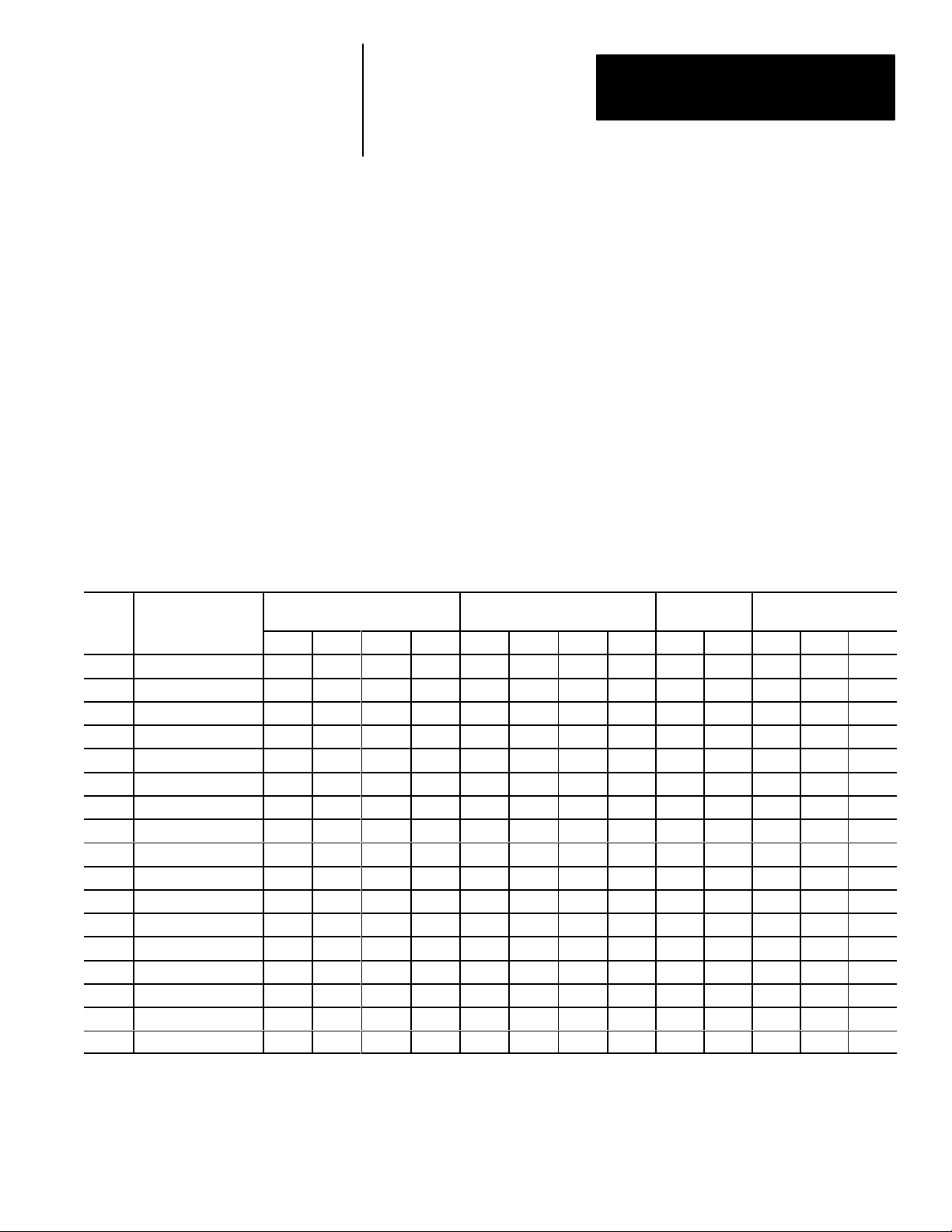

Using the Output Line Planning Sheet

The Output Line Planning Sheet is a form on which you can lay out your

plans for each output line. On this form you can account for:

• The 14 output lines.

• The six output line functions.

• The 64 gages and their warning and fault outputs.

• The 48 windows and their warning and fault outputs.

• The 6 reference tools and their “pass/fail” outputs.

• The light probe with its separate red, green, and blue warning and fault

outputs.

Here is an example of how an Output Line Planning Sheet could be filled

out:

Table 3.A

Example Color CVIM Output Line Planning Sheet

Output Line Functions and Tool Assignments

Line Output Line

No. Function

1 Results 1 W 2 W 1 W 2 W

″ ″ 3 W 4 W

2 Results 1 F 2 F 1 F 2 F

″ ″ 3 F 4 F

3 Results 1 1

4 Results W W W

5 Results F F F

6 Results 1 W 1 F

″ ″ 2 W 2 F

7 Strobe

8 Trig. Nak

9 Master Fault

10 Data Valid

11 Module Busy

12 Not Used

13 Not Used

14 Not Used

No. Rng. No. Rng. No. Rng. No. Rng. Line Win. Red Green Blue

Gage Window

Reference

Tool

Light Probe

3–3

Page 24

Chapter 3

Using Local I/O

Using the Output Line

Planning Sheet (cont’d)

The entries for the output lines have the following meanings:

• Output Line 1: The Results function is assigned to line 1. The Warning

Range results (W) for gages 1–4 and windows 1 and 2 are assigned to

output line 1.

• Output Line 2: The Results function is assigned to line 2. The Fault

Range results (F) for gages 1–4 and windows 1 and 2 are assigned to

output line 2.

• Output Line 3: The Results function is assigned to line 3. The “pass/fail”

results for reference line 1 and reference window 1 are assigned to line 3.

• Output Line 4: The Results function is assigned to line 4. The Warning

Range result from the red, blue and green light probe is assigned to line 4.

• Output Line 5: The Results function is assigned to line 5. The Fault

Range result from the red, blue and green light probe is assigned to line 5.

• Output Line 6: The Results function is assigned to line 6. The Warning

and Fault Range results for gages 1 and 2 are assigned to line 6.

• Output Line 7: The Strobe function is assigned to line 7.

• Output Line 8: The Trigger NAK function is assigned to line 8.

• Output Line 9: The Master Fault function is assigned to line 9.

• Output Line 10: The Data Valid function is assigned to line 10.

• Output Line 11: The Module Busy function is assigned to line 11.

• Output Lines 12–14: These lines are not used.

Note: Output lines 1–6 are assigned the Results function. These lines will

carry “pass/fail” results from the analysis tools to your production

equipment. Lines 7– 11 are assigned other functions. Lines 12–14 are not

used.

Here is a brief explanation of the signal functions that you can assign to the

output lines:

• Module Busy: This signal goes high when the Color CVIM system enters

the configuration mode and during a configuration download operation.

Module Busy goes low when the system enters the run mode (whether or

not triggers are present).

You can assign the Module Busy function to only one output line.

3–4

Page 25

Chapter 3

Using Local I/O

Using the Output Line

Planning Sheet (cont’d)

Note: All of the remaining signal functions (except Strobe, Module Busy,

and Trigger NAKs) can be configured to produce a pulse whose duration

depends on the number of milliseconds that you assign to the Duration

parameter.

• Results: This signal occurs when the results of a tool inspection exceed

the warning and/or fault limits. (The tool must be assigned to an output

line that has already been assigned the Results function.)

You can assign the Results signal function to any unassigned output line.

As noted above, the Results signal function must be assigned to an output

line before any tool can be assigned to that line. Thus, if you wanted

inspection results from Ref. Line # 2 to be assigned to output line #10, you

would first have to assign the Results signal function to output line #10.

Note: You can assign the inspection results from any tool to an output line to

which you have already assigned the Results signal function.

• Data Valid: This signal occurs when the Color CVIM system has

completed an inspection. Data Valid signals (the “data”) are stable on all

output lines assigned to the Results signal function. Data Valid goes low

after the next trigger or the selected Duration time.

Note: Data Valid does not indicate whether an inspection has passed or

failed. That is the task of the output lines assigned to the Results signal

function.

You can assign the Data Valid function to only one output line.

• Trigger NAK: This signal occurs when the Color CVIM system receives

a trigger input signal, but cannot process that trigger. The signal goes low

upon the next “accepted trigger”.

You can assign the Trigger NAK function to only one output line.

• Master Fault: This signal occurs when any (one or more) analysis tools

in the Color CVIM system detects a Fail condition.

You can assign the Master Fault function to only one output line.

3–5

Page 26

Chapter 3

Using Local I/O

Using the Output Line

Planning Sheet (cont’d)

• Strobe: This signal is used to trigger the strobe flash unit (if used). The

signal occurs within 1 ms after the Color CVIM system receives a trigger

input signal.

You can assign the Strobe function to only one output.

• Duration (n)ms: From 1msec to 2000msec. This value determines the

pulse duration, in milliseconds (and with an accuracy of ±5 milliseconds),

of all pulse–type signals. A setting of zero means the signal will remain in

its present state until updated by a subsequent inspection.

Note: The output duration may vary if subsequent inspections occur before

the specified output duration has elapsed.

In your application, the function and tool assignment(s) for each output line

will of course depend on the specific requirements of your production

equipment.

You will find a full–page, blank copy of the planning sheet on the last page

of this chapter. We suggest that you do not mark that page, but use it instead

as a copy master, and use the copies to prepare your output line plans.

Keep in mind that a completed planning sheet can serve also as a record of

your output line usage. You may find it desirable to store your filled–out

planning sheets in a file folder or loose leaf binder.

3–6

Page 27

Chapter 3

Using Local I/O

Using Output Signal

Timing Data

To make proper use of the signal data available to the output lines, you must

first understand the timing relationships that exist between the trigger input

signal (which starts each inspection cycle) and the output signals.

Knowing these signal timing relationships enables you to accurately

synchronize the inspection cycles with your production equipment.

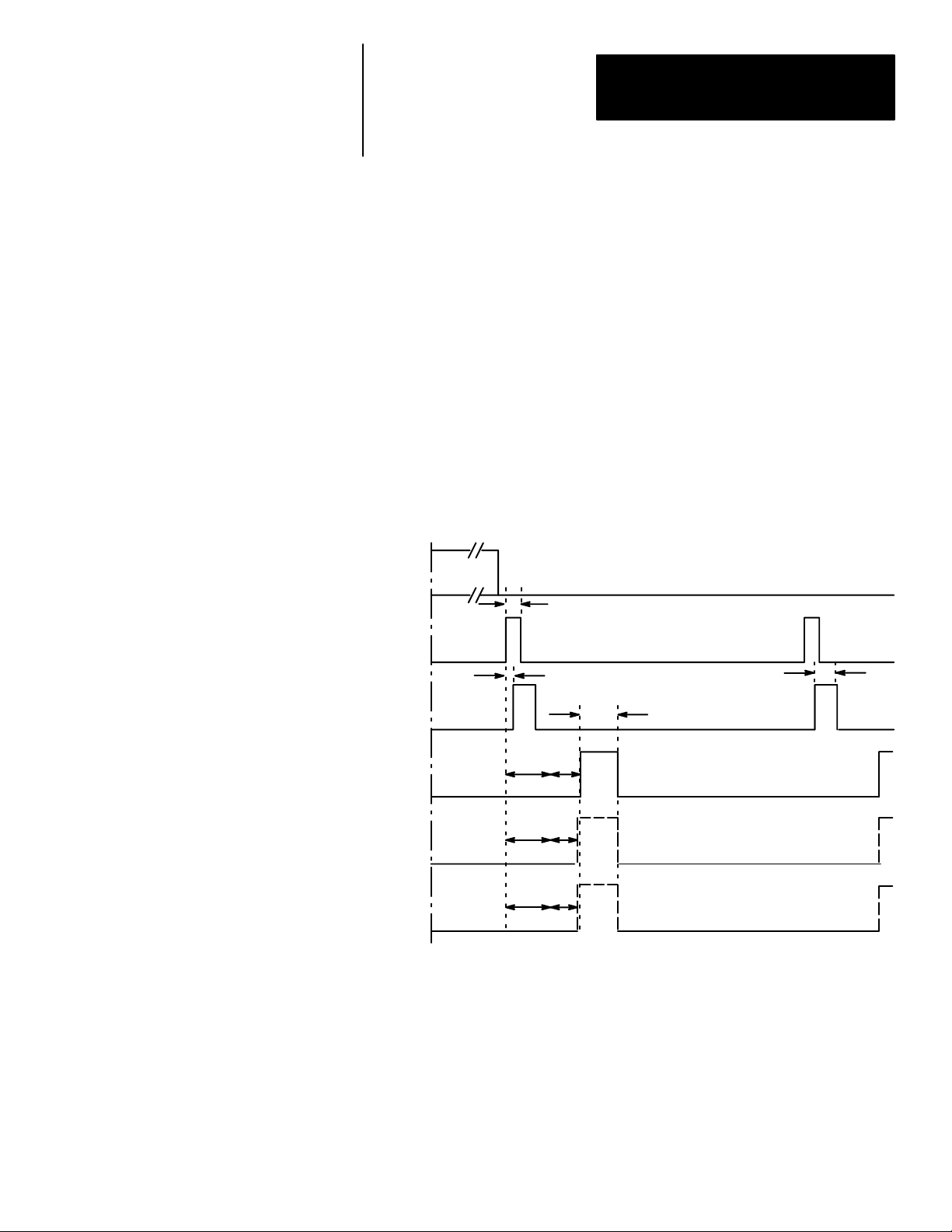

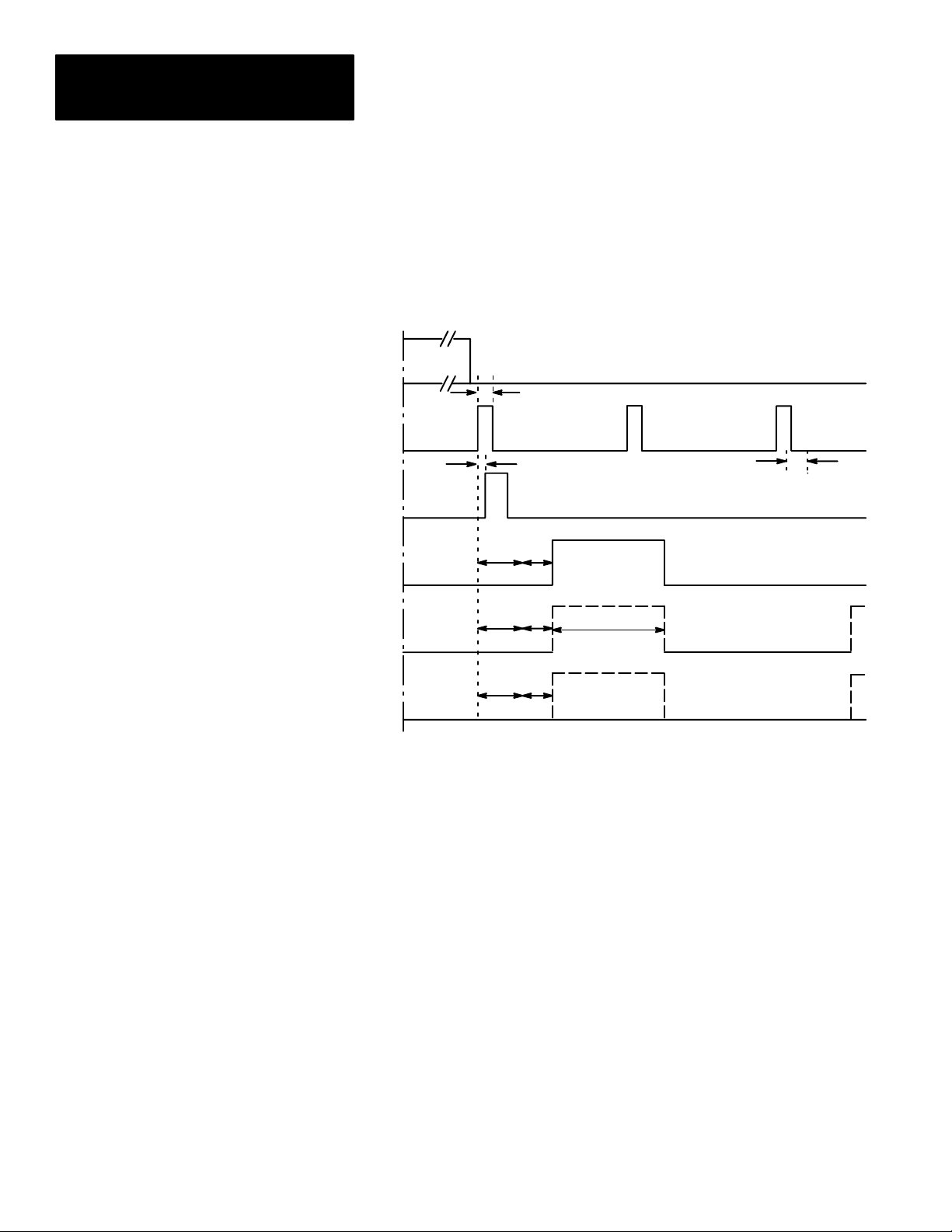

Timing charts (Figures 3.2, 3.3, and 3.4) show the timing relationships in

various circumstances.

Figure 3.2 shows the relationship between the trigger leading edge and the

Strobe, Data Valid, and Results signals, where the last three appear as pulses

whose duration you determine during configuration.

Figure 3.2

Timing Diagram — Pulsed I/O

MODULE

BUSY

Min. trigger ≈ 2ms*

Trigger

(Input)

STROBE

DATA

VALID

RESULTS

Trigger

pulse #1

Max. lag ≈ 1ms

** ***

** ***

Strobe ≈ 2ms

You can select a

pulse width of 1

to 2000ms

DATA VALID will always pulse high

when inspection

processing is complete.

RESULTS signal will

pulse high if an analysis tool range limit

is exceeded.

Trigger

pulse #2

MASTER RANGE

signal will pulse

MASTER

RANGE

* As seen by the Color CVIM when the trigger is directly connected through the JMB

board, and not provided by a host device.

** Minimum acquisition time: 17ms for 256x256 and 512x256 Res; 34 ms for 512x512 res.

*** Analysis time (variable).

** ***

high if any tool detects a failure condition.

3–7

Page 28

Chapter 3

Using Local I/O

Using Output Signal

Timing Data (cont’d)

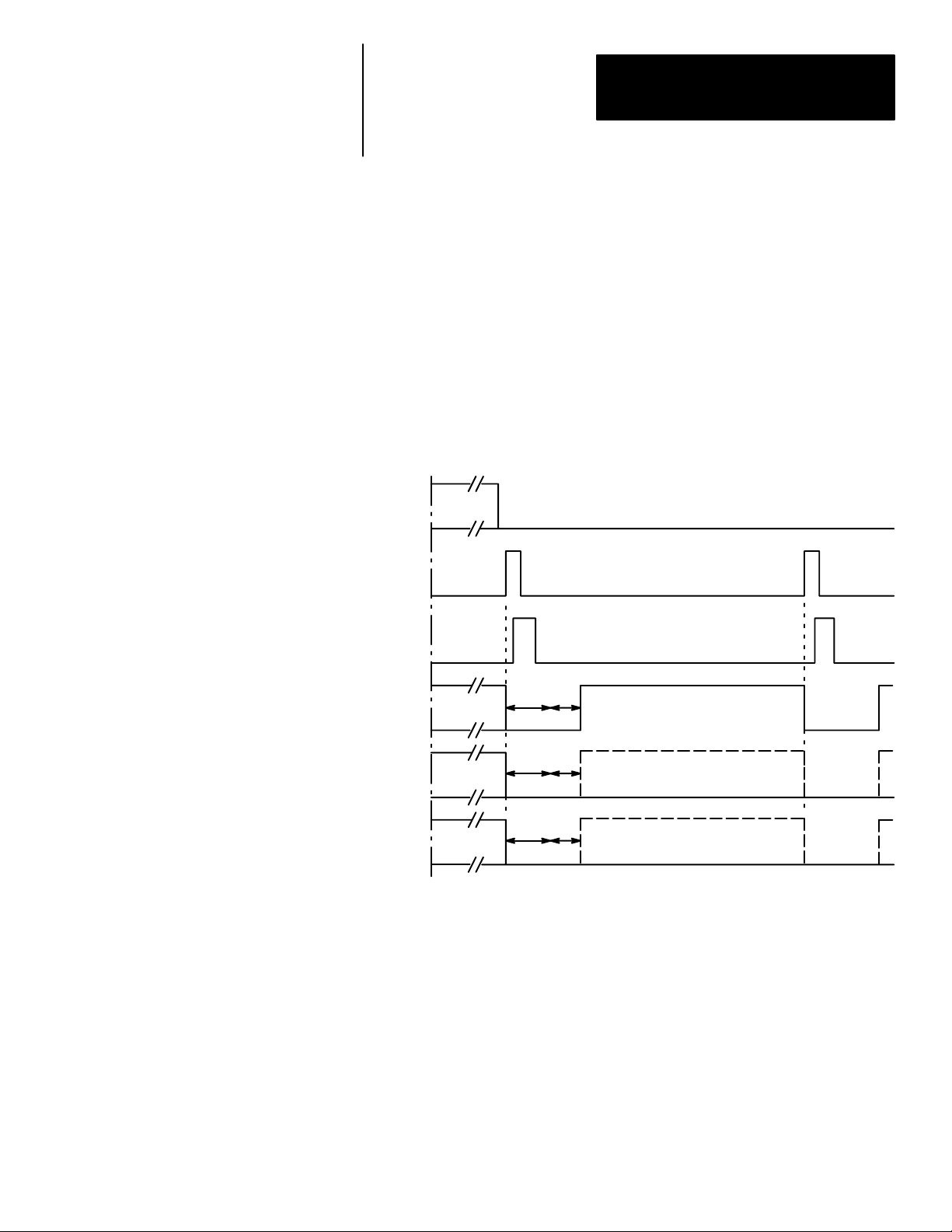

In Figure 3.3, trigger pulse #2 occurs before the Color CVIM module has

finished the pulsed output duration of the outputs from trigger #1.

Figure 3.3

Timing Diagram — Trigger #2 During Data Valid, Pulsed I/O

MODULE

BUSY

Trigger

(Input)

STROBE

DATA

VALID

RESULTS

Min. trigger ≈ 2ms*

Trigger

pulse #1

Max. lag ≈ 1ms

** ***

** ***

DATA VALID will always pulse high when

inspection processing is complete

Trigger

pulse #2

Strobe ≈ 2ms

For Trigger #1

You can select

a pulse width

of 1 to 2000 ms

************

Trigger

pulse #3

MASTER

RANGE

* As seen by the Color CVIM when the trigger is directly connected through the JMB

board, and not provided by a host device.

** Minimum acquisition time: 17ms for 256x256 and 512x256 Res; 34 ms for 512x512 res.

*** Analysis time (variable).

****RESULTS will pulse high if an analysis tool range is exceeded.

** ***

3–8

Page 29

Chapter 3

Using Local I/O

Using Output Signal

Timing Data (cont’d)

Whenever these signals go high, they will go low again at the end of the

specified pulse duration (1 to 2000ms).

In Figure 3.4, the Data Valid, and Results signals appear as changes in signal

levels. This will occur if, during system configuration, you select a pulse

“duration” of 0 (zero) milliseconds. Data Valid will stay high until the

leading edge of the next valid trigger signal (Trigger Pulse #2). Results stay

in their current state until the leading edge of the next Trigger pulse, then

change depending upon the results.

Figure 3.4

Timing Diagram — Non–Pulsed I/O

MODULE

BUSY

Trigger

(Input)

STROBE

Trigger

pulse #1

Trigger

pulse #2

DATA

VALID

RESULTS

MASTER

RANGE

DATA VALID will go high when inspection proc-

***

***

***

*Minimum acquisition time: 17ms for 256x256 Res.; 34ms for 512x512 Res.

**Analysis time.

essing is complete, and will go low with the

leading edge of the next valid trigger.

RESULTS signal will go

high if an analysis tool

range limit is exceeded.

MASTER RANGE signal

will go high if any tool detects a failure condition.

3–9

Page 30

Chapter 3

Using Local I/O

Using Output Signal

Timing Data (cont’d)

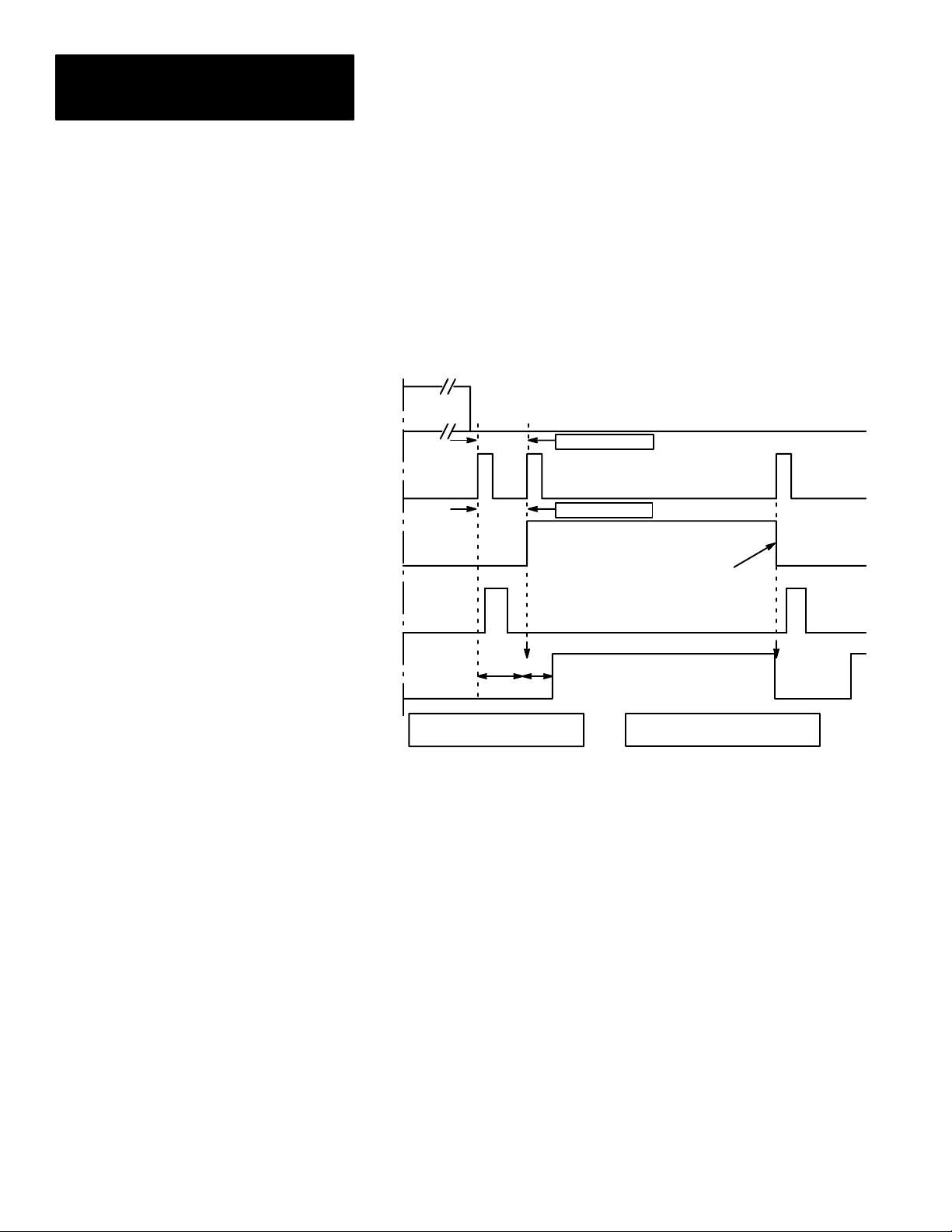

In Figure 3.5, trigger pulse #2 occurs before the Color CVIM system is

finished processing the inspection cycle started by trigger pulse #1. This

causes the Trigger NAK signal to go high. Trigger NAK will stay high until

leading edge of the next valid trigger pulse (trigger pulse #3).

Figure 3.5

Timing Diagram– Missed Trigger

MODULE

BUSY

See NOTE 1 below

Trigger

(Input)

TRIGGER

NAK

STROBE

DATA

VALID

Trigger

pulse #1

Trigger

pulse #2

TRIGGER NAK goes high because

trigger 2 cannot be processed. (Trigger 1 processing is not yet complete.)

***

NOTE 1: If Trigger 2 occurs within

5ms of Trigger 1, it is assumed to be

trigger “bounce” and is ignored.

See NOTE 2 below

TRIGGER NAK goes low

because trigger 3 can be

processed. (Trigger 1

processing is now complete.)

*Min. processing time:

17ms, 256x256 Res.

17ms, 512x256 Res.

34ms, 512x512 Res.

**Analysis time.

NOTE 2: In delayed trigger reject (DTR)

mode, the Trigger NAK signal can occur up

to ≈ 15ms after the rising edge of Trigger 2.

Trigger

pulse #3

3–10

Page 31

Chapter 3

Using Local I/O

Planning Output Line Connections

Connections to RS–232 Ports

(2801–N27 Interface Box)

P

O

R

T

A

P

O

R

T

B

This section provides diagrams of electrical connections for correctly

connecting your production equipment to the Color CVIM module’s discrete

output and RS–232 lines.

Figure 3.6 shows the cable connectors and their pin numbers on the Catalog

No. 2801–N27 I/O Interface Box.

Figure 3.6

Pinouts– Catalog No. 2801–N27 I/O Interface Box

1

2345

789

6

Cable connectors to

RS–232 devices.

C

V

I

M

18

Cable connector from Module

I/O connector on Color CVIM

Module..

1

2345671089

11121314151617

19

20212223242526

I/O Interface Box (Catalog No.

2801–N27)

3–11

Page 32

Chapter 3

Using Local I/O

Connections to RS–232 Port

(2801–N21 Interface Box)

I/O Interface Box (Catalog No. 2801–N21)

Figure 3.7 shows the cable connectors and their pin numbers on the Catalog

No. 2801–N21 I/O Interface Box.

Figure 3.7

Pinouts– Catalog No. 2801–N21 I/O Interface Box

8

9

18

Cable connector from Module

I/O connector on Color CVIM

Module..

2345

789

6

Cable connectors to

RS–232 devices.

1

234567

10

11121314151617

19

20212223242526

1

3–12

Page 33

Chapter 3

Using Local I/O

Color CVIM Module I/O Interface Box Connections

Tables 3.B through 3.E show the connector pin assignments for the Color

CVIM module connected to Catalog No. 2801–N21, –N27 I/O Interface Box.

ATTENTION:

!

Making discrete I/O connections directly to the front of the

Color CVIM module will result in damage to the equipment

and void your warranty.

Table 3.B

Color CVIM Module I/0 Connector

Pin Number Function Pin Number Function

1

2 Not Used 15 Not Used

3 Output Line #1 16 Output Line #14

4 Output Line #2 17 Reserved

5 Output Line #3 18 Reserved

6 Output Line #4 19 Ground (Power)

7 Output Line #5 20 Ground (Power)

8 Output Line #6 21 Ground (Chassis)

9 Output Line #7 22 Ground (Signal)

10 Output Line #8 23

11 Output Line #9 24

Trigger Input

Line #1

14 Output Line #12

TXD (Transmit

Data: RS–232 A)

TXD (Transmit

Data: RS–232B)

12 Output Line #10 25

13 Output Line #11 26

RXD (Receive

Data: RS–232 A)

RXD (Receive

Data: RS–232 B)

Table 3.C

I/O Interface Box (Catalog No. 2801–N21):

RS–232 Connector with Series A Color CVIM Module

Pin Number Function Pin Number Function

1 No Connection 6 No Connection

2

3

4 Ground (Chassis) 9 No Connection

5 Ground (Signal)

RXD (Receive

Data: RS–232A)

TXD (Transmit

Data: RS–232A)

7

8

TXD (Transmit

Data: RS–232 B)

RXD (Receive

Data: RS–232 B)

3–13

Page 34

Chapter 3

Using Local I/O

Color CVIM Module I/O

Interface Box Connections

(cont’d)

Table 3.D

I/O Interface Box (Catalog No. 2801–N27):

RS–232 Port A Connector with Color CVIM Module

Pin Number Function Pin Number Function

1 No Connection 6 No Connection

2

3

4 + 5V DC* 9 No Connection

5 Ground (Signal)

*Not to be used to power external devices.

Table 3.E

I/O Interface Box (Catalog No. 2801–N27):

RS–232 Port B Connector with Color CVIM Module

Pin Number Function Pin Number Function

1 No Connection 6 No Connection

2

3

4 + 10V DC* 9 No Connection

5 Ground (Signal)

*Not to be used to power external devices.

RXD (Receive

Data: RS–232A)

TXD (Transmit

Data: RS–232A)

RXD (Receive

Data: RS–232B)

TXD (Transmit

Data: RS–232B)

7 + 5V DC*

8 No Connection

7 + 10V DC*

8 No Connection

Connections to

2801–JMB Interface

3–14

The 2801–JMB interface board is designed for direct edge connection to the

I/O Interface Box, Catalog Nos. 2801–N21, –N27.

If you intend to use the 2801–JMB board and the I/O Interface Box, you will

need to know the relationship between the discrete I/O line numbers and the

LED numbers, the optic–isolator type, and the terminal block screws

numbers on the 2801–JMB board. These are shown in the figure and table

that follows.

ATTENTION:

!

To power the JMB logic components, you must connect an

external +5VDC power supply to the (+) and (–) terminal

screws shown on the board layout that follows.

Page 35

Chapter 3

Using Local I/O

Connections to

2801–JMB Interface

(cont’d)

Color CVIM

Module

Overlay

T

R

I

1

G

G

E

2

R

S

1

2

3

Figure 3.8 shows the layout of the 2801–JMB interface board and the

adhesive–backed overlay.

Figure 3.8

Local I/O Board ( Catalog No. 2801–JMB).

Teminal screws for external

+5VDC power supply

0 1 2 3 4 5 6 7 9 10 11 12 13 14 15

In

+

–

1 2 3 4 5 6 7 8 9 10 11 1213 14 15 16 17 18 19 20 21 22 2324 26 27 28 29 30 31 32

Not Used

Out

Out

Out

O

U

U

4

5

T

6

P

T

7

S

8

8

9

10

11

13

13

14

Out

Out

Out

Out

Out

Out

Out

25

Out

Out

Out

Out

3–15

Page 36

Chapter 3

Using Local I/O

Connections to

2801–JMB Interface

(cont’d)

Table 3.F shows the relationship between the I/O line and optic–isolator

numbers shown in Figure 3.8.

Table 3.F

Color CVIM I/O Output Numbering

Discrete I/O

Line Number

Input Output

1 0 1 2

2* NA 3/NC** this

1 2 5 6

2 3 7 8

3 4 9 10

4 5 11 12

5 6 13 14

6 7 15 16

7 8 17 18

8 9 19 20

9 10 21 22

10 11 23 24

11 12 25 26

12 13 27 28

13 14 29 30

14 15 31 32

LED and I/O

Module

Module

Number

Terminal Screw

and Polarity

+ –

4/NC

input is not

used by Color

CVIM.

3–16

Note: A self–adhesive decal is provided with the 2801–JMB Local I/O

board. This decal identifies the I/O lines. Use this chart if the decal is not in

place.

* This input is not used by Color CVIM.

** Not Connected

Page 37

Chapter 3

Using Local I/O

Connections to

2801–JMB Interface

(cont’d)

Line Output Line

No. Function

Table 3.G

Color CVIM Output Line Planning Sheet

Output Line Functions and Assignments

Gage Window

No. Rng. No. Rng. No. Rng. No. Rng. Line Win. Red Green Blue

Reference

Tool

Light Probe

3–17

Page 38

Chapter

Using the Remote I/O Link

4

Chapter Objectives

Remote I/O Communications

In this chapter we provide:

• Basic description of Remote I/O communications.

• Connection diagrams.

• Description of Color CVIM module setup requirements.

• Three example PLC programs for accessing Color CVIM module data.

• An example 6008–SI program.

As stated earlier, the Remote I/O port is located on the front of the Color

CVIM module and is labeled RIO. This port allows the Color CVIM module

to become a link in an Allen–Bradley Remote I/O network which can be up

to 10,000 feet long. Data on the network can be transmitted at baud rates as

high as 230K.

Maximum

Link Length

(Feet)

10,000 57.6K

5,000 115.2K

2,500 230.4K

Baud Rate

Use twin–axial cable (Catalog No. 1770–CD) to connect the Color CVIM

module to other devices. This cable connects to the Remote I/O port (labeled

RIO) and the next device on the network. Refer to Figures 4.1 through 4.8

for connection diagrams.

4–1

Page 39

Chapter 4

Using the Remote I/O Link

Remote I/O Communications

(cont’d)

Figure 4.1

PLC–5 to Color CVIM Module– Remote I/O Link

1771 I/O Rack

PLC

5/15

5/25

5/30

5/40

5/60

Catalog No.

1770–CD

Cable

Color

CVIM Module

RIO

Figure 4.2

6008 SI IBM PC/AT Scanner to Color CVIM Module– Remote I/O Link

Color

CVIM Module

6008 SI I/O Scanner

IBM PC/AT

Catalog No.

1770–CD

Cable

Figure 4.3

6008 SV VME Scanner to Color CVIM Module– Remote I/O Link

CVIM Module

6008 SV I/O Scanner

Host

Computer

Catalog No.

1770–CD

Cable

RIO

Color

RIO

4–2

Page 40

Chapter 4

Using the Remote I/O Link

Remote I/O Communications

(cont’d)

Figure 4.4

6008 SQH1/2 Q–BUS Scanner to Color CVIM Module–Remote I/O Link

Color

CVIM Module

6008 SQH1/2 I/O Scanner

Host

Computer

RIO

Catalog No.

1770–CD

Cable

Figure 4.5

Mini PLC–2 to Color CVIM Module– Remote I/O Link

1771 I/O Rack

MINI PLC–2

2/02

2/15

2/16

2/17

Catalog No. 1771–SN

Sub I/O Scanner Module

Catalog No.

1770–CD

Cable

Color

CVIM Module

RIO

Figure 4.6

PLC–2 to Color CVIM Module– Remote I/O Link

Catalog No. 1772–CS

Cable

Catalog No.

PLC–2/20

–2/30

Catalog No.1771–CJ/CK

Power Cable

1772–SD2

Scanner

Distribution

Module

Catalog No.

1770–CD

Cable

Color

CVIM Module

RIO

4–3

Page 41

Chapter 4

Using the Remote I/O Link

Remote I/O Communications

(cont’d)

Figure 4.7

PLC–3 to Color CVIM Module–Remote I/O Link

Catalog No. 1775–

S4A/S4BS5/SR/SR5

PLC–3

I/O Scanners

Catalog No.

1770–CD

Cable

Figure 4.8

PLC–5/250 to Color CVIM Module– Remote I/O Link

Pyramid Integrator

Rack

Remote Scanner

PLC–5/250

Color

CVIM Module

RIO

Color

CVIM Module

Catalog No.

1770–CD

Cable

RIO

4–4

Page 42

Chapter 4

Using the Remote I/O Link

Remote I/O Communications

(cont’d)

2801

Figure 4.9

Typical Hardware Layout for Remote I/O

Color

2705–P11J1 RediPANEL

Note: If the duration of the Data Valid signal is less than 3 PLC

scans, its change of state may not be recognized.

Note: You can also read the data valid signal over the remote I/O link.

4–5

Page 43

Chapter 4

Using the Remote I/O Link

Remote I/O Communications

(cont’d)

What Functions can be Performed over the Remote I/O Network?

When installed on a Remote I/O network, the Color CVIM module acts as a

slave device. Another device such as a PLC or computer will act as a host

device. This means that the Color CVIM module will not initiate the sending

of any data until a request is made by the host. To a host device, the Color

CVIM module will appear simultaneously as both a full I/O rack on the

network (256 input bits and 128 output bits) and as an intelligent module

with block transfer capability in group 0, slot 0 in the same rack. Refer to

Appendix B for a description of discrete bit data.

Note: If the Color CVIM module is the last node on a network, you must

terminate the communication line (refer to Figure 4.9 for an example).

Any Color CVIM communications port can be used by an external device to

read inspection result information. (Refer to Appendices B and C for more

information.) In addition, any device selected as a system (SYS) host can:

Change run–time display menus.

Enable/Disable local I/O board.

Force local I/O On or Off

A host device selected as a configuration host can also:

Upload or download Color CVIM module configurations for inspections.

Refer to Appendix D.

Issue Configuration Read/Write commands between the following Color

CVIM module memory locations:

4–6

Page 44

Chapter 4

Using the Remote I/O Link

Obtaining Inspection Result Information

Color CVIM Module Configuration Instructions

You can obtain inspection result information for each of the inspection tools

over the Remote I/O link. There are two levels of access to this information:

Discrete Bits. These bits indicate pass/fail/warning data. Note that there

are 256 input bits from the Color CVIM to the PLC. That input consists

of two pages of 128 bits each. The first 128 bits refer to the first half of

the toolset, and the second 128 bits refer to the second half of the toolset.

Result Data Words. These words contain actual inspection result data such

as measured lengths, number of black pixels, etc.

Note: Refer to Appendix B for a description of the discrete bit results and

Appendix C for a description of numerical results data blocks.

If you are using the Remote I/O link to communicate with a PLC–2, –3, or

–5 (or PLC–5/250 in another rack), you must configure the Color CVIM

module as follows:

Select the Remote I/O port for communications:

Note: This step is not required if you are only reading results.

1. Select the setup menu <Setup>.

2. Select the environment menu <Envir/Cam>.

3. Select the system menu <System>.

4. Select a Host menu <CFG Host> or <SYS Host>.

5. Select remote I/O option <Remote I/O>.

Note: Unless a separate configuration host is being used, set both the CFG

Host & SYS Host for Remote I/O.

Configure Color CVIM module I/O parameters:

6. Select the I/O menu <I/O>.

7. Select <1771 Remote I/O> option.

8. Enable the Remote I/O port by selecting <Enabled>.

9. Select the rack address (octal) using the keypad.

10.Select the baud rate <57.6Kbaud> or other options.

Select the Color CVIM module trigger source:

11.Select the trigger source menu <Trigger Source>.

12.Select either <I/O>, <Hosted>, or <Internally Triggered> trigger sources.

Note: The example connection diagram shown on Figure 4.9 shows a trigger

using the local I/O board.

4–7

Page 45

Chapter 4

Using the Remote I/O Link

Accessing Discrete Bit Information

A PLC can directly access discrete bit information using a simple ladder

program. For example:

You can use the following rung to examine the data valid bit and energize an

output if the data is valid. Refer to Chapter 3 for a description of the local

I/O. This example assumes that the Color CVIM module is in Rack 02 and

the output device is in Rack 01.

Although the same basic information is provided in Appendix B, Tables 4.A

and 4.B illustrate the word and bit locations of the discrete bits that can be

read or manipulated using simple ladder programs. We have organized the

data so that it is formatted similar to a PLC setup screen. Table 4.A shows

the first part of discrete bits results (Color CVIM module to PLC). Table 4.B

shows the second part. You can tell the difference by examining word 0, bit

5, which has a value of 0 for the first part and 1 for the second part. Table

4.C shows the Color CVIM remote outputs (PLC to Color CVIM module).

Important Note: To read results data, you must set one of the following bits

(assuming Color CVIM module is rack 02):

O:22/00 (Post First Part of Results to Remote I/O)

O:22/01 (Post Second Part of Results to Remote I/O)

Note to PLC–2 Users:

When you use any PLC–2 family processor with the Color CVIM module,

you should understand the operation of the PLC Block Transfer Done bits for

Read and Write instructions. PLC–2 family processors use the input image

table for these bits, all other PLCs can specify integer files for this function.

This means that a PLC–2 user must use proper programming techniques to

avoid confusion between the following bits:

Color CVIM module discrete I/O input word 0, bit 6 (data valid) and bit 7

(not used).

PLC–2 family input image table word 0, bit 6 (BTW done bit) and bit 7

(BTR done bit).

Remember that word 27 is a reserved word in the PLC–2 data table, and

should not be used for any other purpose.

4–8

Page 46

Chapter 4

21

22

23

24

25

26

27

Using the Remote I/O Link

Accessing Discrete

Bit Information (cont’d)

07

–––

17

(Not used)

1 = Master

Fault

1 = Window 4

Fault

1 = Window 8

Fault

1 = Window

12 Fault

1 = Window

16 Fault

1 = Window

20 Fault

1 = Window

24 Fault

06

–––

16

1=Data Valid 0=First Bits

1 = Light

Probe Failed

1 = Window 4

Warning

1 = Window 8

Warning

1 = Window

12 Warning

1 = Window

16 Warning

1 = Window

20 Warning

1 = Window

24 Warning

05

–––

15

Results

1 = Reference

Window 3

Failed

1 = Window 3

Fault

1 = Window 7

Fault

1 = Window

11 Fault

1 = Window

15 Fault

1 = Window

19 Fault

1 = Window

23 Fault

Table 4.A

Color CVIM Module Remote I/O Inputs (Color CVIM Module to PLC)

if Color CVIM Module is Rack 02 (First Discrete Bits Results)

04

–––

14

1 = Trigger

Missed

1 = Reference

Window 2

Failed

1 = Window 3

Warning

1 = Window 7

Warning

1 = Window

11 Warning

1 = Window

15 Warning

1 = Window

19 Warning

1 = Window

23 Warning

03

–––

13

1 = Module

Busy

1 = Reference

Window 1

Failed

1 = Window 2

Fault

1 = Window 6

Fault

1 = Window

10 Fault

1 = Warning

14 Fault

1 = Window

18 Fault

1 = Window

22 Fault

02

–––

12

1 = PLC is

Master

1 = Reference

Line 3 Failed

1 = Window 2

Warning

1 = Window 6

Warning

1 = Window

10 Warning

1 = Window

14 Warning

1 = Window

18 Warning

1 = Window

22 Warning

01

–––

11

1 = Config.

Error

1 = Reference

Line 2 Failed

1 = Window 1

Fault

1 = Window 5

Fault

1 = Window 9

Fault

1 = Window

13 Fault

1 = Window

17 Fault

1 = Window

21 Fault

BIT

00

–––

10

(Not Used)

1 = Reference

Line 1 Failed

1 = Window 1

Warning

1 = Window 5

Warning

1 = Window 9

Warning

1 = Window

13 Warning

1 = Window

17 Warning

1 = Window

21 Warning

W

O

R

D

20

1 = Gage 4

Fault

1 = Gage 8

Fault

1 = Gage 12

Fault

1 = Gage 16

Fault

1 = Gage 20

Fault

1 = Gage 24

Fault

1 = Gage 28

Fault

1 = Gage 32

Fault

1 = Gage 4

Warning

1 = Gage 8

Warning

1 = Gage 12

Warning

1 = Gage 16

Warning