Page 1

Installation Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Bulletin 45CPD Analog Laser Sensor

Description

The 45CPD sensor is a Class 1 infrared laser sensor that provides

long distance sensing with both analog and discrete outputs. It is

set up using the Teach-In buttons on the top of the sensor and

can be programmed for several modes depending on the

application: object detection (single or dual output), object

position (analog output), object detection (background

suppression), or object detection (reflector mode).

This sensor utilizes the time of flight principle and has a relatively

small beam spot for applications typical for this sensing range (up

to 6 m). The sensor is completely self contained in an IP67

enclosure and does not require any external control devices

which add cost and require additional mounting space.

For convenience purposes, the 45CPD utilizes a visible red Class 2

laser for alignment purposes during the set up of the sensor in an

application. The Class 2 laser is automatically shut down when the

sensor is placed in normal operation and the Class 1 “eye safe”

laser is used.

The 45CPD can be easily set up by mounting the sensor such that

the target is within the operating range of the sensor, and

teaching in the appropriate set points required for the

application. The sensor can be set with any combination of 1 or 2

discrete PNP outputs and 4…20 mA analog output. The discrete

outputs can be set for Light Operate (L.O.) or Dark Operate (D.O.)

and the analog output is automatically scaled between the

taught set points with either a positive or negative slope.

The 45CPD is an excellent solution for long range detection and

measurement applications including: distance measurement,

verifying material position, stack level, thickness measurement,

roll diameter, web winding/unwinding, positioning fixtures, error

proofing, inspection, long standoff distance (hot or limited space),

level monitoring, and box width measurement.

Features

• Eye Safe Class 1 laser for operation

• Visible red Class 2 laser for set-up

• Six meter sensing range

• Two discrete outputs (PNP) and analog output (4…20 mA)

• Easy set-up using teach-in buttons

• IP67 enclosure

• Self-contained sensor

Specifications

Current Consumption 125 mA @ 24V DC

Supplied Accessories None

Optional Accessories Cordsets, mounting bracket

Operating Environment IP67

Operating Temperature

Sensing Beam Class 1 laser, IR 905 nm

Alignment Beam Visible red Class 2 laser, 650 nm

Spot Size 4 x 7 mm @ 2 m

(0.16 x 0.27 in. @ 6.56 ft)

4 x 12 mm @ 6 m

(0.16 x 0.47 in. @ 19.7 ft)

Sensing Range 0.20…6 m (0.7…19.78 ft)

Linearity 40 mm (1.57 in)

Repeatability Fast /slo w: 15 mm/10 mm

(0.6 in./0.4 in.)

Hysteresis 30 mm (1.2 in.) (fixed)

Tem pe ratu re Drift 1.2 mm/°C

Supply Voltage 18…30V DC

Circuitry Protection Short circuit, overload, false

pulse, transient noise, reverse

polarity protection

Output Type Two discrete PNP (L.O./D.O)

Analog Current 4…20 mA

Output Rating 100 mA max. for discrete outputs;

500 max. impedance for

analog output

Response Time Fast/slow: 13 ms/30 ms

Housing Material Plastic—ABS

Lens Material PMMA

LED Indicators Green: Power; Yellow: (2) Q

ouput; Orange: speed mode; Red:

(4) Teach-in indication

Connection Types 5-pin DC micro

Vibra tion 10…55 Hz, 1.5 mm amplitude; 3

planes; meets or exceeds IEC

60947-5-2

Shock 30 g; 11 ms; meets or exceeds

60947-5-2

C (F) -20…+60° (-4…140°)

Approvals UL, cULus and CE marked for all

applicable directives

A, QB

1

Page 2

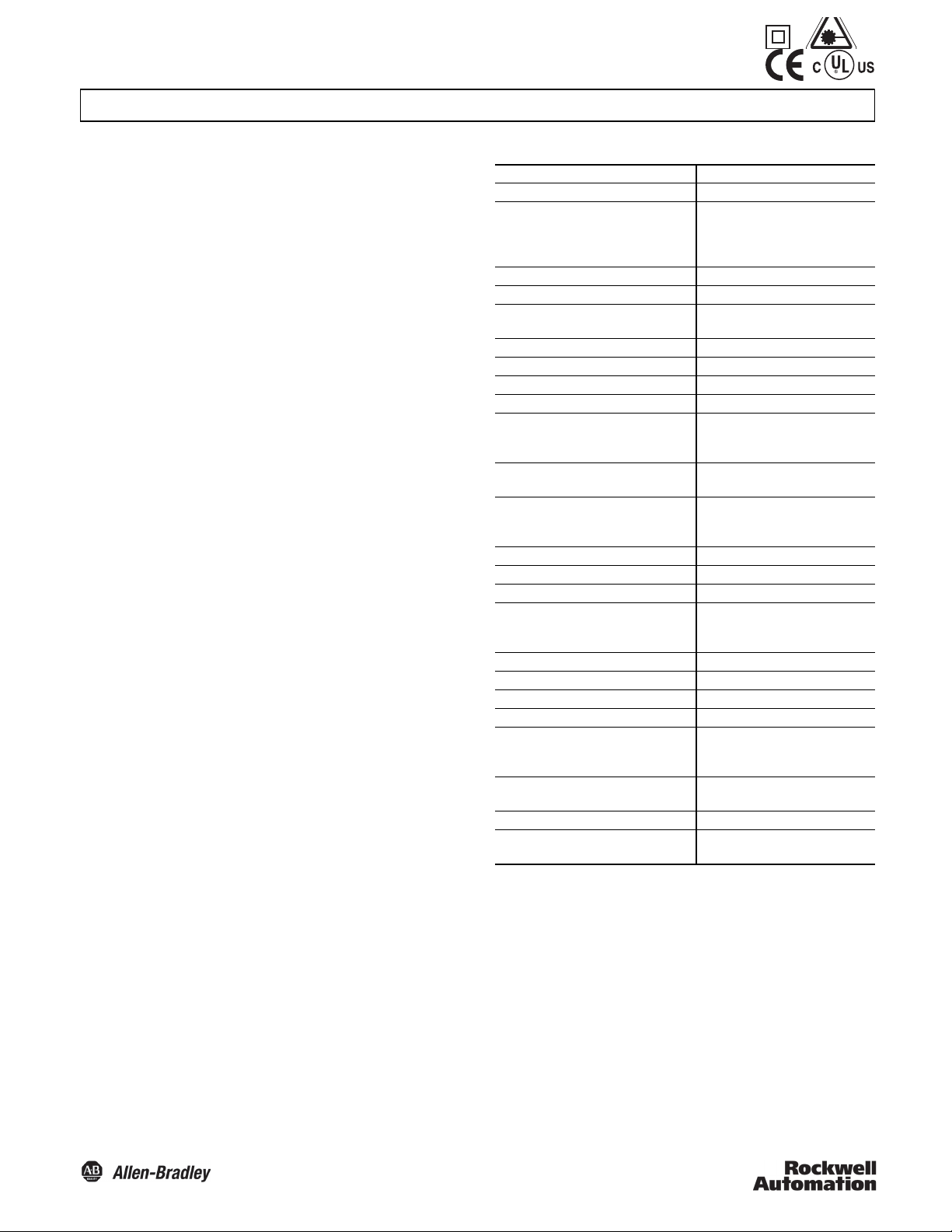

This installation instruction should be read and understood

Operating Mode

Laser Class 1 (Infrared)

Set-up Mode

Laser Class 2 (Visible Red)

Do not stare into beam.

20

(0.78)

12.3

(0.48)

5.75

(0.226)

M12 x 1

94.39 (3.71)

81.5

(3.2)

93

(3.66)

42 (1.65) 43 (1.69)

42 (1.65)

(

)

(1) Brown

(4) Black

(2) White

(5) Grey

(3) Blue

18…30V

0V

Switch Output Q

A

Switch Output QB

Analog Output 4…20mA

Teach-In

Pad

Q

B

Output

(Yellow)

Speed Mode

(Orange)

Power

(Green)

Q

A

Output

(Yellow)

before operating the sensor.

The 45CPD sensor should only be installed by qualified personnel.

The 45CPD is not a safety component as described by the EU

machinery directives.

Mounting Bracket Dimensions—mm (inches)

45CPD –BKT1

45˚

R30

25 (0.98)

50 (1.96)

11 (0.43)

140.5 (5.53)

90.5 (3.56)

53 (2.08)

3.1 (0.12)

Dia.

R81.5

The 45CPD sensor is a Class 2 laser product. It utilizes a Class 2

visible red laser for alignment purposes during the set up. After

the sensor has been set up and is placed in the normal operation

mode, the Class 2 laser is shut down and a Class 1 Infrared laser

operates the device.

There is a natural eye aversion when looking into the laser beam

of a Class 2 laser. Do not look directly into the laser beam or

suppress the reflex to close your eyes.

The 45CPD should be mounted such that it is not directed at

people (head height) and the beam path is terminated at the end

of its functional path.

The laser safety label on the 45CPD sensor should be visible after

installation.

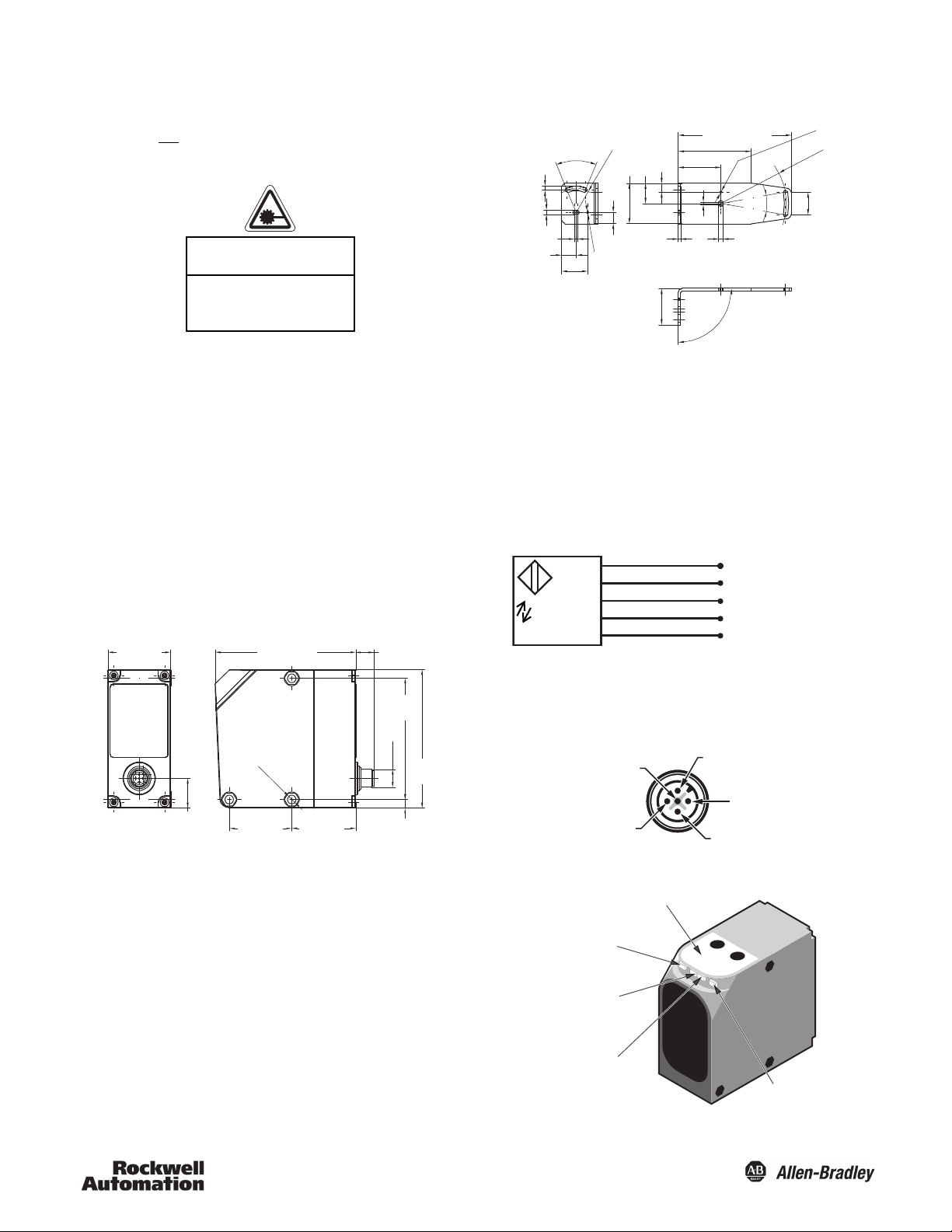

Dimensions—mm (inches)

5.2 (0.2)

5.2 (0.2)

4 (0.15)

18 (0.7)

32 (1.25)

14 (0.55)

3.1 (0.12)

Dia.

4 (0.15)

3

(0.11)

45

(1.77)

0.06

0.002

5.2 (0.2)

20˚

28

(1.1)

Wiring

The 45CPD photoelectric sensor is available with a micro quickdisconnect for ease of installation and maintenance. Rockwell

Automation recommends the use of the 889 Series of cordsets

and patchcords for quick disconnect model sensors. All external

wiring should conform to the National Electric Code and all

applicable local codes.

Wiring Diagram (45CPD-8LTB1-D5)*

Mounting

Securely mount the sensor on a firm, stable surface or support for

reliable operation. A mounting which is subjected to excessive

vibration or shifting may cause intermittent operation. The

45CPD-BKT1 mounting bracket is available for installation

convenience. Once securely mounted, the sensor can be wired

per the attached wiring diagram.

* For 45CPD-8LJB1-D5: (2) White = Analog output 4…20 mA and

(5) Grey = Switch output Q

B

Connection

5

3

2

1

4

Teach-In Pad and Indicators

2

Page 3

SPEED

Q

A

Q

B

As2

As1

PWR

0% analog

100% analog

INV.

SET

Bs2

Bs1

INV.

Allen-Bradley

Teach-In Buttons/Indicators

repeatability. Selection will depend on the requirements in the

application. The Speed mode is set by pressing the

button until

the Speed LED (Orange) is blinking fast. To select the slower speed

function press SET and the Speed LED will blink approximately

once per second. To select the higher speed function, press SET

and the Speed LED will blink approximately three times per

second. To teach the setting for either slow or fast speed, press

SET for approximately three seconds. The four teach-in indicators

will blink three times when complete. When the sensor is put in

Slow mode has a slower switching frequency with higher

The SET button sets the function that is currently indicated by the

Teach-In LEDs. To SET, press button for approximately three seconds

until LED blinks three times.

The button advances to the next function. After advancing

through the entire menu, it will begin at the first function.

Teach-In Indicators

AS1 AS2 BS1 BS2 Speed

Turn on switchpoint for QA X

Turn off switchpoint for QA X

Invert Output for QA (L.O./

D.O.)

Turn on switchpoint for QB X

Turn off switchpoint for QB X

Invert Output for QB (L.O./

D.O.)

0% point for Analog

Output

100% point for Analog

Output

Speed Mode X

XX

XX

XX

XX

The discrete and analog output functions can be set in

combination (e.g., two discrete outputs and the analog output).

General Set Up

The 45CPD is set up using the pushbuttons (SET and

) and the

LED indicators on the top of the sensor.

To begin the Teach-In process, Press the SET button for three

seconds.

This will automatically turn on the visible red alignment laser.

Scrolling through the Teach-In functions is done using the

button. After the last function is reached the menu is started

again from the first function.

To teach the selected function indicated by the teach-in LEDs as

shown in table above, press SET for approximately three seconds.

The LED will blink three times when complete.

After the desired functions are set, press SET and

simultaneously for approximately one second to exit the Teach-In

mode. The sensor will begin normal operation based on the

Teach-In settings. The visible red Class 2 laser will turn off and the

infrared Class 1 laser will turn on.

(Note: To reset the sensor to the factory setting, sensor should be

in the operating mode. Press the

button for approximately 15

operation, the LED will be turned on when running in the Slow

mode.)

Modes of Operation for Typical Applications:

Object Detection—Single Output

To set the output for Q

AS1 LED and a switch off point indicated by the AS2 LED.

Q

Output

A

Once in the Teach-In mode press the

Position the target at the desired switch on point and then press

the SET button.

(If the target is not within the measuring range or cannot be

detected the AS1 LED will blink.)

Press the button to advance to the AS2 function which is

indicated by the teach-in LED.

Position the target at the desired switch off point and then press

the SET button.

If desired, the output can be inverted for this switching window

(L.O./D.O. function). Press until both the AS1 and AS2 LEDs are

turned ON and then press the SET button. This is also indicated

by the “INV” text on the teach-in pad.

After this Q

A setting has been completed, press SET and

simultaneously for approximately one second to begin normal

operation.

Object Detection—Dual Output

To set the output for both Q

procedure as the Q

additionally teach the QB output using the BS1 and BS2 LEDs.

A there is a switch-on point indicated by the

A

S1

until the AS1 LED turns ON.

A and QB, follow the same teach-in

A Single Output (shown above) and

A

S2

seconds until the menu LEDs turn on briefly.)

(Note: The Speed Mode of the 45CPD can be adjusted for either a

Fast or Slow mode of operation. The Fast mode enables faster

switching speeds which have a slightly lower repeatability. The

3

Page 4

Object Position—Analog Output (4 to 20mA)

Q

B

Output

B

S2

B

S1

Q

A

Output

A

S2

A

S1

AS1 & BS1

0%

AS2 & BS2

100%

Analog Output

Analog Current (mA)

20

4

Background

Target Used

as Reflector

A

S2

A

S1

Once in the Teach-In mode press the button and advance until

both the A

S1 and BS1 function LEDs are turned on. This is also

indicated by “0% analog” on the teach-in pad.

Position the target at the desired 0% position (4 mA) and then

press the SET button.

(If the target is not within the measuring range or cannot be

detected both AS1 and BS1 LEDs will blink.)

Press the button and advance until both the AS2 and BS2

function LEDs are turned on. This is also indicated by “100%”

analog on the teach-in pad.

Position the target at the desired 100% position (20 mA) and then

press the SET button.

The 4…20 mA analog output is automatically scaled between the

0% and 100% positions which have been set.

shown in the diagram below (creates a larger switching window).

Background targets will be suppressed beyond the A

S2 switch

point.

Background

Is Suppressed

A

S2

QA Output

A

S1

Object Detection—Reflector Mode Using a Background

Object as the Reflector

To set the output for Q

procedure as in the single output

A in the reflector mode, follow the same

mode above. Set the AS1 and AS2

switch points such that the background “reflector” will be

approximately midway between them as shown in the figure

below. The background object can be a floor, wall, conveyor, etc.

The output can be set up for Light Operate or Dark Operate by

inverting the output. Press

until both the AS1 and AS2 LEDs are

turned ON and then press the SET button. This is also indicated

by “INV” on the teach-in pad.

After the settings have been completed successfully, press SET

and

simultaneously for approximately one second to begin

normal operation.

(Note: The minimum measuring range for the analog output is

600 mm. If the setpoints are less than 600 mm apart, the sensor

will automatically scale the analog output (0…100%) to 600 mm

and the midpoint of this will be automatically set at the midpoint

between the two original setpoints.)

(Note: To invert the slope, the 0% position and 100% position

settings will need to be reversed and reset. The 0% setting is the

“close” setting for a positive slope. For a negative slope the 0%

setting should be the “far” setting.)

Object Detection—Background Suppression

To set the output for Q

follow the same procedure as in the single output

except move the switch on point

A in a background suppression mode,

(AS1) closer to the sensor as

mode above,

Application Notes

1. The sensor should be powered for approximately five minutes

for maximum precision.

Accessories

Description Cat. No.

2 m (6.5 ft) micro DC cordset 889D-F5AC-2

Mounting Bracket 45CPD-BKT1

Publication 75009-268-01(C)

[068-13807]

April 2008

4

Loading...

Loading...